End shearing method in middle-thickness plate rolling process

A technology of rolling process and shearing machine, which is applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., and can solve the problem that the cracked part at the end of the rolled piece cannot be accurately positioned and cut.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

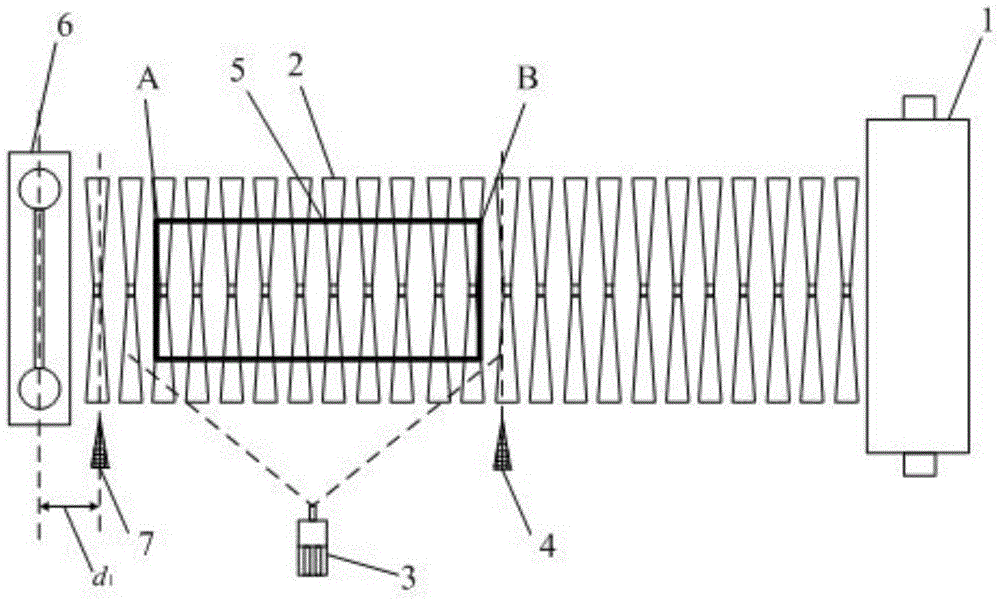

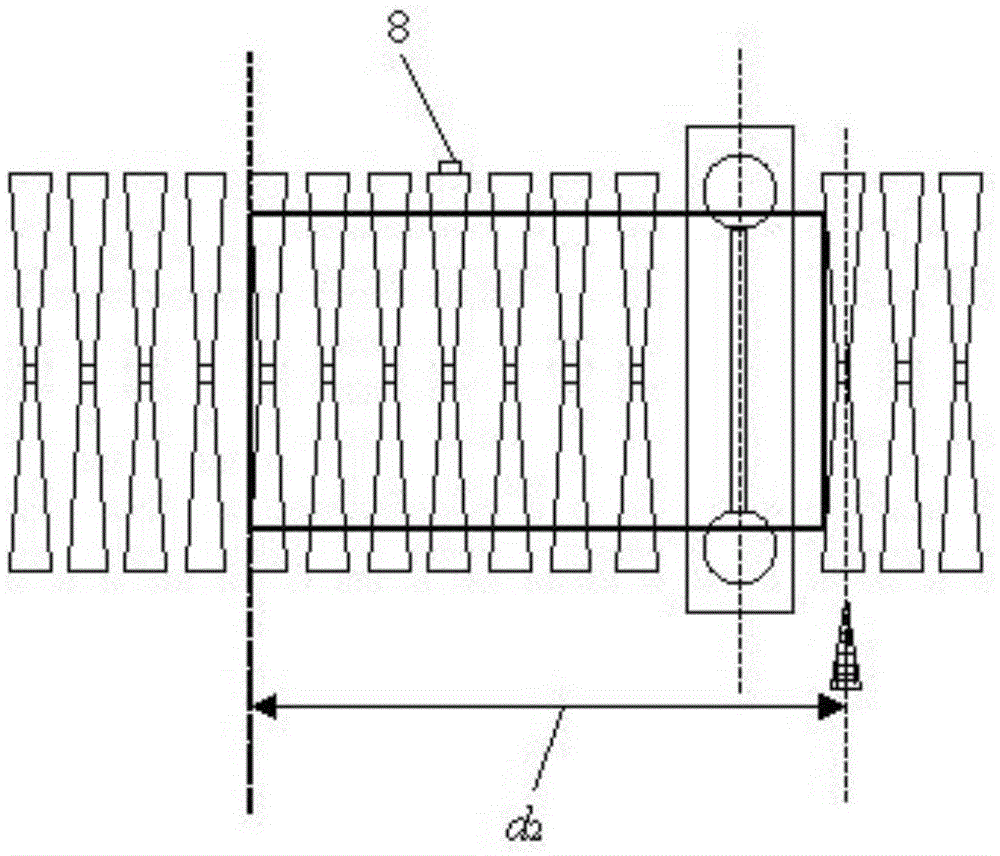

[0039] Such as figure 1 with image 3 As shown, the present invention installs an industrial CCD camera 3, the first metal detector 4 and the second metal detector 7 on one side of the transport roller table 2 between the rolling mill 1 and the shearing machine 6, by adjusting the camera and the transport roller 2 to ensure that the industrial CCD camera 3 can capture the shape of the end of the rolled piece 5 at the same time; when installing, it should be ensured that the installation distance between the first metal detector 4 and the second metal detector 7 should be greater than that before the uncut end The rolling piece 5 length. The shearing machine 6 of this embodiment is a heavy-duty shear, and the rollers are tapered rollers. A rotary encoder 8 is installed on the roller of another transport roller table 2 adjacent to the shearing machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com