Patents

Literature

595 results about "Water jet cutter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A water jet cutter, also known as a water jet or waterjet, is an industrial tool capable of cutting a wide variety of materials using a very high-pressure jet of water, or a mixture of water and an abrasive substance. The term abrasive jet refers specifically to the use of a mixture of water and abrasive to cut hard materials such as metal or granite, while the terms pure waterjet and water-only cutting refer to waterjet cutting without the use of added abrasives, often used for softer materials such as wood or rubber.

Ultrasonic waterjet apparatus

ActiveUS7594614B2Reduce cleaningReduce pressureLiquid surface applicatorsPiezoelectric/electrostriction/magnetostriction machinesSonic nozzleUltrasonic nozzle

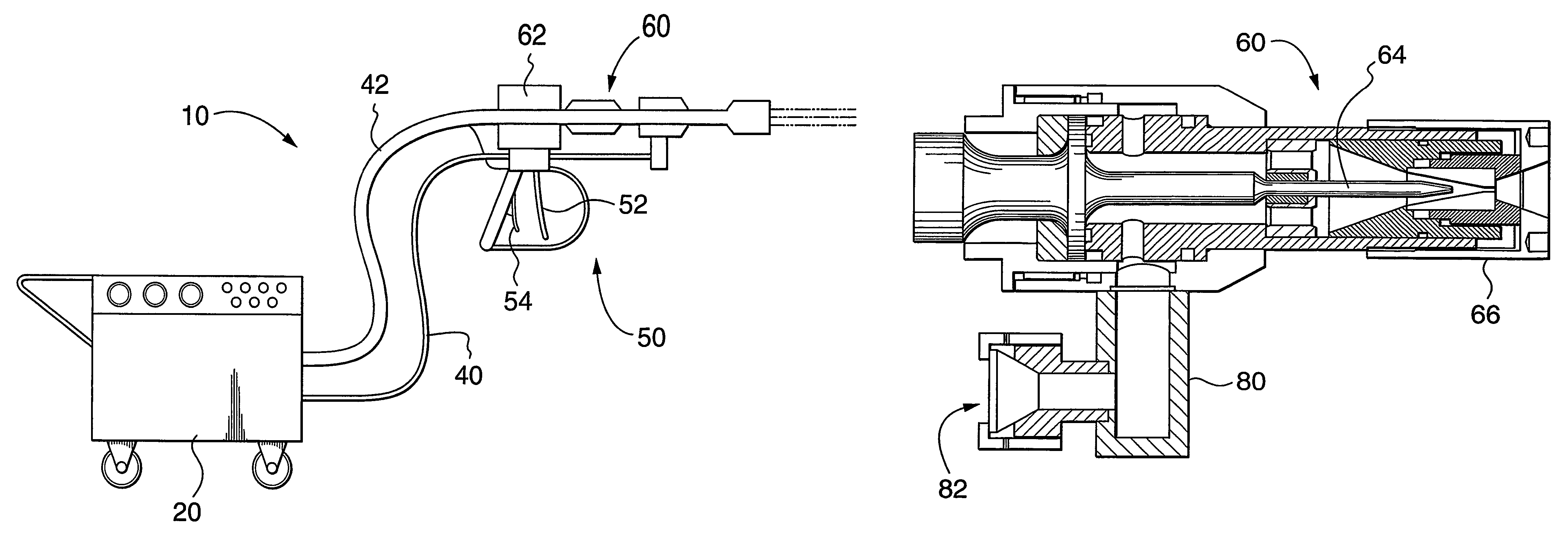

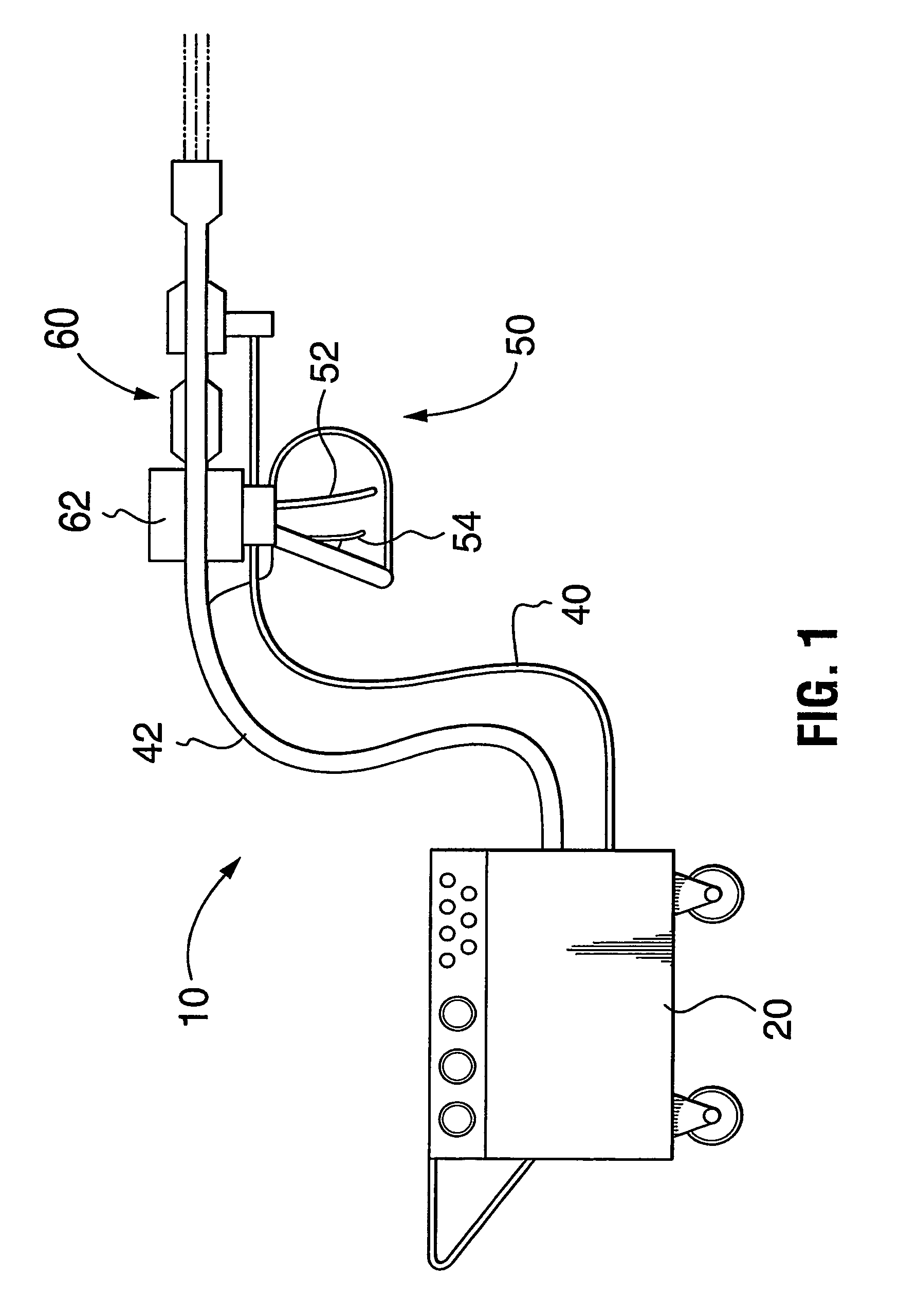

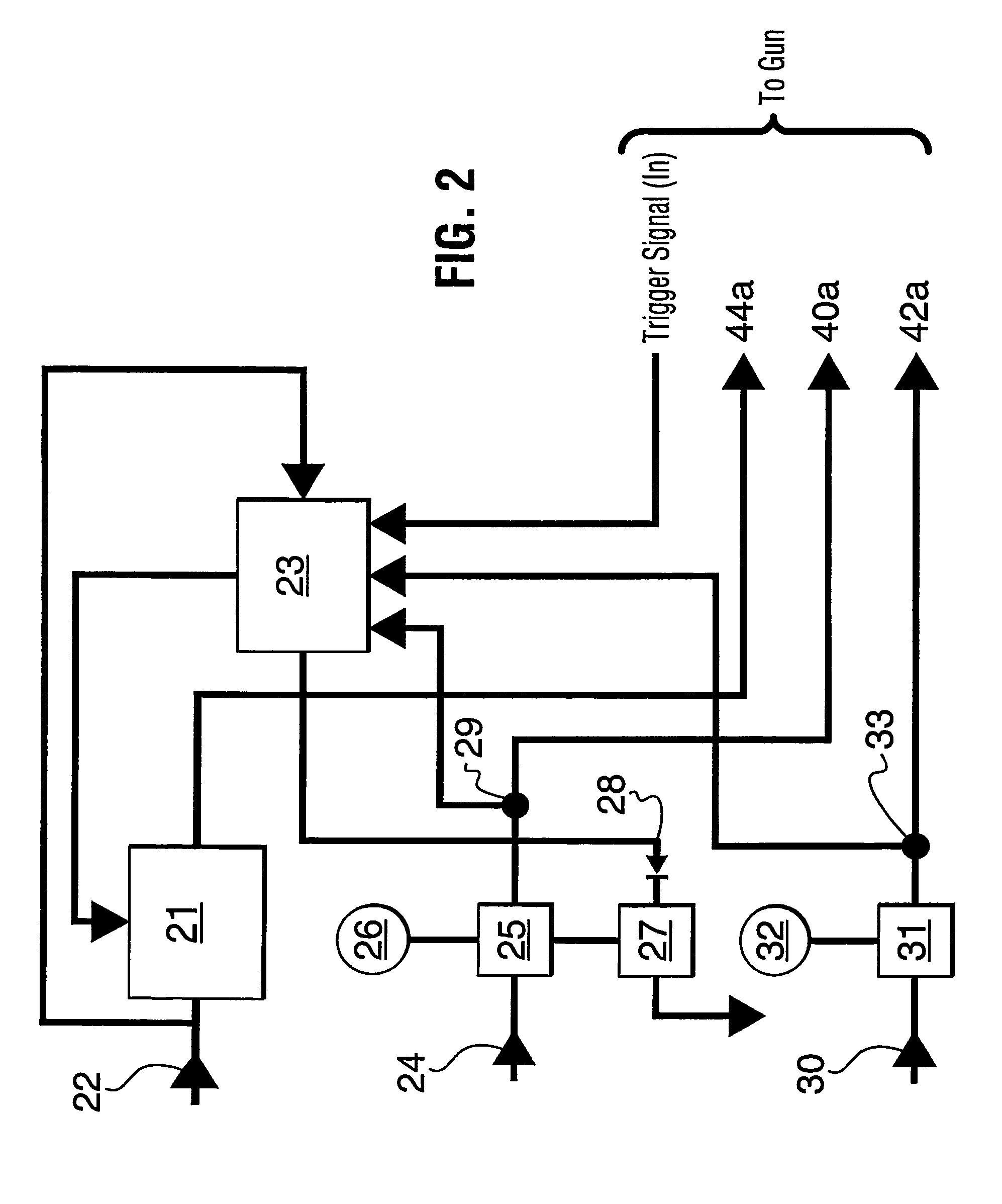

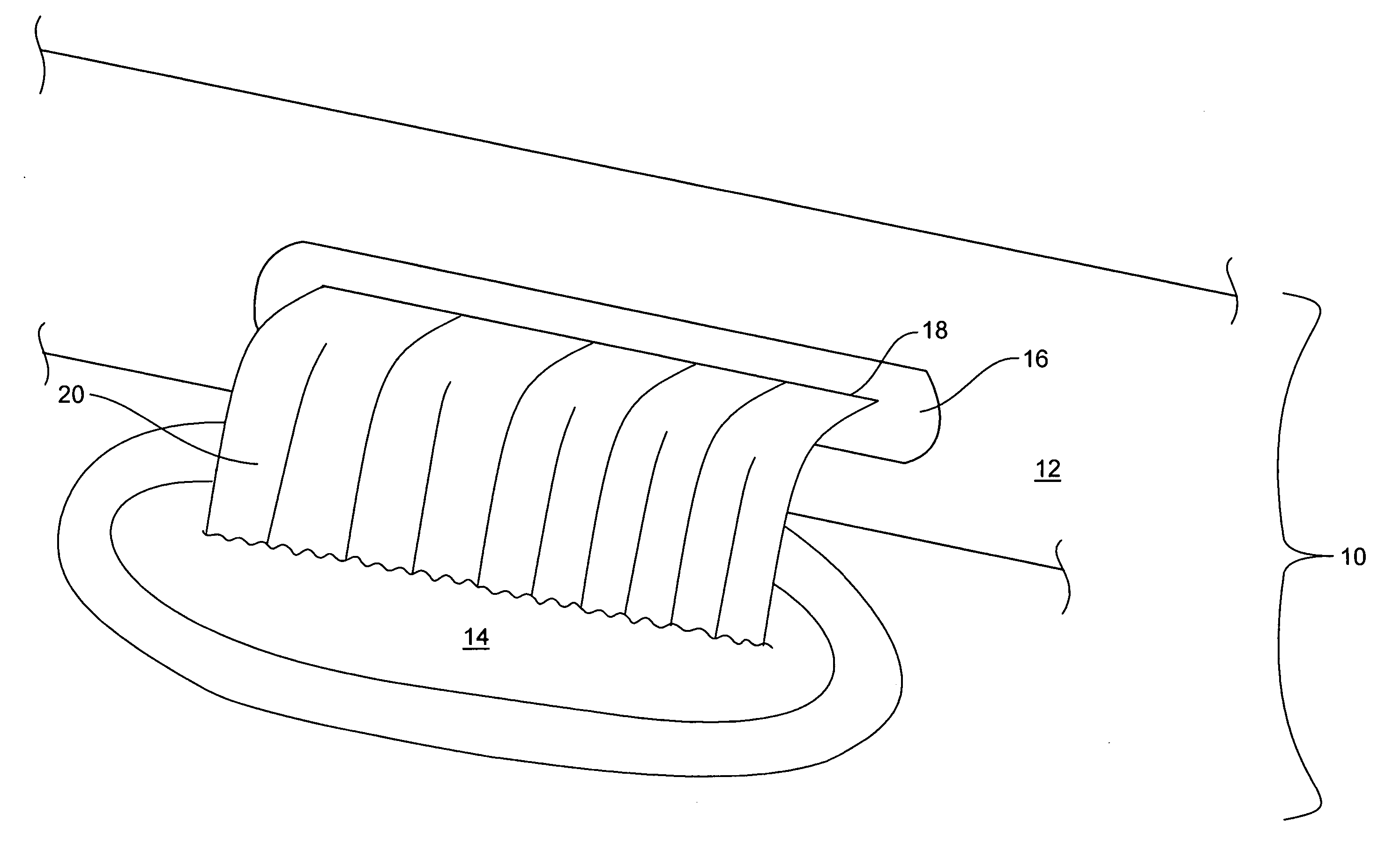

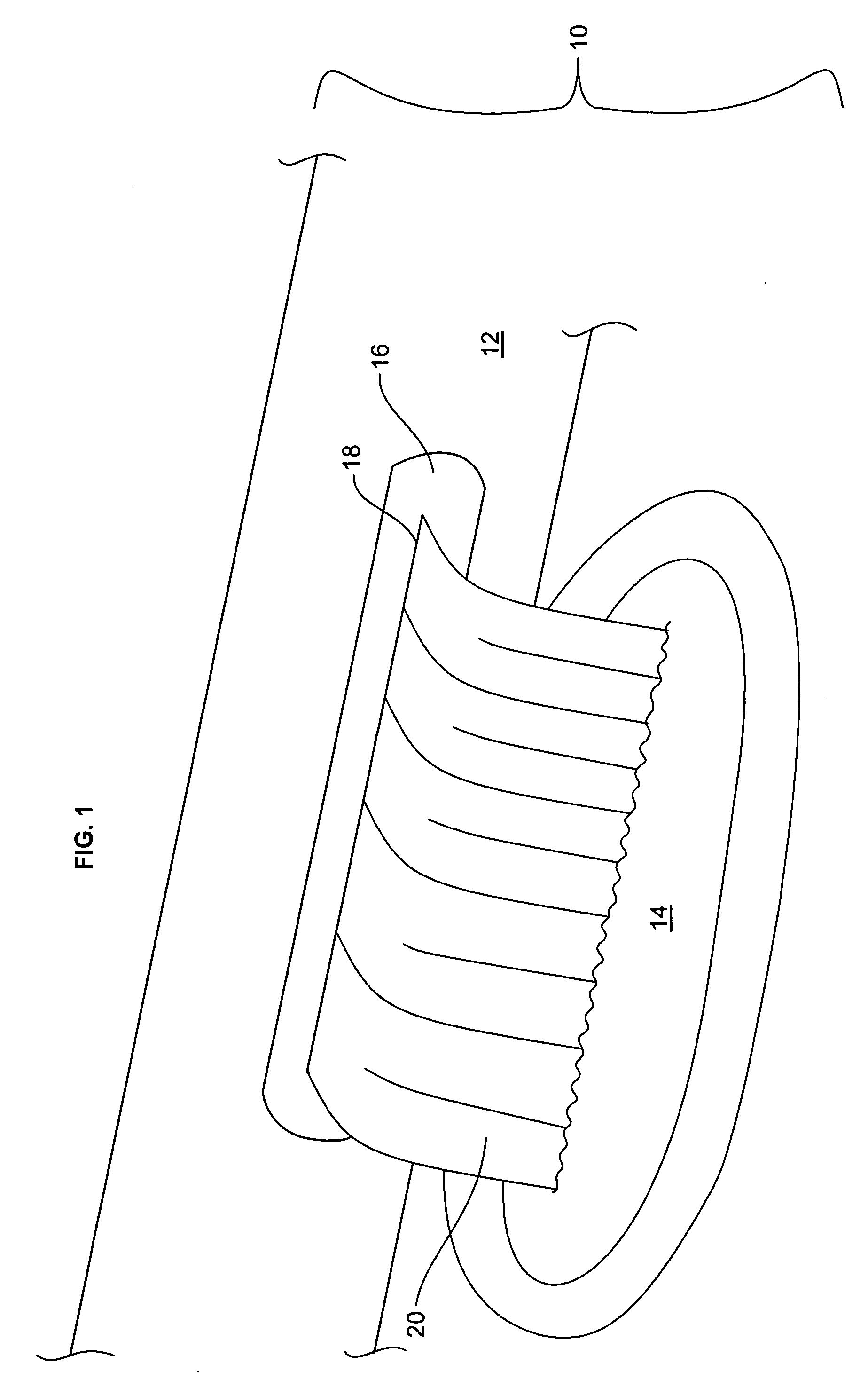

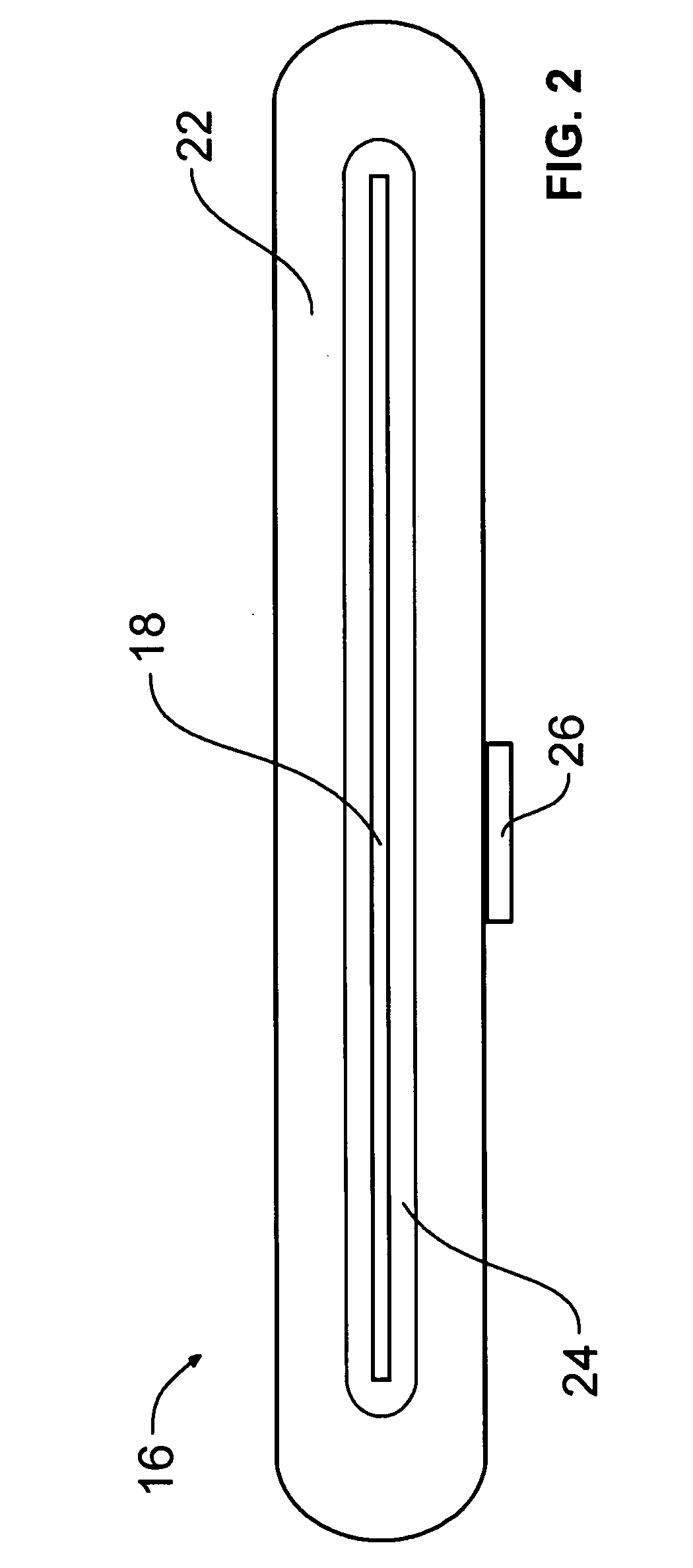

An ultrasonic waterjet apparatus (10) has a mobile generator module (20) and a high-pressure water hose (40) for delivering high-pressure water from the mobile generator module (20) to a hand-held gun (50) with a trigger and an ultrasonic nozzle (60). An ultrasonic generator in the mobile generator module (20) transmits high-frequency electrical pulses to a piezoelectric or magnetostrictive transducer (62) which vibrates to modulate a high-pressure waterjet flowing through the nozzle (60). The waterjet exiting the ultrasonic nozzle (60) is pulsed into mini slugs of water, each of which imparts a waterhammer pressure on a target surface. The ultrasonic waterjet apparatus (10) may be used to cut and de-burr materials, to clean and de-coat surfaces, and to break rocks. The ultrasonic waterjet apparatus (10) performs these tasks with much greater efficiency than conventional continuous-flow waterjet systems because of the repetitive waterhammer effect. A nozzle with multiple exit orifices or a rotating nozzle (76) may be provided in lieu of a nozzle with a single exit orifice to render cleaning and de-coating large surfaces more efficient. A water dump valve (27) and controlling solenoid are located in the mobile generator module (20) rather than the gun (50) to make the gun lighter and more ergonomic.

Owner:PRATT & WHITNEY MILLTARY AFTERMARKET SERVICES

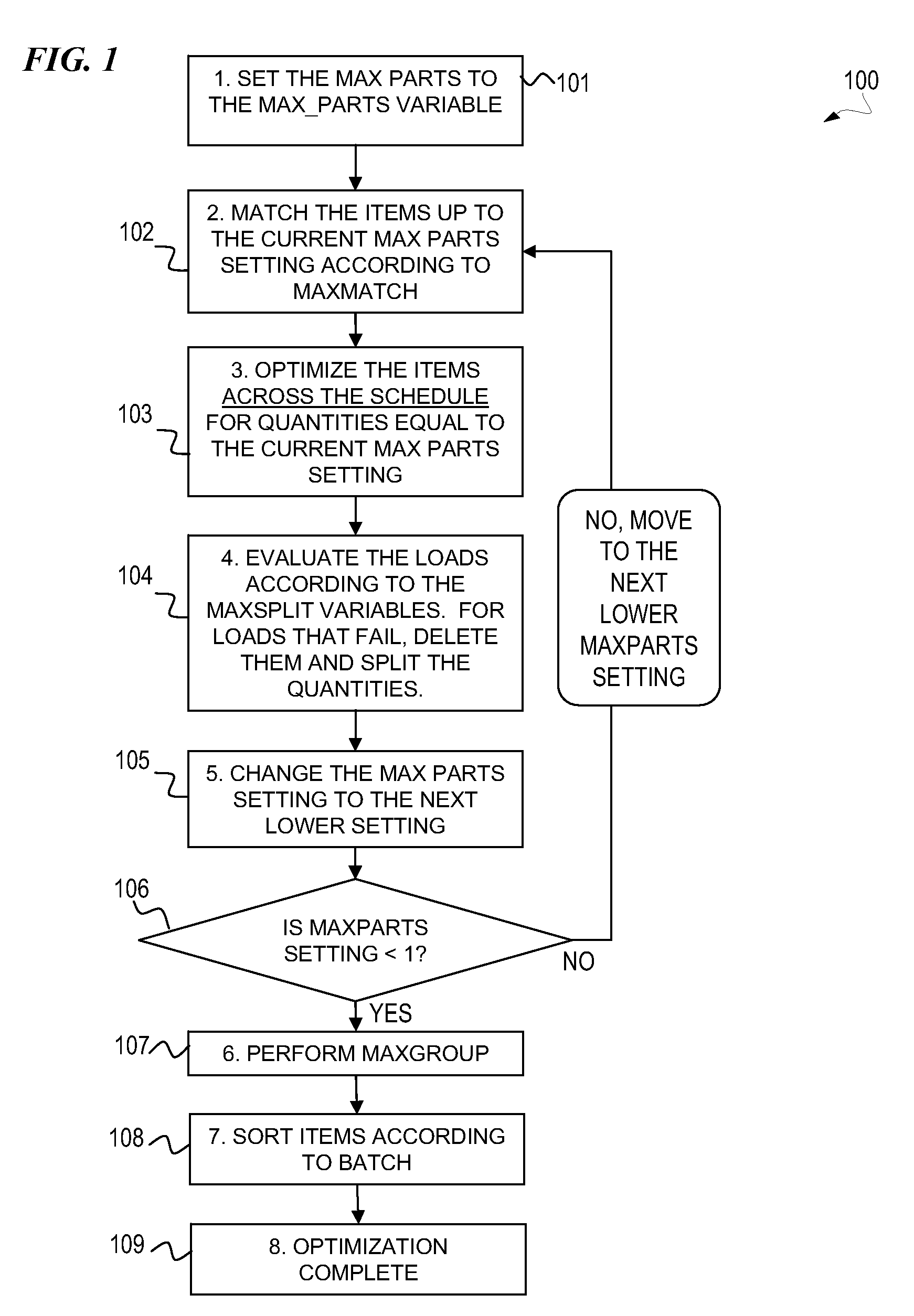

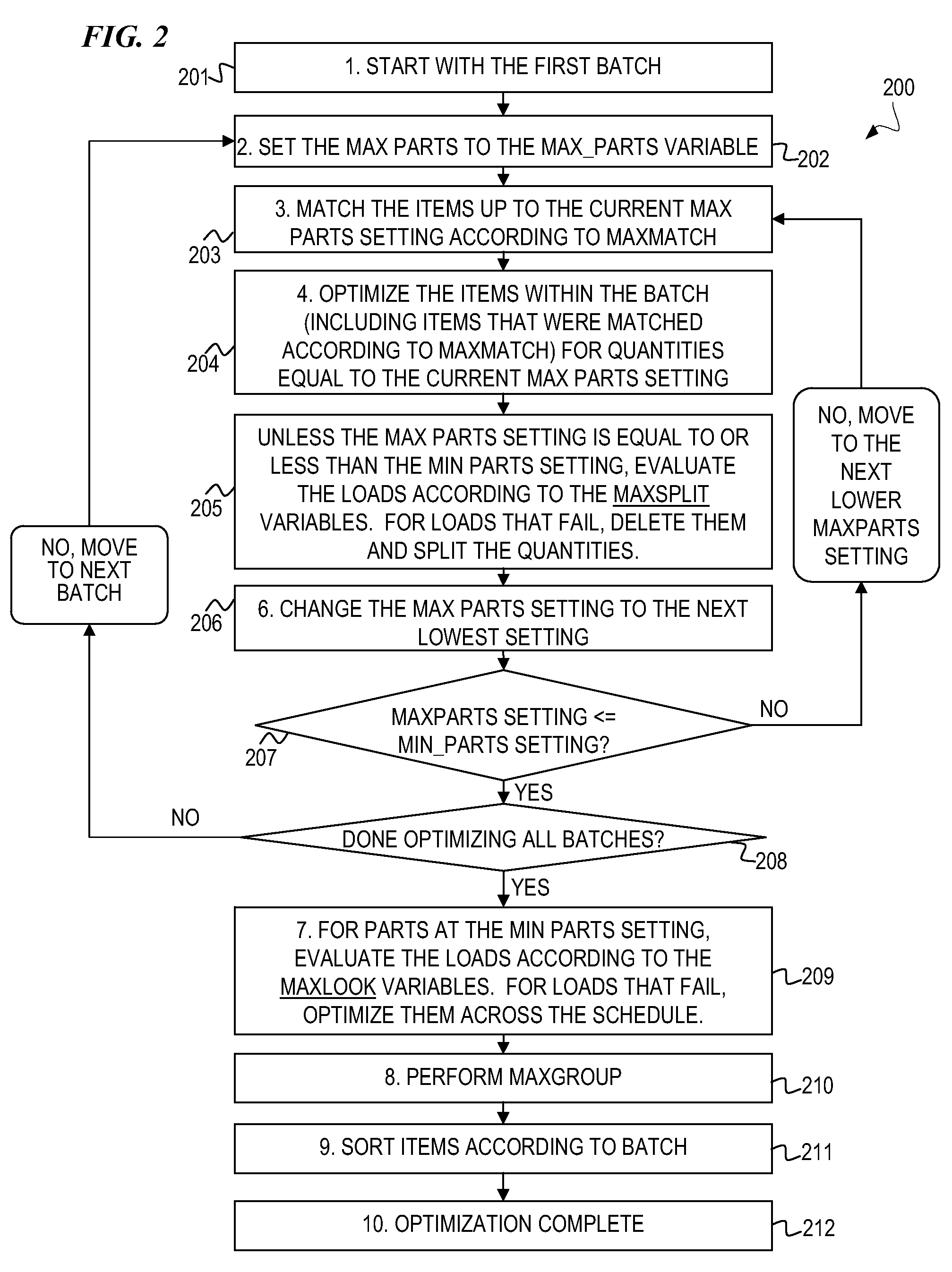

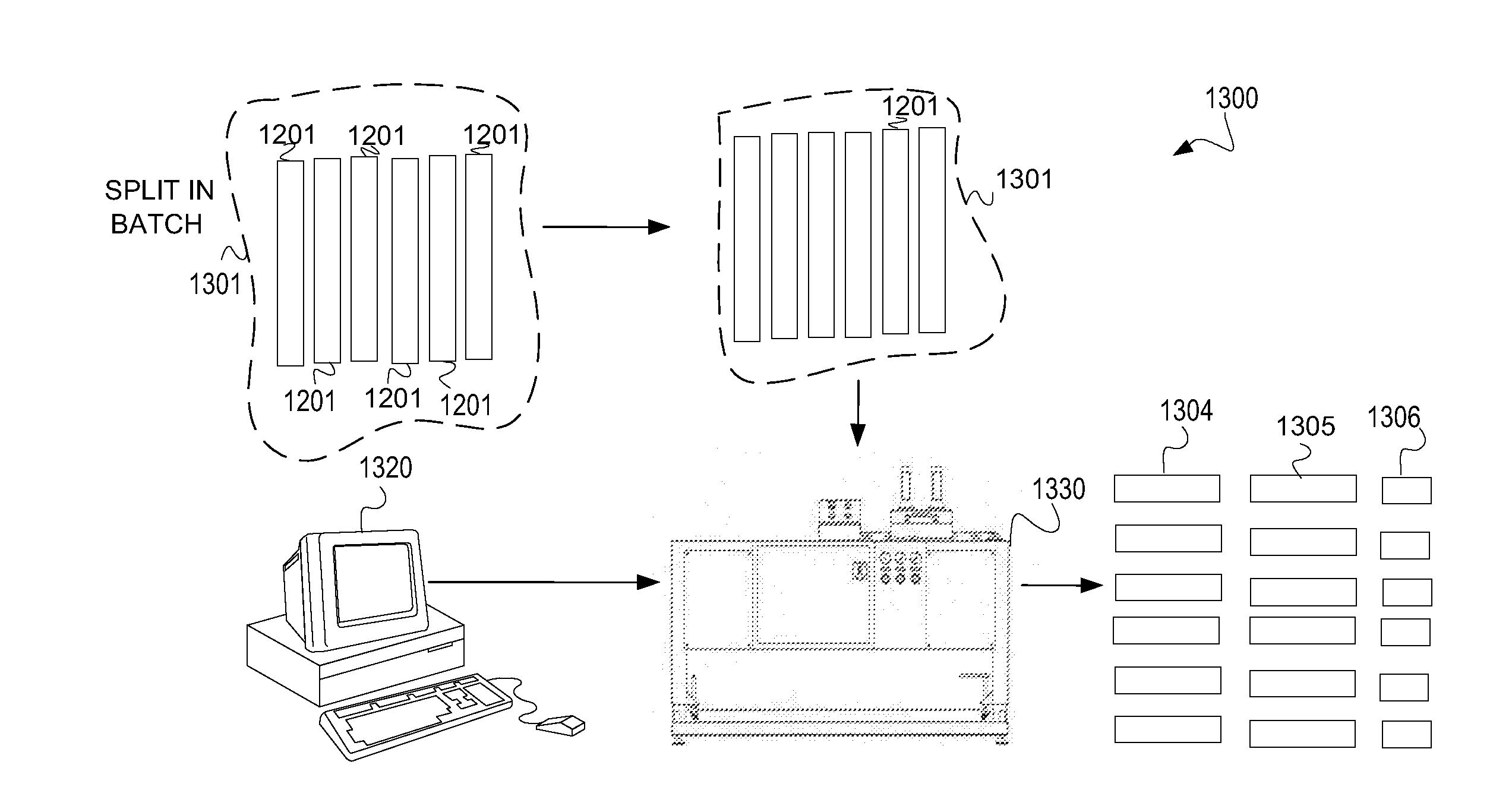

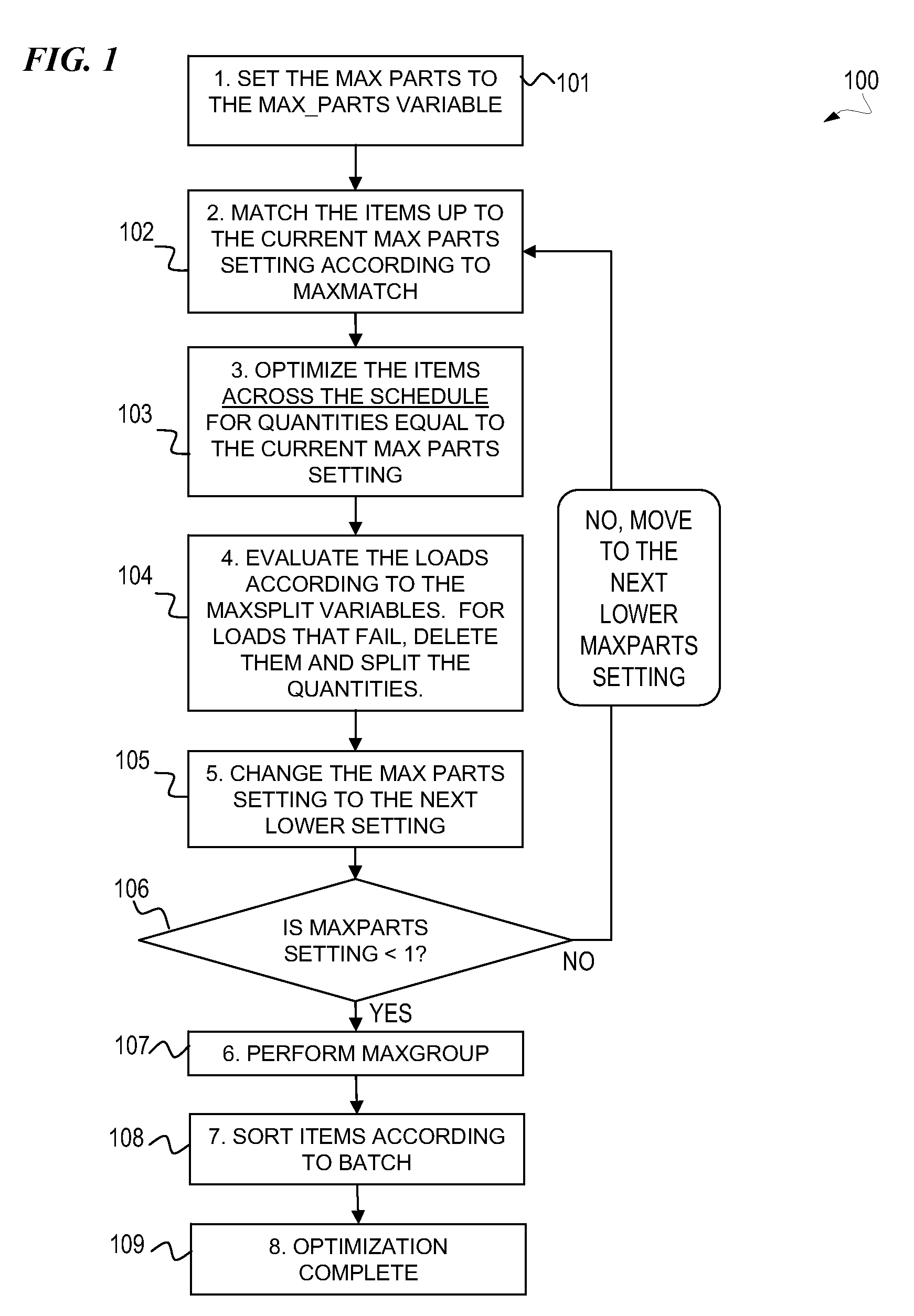

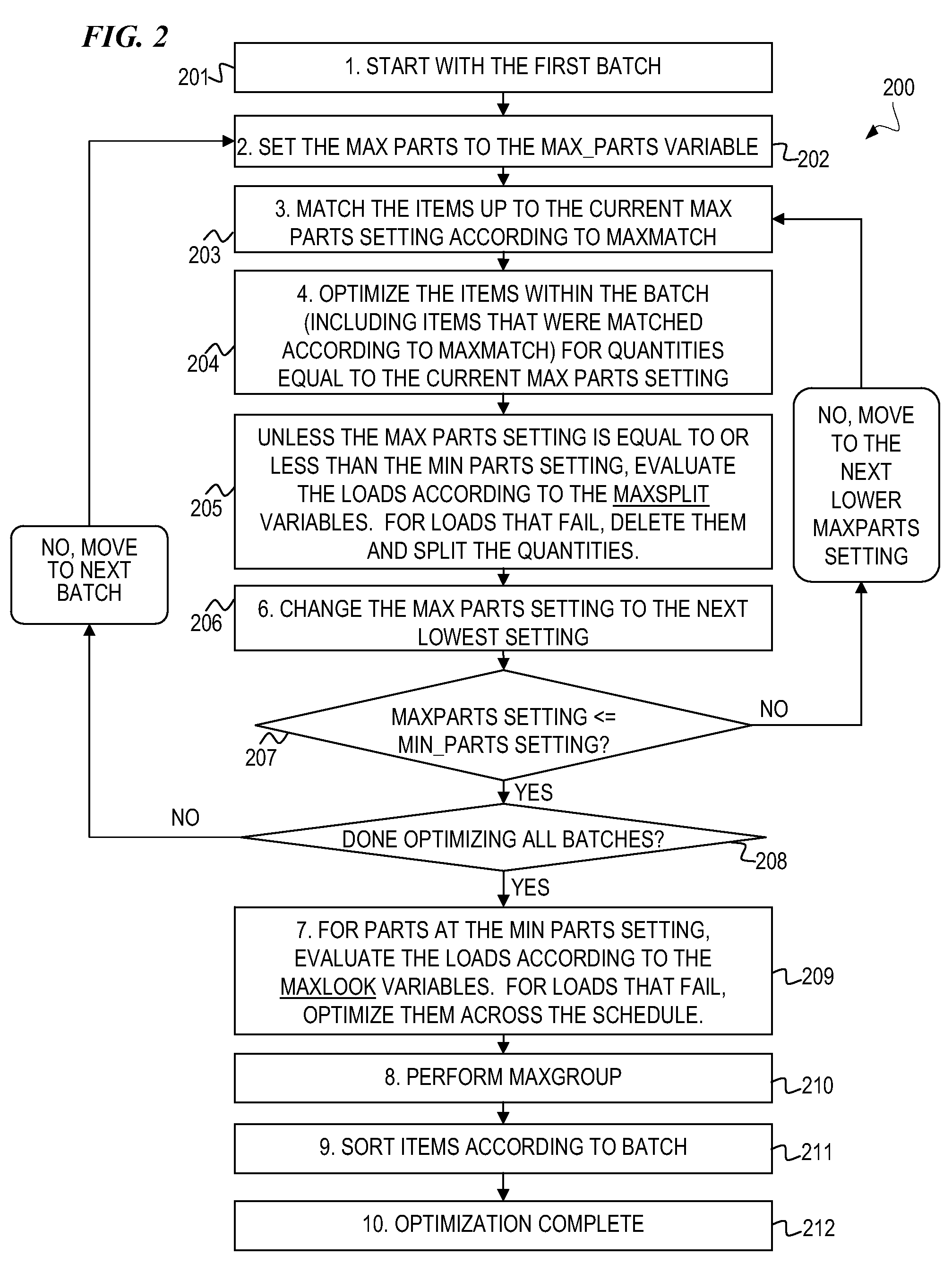

System and method for cutting-stock optimization across schedules and batches

ActiveUS20070270996A1Reduce in quantityReduce laborResourcesSpecial data processing applicationsComputer optimizationWater jet cutter

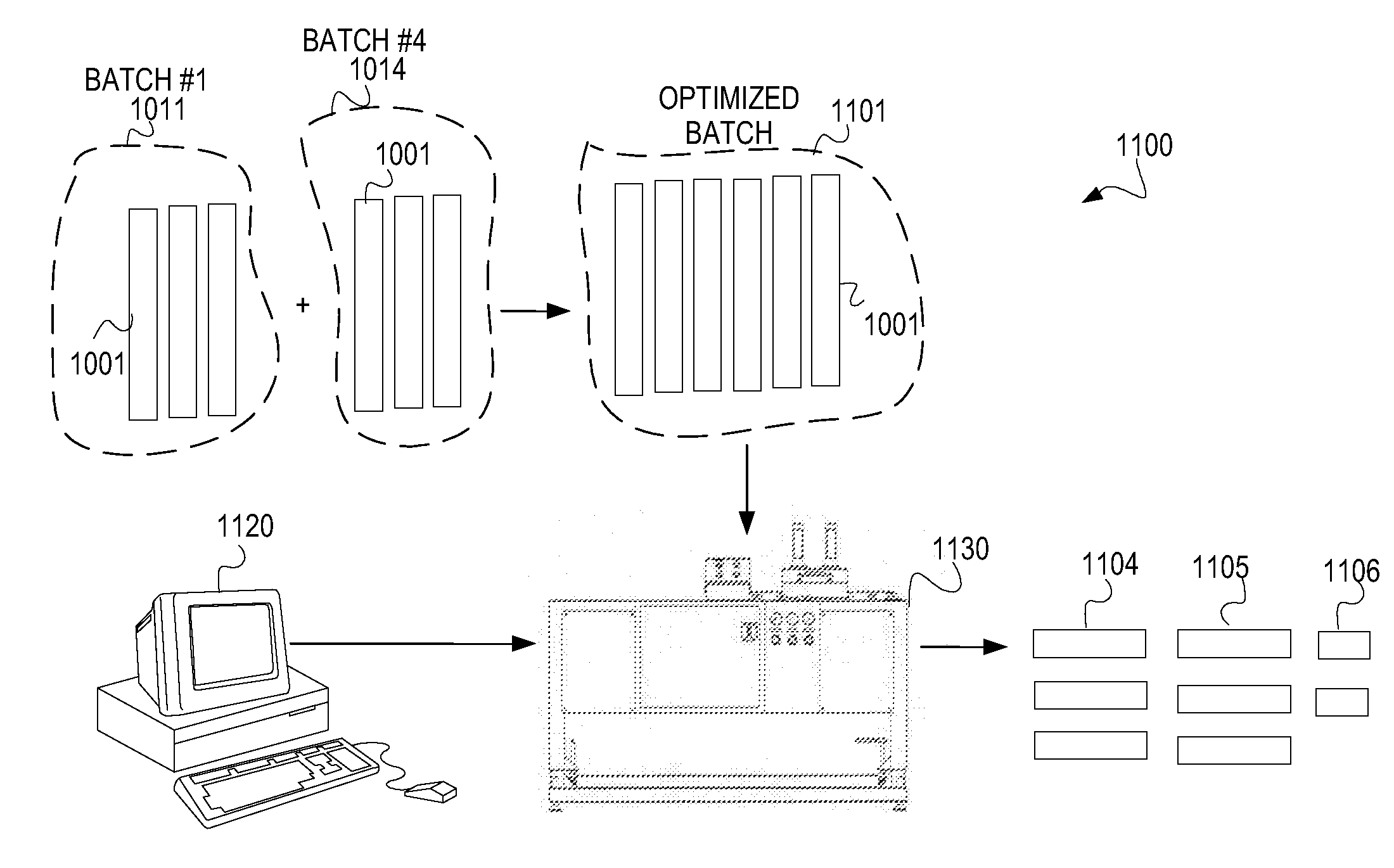

A method and system for optimizing cutting of various materials. In some embodiments, an algorithm optimizes cutting by grouping items to be cut, wherein a plurality of cutting-stock pieces are grouped together and aligned such that a single cut simultaneously cuts items from all of the pieces. Some embodiments optimize a combination of reduced labor cost, reduced materials cost (e.g., reducing scrap), and / or reduced time needed to obtain an inventory of pieces cut to specified lengths and shapes (checking the various permutations). Overall optimization of labor and material is achieved by a combination of fewer cuts and reduced waste. Some embodiments include a computer-readable medium having instructions executed by a computer that optimizes placement of cuts to obtain cut-part items, and optionally controls a saw, laser, water-jet cutter or the like. In some embodiments, a human operator making the cuts is instructed by the computer to achieve the optimization.

Owner:ROISE GEOFFREY J

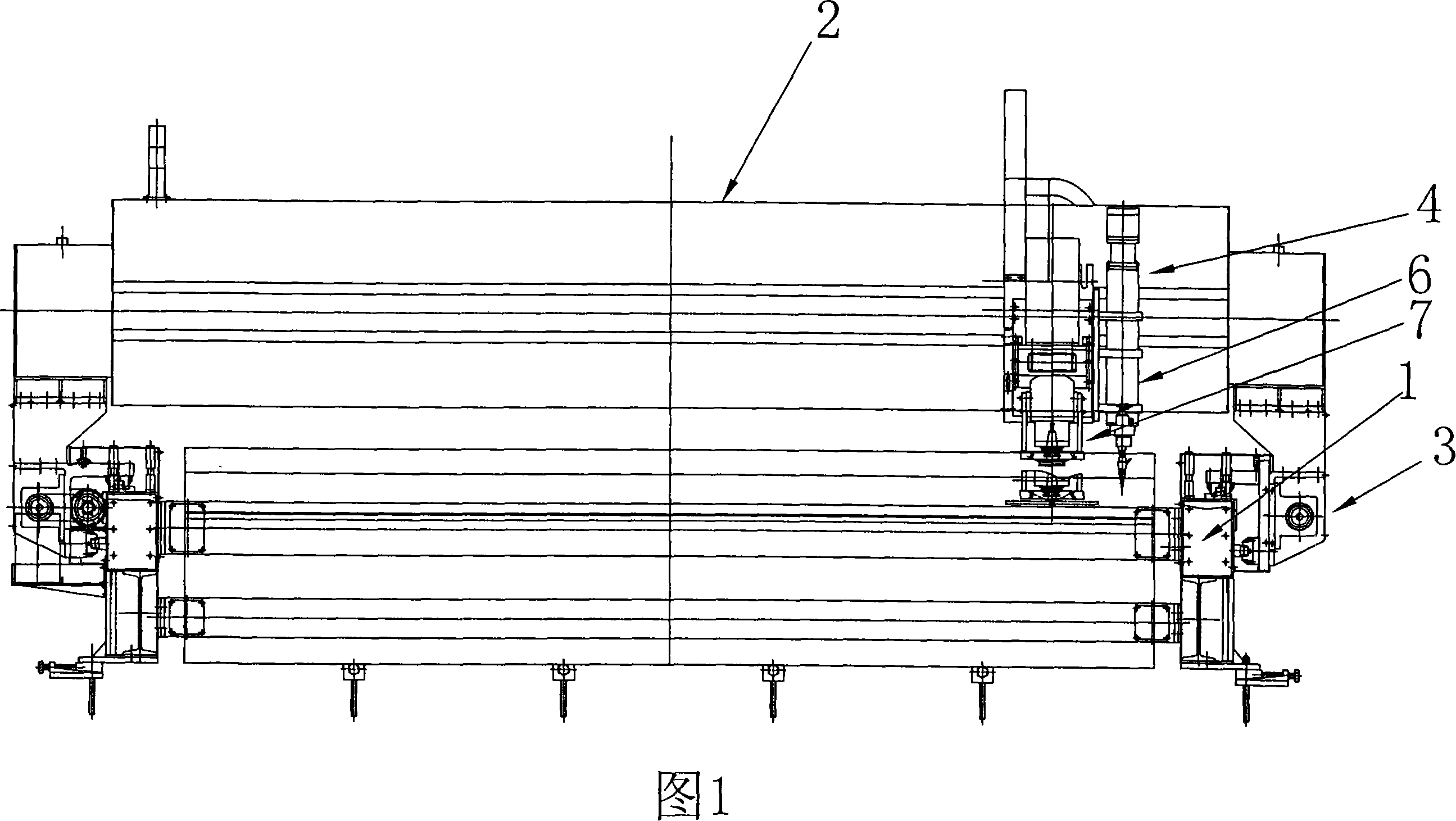

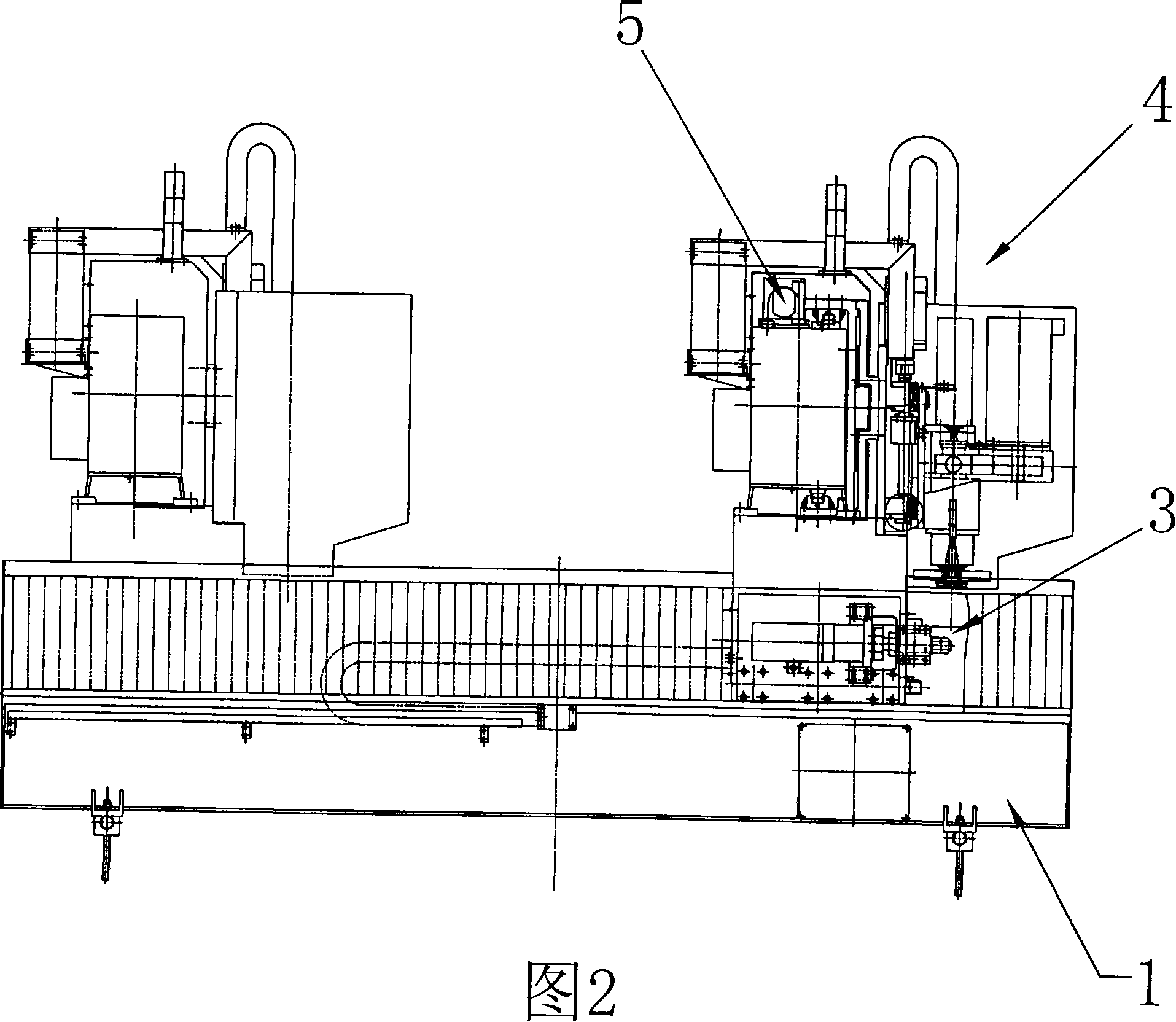

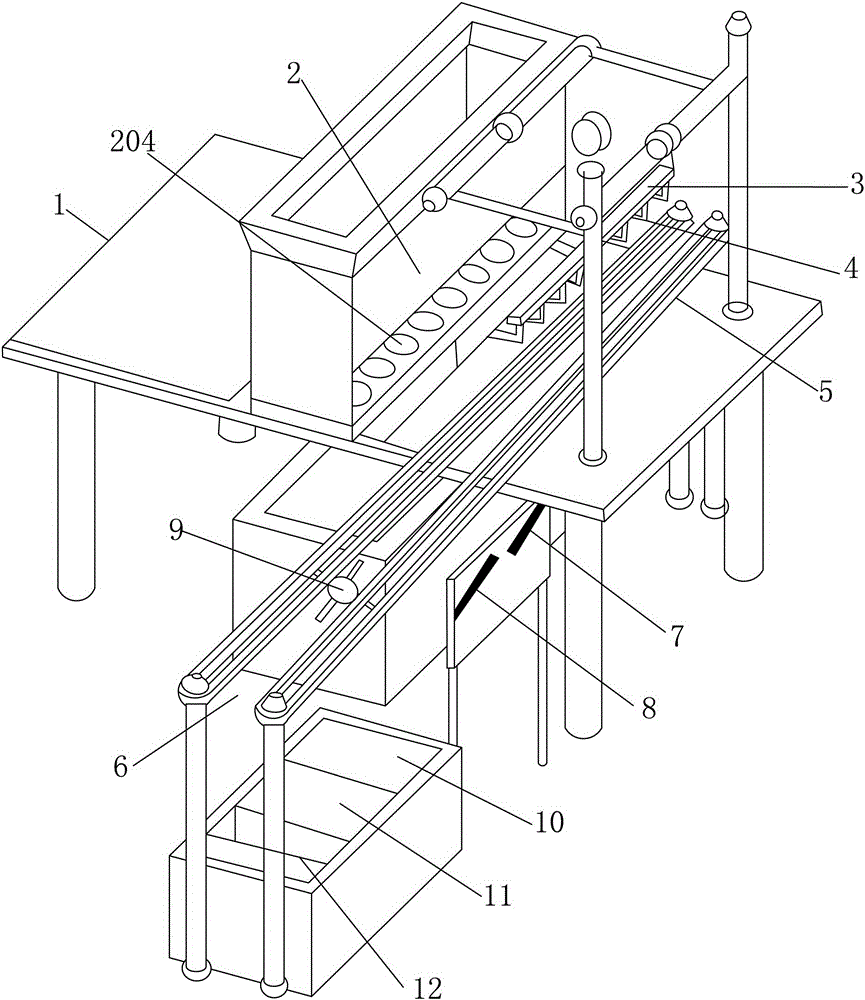

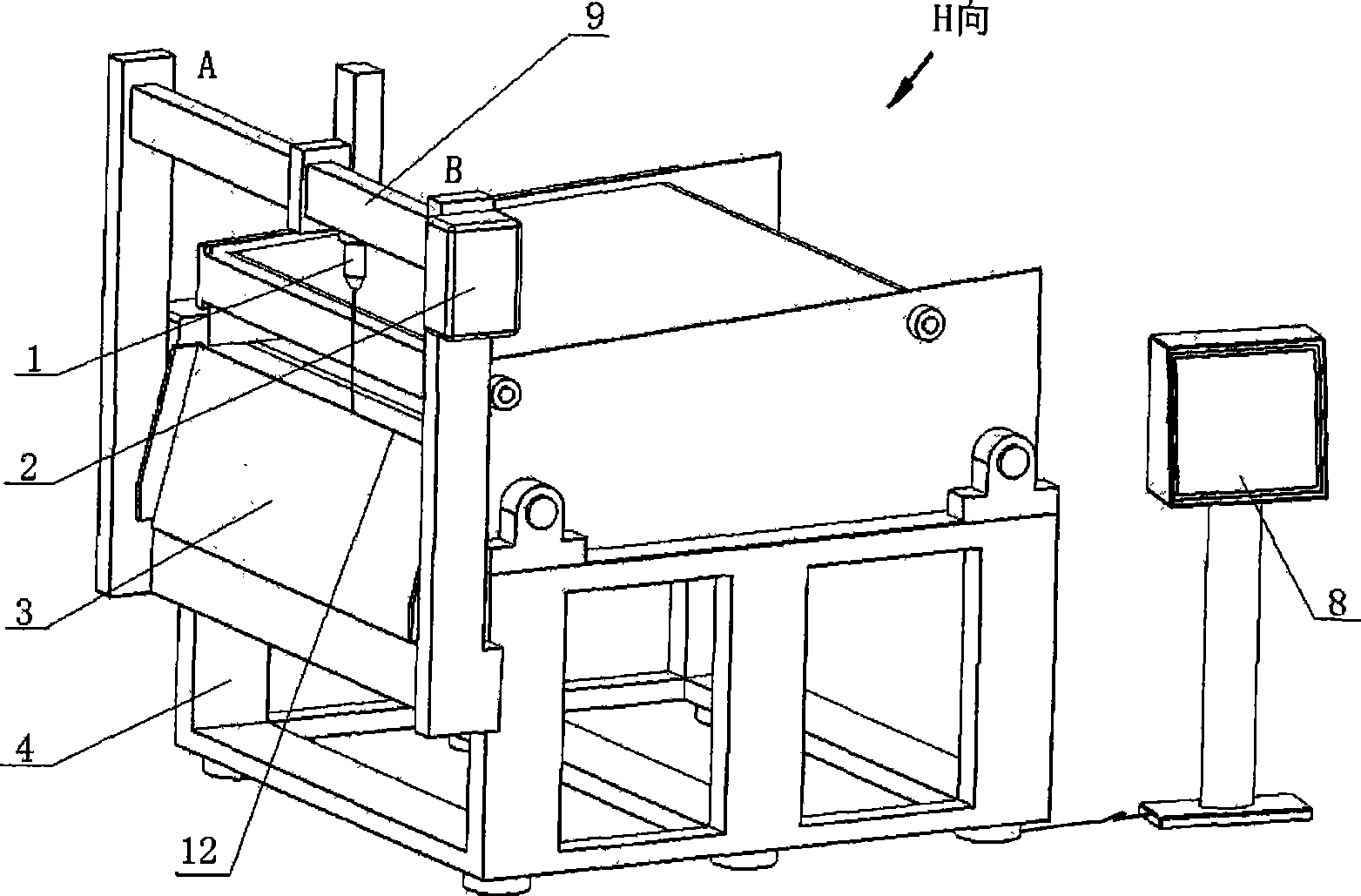

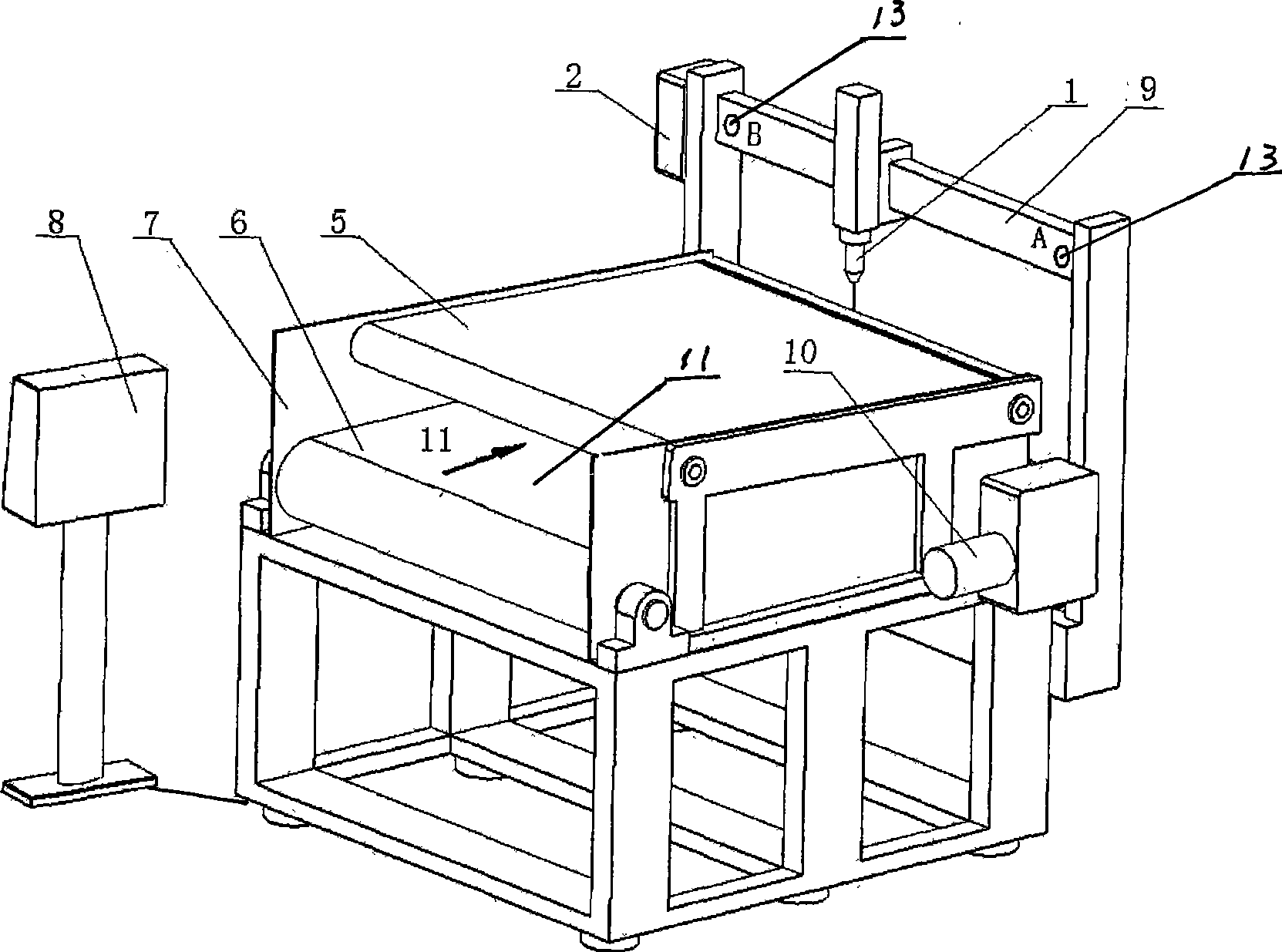

Multi-function water cutter

InactiveCN101121286ASolve processing problemsBroaden the application marketStone-like material working toolsWater jet cutterEngineering

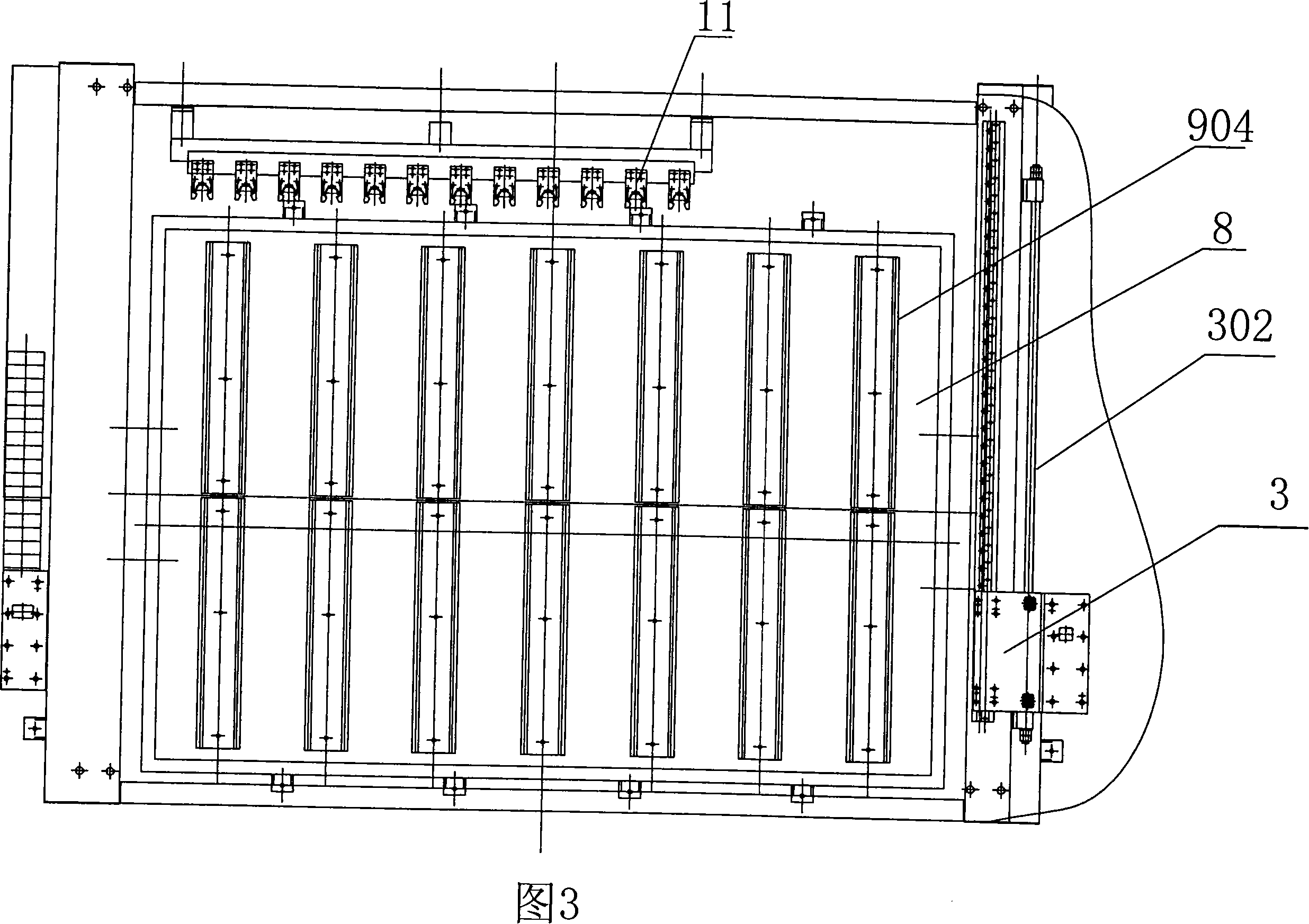

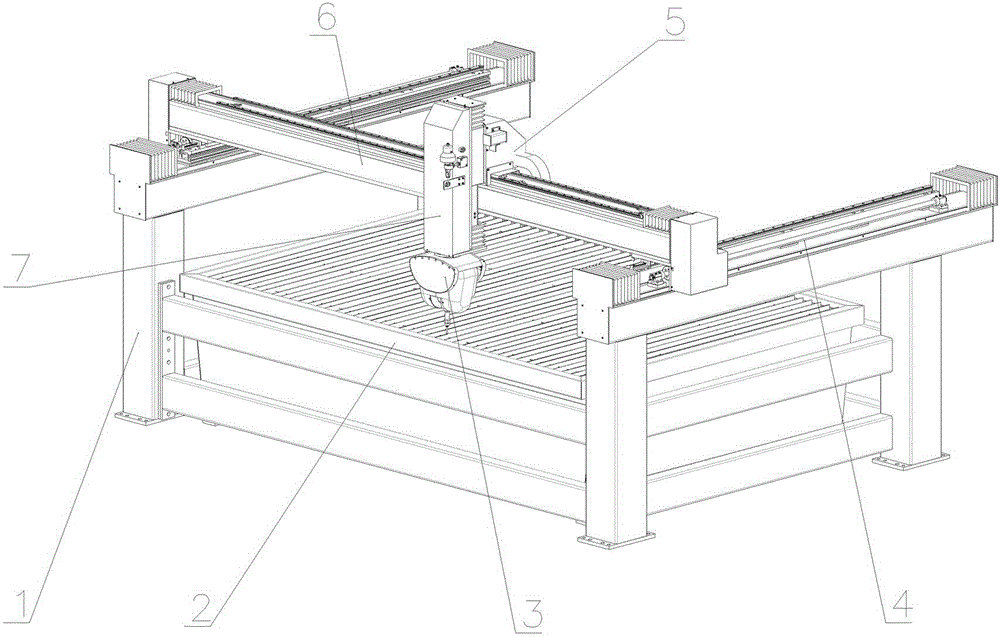

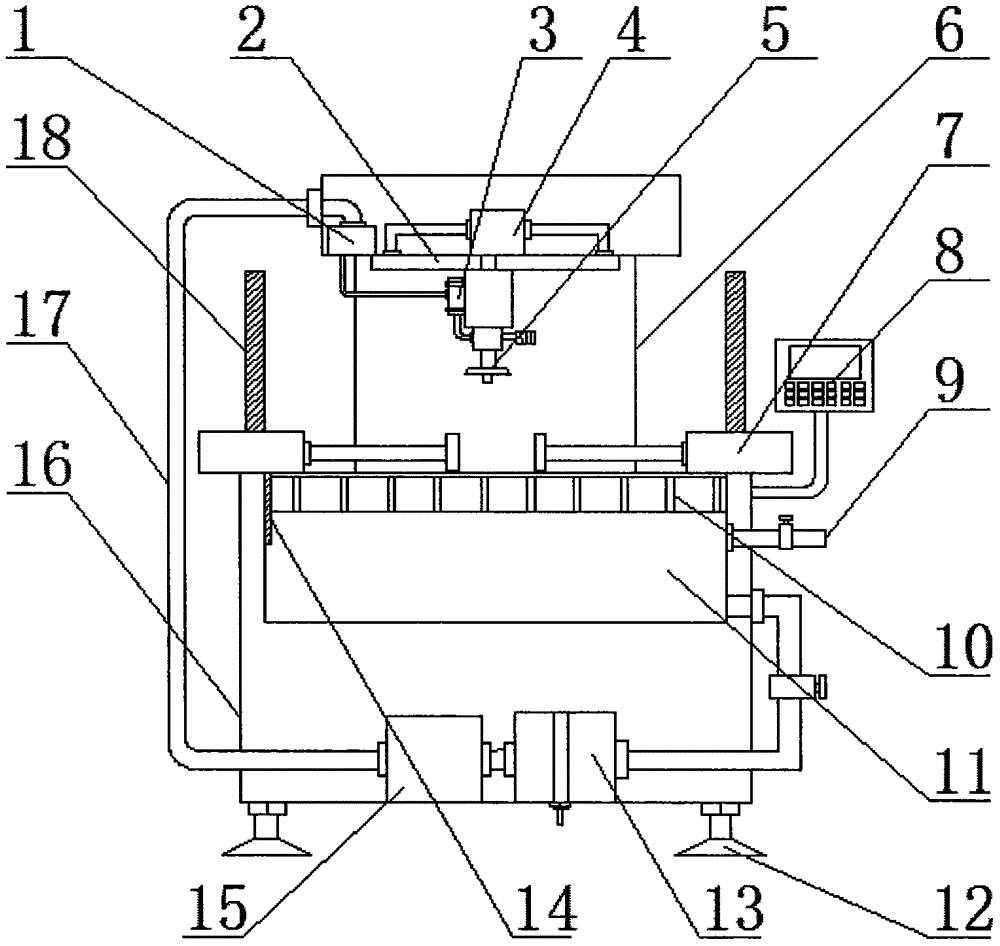

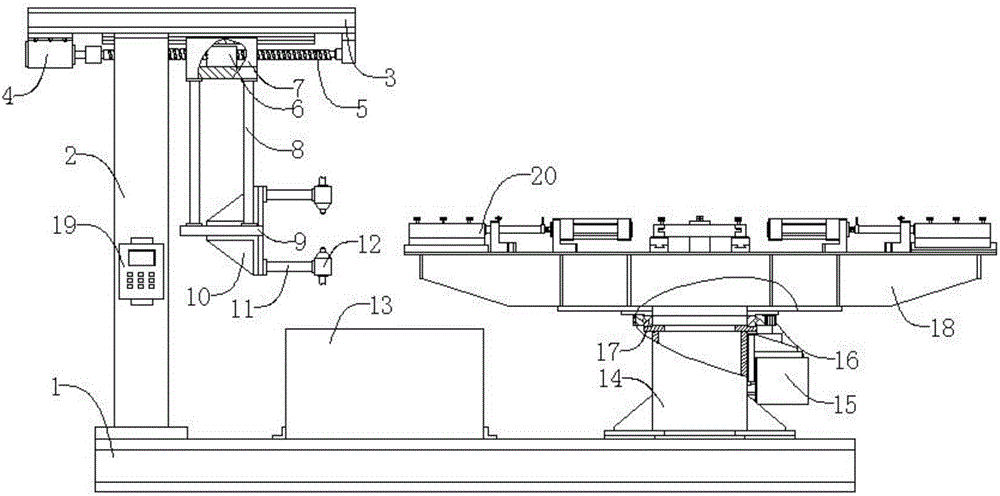

A multifunction water jet cutter belongs to the technical field of non-metal processed equipment; the water jet cutter comprises a bedstead (1) and a gantry beam (2); the gantry beam (2) is supported on a vertical guide way of the bedstead (1); the outside of the bedstead (1) is also installed with a vertical driving device for the gantry beam (2); a horizontal guide way is equipped on the gantry beam (2); the water jet cutter is characterized in that the horizontal guide way is installed with a cutting and milling bracket comprising a water jet cutting device (6) and a mechanical milling device (7); the cutting and milling bracket is connected with a horizontal driving device which drives the bracket to move horizontally; the water jet cutting device (6) is installed with a water jet cutting head (601) and the mechanical milling device (7) is installed with a cutting tool (701) for further processing of the incision; a water jet cutter table (8) is installed with a work piece clamping device (9). The present invention solves the problem of the single function of the present water cutting device and boasts of high processing efficiency; with the present invention, the rate of finished products made of brittle materials can be greatly promoted.

Owner:DARDI INT CORP

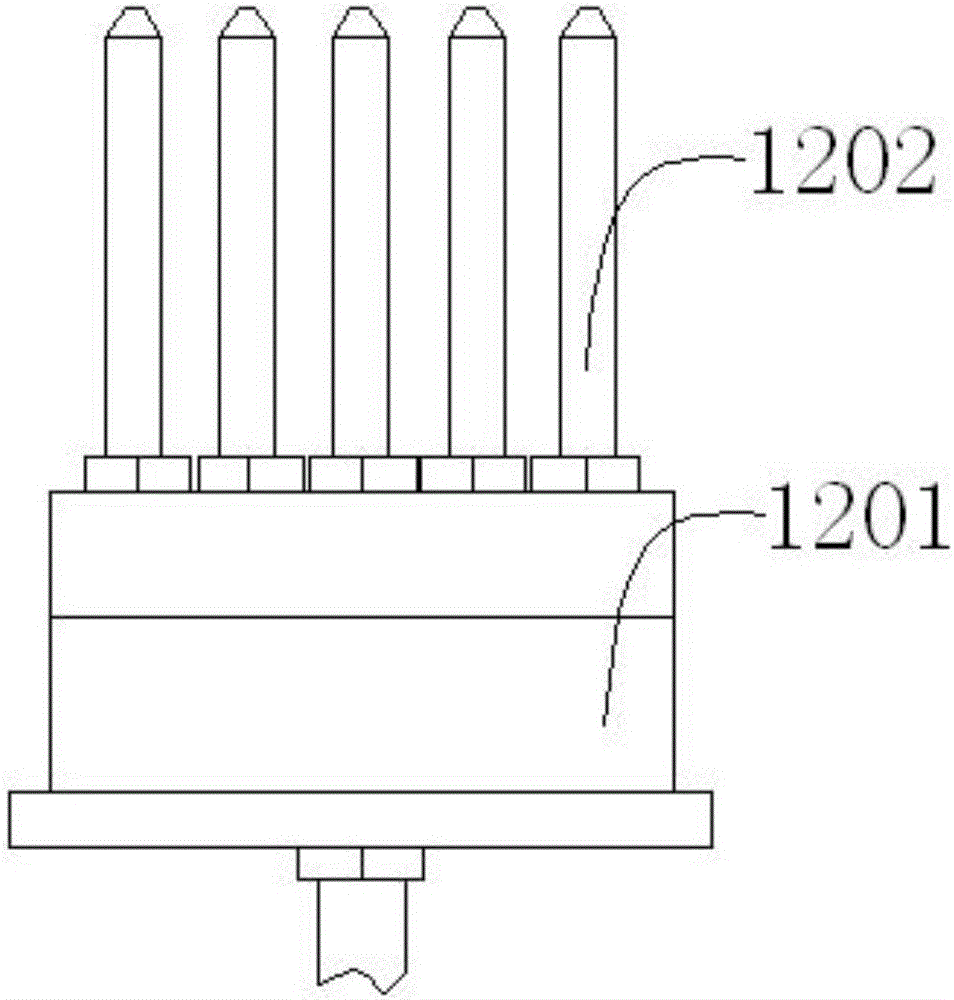

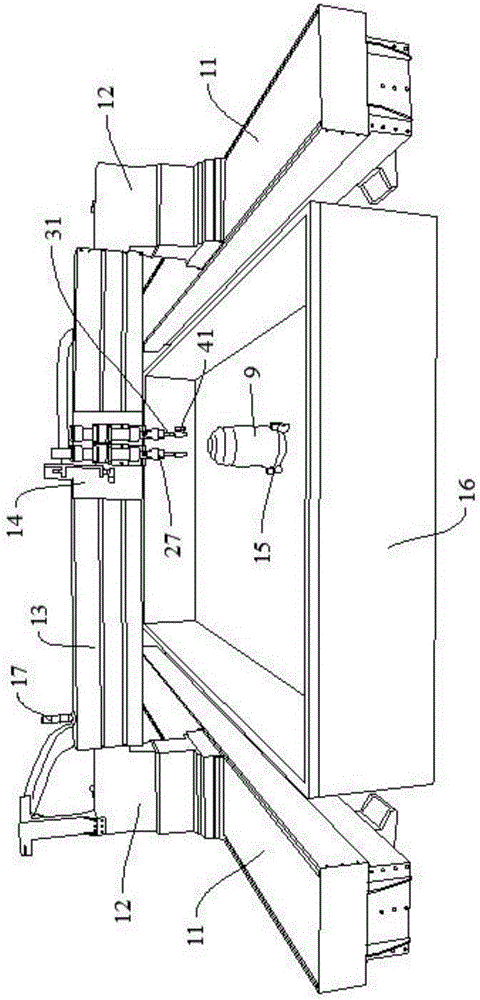

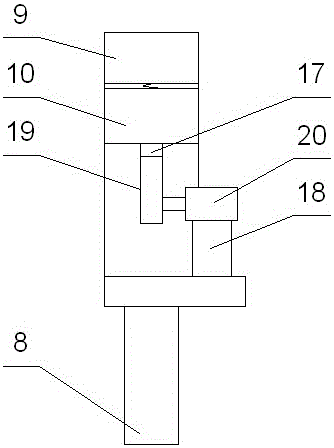

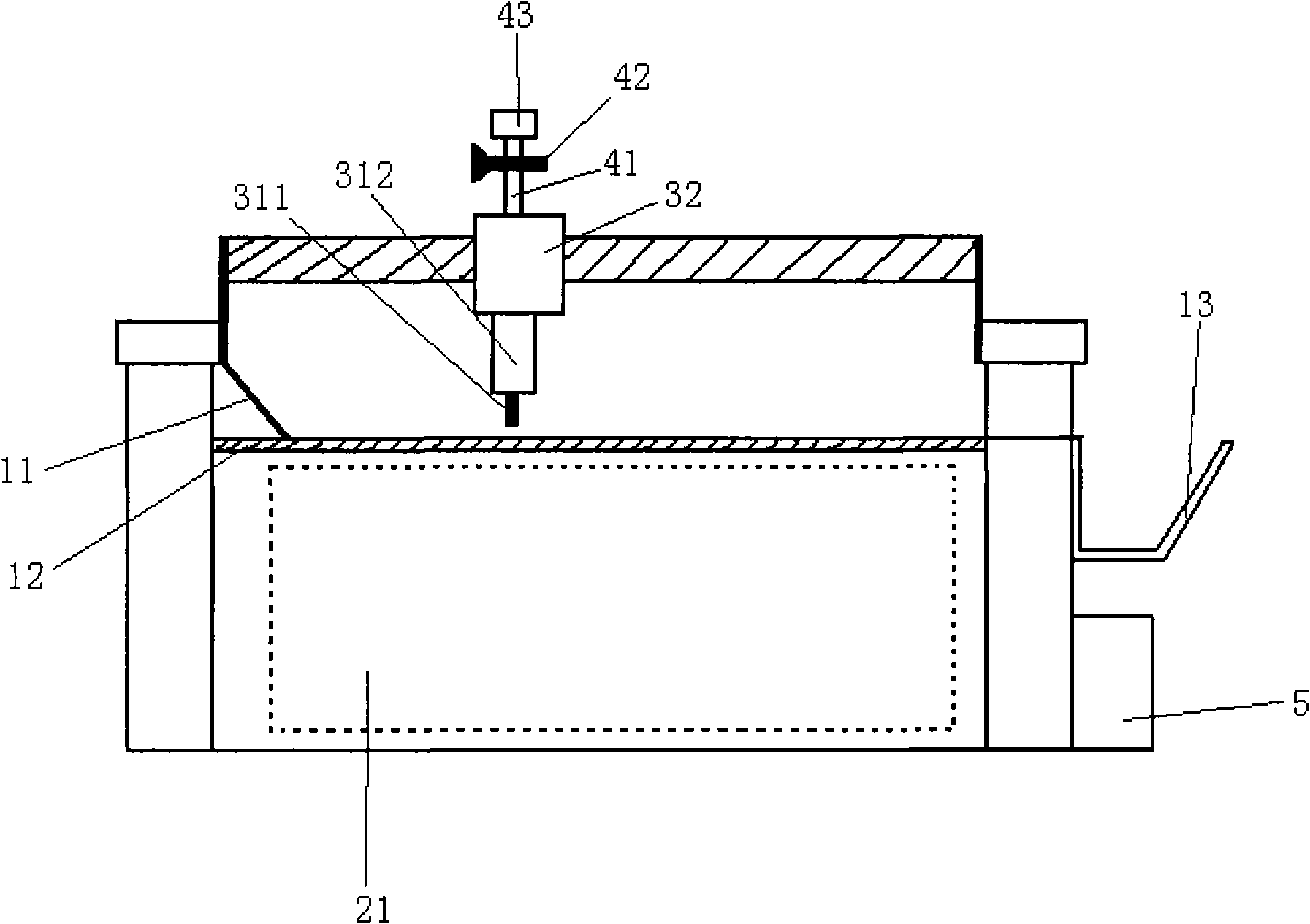

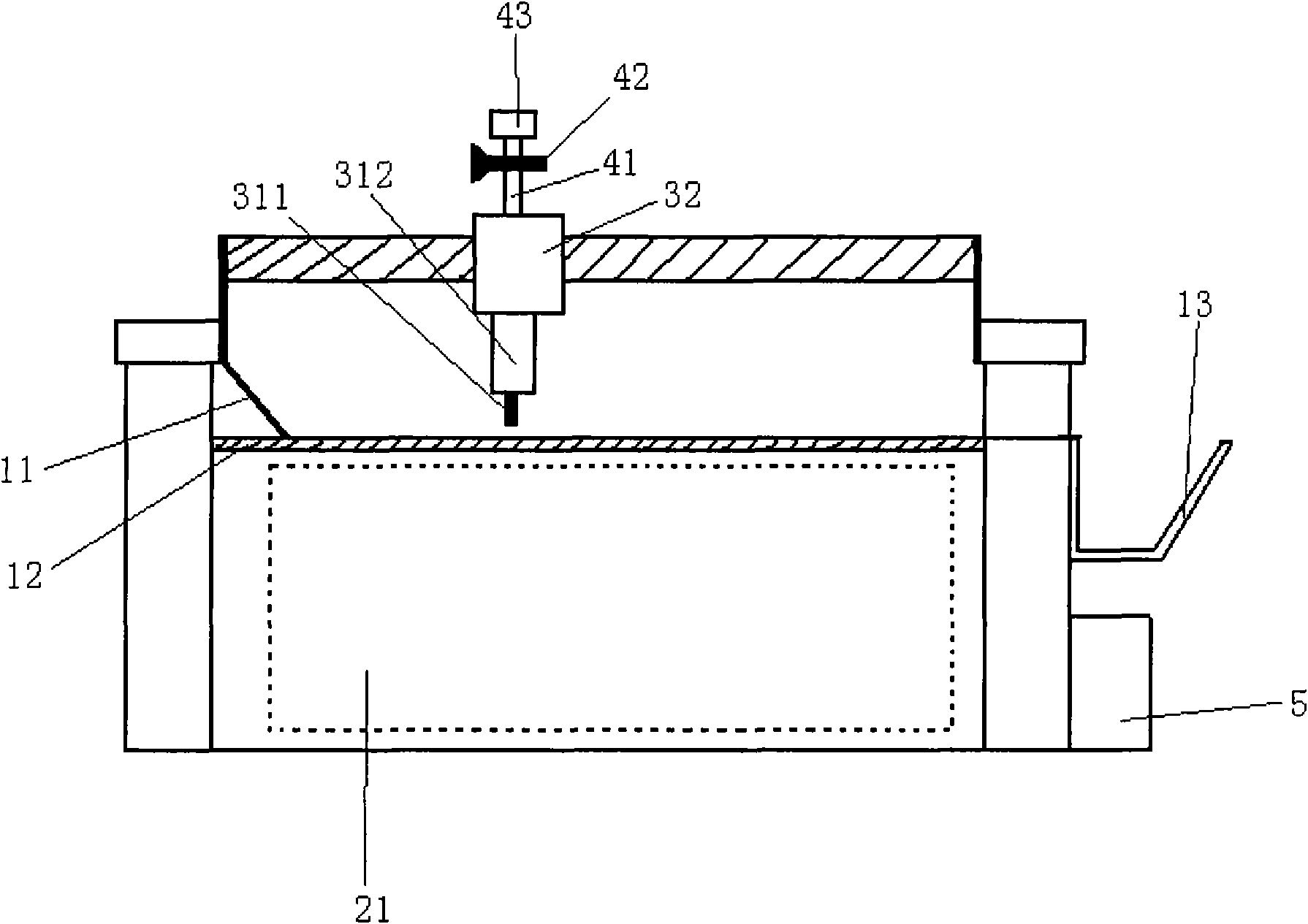

Numerical-control six-shaft intelligent water jet cutter

InactiveCN104526765AOvercome the defect that the cutting cannot be completed at one timeReduce processing costsMetal working apparatusNumerical controlRotation function

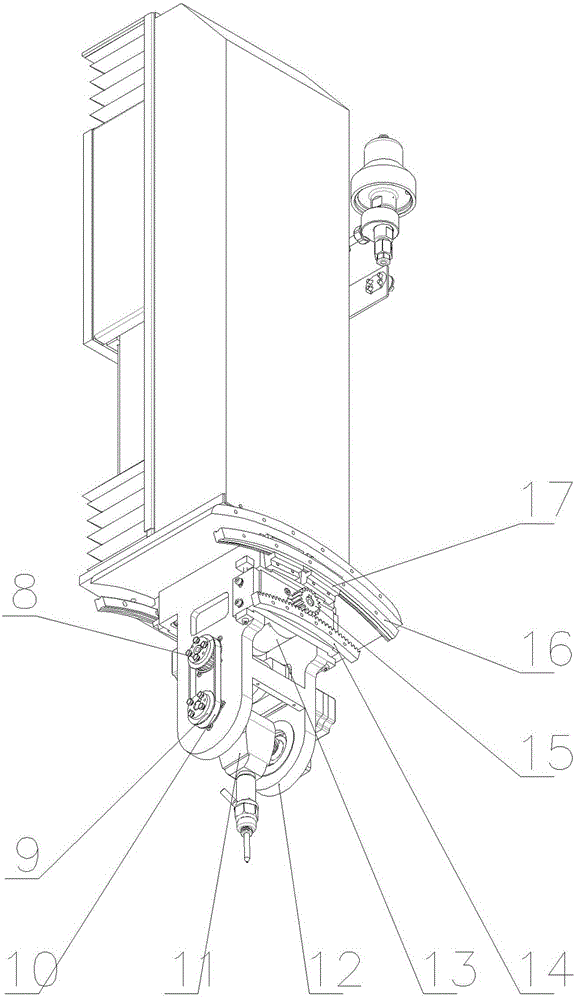

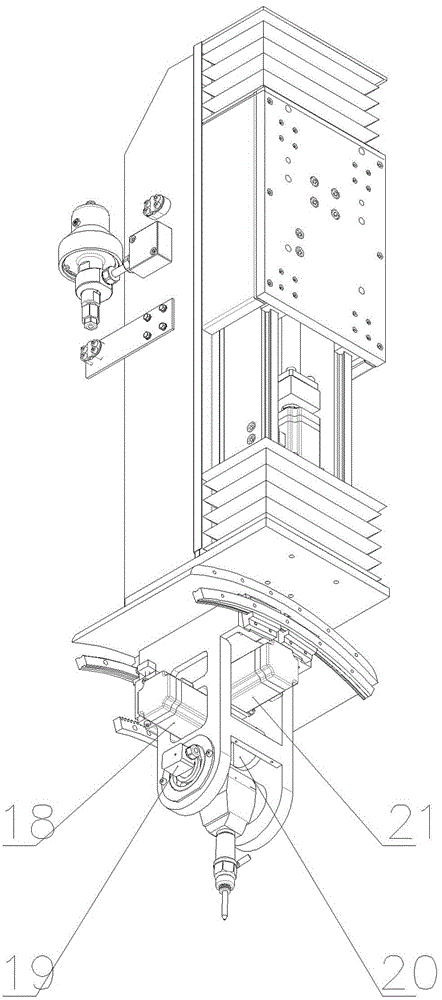

The invention discloses a numerical-control six-shaft intelligent water jet cutter. The numerical-control six-shaft intelligent water jet cutter comprises a water jet cutting platform composed of a side frame, a transverse beam and a water tank, an X-shaft transmission mechanism, a Y-shaft transmission mechanism, a Z-shaft transmission mechanism and a cutting head installed on a Z shaft, wherein the X-shaft transmission mechanism, the Y-shaft transmission mechanism and the Z-shaft transmission mechanism are installed on the water jet cutting platform. The cutting head is a cutting head with the A-shaft, B-shaft and C-shaft transmission combined rotation function, an A-shaft driven belt wheel installed on an A-shaft frame is driven by an A-shaft motor, a water jet nozzle is fixed to the A-shaft driven belt wheel, and the water jet nozzle and the A-shaft driven belt wheel synchronously rotate. A B-shaft motor drives the A-shaft frame through the B-shaft transmission mechanism to perform arc rotation. A C-shaft motor drives a B-shaft frame to rotate, and a C-shaft flange shaft is connected with a C-shaft frame fixed to the Z shaft. Under the control of a master programmable controller, an X shaft, a Y shaft, the Z shaft, an A shaft, a B shaft and a C shaft are linked to control the position and the direction of the water jet nozzle, the defect that a traditional water jet cutting device can not complete cutting at a time under some conditions is overcome, the cutting head posture adjustment time is shortened, the cutting accuracy and the cutting efficiency are improved, and the water jet cutting machining cost is reduced.

Owner:奥拓福水刀有限公司

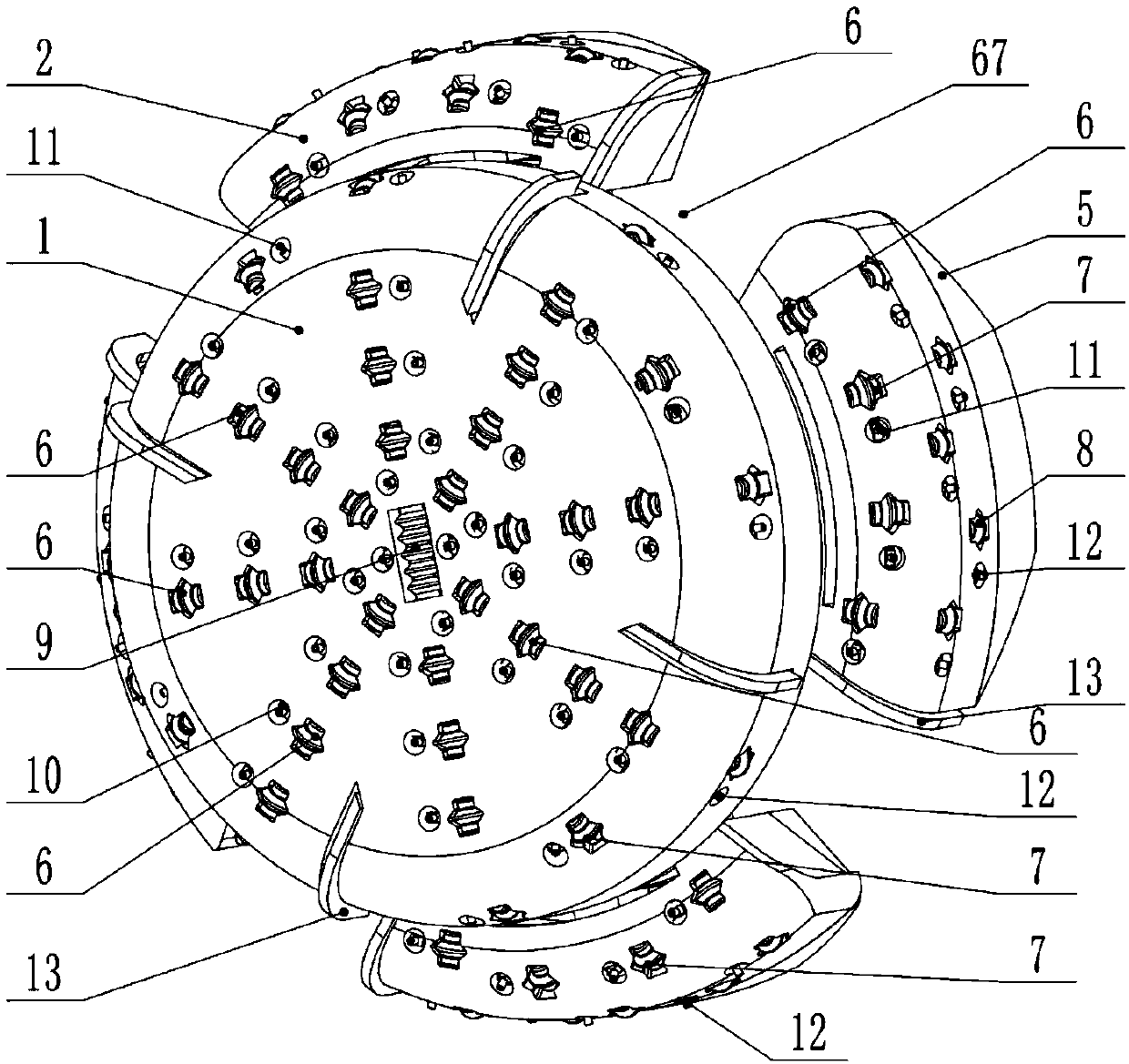

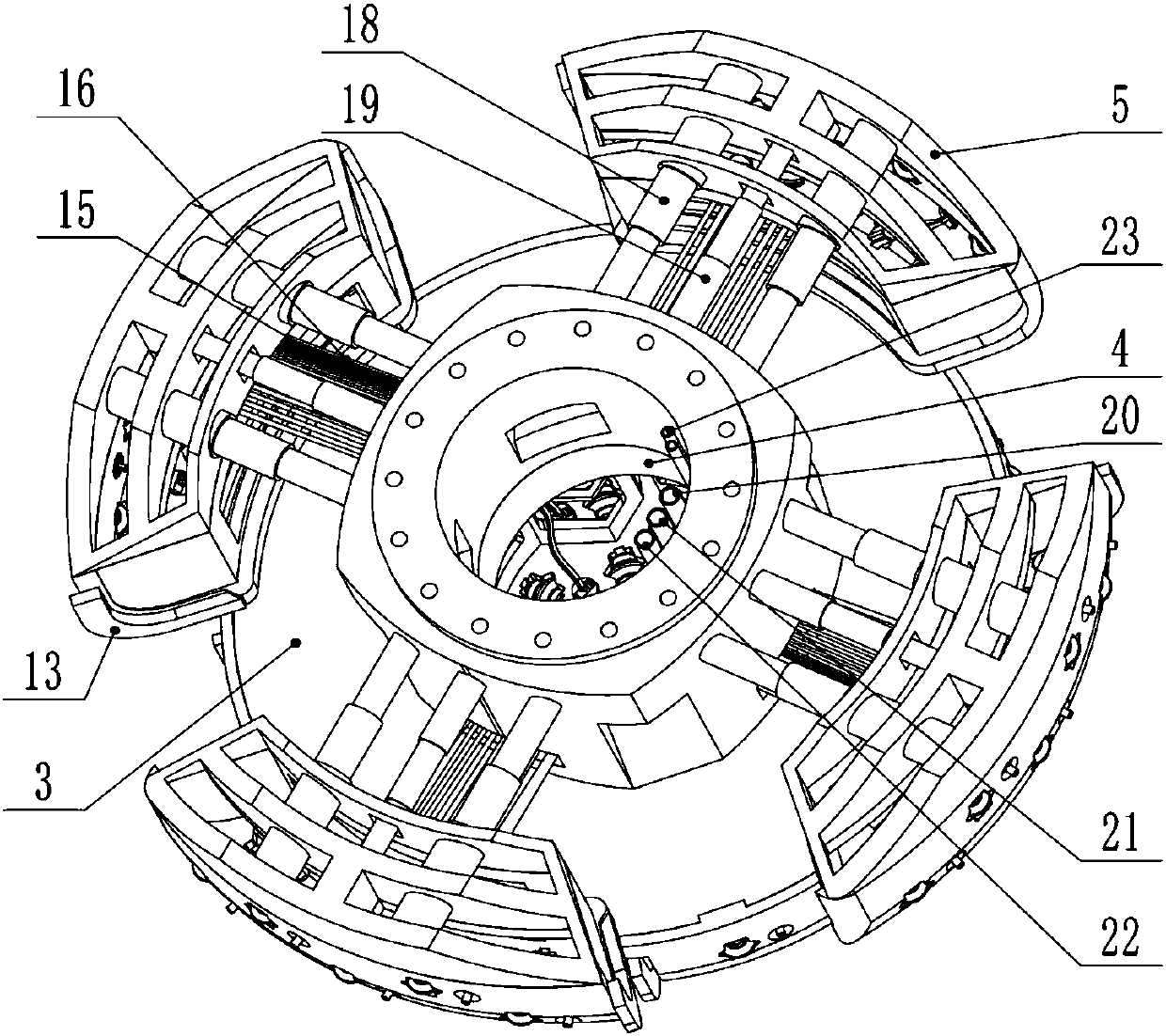

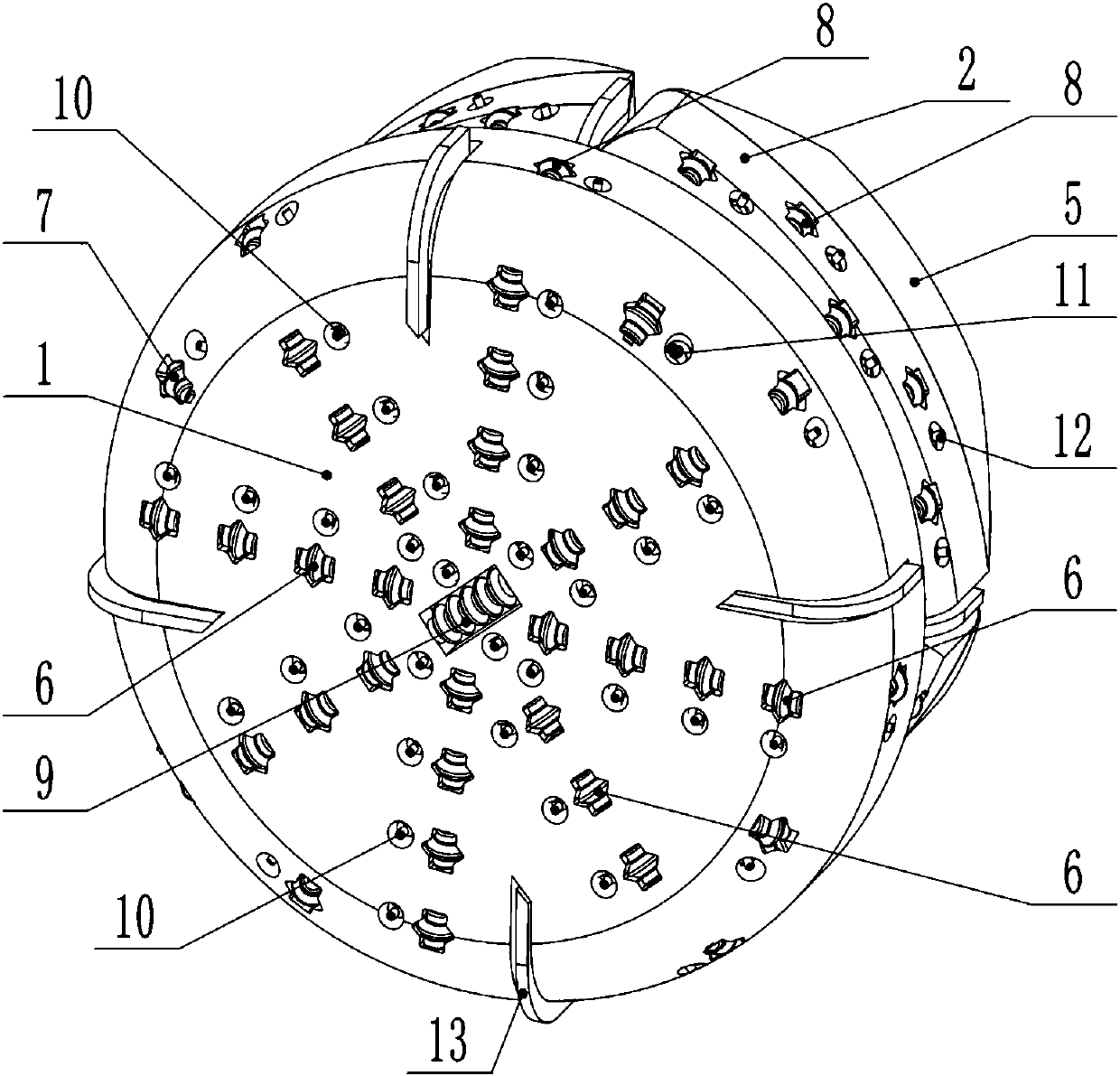

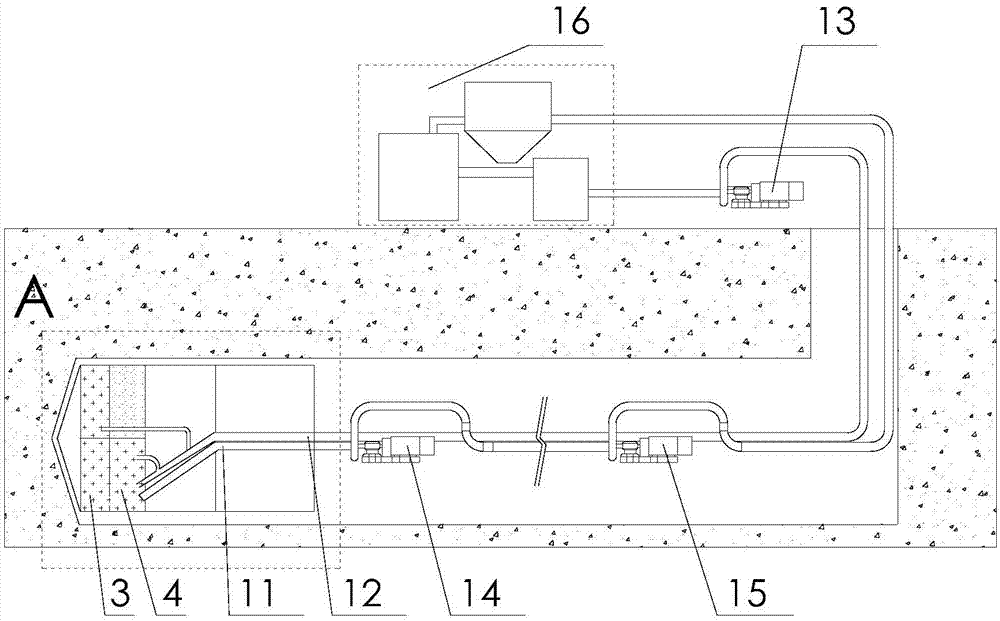

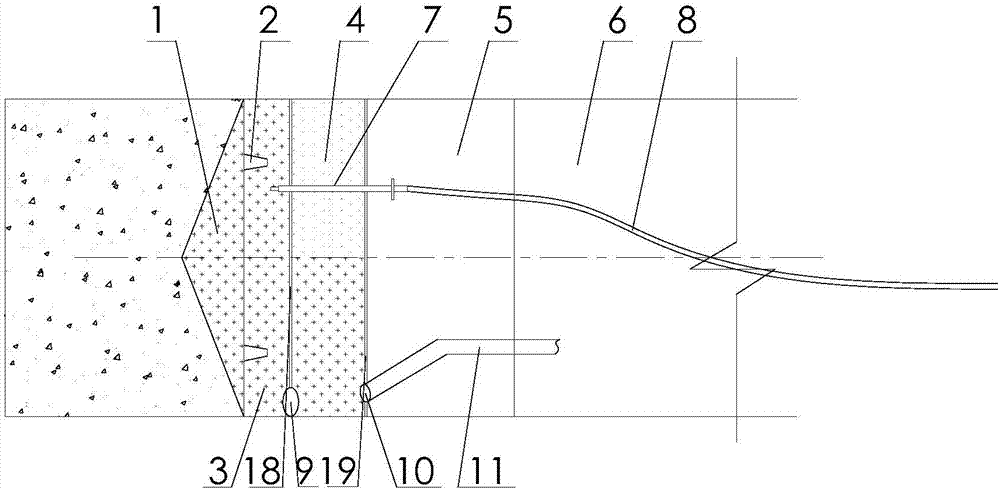

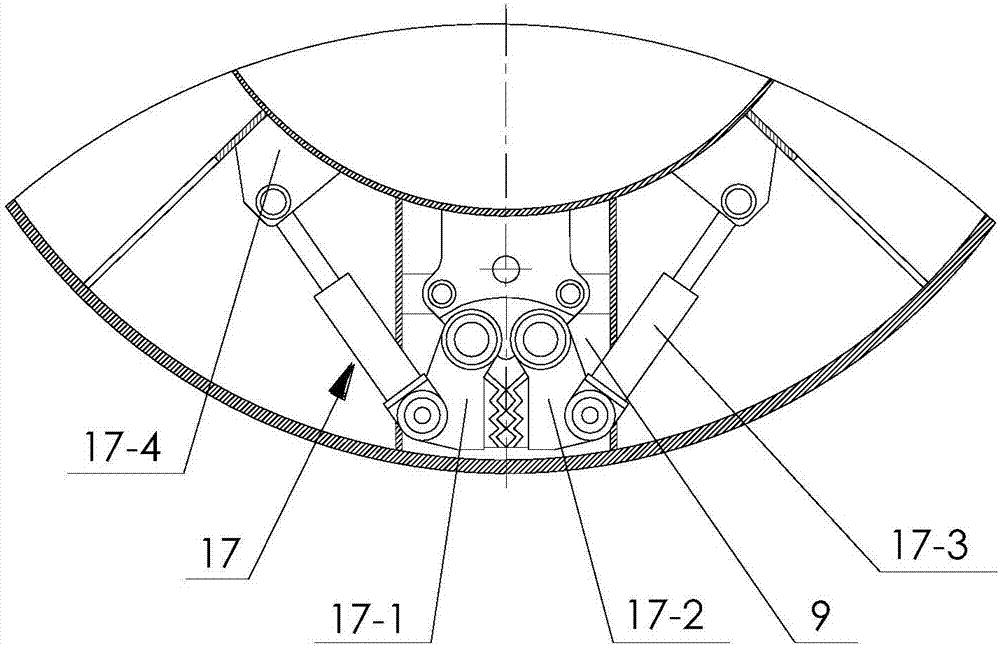

Full-fracture-surface hard-rock tunneling machine cutter disc and tunneling method

The invention belongs to the technical field of engineering machinery, and particularly discloses a full-fracture-surface hard-rock tunneling machine cutter disc and a tunneling method. The tunnelingmachine cutter disc comprises a main cutter disc mechanism, an expansion cutter disc mechanism and a connector; the connector is provided with connector mounting holes for connecting a cutter disc driving mechanism; the main cutter disc mechanism comprises a main cutter disc, a first slag removing cutter, a first hob assembly and a first water jet cutter assembly; the expansion cutter disc mechanism includes multiple auxiliary cutter disc mechanisms; each auxiliary cutter disc mechanism includes an auxiliary cutter disc, an auxiliary cutter disc mounting frame and a retractable mechanism; thecutting end of each auxiliary cutter disc is provided with a second hob assembly, a second water jet cutter assembly and a second slag removing cutter. The water jet cutter assembles of the cutter disc can carry out hydraulic incision on tunnel rock, the tunnel rock subjected to hydraulic incision is much looser, then the hob assemblies can roll and crush the much looser tunnel rock, the tunnelingstress is effectively reduced, and hobs are protected; the retractable mechanisms connected with the auxiliary cutter discs can change the cutting diameter of the auxiliary cutter discs, and the full-fracture-surface hard-rock tunneling machine cutter disc is capable of meeting demands of tunnels different in diameter.

Owner:陈南南

Method for producing automotive sound-insulating pad

ActiveCN101987511AReduce weightMeet the requirements of lightweight designDomestic articlesFlat articlesThermoplasticEngineering

The invention relates to a method for producing an automotive sound-insulating pad. The method for producing the automotive sound-insulating pad comprises the following steps of: a, laying a raw material, namely laying a thermoplastic felt material on the network chain of an oven; b, baking and softening, namely feeding the thermoplastic felt material into the oven through the network chain of the oven for baking and softening, wherein the temperature of an upper heating zone in the oven is between 230 and 250 DEG C, the temperature of a lower heating zone is between 310 and 330 DEG C, and the baking time is 255 to 285 s; c, performing compression molding, namely performing compression and cooling on the baked and softened thermoplastic felt material to be a semi-finished product, wherein during the compression and cooling molding, the molding pressure is 16 to 17 MPa, the molding time is 90 to 110 s, and the cooling temperature is between 20 and 30 DEG C; d, performing water jet cutting, namely positioning the semi-finished product subjected to the compression cooling, and performing water jet cutting to obtain the required sound-insulating pad, wherein the cutting water pressure is 40,000 to 50,000 psi, and the cutting air pressure is 0.6 to 0.8 MPa; and e, inspecting, namely inspecting the sound-insulating pad, and packing and warehousing. The method for producing the automotive sound-insulating pad is simplified, energy-saving and environment-friendly, the automotive sound-insulating pad has high strength, the production efficiency of the method is high, and the method can reduce labor intensity.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

Water-saving water jet cutter special for mechanical part cutting

InactiveCN105856328AEasy to recycleReal-time detection of recyclingWorking accessoriesMetal working apparatusWater savingMachine parts

The invention discloses a water-saving water jet specially used for cutting mechanical parts, which comprises a hydraulic pipe, a control panel, a water tank and a main machine shell. A supporting column is arranged above the main machine shell, and the hydraulic tube is installed on the supporting column. In addition, a hydraulic pump is provided above the hydraulic pipe, a water pressure control device is provided on the left side of the hydraulic pump, a water pressure detection device is provided on the left side of the water jet cutting head, and the water tank is embedded and installed in the shell of the main engine. Above, the upper two ends of the hollow baffle are provided with hydraulic fixing devices. The invention has a scientific and reasonable structure, safe and convenient use, the water mist baffle can effectively prevent water splashing, and reduces unnecessary waste of resources, and the liquid level detection device can detect the liquid level in the water tank in real time to avoid damage to the hollow baffle due to too low water level The hydraulic fixing device can fix the parts during cutting, and the filtering device facilitates the recycling of water resources and prevents debris from clogging the cutter head.

Owner:XINCHANG COUNTY YULIN STREET SHANGDA BEARING PLANT

Waterfall waterjet with debris removing outlet

A device for producing a waterfall comprising a waterfall waterjet with at least one chamber, at least one primary outlet, at least one debris outlet, a water source fluidly connected to the waterfall waterjet, a means of opening and closing the debris outlet, and a means of anchoring the waterfall waterjet to a spa.

Owner:CUSTOM MOLDED PROD

Production process for cutting and edge wrapping of once-formed skylight of automobile roof

ActiveCN102442046AImprove qualityImprove stabilityLaminationLamination apparatusGlass fiberAcoustic absorption

The invention relates to a production process for cutting and edge wrapping of a once-formed skylight of an automobile roof, and belongs to the technical field of automobile interior ornaments. The production process comprises the following steps of: mainly selecting polyurethane (PU) foam cotton as the roof substrate; rolling rubber and spraying softened water to both sides of the roof substrate; then laying the materials of knitting fabrics, glass fiber A, PU foam cotton, glass fiber B, non-aeration zone membranes, non-woven fabrics successively in order; and carrying out pressure molding, cooling shaping, cutting by a water cutter, skylight cutting and edge wrapping, and testing, thus completing the production process. The roof produced by the production process provided by the invention reaches the advanced level of international Class 3 acoustic absorption criterion. The bonding fastness of the fabrics and the substrate material is increased; insufficient bonding does not occur; and the bonding is more durable. In the whole manufacturing process, the labor intensity of workers in the manufacturing process is greatly reduced; and the production efficiency is increased; the numbers of molds and personnel are reduced, and the manufacturing cost is greatly lowered. No harmful substance is generated in the whole manufacturing process, and the product is environmentally-friendly.

Owner:湖北吉兴汽车部件有限公司

Method for producing roof sun visor of automobile

InactiveCN101654059ASolve sound absorptionReduce weightWindowsLamination ancillary operationsHazardous substanceSoftened water

The invention relates to a method for producing a roof sun visor of an automobile. The method is characterized by adopting the following process sequences: preprocessing basal body PU material: including roll gluing, softened water spreading and the combined laying of materials for the roof sun visor; pressing the laid materials in a mould so as to form a semi-finished product; carrying out vacuumadsorption cooling molding on the semi-finished product formed by pressing; and then carrying out water cutting on the cooled and molded semi-finished product. The invention can greatly reduce the weight and achieve high rigidity without breaking and sagging; and besides, the invention can greatly reduce the labor intensity of workers in the process of production without generating harmful substances in the process of production and can increase the production efficiency.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

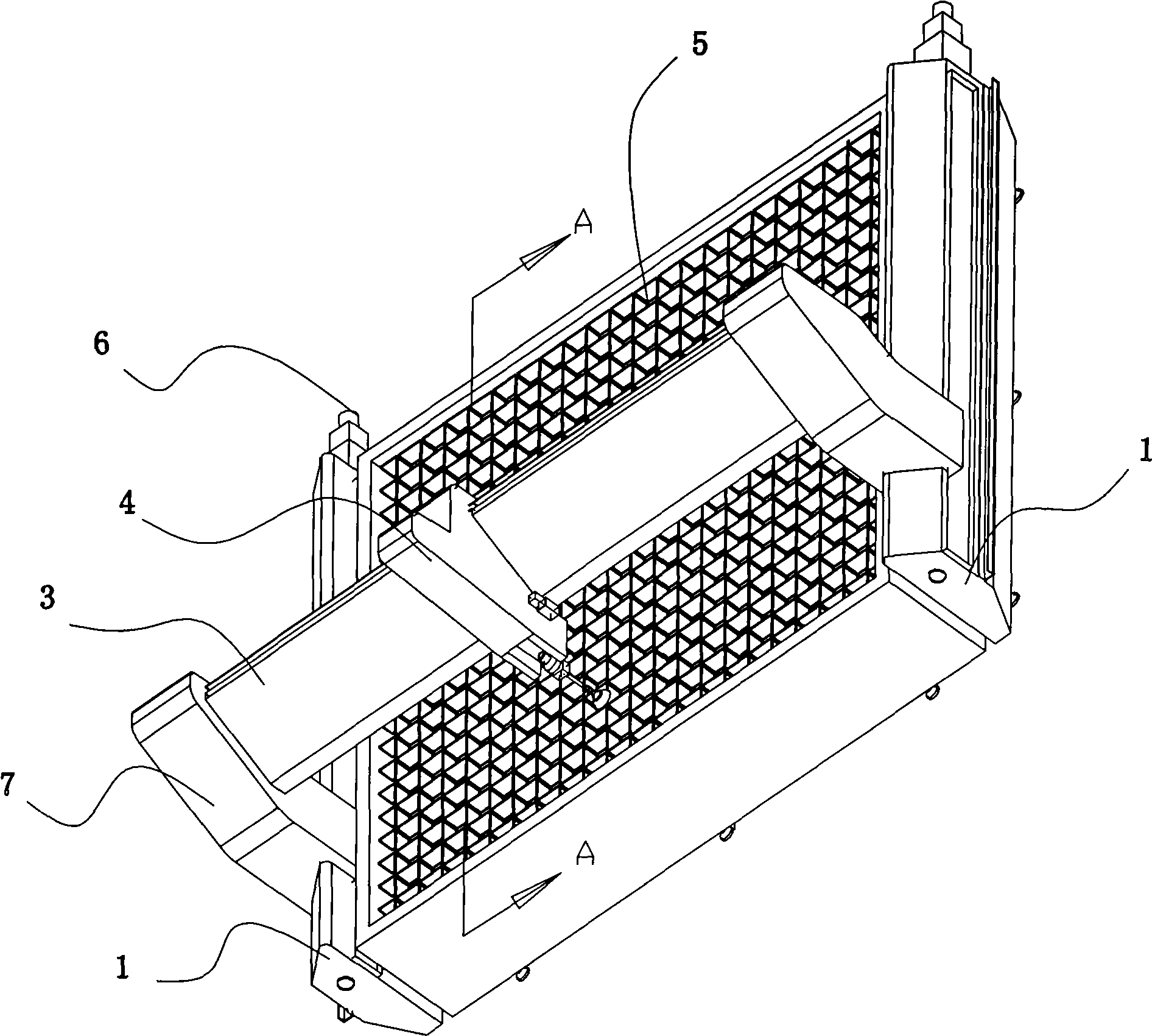

Rotary automatic PCB cleaning device

ActiveCN106111607AEfficient removalImprove water resource utilizationCleaning using liquidsConductive pattern polishing/cleaningElectric machineWater resources

The invention discloses a rotary automatic PCB cleaning device. The rotary automatic PCB cleaning device comprises a base, two stand columns, a top frame, a first servo motor, a lead screw, a feed nut, a sliding seat, two supporting rods, a support plate, triangular supporting plates, extension rods, water jet cutter mechanisms, a trough, a supporting seat, a second servo motor, a gear, a slewing bearing, a working table, a controller and more than two feeding mechanisms, wherein the two stand columns are arranged in parallel along the base; the two supporting rods are symmetrically arranged along the sliding seat; the triangular supporting plates are arranged symmetrically along the support plate; a PCB is placed in a slot and is fixed by manually tightening hand screws; the second servo motor drives the working table to rotate at a set angle; after an electric push rod pushes a U-shaped clamping frame to move forwards in place, the first servo motor drives the sliding seat to move towards the U-shaped clamping frame by a set distance, then high-pressure water is pumped into the water jet cutter mechanisms, and chippings on the surface of the PCB and in holes of the PCB are eliminated. The device is simple in structure, good in cleaning effect, high in water resource utilization rate, high in degree of automation and high in cleaning efficiency.

Owner:苏州市相城区姑苏线路板厂

System and method for cutting-stock optimization across schedules and batches

ActiveUS8010216B2Reduce in quantityReduce laborResourcesSpecial data processing applicationsComputer optimizationWater jet cutter

A method and system for optimizing cutting of various materials. In some embodiments, an algorithm optimizes cutting by grouping items to be cut, wherein a plurality of cutting-stock pieces are grouped together and aligned such that a single cut simultaneously cuts items from all of the pieces. Some embodiments optimize a combination of reduced labor cost, reduced materials cost (e.g., reducing scrap), and / or reduced time needed to obtain an inventory of pieces cut to specified lengths and shapes (checking the various permutations). Overall optimization of labor and material is achieved by a combination of fewer cuts and reduced waste. Some embodiments include a computer-readable medium having instructions executed by a computer that optimizes placement of cuts to obtain cut-part items, and optionally controls a saw, laser, water-jet cutter or the like. In some embodiments, a human operator making the cuts is instructed by the computer to achieve the optimization.

Owner:ROISE GEOFFREY J

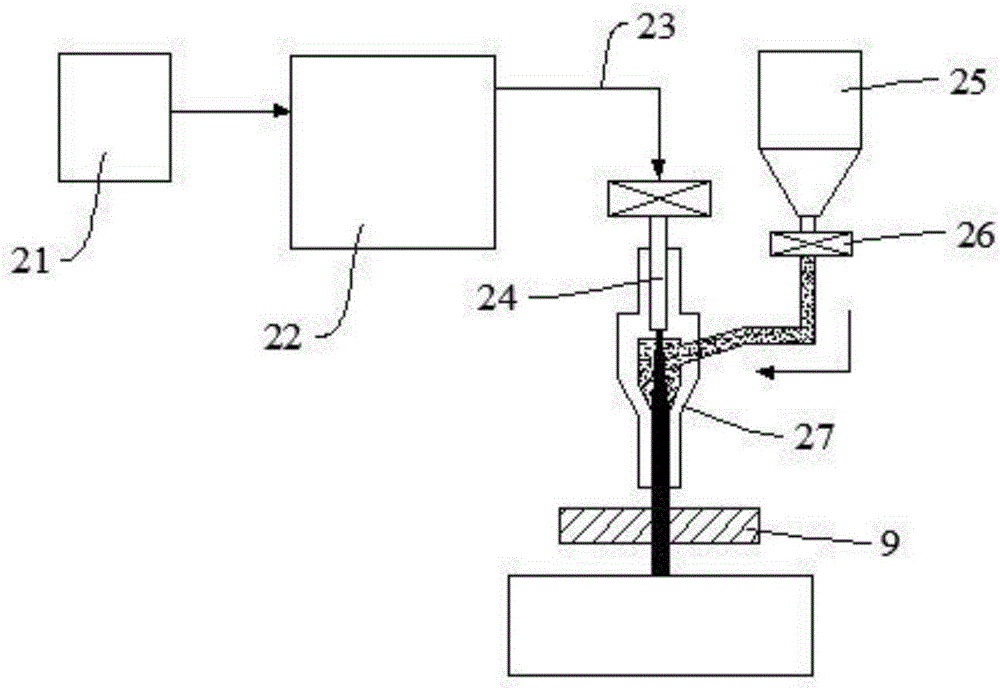

Water cutter device for cutting sapphires

ActiveCN106217666ASolve difficult to cutSolve the costFine working devicesComputer control systemInstability

The invention discloses a water cutter device for cutting sapphires. The water cutter device comprises a water cutter machine tool, a computer control system, an abrasive water jet system, an acid liquor spray system and a laser positioning device; the computer control system is used for controlling coordinated action of parts of the water cutter machine tool, and controlling start and stop of the abrasive water jet system and the acid liquor spray system as well as jet pressure of the abrasive water jet system; the abrasive water jet system is used for jetting ultrahigh-pressure abrasive water jet flow to cut the sapphires; the acid liquor spray system is used for applying acid liquor to a cut, so that acid liquor impacts the sapphires at a high speed after being forced out by the ultrahigh-pressure abrasive water jet flow to carry out cooperative chemical processing; and the laser positioning device is used for assisting the acid liquor spray system to locate by projecting spots on workpiece cutting points. According to the water cutter device disclosed by the invention, water cutter cutting is introduced into the sapphire processing field, so that the problems that sapphires are difficult to cut and are high in processing cost are solved; and meanwhile, the characteristics of the sapphires and instability, caused by ultrahigh-pressure jet flow, of processing materials are combined, so that chemically assisted processing is designed.

Owner:TDG YINXIA NEW MATERIAL CO LTD

Punching device for aluminum foil or copper foil of lithium battery and production technology

InactiveCN105762330AHigh Efficiency Drilling OperationExtend your lifeElectrode manufacturing processesPunchingEngineering

The invention relates to a punching device for aluminum foil or copper foil of a lithium battery and a production technology.The punching device comprises a machine frame, a pressurization water pump, a water jet cutter, an upper cutting die provided with multiple holes, a feeding roller, a conveying roller and a lower punching die work table, wherein water is pressurized and fed into the water jet cutter through the pressurization water pump, a feeding roller for the aluminum foil or copper foil is sent to the lower punching die work table through the conveying roller, and high-pressure water of the water jet cutter is sent to the lower punching die work table through a pore pair of the upper cutting die to punch the aluminum foil or copper foil.The punching technology comprises the steps of 1, installing an aluminum foil or copper foil roll on the feeding roller; 2, sending the aluminum foil or copper foil onto a work table to be processed through the feeding roller; 3, pressurizing water through the pressurization water pump; 4, sending the upper cutting die provided with multiple holes to the work table to be processed close to the aluminum foil or copper foil, and turning on a water jet cutter cutting switch to enable high-pressure water to penetrate through the holes in the upper cutting die so as to conduct punching on the aluminum foil or copper foil.

Owner:廖雪光

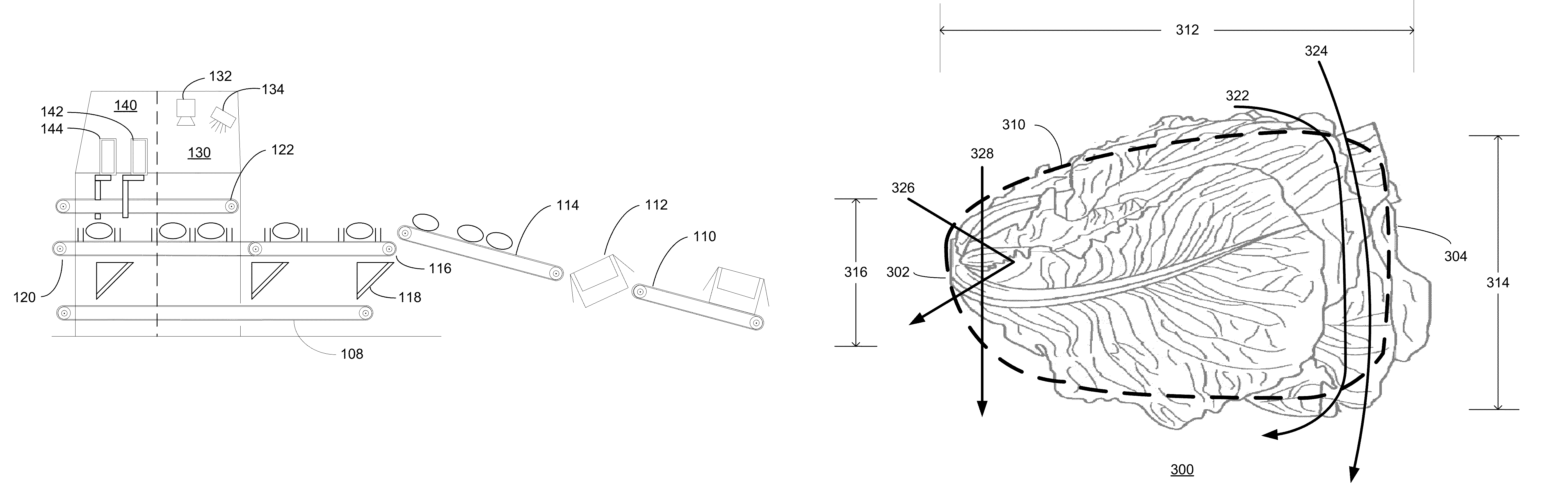

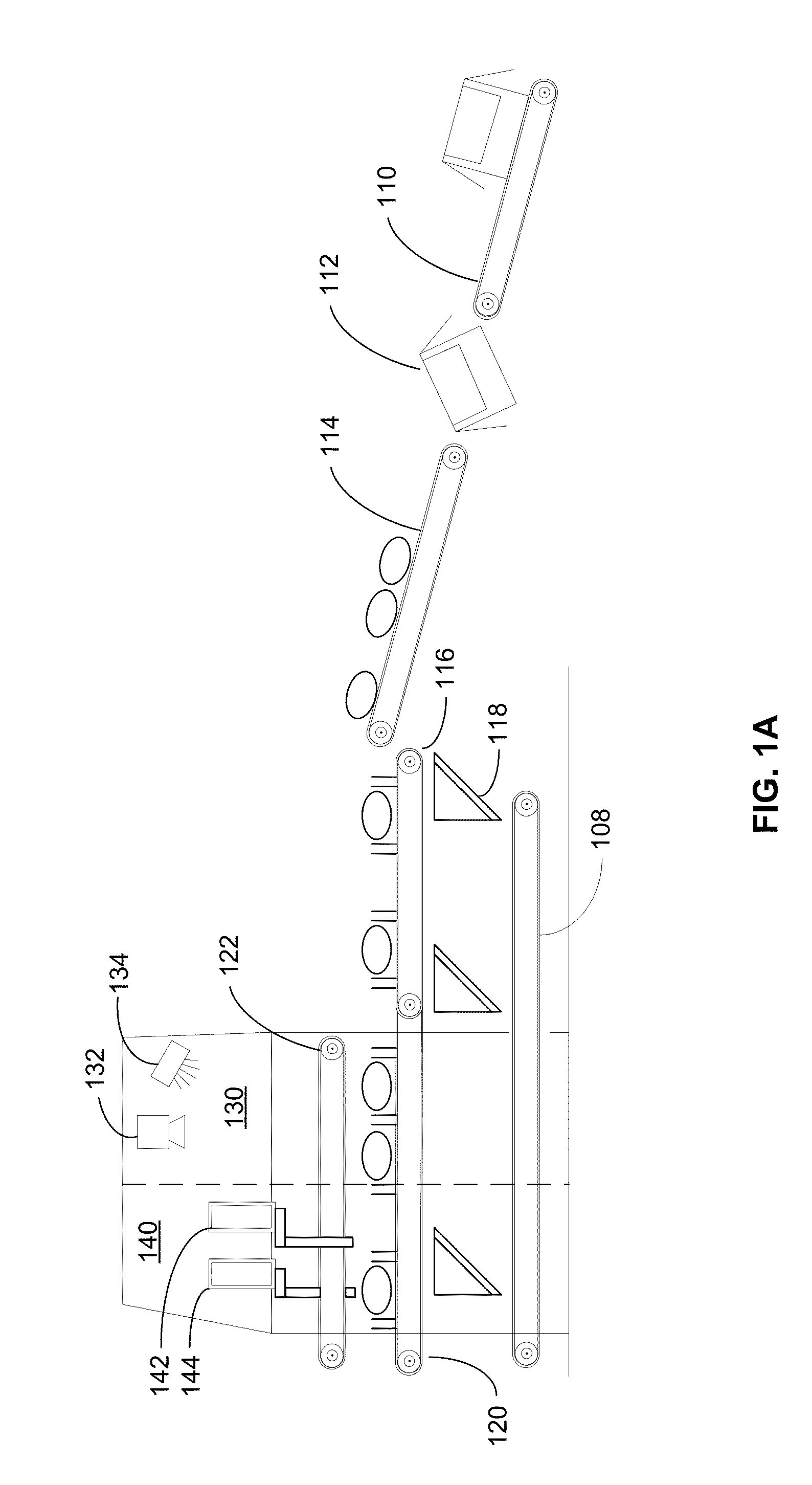

System for topping and tailing lettuce heads using a camera-guided servo-controlled water knife

A system for trimming a lettuce head using a digital imaging system and cutting mechanism. The lettuce head is conveyed between a lower feed conveyor and an upper feed conveyor that is disposed a fixed distance over and substantially aligned with a lower feed conveyor. The digital imaging system is configured to capture an image of the lettuce head and determine a cutting profile using the image. The cutting mechanism is disposed over the lower feed conveyor and includes: a servo motor mechanically coupled to a drive shaft; an armature with a pivot end mounted to the drive shaft and a sweep end disposed a radial distance from the pivot end; a cutting nozzle, mounted to the sweep end of the armature, configured to trim the lettuce head; and servo-control circuitry configured to articulate the cutting nozzle through a cutting arc based on the cutting profile.

Owner:BUD ANTLE

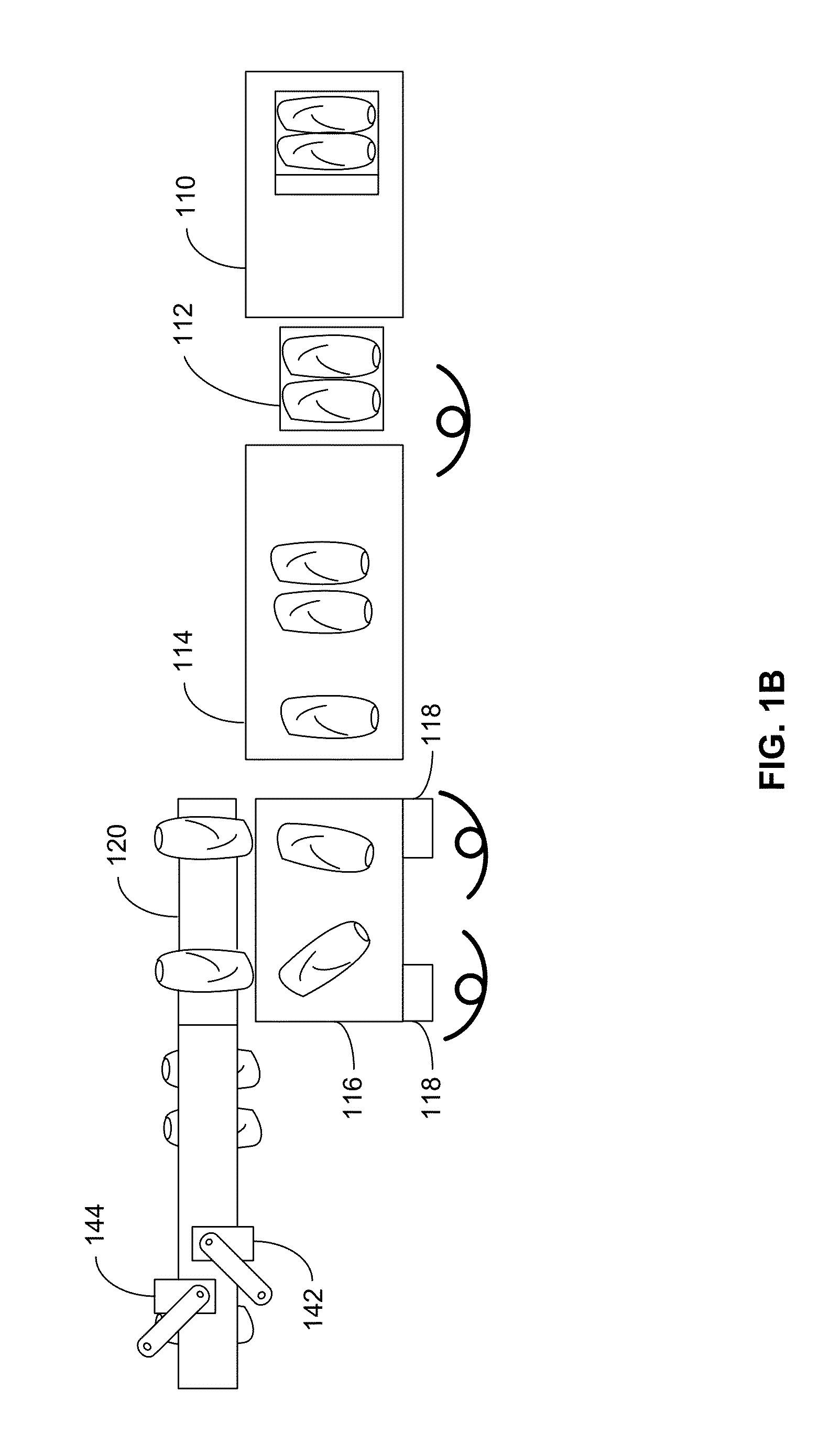

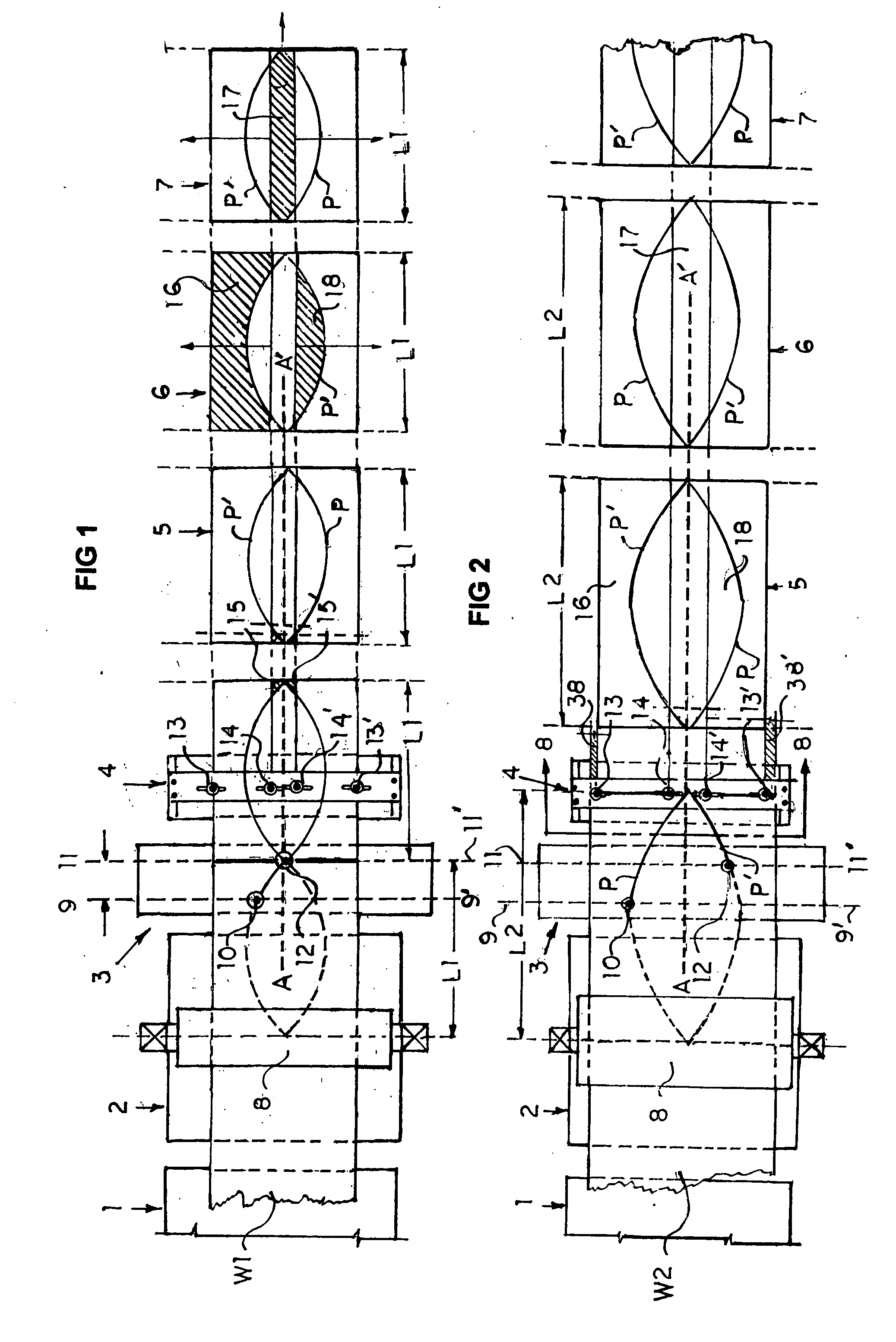

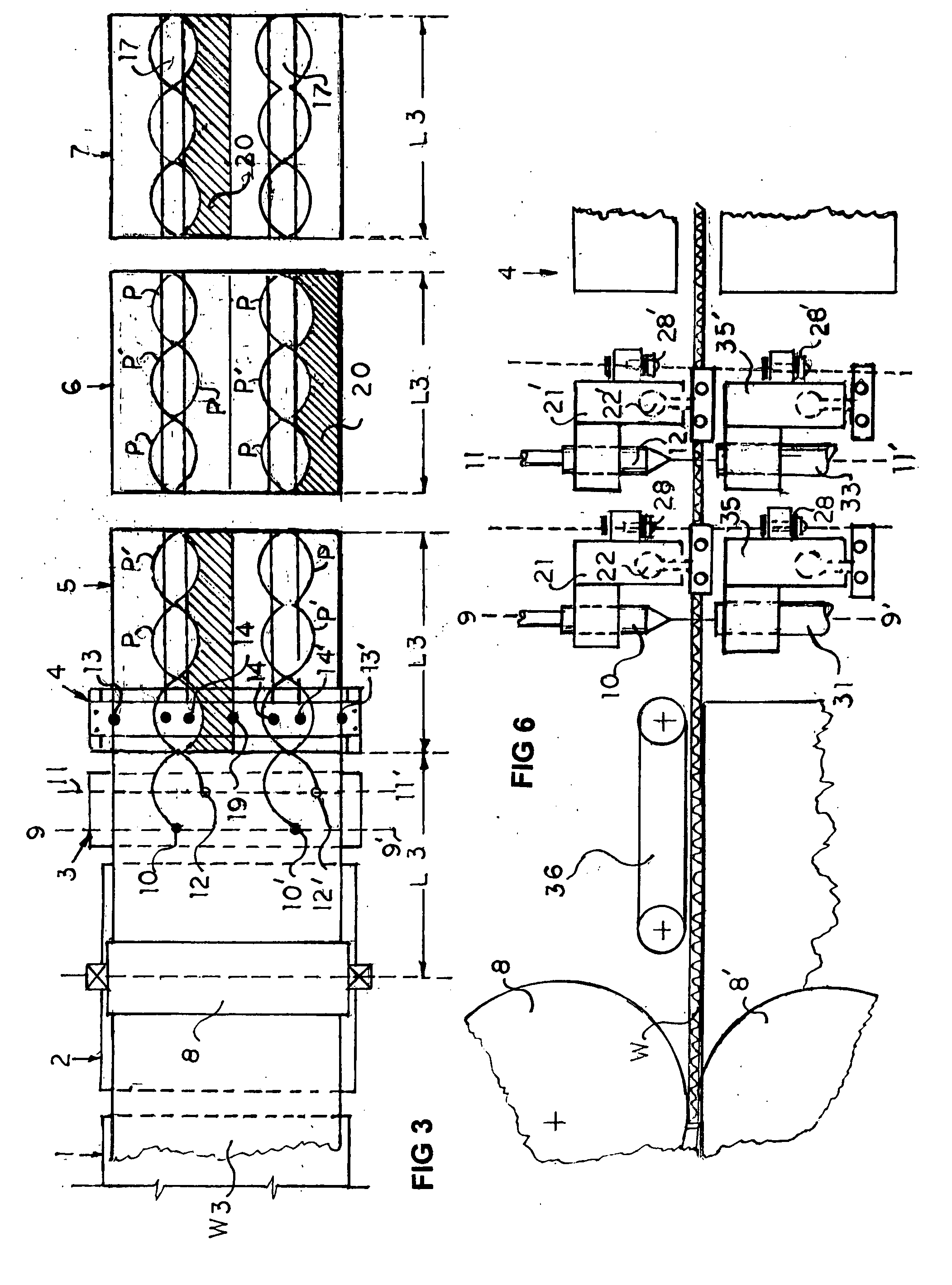

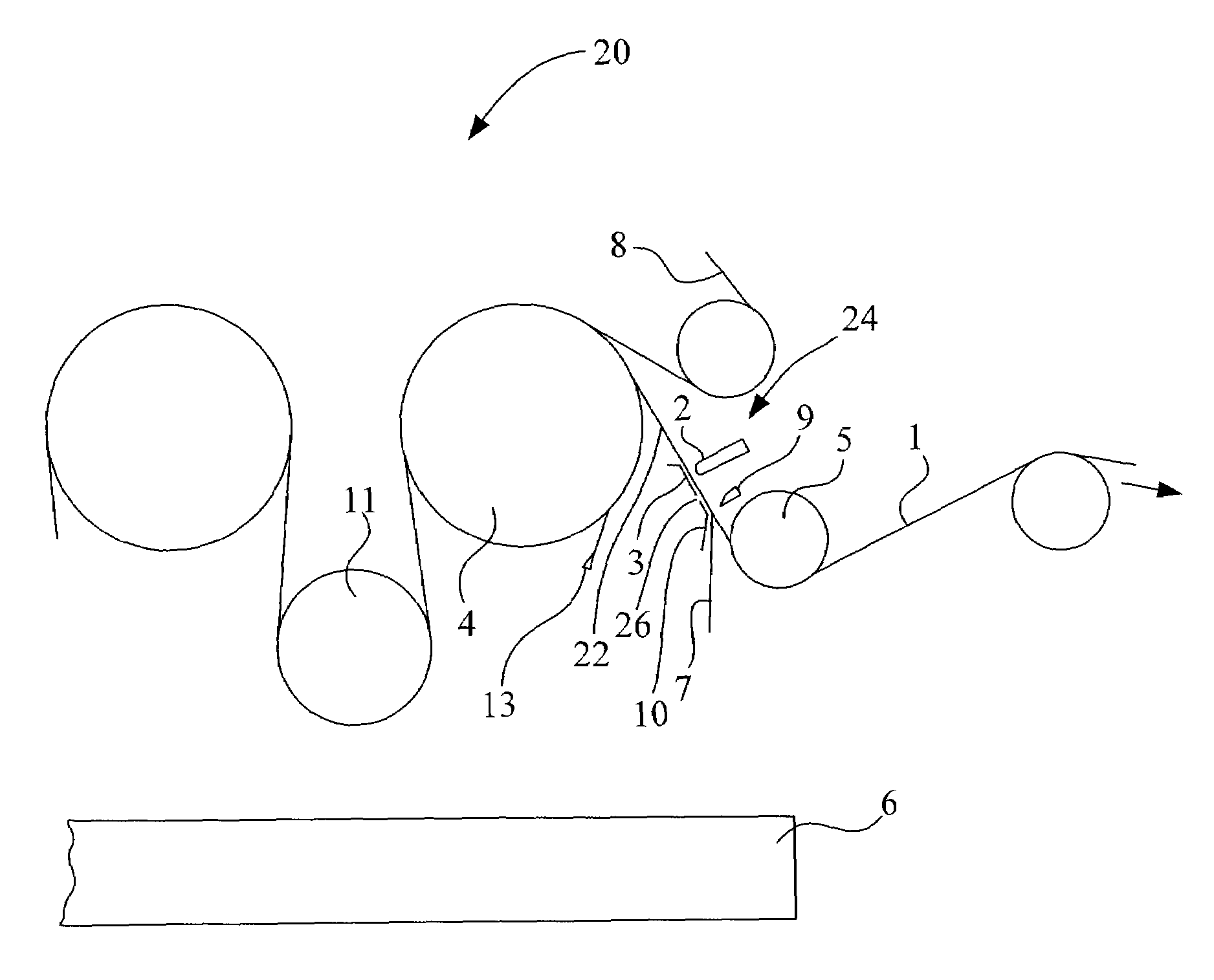

Method and apparatus for cutting parabolic shaped segments on a corrugating machine

Method and apparatus for water jet cutting parabolic shaped segments that support reflective surfaces of a concentrating solar collectors. Apparatus describes corrugating machine cutoff, parabolic curve water jet cutters longitudinal slitters, transfer / diverters, and stackers. Parabolic curve cutting involves at least one cutter on a first transverse path with means for reversing movement over a moving web in cooperation with a cutter on a parallel second path with means for mirror image movement to make a pair of opposite curves which intersect at segment ends. Jet cutter reversing servo motor drive means programmable for different parabolic curves. Includes use of plurality of cutter pairs to make segments with multiple parabolic curves per length. Apparatus includes means to make standard corrugated board or parabolic segments by electronic switching without machine adjustments.

Owner:NIEDERMEYER WILLIAM PAUL

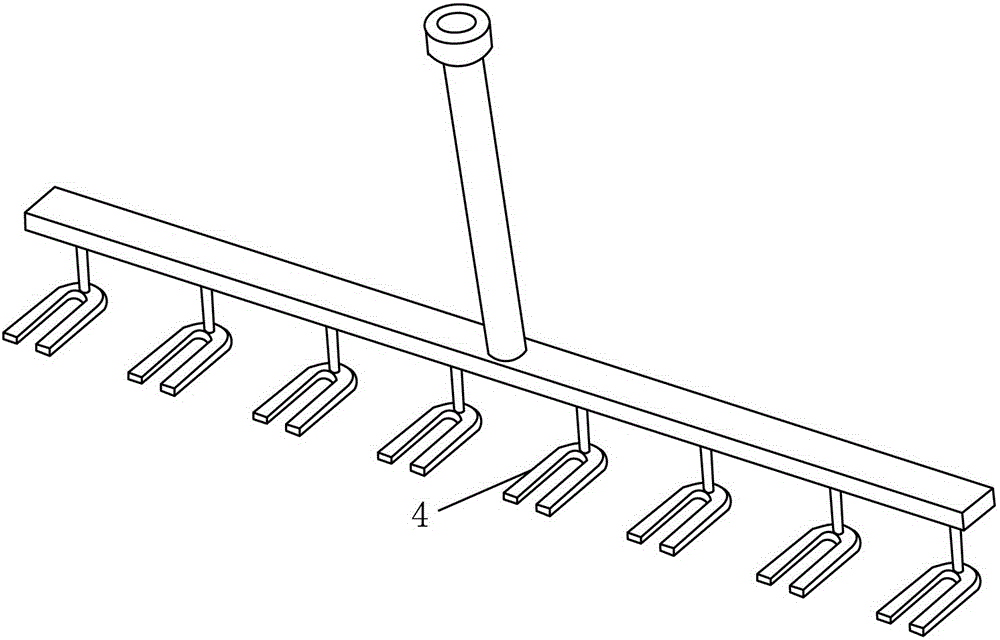

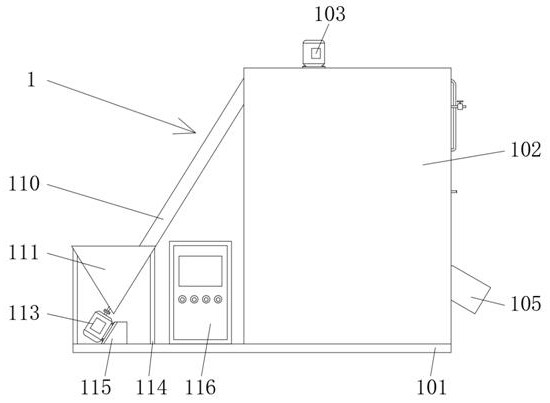

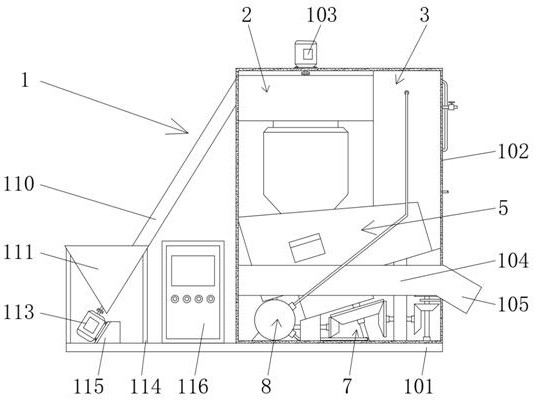

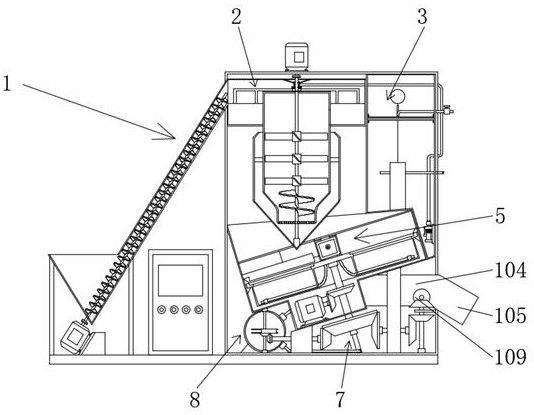

Full-automatic root removal, stem removal and quality separator for shiitake

The invention provides a full-automatic root removal, stem removal and quality separator for shiitake and effectively solves the problems of low efficiency and persistently high production cost in the prior art. The full-automatic root removal, stem removal and quality separator for the shiitake comprises a rack, wherein a vibrating screen capable of removing defective shiitake is arranged on the rack; a mechanical arm is arranged on the rack on one side of the vibrating screen; a plurality of linearly distributed U-shaped clamping hands are fixed at a free end part of the mechanical arm at equal intervals; two first conveyor belts with belt surfaces arranged vertically are arranged behind the U-shaped clamping hands, opposite sides of the two first conveyor belts arranged in an inverted V-shape, and an inverted-V-shaped conveyor belt is formed; a photoelectric coordinate sensor is arranged on one side of the inverted-V-shaped conveyor belt; a water jet cutter is arranged at the lower part of the inverted-V-shaped conveyor belt; a stem cutter is arranged below the inverted-V-shaped conveyor belt behind the water jet cutter; a first receiving frame is arranged below the water jet cutter; a second receiving frame is arranged below the stem cutter; a third receiving frame is arranged below the inverted-V-shaped conveyor belt behind the second receiving frame.

Owner:漯河桂馥农业科技开发有限公司

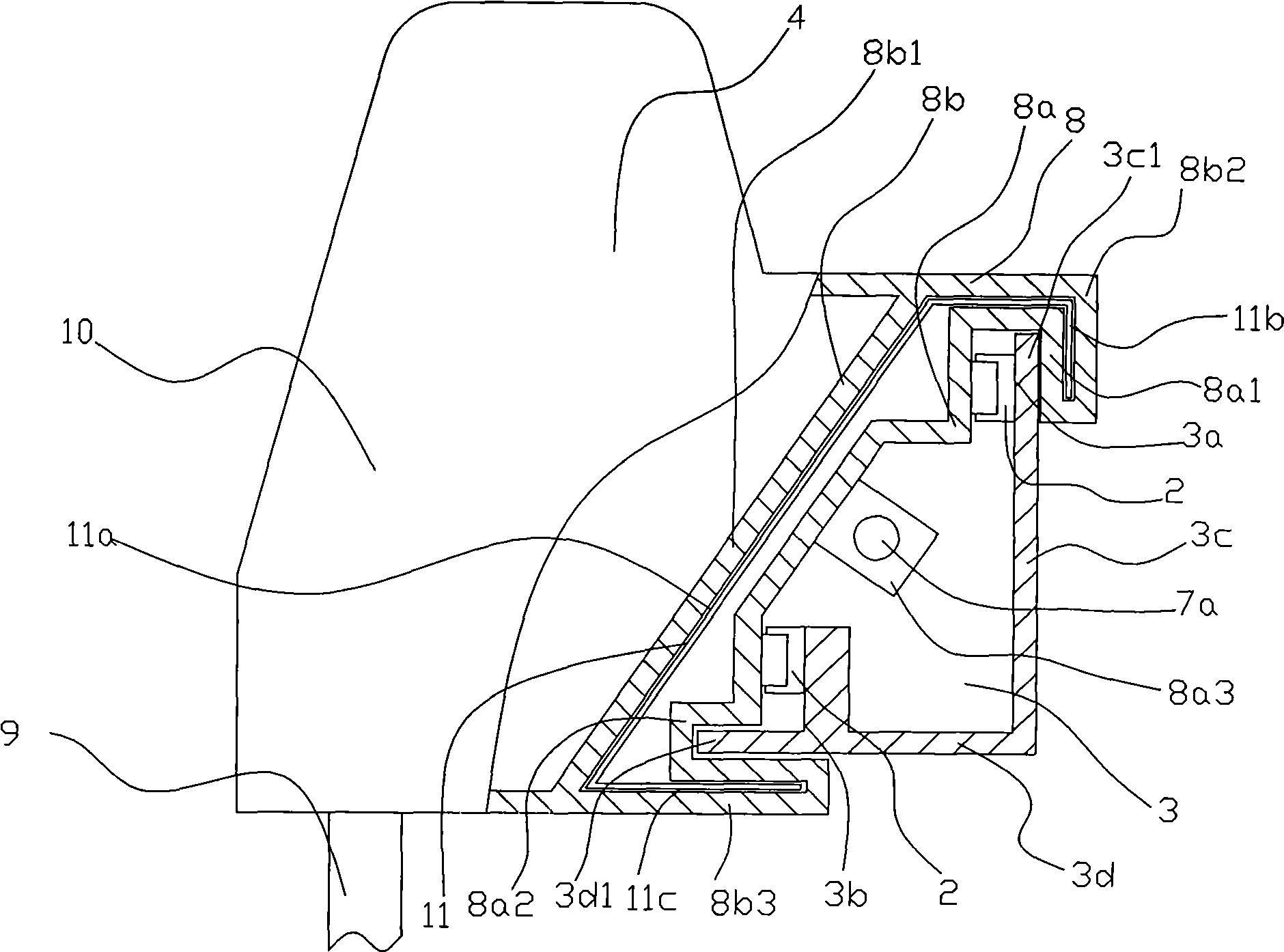

Water-jet cutting machine

The invention relates to a waterjet cutter which is characterized in that the waterjet cutter comprises a front and back moving frame with a vertical guide rail, a left and right moving frame which is connected with the vertical guide rail and is provided with a transverse guide rail, a waterjet cutting head which is arranged on the transverse guide rail in a left and right moving way and a workpiece bearing platform which is arranged under the waterjet cutting head. A support base comprises an inner support base and an external support base. Two ends of the inner support base are wrapping edges for wrapping the back front end and the bottom front end of the left and right moving frame. The external support base comprises a sloping plate and a turned-over edge which is arranged on the two ends of the sloping plate and turns inwards along the wrapping edges on the two ends of the inner support base. A protective cover plate is arranged between the inner support base and the external support base. The protective cover plate comprises a sloping cover plate, a turned-over edge angle plate which is arranged on the upper end of the sloping cover plate and a turned-over edge flat slab which is arranged on the lower end of the sloping cover plate. Compared with the prior art, the waterjet cutter has the advantages that back-washing water and sands during the workpiece processing can be prevented from polluting the guide rails, the swing amplitude of a waterjet cutting spray-head is small so that the mechanical processed workpiece precision cannot be influenced.

Owner:刘永钦

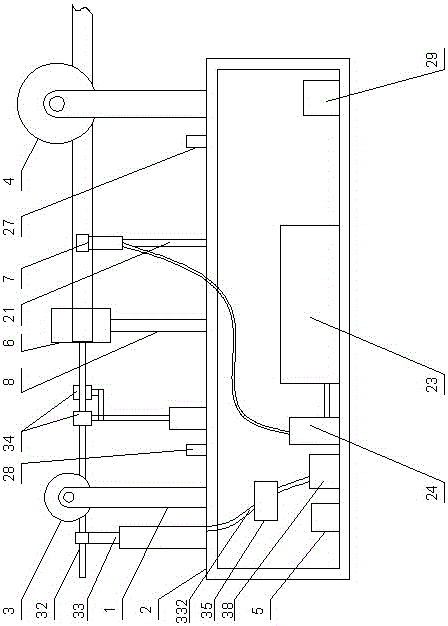

Ice and snow removing apparatus for power transmission line

The invention discloses an ice and snow removing apparatus for a power transmission line. The ice and snow removing apparatus comprises a walking mechanism and a rack connected below the walking mechanism through mechanical arms, wherein the walking mechanism comprises a back walking wheel which is clamped at a part, where icing is removed, of the power transmission line, and a front walking wheel which is clamped at a part, where icing is not removed, of the power transmission line; the rack is provided with a de-icing mechanism; a wireless controller is arranged on the left side of the interior of the rack; the de-icing mechanism comprises an icing smashing module and a water jet cutter cutting module from left to right in sequence; an opening is formed in the top of a water tank; an ice and snow receiving funnel is arranged on the opening; notches are formed in a position, corresponding to the ice and snow receiving funnel, of the top of the rack, and used for collecting ice blocks falling from the power transmission line; and a heating module is arranged at the bottom of the water tank and is in electric signal connection with the wireless controller. Water pressure of the water jet cutter cutting module can be adjusted according to the detected thickness of an icing layer, so that efficient de-icing can be realized during cutting the surface icing without being affected by the thickness of the icing layer, and a line is not damaged either.

Owner:STATE GRID HENAN ELECTRIC ZHOUKOU POWER SUPPLY +1

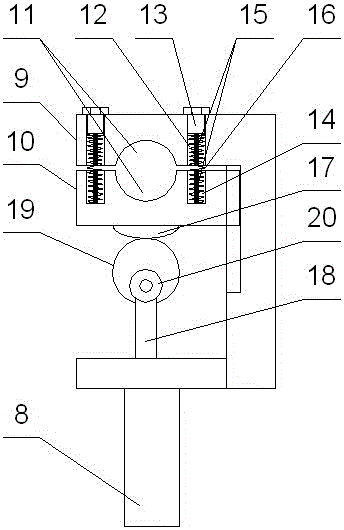

On-line de-icing device for power transmission line

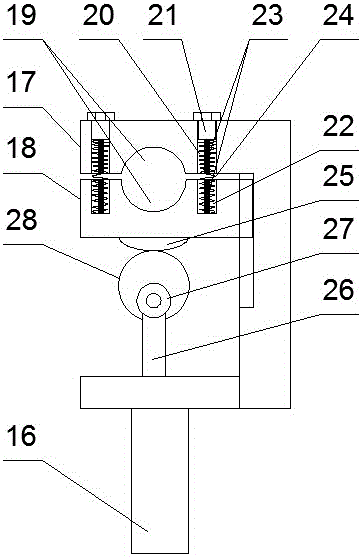

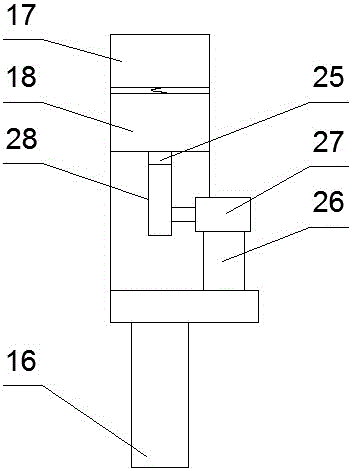

ActiveCN106329450AWon't stayReduce mutual consumptionOverhead installationComputer moduleEngineering

The invention discloses an on-line de-icing device for a power transmission line. The on-line de-icing device comprises a walking mechanism and a rack which is connected to the lower portion of the walking mechanism through mechanical arms. The walking mechanism comprises a rear walking wheel and a front walking wheel, wherein the rear walking wheel is clamped on the de-iced portion of the power transmission line, and the front walking wheel is clamped on the icing portion of the power transmission line, a de-icing mechanism is arranged on the rack and located between the rear walking wheel and the front walking wheel, a wireless controller is arranged on the left side inside the rack, and the walking mechanism is connected with the wireless controller through electric signals; the de-icing mechanism comprises an ice cover crashing module and a water jet cutter dividing module in sequence from left to right. The water pressure of the water jet cutter dividing module can be adjusted according to the detected thickness of an ice cover layer, so that the on-line de-icing device efficiently carries out de-icing without being affected by the thickness of the ice cover layer when the surface ice cover is divided, and also will not damage the line.

Owner:XICHUAN COUNTY POWER BUREAU

Stirring device for in-situ remediation of heavy metal contaminated soil for solidification and stabilization

InactiveCN111906132AImprove practicalityAchieve recyclingContaminated soil reclamationSoil scienceIn situ remediation

The invention discloses a stirring device for in-situ remediation of heavy metal contaminated soil solidification stabilizer. The stirring device comprises a remediation main body, and a stirring device, a liquid storage device, a dehydration device, a transmission device and a suction device are arranged in the remediation main body; through cooperation of the stirring device and the liquid storage device, soil enters the stirring device and then is sequentially subjected to kneading, water jet cutting and pulping, so that the soil is promoted to rapidly form uniform slurry, the solidification effect of heavy metal is improved, and a solidification agent solution is automatically supplemented through the liquid supplementing device; by cooperation of the dehydration device, the slurry scraping device, the transmission device and the suction device, the slurry is subjected to suction filtration, the purposes of recovering a curing agent solution and separating heavy metals are achieved, the usage amount of the curing agent is greatly reduced, the remediation cost is reduced, the heavy metals are thoroughly separated from soil, the problem of heavy metal pollution rebound is avoided, and the treatment effect is good; therefore, the practicability of the stirring device for in-situ remediation of the heavy metal contaminated soil for solidification and stabilization is improved.

Owner:欧其琴

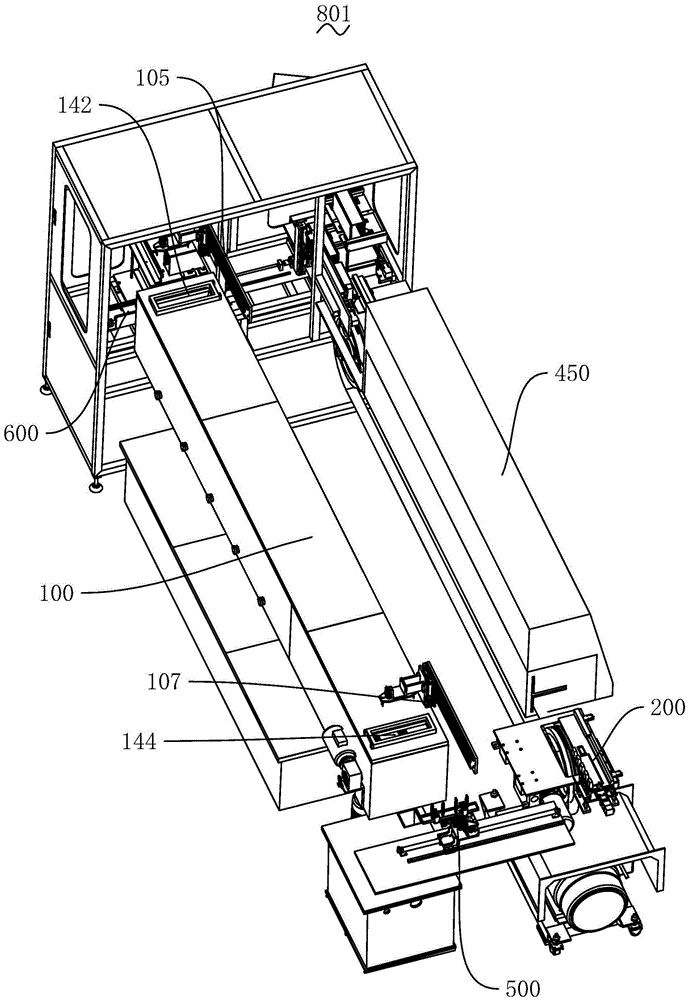

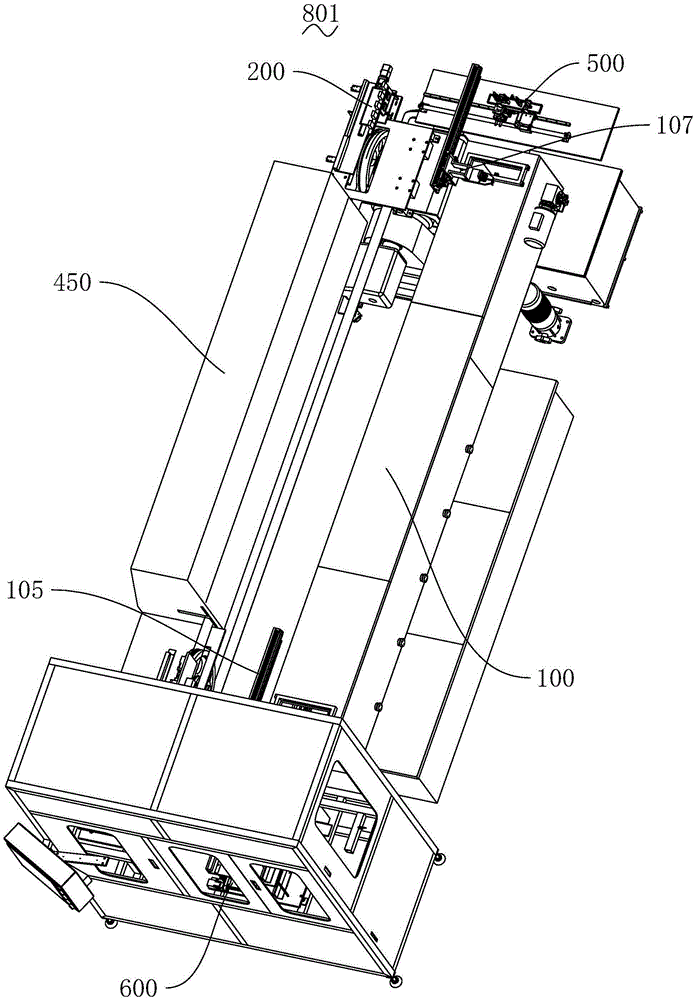

Treatment production line of lead frame

ActiveCN105428284AEasy to moveAvoid damageSemiconductor/solid-state device manufacturingProduction lineChemical treatment

The invention discloses a treatment production line of a lead frame. The treatment production line of the lead frame comprises a material taking mechanism, a lead frame treatment groove, a lead frame jig, lead frame pushing equipment and a water jet cutter, wherein a material pushing device of the material taking mechanism is driven by a first driving device and can realize automatic working; an immobilizing mechanism of the lead frame treatment groove is used for maintaining a semiconductor lead frame at a vertical position, so that the semiconductor lead frame is small in occupied space and long in soaking time, and a better soaking effect is obtained; a liquid receiving groove formed in the lead frame jig can be used for completely receiving a chemical treatment solution dripping from the lead frame, so that the phenomenon that since the chemical treatment solution drips on structures such as an air cylinder and guide rails, the corrosion is caused is avoided.

Owner:SHANGHAI SINYANG SEMICON MATERIALS

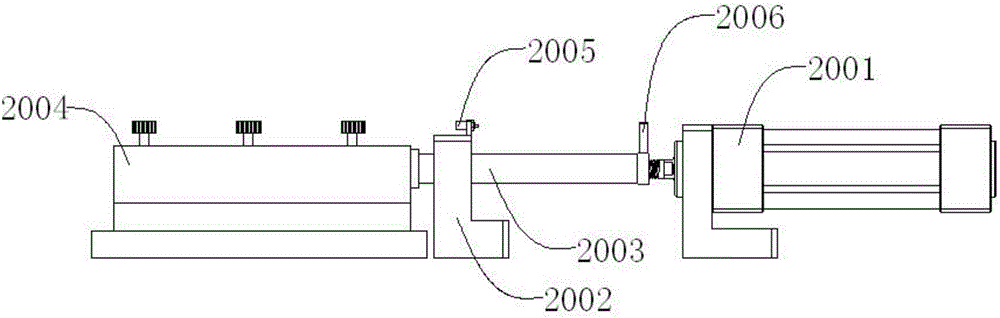

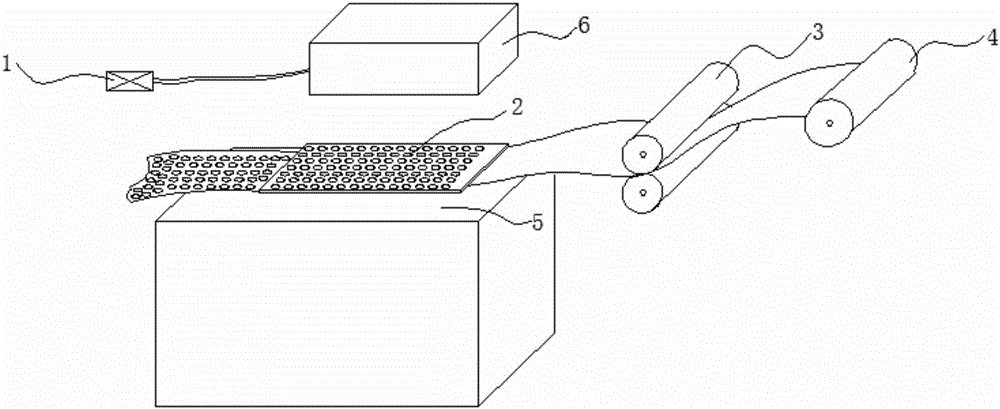

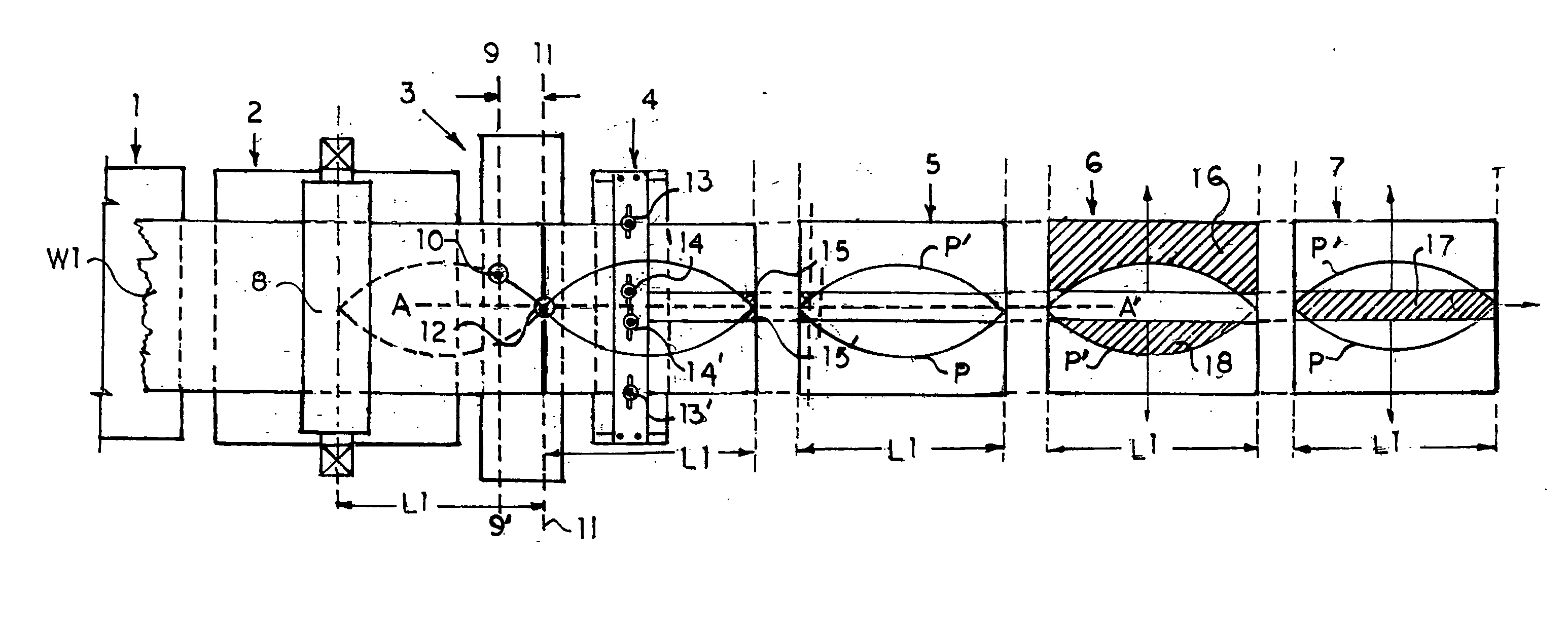

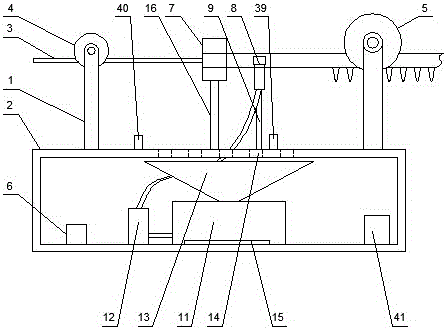

Tobacco shred cutting method using water cutting machine and device thereof

InactiveCN101385573ALow costLess nutrientsTobacco treatmentMetal working apparatusEngineeringWater jet cutter

The invention belongs to the technical field of tobacco shred processing in the cigarette manufacture, and more particularly relates to a method for cutting the tobacco shred by a water jet and a device thereof. The method for cutting the tobacco shred by the water jet comprises: 1. tobacco leaves are prepared; 2. the tobacco leaves are put into a delivery mechanism of the device for cutting the tobacco shred to be conveyed to the cut position of the water jet; 3. high-pressure water sprayed out by a nozzle forms a water shooting flow jet to lead the tobacco leaves to be cut into the tobacco shred; 4. the cut tobacco shred are conveyed to the next working procedure; 5. after being cut by the high-pressure water, the tobacco shred enters a water recovery machine. The method is managed and controlled by a computer. The device for cutting the tobacco shred by the water jet is provided with a main conveyer belt and a carding conveyer belt on a frame, wherein, the carding conveyer belt is inclined, rotation shafts of the main conveyer belt and the carding conveyer belt are respectively connected with a motor shaft, and the sides of the two conveyer belts are provided with side baffles; the upper part of a manhole and the frame are connected with a guideway which is provided with the nozzle of the water jet, a control device is arranged on the frame, and the water recovery device is arranged under the manhole; the main conveyer belt, the carding conveyer belt, the nozzle of the water jet and a motion control device of the nozzle are connected with a appliance of the computer. The invention can maintain the active ingredients in the tobacco leaf to the utmost extent, improves the quality of the tobacco shred, simplifies the technique for tobacco shred processing, saves energy, reduces consumption and the cost for manufacturing the tobacco shred, and can be used for the planted tobacco leaf and artificial tobacco sheet.

Owner:昆明烟机集团二机有限公司

Water knife cutting control system

InactiveCN101837599AHigh precisionFast cutting speedAutomatic control devicesFeeding apparatusControl systemHigh acceleration

The invention relates to a water knife cutting control system for cutting finished products. The system comprises a feed system, a recovery system, a water knife movement control system, a water flow control system and a work station, wherein the work station simultaneously controls the feed system, the recovery system, the water knife movement control system and the water flow control system. The water knife cutting control system has the advantages in the conventional high pressure water knife cutting system; and compared with the conventional high pressure water cutting system using a cantilever type drive structure, the invention also has the advantages of small size, high rigidity and the like, and can bear high speed and provide high acceleration. In addition, the high pressure water knife cutting system of the invention can greatly enhance the cutting accuracy for finished products, prevent the finished products from damage during cutting, increase the finished product cutting speed and yield, and save the manufacturing cost at the same time.

Owner:SHANGHAI YI CHEN INFORMATION TECH DEV

Method for producing front wall sound insulation pad of automobile driving cabin

ActiveCN102310613AMeet the requirements of lightweight designReduce weightLamination ancillary operationsSynthetic resin layered productsThermoplasticPerformance index

The invention relates to a method for producing a front wall sound insulation pad of an automobile driving cabin, belonging to the technical field of automobile interior part processing. The method provided by the invention comprises the following steps of: placing a hard thermoplastic felt on a bottom layer, placing a hot melt film on a middle layer, placing a soft thermoplastic felt on an upper layer, and paving the raw materials on a net chain of an oven; feeding the raw materials into the oven through the net chain of the oven for drying and softening, and sufficiently dissolving the hot melt film on the middle layer; placing the materials in a mould after drying the materials in the oven, and pressing and cooling the materials in the mould to form a semi-finished product; locating the semi-finished product, and executing water jet cutting on the semi-finished product to obtain the required front wall sound insulation pad of the driving cabin; and boxing and warehousing after checking up. According to the method provided by the invention, the performance index requirements, such as sound absorption, sound insulation, environment friendliness, light weight and the like, of the front wall sound insulation pad assembly of the driving cabin can be satisfied; the weight of the front wall sound insulation pad of the driving cabin is greatly reduced; and the requirement for integral lightweight design is satisfied.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

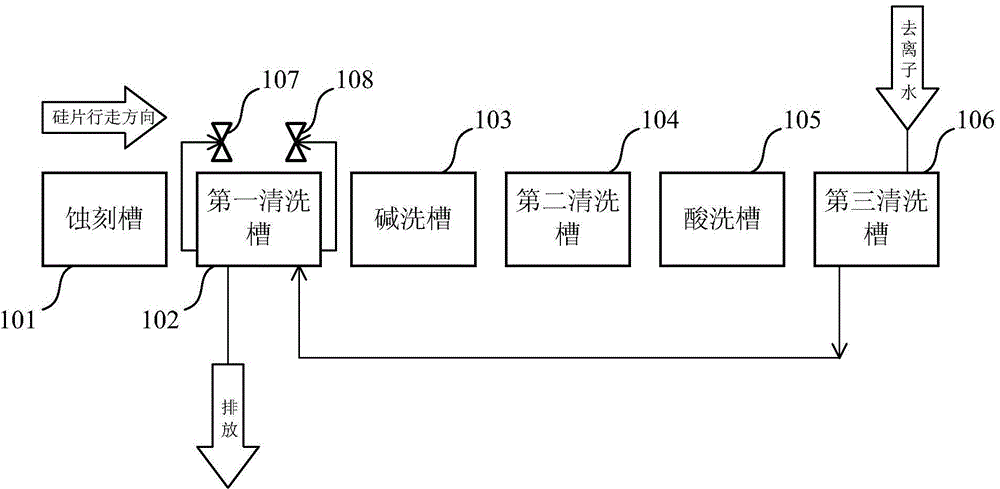

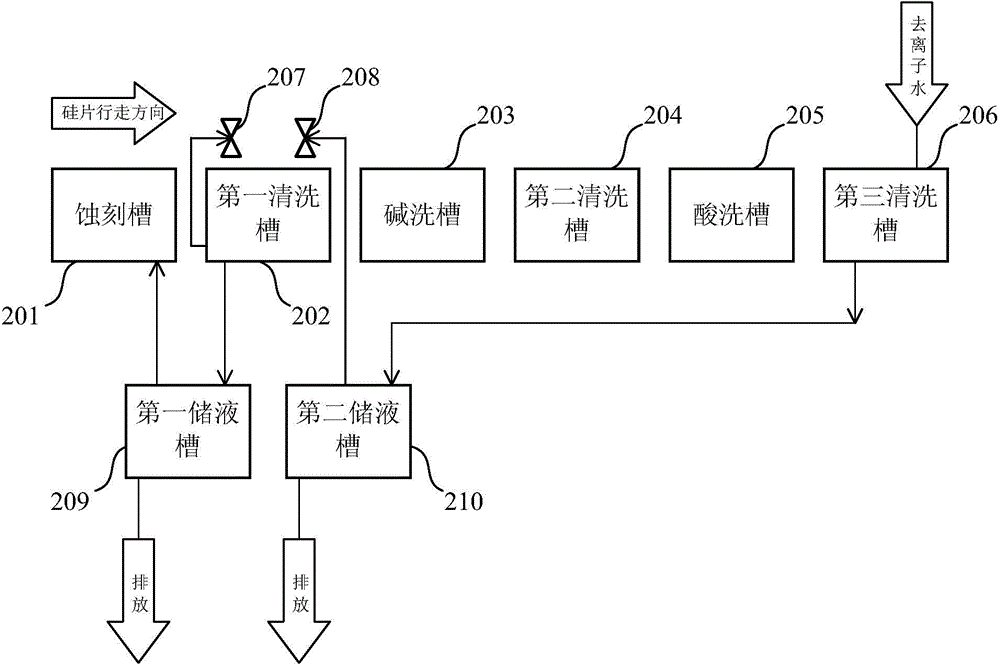

Wet etching method and device for solar cells

InactiveCN104409396AEmission reductionReduce generationFinal product manufactureSemiconductor/solid-state device manufacturingEtchingWater discharge

The invention provides a wet etching method and device for solar cells. The wet etching device comprises an etching tank, a first washing tank, an alkaline washing tank, a second washing tank, a pickling tank and a third washing tank. An inlet and an outlet of the first washing tank are provided with a first water jet cutter and a second water jet cutter respectively. The wet etching device further comprises a first liquid storage tank and a second liquid storage tank which are connected with the third washing tank and the second water jet cutter through connecting pipelines, respectively.as liquid in the third washing tank reaches a preset water level, redundant liquid is discharged into the second liquid storage tank which supplies the liquid for the second water jet cutter. The first liquid storage tank is connected with the first washing tank and the etching tank respectively through the connecting pipelines. The first washing tank supplies the liquid for the first water jet cutter. As the liquid in the first washing tank reaches the preset water level, the redundant liquid is discharged into the first liquid storage tank used for supplying water and distributing liquid for the etching tank. By the use of the wet etching method and device, nitrogenous waste water discharge is reduced, and production cost is lowered.

Owner:TAINERGY TECH KUNSHAN

Manufacturing technology of lightweight environment-friendly type automobile ceiling

InactiveCN102431249AGood compatibilityEasy to recycleLamination ancillary operationsSynthetic resin layered productsManufacturing technologyEngineering

The invention relates to a manufacturing technology of a lightweight environment-friendly type automobile ceiling, and specifically relates to a manufacturing technology of an environment-friendly automobile ceiling used for reducing the automobile weight. The invention belongs to the technical field of automobile interior decorative part production. According to the invention, a surface material, a film and a foamed board are warmed by baking, and are subject to cold pressing and molding, such that the automobile ceiling is manufactured. The technology comprises steps of material paving, warming by baking, softening, molding by cold pressing, and water-jet cutting. With the technology provided by the invention, the lightweight environment-friendly type automobile ceiling is advantaged in light weight, good compatibility among materials, and easy molding and production. The automobile ceiling is environment-friendly. The produced rim leftovers can easily be recovered and reused. Therefore, application requirements of clients can be satisfied.

Owner:WUXI GISSING AUTO PARTS CO LTD

Tunneling method of shield equipment in high-viscosity mudstone

The invention discloses a tunneling method of shield equipment in high-viscosity mudstone. The method comprises steps as follows: 1, a water-jet cutter device is mounted, and whether a washing pipeline is smooth is checked; 2, whether mud cakes are attached to a cutter head is checked; 3, pre-cleaning is performed, and circulation parameters and tunneling parameters of a shield machine are set; 4, shield tunneling is performed, and operation parameters of the shield equipment are detected in real time; 5, whether the slag discharge amount is reduced is judged; 6, whether pressure of a mud water bin fluctuates abnormally is judged; 7, whether shield tunneling ends is judged; 8, delayed cleaning is performed. The water-jet cutter device is arranged for washing and cutting mud blocks effectively, and bin opening for manual cleaning is avoided; by means of a stone breaker, small mud blocks, mixed stone and other hard articles in mud are broken, blockage in the circulation process of slurry is avoided; the inverse cleaning procedure is set, so that the washing pipeline can be more effectively and automatically cleaned.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

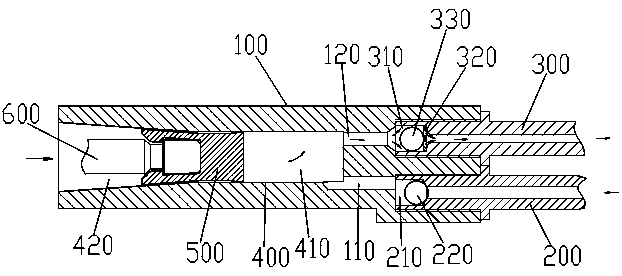

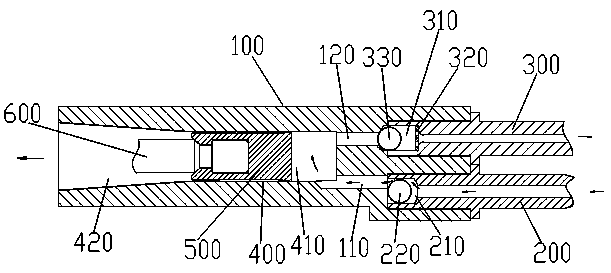

Medical high-pressure pump

InactiveCN104265619AQuick changeQuick to usePositive displacement pump componentsLiquid fuel engine componentsInlet channelEngineering

The invention discloses a medical high-pressure pump. The medical high-pressure pump comprises a pump body which is provided with a fluid inlet channel and a fluid outlet channel, a low-pressure pipe base which is arranged inside the fluid inlet channel, a high-pressure pipe base which is arranged inside the fluid outlet channel, a pressure channel which is arranged inside the pump body and connected with the fluid inlet channel and the fluid outlet channel, a piston which is arranged inside the pressure chamber, a transmission rod which drives the piston to move and is connected with a piston opening end which is close to the pressure chamber of the piston. According to the medical high-pressure pump, the pump and a motor transmission structure are separated, the pump and the transmission structure are connected through a standard interface, only the pump body with a simple structure is required to be sterilized before a surgery, medical liquid only flows inside a sterile pipeline of a medical pump after sterilization, infectious risks caused by instruments are reduced, and accurate pressure control of a medical water jet cutter is achieved. The medical high-pressure pump has the advantages of being simple in structure, convenient to operate and safe and reliable, enabling the instruments and pipelines to be rapidly replaced and used and being sterilized.

Owner:罗凤玲

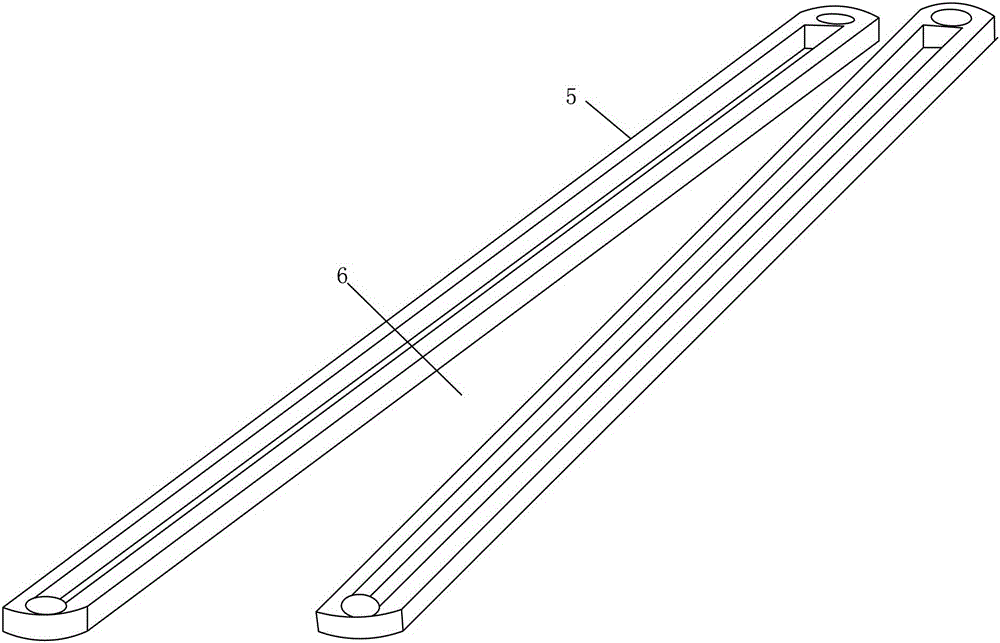

Water jet cutter

A water jet cutter for separation of a trim strip from a moving paper, cardboard, tissue or other type of fiber web, in a machine for the production and / or conversion of the fiber web, including at least one nozzle whose water jet is directed onto the fiber web. An advantage of the present invention is to simplify the construction of the device while maintaining at least equal operational reliability, and to enable installation above a pulper in order to eliminate the necessity for removal and extraction systems.

Owner:VOITH PATENT GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com