Patents

Literature

136 results about "Sonic nozzle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sonic Nozzles. Sonic nozzle, also known as critical flow venturi nozzle, is one of the most repeatable and high quality transfer standard used by industries and calibration laboratories worldwide.

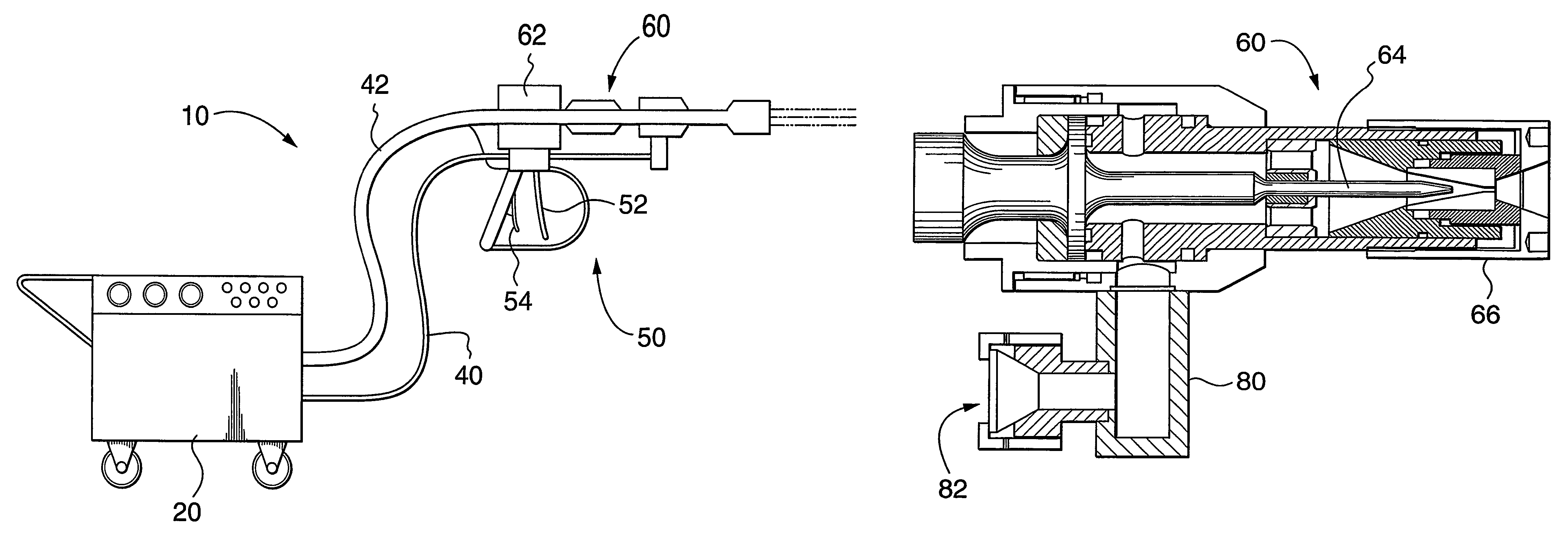

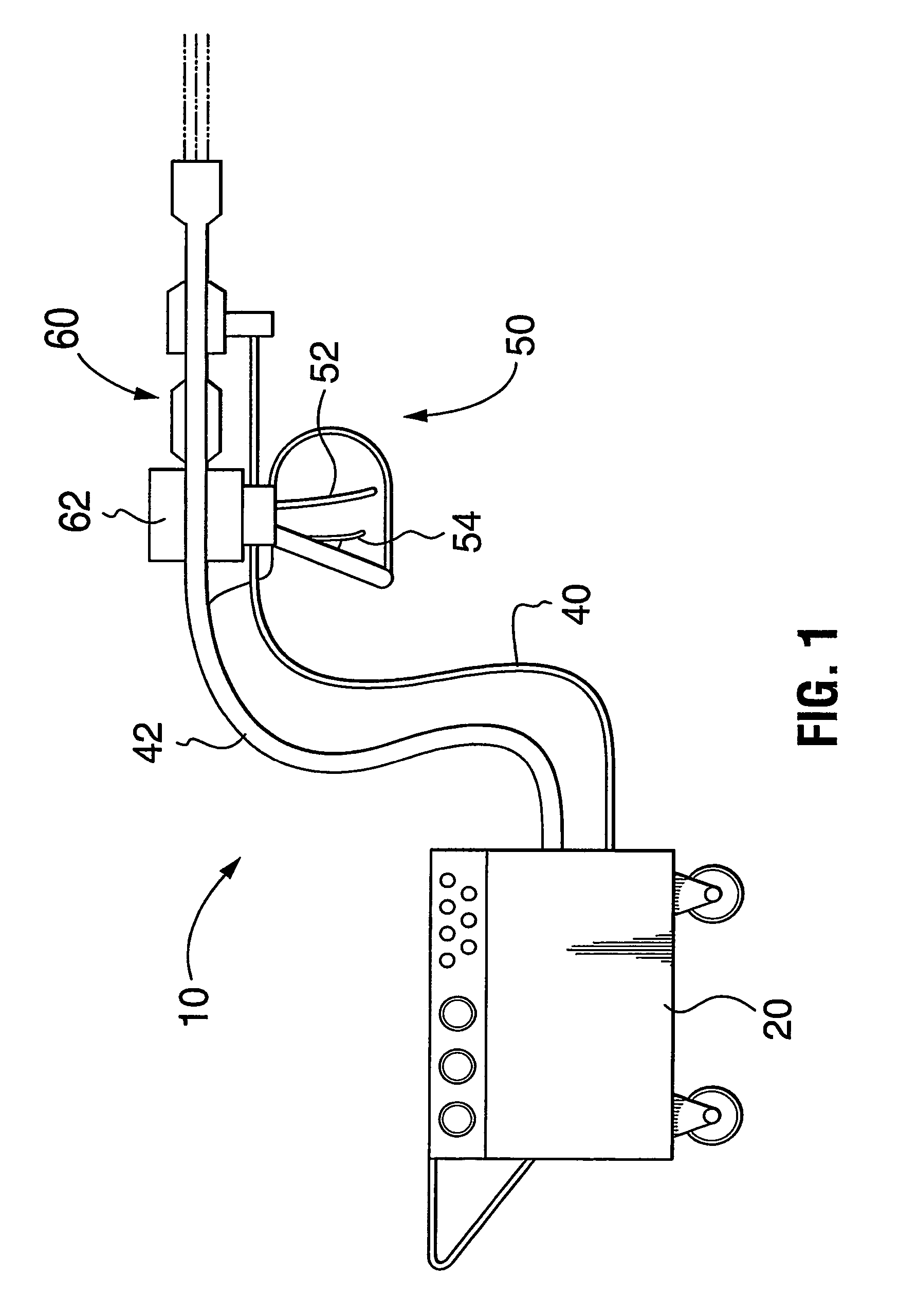

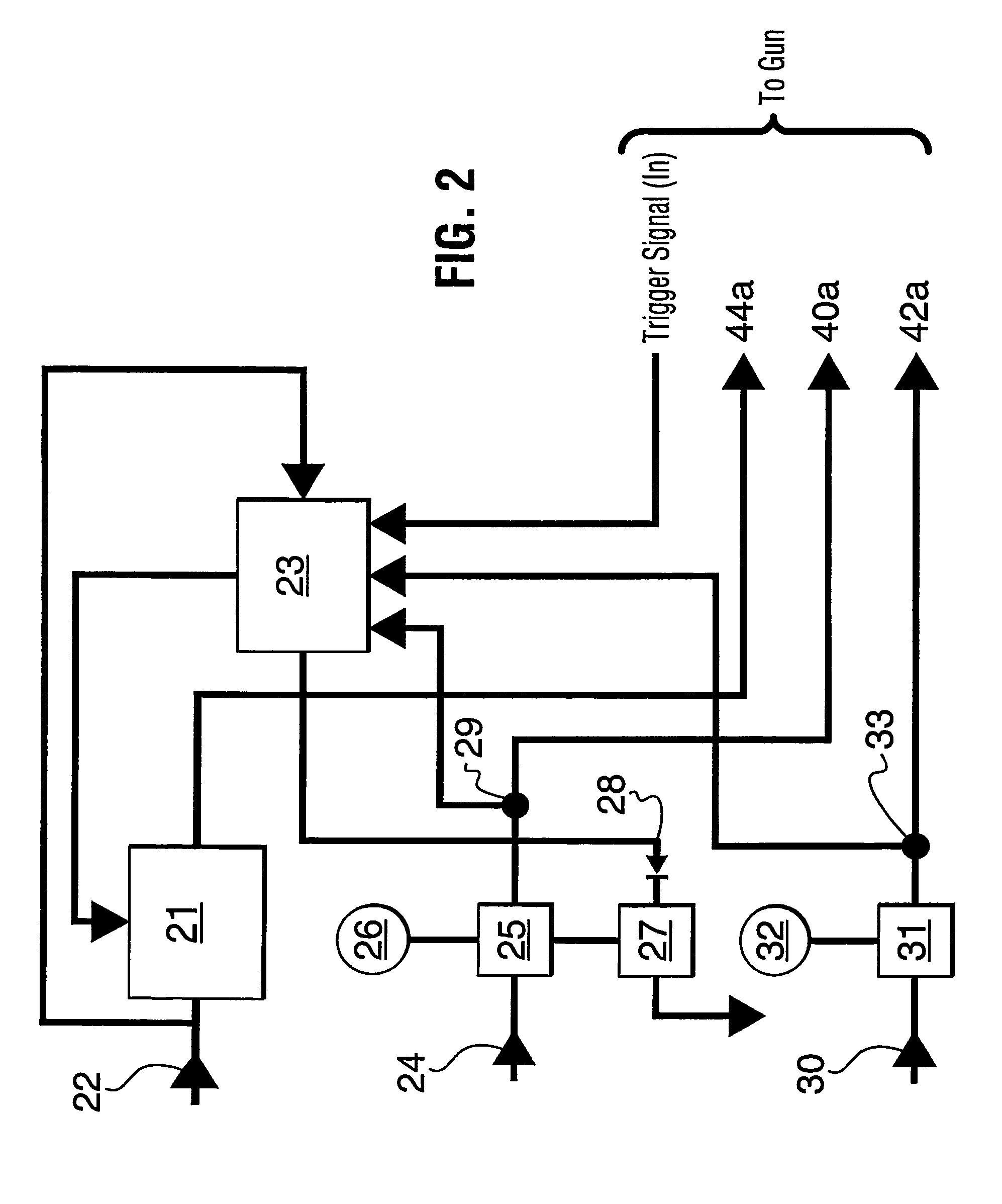

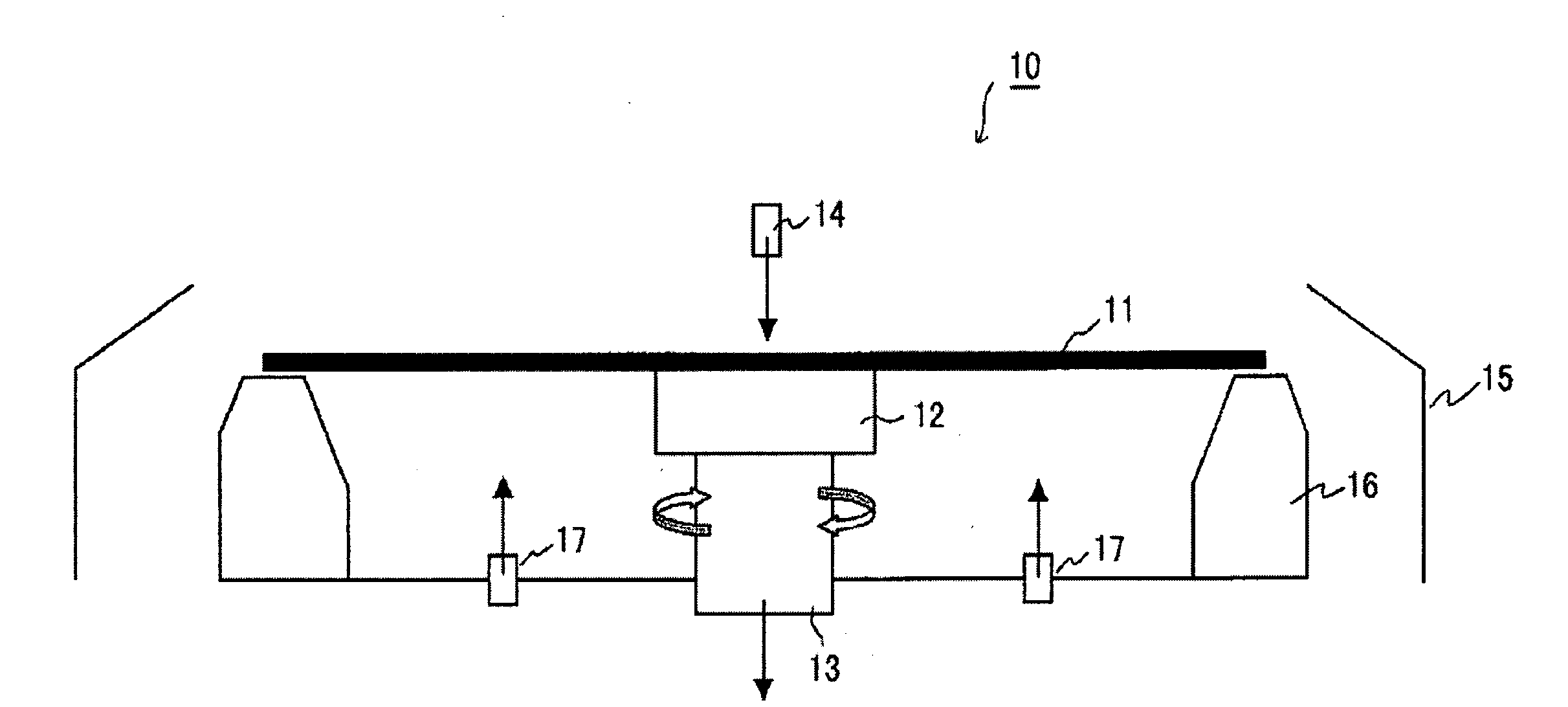

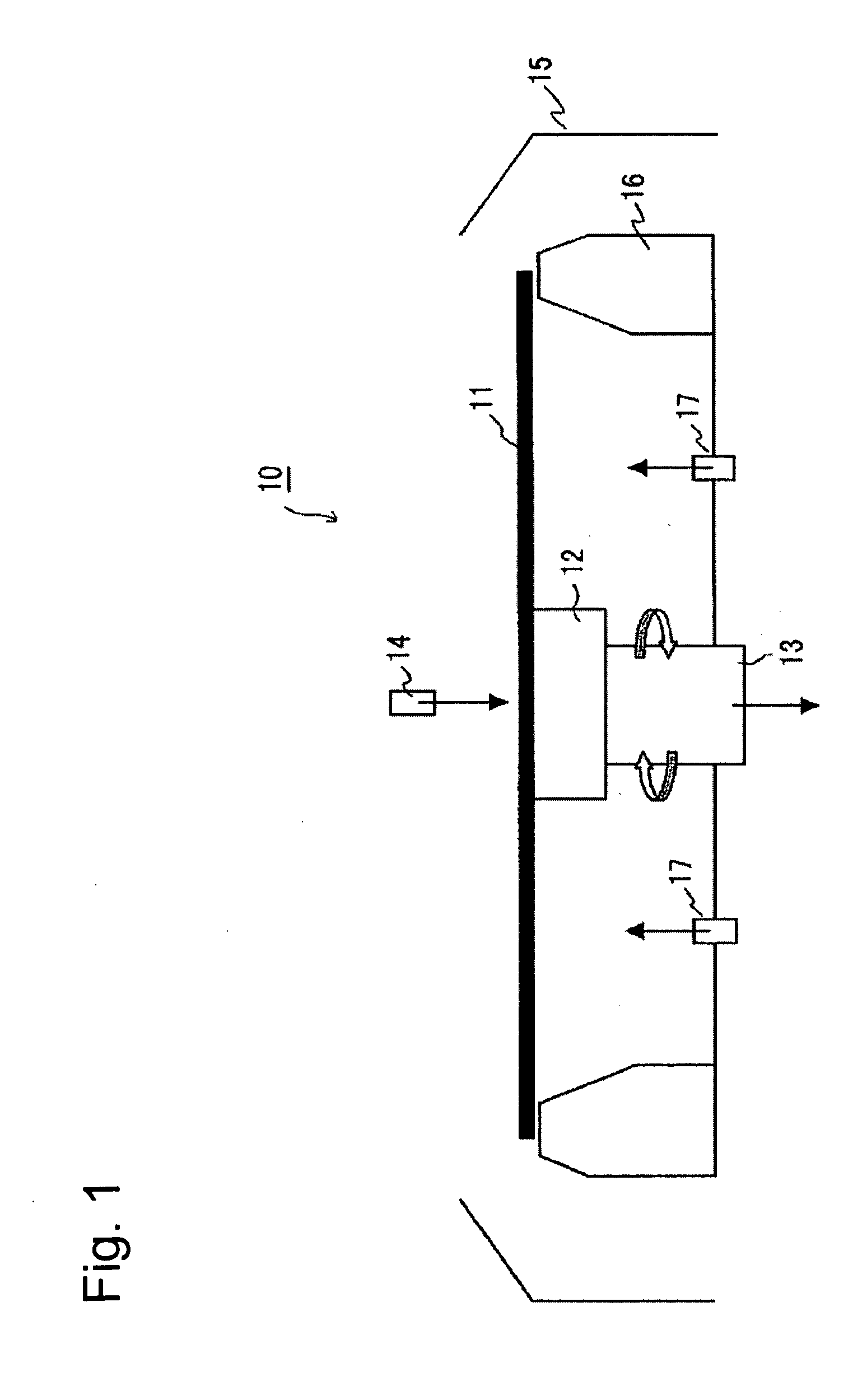

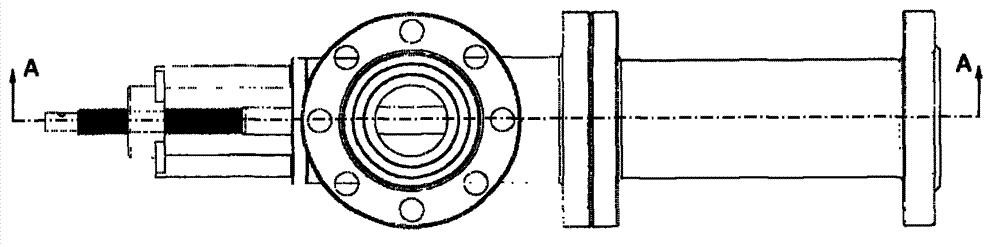

Ultrasonic waterjet apparatus

ActiveUS7594614B2Reduce cleaningReduce pressureLiquid surface applicatorsPiezoelectric/electrostriction/magnetostriction machinesSonic nozzleUltrasonic nozzle

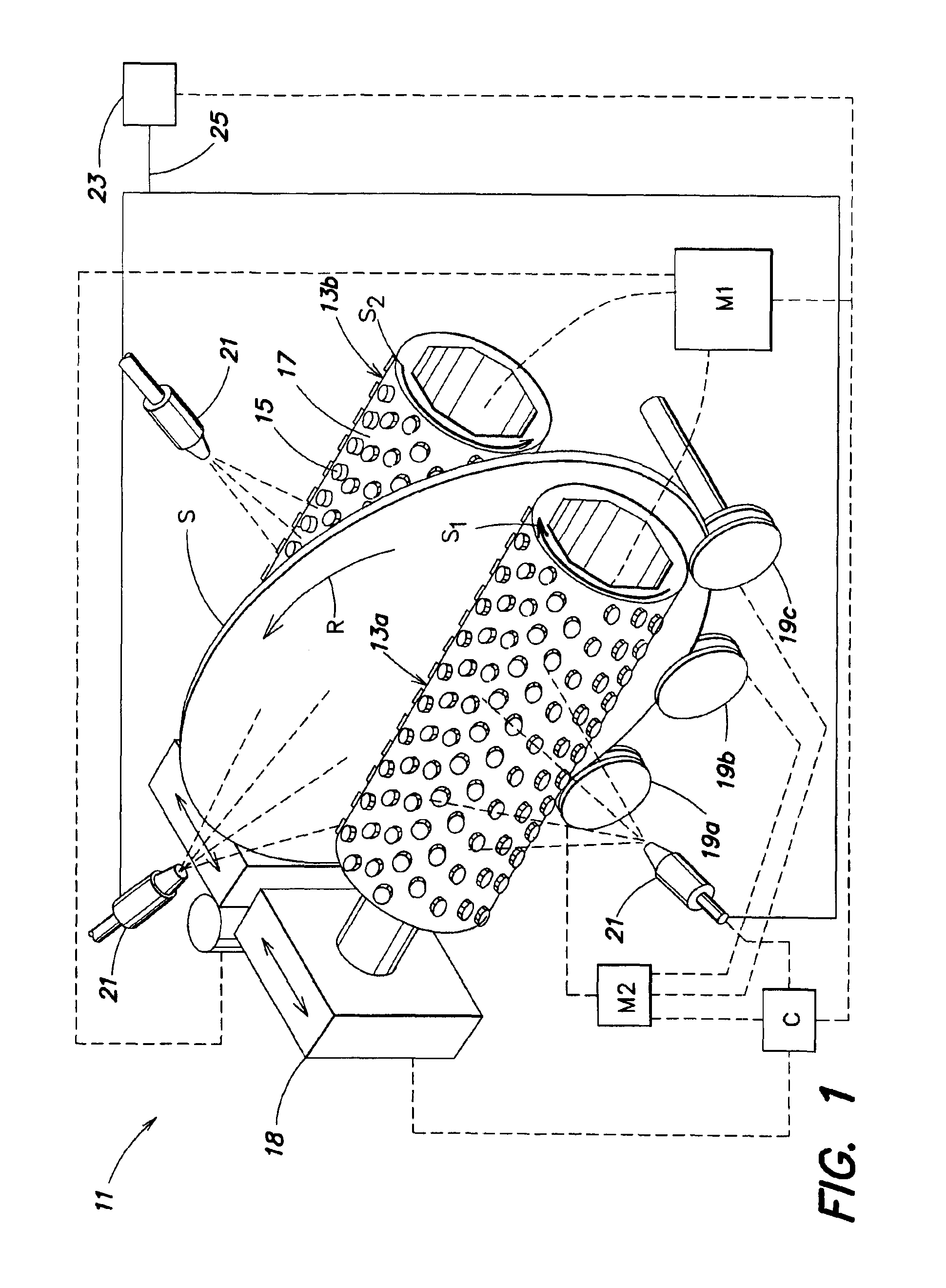

An ultrasonic waterjet apparatus (10) has a mobile generator module (20) and a high-pressure water hose (40) for delivering high-pressure water from the mobile generator module (20) to a hand-held gun (50) with a trigger and an ultrasonic nozzle (60). An ultrasonic generator in the mobile generator module (20) transmits high-frequency electrical pulses to a piezoelectric or magnetostrictive transducer (62) which vibrates to modulate a high-pressure waterjet flowing through the nozzle (60). The waterjet exiting the ultrasonic nozzle (60) is pulsed into mini slugs of water, each of which imparts a waterhammer pressure on a target surface. The ultrasonic waterjet apparatus (10) may be used to cut and de-burr materials, to clean and de-coat surfaces, and to break rocks. The ultrasonic waterjet apparatus (10) performs these tasks with much greater efficiency than conventional continuous-flow waterjet systems because of the repetitive waterhammer effect. A nozzle with multiple exit orifices or a rotating nozzle (76) may be provided in lieu of a nozzle with a single exit orifice to render cleaning and de-coating large surfaces more efficient. A water dump valve (27) and controlling solenoid are located in the mobile generator module (20) rather than the gun (50) to make the gun lighter and more ergonomic.

Owner:PRATT & WHITNEY MILLTARY AFTERMARKET SERVICES

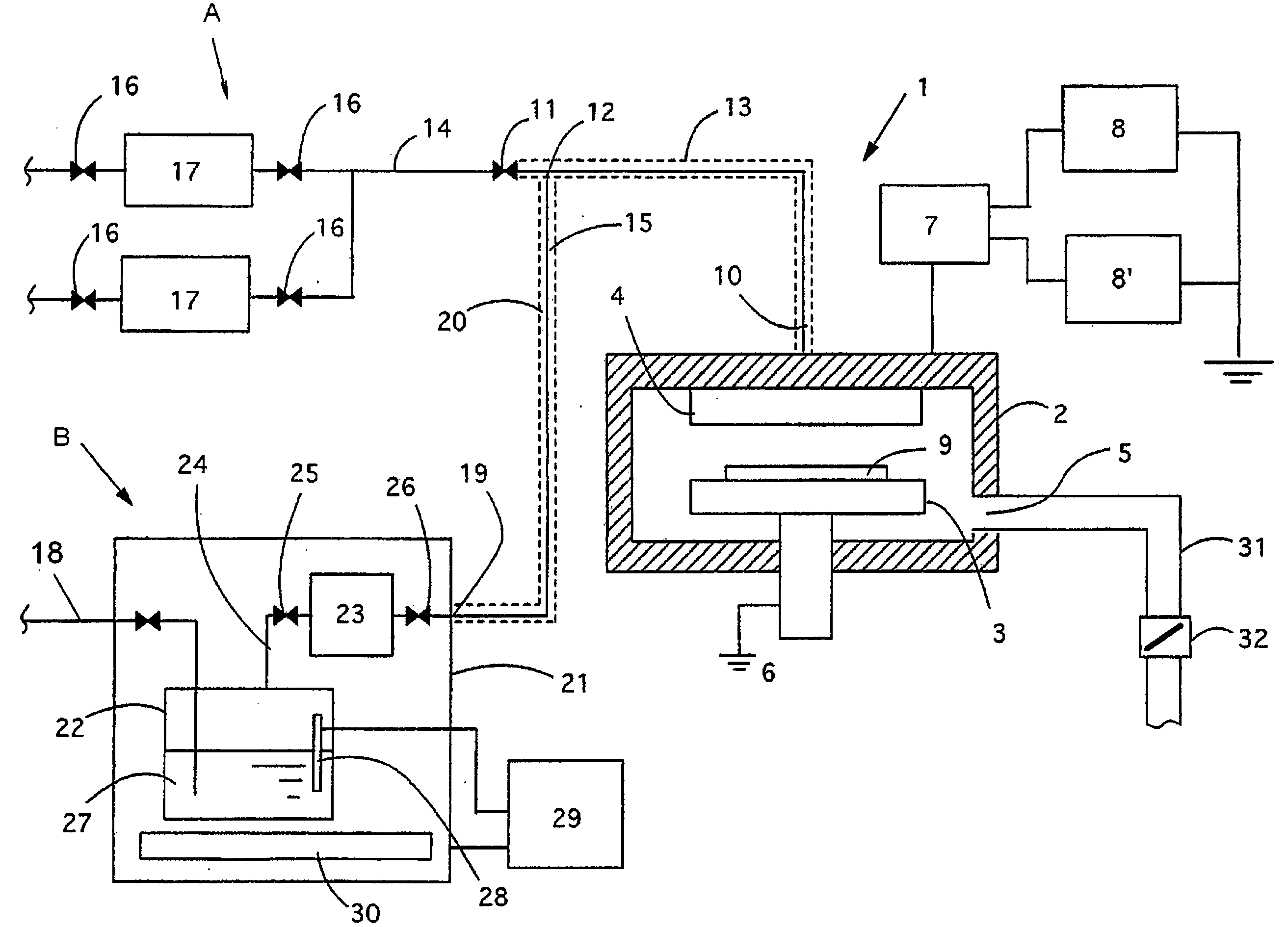

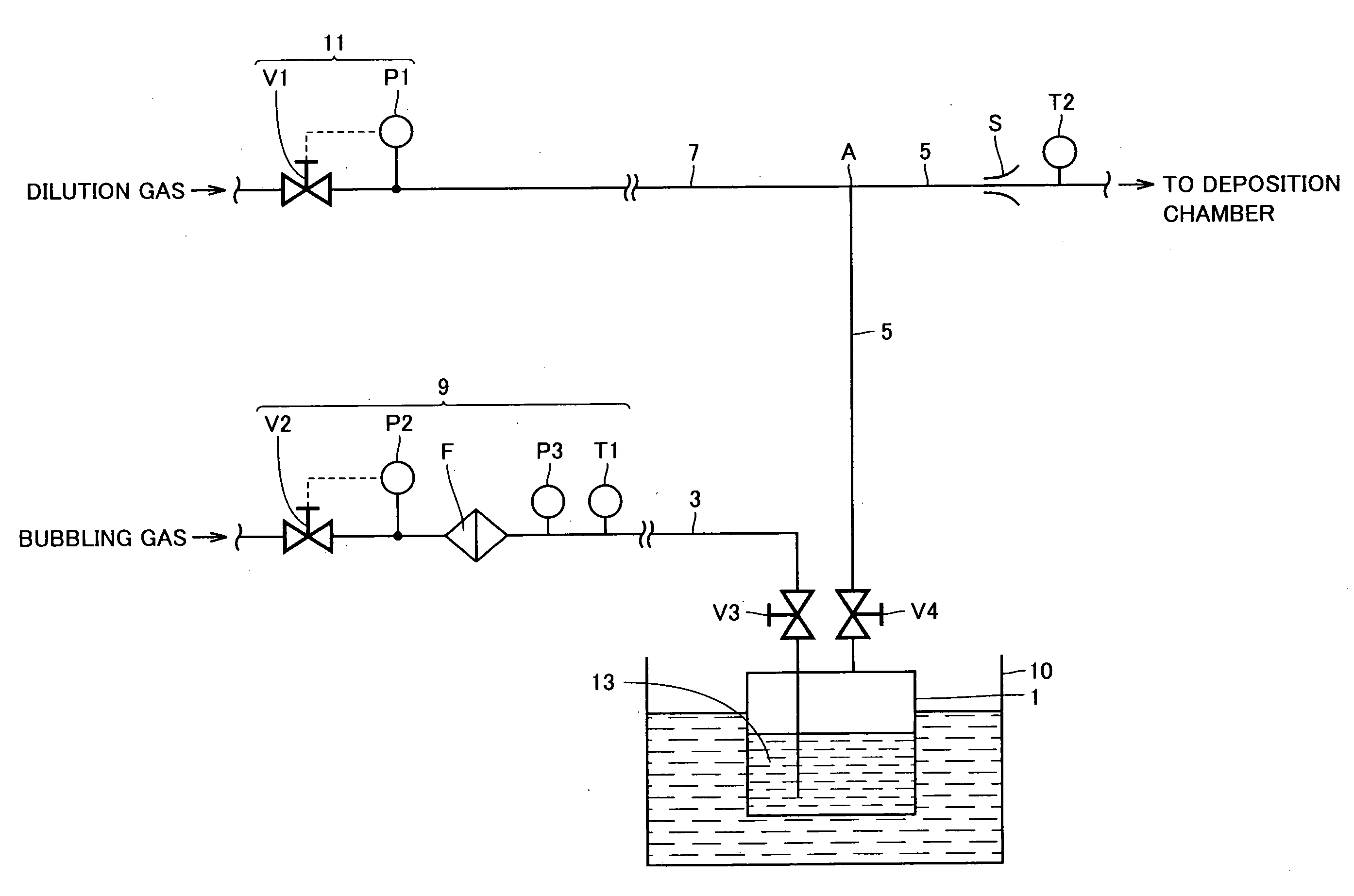

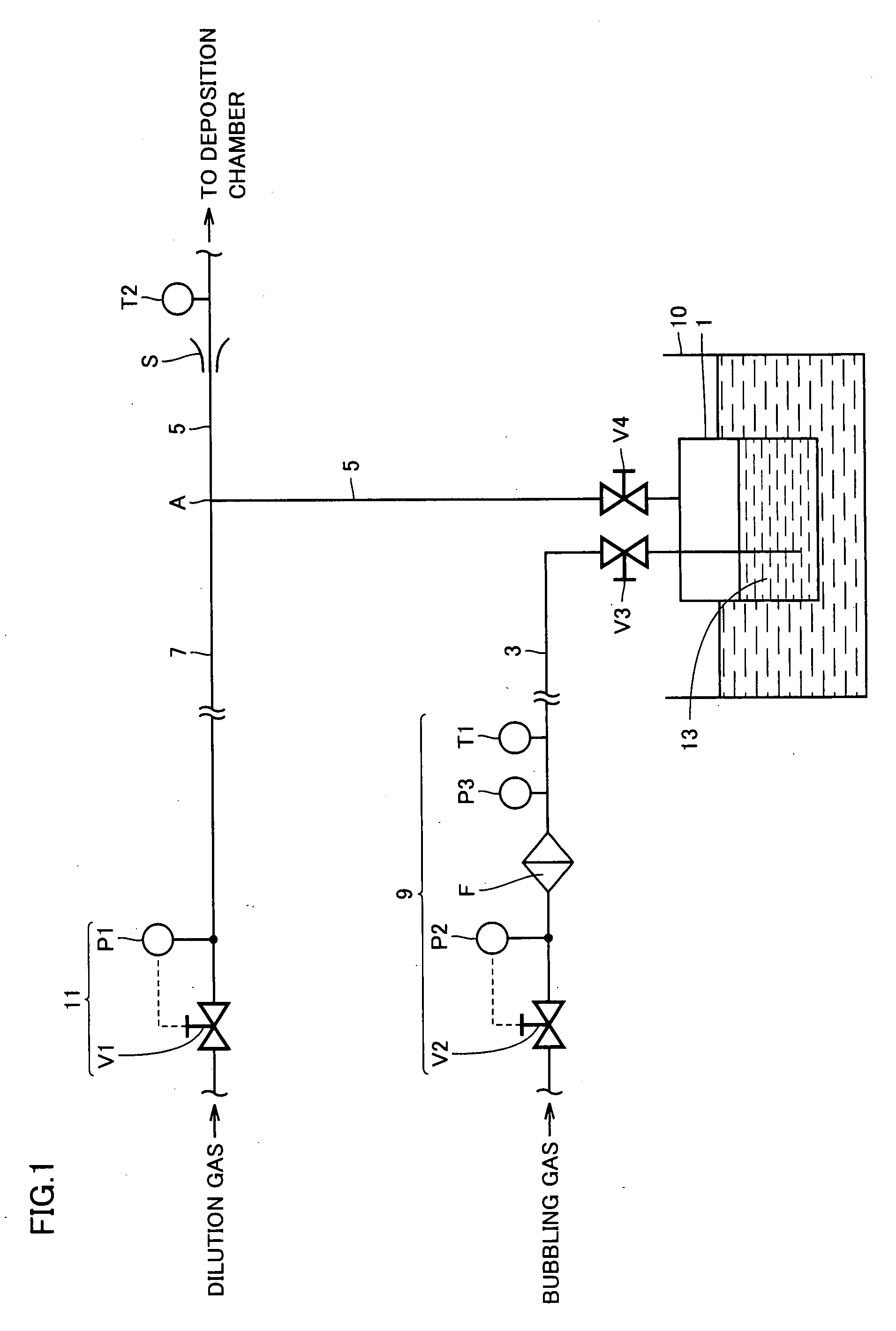

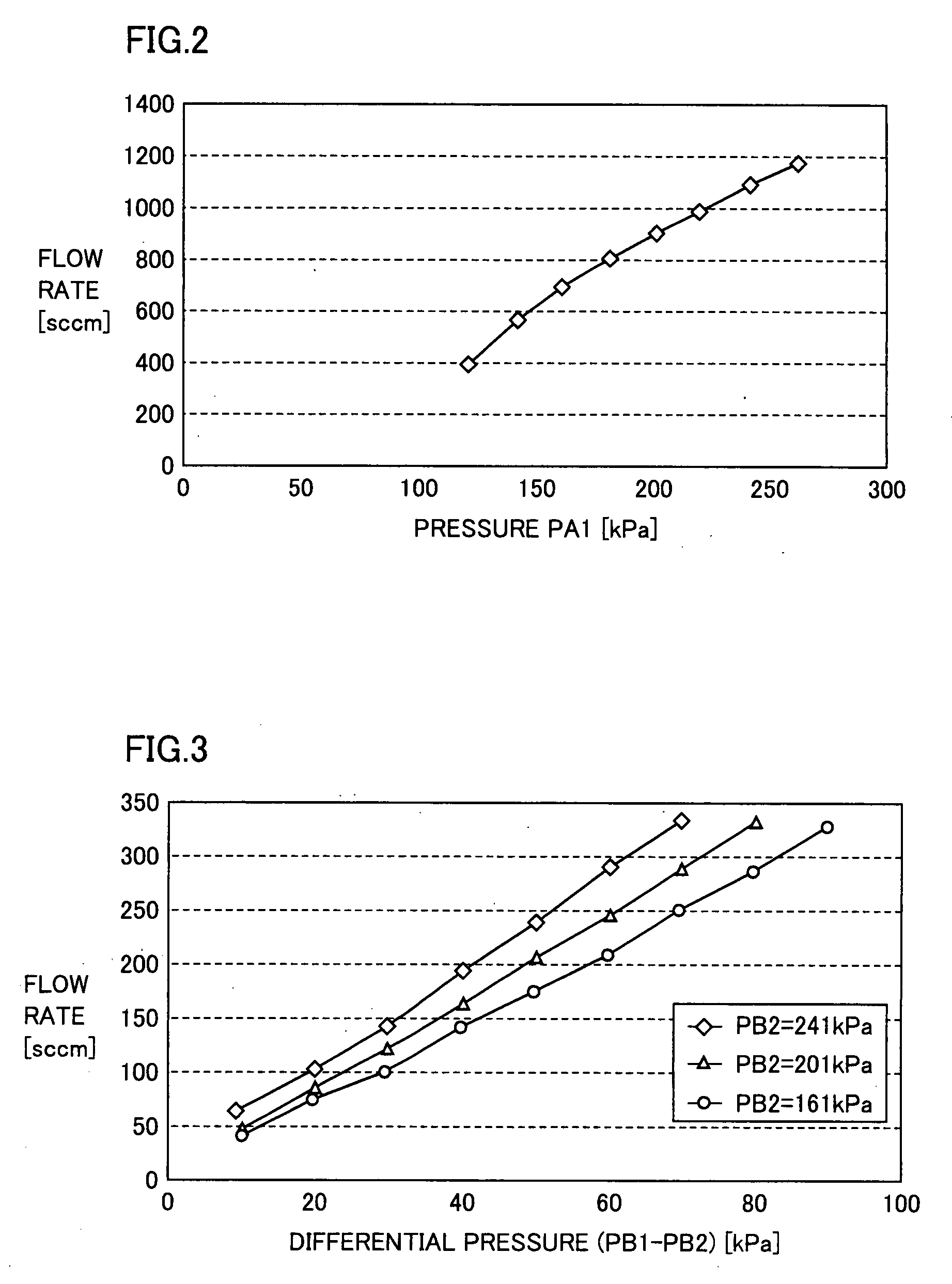

Source gas flow control and CVD using same

InactiveUS20050098906A1Good reproducibilityEnsure efficient flowSemiconductor/solid-state device testing/measurementLighting and heating apparatusSonic nozzleAcoustic wave

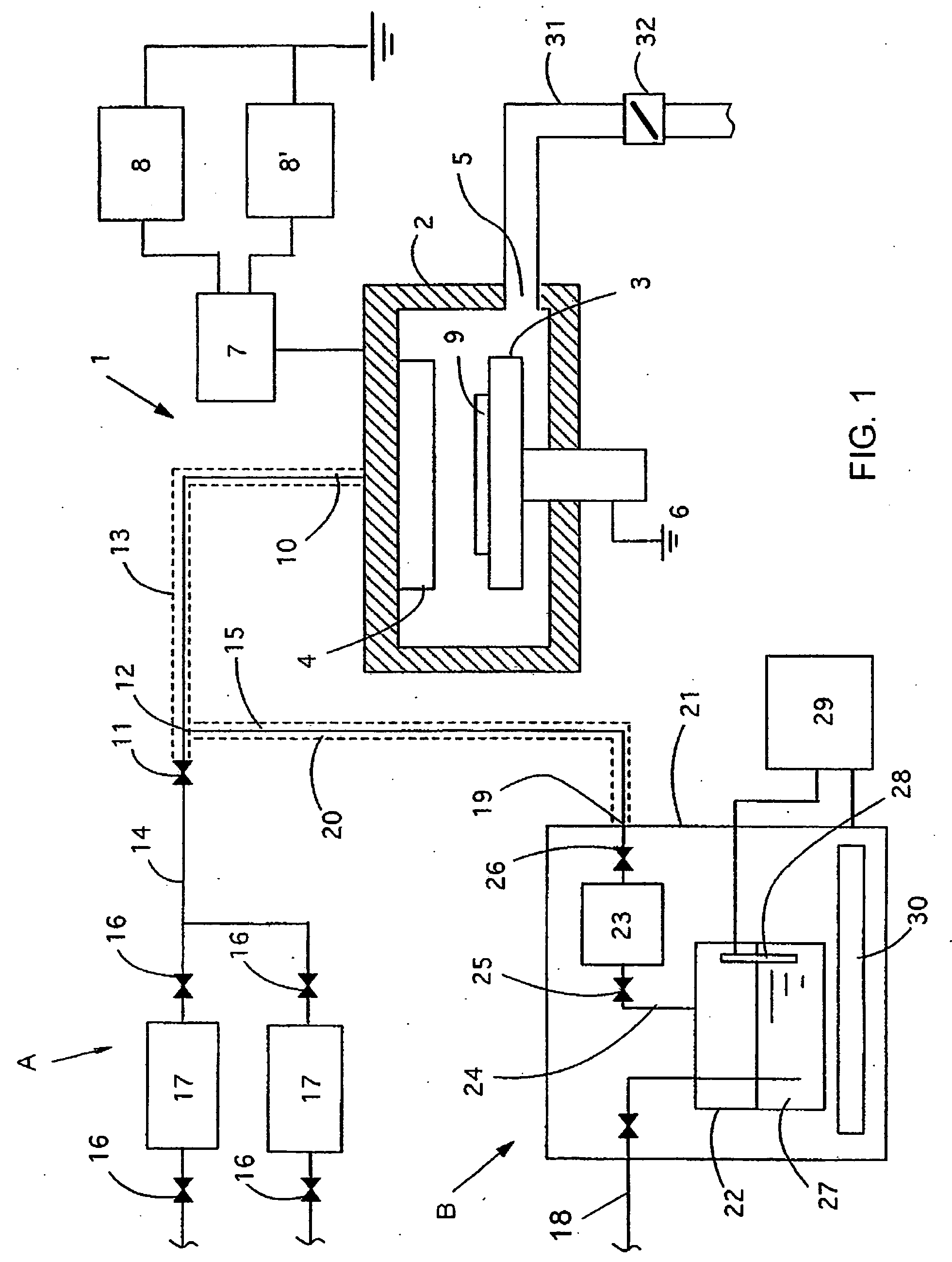

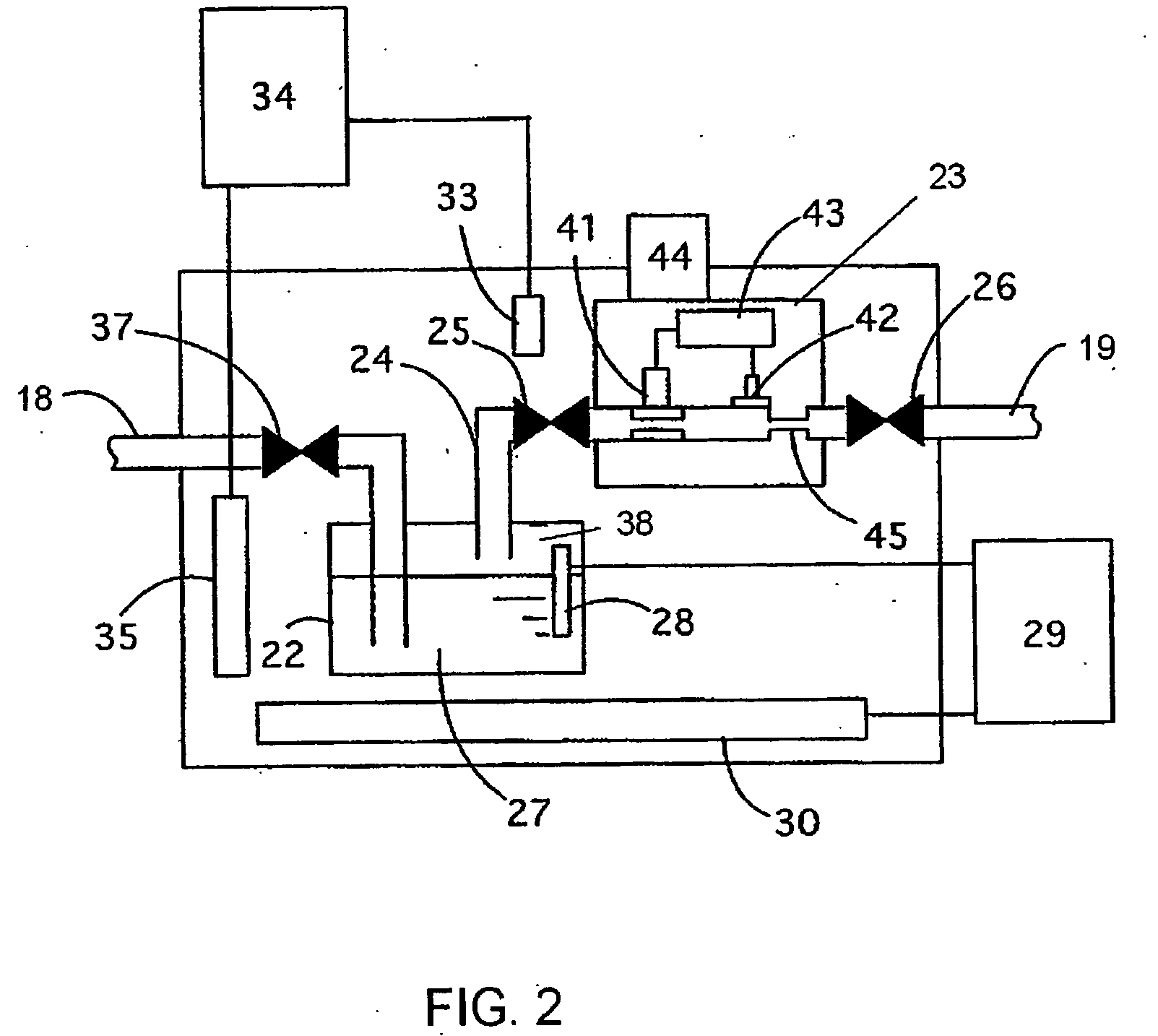

A source-gas supply apparatus for supplying a source gas into a CVD reactor includes: a reservoir for storing a liquid material; a gas flow path connected the reservoir and the CVD reactor; a sonic nozzle disposed in the gas flow path, through which the source gas is introduced into the CVD reactor; a pressure sensor disposed in the gas flow path upstream of the sonic nozzle; a flow control valve disposed in the gas flow path upstream of the pressure sensor; and a flow control circuit which receives a signal from the pressure sensor and outputs a signal to the flow control valve to adjust opening of the flow control valve as a function of the signal from the pressure sensor.

Owner:ADVANCED ENERGY JAPAN +1

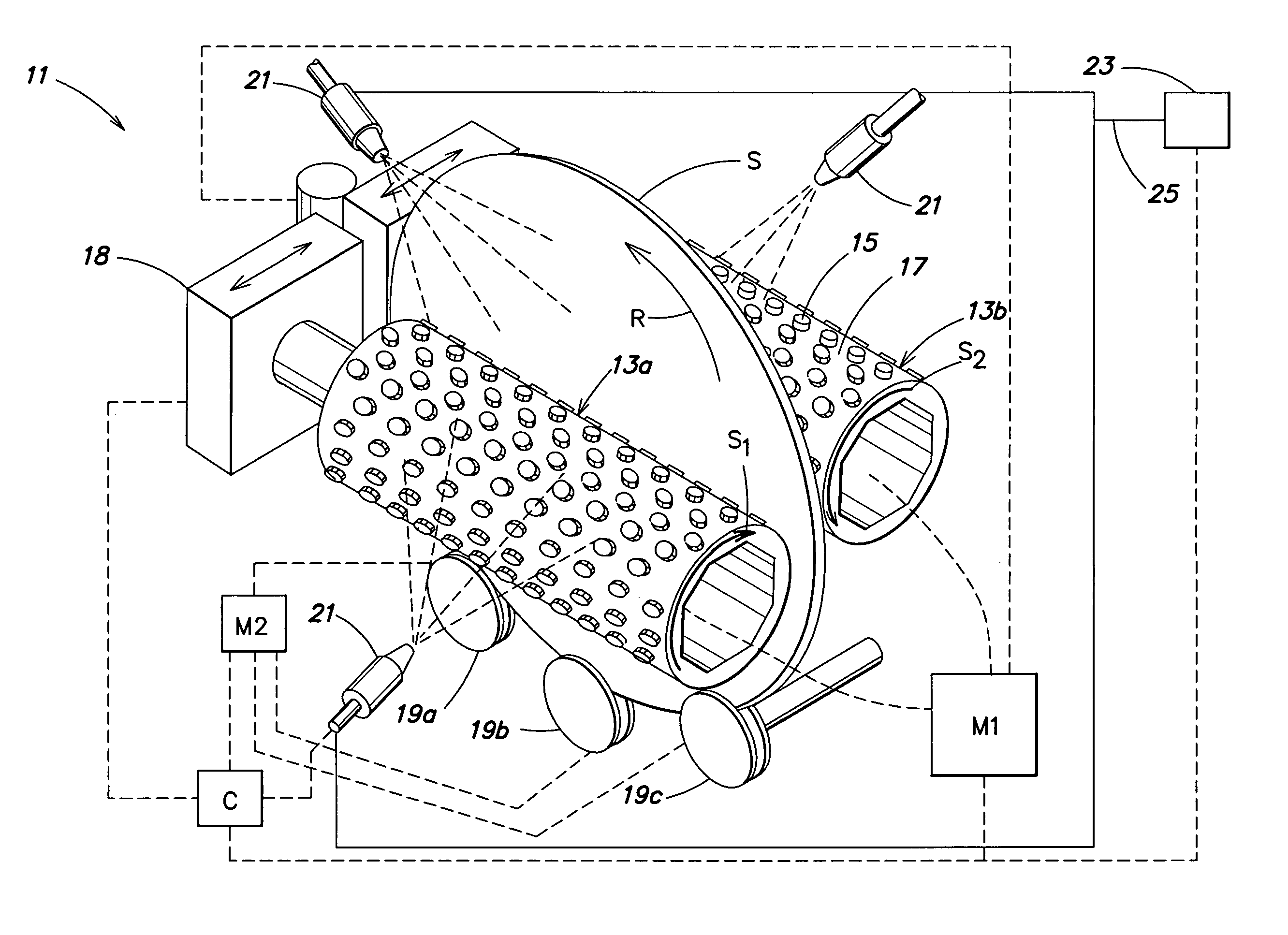

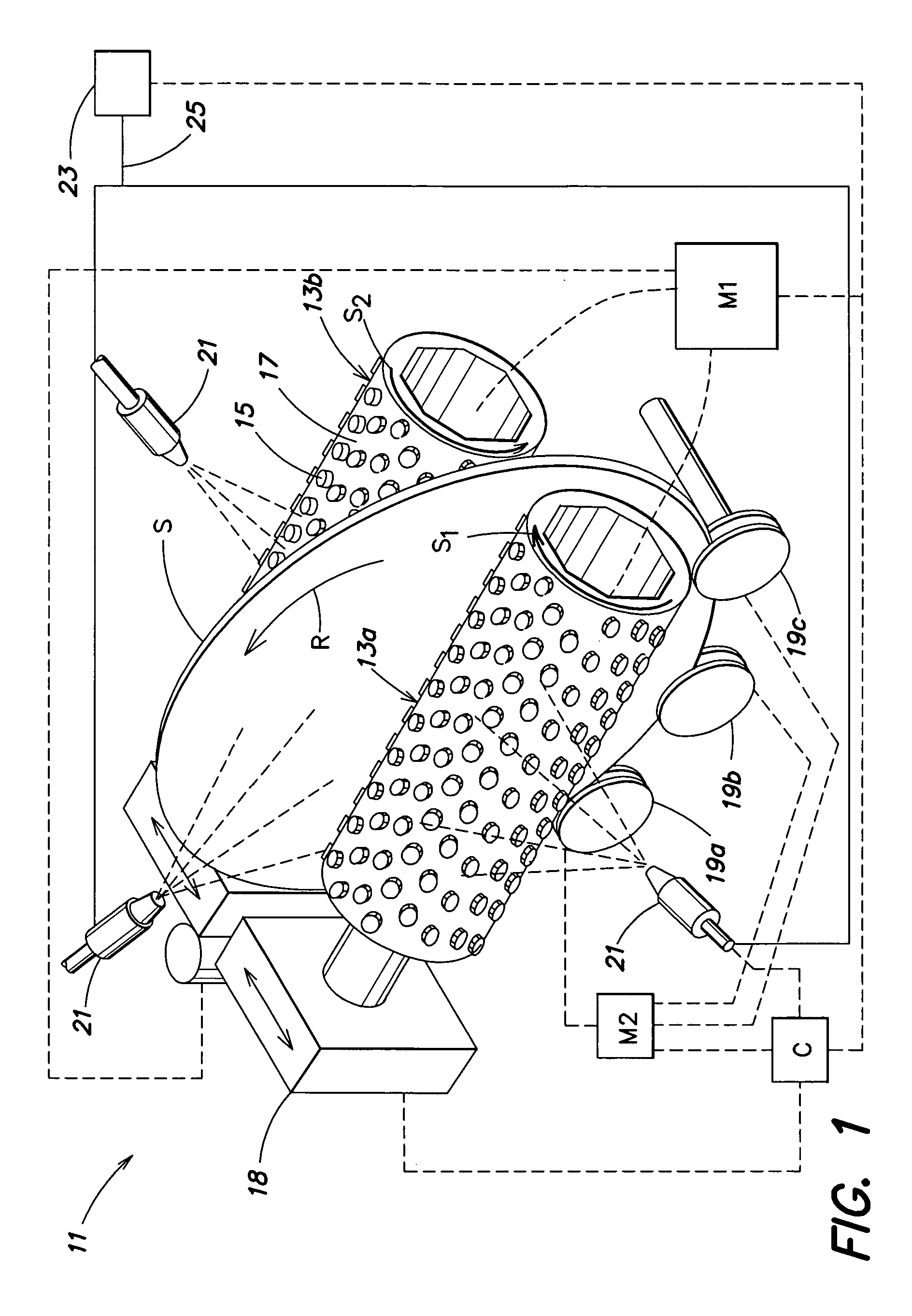

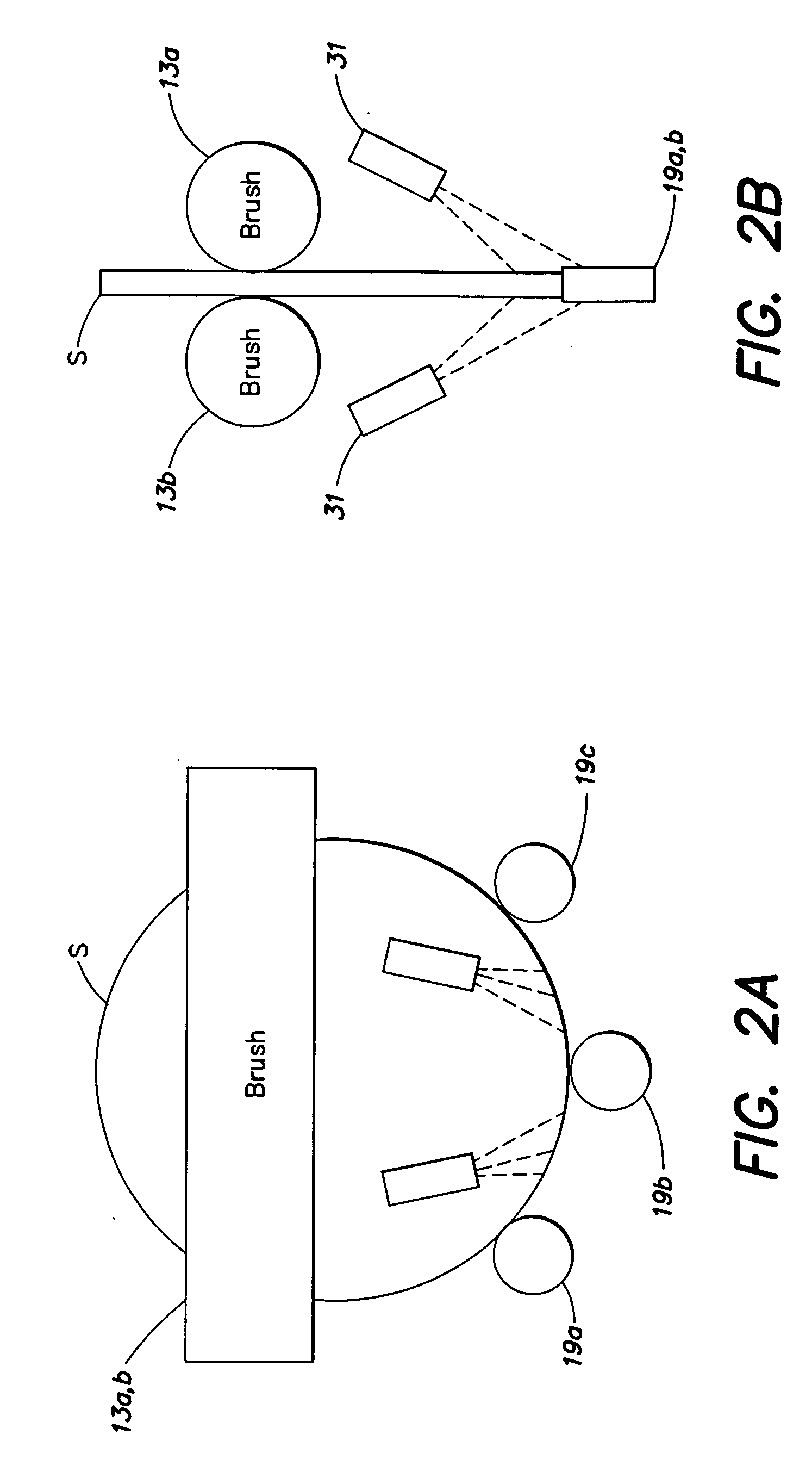

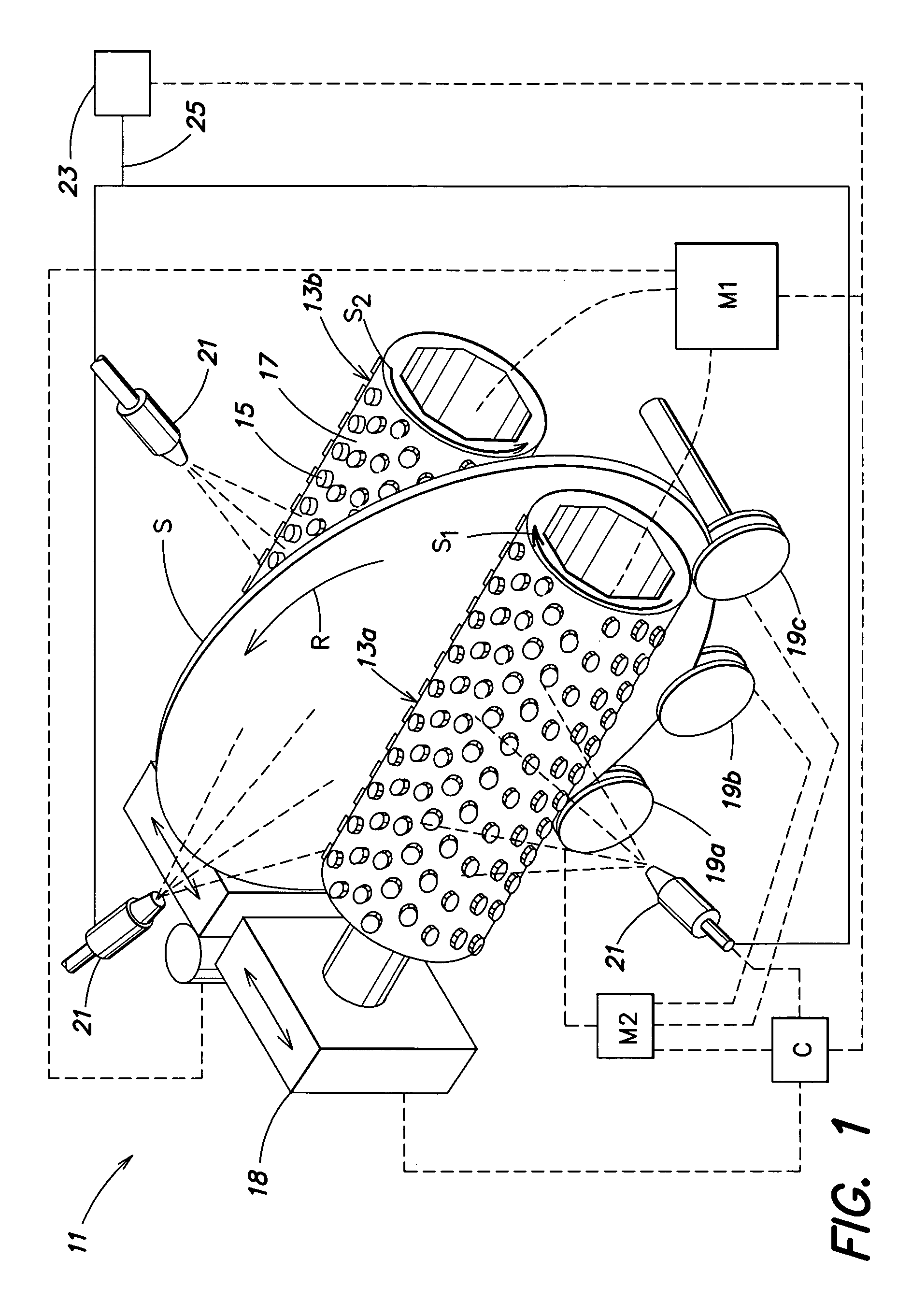

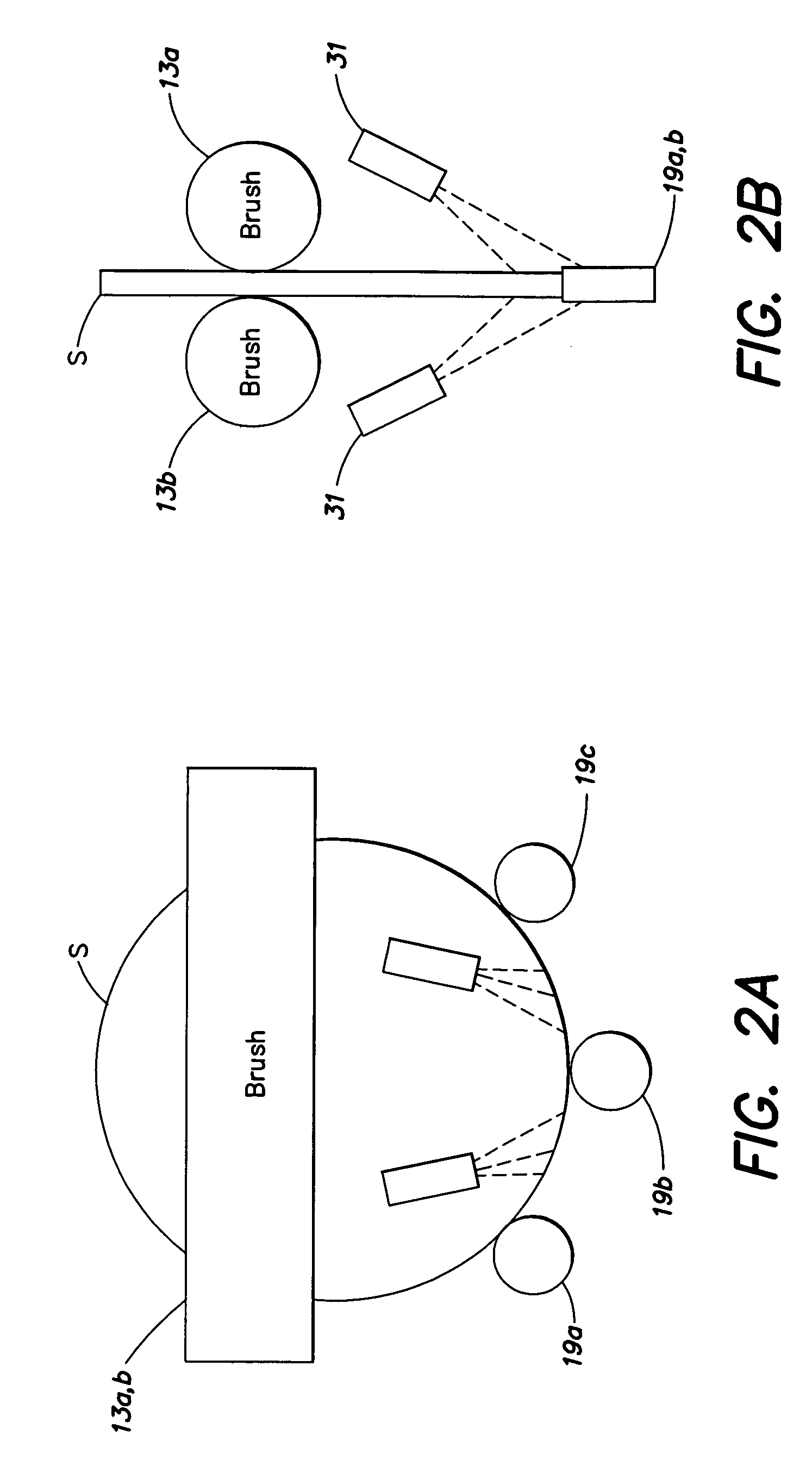

Scrubber with sonic nozzle

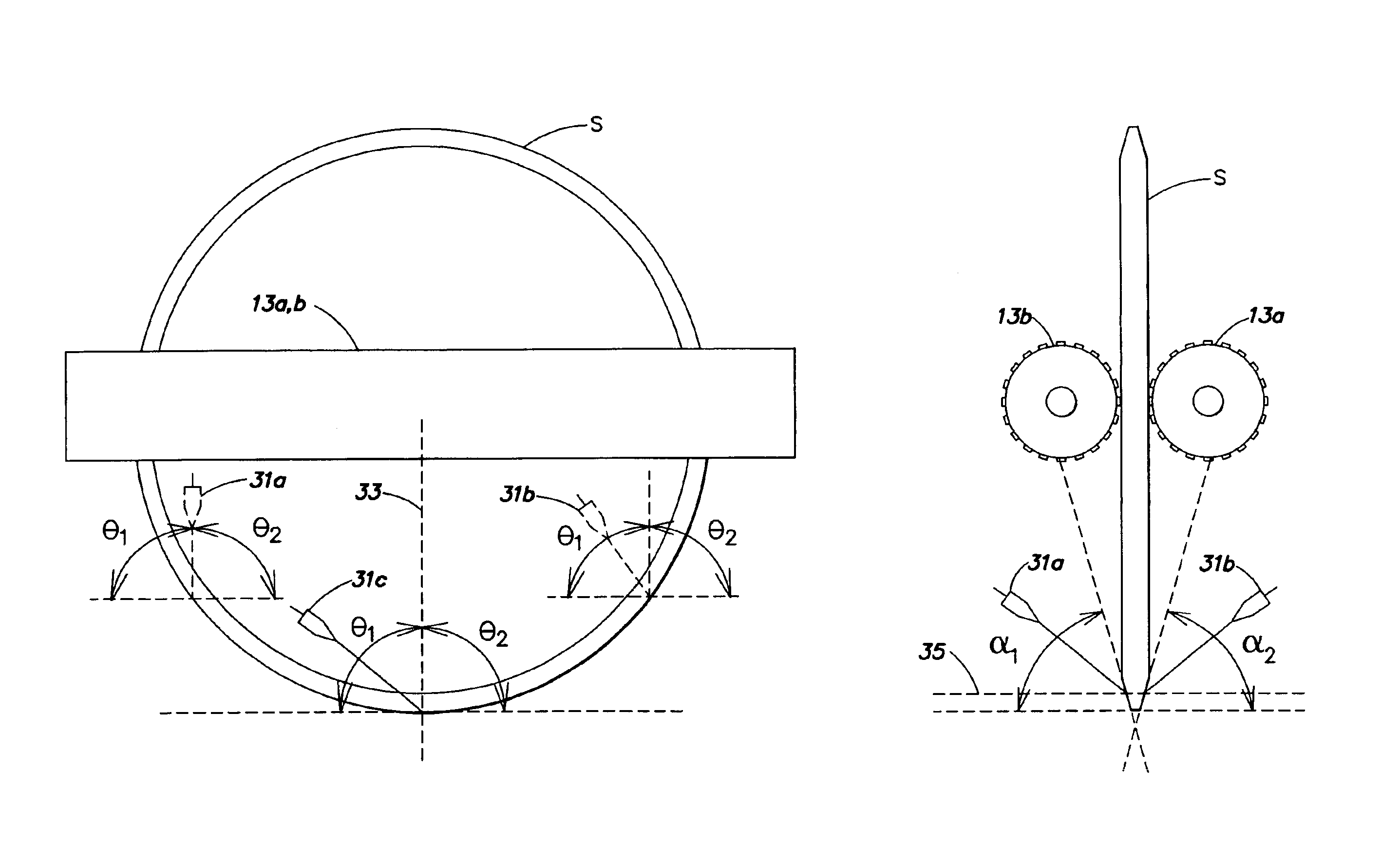

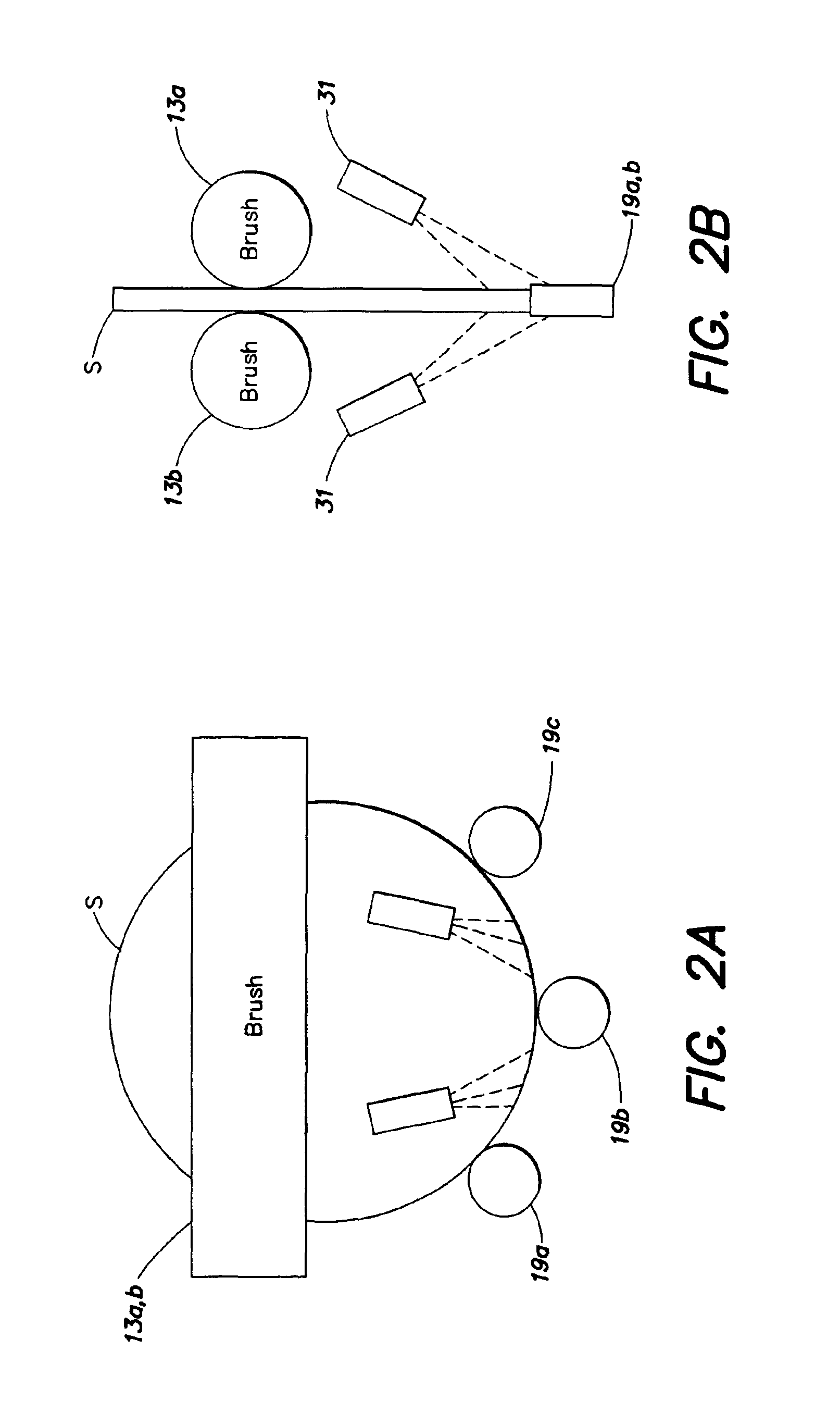

An apparatus for cleaning a substrate is provided. The apparatus comprises a plurality of rollers adapted to support a substrate in a vertical orientation, a scrubber brush adapted to contact a substrate supported by the plurality of rollers, and a sonic nozzle positioned at an elevation below the elevation of the scrubber brush and adapted so as to output a sonicated fluid spray that contacts a beveled edge or a major surface of the substrate such that fluid having sufficient sonic energy to harm the scrubber brush will not contact the scrubber brush.

Owner:APPLIED MATERIALS INC

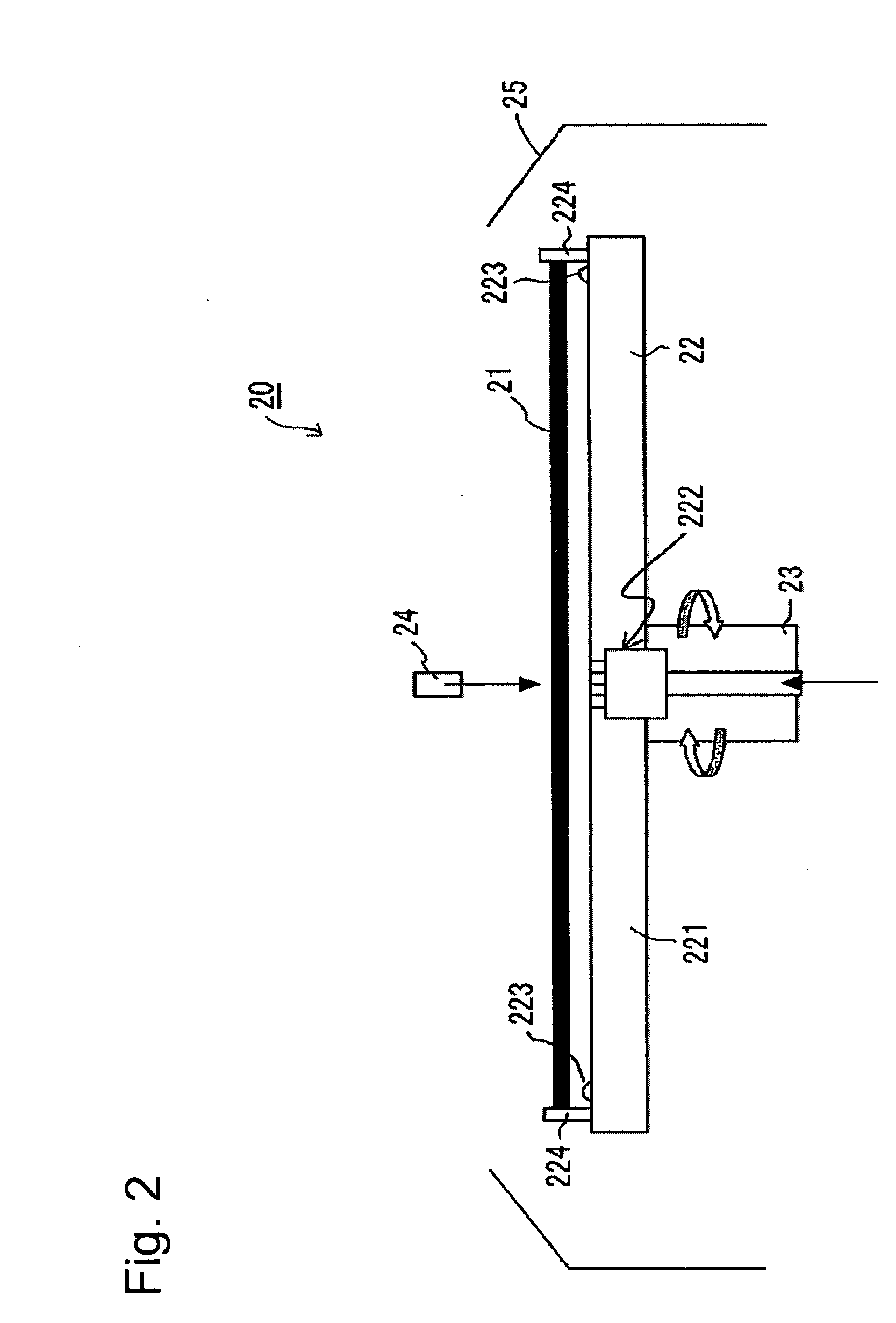

Film coating apparatus

InactiveUS20090277379A1Uniform film thickness distributionAvoid high speed rotationLiquid surface applicatorsPhotomechanical apparatusResistSonic nozzle

A gas ejected from a sonic nozzle toward the rear surface of a wafer. The flow speed of the gas flowing to the outer circumference side along the rear surface of the wafer is increased between the rear surface of the wafer and a second cup and is kept by Bernoulli's effects. Thus, flapping of wafer is suppressed. Furthermore, a resist solution is prevented from flowing around to the rear surface.

Owner:TOKYO ELECTRON LTD +1

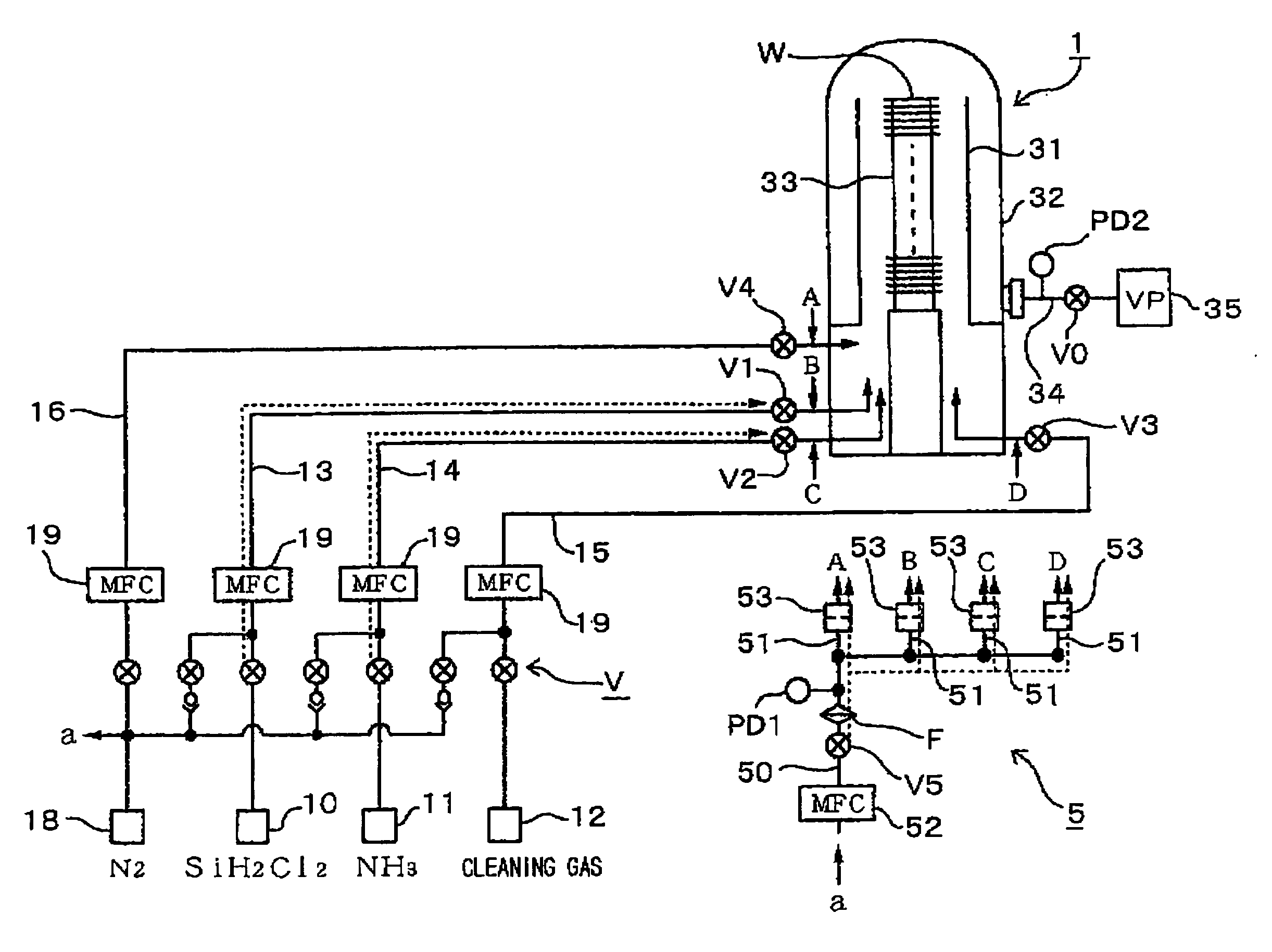

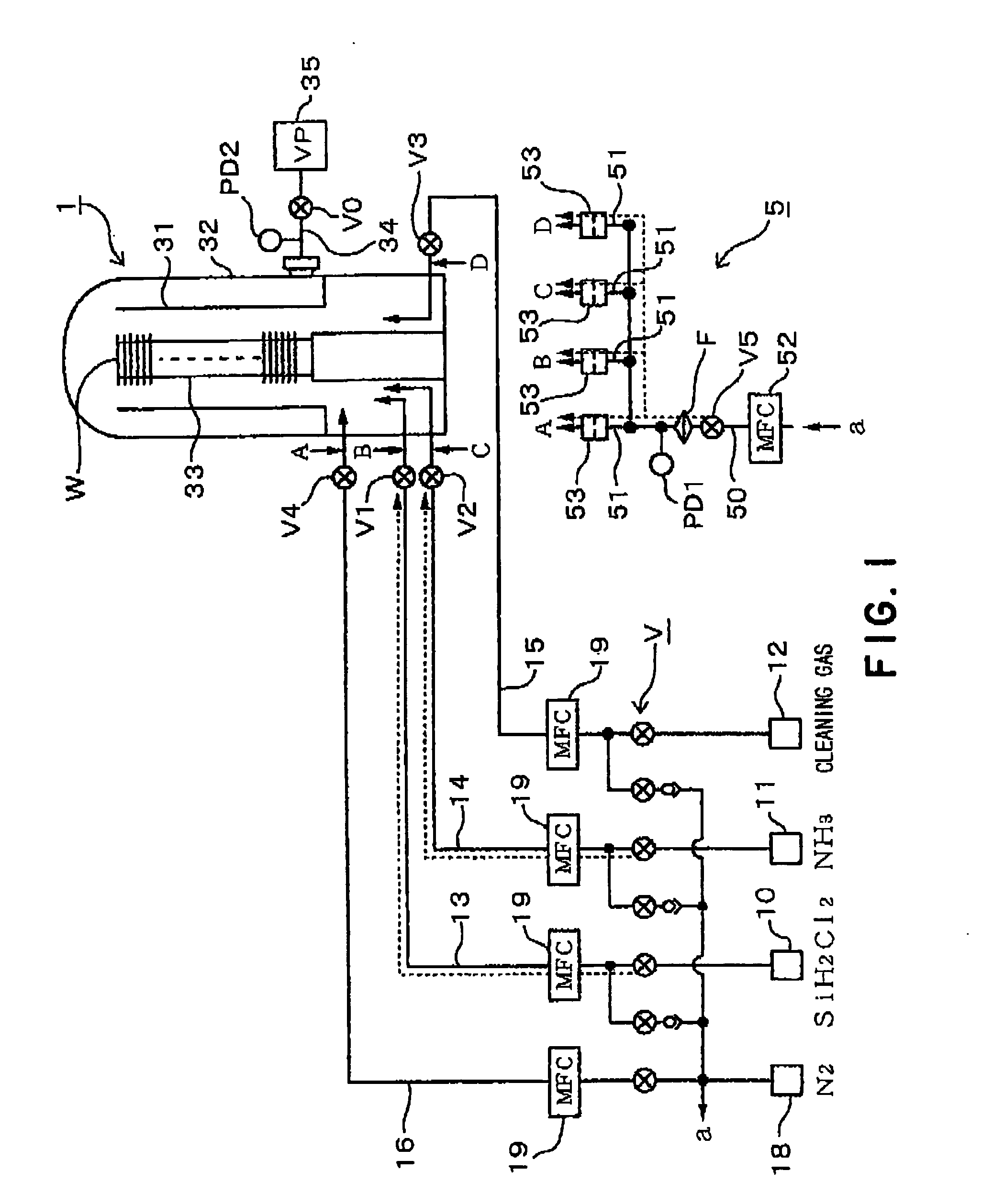

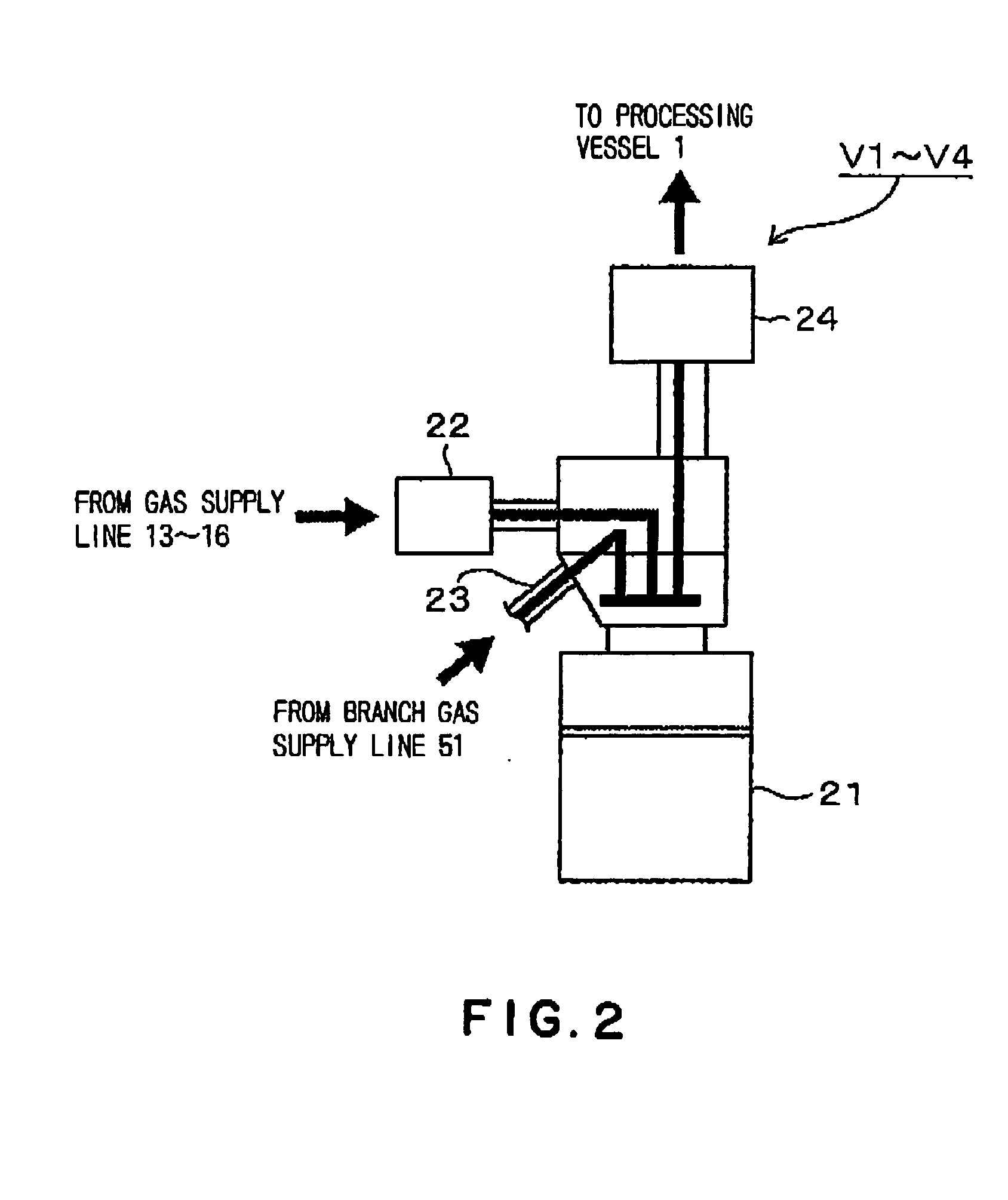

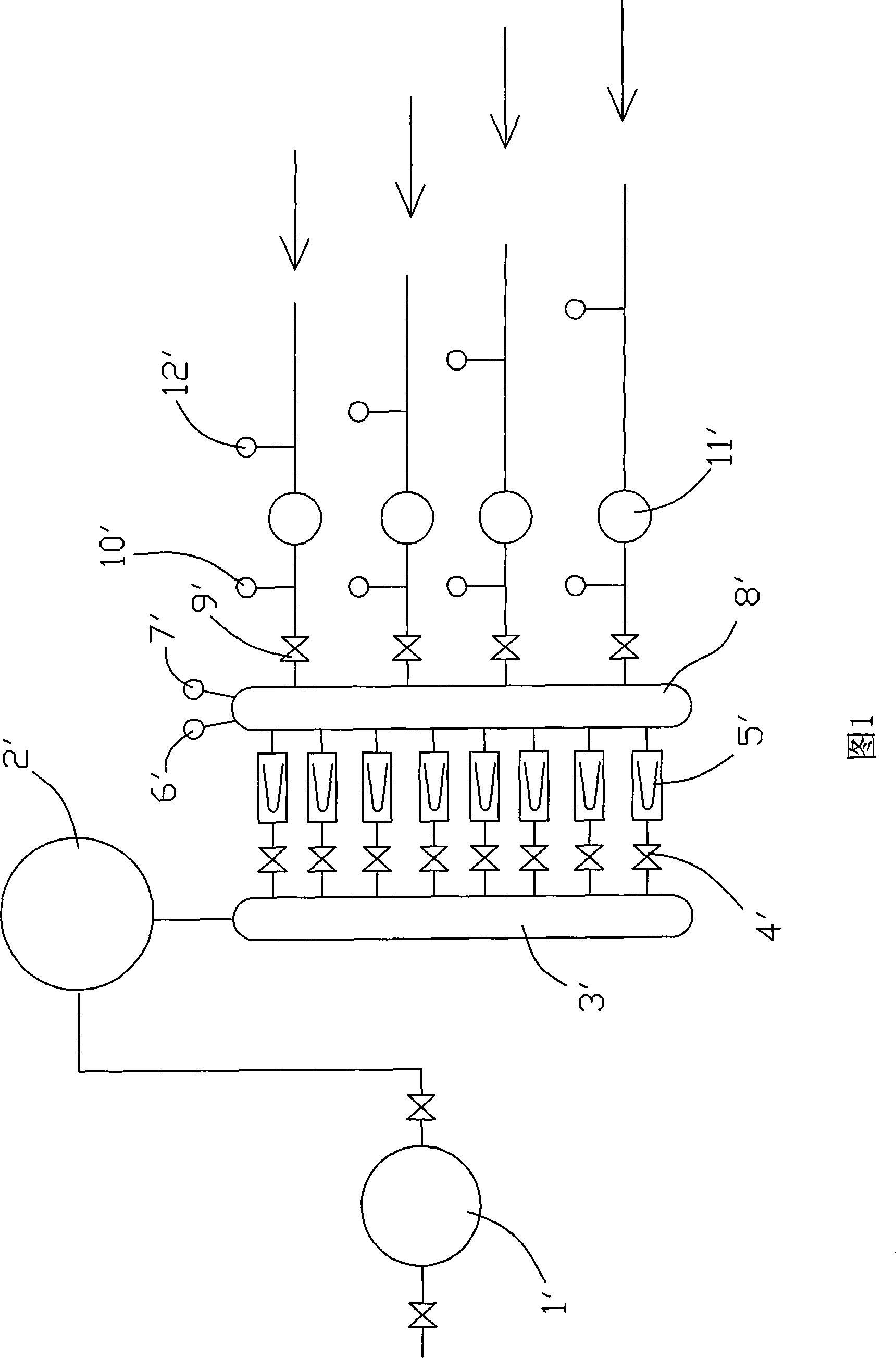

Semiconductor device fabricating system and semiconductor device fabricating method

InactiveUS20050087299A1Stably carry-outEasy to controlSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSonic nozzleStream flow

Shutoff valves are placed in parts of the process gas supply lines at positions near the processing vessel. A main purge gas supply line branches into branch purge gas supply lines, each of which is provided with an orifice called sonic nozzle. The branch purge gas supply lines are connected to parts of the process gas supply lines extending between the shutoff valves and the processing vessel. The ratio P1 / P2, where P1 is primary pressure on the primary side of the orifice and P2 is secondary pressure on the secondary side of the orifice, is controlled to be not less than a predetermined value, for example, two, thereby, the purge gas can always be supplied at equal flow rates into the process gas supply lines. The total flow rate of the purge gas is controlled by a mass flow controller placed in the main purge gas supply line.

Owner:TOKYO ELECTRON LTD

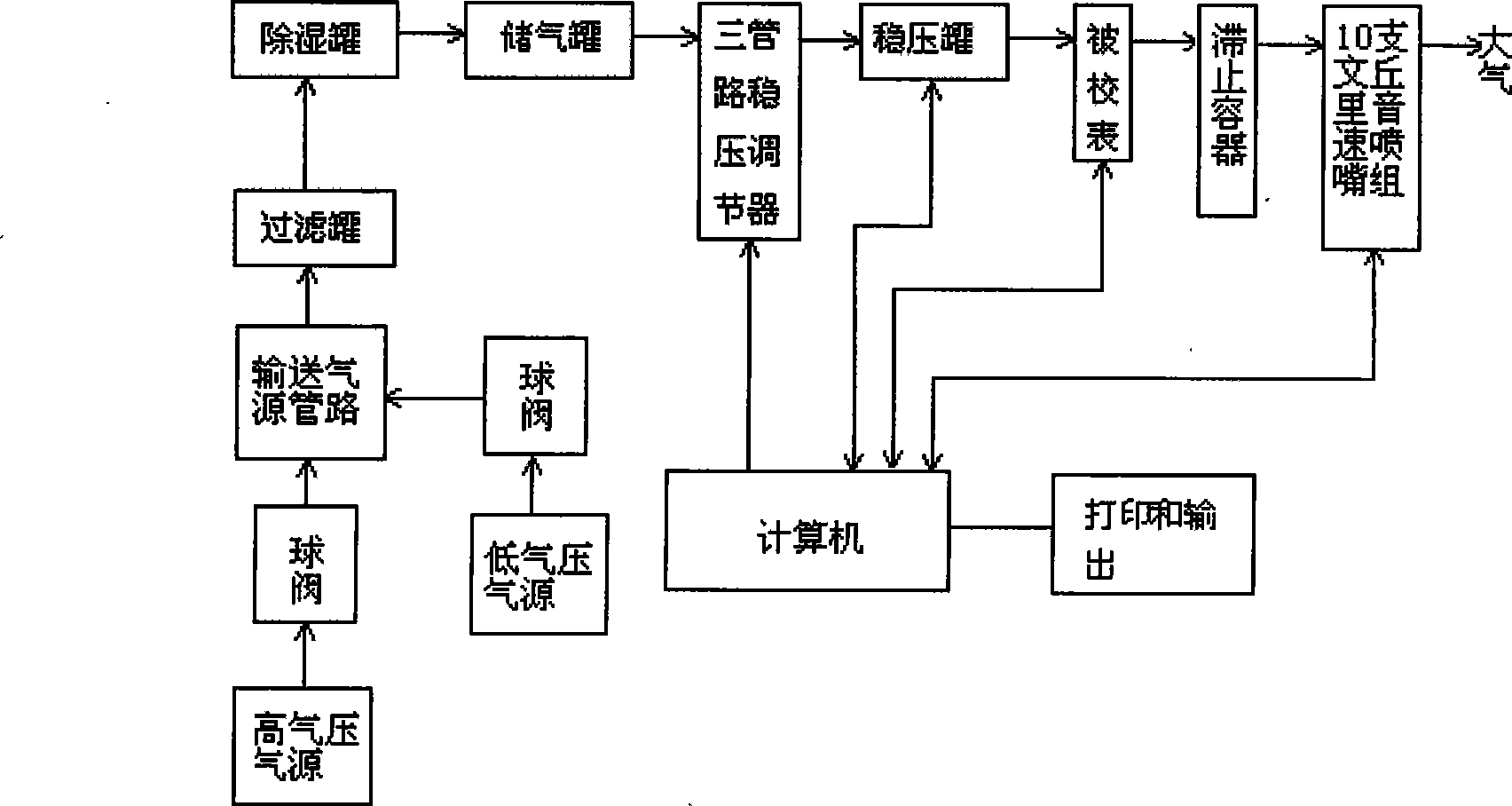

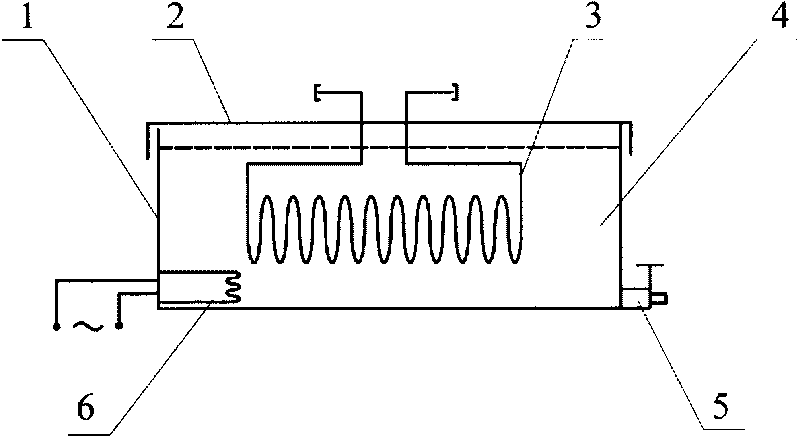

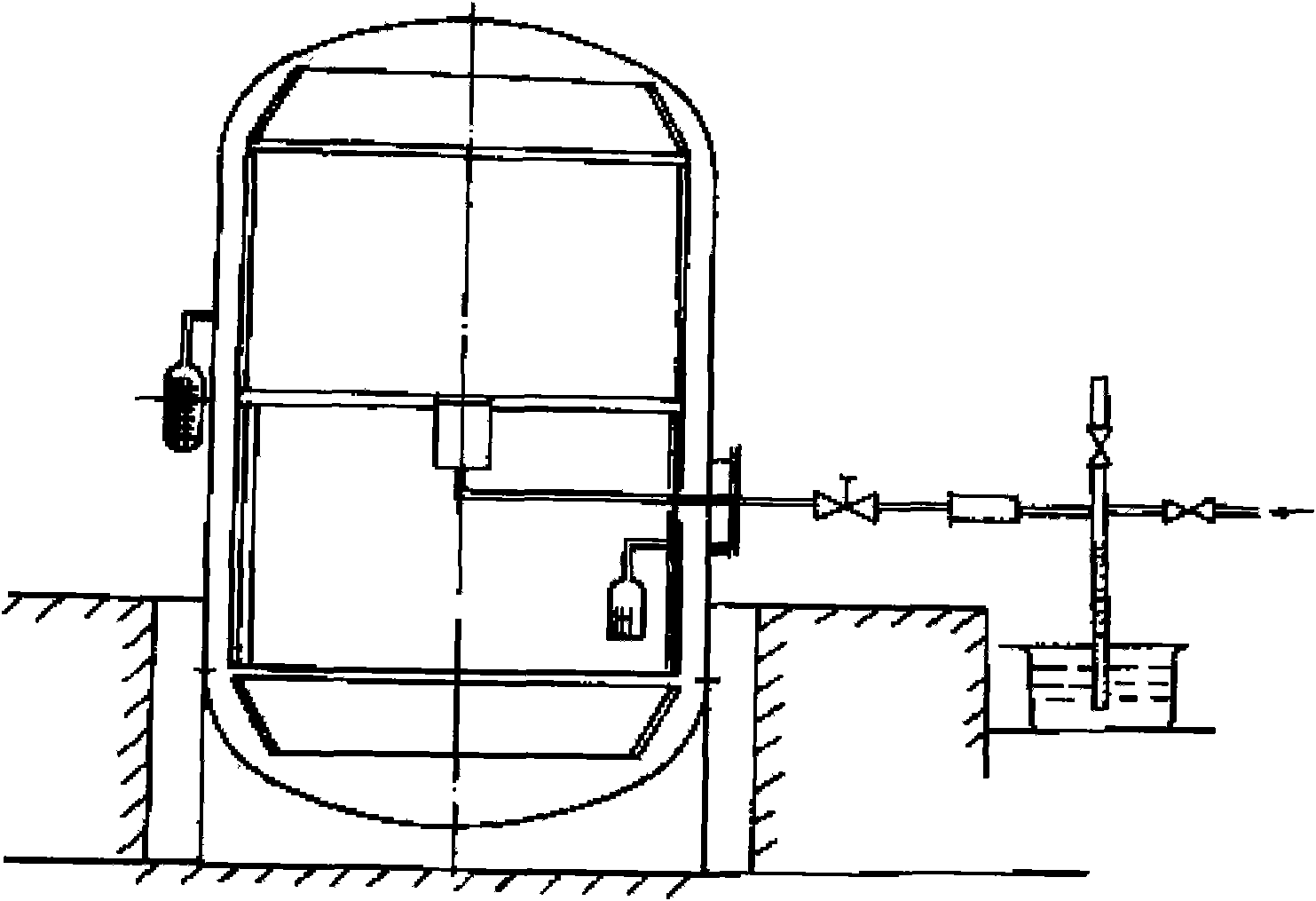

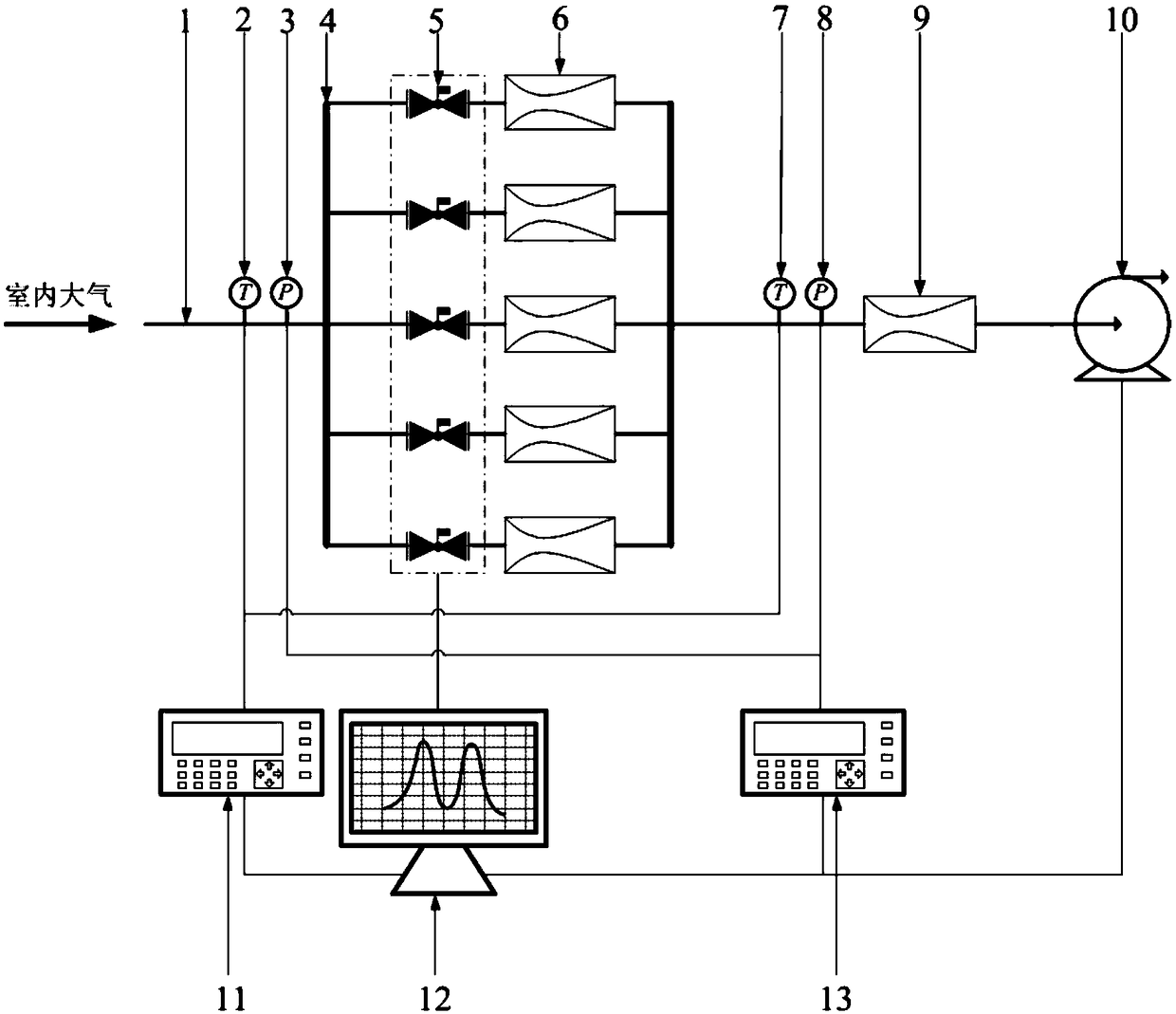

Calibration device for sonic nozzle gas flowmeter by positive-pressure method and application method

InactiveCN101419088ASave energyFast pressure regulationTesting/calibration apparatusSonic nozzlePositive pressure

The invention relates to a positive pressure method sonic nozzle gas flowmeter calibrating device and an application method. The calibrating device comprises a filter tank, a dehumidification tank, an air storage tank, a three-pipeline pressure-stabilizing regulator, a pressure-stabilizing tank, a ten-venturi sonic nozzle group, a stagnation container and a computer; and an air source conveying pipeline is provided with a double air source structure with two air source pipelines with different pressures for switching air supply; the three-pipeline pressure-stabilizing regulator is arranged between the air storage tank and the pressure-stabilizing tank; and the calibrating device can realize calibrating of a steam meter through air medium. The invention adopts the positive pressure method, can be suitable for air sources with different pressures for detection, and saves energy. In addition, an air flow meter calibrating device and a steam meter calibrating device are integrated, thereby properly reducing the volume of the device, reducing investment and operation cost, and having simple operation.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

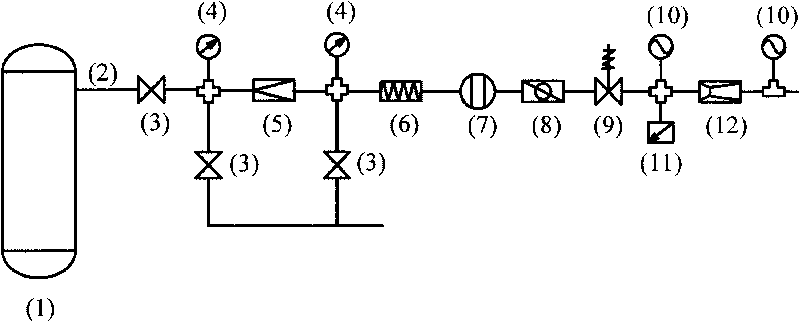

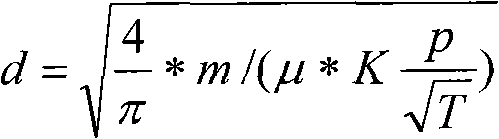

Low-flow gas control device and using method thereof

InactiveCN101727108AStable supplyGuaranteed pure gas phaseFlow control using electric meansFlow control without auxillary powerSonic nozzleGas cylinder

The invention discloses a low-flow gas control device, which is characterized in that: a gas cylinder outlet is sequentially connected with a manual valve, a decompressor, a heat exchanger component, a filter, a mass flowmeter, a solenoid valve and a sonic nozzle component through pipelines, wherein the inlet and outlet of the decompressor respectively lead to a branch pipeline connecting a pressure gauge and the manual valve; a temperature sensor and a pressure sensor are connected to the inside of the pipeline in front of the sonic nozzle component; and another pressure sensor is connected to the inside of the pipeline behind the sonic nozzle component. The method can respectively realize flow control in different ranges by adjusting pressure in front of a sonic nozzle or replacing the sonic nozzle with the sonic nozzles with different throat diameters; can realize stable supply of a gas flow by using the performance characteristics of the sonic nozzle and can eliminate two-phase flow influence by gasifying a small amount of liquid contained in an incoming flow with a heat exchanger. The device can realize accurate and stable micro flow control requirements under the condition of a pure gas phase, can meet the requirements on the small flow control under the condition of containing a small amount of liquid drops in the incoming flow, and can work under the condition of relatively high pressure.

Owner:BEIHANG UNIV

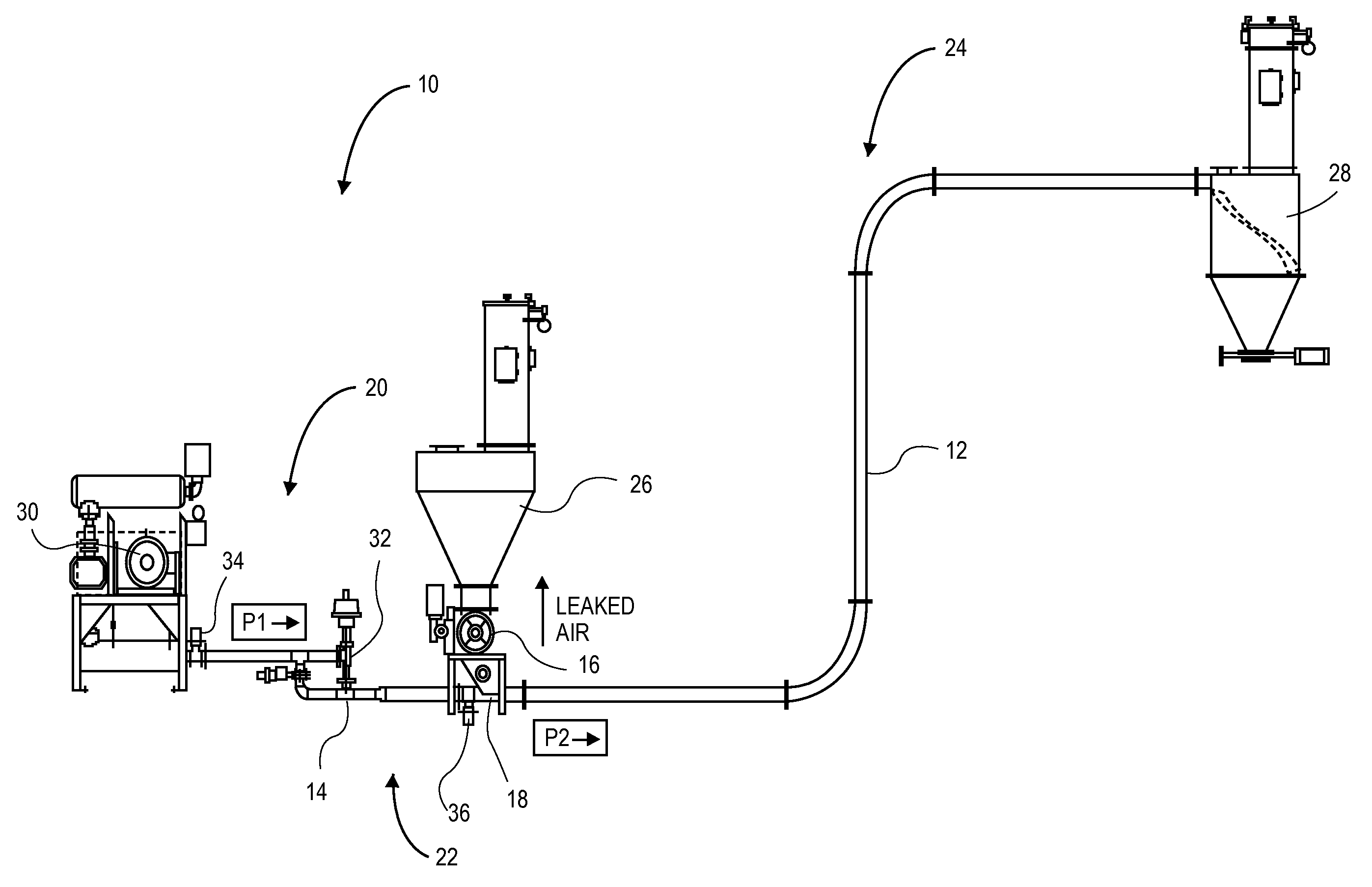

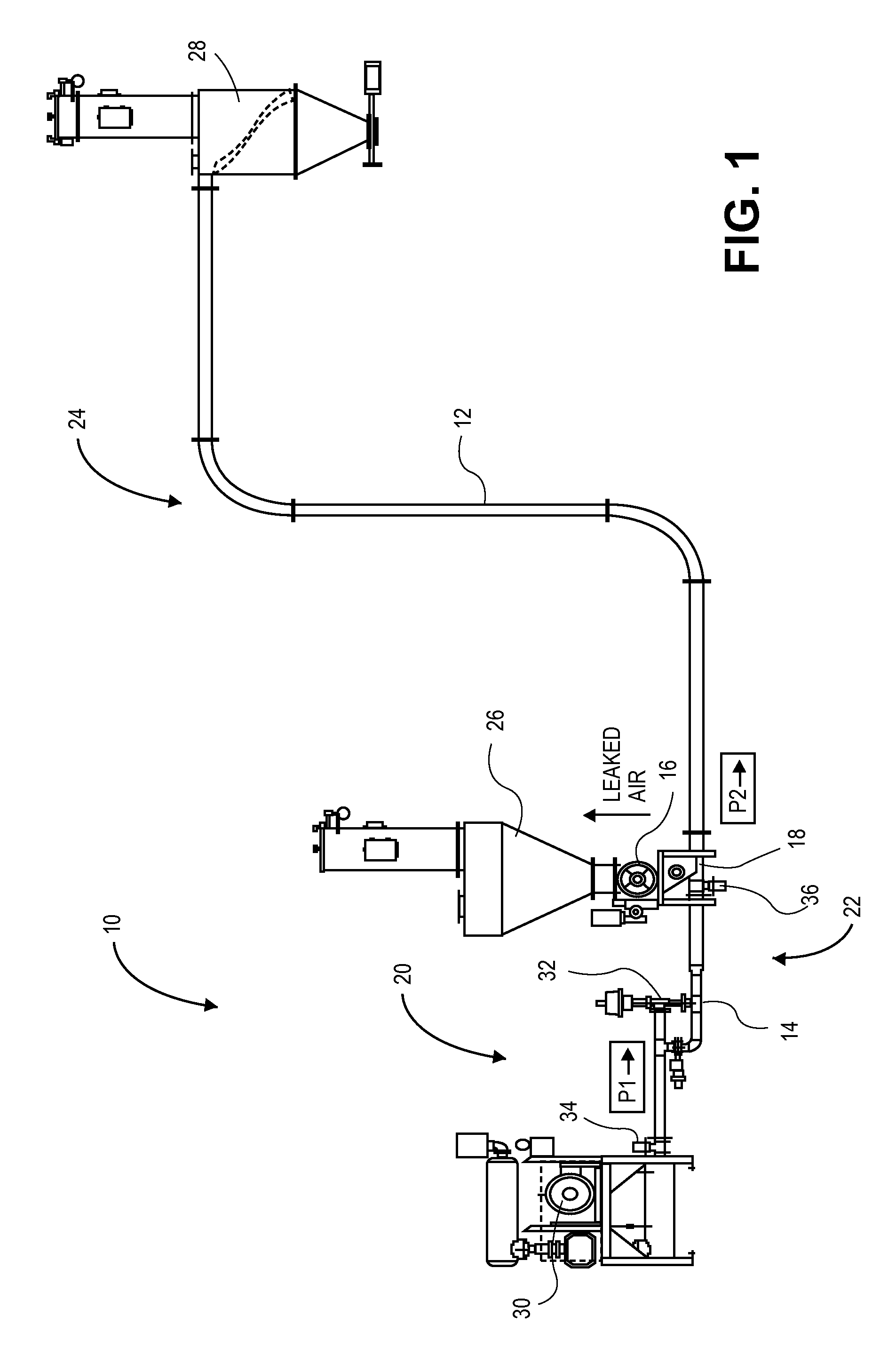

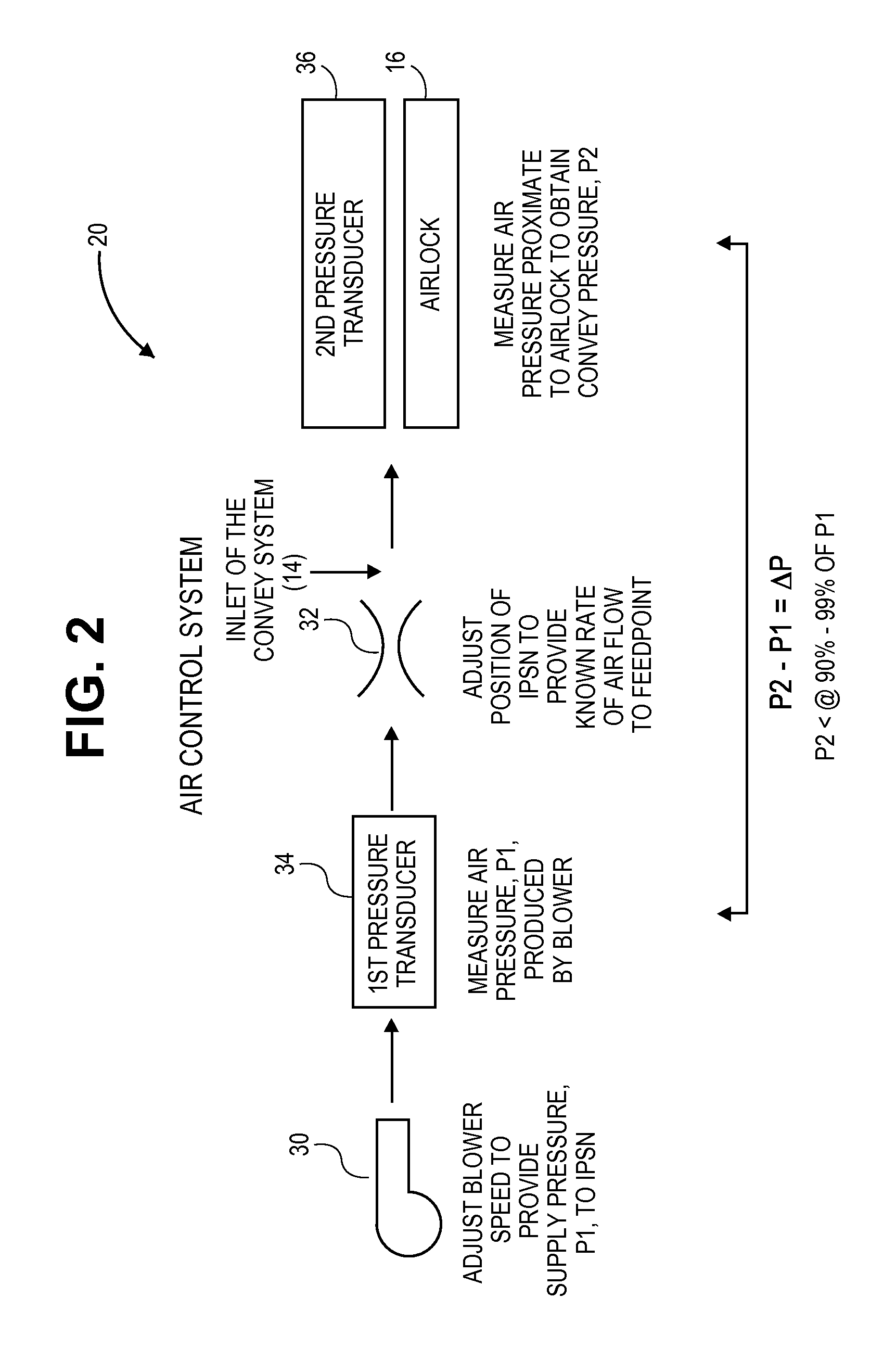

Low pressure continuous dense phase convey system using a non-critical air control system

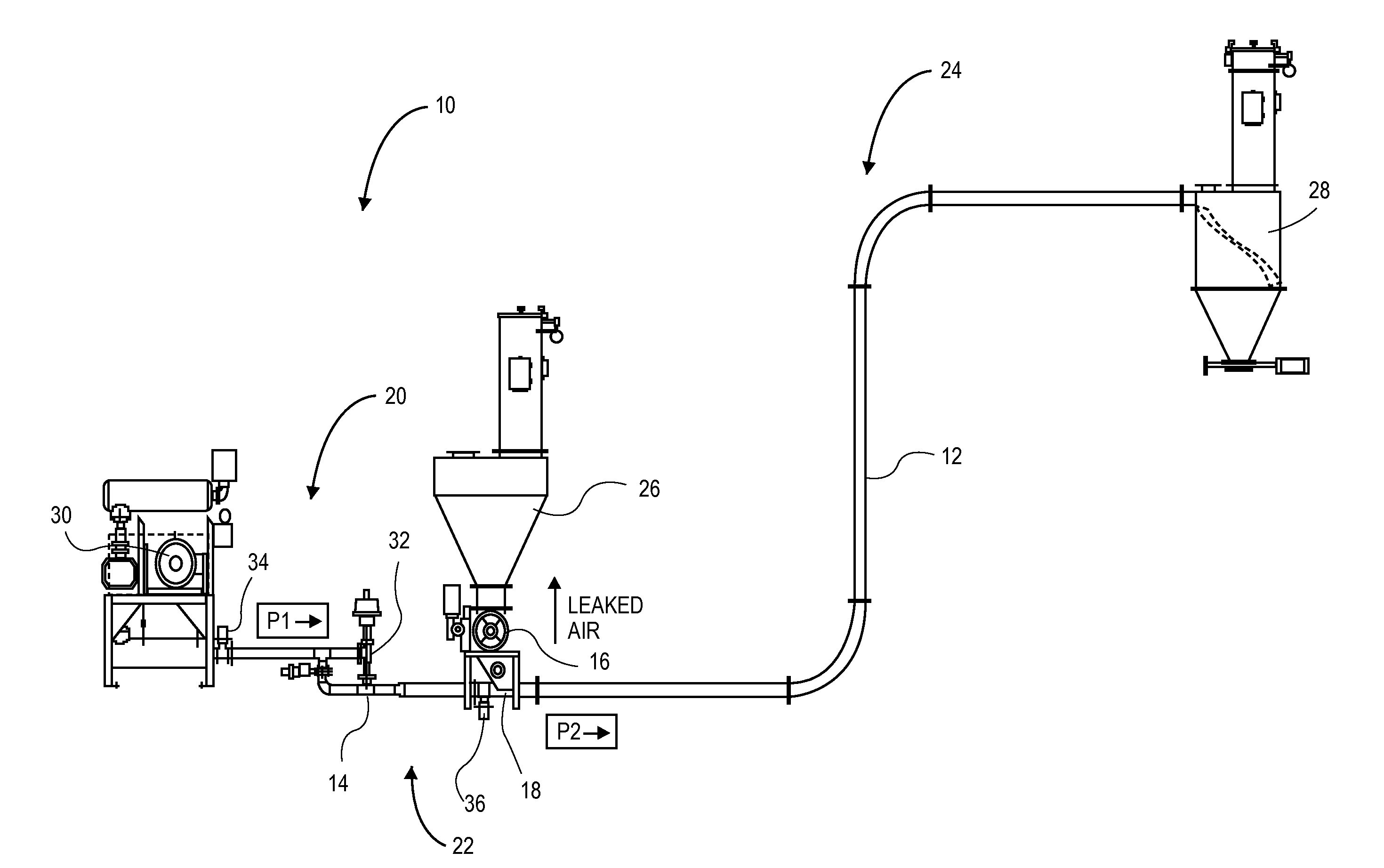

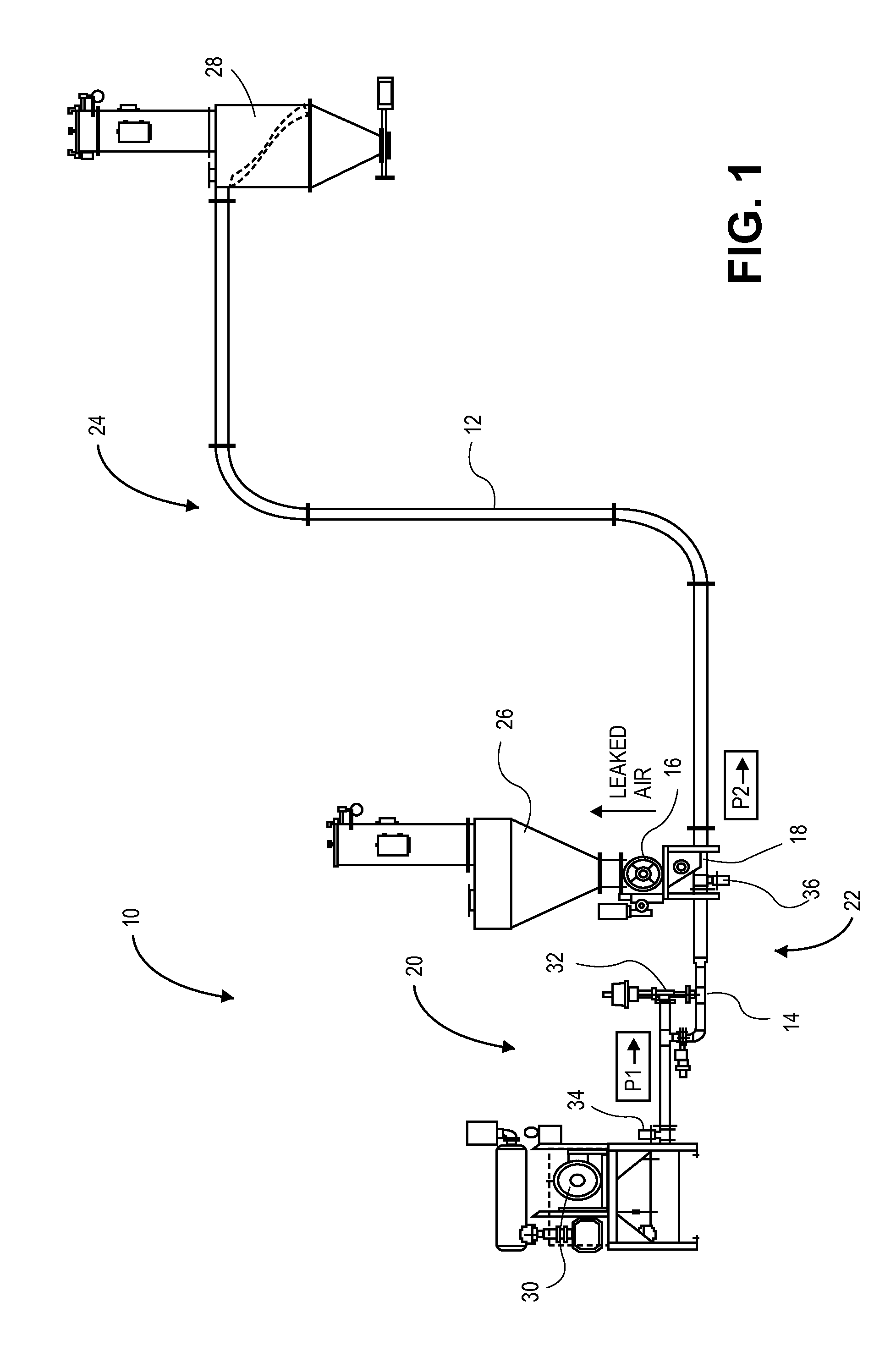

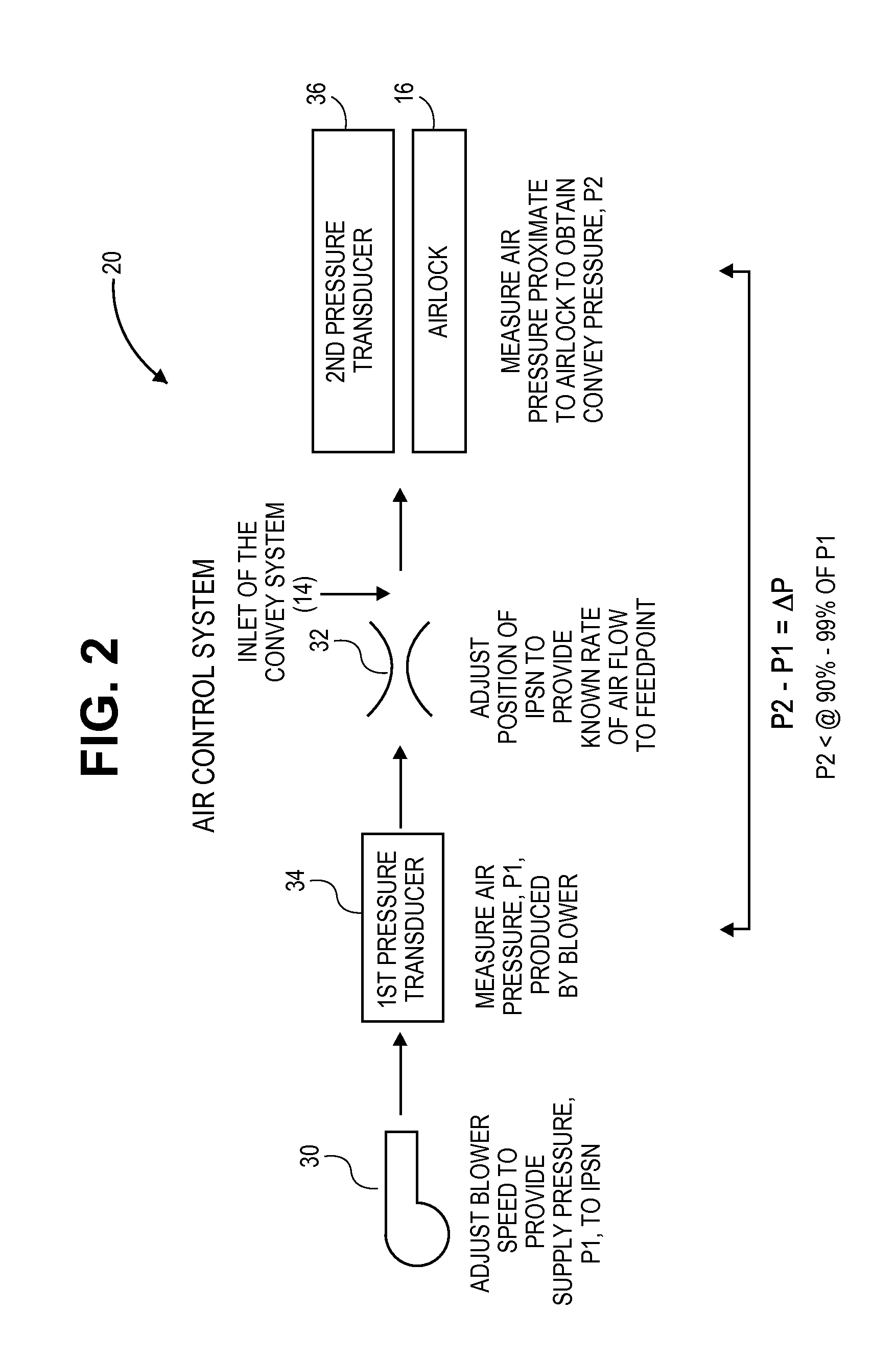

An air control system for a low pressure continuous dense phase convey system employs a non-critical air flow control system that allows for a supply pressure to be only incrementally larger than a convey pressure. The convey system has an inlet for introduction of pressurized air into the system and an airlock associated with a feedpoint for introduction of particulate into the system. A first pressure sensor is positioned immediately downstream of an air source to measure the supply pressure, and a second pressure transducer is positioned proximate an airlock to measure the convey pressure. The non-critical air flow control system is dependent on the supply and convey pressures and a position of a control valve, such as a sonic nozzle. The difference between the convey pressure and the supply pressure is less than 10% of the supply pressure.

Owner:SCHENCK PROCESS LLC

Low pressure continuous dense phase convey system using a non-critical air control system

An air control system for a low pressure continuous dense phase convey system employs a non-critical air flow control system that allows for a supply pressure to be only incrementally larger than a convey pressure. The convey system has an inlet for introduction of pressurized air into the system and an airlock associated with a feedpoint for introduction of particulate into the system. A first pressure sensor is positioned immediately downstream of an air source to measure the supply pressure, and a second pressure transducer is positioned proximate an airlock to measure the convey pressure. The non-critical air flow control system is dependent on the supply and convey pressures and a position of a control valve, such as a sonic nozzle. The difference between the convey pressure and the supply pressure is less than 10% of the supply pressure.

Owner:SCHENCK PROCESS LLC

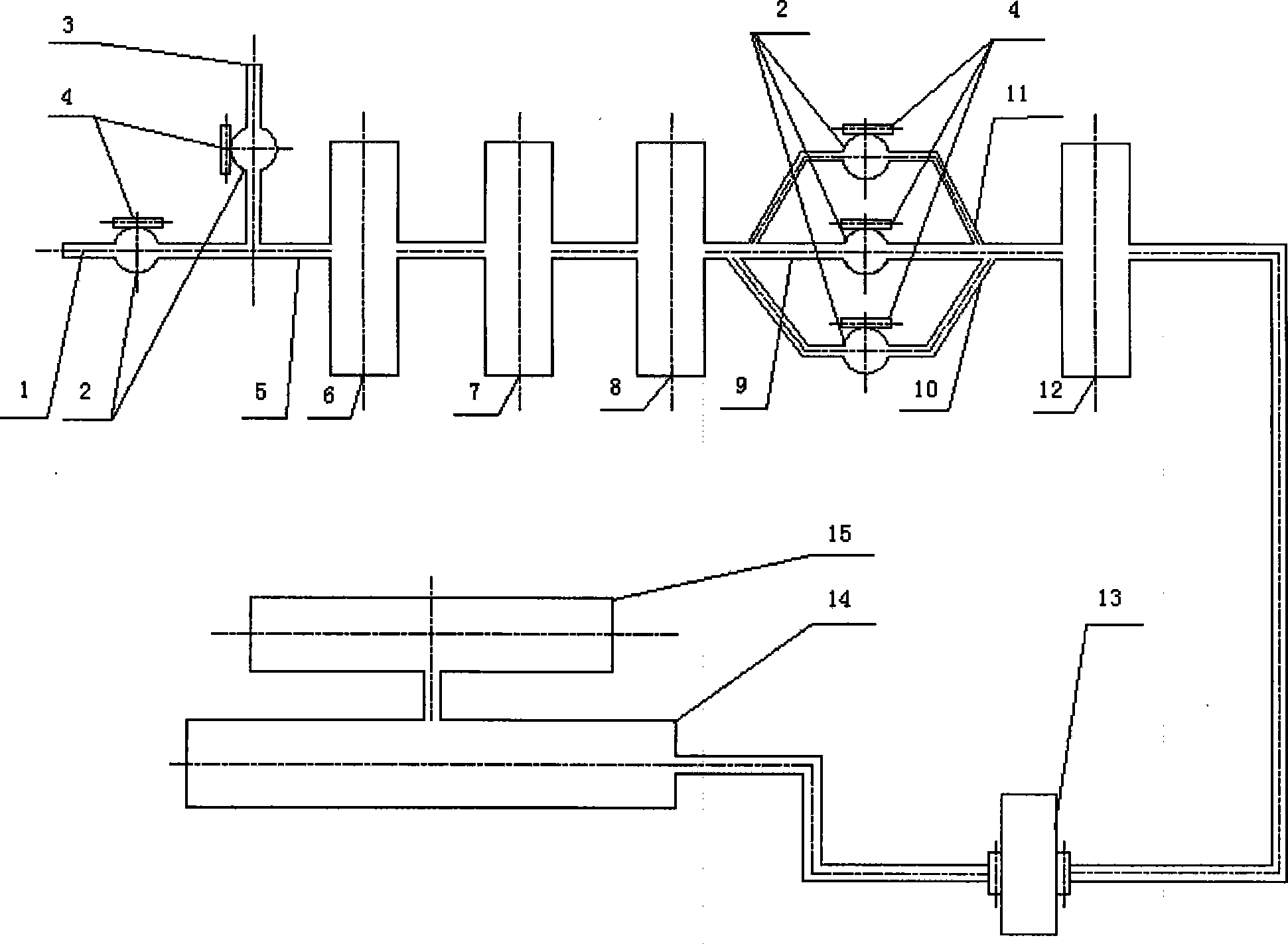

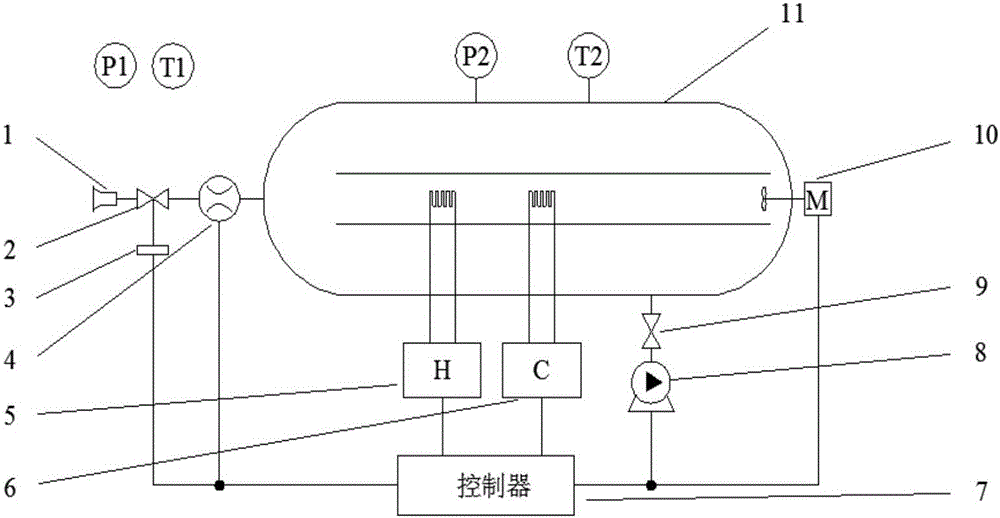

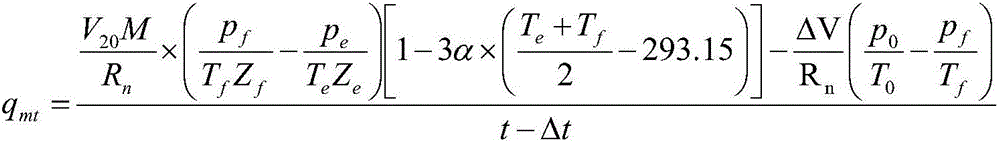

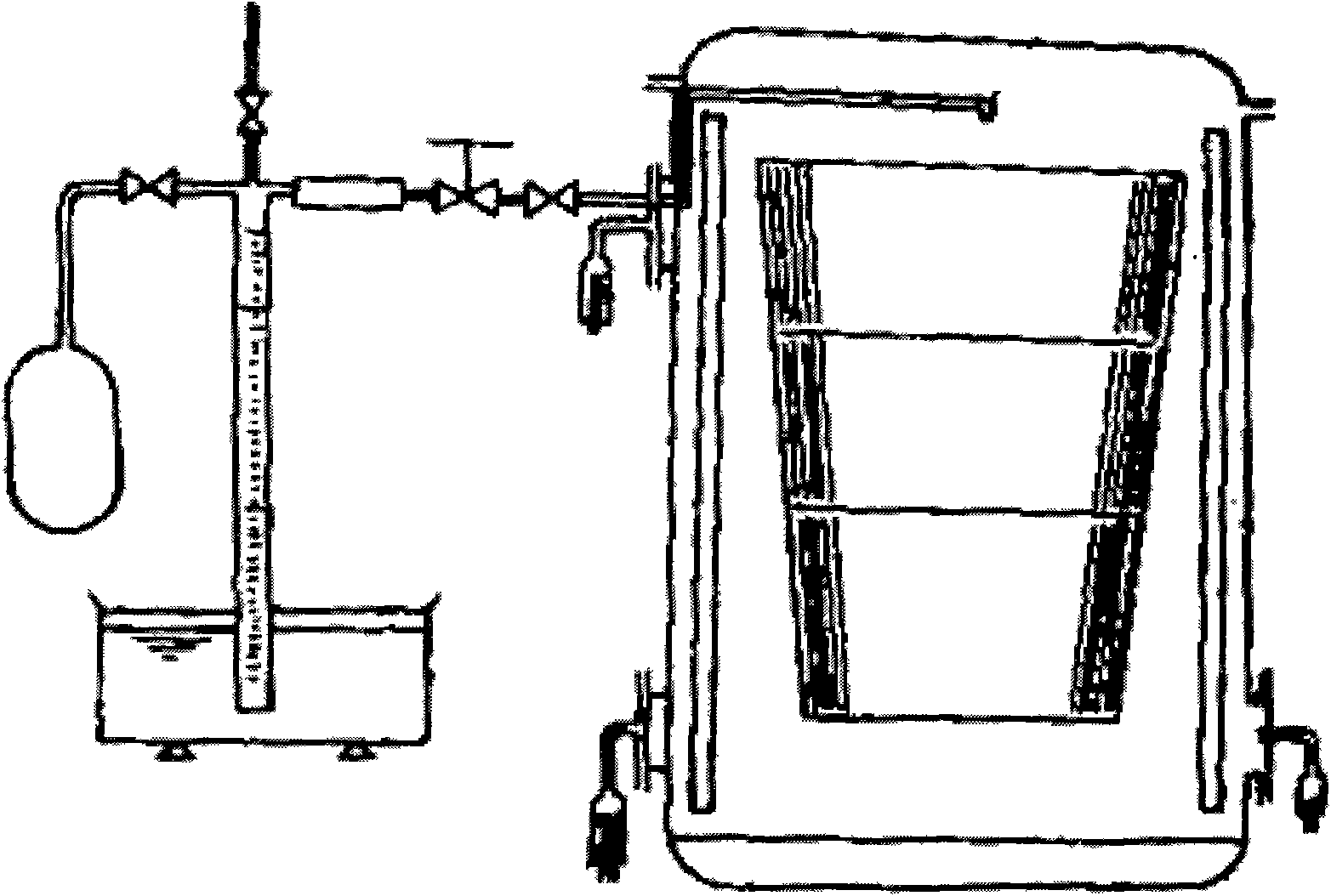

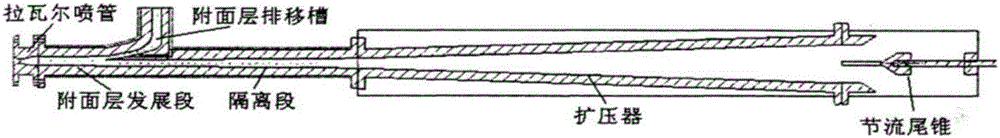

Rapid detection pVTt methodgas flow standard device and detection method

InactiveCN105928592ARapid temperature stabilizationSolve the problem that it takes a long time to stabilize the temperature fieldTesting/calibration apparatusSonic nozzleEngineering

The invention discloses a rapid detection pVTt methodgas flow standard device and a detection method. The device comprises a standard container, a controller, a heating device, a refrigeration device, an electric fan, and a vacuum pump. The standard container is internally provided with a horizontal air channel from the front end to the rear end. A detected sonic nozzle is connected with the front end of the horizontal air channel through a flow sensor. The rear end of the horizontal air channel is provided with the electric fan. The standard container is connected with the vacuum pump, the heating device, and the refrigeration device. The upper ends of the heating device and the refrigeration device extend into the horizontal air channel. A flow sensor, the heating device, the refrigeration device, the electric fan, and the vacuum pump are connected with the controller. The method comprises: adjusting temperature to keep constant temperature, measuring parameters of the balance states of the standard container before air intake and after air intake, calculating to obtain detected mass flow rate, comparing the detected mass flow rate with theoretical mass flow rate, to obtain a detection result of whether qualified. The device is simple in structure, low in price, high in measuring precision, high in measuring efficiency, and repeatability is better than 0.06%.

Owner:CHINA JILIANG UNIV

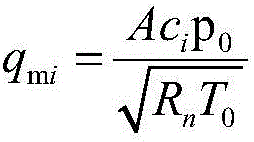

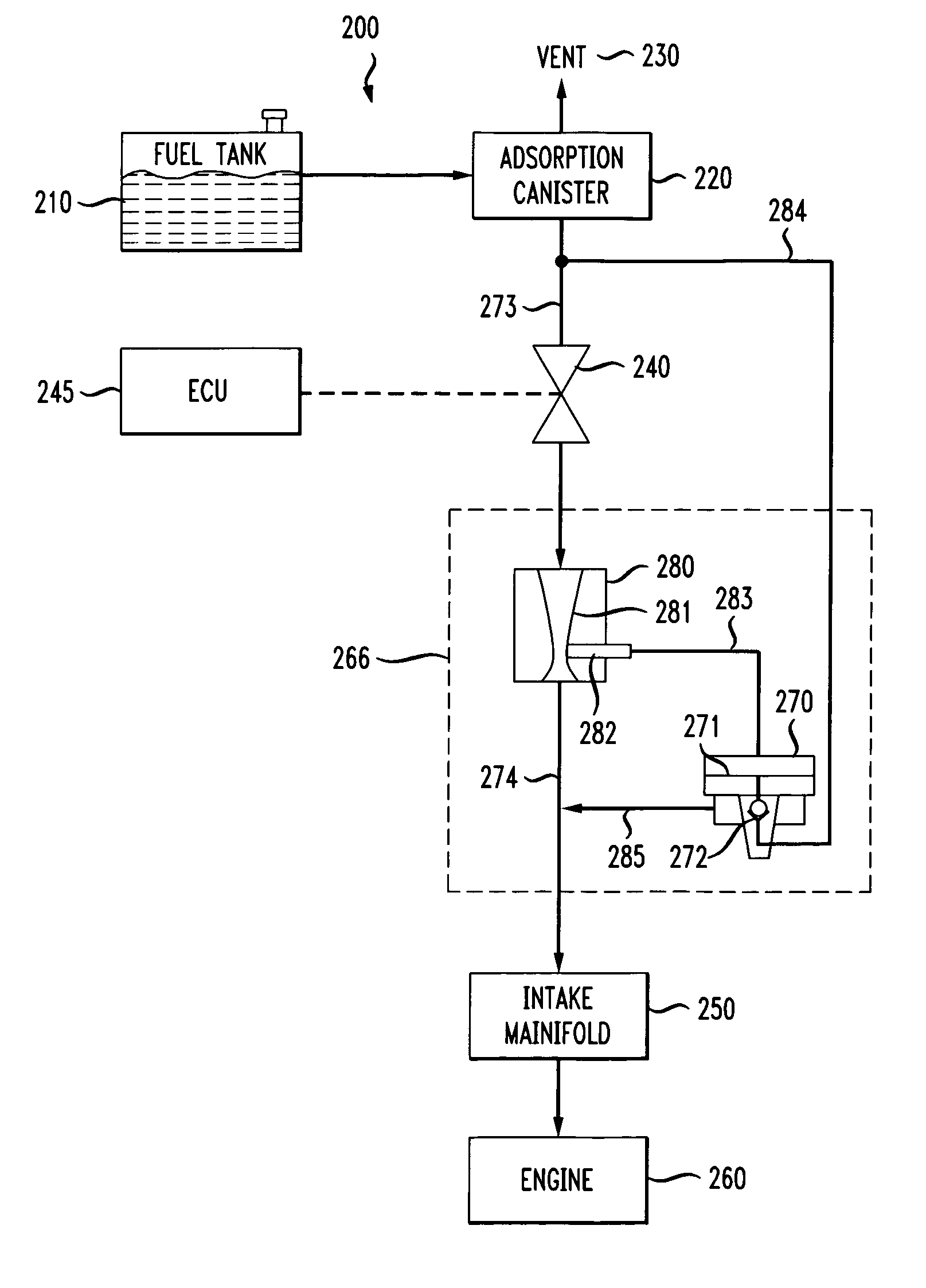

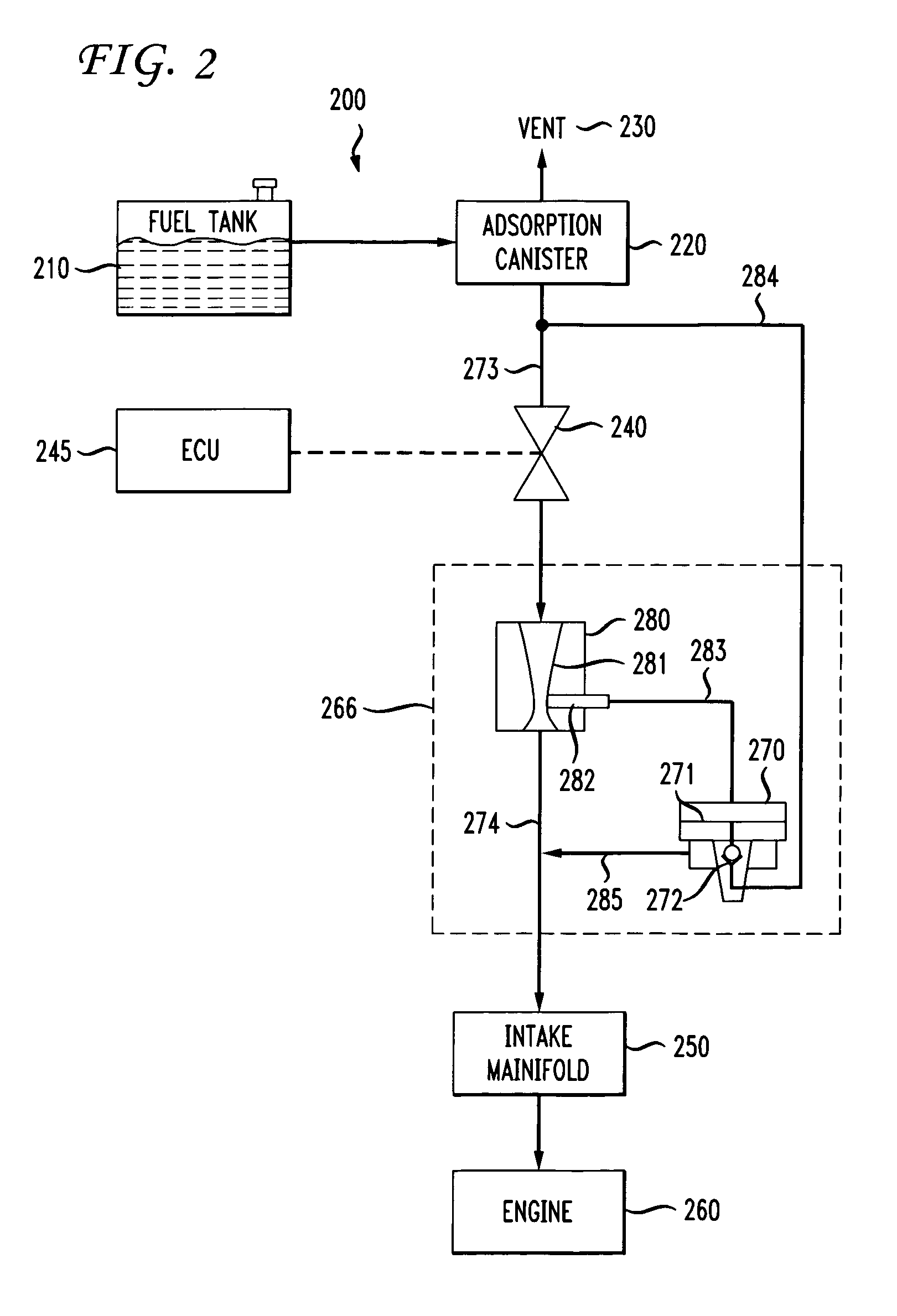

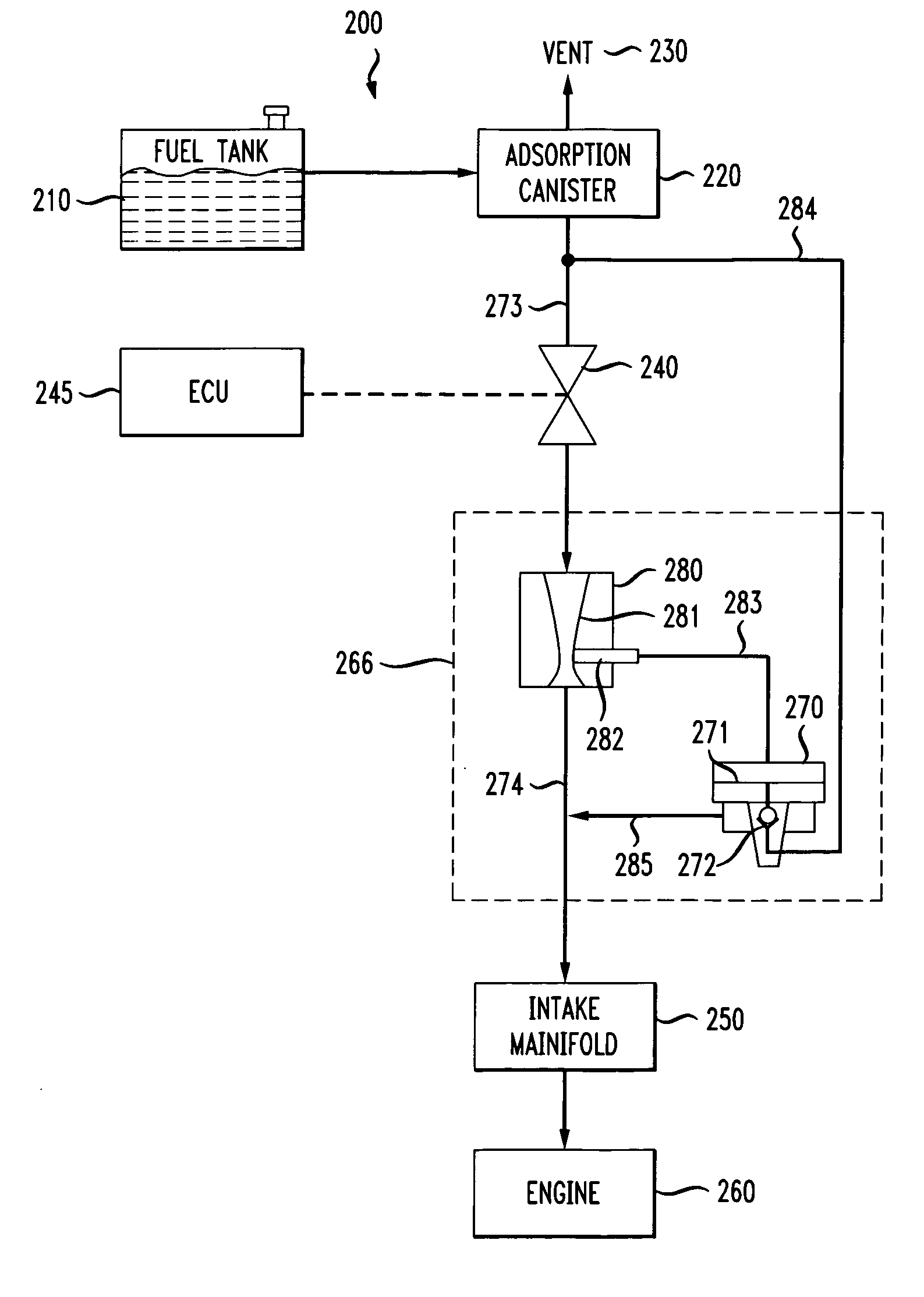

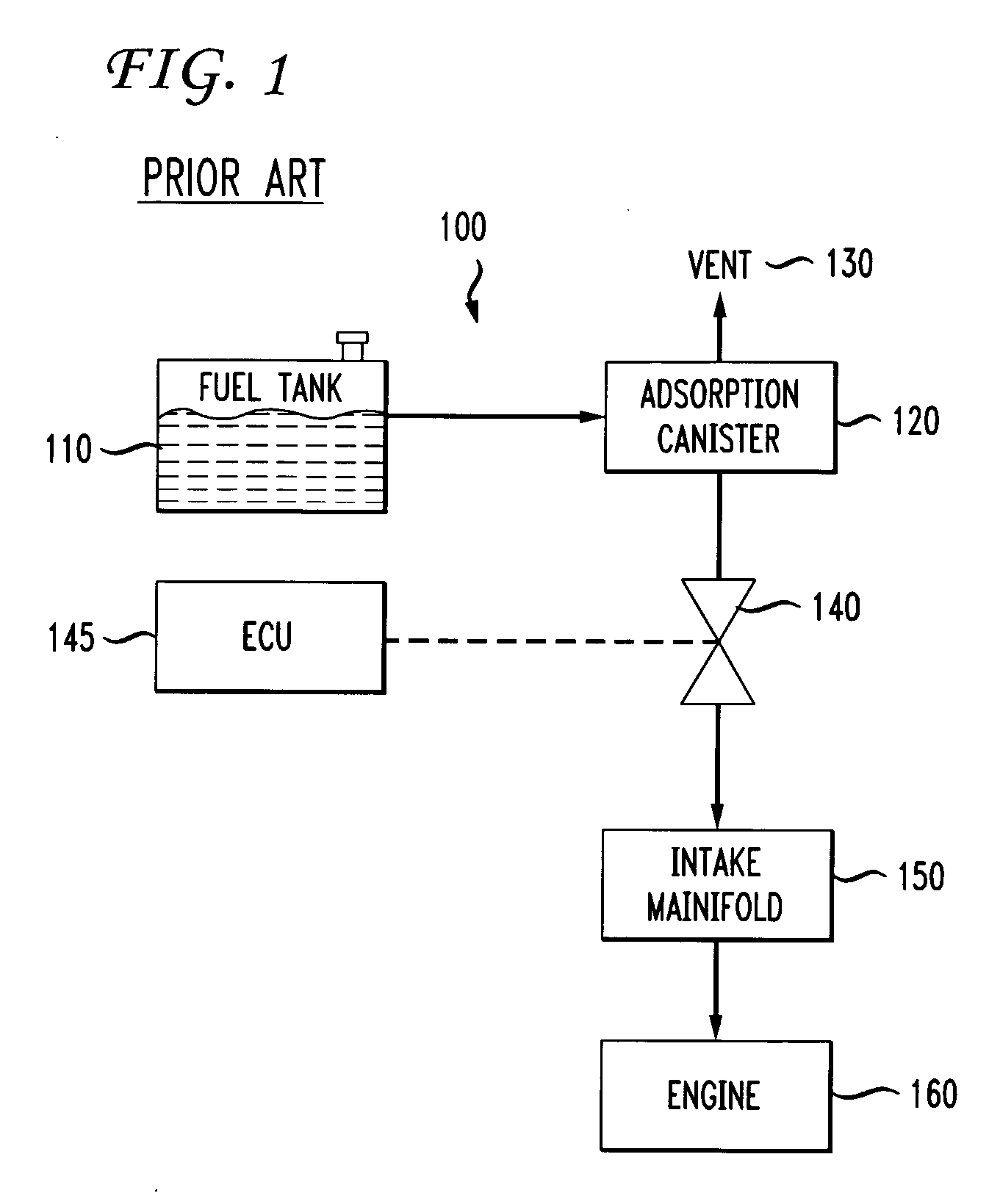

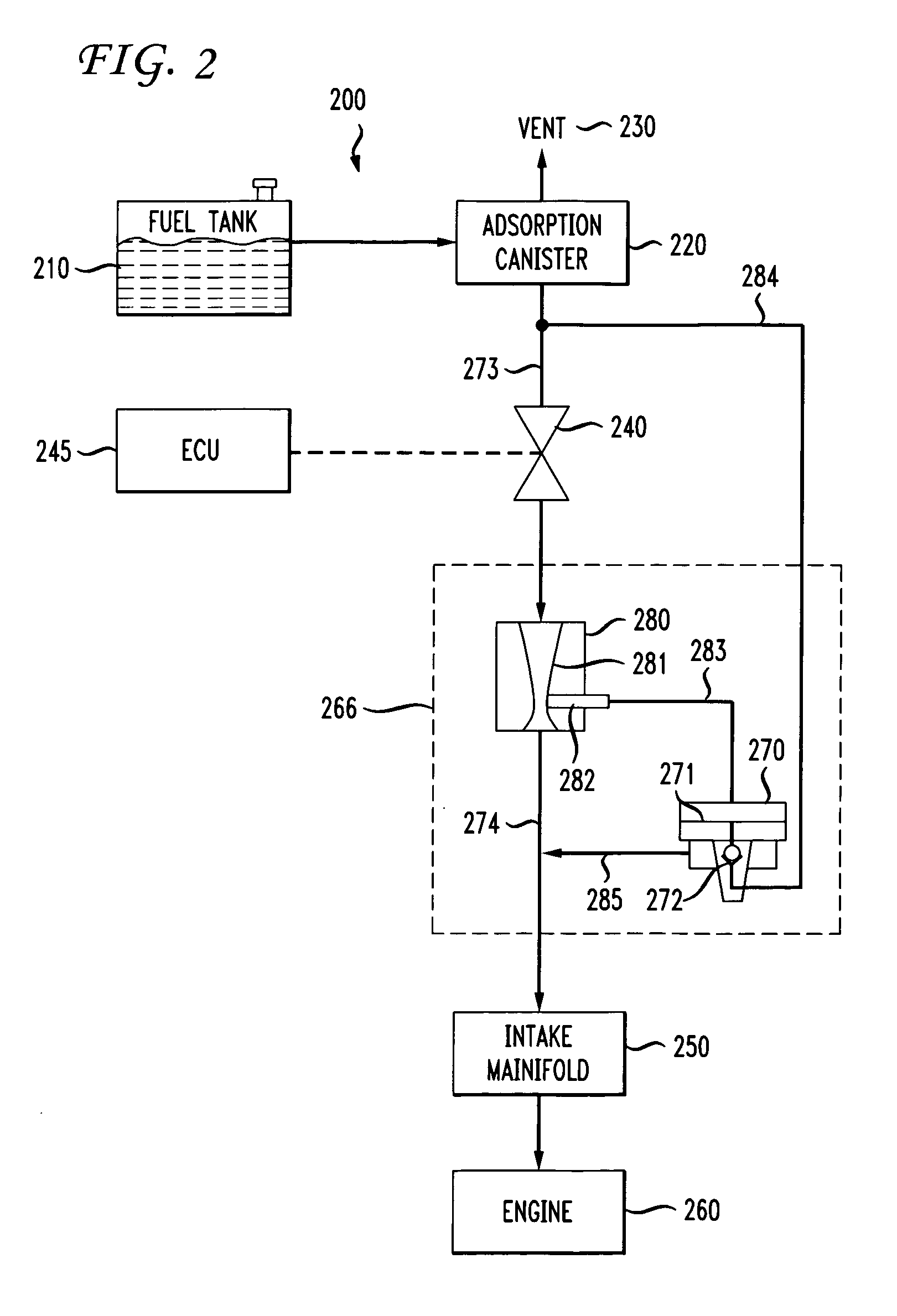

High flow, low vacuum carbon canister purge valve

A technique is provided for purging an adsorption canister in a fuel tank vent system. The technique provides a relatively high purge flow under conditions wherein the intake manifold vacuum is relatively low. A sonic nozzle is placed in the purge line between the existing purge valve and the adsorption canister. The sonic nozzle includes a tap at its throat for producing a vacuum in response to flow in the purge line. The vacuum is used to control a vacuum operated diaphragm valve in a parallel purge line. The system therefore supplements purge flow through the adsorption canister to the intake manifold.

Owner:SIEMENS VDO AUTOMOTIVE INC

Scrubber with sonic nozzle

InactiveUS20050268937A1Semiconductor/solid-state device manufacturingElectrostatic cleaningSonic nozzleEngineering

Owner:APPLIED MATERIALS INC

Metal-organic vaporizing and feeding apparatus, metal-organic chemical vapor deposition apparatus, metal-organic chemical vapor deposition method, gas flow rate regulator, semiconductor manufacturing apparatus, and semiconductor manufacturing method

InactiveUS20070292612A1Simple processSimple equipmentChemical vapor deposition coatingSonic nozzleGas phase

A metal-organic vaporizing and feeding apparatus includes: a retention vessel for retaining a metal-organic material; a bubbling gas feeding path connected to the retention vessel, for feeding bubbling gas to the metal-organic material; a metal-organic gas feeding path connected to the retention vessel, for feeding metal-organic gas generated in the retention vessel and dilution gas to a deposition chamber; a dilution gas feeding path connected to the metal-organic gas feeding path, for feeding the dilution gas to the metal-organic gas feeding path; a flow rate regulator provided in the bubbling gas feeding path, for regulating flow rate of the bubbling gas; a pressure regulator for regulating pressure of the dilution gas; and a sonic nozzle disposed in the metal-organic gas feeding path on a downstream side of a connecting position between the metal-organic gas feeding path and the dilution gas feeding path.

Owner:SUMITOMO ELECTRIC IND LTD +1

Apparatus for calibrating gas instrument

ActiveCN101251405AChange of pumping methodAvoid noise pollutionTesting/calibration apparatusLow noiseSonic nozzle

The invention discloses a gas instrument calibration device, which comprises a calibration platform for assembling a flowmeter to be tested. The calibration platform is at least connected with a stagnation container, a sonic nozzle, a negative pressure pipe and a Roots vacuum pump adopting the variable frequency control in turn. The calibration platform and the gas inlet of the calibration platform are arranged in a lockable calibration chamber, and the gas outlet of the vacuum pump is communicated with the calibration chamber through an underground duct. The gas instrument calibration device which has the advantages of low noise pollution, low energy consumption and small error is particularly suitable for the calibration of a gas flow measuring instrument.

Owner:YUYAO YINHUAN FLOWMETER

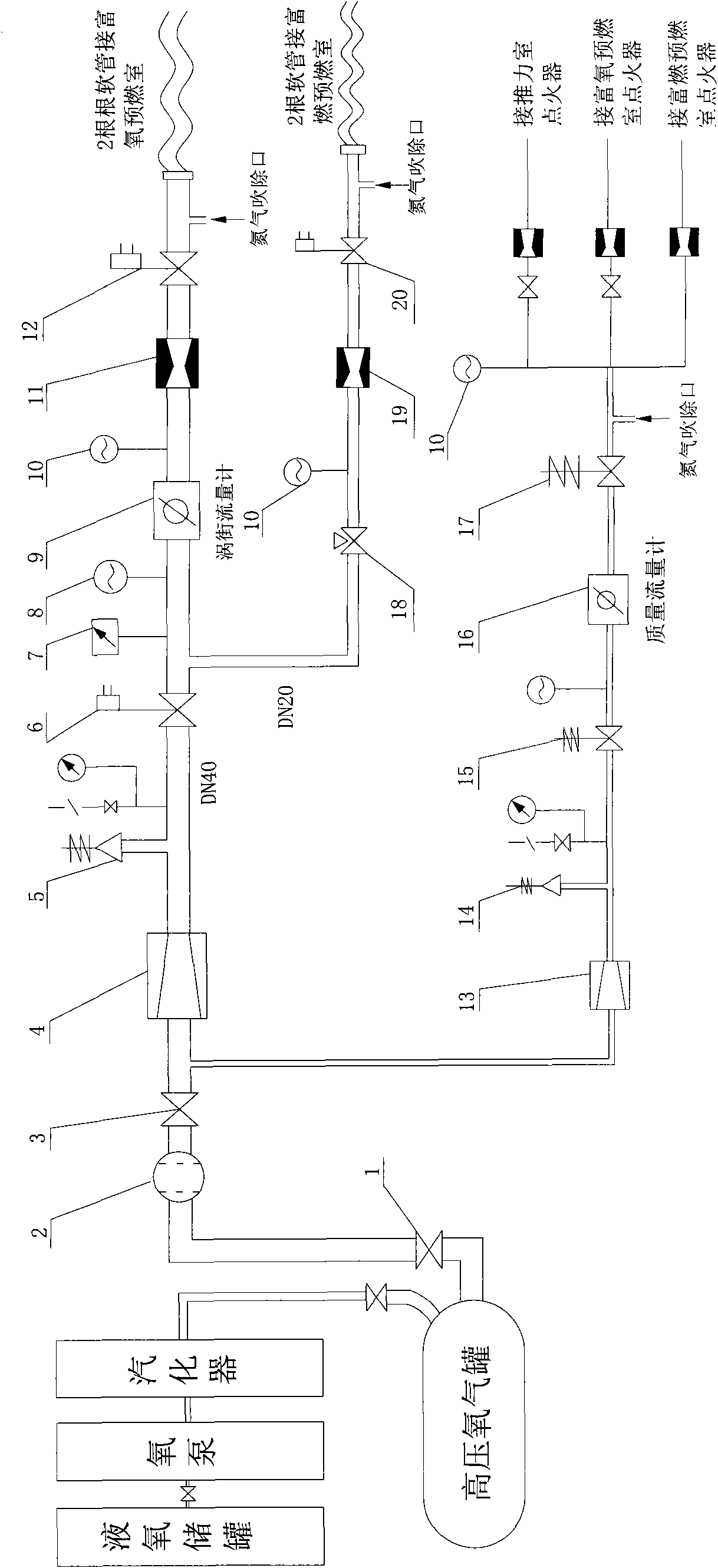

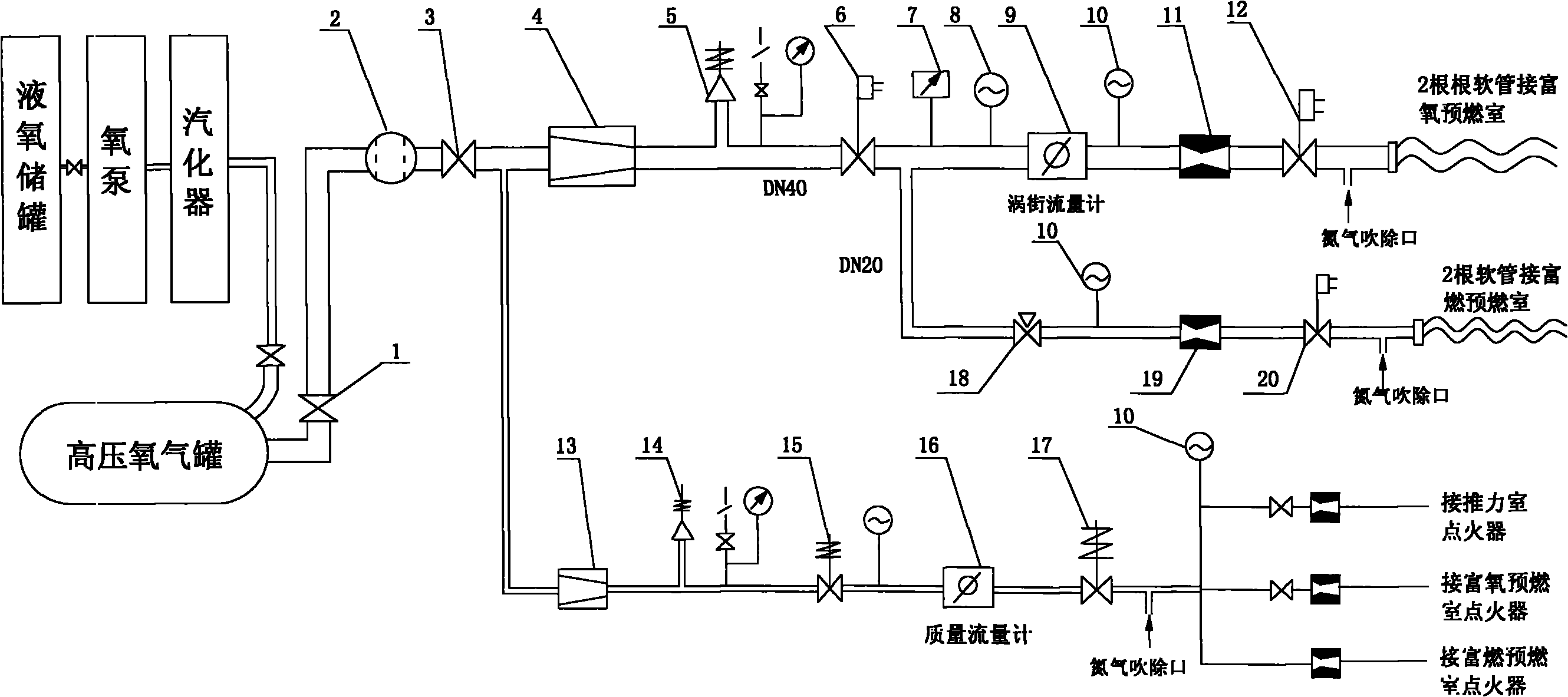

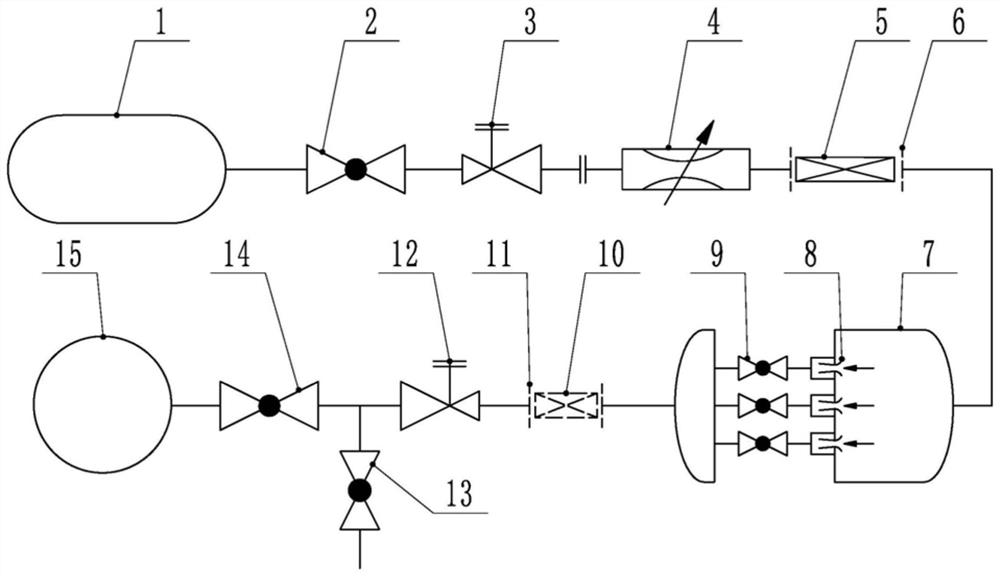

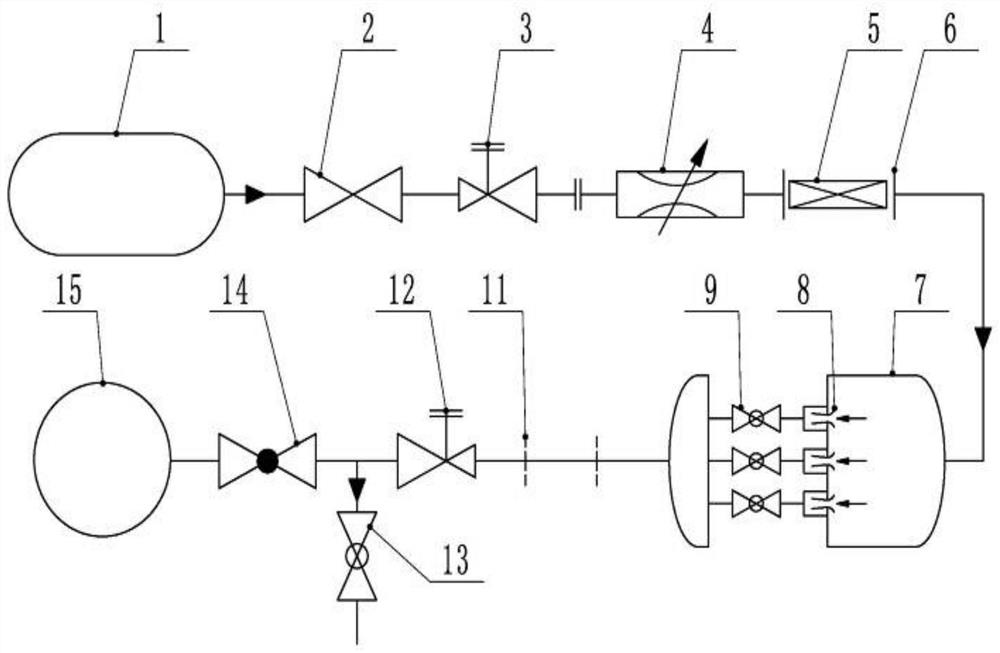

Full-flow test bed oxygen system

The invention discloses a design of a full-flow test bed oxygen system, which can accurately control the flow of the oxygen, and realizes the feed and cut-off of an oxygen medium. The full-flow test bed oxygen supply system consists of a liquid oxygen storage tank, a liquid oxygen pump, a gasifier, a high-pressure storage tank, a valve, a pressure reducer and a sonic nozzle. After passing through a manual ball valve, the oxygen is divided into two paths, namely a main oxygen path for supplying oxygen for test pieces and an ignition oxygen path for providing oxygen for an igniter. A nitrogen interface is designed in the oxygen supply system, and a safety valve is designed at the rear of the pressure reducer. Therefore, the oxygen test system has high reliability and safety.

Owner:BEIHANG UNIV

Scrubber with sonic nozzle

InactiveUS7063749B2Electrostatic cleaningSemiconductor/solid-state device manufacturingSonic nozzleAcoustic wave

An apparatus for cleaning a substrate is provided. The apparatus comprises a plurality of rollers adapted to support a substrate in a vertical orientation, a scrubber brush adapted to contact a substrate supported by the plurality of rollers, and a sonic nozzle positioned at an elevation below the elevation of the scrubber brush and adapted so as to output a sonicated fluid spray that contacts a beveled edge or a major surface of the substrate such that fluid having sufficient sonic energy to harm the scrubber brush will not contact the scrubber brush.

Owner:APPLIED MATERIALS INC

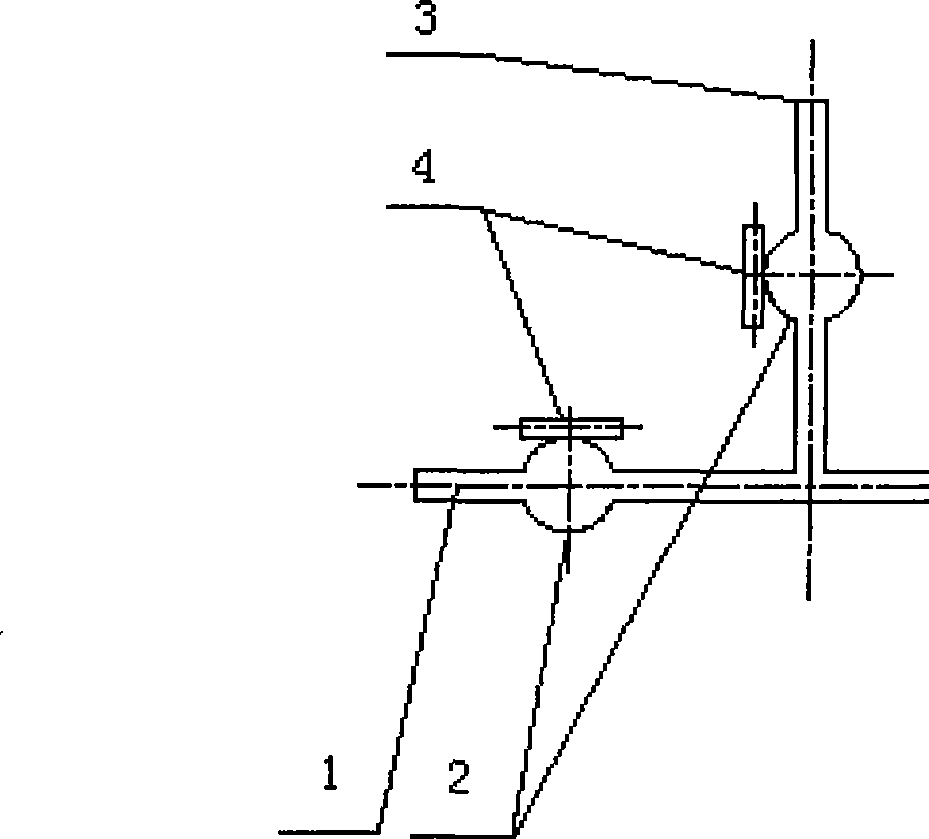

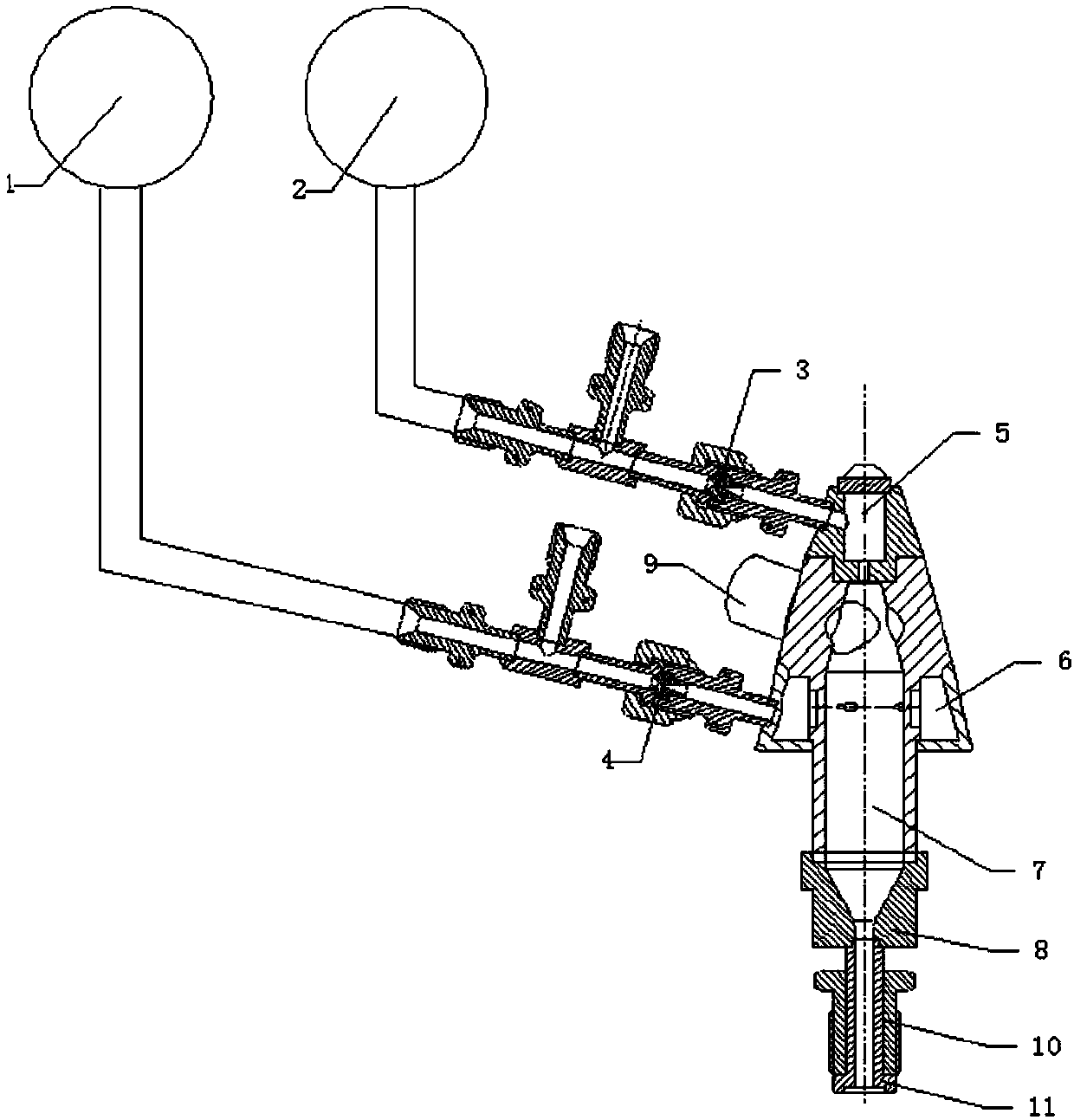

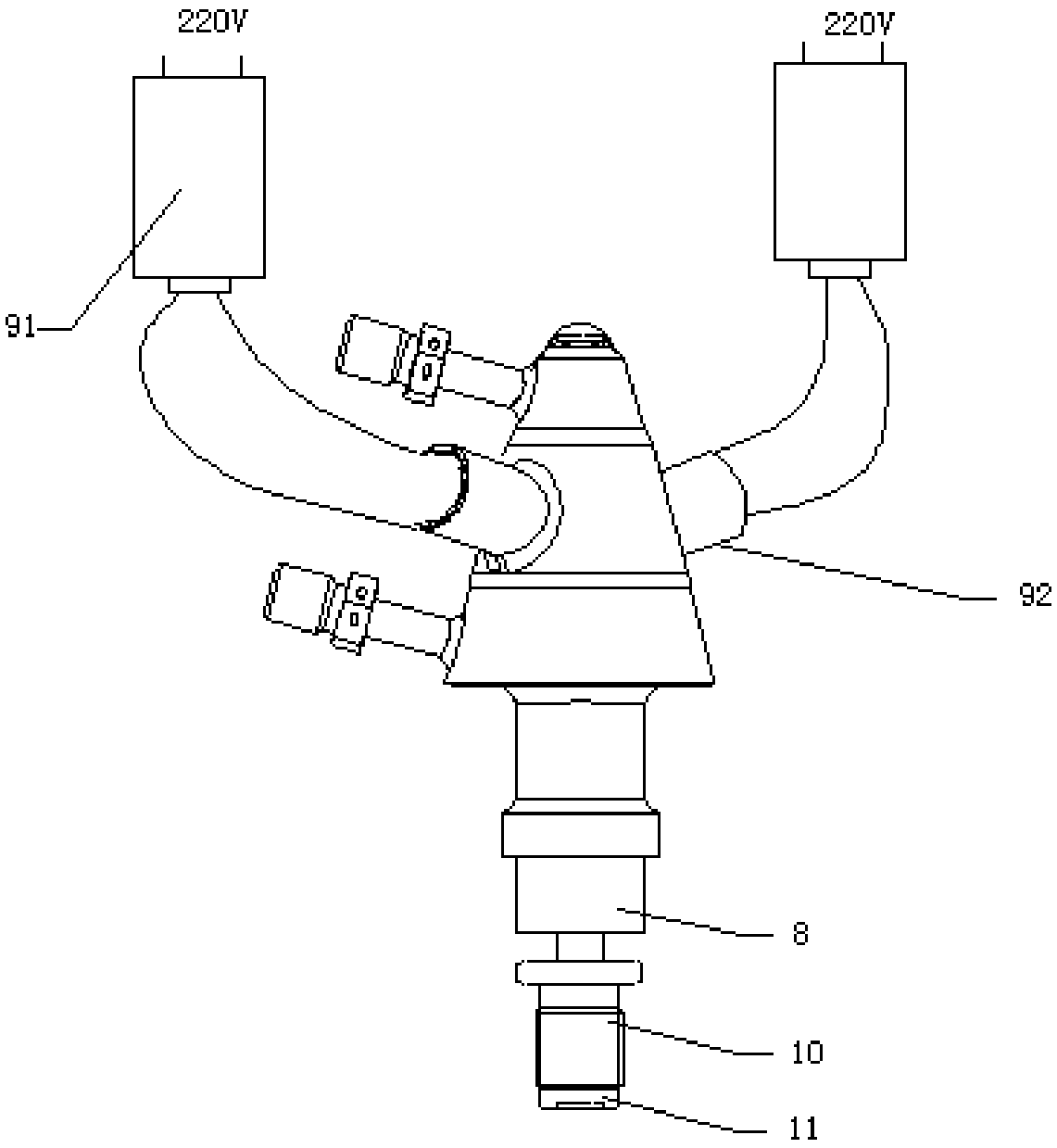

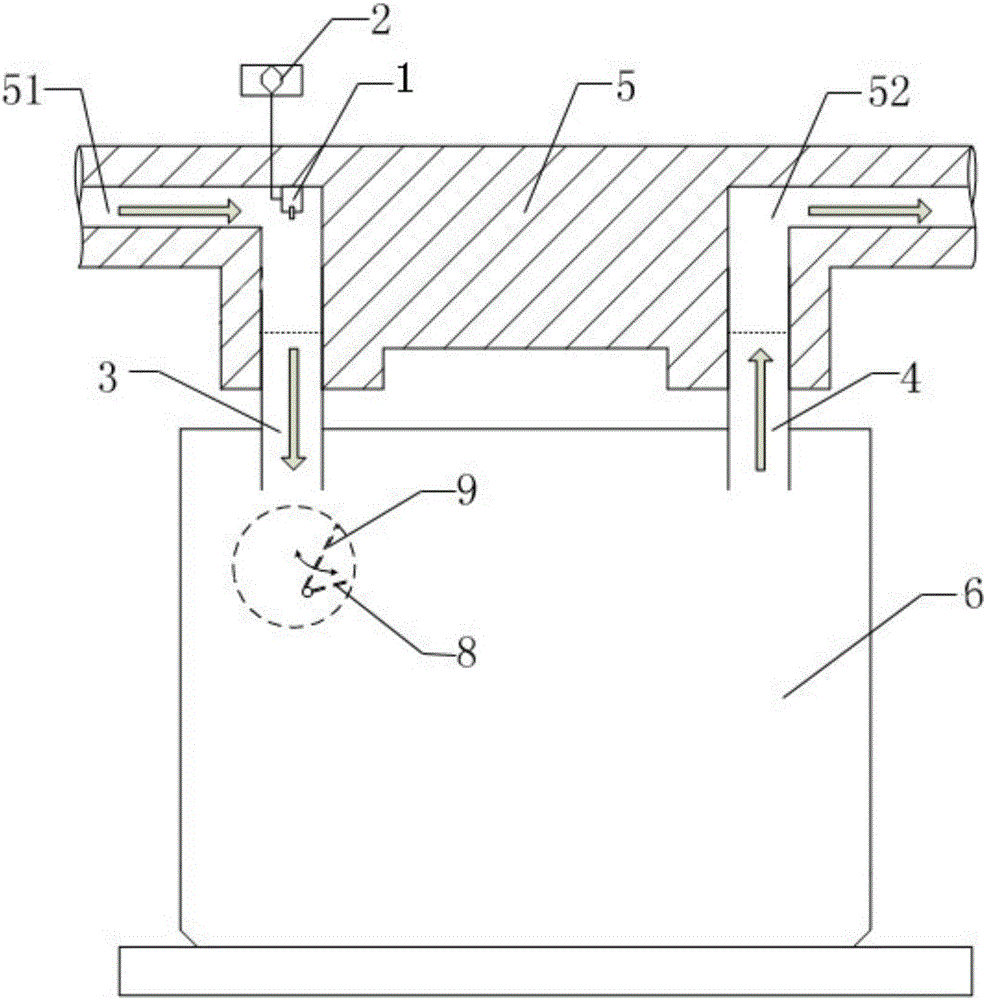

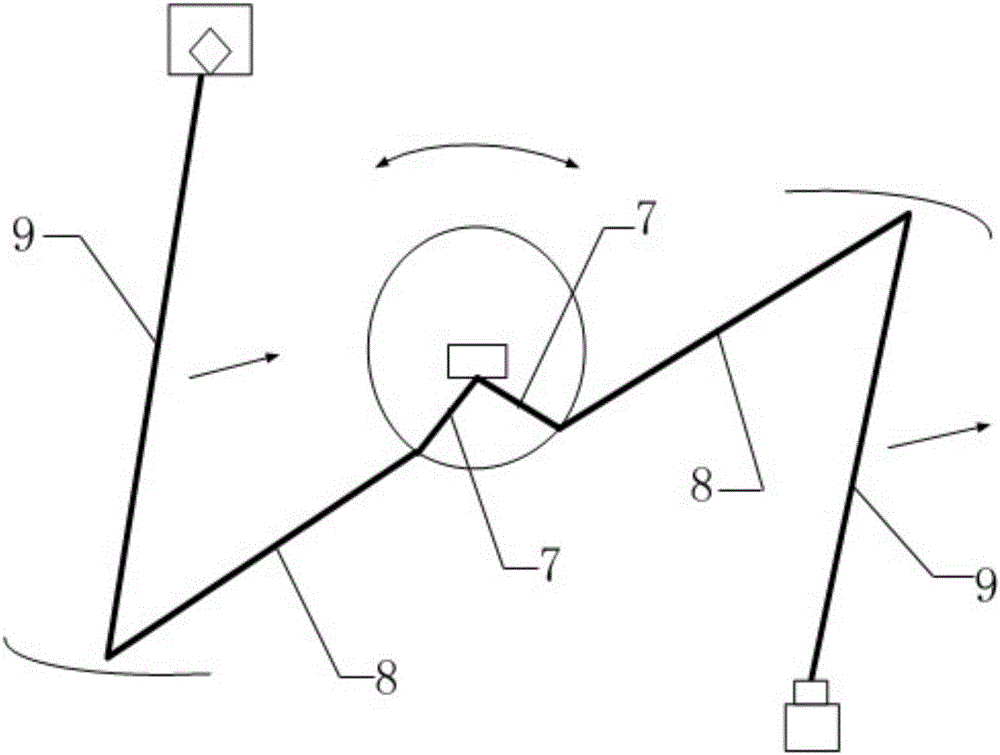

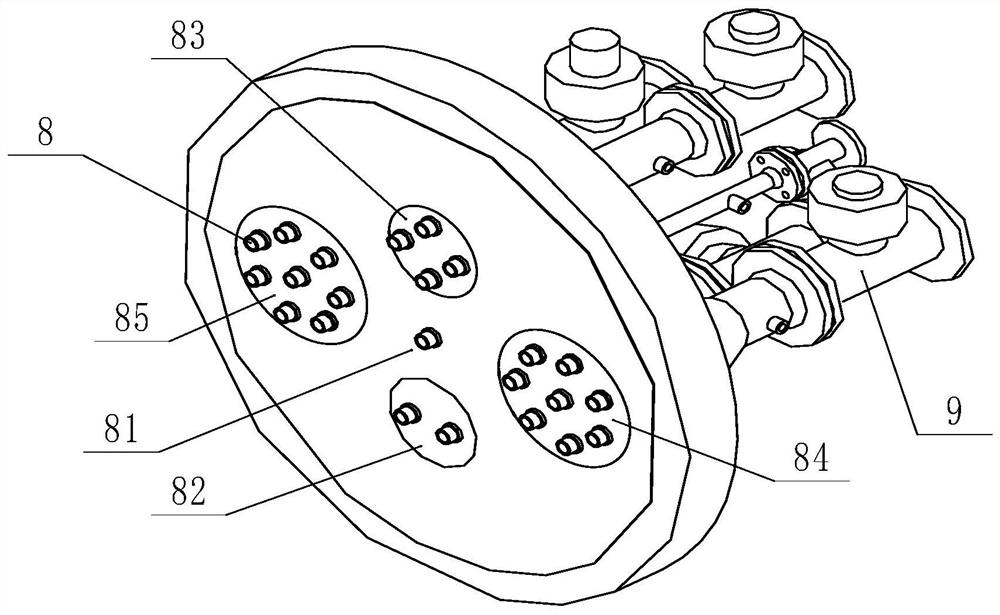

Torch type electric ignition device for gaseous hydrogen and gaseous oxygen

The invention discloses a torch type electric ignition device for gaseous hydrogen and gaseous oxygen. The electric ignition device comprises a hydrogen bottle (1), an oxygen bottle (2), an oxygen sonic nozzle (3), a hydrogen sonic nozzle (4), an ignition body, a convergence section (8) and an electric spark plug device (9); an oxygen cavity (5), a hydrogen cavity (6) and an ignition chamber (7) are arranged in the ignition main body; the hydrogen bottle (1) communicates with the hydrogen cavity (6) of the ignition main body through the hydrogen sonic nozzle (4); the oxygen bottle (2) communicates with the oxygen cavity (5) of the ignition main body through the oxygen sonic nozzle (3); a direct flow hole is formed in the central axis of the ignition chamber (7) and communicates with the oxygen cavity (5); tangential holes (71) are formed in the side wall of the ignition chamber (7) and communicate with the hydrogen cavity (6); the ignition chamber (7) communicates with the convergencesection (8); and the electric spark plug device (9) is installed on the outer surface of the ignition main body, is inserted into the ignition chamber (7) and is located between the direct flow hole and the tangential holes (71).

Owner:BEIJING AEROSPACE PROPULSION INST

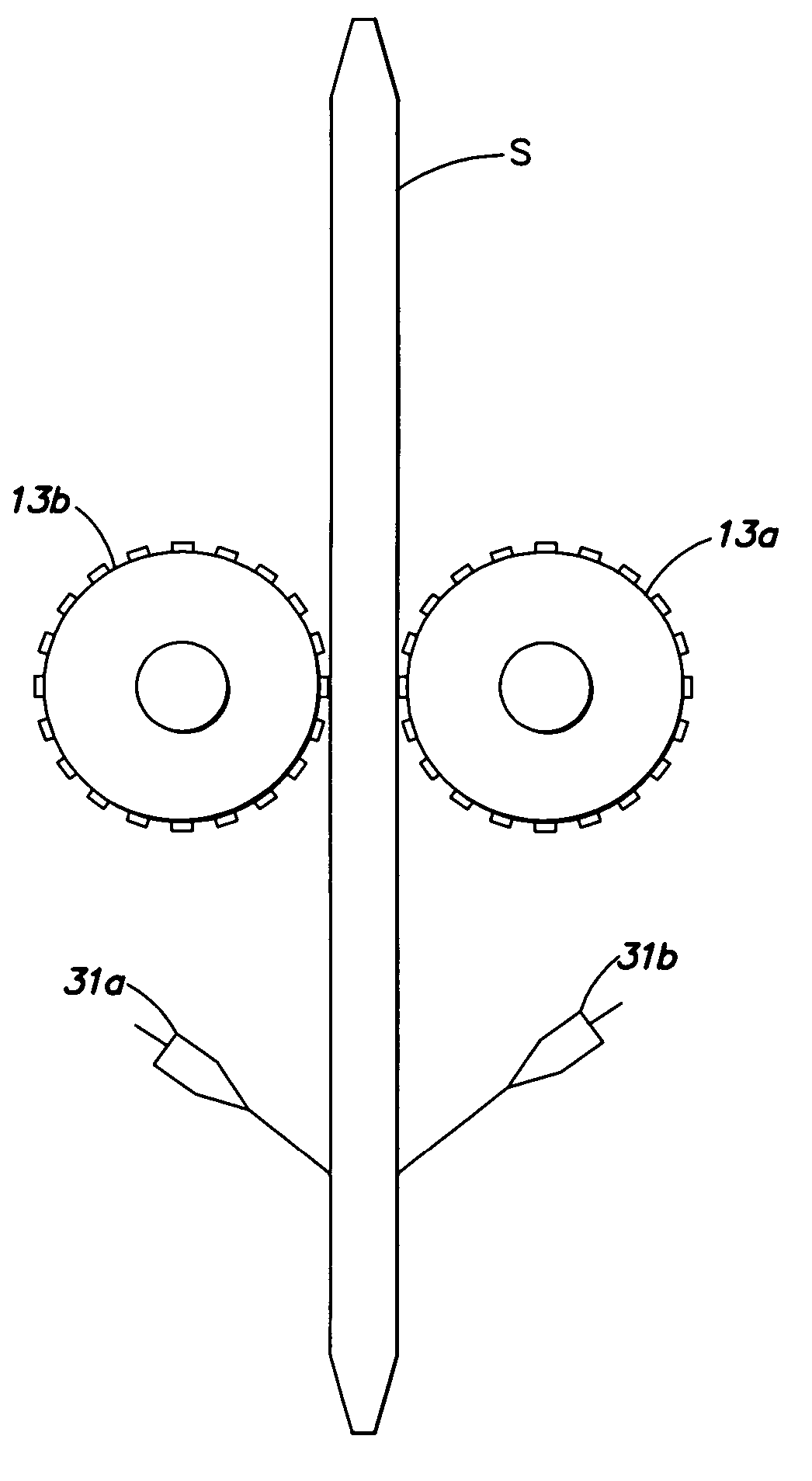

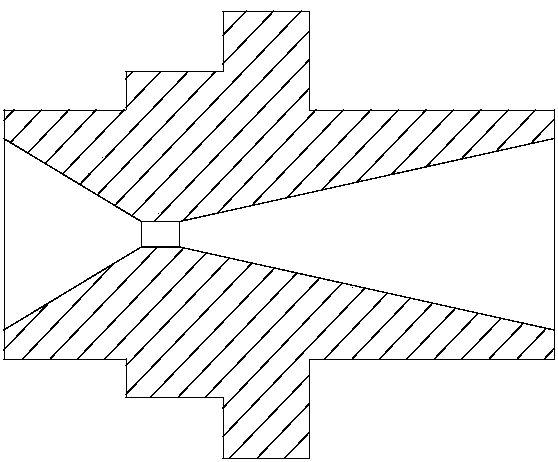

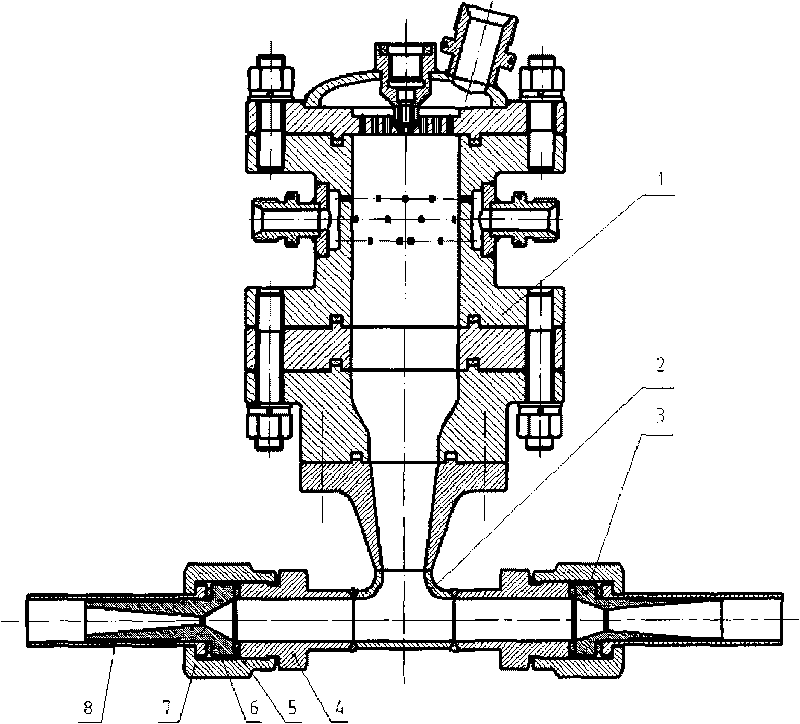

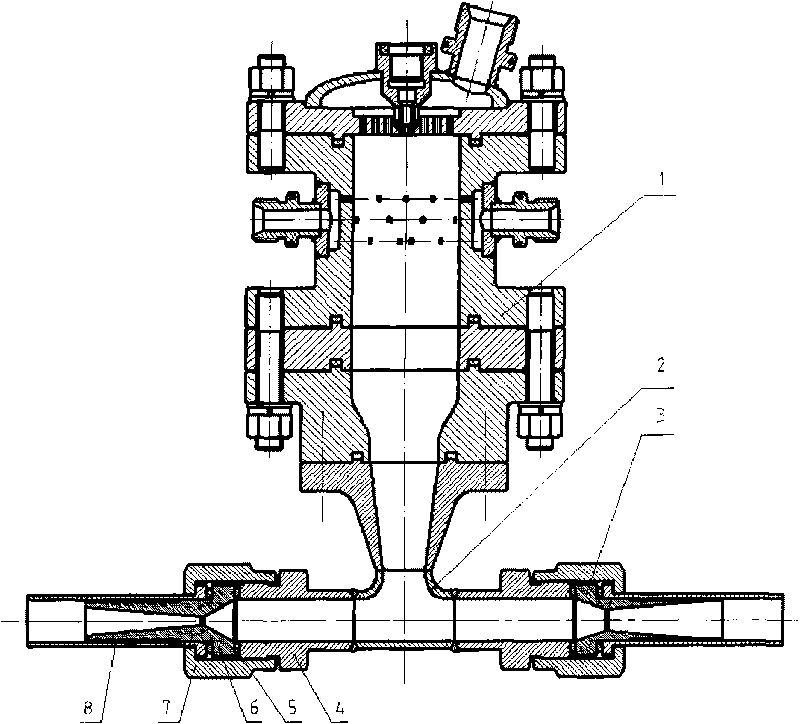

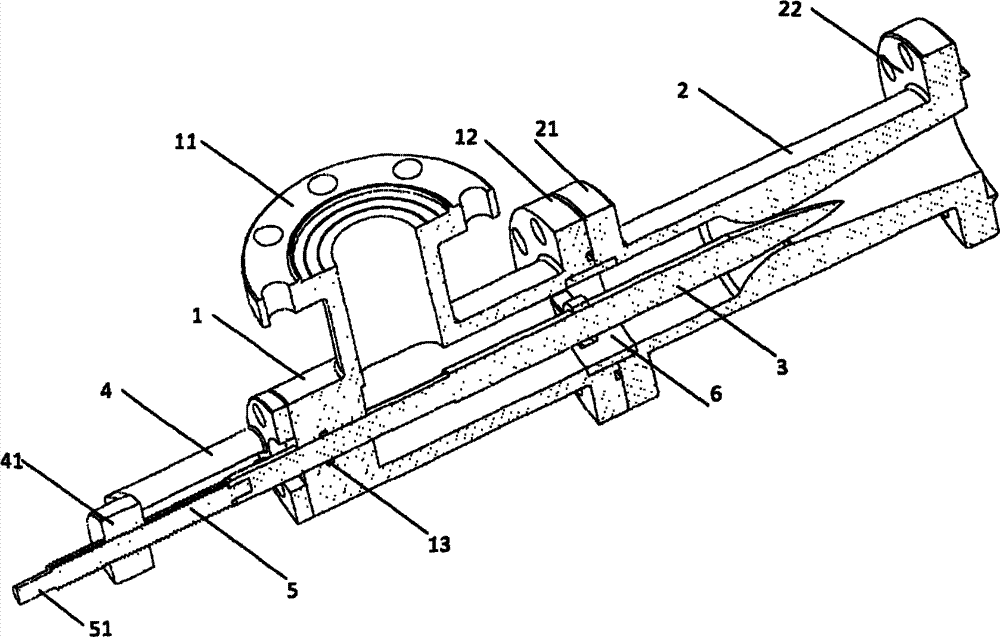

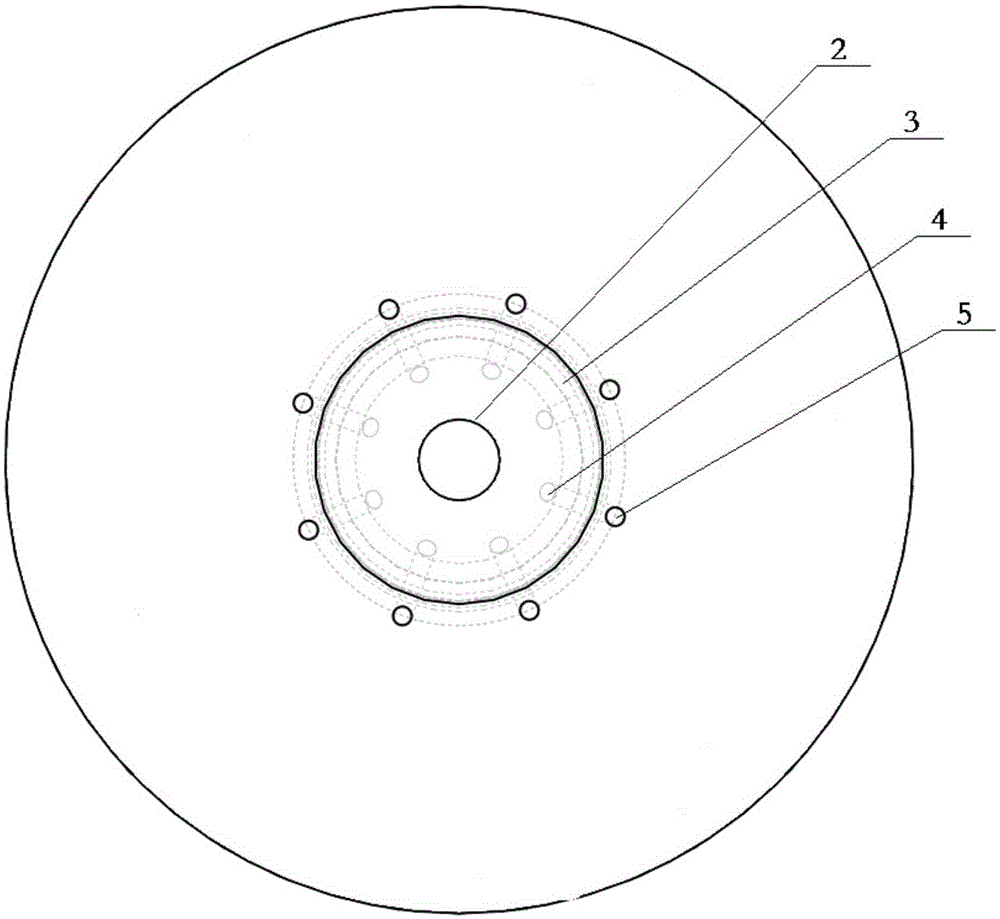

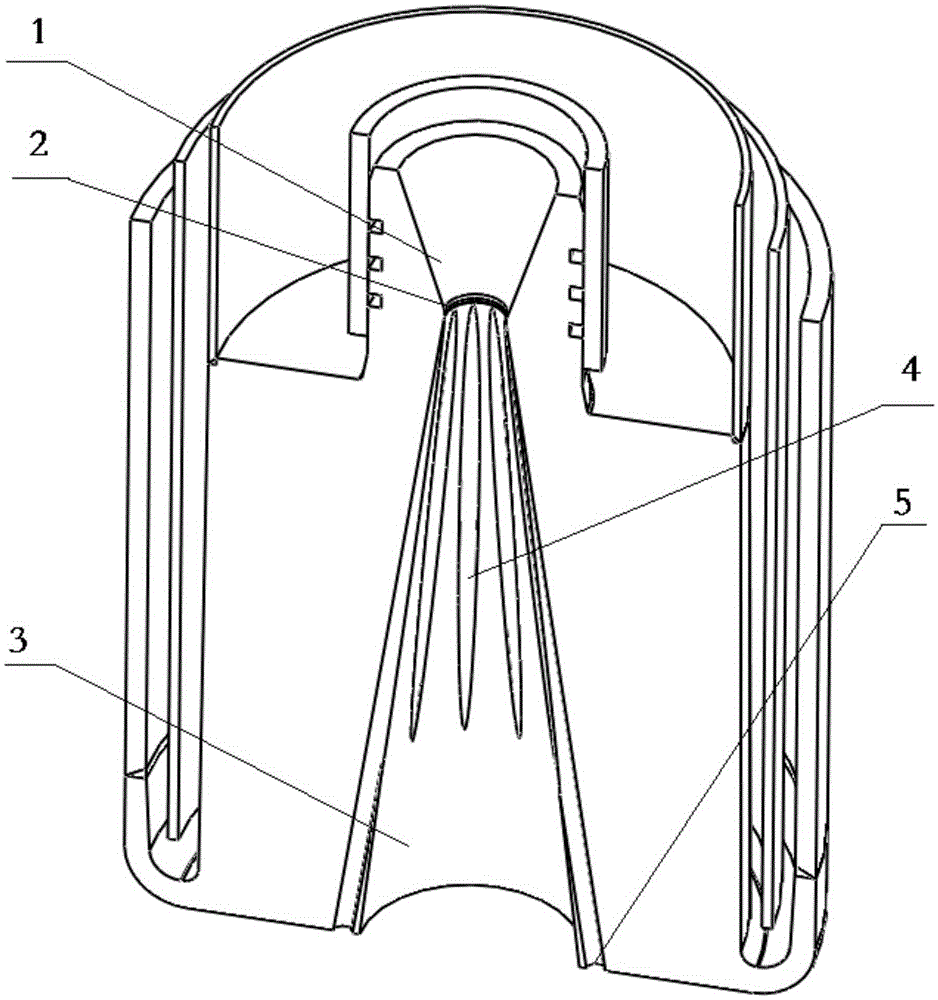

Oxygen-enriched fuel gas supply device and method for fuel gas injector

InactiveCN101738319AHigh trafficEasy to controlGas-turbine engine testingRocket engine plantsSonic nozzleAtmospheric air

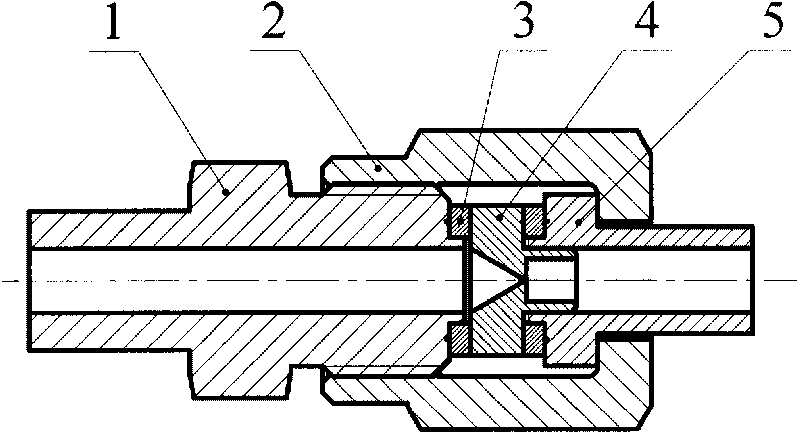

The invention relates to oxygen-enriched fuel gas device and method for a fuel gas injector and belongs to the field of the design of a propellant feed system of a rocket engine. The oxygen-enriched fuel gas device comprises an oxygen-enriched precombustion chamber (1), a tee adapter (2), an outfall sonic nozzle (3), a filler neck (4), a red copper sealing washer (5), an inlet sonic nozzle (6) of the oxygen-enriched fuel gas, a screw cap (7) and a pipe joint component (8). Part of the oxygen-enriched fuel gas enters the fuel gas injector through the tee adapter (2) by the inlet sonic nozzle (6) of the oxygen-enriched fuel gas, and the other part of the oxygen-enriched fuel gas is introduced into the atmosphere through the outfall sonic nozzle (3). The sonic nozzles are arranged between the filler neck (4) and the pipe joint component (8), and sealing is realized by the pressure of the tightening action of the screw cap (7) on the red copper sealing washer (5). By adopting a certain method to regulate the flow rate of the oxygen-enriched fuel gas and replace the inlet sonic nozzle (6) and the outfall sonic nozzle (3) of the oxygen-enriched fuel gas, the parameter requirement of the fuel gas injector is met. The design difficulty of the oxygen-enriched precombustion chamber can be lowered, and the cost and the workload of the test of the flow rate of the fuel gas injector are obviously lowered.

Owner:BEIHANG UNIV

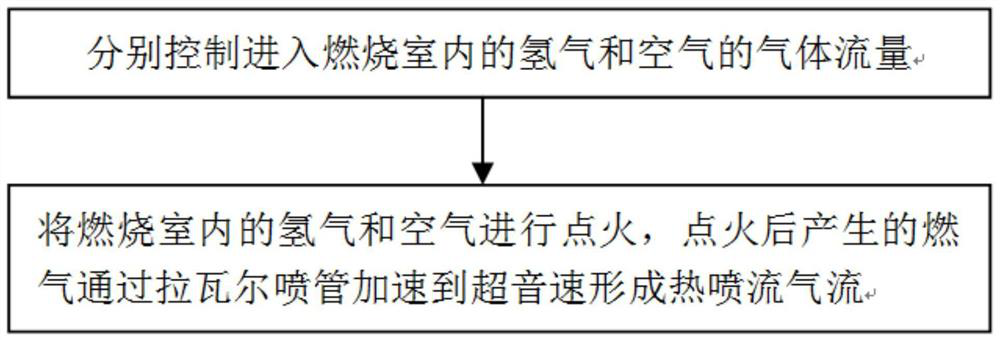

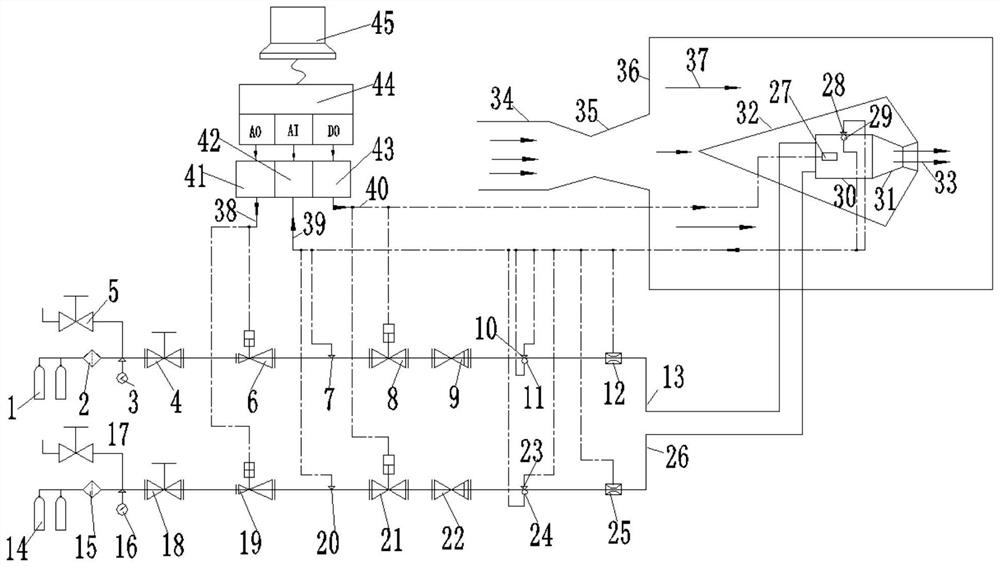

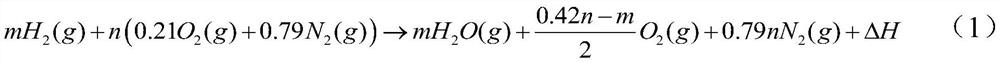

Thermal jet experiment method for shock tunnel

ActiveCN113375889ASimple structureImprove stabilityAerodynamic testingSonic nozzleCombustion chamber

The invention discloses a thermal jet experiment method for a shock tunnel. The thermal jet experiment method comprises the following steps: 1) respectively controlling the gas flow of hydrogen and air entering a combustion chamber; (2) igniting hydrogen and air in the combustion chamber, and accelerating fuel gas generated after ignition to supersonic speed through a Laval nozzle to form hot jet airflow. The hydrogen and the air are respectively conveyed into the combustion chamber through a gas pipeline, and the control of the gas flow comprises the following steps: firstly, regulating the gas pressure in the gas pipeline through a gas pressure reducing valve; and the adjusting the gas flow by a sonic nozzle flowmeter. The thermal jet flow experiment method solves the technical problems that a thermal jet flow experiment method in the prior art is complex in device structure, and jet flow parameters such as flow and temperature are limited in range and difficult to control.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

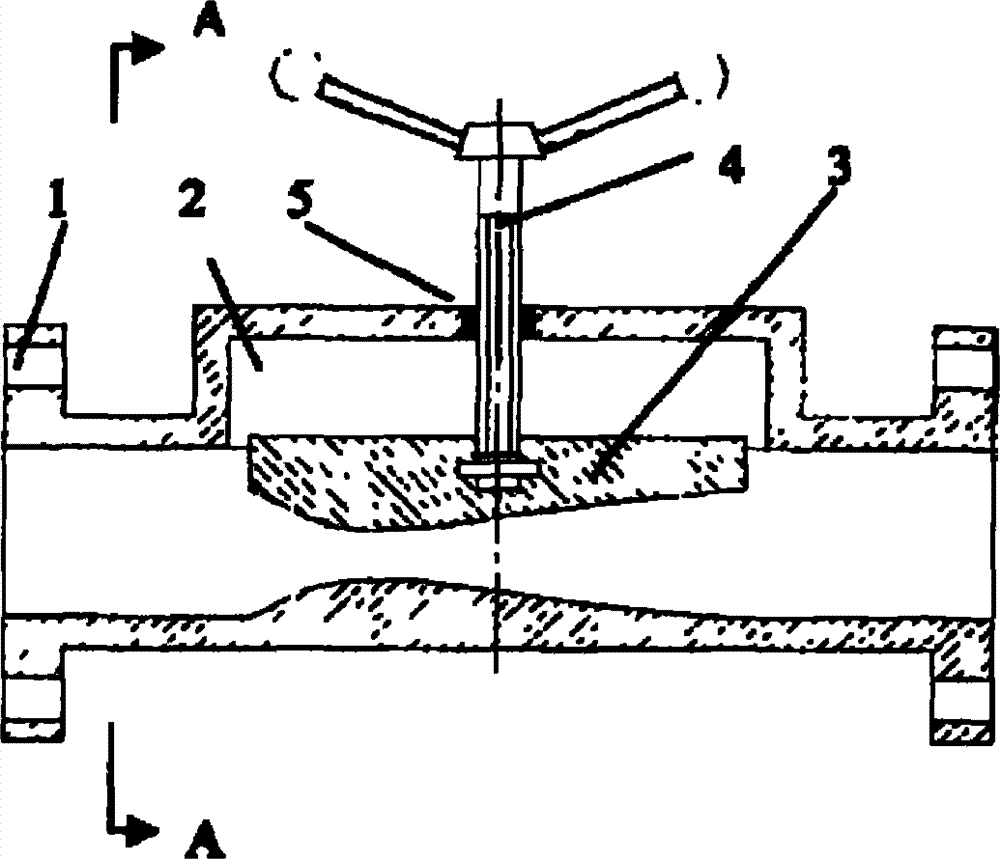

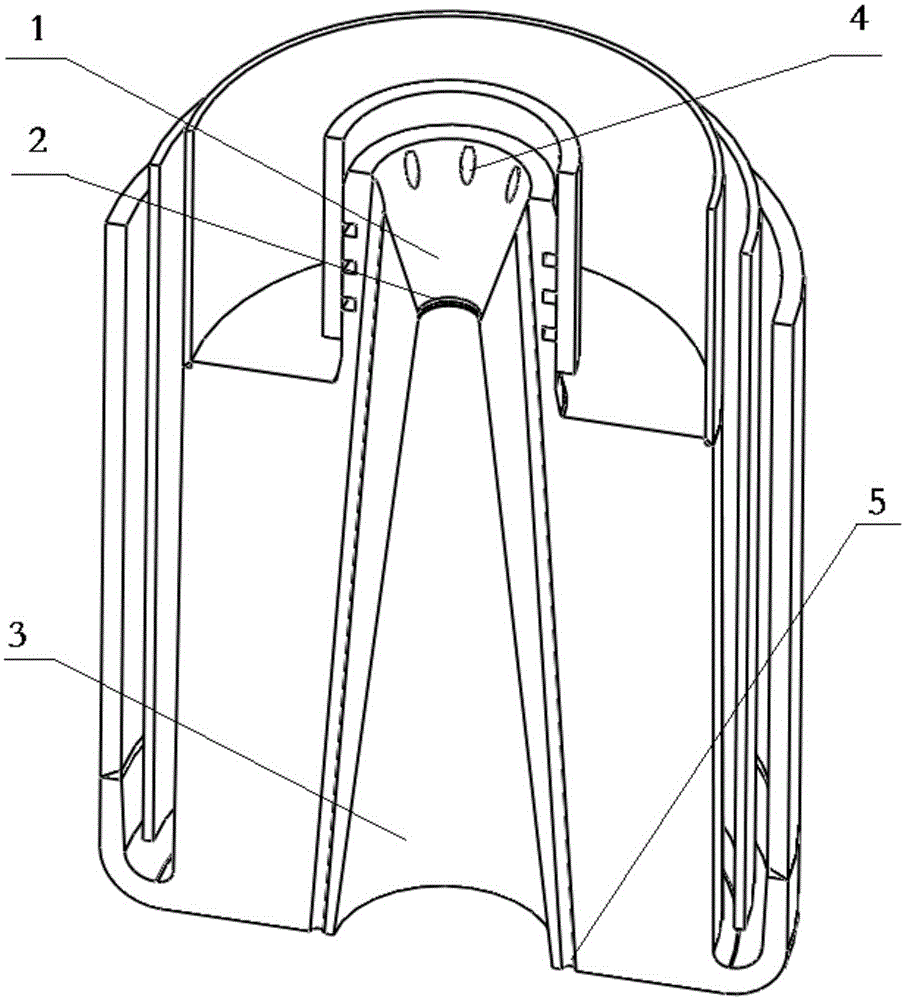

Continuously-adjustable sonic nozzle

ActiveCN103032581AChange actual throat areaAchieve regulationOperating means/releasing devices for valvesLift valveHysteresisSonic nozzle

The invention provides a continuously-adjustable sonic nozzle, which comprises a valve body 1 and a sonic nozzle 2, wherein the valve body 1 is connected with the sonic nozzle 2; the sonic nozzle 2 is a body of revolution; and an inner molding surface is partitioned into an equal-diameter inlet section 24, a circular-arc-shaped contraction section 25, an equal-diameter throat section 26 and a linear expansion section 27. The continuously-adjustable sonic nozzle is characterized by further comprising a plug cone 3, wherein the plug cone 3 is a body of revolution; the front end of the plug cone 3 is conical; the inlet 11 and the outer 12 of the valve body 1 are non-colinear; the outlet 12 of the valve body, the sonic nozzle 2 and the plug cone 3 are coaxial; and the plug cone 3 moves along the axis of the sonic nozzle 2 to change the minimum flow area of the circular-arc-shaped contraction section 25. Continuous adjustment of flow is realized; and the continuously-adjustable sonic nozzle has the characteristics of simple structure, high flow adjusting accuracy, high repeatability, high hysteresis, small operation force and small interference to flow fields.

Owner:NAT UNIV OF DEFENSE TECH

High flow, low vacuum carbon canister purge valve

InactiveUS20070113833A1Reduce stressNon-fuel substance addition to fuelMachines/enginesSonic nozzleFuel tank

A technique is provided for purging an adsorption canister in a fuel tank vent system. The technique provides a relatively high purge flow under conditions wherein the intake manifold vacuum is relatively low. A sonic nozzle is placed in the purge line between the existing purge valve and the adsorption canister. The sonic nozzle includes a tap at its throat for producing a vacuum in response to flow in the purge line. The vacuum is used to control a vacuum operated diaphragm valve in a parallel purge line. The system therefore supplements purge flow through the adsorption canister to the intake manifold.

Owner:SIEMENS VDO AUTOMOTIVE CORP

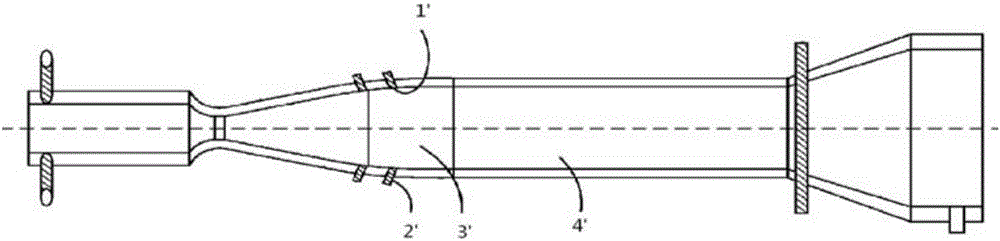

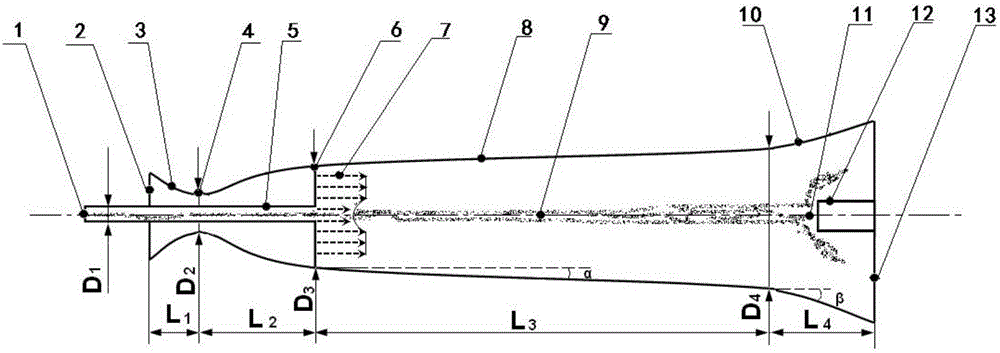

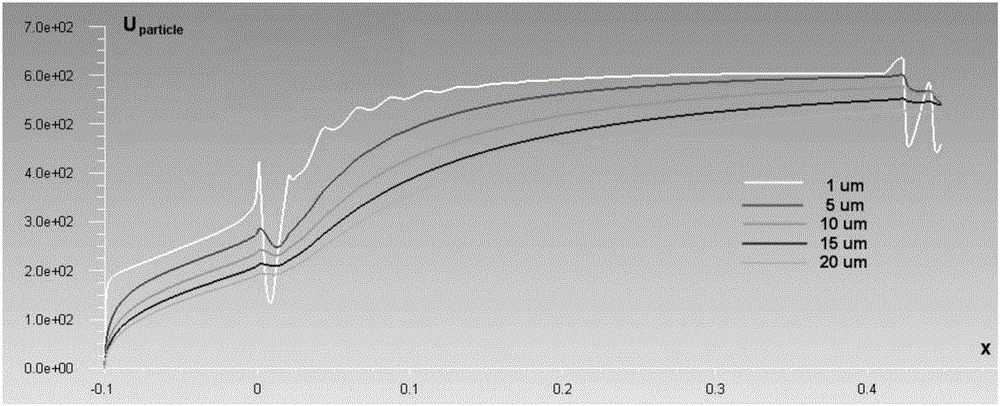

Supersonic nozzle

InactiveCN106693876AUniform flow fieldExact collisionChemical/physical/physico-chemical nozzle-type rreactorsSonic nozzleParticle dynamics

The invention relates to a supersonic nozzle which consists of a ring-shaped shrinking-expanding nozzle, an injected charging pipe, an accelerating pipe and a target head, wherein supersonic gas flow of the ring-shaped shrinking-expanding nozzle is used for injecting and accelerating low-speed gas flow of a central charging circular pipe to an supersonic state, so that material particles obtain enough dynamic energy along with the gas flow, and can be gathered at the gas flow center to crash the fixed target head at the downstream in a focused mode, and therefore, the problems such as difficult charging, low material particle dynamic energy and low collision reaction efficiency in high-speed gas flow solid-phase reaction are solved.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

Method and device for detecting gyration period of diaphragm gas meter based on image acquisition

ActiveCN106153158ASolve acquisition problemsImprove test efficiencyTesting/calibration for volume meteringTemplate matchingSonic nozzle

Provided are a method and a device for detecting a gyration period of a diaphragm gas meter based on image acquisition. Based on an original diaphragm gas meter calibrating device which is based on a sonic nozzle, a camera and an image acquisition and processing module are added. The camera and the image acquisition and processing module are fixed on a meter clamping component of the diaphragm gas meter calibrating device which is based on a sonic nozzle. The camera is on the right upper end of a diaphragm gas meter air inlet. An image in which an oscillating bar and a connecting rod are exposed is acquired and is used as a comparison template. After the image acquisition and processing module identifies the camera, and when the shot image in which the oscillating bar and the connecting rod are exposed can be matched with the comparison template, the interval of acquisition time is the gyration period of the diaphragm gas meter. The identification processing steps of the image acquisition and processing module comprise: (1) converting a grey-scale map; (2) performing image binaryzation; (3) and identifying images based on template matching. The detection method solves a problem that detection difficulty of to-and-fro movement period of reciprocating pieces in a diaphragm gas meter is large.

Owner:ZHEJIANG UNIV CITY COLLEGE

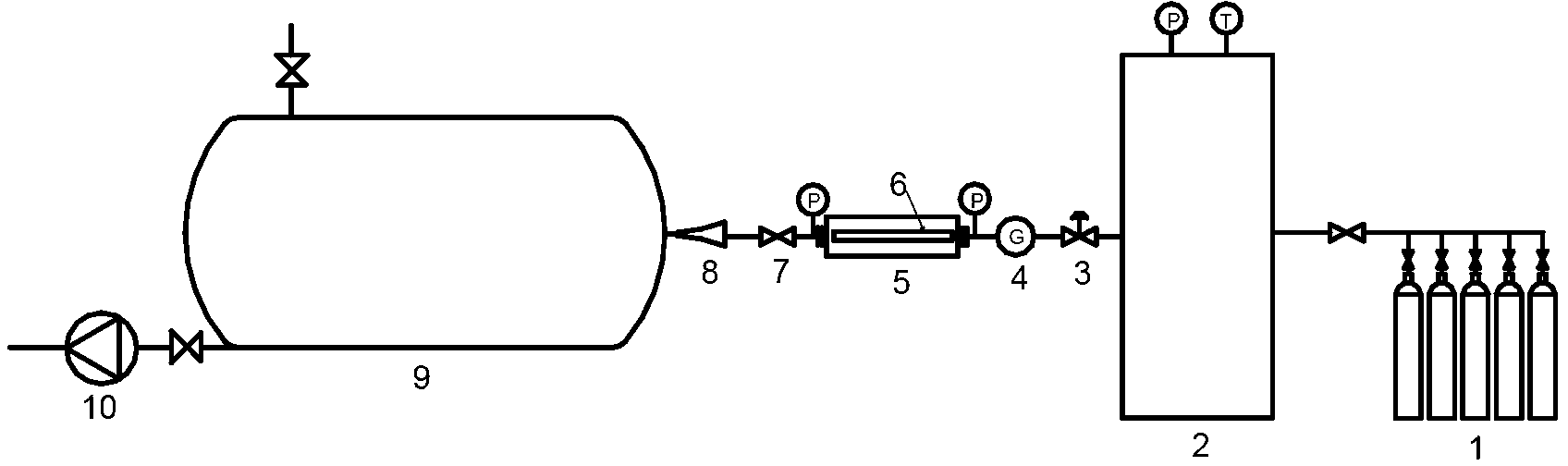

Device and method for analyzing heavy suspension rules of graphite dust in high-temperature heap breach accident

The invention provides a device and a method for analyzing heavy suspension rules of graphite dust in a high-temperature heap breach accident. The device comprises a high-pressure gas cylinder, a high-pressure air storage system, an electromagnetic valve, a flow meter, a discharge pipeline, a dust deposition wall surface, a stop valve, a sonic nozzle, a vacuum tank, and a vacuum pump. The device simulates the sound emission of a high-temperature heap breach through the sonic nozzle; the wall surface on which the graphite dust is deposited is arranged inside the discharge pipeline; high-pressure gas flow in the high-pressure air storage system is discharged into the vacuum tank via the sonic nozzle through the discharge pipeline under the differential pressure effects of the high-pressure air storage system and the vacuum tank in measurement; the deposited graphite dust in the discharge pipeline generates heavy suspension in the process. Thus, the heavy suspension rules of the graphite dust in the discharge process can be detected.

Owner:TSINGHUA UNIV

Device and method for measuring built-in low-temperature pumping speed

InactiveCN101576075AReduced influence of pumping speed measurementHigh precisionPump testingPumpsSonic nozzleMeasurement device

The invention provides a measurement device used for measuring a large built-in low-temperature pumping speed, firstly provides an unconcentrated flow device (16) of a dual-layer cylindrical structure that effectively reduces the effects of the gas jet effect on the large built-in low-temperature pumping speed, firstly applies a method (matching a pressure reducer (23) with a sonic nozzle (22) to precisely adjust the volume flow) to the field of the built-in low-temperature pumping speed measurement, provides a sonic nozzle-type gas supply device and provides a method for measuring the sonic nozzle-type large built-in low-temperature pumping speed by aiming at the gas supply mode.

Owner:BEIHANG UNIV

Supersonic nozzle preventing from slag entrapment

The invention provides a supersonic nozzle preventing from slag entrapment, belonging to the field of steel making. The supersonic nozzle is composed of a main oxygen channel and an auxiliary oxygen channel positioned on the periphery of the main oxygen channel, wherein a center hole of a Laval tube forms the main oxygen channel, a plurality of narrow-long orifices are formed in the Laval tube, and the orifices are positioned in the periphery of the center hole and form the auxiliary oxygen channel. An auxiliary oxygen flow forms a surrounded accompanying flow outside a central supersonic jet flow, a low pressure area generated by the supersonic jet flow is weakened and canceled, and the suction enabling steel slag to be involved in the nozzle is eliminated; meanwhile, the expansion and attenuation of the central supersonic jet flow can be much smaller, the supersonic jet flow is longer, and the penetration depth and the stirring intensity of the oxygen jet flow for a molten pool are improved; the gun position is heightened so that liquid steel splash and slag bonding of a gun head are reduced, and the service life is prolonged. In the RH vacuum refining process, the main oxygen flow impacts liquid steel and reacts with carbon in the liquid steel to generate carbon monoxide, the carbon monoxide overflowing the liquid steel generates secondary combustion with the auxiliary oxygen flow of the surrounded accompanying flow to heat a vacuum tank, and the temperature drop of liquid steel is reduced.

Owner:CISDI ENG CO LTD

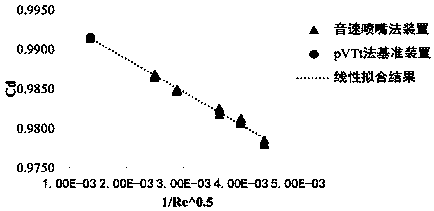

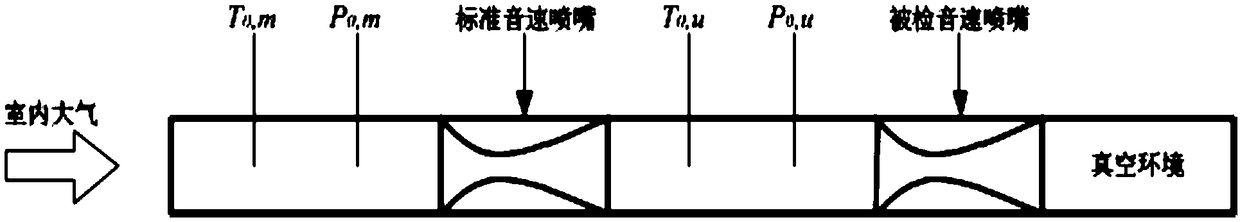

Low-pressure critical flow Venturi nozzle calibration device

The invention discloses a low-pressure critical flow Venturi nozzle calibration device. The low-pressure critical flow Venturi nozzle calibration device comprises an inlet pipe section, wherein one end of the inlet pipe section is directly connected to the atmosphere; the other end of the inlet pipe section extends to the inlet of a manifold; a plurality of channels are formed between the outlet of the manifold and the inlet of a reverse manifold; a pneumatic valve and a standard sonic nozzle are arranged in each channel; the standard sonic nozzles in the plurality of channels have different throat diameters; a plurality of pipelines are connected to a sonic nozzle to be measured; the outlet end of the sonic nozzle to be measured is a vacuum environment; a control part measures the temperatures and pressures of the standard sonic nozzles and the sonic nozzle to be measured; and the pneumatic valves in the plurality of channels are connected to the control part. A set of low-pressure sonic nozzle calibration device suitable for direct calibration and quantity traceability of the sonic nozzles under the conditions of ultra-low pressure and large flow rate is established, so that thetest condition of stagnation pressure being as low as 10kPa of a sonic nozzle under measurement can be realized.

Owner:NAT INST OF METROLOGY CHINA +1

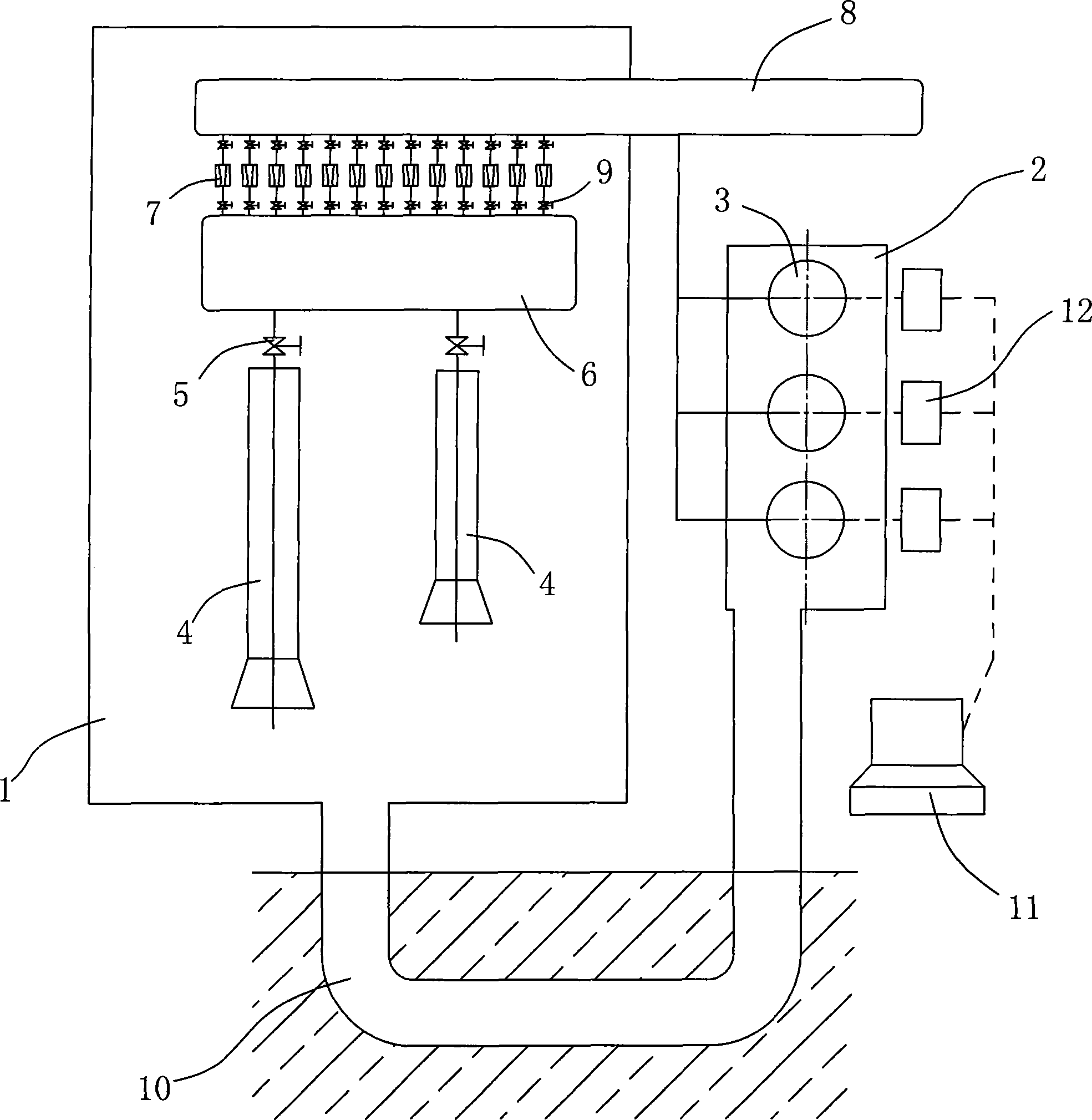

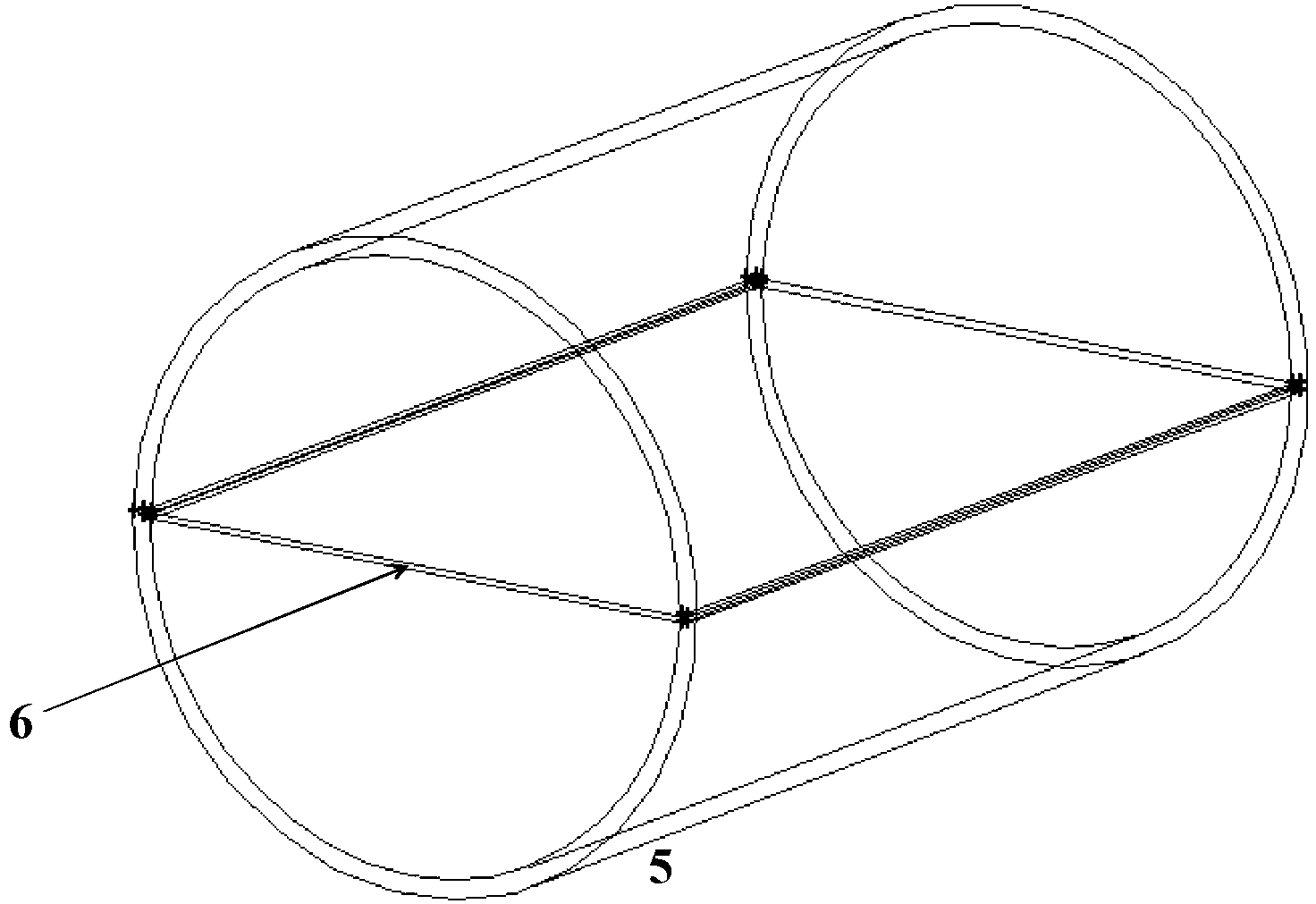

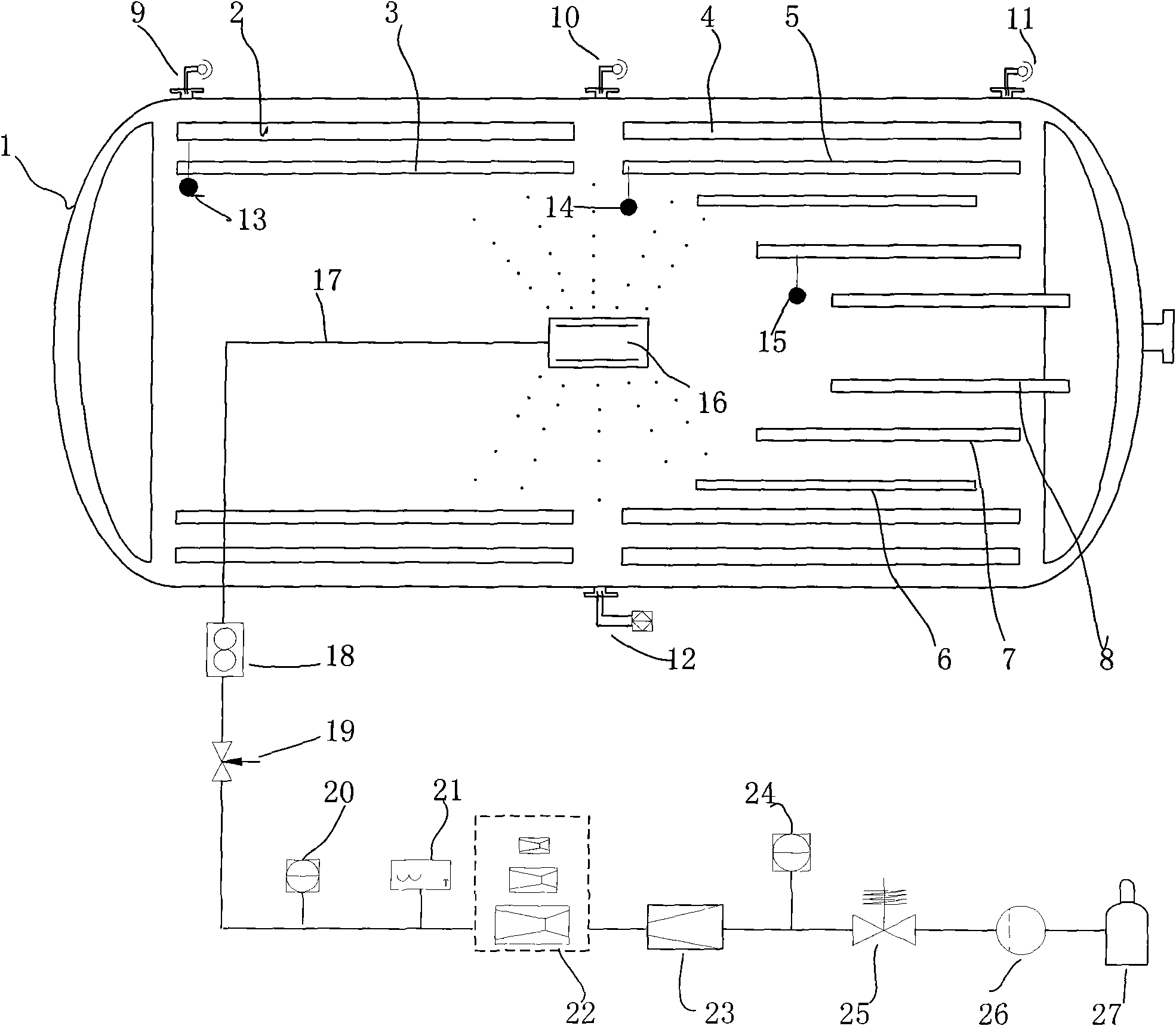

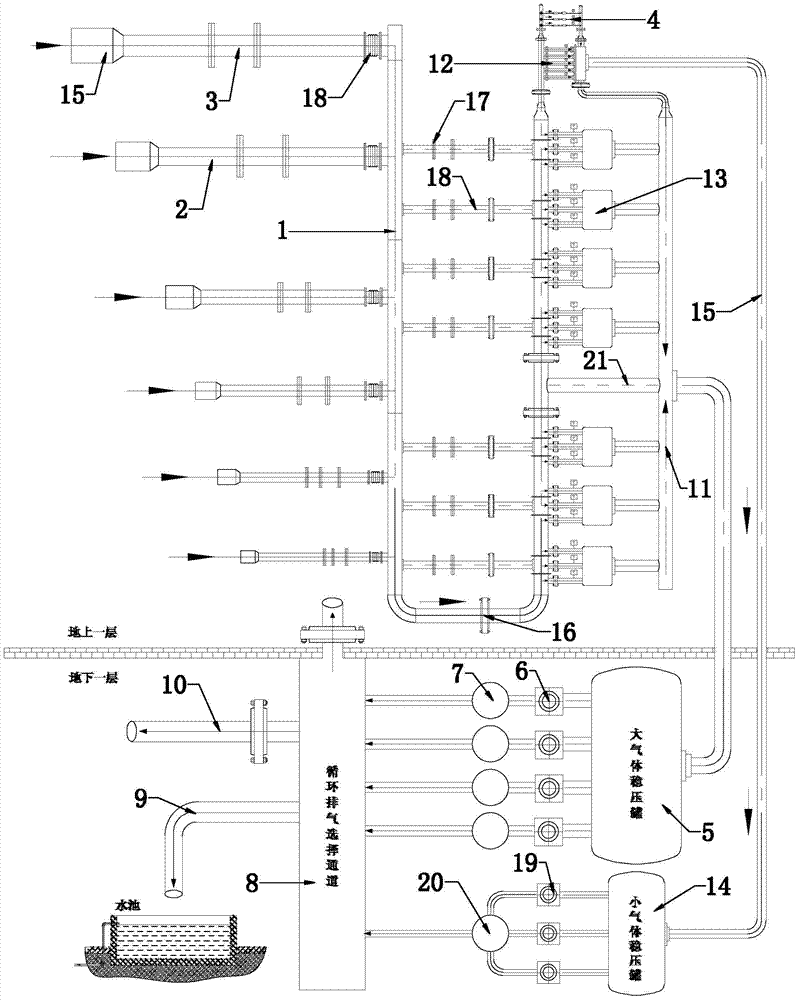

Ultra-large diameter sonic nozzle block type gas flowmeter calibrating device

The invention discloses an ultra-large diameter sonic nozzle block type gas flowmeter calibrating device. The ultra-large diameter sonic nozzle block type gas flowmeter calibrating device comprises a gas flow calibrating part located above the ground and a gas discharge part located under the ground; the gas flow calibrating part comprises a U-shaped header which is divided into front and rear two sections; a detection pipeline is connected to the front section of the U-shaped header, while sonic nozzles are connected to the rear section of the U-shaped header; the underground gas discharge part comprises a first gas pressure stabilizing tank which is provided with a plurality of outlets; each outlet is connected to a cyclic gas discharge selecting channel; the cyclic exhaust selecting channel is provided with a water discharge channel and a gas discharge channel; each sonic nozzle is connected to one first nozzle outlet header which is connected to the first gas pressure stabilizing tank. The ultra-large diameter sonic nozzle block type gas flowmeter calibrating device has the advantages that the space is effectively utilized, the noise quantity of the space of the part above the ground is reduced and the working environment is improved, and furthermore, the energy consumption is greatly reduced and the calibration result is accurate.

Owner:ZHENJIANG MEASUREMENT VERIFICATION TEST CENT

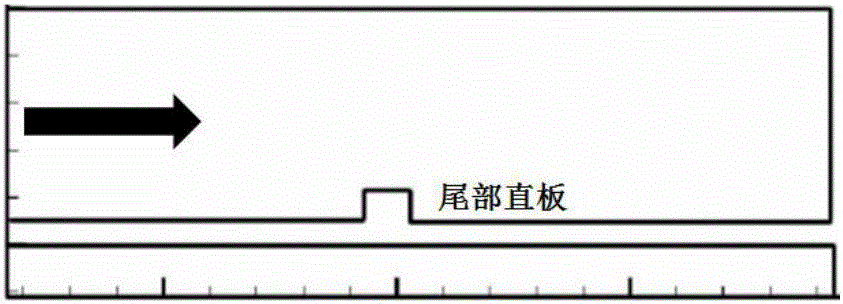

Flow rate measurable air intake duct throttling device

ActiveCN106441781ASmooth rotationPlay a limiting roleAerodynamic testingSonic nozzleObservational error

The invention discloses a flow rate measurable air intake duct throttling device, comprising a throttling butterfly valve, a throttling butterfly valve driving mechanism, a throttling cylinder and a sonic nozzle, wherein the throttling butterfly valve is vertically inserted into the throttling cylinder relative to the axis, the throttling butterfly valve driving mechanism is arranged outside the throttling cylinder, the throttling butterfly valve rotates under the drive of the throttling butterfly valve driving mechanism to change the blocking area in the throttling cylinder so as to adjust the magnitude of negative pressure, and the sonic nozzle is installed at the outlet end of the throttling cylinder. The throttling butterfly valve in the device is subjected to a relatively small aerodynamic resistance torque, so that the required power of a driving motor is relatively low; the motor for driving the throttling butterfly valve to rotate is installed outside a runner, so that the length of the throttling device is greatly shortened. The throttling device connected in series with the sonic nozzle can obtain the flow rate of an air intake duct in real time while adjusting the negative pressure at the outlet of the air intake duct, and has small measurement error.

Owner:NAT UNIV OF DEFENSE TECH

Gas flow standard device with high and low pressure double calibration sections, and calibration method thereof

PendingCN111735520AExpand the range of working conditionsImprove calibration accuracyTesting/calibration apparatusSonic nozzleEngineering

The invention discloses a gas flow standard device with high and low pressure double calibration sections, and a calibration method thereof, and belongs to the field of gas flow metering calibration and verification. The flow standard device with the high and low pressure double calibration sections, and the calibration method thereof are provided in order to overcome the defects that an existingflow meter can only be calibrated under the positive pressure working condition and is narrow in calibration range and high in cost. In the invention, an outlet of a high-pressure gas source is sequentially communicated with a high-pressure stop valve, a high-pressure regulating valve, an adjustable throttle valve, a high-pressure calibration section, a stagnation container, a low-pressure calibration section, a low-pressure regulating valve, a low-pressure stop valve and a vacuum gas source, and a high-pressure calibrated flow meter is arranged in the high-pressure calibration section; and acritical flow sonic nozzle standard meter and a branch stop valve are arranged in the stagnation container, a low-pressure calibrated flow meter is arranged in the low-pressure calibration section, and the critical state high-pressure flow meter, the non-critical state high-pressure flow meter and the low-pressure flow meter are calibrated by adjusting the high-pressure calibrated flow meter and the low-pressure calibrated flow meter. The gas flow calibration device and method are mainly used for calibrating and detecting the gas flow.

Owner:AVIC SHENYANG AERODYNAMICS RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com