Patents

Literature

790 results about "Sound emission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

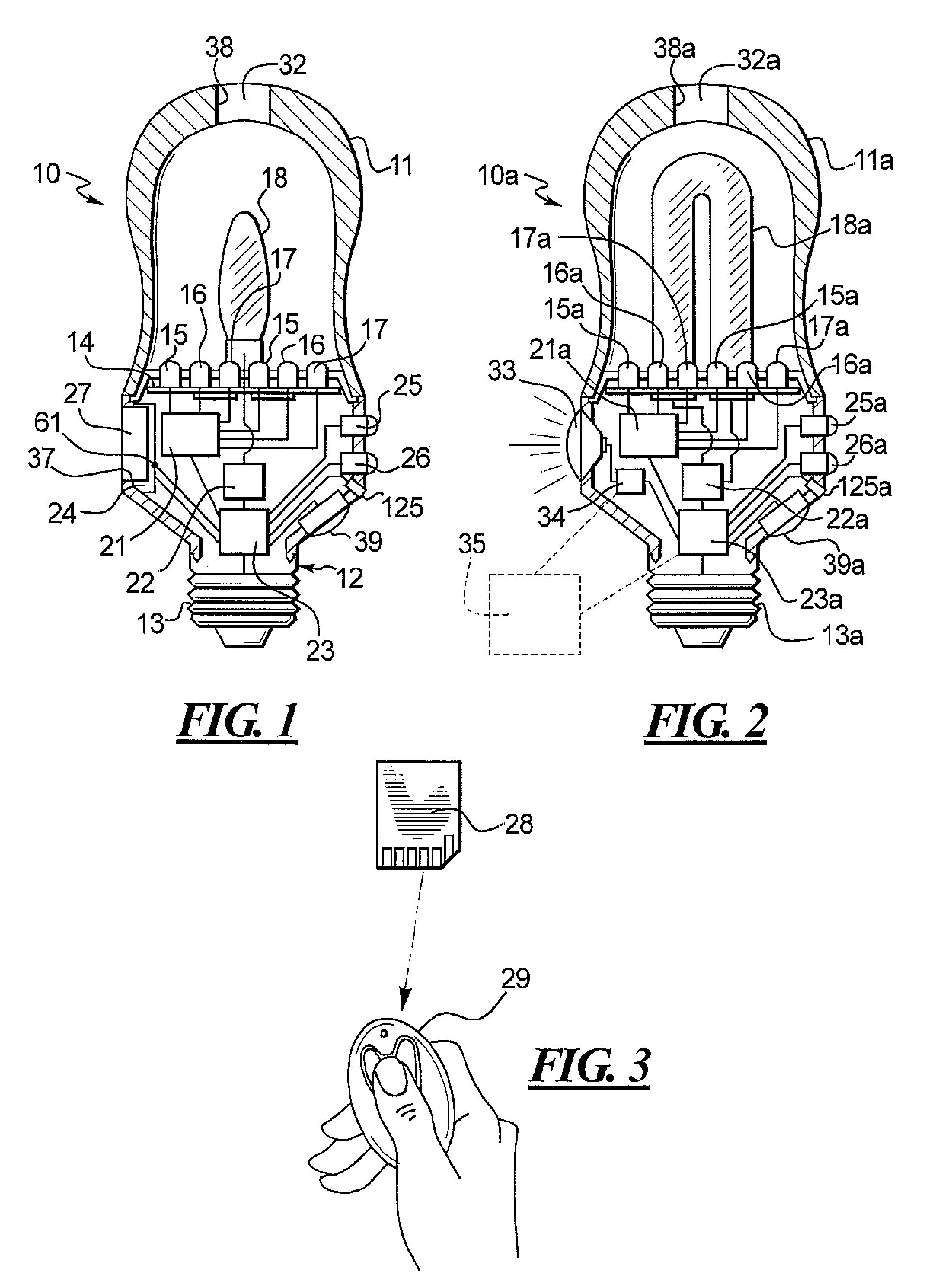

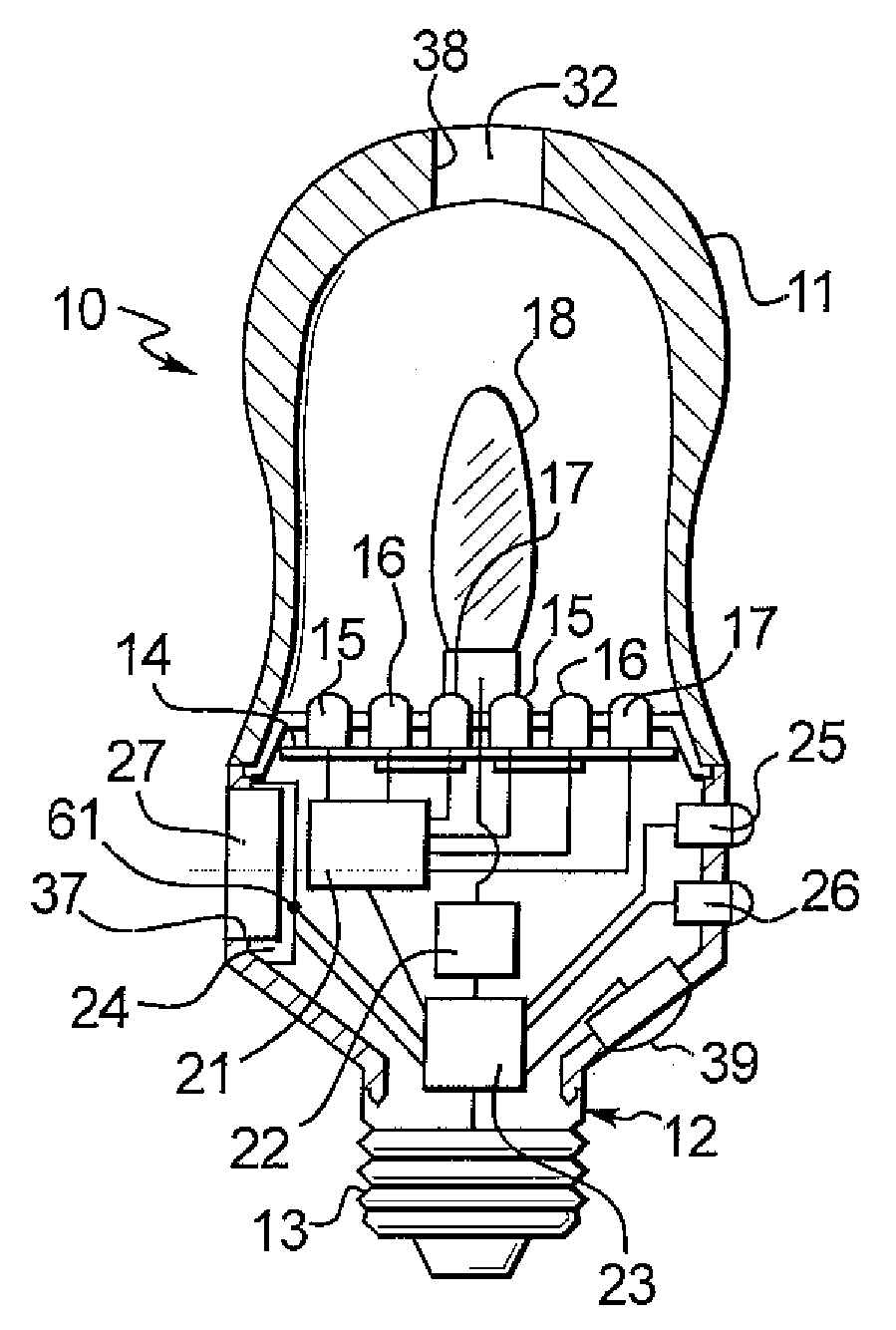

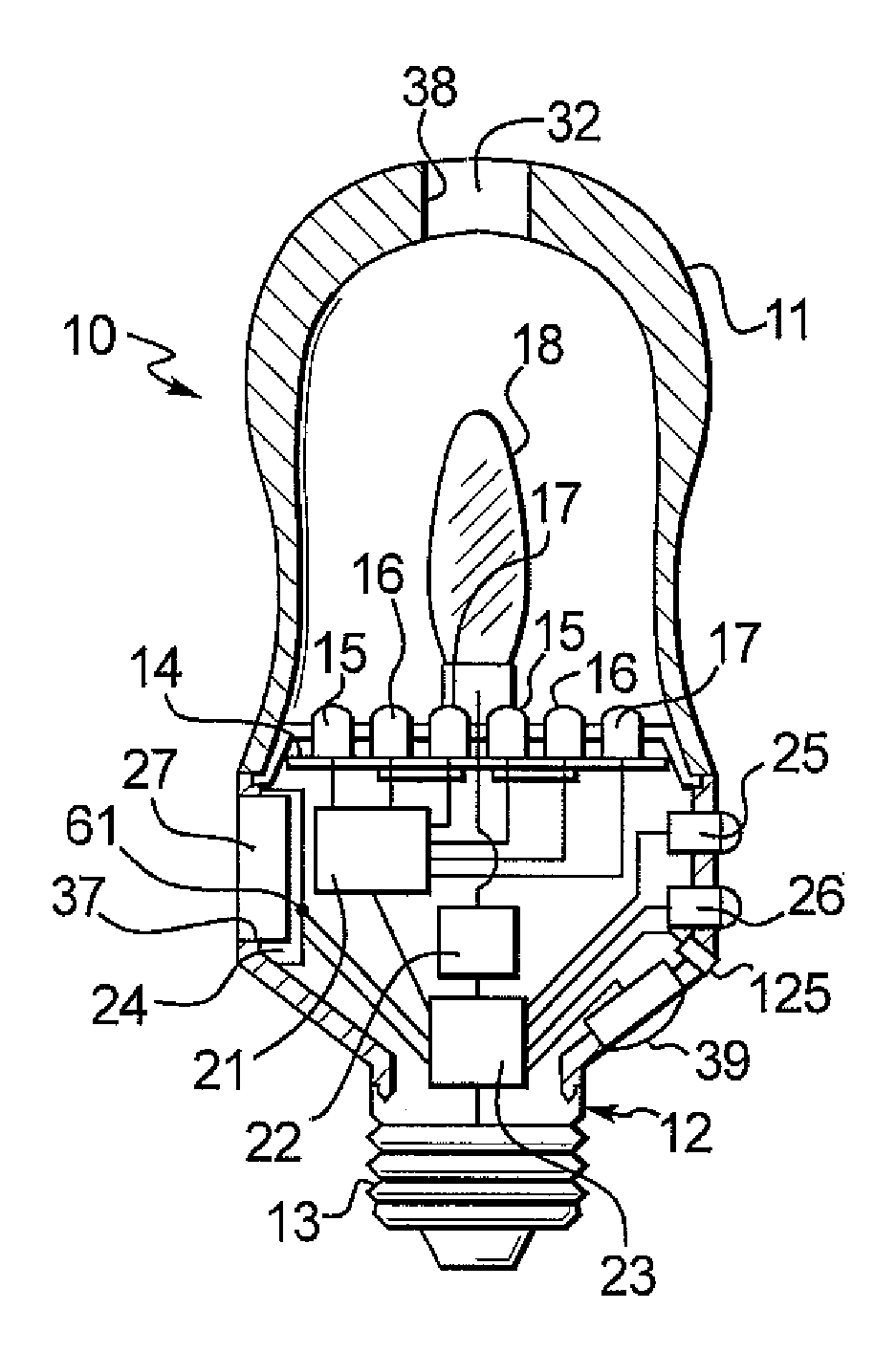

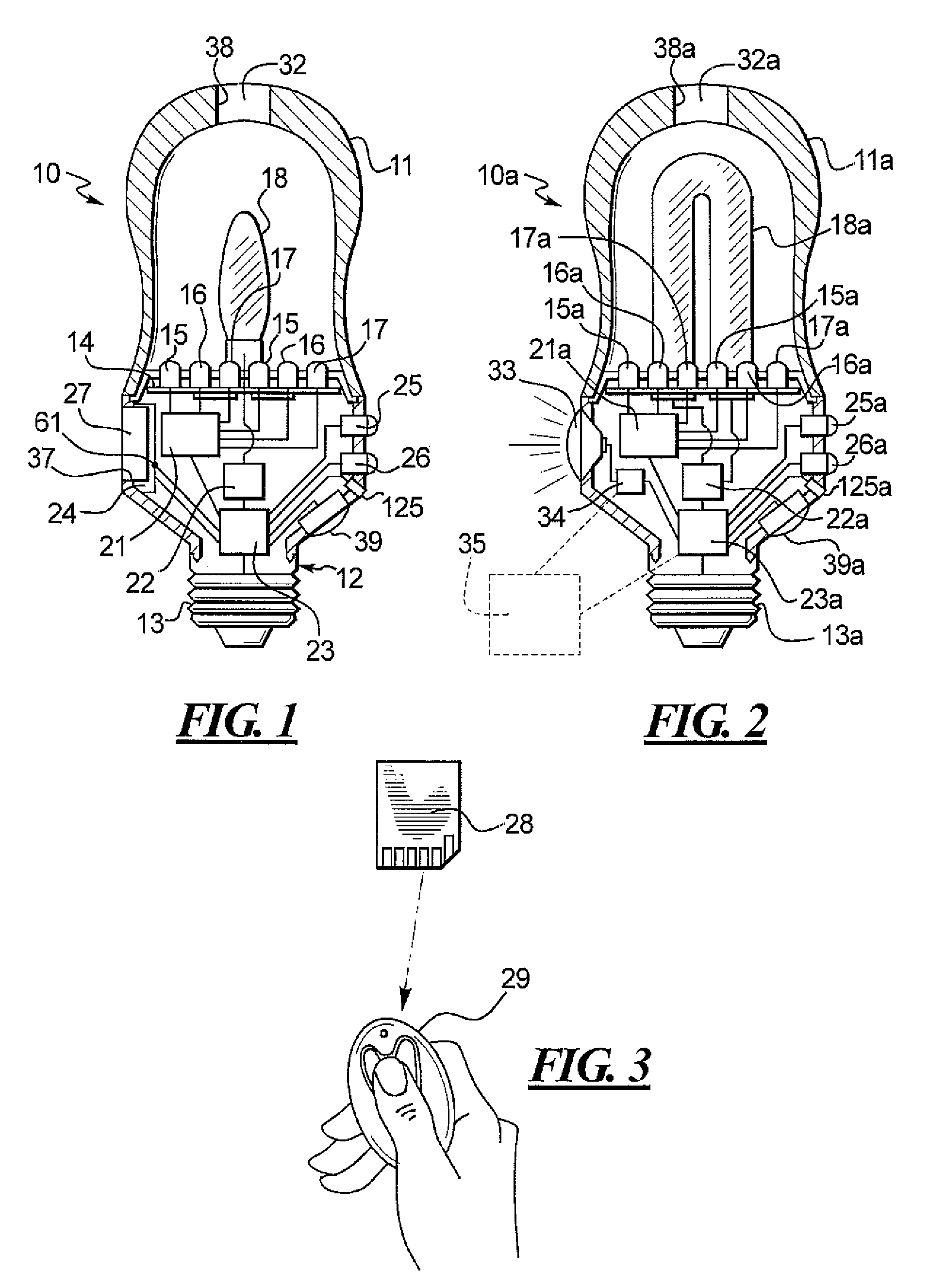

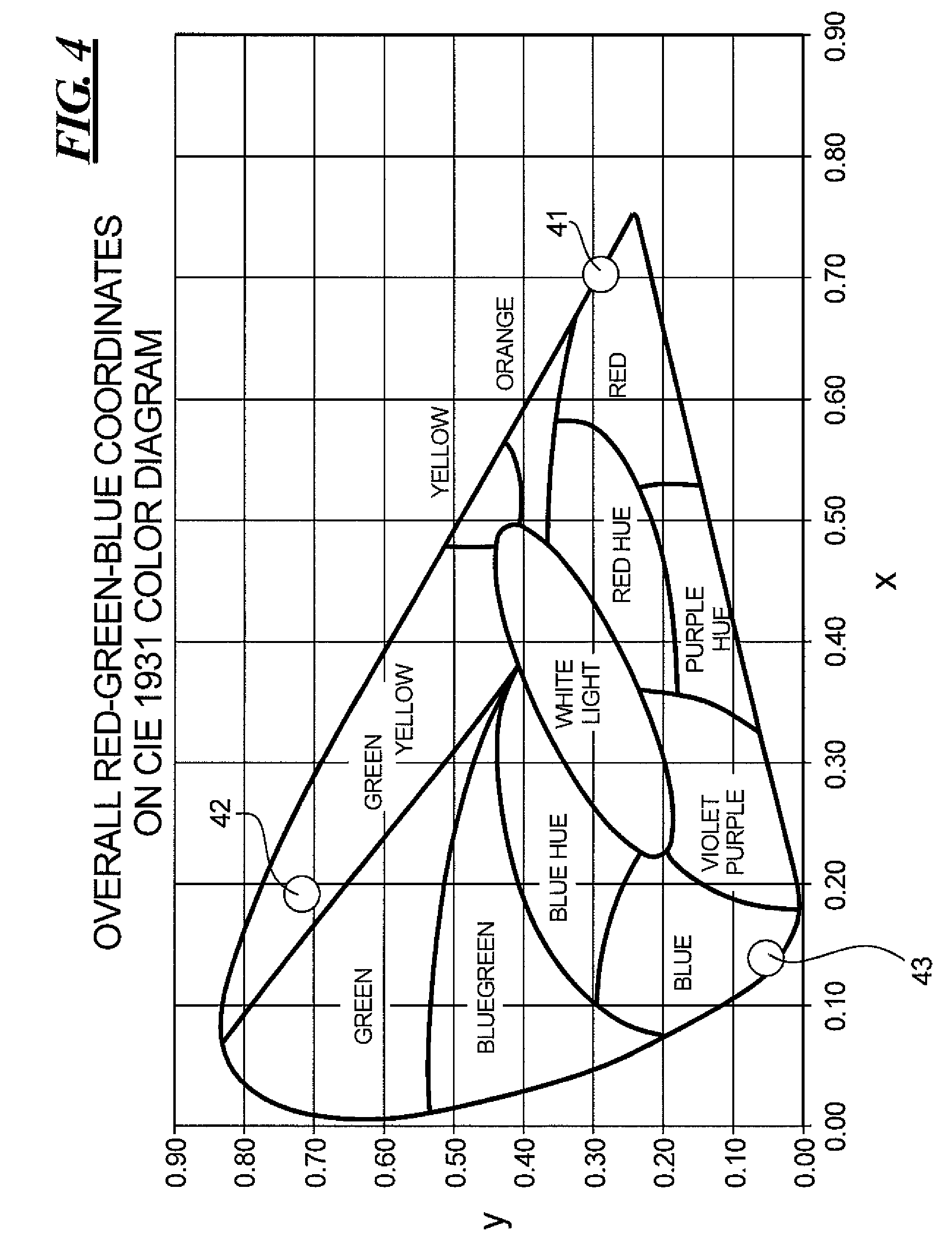

Color changing outdoor lights with active ingredient and sound emission

InactiveUS20070109763A1Different effectVersatile in design and constructionCoupling device connectionsLight source combinationsMotion detectorEffect light

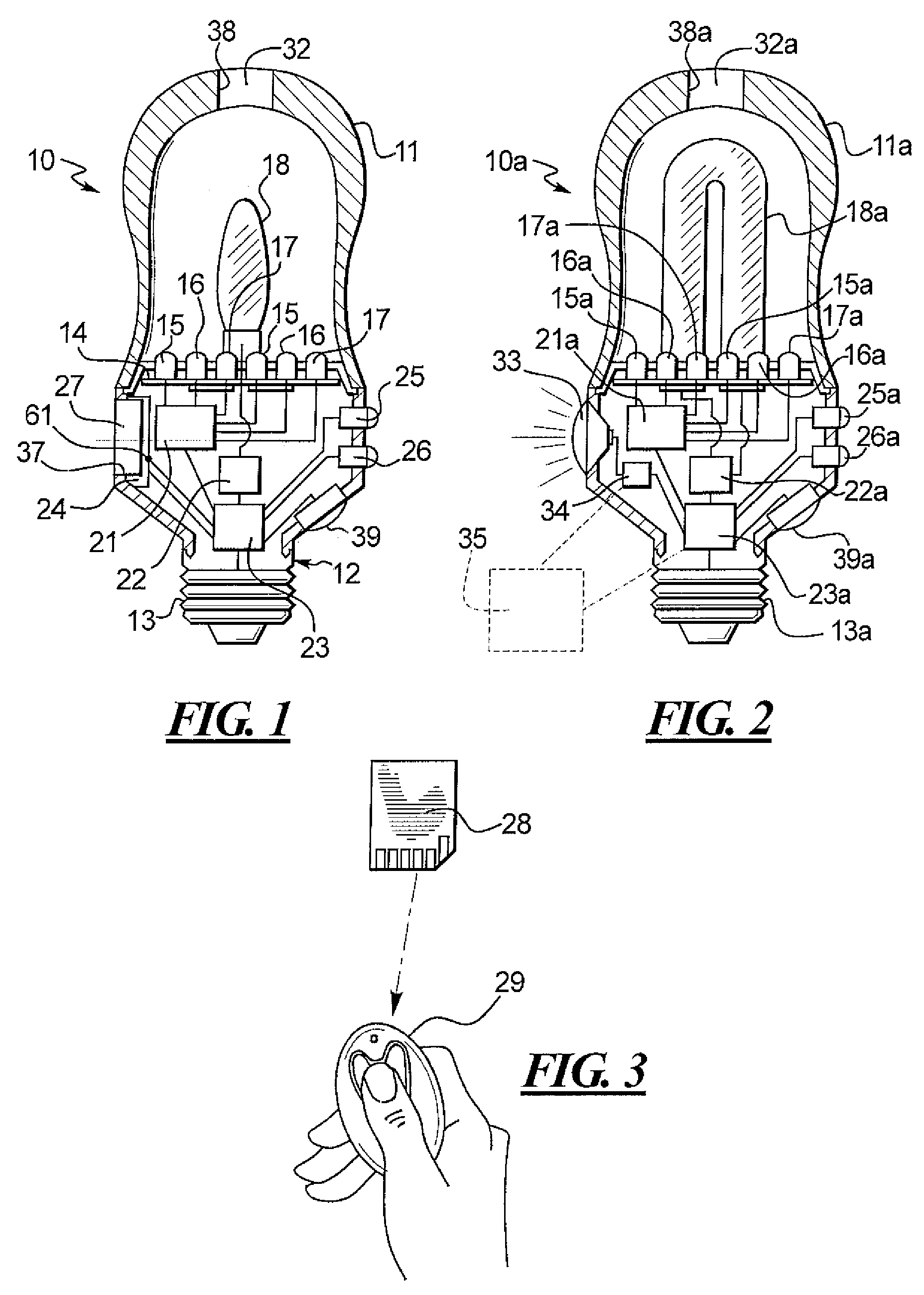

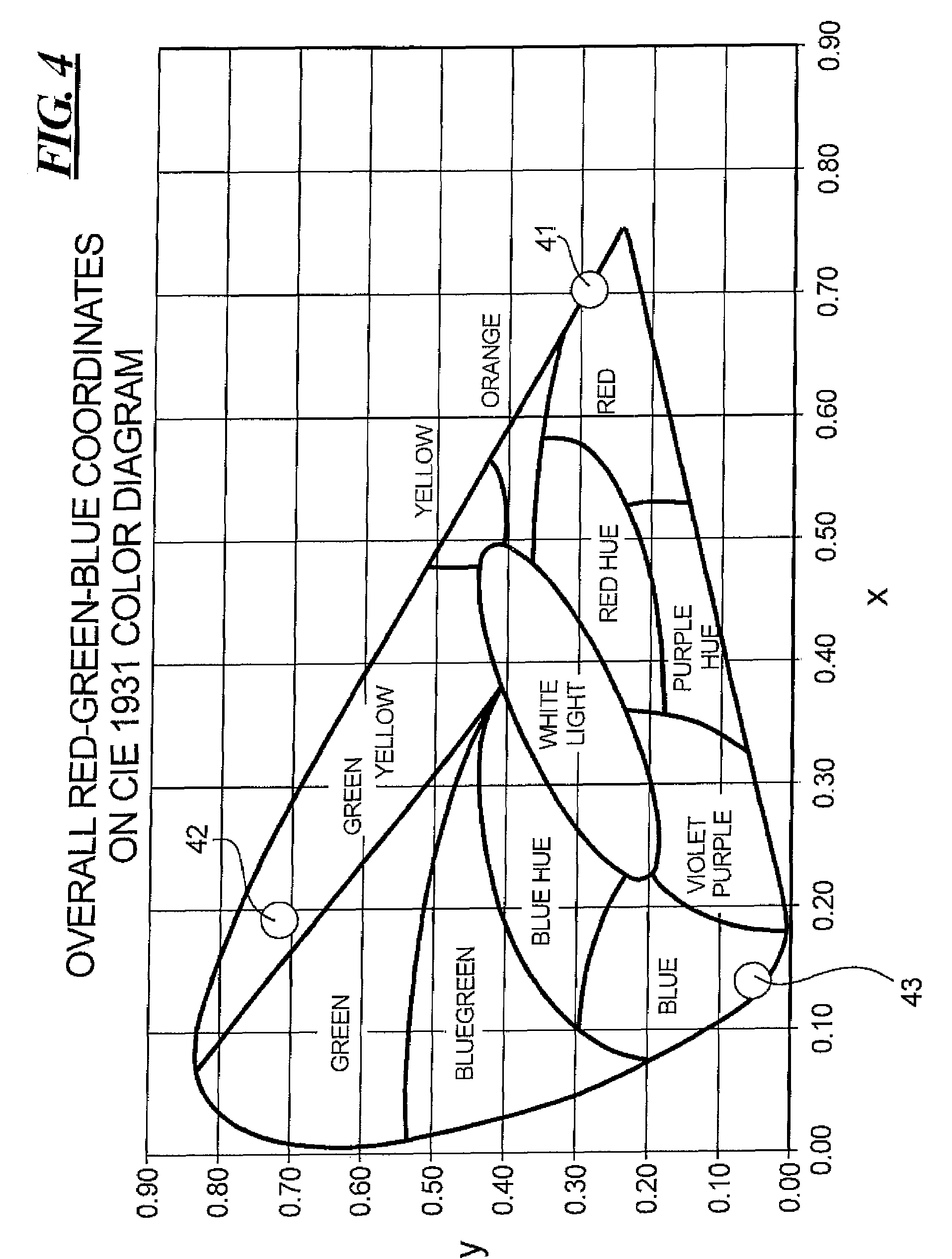

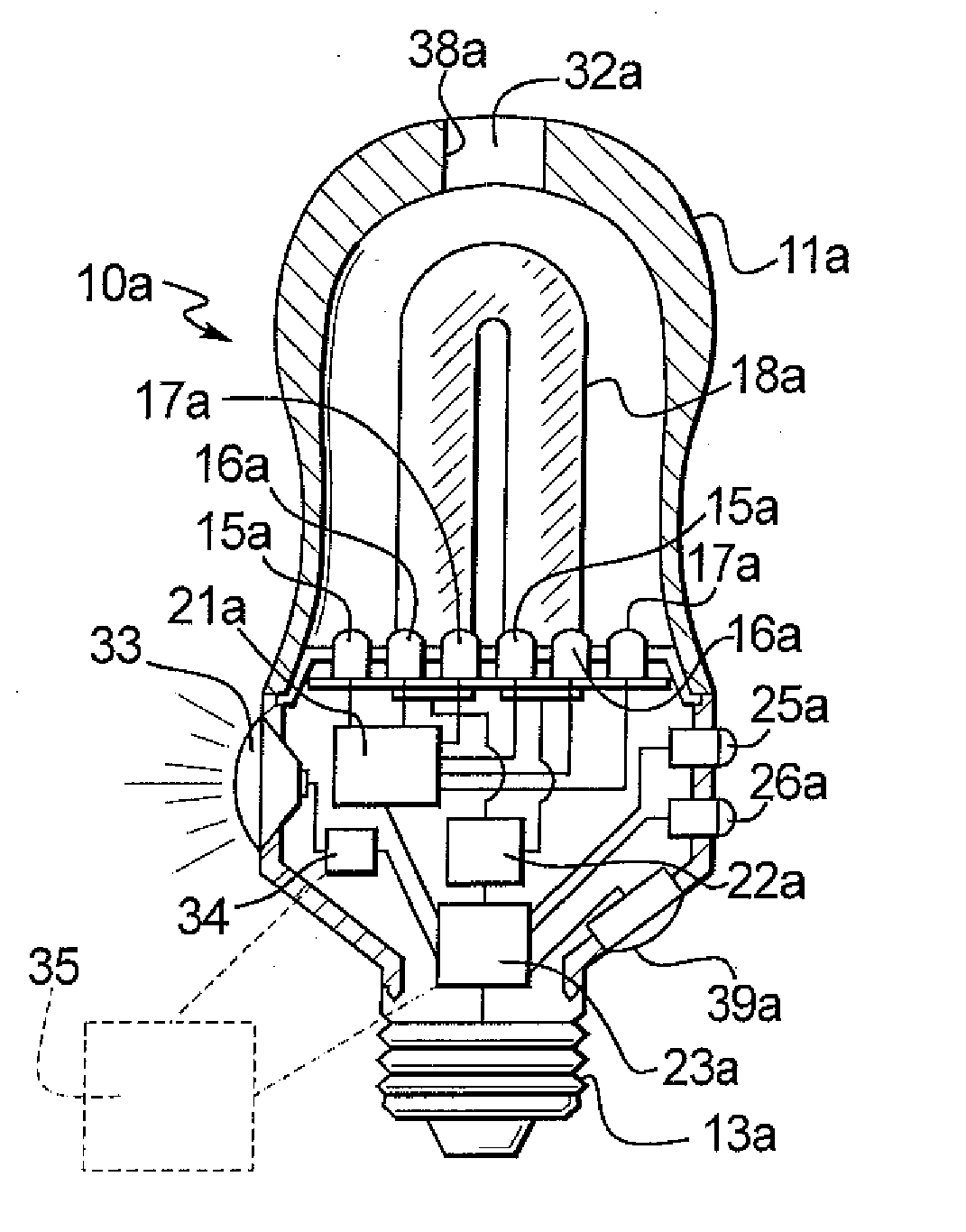

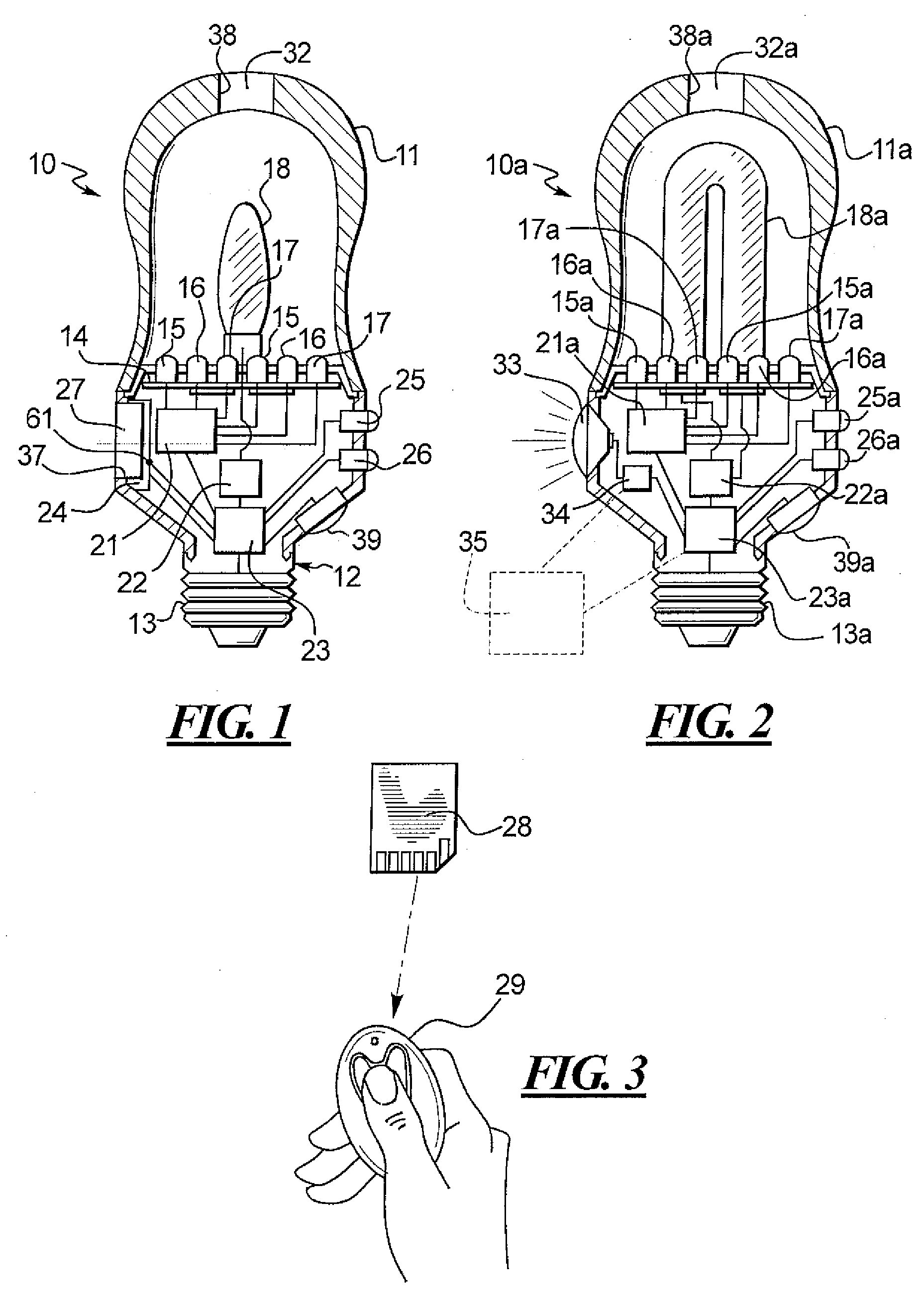

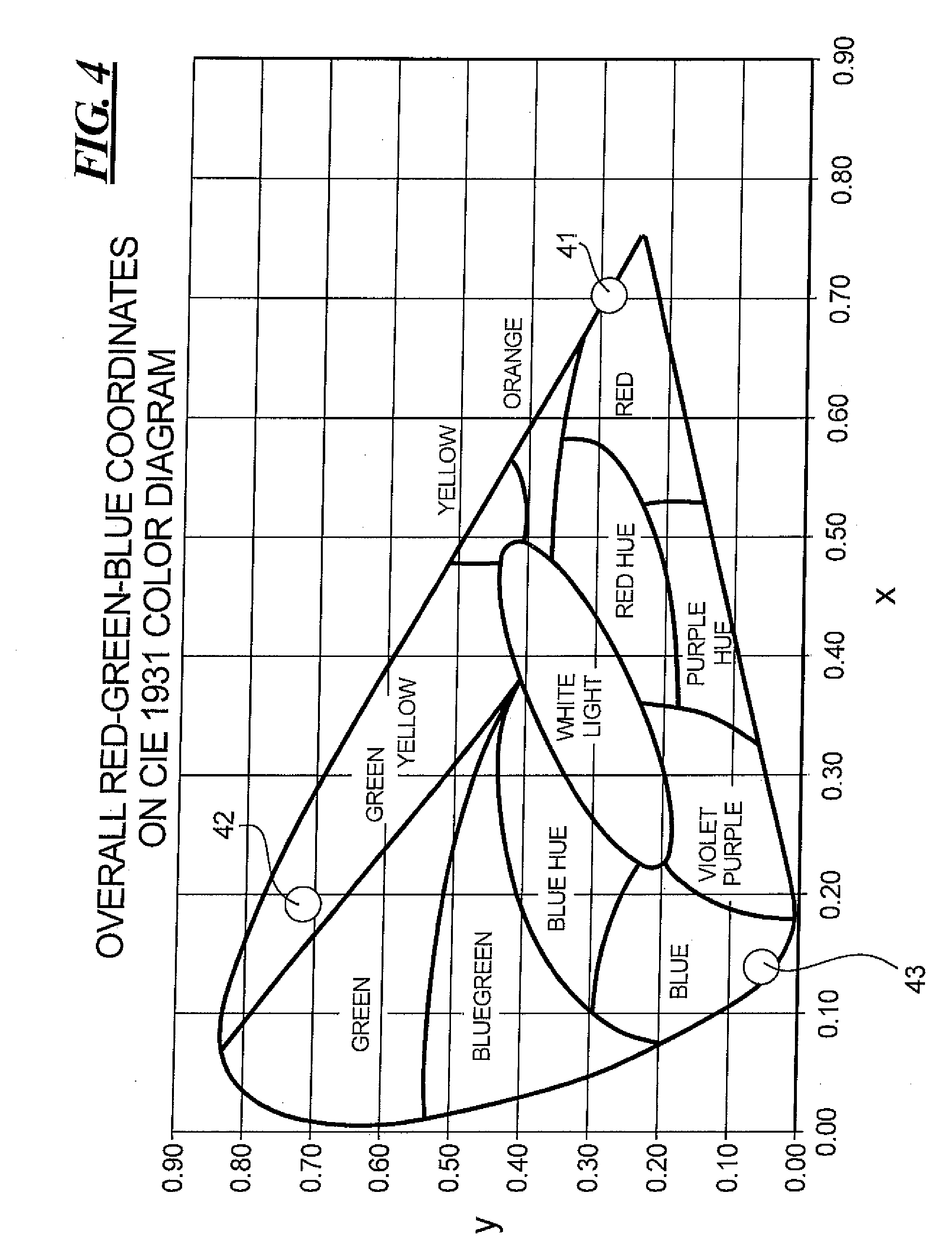

An outdoor light system comprising a plurality light elements linked to a central controller. Each light element include a translucent shell, plurality of LEDs positioned so as to emit a light show through the shell A compartment for receiving and securing a replaceable volatile active cartridge and a heater for enabling the device to effectively emit an active ingredient from the cartridge when the cartridge is secured in the compartment. A white light source may be provided in each device as a source of illumination along with the LEDs The devices can be used as white light sources, for displaying a coordinated colored light shows, for displaying colored light schemes and for volatile active emission. The devices of disclosed the system may include an acoustic transducer for producing light and sound shows. The device may also include a light sensor, a motion detector and / or a microphone or acoustic receiver thereby enabling the light and sound shows to be dependent upon ambient light intensity, motion detection and / or ambient noise. The devices and systems are suitable for outdoor home lighting, porch and deck lighting and path / driveway lighting.

Owner:SC JOHNSON & SON INC

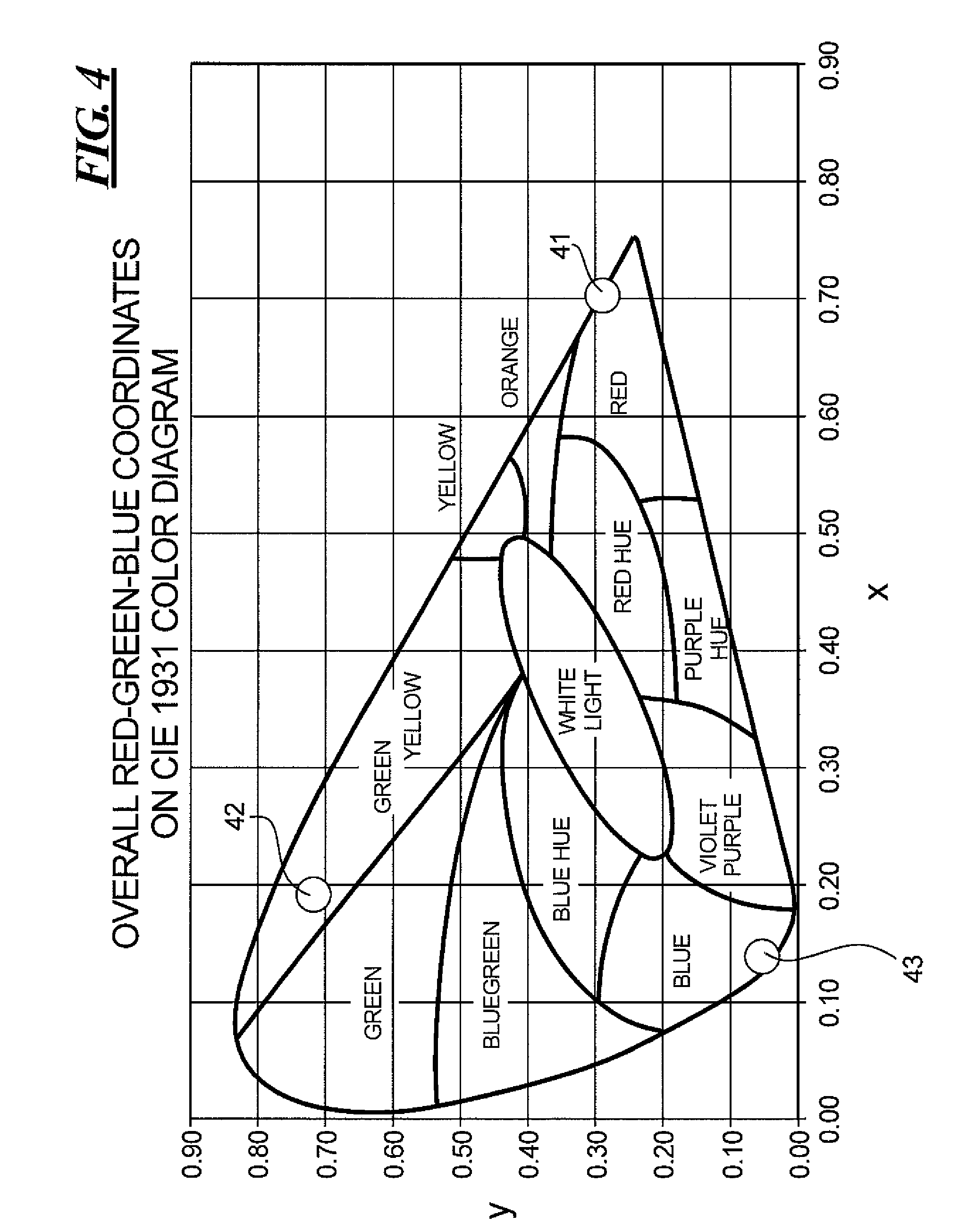

Color changing light devices with active ingredient and sound emission for mood enhancement

InactiveUS7476002B2Designed withCoupling device connectionsLight source combinationsMotion detectorEngineering

A light element includes a translucent shell and a base. The base supports a plurality of LEDs positioned so as to emit a light show through the shell. The device also includes a compartment for receiving and securing a replaceable volatile active cartridge and a heater for enabling the device to effectively emit an active ingredient from the cartridge when the cartridge is secured in the compartment. A white light source is provided in the shell as a source of illumination along with the LEDs The device can be used as a white light source, for displaying a colored light show, for displaying colored light schemes and for volatile active emission The devise may include an acoustic transducer for producing light and sound show. The devise may also include a light sensor, a motion detector and / or a microphone or acoustic receiver thereby enabling the light and sound show to be dependent upon ambient light intensity, motion detection and or / ambient noise.

Owner:SC JOHNSON & SON INC

Methods and apparatus for processing spatialised audio

The invention relates to an apparatus for sound reproduction of a sound information signal having spatial components, the apparatus includes: sound input means adapted to input the sound information signal; headtracking means for tracking a current head orientation of a listener listening to the sound information signal via sound emission sources and to produce a corresponding head orientation signal; sound information rotation means connected to the sound input means and the headtracking means and adapted to rotate said sound information signal to a substantially opposite degree to the degree of orientation of said current head orientation of the listener to produce a rotated sound information signal; and sound conversion means connected to the sound information rotation means for converting the rotated sound information signal to corresponding sound emission signals for outputting by the sound emission sources such that the spatial components of the sound information signal are substantially maintained in the presence of movement of the orientation of head of the listener.

Owner:DOLBY LAB LICENSING CORP

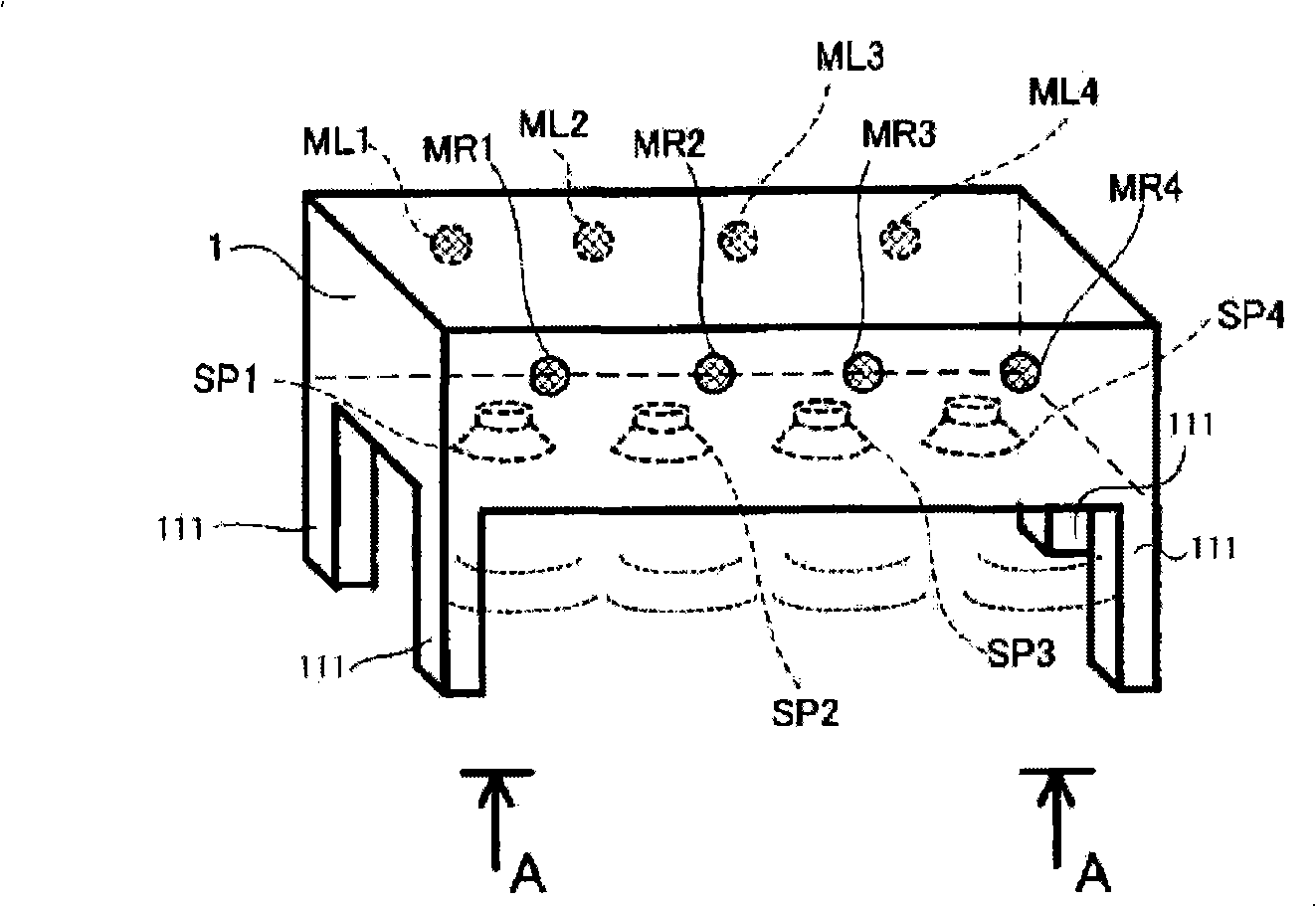

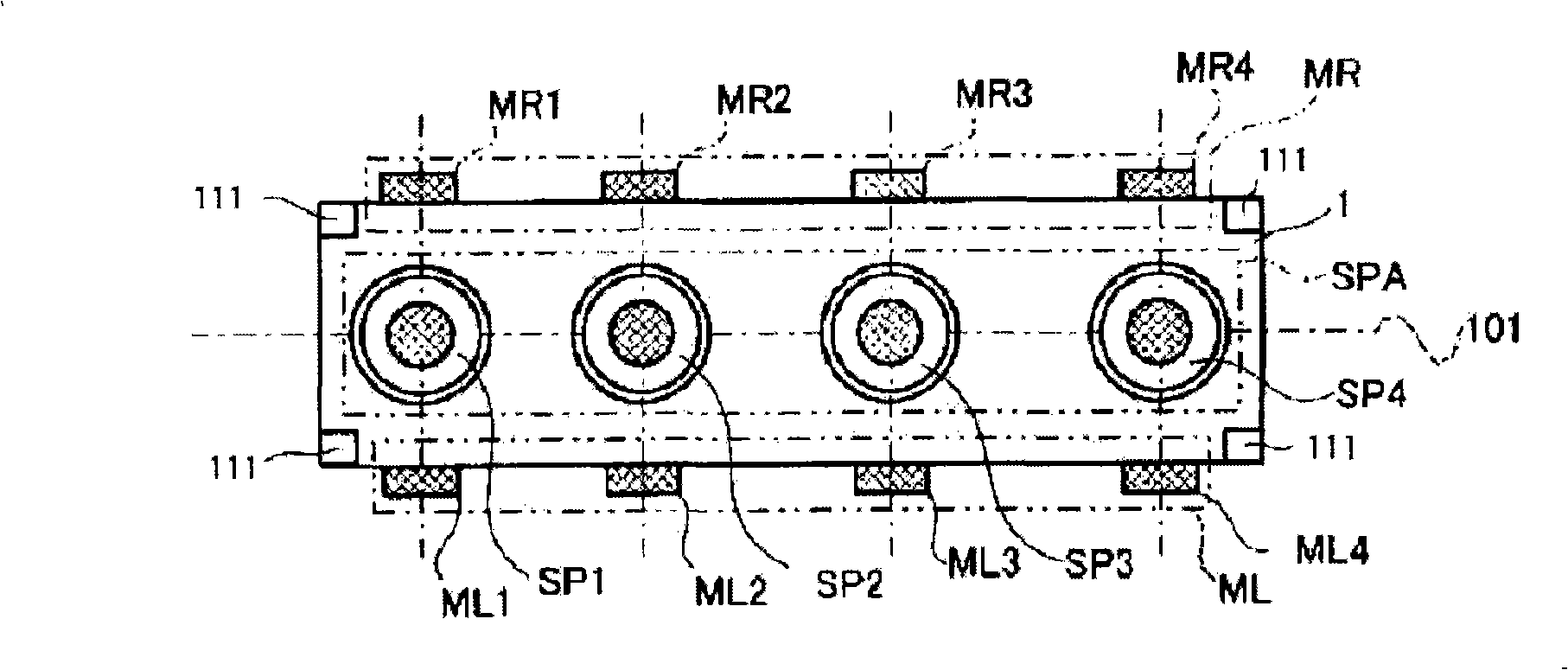

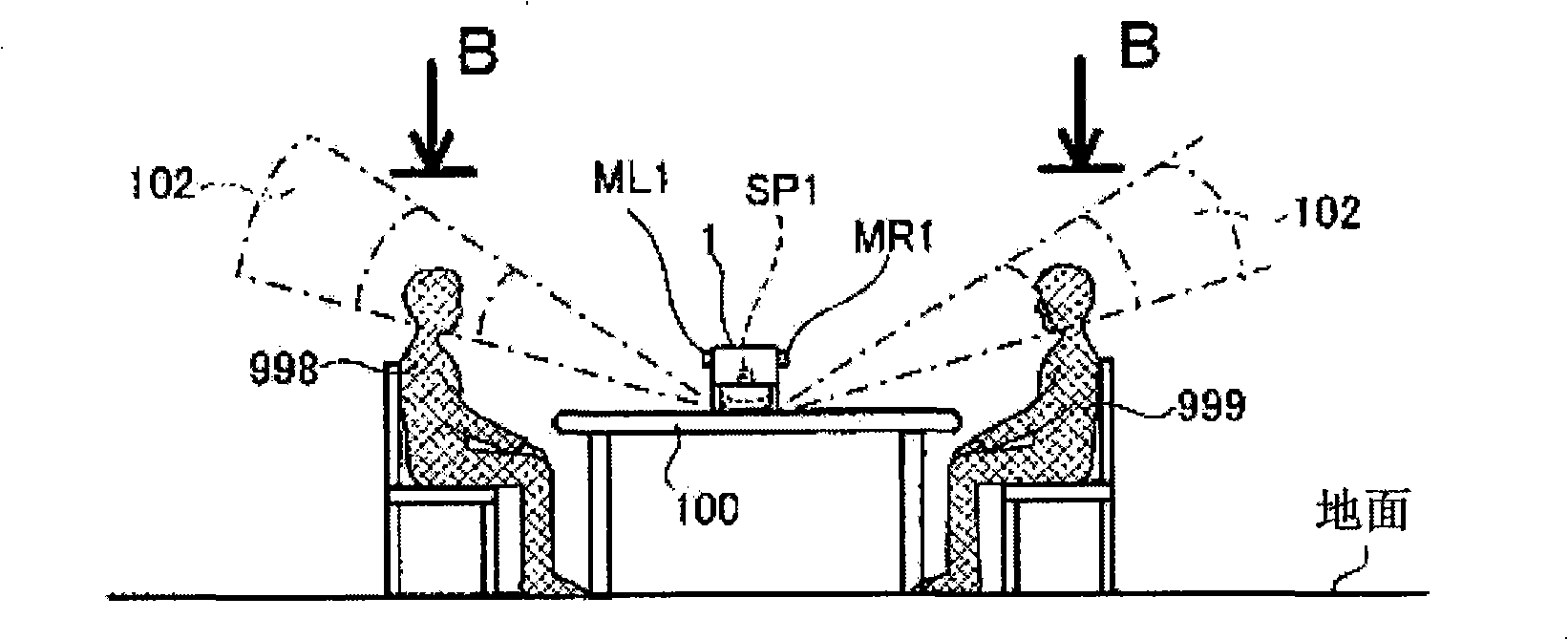

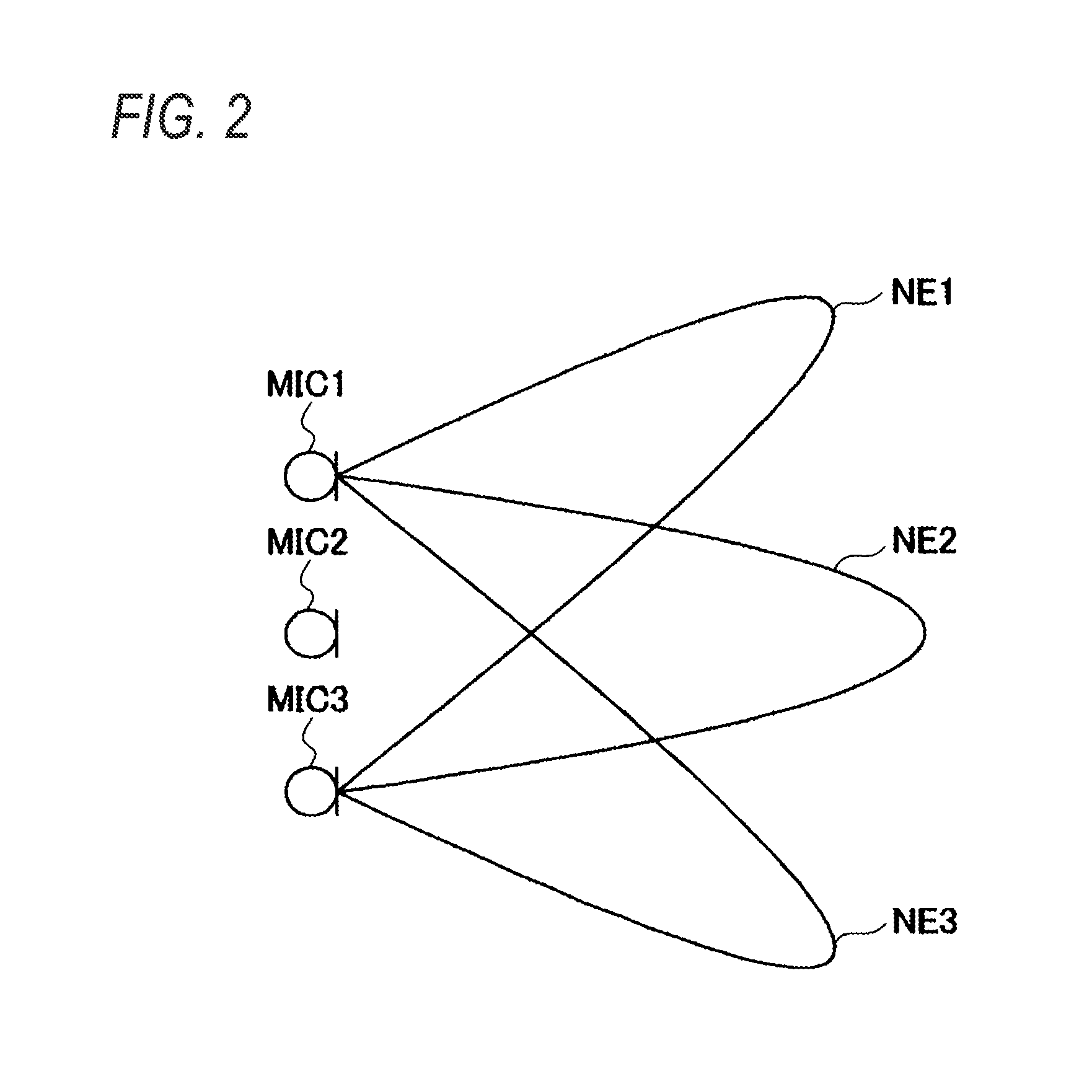

Teleconference device and sound emission/collection device

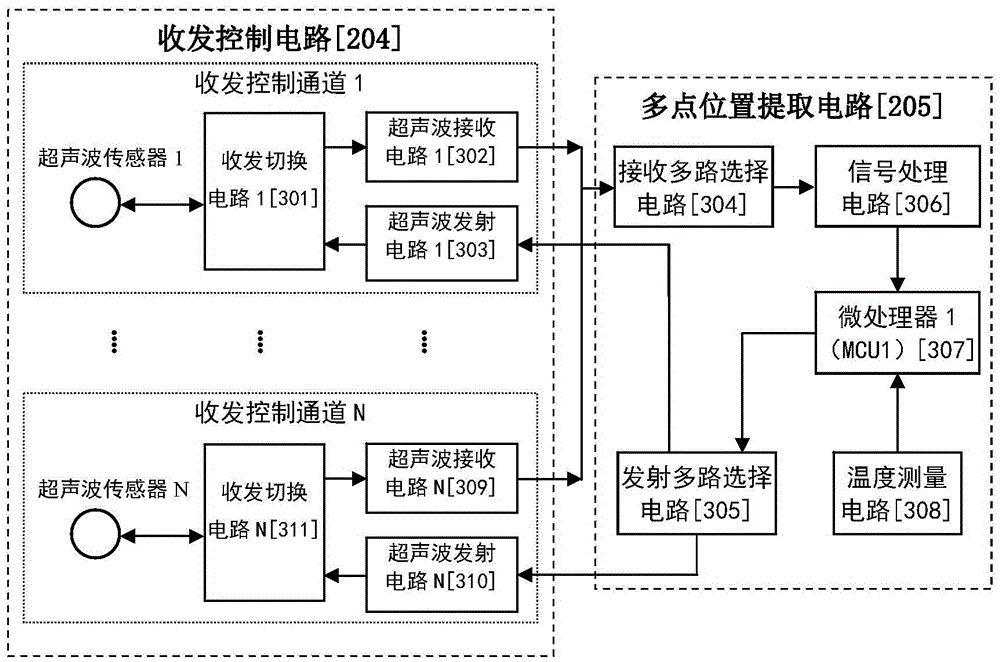

ActiveCN101310558AEffective pickupAccurate detectionFrequency/directions obtaining arrangementsTransducer circuitsAcquisition apparatusWave height

A teleconference device includes a loudspeaker array and microphone arrays arranged at the both sides of the loudspeaker array. A plurality of focal points are set in front of the respective microphone arrays and symmetrically with respect to the center line of the loudspeaker array. A flux of sound collection beams toward the focal points is outputted. By calculating a difference between the sound collection beams toward the focal points symmetric with respect to the center line, a sound component coming into the microphone from the loudspeaker array SPA is cancelled. Furthermore, a total of squares of wave height value of the difference value for a particular time is used to estimate which of the set focal points is the nearest. Furthermore, by comparing the totals of squares of the wave height values of the sound collection beams toward the focal points symmetric to each other, it is possible to judge the position of the speaker.

Owner:YAMAHA CORP

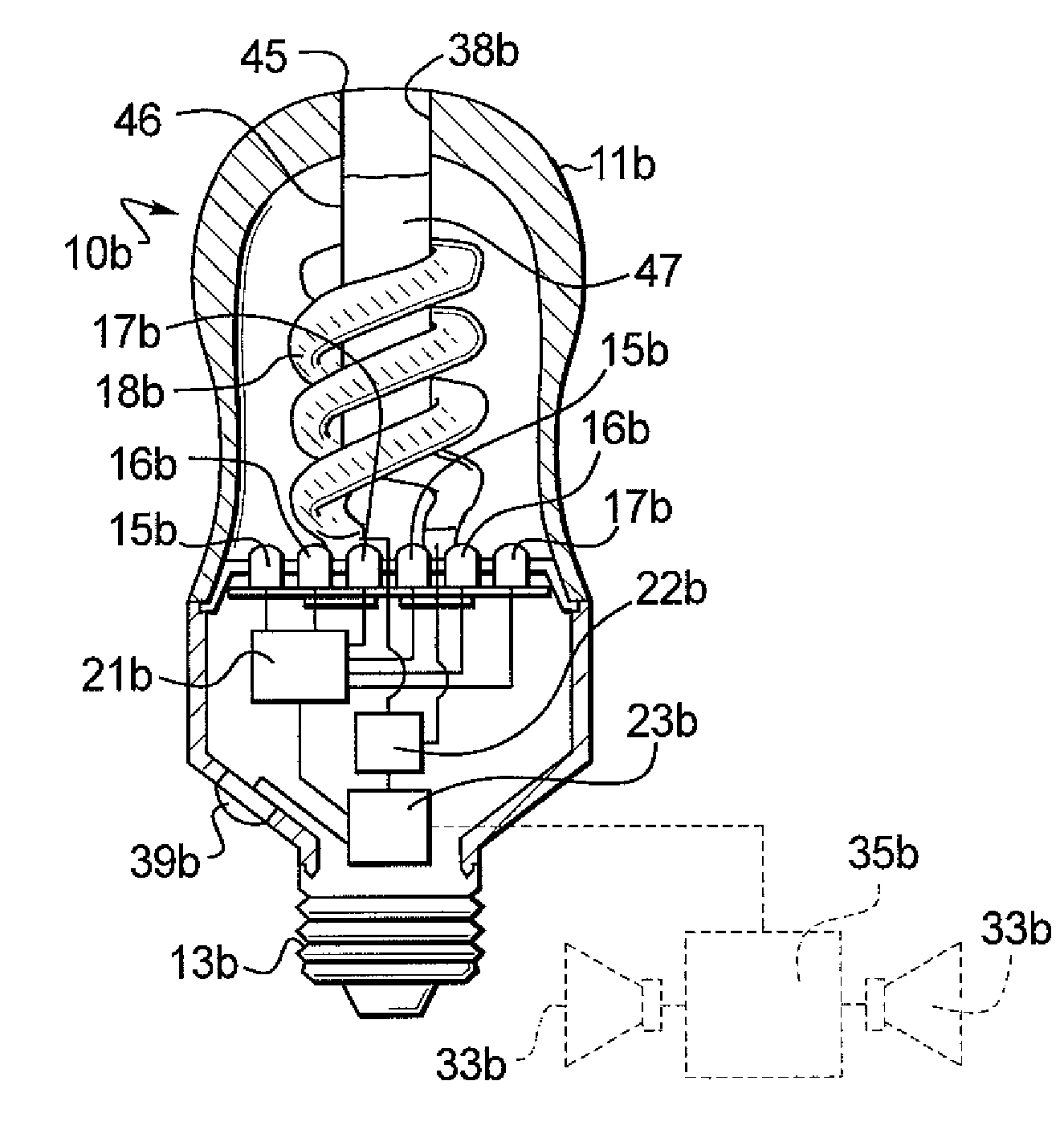

Color changing outdoor lights with active ingredient and sound emission

InactiveUS7604378B2Versatile in design and constructionCoupling device connectionsLight source combinationsMotion detectorEffect light

An outdoor light system comprising a plurality light elements linked to a central controller. Each light element include a translucent shell, plurality of LEDs positioned so as to emit a light show through the shell. A compartment for receiving and securing a replaceable volatile active cartridge and a heater for enabling the device to effectively emit an active ingredient from the cartridge when the cartridge is secured in the compartment. A white light source may be provided in each device as a source of illumination along with the LEDs The devices can be used as white light sources, for displaying a coordinated colored light shows, for displaying colored light schemes and for volatile active emission. The devices of disclosed the system may include an acoustic transducer for producing light and sound shows. The device may also include a light sensor, a motion detector and / or a microphone or acoustic receiver thereby enabling the light and sound shows to be dependent upon ambient light intensity, motion detection and / or ambient noise. The devices and systems are suitable for outdoor home lighting, porch and deck lighting and path / driveway lighting.

Owner:SC JOHNSON & SON INC

Color changing light devices with active ingredient and sound emission for mood enhancement

InactiveUS20070121319A1Designed withCoupling device connectionsLight source combinationsEnvironmental noiseMotion detector

A light element includes a translucent shell and a base. The base supports a plurality of LEDs positioned so as to emit a light show through the shell. The device also includes a compartment for receiving and securing a placeable volatile active cartridge and a heater for enabling the device to effectively emit an active ingredient from the cartridge when the cartridge is secured in the compartment. A white light source is provided in the shell as a source of illumination along with the LEDs The device can be used as a white light source, for displaying a colored light show, for displaying colored light schemes and for volatile active emission The devise may include an acoustic transducer for producing light and sound show. The devise may also include a light sensor, a motion detector and / or a microphone or acoustic receiver thereby enabling the light and sound show to be dependent upon ambient light intensity, motion detection and or / ambient noise

Owner:SC JOHNSON & SON INC

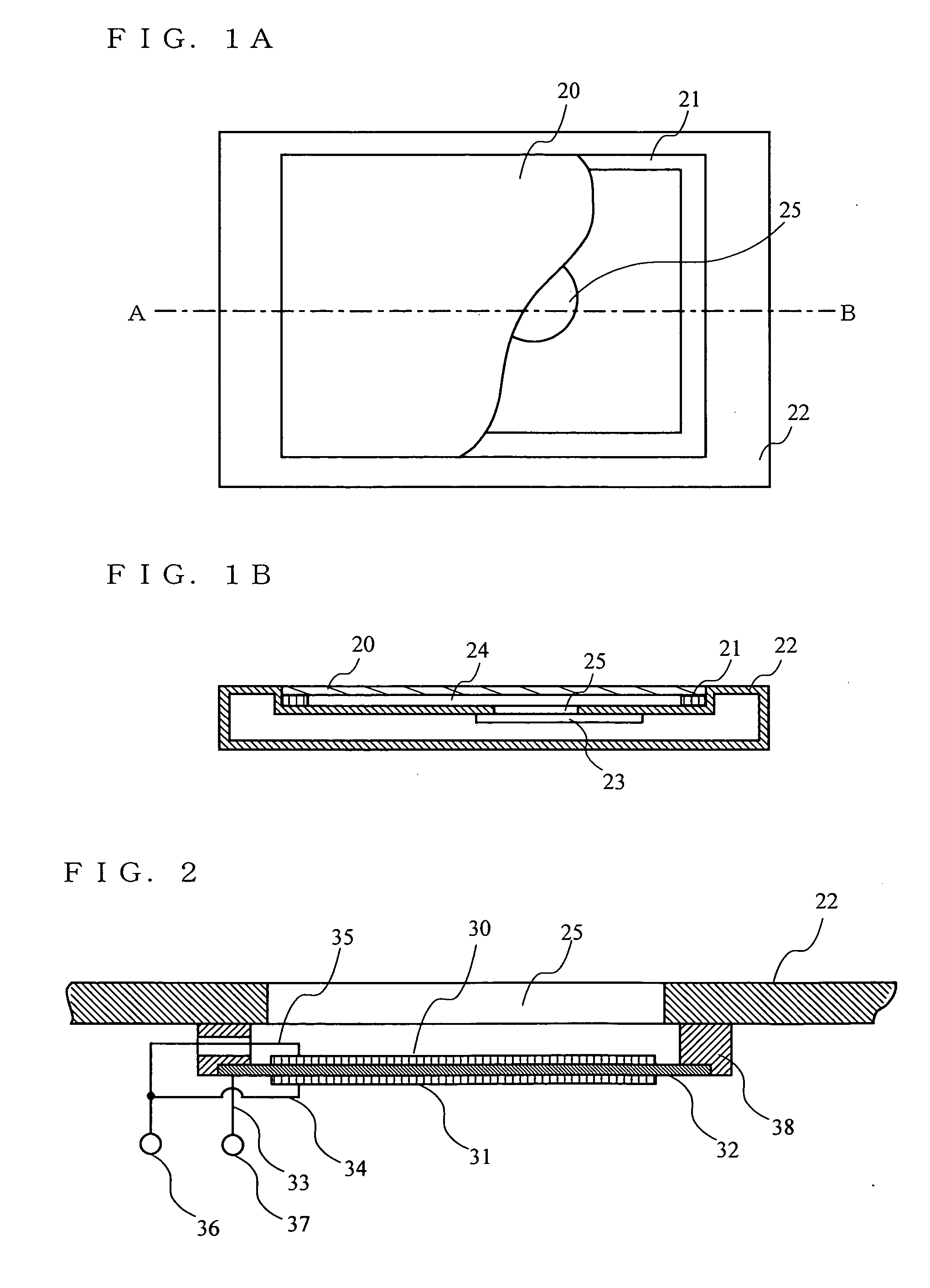

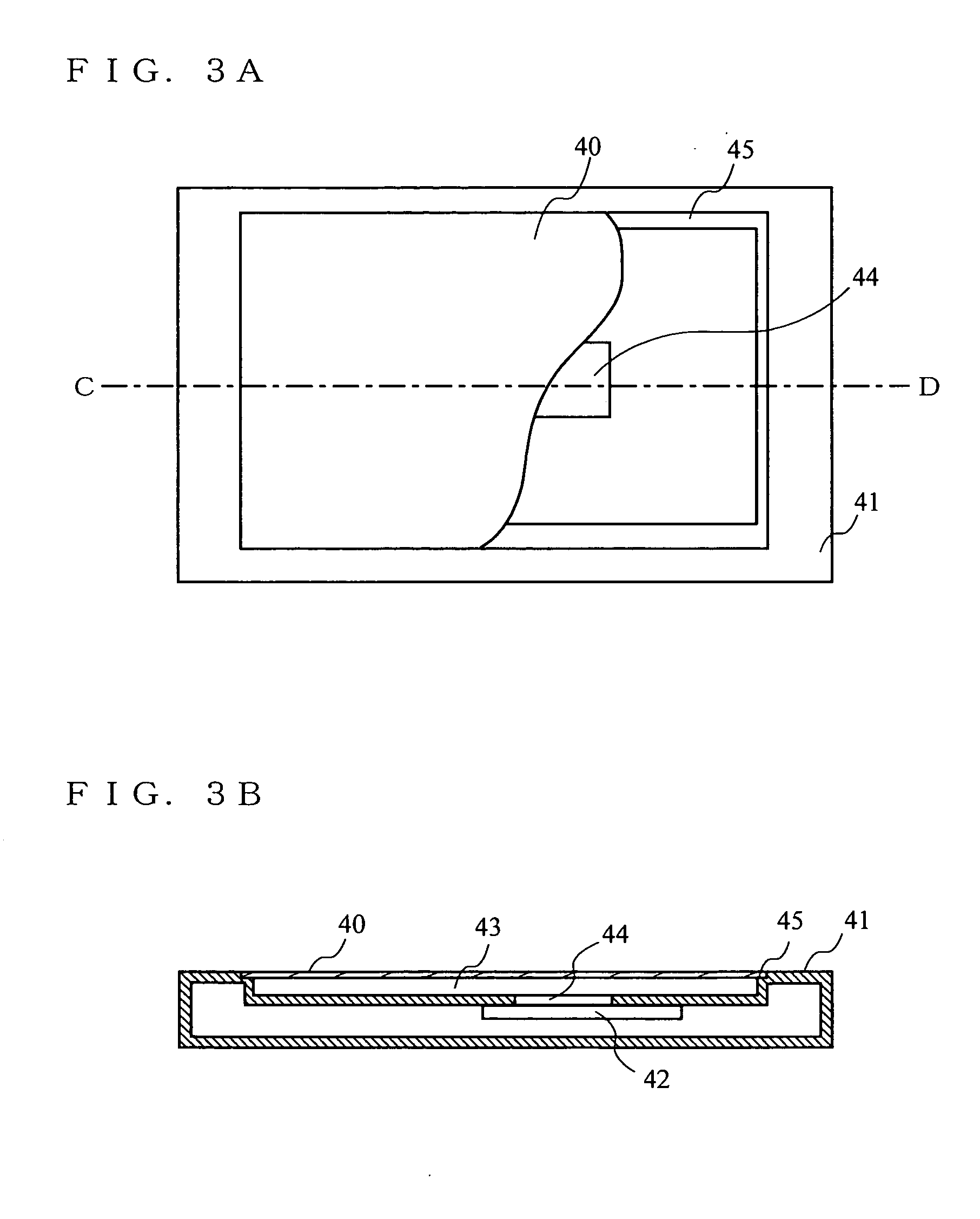

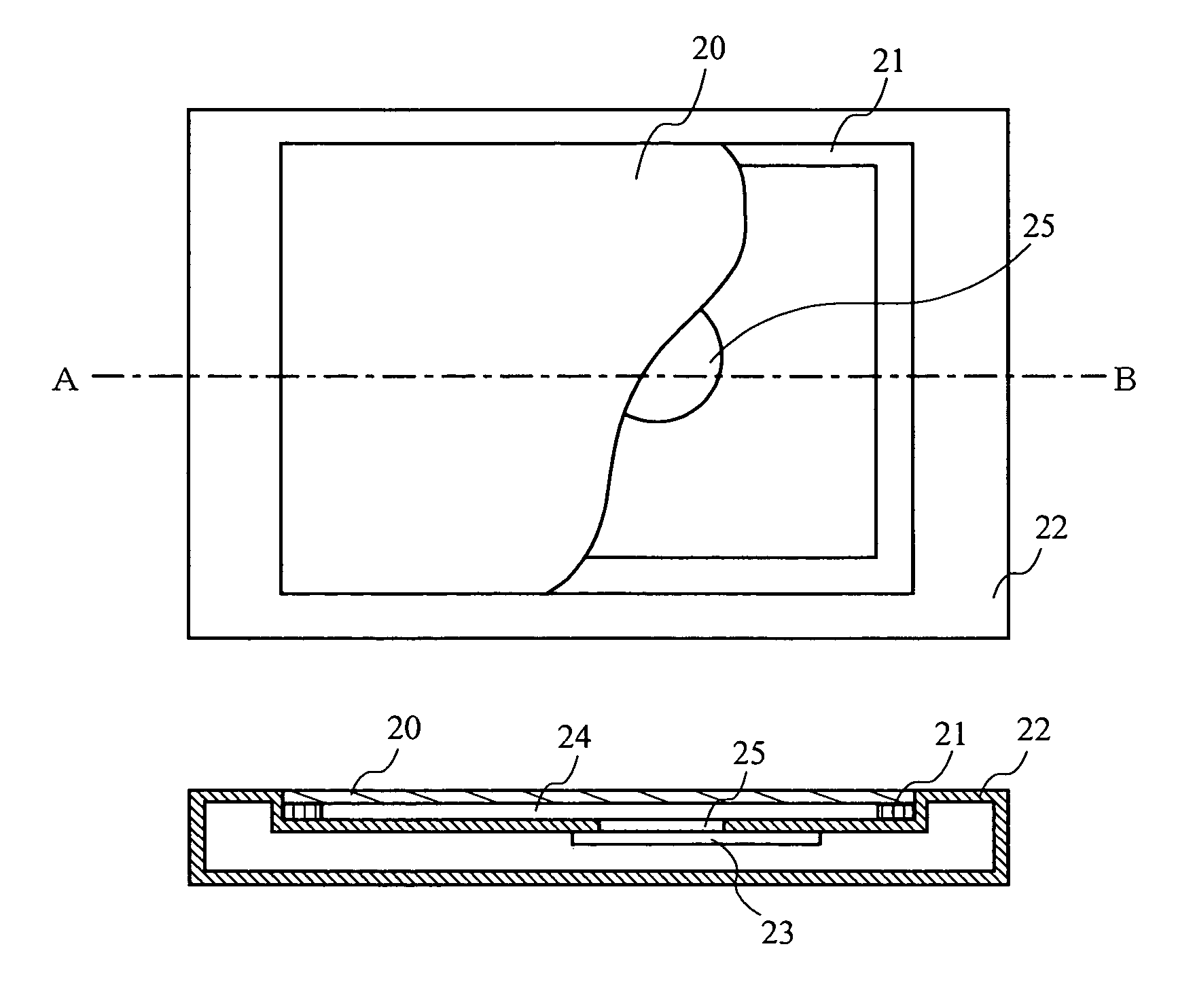

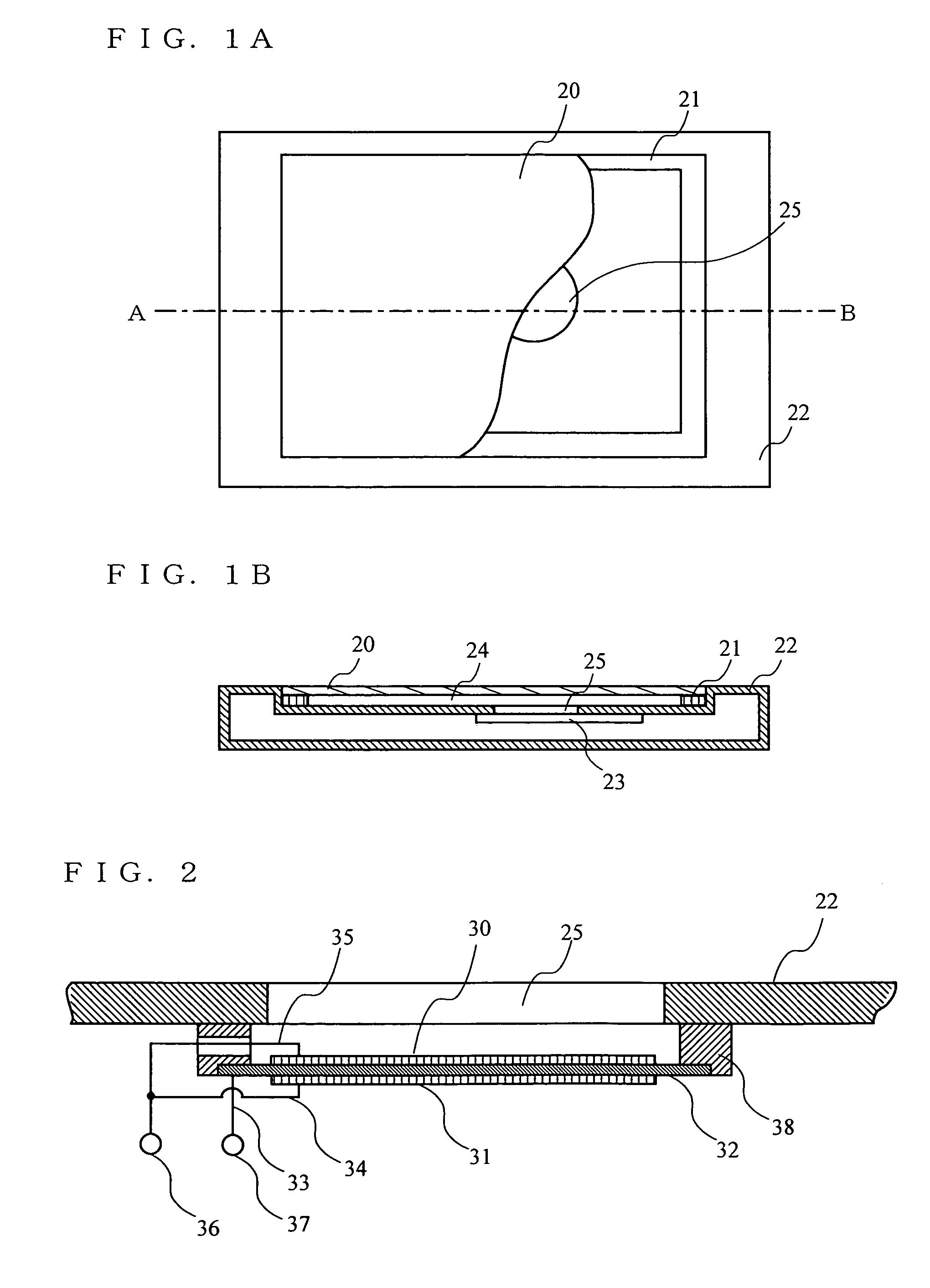

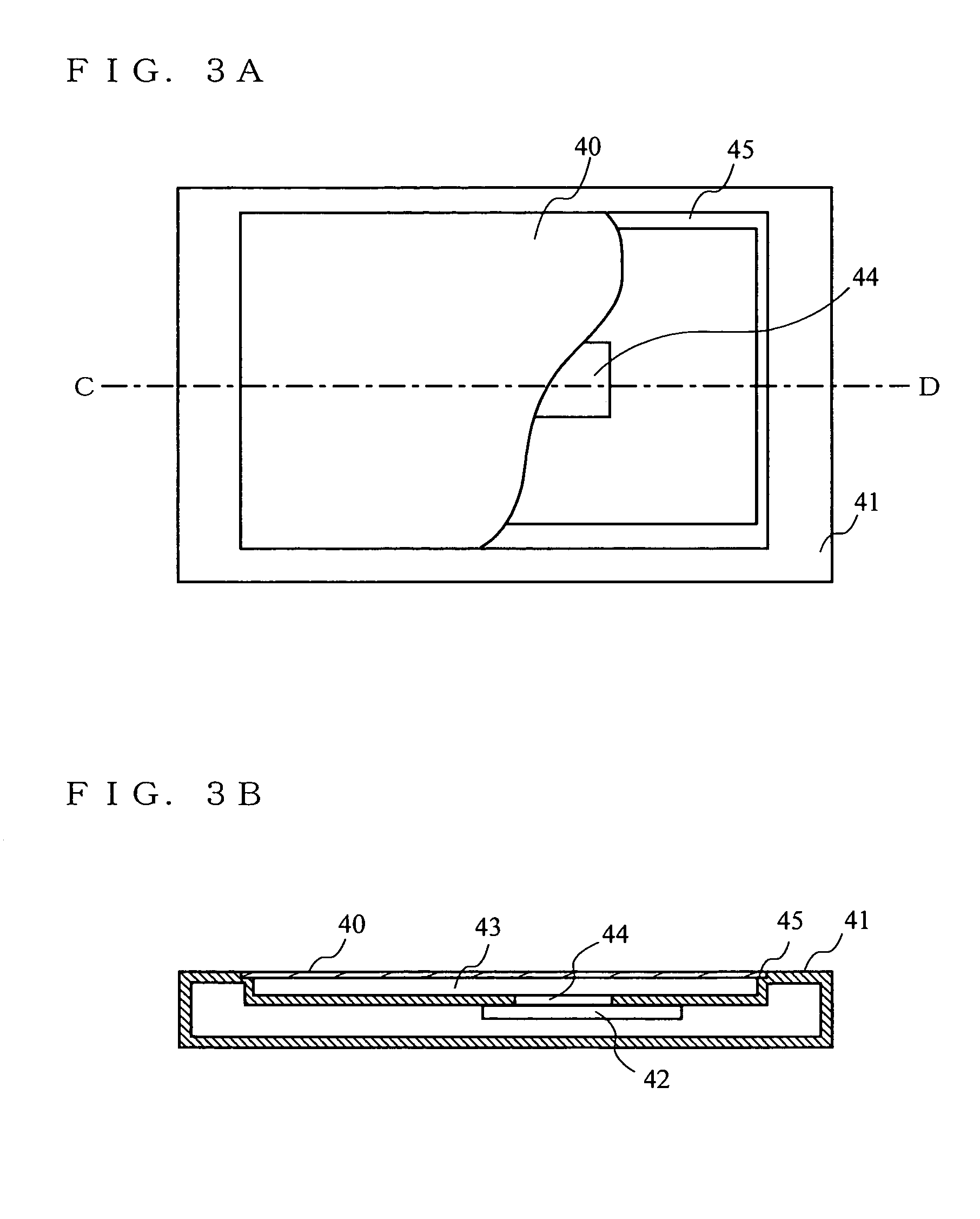

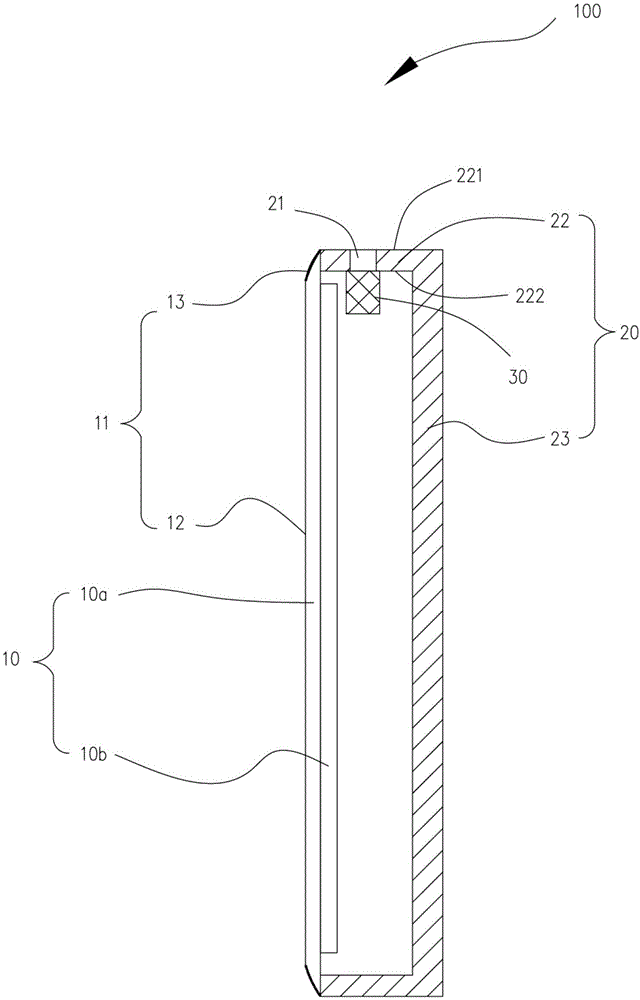

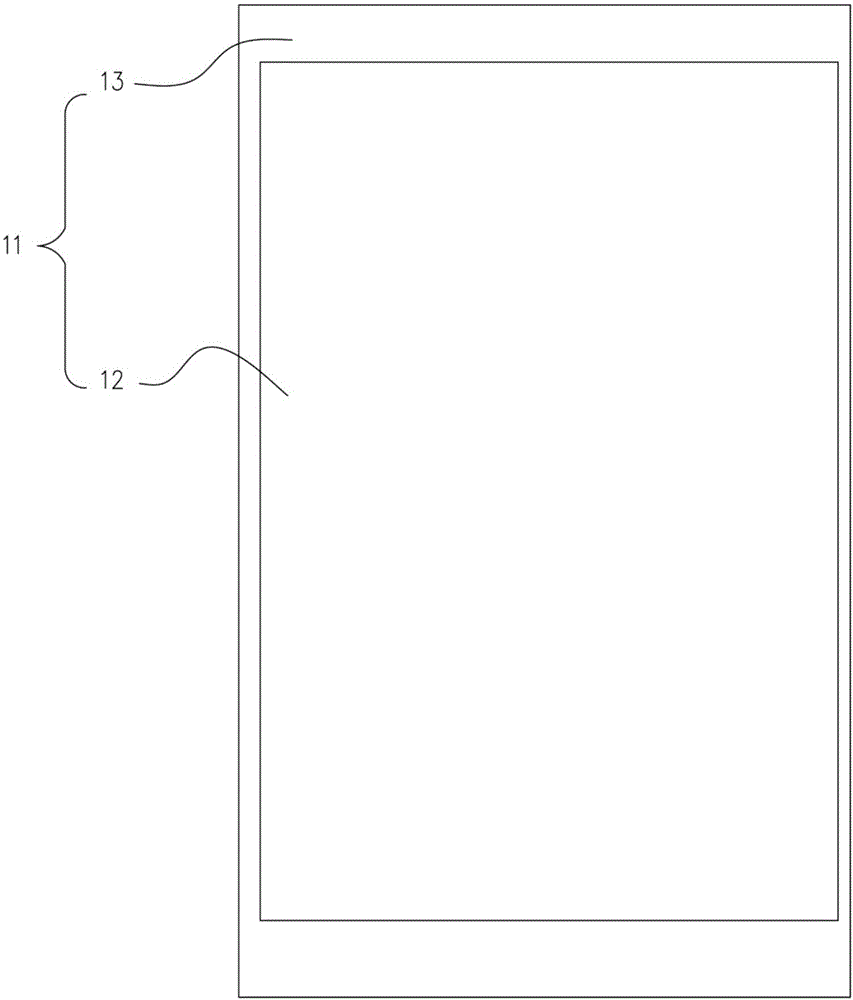

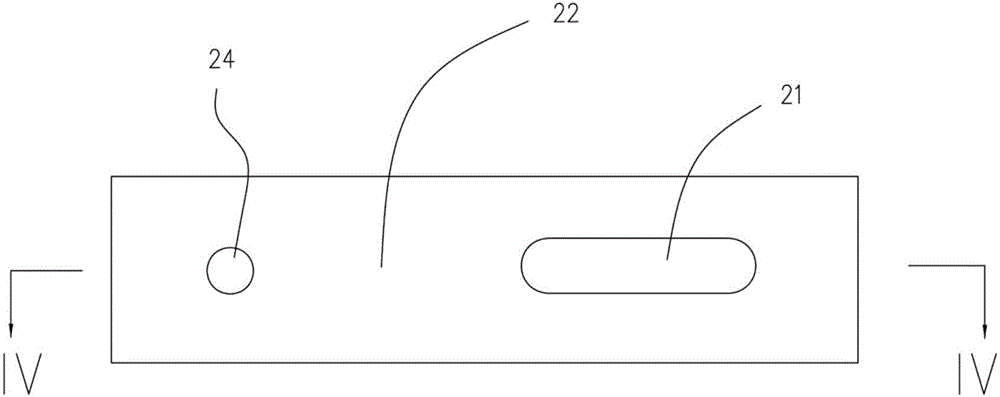

Sound reproduction device and portable terminal apparatus

ActiveUS20050025330A1Improved sound reproduction capabilityImprove rendering capabilitiesTransmissionPlane diaphragmsLiquid-crystal displayTransducer

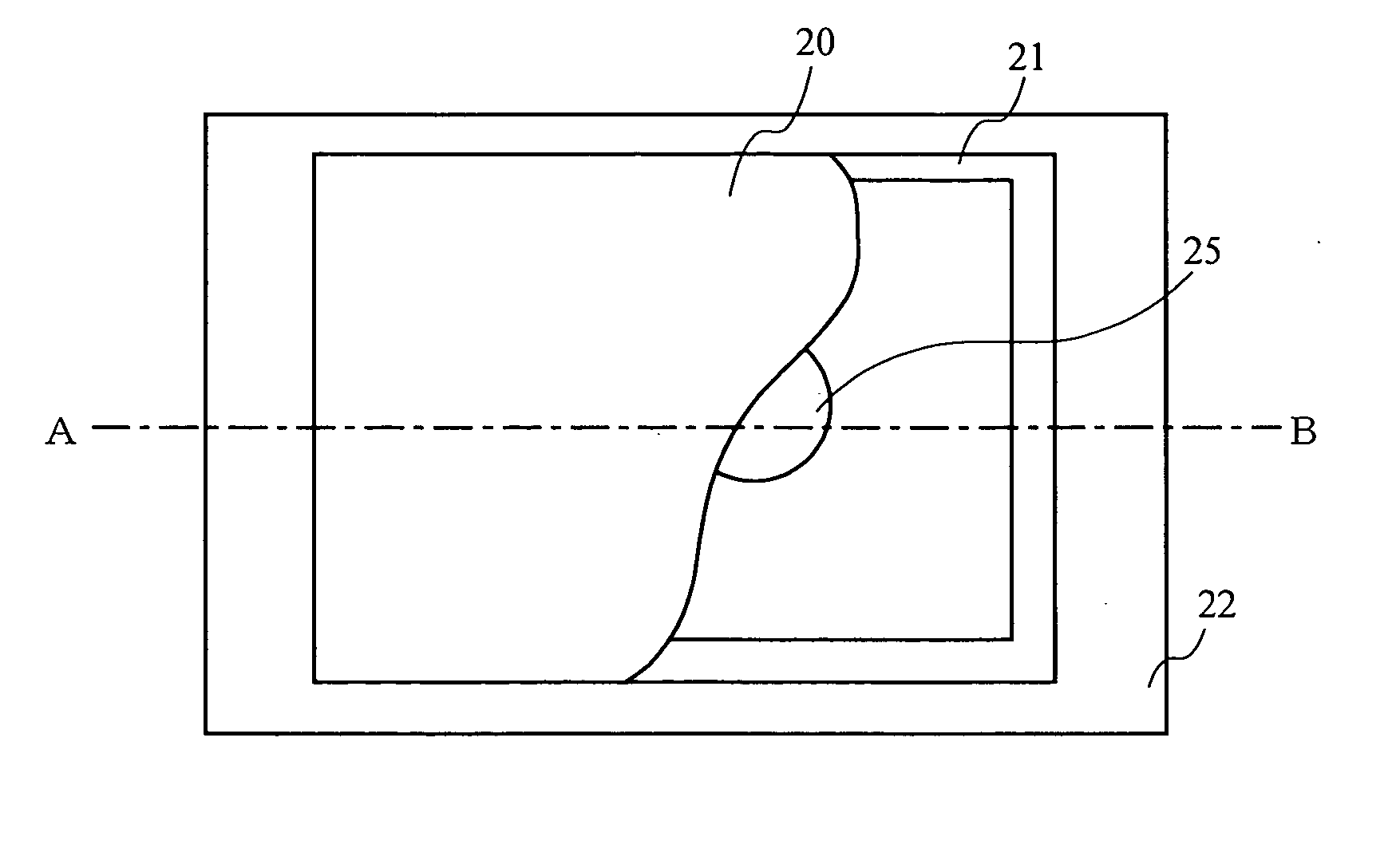

The present invention is directed to a sound reproduction device which includes an LCD 20, which is an exemplary front panel, a case 22, and an electromechanical acoustic transducer 23. The LCD 20 is operable to perform a predetermined operation in response to an electrical signal applied thereto. A space 24 for sound emission is formed between the case 22 and the LCD 20. The electromechanical acoustic transducer 23 is connected to the case 22, and emits sound to the space 24. If the electromechanical acoustic transducer 23 emits the sound to the space 24, energy of the emitted sound causes the LCD 20 to vibrate and thereby to externally output the sound.

Owner:PANASONIC CORP

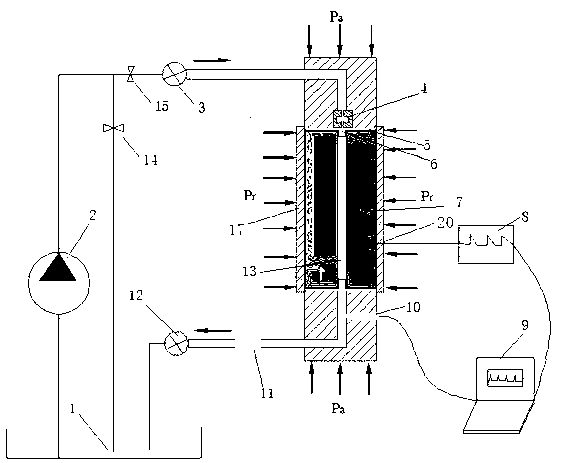

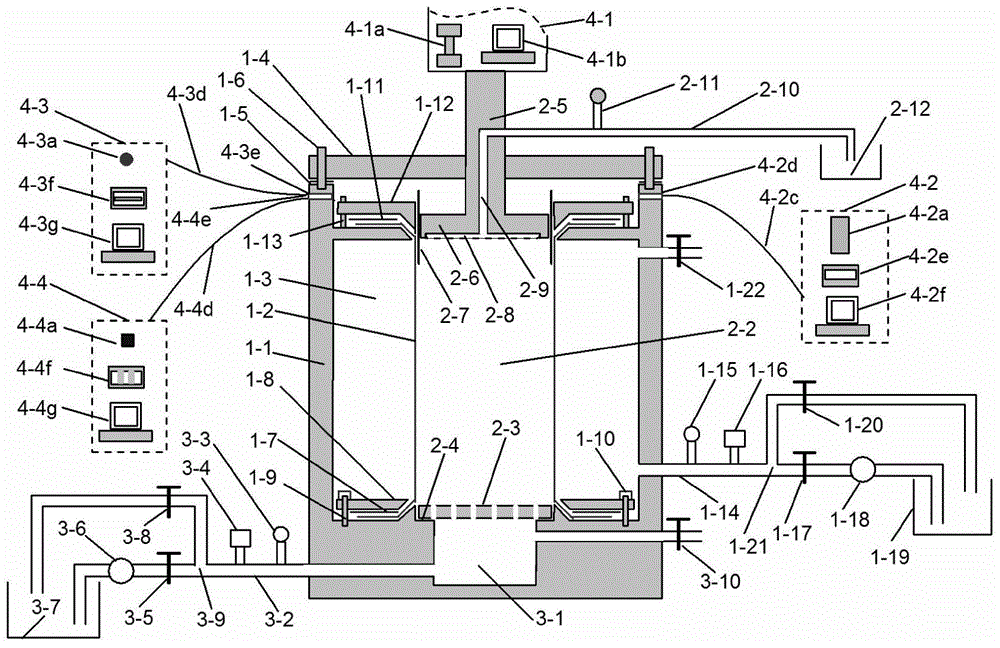

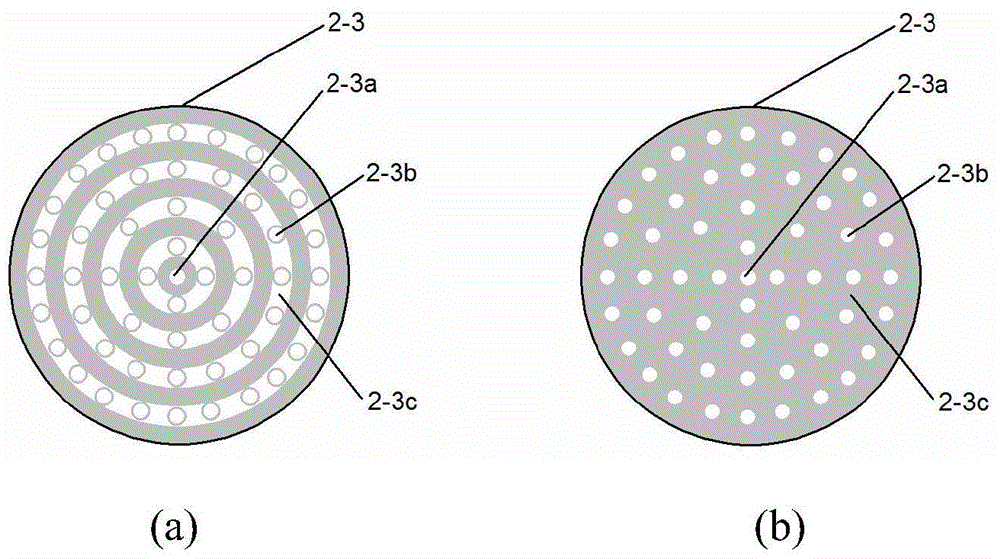

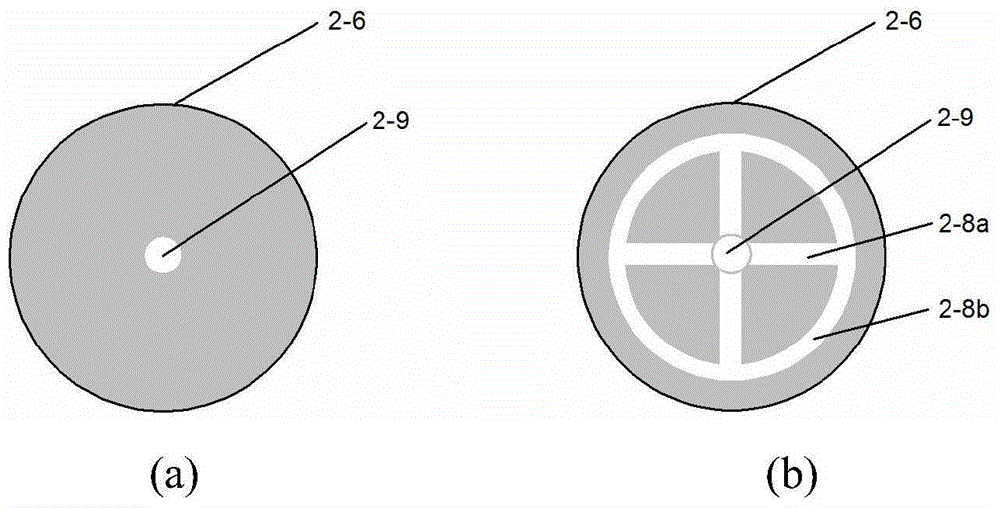

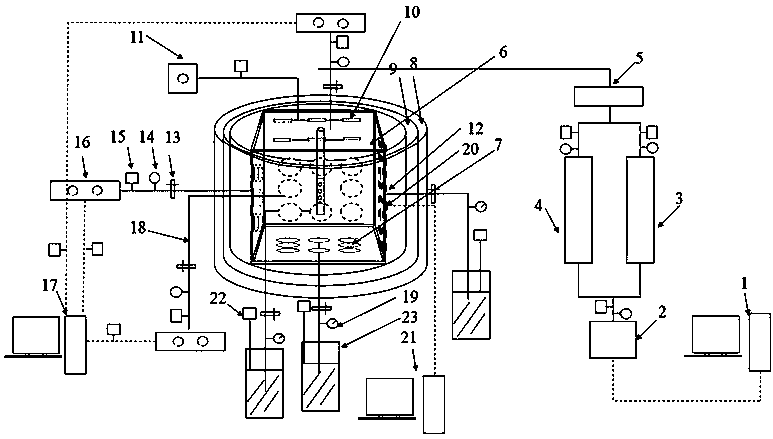

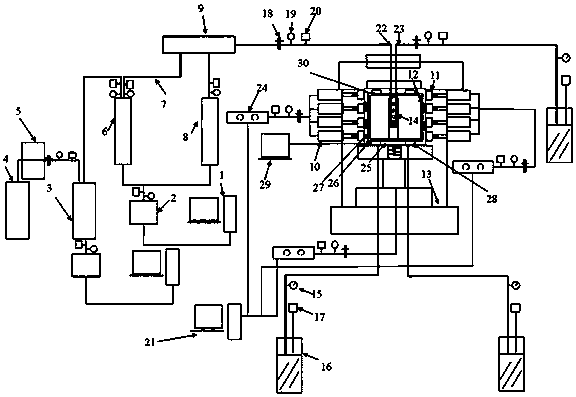

Experimental device and method for pulse hydrofracture transforming of shale gas storing layer

ActiveCN103196762AMonitor developments in real timeGenerating type of real-time monitoringSurface/boundary effectMaterial strength using repeated/pulsating forcesImpulse frequencyFracturing fluid

The invention relates to an experimental device and method for pulse hydrofracture transforming of a shale gas storing layer. The experimental device comprises a high pressure water pump, a fracturing fluid pond, a filtering device, a waterpower pulse generating device, a triaxial stress loading device, a pressure sensor, a sound emission device, a throttle valve, an overflow valve, a data collection recording system and a core test specimen. The device provided by the invention can simulate the operating environment of a shale sample under main operating parameter such as different pulse pressures and impulse frequencies on a certain confining pressure condition; moreover, the device can monitor a space-time developing rule of cracks and can test permeability change before and after fracture in real time; therefore, an experimental platform is provided for researching pulse hydrofracture of a shale gas storing layer. The experimental device provided by the invention has strong practicality, is easy to assemble, convenient to operate, is compact in structure, and can better imitate fracture damage and permeability change mechanism of a shale sample of the shale gas storing layer under the actions of static pressure and pulse hydrofracture.

Owner:CHONGQING INST OF GEOLOGY & MINERAL RESOURCES

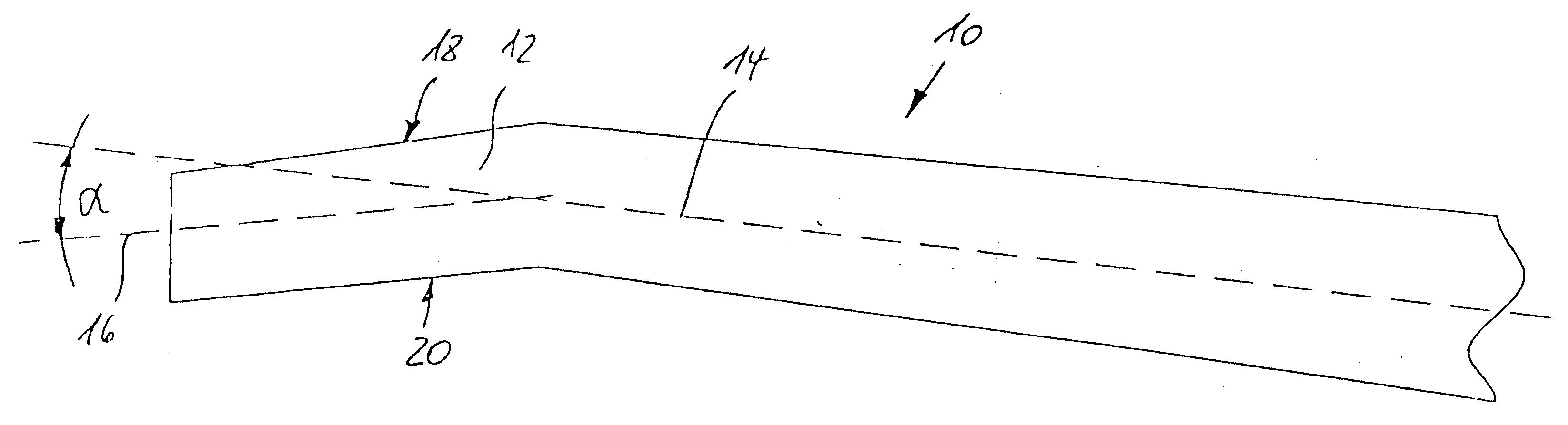

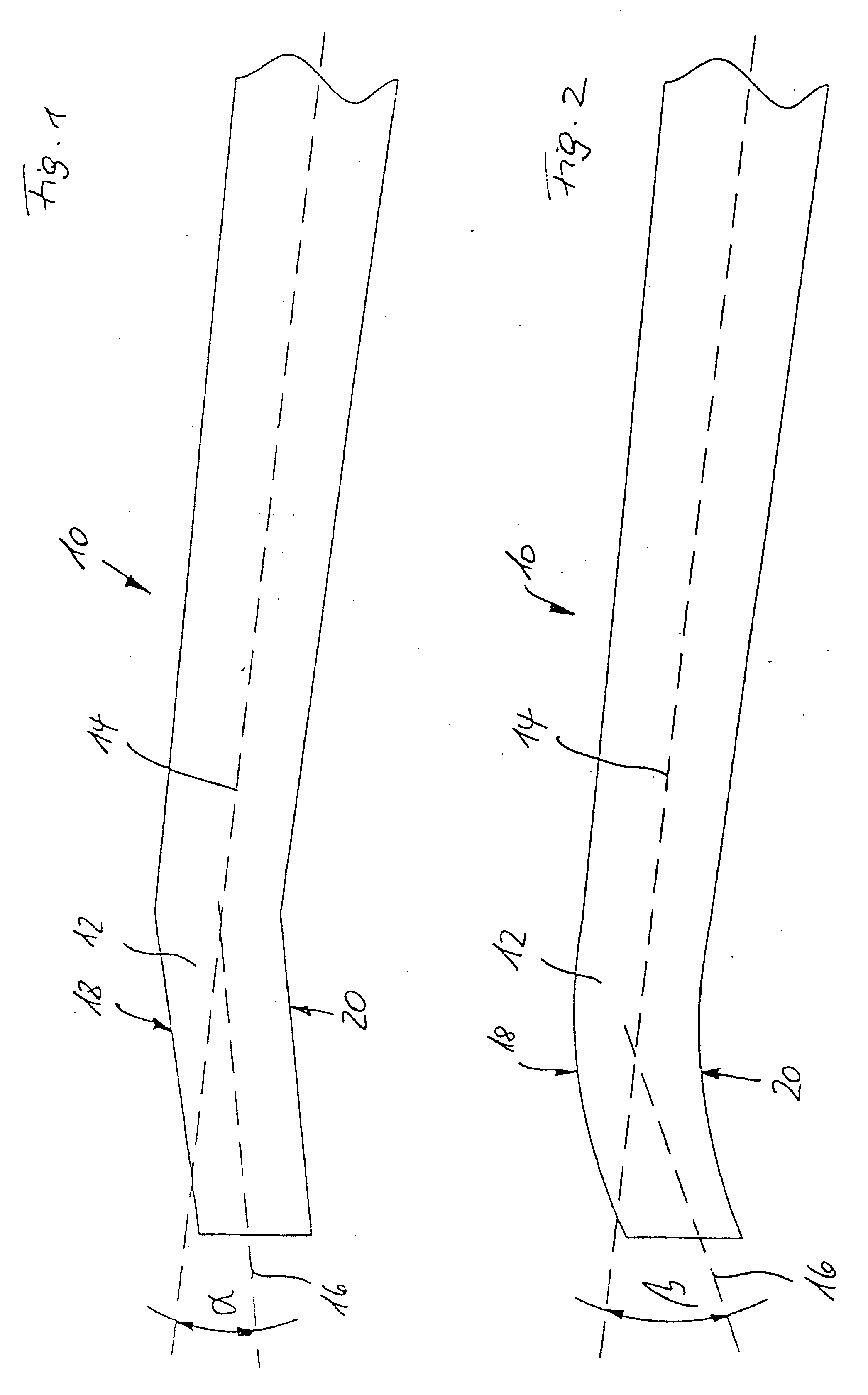

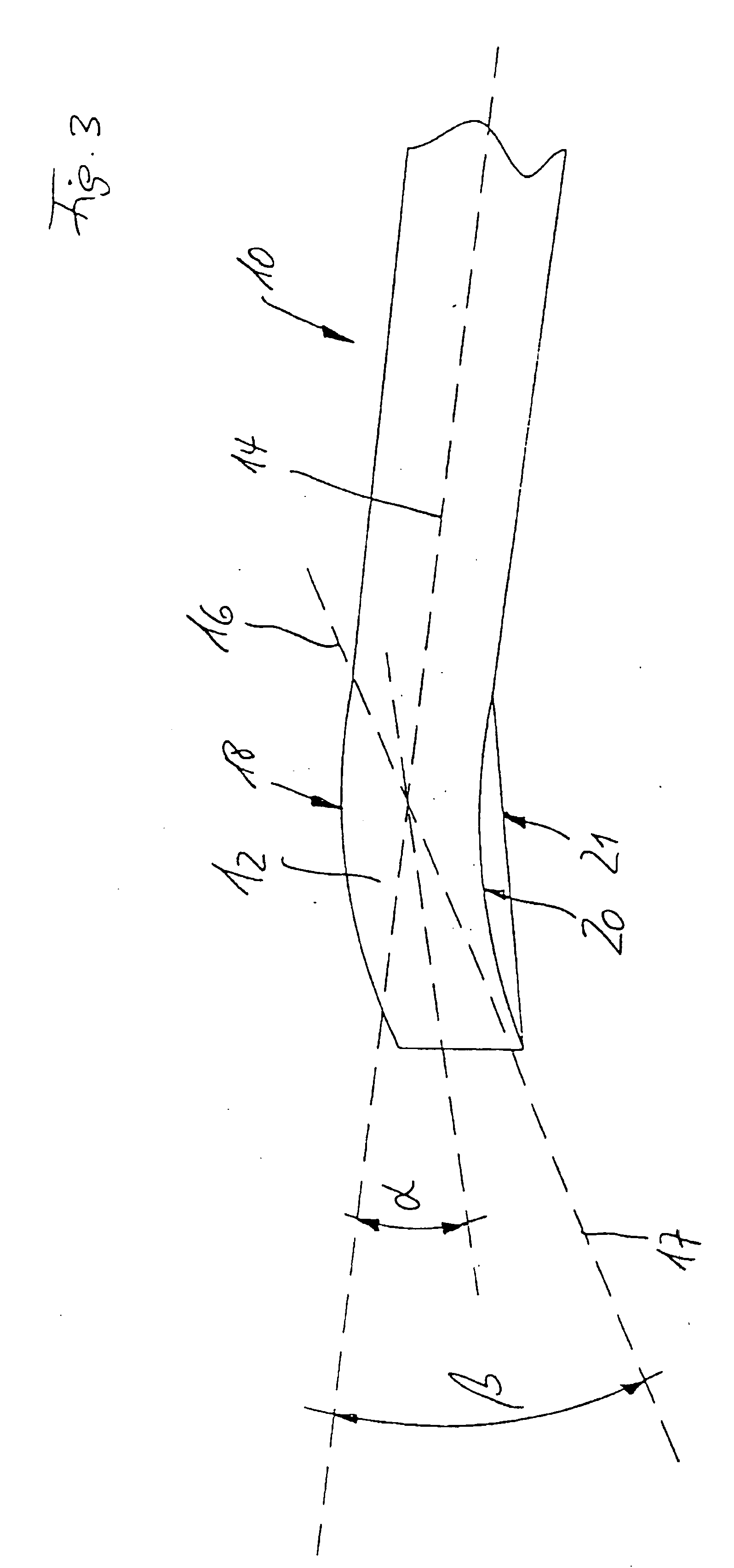

Rotor blade for a wind power plant

Owner:WOBBEN ALOYS

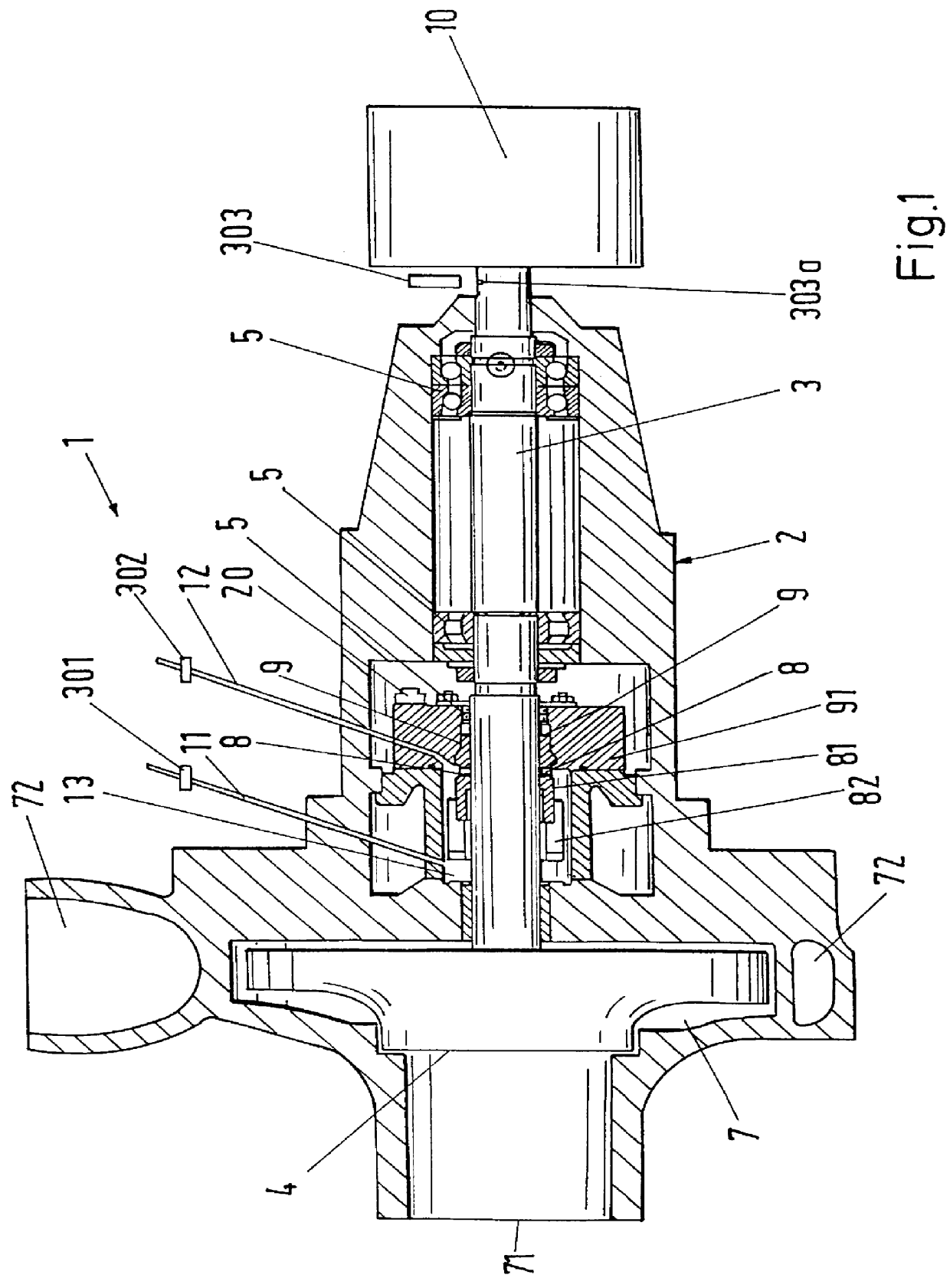

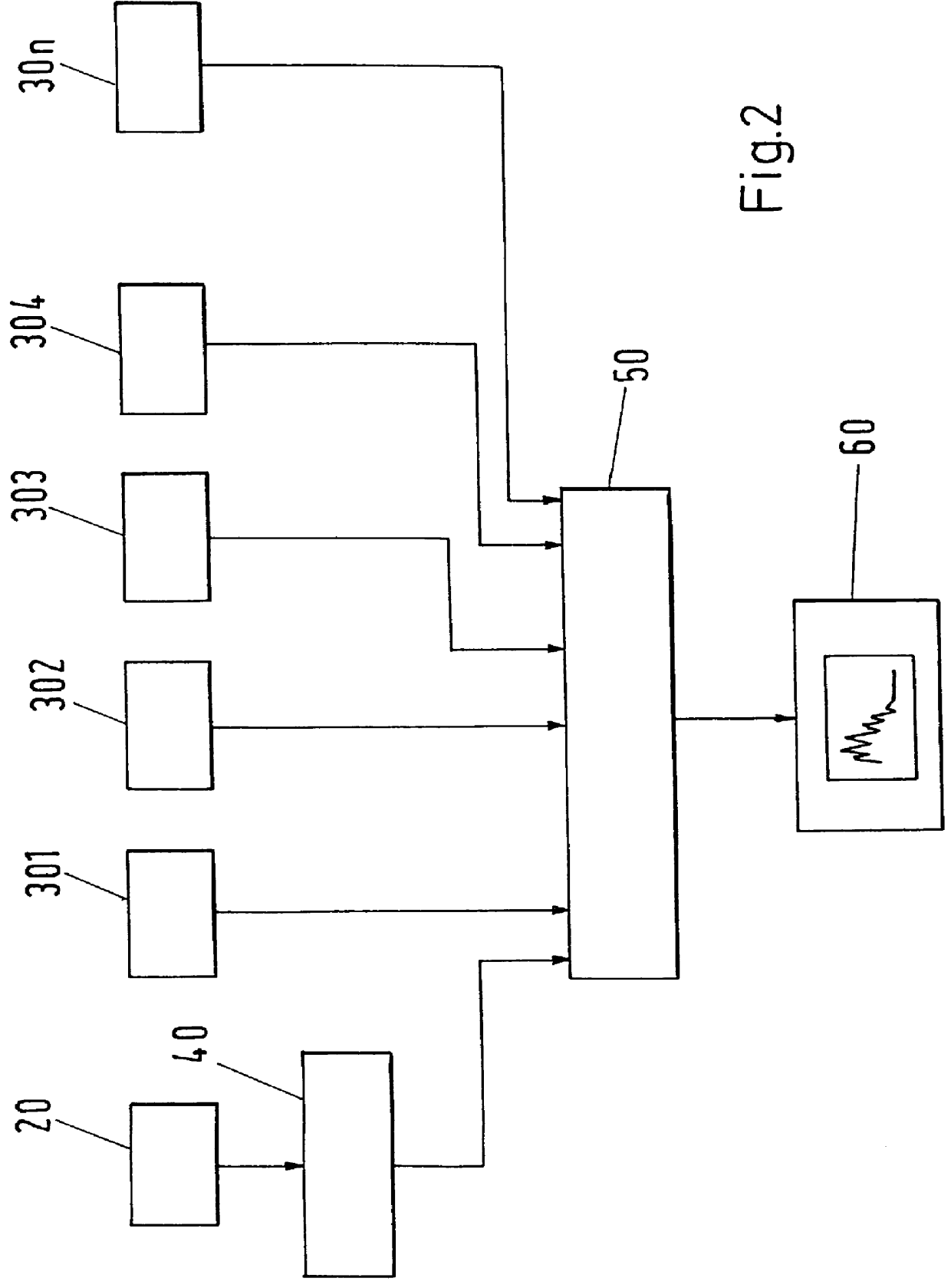

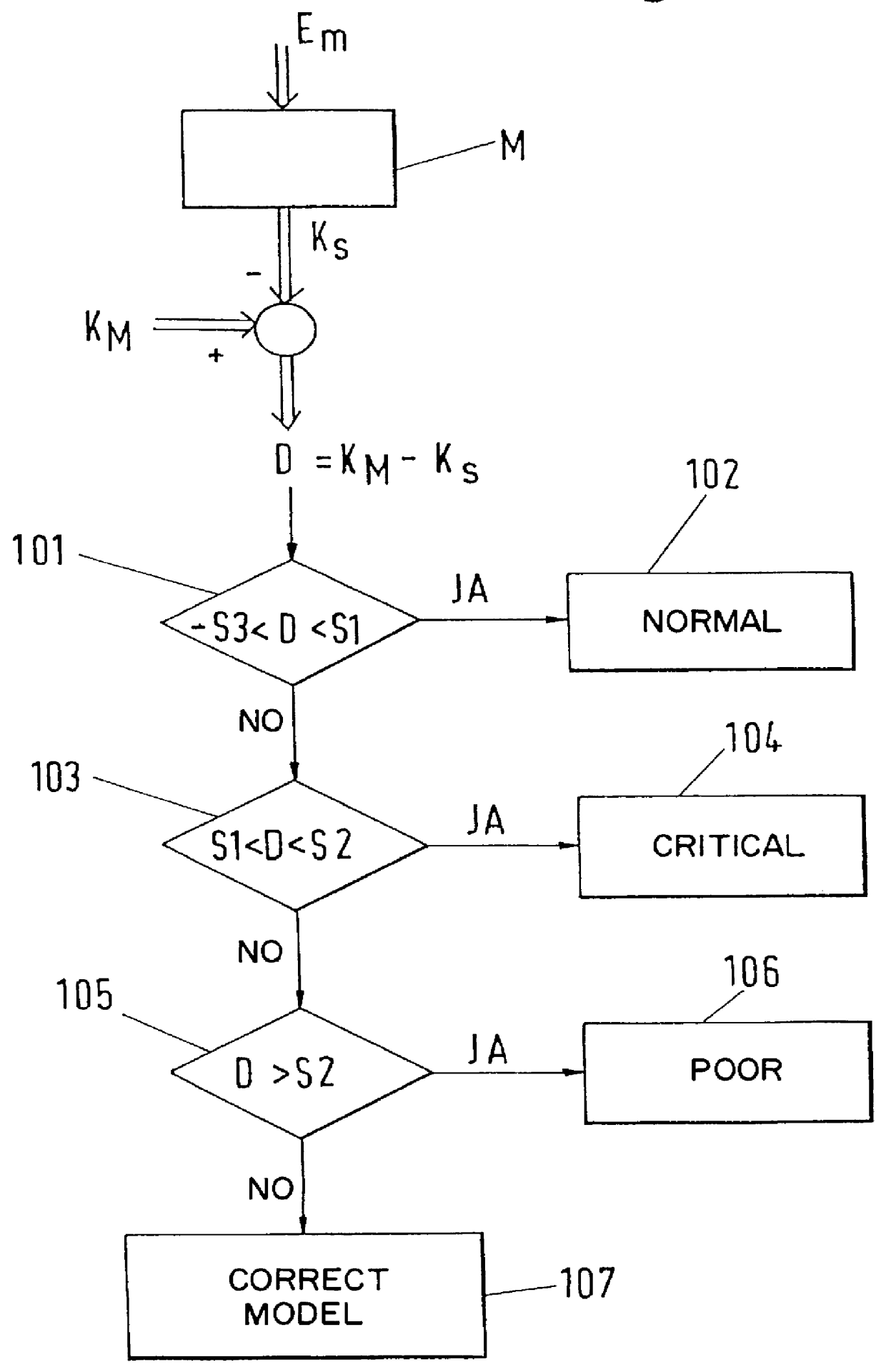

Method for monitoring the condition of a mechanical seal

InactiveUS6065345ALow costEconomical and simpleVibration measurement in solidsMachine part testingEngineeringSound emission

In a method for monitoring the condition of a mechanical seal in an apparatus provided with a rotating part, in particular in a pump which has a rotating shaft for the forwarding of a fluid, the sound emission of the seal is continually measured at discrete times in the operating state of the apparatus and at least one statistical characteristic value is won from the acoustic signals. The analog acoustic signals are converted prior to the determination of the statistical characteristic value into analog demodulated signals, the maximum frequency of which is less than about 50 kHz.

Owner:SULZER PUMPEN

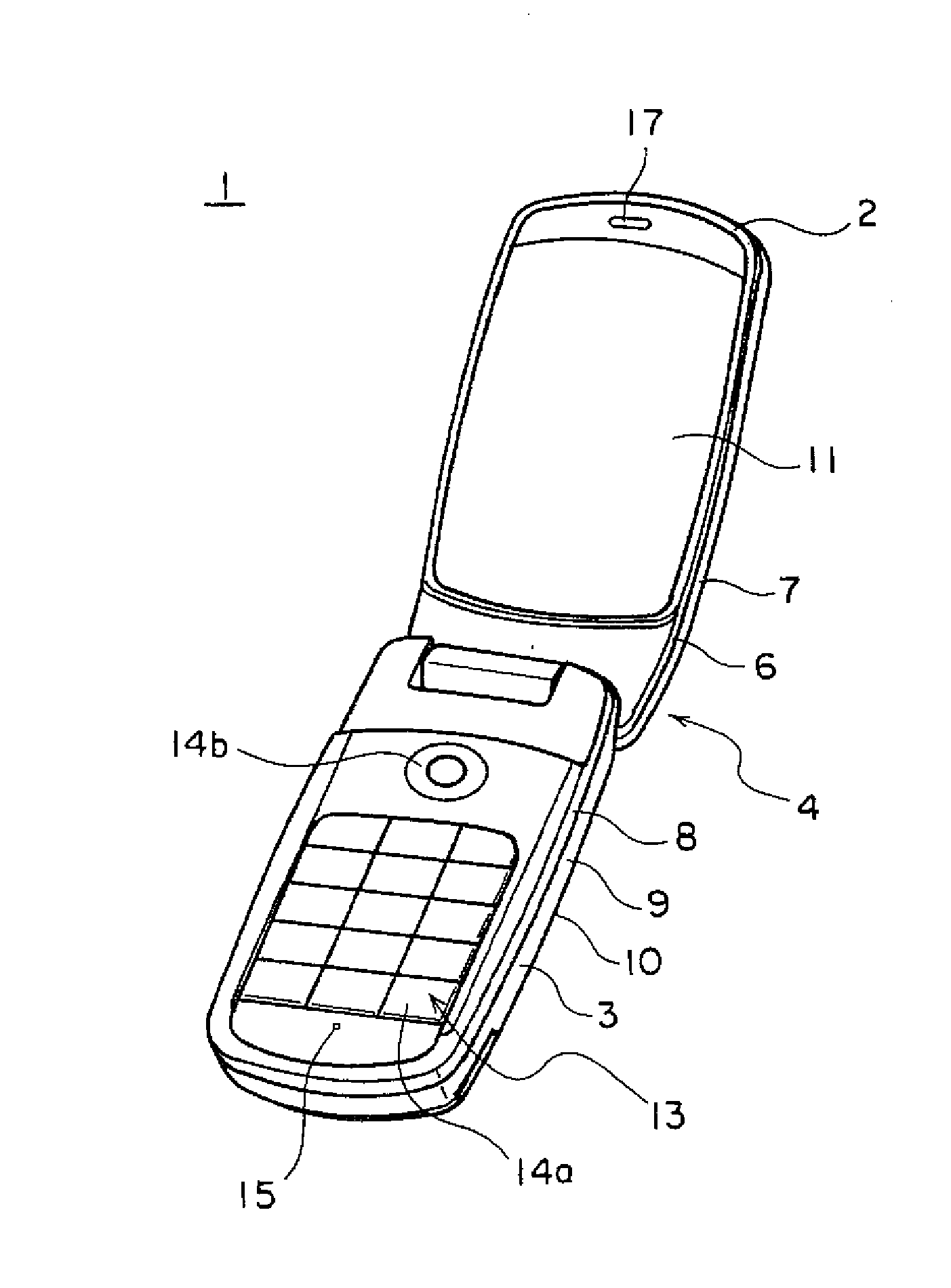

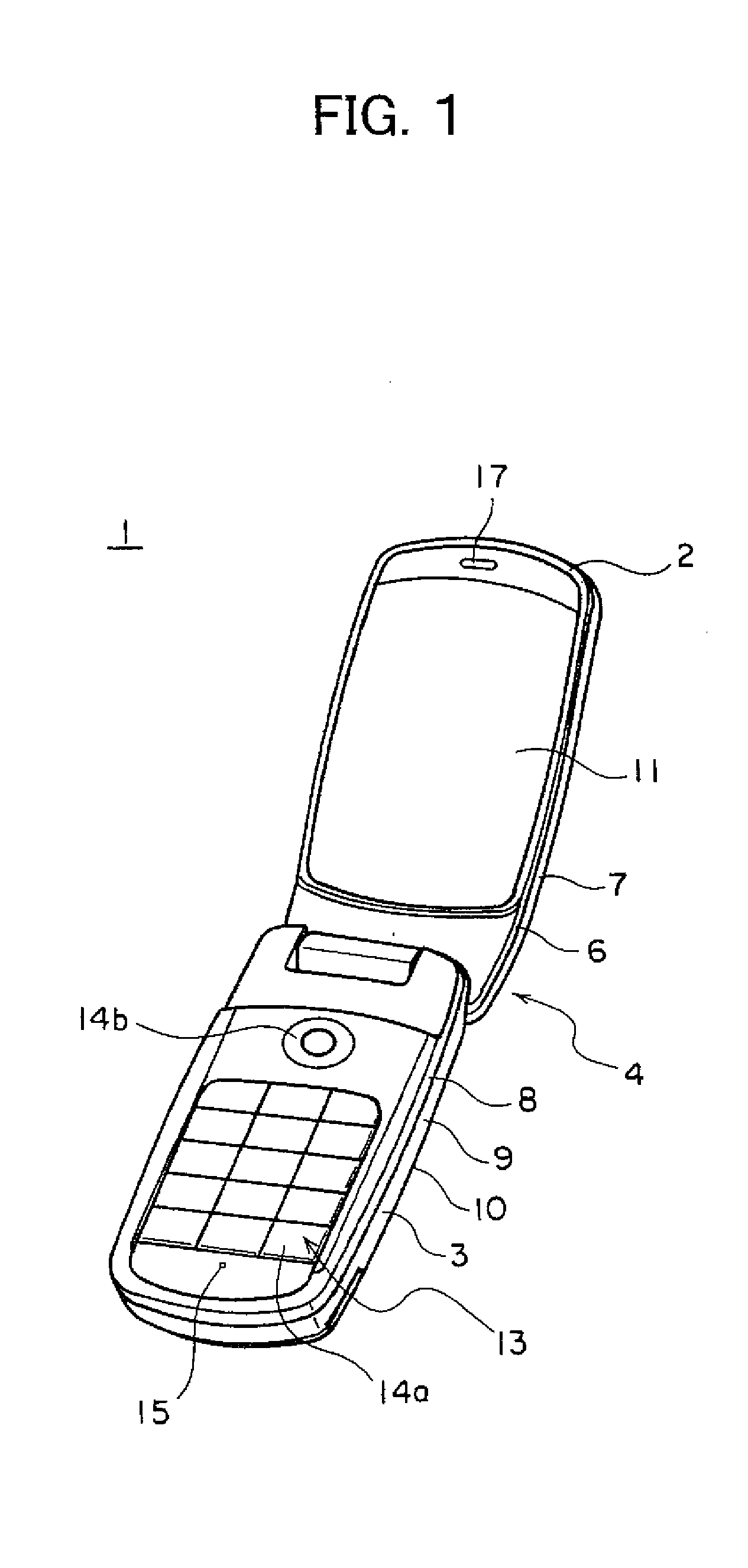

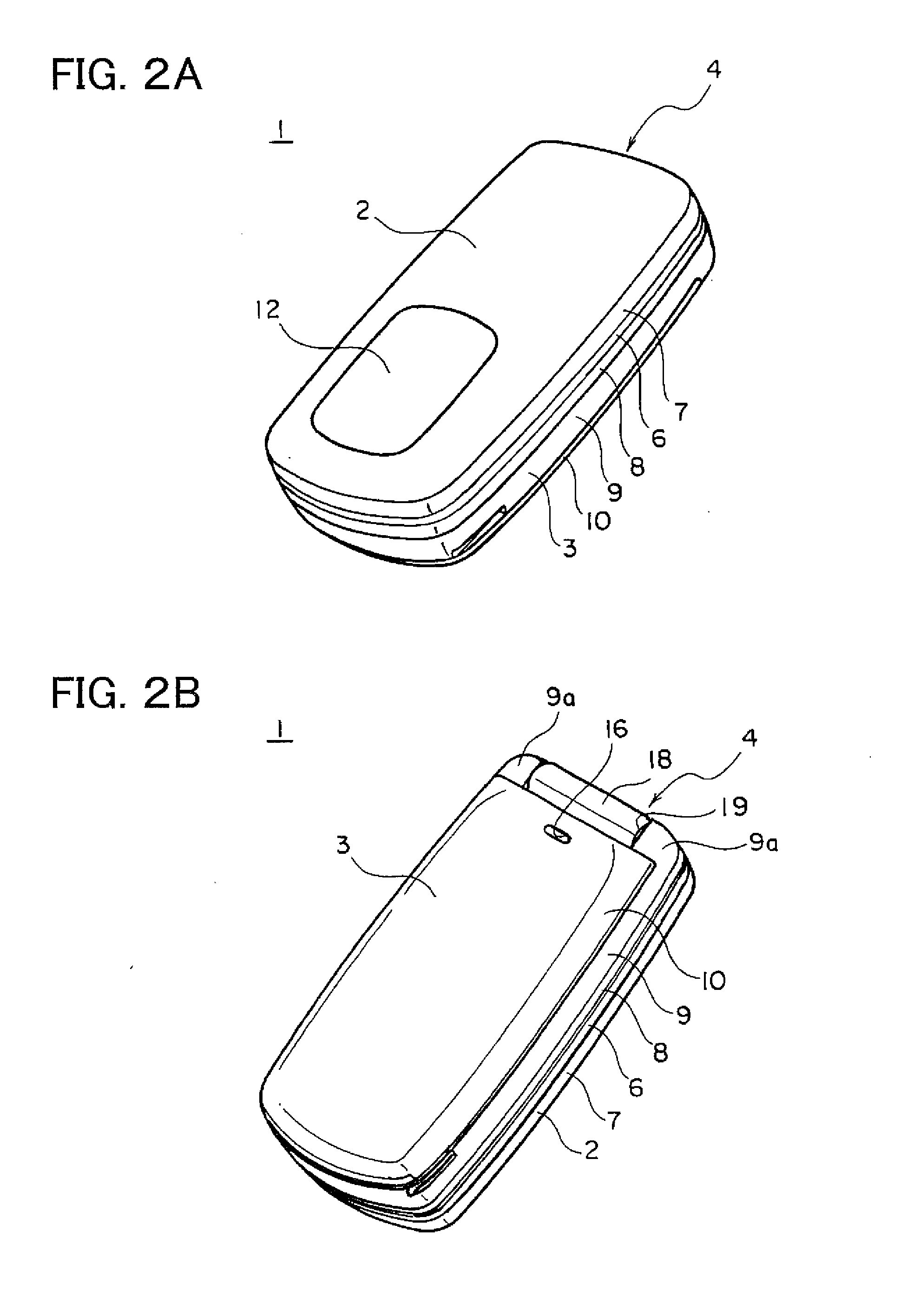

Mobile Terminal

InactiveUS20070178949A1Effective informationEfficient emissionsDevices with multiple display unitsTransmissionEngineeringLoudspeaker

A mobile terminal able to emit an information sound outwardly even in a case where it is set down in a closed state, in particular a mobile phone including a first housing having a projecting part at one end and having a second housing having a recess in which the projecting part is fitted on one end and having a built-in information speaker, the projecting part being pivotably connected to the inside of the recess so as to enable the first housing and the sender housing to be opened and closed, wherein a top surface of the projecting part is located at an inside from the plane including a back surface of the sender housing on an opposite side to a facing surface in the closed state of the mobile phone, a space is provided between the projecting part and the recess, and sound emission ports for emitting sound from the information speaker are provided in a wall surface of the recess forming that space.

Owner:KYOCERA CORP

Sound reproduction device and portable terminal apparatus

ActiveUS7382890B2Improve rendering capabilitiesTransmissionPlane diaphragmsTerminal equipmentTransducer

A sound reproduction device includes an LCD 20, which is an exemplary front panel, a case 22, and an electromechanical acoustic transducer 23. The LCD 20 is operable to perform a predetermined operation in response to an electrical signal applied thereto. A space 24 for sound emission is formed between the case 22 and the LCD 20. The electromechanical acoustic transducer 23 is connected to the case 22, and emits sound to the space 24. If the electromechanical acoustic transducer 23 emits the sound to the space 24, energy of the emitted sound causes the LCD 20 to vibrate and thereby to externally output the sound.

Owner:PANASONIC CORP

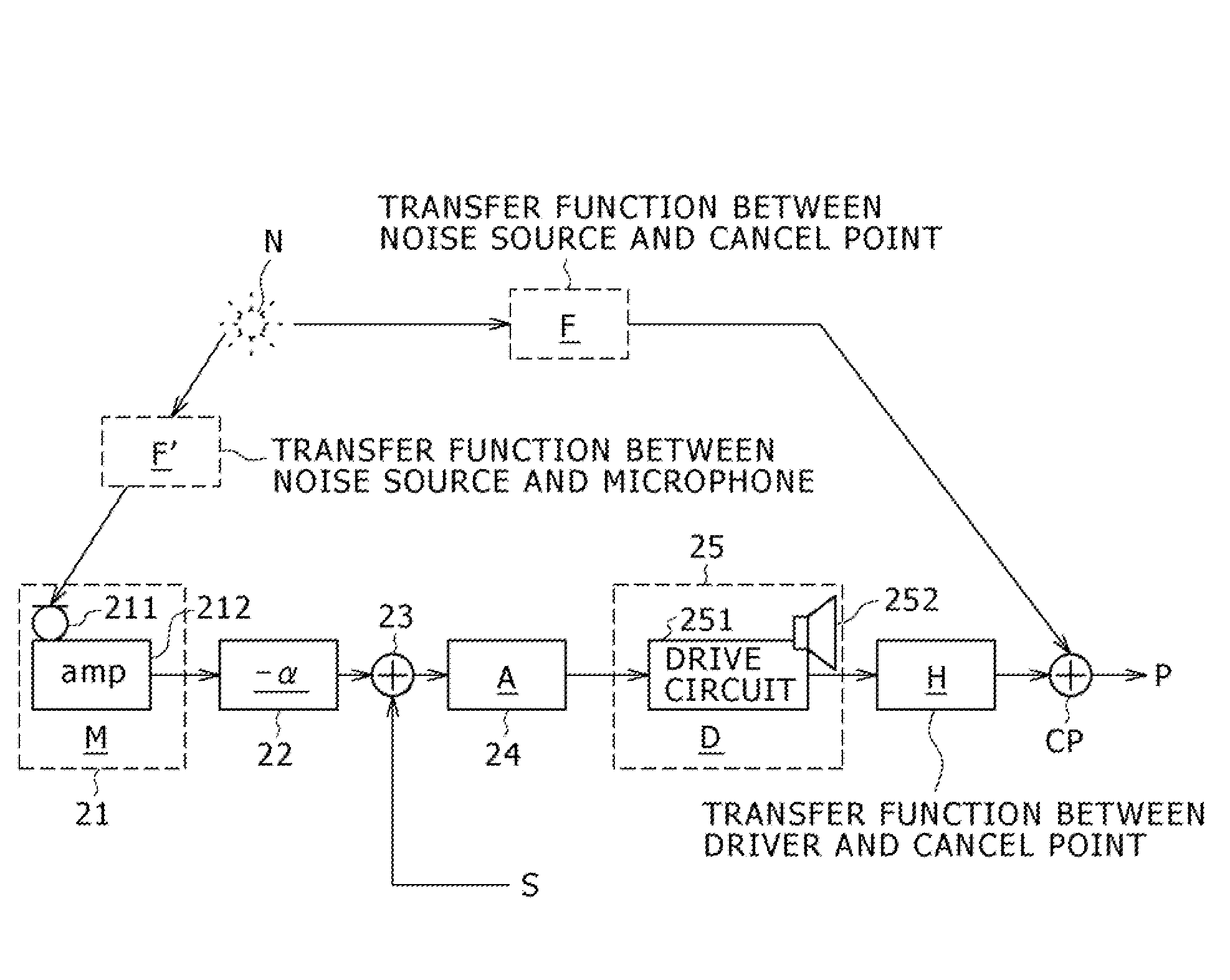

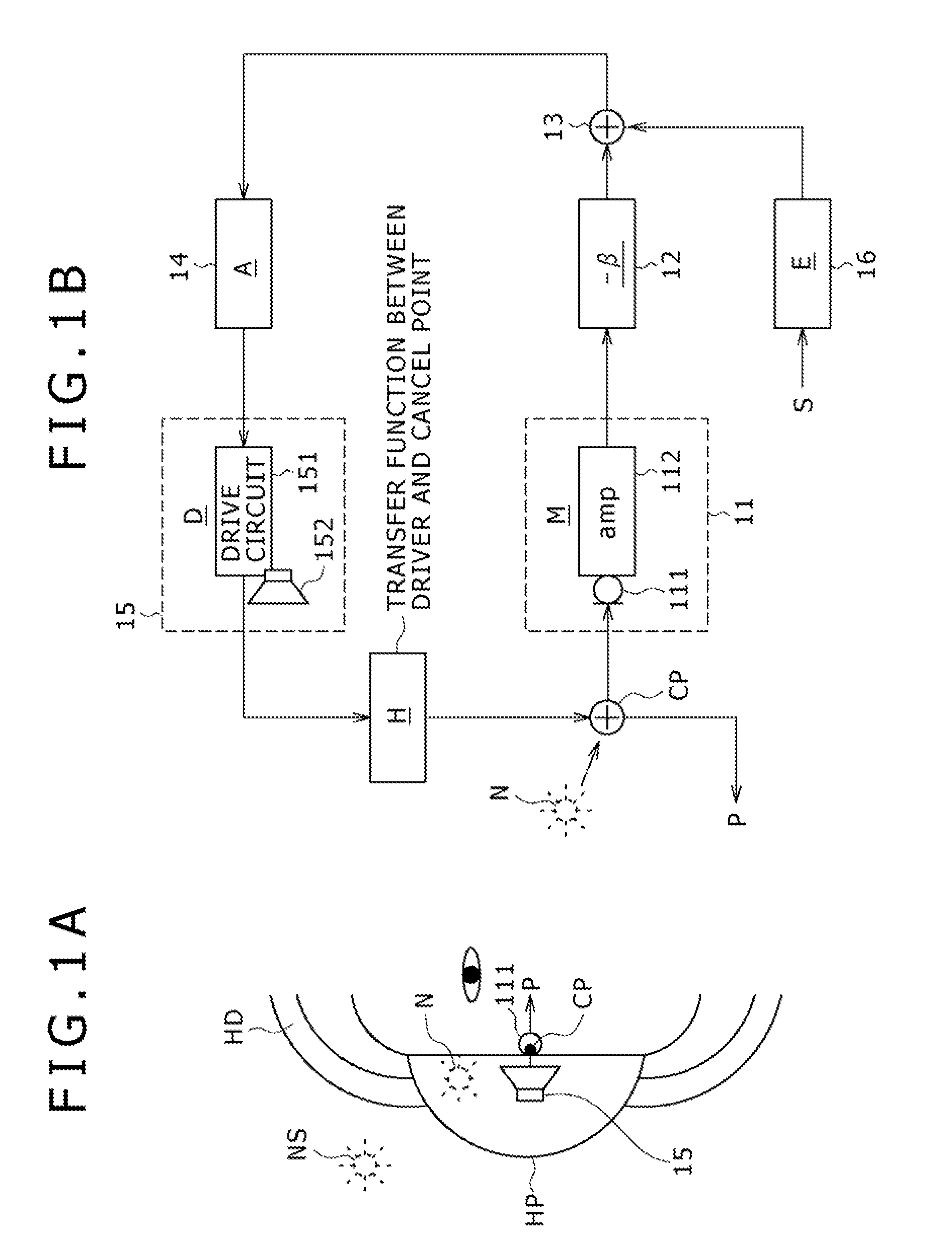

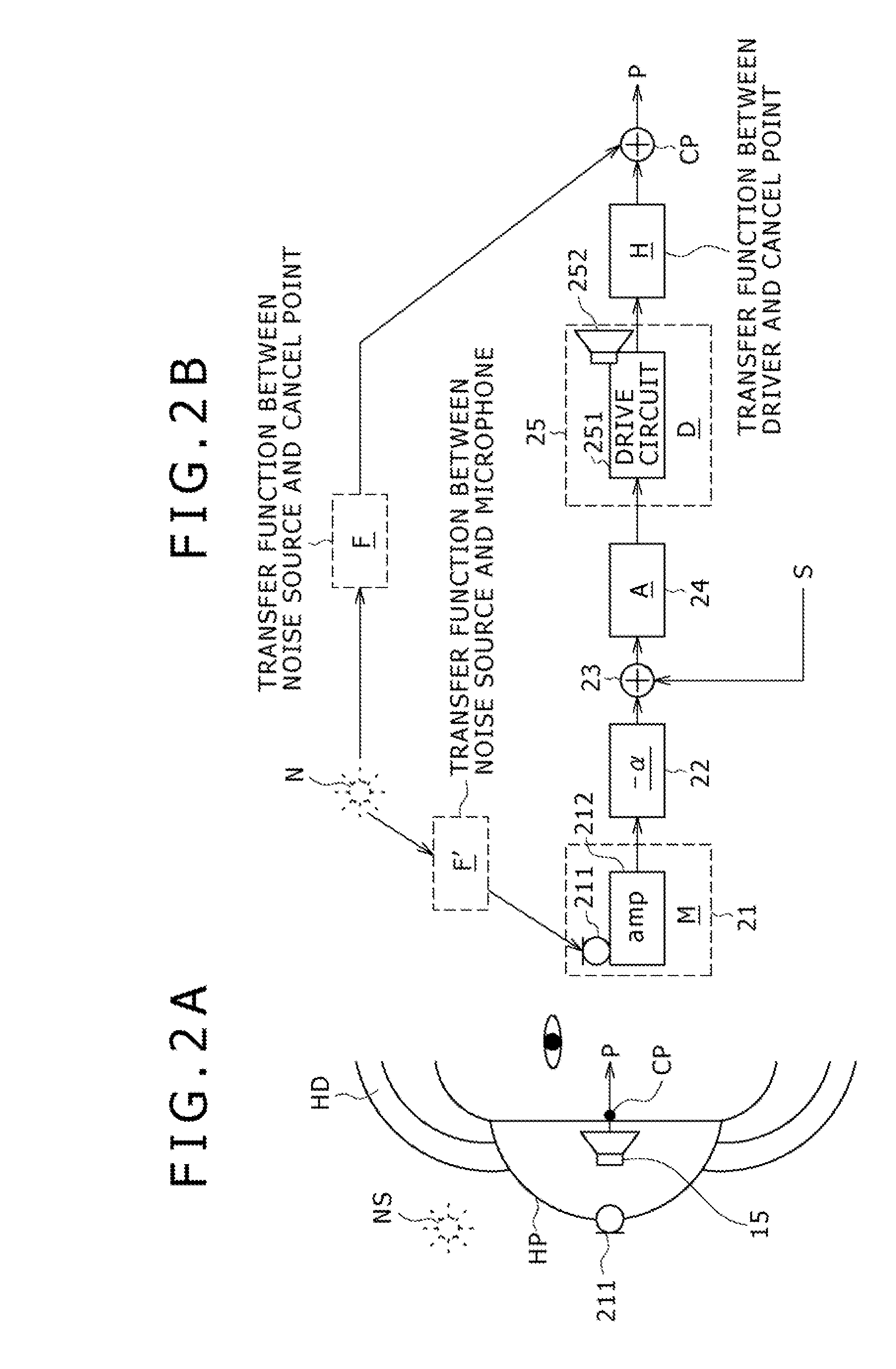

Noise canceling system and noise canceling method

ActiveUS20080310645A1Improve noise reductionStablyMicrophonesEar treatmentEngineeringNoise reduction

Disclosed herein is a noise canceling system, including: a first sound collection section configured to collect noise and output a first noise signal; a first signal processing section configured to produce a first noise reduction signal for reducing the noise at a predetermined cancel point; a sound emission section configured to emit noise reduction sound based on the first noise reduction signal; a second sound collection section configured to collect noise and output a second noise signal; and a second signal processing section configured to produce a second noise reduction signal for reducing noise at the cancel point. In the noise canceling system, the sound emission section emitting the noise reduction sound based on the first and second noise reduction signals

Owner:SONY CORP

Pressure rock failure and instability process and dynamic permeability test apparatus and method thereof

ActiveCN104977234AEasy to replaceUniform confining pressureAnalysing solids using sonic/ultrasonic/infrasonic wavesPermeability/surface area analysisCouplingInstability

The invention relates to a pressure rock failure and instability process and dynamic permeability test apparatus and a method thereof. A stress strain signal, a sound emission signal and an apparent resistivity signal in the pressure rock failure and instability process are acquired and processed by using a large pressure rock permeability test device to obtain the stress strain relationship, the quantity and positions of sound emission events and the rock apparent resistivity change rule induced by pressure water permeability increase in large pressure rock failure and instability process in order to obtain the dynamic evolution role of crack expansion, perforation and instability in the rock failure process under hydraulic-mechanical coupling action and the corresponding dynamic permeability. The hydraulic-mechanical coupling failure mechanism and the pressure permeability of rocks, and the deformation and strength characteristics, the crack expansion, perforation and failure characteristics and the permeability evolution rule of pressure water in the crack expansion-perforation-failure process of the rocks under the hydraulic-mechanical coupling action are researched in the invention. The apparatus and the method have important engineering values in realization of safe mining under water pressure on pressure water.

Owner:ANHUI UNIV OF SCI & TECH

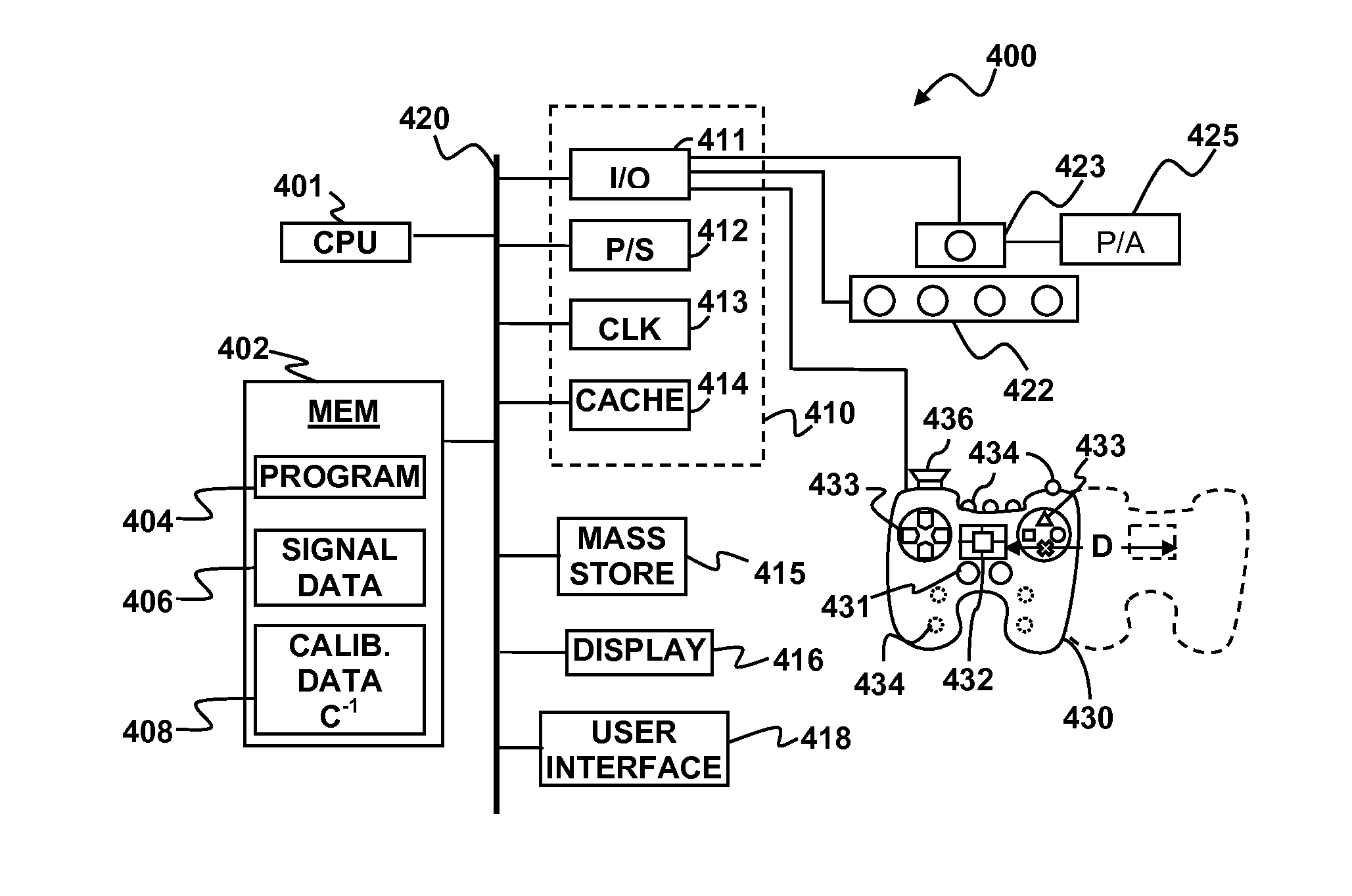

Tracking device with sound emitter for use in obtaining information for controlling game program execution

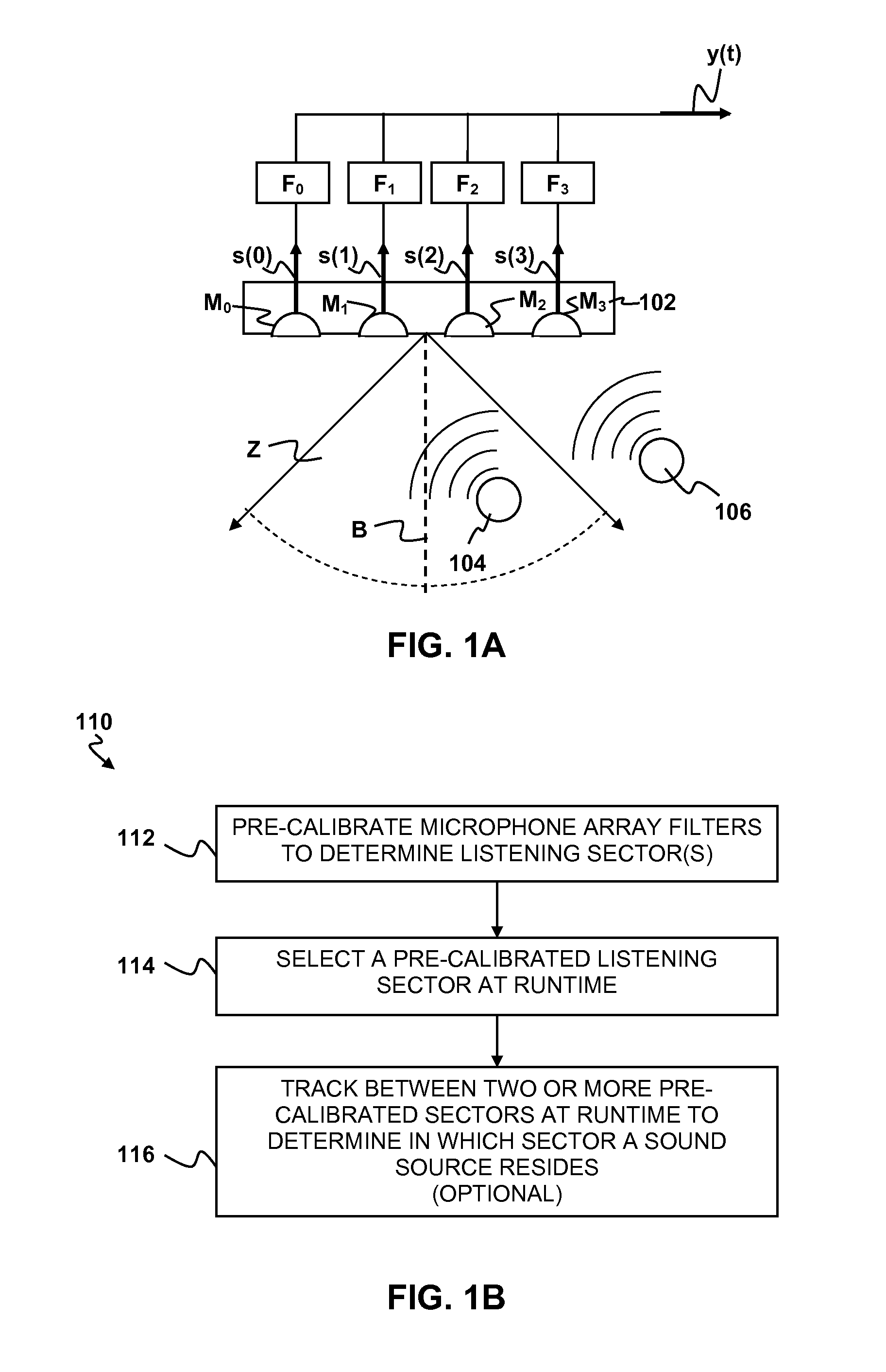

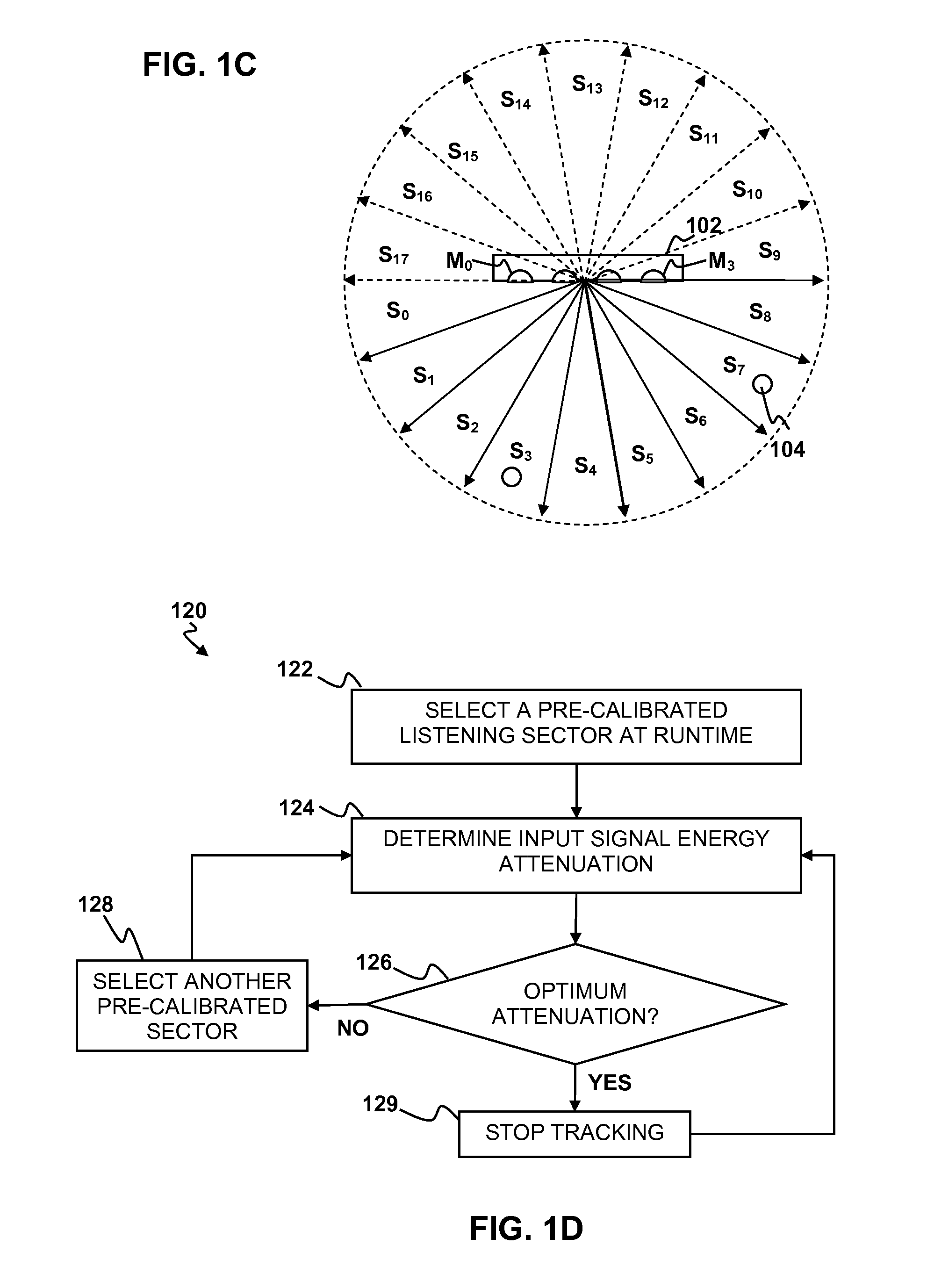

A tracking device may include a body, a sound emitter operable to emit a sound, an array of two or more microphones adapted to produce discrete time domain input signals at a runtime, one or more processors coupled to the array of two or more microphones; and a memory coupled to the microphones and the processor. The memory has a set of processor readable instructions embodied therein. The instructions include one or more instructions for:determining a listening direction of the sound source relative to the microphone array from the discrete time domain input signals; using the listening direction in a semi-blind source separation to select filtering functions that separate out sounds from the sound emitter from the discrete time domain input signals; identifying a listening zone containing the sound emitter from the filtering functions; and determining a location of the sound emitter from the identified listening zone.

Owner:SONY COMPUTER ENTERTAINMENT INC

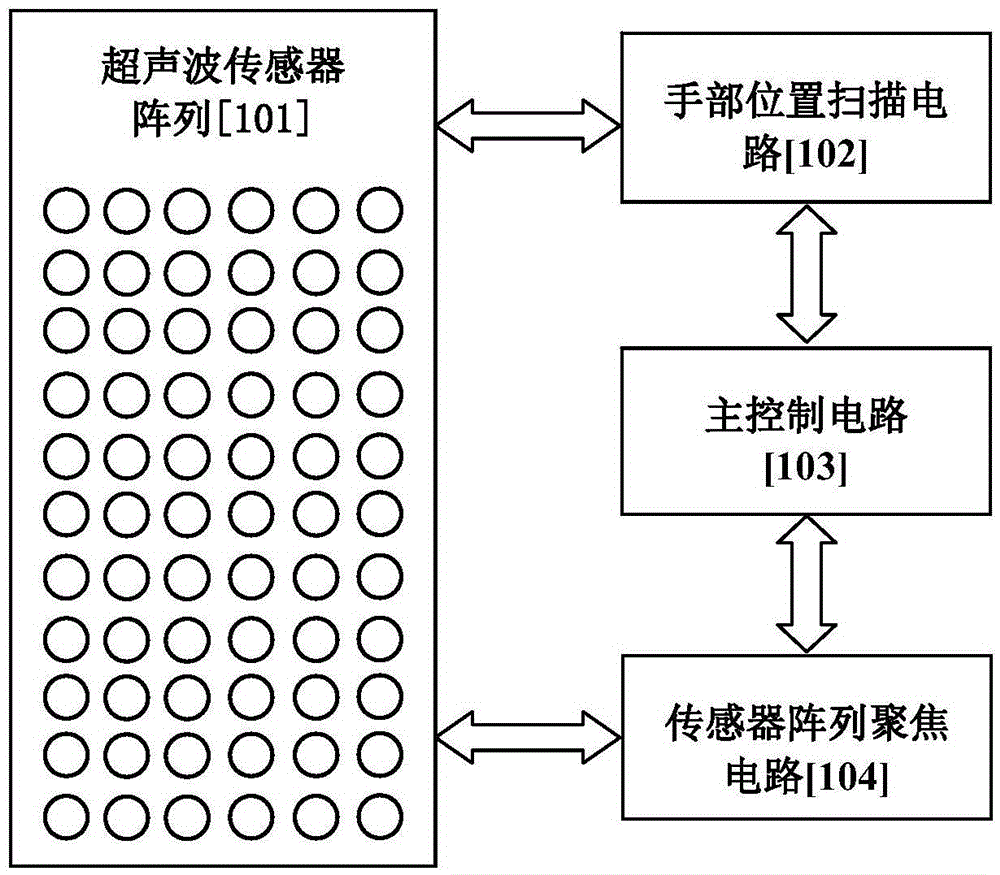

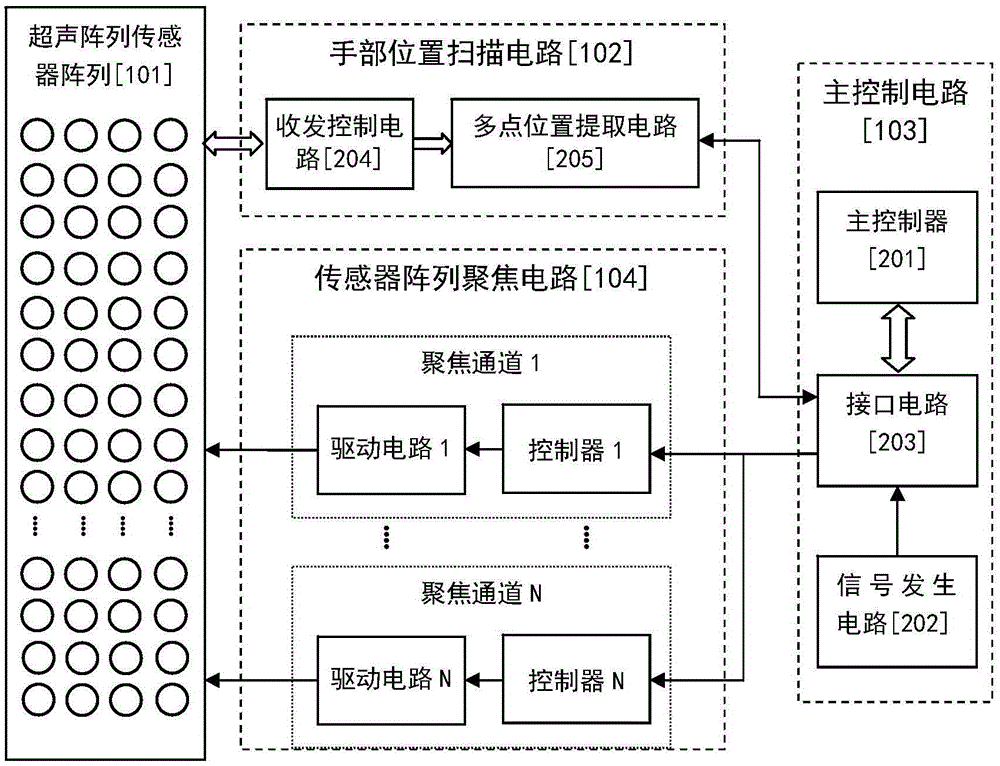

Ultrasonic focus based haptic feedback system and method

ActiveCN105426024ALow costSimple structureInput/output processes for data processingSensor arraySonification

The invention relates to an ultrasonic focus based haptic feedback system and method, and belongs to the field of haptic feedback. The system comprises a main control circuit, a hand position scanning circuit, a sensor array focus circuit and an ultrasonic sensor array. A hand position is obtained in a scanning mode by utilizing the ultrasonic array; a system determines ultrasonic focus points according to the hand position and calculates time delay of emitting ultrasonic waves by each sensor of the array to control a moment of emitting an ultrasonic signal by each sensor, thereby realizing the focus of the ultrasonic array; sound emission force is generated and acts on the hand skin to generate a haptic feeling; and the system needs to use a hand skin sensitive frequency to modulate an ultrasonic resonant frequency to generate an ultrasonic focus signal. According to the haptic feedback system and method, the scanning and haptic feedback of the hand position are realized through the same ultrasonic array, and a non-contact haptic feedback function in a three-dimensional space can be realized.

Owner:JILIN UNIV

Hydraulic fracturing simulation experimental device and method of hot dry rock enhanced type geothermal system

InactiveCN107893652AAccurate calculation of hydraulic fracturing heat transfer efficiencySimulation is accurateSurveyFluid removalHydraulic fracturingHigh pressure

The invention relates to a hydraulic fracturing simulation experimental device and method of a hot dry rock enhanced type geothermal system. A hot dry rock high-pressure and high-temperature generating environment is simulated, precise stress is applied to a rock core by designing a multistage piston, the permeability of hot dry rock fluid is maintained by adopting a pressureproof and temperature-resistant perforated plate, the hot dry rock fluid is externally connected to a fluid collection chamber through a flow guiding groove, and meanwhile an adjustable sound emission probe is embedded into a true-triaxial high-pressure axe to monitor a sound emission event happening when a fracture expands in the hydraulic fracturing process, integrated collection of information of rock hydraulic fracturing, sound emission, heat energy recovery efficiency and the like under the triaxial confining pressure condition can be achieved by utilizing the device, and therefore the fracture initiation andexpanding situations of the hot dry rock hydraulic fracture can be studied. The hydraulic fracturing simulation experimental device and method have the beneficial effects that warming and heat preservation effects are good, a sealed part is simple to replace and convenient to maintain, a sound emission embedded part can be adjusted according to the requirements for the probe sizes, in addition, the whole device further has the characteristics that operation is convenient, and the protection and maintenance period is short, and the device is an important technological innovation at the aspect of dry hot rock enhanced type geothermal system hydraulic fracturing testing device detection.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

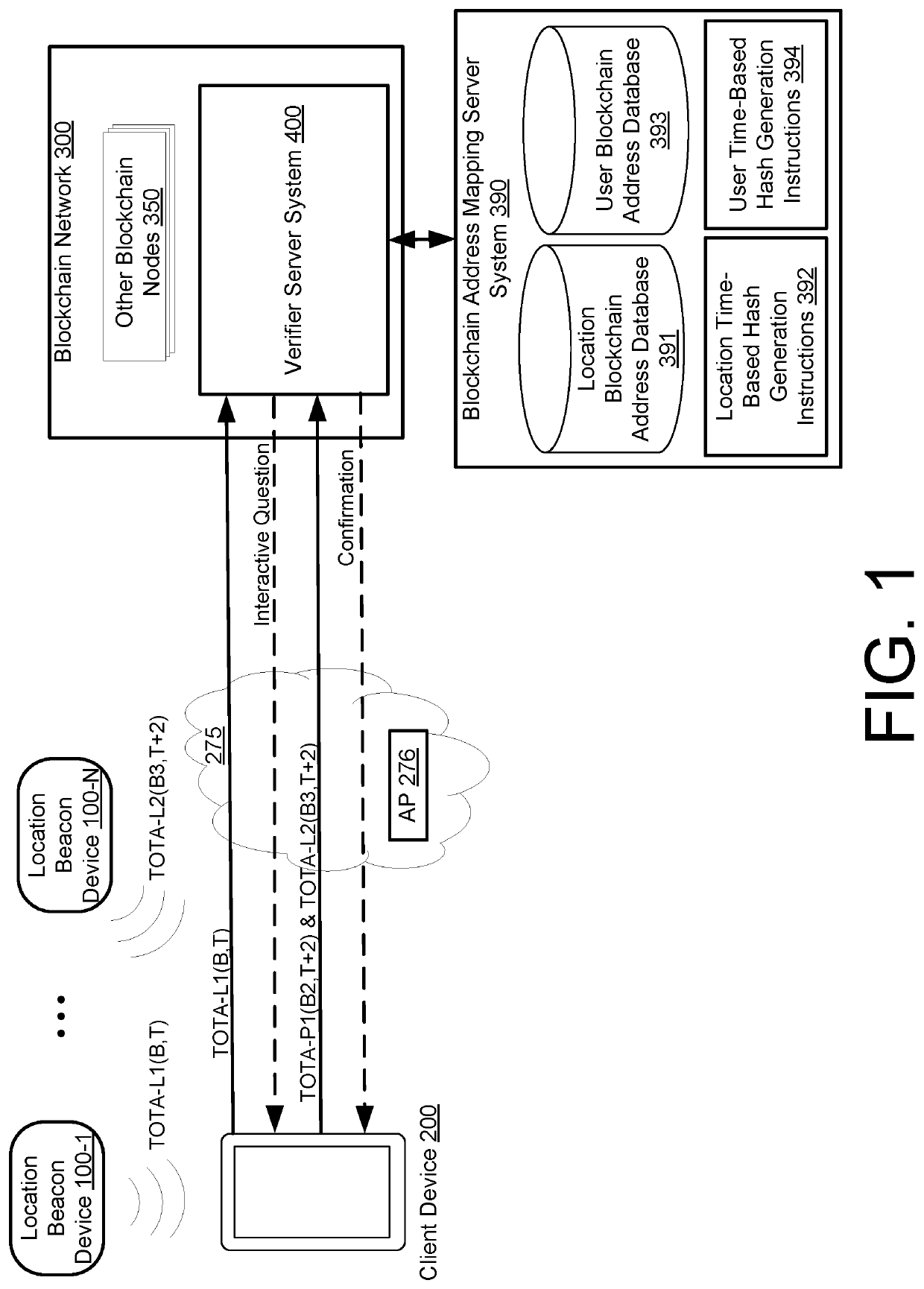

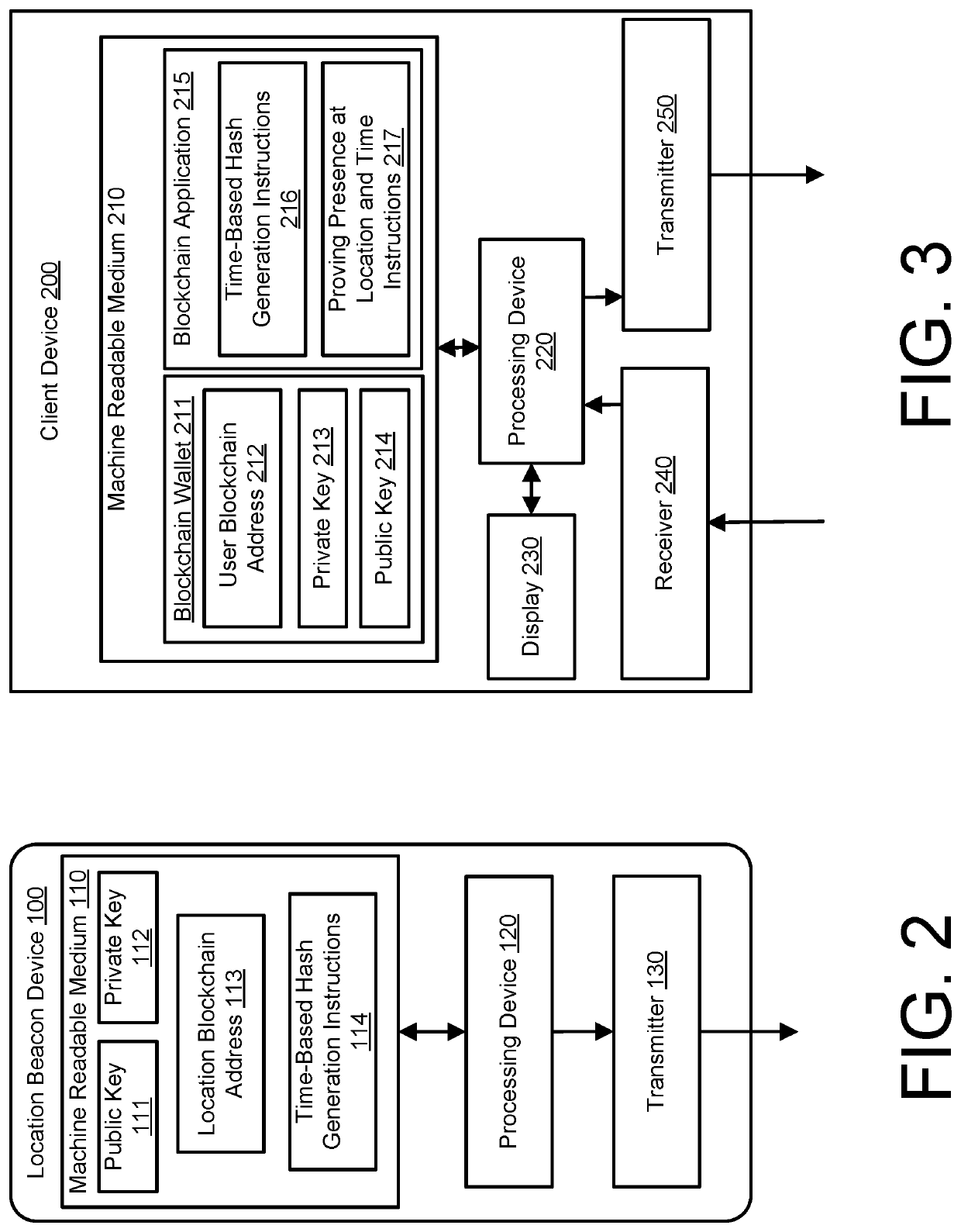

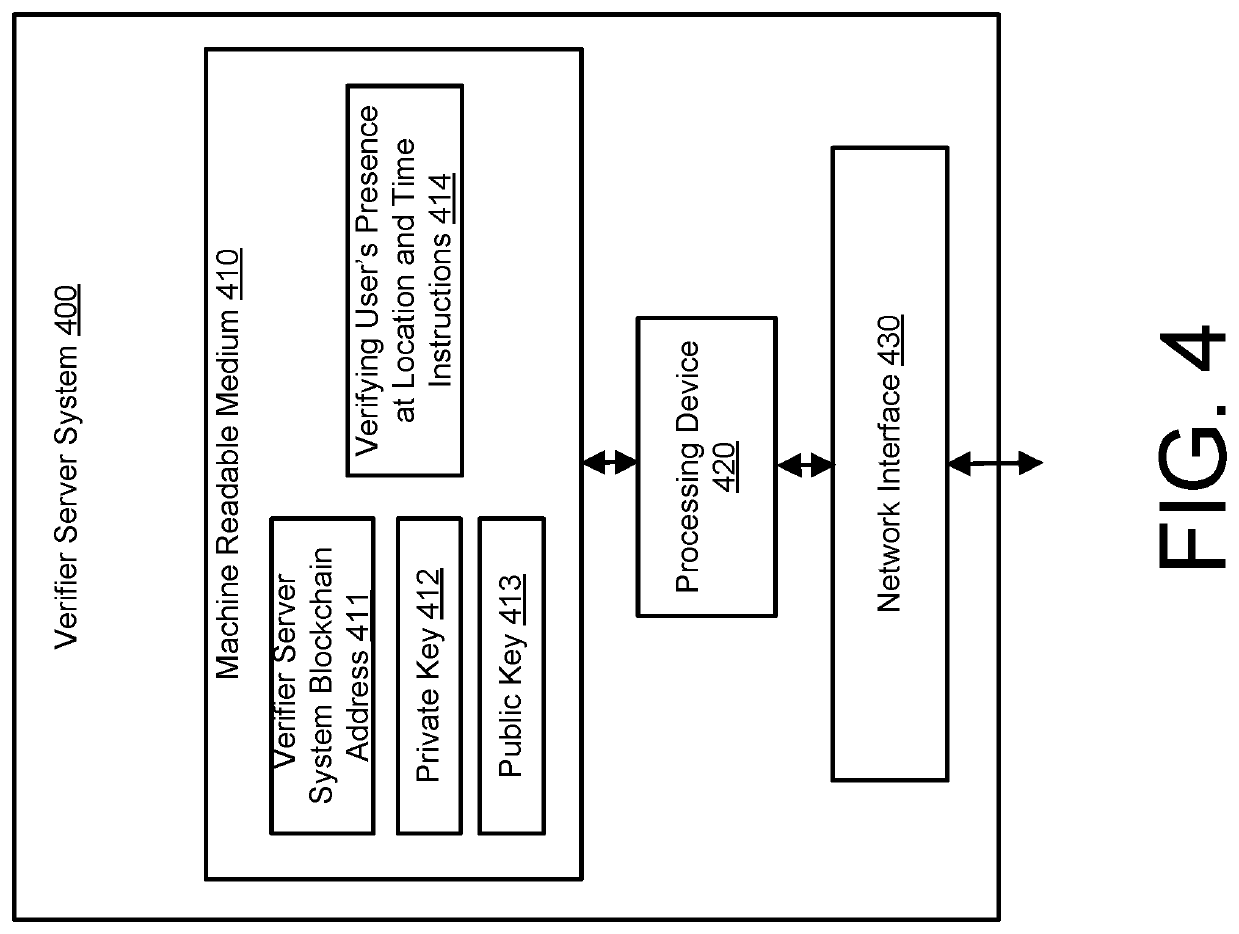

Systems and methods for using smart contract and light and sound emitting assets provisioned with distributed ledger addresses to identify and locate assets

InactiveUS20200037158A1Cryptography processingElectroluminescent light sourcesSmart contractEmbedded system

Systems and methods described herein are directed to using a smart contract to track and identify assets having tags, in accordance with implementations of the disclosure. In some implementations, an apparatus includes: a sound emitter or light emitter; a machine readable medium to store a blockchain address associated with an asset; a transmitter to transmit a secured representation of the blockchain address; a receiver to receive a message including a request to self-identify; and a processor to: generate the secured representation of the blockchain address; and in response to receiving the message, cause the sound emitter to emit sound or the light emitter to emit light.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

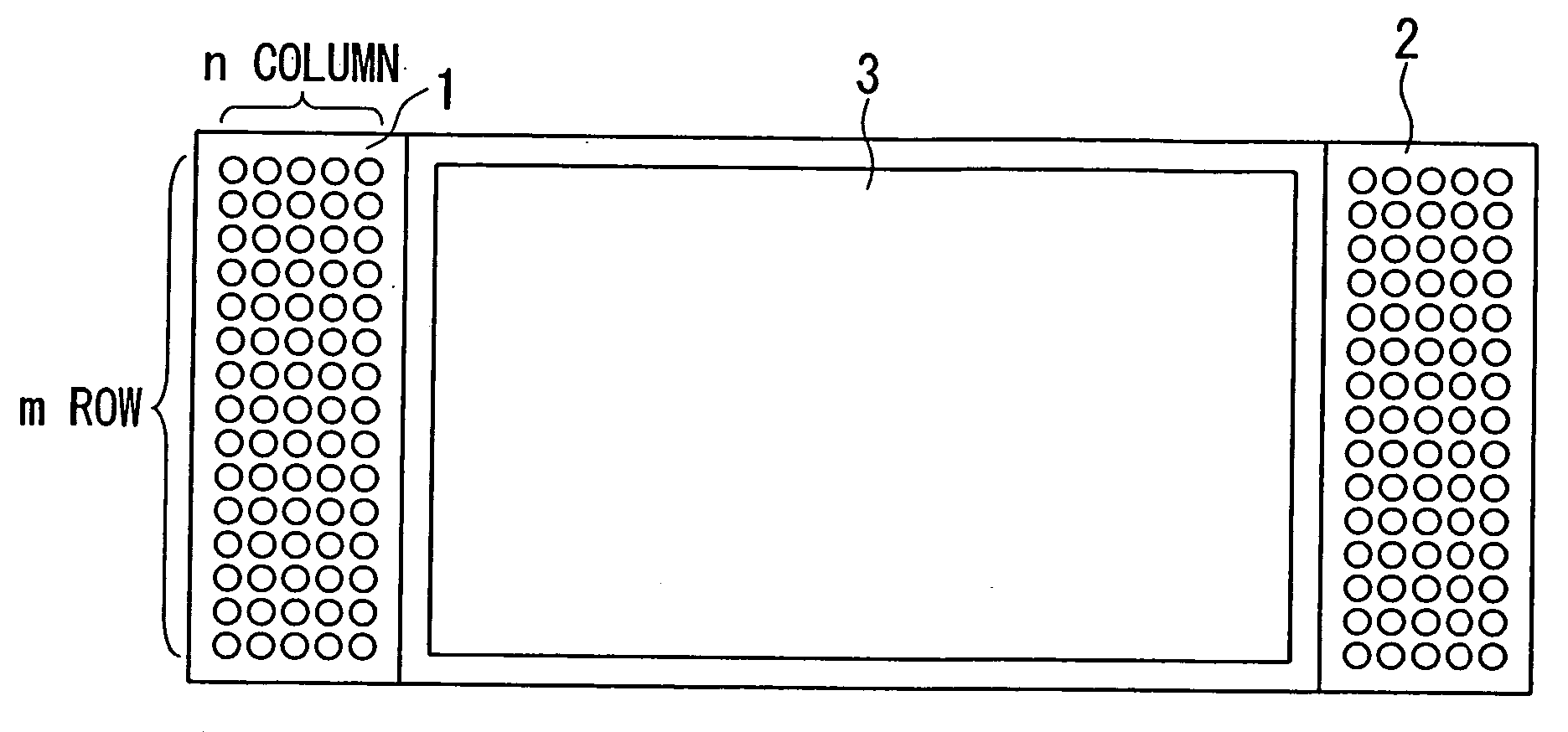

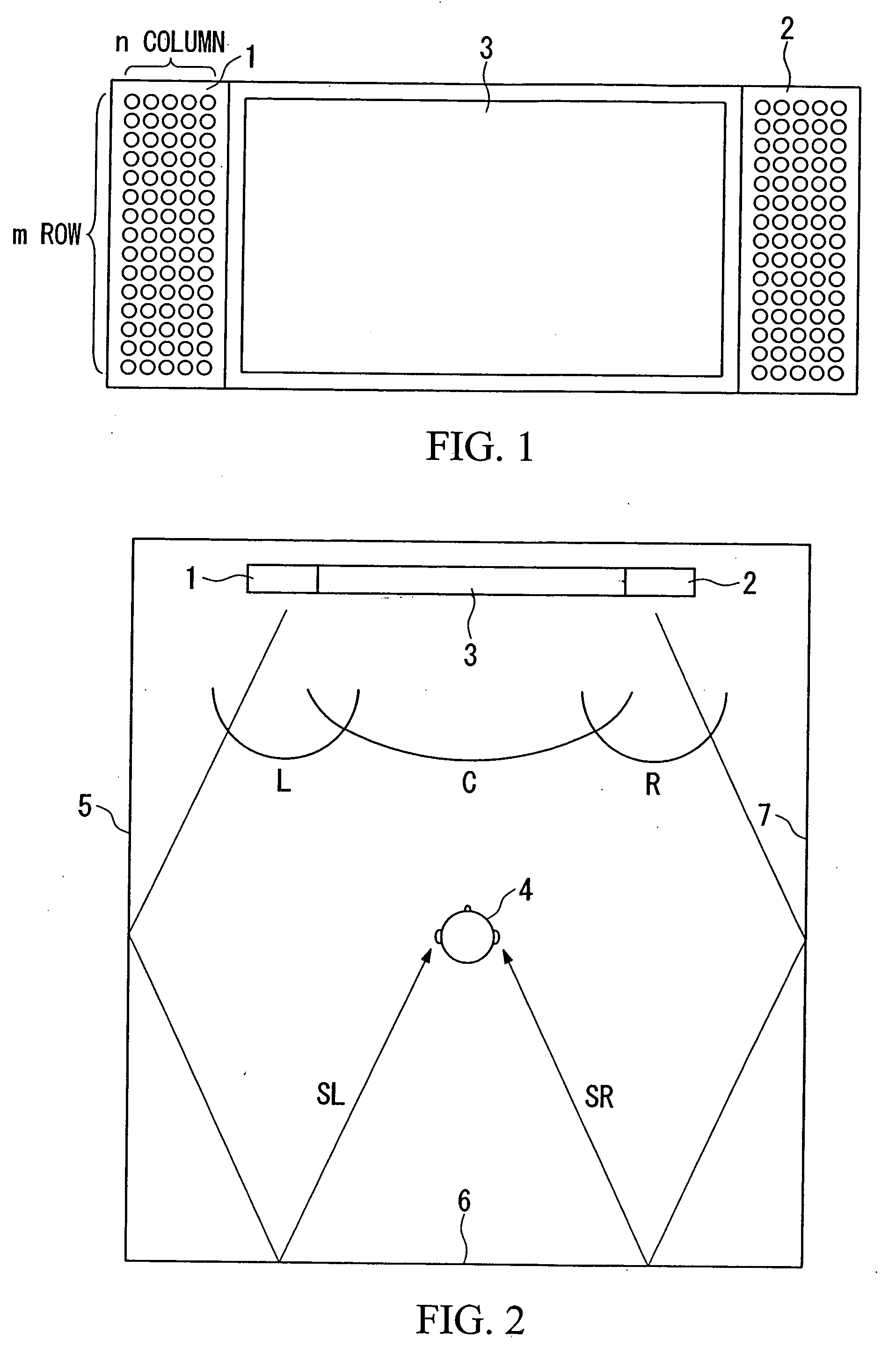

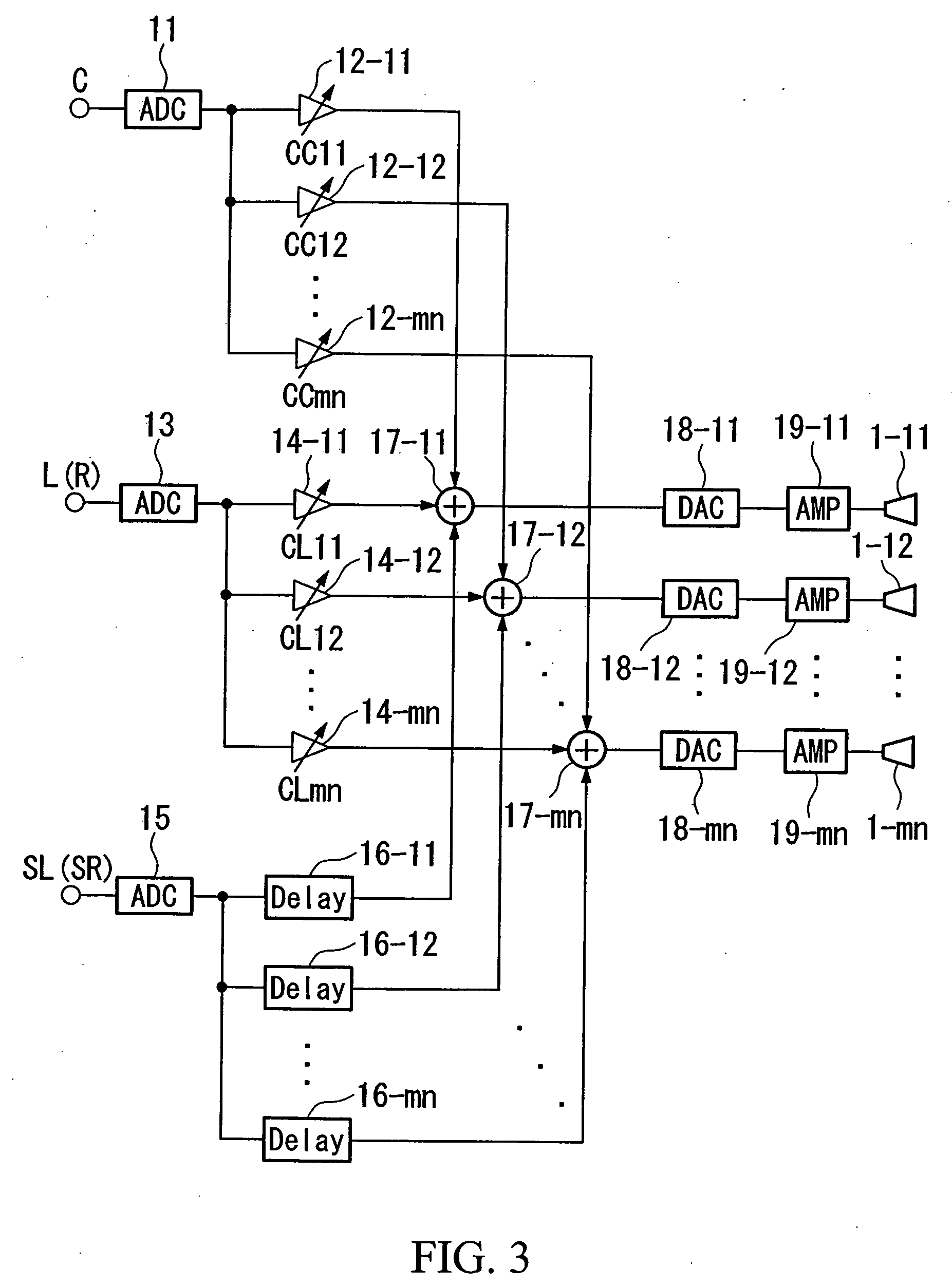

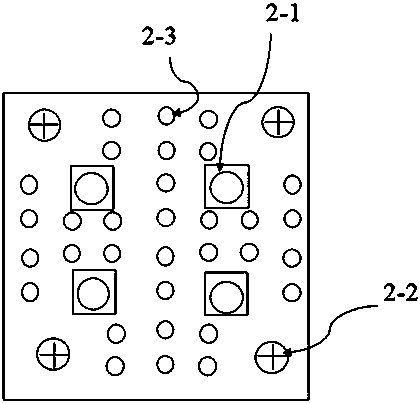

Array speaker system

InactiveUS20070019831A1Signal processingTransducers for sound channels pluralityWeight coefficientEngineering

In an array speaker system that performs multi-channel reproduction using an array speaker constituted by arraying a plurality of speaker units in a matrix manner, a left channel signal, a right channel signal, and a center channel signal, all of which instruct reproduction of sound at a front side of a listener, are subjected to weighting using weight coefficients based on a Bessel function so as to drive the speaker units, thus realizing spherical sound emission characteristics. In addition, a surround left channel signal and a surround right channel signal, both of which instruct reproduction of sound at a rear side of the listener, are subjected to beam processing, whereby sound is reflected on a sound reflection position such as a wall surface or a ceiling and is then emitted in the form of a sound beam reaching the rear side of the listener.

Owner:YAMAHA CORP

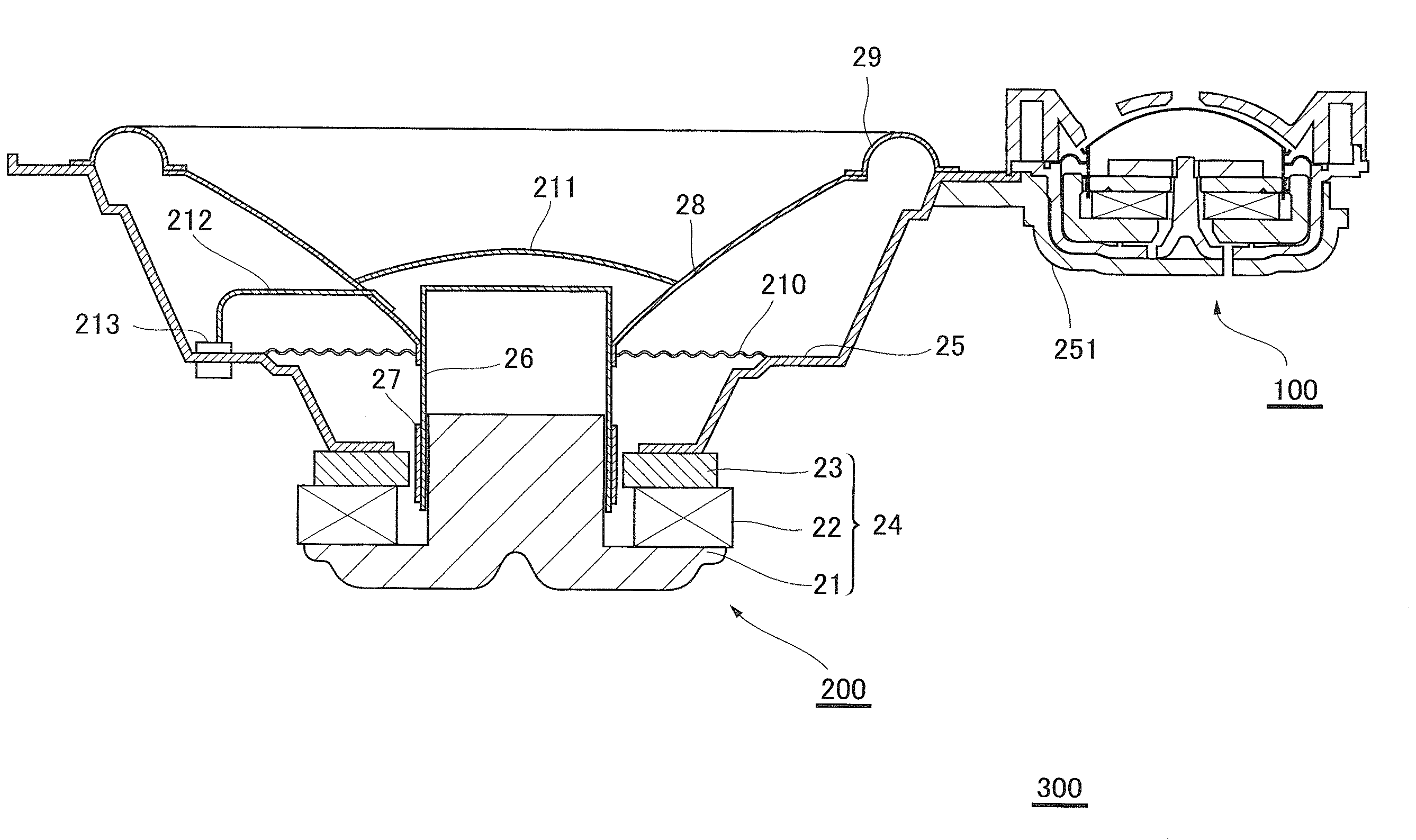

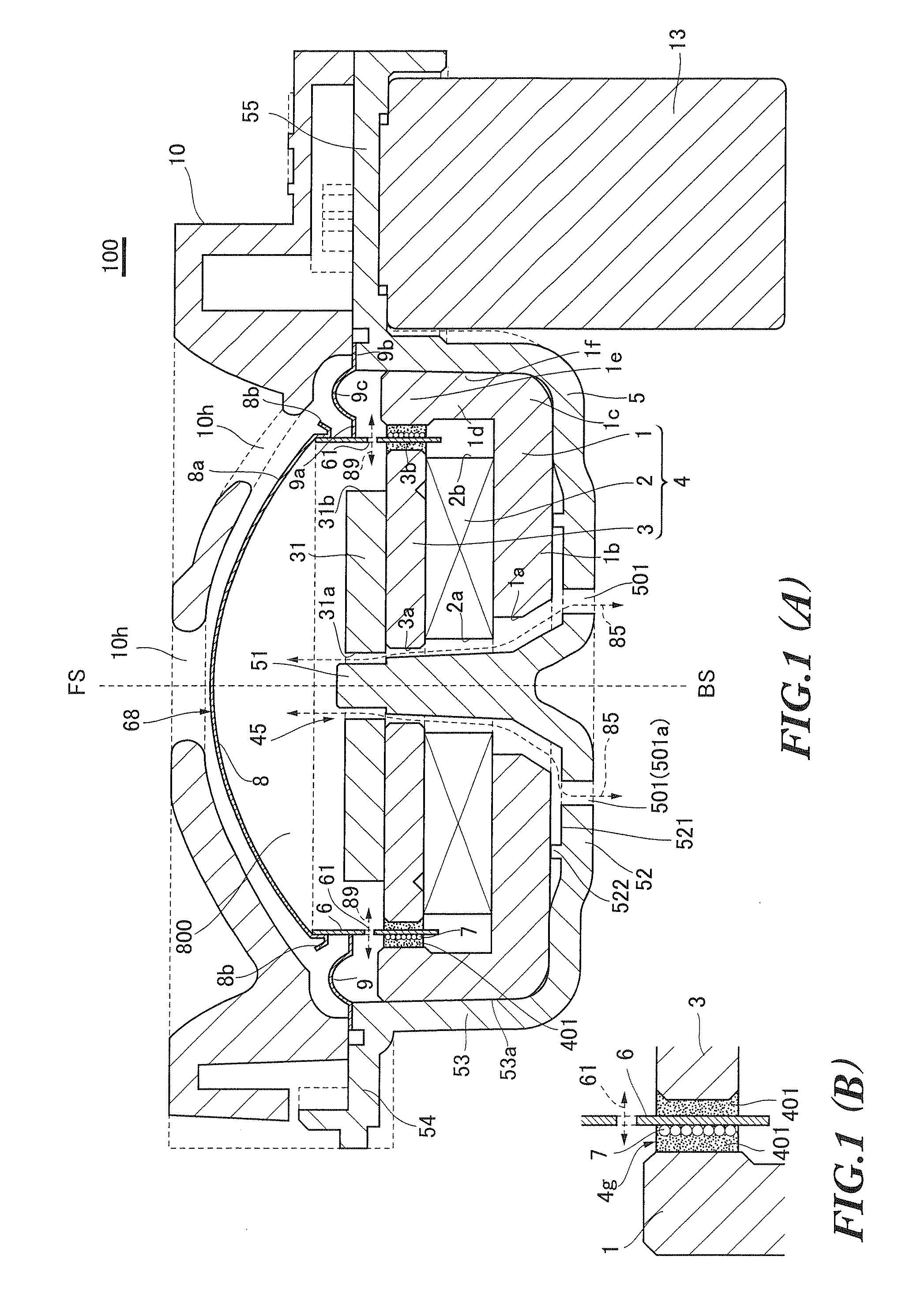

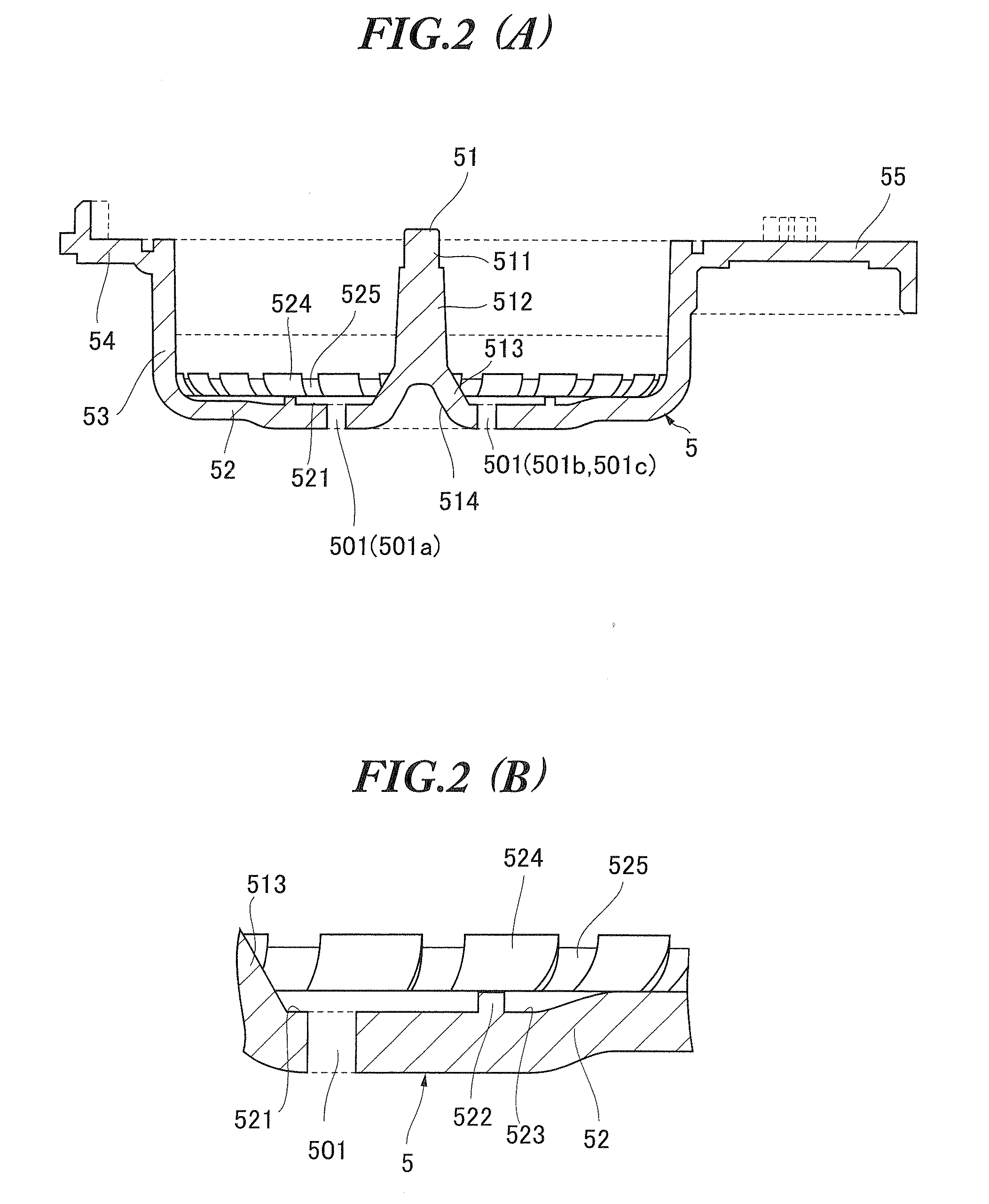

Speaker device and speaker unit

InactiveUS20090180648A1Simple structureAvoid sound qualityFrequency/directions obtaining arrangementsTransducer casings/cabinets/supportsBobbinEngineering

A simple structure will achieve dissipation of heat from the area inside a voice-coil bobbin and a diaphragm without a reduction in sound quality, in which a process for assembling a speaker device with high accuracy is performed in a simple operation. A speaker device comprises a recess-shaped frame 5 which supports, through an edge 9, a vibration system member 68 provided with a diaphragm 8 coupled to a voice-coil bobbin 6, and a magnetic circuit 4 which comprises an approximately ring-shaped magnet 2 and an approximately ring-shaped plate 3 which are mounted on a yoke 1 disposed in the frame 5, and a magnet gap 4g in which a voice coil 7 wound on a voice-coil bobbin 6 is disposed. In the magnetic circuit 4 a through hole 45 extending in the vibration direction of the diaphragm is fitted over a center boss 51 of a shape protruding from the bottom of the frame 5 in the direction of the sound emission, so that the magnetic circuit 4 is positioned and fixed with respect to the frame 5. An air passage 85 is formed along the center boss 51 fitted into the through hole 45 of the magnetic circuit 4 to establish communication between the inside of the voice-coil bobbin 6 and the outside of the frame.

Owner:PIONEER CORP +1

Supercritical CO2 fluid fracturing enhancement type geothermal system experimental device and method

InactiveCN107905778AAccurate calculation of effectivenessSurveyConstructionsRock coreHydraulic fracturing

The invention relates to a supercritical CO2 fluid fracturing enhancement type geothermal system experimental device and method. Supercritical CO2 is injected through a gas source supply system and gas source supercharging equipment, accurate stress is applied to a rock core by designing a piston device, the permeability of hot dry rock fluid is maintained by adopting a pressure-proof and temperature resistant perforated plate, the hot dry rock fluid is externally connected to a fluid collecting chamber through a flow guiding groove, and meanwhile an adjustable sound emission probe is embeddedinto the fluid collecting chamber to monitor a sound emission event happening when a fracture expands in the hydraulic fracturing process. The supercritical CO2 fluid fracturing enhancement type geothermal system experimental device and method have the beneficial effects that integrated collection of information of hydraulic fracturing, strain, sound emission, permeability, heat energy recovery efficiency and the like of rock can be achieved under a confining pressure condition by utilizing the device, and the fracture initiation and expanding situations of a hydraulic fracture of the hot dryrock are researched; and a fracture initiation behavior and an expansion state of the hydraulic fracture under the high-temperature and high-pressure environmental conditions can be monitored in realtime, and meanwhile the heat energy mining rate can be calculated.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Speaker for mobile communication terminal

A speaker for a mobile communication terminal is provided. The speaker with an upper case, a frame, a vibration plate, a voice coil, a yoke, a magnet, a top plate and a printed circuit board (PCB) includes a housing for accommodating the vibration plate, the voice coil, the yoke, the magnet and the top plate, the housing being formed by coupling the upper case and the frame, a sound emission hole formed in one side surface of the housing, a sound pressure adjustment hole formed by penetrating the upper case, and a resonance space formed in an outer circumference of the upper case. In the speaker, it is possible to elevate degree of space utilization in the mobile communication terminal, to easily manufacture a mobile communication terminal which parallels the trend toward miniaturization, slimness and lightness, to improve the characteristics of low frequency sound, and thus to improve sound quality.

Owner:SAMSUNG ELECTRONICS CO LTD +1

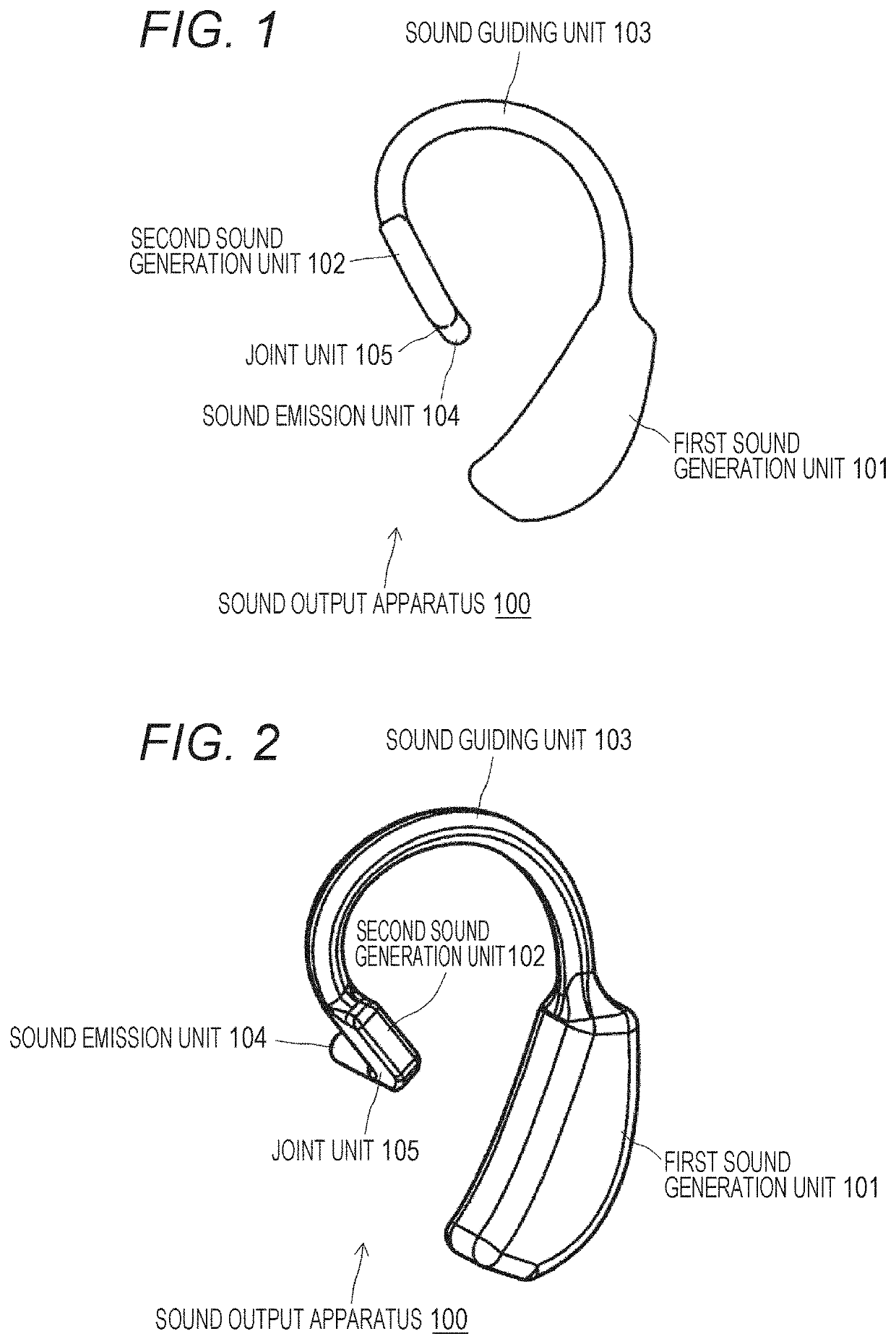

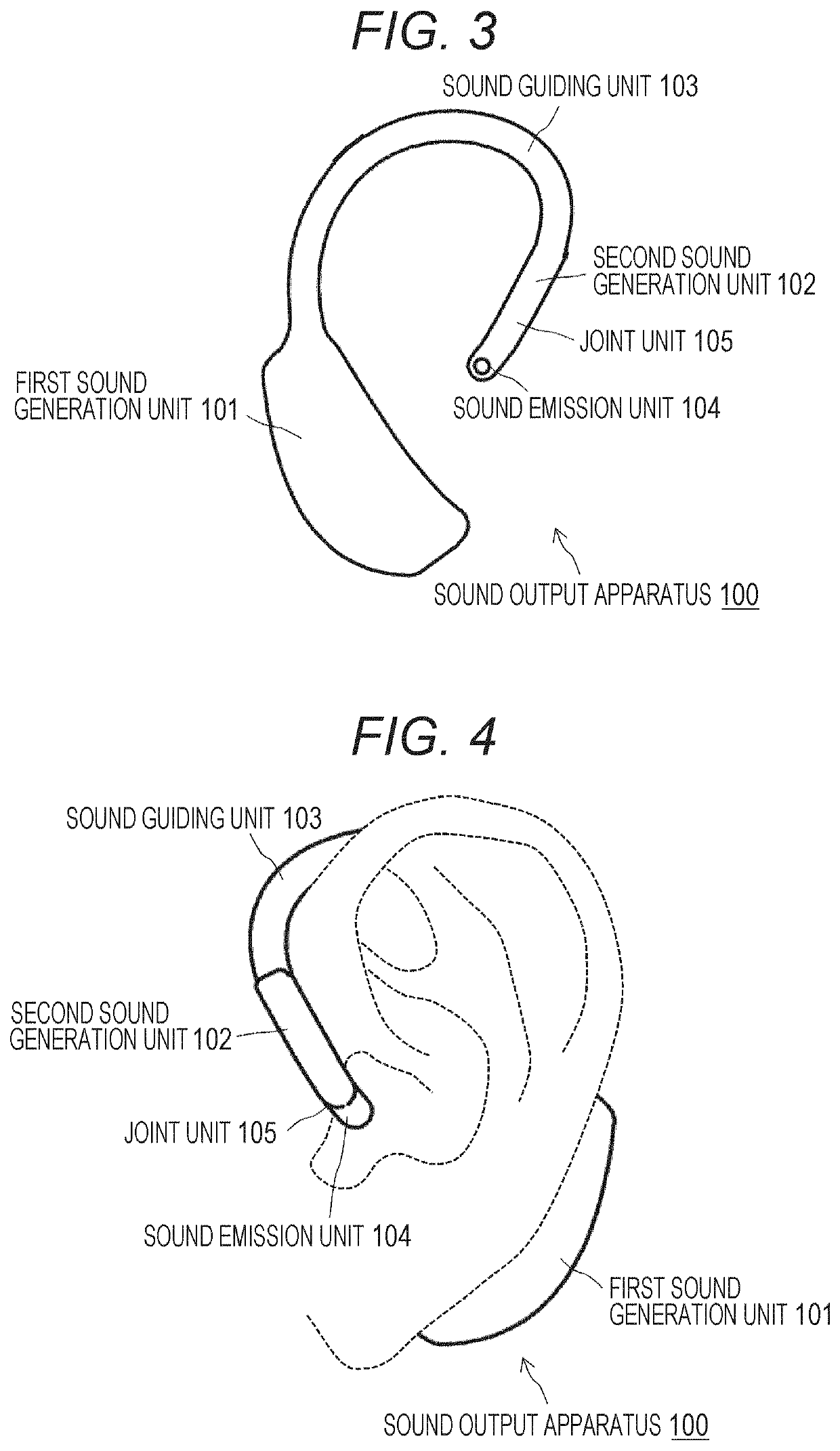

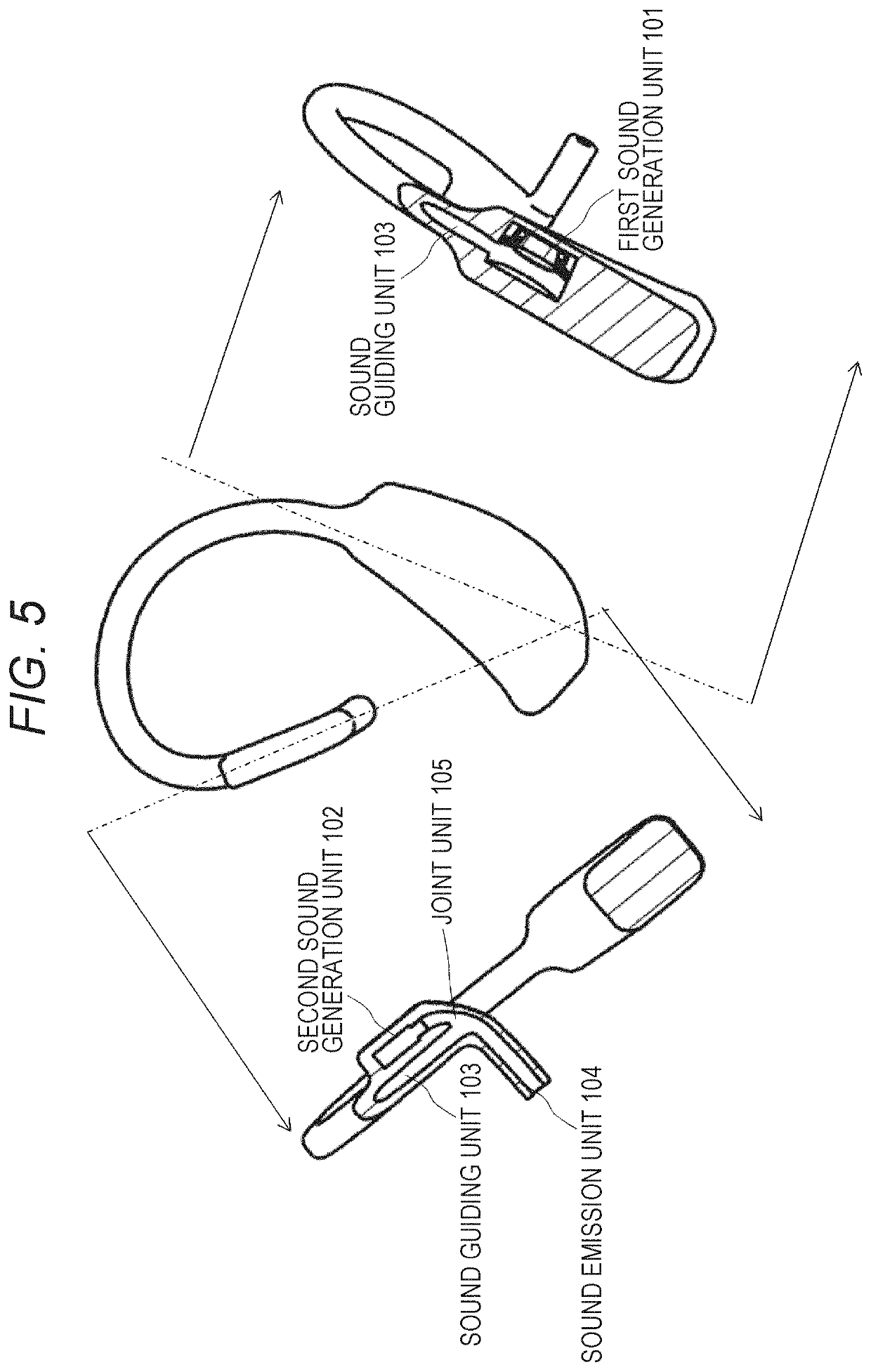

Sound output apparatus

ActiveUS20200137476A1BandwidthIntra aural earpiecesLoudspeaker signals distributionSound generationLow frequency band

Provided is a sound output apparatus that is used by being worn in the vicinity of the ear of a listener and is capable of outputting sound over a wide frequency band.The sound output apparatus includes: a first sound generation unit configured to generate a low frequency band; a sound guiding unit with a hollow structure, having one end coupled to the first sound generation unit, and the other end as a sound emission unit including an open end; and a second sound generation unit that is disposed at a place closer to the sound emission unit than the first sound generation unit and generates a high frequency band. It is preferable that the sound guiding unit have a joint unit that takes in the sound from the second sound generation unit and a section from the joint unit to the sound emission unit have a low impedance.

Owner:SONY CORP

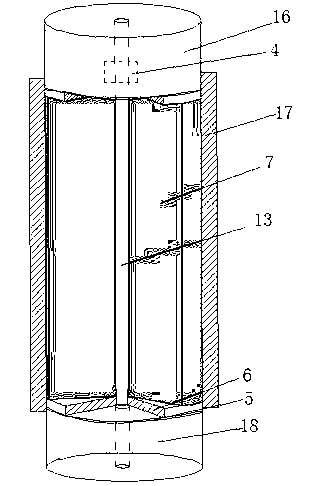

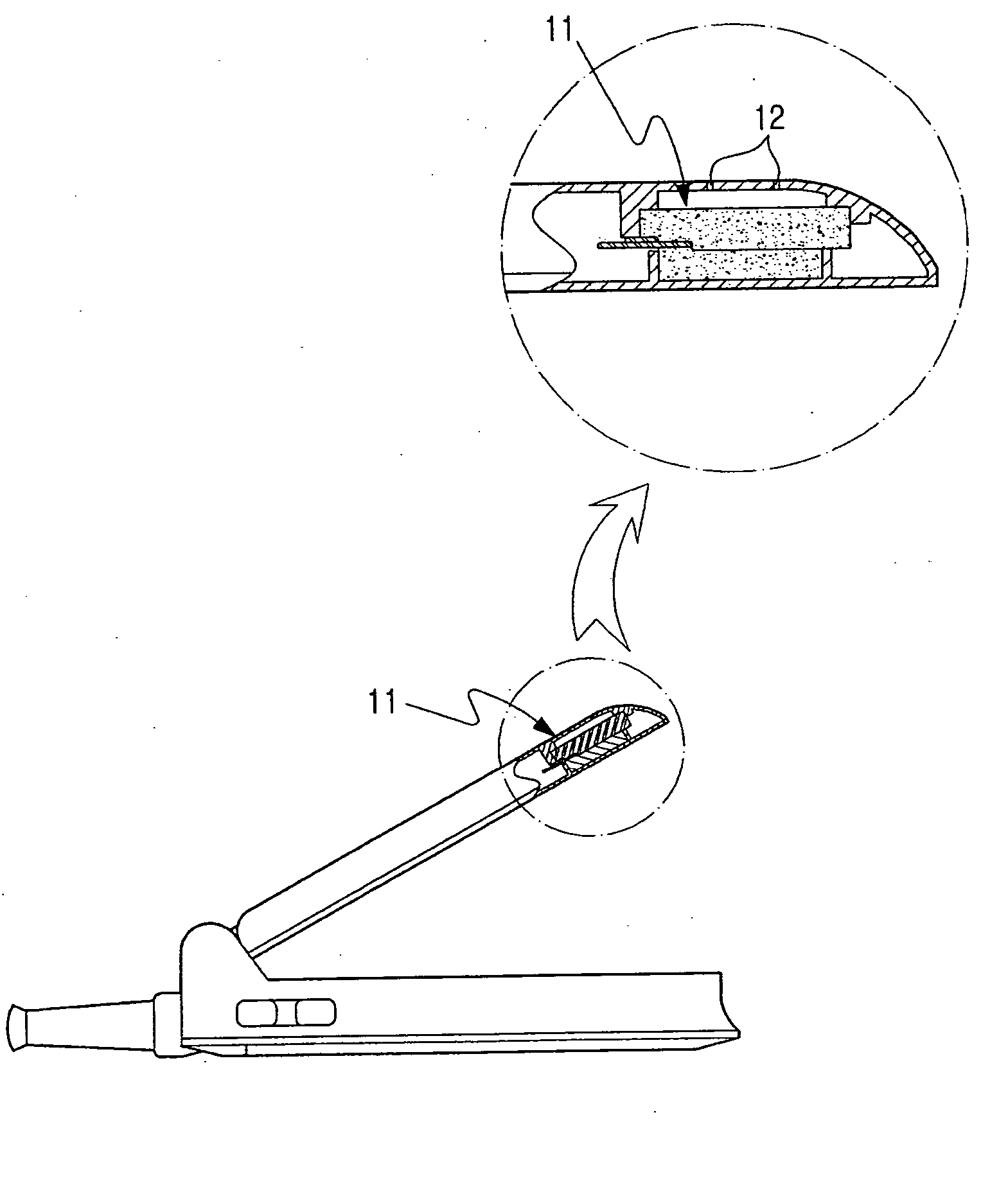

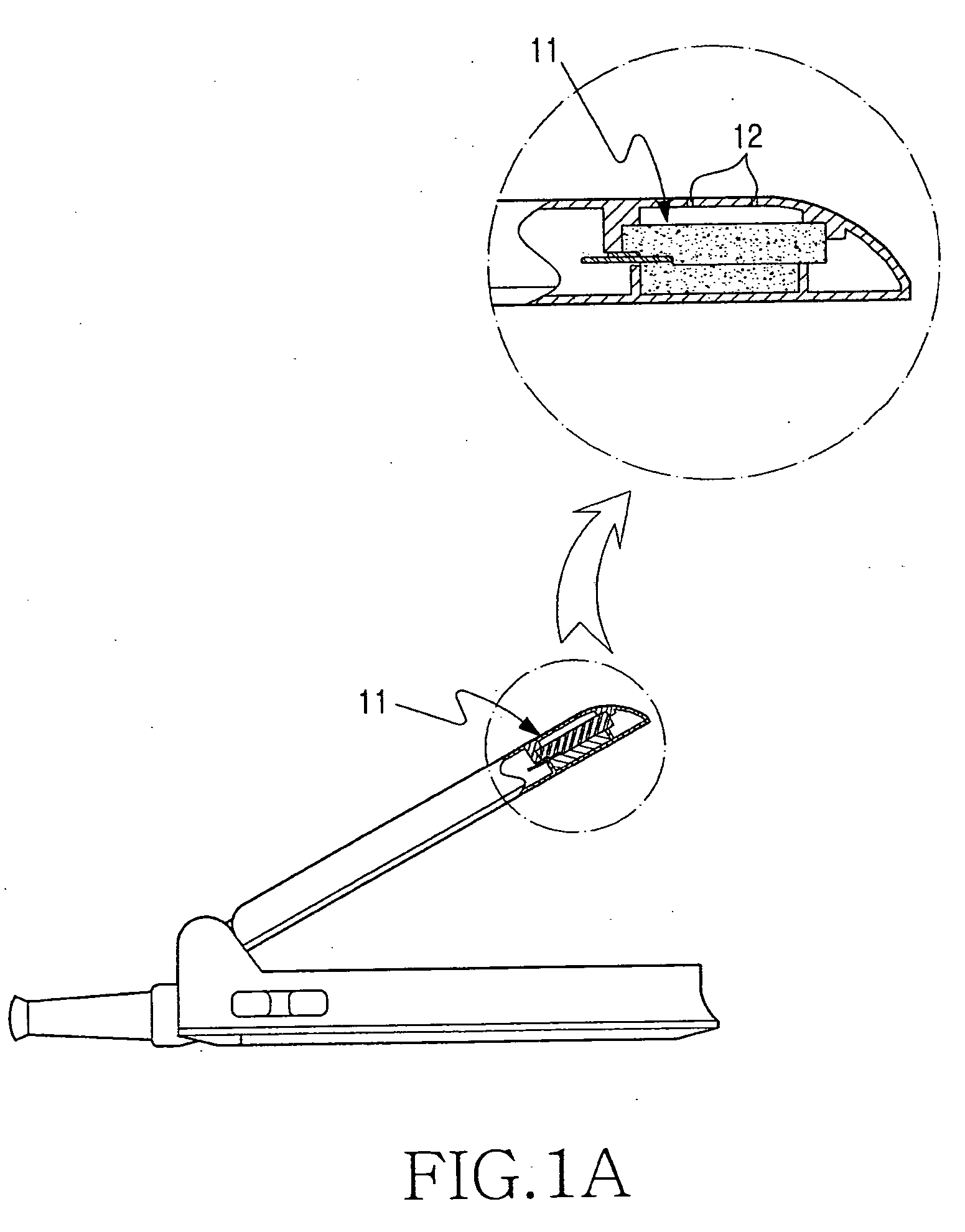

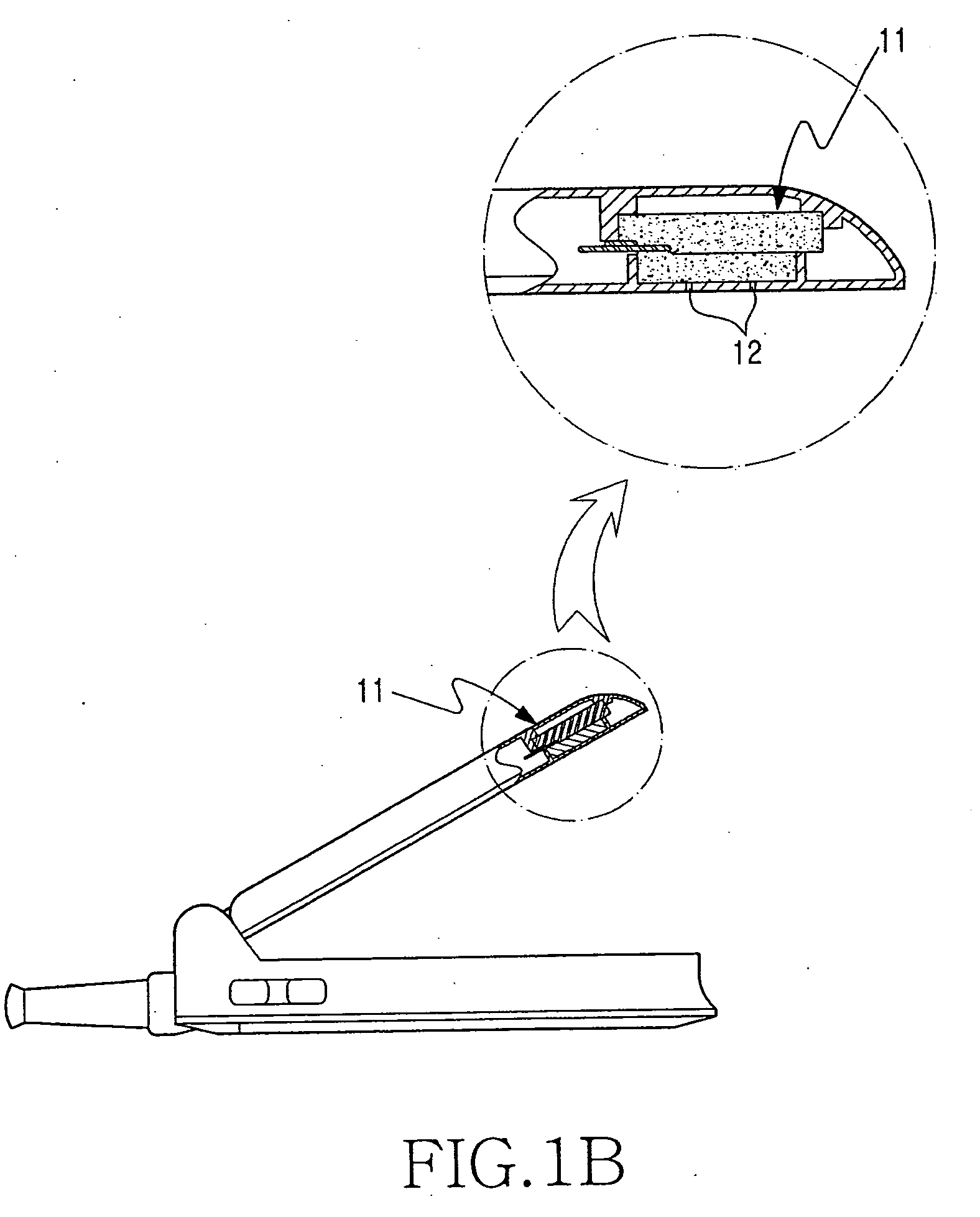

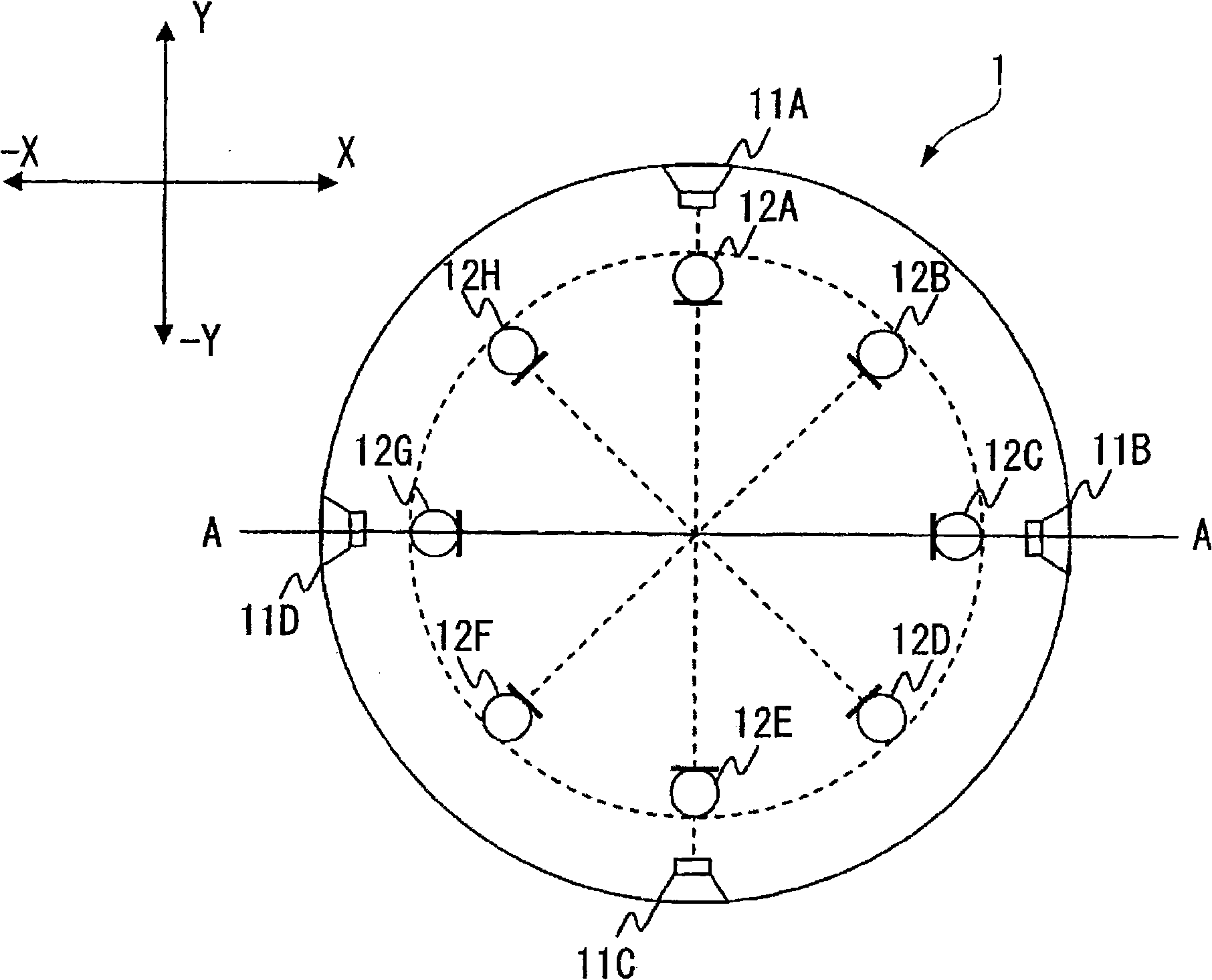

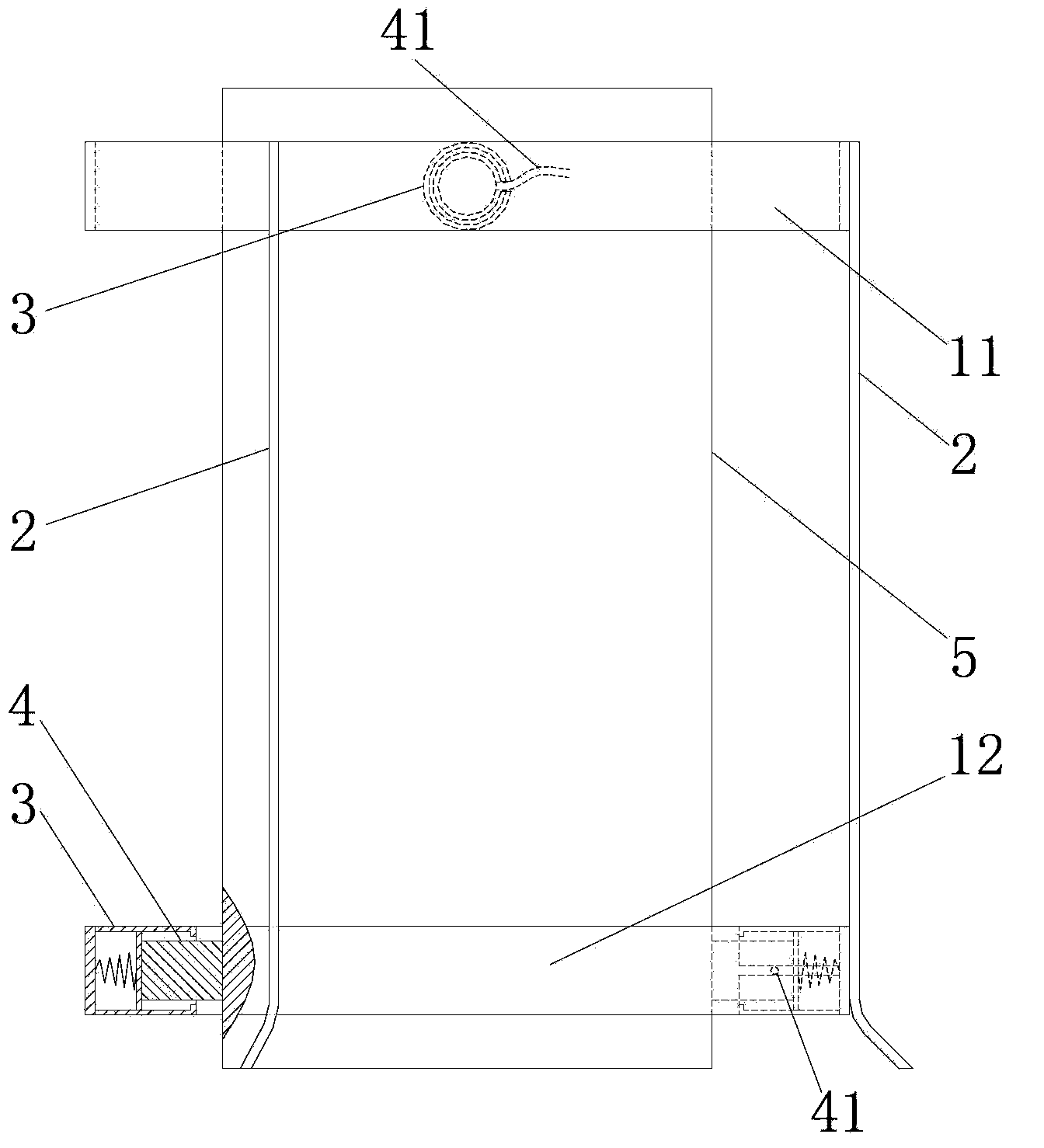

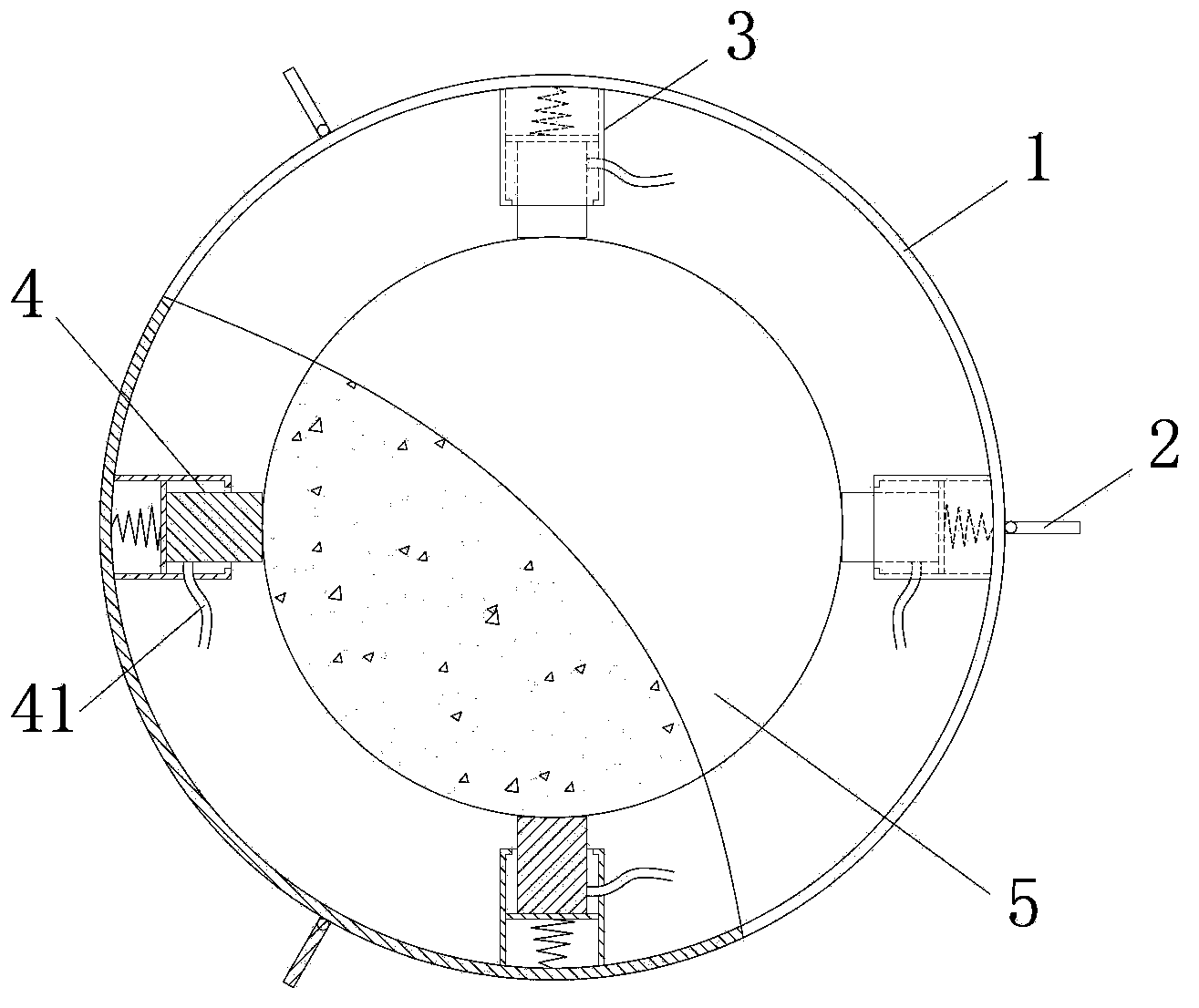

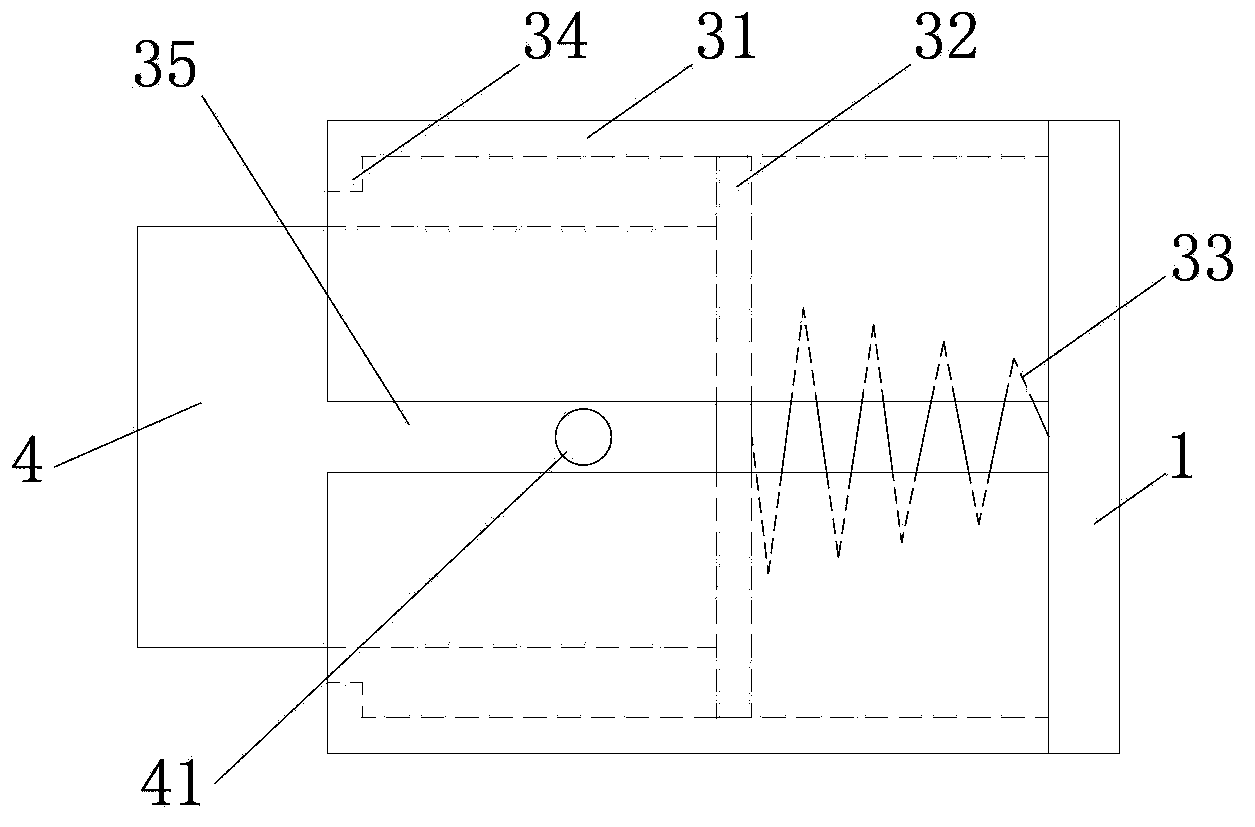

Sound emission and collection device

InactiveCN101331793AImprove signal-to-noise ratioSuppress surround componentsTransducer acoustic reaction preventionFrequency/directions obtaining arrangementsEngineeringLoudspeaker

It is possible to provide a sound emission and collection device having a compact configuration and capable of suppressing sound coming from a speaker to a microphone and improving the S / N ratio. In the sound emission and collection device, a plurality of speakers (11) have a sound emission surface arranged at the side surface of a case (1) so that a sound can be emitted in all the circumferential direction of the sound emission and collection device. Each of the microphones (12) is arranged with the sound collection direction set in the center direction of the case (1). The microphone (12) and the speaker (11) have directivities opposing to each other. Accordingly, it is possible to minimize the sound coming from the speaker (11) to the microphone (12). Moreover, since the speaker (11) and the microphone (12) are arranged on coaxial circumferences, it is possible to obtain a compact configuration.

Owner:YAMAHA CORP

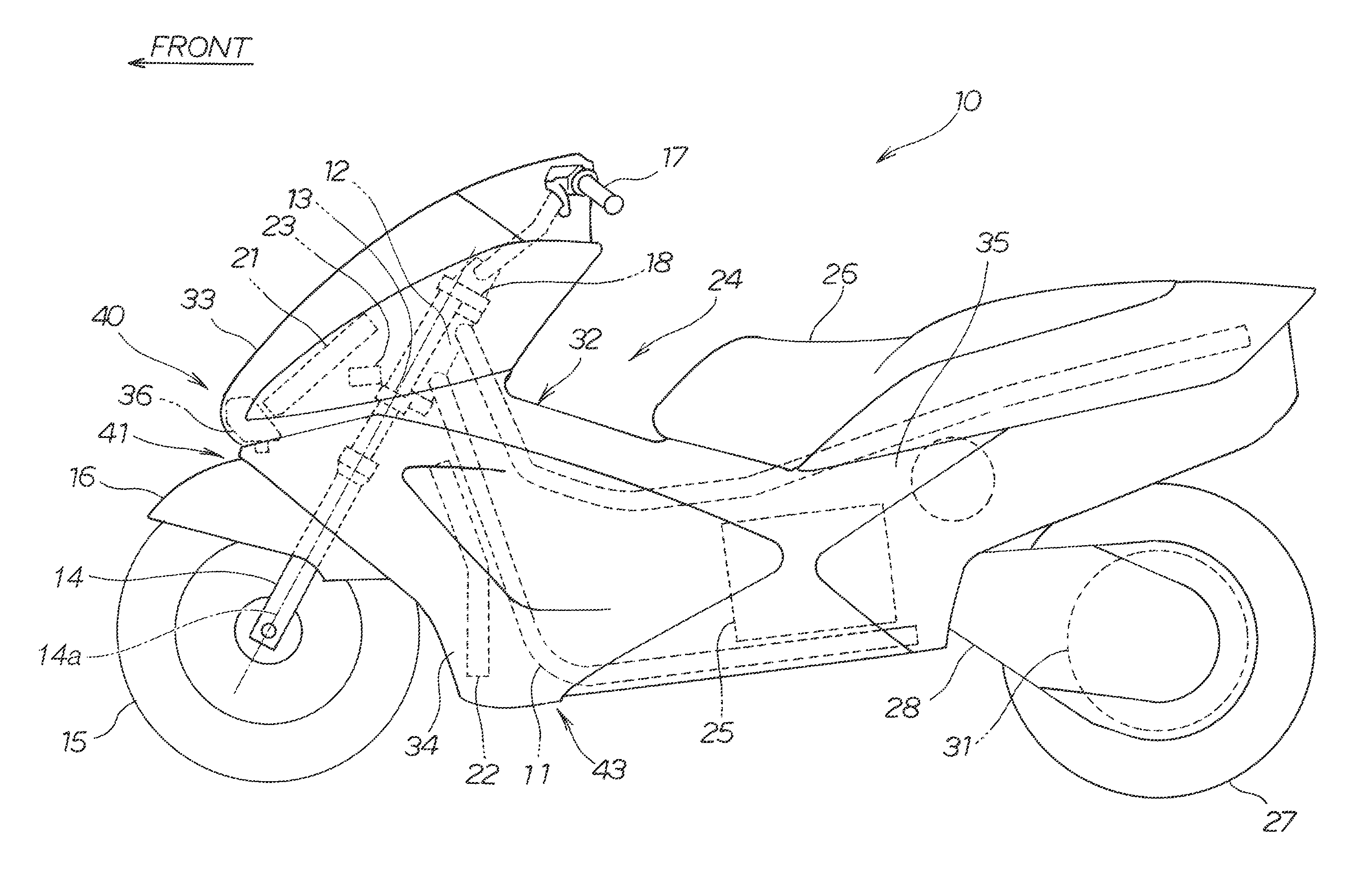

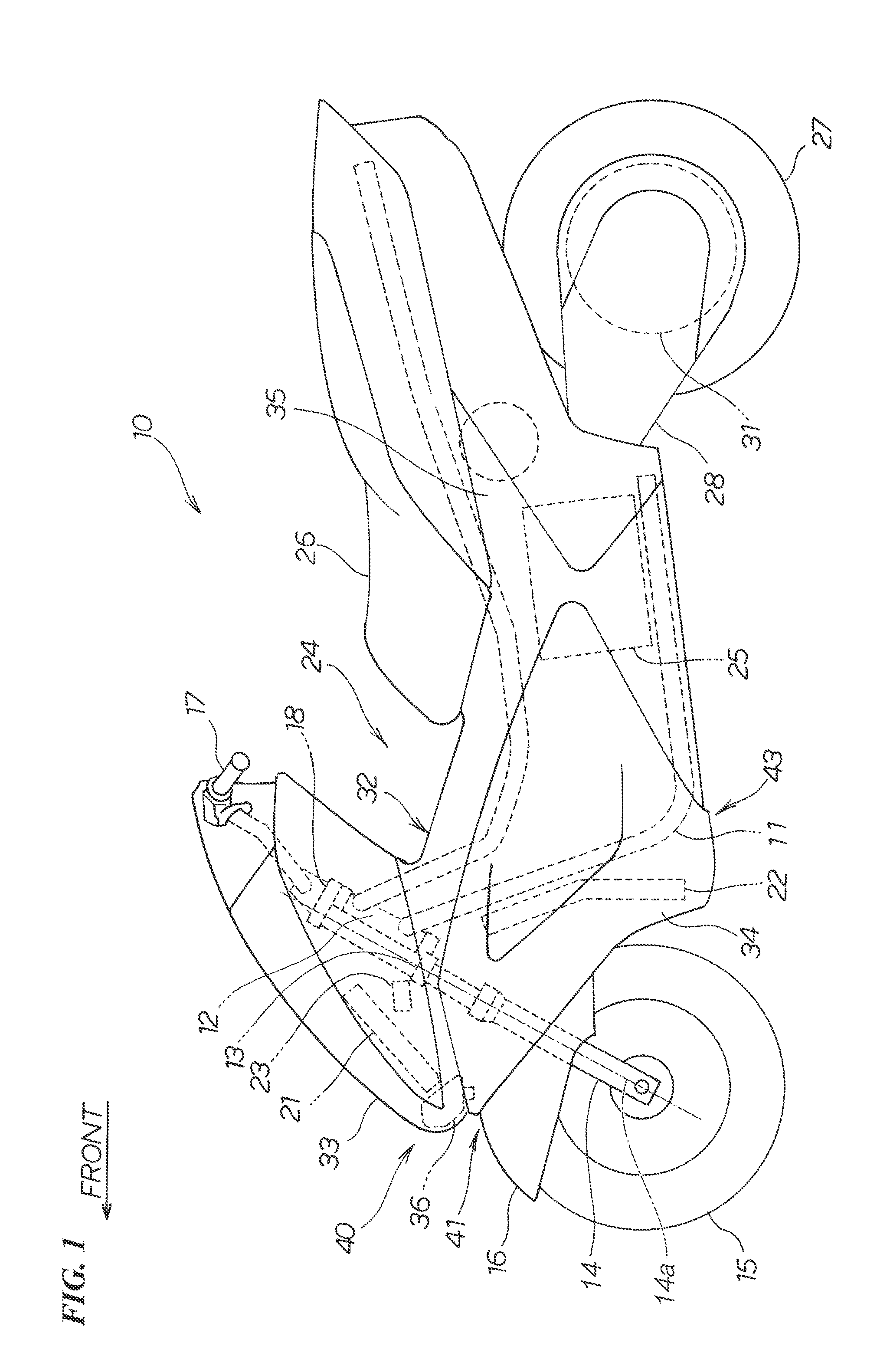

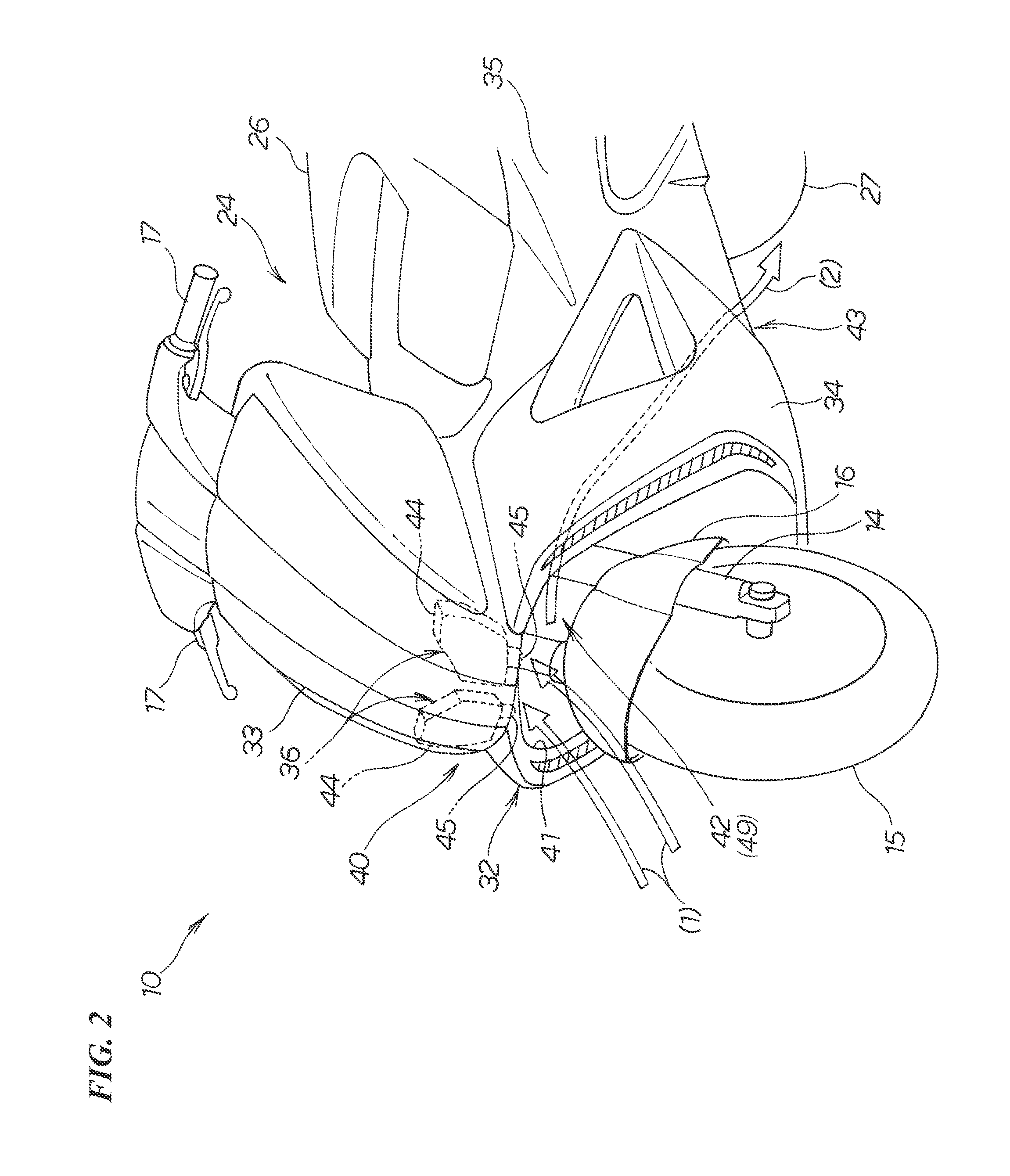

Vehicle approach notification device of saddle-ridden electric-powered vehicle

ActiveUS20120312609A1Achieve compactnessLow costAcoustic signalAcoustic signal devicesElectric powerFront cover

Provided is a vehicle approach notification device of a saddle-ridden electric-powered vehicle that outputs a notification sound for notifying the approach of a vehicle. The saddle-ridden electric-powered vehicle includes a front cover that covers the periphery of a head pipe of a vehicle body frame. The sound emission device is located inside the front cover, the front cover has an air opening for taking in air from an outside, and a ventilation passage that is a passage of the air from the air opening and is used for cooling at least one of a power engine of the saddle-ridden electric-powered vehicle and electric components, and the sound emission device is arranged in the ventilation passage.

Owner:HONDA MOTOR CO LTD

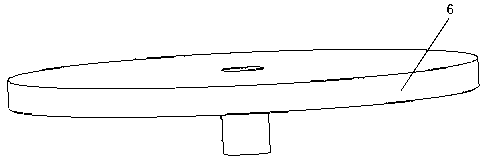

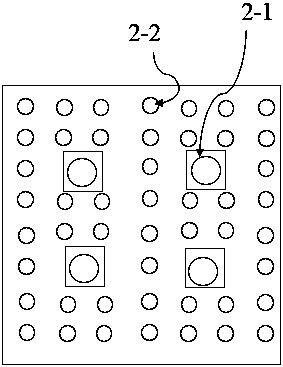

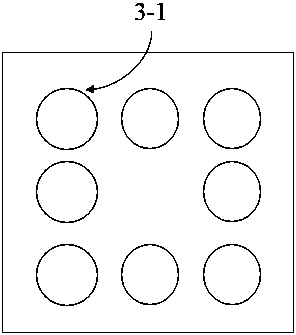

Sensor fixing test rack for uniaxial compression sound emission test of coal petrography and application method of same

InactiveCN103412054AReduce lossGuaranteed reuseMaterial analysis using acoustic emission techniquesUniaxial compressionEngineering

The invention discloses a sensor fixing test rack for a uniaxial compression sound emission test of coal petrography and an application method of the sensor fixing test rack. The test rack comprises a round rack in which a coal petrography sample is arranged, and three foot stools distributed at 120 degrees and used for fixing the round rack, wherein clinging devices used for fixing sound emission sensors in contact with the coal petrography sample are arranged on the round rack; the round rack comprises an upper round rack and a lower round rack which are respectively fixed with the upper parts and the lower parts of the three foot stools; the plurality of clinging devices are respectively fixed on the upper round rack and the lower round rack. When in use, the sensor fixing test rack is placed on a uniaxial compression tester; a coupling agent is uniformly applied on the surfaces of the signal acquisition ends of the sound emission sensors; after the sound emission sensors are mounted, the coal petrography sample is placed, and then the uniaxial compression sound emission test can be performed. The sensor fixing test rack solves the problems that at present, when the uniaxial compression sound emission test is performed in a laboratory, the spatial position of the sensors can not be fixed accurately, the sensors drop in the testing process, and high labor intensity is caused by repeated disassembly and assembly of the sensors.

Owner:CHINA UNIV OF MINING & TECH

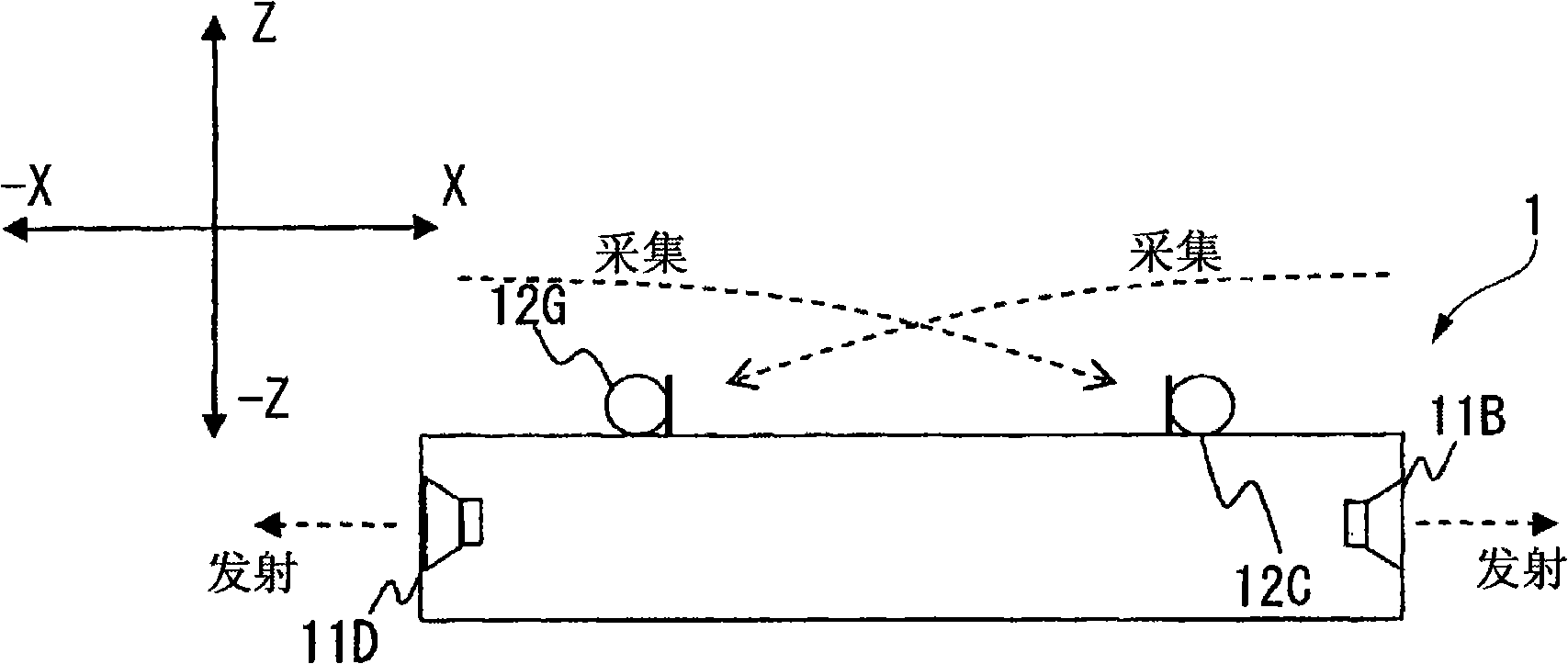

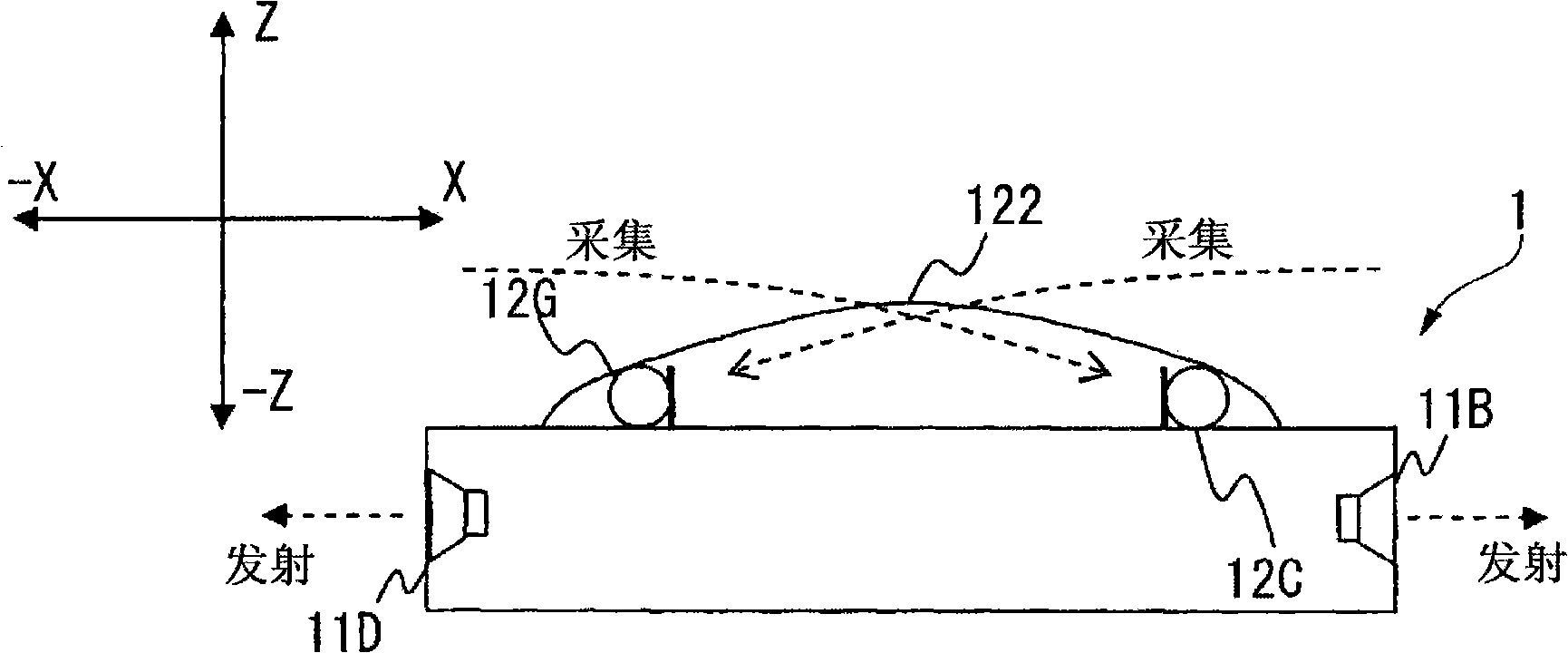

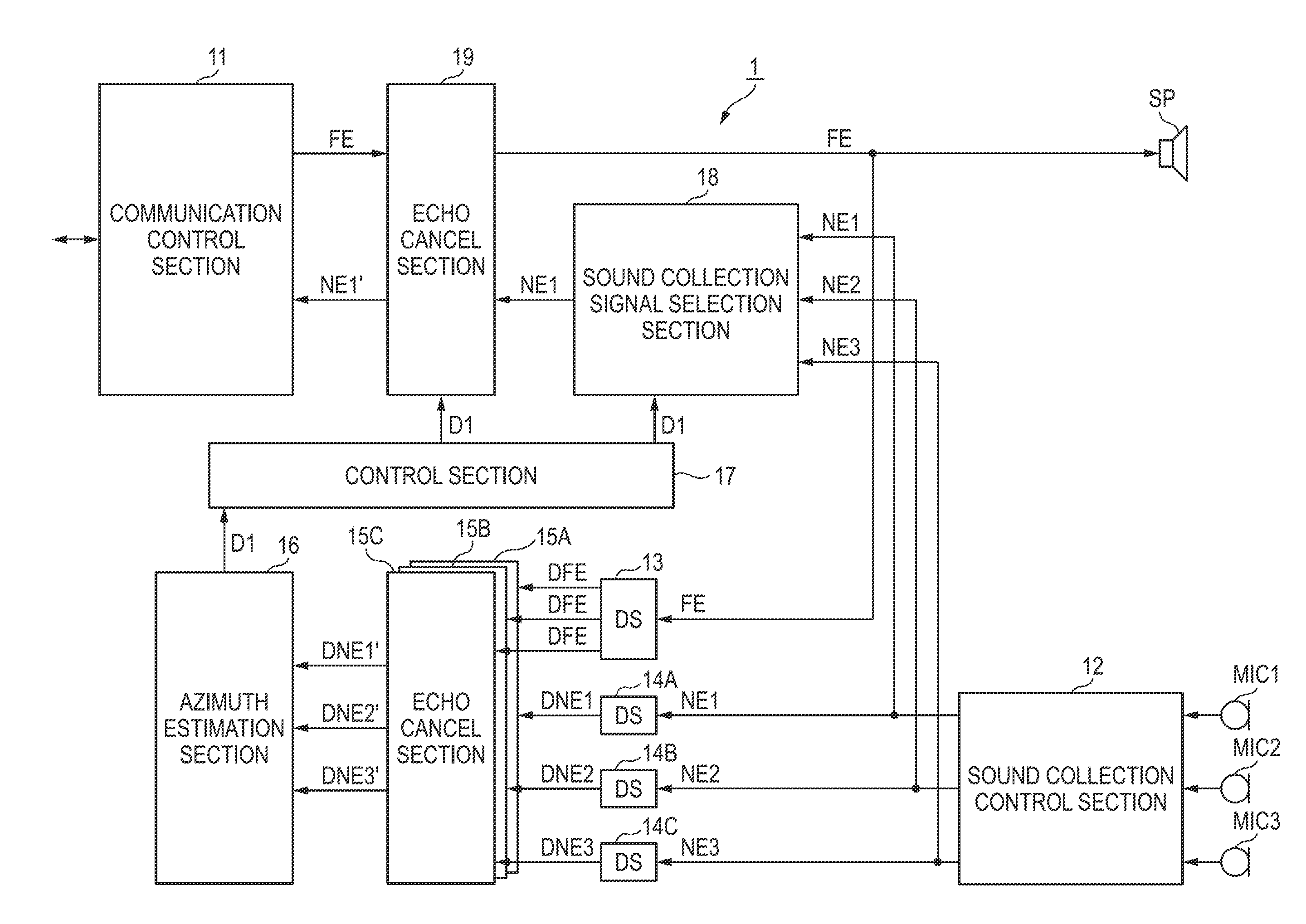

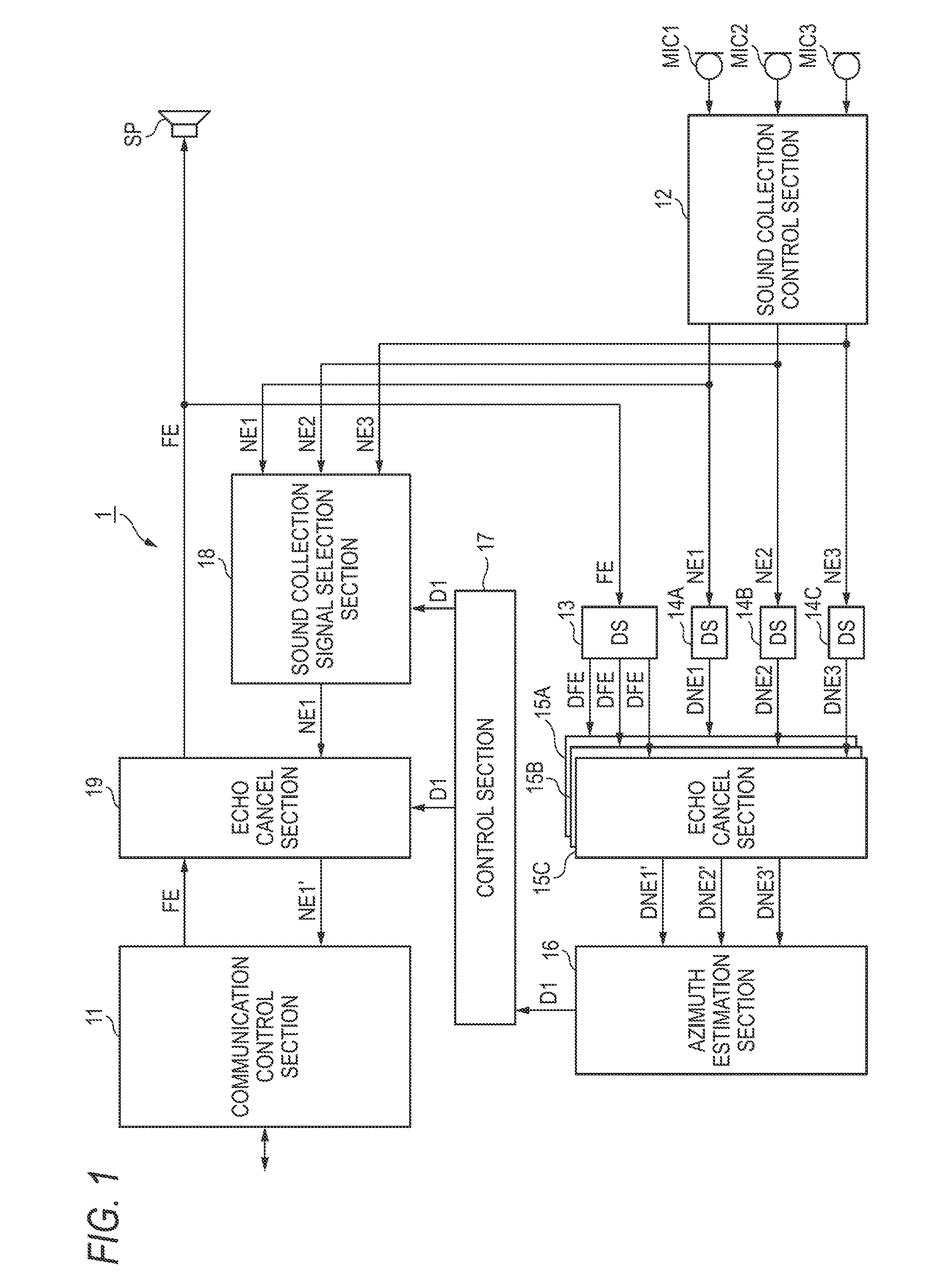

Sound emission and collection device and sound emission and collection method

ActiveUS20110211706A1Reduce processing loadHigh processing loadInterconnection arrangementsSpeech analysisSound sourcesEngineering

Provided is a sound emission and collection device capable of estimating the azimuth of a sound source (such as a main utterer) precisely without any processing load. The sound emission and collection device (1) is connected with another sound emission and collection device via a network or the like. The sound emission and collection device (1) receives a sound signal from another sound emission and collection device, as a sound emission signal (FE), and emits the same from a speaker (SP). The sound emission and collection device (1) collects the sound at microphones (MIC1 to MIC3), and produces sound collection beam signals (NE1 to NE3) of different azimuths. The sound emission and collection device down-samples the individual sound collection beam signals (NE1 to NE3), and filters out the echoes of the down-sampled sound collection beam signals (DNE1 to DNE3). The sound emission and collection device selects the sound collection beam signal (DNE1′) of the highest signal level from the echo-filtered sound collection beam signals (DNE1′ to DNE3′). The sound emission and collection device filters out the echoes of a sound collection beam signal (NE1) from the sound collection azimuth (D1) of the sound collection beam signal (DNE1′), and transmits the same to another sound emission and collection device.

Owner:YAMAHA CORP

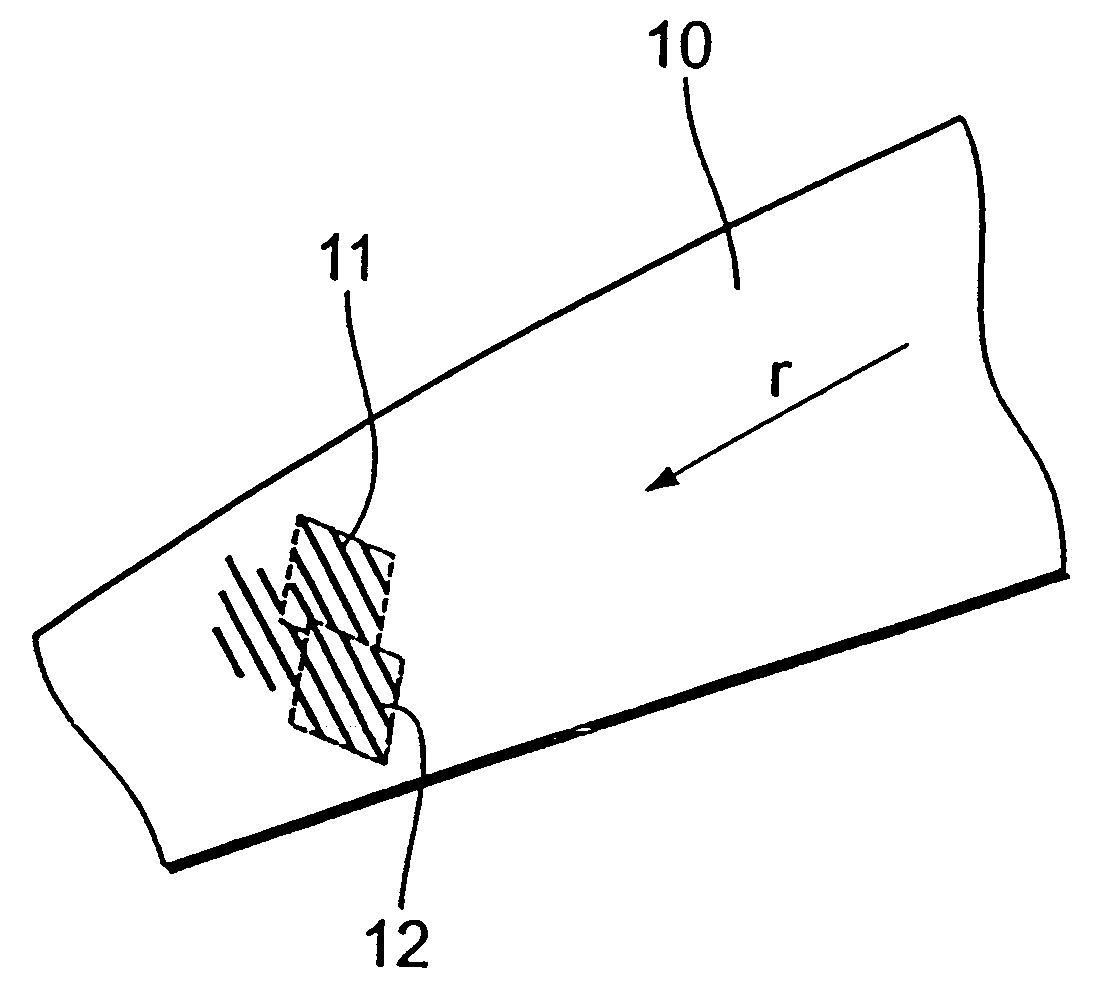

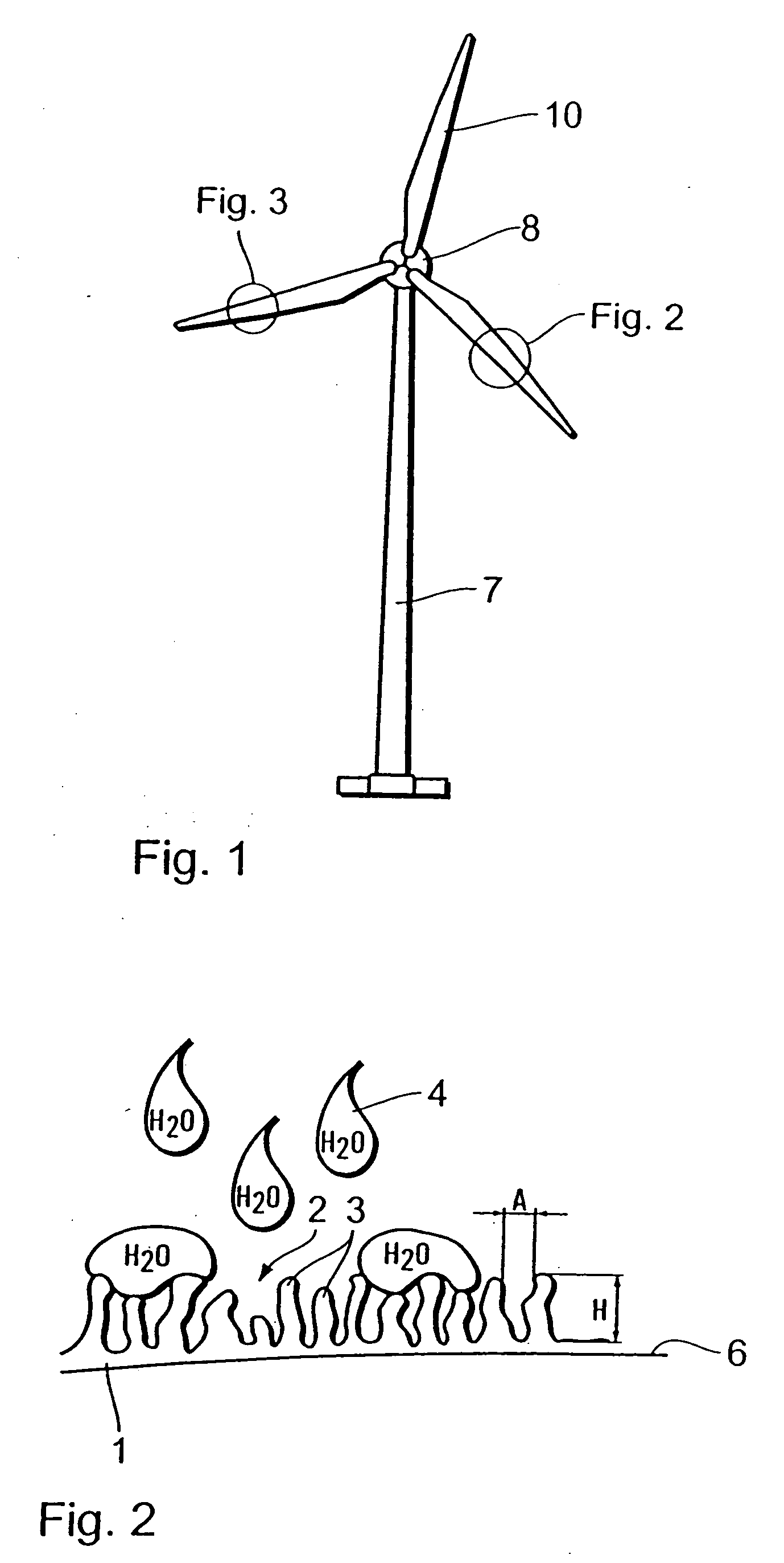

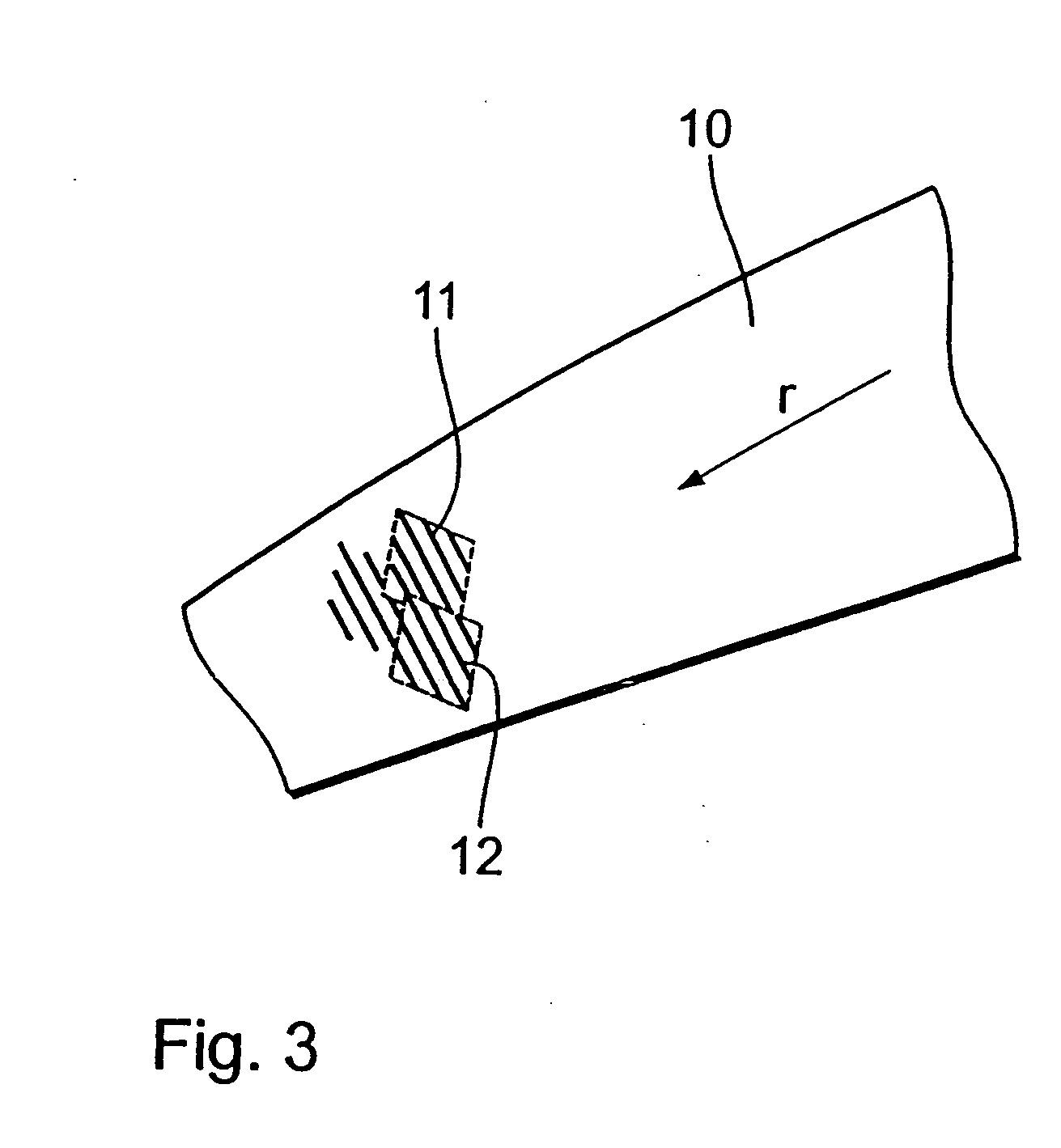

Reduction in the noise produced by a rotor blade of a wind turbine

InactiveUS20050008495A1Increased noise emissionAccelerate emissionsPropellersEngine manufactureSound sourcesEngineering

Rotor blades for wind power installations are known in many different forms. In a wind power installation the rotors or the rotor blades thereof represent the main source of sound. For reasons relating to acceptance and noise prevention laws, the aim should / must be that of minimizing the levels of sound emission as wind power installations are often also set up in the proximity of residential accommodation. The levels of sound emission which hitherto occur with a wind power installation or a wind power converter also mean that wind power installations are faced with resistance from populated areas because of the sound they produce and for that reason such installations can be accepted sometimes with difficulty or not at all as authorities responsible for planning permission refuse permission for wind power installations because of the existing environmental requirements, noise also being an environmentally polluting factor. Therefore the object of the invention is further to improve the noise emission of wind power installations. Wind power installation rotor blade comprising means for reducing the sound produced by a rotor blade, wherein the means is formed by a fluid-repellent layer and / or surface which is provided at least on a surface portion of the rotor blade.

Owner:WOBBEN ALOYS

Mobile terminal

PendingCN106603775AGood lookingImprove integrityTelephone set constructionsComputer engineeringSound emission

The present invention discloses a mobile terminal. The mobile terminal comprises a screen, a shell and a receiver; the screen is combined with the shell in a covering manner and faces a user; the shell is provided with a sound emission hole; and the receiver is fixed in the shell and is aligned with the sound emission hole. According to the mobile terminal, the mobile terminal includes the shell and the screen combined with the shell in a covering manner, the shell is provided with the sound emission hole, and therefore, the integrity of the screen can be protected, and the appearance performance of the mobile terminal can be improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

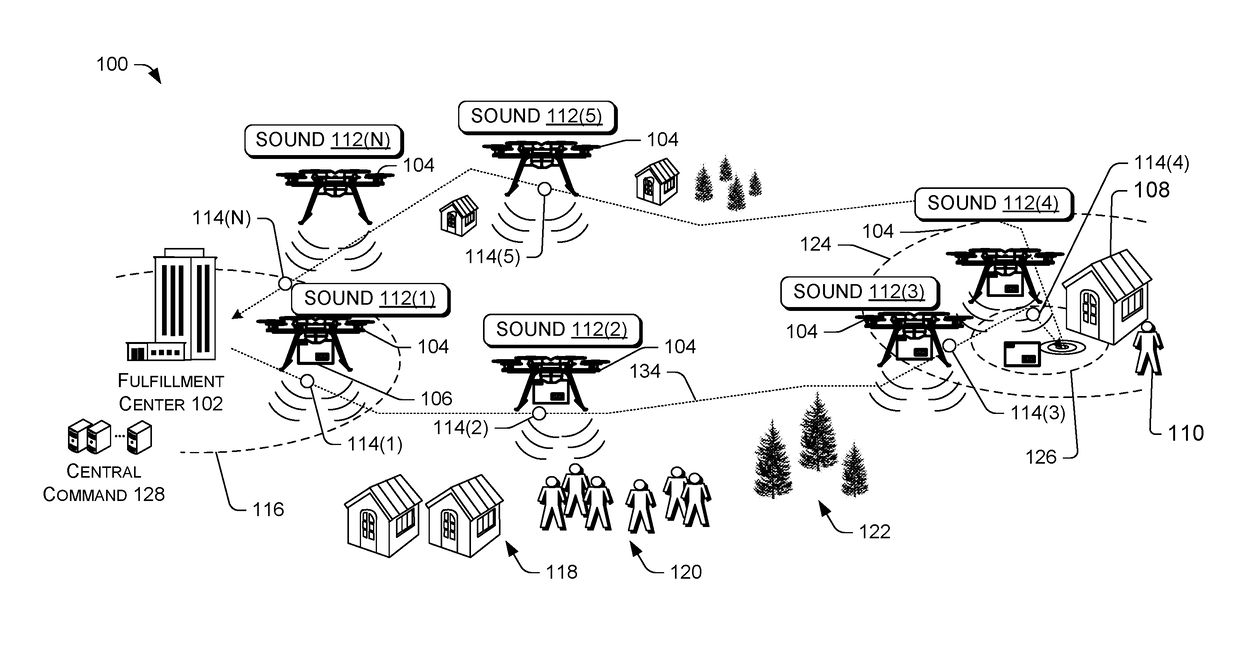

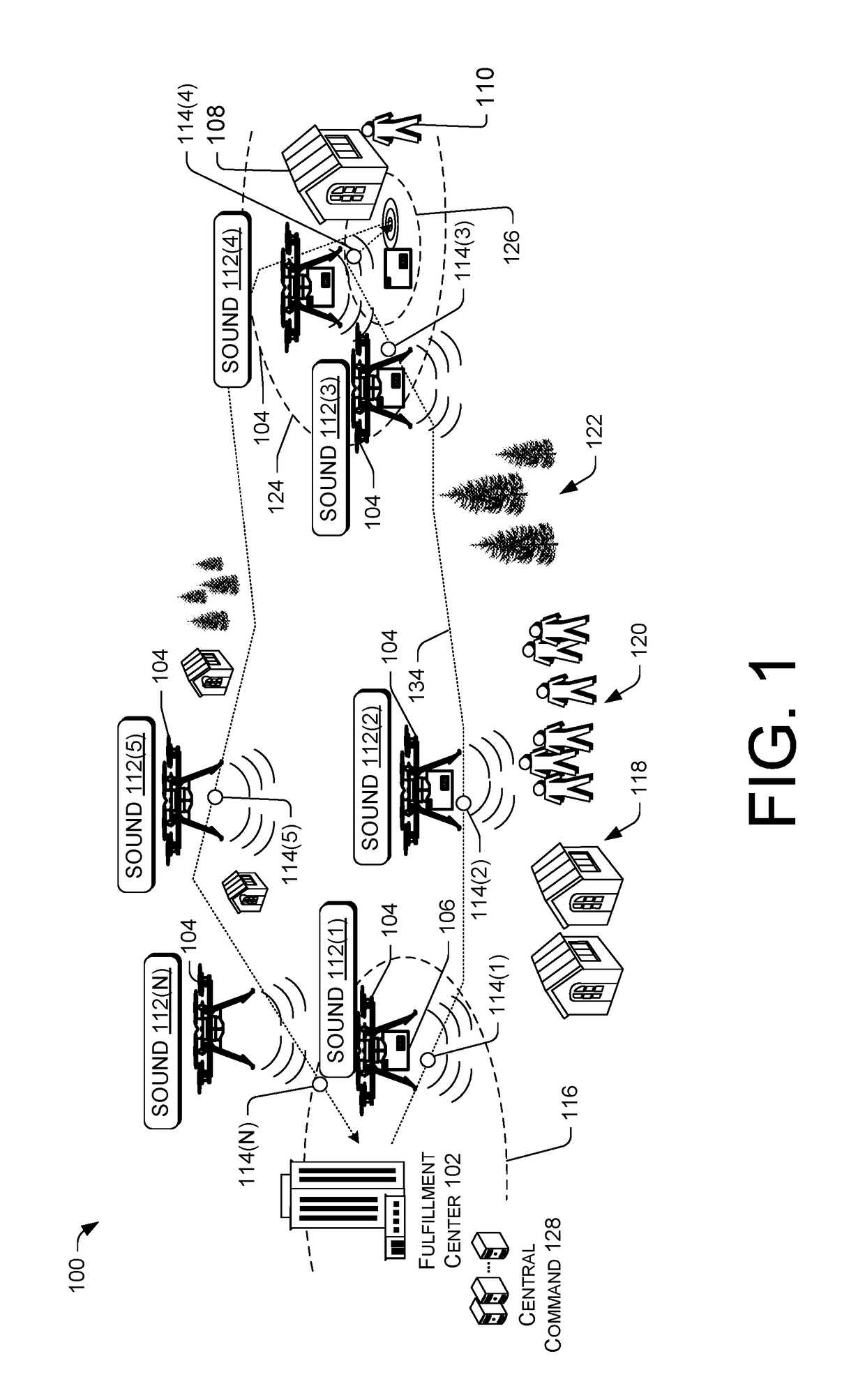

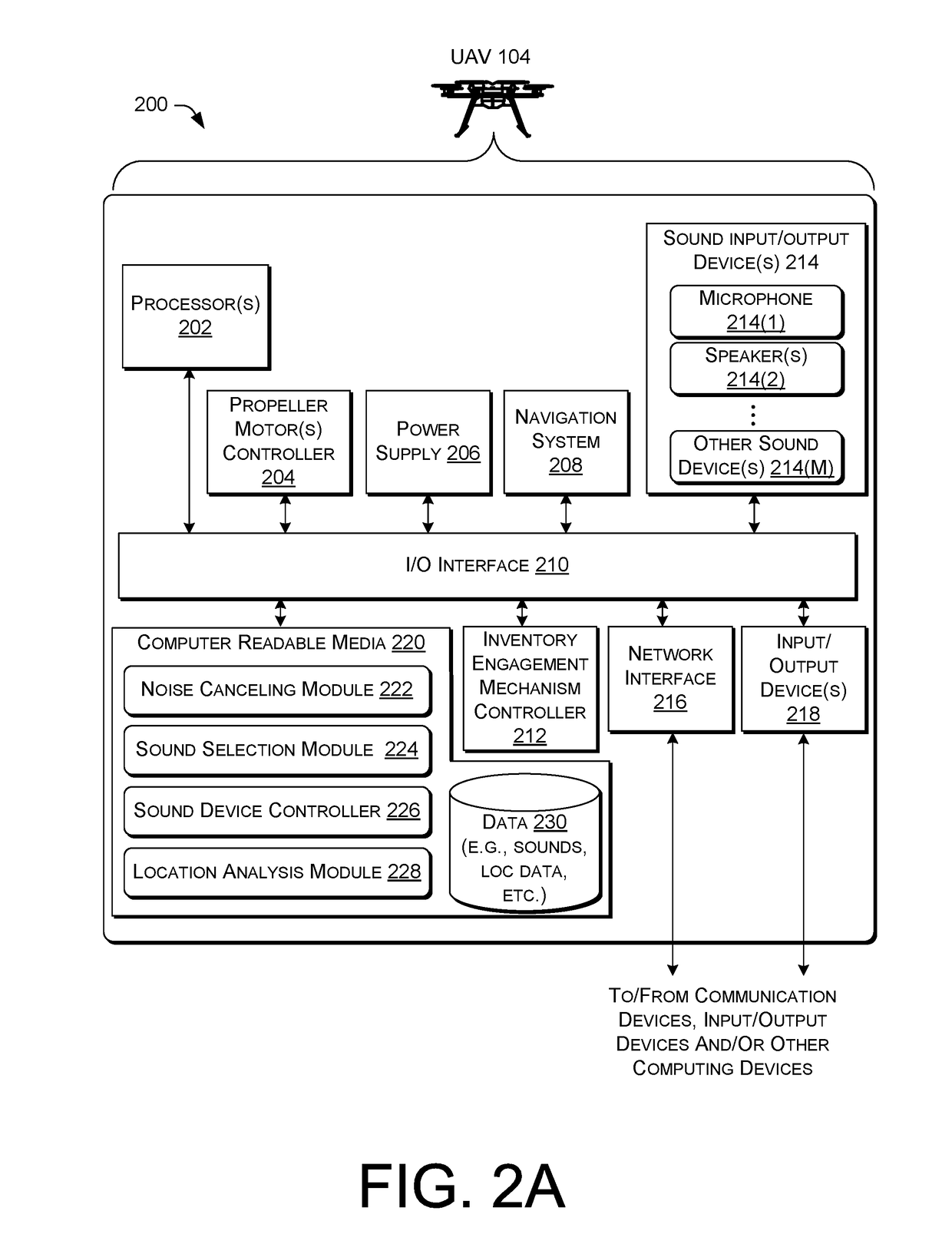

Delivery sound masking and sound emission

An unmanned aerial vehicle (UAV) may emit masking sounds during operation of the UAV to mask other sounds generated by the UAV during operation. The UAV may be used to deliver items to a residence or other location associated with a customer. The UAV may emit sounds that mask the conventional sounds generated by the propellers and / or motors to cause the UAV to emit sounds that are pleasing to bystanders or do not annoy the bystanders. The UAV may emit sounds using speakers or other sound generating devices, such as fins, reeds, whistles, or other devices which may cause sound to be emitted from the UAV. Noise canceling algorithms may be used to cancel at least some of the conventional noise generated by operation of the UAV using inverted sounds, while additional sound may be emitted by the UAV, which may not be subject to noise cancelation.

Owner:AMAZON TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com