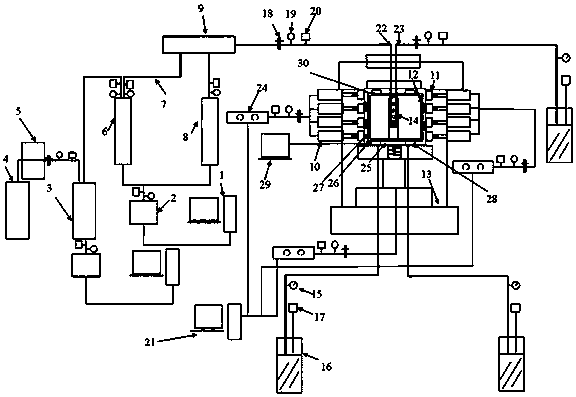

Supercritical CO2 fluid fracturing enhancement type geothermal system experimental device and method

A technology of fluid fracturing and experimental equipment, applied in geothermal energy systems, geothermal energy, mining fluids, etc., can solve the problem of inability to effectively control the phase state, the inability to effectively simulate the generation environment of hot dry rocks, and the inability to analyze hot dry rock reservoirs in real time Hydraulic fracture shape and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0062] Embodiment 2, the supercritical CO2 fluid fracturing enhanced geothermal system experimental device mentioned in the present invention is the same as embodiment 1, the difference is the use method of the supercritical CO2 fluid fracturing enhanced geothermal system experimental device, including the following steps :

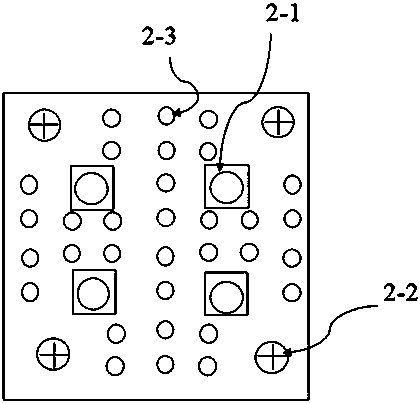

[0063] (1) According to the requirements of the experiment, select different components of cement, quartz sand, clay and water, and mix them and pour them into the mold. After the specimen is placed in the mold for 72 hours, the mold is removed, and then placed in a constant temperature and humidity box. After curing for 14 days, cut and process hot dry rock samples into 300×300×300mm cubes;

[0064] (2) During supercritical CO 2 Before fracturing, it is necessary to first test the air tightness of the entire test device to ensure the integrity of the sample and the safety of the pipeline layout; then install acoustic emission, temperature, strain, and pot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com