Dry ice sublimation hole bottom refrigerating and pressure keeping sampler and sampling method

A technology of sampler and dry ice, which is applied in the direction of earth cube drilling, extraction of undisturbed core devices, wellbore/well components, etc., which can solve the problems that the core cannot maintain the initial pressure, is not easy to do, and the sealing performance is reduced, so as to improve the core quality. The recovery rate, easy operation, and the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

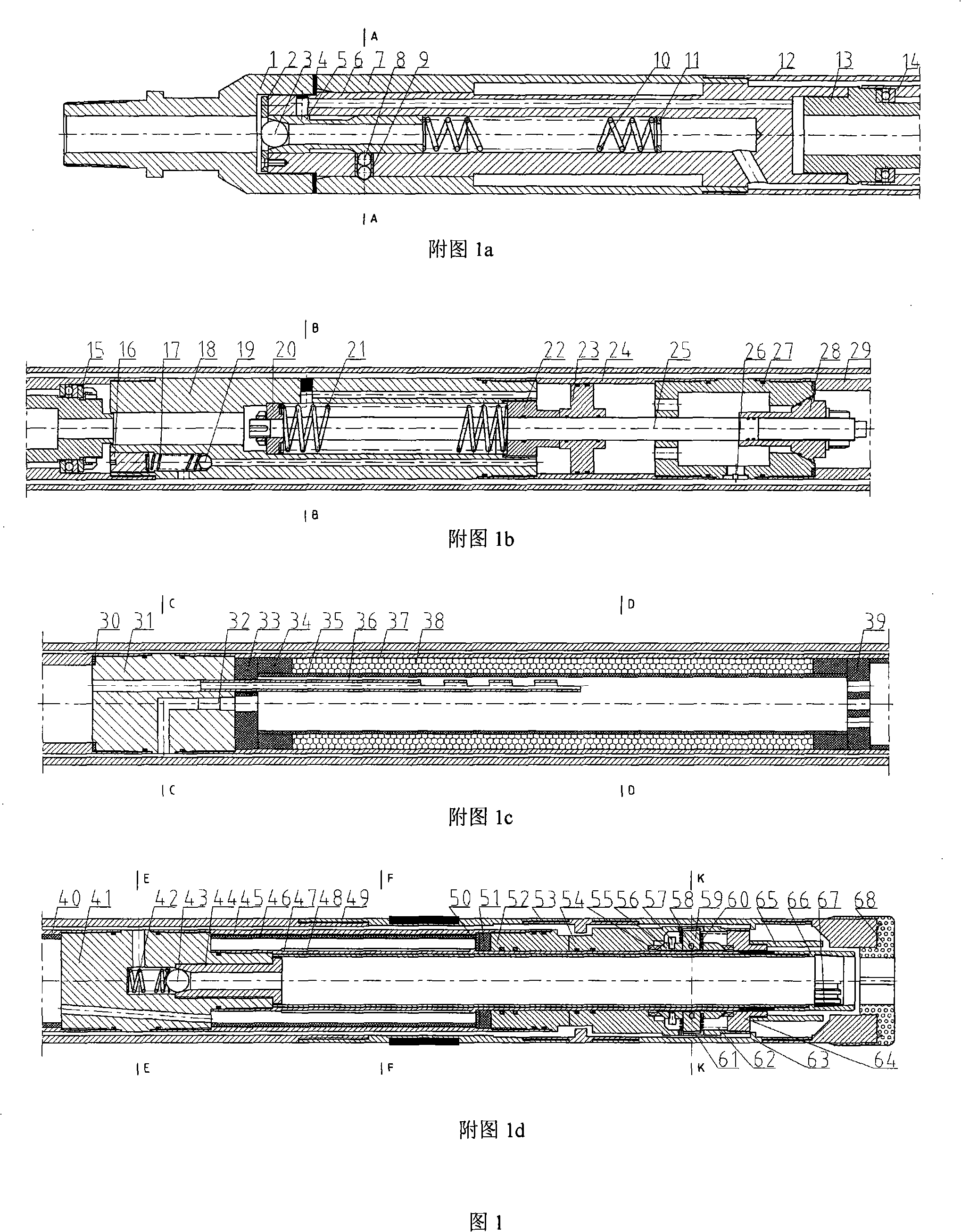

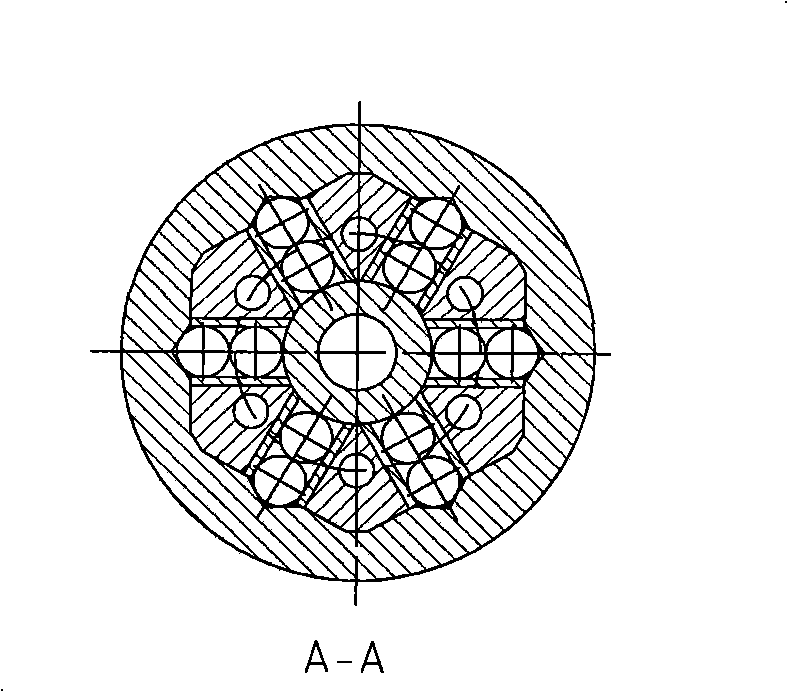

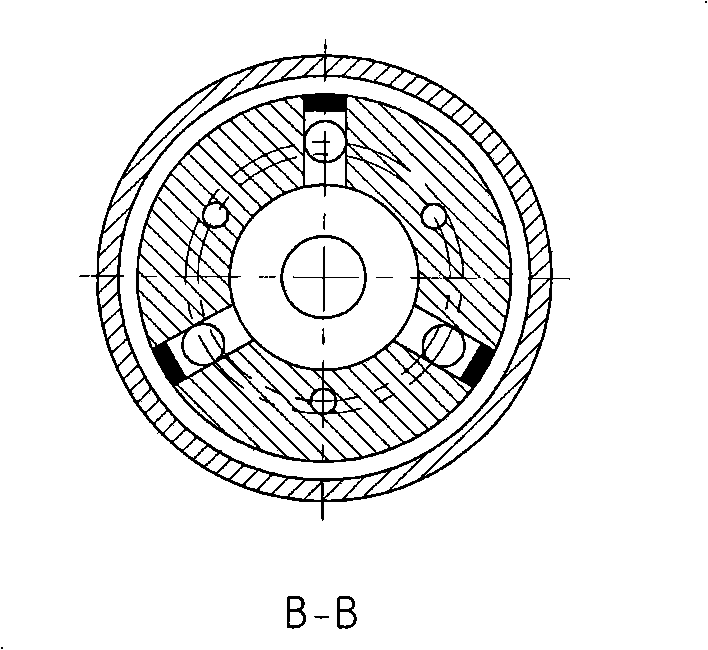

[0040] Suspension differential mechanism: the outer handle 1 is threadedly connected with the upper drill pipe, the outer handle 1 is threaded with the outer hexagonal handle 6, the outer hexagonal handle 6 and the inner hexagonal handle 7 are transmitted through inner and outer hexagonal handles, the inner hexagonal handle 7 and the outer pipe 12 Threaded connection, the stop sleeve 2 is threaded with the outer hexagonal handle 6 through screws, and the stop sleeve 2 restricts the sliding sleeve 5 from sliding outward. Sliding sleeve 5 is slidingly matched with outer hexagonal handle 6. Washer 11 is seated on the step of the inner hole of outer hexagonal handle 6. Sliding sleeve spring 10 is preloaded and installed. The upper and lower ends are respectively supported by washer 11 and sliding sleeve 5. Steel ball 8 is mounted on In the ball sleeve 9, the outer side of the ball sleeve 9 is a tapered surface to prevent the steel ball 8 from sliding outwards. There are 12 steel ba...

Embodiment 2

[0065] Suspension differential mechanism: the outer handle 1 is threadedly connected with the upper drill pipe, the outer handle 1 is threaded with the outer hexagonal handle 6, the outer hexagonal handle 6 and the inner hexagonal handle 7 are transmitted through inner and outer hexagonal handles, the inner hexagonal handle 7 and the outer pipe 12 Threaded connection, the stop sleeve 2 is threaded with the outer hexagonal handle 6 through screws, and the stop sleeve 2 restricts the sliding sleeve 5 from sliding outward. Sliding sleeve 5 is slidingly matched with outer hexagonal handle 6. Washer 11 is seated on the step of the inner hole of outer hexagonal handle 6. Sliding sleeve spring 10 is preloaded and installed. The upper and lower ends are respectively supported by washer 11 and sliding sleeve 5. Steel ball 8 is mounted on In the ball sleeve 9, the outer side of the ball sleeve 9 is a tapered surface to prevent the steel ball 8 from sliding outwards. There are 12 steel ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com