Patents

Literature

12476 results about "Drill pipe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

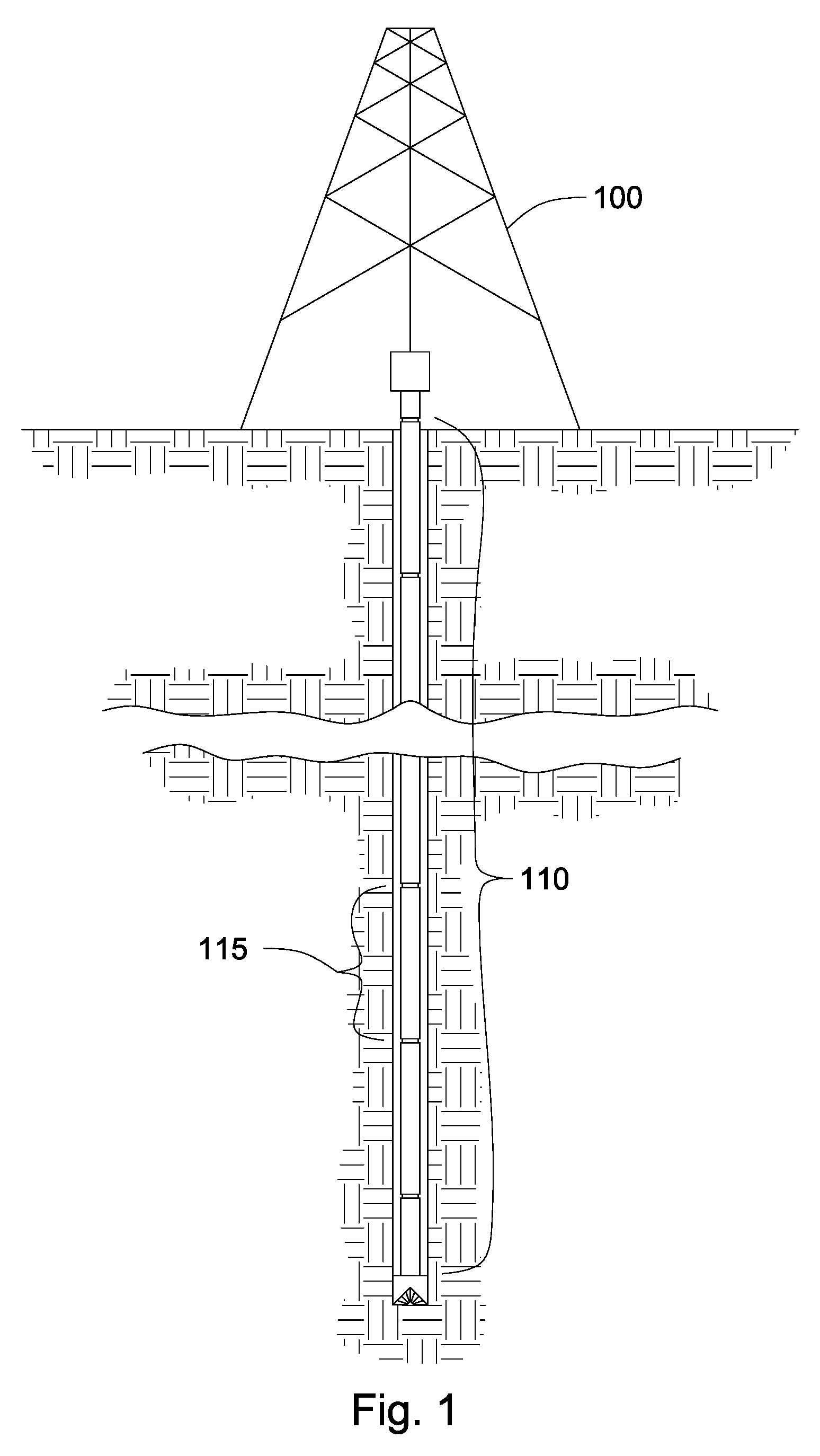

Drill pipe, is hollow, thin-walled, steel or aluminium alloy piping that is used on drilling rigs. It is hollow to allow drilling fluid to be pumped down the hole through the bit and back up the annulus. It comes in a variety of sizes, strengths, and wall thicknesses, but is typically 27 to 32 feet in length (Range 2). Longer lengths, up to 45 feet, exist (Range 3).

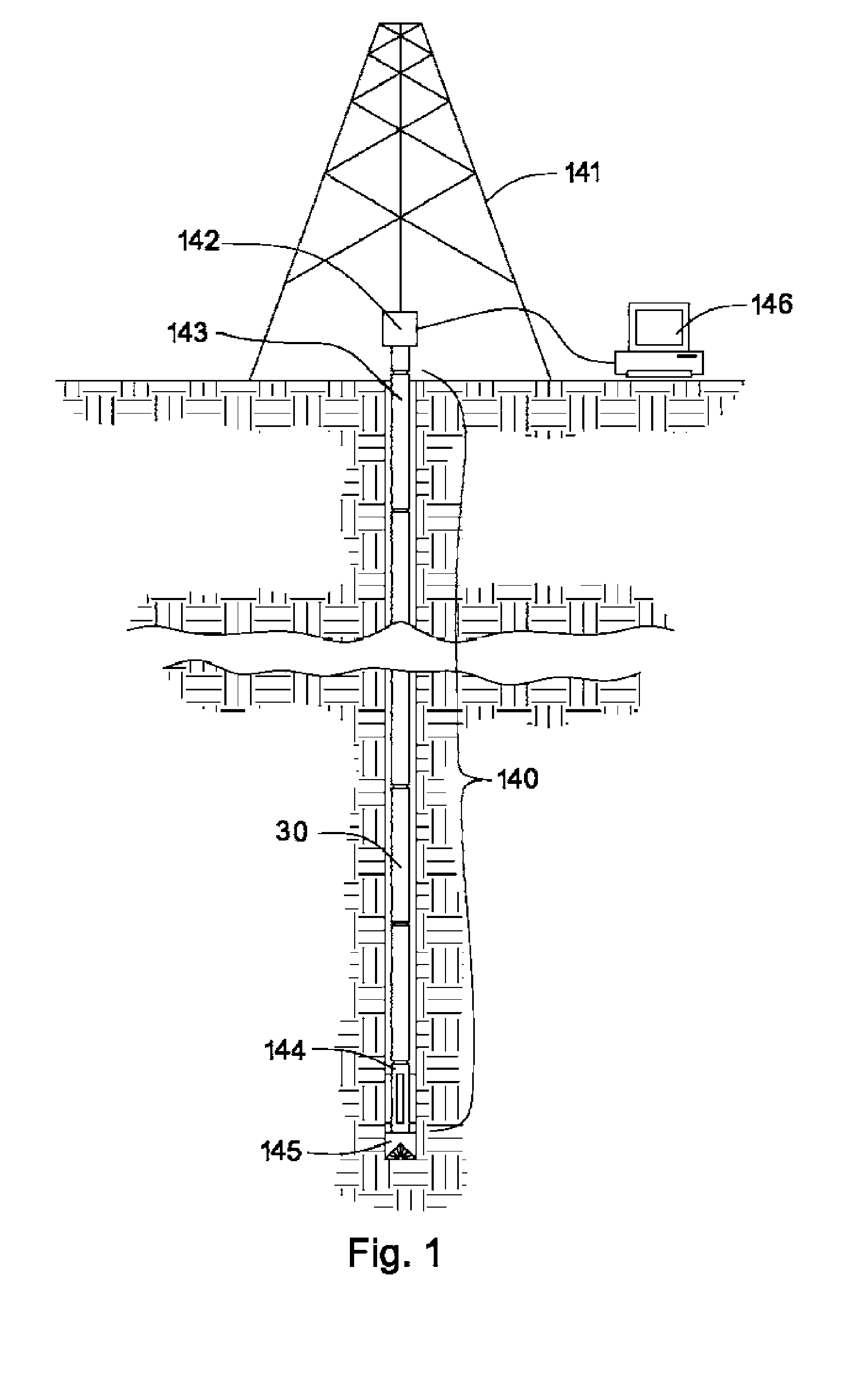

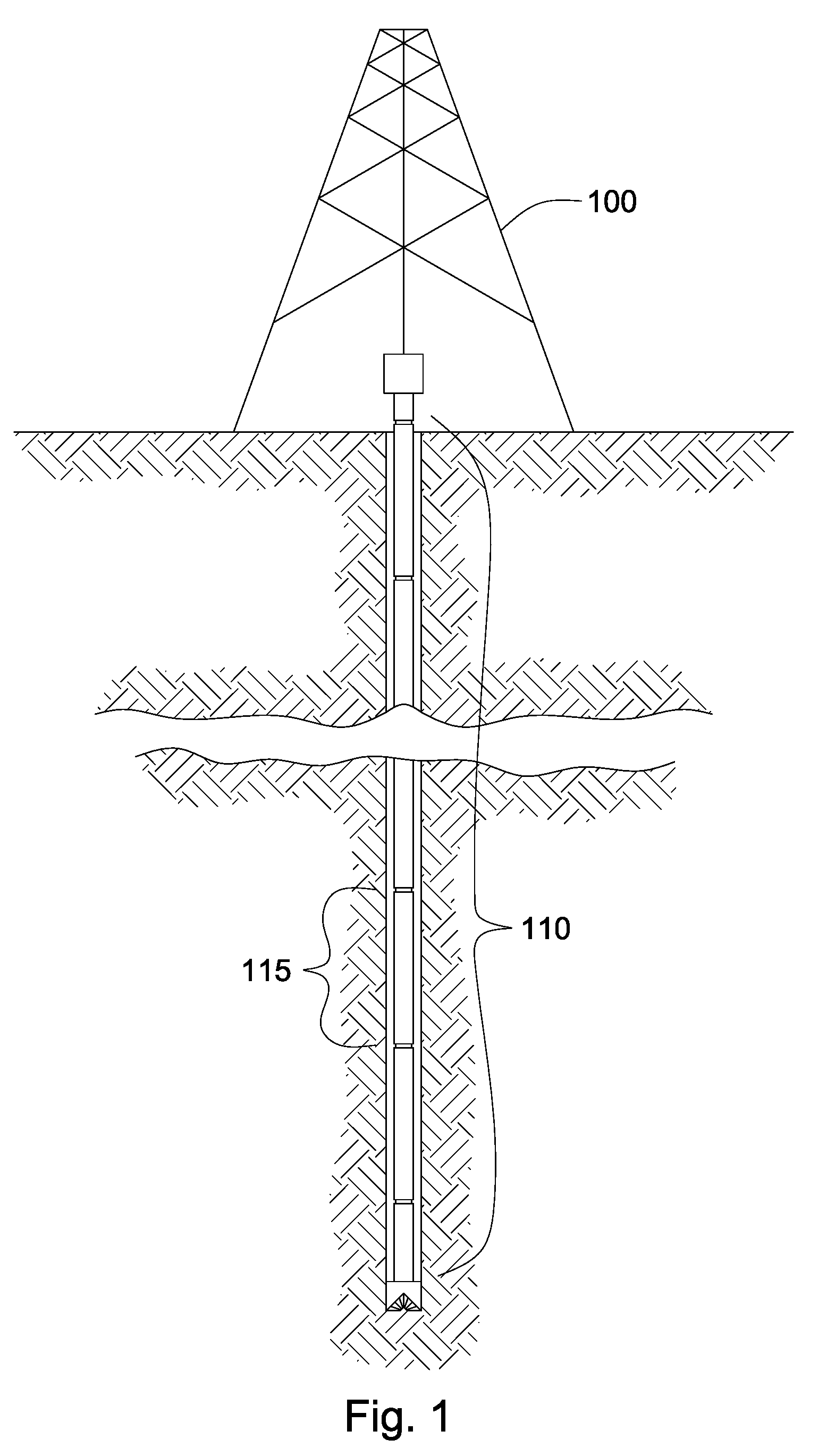

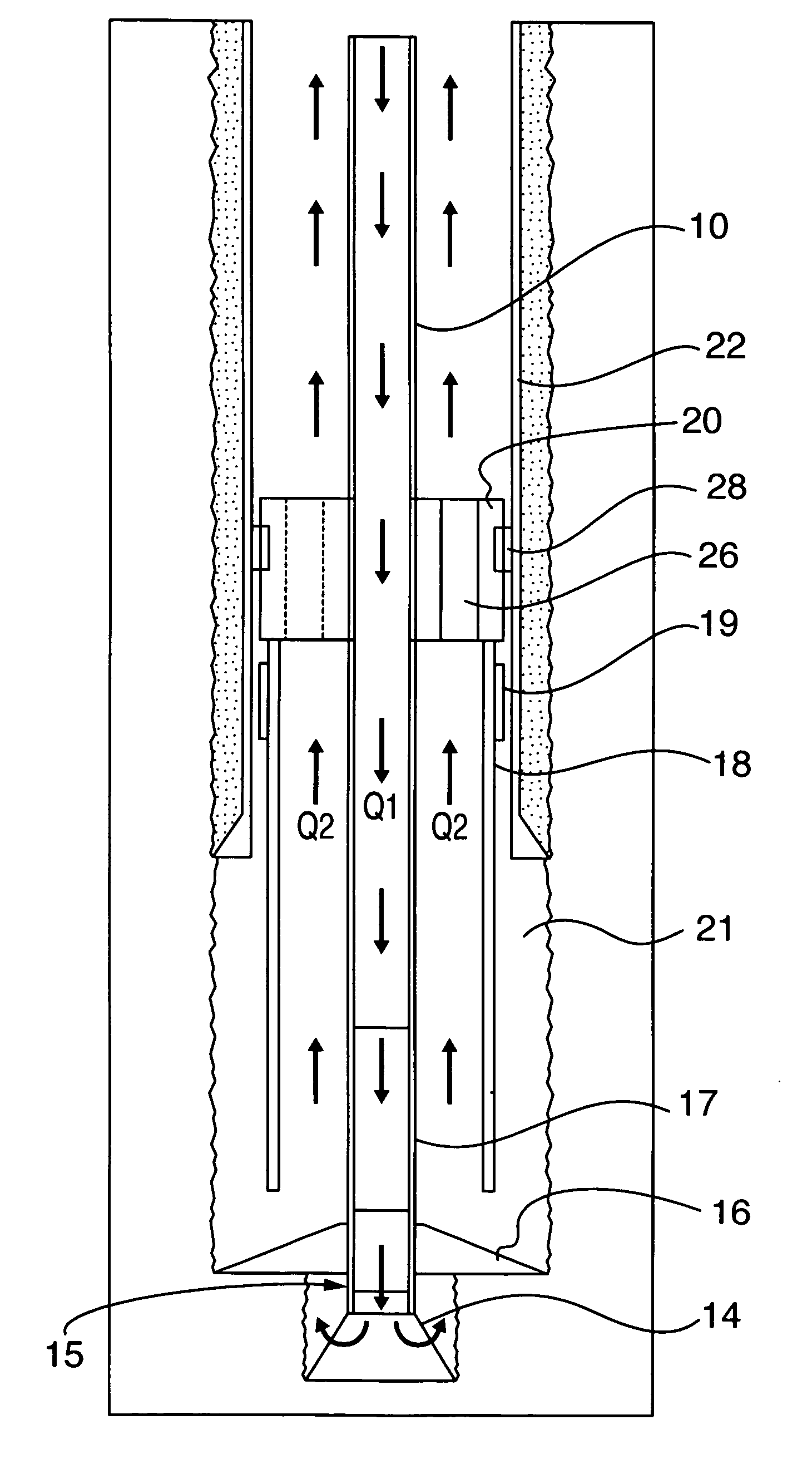

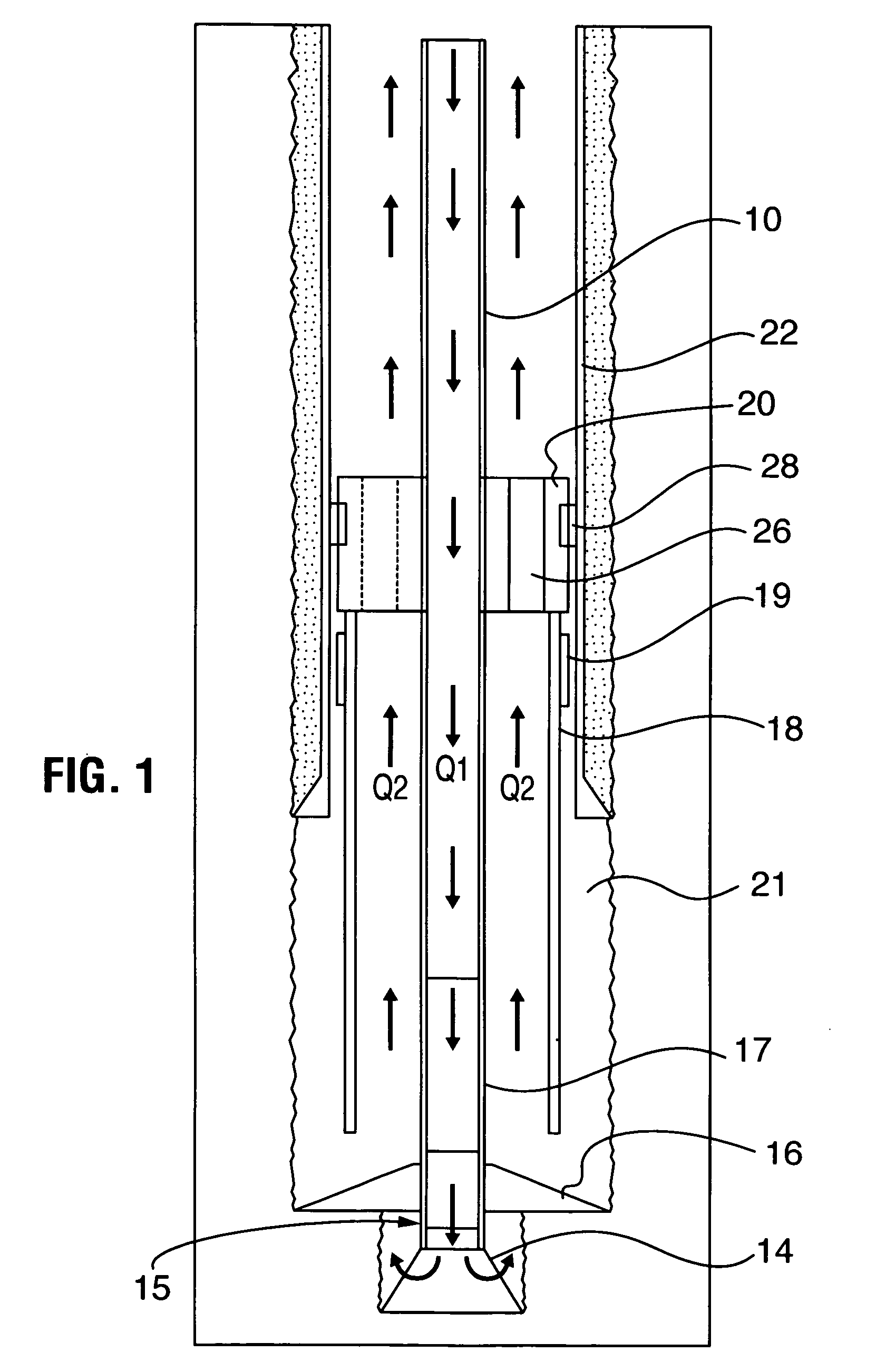

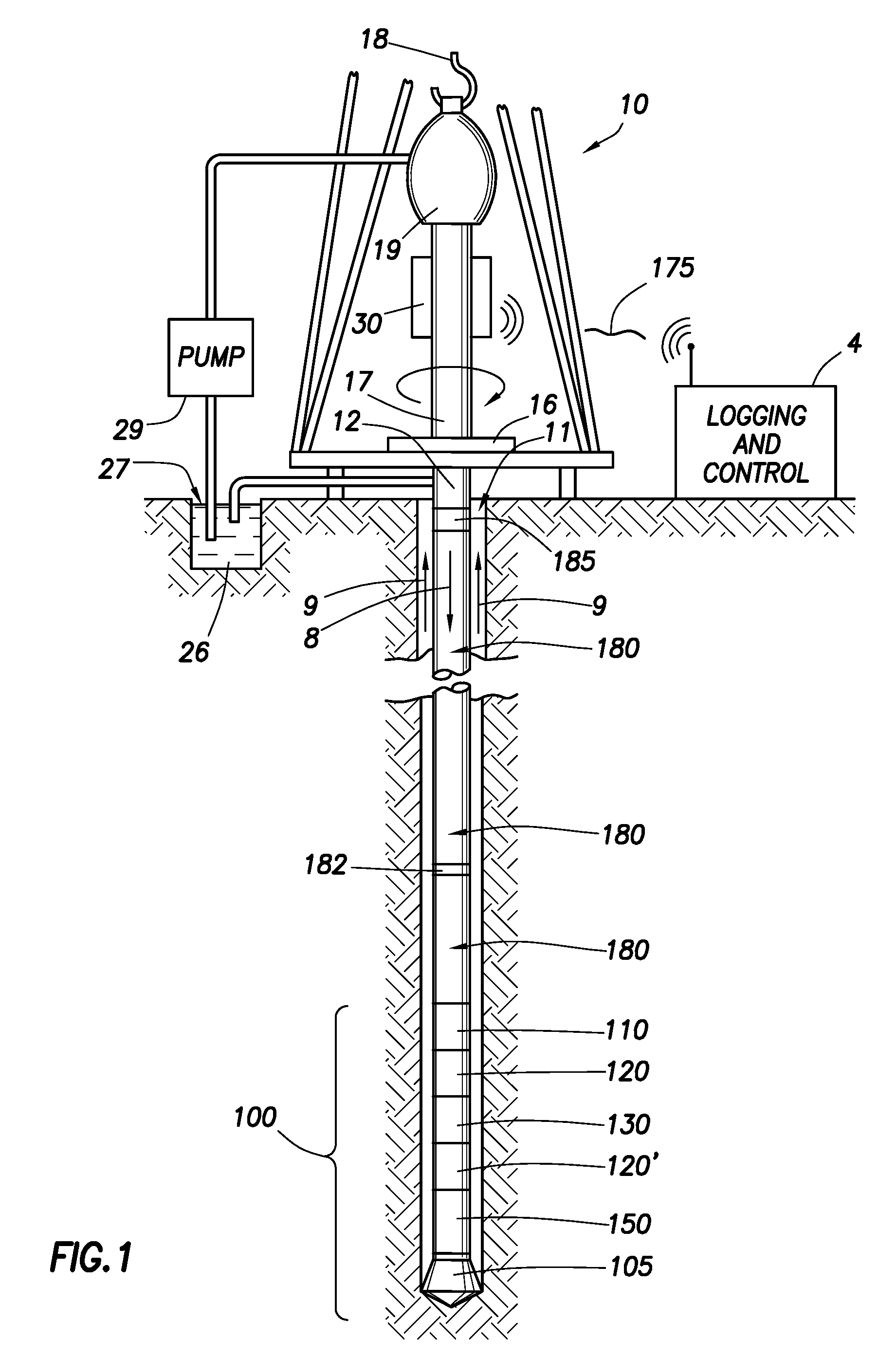

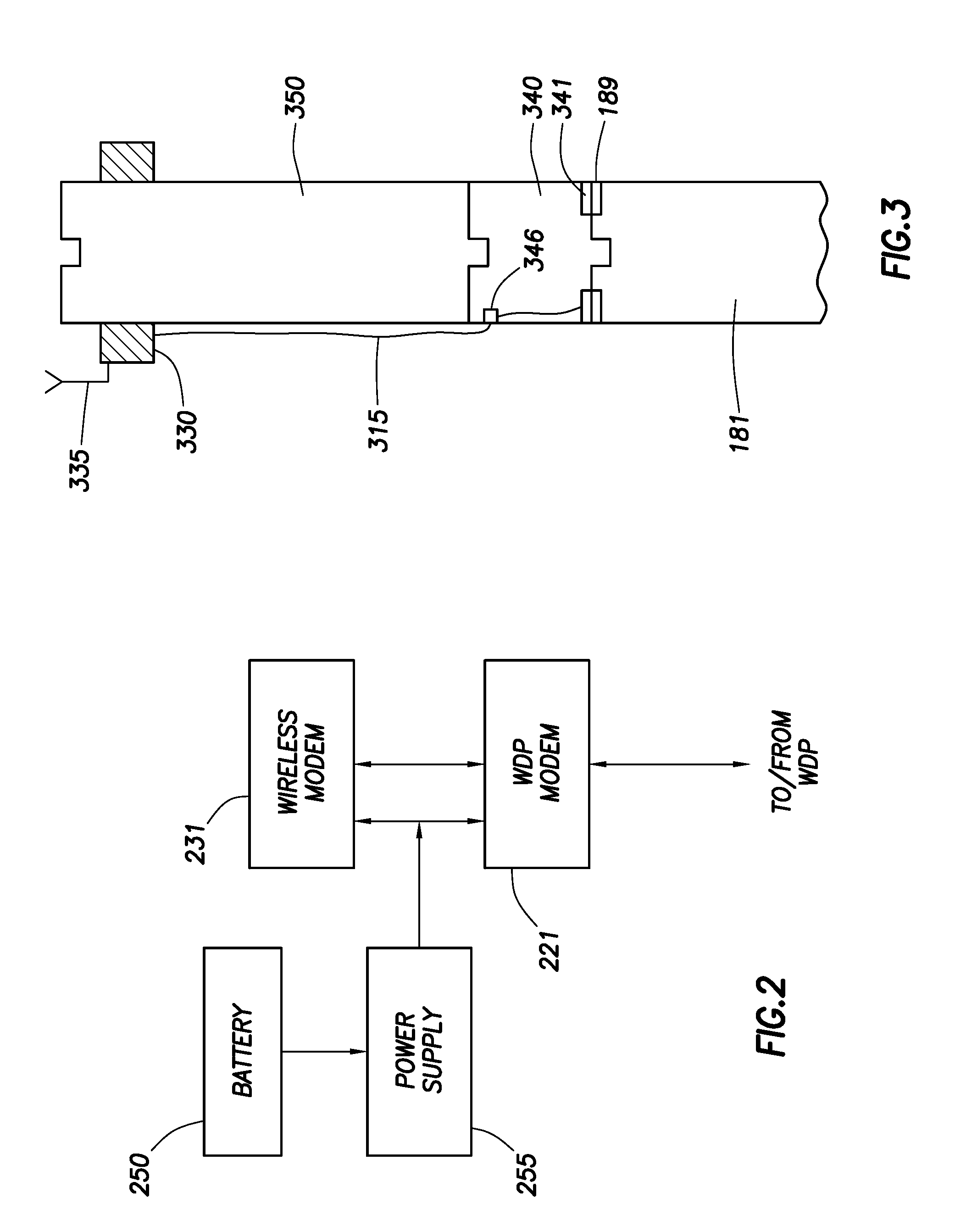

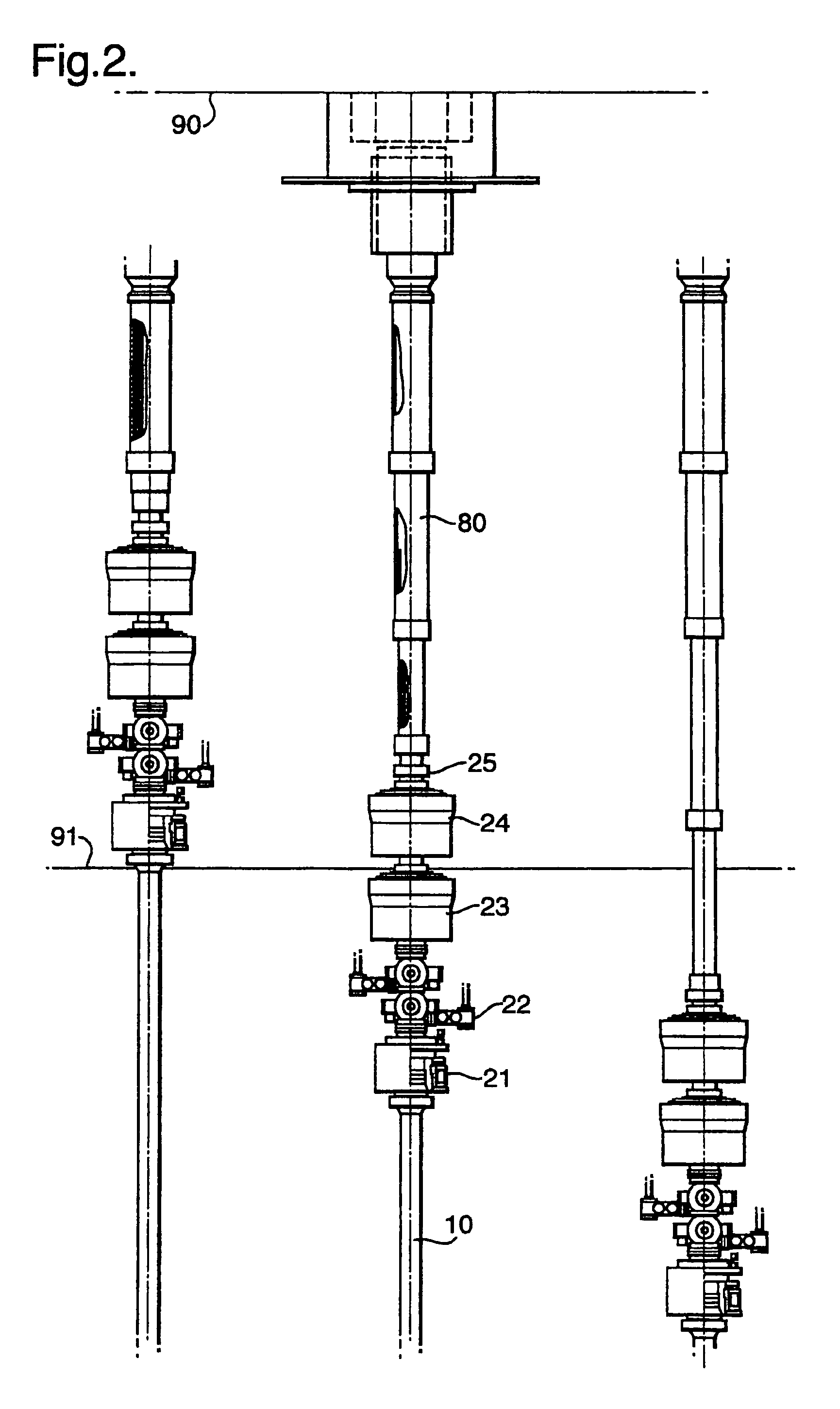

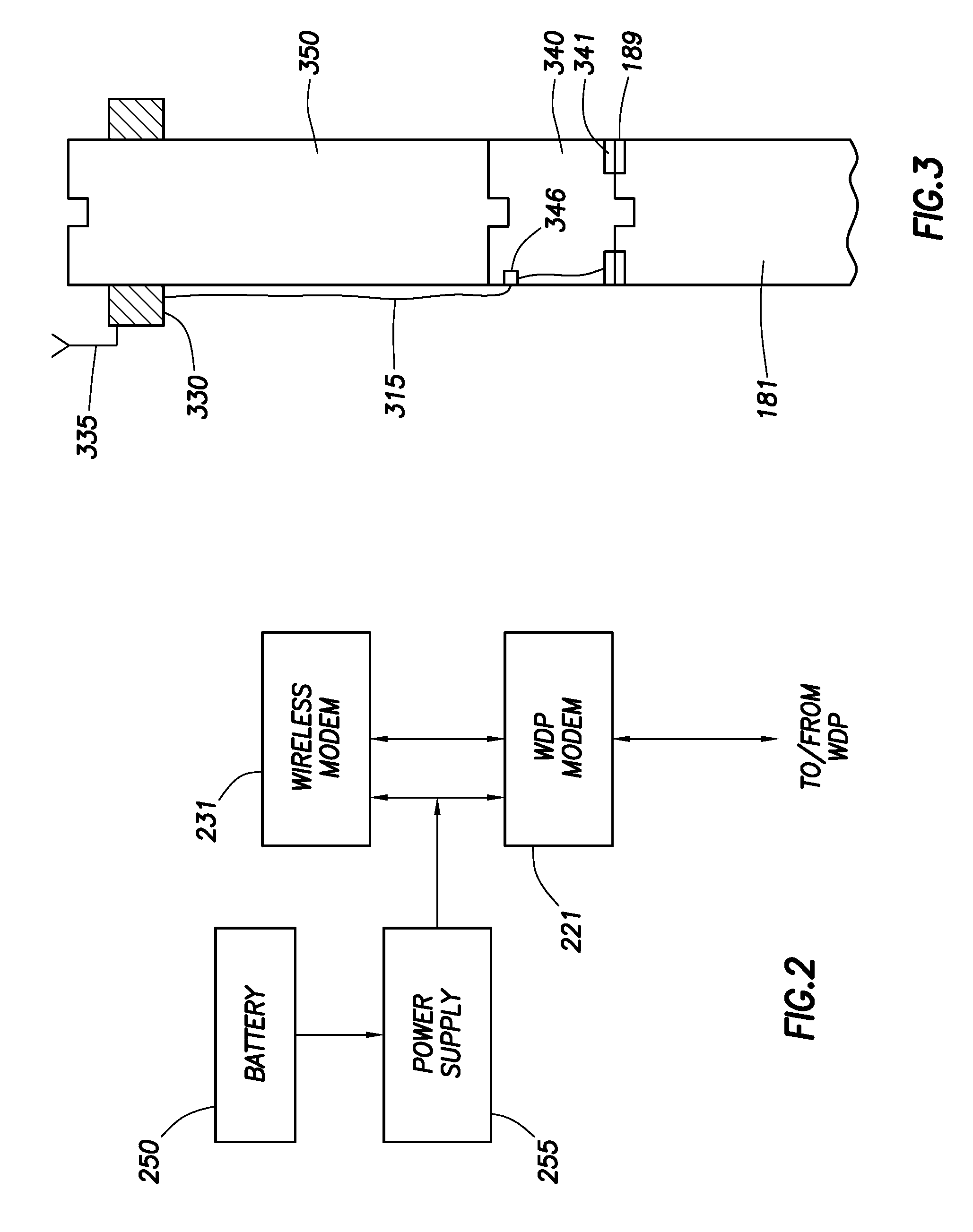

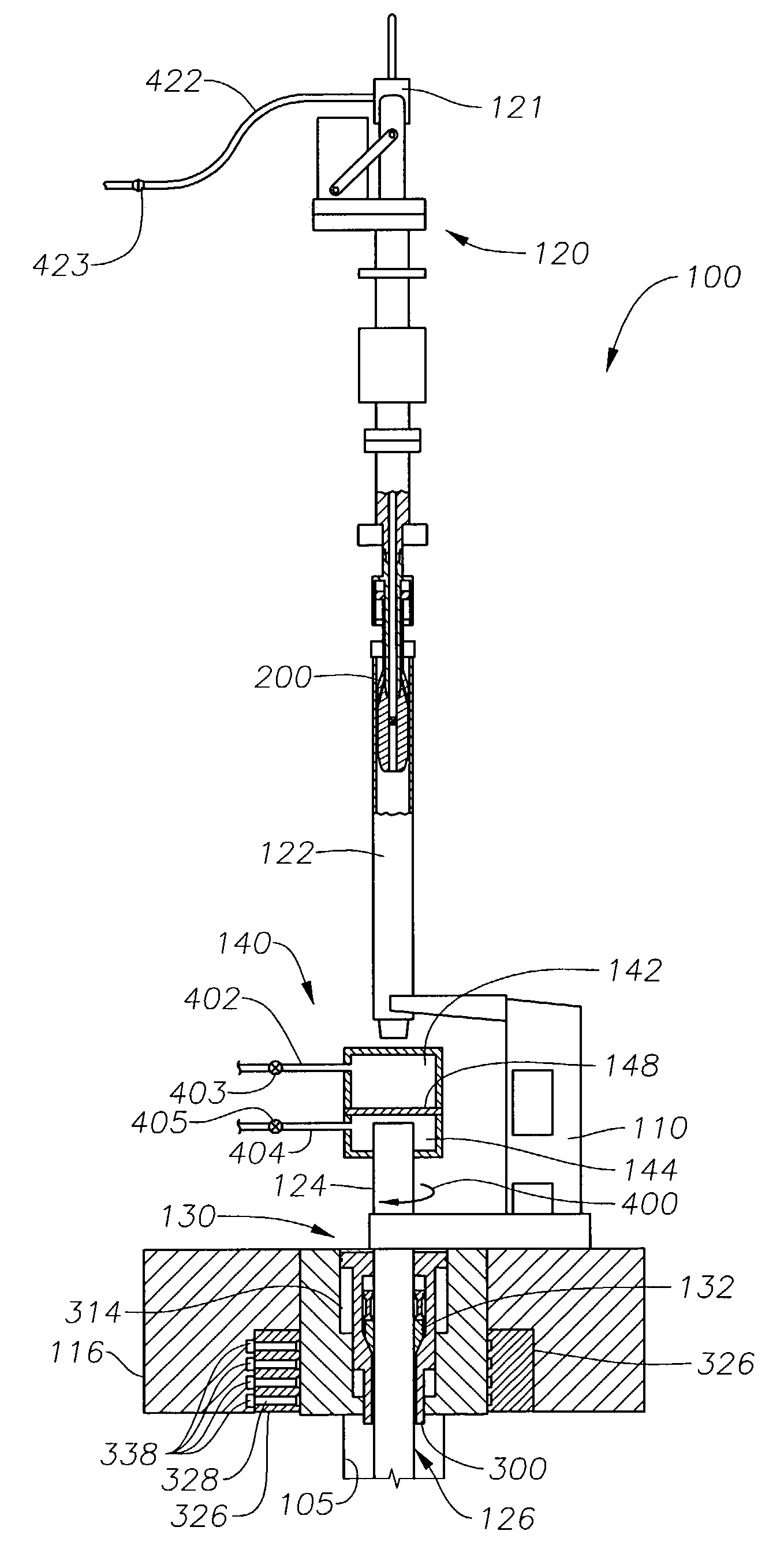

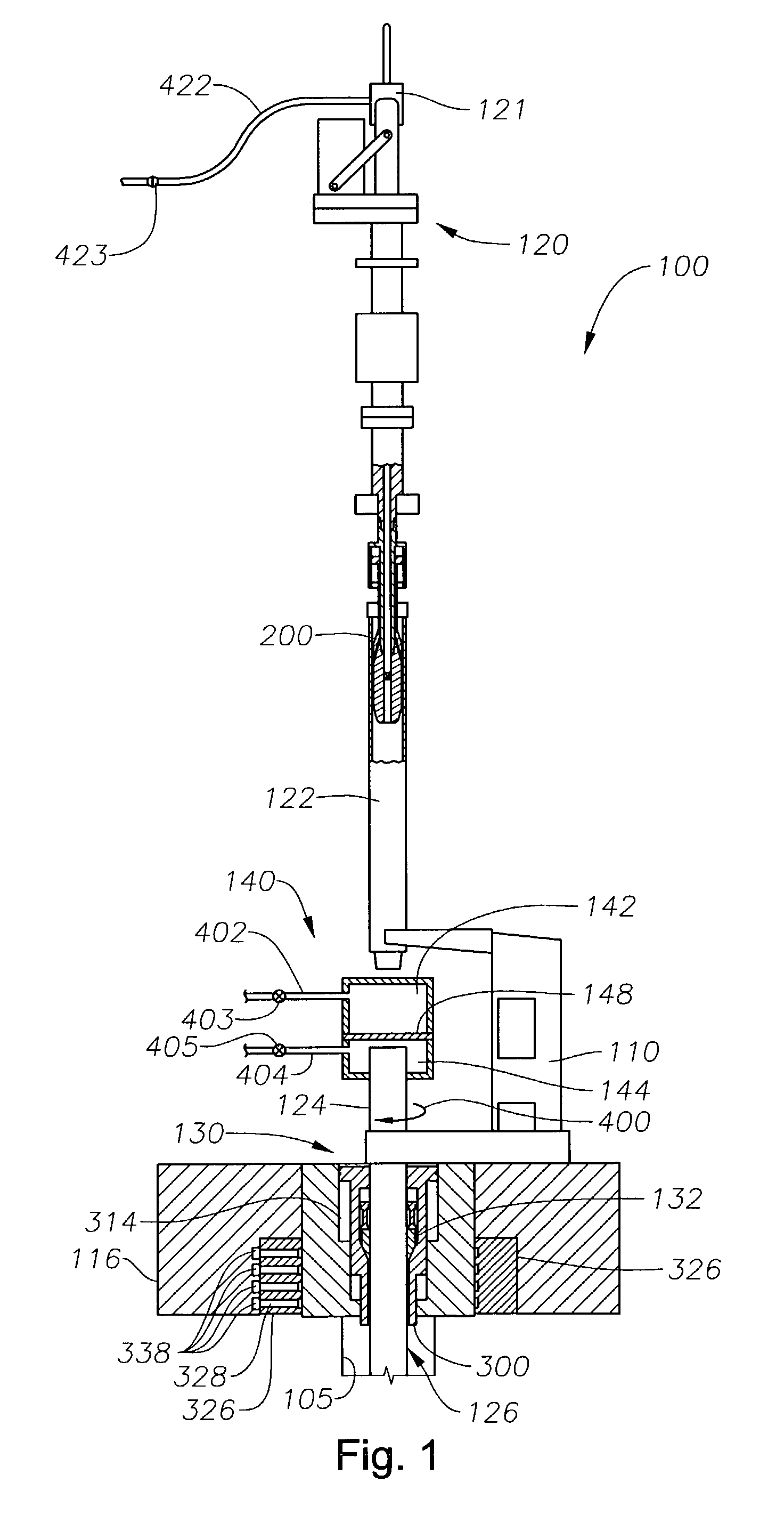

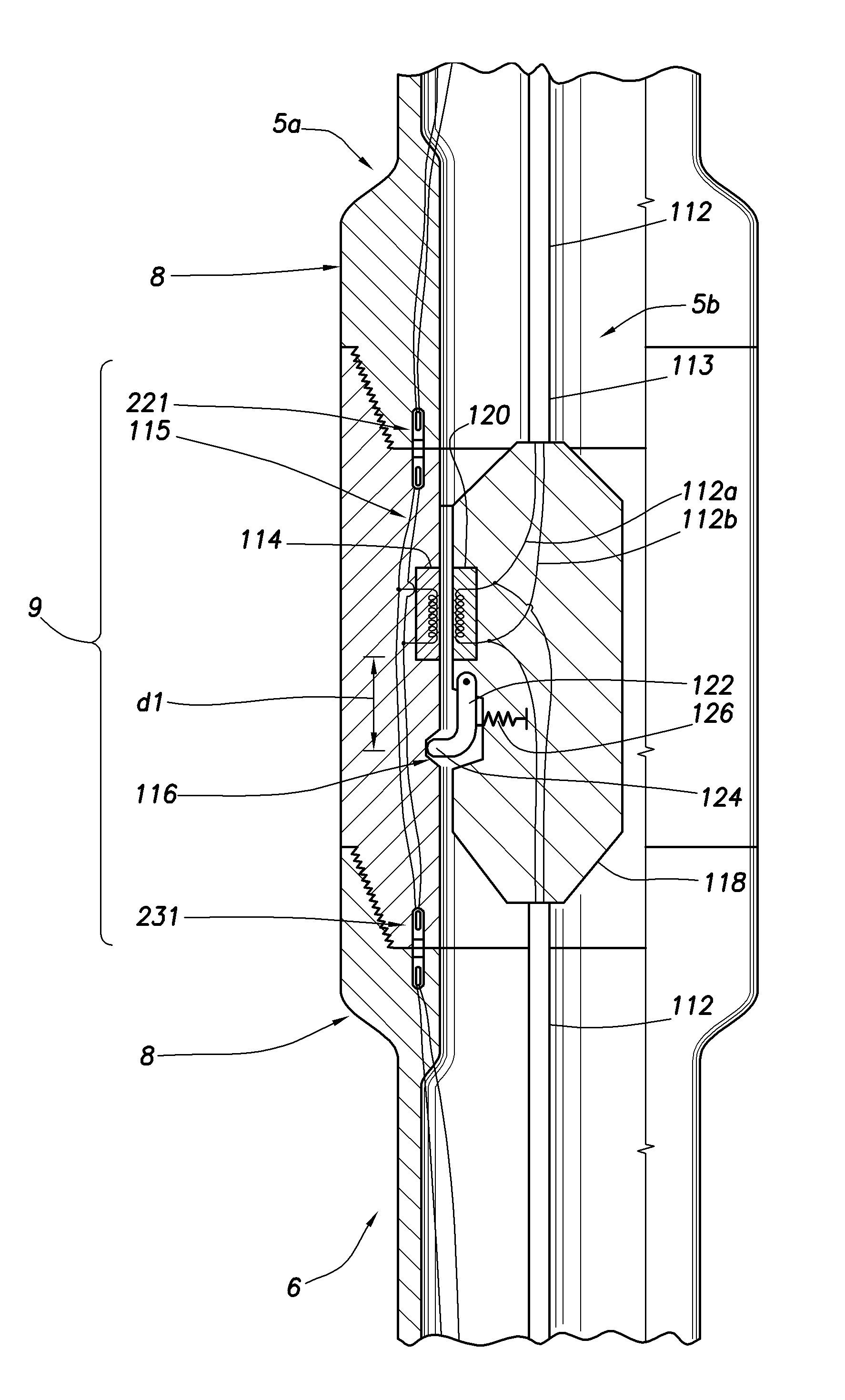

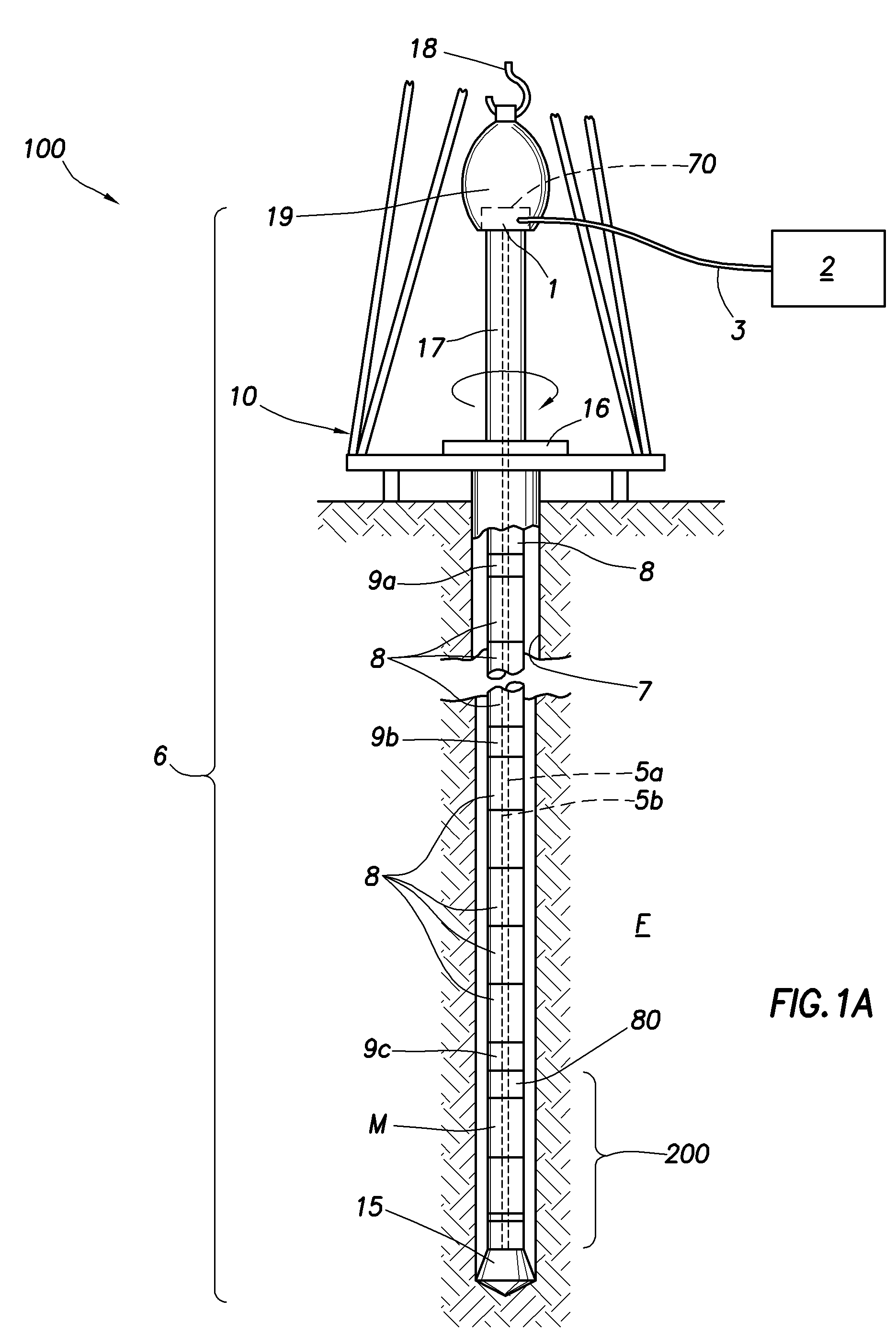

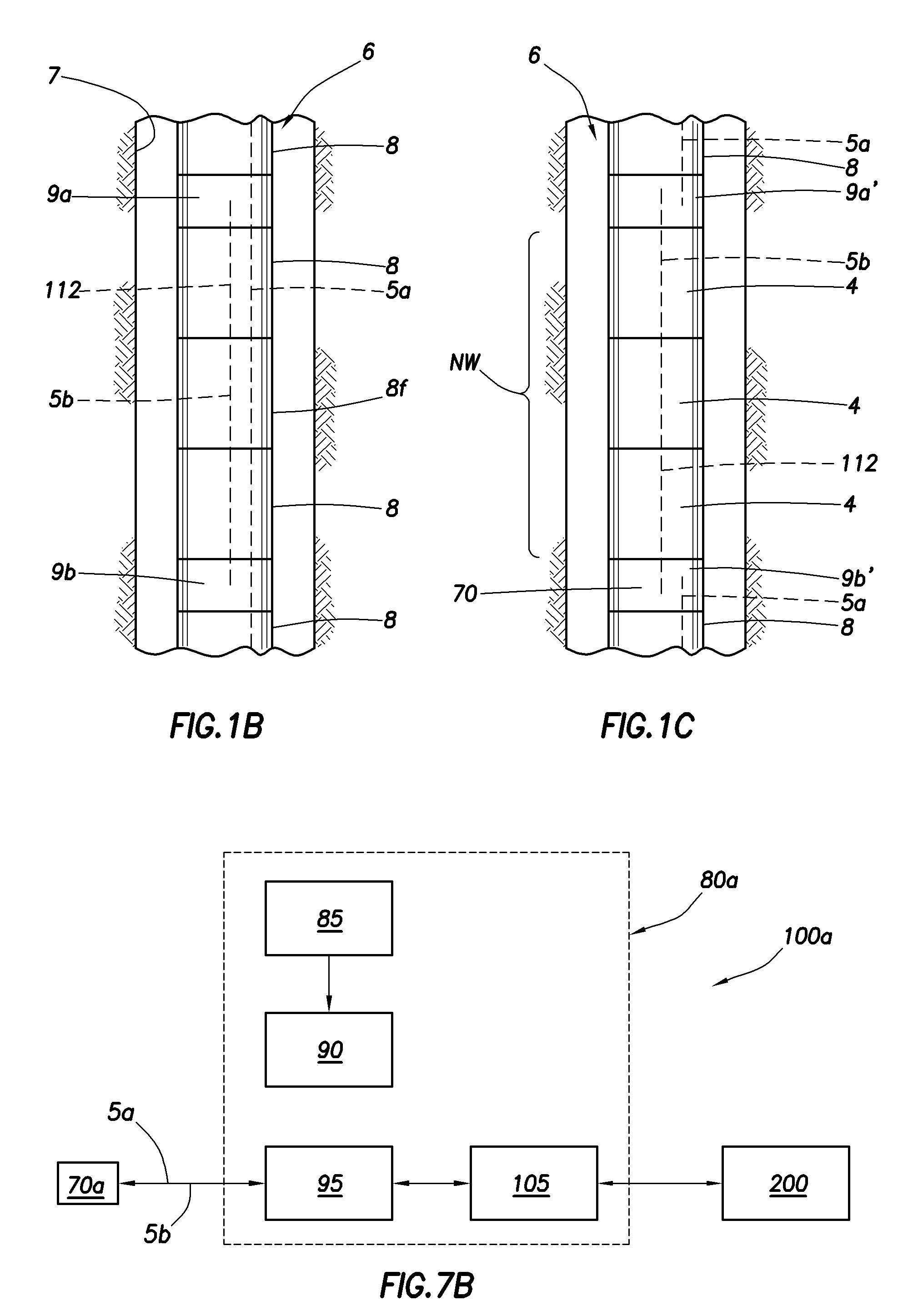

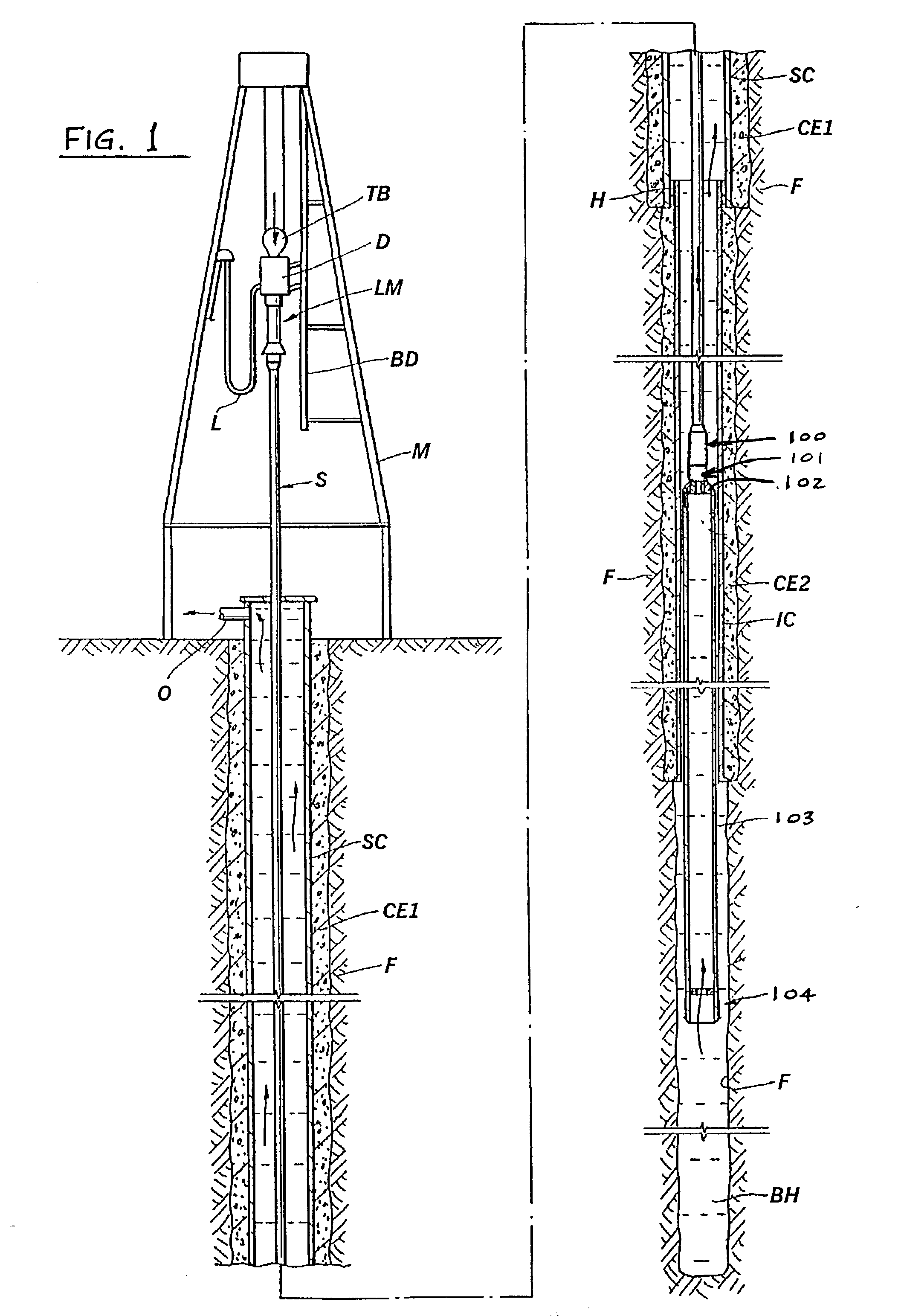

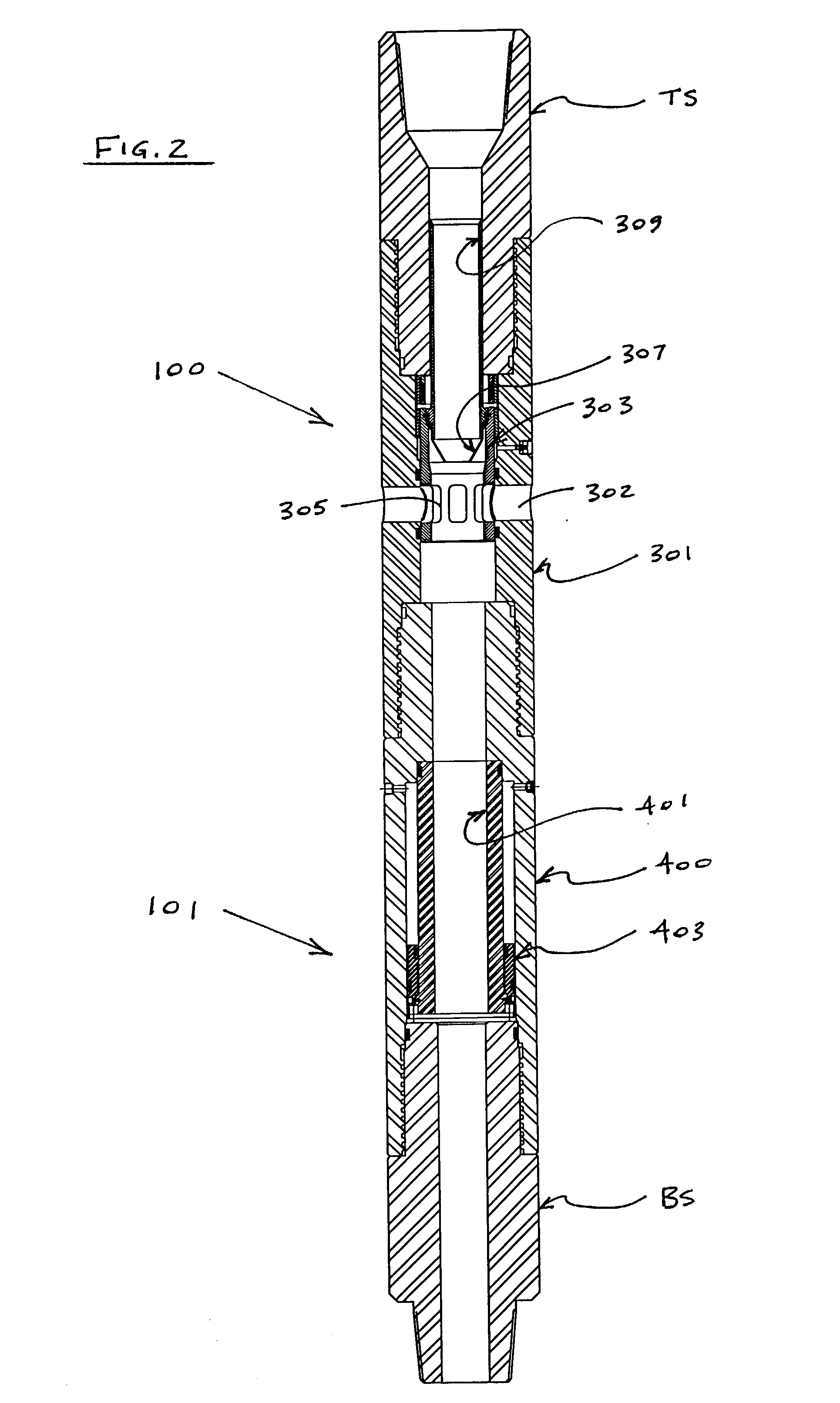

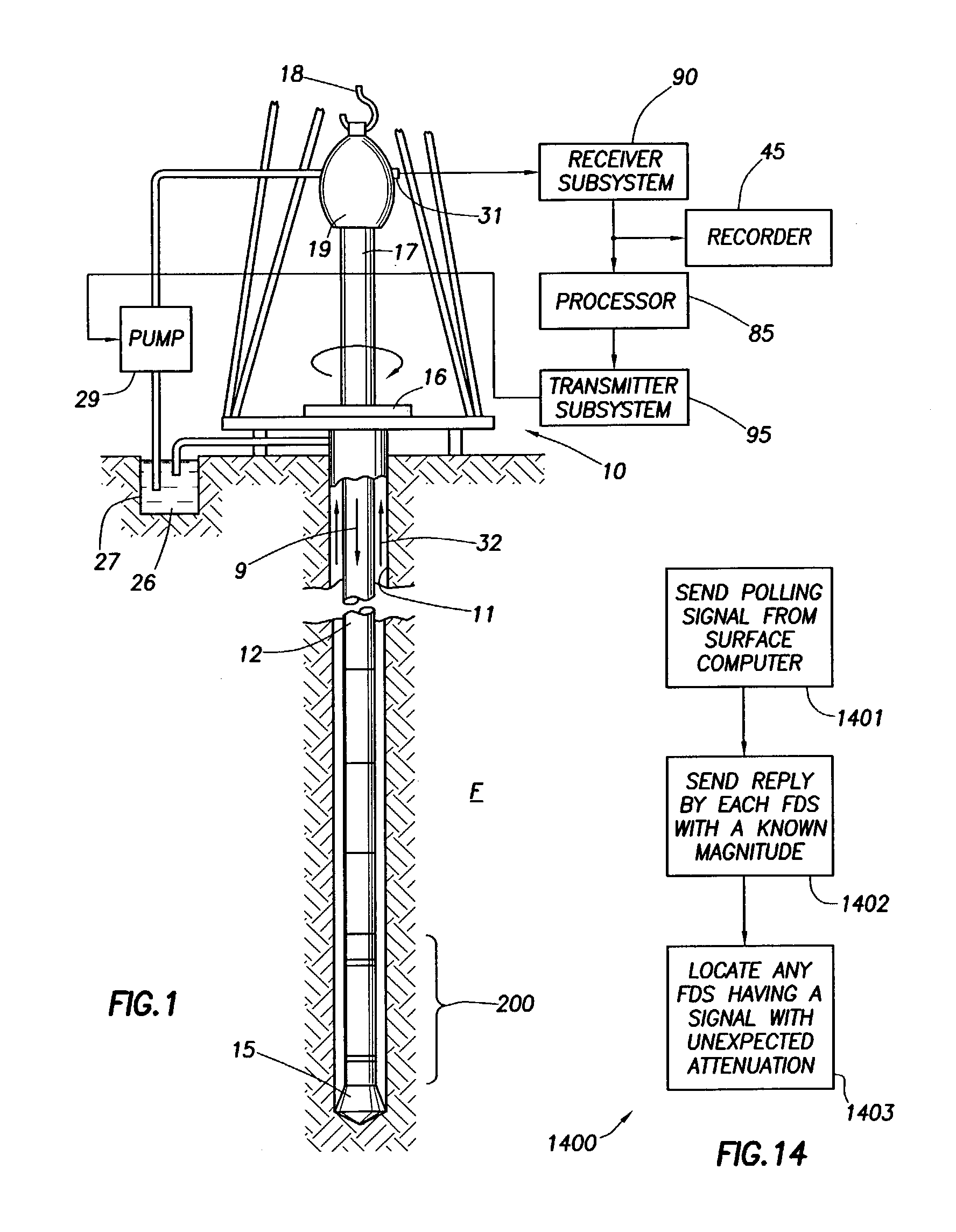

Downhole telemetry system and method

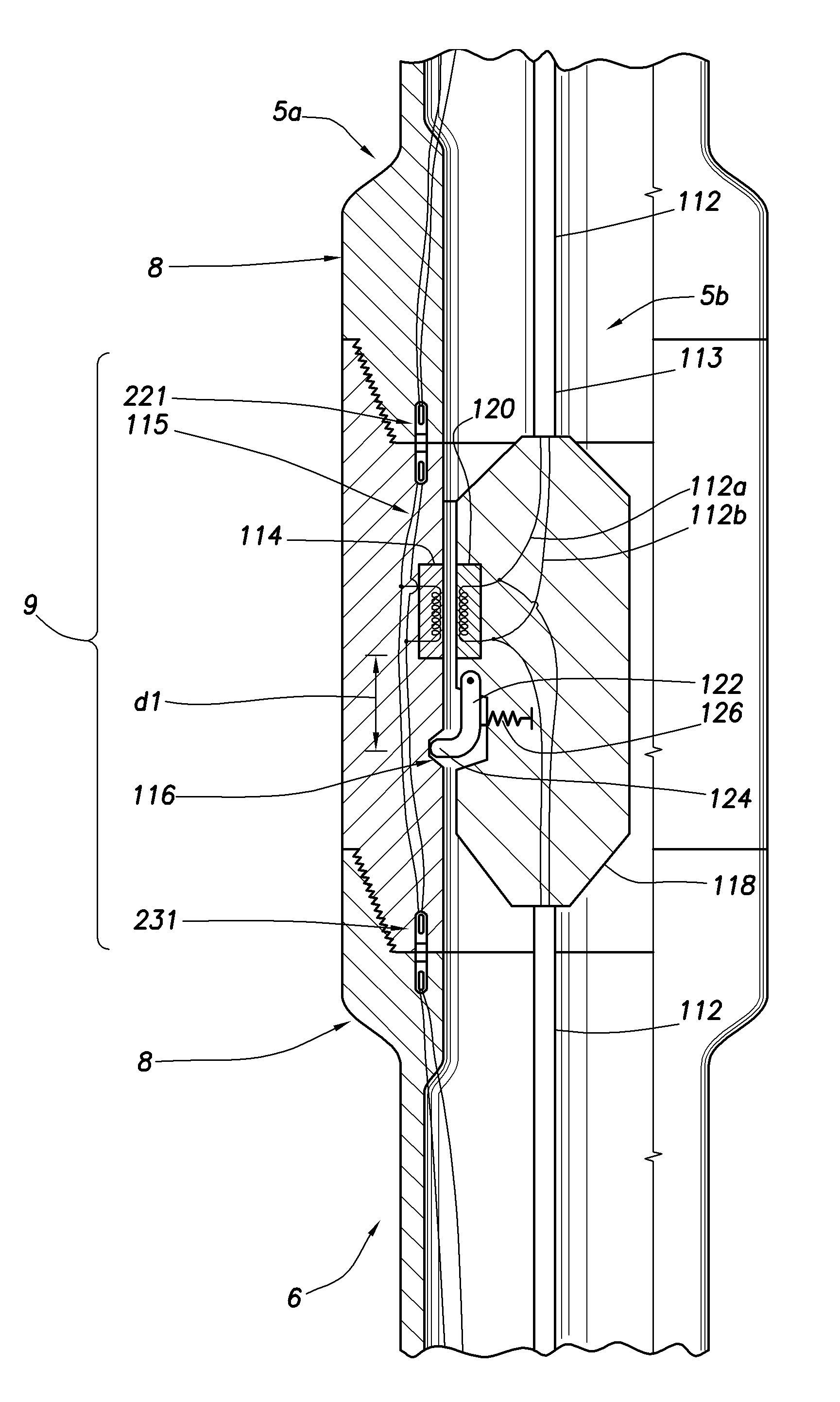

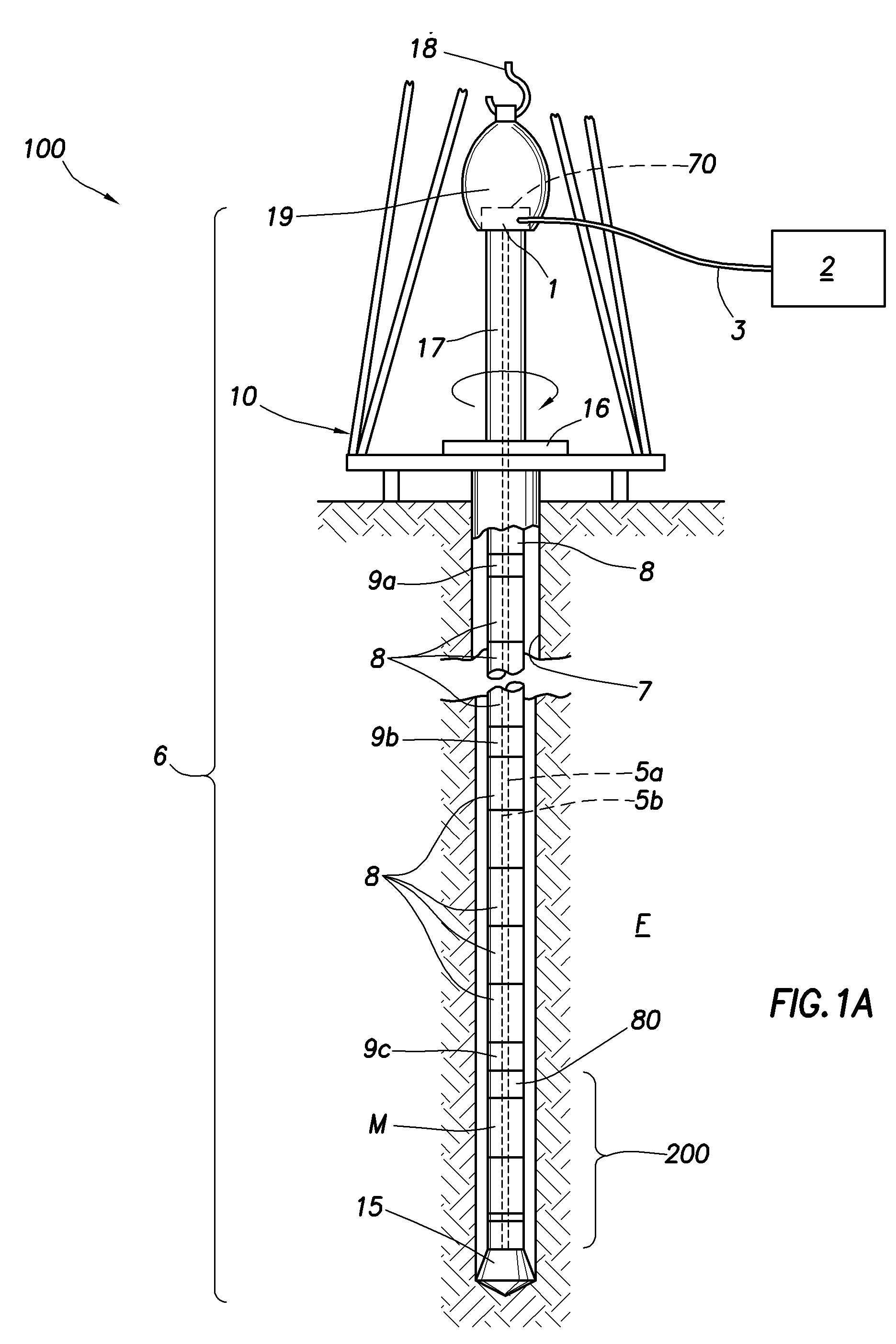

A cabled communication link for a drill string includes spaced apart adapter subs within the drill string and a cable connecting the adapter subs for communication of a signal therebetween. The cabled communication link may be drill pipe joints are interconnected within the drill string between adapter subs to form a piped communication link, whereby the cabled communication link establishes a pathway to the piped communication link for transmitting a signal through the drill string. The cabled communication link may also be in a non-wired section of the drill string is disposed between adapter subs, whereby the cabled communication link establishes a pathway for transmitting a signal through the non-wired section of the drill string. Inductive couplings are preferably used for communication across the adapter subs and wired drill pipe joints. Another aspect of the cabled communication employs wireless transceivers at or near the surface of the wellbore.

Owner:SCHLUMBERGER TECH CORP

Downhole Tool

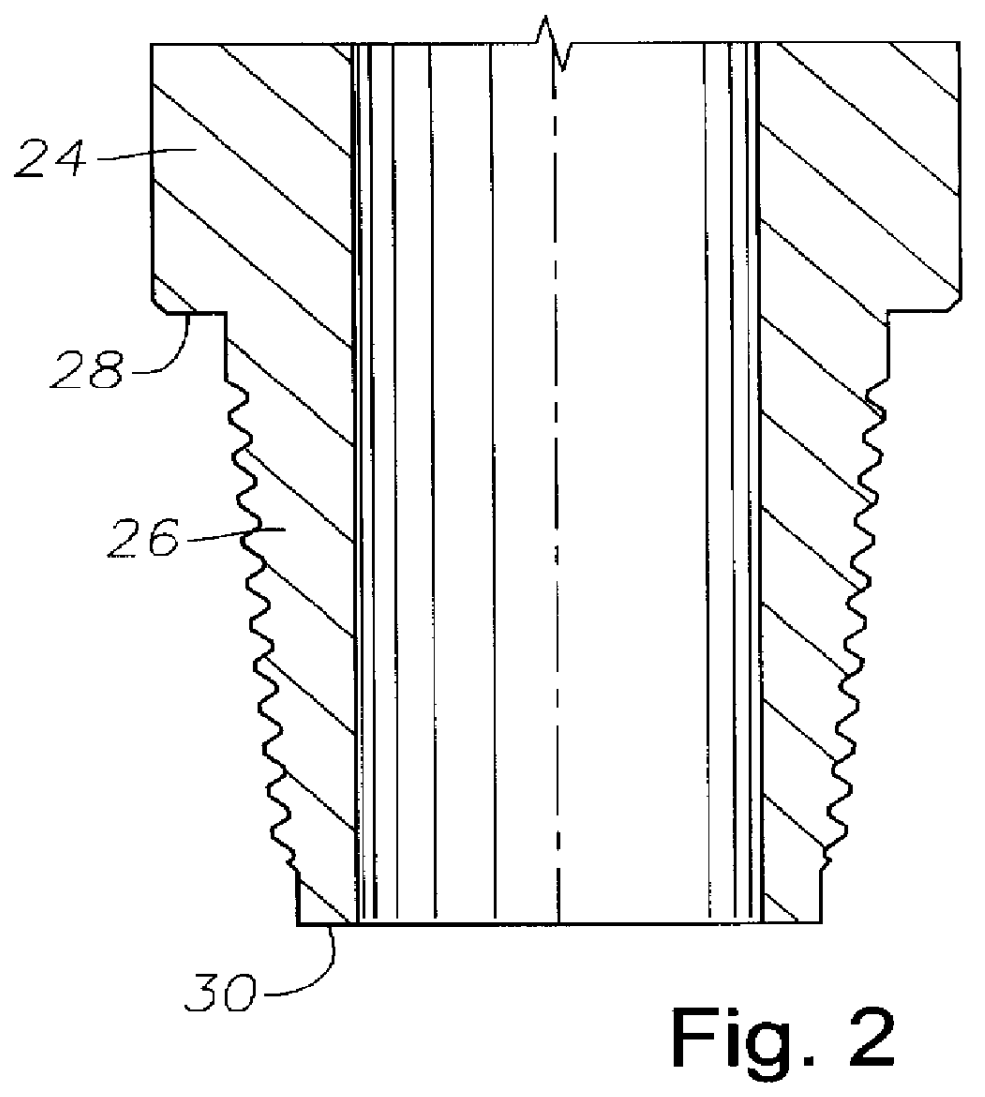

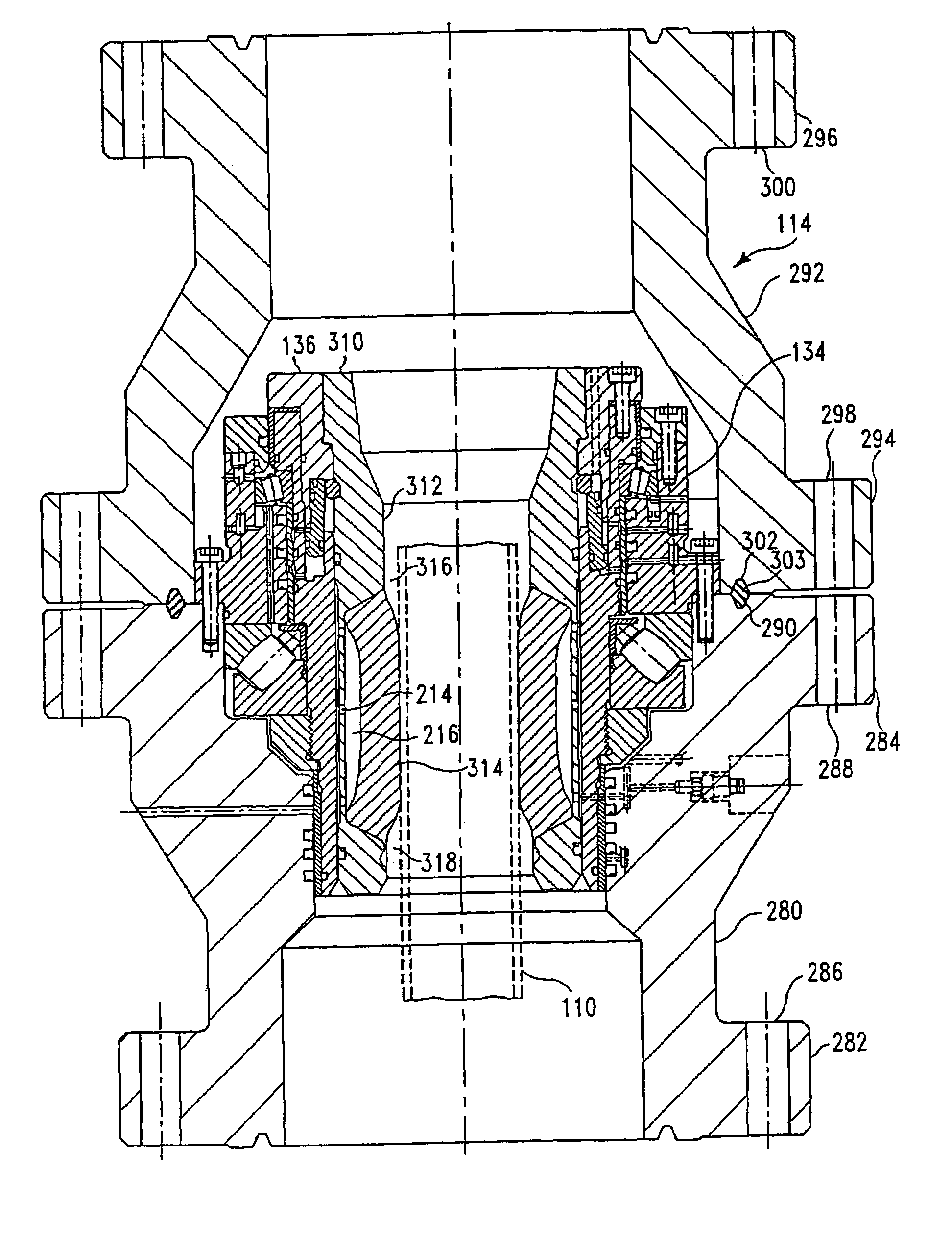

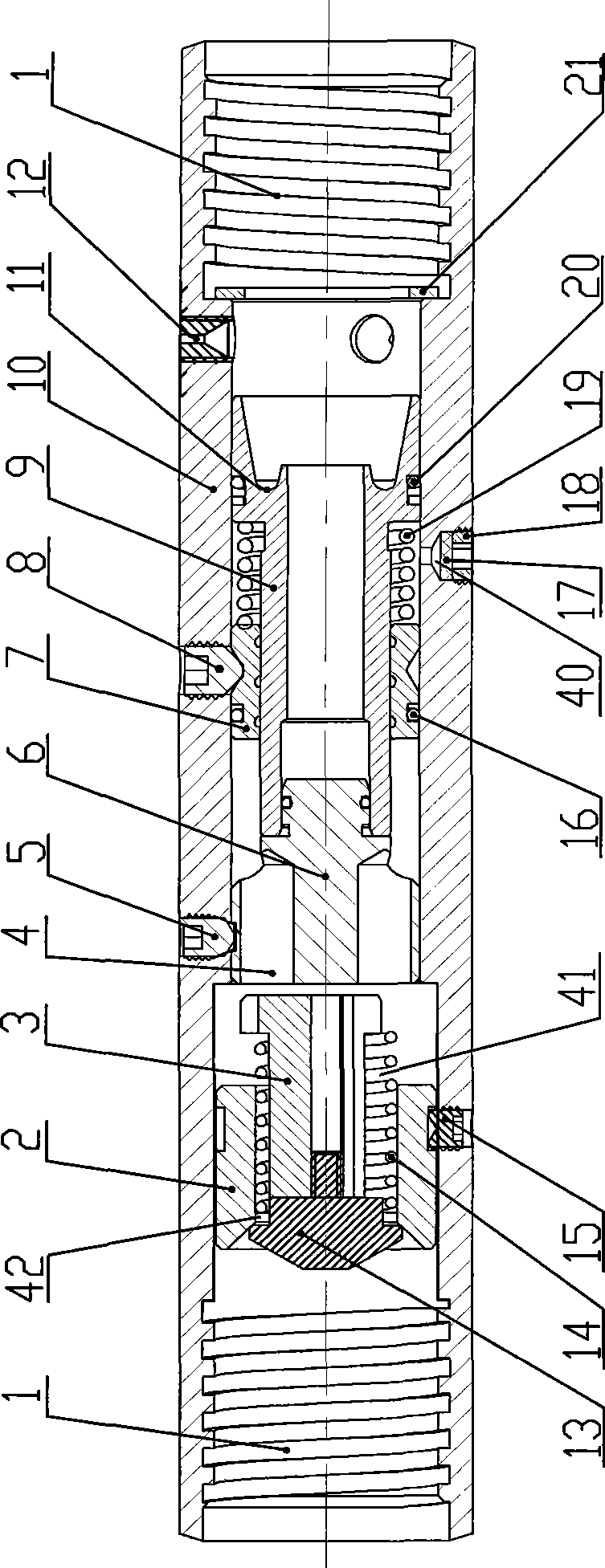

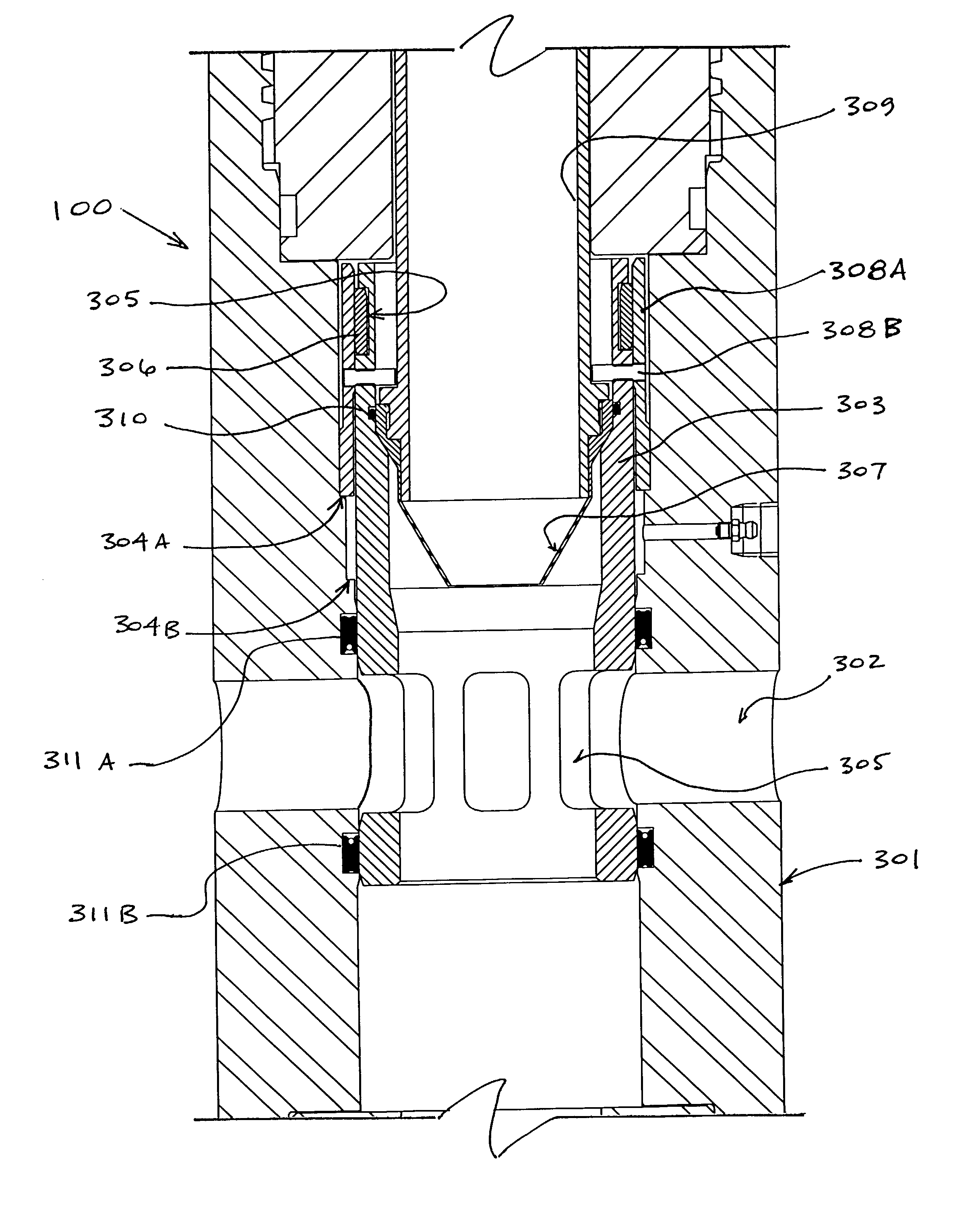

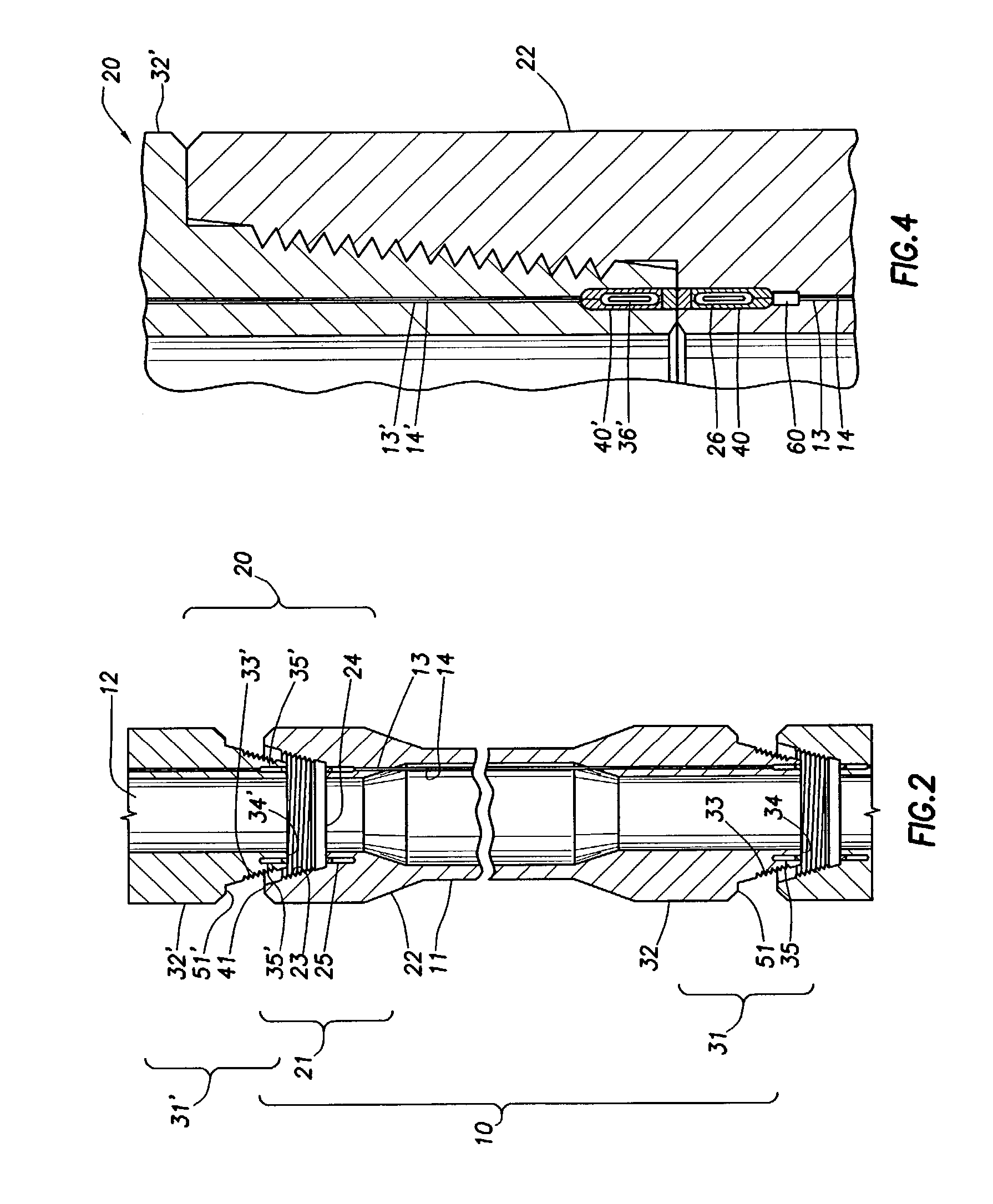

A double shouldered downhole tool connection comprises box and pin connections having mating threads intermediate mating primary and secondary shoulders. The connection further comprises a secondary shoulder component retained in the box connection intermediate a floating component and the primary shoulders. The secondary shoulder component and the pin connection cooperate to transfer a portion of makeup load to the box connection. The downhole tool may be selected from the group consisting of drill pipe, drill collars, production pipe, and reamers. The floating component may be selected from the group consisting of electronics modules, generators, gyroscopes, power sources, and stators. The secondary shoulder component may comprises an interface to the box connection selected from the group consisting of radial grooves, axial grooves, tapered grooves, radial protrusions, axial protrusions, tapered protrusions, shoulders, and threads.

Owner:INTELLISERV

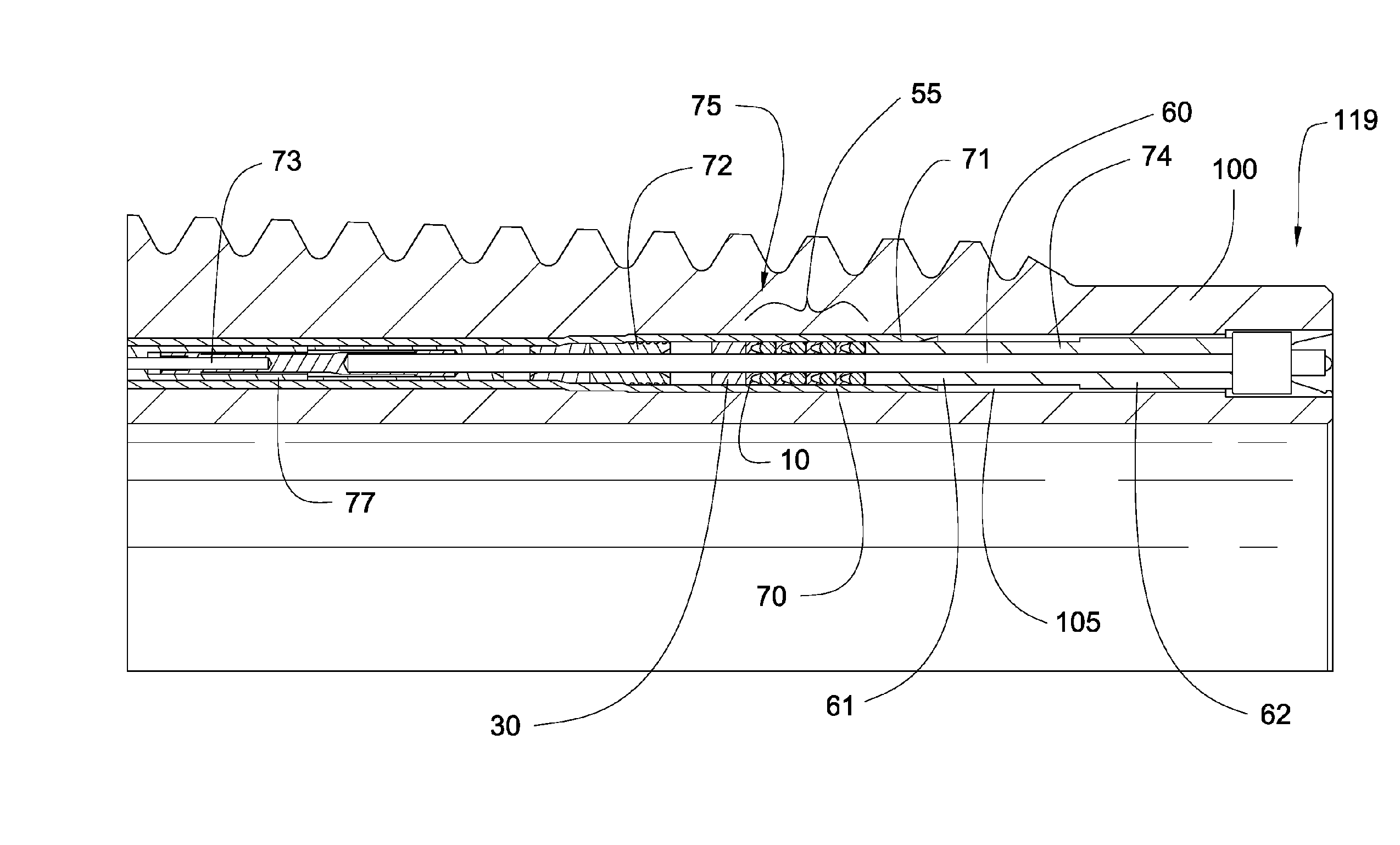

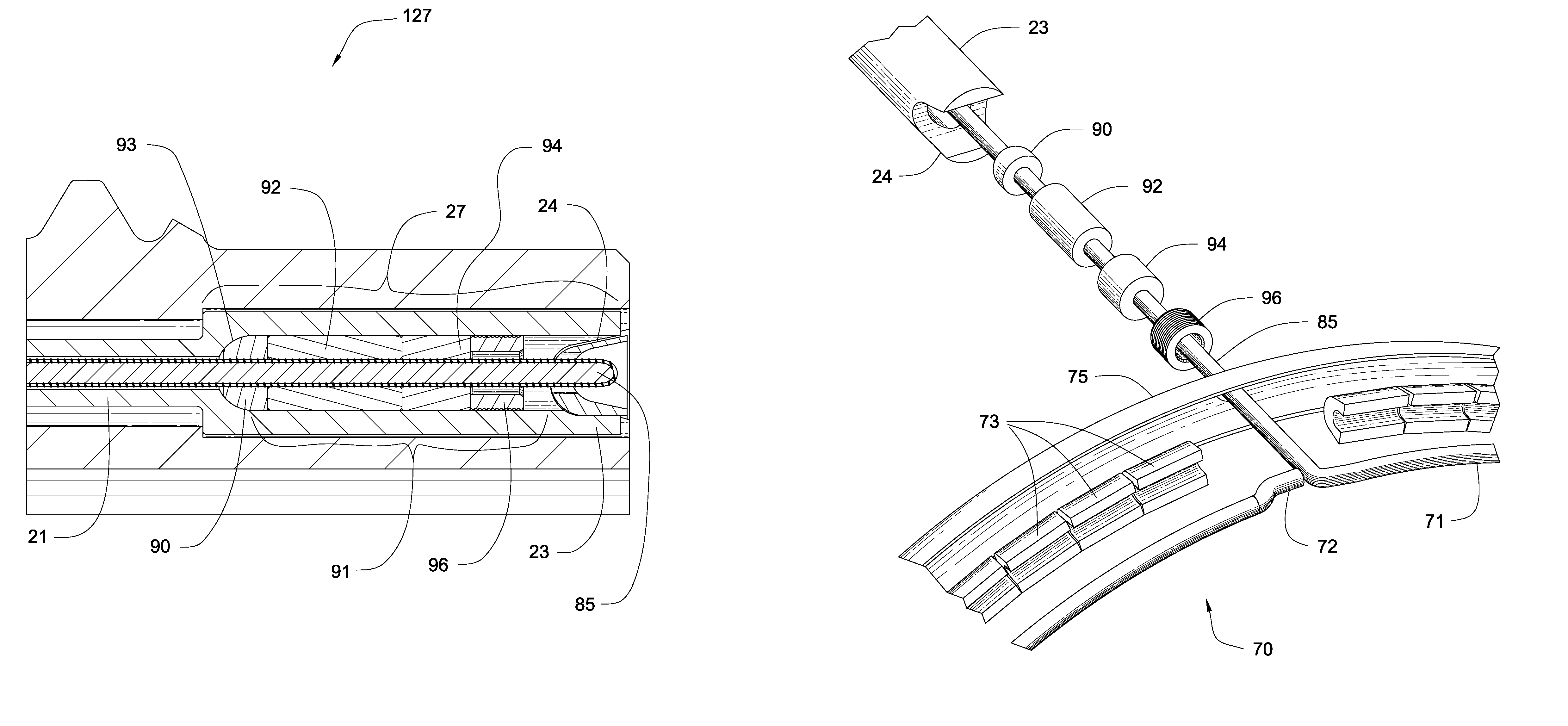

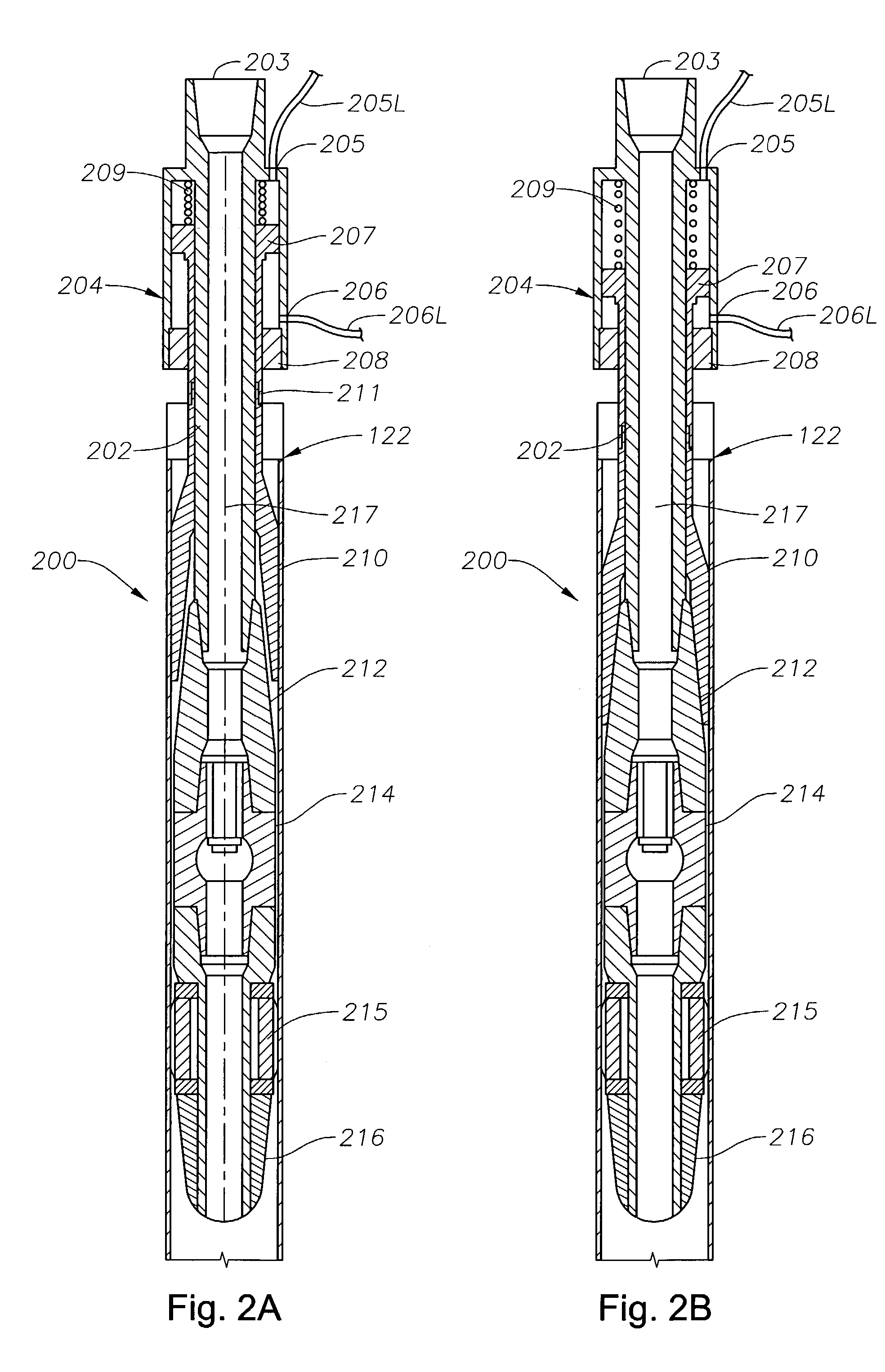

Internal coaxial cable seal system

The invention is a seal system for a coaxial cable and is placed within the coaxial cable and its constituent components. A series of seal stacks including load ring components and elastomeric rings are placed on load bearing members within the coaxial cable sealing the annular space between the coaxial cable and an electrical contact passing there through. The coaxial cable is disposed within drilling components to transmit electrical signals between drilling components within a drill string. The seal system can be used in a variety of downhole components, such as sections of pipe in a drill string, drill collars, heavy weight drill pipe, and jars.

Owner:INTELLISERV

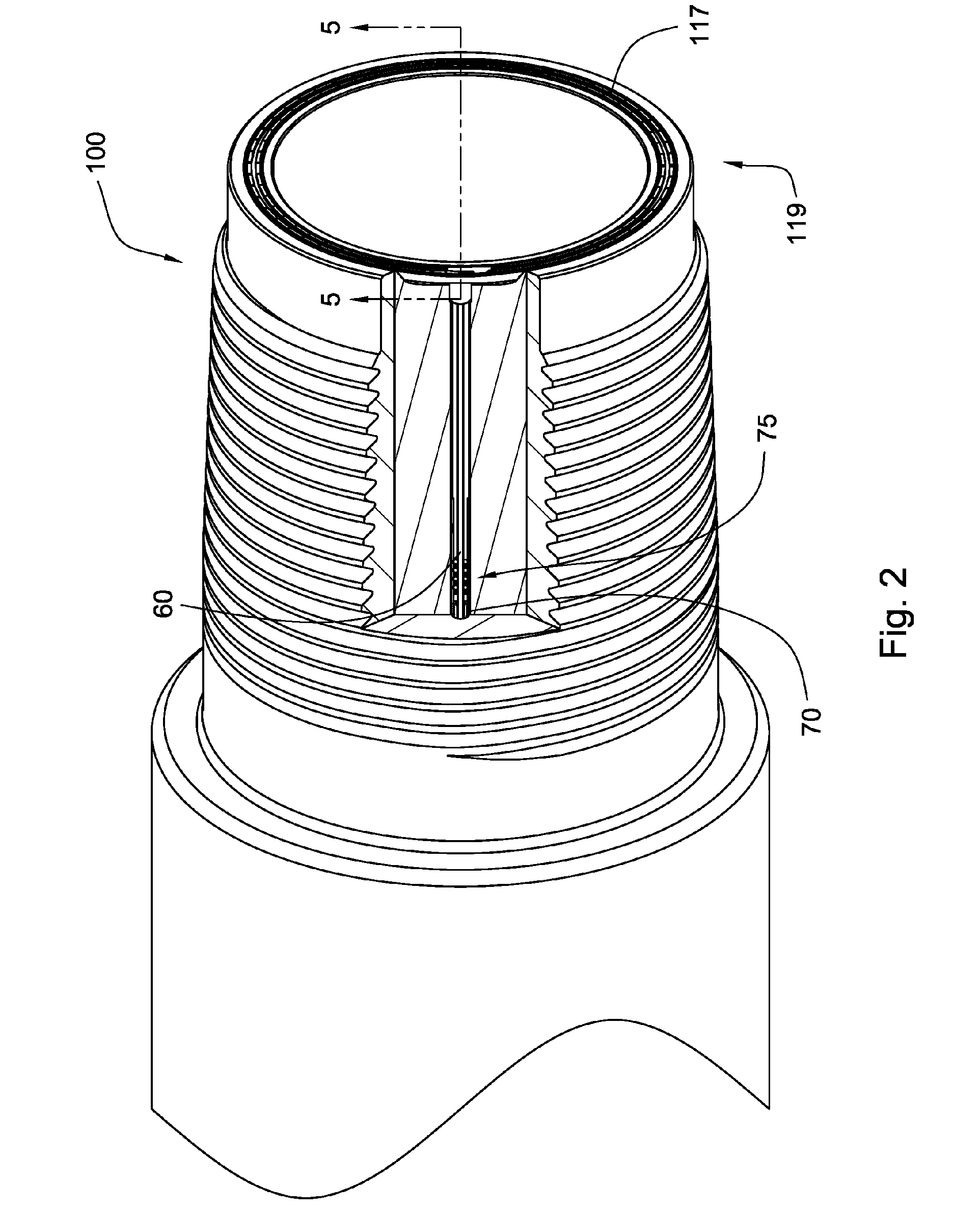

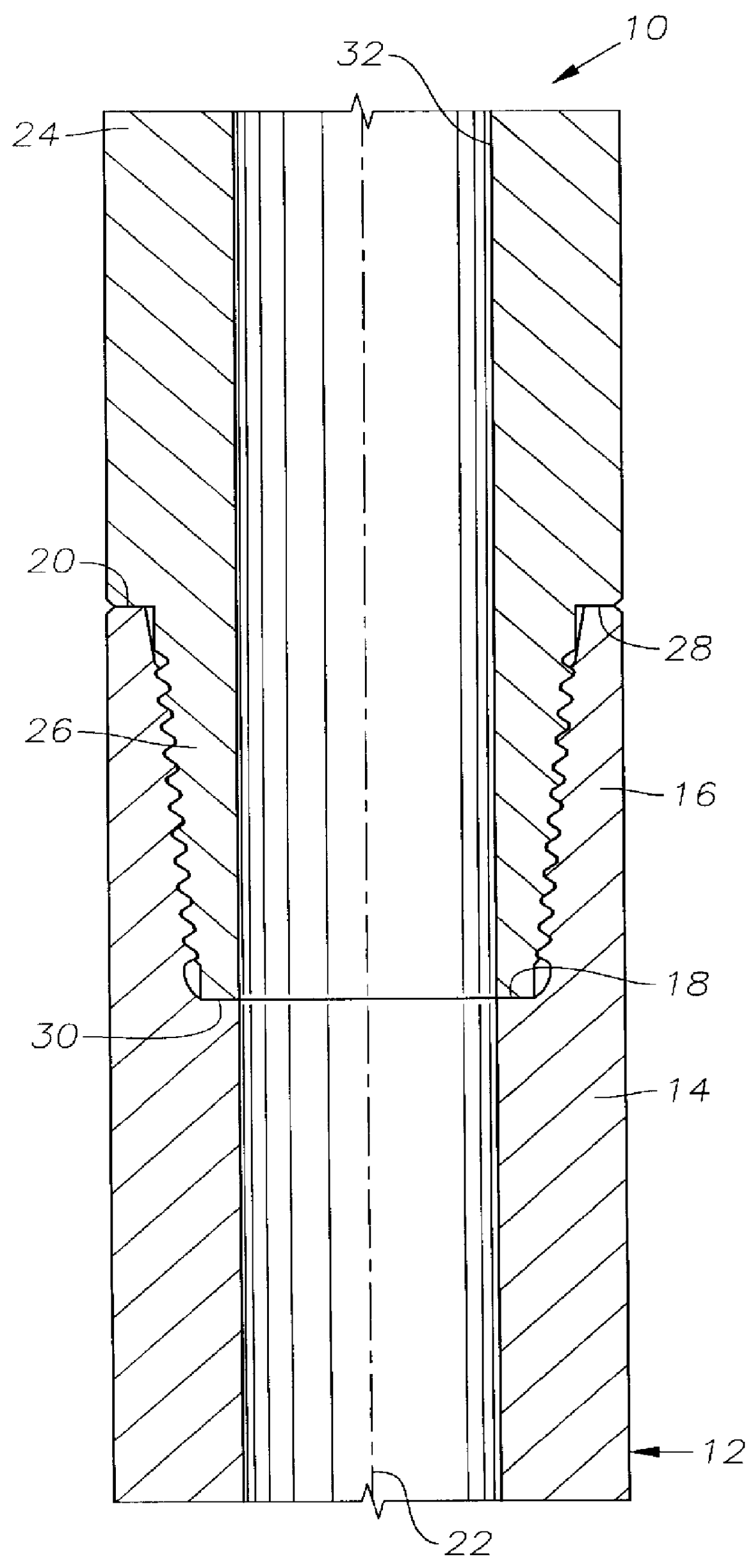

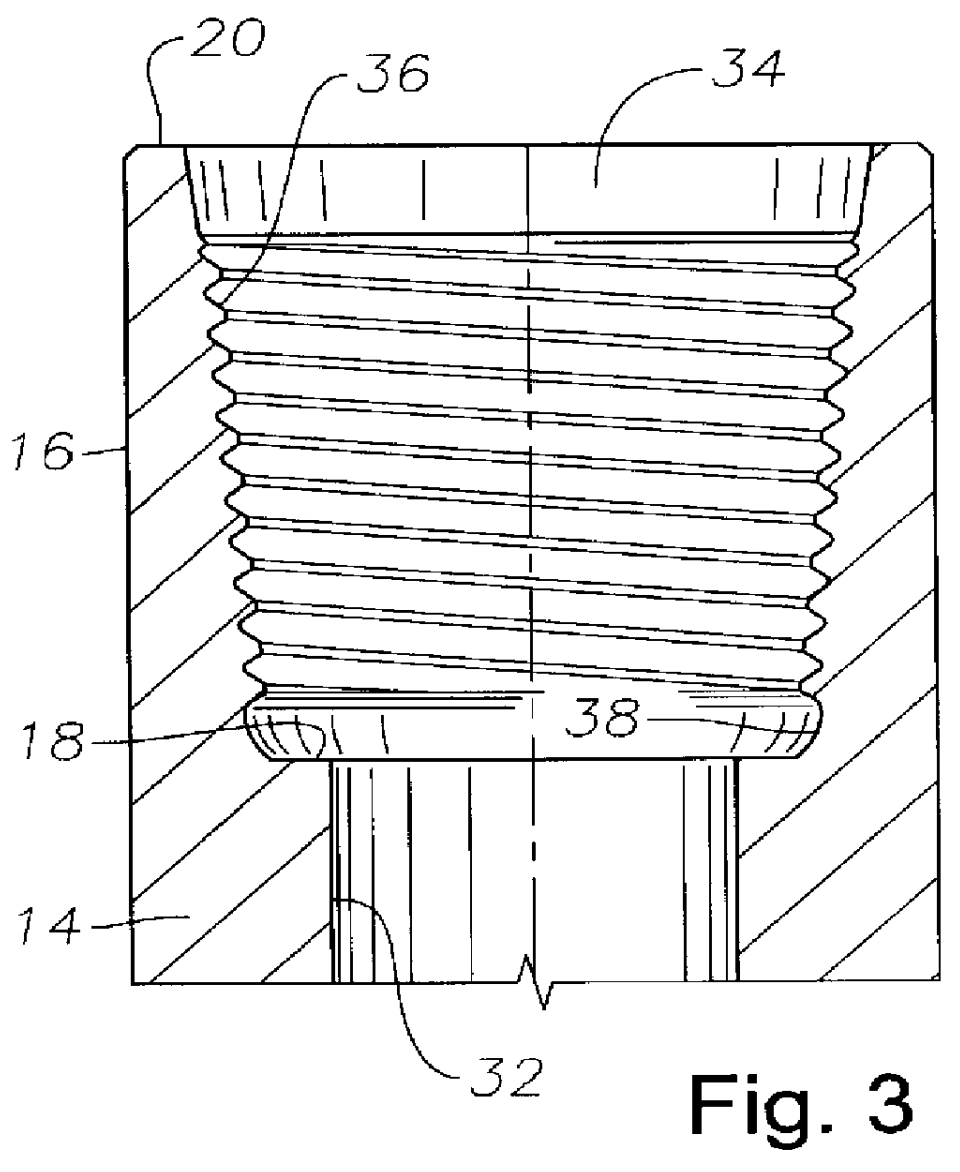

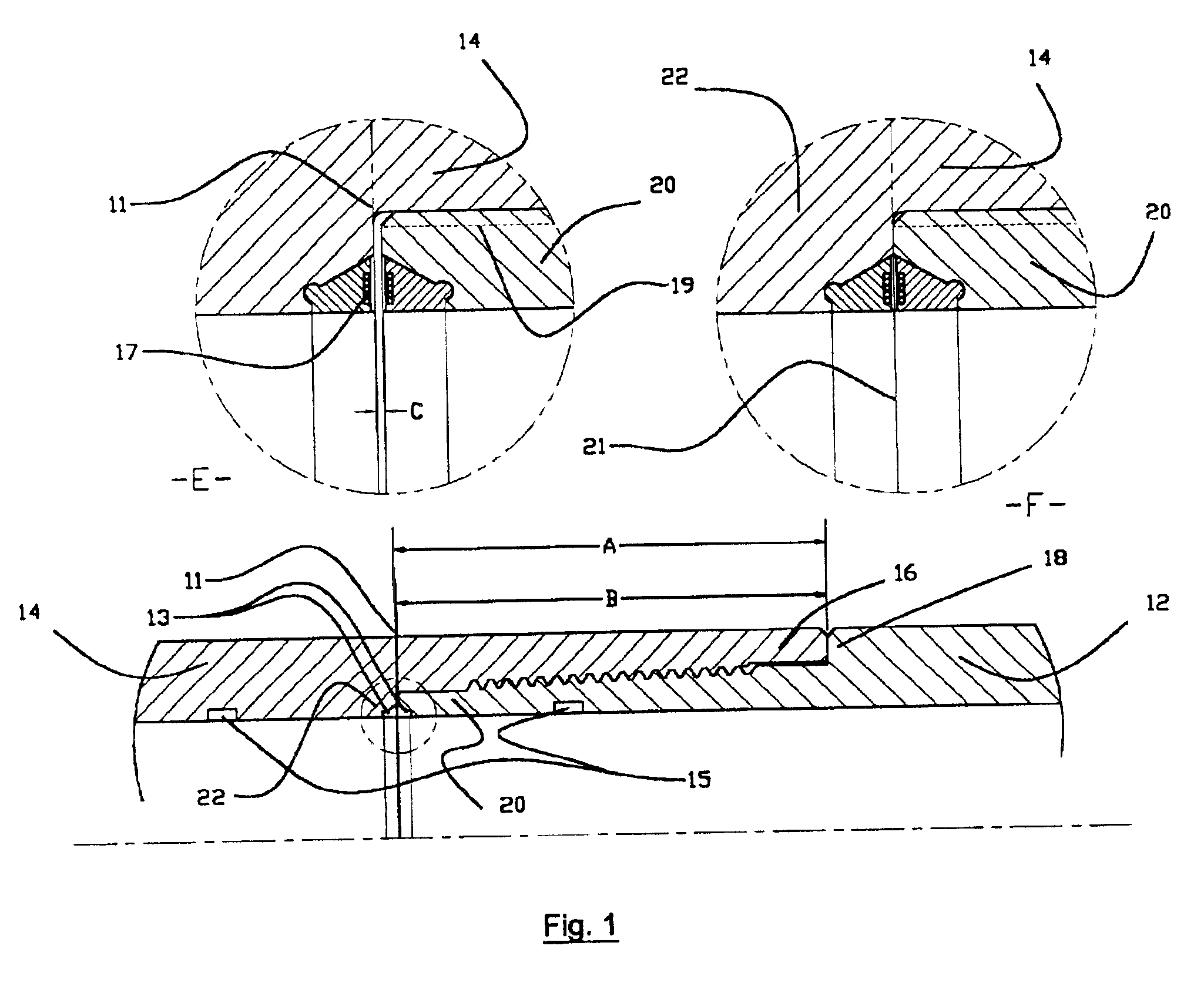

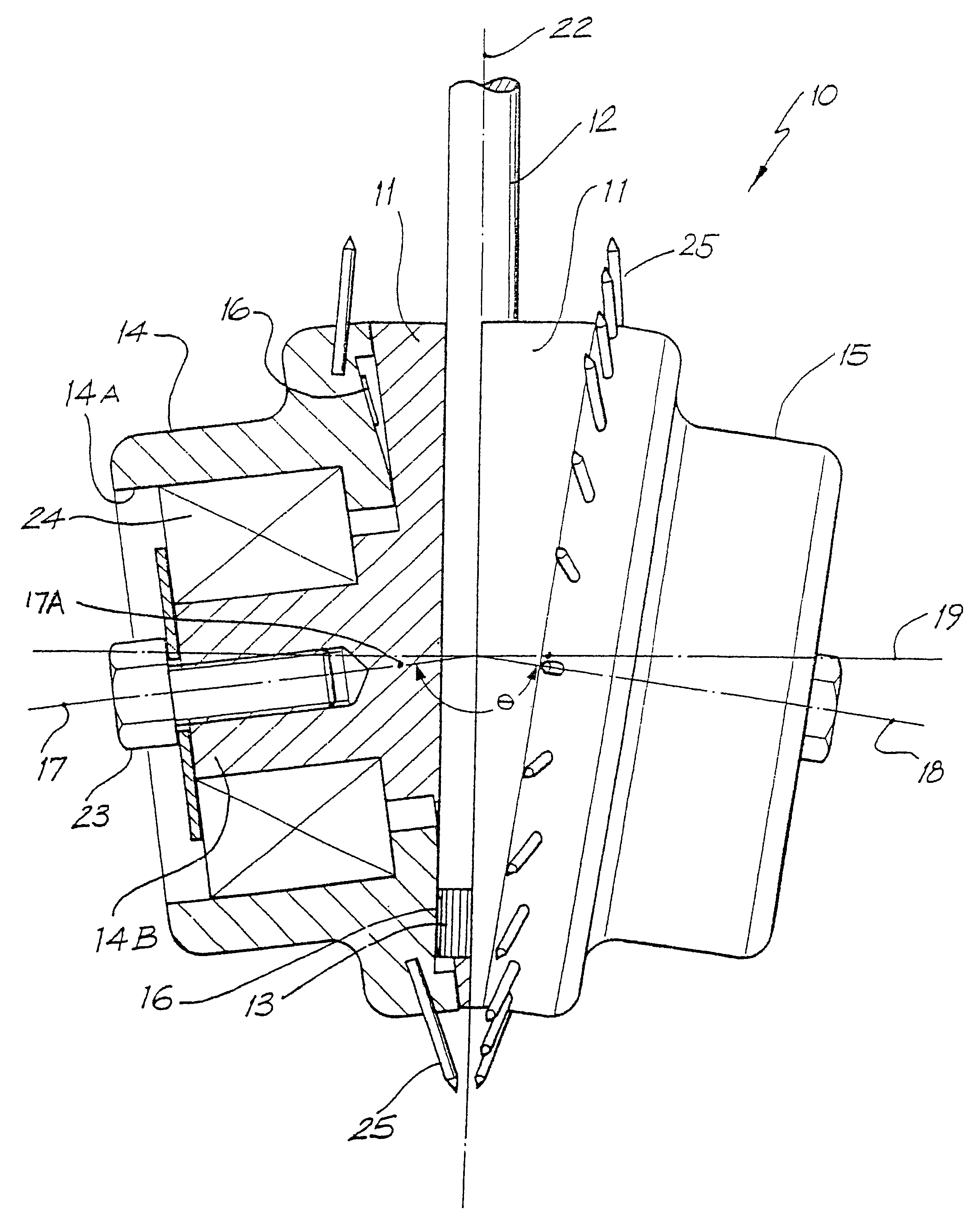

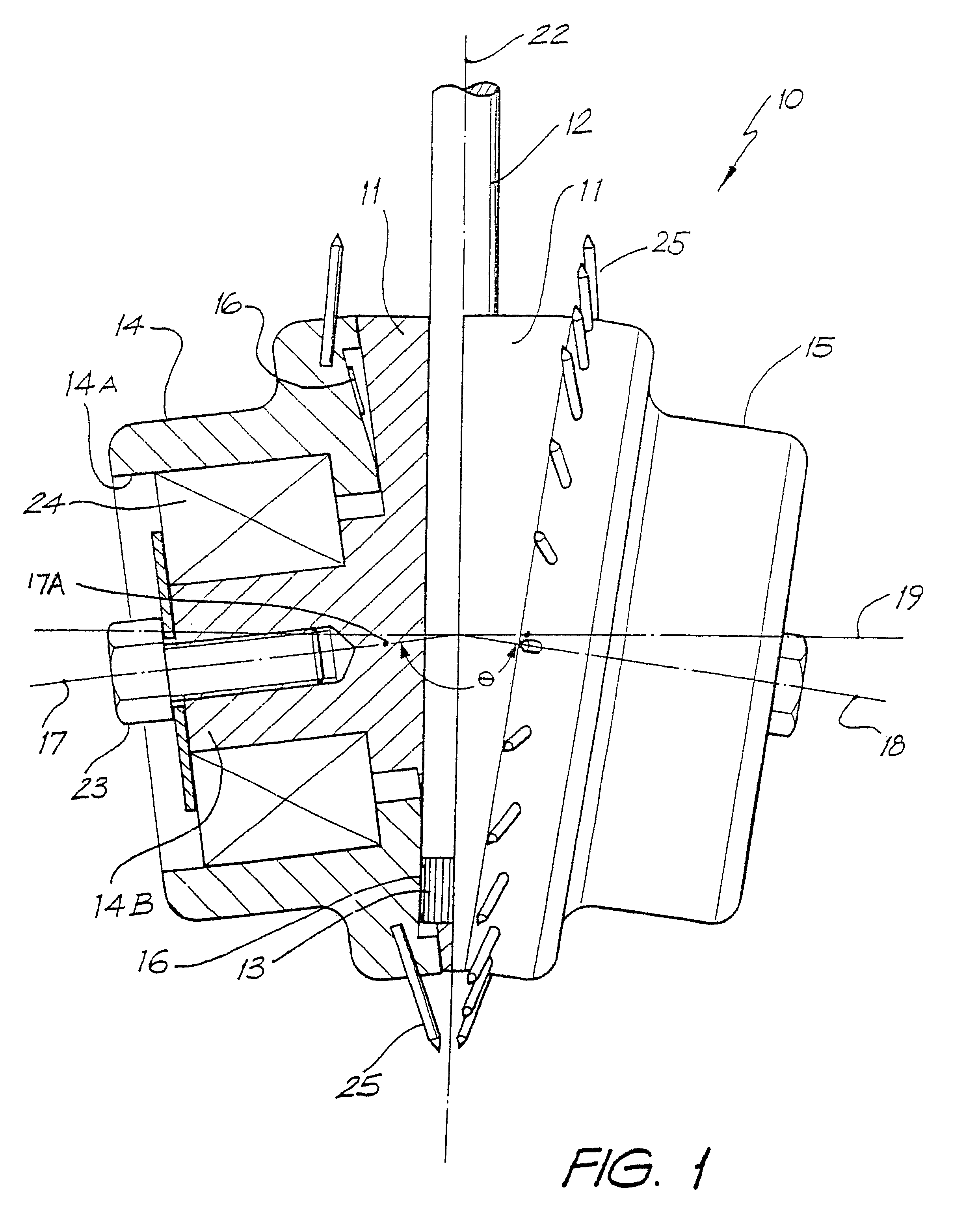

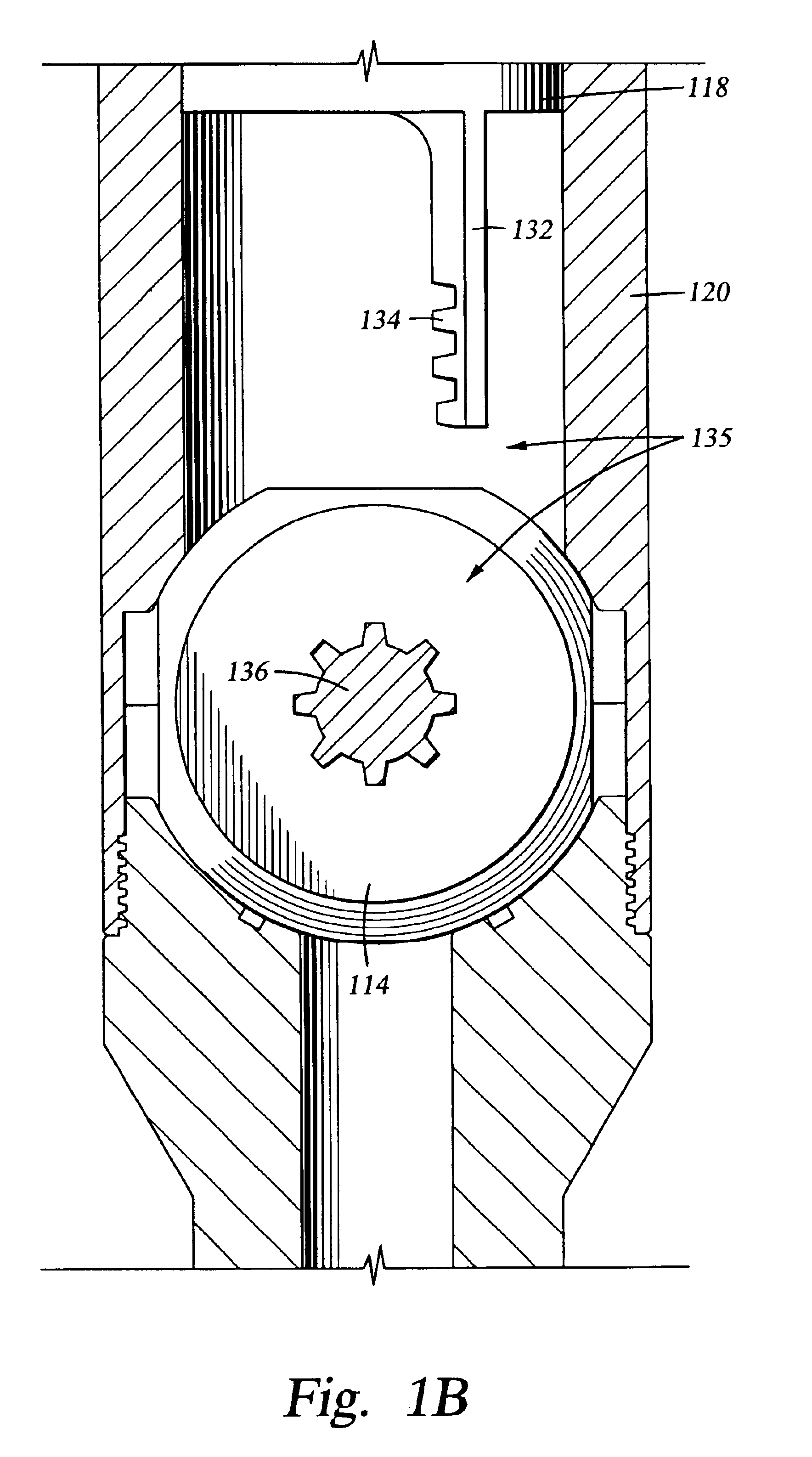

High torque threaded tool joint for drill pipe and other drill stem components

InactiveUS6030004AIncrease torqueEnhancing the torque resisting characteristicsDrilling rodsNutsStress concentrationRoot surface

A double shouldered high torque resistance threaded connection for drill stem components having enhanced resistance to torque forces, tensile loads and material stress and fatigue is disclosed. The tool joint is provided with threads having a 75 DEG included angle between the thread flanks thereof and with generally elliptical root surfaces to minimize material stress and fatigue during operation under high torque and high tensile loads. When made up, the double intrerengaging shoulders of the threaded tool joint are in firm face to face engagement permitting torque forces and tensile loads to propagate through the tool joint in a manner that minimizes bending forces and minimizes high stress concentration so that the resulting service life of the tool joint is significantly enhanced.

Owner:VALLOUREC OIL & GAS FRANCE SAS

Seal for coaxial cable in downhole tools

ActiveUS6945802B2Improve sealingImprove robustnessDrilling rodsSecuring/insulating coupling contact membersElectrical conductorCoaxial cable

A seal for a coaxial cable electrical connector more specifically an internal seal for a coaxial cable connector placed within a coaxial cable and its constituent components. A coaxial cable connector is in electrical communcation with an inductive transformer and a coaxial cable. The connector is in electrical communication with the outer housing of the inductive transformer. A generally coaxial center conductor, a portion of which could be the coil in the inductive transformer, passes through the connector, is electrically insulated from the connector, and is in electrical communication with the conductive core of the coaxial cable. The electrically insulating material also doubles as a seal to safegaurd against penetration of fluid, thus protecting against shorting out of the electrical connection. The seal is a multi-component seal, which is pre-compressed to a desired pressure rating. The coaxial cable and inductive transformer are disposed within downhole tools to transmit electrical signals between downhole tools within a drill string. The internal coaxial cable connector and its attendant seal can be used in a plurality of downhole tools, such as sections of pipe in a drill string, drill collars, heavy weight drill pipe, and jars.

Owner:INTELLISERV LLC

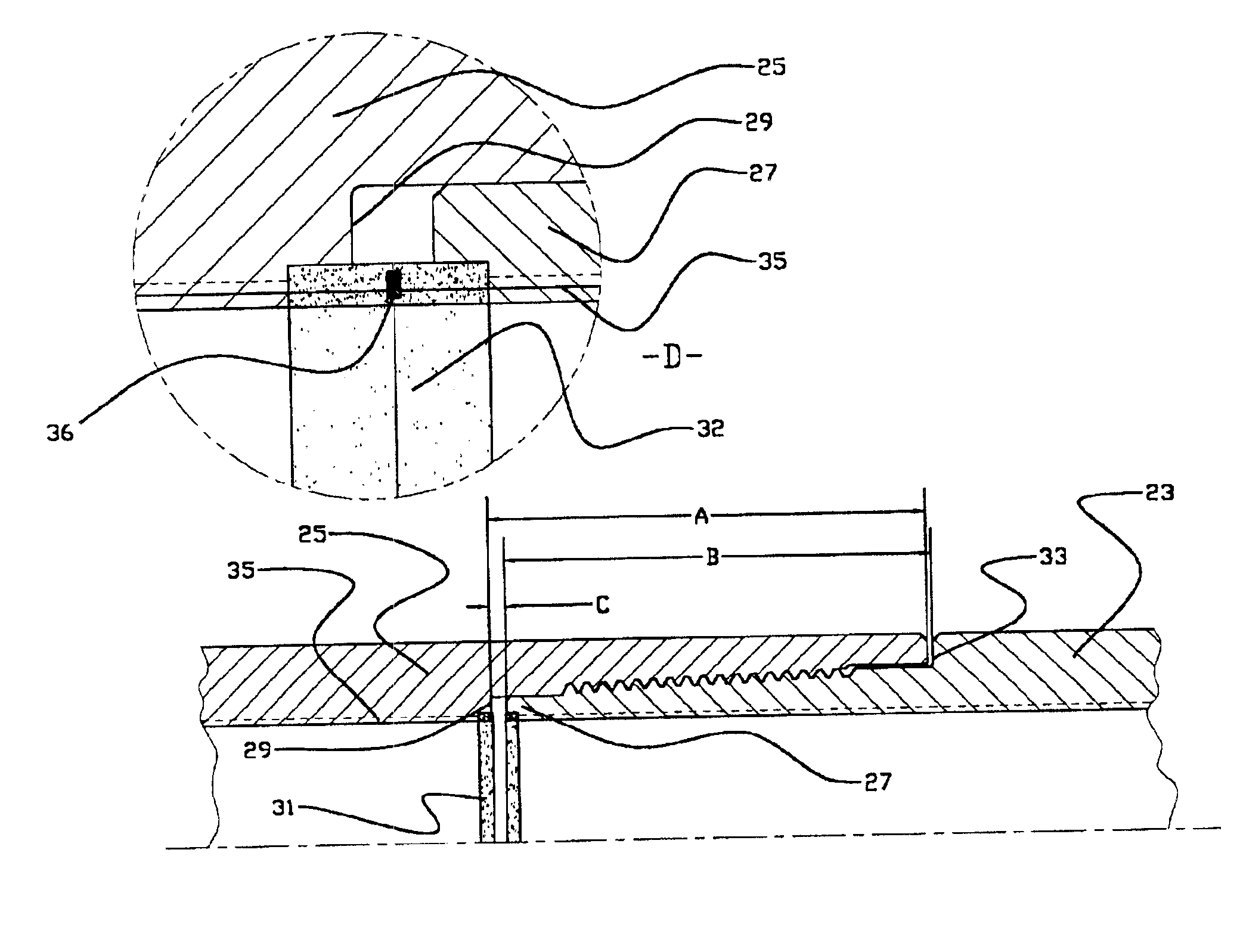

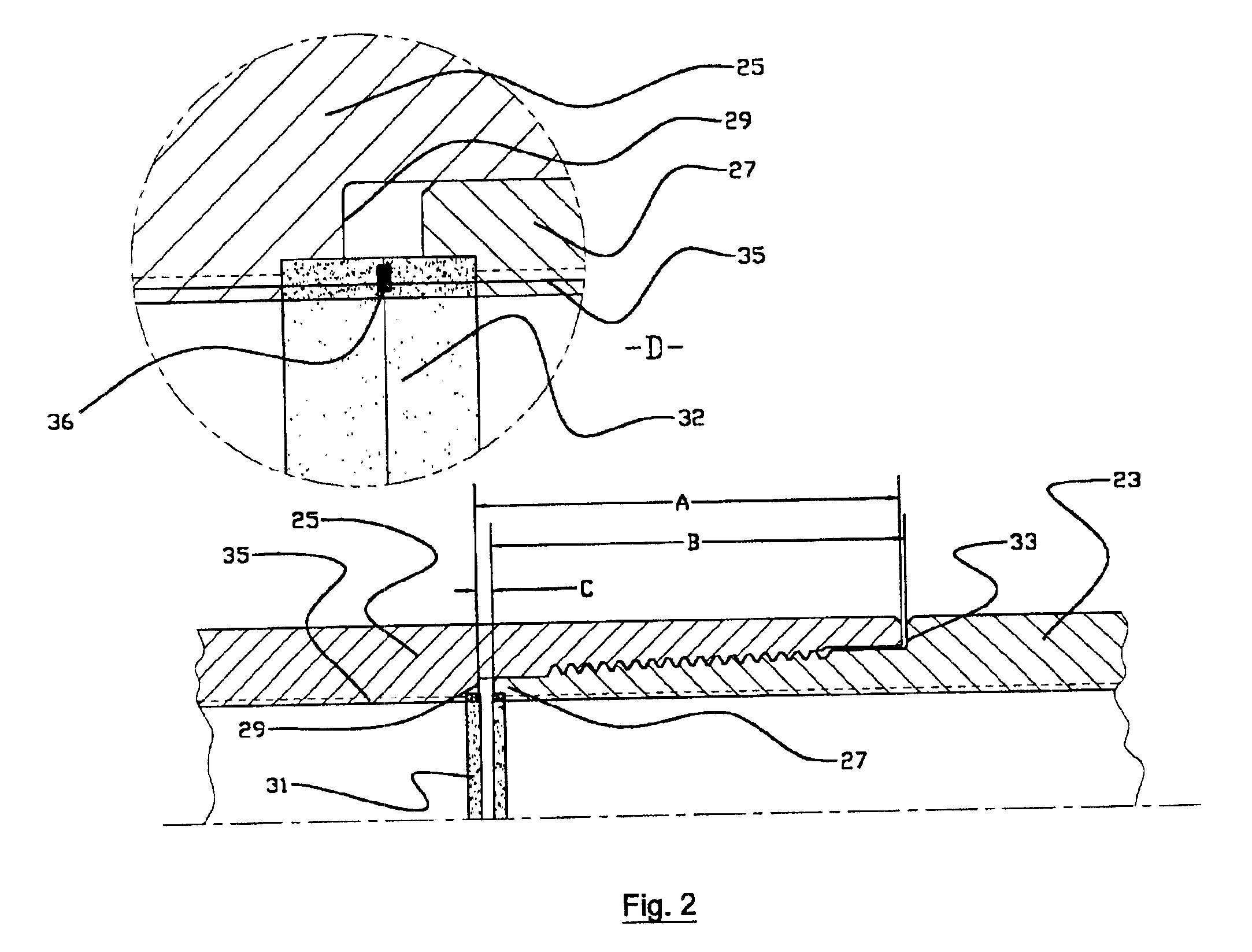

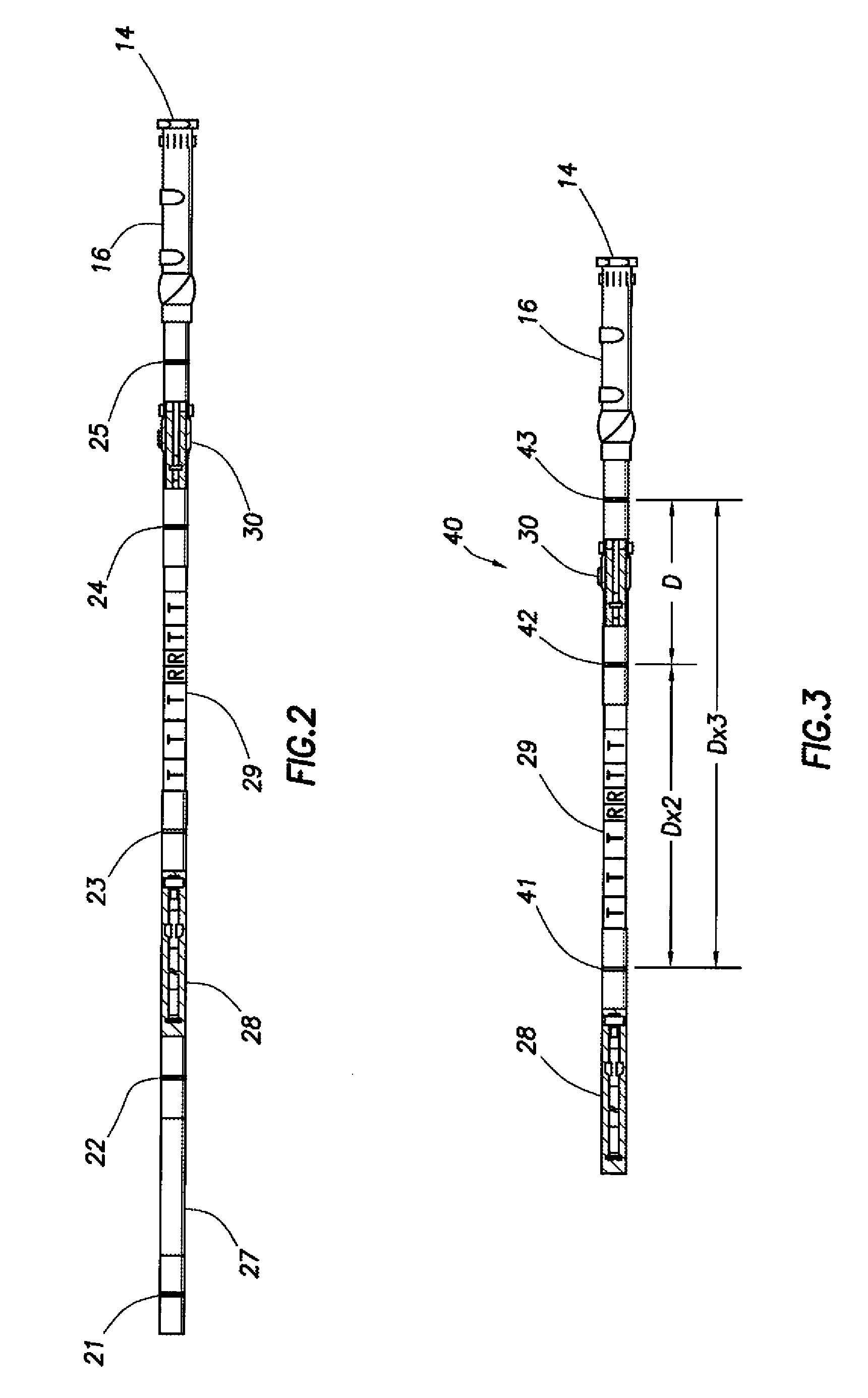

Repeatable reference for positioning sensors and transducers in drill pipe

InactiveUS6888473B1Precise positioningReliable indicationSurveyDrilling rodsTransmitted powerData acquisition

A drill pipe having a box end having a tapered thread, and an internal shoulder and an external face for engagement with a drill pipe pin end having a tapered mating thread, and an external shoulder and an external face adapted for data acquisition or transmission. The relative dimensions of the box and pin ends are precisely controlled so that when the tool joint is made up, a repeatable reference plane is established for transmitting power and tuning downhole sensors, transducers, and means for sending and receiving data along the drill string. When the power or data acquisition and transmission means are located in the tool joint, the dimensions of the tool joint are further proportioned to compensate for the loss of cross-sectional area in order maintain the joints ability to sustain nominal makeup torque.

Owner:INTELLISERV

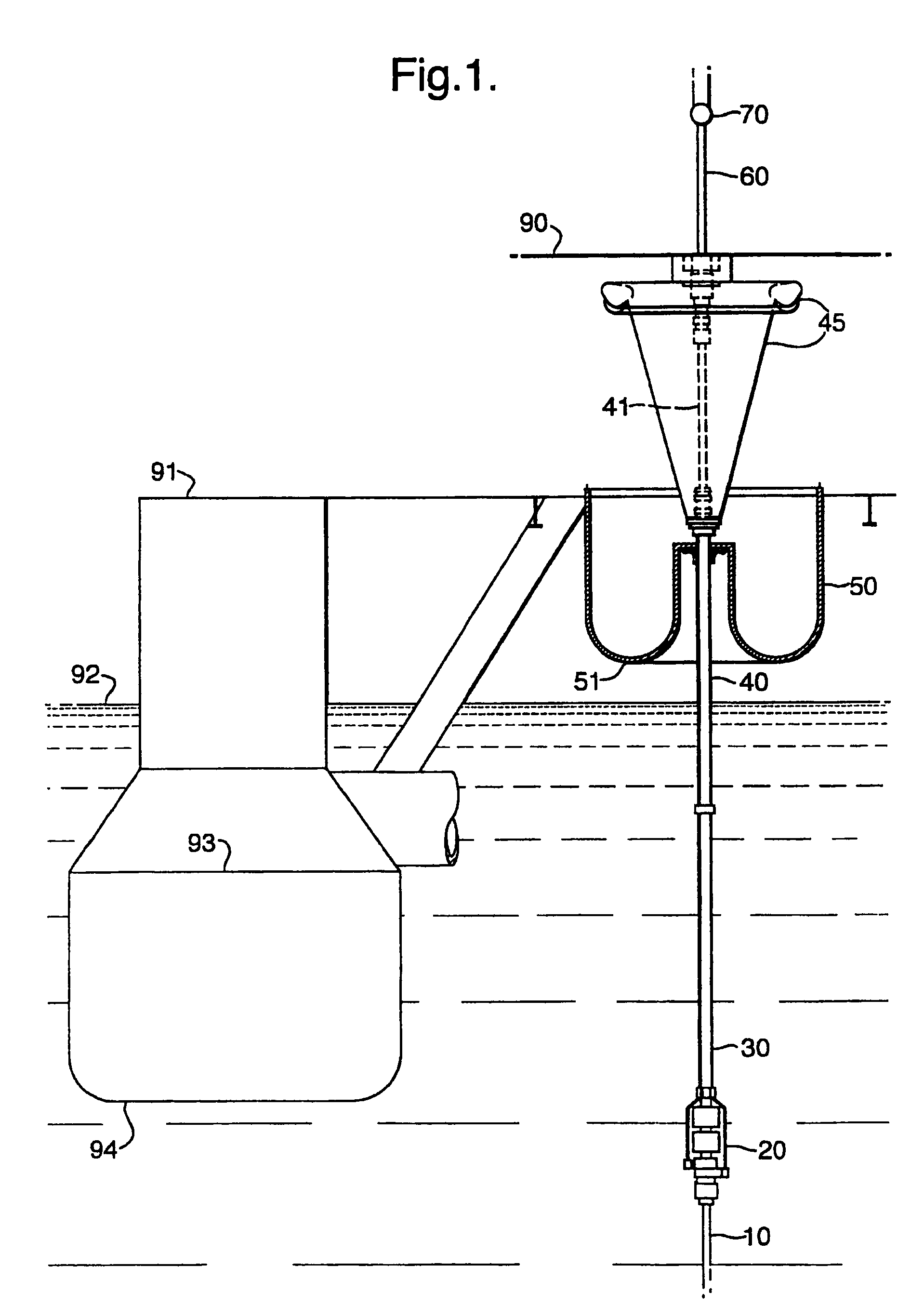

Method and apparatus for drilling a borehole with a borehole liner

A method for drilling a borehole includes; providing a drill string of drill pipe including a center bore, a distal end, a bit assembly at the distal end; hanging a liner from the drill string, thereby forming an annular space between the drill string and the liner and with the bit assembly extending from a lower end of the liner; positioning the drill string with the liner attached thereto in a borehole such that a second annular space is formed between the liner and the borehole wall; operating the bit assembly to proceed with drilling the borehole; and circulating drilling fluid down through the center bore of the drill string out through the bit assembly and down through the second annular space between the liner and the borehole wall, the drilling fluid returning up through the annular space between the drill string and the liner.

Owner:TESCO CORPORATION +1

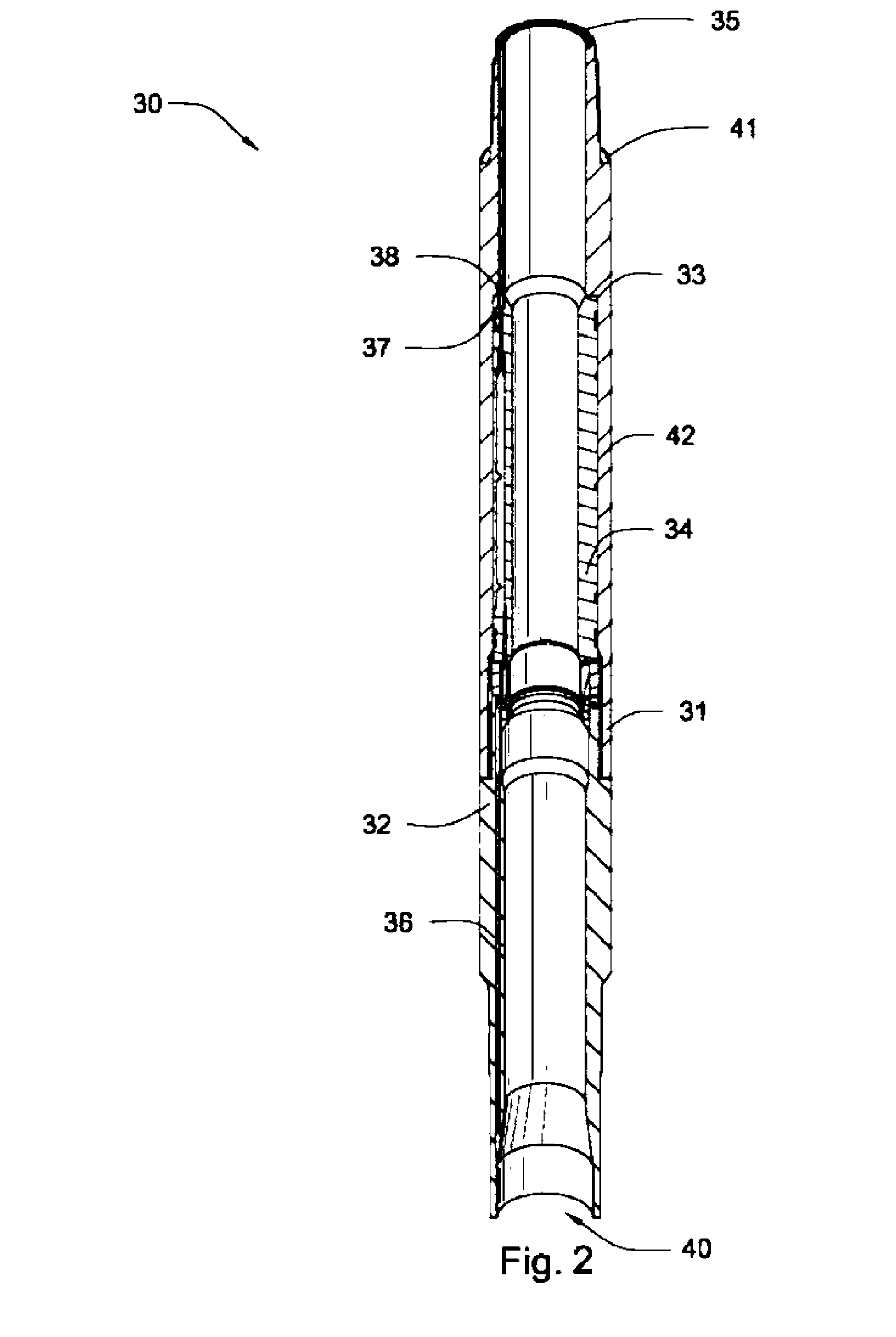

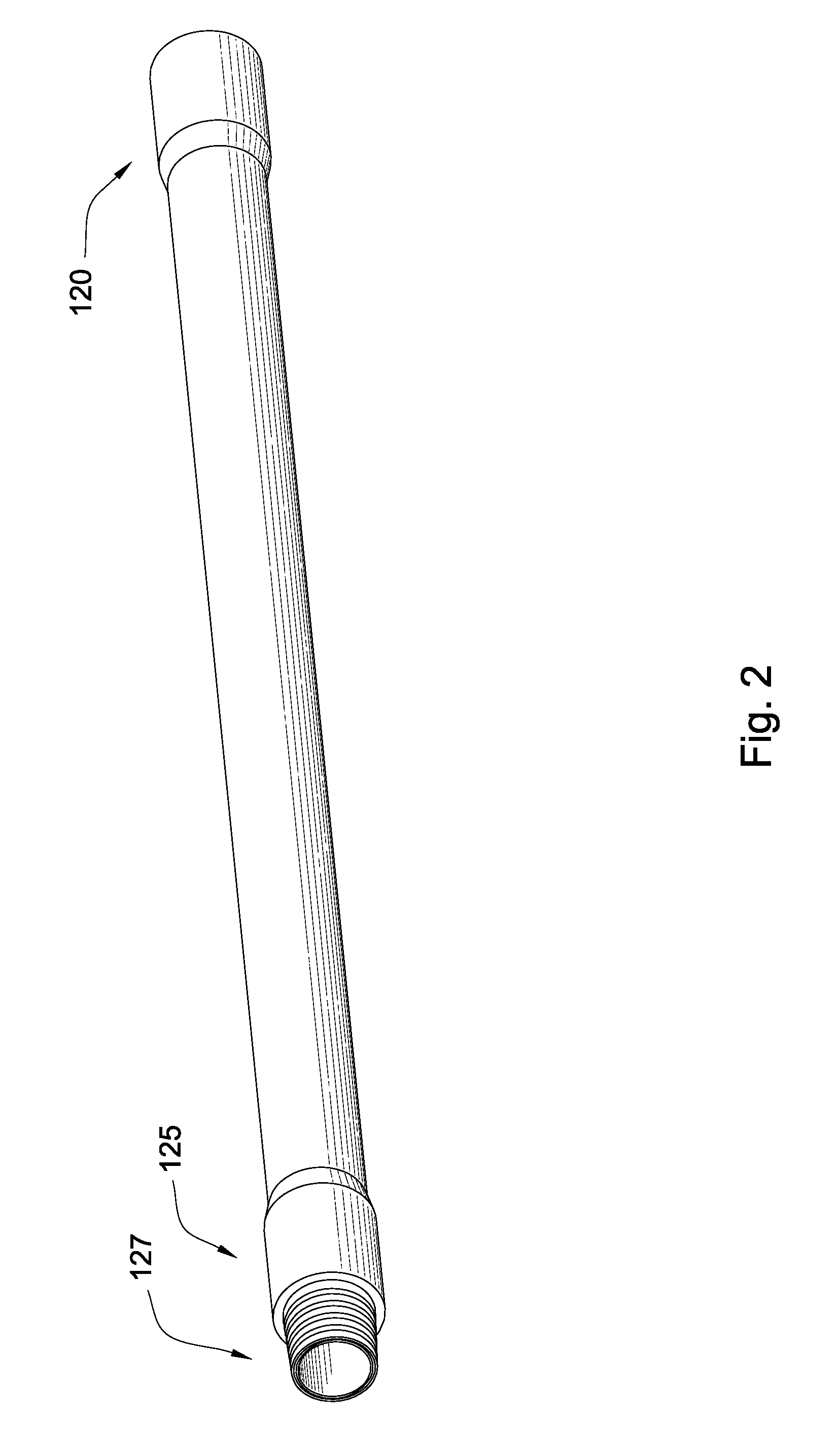

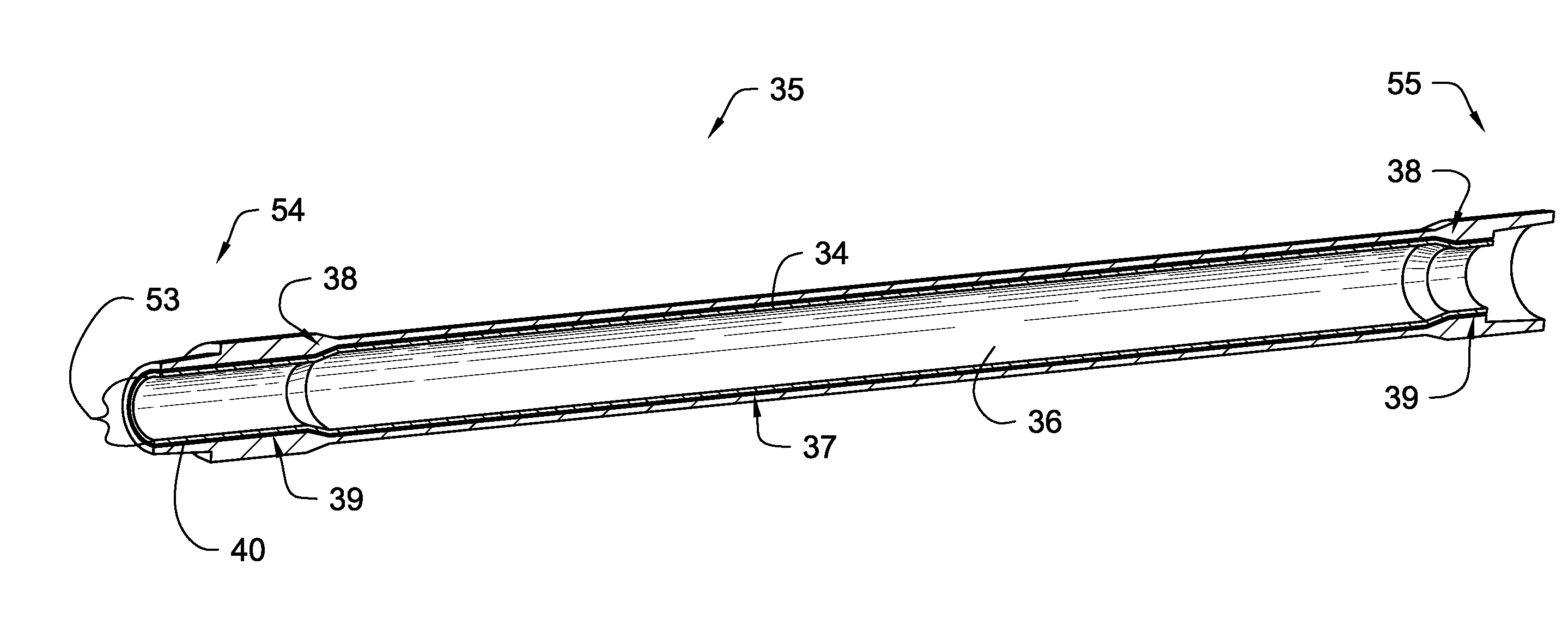

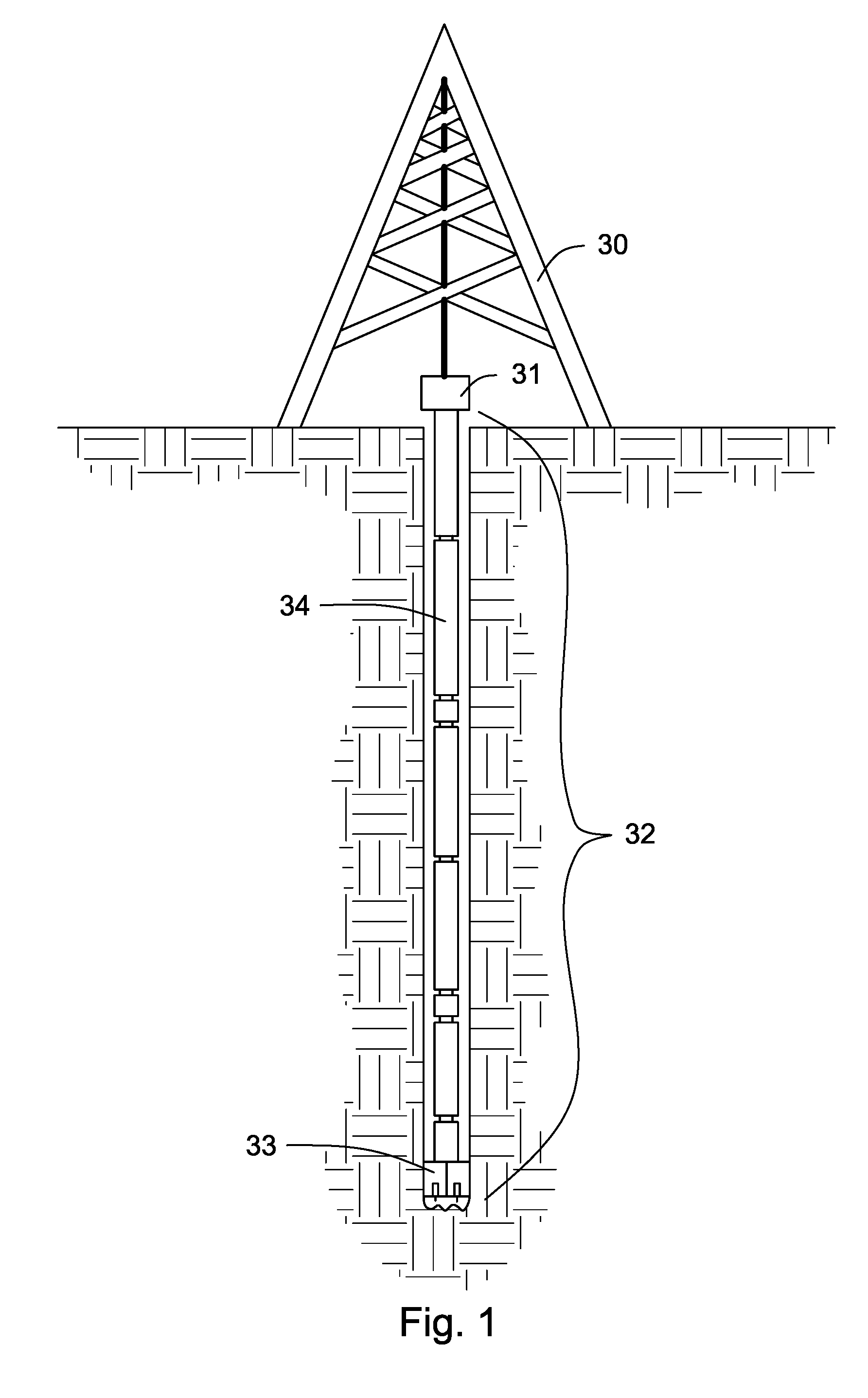

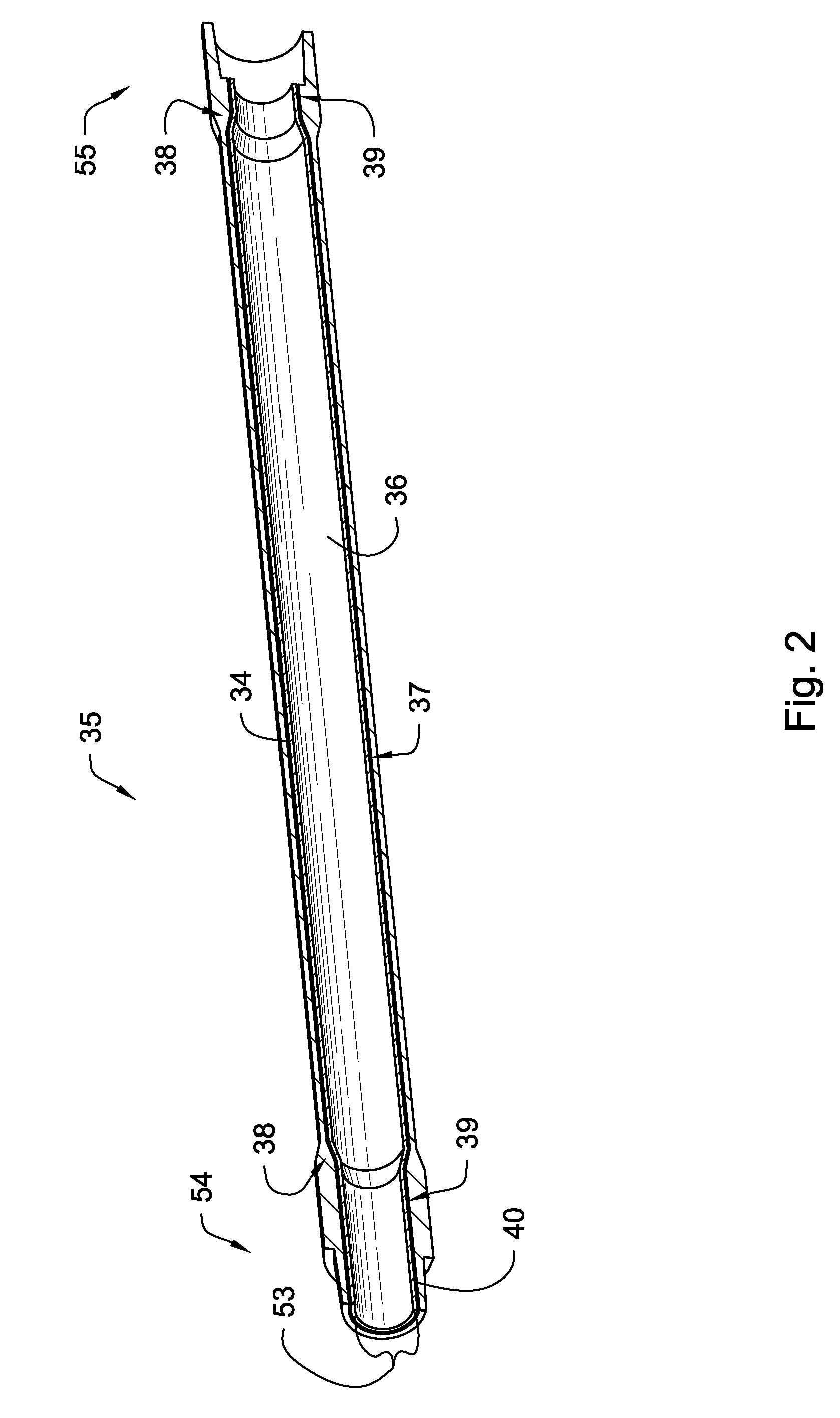

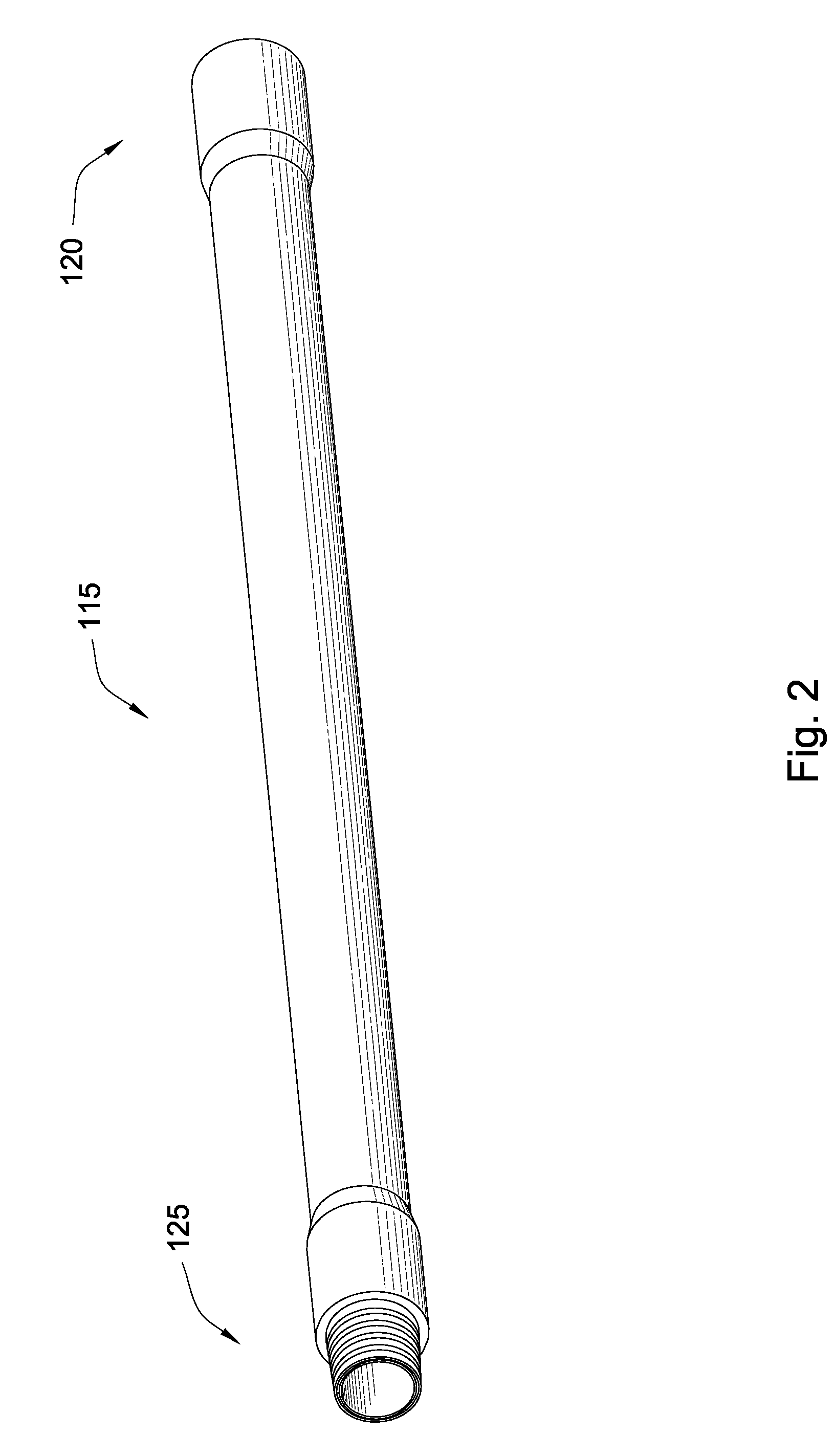

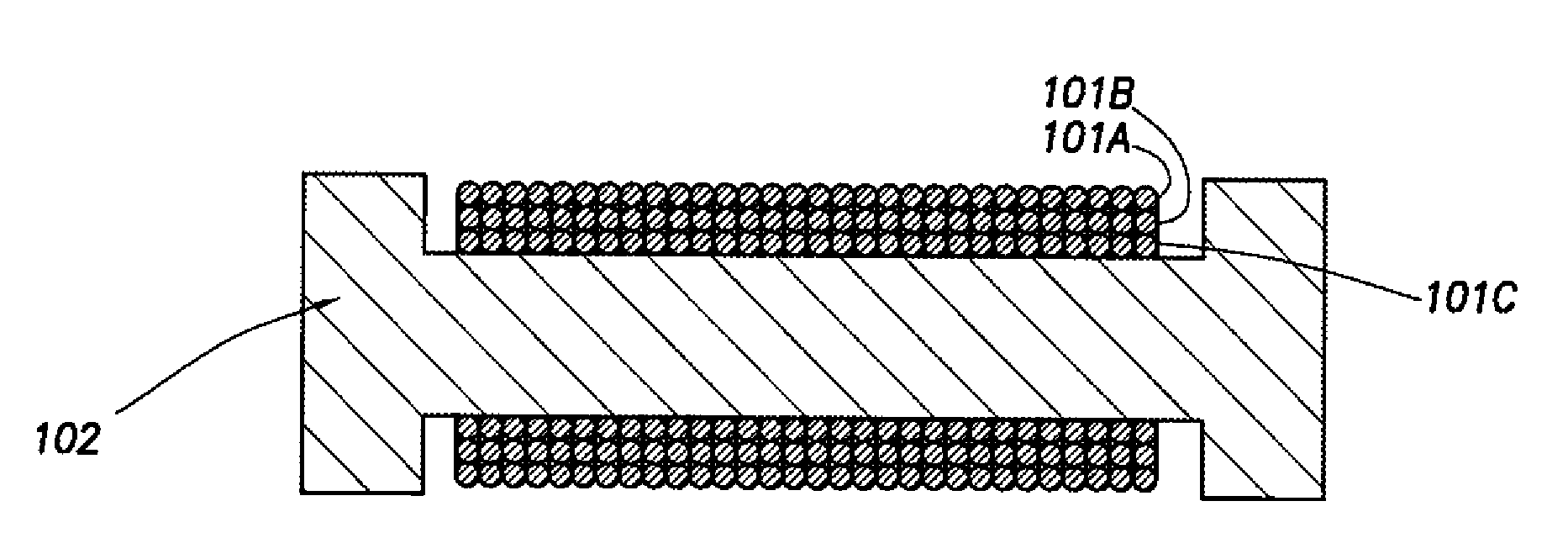

Conformable Apparatus in a Drill String

An apparatus in a drill string comprises an internally upset drill pipe. The drill pipe comprises a first end, a second end, and an elongate tube intermediate the first and second ends. The elongate tube and the ends comprising a continuous an inside surface with a plurality of diameters. A conformable metal tube is disposed within the drill pipe intermediate the ends thereof and terminating adjacent to the ends of the drill pipe. The conformable metal tube substantially conforms to the continuous inside surface of the metal tube. The metal tube may comprise a non-uniform section which is expanded to conform to the inside surface of the drill pipe. The non-uniform section may comprise protrusions selected from the group consisting of convolutions, corrugations, flutes, and dimples. The non-uniform section extends generally longitudinally along the length of the tube. The metal tube may be adapted to stretch as the drill pipes stretch.

Owner:INTELLISERV

An internal coaxial cable electrical connector for use in downhole tools

ActiveUS20050095827A1Reliable coaxial electrical connectionImprove robustnessTwo pole connectionsDrilling rodsCoaxial cableElectrical conductor

A coaxial cable electrical connector more specifically an internal coaxial cable connector placed within a coaxial cable and its constituent components. A coaxial cable connector is in electrical communication with an inductive transformer and a coaxial cable. The connector is in electrical communication with the outer housing of the inductive transformer. A generally coaxial center conductor, a portion of which could be the coil in the inductive transformer, passes through the connector, is electrically insulated from the connector, and is in electrical communication with the conductive core of the coaxial cable. A plurality of bulbous pliant tabs on the coaxial cable connector mechanically engage the inside diameter of the coaxial cable thus grounding the transformer to the coaxial cable. The coaxial cable and inductive transformer are disposed within downhole tools to transmit electrical signals between downhole tools within a drill string. The internal coaxial cable connector can be used in a plurality of downhole tools, such as sections of pipe in a drill string, drill collars, heavy weight drill pipe, and jars.

Owner:INTELLISERV

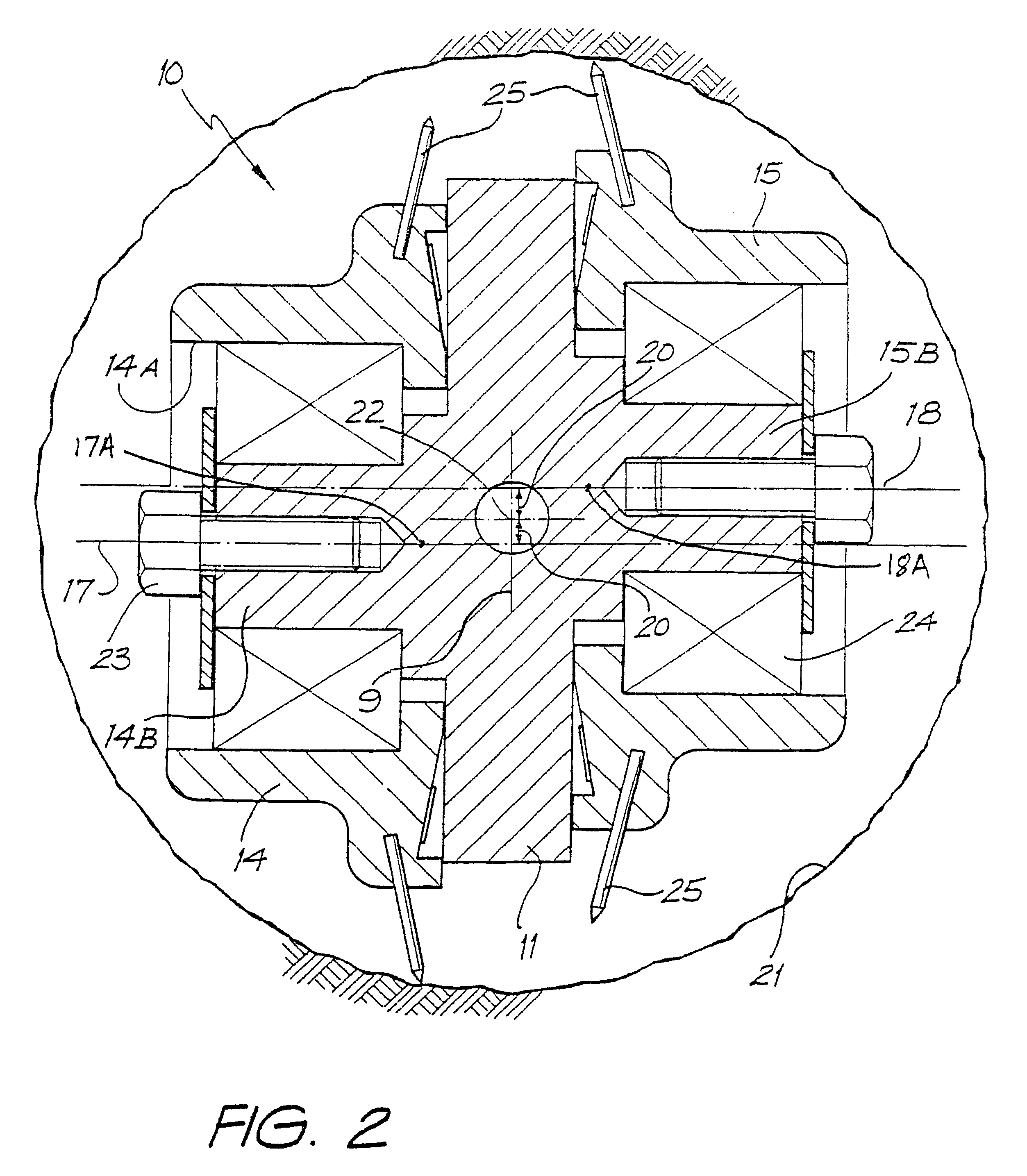

Excavation bit for a drilling apparatus

The invention provides an excavation bit, which is constructed from either a single or double carrier. If two carriers are present the carriers are contra-rotating. By the off setting of the axes of rotation of single or dual carriers from a longitudinal axis of the bit, and by driving to carriers to rotate, a ground engaging thrust is produced, as well as the rotation of the excavation bit in the ground as a consequence of the rotation of the carriers, and not vice versa as is the case with prior art. By the invention, there can result sufficient thrust on the bit, by the rotation of the carriers, so that the need to apply thrust down the bore via the drill rod is reduced or eliminated. As a result of the invention the number and or size of the ground engaging tools are not a function of the bore diameter to be drilled. Thus as the excavation bit is scaled up for larger diameter bores more ground engaging tools and or an increase in their size is not required. By the invention, thrust applied (either via the drill rod or from the rotation of the carriers) is thought to be, through a quasi lever system, multiplied at some of the ground engaging tools in the radial direction. That is the total thrust in the longitudinal axis direction (whether externally applied or resultant from the contra-rotation of the carriers), is multiplied so that the outward forces exerted (by the cutters onto the rock surface in the region approaching perpendicular to the longitudinal axis of the bore) is thought to be significantly higher than the magnitude of the total thrust.

Owner:MOLLOY ANTHONY

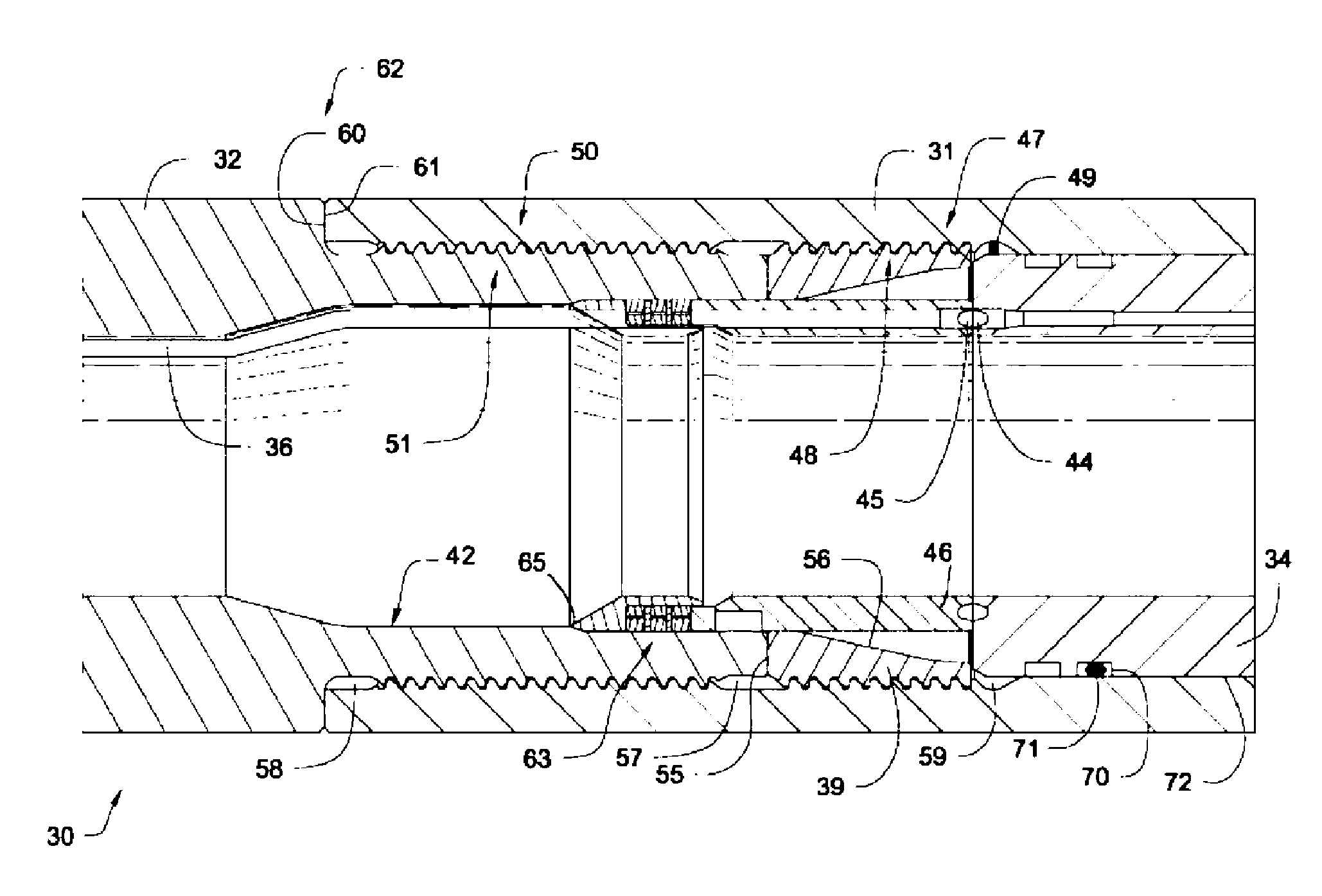

Mechanically opened ball seat and expandable ball seat

A method and apparatus for obstructing the passage of fluid within a fluid flow conduit and subsequently reconfiguring the tool to allow substantially full-bore passage therethrough. Pressure developed upstream of the obstruction can be utilized to operate pressure actuated tools such as liner hangers. Equipment used in subsequent wellbore operations such as drill pipe darts can pass undamaged through the opened port. In an embodiment, the flow through a tubular is obstructed by placing a ball on an expandable ball seat, developing a pressure differential across the ball seat, equalizing the pressure after the hydraulically actuated tool completes its function, and mechanically manipulating the drill string to open the expandable ball seat and allow the ball to pass through.

Owner:WEATHERFORD TECH HLDG LLC

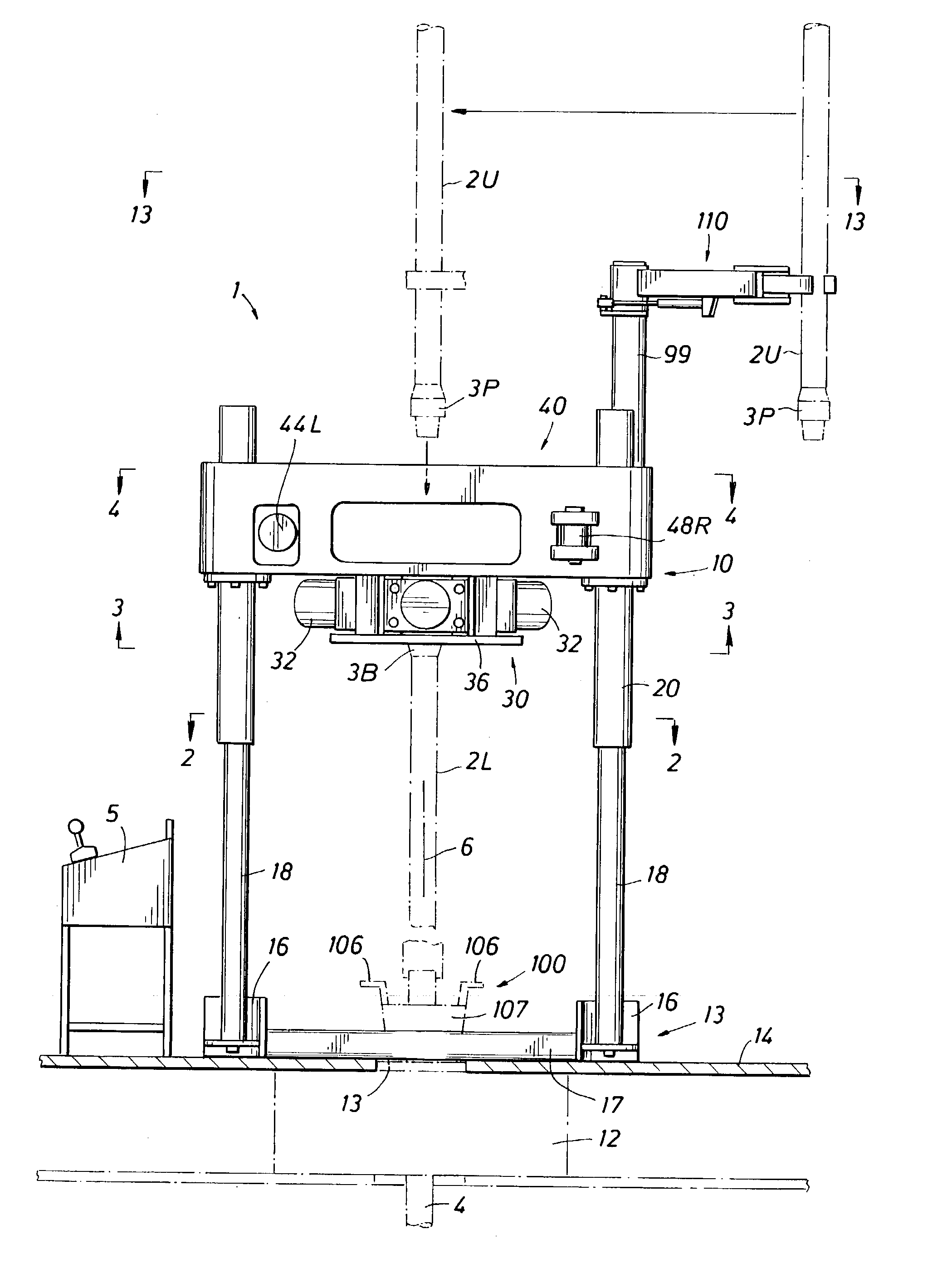

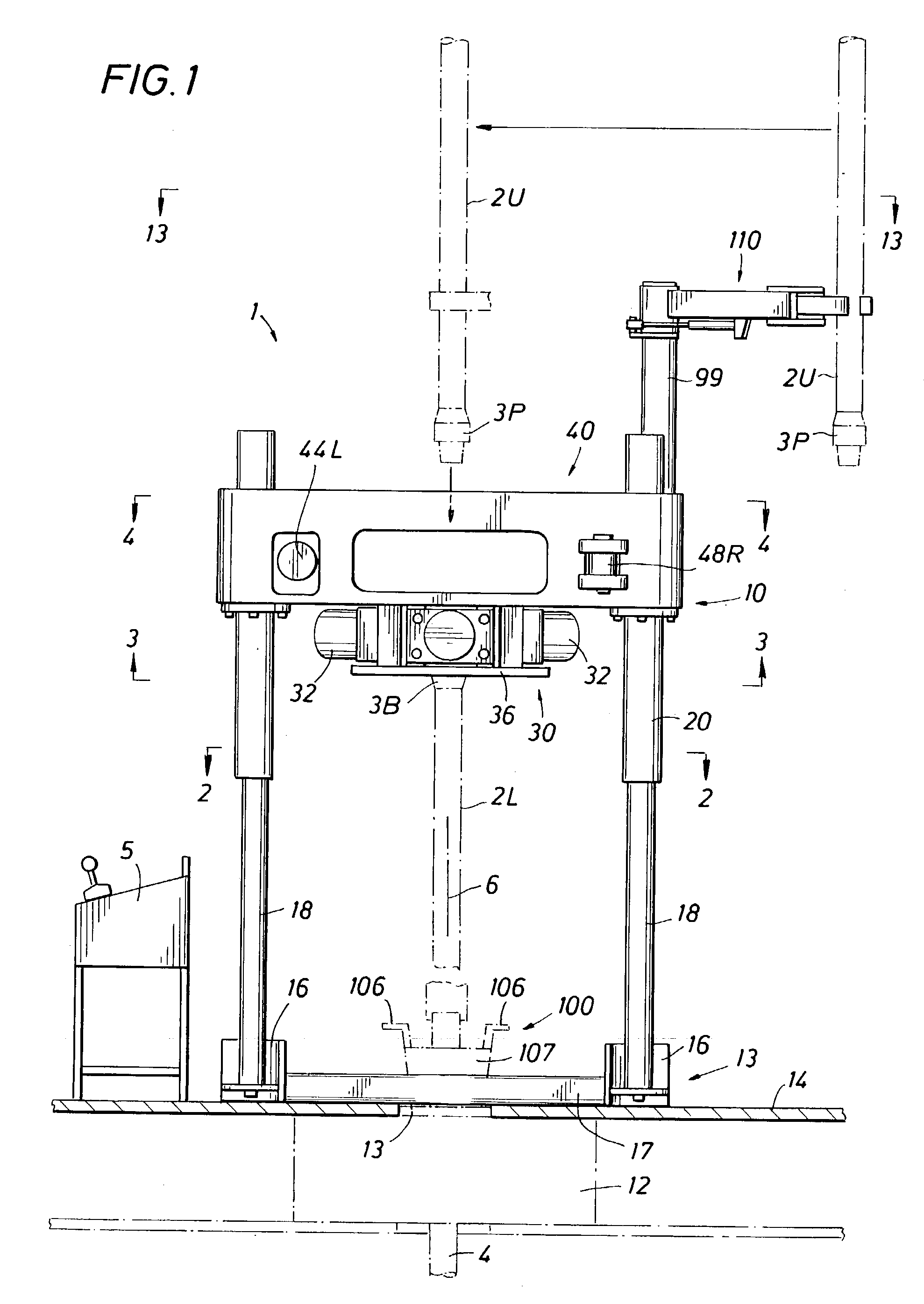

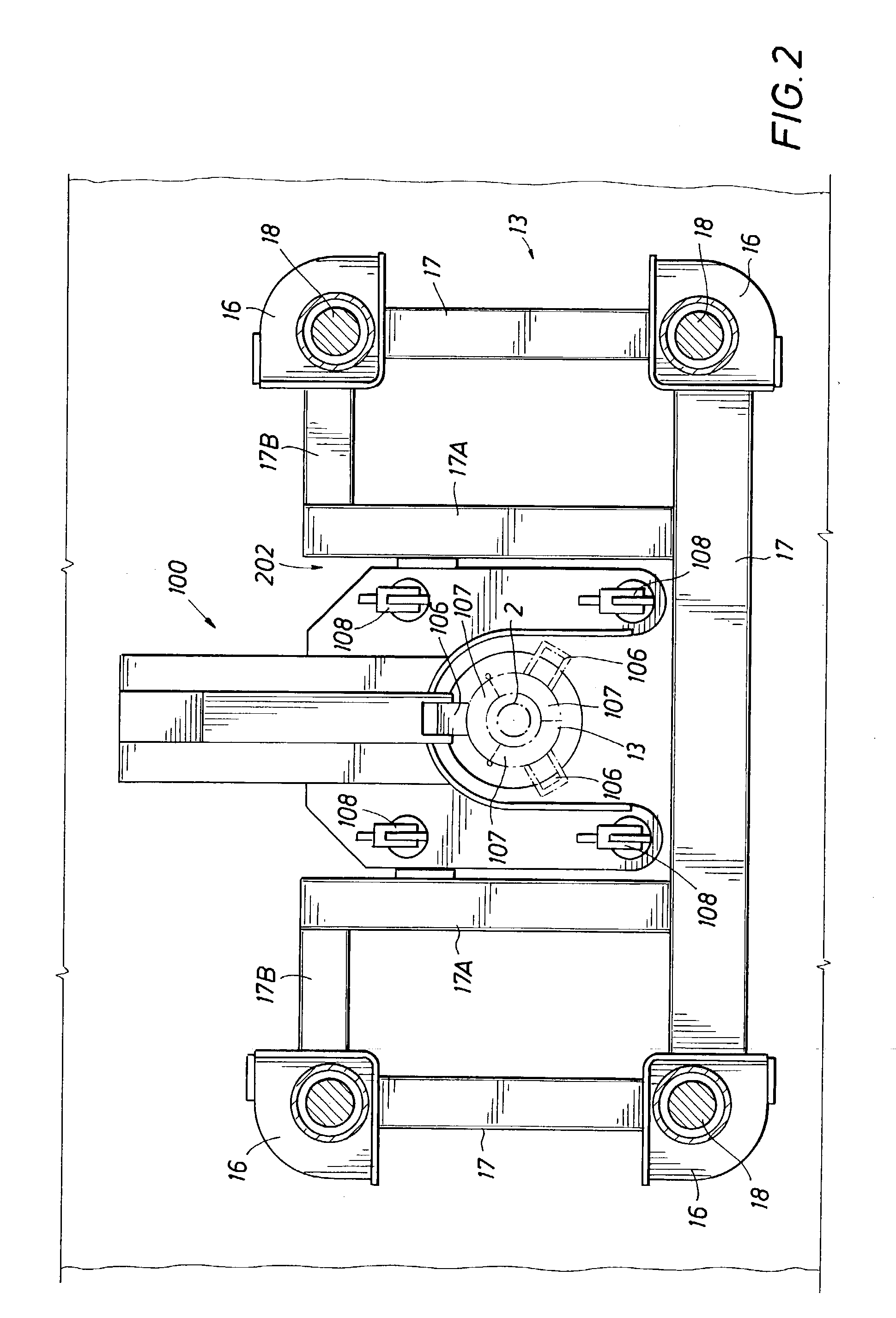

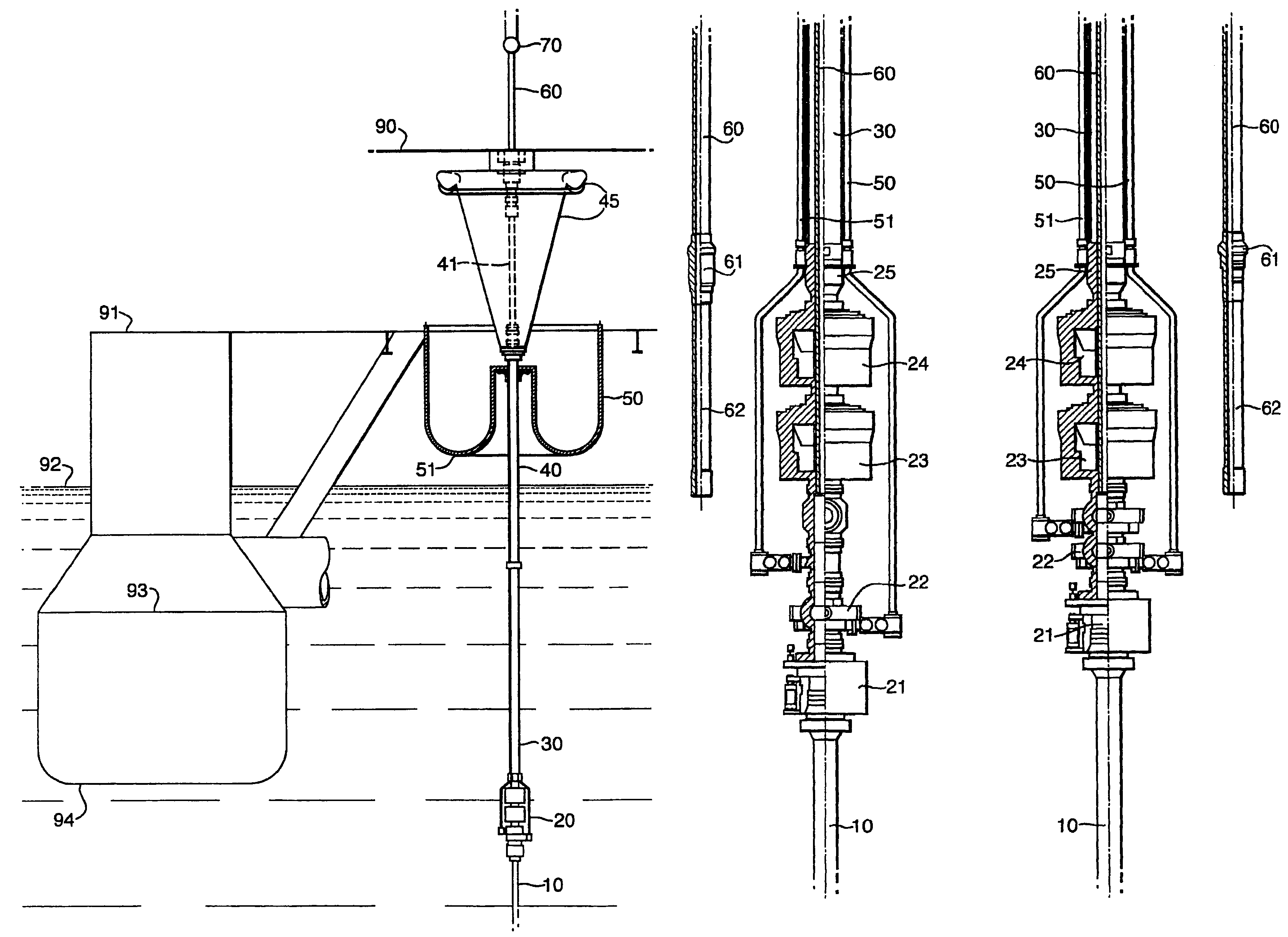

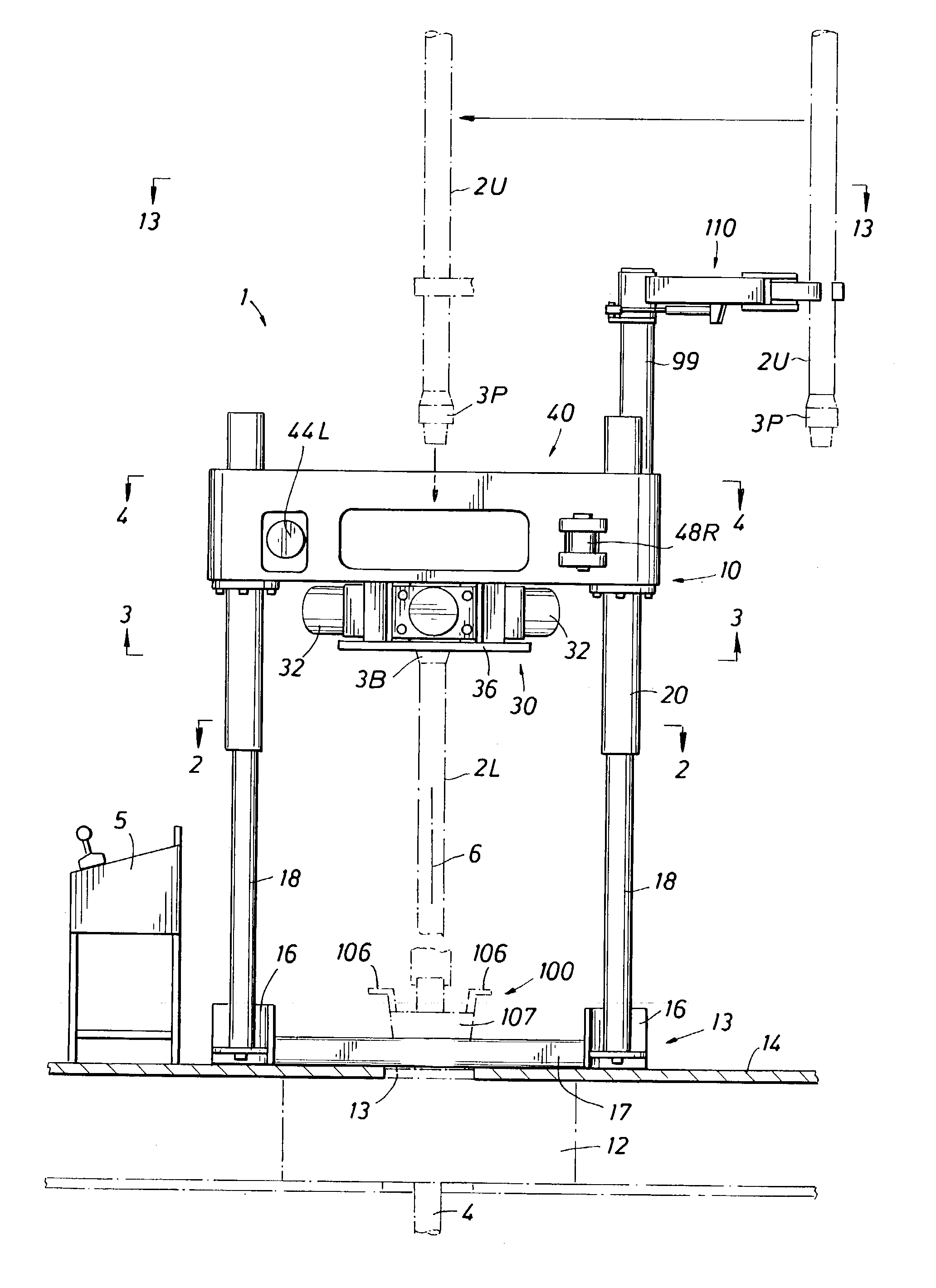

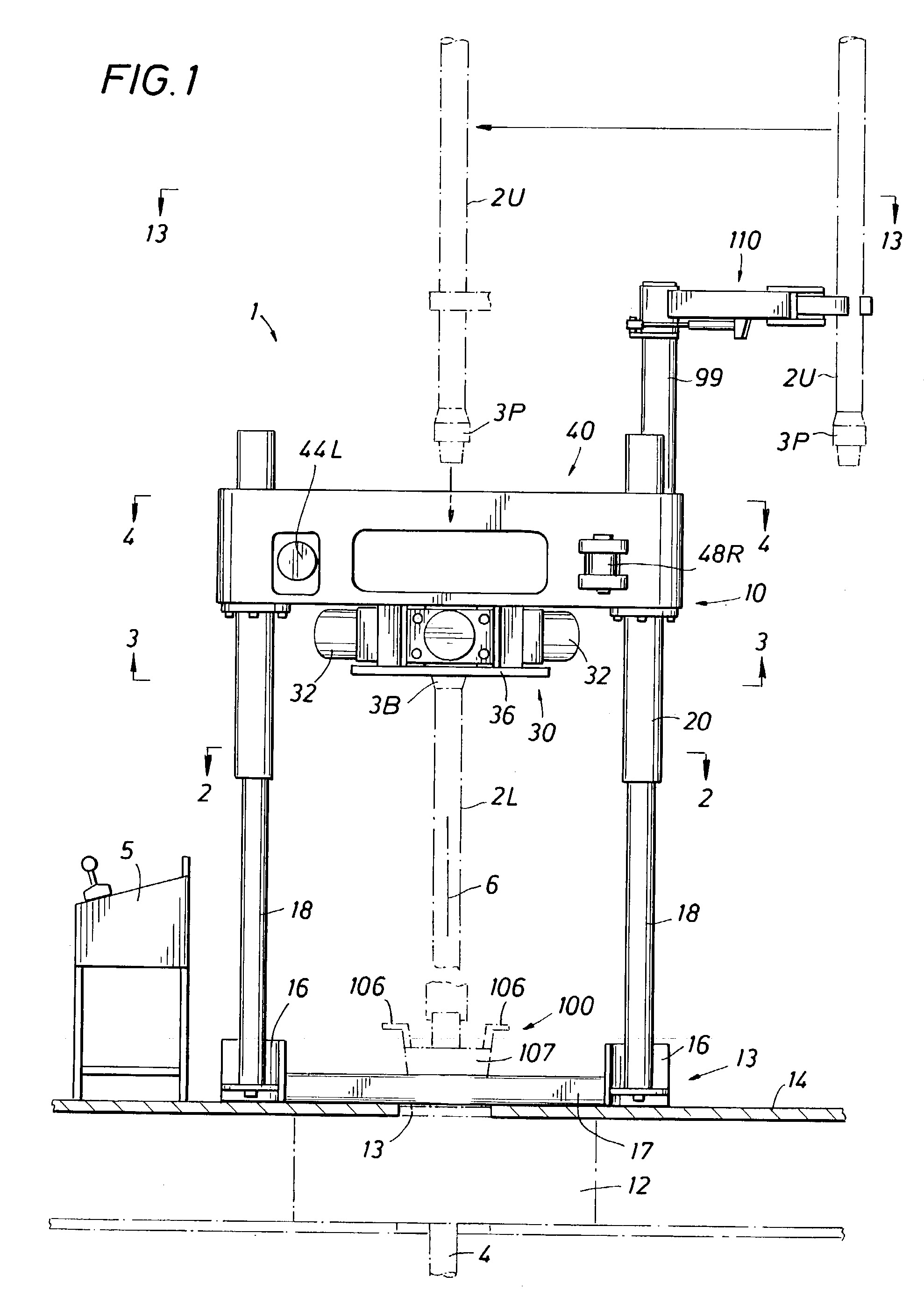

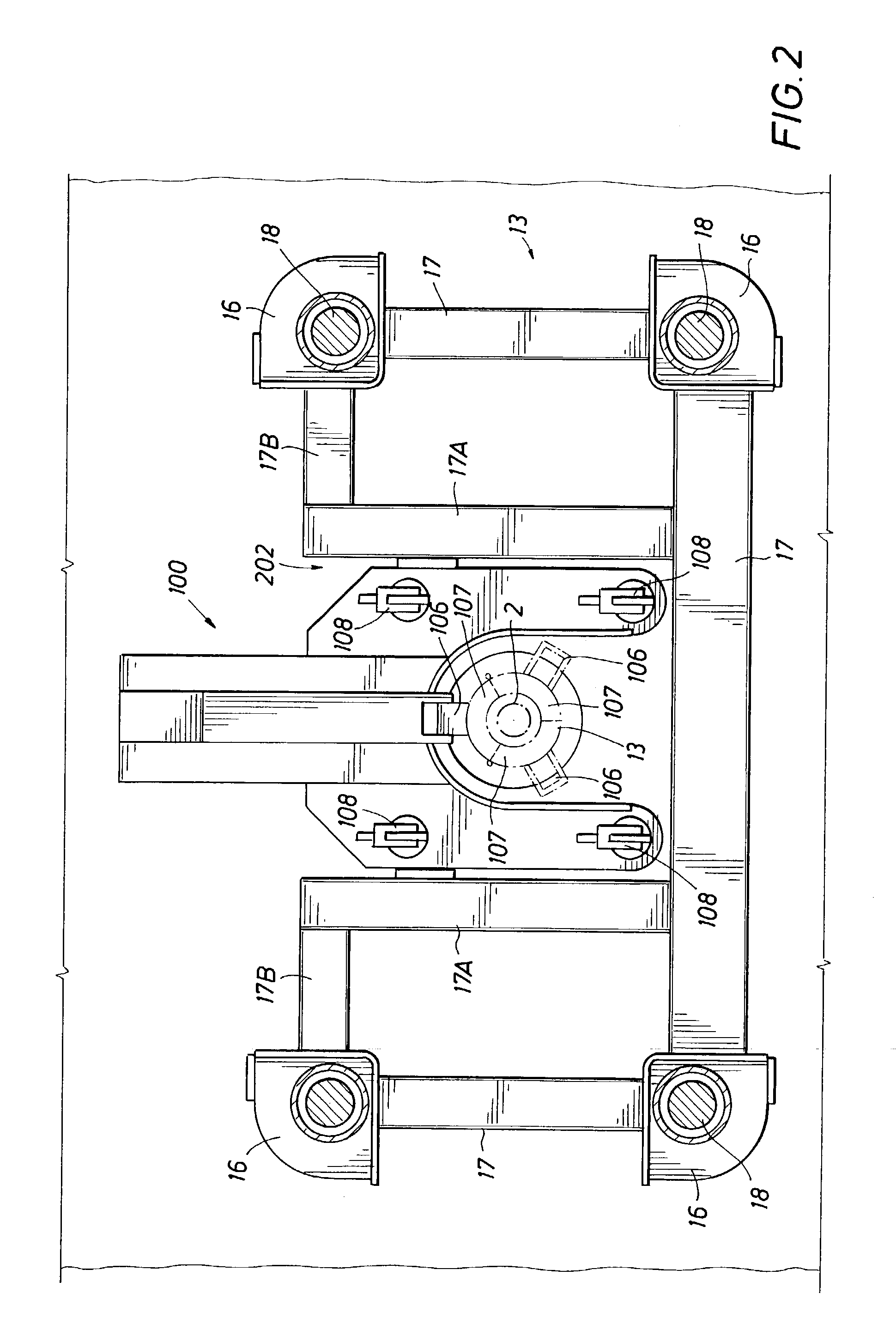

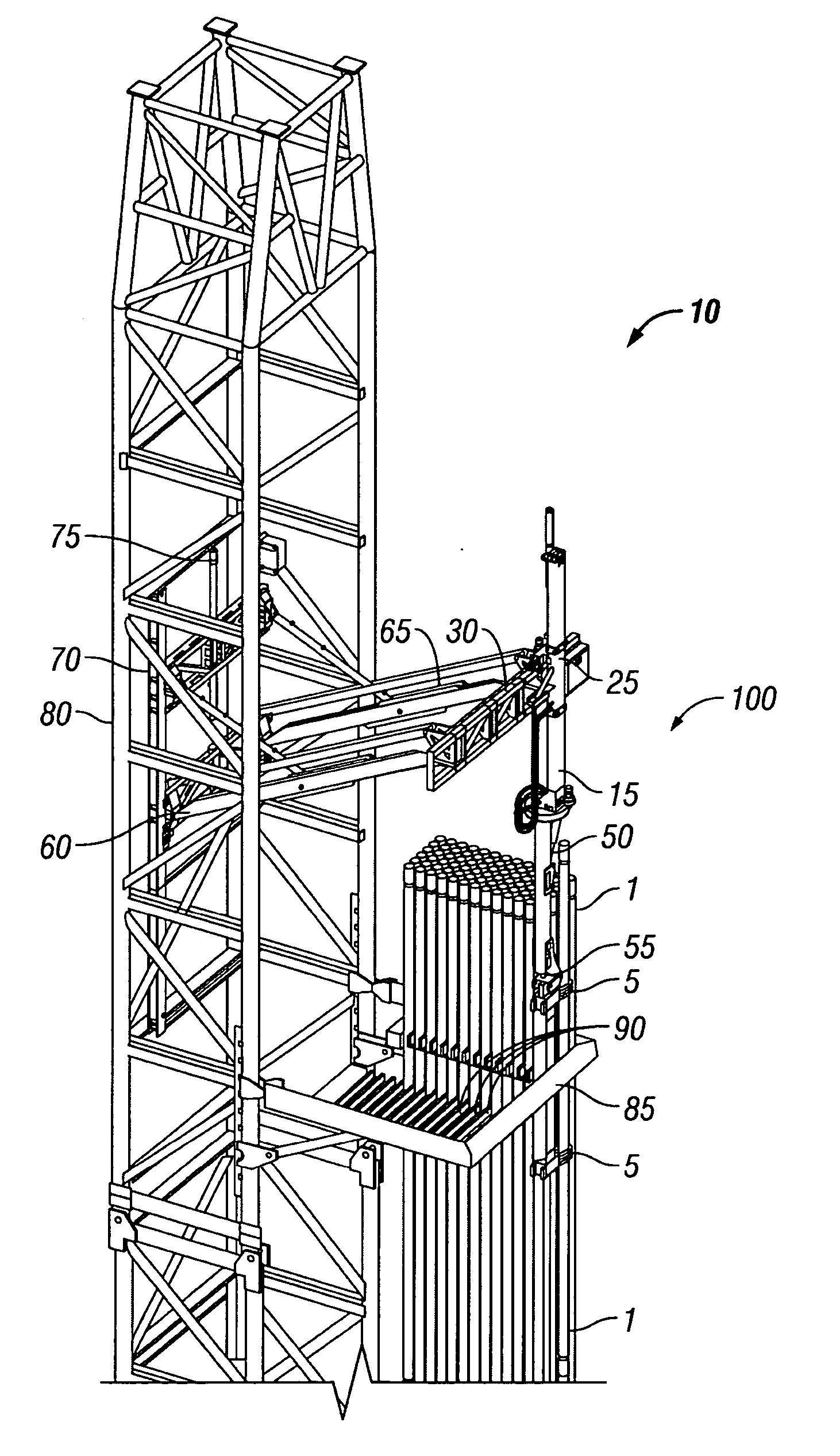

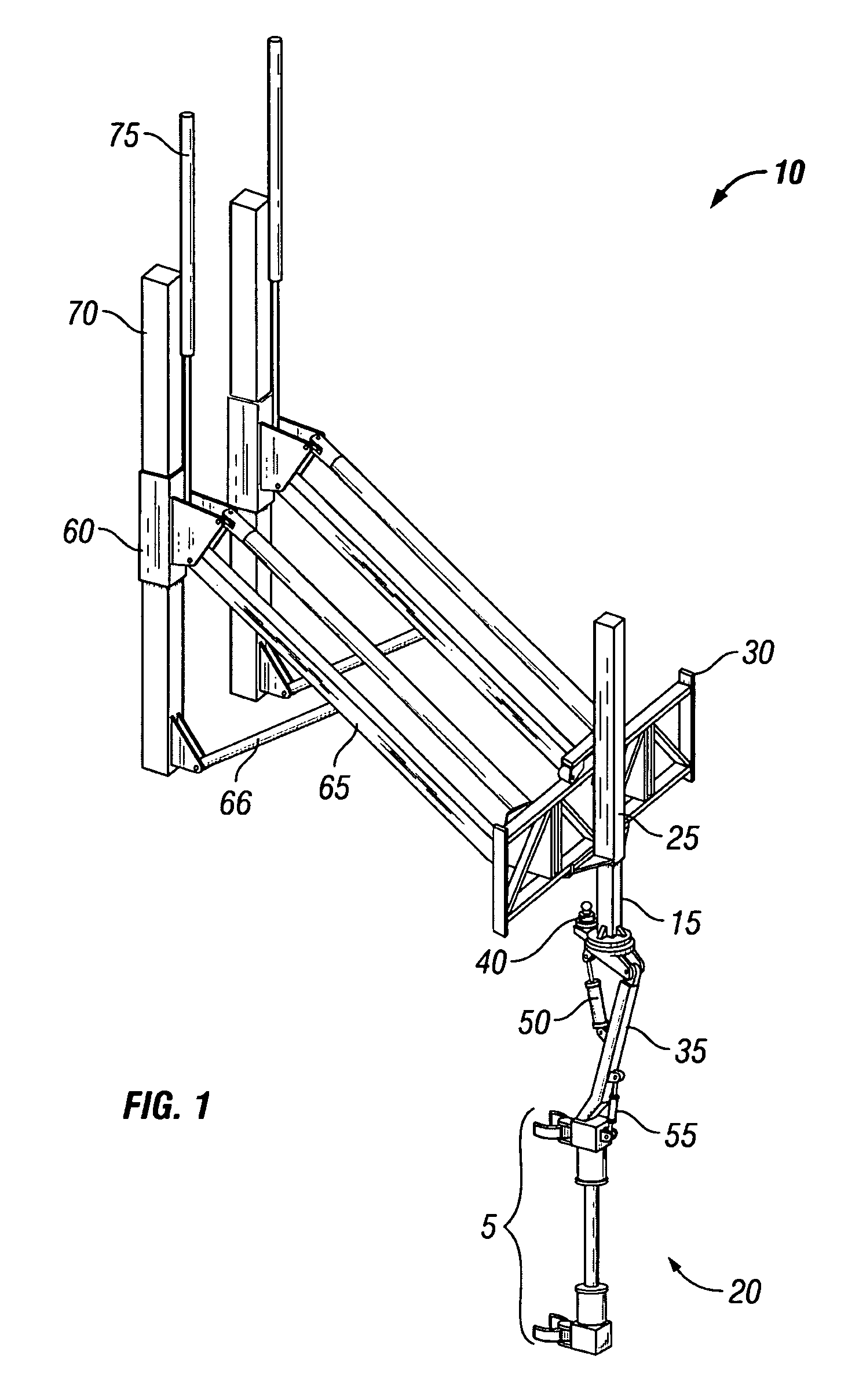

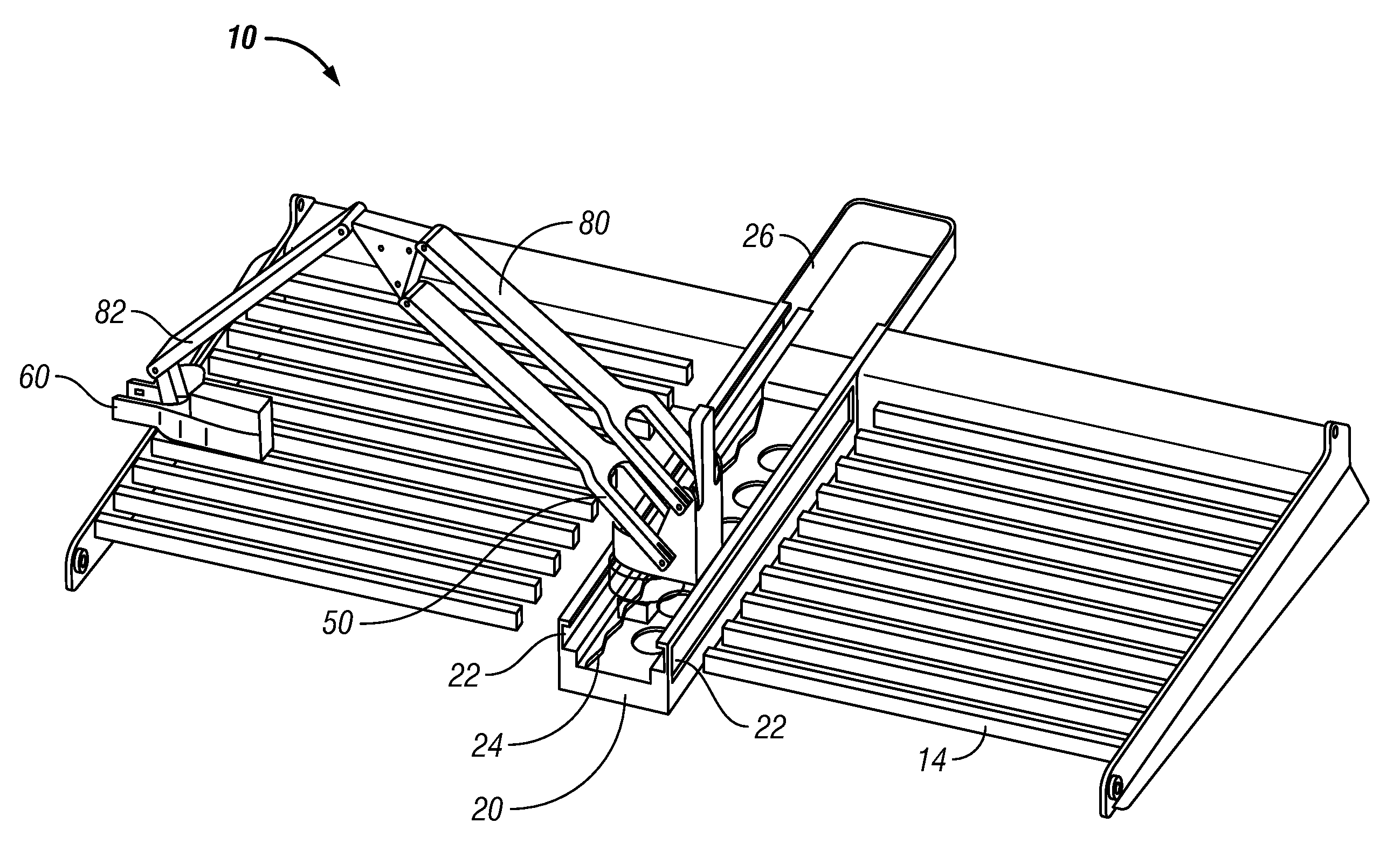

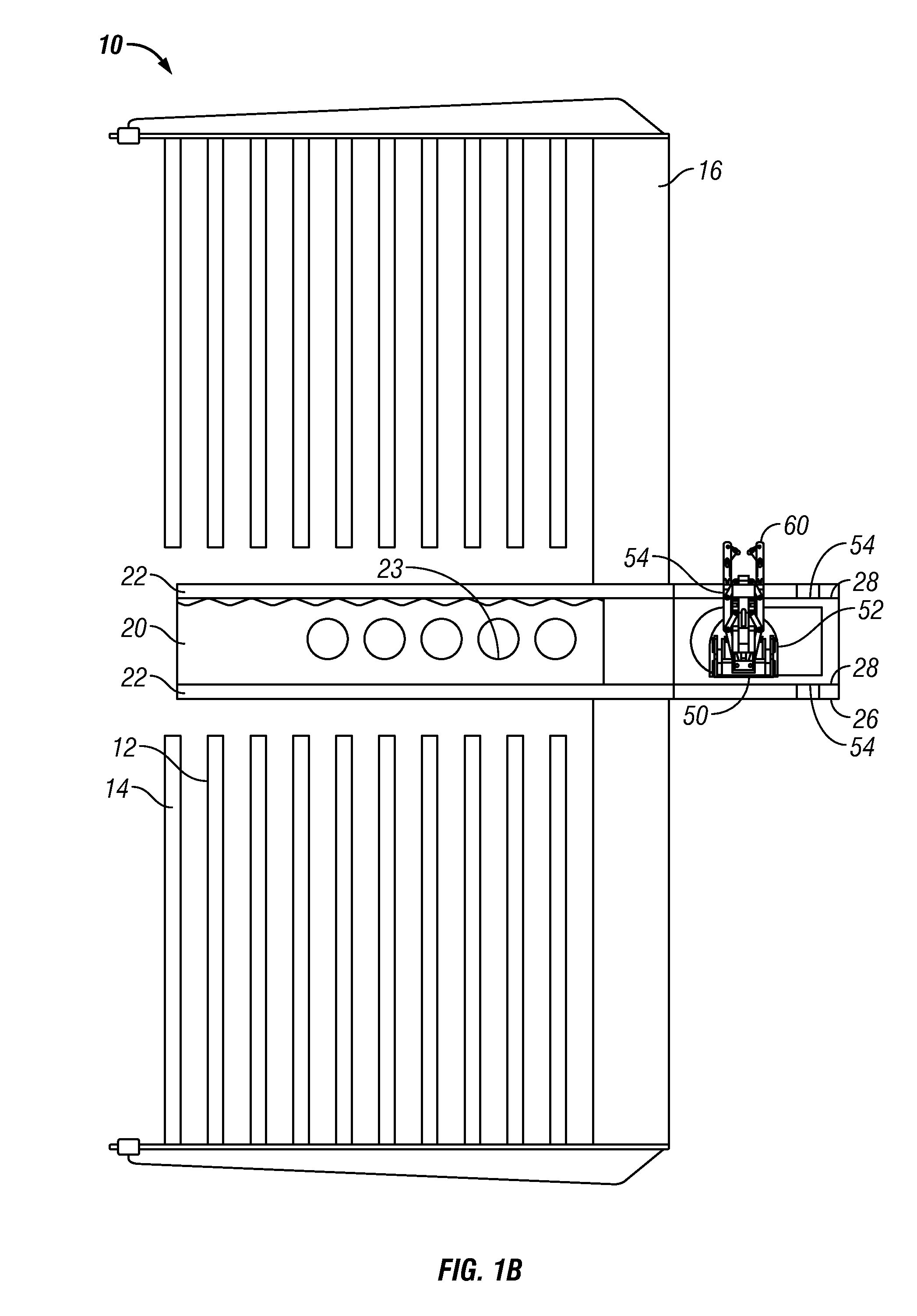

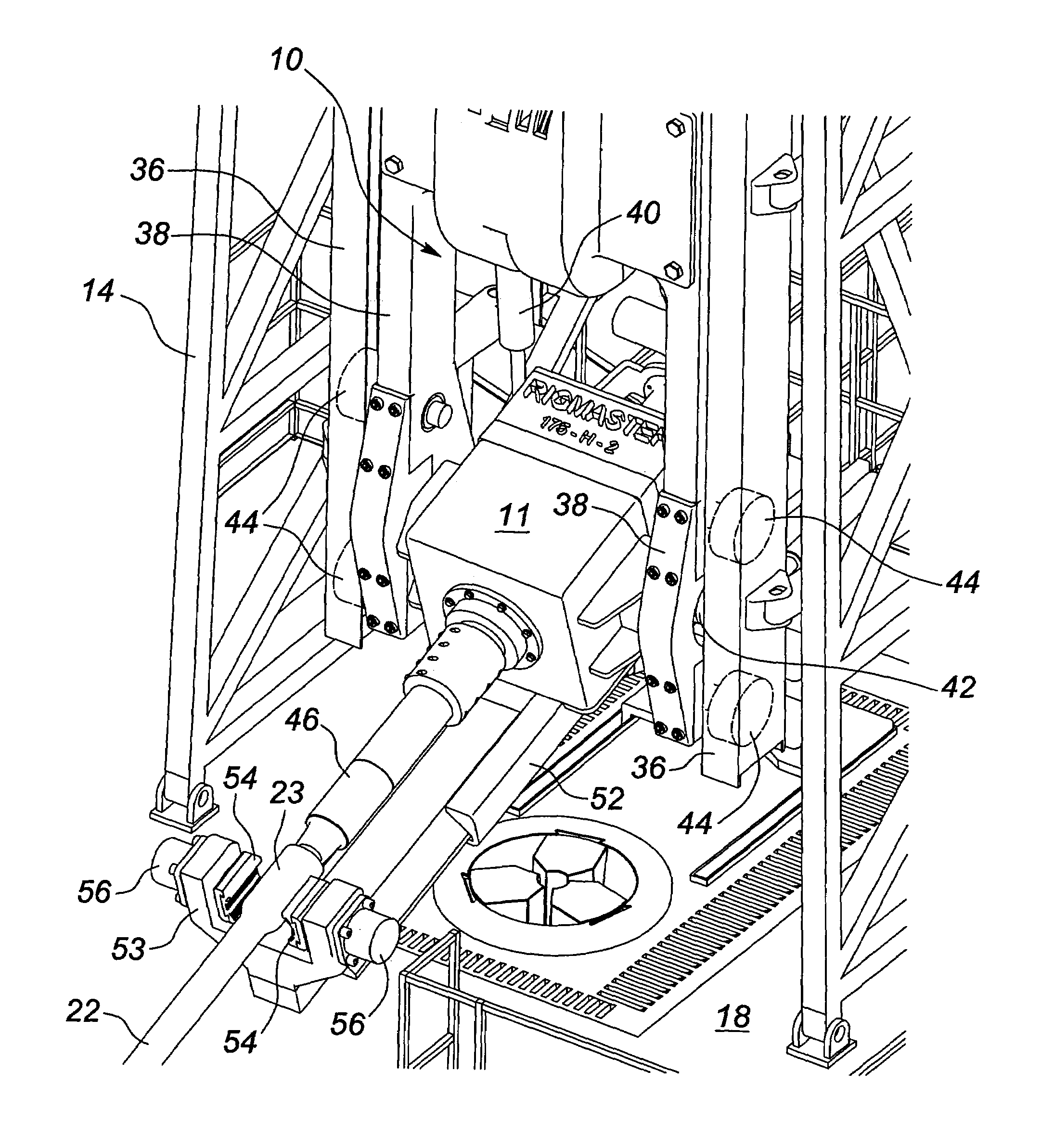

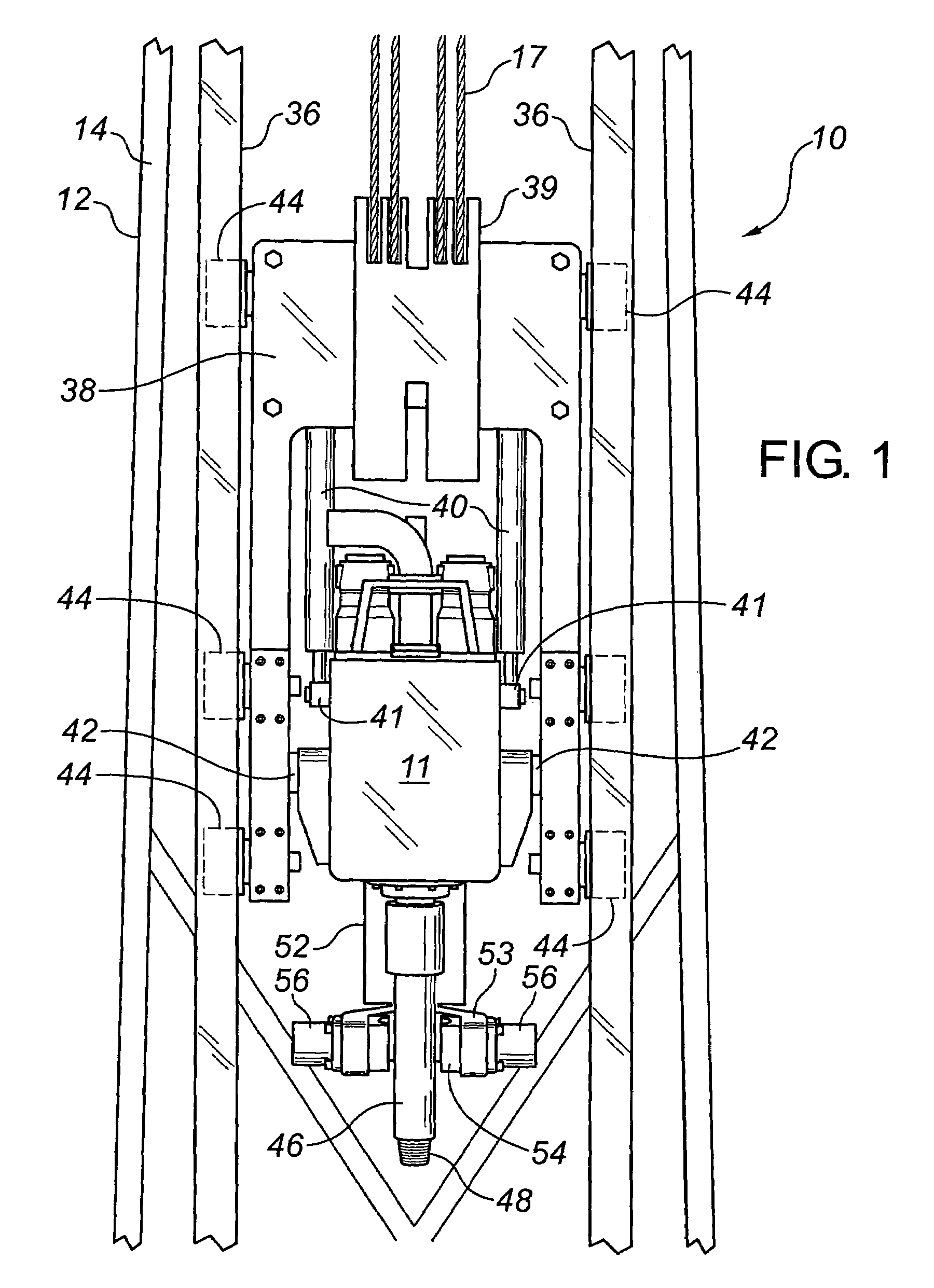

Drill pipe connecting and disconnecting apparatus

Drilling rig apparatus for connecting and disconnecting well pipe at a drilling rig. A remotely controlled power wrench assembly is mounted on a remotely controlled lifting mechanism attached to a base spaced about the well axis on the rig floor. The wrench assembly includes upper and lower wrenches carried by the lifting mechanism. The wrench assembly includes a lower wrench for gripping a lower box coupling of a drill pipe section at the well center. An upper wrench is provided for spinning an upper pin coupling into or out of threaded engagement with the lower box coupling. The upper wrench has two opposed spinner-roller pairs which translate between open and closed positions for spinning the upper pin coupling when in a closed position. The upper wrench also has two opposed jaw blocks which translate between open and closed positions for gripping the pin coupling in a closed position. The spinner roller pairs and the jaw blocks move in directions perpendicular to each other into and out of a cavity through which the well axis passes vertically. Torque cylinders are provided by which the upper wrench is torqued in a first or "torquing up" direction while the jaw blocks are gripping the pin coupling and in a second or "breaking loose" direction. A manipulator is pivotably carried on a rod supported from the wrench assembly. The manipulator includes a remotely controlled arm and hand assembly which captures a drill pipe section in its hand and transfers the drill pipe while being supported vertically by the drilling rig between the well axis and a position at the side-of the wrench assembly. The drilling rig apparatus includes a bore arranged and designed for placement on the rig floor around the well axis. A slot is provided between frame members for placement of a pneumatically remotely controlled power slip manipulator for setting and releasing slips in the rotary table for supporting the drill pipe string in the well bore during connecting and disconnecting operations of drill pipe sections.

Owner:FORUM US

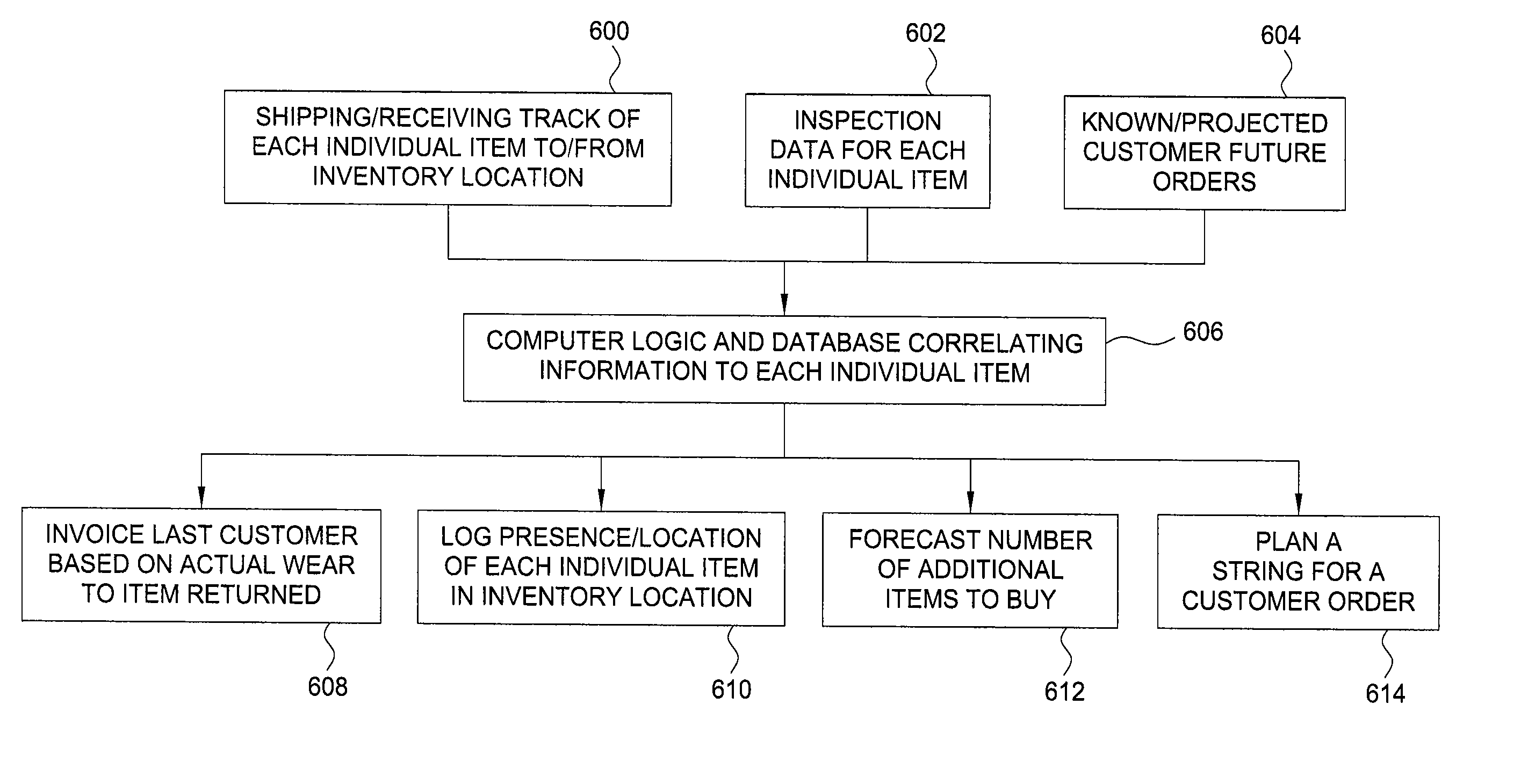

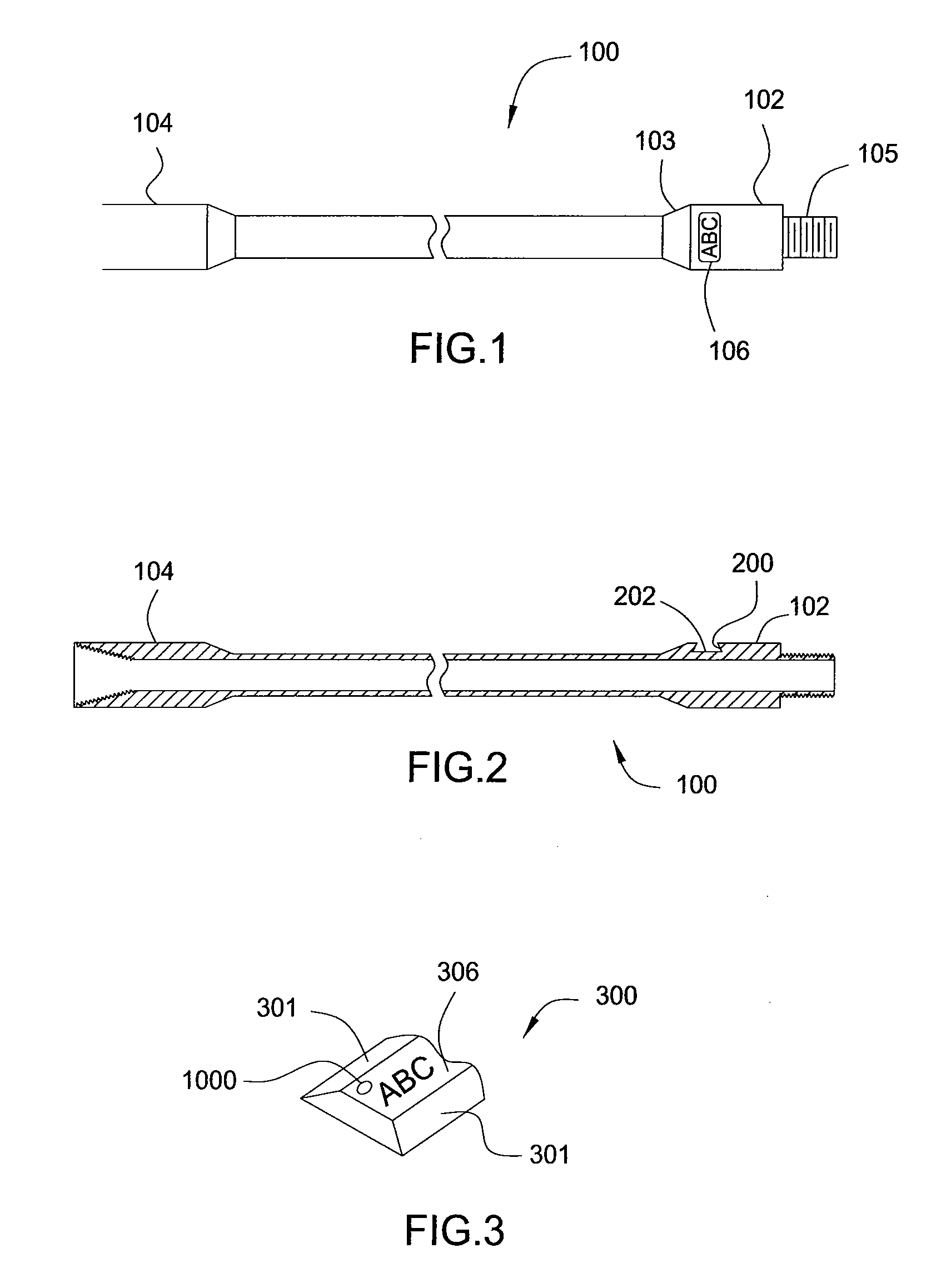

Serialization and database methods for tubulars and oilfield equipment

Methods and apparatus identify downhole equipment and correlate input data with the equipment to improve planning and / or inventory operations. For some embodiments, oilfield equipment or tubular goods such as drill pipe include a shaped recess along an outer circumference for receiving a tag cartridge by shrink fitting. Once tagged, detector system configurations at pipe yards may facilitate logging the presence and location of each drill pipe and correlating specific data, such as inspection data, to each drill pipe. Further, this correlation populates a database utilized to achieve other business functions such as forecasting number of additional drill pipe needed to purchase, invoicing customers according to actual tracked wear / use of the drill pipe being returned, and providing well or job specific drill string population using known history pipe joints.

Owner:WEATHERFORD TECH HLDG LLC

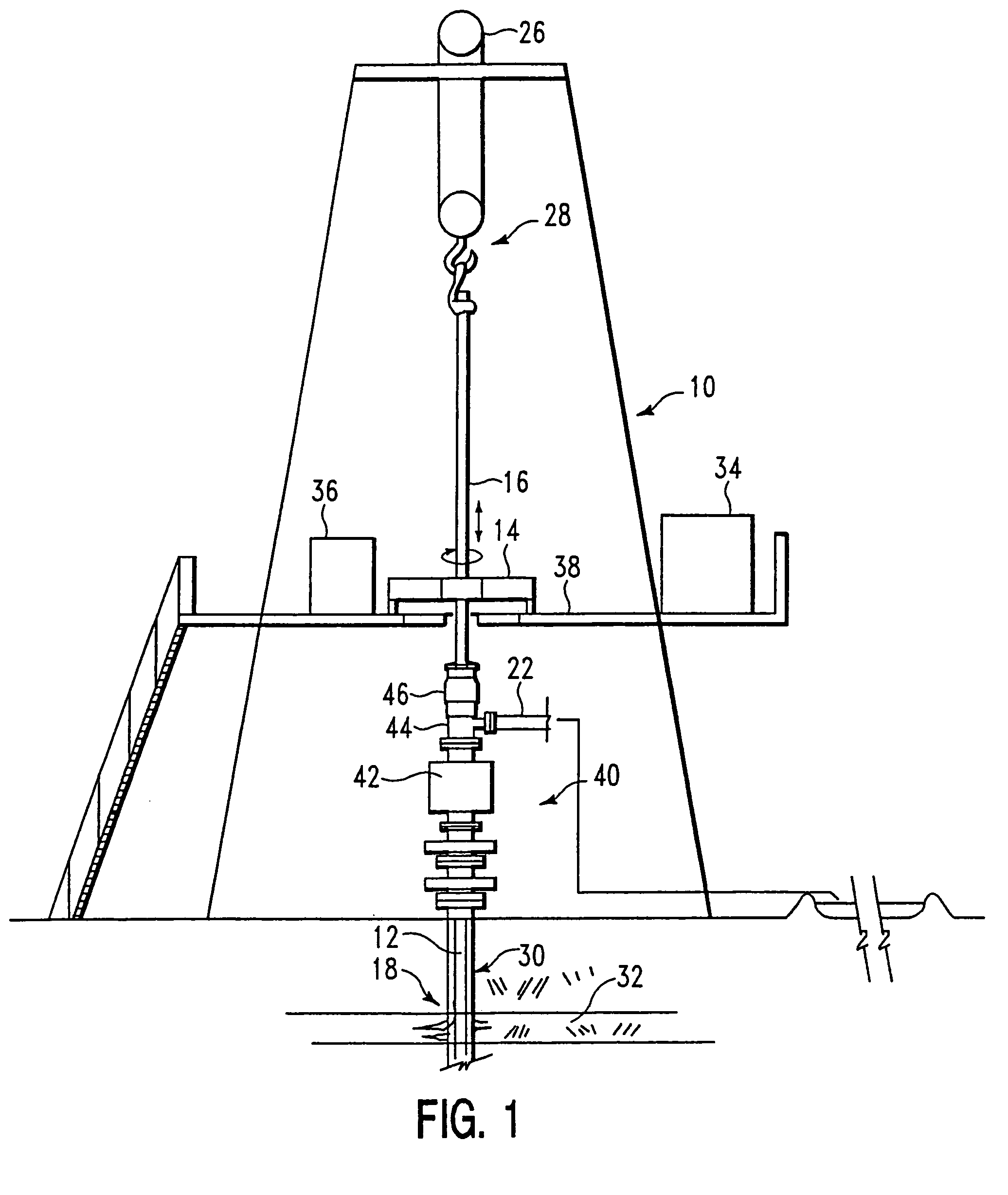

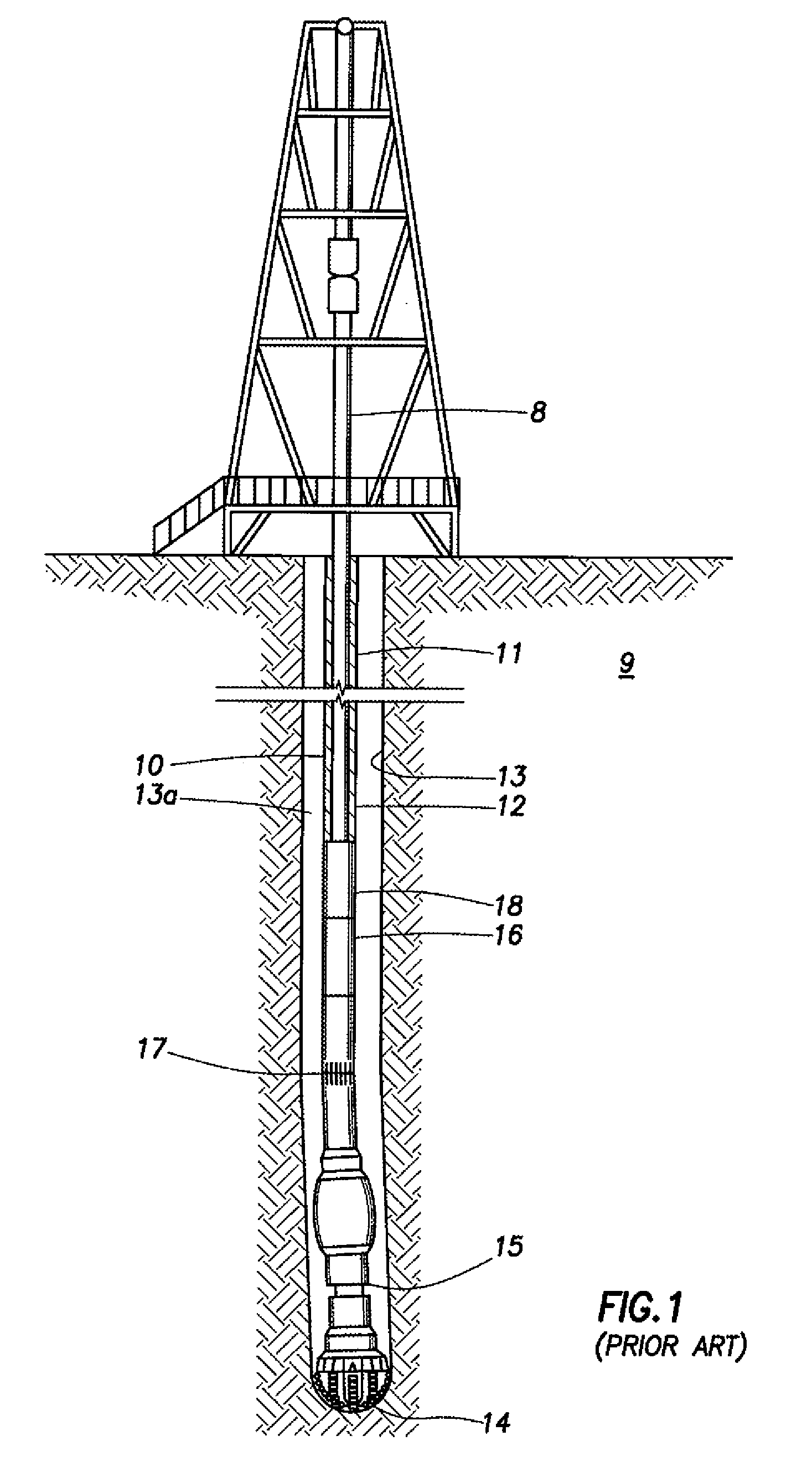

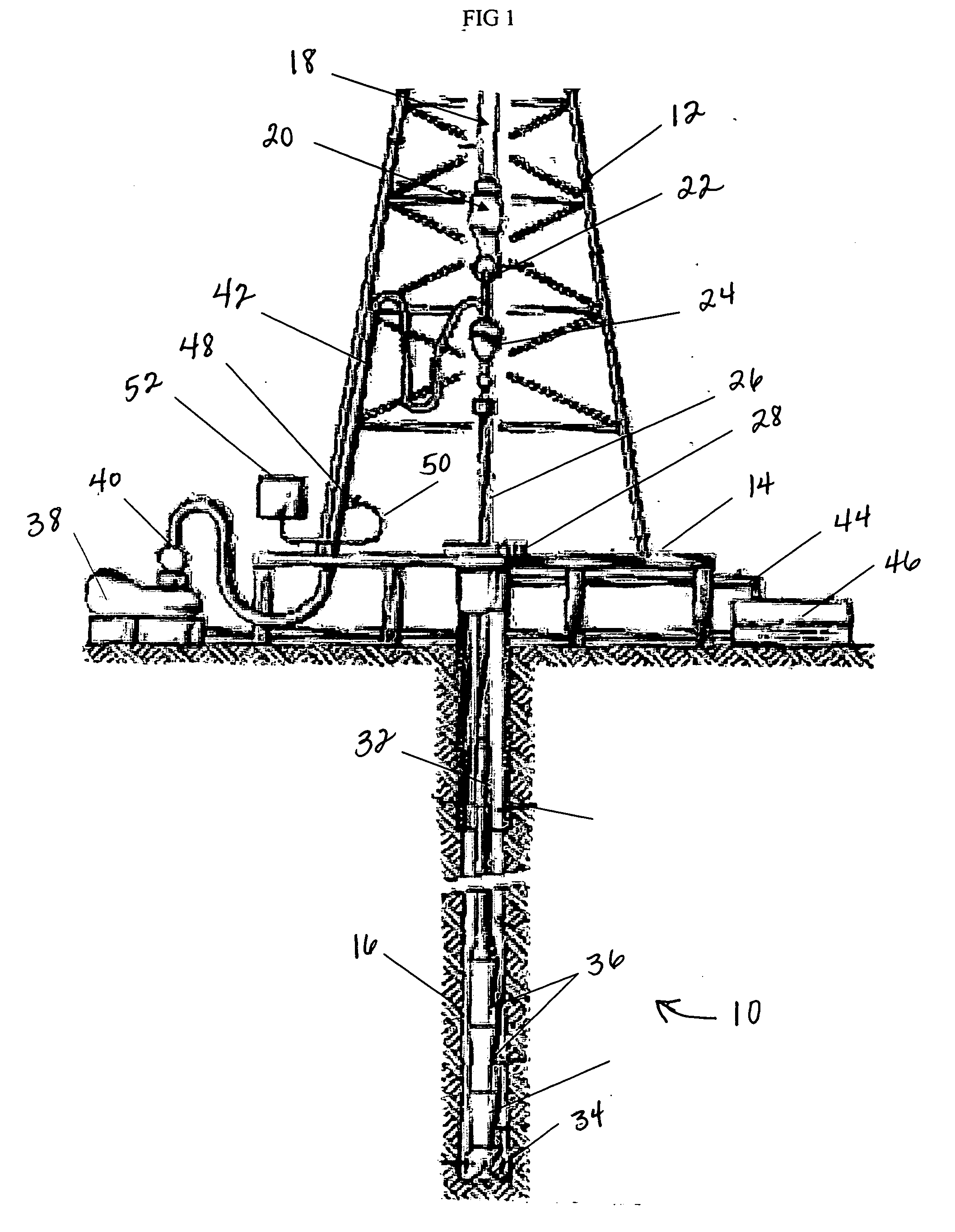

Surface communication apparatus and method for use with drill string telemetry

An operation of drilling an earth borehole uses a drilling rig, a drill string of drill pipes having its generally upper end mechanically coupleable with and suspendable from the drilling rig, a drive string portion of the drill string, mechanically coupleable with the topmost drill pipe of said drill string, and a drive mechanism mechanically coupleable with the drive string for rotating the drive string and the drill string. A system for generating electric power in the region of the drive string includes an electric generator, which includes a rotating generator component mounted on said drive string for rotation therewith and a stationary generator component mounted on a stationary portion of the drilling rig. The rotating generator component produces electric power in the region of the drive string.

Owner:INTELLISERV LLC

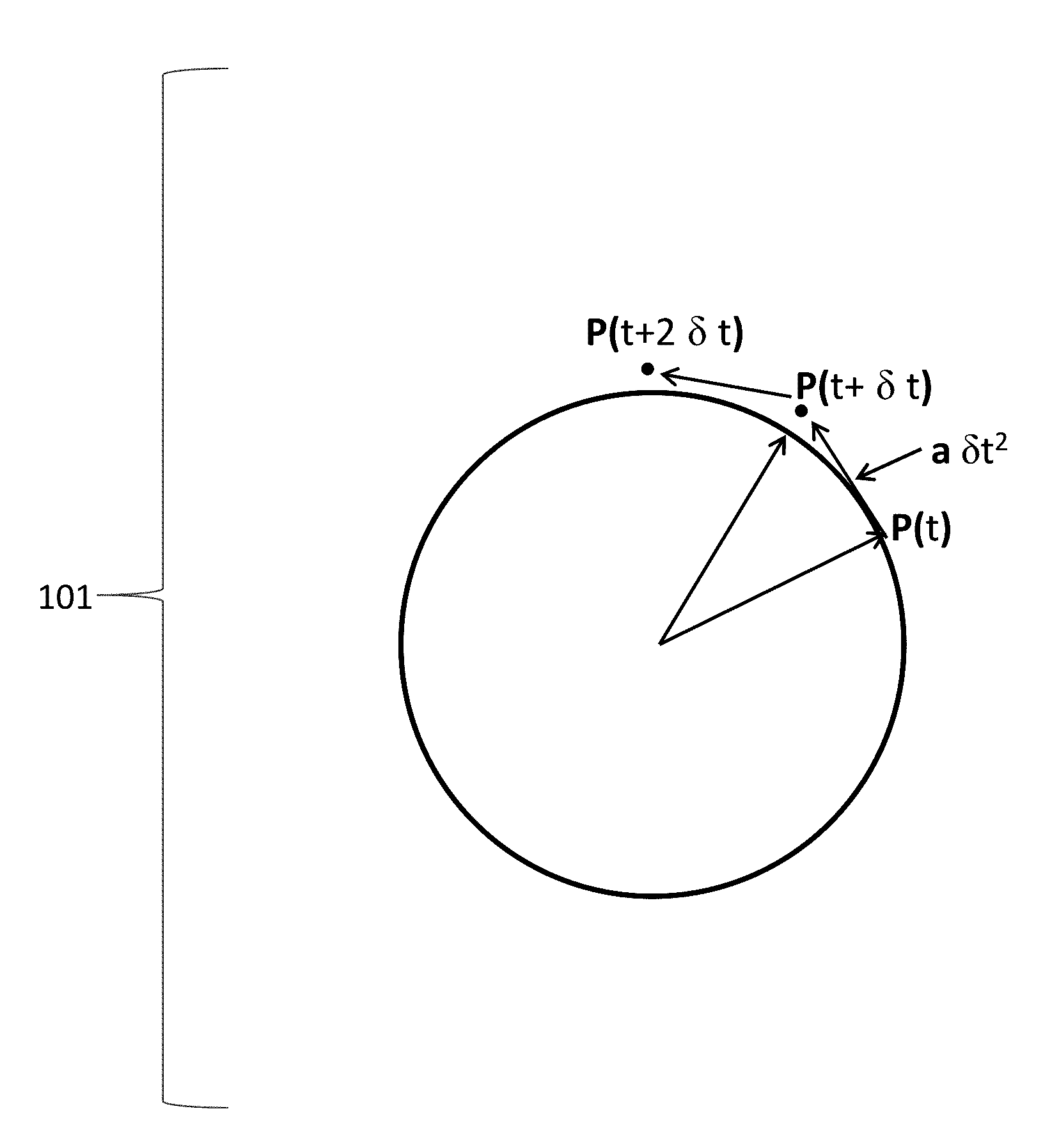

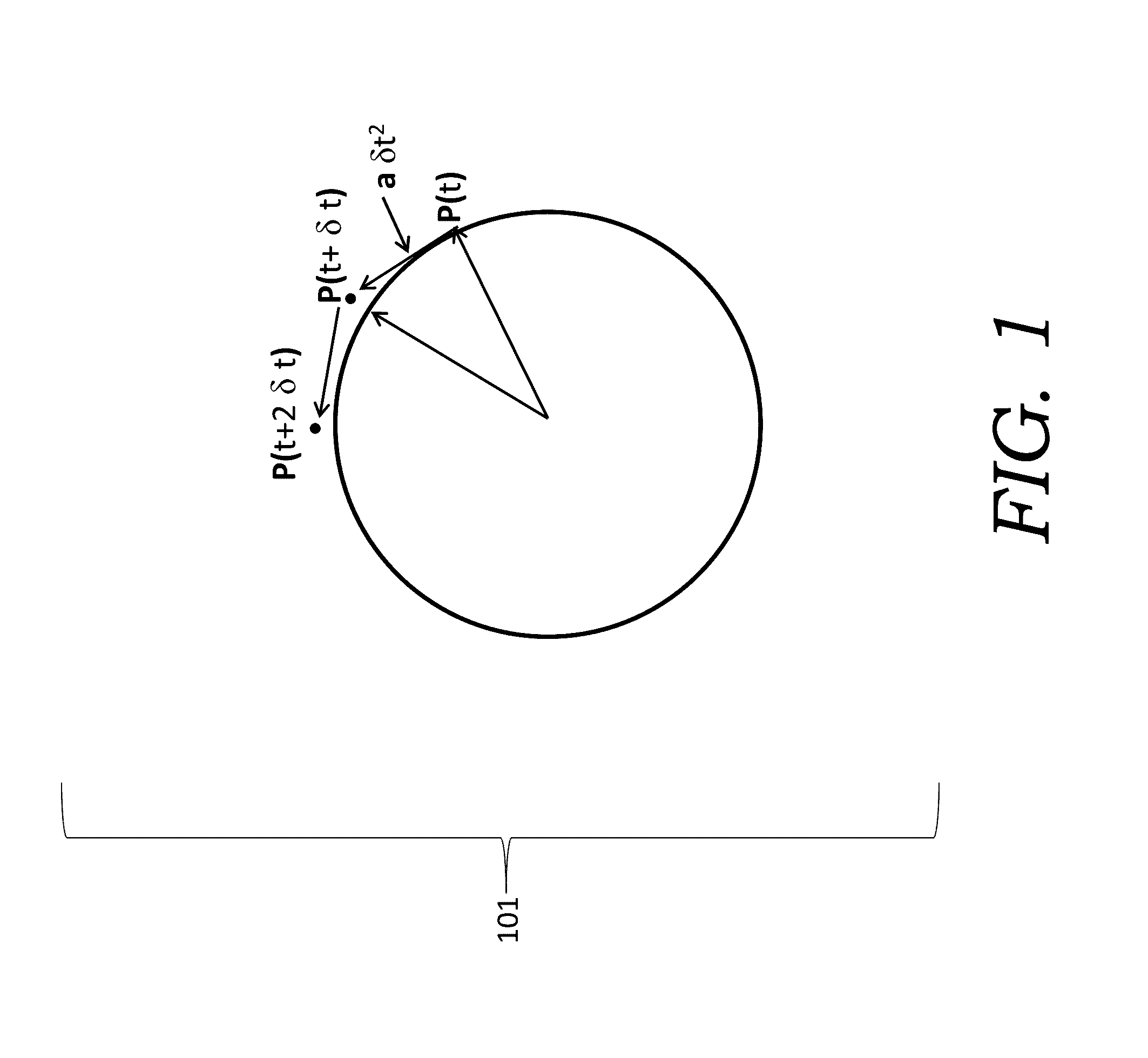

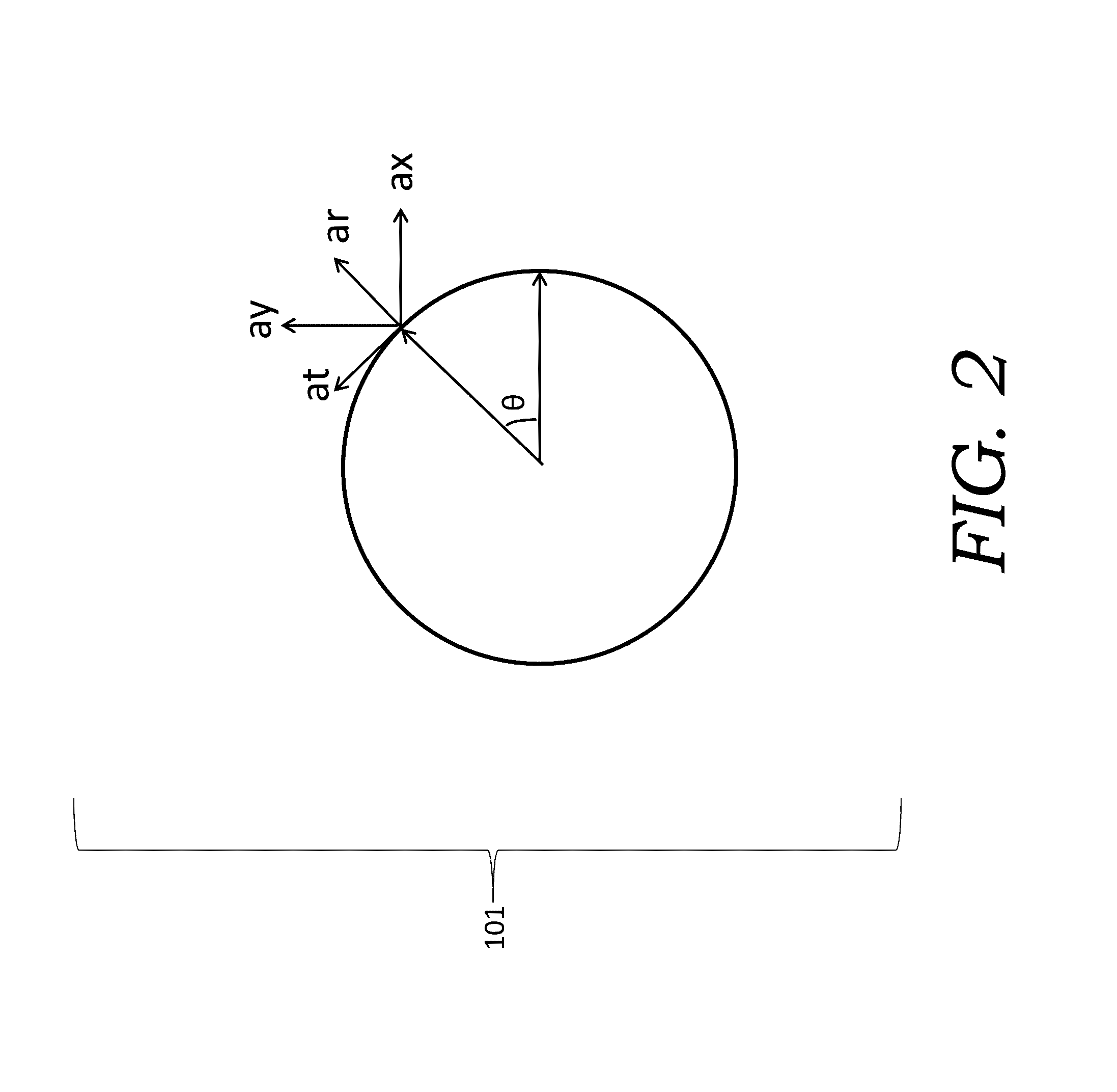

System and method for determining drill string motions using acceleration data

ActiveUS20160334306A1Easy to understandReduce vibrationSurveyStructural/machines measurementWell drillingData system

Systems and methods compute dysfunctions via mapping of tri-axial accelerations of drill pipe into drill-string motions. The methods remove gravitational and centripetal accelerations to yield corrected acceleration data due to the vibration only, transform the corrected acceleration data, and maps resulting transformed acceleration data into continuous drill-string positions. The maps provide 2D / 3D visualization of drill-string motions to enable real-time optimization and control of well drilling operations and other scenarios where proactive detection of temporal events in automated systems may aid in avoiding failures.

Owner:CONOCOPHILLIPS CO

High pressure system

An arrangement and method for integrating a high pressure riser sleeve from the upper end of a high pressure drilling and workover riser terminated by an upper BOP close to sea level in one end and by a sub-sea blowout preventer BOP or a low riser package LRP close to the seabed in the lower end. The high pressure riser sleeve being installed, connected and integrated to the high pressure drilling and workover riser and extending up to and above the drill floor, inside a low pressure drilling riser slip joint which is connected to the drilling and workover riser. This relates to offshore drilling and well activities preformed from a floating drilling or workover rig or vessel. Operations can be switched from drilling with jointed drillpipe in a conventional manner, into performing underbalanced wireline and / or coiled tubing activities with full well pressure, much more effectively than with prior art.

Owner:ENHANCED DRILLING

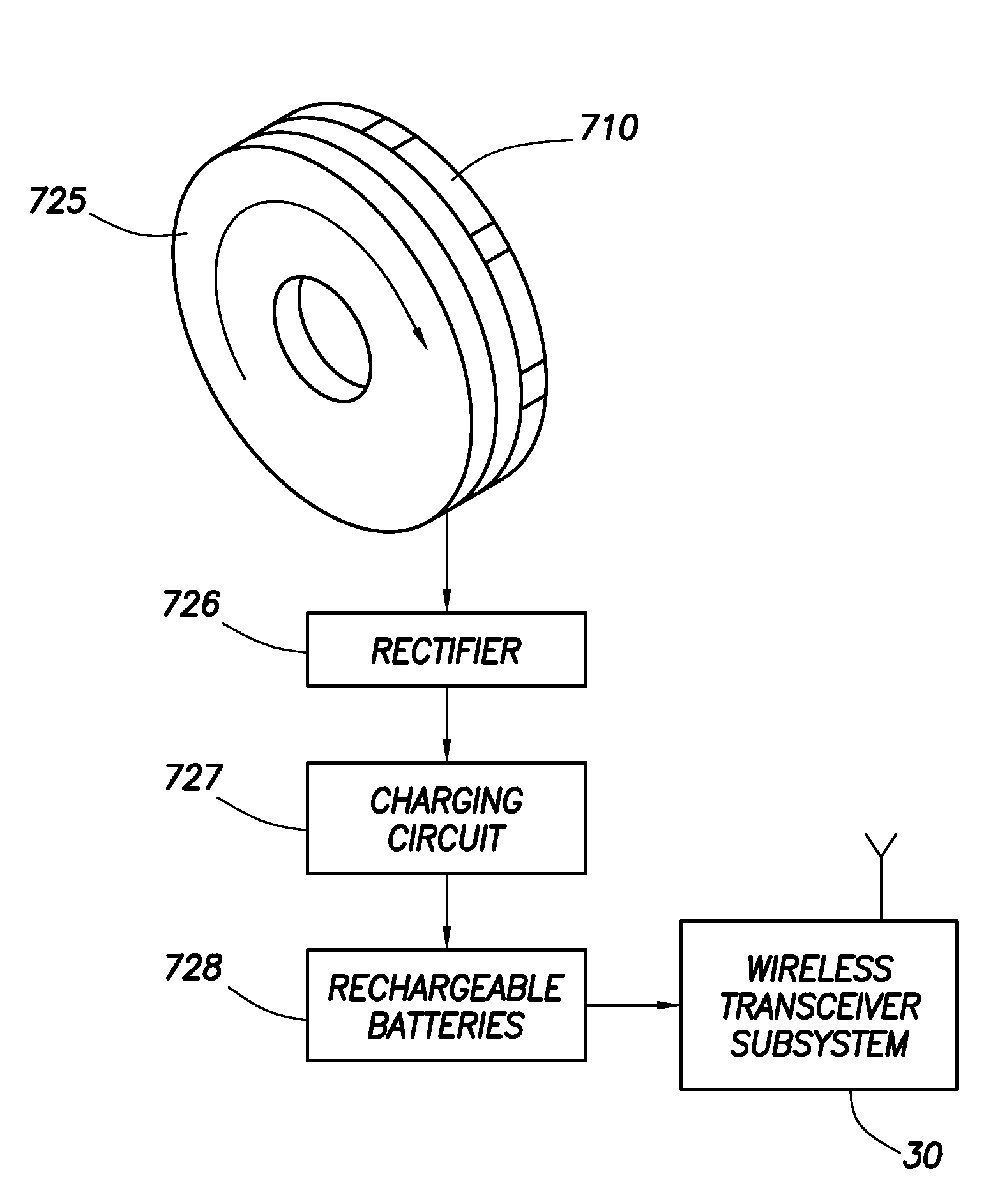

Surface communication apparatus and method for use with drill string telemetry

A system for bidirectional communication between the downhole equipment and a processor subsystem at the earth's surface, including: a section of wired drill pipes comprising at least the upper portion of a string of drill pipes, and forming at least a portion of a bidirectional communication link between downhole equipment and the top of the string of drill pipes; a drive string portion of the drill string, mechanically coupleable with the topmost wired drill pipe; a drive mechanism mechanically coupleable with said drive string portion, for rotating the drill string; a first wireless transceiver subsystem mounted on the drive string portion of the drill string, for rotation in conjunction with the drill string; a cable, electrically coupled between the top joint of the topmost wired drill pipe and the first transceiver subsystem; and a second wireless transceiver subsystem coupled with the uphole processor subsystem, the second wireless transceiver subsystem communicating bidirectionally with the first wireless transceiver subsystem.

Owner:INTELLISERV

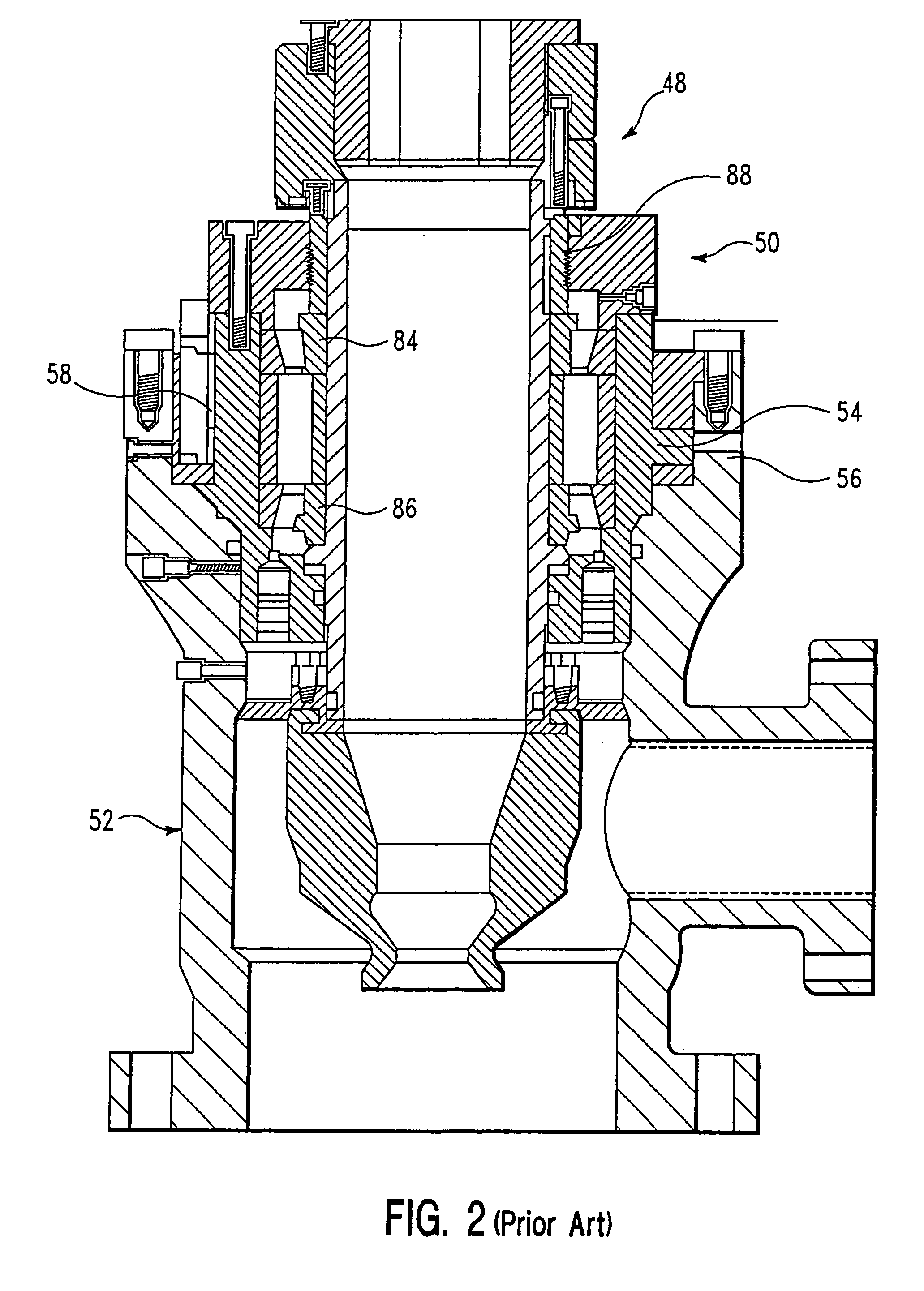

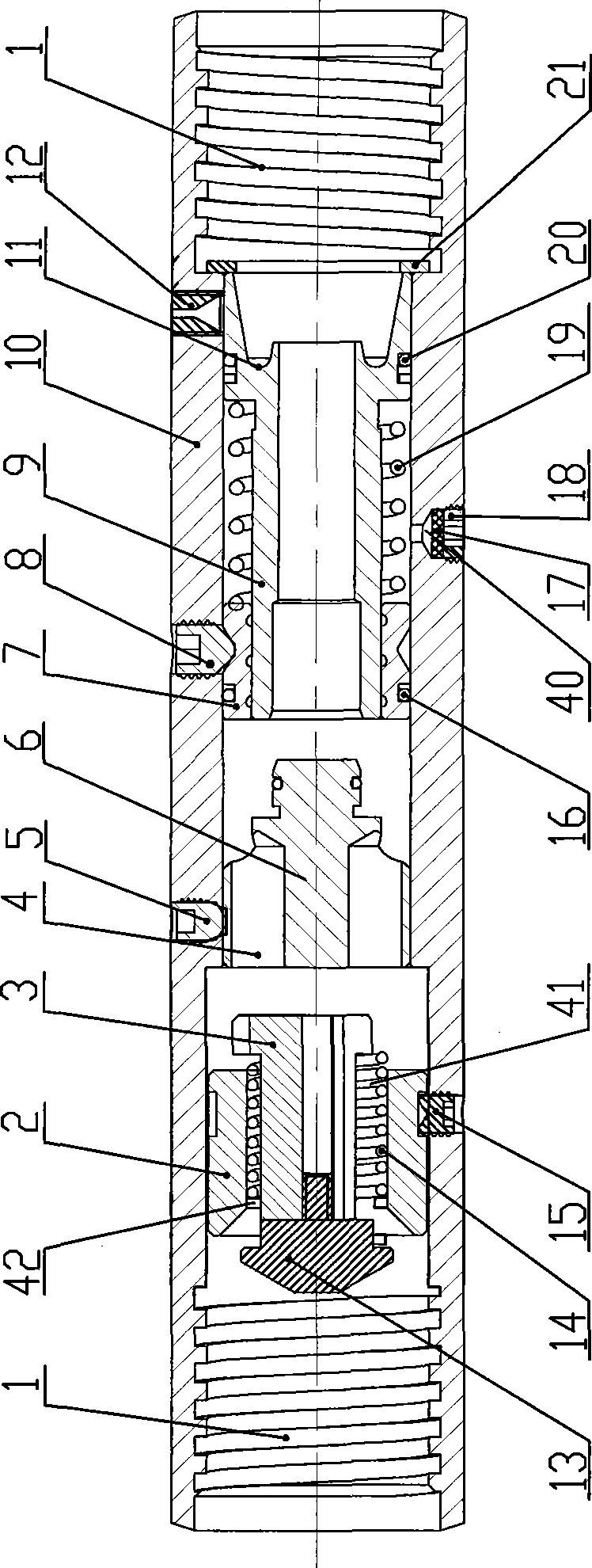

High pressure rotating drilling head assembly with hydraulically removable packer

The present invention generally provides a reduced downtime maintenance apparatus and method for replacing and / or repairing a subassembly in sealing equipment for oil field use. The invention allows the removal of rotating portions of a rotary drilling head without having to remove non-rotating portions. The reduction in weight and size allows a more efficient repair and / or replacement of a principal wear component such as a packer. Specifically, the packer in a rotary drilling head can be removed independent of bearings and other portions of the rotary drilling head. Furthermore, because of the relatively small size and light weight, the packer can be removed typically without having to use a crane to lift a rotary BOP and without disassembling portions of the drilling platform. In some embodiments, the packer can be removed with the drill pipe without additional equipment. Furthermore, the packer can be removed remotely without necessitating manual disengagement typically needed below the platform. The invention also provides a fluid actuated system to maintain a pre-load system on the bearing.

Owner:WEATHERFORD TECH HLDG LLC

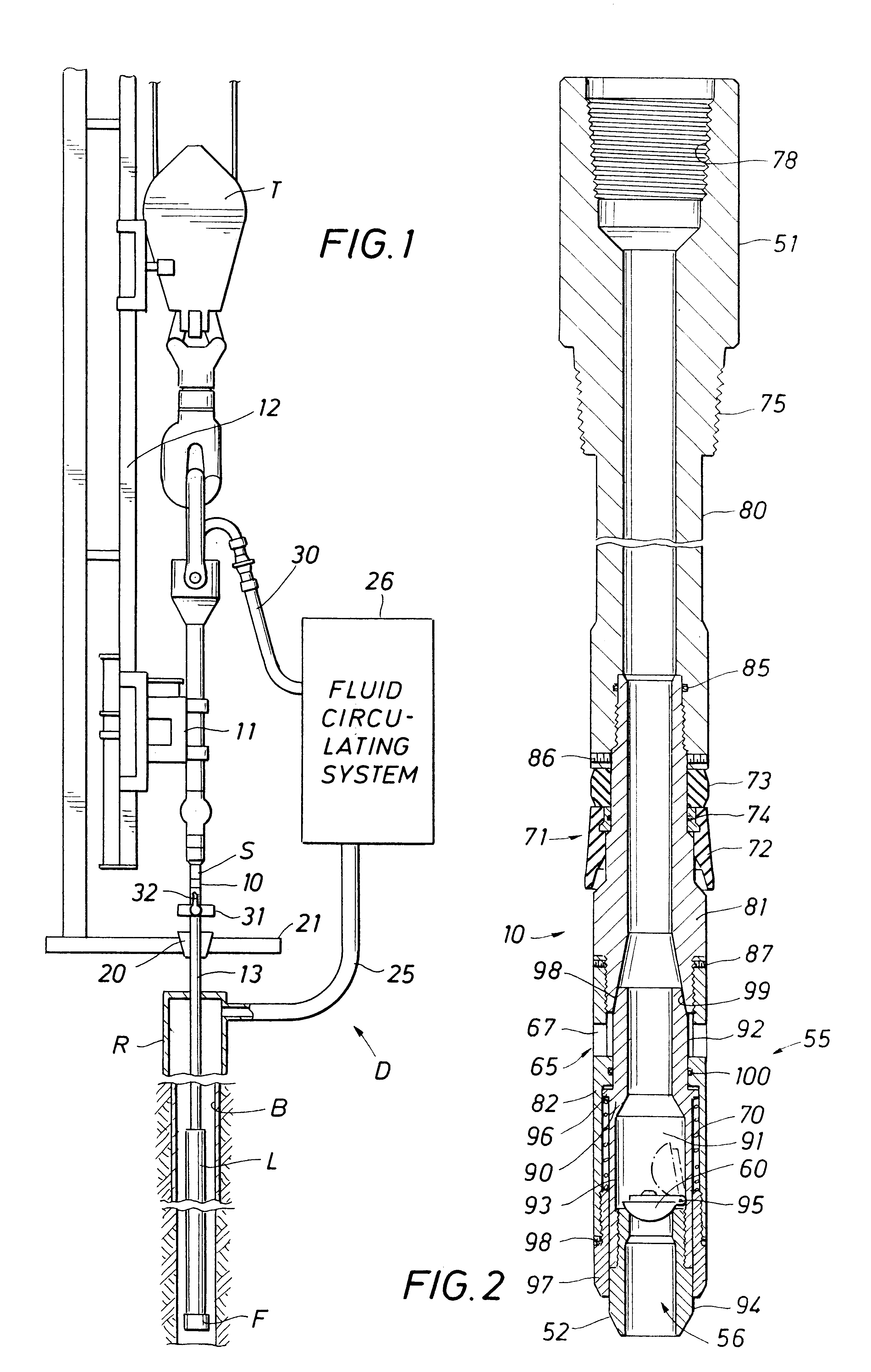

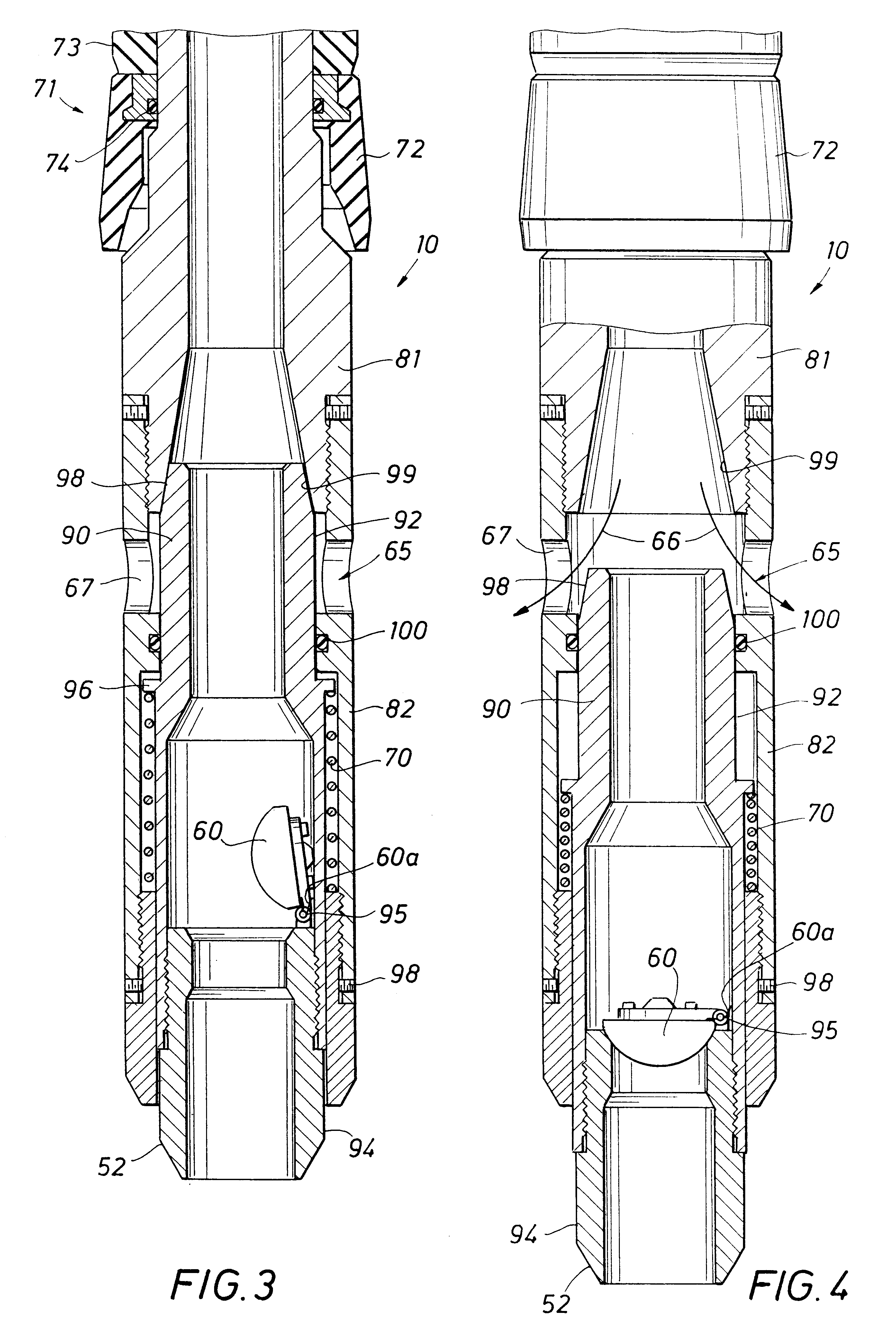

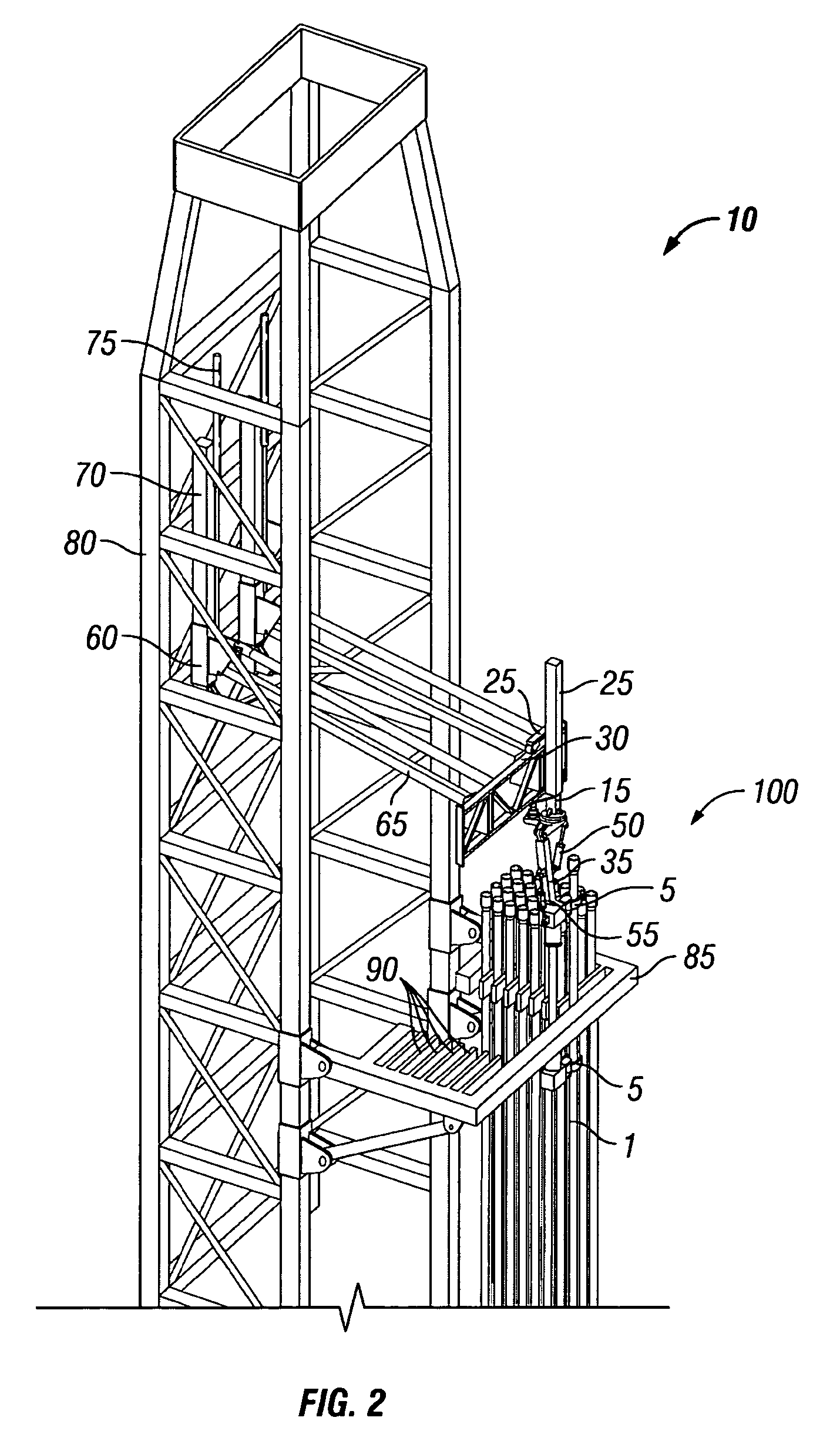

Methods and apparatus for connecting tubulars while drilling

The present invention provides an apparatus that permits sections of tubulars to be connected to or disconnected from a string of pipe during a drilling operation. The apparatus further permits the sections of drill pipe to be rotated and to be axially translated during the connection or disconnection process. The apparatus further allows for the continuous circulation of fluid to and through the tubular string during the makeup or breakout process. The apparatus defines a rig assembly comprising a top drive mechanism, a rotary drive mechanism, and a fluid circulating device. Rotation and axial movement of the tubular string is alternately provided by the top drive and the rotary drive. Additionally, continuous fluid flow into the tubular string is provided through the circulation device and alternately through the tubular section once a connection is made between an upper tubular connected to the top drive mechanism and the tubular string.

Owner:WEATHERFORD TECH HLDG LLC

Downhole telemetry system and method

Owner:SCHLUMBERGER TECH CORP

Drill pipe connecting and disconnecting apparatus

Drilling rig apparatus for connecting and disconnecting well pipe at a drilling rig. A remotely controlled power wrench assembly is mounted on a remotely controlled lifting mechanism attached to a base spaced about the well axis on the rig floor. The wrench assembly includes upper and lower wrenches carried by the lifting mechanism. The wrench assembly includes a lower wrench for gripping a lower box coupling of a drill pipe section at the well center. An upper wrench is provided for torquing and spinning an upper pin coupling into or out of threaded engagement with the lower box coupling. A manipulator is pivotably carried on a rod supported from the wrench assembly. The manipulator captures a drill pipe section and transfers the drill pipe section between the well axis and a position at the side of the wrench assembly. A slot is provided between frame members of the base for placement of a power slip manipulator for setting and releasing slips in the rotary table.

Owner:FORUM US

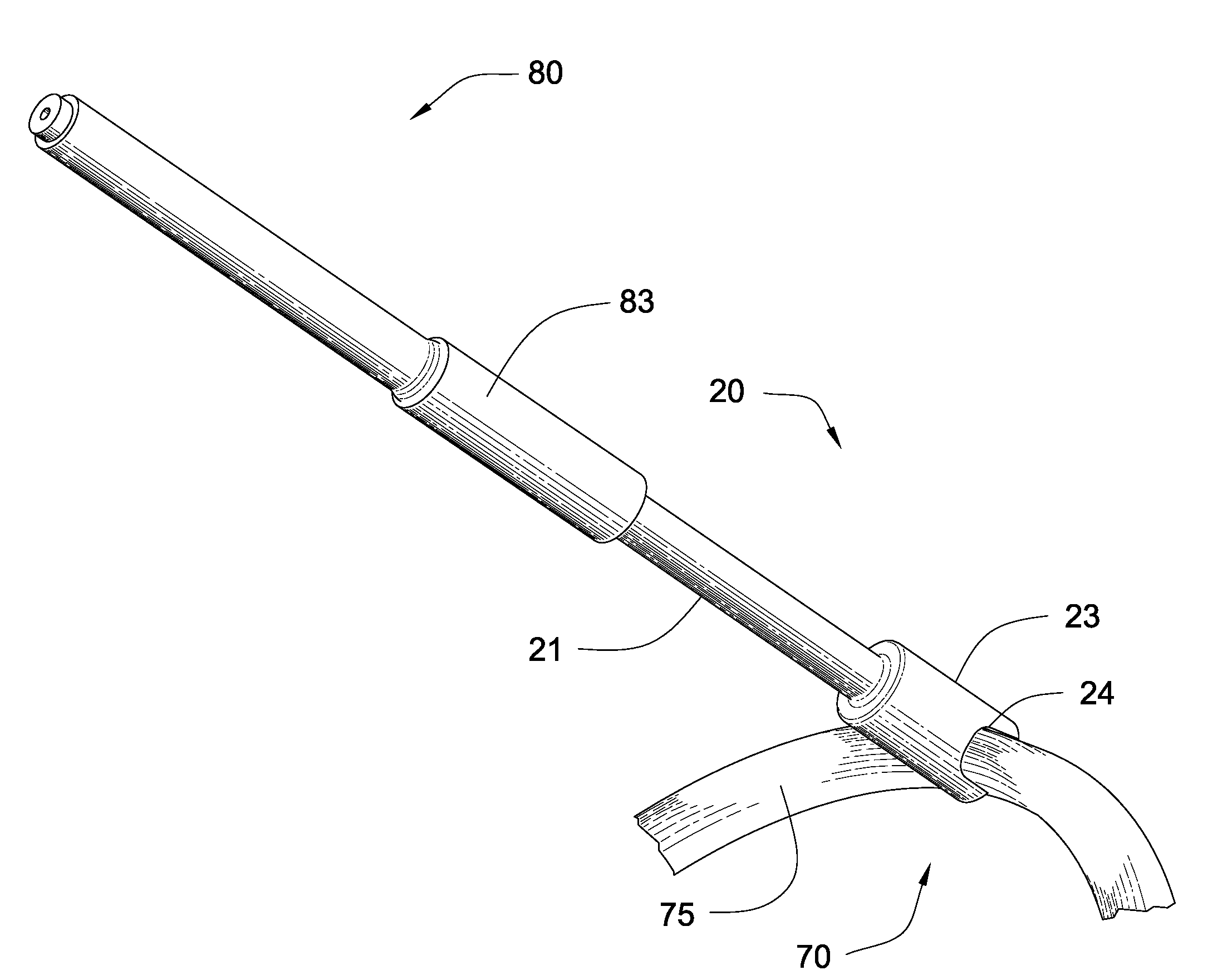

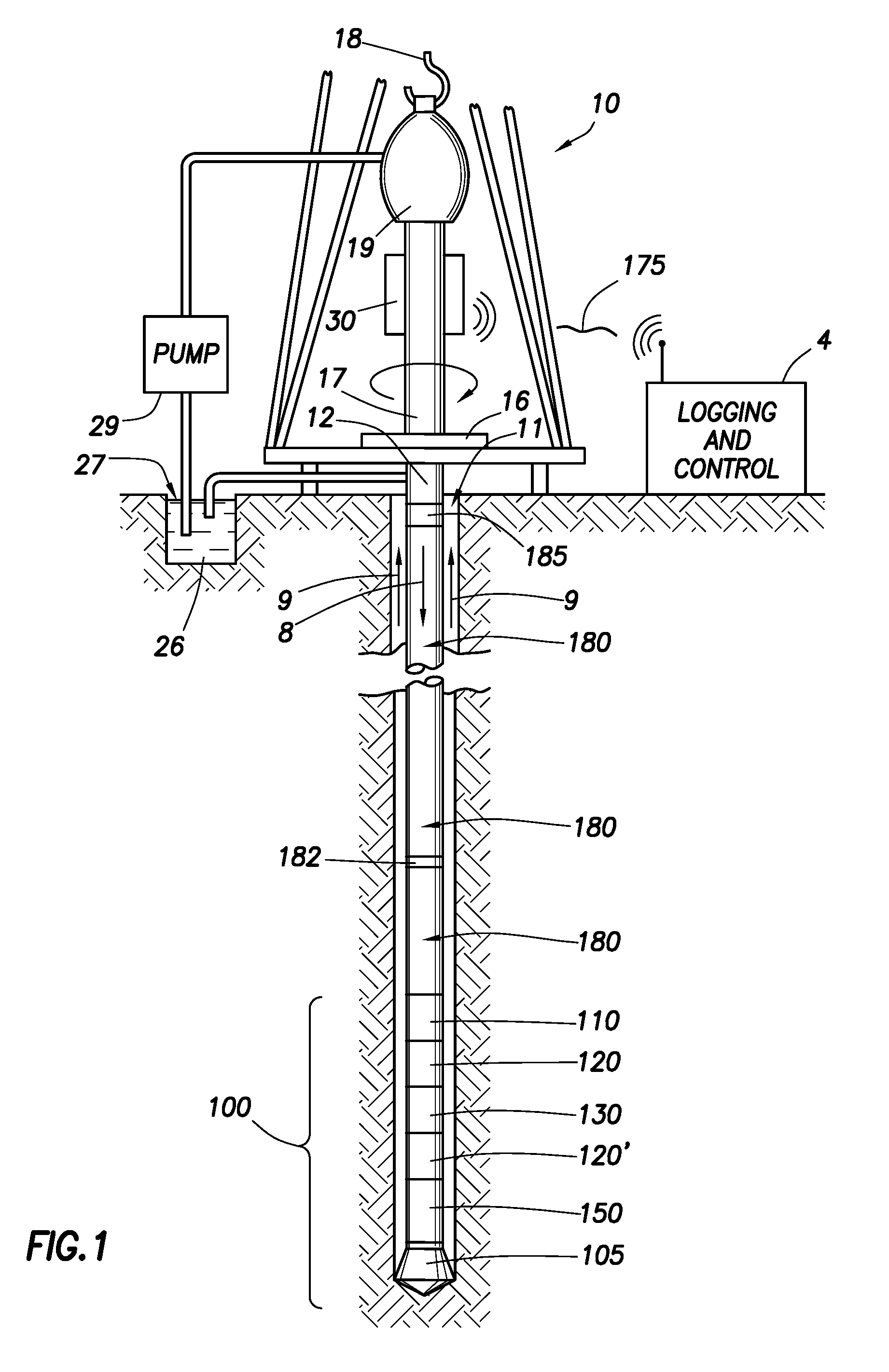

Apparatus and system for well placement and reservoir characterization

ActiveUS20080136419A1Electric/magnetic detection for well-loggingConstructionsComputer moduleEngineering

A modular downhole apparatus to determine a formation property, the apparatus being incorporated into a drill string comprising one or more downhole tools and drill pipe, the drill pipe being of the same or various lengths, the modular downhole apparatus comprising a first module having one or more antennas, wherein the first module has connectors on both ends adapted to connect with the drill string; and a second module having one or more antennas, wherein the second module has connectors on both ends adapted to connect with the drill string; wherein the first module and the second module are spaced apart on the drill string; and wherein one or more of the one or more antennas of one or both of the modules has a dipole moment that is tilted or transverse.

Owner:SCHLUMBERGER TECH CORP

Measurement while drilling apparatus and method of using the same

Owner:PNC BANK NAT ASSOC +2

Fill up tool and mud saver for top drives

InactiveUS6571876B2Prevent leakageMinimal drilling fluid lossDrilling rodsFluid removalTop driveEngineering

A tubular tool body carried at the end of a drilling rig top drive is received within a drill string being used as a landing string to position casing in a wellbore. External threads on the tool body can be mated with the box threads of the drill string to secure the top drive and drill string together for simultaneous drill string movement and fluid circulation. An annular seal carried about the tool body engages and seals with the internal wall of the drill pipe to prevent drilling fluid leakage when the tool body is received within the drill pipe without thread engagement. The tool has an internal check valve that opens to allow back flow of drilling fluid that may be displaced from the drill pipe as the pipe is lowered into the well. The check valve prevents standing fluid in the top drive from spilling onto the rig floor when the tool is withdrawn from the drill string. Pump pressure applied through the top drive axially moves the check valve against a biasing spring to open a bypass through the wall of the tool to permit forward circulation through the drill string and casing. The spring bias force is sufficient to withstand the hydrostatic force exerted by the standing column of fluid in the top drive and associated piping.

Owner:HALLIBURTON ENERGY SERVICES INC

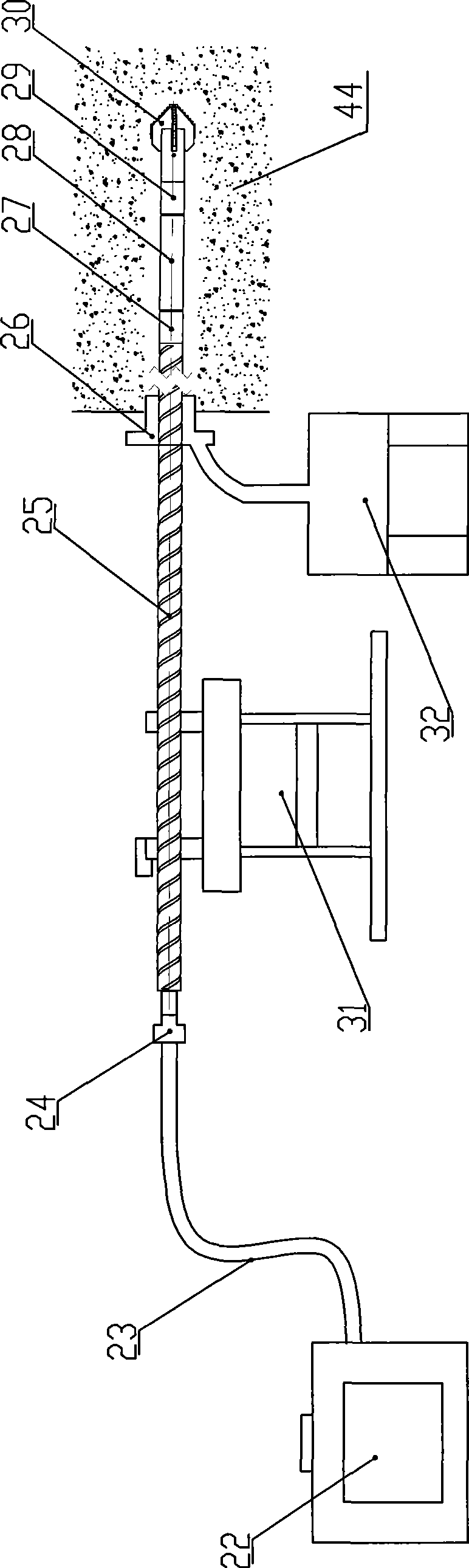

In-hole drilling tool integrating drilling, slotting and punching coal seam and using method thereof

InactiveCN101532391AGuaranteed cleanlinessAvoid enteringDrill bitsLiquid/gas jet drillingHigh pressure waterHigh pressure

The invention discloses an in-hole drilling tool integrating drilling, slotting and punching a coal seam and a using method thereof. The in-hole drilling tool comprises a water supple device or an air supple device, a high-pressure sealing drill pipe, a slotting and punching valve and a drill bit. The water supply device and the air supply device are connected with the high-pressure sealing drill pipe at an orifice. The slotting and punching valve is installed between the high-pressure sealing drill pipe and the drill bit. The in-hole drilling tool is essentially used for drilling and anti-reflective outburst eliminating after drilling of soft outburst coal seam. The using method is as follows: after the drilling construction is finished, a water supplier with a pressure release valve is used for starting a high-pressure pumping station to improve the pressure and the flux for water supply; high-pressure water current at the pumping station drives the slotting and punching valve to act for closing an axial liquid passage and opening a radial liquid passage; and high-pressure jet current realizes slotting or punching through a cutting nozzle or a punching nozzle. The invention has novel design and easy operation, is safe and reliable, improves the outburst elimination efficiency and realizes the integrated operation of drilling, slotting or punching and outburst eliminating.

Owner:HENAN POLYTECHNIC UNIV

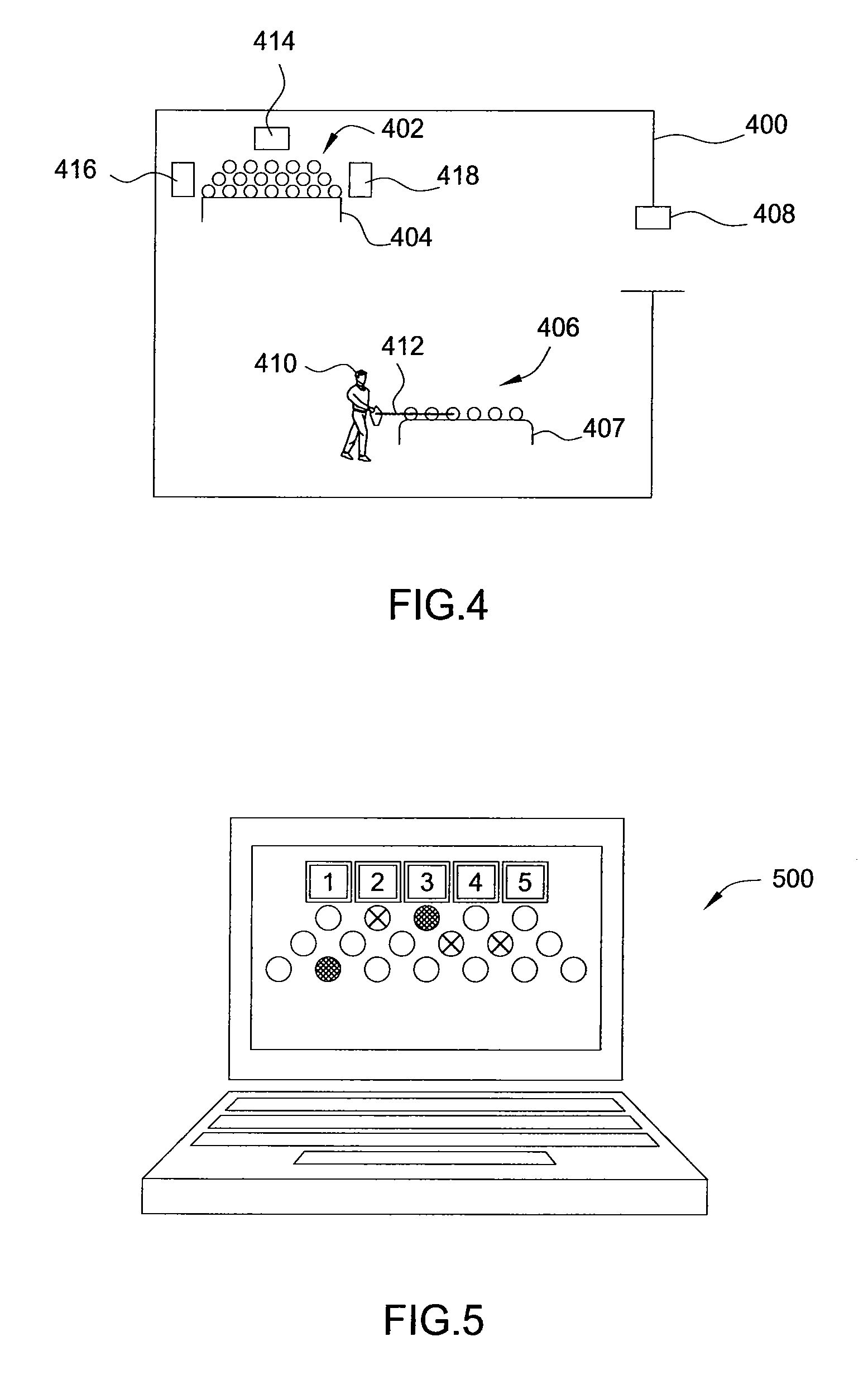

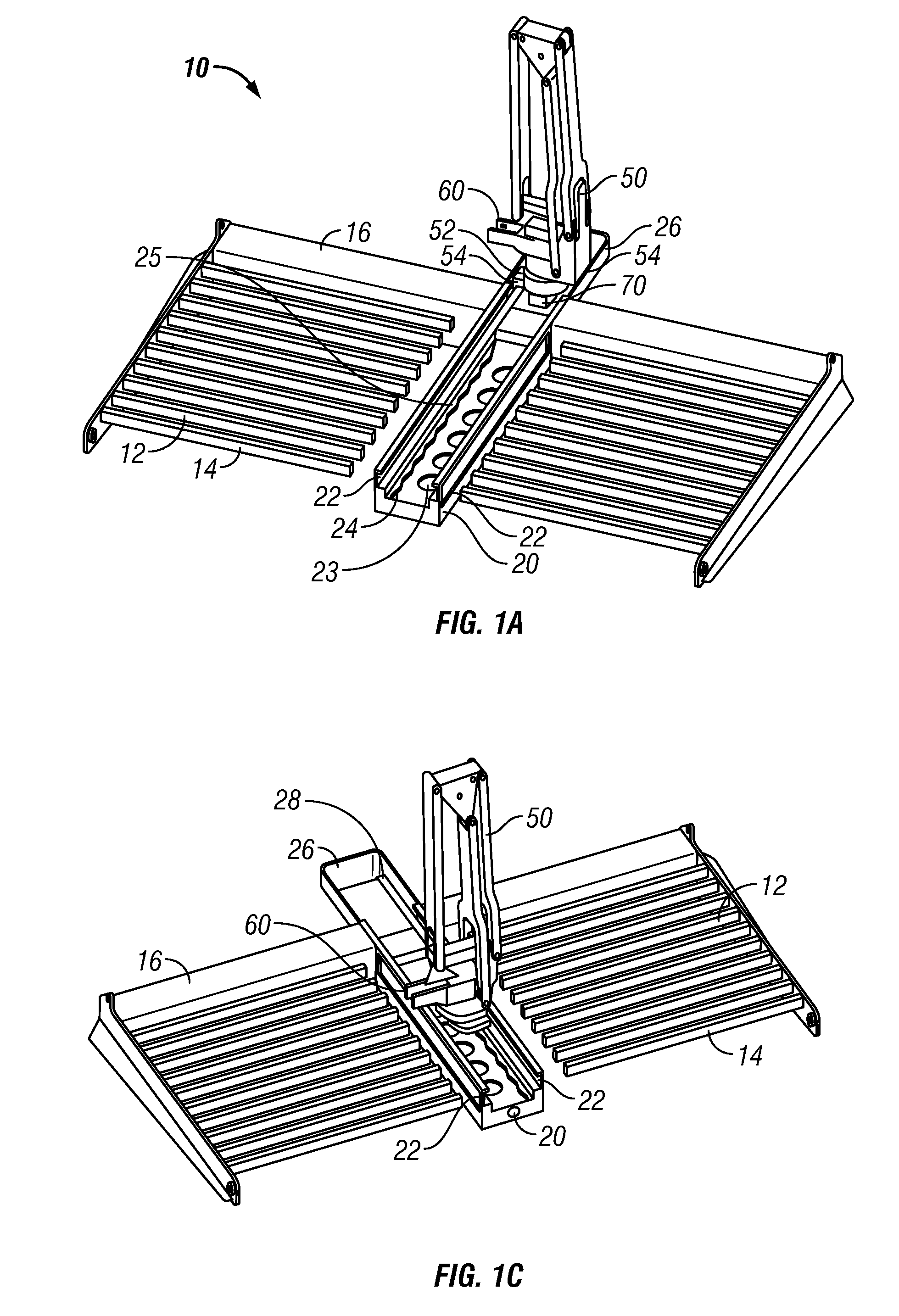

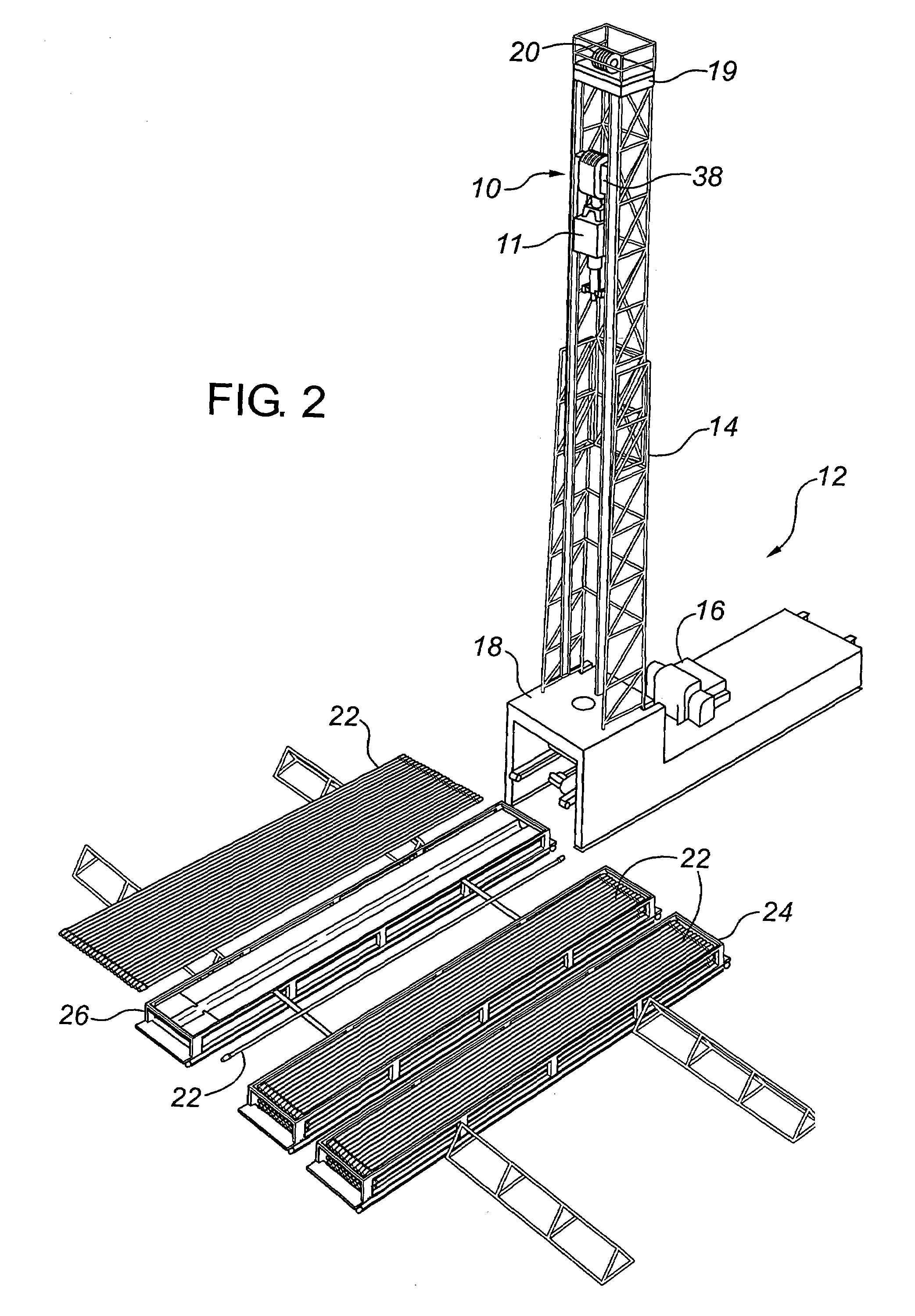

Pipe racking system

ActiveUS20060104747A1Safe and efficient movementReduce the risk of injuryDrilling rodsLifting devicesSystems designWell drilling

The pipe racking system is designed to handle drilling tubulars (primarily drill pipe and drill collars) between the racked or setback position and the well center. The racking system can mechanically grasp a stand of pipe, lift the pipe sufficient for free movement, and deliver the pipe to either the setback area for storage or to well center to be added to the drilling string. The purpose of this newly developed system is to move pipe safely and efficiently in the vertical position for drilling operations. Together with the use of its mechanized fingerboard, the system automates the process of handling and storing pipe vertically, thus eliminating the need for a worker at the racking board level. The system is capable of being installed within the masts of smaller rigs and may remain installed in the mast during rig moves thus minimizing any disassembly for rig-down.

Owner:NAT OILWELL DHT

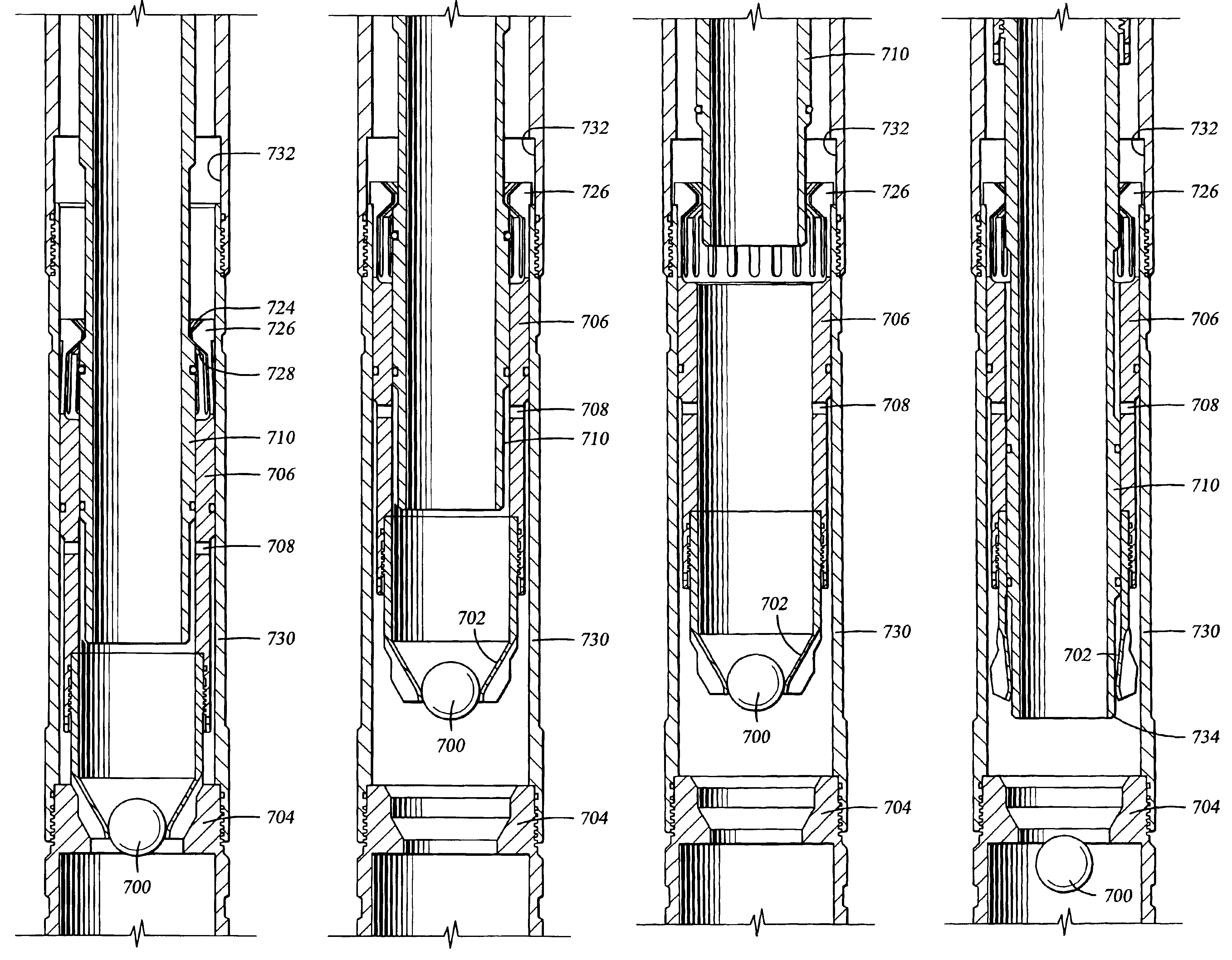

Downhole surge reduction method and apparatus

InactiveUS20040000406A1Facilitate surge pressureEasy to operateDrilling rodsFluid removalPressure reductionMechanical engineering

A method and apparatus for use in the oil well industry for running in drilling / production liners and sub-sea casings down a borehole through drilling fluid on a drill pipe using a running tool with the benefits of surge pressure reduction are disclosed. In accordance with the present invention, a surge pressure reduction tool includes a diverter device having a housing with a set of flow holes formed therein and a sliding sleeve residing within the housing having a set of flow ports formed therein. By aligning the set of flow holes of the housing with the set of flow ports of the sleeve, the tool is set in a "surge pressure reduction" mode. By shifting, or axially indexing, the sleeve downward, the set of flow holes is blocked by the sleeve thus setting the tool in a "cementing" or "circulation" mode. This shifting or indexing is accomplished using an indexing mechanism. The indexing mechanism of the present invention includes a spring ring which is initially compressed and set in a circumferential groove formed around the top of the sleeve. As the sleeve is shifted downward from surge reduction mode to cementing / circulation mode, the spring ring decompresses radially outward to engage a circumferential groove formed in the housing. This effectively locks the sliding sleeve in the cementing / circulation mode. In accordance with the present invention, a surge pressure reduction tool further includes a volume compensation device which enables the diverter device to be shifted axially downward into the cementing / circulation mode even where the drilling / production liner or sub-sea casing is plugged with drill cuttings or downhole debris. In the cementing / circulation mode, a flow path is established for cement or drilling fluid to flow downward from the drill pipe, through the diverter device, volume compensation device, and running tool, and out into the borehole via the drilling / production liner or sub-sea casing. In the surge pressure reduction mode, an alternative flow path is established for drilling fluid to flow upward from the borehole into the drilling / production liner or sub-sea casing, through the running tool and volume compensation device, and into an annular space between the drill pipe and the borehole via the set of flow holes of the diverter device.

Owner:ALLAMON INTEREST +1

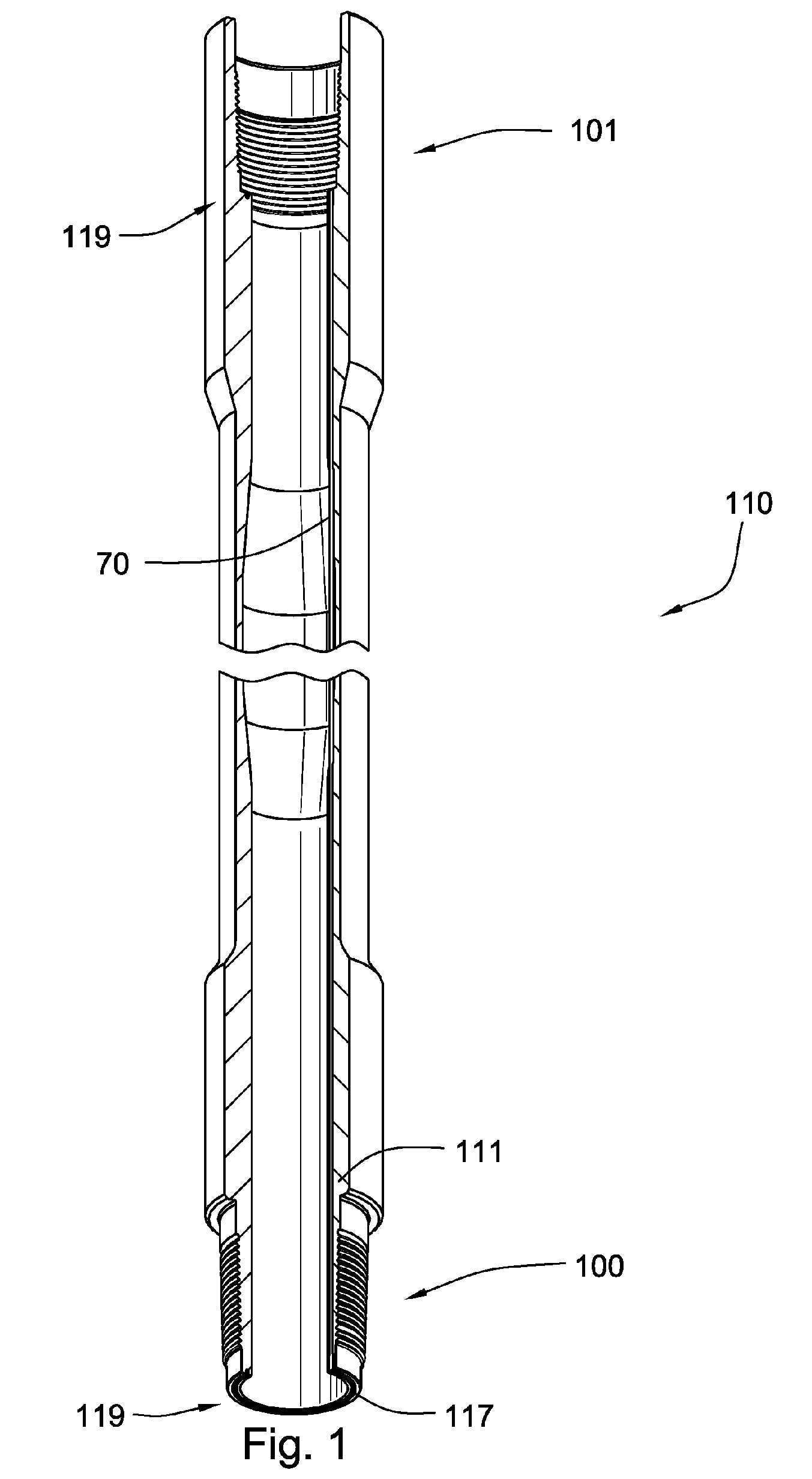

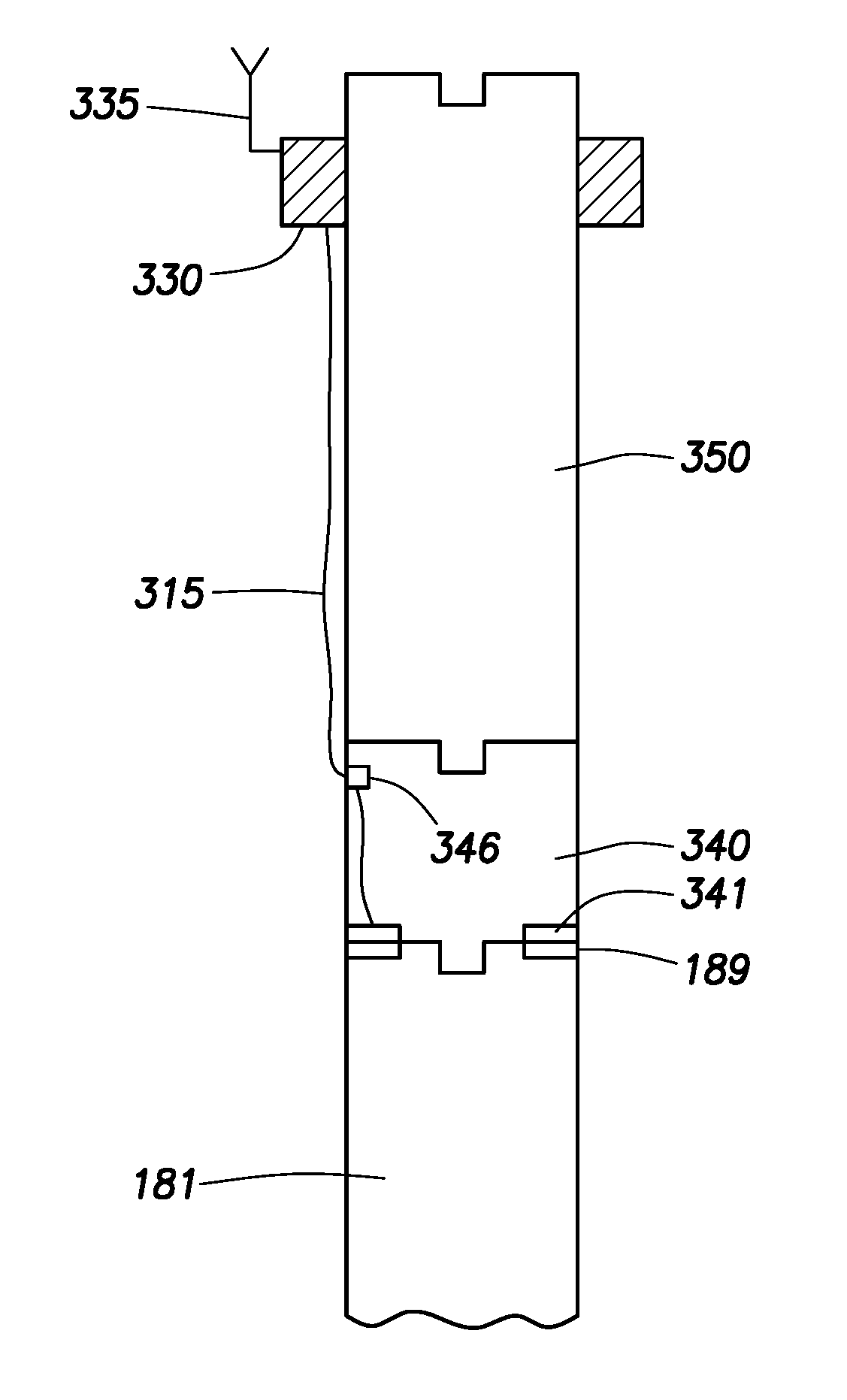

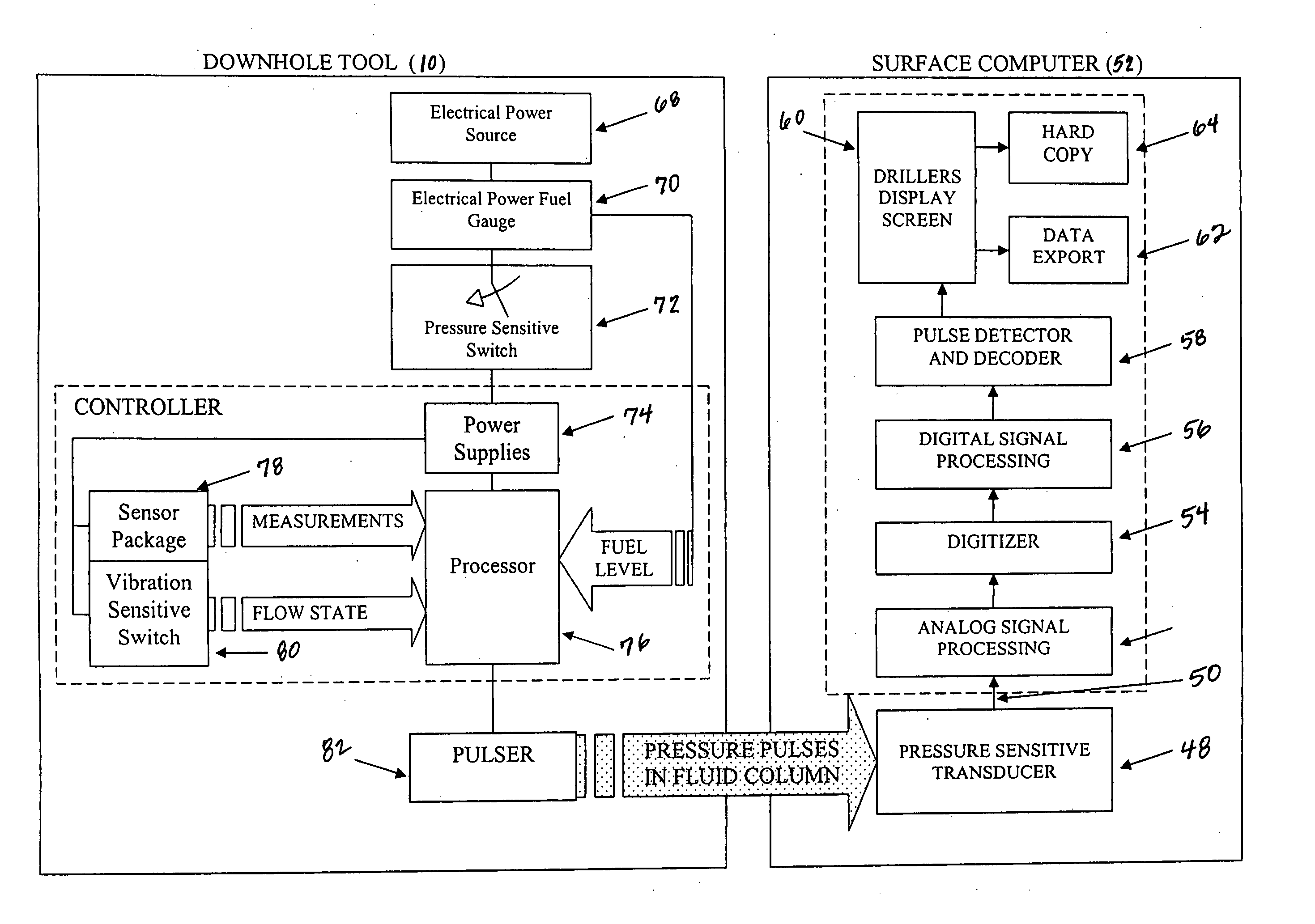

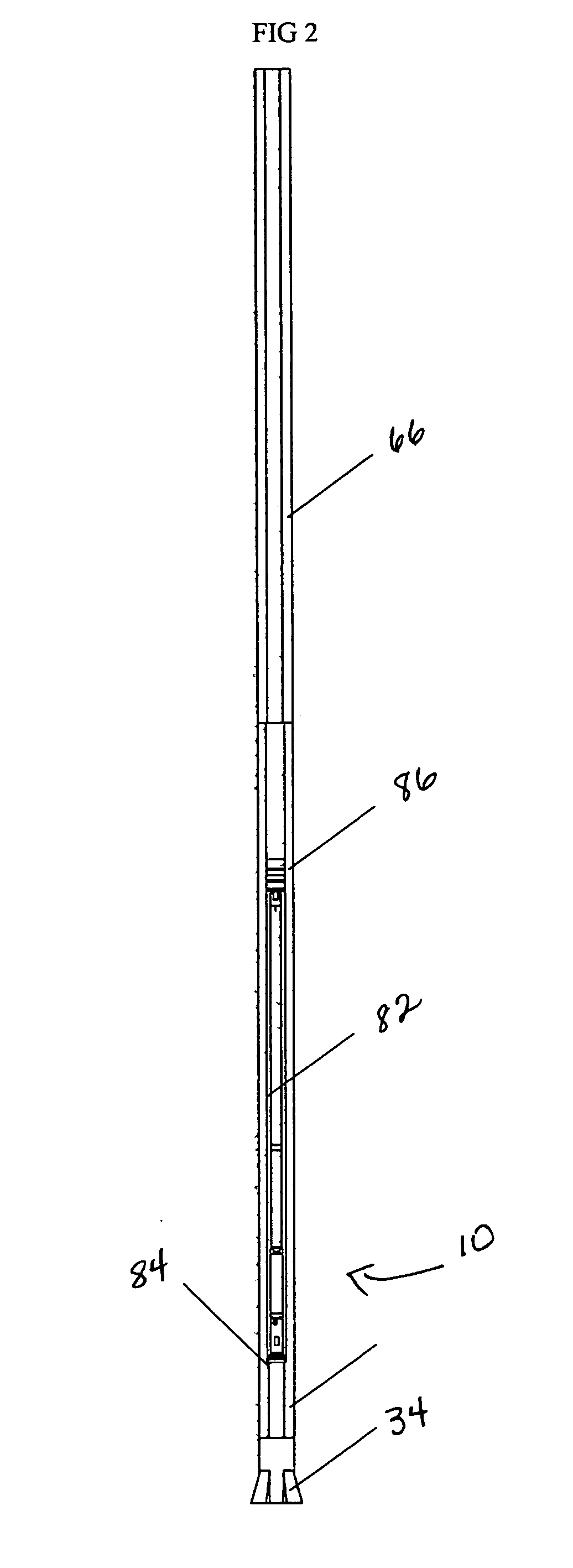

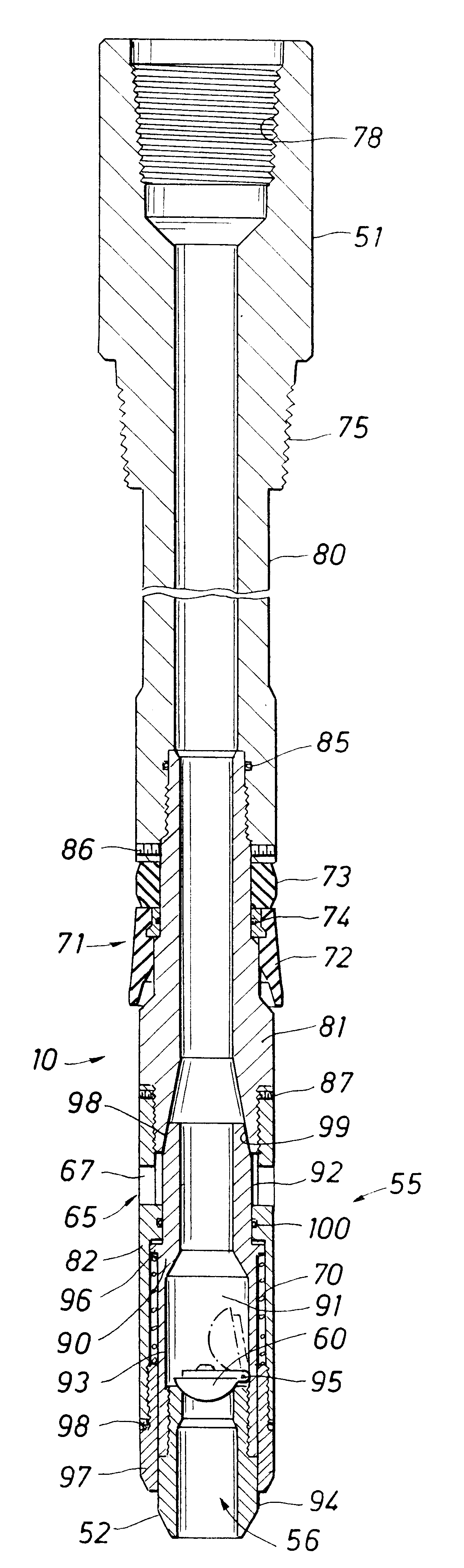

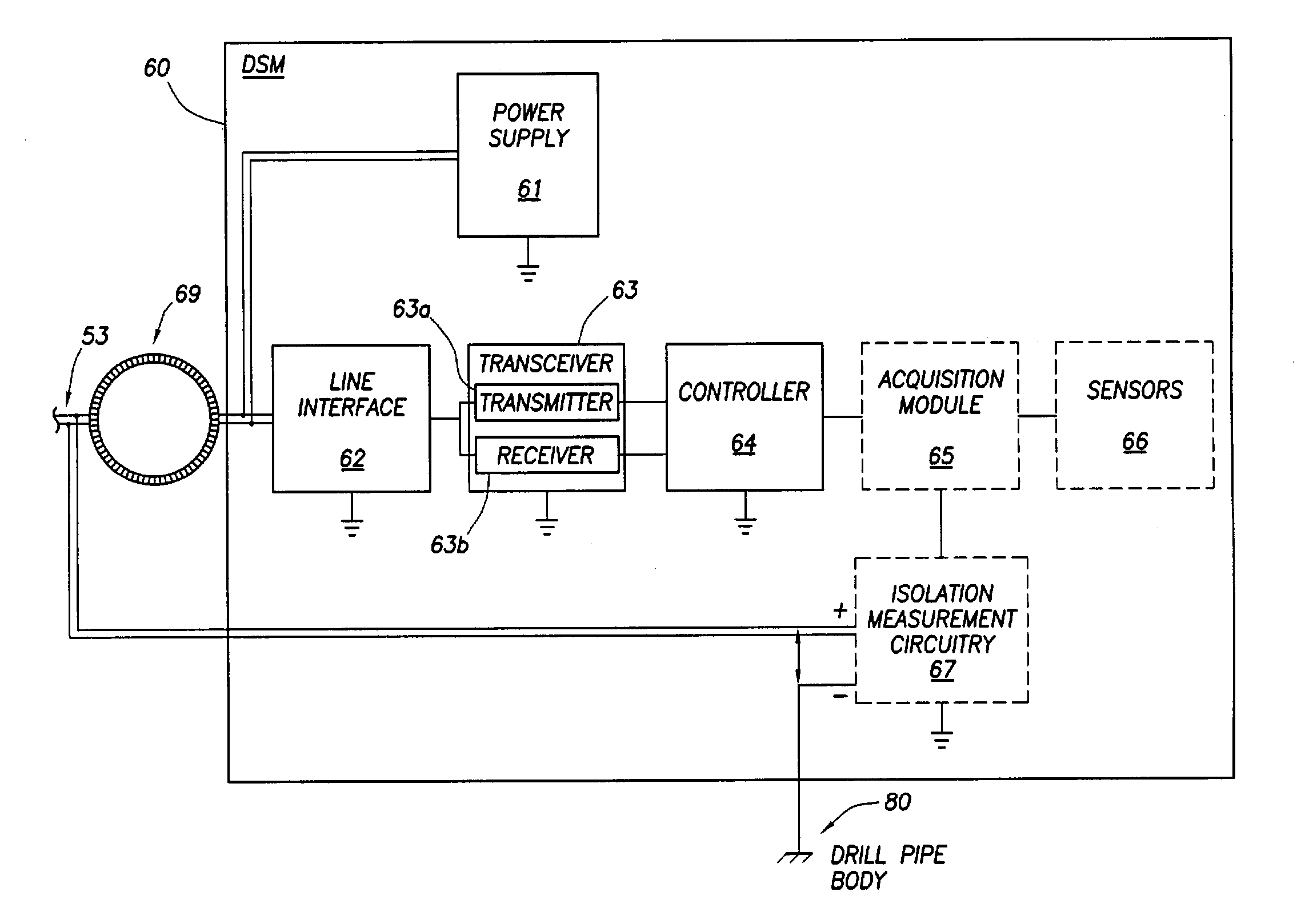

Method and apparatus for performing diagnostics in a wellbore operation

A wired drill pipe telemetry system includes a surface computer; and a drill string telemetry link comprising a plurality of wired drill pipes each having a telemetry section, at least one of the plurality of wired drill pipes having a diagnostic module electrically coupling the telemetry section and wherein the diagnostic module includes a line interface adapted to interface with a wired drill pipe telemetry section; a transceiver adapted to communicate signals between the wired drill pipe telemetry section and the diagnostic module; and a controller operatively connected with the transceiver and adapted to control the transceiver.

Owner:SCHLUMBERGER TECH CORP

Pipe stand transfer systems and methods

ActiveUS20100303586A1Promote sportsEasy to participateDrilling rodsSemiconductor/solid-state device manufacturingTransfer systemWellbore

Owner:NAT OILWELL VARCO LP

Method and system for connecting pipe to a top drive motor

Method and system for connecting a joint of pipe to a top drive motor just above the drilling platform of a drilling rig where the connection can be made quickly and safely by a drilling operator. The system includes a top drive motor that tilts about a horizontal axis and a pipe launcher that brings joints of pipe up to the drilling platform for connection with a top drive motor at a safe and convenient height above the platform. The top drive motor further includes a clamping assembly that grasps and pulls the joint of pipe to the motor as the connection is being made. The clamp assembly supports the motor-pipe connection as the top-drive motor is raised in the drilling mast of the rig bringing the joint of pipe up into a vertical orientation for connection with the drill tubing string.

Owner:LESKO GERALD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com