Patents

Literature

130 results about "Shrink-fitting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shrink-fitting is a technique in which an interference fit is achieved by a relative size change after assembly. This is usually achieved by heating or cooling one component before assembly and allowing it to return to the ambient temperature after assembly, employing the phenomenon of thermal expansion to make a joint. For example, the thermal expansion of a piece of a metallic drainpipe allows a builder to fit the cooler piece to it. As the adjoined pieces reach the same temperature, the joint becomes strained and stronger.

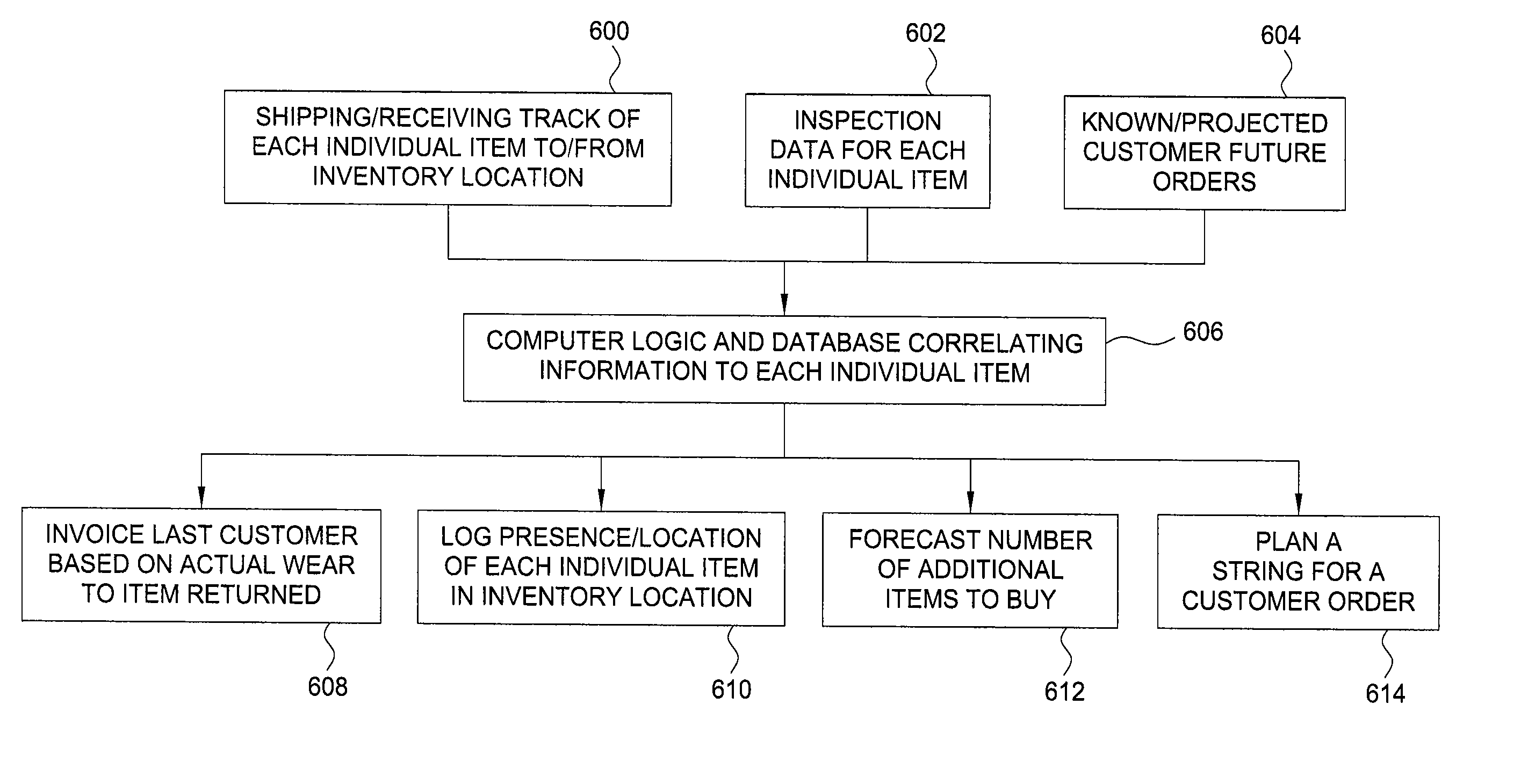

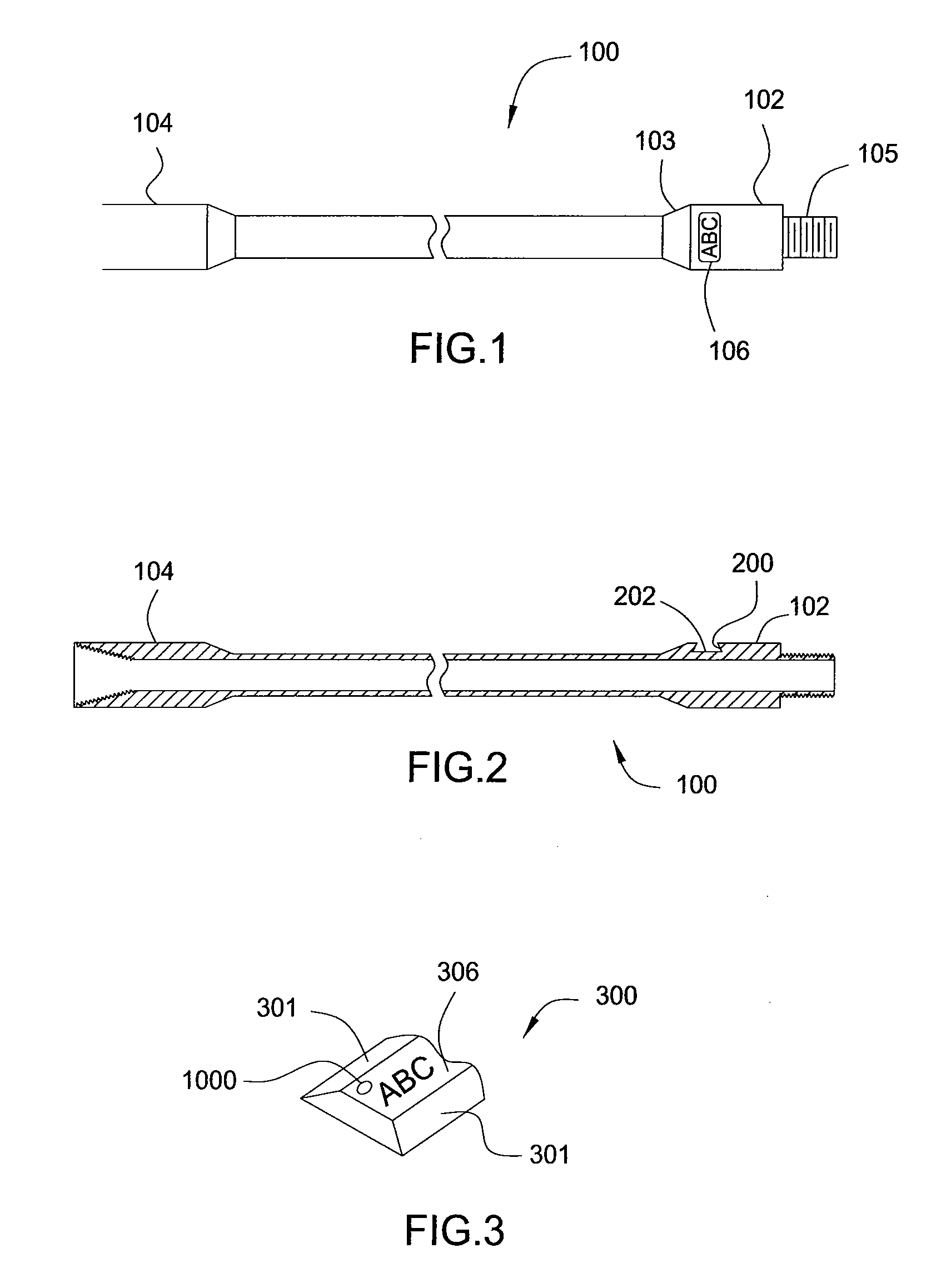

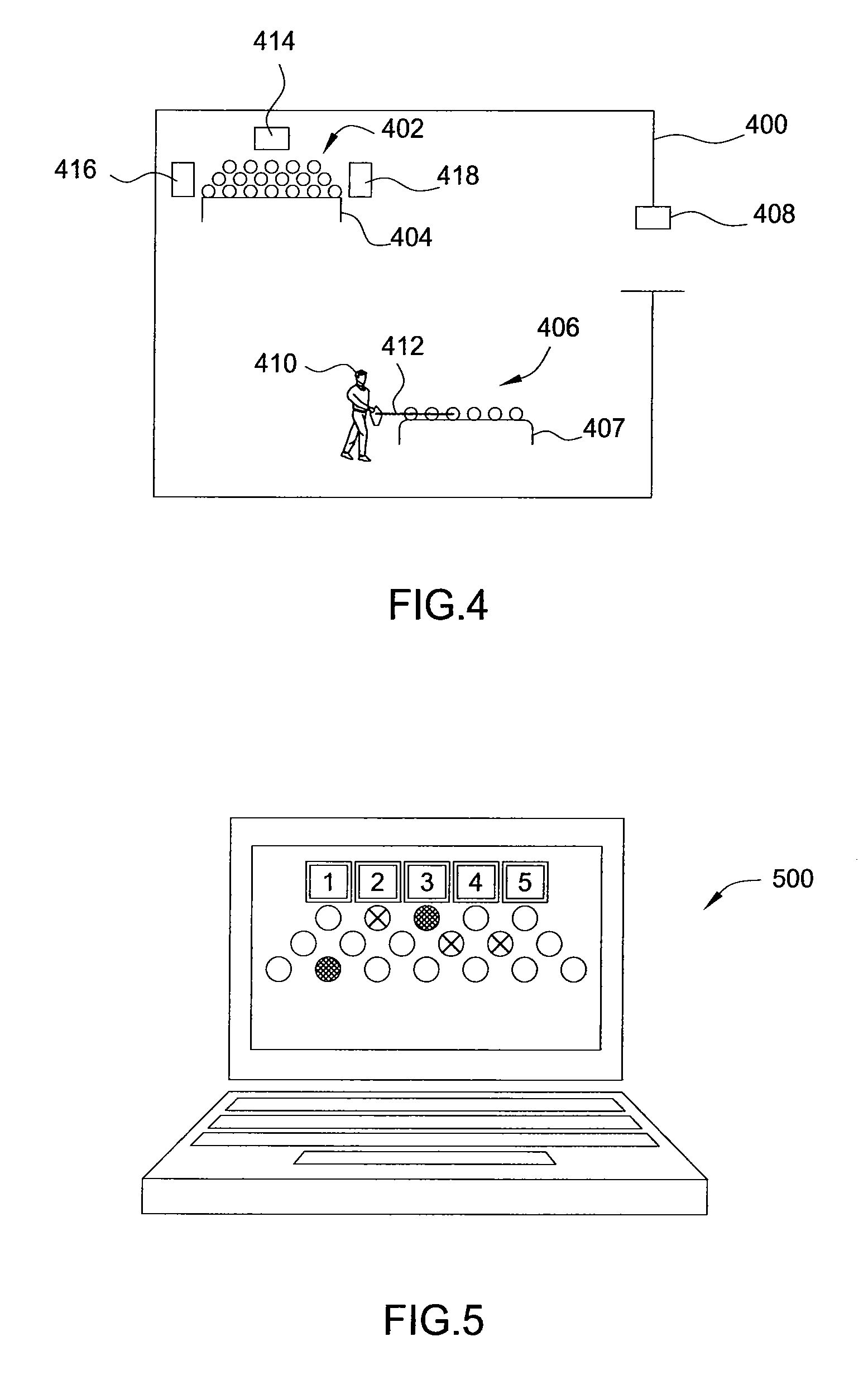

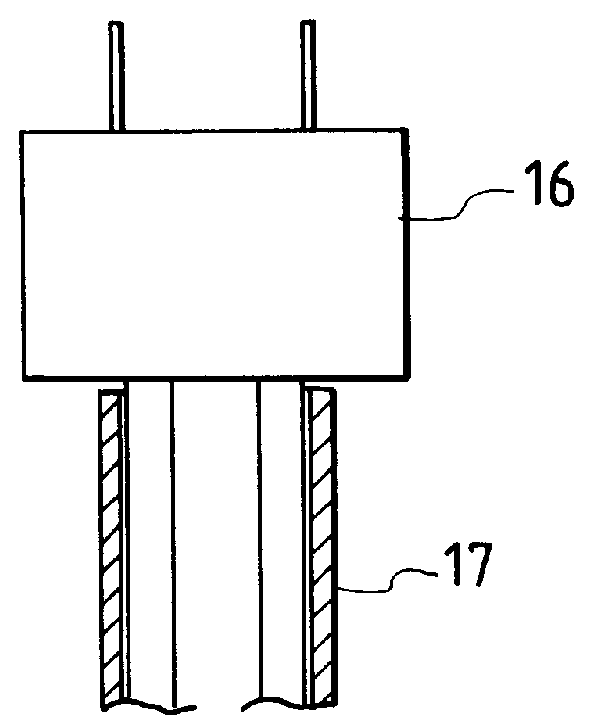

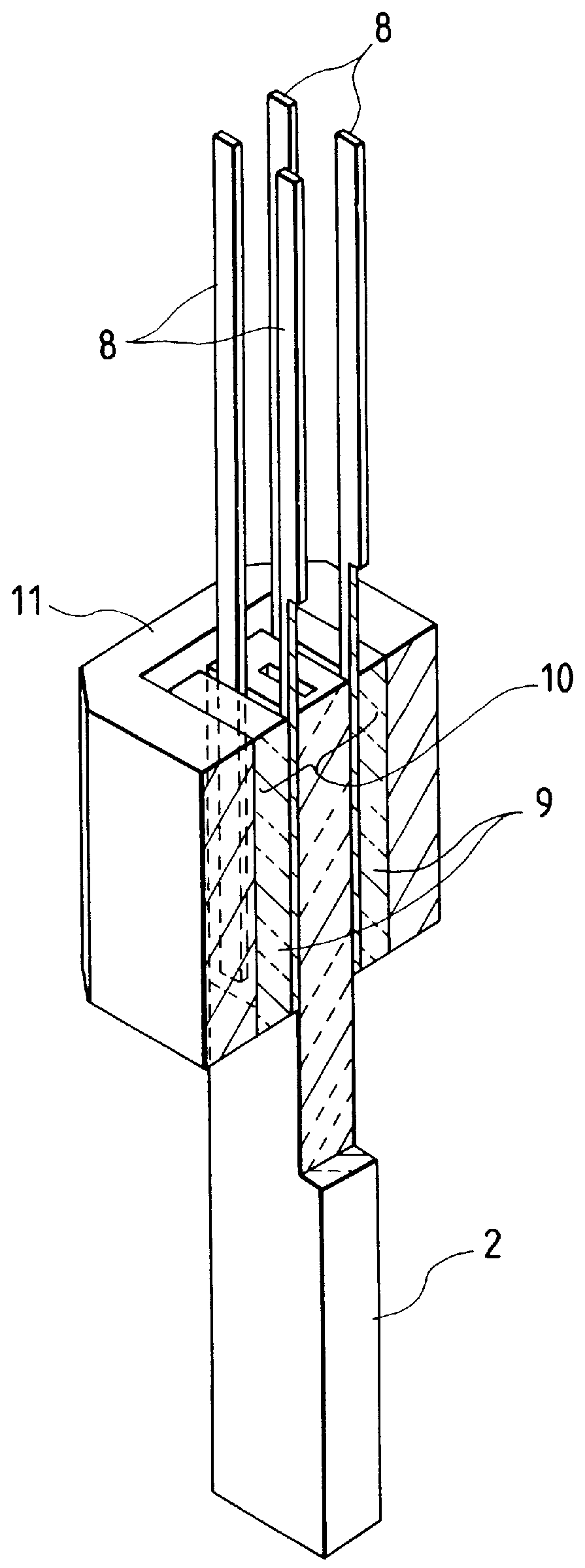

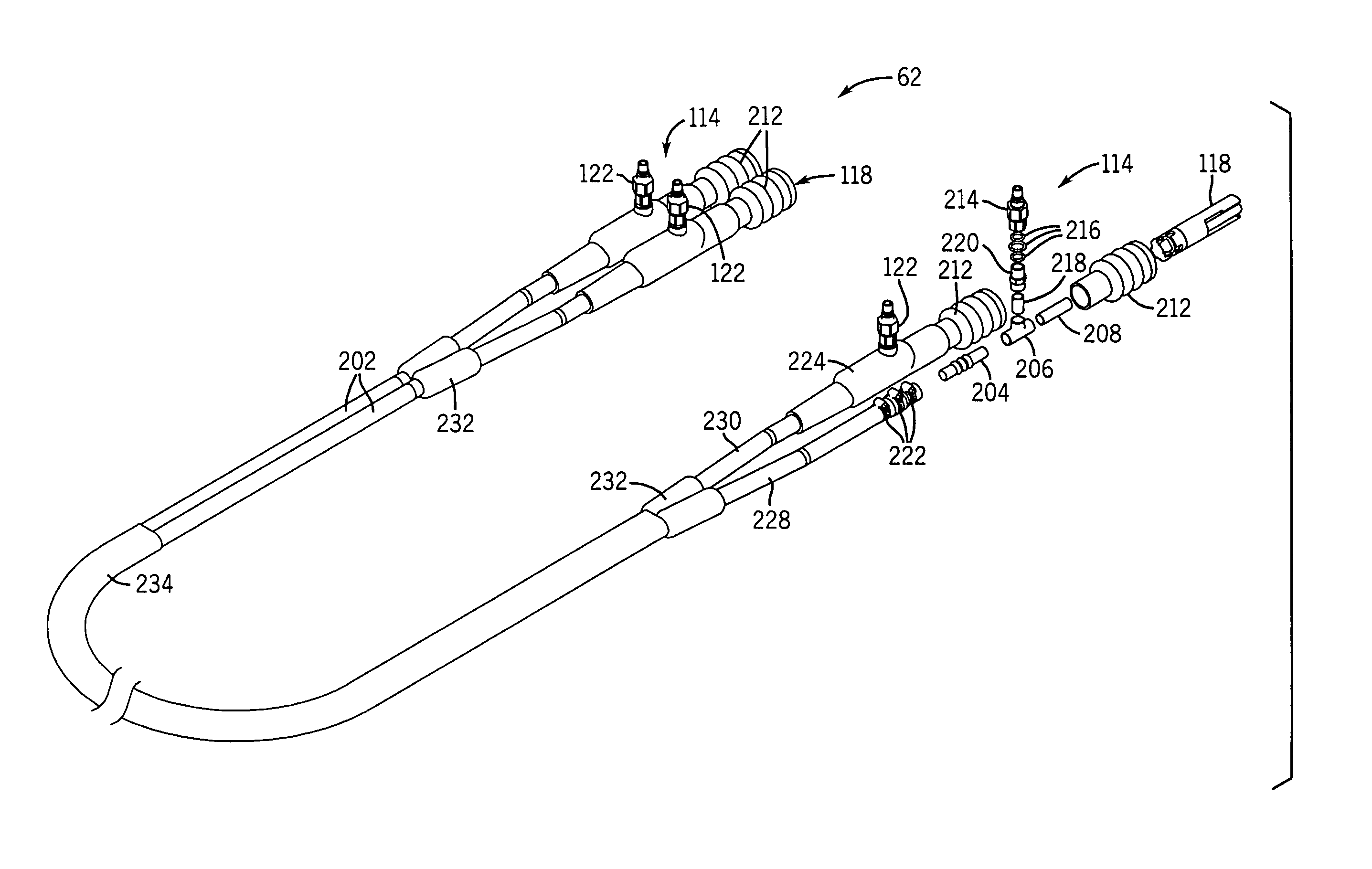

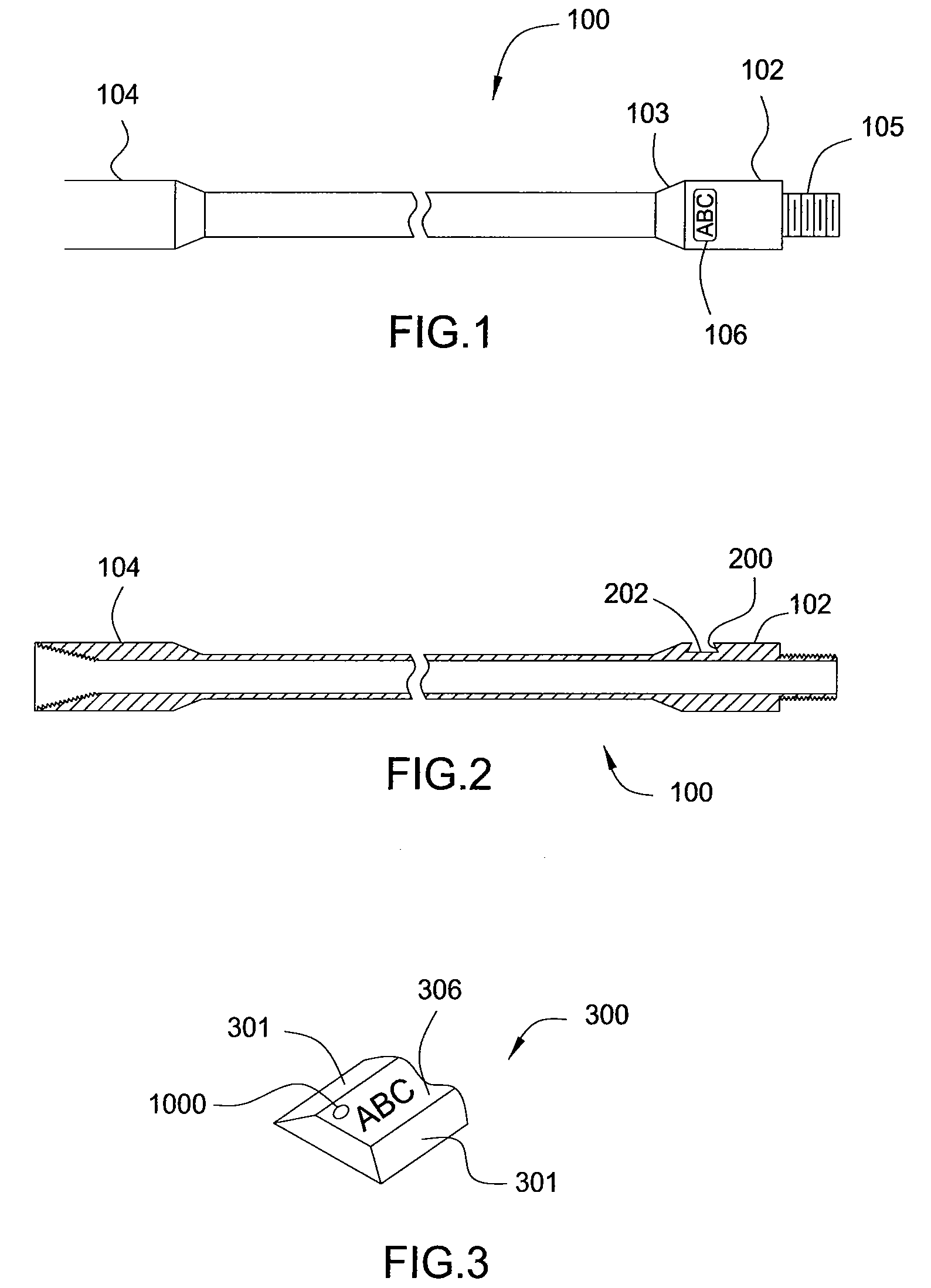

Serialization and database methods for tubulars and oilfield equipment

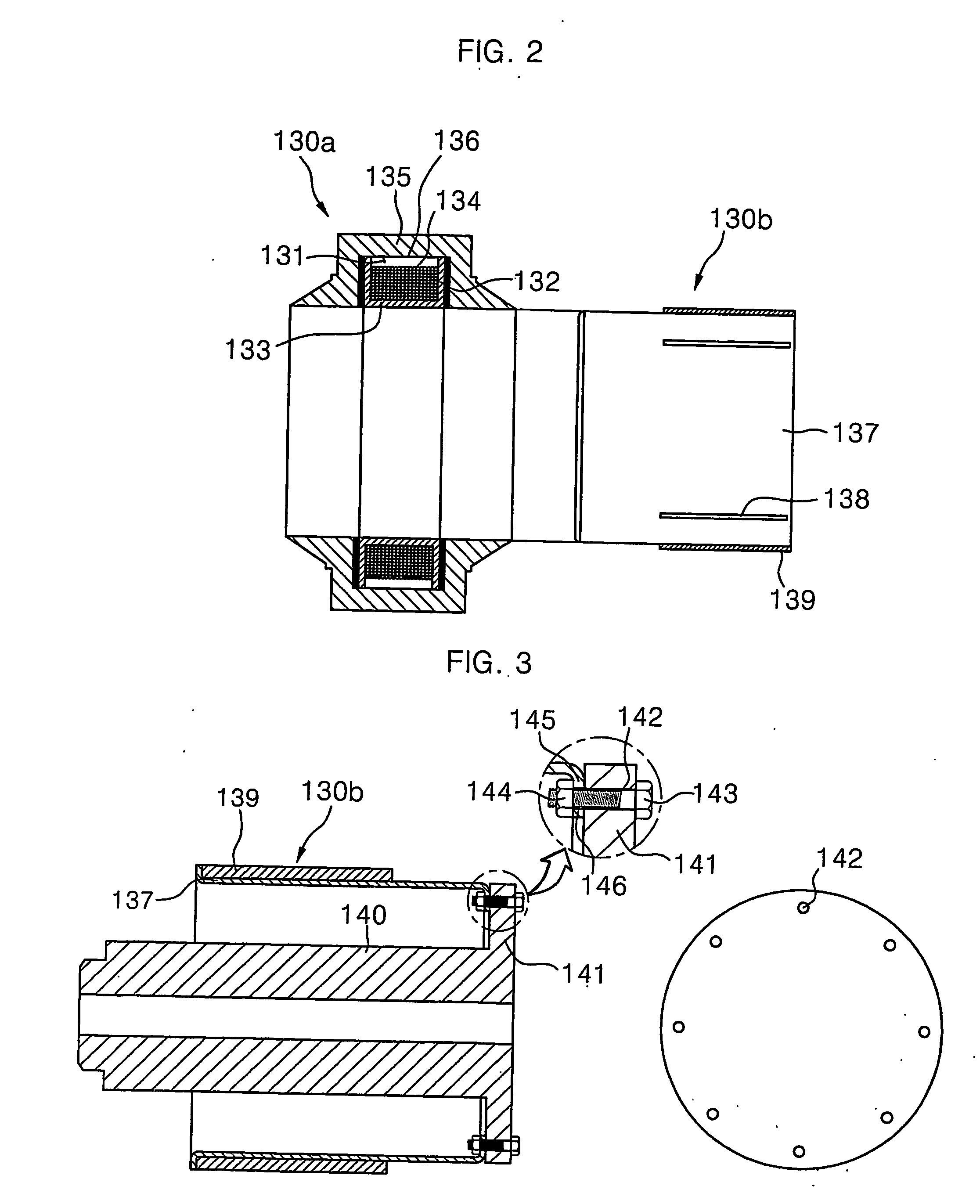

Methods and apparatus identify downhole equipment and correlate input data with the equipment to improve planning and / or inventory operations. For some embodiments, oilfield equipment or tubular goods such as drill pipe include a shaped recess along an outer circumference for receiving a tag cartridge by shrink fitting. Once tagged, detector system configurations at pipe yards may facilitate logging the presence and location of each drill pipe and correlating specific data, such as inspection data, to each drill pipe. Further, this correlation populates a database utilized to achieve other business functions such as forecasting number of additional drill pipe needed to purchase, invoicing customers according to actual tracked wear / use of the drill pipe being returned, and providing well or job specific drill string population using known history pipe joints.

Owner:WEATHERFORD TECH HLDG LLC

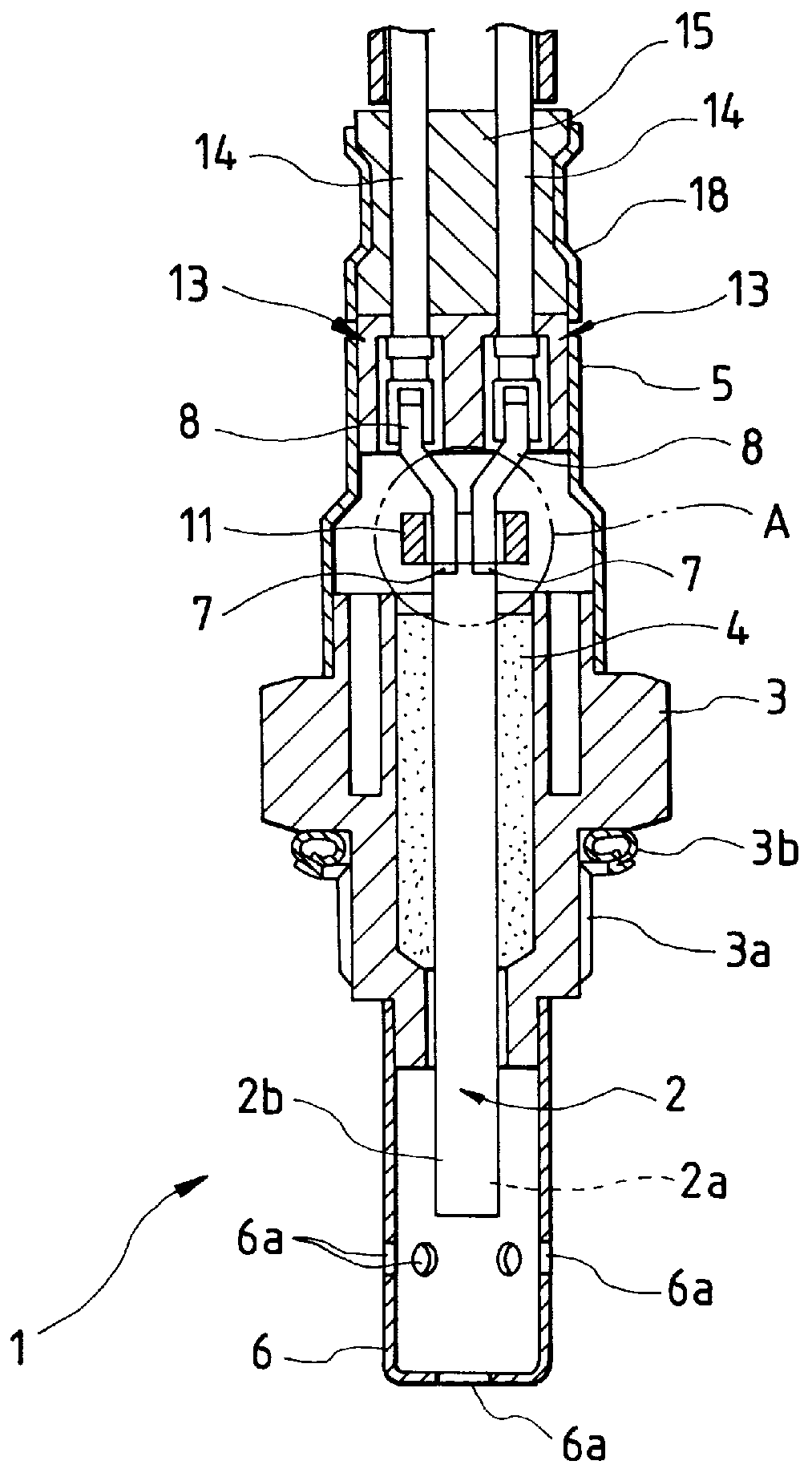

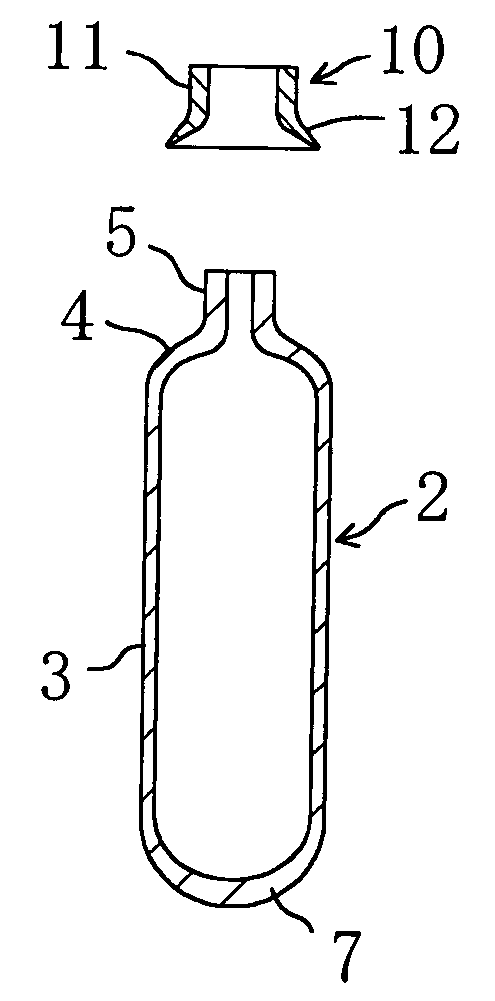

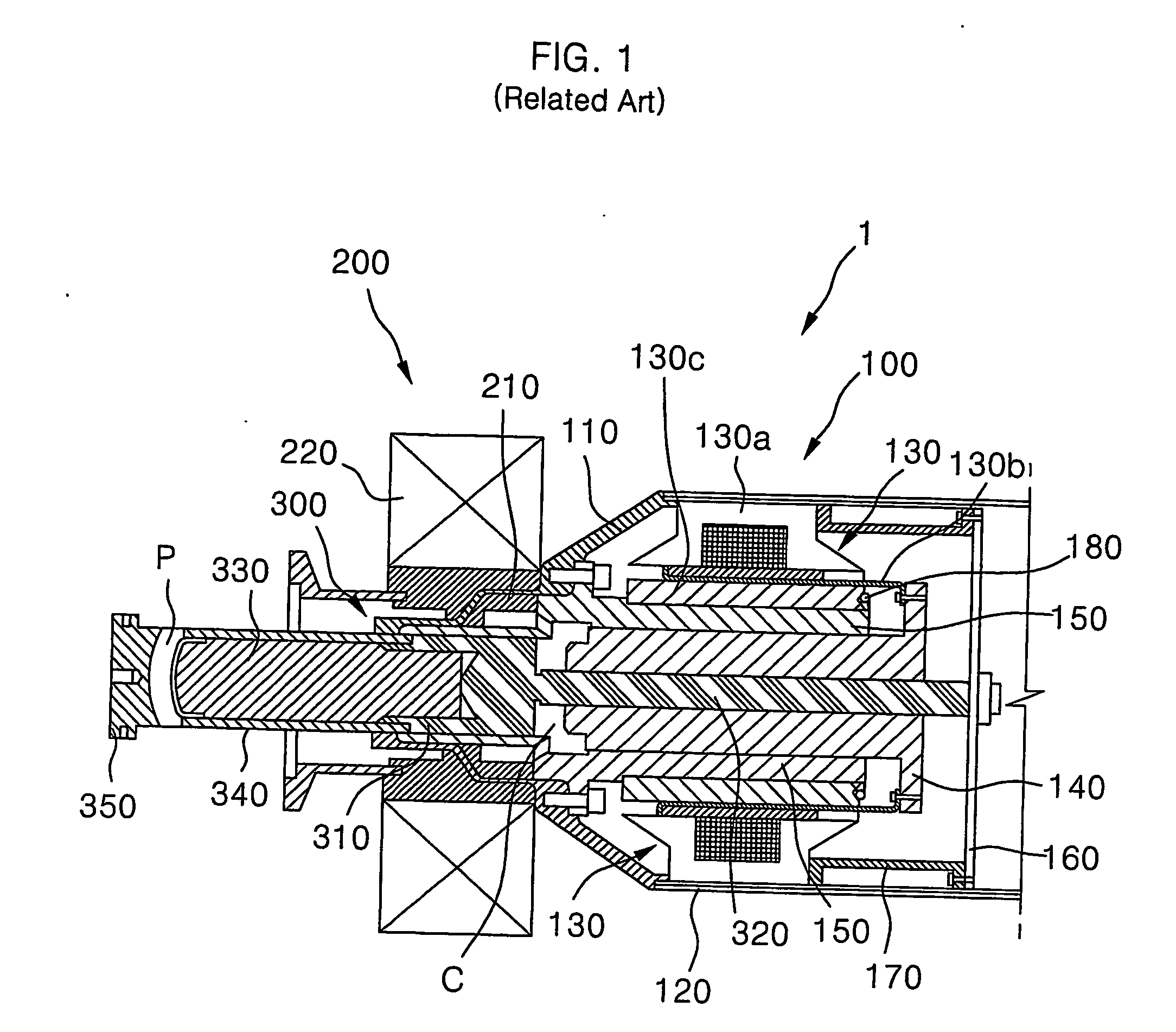

Electronic component having terminal connecting leads with a high temperature ceramic element and a method of making the same

InactiveUS6082175AMore strenuousImprove performanceMaterial resistanceConnection contact member materialShrink-fittingWaspaloy

This discloses an electronic component of a miniature size to be used as e.g. automobile engine peripheral components, such as an exhaust gas oxygen sensor, a heat sensor, and a heater. More specifically, the invention provides an electronic component integral with a heat resistant terminal that is pressure-fitting or shrink-fitted on a ceramic element of the electronic component. This electronic components shows great mechanical and electrical performance, withstanding the high temperature environment over 400 and up to 800 DEG C. to which the ceramic element of the component required expose. The terminal incorporated in this high temperature electronic component comprises a plurality of metal wire leads that electrically connect to a surface of a bar-like ceramic element, at least two ceramic insulators that surround the leads, and a thermal resistant metal ring that shrink-fits or pressure-fits around the ceramic insulators so that the metal leads press in a radial direction holding the element firmly. The thermal resistant metal ring to be used for this shrink fit or pressure fit is preferably made of an alloy, such as Incoloy 909, Inconel 650, and Waspaloy, and the like, thereby preventing the metal leads from coming off at high temperature. The terminal integrated with the ceramic element by the shrink fitting method according to the invention, minimizes the number of parts, attaining a miniaturization of such high temperature electronic component at a low cost.

Owner:NGK SPARK PLUG CO LTD

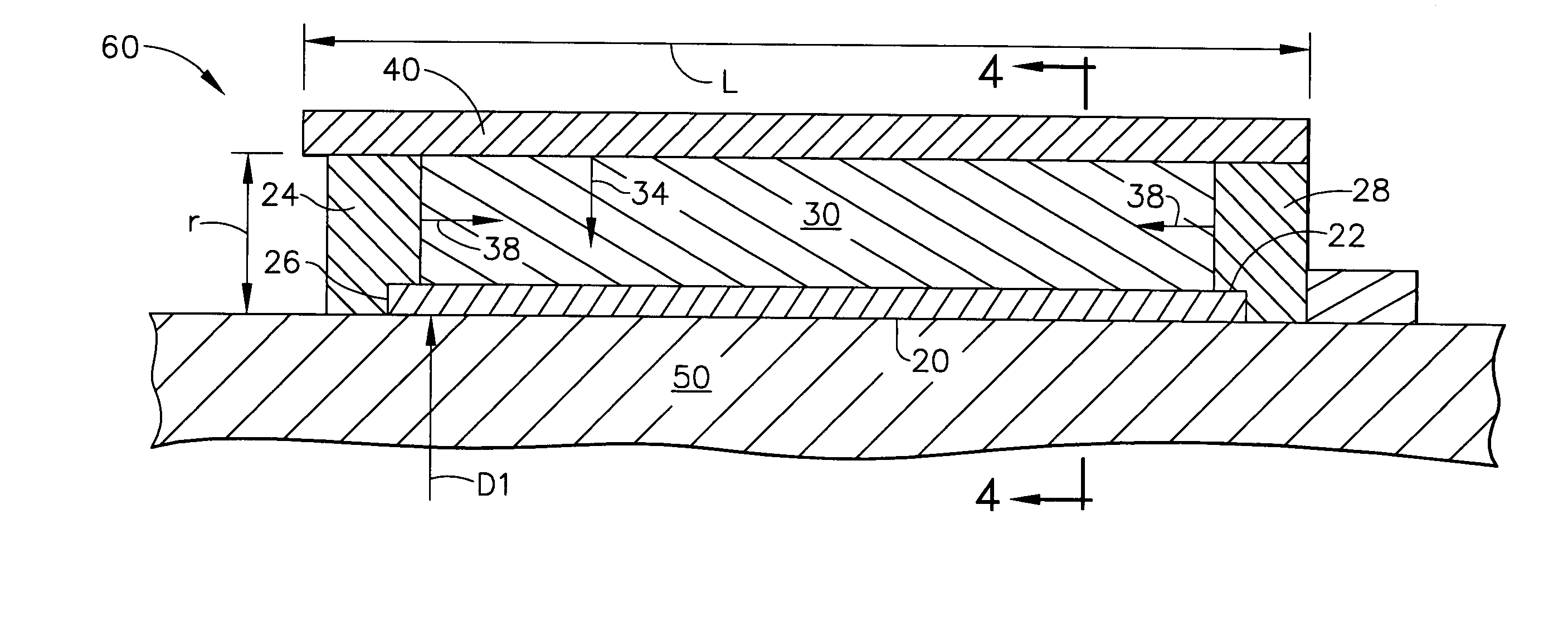

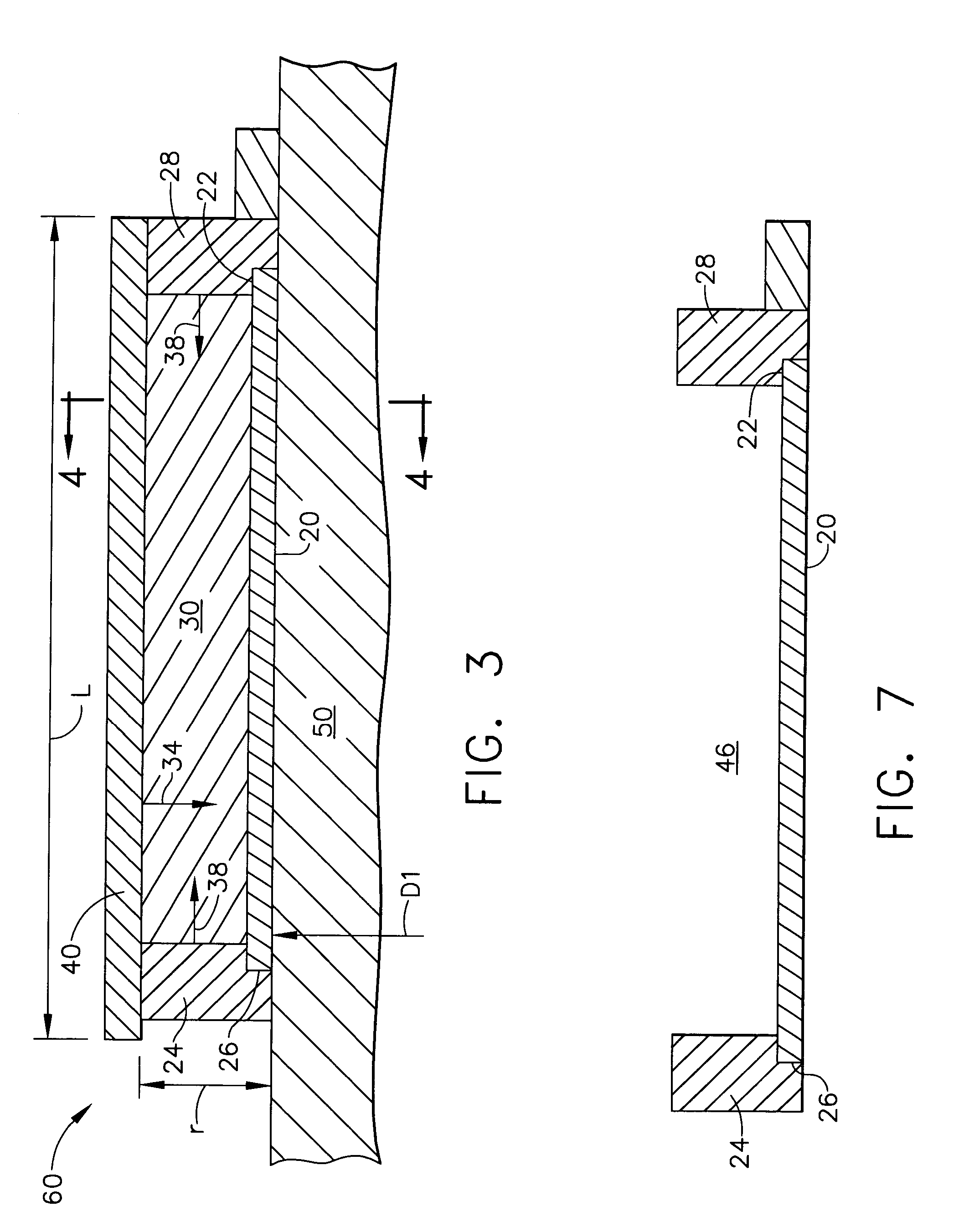

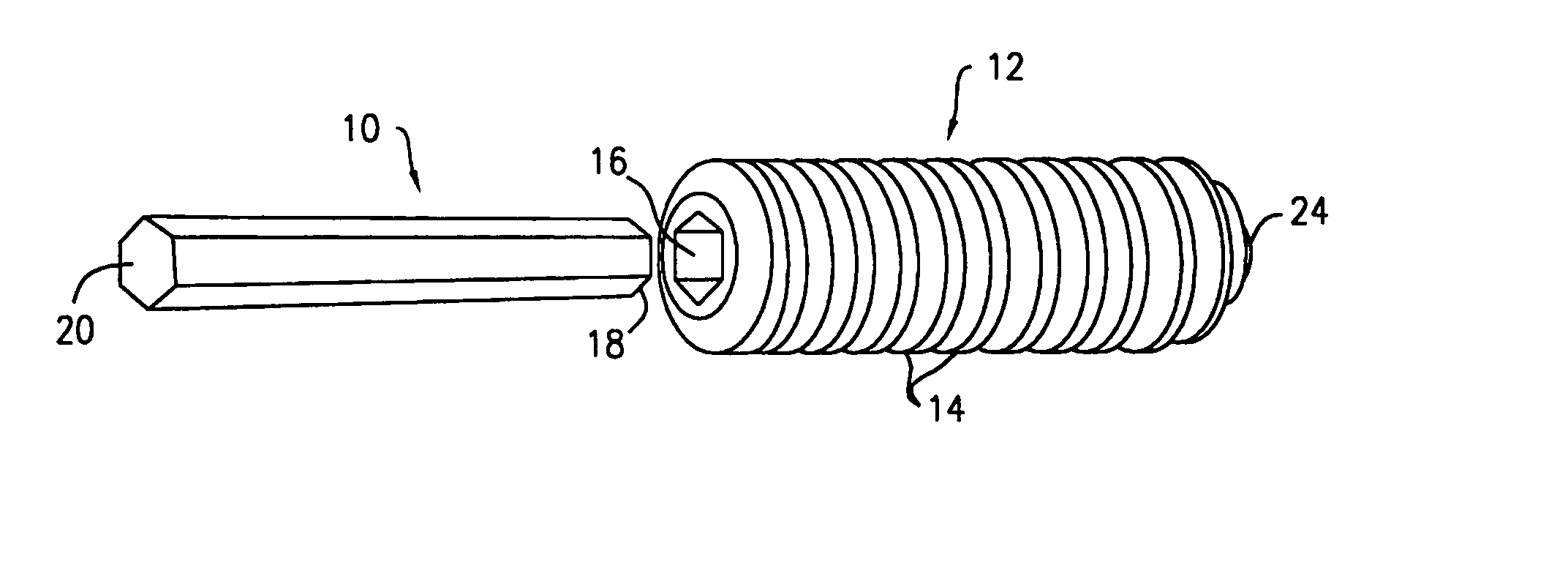

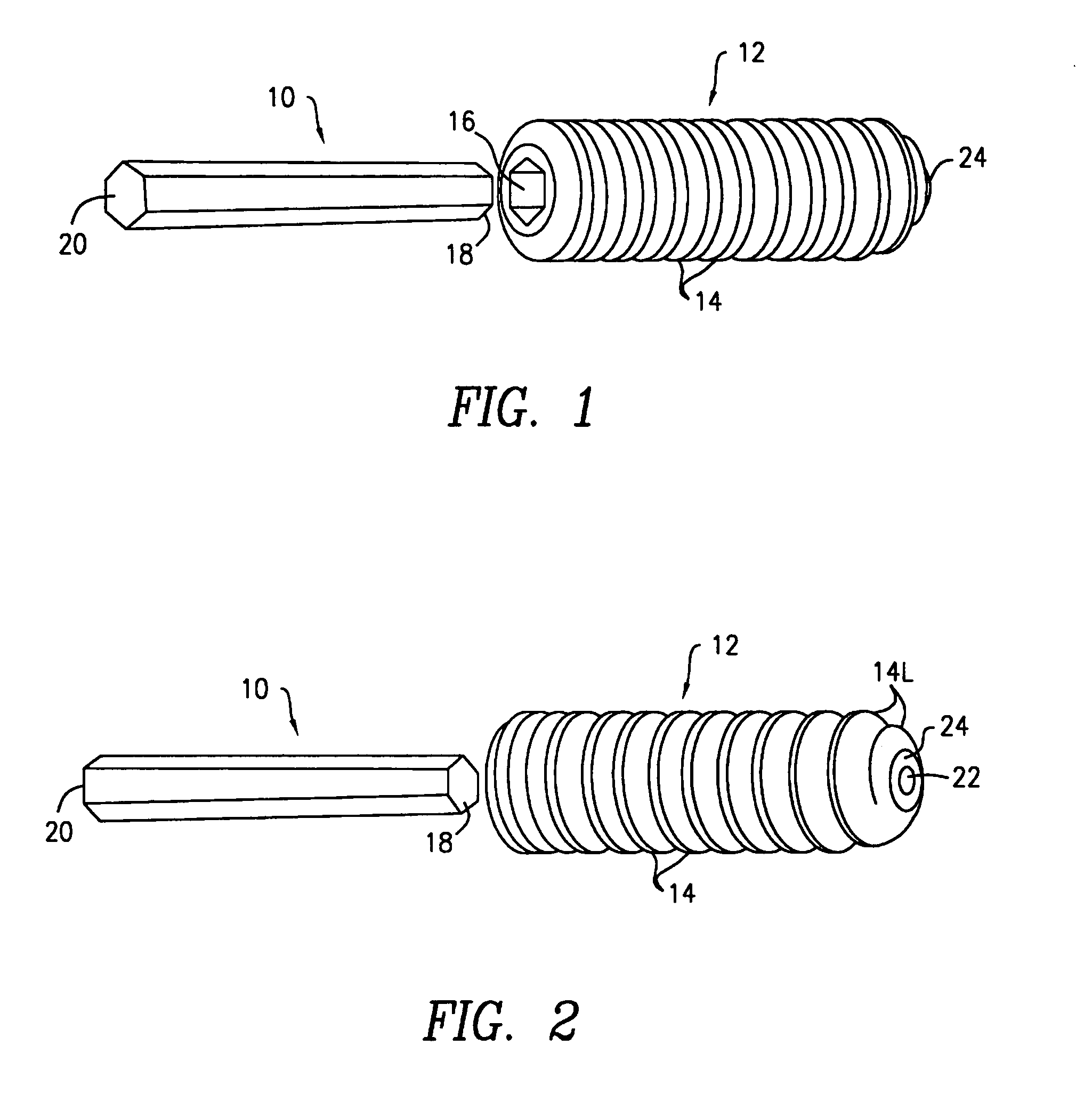

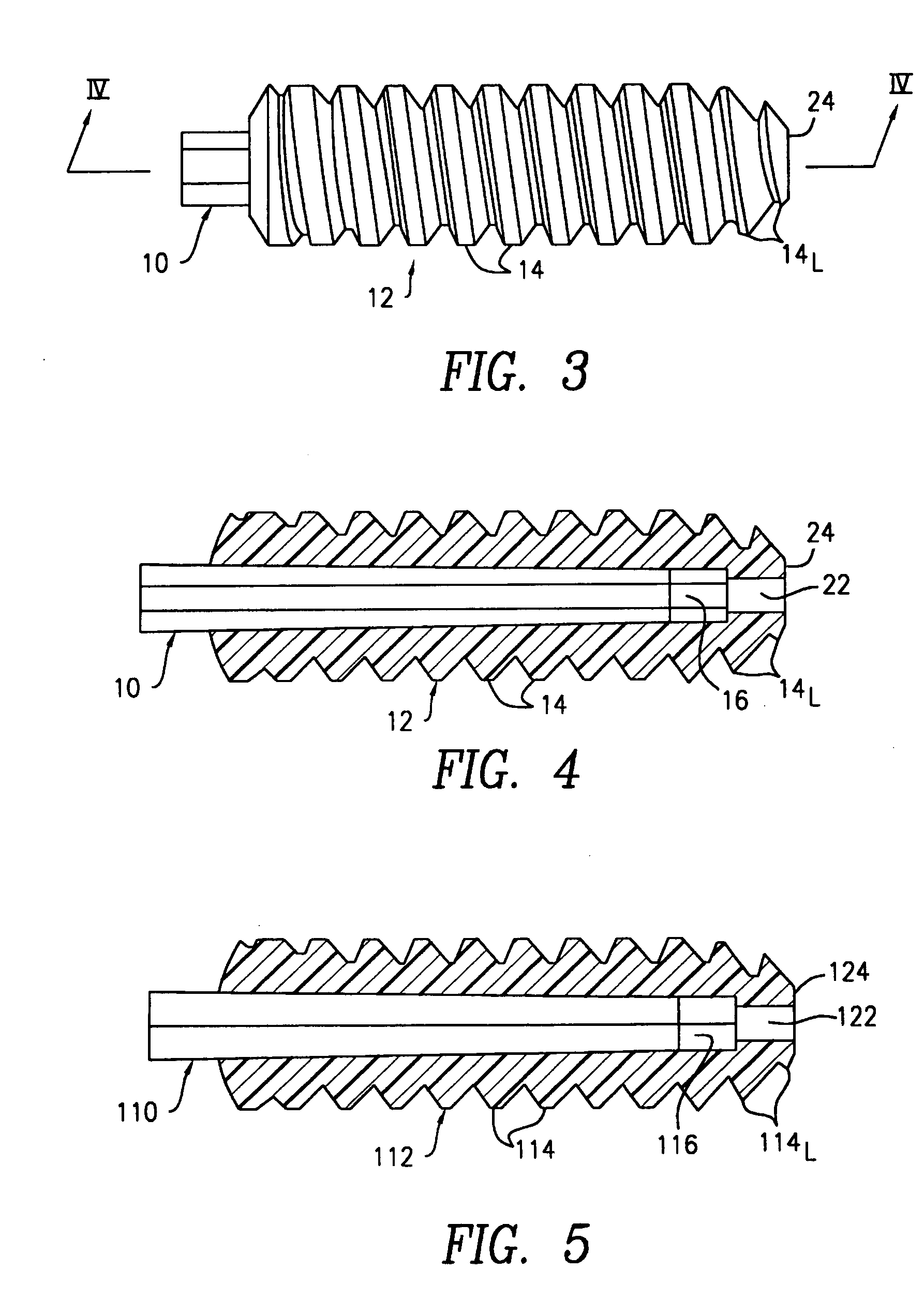

Elongated member/radially expandable member assembly and methods of assembling the same

At least one embodiment generally relates to using an installation tool to pass an expansion mandrel through an elongated member to at least locally, radially expand at least a portion of the elongated member and achieve an interference fit with a radially expandable member located about an outer surface of the elongated member. In one embodiment, the elongated member is radially expanded over its entire length and may include a stepped feature so that only a portion of the elongated member achieves the interference fit with the radially expandable member. During the radial-expansion process, both the radially expandable member and the elongated member may be at the same or approximately the same temperature. Before the radial-expansion process, the radially expandable member may be assembled using press-fit techniques, shrink fit techniques, clearance fitting techniques, or combinations thereof.

Owner:FATIGUE TECH

Threaded inner sleeve for generator magnet

ActiveUS7075204B2Magnetic circuit rotating partsSupports/enclosures/casingsShrink-fittingEngineering

Owner:HONEYWELL INT INC

Polymer-based orthopedic screw and driver system with increased insertion torque tolerance and associated method for making and using same

An orthopedic screw with an internal bore and mating driver has a bioabsorbable polymer component. To increase the torque tolerance of the screw and to minimize the likelihood of the driver stripping inside the bore of the screw, the screw and driver are heat treated together to shrink fit the screw onto the driver thereby increasing the driver-to-screw contact and distributing the loading force over a greater area to protect against material failure. The heat treatment involves heating the screw to an elevated temperature and holding that temperature for a period to promote stress relaxation and / or crystallization of the material.

Owner:ETHICON INC

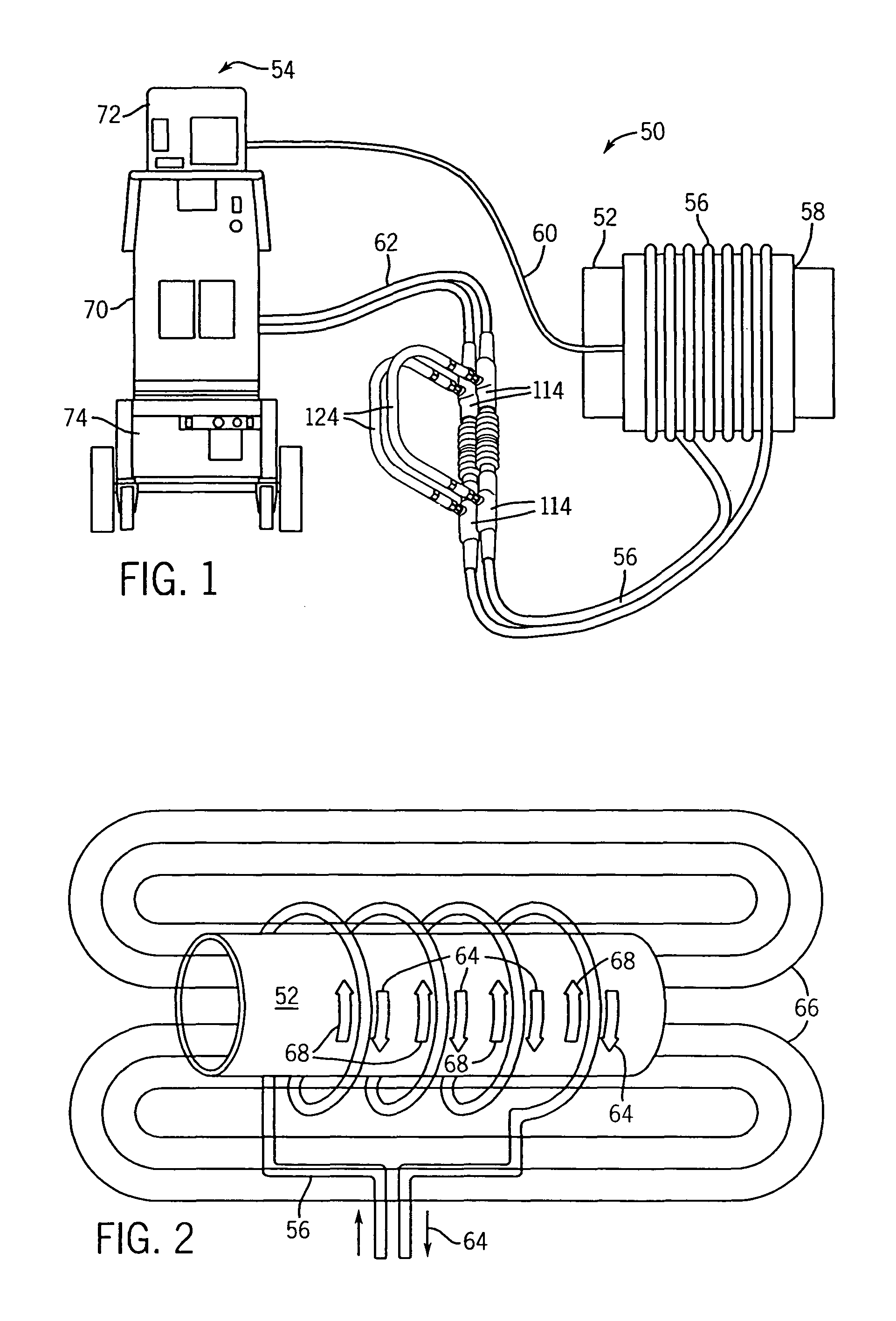

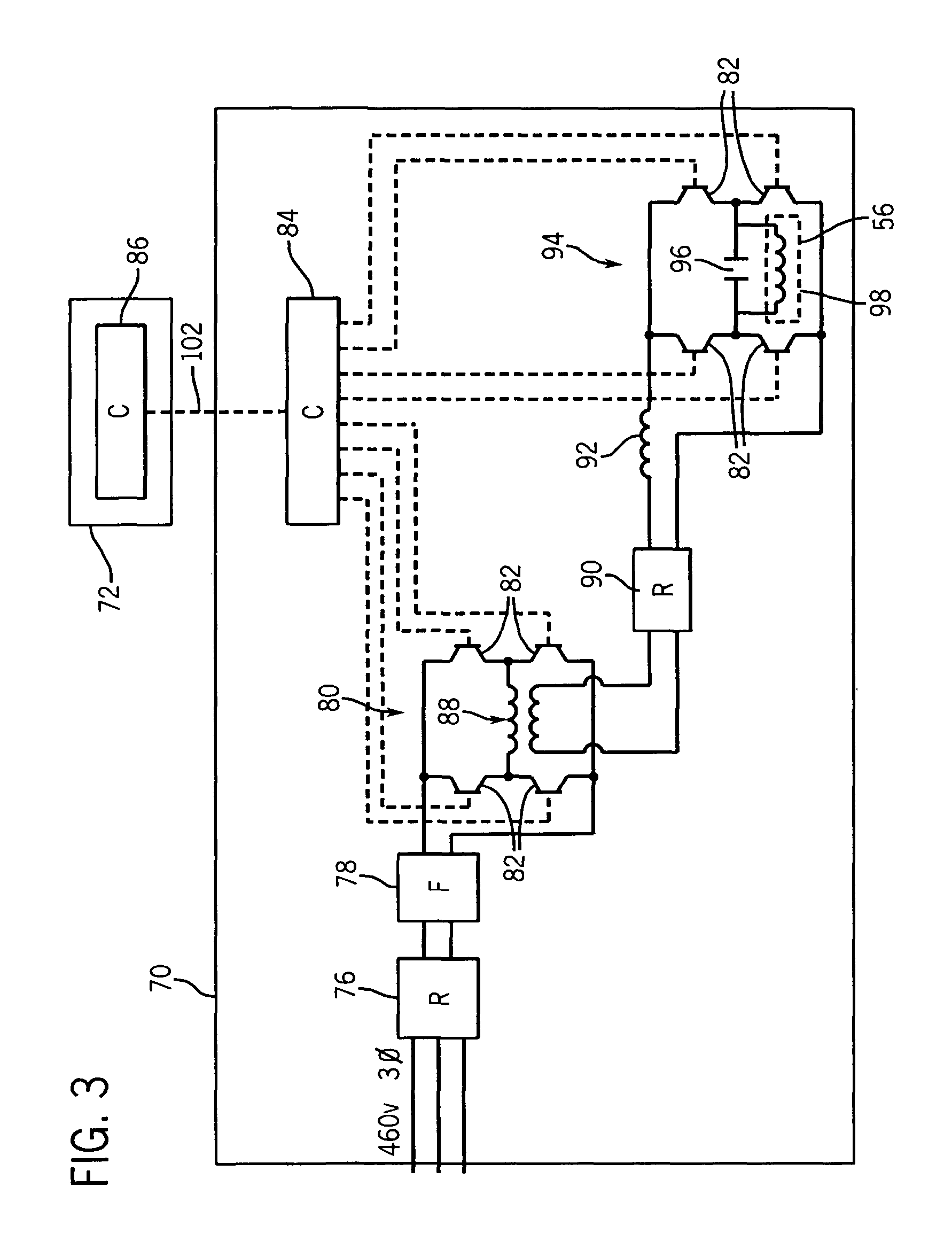

On-site induction heating apparatus

A method and apparatus for heating a workpiece. An induction heating system is used to induce magnetic fields in a workpiece to inductively heat the workpiece. The induction heating system may comprise a portable power source, a portable power source controller, a fluid-cooled induction heating cable, and a portable cooling unit. The induction heating system may be used to perform a variety of induction heating operations, including: annealing, surface hardening, heat treating, stress-relieving, curing, shrink-fitting, etc.

Owner:ILLINOIS TOOL WORKS INC

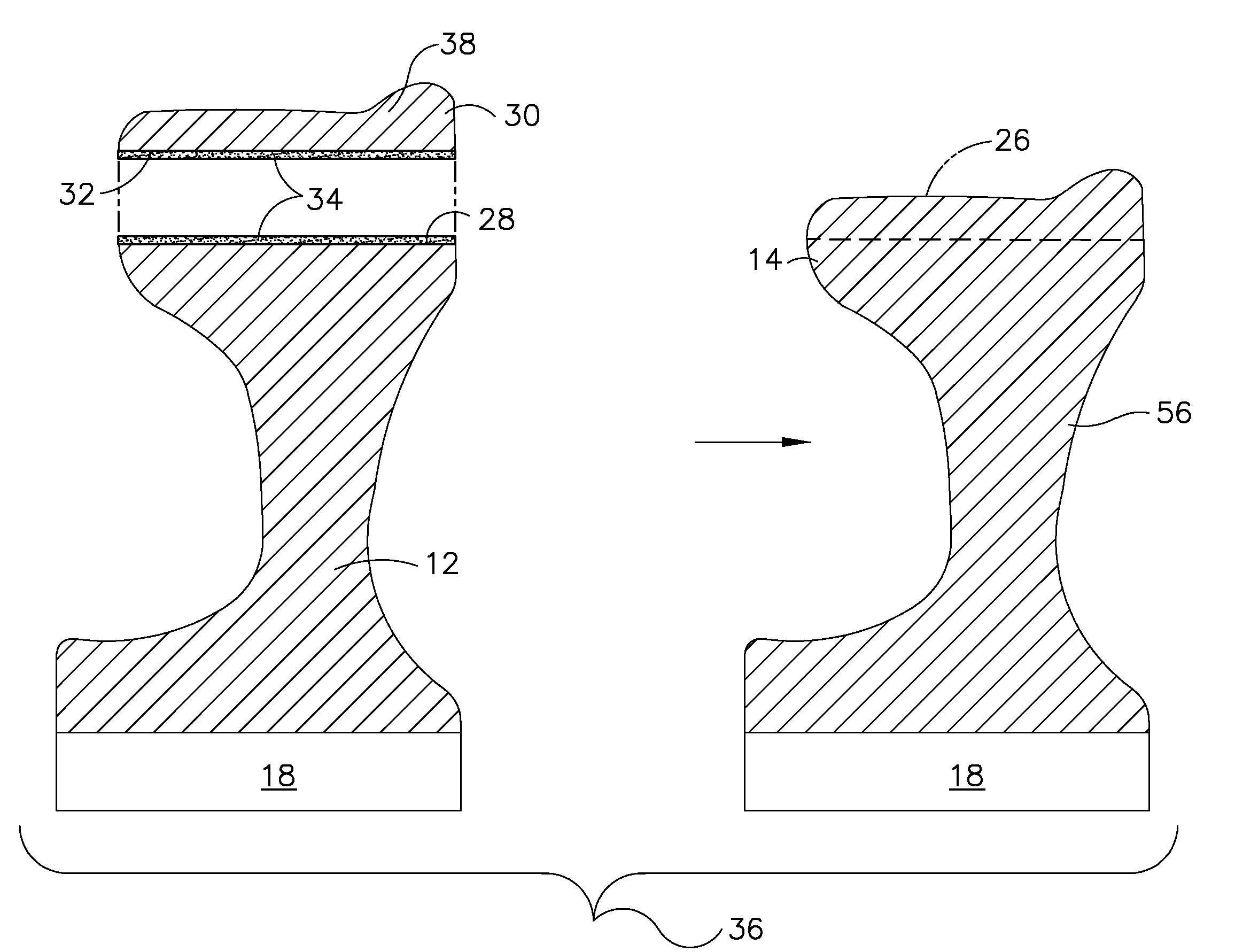

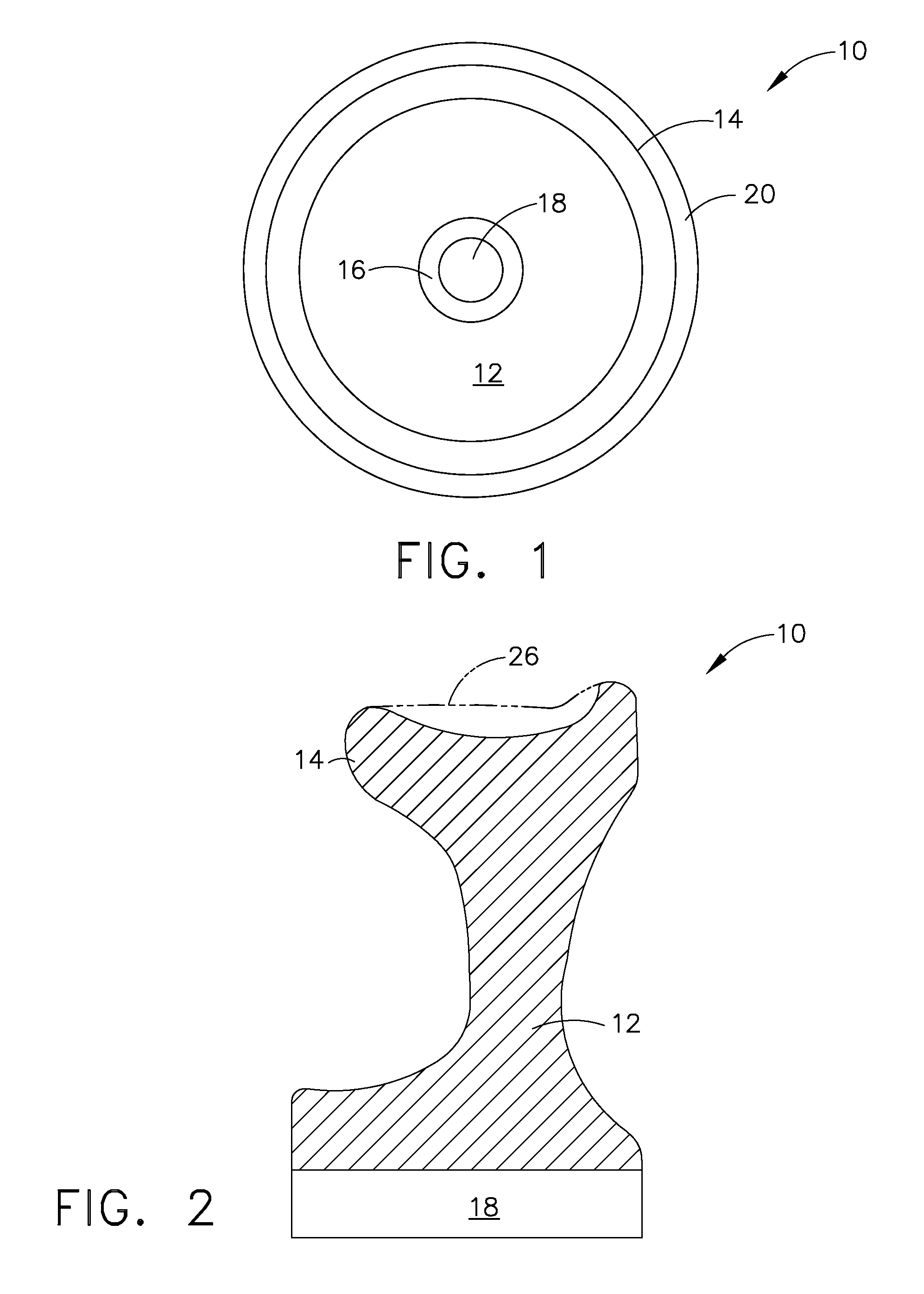

Method for repair of rail wheels and repaired article

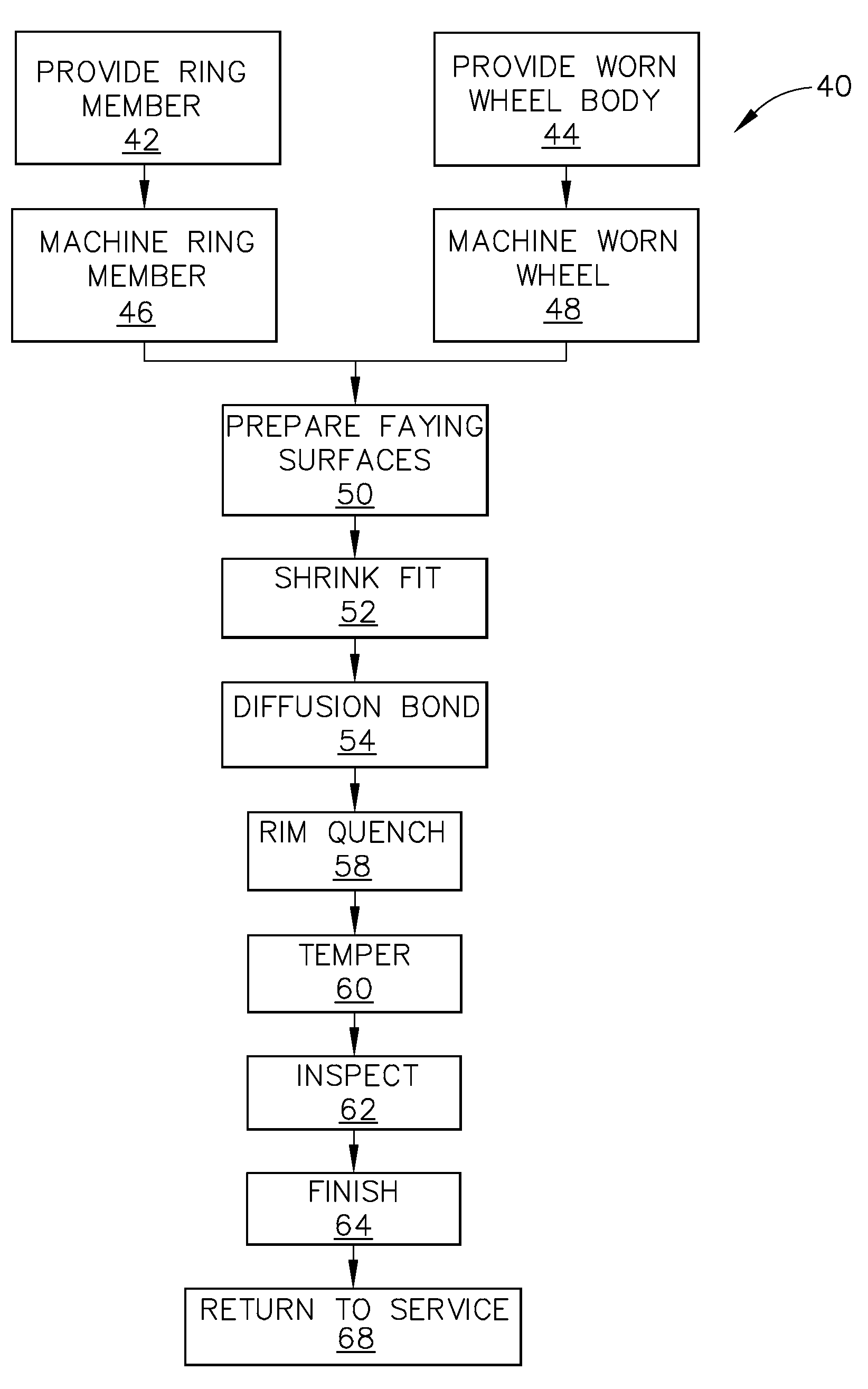

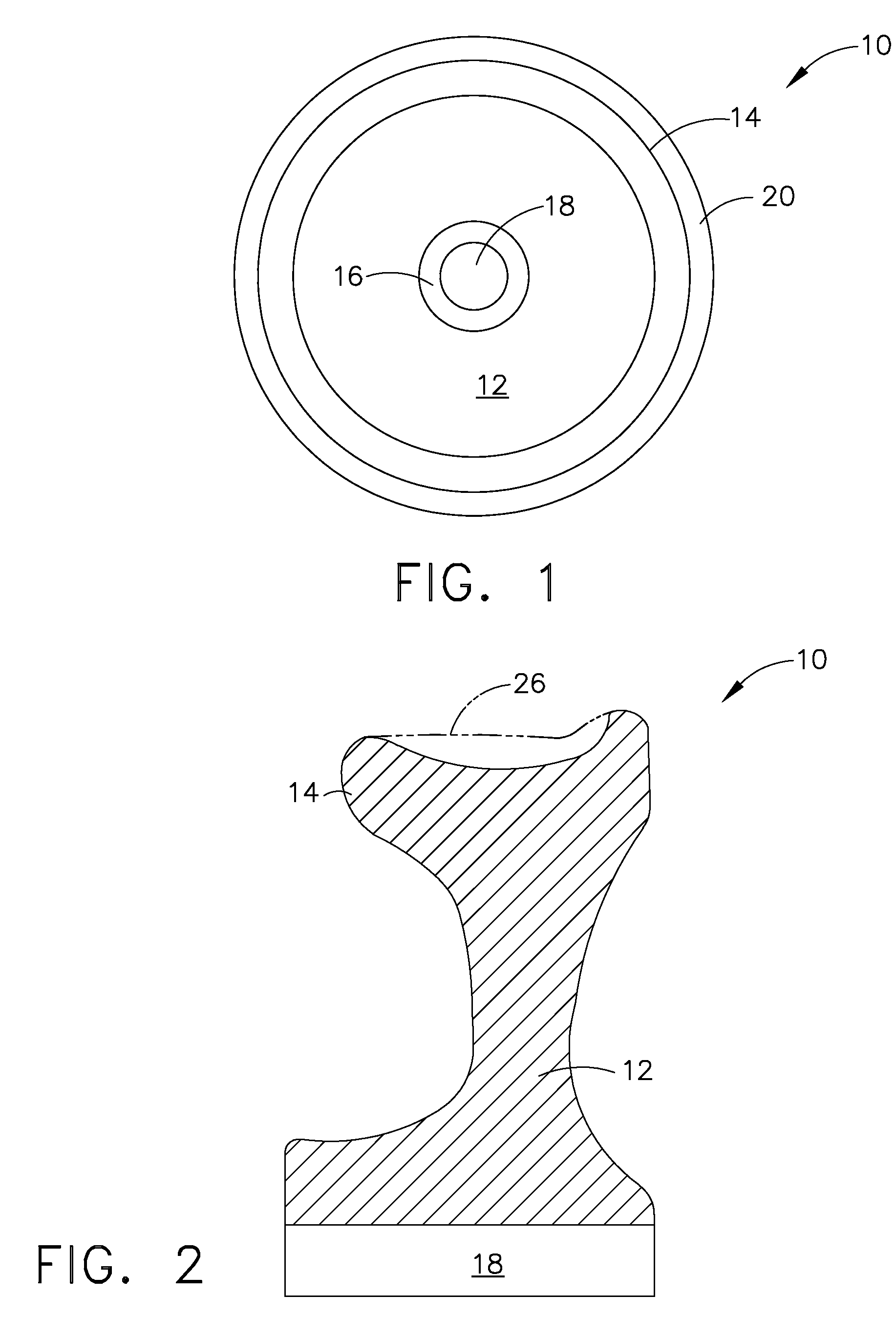

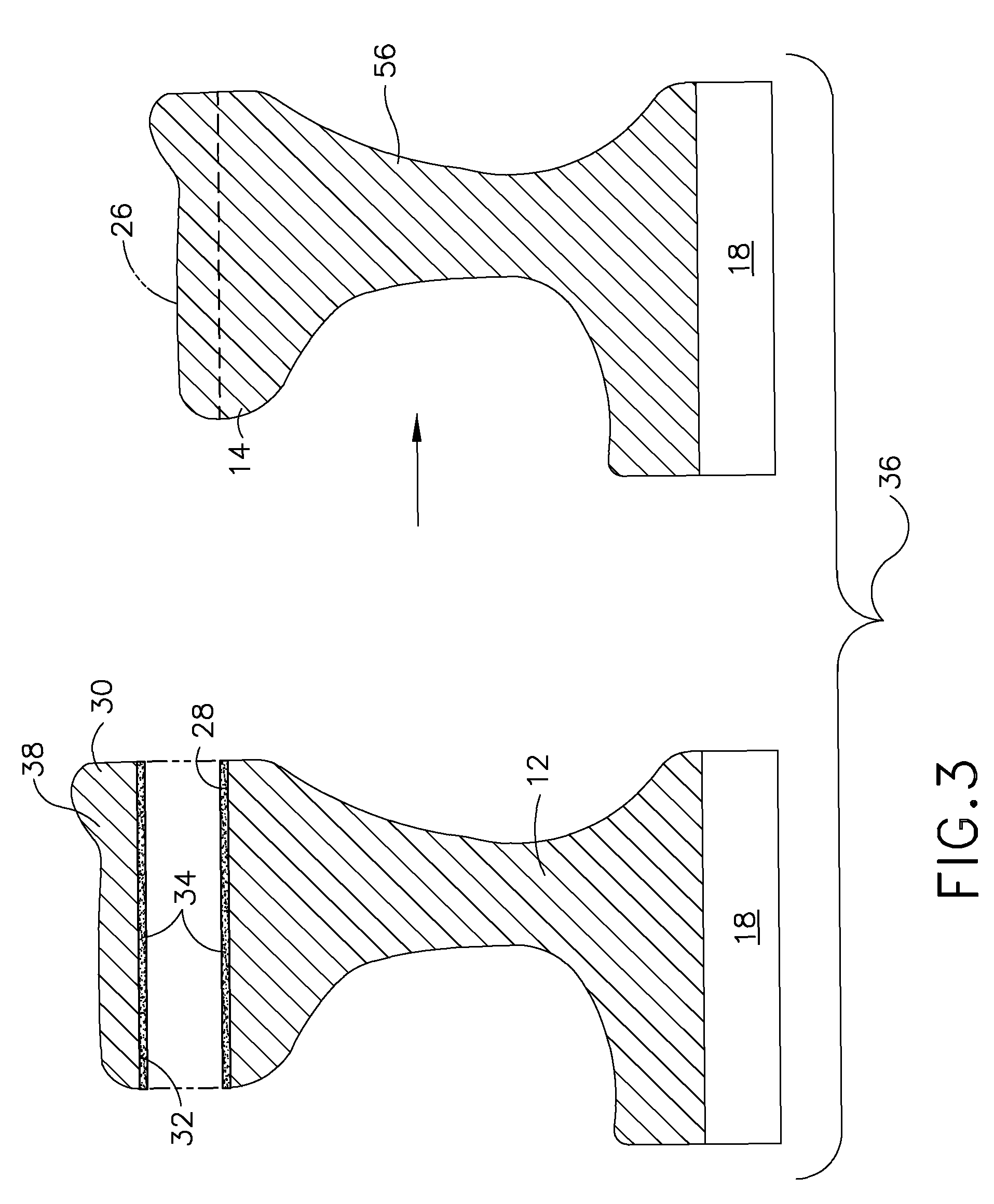

A method includes shrink fitting a ring member about a railroad wheel body and metallurically bonding the ring member to the railroad wheel body. A wheel assembly includes an inner portion obtained from a worn railroad wheel, a ring member disposed about the inner portion, and suitable electroplating material disposed on at least one of the faying surfaces. The wheel assembly may be heated under suitable conditions to provide diffusion bonding across interfacing faying surfaces to produce an integral wheel structure. Appropriate quenching, tempering, and finishing processes may be utilized to obtain desired properties. An article formed thereby includes an inner body portion obtained from a worn railroad wheel and a metallurically bonded outer circumferential portion. The outer portion may comprise a composition selected for desired wear characteristics.

Owner:GENERAL ELECTRIC CO +1

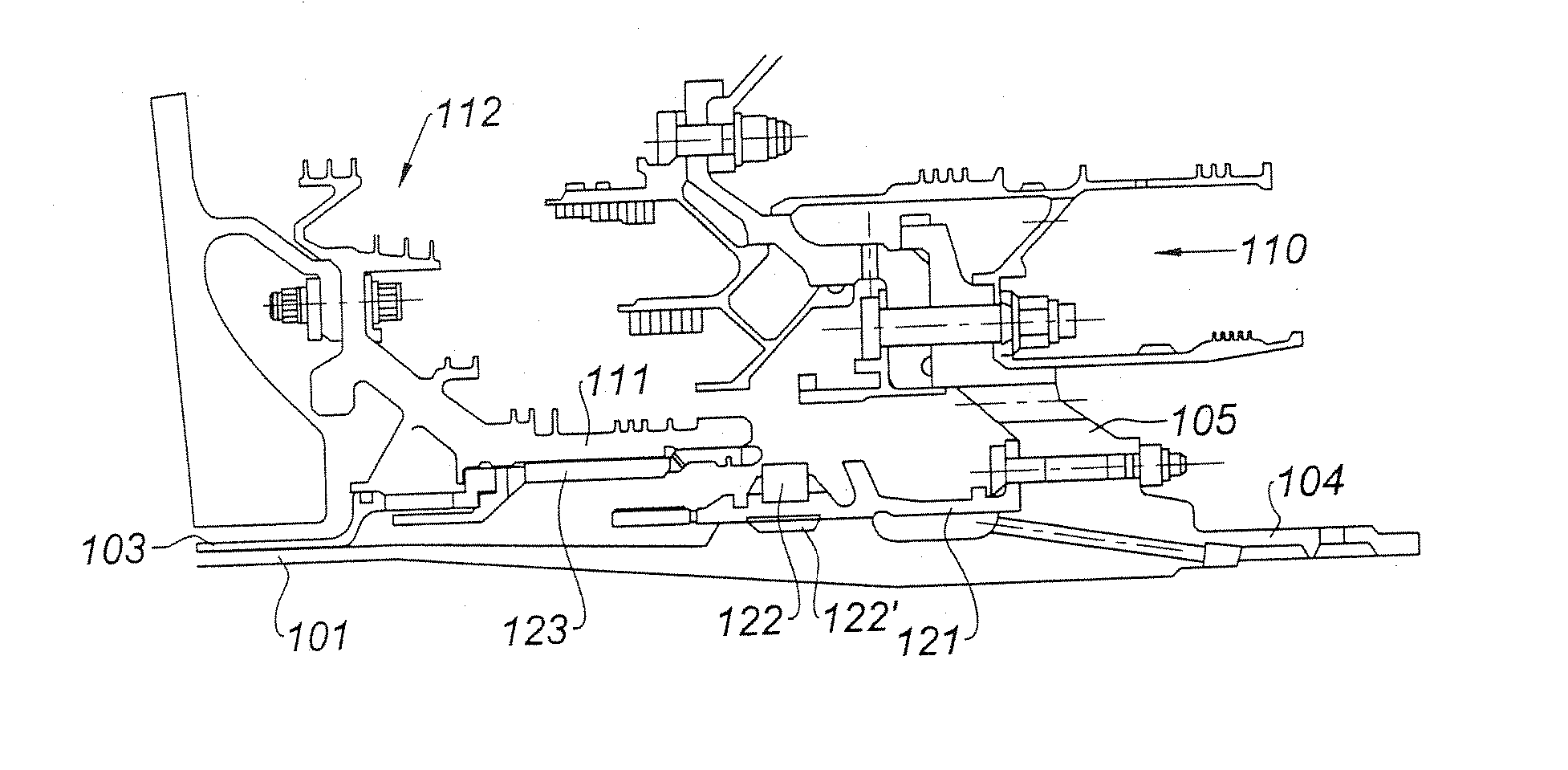

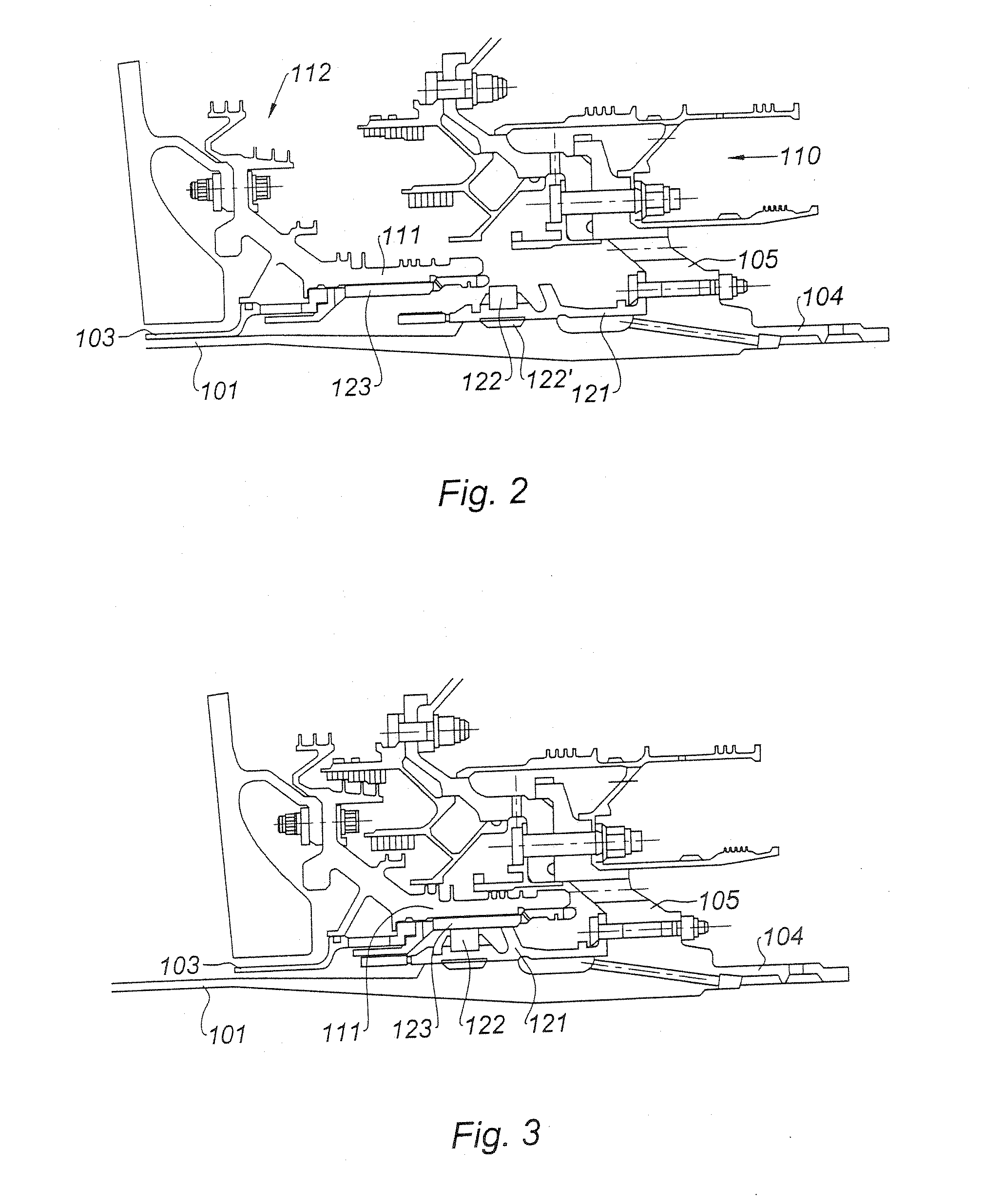

Method of assembling a turbomachine

ActiveUS20070044307A1Improve assembly conditionsReduce risk of damagePump componentsBlade accessoriesShrink-fittingEngineering

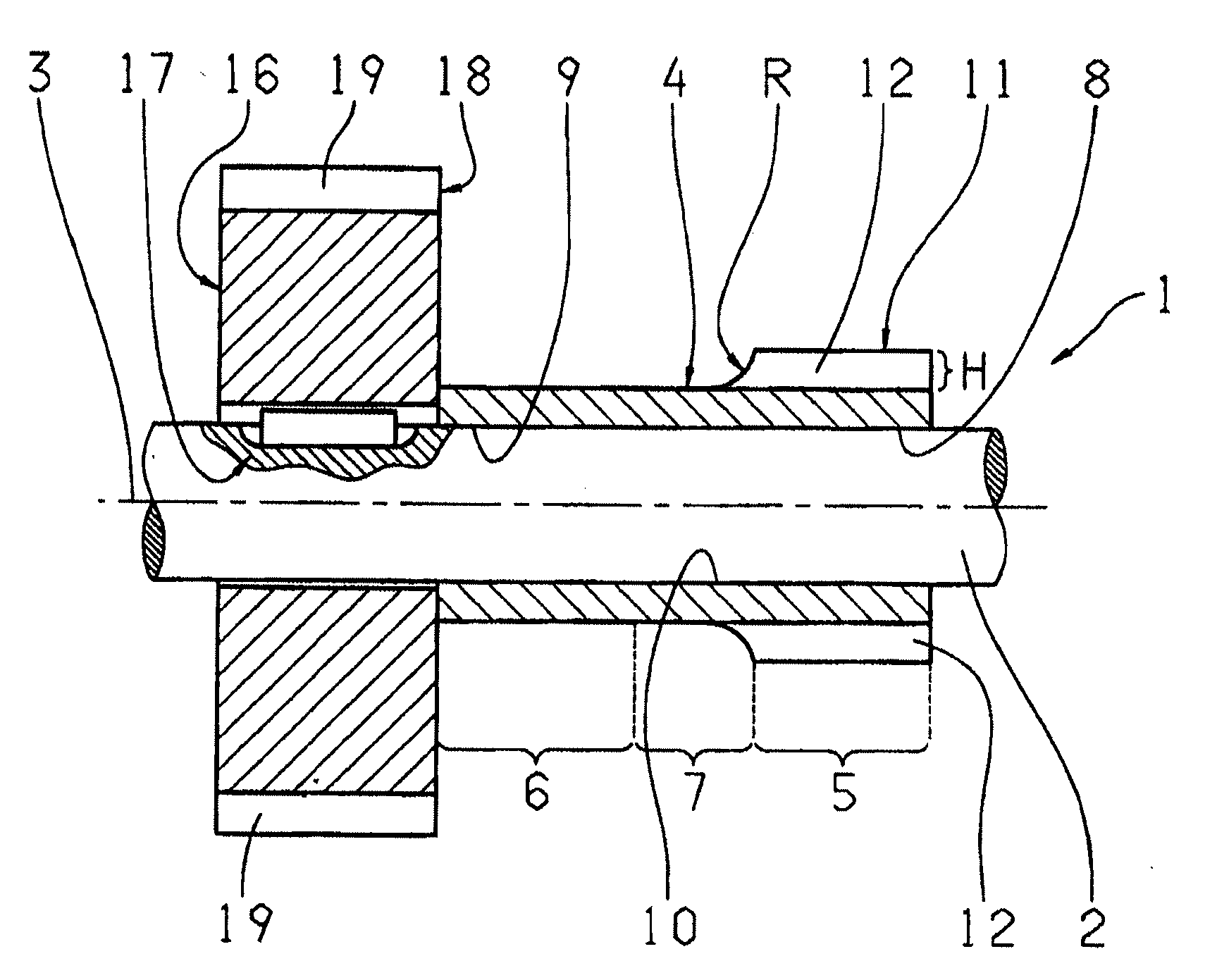

The invention relates to a method of assembly of a turbomachine, in particular of a gas turbine engine, comprising at least a first module and a second module a second shaft assembled by a bearing, said bearing comprising an outer ring shrink-fitted inside a journal integral with the first module and an inner ring integral with the second shaft, according to which the second module is assembled on the first module by engagement of the second shaft, with said inner ring, inside the journal comprising said outer ring, wherein it comprises the following steps: mating the second module with the second shaft up to a determined distance from the journal, centering the second shaft with respect to the journal, said centering being controlled on the basis of measuring distance deviations with respect to a reference on the journal, expansion of the journal by heating its outer surface, completion of the mating of the second shaft.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

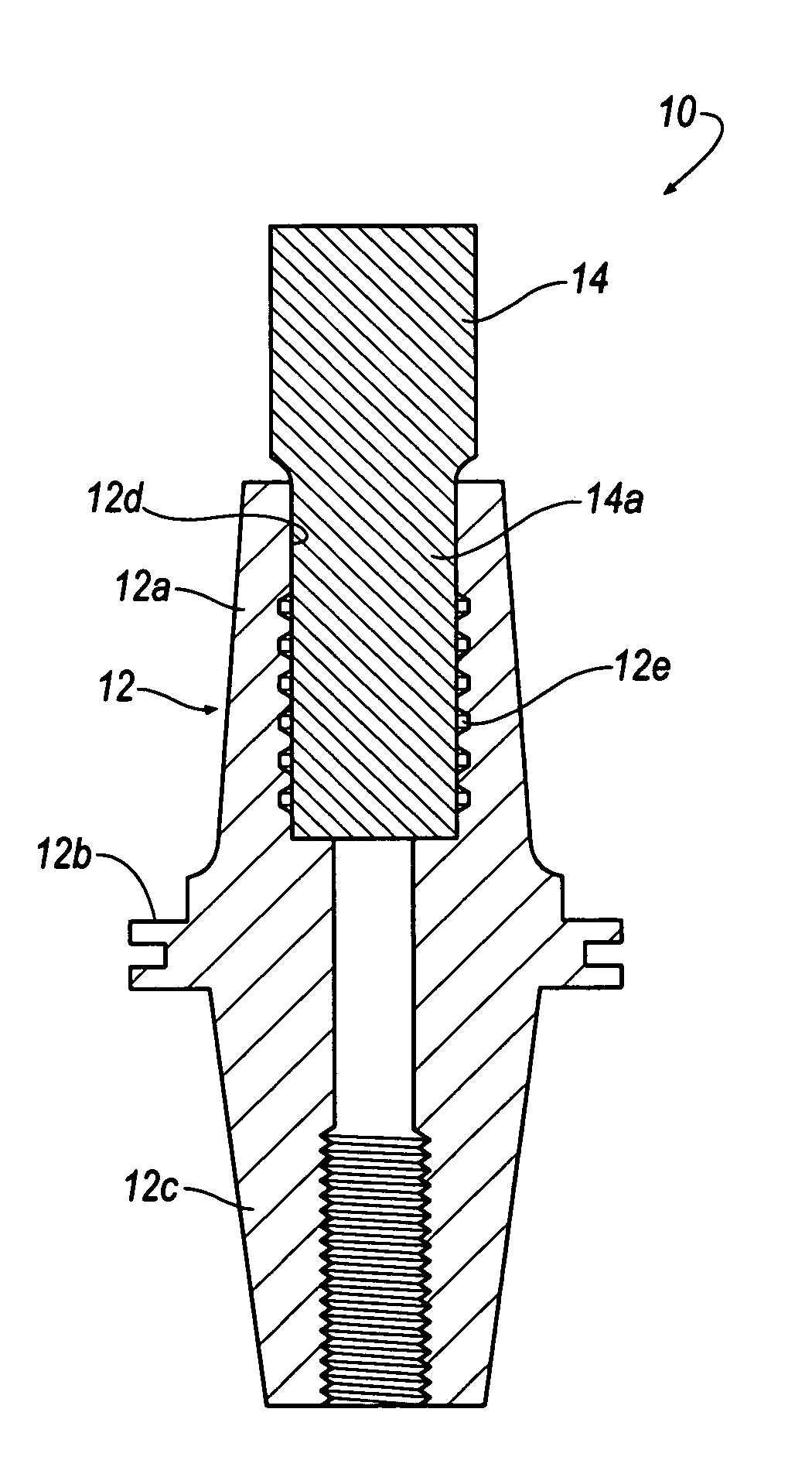

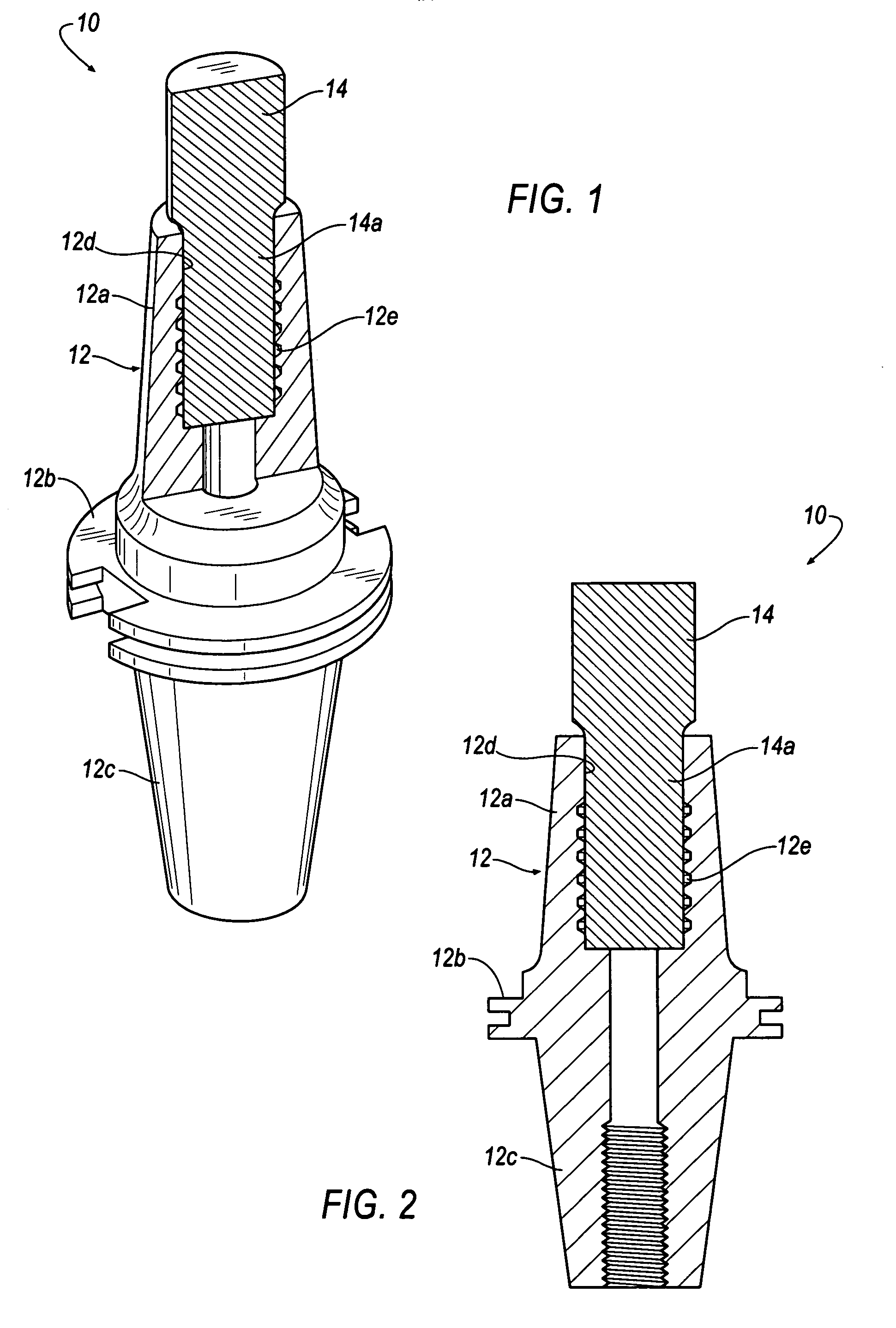

Shrink fit tool holder with grooves

InactiveUS7367763B2Reduce the amount requiredReduce areaSleeve/socket jointsAttachable milling devicesShrink-fittingEngineering

A shrink fit tool holder includes a shank or body that includes a tool holder portion, a flange member, a tapered outer surface that generally corresponds to a tapered bore of a spindle, and a central bore or aperture for accommodating a cutting tool. The central bore includes a plurality of grooves formed in a predetermined pattern that decrease a surface contact area between the tool holder portion and the cutting tool, thereby reducing an amount of conductive heat transfer between the tool holder portion and the cutting tool. As a result, there is less expansion in the tool shank relative to the tool holder.

Owner:KENNAMETAL INC

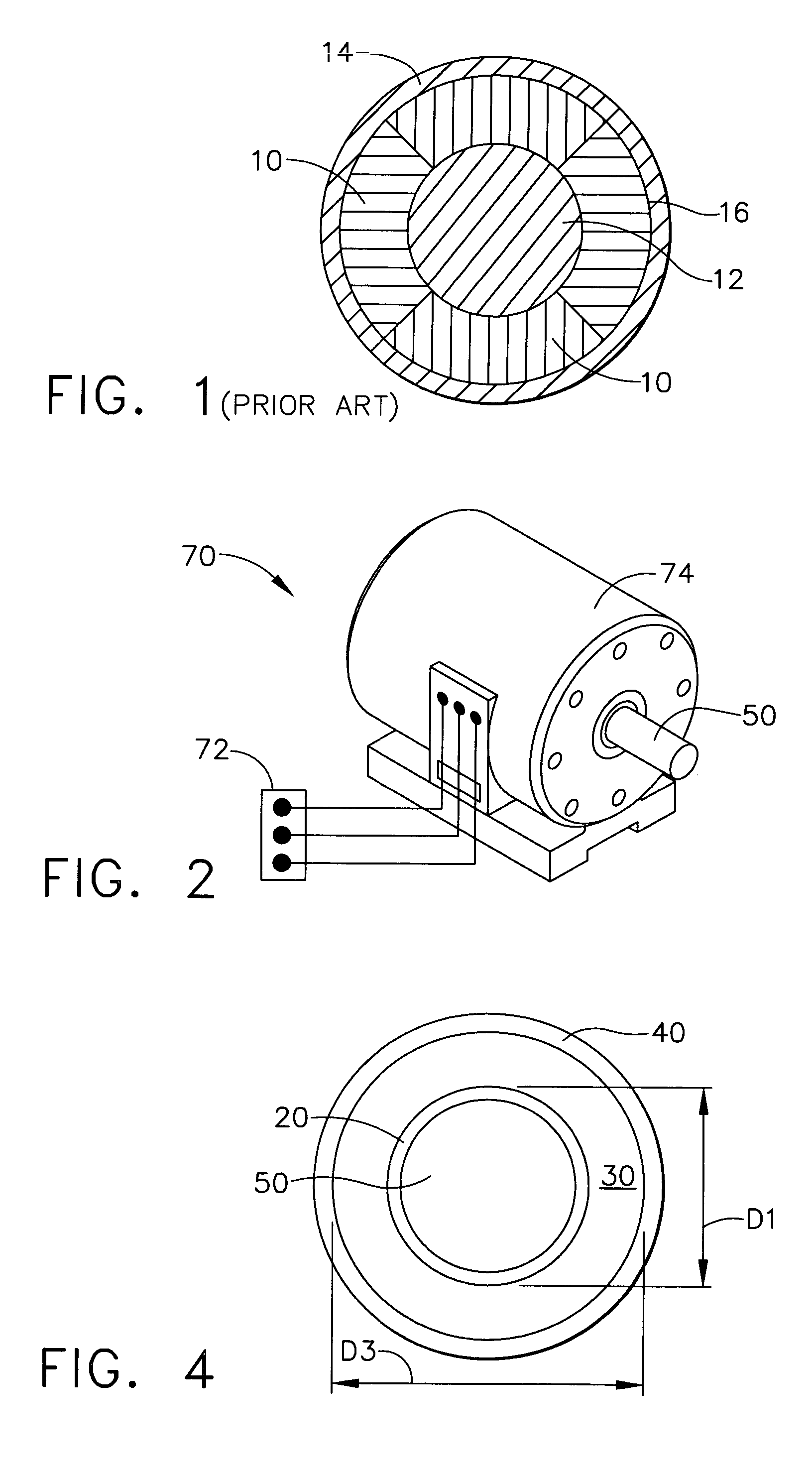

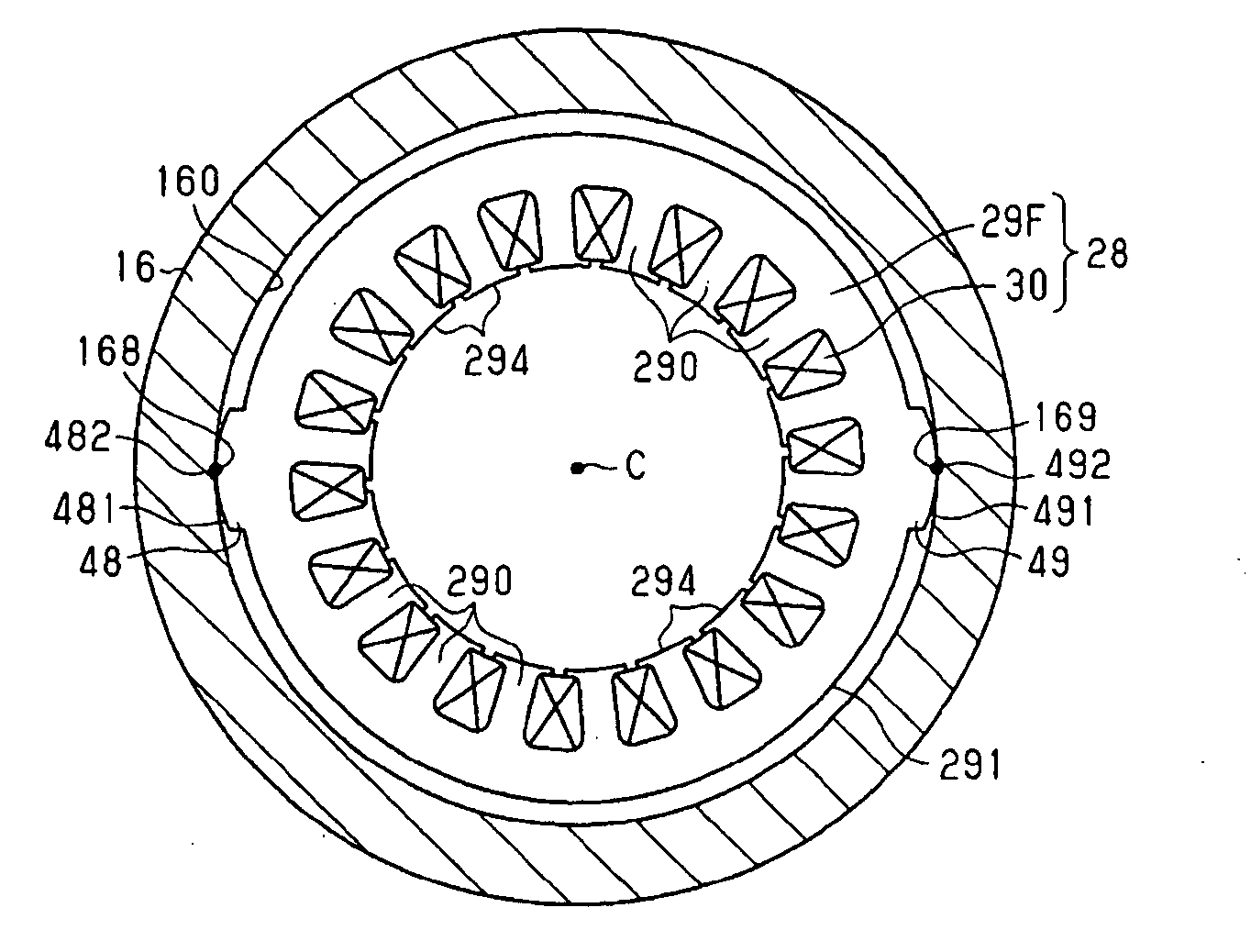

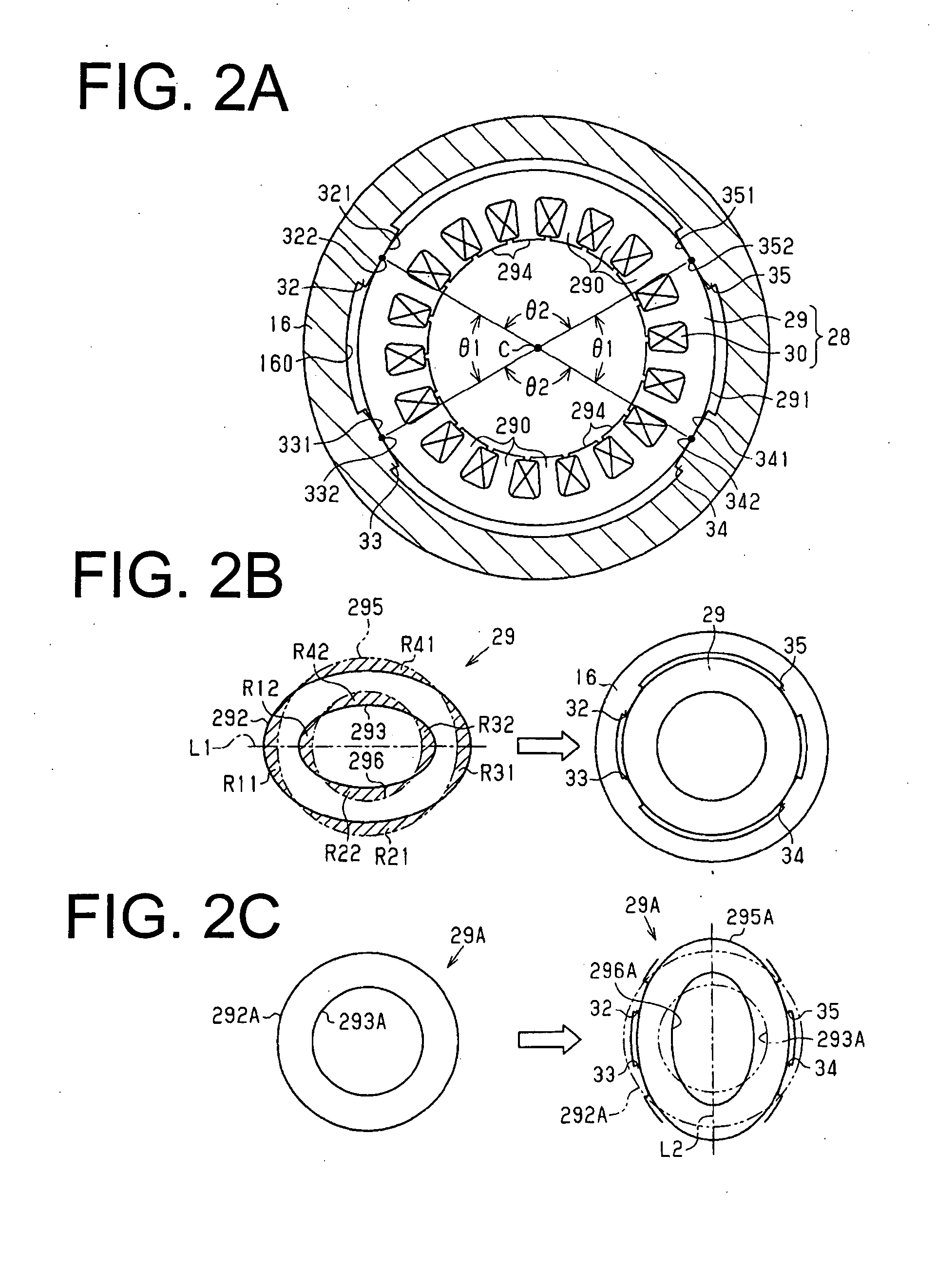

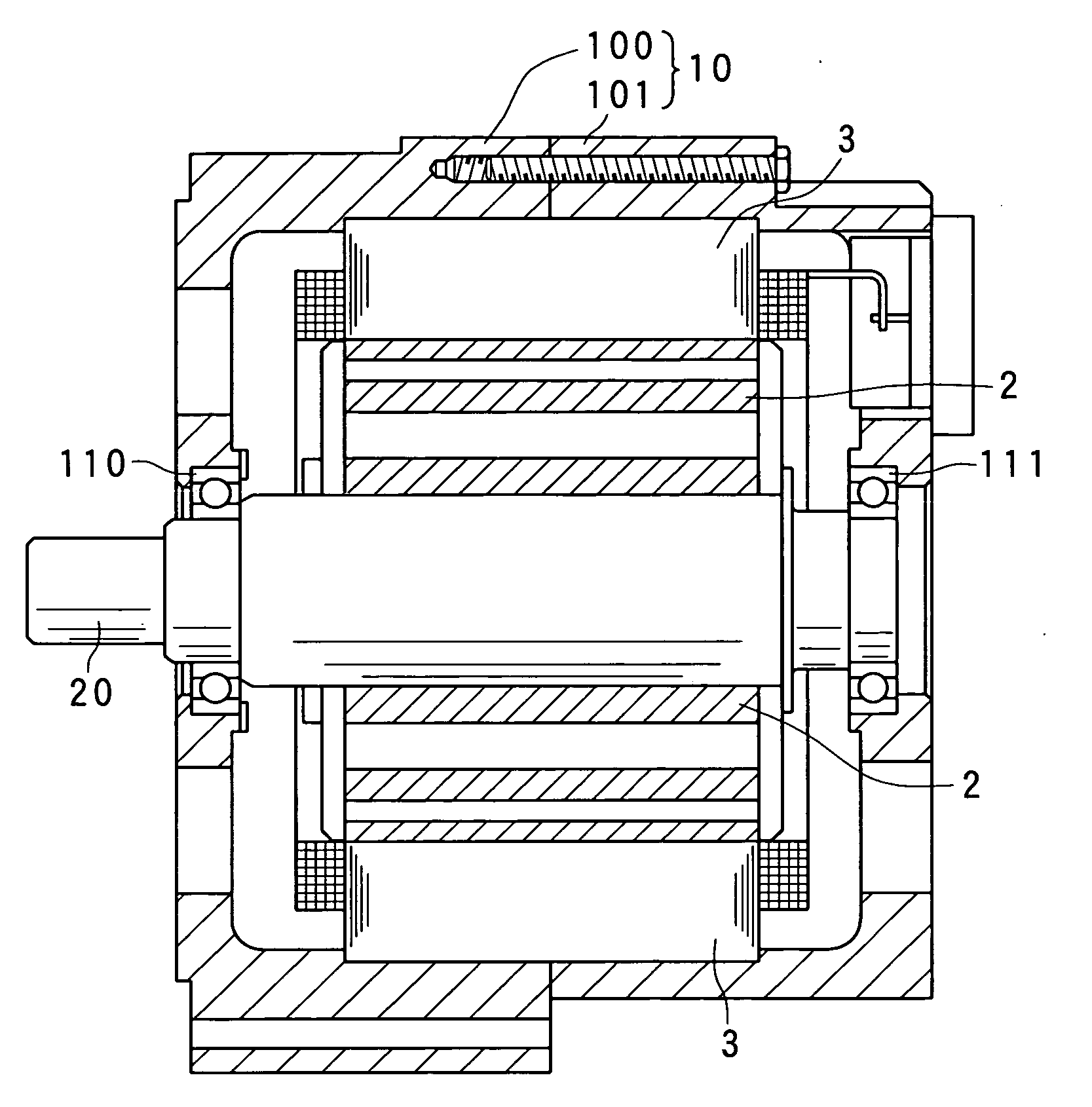

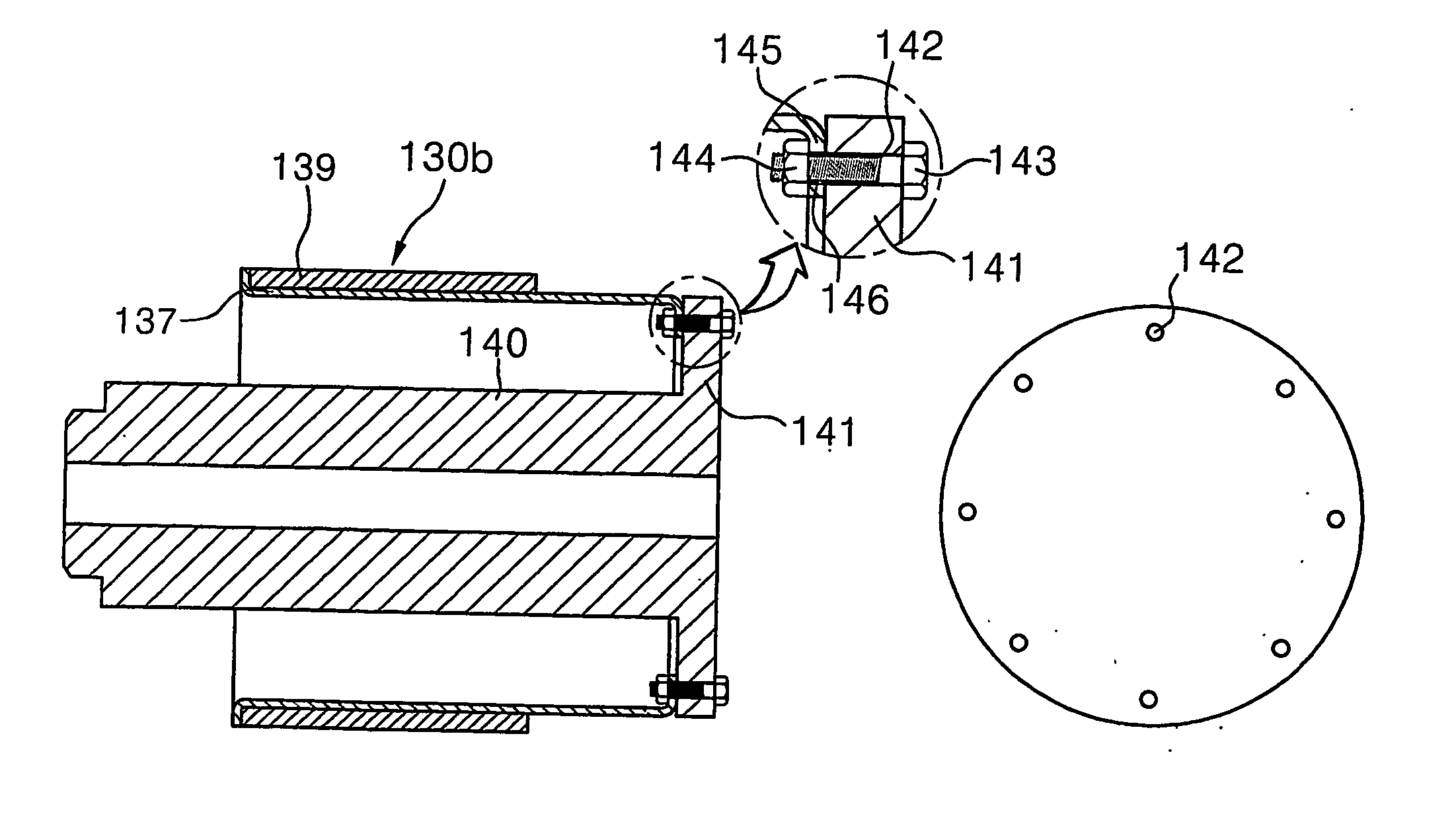

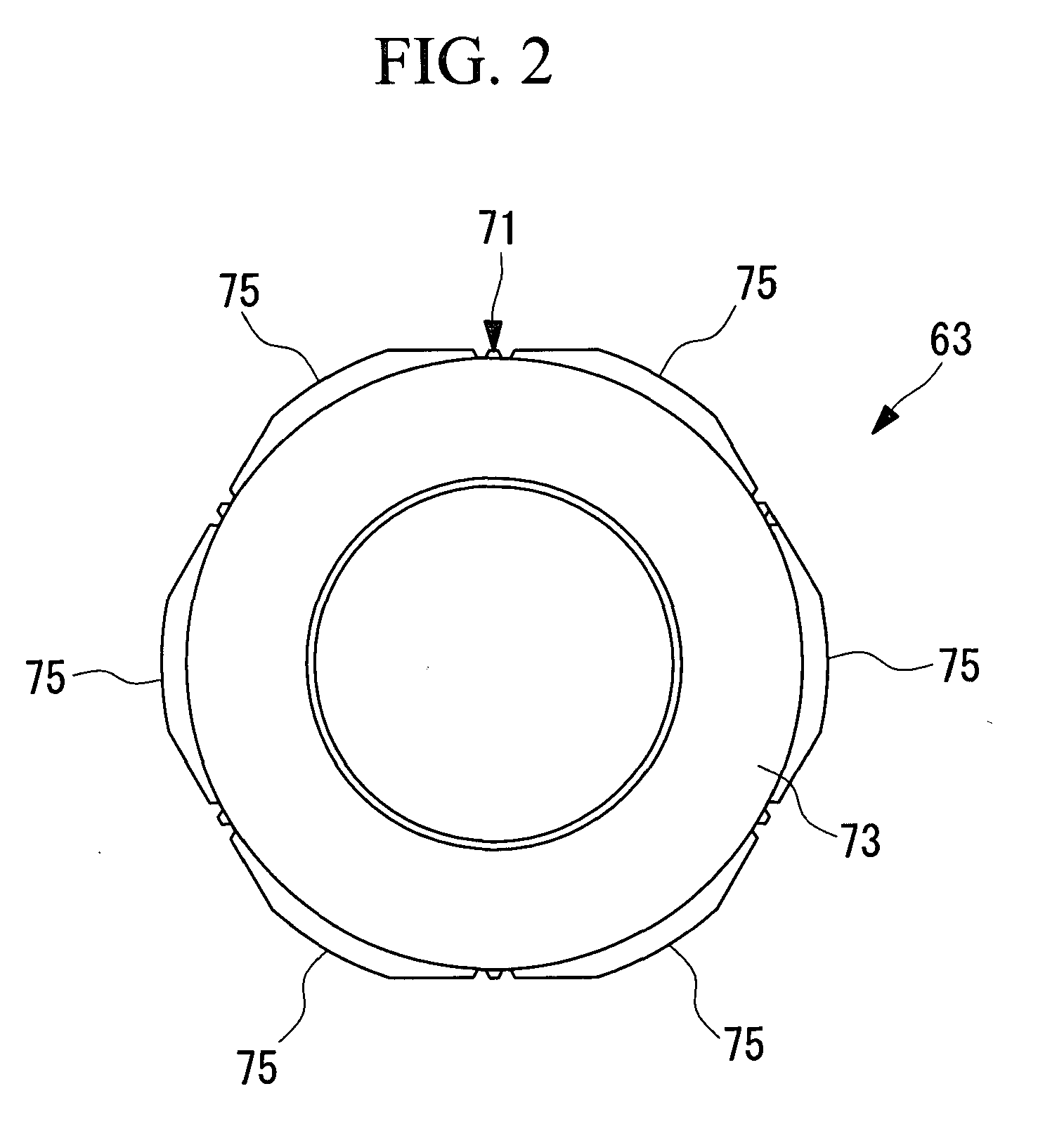

Electric motor and method of manufacturing the same

InactiveUS20070210669A1Positive displacement pump componentsMagnetic circuit stationary partsShrink-fittingElectric motor

An electric motor includes an annular housing and an annular stator core having the inner periphery the shape of which differs from a perfect circle. The stator core is supported by the housing in such a manner that the outer periphery of the stator core and the inner periphery of the housing are partially in contact with each other. The inner periphery of the stator core is deformed to become close to the shape of the perfect circle when the stator core is securely fitted in the housing by shrink fitting.

Owner:TOYOTA IND CORP

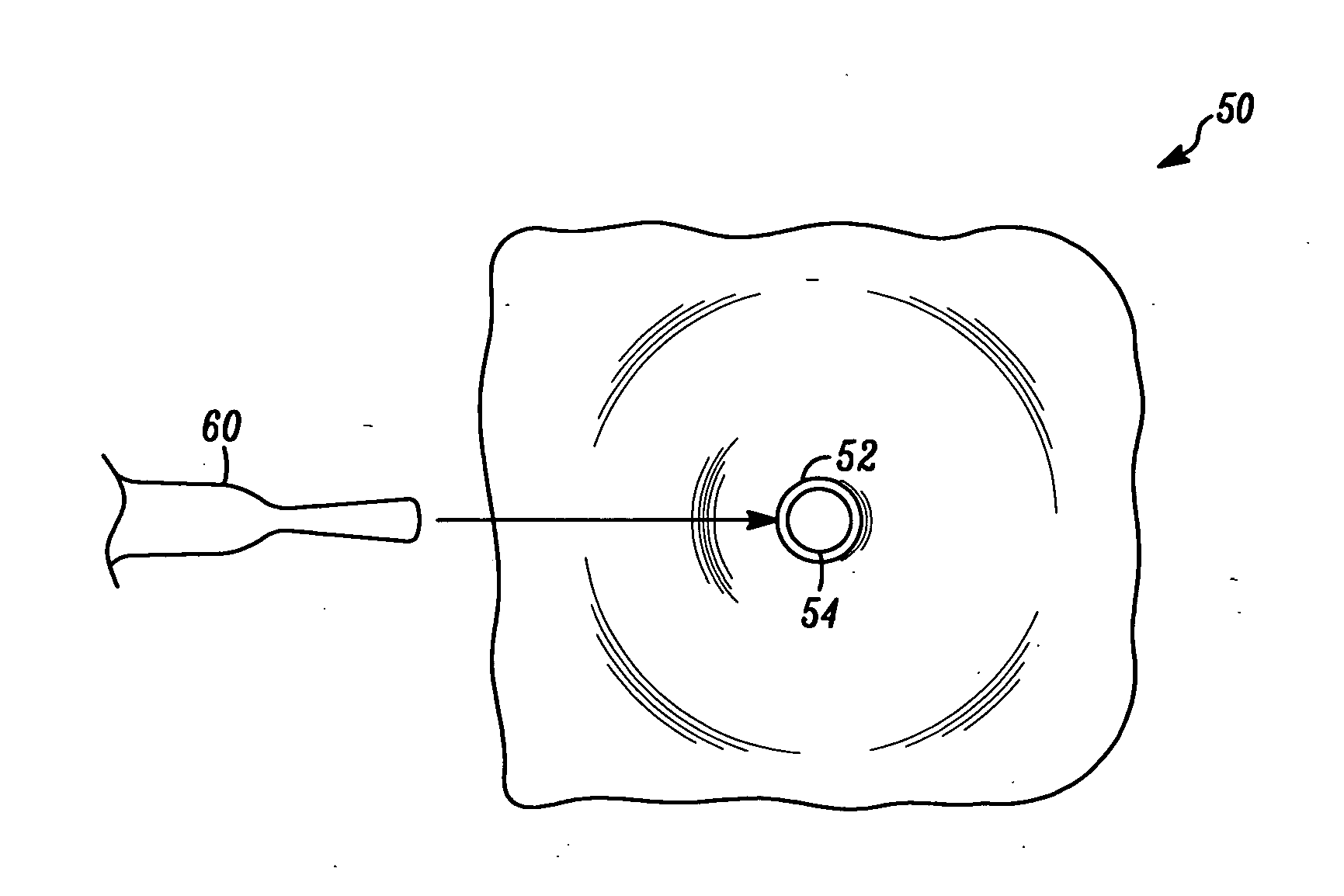

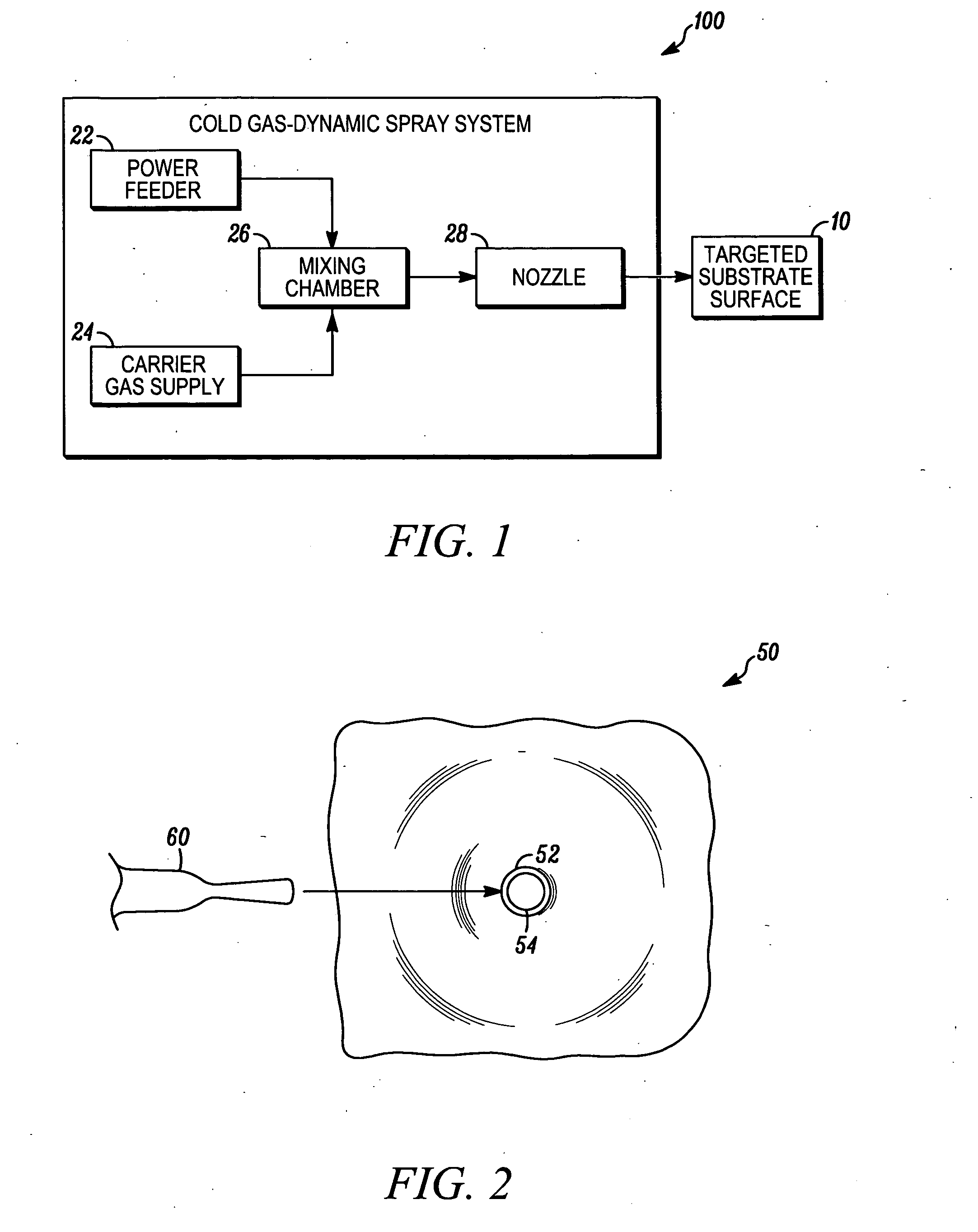

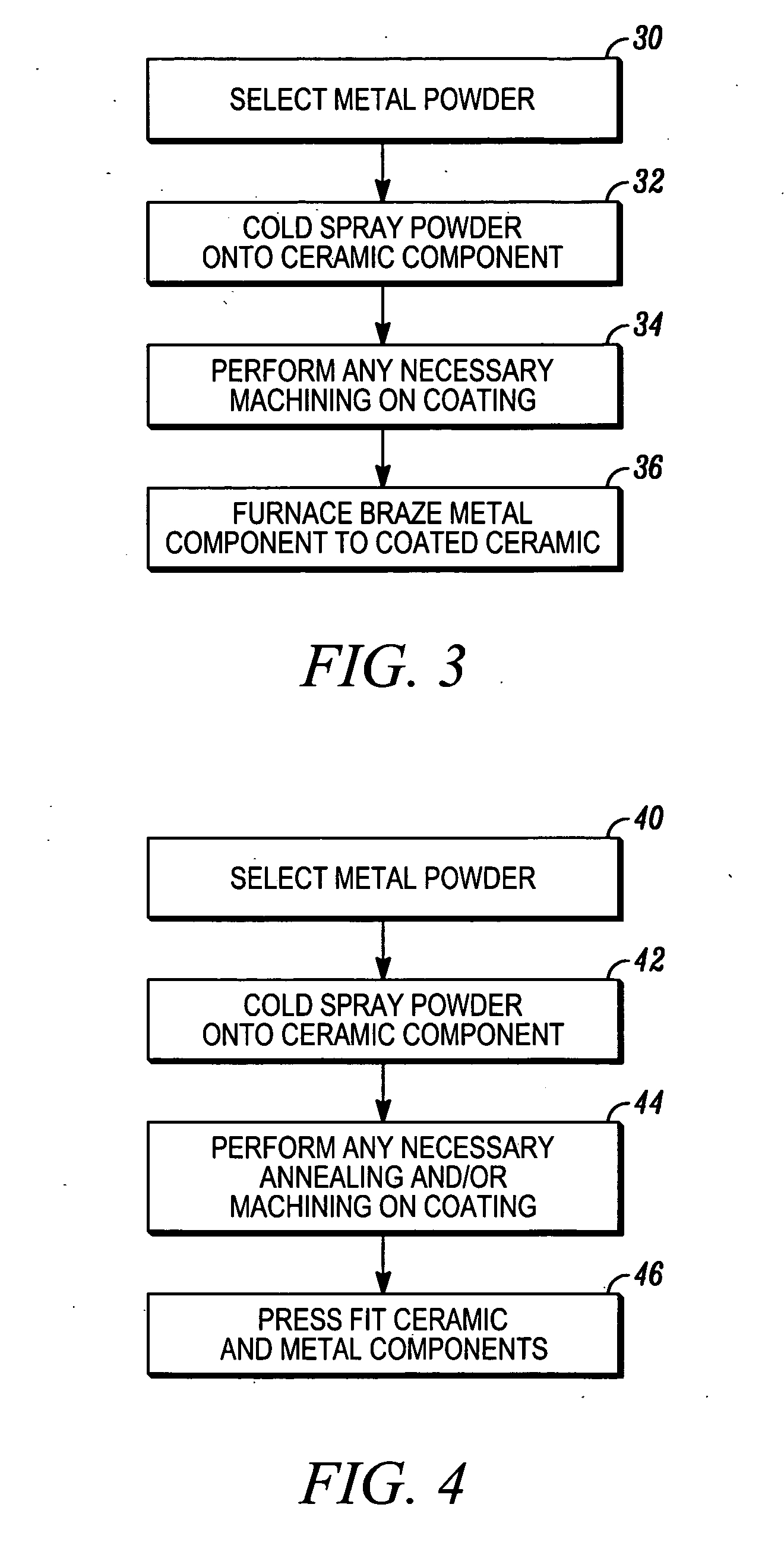

Cold gas-dynamic spraying method for joining ceramic and metallic articles

InactiveUS20070215677A1Welding apparatusPressure inorganic powder coatingInterference fitMetal coating

A method for joining a first component surface to a ceramic component surface includes cold gas-dynamic spraying a first metal powder onto the ceramic component surface to form a first metal coating. The first component surface is then bonded to the metal coating on the ceramic component surface. The bonding step may be a thermal process such as a brazing process. A mechanical bond may also be formed by an interference fitting such as press or shrink fitting.

Owner:HONEYWELL INT INC

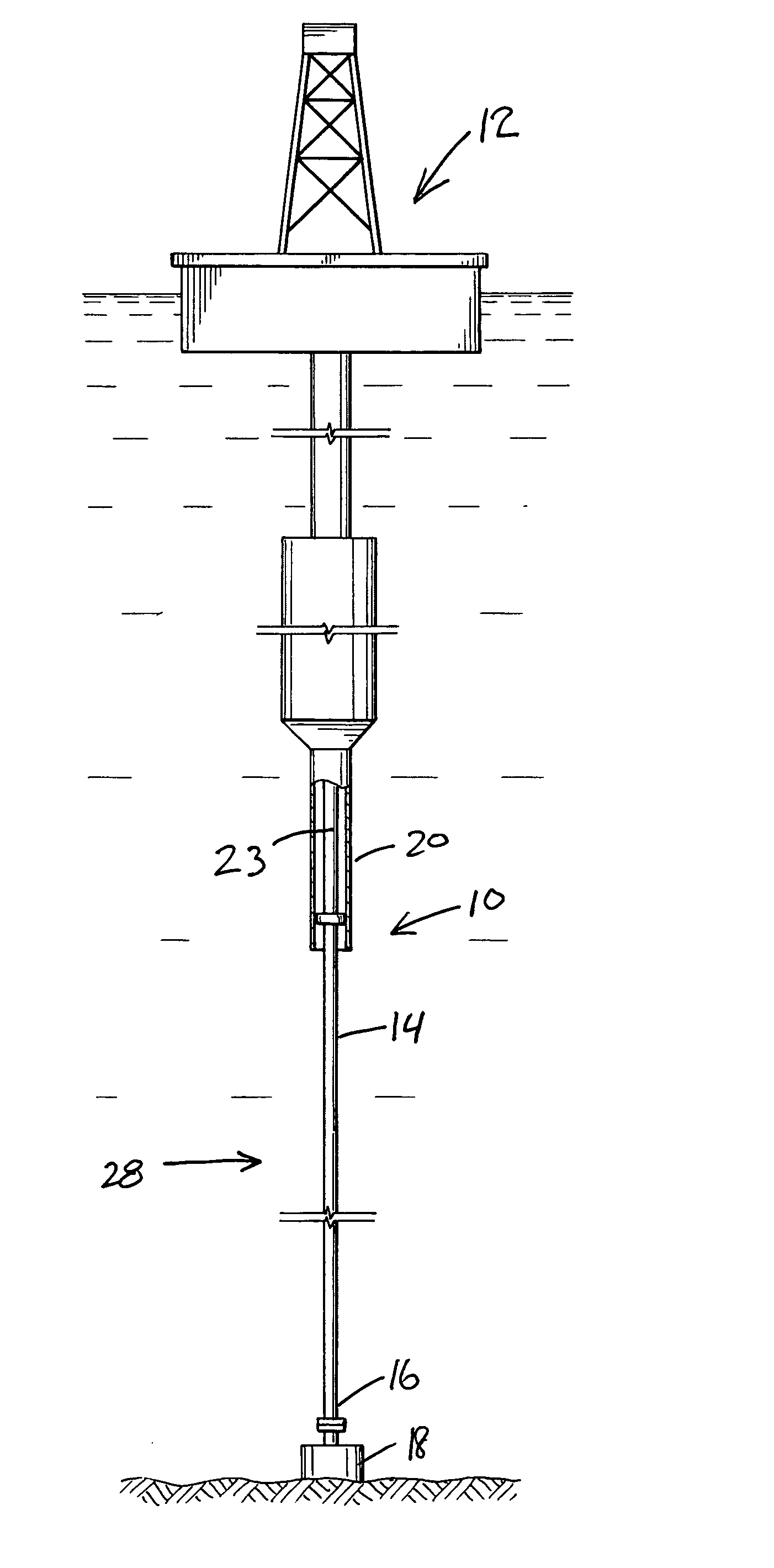

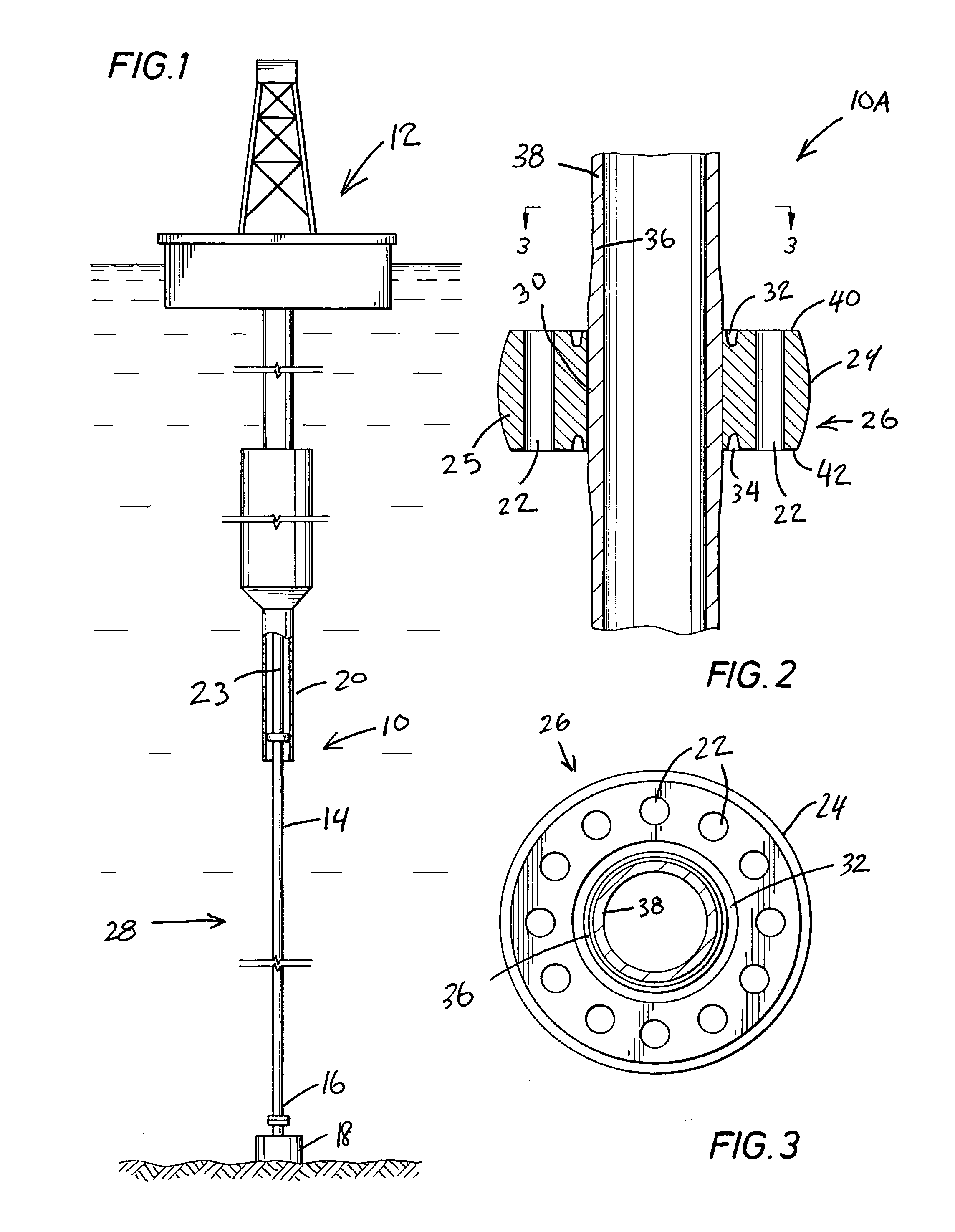

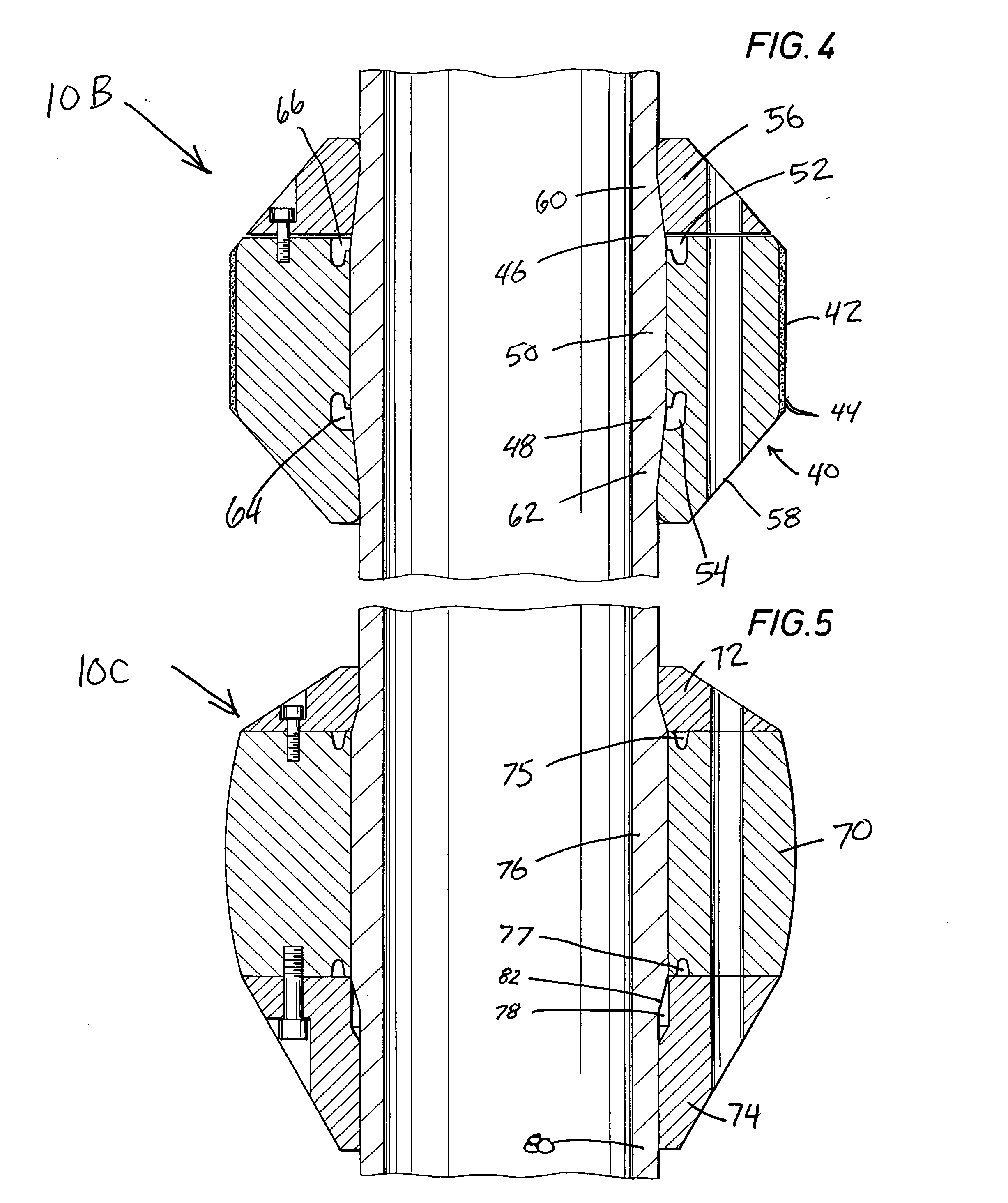

Shrink fit centralizer assembly and method

InactiveUS20050084337A1Reduce the applied forceRelieve pressureDrilling rodsProtective foundationShrink-fittingKeel

A centralizer system is provided for use in a marine riser system to provide a stress joint or keel joint with a upset portion. The centralizer is preferably heat-shrink fitted to the upset portion of the keel joint. The upset portion has tapered sections on the upper and lower ends which may be of various shapes and lengths that gradually blend into the outer diameter of the pipe used as the keel joint. The centralizer may also be heat-shrink fitted to one of the tapered sections. The centralizer may or may not utilize guide sections mounted on either end thereof. In a preferred embodiment, the centralizer comprises axially extending annular grooves in surrounding relationship to the upset portion, the grooves serving to permit forces acting on the centralizer to be redirected or dissipated to thereby prevent excessive buildup on a selected region of the upset portion adjacent the radial grooves. In one embodiment, the grooves are formed annularly around the ends of the upset portion to thereby limit stresses that otherwise tend to build up on the ends of the upset portion.

Owner:NAT COUPLING

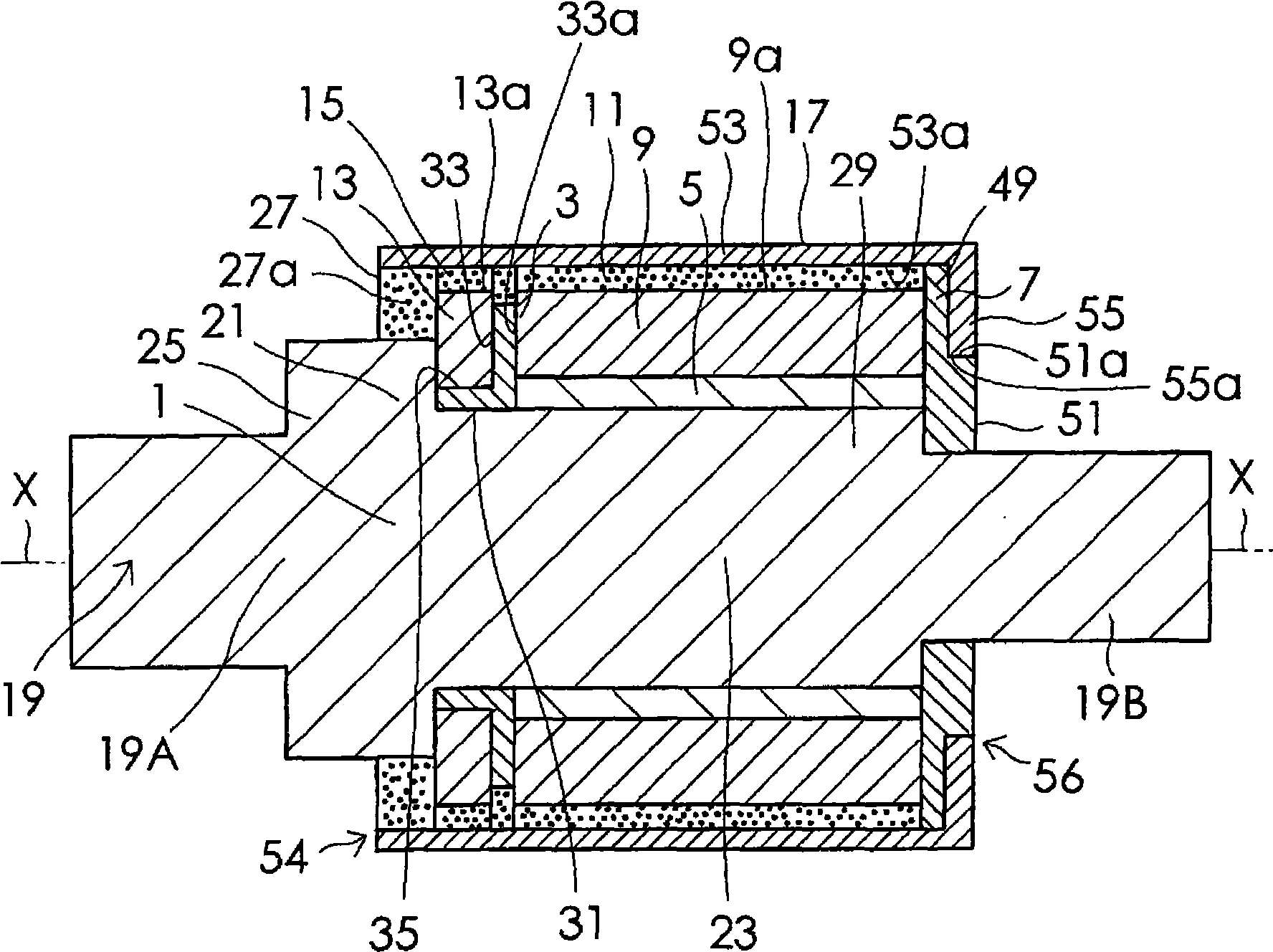

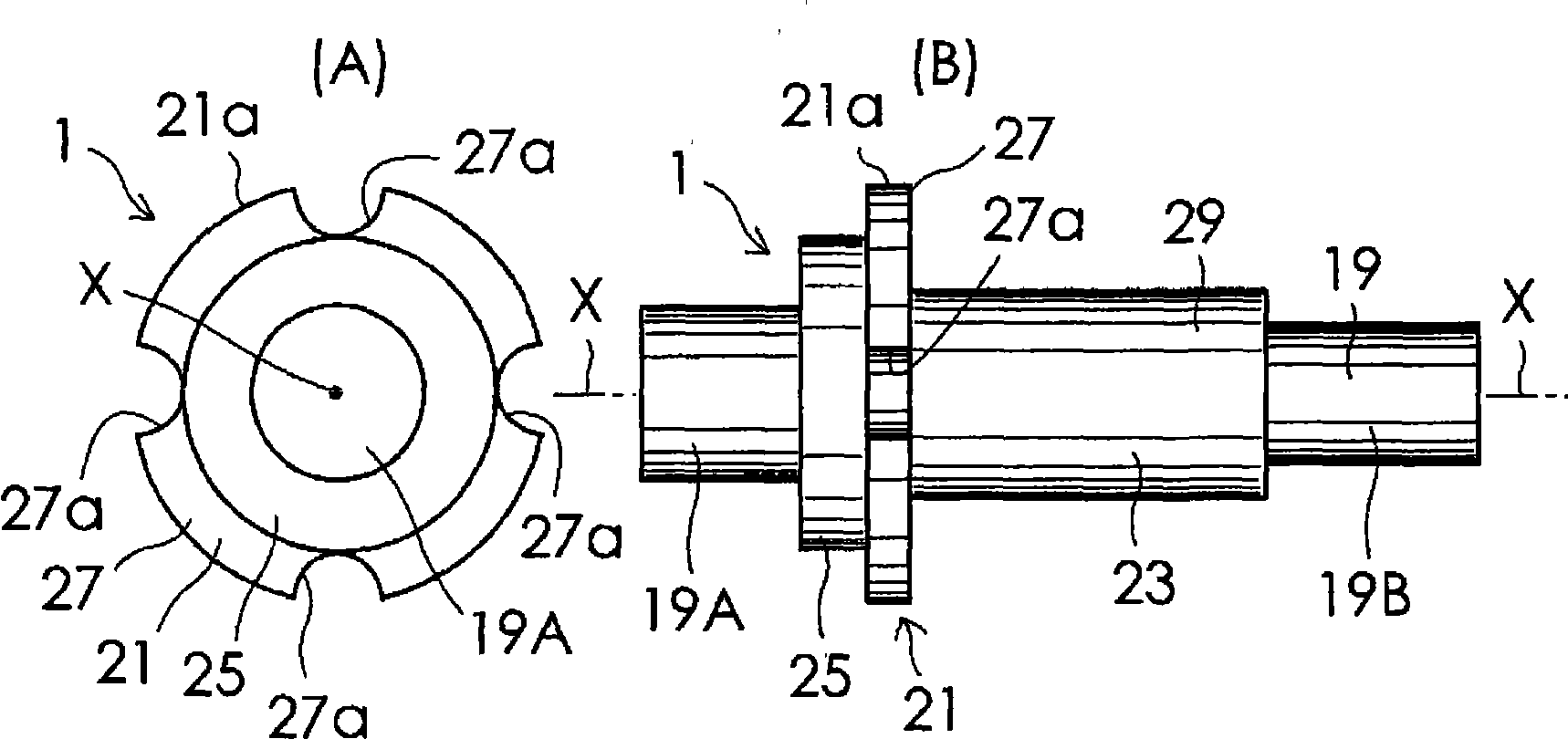

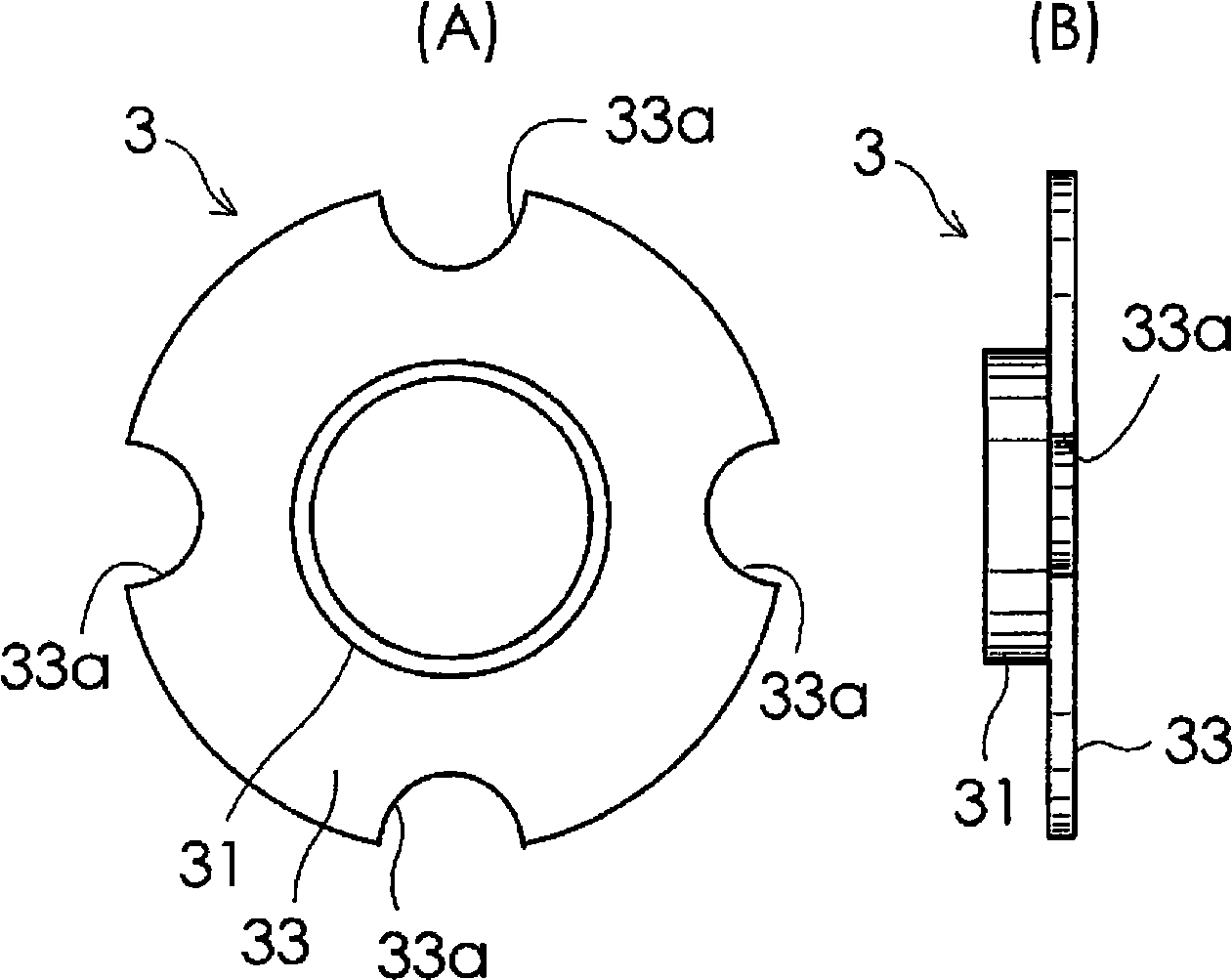

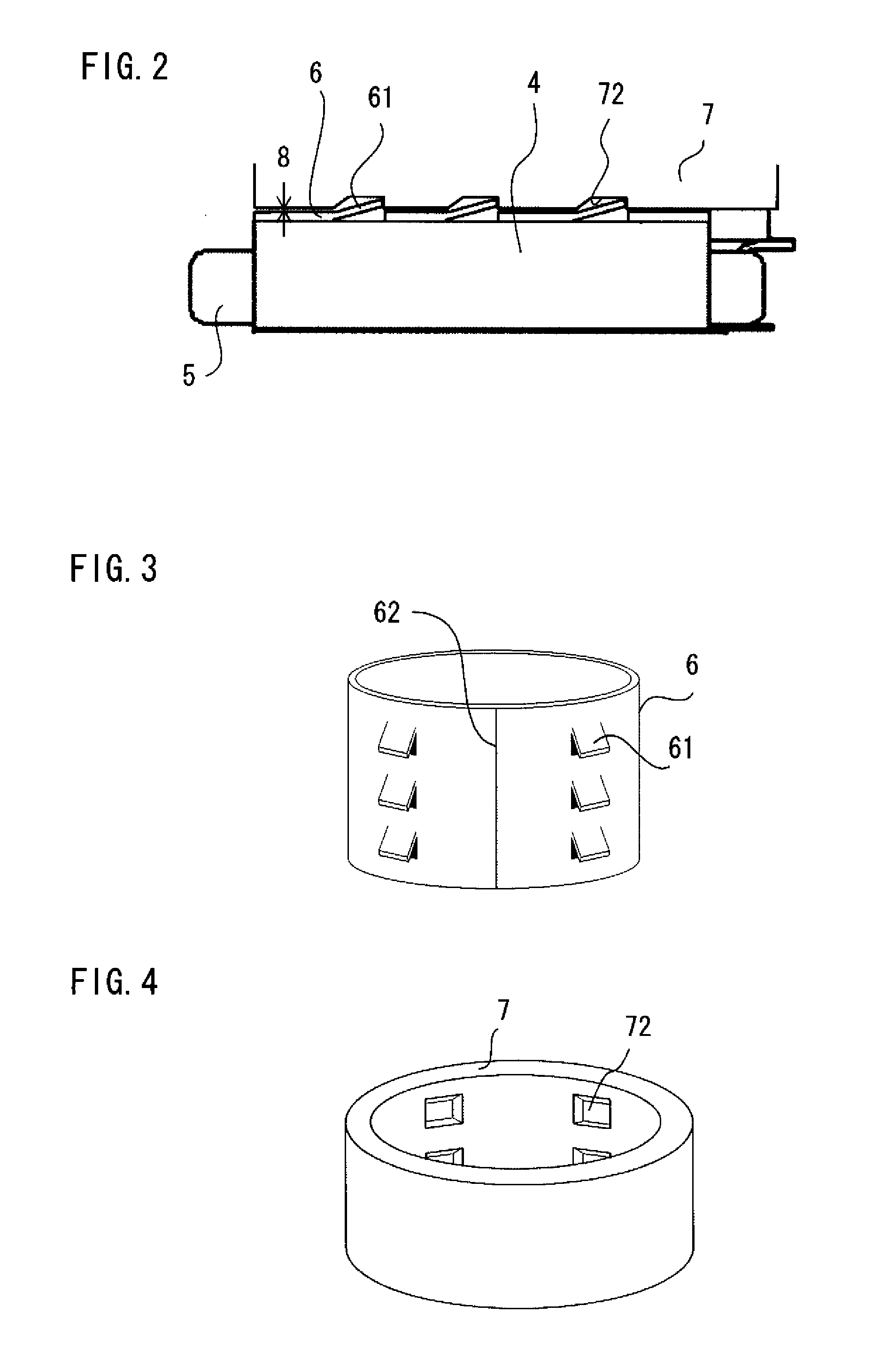

Rotator for motor and method for manufacturing the same

InactiveCN101523699AEasy to installMagnetic circuit rotating partsManufacturing stator/rotor bodiesFiberYarn

The invention provides a rotator for a motor, which, even when rotated at a high speed, can prevent breakage of a resin impregnated into a yarn winding layer. A yarn formed of a reinforcing fiber material is wound on a permanent magnet layer (5) to such an extent that a space is formed between a yarn winding layer (9) on its outer peripheral face (9a) and a cylindrical body (53) on its inner peripheral face (53a), whereby the yarn winding layer (9) is formed. A curable resin is impregnated into the yarn winding layer (9). A continuous yarn continuous to the yarn constituting the yarn winding layer (9) is placed within an annular passage (35) through a yarn passage recess part (33a) and is wound at a high level of tension on the bottom of the passage (35) to form a continuous yarn winding layer (13). A curable resin is impregnated into the continuous yarn winding layer (13). A cylinder (17) is mounted on the first and second annular members (21, 7) by shrink fitting. A curable resin is filled into a space between the yarn winding layer (9) on its outer peripheral face (9a) and the cylindrical body (53) on its inner peripheral face (53a) through a resin filling passage (27a) and the yarn passage recess part (33a). A curable resin is filled into a space between the continuous yarn winding layer (13) on its outer peripheral face (13a) and the cylindrical body (53) on its inner peripheral face (53a) through the resin filling passage (27a). Air bubbles contained in the curable resin is deaerated through the resin filling passage (27a) and the yarn passage recess part (33a), followed by heating to cure the resin.

Owner:SANYO DENKI CO LTD

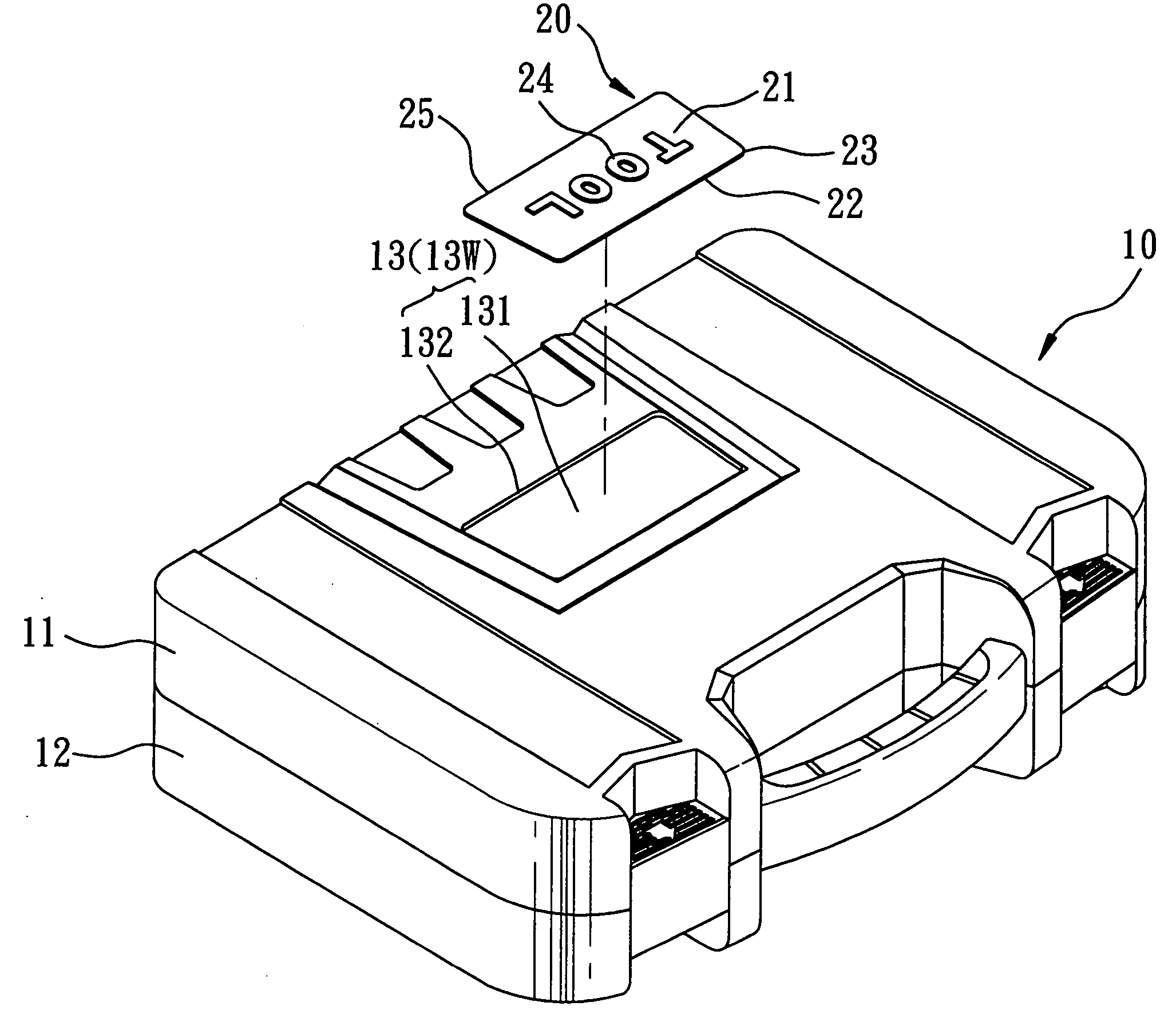

Tool box with a logo plate thereon

InactiveUS20050109650A1Avoid it happening againPrevent removalLuggageOther accessoriesShrink-fittingEngineering

A tool box includes a molded box body and a logo plate mounted securely within a recess formed in an outer face of the molded box body through a shrink-fit process. The recess is confined by a recess-defining wall that has a bottom wall portion and a peripheral wall portion extending from the bottom wall portion to the outer face. The logo plate is retained securely by the peripheral wall portion. The logo plate is fitted into the recess while the molded box body, which is formed through a hot molding process, is still in a hot softened state.

Owner:STANLEY CHIRO INT

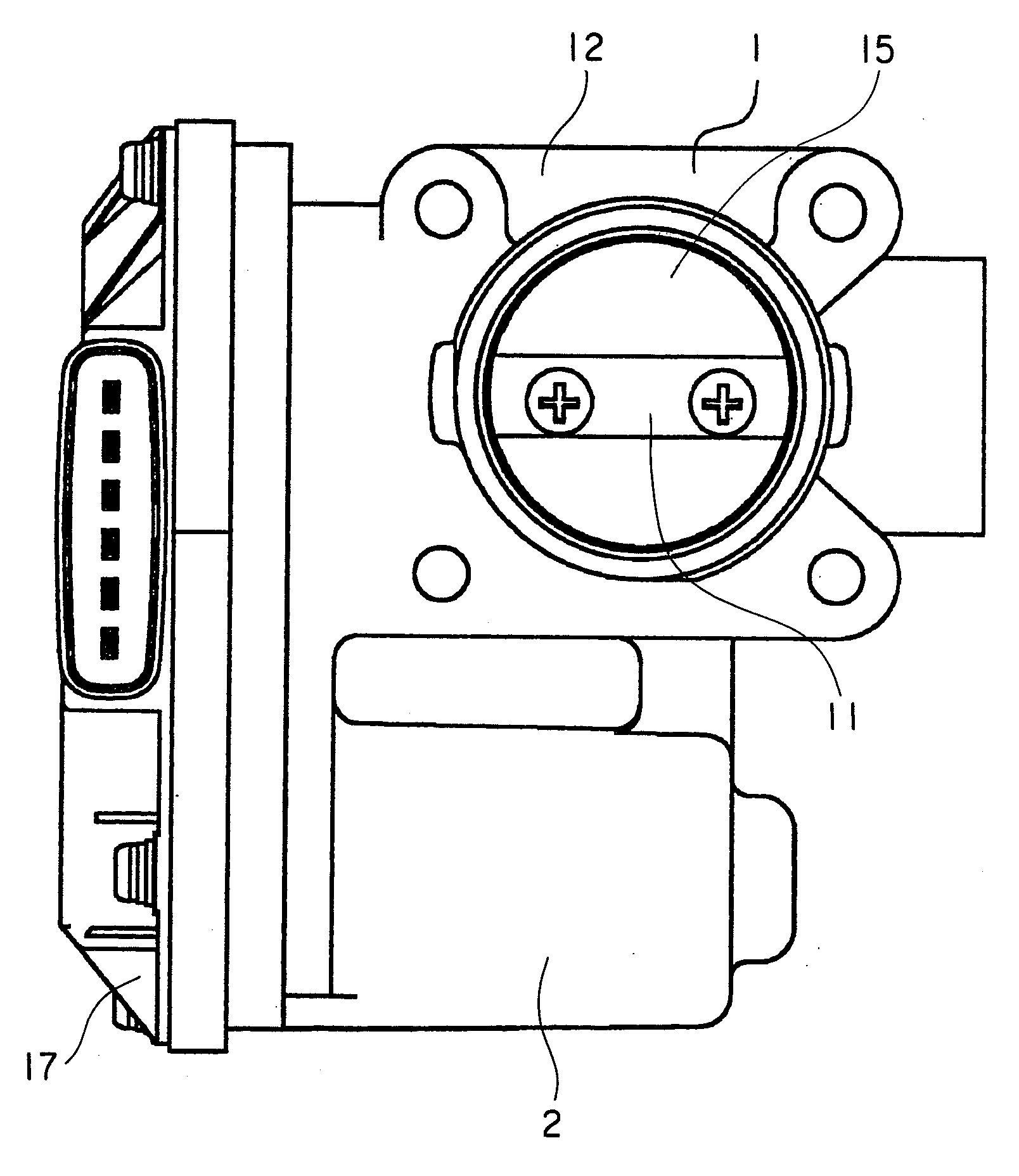

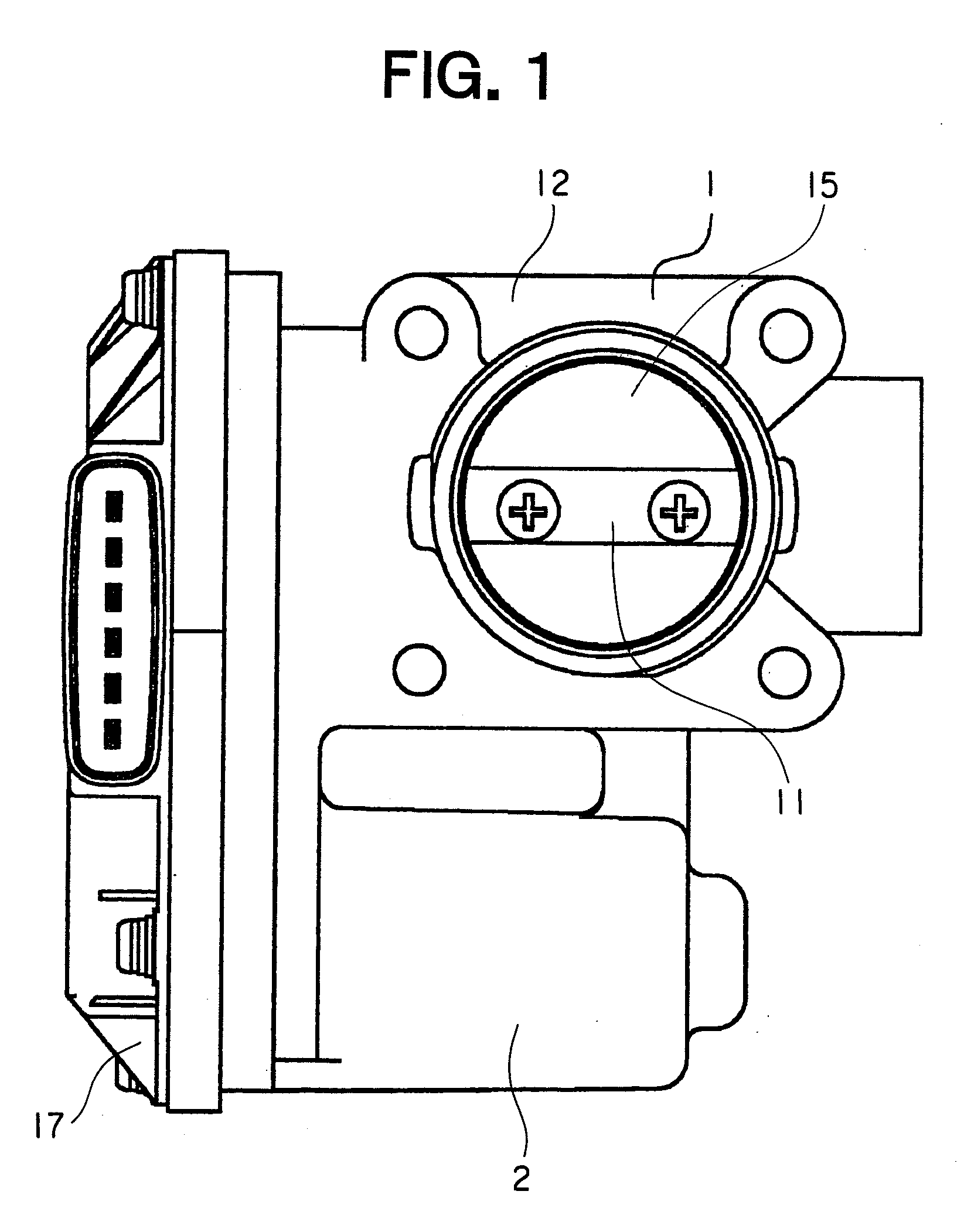

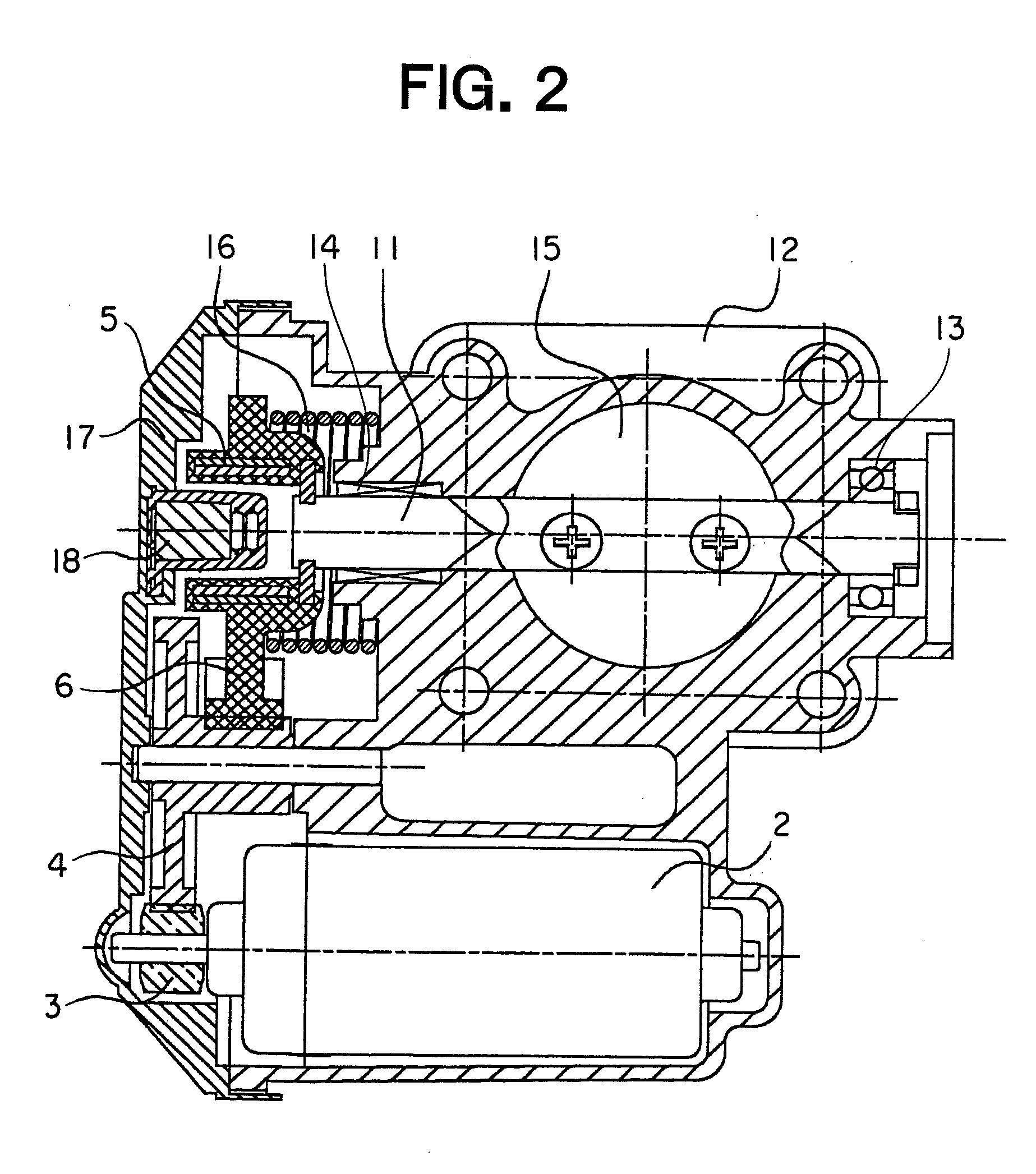

Non-contact type rotational angle detection apparatus and manufacturing method thereof

InactiveUS20090151436A1Reduce in quantityImprove productivityInternal combustion piston enginesNon-fuel substance addition to fuelRelative displacementInterior space

A non-contact type rotational angle detection apparatus can reduce the number of parts required, improve productivity, and prevent a relative displacement between a permanent magnet and a yoke. An insert molded body is fixedly secured to a shaft and is composed of a permanent magnet and a yoke formed integrally with each other by insert molding of a resin. A non-contact sensor is disposed in an inner space formed in the insert molded body. The non-contact sensor detects a rotation angle of the shaft by detecting an azimuth of magnetic flux lines generated by the permanent magnet. The cylindrical yoke is fixedly secured by shrinkage fitting to the cylindrical permanent magnet disposed at an inner side thereof. An engagement margin between the permanent magnet and the yoke is set equal to or greater than a value which restrains a relative displacement between the permanent magnet and the yoke.

Owner:MITSUBISHI ELECTRIC CORP

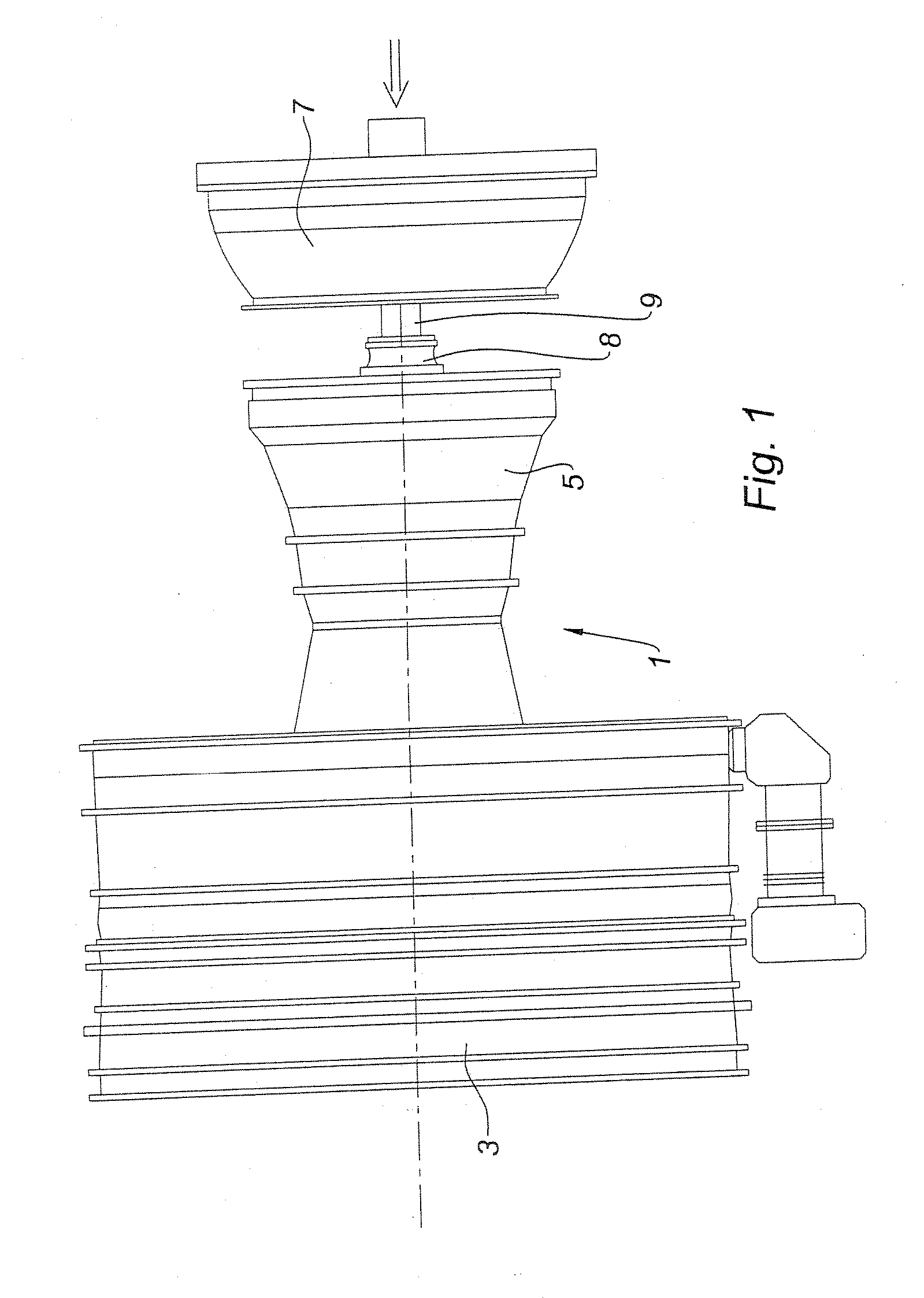

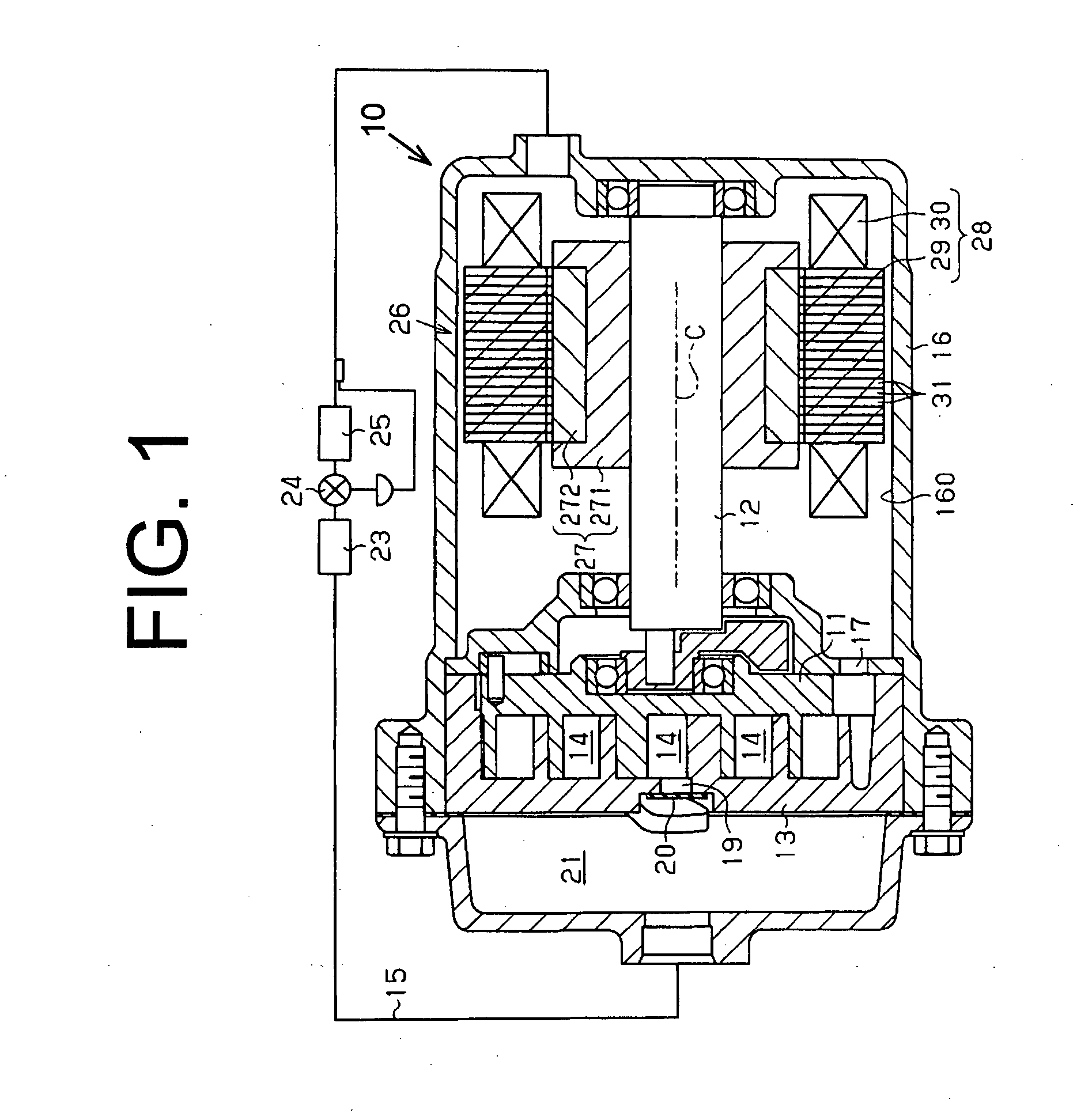

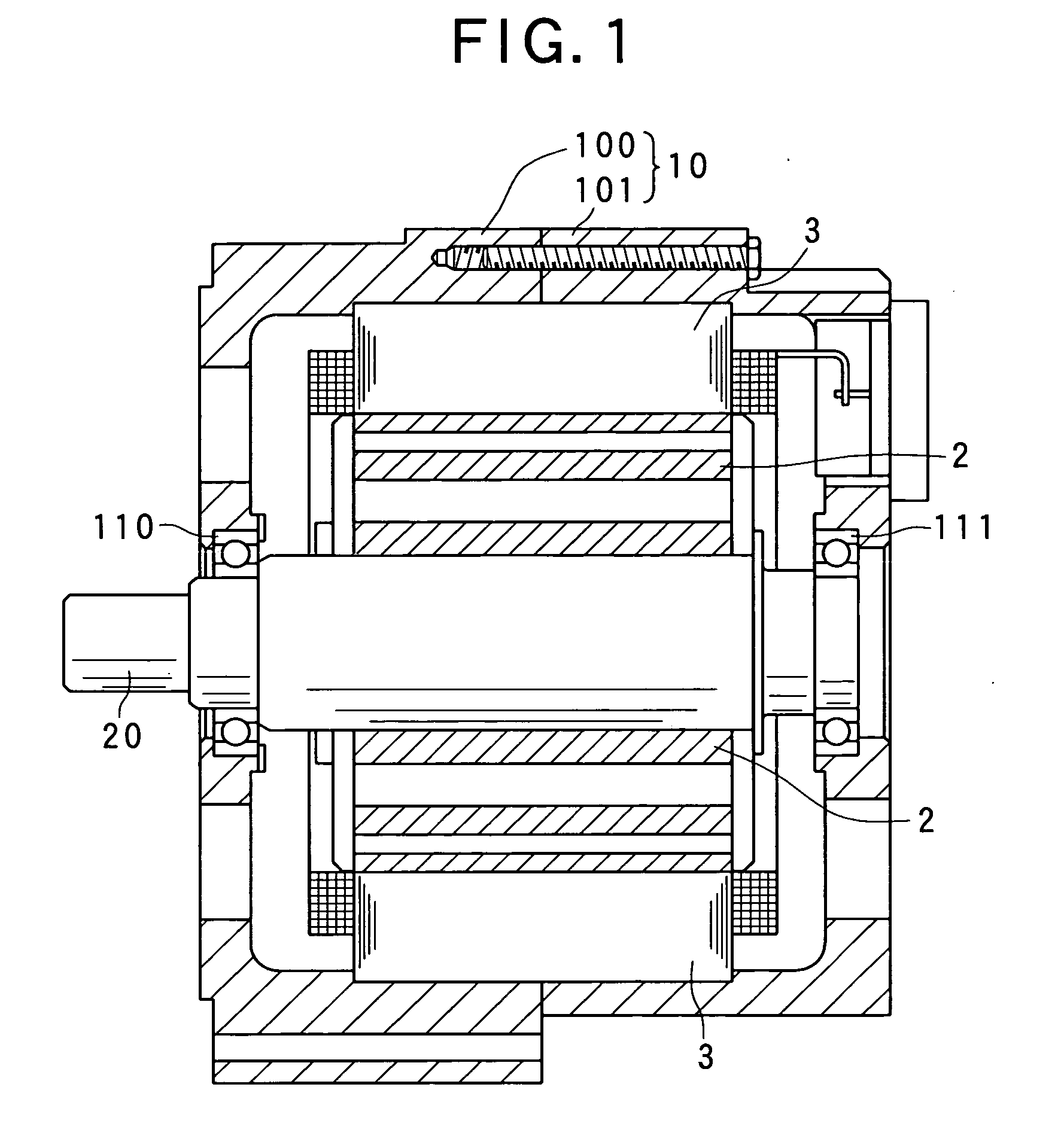

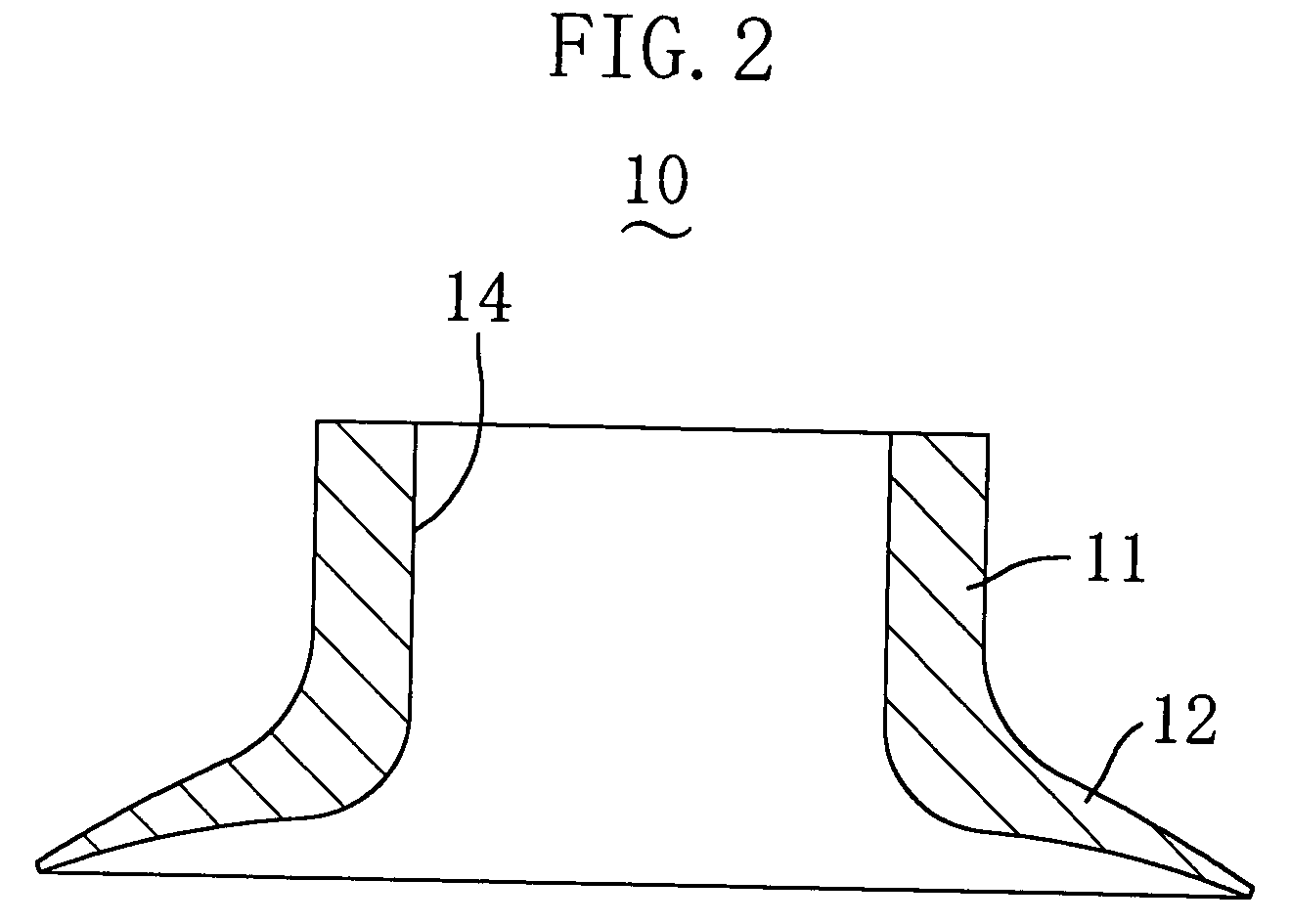

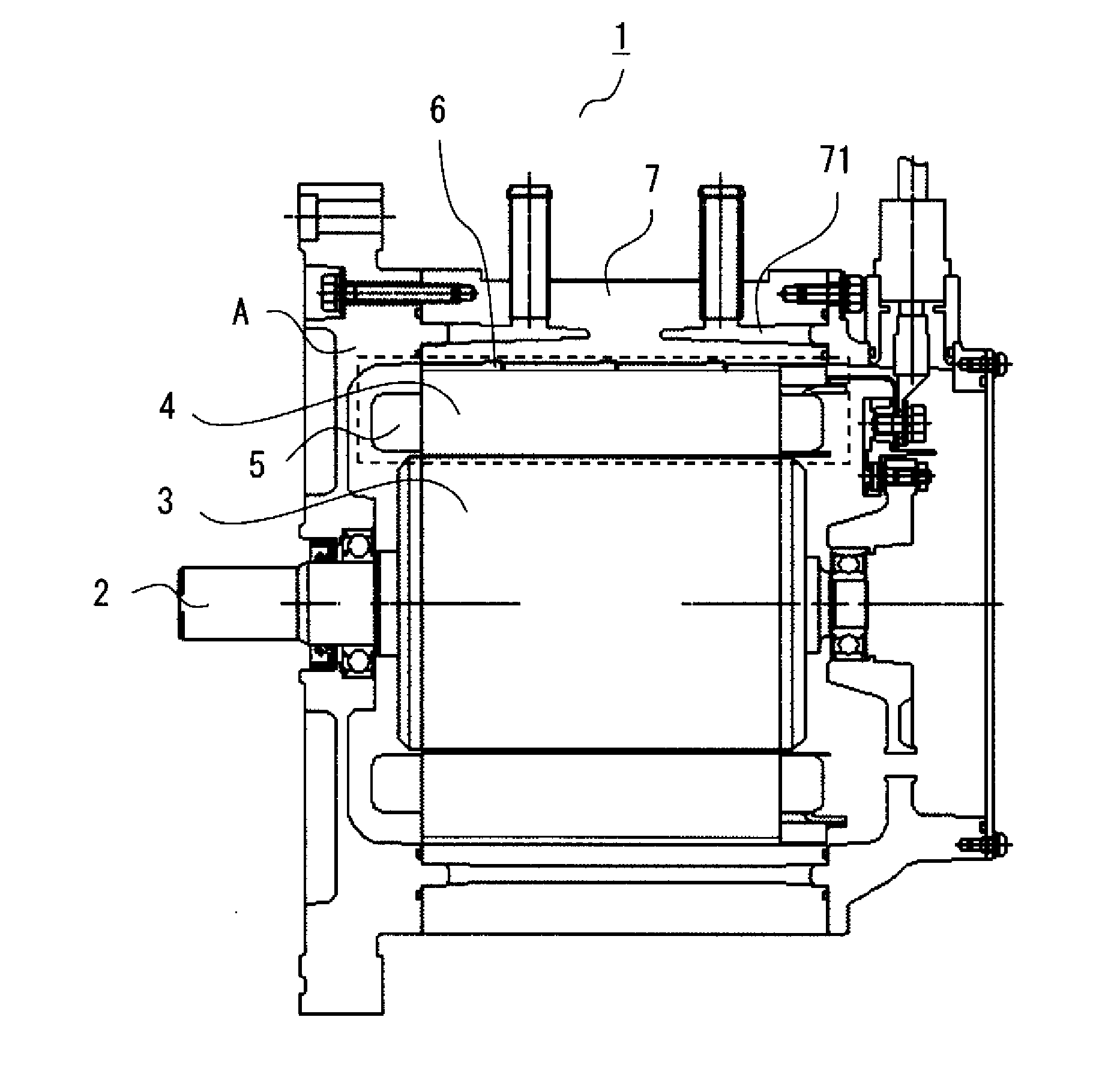

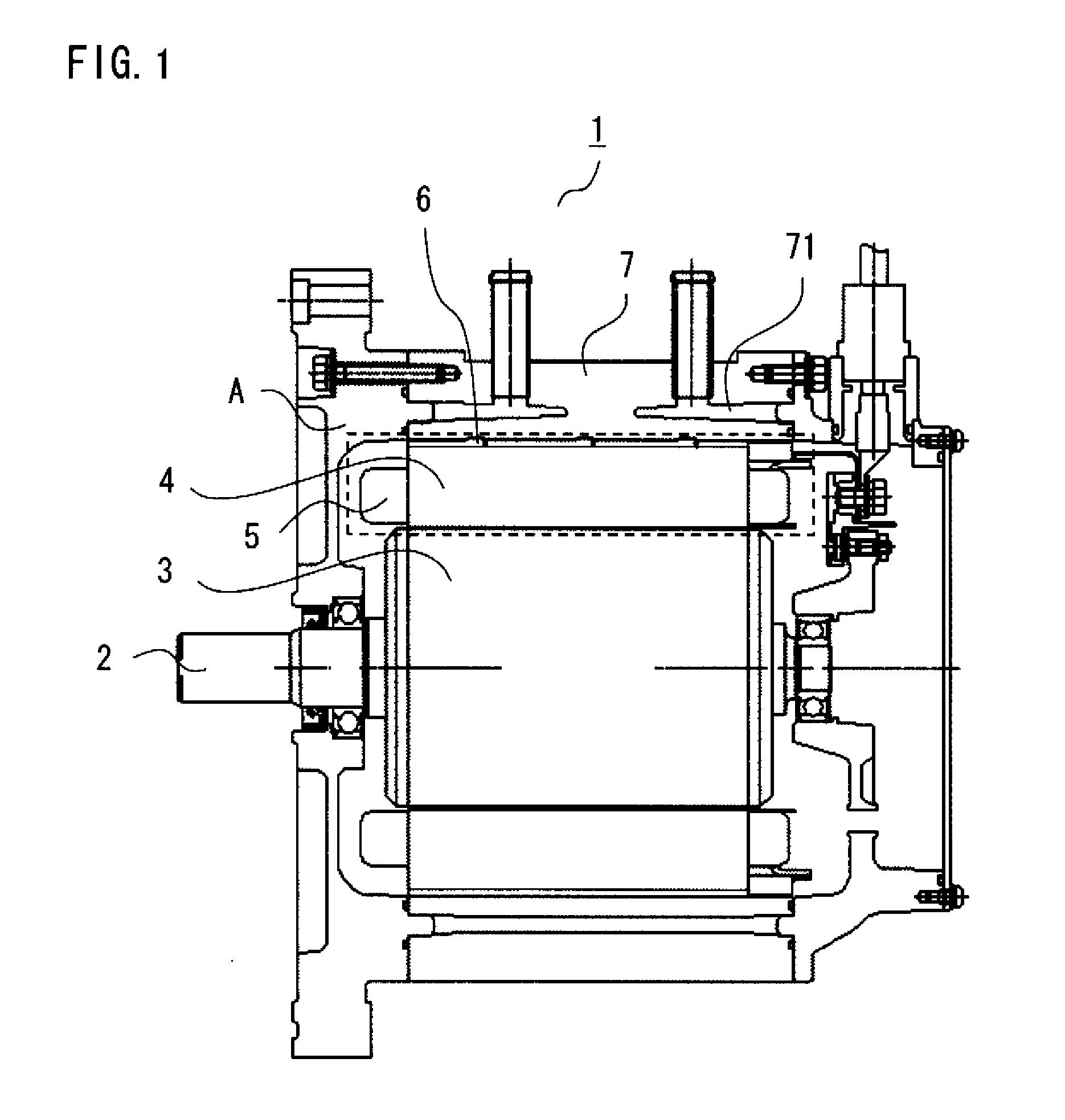

Stator manufacturing apparatus and method for rotary electric machines

ActiveUS20100000075A1Easily and evenly performing radial shrinkageUniform diameterManufacturing dynamo-electric machinesMetal working apparatusShrink-fittingElectric machine

A method is provided, for manufacturing a stator for a rotary electric machine by shrink-fitting an outer cylinder to a core assembly where a cage-shaped wound coil is assembled with segment cores. The assembly is inserted into the outer cylinder having a diameter increased by thermal expansion caused by the heat from a heating unit, while the outer diameter of the assembly is being reduced by permitting the assembly to pass through a tapered guide unit. The guide unit has a portion whose diameter is larger than an outer diameter of the assembly, and a portion whose diameter is larger than an inner diameter of the outer cylinder and smaller than an inner diameter of the cylinder in the thermally expanded state, and a tapered through hole vertically passing through the guide unit. Thus, the size of the assembly is radially reduced, with a uniform diameter being obtained throughout the assembly.

Owner:DENSO CORP

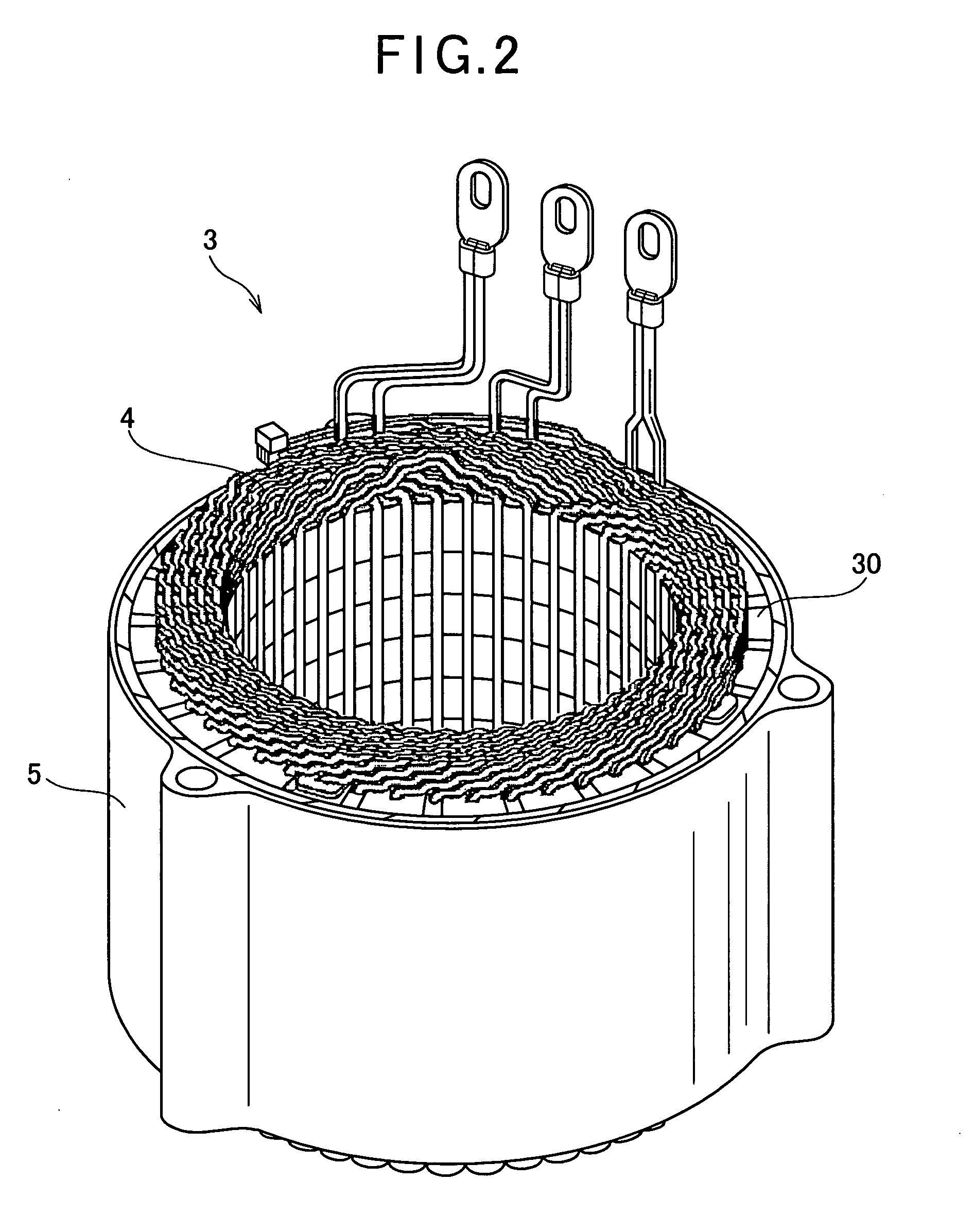

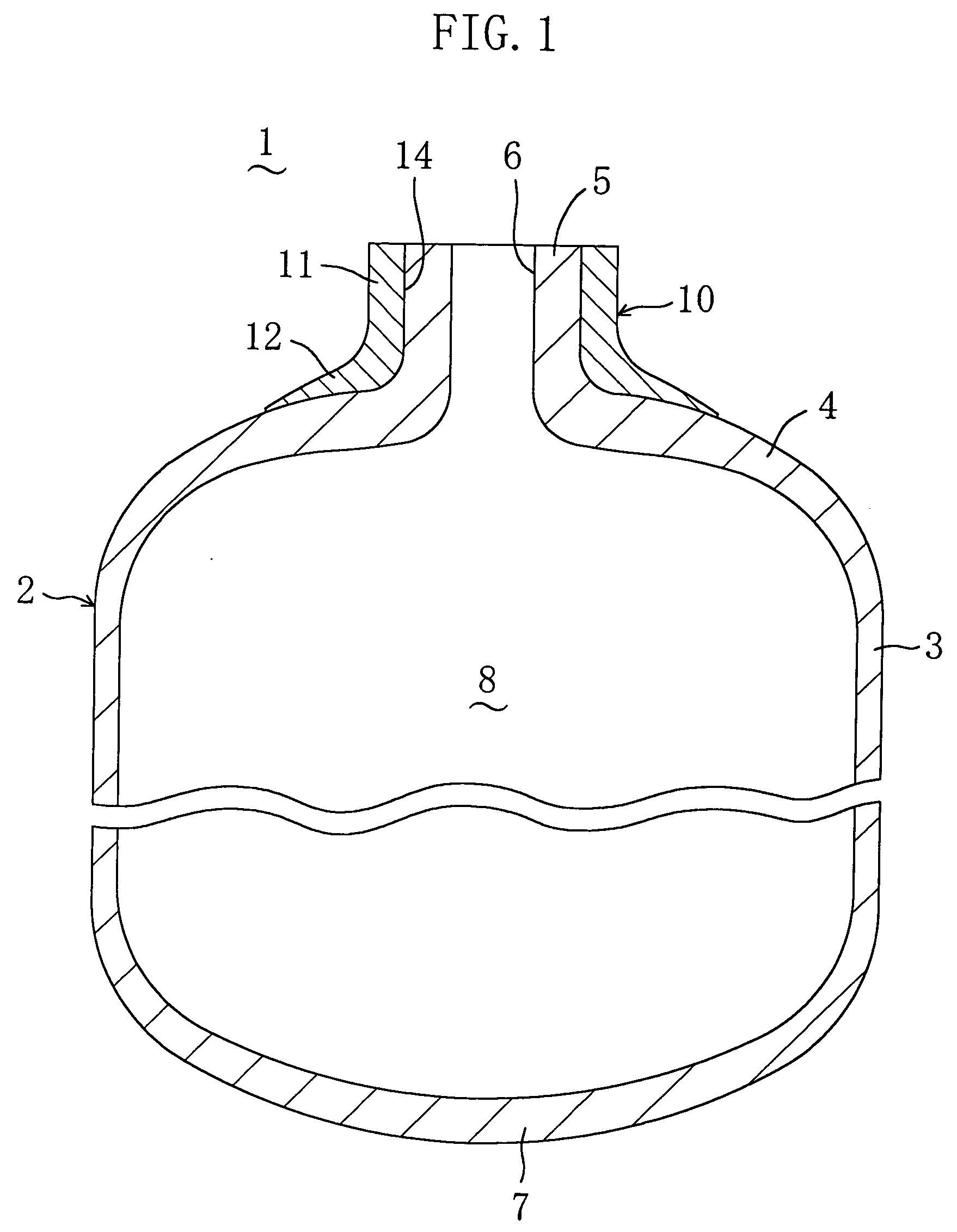

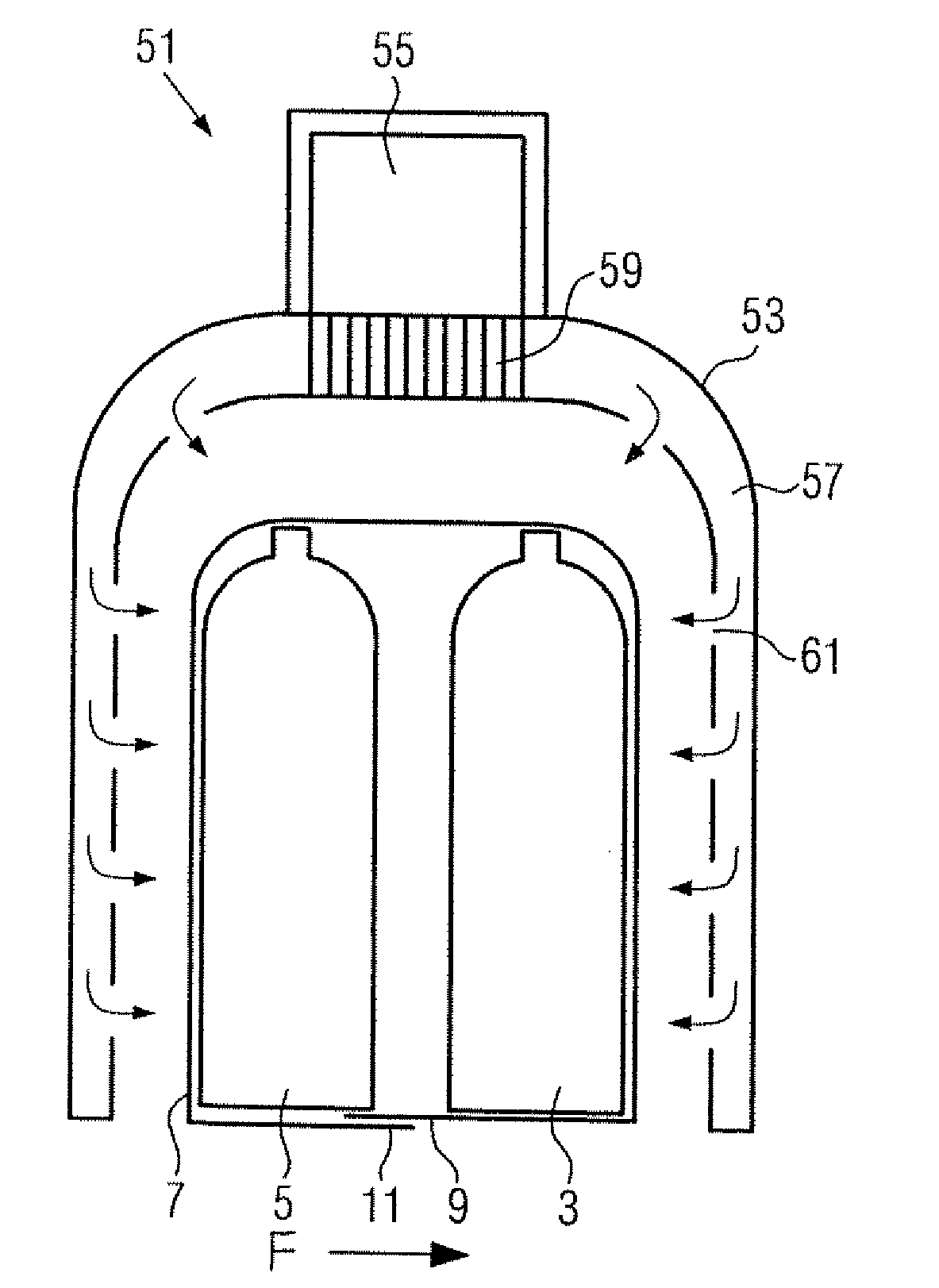

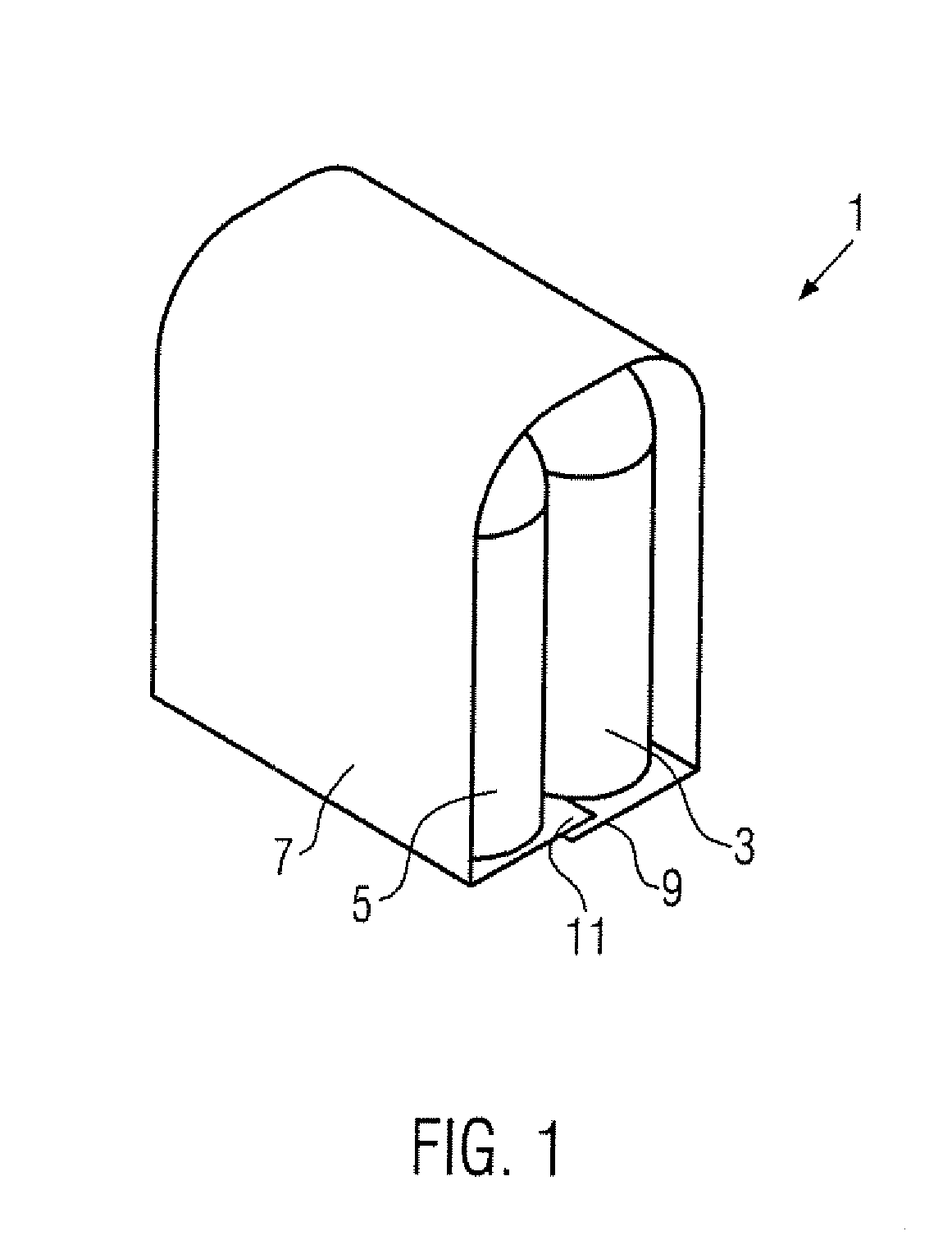

High-pressure tank and method for fabricating the same

A cylindrical reinforcing collar is fitted onto a cylindrical gas discharge section of a tank body and then engaged integrally on the exterior of the tank body between the cylindrical gas discharge section and the dome section by shrink fitting. This provides, easily and inexpensively, a high-pressure tank capable of withstanding high pressures of 35 to 75 MPa while keeping its lightness in weight.

Owner:SAM TECHOLOGY +2

Piston assembly of cooler

InactiveUS20070048156A1Low production costImprove productivityMagnetic circuit rotating partsPositive displacement pump componentsCircular discShrink-fitting

There is provided a piston assembly configured to include: a hollow cylinder-shaped magnet sleeve having a magnet(s) bonded on external circumferential surface thereof; a hollow cylinder-shaped piston inserted into a hollow space of the magnet sleeve; and a hollow disc-shaped ring fixed to the piston by a shrink fitting process, and welded to the magnet sleeve which is made of the same material as the ring so as to obtain a configuration of the piston assembly in which the magnet sleeve and the piston are coupled to each other.

Owner:LG ELECTRONICS INC

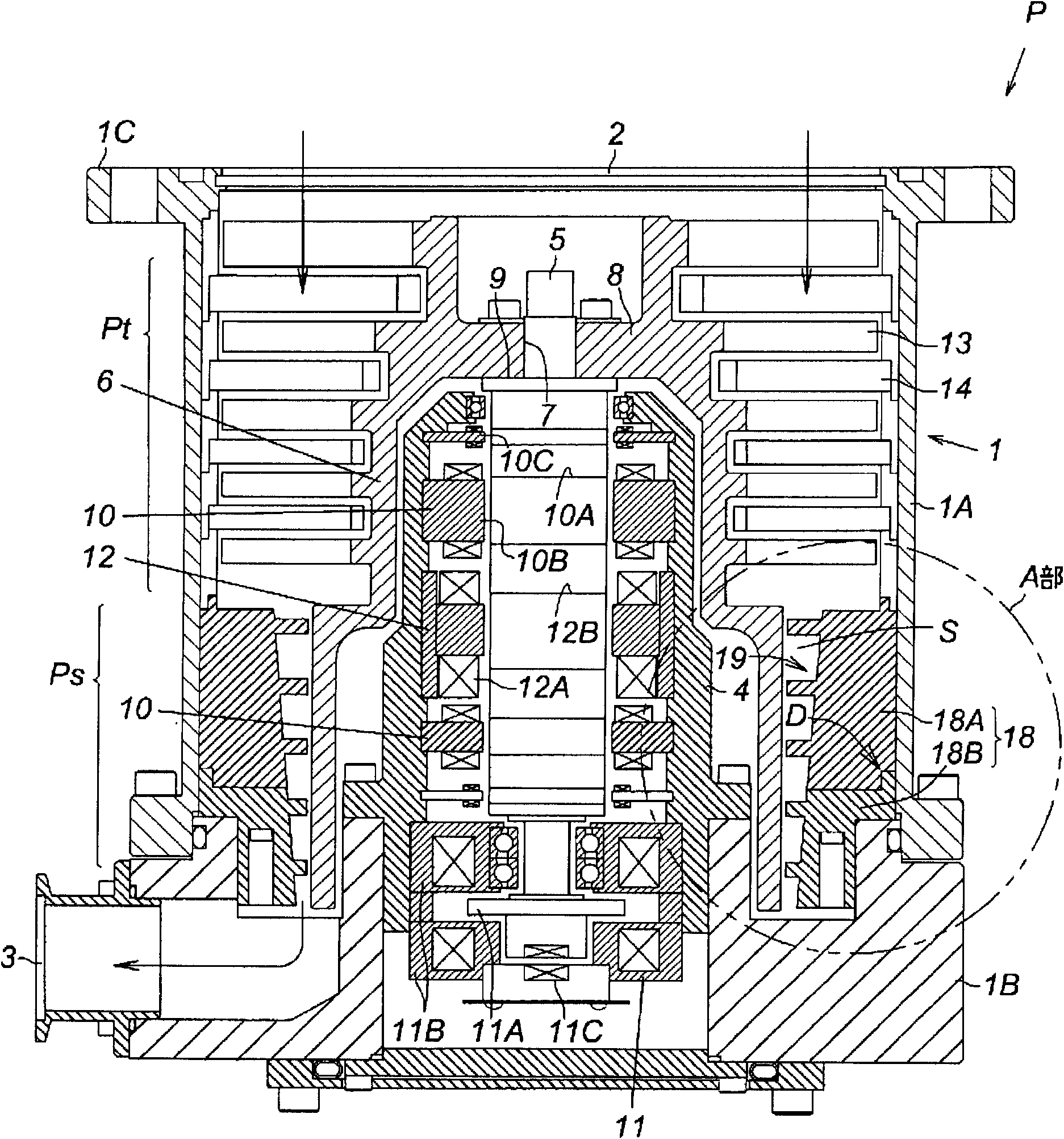

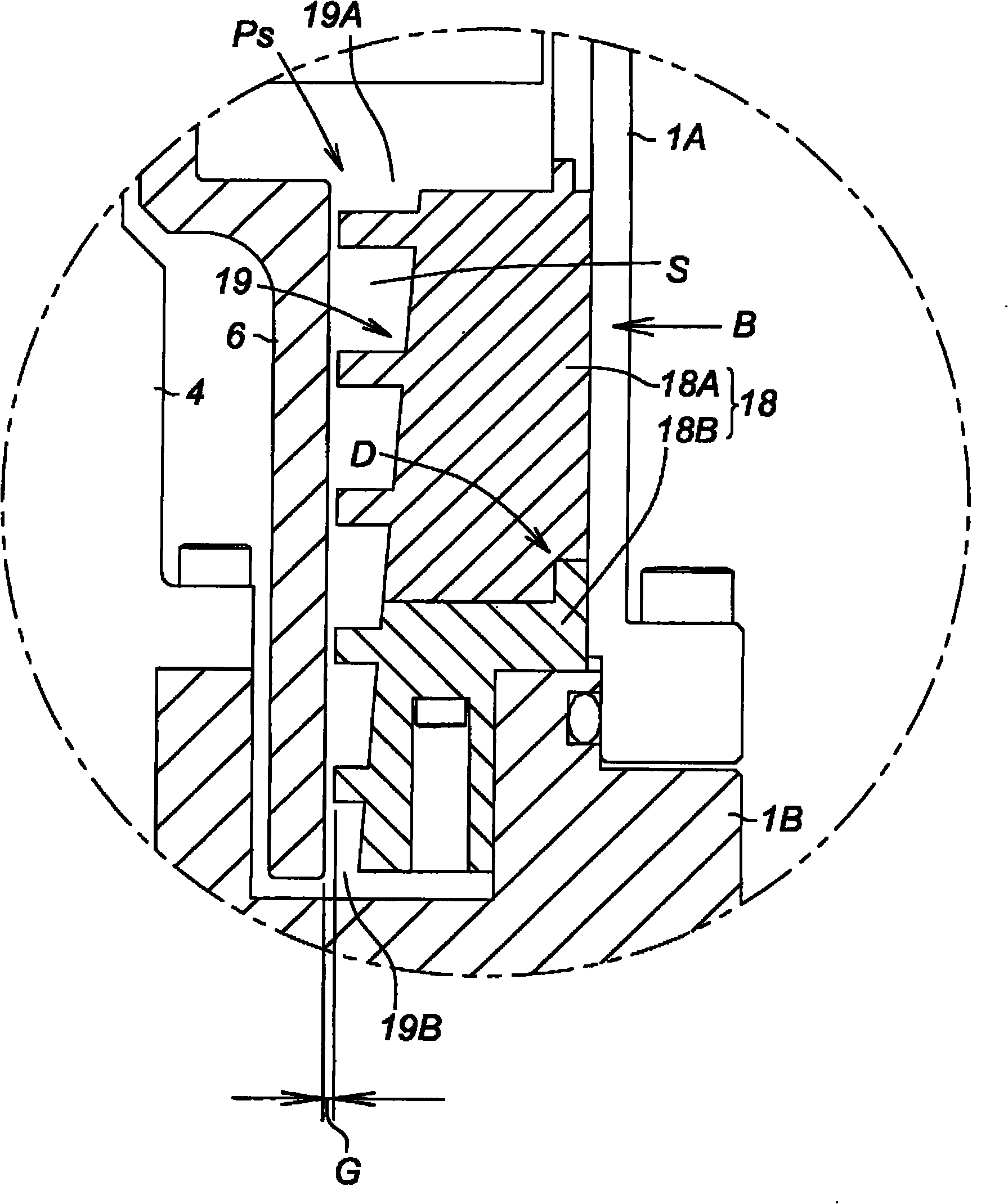

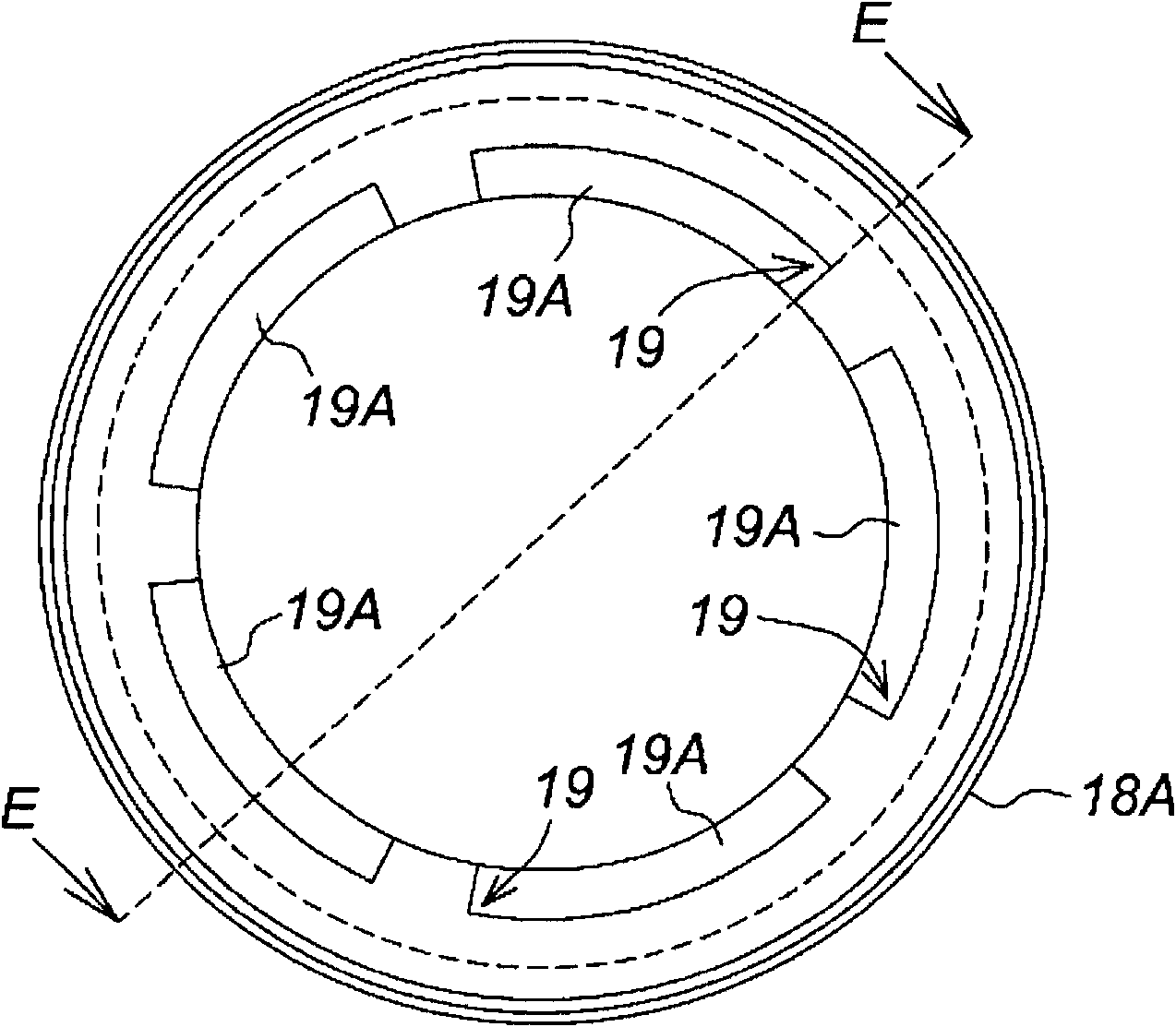

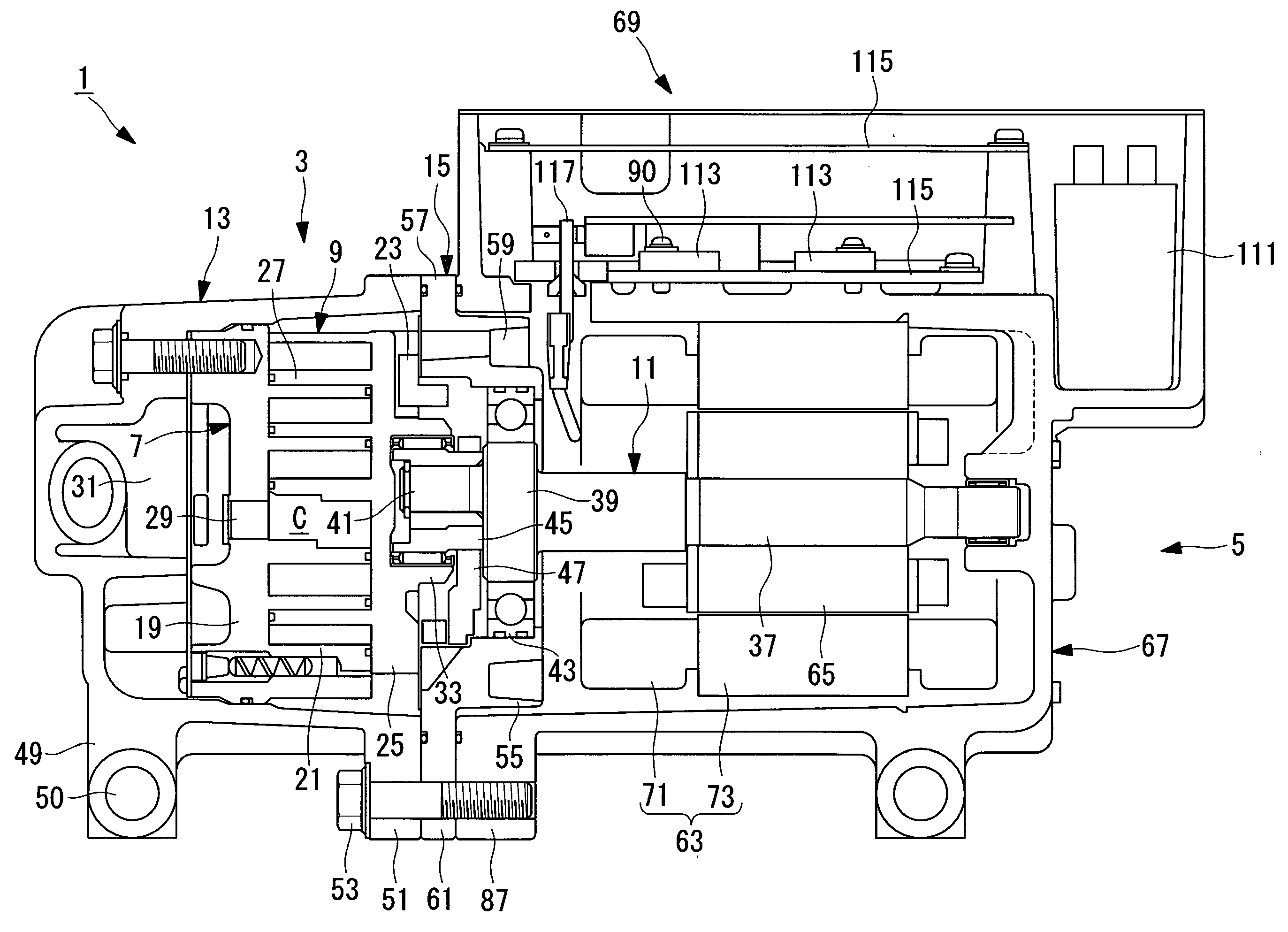

Cylindrical fixed member of thread-groove exhaust unit and vacuum pump using same

ActiveCN102667169AGuaranteed StrengthLow costPump componentsAxial flow pumpsShrink-fittingEngineering

Disclosed is a cylindrical fixed member of a thread-groove exhaust pump unit, with which the cost of a vacuum pump can be reduced while the strength thereof against breakdown torque is maintained, in which thread grooves having complicated shapes of which width, depth, lead angle, and the like change in the rotation-axis direction of a rotating member of the thread-groove exhaust unit can be easily formed, and that is suitable for improving exhausting performance and compression performance of the entire vacuum pump by using such thread grooves. A cylindrical fixed member (thread-groove exhaust unit stator (18)) of a thread-groove exhaust unit (Ps) disposed so as to enclose the outer circumference of a rotating member (substantially the lower half of a rotor (6)) of the thread-groove exhaust unit (Ps) forms a helical thread-groove exhaust path (S) for exhausting gas between the rotating member and the cylindrical fixed member. This cylindrical fixed member includes two or more separable pieces (18A, 18B) that can be divided in the rotation-axis direction of the rotating member, and the separable pieces are joined together using a fastening means such as bolts or a joining means such as shrink fitting.

Owner:EDWARDS JAPAN

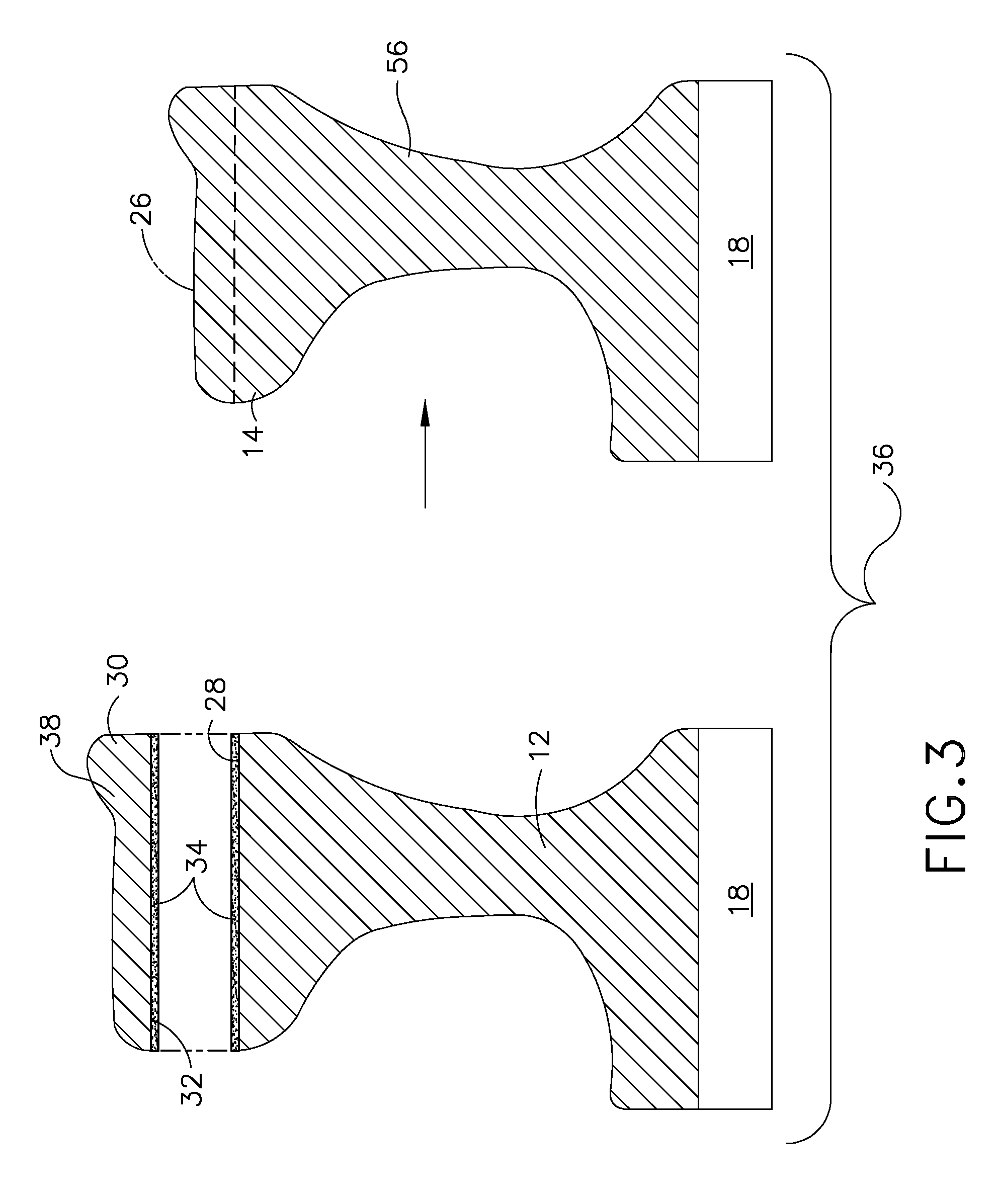

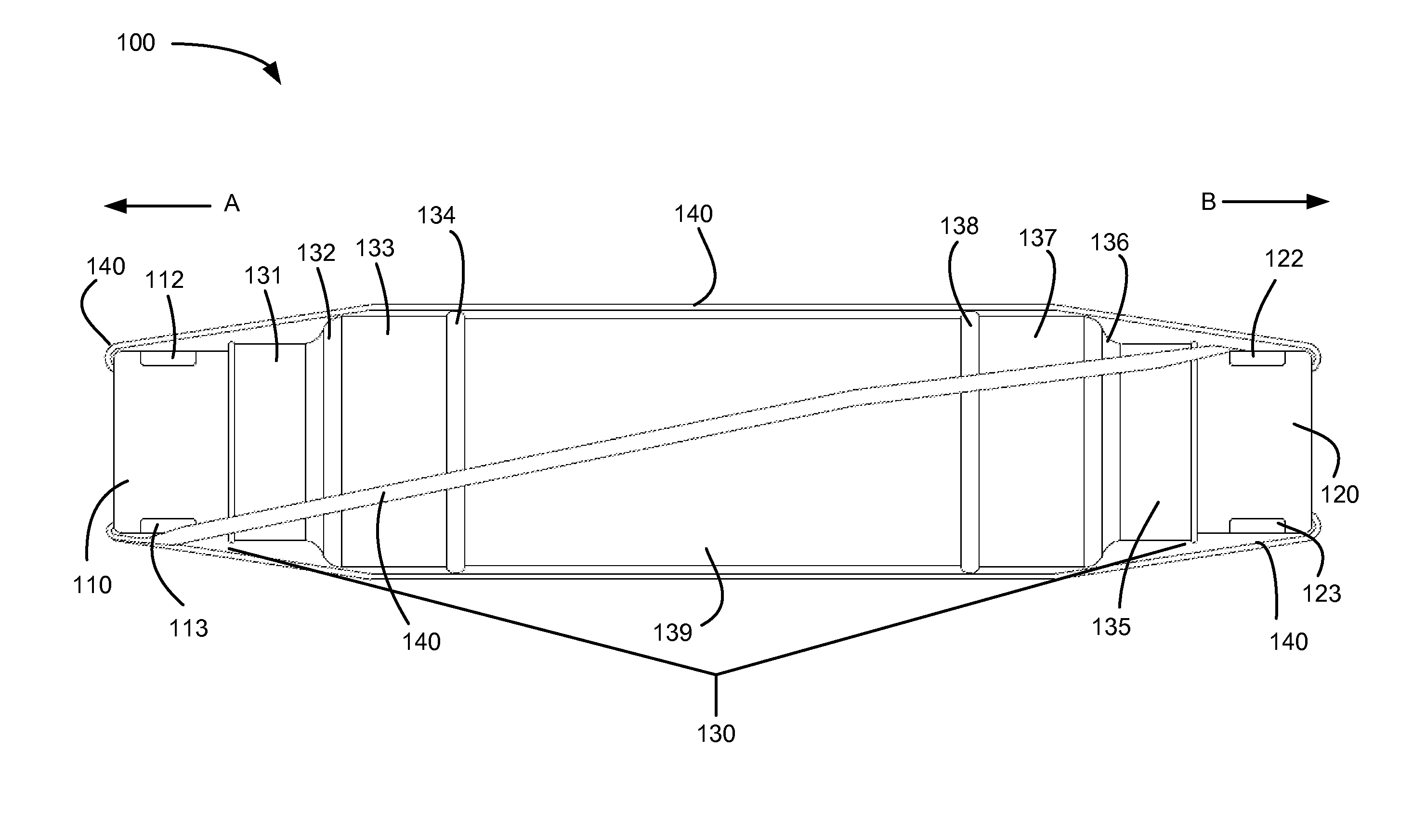

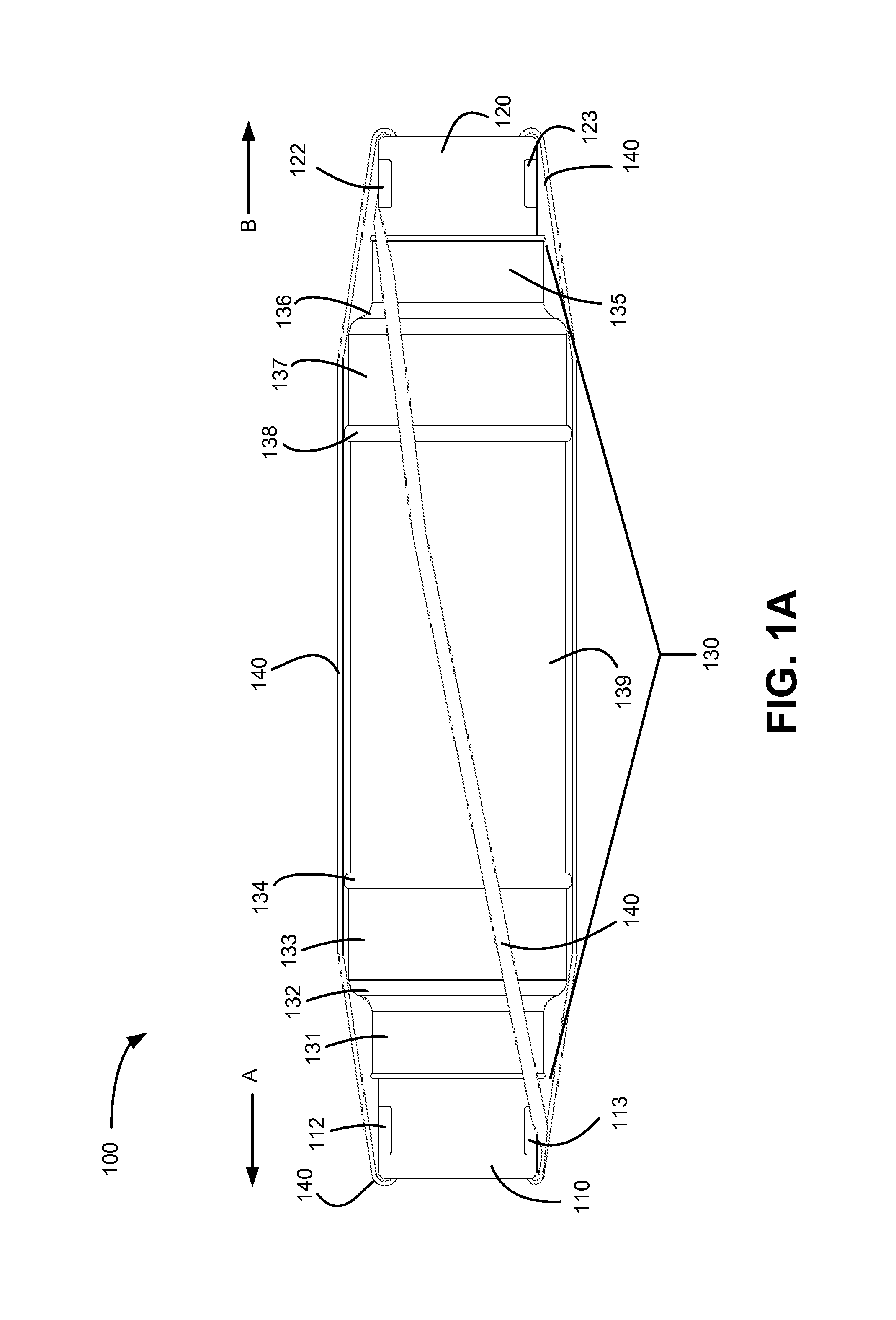

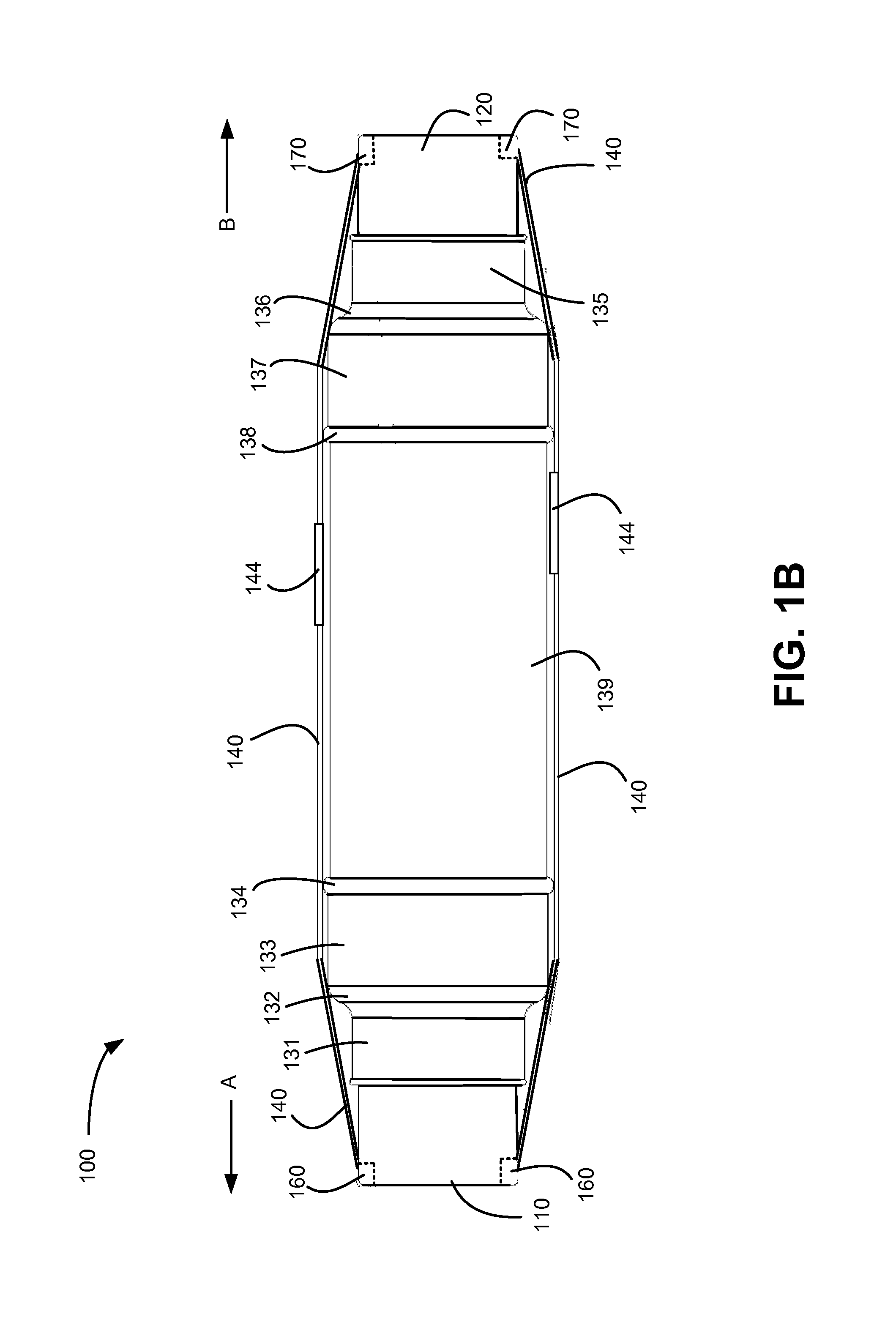

Cold shrink assembly

A cold shrink assembly includes a first member, a second member, a shrink fit joint and a band. The first member has a tapered shape and includes a first opening or first notch. The second member has a tapered shape and includes a second opening or second notch. The shrink fit joint is disposed over a portion of the first and second members. The band is configured to secure the first and second members in a predetermined position. The band extends through the first opening or first notch, along a first portion of an outer surface of the cold shrink assembly, through the second opening or second notch, and loops back to the first opening or first notch along a second portion of the outer surface of the cold shrink assembly.

Owner:THOMAS & BETTS INT INC

Insulated code stud for rotor and stator laminations

InactiveUS6949858B2Less susceptible to ruptureNot easy to damageMagnetic circuit shape/form/constructionShrink-fittingEngineering

An insulated core stud for use in the core structure of at least one of a stator and a rotor of a dynamoelectric machine is adapted to pass through holes contained in laminations of the core structure. The insulated core stud has a central portion and a first layer of heat shrinkable tubular insulation shrunk fit onto and covering at least the central portion of the core stud that passes through the laminations. One or more additional layers of heat shrinkable tubular insulation are shrunk fit onto at least a portion of the first layer of insulation that passes through the laminations. These second layers provide mechanically protection to the underlying layers of insulation against breaks occurring in the electrical insulation when the laminations and core studs are assembled into the core structure.

Owner:GENERAL ELECTRIC CANADA INC A CO OF CANADA

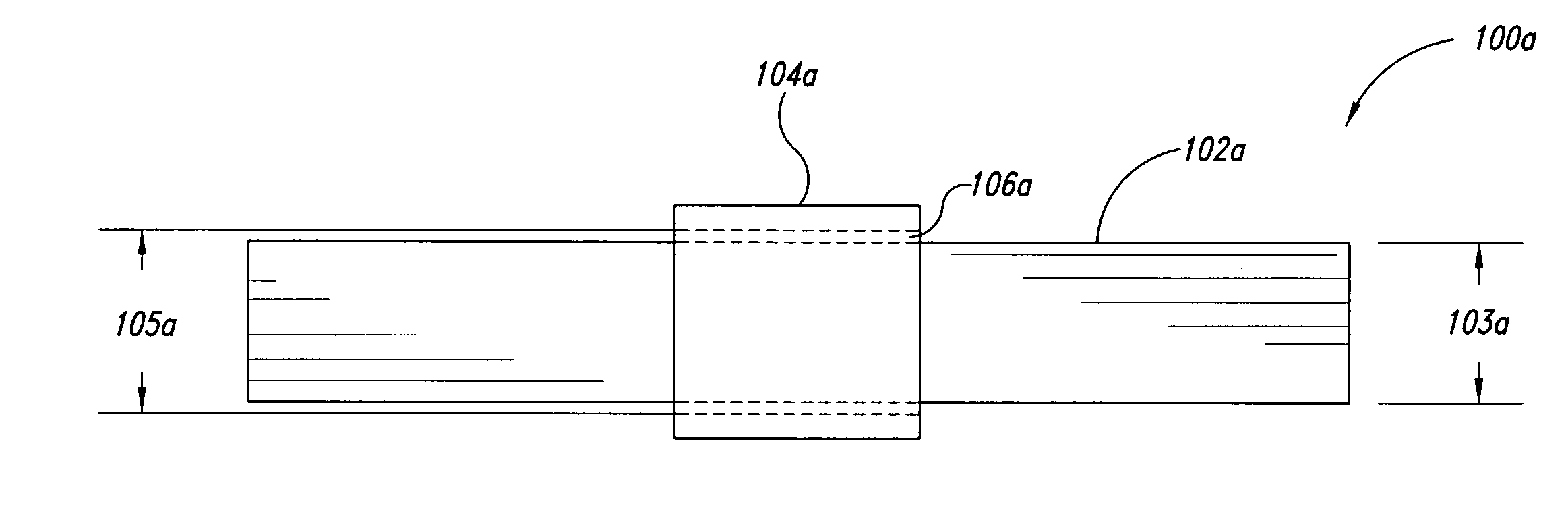

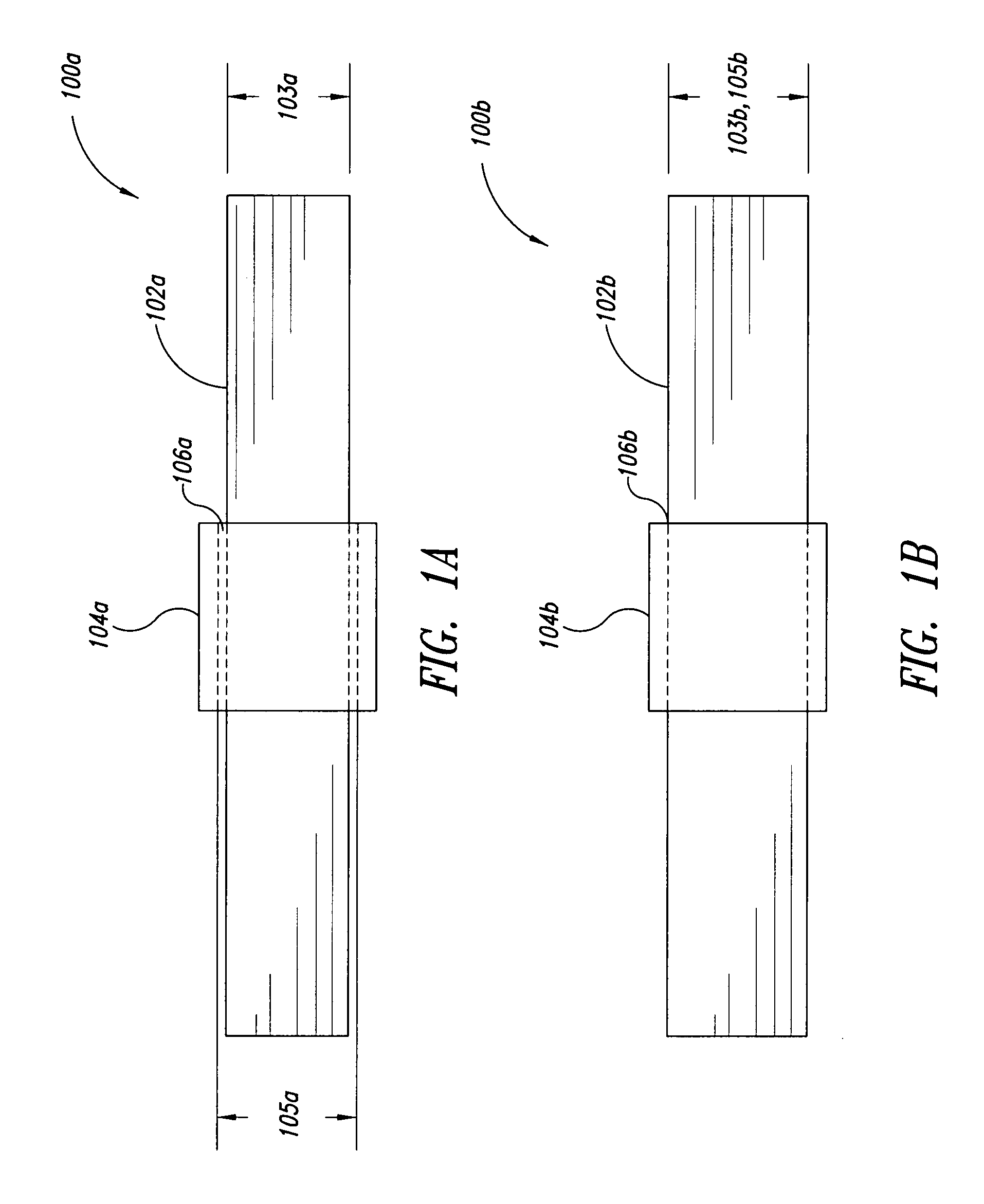

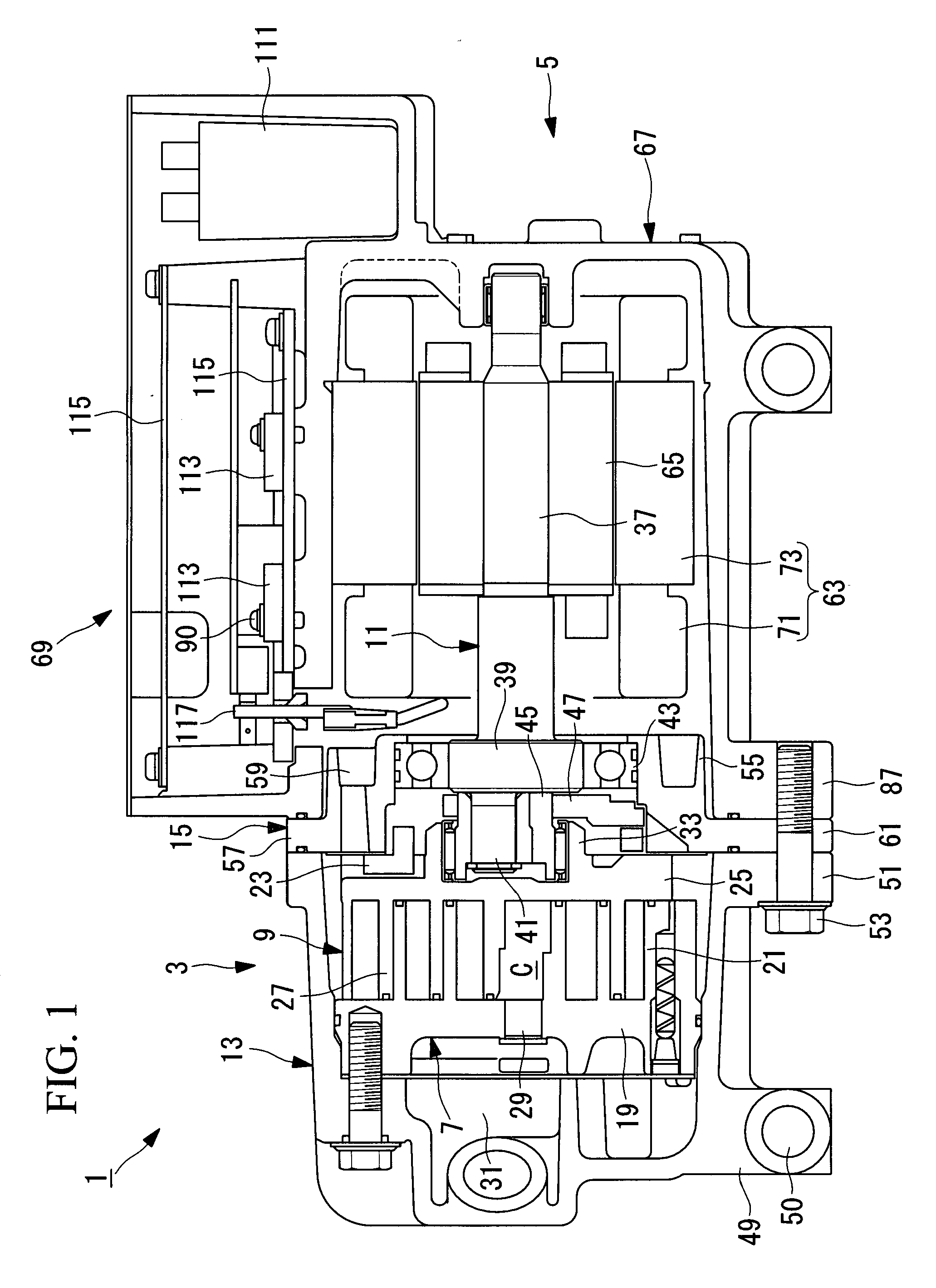

Electric compressor

ActiveUS20100084933A1Avoid insufficient thicknessWithstanding stressMagnetic circuit stationary partsRotary piston pumpsShrink-fittingEngineering

To provide an electric compressor in which the occurrence of shrink-fitting failures can be prevented when a stator is shrink-fitted in a motor case. Provided are a casing (67) in which the inner circumferential surface of the cylinder is provided with a first inner circumference (101) and a second inner circumference (103) whose radius is larger than the first inner circumference (101), the inner circumference (101) having an inclination that becomes more distant from a central axis (C) from a bottom face (79) toward an opening (85); a compressing unit that compresses fluid; and a rotor and a stator that rotationally drive the compressing unit, wherein the first inner circumference (101) and the second inner circumference (103) are provided with a substantially cylindrical insertion surface (105) whose radius is larger than the second inner circumference (103) and in which the stator is inserted; and at least the first inner circumference (101) is provided with an enlarged diameter portion (109) whose radius is larger than the insertion surface (105) and which makes the distance from the end at the opening (85) side of the insertion surface (105) to the opening (85) substantially equal.

Owner:MITSUBISHI HEAVY IND LTD

Rotary electric machine

InactiveUS20130093273A1Improve cooling effectImprove magnetic propertiesMagnetic circuit rotating partsCooling/ventillation arrangementShrink-fittingElectric machine

A rotary electric machine includes a rotor, a stator having coils wound to surround the rotor, a cylindrical ring member fixedly mounted on the stator by shrinkage fitting, and a frame disposed on the outside of the ring member with a gap created in between. The distance of the gap varies as a result of thermal expansion of the stator and the ring member. An outer surface of the ring member goes into contact with the frame when the stator and the ring member thermally expand, whereby the stator and the ring member are efficiently cooled.

Owner:MITSUBISHI ELECTRIC CORP

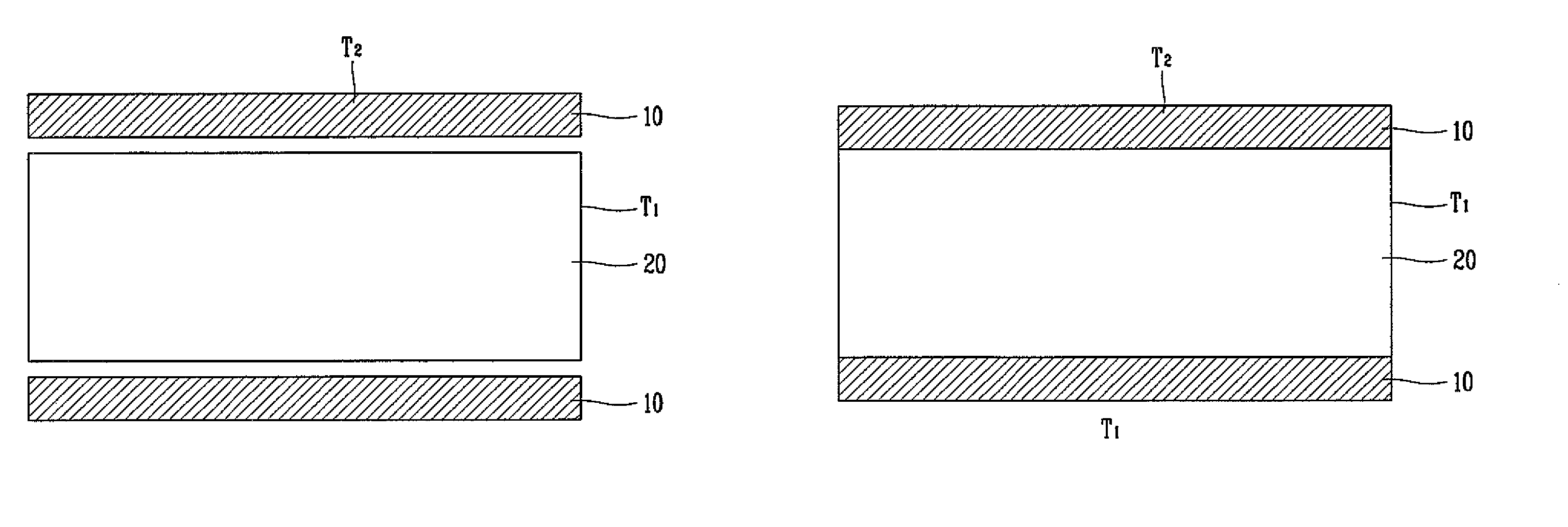

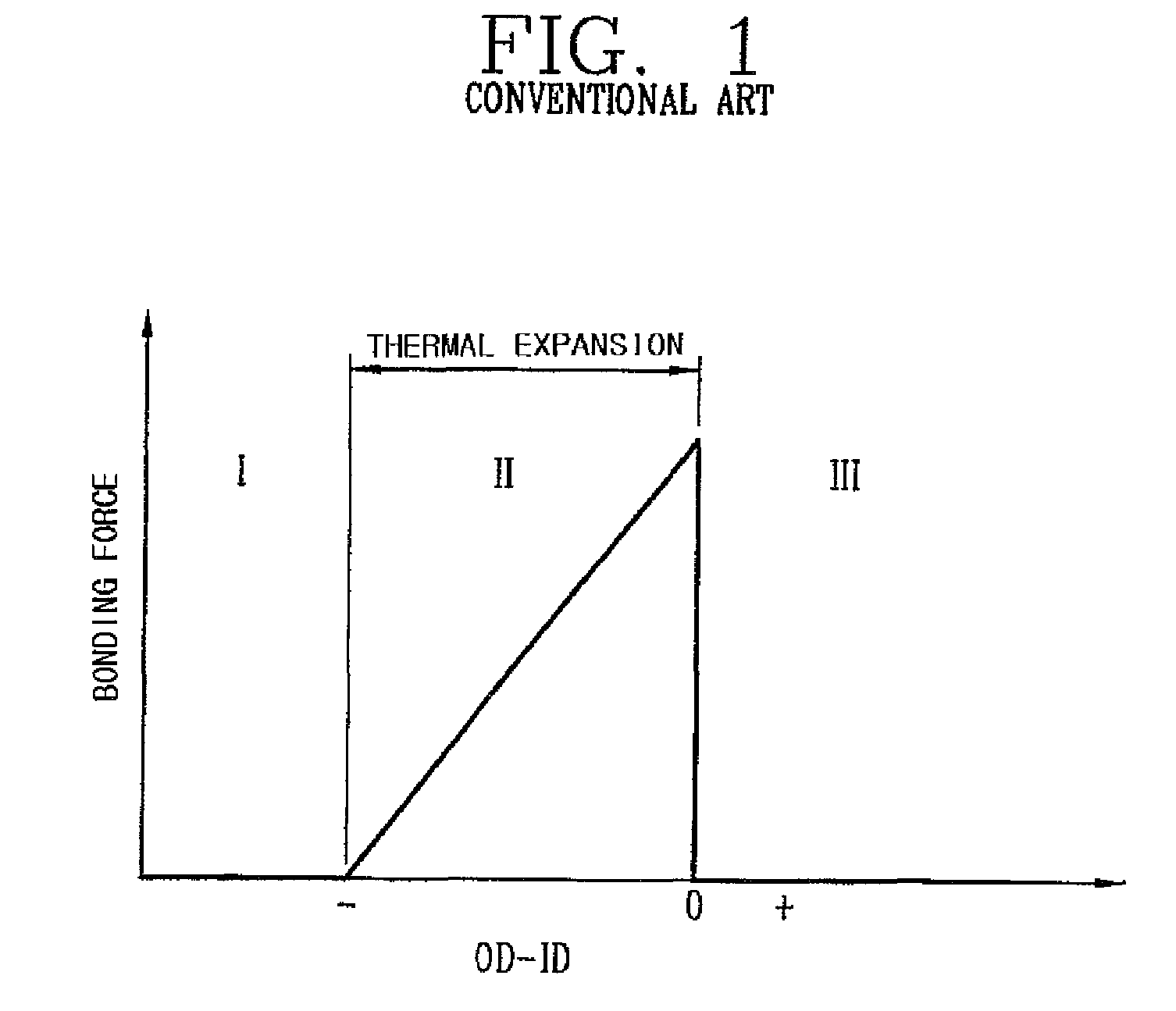

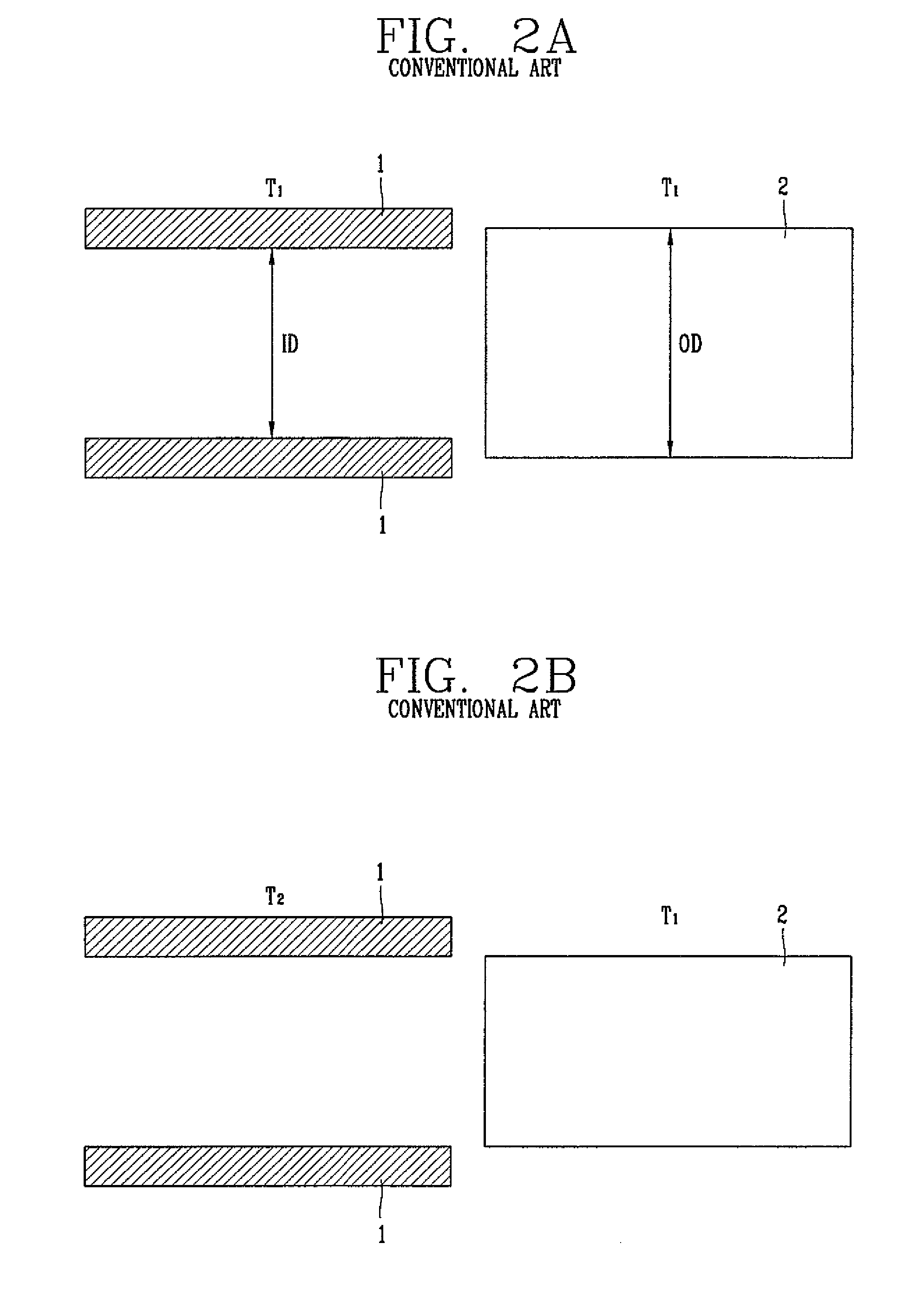

Shrink fitting method including deformation

InactiveUS7774916B2Joints with sealing surfacesRopes and cables for vehicles/pulleyShrink-fittingEngineering

A new shrink fitting method including deformation is disclosed, in which a high bonding force can be obtained without accurate mechanical process such as forming an insertion body having an outer diameter greater than an inner diameter of an object for receiving the insertion body. The shrink fitting method comprises preparing a pipe and a rod material whose inner and outer diameters are different from each other; bonding the pipe and the rod material to each other in a state that the pipe or the rod material is deformed by heating; deforming the pipe to allow the inner diameter of the pipe to be equal to the outer diameter of the rod material; and cooling the bonded pipe and rod material. The shrink fitting method can be widely used for various mechanical parts.

Owner:KOREA INST OF SCI & TECH

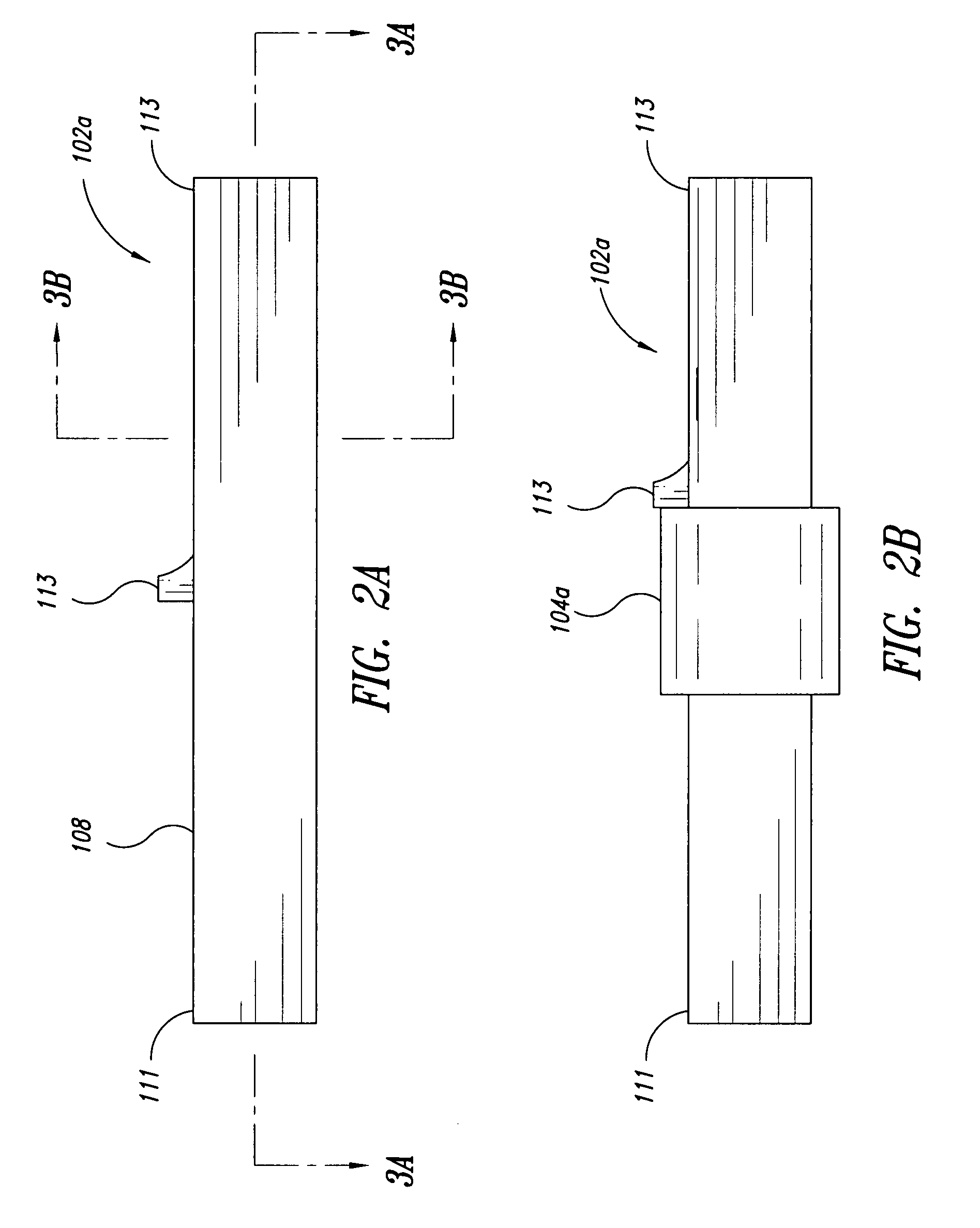

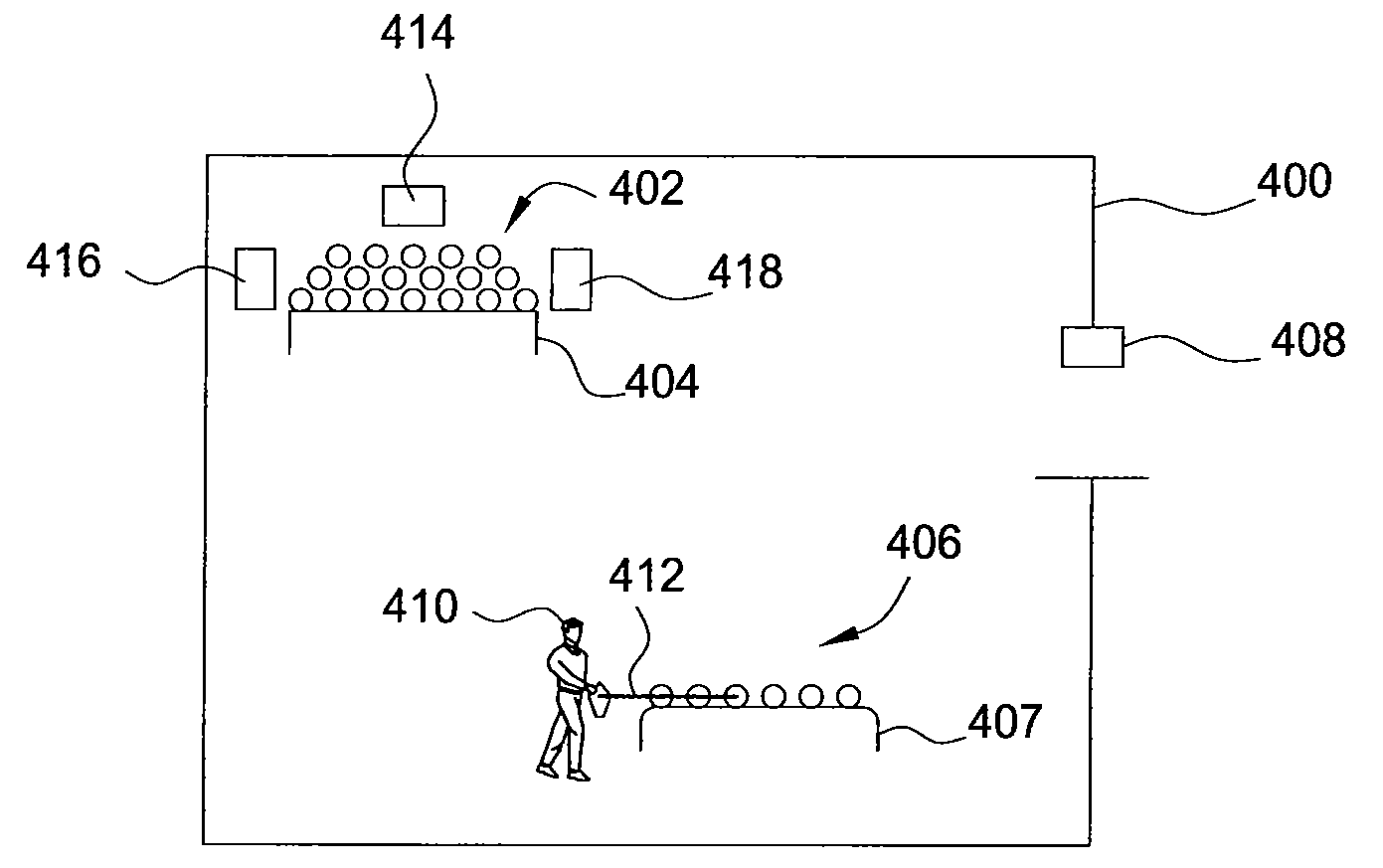

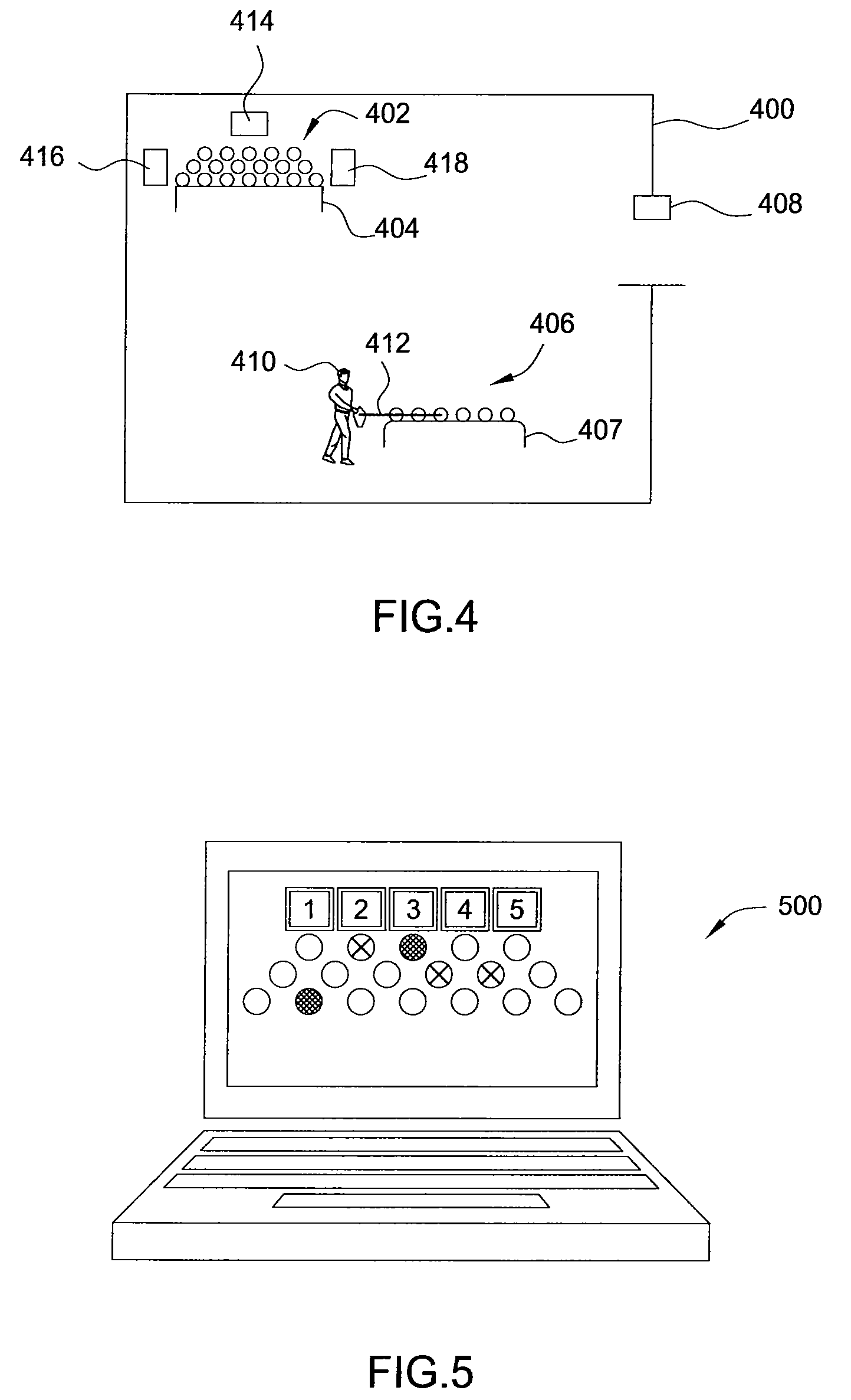

Serialization and database methods for tubulars and oilfield equipment

Methods and apparatus identify downhole equipment and correlate input data with the equipment to improve planning and / or inventory operations. For some embodiments, oilfield equipment or tubular goods such as drill pipe include a shaped recess along an outer circumference for receiving a tag cartridge by shrink fitting. Once tagged, detector system configurations at pipe yards may facilitate logging the presence and location of each drill pipe and correlating specific data, such as inspection data, to each drill pipe. Further, this correlation populates a database utilized to achieve other business functions such as forecasting number of additional drill pipe needed to purchase, invoicing customers according to actual tracked wear / use of the drill pipe being returned, and providing well or job specific drill string population using known history pipe joints.

Owner:WEATHERFORD TECH HLDG LLC

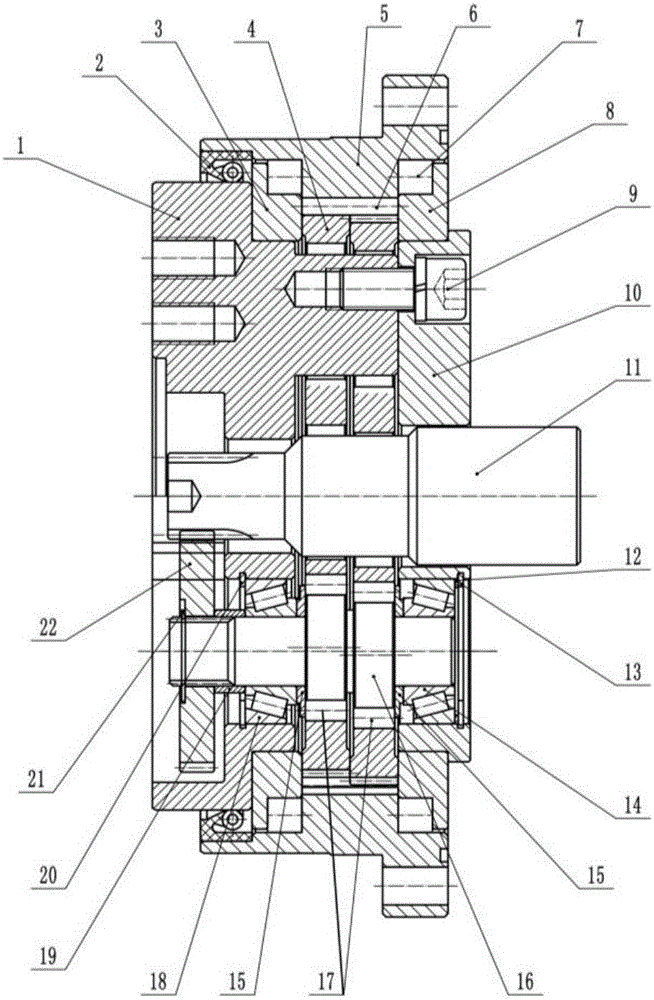

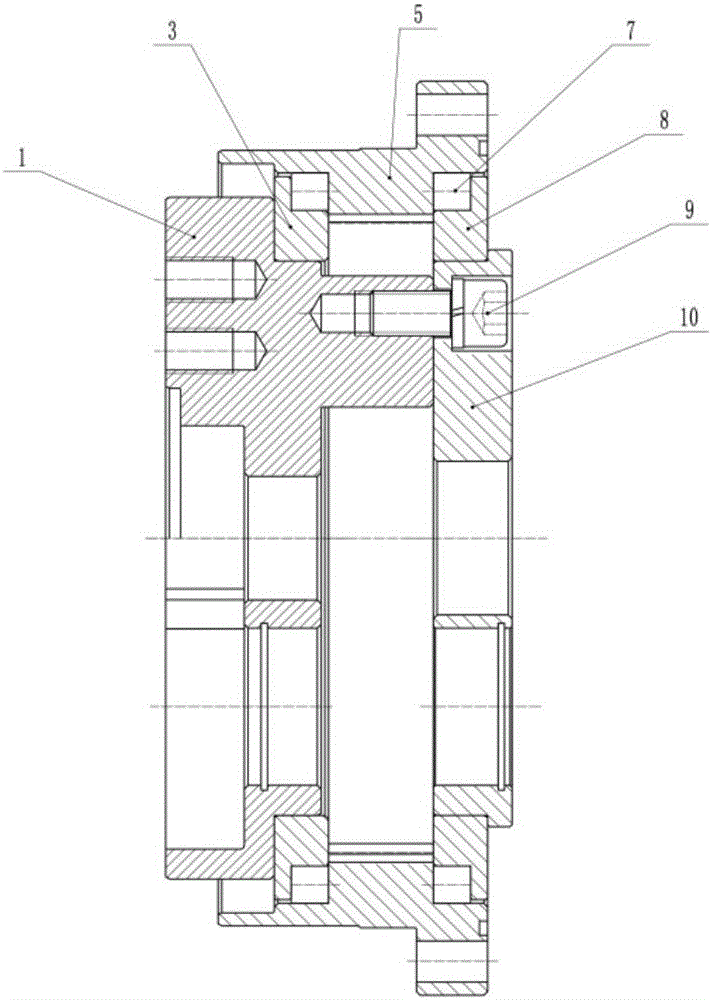

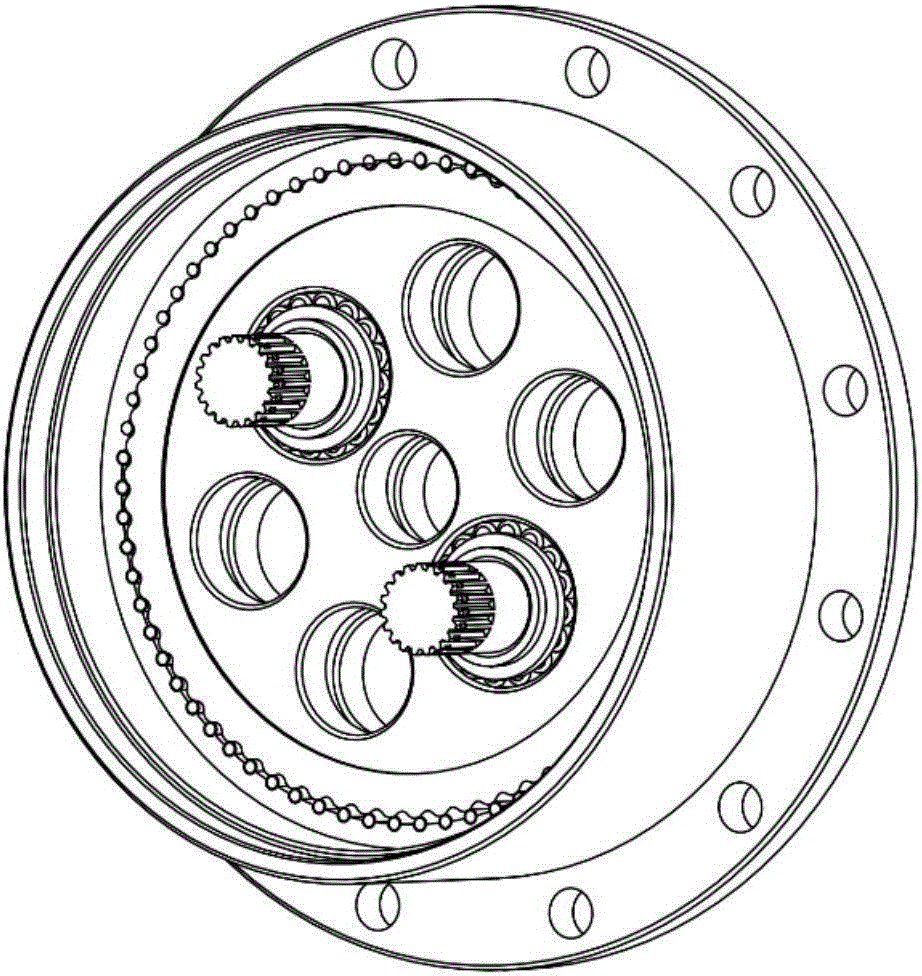

Assembly technology of precise cycloidal speed reducer

InactiveCN106763531AImprove assembly qualityAddress situations prone to interferenceToothed gearingsShrink-fittingGear wheel

The invention discloses an assembly technology of a precise cycloidal speed reducer. The assembly technology of the precise cycloidal speed reducer mainly comprises the following steps of A detecting and grouping key parts, B installing a crankshaft into a coordinate hole of a cycloidal gear, C installing an output disk supporting shaft into an output disk, D assembling an inner gear, E placing the cycloidal gear and a crankshaft assembly into the inner gear, F installing a pin gear, G installing an input end disk, H adjusting the axial clearance of tapered roller bearings of the crankshaft and I installing a planet wheel and a center shaft. According to the assembly technology of the precise cycloidal speed reducer, the key parts are assembled in a grouped manner, the assembly difficulty is lowered, and the tolerance fit precision is improved; shrink fitting is applied to the pin gear, so that the problem that interference is prone to happen in the installation process of the pin gear is solved, the assembly technology is reasonably optimized, and the assembly quality of the whole machine is improved.

Owner:CHONGQING UNIV +1

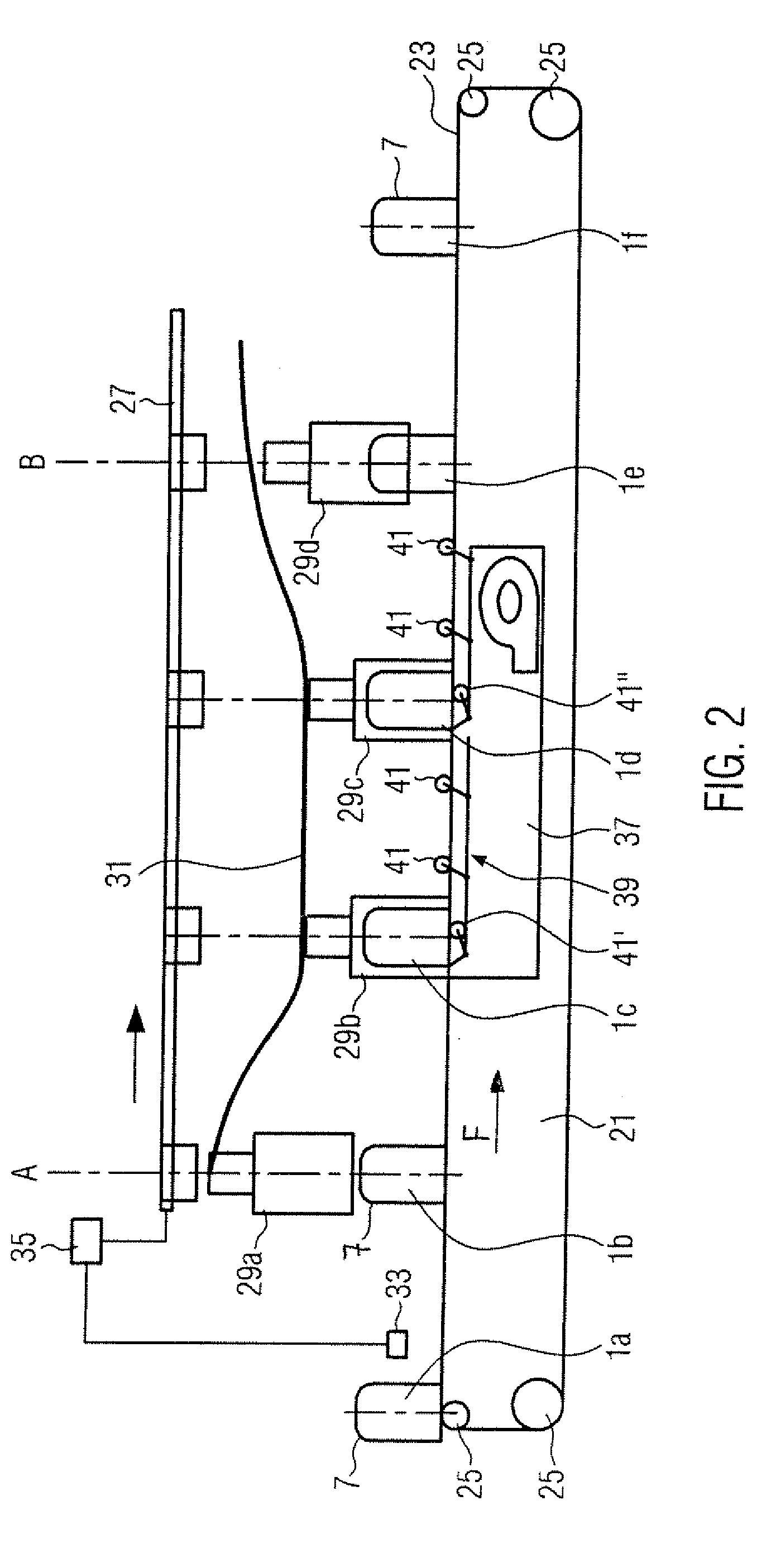

Machine and method for shrink-fitting of shrink wrap film onto packages

A machine and method for shrink-fitting shrink film onto packaged goods, in particular for packaging packing units, having a conveyor for transporting the packaged goods. In order to reduce the energy consumption and simultaneously to improve the shrinking result, the machine has hood type shrink devices which are moved along at least a part of the path with the packaged goods moved on the conveyor.

Owner:KRONES AG

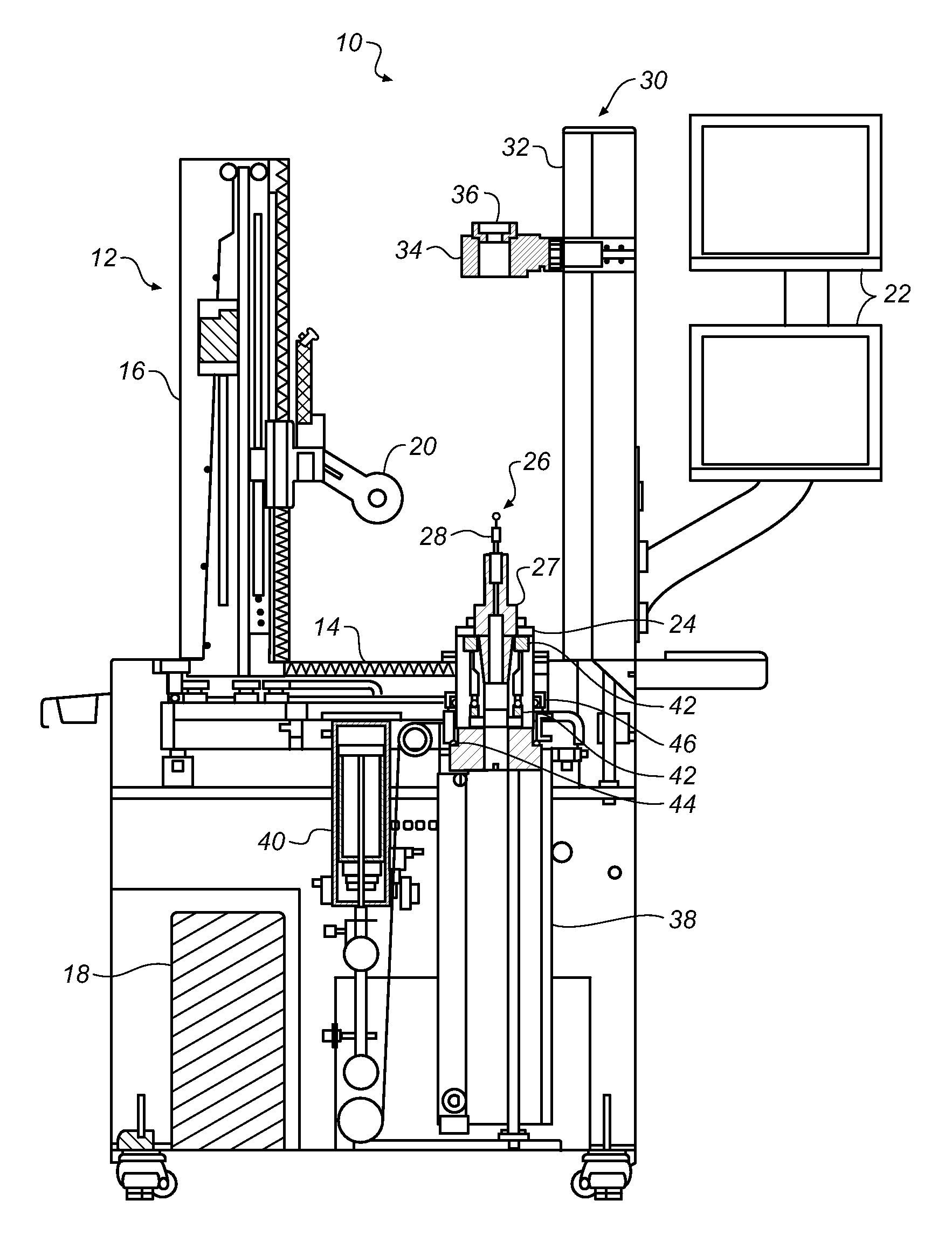

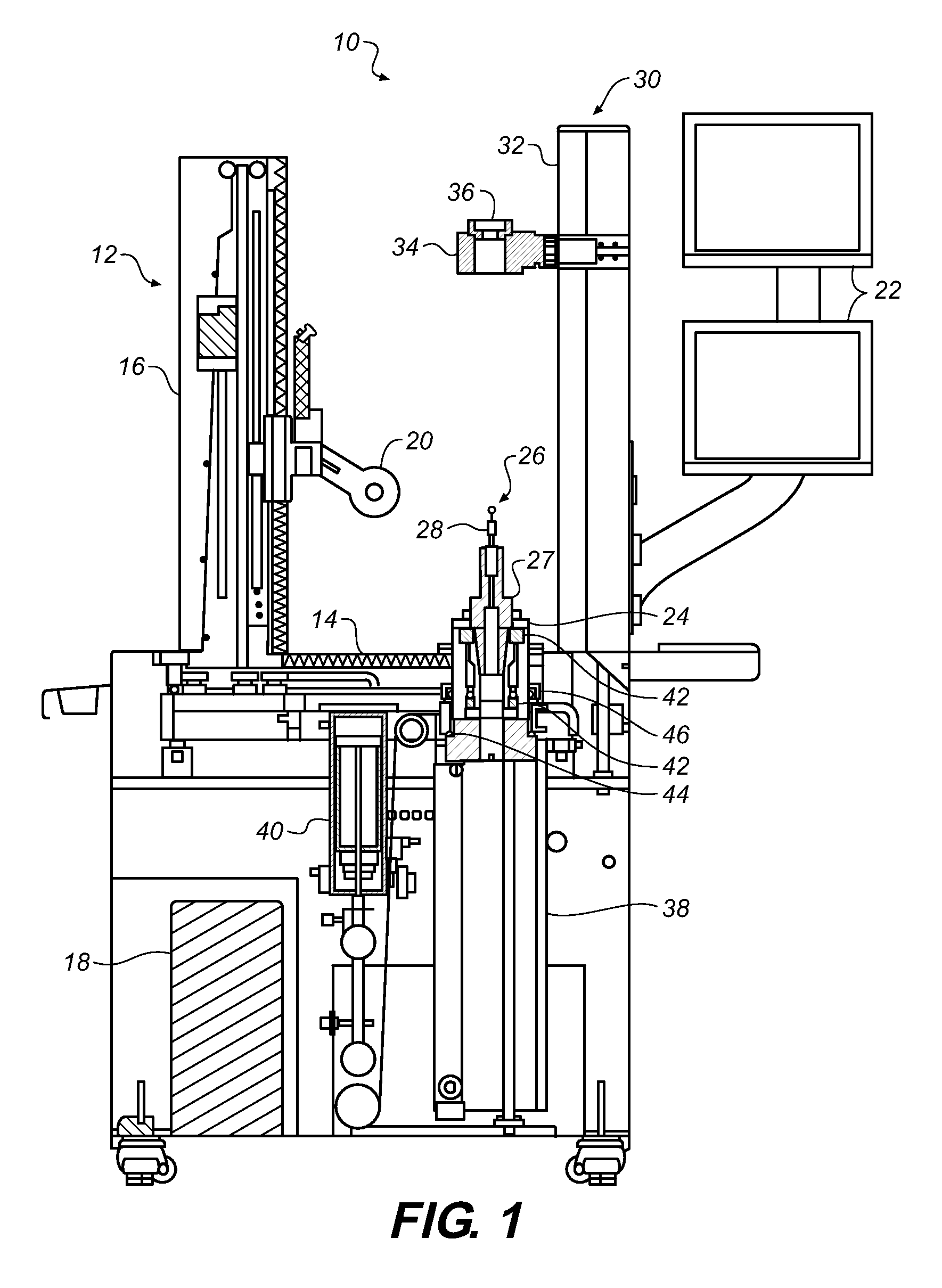

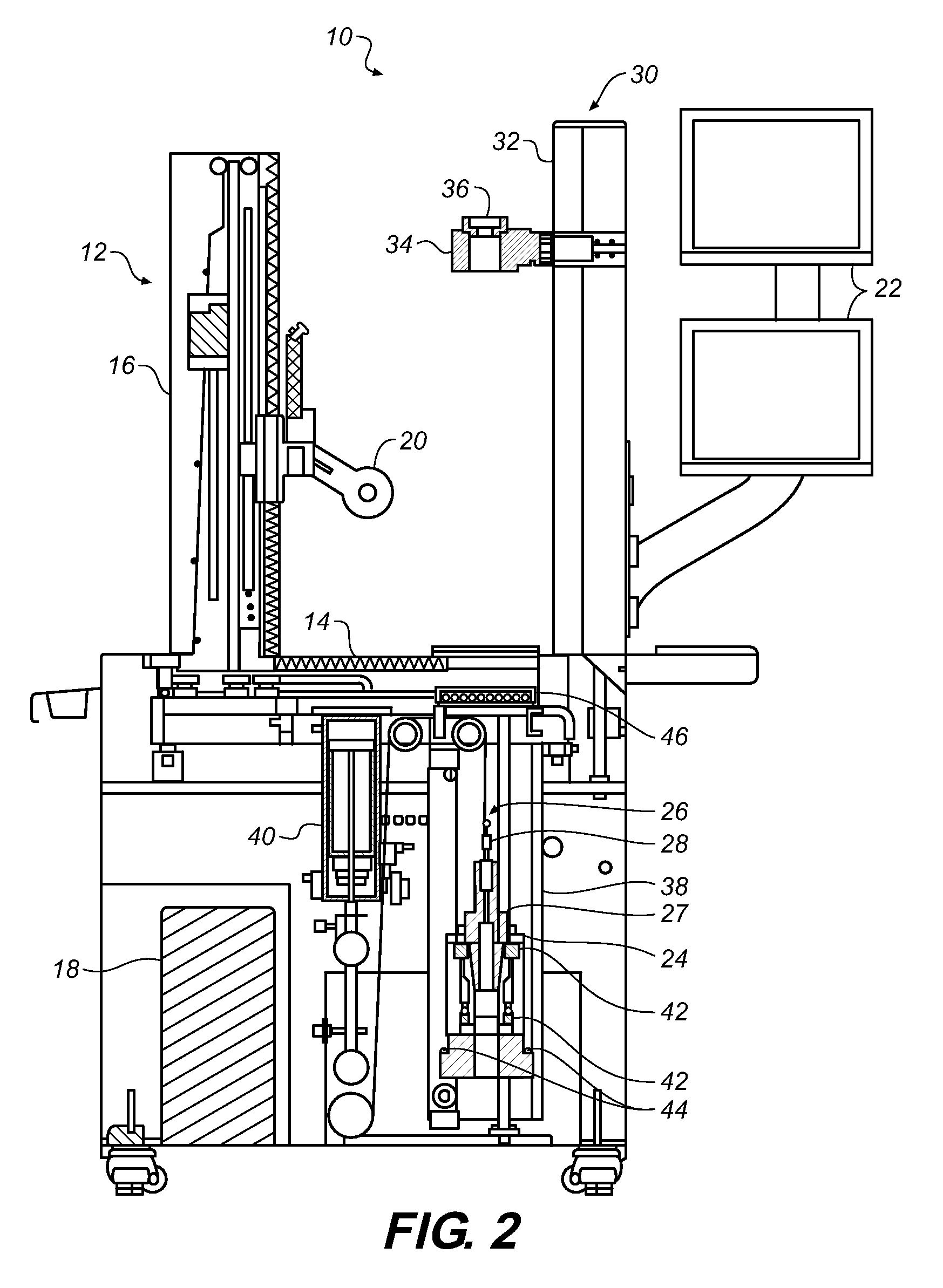

Combination tool presetter and induction heat-shrink apparatus

InactiveUS20100051610A1Accurate locationMeasurement/indication equipmentsChucksShrink-fittingEngineering

An apparatus is disclosed for accurately positioning a tool within a shrink-fit tool holder. The apparatus includes a combined tool presetter and heat-shrink device. The tool assembly is placed in a precision rotating spindle that is able to travel into a contained location for cooling of the tool assembly subsequent to heating the tool assembly through induction. The apparatus is adapted such that the precision rotating spindle precisely returns to a home measuring position subsequent to cooling for final measurement of the tool assembly. The presetter allows for measurements related to the tool assembly both prior to and subsequent to the shrink-fitting process.

Owner:PARLEC

Method for repair of rail wheels

Owner:GENERAL ELECTRIC CO +1

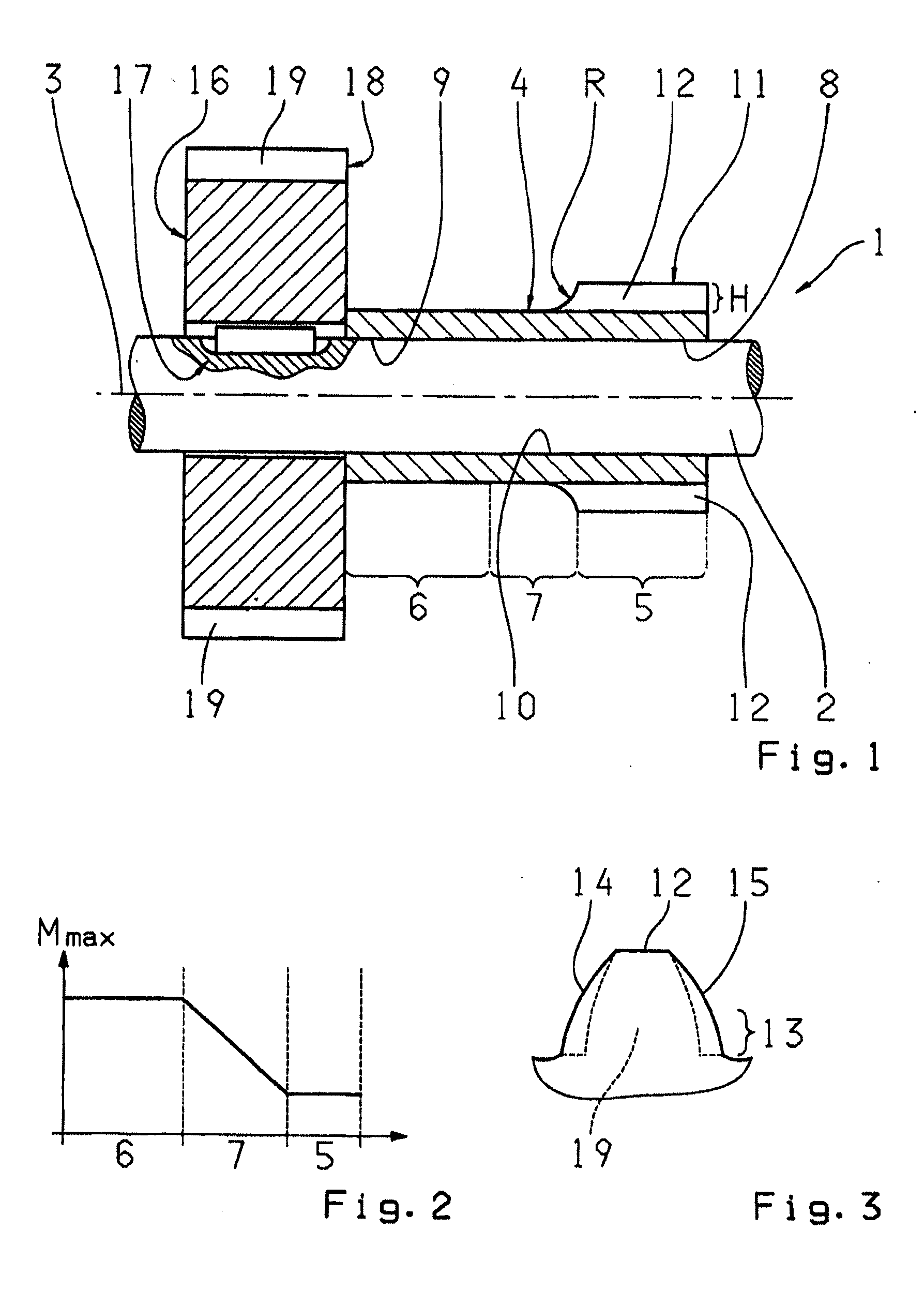

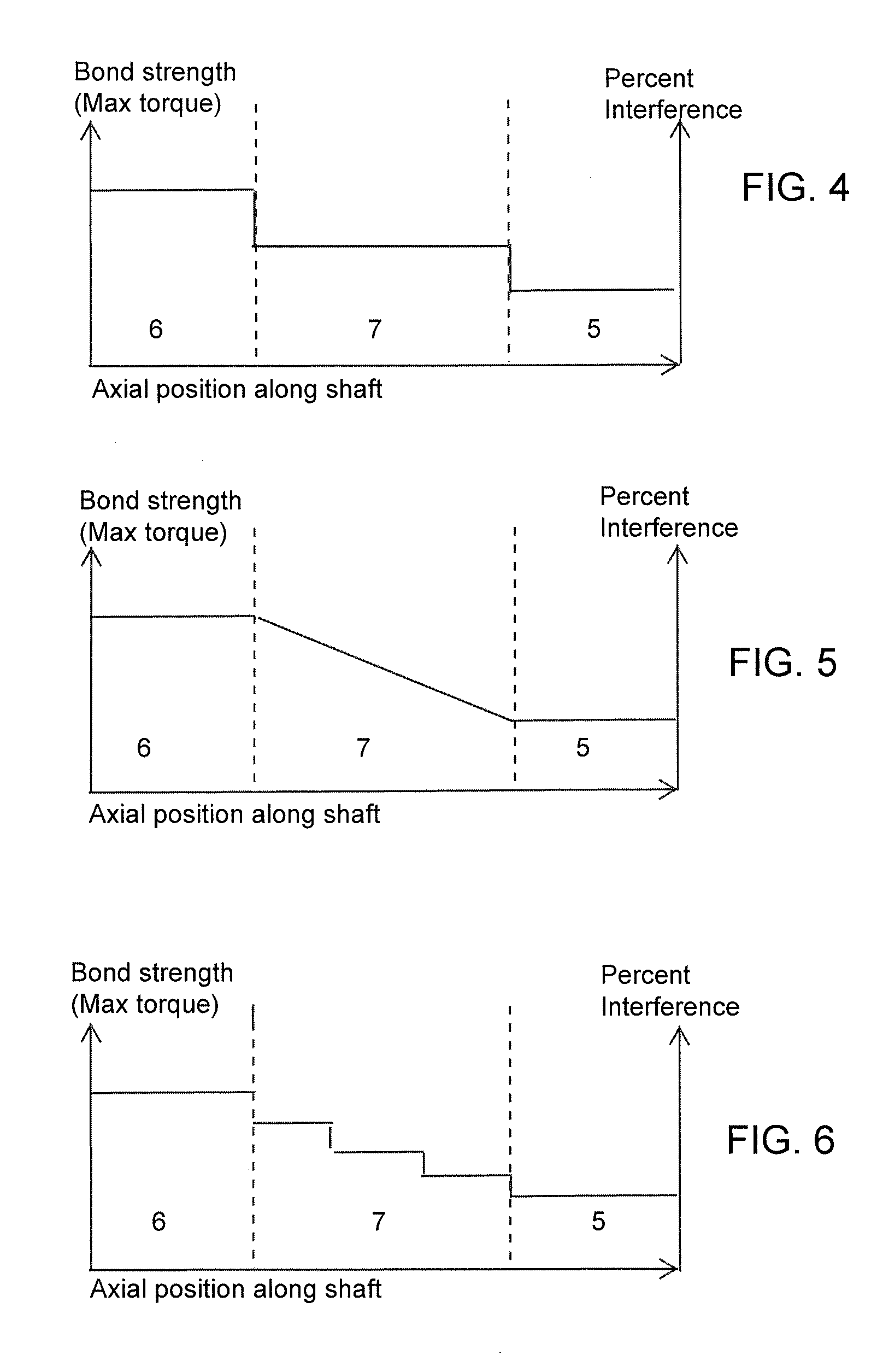

Shaft-gear connection

InactiveUS20120282018A1Avoid damageShrinkage connectionsCouplings for rigid shaftsMaximum torqueShrink-fitting

A shaft-gear connection comprises a shaft and a shrunk-on gear that has an axial first section, attached by a first shrink-fit bond, and an axial second section, attached by a second shrink-fit bond. The second shrink-fit bond is greater than the first shrink-fit bond so that a greater maximum torque to be transmitted from the gear to the shaft by the second shrink-fit bond than by the first shrink-fit bond. An axial intermediate section, attached by a third shrink-fit bond, is located between the axial first section and the axial second section. Both a surface pressure and a maximum torque that can be transmitted by the third shrink-fit bond are greater than the surface pressure and the maximum torque that can be transmitted by the first shrink-fit bond, but are less than the surface pressure and the maximum torque that can be transmitted by the second shrink-fit bond.

Owner:ZF FRIEDRICHSHAFEN AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com