Patents

Literature

2513results about "Pressure inorganic powder coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

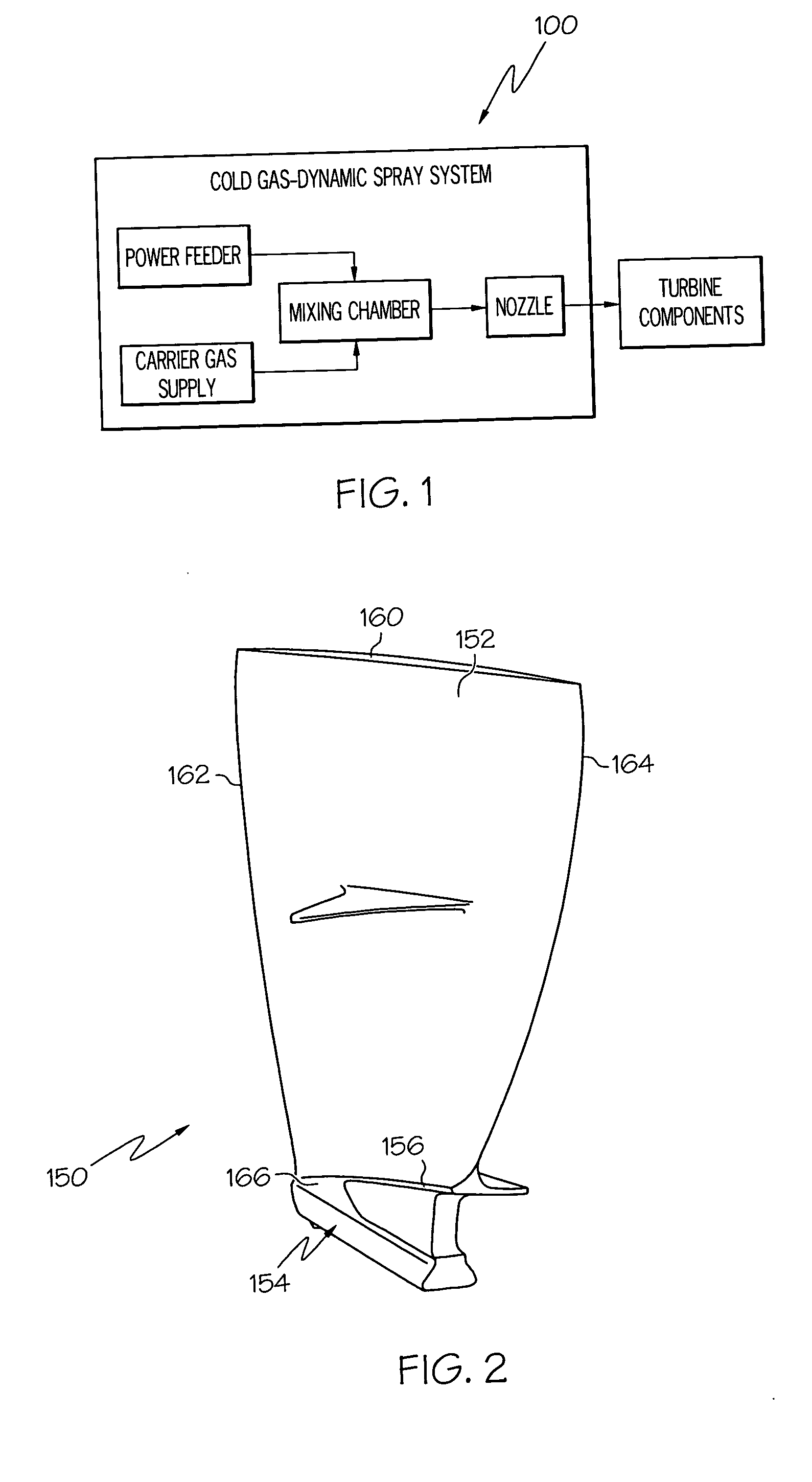

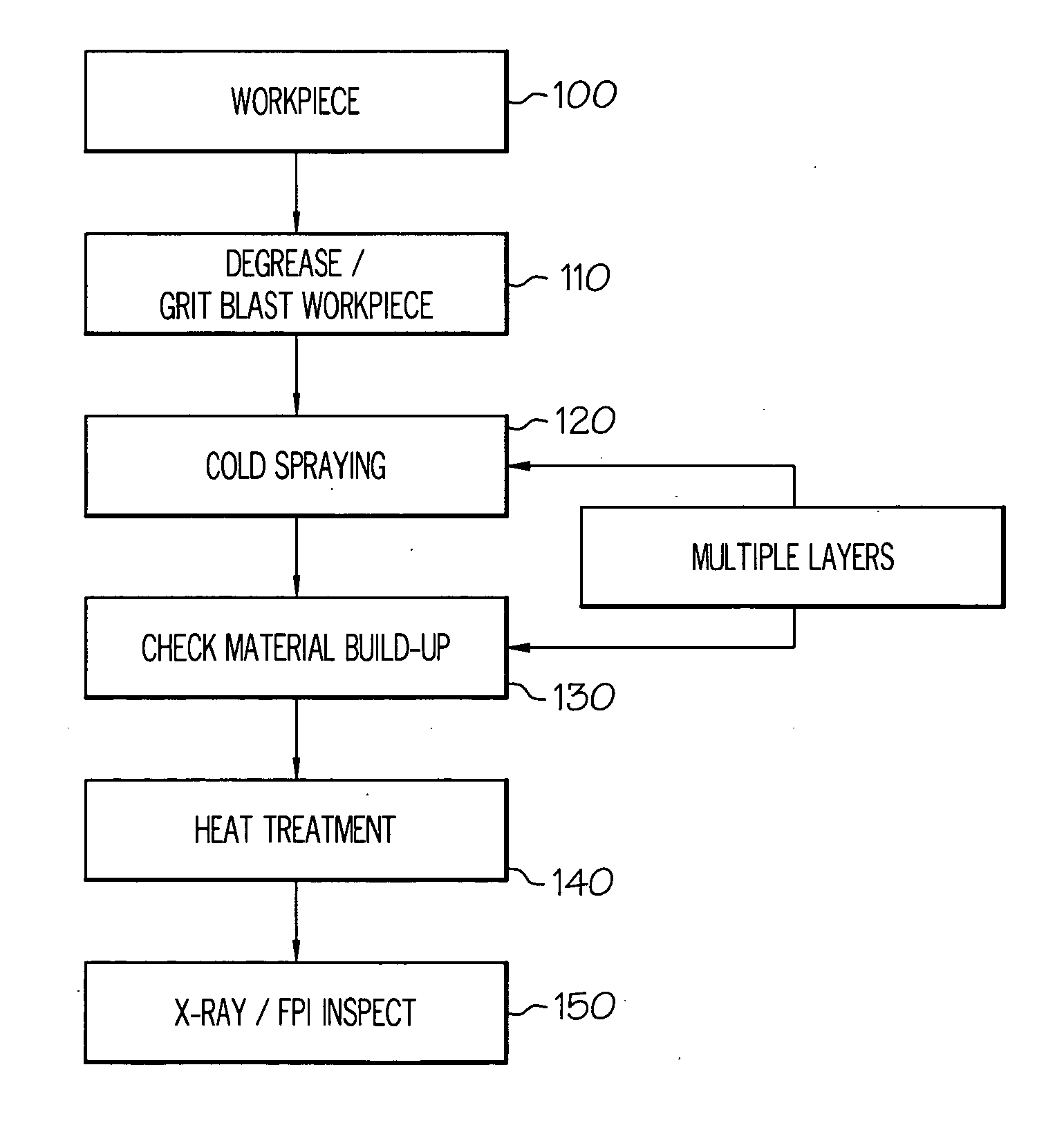

Cold gas-dynamic spray repair on gas turbine engine components

ActiveUS6905728B1Simple methodEasy to weldLayered productsBlade accessoriesTarget surfaceTurbine blade

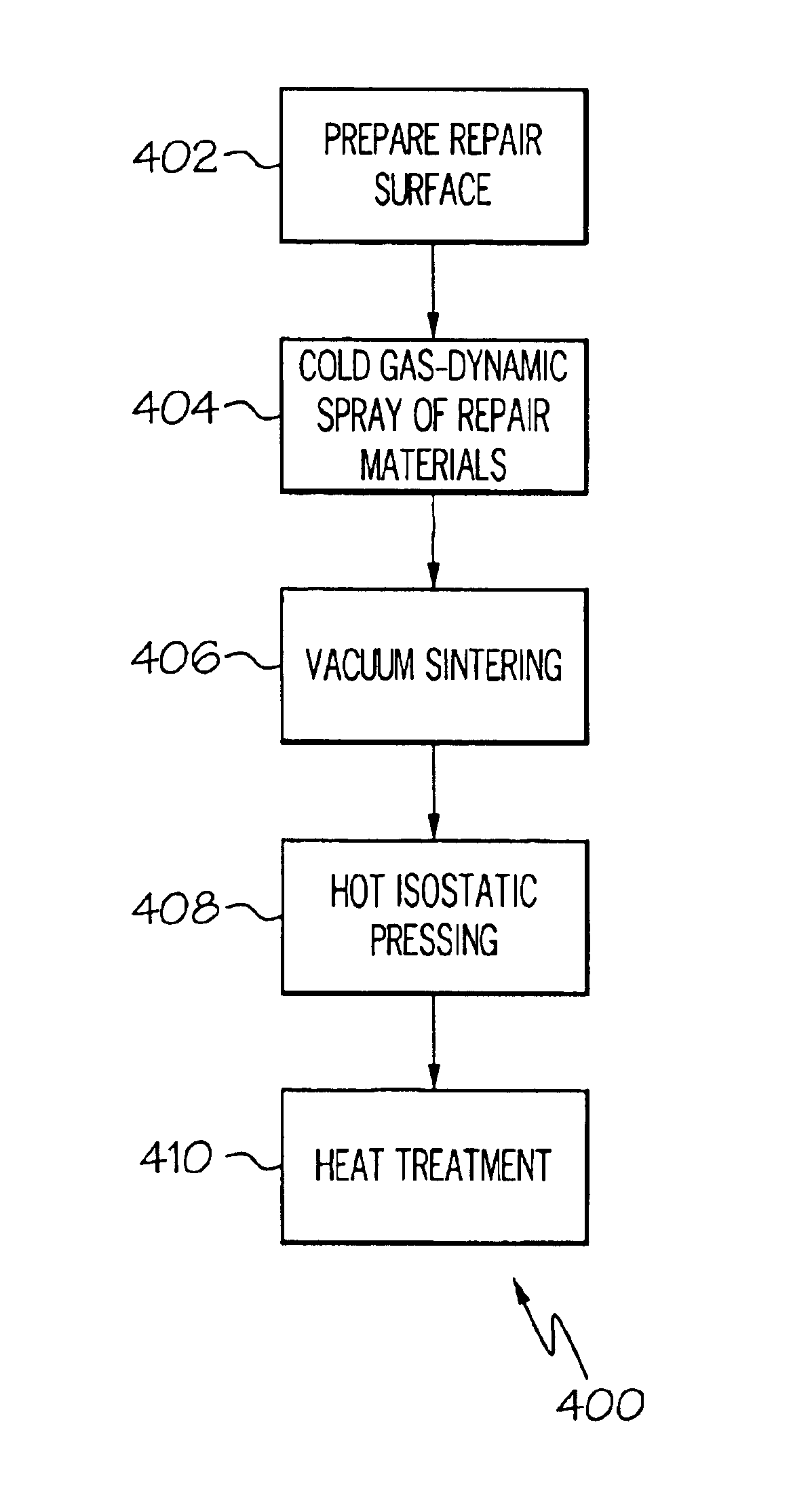

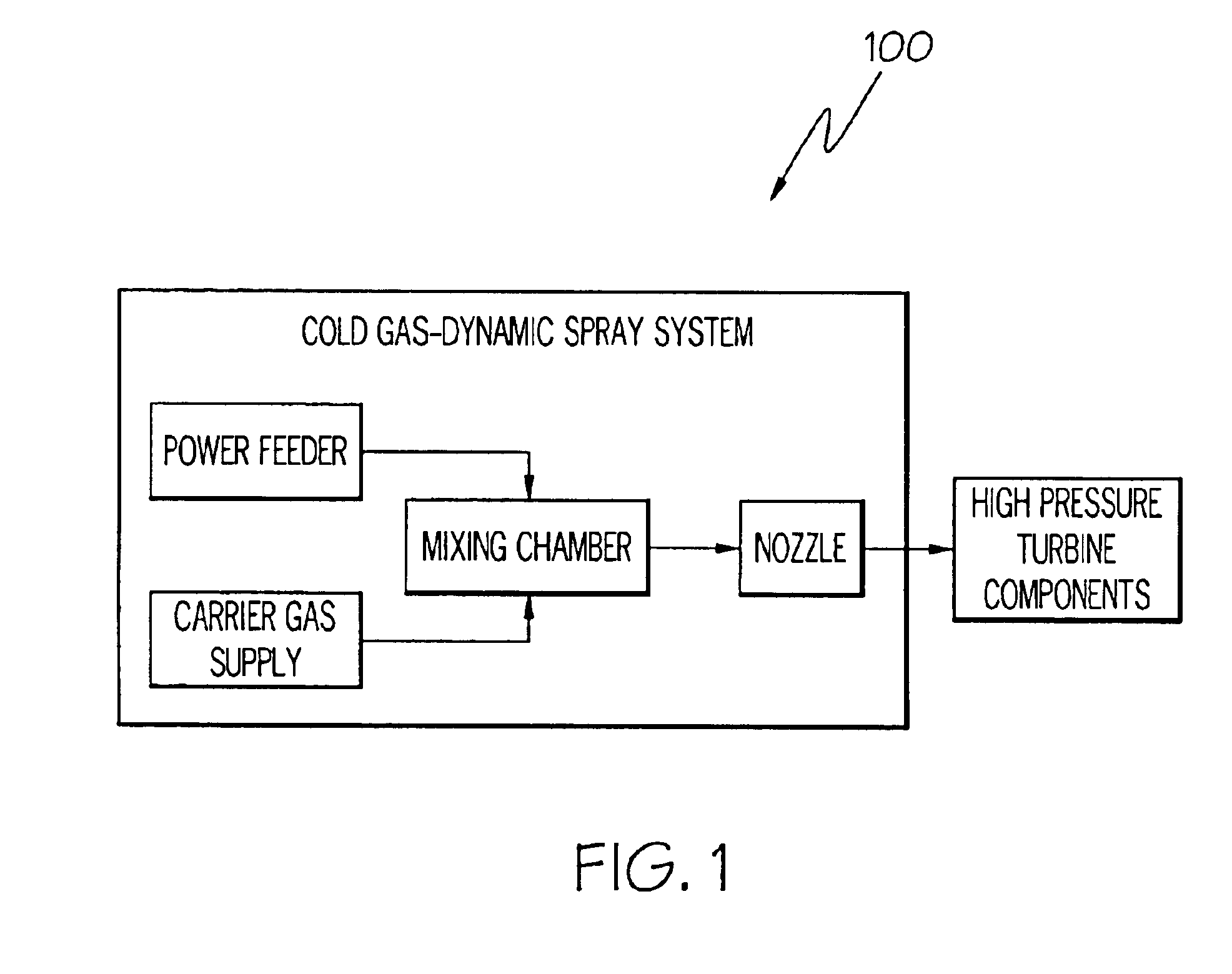

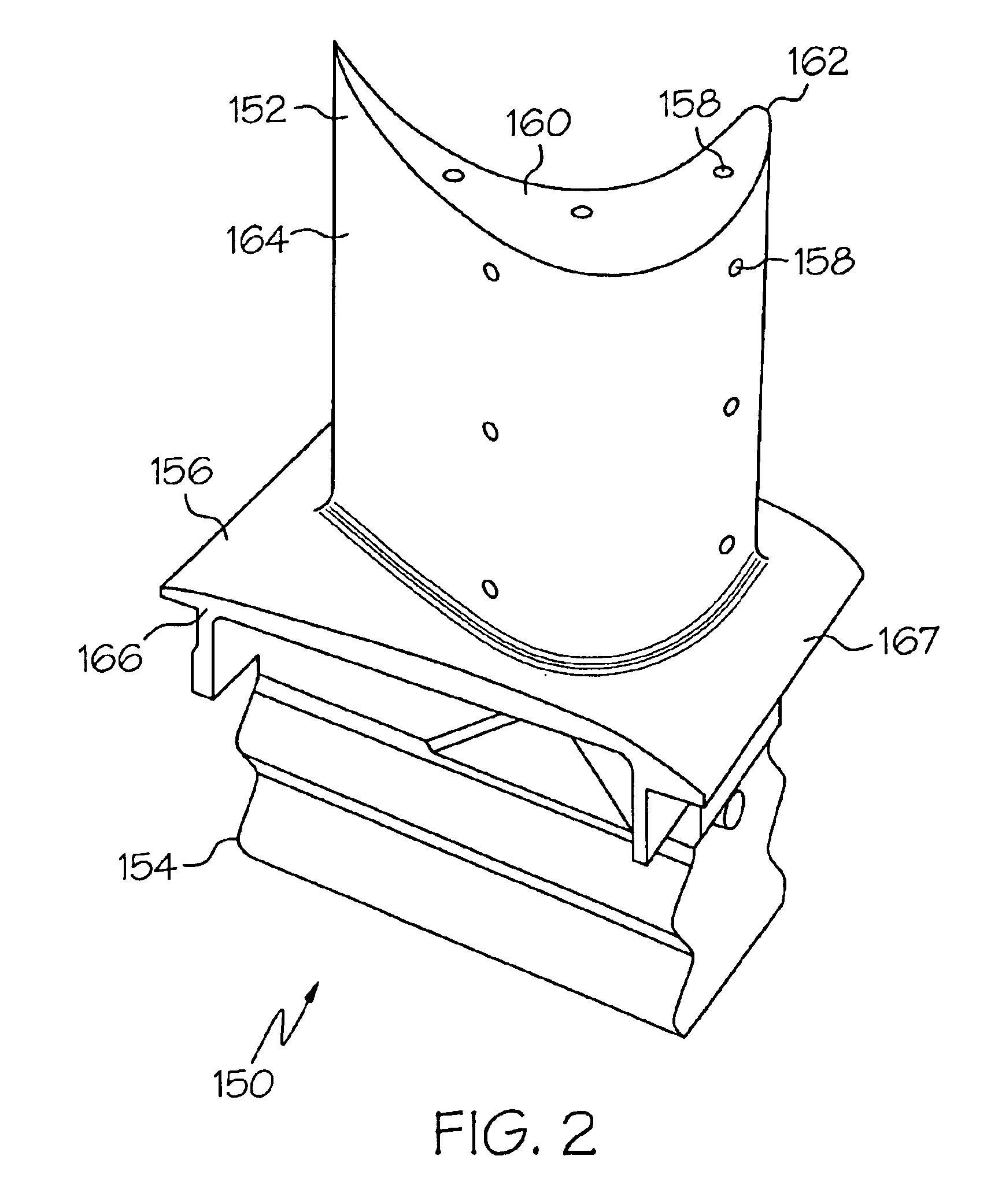

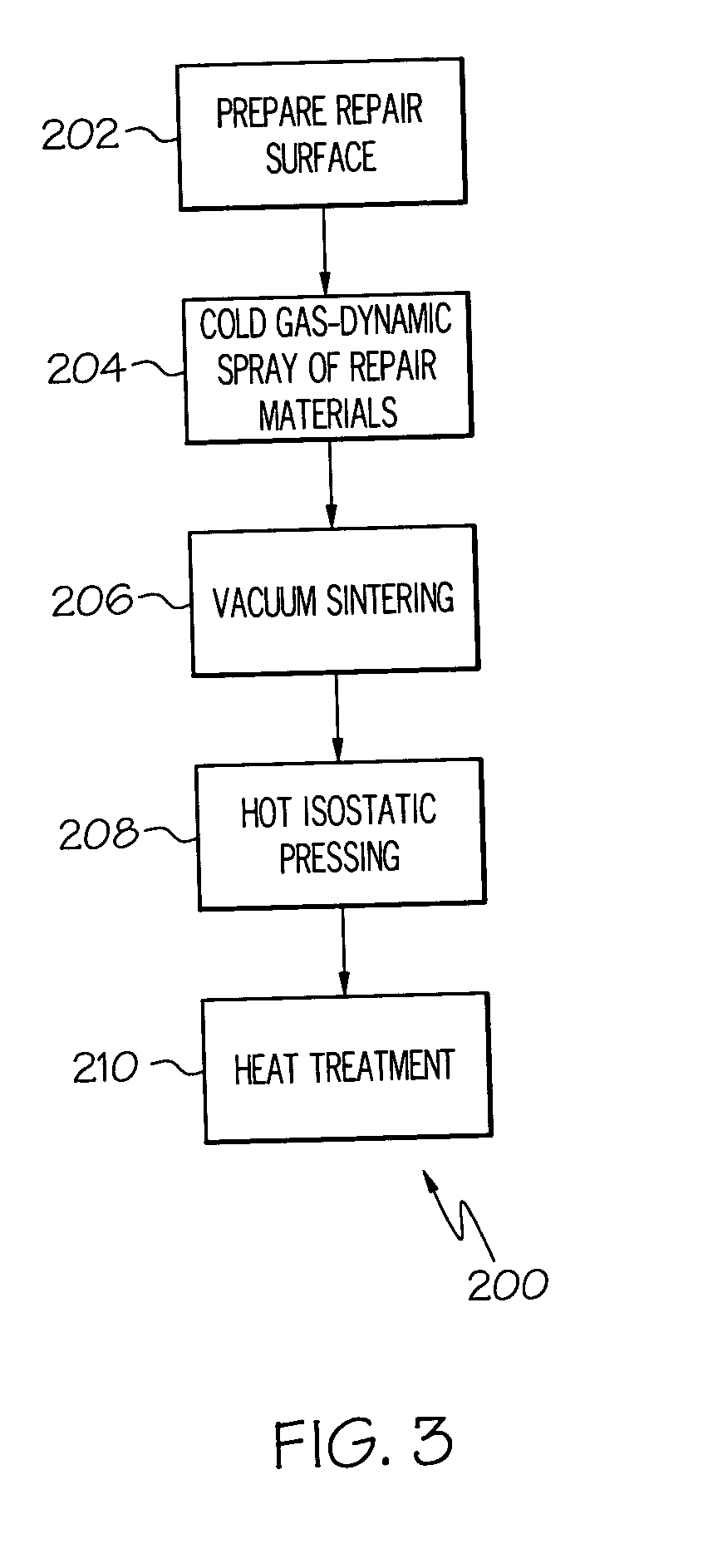

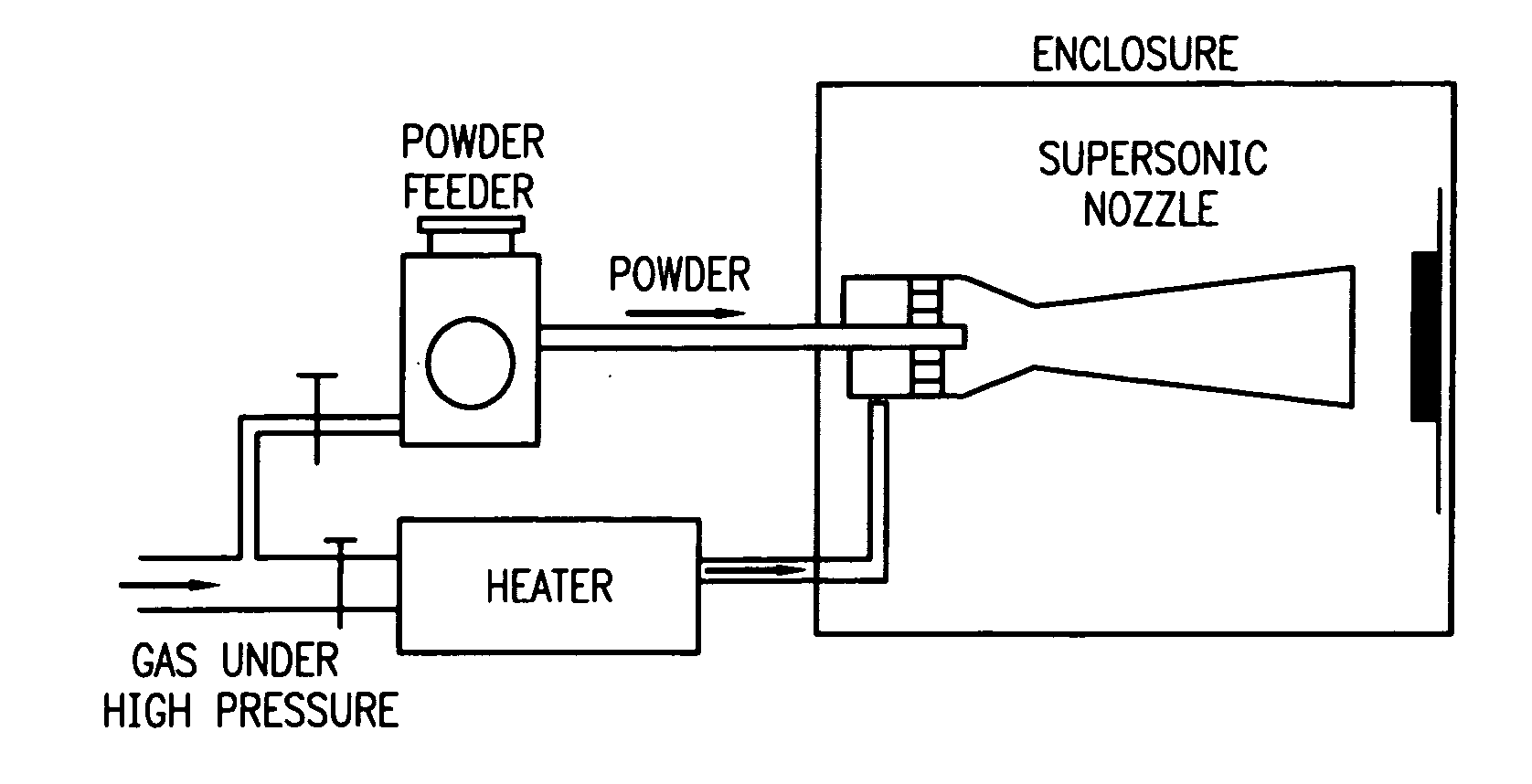

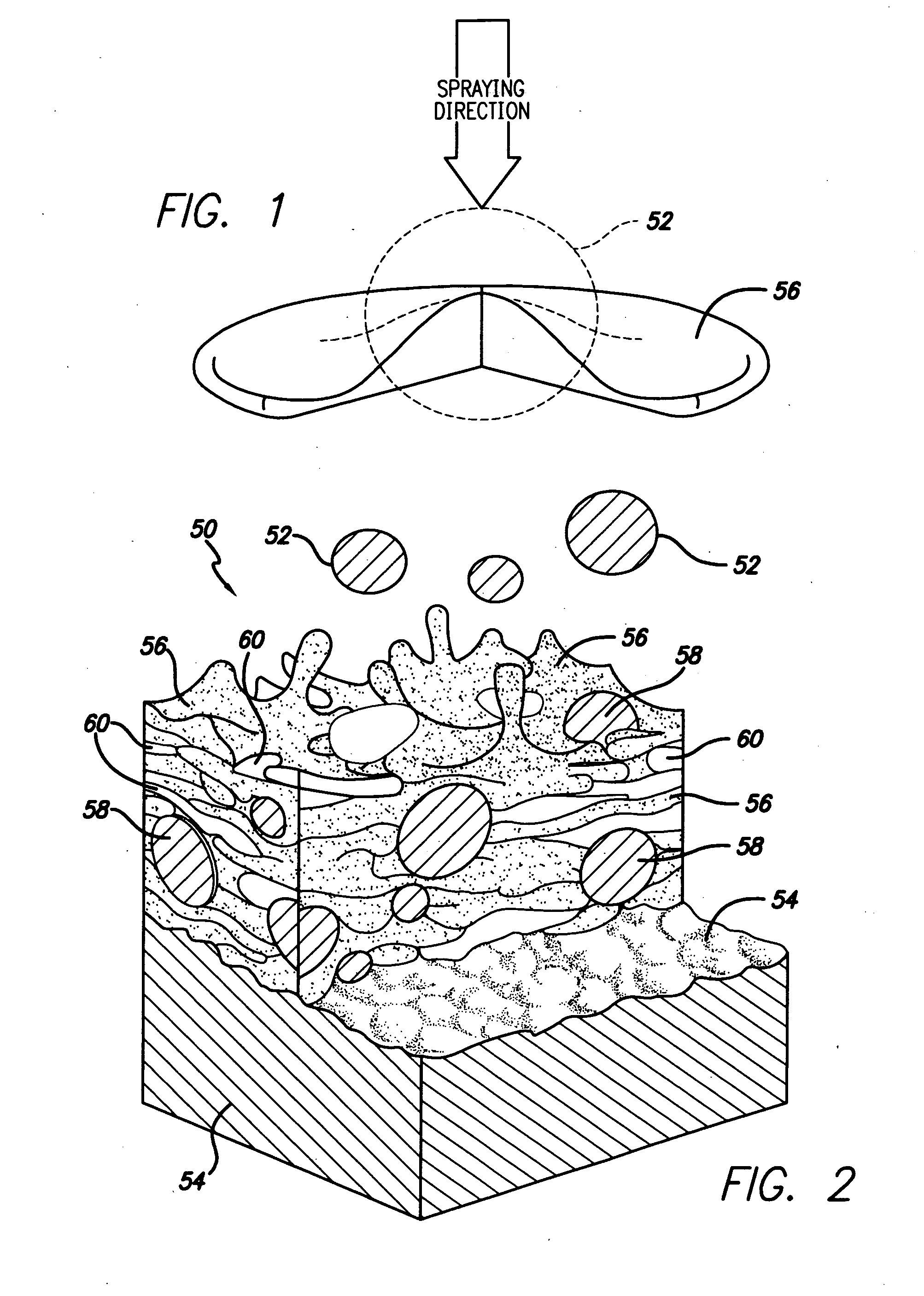

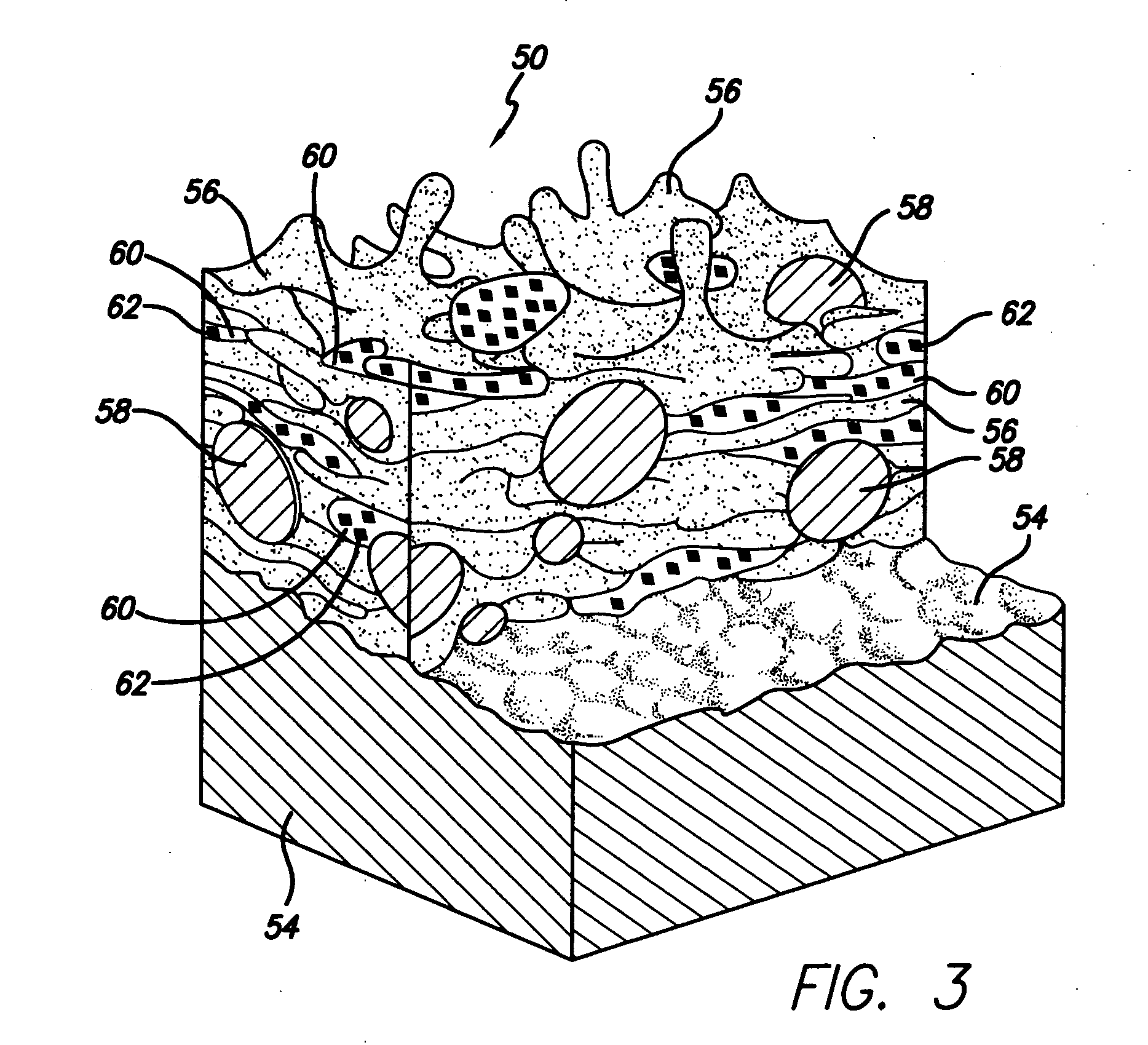

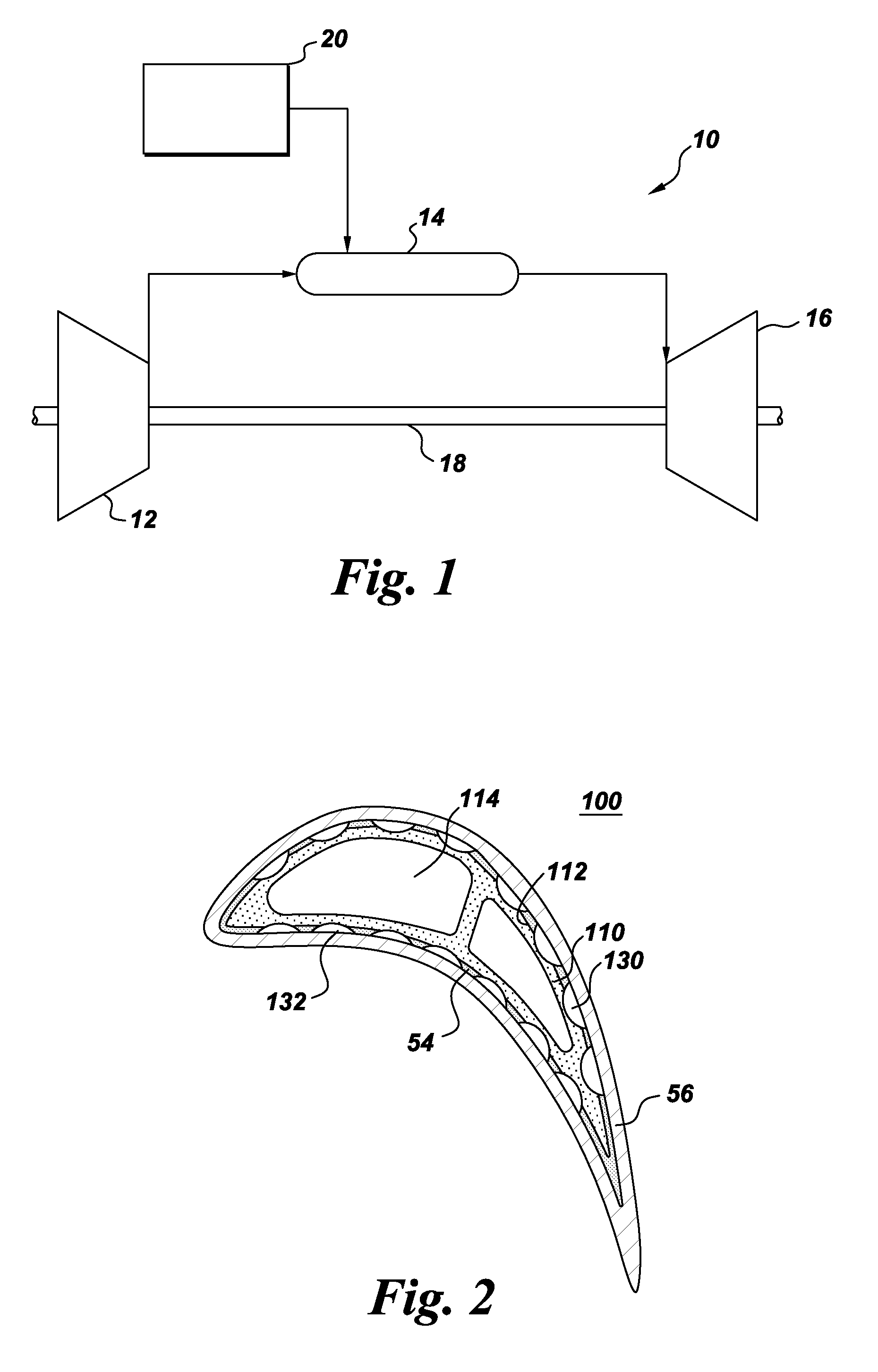

A new method for repairing turbine engine components is provided. The method utilizes a cold gas-dynamic spray technique to repair degradation on turbine blades, vanes and other components. In the cold gas-dynamic spray process particles at a temperature below their fusing temperature are accelerated and directed to a target surface on the turbine blade. When the particles strike the target surface, the kinetic energy of the particles is converted into plastic deformation of the particle, causing the particle to form a strong bond with the target surface. Post-spray processing is then performed to consolidate and homogenize the applied materials and restore integrity to the material properties in the repaired turbine component. Thus, the cold gas-dynamic spray process and post-spray processing can be employed to effectively repair degraded areas on gas turbine components.

Owner:HONEYWELL INT INC

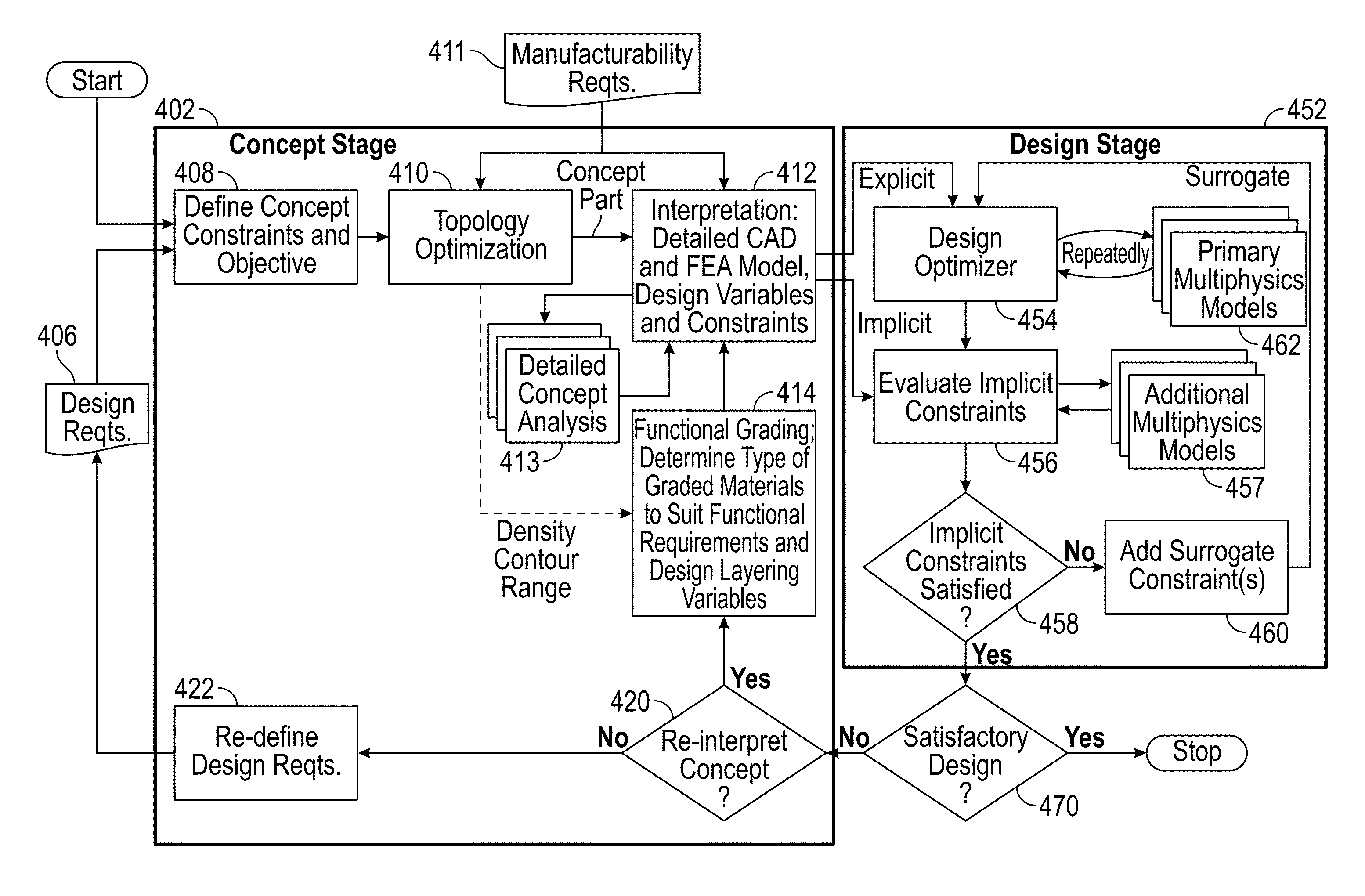

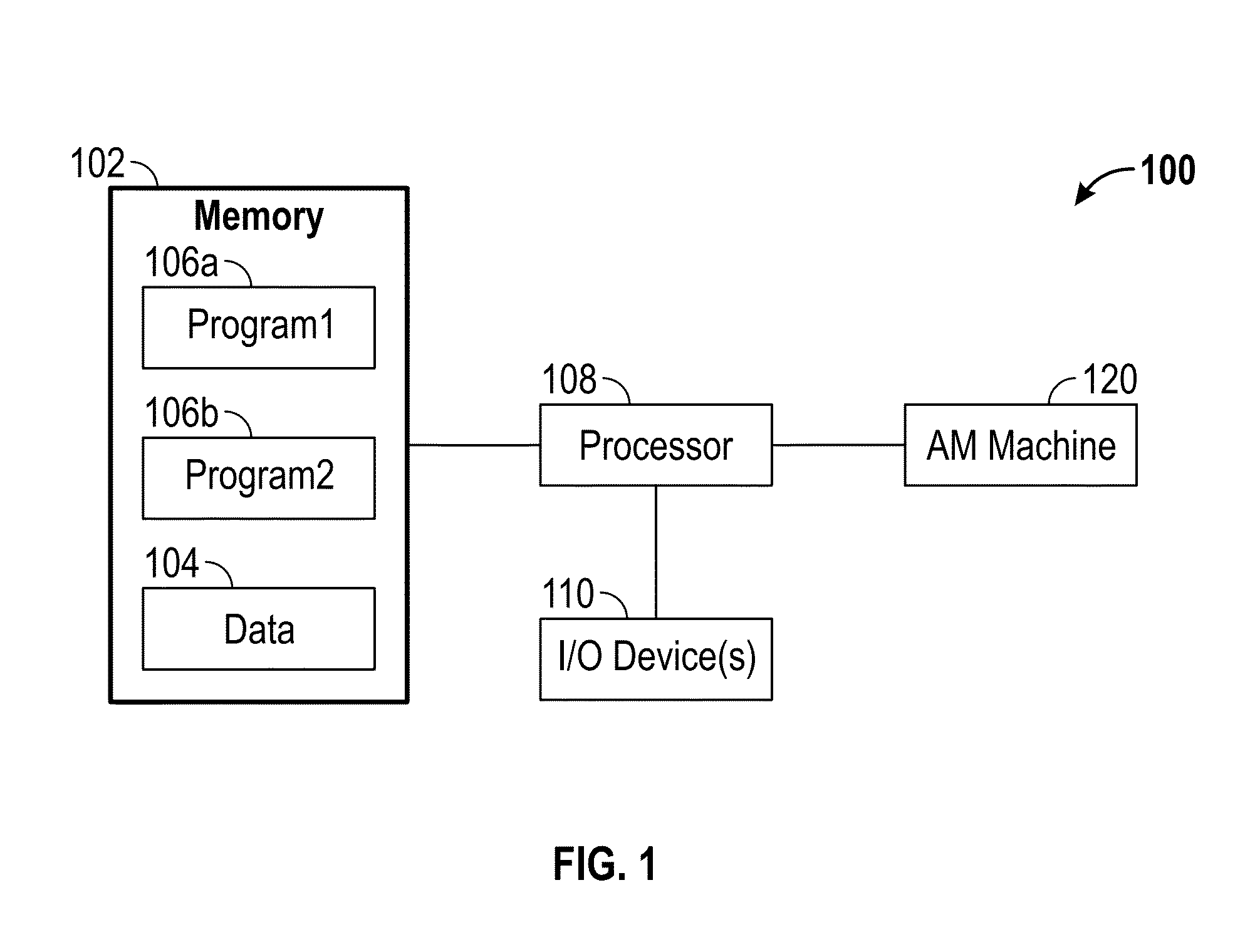

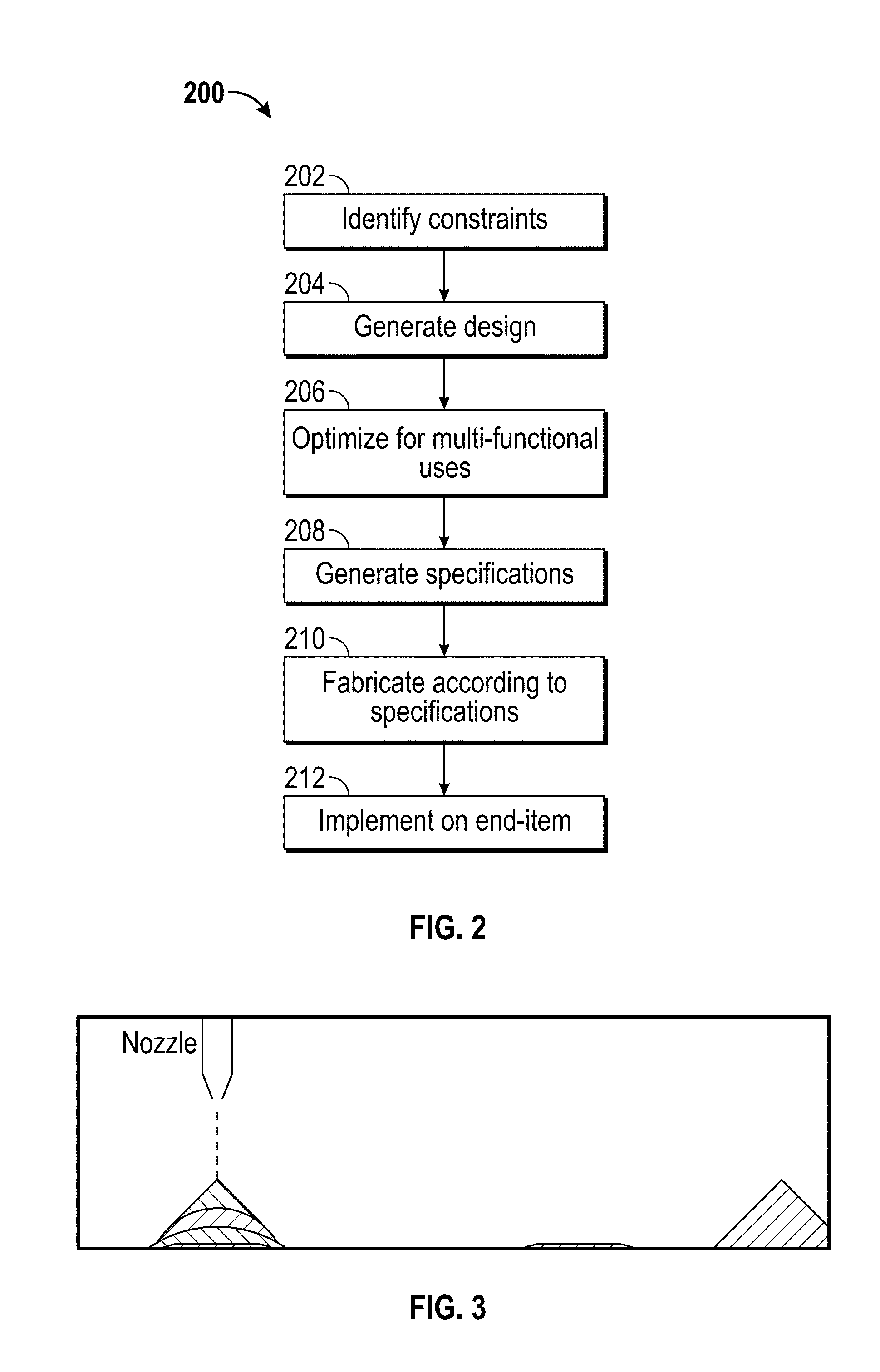

Additive topology optimized manufacturing for multi-functional components

InactiveUS20140277669A1Programme controlAdditive manufacturing apparatusTopology optimizationAdditive layer manufacturing

Owner:SIKORSKY AIRCRAFT CORP

Corrosion resistant multilayer member

ActiveUS20070111030A1Improve corrosion resistanceRestrains particle contaminationMolten spray coatingElectric discharge tubesPorosityHalogen

A corrosion resistant member to be exposed to a halogen-containing gas atmosphere or a halogen-containing gas plasma atmosphere, comprising a substrate and a plurality of layers deposited thereon including a layer of rare earth fluoride providing the outermost surface and a layer of rare earth oxide having a porosity of less than 5% underlying the rare earth fluoride layer.

Owner:SHIN ETSU CHEM IND CO LTD

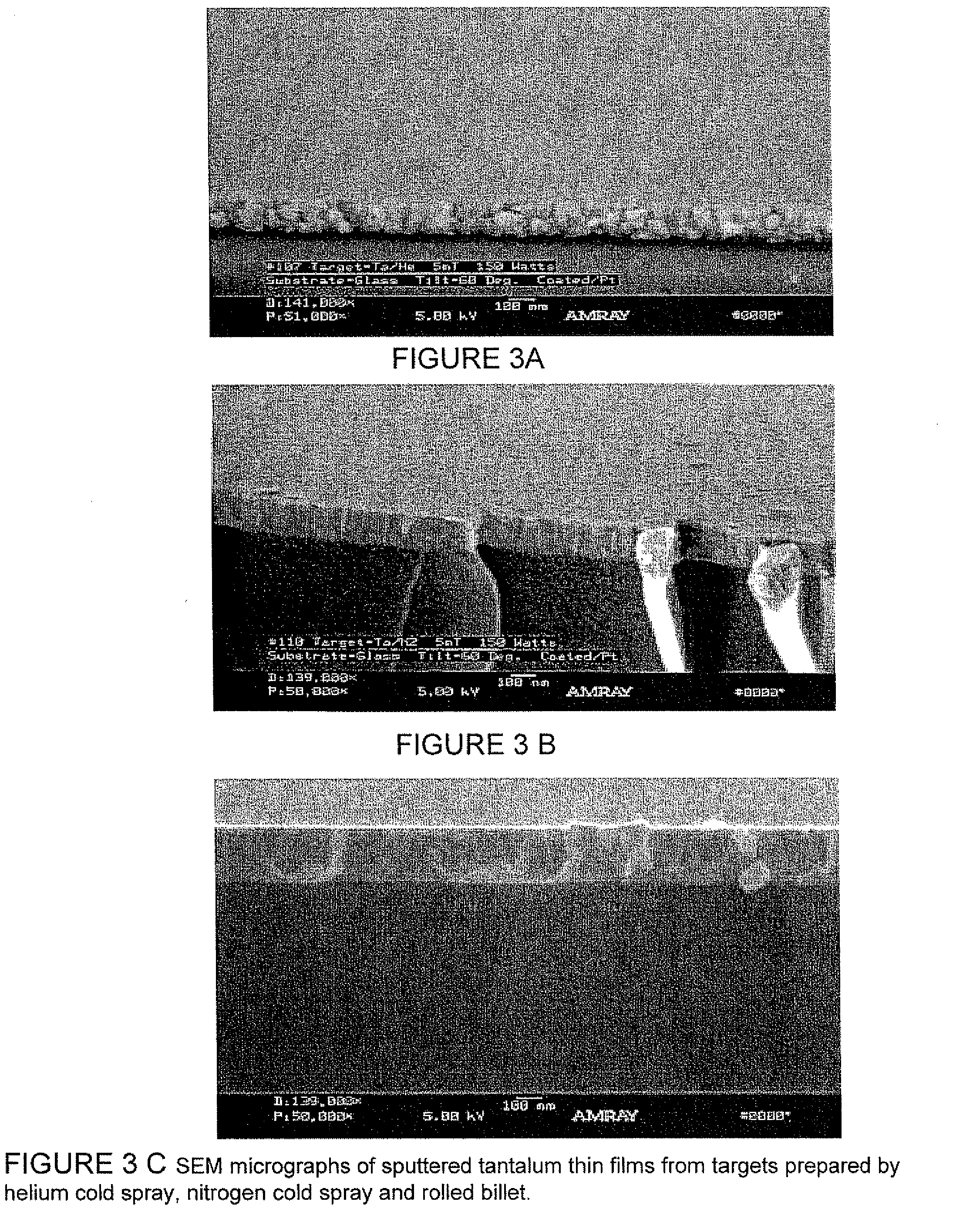

Fine Grained, Non Banded, Refractory Metal Sputtering Targets with a Uniformly Random Crystallographic Orientation, Method for Making Such Film, and Thin Film Based Devices and Products Made Therefrom

ActiveUS20080271779A1Cost-effectively createCost effectiveLiquid surface applicatorsMolten spray coatingFilm baseThermal expansion

The invention relates to a sputtering target which has a fine uniform equiaxed grain structure of less than 44 microns, no preferred texture orientation as measured by electron back scattered diffraction (“EBSD”) and that displays no grain size banding or texture banding throughout the body of the target. The invention relates a sputtering target with a lenticular or flattened grain structure, no preferred texture orientation as measured by EBSD and that displays no grain size or texture banding throughout the body of the target and where the target has a layered structure incorporating a layer of the sputtering material and at least one additional layer at the backing plate interface, said layer has a coefficient of thermal expansion (“CTE”) value between the CTE of the backing plate and the CTE of the layer of sputtering material. The invention also relates to thin films and their use of using the sputtering target and other applications, such as coatings, solar devices, semiconductor devices etc. The invention further relates to a process to repair or rejuvenate a sputtering target.

Owner:H C STARCK GMBH +1

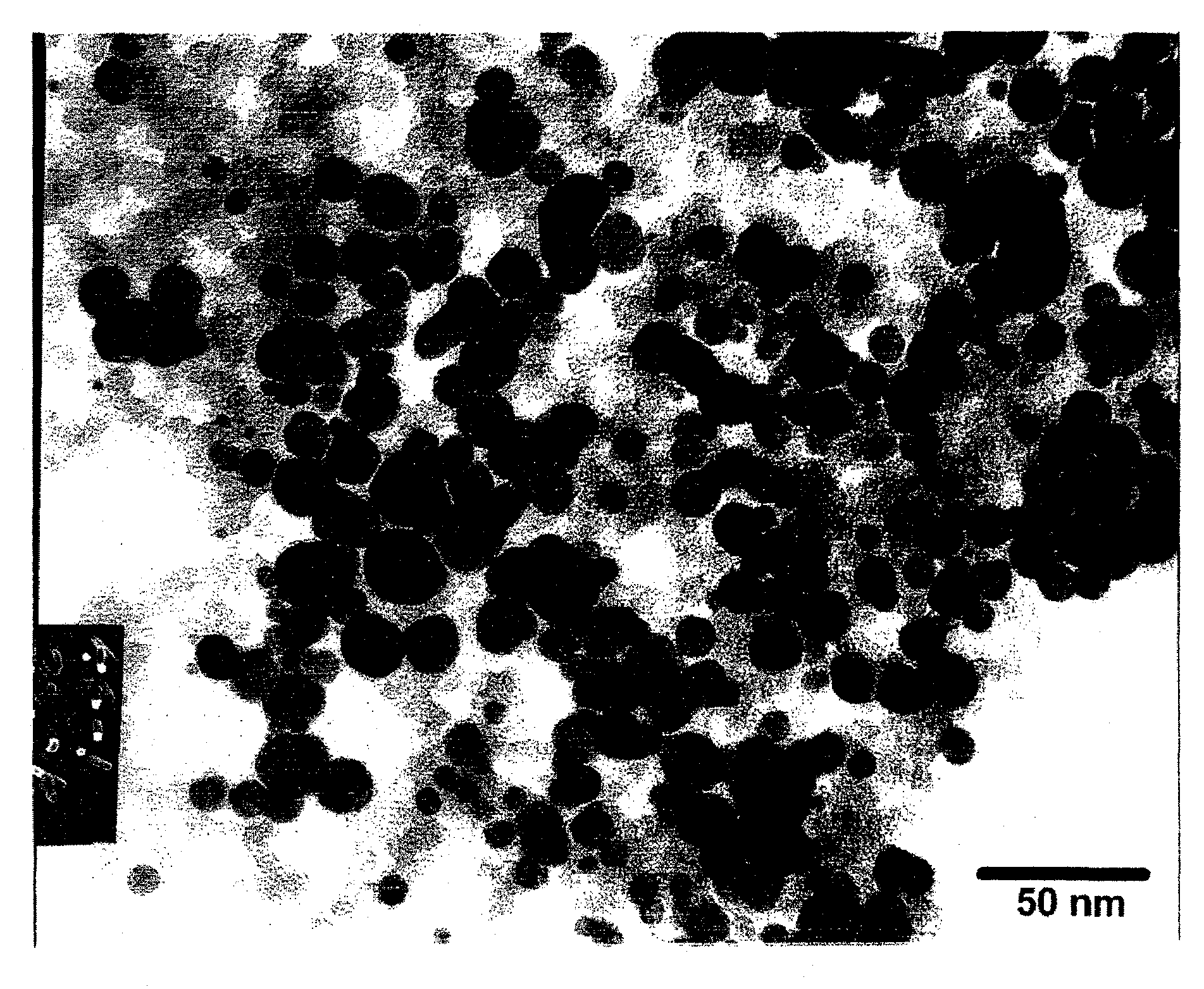

Nanoparticle-based power coatings and corresponding structures

Methods are described that have the capability of producing submicron / nanoscale particles, in some embodiments dispersible, at high production rates. In some embodiments, the methods result in the production of particles with an average diameter less than about 75 nanometers that are produced at a rate of at least about 35 grams per hour. In other embodiments, the particles are highly uniform. These methods can be used to form particle collections and / or powder coatings. Powder coatings and corresponding methods are described based on the deposition of highly uniform submicron / nanoscale particles.

Owner:NANOGRAM

Method of doping surfaces

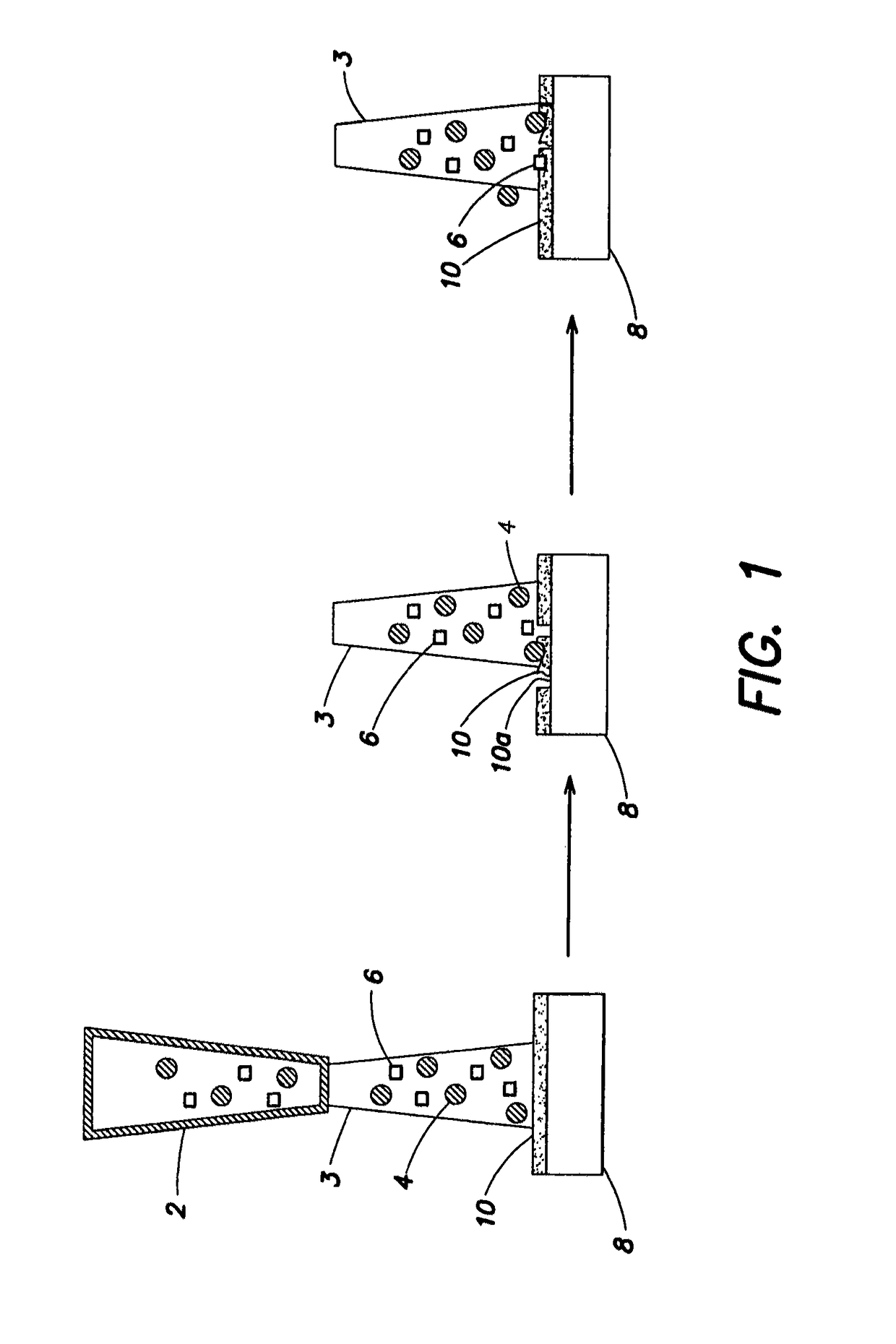

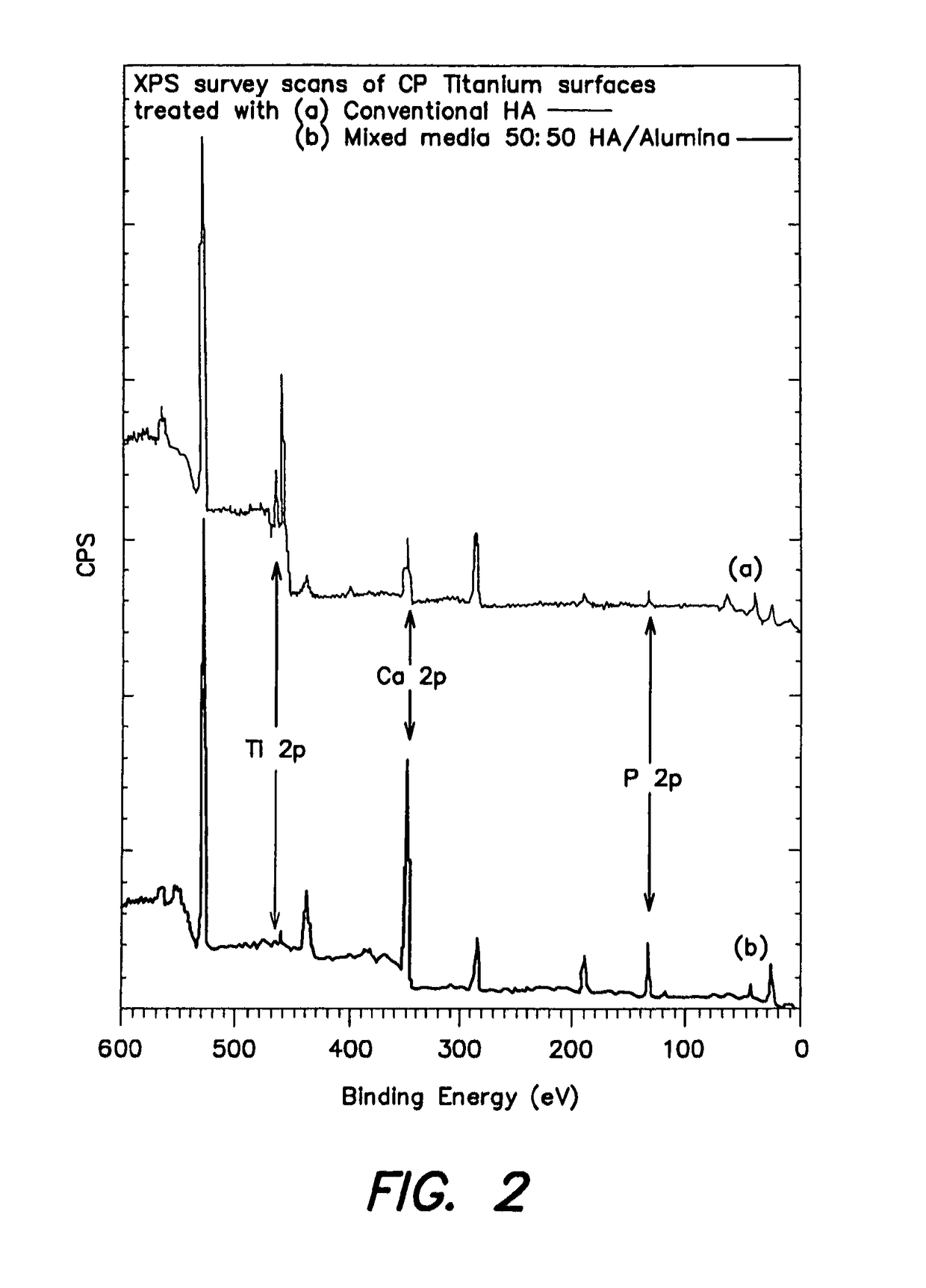

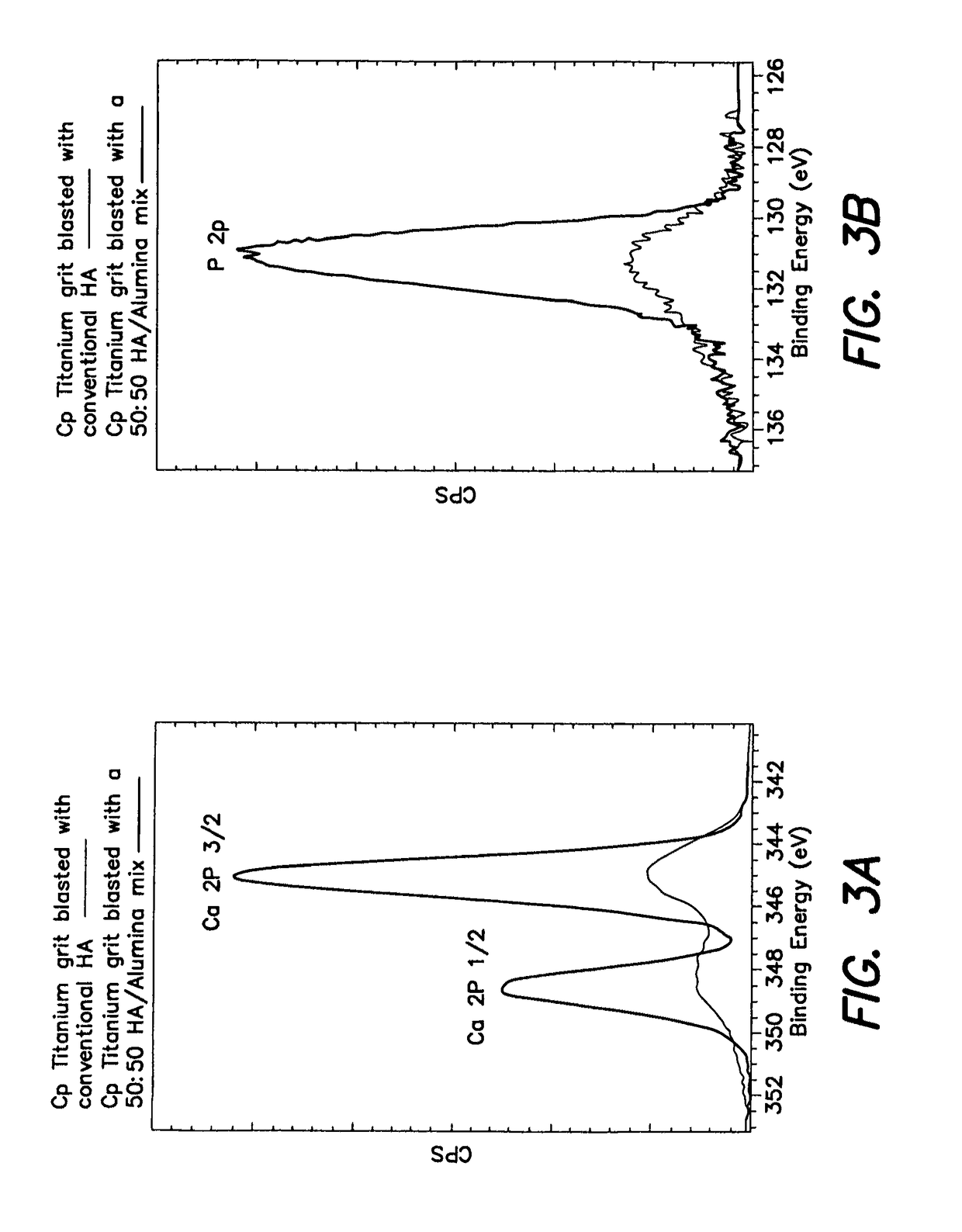

Disclosed herein are methods of treating an article surface. The method comprises removing a metal oxide surface from the metal substrate to expose a metal surface; and delivering particles comprising a dopant from at least one fluid jet to the metal surface to impregnate the surface of the article with the dopant. The method also comprises delivering substantially simultaneously a first set of particles comprising a dopant and a second set of particles comprising an abrasive from at least one fluid jet to a surface of an article to impregnate the surface of the article with the dopant.

Owner:ENBIO

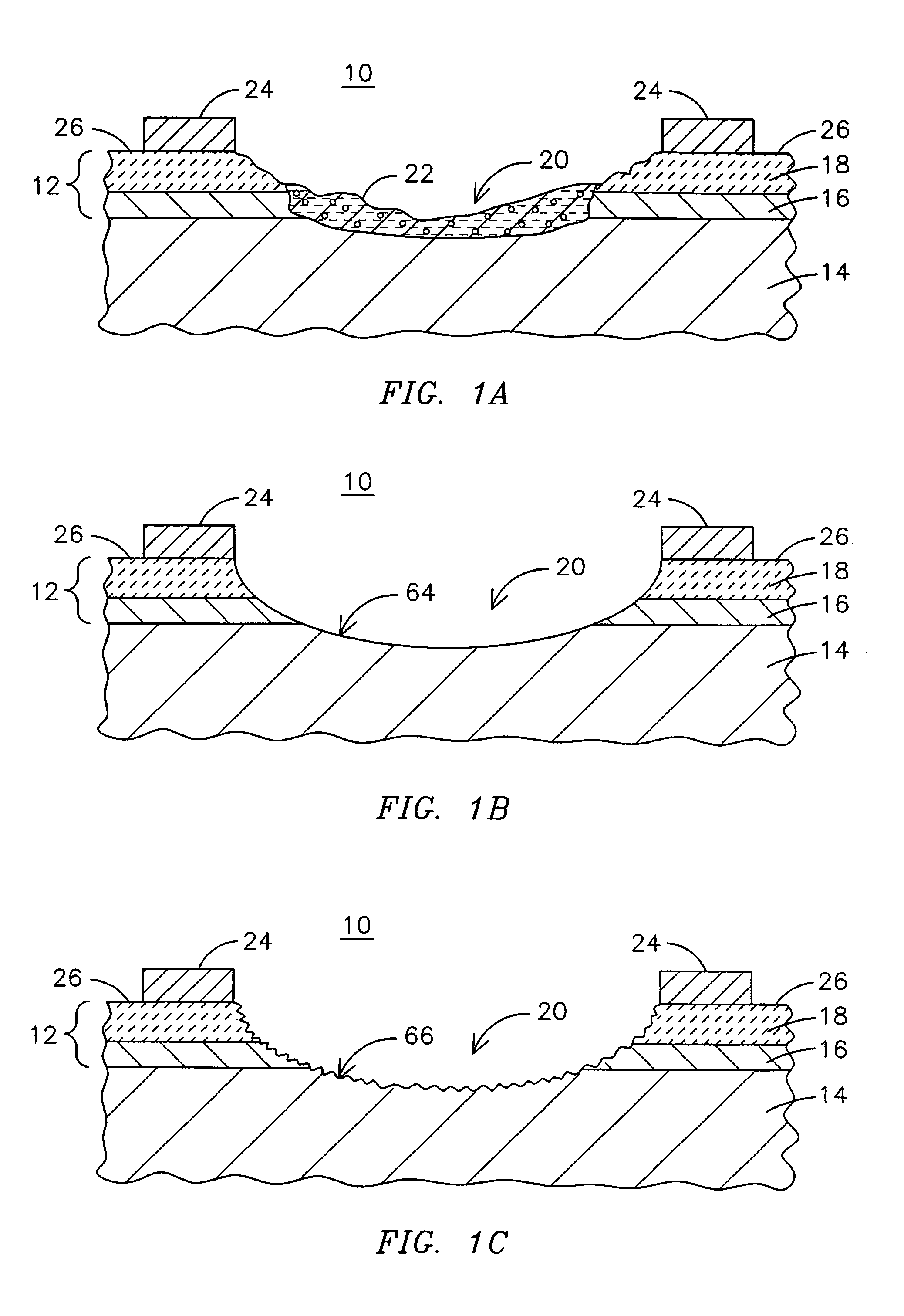

In-frame repair of gas turbine components

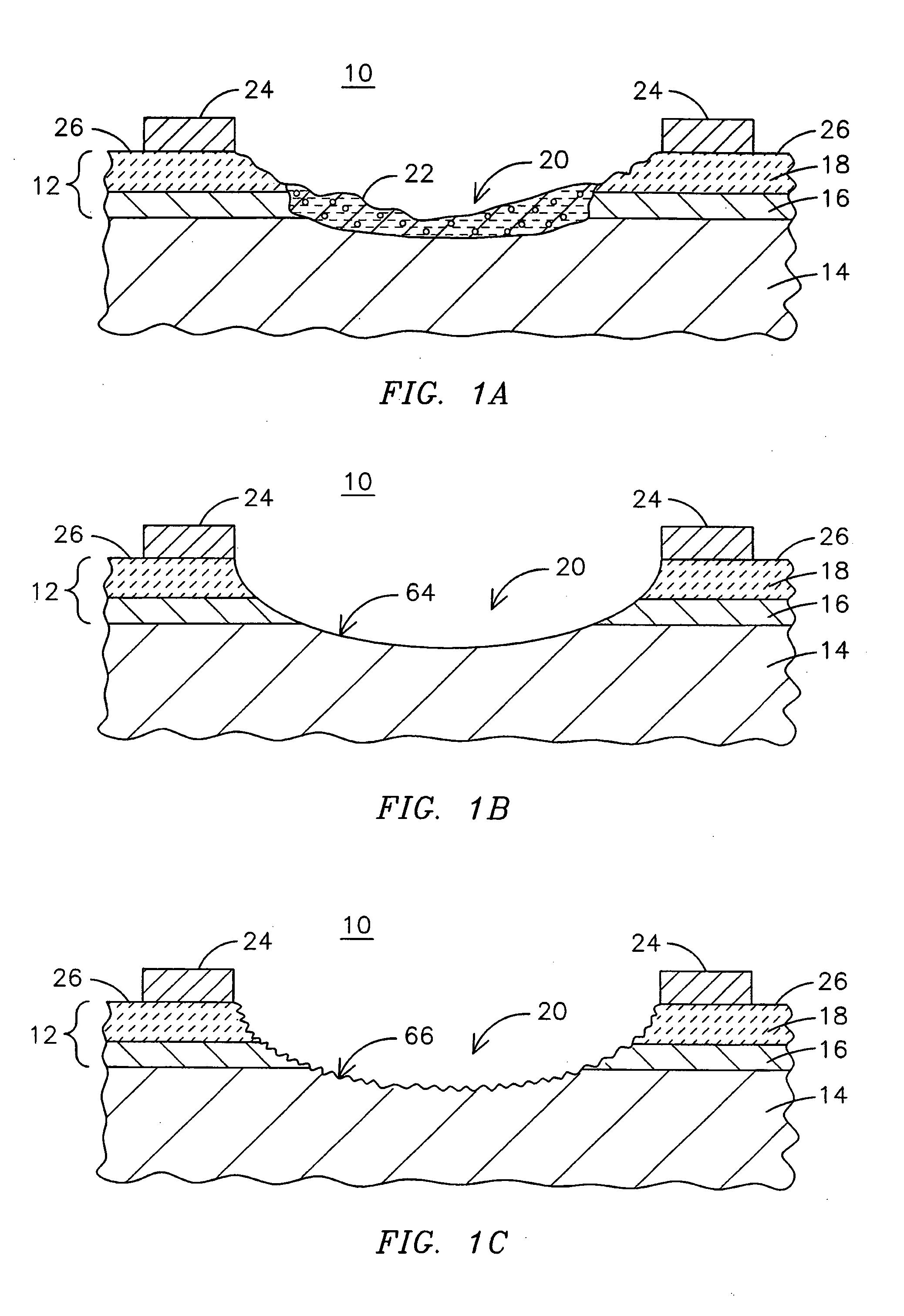

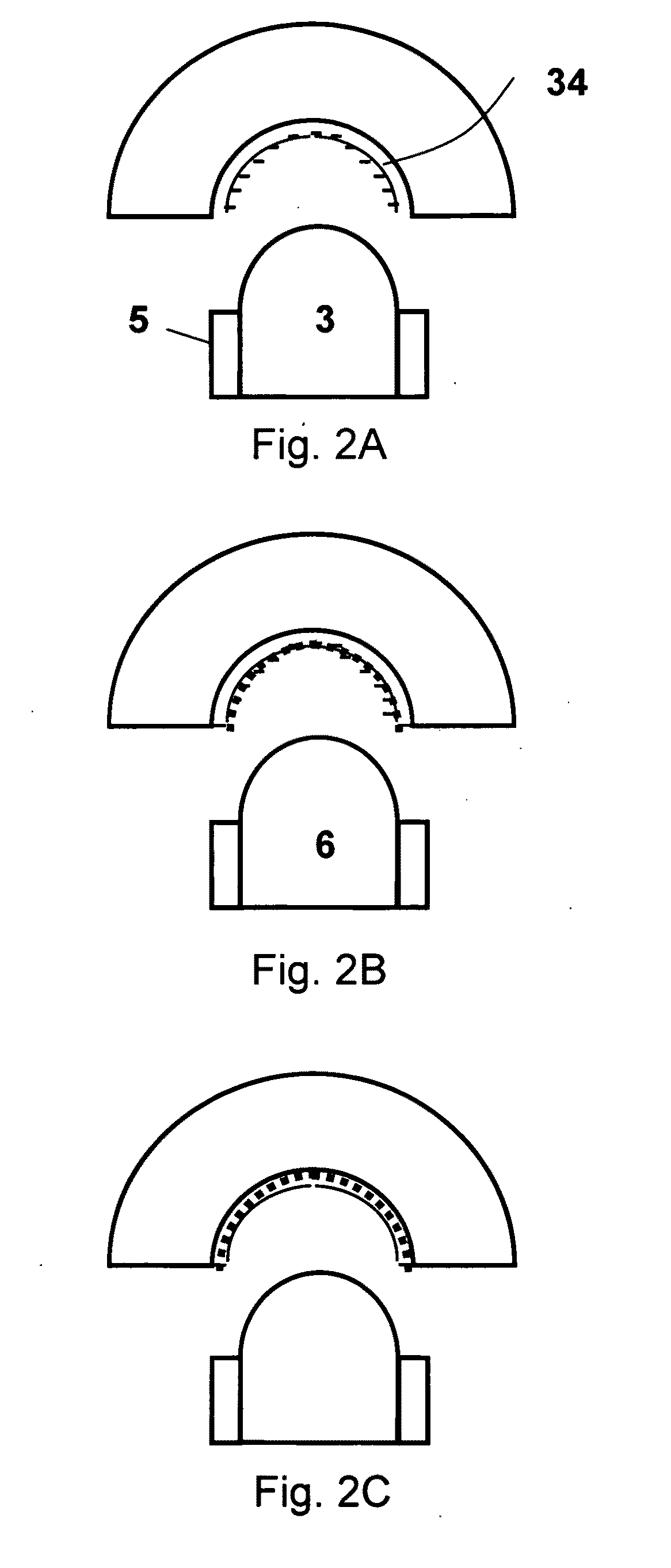

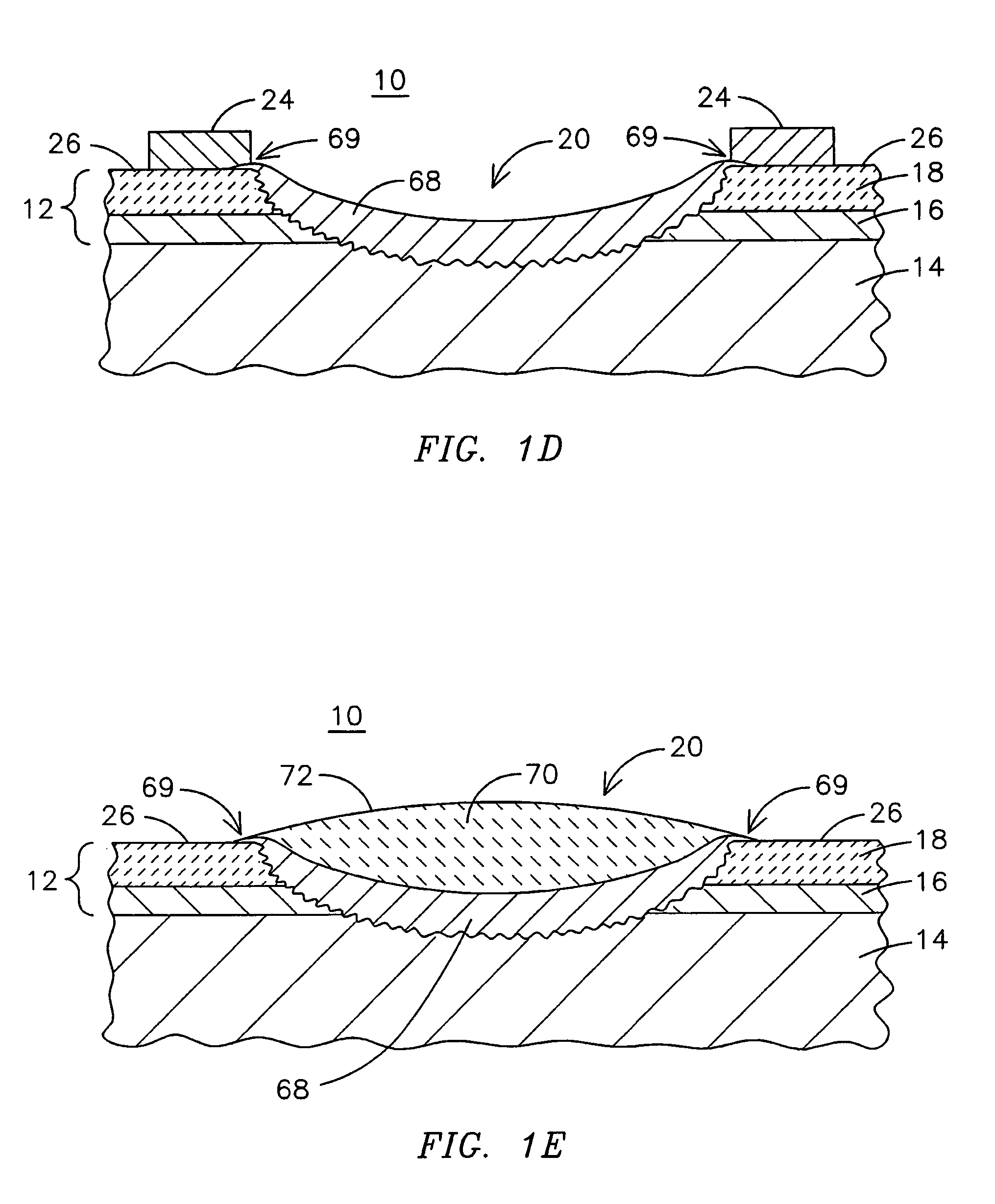

A method for in-frame repairing of a thermal barrier coating (12) on a gas turbine component includes cleaning a desired surface portion (10) of the component without removing the component from the gas turbine. The method also includes roughening the surface portion in-frame, applying a bond coat (68) to the surface portion in-frame, and applying a ceramic topcoat (70) to the bond coat, in-frame. A system (28) for cleaning the surface portion in-frame includes an abrasive media (34) having a state change characteristic occurring at a temperature lower than an operating temperature of the gas turbine so that the abrasive media changes from a solid state to another state allowing the media to exit the gas turbine during operation. The system also includes an abrasive media sprayer (36) to direct a spray of the abrasive media at the desired surface portion.

Owner:SIEMENS ENERGY INC

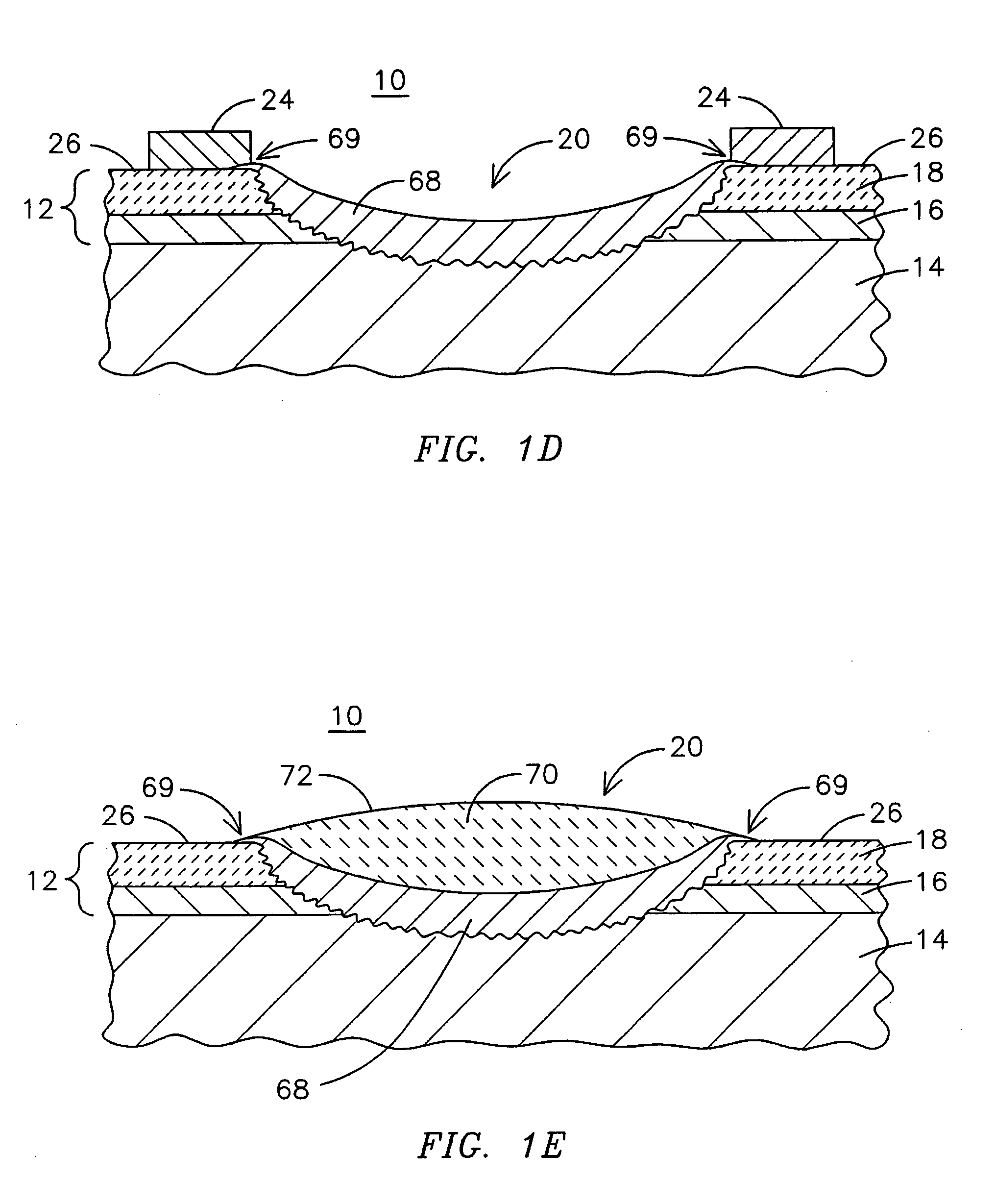

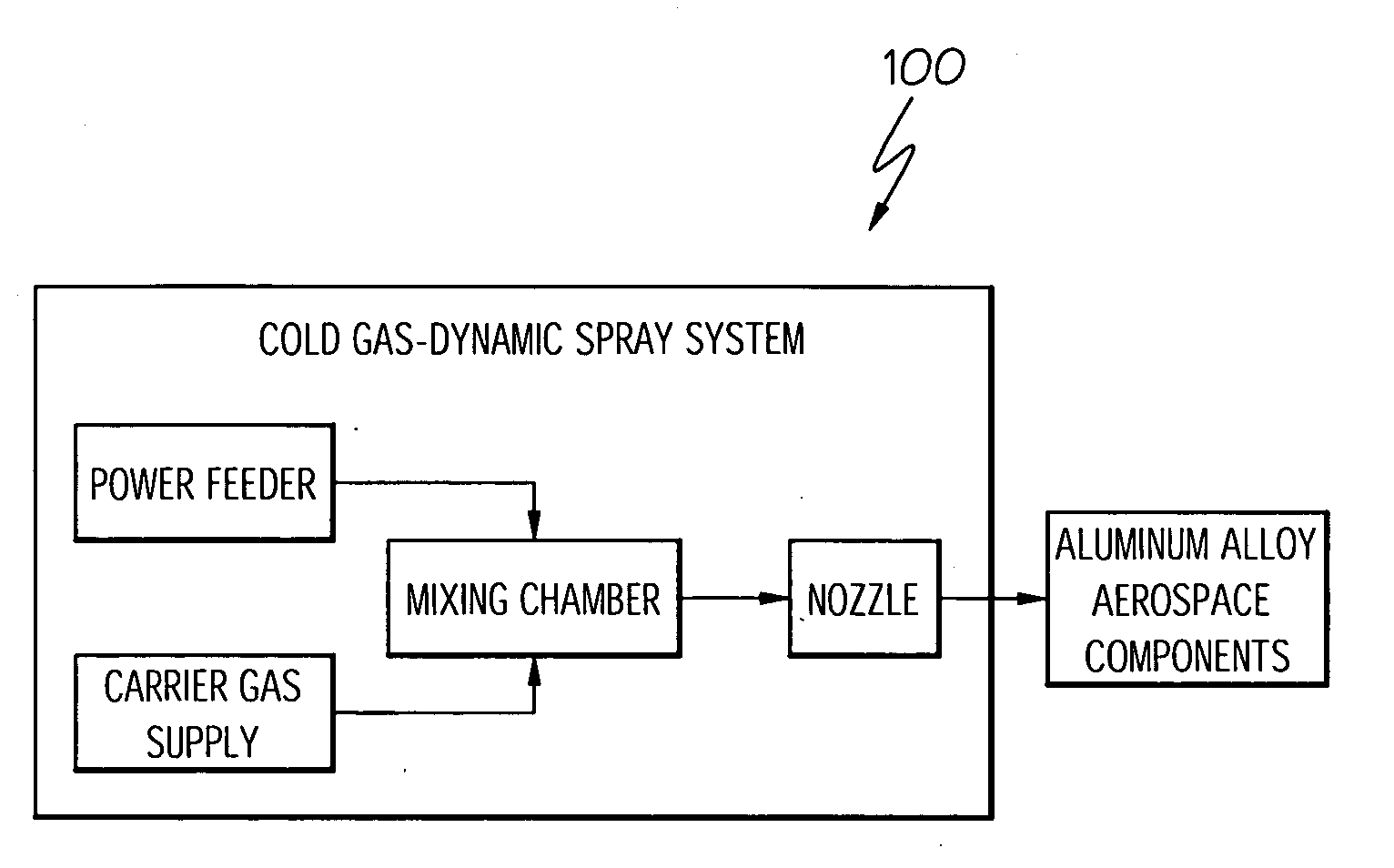

Aluminum articles with wear-resistant coatings and methods for applying the coatings onto the articles

InactiveUS20060093736A1Liquid surface applicatorsSuperimposed coating processWear resistantTitanium alloy

A method for coating a surface of a component formed from aluminum or an alloy thereof includes the step of cold gas-dynamic spraying a powder material on the component surface to form a coating, the powder material comprising at least one alloy from the group consisting of titanium, a titanium alloy, nickel, a nickel alloy, iron, an iron alloy, aluminum, an aluminum alloy, copper, a copper alloy, cobalt, and a cobalt alloy. In one embodiment, the method further includes the step of heat treating the turbine component after the cold gas-dynamic spraying.

Owner:HONEYWELL INT INC

System and process for solid-state deposition and consolidation of high velocity powder particles using thermal plastic deformation

InactiveUS20050153069A1Reduced strengthEnhanced dynamic recovery of dislocation densityLiquid surface applicatorsMolten spray coatingFlow stressAcoustic wave

The invention relates to an apparatus and process for solid-state deposition and consolidation of powder particles entrained in a subsonic or sonic gas jet onto the surface of an object. Under high velocity impact and thermal plastic deformation, the powder particles adhesively bond to the substrate and cohesively bond together to form consolidated materials with metallurgical bonds. The powder particles and optionally the surface of the object are heated to a temperature that reduces yield strength and permits plastic deformation at low flow stress levels during high velocity impact, but which is not so high as to melt the powder particles.

Owner:INNOVATION TECH INC

Fine-grained metallic coatings having the coefficient of thermal expansion matched to the one of the substrate

ActiveUS7320832B2Good thermal cycle performanceHigh strengthMaterial nanotechnologyRodsParticulatesChemical composition

Owner:INTEGRAN TECH

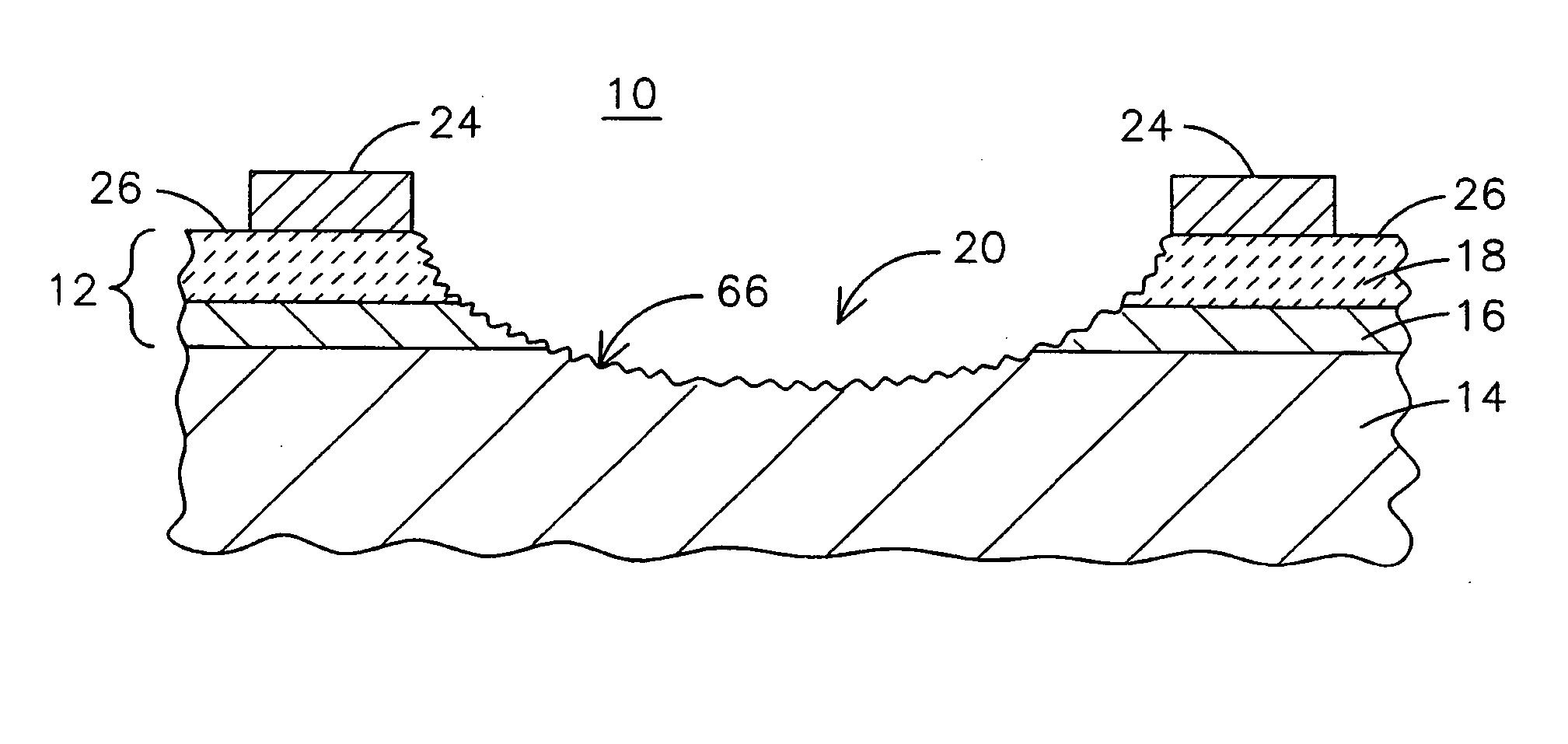

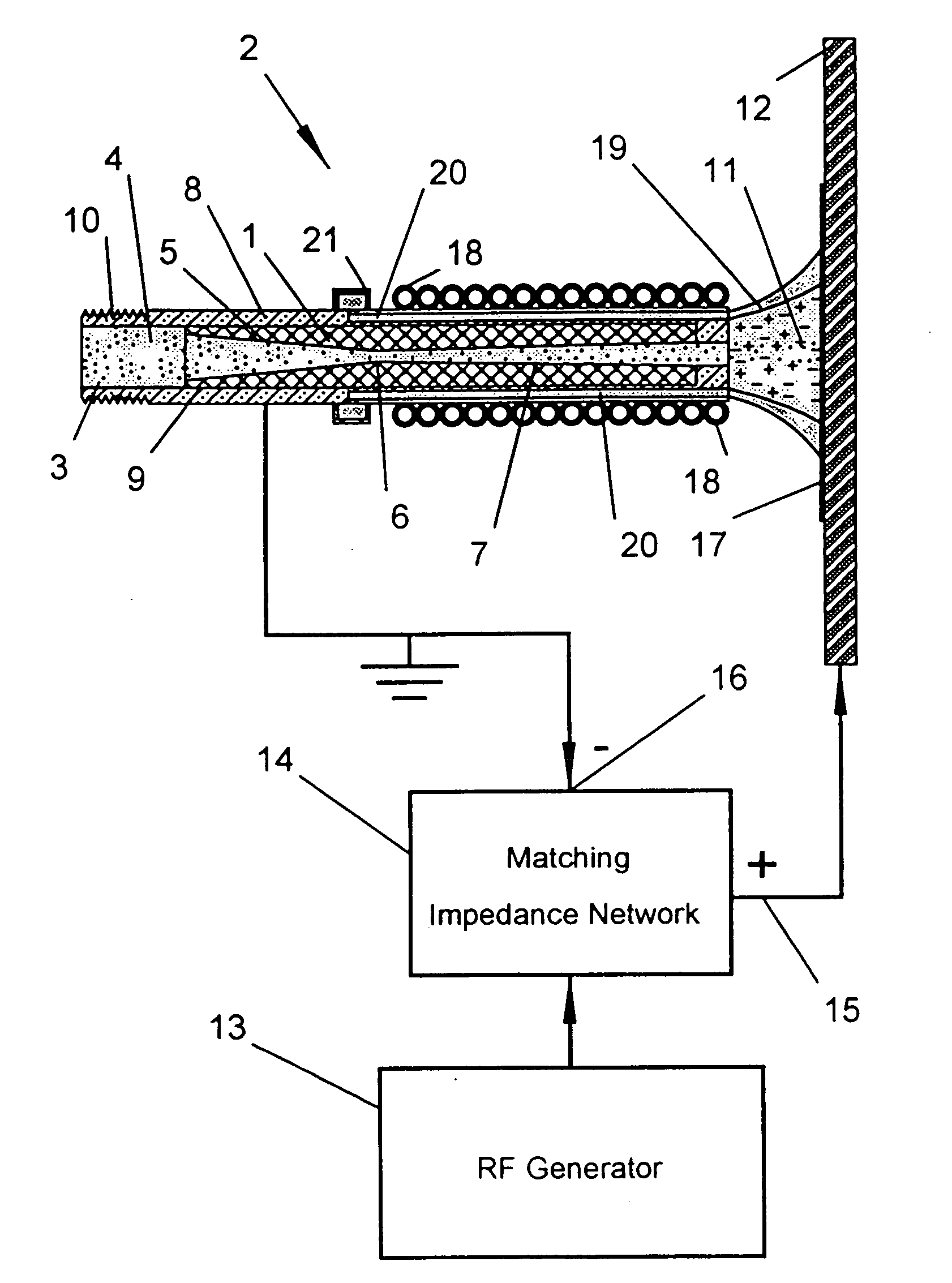

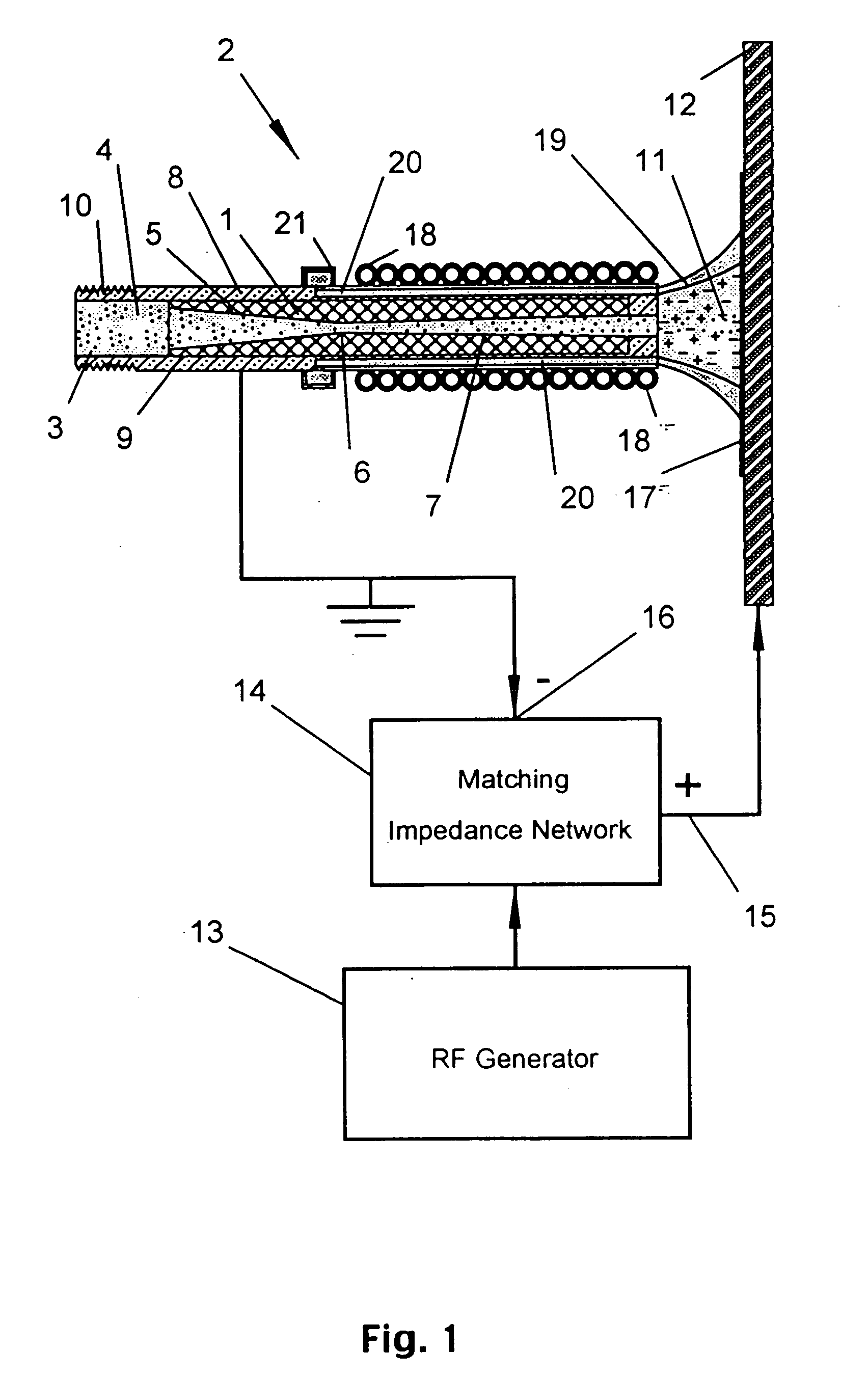

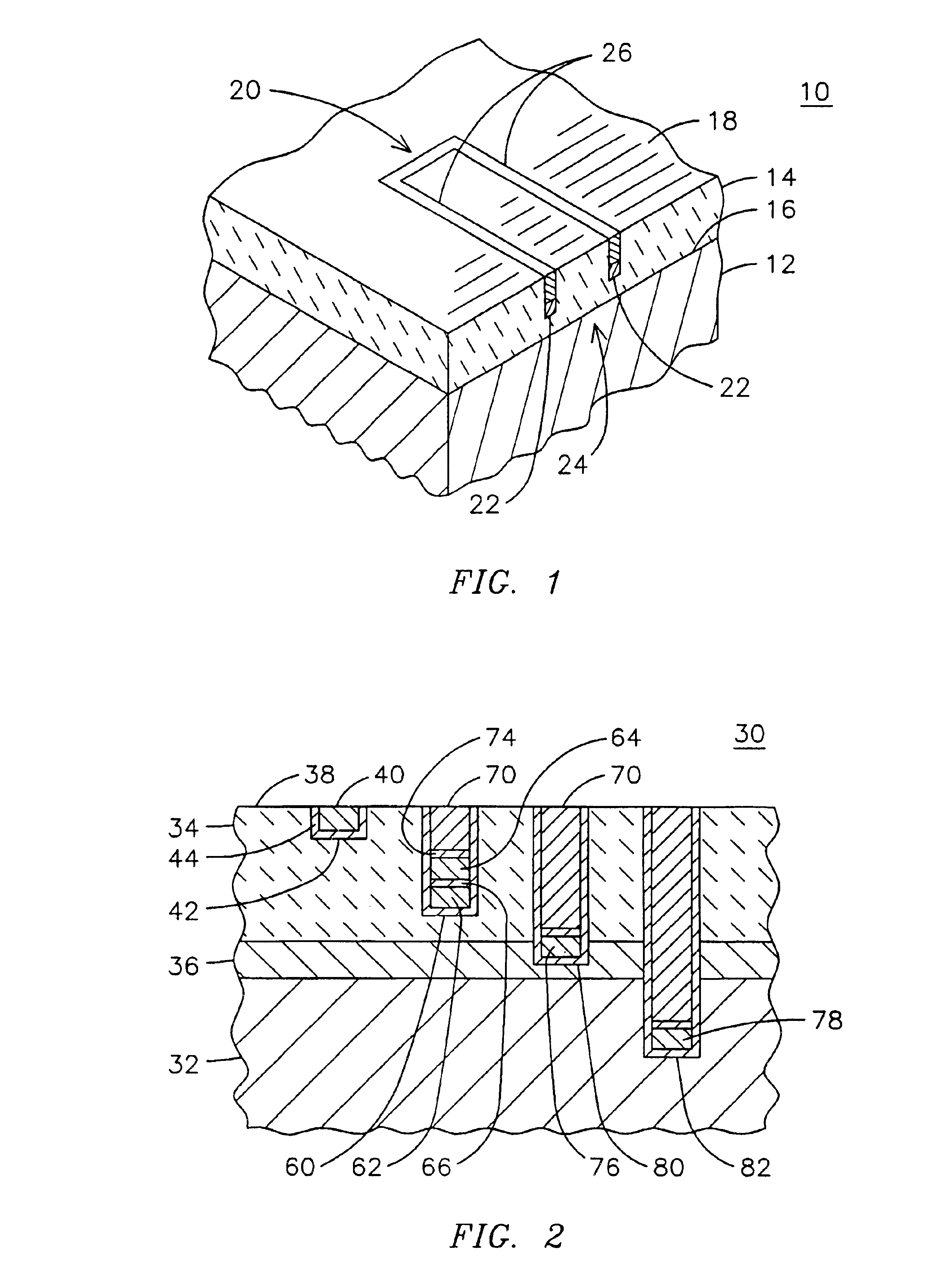

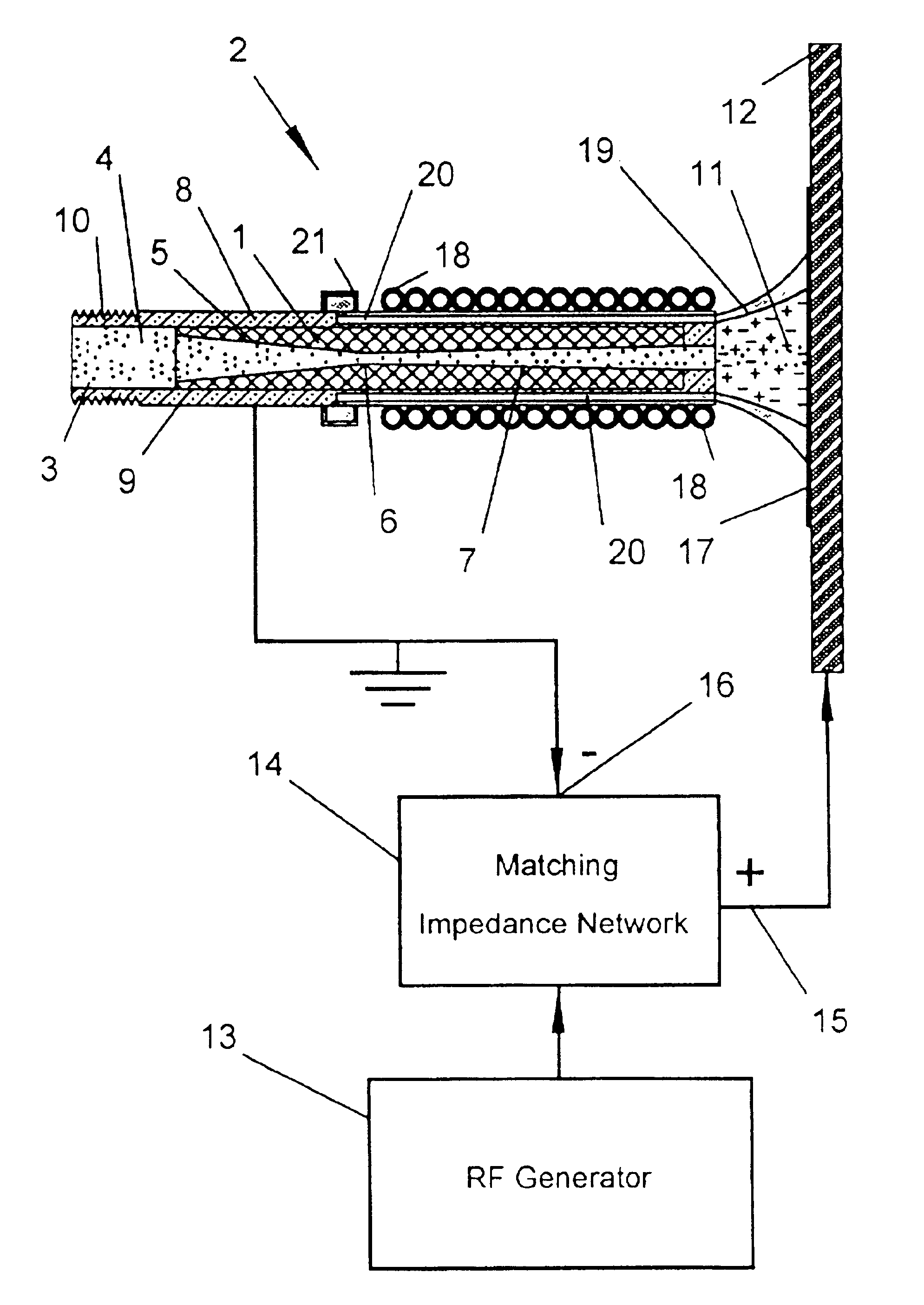

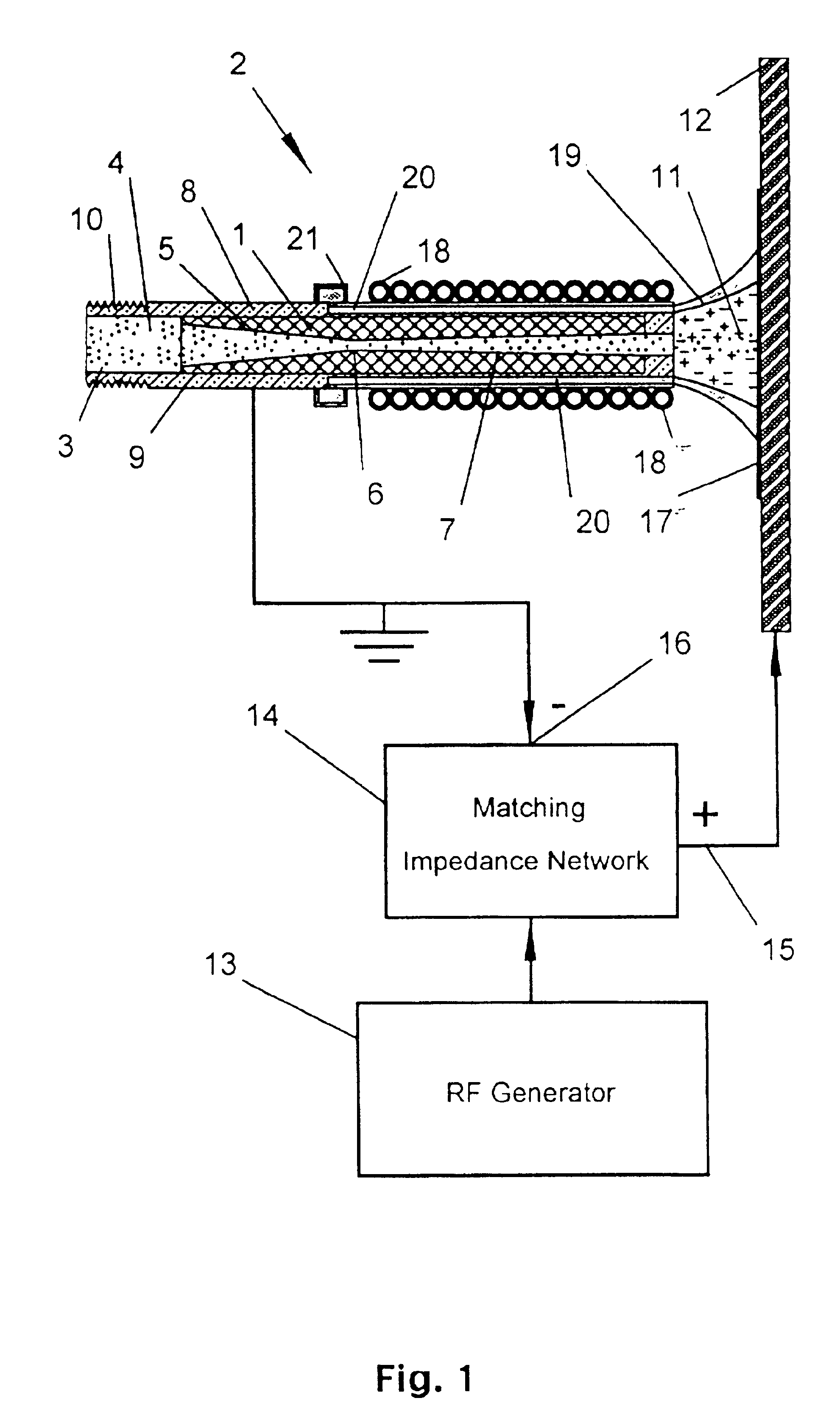

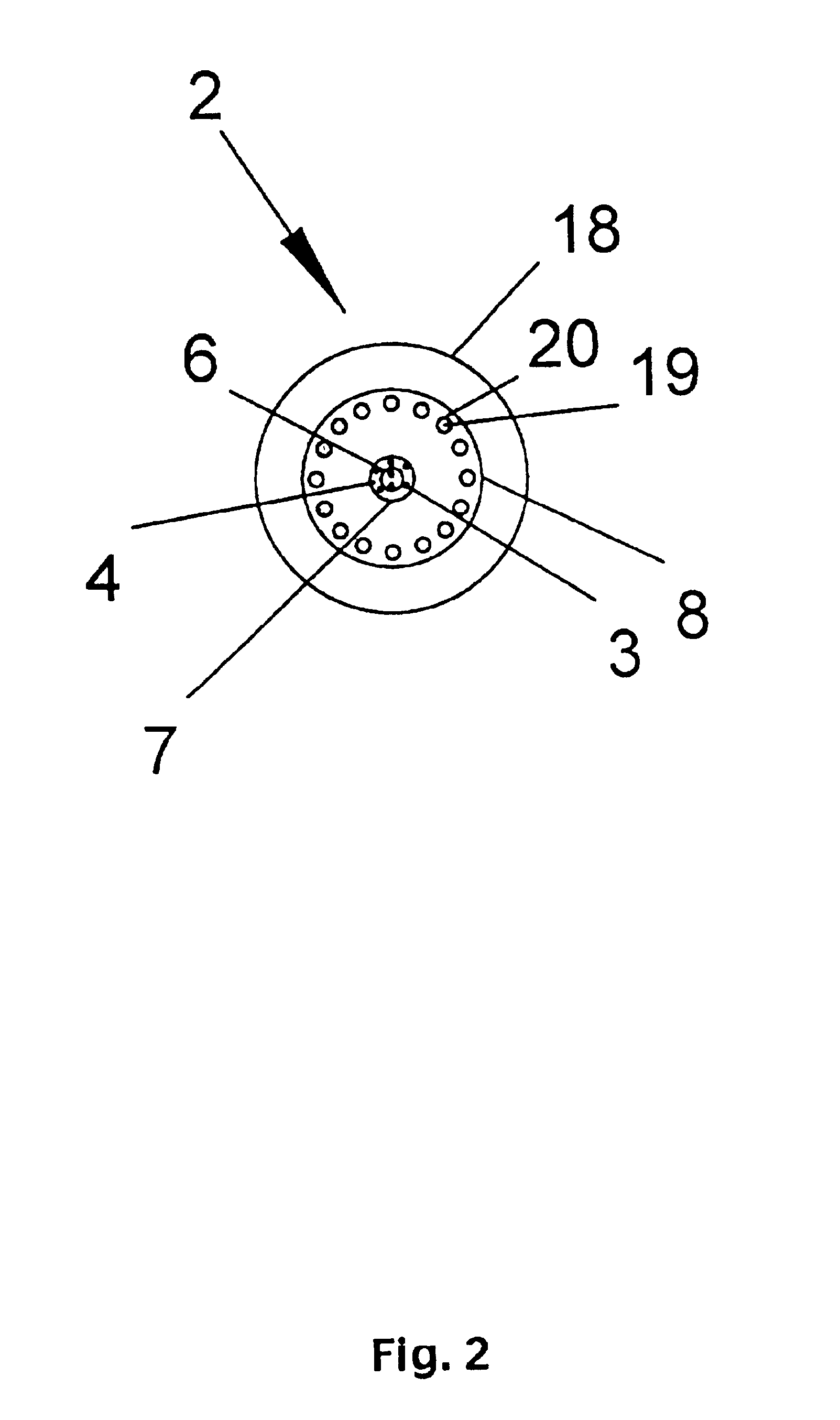

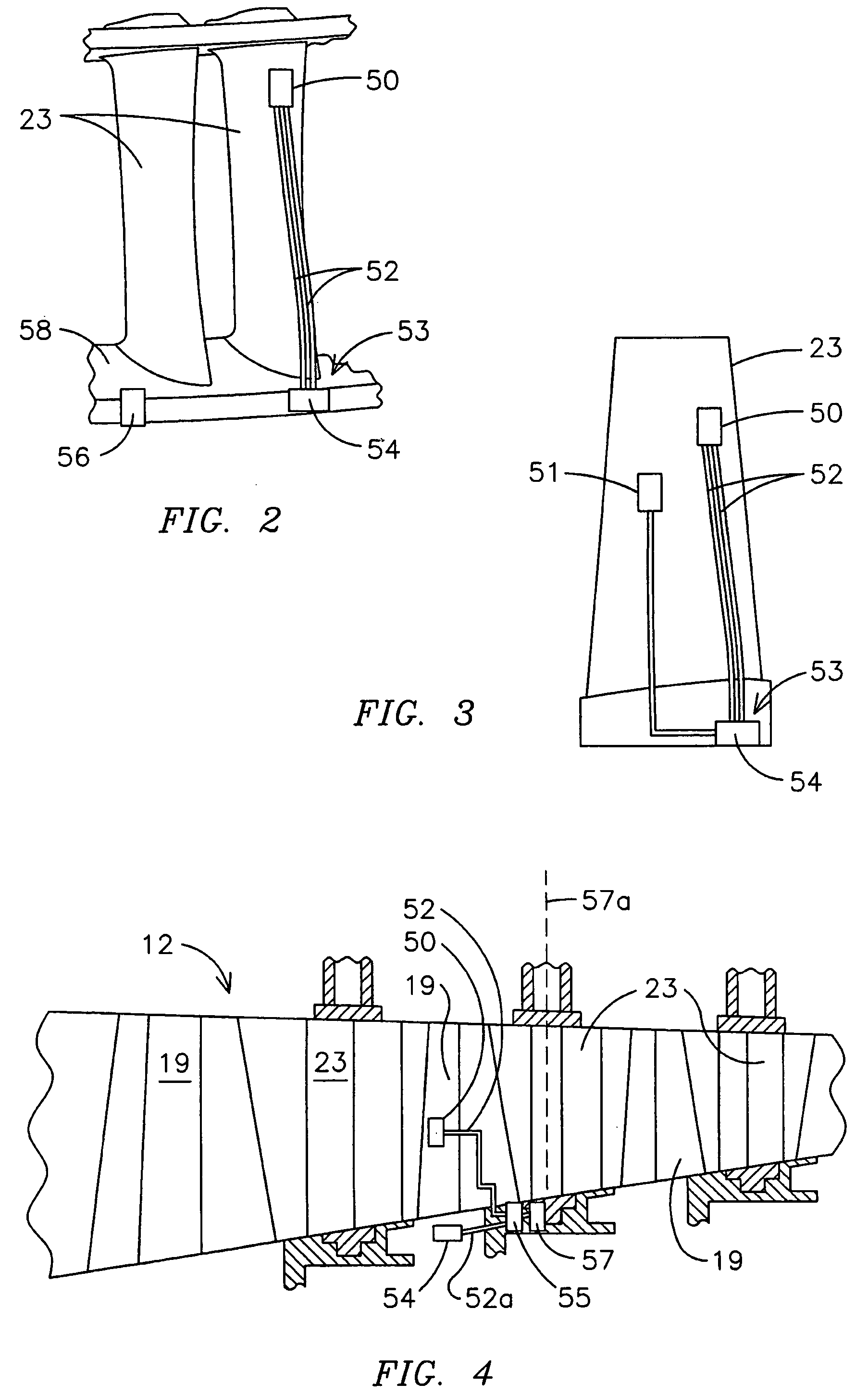

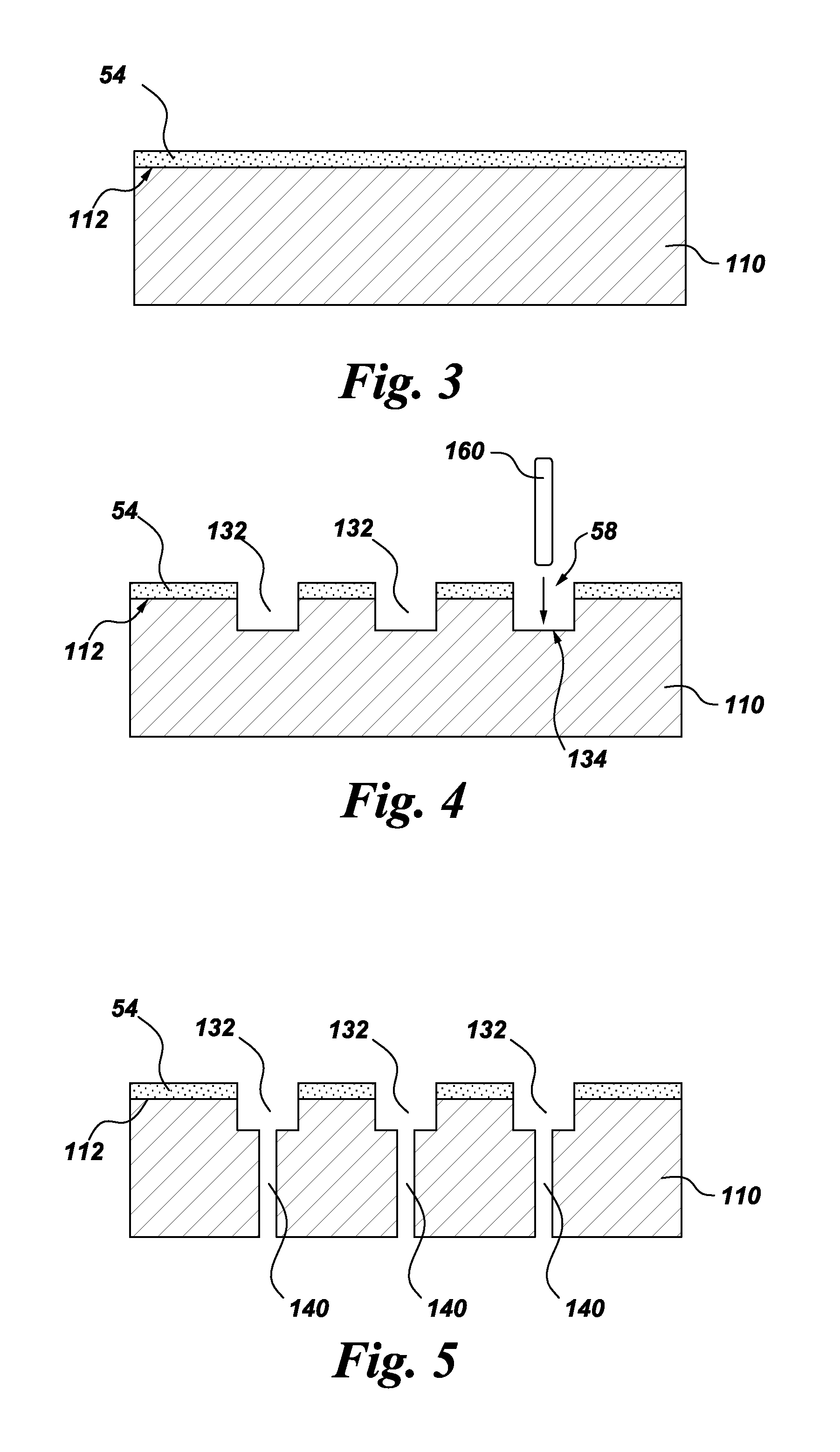

Method and apparatus for instrumenting a gas turbine component having a barrier coating

InactiveUS6838157B2Molten spray coatingVacuum evaporation coatingSelective laser meltingElectrical conductor

A method (50) of instrumenting a component (10) having a barrier coating (14). A sensor (76) is embedded within or below the coating. Material forming the sensor is deposited within a trench (80) formed into the barrier coating. The trench is then backfilled with material (70) to protect the sensor from the environment within which the component is operating. In this manner, the sensor may be embedded at any desired location and any desired depth within a barrier coating on a previously fabricated component. An array of sensors (98, 100, 102) may be embedded across the depth of the coating to provide signals indicative of operating conditions across the coating. The signals may be conducted to a connection location (24) by conductors (62, 64) that are deposited within the trench. The trench may be formed with a laser engraving process (54) and the material for the sensor and conductors may be deposited with a selective laser melting process (58).

Owner:SIEMENS ENERGY INC

Methods and apparatus for forming uniform particle layers of phosphor material on a surface

InactiveUS20100291313A1Easy to controlHigh bulk densityLiquid surface applicatorsElectric shock equipmentsPhosphorStatic electricity

A method for forming a layer of an LED phosphor material includes disposing a first surface in a proximity of a powder that includes an LED phosphor material, forming electrostatic charges on the first surface, and forming a layer of the LED phosphor material on the first surface at least partially by using the electrostatic charges. In an embodiment, the method includes disposing the first surface in an interior of a chamber and forming an airborne distribution of the powder in the interior of the chamber in a vicinity of the first surface. In another embodiment, the method includes providing a reservoir of the powder and applying to said phosphor powder an electrostatic charge opposite to that of said electrostatic charge on the first surface.

Owner:ACHROLUX

System and process for solid-state deposition and consolidation of high velocity powder particles using thermal plastic deformation

InactiveUS6915964B2Modulus is reducedLower yield strengthMolten spray coatingSurface layering apparatusFlow stressAcoustic wave

The invention relates to an apparatus and process for solid-state deposition and consolidation of powder particles entrained in a subsonic or sonic gas jet onto the surface of an object. Under high velocity impact and thermal plastic deformation, the powder particles adhesively bond to the substrate and cohesively bond together to form consolidated materials with metallurgical bonds. The powder particles and optionally the surface of the object are heated to a temperature that reduces yield strength and permits plastic deformation at low flow stress levels during high velocity impact, but which is not so high as to melt the powder particles.

Owner:INNOVATION TECH INC

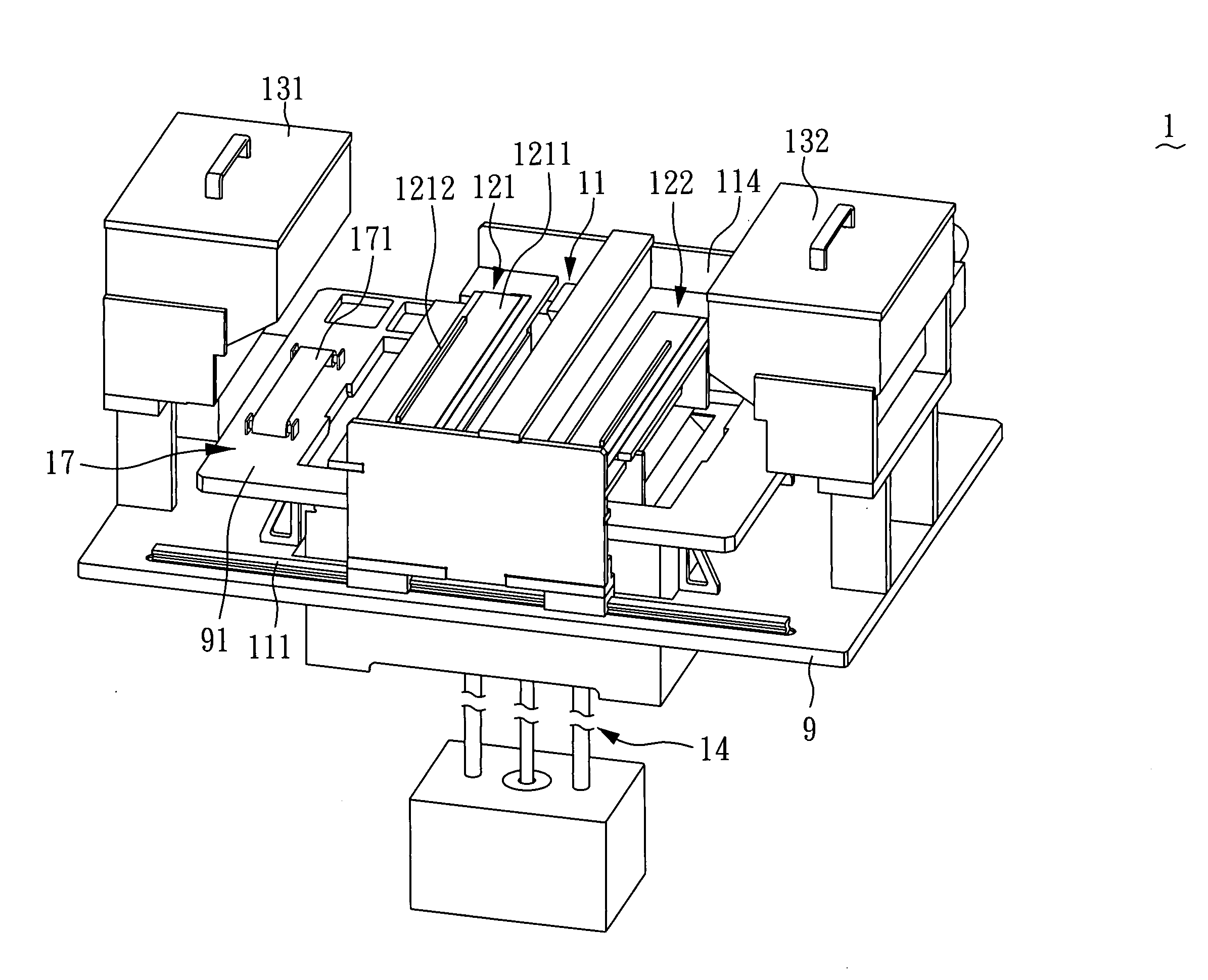

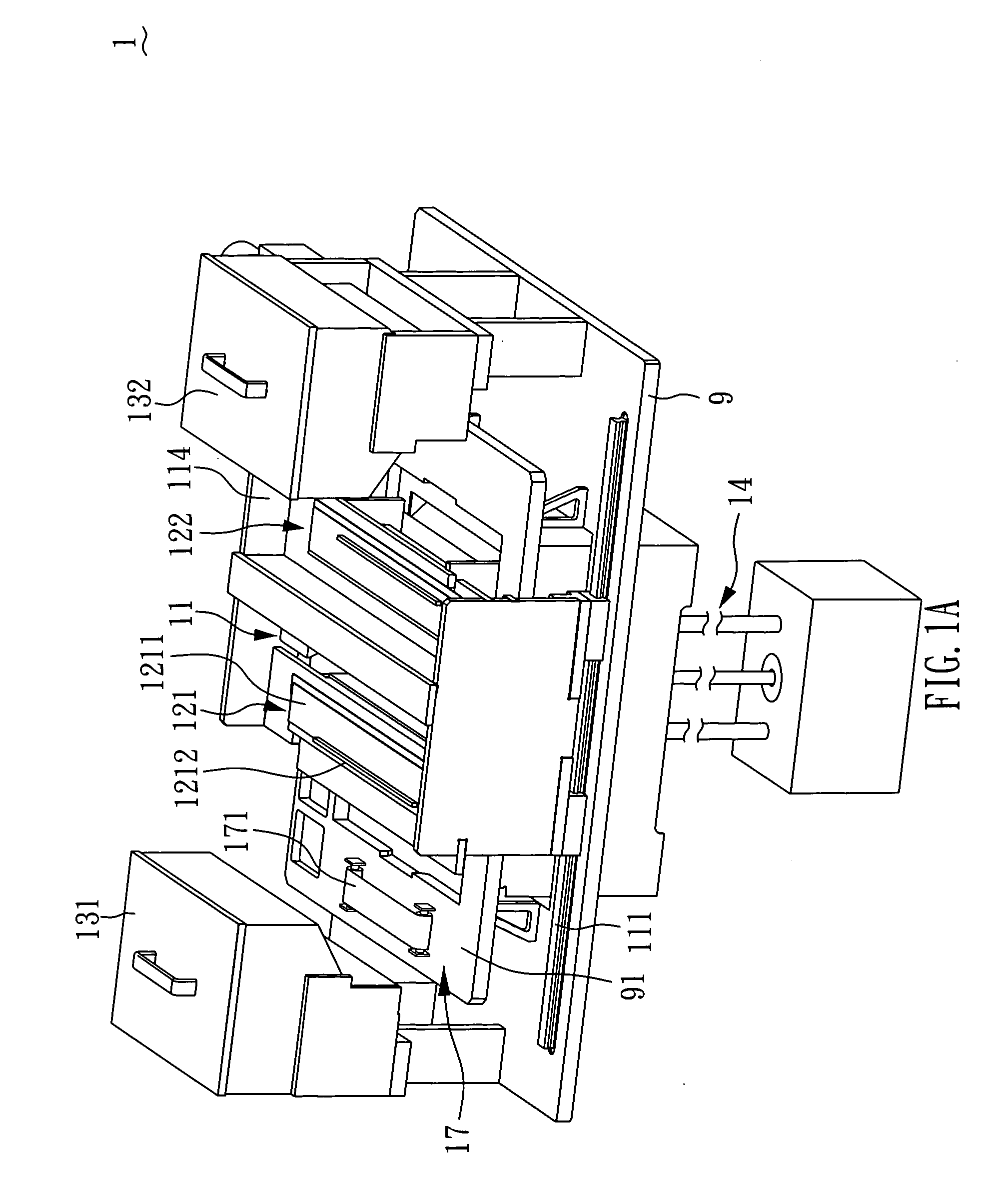

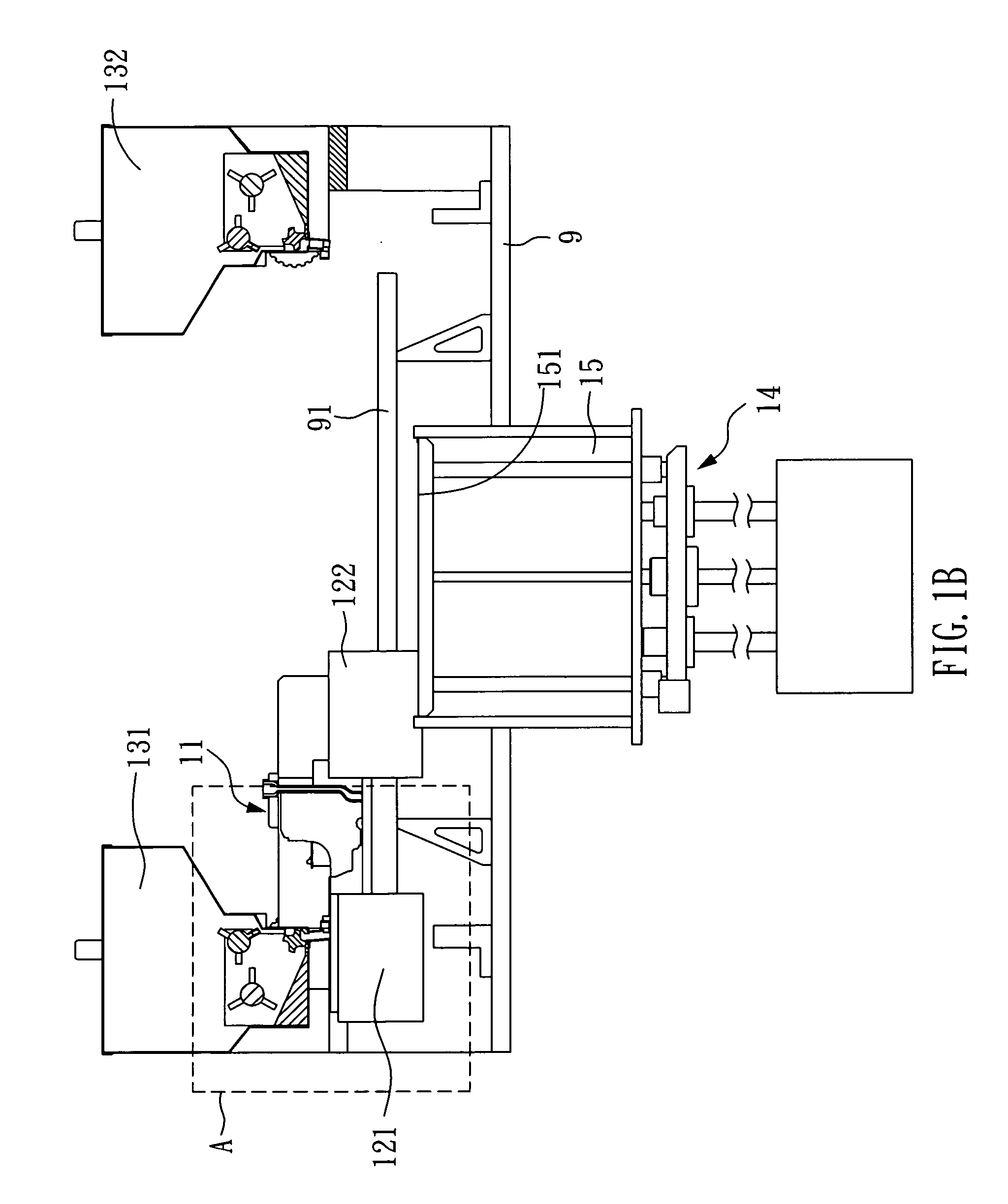

Three-dimensional object forming apparatus and method for forming three-dimensional object

InactiveUS20100247742A1Avoid pollutionLiquid surface applicatorsConfectioneryComputer moduleEngineering

Owner:MICROJET TECH

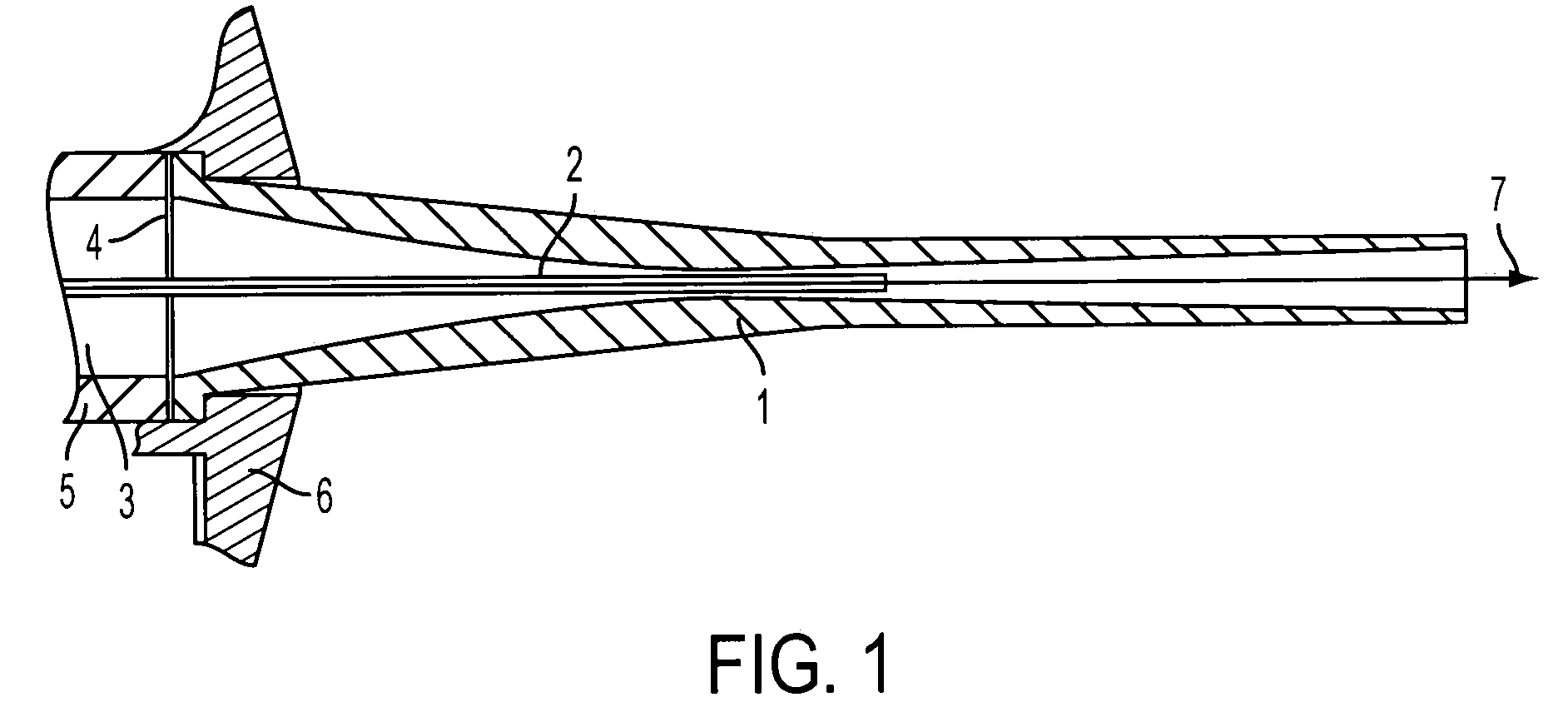

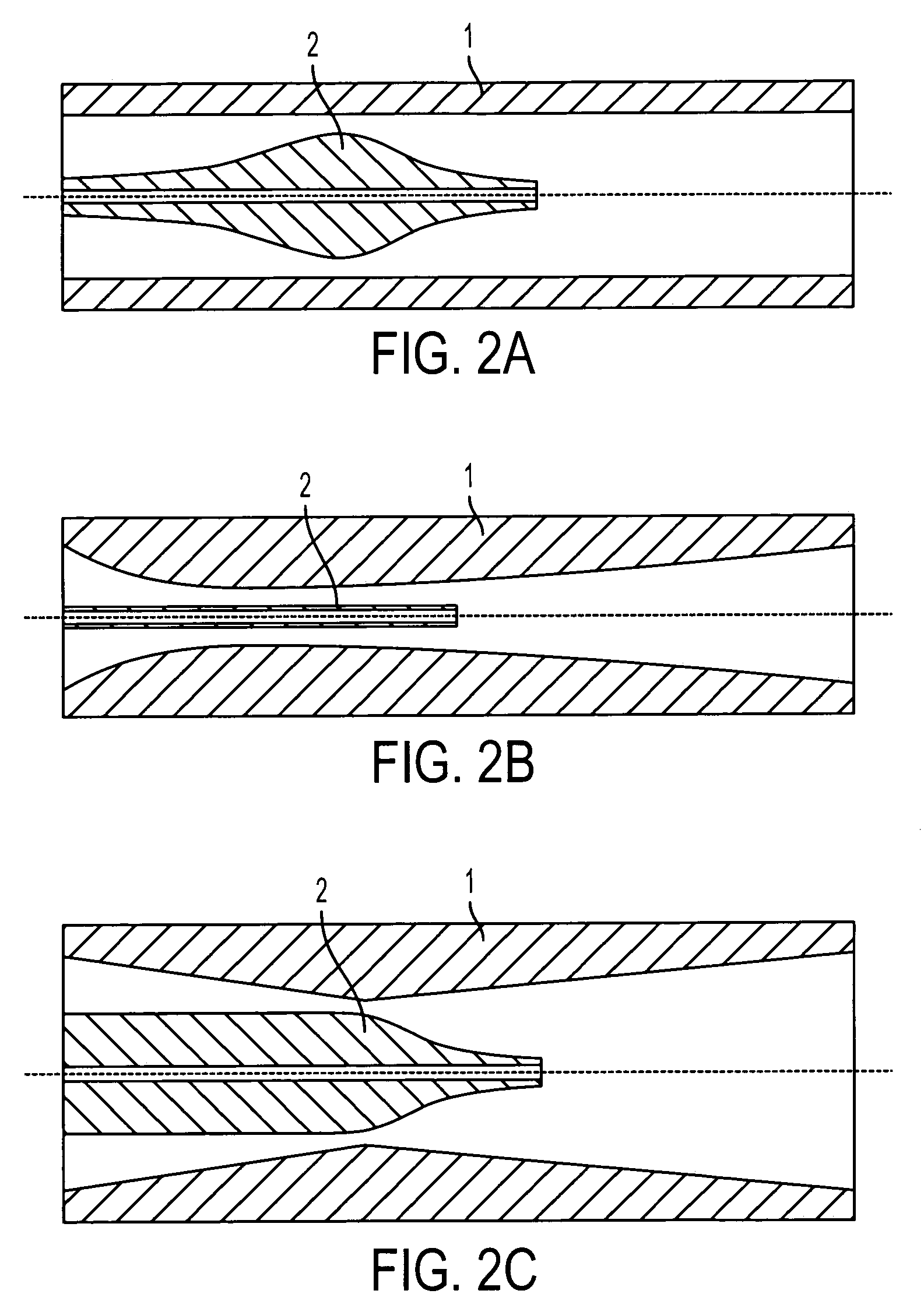

Method and system for cold gas spraying

InactiveUS7143967B2Simple spraying particle injection methodSpeed up the gas flowBurnersMolten spray coatingMaterials scienceAirflow

Owner:SULZER METRO AG

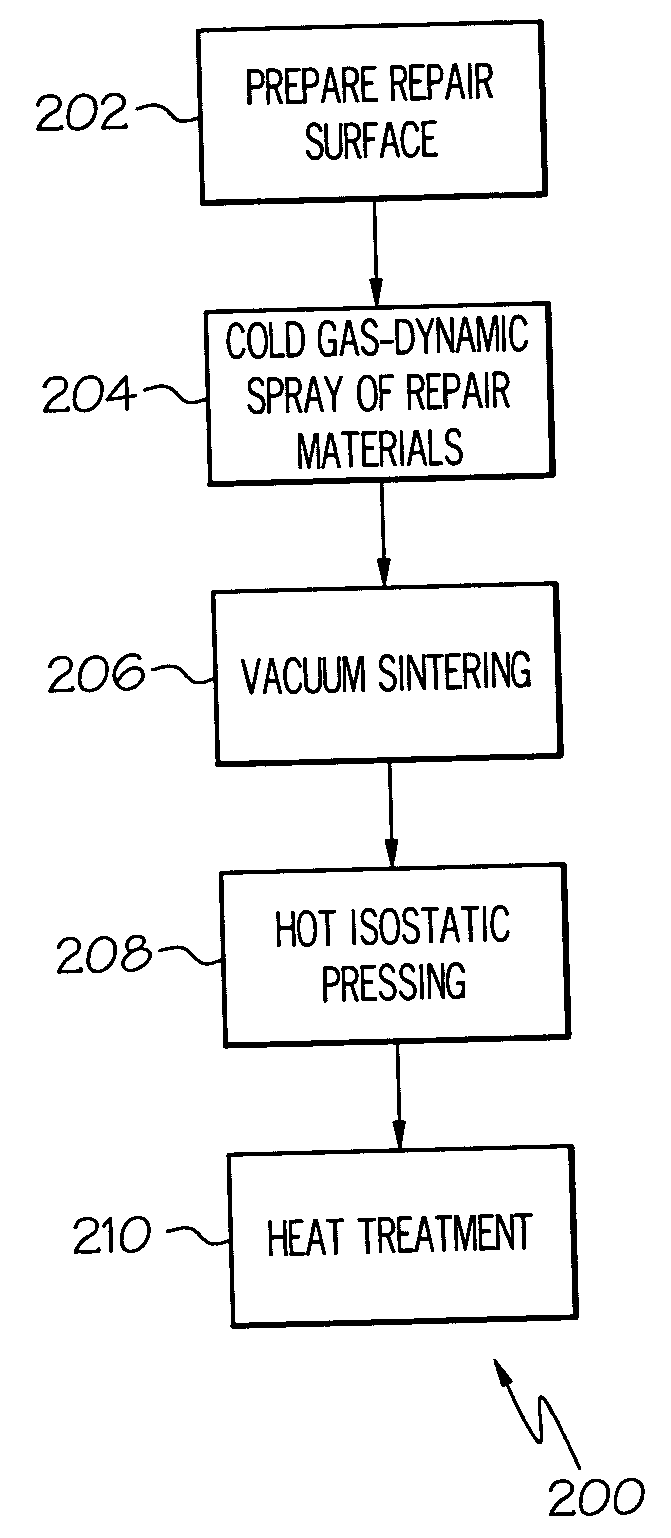

Method for repairing titanium alloy components

A method for repairing a titanium alloy surface of a turbine component includes the step of cold gas-dynamic spraying a powder material comprising at least one titanium alloy directly on the titanium alloy surface. The method may further include the steps of hot isostatic pressing the cold gas-dynamic sprayed turbine component, and performing a separate heat treating step after the hot isostatic pressing. Thus, the cold gas-dynamic spray process and post-spray processing can be employed to effectively repair degraded areas on compressor turbine components.

Owner:HONEYWELL INT INC

Method and apparatus for spray processing of porous medical devices

InactiveUS20070036905A1Minimize contaminationMinimize oxidationMolten spray coatingPretreated surfacesPorous substrateThermal spraying

Owner:ABBOTT CARDIOVASCULAR

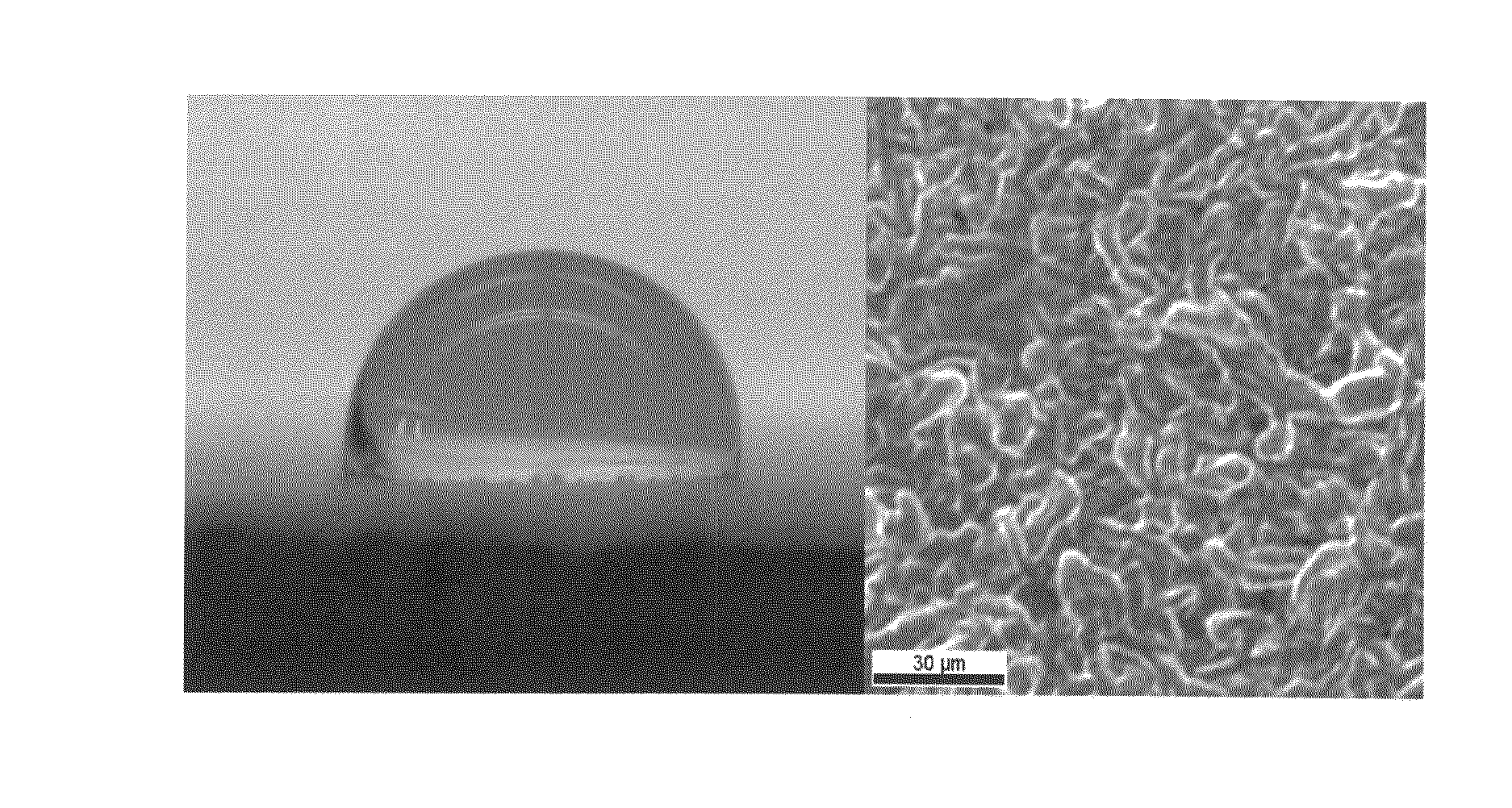

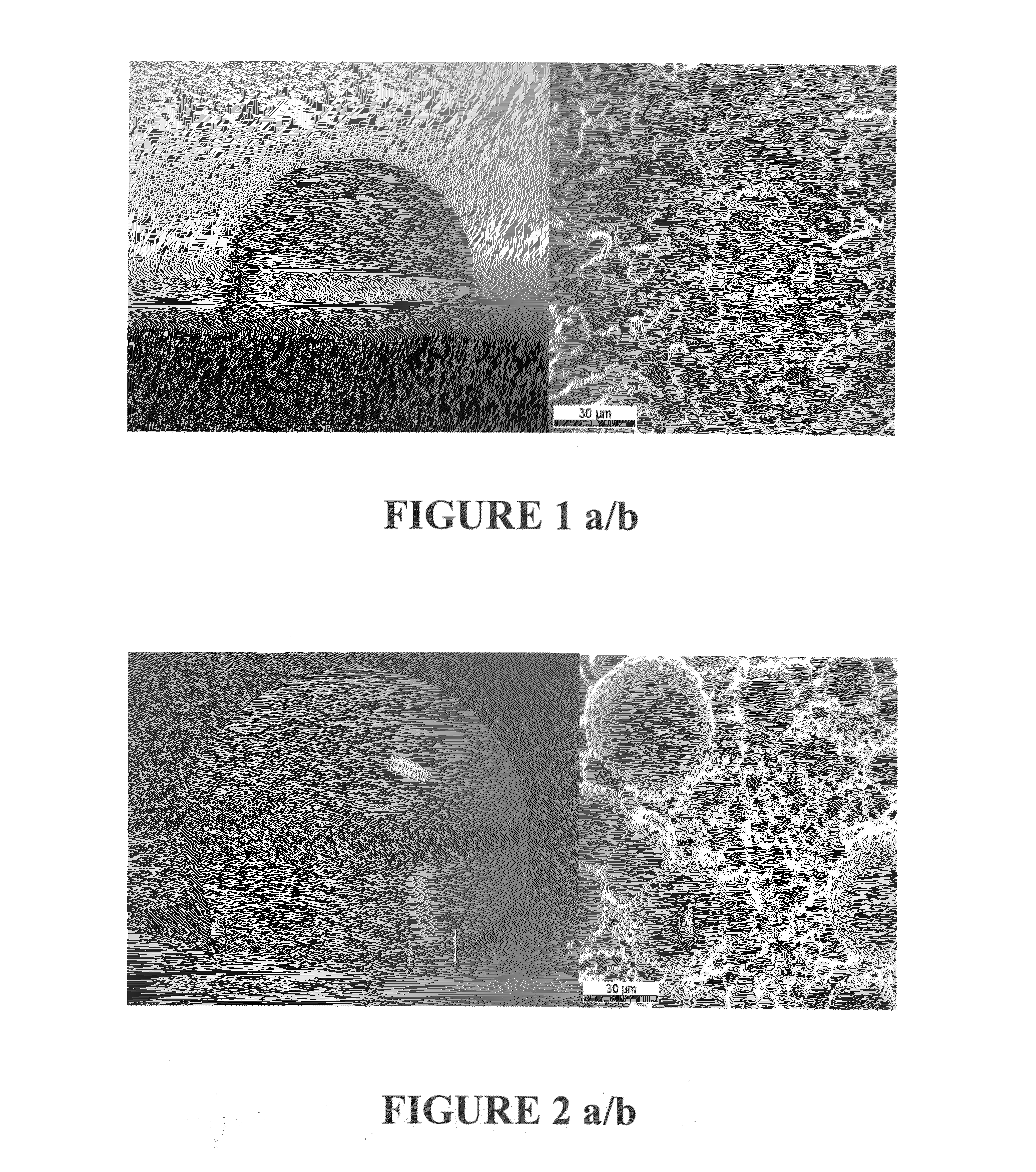

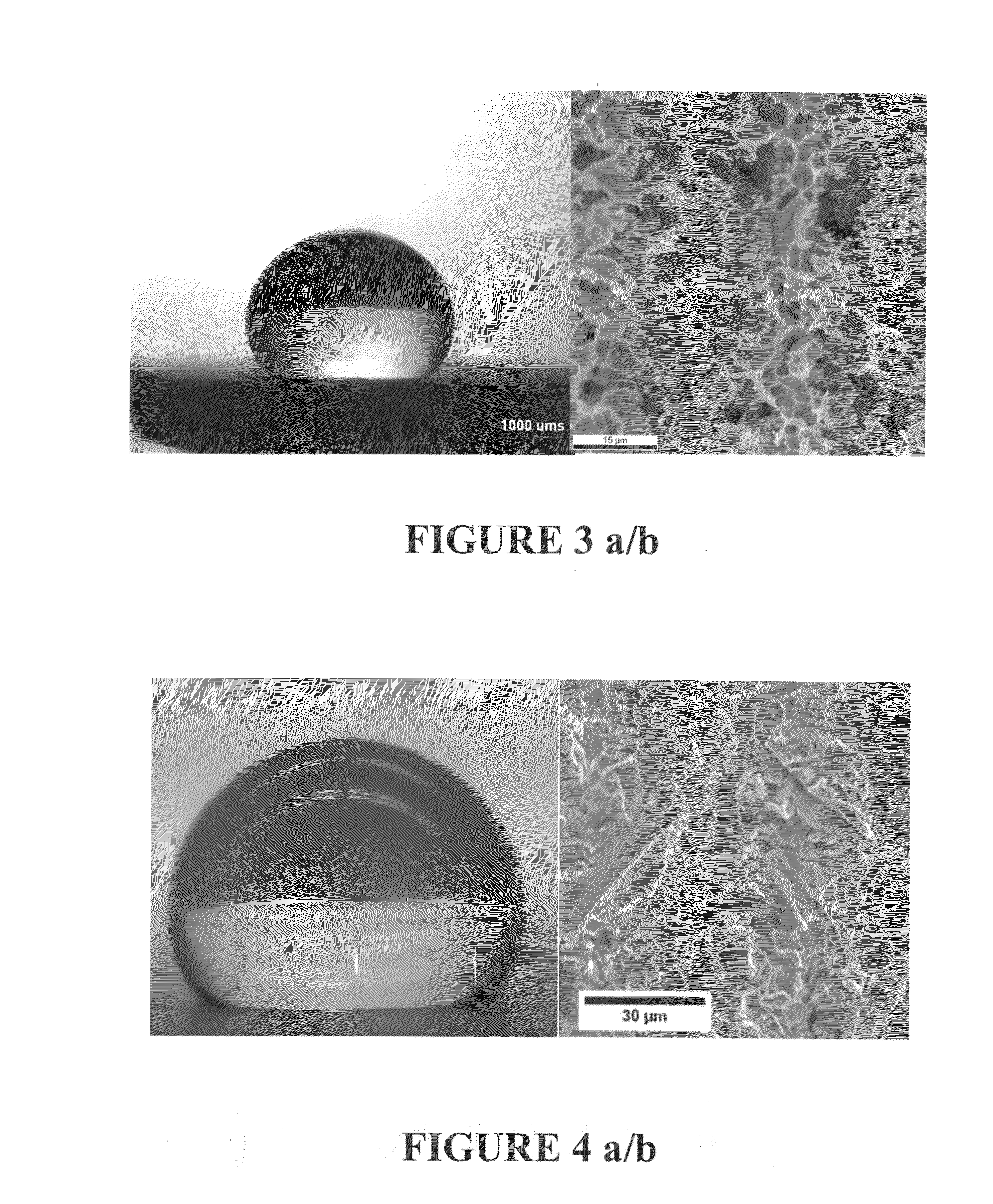

Metallic articles with hydrophobic surfaces

ActiveUS20110287223A1Lower contact angleLarge scaleElectrolysis componentsPretreated surfacesMetal coatingMetallic materials

Articles containing fine-grained and / or amorphous metallic coatings / layers on at least part of their exposed surfaces are imprinted with surface structures to raise the contact angle for water in the imprinted areas at room temperature by equal to or greater than 10°, when compared to the flat and smooth metallic material surface of the same composition.

Owner:INTEGRAN TECH

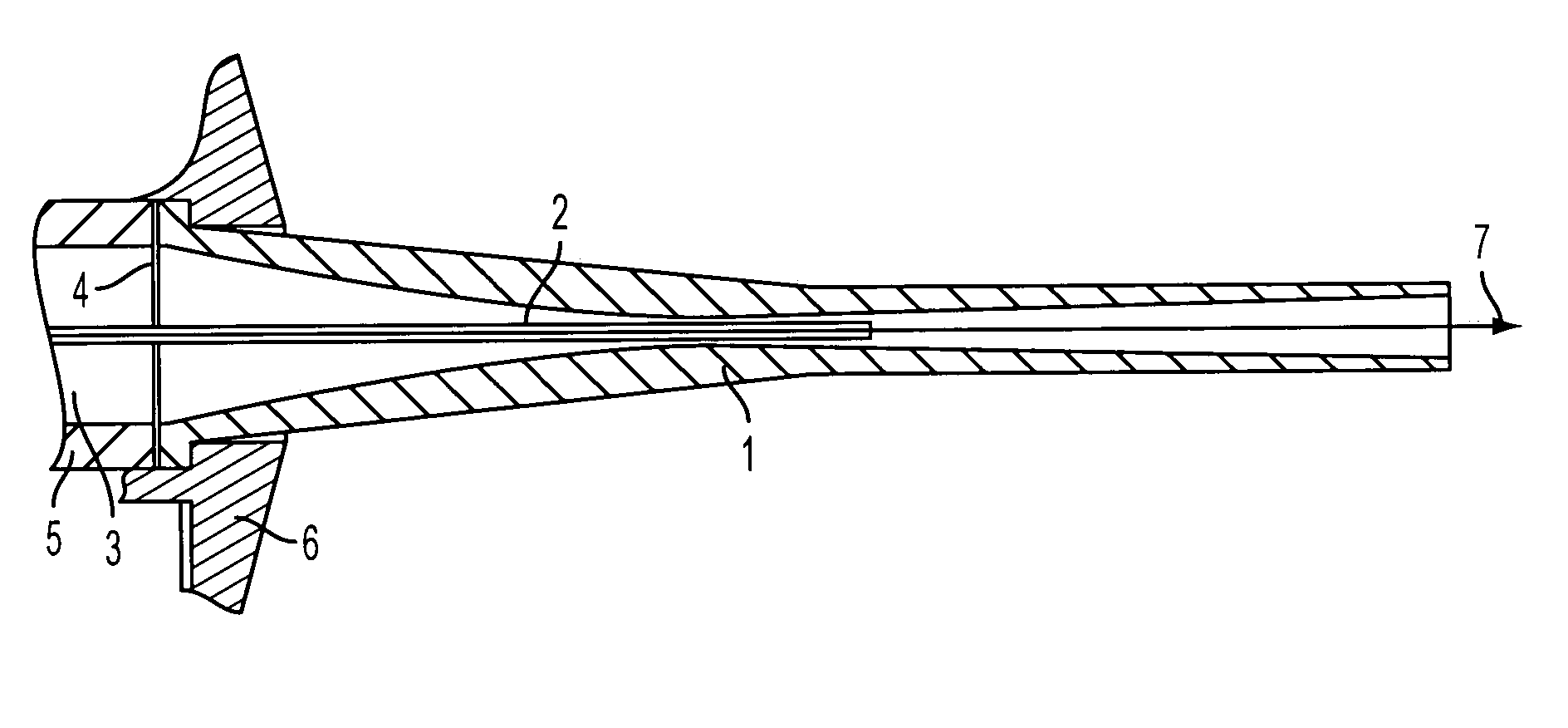

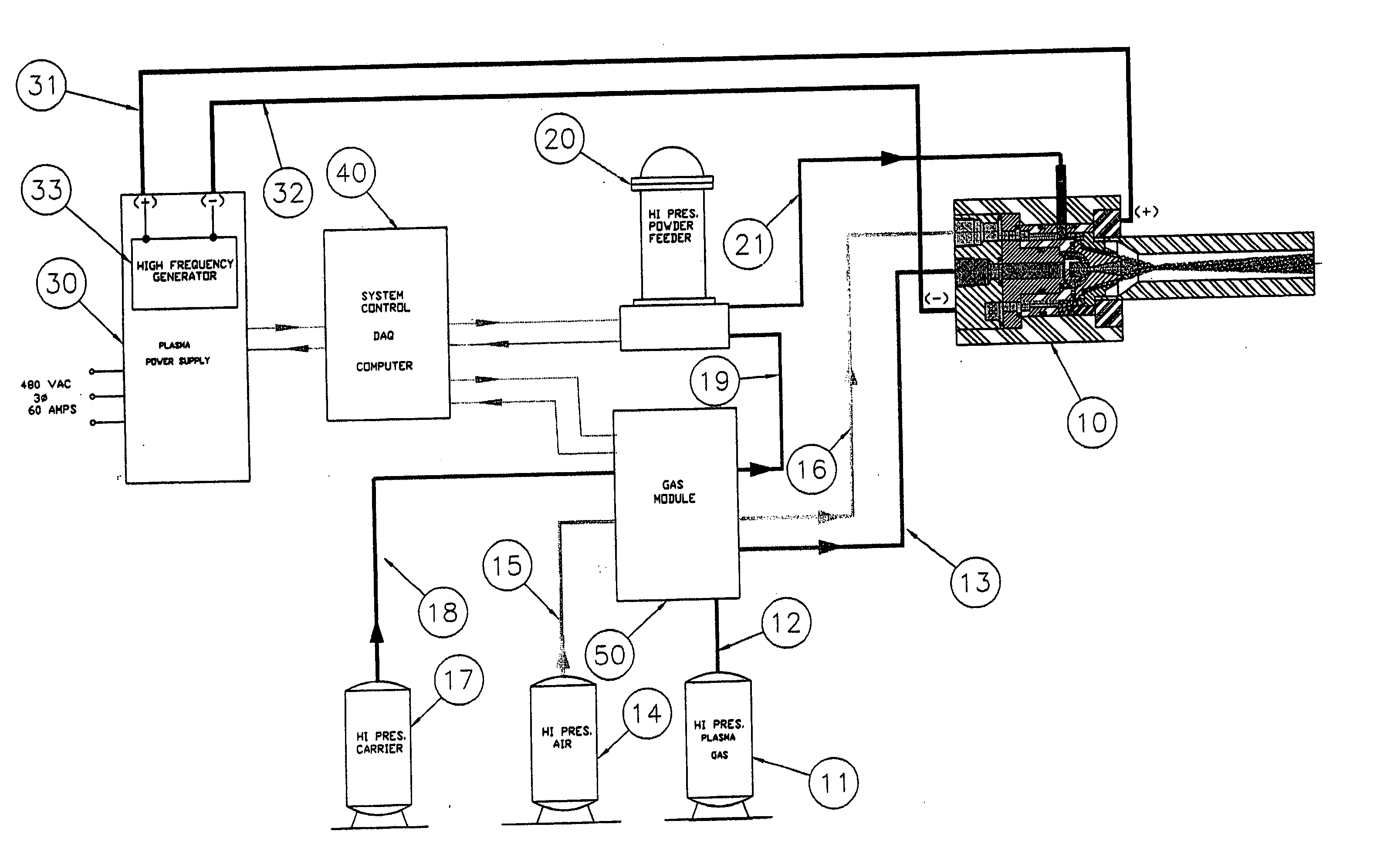

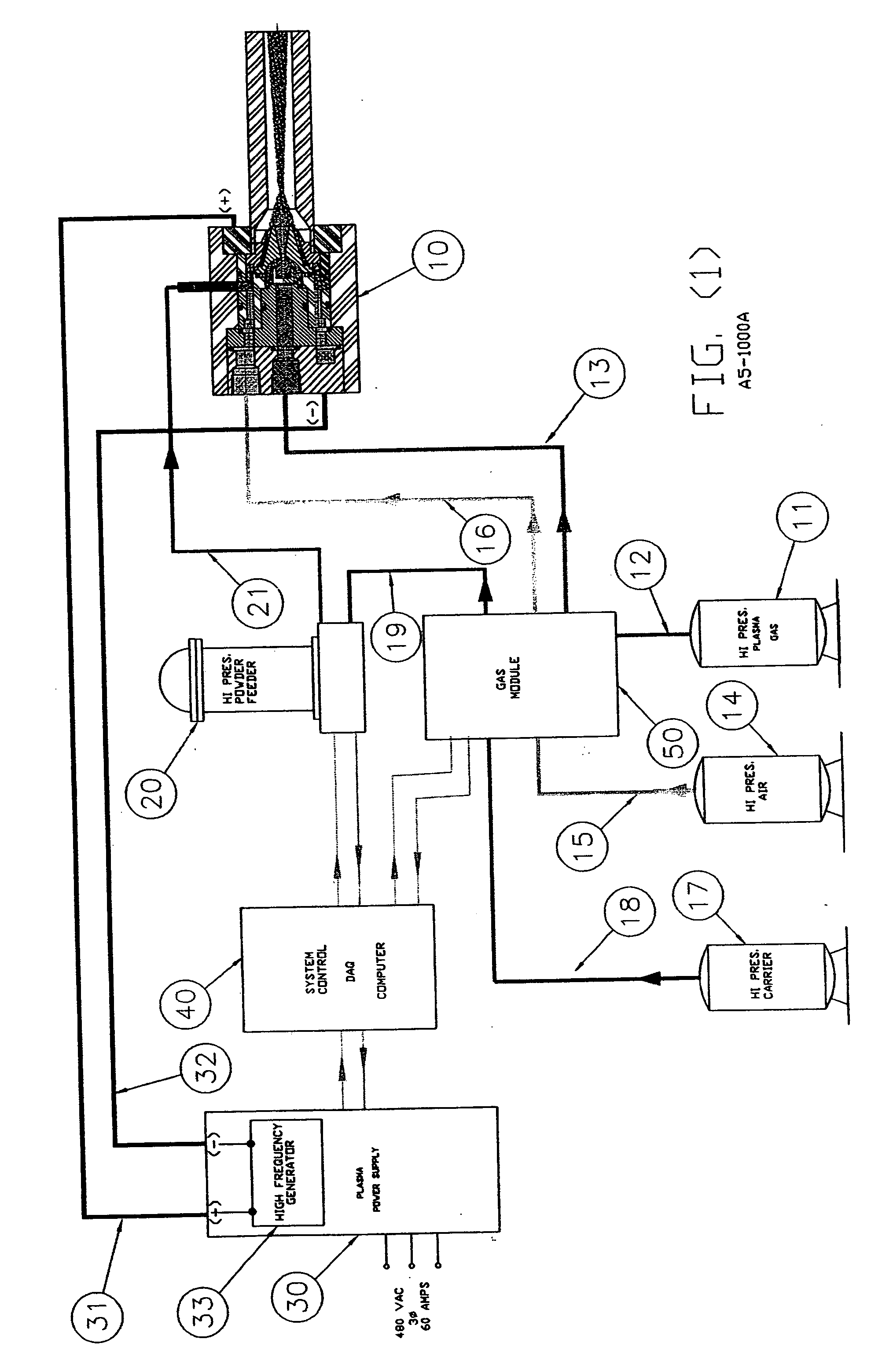

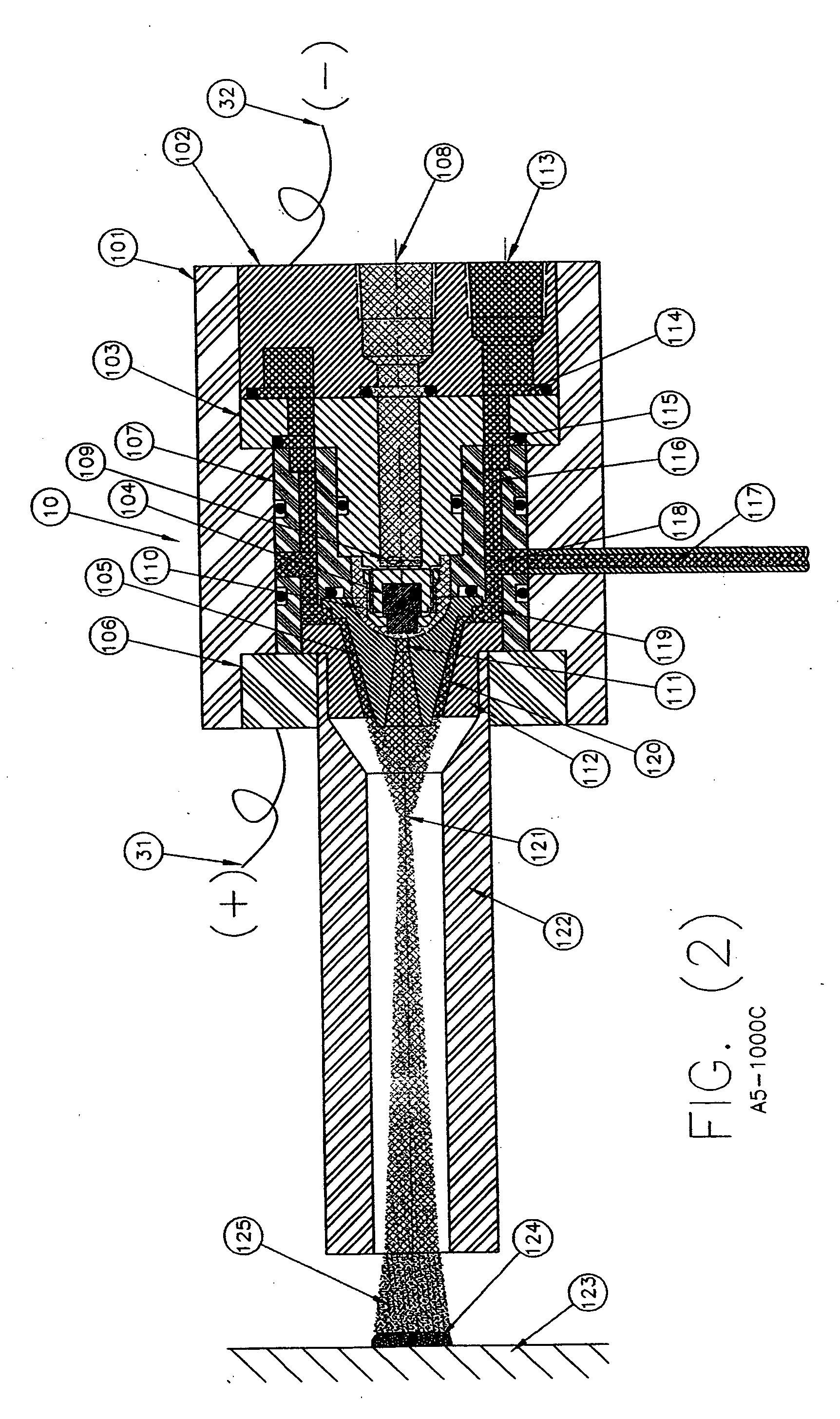

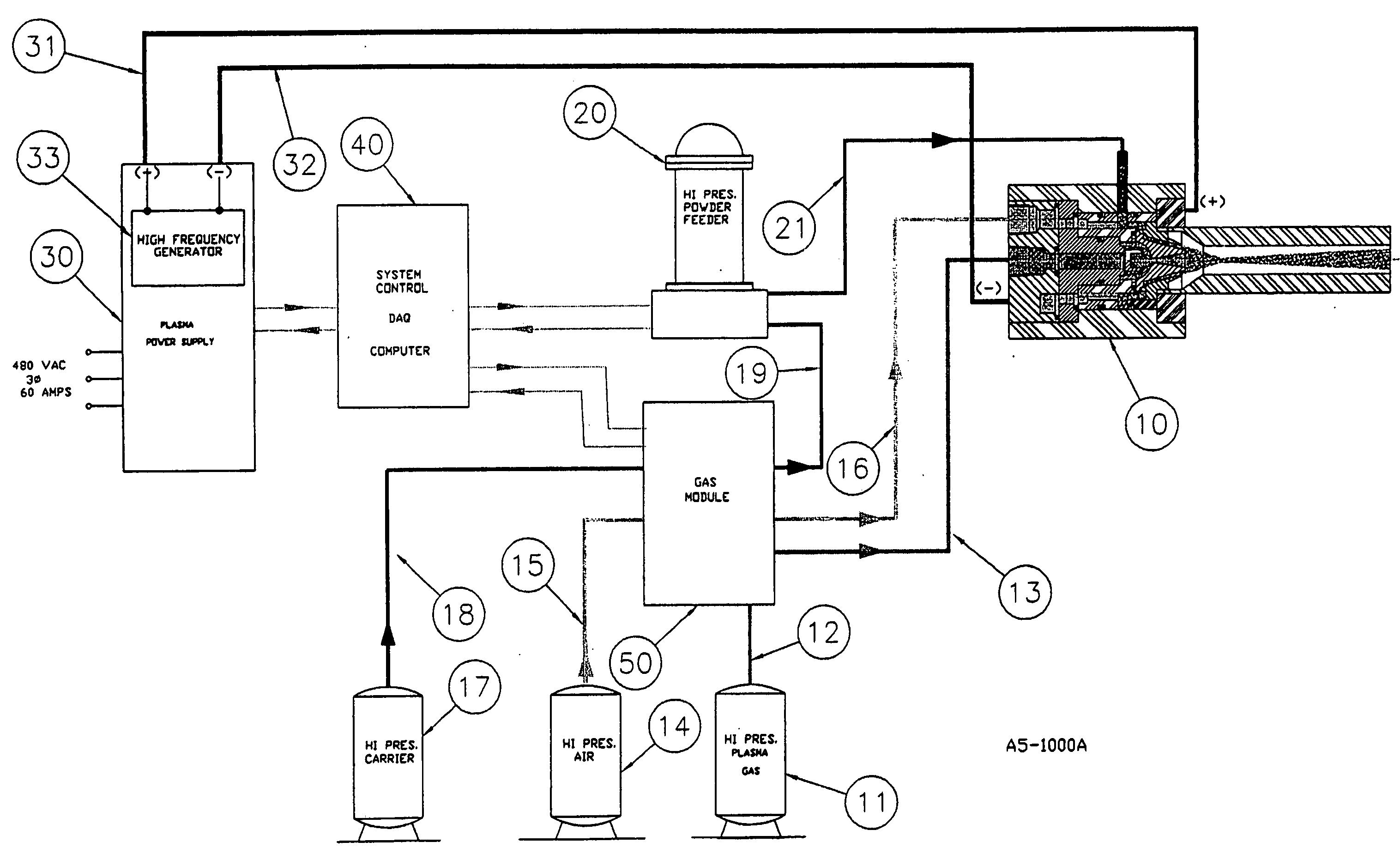

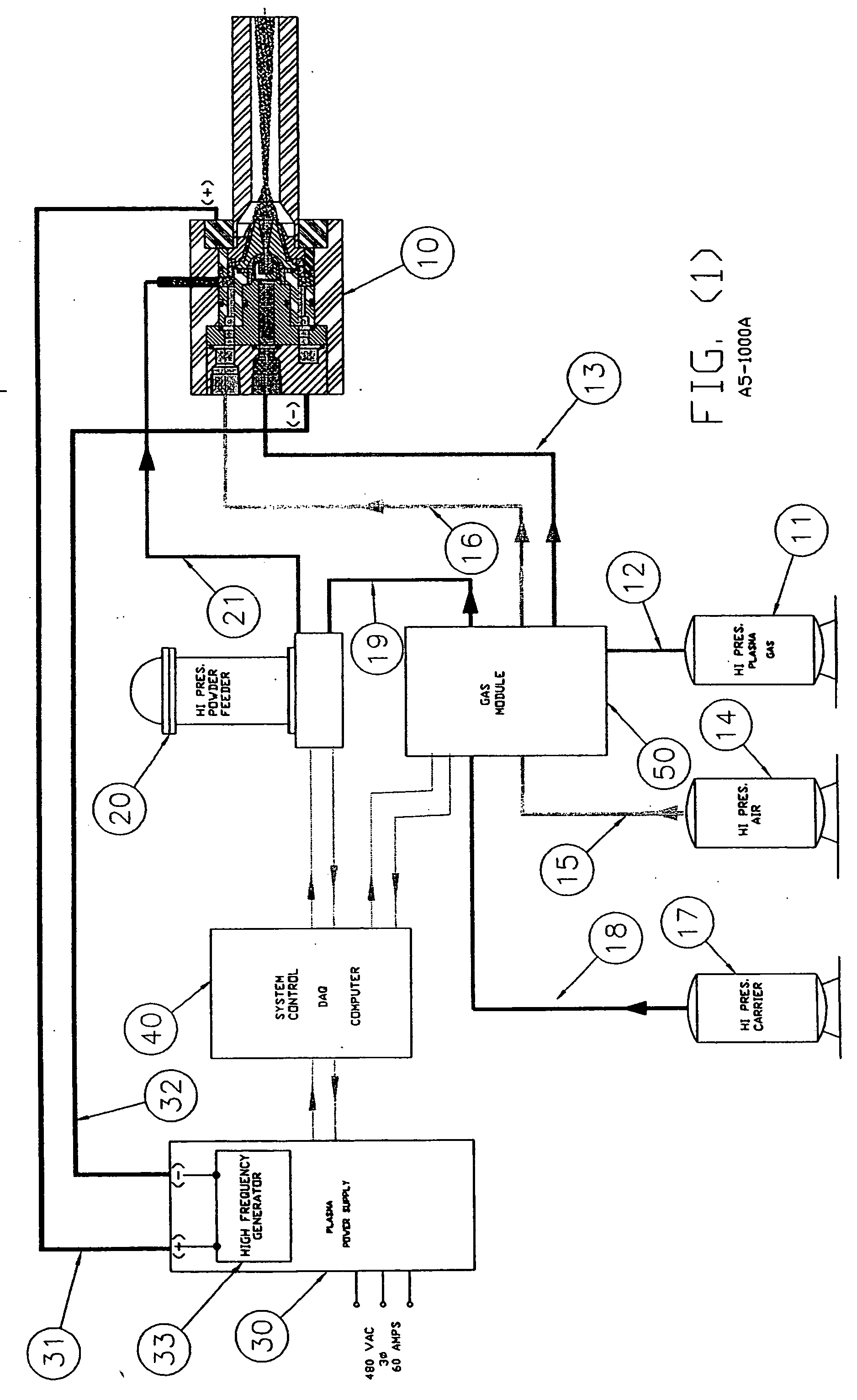

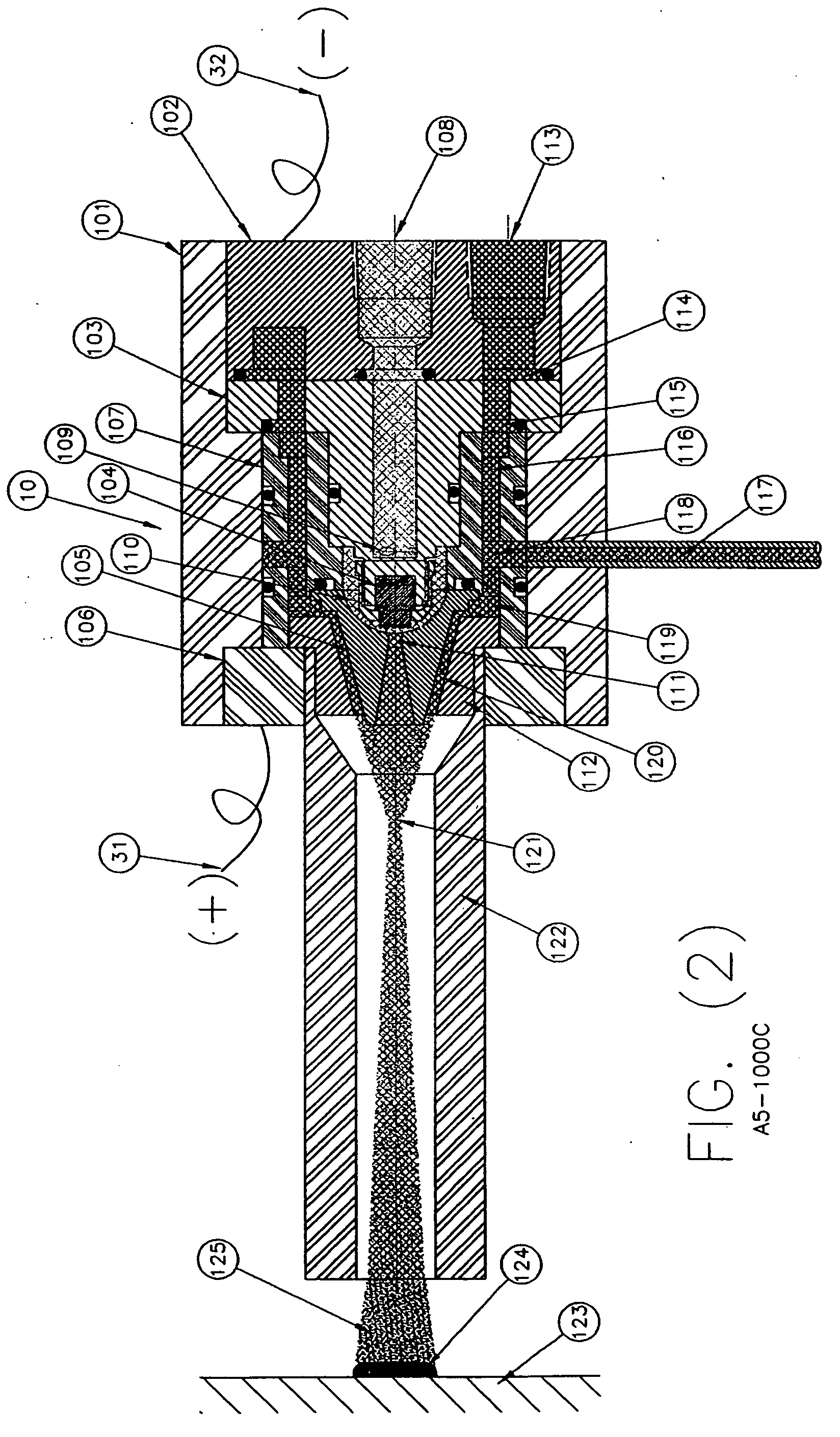

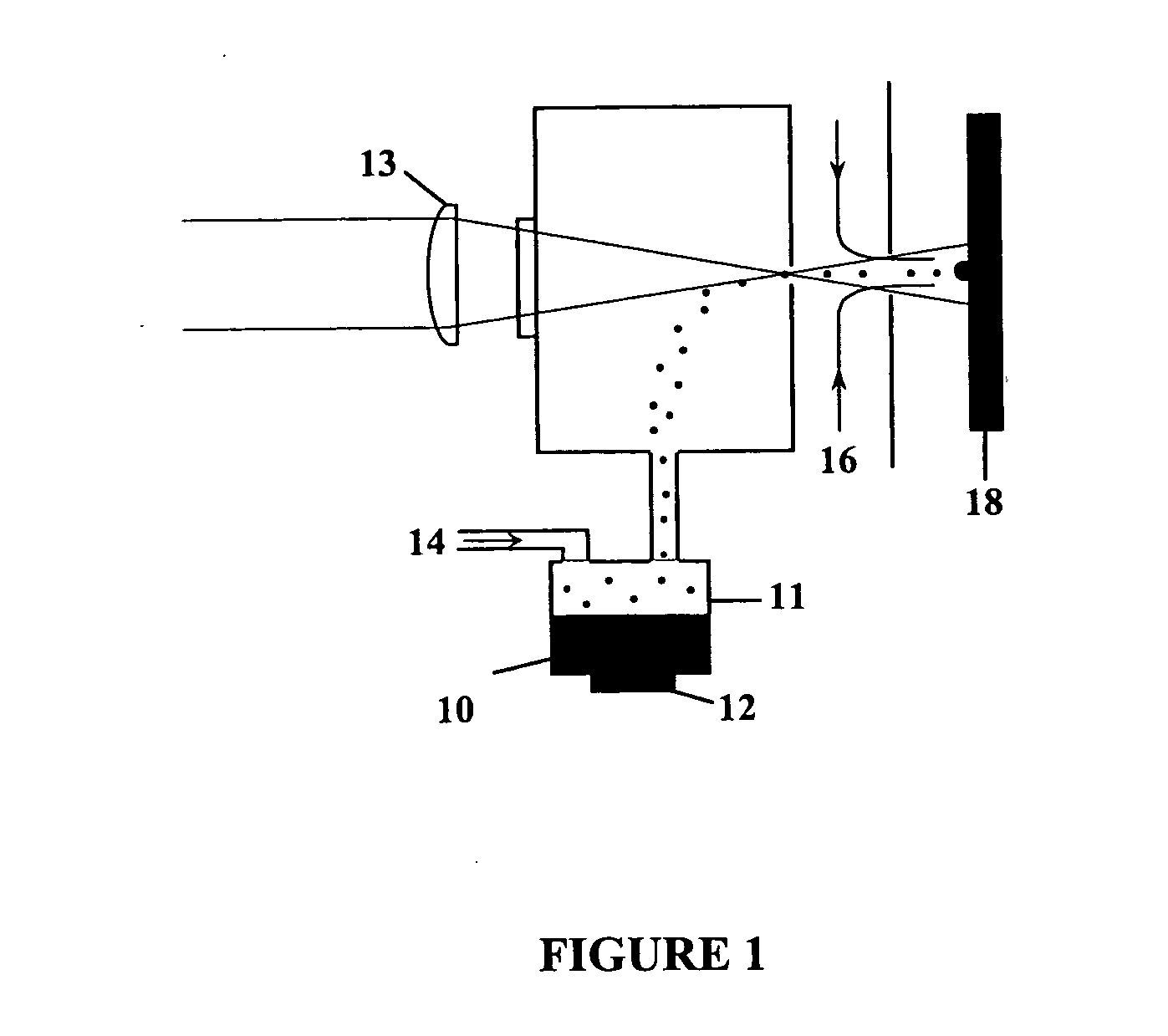

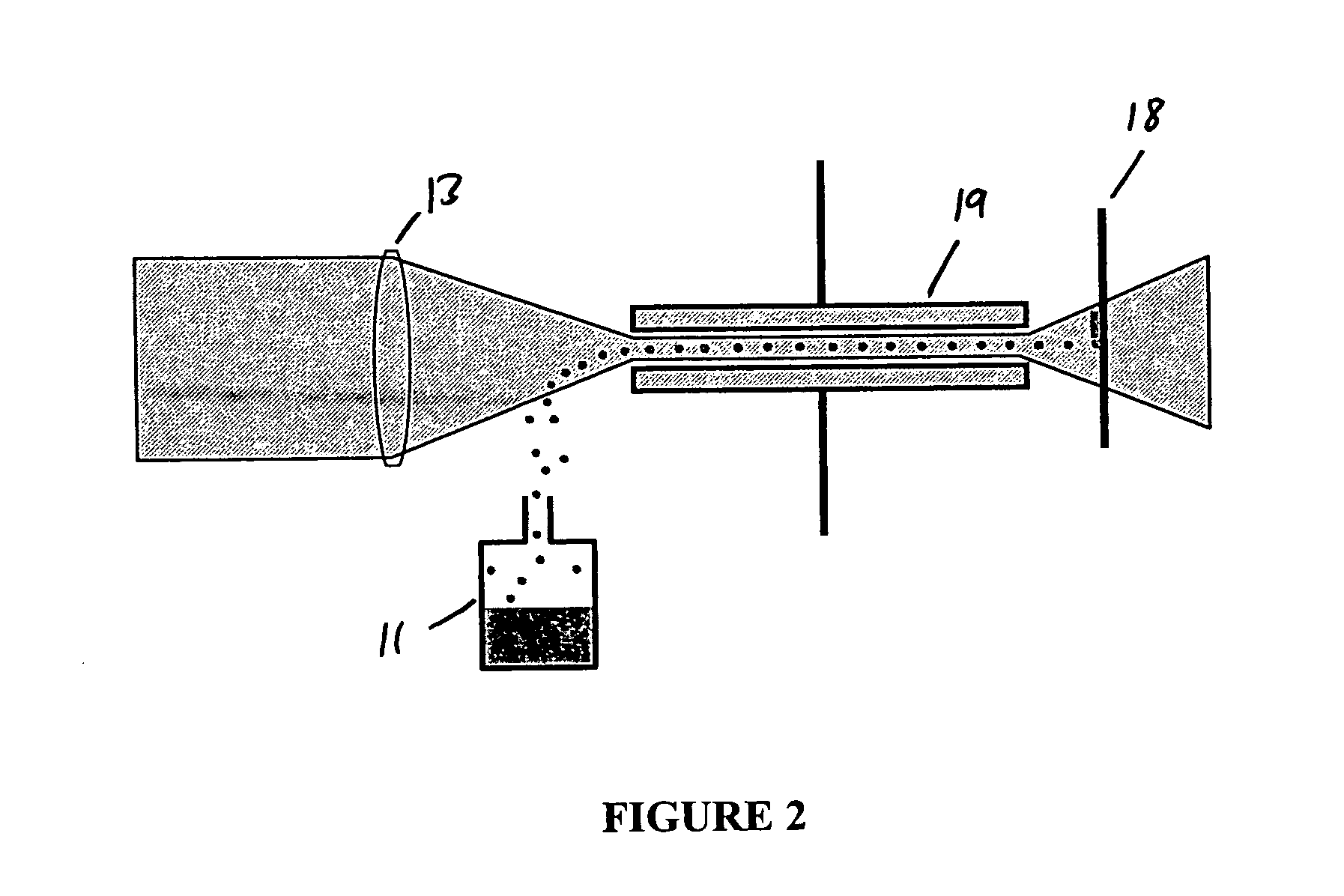

Plasma spray method and apparatus for applying a coating utilizing particle kinetics

InactiveUS20050120957A1Efficient systemUniform compositionLiquid surface applicatorsMolten spray coatingPlasma generatorAlloy

A method of operation of a plasma torch and the plasma apparatus to produce a hot gas jet stream directed towards a workpiece to be coated by first injecting a cold high pressure carrier gas containing a powder material into a cold main high pressure gas flow and then directing this combined high pressure gas flow coaxially around a plasma exiting from an operating plasma generator and converging directly into the hot plasma effluent, thereby mixing with the hot plasma effluent to form a gas stream with a net temperature based on the enthalpy of the plasma stream and the temperature and volume of the cold high pressure converging gas, establishing a net temperature of the gas stream at a temperature such that the powdered material will not melt or soften, and projecting the powder particles at high velocity onto a workpiece surface. The improvement resides in mixing a cold high pressure carrier gas with powder material entrained in it, with a cold high pressure gas flow of gas prior to mixing this combined gas flow with the plasma effluent which is utilized to heat the combined gas flow to an elevated temperature limited to not exceeding the softening point or melting point of the powder material. The resulting hot high pressure gas flow is directed through a supersonic nozzle to accelerate this heated gas flow to supersonic velocities, thereby providing sufficient velocity to the particles striking the workpiece to achieve a kinetic energy transformation into elastic deformation of the particles as they impact the onto the workpiece surface and forming a dense, tightly adhering cohesive coating. Preferably the powder material is of metals, alloys, polymers and mixtures thereof or with semiconductors or ceramics and the powder material is preferably of a particle size range exceeding 50 microns.

Owner:FLAME SPRAY IND

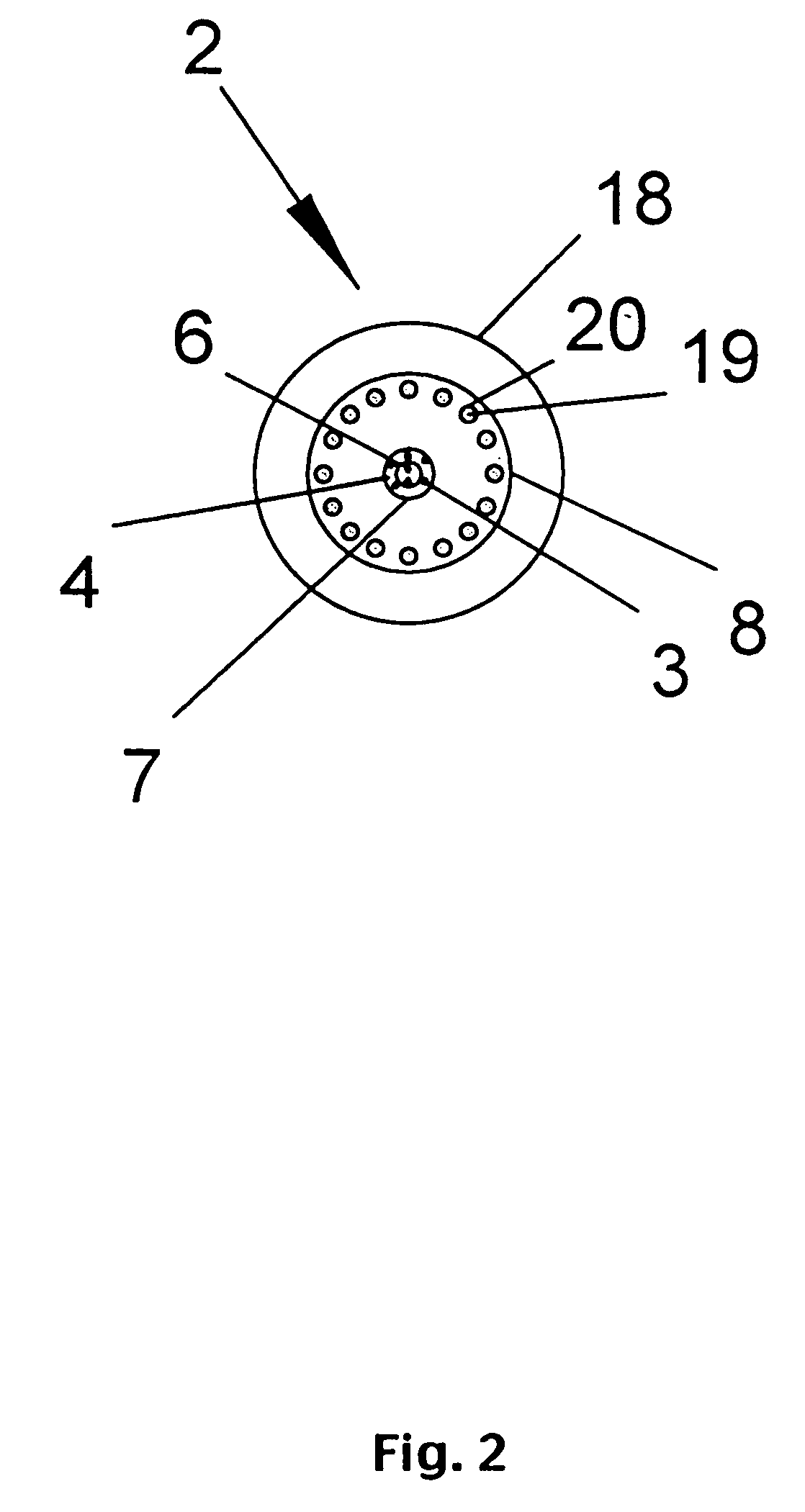

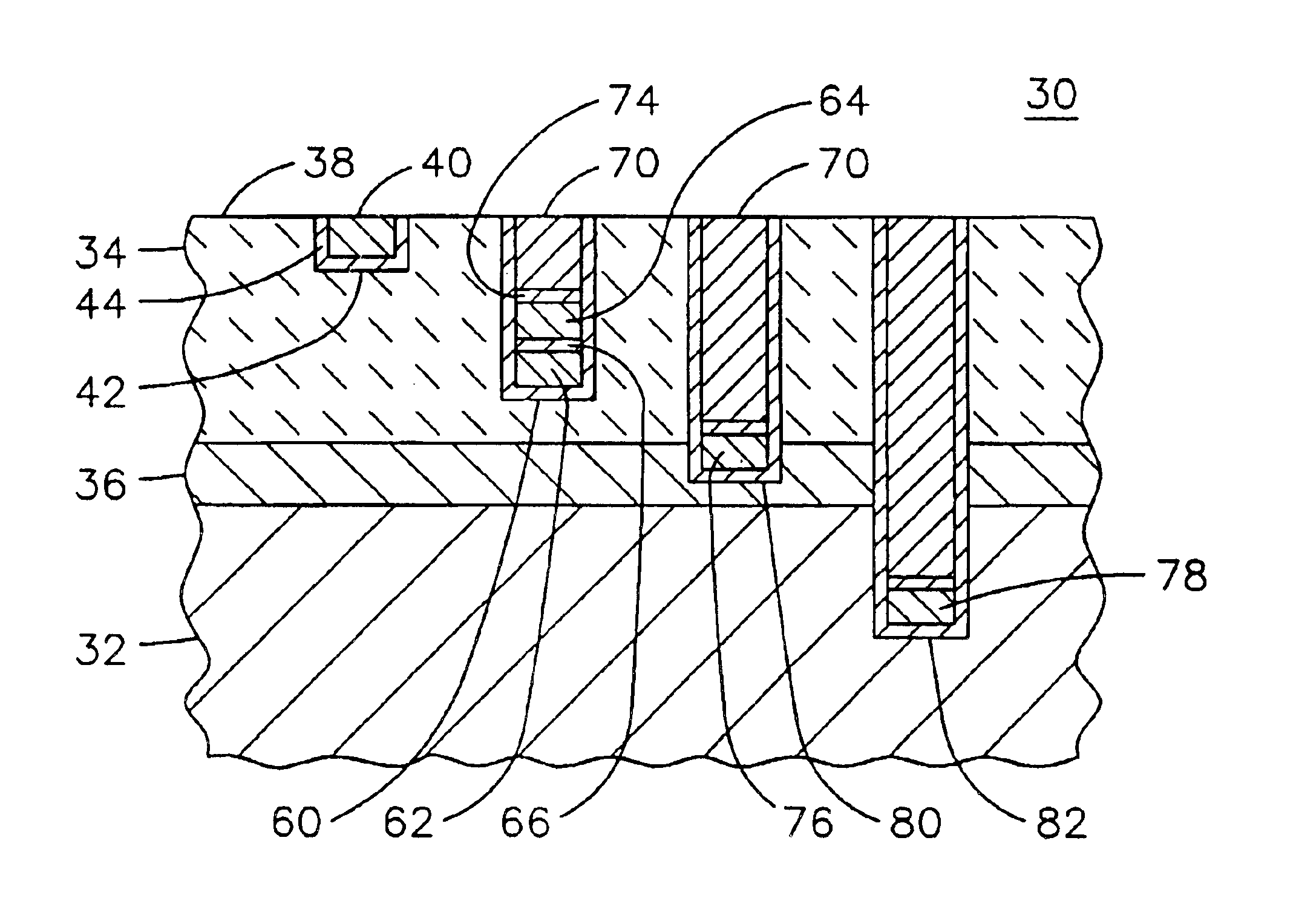

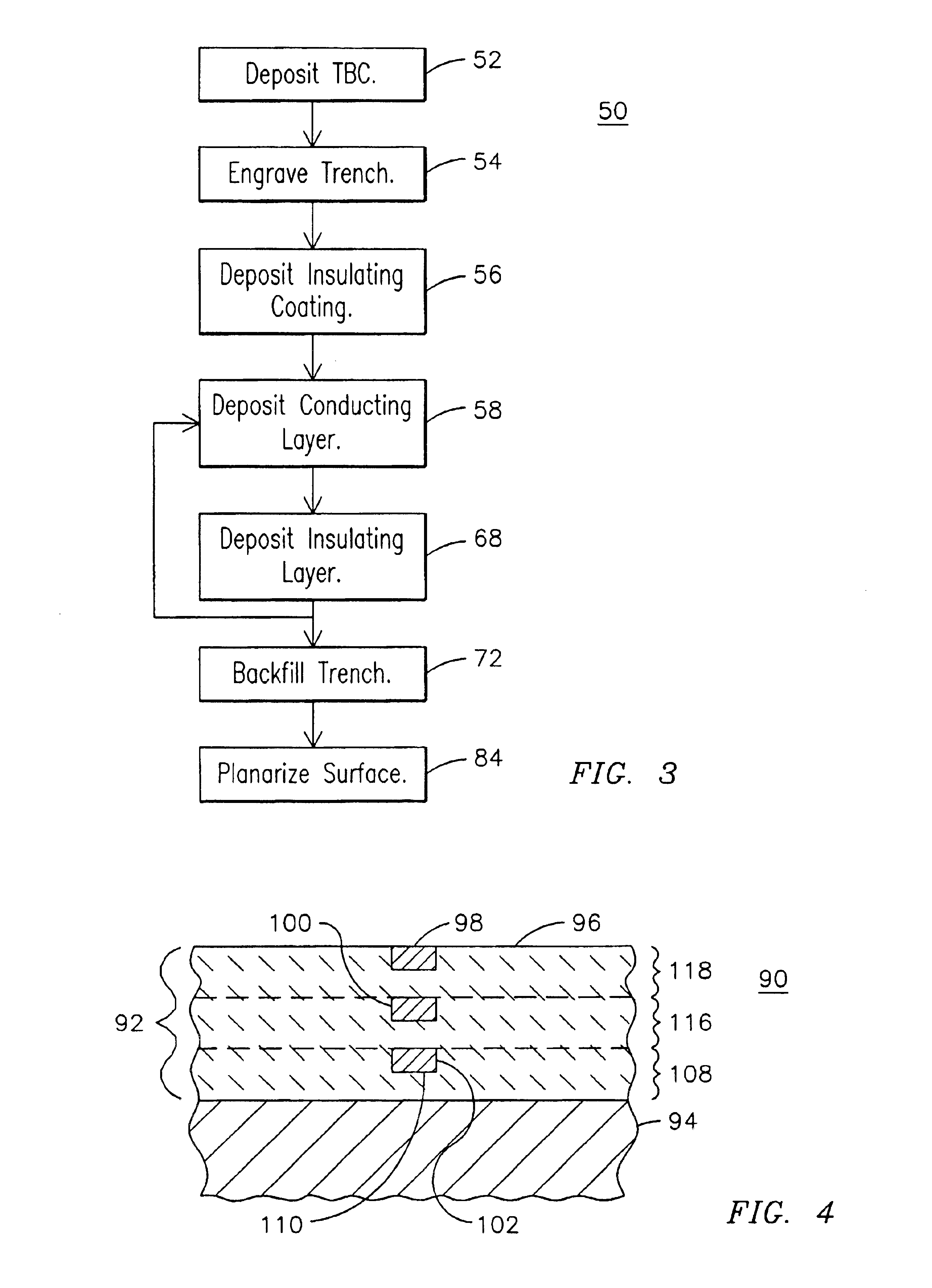

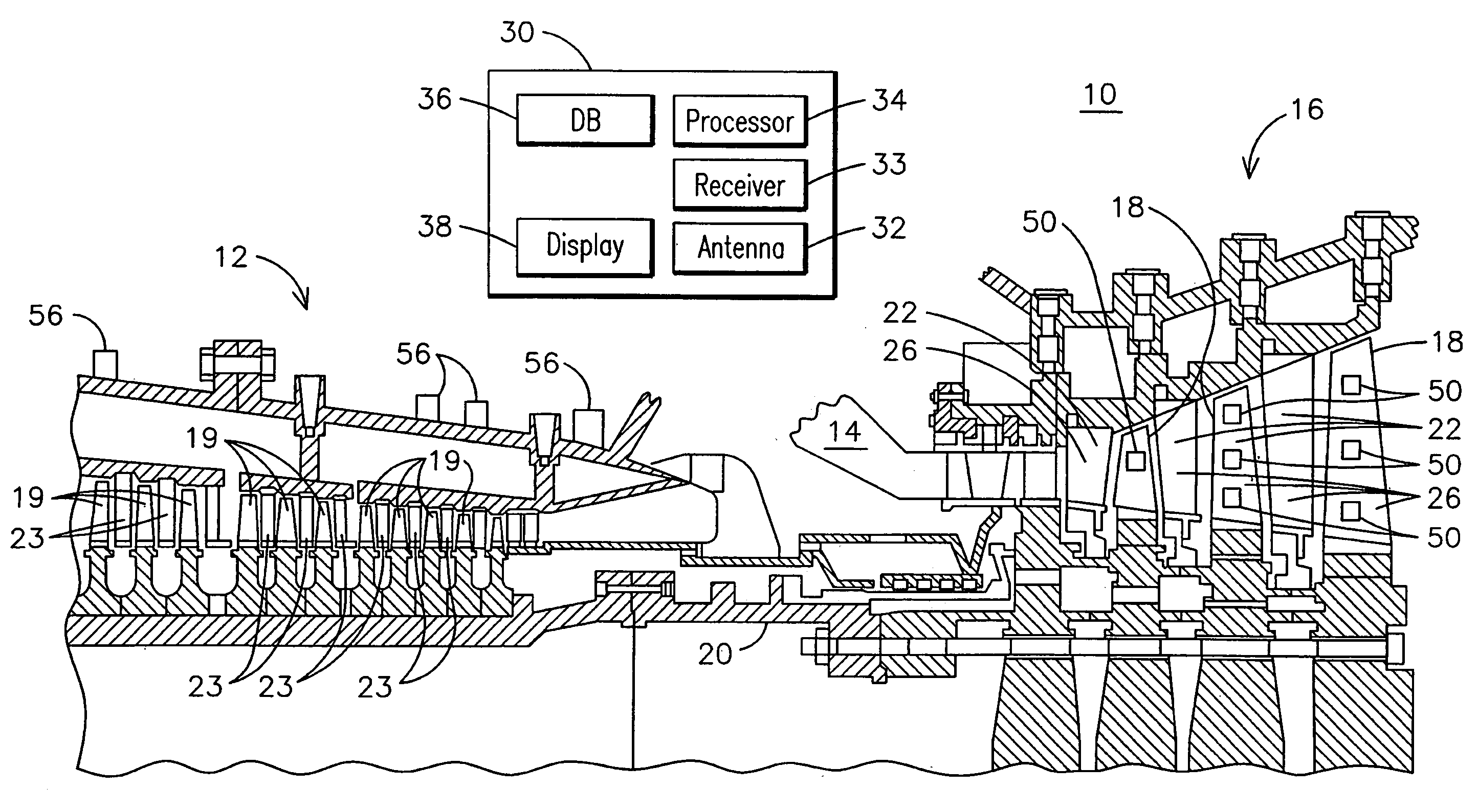

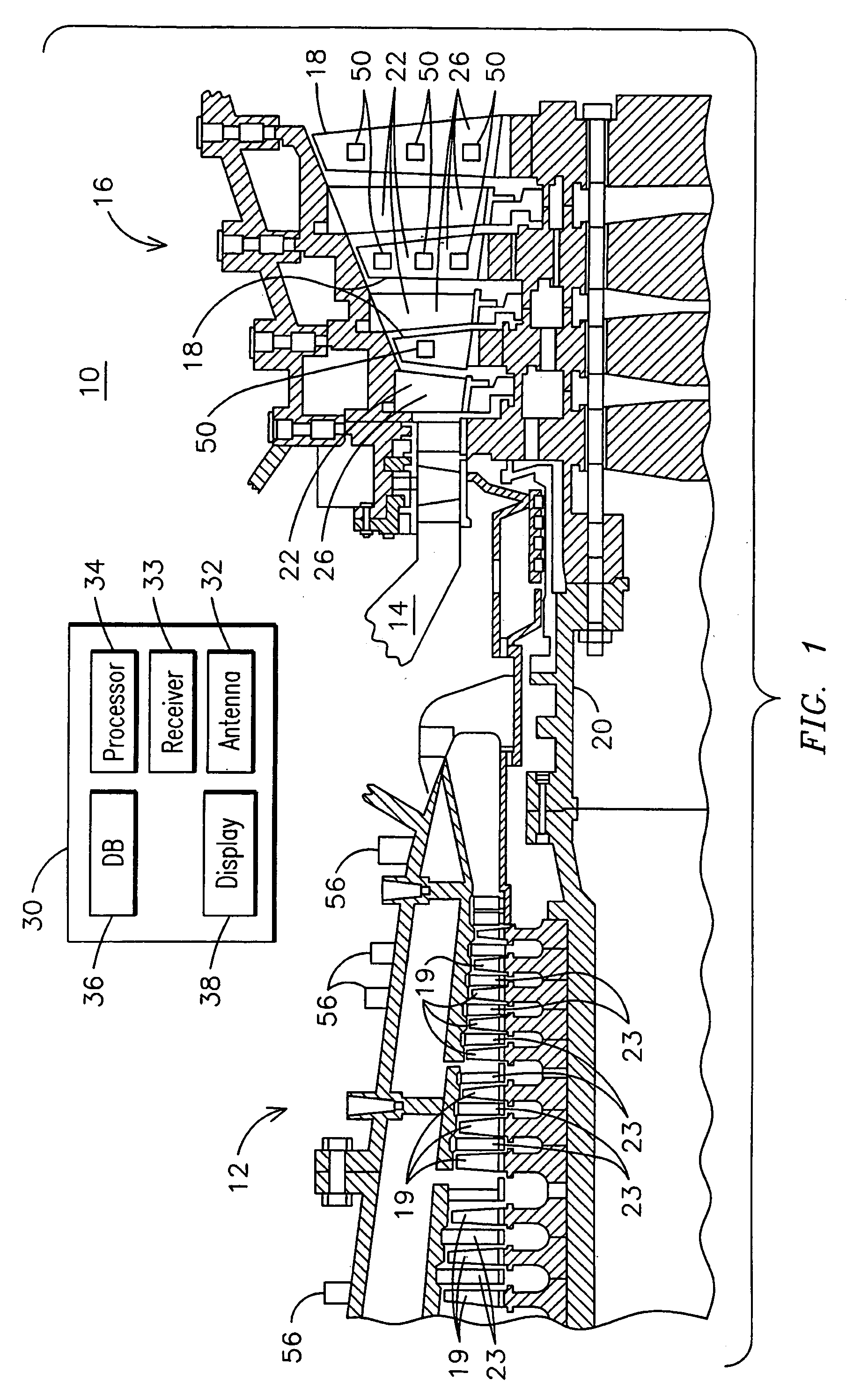

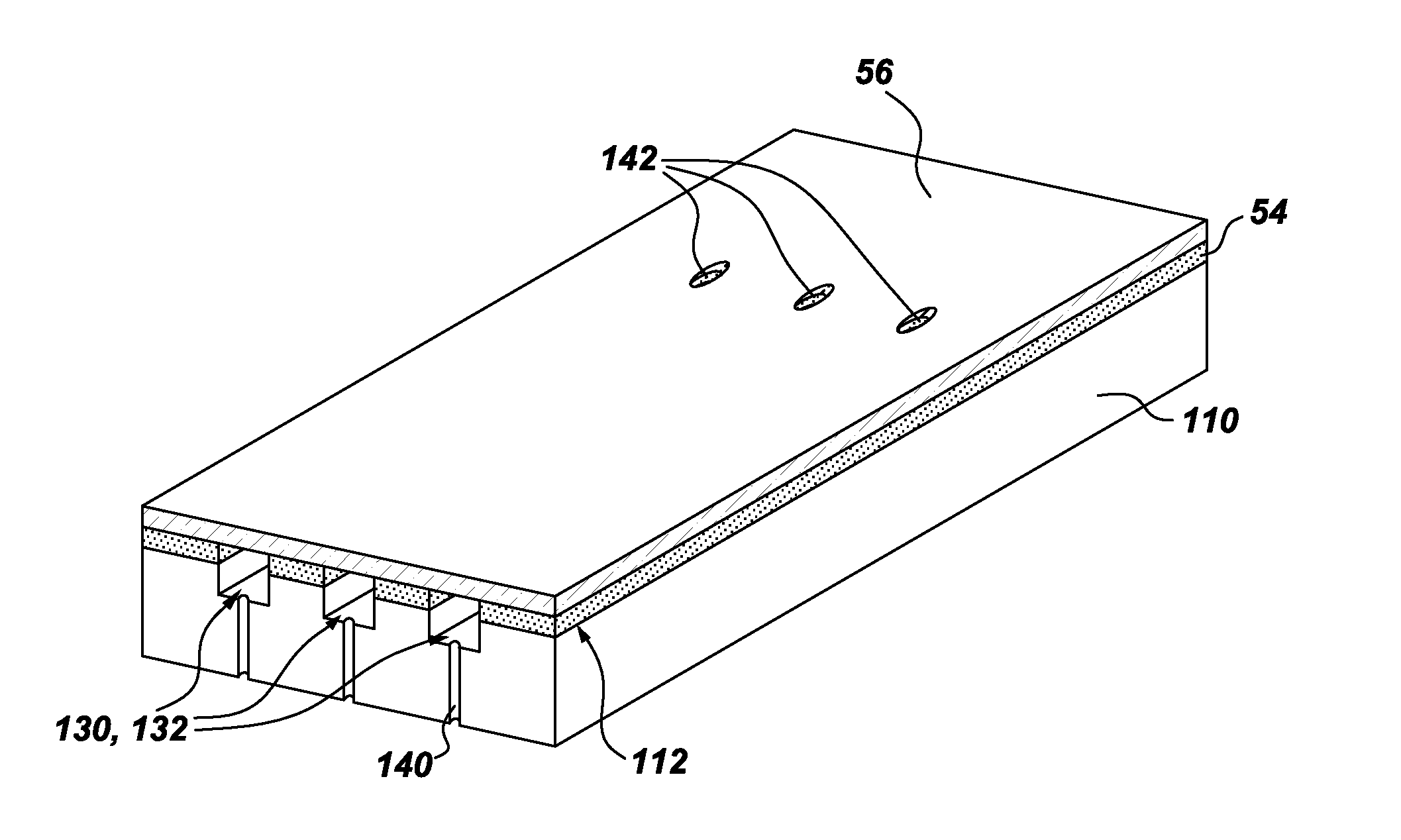

Apparatus and method of detecting wear in an abradable coating system

A component for use in a combustion turbine (10) is provided that includes a substrate (212) and an abradable coating system (216) deposited on the substrate (212). A planar proximity sensor (250) may be deposited beneath a surface of the abradable coating system (216) having circuitry (252) configured to detect intrusion of an object (282) into the abradable coating system (216). A least one connector (52) may be provided in electrical communication with the planar proximity sensor (250) for routing a data signal from the planar proximity sensor (250) to a termination location (59). A plurality of trenches (142) may be formed at respective different depths below the surface of the abradable coating system (216) with a planar proximity sensor (250) deposited within each of the plurality of trenches (142). A processing module (34) may be programmed for receiving data from the planar proximity sensor (250) and calculating a clearance between a row of blades (18,19) within a combustion turbine and the planar proximity sensor (250). The processing module (34) may control a clearance between the row of blades (18) and a ring segment (284) based on data received from the planar proximity sensors (250).

Owner:SIEMENS ENERGY INC

Plasma spray method and apparatus for applying a coating utilizing particle kinetics

InactiveUS20050252450A1Efficient systemUniform compositionLiquid surface applicatorsMolten spray coatingPlasma generatorAlloy

A method of operation of a plasma torch and the plasma apparatus to produce a hot gas jet stream directed towards a workpiece to be coated by first injecting a cold high pressure carrier gas containing a powder material into a cold main high pressure gas flow and then directing this combined high pressure gas flow coaxially around a plasma exiting from an operating plasma generator and converging directly into the hot plasma effluent, thereby mixing with the hot plasma effluent to form a gas stream with a net temperature based on the enthalpy of the plasma stream and the temperature and volume of the cold high pressure converging gas, establishing a net temperature of the gas stream at a temperature such that the powdered material will not melt or soften, and projecting the powder particles at high velocity onto a workpiece surface. The improvement resides in mixing a cold high pressure carrier gas with powder material entrained in it, with a cold high pressure gas flow of gas prior to mixing this combined gas flow with the plasma effluent which is utilized to heat the combined gas flow to an elevated temperature limited to not exceeding the softening point or melting point of the powder material. The resulting hot high pressure gas flow is directed through a supersonic nozzle to accelerate this heated gas flow to supersonic velocities, thereby providing sufficient velocity to the particles striking the workpiece to achieve a kinetic energy transformation into elastic deformation of the particles as they impact the onto the workpiece surface and forming a dense, tightly adhering cohesive coating. Preferably the powder material is of metals, alloys, polymers and mixtures thereof or with semiconductors or ceramics and the powder material is preferably of a particle size range exceeding 50 microns. The system also includes a rotating member for coating concave surfaces and internal bores or other such devices which can be better coated using rotation.

Owner:FLAME SPRAY IND

Coating process for manufacture or reprocessing of sputter targets and x-ray anodes

ActiveUS20080216602A1Low heat introductionWide applicabilityLiquid surface applicatorsMolten spray coatingPowder mixtureNiobium

Disclosed is a process for the reprocessing or production of a sputter target or an X-ray anode wherein a gas flow forms a gas / powder mixture with a powder of a material chosen from the group consisting of niobium, tantalum, tungsten, molybdenum, titanium, zirconium, mixtures of two or more thereof and alloys thereof with at least two thereof or with other metals, the powder has a particle size of 0.5 to 150 μm, wherein a supersonic speed is imparted to the gas flow and the jet of supersonic speed is directed on to the surface of the object to be reprocessed or produced.

Owner:H C STARCK SURFACE TECH & CERAMIC POWDERS GMBH

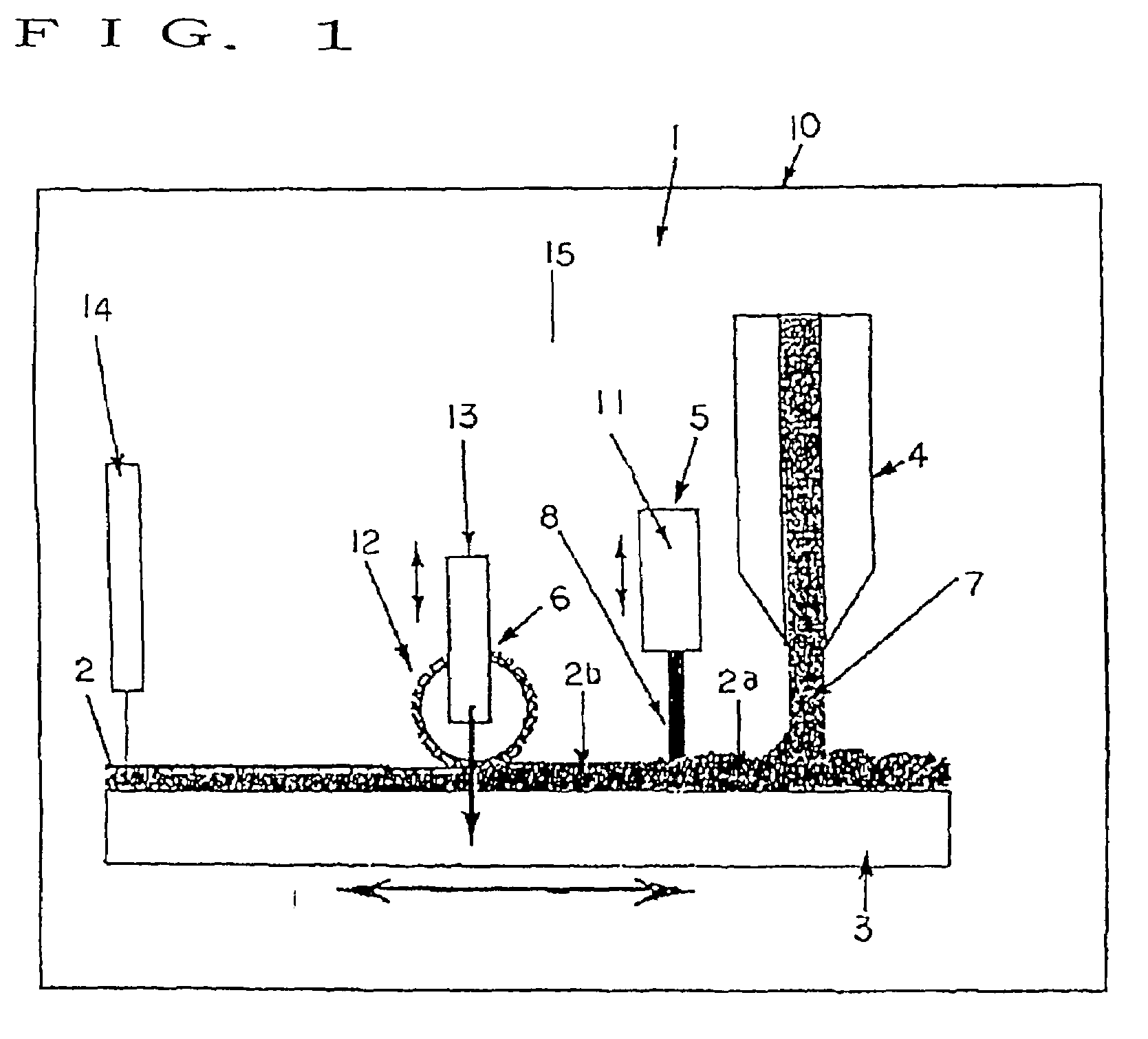

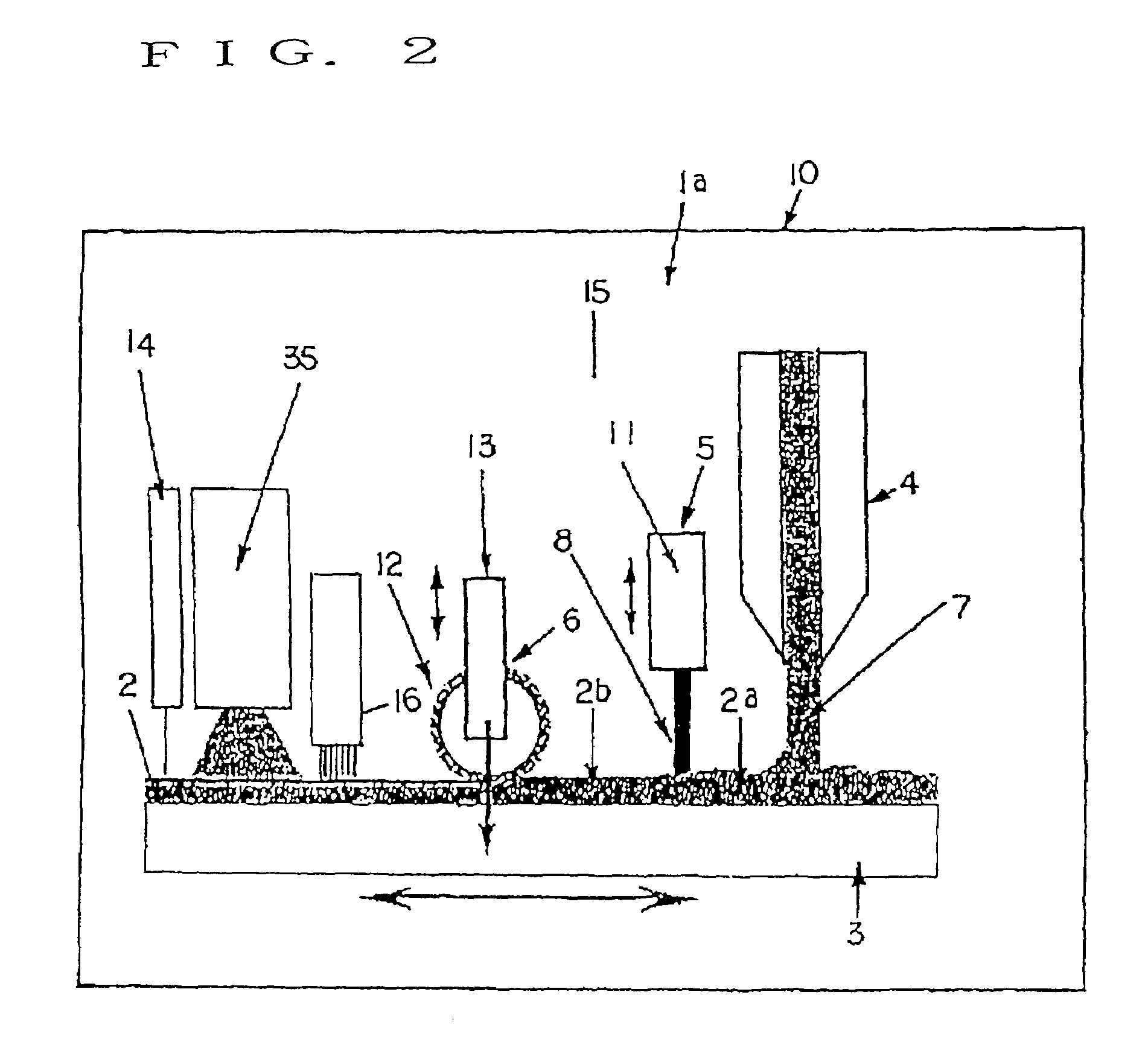

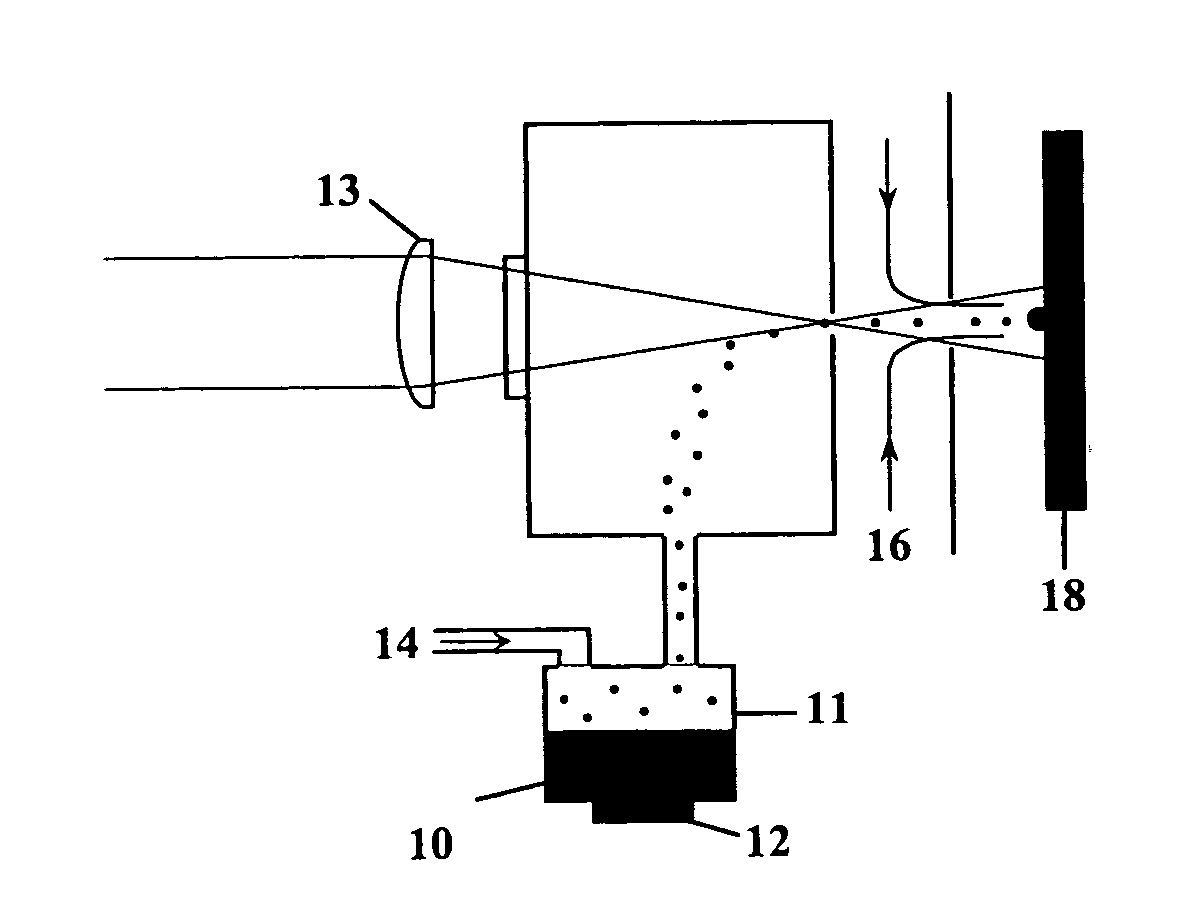

Ultra fine particle film forming method and apparatus

A ultra fine particle film forming apparatus is provided which is capable of forming a ultra fine particle film which has ultra fine particles sufficiently bonded together, sufficient density, flat surface and uniform density. A planarized ultra fine particle film forming method for forming a planarized ultra fine particle film from a deposited film of ultra fine particles formed by supplying the ultra fine particles to a substrate, the method comprising one or more of a planarizing step of planarizing a surface of the deposited film of the ultra fine particles supplied to the substrate.

Owner:NAT INST OF ADVANCED IND SCI & TECH

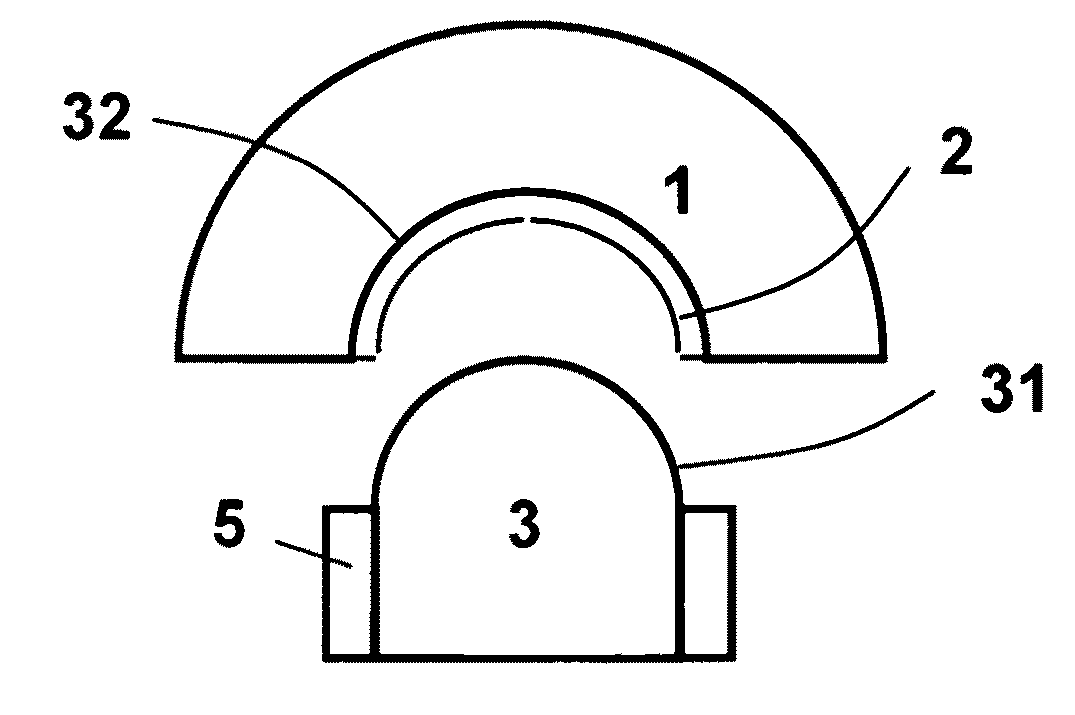

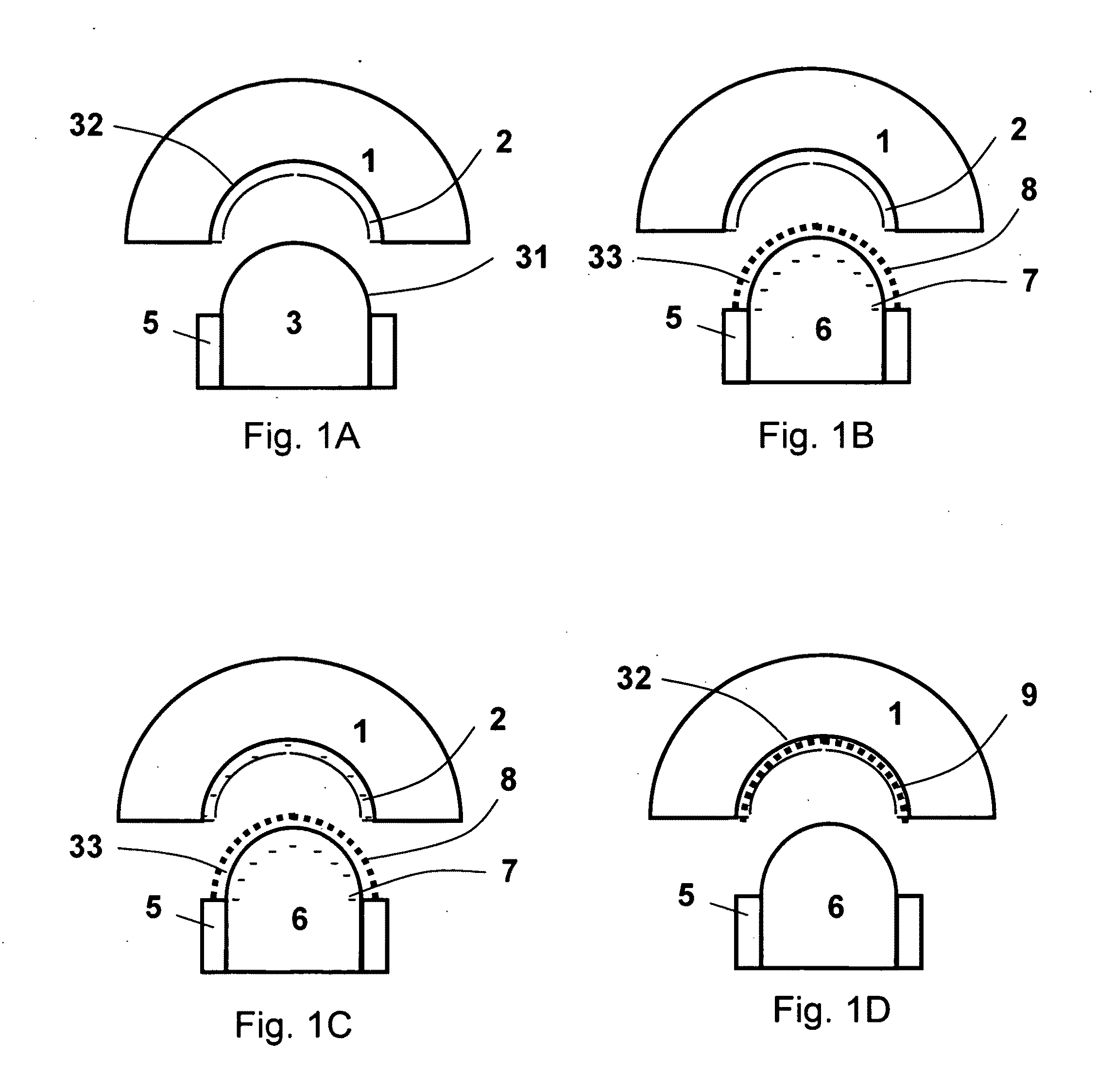

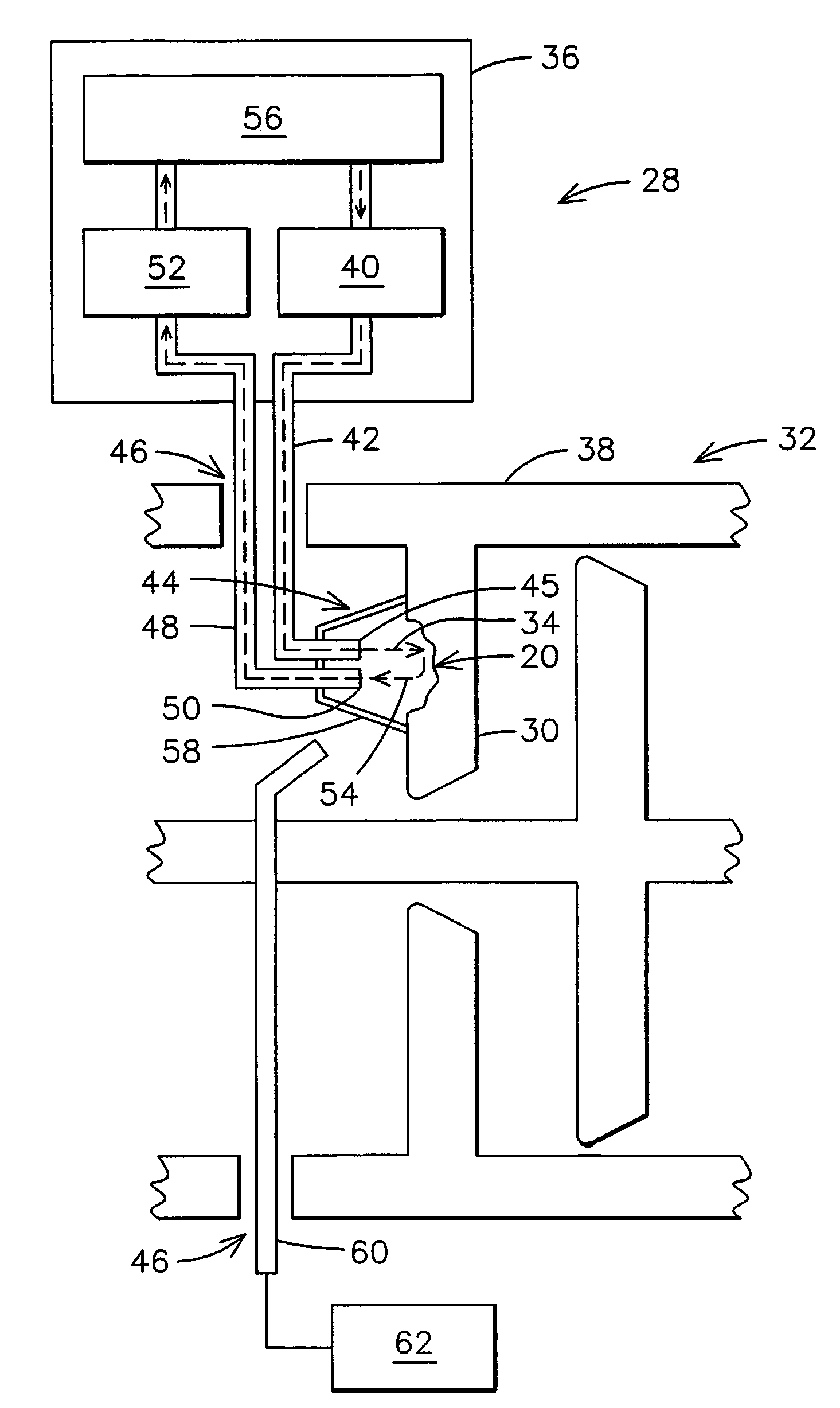

In-frame repairing system of gas turbine components

A method for in-frame repairing of a thermal barrier coating (12) on a gas turbine component includes cleaning a desired surface portion (10) of the component without removing the component from the gas turbine. The method also includes roughening the surface portion in-frame, applying a bond coat (68) to the surface portion in-frame, and applying a ceramic topcoat (70) to the bond coat, in-frame. A system (28) for cleaning the surface portion in-frame includes an abrasive media (34) having a state change characteristic occurring at a temperature lower than an operating temperature of the gas turbine so that the abrasive media changes from a solid state to another state allowing the media to exit the gas turbine during operation. The system also includes an abrasive media sprayer (36) to direct a spray of the abrasive media at the desired surface portion.

Owner:SIEMENS ENERGY INC

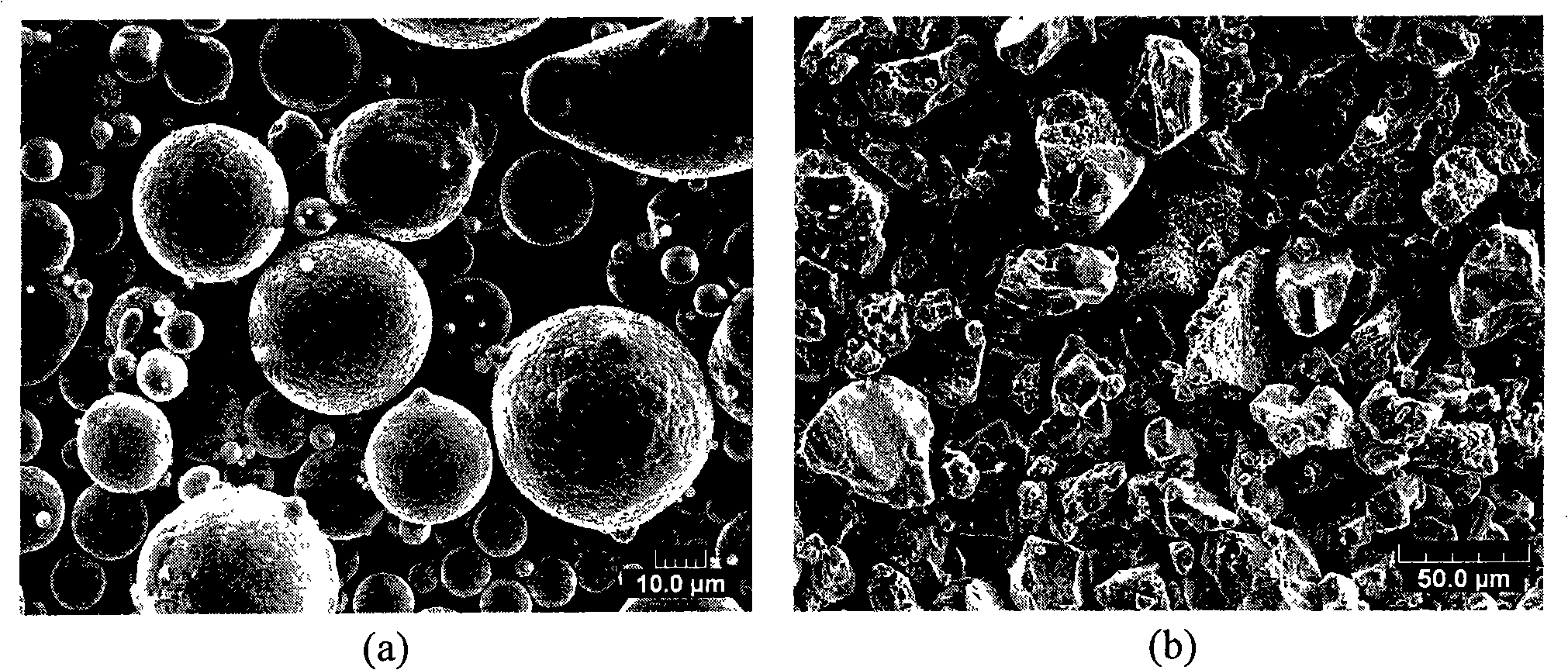

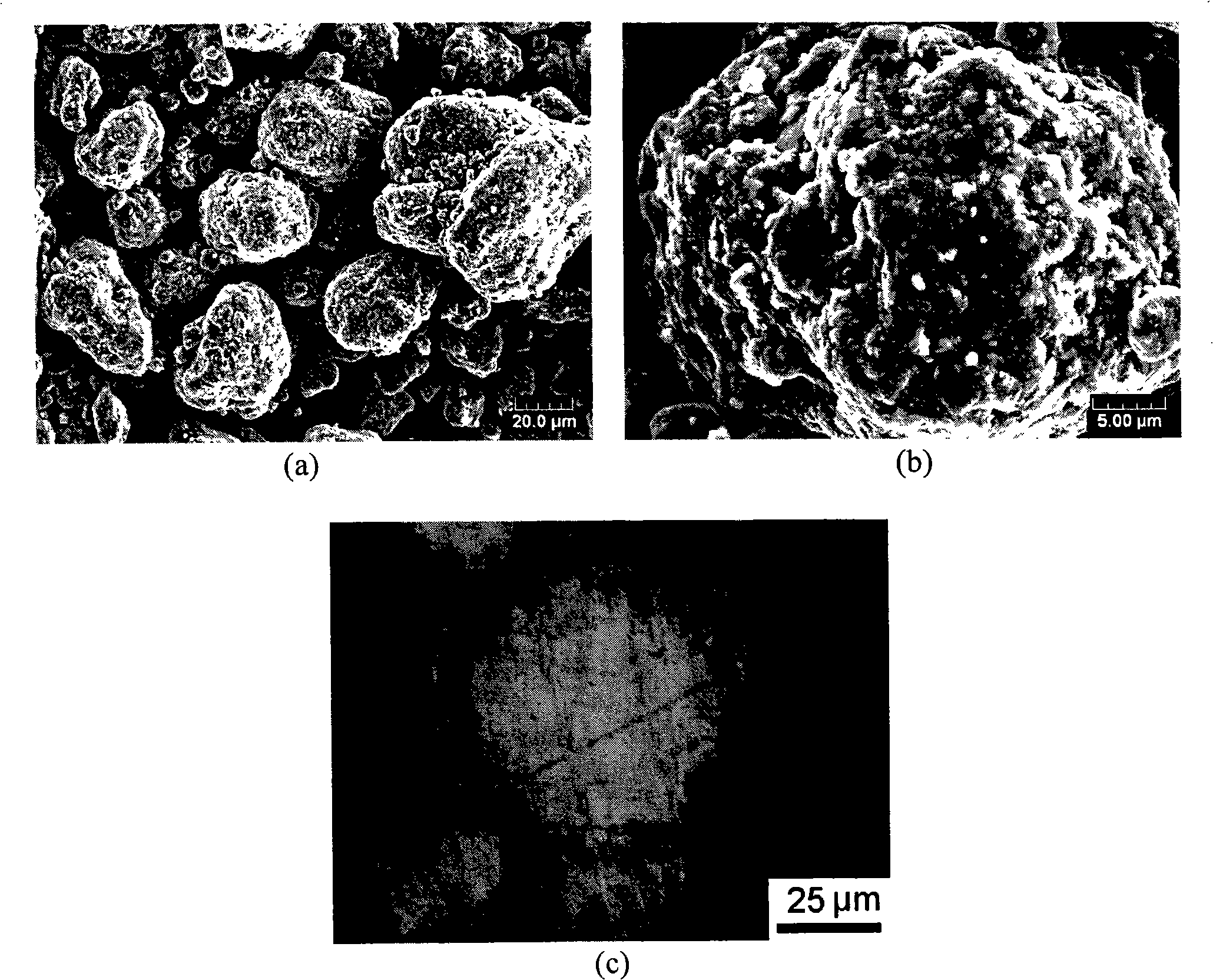

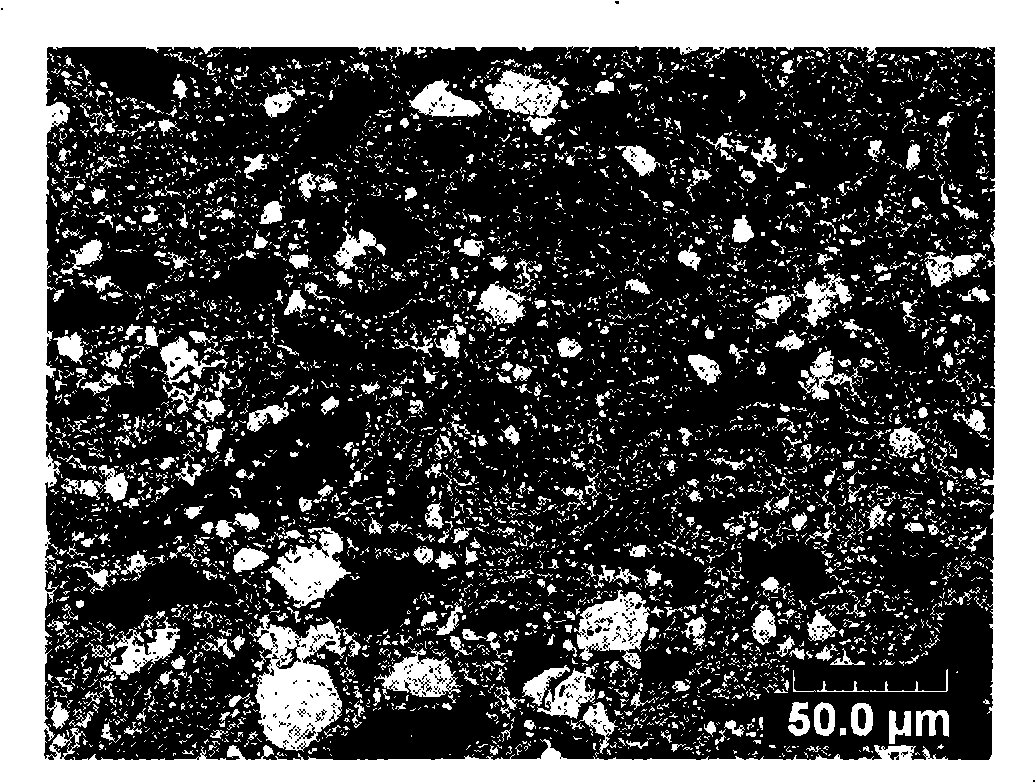

Method for preparing particulate reinforced metal-based composite material

InactiveCN101285187AImprove performanceDense tissuePressure inorganic powder coatingParticulatesHigh energy

The invention relates to a method for preparing a particulate reinforced metallic matrix composite material. The method is characterized in that: metal powder and hard phase powder are mechanically mixed and the mixture is added into a high-energy globe mill container for ball milling; powder after ball milling is sieved; sandblasting coarsing pretreatment is performed on the matrix surface and the ball milling powder is sprayed on a matrix by adoption of the cold spraying method, and then the particulate reinforced metallic matrix composite material is obtained. The preparation method adopts the high-energy ball milling method to prepare and spray the powder, and can make distribution of hard phases more uniform on one hand and thin metallic matrix crystal grains through ball milling on the other hand, thereby the performance of the MMC material prepared is further improved. The particulate reinforced metallic matrix composite material prepared by the method has compact tissue and excellent performance, and not only can prepare a coating but also can realize near-net forming of parts. The method has simple technique, good controllability, low production cost and high production efficiency, and is favorable for realizing industrialized application.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

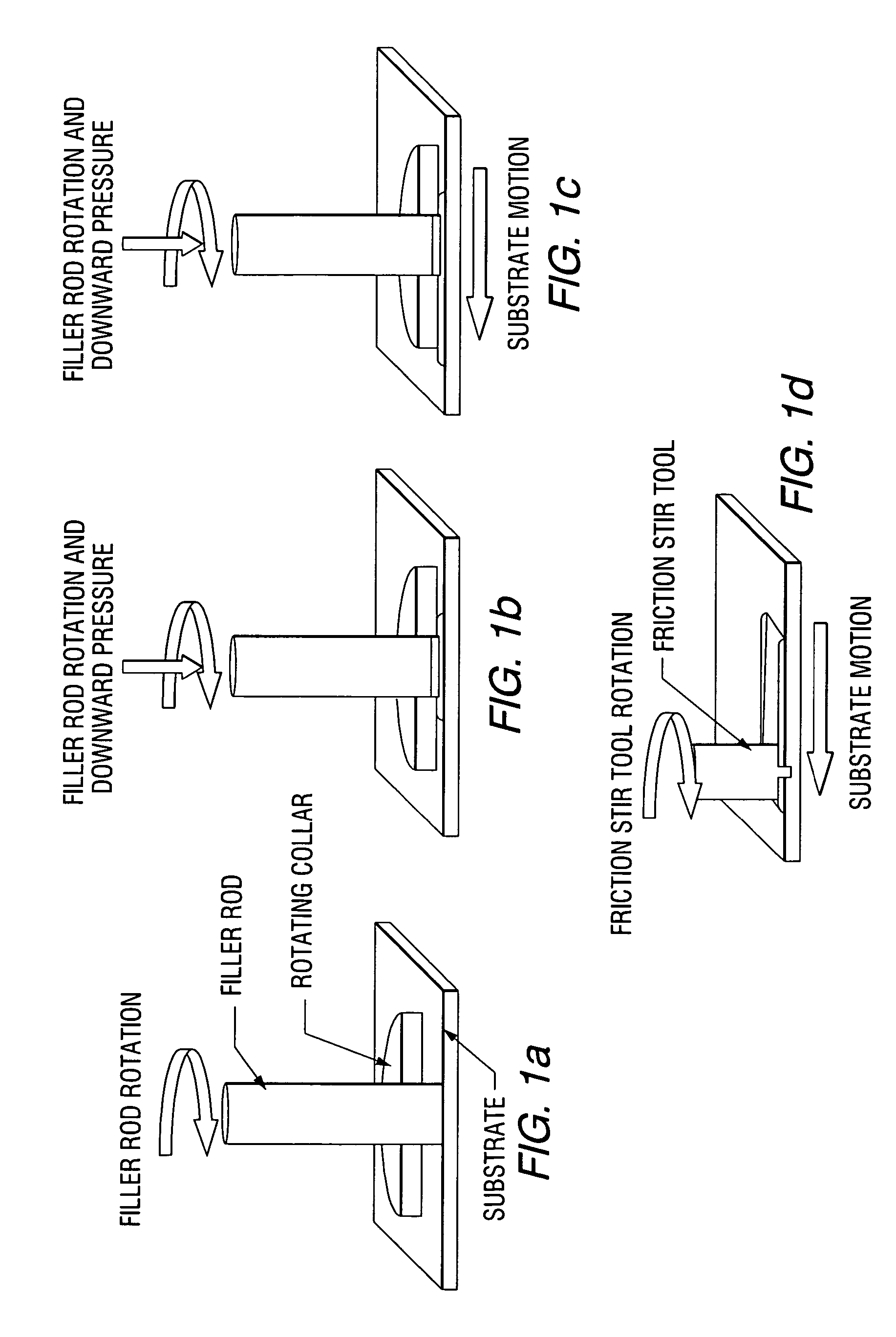

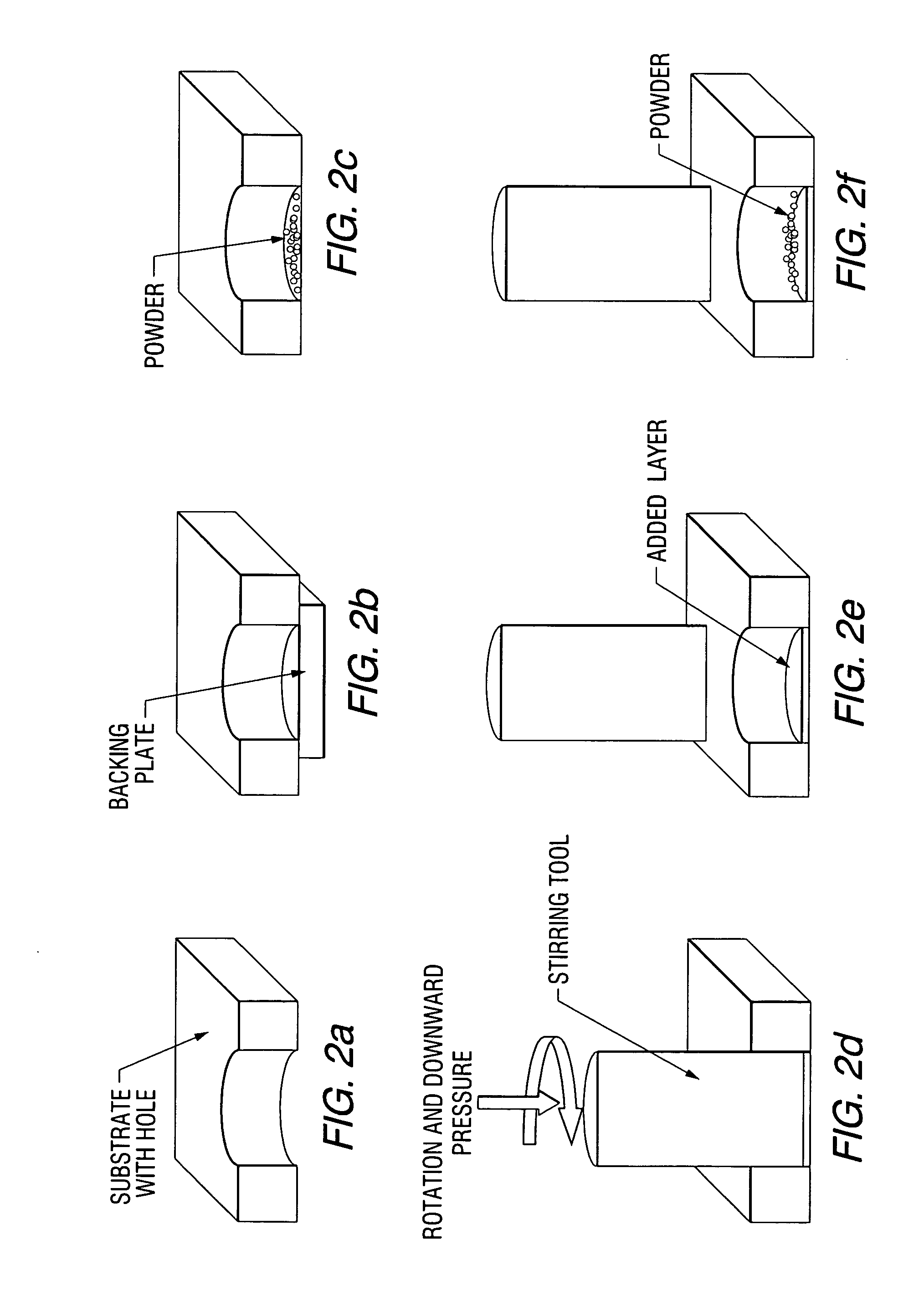

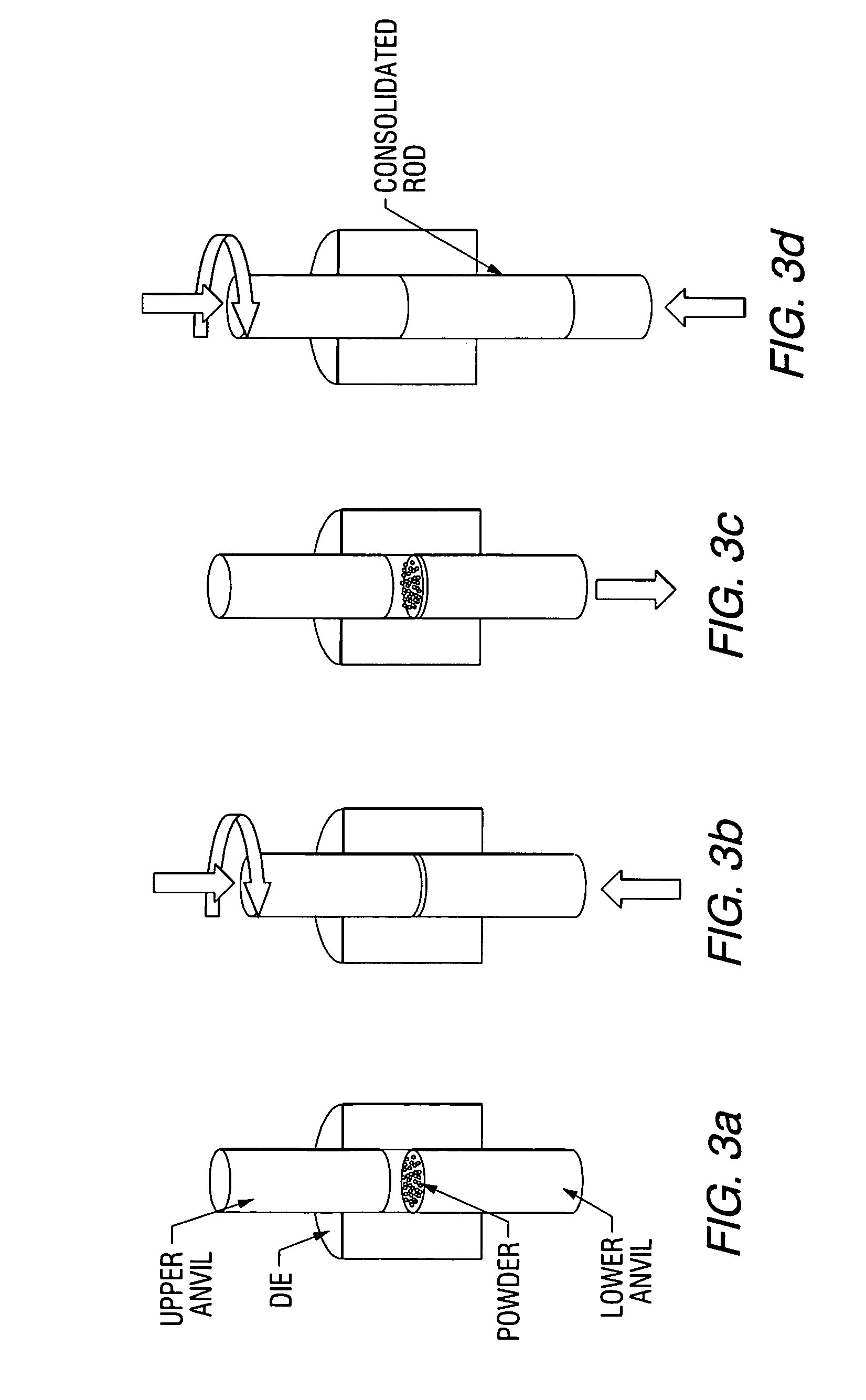

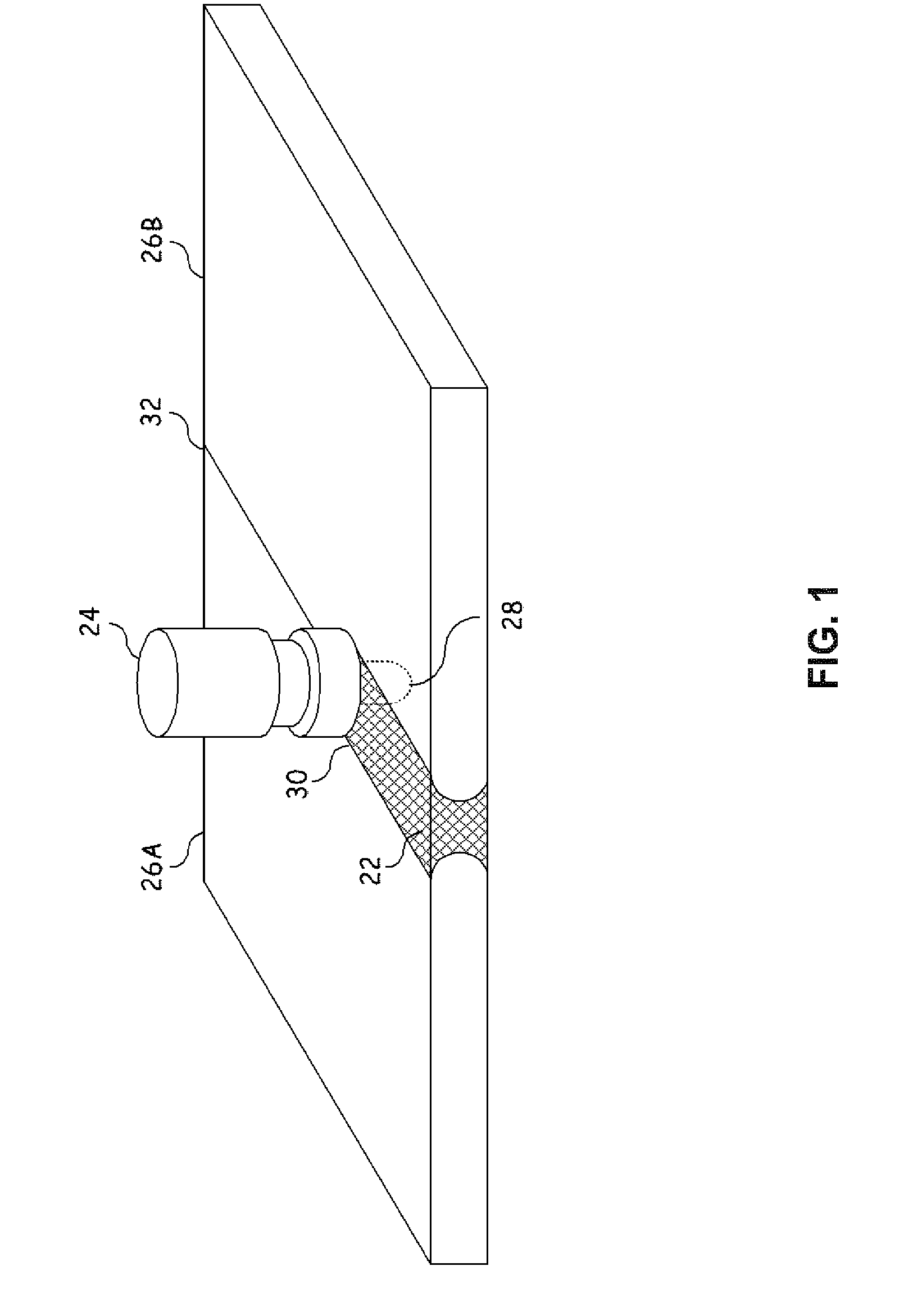

Friction stir fabrication

InactiveUS20080041921A1High bonding strengthHigh densityCooking-vessel materialsPressure inorganic powder coatingMetal matrix compositeFriction stir processing

A low-temperature friction-based coating method termed friction stir fabrication (FSF) is disclosed, in which material is deposited onto a substrate and subsequently stirred into the substrate using friction stir processing to homogenize and refine the microstructure. This solid-state process is capable of depositing coatings, including nanocrystalline aluminum and / or metal matrix composites and the like, onto substrates such as aluminum at relatively low temperatures. A method of making rod stock for use in the FSF process is also disclosed.

Owner:MELD MFG CORP

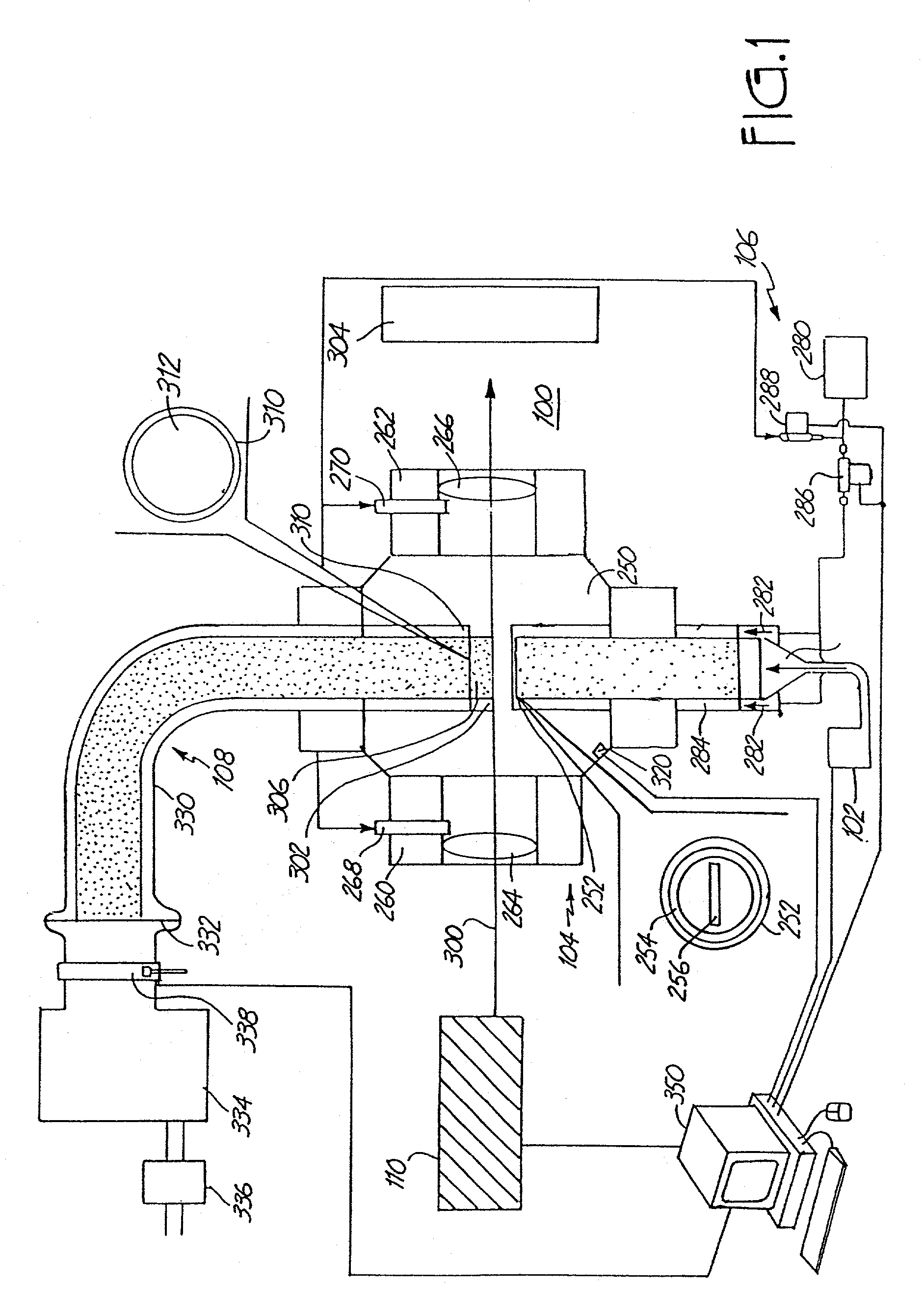

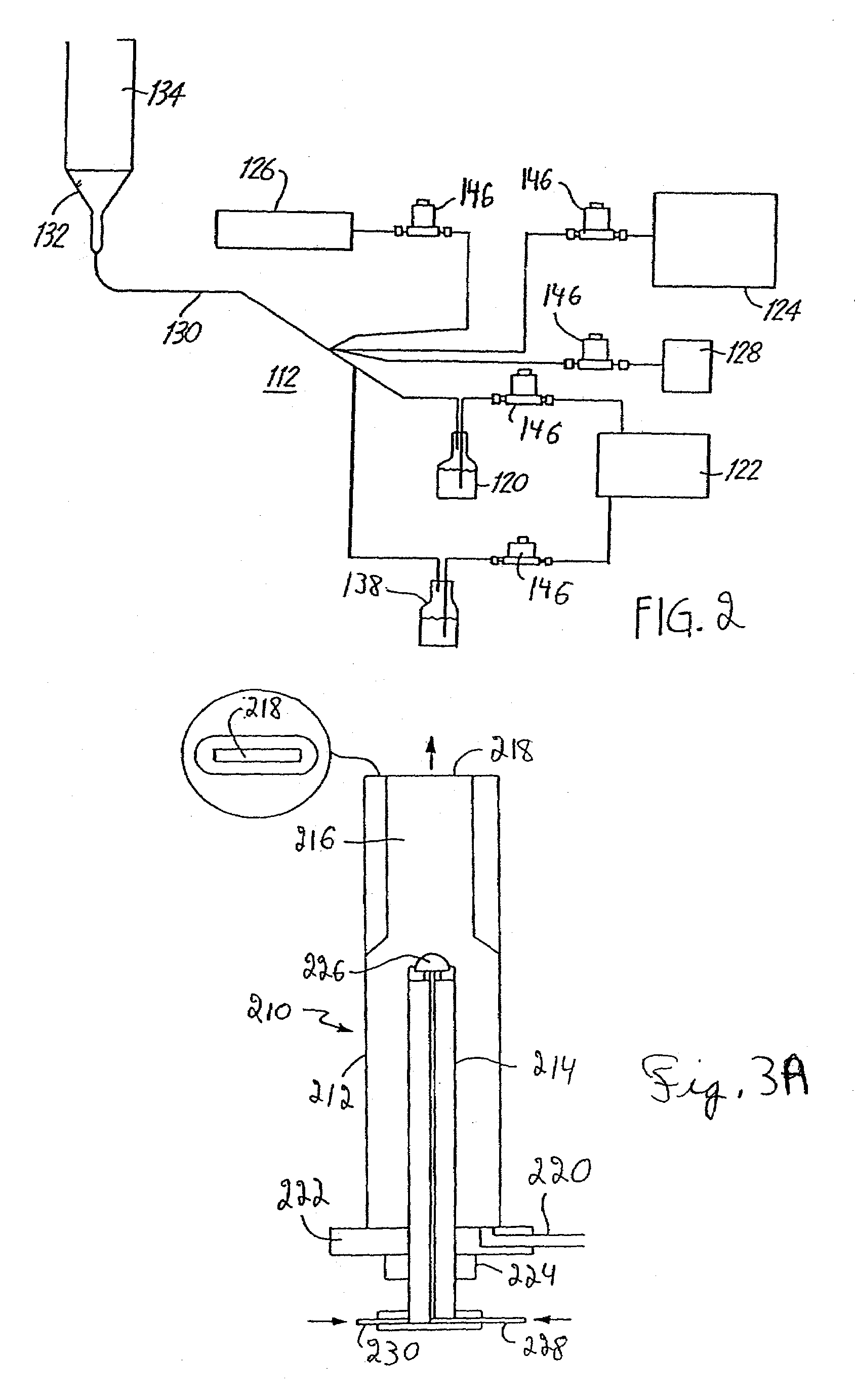

Direct writeTM system

Although the present invention has been described in detail with reference to particular preferred and alternative embodiments, persons possessing ordinary skill in the art to which this invention pertains will appreciate that various modifications and enhancements may be made without departing from the spirit and scope of the Claims that follow. The various configurations that have been disclosed above are intended to educate the reader about preferred and alternative embodiments, and are not intended to constrain the limits of the invention or the scope of the Claims. The List of Reference Characters which follows is intended to provide the reader with a convenient means of identifying elements of the invention in the Specification and Drawings. This list is not intended to delineate or narrow the scope of the Claims.

Owner:OPTOMEC DESIGN CO

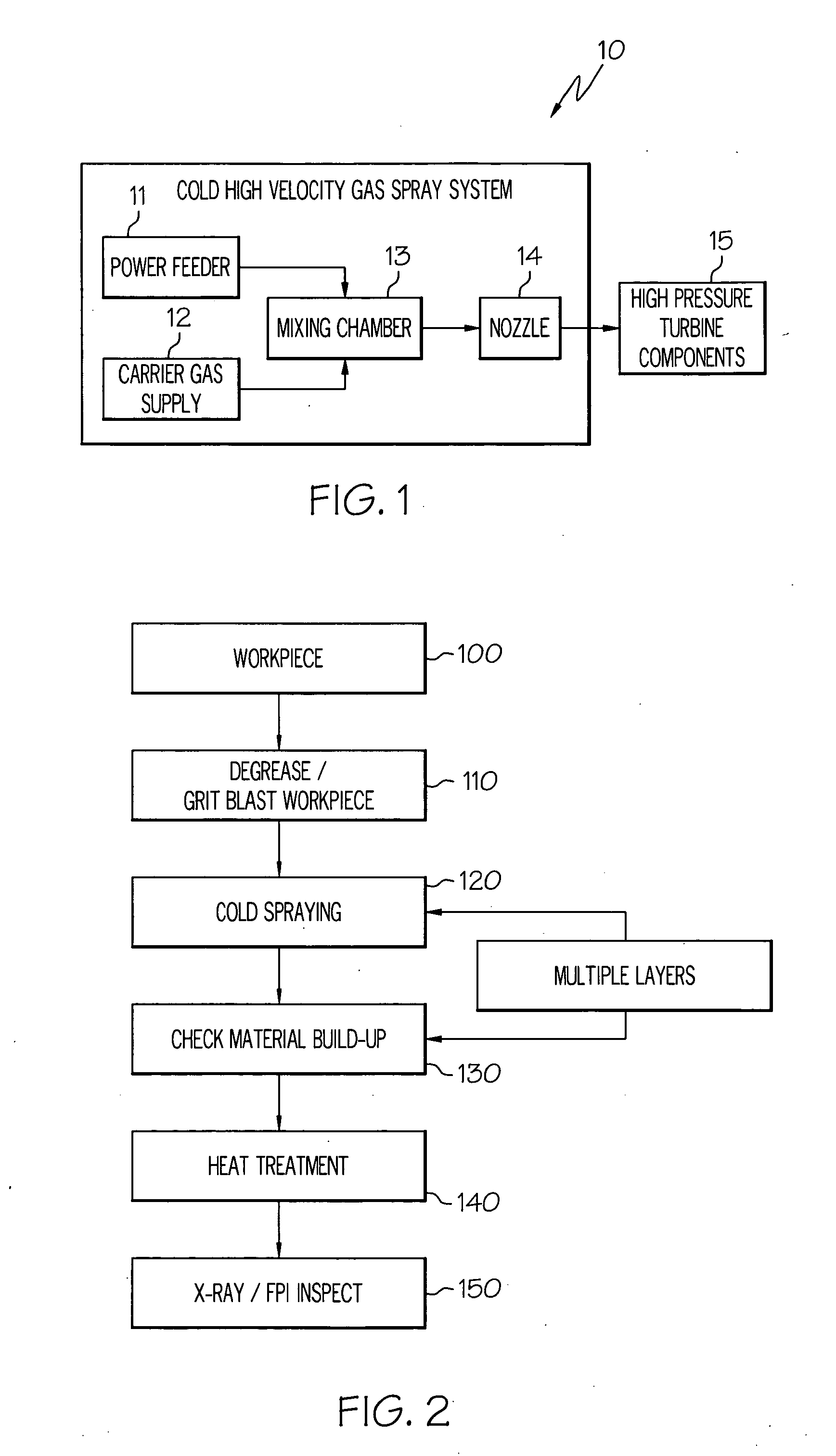

High strength amorphous and microcrystaline structures and coatings

ActiveUS20060166020A1Avoid excessive heatPretreated surfacesThin material handlingAlloyMaterials science

The present invention thus provides an improved method for coating turbine engine components. The method utilizes a cold high velocity gas spray technique to coat turbine blades, compressor blades, impellers, blisks, and other turbine engine components. These methods can be used to coat a variety of surfaces thereon, thus improving the overall durability, reliability and performance of the turbine engine itself. The method includes the deposition of powders of alloys of nickel and aluminum wherein the powders are formed so as to have an amorphous microstructure. Layers of the alloys may be deposited and built up by cold high velocity gas spraying. The coated items displayed improved characteristics such as hardness, strength, and corrosion resistance.

Owner:HONEYWELL INT INC

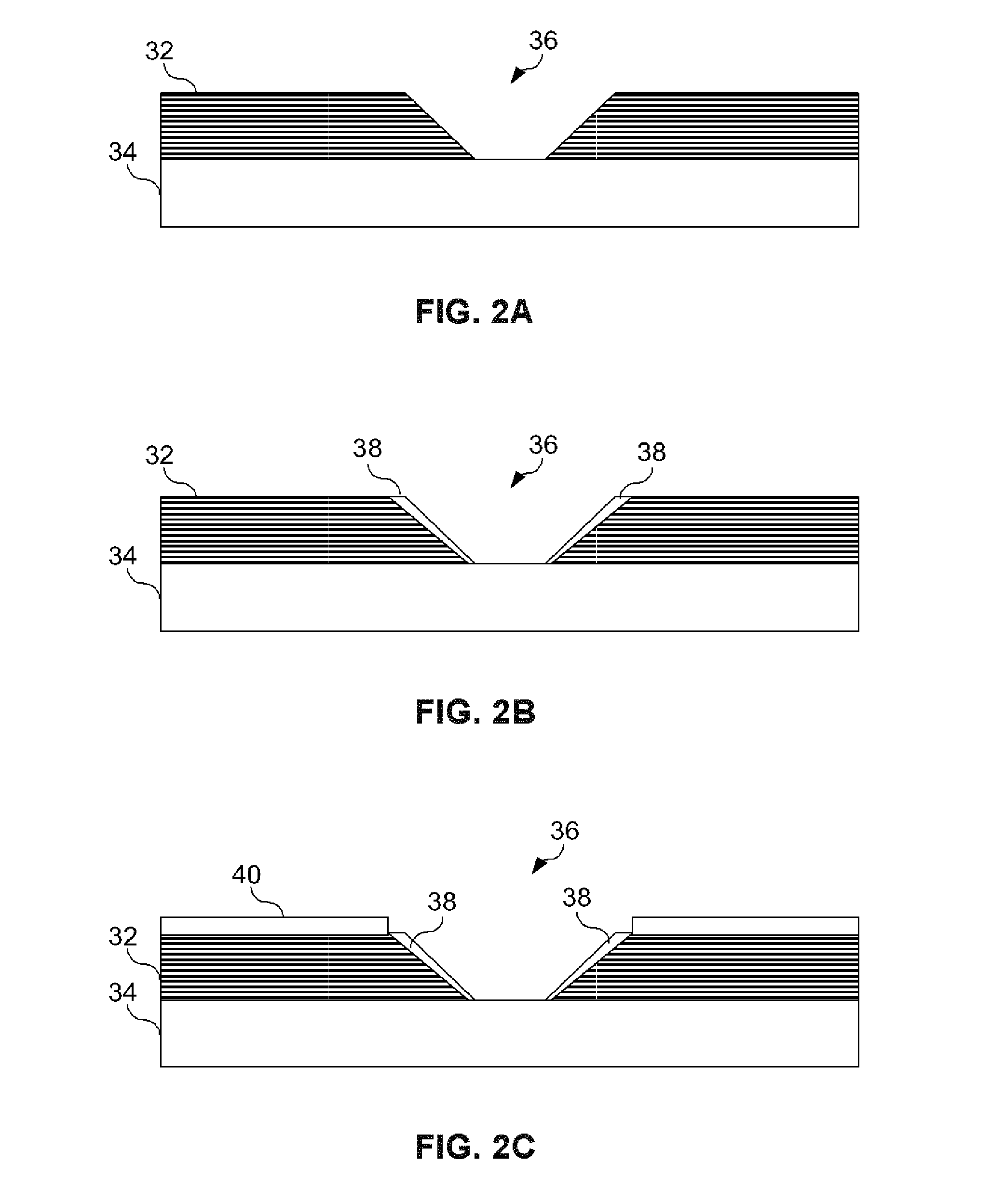

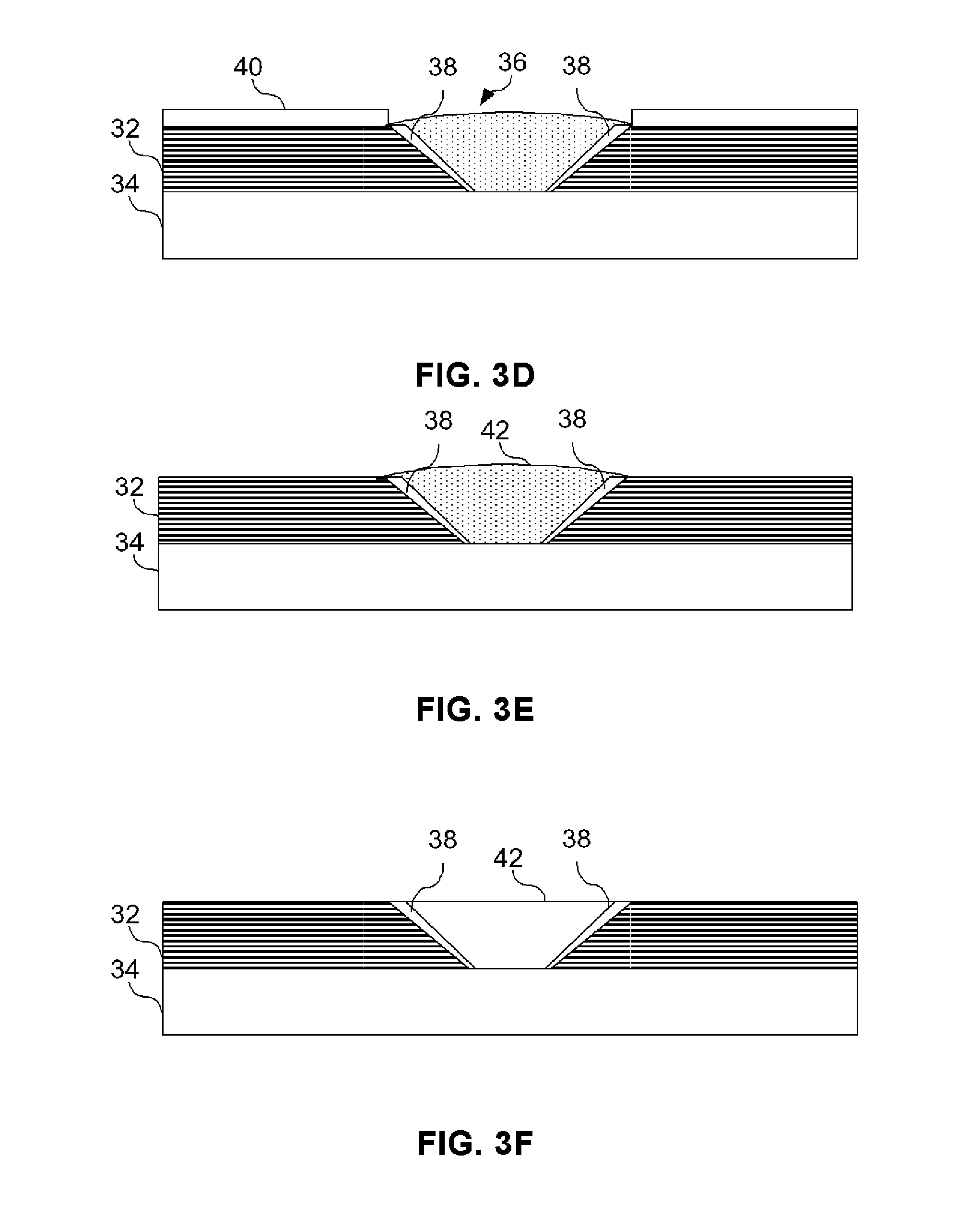

Perforated composites for joining of metallic and composite materials

ActiveUS20070241164A1Improve carrying capacityCooking-vessel materialsPressure inorganic powder coatingCarrying capacityMetallic substrate

Embodiments in the present invention provide a system and method of joining structural members. This method involves aligning the first structural member to a metallic substrate when the first structural member has at least one tapered hole or cavity. A metallic or other like material suitable to cold spraying technology is deposited into the tapered cavity to form a shaped or tapered fastener bonded to the metallic substrate. The shape of the fastener secures the first structural member to the metallic substrate. Additionally, a protective insert may be placed within the shaped or tapered cavity to protect the first structural member during hoe cold spraying deposition when the first structural member is a composite material or other like material susceptible to erosion during the cold spraying technique. After the material has been deposited using cold spray techniques this material may be further solidified and bonded to the metallic substrate using a technique such as friction stir welding in order to increase the load carrying capacity of the in-situ shaped fastener.

Owner:LOCKHEED MARTIN CORP

Method of fabricating a component using a two-layer structural coating

A method of fabricating a component is provided. The fabrication method includes depositing a first layer of a structural coating on an outer surface of a substrate. The substrate has at least one hollow interior space. The fabrication method further includes machining the substrate through the first layer of the structural coating, to define one or more openings in the first layer of the structural coating and to form respective one or more grooves in the outer surface of the substrate. Each groove has a respective base and extends at least partially along the surface of the substrate. The fabrication method further includes depositing a second layer of the structural coating over the first layer of the structural coating and over the groove(s), such that the groove(s) and the second layer of the structural coating together define one or more channels for cooling the component. A component is also disclosed.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com