Method for repairing titanium alloy components

a technology of titanium alloy and components, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of significant operating expense and time out of service, stress loading of lpc/hpc components, and deformation of lpc/hpc components over tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following detailed description of the invention is merely exemplary in nature and is not intended to limit the invention or the application and uses of the invention. Furthermore, there is no intention to be bound by any theory presented in the preceding background of the invention or the following detailed description of the invention.

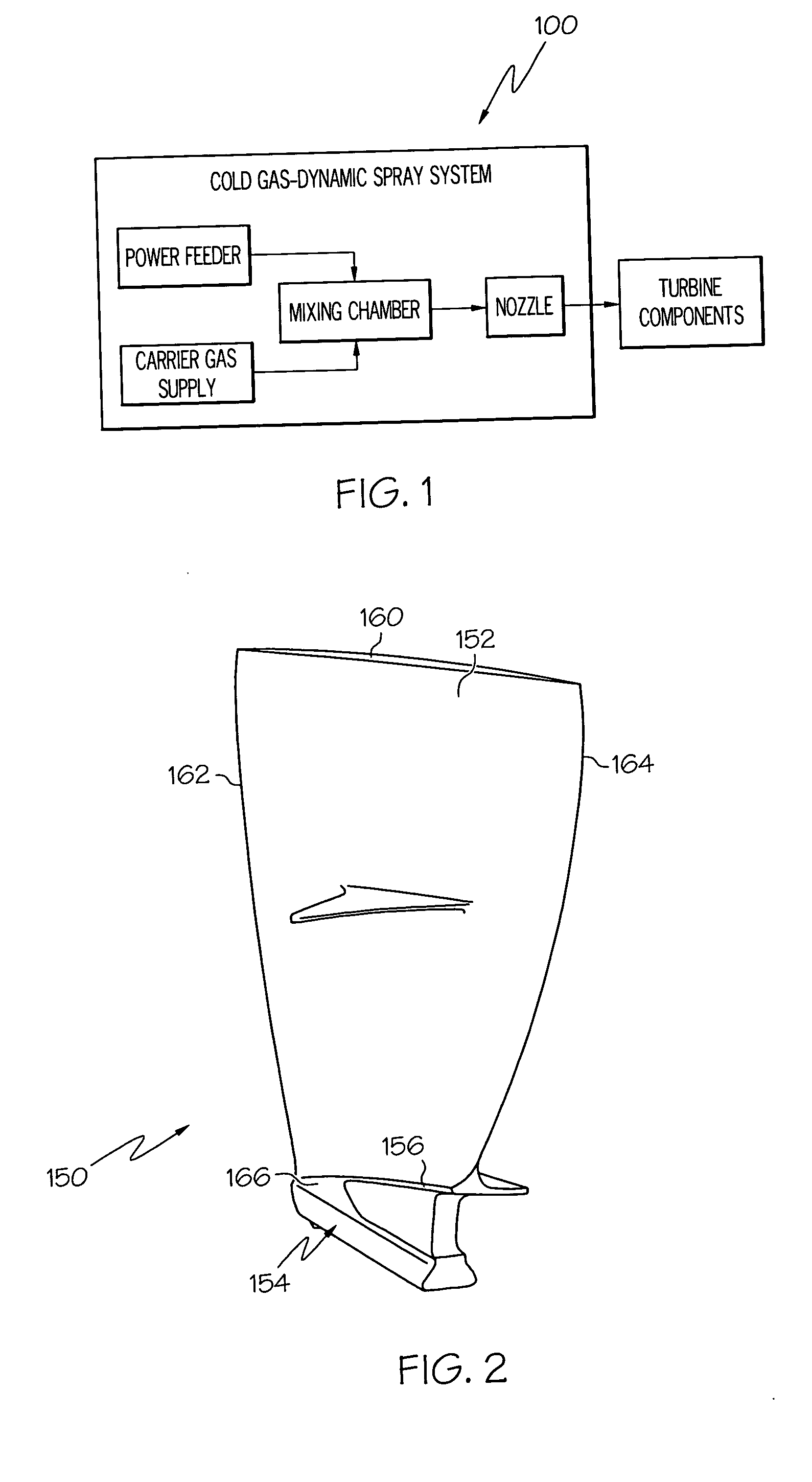

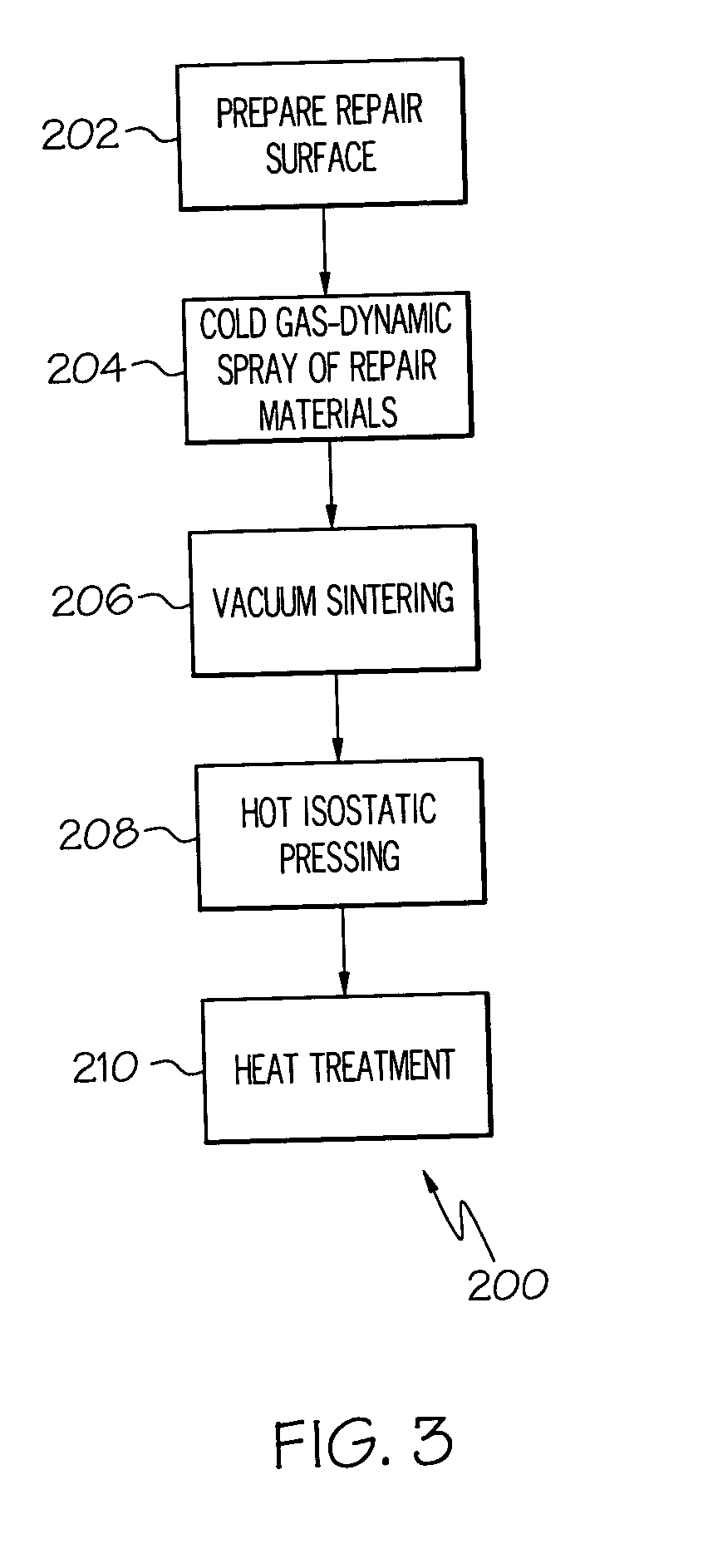

[0015] The present invention provides an improved method for repairing LPC / HPC components. The method utilizes a cold gas-dynamic spray technique to apply high-strength titanium alloy materials to worn LPC / HPC component surfaces. These materials can be used to repair components such as compressor and fan blades and vanes, including impeller and blisk blades, which have been degraded due to erosion and foreign object damage, to name several examples.

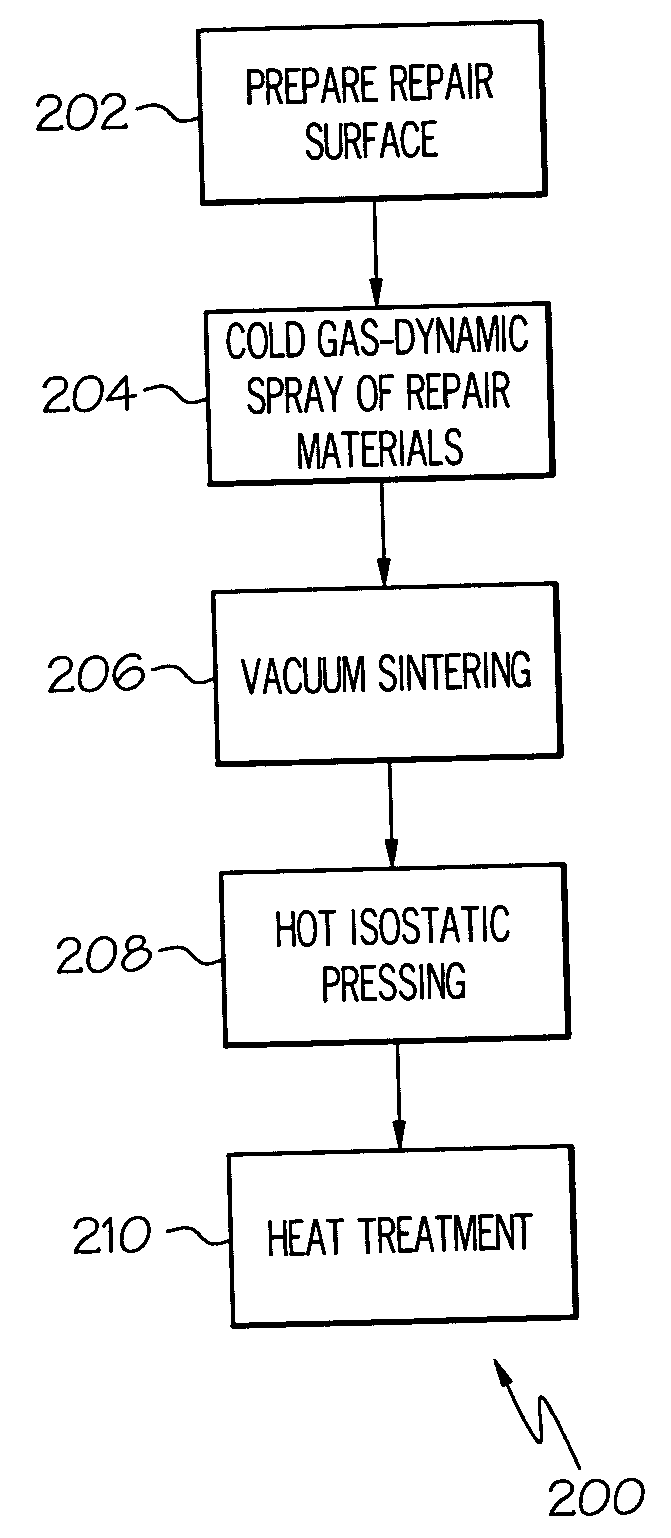

[0016] Turning now to FIG. 1, an exemplary cold gas-dynamic spray system 100 is illustrated diagrammatically. The system 100 is illustrated as a general scheme, and additional features and comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com