Processing method of titanium and titanium alloy strip coils

A processing method and technology for titanium alloys, applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of low yield, inability to produce titanium plates, low efficiency, etc., to improve yield, improve efficiency, improve The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

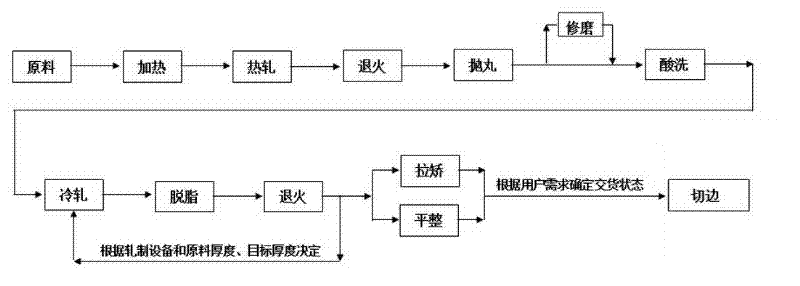

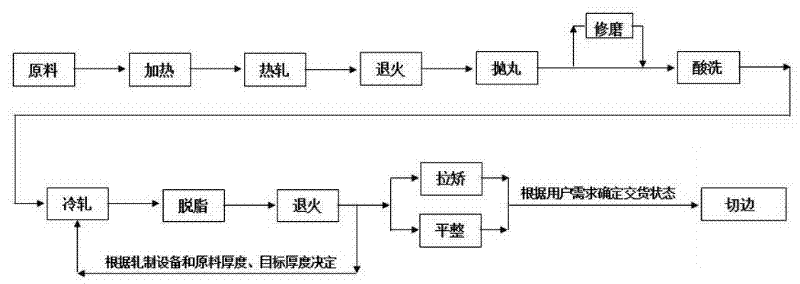

Image

Examples

Embodiment 1

[0034] Embodiment 1 The processing method of a titanium strip and a titanium plate with a thickness of 1.5mm and a width of 1000mm

[0035] The process steps of this embodiment are:

[0036] 1. Raw material The thickness of the titanium slab is 180mm, the width is 1050mm, and the length is 10000mm;

[0037] 2. Heating The titanium slab is heated to 950°C through a gas heating furnace;

[0038] 3. Rolling The titanium slab is rolled and processed into a titanium strip with a thickness of 3.2mm by a double-stand stecket rolling mill and wrapped into a coil to become a hot-rolled titanium strip coil;

[0039] 4. Annealing Hot-rolled titanium coils are annealed in a bell annealing furnace under the protection of an argon inert gas atmosphere with a furnace temperature of 550°C in the coiled state, making it an annealed hot-rolled titanium coil;

[0040] 5. Shot blasting treatment The annealed hot-rolled titanium strip is opened by the uncoiler of the shot blasting unit, and the ...

Embodiment 2

[0052] Embodiment 2 The processing method of the titanium coil of thickness 0.7mm, width 250mm

[0053] The process steps of this embodiment are:

[0054] 1. Raw material The thickness of the titanium slab is 180mm, the width is 1050mm, and the length is 10000mm;

[0055] 2. Heating The titanium slab is heated to 950°C through a gas heating furnace;

[0056] 3. Rolling A 7-stand continuous rolling mill is used to roll and process titanium slabs into titanium strips with a thickness of 3.5 mm and wrap them into coils to become hot-rolled titanium strip coils;

[0057] 4. Annealing When the hot-rolled titanium coil is in the coiled state, it is annealed in a bell-type annealing furnace under the protection of a helium inert gas atmosphere with a furnace temperature of 560 ° C to make it an annealed hot-rolled titanium coil;

[0058] 5. Shot blasting treatment The annealed hot-rolled titanium strip is opened by the uncoiler of the shot blasting unit, and the oxide scale on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com