Patents

Literature

294results about How to "Improve processing effectiveness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

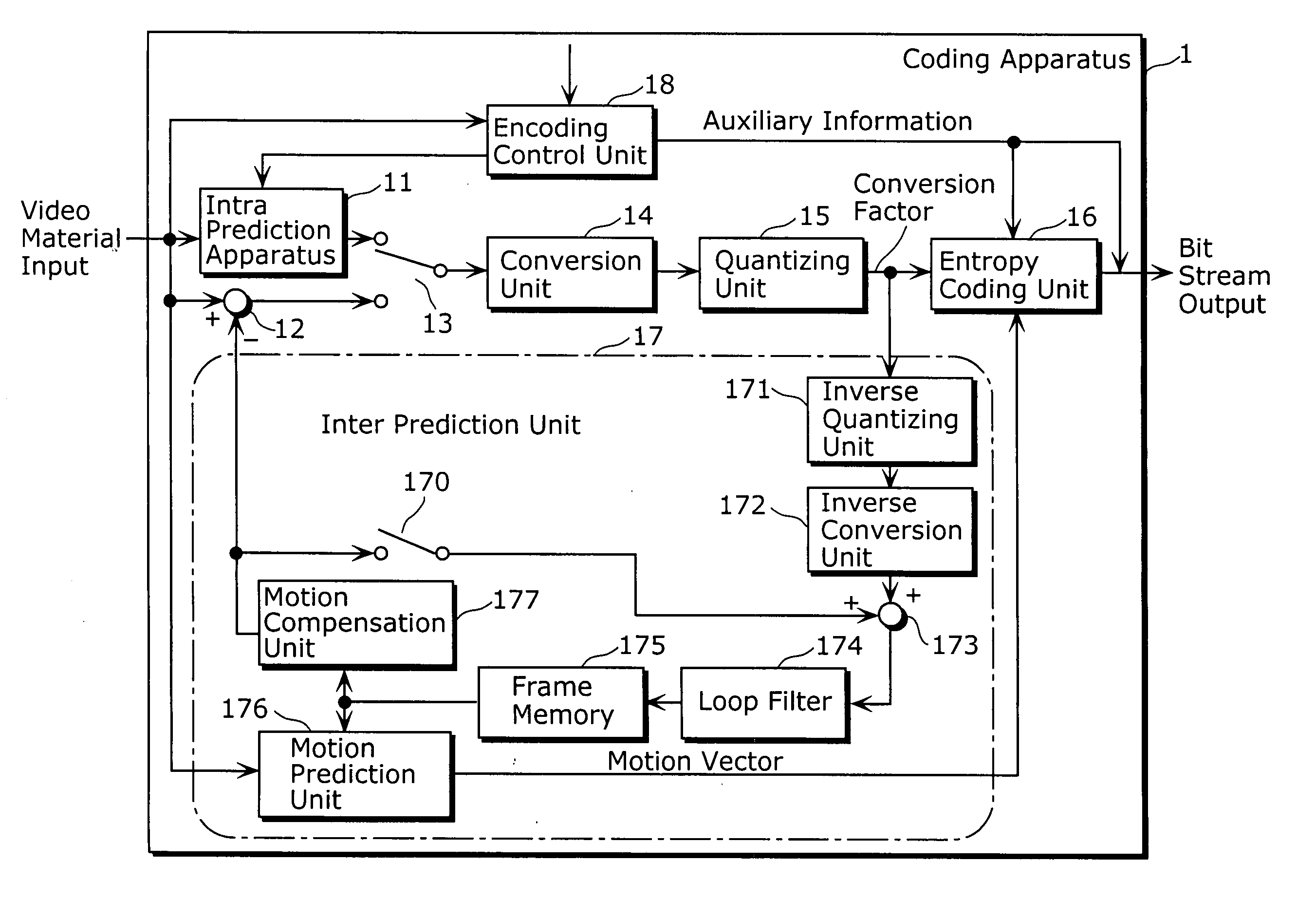

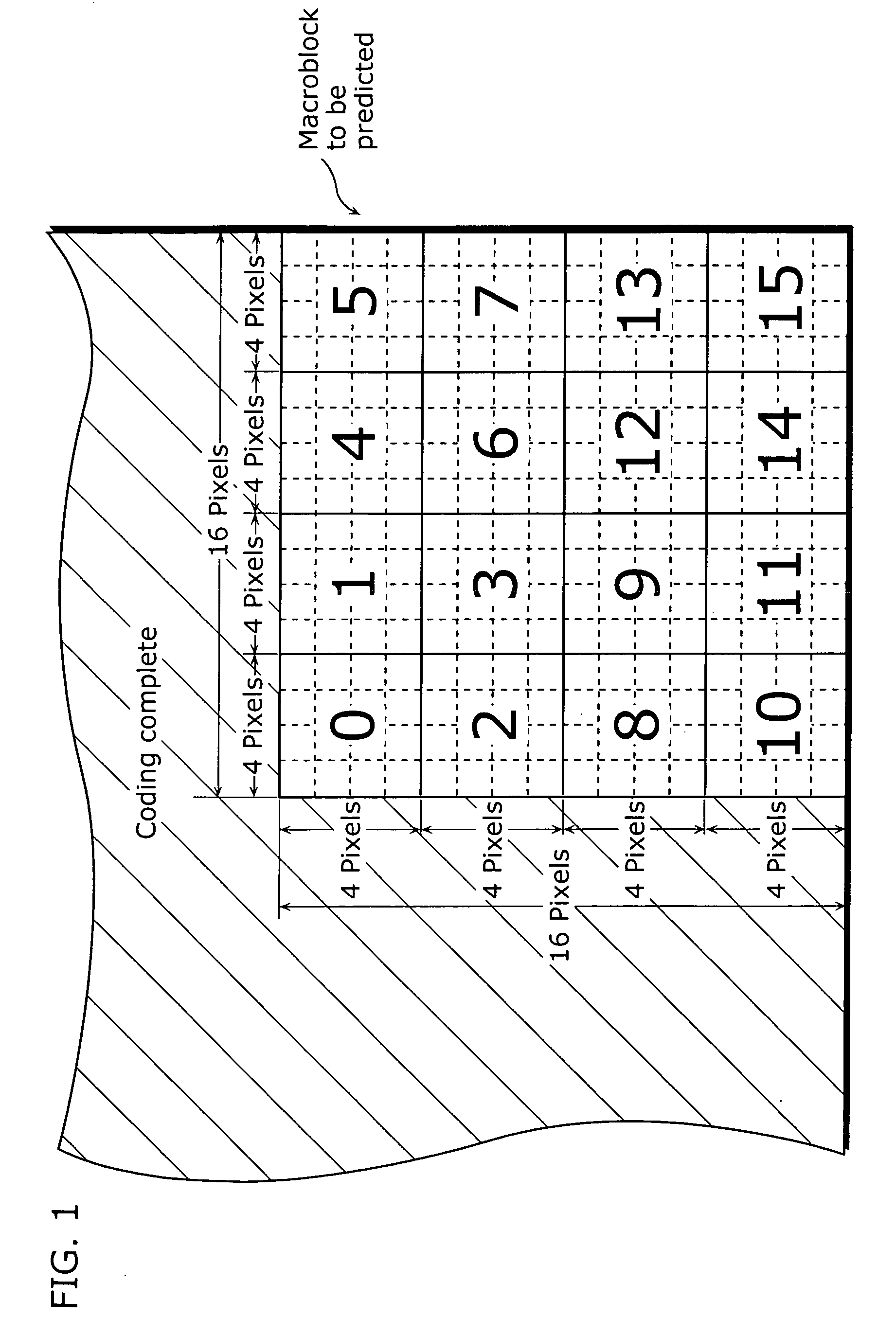

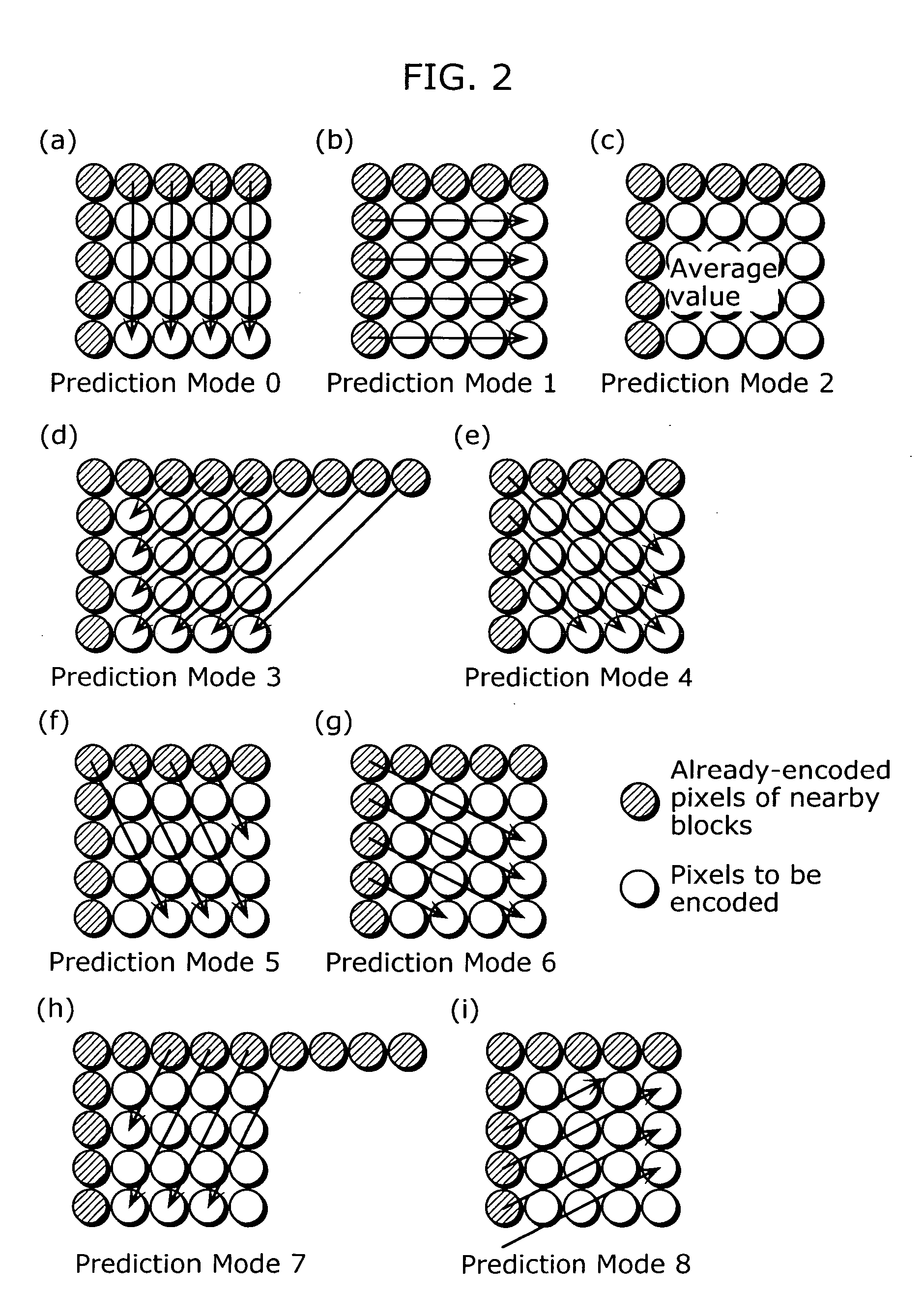

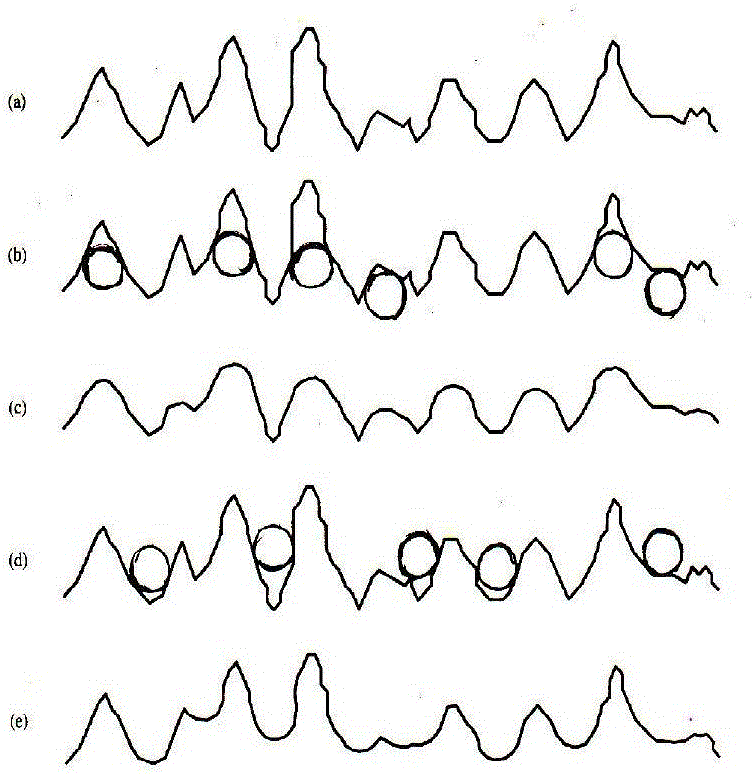

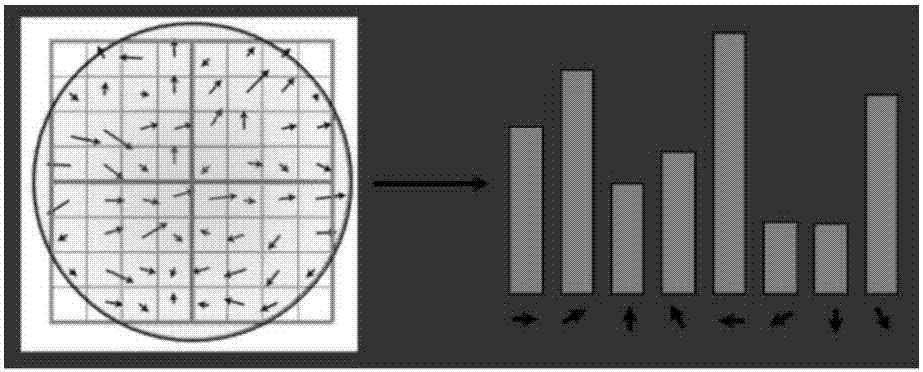

Intra prediction apparatus

InactiveUS20060120456A1Improve efficiencyImprove picture qualityColor television with pulse code modulationColor television with bandwidth reductionParallel computingExecution unit

An intra prediction apparatus includes: a candidate narrowing-down unit which narrows down, from a plurality of intra prediction directions, an intra prediction direction candidate which is applied to a block of multiple pixels that constitutes a video in accordance with a characteristic of the video; and an intra prediction execution unit which executes intra prediction in the intra prediction direction narrowed down by said candidate narrowing-down unit. Through this, computational load can be lightened while contributing to improvement in picture quality and encoding efficiency.

Owner:GK BRIDGE 1

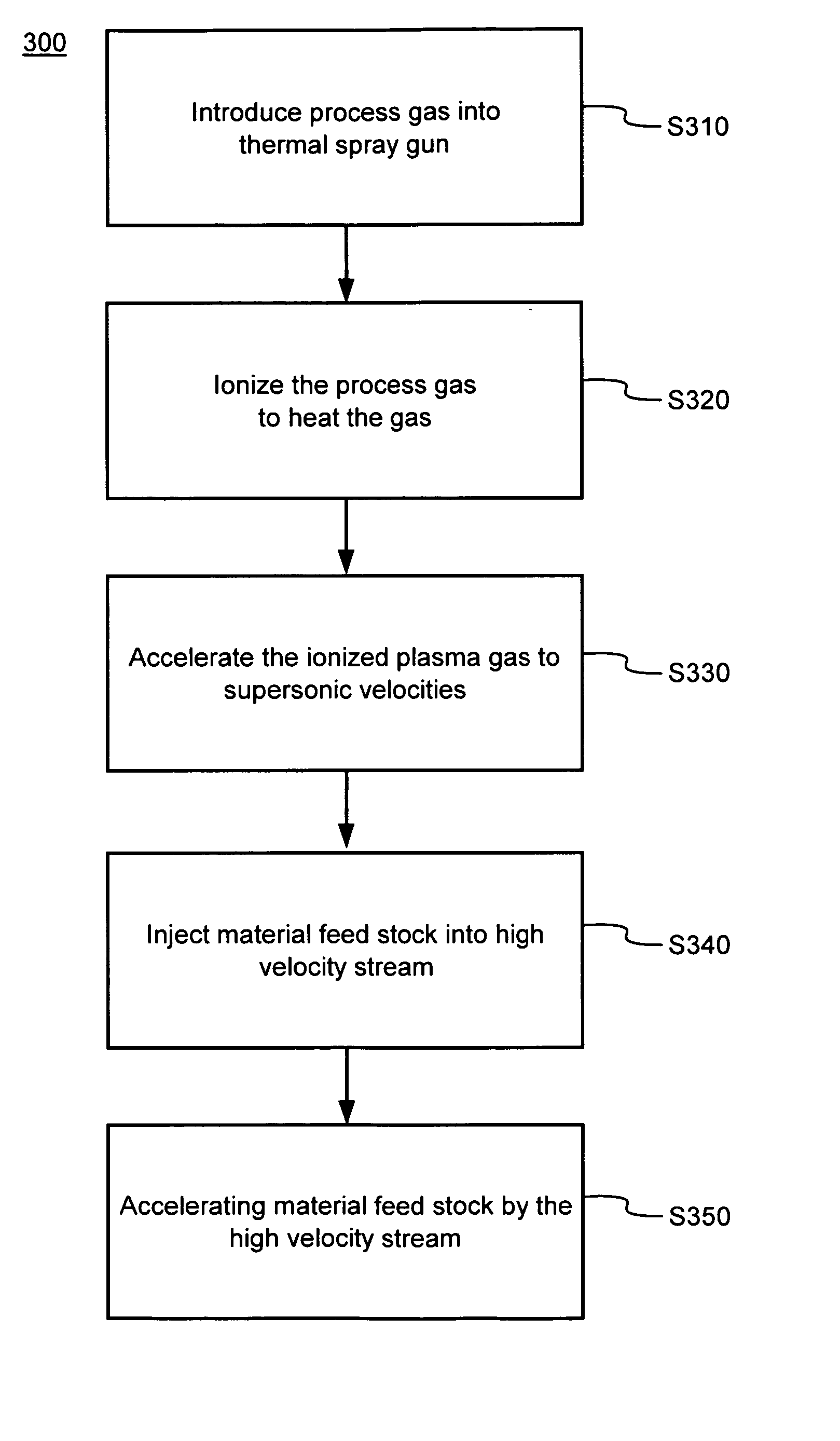

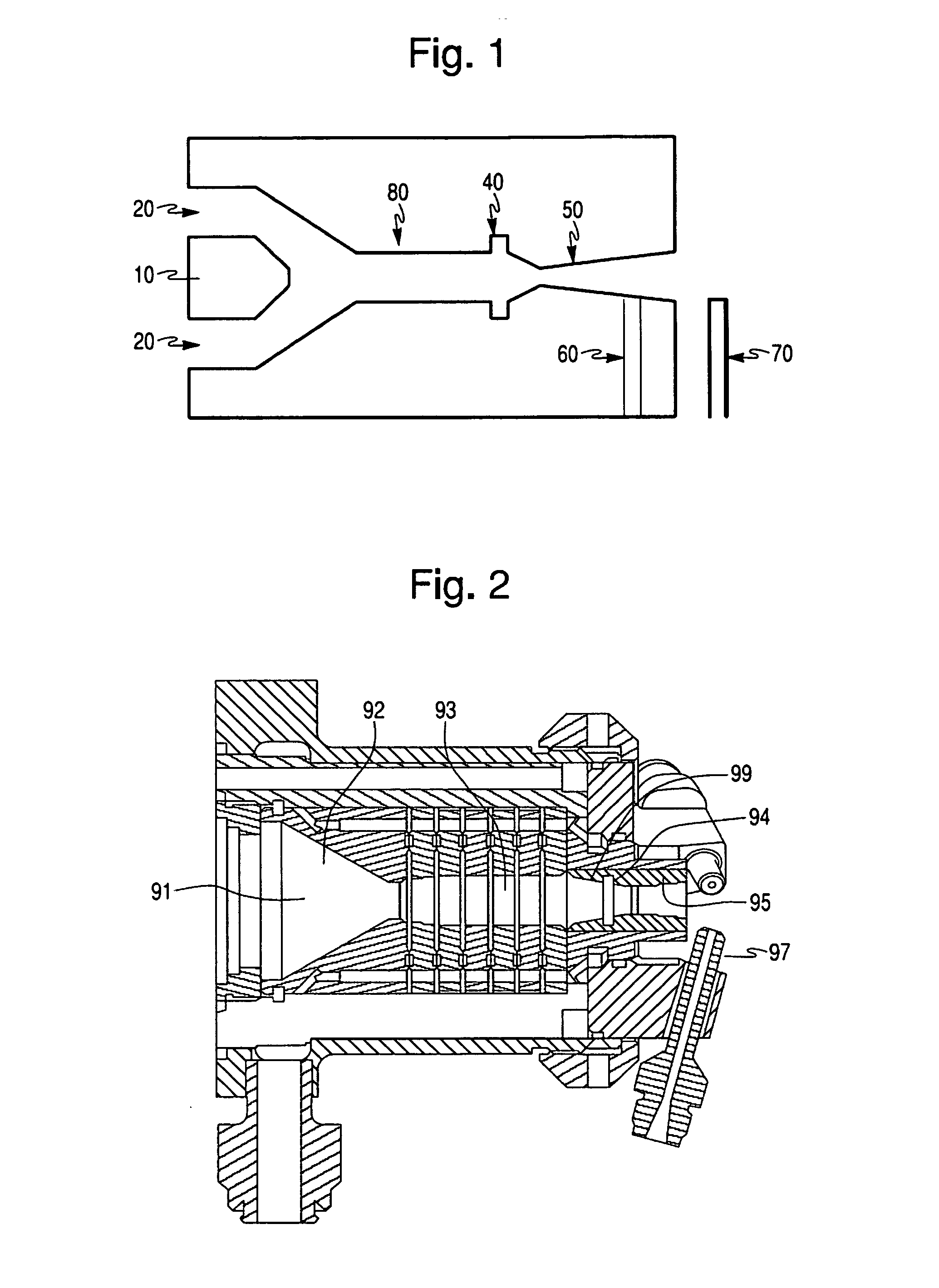

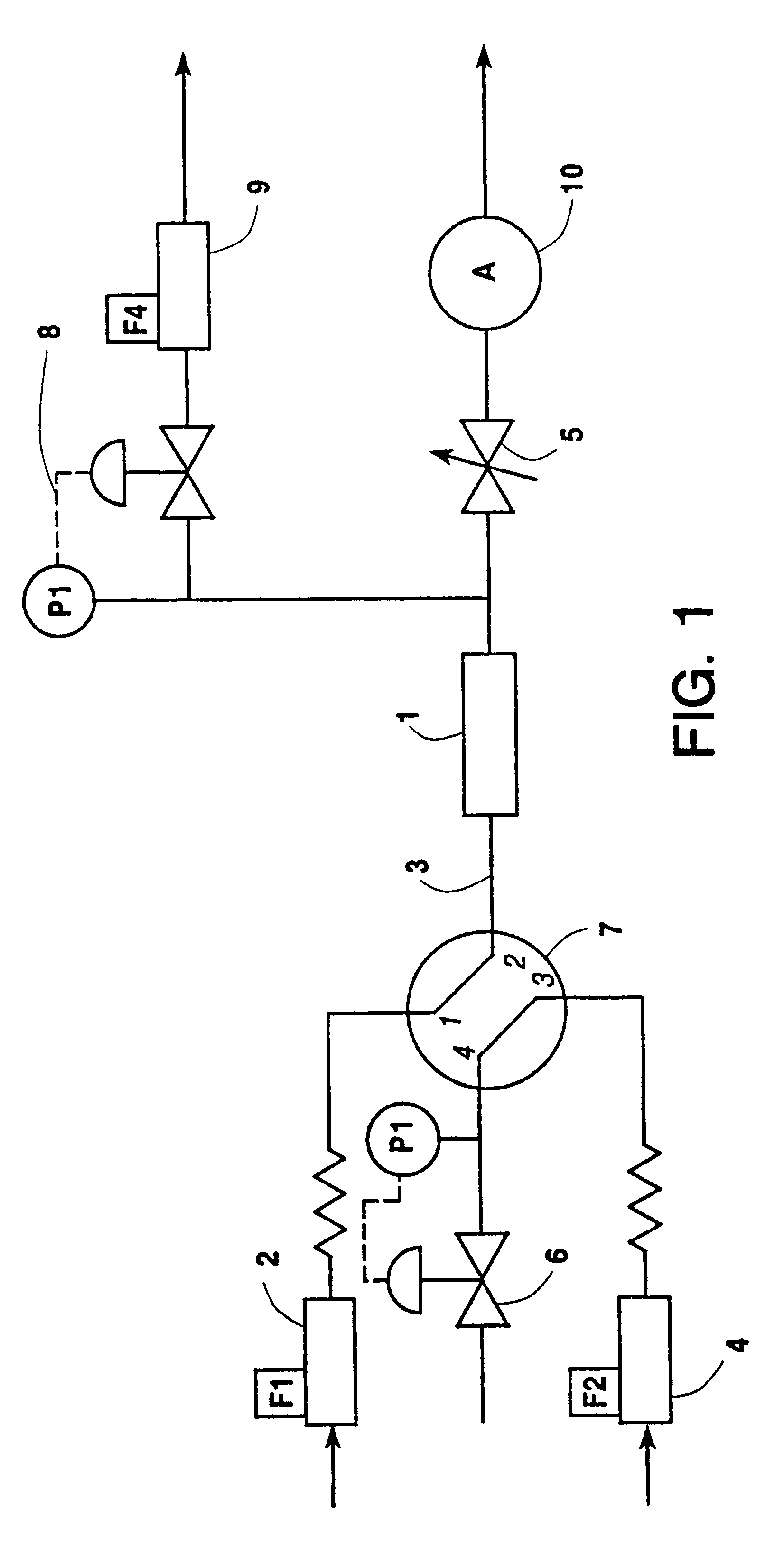

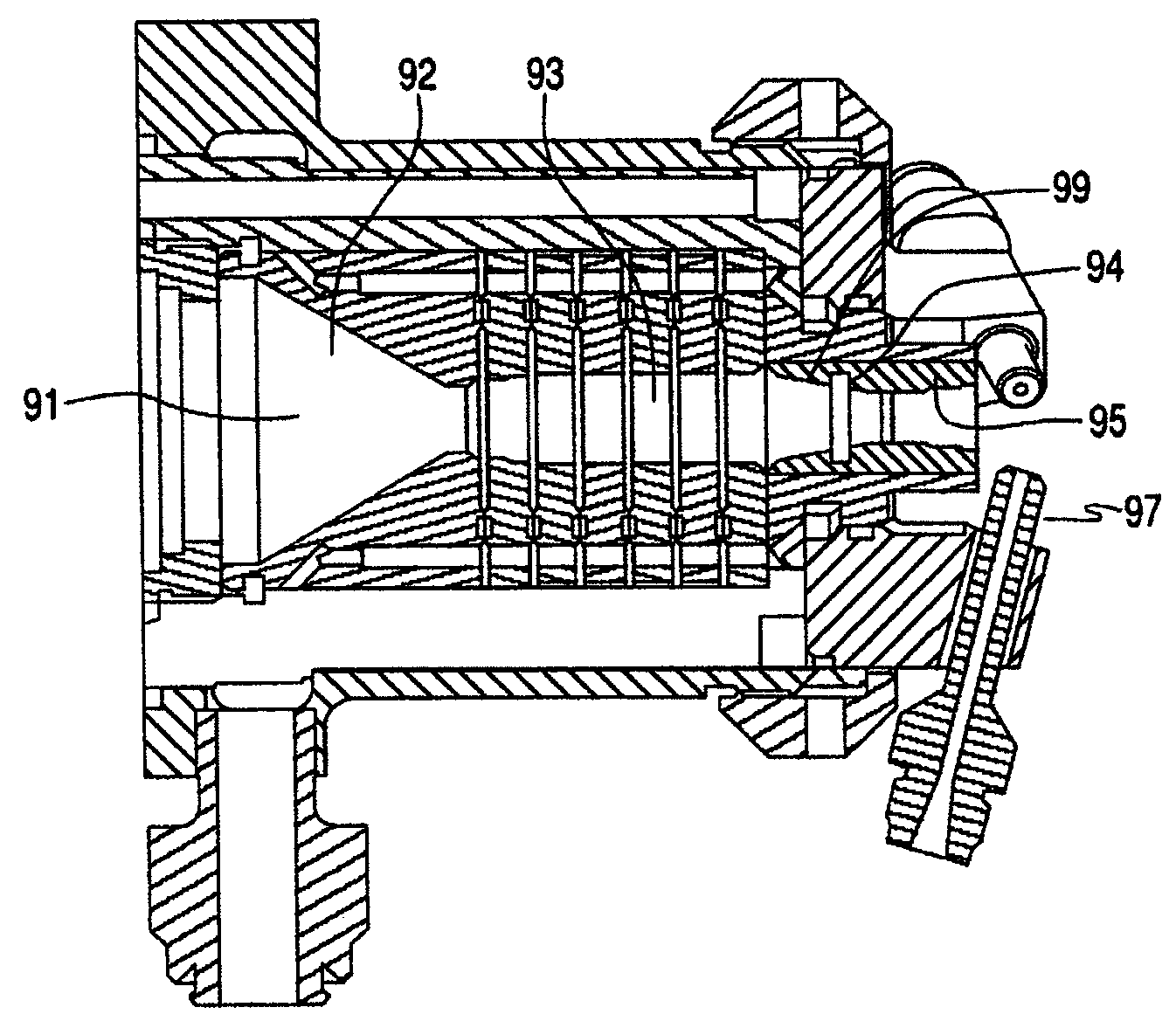

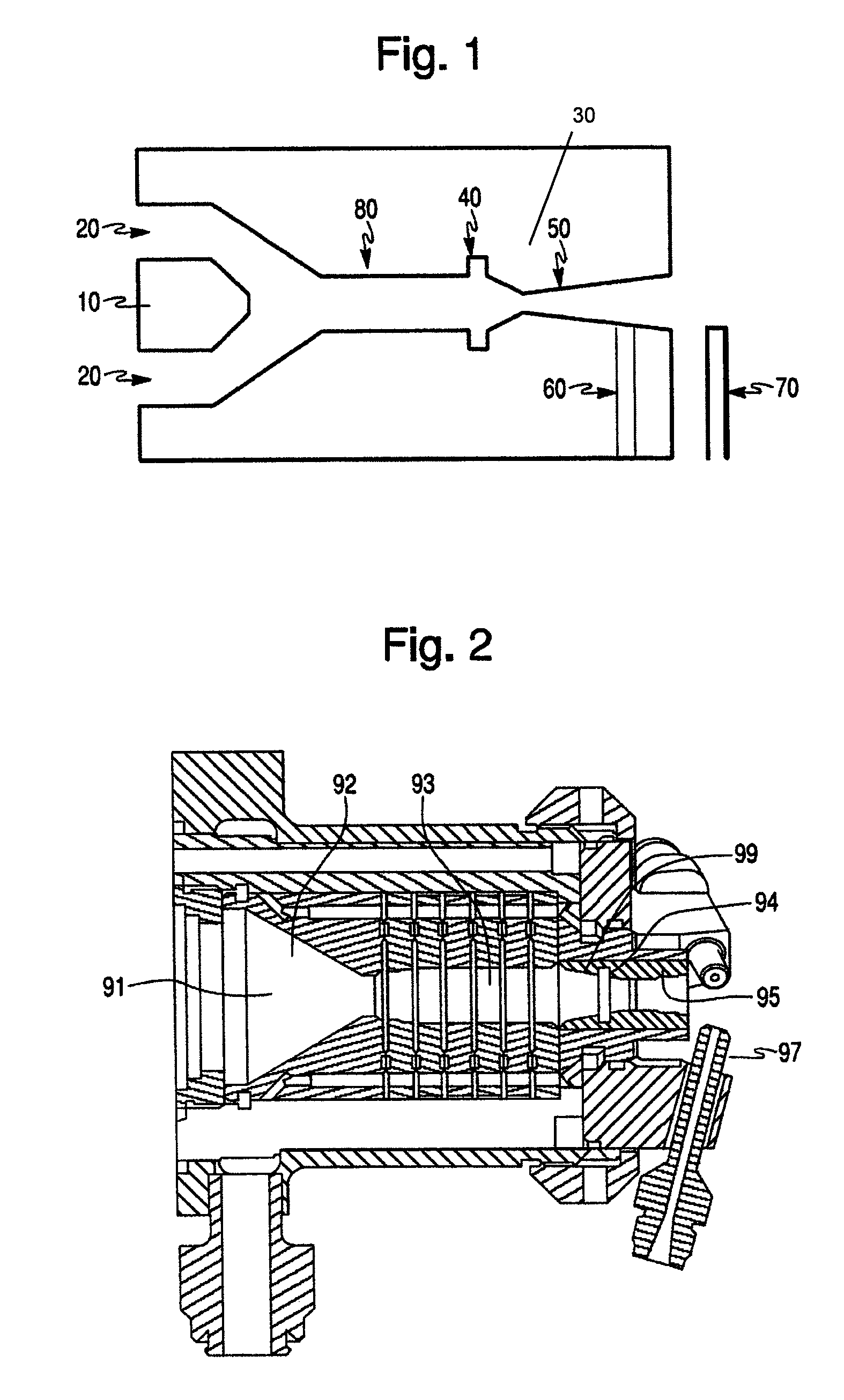

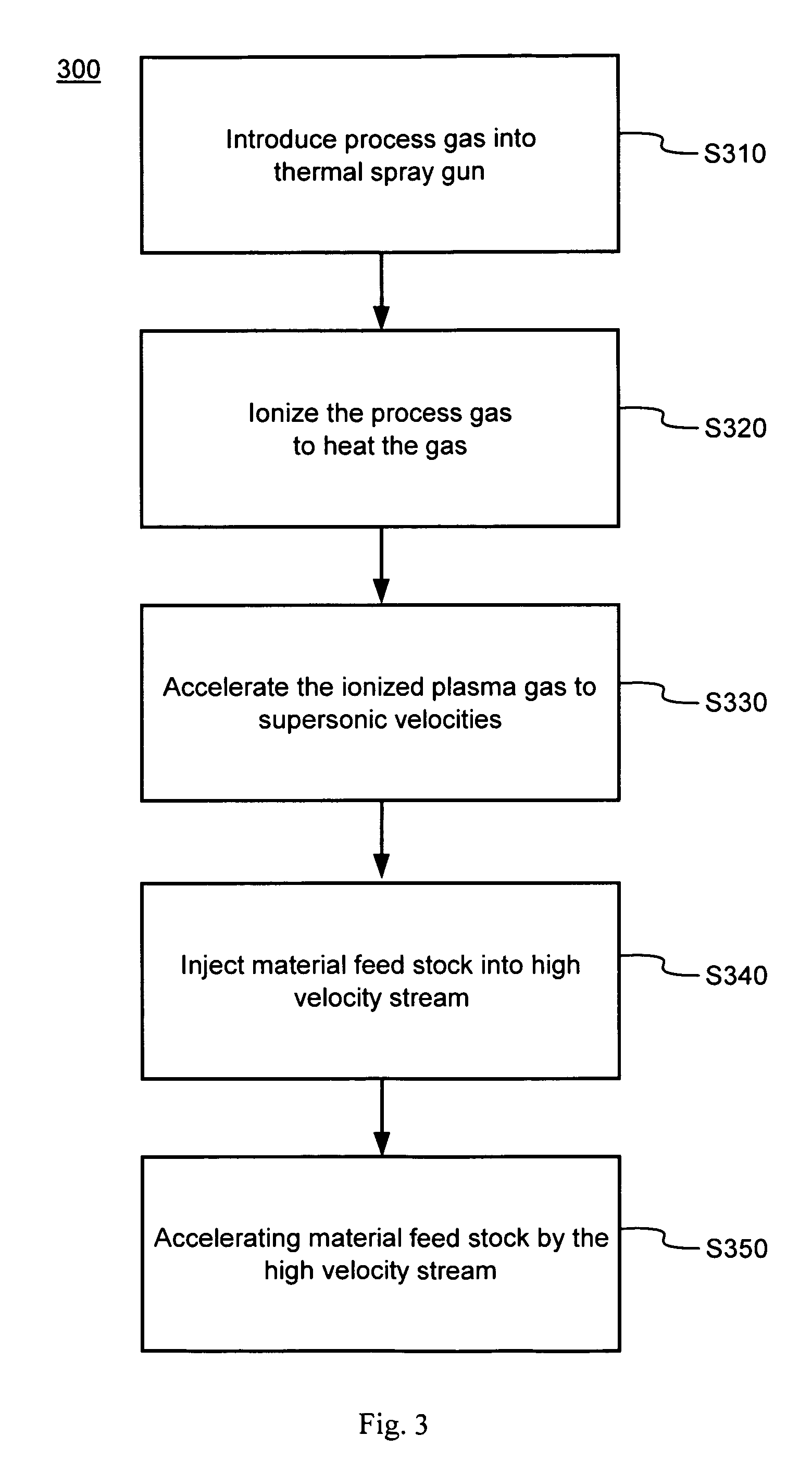

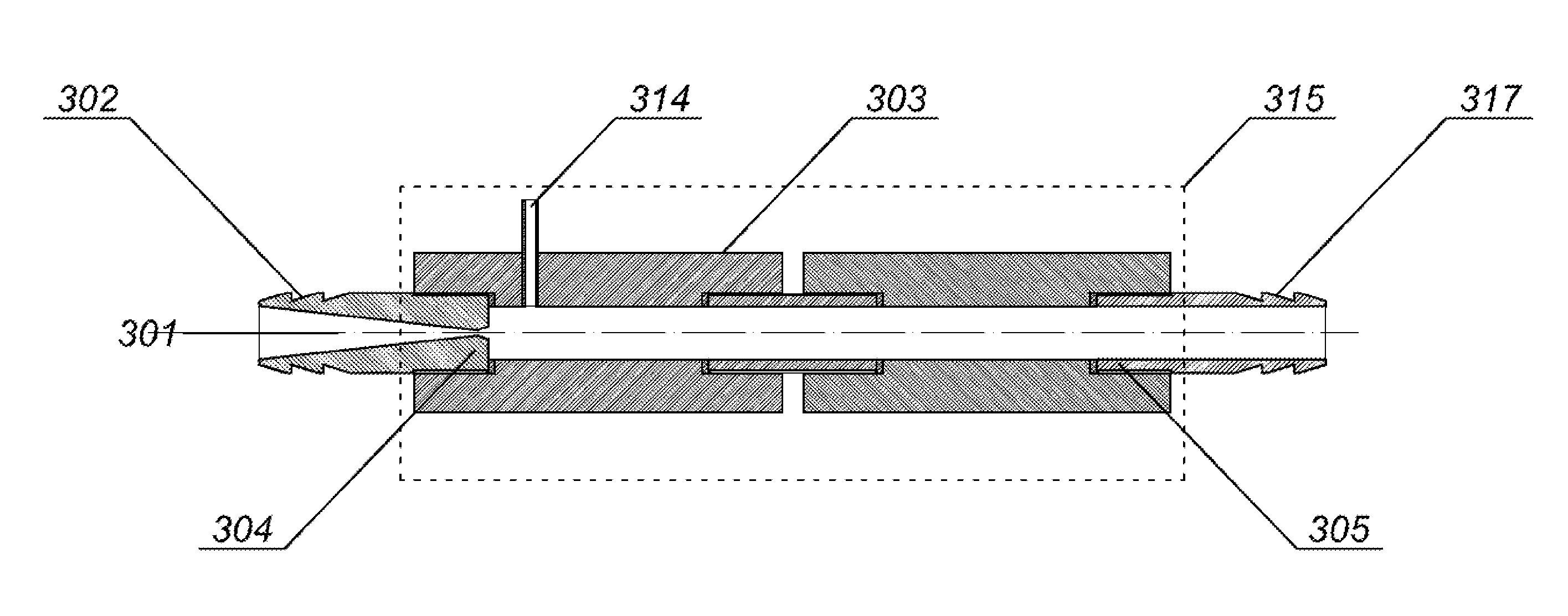

Hybrid plasma-cold spray method and apparatus

ActiveUS20070138147A1High processing efficiencyLow gas consumptionMolten spray coatingArc welding apparatusProcess engineeringSpray method

The present invention provides a method and apparatus of producing a dense coating with desirable stress conditions similar to coatings produced by a cold spray processes, but with higher process efficiencies and lower gas consumption. The inventive process combines features of a plasma process method of gas heating and a cold spray process to accelerate the gas, incorporating these elements into a single hybrid process.

Owner:SULZER METCO (US) INC

Method for separating and purifying nucleic acid

InactiveUS20060051799A1Effective recoveryHigh yieldSugar derivativesMicrobiological testing/measurementPurification methodsWhole blood units

Nucleic acid contained in a sample is highly efficiently recovered at a high recovery ratio by a method for separating and purifying nucleic acid using whole blood as the sample, which is a method for separating and purifying nucleic acid, comprising: preparing a sample solution containing nucleic acid; putting the sample solution containing nucleic acid in contact with a solid phase to allow nucleic acid to be adsorbed to the solid phase; putting a washing solution in contact with the solid phase to wash the solid phase at the state of nucleic acid adsorbed thereon; and putting a elution solution in contact with the solid phase to allow nucleic acid to be desorbed from the solid phase, wherein the step of preparing a sample solution containing nucleic acid comprises at least one selected from the group consisting of vortexing, mixing with inversion, and pipetting.

Owner:KURASHIKI BOSEKI KK

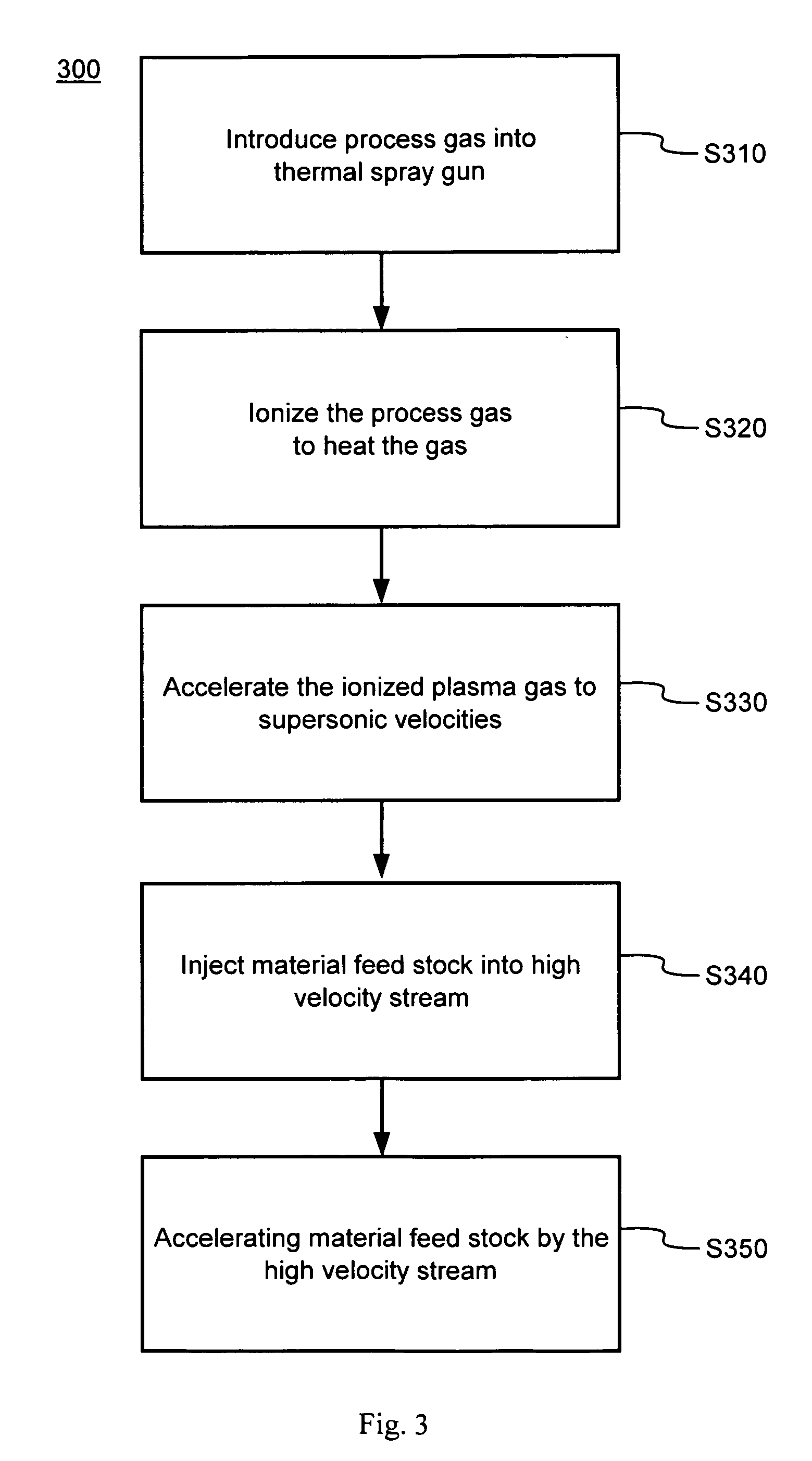

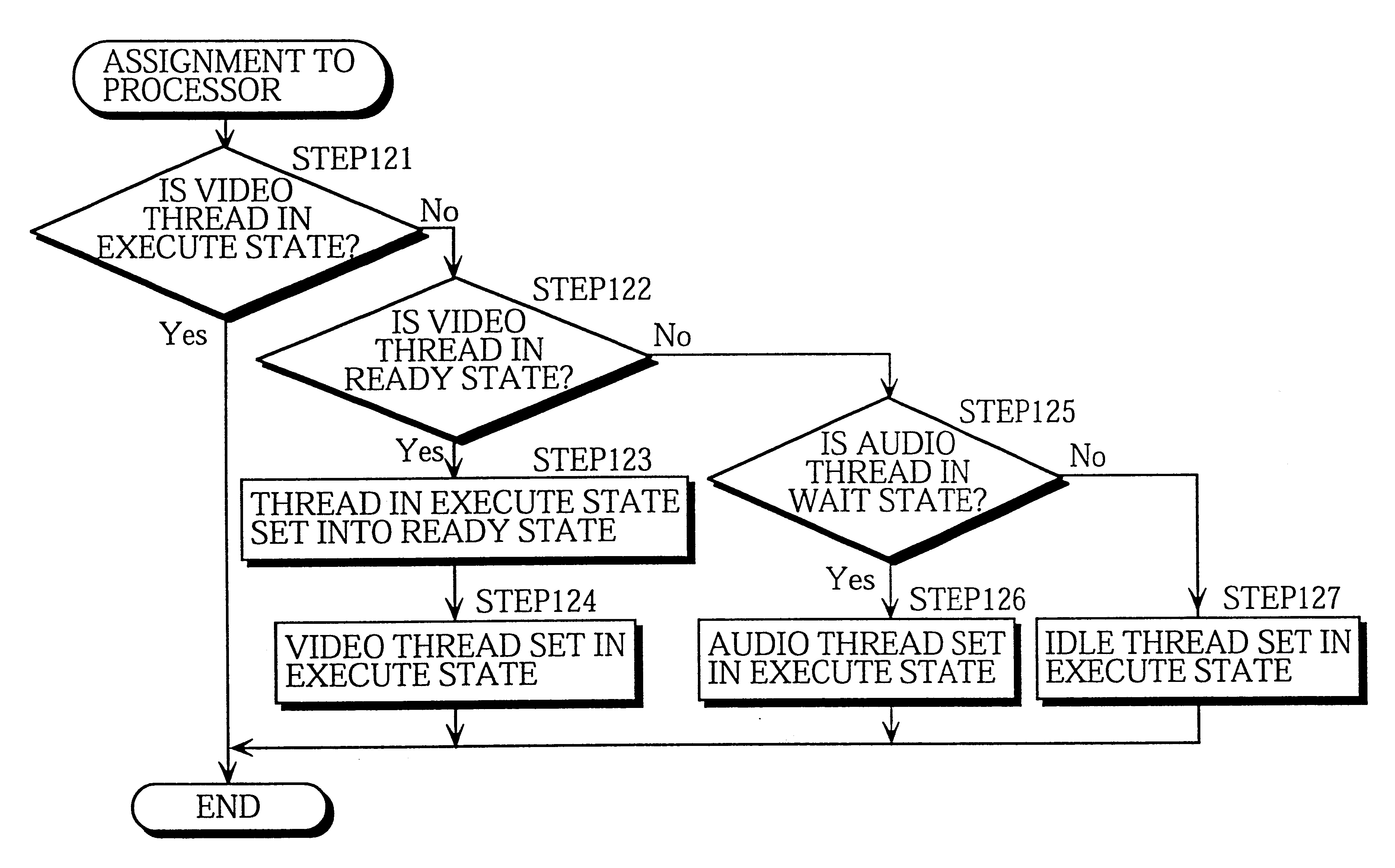

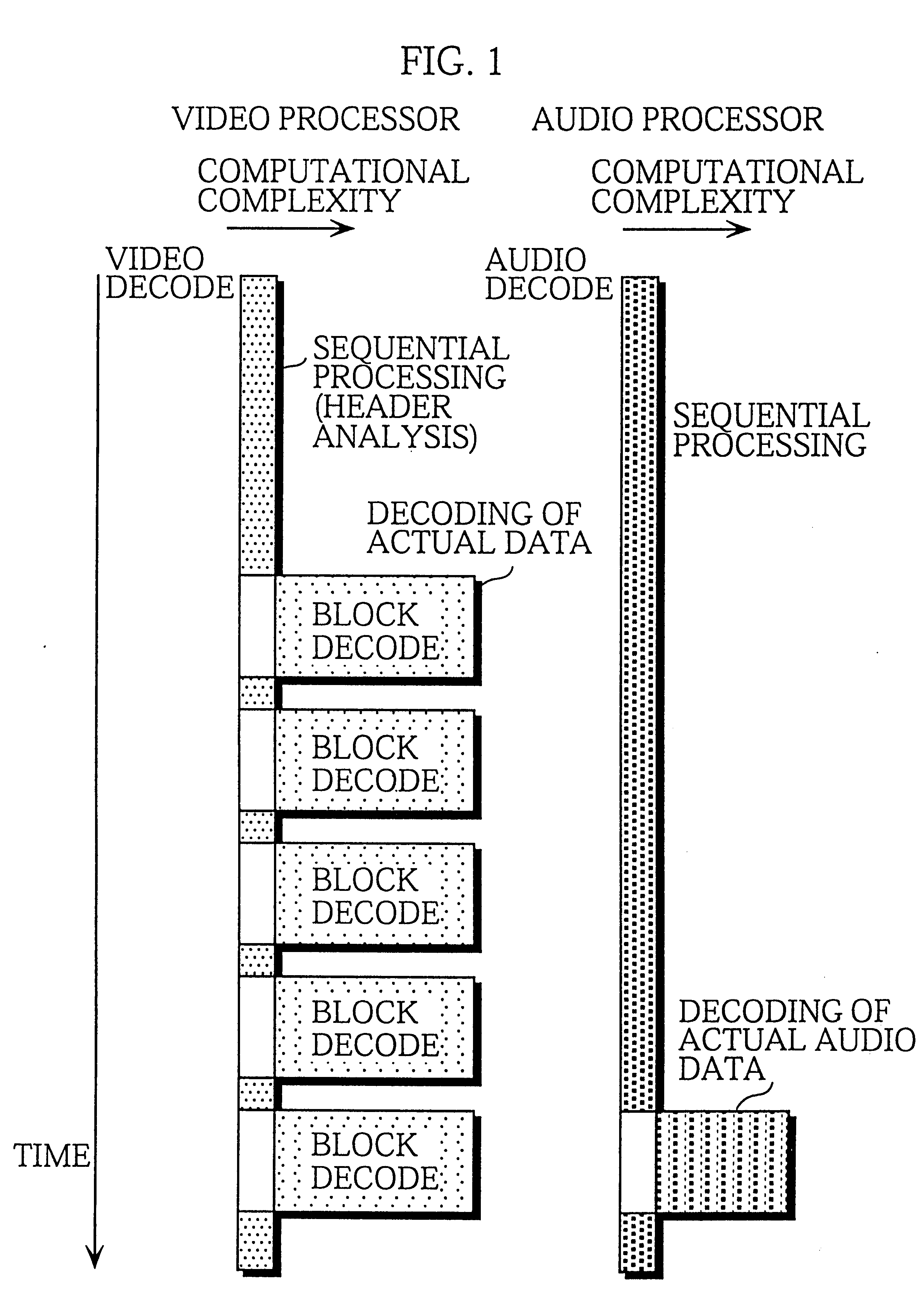

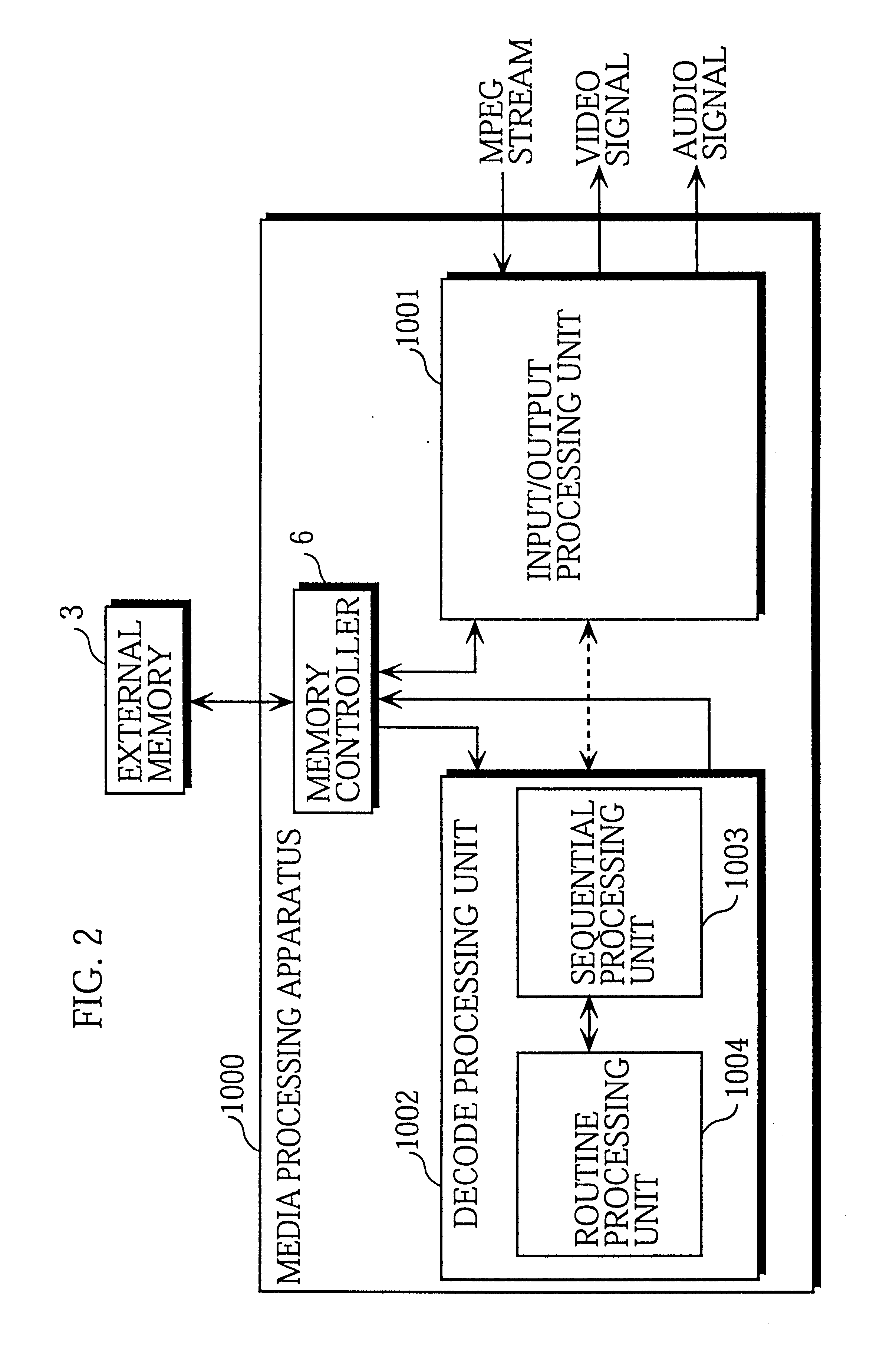

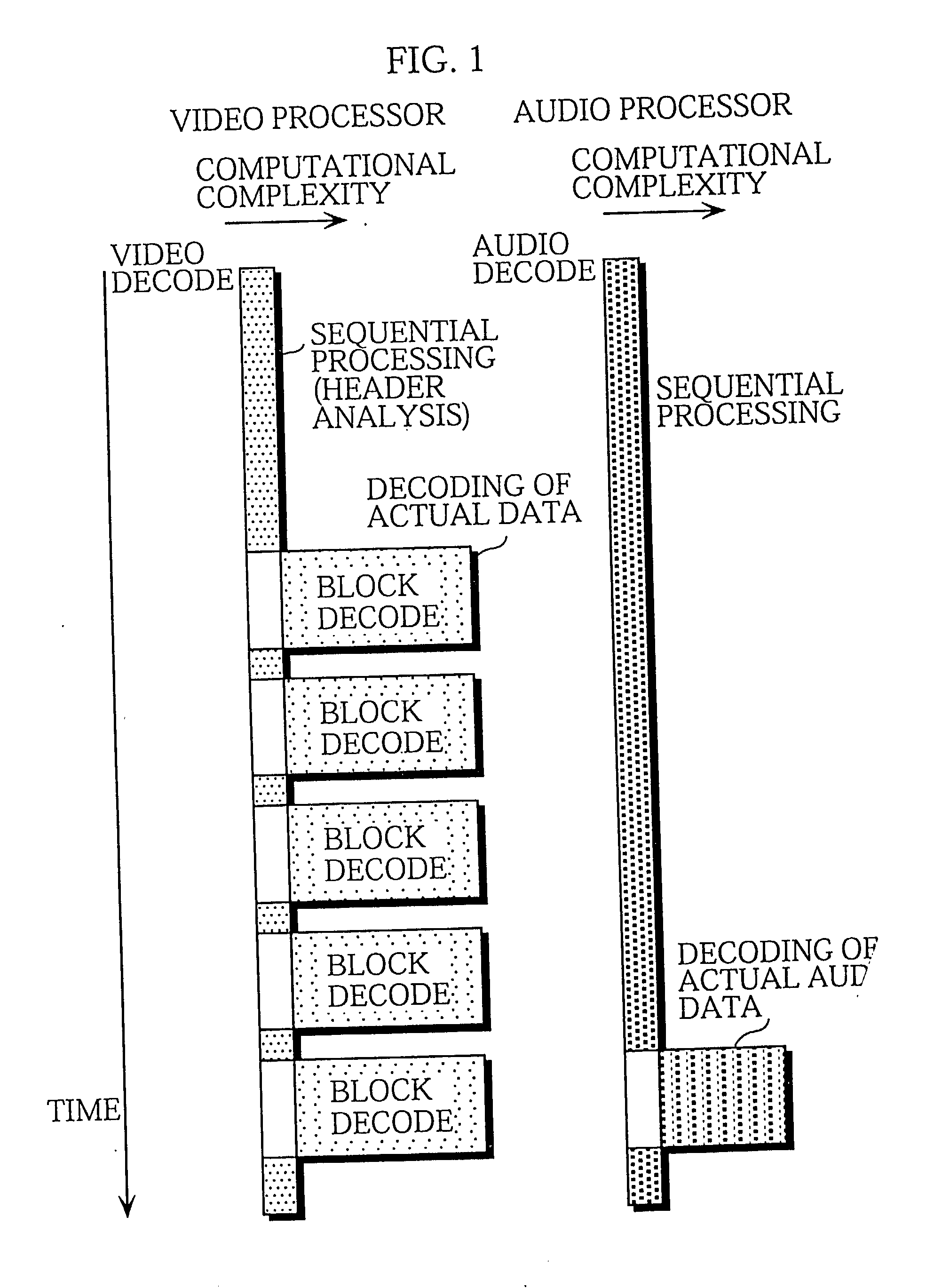

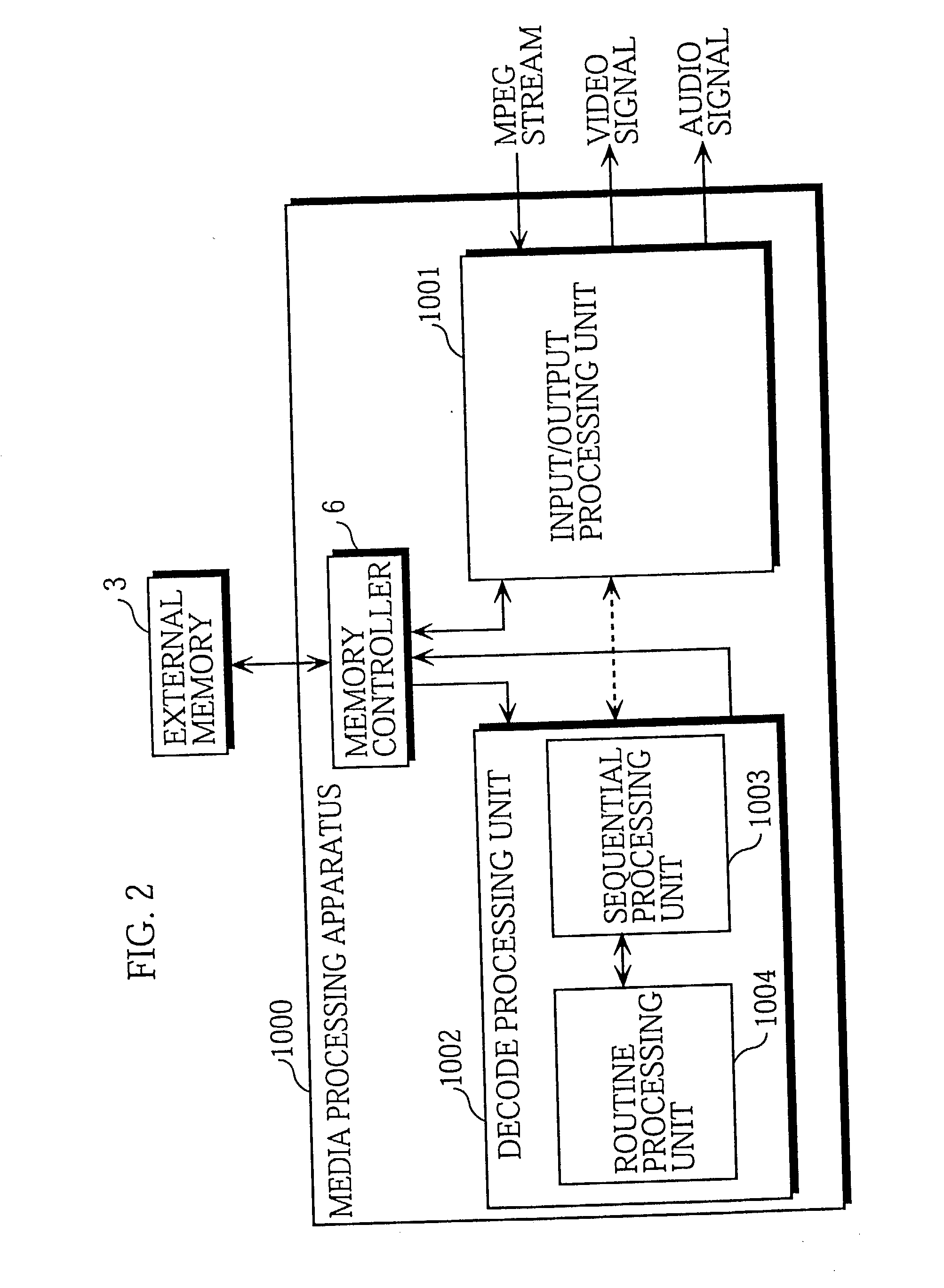

Media processing apparatus that operates at high efficiency

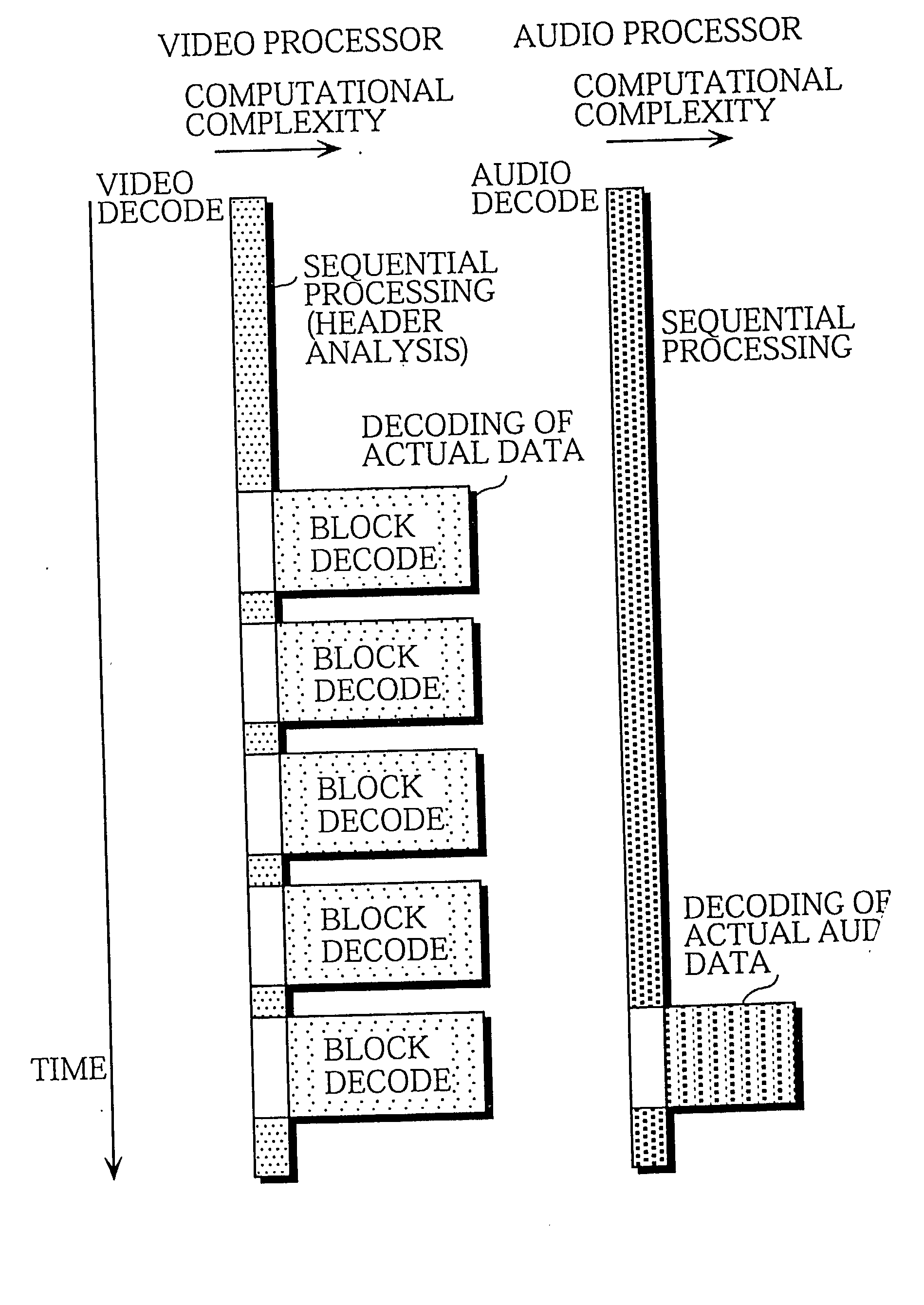

InactiveUS6782368B2Process can be speededImprove performanceTelevision system detailsSpeech analysisData streamParallel computing

A media processing apparatus includes an input / output processing unit that performs input / output processing that is asynchronously caused by external factors and a decode processing unit that operates in parallel with the input / output processing unit and mainly performs decode processing for a data stream stored in a memory. The input / output processing receives an asynchronous input of a data stream from outside, stores the data stream into the memory, and supplies a data stream stored in the memory to the decode processing unit. The decode processing unit includes a sequential processing unit and a routine processing unit. The sequential processing unit performs header analysis for compressed video data in the data stream and a complete decode for compressed audio data in the data stream. Based on the results of the header analysis, the routine processing unit performs all of the decoding of the compressed video data aside from the header analysis. In the sequential processing unit, the header analysis is given priority over the decoding of the compressed audio data.

Owner:GK BRIDGE 1

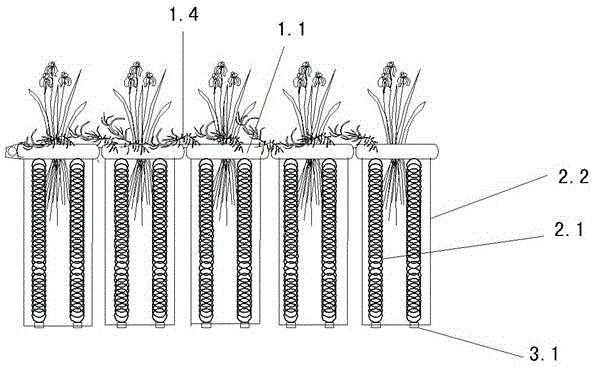

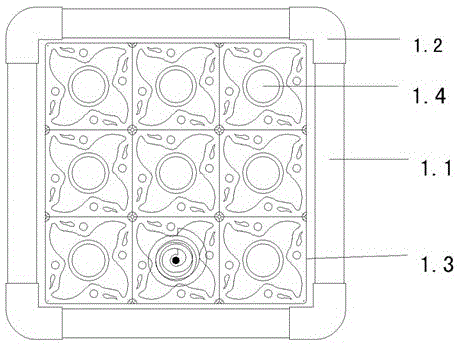

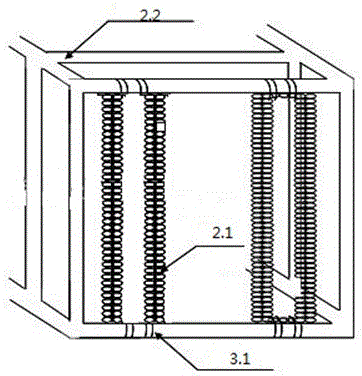

Three-dimensional ecological floating bed used for urban black and odorous riverway water quality improving and water purifying

InactiveCN105110476AGood purification effectAchieve transitionalBiological water/sewage treatmentEnvironmental engineeringWater transparency

The invention discloses a three-dimensional ecological floating bed used for urban black and odorous riverway water quality improving and water purifying. The ecological floating bed structurally comprises a floating bed structure body, biological stuffing and biolith. The structure forming method includes the step that the three-dimensional ecological floating bed is formed in a river or lake which flows slowly or is still through simple assembly. The ecological floating bed is mainly used for removing N and P nutritive salt in an urban black and odorous riverway and other organic pollution loads in water, improving the water transparency and increasing dissolved oxygen. The three-dimensional ecological floating bed has the advantages that the concept of the aquatic plant-biological stuffing microorganism-biolith combined ecological floating bed is provided for the first time by a water quality improving and water purifying method of the three-dimensional efficient ecological floating bed, and ecological floating bed plants, biological stuffing contact oxidation and biolith microorganisms have a successive relation for treating a water body and effectively complete functional complementation; particularly in winter or other kinds of low-temperature weather, the biological stuffing and the biolith can effectively compensate vacancy of the aquatic plants in a withered state to continuously and efficiently purify the urban black and odorous water body heavily polluted and recover and reconstruct water ecology and water functions.

Owner:TONGJI UNIV

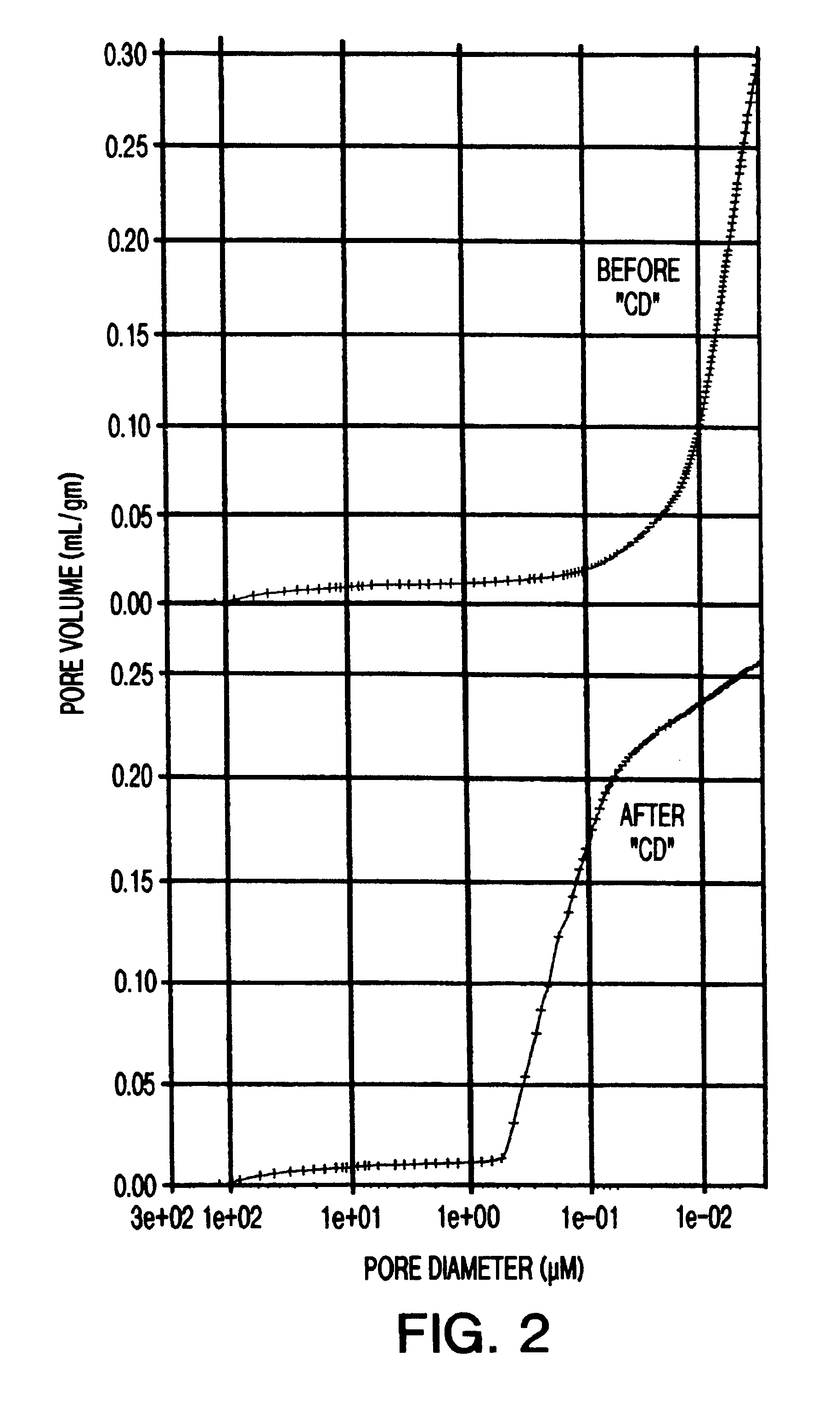

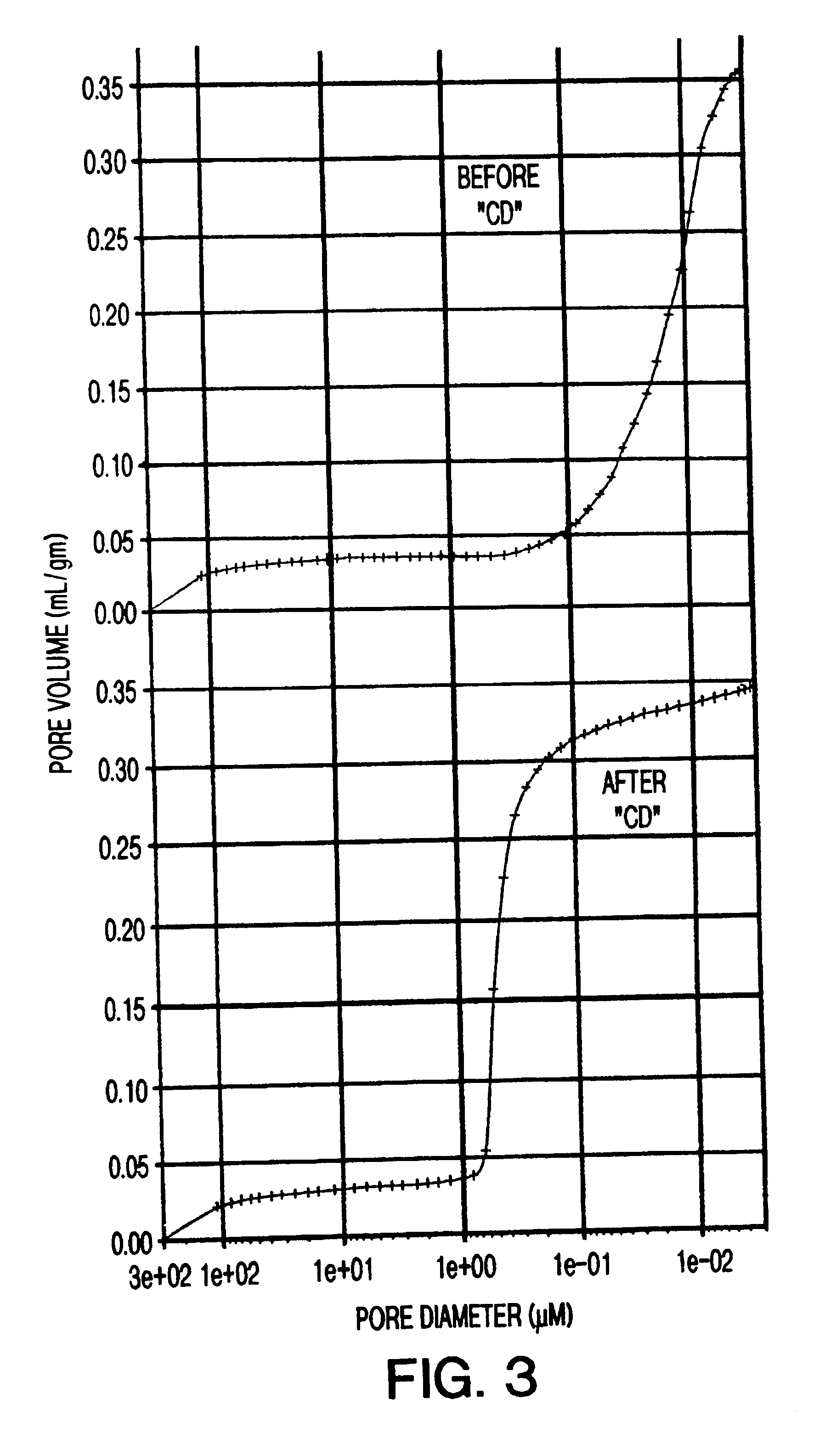

Advanced adsorbent for PSA

InactiveUS6425940B1Increase mass transfer rateMass transfer speedGas treatmentMolecular sieve catalystsSorbentOrganic chemistry

The invention relates to adsorbent materials having comparatively high intrinsic adsorption rates. Methods are disclosed whereby such rates can be achieved. In preferred embodiments, the adsorbent is a LiX zeolite material.

Owner:PRAXAIR TECH INC

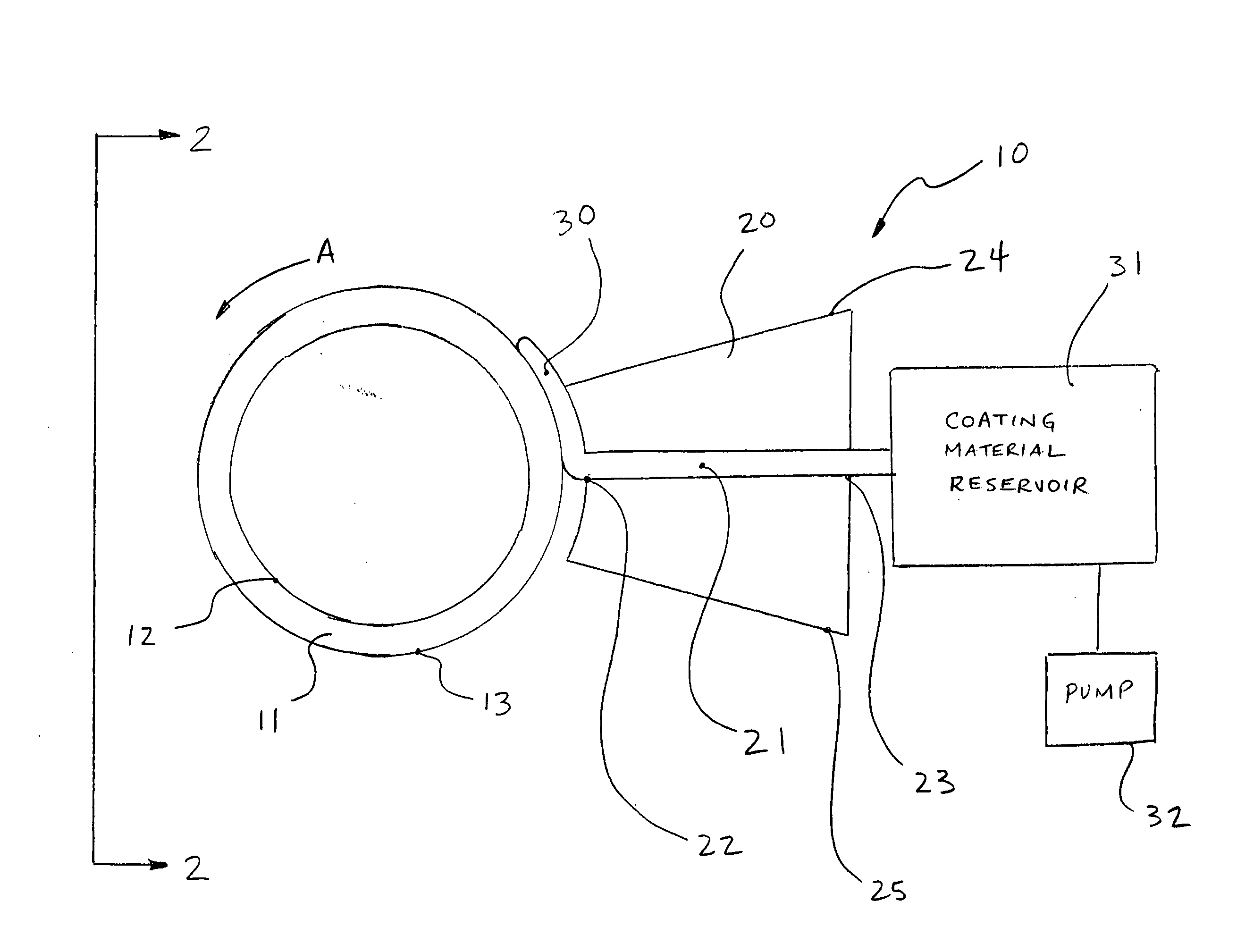

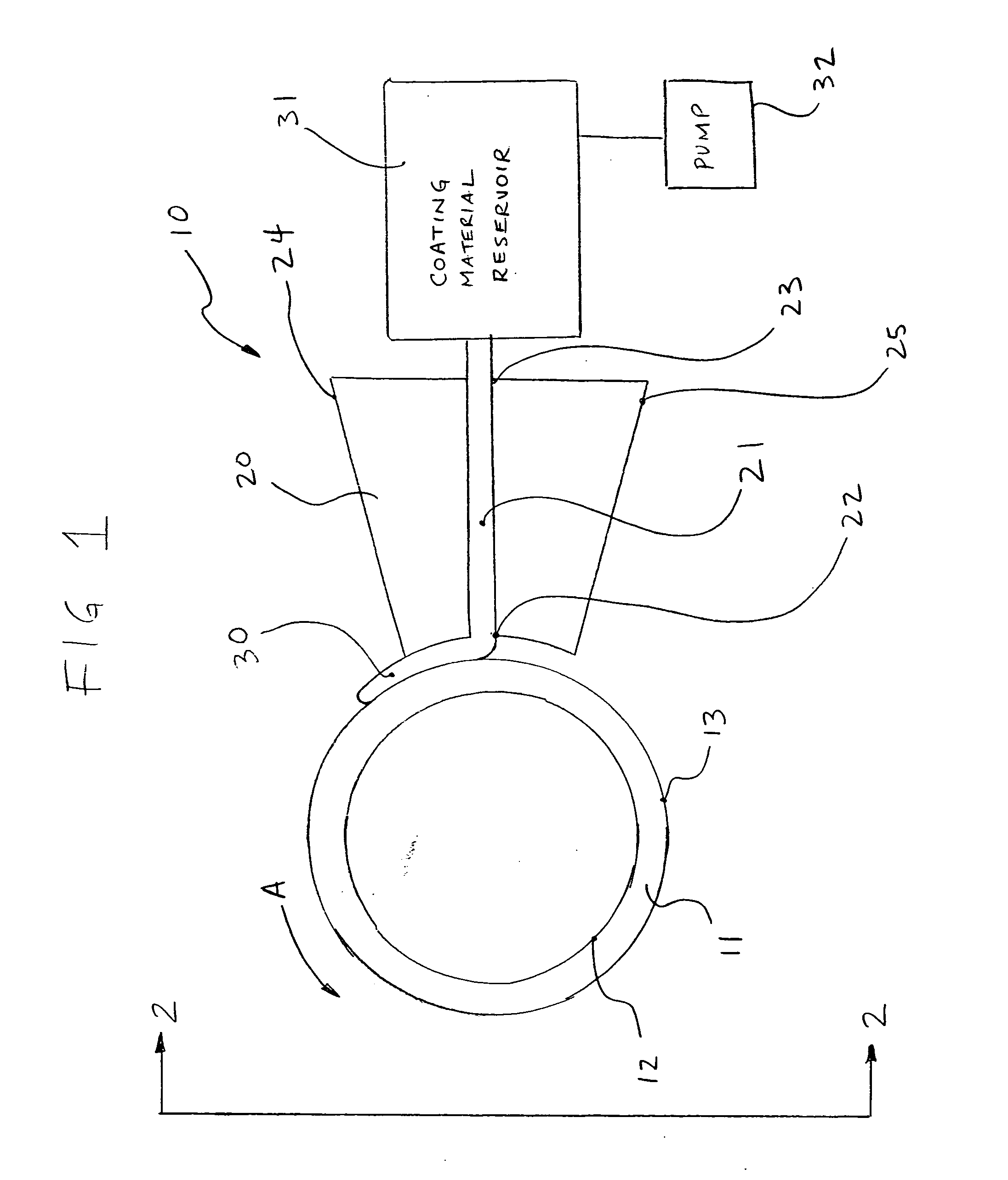

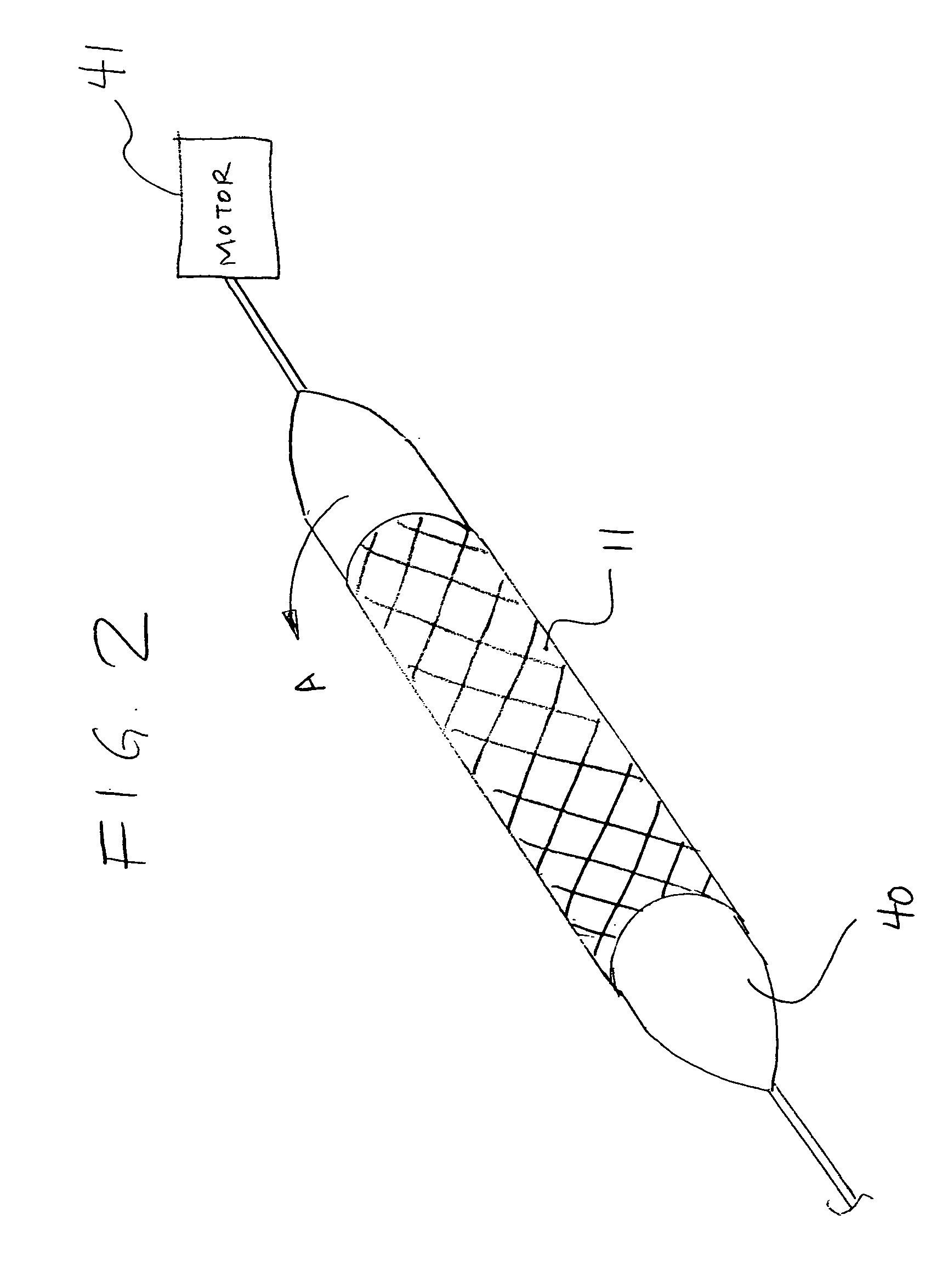

Method and apparatus for coating a medical device using a coating head

Methods and apparatuses for coating surface of medical devices using coating heads are disclosed. In one embodiment, the invention includes a coating method using a coating head, wherein the coating head comprises at least one outlet orifice from which flows a coating material, to deposit at least one layer of coating material dispelled through the outlet orifice onto the surface of the medical device. In another embodiment, a slide coating head is used to deposit multiple layers of superposed coating materials. These methods are used to apply one or more coating materials, simultaneously or in sequence. In certain embodiments of the invention, the coating materials include therapeutic agents, polymers, sugars, waxes, or fats.

Owner:BOSTON SCI SCIMED INC

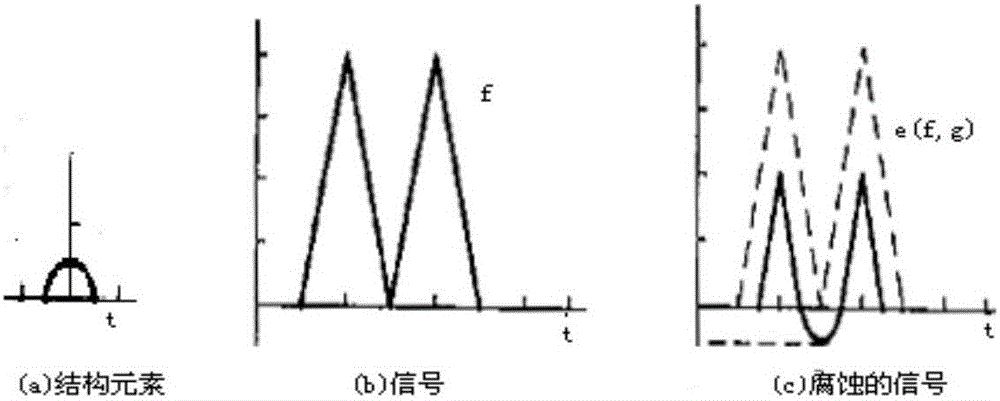

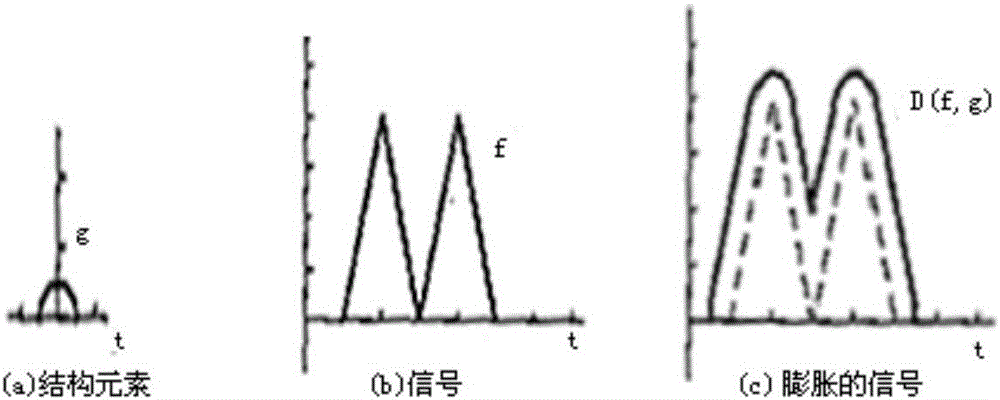

Morphological filtering-based electrical imaging reservoir fracture and cave body quantitative characterization method and system

ActiveCN106443802AImprove signal-to-noise ratioEasy to identifyElectric/magnetic detection for well-loggingAcoustic wave reradiationPore distributionMorphological filter

The present invention discloses a morphological filtering-based electrical imaging reservoir fracture and cave body quantitative characterization method and system. The method includes the following steps that: 1) noise suppression and blank band encryption interpolation are performed on original electric imaging logging data to obtain full-coverage rate electrical imaging logging data; 2) structural elements of appropriate shapes and scales are selected, and morphological filtering is performed on the obtained electrical imaging logging data in the step 1), so that fracture and cave pore distribution of different scales can be determined; and 3) the proportion of the porosity of fractures and the proportion of the porosity of corroded caves are calculated according to the fracture and cave pore distribution of different scales, so that a fracture and cave porosity spectrum which can indicate pore throat size and porosity distribution relationships can be obtained. According to the method of the invention, a mathematical morphological filtering method is introduced into imaging logging data processing; based on the filtering and anomaly recognition technologies of conductivity signals of different scales, the signal-to-noise ratio and identifiability of fracture and cave abnormal signals are improved; and exact information such as intuitive fracture and cave shapes and scale distribution can be provided for the processing and interpretation of electrical imaging logging data.

Owner:CHINA PETROLEUM & CHEM CORP +4

Hybrid plasma-cold spray method and apparatus

ActiveUS7582846B2Wide range of operationsImprove processing effectivenessMolten spray coatingArc welding apparatusStress conditionsProcess engineering

The present invention provides a method and apparatus of producing a dense coating with desirable stress conditions similar to coatings produced by a cold spray processes, but with higher process efficiencies and lower gas consumption. The inventive process combines features of a plasma process method of gas heating and a cold spray process to accelerate the gas, incorporating these elements into a single hybrid process.

Owner:SULZER METCO (US) INC

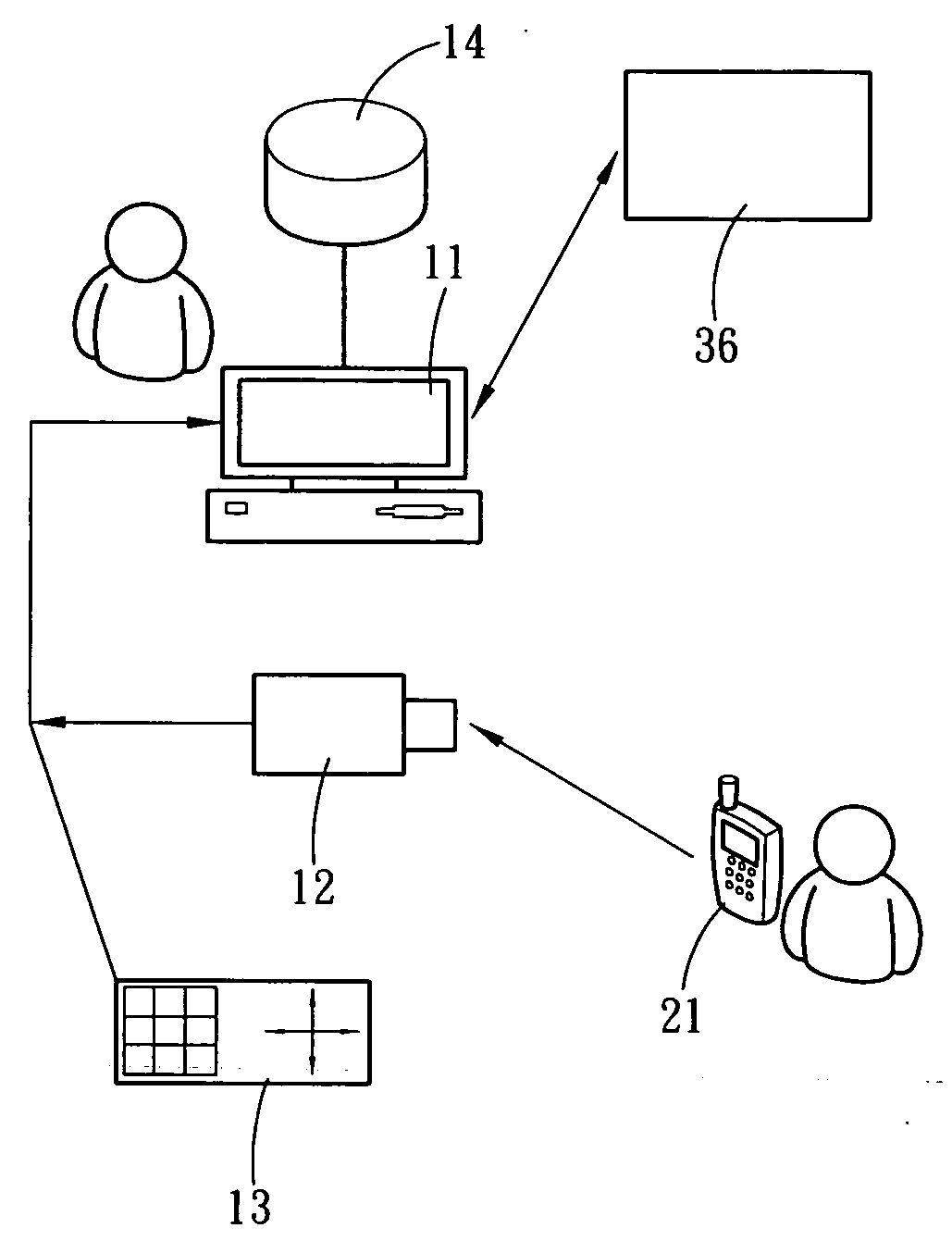

Electronic ticket management system

InactiveUS20080223940A1Eliminate riskLow costReservationsCharacter and pattern recognitionGraphicsProcess module

An electronic ticket management system mainly includes a vendor module, a ticket process module, a Web module, a ticket order module, a delivery module and a ticket verification module. After a consumer has purchased a ticket through a communication network, a service center transmits the information of the electronic ticket to a designated mobile communication device equipped with graphic display capability. When in use the consumer displays bar code graphics of the electronic ticket. Through a scanner at a ticket verification end the graphics of the electronic ticket on the mobile communication device can be captured, and identification result is verified online. Thus the total process does not have physical contact. The risk of carrying the currency can be prevented. The costs of manual operation and paper ticket can be saved. Therefore ticket processing efficiency increases.

Owner:LEE SHAO HSUAN +2

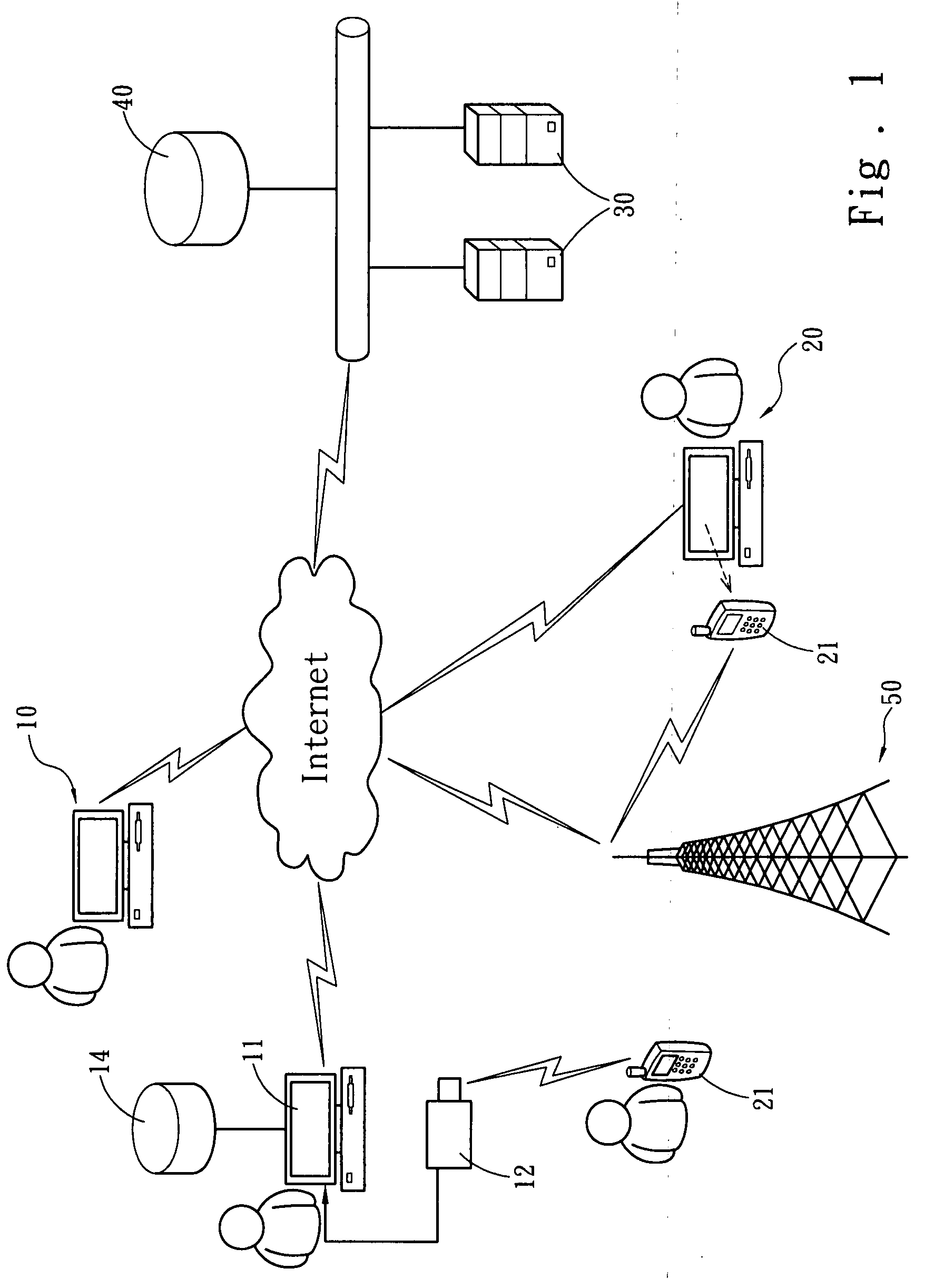

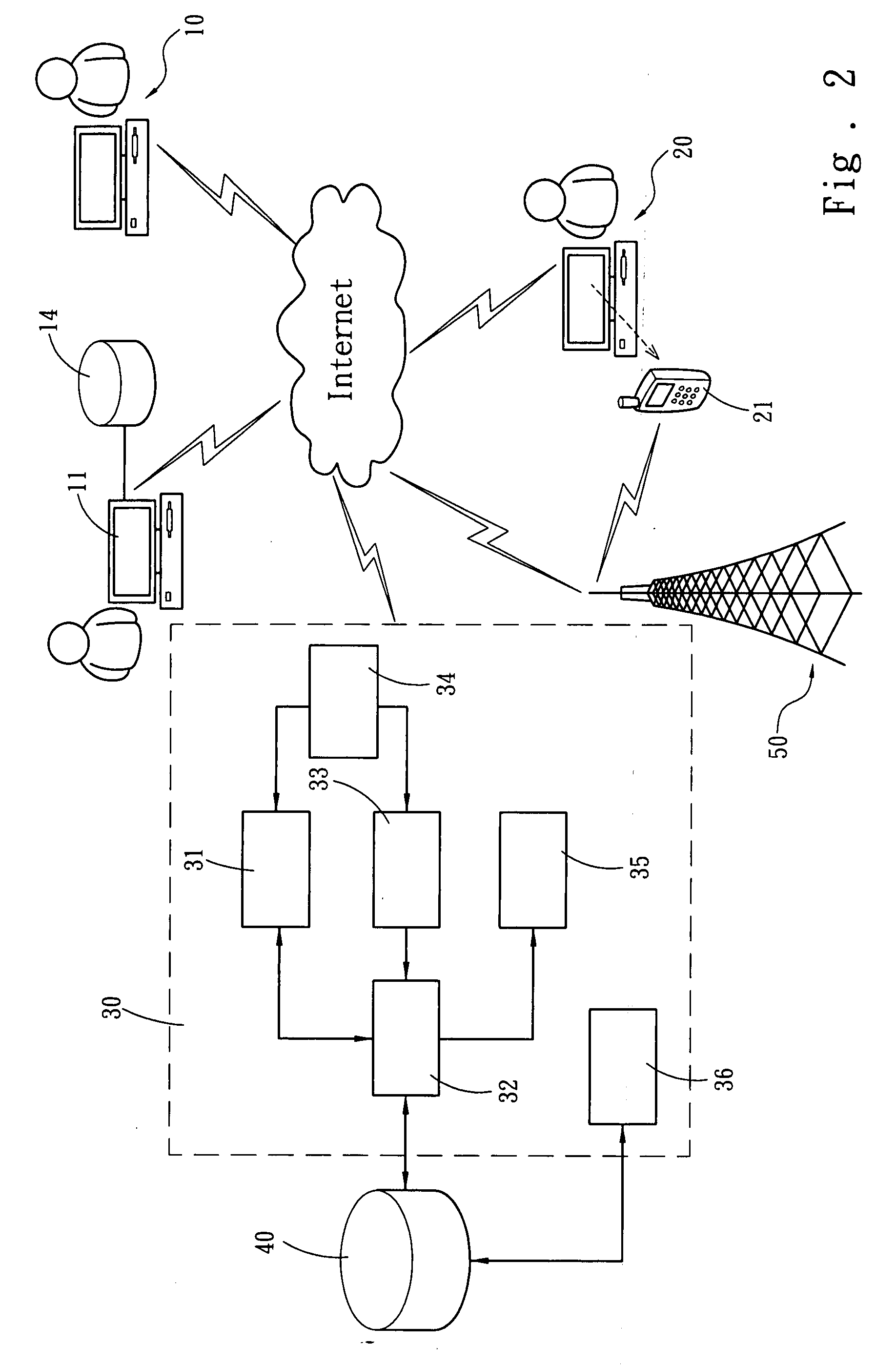

Media processing apparatus that operates at high efficiency

InactiveUS20030014264A1Process can be speededImprove performanceTelevision system detailsSpeech analysisData streamParallel computing

A media processing apparatus includes an input / output processing unit that performs input / output processing that is asynchronously caused by external factors and a decode processing unit that operates in parallel with the input / output processing unit and mainly performs decode processing for a data stream stored in a memory. The input / output processing receives an asynchronous input of a data stream from outside, stores the data stream into the memory, and supplies a data stream stored in the memory to the decode processing unit. The decode processing unit includes a sequential processing unit and a routine processing unit. The sequential processing unit performs header analysis for compressed video data in the data stream and a complete decode for compressed audio data in the data stream. Based on the results of the header analysis, the routine processing unit performs all of the decoding of the compressed video data aside from the header analysis. In the sequential processing unit, the header analysis is given priority over the decoding of the compressed audio data.

Owner:GK BRIDGE 1

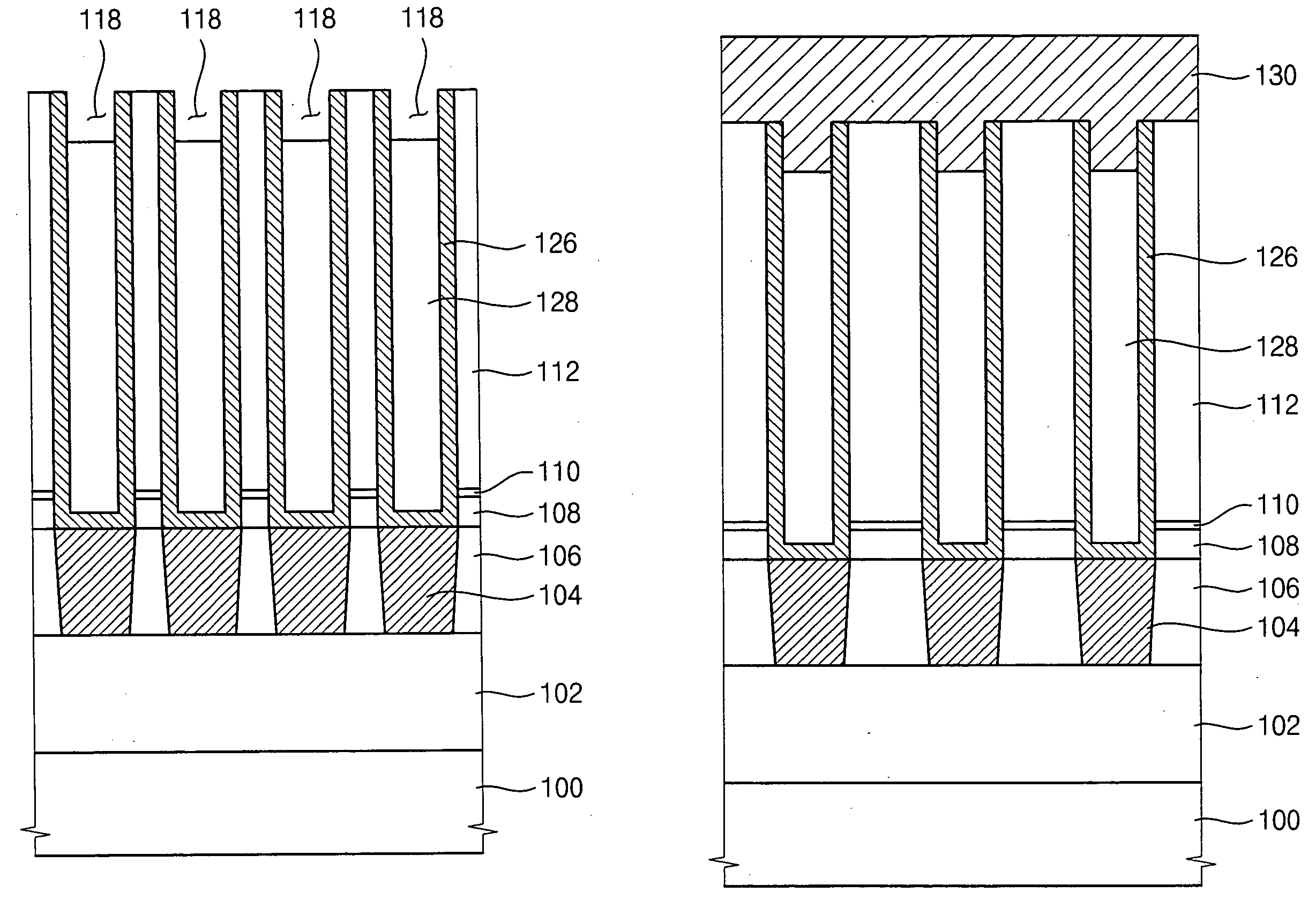

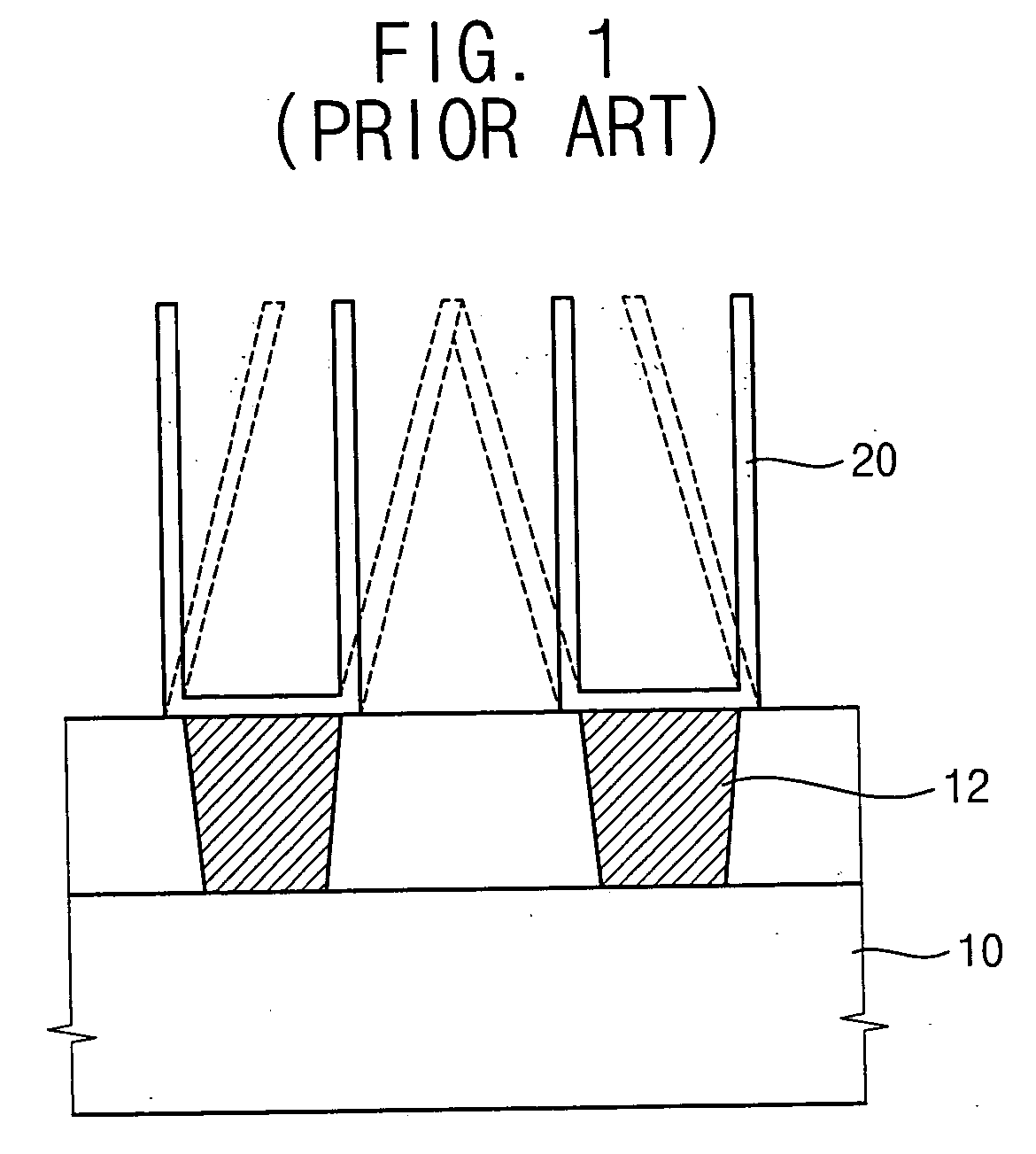

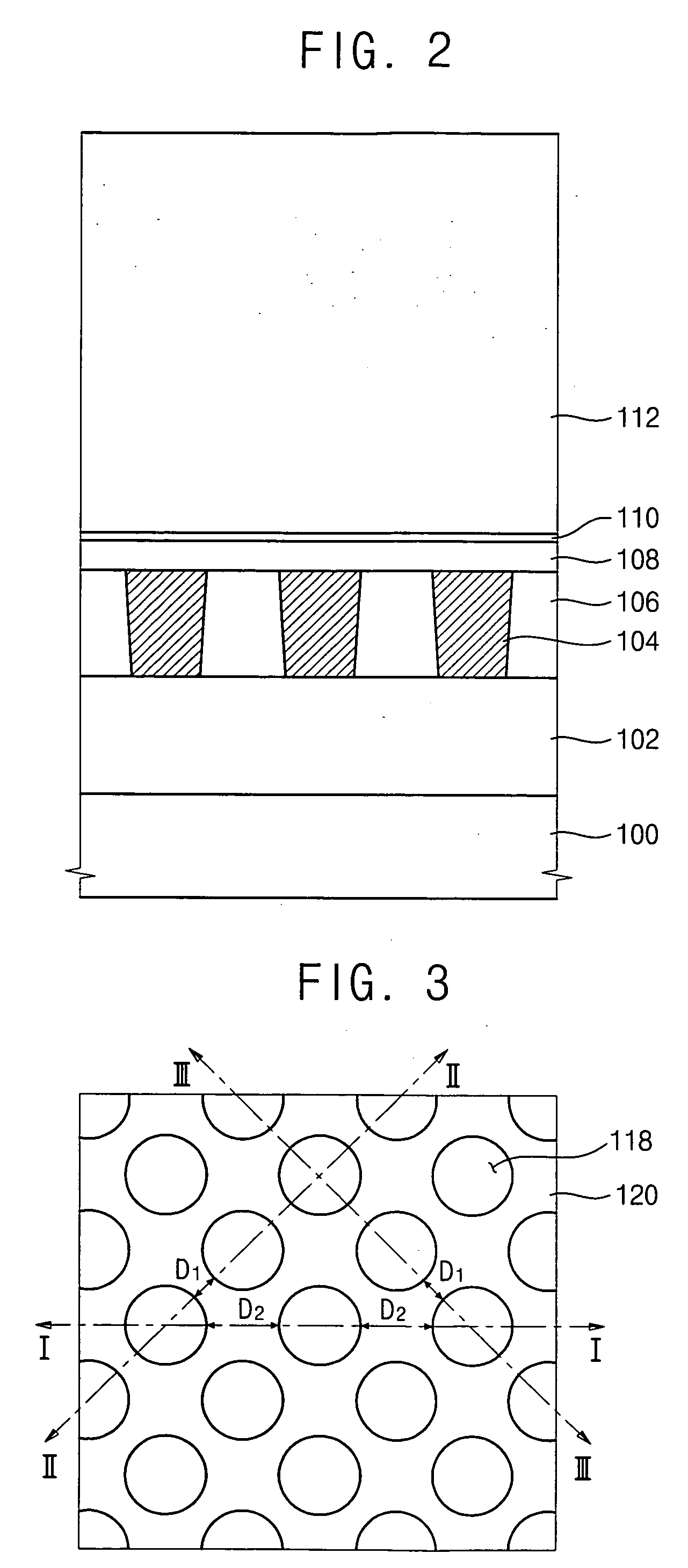

Method of forming a capacitor for a semiconductor device

InactiveUS20060046382A1Improve structural stabilityLow heat budgetSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialEngineering

In an embodiment, a method of forming a capacitor for a semiconductor device of which structural stability is improved is shown. Cylindrical storage electrodes are formed in a matrix pattern on a substrate that includes an insulation interlayer having contacts therein so that a mold layer surrounds the cylindrical storage electrodes. Sacrificial plugs are formed with a cap within these electrodes. A stabilizing layer is formed on the etched mold layer and the cylindrical storage electrode by partially etching the mold layer. The stabilizing layer is etched until the sacrificial plug is exposed, thereby forming a spacer. While the sacrificial plug and the mold layer are fully removed, the spacer is partially removed, thereby forming a stabilizing member for supporting neighboring storage electrodes adjacent to each other. Accordingly, a structural stability of the capacitor is improved.

Owner:SAMSUNG ELECTRONICS CO LTD

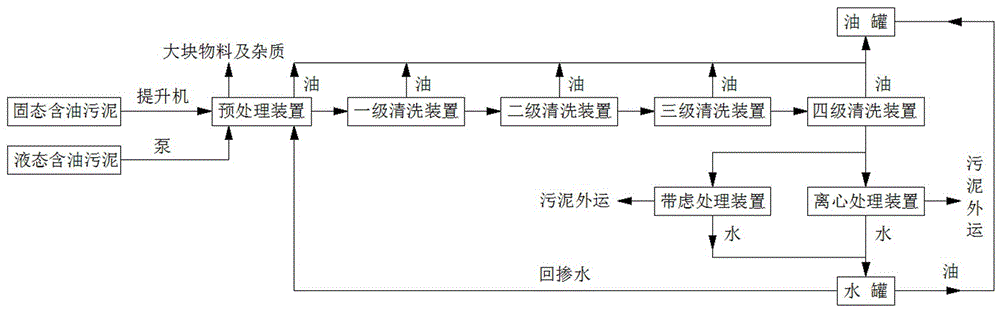

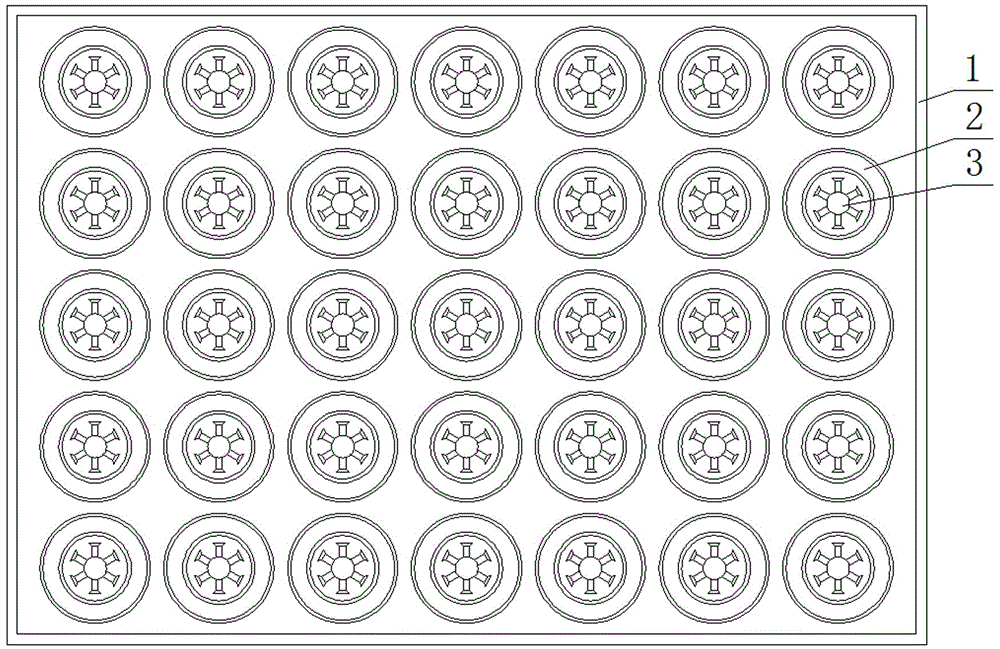

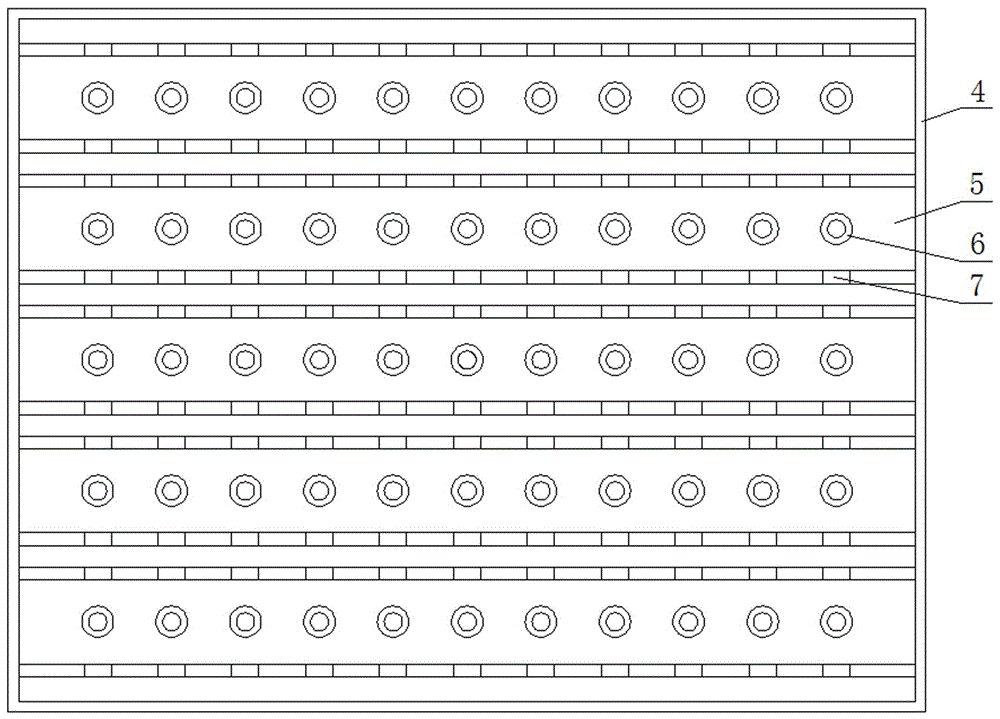

Technological method for treatment of oil field oil sludge

ActiveCN106242205AAvoid lossAvoid high temperature burnsSludge treatment by de-watering/drying/thickeningMelting tankFuel tank

Belonging to the technical field of oil sludge treatment, the invention specifically relates to a technological method for treatment of oil field oil sludge. The technological method consists of: solid oily sludge screening, solid oily sludge dry steam oil melting, solid oily sludge high-pressure water crushing, liquid oily sludge pretreatment, first level cleaning, second level cleaning, third level cleaning, fourth level cleaning, dehydration treatment and oil-water recovery. Specifically, an oil melting tank includes a box body, uniformly distributed ring cavity sieve columns and dry steam nozzles, the dry steam nozzles are located in the ring cavity sieve columns, the diameter of sieve pores on the inner and outer walls of the ring cavity sieve columns is 5mm, and the bottoms of the ring cavity sieve columns are provided with turnable discharge cover plates. A crushing box includes a shell, uniformly distributed material bins and high pressure water spray guns, the high pressure water spray guns are located at the top of the material bins, and both side walls of the material bins are provided with uniformly distributed round holes. The process involved in the invention has the advantages of reasonable design, safety and environmental protection, good treatment effect, high treatment efficiency, strong treatment capacity, and cost saving, and is economical and applicable.

Owner:大庆世纪新风环保科技有限公司

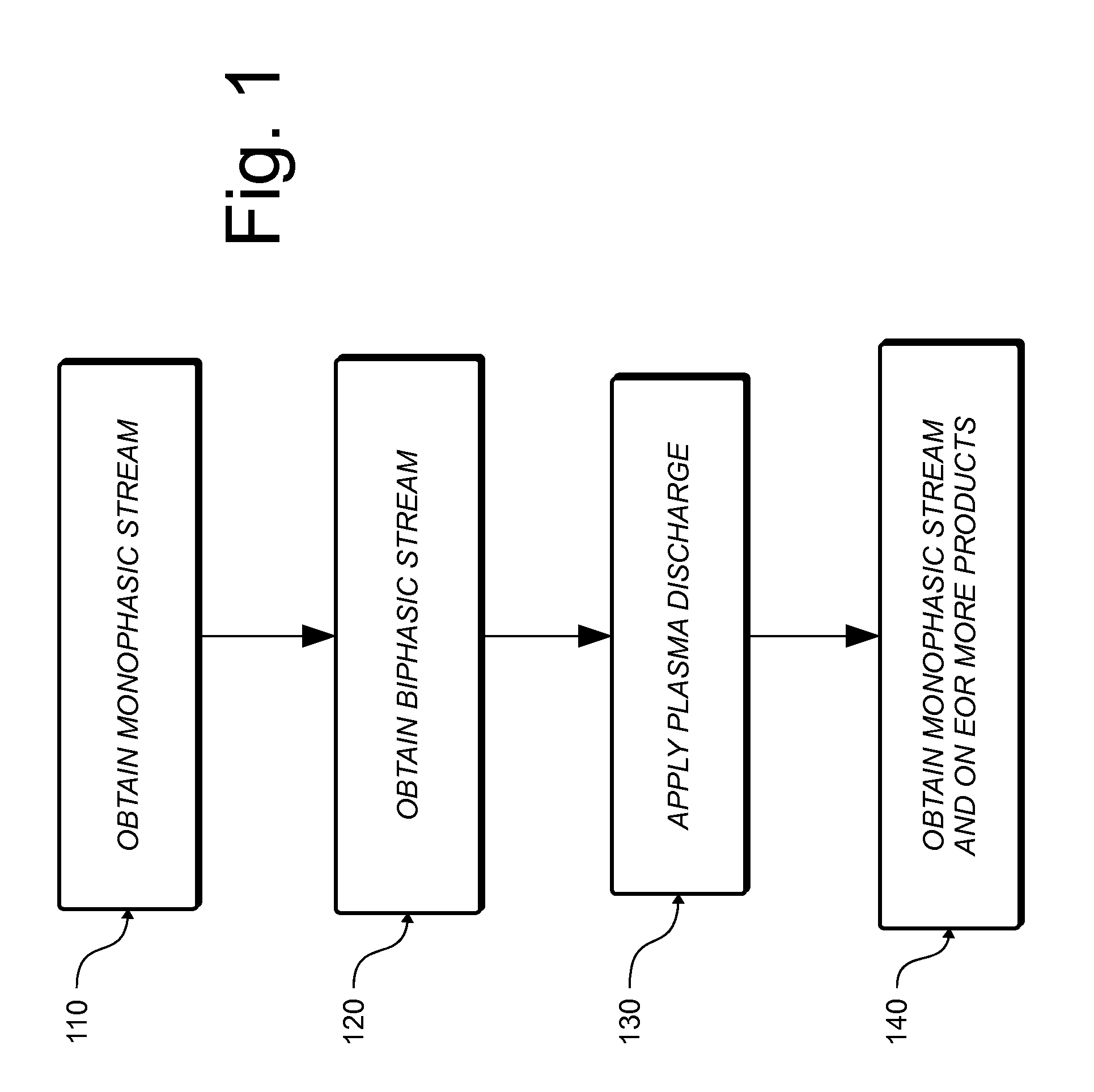

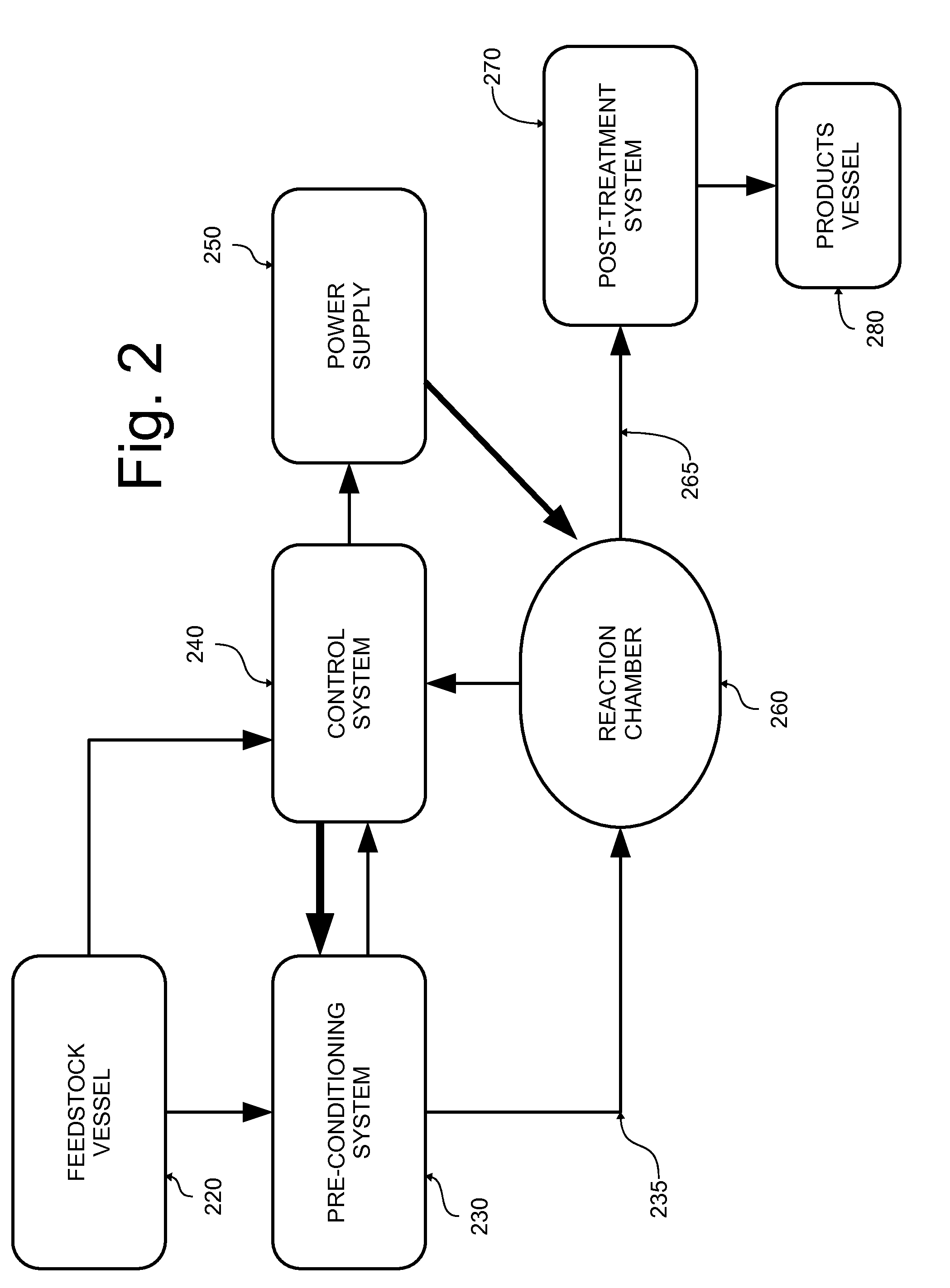

Method and apparatus for applying plasma particles to a liquid and use for disinfecting water

ActiveUS20110240567A1Short amount of timeDiffusion process is efficientWater treatment parameter controlClimate change adaptationWater useDouble phase

The invention provides a method and apparatus for creating plasma particles and applying the plasma particles to a liquid. Liquid feedstock (e.g., water and / or hydrocarbons mixed with biomass) is pumped through a pipeline; the single-phase stream is then transformed into a biphasic liquid-and-gas stream inside a chamber. The transformation is achieved by transitioning the stream from a high pressure zone to a lower-pressure zone. The pressure drop may occur when the stream further passes through a device for atomizing liquid. Inside the chamber, an electric field is generated with an intensity level that exceeds the threshold of breakdown voltage of the biphasic medium leading to a generation of a plasma state. Furthermore, the invention provides an energy-efficient highly adaptable and versatile method and apparatus for sanitizing water using plasma particles to inactivate biological agents contaminating water.

Owner:GARRETON ALFREDO ZOLEZZI +1

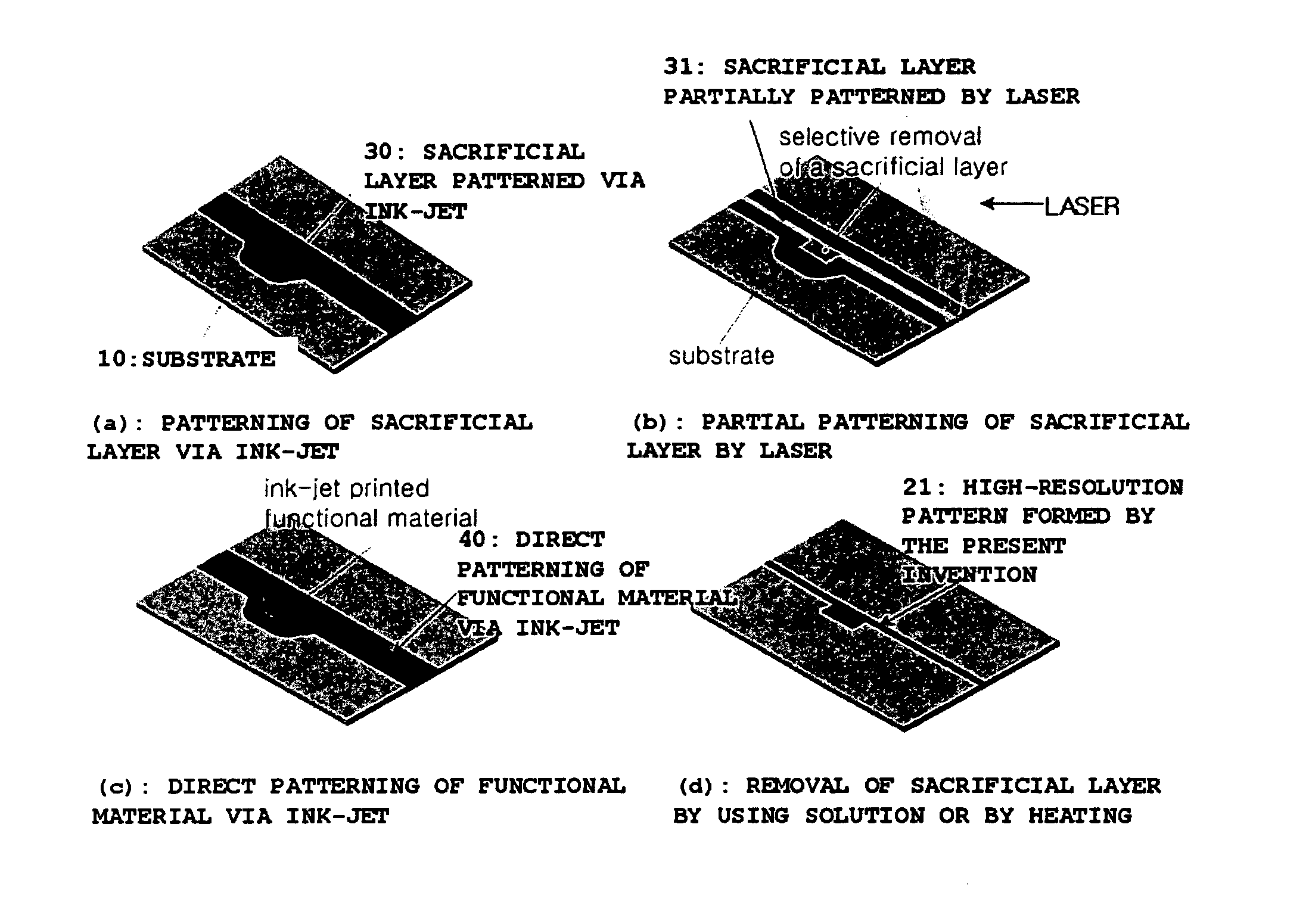

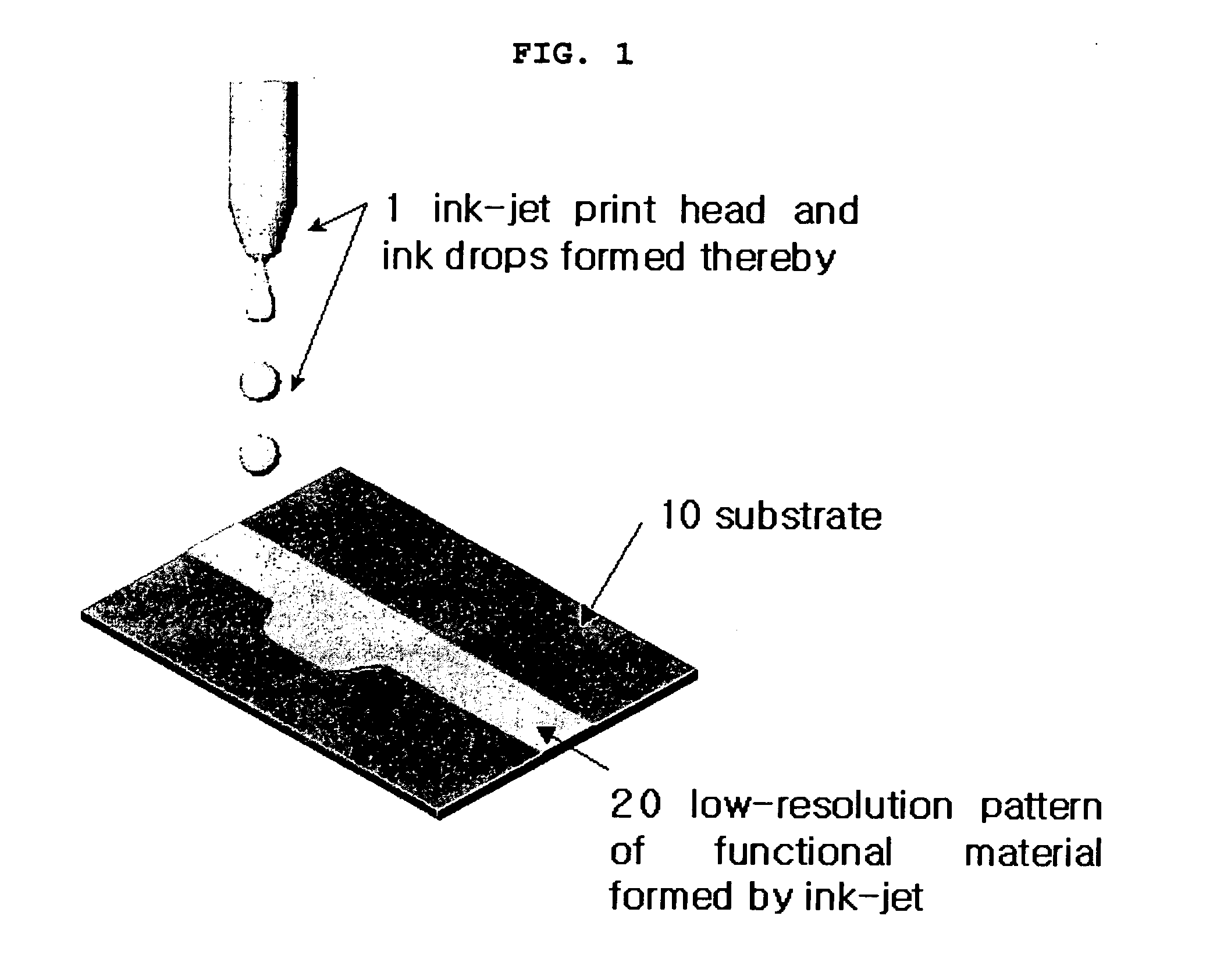

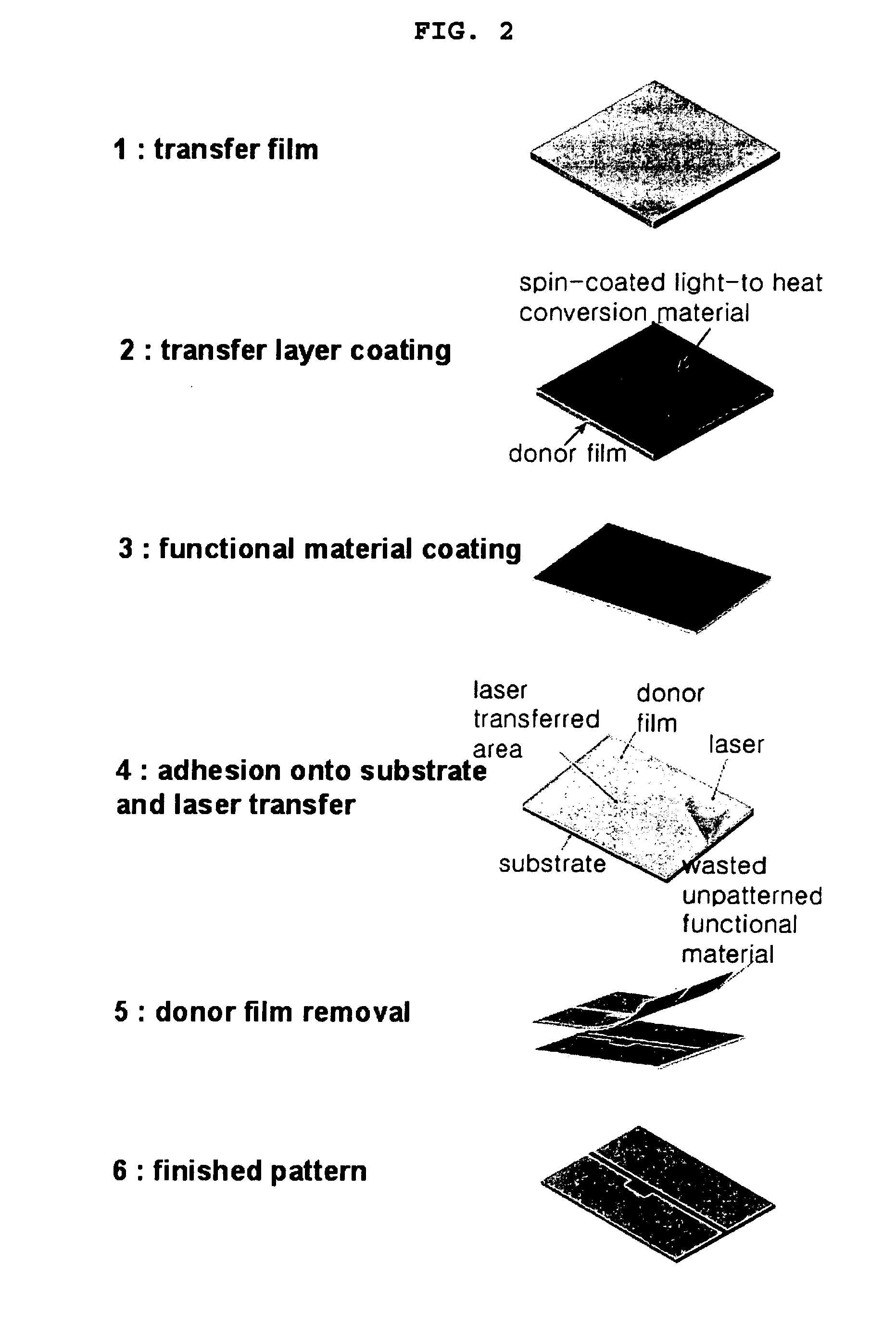

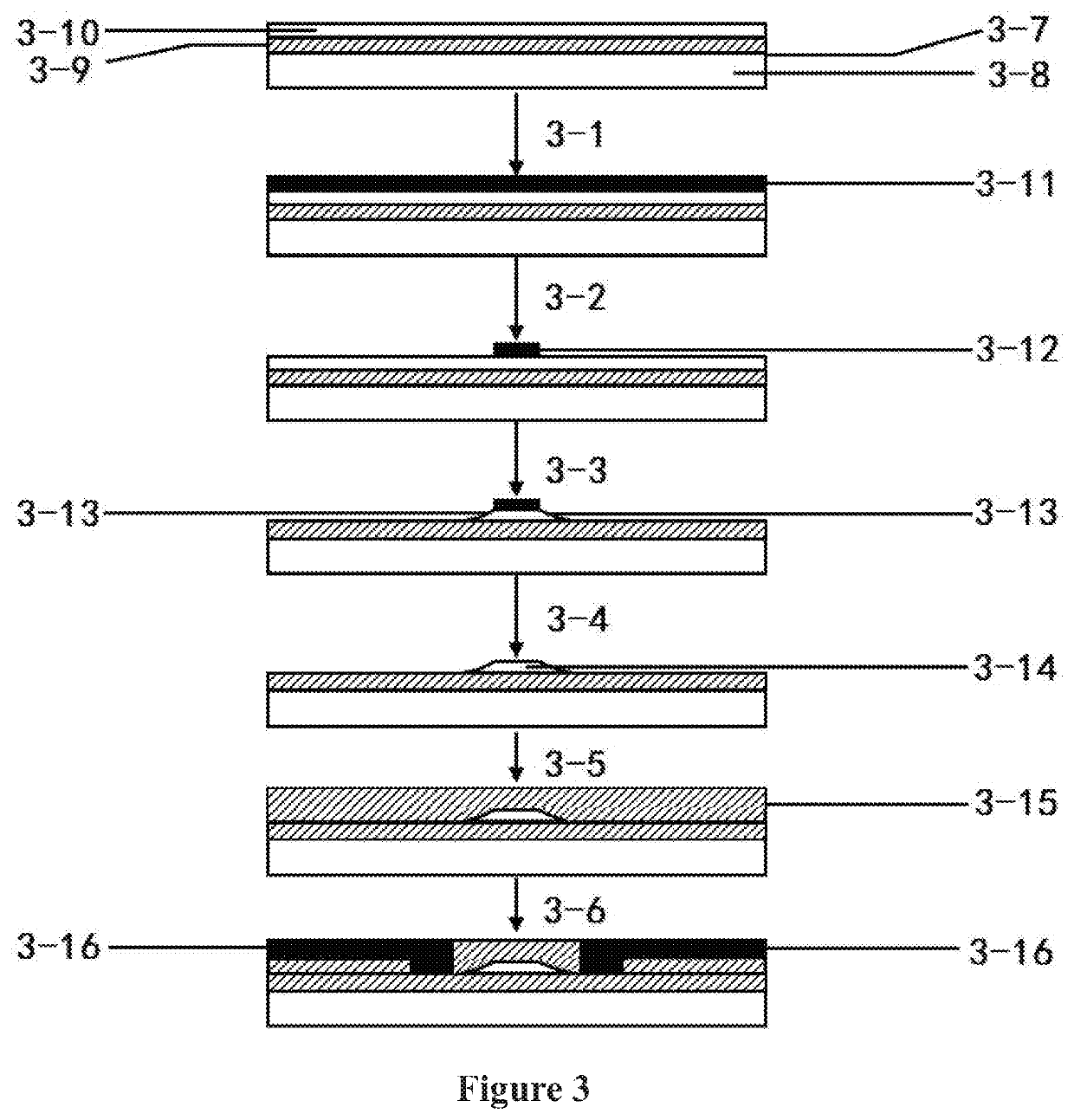

Method for forming high-resolution pattern with direct writing means

ActiveUS20060281333A1High resolutionAvoid huge wasteSemiconductor/solid-state device detailsSolid-state devicesImage resolutionLine width

Disclosed is a method for forming a pattern which comprises the steps of: (a) providing a substrate having a sacrificial layer made of a first material, partially or totally formed on the substrate; (b) forming pattern grooves, which are free from the first material and have a line width of a first resolution or lower, on the sacrificial layer by using a first means, by which the sacrificial layer is directly processed to form a line; (c) filling the pattern grooves with a second material to a second resolution by using a second means, to form a pattern of the second material on the substrate. A substrate having a pre-pattern formed by the method is also disclosed. The method for forming a pattern provides a high-resolution pattern with little or no waste of the second material, thereby reducing production costs. The method includes use of the first means with a high resolution, such as focused energy beams of laser, combined with the second means with a low resolution, such as ink-jet, and provides a high-resolution pattern with high processing efficiency.

Owner:LG CHEM LTD

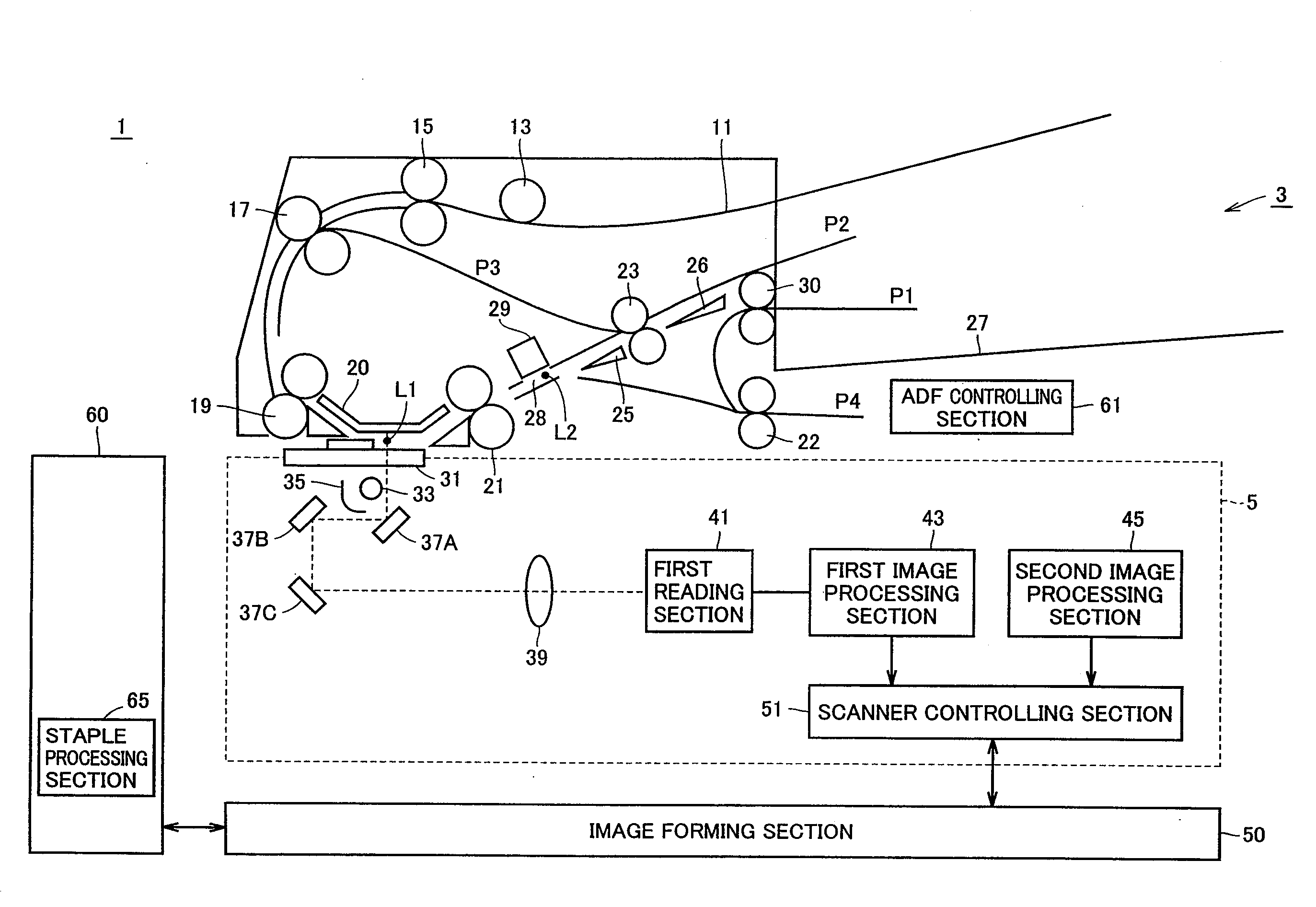

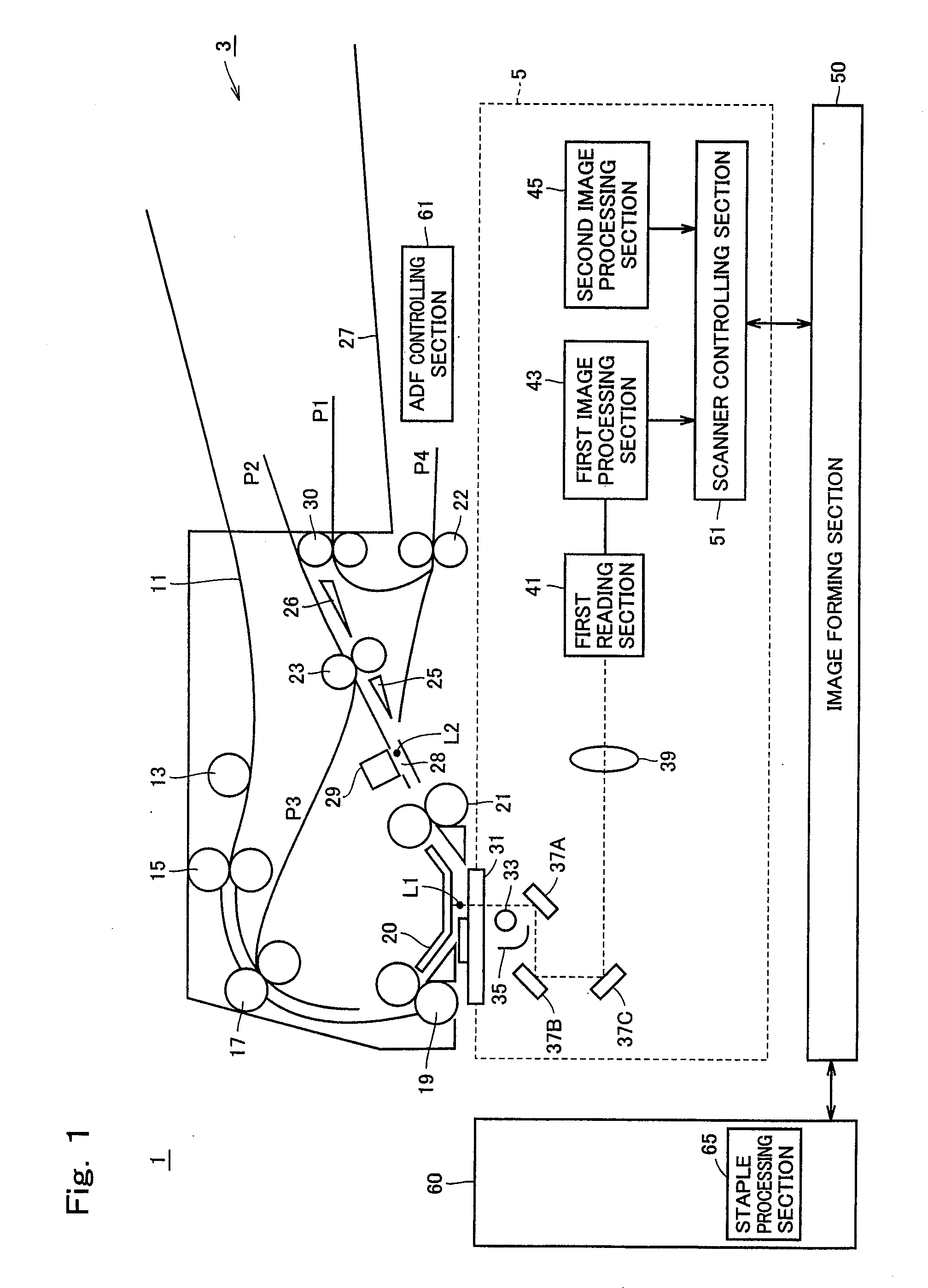

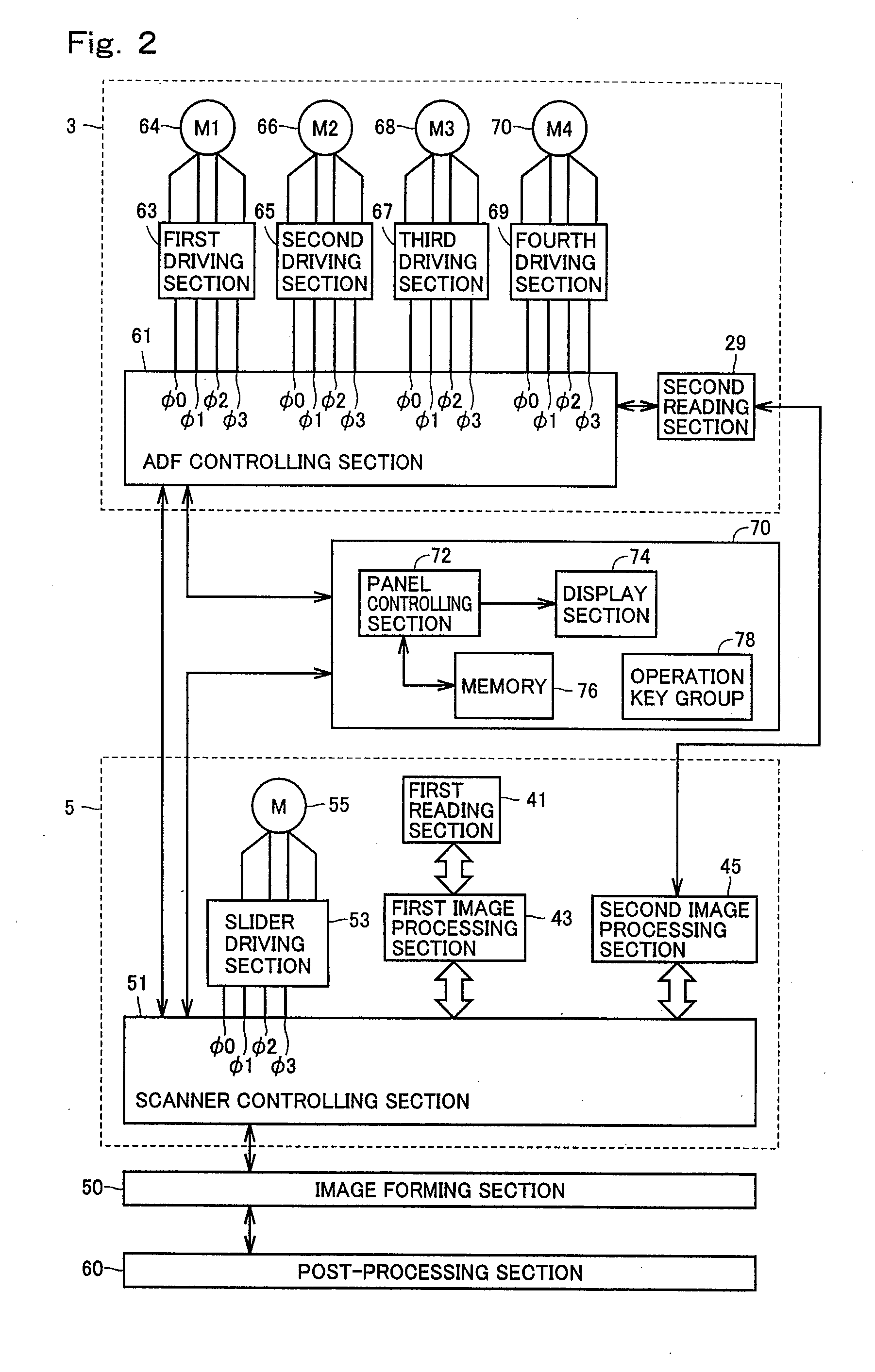

Double-side image reading device and image forming apparatus capable of executing reading of original with high throughput while taking image quality of read original into account

InactiveUS20090122365A1Improve processing effectivenessPictoral communicationTelecommunicationsImaging quality

Owner:KONICA MINOLTA BUSINESS TECH INC

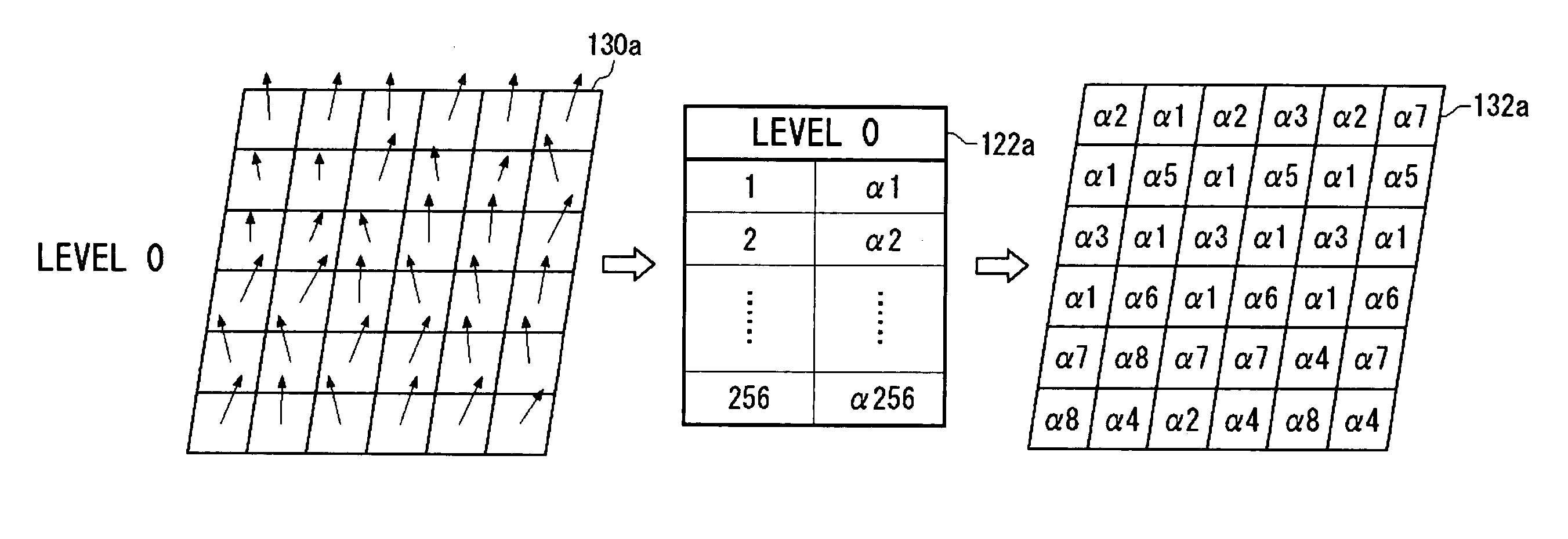

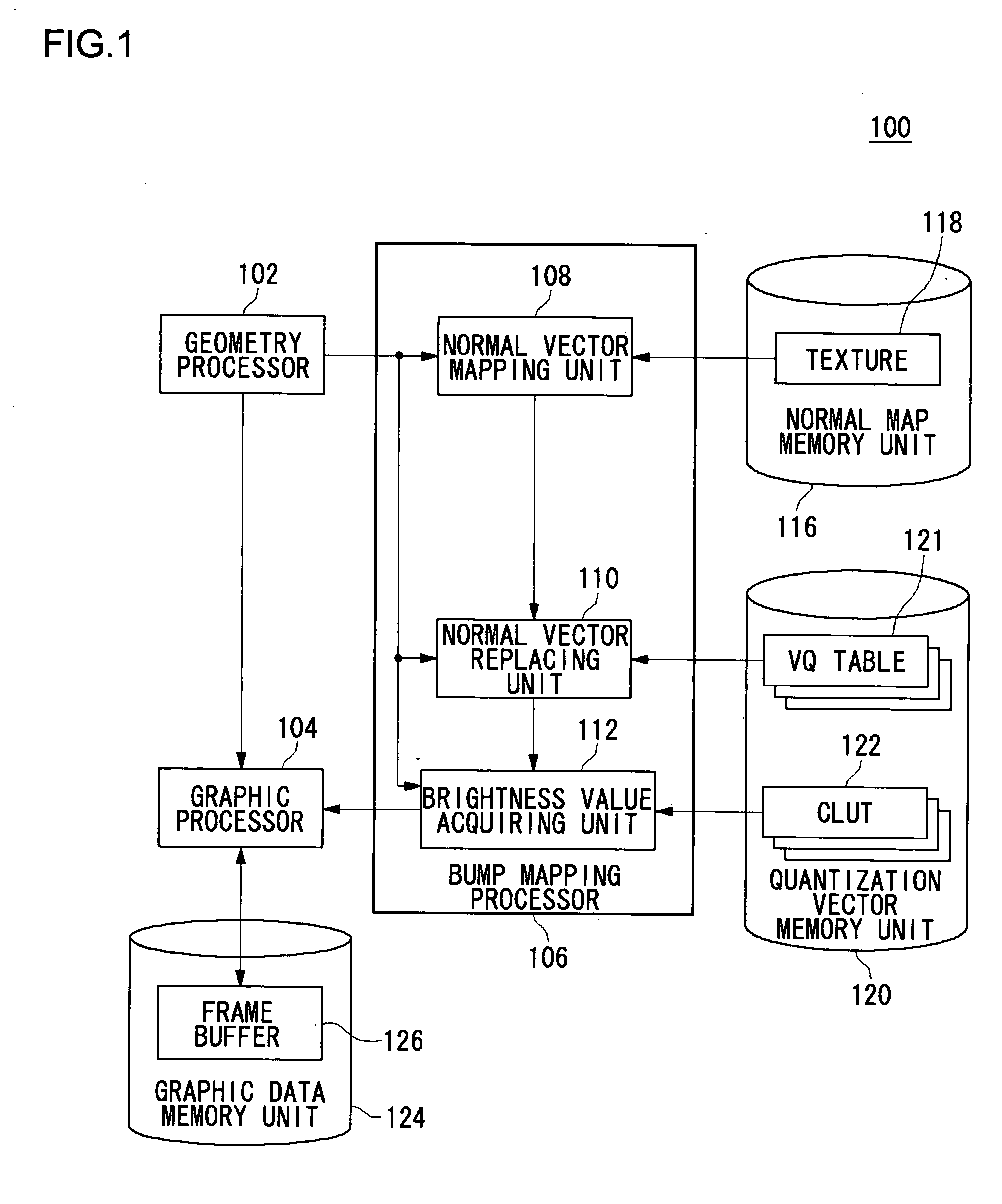

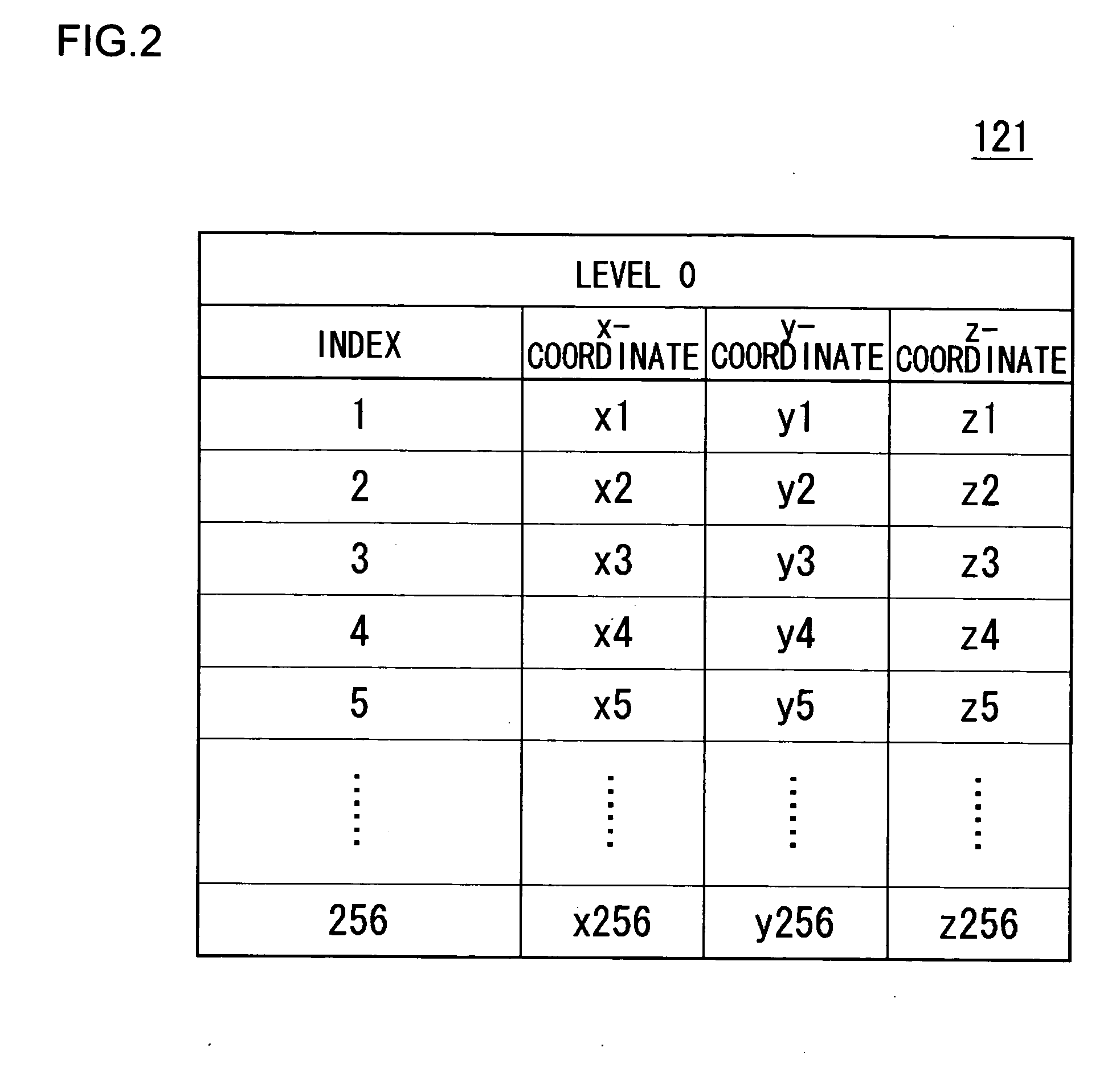

Graphic processing apparatus and method

ActiveUS20060170681A1Improve image qualityImprove processing effectivenessCathode-ray tube indicators3D-image renderingGraphicsLevel of detail

A normal vector mapping unit maps a texture of the MIP-map level corresponding to a level of detail (LOD) of a polygon onto a polygon surface to generate a pseudo-normal vector on the polygon surface. A normal vector replacing unit refers to the vector quantization (VQ) table of the relevant MIP-map level and replaces the pseudo-normal vector on the polygon surface with a quantized reference normal vector. A brightness value acquiring unit refers to the color lookup table (CLUT) of the relevant MIP-map level, and acquires the brightness value corresponding to the reference normal vector on the polygon surface. The brightness value acquiring unit also interpolates brightness values between different MIP-map levels. A graphic processor combines the RGB value of each pixel of the polygon surface with the brightness value acquired by the brightness value acquiring unit to write the combined data into a frame buffer.

Owner:SONY COMPUTER ENTERTAINMENT INC

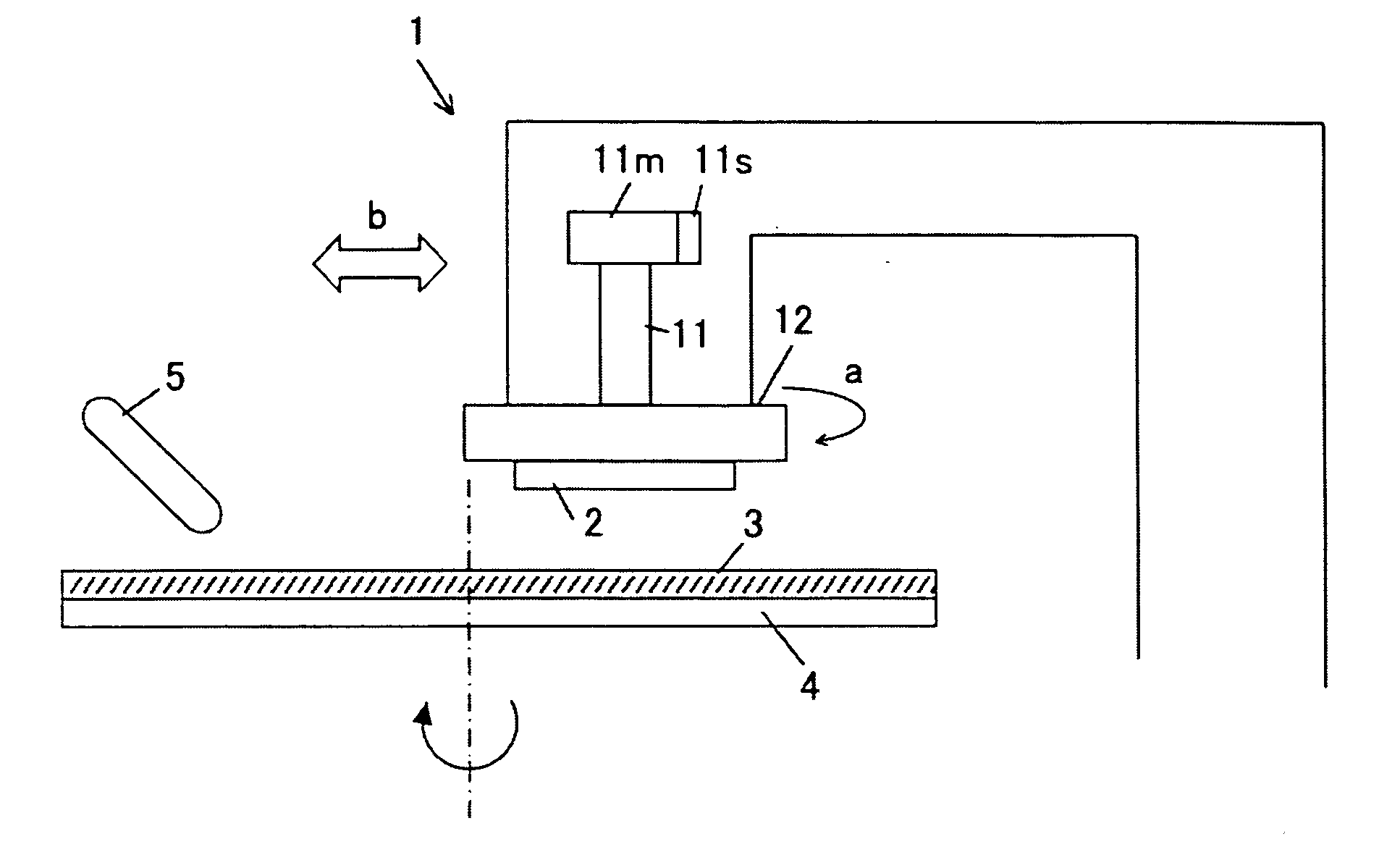

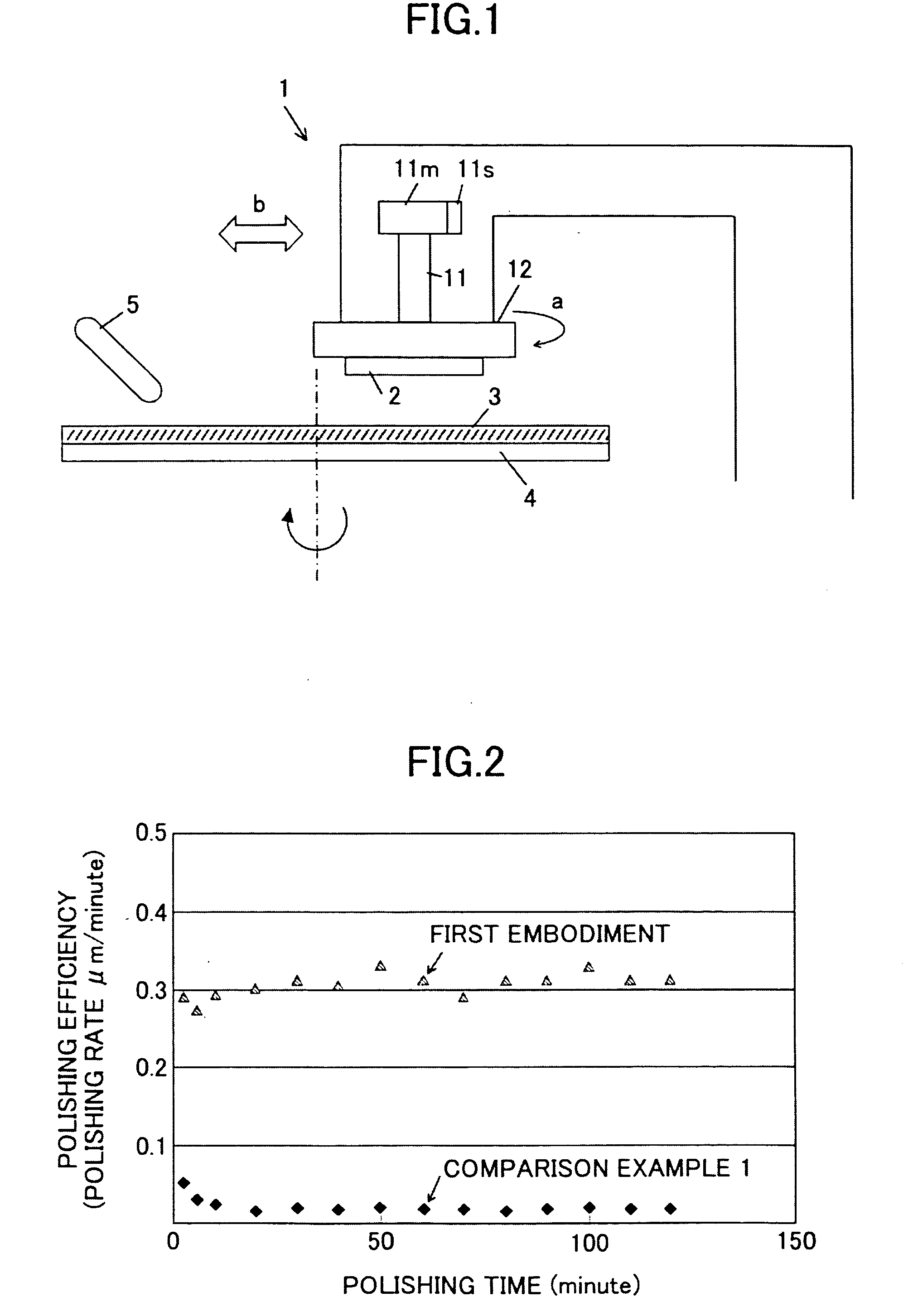

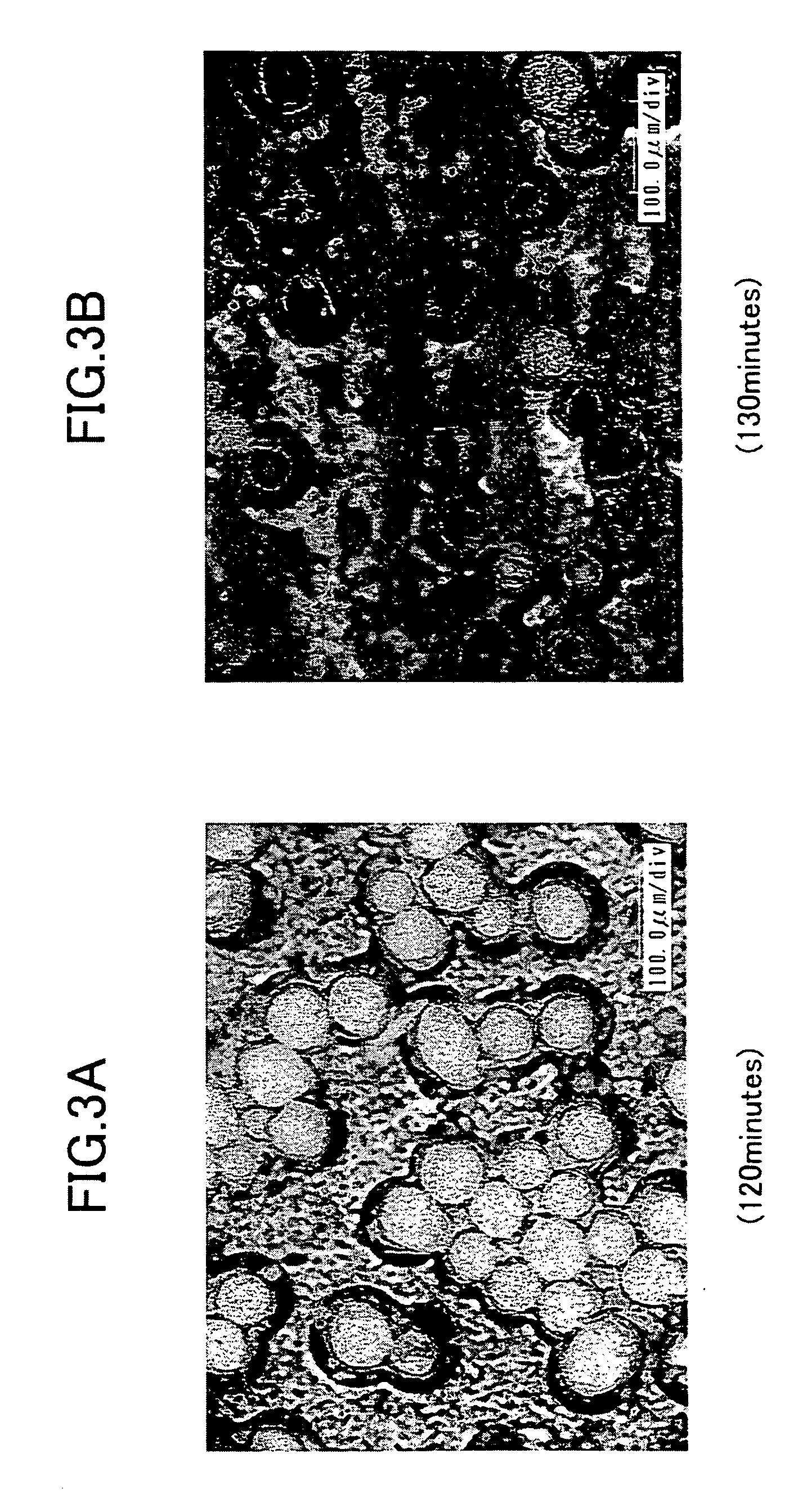

Surface polishing method and apparatus thereof

ActiveUS20060172663A1Improve surface roughnessStable high processing efficiencySemiconductor/solid-state device manufacturingLapping machinesSlurrySilicon

A surface polishing method that polishes the surface of a hard brittle material, such as a glass substrate, an oxide film of a silicon wafer, and a ceramic substrate is disclosed. In the surface polishing method, a fixed abrasive grain polishing tool is used, in which the fixed abrasive grains are a porous substance of granule type in which many primary grains are partially bonded with each other with spaces among them without having the binder therein. The surface polishing method includes the steps of supplying loose abrasive grain slurry between the fixed abrasive grain polishing tool and a surface to be polished of an object, and dressing the top parts of the abrasive grains of the fixed abrasive grain polishing tool which parts contact the surface to be polished of the object by the supplied loose abrasive grains.

Owner:RICOH KK

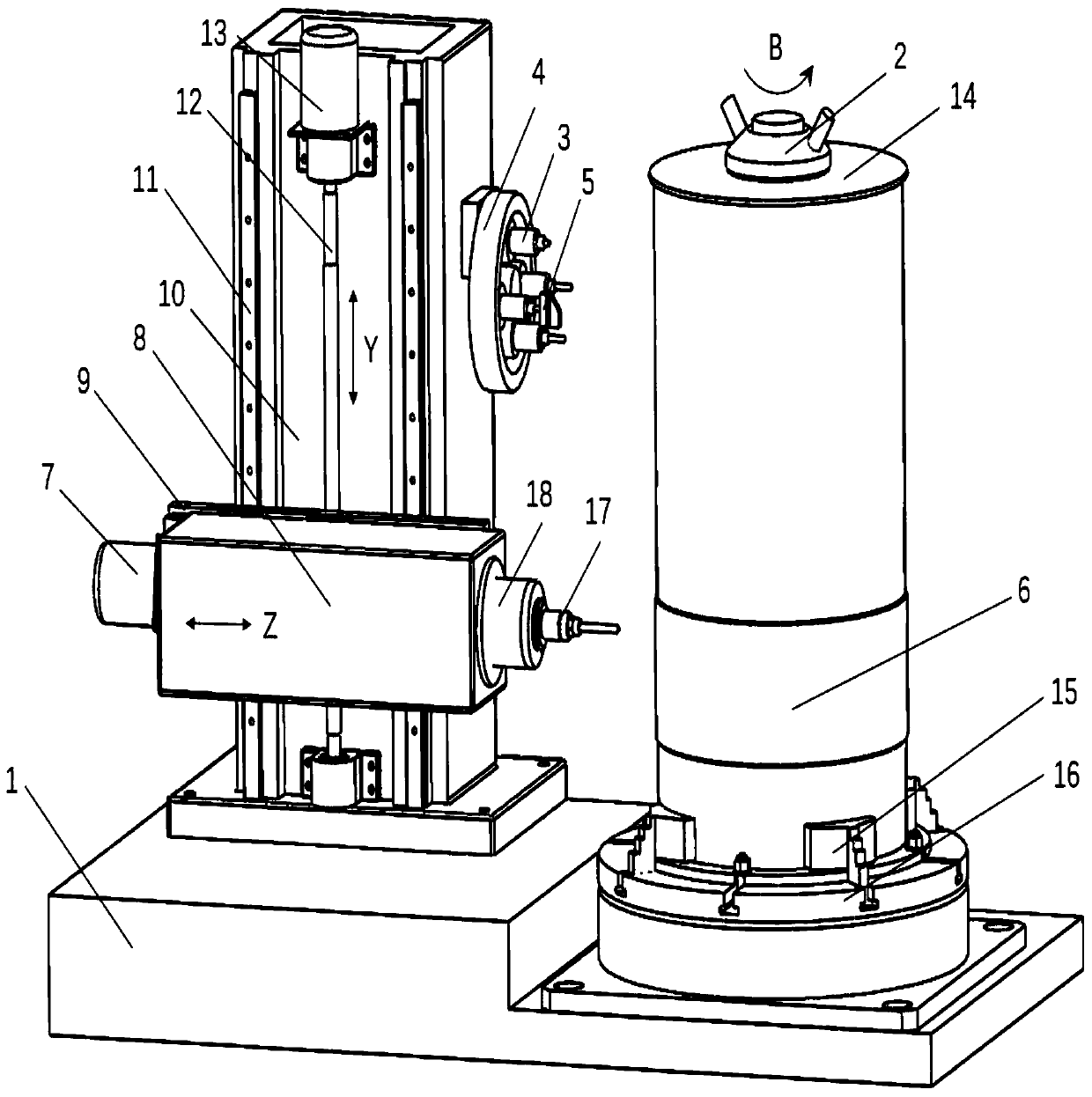

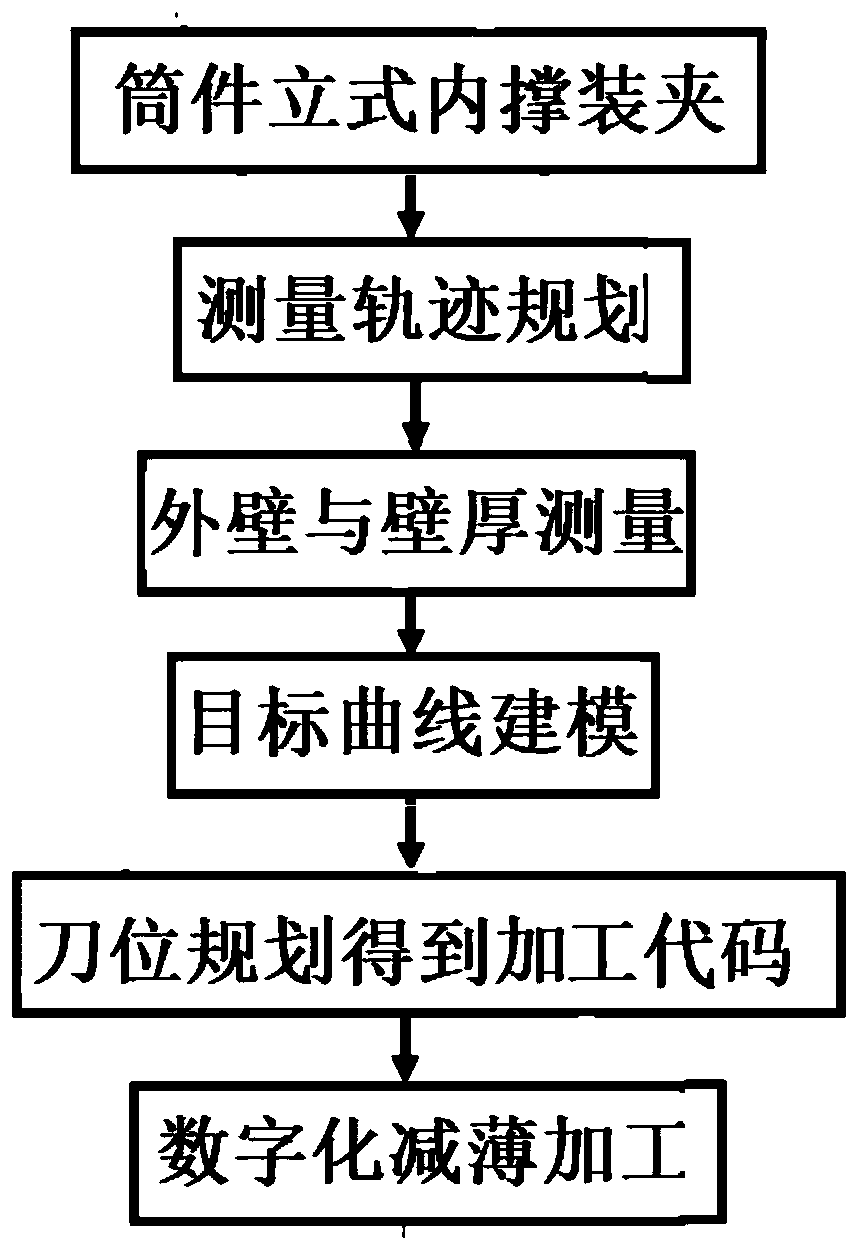

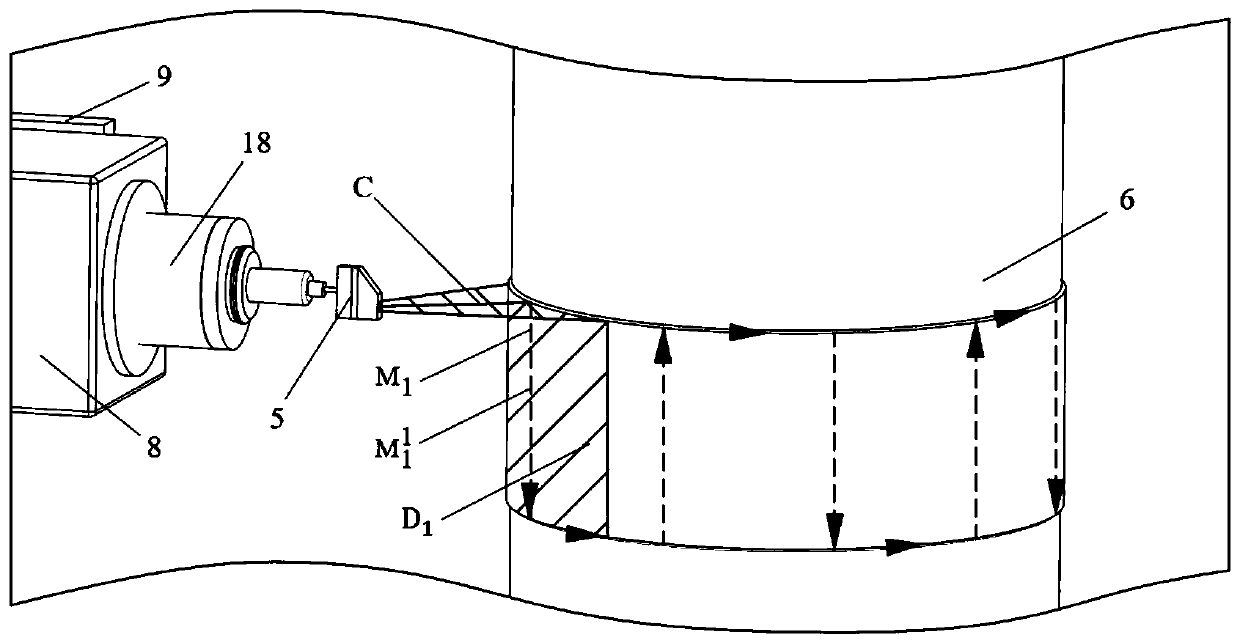

Digitalized thinning machining method for large thin-walled cylinder part

ActiveCN111195830AGuaranteed processing reliabilityEfficient digital thinning processingAutomatic control devicesMeasurement/indication equipmentsNumerical controlEngineering

The invention discloses a digitalized thinning machining method for a large thin-walled cylinder part, and belongs to the technical field of machining. The method comprises the following steps that firstly, a vertical inner support of the large thin-walled cylinder part is clamped, and the external contour and the wall thickness of a thinning section of the cylinder part are scanned and measured on a machine tool by using a line laser measurement device and an ultrasonic measurement device; then by utilizing the actual measurement data of the external contour and the wall thickness of the thin-walled cylinder part and considering the requirement for machining the residual wall thickness, a machining target curved surface of the thinning section is re-established, and a thinning machining code is automatically generated; and finally, the numerical control machine tool finishes thinning machining of the large thin-walled cylinder part through inspection. According to the method, the thinning machining target curved surface associated with the residual wall thickness is re-established by using the part external contour and wall thickness data measured on the machine tool, and the thinning machining code is generated, so that the function integration of CAD, CAM and CNC in the thinning machining of the large thin-walled cylinder part is effectively realized, the manual interventionis reduced, and partitioned thinning machining and equal-wall-thickness or variable-wall-thickness controllable machining of the large thin-wall cylinder part are achieved.

Owner:DALIAN UNIV OF TECH

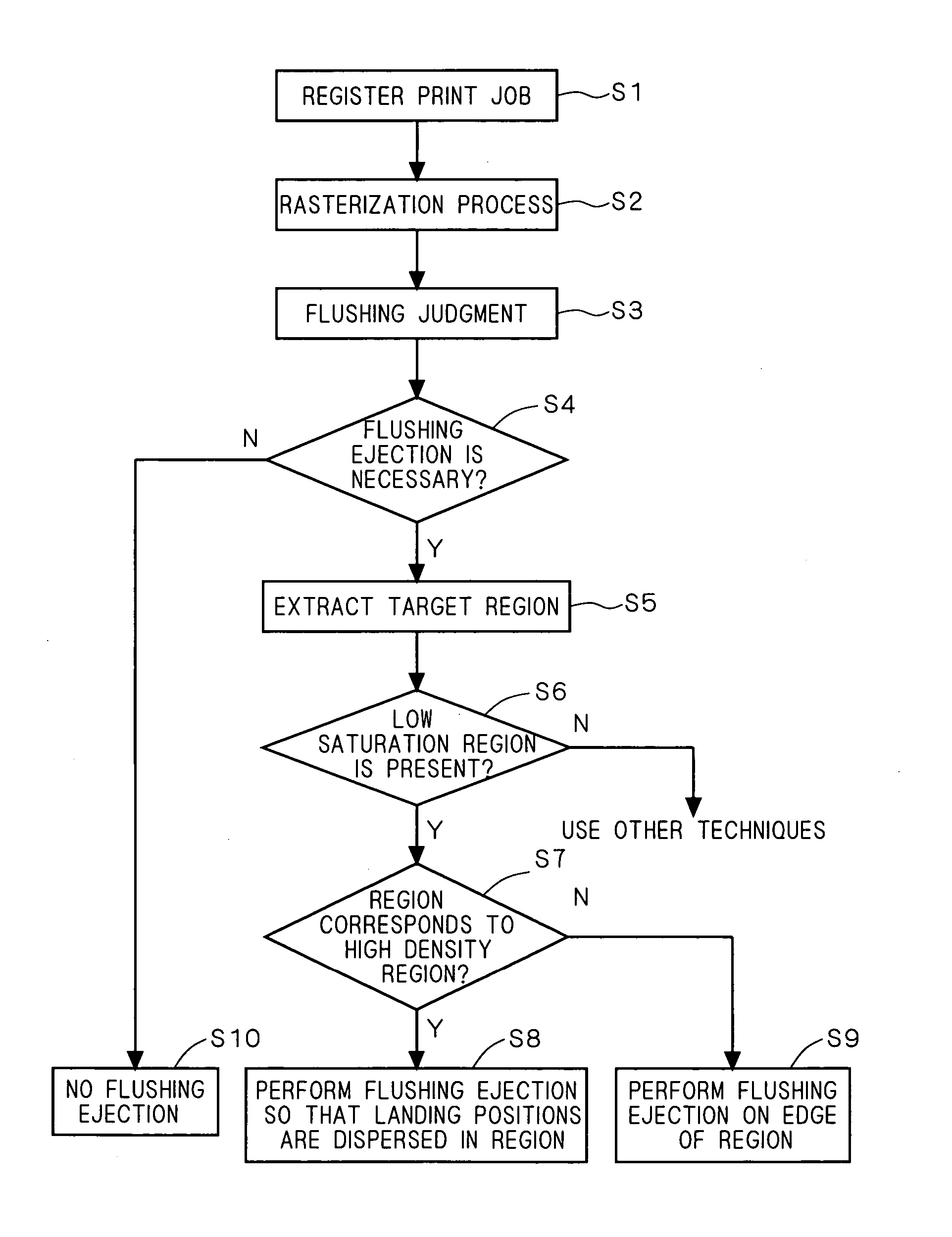

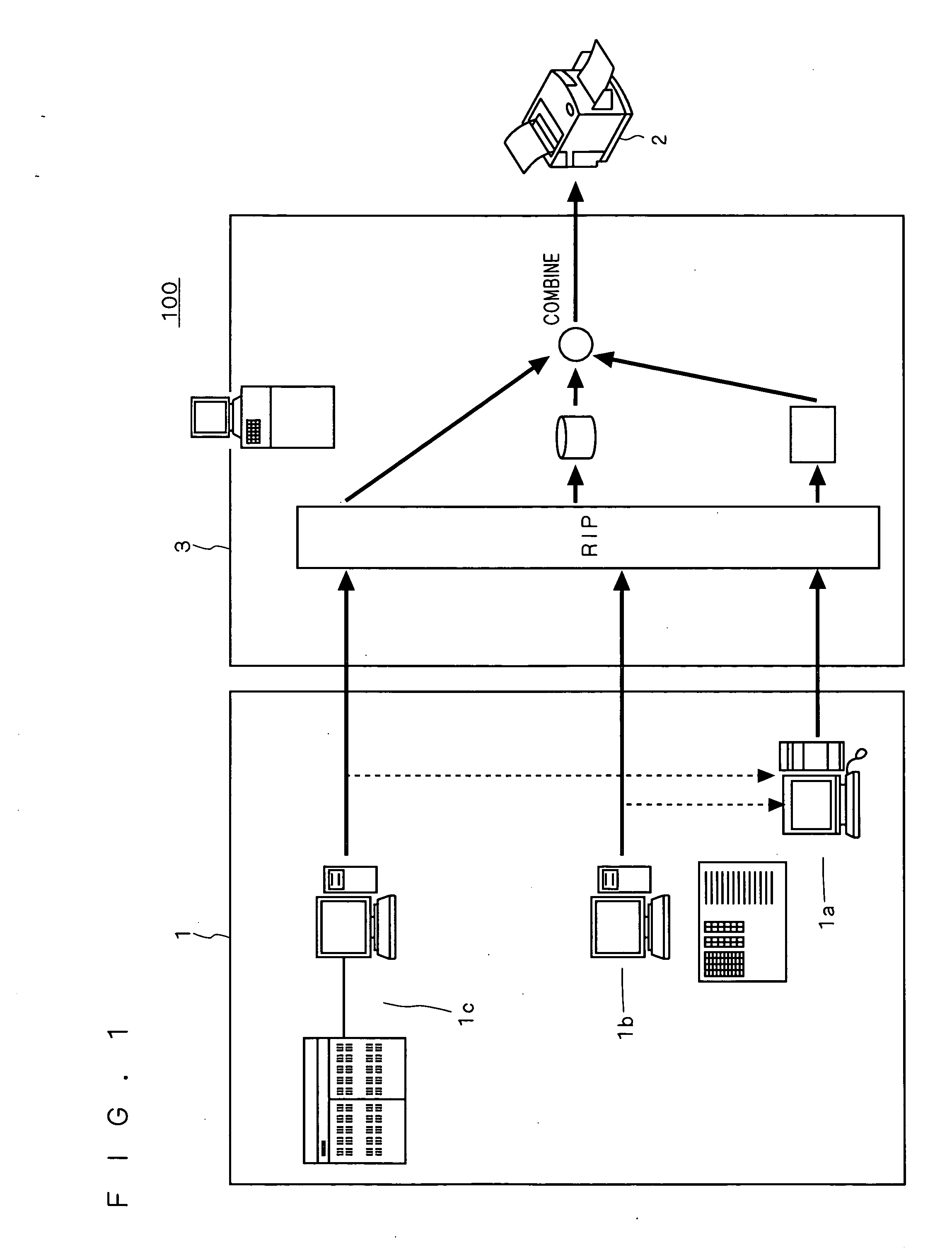

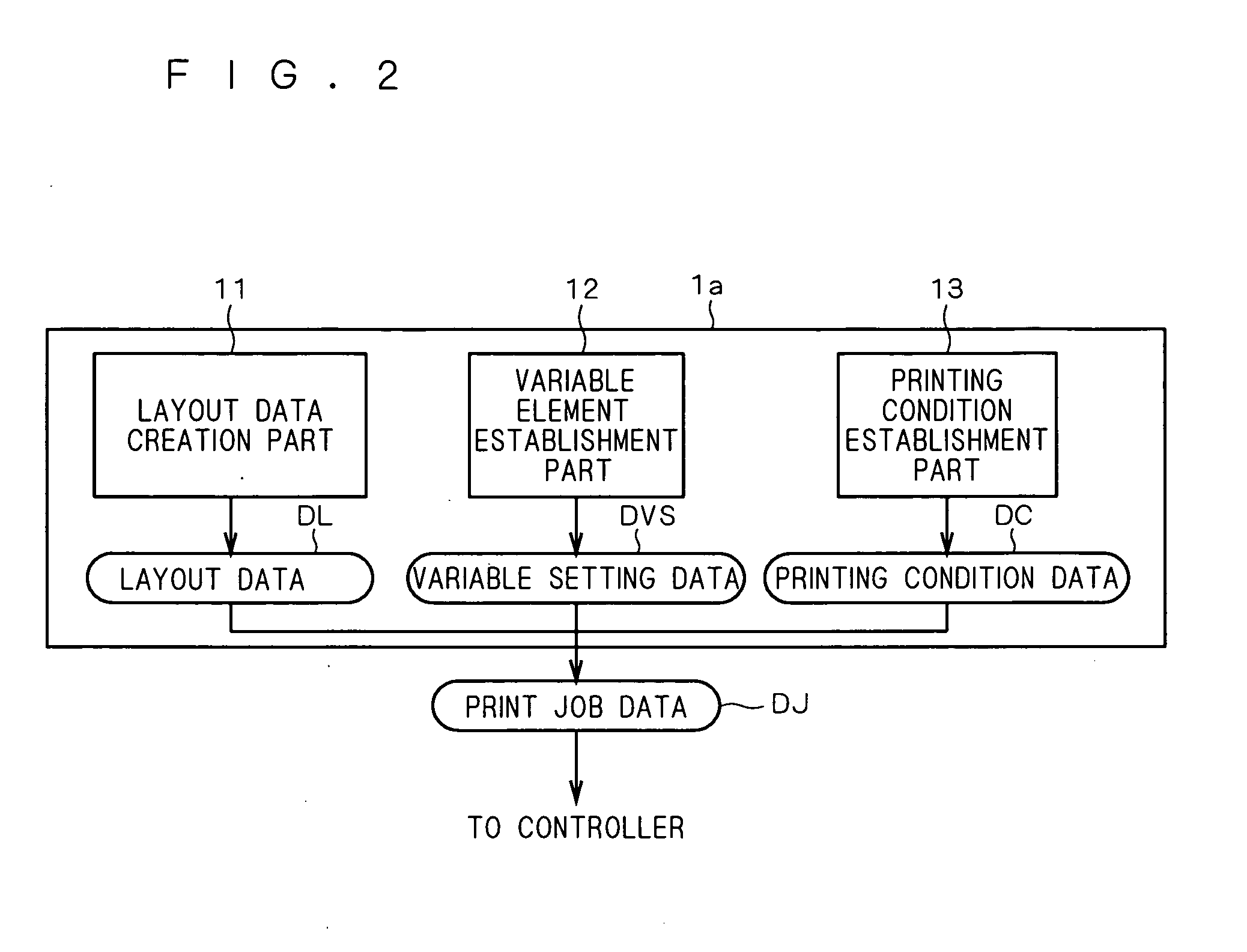

Printing system, controller for printing apparatus, method of executing printing process, and program

InactiveUS20060290739A1Improve processing effectivenessReliable flushingPrintingHigh densityEngineering

For a low saturation and high density region in a printed sheet identified based on rasterized data, flushing ejection is executed, with landing positions dispersed in the above-mentioned region. For a region which is low in saturation but is not high in density, an edge portion of the above-mentioned region is determined as the landing positions. During these processes, the adjustment is additionally made to the ejection from inkjet nozzles for color components which are not to be subjected to the flushing ejection, to thereby maintain the original hue of the above-mentioned region. This achieves the flushing ejection while minimizing the degradation of the quality of the printed sheet. Further, in the variable printing, whether the flushing ejection is necessary or not is judged based on details to be printed on a base page. This causes the execution of the flushing ejection whenever individual printed sheets are produced. Therefore, the print quality is held uniform during the production of a multiplicity of different printed sheets.

Owner:DAINIPPON SCREEN MTG CO LTD

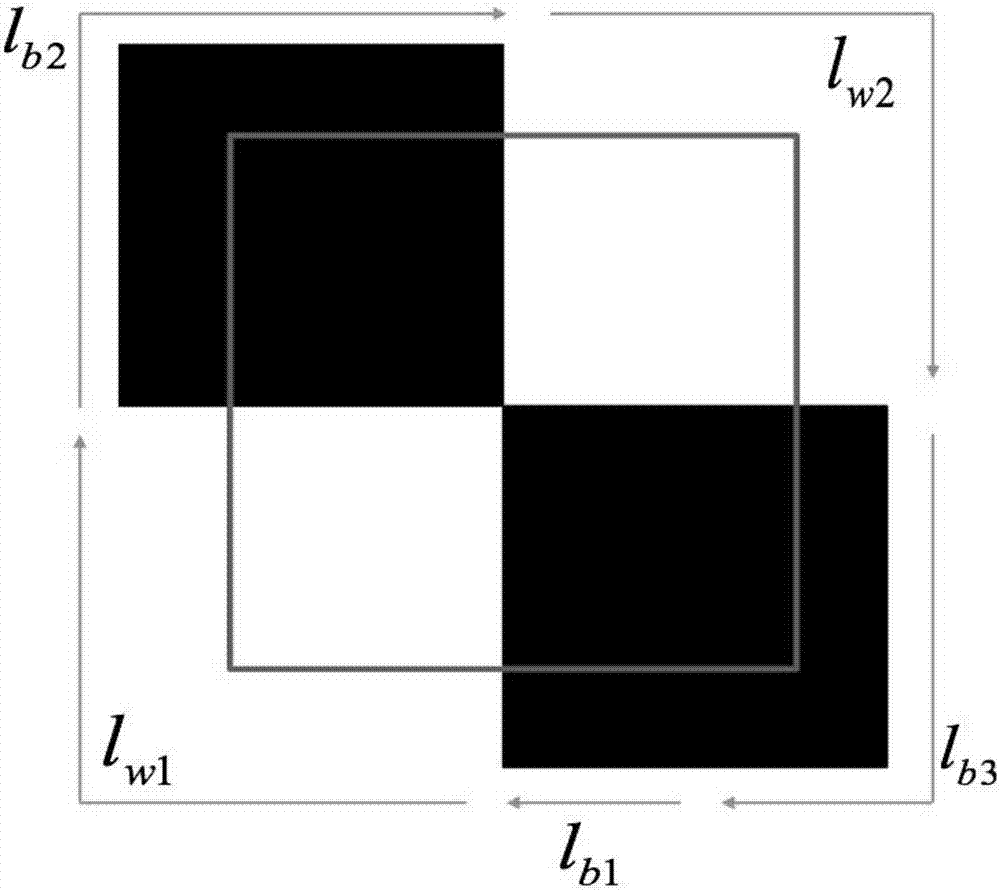

Depth information extraction-based wall flatness detection method

InactiveCN106981081AImprove processing effectivenessImprove matching efficiencyImage analysisImage pairVisual perception

The invention discloses a depth information extraction-based wall flatness detection method and belongs to the distance measurement technique based on binocular vision. According to the technical scheme of the invention, the depth information from a camera to a wall surface is extracted by a binocular camera. Two sets of image pairs of a to-be-detected region, namely two depth information graphs, are respectively acquired from different angles, and then the corresponding depth information is obtained. During the acquisition process of the depth information graphs, the existing Hhartley correction method is improved, and the real-time performance and the accuracy of the correction process are improved. Meanwhile, one depth information graph is rotated and translated, so that the coordinates of the imaging spaces of the two depth information graphs are overlapped. In this way, a reinforced depth information graph is generated. The mode of the depth value of the reinforced depth information graph is adopted as the distance value of the to-be-detected region. Based on the size relationship between the distance value and a preset threshold, the flatness of the to-be-detected region is judged. The method can be applied to the intelligent plastering operation and has the advantages of simple, convenient and intelligent operation, high flatness detection timeliness and high accuracy.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

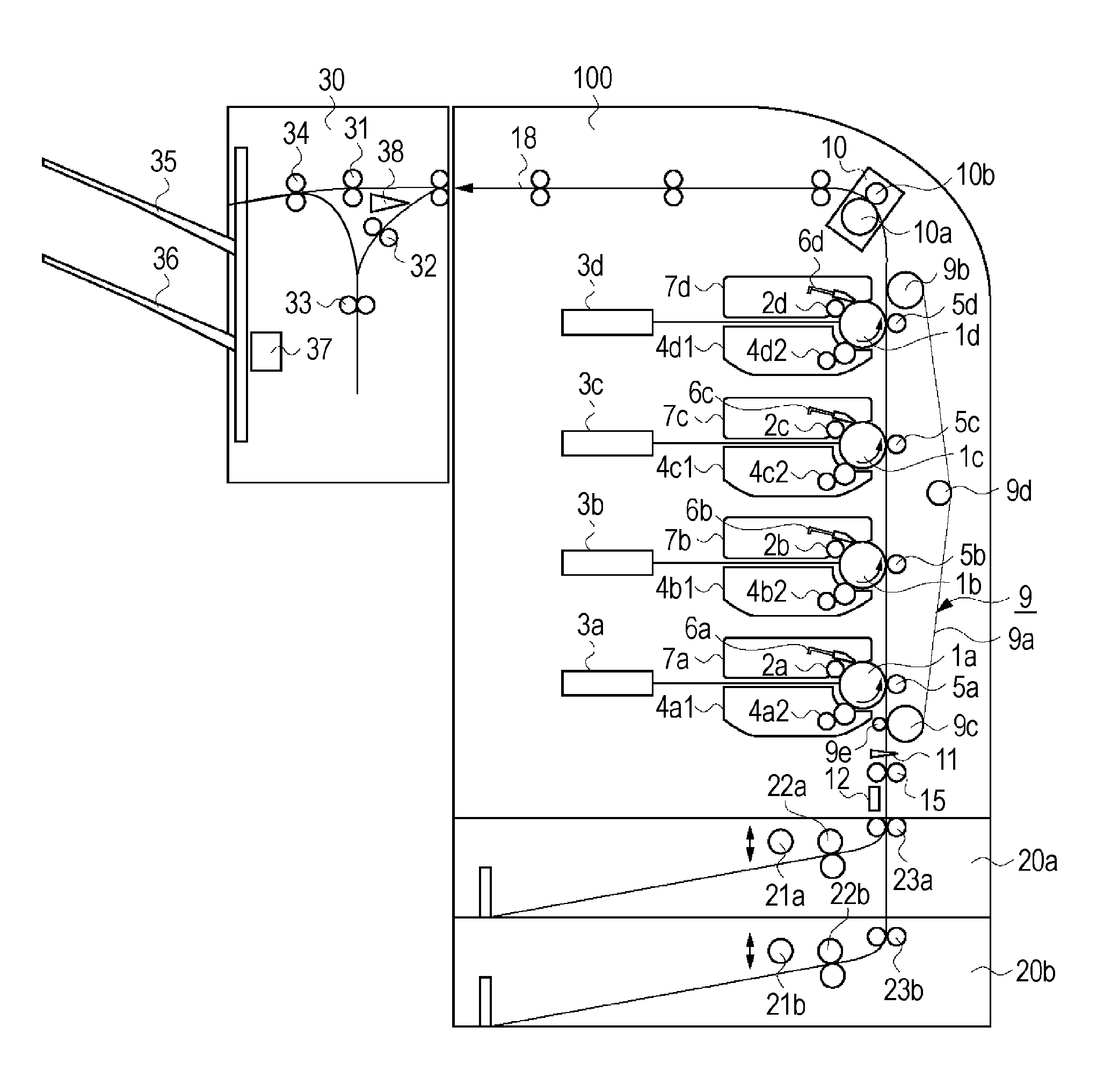

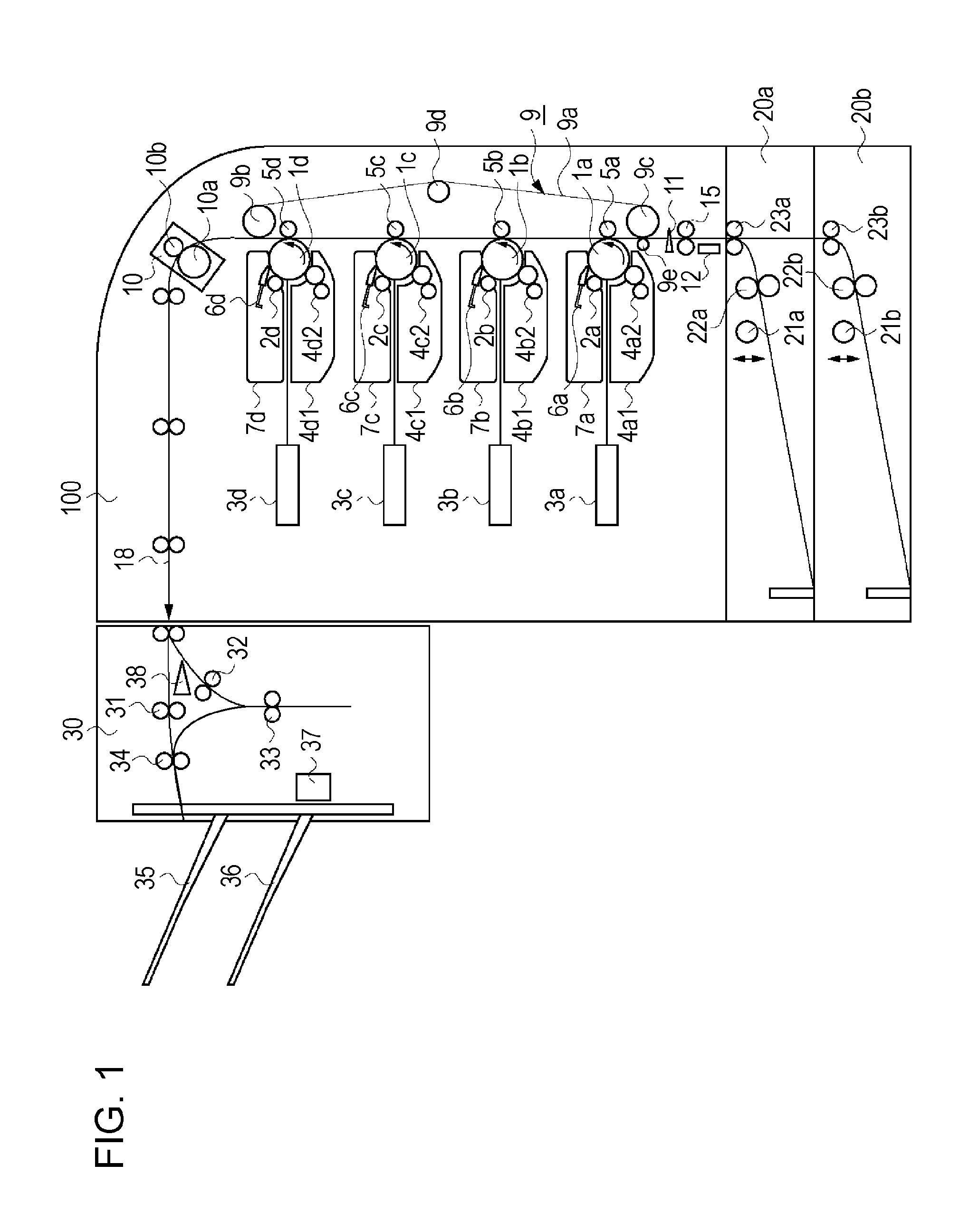

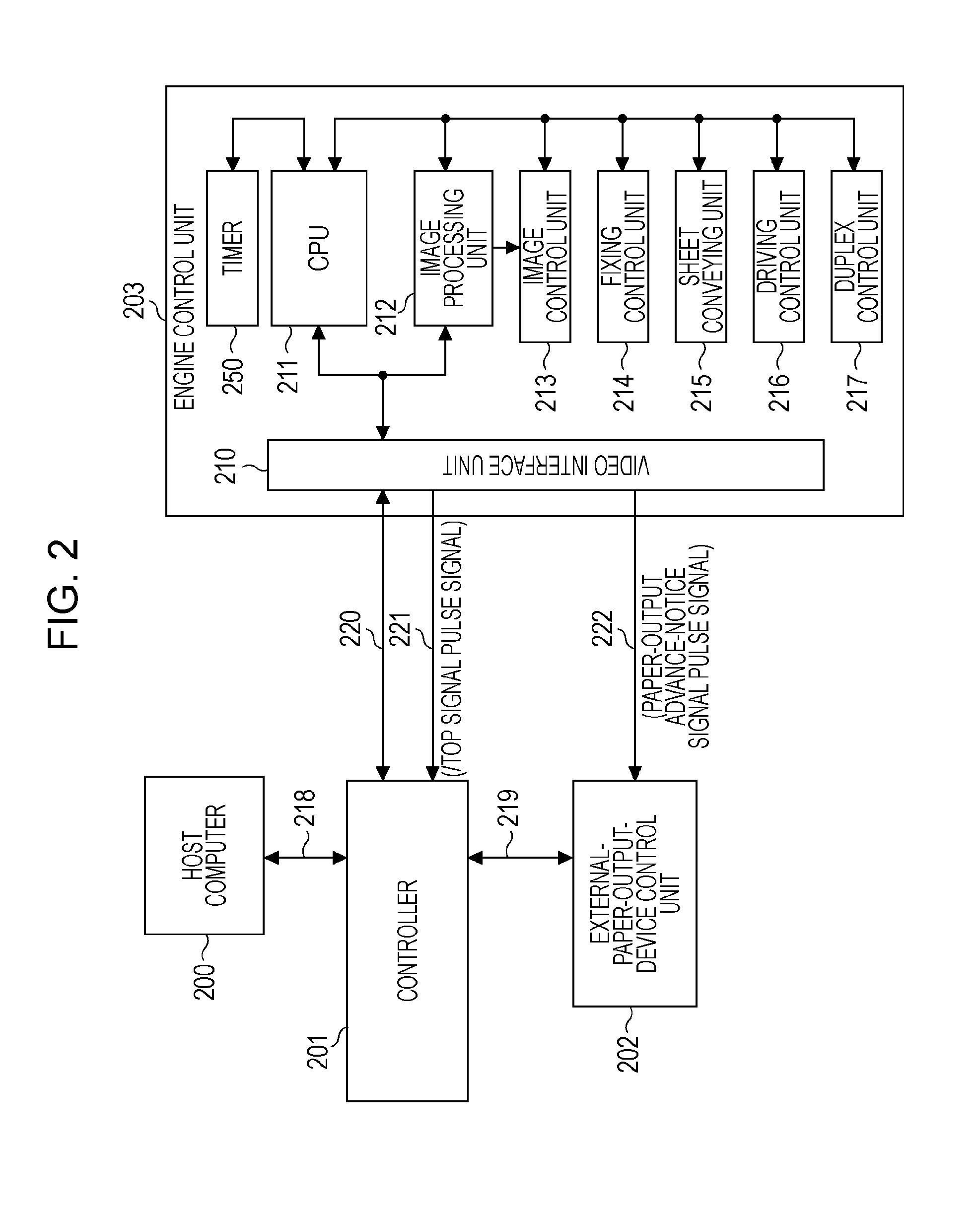

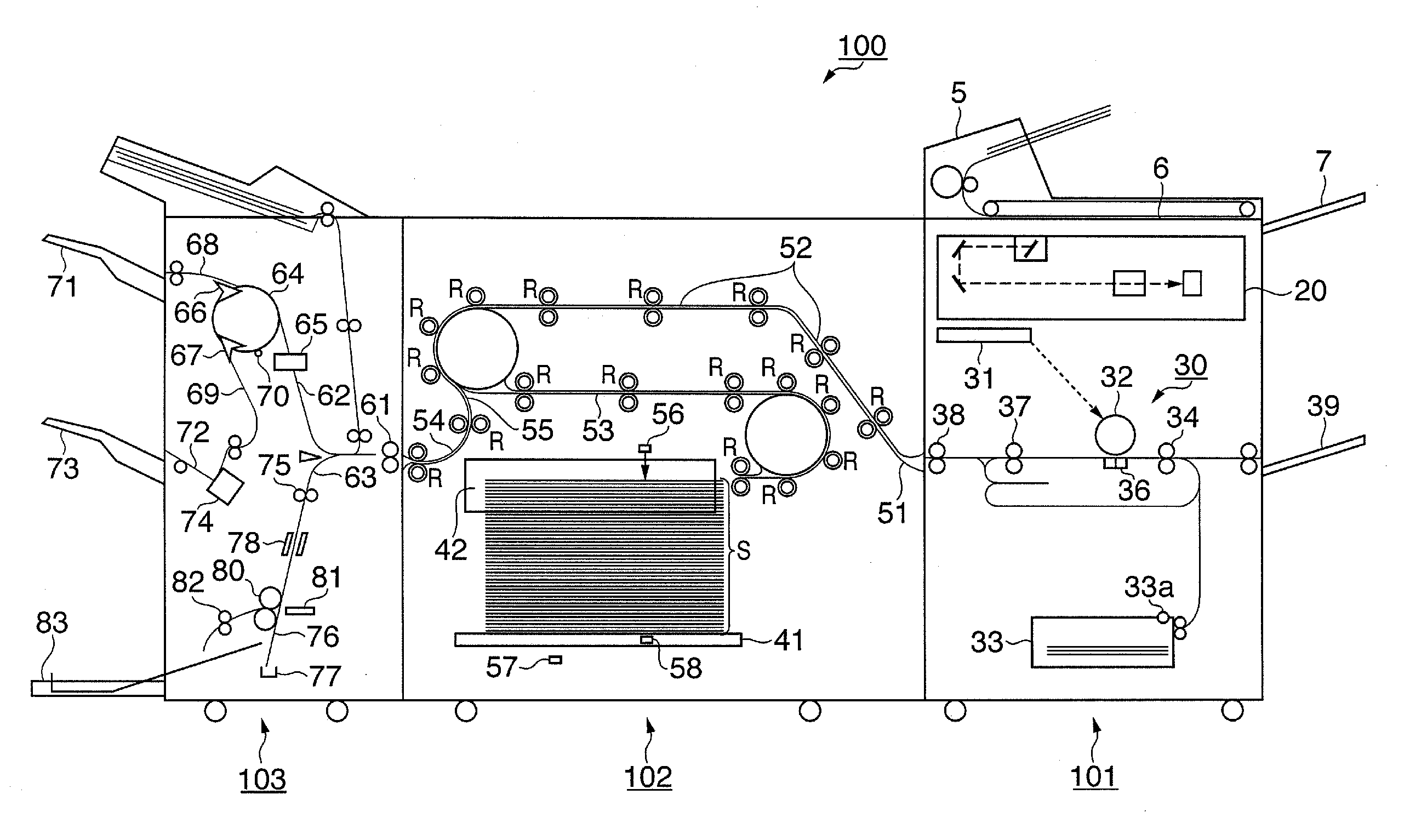

Image forming apparatus and method for controlling feeding of sheets

InactiveUS20080187344A1Reduce waiting timeImprove processing efficiencyElectrographic process apparatusImage formationEngineering

An image forming apparatus, to which a paper-output device for processing a sheet after image formation is attached, includes a paper-feed unit for feeding a sheet for image formation; a detection unit for detecting a type of the sheet fed from the paper-feed unit; an image forming section for forming an image on the sheet fed from the paper-feed unit; and a control unit for determining a sheet-feed timing based on a sheet-processing time used by the paper-output device corresponding to a preset sheet type. If the preset sheet type matches the sheet type detected by the detection unit, the control unit determines the sheet-feed timing based on the sheet-processing time corresponding to the preset sheet type. If not, the control unit determines the sheet-feed timing based on the sheet-processing time corresponding to the sheet type detected by the detection unit.

Owner:CANON KK

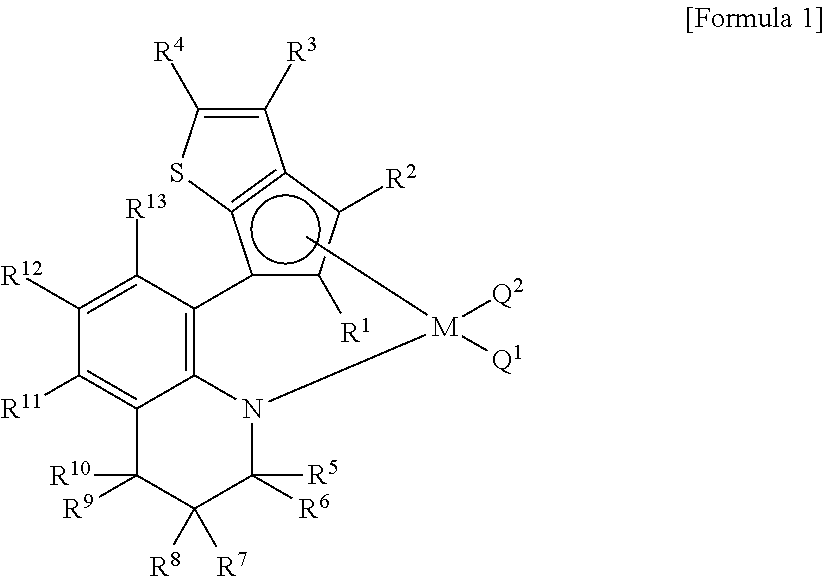

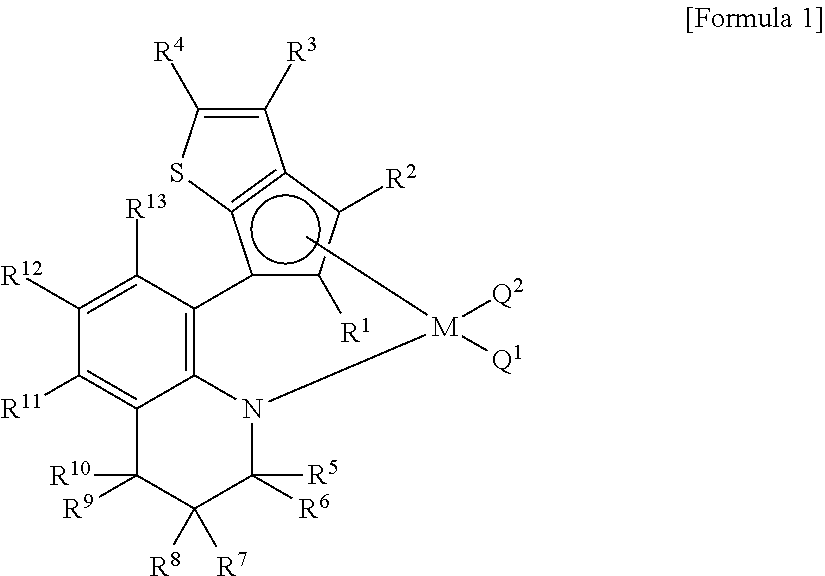

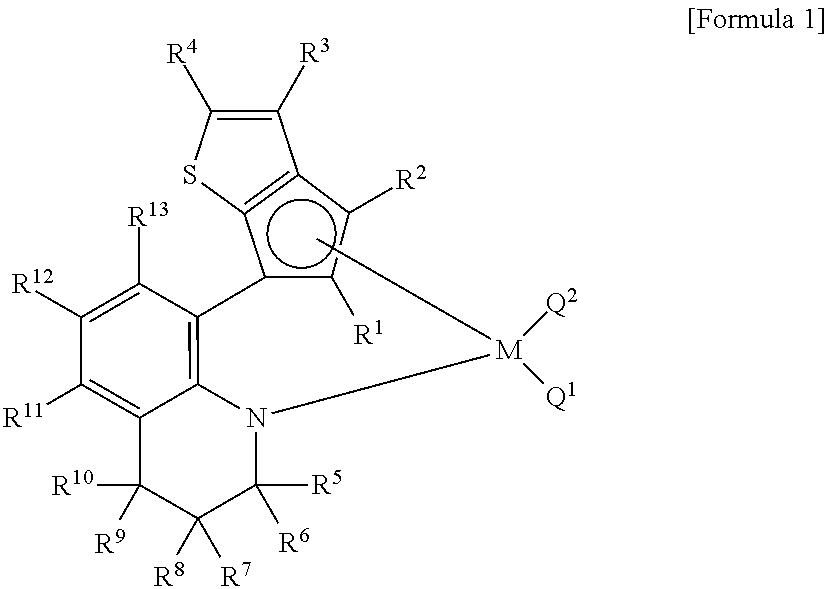

Method for preparing olefin-diene copolymer using transition metal compound containing thiophene-fused cyclopentadienyl ligand

ActiveUS20130211024A1High catalytic activityEasy to controlOrganic-compounds/hydrides/coordination-complexes catalystsTitanium organic compoundsFine structureProcess efficiency

The present invention relates to a preparation method for olefin-diene copolymer that comprises polymerizing at least one olefin-based monomer and at least one diene-based monomer in the presence of a catalyst comprising a novel transition metal compound. Using the novel transition metal compound as a catalyst, the preparation method for olefin-diene copolymer according to the present invention can not only acquire high catalytic activity for copolymerization of the olefin and diene monomers to achieve high process efficiency but allow it to easily control the fine-structure characteristics of the copolymer, thereby providing an olefin-diene copolymer having desired properties with ease.

Owner:LOTTE CHEM CORP

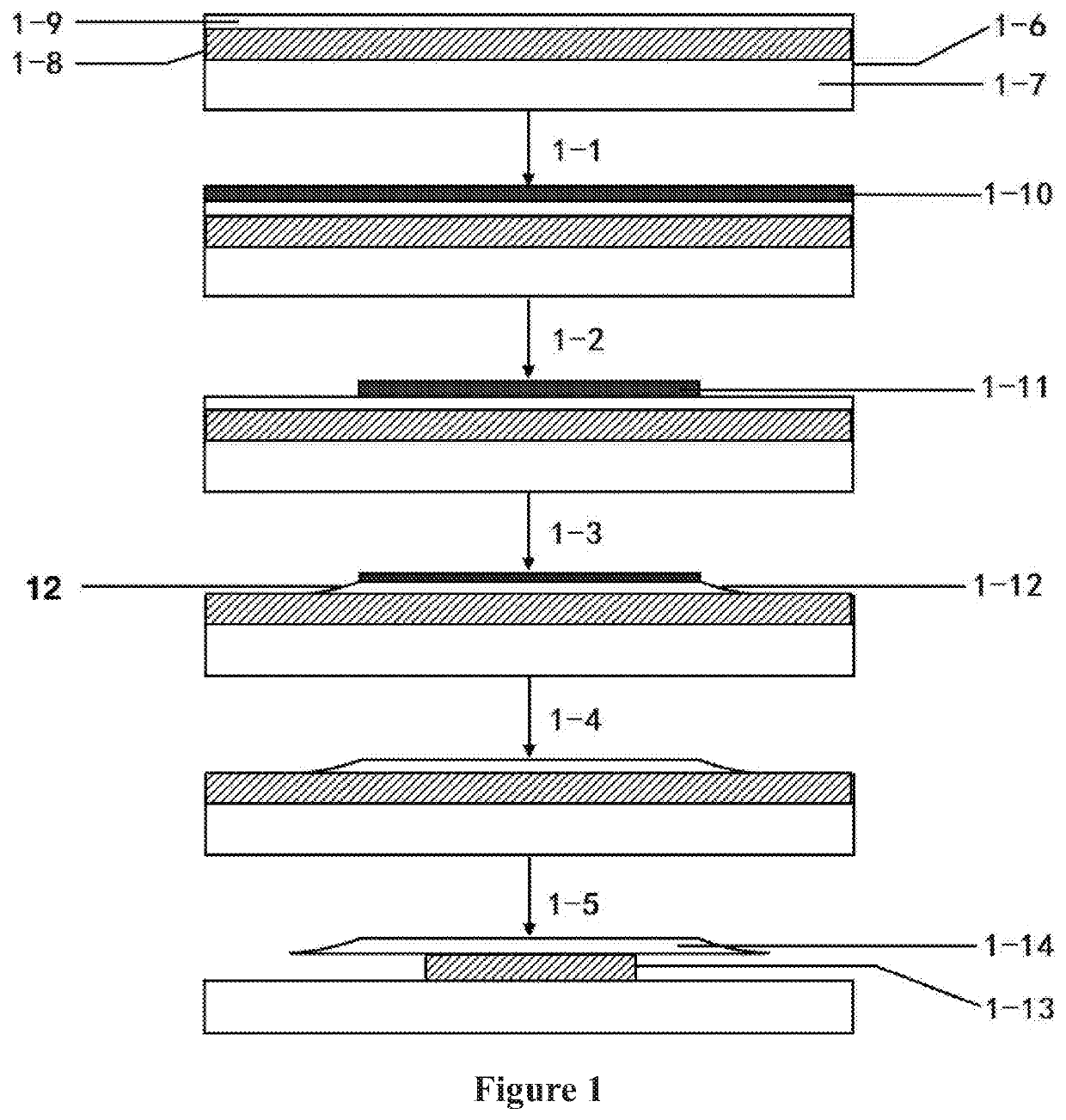

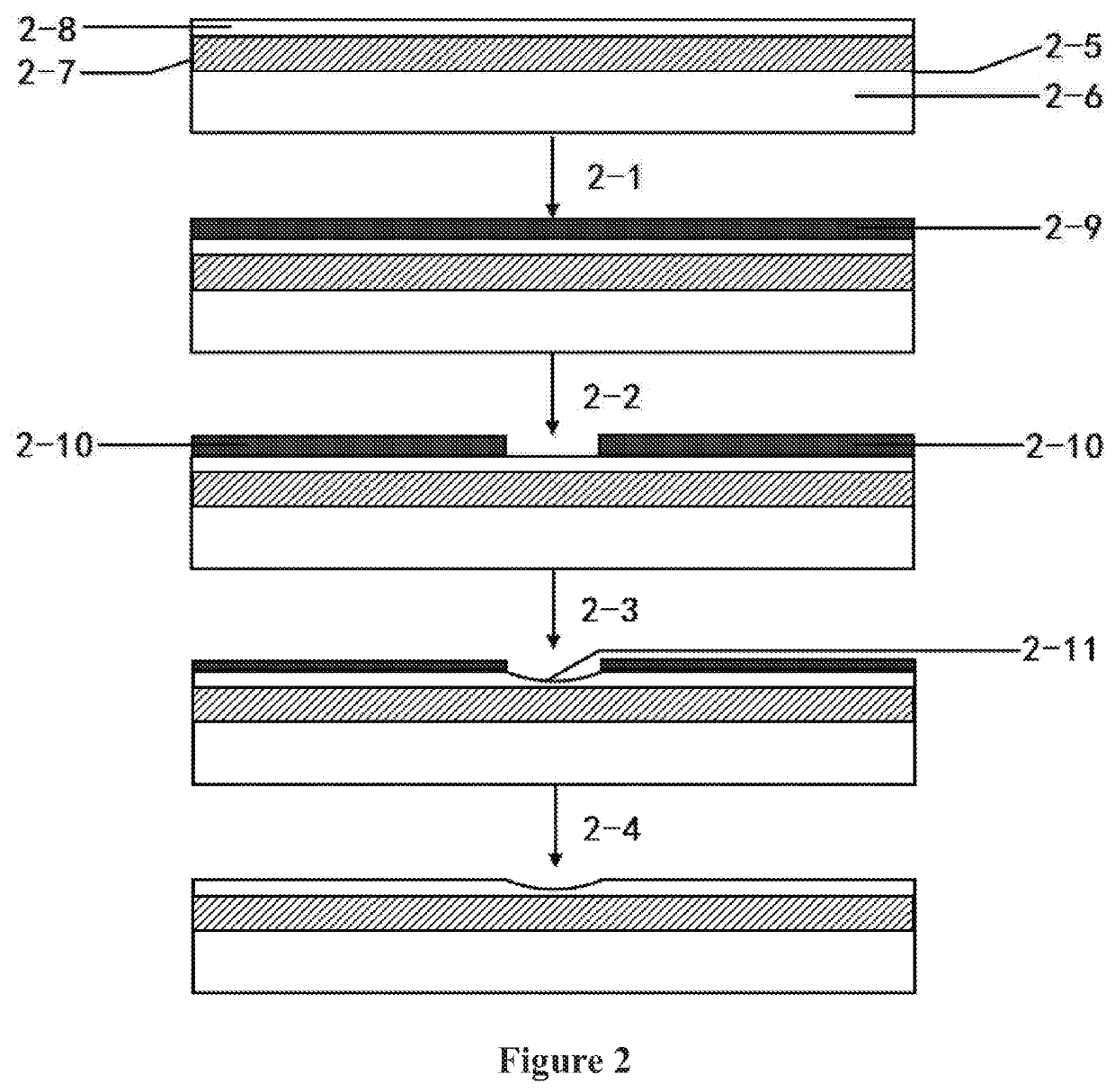

Method for preparing film micro-optical structure based on photolithography and chemomechanical polishing

ActiveUS20190346625A1Shape controllableReduce lossPhotomechanical apparatusOptical light guidesFilm baseSingle crystal

Method for preparing micro-optical structure on a film based on chemical mechanical polishing etching, combining photolithography technology with chemical mechanical polishing technology to make preparation and large-scale integration of large-size high-quality micro optical devices on-chip possible. The method comprises coating metal on film surface, selectively removing the metal film by photolithography (such as femtosecond laser selective ablation, ultraviolet photolithography, electron beam etching, ion beam etching, and reactive ion etching), chemical mechanical polishing, chemical corrosion or over polishing and other steps. Micro-optical devices on-chip prepared by the method have extremely high surface finish and extremely low optical loss. The method is applicable to preparing high-quality micro-optical structures (including but not limited to microdisc cavities, microring cavities, optical waveguides and coupled devices thereof) on various films on-chip (including but not limited to lithium niobate single crystal films, quartz films, silicon films, silicon dioxide films, diamond thin films, etc.).

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

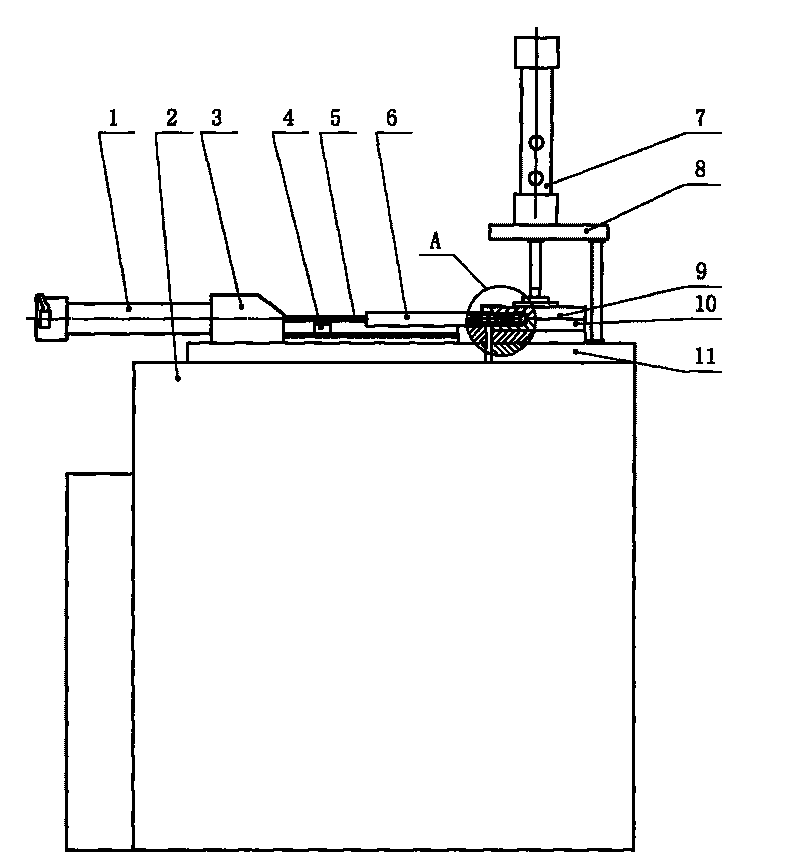

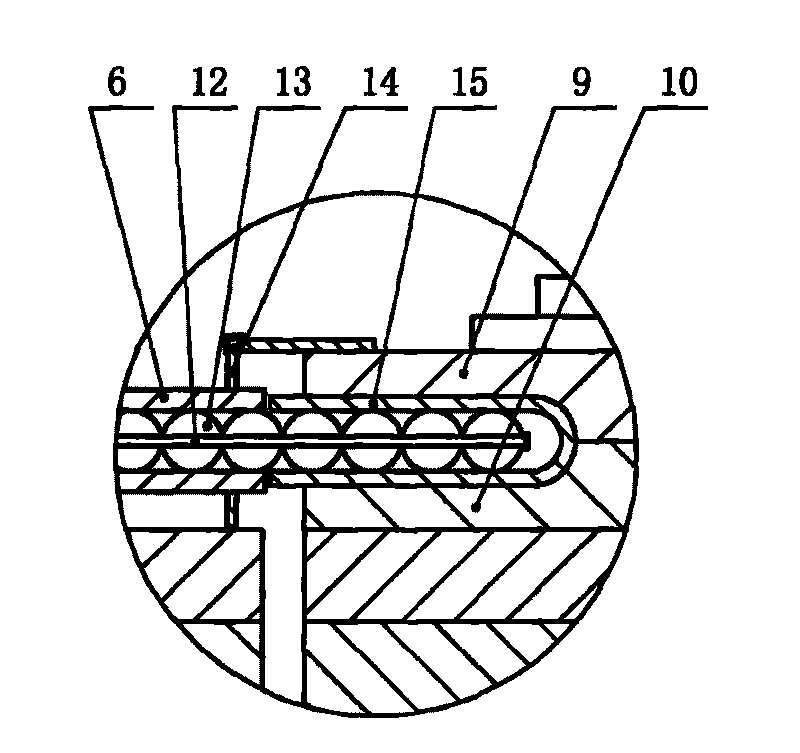

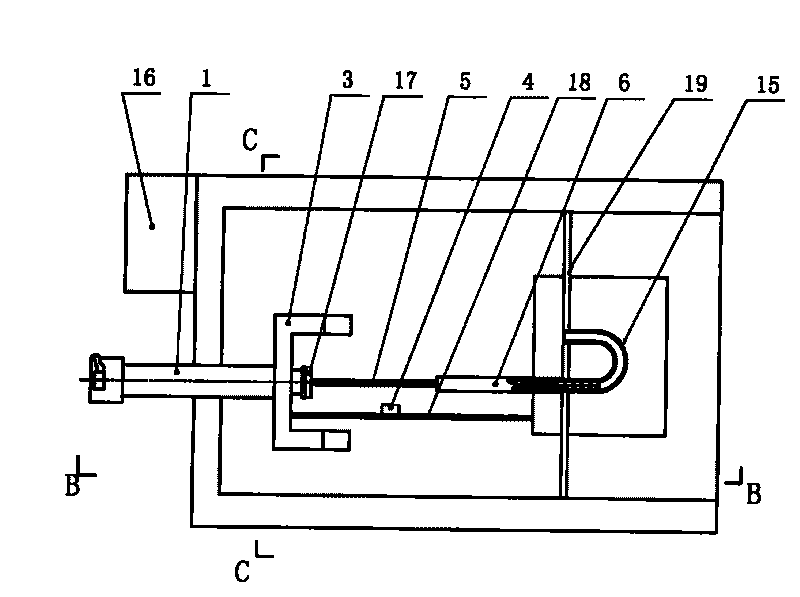

Automatic equal-diameter elbow roundness shaping and cutting all-in-one machine

InactiveCN101722418AAvoid breakingGood plastic effectMetal sawing devicesOther manufacturing equipments/toolsSteel ballEngineering

The invention relates to an automatic equal-diameter elbow roundness shaping and cutting all-in-one machine which comprises a main body, a worktable, an upper die plate, a lower die plate and a pressing die cylinder, wherein the worktable is horizontally and fixedly provided with a cylinder in the position corresponding to a port of an equal-diameter semicircular curved furrow composed of the upper die plate and the lower die plate; the tail end of the push rod of the cylinder is fixedly provided with a steel ball string threaded by a steel wire; and the worktable is fixedly provided with a guiding cylinder in which the steel ball string slides; an elevating sawtooth disk is longitudinally arranged in the main body; the lengthwise position of the sawtooth disk corresponds to the port of the equal-diameter semicircular curved furrow composed of the upper die plate and the lower die plate of the worktable; and the worktable is provided with a cutting passage corresponding to the position of the sawtooth disk. The invention has high automation level, integrates the roundness shaping with the end processing allowance cutting, has the advantages of short consumed time for shaping and processing, high working efficiency, high working accuracy, good product quality, conforms to the requirement for product shape roundness, and is suitable for industrial mass production of horn instrument equal-diameter elbows.

Owner:TIANJIN JINBAO MUSICAL INSTR

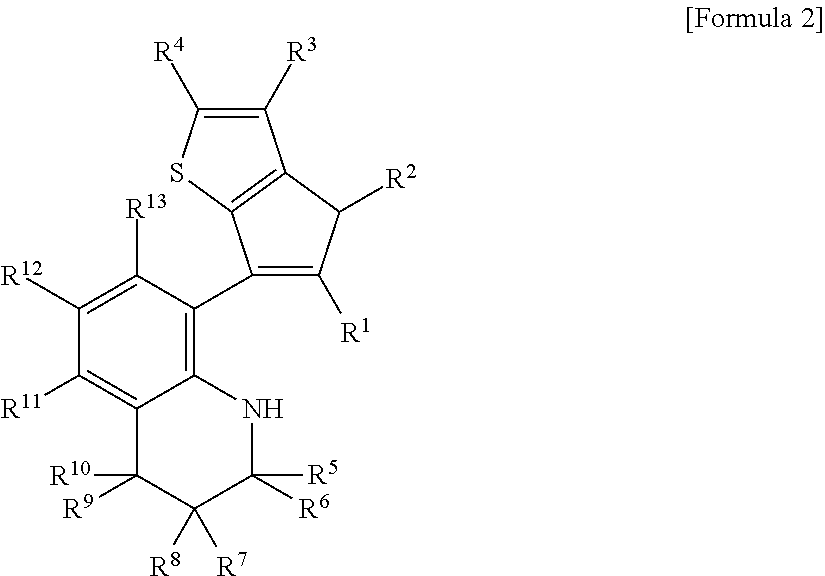

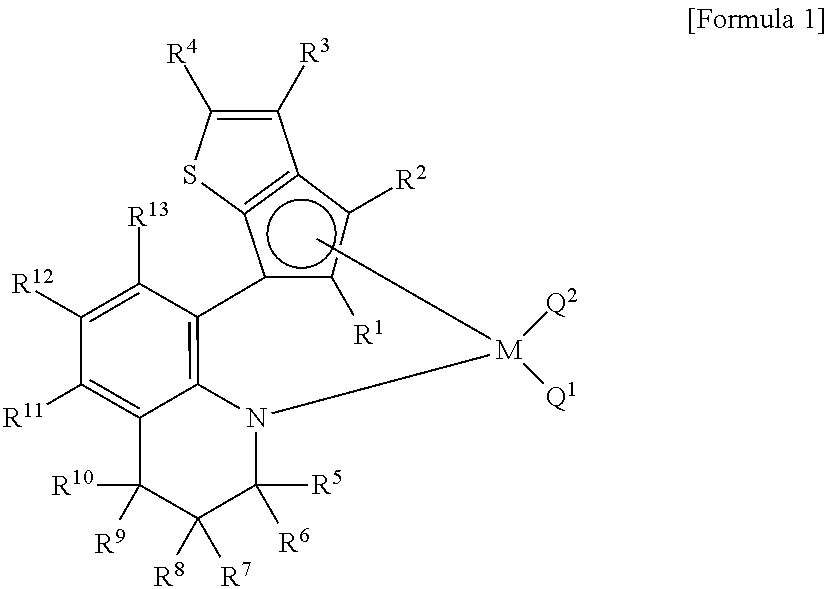

Method for preparing polypropylene using transition metal compound containing thiophene-fused cyclopentadienyl ligand

ActiveUS20130211021A1High catalytic activityEasy to controlOrganic-compounds/hydrides/coordination-complexes catalystsTitanium organic compoundsFine structurePolypropylene

The present invention relates to a preparation method for polypropylene that comprises polymerizing a propylene monomer in the presence of a catalyst comprising a novel transition metal compound. Using the novel transition metal compound as a catalyst, the preparation method for polypropylene according to the present invention can not only acquire high catalytic activity for polymerization to achieve high efficiency of the process but allow it to easily control the fine-structure characteristics of the polymer, thereby providing polypropylene having desired properties with ease.

Owner:LOTTE CHEM CORP

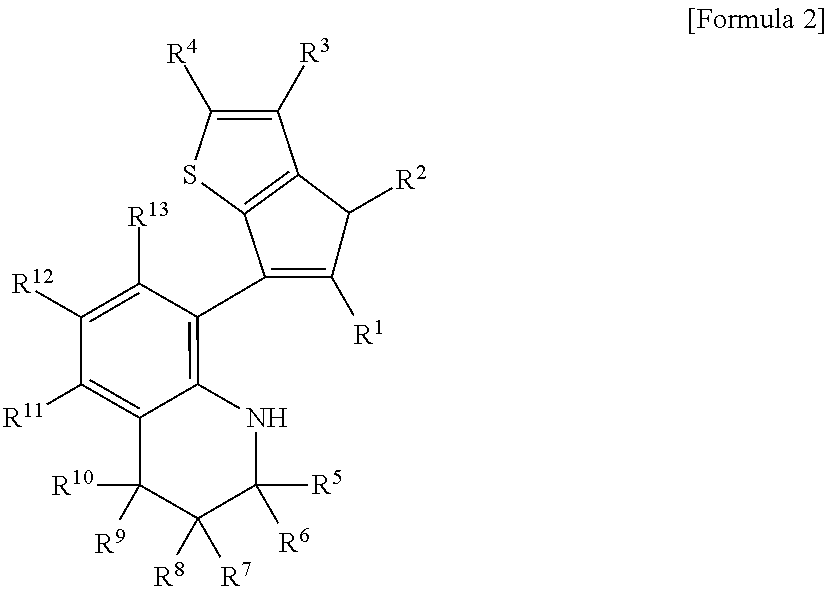

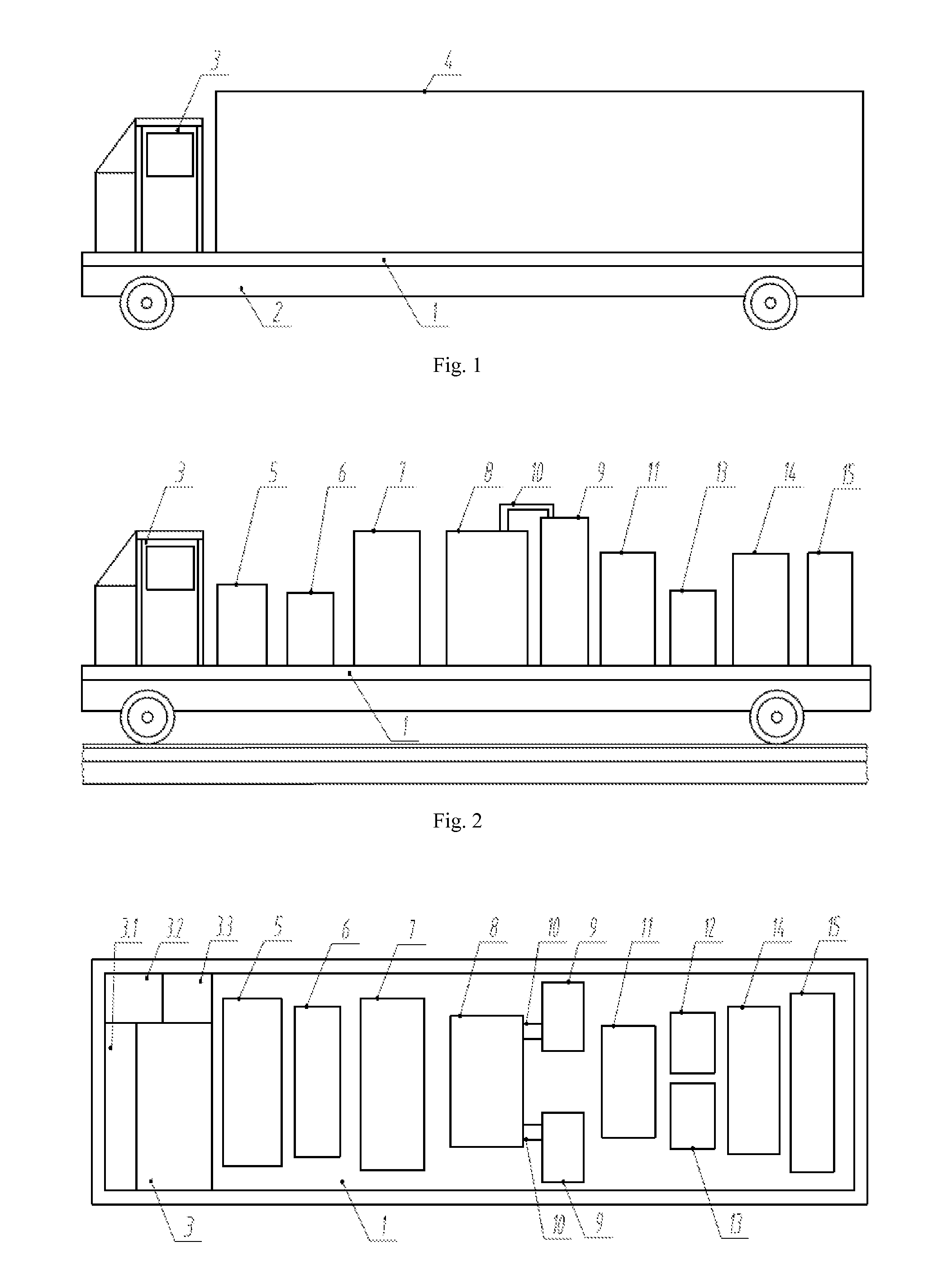

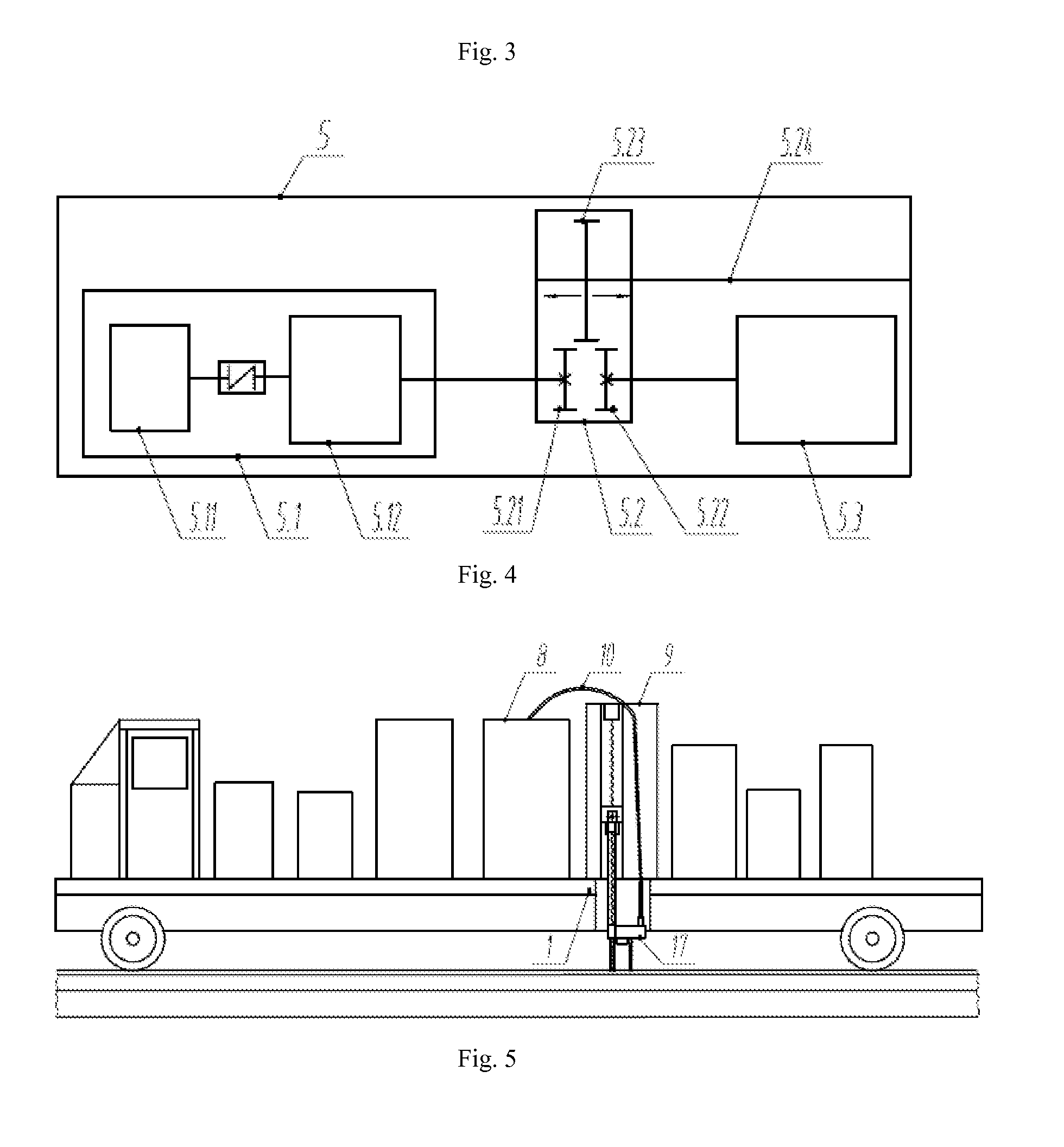

Onsite steel rail laser processing vehicle

ActiveUS20150020707A1Save timeImprove flexibilityRail and road vehiclesRailway track constructionMoving speedControl room

The invention discloses an on-line laser processing vehicle for a rail, including a chassis, a vehicle body, a steer-control chamber and a container; the steer-control chamber includes a console, a CCD monitoring system and a drive-switching operating system; a dual driving system and switching mechanism, which with a process-operation driving system, a conventional operation driving system and a switching mechanism, is disposed in the container; the process-operation driving system operates to provide driving power for the laser processing vehicle during laser processing, and precisely controls moving speed and distance of the laser processing vehicle; the switching mechanism operates to implement switching between the conventional operation driving system and the process-operation driving system. The invention ensures accurate processing trajectories of the laser processing vehicle during laser processing; facilitates on-line laser processing of a variety of rails, such as the rails of main line, curved rails, guard rails, switch rails and so on, so that wear resistance of the processed rail is greatly improved, and meets requirements of high-speed and heavy haul trains for wear resistance of the rail.

Owner:WUHAN HIVALUE INTELASER LTD

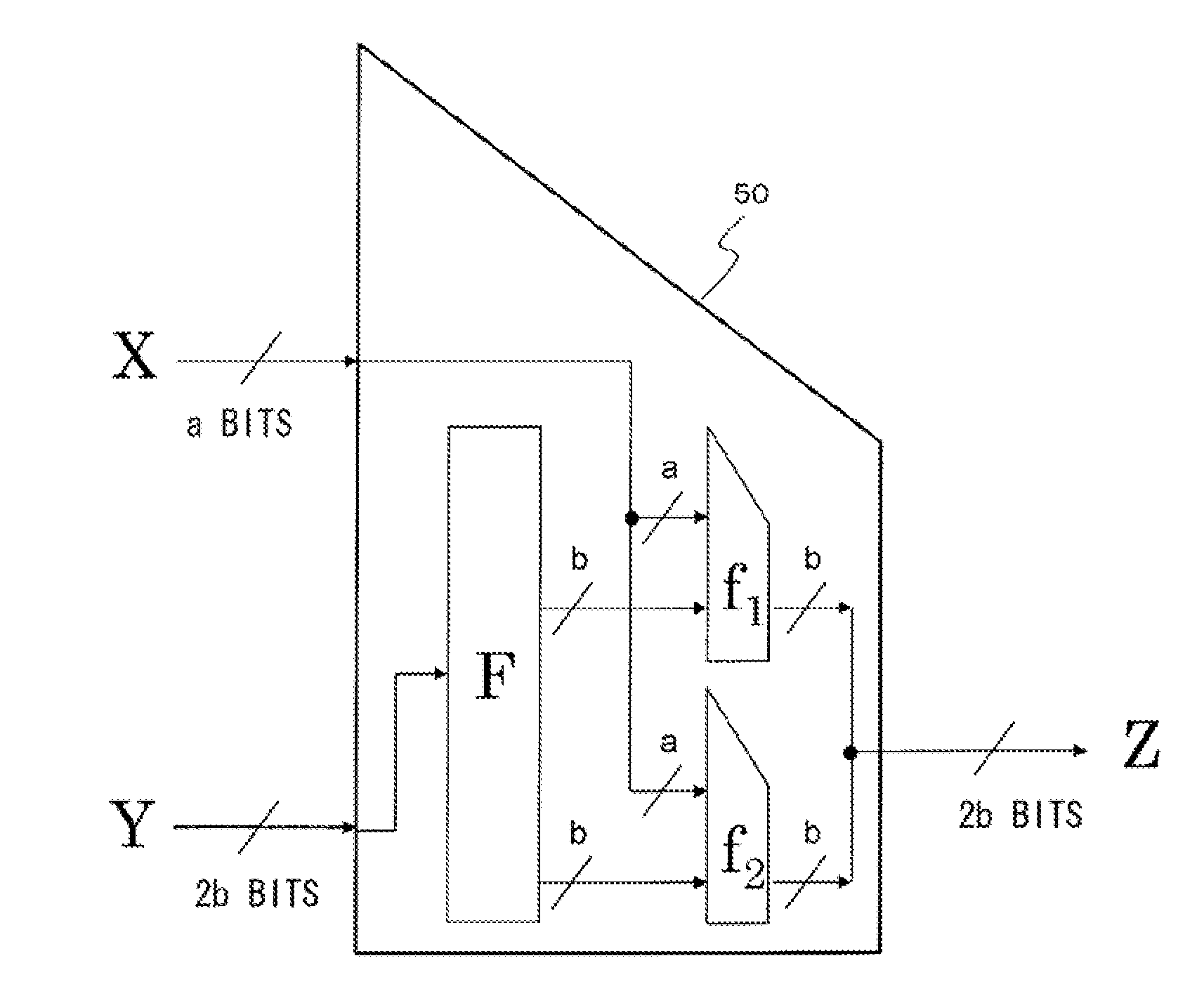

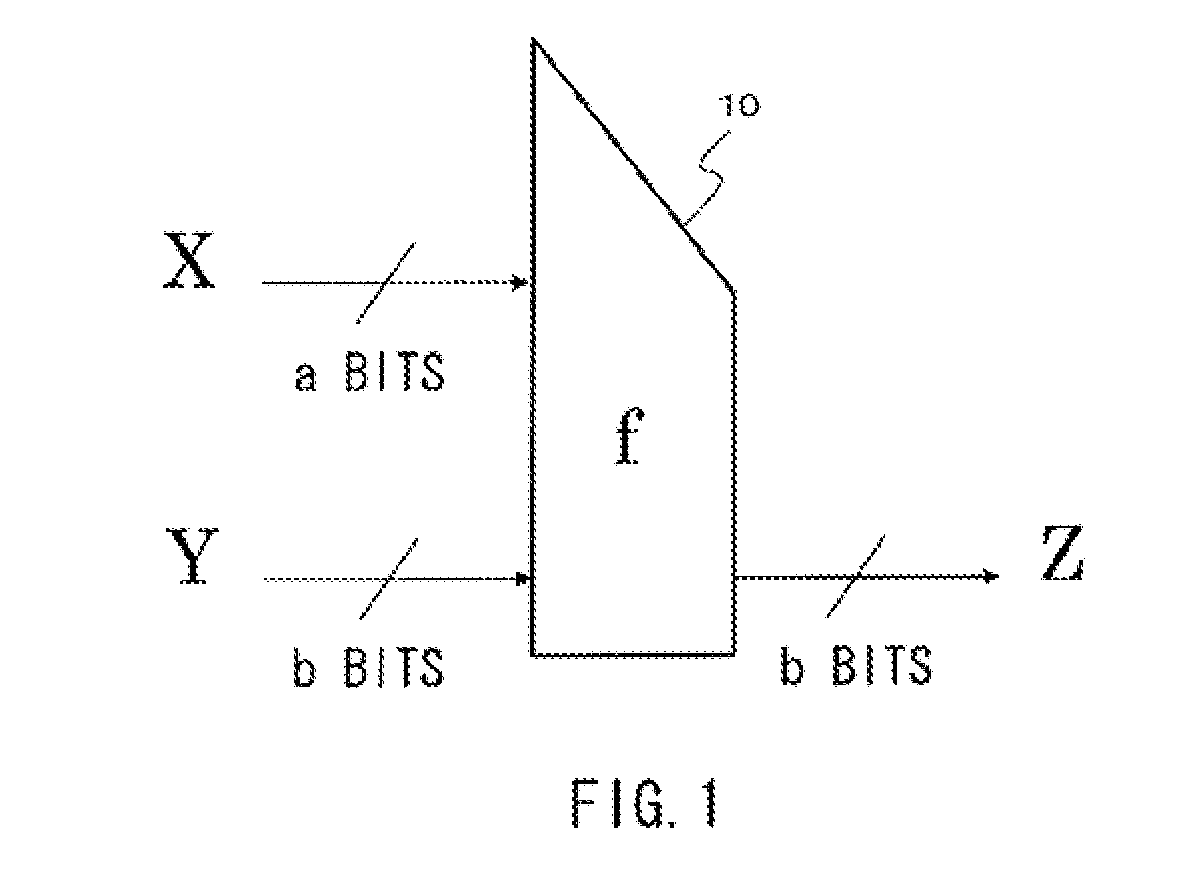

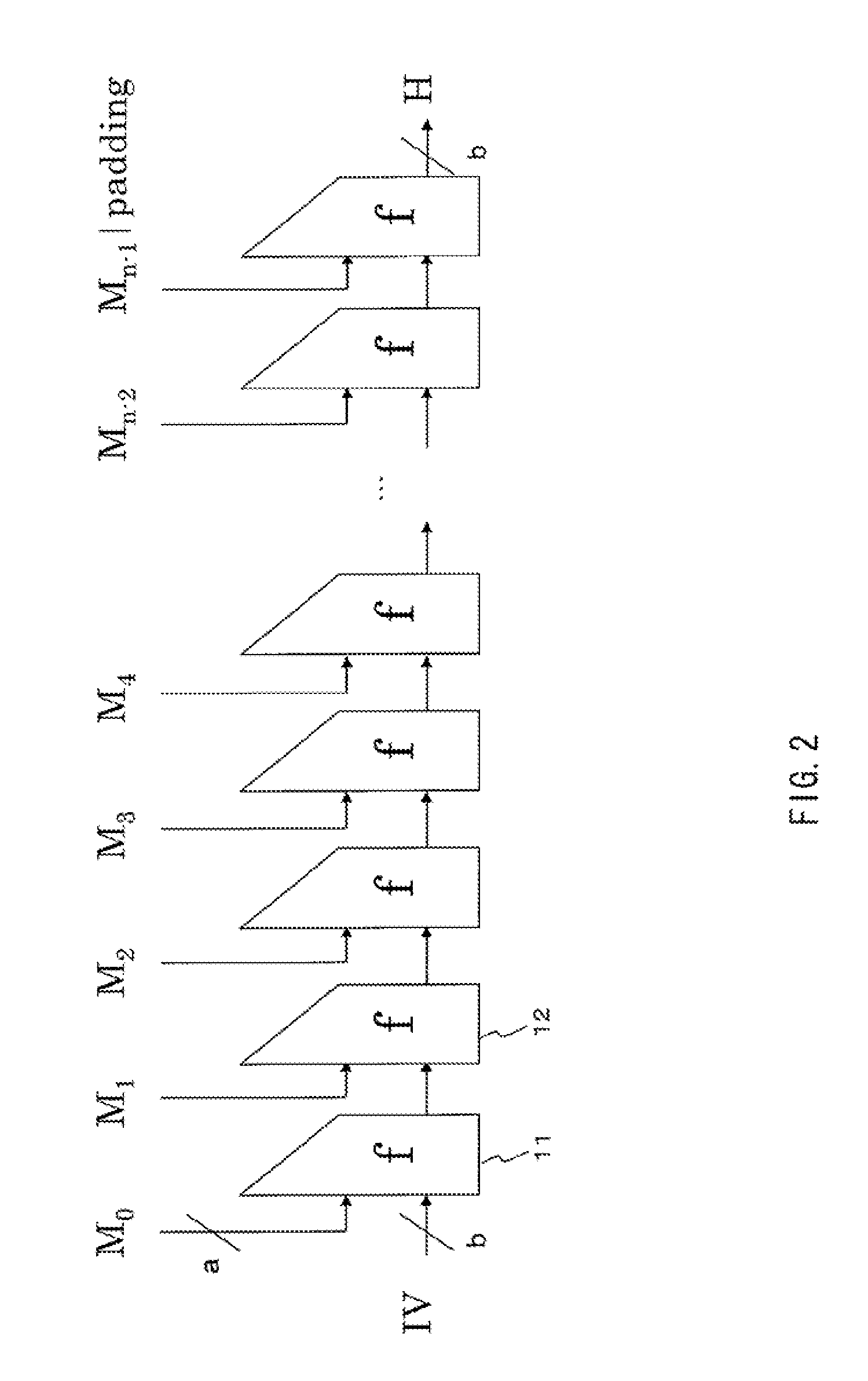

Data converter, data conversion method and program

InactiveUS20110211688A1Improve processing effectivenessImprove securitySecret communicationSecuring communicationStructure of Management InformationParallel processing

A construction with an improved compression-function execution section is achieved. A data conversion process with use of a plurality of compression-function execution sections and through a plurality of process sequences in which divided data blocks constituting message data are processed in parallel is executed. Each of the plurality of compression-function execution sections performs a process with use of a message scheduling section which receives a corresponding divided data block of the message data to perform a message scheduling process, and a process with use of a chaining variable processing section which receives both of an output from the message scheduling section and an intermediate value as an output from a preceding processing section to generate output data whose number of bits is same as that of the intermediate value through compression of received data. The plurality of compression-function execution sections, respectively performing parallel processing commonly use one or both of the message scheduling section and the chaining variable processing section, and allow a single message scheduling section or a single chaining variable processing section to be utilized. Downsizing of a hardware configuration and simplification of processing steps are achieved by such a construction.

Owner:SONY CORP

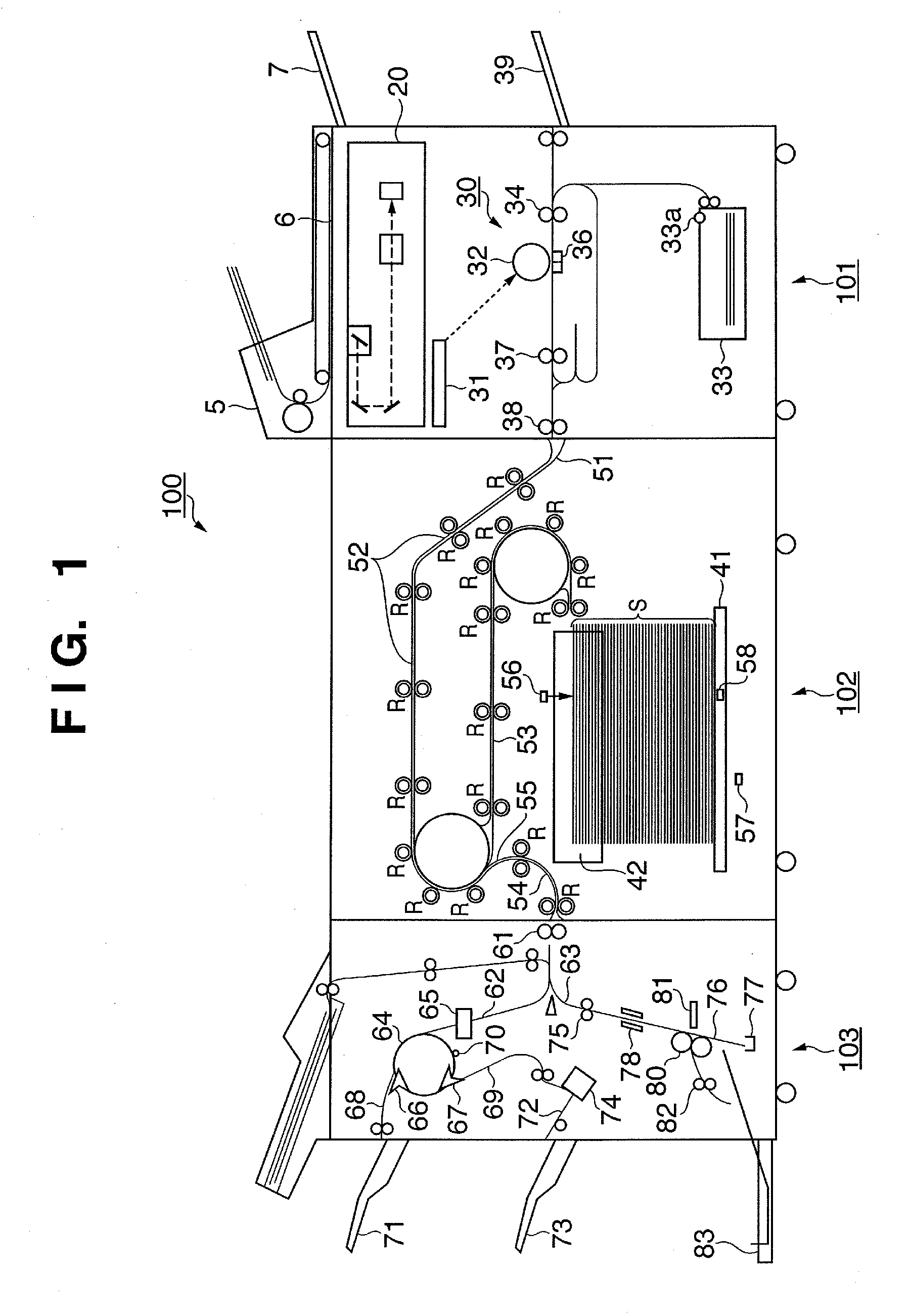

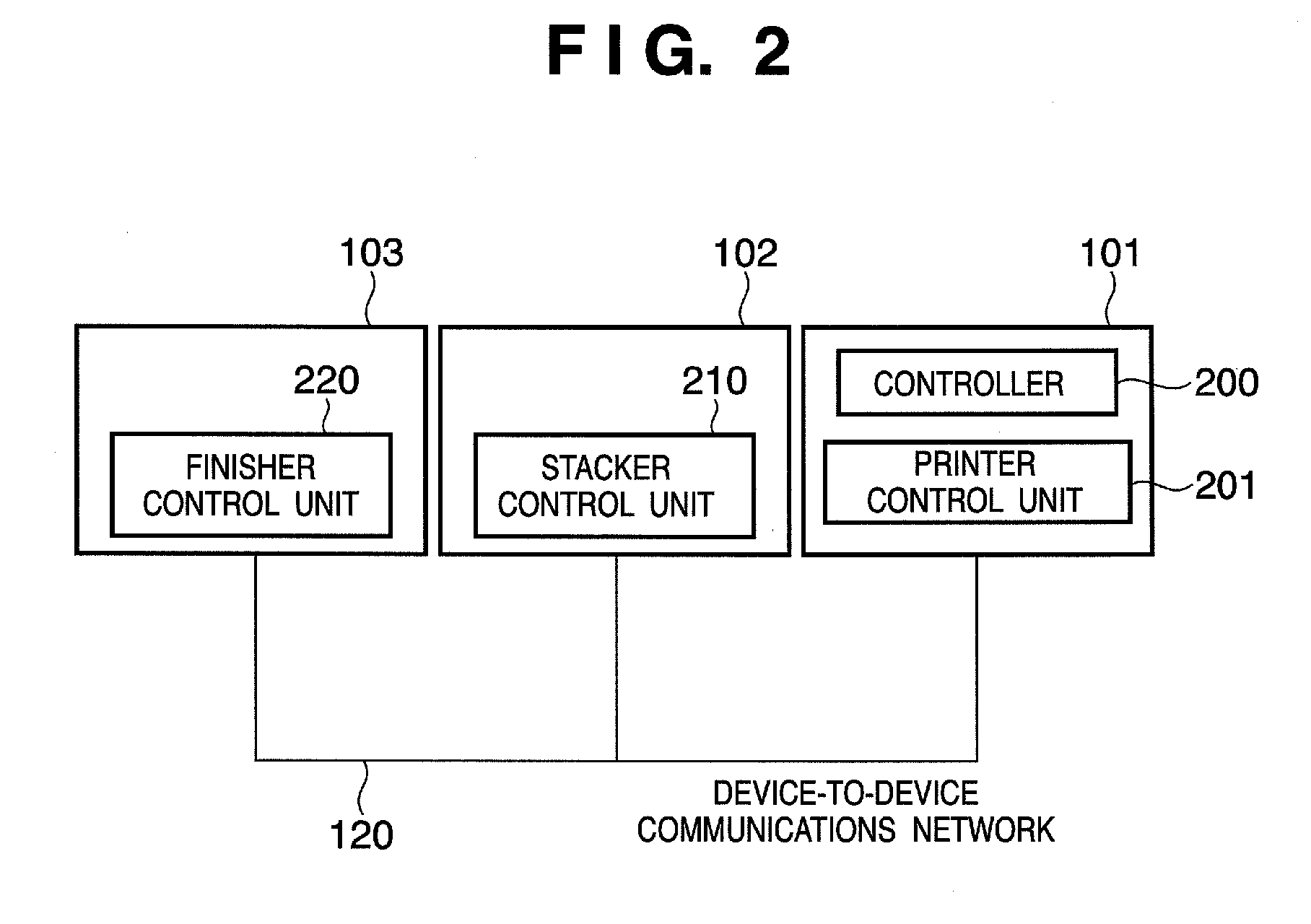

Image forming apparatus

ActiveUS20070057446A1Improve processing effectivenessFunction indicatorsElectrographic process apparatusTransit timePaper sheet

Timing information for use to determine the timing to discharge a sheet from an image forming apparatus is transmitted. The timing information is relayed, by being edited repeatedly, from a first sheet processing apparatus connected directly with the image forming apparatus to a second sheet processing apparatus which actually processes the sheet. The timing information is edited on each sheet processing apparatus by considering, for example, transit time of the sheet, processing time of the sheet, preparation time for the sheet to get ready to be processed, and the like. The second sheet processing apparatus transmits the timing information to the image forming apparatus. The image forming apparatus determines the discharge timing of the sheet based on the received timing information and discharges the sheet with the determined discharge timing.

Owner:CANON KK

Sheet post-processing apparatus

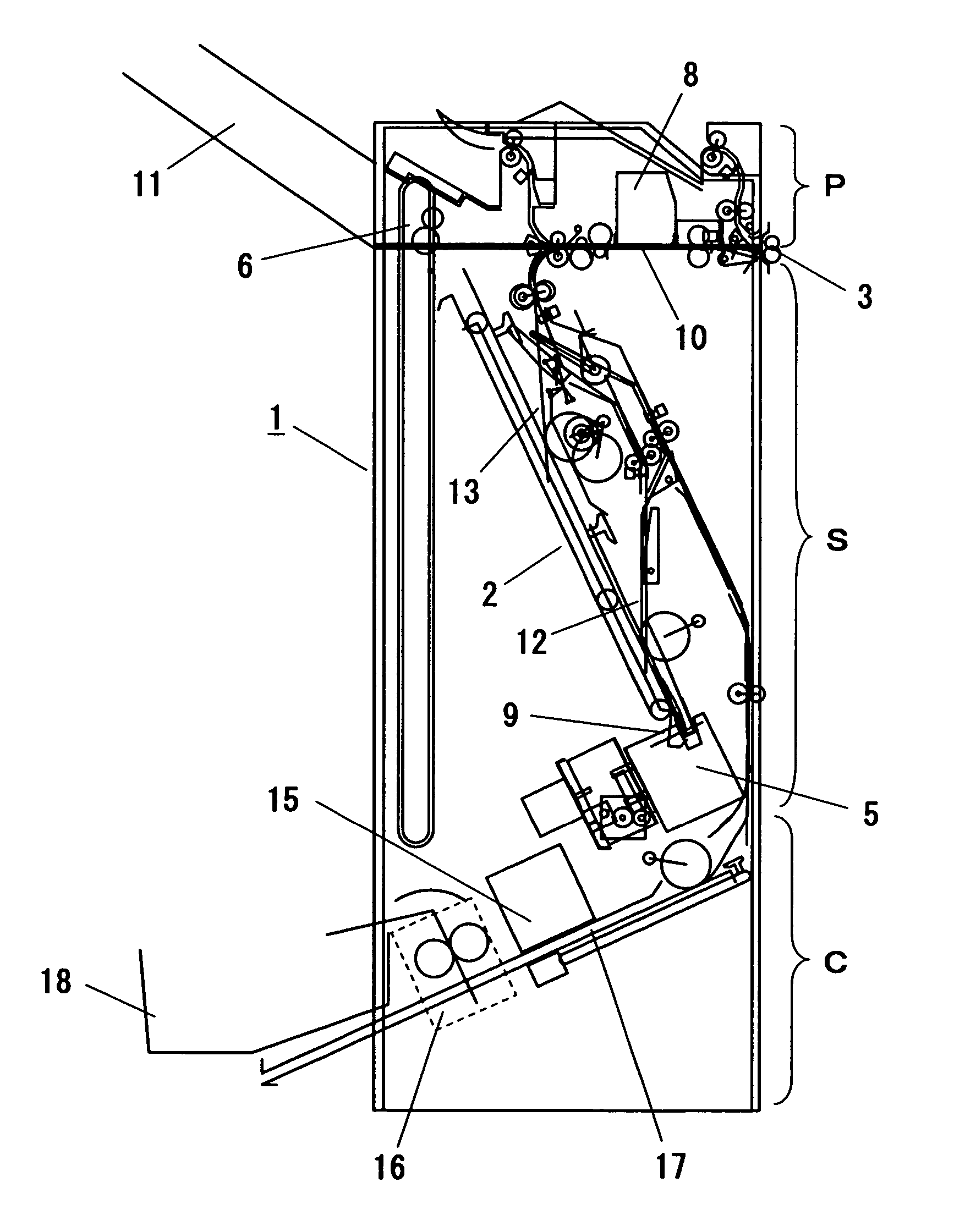

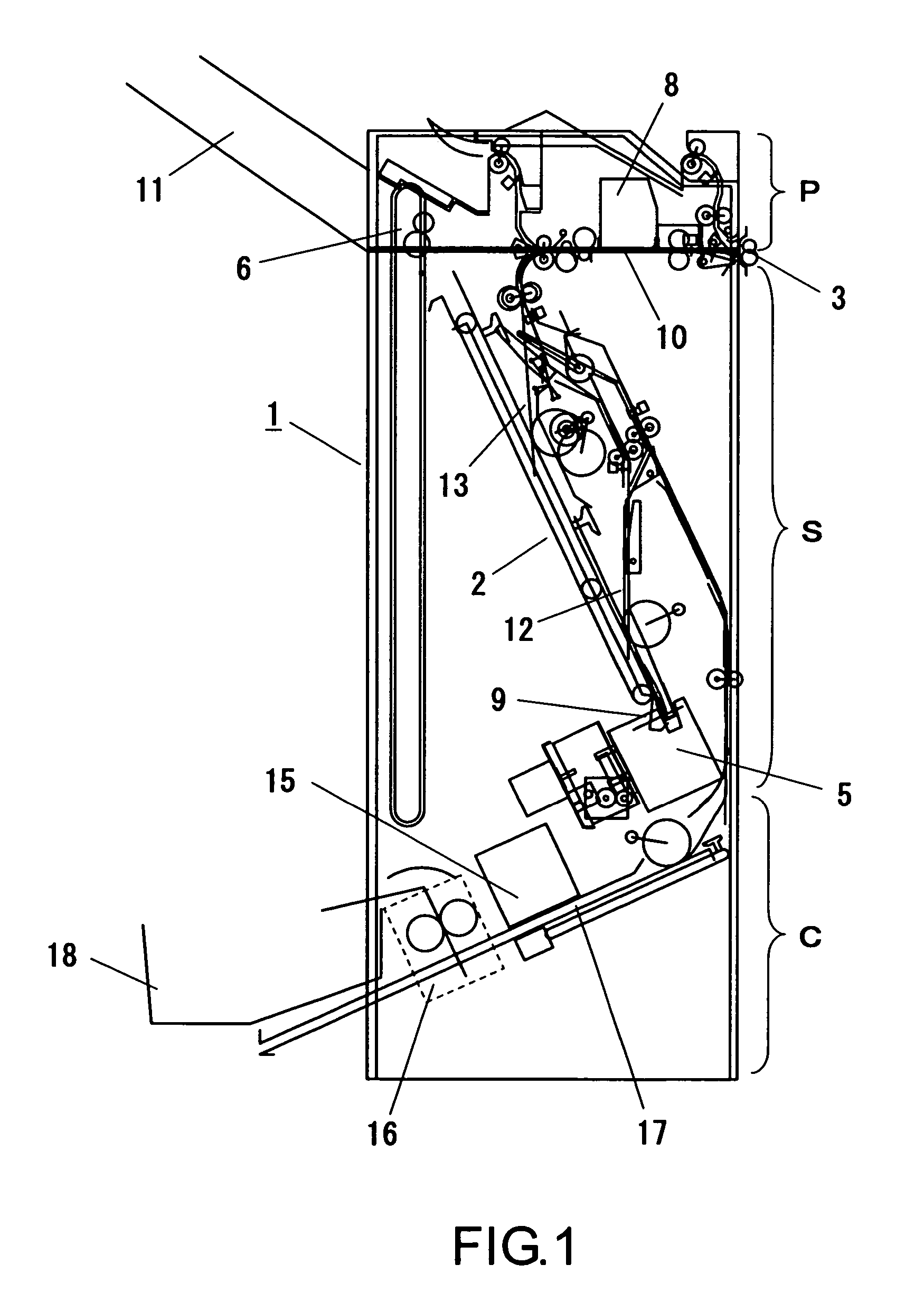

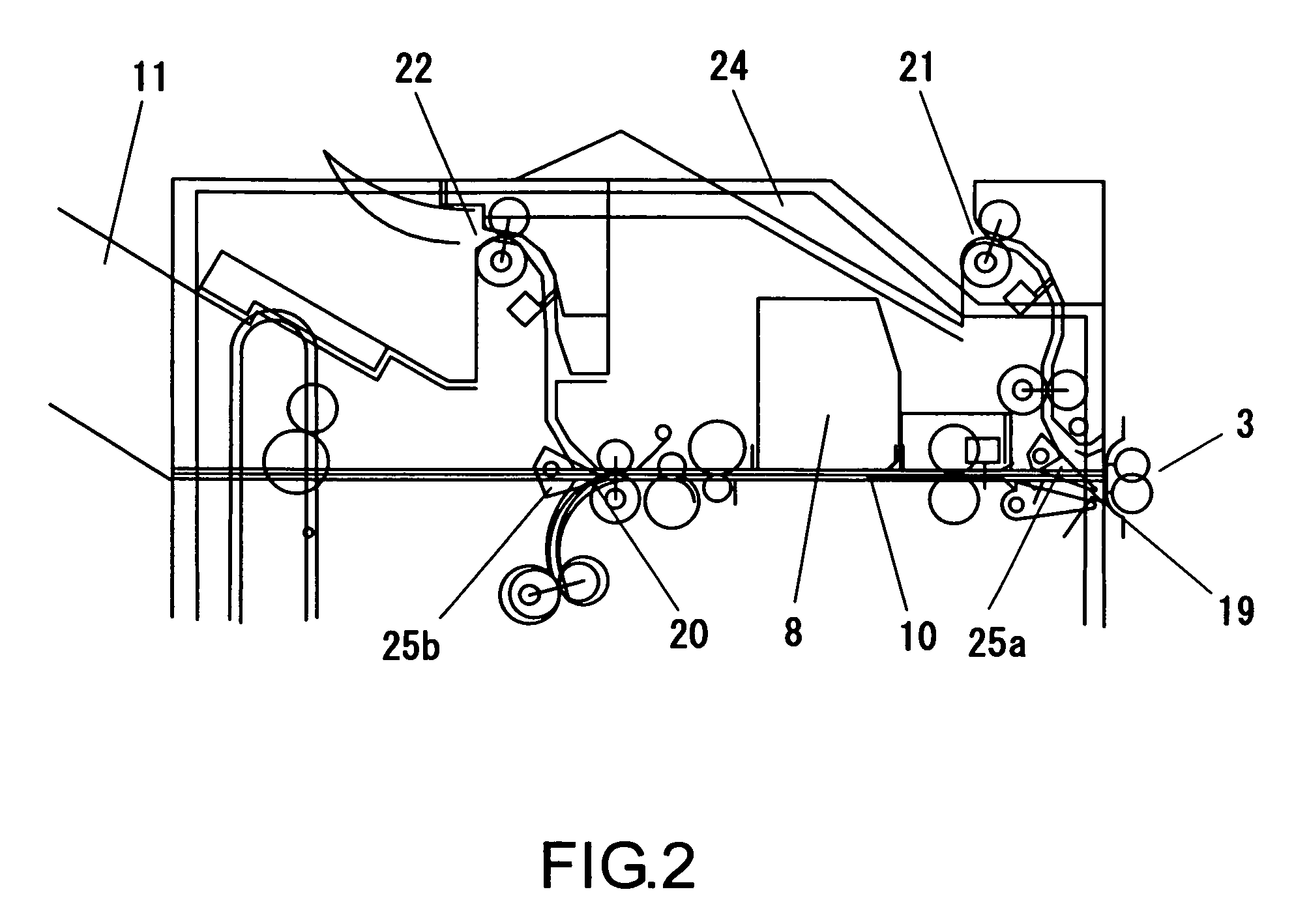

InactiveUS7497425B2Simple structureImprove processing effectivenessFunction indicatorsFolding thin materialsPunchingEngineering

A sheet post-processing apparatus (1) includes a punching unit (P), an end-binding unit (S) which aligns end portions of a sheet bundle piled on a processing tray (2) and performs a stapling process, and a middle-binding and middle-folding unit (C) which performs a stapling process on the center of the sheet bundle and then folds centering around the stapling portion to be in a brochure form. The middle-binding and middle-folding unit (C) is independently provided on the lower side of the end-binding unit (S) and a middle-binding and middle-folding feeding path (27) feeds sheets to the middle-binding and middle-folding unit (C) without via the processing tray (2) of the end-binding unit (S).

Owner:KYOCERA DOCUMENT SOLUTIONS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com