Technological method for treatment of oil field oil sludge

A process method and sludge sludge technology, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of small treatment volume, complicated treatment process, secondary pollution, etc., and achieve heat prevention The effect of loss, reasonable process design and strong processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

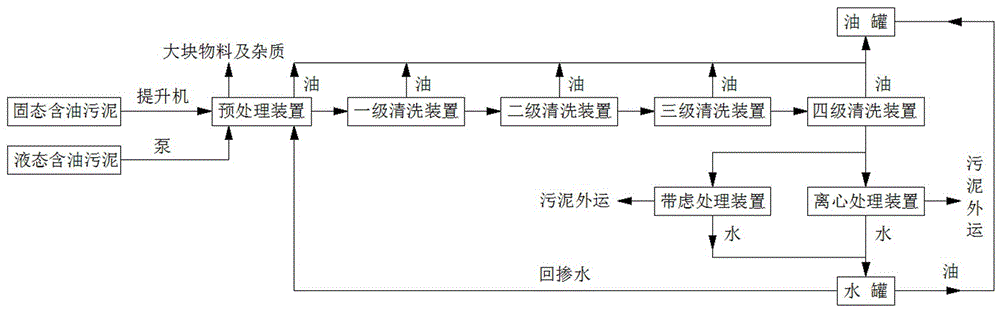

[0032] refer to figure 2 and image 3 , a process method for treating oilfield sludge, the process method is:

[0033] Step 1. Solid oily sludge screening

[0034] The solid oily sludge is broken up by a sludge sorting device, and the broken solid sludge is screened by a vibrating screening machine, and the particles larger than 2 cm in the sludge are transported to the sludge sorting device for re-dispersion. Sludge blocks smaller than 2 cm are transported to the carburetor tank for treatment, and stones, fibers, weeds, construction waste and other debris are sorted into the collection box during the vibration screening process;

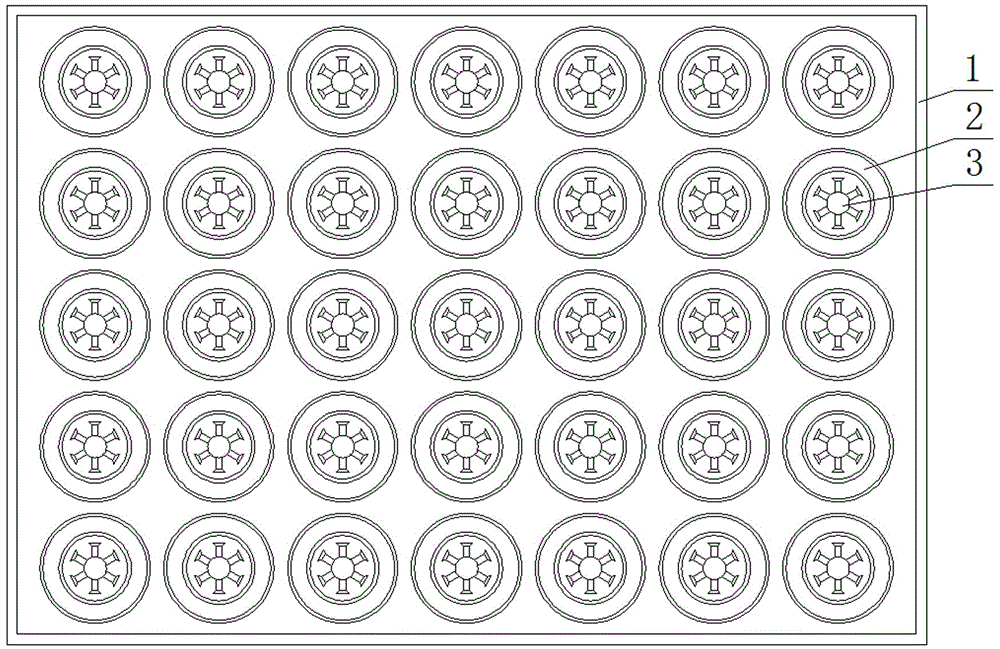

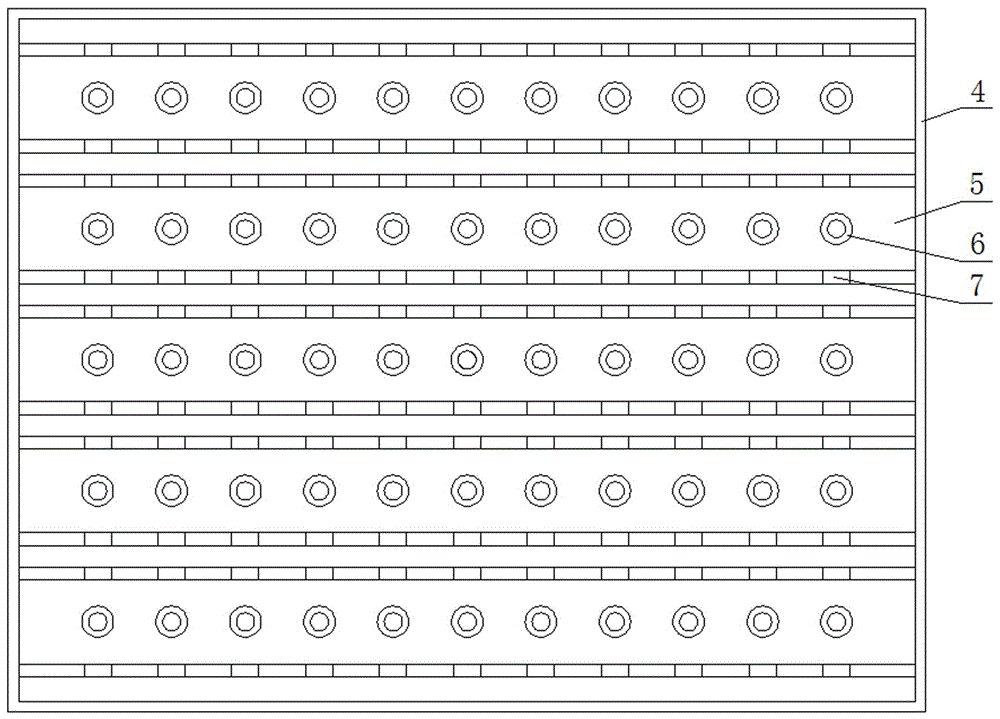

[0035] Step 2. Dry steaming of solid oily sludge to oil

[0036] The sludge particles no larger than 1 cm screened out by the vibrating screen machine are transported to the ring cavity sieve column 2 of the carburetor through the screw feeder. After the ring cavity sieve column 2 is filled with sludge particles, the ring cavity sieve column 2 ...

Embodiment 2

[0054] refer to figure 1 , a process method for treating oilfield sludge, the process method is

[0055] Step 1. Automatic feeding

[0056] Due to the wide sources of oily sludge in various places, it is mainly composed of crude oil, water and solid particles, which also contains some bulky materials and solid waste. For example, the geographical location of Liaohe Oilfield has a large temperature difference in four seasons. The high temperature in summer causes the crude oil in the oily sludge to precipitate, forming an oil slick with strong fluidity. The solid particles in the mud are deposited at the bottom of the mud storage tank, between the solid and the slick There is an aquifer; when the temperature drops in autumn, the upper layer of slick oil condenses to form an oil cap. As the temperature drops, the fluidity of the sludge weakens and freezes in winter. Therefore, the feed of liquid sludge and solid semi-solid sludge should be considered in the feed of oily sludge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com