Patents

Literature

93results about How to "Avoid high temperature burns" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

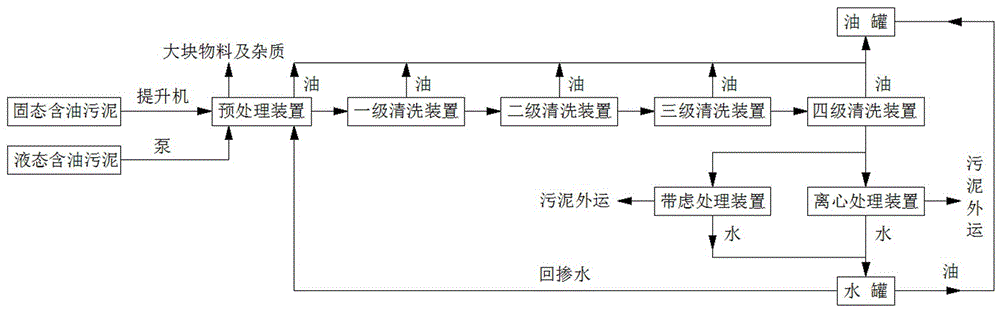

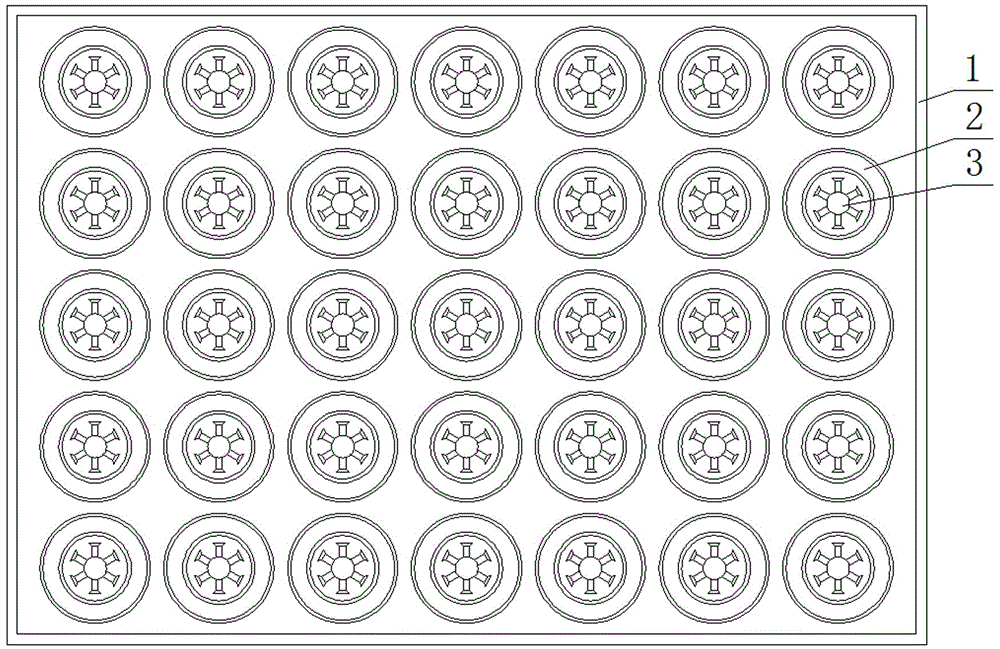

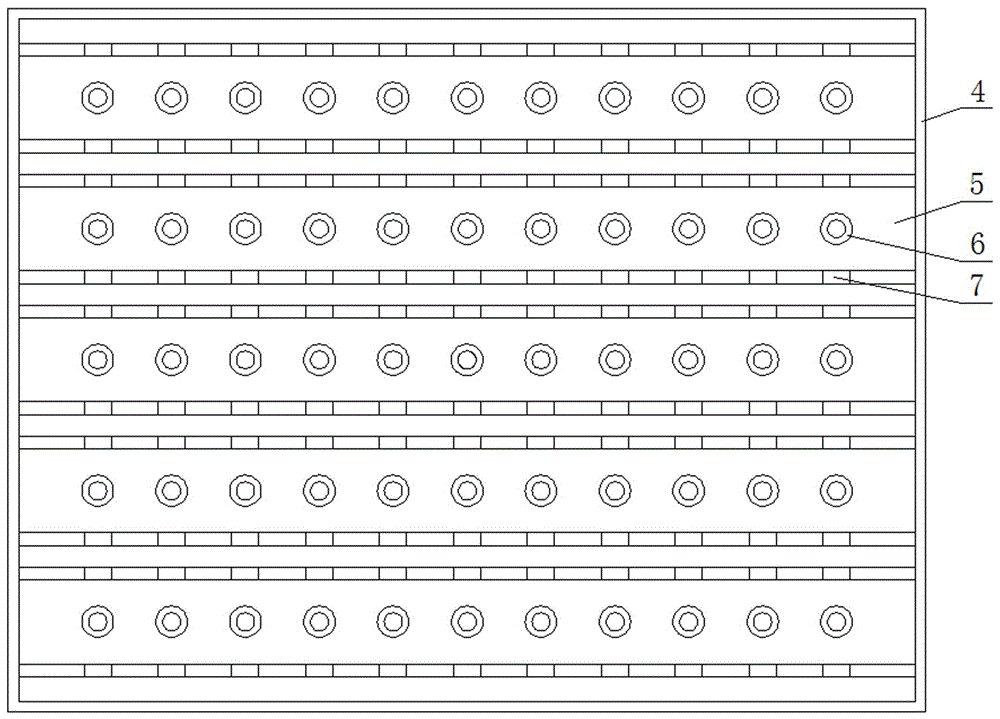

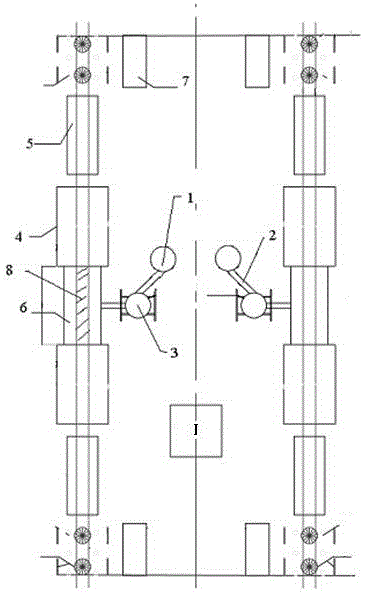

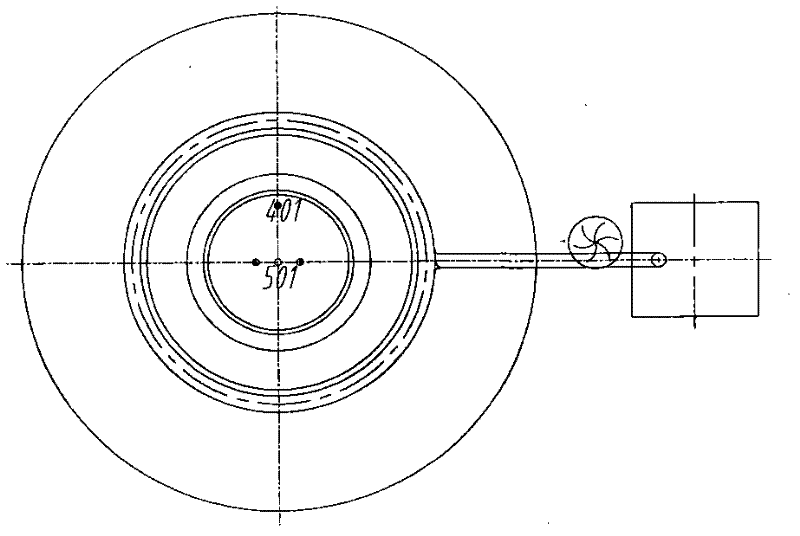

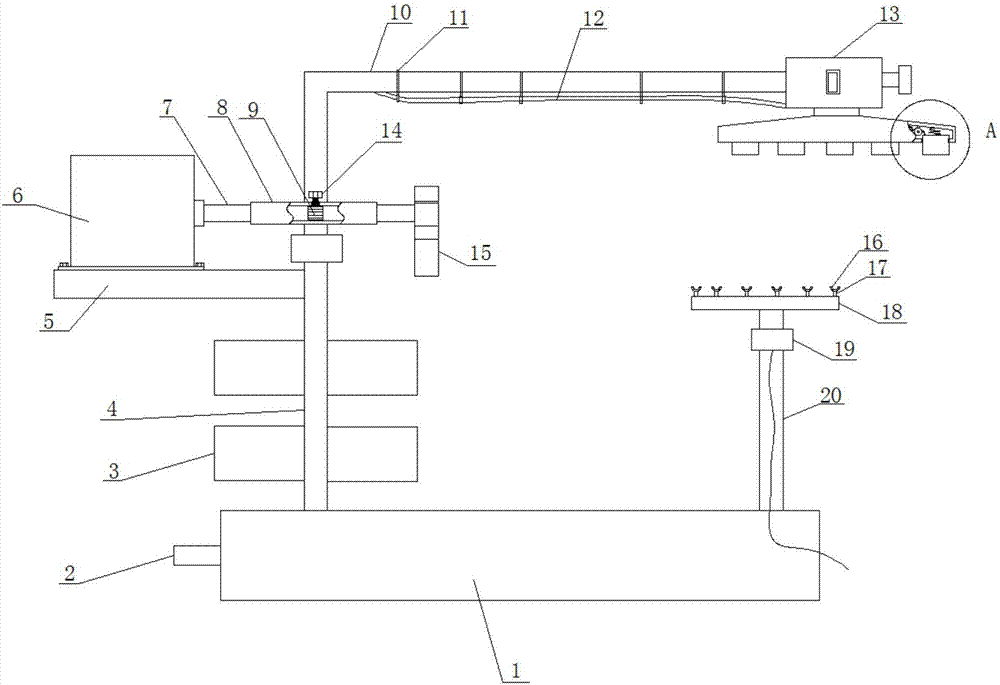

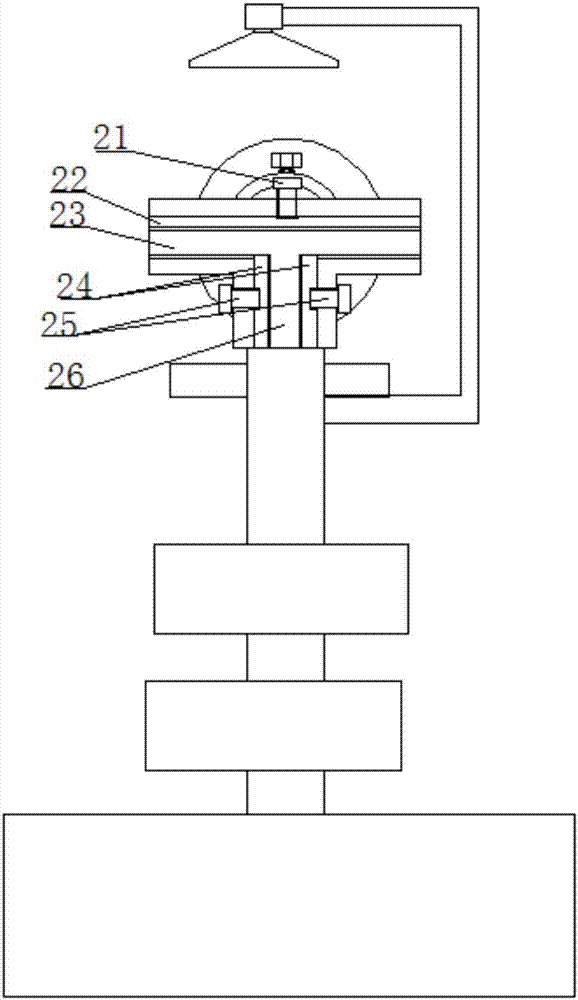

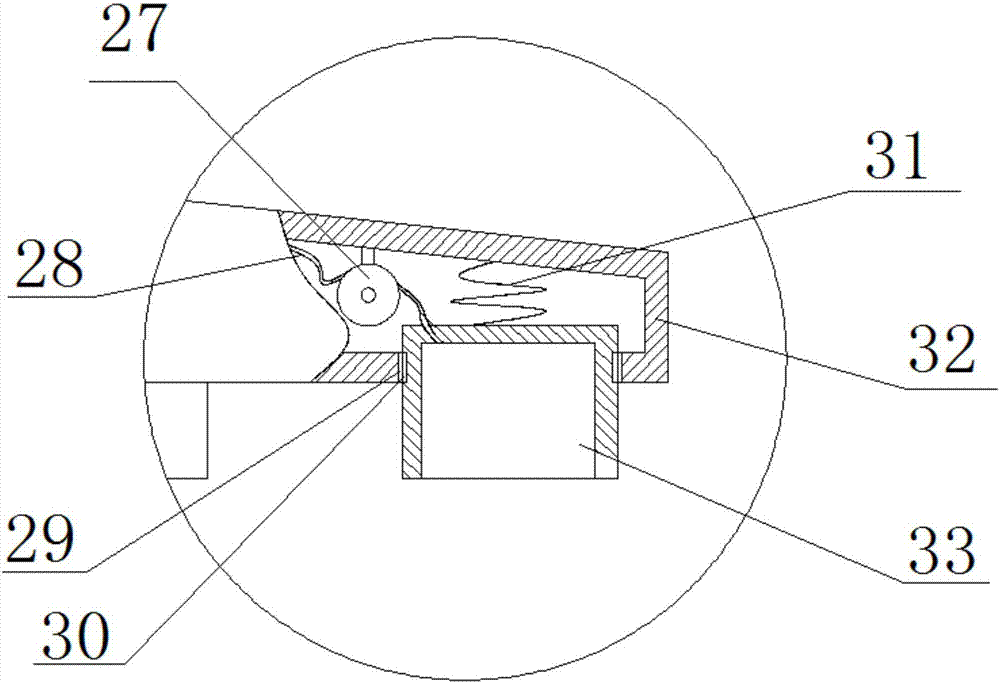

Technological method for treatment of oil field oil sludge

ActiveCN106242205AAvoid lossAvoid high temperature burnsSludge treatment by de-watering/drying/thickeningMelting tankFuel tank

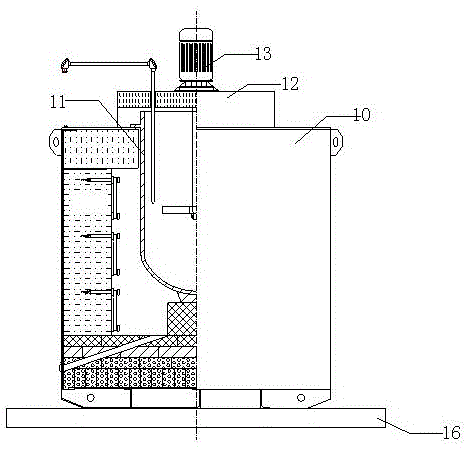

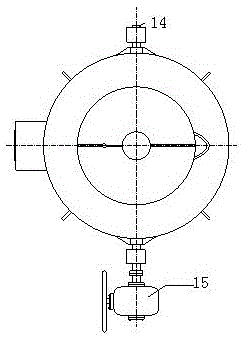

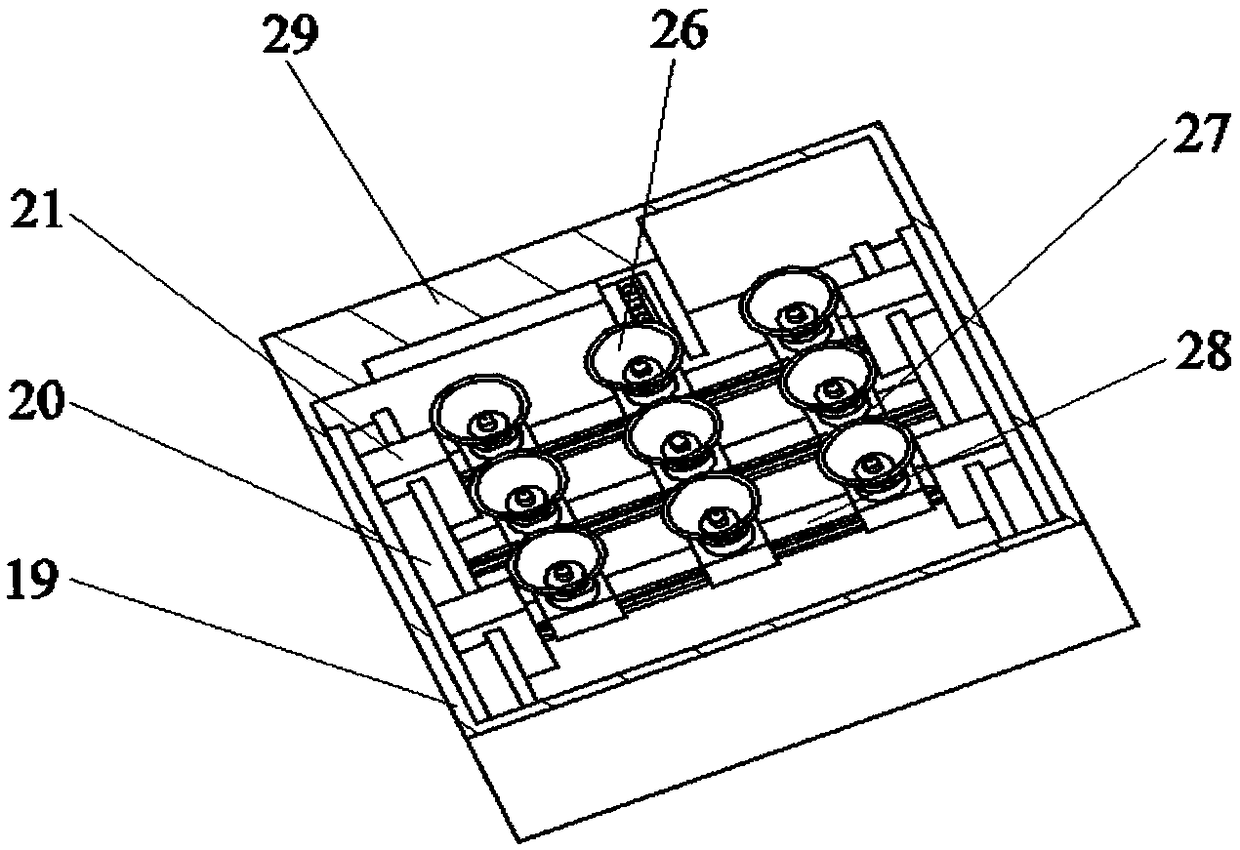

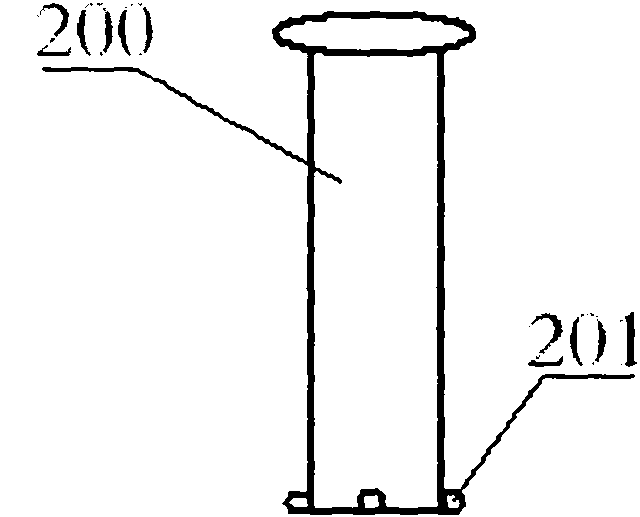

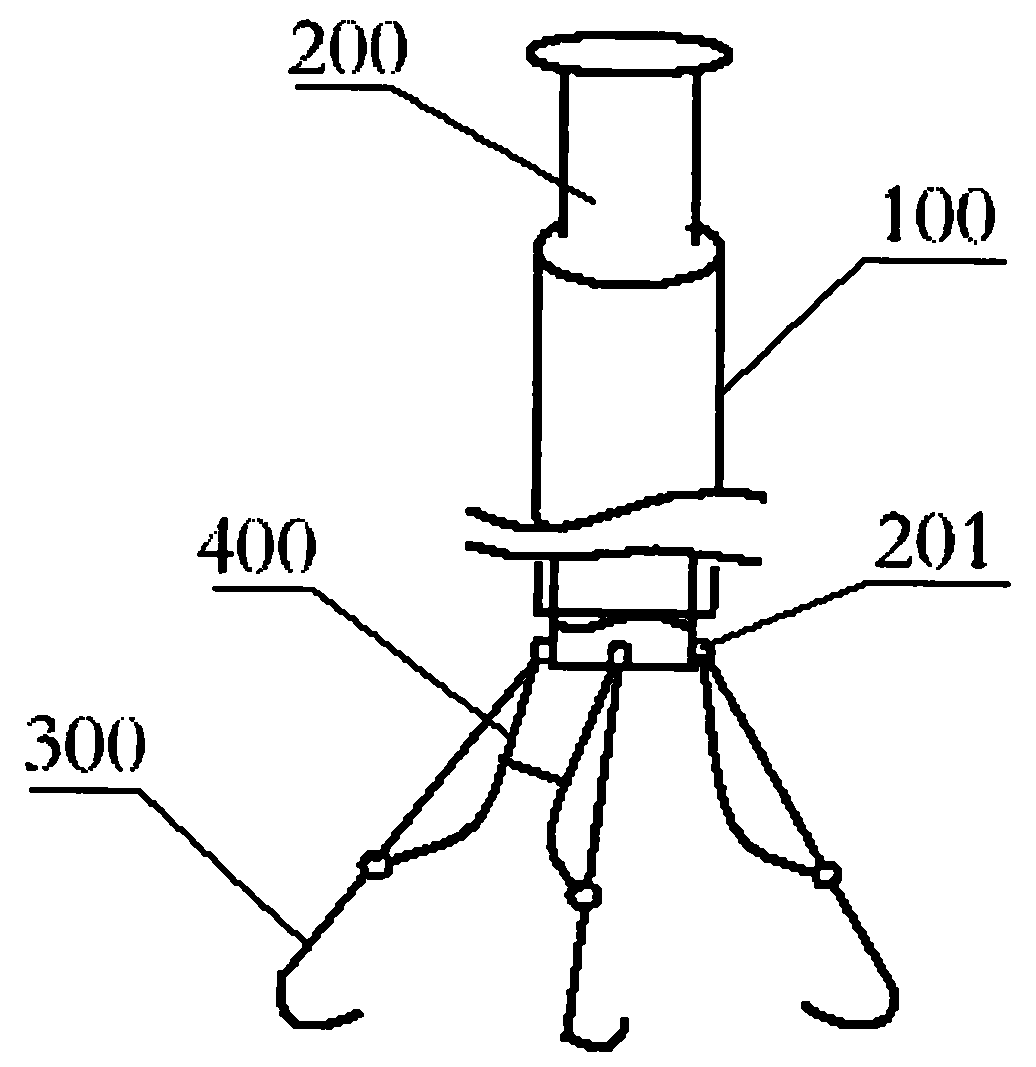

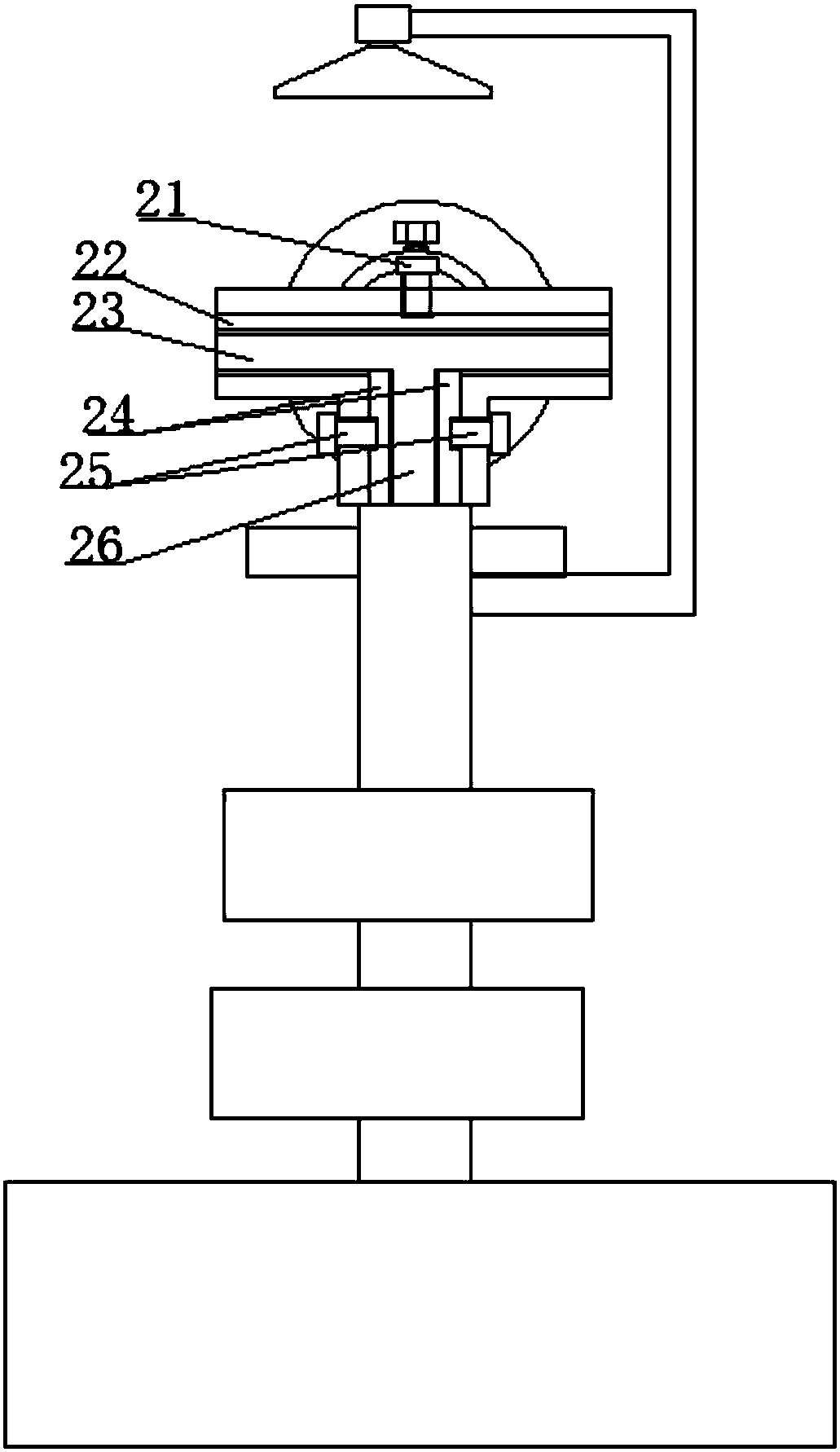

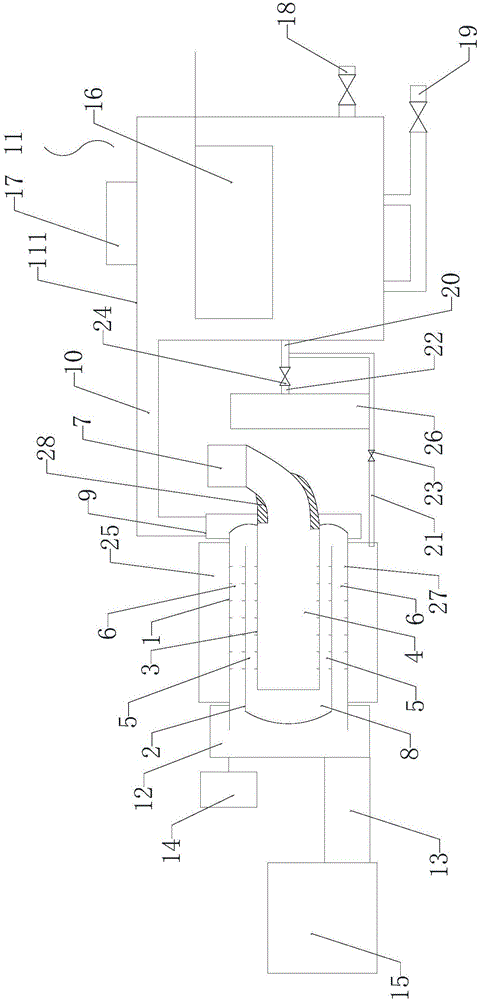

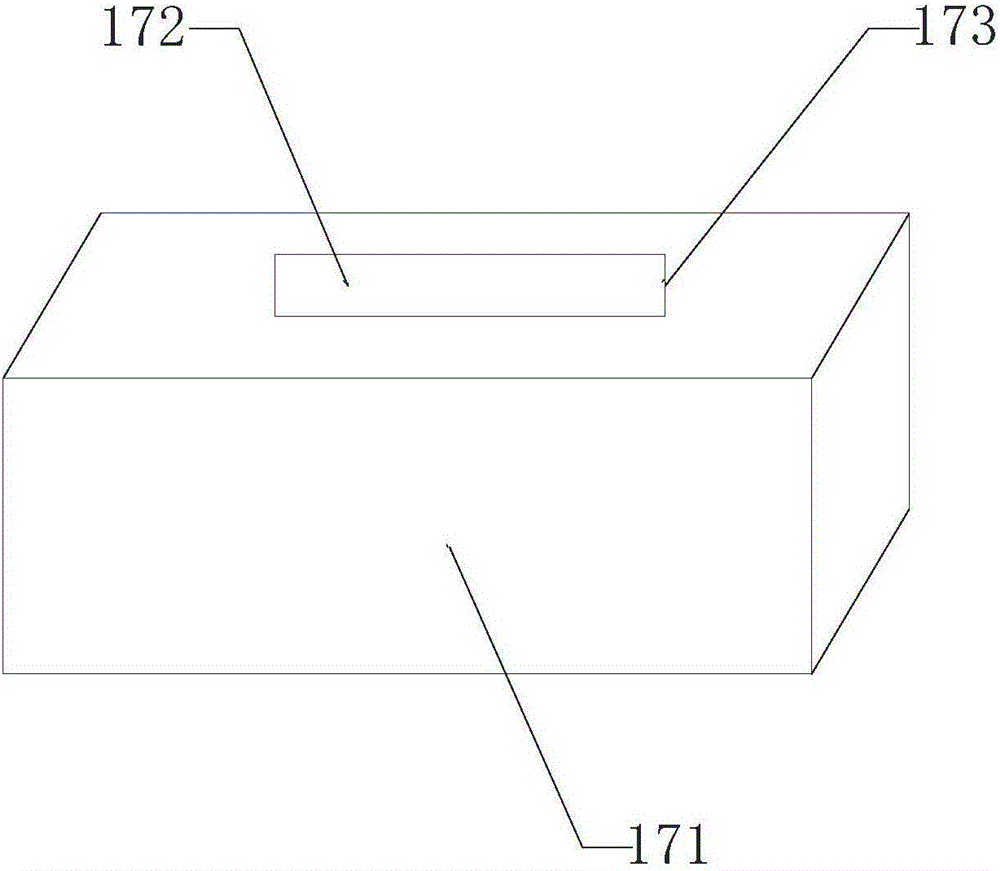

Belonging to the technical field of oil sludge treatment, the invention specifically relates to a technological method for treatment of oil field oil sludge. The technological method consists of: solid oily sludge screening, solid oily sludge dry steam oil melting, solid oily sludge high-pressure water crushing, liquid oily sludge pretreatment, first level cleaning, second level cleaning, third level cleaning, fourth level cleaning, dehydration treatment and oil-water recovery. Specifically, an oil melting tank includes a box body, uniformly distributed ring cavity sieve columns and dry steam nozzles, the dry steam nozzles are located in the ring cavity sieve columns, the diameter of sieve pores on the inner and outer walls of the ring cavity sieve columns is 5mm, and the bottoms of the ring cavity sieve columns are provided with turnable discharge cover plates. A crushing box includes a shell, uniformly distributed material bins and high pressure water spray guns, the high pressure water spray guns are located at the top of the material bins, and both side walls of the material bins are provided with uniformly distributed round holes. The process involved in the invention has the advantages of reasonable design, safety and environmental protection, good treatment effect, high treatment efficiency, strong treatment capacity, and cost saving, and is economical and applicable.

Owner:大庆世纪新风环保科技有限公司

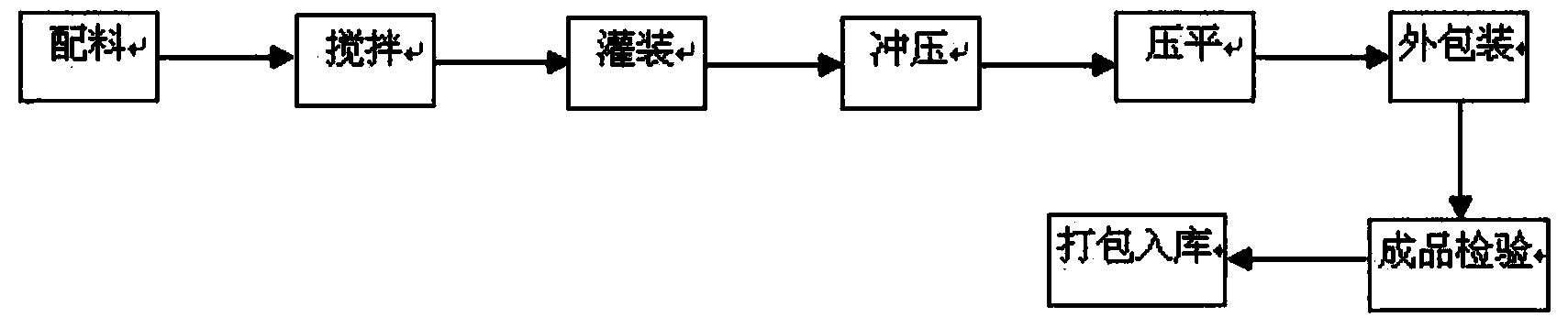

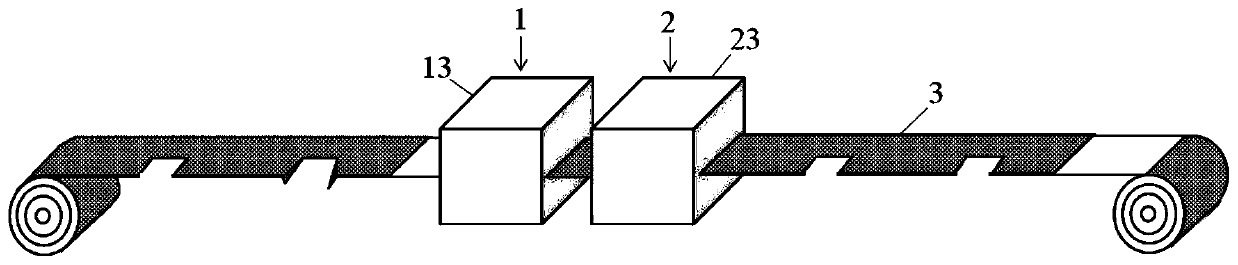

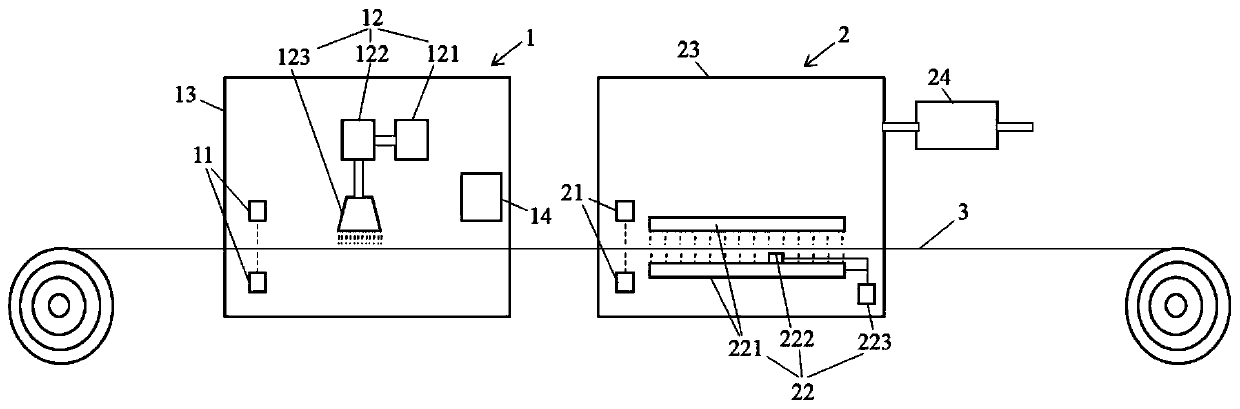

A production system and production method of foamed aluminum

Owner:丹阳翊德炉业有限公司

Chinese medicine hot compress plaster for improving microcirculation and relieving pain

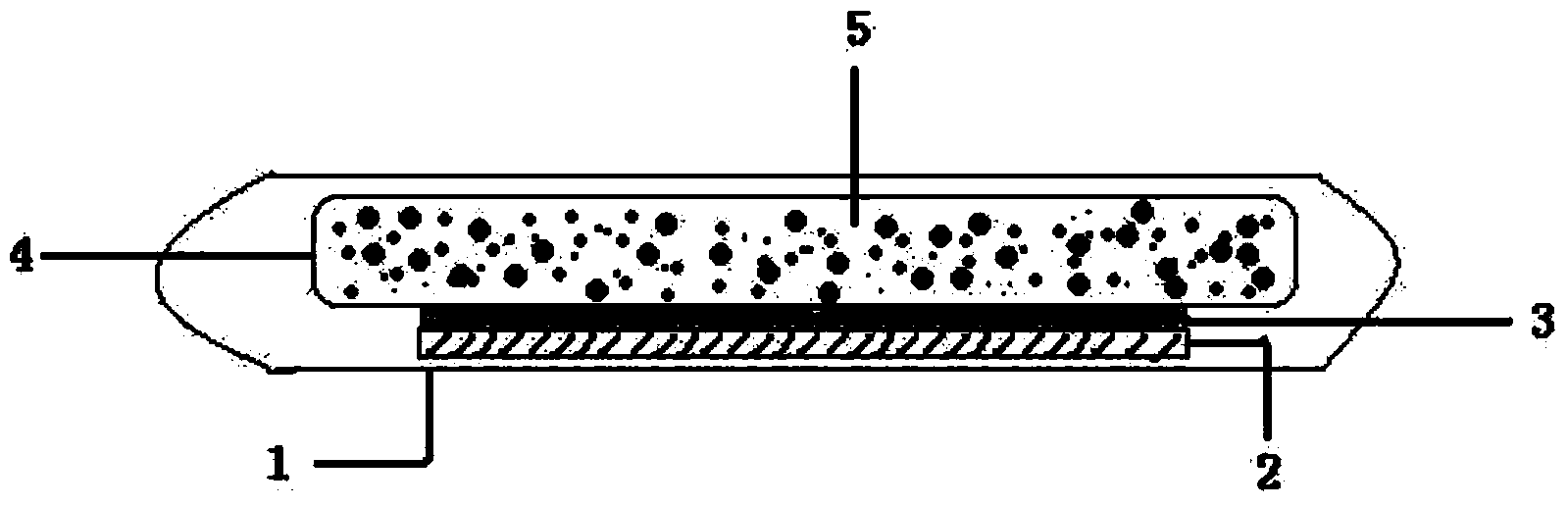

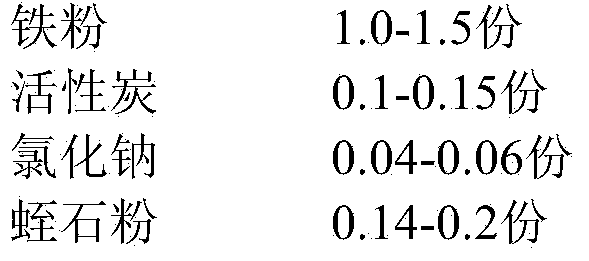

The invention provides a Chinese medicine hot compress plaster which is capable of improving microcirculation, promoting blood circulation, preventing histanoxia and relieving local organ and tissue pain. The Chinese medicine hot compress plaster sequentially comprises an outer packaging bag, an inner packaging bag, a heating material and an optional Chinese medicine composition from outside to inside. The Chinese medicine hot compress plaster is characterized in that the outer packaging bag is a vacuum packaging bag or a non-vacuum packaging bag, the inner packaging bag is made of a nonwoven fabric, and the heating material is prepared from iron powder, active carbon, sodium chloride, vermiculite, expanded crushed crude pearlite and magnetized water. The Chinese medicine hot compress plaster can be directly plastered on underwear after being unsealed, is high in heating speed, balanced in heating power, appropriate in temperature, and long in heating duration, and has the functions of promoting local blood circulation of a human body, improving microcirculation, preventing histanoxia and relieving local organ and tissue pain through conveying the heating power.

Owner:辽宁康鑫医疗器械有限公司

Stub-leaving no-tillage spring-manure wheat sowing and cultivation method

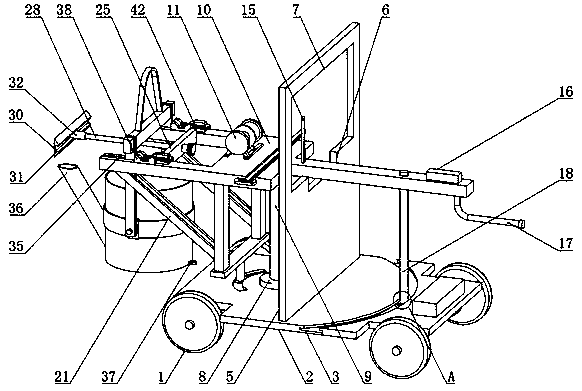

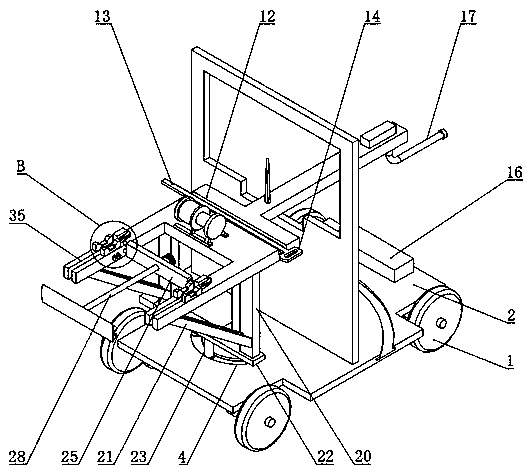

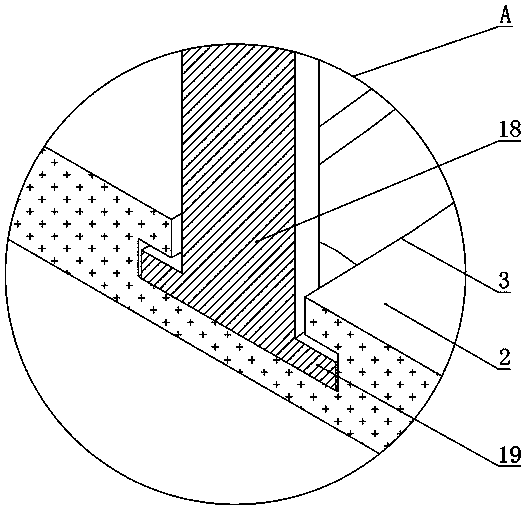

The invention relates to a sowing technique, in particular to a stub-leaving no-tillage mechanical sowing cultivation method. The stub-leaving no-tillage mechanical spring-manure wheat sowing cultivation method comprises the steps of harvesting wheat, irrigating in winter, performing medical treatment on selected spring-manure wheat seeds, mixing the selected spring-manure wheat seeds with chemical fertilizer, performing stub-leaving no-tillage mechanical spring-manure wheat sowing, performing field management of stub-leaving no-tillage spring-manure wheat, and performing stub-leaving no-tillage spring-manure wheat harvesting and the like. The method has the advantages of increasing moisture in soil, reducing wind corrosion and waster and soil loss, regulating ground temperature, increasing nutrients in soil, improving activity of soil enzymes and the like.

Owner:GANSU AGRI UNIV

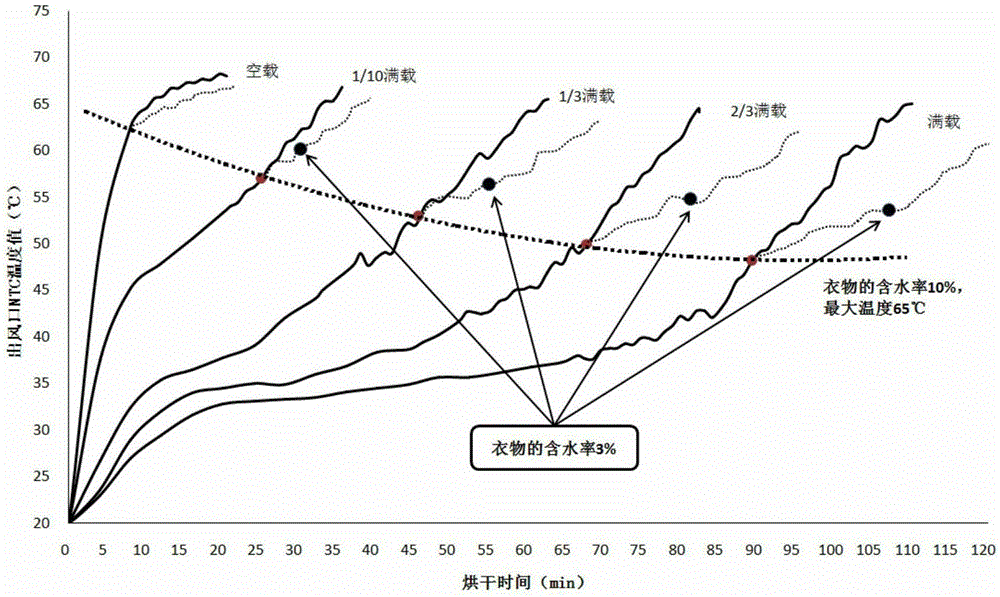

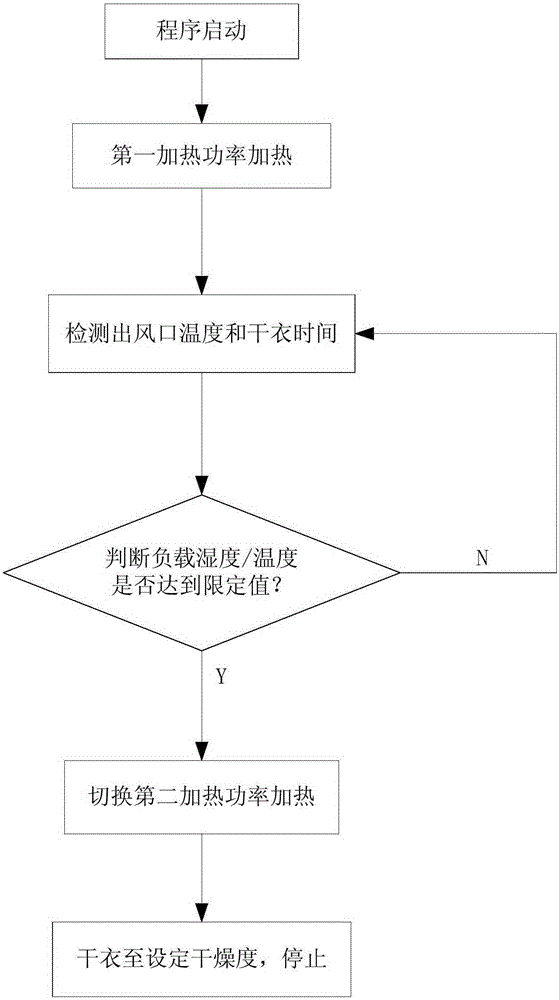

Clothes dryer control method

ActiveCN106498678AAvoid high temperature burnsPrevent shrinkage and even high temperature damageTextiles and paperLaundry driersProcess engineeringLimit value

The invention discloses a clothes dryer control method. A clothes dryer heating device is provided with at least two heating powers; At the beginning of clothes drying, the heating device is controlled to heat at a first heating power; the air outlet temperature and the drying time are detected in real time; whether the load water content and / or load temperature reach to preset limit values is determined according to the detected air outlet temperature and the drying time; when the load water content and / or load temperature reach to the preset limit values, the heating device is controlled to heat at a second heating power for a set time period, then clothes drying is completed. The method is simple and reliable, which can meet the needs of users and reduce cost. At the beginning of a clothes drying process, the heating device heats at a higher heating power; and under the condition that the dryness of clothes reaches to a preset value, the heating device is controlled to heat at a lower heating power for a set time period. By means of the method, burn of clothes due to high temperature can be avoided; the final water content of clothes can be accurately controlled, which effectively increase drying effect.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Polyurethane polishing wheel and preparation method thereof

ActiveCN109048698AImprove durabilityReduce surface roughness valueBonded abrasive wheelsGrinding devicesPolyesterFoaming agent

The invention provides a polyurethane polishing wheel and a preparation method thereof. The polyurethane polishing wheel comprises a plurality of nylon fiber non-woven fabrics coated with wear-resistant slurry, the wear-resistant slurry comprises the following components in parts by weight, 100 parts of end-capped polyurethane prepolymer, 10-40 parts of chain extender, 5-15 parts of a solvent, 0.01-0.5 parts of a foaming agent, 0.01-0.5 parts of a catalyst, 0.1-0.8 parts of an antioxidant, 100-500 parts of an abrasive, 2-20 parts of a lubricant and 0.5-5 parts of toner; and the end-capped polyurethane prepolymer is selected from one or two of a polyester type end-capped polyurethane prepolymer and a polyester type end-capped polyurethane prepolymer. The polyurethane polishing wheel disclosed is compared with the polishing wheel in the same type in the market, the durability is improved by about 1 time, and the surface roughness value is reduced by about 50%.

Owner:广东伟艺精细研磨科技有限公司

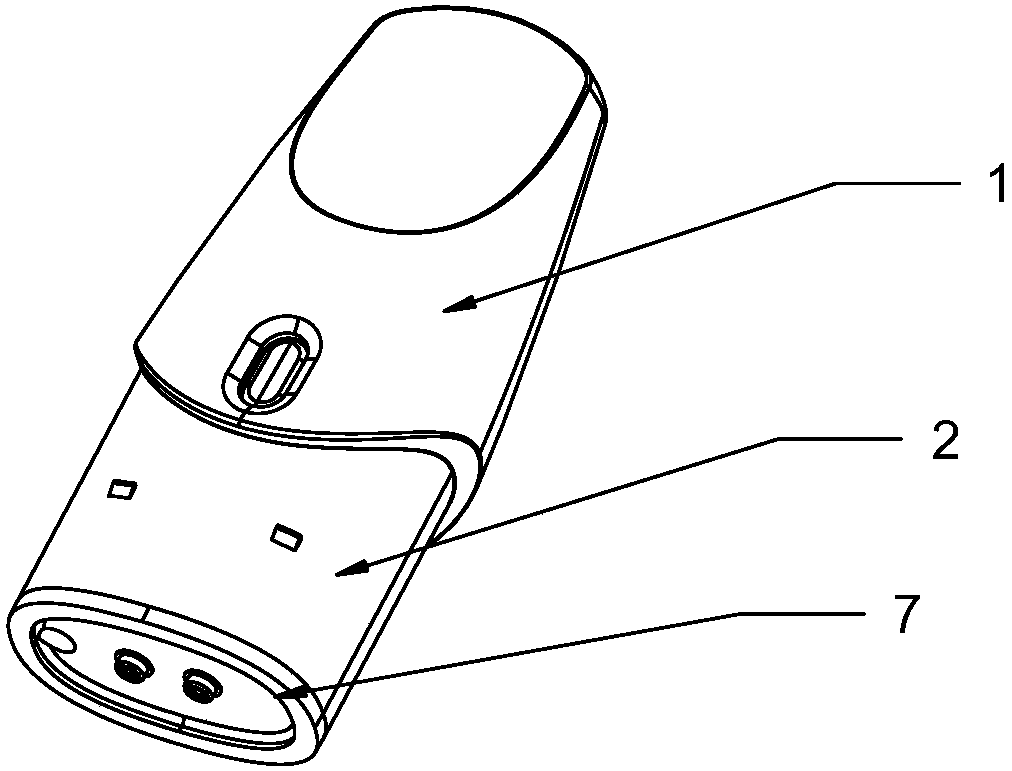

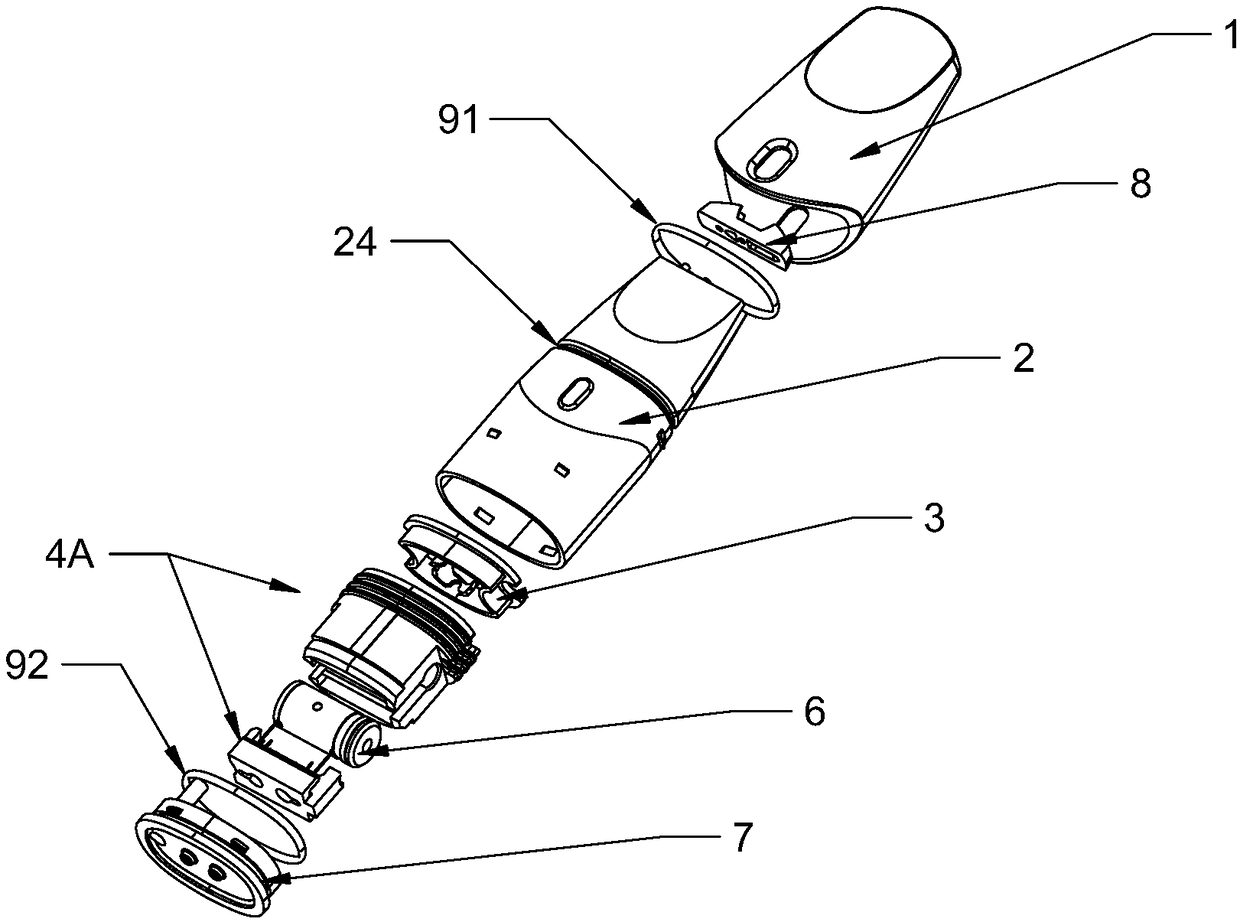

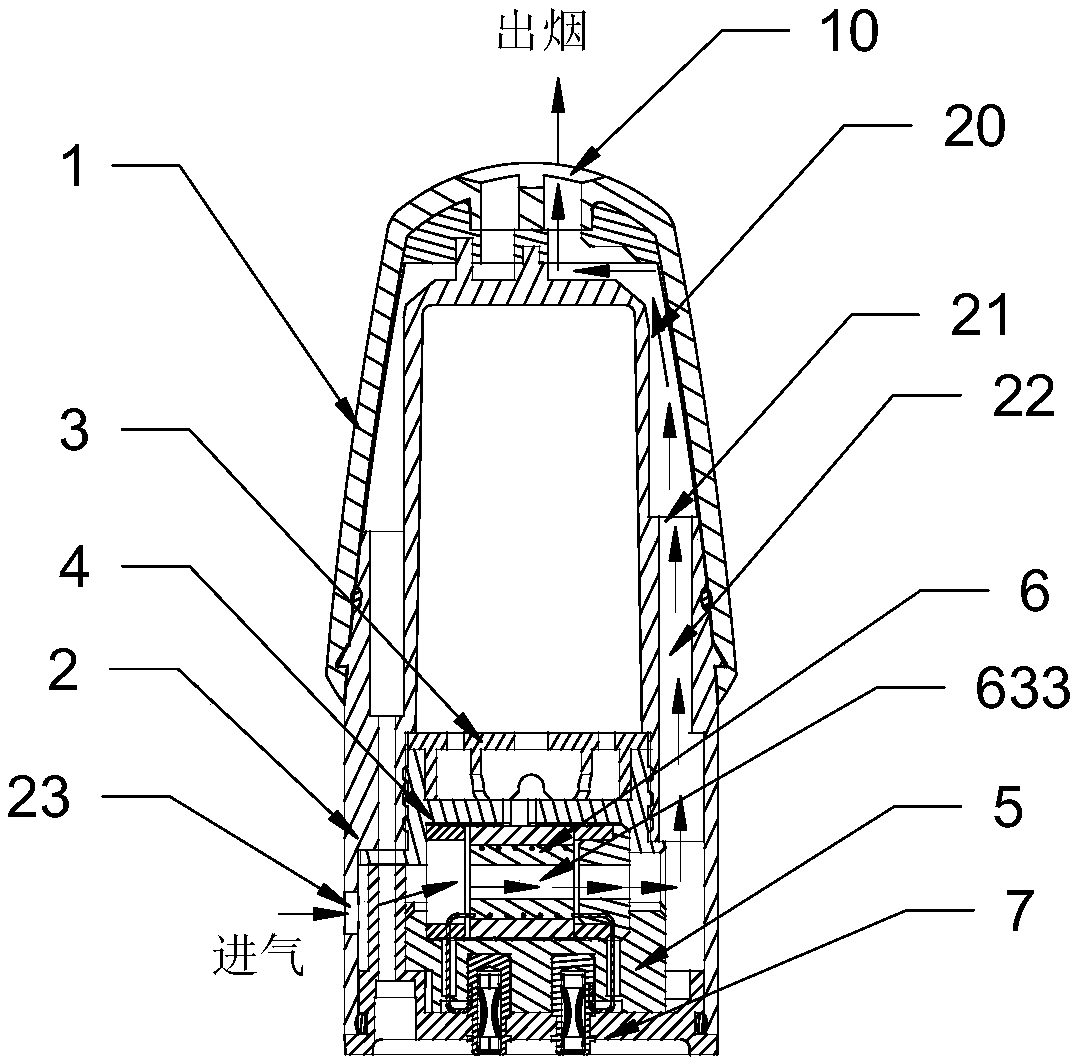

Atomizer with integrated horizontal atomizing core and electronic cigarette with same

PendingCN108576938AOvercome leaksOvercomes very little smoke generationTobacco devicesElectricityTar

The invention discloses an atomizer with an integrated horizontal atomizing core, comprising a mouthpiece, a liquid storage shell, an upper atomizing seat, a lower atomizing seat, the integrated horizontal atomizing core and a bottom cover; the integrated horizontal atomizing core includes an atomizing tube, a tubular liquid storage, a tubular electric heating core, an isolating ring and an electrode cap; the tubular liquid storage and atomizing tube herein can insulate heat and prevent radiation, and burn of the atomizing seats due to high heat when an electric eating wire operates directly in the atomizing seats is avoided; the tubular liquid storage and the tubular electric heating core can fully absorb electronic cigarette tar, direct erosion by the electric heating wire due to insufficiency of a conductive liquid is avoided, and the failures are overcome that, for instance, the atomizer easily leaks liquid during operating at high temperature, little smoke is produced and burnt smell occurs.

Owner:HUIZHOU HAPPY VAPING TECH LTD

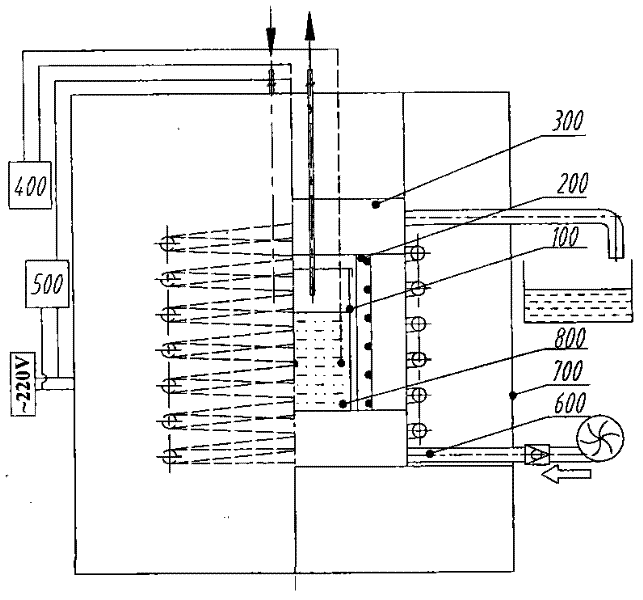

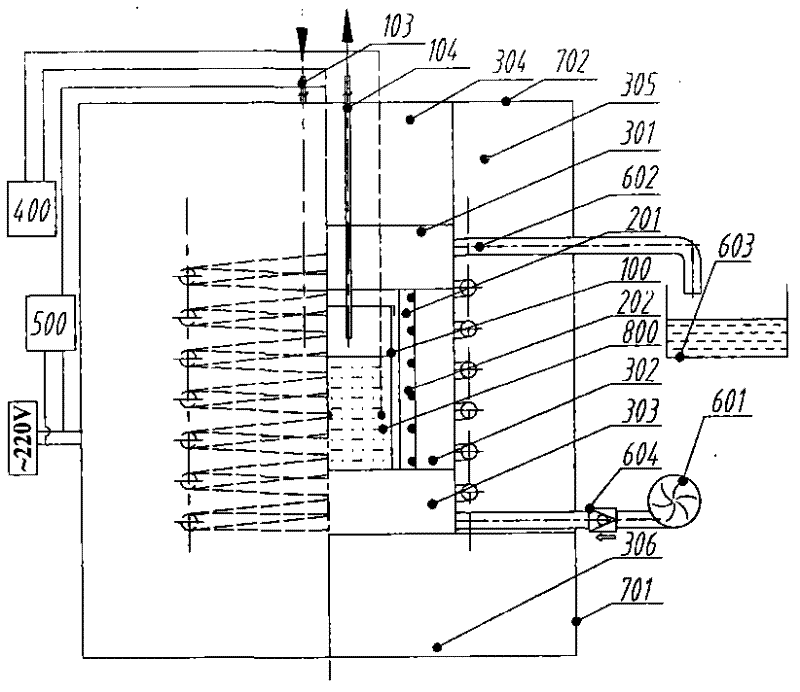

Automatic control device of material cold and hot circulation performance and operating method thereof

InactiveCN102495095AReduce labor intensityRealize the goal of intelligent controlInvestigating phase/state changeAutomatic controlThermal insulation

The invention discloses an automatic control device of material cold and hot circulation performance. The device includes a sample chamber in a resistance wire heating cylindrical heating cavity, wherein a spiral cooling water pipe is wound outside the heating cavity; the whole heating cavity is arranged in a thermal insulation device; a high-low limit PID intelligent temperature controller and a relay module control the heating temperature and the on / off of a cooling system; a thermocouple and a data acquisition instrument are adopted to measure temperature and record data; and the device comprises simple structure, efficient experiment and can reduces the labour intensity of experimenter.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

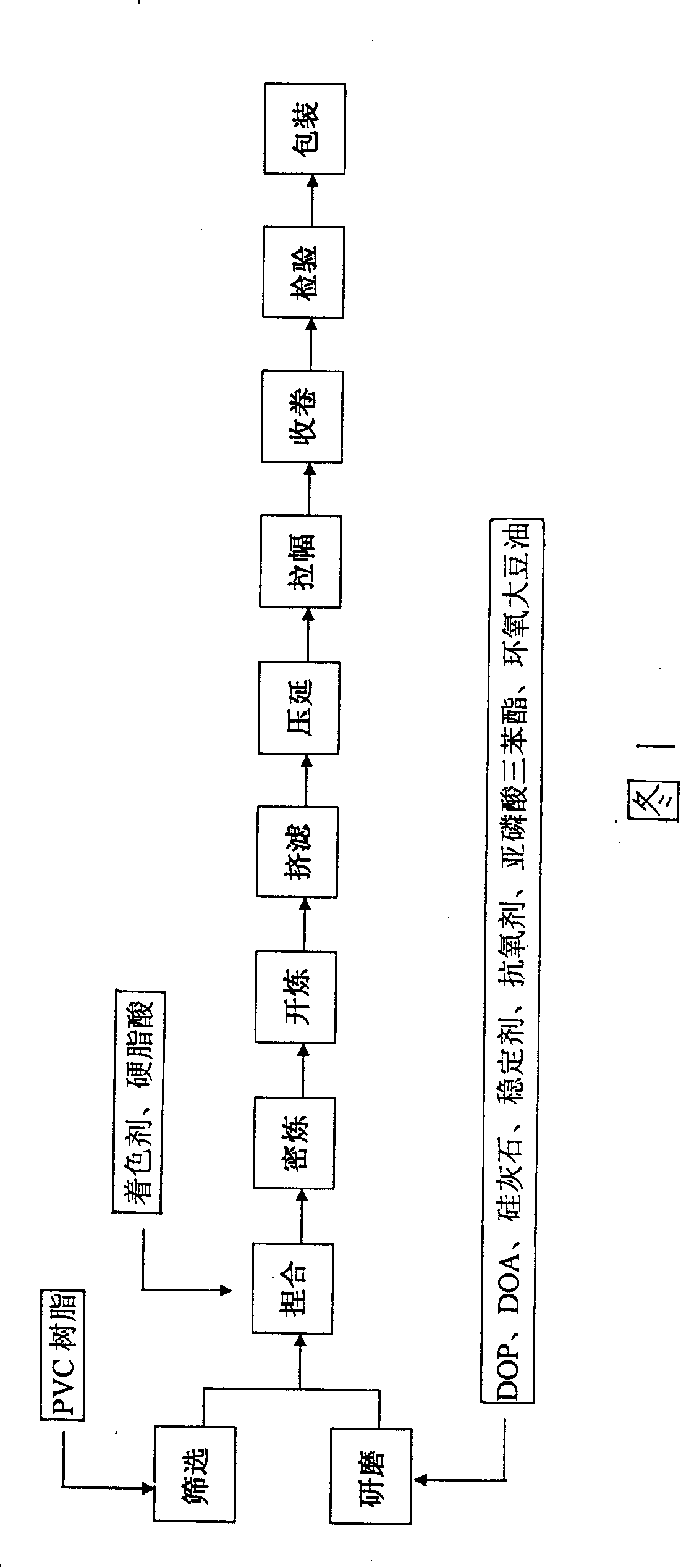

Polyvinyl chloride membrane for ginseng

InactiveCN101235154AImprove the growing environmentIncrease contentPlant protective coveringsAging resistancePolyvinyl chloride

The invention relates to an agriculture polyvinyl chloride gen-seng special membrane, which is suitable for gen-seng growth habit, can reduce the transmission of direct light and can improve diffuse reflection illumination quantity. The invention uses polyvinyl chloride resin as substrate, added with elasticizer, stabilizer, filling agent, lubricant and paint to be plasticized, calendered and extended. The invention overcomes the defects of prior art, such as the invention has incident light adjustment and the application for reducing direct light (transmission is 50-80%), adds diffuse reflection illumination function (haze is 35-50%), and realizes better ageing resistance and long service life.

Owner:白山市喜丰塑业有限公司

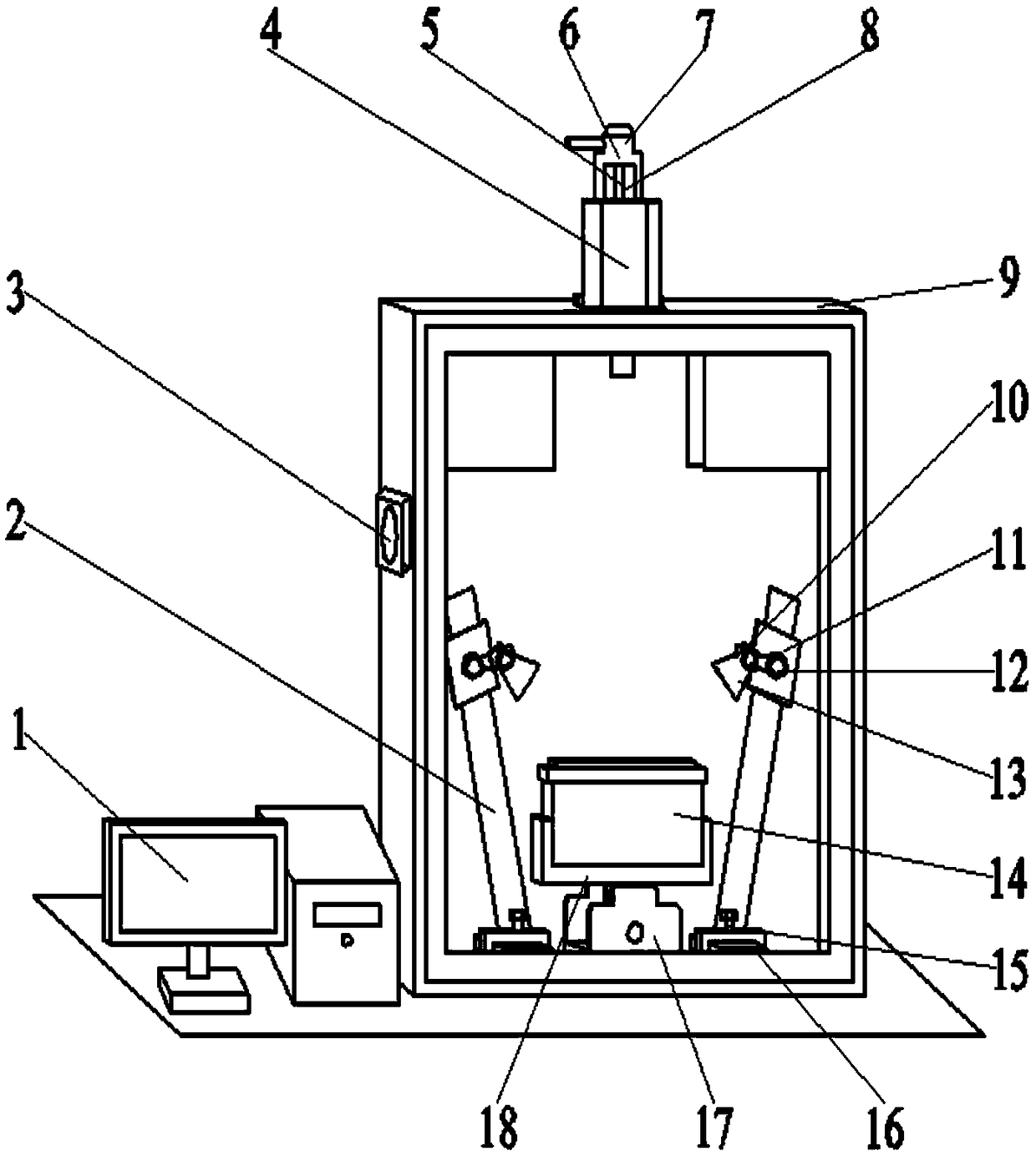

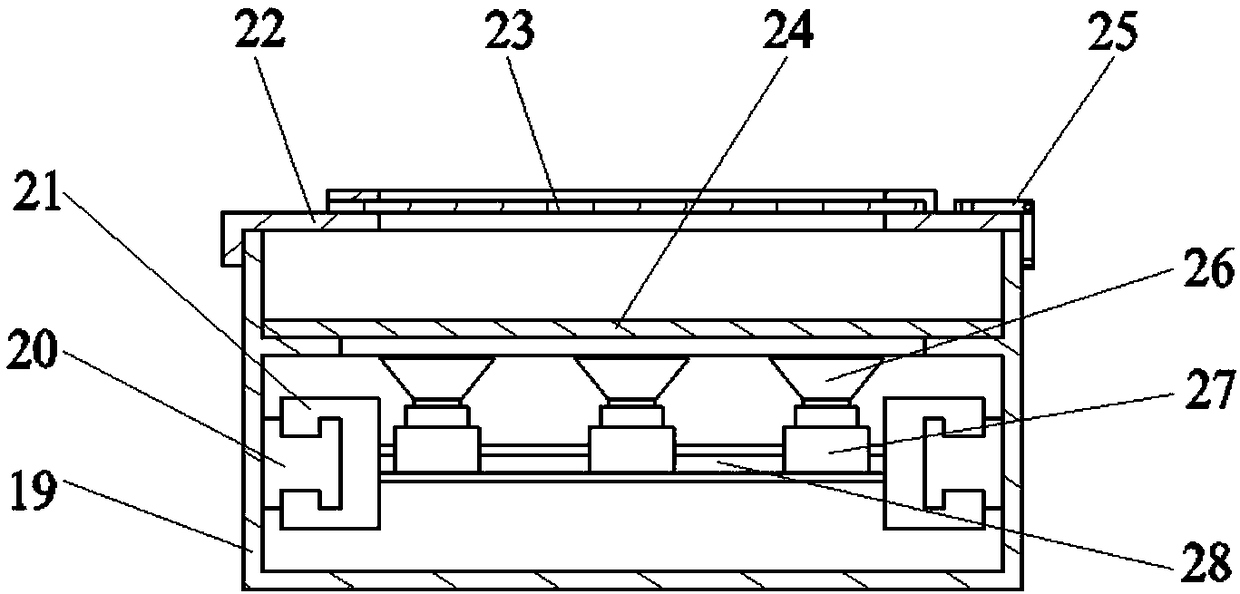

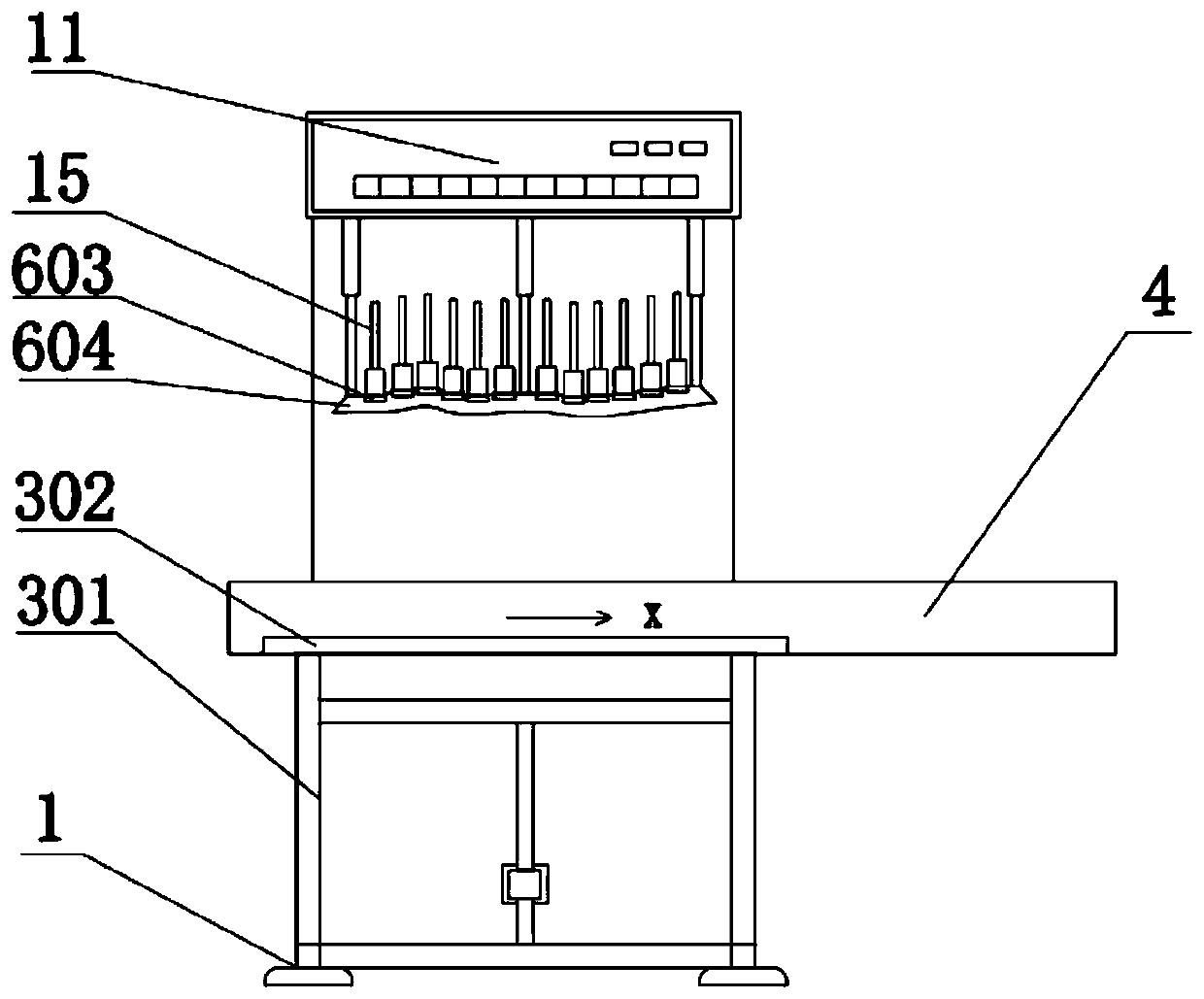

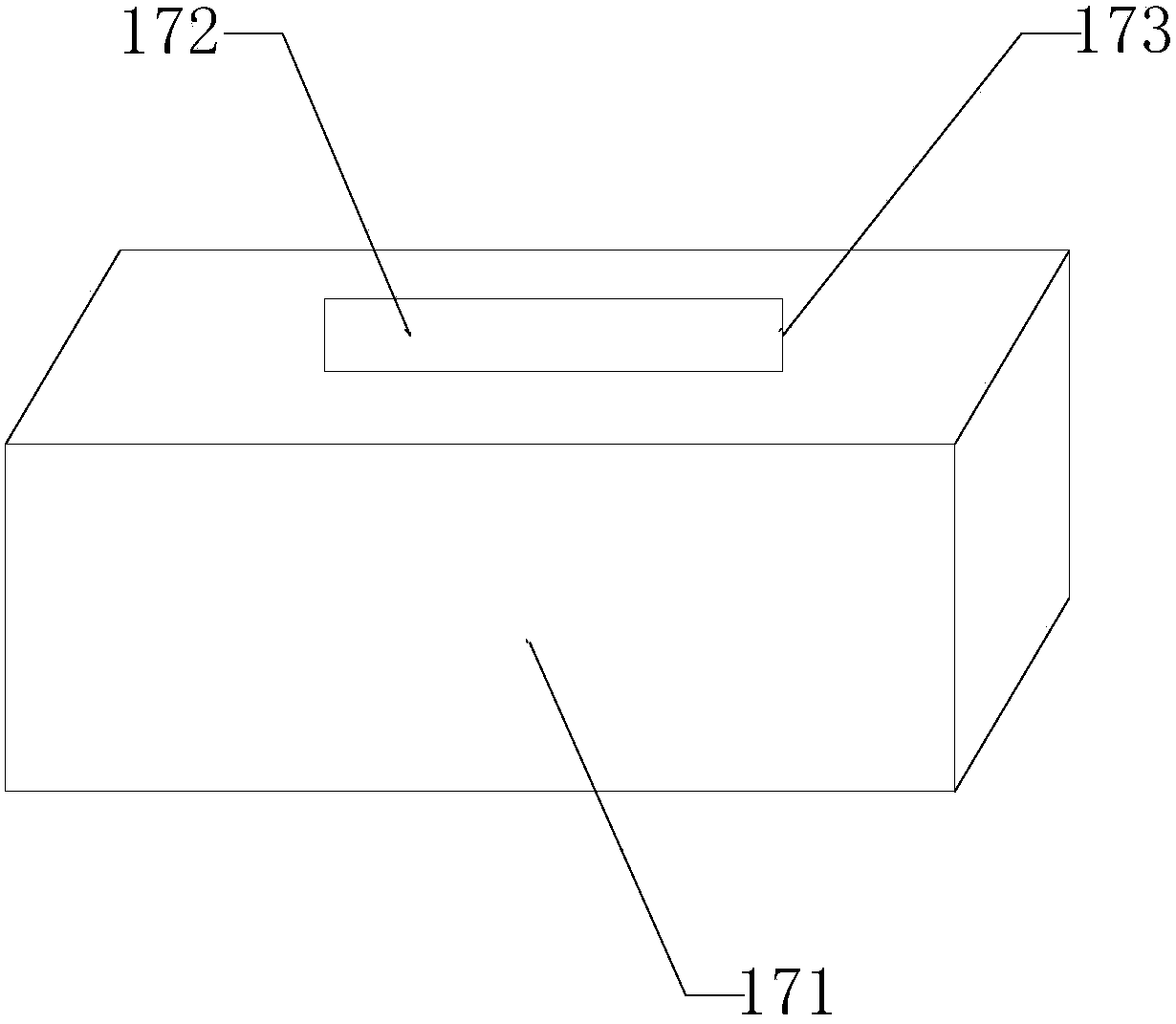

Hyperspectral imaging system and method integrating reflection and transmission

ActiveCN109060670AQuick collectionRealize acquisitionScattering properties measurementsColor/spectral properties measurementsNon destructiveNondestructive testing

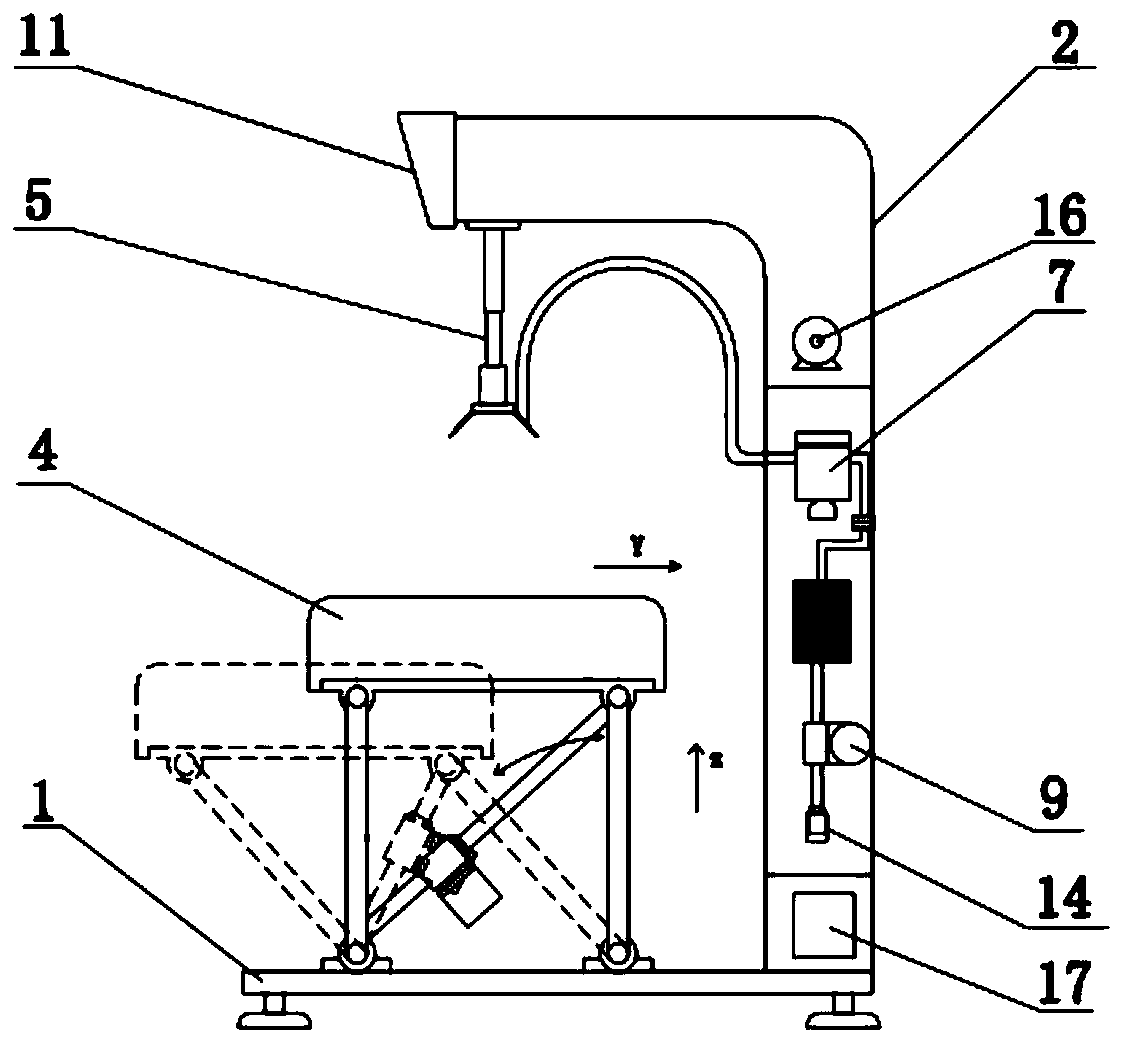

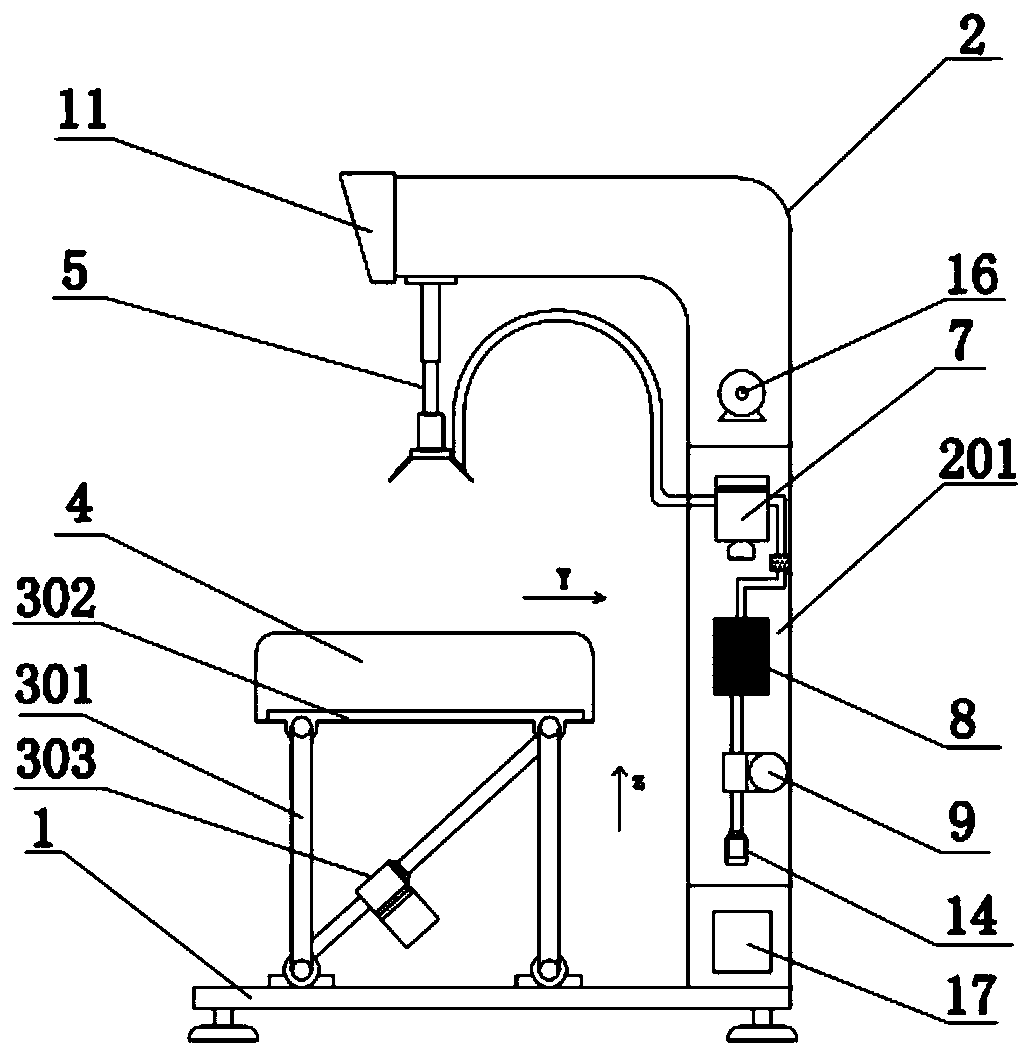

The invention belongs to the technical field of non-destructive testing of agricultural product quality, and specifically discloses a hyperspectral imaging system and method integrating reflection andtransmission. The system comprises a box body, an imaging device arranged at the top of the box body and a transmission device arranged in the box body, the imaging device is used for obtaining an emission hyperspectral image and a transmission hyperspectral image of a sample to be detected, and is connected with a height adjustment device; and the transmission device is located below the imagingdevice, and comprises a displacement platform and a transmission unit mounted on the displacement platform, the transmission unit realizes position adjustment under the drive of the displacement platform for generating a transmission light source, and reflection light source components for generating reflection light sources are further arranged on the two sides of the transmission unit. The hyperspectral imaging system provided by the invention can not only collect the reflection hyperspectral images of various agricultural products, but also can collect the transmission hyperspectral imagesof different kinds of agricultural products, and has the advantages of high detection precision and convenient maintenance, and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

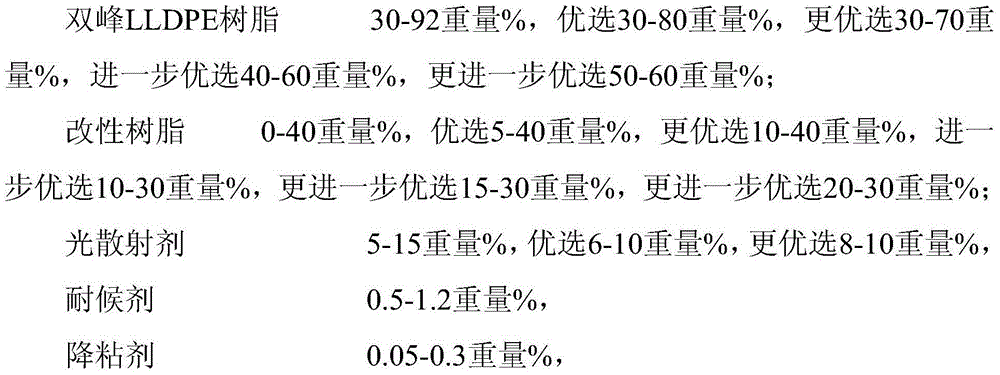

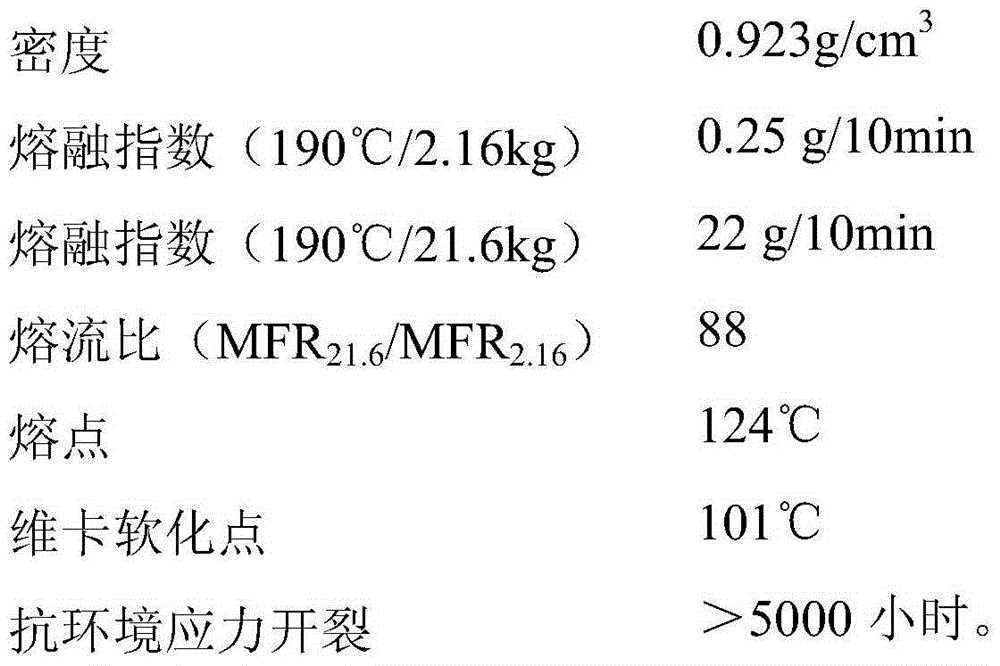

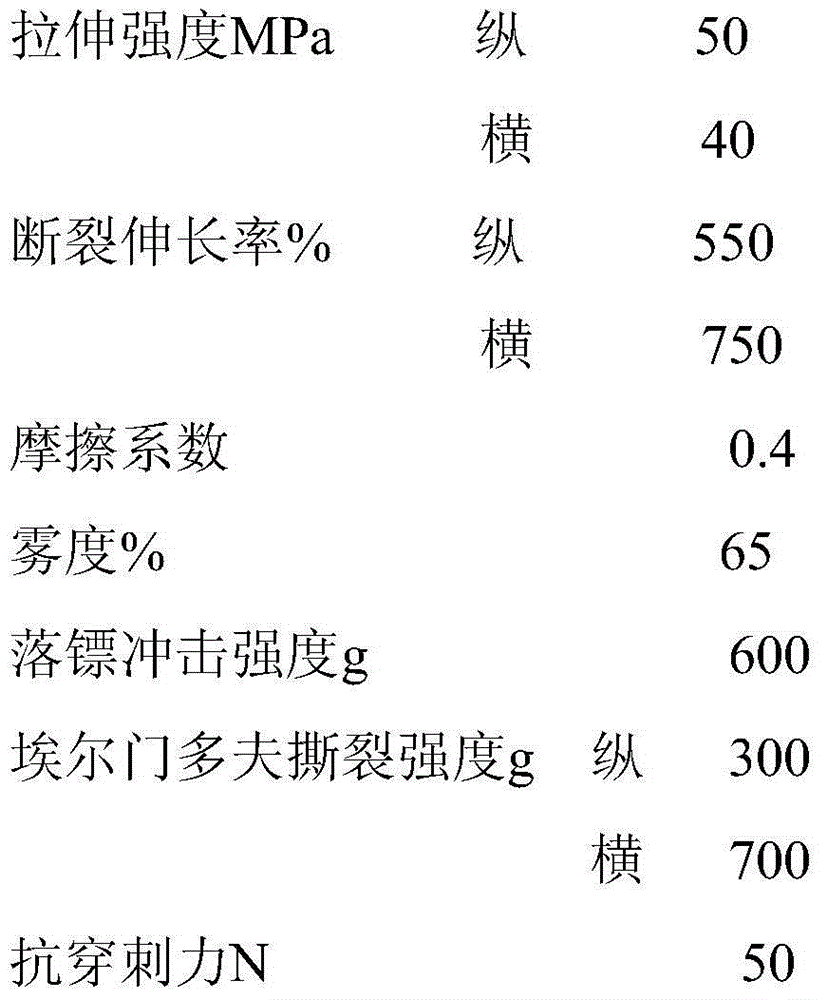

Light scattering type agricultural film as well as manufacturing method and application thereof

ActiveCN104441869AImprove light efficiencyUniform light receivingSynthetic resin layered productsPlant protective coveringsPhysicsAgricultural crops

The application relates to a light scattering type agricultural film as well as a manufacturing method and application thereof, and belongs to the technical field of agriculture. The agricultural film provided by the application can diffuse a spectrum from a point light source and a line light source to an area light source, so that the luminous efficacy is greatly improved, the uniform light guiding on agricultural crops is implemented, and the defects that the end part leaf surface is burned by high temperature and the possibility of insufficient illumination of low end leaf surface is reduced are prevented. The agricultural film provided by the application has excellent mechanical property, weather resistance, anti-drop property, fog dissipation property, heat preservation property and the like.

Owner:华盾雪花塑料(固安)有限责任公司

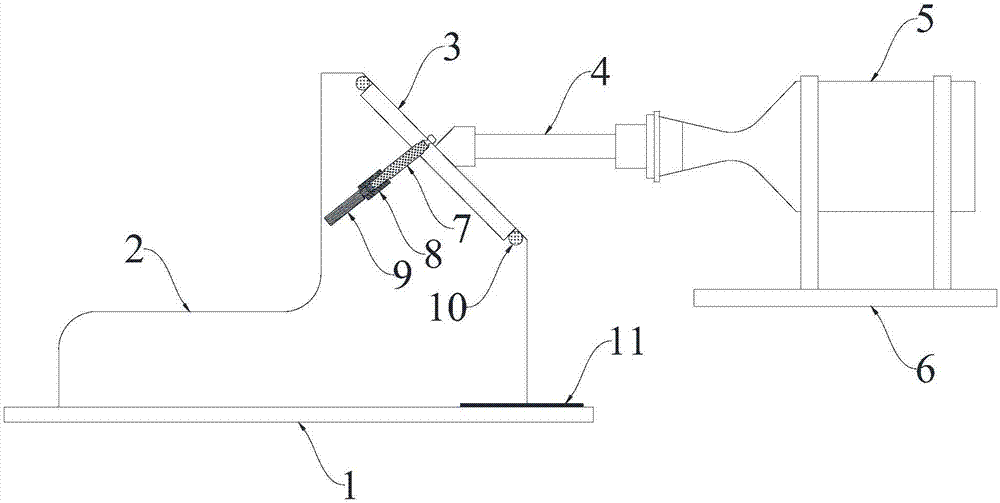

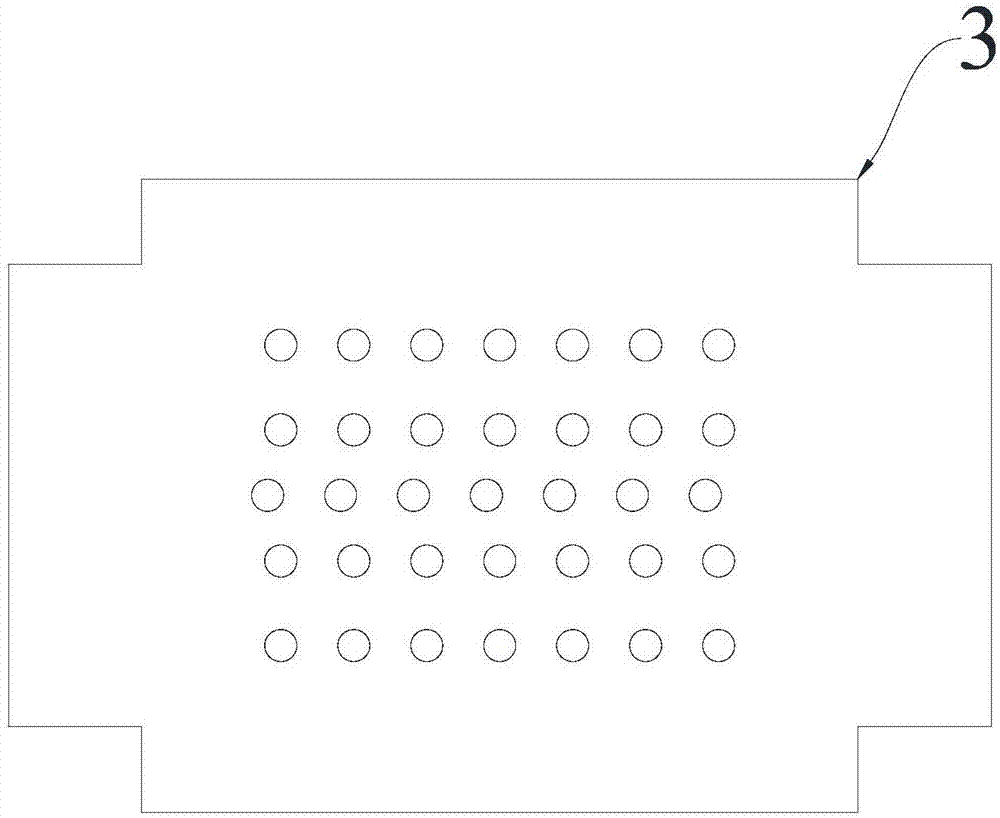

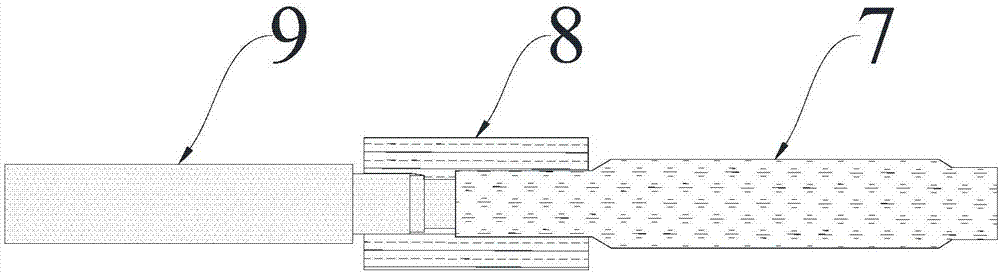

Rocket launching combustion gas flow impact simulation test device

The invention discloses a rocket launching combustion gas flow impact simulation test device, which comprises a test bed plate, a test rack, a test plate, a tapered head guide rod, an engine and a fixed support, wherein the upper surface of the test bed plate is provided with a bar-shaped sliding groove; the bottom end of the test rack is arranged in the sliding groove; the test bed plate and the test rack are fixedly connected through a bolt; the test plate is fixed on the test rack; the tapered head guide rod is provided with a tapered head front end and a flat head tail end, the tapered head front end abuts against the outer side surface of the test plate, and the flat head tail end is connected with a nozzle of the engine; the inner side surface of the test plate is fixedly connected with a sensor; and the engine is fixed on the fixed support. The rocket launching combustion gas flow impact simulation test device has the outstanding advantages of short production cycle, short test time, simple structure, low cost and the like.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

High-yield culture method of true konjac seeds

ActiveCN108849344AAvoid Slow BreedingAvoid heavy diseaseFertilising methodsRoot crop cultivationZoologyCold storage

The invention relates to a high-yield culture method of true konjac seeds. The method includes the following steps of 1, selecting true konjac seeds resistant to low temperature and chilling damage; 2, classifying the true konjac seeds which are harvested in July and August and are resistant to the low temperature and the chilling damage according to the weight of one hundred of true konjac seeds,and then drying and storing the true konjac seeds in a constant-temperature freezer in a hoarding pattern or a sand storage pattern; 3, conducting centralized sprouting acceleration in an illumination incubator or a sprouting acceleration house in the period from February to April of the next year, and then selecting out the true konjac seeds with sprouts which are 0.5-2 cm long 23-40 days aftercentralized sprouting acceleration; 4, coating or directly sowing the true konjac seeds after centralized sprouting acceleration, and then conducting covering or shading treatment; 5, after covering treatment, spraying foliage fertilizer from a konjac head replacement period to a konjac corm expansion period. The method has the advantages that the emergence rate is increased, the field morbidity is decreased, the resistance of the true konjac seeds is improved, and the yield of the cultured true konjac seeds is increased.

Owner:ACAD OF AGRI SCI ENSHI TUJIA MIAOAUTONOMOUS PREFECTURE +2

Preparation method of transparent tin antimony oxide electric heating film

InactiveCN102925880AReduce pollutionReduce close contactSolid/suspension decomposition chemical coatingElectric arc furnaceSolvent

The invention provides a preparation method of a transparent tin antimony oxide electric heating film, which belongs to the field of thin-film materials. The preparation method comprises the steps that tin and antimony raw materials and an additive are dissolved in a solvent to form a solution; a pH value of a system is adjusted to be neutral or slightly alkaline; the solution is put in an ultrasonic atomizer; a nozzle of the ultrasonic atomizer is positioned at the top of an electric box furnace; glass tubes or ceramic tubes to be coated are placed on a rack orderly and vertically; the rack on which the glass tubes or the ceramic tubes are placed is placed in the electric box furnace; a door of the electric box furnace is closed; the electric box furnace is switched on; the ultrasonic atomizer is switched on; and drops of the solution containing tin and antimony are deposited on the external surfaces of the glass tubes or the ceramic tubes uniformly to form transparent tin antimony oxide conductive films. The glass tubes or the ceramic tubes coated with the transparent tin-antimony oxide conductive films can be used as heating elements for heating liquid, gas, solid and the like.

Owner:NINGBO CIXI ELECTRICAL APPLIANCE

Burn-proof safety grab bucket for bowls and dishes

Owner:THE SECOND FOREIGN LANGUAGE SCHOOL AFFILIATED TO SHANGHAI NORMAL UNIV

Smokeless temperature-controllable governor meridian moxibustion machine

ActiveCN110897876AEasy to get on and offEasy to get in and out of bedDevices for heating/cooling reflex pointsCombination devicesPhysical medicine and rehabilitationCombustion chamber

The invention discloses a smokeless temperature-controllable governor meridian moxibustion machine, which belongs to the technical field of moxibustion physiotherapy devices. The moxibustion device comprises an L-shaped rack body and an electric moxibustion bed, a bed surface is slidably arranged on the electric moxibustion bed; the other end of the L-shaped rack body is fixedly connected with a lifting rod; the lifting rod is fixedly connected with a moxa stick combustion control device; the moxa stick combustion control device is in a long strip shape formed by N moxibustion devices in parallel, wherein N is larger than or equal to 1, an axial flow fan for supplying oxygen is arranged on the side wall of the moxibustion device, the moxibustion device comprises a combustion chamber assembly, a protective cover and a sealing cover, a negative pressure smoke suction port is formed in the sealing cover and connected with a tobacco tar conversion device, the tobacco tar conversion deviceis connected with a filtering device, and the filtering device is connected with a vacuum pump. The electric moxibustion bed capable of achieving free parallel movement in the X-axis direction, the Y-axis direction and the Z-axis direction is arranged, and a person to-be-moxibustion can get in and out of the bed and align to acupuncture points conveniently; a temperature sensor is used for readinghuman skin temperature data so as to control the speed of active oxygen supply of the axial flow fan, and automatic control over the temperature is achieved.

Owner:上海开司绫科技有限公司

Extrusion forming device for production of plastic granules

InactiveCN111469370AAvoid cakingHas the function of cushioning and shock absorptionNon-rotating vibration suppressionElectric machineryDrive motor

The invention relates to the technical field of production of plastic granules, and discloses an extrusion forming device for production of the plastic granules. The extrusion forming device comprisesan extrusion cylinder and a cooling cylinder, the cooling cylinder is fixed to the right side of the extrusion cylinder, and an extrusion structure and a cooling structure are arranged in the extrusion cylinder and the cooling cylinder. The extrusion structure comprises a driving motor, a rotary rod, an auger, electric heating pipes, a scraping slot, an extension rod and a scraper, wherein the rotary rod is transversely and rotationally installed in the extrusion cylinder through a first bearing, the auger fixedly surrounds the outer ring of the rotary rod through welding, the electric heating pipes are fixedly embedded into the inner wall and the outer wall of the extrusion cylinder, and the electric heating pipes is arranged around the inside of the outer wall of the extrusion cylinder.By fixedly welding three mesh plates to the lower side in the cooling cylinder, and arranging fans above the cooling cylinder to blow air into the cooling cylinder, agglomerate plastic granules can be broken up under the action of through holes of the mesh plates, the plastic granules can be cooled by the fan through blowing, and the plastic granules can be well prevented from being caked.

Owner:高邮亚普塑业有限公司

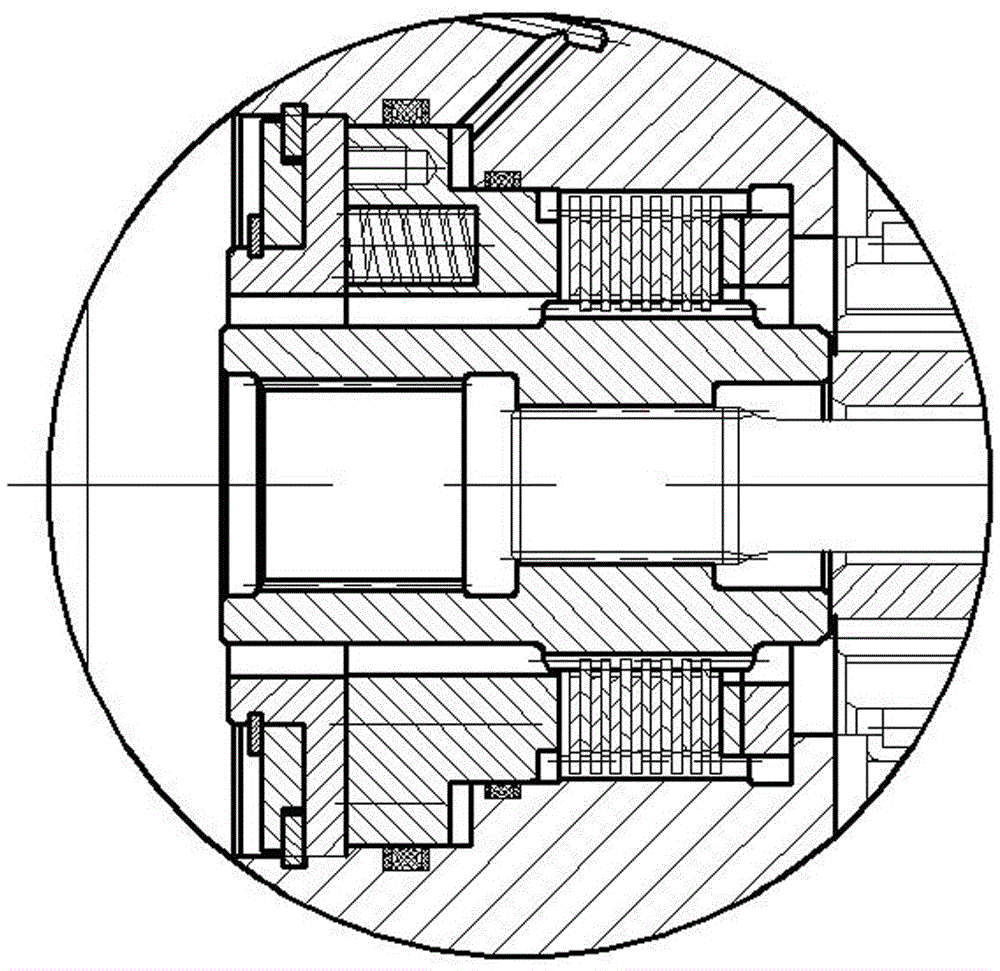

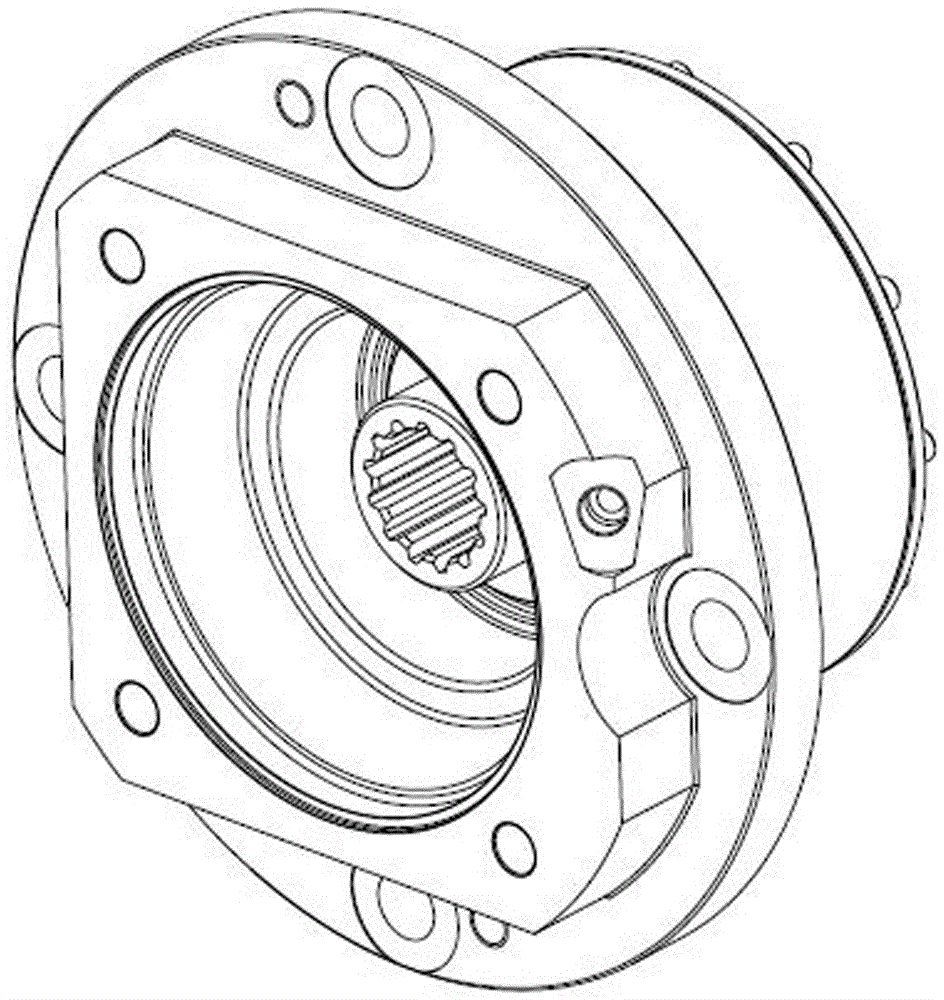

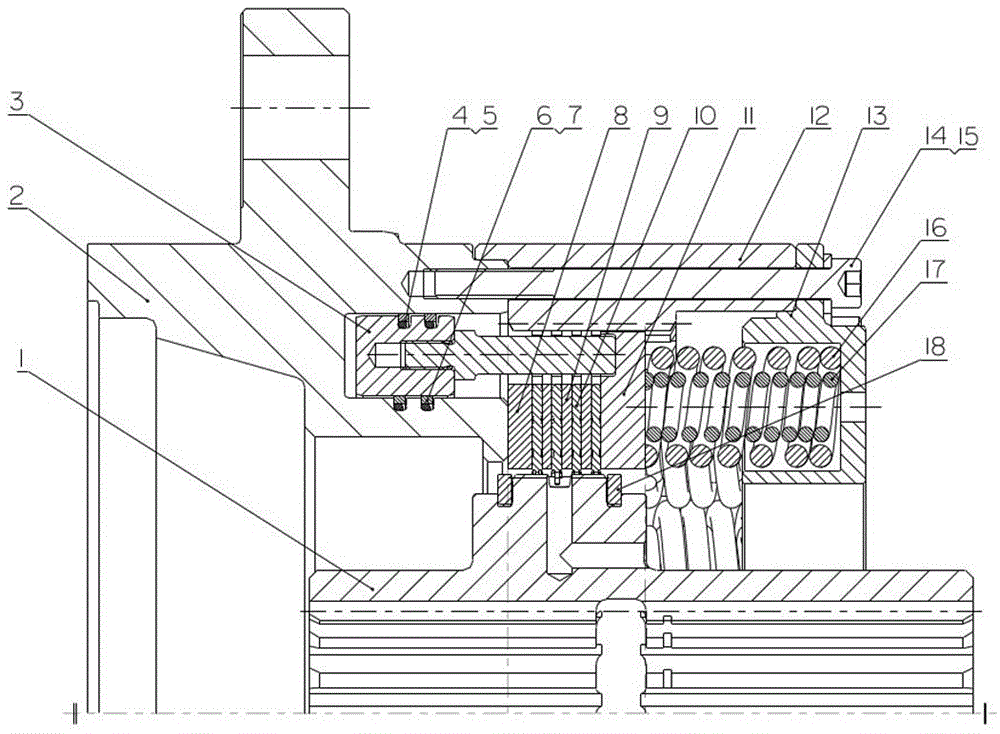

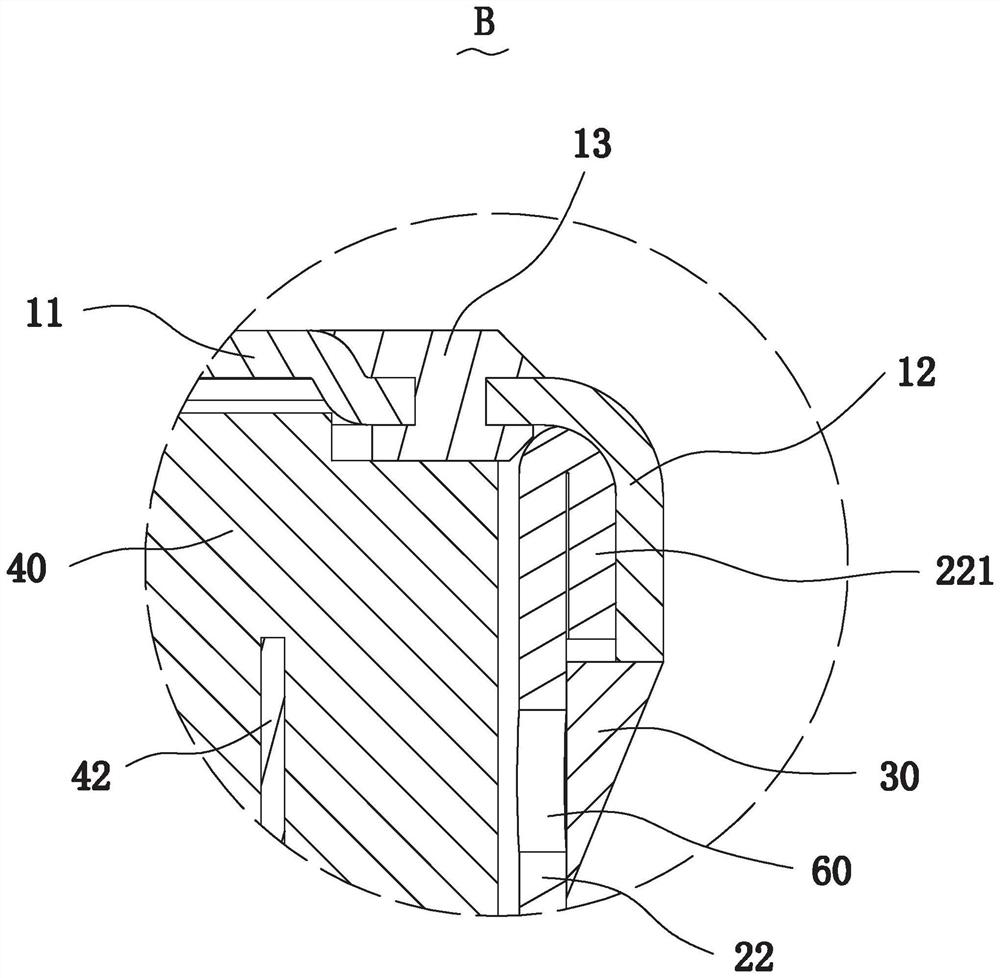

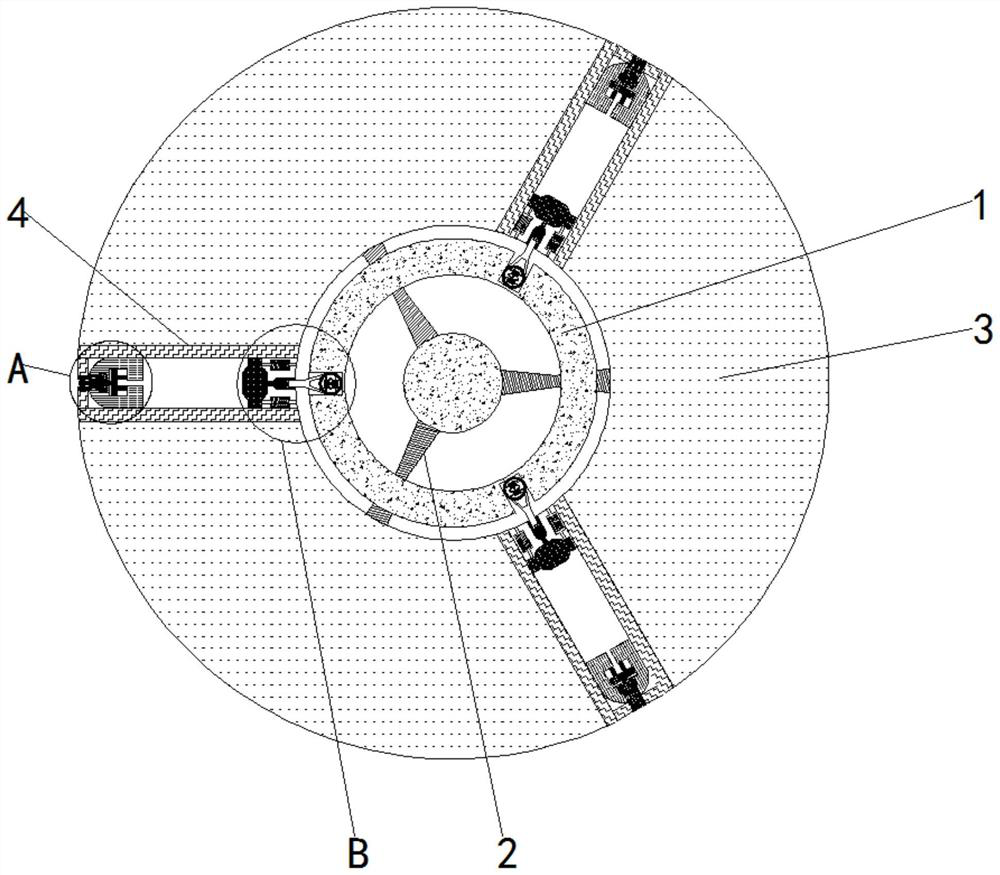

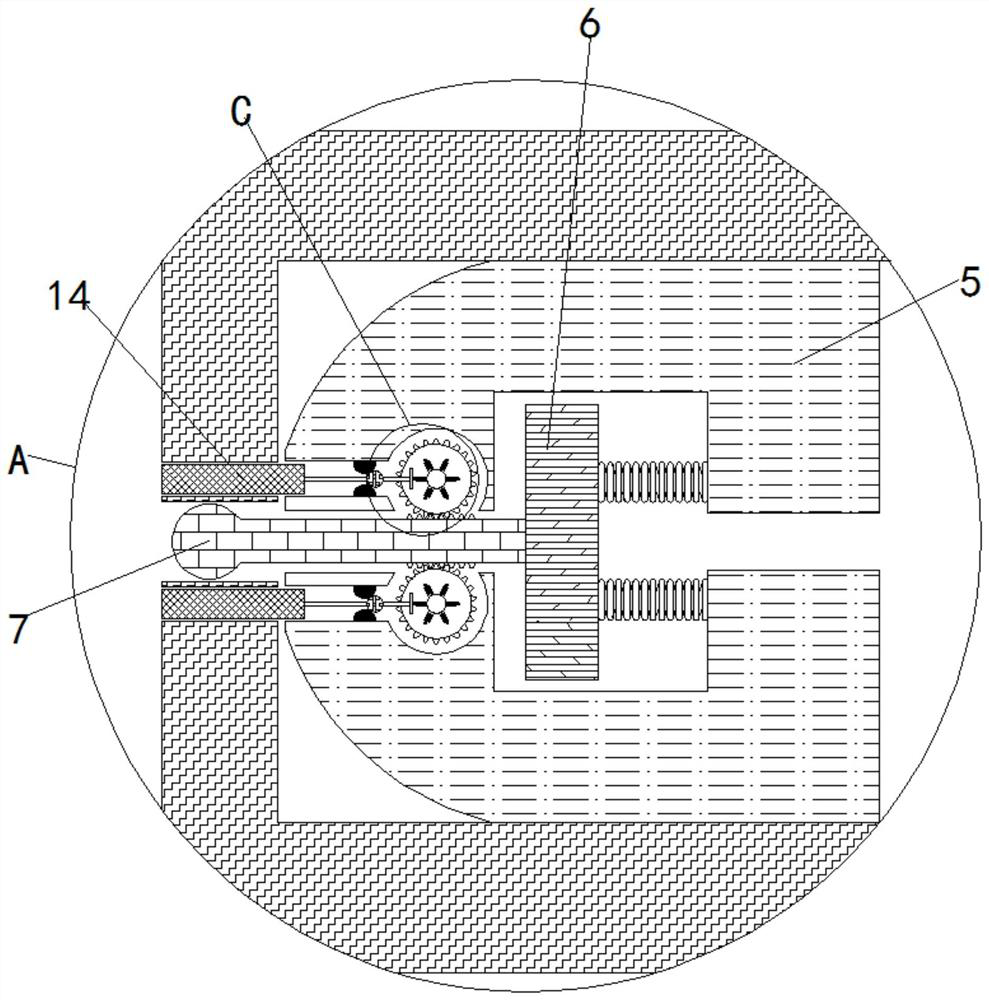

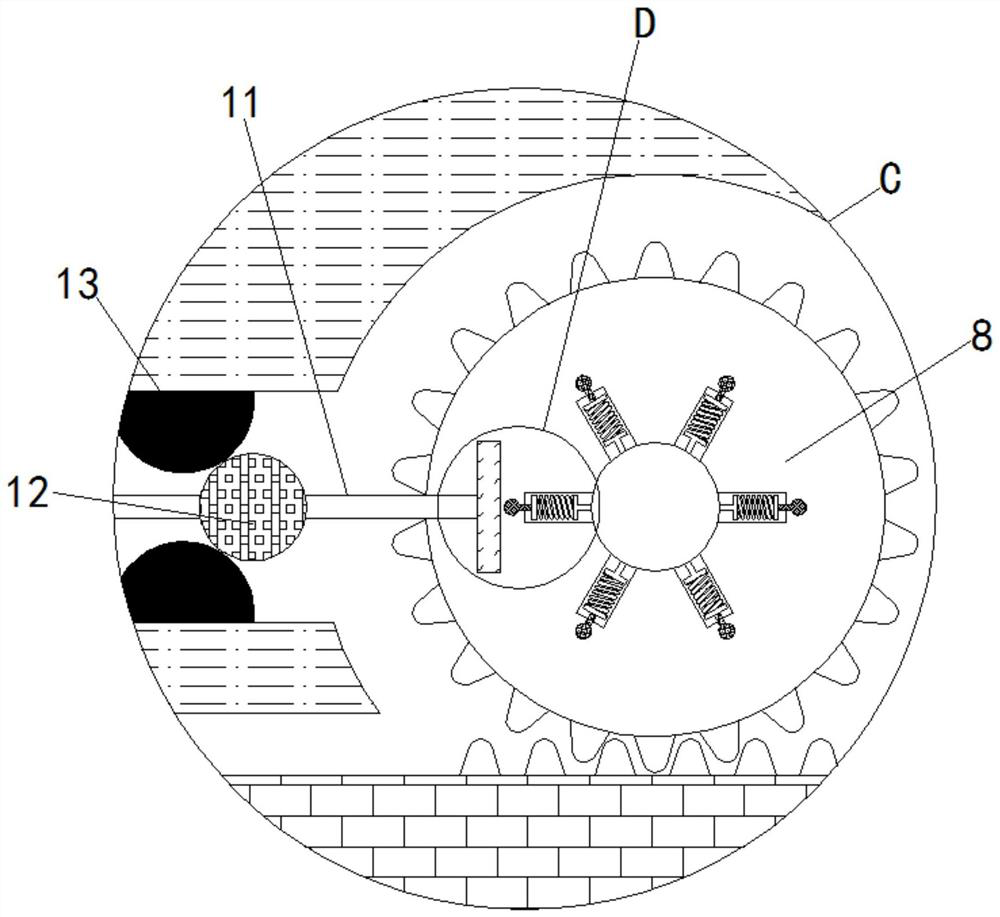

Brake for hydrostatic drive

ActiveCN106286648AImprove general performanceBig spaceBrake actuating mechanismsActuatorsEngineeringCylinder block

The invention discloses a brake for hydrostatic drive, and relates to engineering machinery field. The brake comprises cylinder body, piston group, and power take-off shaft having left-end internal spline, right-end internal spline and top-end spline connected with friction pair, wherein the stop collar is set on the both side of the top-end spline; the friction pair comprises friction plate and steel sheet, and the pressure-bearing disc is set on the both sides of the friction pair; a steel bushing is connected with one end of the cylinder body, and the gland is pressing and jointing with the end face of the steel bushing; a spring is installed in the inner side of the gland, one end of the spring is pressing and jointing with the gland, and the other end of the spring is pressing and jointing on the pressure-bearing disc; the cylinder has oil path hole and oil cavity, the piston group comprises piston and push rod, one end of the push rod is connected with the piston, and the other end of the push rod is installed in the groove of the pressure-bearing disc; the friction plate and pressure-bearing disc is connected with the steel bushing through the spline inside the steel bushing, and the steel sheet is connected with the power take-off shaft through the top-end spline. The invention can solve the problems such as complex brake processing, assembly and maintenance, easy-to-wear and high cost of the piston.

Owner:GUANGXI LIUGONG MASCH CO LTD

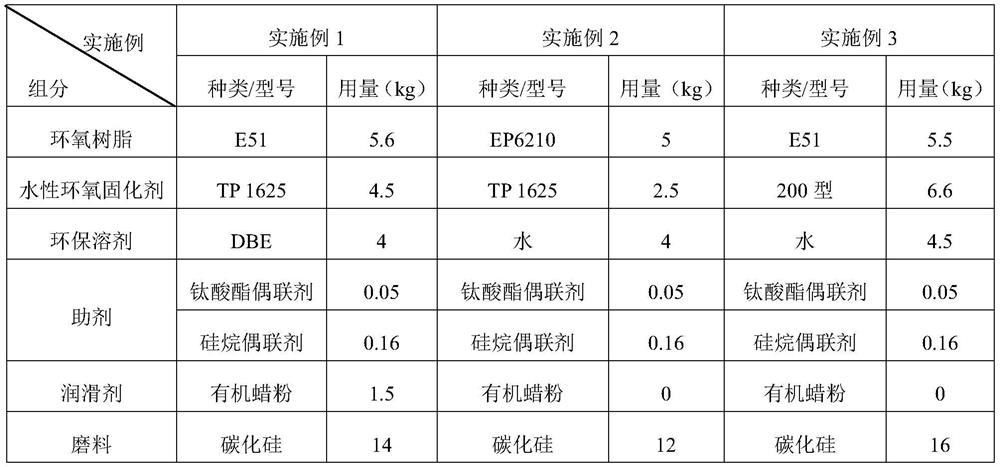

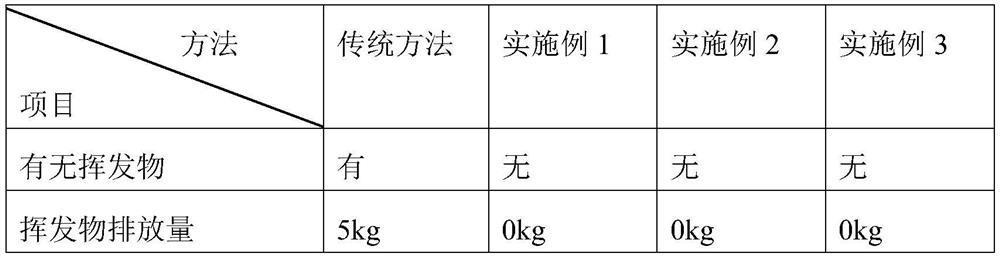

Waterborne epoxy curing agent-based nylon wheel and preparation method thereof

InactiveCN113215835AImprove emission pollutionSimple production processGrinding devicesTextiles and paperAdhesive cementPolymer science

The invention provides a waterborne epoxy curing agent-based nylon wheel and a preparation method thereof. The nylon wheel comprises a nylon fiber non-woven fabric and wear-resistant adhesive cement coating the nylon fiber non-woven fabric, and the wear-resistant adhesive cement comprises the components in parts by weight of 100 parts of epoxy resin, 50-250 parts of a waterborne epoxy curing gent, 150-300 parts of an abrasive, 40-100 parts of an environment-friendly solvent, 2-10 parts of an auxiliary agent and 0-50 parts of a lubricant. According to the nylon wheel, the problem of organic volatile matter emission pollution existing in the process of manufacturing a polishing wheel through an epoxy system is effectively solved, the production process can be improved in the green and environment-friendly direction by using the environment-friendly solvent, and the production process is a green and environment-friendly non-woven fabric polishing wheel production process.

Owner:广东伟艺抛磨材料有限公司

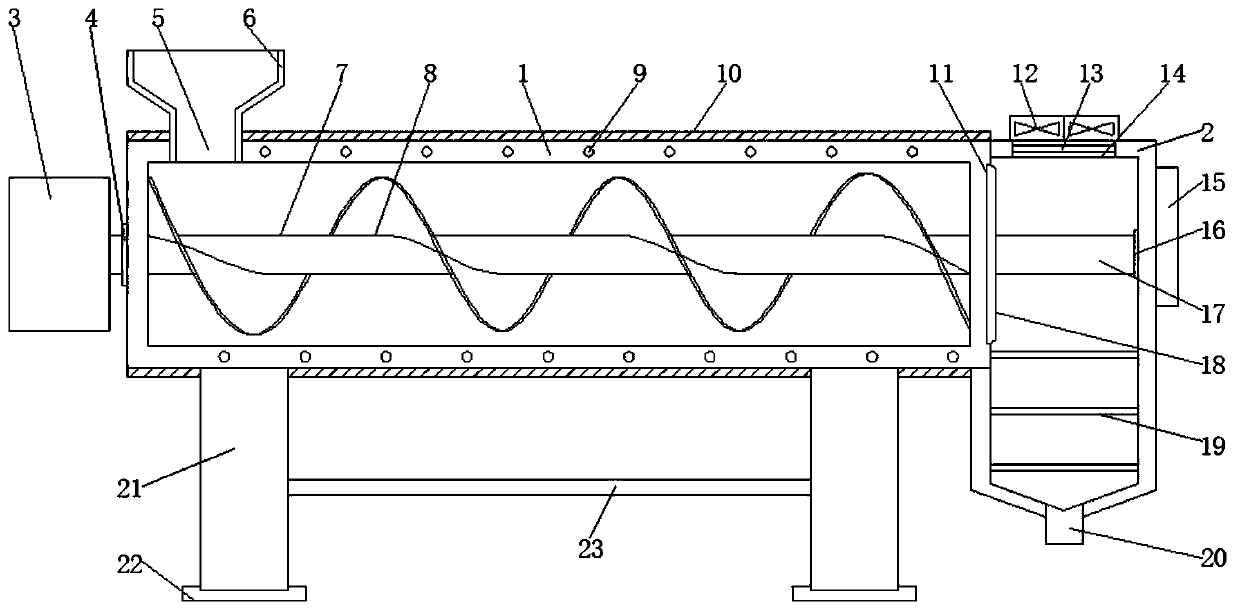

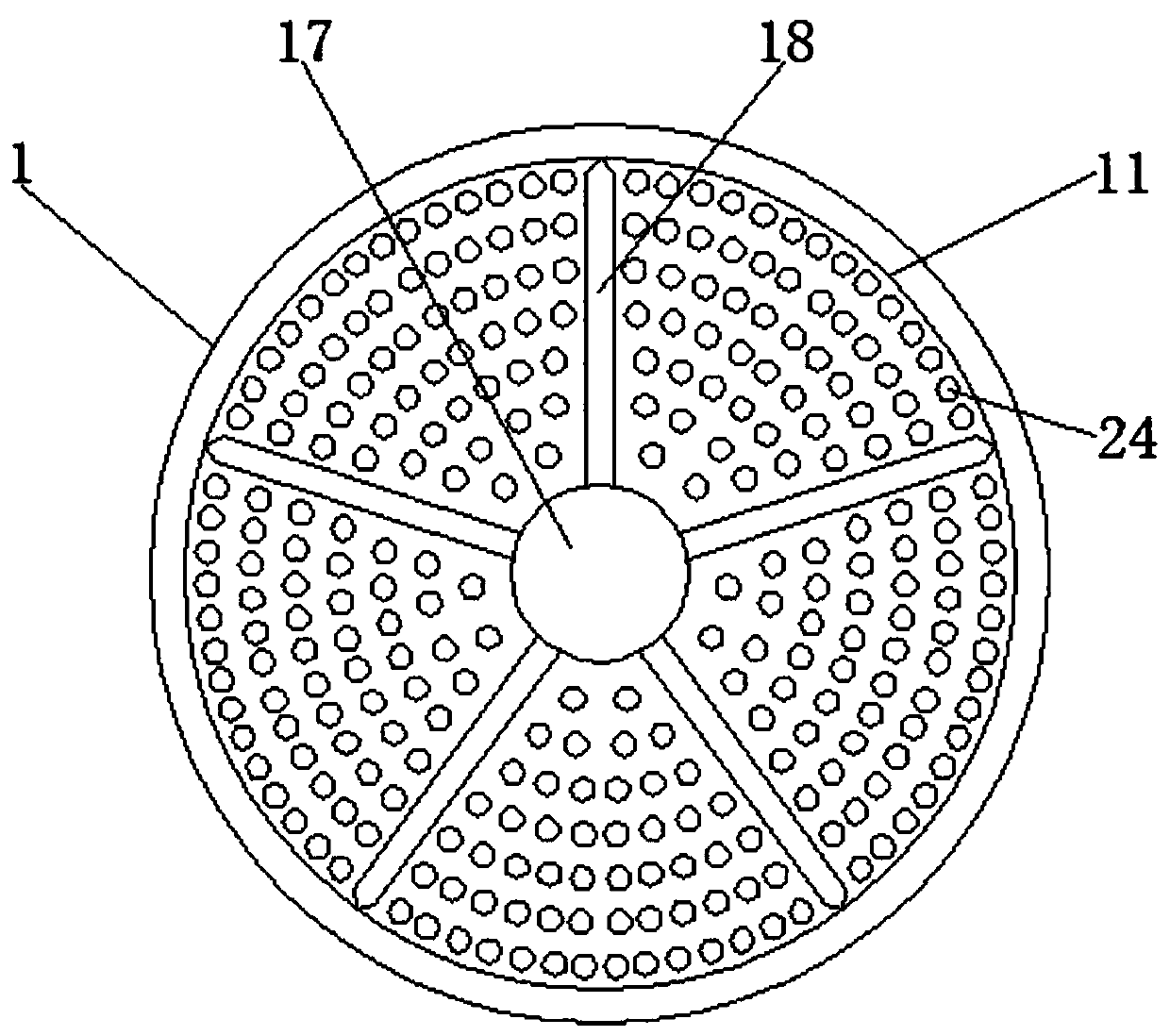

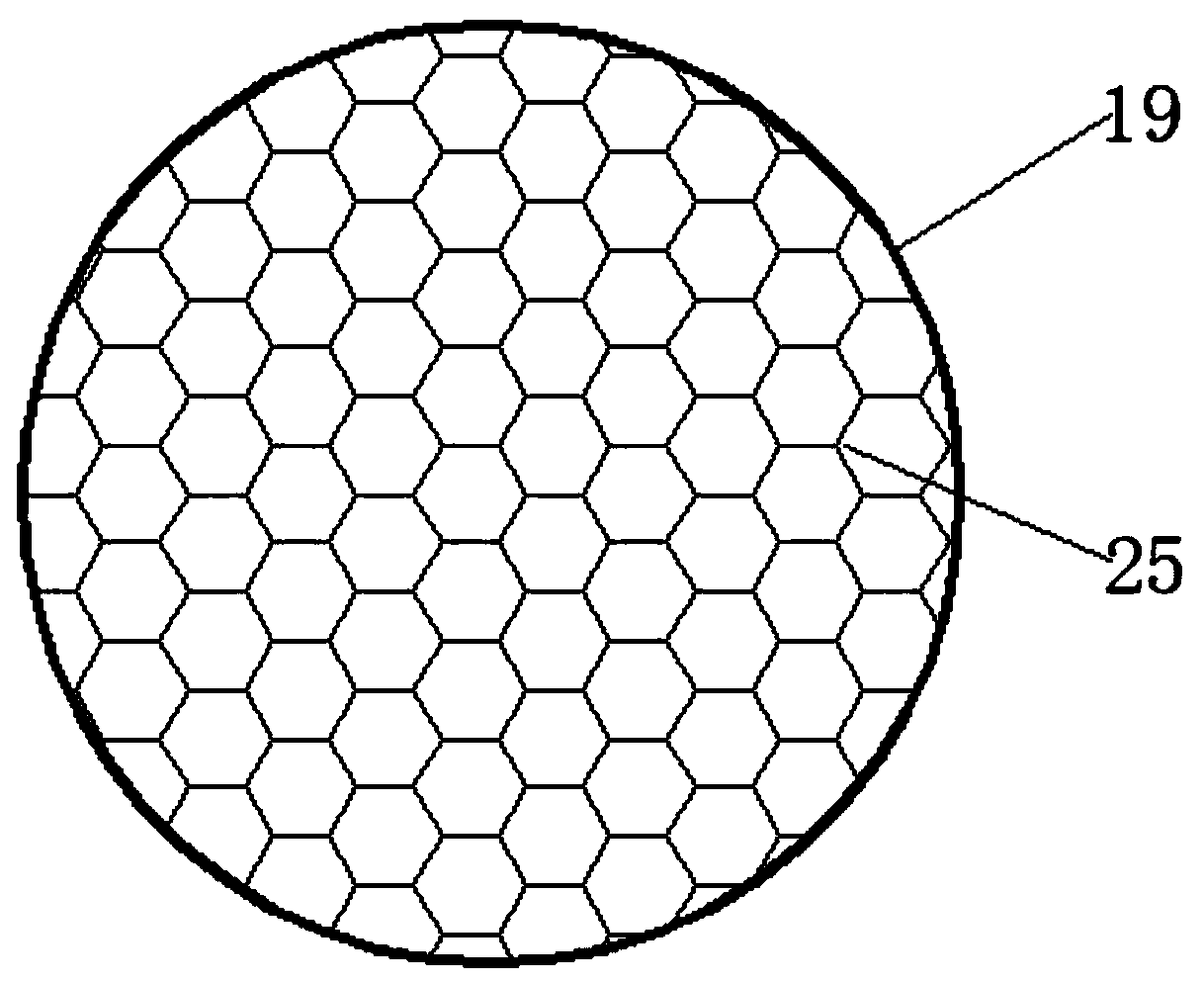

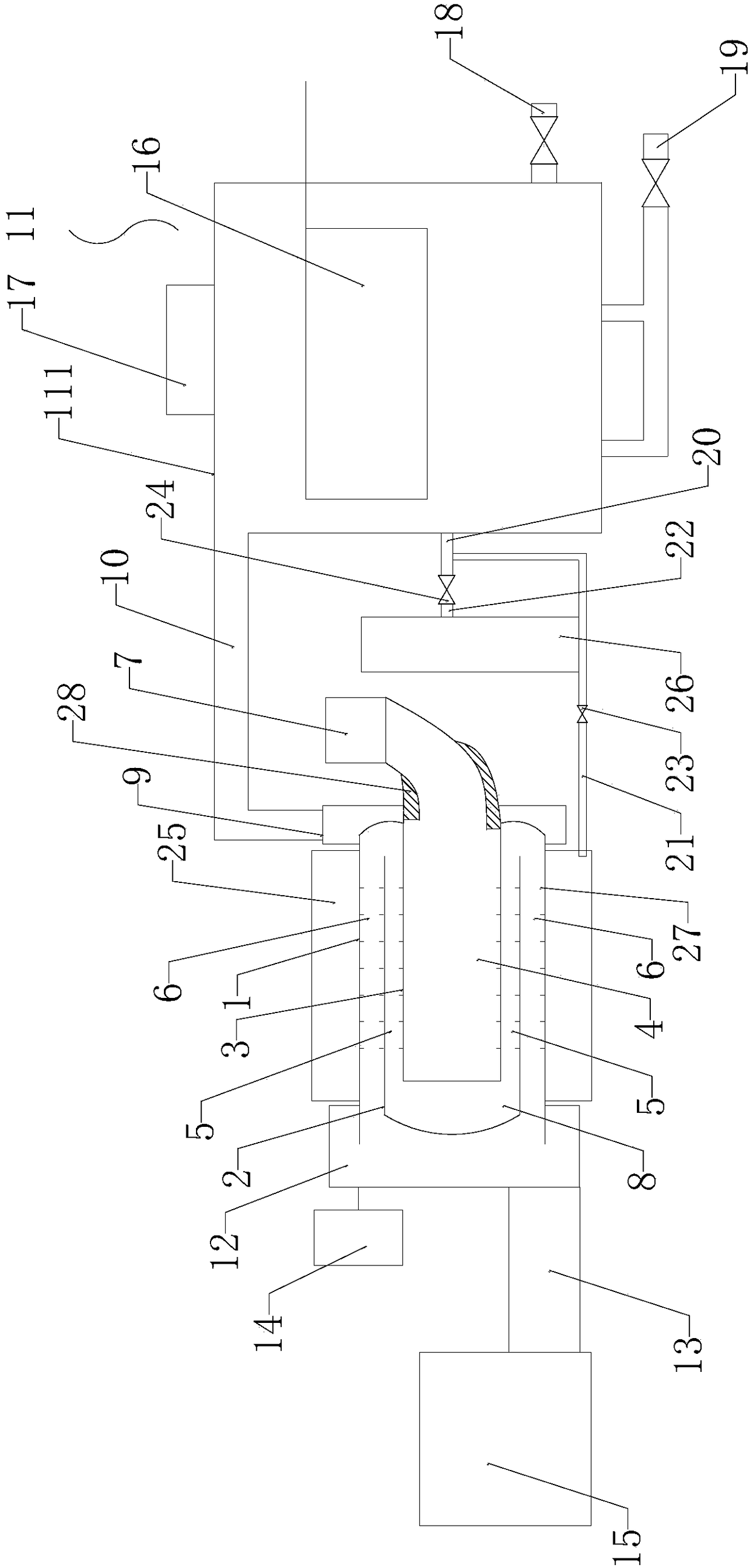

Environmentally friendly rotary multi-layer dry distillation, drying and carbonization integrated furnace

The invention belongs to the technical field of carbonization furnaces and provides an environment-friendly rotational type multi-layer dry-distillation, drying and carbonization integrated furnace. The furnace comprises an outer rotating cylinder, a middle rotating cylinder and an inner rotating cylinder which are arranged from outside to inside sequentially, wherein the outer rotating cylinder and the middle rotating cylinder are opened oppositely, and the outer rotating cylinder and the inner rotating cylinder are opened in the same direction; the outer rotating cylinder is arranged in a combustion chamber; a drying layer, a pre-carbonization layer, a carbonization layer which are communicated sequentially are arranged in the inner rotating cylinder, between the inner rotating cylinder and the middle rotating cylinder as well as between the outer rotating cylinder and the middle rotating cylinder; the inner rotating cylinder is connected with a feeding bin; a gas outlet is formed in one end of the outer rotating cylinder, and the other end is connected with a collecting tank; the gas outlet is connected with a flue gas recovery unit through a gas collecting device; guide plates are arranged on the outer rotating cylinder, the middle rotating cylinder and the inner rotating cylinder. The furnace is ingenious in conception, and solves the technical problems of simple design, lower heat energy utilization rate, high fuel consumption, long production cycle and unstable product quality of a single carbonization furnace in the prior art.

Owner:张启泰

Welding clamping device for trapezoidal workpiece

InactiveCN107825043AEasy to weldReduce welding difficultyWelding/cutting auxillary devicesAuxillary welding devicesSlide plateTorch

The invention relates to a welding clamping device for a trapezoidal workpiece, comprising a base, a clamping device and a welding torch fixing device are arranged on both sides of the upper end of the base; the trapezoidal groove of the clamping body includes interconnected horizontal grooves and vertical grooves. A straight groove, a horizontal slide plate is arranged in the horizontal groove, the horizontal slide plate is rotatably connected with a first adjusting screw, the first adjusting screw fits with the thread on the upper end of the clamping body and extends through the upper end of the clamping body; the vertical concave There are also two vertical slides oppositely arranged in the groove, and the two vertical slides are rotatably connected with second adjustment screws. support body. The clamping body of the present invention can adjust the width of the trapezoidal groove through the horizontal slide plate and the vertical slide plate, so that it can be adjusted according to the thickness or width of the trapezoidal steel, and is applicable to the use of multiple specifications of the trapezoidal steel.

Owner:CHENGDU ZHONGFU LIXIANG TECH

Ladle pouring vehicle facilitating cleaning of residues in ladle

The invention discloses a ladle pouring vehicle facilitating cleaning of residues in a ladle. The ladle pouring vehicle comprises an installing frame, a winch, a scraper, a waste residue storage groove, a damping block and a damping gasket. The winch is arranged above the middle portion of the installing frame. The waste residue storage groove is formed in the middle portion of one side of the scraper. The damping gasket is arranged at the middle portion of the damping block. The ladle pouring vehicle is scientific and reasonable in structure and safe and convenient to use; the damping gasketand the damping spring are arranged, the up-down swinging frequency of the ladle in a clamping groove in the transportation process is reduced, and the situation that molten iron in the ladle is splashed is avoided. The scraper is arranged so that residues at the bottom of the ladle can be effectively scraped away, and the situation that the residues are congealed at the bottom of the ladle, and the purity of the molten iron is disturbed is avoided; and the installing frame and a push rod are arranged, the installing frame swings through cooperative installation of a fixing rotation shaft anda bearing block installing base, the clamping groove can better bear the ladle transported through a roof crane, and cooperative usage of a pouring vehicle body and the roof crane is facilitated.

Owner:TONGLING HEWU MACHINERY MFG

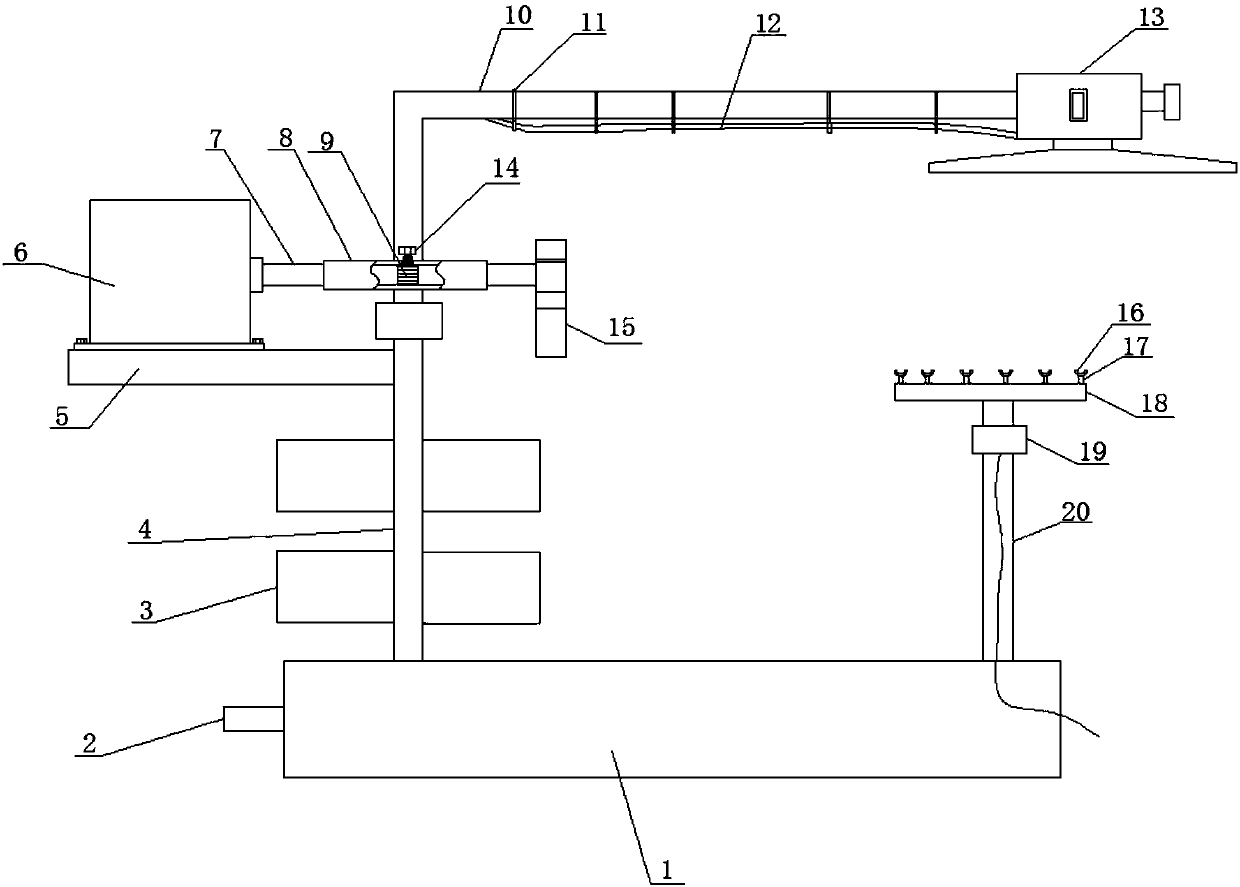

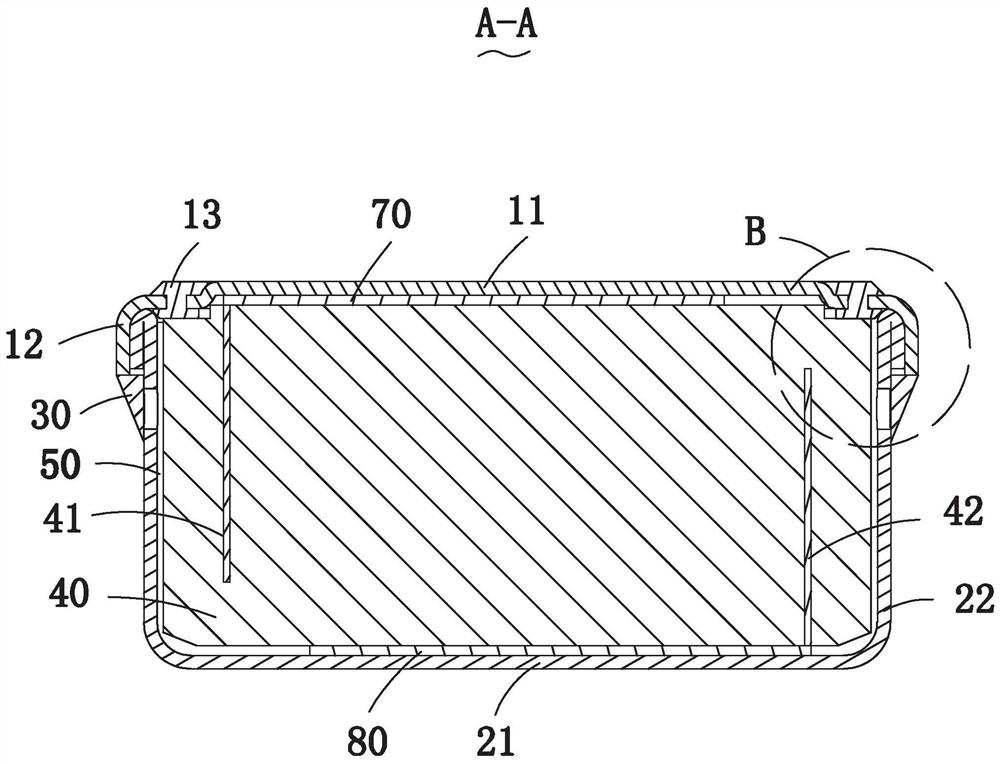

Device and method for improving battery pole piece slit curling

PendingCN110311090AImprove cut curlImprove single sided curlElectrode thermal treatmentPretreated surfacesBiochemical engineeringPole piece

The invention belongs to the technical field of a battery and particularly relates to a device for improving battery pole piece slit curling. The device includes a coating module (1) and a drying module (2), wherein the coating module (1) is used for identifying a single-sided pole piece having a profiled slit and coating the single-sided pole piece having the profiled slit, and the drying module(2) is used for identifying the single-sided pole piece having the profiled slit from the coating module (1) and drying the single-sided pole piece having the profiled slit. The device is advantaged in that the structure is simple, a problem of pole piece slit curling is effectively solved, and the device is intelligent and efficient and is convenient to use. The invention further provides a method for improving battery pole piece slit curling, and work stability and efficiency are improved.

Owner:HUIZHOU LIWINON NEW ENERGY TECH CO LTD

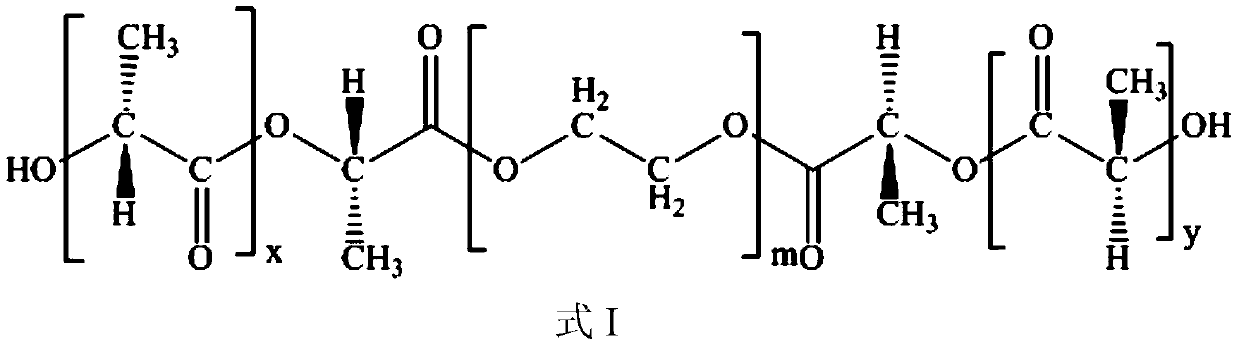

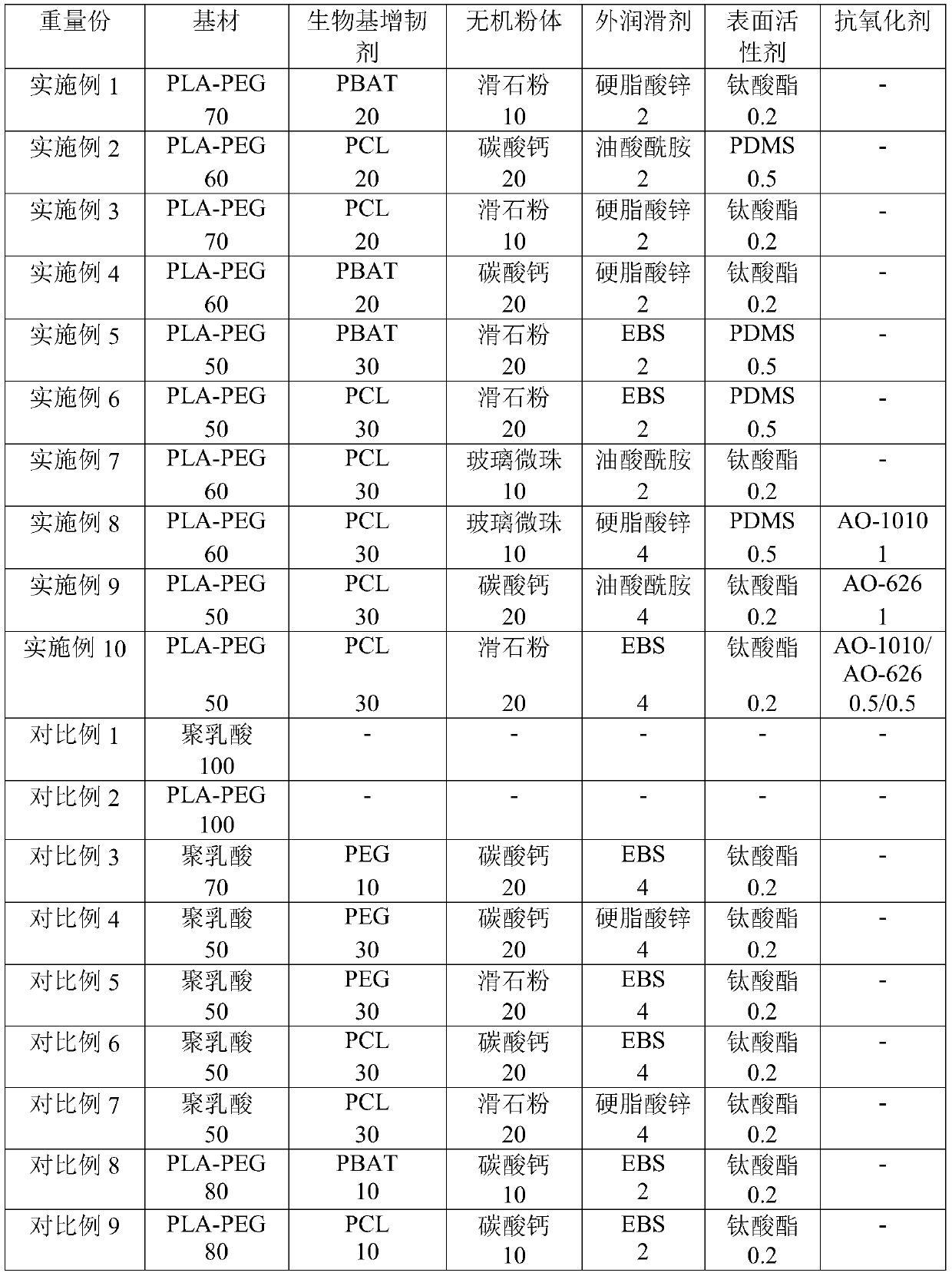

3D printing polylactic resin material and preparation method thereof

InactiveCN111484707AFast degradation rateImprove toughnessAdditive manufacturing apparatus3d printPolymer science

The invention relates to a 3D printing polylactic resin material, and is characterized in that the 3D printing polylactic resin material comprises (A) about 40 to 75 parts of polylactic acid-b-polyethylene glycol segmented copolymer, (B) about 15 to 40 parts of bio-based flexibilizer, (C) about 5 to 25 parts of inorganic powder, (D) about 1 to 10 parts of an external lubricant and (E) about 0.1 to5 parts of a surfactant. The invention also relates to a preparation method and an application of the 3D printing polylactic resin material. The invention also relates to application of the polylactic acid-b-polyethylene glycol segmented copolymer in preparation of a polylactic acid resin material for 3D printing.

Owner:ZHEJIANG HISUN BIOMATERIALS

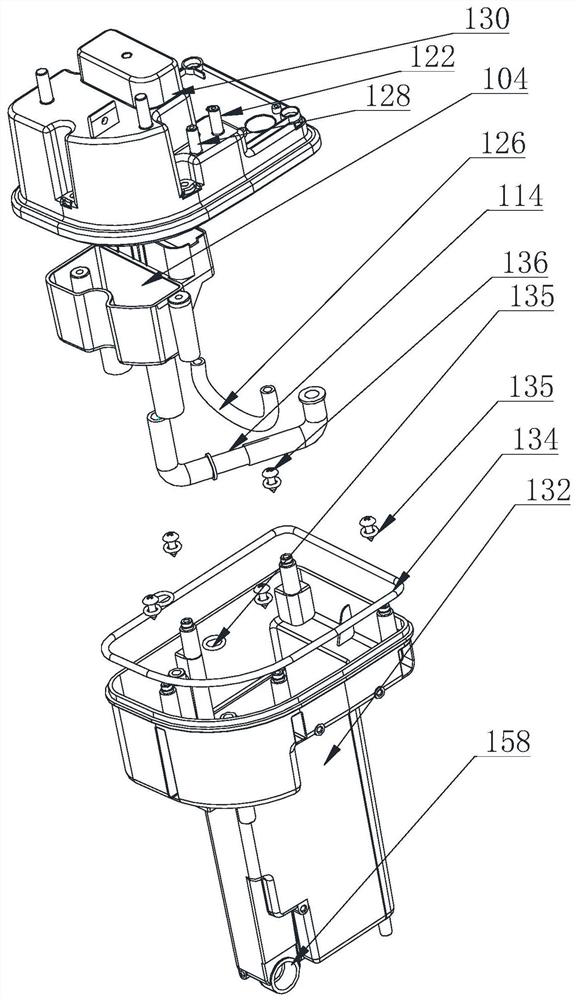

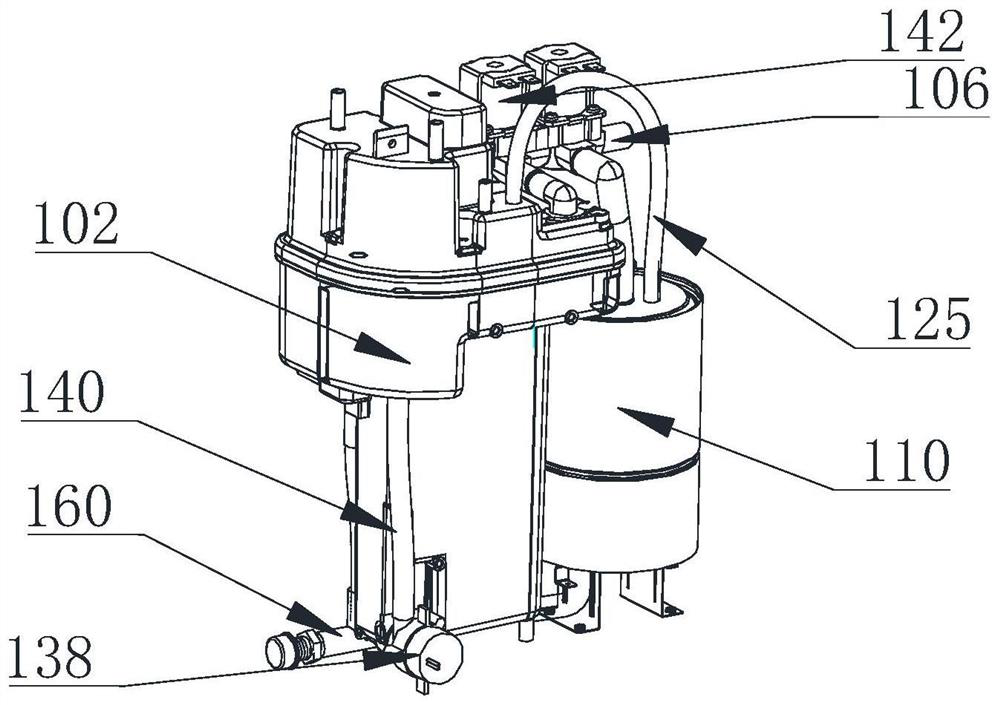

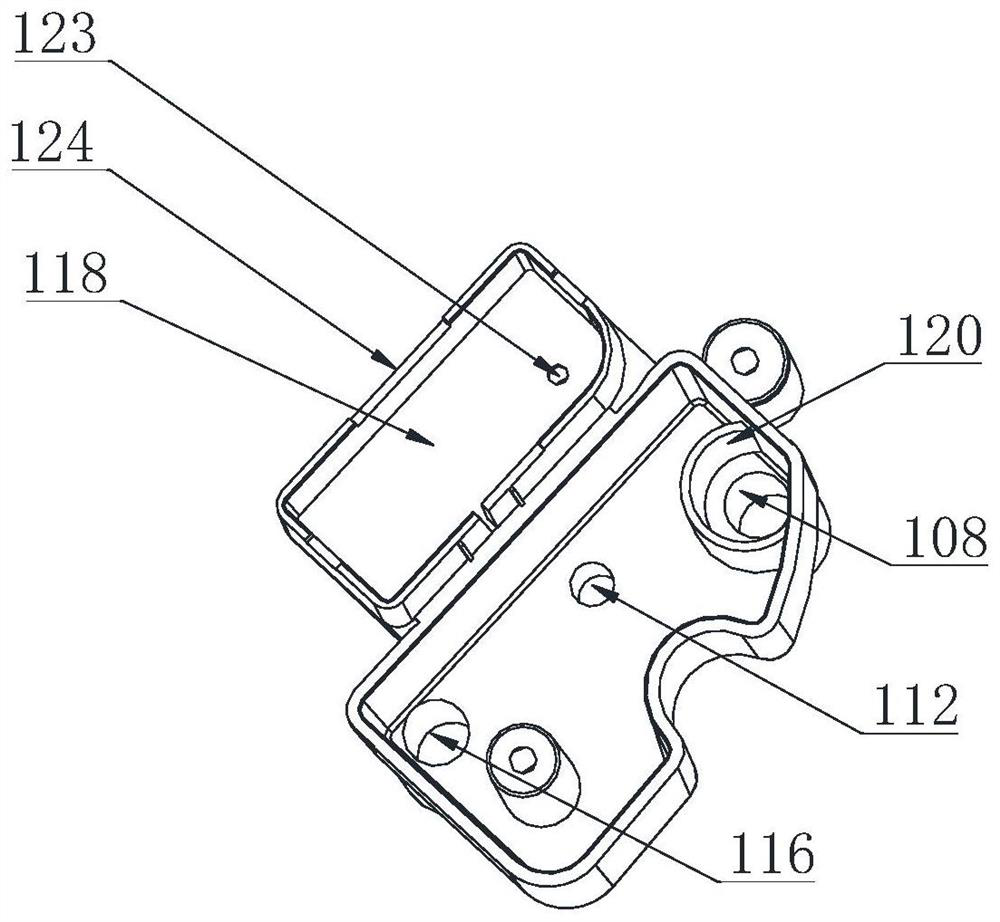

Water purification equipment

ActiveCN112678897AAvoid dischargeAvoid high temperature burnsMultistage water/sewage treatmentWater/sewage treatment by heatingWater tanksWater vapor

The invention relates to the technical field of water purification, and provides water purification equipment. The water purification equipment comprises a purified water tank; a heating device which comprises a heating container and a water vapor chamber formed in the top of the heating container, and the water vapor chamber is communicated with the interior of the purified water tank. According to the water purification equipment, the water vapor chamber is communicated with the interior of the purified water tank, so that water vapor can flow into the purified water tank from the water vapor chamber along with certain air pressure generated by the water vapor formed in the heating container, and high-temperature water vapor is prevented from flowing out of the water outlet nozzle to cause scalding. Moreover, as the water vapor enters the water purification tank, the water vapor is condensed into water under specific conditions, and then the water vapor can be recycled.

Owner:FOSHAN SHUNDE MIDEA WATER DISPENSER MFG +1

Environment-friendly rotational type multi-layer dry-distillation, drying and carbonization integrated furnace

The invention belongs to the technical field of carbonization furnaces and provides an environment-friendly rotational type multi-layer dry-distillation, drying and carbonization integrated furnace. The furnace comprises an outer rotating cylinder, a middle rotating cylinder and an inner rotating cylinder which are arranged from outside to inside sequentially, wherein the outer rotating cylinder and the middle rotating cylinder are opened oppositely, and the outer rotating cylinder and the inner rotating cylinder are opened in the same direction; the outer rotating cylinder is arranged in a combustion chamber; a drying layer, a pre-carbonization layer, a carbonization layer which are communicated sequentially are arranged in the inner rotating cylinder, between the inner rotating cylinder and the middle rotating cylinder as well as between the outer rotating cylinder and the middle rotating cylinder; the inner rotating cylinder is connected with a feeding bin; a gas outlet is formed in one end of the outer rotating cylinder, and the other end is connected with a collecting tank; the gas outlet is connected with a flue gas recovery unit through a gas collecting device; guide plates are arranged on the outer rotating cylinder, the middle rotating cylinder and the inner rotating cylinder. The furnace is ingenious in conception, and solves the technical problems of simple design, lower heat energy utilization rate, high fuel consumption, long production cycle and unstable product quality of a single carbonization furnace in the prior art.

Owner:张启泰

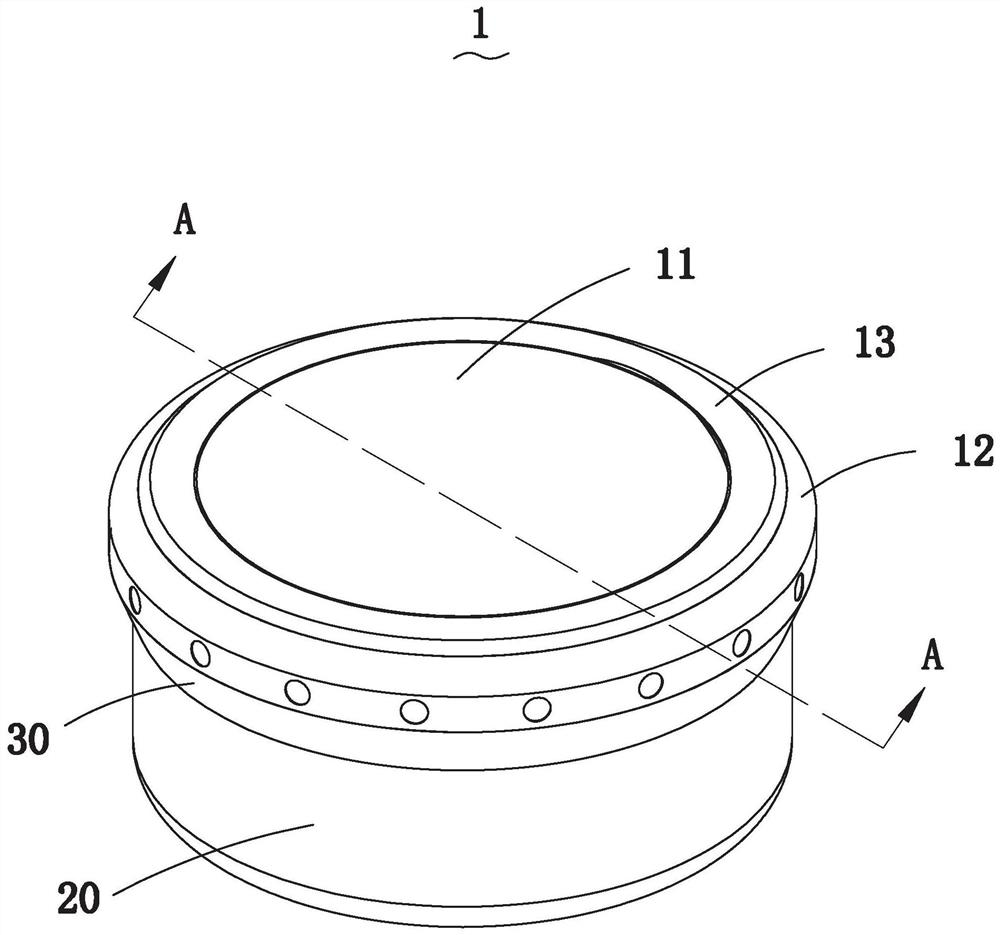

Button cell

PendingCN111682130ADoes not affect normal workAvoid high temperature burnsCell component detailsButton batteryEngineering

The invention provides a button cell. The button cell comprises a first electrode cover assembly, a second electrode cover assembly in insulation connection with the first electrode cover assembly, asealing piece and a cell body with a positive electrode and a negative electrode; the first electrode cover assembly and the second electrode cover assembly enclose to form an accommodating cavity foraccommodating the cell body; one of the positive electrode and the negative electrode of the cell body is connected with the first electrode cover assembly, and the other one is connected with the second electrode cover assembly; a through hole communicated with the accommodating cavity is formed in the second electrode cover assembly in a penetrating manner; the first electrode cover assembly and the second electrode cover assembly are sealed through the sealing piece, and the sealing piece covers the through hole; when the temperature of the cell body exceeds a threshold value, the sealingpiece is heated to be molten, and gas in the button cell is diffused to the outside through the through hole and a gap between the first electrode cover assembly and the second electrode cover assembly, so that the safety accident of high-temperature scalding or explosion caused by continuous rising of the temperature in the button cell and rising of the pressure in the button cell is avoided.

Owner:AAC TECH NANJING

Self-protection yo-yo based on intelligent manufacturing

ActiveCN112169347AReduce frictionAvoid frictional damageTopsStructural engineeringMechanical engineering

The invention relates to the technical field of toys, and discloses a self-protection yo-yo based on intelligent manufacturing. The yo-yo comprises an inner ring, a support rod is fixedly connected tothe surface of the inner ring, an outer ring is fixedly connected to one side, far away from the inner ring, of the support rod, and a bearing air pipe is inserted into the side surface of the outerring; an inflation block is fixedly connected into the bearing air pipe, an air pressure plate is slidably connected to the side, away from the inflation block, of the bearing air pipe, a delay screwis rotatably connected to the side, close to the wheel center, of the air pressure plate, a delay screw pipe is connected to the side face of the delay screw in an engaged mode, and a push rod is rotatably connected to the side, close to the wheel center, of the delay screw. The side, close to the wheel center, of the push rod is fixedly connected with an inflatable bag. According to the self-protection yo-yo based on intelligent manufacturing, through cooperative use of the inflation block and the impact rod, the effect that when the yo-yo is used, friction between the yo-yo and the ground isavoided, and the yo-yo is prevented from being damaged is achieved.

Owner:台州云造智能科技有限公司

Welding clamping device

InactiveCN108000037AEasy to weldReduce welding difficultyWelding/cutting auxillary devicesAuxillary welding devicesLine tubingMetal hose

The invention relates to a welding clamping device. The welding clamping device comprises a base. A clamping device and a welding gun fixing device are arranged on the two sides of the upper end of the base correspondingly. The welding clamping device further comprises a welding smoke absorbing device. The welding smoke absorbing device comprises a smoke suction pipe. The smoke suction pipe is sleeved with a movable smoke suction cover. The movable smoke suction cover comprises a cover body. A plurality of installation holes are formed in the lower end of the cover body. Each installation holeis internally provided with a detachable movable smoke suction barrel. The upper end of each movable smoke suction barrel is connected with the cover body through a snakelike metal hose. Each movablesmoke suction barrel communicates with a smoke conveying branch pipe. The cover body is internally provided with a pipe wire coil for taking up and paying off each smoke conveying branch pipe. A first permanent magnet is arranged on the hole wall of each installation hole. A second permanent magnet is arranged on the circumferential surface of each movable smoke suction barrel. According to the welding clamping device, the movable smoke suction cover can be divided into the multiple small movable smoke suction barrels, the movable smoke suction barrels can stretch out of the movable smoke suction cover and thus can be applied to the situation that welding is conducted at the same time in many positions, welding smoke adsorbing can be conducted on many welding points at the same time, andthe welding smoke adsorbing effect is good.

Owner:CHENGDU ZHONGFU LIXIANG TECH

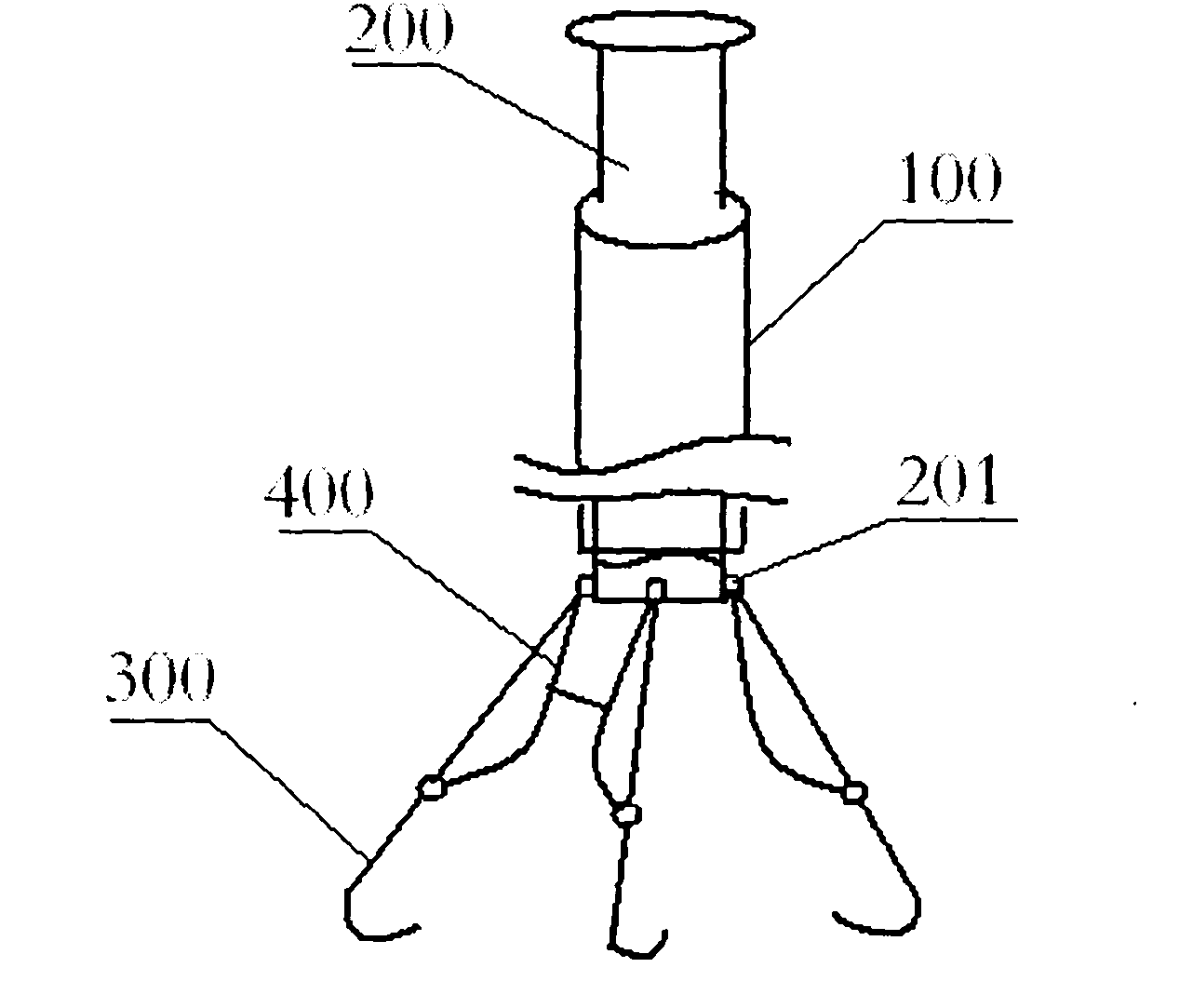

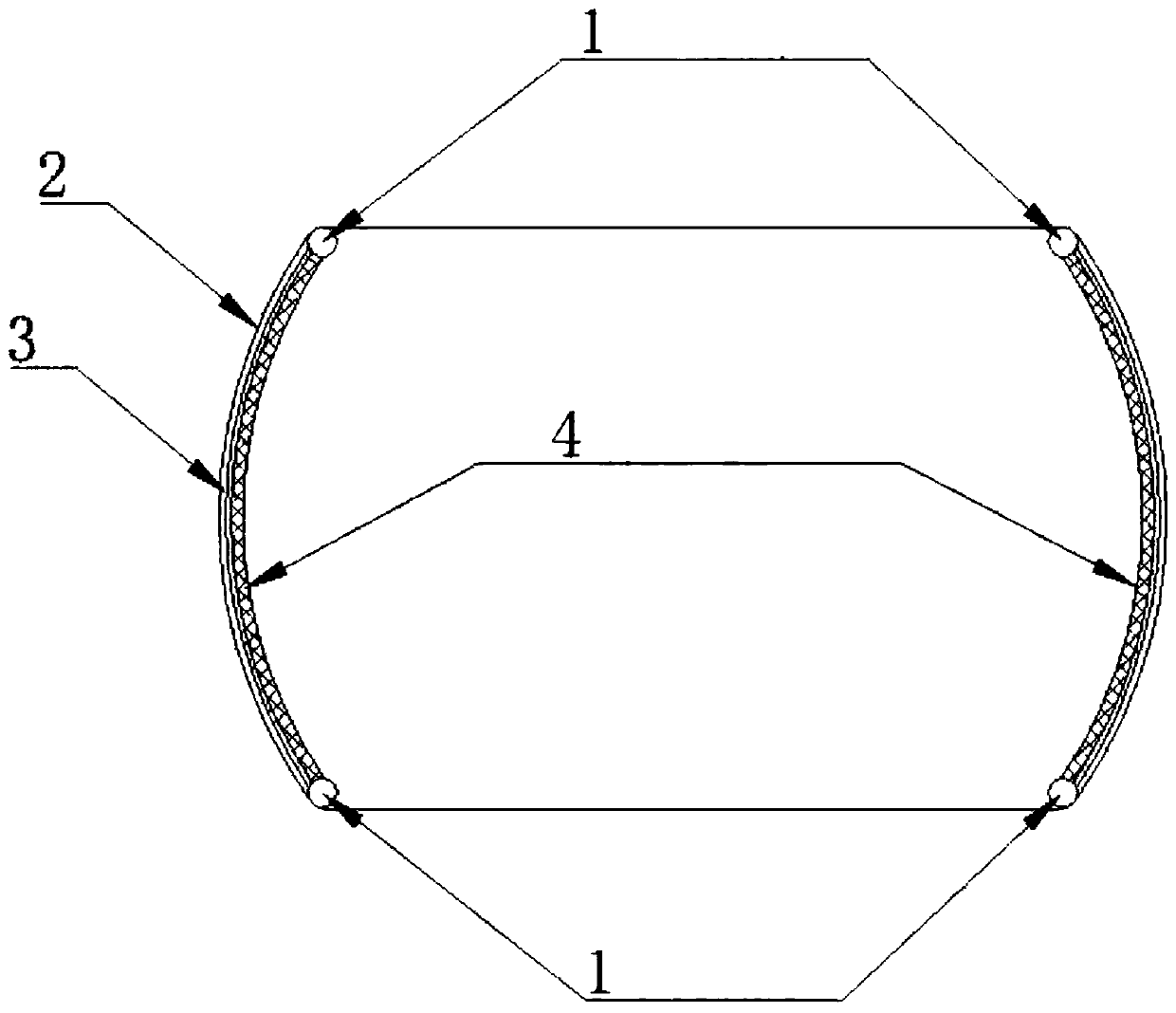

Method and tooling for coating isolating agent onto surface of vulcanized capsule

PendingCN110665731AApply evenlyImprove operational efficiencyLiquid surface applicatorsCoatingsVulcanizationEngineering

The invention discloses a method and tooling for coating an isolating agent onto the surface of a vulcanized capsule. The cooling is composed of two end circle frameworks, a lacing layer, an isolatinglayer and an isolating agent absorbing layer, the two end circle frameworks are located at the upper and lower ends of the tooling, the lacing layer, the isolating layer and the isolating agent absorbing layer are arranged between the two end circle frameworks, the two ends of each layer are connected to the two end circle frameworks and to form a ball surface by surrounding, the lacing layer, the isolating layer and the isolating agent absorbing layer are sequentially arrayed from outside to inside and tightly keep contact with one another, and the inner side of the isolating agent absorbinglayer is provided with an arc surface capable of being attached to the surface of the vulcanized capsule during expanding. By using the tooling, outside of a vulcanization work producing line, the isolating agent is coated in the tooling firstly, then the tooling is arranged on the vulcanized capsule in a sleeving mode, the surface of the vulcanized capsule and the isolating agent absorbing layerare in contact with each other fully and stick to the isolating agent by reverse sticking, and then the tooling is removed. The tooling and the coating method improve the operation efficiency, and high temperature burns can be prevented.

Owner:SICHUAN YUANXING RUBBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com