Patents

Literature

589results about How to "Reduce welding difficulty" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

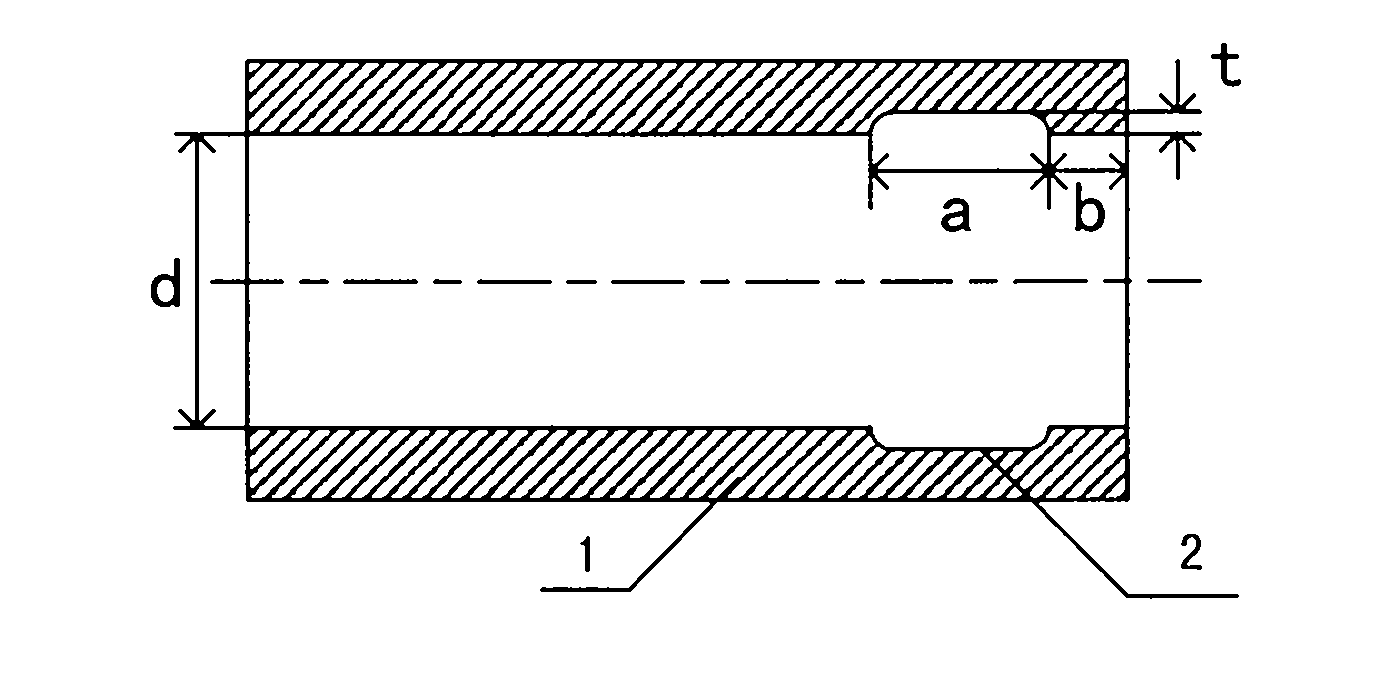

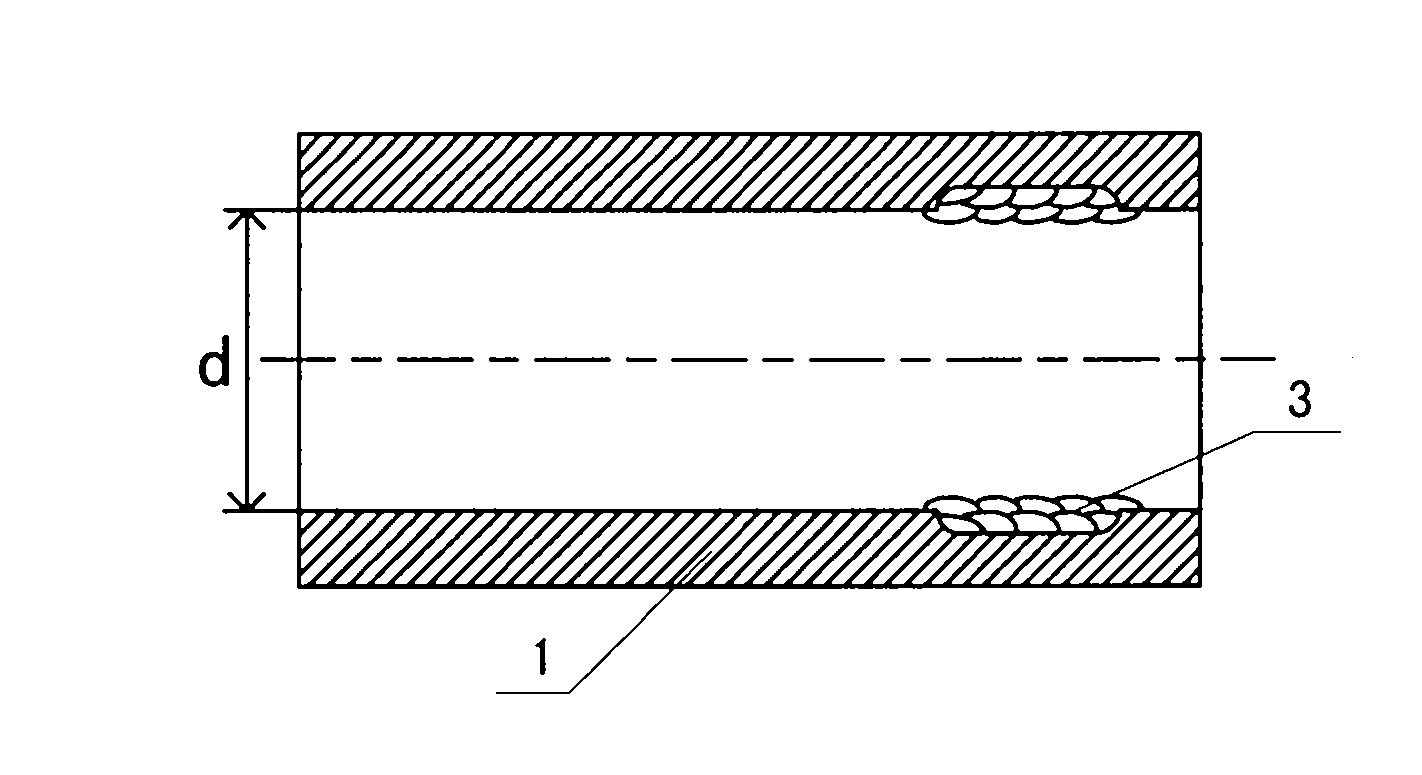

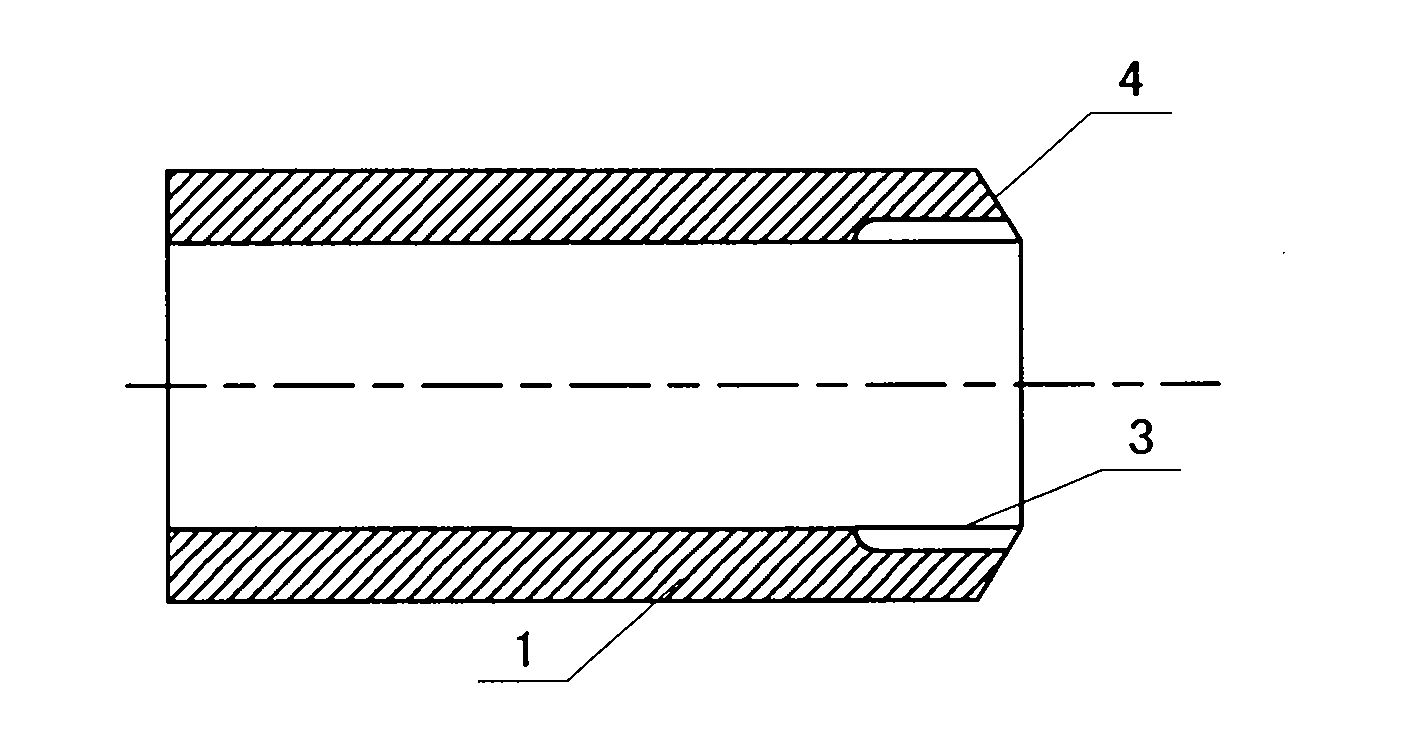

Method for welding anticorrosion steel pipeline with no internal repaired mouth

InactiveCN103008988AReduce the chance of welding defectsRigid enoughArc welding apparatusChemical industryAlloy

The invention provides a method for welding an anticorrosion steel pipeline with no internal repaired mouth, which is applicable to the anticorrosion treatment of a steel pipeline welding connector with an anticorrosion coating in the petroleum industry and the chemical industry. The method is characterized in that a groove with a certain length and depth is machined on a position which is at a certain distance from the end part of the steel pipe, an anticorrosion alloy material is surfaced on the groove, the end part of the surfaced steel pipe is machined into a V-shaped groove, an anticorrosion coating with sufficient thickness is coated on the inner wall of the steel pipe, the anticorrosion coating covers sufficient length of the anticorrosion alloy surfacing layer, then two steel pipes are in butt connection with each other, layering welding is carried out after the two steel pipes are fixed on one point, an argon tungsten-arc welding method is adopted, the anticorrosion alloy material which is identical to that of the surfacing is selected as the filling material, and argon is filled into the pipe to protect the pipe in the welding process. Due to the adoption of the novel technology for welding the anticorrosion steel pipeline with no internal repaired mouth, the corrosion resistance of the inner wall and a weld mouth of the pipeline can be guaranteed, the internal mouth repairing technology on the spot after the welding can be avoided, characteristics such as simplicity in construction and reliability in performance can be realized, and the method is suitable for the real engineering application of the petroleum and chemical industry fields.

Owner:HARBIN INST OF TECH

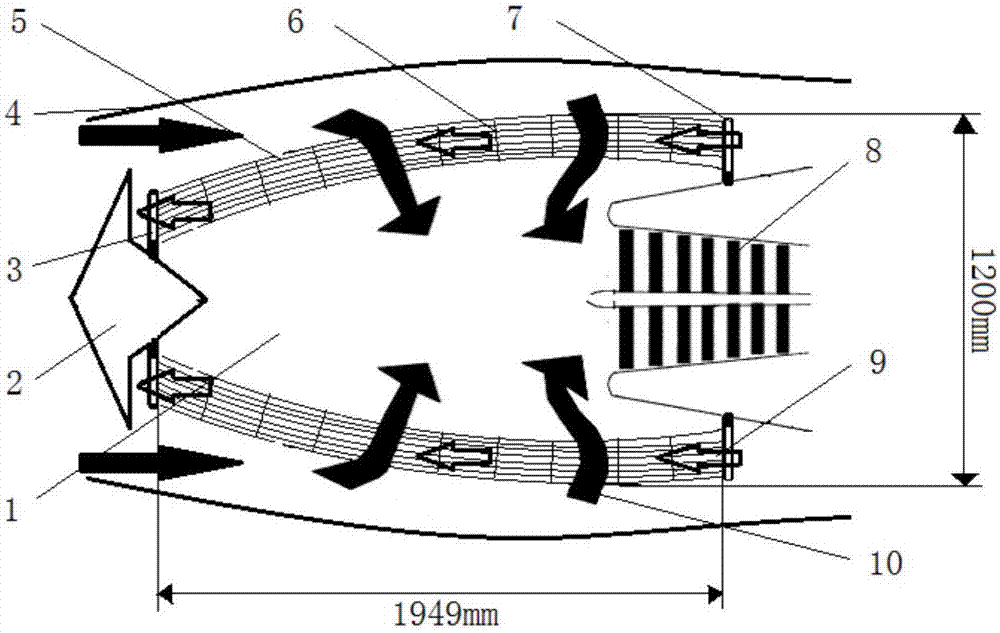

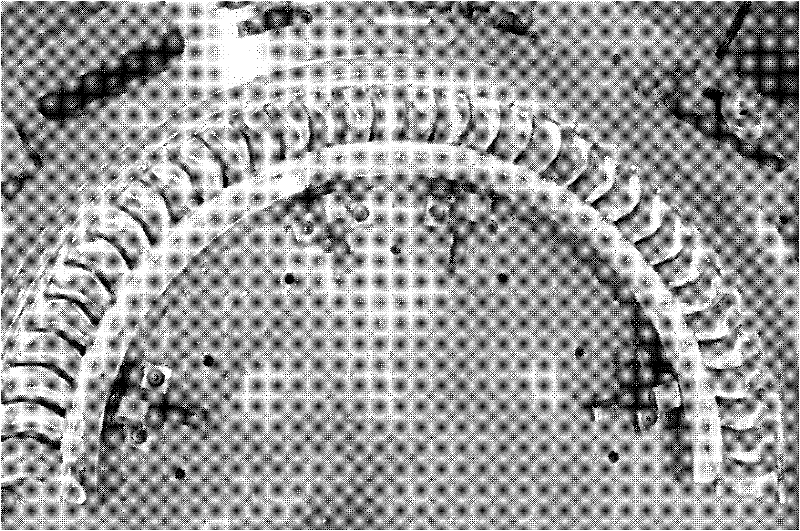

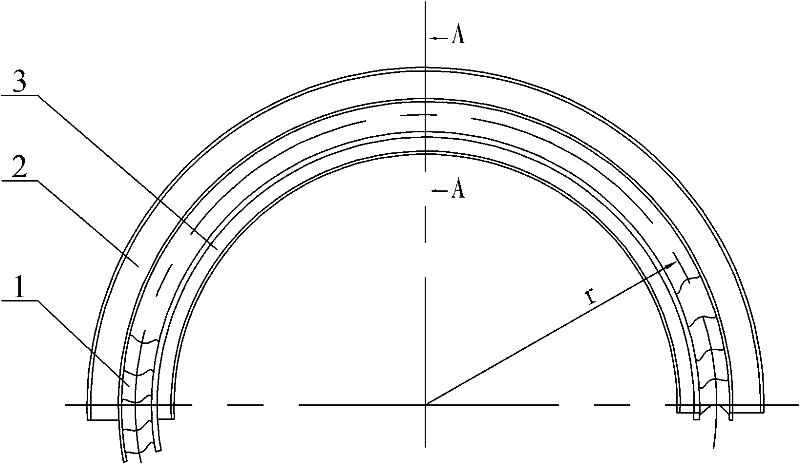

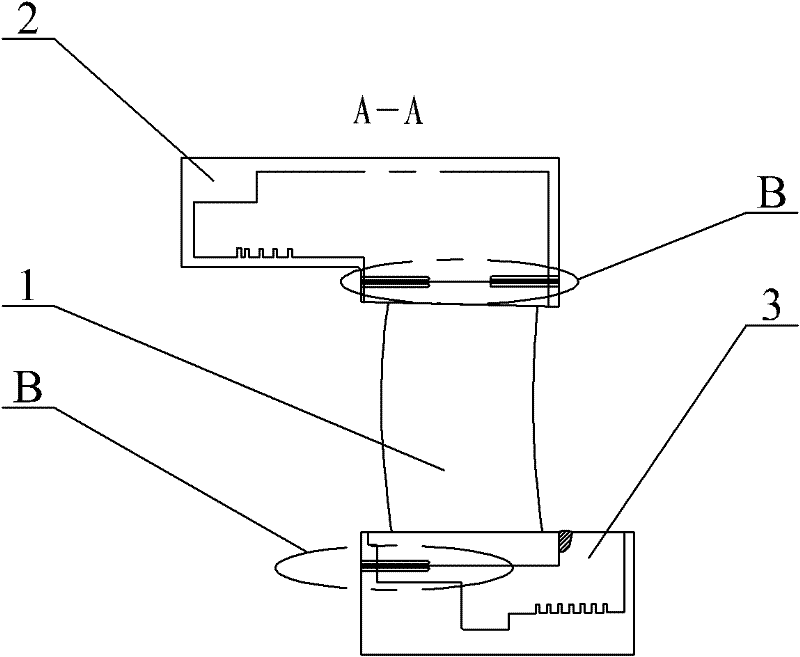

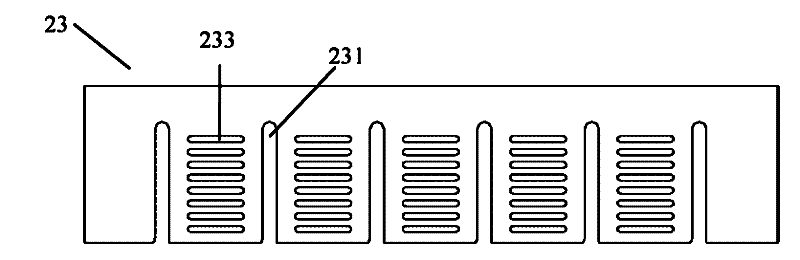

Efficient and compact pre-cooling heat exchanger for pre-cooling gas sucking type engine

ActiveCN107218133AGuaranteed heat exchange effectReduce welding difficultyTurbine/propulsion engine coolingGas turbine plantsEngineeringCurrent technology

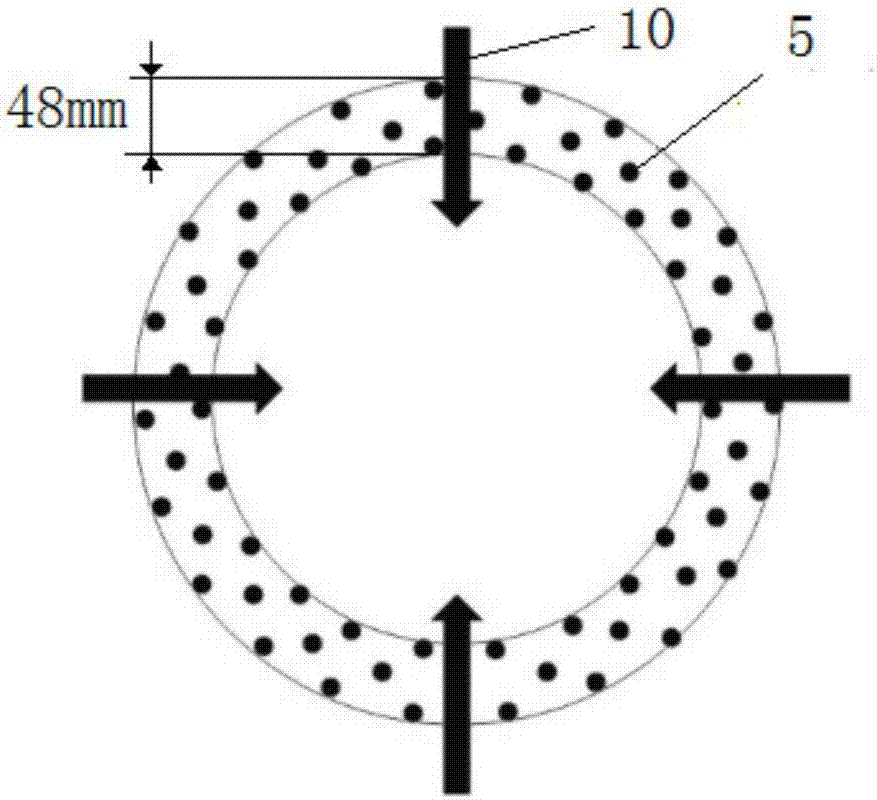

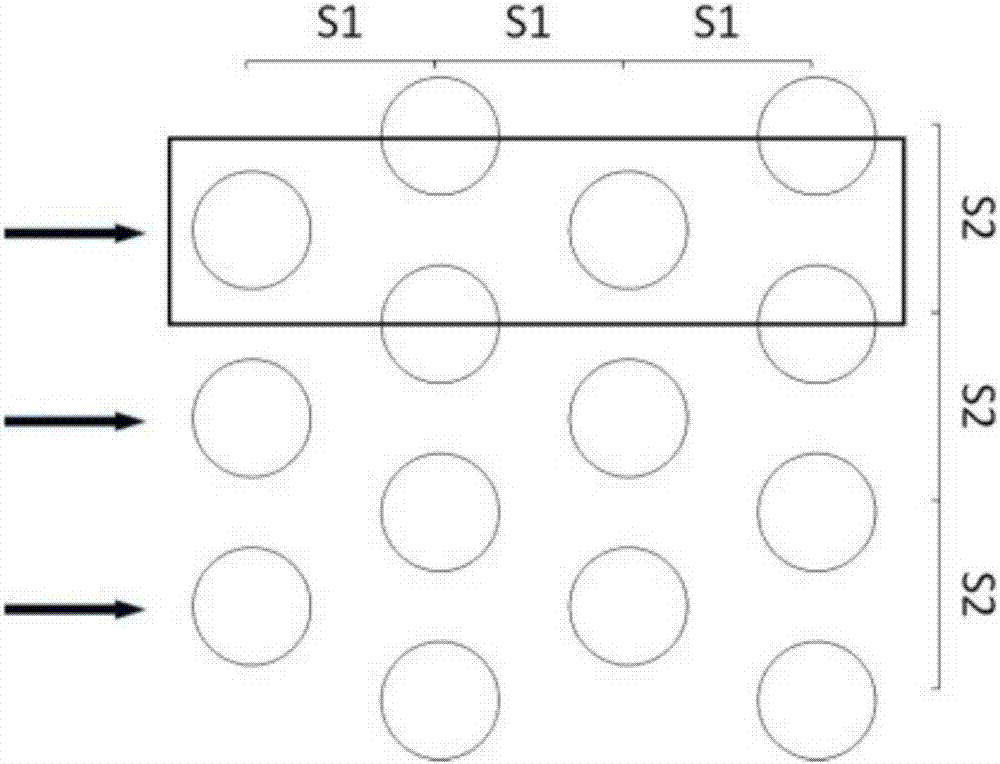

The invention discloses an efficient and compact pre-cooling heat exchanger for a pre-cooling gas sucking type engine. The efficient and compact pre-cooling heat exchanger for the pre-cooling gas sucking type engine comprises a pre-cooling heat exchanger body in the shape of a similar cylinder; the cross section of the similar cylinder is in the shape of a ring different in diameter; the longitudinal section of the similar cylinder is formed by two symmetrically arranged arc segments; the center angle of each arc segment is 45 degrees; the pre-cooling heat exchanger body comprises a cold flow outlet pipe, a cold flow inlet pipe and a plurality of heat exchanging pipes; each heat exchanging pipe is in the shape of an arc; the arc-shaped center angle of each heat exchanging pipe is 45 degrees; and the heat exchanging pipes are distributed into the similar cylinder in a crossed manner. The efficient and compact pre-cooling heat exchanger for the pre-cooling gas sucking type engine can have the engineer realizability on the premise that the heat exchanging effect is guaranteed, so that air incoming flow in front of a gas compressor can be pre-cooled, the high temperature over-running problem of gas compressor blades is solved, the engine thrust is increased, the flight envelop is extended, the welding difficulty is effectively reduced, the frosting blockage problem is effectively solved, the engineer realizability is achieved under the current technology, and after the efficient and compact pre-cooling heat exchanger for the pre-cooling gas sucking type engine is applied to the pre-cooling gas sucking type engine, the engine performance can be substantially improved.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

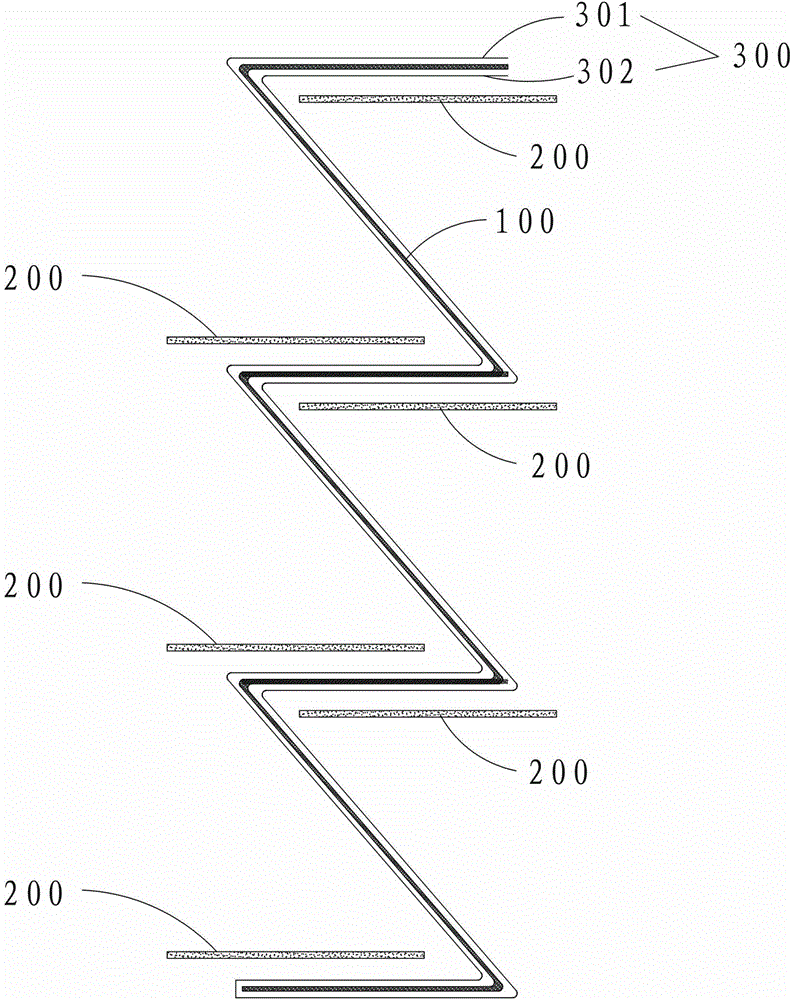

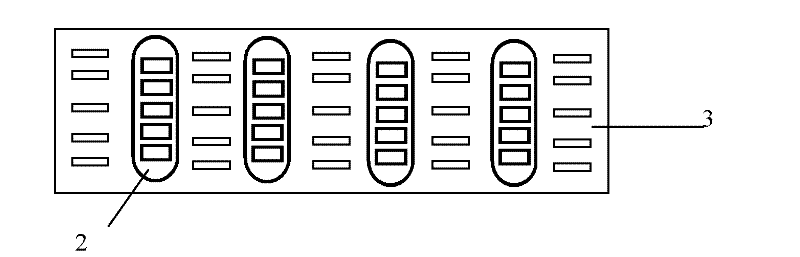

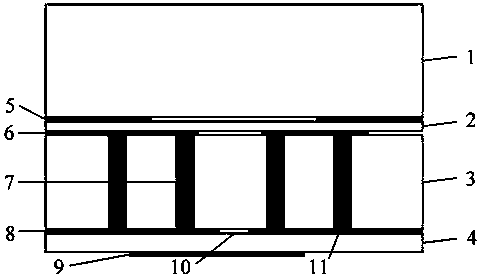

Laminated lithium ion battery and production process thereof

InactiveCN104900905AIncrease capacityImprove securityFinal product manufactureSecondary cellsLithium-ion batteryBattery cell

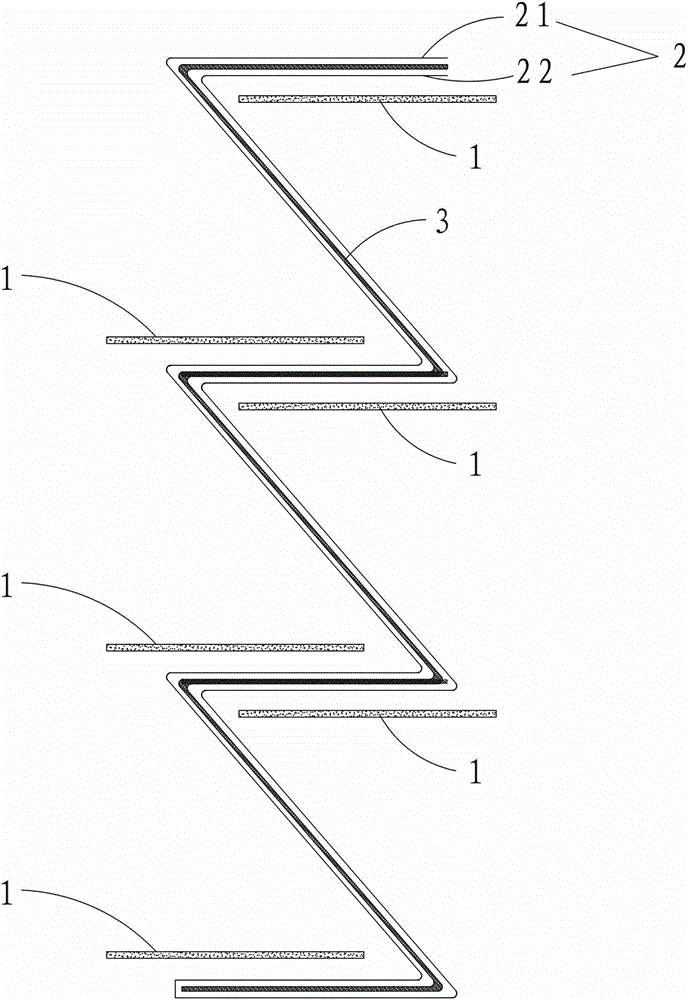

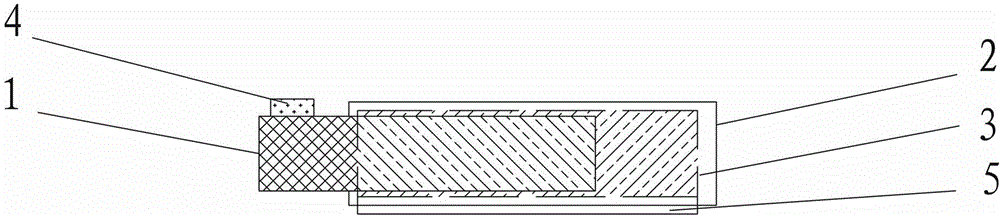

The invention discloses a laminated lithium ion battery. The laminated lithium ion battery comprises a lithium ion battery cell, wherein the lithium ion battery cell comprises positive electrode plates, a belt type negative electrode plate and membranes, the belt type negative electrode plate is of a continuous non-cutting belt type structure and is wrapped by two layers of membranes to form a coating body, and the two layers of membranes are marked as a first membrane and a second membrane from top to bottom; the coating body is continuously folded to form a Z shape, the positive electrode plates are arranged at the folding parts of the Z-shaped coating body, and the sequence along the vertical direction is: the first membrane, the belt type negative electrode plate, the second membrane, the positive electrode plate, the second membrane, the belt type negative electrode plate, the first membrane and the positive electrode plate, and then the sequence is repeated. Compared with the conventional laminated battery, the laminated lithium ion battery has the advantages that the negative electrode is not cut and forms the coating body together with the membranes to be folded together, so that the production efficiency is improved, and the battery safety and the rate property are better.

Owner:深圳市迪凯特电池科技有限公司

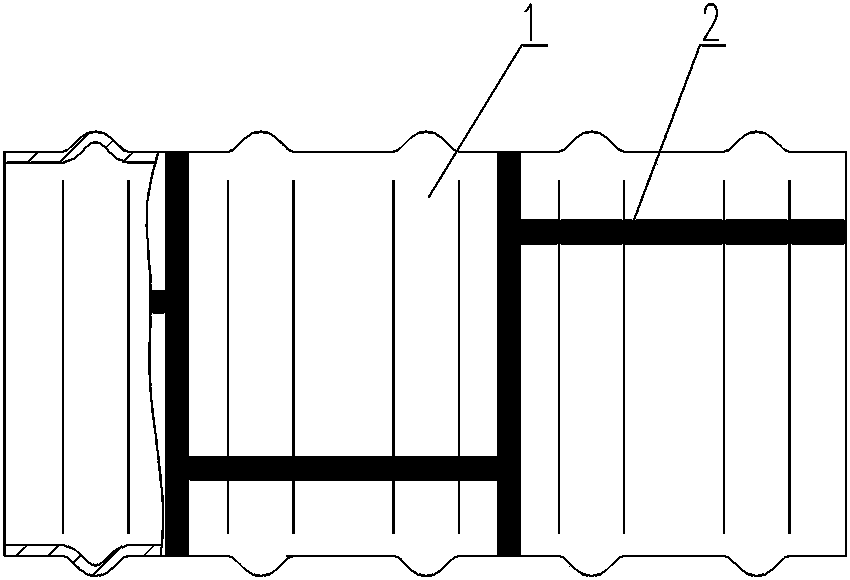

An electron beam welding method for an ultra-supercritical partition

ActiveCN102294541AReduce welding distortionControl pitch circle sizeElectron beam welding apparatusPower flowSeam welding

The invention discloses an electron beam welding method for ultra supercritical partition plates, and relates to a welding method for ultra supercritical partition plates for solving the problems of difficulty in welded seam formation, high welding deformation, difficulty in clearing seams, difficulty in ensuring the welding quality and the like in a manual welding or gas protection welding process during welding the ultra supercritical partition plates. The method comprises the following steps of: ruling, assembling, checking, spot welding, vacuumizing, welding seams, turnover welding, checking, and performing thermal treatment. In the seam welding step, the accelerating voltage is 55 to 60kV, the welding speed is 200 to 800mm / min, the electron beam current is 50 to 350mA, the focusing current is 1,500 to 2,000mA, the scanning oscillation amplitude of electron beams in the X direction is 0 to 5.4, the scanning oscillation amplitude of the electron beams in the Y direction is 0 to 6.0, the gun distance is 220 to 320 millimeters, and the scanning waveform is circular. The method is used for electron beam welding of the ultra supercritical partition plates of a steam turbine.

Owner:HARBIN TURBINE +1

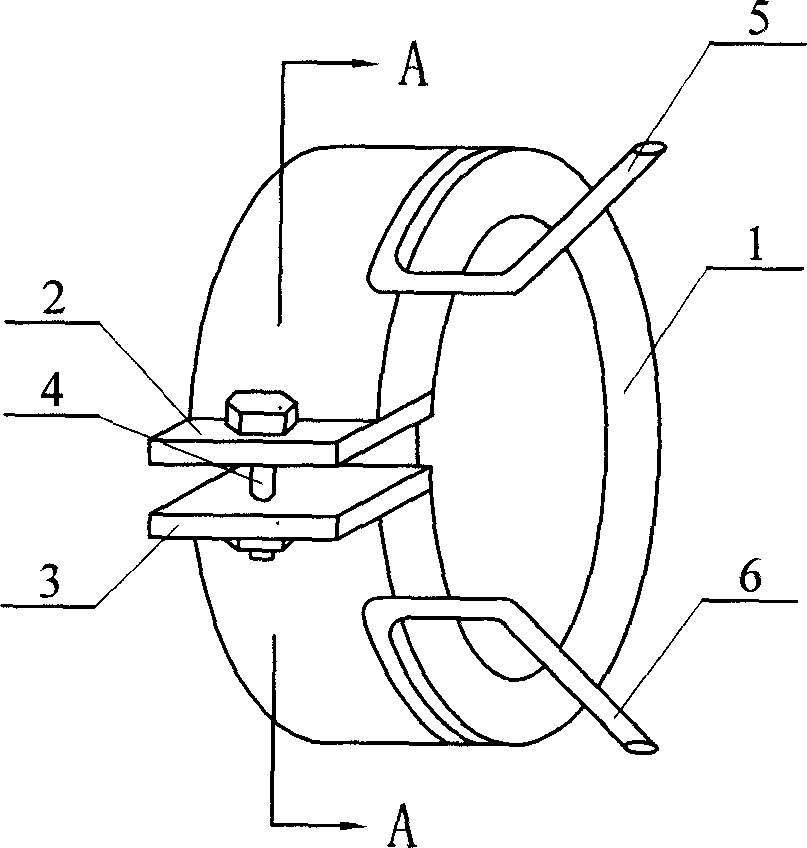

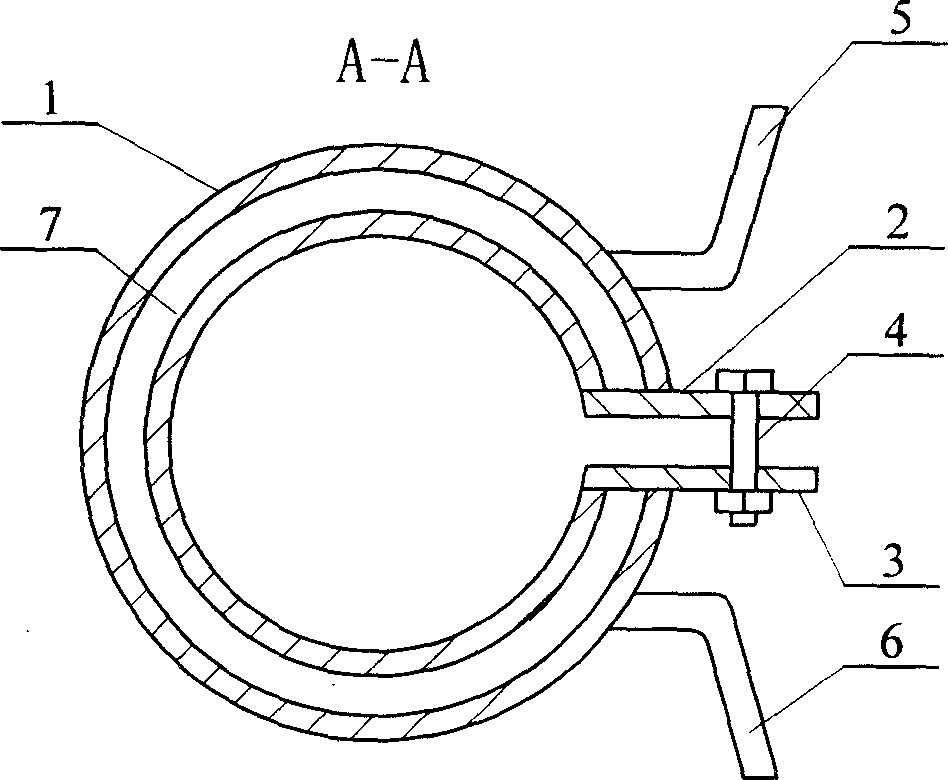

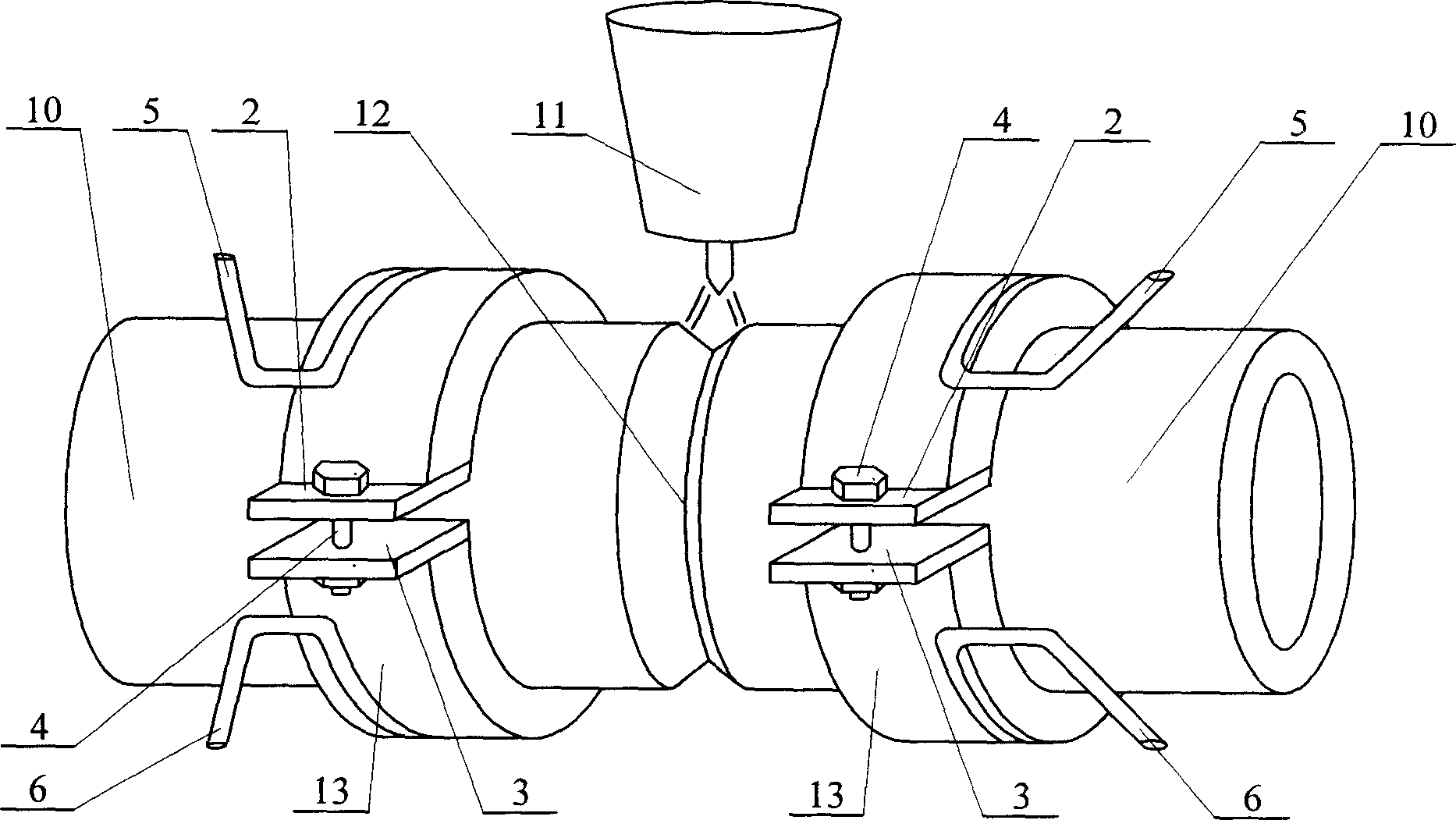

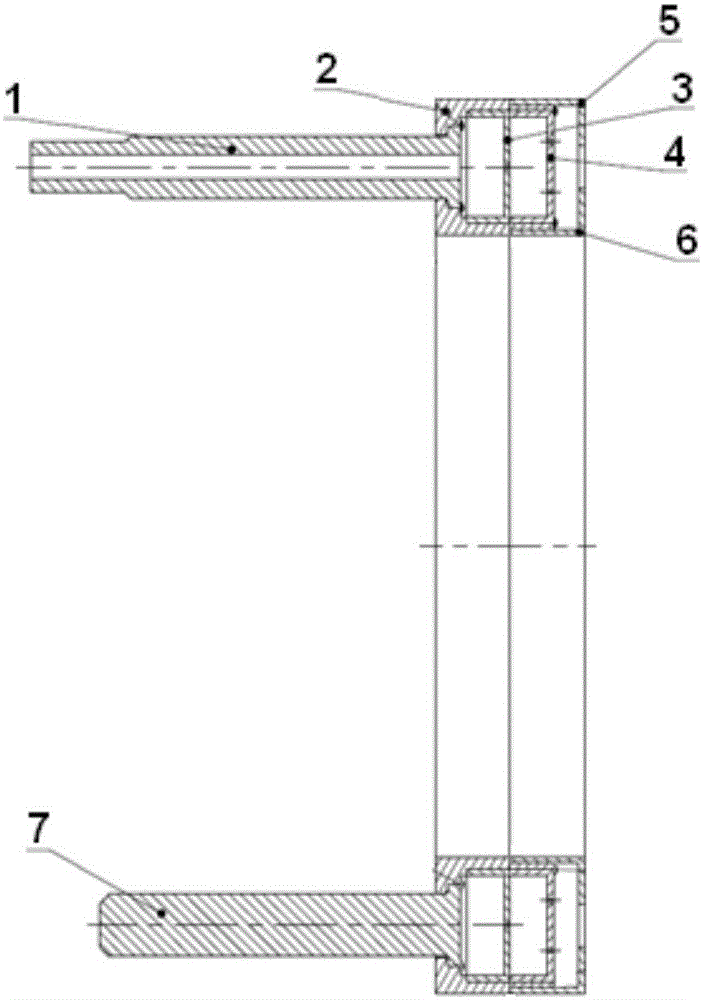

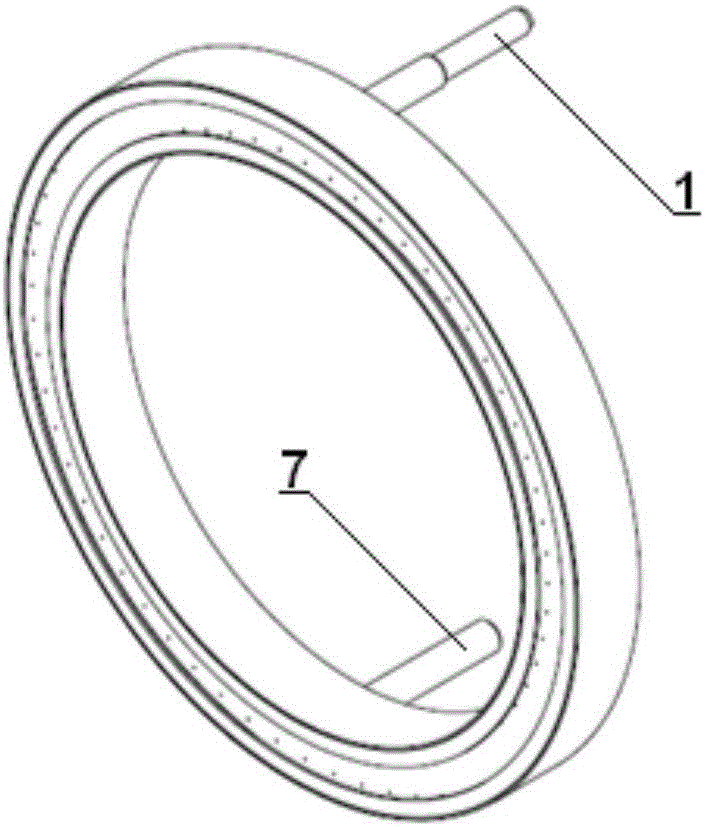

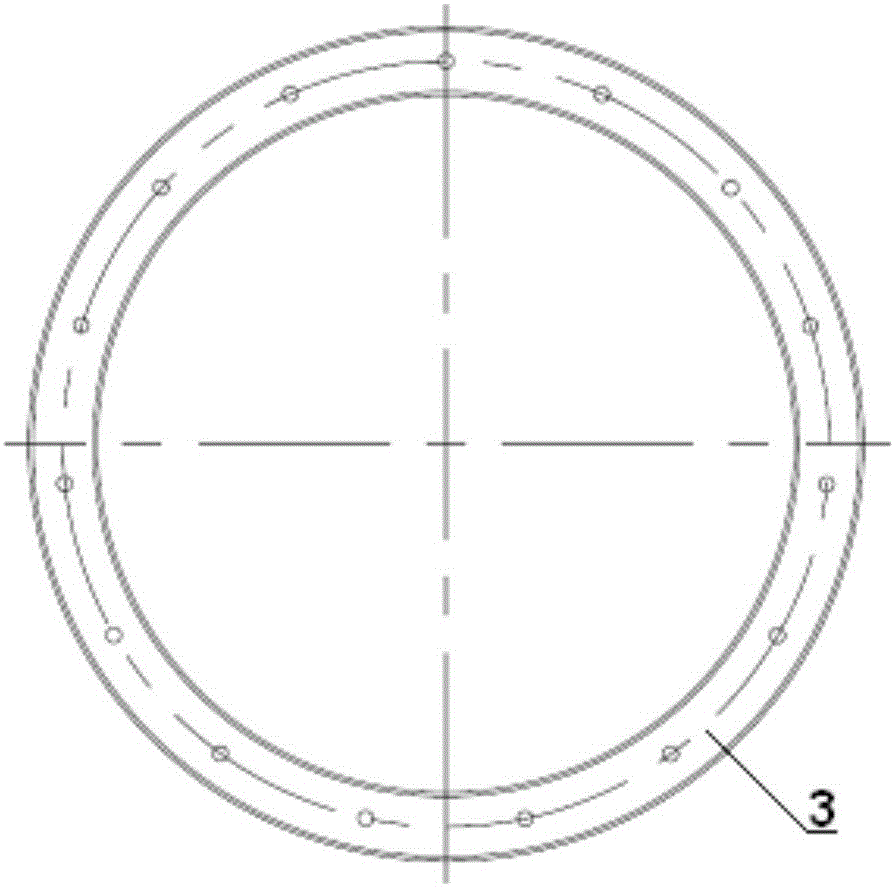

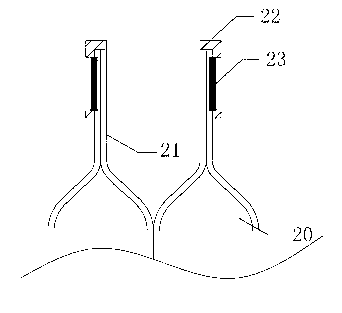

Water cooling jacket for titanium alloy tube ring seam by tungsten argon arc welding and seam following cooling welding method

The present invention relates to water cooling jacket for welding and corresponding welding method by means of using the water cooling jacket. The water cooling jacket has upper connecting plate with one side plane connected hermetically with the upper end of the C-shaped sleeve, and lower connecting plate with one side plane connected hermetically with its lower end. The welding method includes screwing the water cooling jacket tightly to the titanium alloy tube. The water cooling jacket of the present invention has simple structure and high cooling effect, and the welding and cooling method is simple, high in weld seam cooling speed, high welding quality, high welding efficiency, less argon consumption and low welding cost.

Owner:HARBIN INST OF TECH

Flash butt welding machine for vehicle door corner welding

ActiveCN101979208AEffortless pushLabor-saving operationResistance welding apparatusButt weldingServo drive

The invention discloses a flash butt welding machine for vehicle door corner welding, which comprises a base, clamping devices, an upsetting mechanism and an electric controller, wherein the clamping devices comprise a first clamping device for clamping a right welding piece and a second clamping device for clamping a left welding piece. The flash butt welding machine is characterized by also comprising a clamp adjusting device and an adjusting bottom plate capable of moving freely in a space, wherein the second clamping device is fixedly arranged on the adjusting bottom plate; an upsetting device comprises a guide rail seat, a moving component slipping along the guide rail seat and a servo driving device for driving the moving component to move; the first clamping device is fixedly arranged on the moving component; and a first insulating plate is arranged between the bottom of the clamp adjusting device and the base, and a second insulating plate is arranged between the bottom of theguide rail seat and the base. Compared with the prior art, the flash butt welding machine can randomly adjust the space placing position of the welding piece to ensure the welding quality and the appearance and profile requirements of a welded product; and the clamp adjusting device is convenient and simple in operation, and improves the welding efficiency.

Owner:NINGBO XINTAI MACHINERY

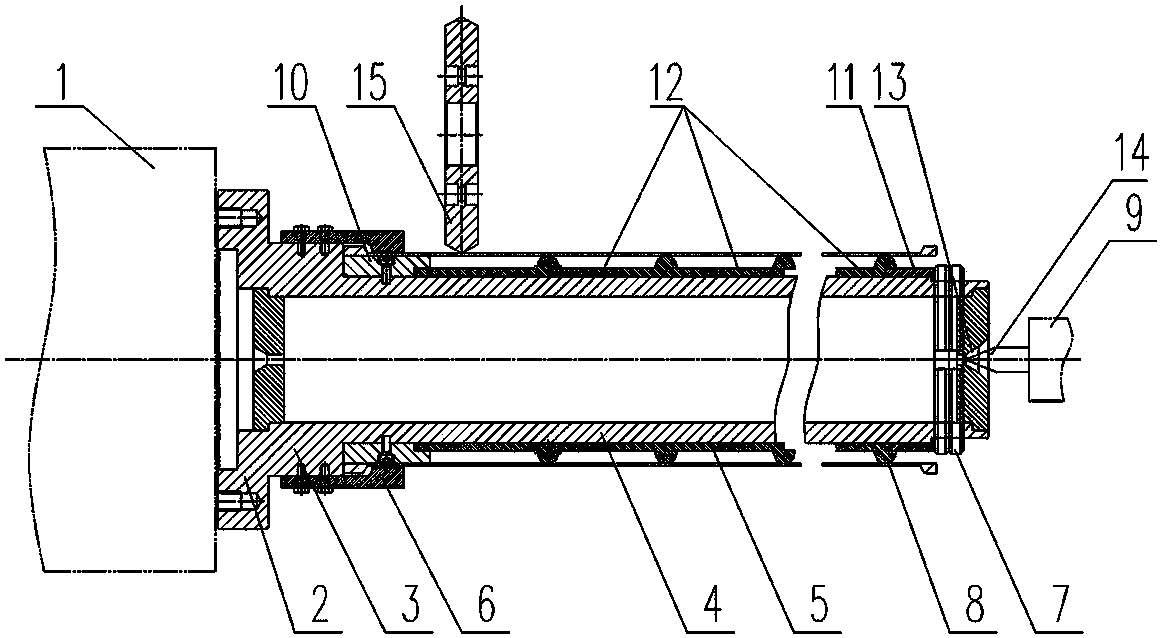

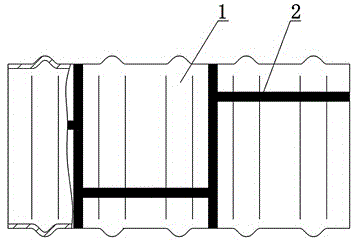

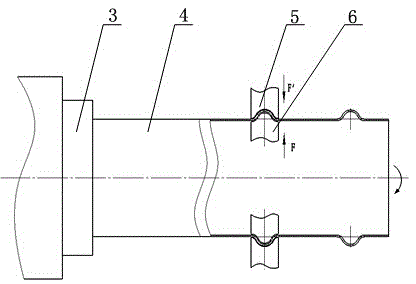

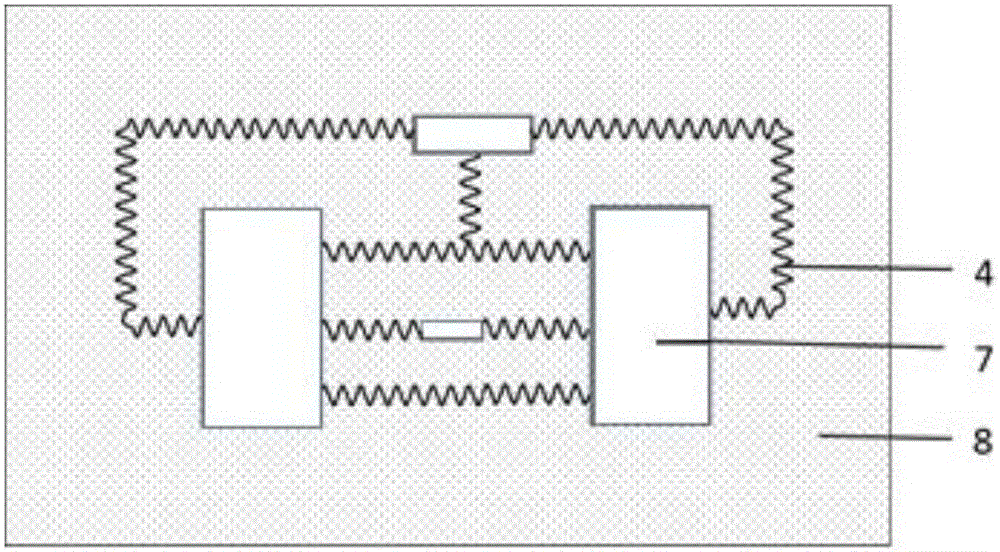

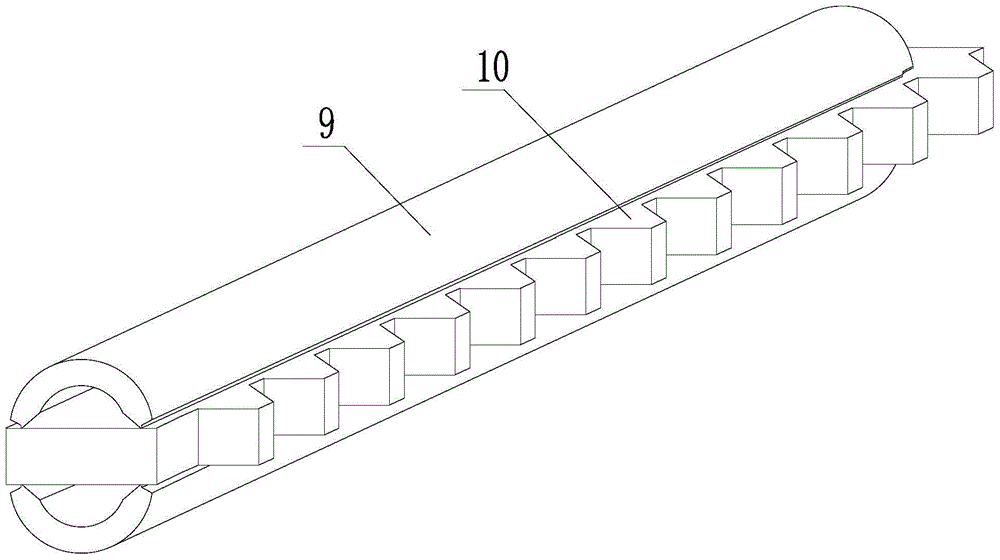

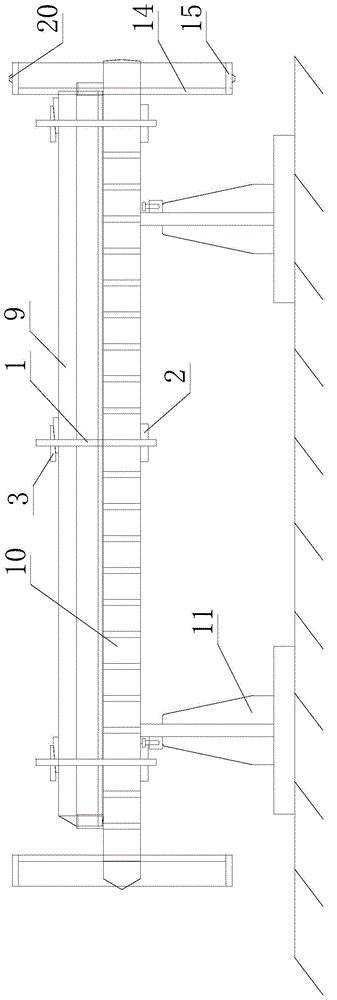

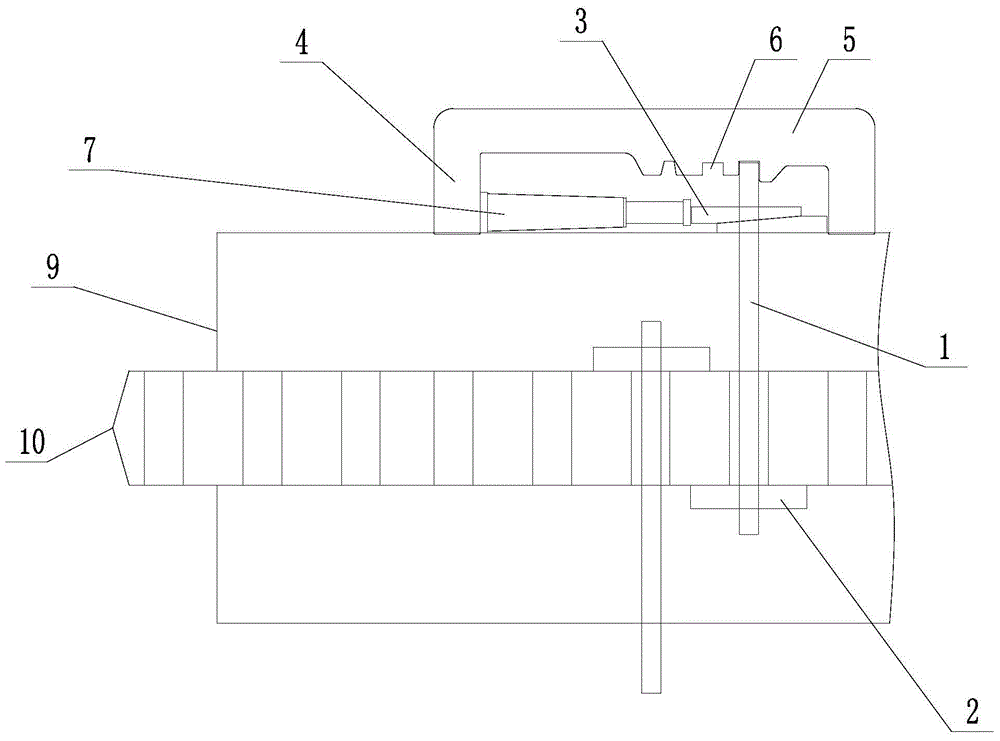

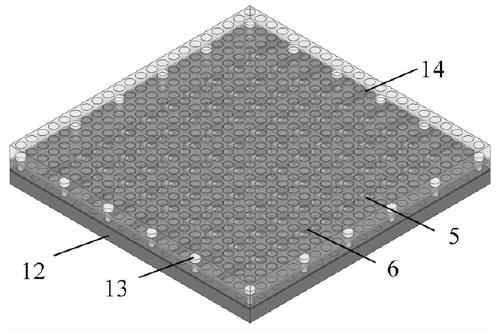

Spinning part support type corrugated pipe spinning equipment and forming method

ActiveCN104028606APrevent deformation defectsSimple structureShaping toolsSpinningIndustrial engineering

The invention discloses spinning part support type corrugated pipe spinning equipment which comprises a mandrel (2) connected onto a spinning machine spindle (1), wherein a press block (6) is arranged on a large-diameter section (3) of the mandrel (2); a small-diameter section (4) of the mandrel (2) is sleeved with a corrugated die (5); the press block (6) is tightly pressed on the outer surface of the corrugated die (5); a locking nut (7) at the tail end of the mandrel (2) is used for fixing the corrugated die (5); and the tail end of the mandrel (2) is tightly pressed and supported by a spring guide (9). The invention further discloses a corrugated pipe forming method adopting the equipment. The spinning part support type corrugated pipe spinning equipment and the corrugated pipe forming method adopting the equipment have the benefits as follows: the equipment is simple in structure and reasonable in design, the corrugation processing accuracy is high, the deformation defect of a pipe during the forming process is effectively prevented, and accordingly, the forming quality is improved; the corrugated die is suitable for processing pipes with different lengths, further, the dismounting is convenient, and the structure is firm; and besides, the circumferential weld of a product is reduced, the product quality is good, and the service life is greatly prolonged.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

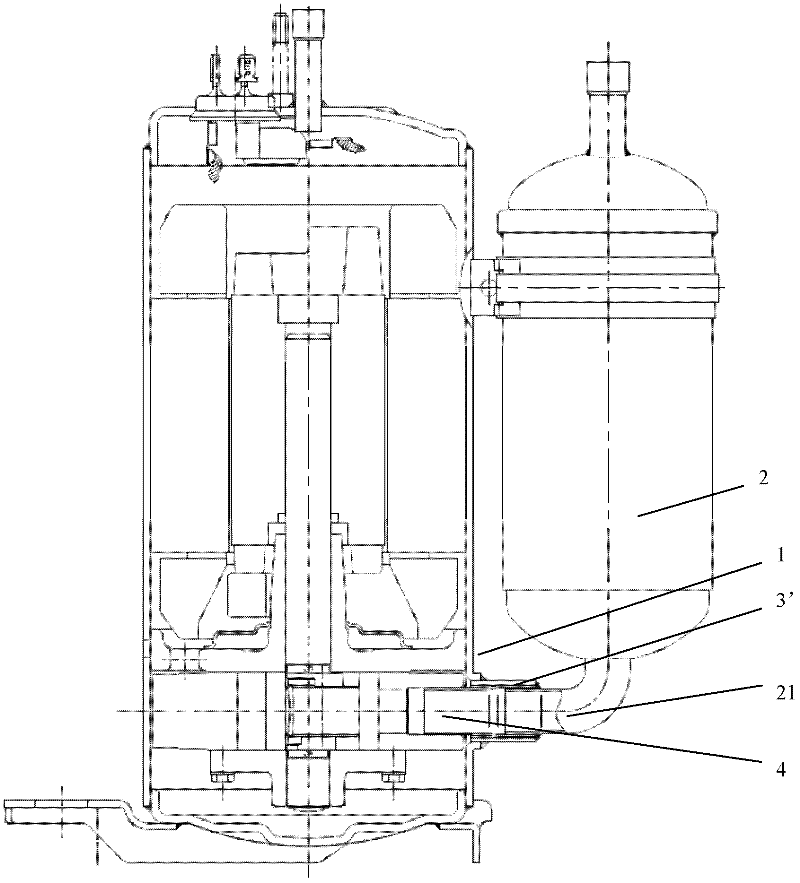

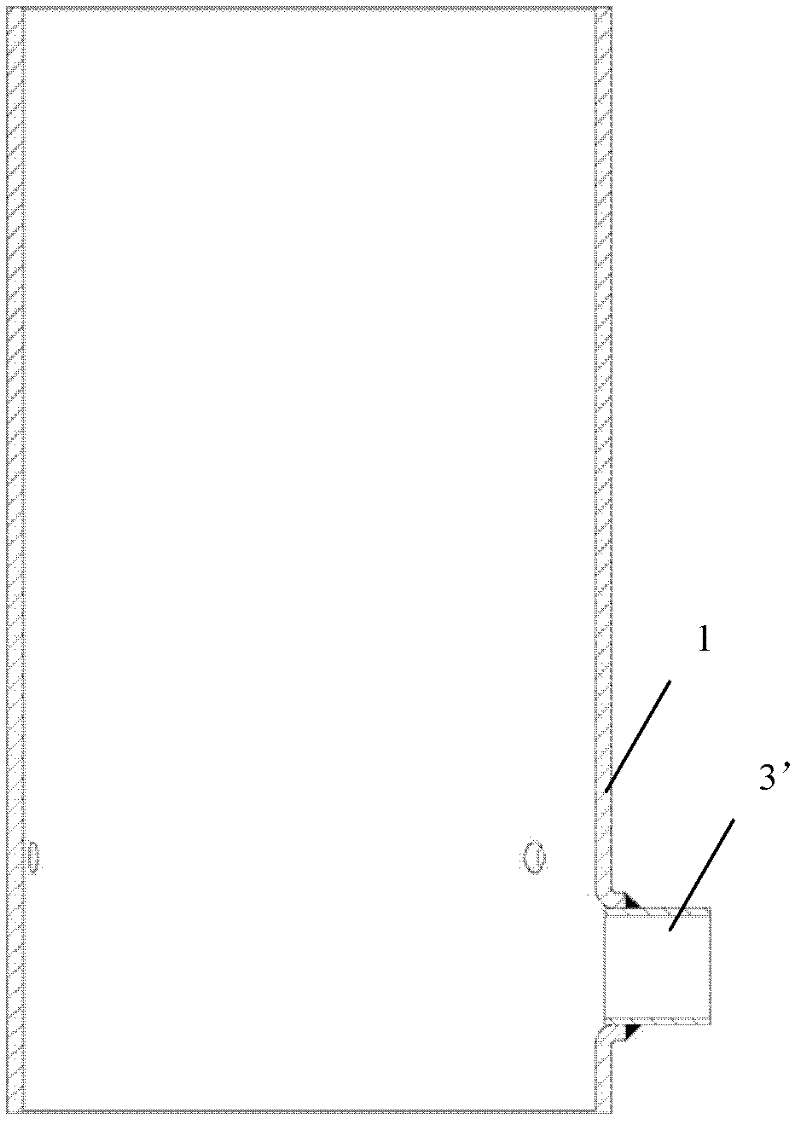

Resistance welding tube and manufacturing method and application thereof

InactiveCN102407410AEasy to makeReduce welding costsWelding/cutting media/materialsSoldering mediaElectrical resistance and conductanceLeakage rate

The invention discloses a resistance welding tube and a manufacturing method and an application thereof. The resistance welding tube disclosed by the invention adopts an iron basis material and is provided with an iron welding position and a copper welding position, wherein the copper welding position is covered with a copper layer; and the iron basis material is exposed on the iron welding position. The manufacturing method provided by the invention is simple; a welding tube formed by compounding copper and iron is obtained, wherein the part for being used to be welded with the iron (such as a compressor shell) is an iron material; the iron materials can be welded by resistance welding; compared with the existing technology that the iron material and the copper material are welded by silver solder and flame welding, the welding cost and the welding difficulty are lowered, the welding mechanical strength of the manufacturing method is improved by above 30%, the pressure resistance strength is improved by above 20% and the welding airtight leakage rate is reduced by above 70%; and the part for being used to be welded with the copper (such as a compressor copper tube) is a copper material, and the copper materials can be still welded by flame welding.

Owner:DONGGUAN JINRUI HARDWARE PROD

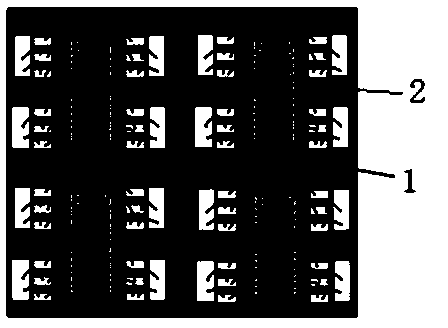

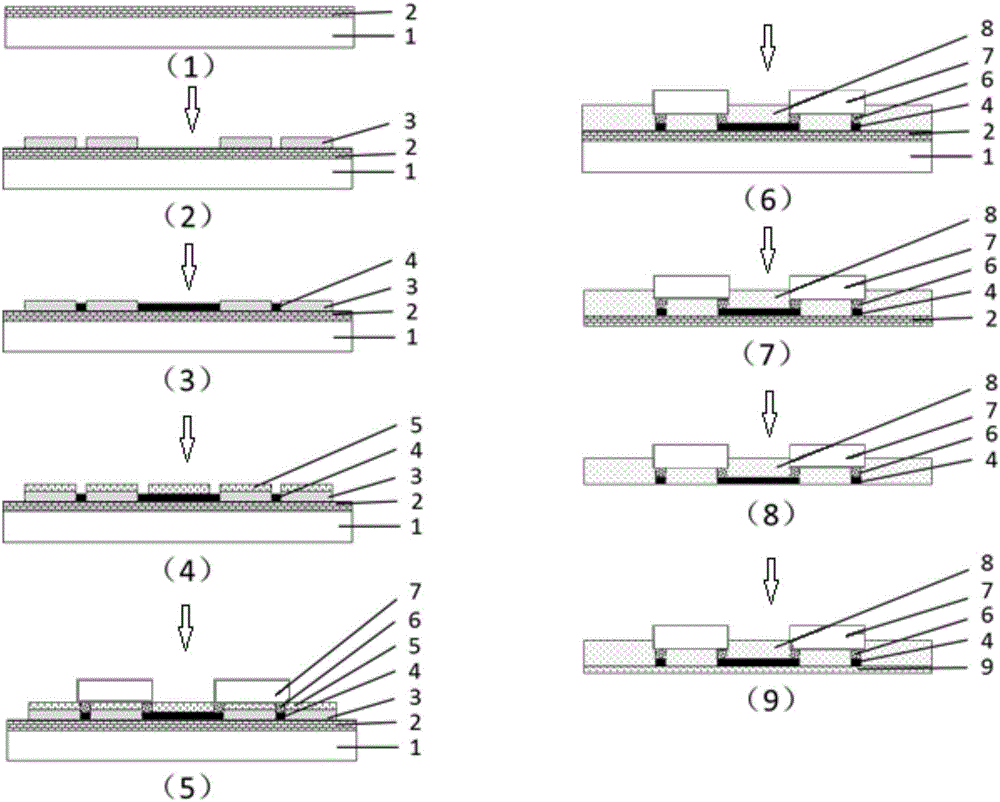

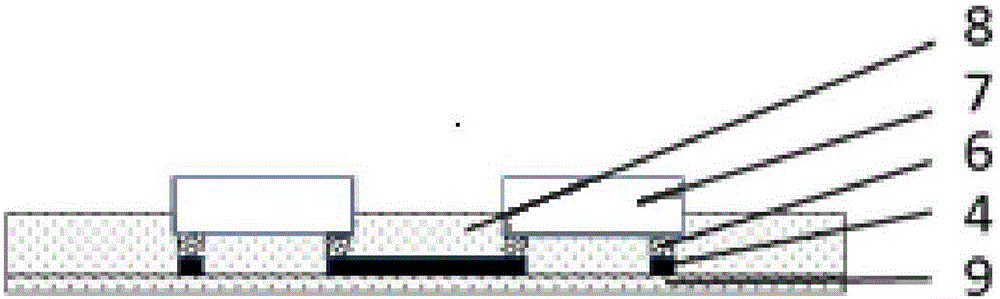

COB packaging structure of light-emitting diode

InactiveCN103594464AReduce design difficultyReduce wiring difficultySemiconductor/solid-state device detailsSolid-state devicesHigh densityChipset

The invention relates to a COB packaging structure of a light-emitting diode. The COB packaging structure comprises a substrate, n drive chips and n light-emitting diode chip sets, wherein each light-emitting diode chip set comprises N light-emitting diode chips, n and N are integers, n is larger than or equal to 1, N is larger than or equal to 1, the n drive chips and the n light-emitting diode chip sets are packaged on the front face of the substrate in a modular mode to form n sets of COB display modules, the n drive chips and the n light-emitting diode chip sets form lamp-driver co-plane devices in a one-to-one connection mode, a fixed number of bonding pads are arranged on the back face of the substrate, and all the drive chips and all the light-emitting diode chip sets are communicated with the bonding pads on the back face of the substrate in a routing and hole passing mode. The n lamp-driver co-plane devices are packaged to form a new COB device, the number of the bonding pads on the back face of the substrate is fixed and independent of the number of sets of the drive chips, and therefore a large number of pins are saved, external device cables are greatly reduced, and the higher density can be achieved compared with the density achieved through traditional packaging.

Owner:GUANGDONG VTRON TECH CO LTD

Preparation method of martensite matrix 1,100-MPa-grade rare earth Q and P steel

The invention relates to a preparation method of martensite matrix 1,100-MPa-grade rare earth Q and P steel. The steel is prepared from 0.15-0.22% of C, 0.60-1.70% of Si, 1.10-2.40% of Mn, 0.1-0.5% ofMo, 0.1-0.5% of Al, 0.05-0.11% of V, 0.01-0.05% of Y, 0.02-0.04% of P, 0.005% or below of S, 0.040-0.0700% of Nb, 0.0060% or below of N, 0.001-0.006% of B and the balance Fe and unavoidable impurities. After batching, the raw materials are smelt by a converter and refined and continuously cast by a vacuum furnace to obtain a cast blank, then trace alloy powder is added into an arc-melting furnace, a secondary cast blank is obtained, and heating and hot rolling are conducted in sequence; cold rolling is conducted after acid pickling; then the blank is heated to a two-phase region for heat preservation; carbon partitioning and tempering are conducted to obtain the final steel. According to the preparation method, through the addition of an appropriate quantity of various beneficial alloy elements, the contents of C, Si, Mn and other elements in traditional steel species are reduced, the weldability and corrosion resistance are improved, crystal grains are refined, produced steel plateshave good comprehensive mechanical properties, and lightweight, energy conservation and emission reduction of vehicles are facilitated.

Owner:SHANDONG JIANZHU UNIV

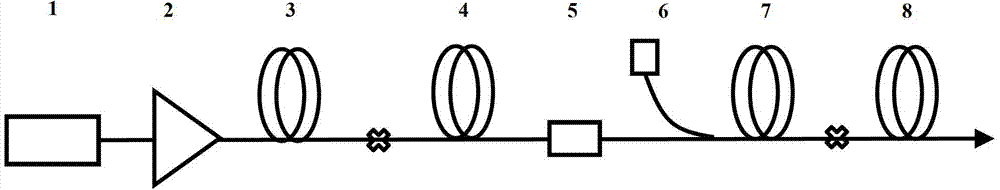

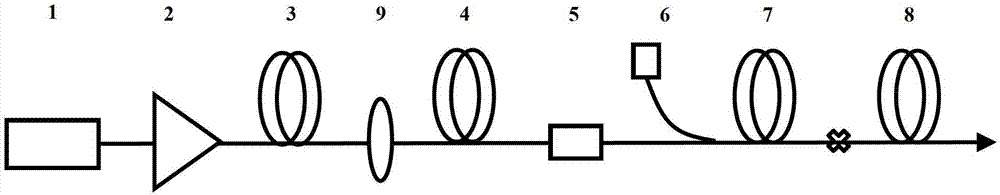

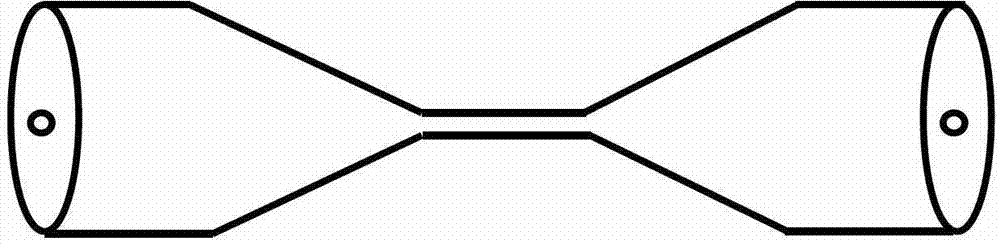

Intermediate/far infrared super-continuum spectrum fiber laser

InactiveCN102856783AIncrease powerLow costActive medium materialActive medium shape and constructionInfraredChalcogenide glass

The invention discloses an intermediate / far infrared super-continuum spectrum fiber laser which relates to the field of laser photoelectrons. The intermediate / far infrared super-continuum spectrum fiber laser comprises a pulse fiber laser, a quartz photonic crystal fiber, a passive intermediate infrared chalcogenide glass fiber, a passive intermediate / far infrared chalcogenide glass fiber, a filter, an excitation source and a rare earth ion doped chalcogenide glass fiber, wherein a super-continuum spectrum laser is generated by the pulse laser emitted by the pulse fiber laser through the quartz photonic crystal fiber to excite the passive intermediate infrared chalcogenide glass fiber so as to generate an intermediate infrared super-continuum spectrum laser; the intermediate infrared super-continuum spectrum laser is filtered by the filter; the filtered intermediate infrared super-continuum spectrum laser is used as a seed resource laser and amplified through the rare earth ion doped chalcogenide glass fiber; and the amplified intermediate laser is used for exciting the passive intermediate / far infrared chalcogenide glass fiber so as to generate an intermediate / far infrared super-continuum spectrum laser with a wavelength of 5-14 micrometers. According to the intermediate / far infrared super-continuum spectrum fiber laser, the shortage of light sources of intermediate / far infrared lasers is solved and the output of the intermediate / far infrared super-continuum spectrum laser is realized.

Owner:BEIJING UNIV OF TECH

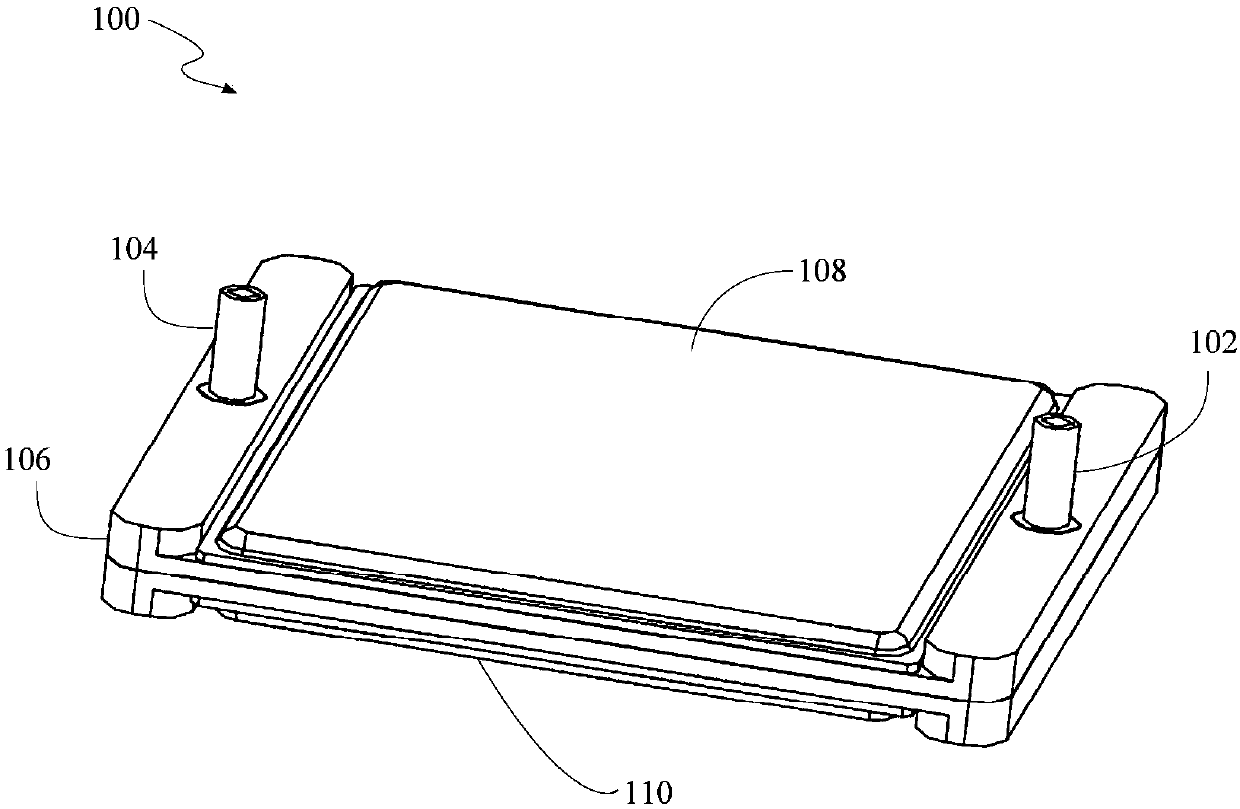

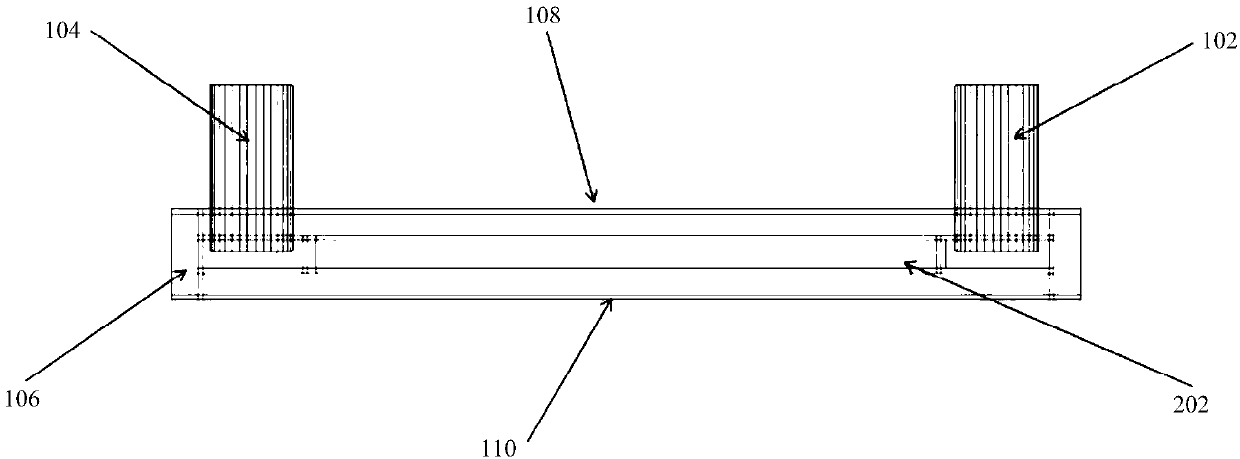

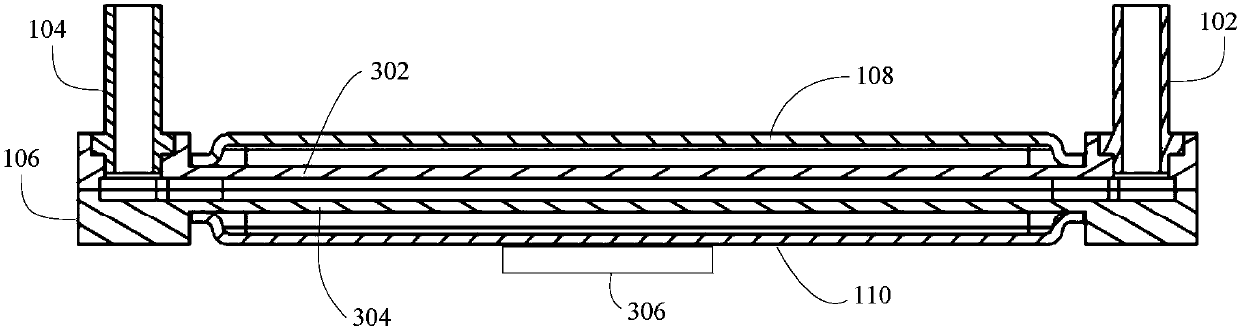

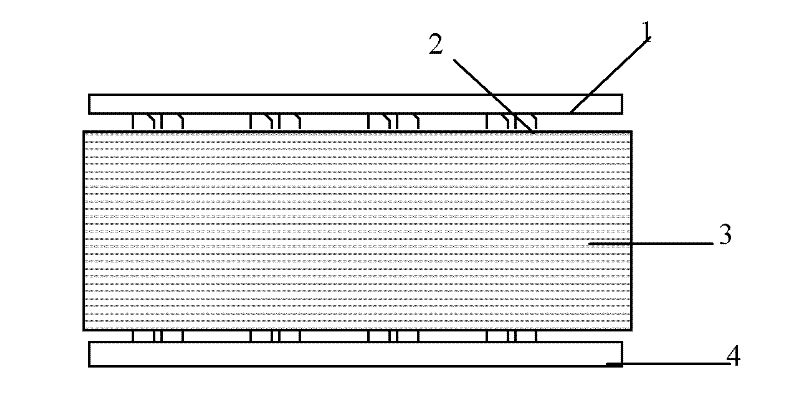

Liquid cooling heat dissipation device

ActiveCN107567248AReduce welding costsReduce welding difficultyCooling/ventilation/heating modificationsHeat transmissionEngineering

The invention discloses a liquid cooling heat dissipation device, comprising one or a group of vapor chambers and one or a group of suspended cold plates. The vapor chamber comprises four peripheral walls of the vapor chamber, a vapor chamber upper cover plate and a vapor chamber lower cover plate; the exterior of the suspended cold plate is fixed by the four peripheral walls of the vapor chamberor a supporting structure between vapor chamber upper and lower shells; and the vapor chamber comprises a heat absorption area for absorbing heat produced by a heat source, wherein a heat exchange path is formed by the fact that the heat source is transmitted to cooling liquid through the vapor chamber lower cover plate, the cooling liquid is vaporized to a steam chamber, heat exchange condensation is carried out on steam and the outer surface of the cold plate, the heat is transmitted to the cold plate, the cold plate transmits the heat to the cooling liquid through the wall surface of the cold plate, and the condensed liquid on the surface of the cold plate flows back to the position of the heat source along the wall surface of the cold plate and the supporting structure between the coldplate and the vapor chamber, thereby carrying out next-time circulation. According to the liquid cooling heat dissipation device provided by the invention is integrally formed by the vapor chamber and the liquid cooling cold plate, the welding cost and difficulty are reduced, a heat transmission path is reduced, a heat dissipation area is increased, and the heat dissipation efficiency is improved.

Owner:中微冷却技术(深圳)有限公司

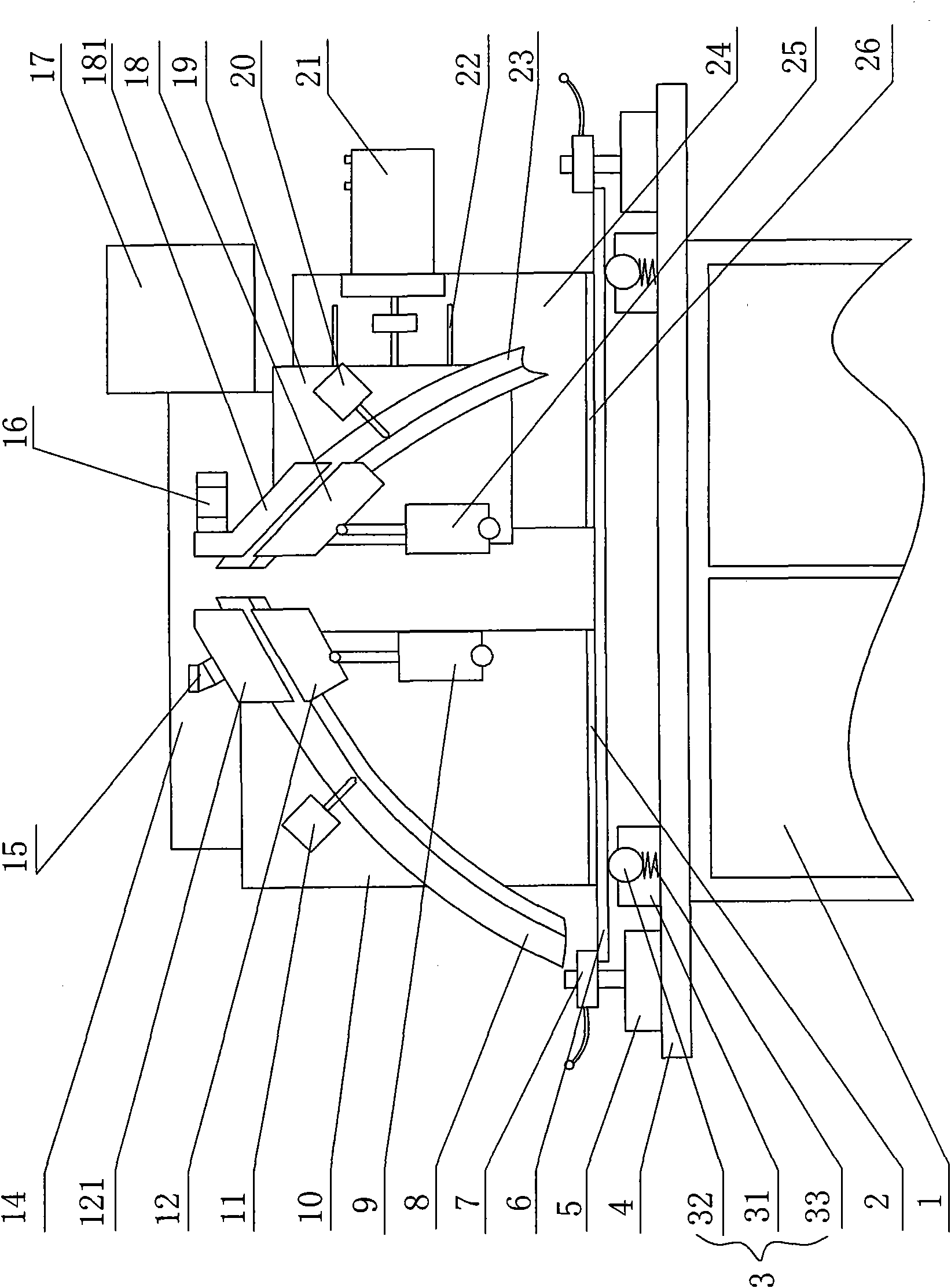

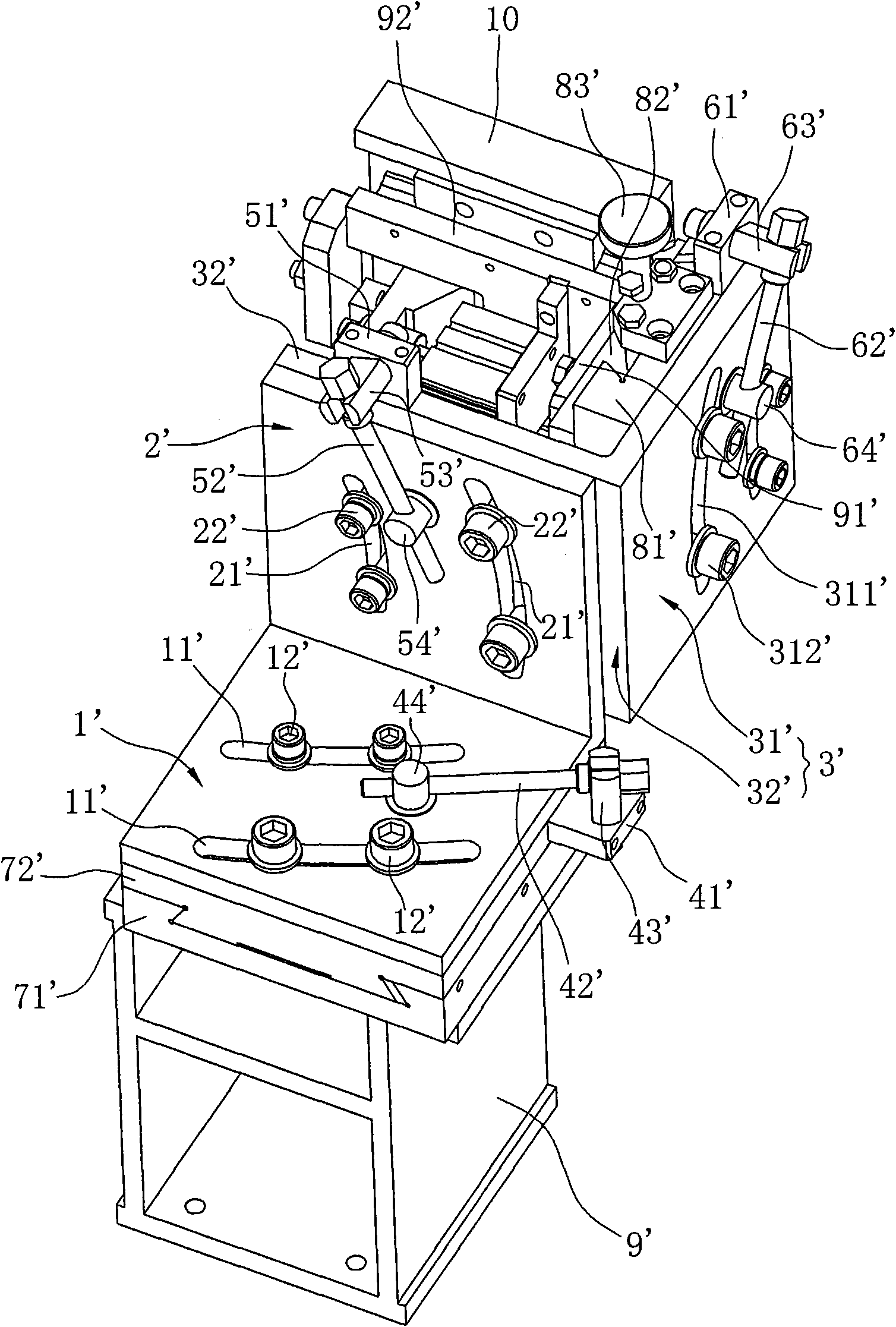

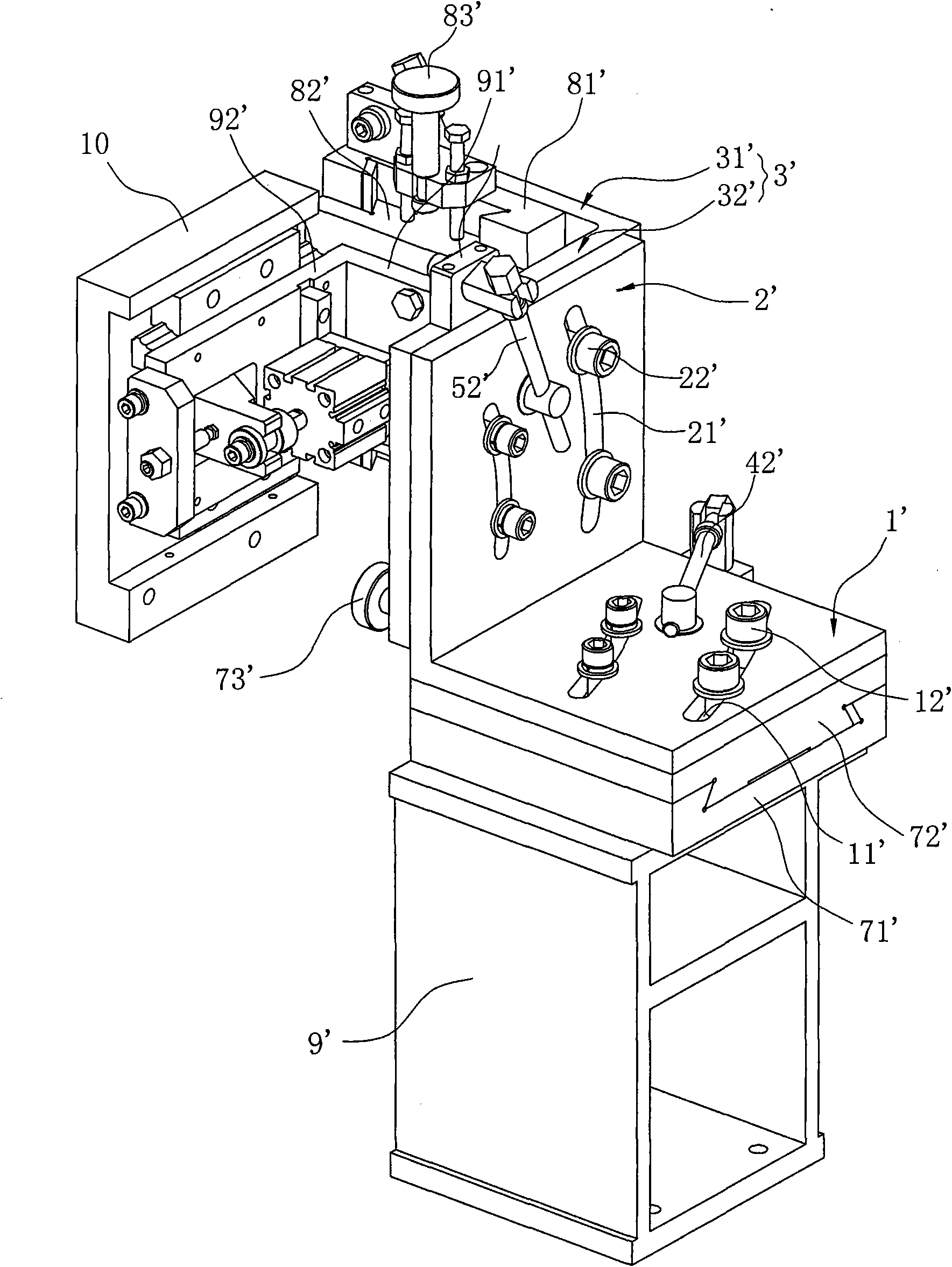

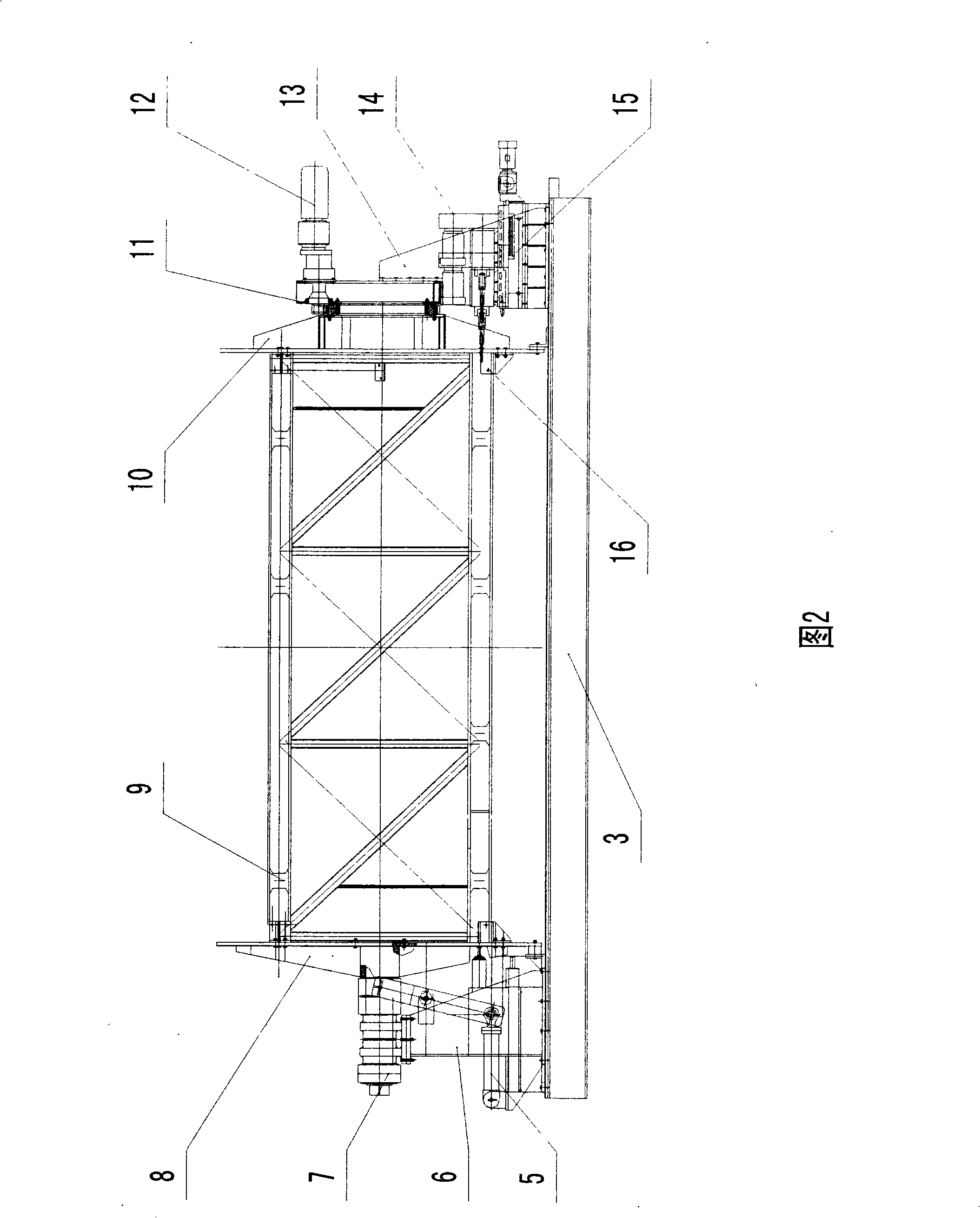

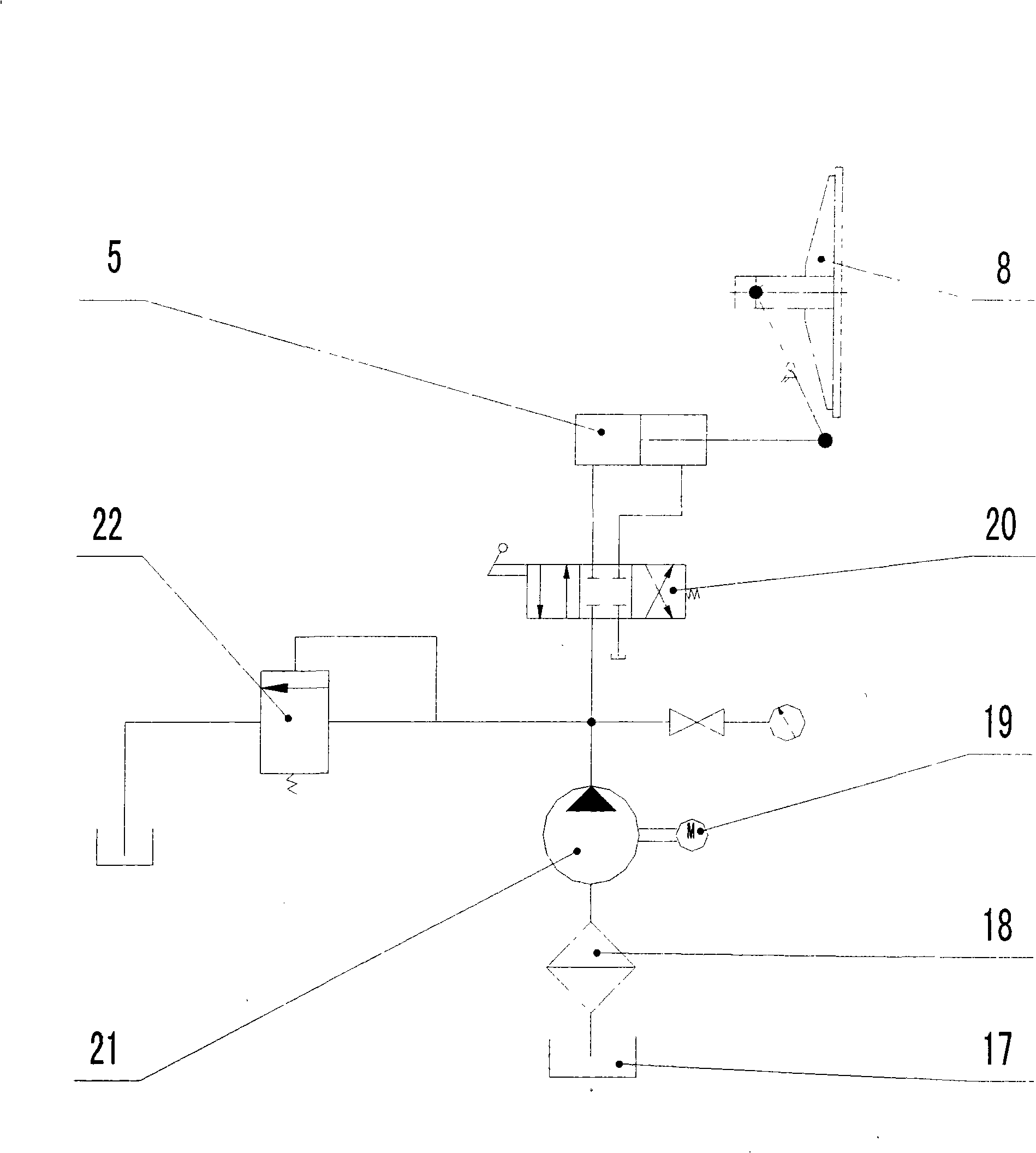

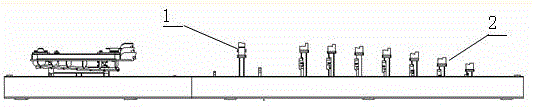

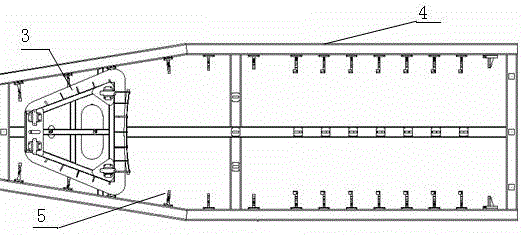

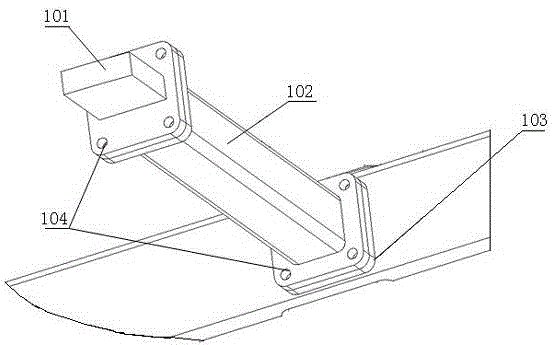

Column crane mast section rotating assembly tire

InactiveCN101352791AReduce welding difficultyGuarantee welding qualityWelding/cutting auxillary devicesAuxillary welding devicesMoving speedEngineering

The invention discloses a rotary jointed tire of a standard joint of a stacker crane which includes a base and a left rotating disc and a right rotating disc arranged at the two ends of the base; the left rotating disc is connected on the base by a bearing seat and a left supporting frame; the outer side of the left rotating disc is provided with a hydraulic cylinder and a hydraulic transmission mechanism that are horizontally impelled; the outer side of the right rotating disc is provided with a rotating supporter and a reducer driven by a motor; the right rotating disc is connected on the base by the rotating supporter and a right supporting frame. The rotary jointed tire of a standard joint of a stacker crane can lead a workpiece to rotate, can stop at any position, thus reducing the welding difficulty and ensuring the welding quality. Simultaneously, hydraulic transmission is adopted by the invention to draw the left rotating disc to move front and back and lead a jointed workpiece to enter and go out of a frock; compared with the screw rod transmission used by an old frock, the rotary jointed tire has the advantages that: working intensity is low, the moving speed is fast and the production efficiency is improved.

Owner:抚顺永茂建筑机械有限公司

Internal spinning forming method for corrugated tube

ActiveCN105537345AImprove product qualityReduced circumferential weldsEngineeringMechanical engineering

The invention discloses an internal spinning forming method for a corrugated tube. The internal spinning forming method for the corrugated tube comprises the following steps that a tube billet is installed on a main shaft of a spinning machine, and a length thin tube is driven by the main shaft to rotate; the interior and the exterior of the tube billet are respectively provided with an inner spinning roller and an outer spinning roller for forming corrugations; the inner spinning roller and the outer spinning roller synchronously work; a feed rate of the inner spinning roller is paused until a gap between a convex molded surface of the inner spinning roller and a concave molded surface of the outer spinning roller is 1.1 to 1.3 times of the thickness of the tube billet, and the gap is kept for forming for 3 to 5 seconds until one position machining is finished; the inner spinning roller and the outer spinning roller synchronously move for one pitch of waves along the axial direction of the tube billet, and the steps are repeated until the corrugated tube of a required length is formed. The internal spinning forming method disclosed by the invention is higher in forming precision and low in forming cost; moreover, a metallographic structure is even and compact due to grain refinement and spinning deformation of the corrugated tube during a spinning process; meanwhile, grains are squashed and stretched to form a fibrous tissue in a spinning direction; product quality is high, and the service life is greatly prolonged.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

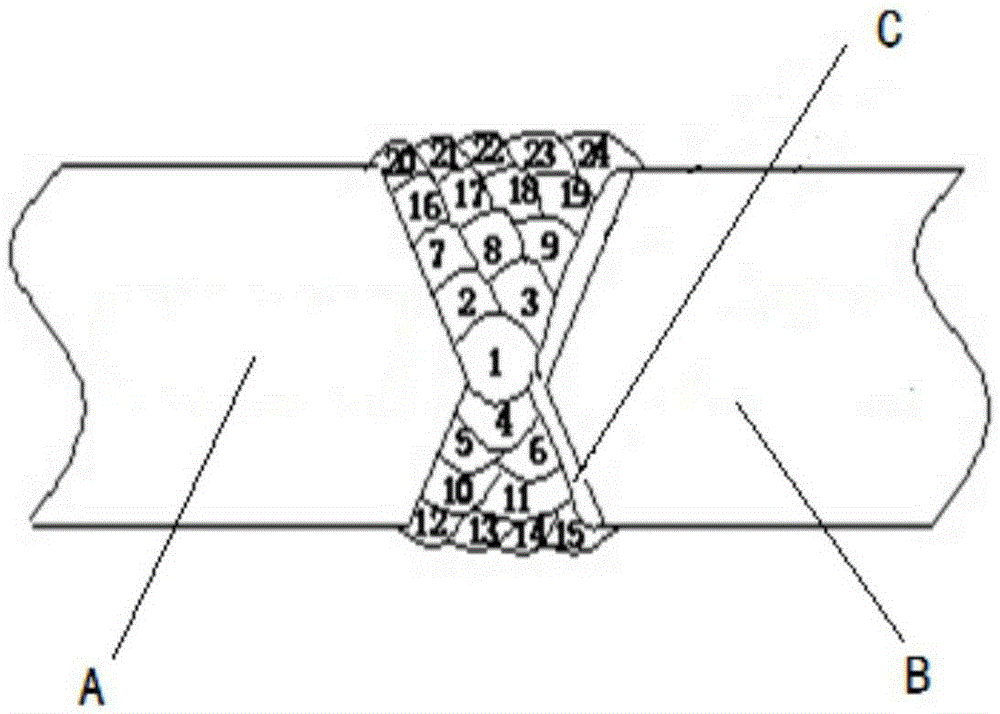

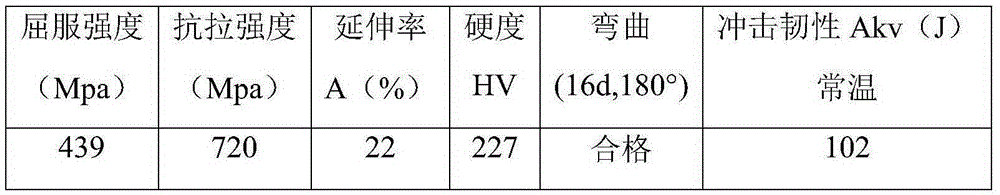

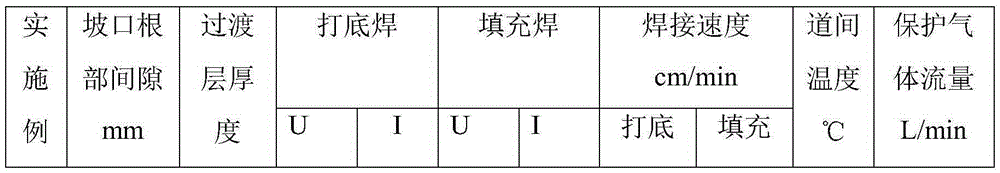

Gas metal arc welding process of medium-manganese wear-resistant steel and Q345B low-alloy steel

ActiveCN105345233AReduce construction costsImprove welding efficiencyArc welding apparatusWelding/soldering/cutting articlesWear resistantShielding gas

The invention creatively provides a gas metal arc welding process of medium-manganese wear-resistant steel and Q345B low-alloy steel. The process is characterized in that the welding current, welding voltage, welding speed and interpass temperature are optimized, and proper protecting gas and gas flow rate are selected, and the tensile strength of an obtained welded joint is more than 470MPa; the tensile failure occurs at the Q345B low-alloy steel side; the impact energy Akv of a welding seam is more than 100J; the welded joint is qualified in a bending test in which the bending diameter is 8d and a bending center angle is 180 degrees. Compared with a traditional welding process, the gas metal arc welding process has the advantages that a base material is free of preheating treatment before welding, and the welding seam is free of stress relief annealing treatment after welding, so that the construction cost can be saved, the welding efficiency can be improved, the welding difficulty is reduced, and the industrial popularization can be conveniently carried out for a construction site.

Owner:TIANJIN WILL LONG SCI &TECH CO LTD

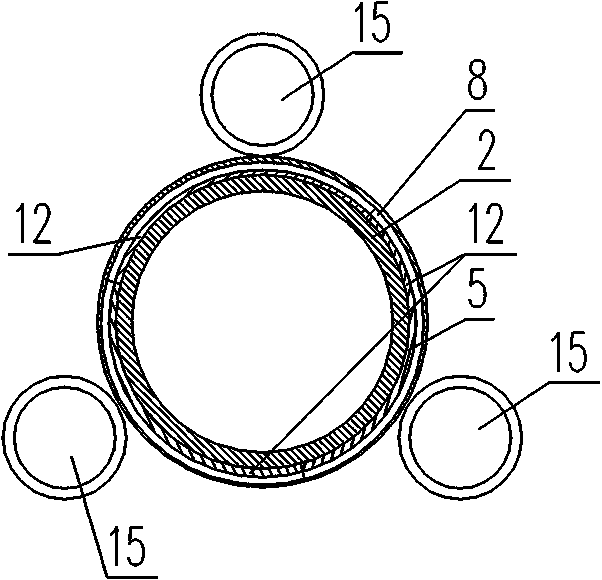

Double-layer pore plate type gas distributor easy to assemble

ActiveCN106640569AReduce the number of weldsReduce welding difficultyMachines/enginesUsing plasmaHollow cylinderEngineering

The invention discloses a double-layer pore plate type gas distributor easy to assemble. The double-layer pore plate type gas distributor easy to assemble comprises a gas guiding column, a distributor base, a first-layer pore plate, a second-layer pore plate, an outer baffle, an inner baffle and a fixing column. The gas guiding column, the distributor base, the outer baffle and the inner baffle are all hollow cylinders, the first-layer pore plate and the second-layer pore plate are both hollow circular plates, and the fixing column is a cylinder. One end of the distributor base is provided with holes for installation of the gas guiding column and the fixing column, the other end of the distributor base is provided with grooves for installation of the first-layer pore plate and the second-layer pore plate, and the first-layer pore plate and the second-layer pore plate are both provided with small holes for homogenizing gas. The outer baffle is fixedly connected with the outer side of the second-layer pore plate, the inner baffle is fixedly connected with the inner side of the second-layer pore plate, and the outer baffle and the inner baffle are further fixedly connected with the other end of the distributor base. Through the cooperation of the distributor base, the outer baffle and the inner baffle, the number of weld joints of the gas distributor is reduced, and the problem that a traditional gas distributor has multiple weld joints is solved.

Owner:BEIJING INST OF CONTROL ENG

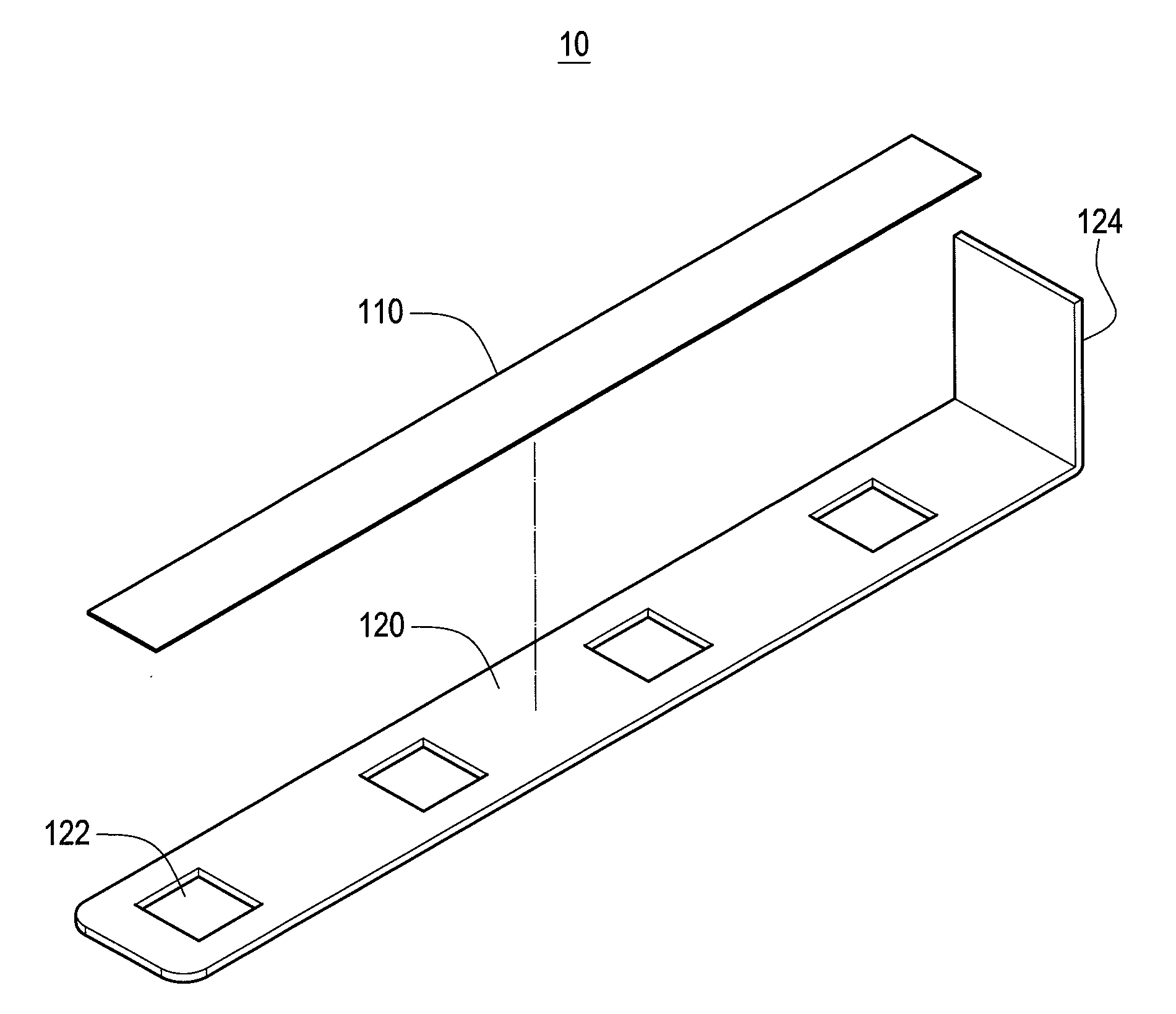

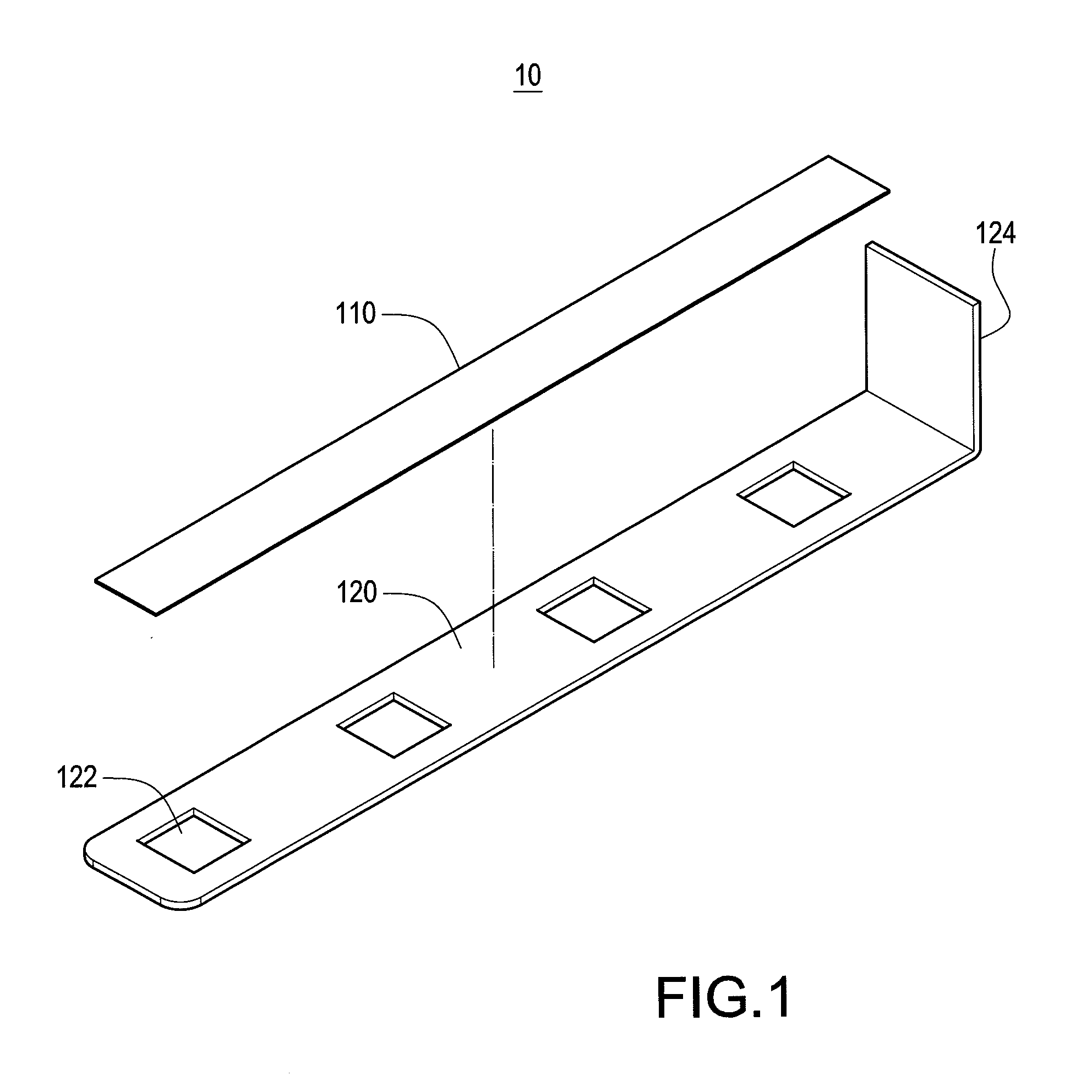

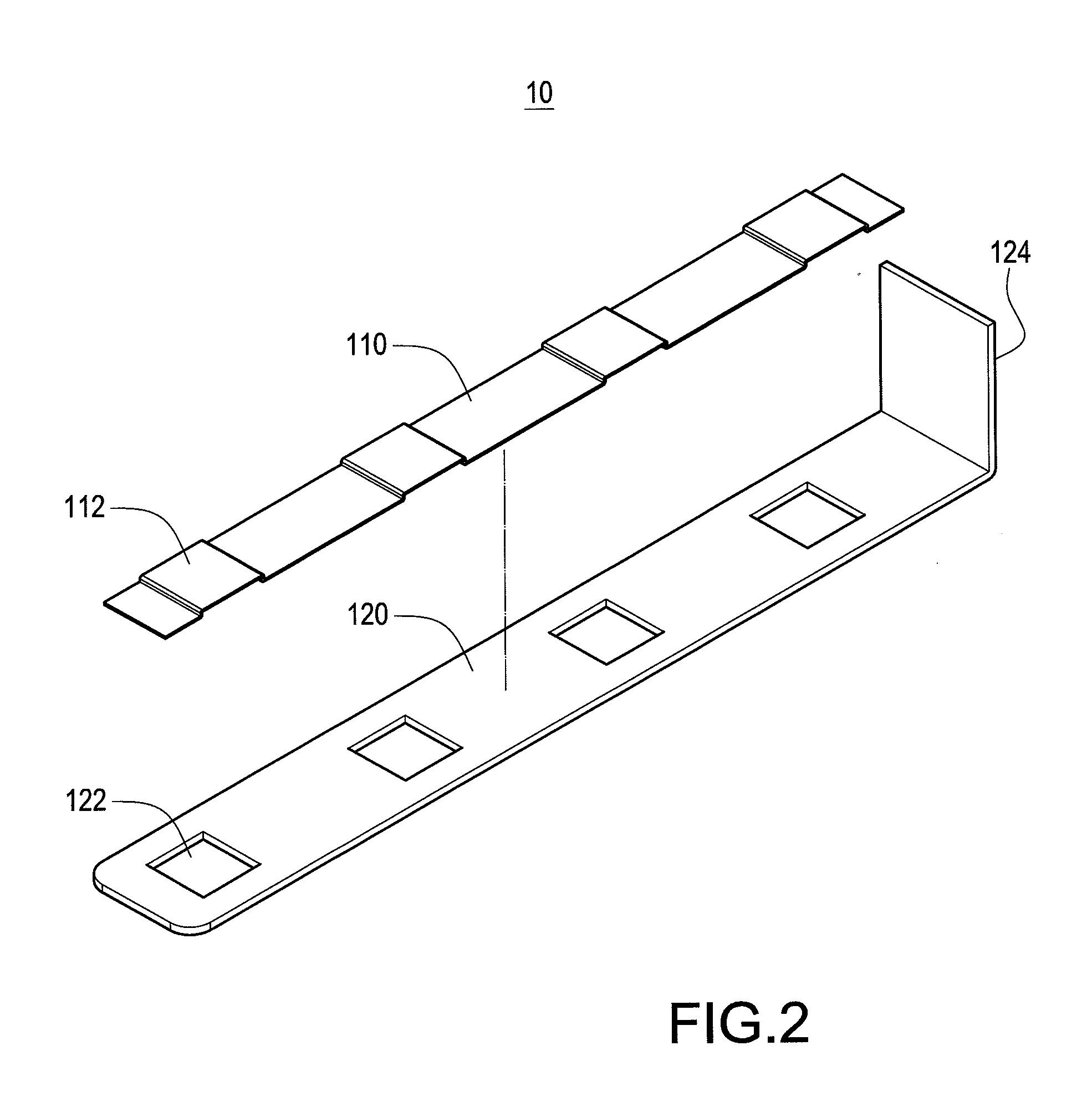

Battery connecting tabs

InactiveUS20110303459A1Improve conductivityImprove thermal conductivityCell component detailsCable junctionsEngineeringElectrical and Electronics engineering

The invention relates to a battery connecting tabs for electrically connecting a plurality of batteries. The battery connecting tabs include a first layer and a second layer adhered to the first layer. The second layer is physically and electrically connected to the first layer, and the second layer has a plurality of holes formed thereon, wherein the conductivity of the second layer is higher than the first layer, the thickness of the second layer is thicker than the first layer, and the first layer is physically and electrically connected to electrodes of the batteries.

Owner:DELTA ELECTRONICS INC

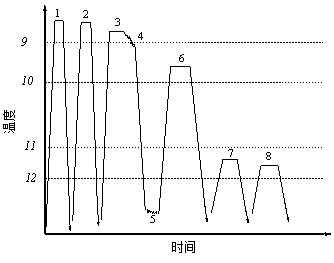

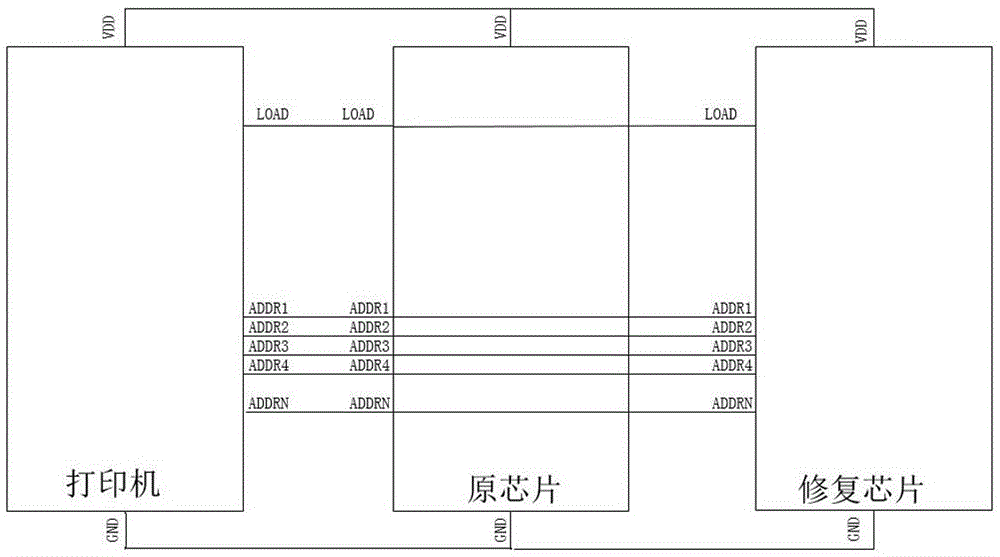

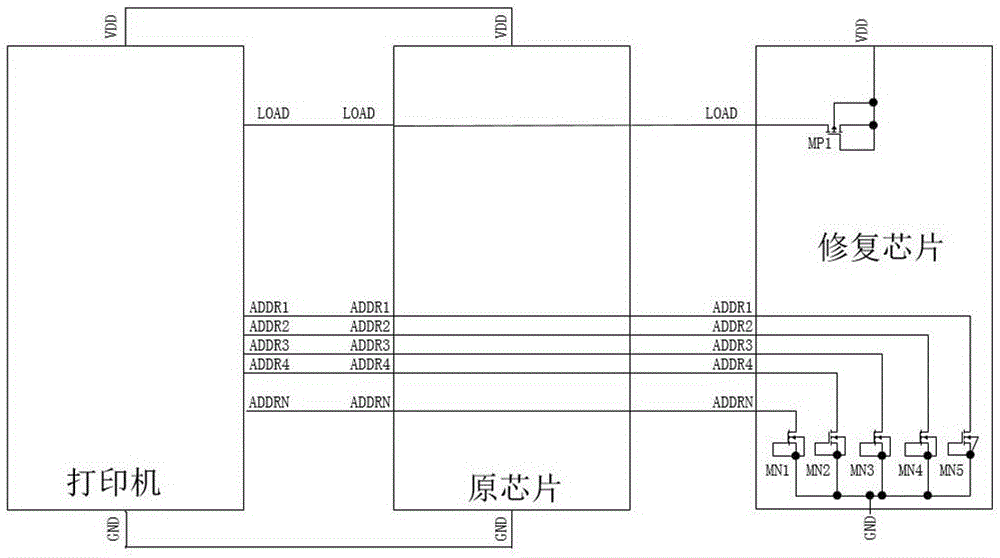

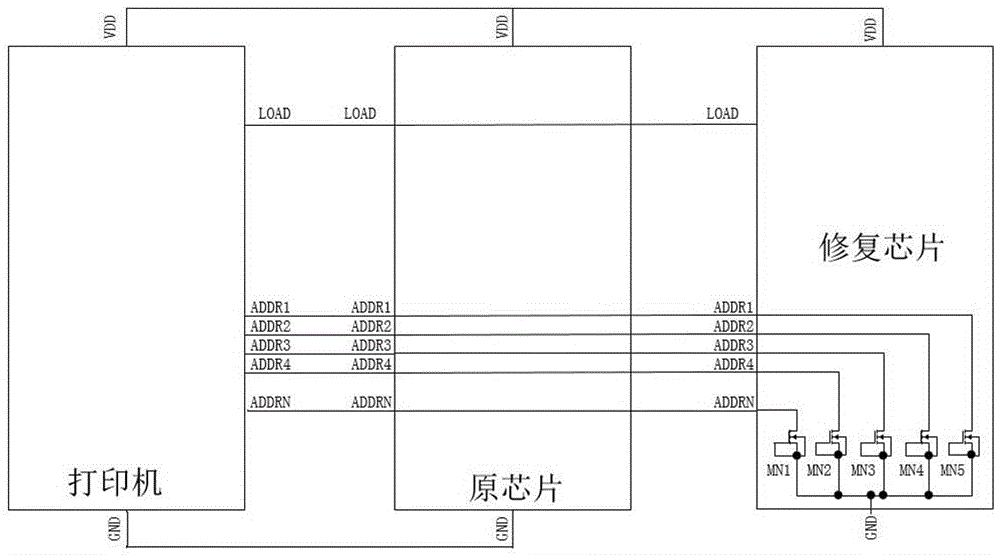

Restoration chip, regeneration chip, regeneration ink box, and printer system

The invention relates to the field of imaging consumable chip regeneration, and especially relates to a restoration chip, a regeneration chip, a regeneration ink box, and a printer system. A pull-up enabling signal on an enabling line of a printer is used for supplying power to the restoration chip in a communication process of the ink box and the printer, or a low-level signal on an address line of the printer is used as a chip reference place in the communication process of the ink box and the printer. At least the electrical connection between the restoration chip and one of a power contact and a ground line contact of an original chip is saved. Therefore, the welding difficulty of the regeneration chip of the ink box is reduced in the production process, and the yield of the regeneration chip is improved. Moreover, the restoration chip can be compatible with an original restoration chip software application, is more stable in operation, and is higher in reliability.

Owner:HANGZHOU CHIPJET TECH

Electrical connector and cell

InactiveCN103296241AReasonable structureSmall footprintCell component detailsLaser beam welding apparatusElectricityElectrical battery

The invention provides an electrical connector comprising at least two accommodating parts which are used to respectively accommodate at least two electrode pole ears of two curled pole cores which are adjacent; an extension which is used to connect to an electrode terminal on a cover plate; and an interconnecting piece which is used to connect the accommodating parts with the extension. The invention also provides a cell with the electrical connector. The electrical connector of the invention is reasonable in structure, and can be used for accommodating more than two curled pole cores via laser welding, so that the occupied space by the electrical connector is reduced, the welding difficulty of electrical connector to the curled pole cores and the cover plate is reduced, and unsoldering and pseudo soldering can be avoided. The electrical connector is beneficial for the integral structure setting of the cell, and enables the volume energy density of the cell to be increased.

Owner:SHENZHEN BYD LITHIUM BATTERY

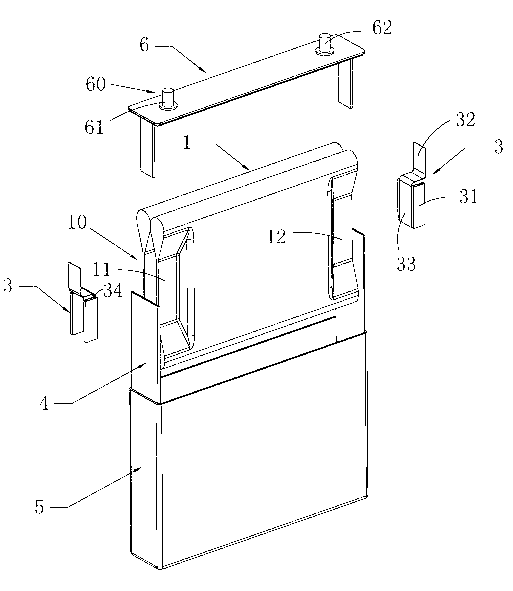

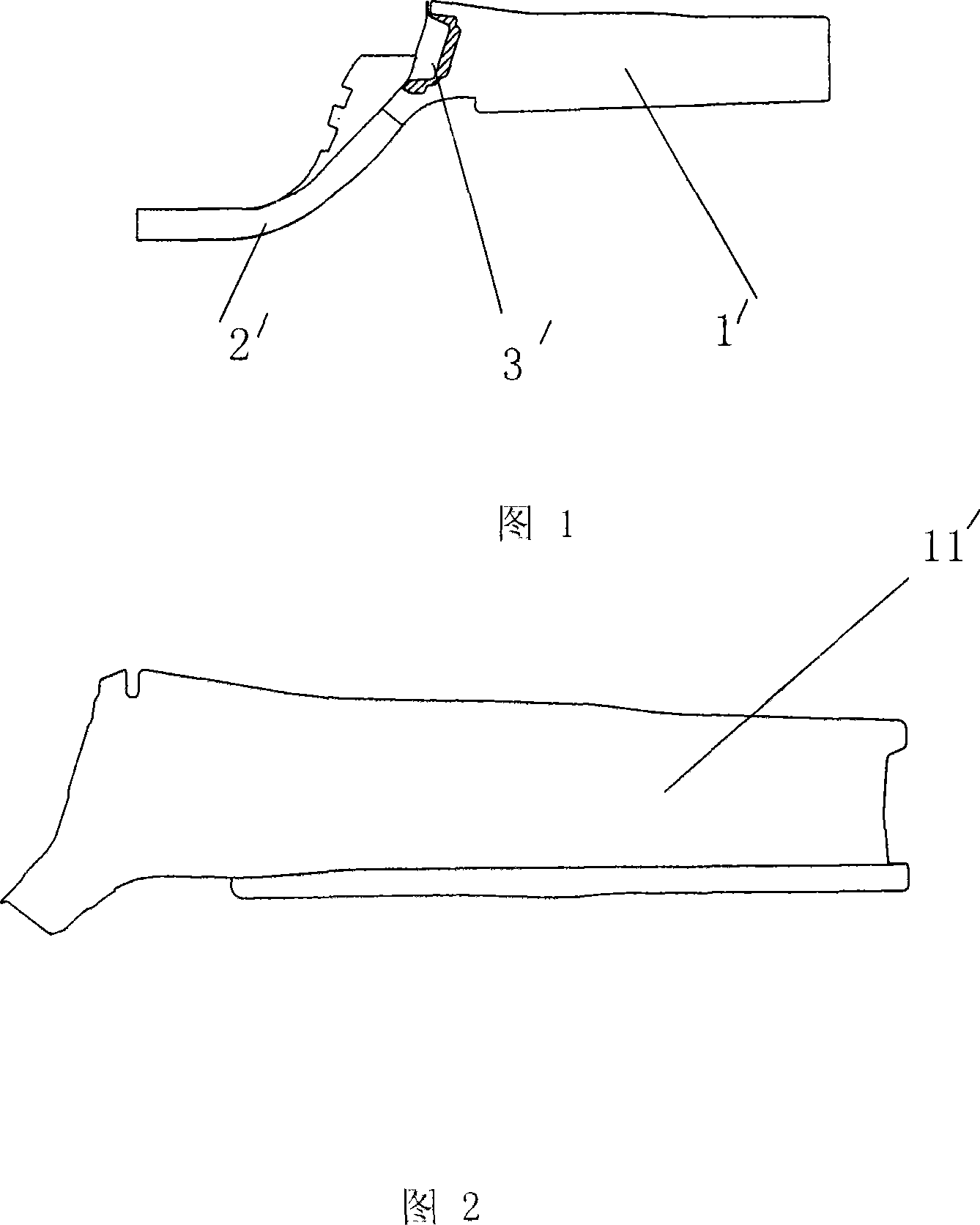

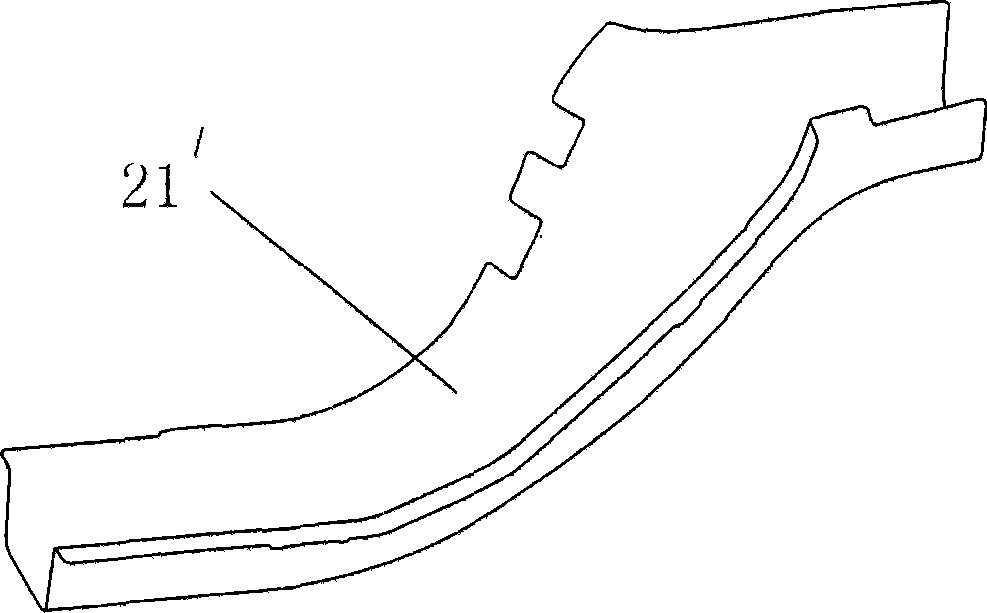

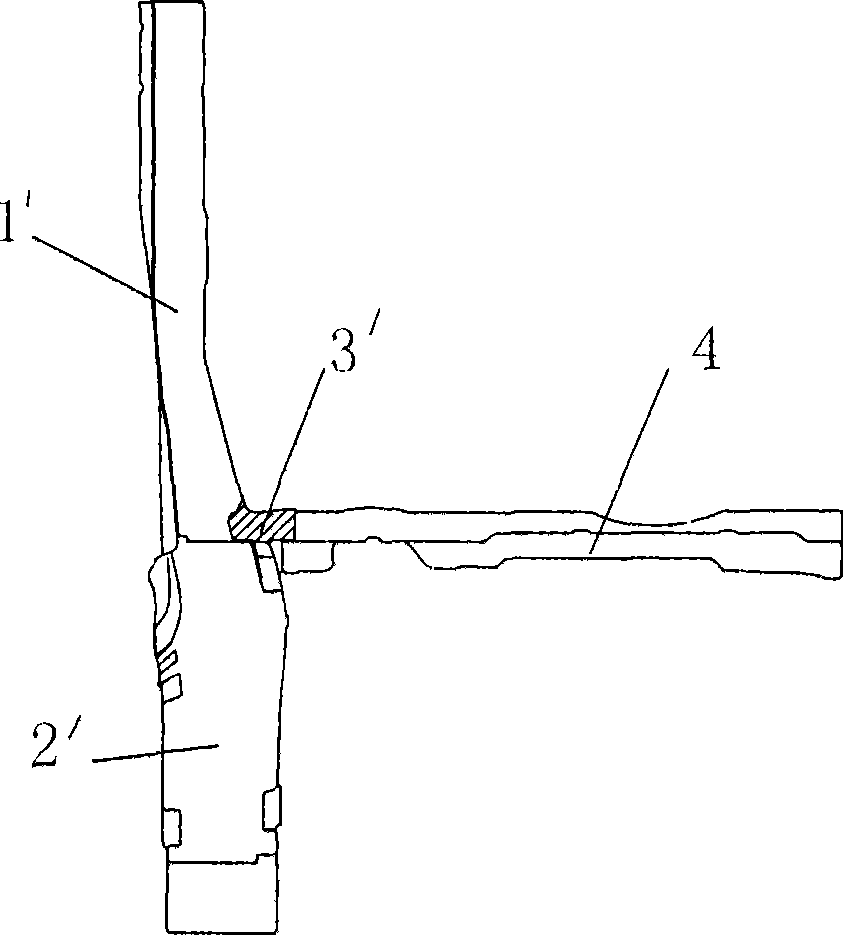

Front stringpiece of vehicle body

ActiveCN101367410AEasy to processGuaranteed Continuity of DeliverySuperstructure subunitsMonocoque constructionsEngineeringClosed cavity

The invention discloses a front longeron of an automobile body, which comprises a front part of the front longeron connected with a front bumper of the automobile and a rear part of the front longeron connected with a front baffle of the automobile, wherein the front part of the front longeron comprises a sealed cavity structure welded by a front body plate of the front longeron and a front outer plate of the front longeron; the rear part of the front longeron comprises a sealed cavity structure welded by a rear body plate of the front longeron; the front lengeron also comprises a connecting piece which connects the front part of the front longeron and the rear part of the front longeron; the connecting piece is in a three-way groove shape; one end of the connecting piece is provided with a connector welded with the front part of the front longeron; and the other end of the connecting piece is provided with a connector welded with the rear part of the front longeron and a connector welded with a middle crossbeam of the front baffle. As the front longeron of the automobile body is designed into three parts, and a bending surface and a welded surface are integrated on the connecting piece, thereby improving the whole strength and proper force dividing transfer; in addition, the front longeron has the advantages of convenient processing and low welding difficulty.

Owner:CHERY AUTOMOBILE CO LTD

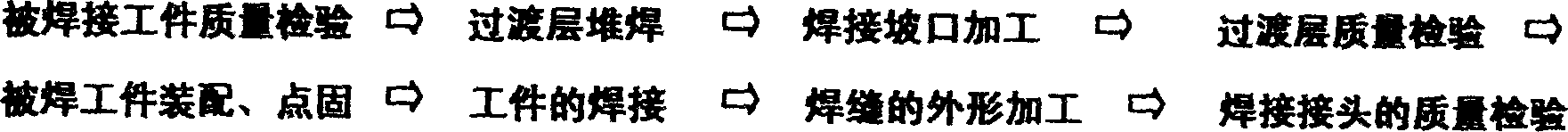

High carbon steel rail and high manganese steel frog welding technology

InactiveCN1442265AEasy to trainLess investmentWelding/cutting auxillary devicesAuxillary welding devicesShielded metal arc weldingHigh carbon

A technology for welding high-C steel rail and high-Mn steel switch fork of railway includes such steps as build-up welding of Cr-Ni-Mo alloy transition layer on the steel rail, build-up welding of Mn-Cr-Ni alloy transition layer on the switch fork and solid dissolving, matching their U-shaped bevel joint surfaces, and manual arc welding. Its advantages are high welding quality and stability and low cost.

Owner:唐山铁路道岔厂 +1

Construction method for butt welding irregular space box-type steel members

InactiveCN102091877AGuaranteed flatnessGuarantee welding qualityWelding apparatusButt weldingStructural engineering

The invention provides a construction method for butt welding irregular space box-type steel members, comprising the following steps of: (1) mounting at least a fabrication hole at an upper wing plate at a welding position; (2) butting two sections of the steel members; (3) entering into the box of the steel box from the fabrication hole, and welding butting positions of a lower wing plate and ribs by means of sectional and symmetrical welding; (4) welding the butting positions of side plates at the external part of the box of the steel box by means of symmetrical welding; and (5) welding a cover plate on the fabrication hole. The construction method provided by the invention is convenient in operation, and capable of removing welding stress and improving welding quality.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

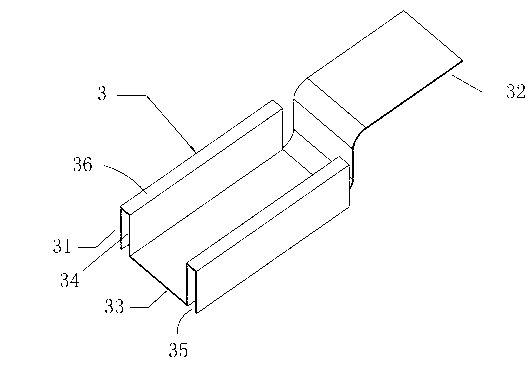

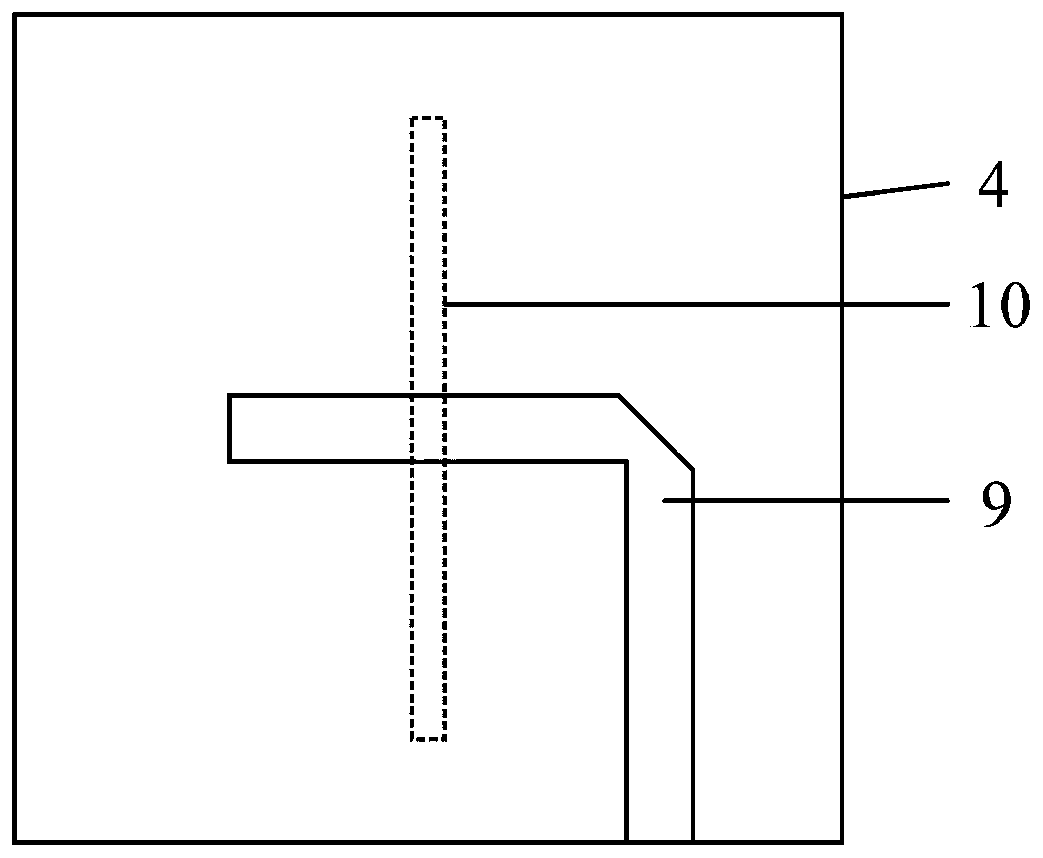

Flat tube heat exchanger and its assembly method

InactiveCN102266992AReduce welding difficultyAvoid interferenceEvaporators/condensersSoldering apparatusShell and tube heat exchangerEngineering

The invention provides an assembly method of a flat tube heat exchanger. The assembly method comprises the following steps: (1) firstly brazing a collecting tube and a flat tube of the heat exchanger at a high temperature to form a heat exchanger framework; (2) arranging a welding material on the surface of the flat tube of the heat exchanger framework; (3) sequentially and alternately fixing fins in a fixed groove of a fixed station regularly, and arranging the opening end of a U-shaped pipe groove outwards; (4) allowing the fixed station to get close to the heat exchanger framework so that the flat tube is correspondingly inserted into a fin pipe groove until the flat tube enters the bottom of the pipe groove; and (5) placing the assembled heat exchanger in a low-temperature brazing furnace for soft soldering so as to complete connection assembly of the heat exchanger. In the assembly method, firstly the flat tube and the collecting tube are welded into the heat exchanger framework and then the fins are assembled, which can well eliminate interference in combination of soft soldering and hard soldering and prevent soft solder from being refused to affect the heat transfer coefficient during the hard soldering process; and meanwhile the welding difficulty of the flat tube and the collecting tube is reduced, and the product quality is improved.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

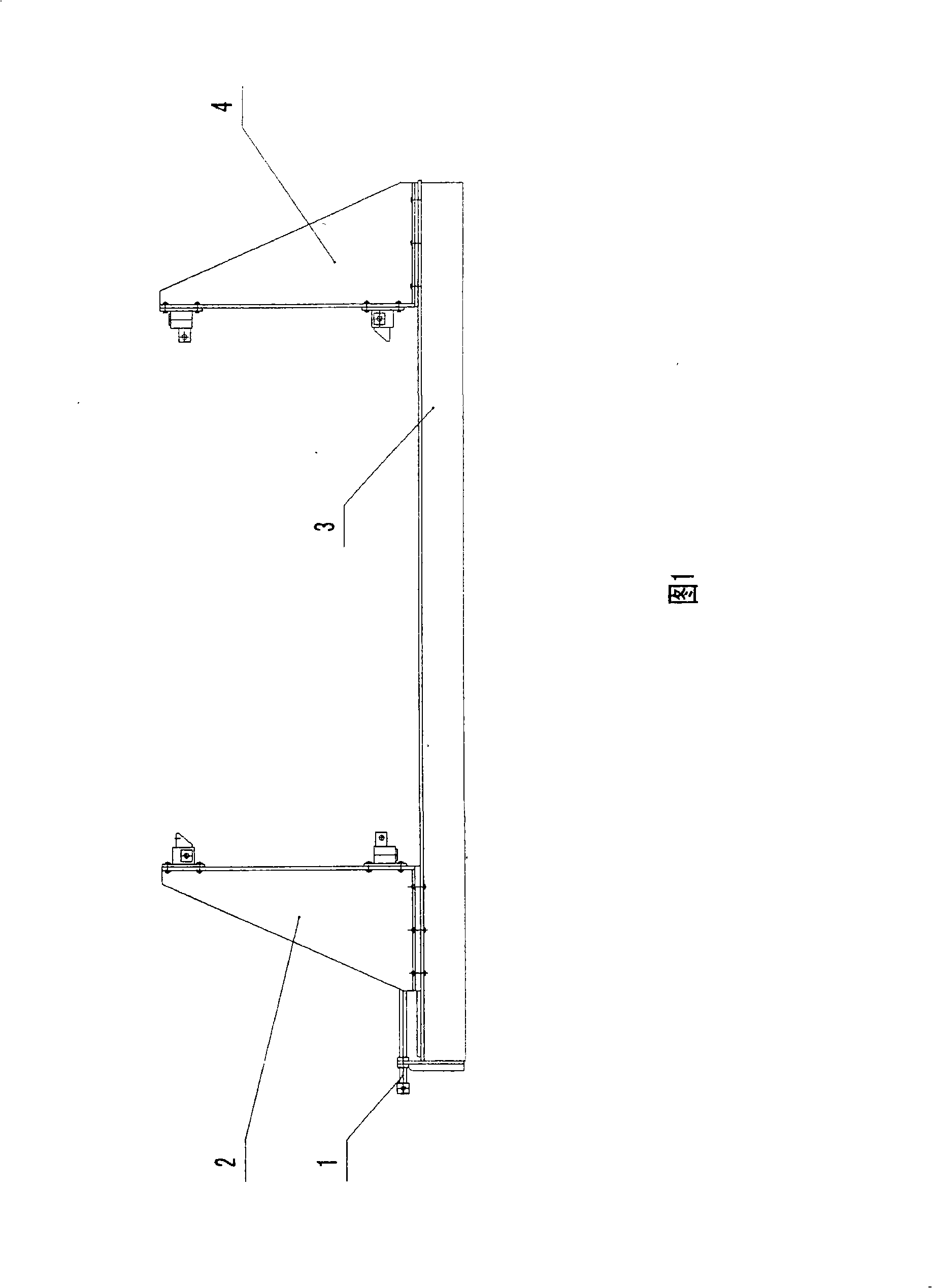

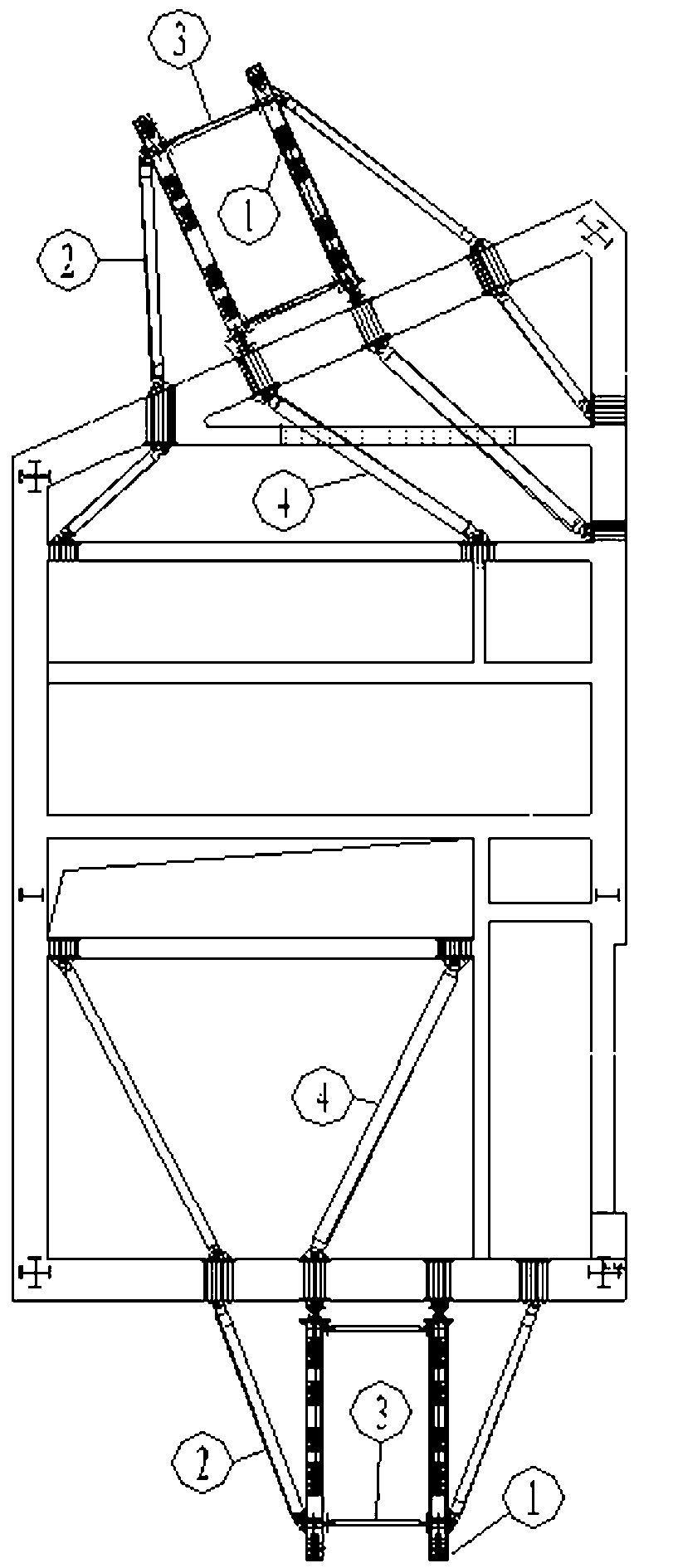

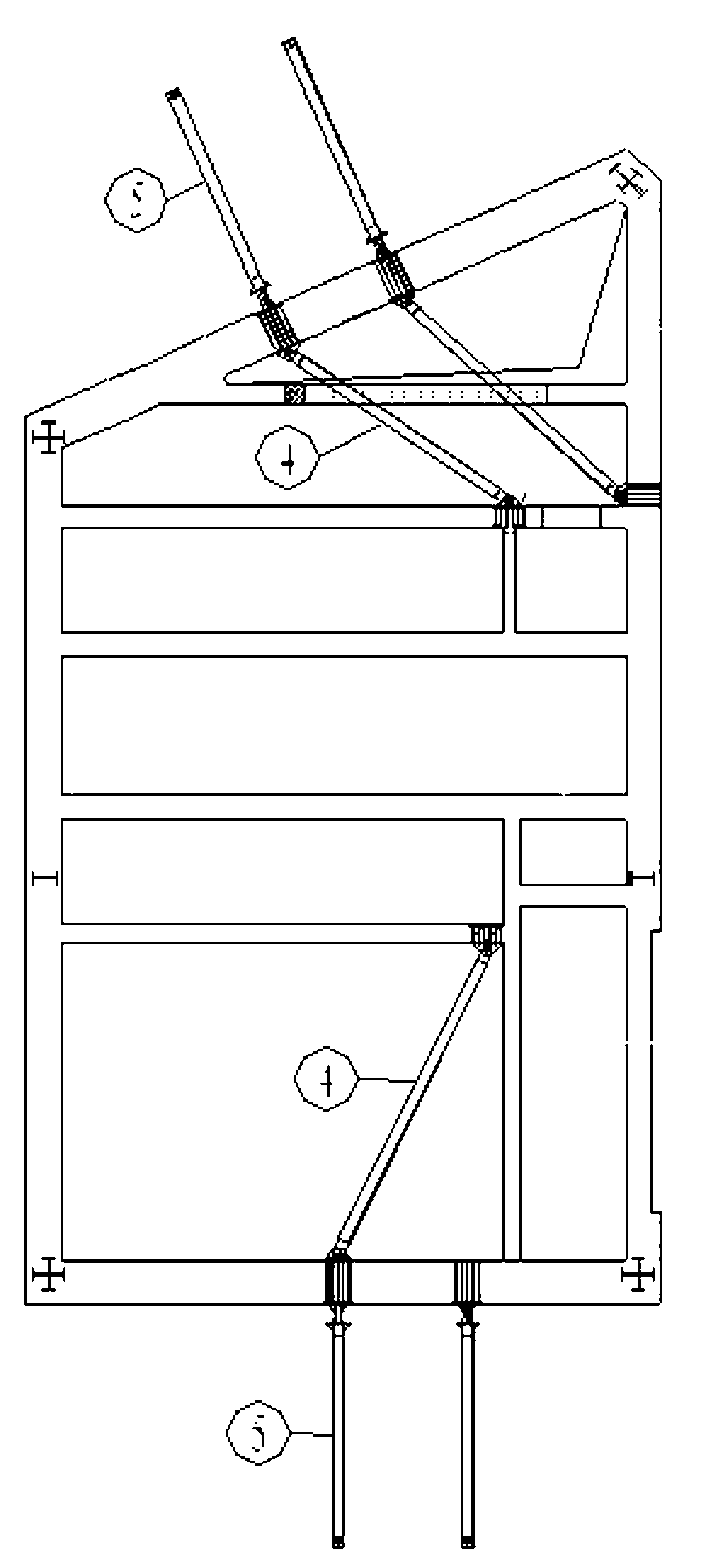

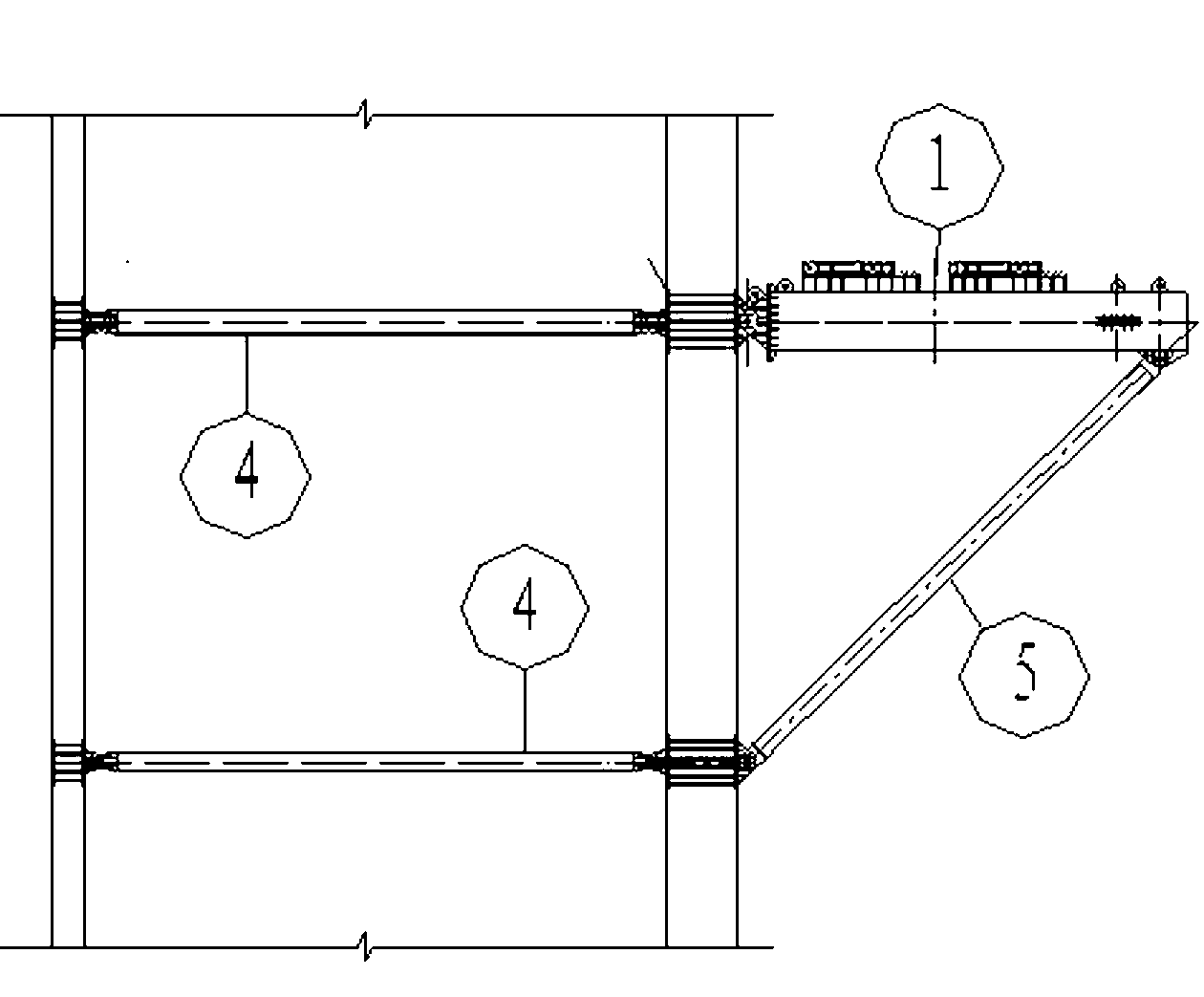

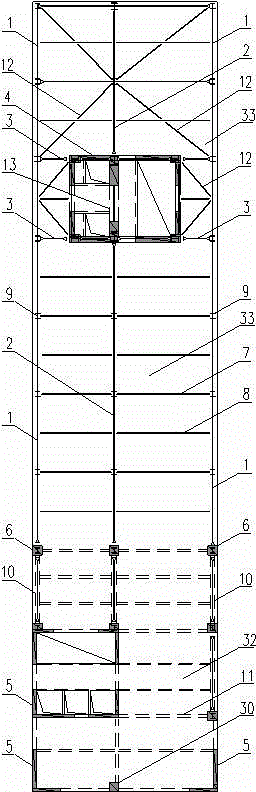

Super high-rise core tube internal and external hanging tower crane support beam structure and construction method thereof

InactiveCN103264968AFull utilization of hoisting rangeReduce the number of jackingsCranesSupporting systemTower crane

The invention relates to a super high-rise core tube internal and external hanging tower crane support beam structure and a construction method thereof. Two parallel horizontal tower crane support girders are arranged, the sections form box shapes, a root part of each girder is connected with a core tube embedded part through a girder ear plate, inclined supports are circular pipes, one end of the inclined support is supported and connected to a core tube, the other end is connected with the vertical tail end of the corresponding girder, one end of a horizontal pull rod is connected to the core tube in an inclined manner, the other end is connected with the horizontal tail end of the corresponding girder, and the two girders are connected by a horizontal connection rod to form a main body frame support system. According to the super high-rise core tube internal and external hanging tower crane support beam structure and the construction method, the structure is simple, a tower crane is externally hung on the outside of the core tube so that influence of structural construction in the core tube is greatly reduced and utilization of the hanging scope of the tower crane is sufficient, the construction is simple, and the cycle is shortened.

Owner:CHINA CONSTR FIRST DIV STEEL STRUCTUREENG

Elastic circuit fabrication method based on metal sacrificial layer process

InactiveCN106376180AOvercome crackingOvercome the open circuit problemPrinted circuit assemblingConductive material chemical/electrolytical removalElectronic componentPhotoresist

The invention discloses an elastic circuit fabrication method based on a metal sacrificial layer process. The elastic circuit fabrication method comprises the following steps of pasting a metal thin film on a substrate; spin-coating photoresist on a surface of the metal thin film, and photoetching a circuit and bonding pad layout; fabricating metal circuits and bonding pads on a circuit and bonding pad layout region, spin-coating photosensitive organic soluble polymers, and photoetching a soldering mask layout; welding electronic components on the bonding pads; removing the photoresist and the photosensitive organic soluble polymers, casting an upper-layer elastic polymer and curing the upper-layer elastic polymer; stripping the metal thin film and an upper-layer structure thereof from the substrate; etching the metal thin film; and spin-coating and curing a lower-layer elastic polymer. By the elastic circuit fabrication method, a metal seed layer is not needed to be deposited, and the problem of metal wire crack or open circuit caused by different matching of the elastic polymers and metal heat is thoroughly solved; and meanwhile, a stress buffer layer is omitted, the process flow is simplified, only processes of photoetching, electroplating and etching are needed, and the elastic circuit fabrication method has the advantages of high yield, simplicity in welding and compatibility of a reflow soldering process.

Owner:SHANGHAI JIAO TONG UNIV

Process method for assembling and welding pile leg of ocean platform

InactiveCN105057857AWelding quality is easy to controlDimensional accuracy is easy to controlArc welding apparatusProduction lineEngineering

The invention discloses a process method for assembling and welding a pile leg of an ocean platform. According to the method, the production speed is high, and the percent of pass of products is high. A pile leg assembly is composed of a rack and two semicircular pipes. Coming cargo examination should be carried out on the rack and the semicircular pipes carefully, and the rack and the semicircular pipes are installed through a tool. The rack is turned over through a turnover device. The assembled pile leg examined to be qualified is lifted to an electric heating furnace stage trolley, conveyed into a furnace and heated, wherein the temperature ranges from 150 DEG C to 200 DEG C. The temperature in a hearth should be kept even. The heated pile leg is placed on the ground. Two welding joints are in the horizontal state. Manual welding rods are used for backing welding. Welding is performed on the pile leg by four welding workers from the middle position. The two sides are simultaneously and symmetrically welded. After welding is finished, the pile leg is turned over and welded continuously. After the welding joints are backed for 1 to 2 layers, the pile leg is lifted to roller carriers on a submerged arc welding production line and then formally welded. The welded pile leg is conveyed into a thermal treatment furnace, the heating temperature ranges from 200 DEG C to 280 DEG C and maintained for 2 to 3 hours, and then the pile leg is delivered out of the thermal treatment furnace.

Owner:张家港润通海洋工程科技有限公司

Assembly welding process method for aluminum structure ceiling of driver cab of motor train unit

ActiveCN104384740AReduce the workload of the synthesis processShorten the compositing timeWelding/cutting auxillary devicesAuxillary welding devicesModularityEngineering

The invention relates to an assembly welding process method for an aluminum structure ceiling of a driver cab of a motor train unit. The assembly welding process method is characterized in that (1) at the premise of not changing the integral structure of the original structure, ceiling modules are separated, the structure of the original driver cab is re-divided, one part of structure is separated from a left side wall structure and a right side wall structure, and is used as a longitudinal edge beam of the ceiling structure, and then bulk parts which cannot be singly combined in the original structure can form the ceiling welding structure; (2) a welding tooling adopting the reverse assembly and outer positioning method is used for positioning and clamping, the welding sequence of the new ceiling structure is adjusted, the welding of a ceiling window frame structure is firstly completed, then the welding of a ceiling skeleton and a front window frame is completed, and finally the welding of a ceiling skin and the skeleton is completed, so a five-shaft processing center can complete processing at one time. The assembly welding process method has the advantages that the existing production technique of the aluminum structure ceiling of the driver cab of the motor train unit is a full new technique, the product quality of the ceiling part is improved, the assembly welding difficulty of the aluminum structure ceiling of the driver cab is decreased, the production cycle and labor intensity of the driver cab assembly are improved, the production modularizing of the driver cab is improved, and the quality is conveniently guaranteed.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

Low-profile broadband wide-angle tight coupling antenna unit and array

PendingCN111525255ACompact structureHighly integratedRadiating elements structural formsIndividually energised antenna arraysRadarSoftware engineering

The invention discloses a low-profile broadband wide-angle tight coupling antenna unit and array, and belongs to the technical field of radar and communication. The antenna unit comprises a wide-anglematching layer, a coupling layer, an antenna layer and a feed layer, wherein the whole structure is processed by adopting a multi-layer printed board process. The antenna array is formed by arrangingantenna units according to a specified unit spacing rule. According to the antenna unit, a multi-layer printed board processing technology is adopted, so that the assembling and welding difficulty ofthe tightly coupled antenna array in the later period is greatly reduced, and the reliability of the antenna array is also improved; and the antenna array adopts a microstrip line aperture coupling feed structure, so that the design of a broadband balun of a traditional dipole tight coupling array antenna is omitted, and the design difficulty of the tight coupling array antenna is greatly simplified.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

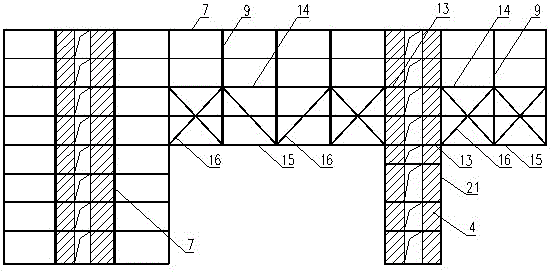

Large-span long-cantilever connection structure and construction technique

ActiveCN104818772AMeet the seismic performance requirementsThe structural system is safe and reliableBuilding material handlingSupporting systemTower

The invention discloses a large-span long-cantilever connection structure and a construction technique. The structure plane is arranged in the form of rectangle, two towers are arranged beneath the standard layer, wherein a tower is a cylinder body (4), the left and right sides of the tower respectively support a large-span and long-cantilever floor at the upper part, and the width of the cylinder body (4) is less than the width of the floor at the upper part, and the vertical face of the tower forms a model with a wide upper part and a narrow lower part; the other one tower is a framework shear wall structure. The large-span and long-cantilever is connected to the two towers through a side-span steel truss (1) and a middle-span steel truss (2) which are penetrated to each other. The side-span steel truss (1) is arranged within the scale of the cylinder (4), and supported on a supporting steel truss (3) extended from the cylinder (4) along the vertical direction. A steel framework beam (7) and a secondary steel beam (8) are equally arranged on the upper floor so as to form a floor cover supporting system. The floor cover adopts a steel bar truss floor support plate. The large-span long-cantilever connection structure solves the technical problem that the vertical face model is the connection structure with the wide upper part and the narrow lower part, and suitable for multi-layer and high rise buildings; moreover, the large-span long-cantilever connection structure has very strong universality and application scale.

Owner:香港华艺设计顾问(深圳)有限公司

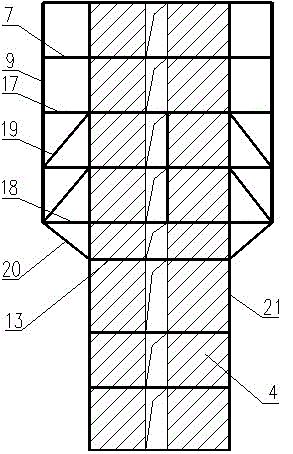

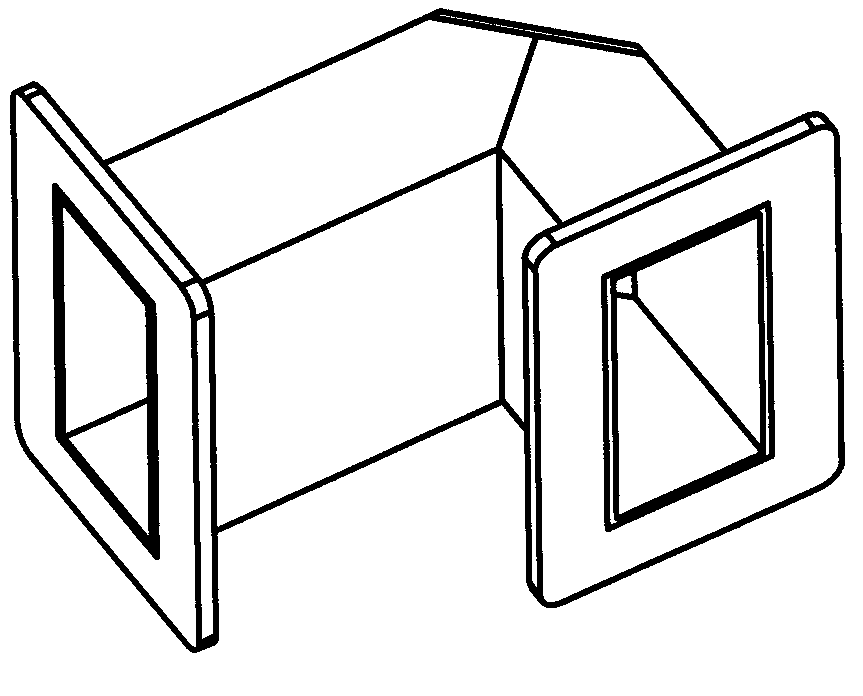

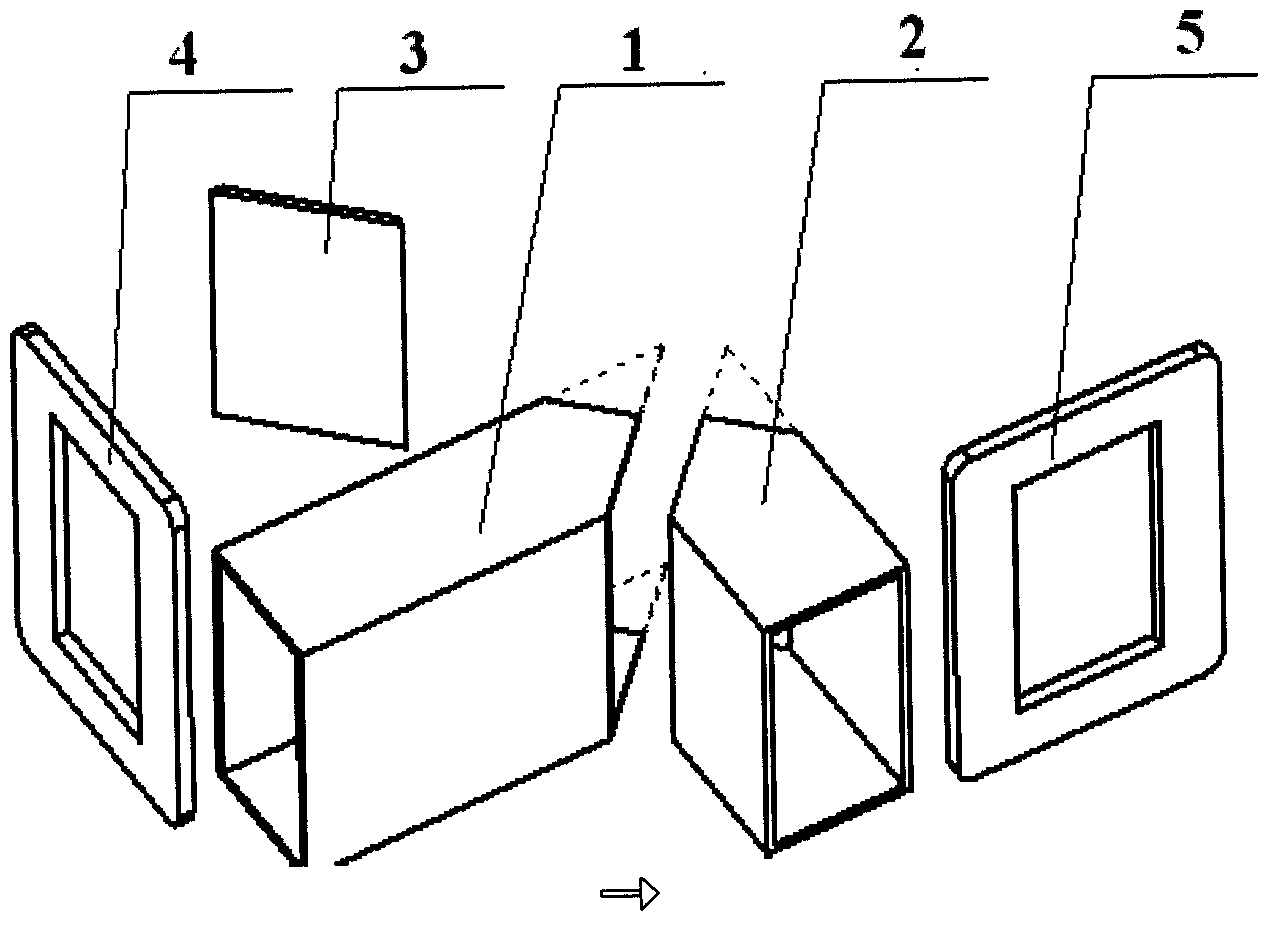

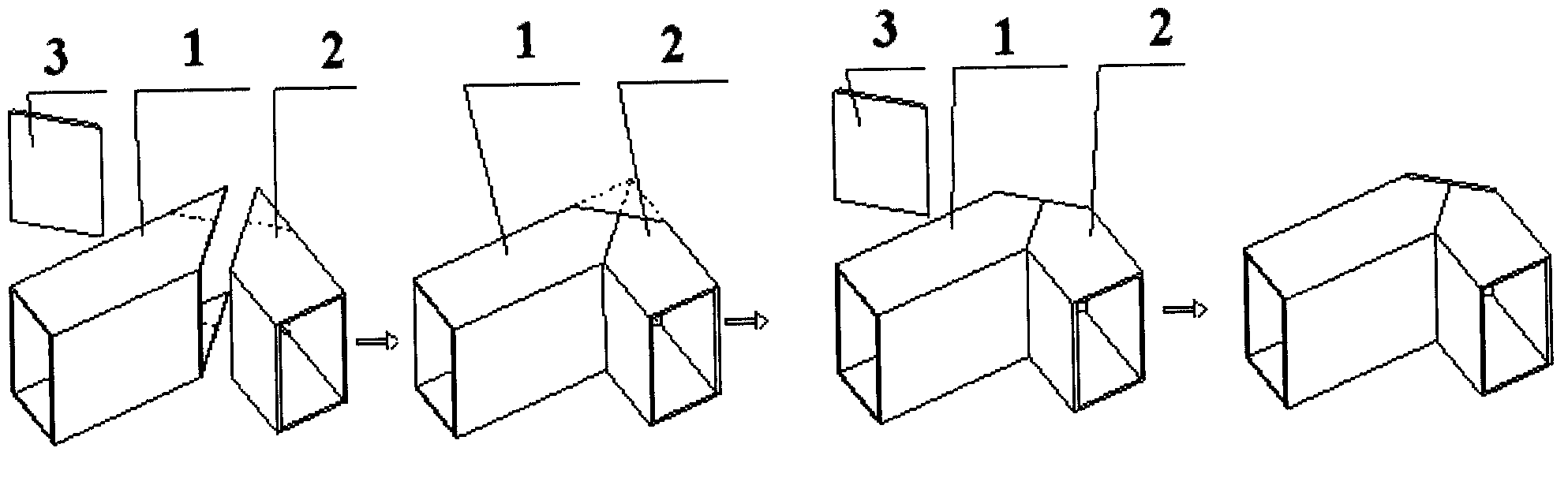

Bending type forming method of corner cut waveguide bend

The invention relates to a bending type forming method of a corner cut waveguide bend, which belongs to the technical field of waveguide forming. Two triangular bending grooves are formed in the rear surface of a waveguide tube and divide the waveguide tube into three parts in the length direction, wherein the center part of the waveguide tube is a bending area. Bending gaps are processed in the front surface, the upper surface and the lower surface of the waveguide tube; the rectangular waveguide tube is folded forwards along the two triangular bending grooves; and flanges are welded at the two ends of the formed waveguide tube to obtain the corner cut waveguide bend. According to the bending type forming method, the same waveguide tube is adopted for forming, so that the dimension error of an inner cavity assembled by different waveguide tube blanks is reduced, and the probability of dislocation deficiency of the splicing surface of the inner cavity is reduced; a bending type self-positioning structure is adopted to control the inner cavity forming, so that the effects of assembling and welding on the precision of the dimension, shape and position of the inner cavity are reduced, and the forming precision of the inner cavity is improved; the waveguide tube part is subjected to once weld forming, so that welded joints of the inner cavity are decreased; the difficulty in welding is reduced; the stability of the welding quality is improved; and the welding efficiency is improved.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com