Construction method for butt welding irregular space box-type steel members

A construction method and technology for steel components, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve problems such as uneven welding positions and easy deformation of box-shaped steel components, so as to eliminate welding stress, improve welding quality, and reduce welding stress. effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

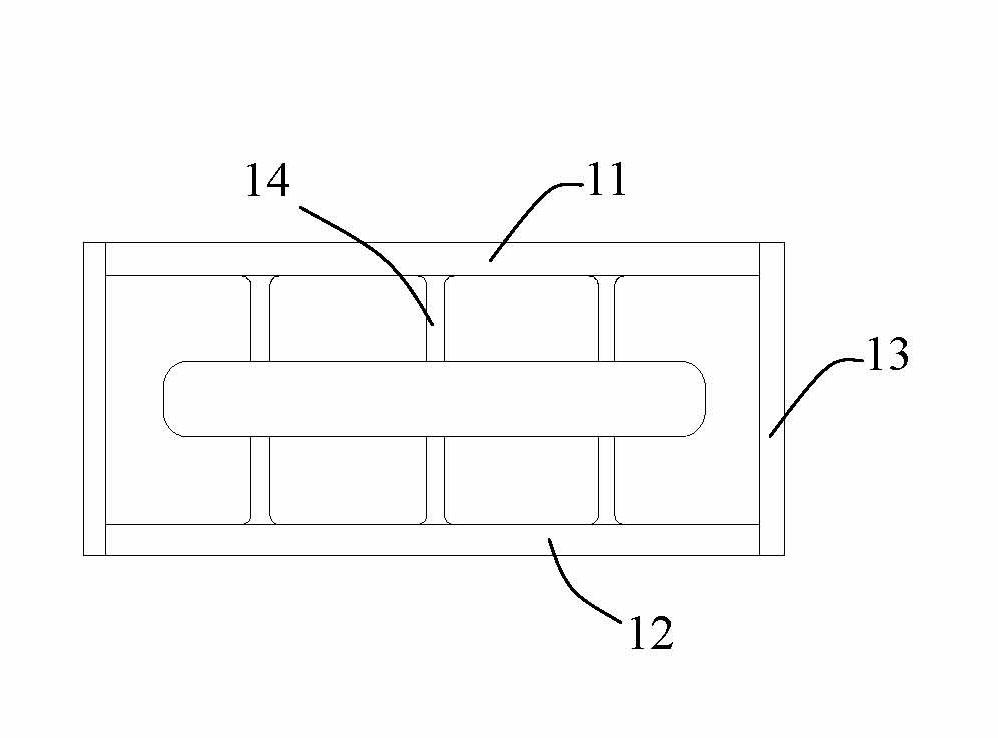

[0034] Such as figure 2 As shown, the butt welding construction method of the special-shaped space box steel member in this embodiment includes the following steps:

[0035] S201, opening at least one process hole on the upper flange at the welding position.

[0036] S202, butt the two sections of steel members.

[0037] S203, enter the inside of the box body of the steel member from the process hole, and adopt a segmented symmetrical welding method to weld the butt joint position of the lower wing plate and the rib plate.

[0038] S204, use symmetrical welding on the outside of the box body of the steel member, and weld the butt joint position of the side plate.

[0039] S205, welding a cover plate on the process hole.

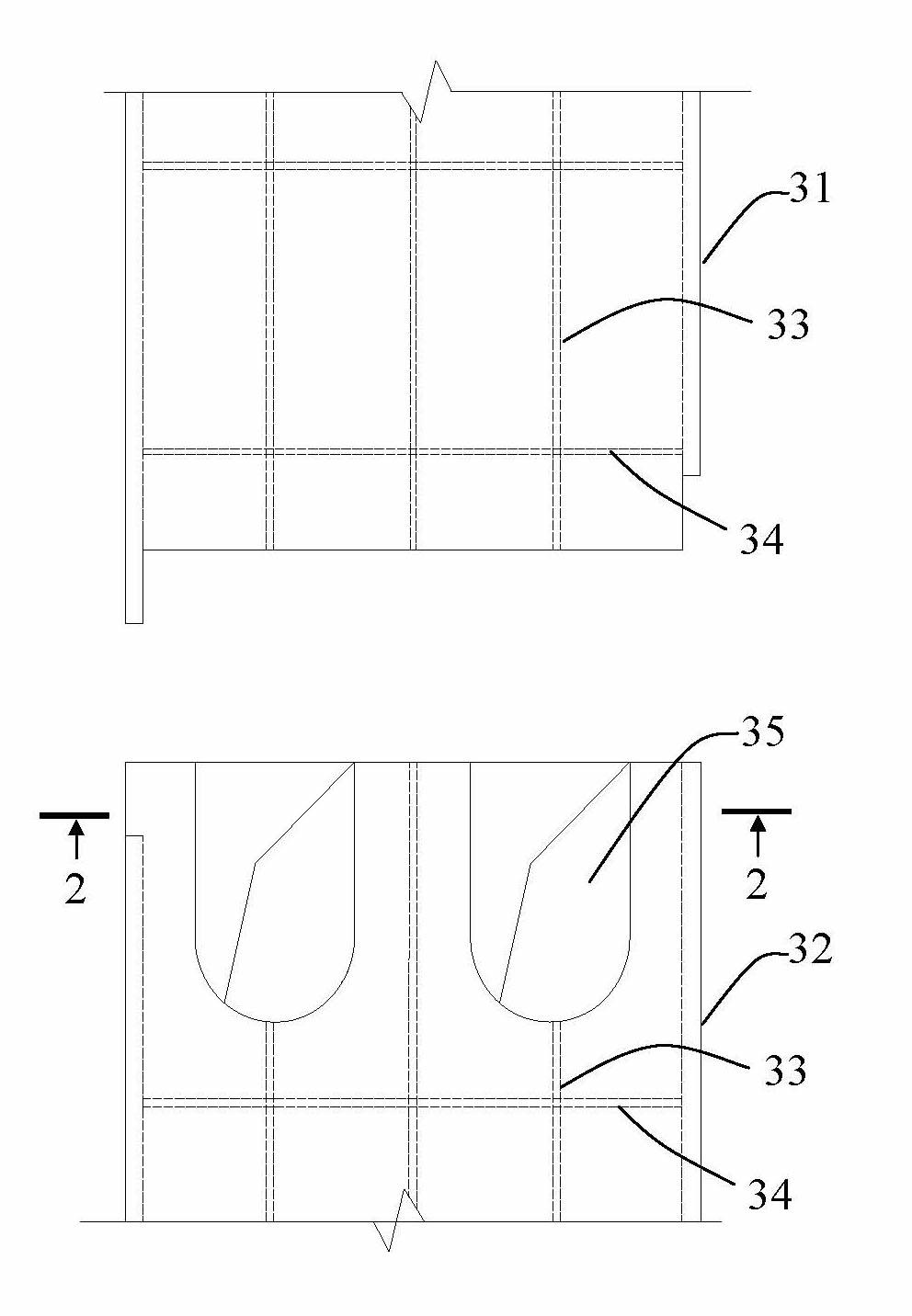

[0040] Please refer to image 3 with Figure 4 , image 3 is a schematic diagram of the butt joint of two steel members, Figure 4 yes image 3 Sectional view of position 2-2 in the center. Depend on image 3 It can be seen that there are many ribs...

Embodiment 2

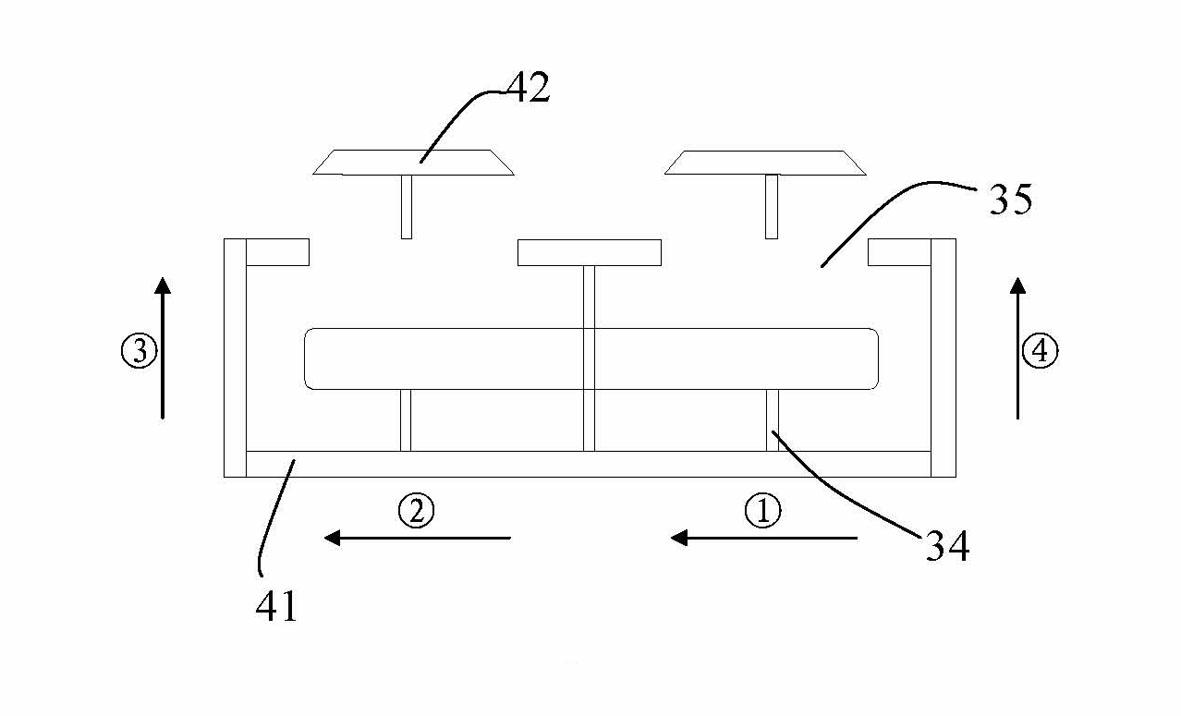

[0045] Such as Figure 5 As shown, the butt welding construction method of the special-shaped space box steel member in this embodiment includes the following steps:

[0046] S501, set connecting plates on two sections of steel members respectively.

[0047] S502, respectively position the welded horse plate at the joint position of the two sections of steel members.

[0048] S503, opening at least one process hole on the upper flange at the welding position.

[0049] S504, use the horse board to butt the two sections of steel members, and ensure that the connection of the two sections of steel members is consistent.

[0050] S505, Welding together connecting plates on two sections of steel members.

[0051] S506, add a copper backing plate at the bottom of the welding position of the lower wing plate.

[0052] S507, preheating the butt joint position of the two sections of steel components.

[0053] S508, enter the inside of the box body of the steel member from the proces...

Embodiment 3

[0074] Such as Figure 8 As shown, the butt welding construction method of the special-shaped space box steel member in this embodiment includes the following steps:

[0075] S801, opening at least one process hole on the upper flange at the welding position.

[0076] S802, opening at least one side hole on the side plate.

[0077] S803, butt joint two sections of steel members.

[0078] S804, enter the inside of the box body of the steel member from the process hole, and adopt a segmented symmetrical welding method to weld the butt joint position of the lower wing plate and the rib plate.

[0079] In S805, symmetrical welding is adopted on the outside of the box body of the steel member, and the butt joint position of the side plate is welded.

[0080] S806, welding a cover plate on the process hole.

[0081] S807, enter the inside of the box body of the steel member from the side hole, and weld the butt ribs at the position of the process hole.

[0082] Compared with Em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com