Patents

Literature

119results about How to "Good flatness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

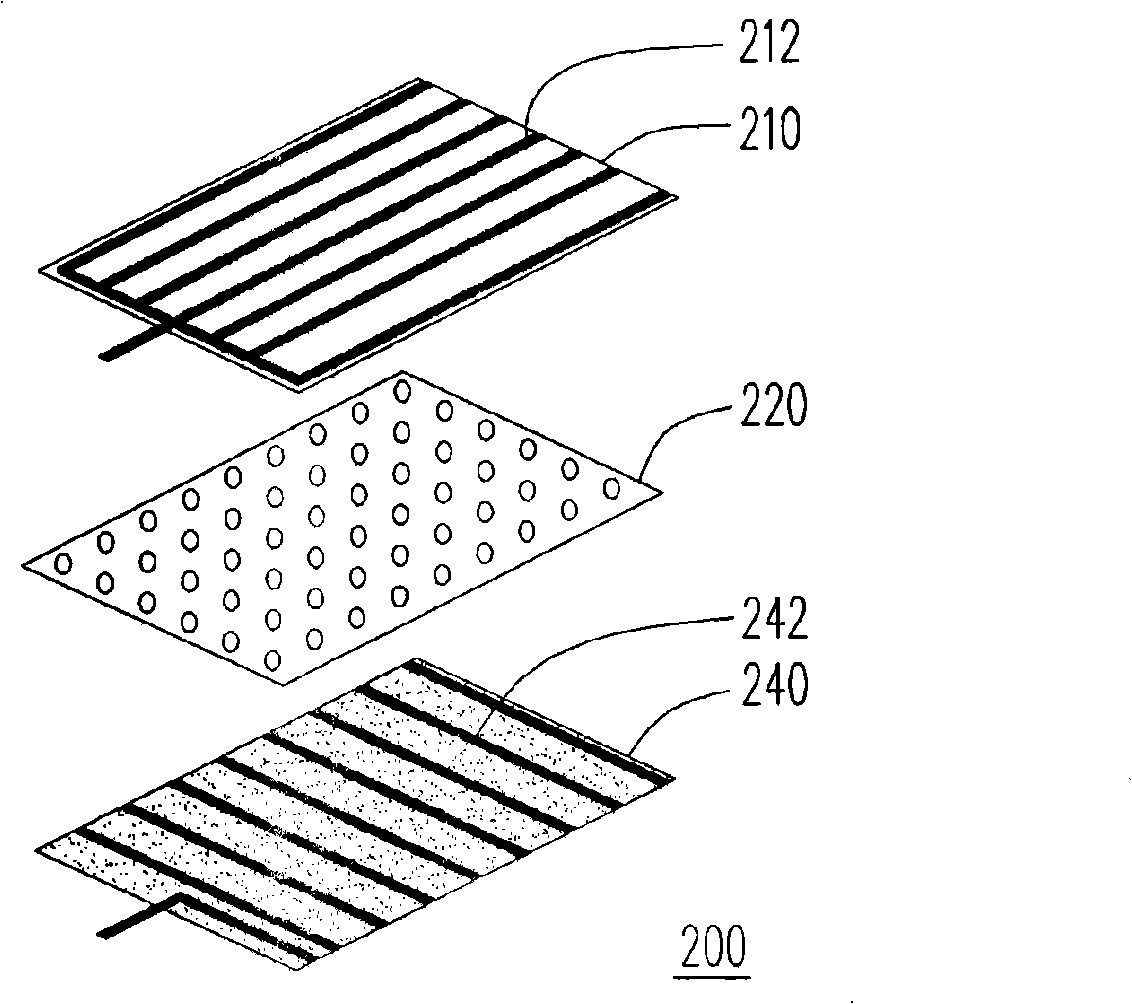

Lithium ion battery diaphragm and preparation method thereof

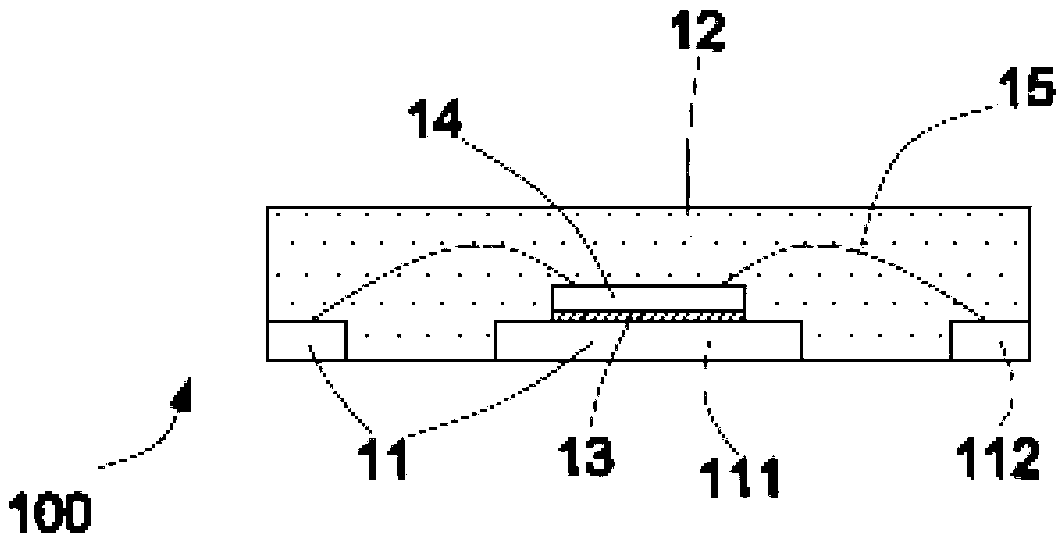

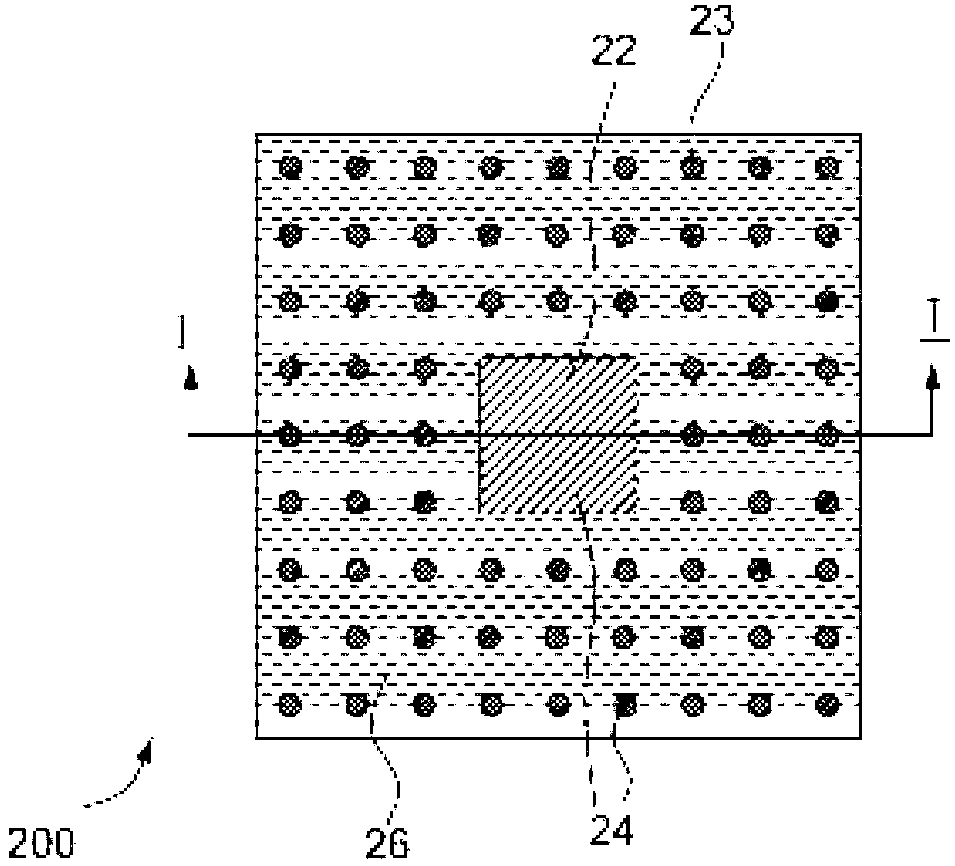

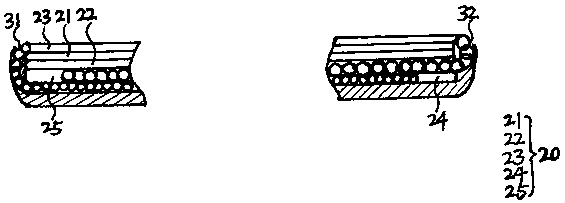

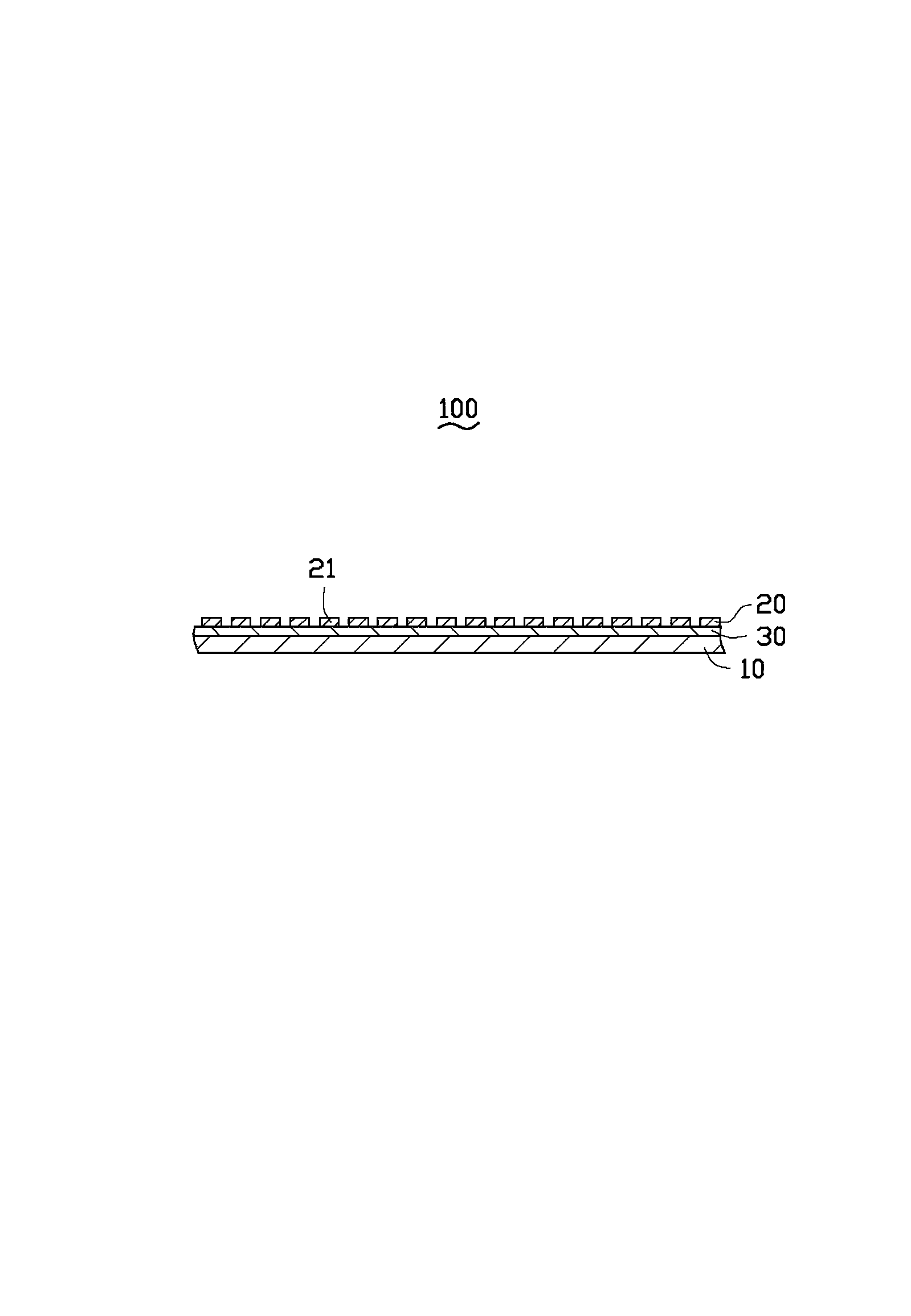

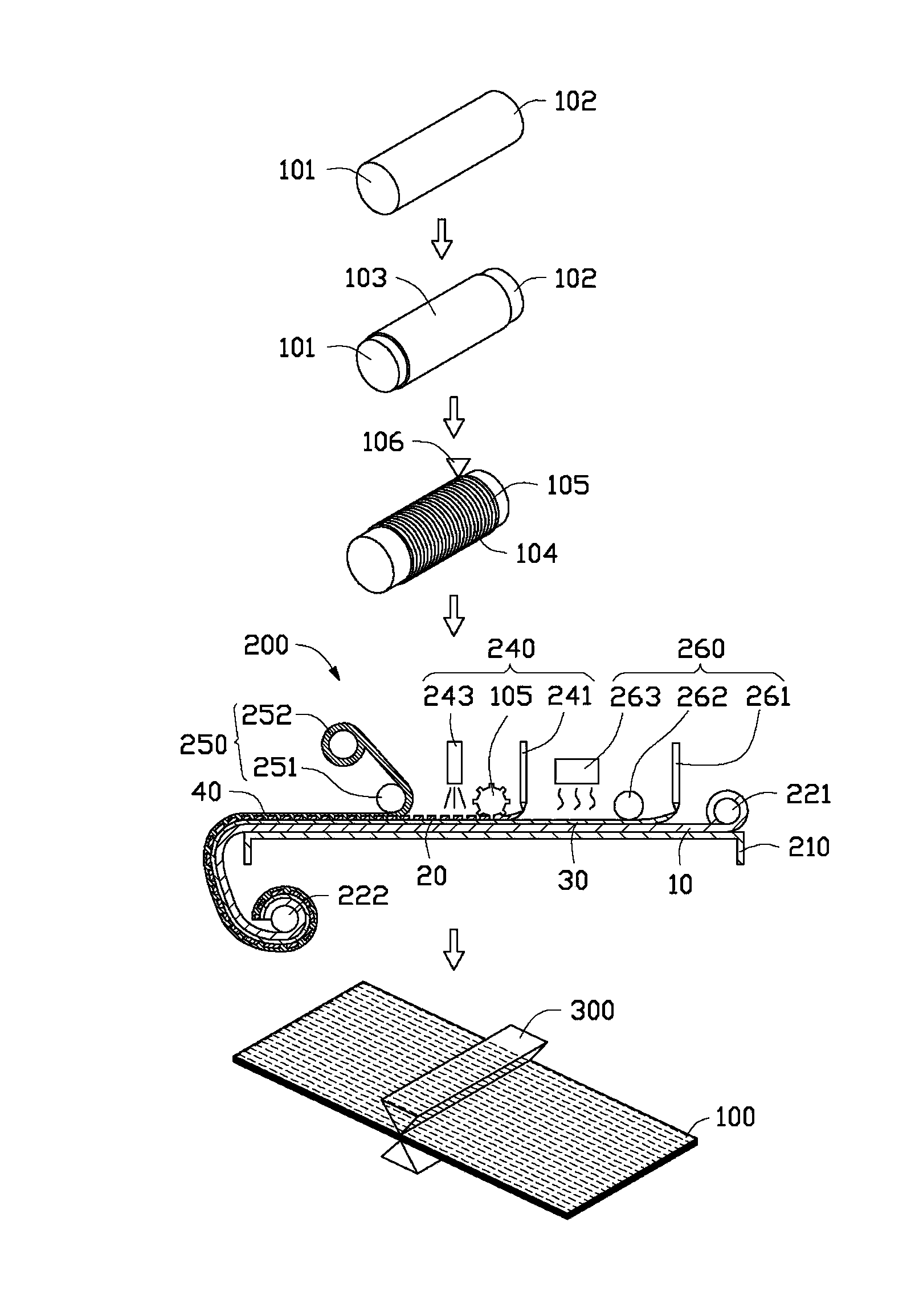

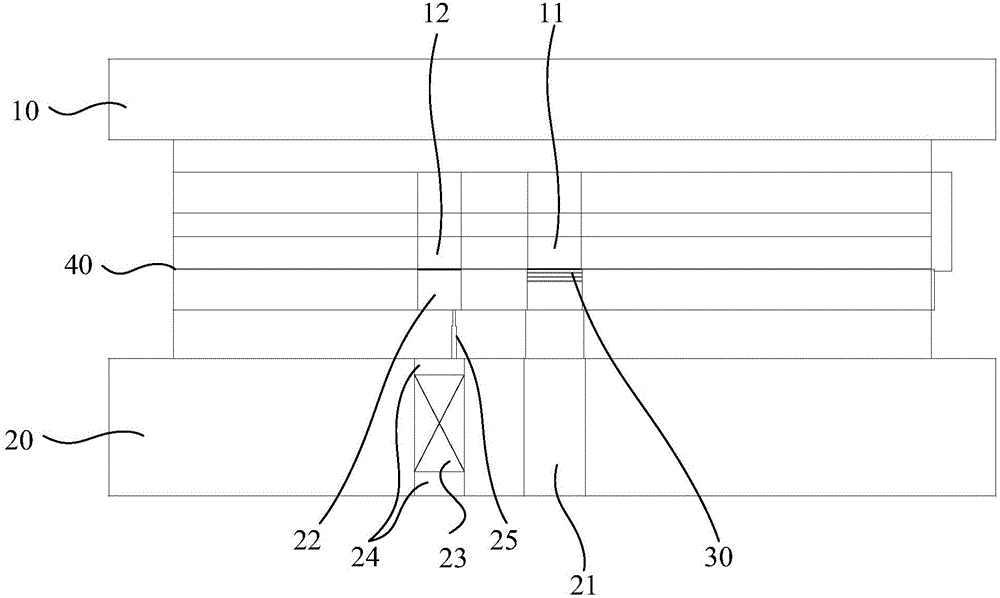

The invention relates to a lithium ion battery diaphragm. The lithium ion battery diaphragm comprises a polyolefin substrate and a composite coating, wherein the coating is connected with the polyolefin substrate through a binder, the coating is formed by stacking a plurality of inorganic particle layers, and each two adjacent inorganic particle layers of the coating are connected with each other through a binder; each inorganic particle layer consists of flaky inorganic particles, and the flaky inorganic particles are distributed in parallel or at a small angle in the coating. The invention also relates to a preparation method of the lithium ion battery diaphragm. The preparation method comprises the following steps: preparing flaky inorganic particles; screening first inorganic particles and second inorganic particles; preparing coating slurry; coating the polyolefin substrate with the coating slurry, and drying the polyolefin substrate with the coating to obtain a product. The lithium ion battery diaphragm is high in flatness, low in coarseness, low in water absorption rate, low inn coating expansion degree, capable of effectively reducing the natural crimpness of single-side coated diaphragm and capable of improving the assembling efficiency and rate of finished products of a laminated battery.

Owner:河南惠强新能源材料科技股份有限公司

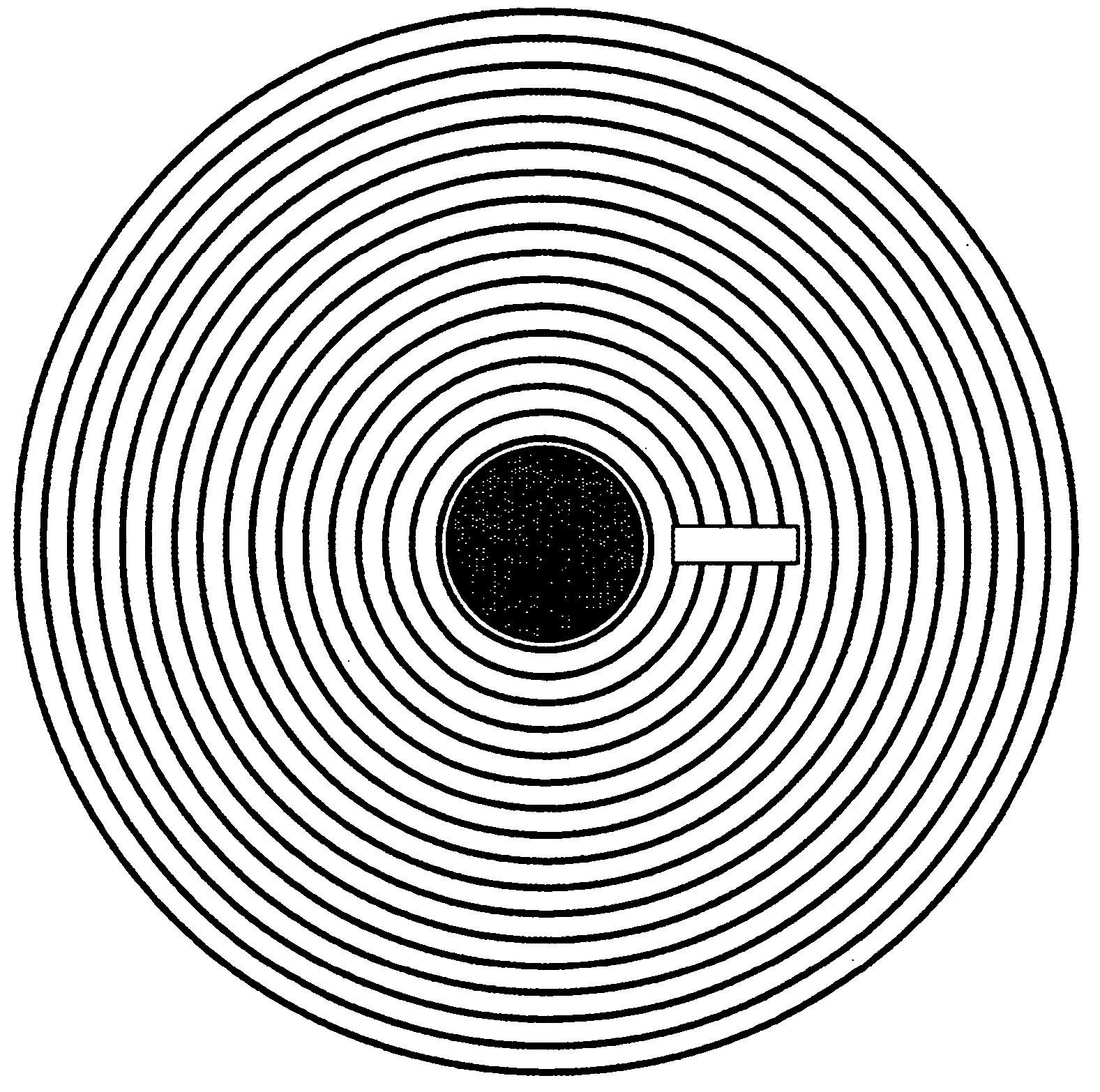

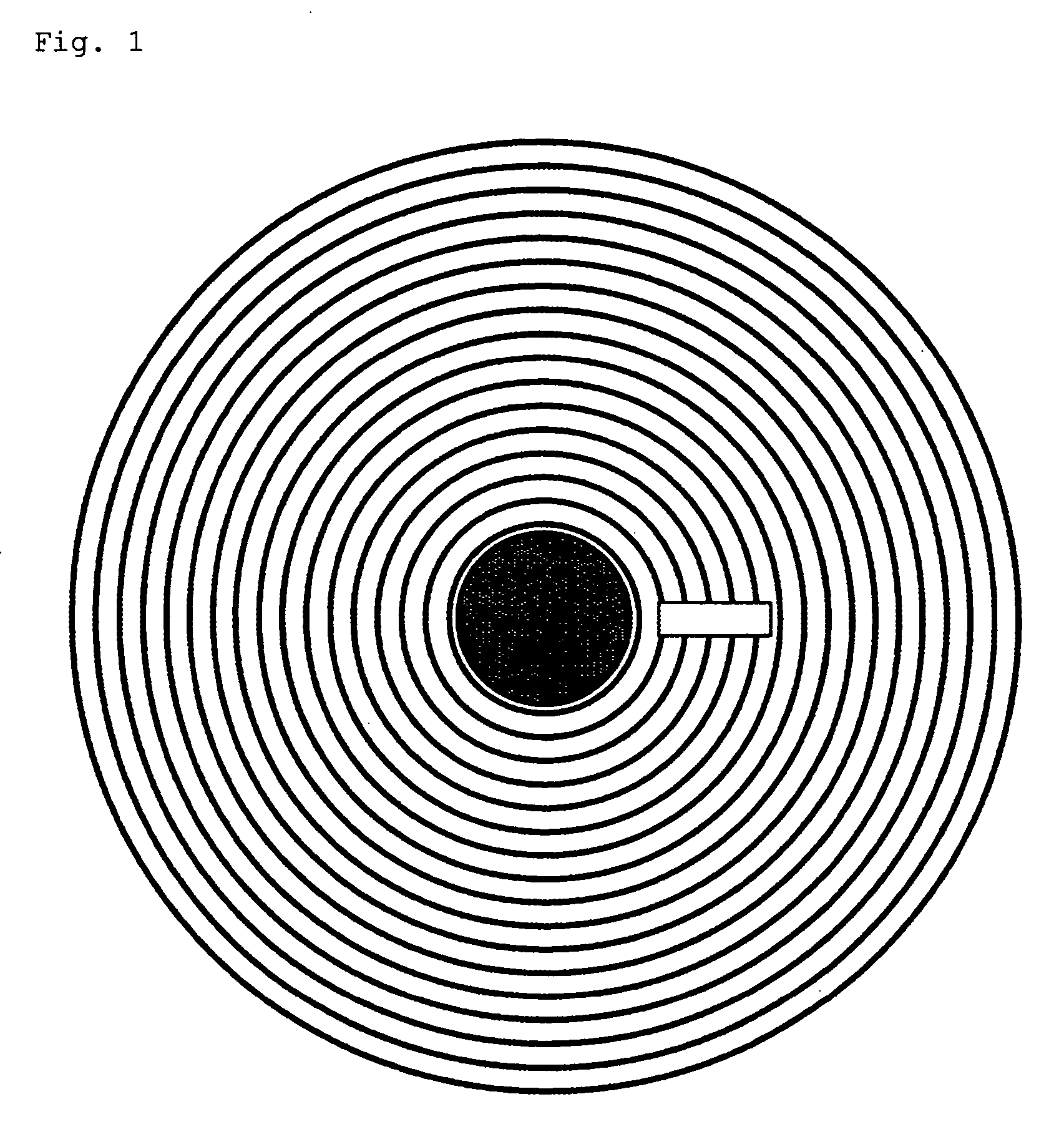

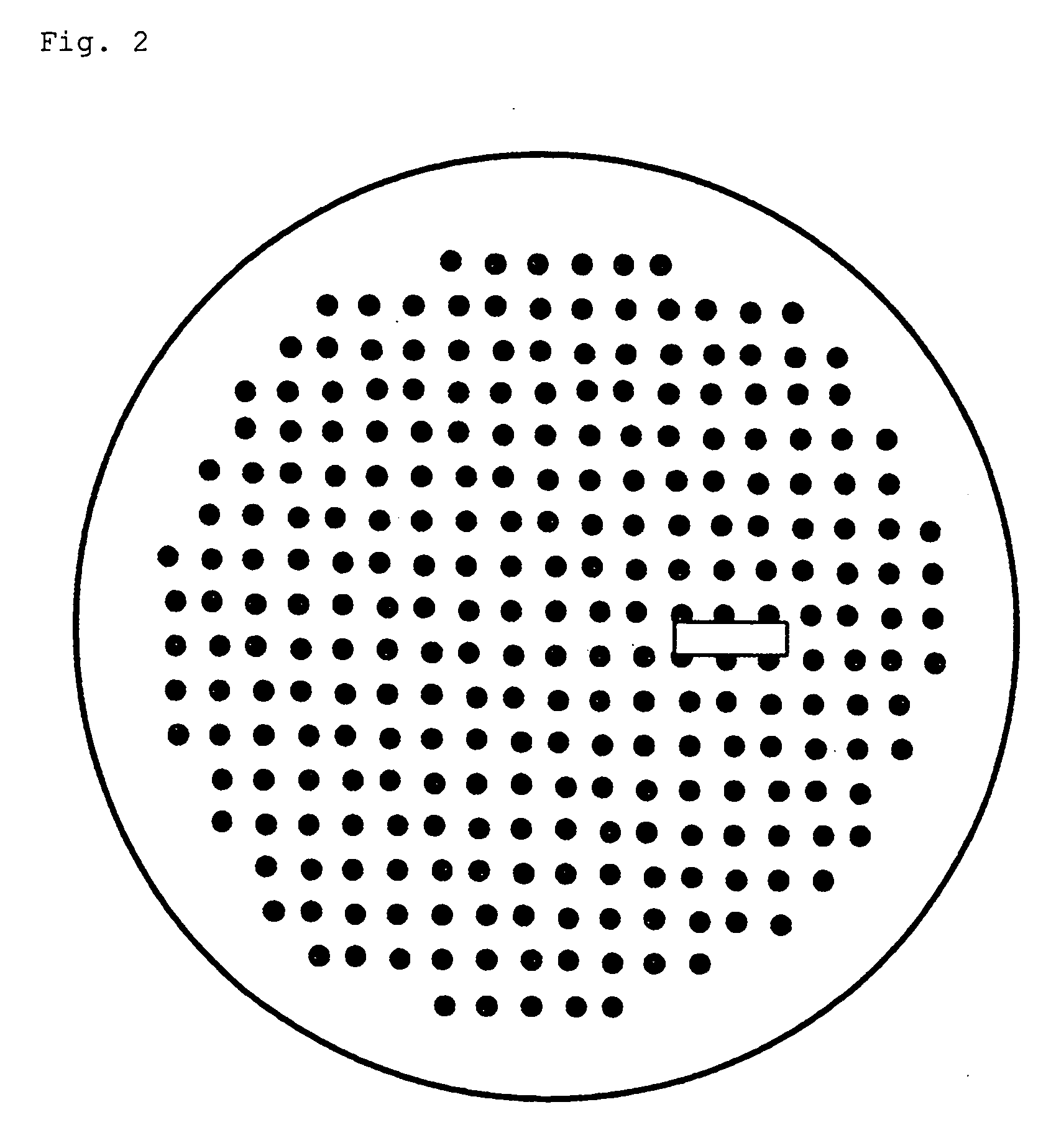

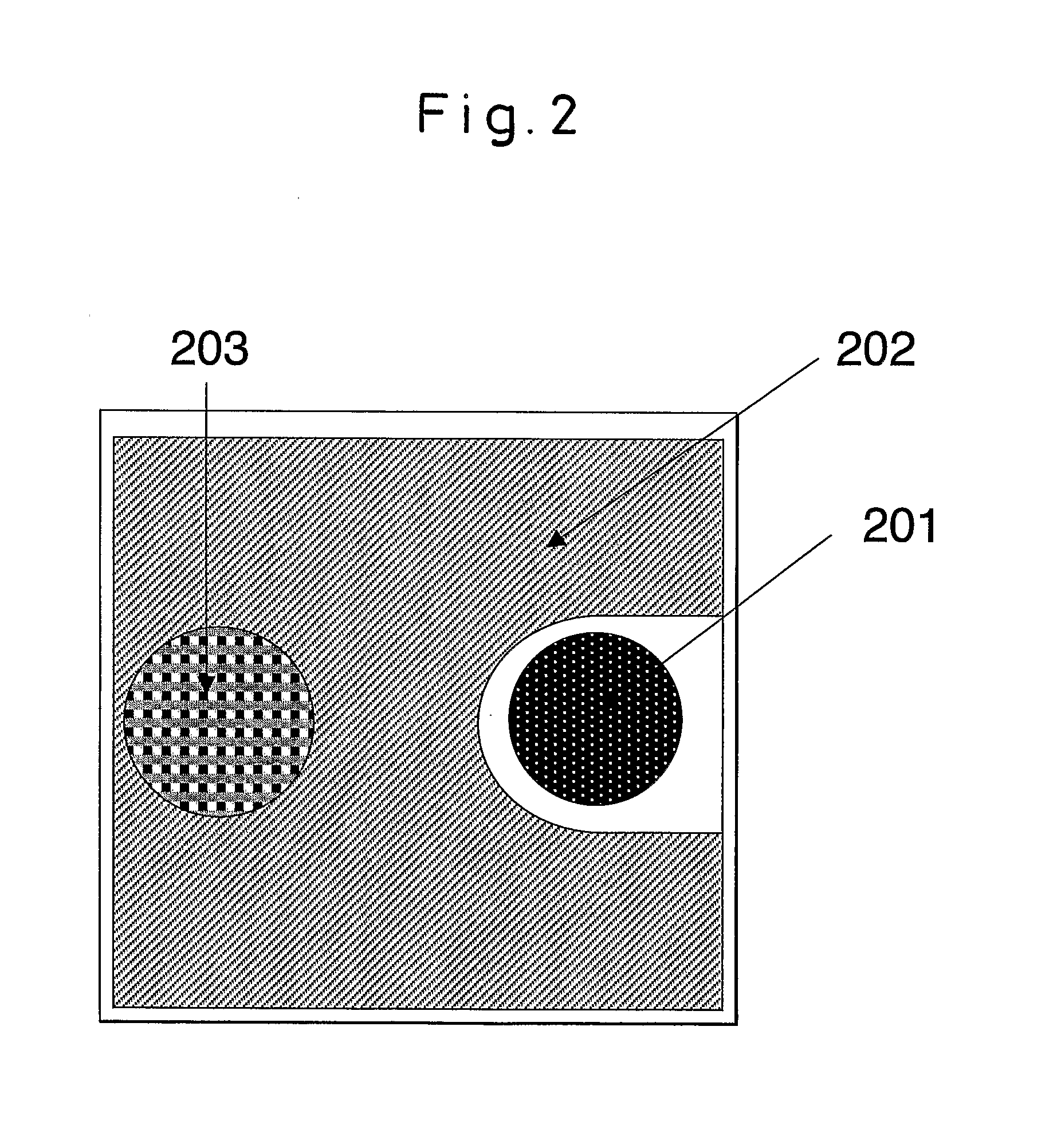

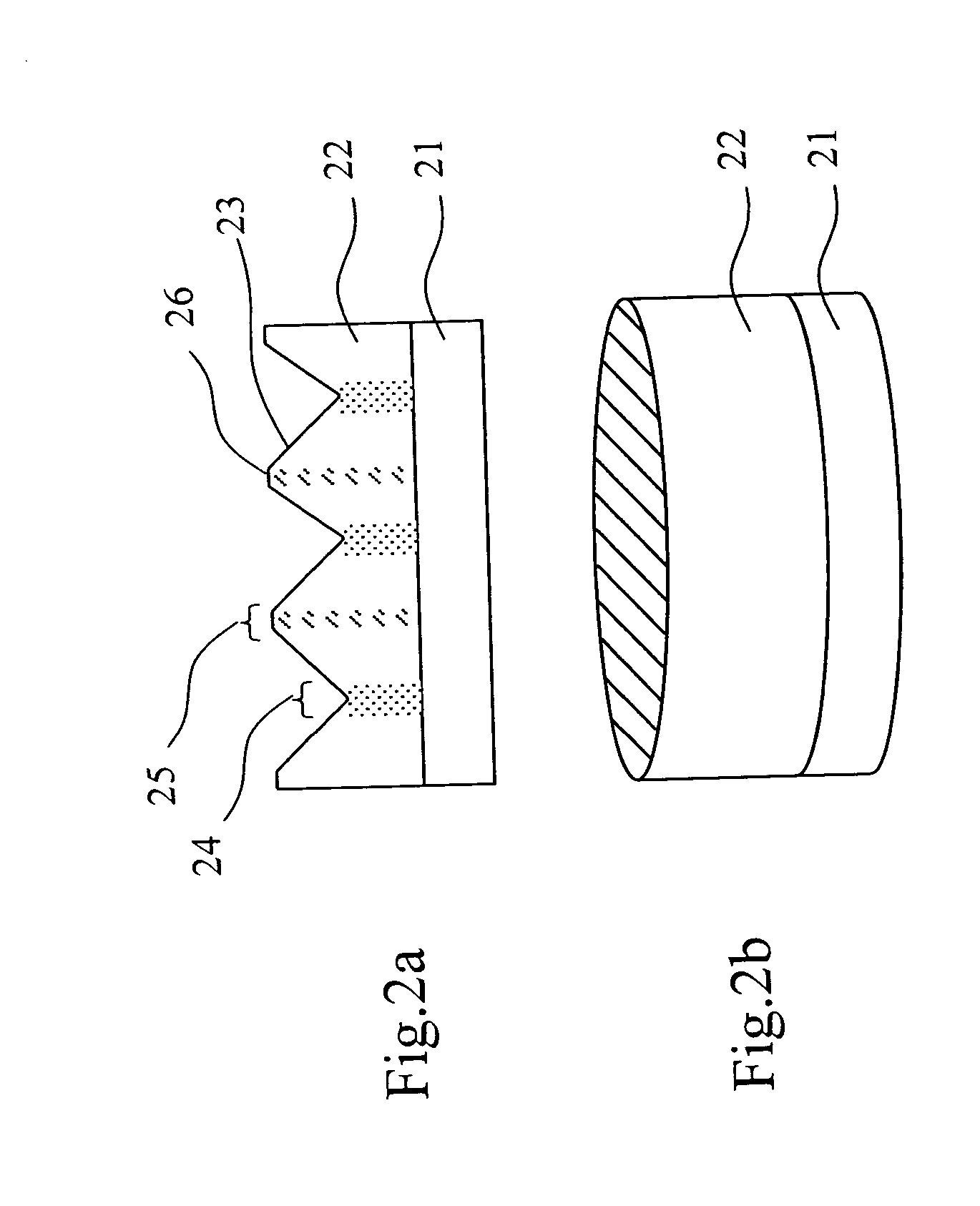

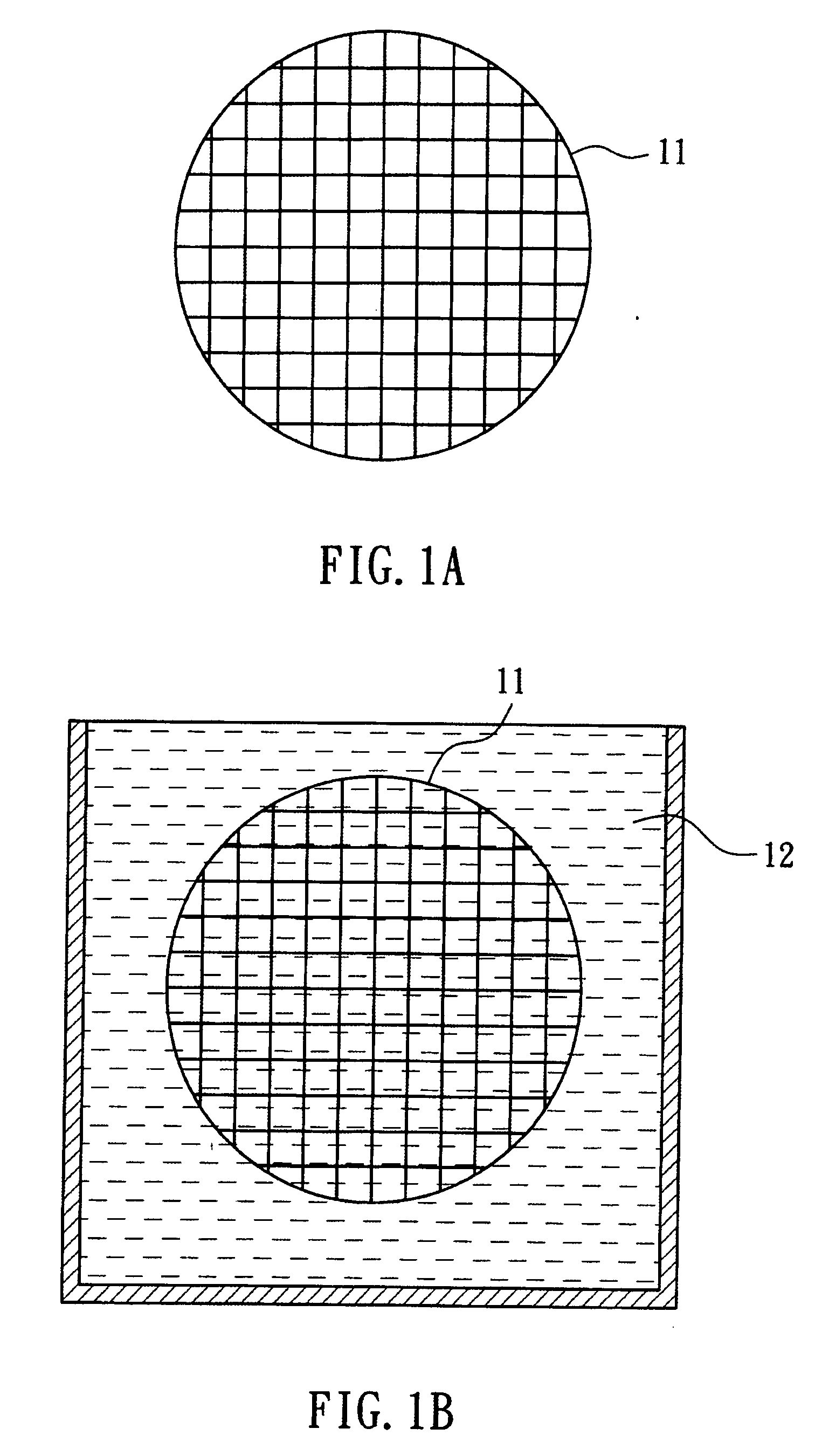

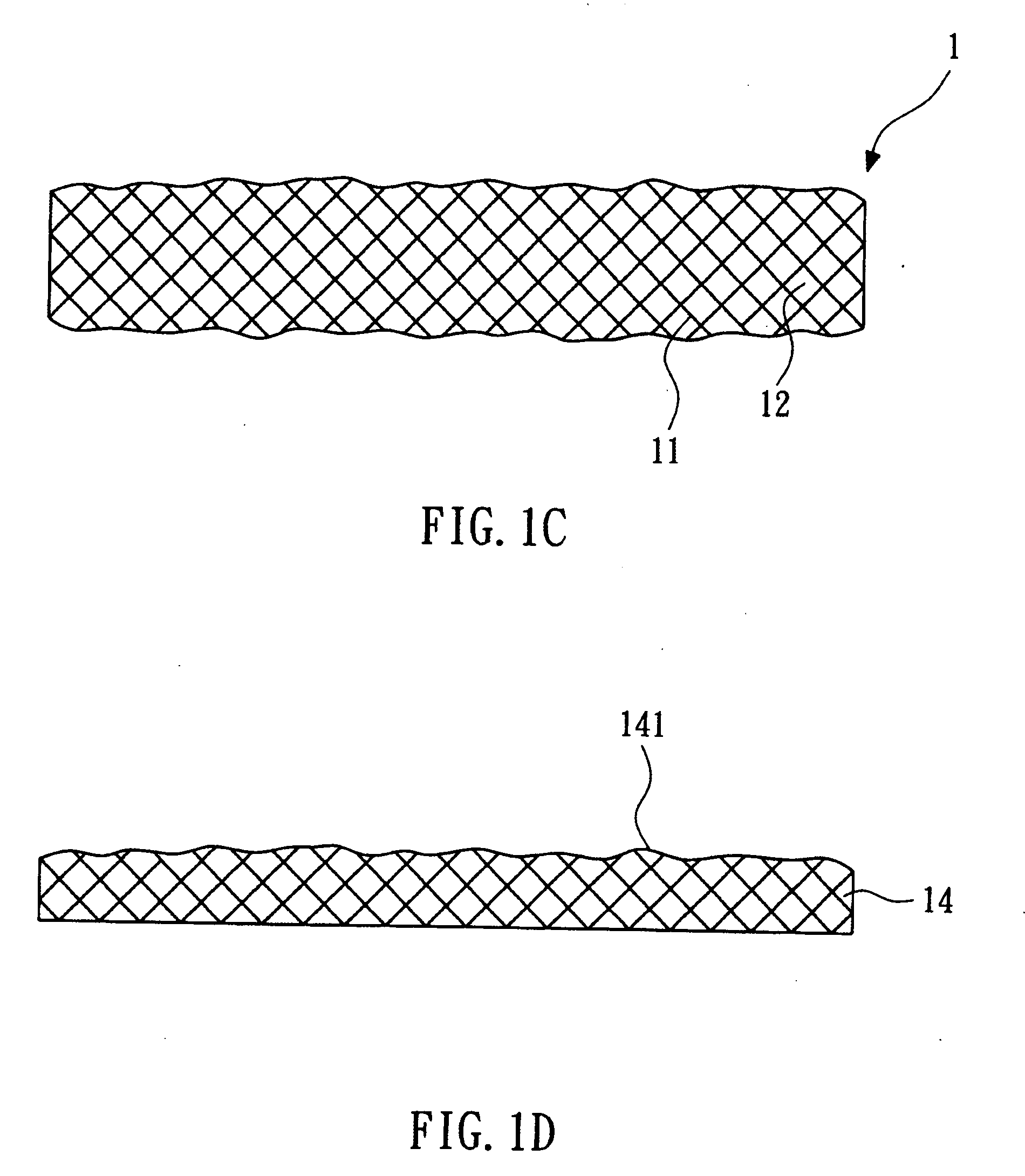

Chemical mechanical polishing pad

InactiveUS20050113011A1Good flatnessImprove flatnessRevolution surface grinding machinesOther chemical processesCompound (substance)Engineering

A chemical mechanical polishing pad having a face for polishing an object to be polished, a non-polishing face opposite to the face and a side face for interconnecting these faces and including the pattern of recessed portions which are formed on the non-polishing face and are open to the non-polishing face and not to the side face.

Owner:JSR CORPORATIOON

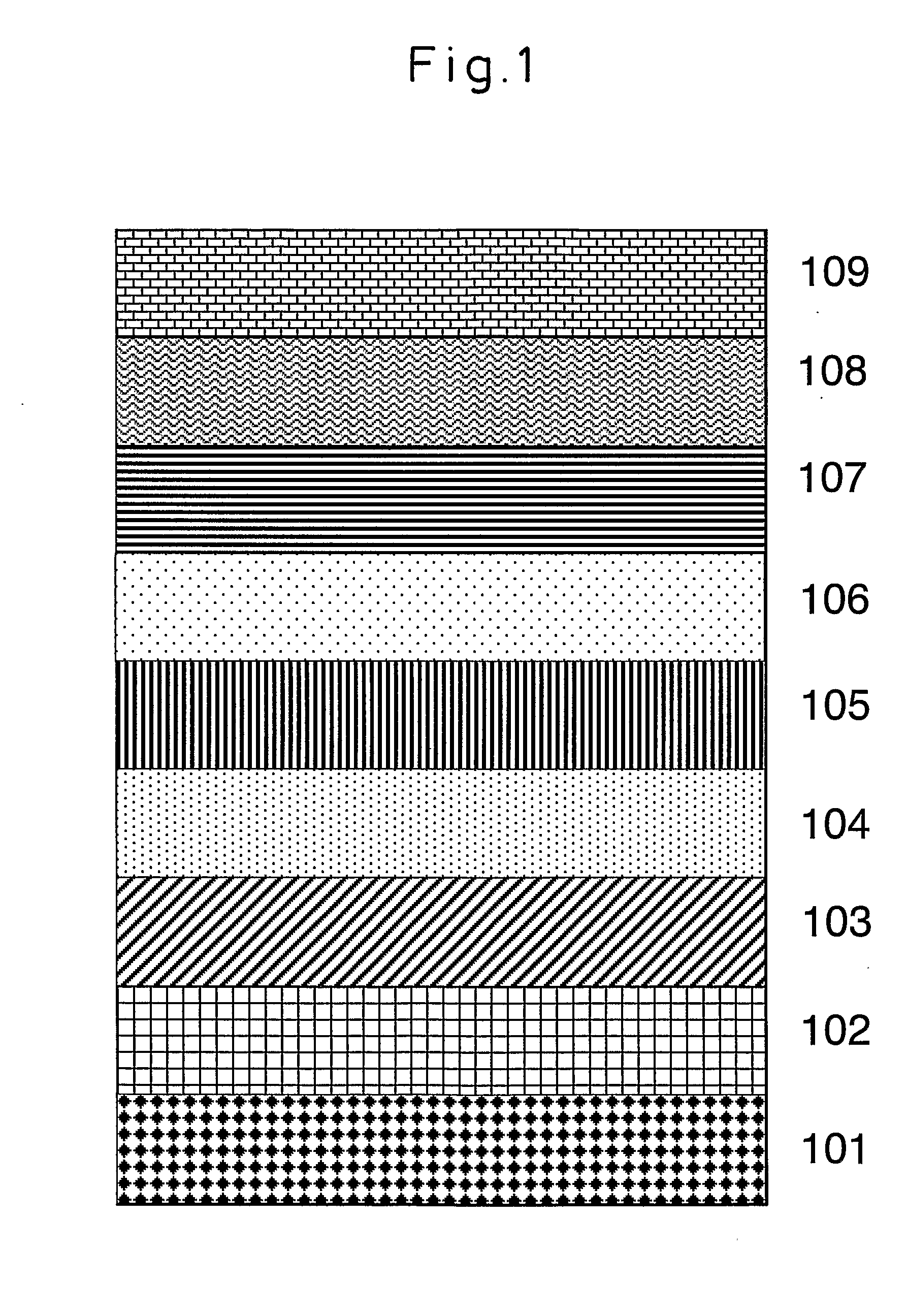

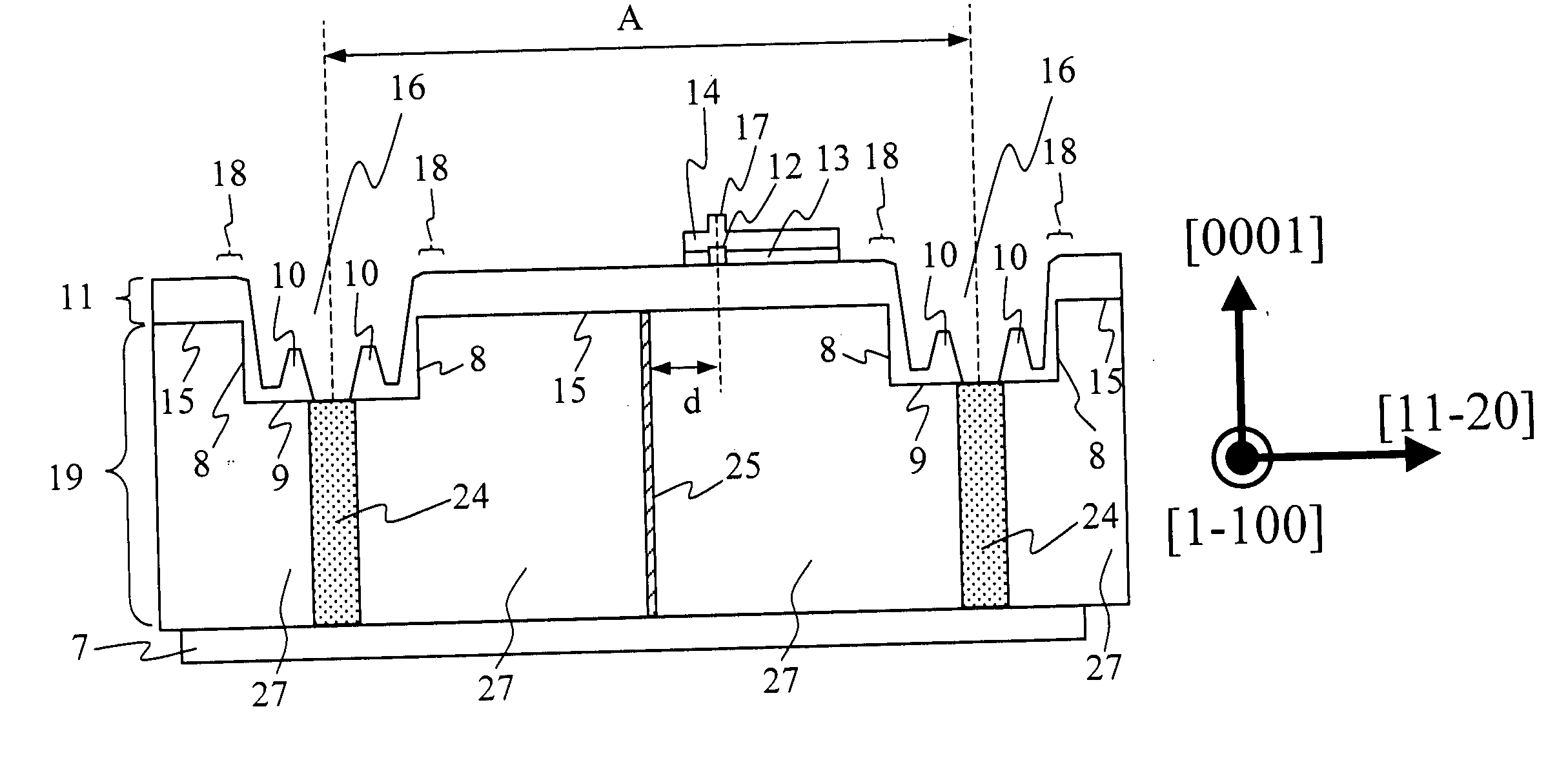

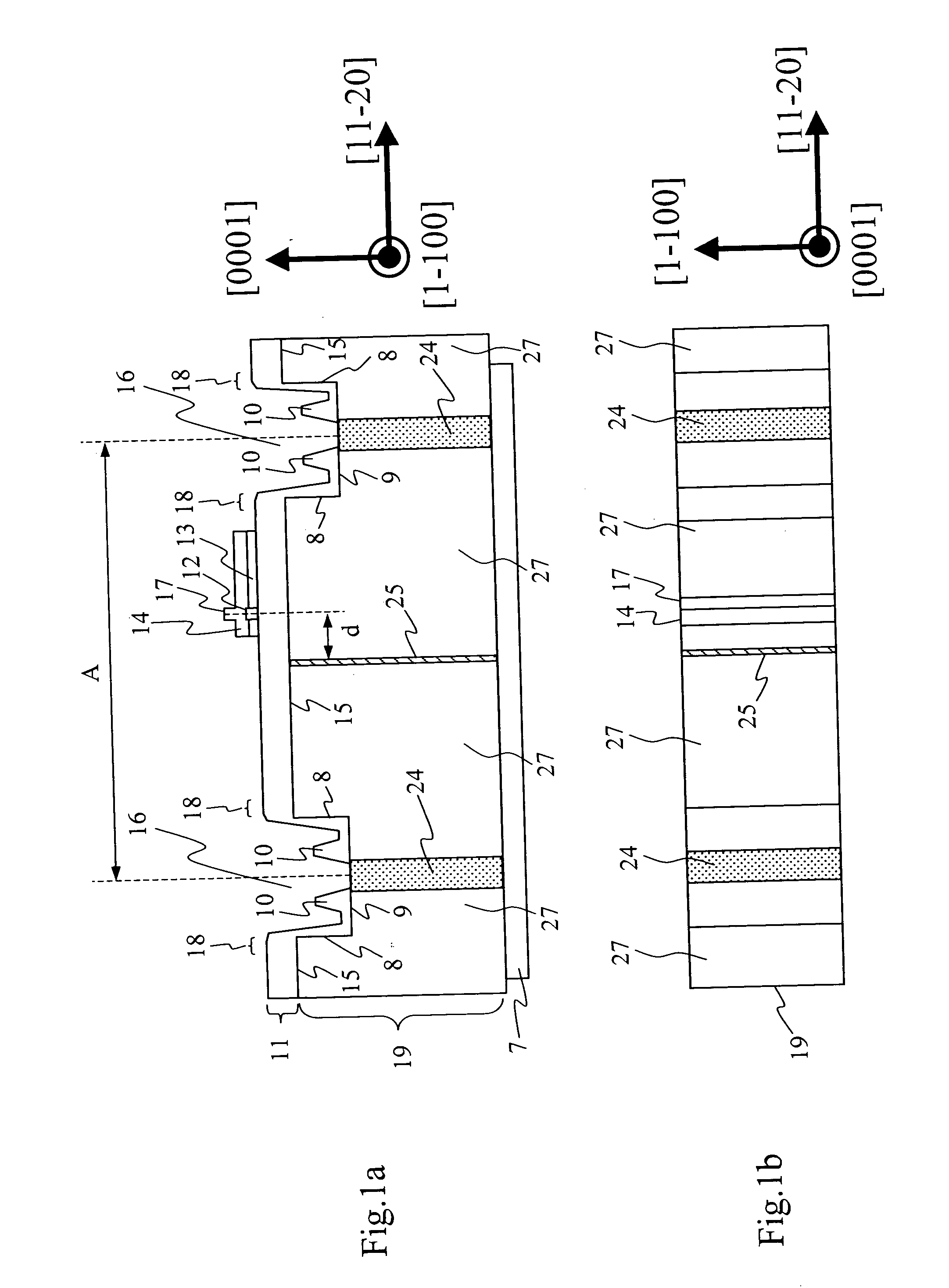

N-Type Group III Nitride Semiconductor Layer Stacked Structure

ActiveUS20080093621A1Good flatnessLow resistanceSolid-state devicesNanoopticsHigh concentrationNitride semiconductors

An object of the present invention provides an n-type Group III nitride semiconductor stacked layer structure of a low resistance having excellent flatness generating few cracks and pits in the uppermost surface. The inventive n-type Group III nitride semiconductor stacked layer structure comprises a first n-type layer which includes a layer containing n-type impurity atoms at a high concentration and a layer containing n-type impurity atoms at a low concentration, a second n-type layer containing n-type impurity atoms at an average concentration smaller than that of the first n-type layer, the second n-type layer neighboring the layer containing n-type impurity atoms at a low concentration in the first n-type layer.

Owner:TOYODA GOSEI CO LTD

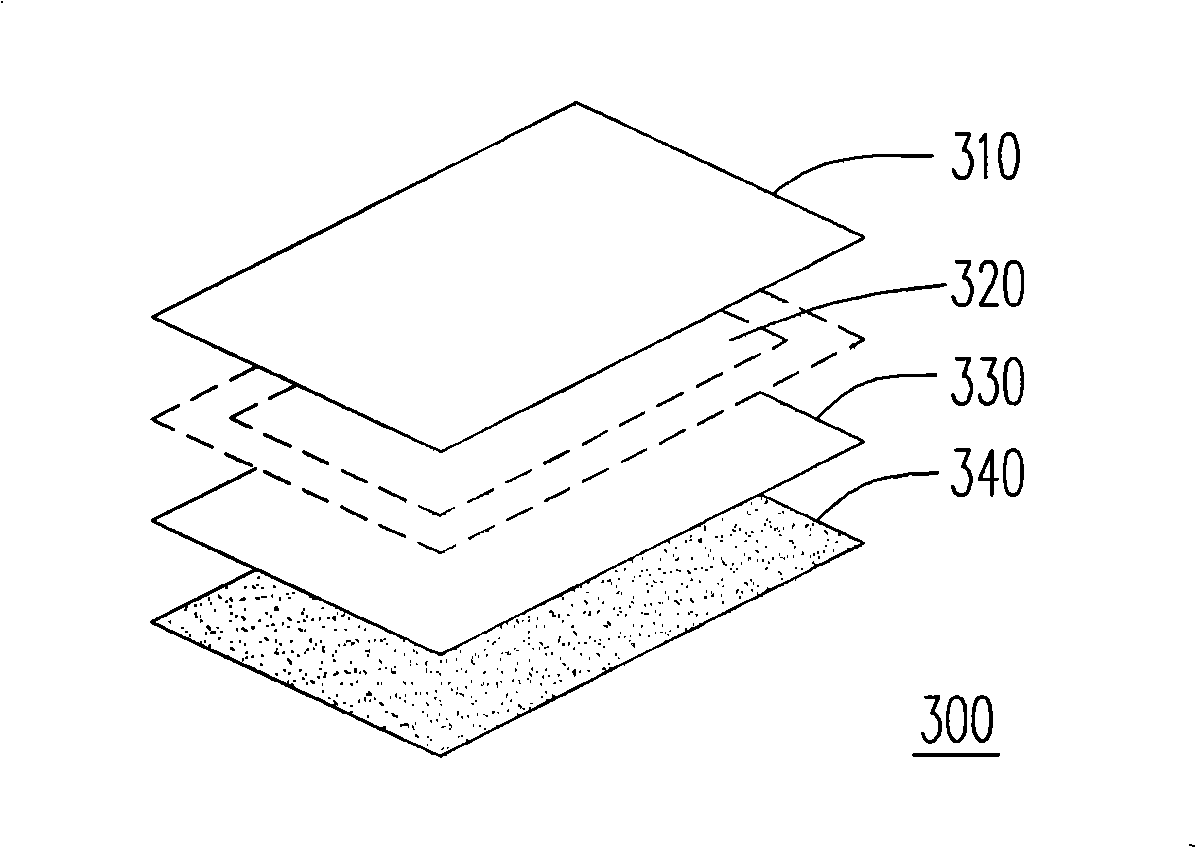

Touch control panel and touch control type LCD device

InactiveCN101408685AReduce usageReduce bonding processStatic indicating devicesInput/output processes for data processingLiquid-crystal displayInter layer

The invention relates to a touch panel and a touch-control liquid crystal display; wherein, the touch panel comprises a polarizing plate which is provided with a plurality of first electrodes, a contact layer which is provided with a plurality of second electrodes and an intermediate layer which is arranged between the polarizing plate and the contact layer. The touch panel utilizes an upper polarizing plate on the liquid crystal displaying panel to replace a glass substrate and can form the structure of the touch panel on the upper polarizing plate directly. Therefore, the integrated process of the touch panel and the liquid crystal displaying panel can be simplified, and the use of the glass substrate is reduced, so that the cost is lowered, and the thickness and weight of the touch-control liquid crystal display are reduced.

Owner:CHUNGHWA PICTURE TUBES LTD

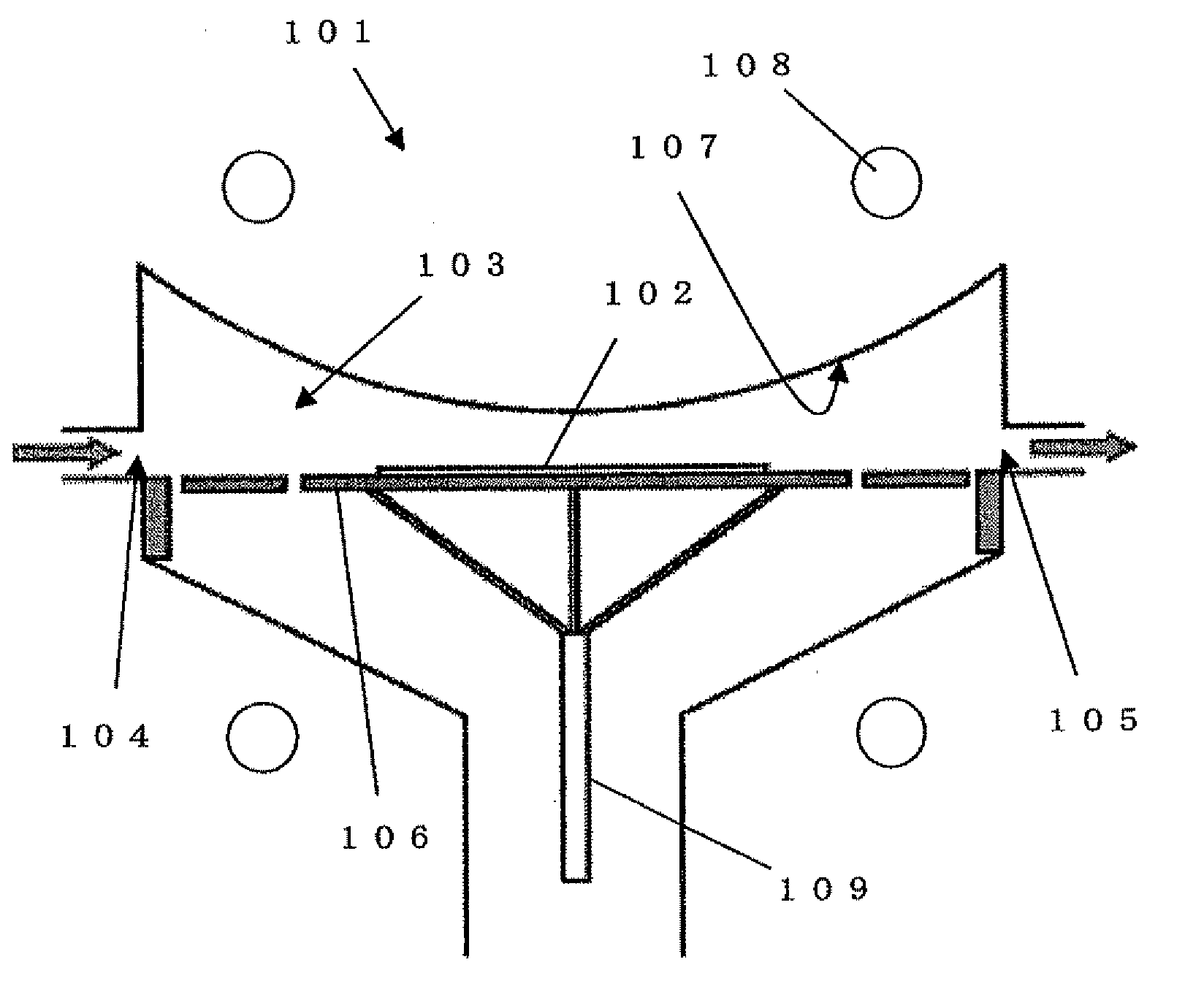

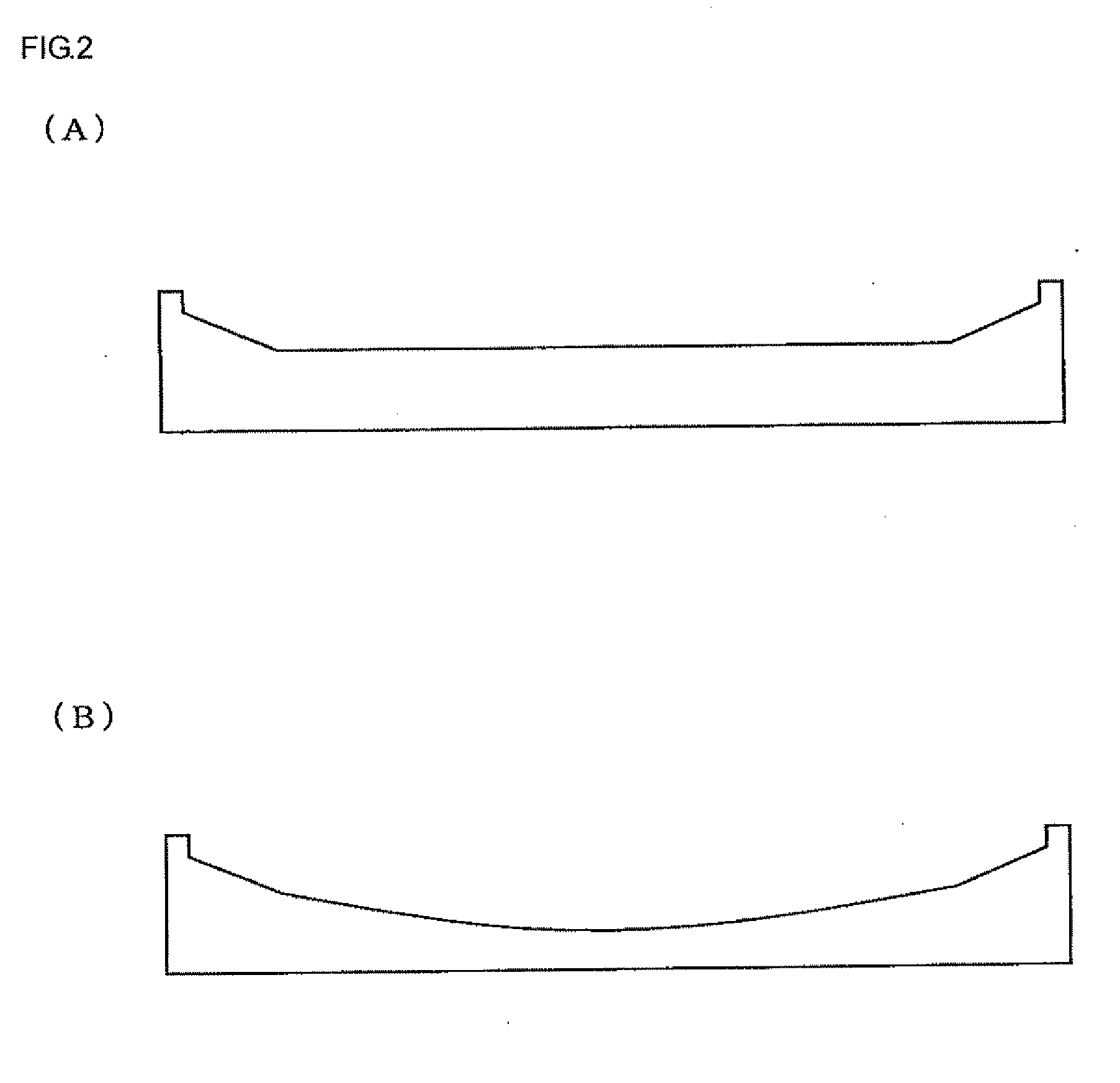

Epitaxial growth susceptor

InactiveUS20110073037A1Avoid degradationGood flatnessSemiconductor/solid-state device manufacturingFrom chemically reactive gasesEngineeringSingle crystal

An epitaxial growth susceptor having a pocket that horizontally supports a single-crystal substrate in an epitaxial growth apparatus in which the pocket has an outer peripheral region with which the single-crystal substrate comes into contact to be supported; and a central region that is surrounded by the outer peripheral region and does not come into contact with the single-crystal substrate, one or more through holes that pierce the epitaxial growth susceptor are formed in the central region of the pocket, and the outer peripheral region of the pocket has a tapered shape that is inclined with a tilt angle that is greater than 0° and less than 1° in such a manner that a depth increases toward the central region, and also has a horizontal width that is 3.3% or more of a diameter of the single-crystal substrate to be supported.

Owner:SHIN-ETSU HANDOTAI CO LTD

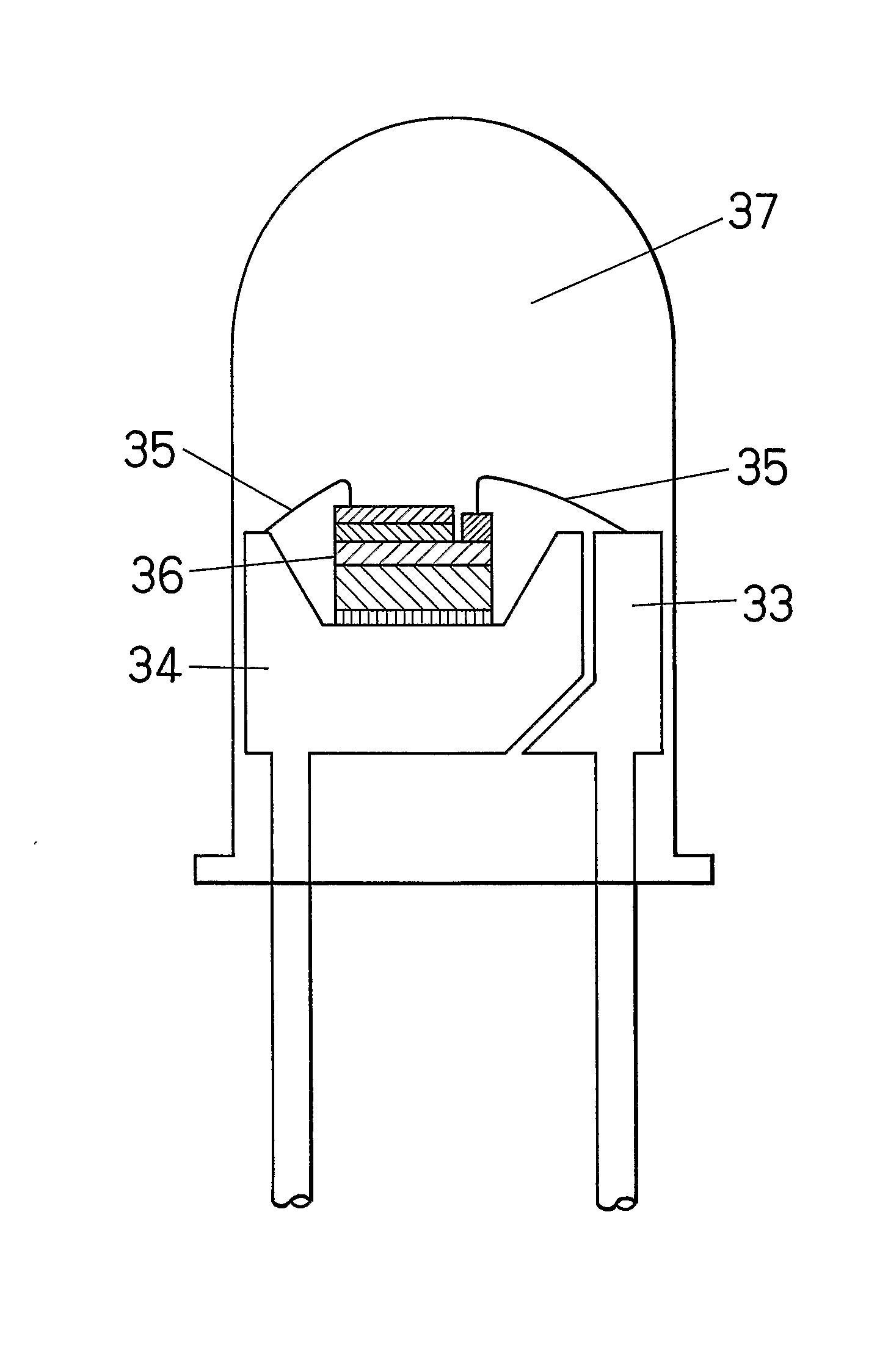

Nitride semiconductor light emitting device

ActiveUS20060038166A1Good flatnessEasy to migrateSolid-state devicesNanoopticsNitride semiconductorsLight emitting device

Owner:SHARP FUKUYAMA LASER CO LTD

Microcrystalline glass with strong breaking resistance and preparation method thereof

The invention discloses microcrystalline glass with strong breaking resistance, which is formed by the following raw materials in parts by weight: 25-30 parts of coal gangue, 20-30 parts of quartz sand, 15-20 parts of fly ash, 10-15 parts of silicon dioxide, 10-15 parts of calcium carbonate, 10-15 parts of alabaster, 6-8 parts of zinc oxide, 5-7 parts of aluminum oxide, 5-7 parts of barium oxide, 3-4 parts of potassium oxide, 3-4 parts of table salt, 2-4 parts of magnesium fluoride, 2-3 parts of calcium fluoride, 2.5-3 parts of wood charcoal, 3-4 parts of clay, 2-3 parts of boron oxide, 2-3 parts of lithium oxide, 2.5-3 parts of tree ash, 2-3 parts of plant ash, 2-3 parts of sodium oxide, 0.25-0.4 part of potassium feldspar, 0.15-0.3 part of sodium tetraborate, 0.15-0.3 part of vanadium pentoxide and 0.15-0.2 part of zirconium dioxide. The microcrystalline glass disclosed by the invention has the advantages of good flatness, high mechanical strength, great hardness, and good heat resistance, bending strength, corrosion resistance and wear resistance; and the product can be made into various types of pipes and sheet materials and can be widely applied to wear-resisting and corrosion-resisting materials and building decoration materials of buildings.

Owner:中山市新感觉玻璃有限公司

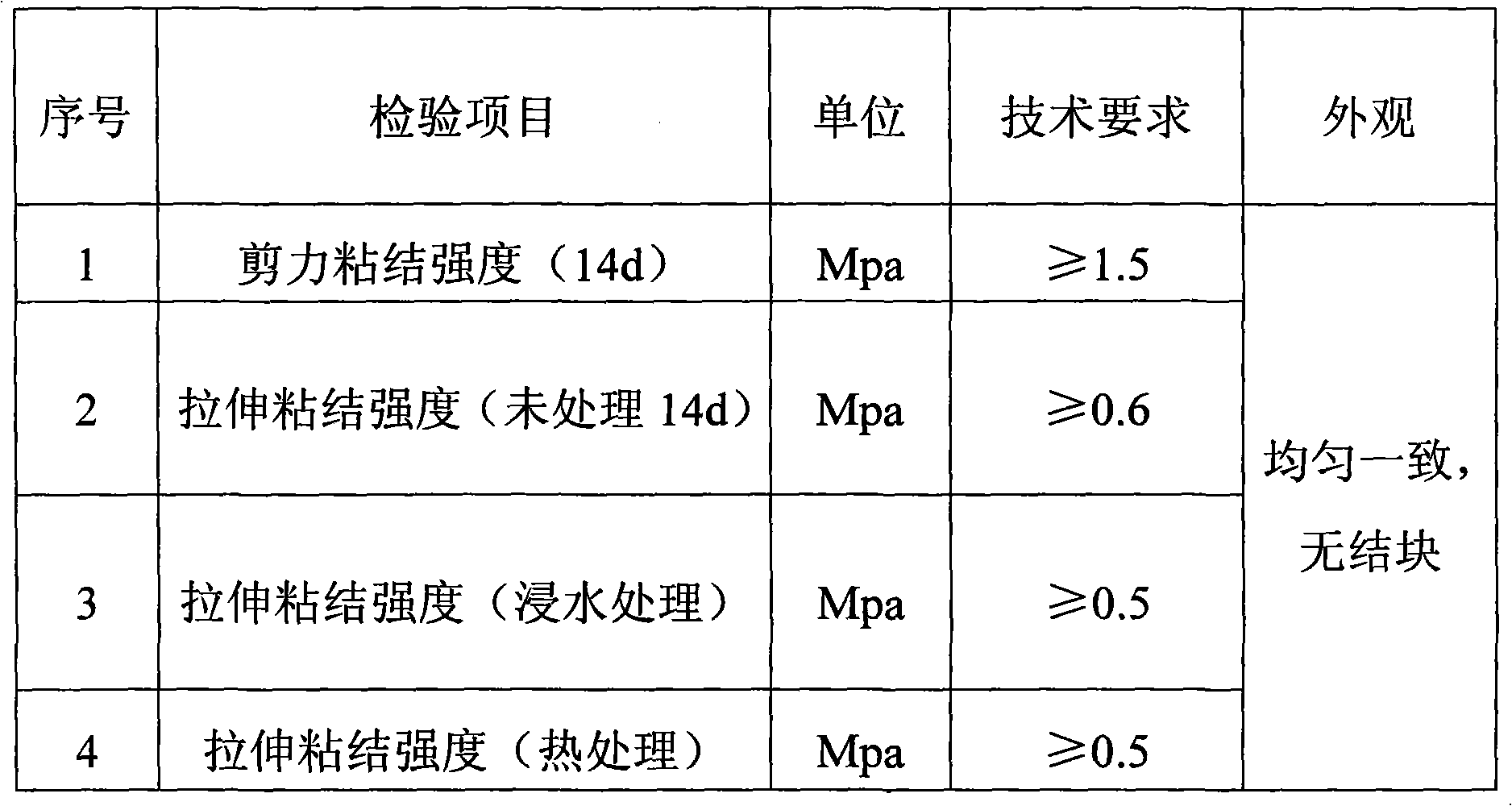

Press polishing method of plastered mesh cloth of inner wall

InactiveCN101886460AGood water retention and adhesionGood flatnessBuilding constructionsSurface finishingTextile

The invention provides a press polishing method of a plastered mesh cloth of an inner wall, relating to the technical field of the surface treatment of the inner wall of a building. The method comprises the steps of: treating a structural base layer; watering to thoroughly wet the base; painting interfacial agent; painting cement mortar at twice; pressing an alkali-proof mesh cloth into mortar which is dried at 70 percents with an iron trowel; rolling water with a rotary drum and engraving floor mortar with wood; press polishing with the iron trowel along the lengthways direction of the alkali-proof mesh cloth; and maintaining in a watering way. The method can play a better role in reducing wall face-painted cracks, prevent the painting face of the inner wall from cracking, control the horizontal cracks of the mortar, the vertical cracks among frame pillars and brick bodies, the cracks among different materials and the hollowness, and guarantee the planeness of the surface of the mortar.

Owner:JIANGSU HONGSHENG CONSTR ENG GROUP

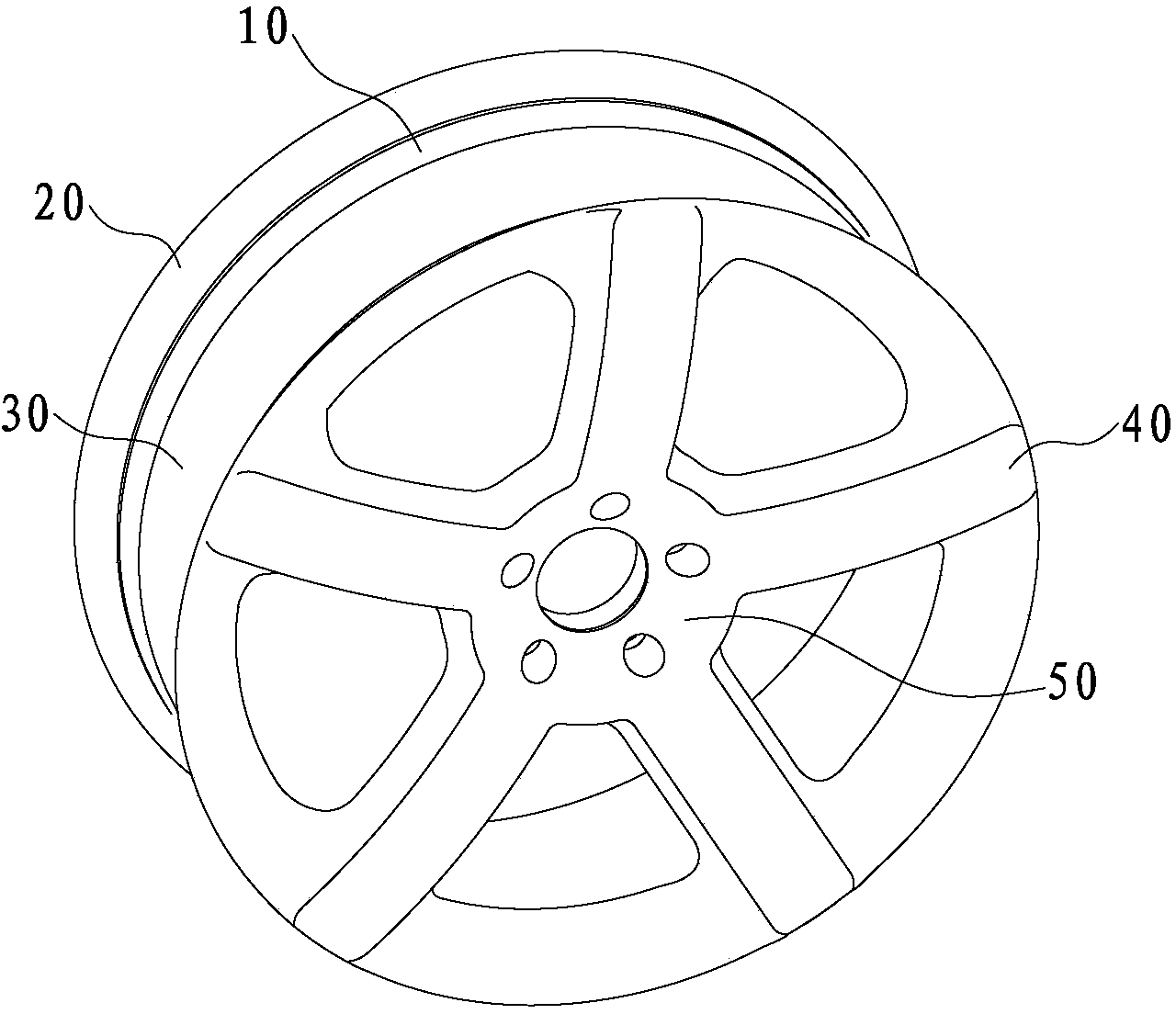

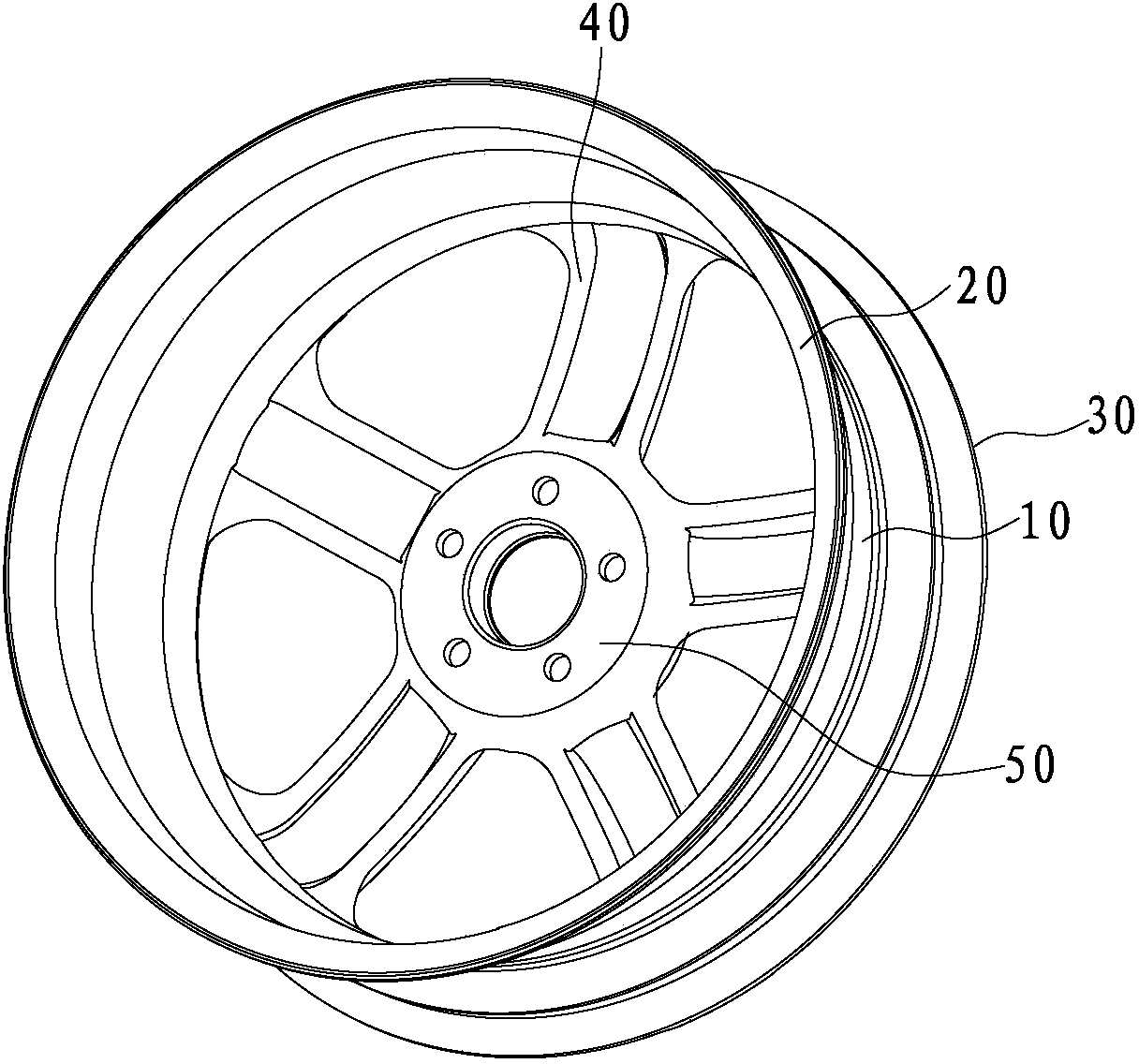

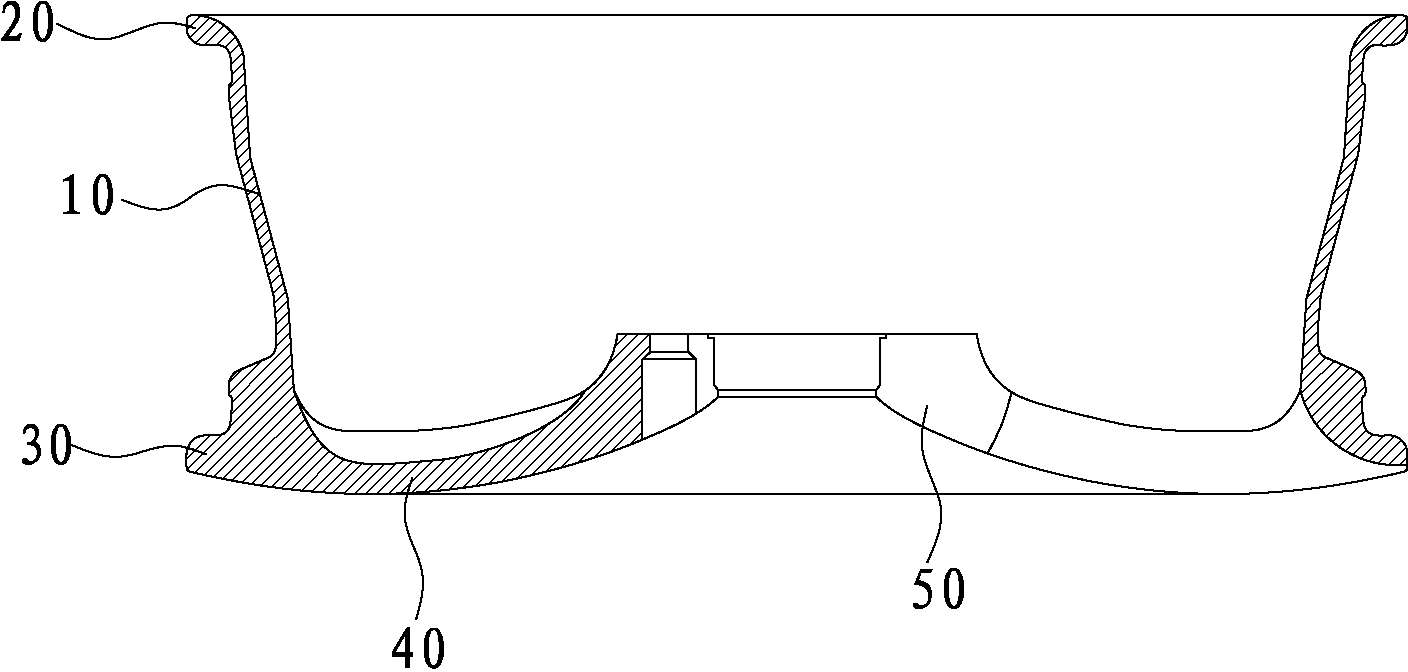

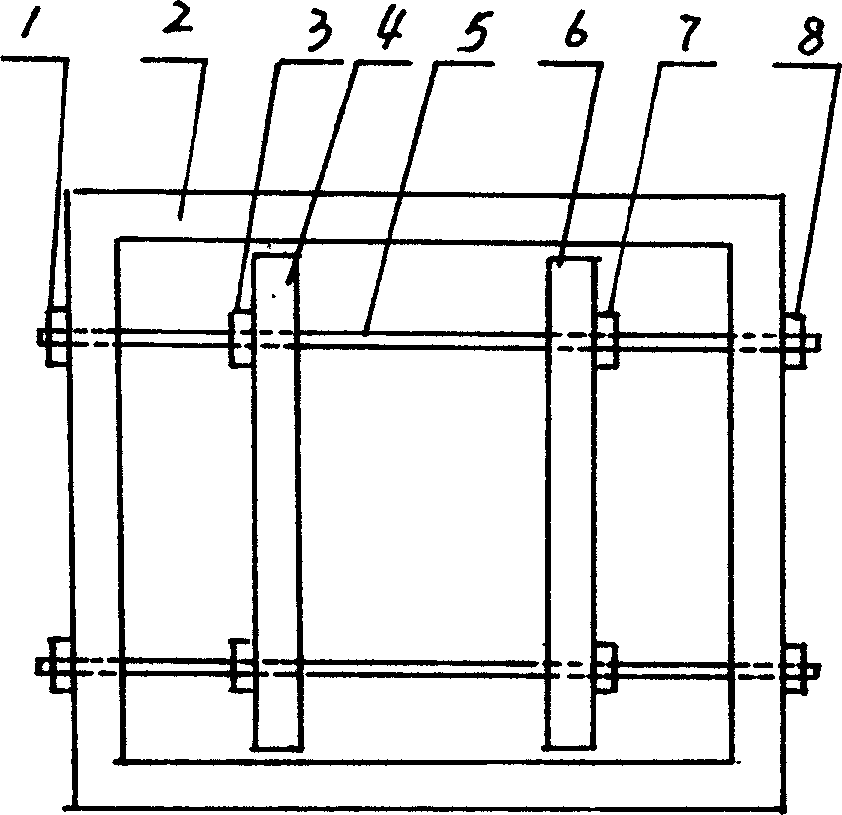

Forming mould and method of carbon fiber rim

The invention discloses a forming mould of a carbon fiber rim. The carbon fiber rim is integrally formed by a rim body, a first wheel flange, a second wheel flange, a spoke and a wheel installing disk. The forming mould comprises an inner mould core, an upper mould, a lower mould, an inner core and at least two side moulds, wherein the inner mould core and the lower mould are locked together to form a cavity of the second wheel flange, the spoke and the wheel installing disk; at least two side moulds form a cylinder in a surrounding manner for forming the outer surface of the rim body; the lower parts of the side moulds are installed on the lower mould; the inner core for forming the inner surface of the rim body is installed inside the cylinder; the upper mould for forming the first wheel flange is installed on the upper parts of the side moulds. The invention further discloses a forming method of the carbon fiber rim. The formed carbon fiber rim is firm in structure, higher in overall strength and relatively high in precision of an assembly size, and relatively high in roundness of the rim body and flatness of the wheel installing disk.

Owner:王明

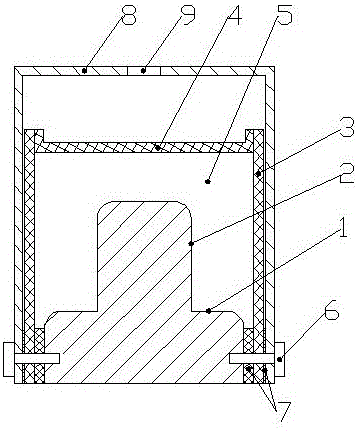

Production method of high-density long-life tungsten-molybdenum alloy crucible

ActiveCN105728708AGood flatnessWear reductionTransportation and packagingMetal-working apparatusDislocationCrystallite

The invention relates to a production method of a high-density long-life tungsten-molybdenum alloy crucible. The production method comprises the steps of preparing tungsten-molybdenum mixed powder, preparing powder blanks, lathing and machining the powder blanks, sintering, performing surface treatment, and then performing hot isostatic pressing. According to the production method, cold isostatic pressing, sintering treatment and the hot isostatic pressing are combined to treat the tungsten-molybdenum powder, so that the dislocation density in a product is high, and dislocations mutually intersect so as to form jogs, so that the intensity of the product is increased. Additionally, fibrous tissues of the blanks formed by the cold isostatic pressing are disconnected again and recrystallized by hot isostatic pressing molding, so that the conditions of tissue delamination, uneven grain distribution and uneven grain size are avoided, the obtained tissues are uniform, small and dense, and the service life is prolonged.

Owner:ACHEMETAL TUNGSTEN & MOLYBDENUM

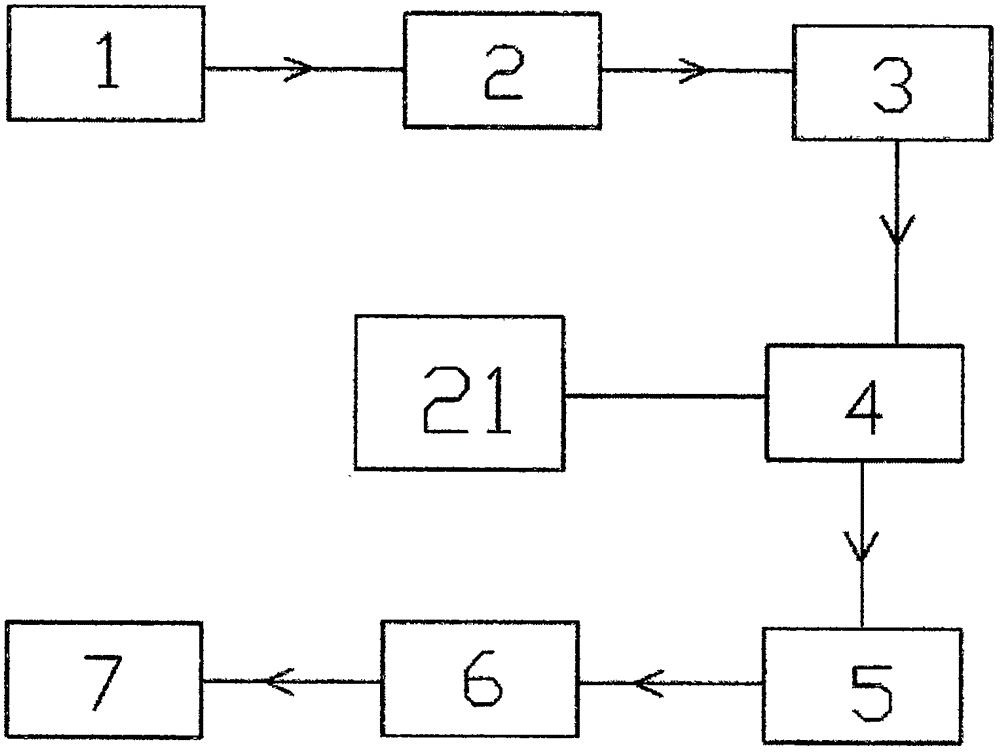

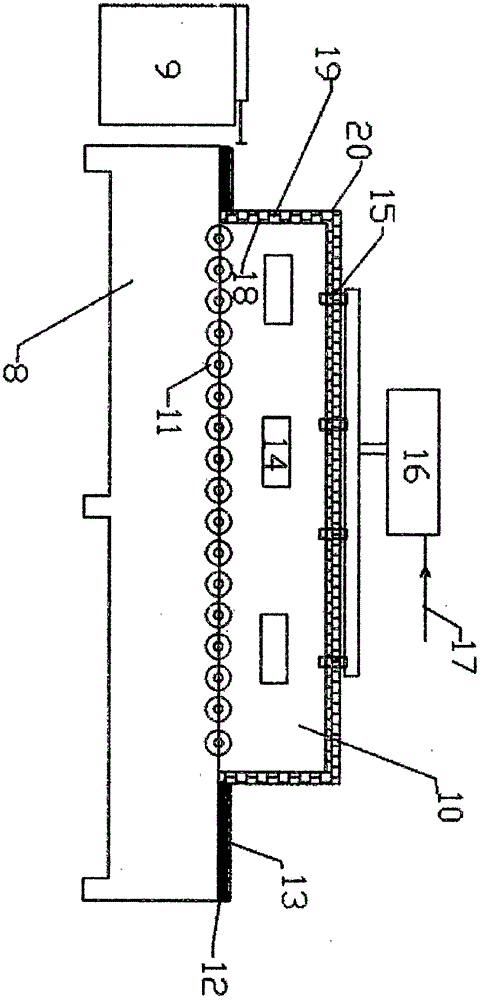

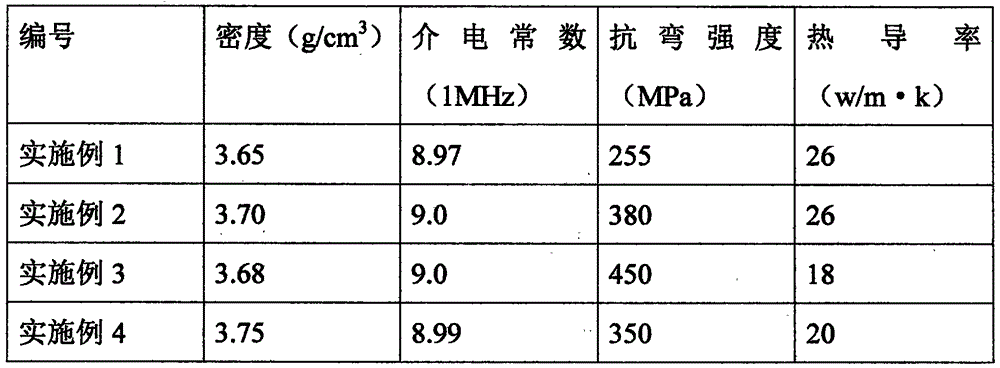

Large-size ceramic substrate, and preparation method and production line thereof

InactiveCN105906331AHigh mechanical strengthGood thermal conductivityCeramic shaping plantsAdhesiveSolvent

The invention discloses a large-size ceramic substrate which is prepared from the following components in parts by weight: 1 part of ceramic powder, 0.04-0.14 part of adhesive, 0.005-0.018 part of dispersing agent, 0.02-0.06 part of plasticizer and 0.3-0.9 part of solvent. The ceramic powder is prepared from the following raw materials in percentage by weight: 93-96% of aluminum oxide, 0.5-3% of silicon dioxide, 0.3-2% of magnesium oxide, 0.2-1% of calcium oxide, 0.1-2% of yttrium oxide, 0.1-2.5% of barium carbonate, 0.05-1% of zirconium oxide and 0.1-2% of bismuth oxide. The invention also discloses a production method of the ceramic substrate and a production line required by the production method. The ceramic substrate has the characteristics of excellent mechanical strength and favorable heat conductivity. The preparation method is simple and is low in cost. The production line is simple, does not occupy the space, and effectively improves the quality of products.

Owner:SINOCERAM TECH (ZHENGZHOU) CO LTD

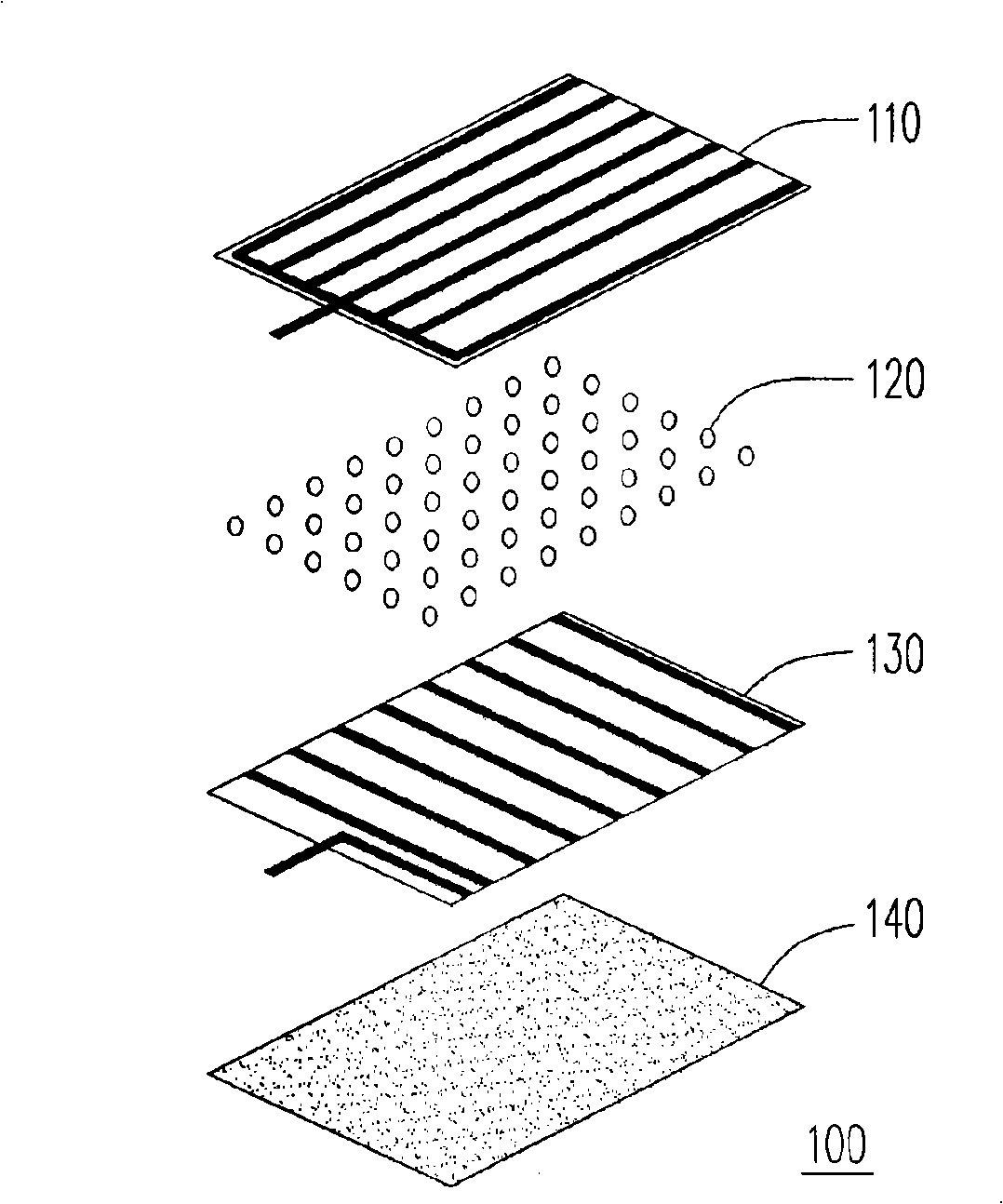

Preparation method for high-refractivity scattering layer and preparation method for organic light-emitting diode (OLED) with high luminous efficiency

ActiveCN102709489AEasy to operateGood flatnessSolid-state devicesSemiconductor/solid-state device manufacturingChemistryPhotoresist

The invention discloses a preparation method for a high-refractivity scattering layer and a preparation method for an organic light-emitting diode (OLED) with high luminous efficiency. The preparation method for the high-refractivity scattering layer comprises the following steps of: S1, preparing grinding dispersion, wherein the grinding dispersion comprises 10 to 60 mass percent of high-refractivity scattering particle, a dispersing agent of which the mass is 1 to 60 percent based on the mass of the high-refractivity scattering particles, 0 to 5 mass percent of anti-settling agent, 0 to 60 mass percent of photoresist and 20 to 89.9 mass percent of organic solvent; S2, filter-pressing the grinding dispersion prepared by the step S1 by using filter paper with filtering hole apertures of 0.8 to 1.2 mu m to obtain a film preparation solution; and S3, photoetching and spinning the film preparation solution prepared by the step S2 to obtain the high-refractivity scattering layer. When the high-refractivity scattering layer is arranged between a substrate and an electrode of the OLED with the high luminous efficiency, the luminous efficiency of the OLED can be greatly improved.

Owner:GUAN YEOLIGHT TECH CO LTD

Preparation method of titanium dioxide supported oxidized cellulose

InactiveCN107876106AHigh aldehyde contentGood flatnessOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationCarboxycelluloseChemistry

The invention provides a preparation method of titanium dioxide supported oxidized cellulose and belongs to the field of material preparation. The preparation method is characterized by comprising thefollowing steps: a cellulose material is placed in a sodium periodate solution, subjected to ultrasonic treatment at room temperature, left to stand in a thermostatic water bath, then left to stand at 60 DEG C, washed, placed in a glycerol solution and washed, and a cellulose material containing aldehyde groups is obtained; the cellulose material is placed in a deionized water mixed solution andwashed sufficiently, a carboxyl cellulose material is obtained and placed in a titanium dioxide suspension, and a titanium dioxide supported cellulose material is obtained; the titanium dioxide supported cellulose material is washed sufficiently, soaked in a sodium copper chlorophyllin solution, washed sufficiently and naturally dried at room temperature, and the material is obtained. The preparedoxidized cellulose material has higher aldehyde group content, better flatness and higher yield. After sensitization of titanium dioxide, agglomeration is relieved, and titanium dioxide is uniformlydistributed on the oxidized fiber material.

Owner:SHAANXI ALLIANCE LOGISTICS

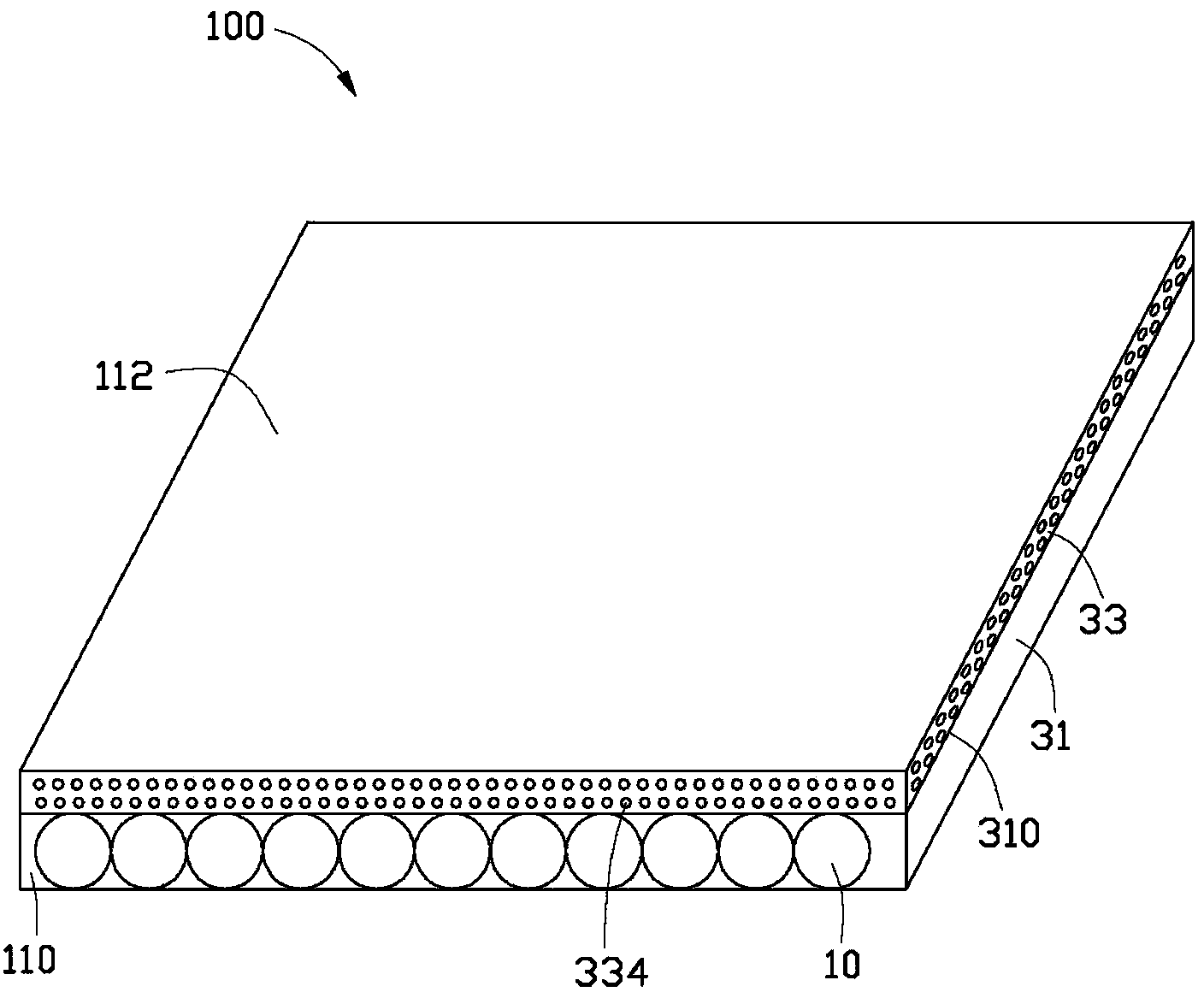

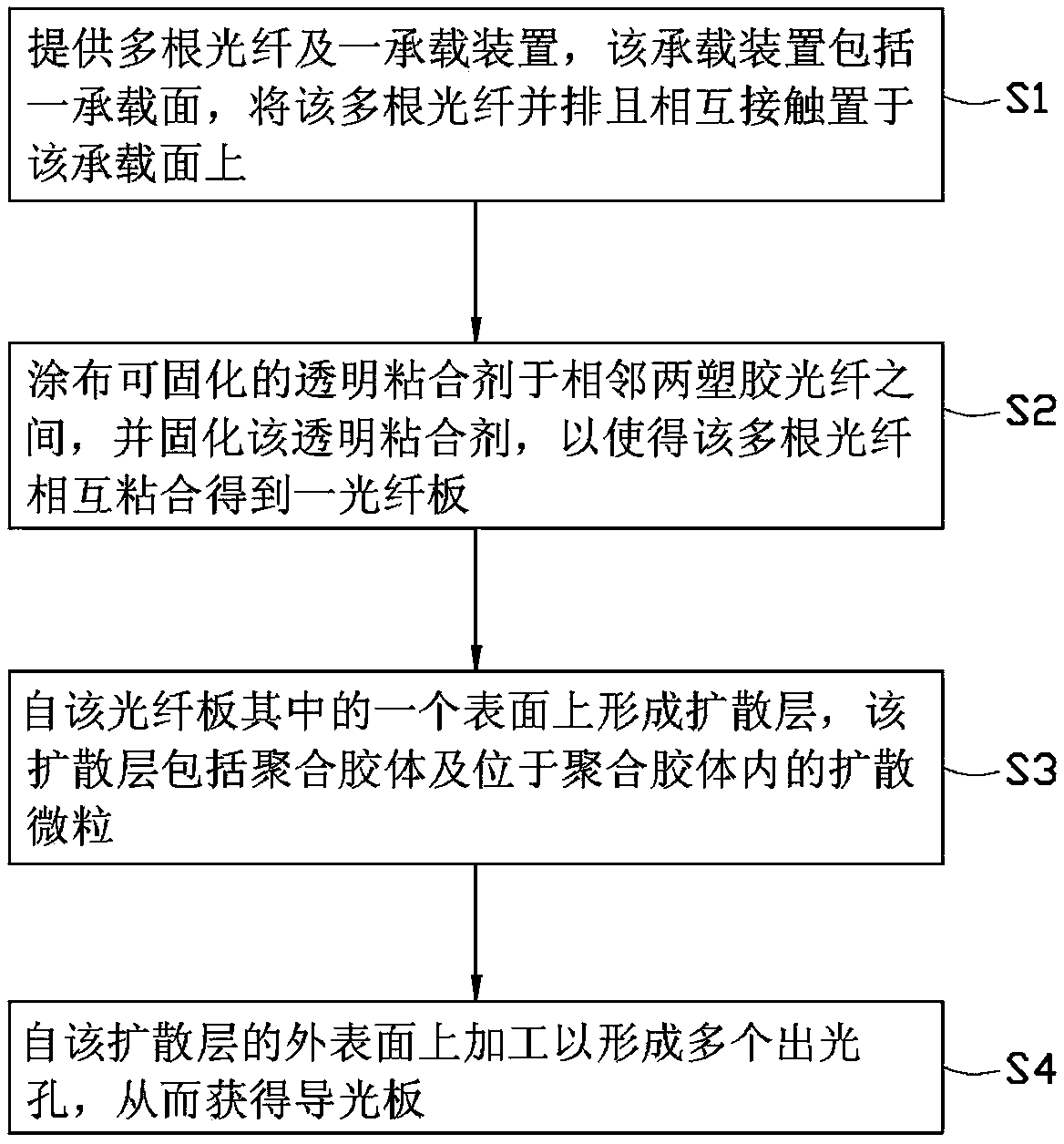

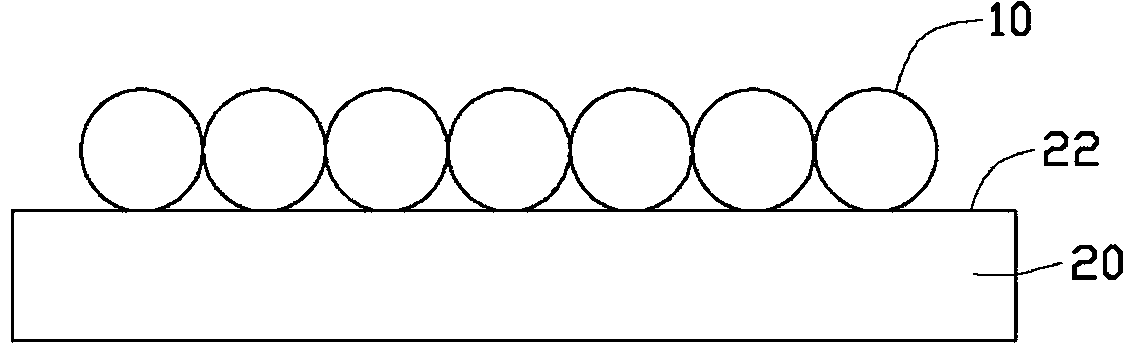

Light guide plate and manufacturing method thereof

The invention relates to a light guide plate. The light guide plate comprises an optical fiber plate and a diffusion layer, wherein the optical fiber plate is formed by a plurality of optical fibers which are adhered side by side, the optical fiber plate is provided with a surface, the diffusion layer is located on the surface and is provided with a light outlet surface, the light outlet surface is a light outlet surface of the light guide plate, light outlet holes are distributed in the light outlet surface, and the light guide plate is provided with a light inlet surface perpendicular to the light outlet surface. The invention further relates to a manufacturing method of the light guide plate.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

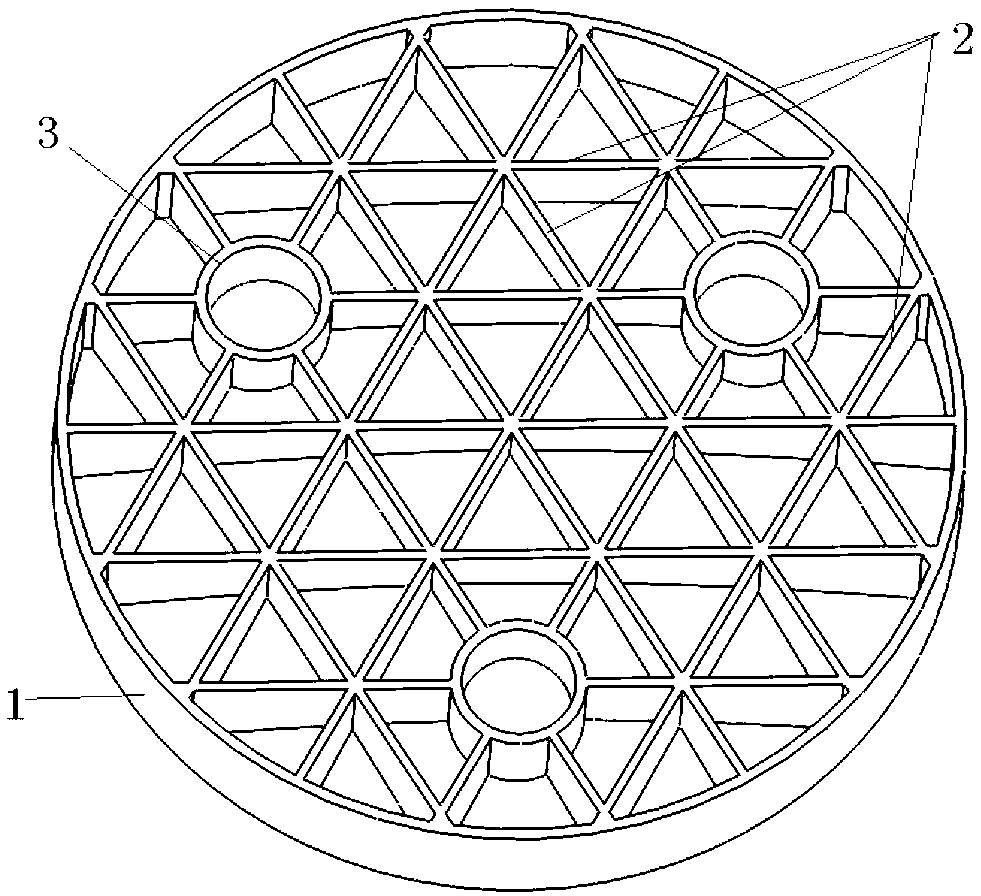

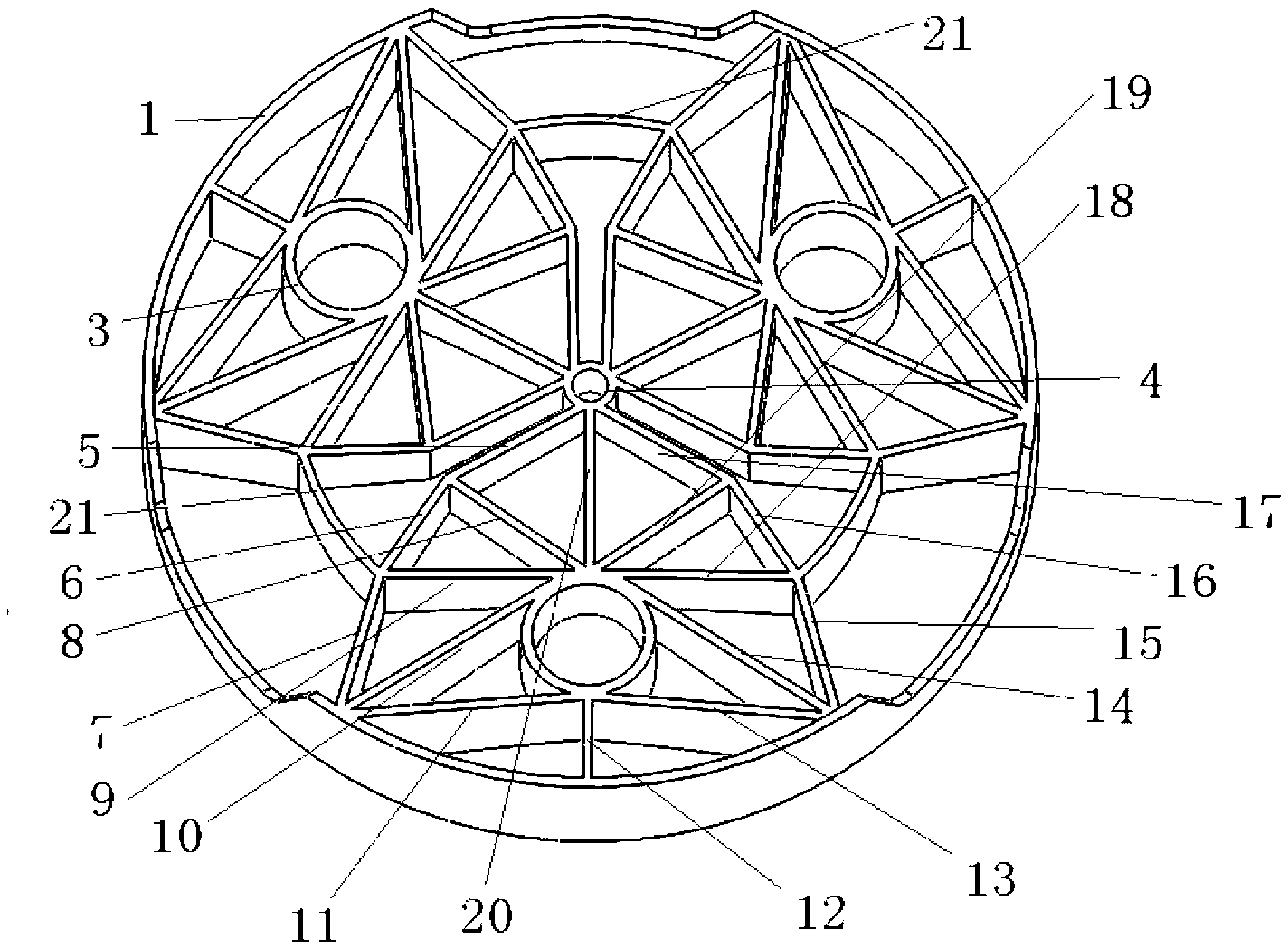

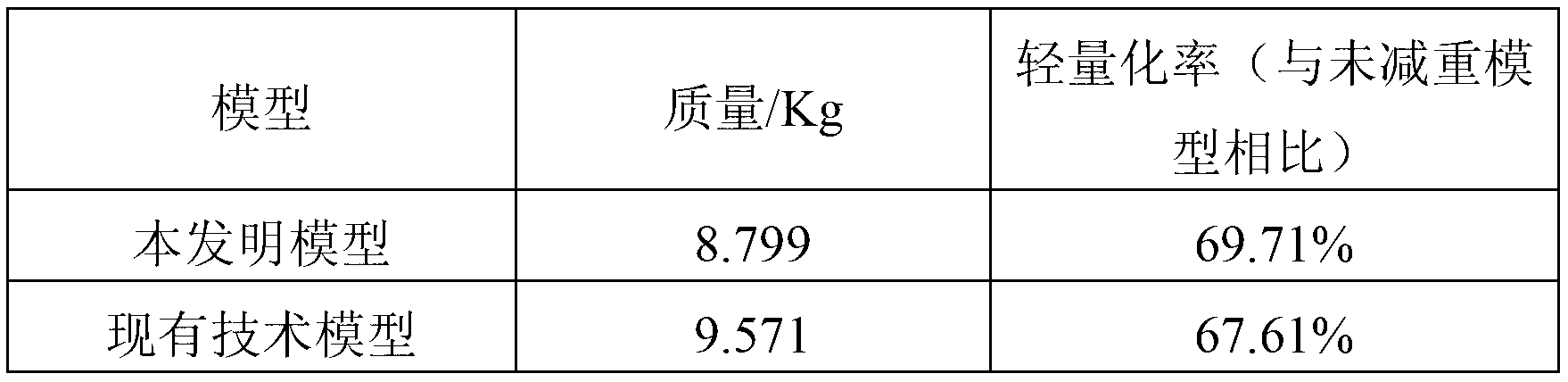

Large-diameter main reflecting mirror

The invention provides a large-diameter main reflecting mirror. The large-diameter main reflecting mirror comprises a mirror surface, a back plate, an external wall, three mounting hole walls and a plurality of reinforcing walls, wherein the external wall is arranged on the outer side of the back plate, the three mounting hole walls are evenly distributed on the back plate in a circle, and the plurality of reinforcing walls are arranged between the external wall and the mounting hole walls. The plurality of reinforcing walls comprise a centre hole wall arranged in the center of the back plate, three reinforcing wall units evenly distributed around the centre hole wall and three connection walls connecting the three reinforcing units. The diameter of the large-diameter main reflecting mirror is 500mm, the large-diameter main reflecting mirror is mounted through the manner of back supporting, and the three parts on the periphery of a hole in the back are symmetrical based on variant densimetry calculation.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

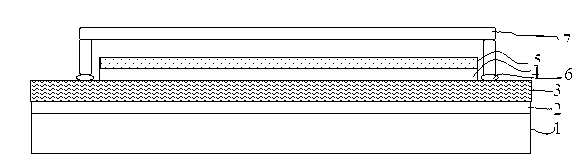

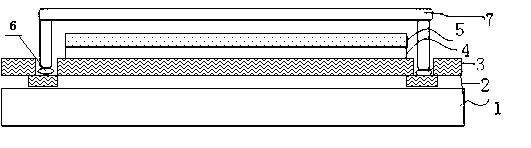

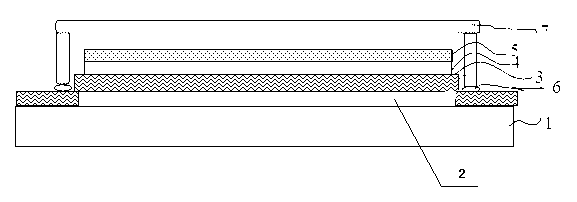

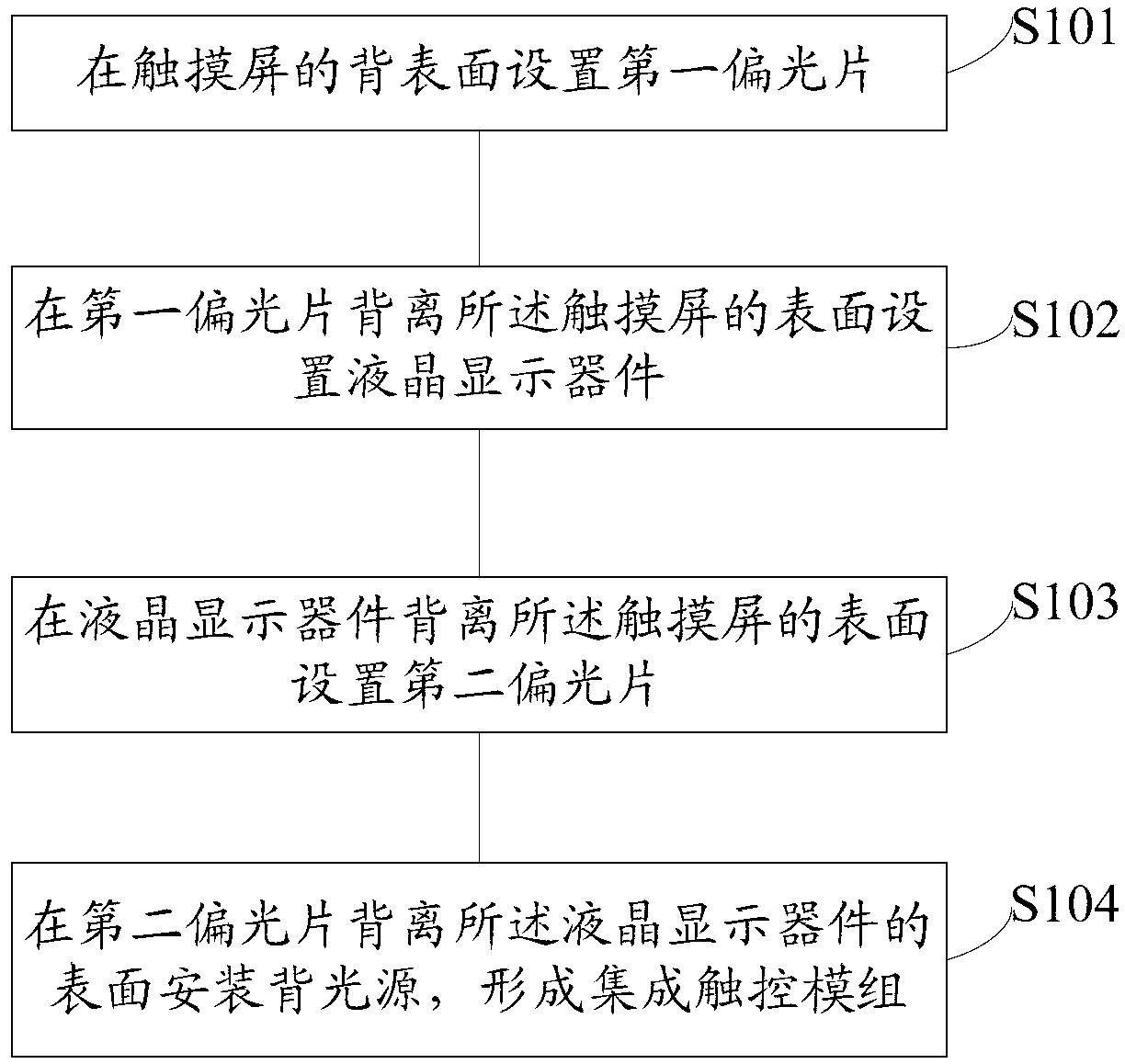

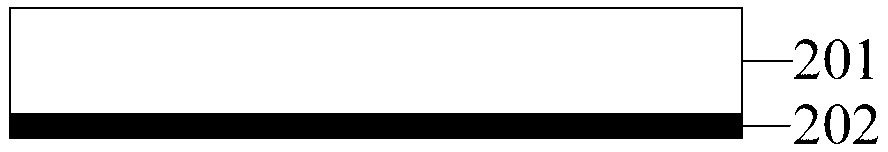

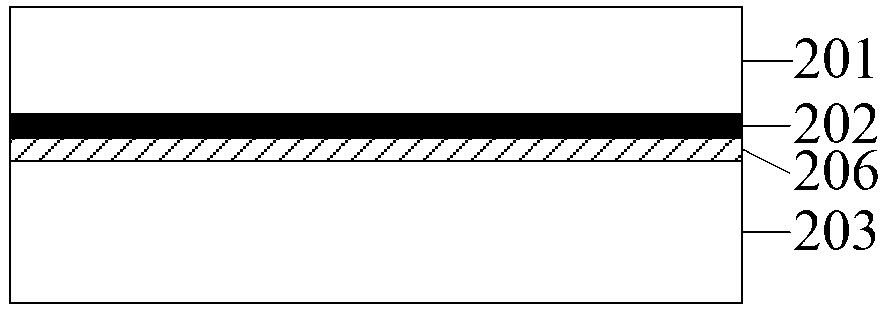

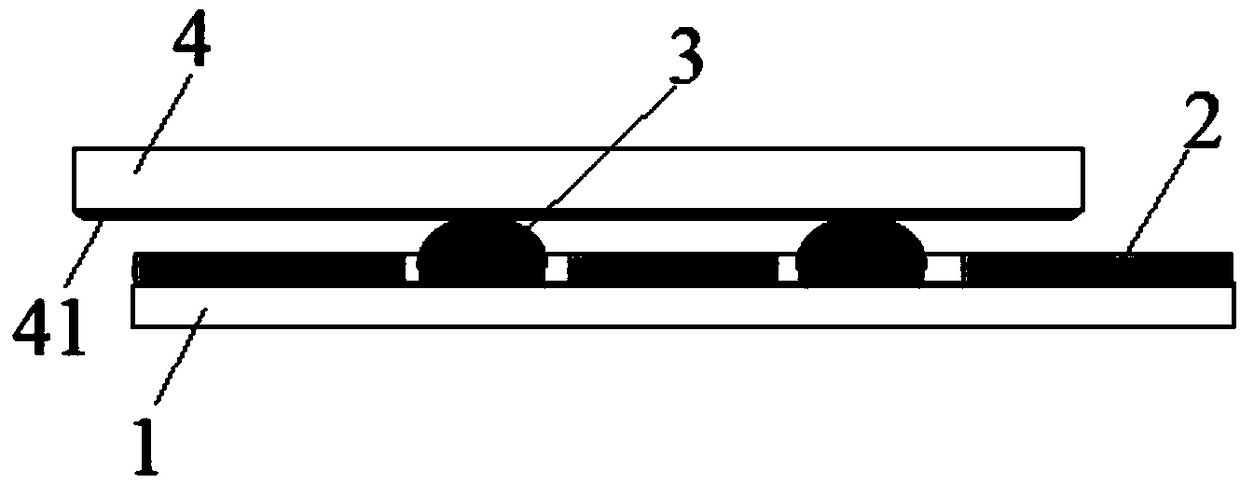

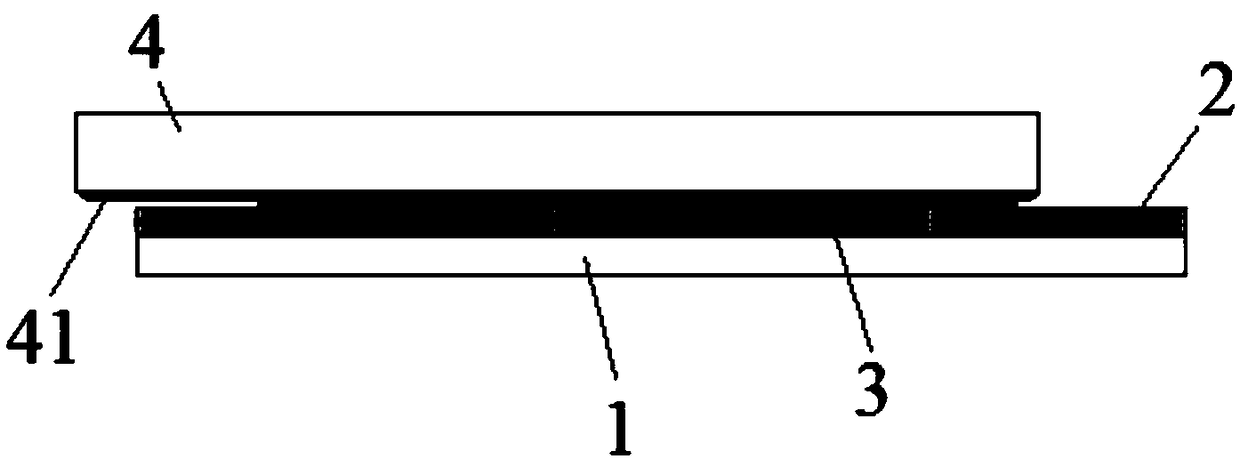

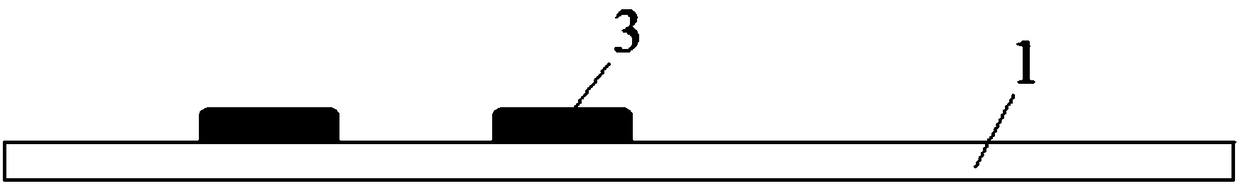

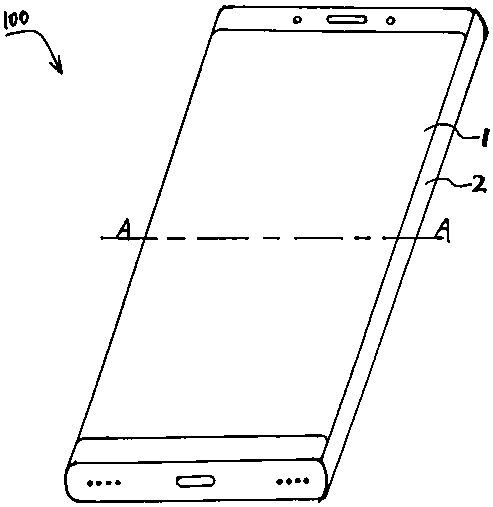

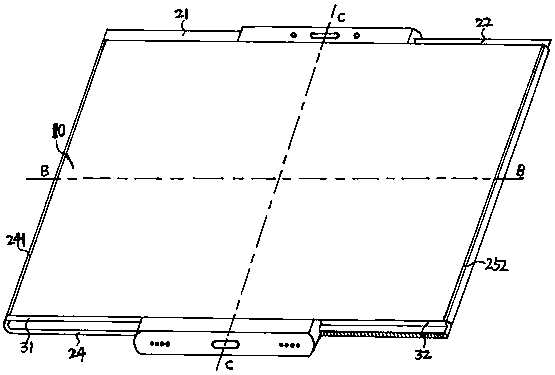

Integrated touch control module, manufacturing method thereof and touch display device

ActiveCN103076694AAvoid warpingGood flatnessNon-linear opticsInput/output processes for data processingLiquid-crystal displayLight source

The invention provides a manufacturing method of an integrated touch control module. The method comprises the following steps of: arranging a first polaroid on the back surface of a touch screen; arranging a liquid crystal display device on the surface, which is deviated from the touch screen, of the first polaroid; arranging a second polaroid on surface, which is deviated from the touch screen, of the liquid crystal display device; and arranging a backlight source on the surface, which is deviated from the liquid crystal display device, of the second polaroid to form the integrated touch module. According to the manufacturing method of the integrated touch control module provided by the invention, the liquid crystal display device can be fully jointed with the touch screen in a relatively flat state in the manufacturing process of the integrated touch module, and the problem of poor flatness between the liquid crystal display device and the touch screen is solved; and on the other hand, the influence of the problem of poor flatness of the backlight source on the display effect of the integrated touch control module can be eliminated, and the problem of displaying of yellow spots on the integrated touch control module is solved on two aspects.

Owner:TRULY OPTO ELECTRONICS

Flagstone positioning clamp and processing method therefor

InactiveCN1699014AImprove efficiencyGood flatnessEdge grinding machinesPositioning apparatusEngineeringMechanical engineering

This invention relates to a stone plate processing location jig and a grinding method, which belongs to location jig and grinding method field. The location jig is on the table surface of jig borer, and the inclined-surface or end-face of the stone plate is in the rectangle frame, the stone plate is fixed by the jack bolt cramped construction or location wedge; the method comprises: adjusting the angle of bistrique and grinding quantity; opening the jig borer; the bistrique will move downwards automatically to contact the stone plate and grind until reach to the designed quantity, or the bistrique move downwards automatically to contact the stone plate, and the table surface of jig borer shift to force the bistrique being grinded until the designed quantity.

Owner:厉国苗

A preparing method for a transparent adhesive layer of a frame hole region of a mobile phone panel

The invention provides a preparing method for a transparent adhesive layer of a frame hole region of a mobile phone panel. The preparing method includes the following steps: a protection film is pasted on the back side of the mobile phone panel, optical adhesive dispensing is performed on induction holes on the back side of the mobile phone panel covered with the protection film, the optical adhesives are pressed flat by a pressure block, the adhesives are solidified, and the pressure block and the protection film are removed. The transparent adhesive layer with good smoothness and no bubblescan be prepared, and the subsequent light transmission effect of the induction holes after the film used for hiding the induction holes is pasted on the transparent adhesive layer is effectively guaranteed. In the process of pasting the protection film on the mobile phone panel, the upper surface of the protection film is provided with an auxiliary film, the total thickness of the film layer adsorbed by a film-absorbing plate can be increased, the generation of wrinkle after the film is adsorbed is avoided, the thickness and the stiffness of the film layer are increased, the thickness of subsequent dispensed adhesive is not influenced, the attaching difficulty is reduced, and the quality of the product is also risen.

Owner:LENS TECH

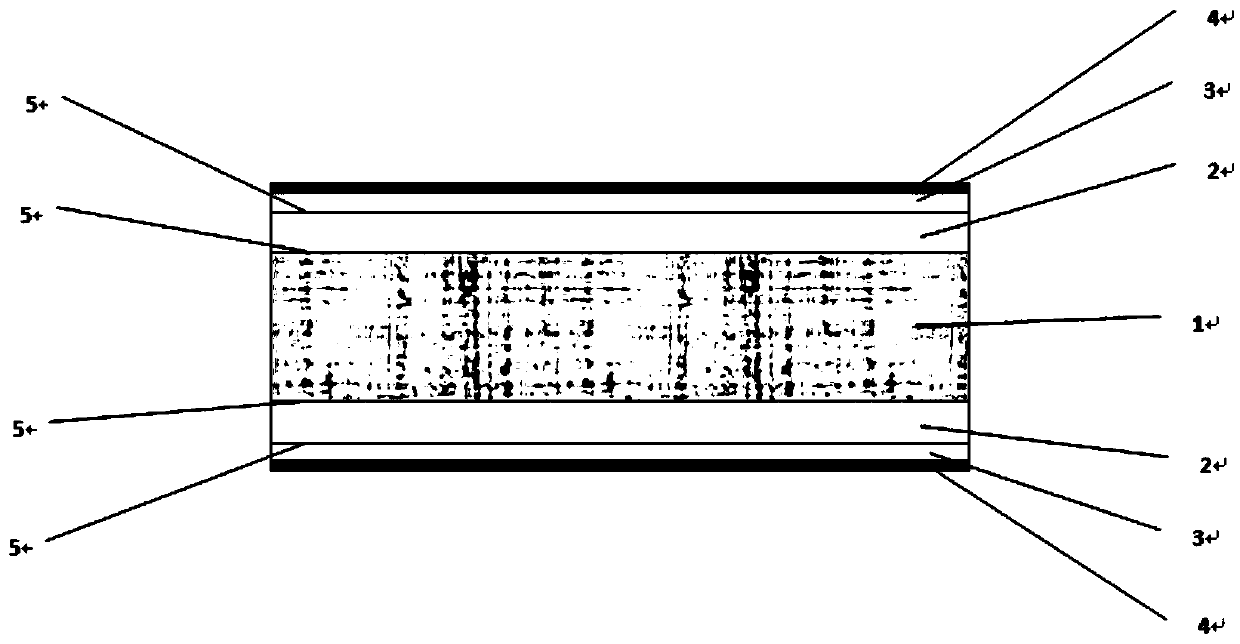

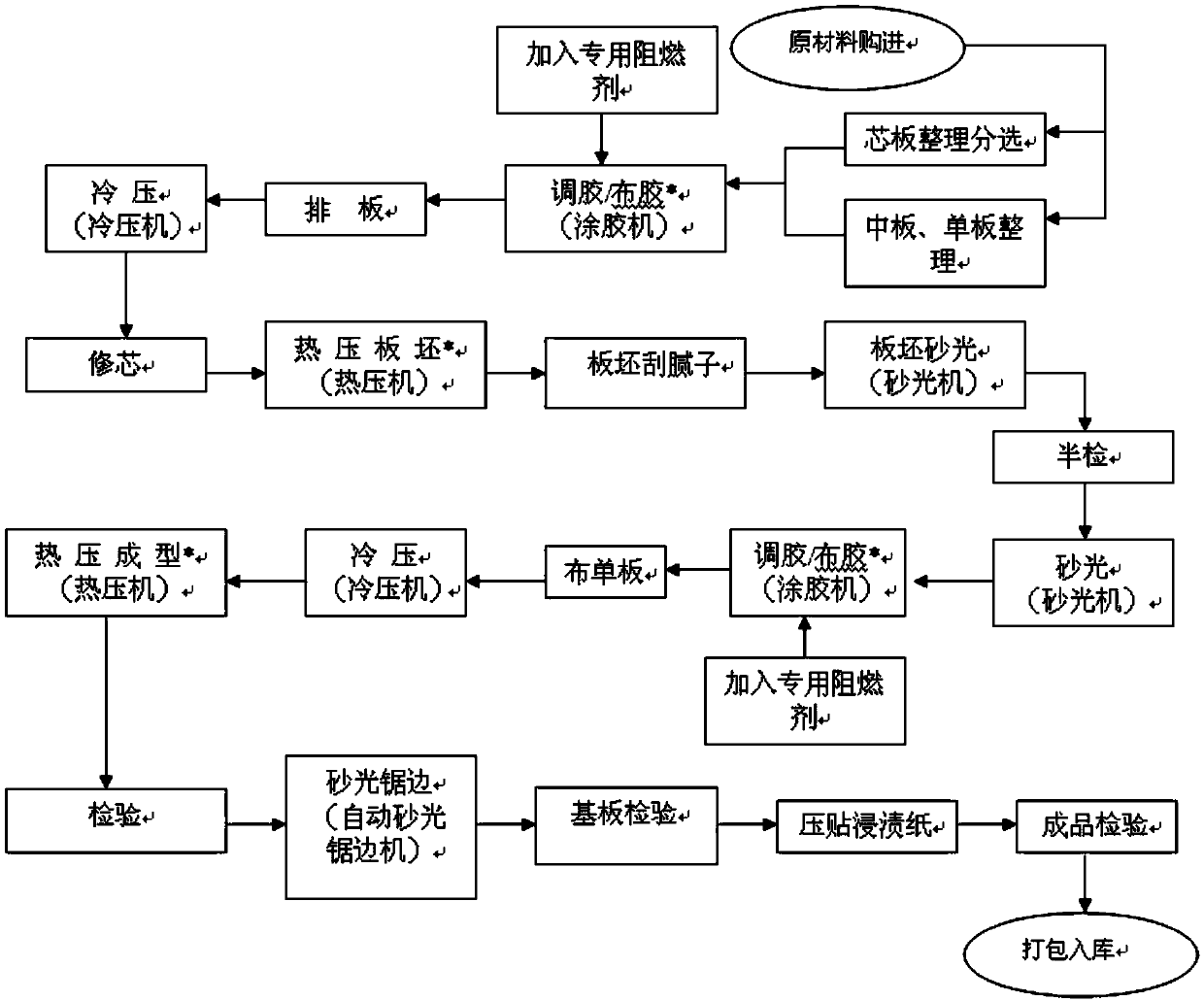

Flame-retardant impregnated film adhesive facing blockboard

PendingCN109514657AThe process is simple and reasonableGood flatnessOther plywood/veneer working apparatusWood veneer joiningAdhesiveEngineering

The invention provides a flame-retardant impregnated film adhesive facing blockboard. The flame-retardant impregnated film adhesive facing blockboard comprises a board core, middle boards, poplar veneers, decorative film adhesive and flame-retardant adhesive layers, wherein the upper surface and the lower surface of the board core are correspondingly covered with the middle boards and are integrally pressed to form a board blank; adhesive connection is correspondingly carried out between the upper surface of the board core and the middle board as well as between the lower surface of the boardcore and the middle board through flame retardant adhesive layers, wherein the flame retardant glue layers are prepared by coating glue added with 25% of a urea glue flame retardant; the upper surfaceand the lower surface of the board blank are correspondingly covered with the poplar veneers and are integrally made into a base board through cold and hot pressing, and the upper surface of the board blank and the poplar veneer and the lower surface of the board blank and the poplar veneer are correspondingly subjected to adhesive connection through the flame retardant adhesive layers, wherein the flame retardant adhesive layers are prepared by coating glue added with the urea glue flame retardant in a proportion of 30%; and the decorative film adhesive is correspondingly pasted on the uppersurface and the lower surface of the base board, and finished products of the flame-retardant impregnated film adhesive facing blockboard are obtained through hot pressing and integral forming, so that the flame retardant performance of the impregnated film adhesive facing blockboard is improved, and meanwhile, environment protection is achieved, and various home decoration requirements of peoplecan be met.

Owner:ZHEJIANG SHENGHUA YUNFENG GREENEO

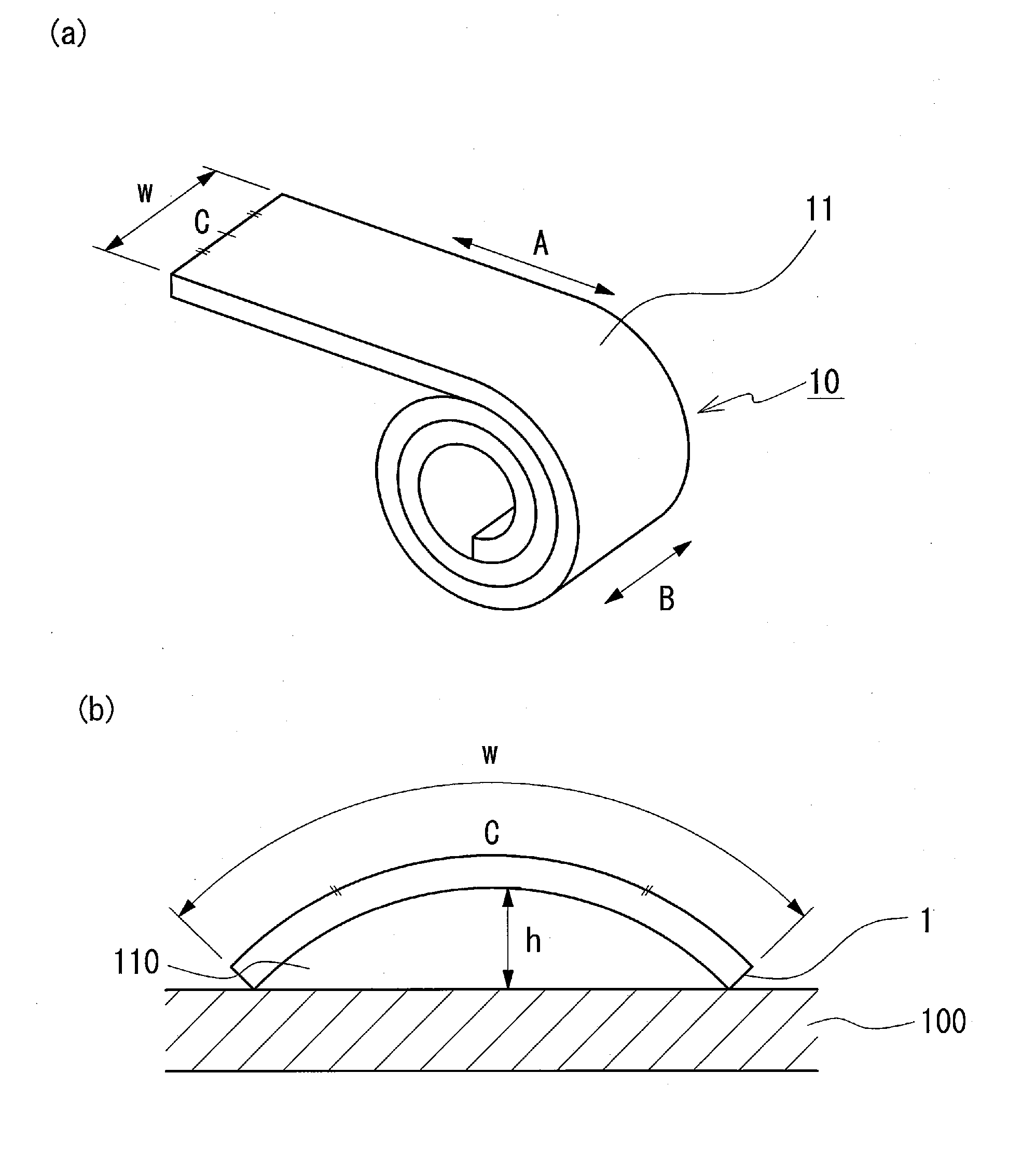

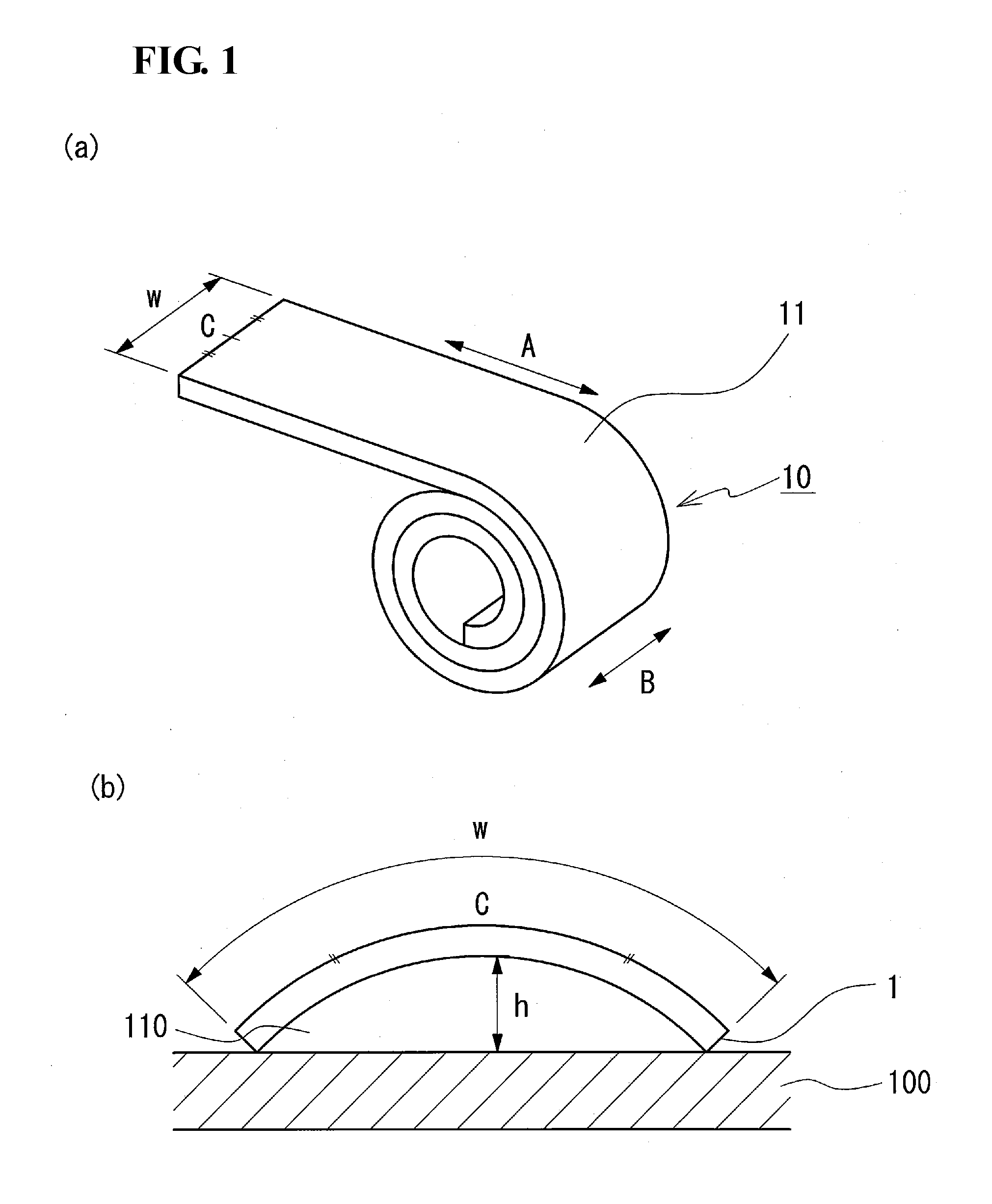

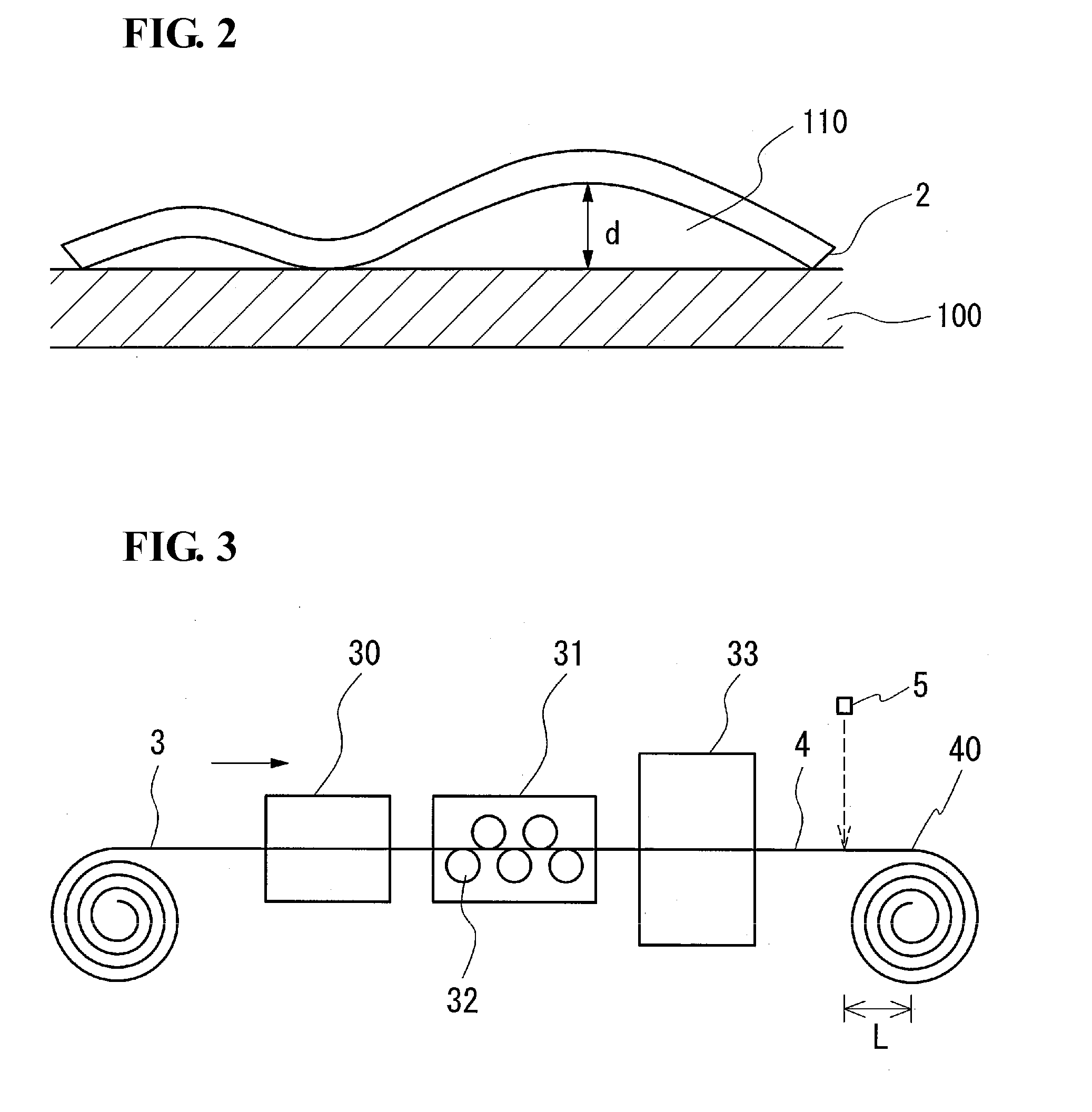

Magnesium alloy coil stock

ActiveUS20120276402A1Good flatnessHigh productivityBuilding componentsThin material handlingMagnesium alloyContinuous casting

Owner:SUMITOMO ELECTRIC IND LTD

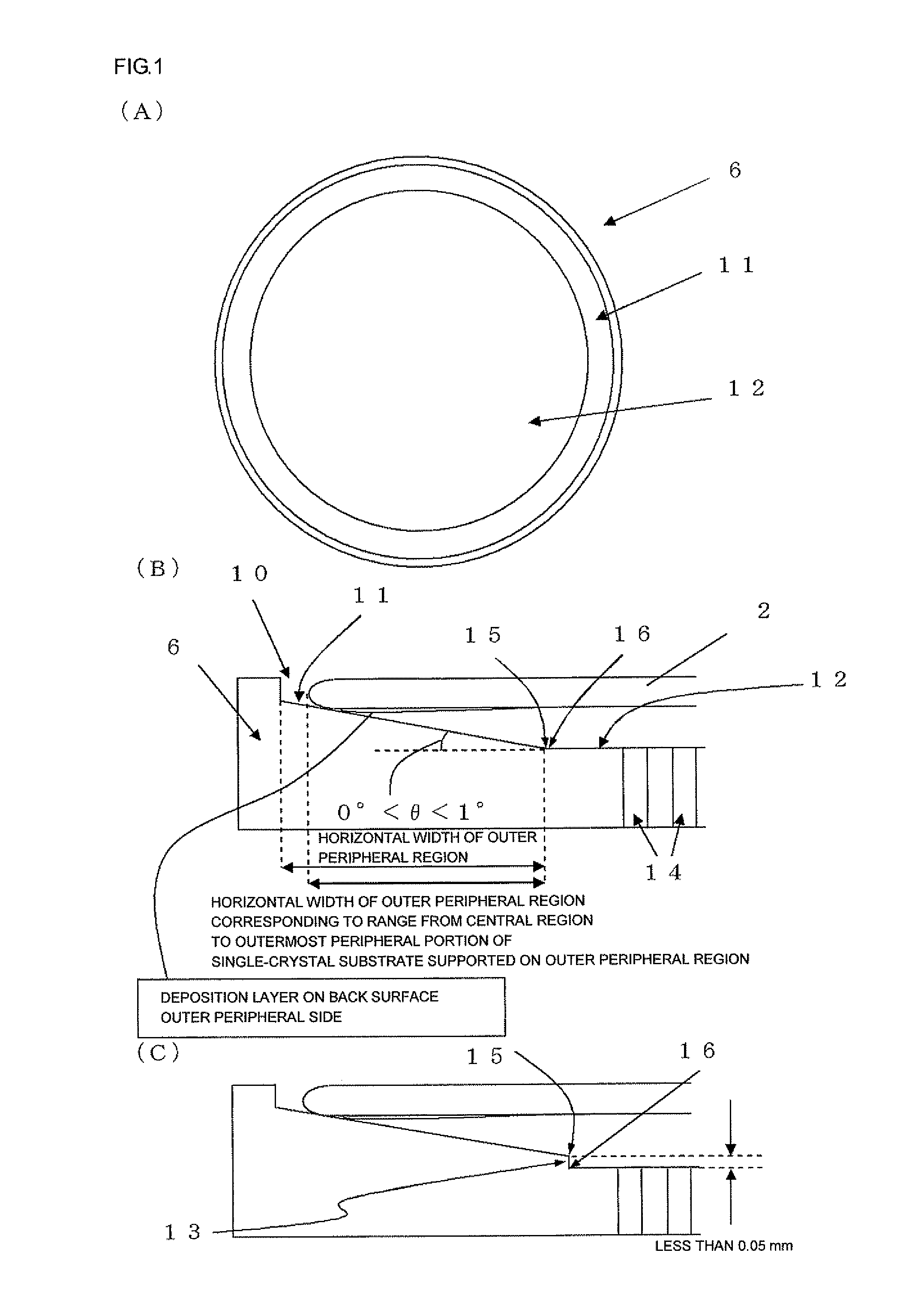

Complex polishing pad and method for making the same

InactiveUS20080268227A1Good flatnessStrong combinationSynthetic resin layered productsLapping toolsEngineering

The present invention relates to a complex polishing pad and method for making the same. The method of the invention comprises the steps of: (a) providing a buffer layer, the buffer layer being continuous-porous material and having a surface; (b) flattening the surface of the buffer layer to form a flattened surface; and (c) disposing a polishing layer on the flattened surface so as to form the complex polishing pad, wherein the polishing layer is used to polish a polishing workpiece. Whereby, the complex polishing pad of the invention has a better flatness, and the buffer layer and the polishing layer have a stronger combination.

Owner:SAN FANG CHEM IND

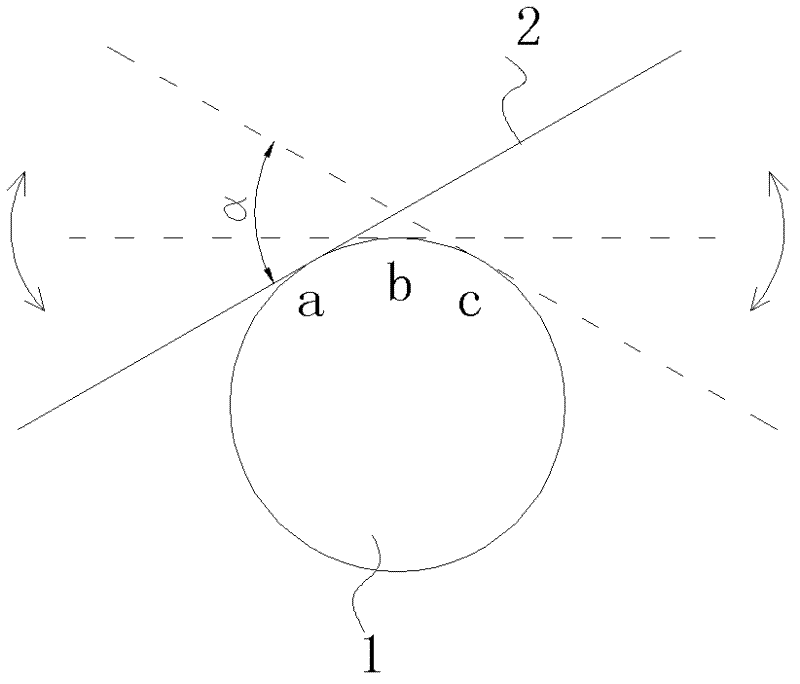

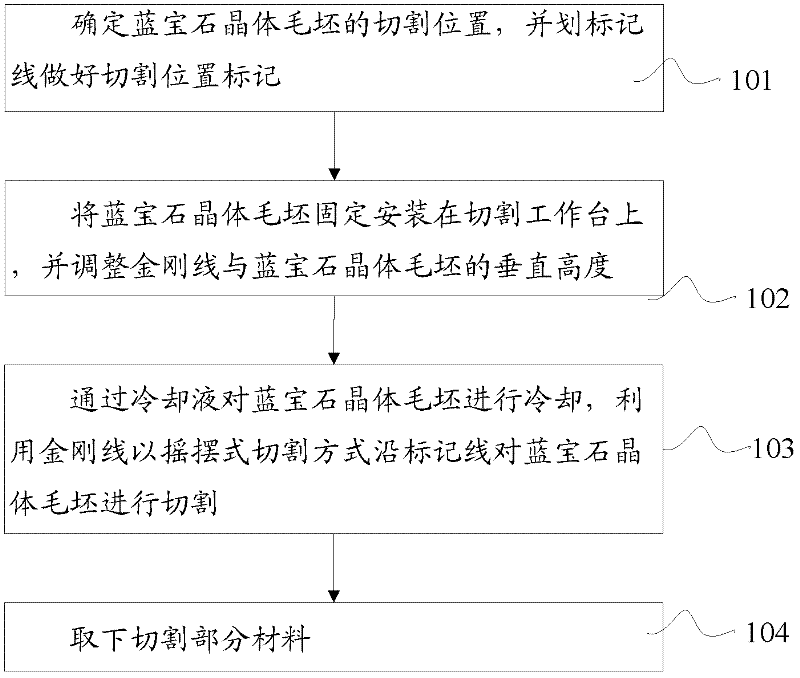

Cutting method of crystal blank

The invention relates to a cutting method of a crystal blank. The cutting method comprises the following steps of: determining a cutting position of a sapphire crystal blank, and drawing a labeled line and making a cutting position mark; then, fixedly installing the sapphire crystal blank on a cutting worktable, and adjusting the vertical height of a diamond wire and the sapphire crystal blank; then, cooling the sapphire crystal blank through a cooling fluid, and utilizing the diamond wire to cut the sapphire crystal blank along the labeled line in a swinging manner; and finally, taking down the material of a cutting part. According to the cutting method provided by the invention, a swinging cutting manner of the diamond wire is adopted, so that not only can the cutting efficiency, cutting quality and cutting precision of the crystal blank be improved, but also oddments can be effectively utilized, the utilization ratio of the crystal blank is improved, and the processing cost is lowered.

Owner:徐州协鑫光电科技有限公司

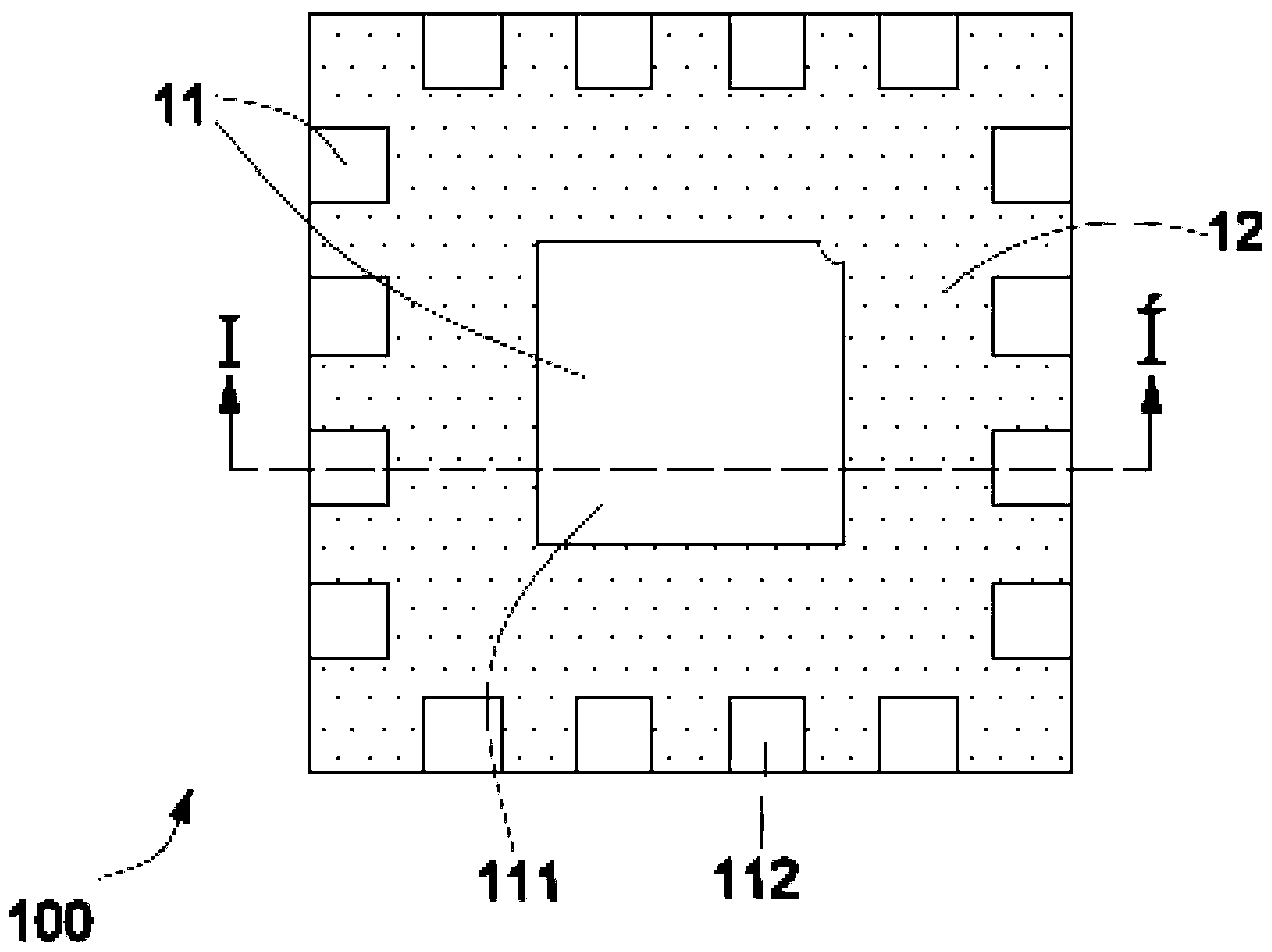

Method for manufacturing QFN (quad flat no-lead) package device

ActiveCN103021890AImprove production accuracyGood flatnessSolid-state devicesSemiconductor/solid-state device manufacturingFilling materialsEngineering

The invention discloses a method for manufacturing a QFN (quad flat no-lead) package device. The chip load and pins of the manufactured QFN package device do not need to be based on a lead frame manufactured in advance, independent chip carriers and pins with step structures are formed by organically combining electroplating, mechanical grinding and cutting methods in a package technical process and are mechanically supported and protected by configured insulated filling materials in the package technical process, the insulated filling materials and plastic package materials are used for secondary coating and sealing, and the manufactured QFN package device has high I / O (input / output) density and fine reliability.

Owner:南通腾龙通信科技有限公司

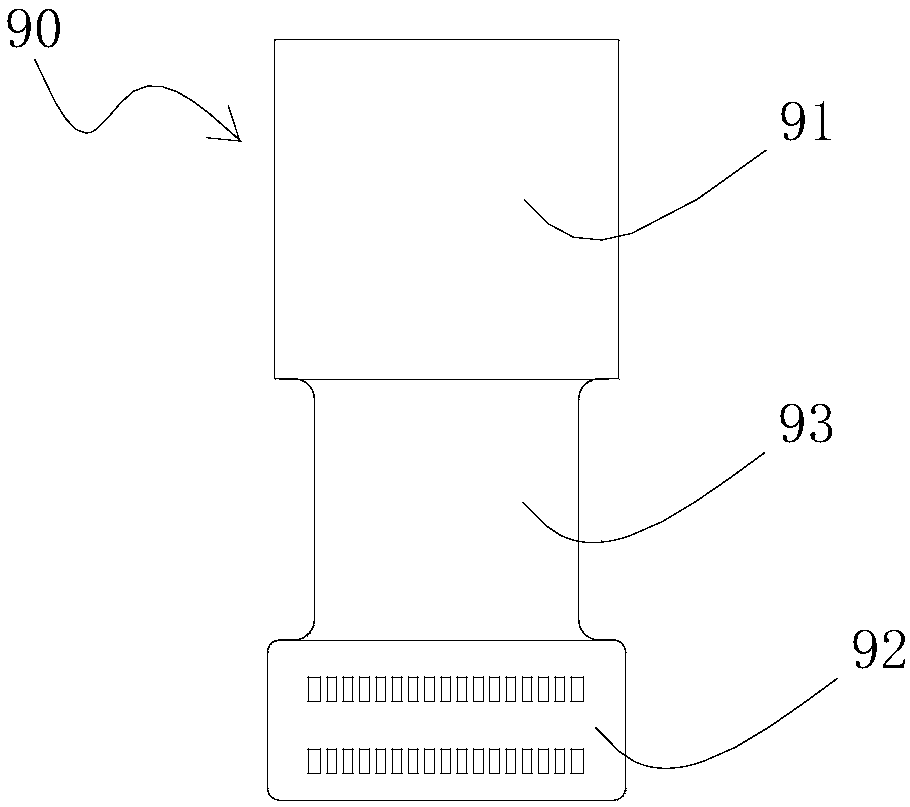

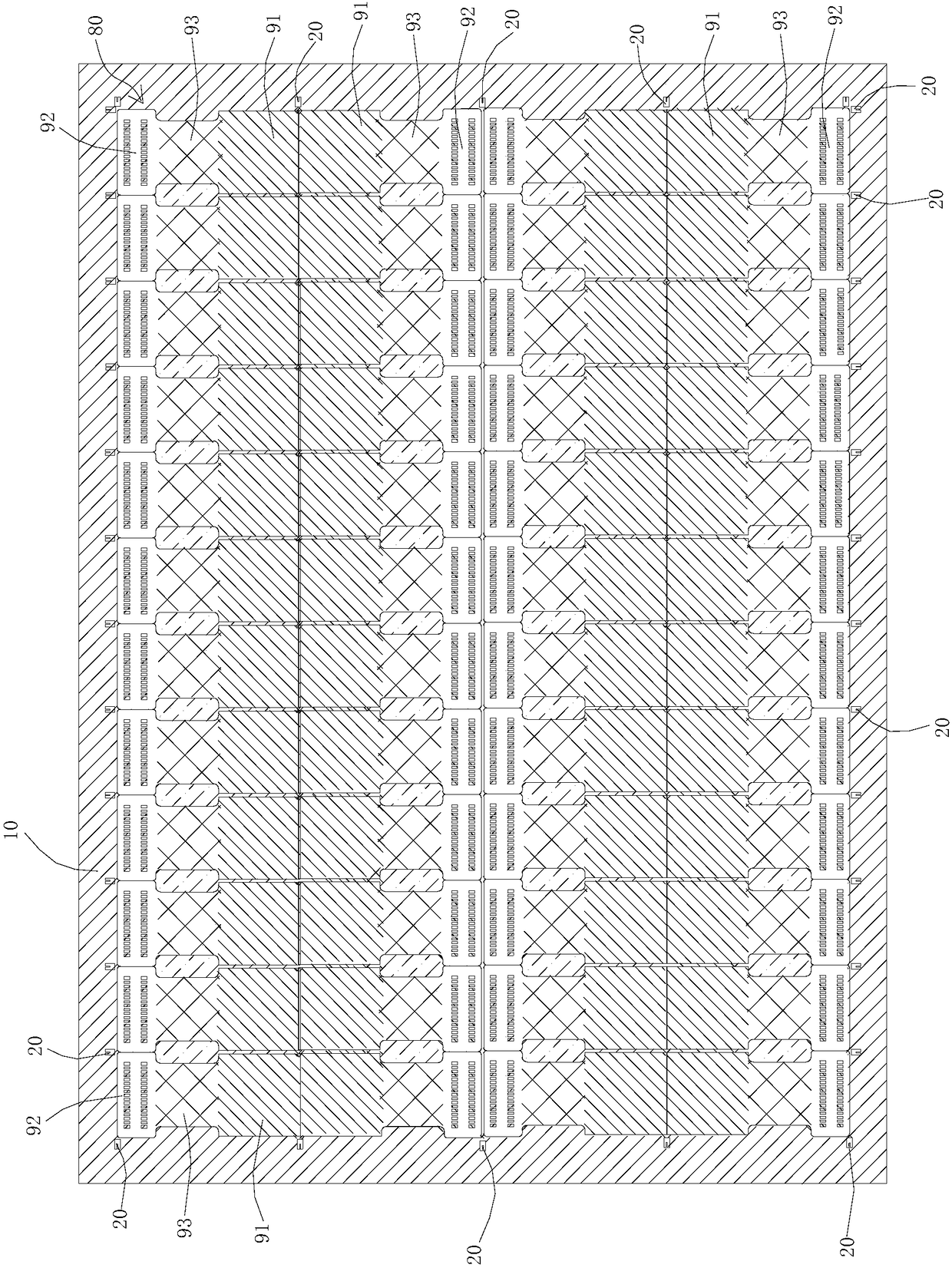

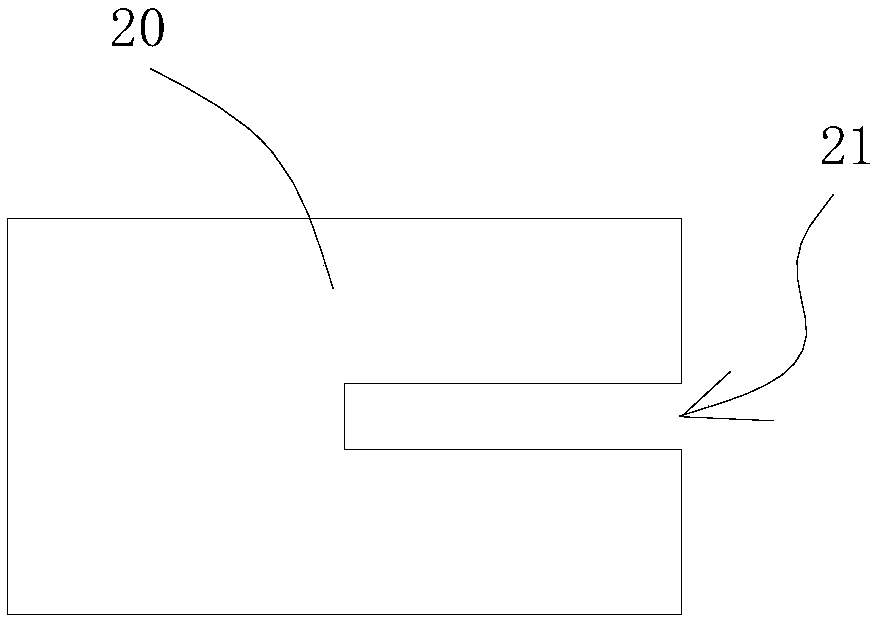

Sliding plate type support structure and flexible display device

PendingCN110580858AProtect the flexible screenGood flatnessIdentification meansEngineeringSlide plate

The invention discloses a sliding plate type support structure and a flexible display device. The support structure comprises a support base, flexible guide layers and drive parts, wherein the supportbase comprises a stacked plate and accommodating cavities, and the stacked plate comprises one fixed plate and 1-2 sliding plates; the flexible guide layers are accommodated in the accommodating cavities and are connected with at least one longitudinal side edge of the fixed plate; and each drive part comprises an output shaft, and each drive part is fixedly arranged on the support base, and is connected with the opposite horizontal side edge of the corresponding sliding plate. When the 1-2 sliding plates slide towards the direction far away from the fixed plate, at least one part of the flexible guide layers is driven out of the accommodating cavities, and cover the faces of the sliding plates, and the thickness of each flexible guide layer is adaptive to the height difference between the covered sliding plate and the fixed plate, so that one side faces of the flexible guide layers on the 1-2 sliding plates and one side faces of the fixed plate are located in the same plane. The flexible display device comprises the sliding plate type support structure and a flexible display screen stacked on the sliding plate type support structure.

Owner:李萌

Optical element and manufacturing method thereof

The invention relates to an optical element and a manufacturing method thereof. The optical element includes a transparent base material and a transparent optical film which is formed on the base material. A surface, which is opposite to the base material, of the optical film is provided with micro-structure patterns. The base material is prepared from an organic polymer. The optical film is prepared from an ultraviolet glue of a monomer containing the organic polymer in a curing manner. The invention also relates to the manufacturing method of the optical element.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

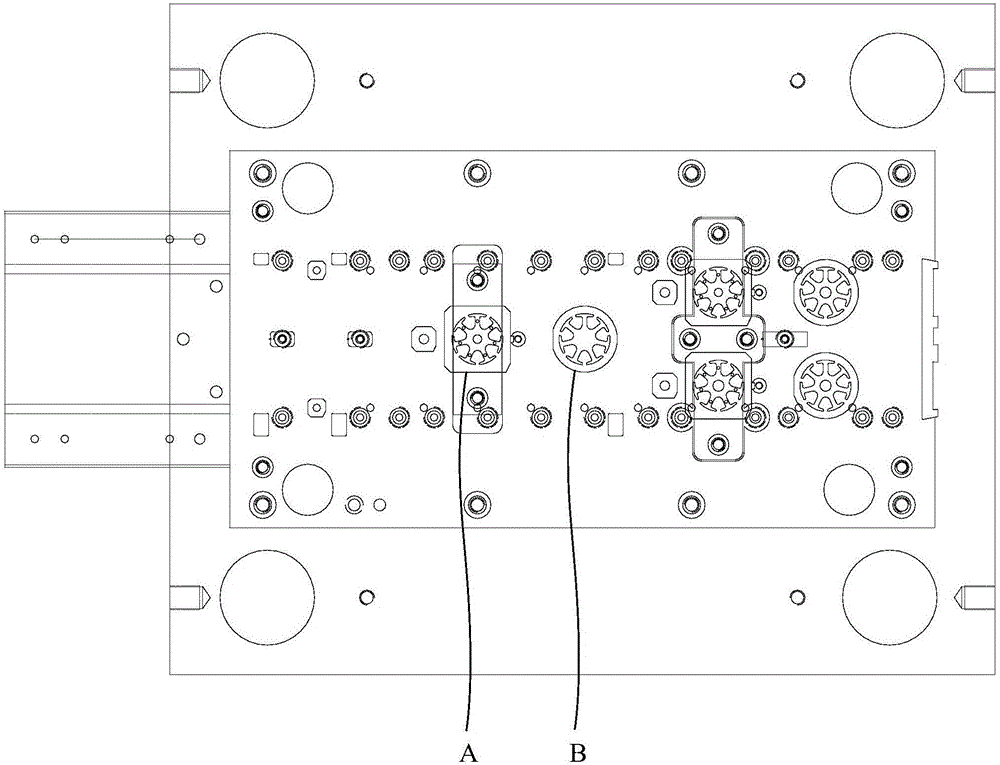

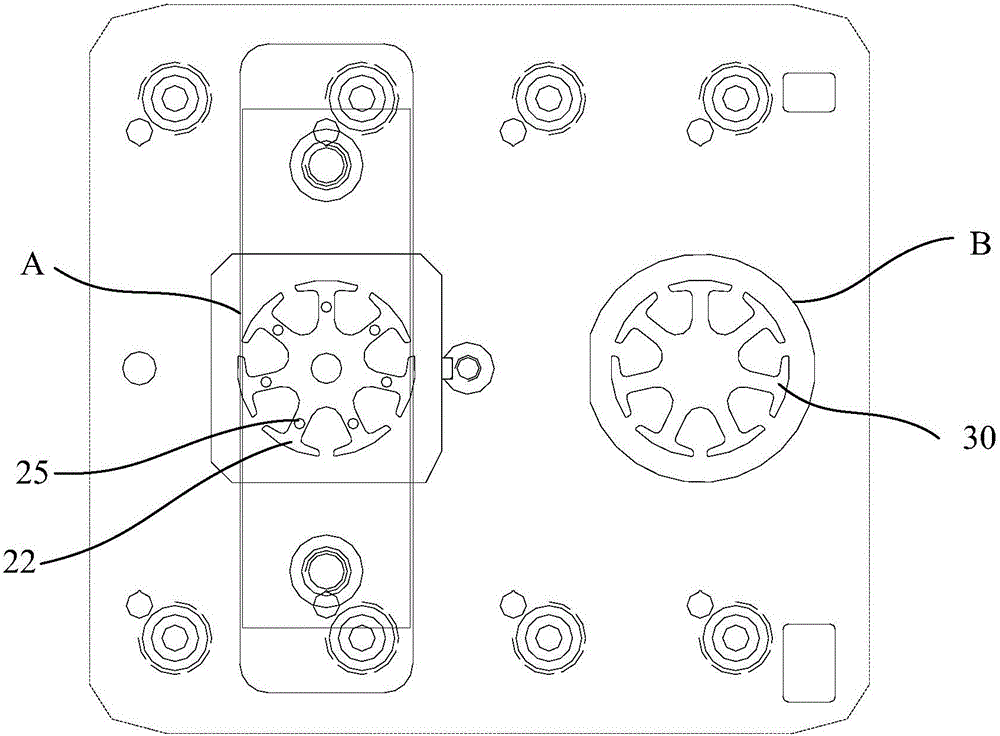

Motor chip punching device and method

InactiveCN106363074AGood flatnessProduct appearance is more attractiveEngineeringElectrical and Electronics engineering

The invention relates to a motor chip punching device which comprises an upper die and a lower die, and further comprises a second male die and a floating roof, wherein the lower die is correspondingly arranged with the upper die; a first male die is arranged on the upper die; a first female die corresponding to the first male die is arranged on the lower die; the first male die and the first female die are matched for punching of a material belt, thereby forming a motor chip; the second male die is arranged on the upper die; the floating roof is arranged on the lower die and corresponds to the second male die; the second male die is used for partially punching the material belt along the thickness direction of the material belt; the floating roof is used for being propped against the material belt, so as to correct the flatness of the material belt when the material belt is partially punched by the second male die; and the first male die is used for punching the material belt again after the material belt is partially punched by the second male die, thereby forming the motor chip. The invention further provides a motor chip punching method. A step-by-step punching mode is adopted, so that the flatness of the motor chip can be corrected during step-by-step punching, and then the motor chip being higher in flatness can be obtained. Meanwhile, the shearing surface of the motor chip becomes brighter, so that the appearance attraction of the motor chip can be further improved.

Owner:SHENZHEN HORENTOP TECH

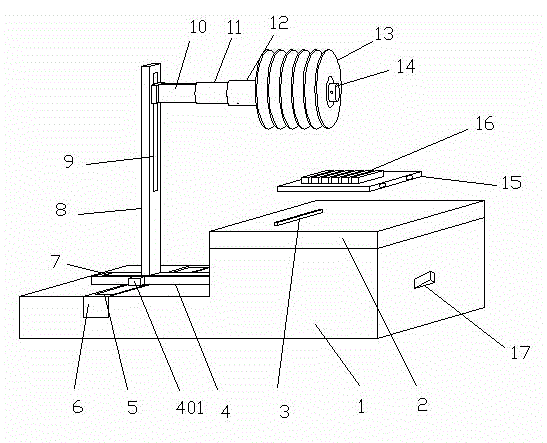

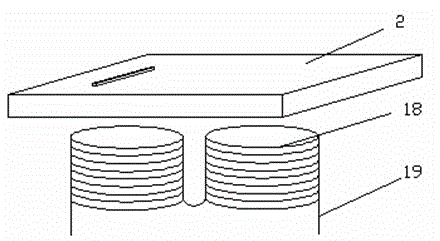

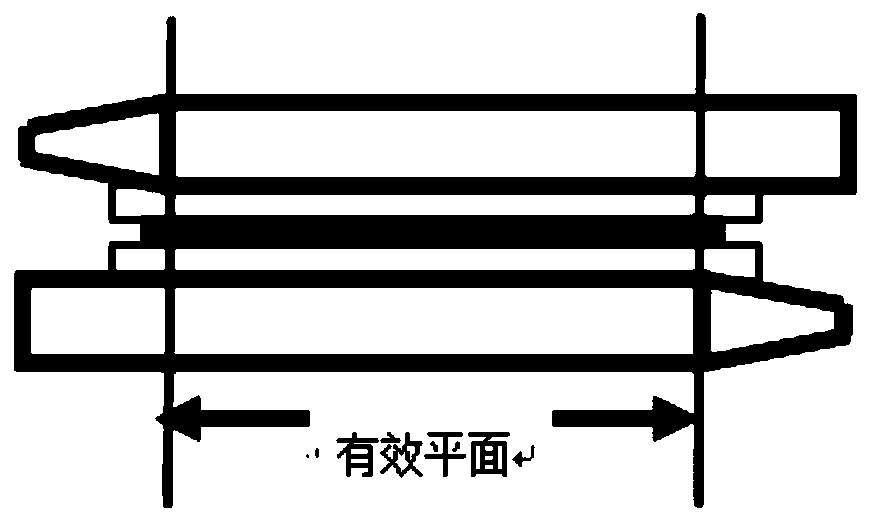

Cutting device of optical part cutting machine

InactiveCN105729641AGood flatnessHigh dimensional accuracyFine working devicesThree dimensional motionReference block

Disclosed is a cutting device of an optical part cutting machine. The cutting device comprises a base, a base plate, a reference block, a transverse frame, a longitudinal guide rail groove, a longitudinal frame, a transverse guide rail groove, a perpendicular vertical pillar, a perpendicular guide rail groove, a connection rod, a cutter frame, a rotary shaft, cutters, fastening clamping seats, a cushion plate, a workpiece, a magnetizing / demagnetizing button, electromagnets, cables, flanges and the like. The base plate is magnetized through the electromagnets at the bottom and attracts the cushion plate tightly through magnetic force, and accordingly the effect that an optical part is installed on the base plate during cutting is ensured. The cutters are installed on a three-dimensional motion mechanism which is capable of moving transversely, longitudinally and perpendicularly to drive the cutters to move. The to-be-cut optical part is fixed through magnetic force, so that deflection of the workpiece during vibration is avoided, and the part is convenient to cut. The three-dimensional motion mechanism is adopted for installing and clamping the cutters, the system design is reasonable, and the cutting device is suitable for cutting the optical part, a silicon wafer and other workpieces.

Owner:SHAANXI ZIZHU ELECTRON

Roll system preparation method and rolling method for rolling ultra-thin ultra-wide stainless steel products

ActiveCN110202001AThickness tolerance fluctuations are smallGood flatnessRollsMetal rolling arrangementsMetallurgyRaw material

The invention discloses a roll system preparation method and rolling method for rolling ultra-thin ultra-wide stainless steel products. The roll system preparation method comprises the following stepsthat the diameter of a working roll is set to be 25-28 mm; and the cone ratio of intermediate rolls is set to be 0.25%; and the convexity curve of the second intermediate rolls is set to be a function curve between the cos of 30-90 degrees. The rolling method comprises the following steps of 1) selecting, specifically, a stainless steel coil raw material with the thickness of 0.08 to 0.1mm and the width of more than 600 mm is selected; and 2) rolling, specifically, cold rolling is carried out for eight times until the thickness is 0.03mm or below, and the pressing rate at the next time is 10%-30%. According to the roll system preparation method and the rolling method for rolling the ultra-thin ultra-wide stainless steel products, the convexity of the second intermediate roll, the taper ofthe intermediate roll and the diameter of the working roll are limited, during rolling, the thickness tolerance fluctuation of the product is small, the flatness of the plate type is good, the rolling process is stable, the yield of the steel coil is high, the product quality is remarkably improved, the method is suitable for industrial mass production, and the high-quality requirement of the high-end industry of the precision stainless steel extremely thin strip is met.

Owner:SHANXI TAIGANG STAINLESS STEEL PRECISION STRIP CO LTD

Processing method for flexible-rigid board of high-pixel camera module

InactiveCN108289375AGood flatnessSimplify processingPrinted circuit simultaneous processingPolarizerMachining process

The invention discloses a processing method for a flexible-rigid board of a high-pixel camera module. The processing method comprises the following steps of etching a plurality of flexible-rigid boardcircuits, arranged without gaps, on an original board to obtain a linkage board of the flexible-rigid board of the high-pixel camera module, and etching copper on a laser cutting path of the originalboard; enabling copper not to be laid at an inner layer and an outer layer on the laser cutting path; respectively etching laser cutting polarizers PAD at longitudinal terminals and transverse terminals needed to be cut by laser on the linkage board to prevent deviation during the laser cutting process; performing component surface mounting on the obtained linkage board; performing linear cuttingfrom a groove of the laser cutting polarizer PAD at one side to a groove of the laser cutting polarizer PAD at the other opposite side by UV laser until all the flexible-rigid boards are cut. Mechanical hard machining such as CNC rolling and die punching is not needed, the flatness is good, the machining process is simplified, the machining cost is reduced, and the utilization ratio of the original board is improved.

Owner:SHENZHEN HUALIN CIRCUIT TECH

Insulating plate manufacture method and insulating plate manufactured by using same

The invention provides an insulating plate manufacture method. The method comprises the following steps: soaking an epoxy resin composition on glass-fiber cloth; baking for 3-10 minutes at 150-230 DEG C by using a glue machine to complete online curing to obtain the insulating plate. According to the method, the soaked resin composition is cured in a short time at a high temperature by virtue of a method for increasing the dosage of an accelerant or selecting a high-performance catalyst, and the insulating plate is produced by an online curing mode, so that the problem of release agent residues in a traditional method can be solved, the production efficiency can be improved, and the insulating plate is good in thickness uniformity and good in flatness.

Owner:GUANGDONG SHENGYI SCI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com