Motor chip punching device and method

A stamping device and chip technology, which is applied in the field of motor parts manufacturing, can solve the problem that the flatness of the motor chip cannot meet the requirements, and achieve the effect of more attractive appearance and good flatness of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The motor chip stamping device provided by the present invention can be used to form stator cores, rotor cores and other chips used in motors.

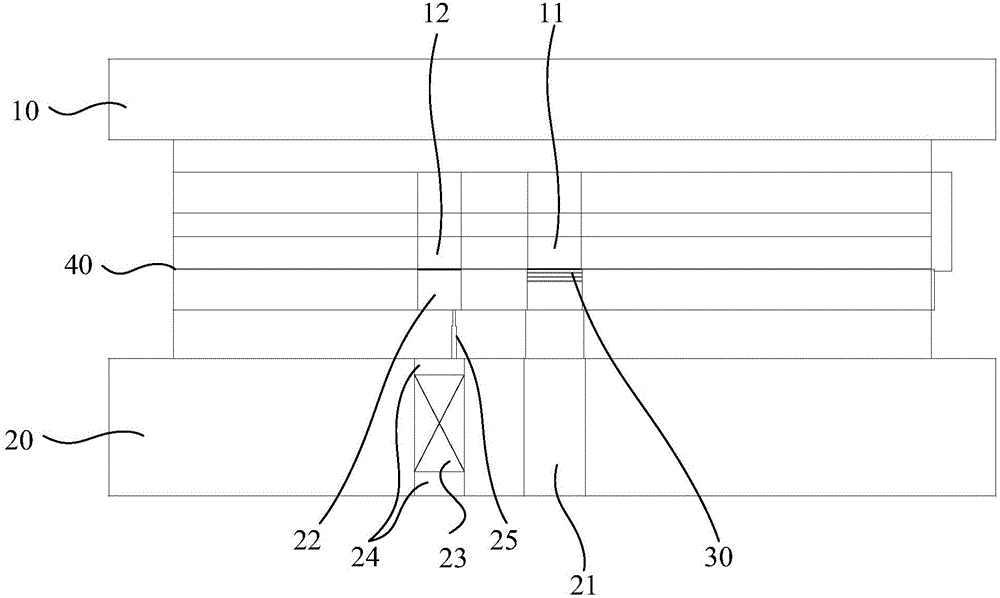

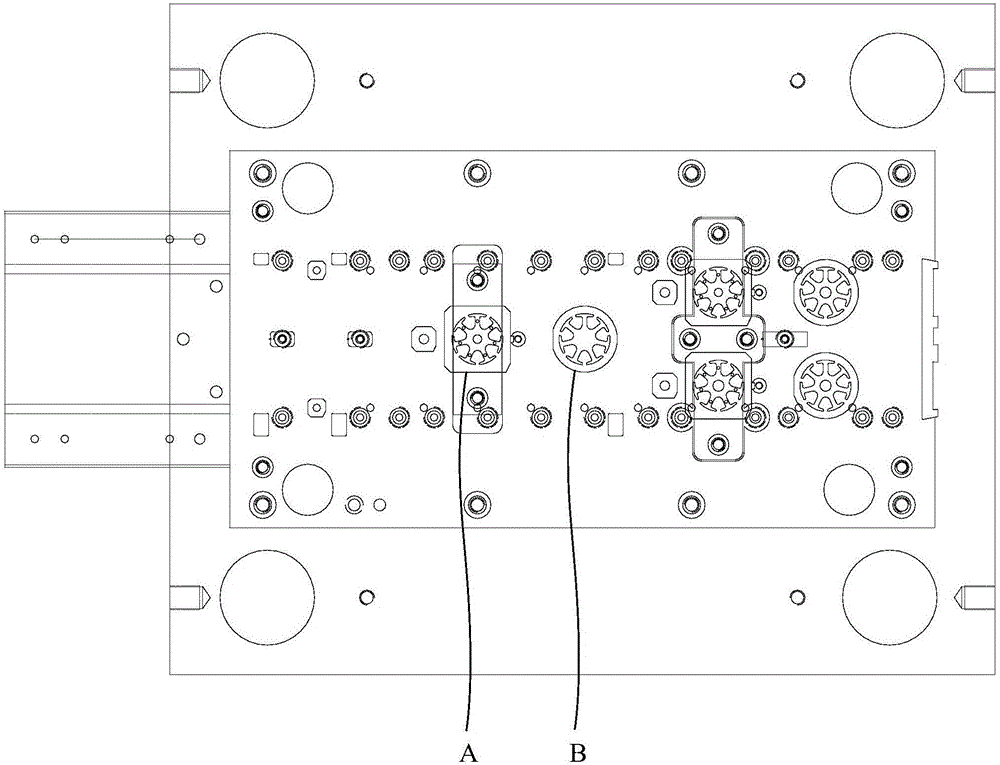

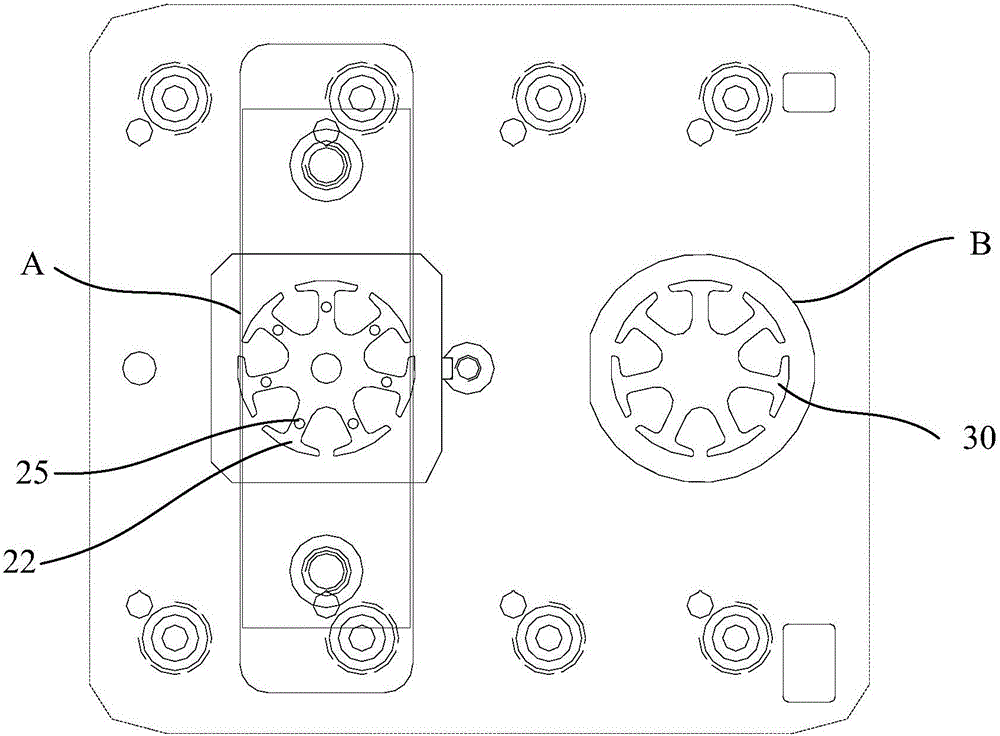

[0021] Such as figure 1 As shown, a motor chip stamping device provided by an embodiment includes an upper die 10 and a correspondingly arranged lower die 20, the upper die 10 is provided with a first punch 11, and the lower die 20 is provided with a corresponding first punch 11. There is a corresponding first concave mold 21 , and the first convex mold 11 and the first concave mold 21 cooperate with the die-cut strip 40 to form the motor chip 30 .

[0022] The first punch 11 can be the punch of the blanking strip 40, and the profile of the punch is designed according to the molding process of the motor chip 30. In this embodiment, the first punch 11 is the last process of forming the motor chip 30. Therefore, the corresponding portion of the material strip 40 is completely punched to be separated from the material strip 40 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com