Patents

Literature

1293 results about "Three dimensional motion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

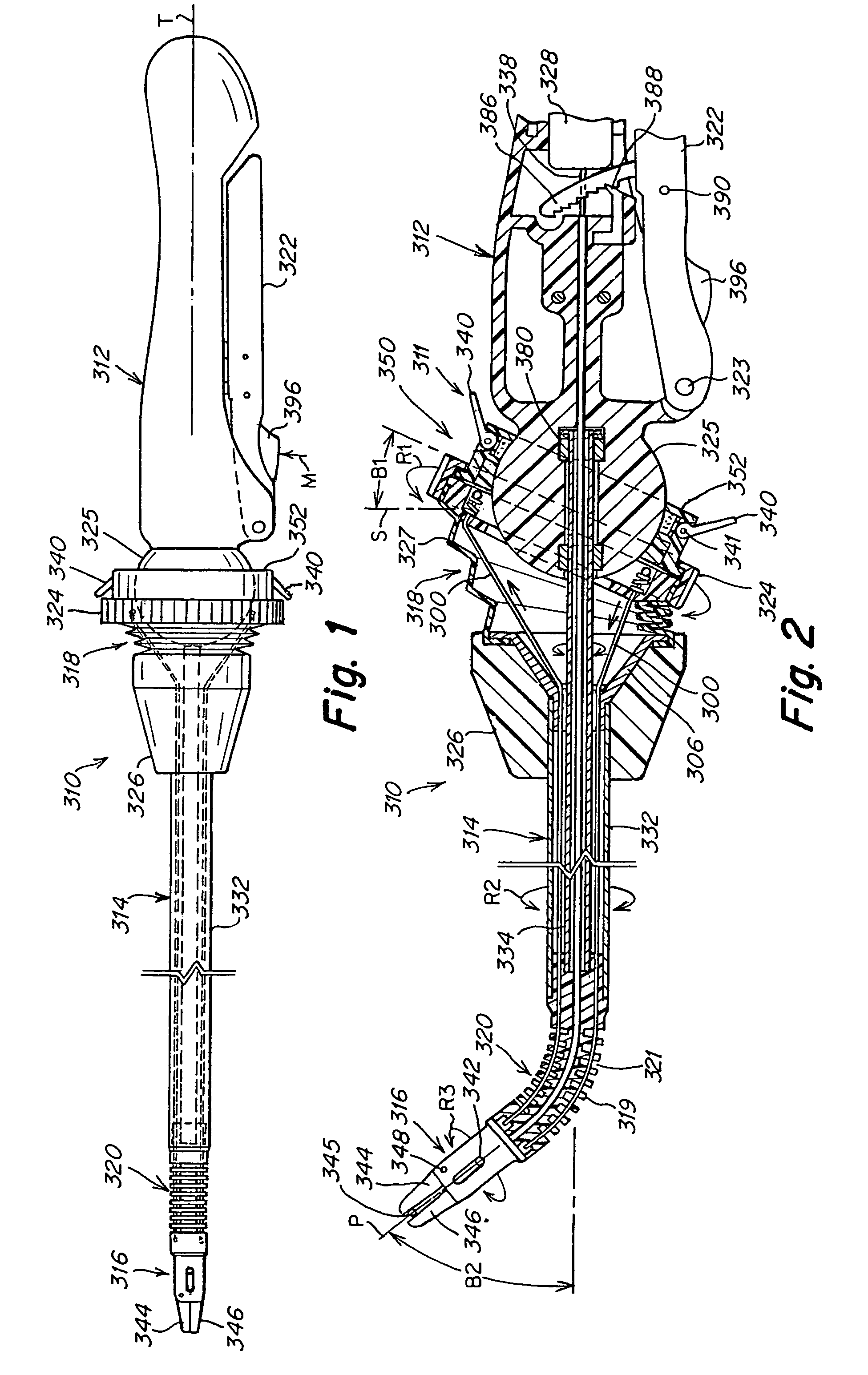

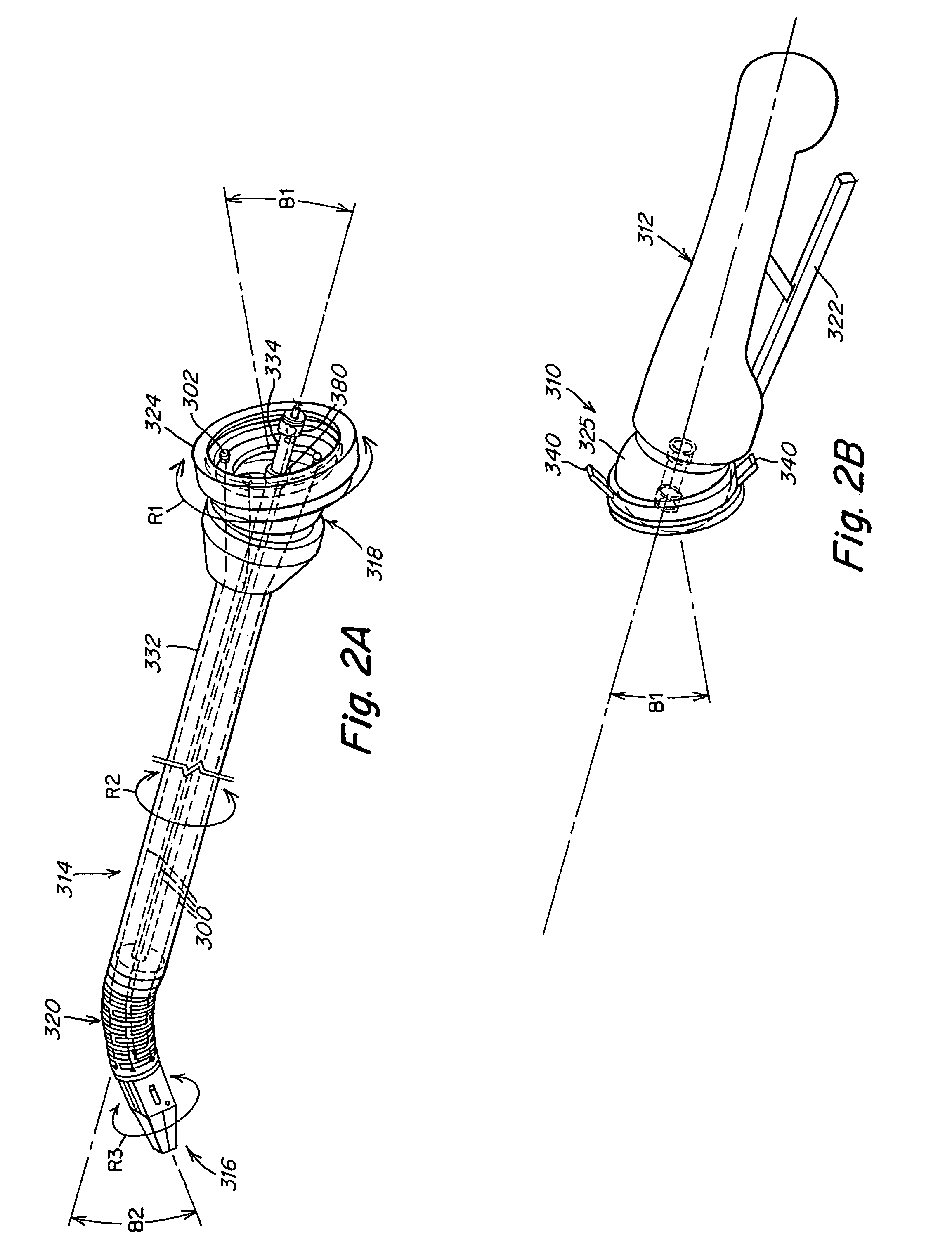

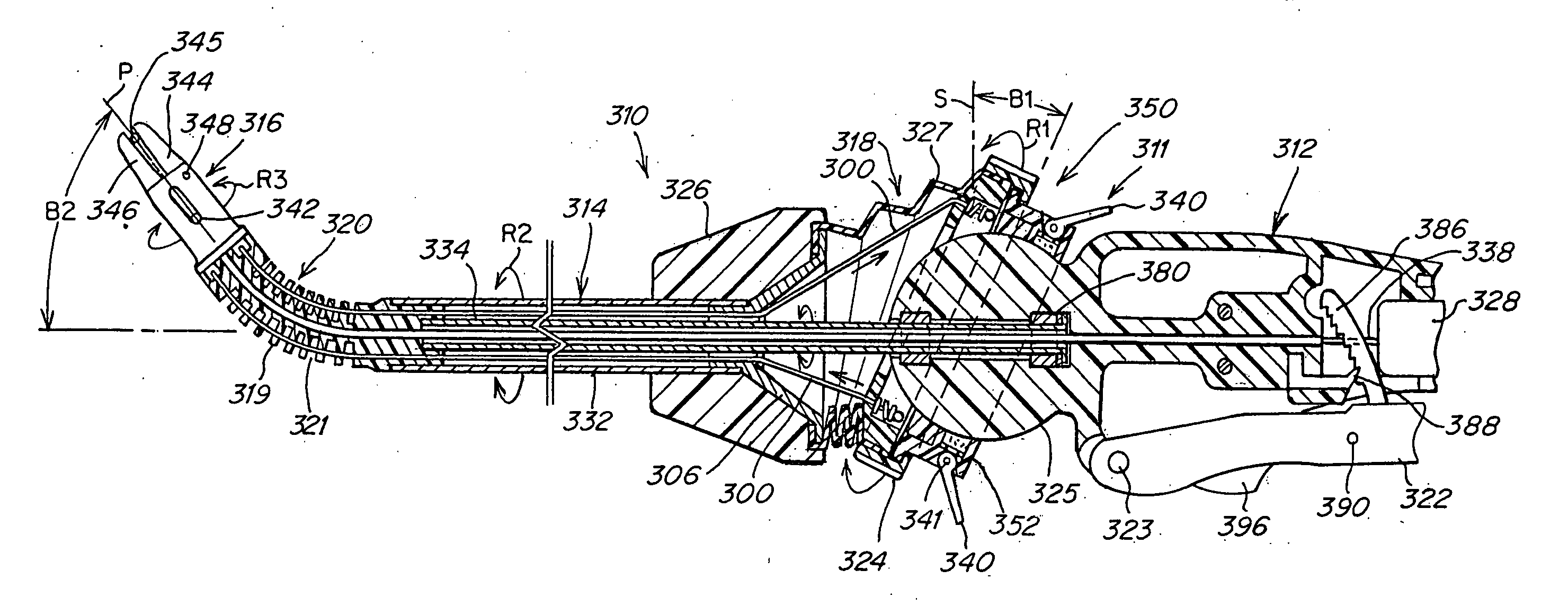

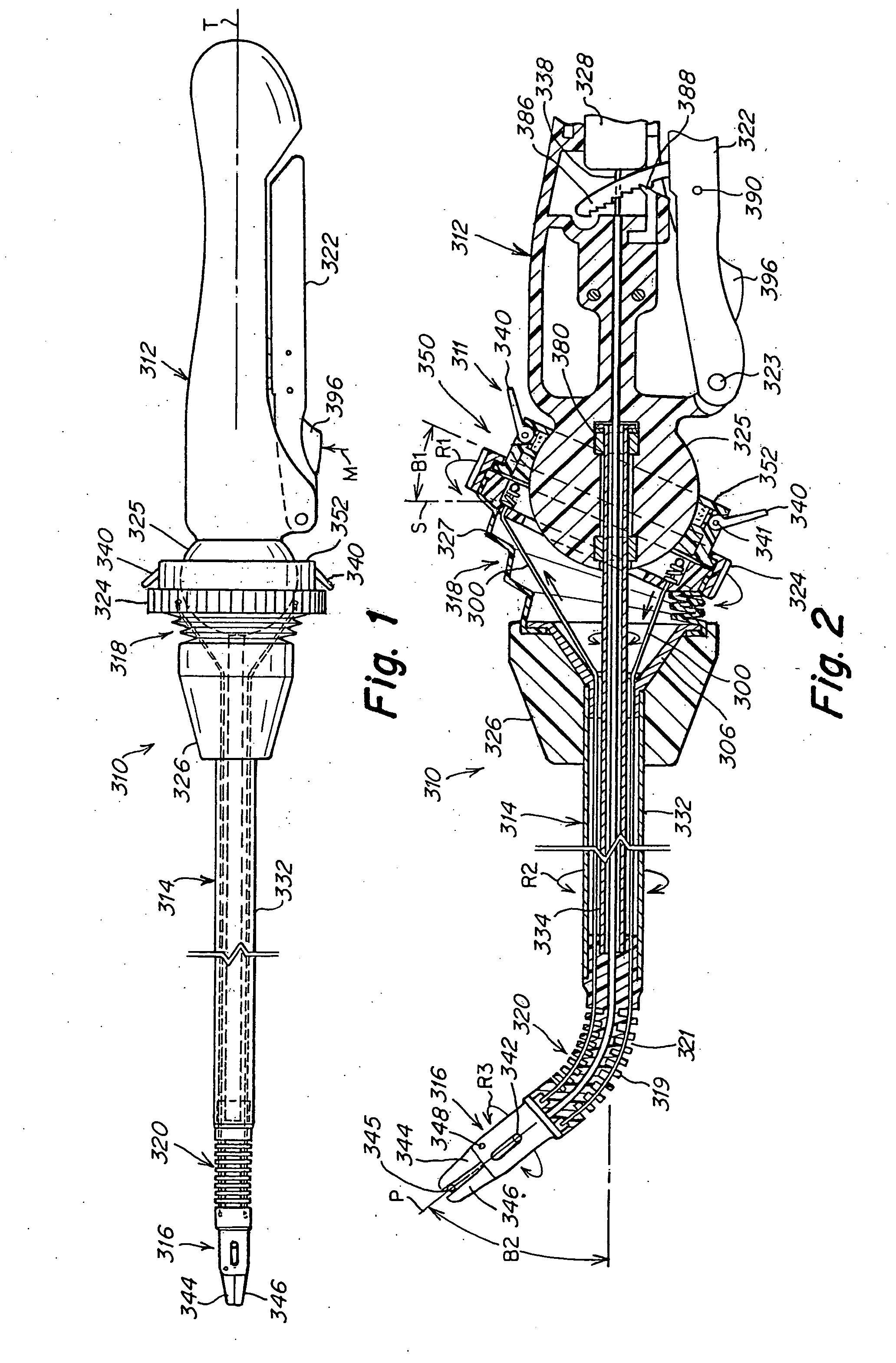

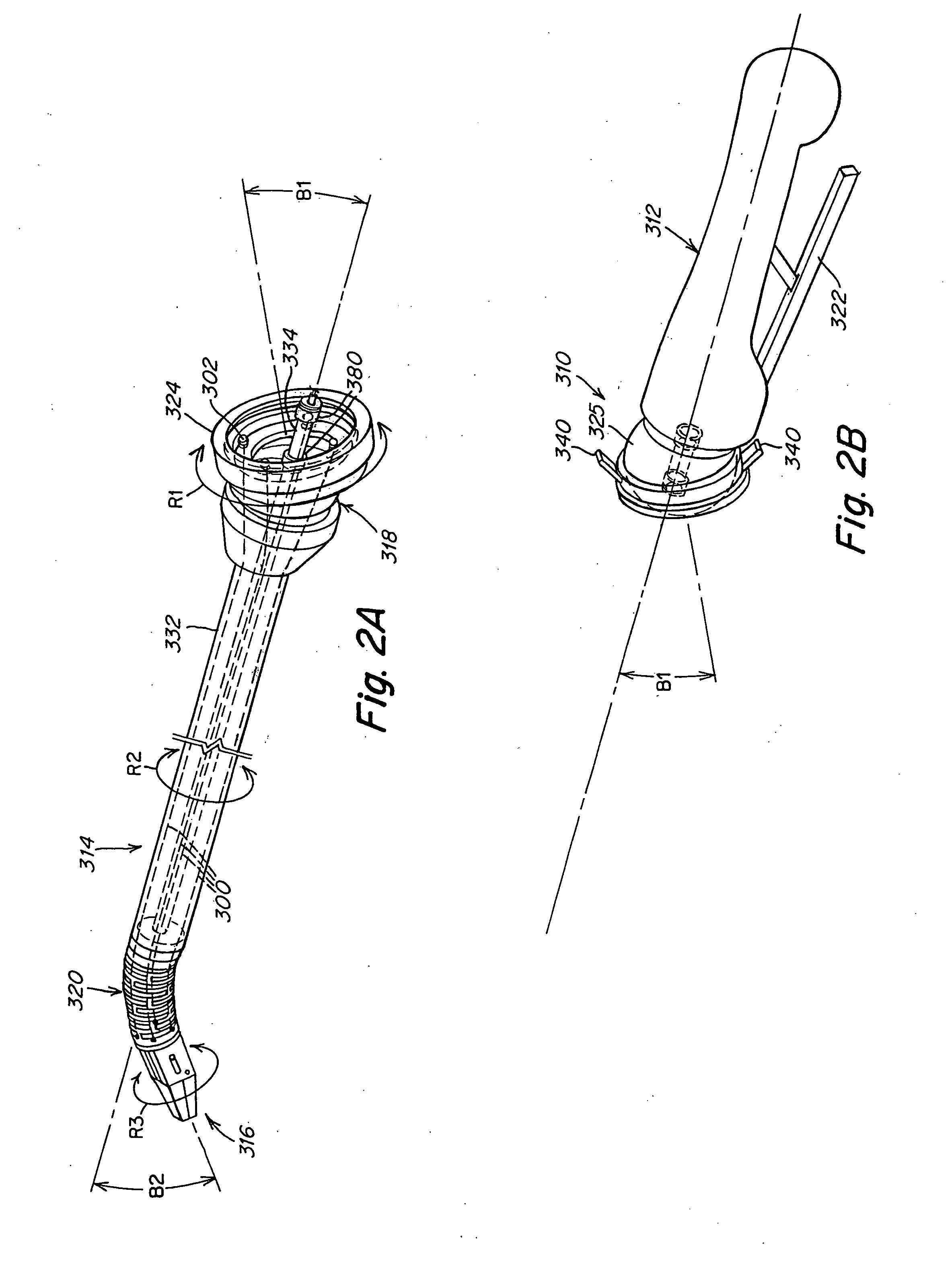

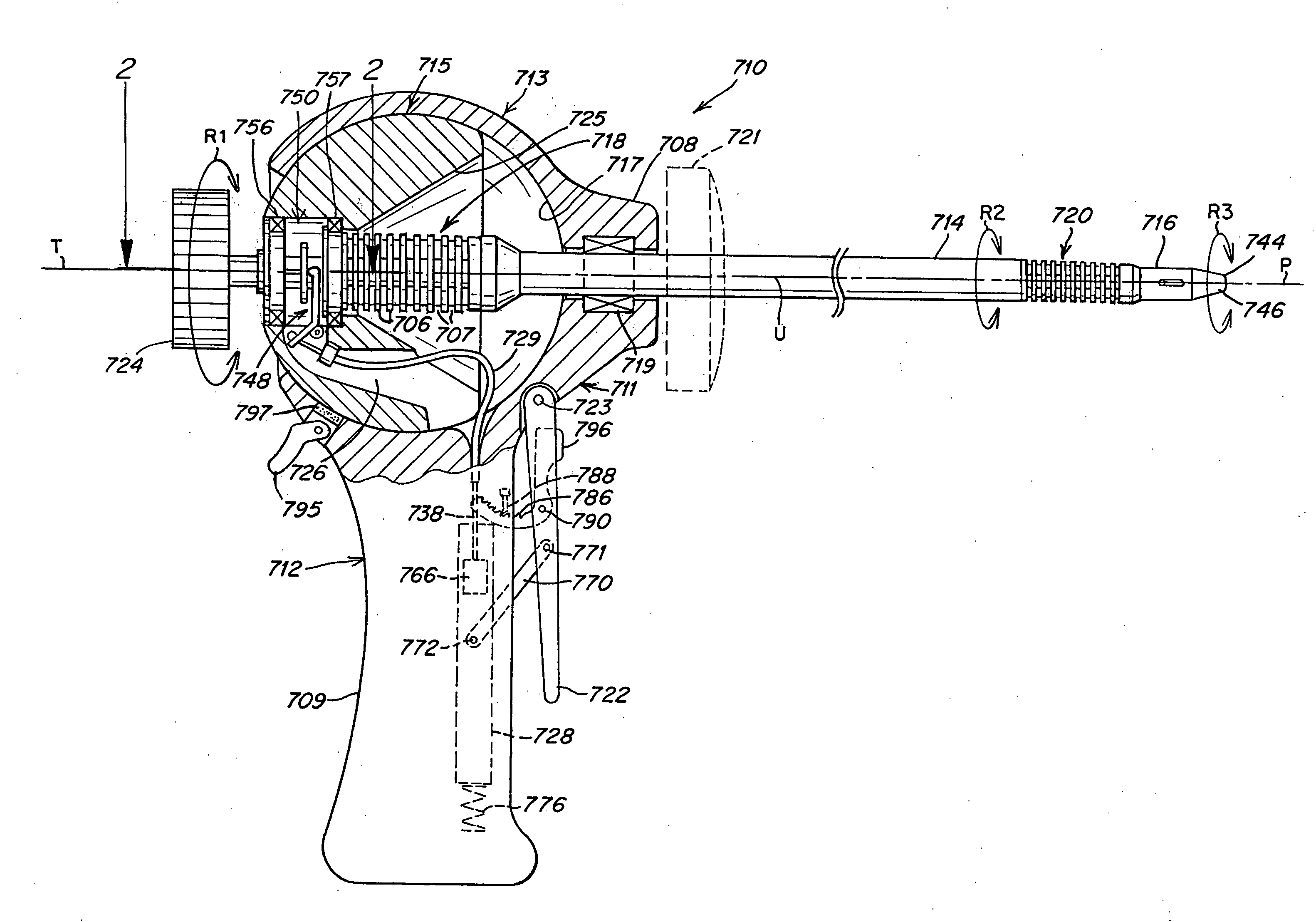

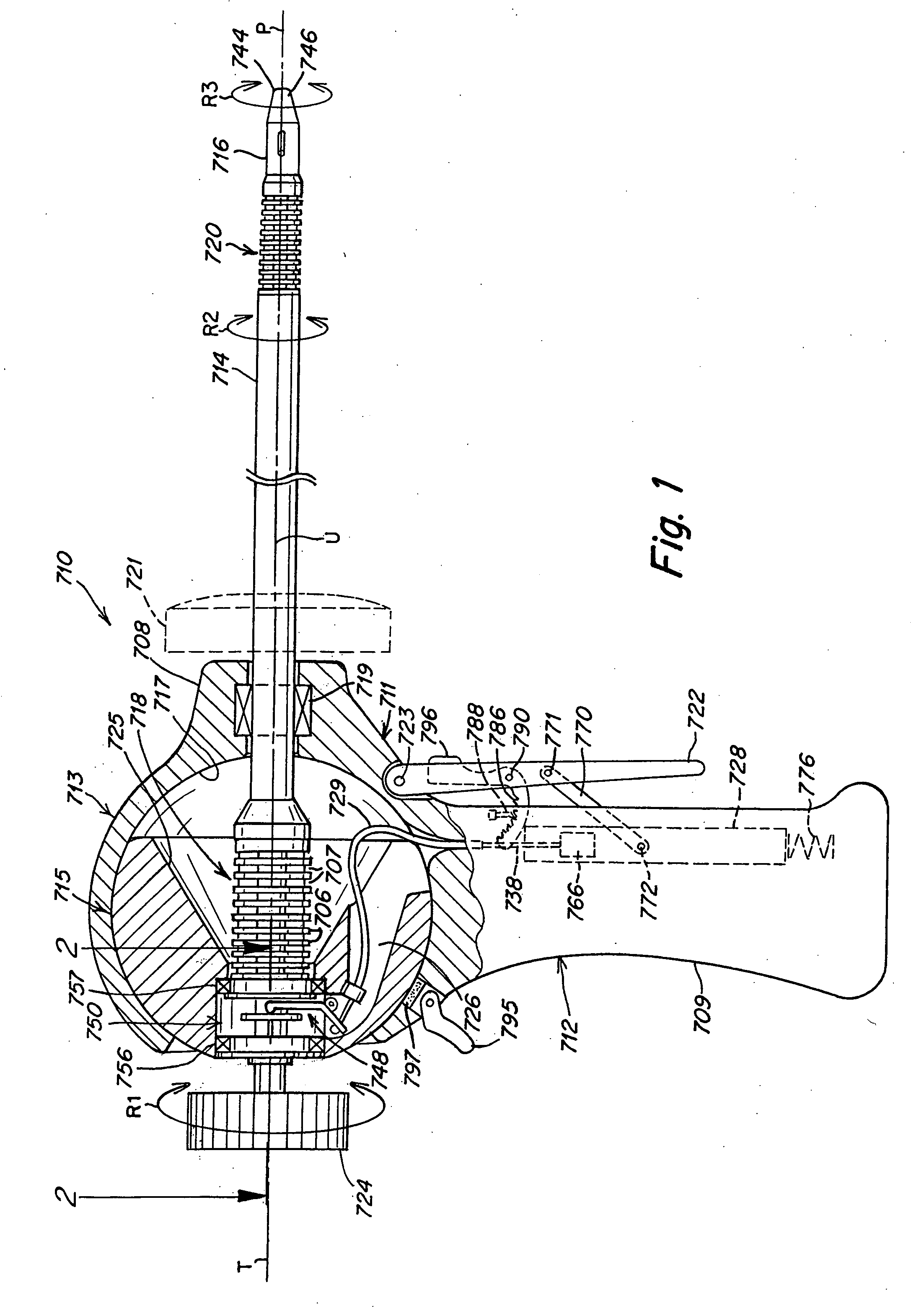

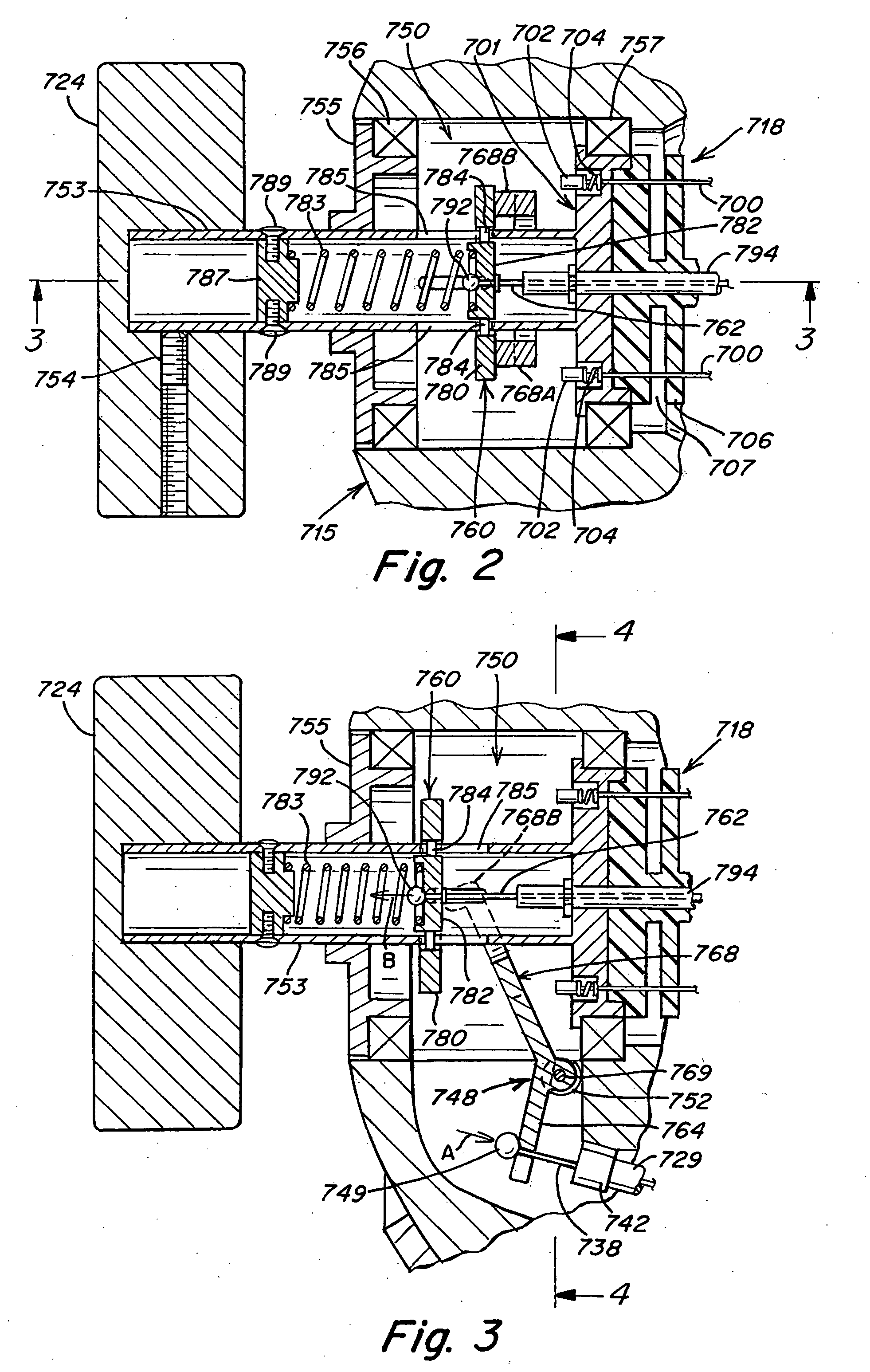

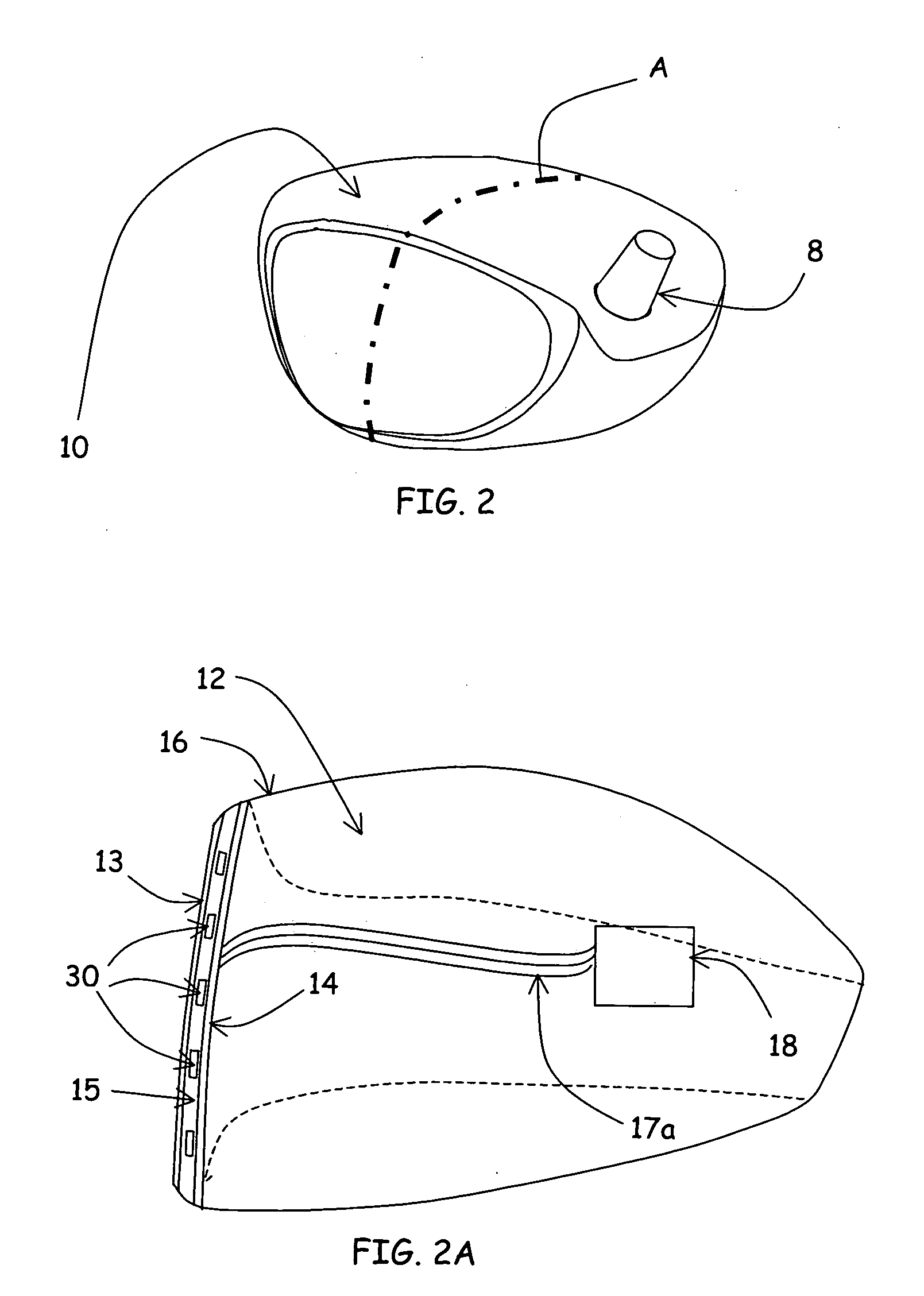

Surgical instrument

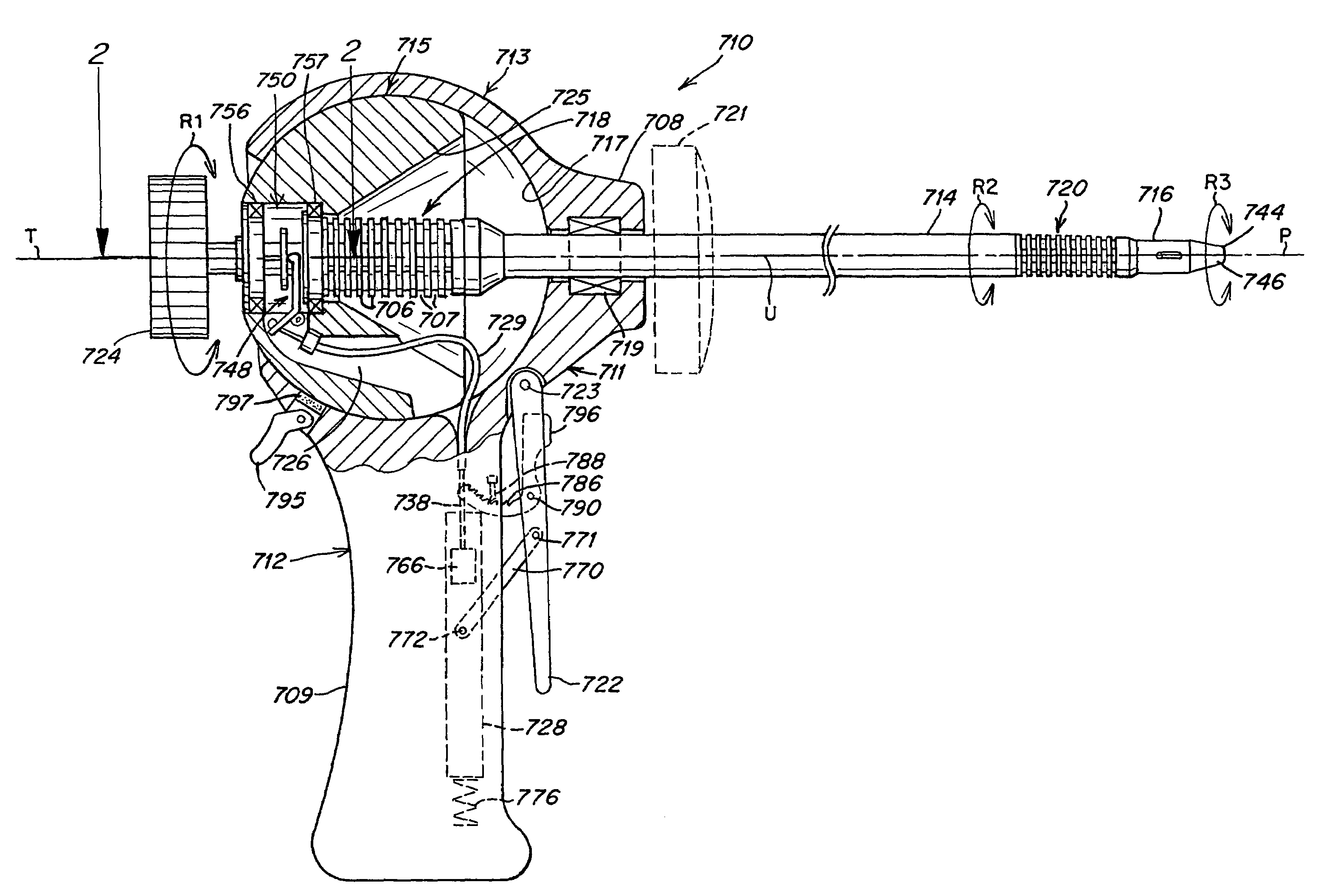

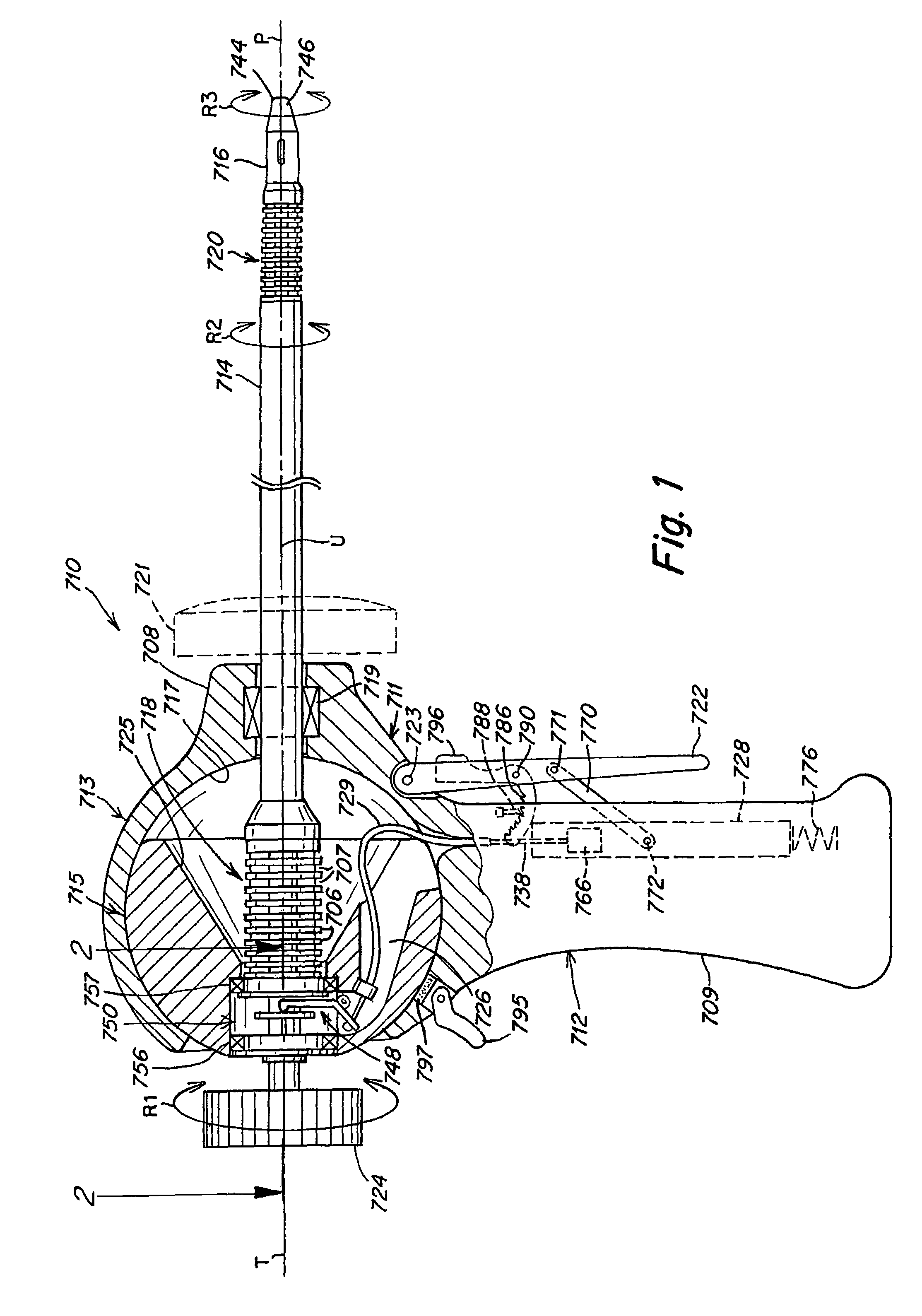

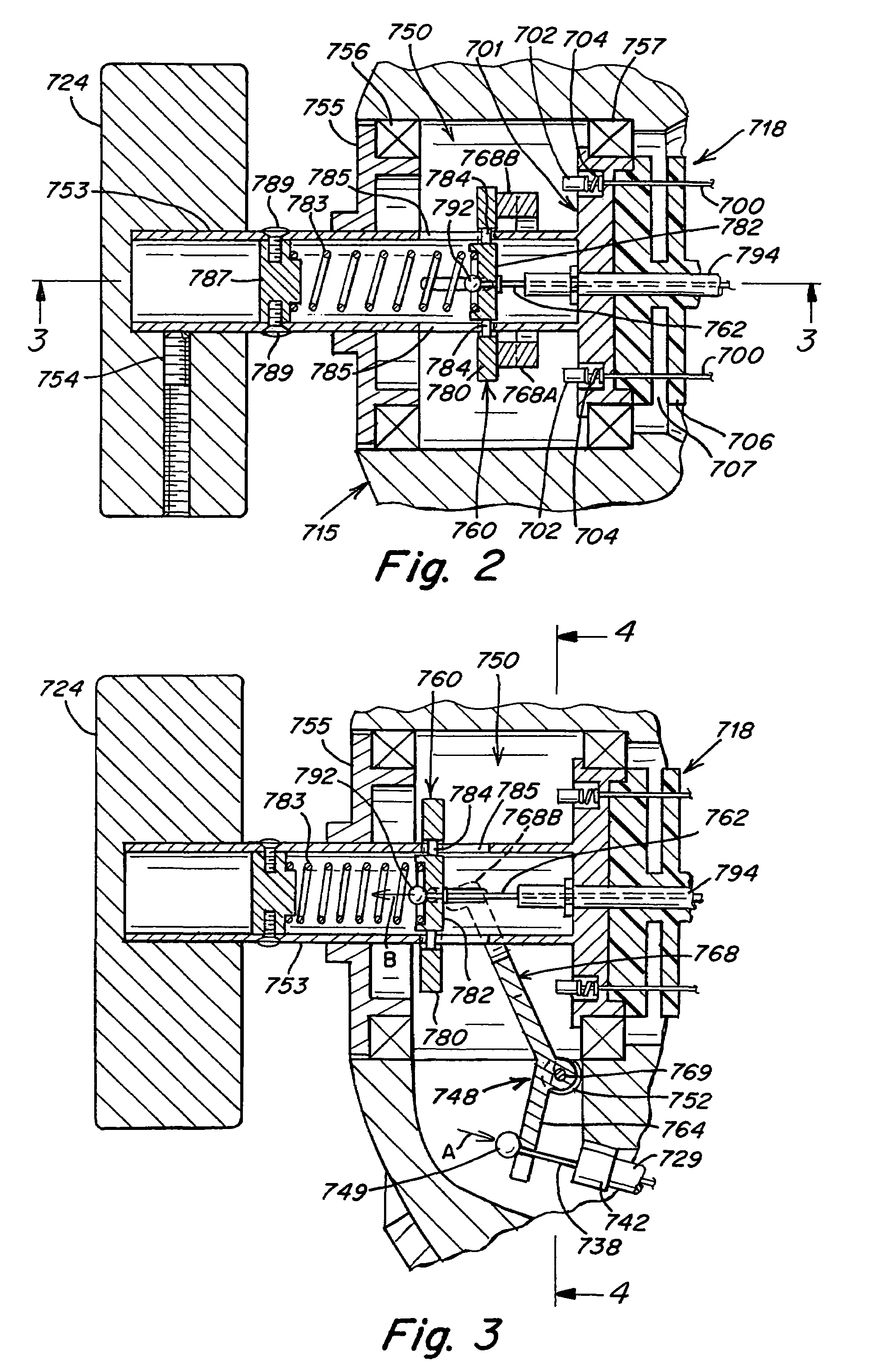

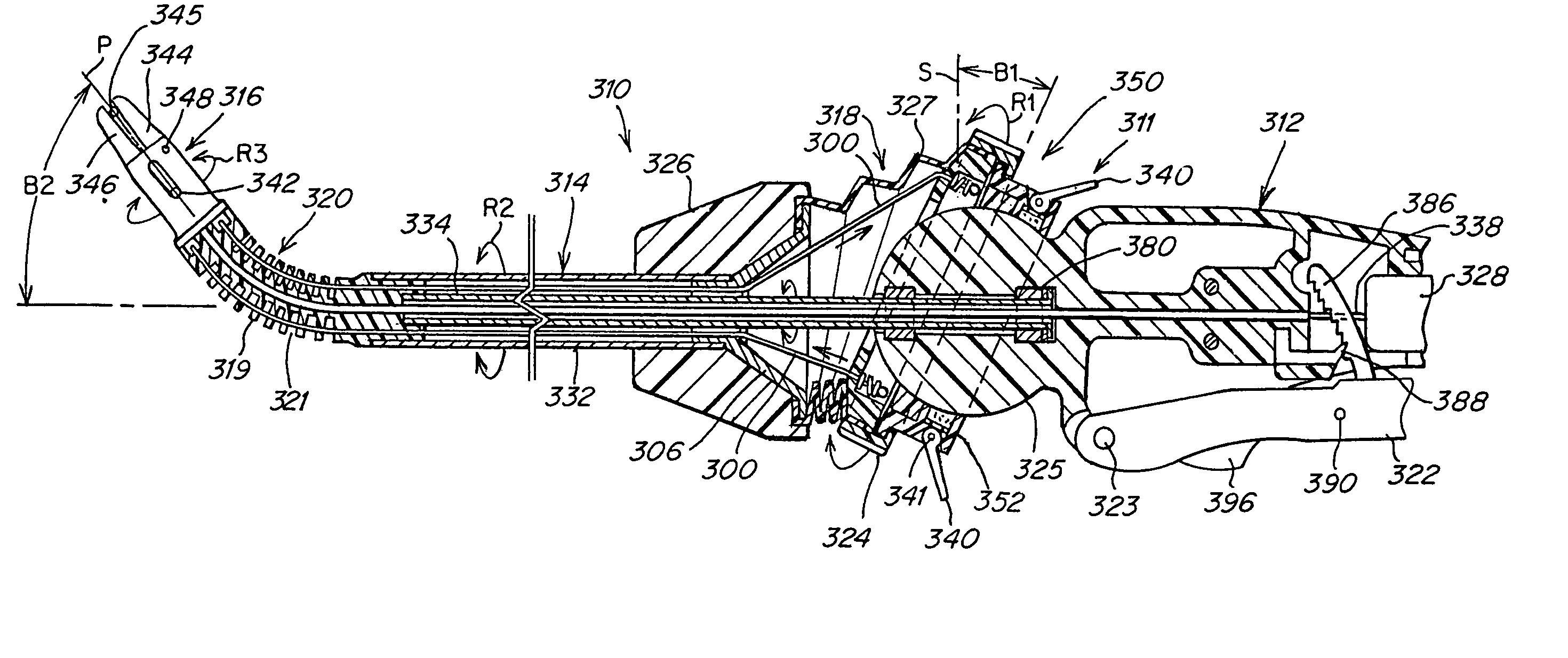

The surgical instrument includes a distal tool, an elongated shaft that supports the distal tool, and a proximal handle or control member, where the tool and the handle are coupled to the respective distal and proximal ends of the elongated shaft via distal and proximal bendable motion members. Actuation means extends between said distal and proximal members whereby any deflection of said control handle with respect to said elongated instrument shaft causes a corresponding bending of said distal motion member for control of said working member. The proximal bendable member comprises a ball and socket assembly supported between the handle and instrument shaft and constructed and arranged for three dimensional motion.

Owner:CAMBRIDGE ENDOSCOPIC DEVICES INC

Surgical instrument

The surgical instrument includes a distal tool, a rigid or flexible elongated shaft that supports the distal tool, and a proximal handle or control member, where the tool and the handle are coupled to the respective distal and proximal ends of the elongated shaft via distal and proximal bendable motion members. Actuation means extends between said distal and proximal members whereby any deflection of said control handle with respect to said elongated instrument shaft causes a corresponding bending of said distal motion member for control of said working member. The proximal movable member comprises a movable ring assembly supported from the handle and adapted for three dimensional motion relative to the handle. A manually rotatable member may be arranged adjacent to the control handle for manually rotating the instrument shaft and working member relative to the control handle. A locking member may be supported from the control handle. The locking member is manually operable by a user and includes a follower the position of which is responsive to the position of the movable members.

Owner:CAMBRIDGE ENDOSCOPIC DEVICES

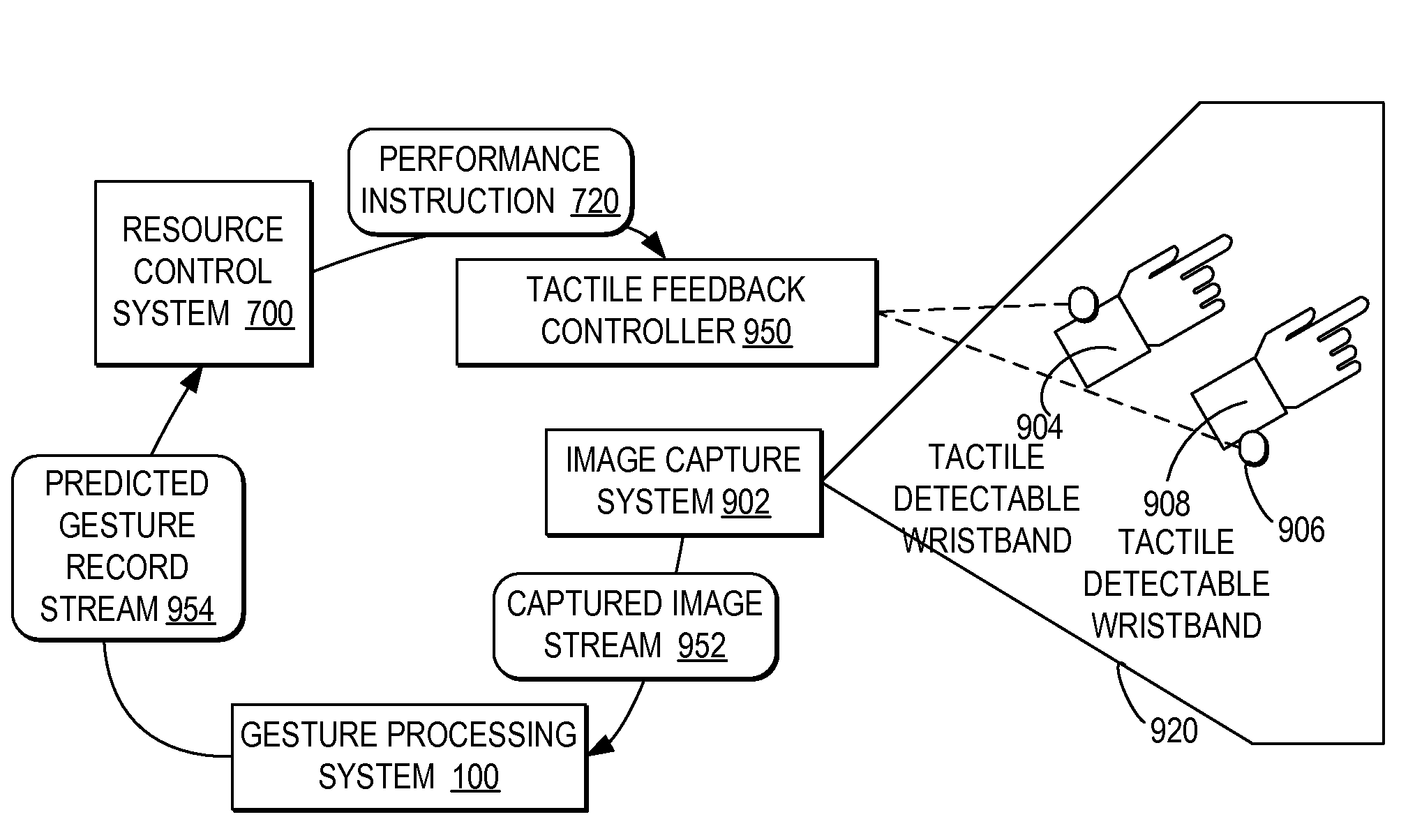

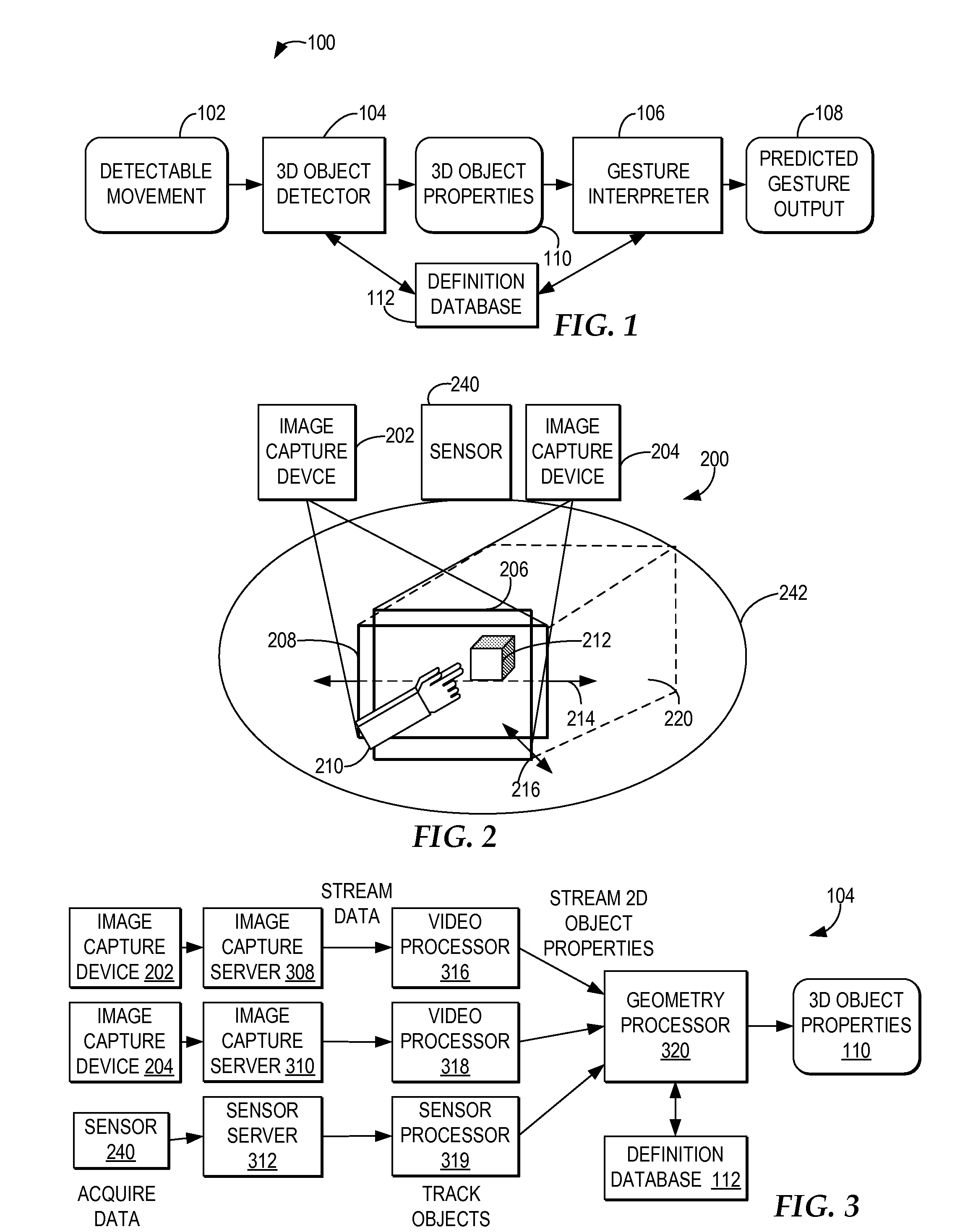

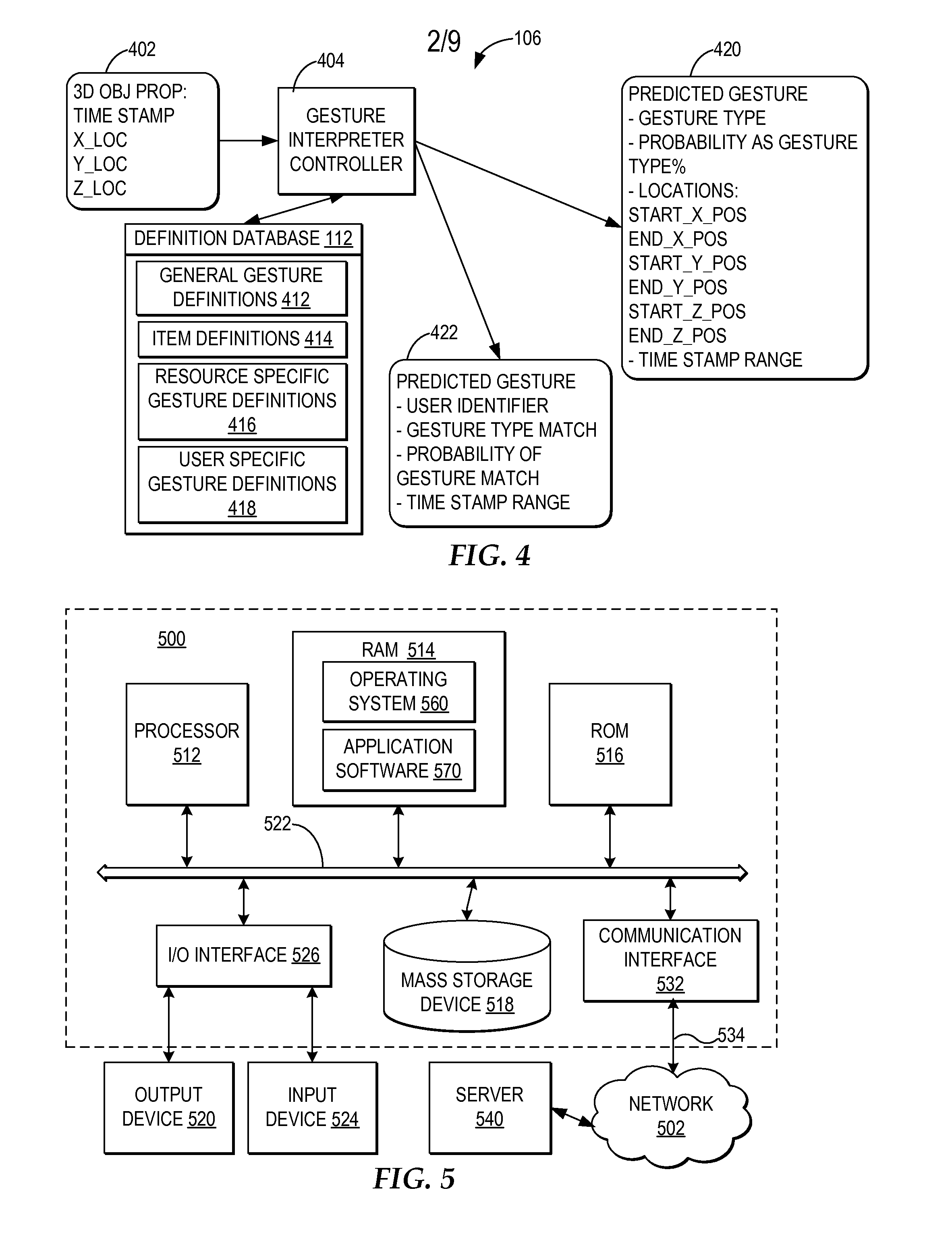

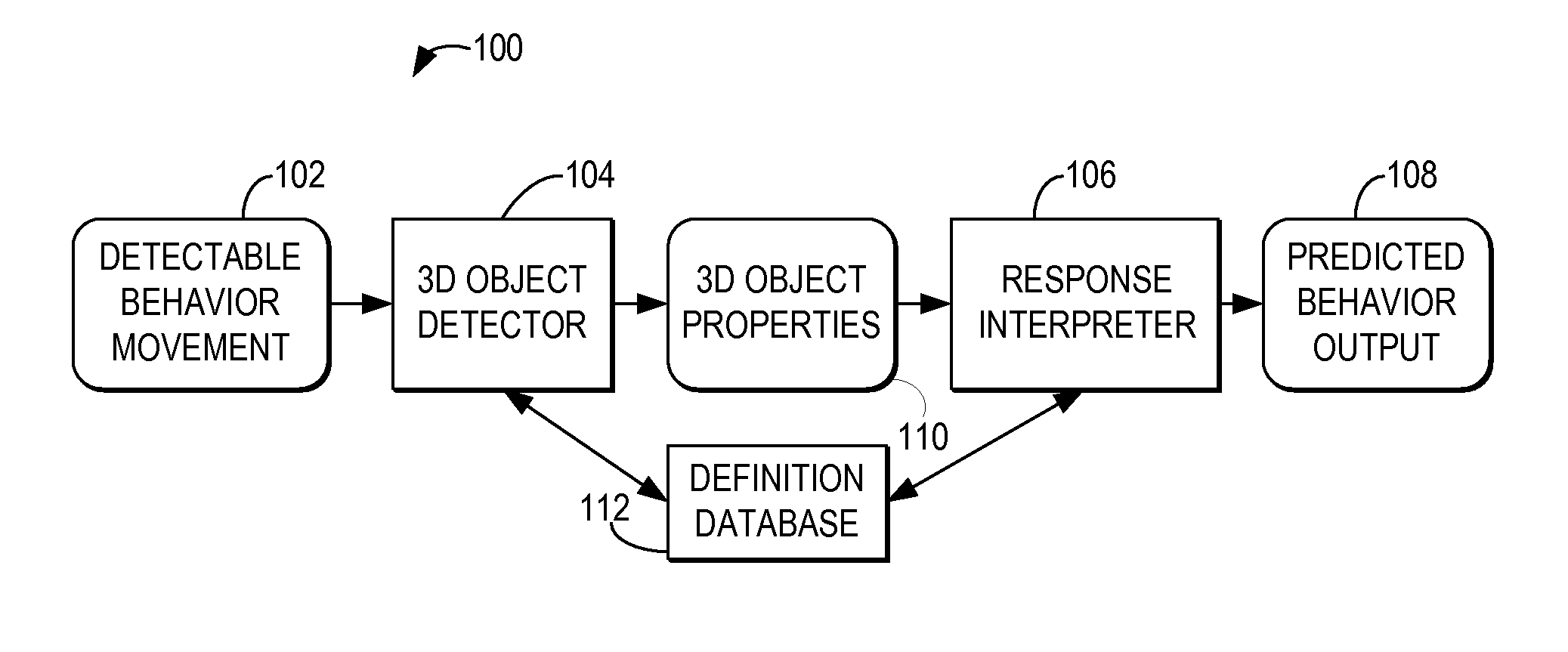

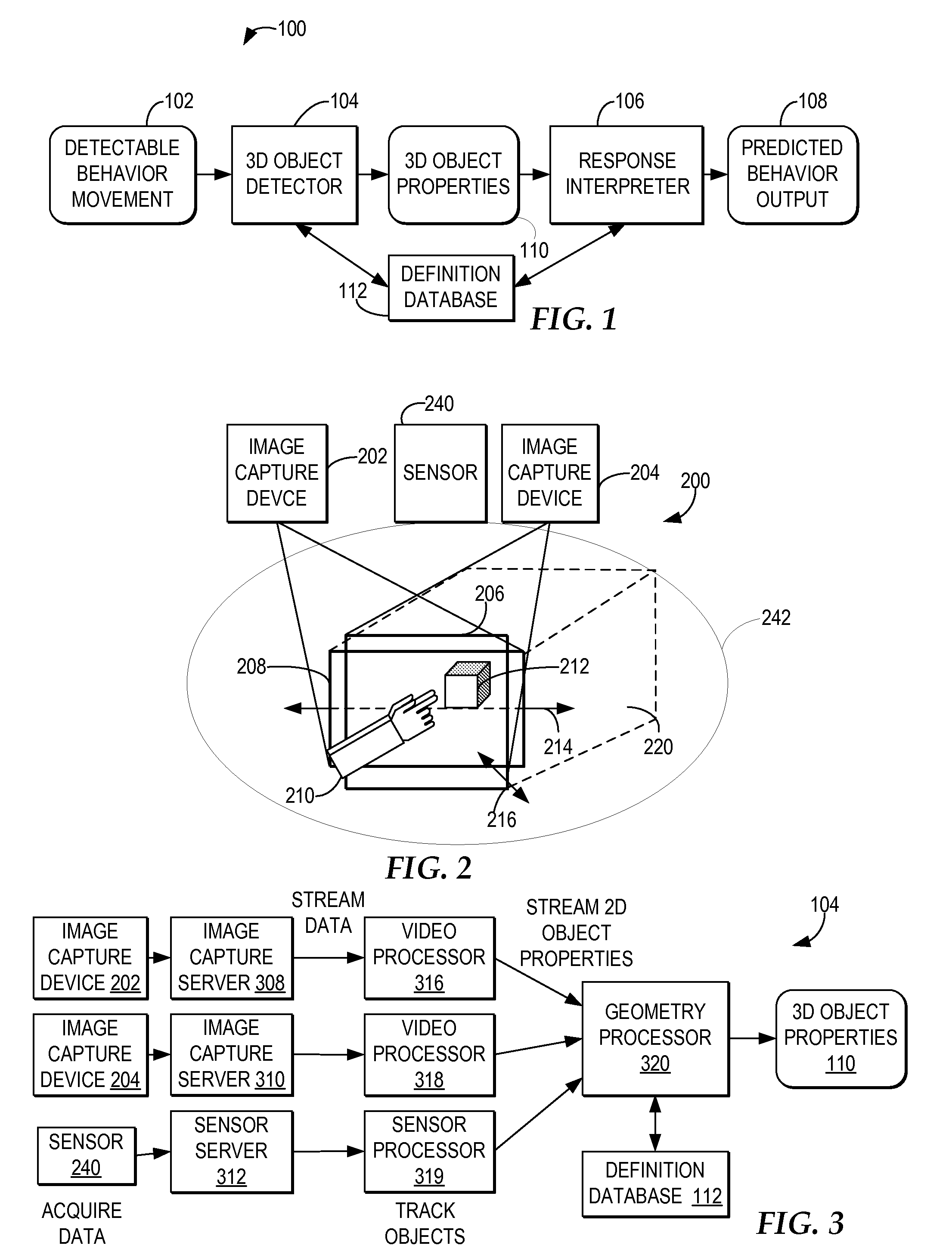

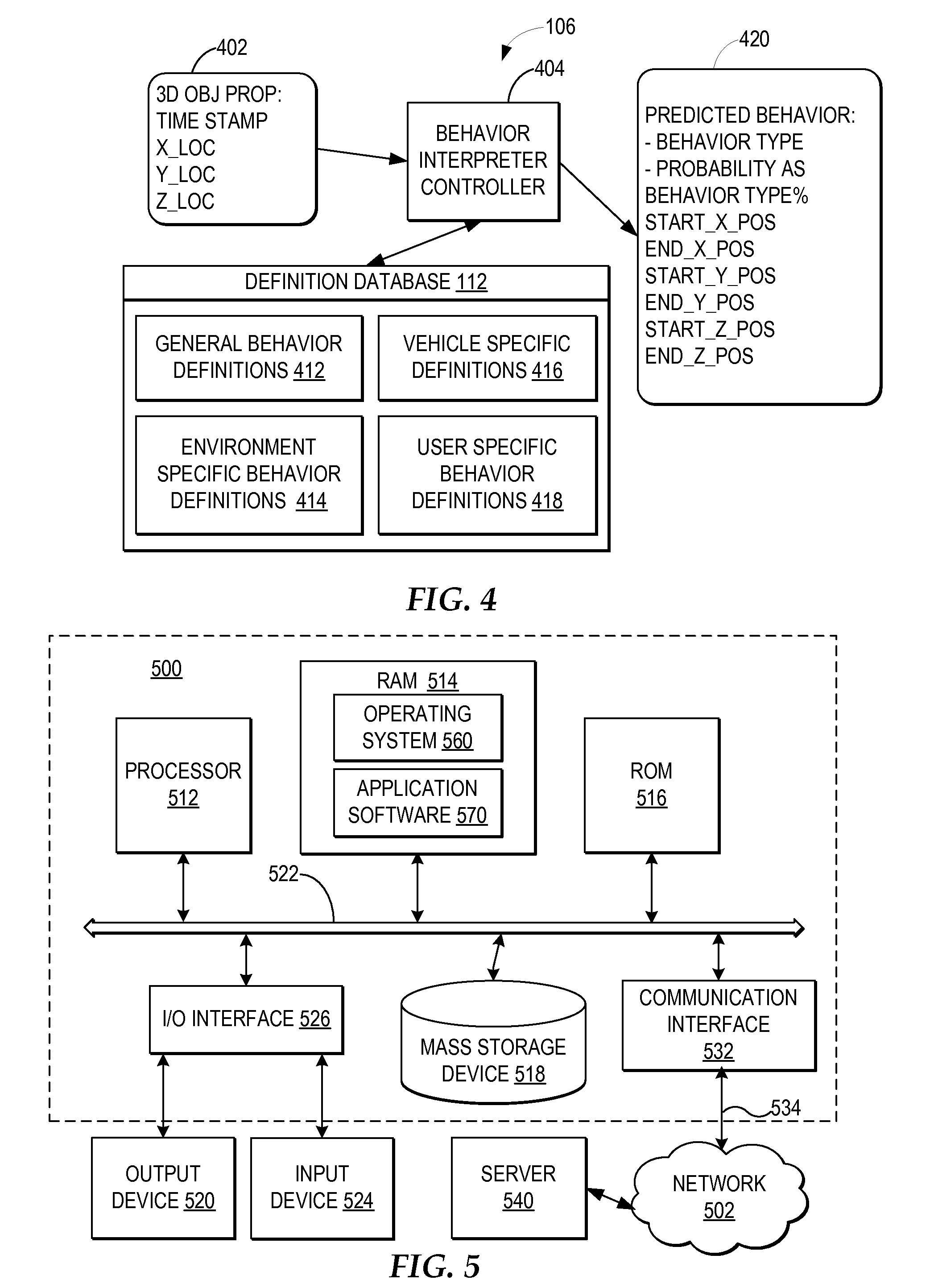

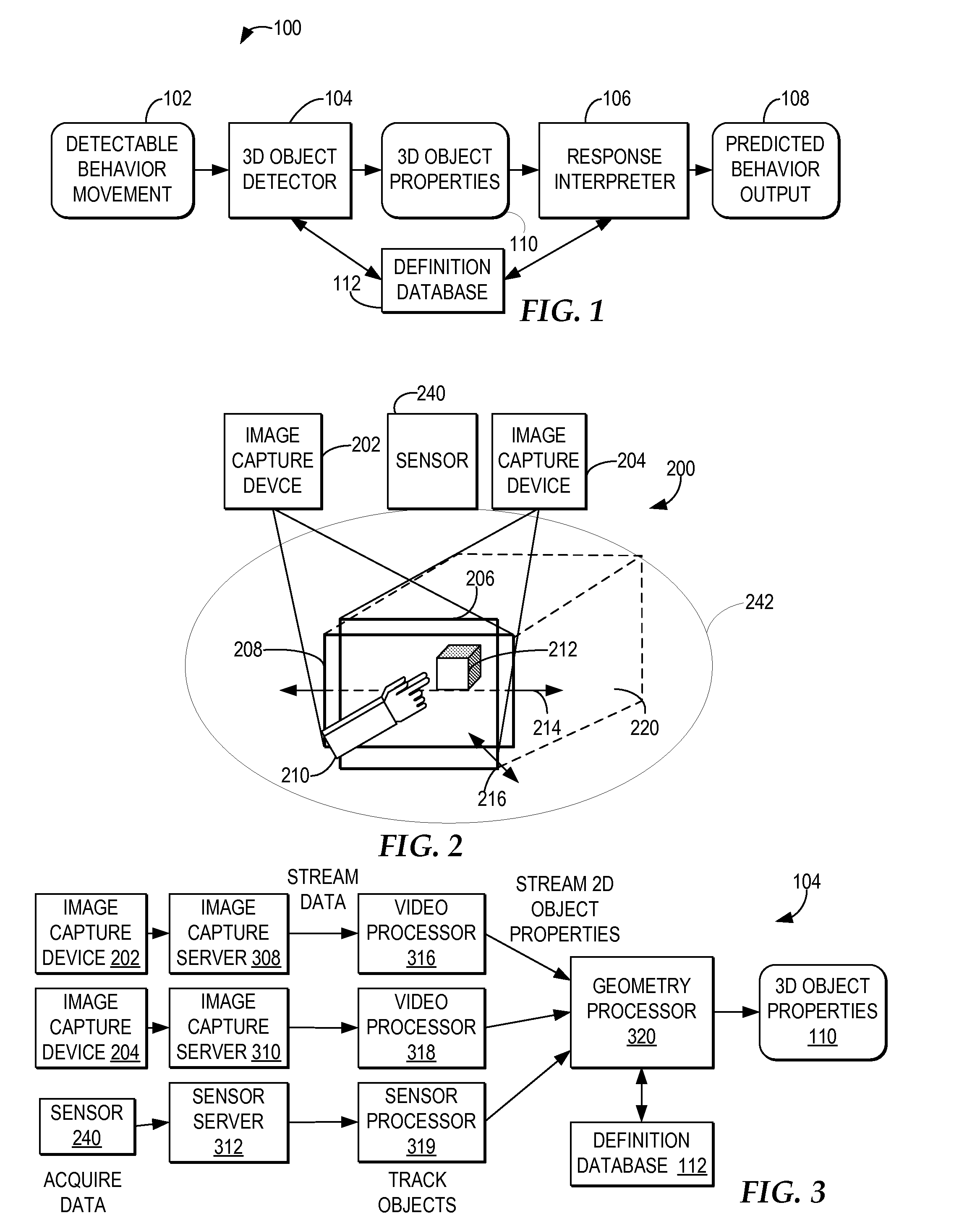

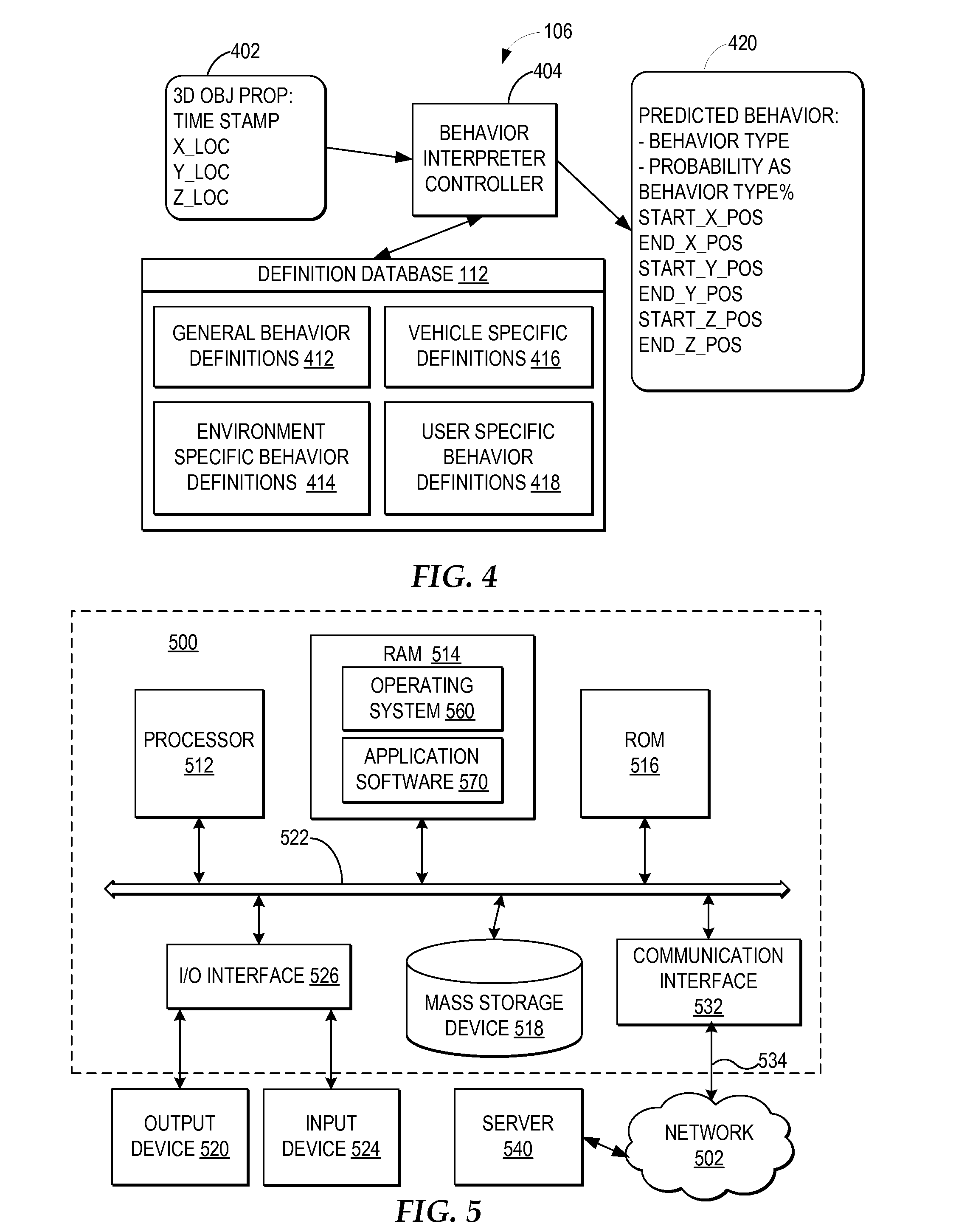

Controlling resource access based on user gesturing in a 3D captured image stream of the user

ActiveUS20080170776A1Improved resource securityIncrease resourcesCharacter and pattern recognitionMultiple digital computer combinationsControl systemResource based

A computer-implemented method, system, and program product comprises a gesture processing system for capturing a three-dimensional movement of a user, wherein the three-dimensional movement is determined using at least one stereoscopic image device aimed at the user to identify and track at least one particular three-dimensional movement of the user. The gesture processing system predicts at least one defined movement within the captured three-dimensional movement matching at least one gesture definition of at least one gesture type from among a plurality of gesture definitions. A resource control system receives a request to access a resource based on the predicted at least one gesture type. The resource control system only allows user access to the resource by matching the predicted at least one gesture type with at least one required gesture type.

Owner:SNAP INC

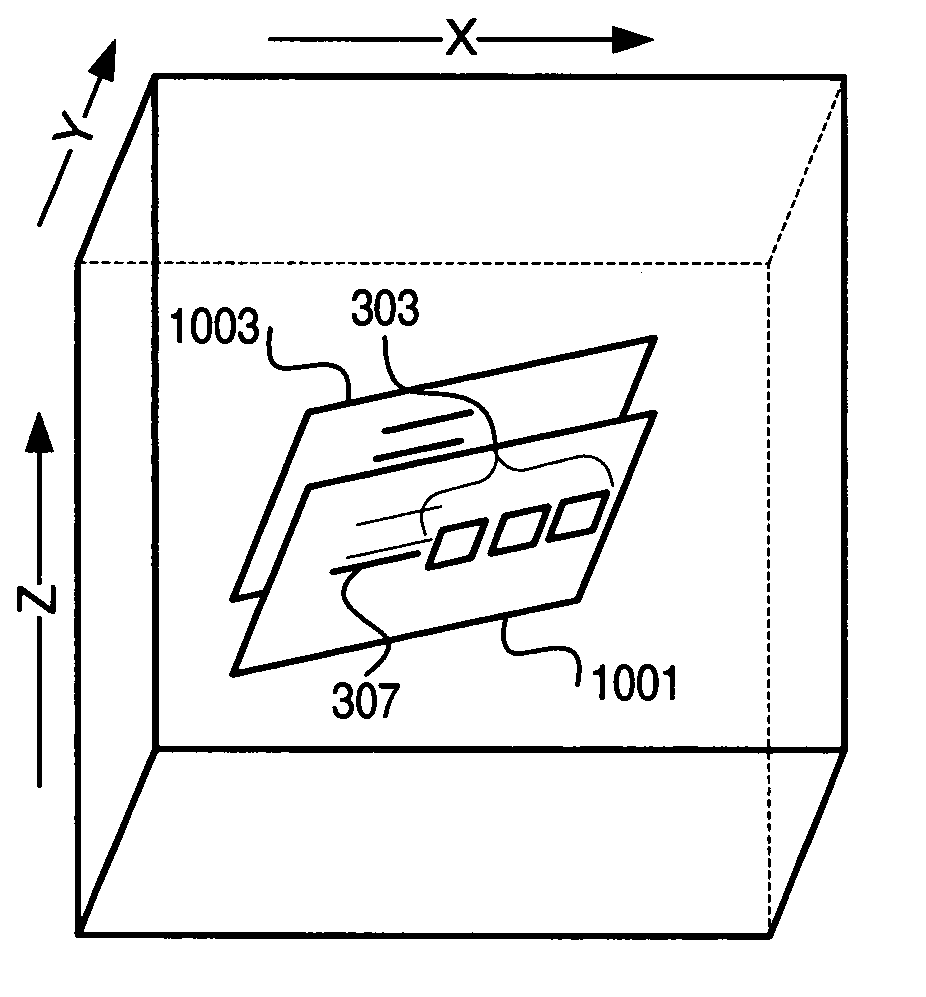

Multi-planar three-dimensional user interface

Owner:MICROSOFT TECH LICENSING LLC

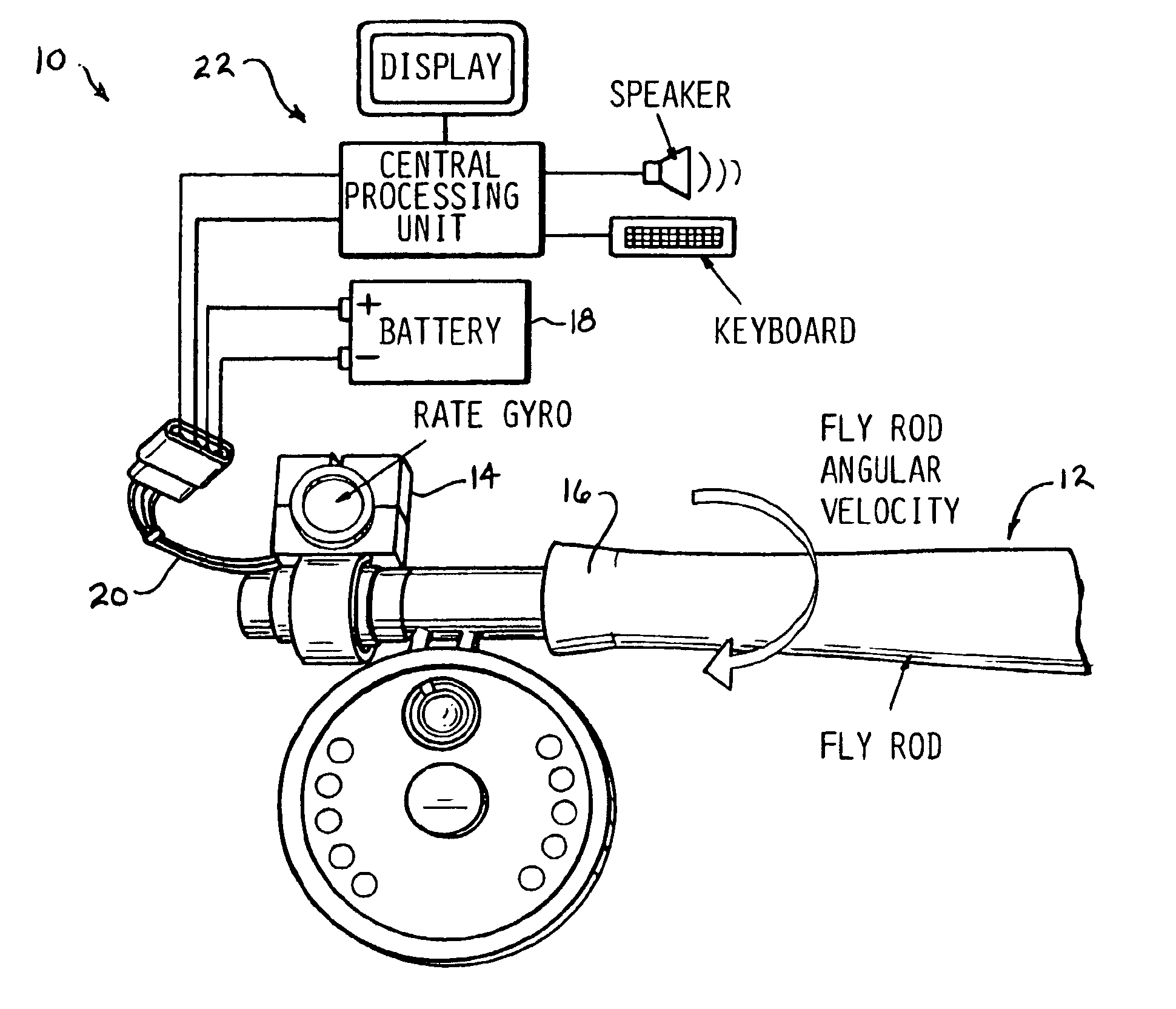

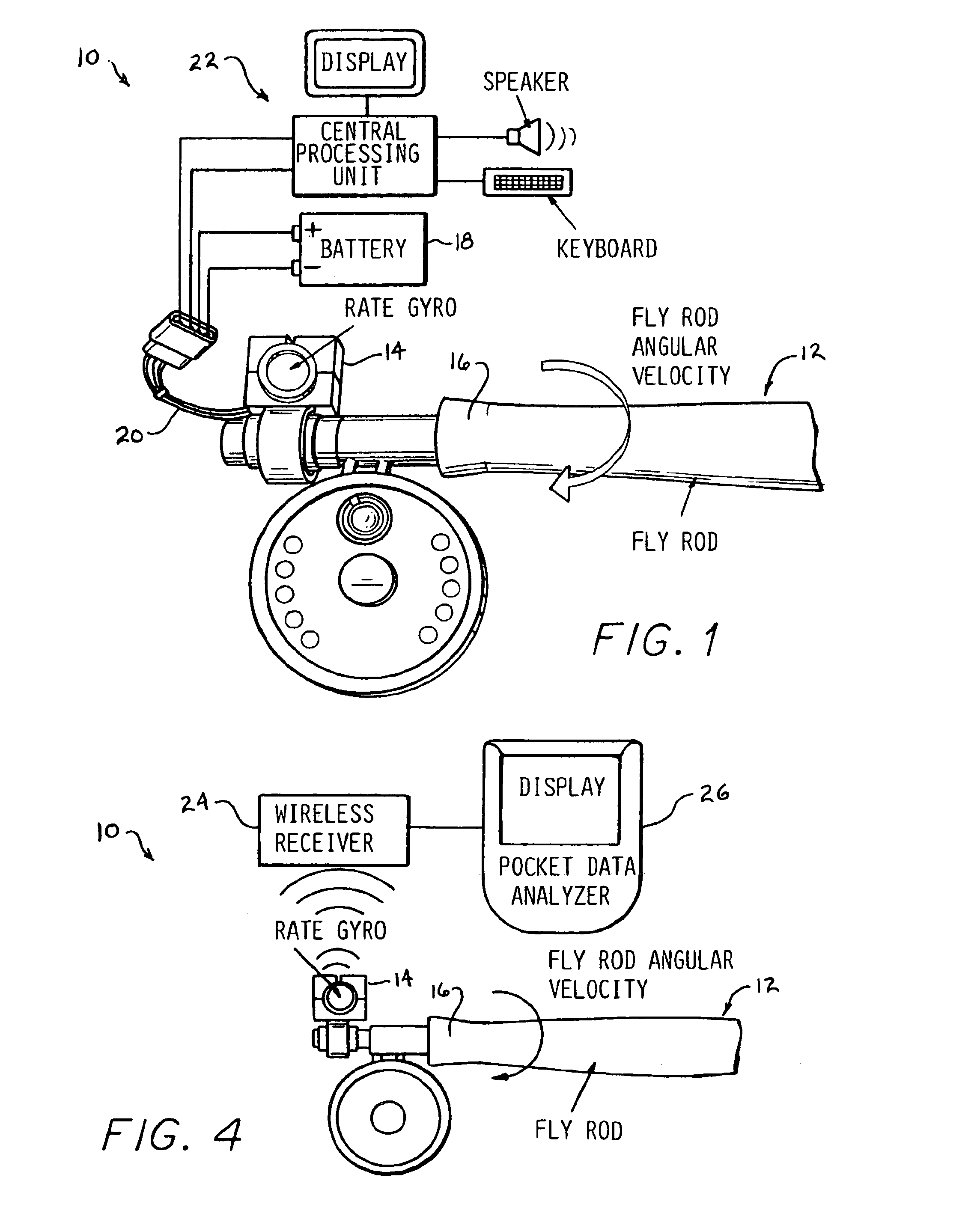

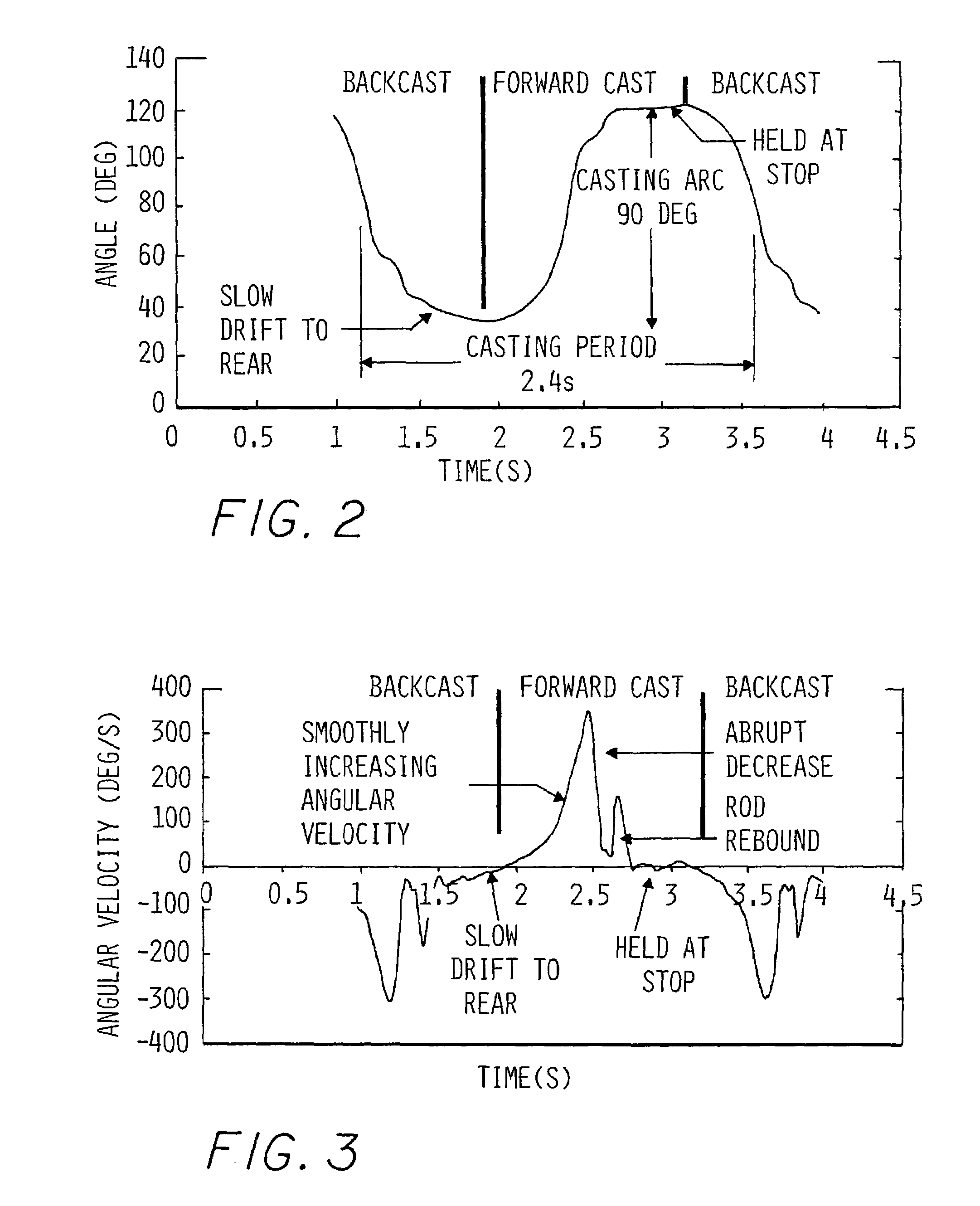

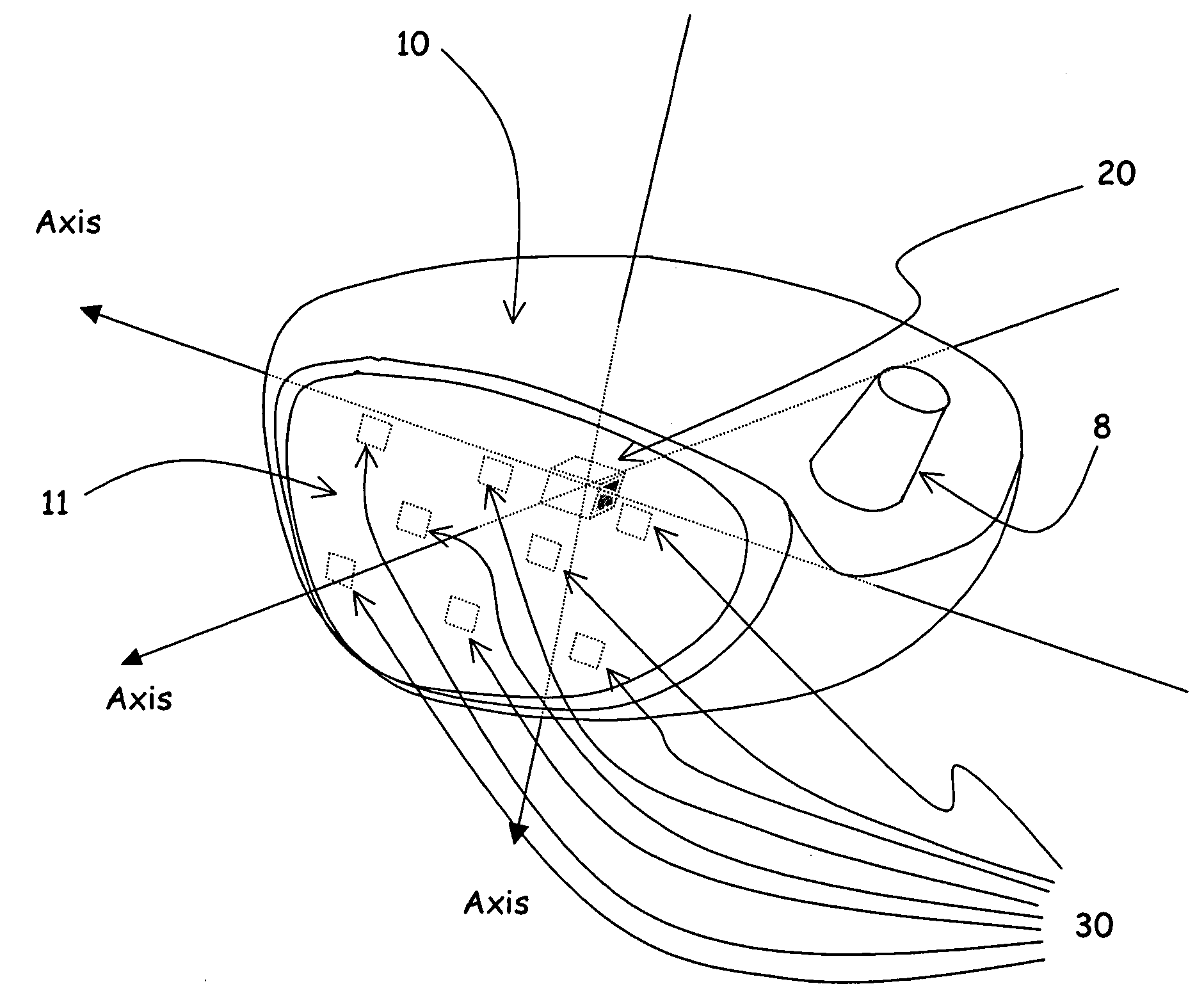

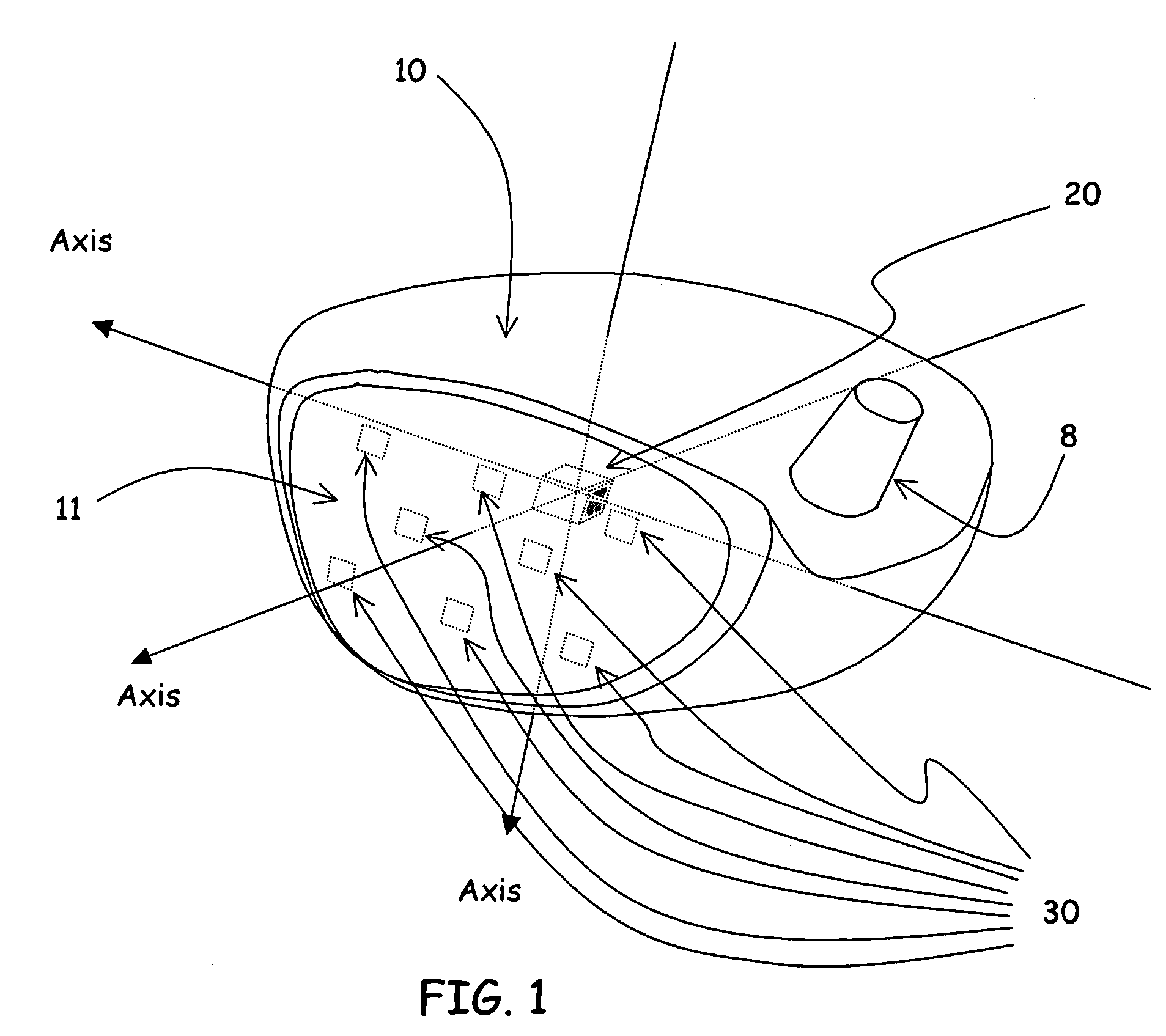

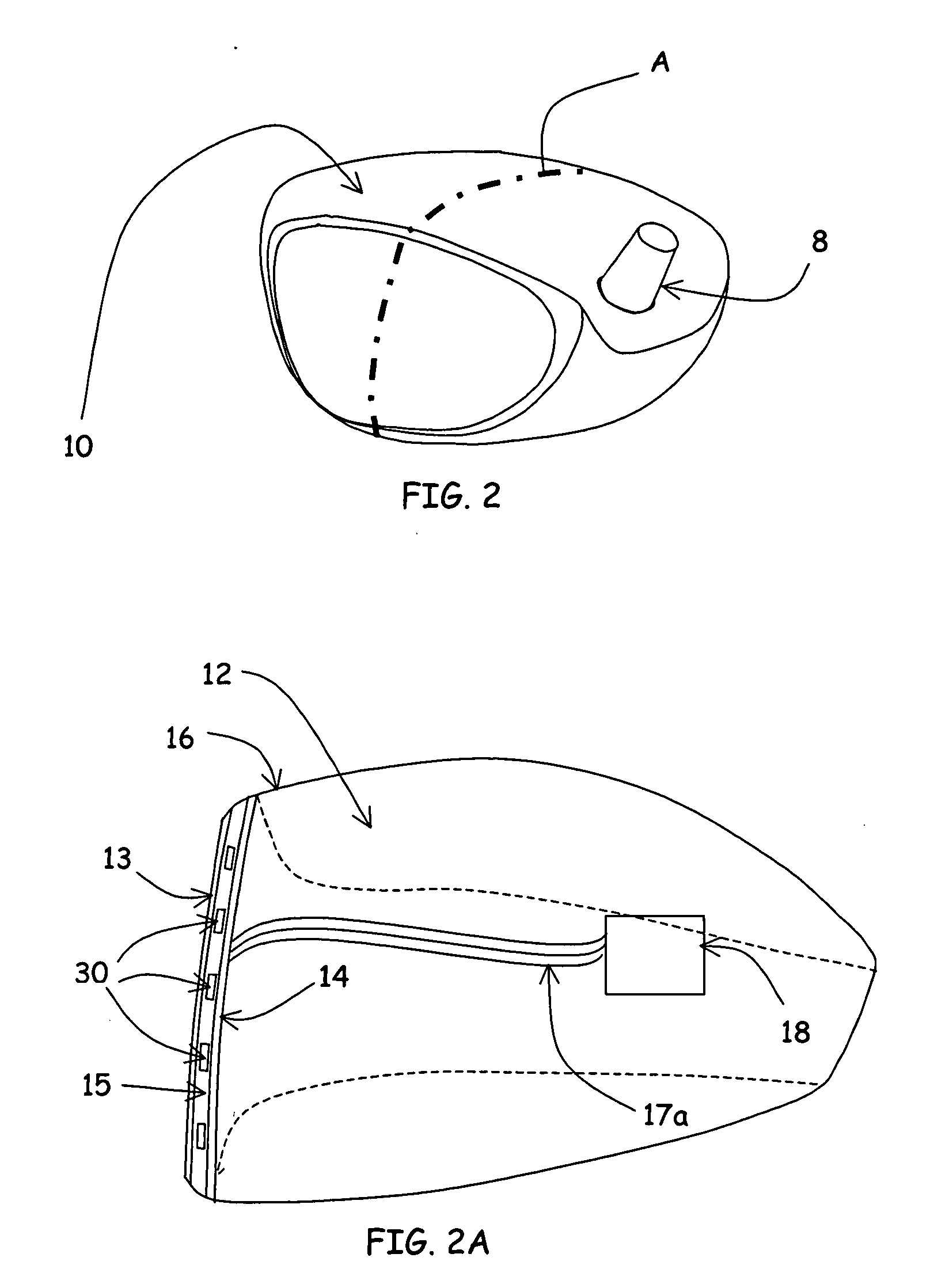

Electronic measurement of the motion of a moving body of sports equipment

An application of rate gyros and accelerometers allows electronic measurement of the motion of a rigid or semi-rigid body, such as a body associated with sporting equipment including a fly rod during casting, a baseball bat, a tennis racquet or a golf club during swinging. For instance, data can be collected by one gyro according to the present invention is extremely useful in analyzing the motion of a fly rod during fly casting instruction, and can also be used during the research, development and design phases of fly casting equipment including fly rods and fly lines. Similarly, data collected by three gyros and three accelerometers is extremely useful in analyzing the three dimensional motion of other sporting equipment such as baseball bats, tennis racquets and golf clubs. This data can be used to support instruction as well as design of the sporting equipment.

Owner:RGT UNIV OF MICHIGAN

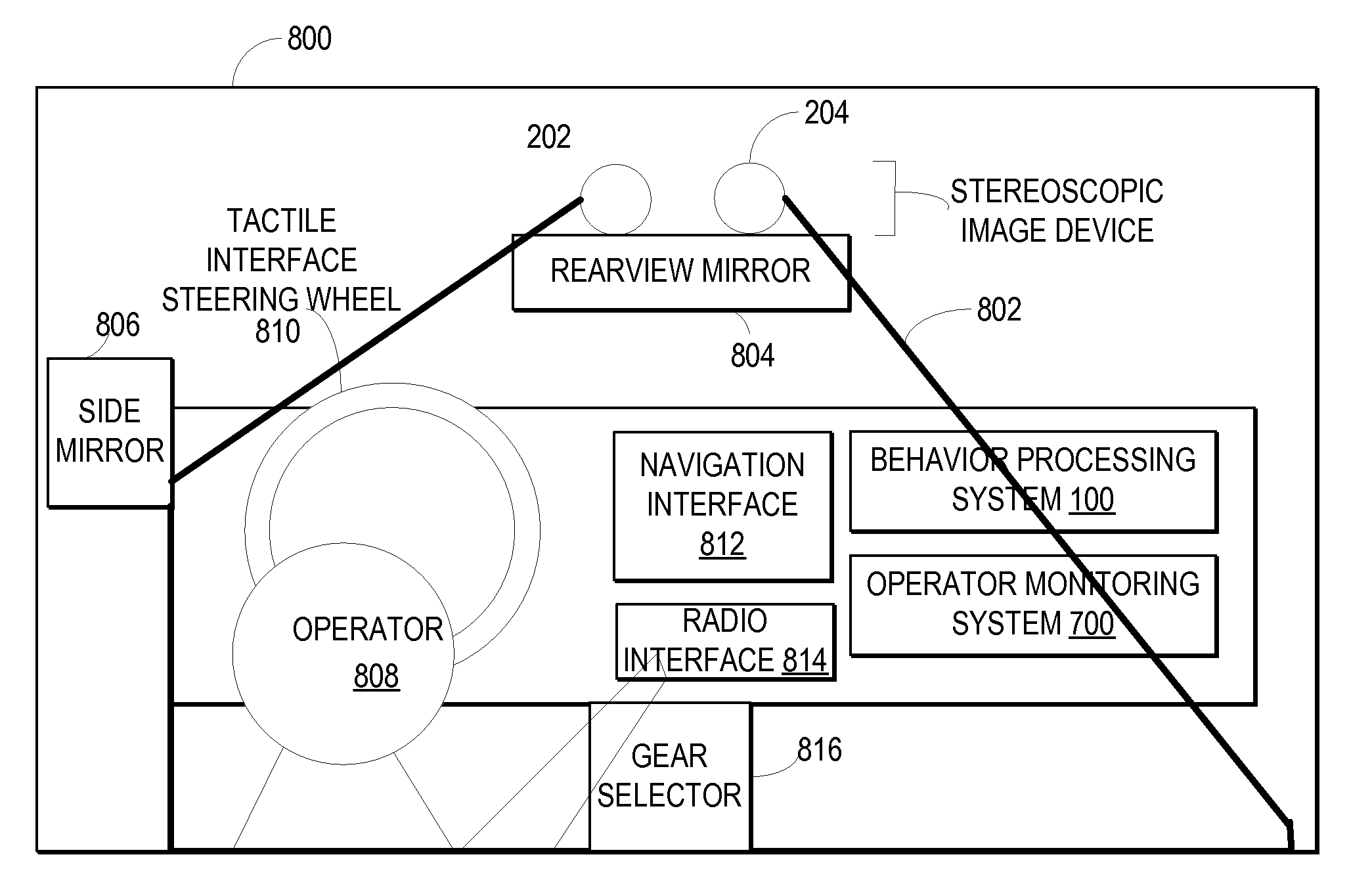

Warning a vehicle operator of unsafe operation behavior based on a 3D captured image stream

InactiveUS7792328B2Digital data processing detailsCharacter and pattern recognitionSimulationMonitoring system

A computer-implemented method, system, and program product includes a behavior processing system for capturing a three-dimensional movement of an operator of a vehicle, wherein the three-dimensional movement is determined by using at least one image capture device aimed at the operator, and identifying at least one behavior of the operator from the captured three-dimensional movement. An operator monitoring system for a vehicle determines whether the predicted behavior and the current operational state of the vehicle indicate unsafe operation of the vehicle and the operator monitoring system notifies the operator when unsafe operator of the vehicle is indicated by the operator's behavior for the current operational state of the vehicle.

Owner:LINKEDIN

Surgical instrument

The surgical instrument includes a distal tool, a rigid or flexible elongated shaft that supports the distal tool, and a proximal handle or control member, where the tool and the handle are coupled to the respective distal and proximal ends of the elongated shaft via distal and proximal bendable motion members. Actuation means extends between said distal and proximal members whereby any deflection of said control handle with respect to said elongated instrument shaft causes a corresponding bending of said distal motion member for control of said working member. The proximal movable member comprises a movable ring assembly supported from the handle and adapted for three dimensional motion relative to the handle. A manually rotatable member may be arranged adjacent to the control handle for manually rotating the instrument shaft and working member relative to the control handle. A locking member may be supported from the control handle. The locking member is manually operable by a user and includes a follower the position of which is responsive to the position of the movable members.

Owner:CAMBRIDGE ENDOSCOPIC DEVICES

Warning a vehicle operator of unsafe operation behavior based on a 3D captured image stream

InactiveUS20080169914A1Digital data processing detailsCharacter and pattern recognitionSimulationMonitoring system

A computer-implemented method, system, and program product includes a behavior processing system for capturing a three-dimensional movement of an operator of a vehicle, wherein the three-dimensional movement is determined by using at least one image capture device aimed at the operator, and identifying at least one behavior of the operator from the captured three-dimensional movement. An operator monitoring system for a vehicle determines whether the predicted behavior and the current operational state of the vehicle indicate unsafe operation of the vehicle and the operator monitoring system notifies the operator when unsafe operator of the vehicle is indicated by the operator's behavior for the current operational state of the vehicle.

Owner:LINKEDIN

Golf swing analysis apparatus and method

A method and integrated golf club apparatus for directly measuring physical parameters of the golf club head motional acceleration swing forces, golf club head face, golf ball impact forces, and subsequent calculations of other metrics useful to a golfer's understanding of the effectiveness of his or her golf swing and impact result in totality. The physical parameters that are directly measured include three dimensional motion force vectors of club head prior to, during and after impact and full impact pressure force profiles across the golf clubface with respect to time. The sensors are connected to electronics which condition, record and store the time varying sensors information electronically, then process and translate the information into one of several forms for delivery to a human interface function.

Owner:GOLF IMPACT

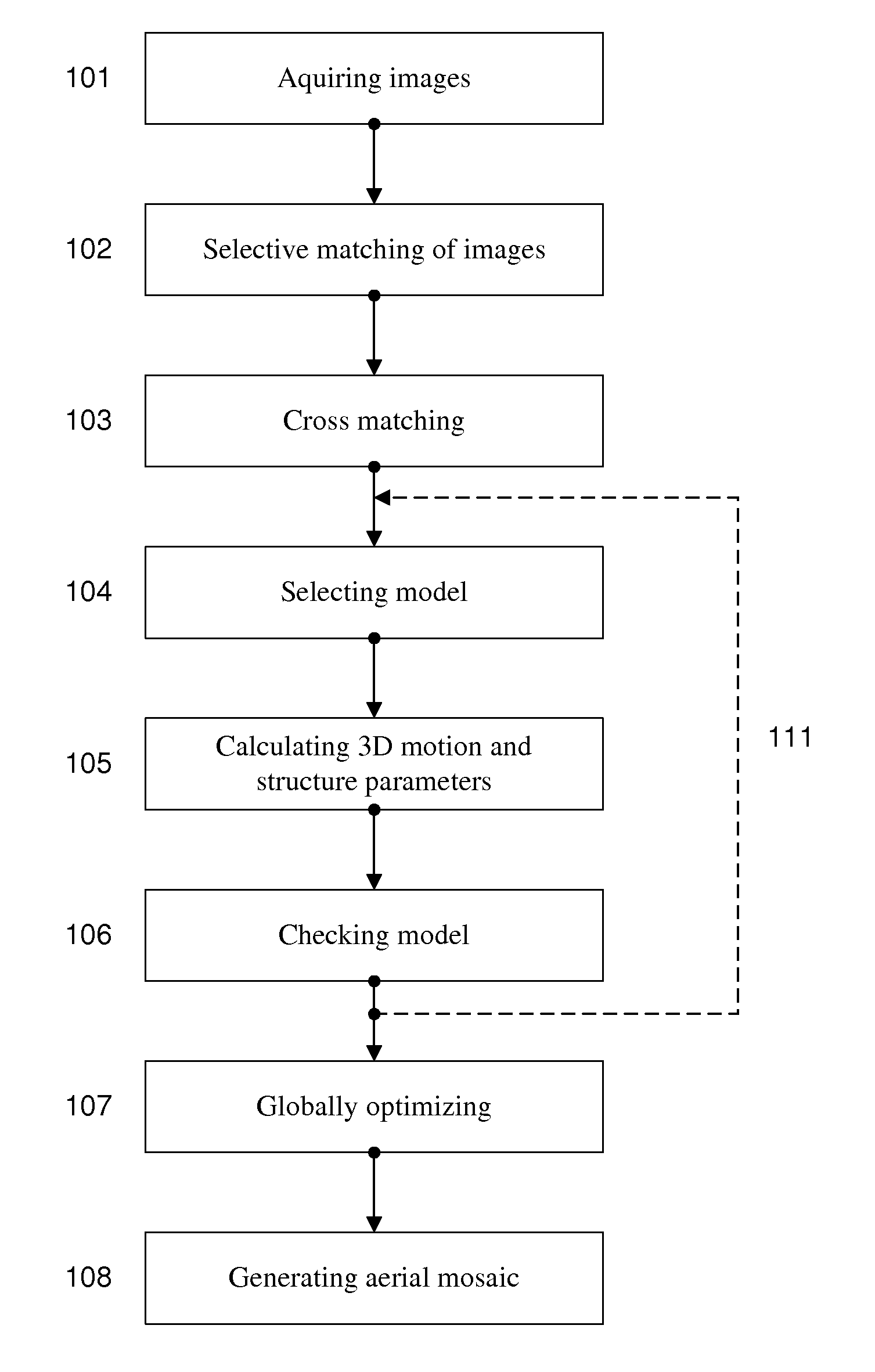

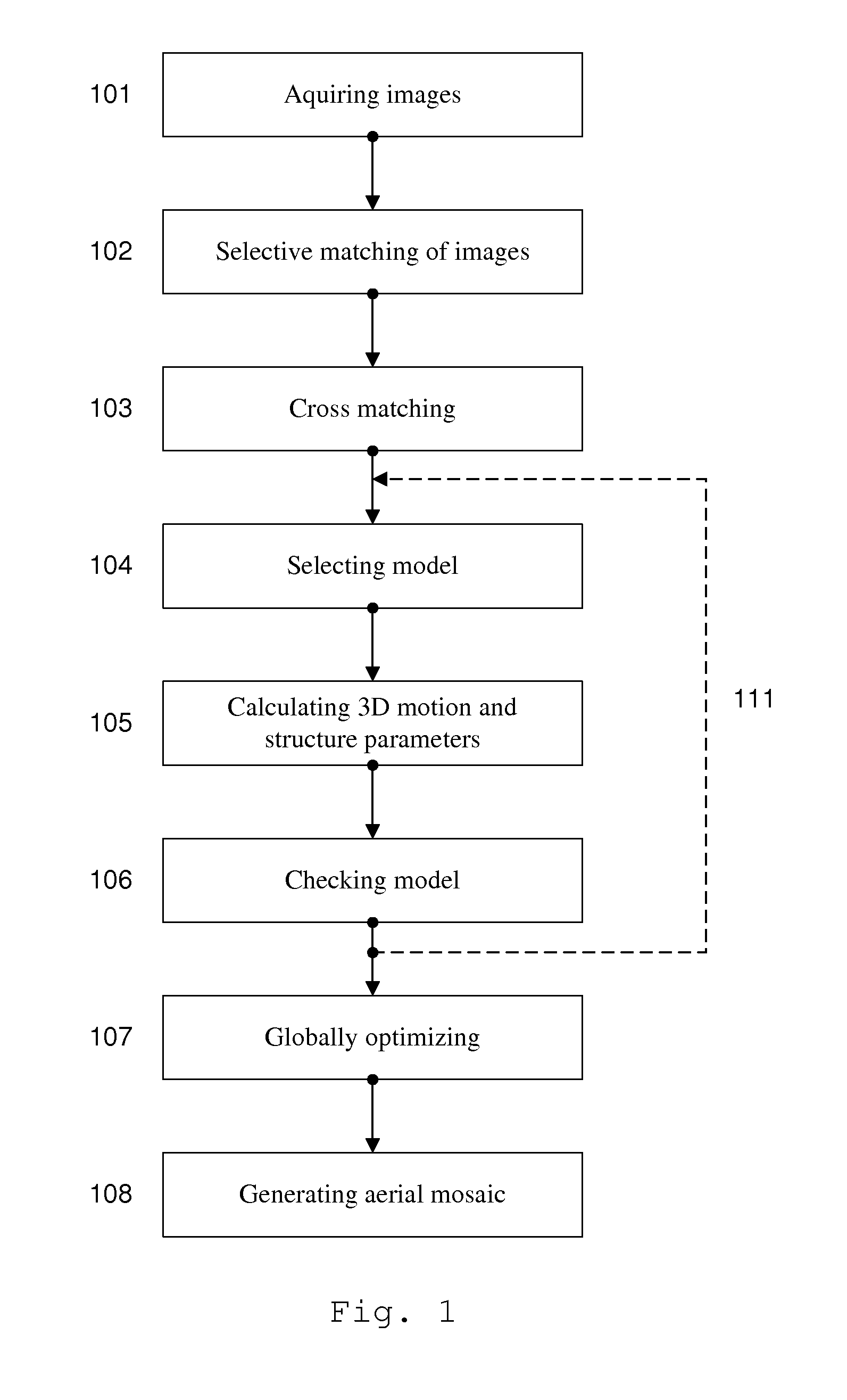

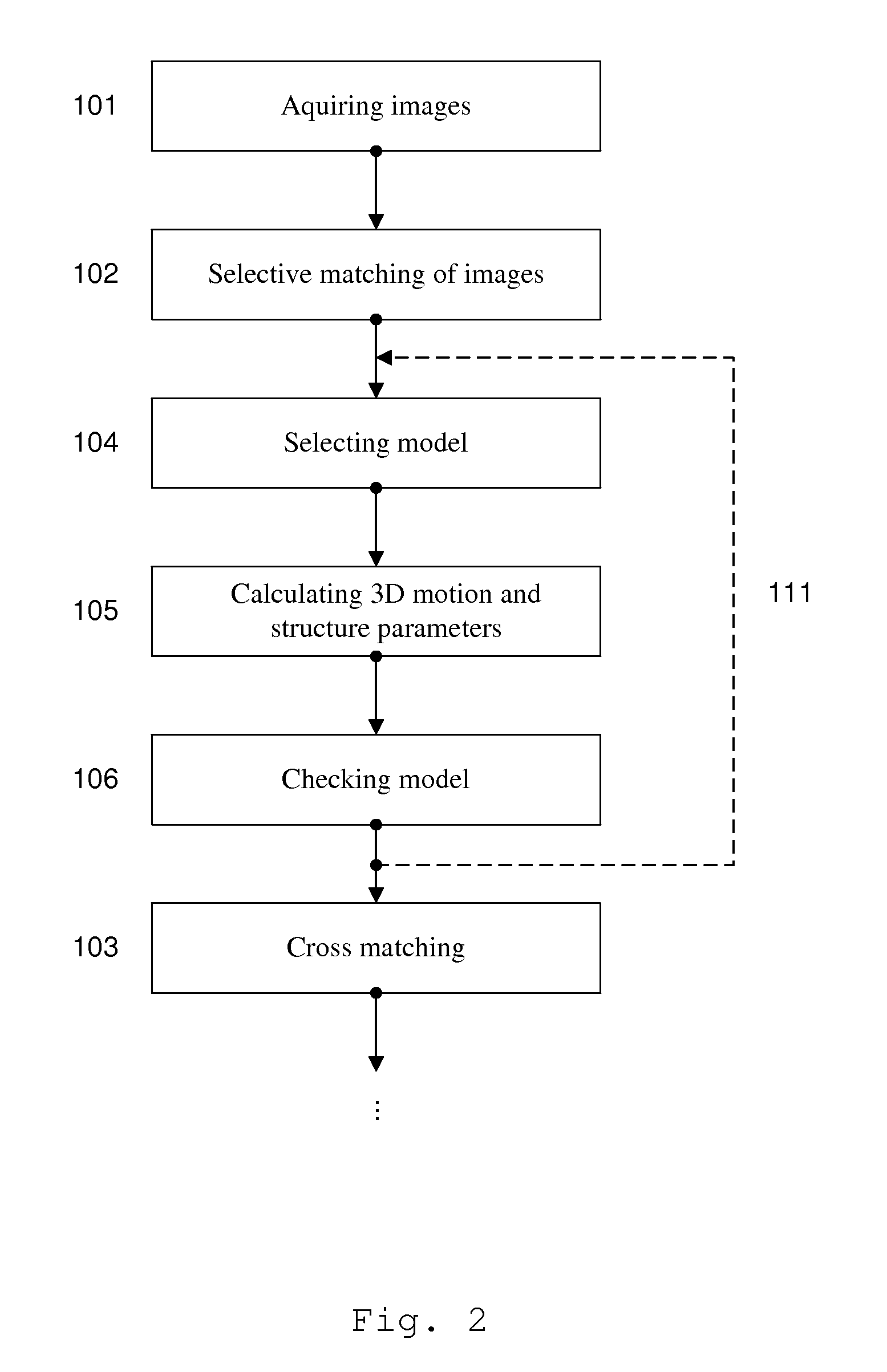

Generation of aerial images

ActiveUS20110090337A1Quality improvementRobust and cheap and lightPhotogrammetry/videogrammetryColor television detailsSingle imageAerial photography

The method according to the invention gene rates an aerial image mosaic viewing a larger area than a single image from a camera can provide using a combination of computer vision and photogrammetry. The aerial image mosaic is based on a set of images acquired from a camera. Selective matching and cross matching of consecutive and non-consecutive images, respectively, are performed and three dimensional motion and structure parameters are calculated and implemented on the model to check if the model is stable. Thereafter the parameters are globally optimised and based on these optimised parameters the serial image mosaic is generated. The set of images may be limited by removing old image data as new images are acquired. The method makes it is possible to establish images in near real time using a system of low complexity and small size, and using only image information.

Owner:IMINT IMAGE INTELLIGENCE AB

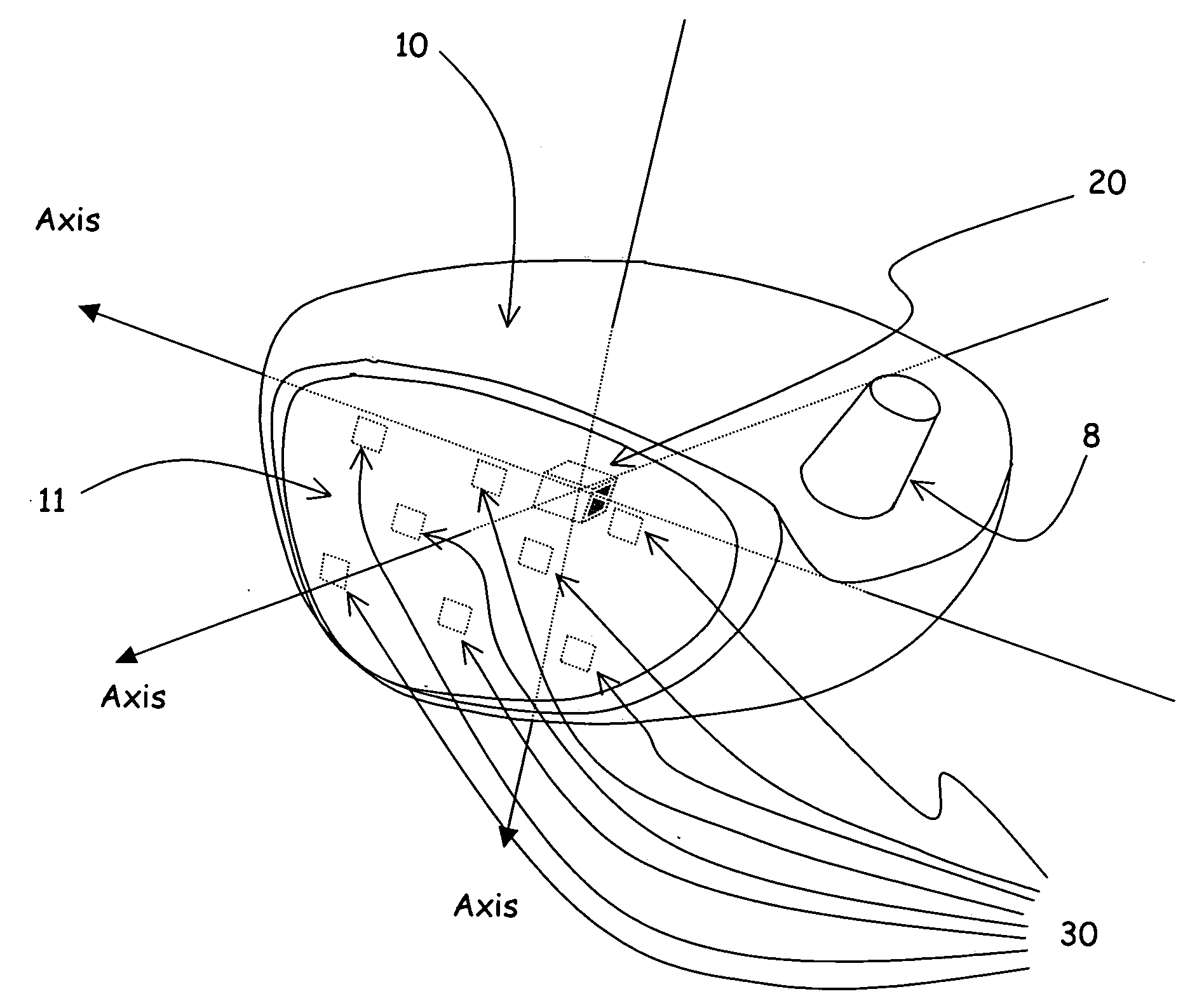

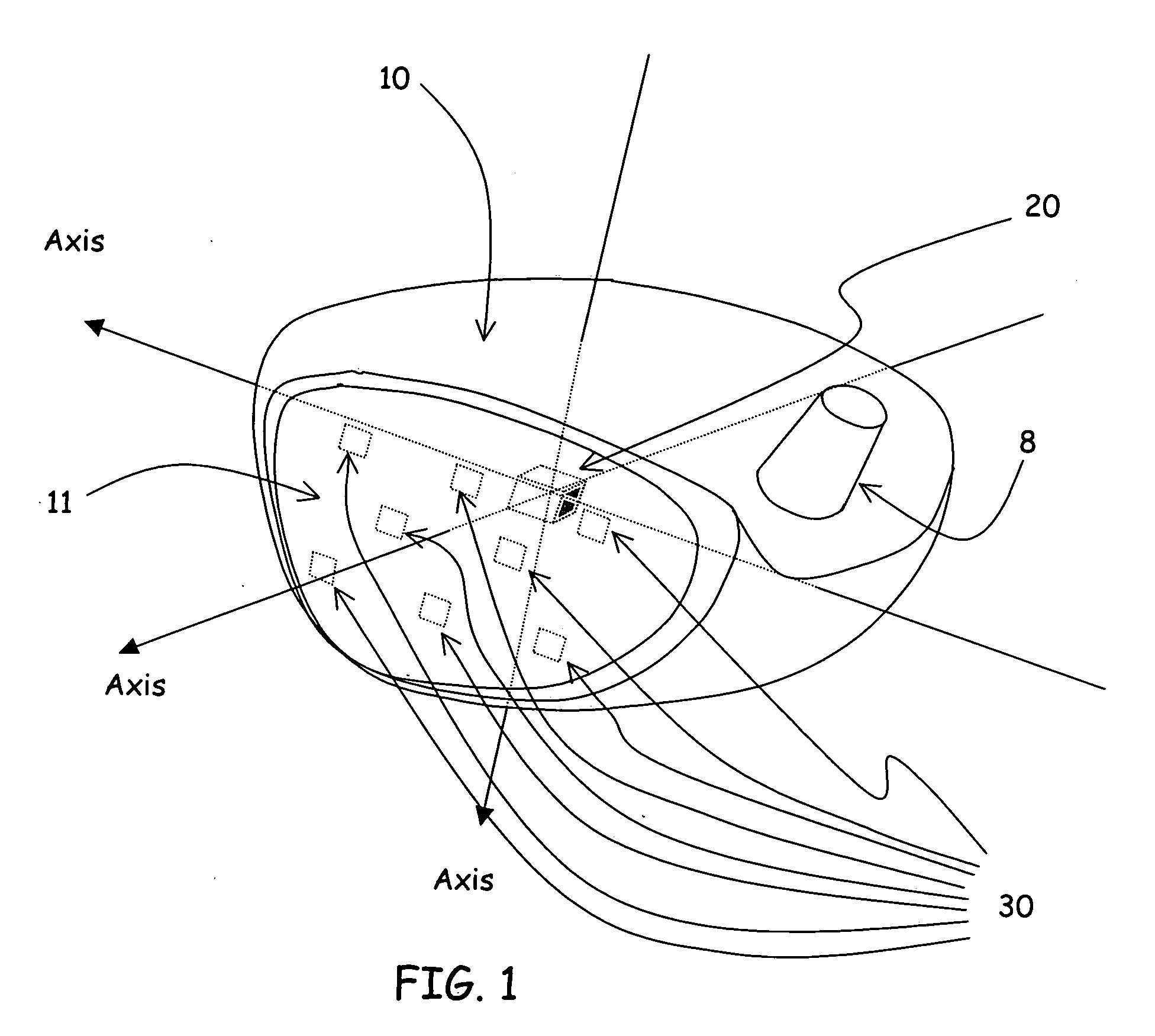

Surgical instrument

The surgical instrument includes a distal tool, an elongated shaft that supports the distal tool, and a proximal handle or control member, where the tool and the handle are coupled to the respective distal and proximal ends of the elongated shaft via distal and proximal bendable motion members. Actuation means extends between said distal and proximal members whereby any deflection of said control handle with respect to said elongated instrument shaft causes a corresponding bending of said distal motion member for control of said working member. The proximal bendable member comprises a ball and socket assembly supported between the handle and instrument shaft and constructed and arranged for three dimensional motion.

Owner:CAMBRIDGE ENDOSCOPIC DEVICES

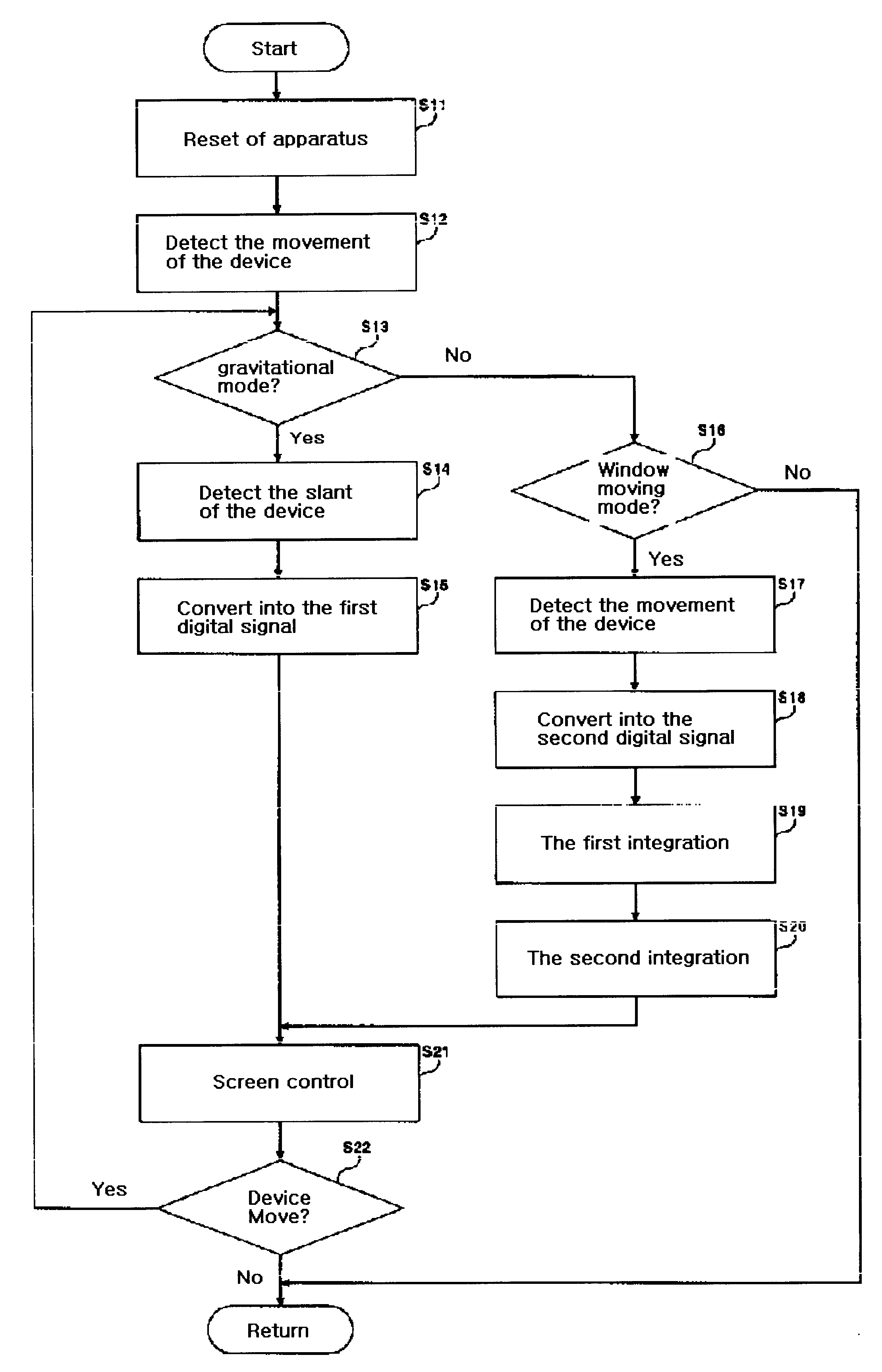

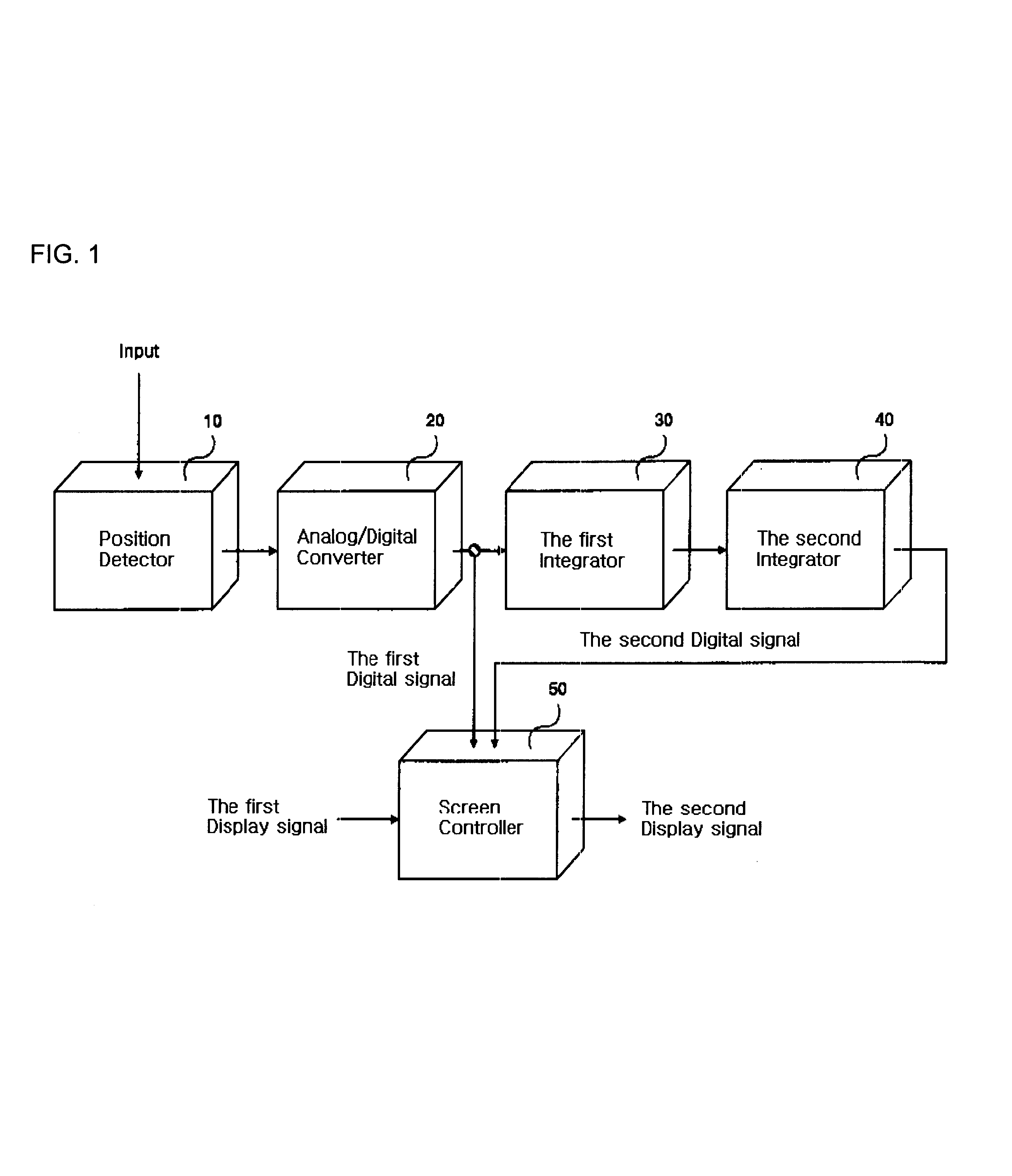

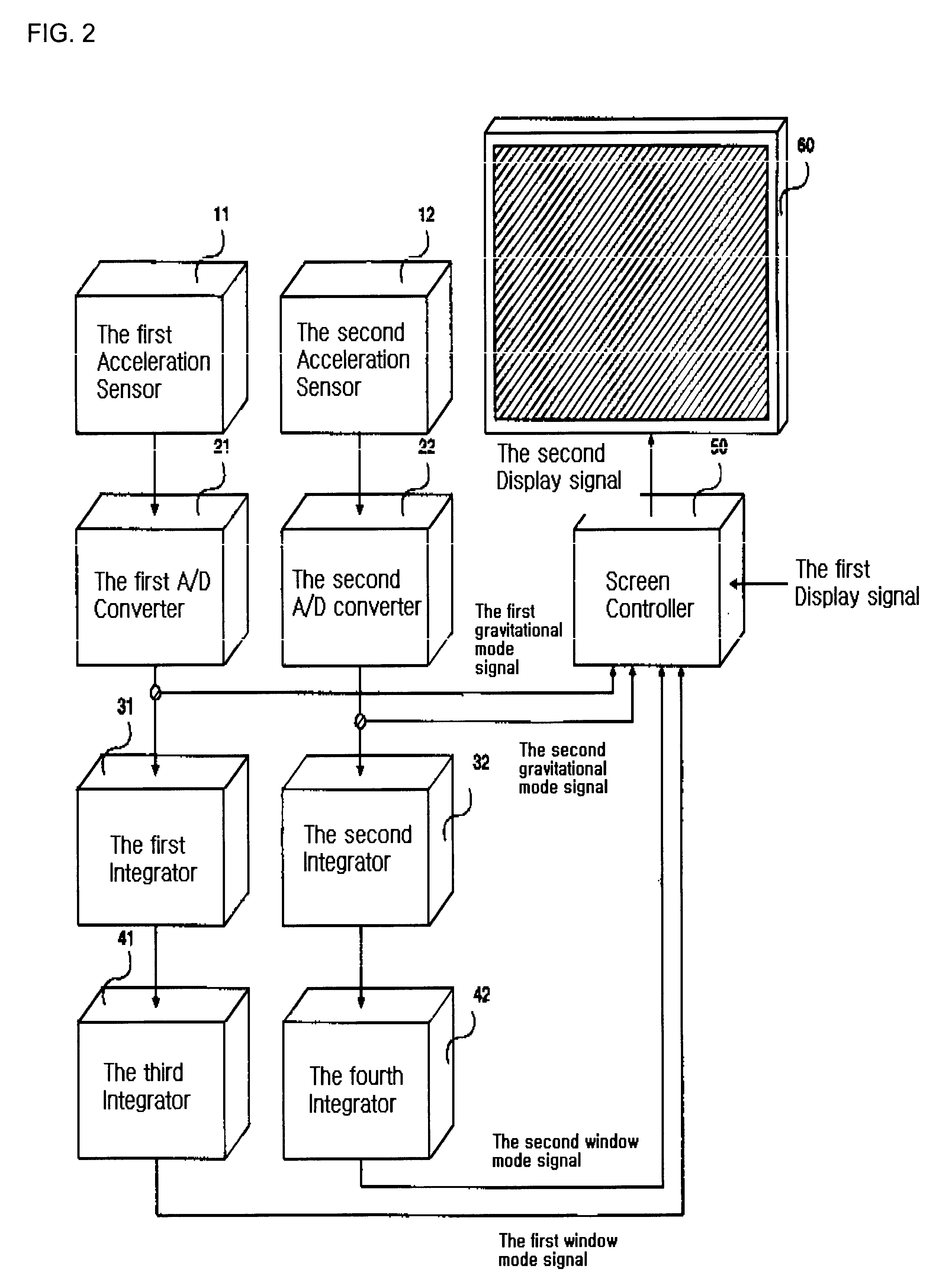

Apparatus for moving display screen of mobile computer device

InactiveUS6856327B2Easy to moveDigital data processing detailsCathode-ray tube indicatorsAnalog signalDigital converter

An apparatus for moving a display screen by detecting the three-dimensional motion of the mobile computer device with acceleration sensors is disclosed. The apparatus includes a position detector for detecting a three-dimensional positional change of the mobile computer device, and then producing analog signals corresponding to the motion of the mobile computer device; an analog / digital converter for converting the analog signals produced by the position detector into digital signals; and a screen controller for receiving a first display signal including all information, and producing a second display signal including a part of information according to the digital signals.

Owner:DOMOTION

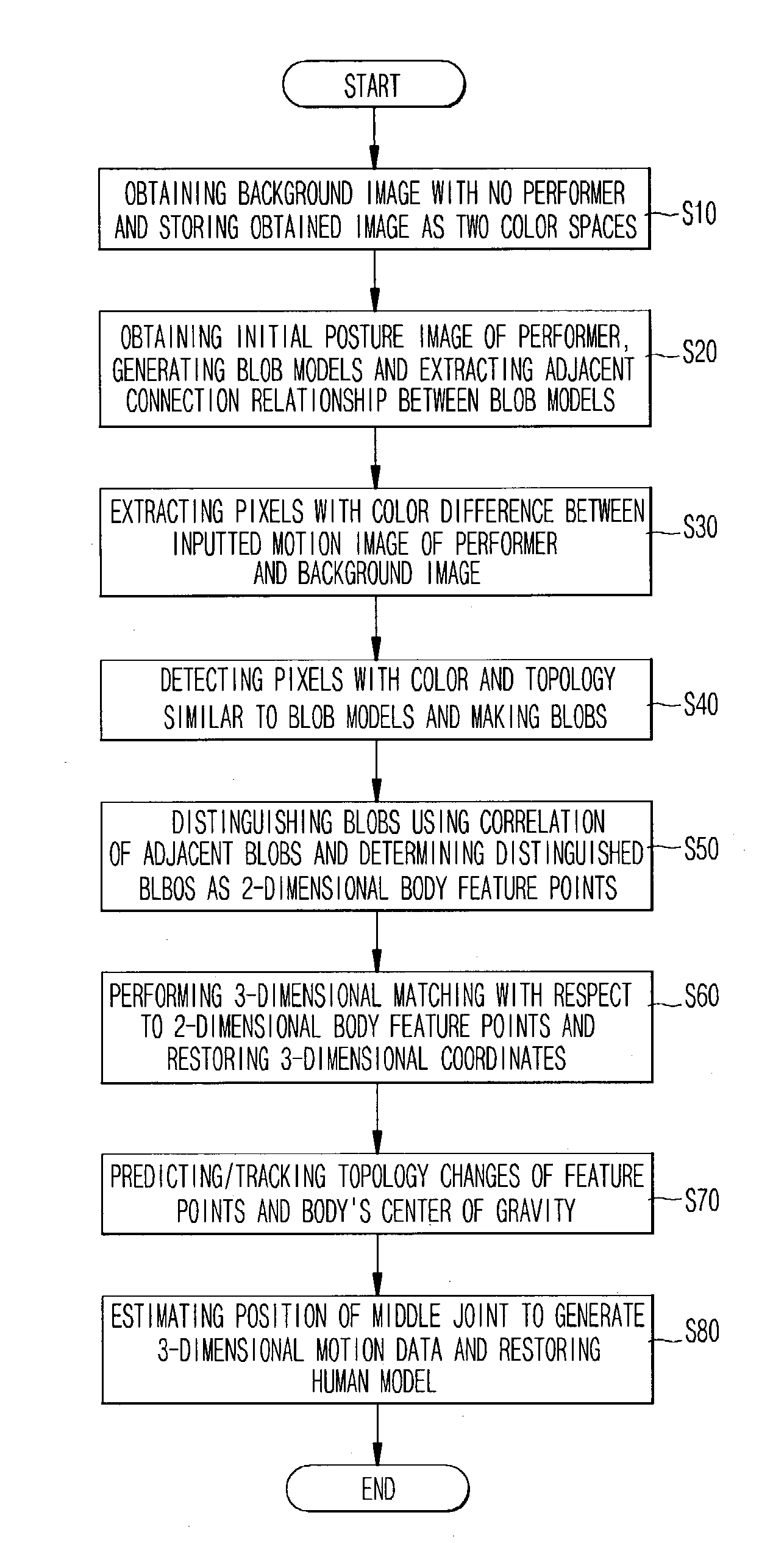

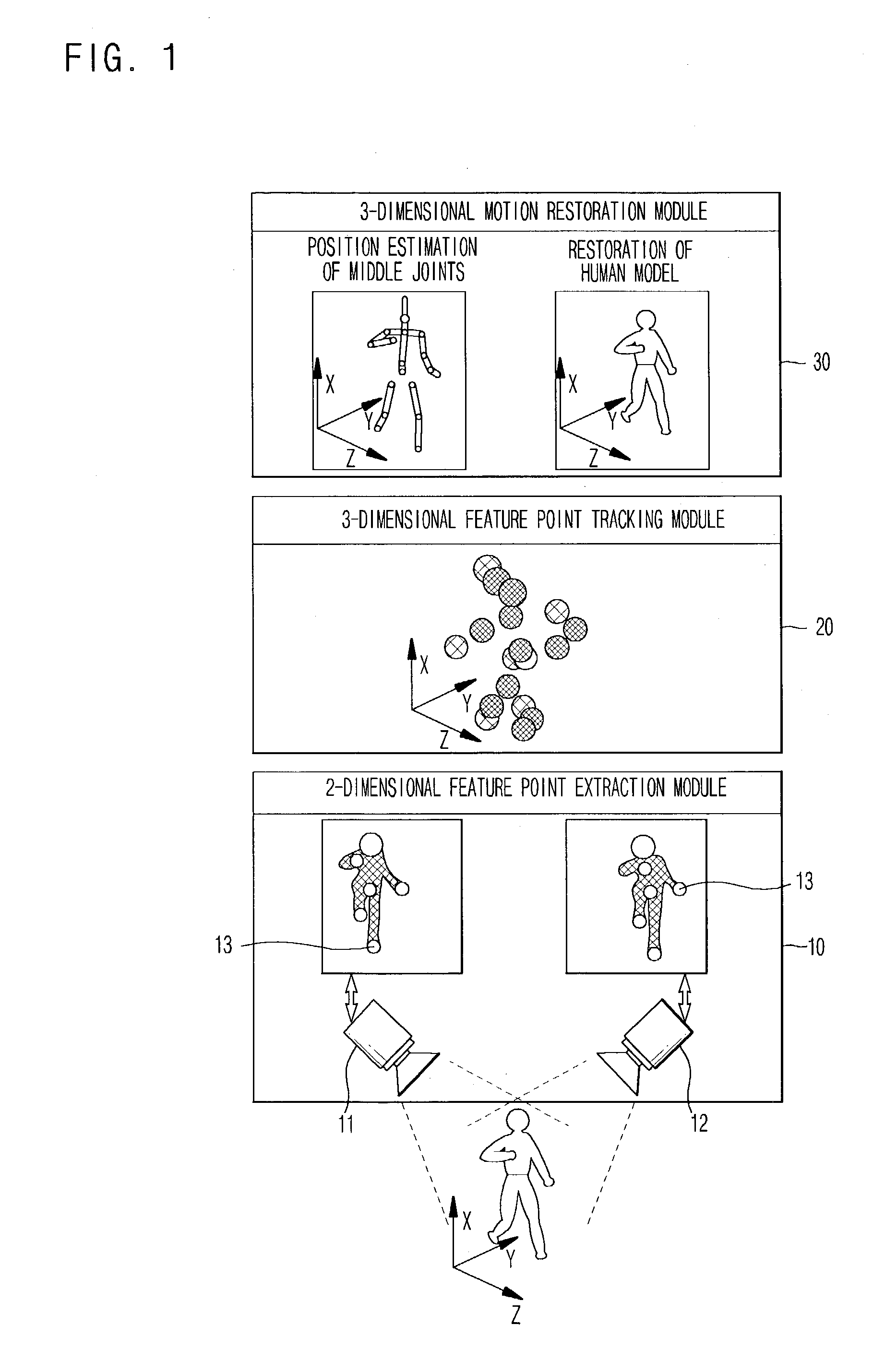

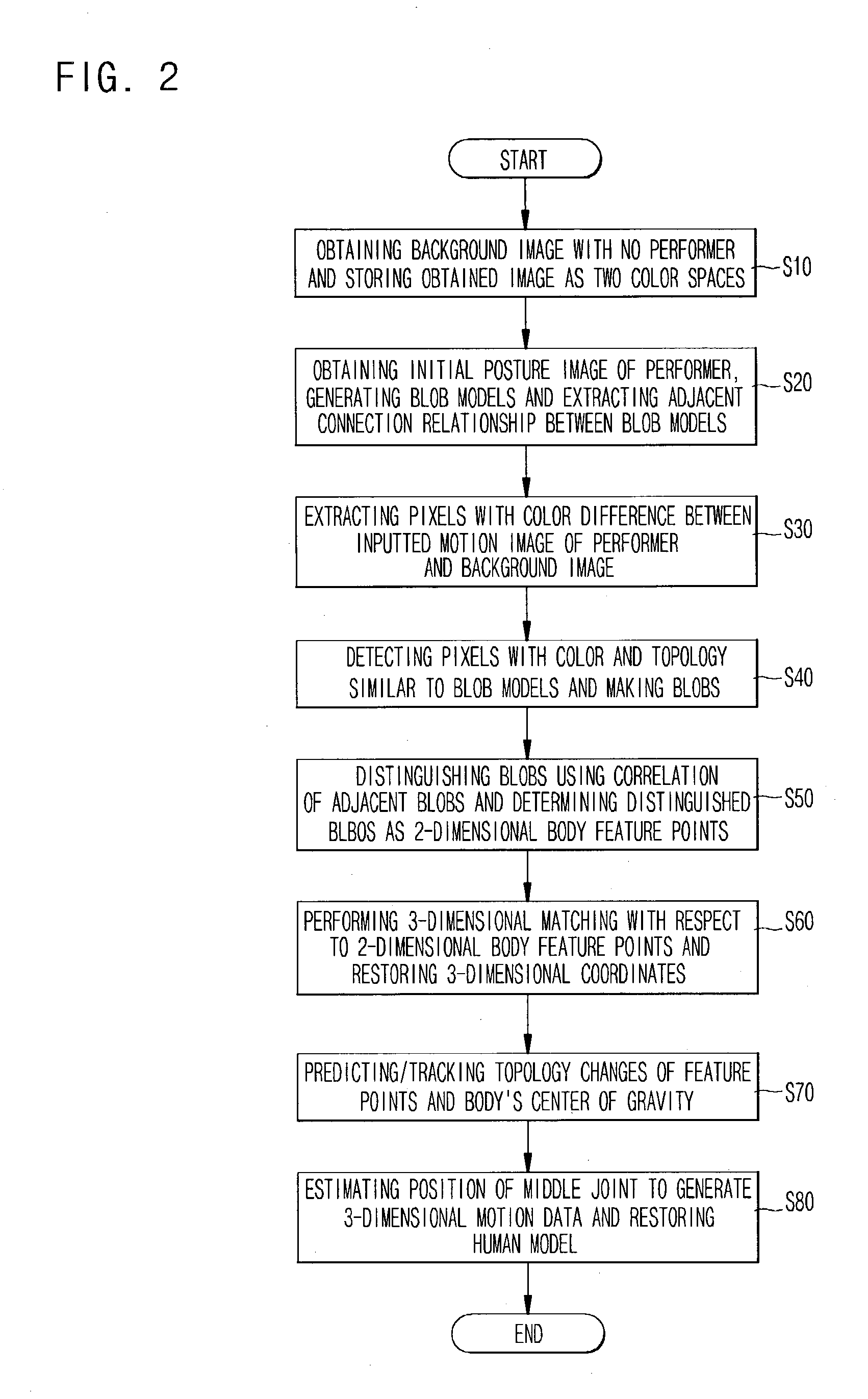

Apparatus and method for high-speed marker-free motion capture

InactiveUS7239718B2Stable trackingEasily color differenceImage enhancementImage analysisComputer graphics (images)Three-dimensional space

A high-speed marker-free motion capture, which is capable of powerfully detecting a body's feature points corresponding to a body's end portions such as a head, hands, feet, trunk, arms and legs at a high speed in an illumination change or background or noises of cameras. The extracted feature points of the body can be directly tracked stably in a 3-dimensional space. The position errors of the feature points due to the change of the illumination conditions or a shadow can be automatically corrected and the feature points can be stably tracked with respect to overlapping and disappearance of the feature points. Further, when coordinates of the middle joints are estimated using 3-dimensional coordinates of the extracted feature points of the body, the present invention restores a human model by estimating the positions of the middle joints of the actor with high accuracy without using a motion database, thereby securing the stability and reality of the 3-dimensional motion data required in the motion capture.

Owner:ELECTRONICS & TELECOMM RES INST

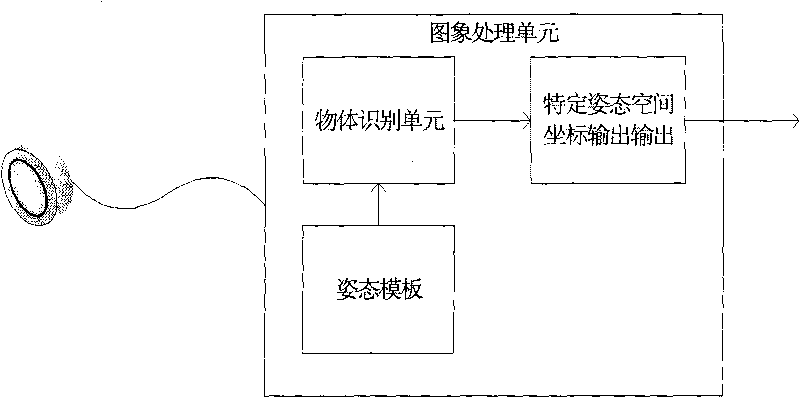

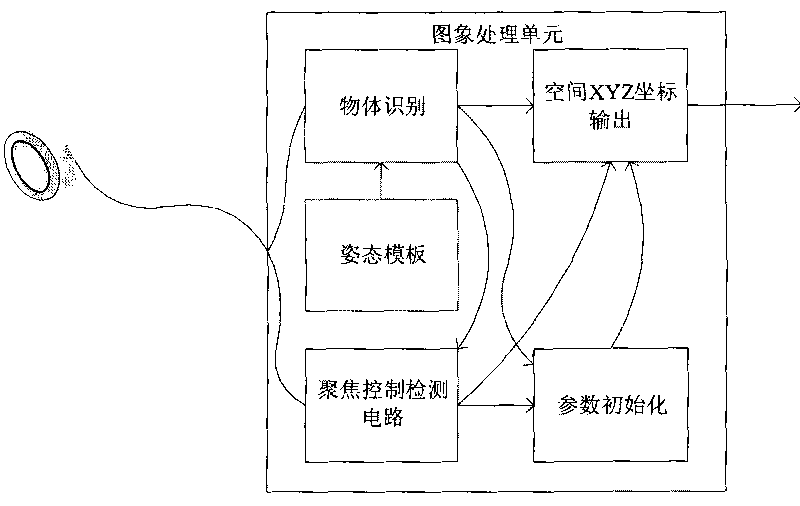

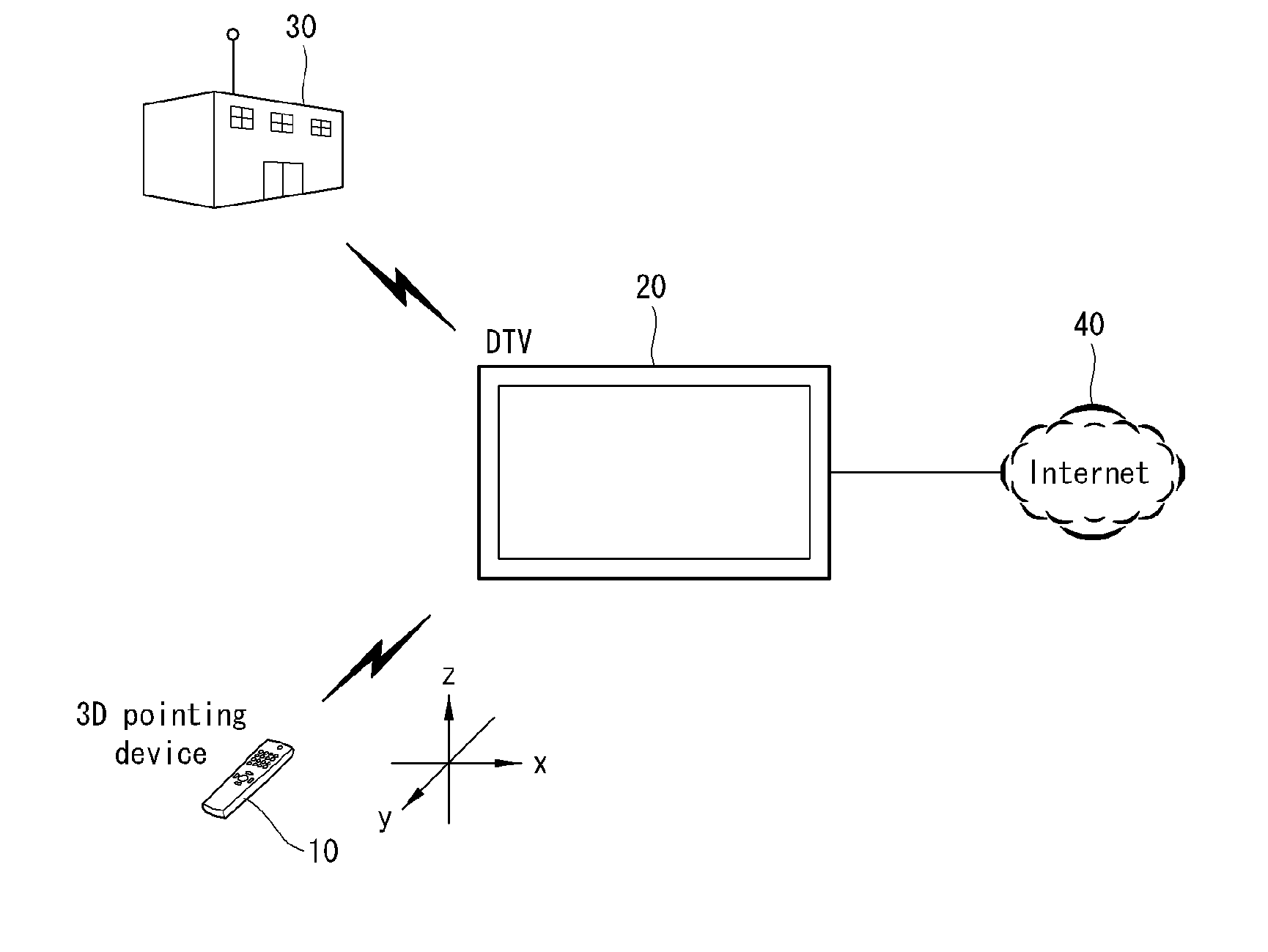

Remote control method for television and system for remotely controlling television by same

ActiveCN101729808ASimple and user-friendly remote control operationAdd entertainment functionTelevision system detailsColor television detailsOperational systemRemote control

The invention discloses a remote control method for a television and a system for remotely controlling the television by same. The remote control method for the television is characterized by comprising the following steps: giving a specific gesture to a camera by an operator; transmitting the acquired specific gesture by the camera to a three-dimensional motion recognition module in the television for the three-dimensional motion and gesture recognition; acquiring three-dimensional motion coordinates of the specific gesture by the module, and outputting a control signal; executing corresponding programs according to the control signal by an executing device in the television. By utilizing the remote control method for the television, the remote control operation on the television can be performed by the gesture; and the remote control operation on the television becomes simpler and more humanized by means of a corresponding remote control operation system. In particular, the recreation functions which can be realized on a computer originally can be finished on the television without a mouse, a keyboard and other peripheral equipment of the computer based on the platform.

Owner:TCL CORPORATION

Golf swing analysis apparatus and method

A method and integrated golf club apparatus for directly measuring physical parameters of the golf club head motional acceleration swing forces, golf club head face, golf ball impact forces, and subsequent calculations of other metrics useful to a golfer's understanding of the effectiveness of his or her golf swing and impact result in totality. The physical parameters that are directly measured include three dimensional motion force vectors of club head prior to, during and after impact and full impact pressure force profiles across the golf clubface with respect to time. The sensors are connected to electronics which condition, record and store the time varying sensors information electronically, then process and translate the information into one of several forms for delivery to a human interface function.

Owner:GOLF IMPACT

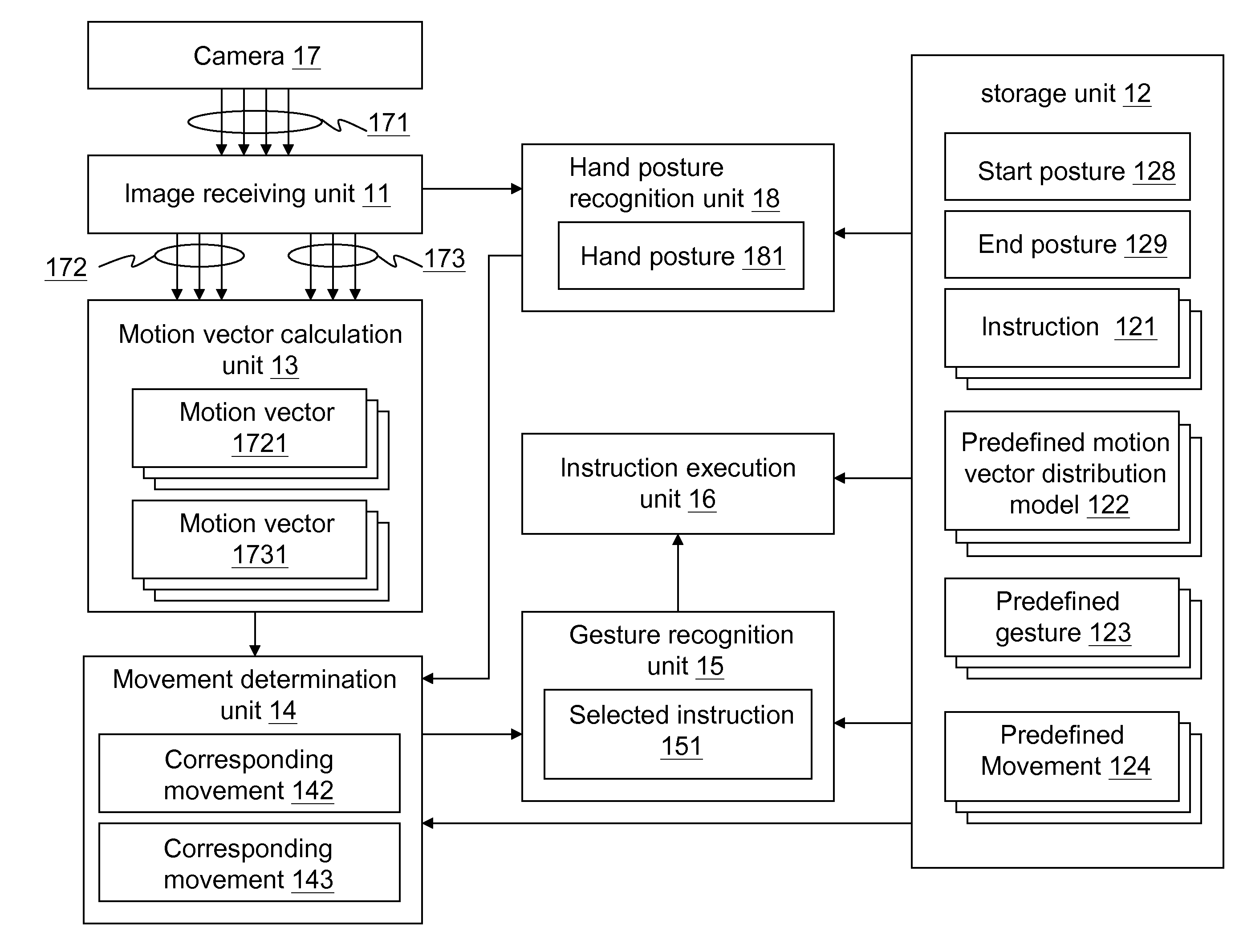

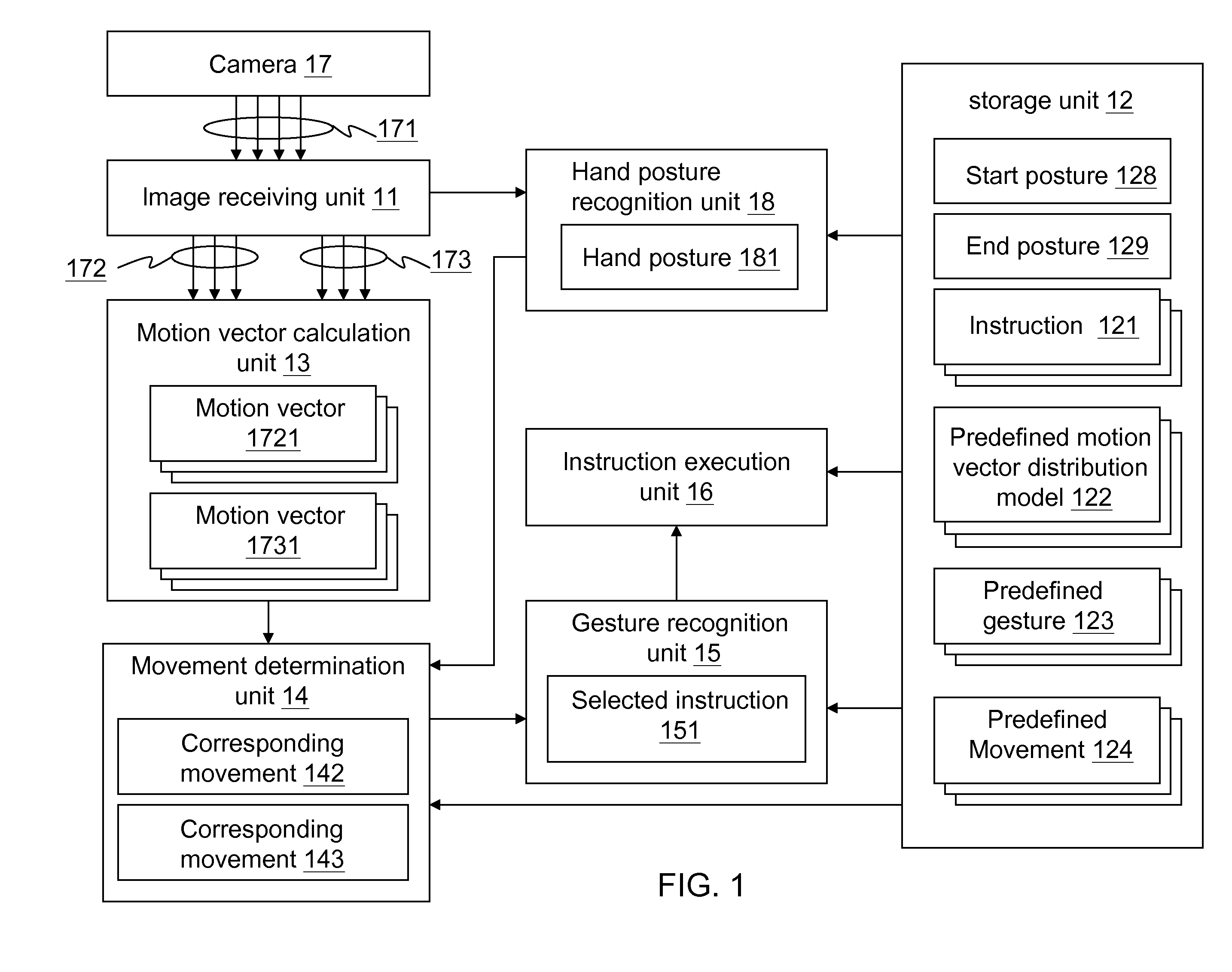

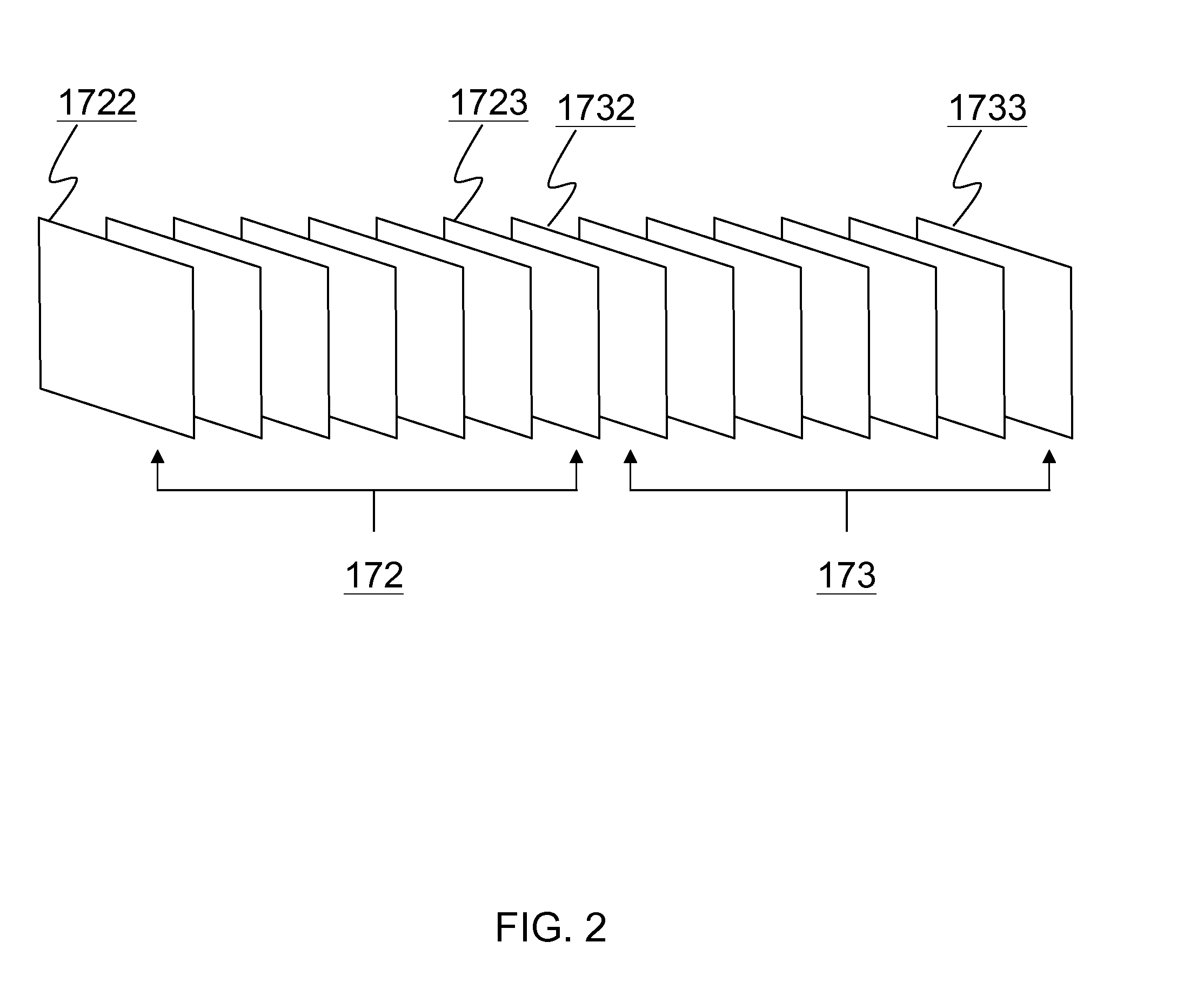

Vision-based hand movement recognition system and method thereof

InactiveUS20110299737A1Improve gesture recognition accuracyCharacter and pattern recognitionInput/output processes for data processingHand movementsMotion vector

A vision-based hand movement recognition system and method thereof are disclosed. In embodiment, a hand posture is recognized according to consecutive hand images first. If the hand posture matches a start posture, the system then separates the consecutive hand images into multiple image groups and calculates motion vectors of these image groups. The distributions of these motion vectors are compared with multiple three-dimensional motion vector histogram equalizations to determine a corresponding movement for each image group. For example, the corresponding movement can be a left moving action, a right moving action, an up moving action or a down moving action. Finally, the combination of these corresponding movements is defined as a gesture, and an instruction mapped to this gesture is then executed.

Owner:ACER INC

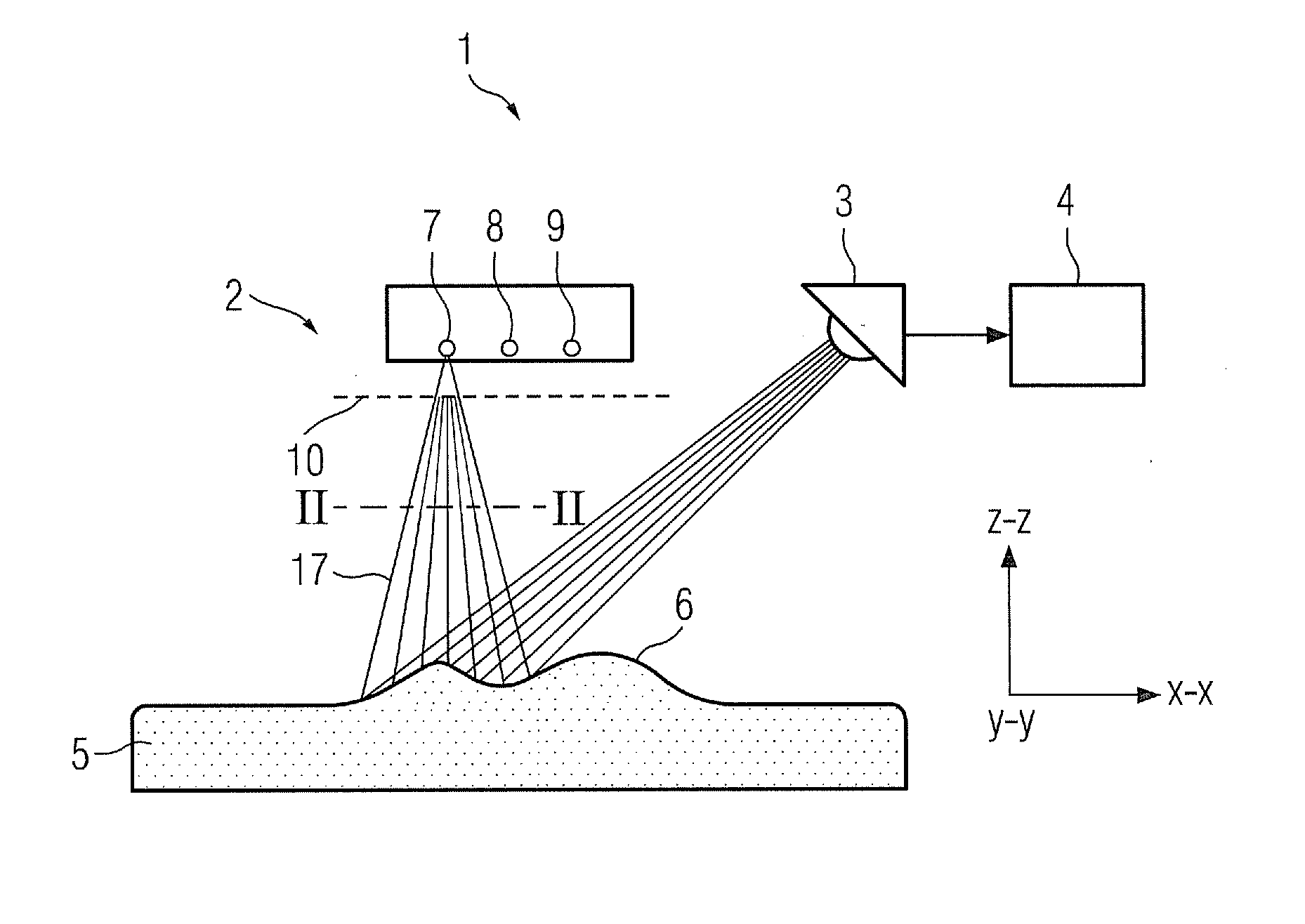

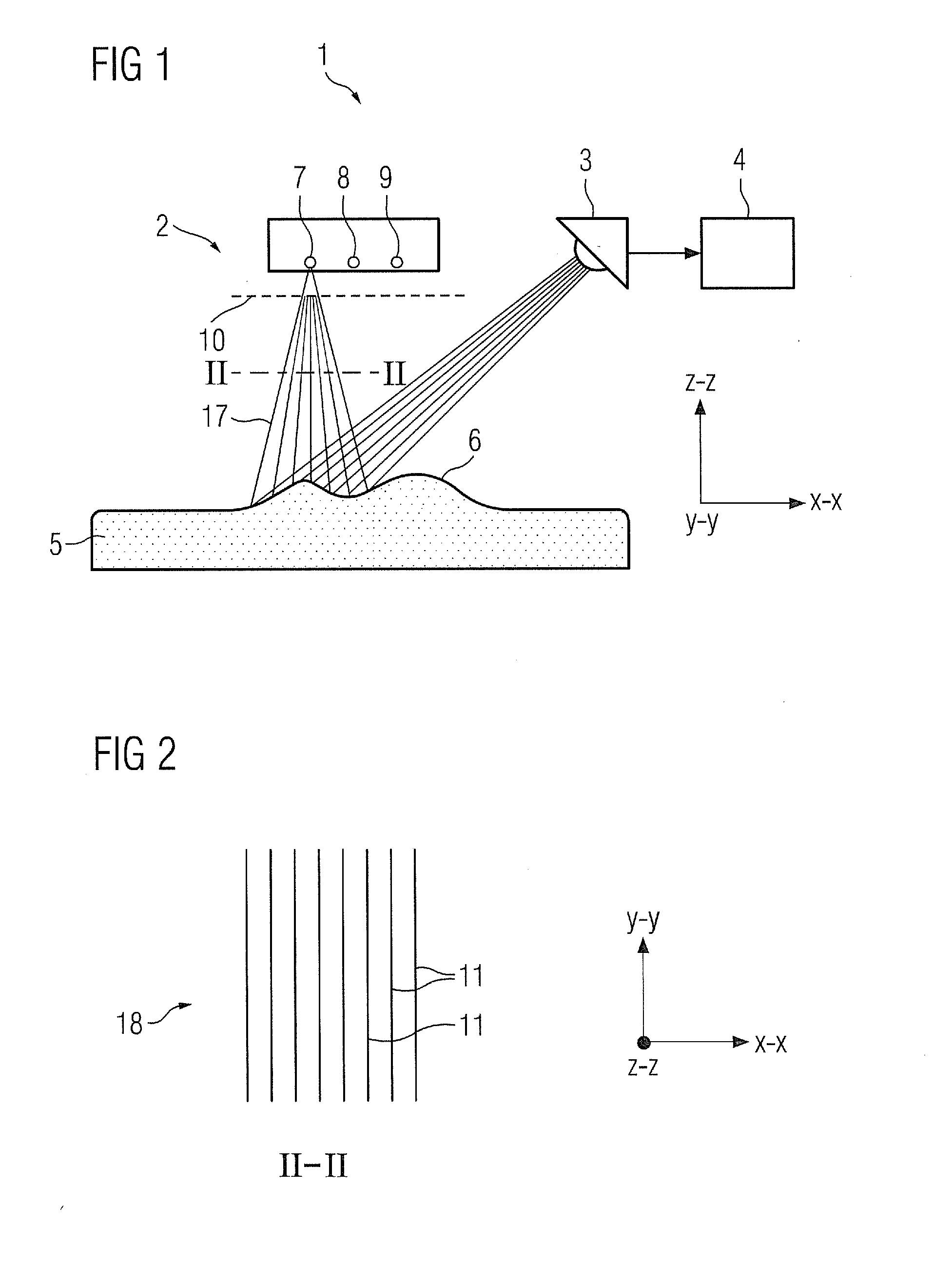

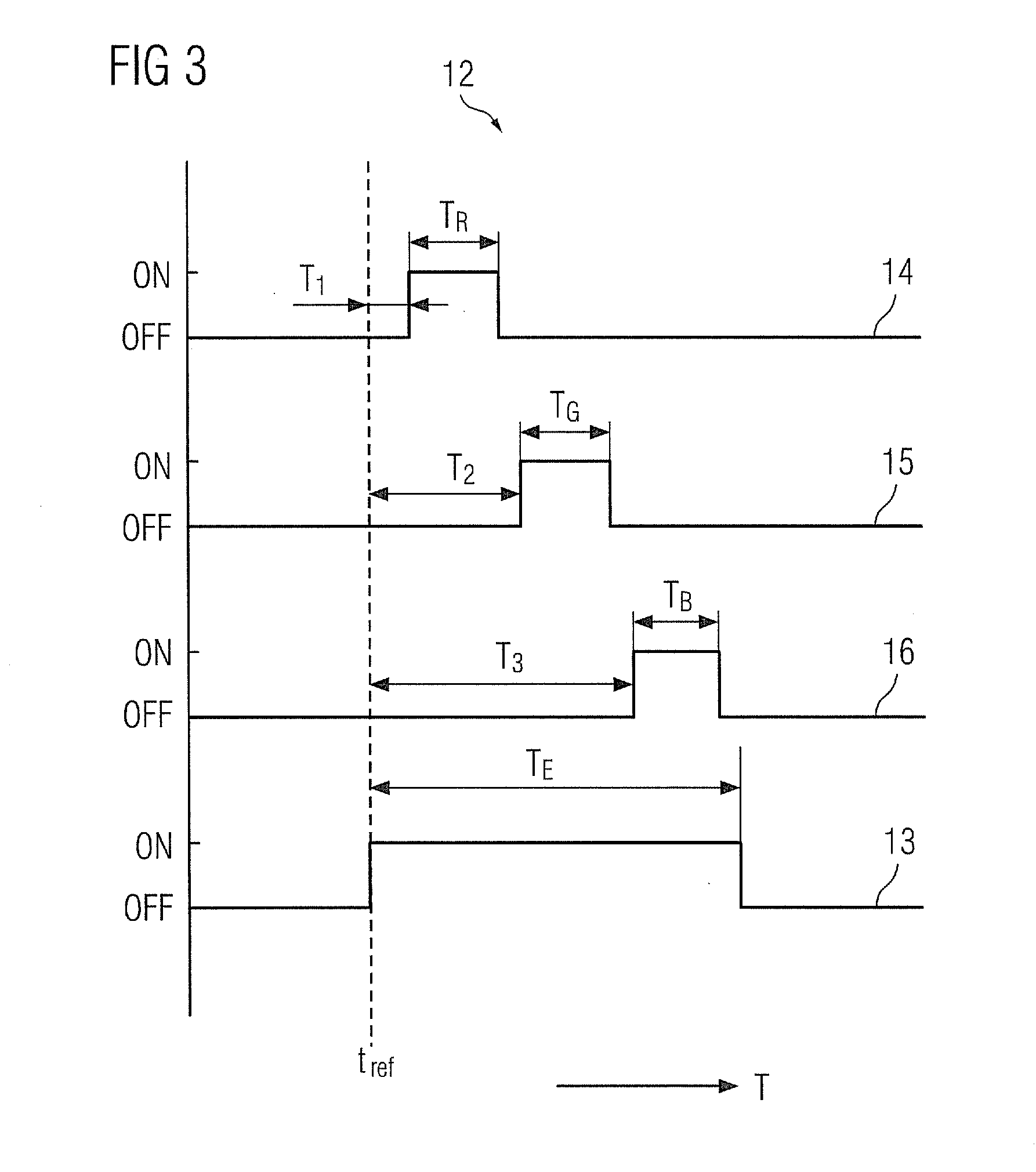

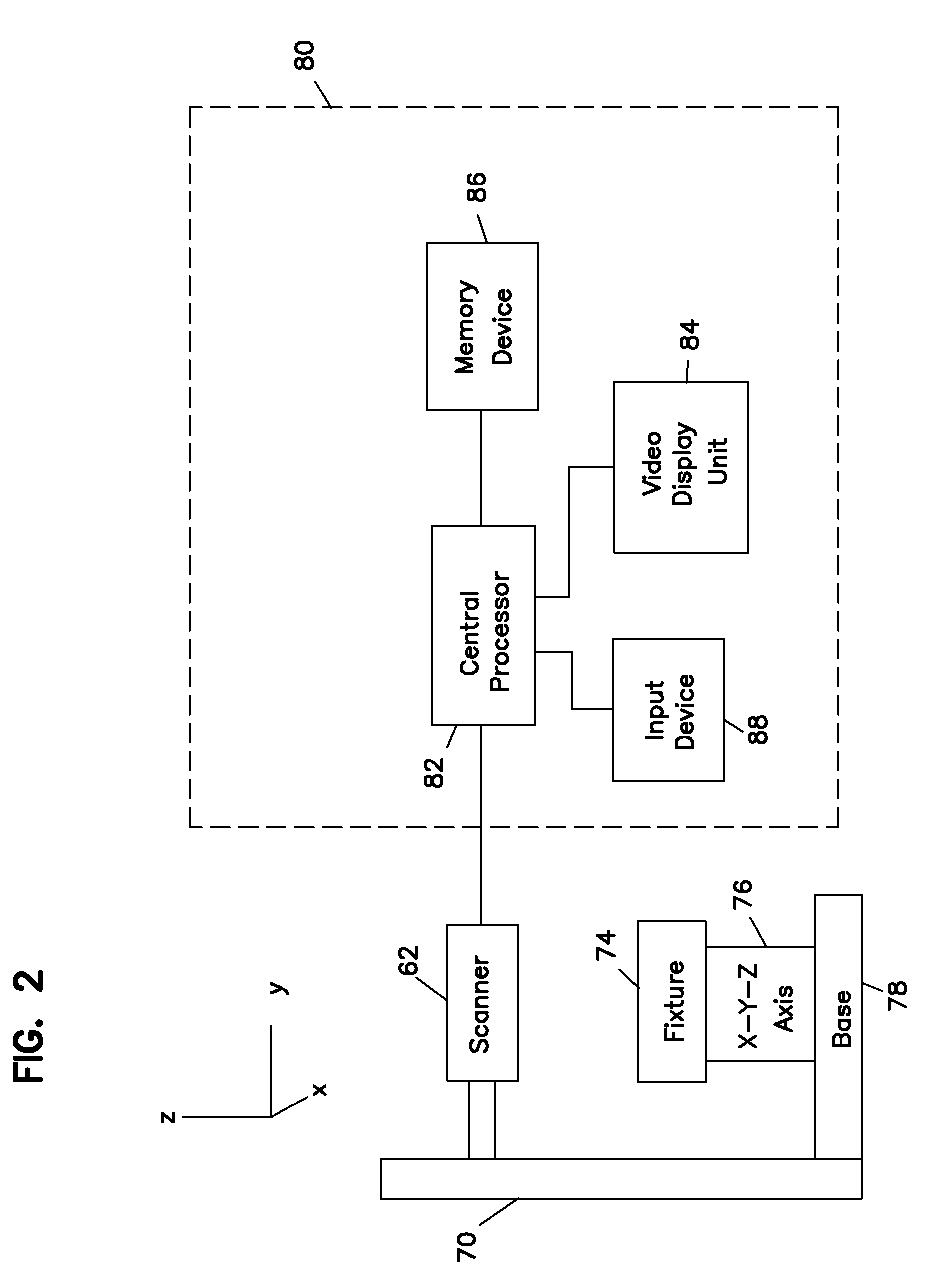

Measurement of three-dimensional motion characteristics

InactiveUS20110249864A1Increase speedAccurate captureSubsonic/sonic/ultrasonic wave measurementCharacter and pattern recognitionObject basedImaging processing

A system for measurement of three-dimensional motion of an object is provided. The system includes a light projection means adapted for projecting, for distinct time intervals, light of at least two different colors with a cross-sectional pattern of fringe lines onto a surface of the object and also includes image acquisition means for capturing an image of the object during an exposure time, wherein the distinct time intervals are within the duration of the exposure time. The system further includes image processing means adapted for processing the image to obtain a different depth map for each color based on a projected pattern of fringe lines on the object as viewed from the position of the image acquisition means, to determine corresponding points on the depth maps of each color, and to determine a three-dimensional motion characteristic of the object based on the positions of corresponding points on the depth maps.

Owner:SIEMENS AG

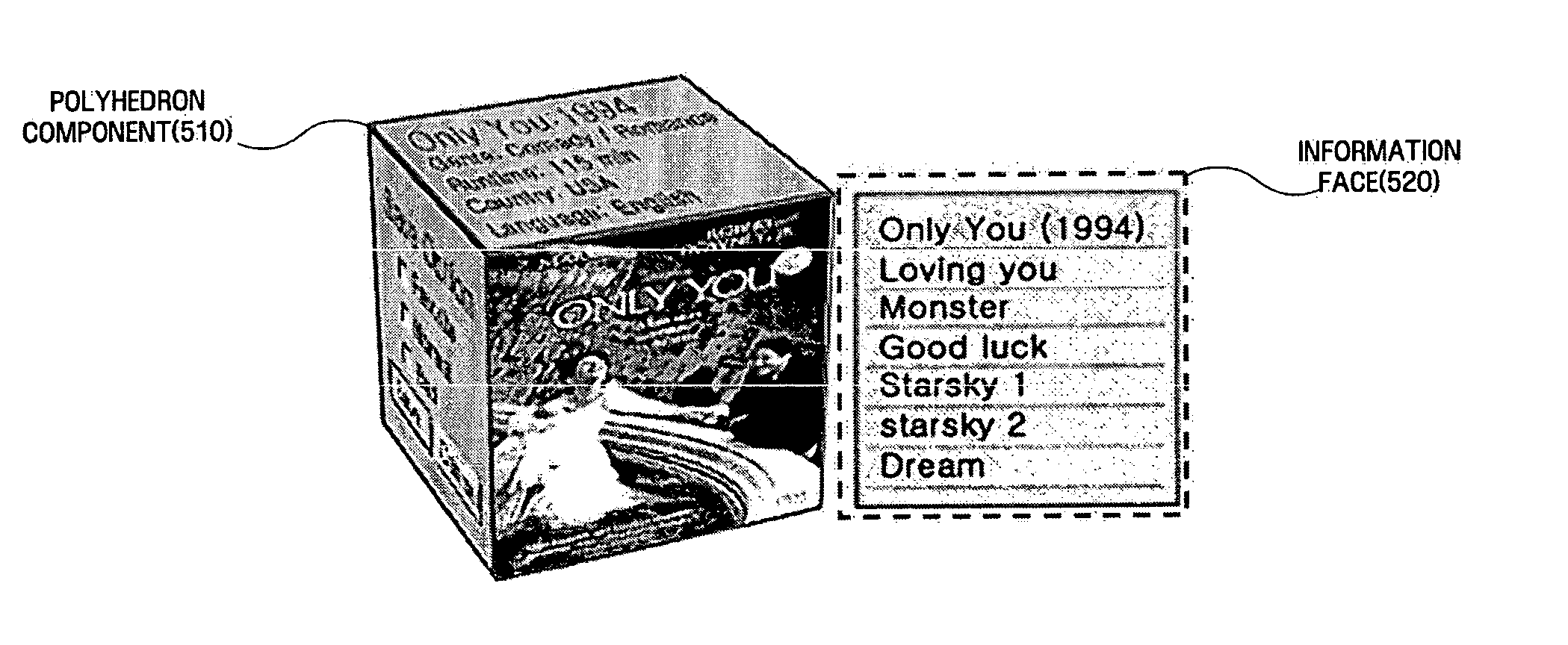

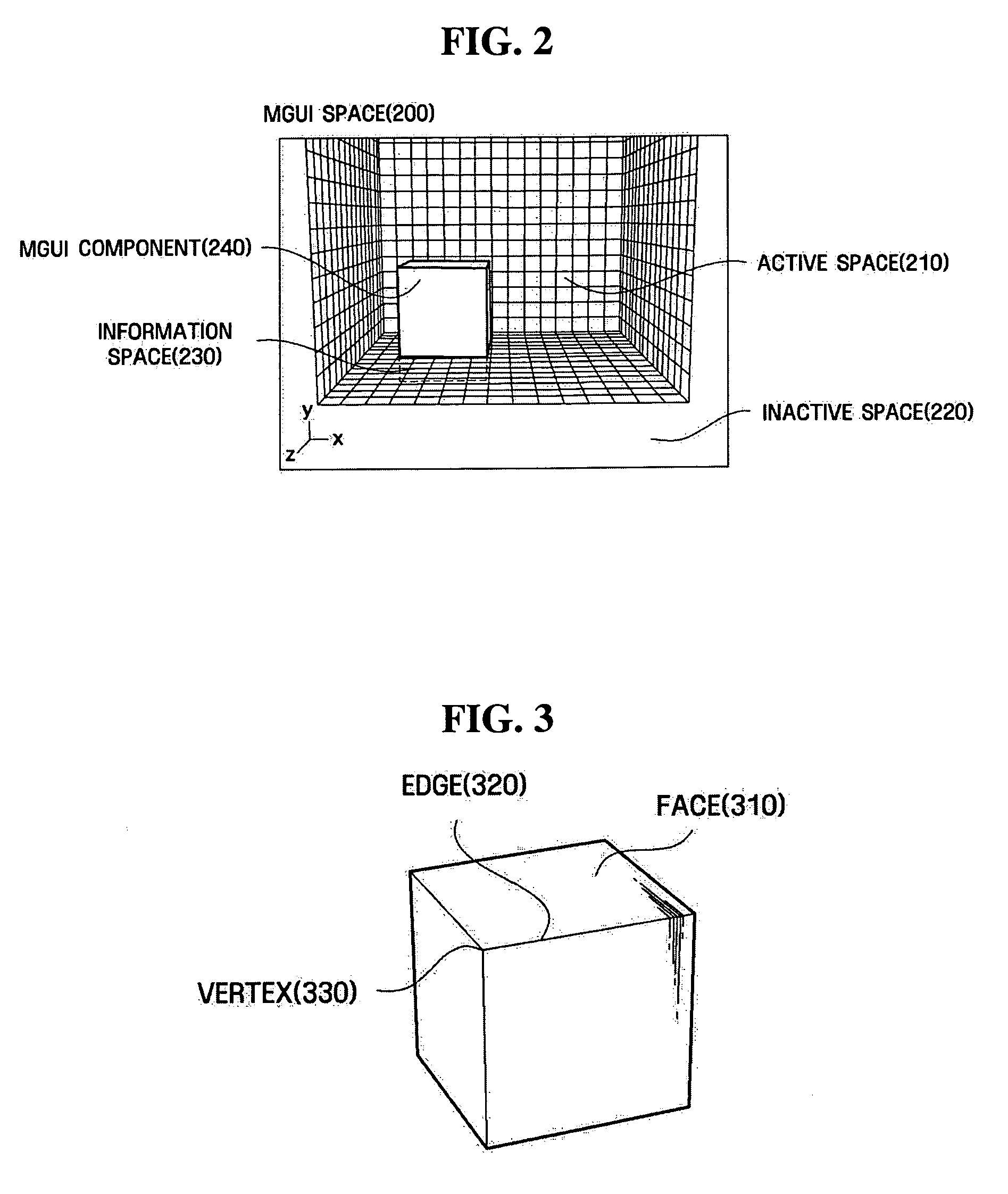

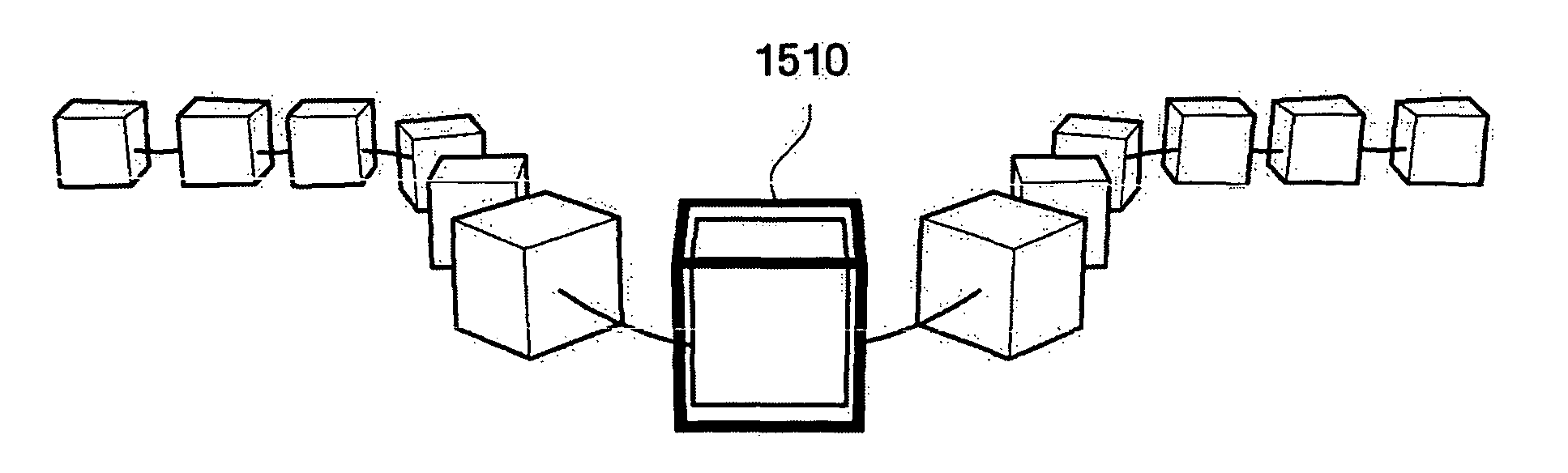

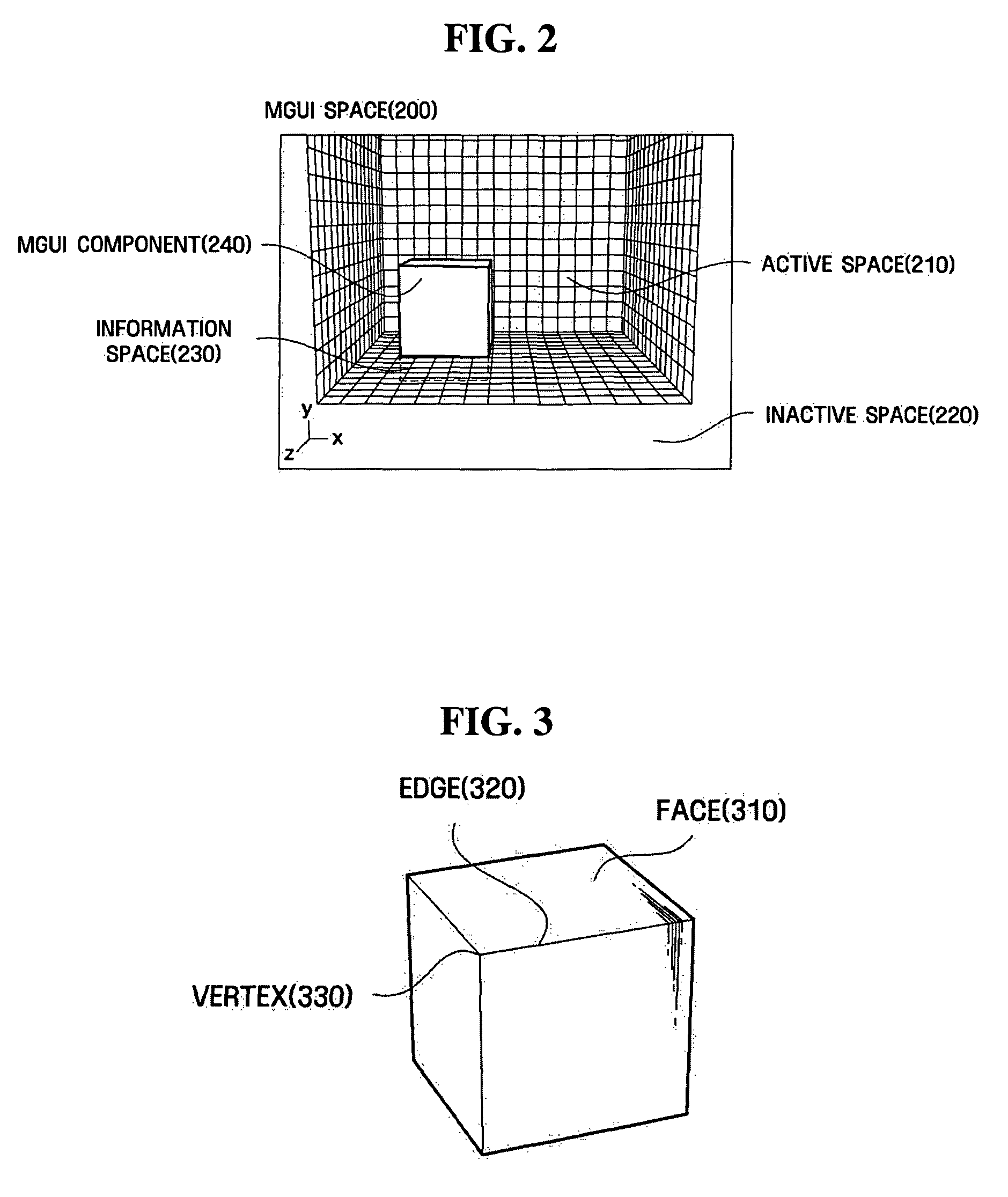

Three-dimensional motion graphic user interface and method and apparatus for providing the same

InactiveUS20060020898A1Reduce errorsClear messageInput/output processes for data processingGraphicsThree dimensional motion

A three-dimensional motion graphic user interface (MGUI) and a method and apparatus for providing the same. The MGUI includes a three-dimensional interface space which has an active space and an inactive space, and a polyhedron component which is three-dimensionally presented in the active space, wherein at least one of a plurality of faces that are subject to the polyhedron component has predetermined attributes, and information displayed on the faces is displayed differently according to the attributes and a presentation relationship between the active space and the polyhedron component.

Owner:SAMSUNG ELECTRONICS CO LTD

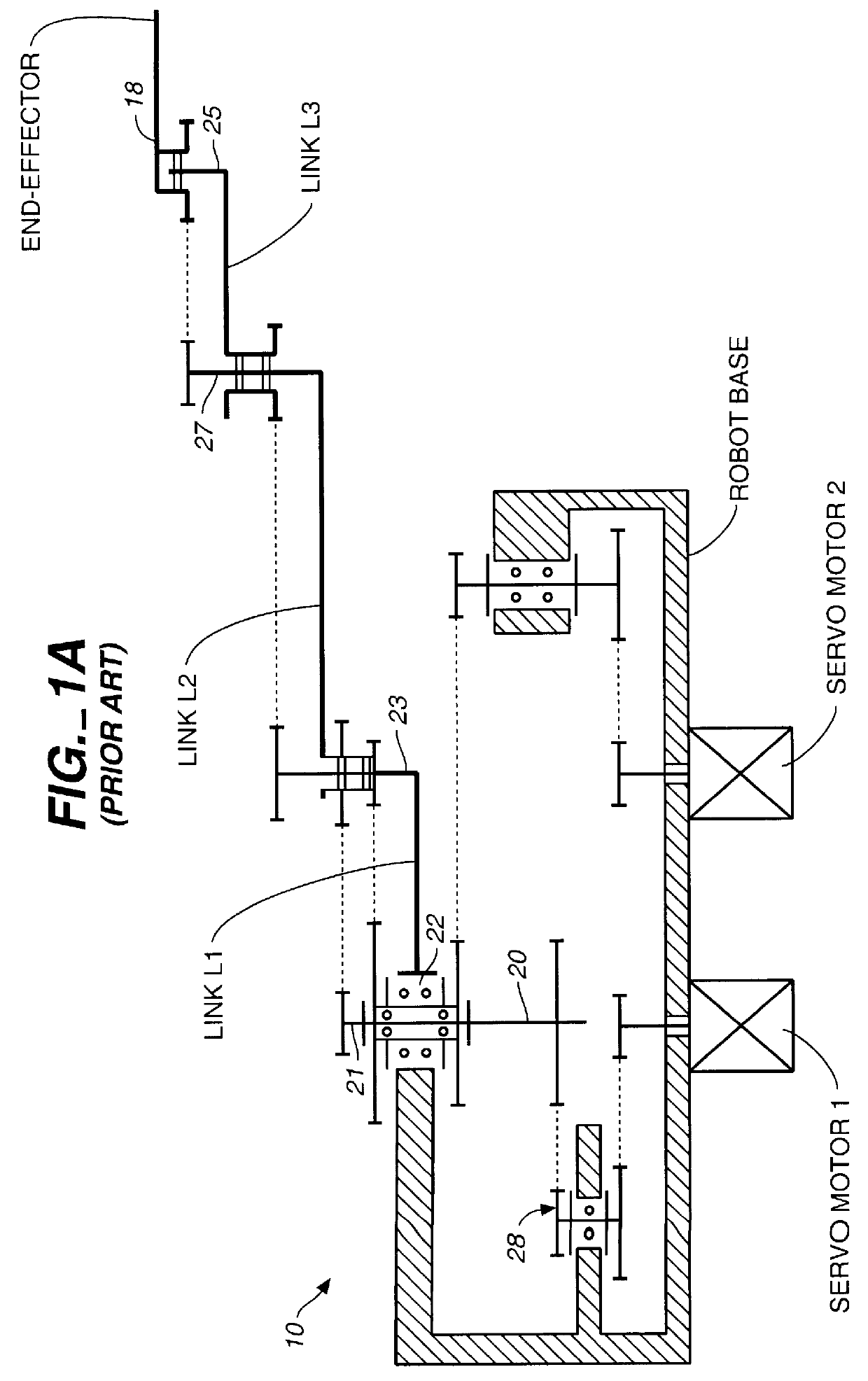

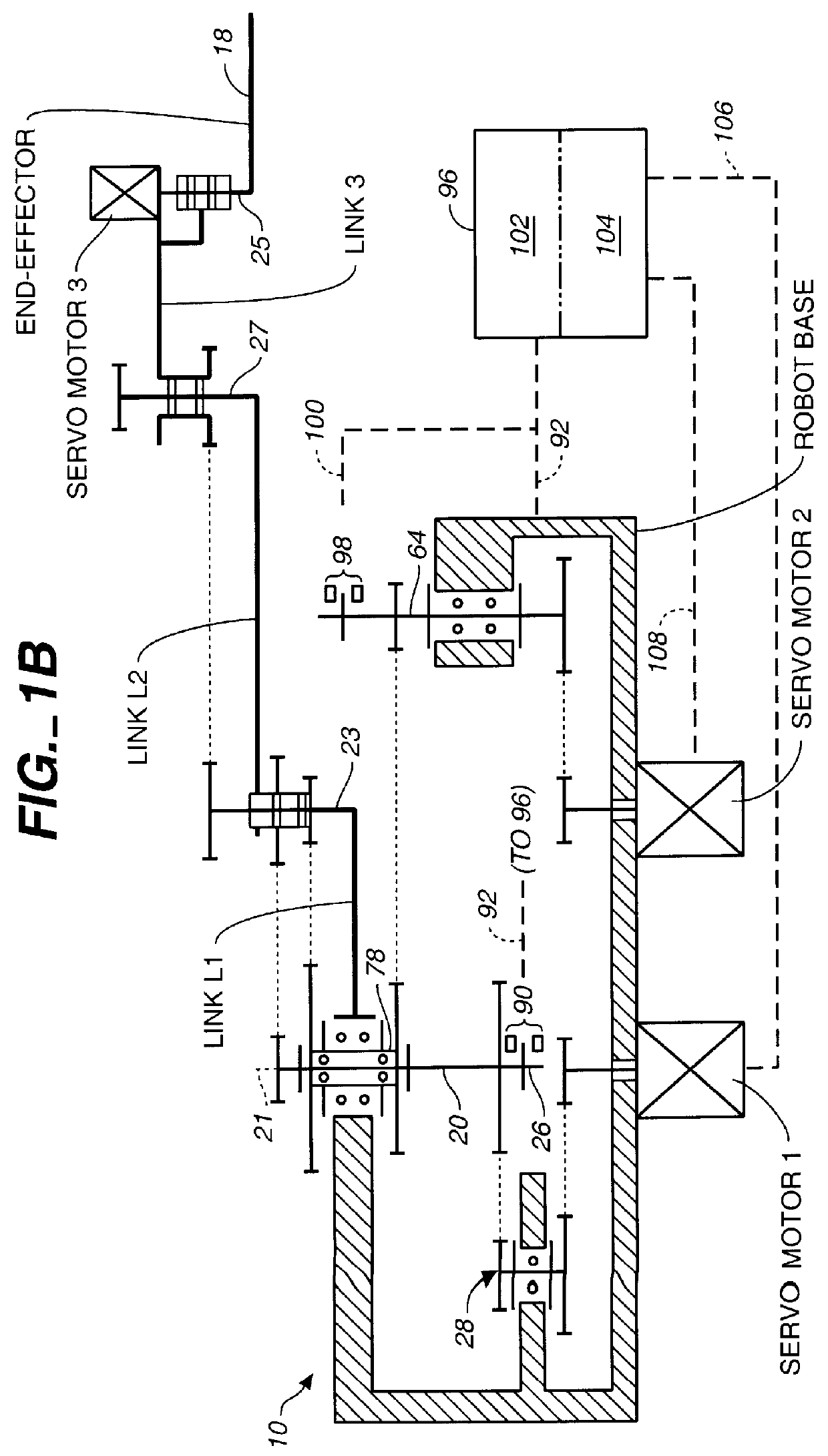

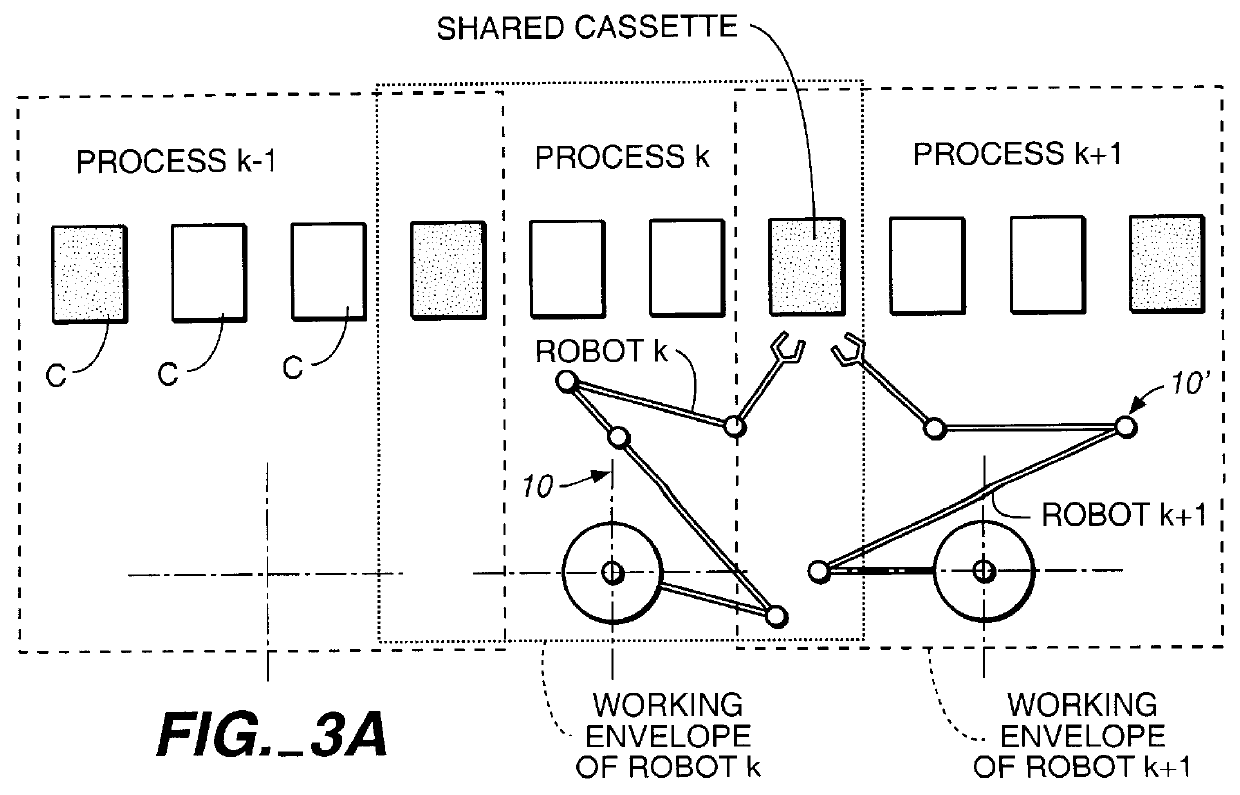

Robot having multiple degrees of freedom

InactiveUS6037733ASmooth and fast waferSmooth and fast and flat panel handlingProgramme-controlled manipulatorData processing applicationsSensor arrayRobotic arm

An improvement is set forth in a robotic arm structure which includes at least two links. theta motion is provided about a primary axis at the proximal end portion of the proximalmost of the links. R motion proceeds radially from the primary axis whereby the distal end portion of the distalmost of the links can be moved in a radially extending straight line. An end effector is pivotally mounted for rotation relative to the distal end portion of the distalmost link about an end effector axis which is parallel to the primary axis. The structure is improved by adding one or more a yaw motor, a roll motor and a pitch motor for rotating the wrist of the arm about the respective axes. A sensor array senses the R, theta , Z and yaw, roll and / or pitch motions and creates and transmits electronic signals representative thereof to a computer controller which monitors and controls the R, theta , Z and yaw, roll and / or pitch motions. Non-radial straight line motion and indeed, in certain embodiments any desired three-dimensional motion, is thereby enabled as is picking up of workpieces such as semiconductor wafers, flat panel displays and data storage disks, which are misaligned in cassettes or at workstations and / or are in cassettes which are misaligned and / or aligned and set up at an angle relative to the usual plane of operation of the arm.

Owner:GENMARK AUTOMATION

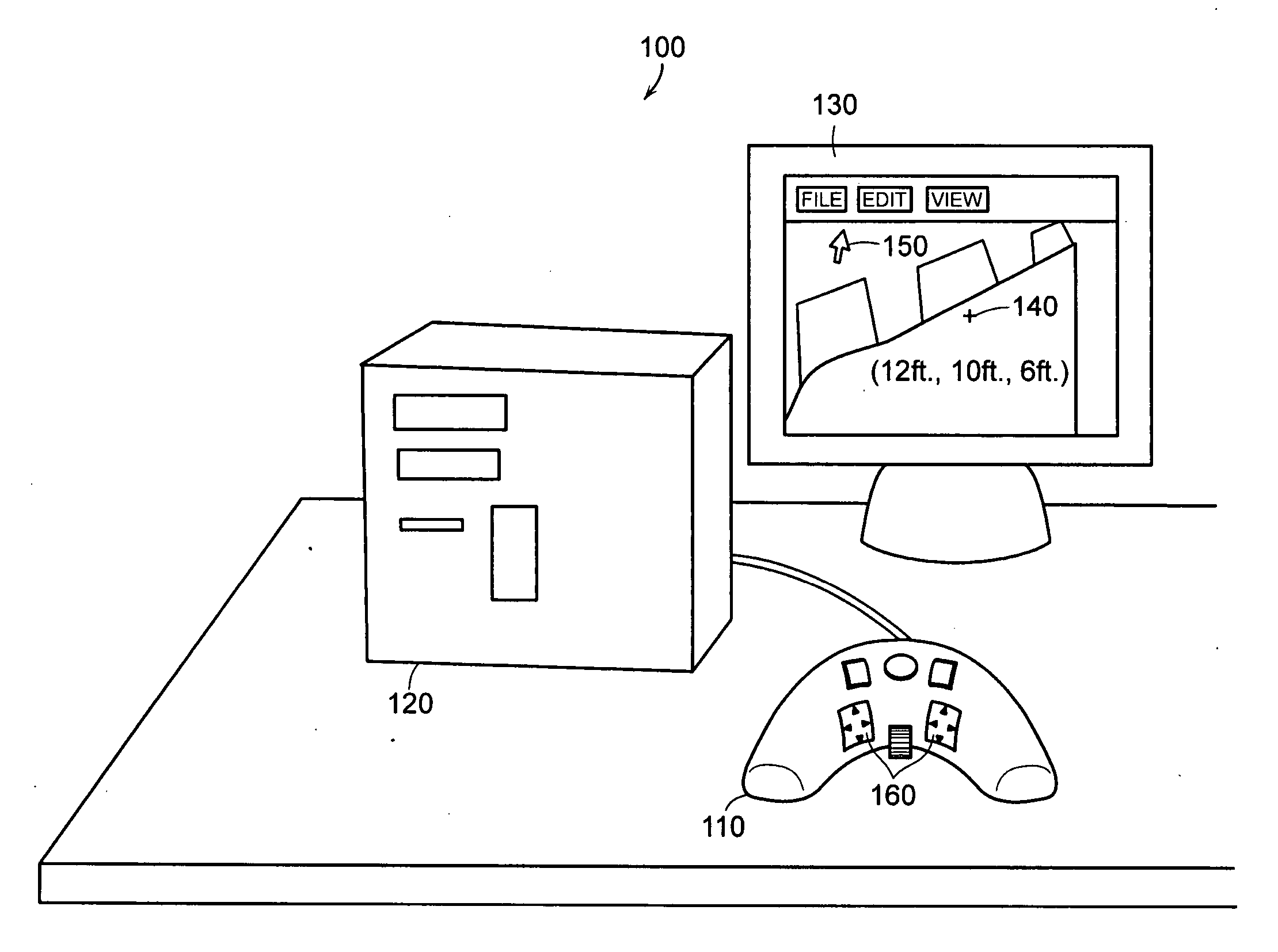

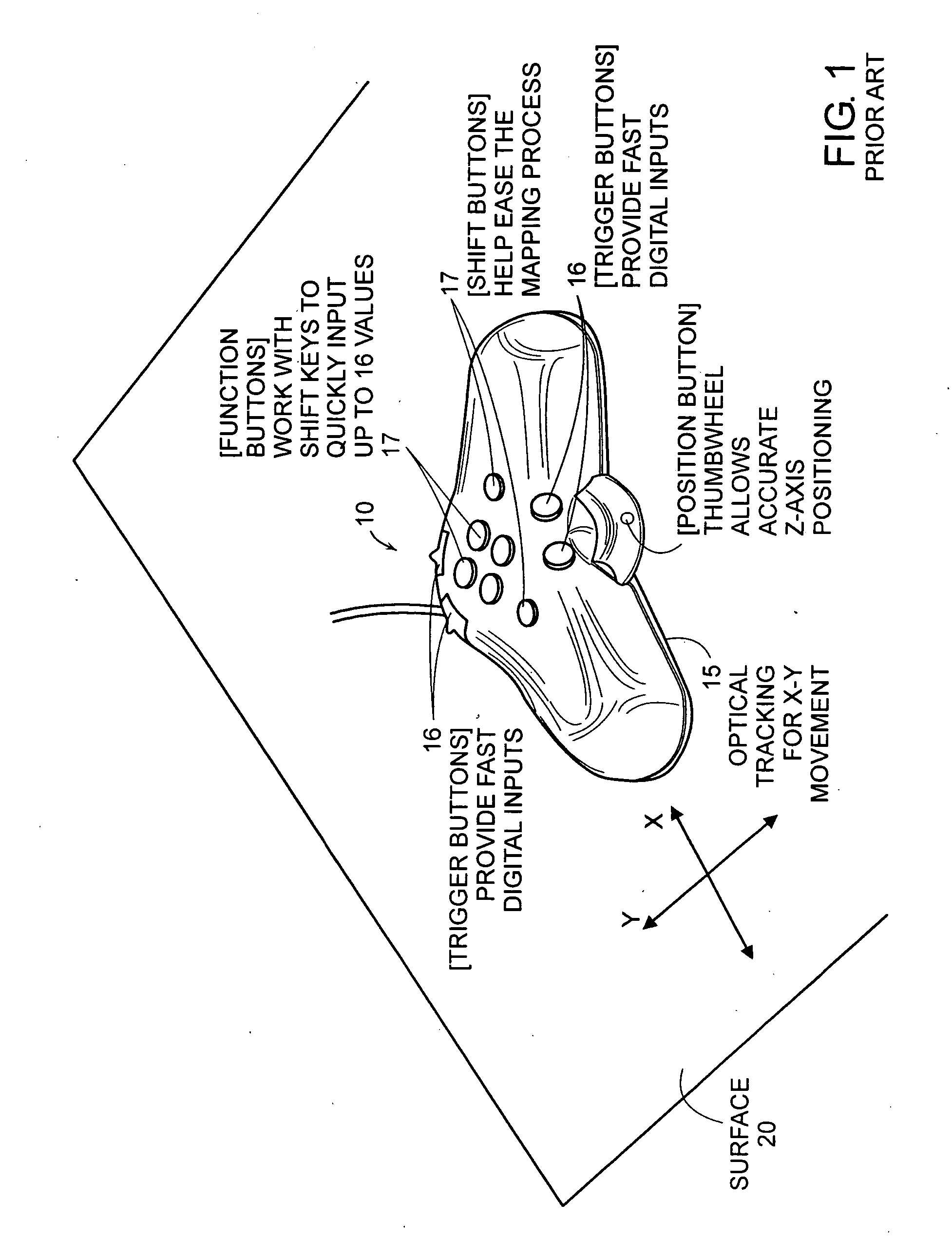

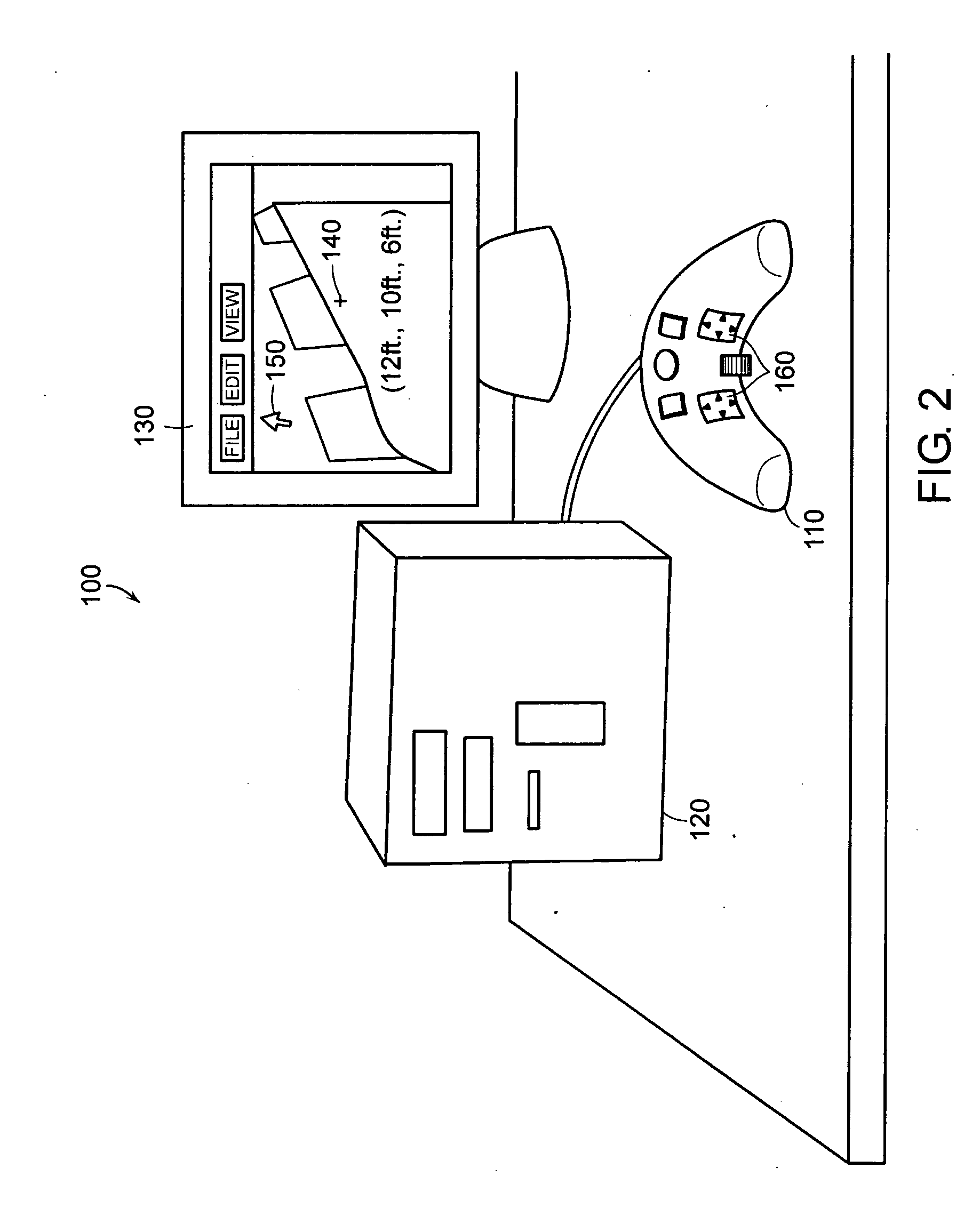

Input device for controlling movement in a three-dimensional virtual environment

InactiveUS20060090022A1Relieve pressureReduce carpal-tunnel syndromeInput/output processes for data processingJoystickVirtual space

A user-controlled input device for use with a computer system is disclosed. The user controlled input device controls at least three-dimensional movement in a three-dimensional virtual space defined by a three axis coordinate system. The device includes a controller body and at least a pressure controlled button joystick coupled to the controller body. Displacement of the button joystick in a first direction translates into directional movement at least about a first axis. The button joystick includes a force sensor wherein an output signal is produced by the button joystick that is proportional to the force placed on the button joystick. The output signal is translated by a computer program into a rate of motion that is proportional to the pressure that is supplied by the user of the input device. In certain embodiments, a second button joystick is coupled to the controller body to control directional movement about a second and a third axis. In such an embodiment, each edge of the force controller controls movement in a different direction. For example, the user can move the cursor using only a single button in both the x and y directions in a three-dimensional virtual space (x,y,z).

Owner:INTERGRAPH HARDWARE TECH

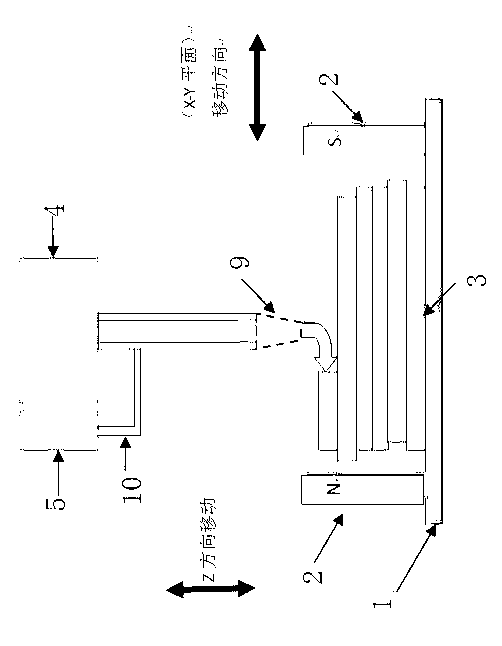

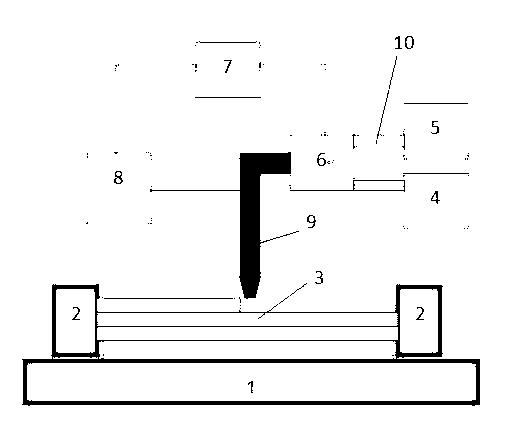

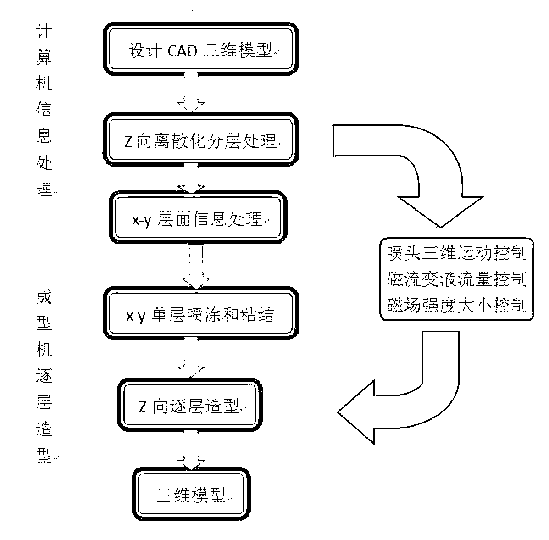

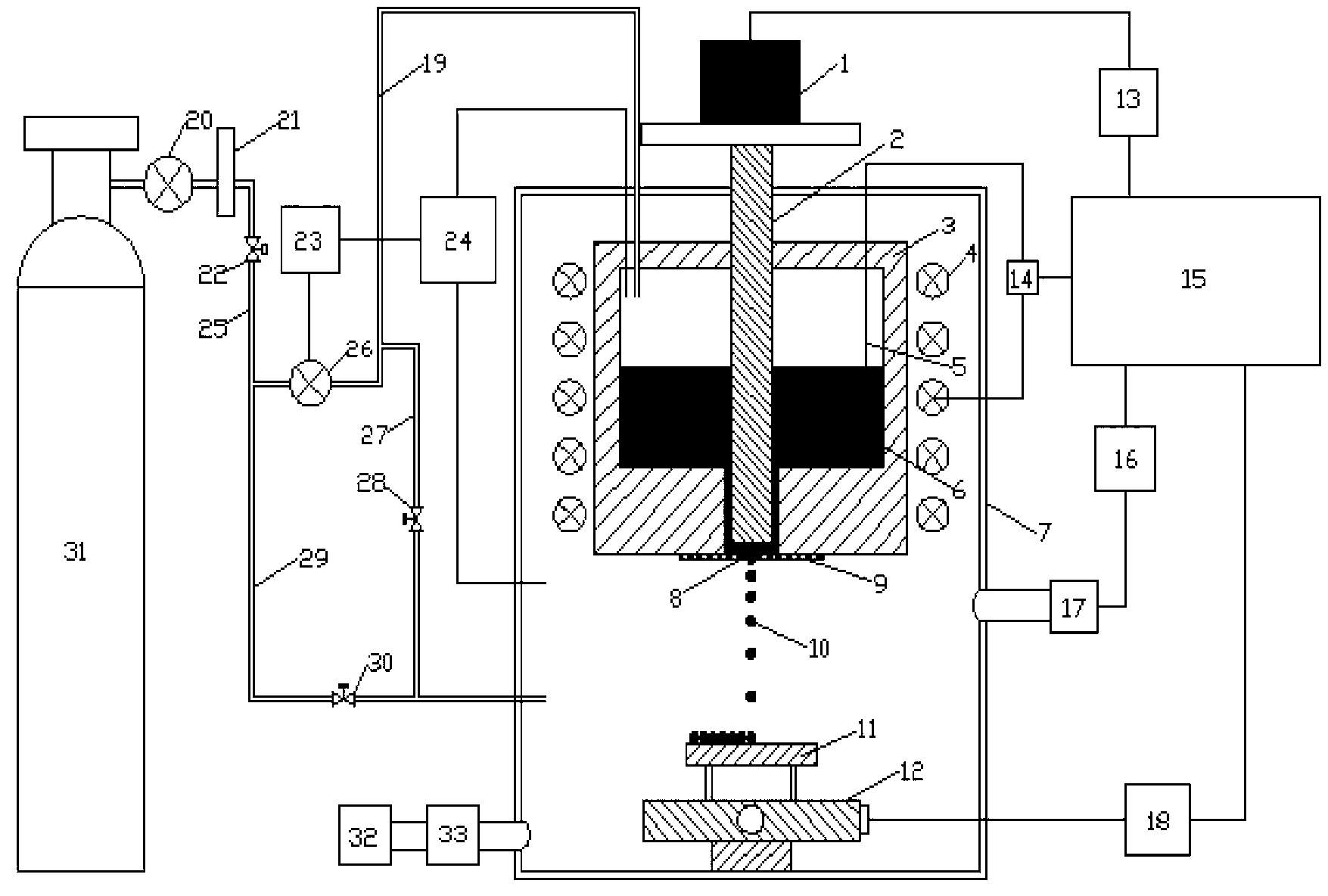

Magnetorheological-material-based 3D (Three-Dimensional) printing type rapid prototyping device and method

The invention relates to a magnetorheological-material-based 3D (Three-Dimensional) printing type rapid prototyping method and device. According to the principle of magnetorheological effect, a magnetorheological material is used as a 3D printing raw material; and a 3D solid model is constructed by spraying the magnetorheological material on a workbench with a magnetic field, rapidly solidifying and prototyping the sprayed magnetorheological material, and then depositing the treated material layer by layer. A computer is provided with three control circuits; one circuit is used for controlling the flow of a driving pump, namely the flow at a spray head; another circuit is used for controlling the 3D motion of the spray head through a servo mechanism; and the rest circuit is used for controlling colour mixing and allocating of a colourized ink box. The magnetorheological material is solidified and prototyped by utilizing the magnetic field generated by an electromagnet. According to the magnetorheological effect of the magnetorheological material, a temperature control module in the traditional melting, spraying and rapid prototyping type 3D printing method is replaced by the magnetic field; in addition, the device disclosed by the invention is also different from a high-pressure electric field required by an electrorheological fluid effect, has the advantages of being simple in structure, low in energy consumption and cost, capable of realizing the microminiaturization and the like, and can be applicable to the fields of process design, art and entertainment, prosthesis model and the like.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

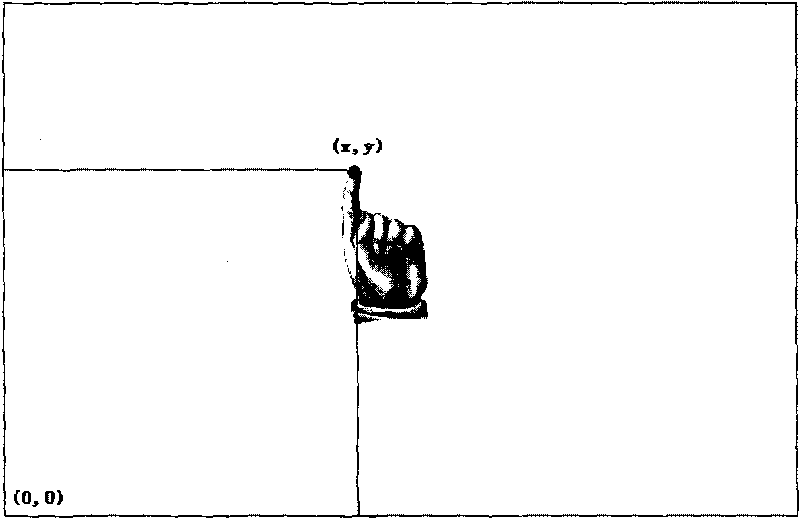

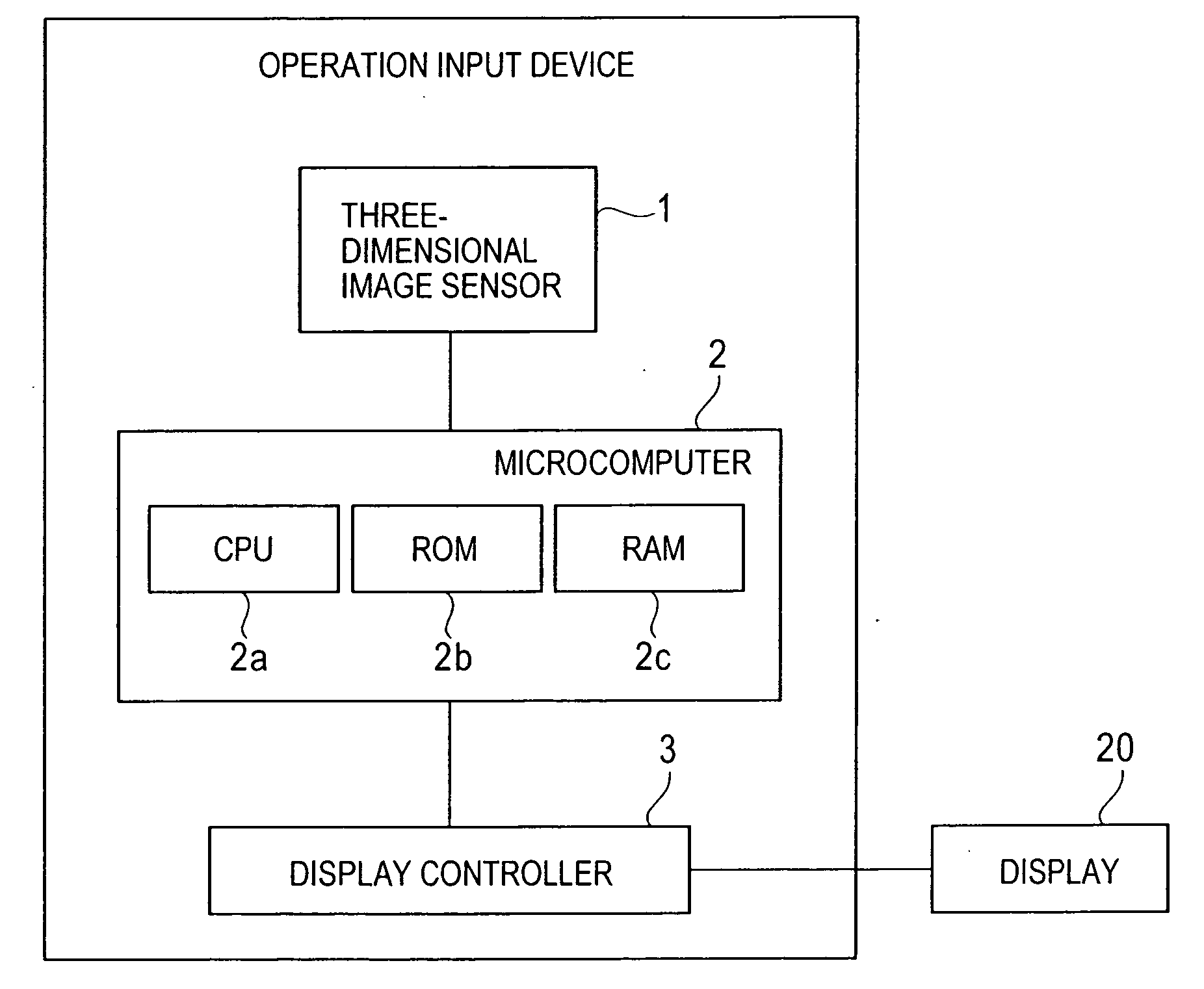

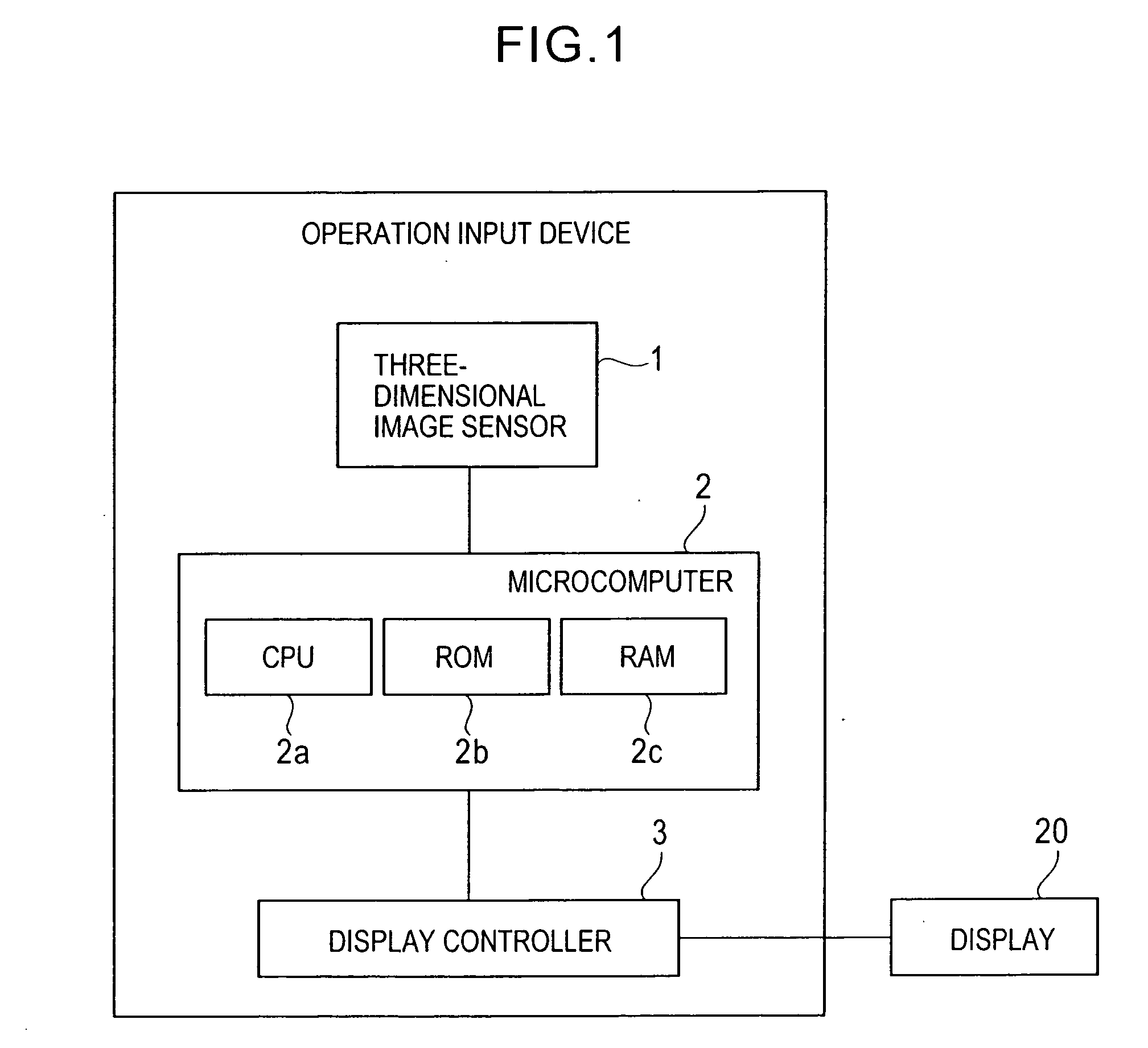

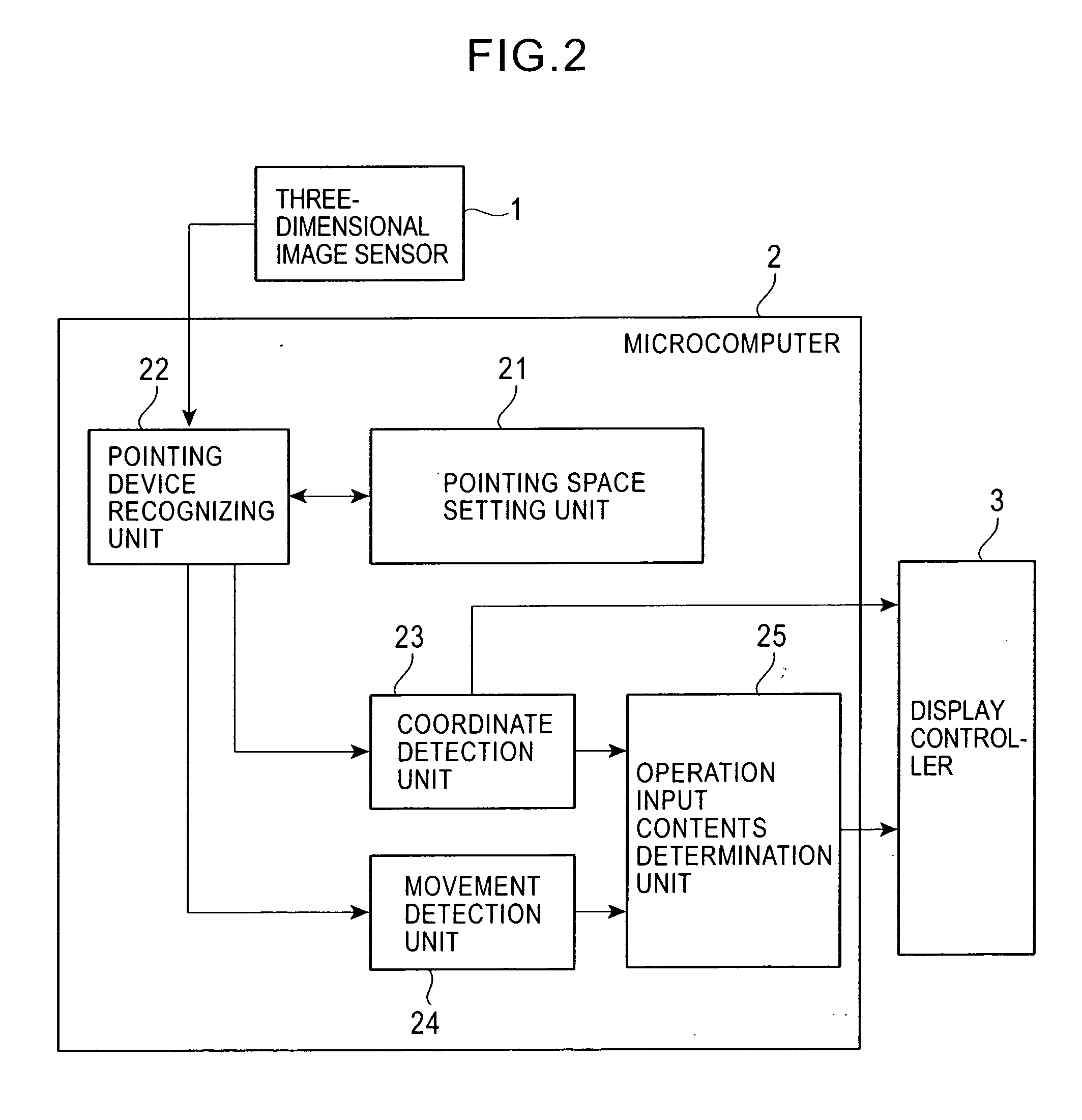

Operation input device and method of operation input

ActiveUS20050248529A1Improve usabilityInput/output for user-computer interactionCathode-ray tube indicatorsObject basedPointing device

A three-dimensional image sensor for detecting the three-dimensional position of an object, a coordinate detection unit for detecting the coordinate position of an objective point on a display screen based on the position of the object in a virtual pointing space, a movement detection unit for detecting the three-dimensional movement of the object in the pointing space, and an operation input contents determination unit for determining an operation based on the three-dimensional movement or the like of the object are provided, so that the inconvenience of moving a pointing device such as a finger to a fixed spatial plane is avoided by setting the pointing space which can be operated by the pointing device as a pyramid shape defined by connecting the display screen and a reference point.

Owner:ALPINE ELECTRONICS INC

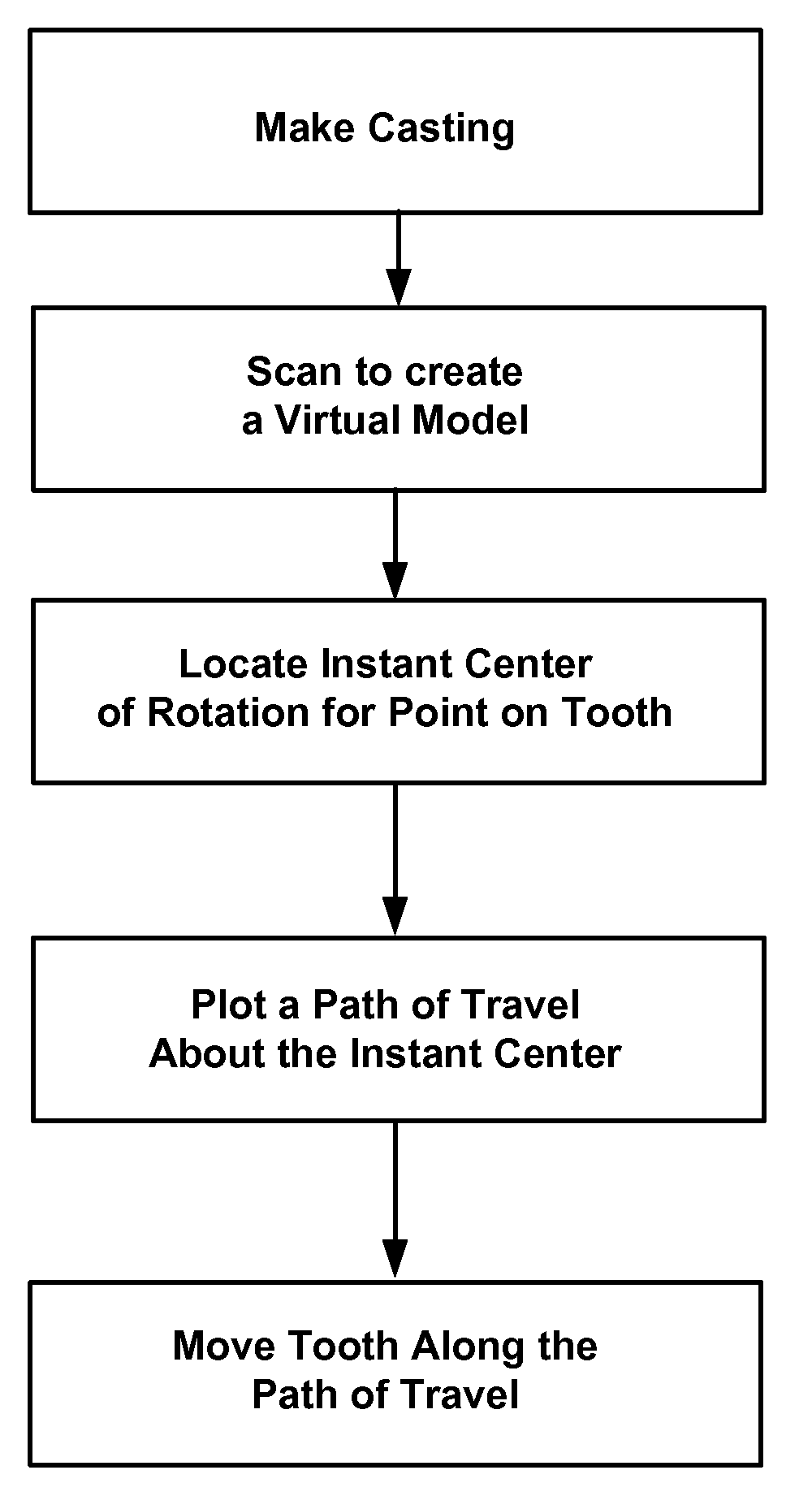

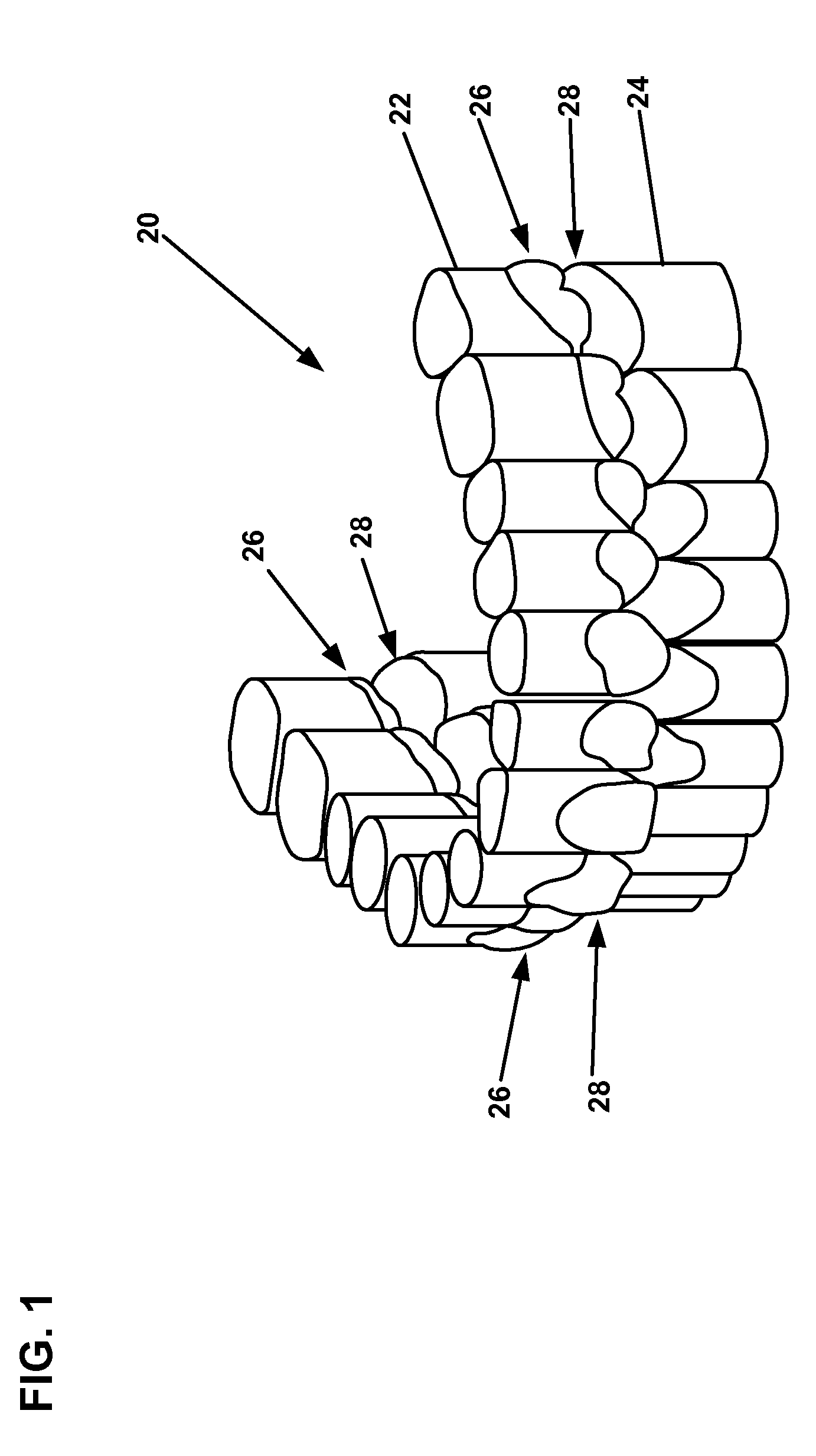

Dental modeling system and method

A method for simulating tooth movement utilizes electronic modeling to represent the teeth. Instant centers of rotation are determined and projected paths of movement are plotted. The electronic model provides improved precision and provides a method for simulating movement in three dimensions. The movement from growth and / or correction is shown with the electronic model. The simulation provides for improved correction.

Owner:HULTGREN DENTAL TECH LLC +1

Three-dimensional motion graphic user interface and method and apparatus for providing the same

InactiveUS7761813B2Reduce errorsClear messageDigital computer detailsInput/output processes for data processingGraphicsHuman–computer interaction

A three-dimensional motion graphic user interface (MGUI) and a method and apparatus for providing the same. The MGUI includes a three-dimensional interface space which has an active space and an inactive space, and a polyhedron component which is three-dimensionally presented in the active space, wherein at least one of a plurality of faces that are subject to the polyhedron component has predetermined attributes, and information displayed on the faces is displayed differently according to the attributes and a presentation relationship between the active space and the polyhedron component.

Owner:SAMSUNG ELECTRONICS CO LTD

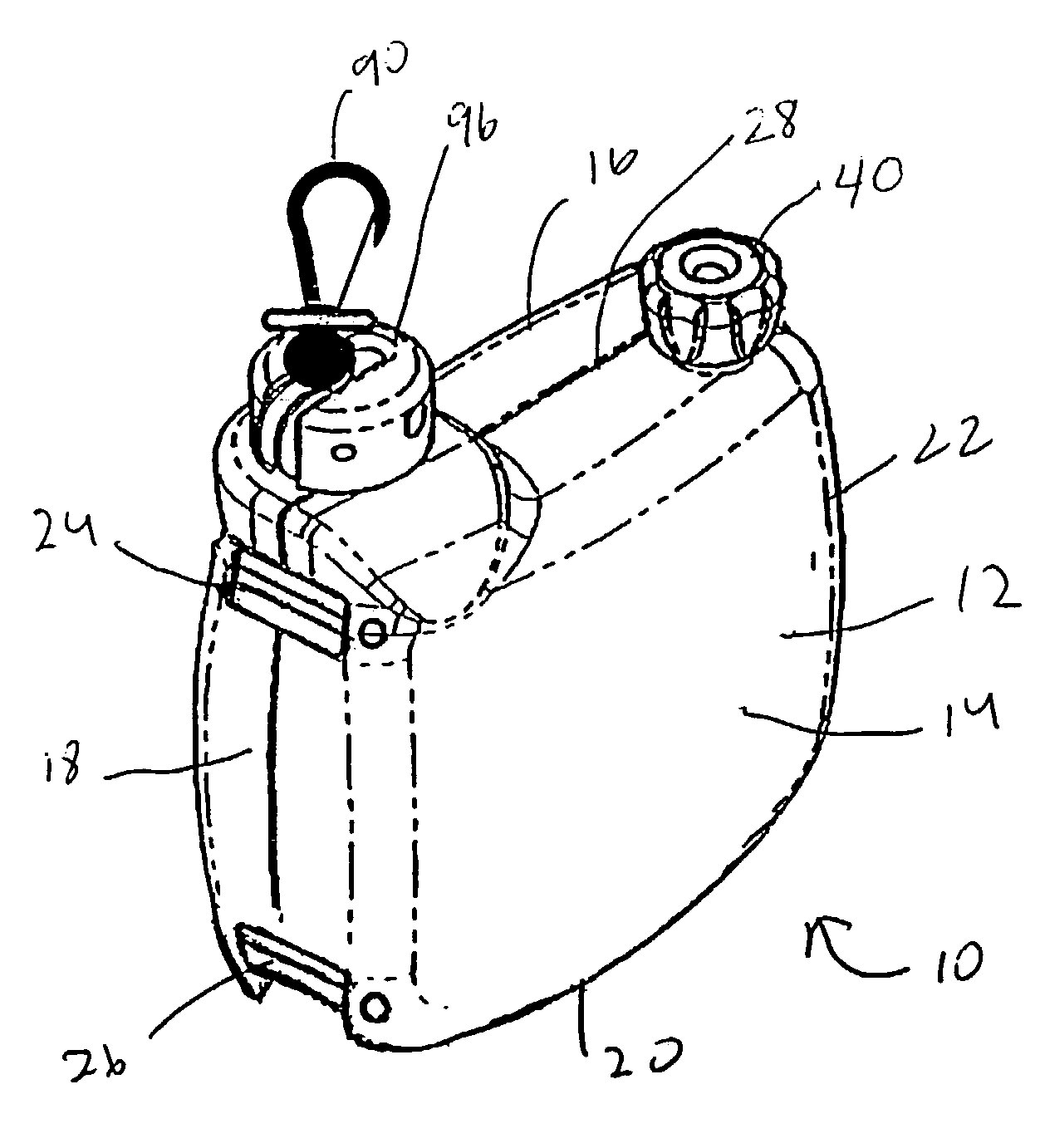

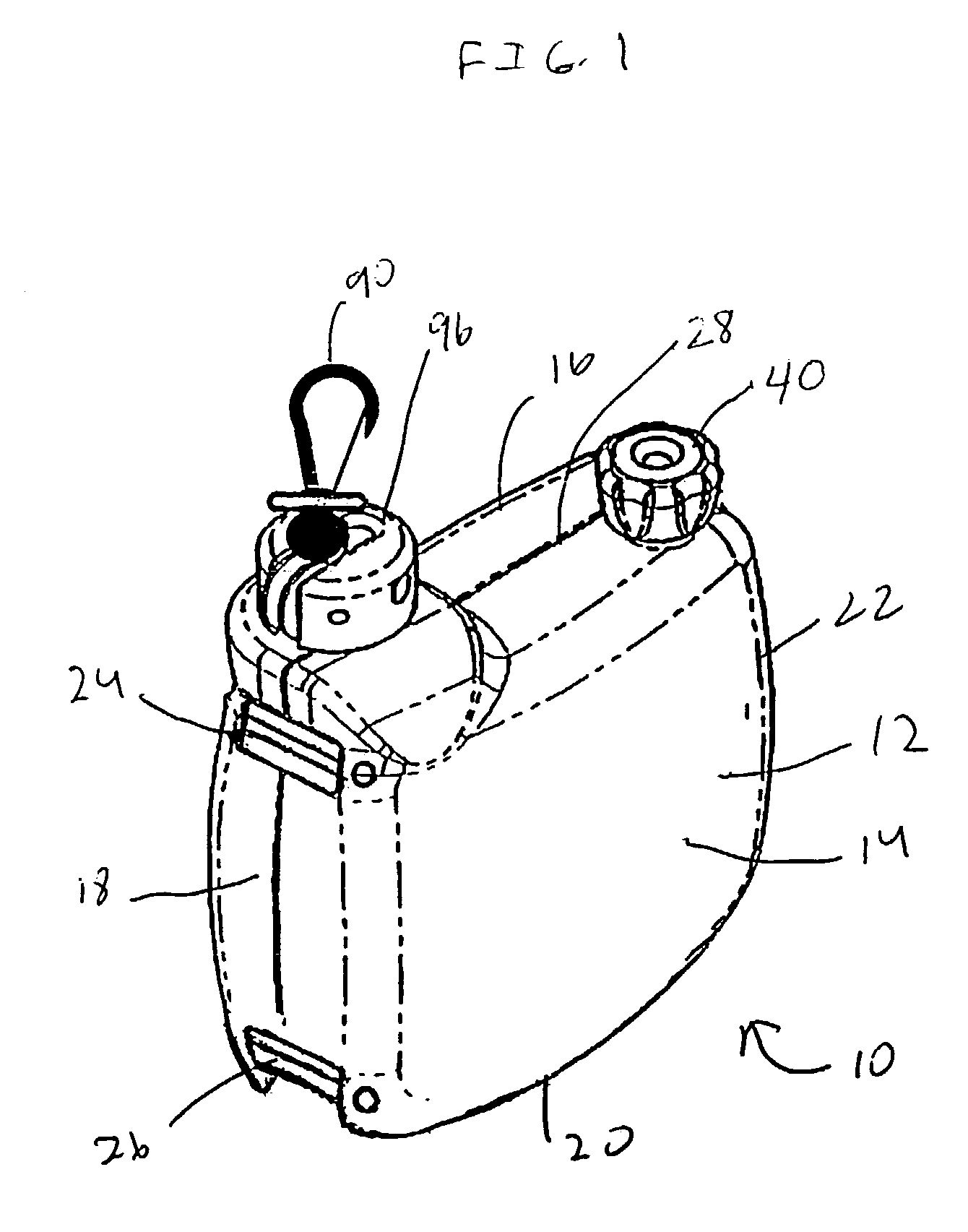

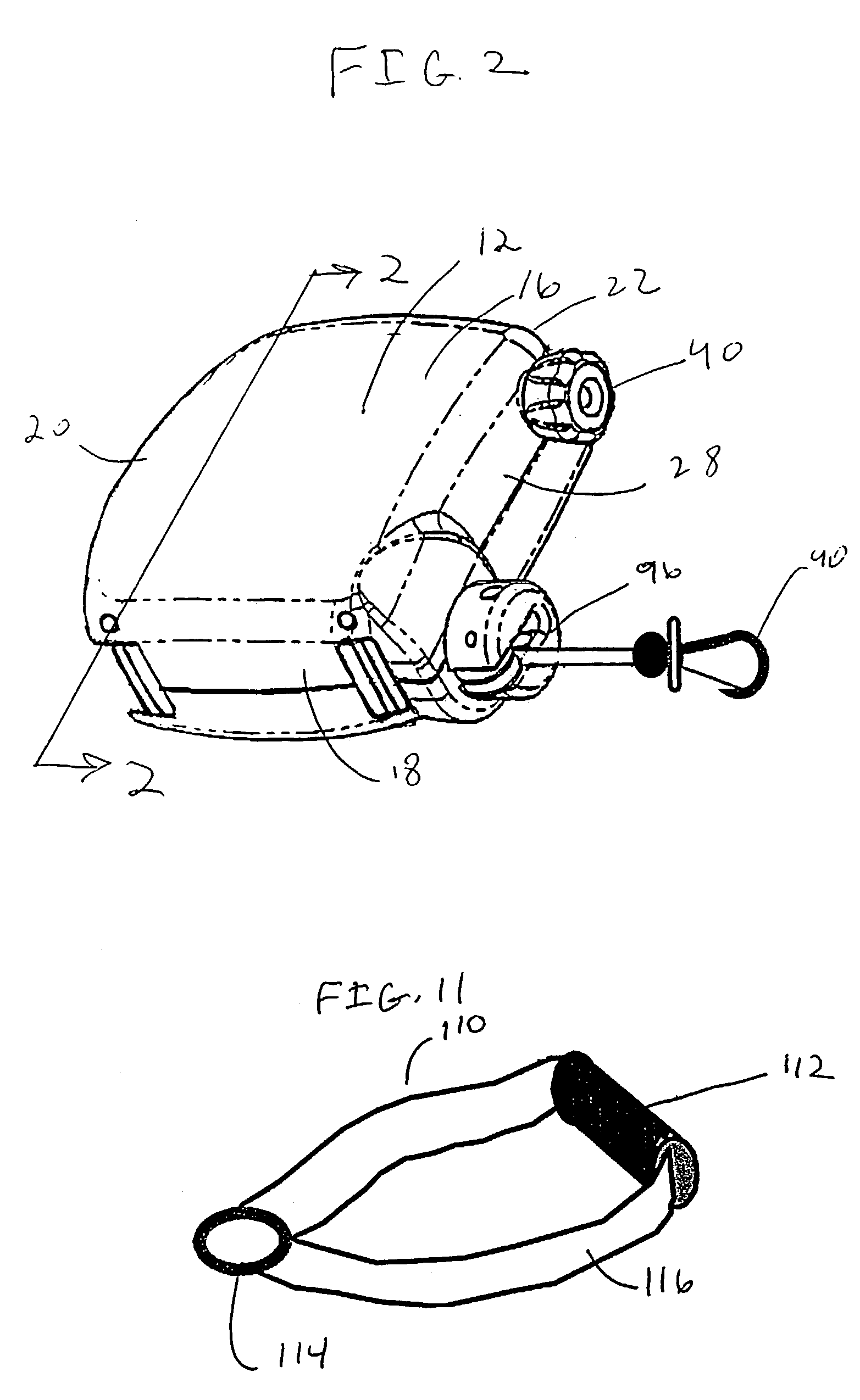

Portable handheld exercise apparatus which can be attached to a multiplicity of body parts

InactiveUS7087001B1Full rangeHigh variationTaming and training devicesFrictional force resistorsBall bearingHand held

The present invention is directed to a portable personal training and exercise device with a cable and pulley mechanism which also is a mobile personal training and exercise device having an ergonomic plastic external housing that with the use of straps fits in the hand as well as against different parts of the body. The present invention has a cable and pulley mechanism inside a housing which has a pulley rotatably mounted on a shaft that spins in only one direction. The pulley spins in both directions so that it is spring biased for rewinding a cord onto the pulley. Next to the pulley is a brake wheel or brake bushing that is attached to the shaft. The brake wheel or brake bushing and a pulley spinning on a single shaft inserts into a sealed ball bearing on both ends. A spring is connected to the bottom of the pulley. In the center of the pulley is a combination ball bearing / one-way clutch that turns the shaft only in one direction. The shaft is attached to the brake wheel or brake bushing. Secured around the outer edge of the brake wheel is a brake band. Secured around the outer edge of the brake bushing is a brake clamp. The brake band or brake bushing can be tightened for variable resistance through a tension adjustment assembly including a tension bolt. There is also a multi-directional guide unit mounted on the housing for allowing the pulley cords to be pulled in multiple directions with variable amounts of friction. The cord, which is wrapped around the pulley, emerges through a multi-directional bearing that rotates 360 degrees, thus allowing full range of three dimensional motion. Therefore, a user may pull the cords of the pulley for exercising various muscles of the user and adjust the resistance force of the cord at an appropriate level from the user. Different attachments can be connected to the snap at the end of the cord or cable such as a grip handle, wrist strap, waistband, ankle strap and foot strap.

Owner:IHLI STEPHEN P

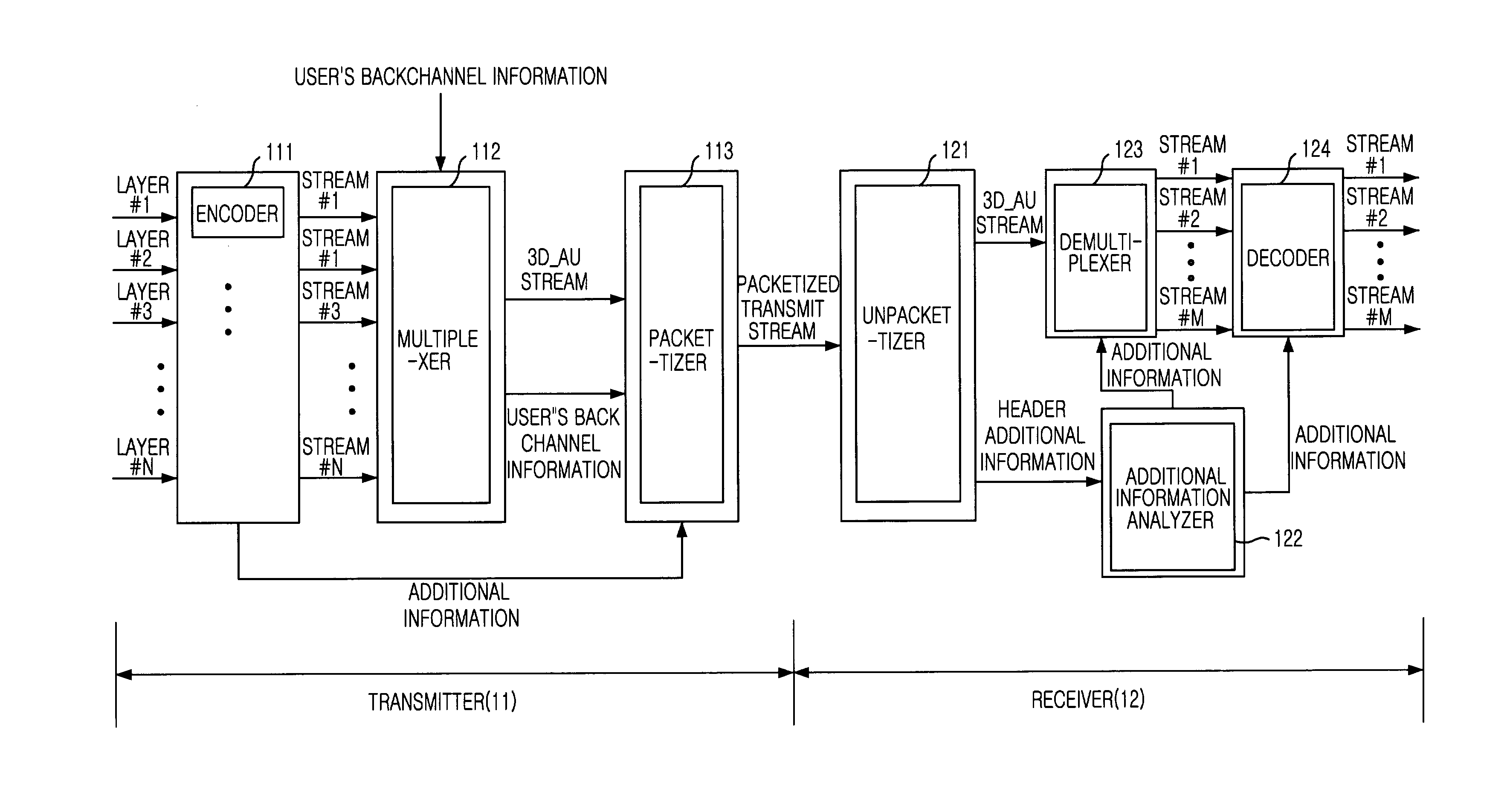

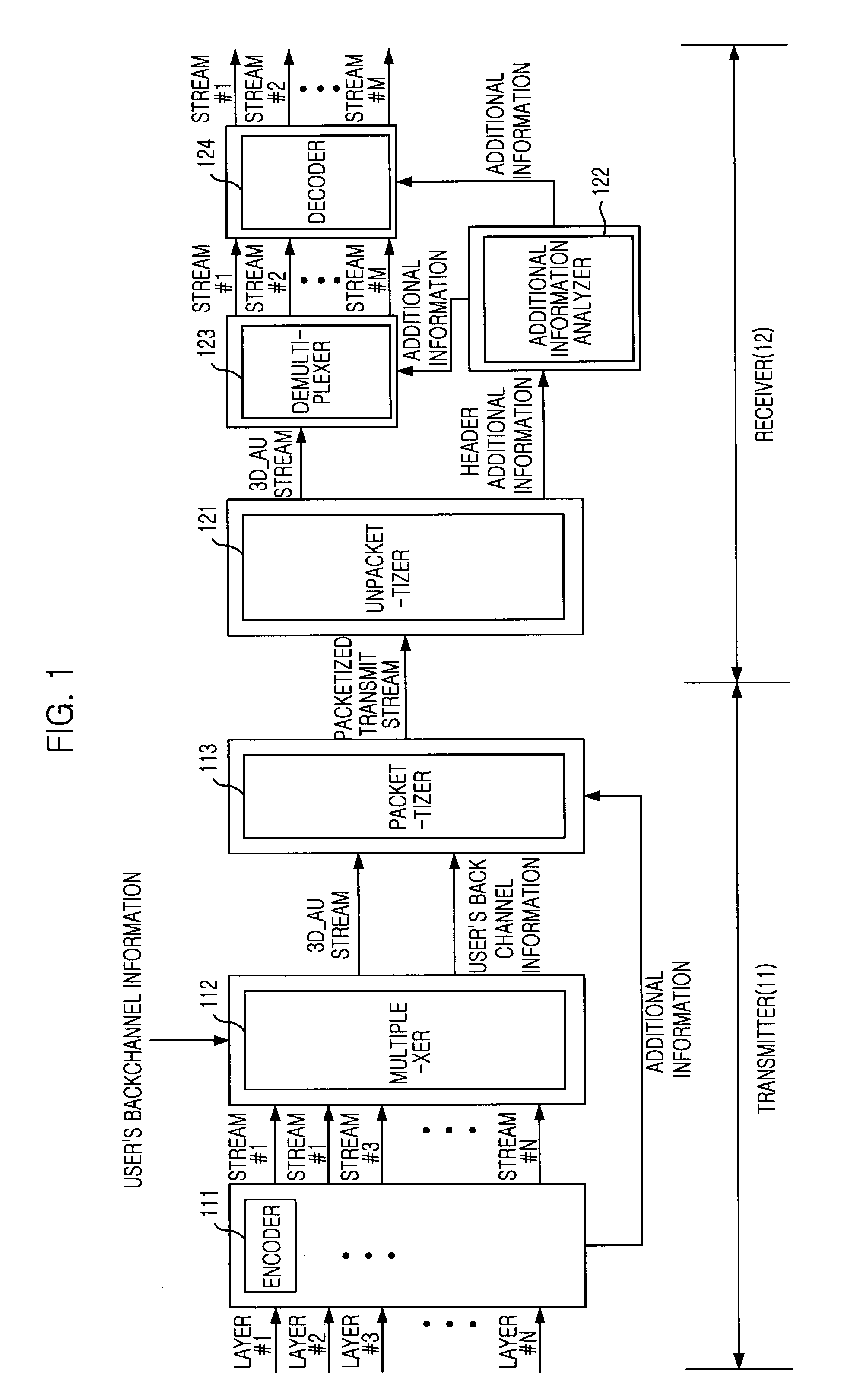

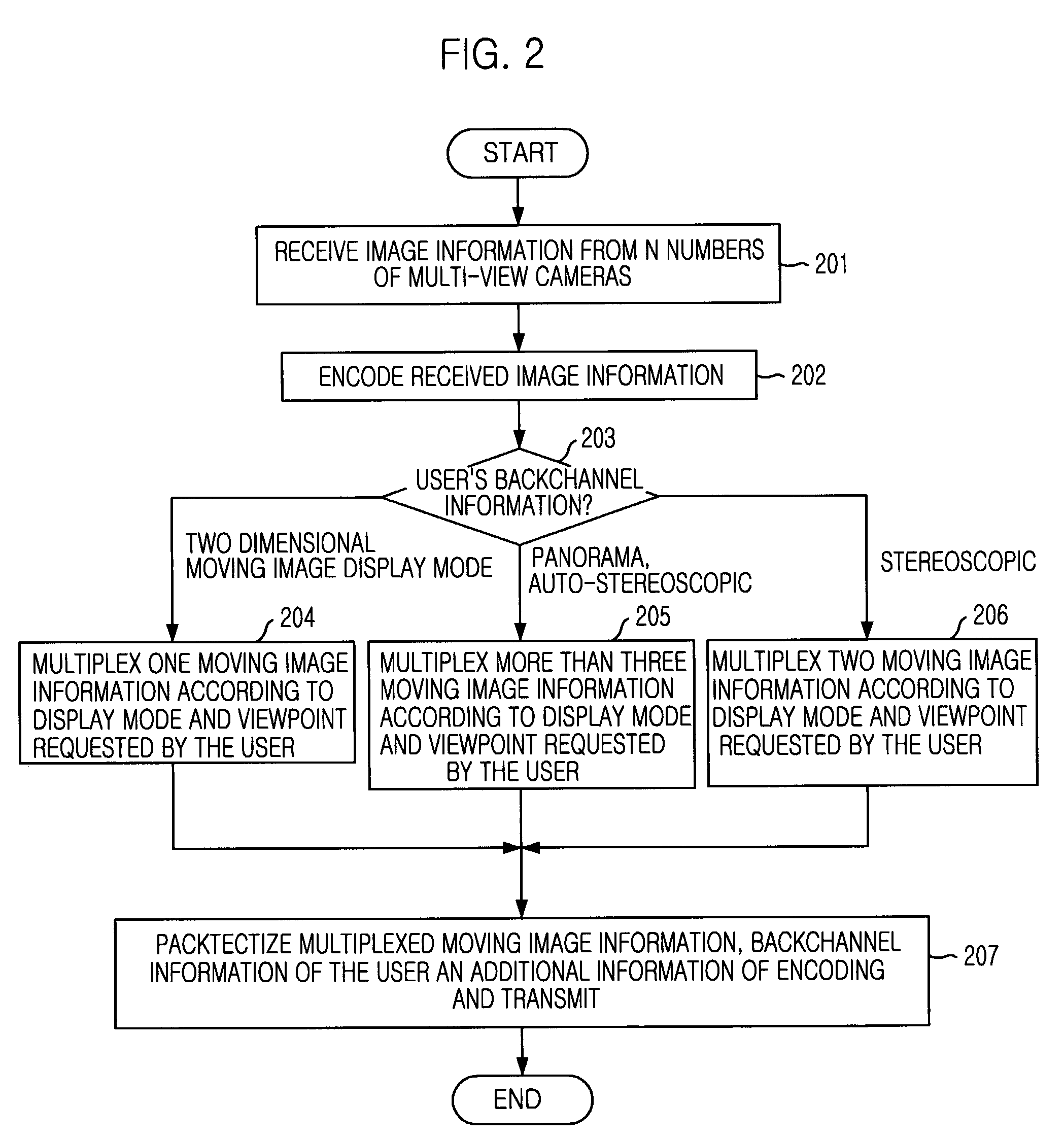

Method and apparatus for multiplexing multi-view three-dimensional moving picture

ActiveUS7136415B2Pulse modulation television signal transmissionPicture reproducers using cathode ray tubesMultiplexingTemporal information

An apparatus and method for multiplexing a multi-view three-dimensional moving picture according to a user's request is disclosed. The apparatus multiplexes a multi-view three-dimensional moving pictures by receiving moving pictures and information inputted from multi-view cameras and generating multi-view encoded streams corresponding to received moving pictures and information, receiving back channel information of the user, selecting necessary multi-view encoded streams according to the back channel information and multiplexing the selected multi-view encoded streams by a frame or a field having same time information. The present invention can effectively process the multi-view three-dimensional moving picture according to the display mode and system environment requested from the user by simplifying a synchronization process.

Owner:ELECTRONICS & TELECOMM RES INST

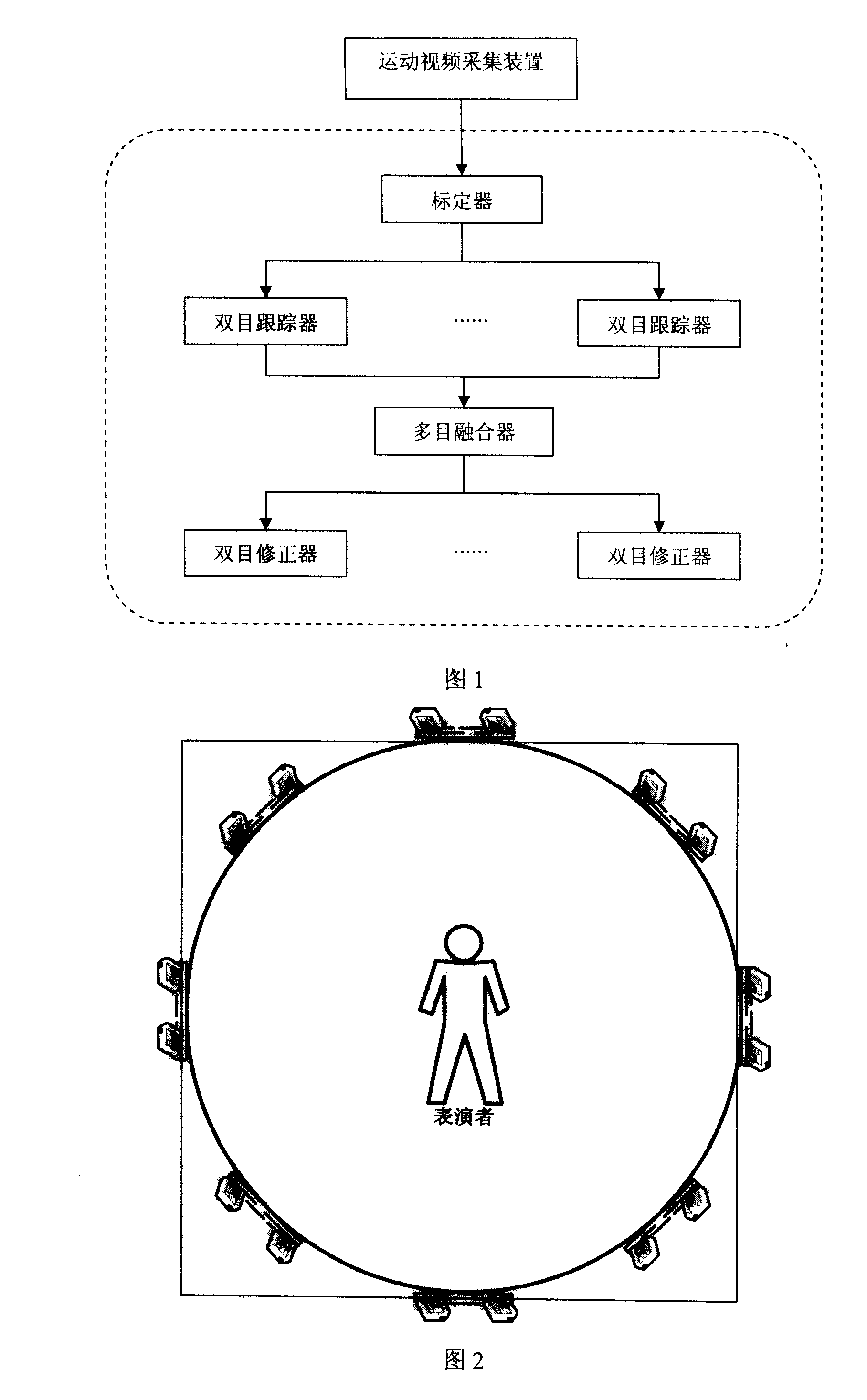

Method for capturing movement based on multiple binocular stereovision

The invention discloses a movement capturing method based on multiple binocular stereo vision. A movement video collecting device is constructed, and human movement video sequences from different orientations are collected by the movement video collecting device. Multiocular movement video sequences shot by a plurality of cameras are calibrated. Marked points matching and tracking of each binocular tracker is finished. Data fusion of three-dimensional tracking result of multiple binocular trackers is completed. The three-dimensional movement information of the marked points acquired by a multiocular fusion device is fed back to the binocular tracker to consummate binocular tracking. On the basis of binocular three-dimensional tracking realized by binocular vision, the invention fuses multiple groups of binocular three-dimensional movement data, resolves parameter acquiring problem of three-dimensional position, tracking, track fusion and the like for a plurality of marked points, increases number of traceable market points and enables the tracking effect to be comparable with three-dimensional movement acquiring device employing multi-infrared cameras for collecting.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

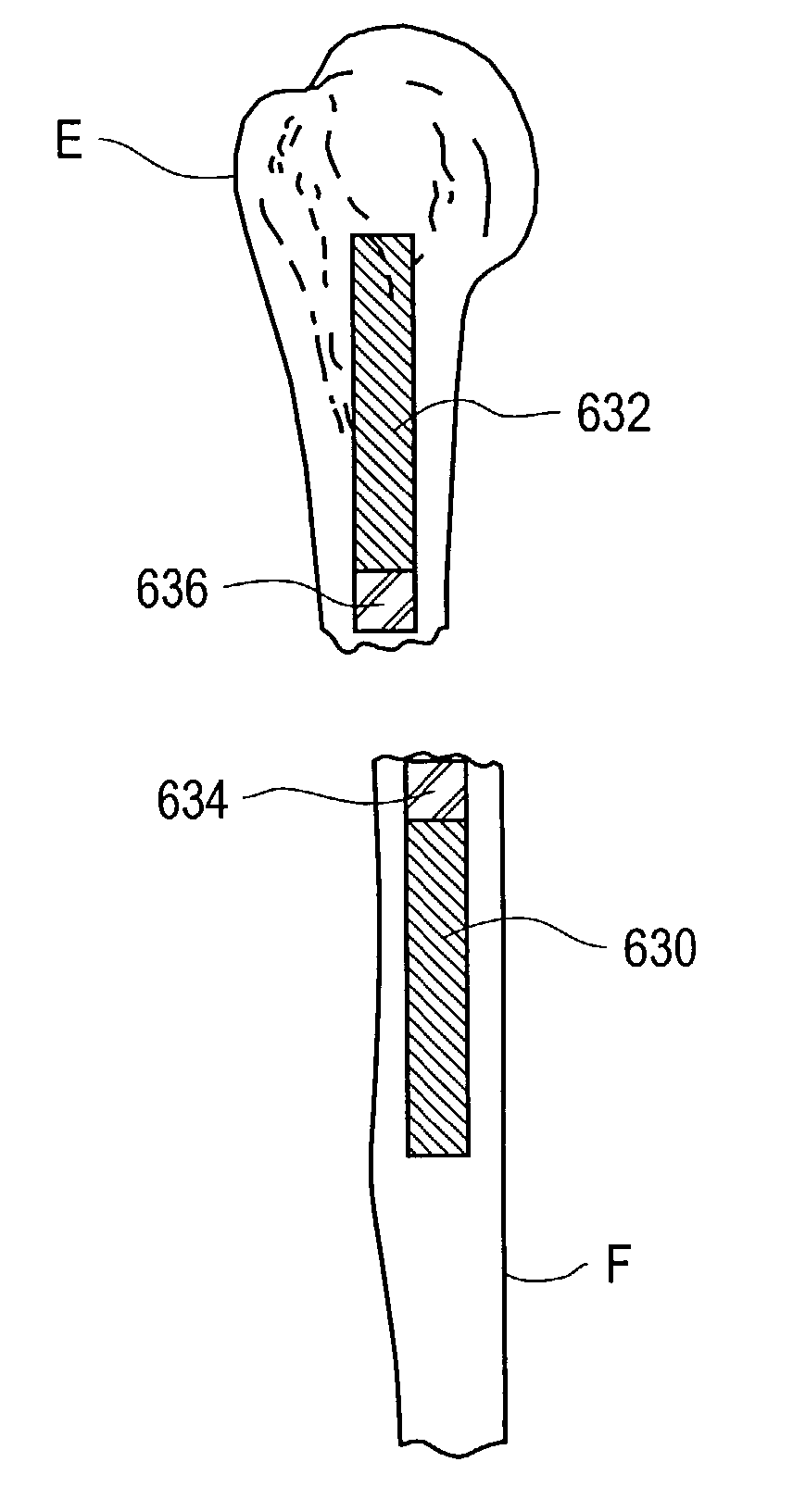

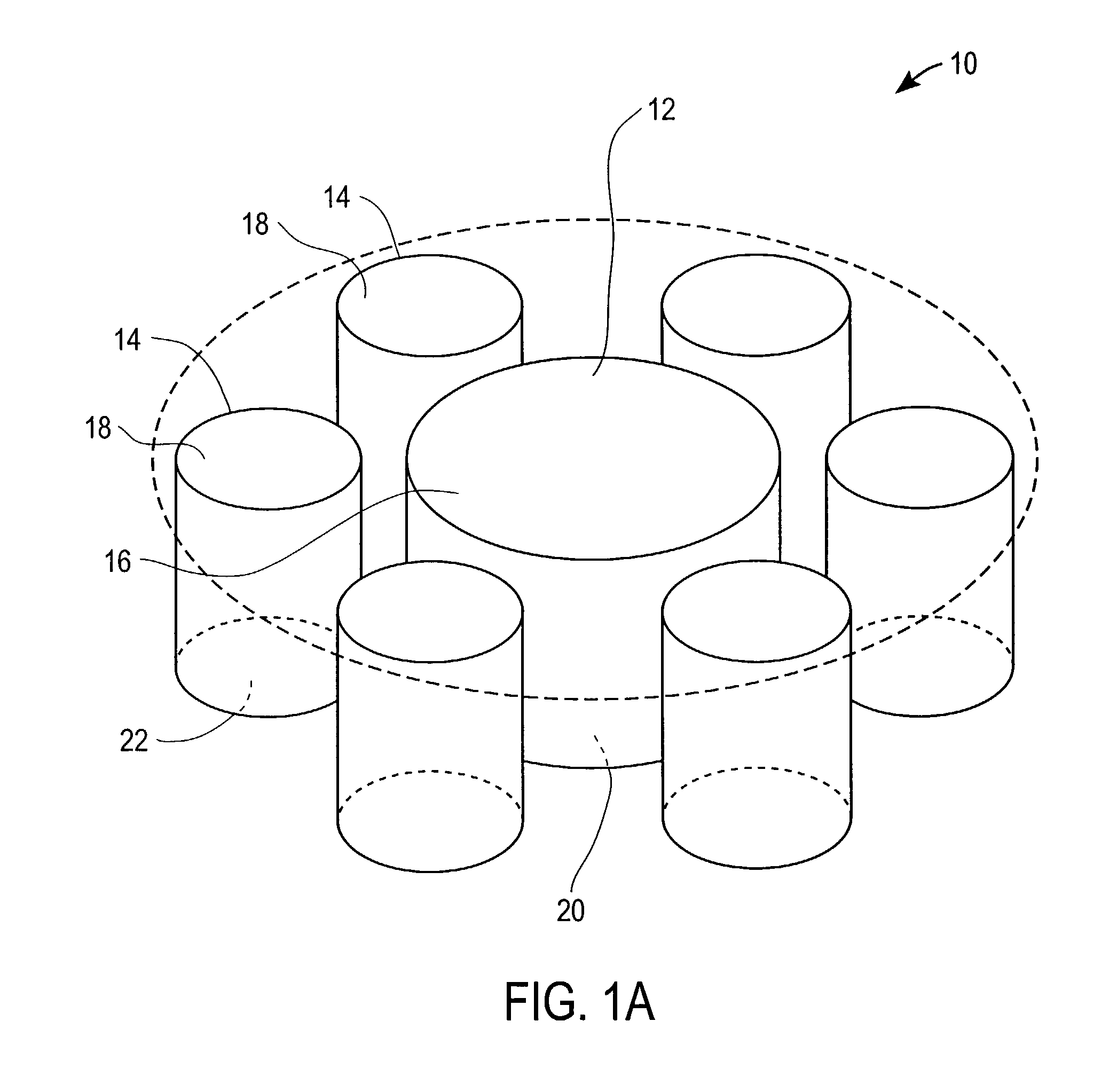

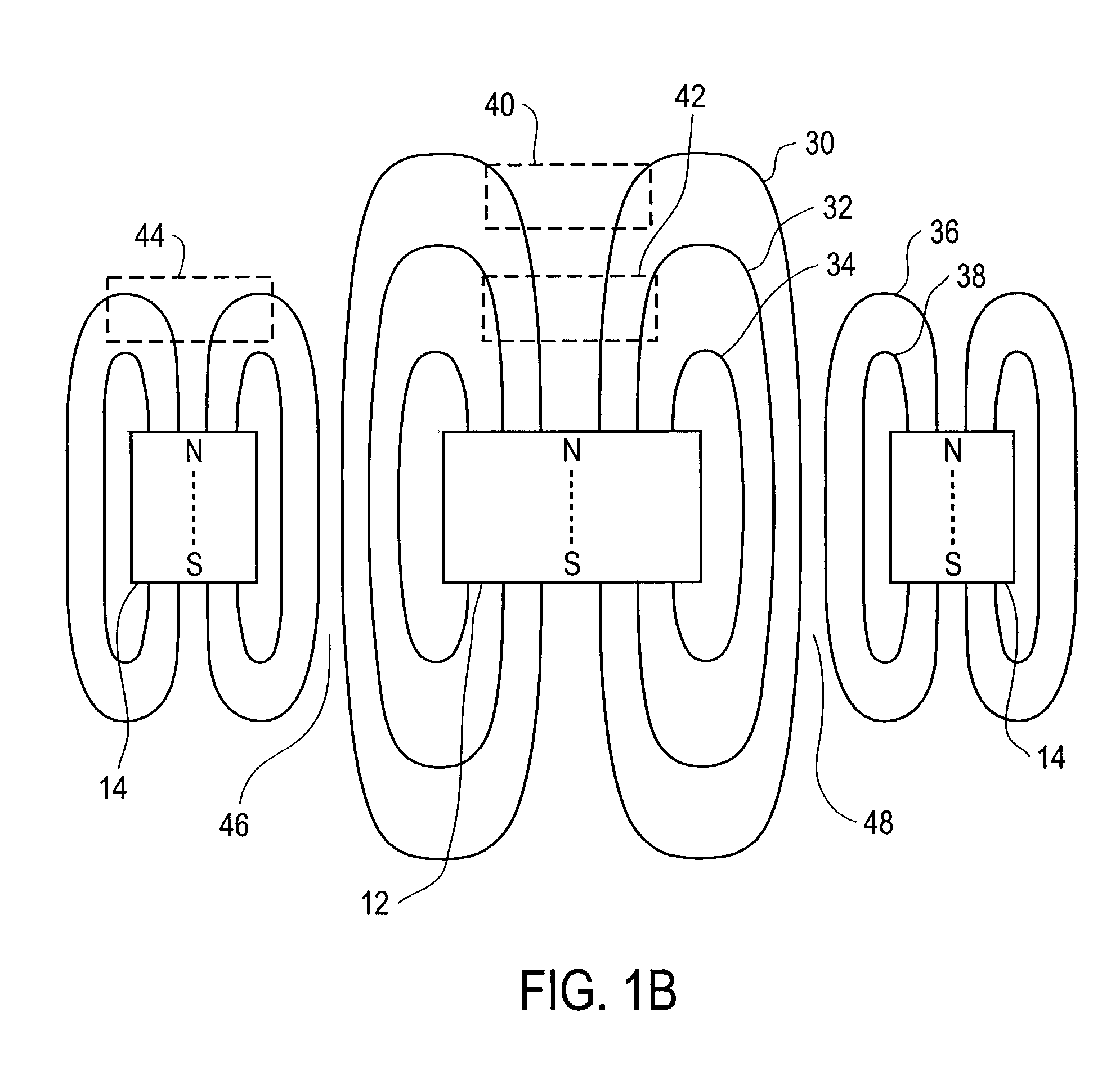

Magnetic array implant

InactiveUS7101374B2Easy to adaptAvoids potentially unpredictable implantationElectrotherapyInternal osteosythesisMechanical energyMagnetic energy

The present invention relates to apparatus and methods for stabilizing and or maintaining adjacent bone portions in predetermined desired relationships and for constraining one, two or three-dimensional motion and / or rotation of the adjacent bone portions. More particularly, the present invention relates to a magnetic apparatus with at least two magnetic arrays, each of which may include any number of magnets arranged in a predetermined manner and each magnetic array generating a magnetic field therearound. Once implanted and secured to the adjacent bone portions, the apparatus provides interacting magnetic fields in the area of the bone portions and transduces magnetic energy into mechanical energy and mechanical energy into potential magnetic energy, thereby reproducing functionally anatomic and / or anatomically advantageous arrangement of the bone portions.

Owner:HYDE EDWARD R

Three-dimensional rapid prototyping method and device based on pulse small hole droplet injection

The invention relates to a three-dimensional rapid prototyping method and device based on pulse small hole droplet injection and belongs to the technical field of three-dimensional rapid prototyping. The three-dimensional rapid prototyping method is characterized in that a heater is used for heating a crucible until the metals in the crucible are in the molten state, a positive differential pressure value is set between the interior of the crucible and a vacuum chamber, simultaneously a piezoelectric ceramic driver applies certain pulse signals to piezoelectric ceramics to lead the piezoelectric ceramics to drive a transmission bar to generate longitudinal infinitesimal displacement, the infinitesimal displacement acts on the metal melt at the bottom of the crucible, tiny droplets are injected from small holes arranged at the bottom of the crucible, one droplet can be formed at the position of the small holes once the piezoelectric ceramics move for one time, size data of the droplets are timely analyzed through a photograph system, further the optimum parameter is obtained through adjustment; and the droplets fall to a moving three-dimensional motion platform to be deposited, and accordingly needed metal parts are formed through depositing. The three-dimensional rapid prototyping method and device based on pulse small hole droplet injection have the advantages that the pulse small holes inject to generate the metal droplets with uniform and controllable sizes, prototyped products are fine and uniform in microstructure, the prototyping process is strong in controllability, and the formed parts are high in accuracy.

Owner:DALIAN UNIV OF TECH

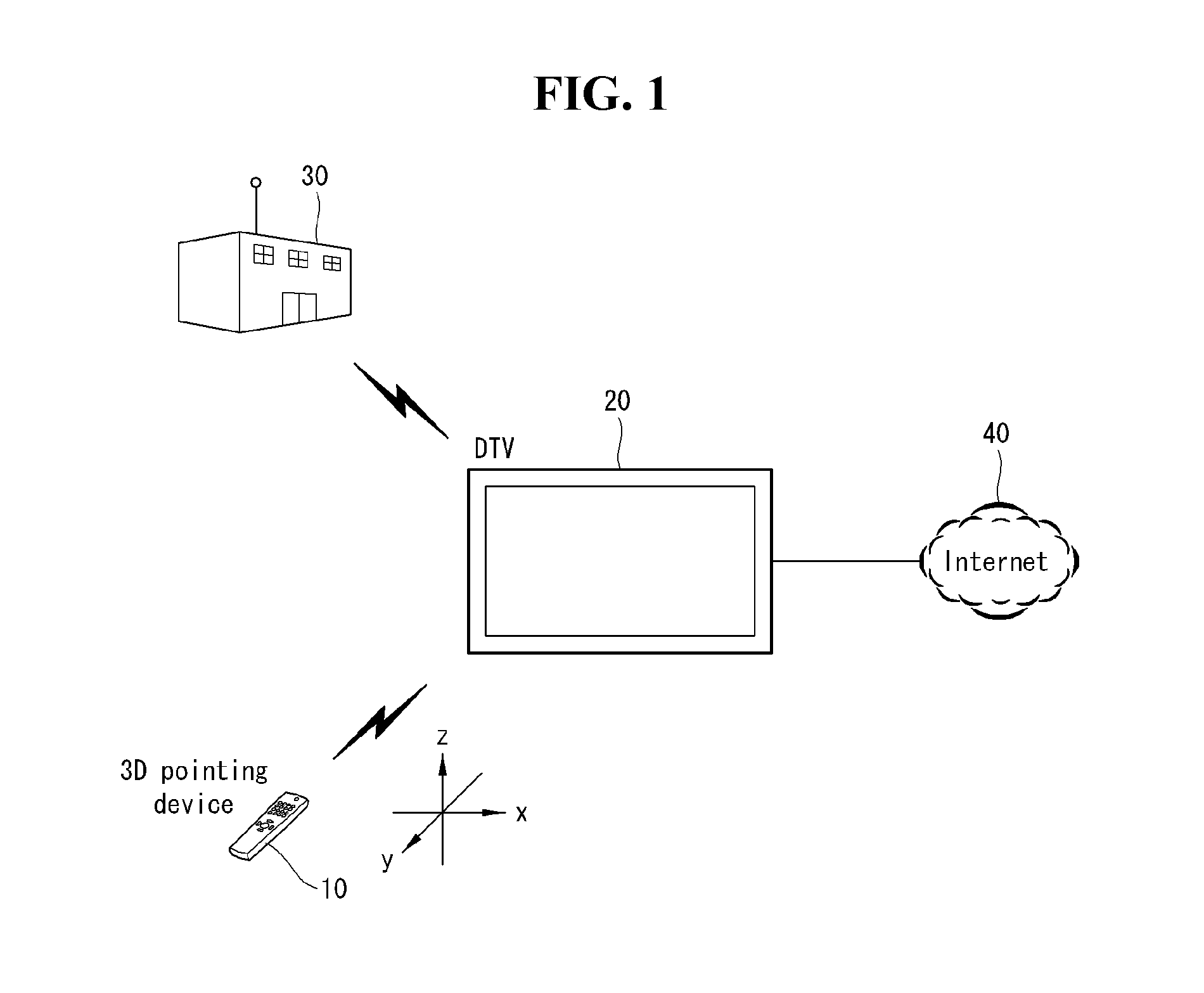

Display device and control method thereof

Owner:LG ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com