Three-dimensional rapid prototyping method and device based on pulse small hole droplet injection

A technology of droplet ejection and droplet ejection part, which is applied in the field of three-dimensional rapid prototyping based on pulse small hole droplet ejection, which can solve the problems of uneven droplet size, high porosity and poor density of parts, and achieve low cost , Strong process controllability, effect of refining grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

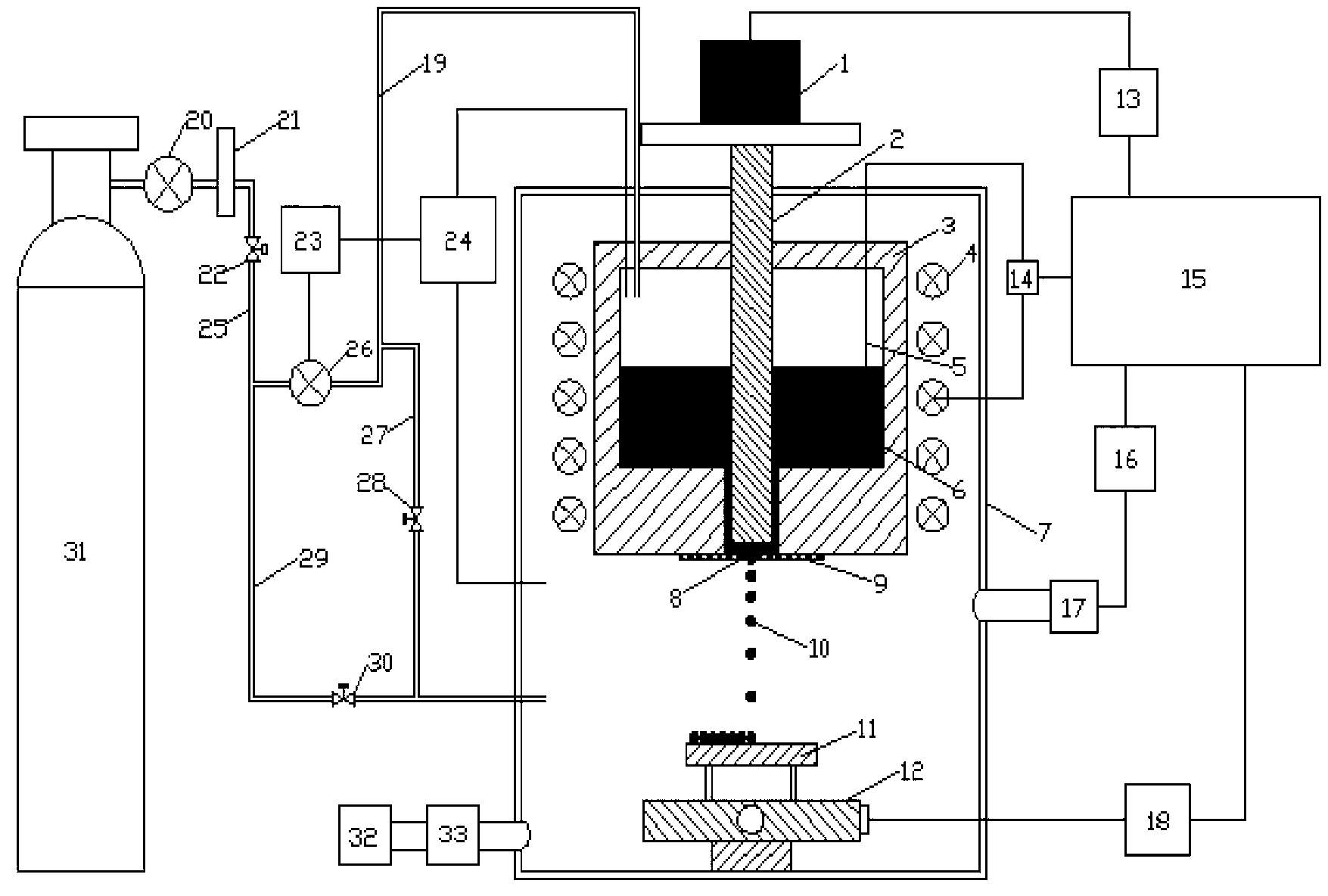

[0023] (1) According to the size parameters of the processed parts, use AutoCAD to draw the 3D CAD solid model of the part, and perform triangulation processing to convert the CAD solid model with smooth surface into STL file format; use slicing software to process the 3D solid according to a certain thickness Carry out slices in the processing height direction, generate a control file with a certain scanning path, and import the control file into the PMAC controller 18; break the Sn63Pb37 eutectic alloy into a block and put it into the crucible 3, and the amount of the put into the crucible 3 reaches 3 / 4.

[0024](2) Use the mechanical pump 32 to pump the crucible 3 and the vacuum chamber 7 of the ejection part to a low vacuum of 5 Pa, and then use the diffusion pump 33 to pump the crucible 3 and the vacuum chamber 7 of the ejection part to a high vacuum of 0.001 Pa; 19 and the cavity inlet pipe 29 feed the inert gas Ar gas into the crucible 3 and the vacuum chamber 7, and op...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com