Patents

Literature

591results about How to "Uniform microstructure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compact foamy thyrite in high intensity and preparation method

The invention provides a high strength compact foam silicon carbide ceramics material and the prodn method. Counting on weight percentage, the material is composed by silicon carbide 90-98 and silicon 10-2, silicon carbide powder and resin with high carbon-producing ration are mixed to slurry, expanded plastice is cut and soaked in the slurry, which is taken out, removing unnecessary slurry, then is treated by semisolidifying, high-temp, high-pressure solidifying, the solidified foam body is pyrolized to obtain foam carbon frame with same shape as original foam shape composed by silicon carbide and pylolized carbon, to open a centre hole on carbon frame by grinding, the silicon slurry is injected into the centre hole until filling by press injection, then is pylolized, by silicizing process, carbon in the carbon frame and gas or liquid phase silicen are reacted to generate silicon carbide and combined with original silicon carbide particles in carbon frame, thus to obtain high strength compact silicon carbide foam ceramics.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

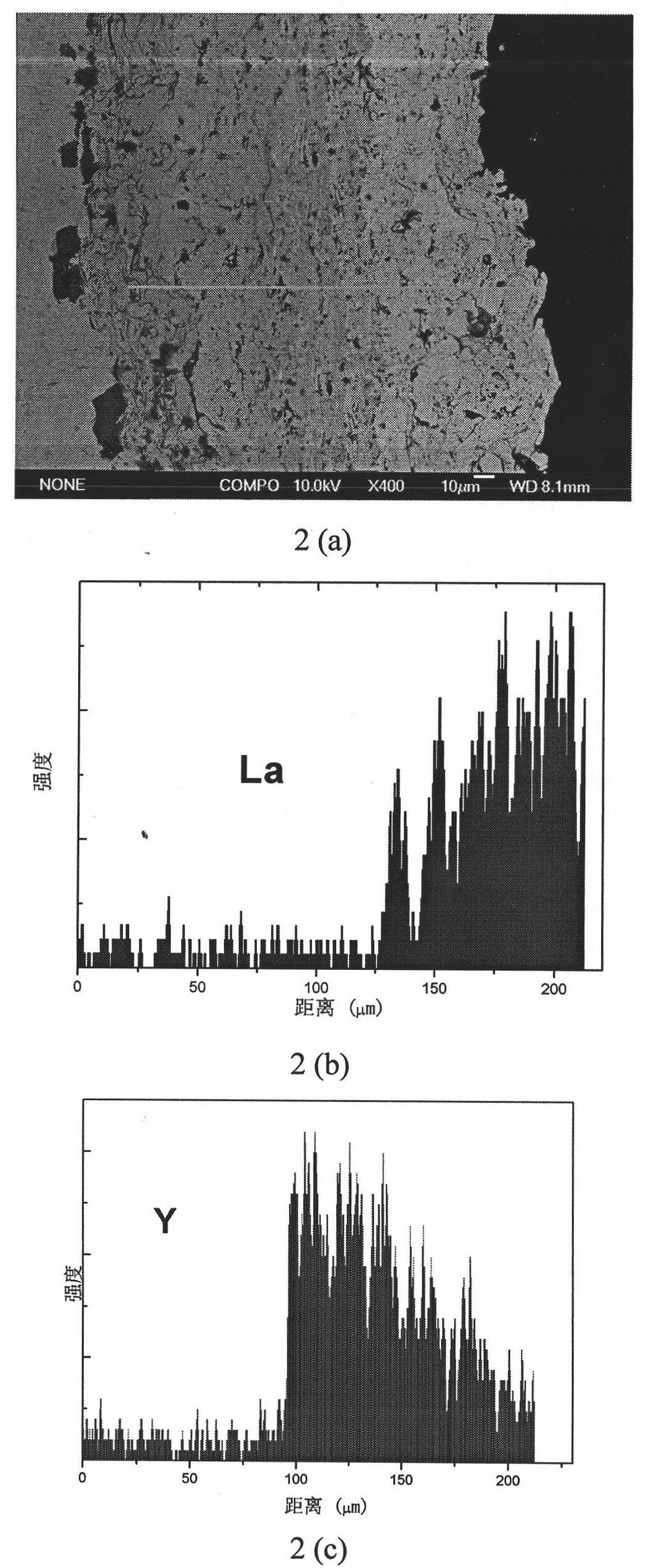

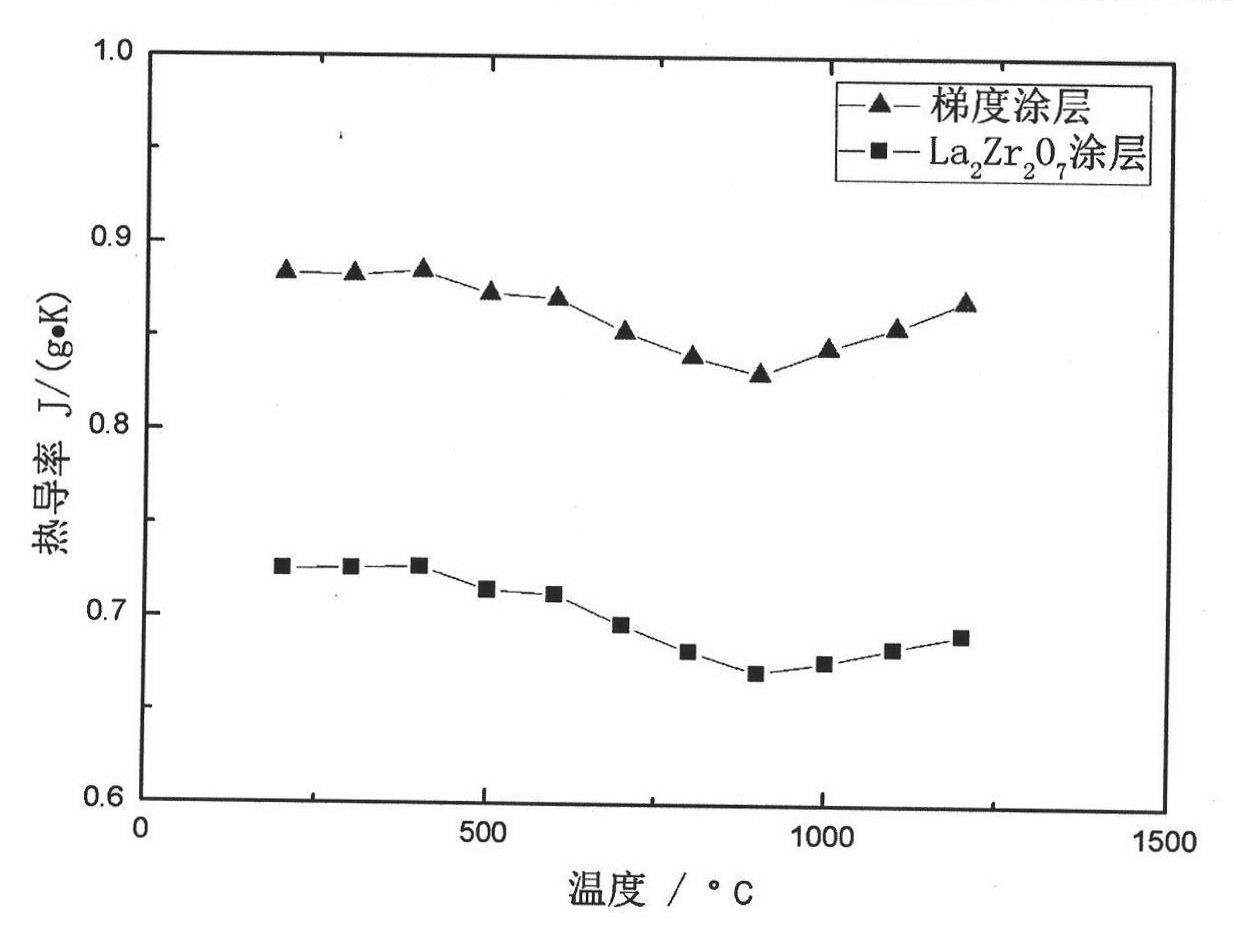

Thermal protection coating with component gradient change and preparation method

InactiveCN101768380AReduce heat stress concentrationImprove thermal shock resistanceMolten spray coatingRare-earth elementLanthanum aluminate

The invention belongs to the field of inorganic materials, particularly relates to a thermal protection coating with component gradient change and a preparation method. The thermal protection coating comprises two components of M1 and M2, wherein the M1 is selected from one of YSZ, lanthanum aluminate, mulite or BSAS, the M2 is selected from one of Ln2Zr2O7, Ln2Ce2O7, Ln2SiO5, Ln2Si2O7 or MoSi2, and Ln is selected from rare earth elements the atom coefficients of which are 57-71, Y or Sc. The thermal protection coating has the characteristics of good coating compactness, high bonding strength with a substrate, low thermal conductivity and the like and has favorable thermal shock resistance.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Microwave curing process for ceramic material gel casting

The invention relates to a microwave curing process for ceramic material gel casting, which comprises the following steps: firstly, dissolving organic monomer and crosslinker in sequence in the solvent, adding a dispersant and obtaining pre-prepared liquid; adjusting the pH value of the pre-prepared liquid to be 7-11, adding ceramic powder to the pre-prepared liquid, stirring the mixture stronglyand mechanically for 1h and obtaining even slurry; adding an initiating agent and a catalytic agent to the slurry and mixing evenly; soon afterward, removing the gas in the slurry by vacuum; casting the slurry into a module; placing the module packed with the slurry in a microwave oven for a curing process, and obtaining a gel casting ceramic body; and drying the ceramic body, and then sintering at the temperature of 1200 DEG C-2200 DEG C for 1-6h, and finally obtaining a ceramic product. Compared with the conventional gel casting curing method, the microwave curing process has the advantagesthat the process has fast heating speed and uniform temperature field, reduces the activation energy of reaction, accelerates the reaction rate, causes the polymerization reaction to be finished rapidly and achieves the purpose of high speed and high quality moulding of materials.

Owner:OCEAN UNIV OF CHINA

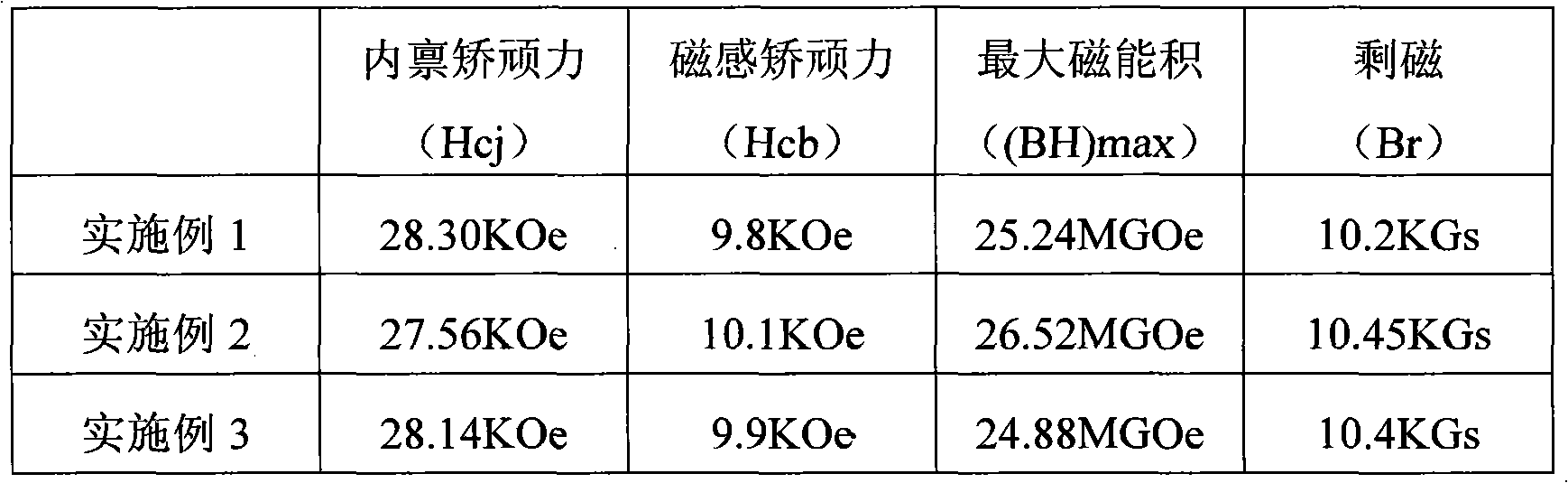

Samarium-cobalt permanent magnet material and preparation method thereof

The invention provides a samarium-cobalt permanent magnet material, which consists of the following components in percentage by mass: 23 to 25.5 percent of samarium, 44 to 50 percent of cobalt, 14 to 20 percent of iron, 3 to 8 percent of copper, 2 to 4 percent of zirconium and 0.5 to 2 percent of heavy rare earth element. The invention also provides a method for preparing the samarium-cobalt permanent magnet material, which comprises the following steps of: mixing; smelting alloys; preparing magnetic power; orienting and forming; sintering and performing solid solution; and ageing. The samarium-cobalt permanent magnet material has the characteristic of high coercive force and can effectively meet the requirement of the field of high and new technology on the high coercive force of a rare earth permanent magnet material.

Owner:NINGBO STAR MATERIALS HI TECH

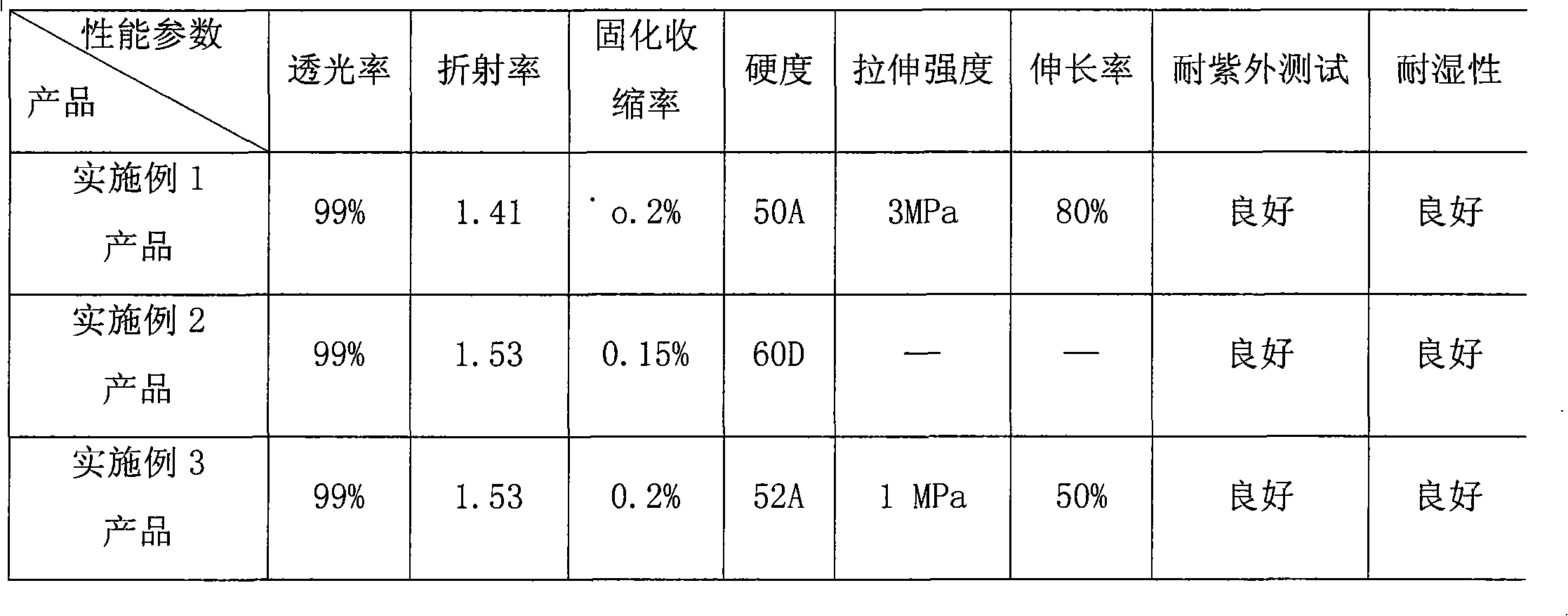

Organ silicon material for encapsulating power-type LED and synthetic method thereof

ActiveCN101608068AFully curedEven distribution of phenyl groupsSemiconductor devicesCross-linkMass ratio

The invention discloses an organ silicon material for encapsulating a power-type LED and a synthetic method thereof. The organ silicon material is mixed with a component A and a component B according to a mass ratio of 1:1 to 1:20, wherein the component A is a mixture of vinyl silicon polymer and a solidify catalyst, and the vinyl silicon polymer comprises vinyl silicon resin and polysiloxane with vinyl; and the component B comprises vinyl hydro silicon resin, poly hydro siloxane and an inhibitor. The organ silicon material has a higher refractive index, high transparency, excellent ultraviolet ageing resistance, good heat ageing resistance, and the like and is an ideal encapsulating material of the power type LED. The invention also discloses a synthetic method of an organ silicon material for encapsulating the power-type LED, the solidification of resin is more complete, and the light transmission and the hardness of the cross-link resin are effectively increased.

Owner:矽时代材料科技股份有限公司

PTC thermistor and substrate applied therein and manufacturing method thereof

InactiveCN102176360AUniform cross-linked structurePromote absorptionPositive temperature coefficient thermistorsHigh resistanceCross-link

A PCT thermistor comprises a substrate and two tinsel-shaped electrodes which are combined with two surfaces of the substrate. The substrate is made of the following components in weight percentage: 28-55% of high-polymer material; 22-32% of conductive filling material; 13-46% of auxiliary filling material; and 1-5% of auxiliary agent in processing. The high-polymer material is obtained through mixing one or multiple materials selected from: polyethylene, polypropylene, maleic anhydride grafted polyethylene, ethane-vinyl acetate copolymer, ethane-acrylic acid copolymer, polyvinylidene fluoride, polycaprolactam, polyhexamethylene adipamide, polydecamethylene sebacamide and polyundecylamide. The auxiliary agent in processing is one component or a mixture of multiple components selected from: an anti-oxidant, a coupling agent, a cross-linking agent and a sensitized cross-linking agent. The sensitized cross-linking agent is one component or multiple components selected from the unsaturated compounds of multiple functional groups with higher decomposition temperature. The PTC thermistor of the invention has the following advantages: high strength, and high resistance for multiple times of large current impact.

Owner:深圳市长园维安电子有限公司

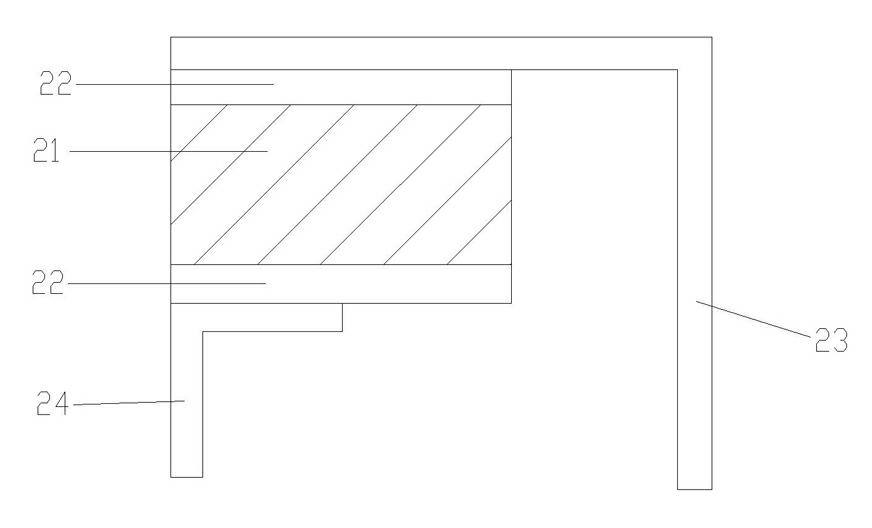

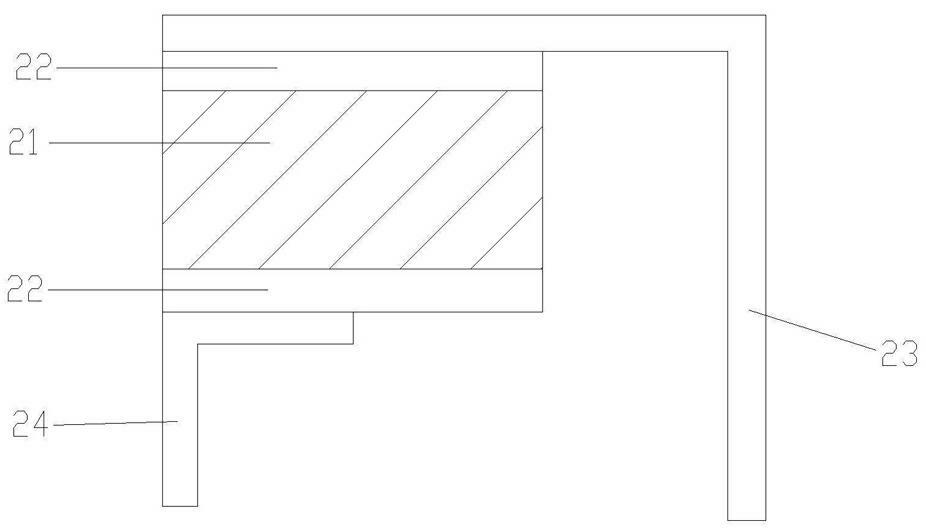

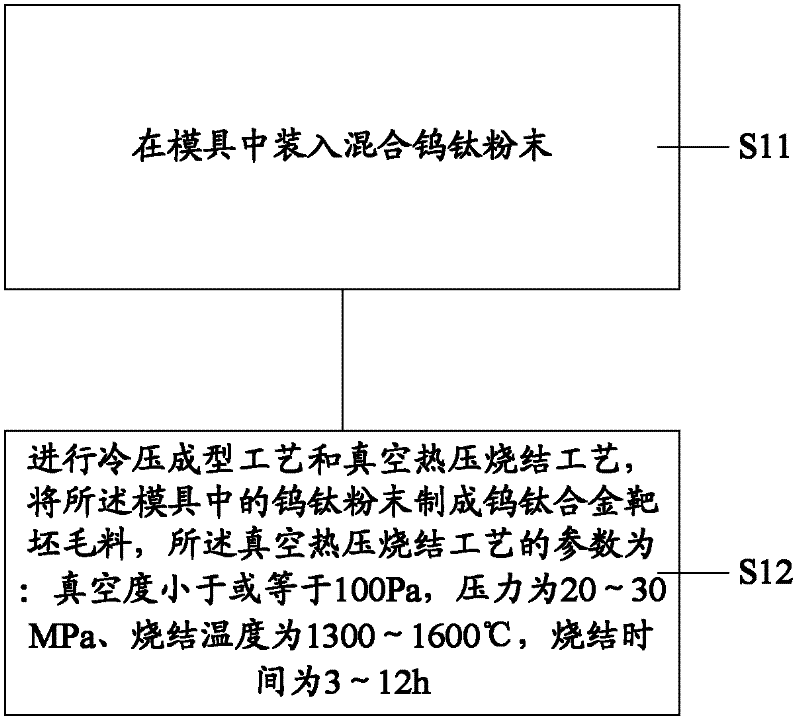

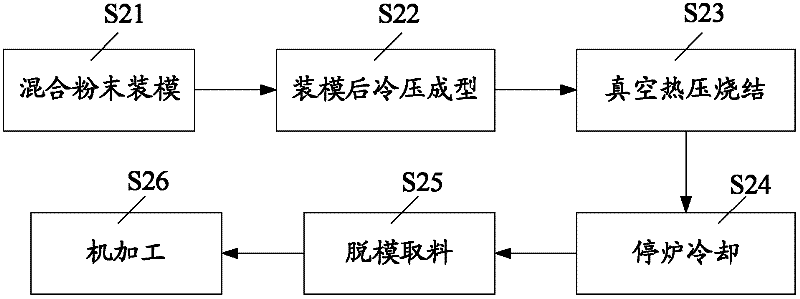

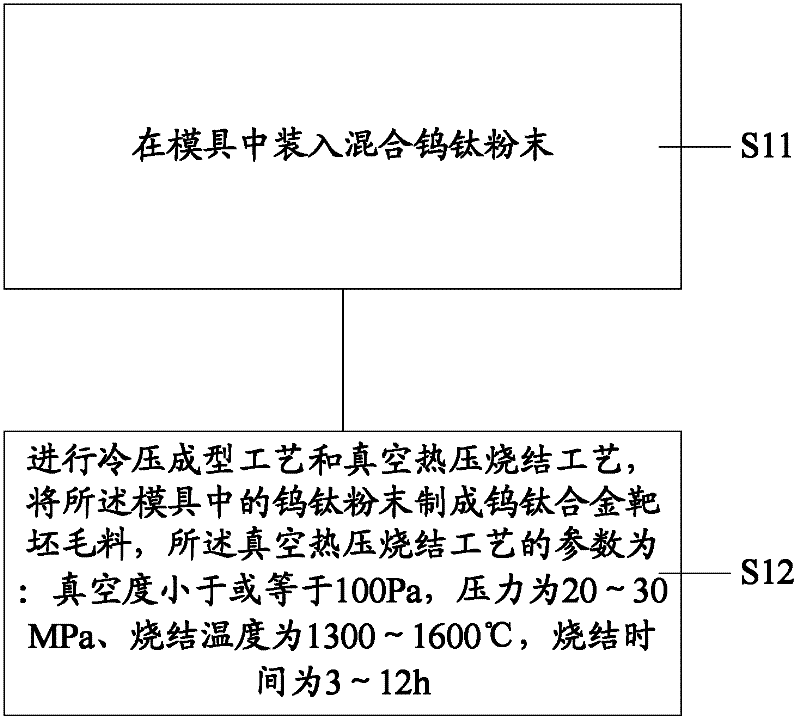

Manufacturing methods of tungsten-titanium alloy target billet and target material

ActiveCN102400004AUniform microstructureHigh densityVacuum evaporation coatingSputtering coatingSputteringTitanium alloy

The invention provides manufacturing methods of a tungsten-titanium alloy target billet and a target material. The manufacturing method of the tungsten-titanium alloy target billet comprises the following steps: loading tungsten and titanium powder into a mold; and carrying out a cold-press moulding process and a vacuum hot pressed sintering process so as to prepare the tungsten and titanium powder in the mold into the tungsten-titanium alloy target billet, wherein the parameters of the vacuum hot pressed sintering process are as follows: the vacuum degree is less than or equal to 100Pa, the pressure is 20-30MPa, the sintering temperature is 1300-1600 DEG C and the sintering time is 3-12 hours. By utilizing the manufacturing method of the tungsten-titanium alloy target billet provided by the technical scheme of the invention, the obtained tungsten-titanium alloy target billet is uniform in microstructure and high in compactness, has no cracks and accords with semiconductor sputtering; and the tungsten-titanium alloy target billet obtained by utilizing the manufacturing method of the tungsten-titanium alloy target billet is low in cost.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

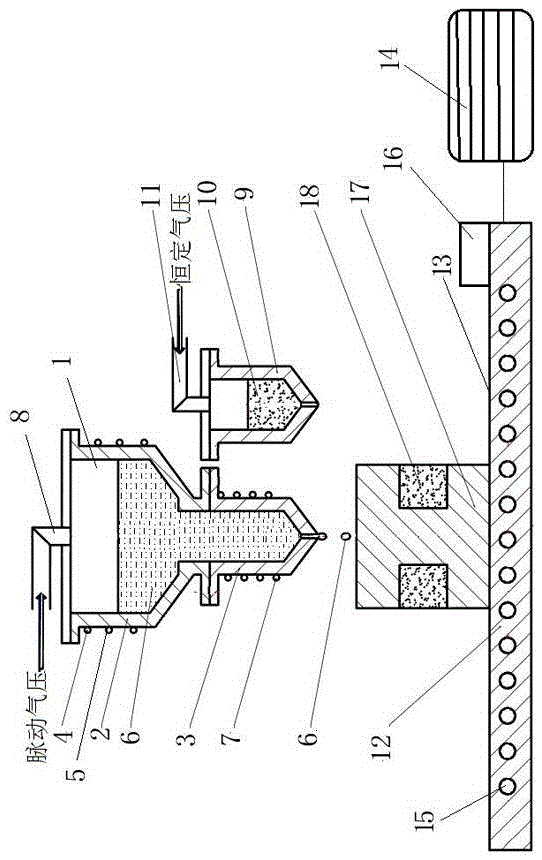

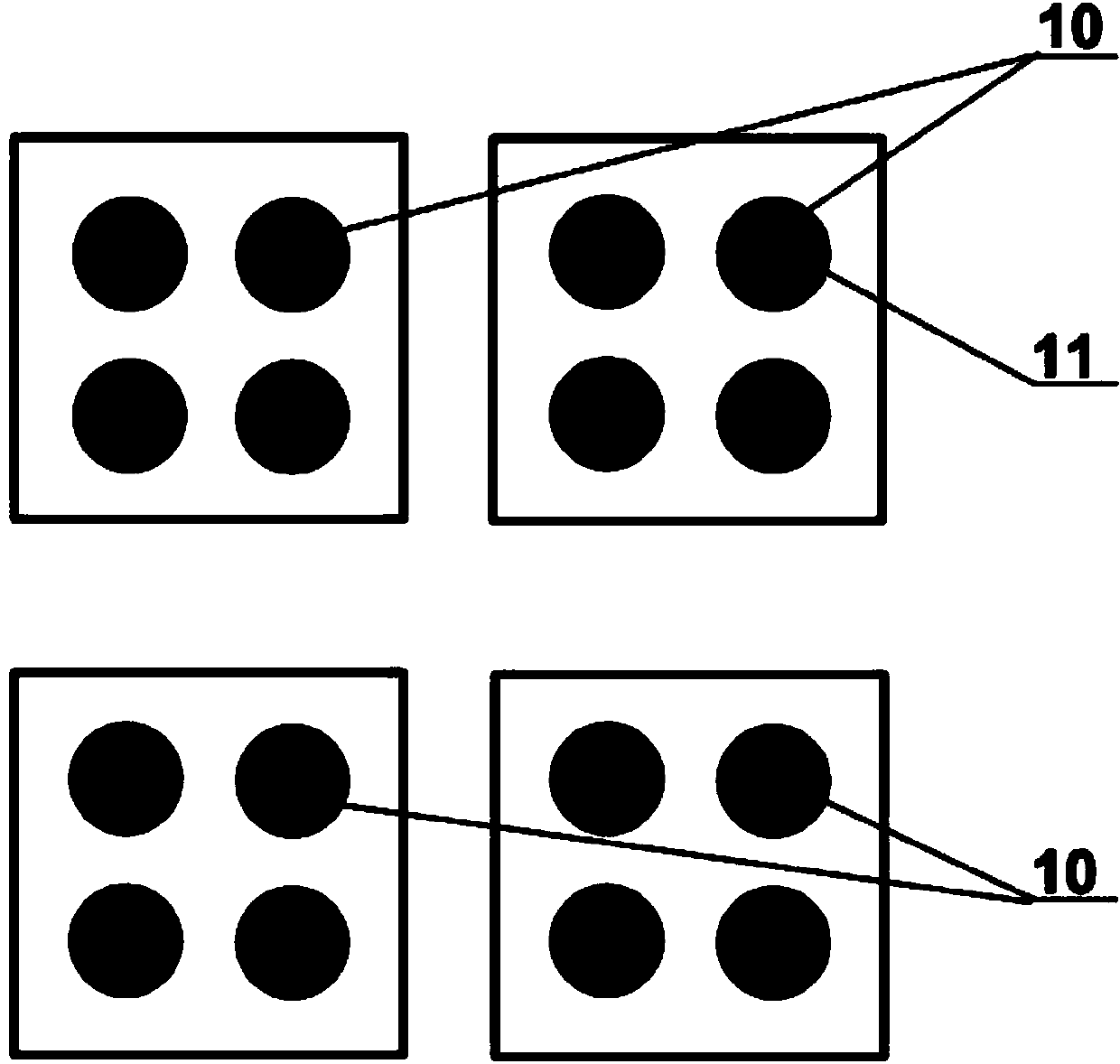

Device for realizing 3D metal printing by virtue of supporting structure

ActiveCN105618756AReasonable structureSimple structureAdditive manufacturing apparatusAutomatic controlShielding gas

The invention relates to a device for realizing 3D metal printing by virtue of a supporting structure. The device comprises a translation stage capable of moving along the X-axis, the Y-axis and the Z-axis. Heating resistance wires and a thermocouple are arranged on a base plate of the translation stage. The heating resistance wires are used for preheating the base plate, so as to enable metal droplet layers to be tightly overlapped. The thermocouple is used for realizing the measurement and the feedback control of a temperature. An electromagnetic induction heating copper pipe and a cooling water pipe are arranged outside a graphite crucible, metallic raw materials are enabled to be molten to form molten metal, the bottom of the graphite crucible is connected with a metal printing spray nozzle, a protective gas is inputted from a gas inlet pipe at the top of the graphite crucible, and under the pulse pressure, molten metal forms regular metal droplets to drip to the base plate of the translation stage. The 3D metal droplet printing is realized through the cooperation with the movement of the translation stage. A supporting material spray nozzle is adjacent to the metal printing spray nozzle. A uniform mixture of gypsum and photosensitive resin is extruded stably under the constant pressure inputted by the gas inlet pipe so as to print the supporting part of a part. The switching between metal and the supporting material is automatically recognized and controlled by a control system. The 3D metal printing device is reasonable, high in operability, high in degree of automation, high in production efficiency, and suitable for being widely popularized, and ensures the molding quality.

Owner:STATE GRID CORP OF CHINA +5

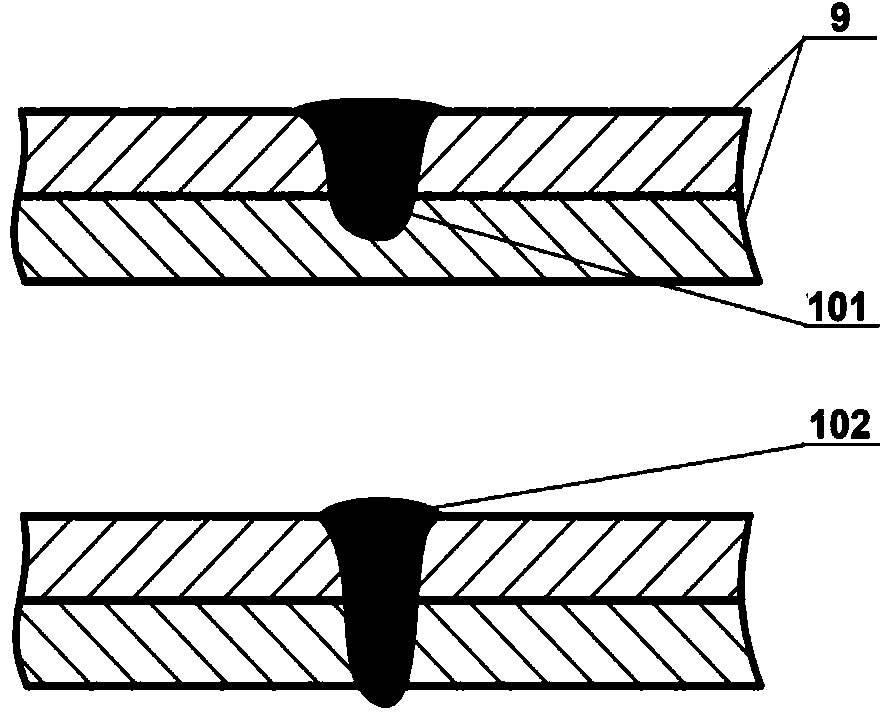

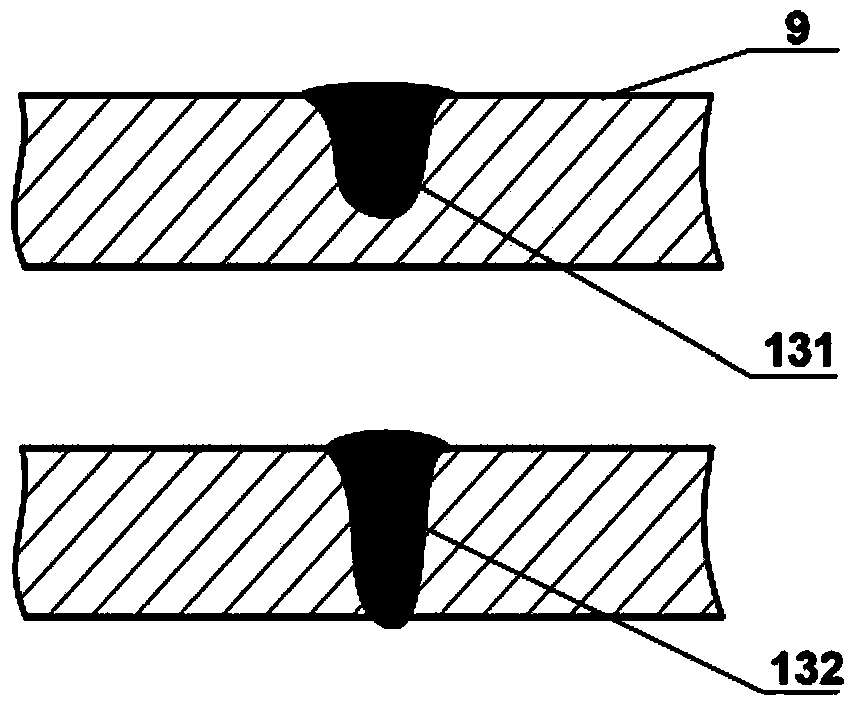

Hybrid welding method and hybrid welding equipment for laser electromagnetic pulse

ActiveCN103737176AImprove adoption efficiencyReduce welding defectsLaser beam welding apparatusStructural deformationMetallic materials

The invention discloses a hybrid welding method and hybrid welding equipment for laser electromagnetic pulse. The method can be used for laser seam welding and laser spot welding technology, a pulsed high magnetic field is applied to a welding region during the process of laser welding on a workpiece with the effect of laser beams so as to mutually react with an induced plasma, a welding pool and a stress strain field through welding and complete welding task. The equipment comprises a laser device, an electromagnetic pulse generator, a numerical control system, an optical transmission system and a laser electromagnetic pulse combined machining head. The combined machining head is used for integrating the laser beams with the pulsed high magnetic field and adjusting the distance between an electromagnetic conversion device and the workpiece; the combined machining head is arranged on a machine tool. The structural deformation can be reduced, the welding quality and machining efficiency are improved, and insurmountable technical problems when a metallic material structure is manufactured through existing single welding technology are solved.

Owner:武汉飞能达激光技术有限公司

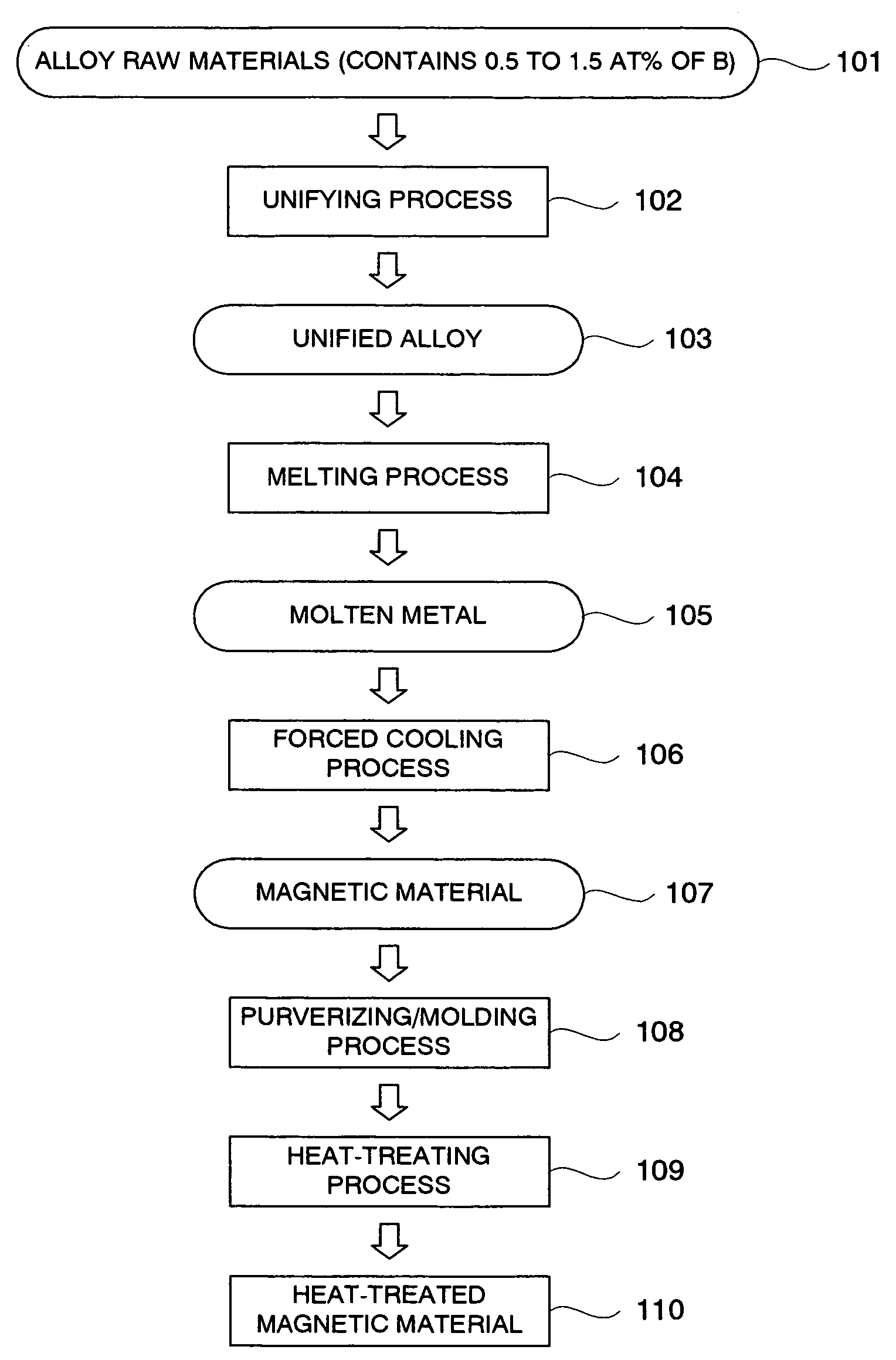

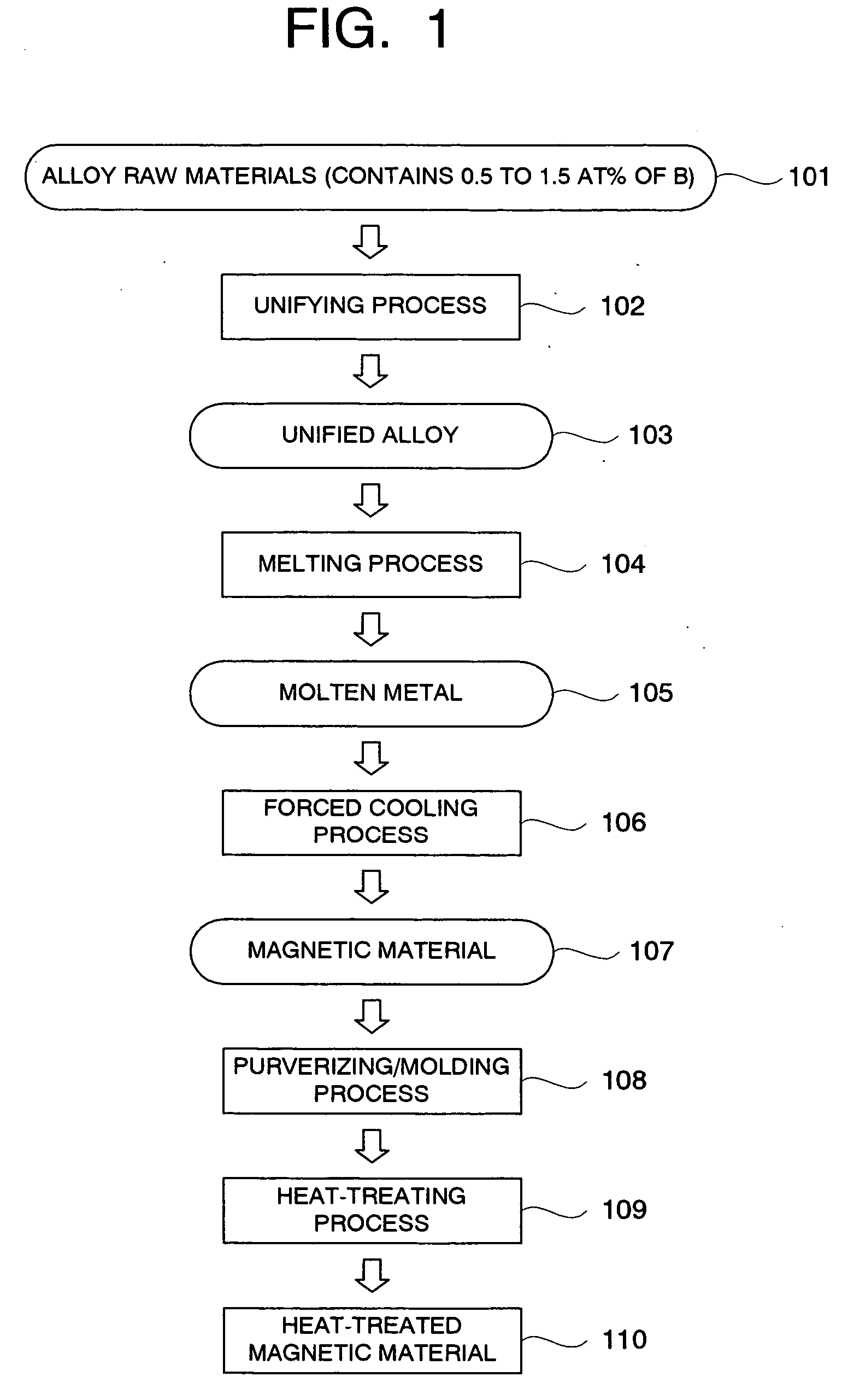

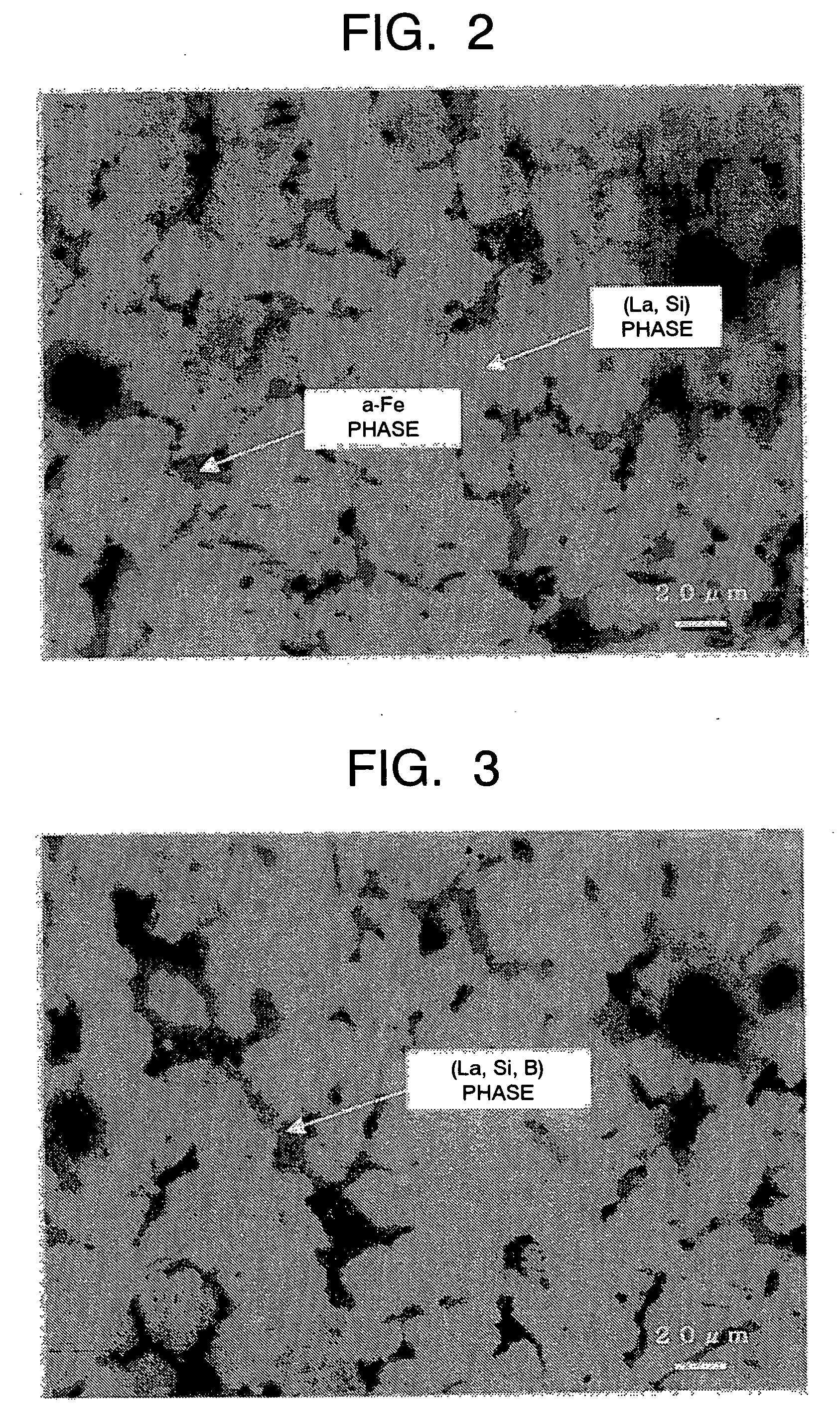

Magnetic refrigeration material and method of manufacturing thereof

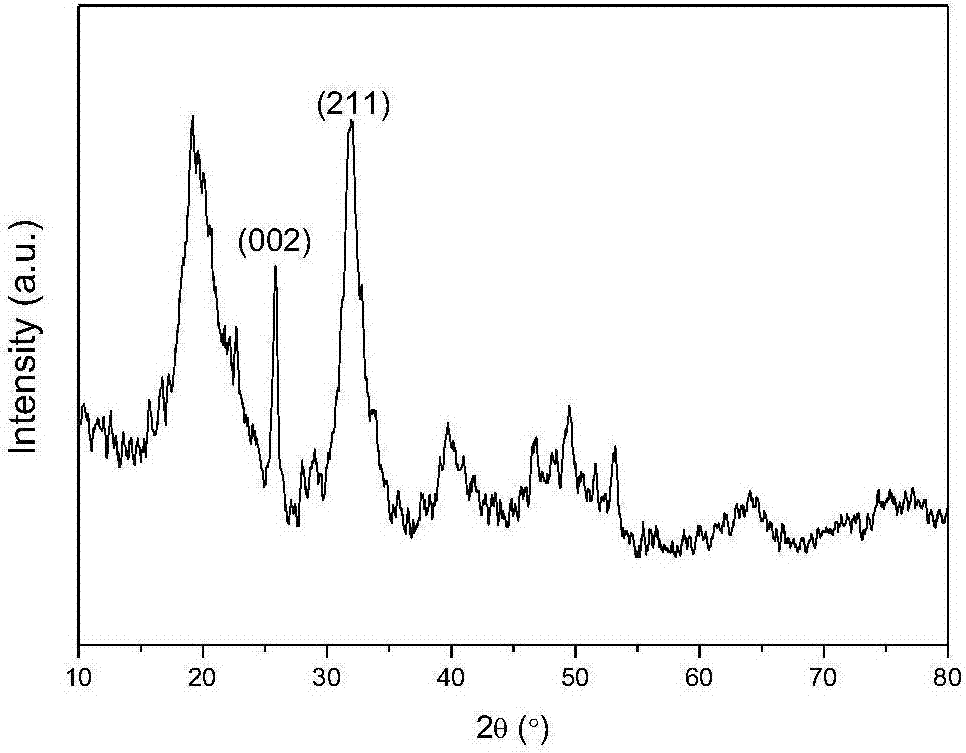

ActiveUS20060213580A1Small sizeImprove uniformityCompression machinesInorganic material magnetismProduction rateCrystal structure

A magnetic material comprising a NaZn13 type crystal structure with uniform and fine microstructure exhibiting excellent characteristics as a magnetic refrigeration material, and a method of manufacturing the magnetic refrigeration material are provided. An alloy composition for forming magnetic material of the NaZn13 type crystal structure was melted comprising 0.5 atomic percent to 1.5 atomic percent of B to molten metal. The molten metal is rapidly cooled and solidified by a forced cooling process. Then, a rapidly cooled alloy having the NaZn13 type crystal structure was obtained. In this manner, magnetic materials comprising the NaZn13 type crystal structure phase, or the NaZn13 type crystal structure phase accompanied with other phases such as α-Fe phase having very small phase regions was manufactured without requiring heat treatment for a long time. As the result, productivity of manufacturing the magnetic refrigeration material is remarkably enhanced.

Owner:KK TOSHIBA

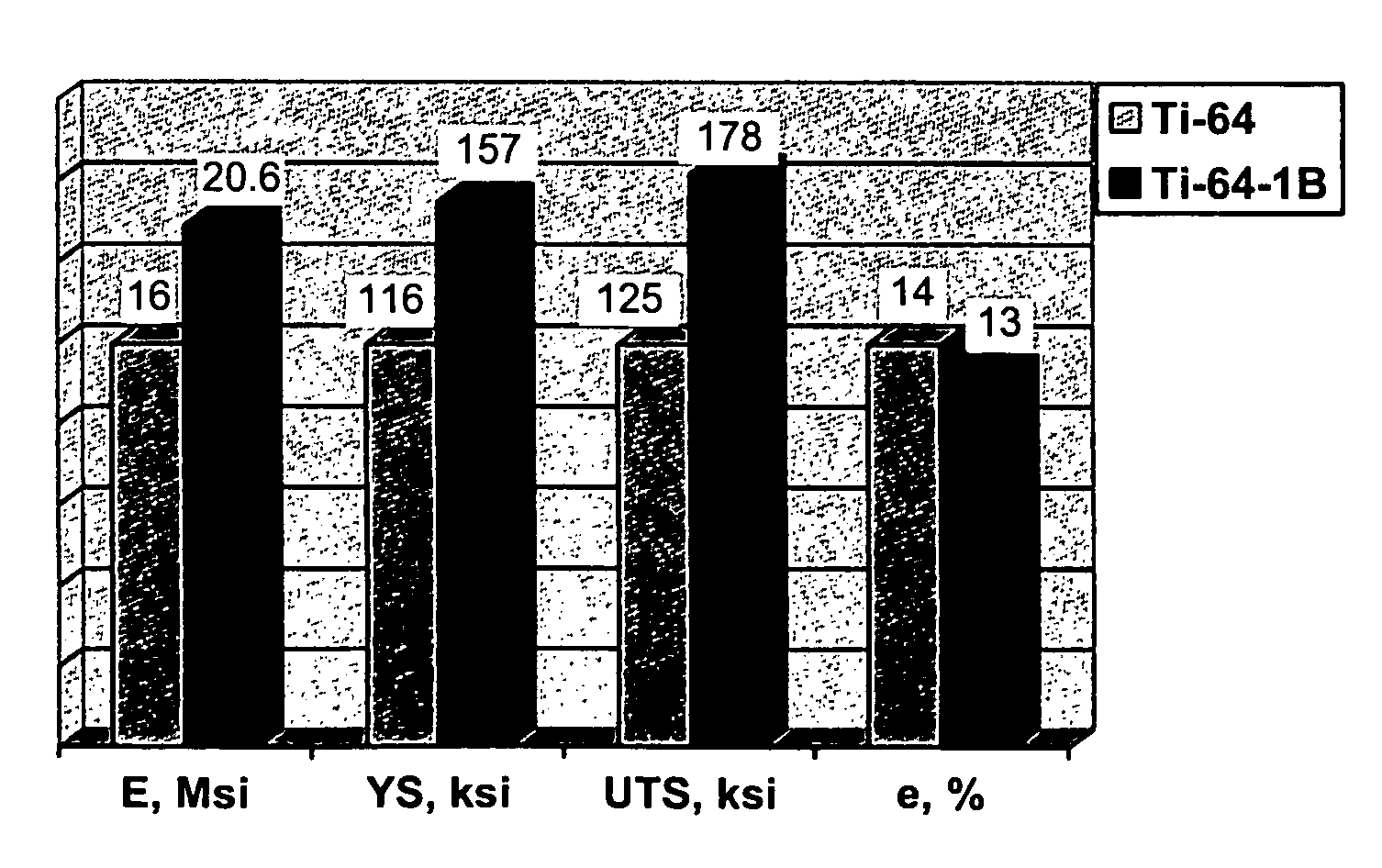

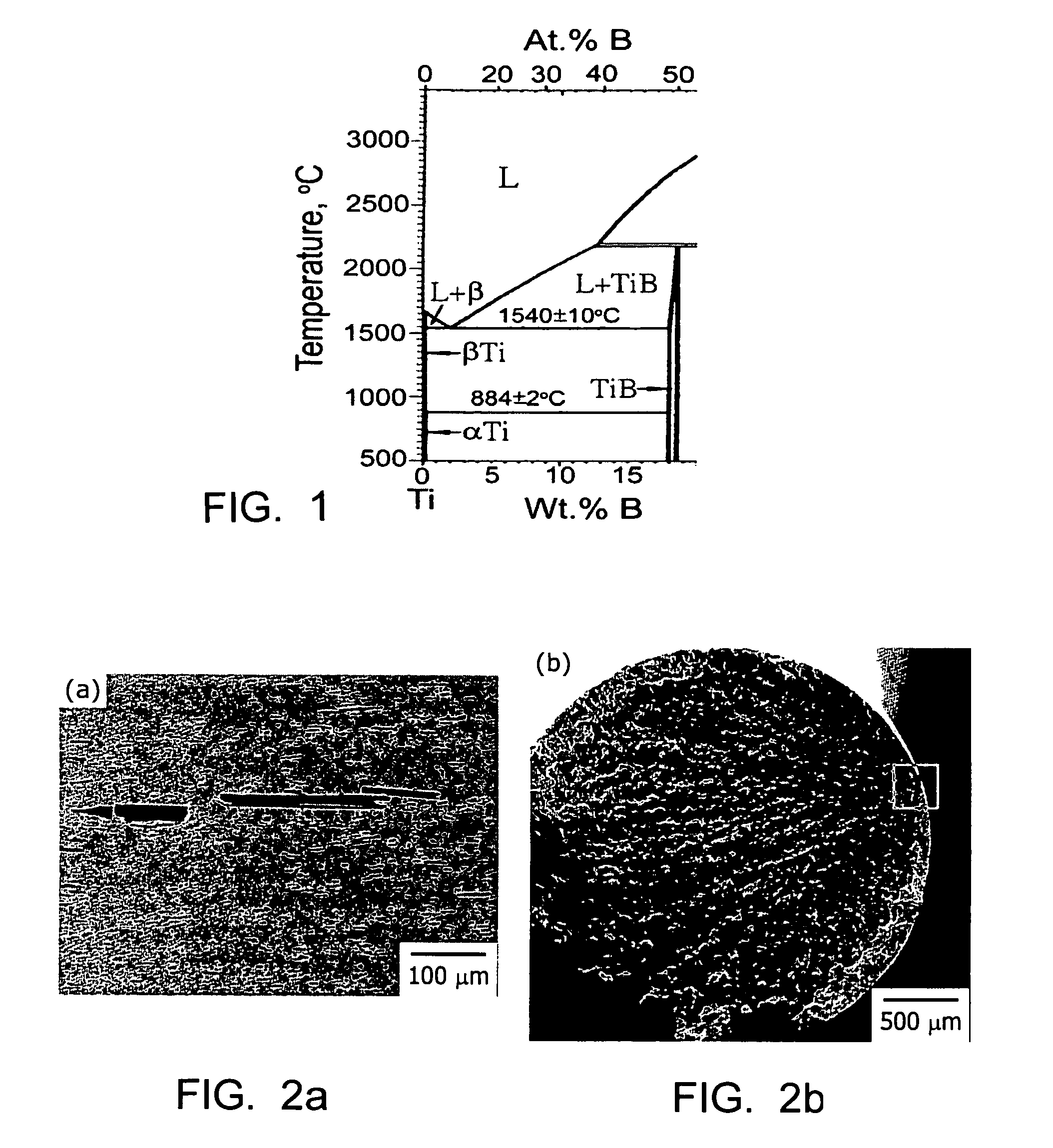

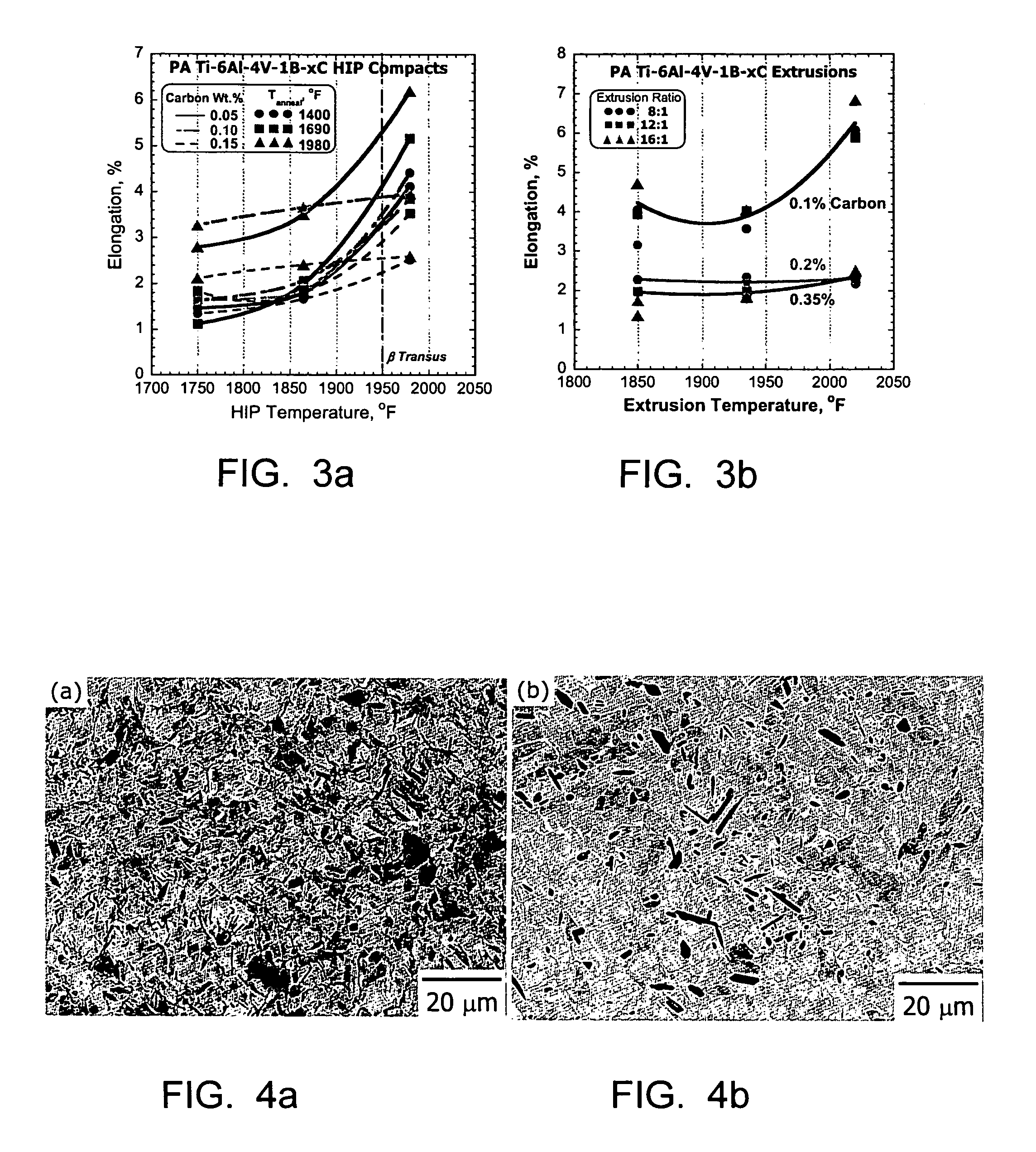

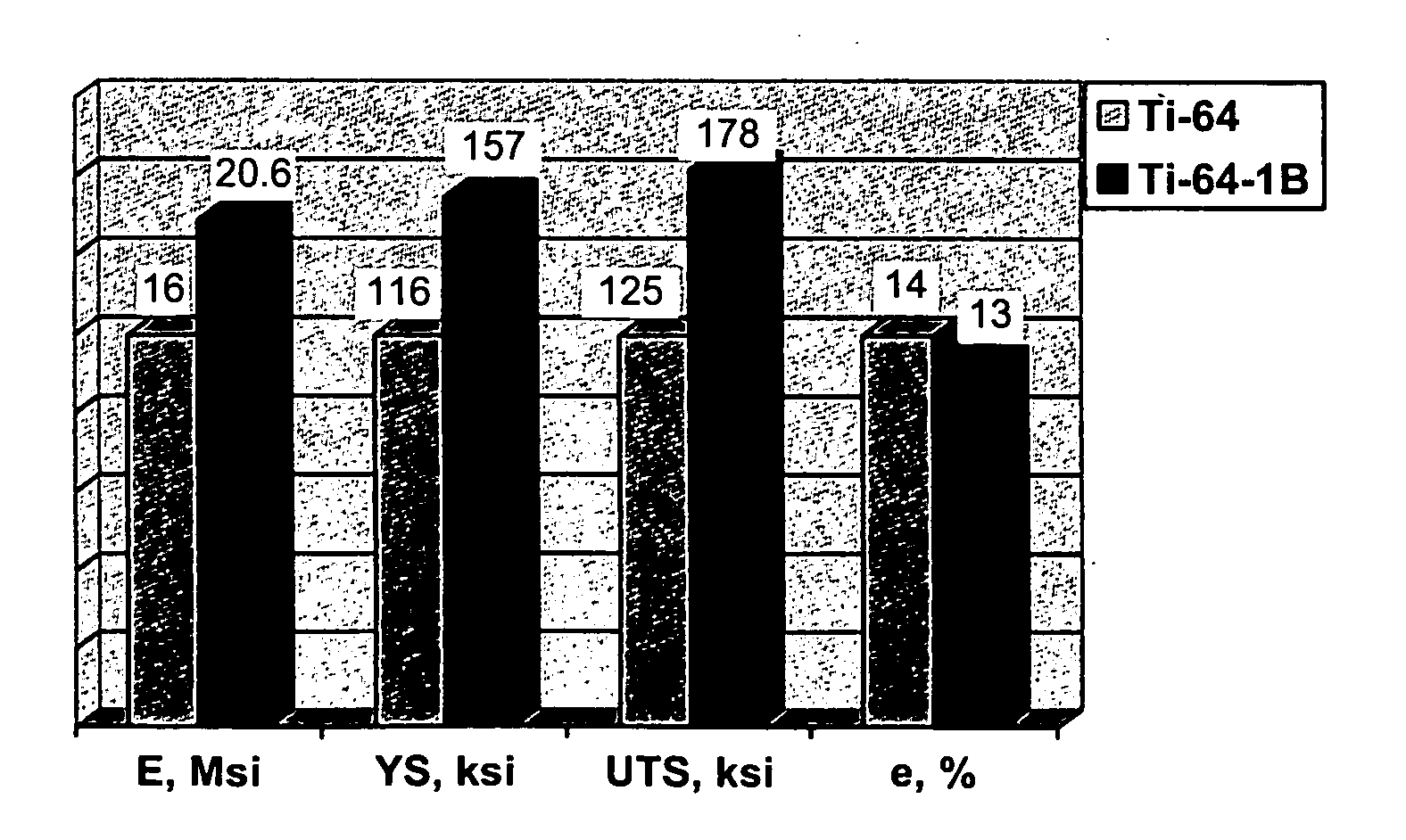

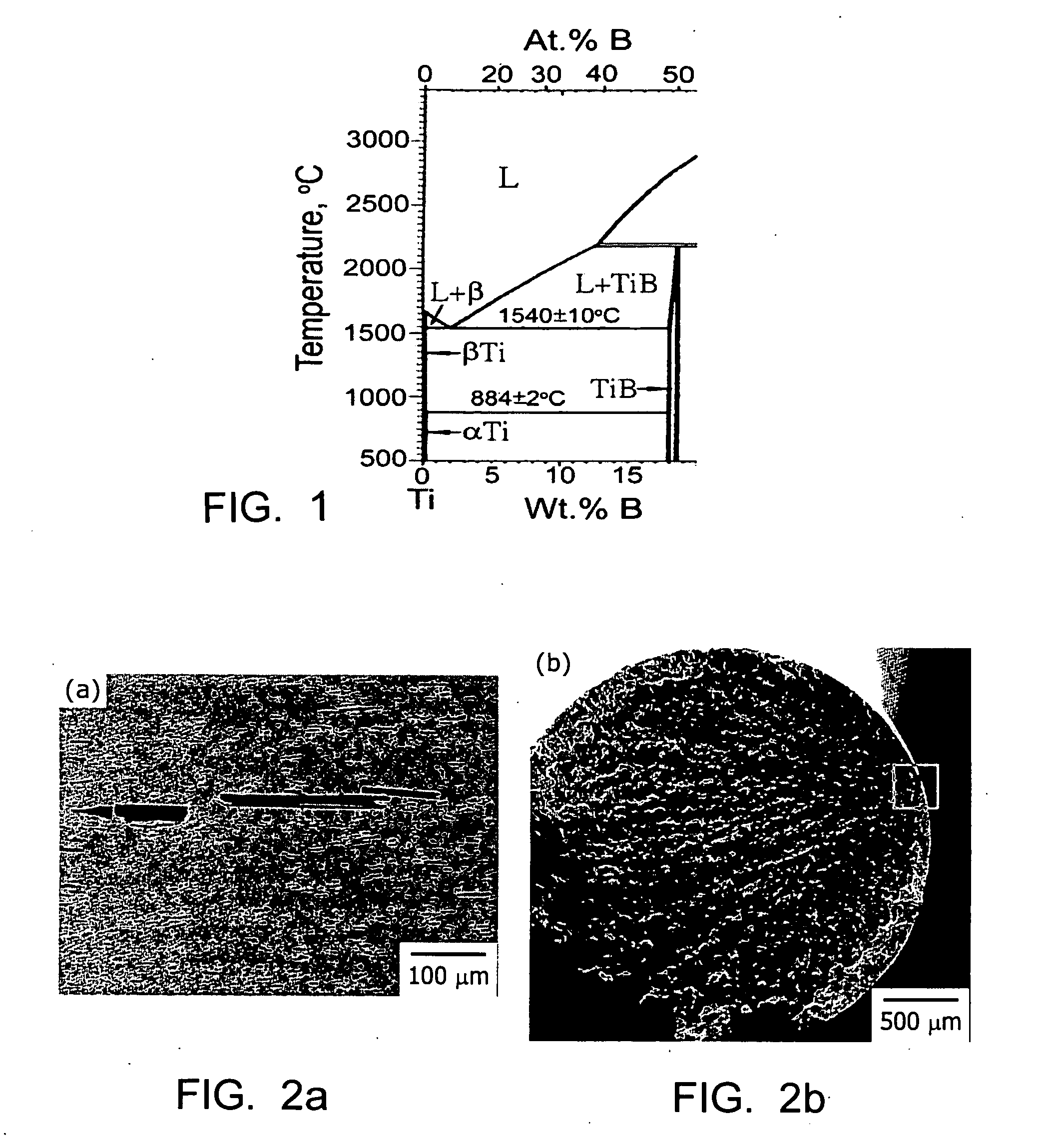

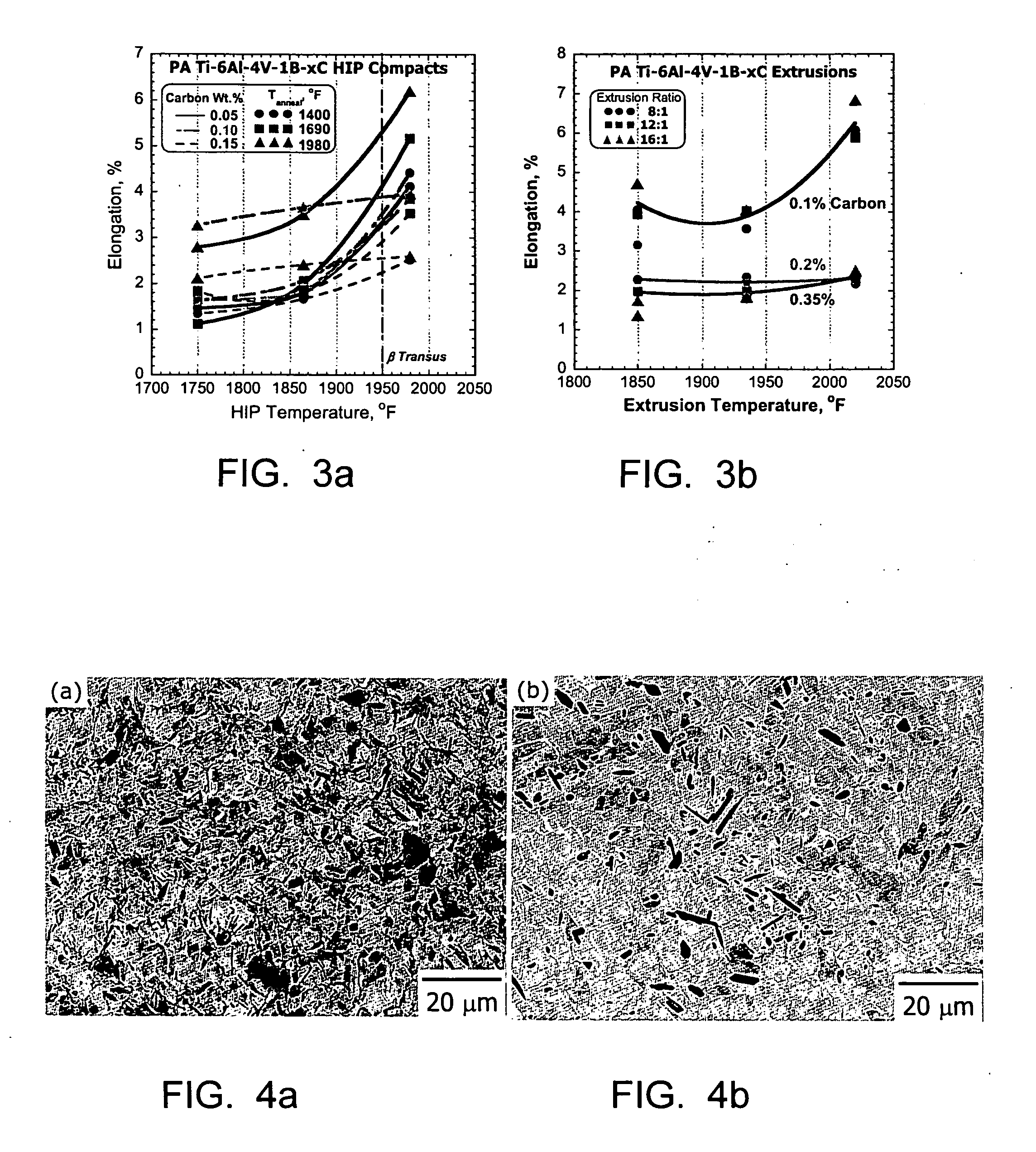

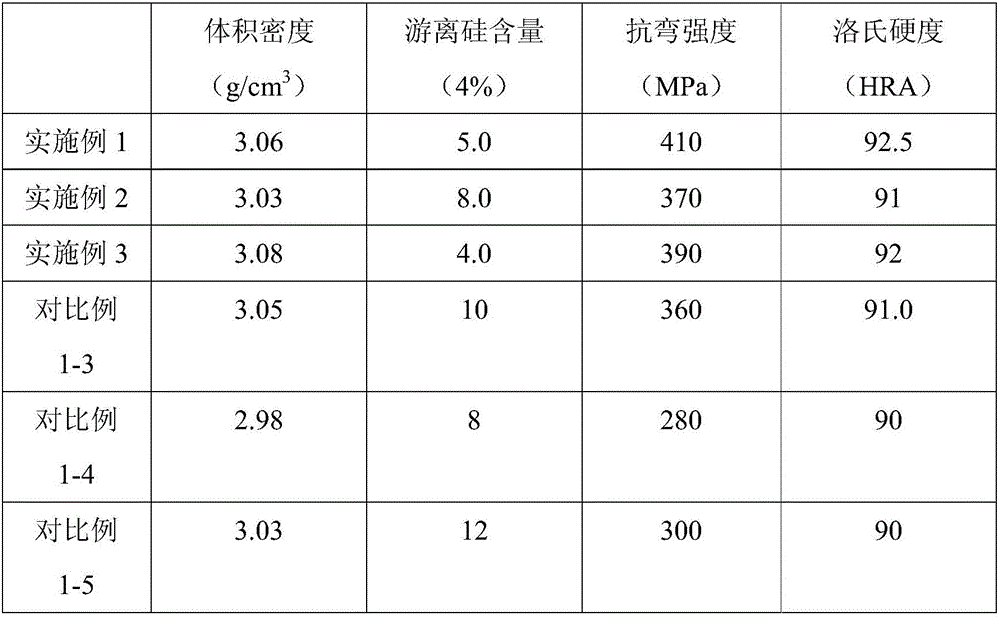

Method of producing high strength, high stiffness and high ductility titanium alloys

A method of producing a high strength, high stiffness and high ductility titanium alloy, comprising combining the titanium alloy with boron so that the boron concentration in the boron-modified titanium alloy does not exceed the eutectic limit. The carbon concentration of the boron-modified titanium alloy is maintained below a predetermined limit to avoid embrittlement. The boron-modified alloy is heated to a temperature above the beta transus temperature to eliminate any supersaturated excess boron. The boron-modified titanium alloy is deformed at a speed slow enough to prevent microstructural damage and reduced ductility.

Owner:ATI PROPERTIES +2

High potential gradient zinc oxide pressure-sensitive resistor material and preparation process thereof

InactiveCN102515742AExtended service lifeReduce energy consumptionVaristor coresHigh energyElectric power system

The invention relates to a high potential gradient zinc oxide pressure-sensitive resistor material and a preparation process thereof. The high potential gradient zinc oxide pressure-sensitive resistor material with uniform particle sizes is obtained by weighing a main material ZnO, a doping oxide, and a product rare earth oxide obtained by carrying out thermal decomposition on a rare earth oxalate or / and carbonate or / and hydroxide according to proportions, carrying out high energy wet grinding, drying, presintering at 200-800DEG C, carrying out high energy dry grinding, and sintering at 800-1100DEG C. The preparation process of the invention has the advantages of simplicity, low cost, environmental protection and low energy consumption, and the prepared zinc oxide pressure-sensitive resistor material can be used for preparing high quality lightning arrester products for ultrahigh electric power systems.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparing method for nanometer toughening ultra-fine grain WC-Co cemented carbide

ActiveCN107475548AUniform particle sizeNarrow normal distribution of particle sizePorosityFlexural strength

The invention discloses a preparing method for nanometer toughening ultra-fine grain WC-Co cemented carbide. The preparing method for the nanometer toughening ultra-fine grain WC-Co cemented carbide comprises the following steps of that 0.1-0.5 micron ultra-fine powder of WC hard phase and Co binder phase is prepared by adopting an airflow crushing classification method and a high-pressure water atomization method correspondingly, and the ultra-fine grain cemented carbide is prepared through material matching and nano-metal mixed additives adding, airflow mixed powder sieving, ball milling waxing and drying sieving, mold pressing and cold isostatic pressing molding and pressure sintering and heat treating, wherein the nano-metal mixed additives are prepared by adopting vacuum electric arc smelting ingot casting plus rapid-in-situ packaging plasma arc process discharging method. The nano-metal mixed additives play the role of refining the cemented carbide granules, improving the material wettability, reducing the porosity and enhancing the local grain boundary strength, so that macro performances such as hardness, flexural strength and fracture toughness of the alloy are improved greatly. The preparing method for the nanometer toughening ultra-fine grain WC-Co cemented carbide has the advantages of being high in production efficiency, low in production cost, high in product quality and purity, and a great deal of man-hour and energy consumption are saved.

Owner:SHENYANG SHENGSHI WUHUAN TECH CO LTD

Method for preparing toughened aluminum oxide ceramic based on stereo lithography appearance namely 3D printing

InactiveCN106673627ASolve technical defects of uneven structureInhibit productionAdditive manufacturing apparatusCeramic shaping apparatusPhotoinitiatorMicrostructure

The invention belongs to the technical field of 3D printing, and particularly relates to a method for preparing toughened aluminum oxide ceramic based on stereo lithography appearance namely 3D printing. The invention provides a composition. The composition comprises the following raw materials: aluminum oxide ceramic powder, a liquid premix, a photoinitiator, a dispersant and a surfactant. The invention further provides a preparation method for preparing zirconium oxide-toughened aluminum oxide ceramic by using the composition. The preparation method comprises the following steps: preparing a slurry, moulding, drying and degreasing, wherein a blank is dried primarily, degreased and post-treated. According to the technical scheme provided by the invention, the ceramic blank is prepared by stereo lithography appearance, so that the moulding efficiency is high and the dimensional accuracy of the product is high; through optimization of parameters in the degreasing step, the blank does not deform and does not crack in the degreasing process; by an infiltrating step, the growth of aluminum oxide crystal grains is inhibited, and through electronic microscopic observation on the product structure, the microstructure of the product is uniform; the technical defect that in the prior art, the structure of the zirconium oxide-toughened aluminum oxide ceramic is nonuniform is overcome.

Owner:GUANGDONG UNIV OF TECH

Method of producing high strength, high stiffness and high ductility titanium alloys

A method of producing a high strength, high stiffness and high ductility titanium alloy, comprising combining the titanium alloy with boron so that the boron concentration in the boron-modified titanium alloy does not exceed the eutectic limit. The carbon concentration of the boron-modified titanium alloy is maintained below a predetermined limit to avoid embrittlement. The boron-modified alloy is heated to a temperature above the beta transus temperature to eliminate any supersaturated excess boron. The boron-modified titanium alloy is deformed at a speed slow enough to prevent microstructural damage and reduced ductility.

Owner:ATI PROPERTIES +2

Method for preparing fine-grain silicon carbide ceramic through reaction sintering

The invention discloses a method for preparing fine-grain silicon carbide ceramic through reaction sintering. The method sequentially comprises the following steps: preparing a main material comprising 75-90wt% of silicon carbide micro-powder and 10-15wt% of active carbon powder; adding a dispersant and deionized water to the main material, sequentially adding an aqueous solution of organic matters containing high temperature carbon residue and a water-soluble polymer binder solution, and stirring and mixing above materials in a ball mill to prepare a uniformly-dispersed water-based silicon carbide slip; and sequentially carrying out spray granulation, dry press molding, dewaxing, vehicle working, high temperature siliconising sintering and alkali treatment desilication to obtain the silicon carbide ceramic.

Owner:浙江东新新材料科技有限公司

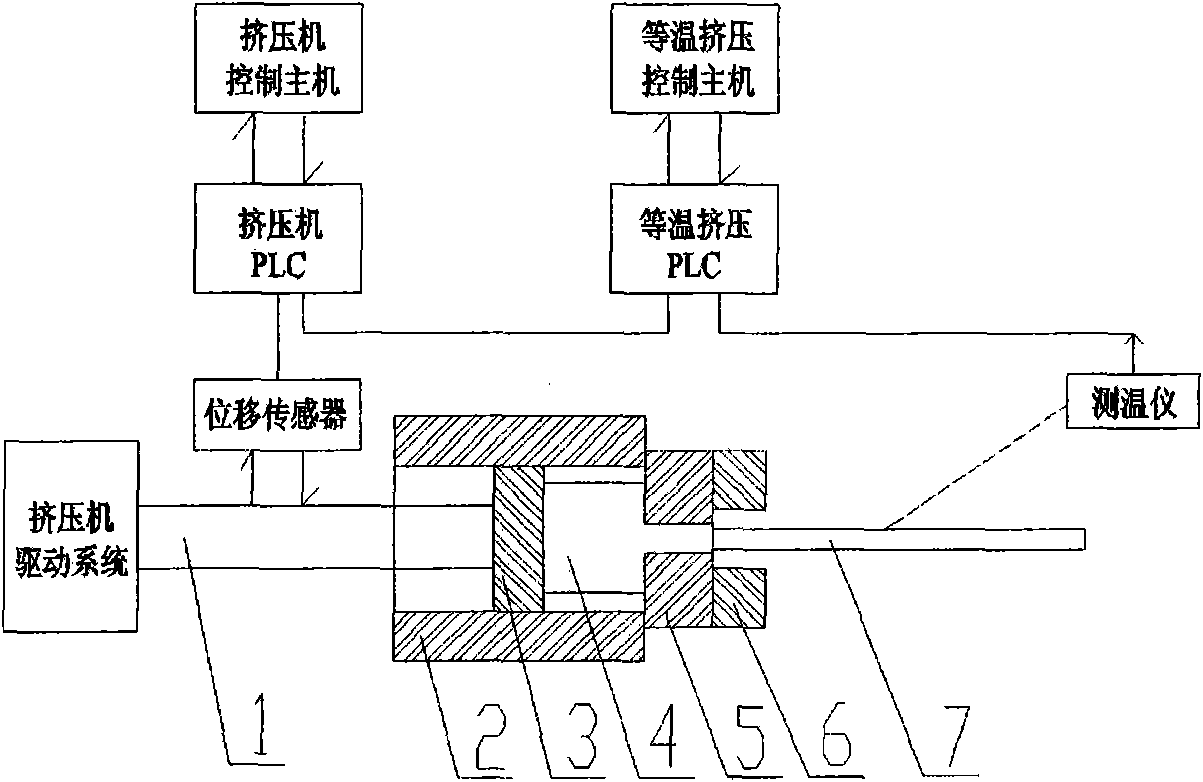

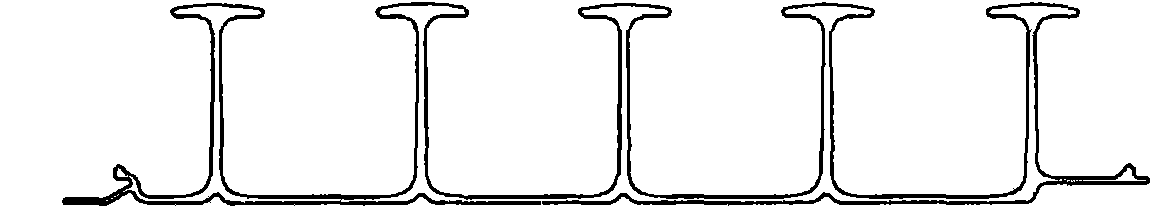

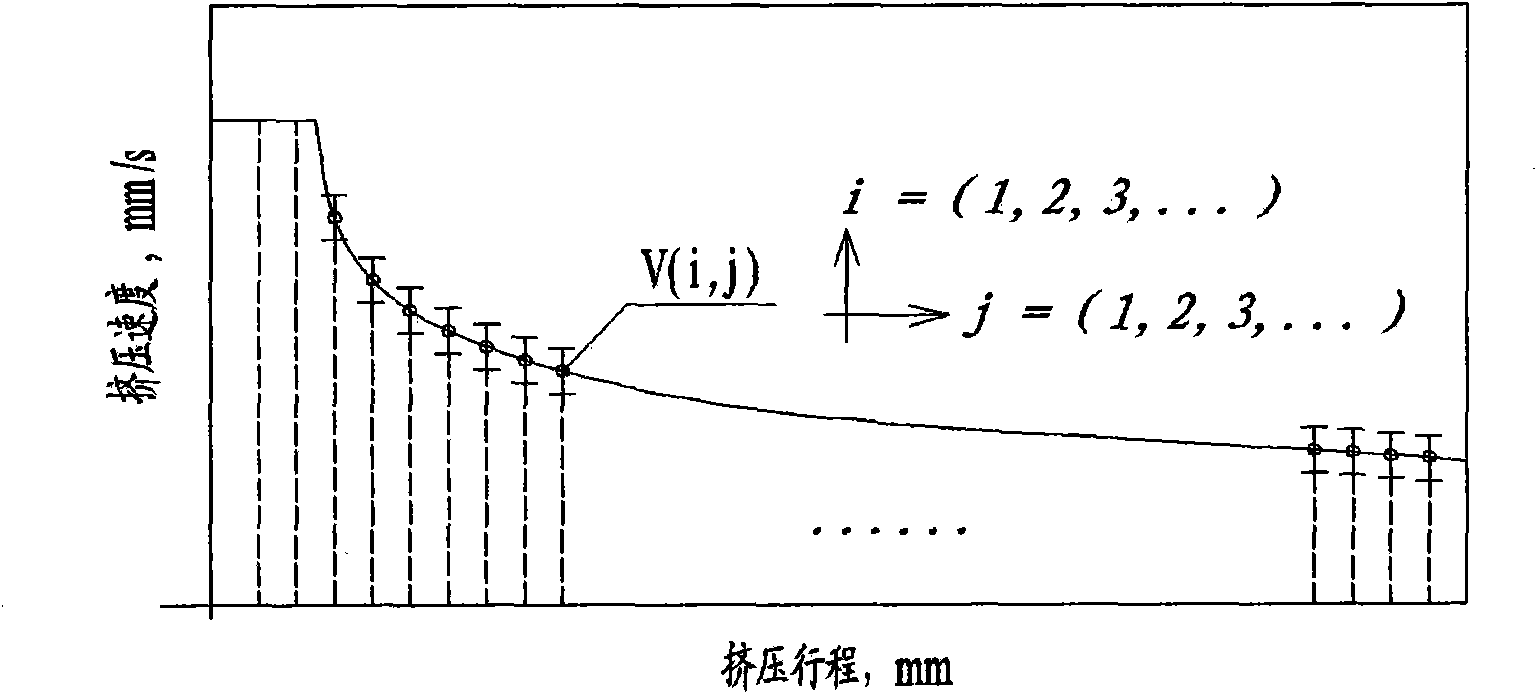

Method for controlling speed regulation of isothermal extrusion of industrial aluminum profiles for transportation

InactiveCN102049426AShort measurement response timeUniform microstructureExtrusion control devicesTemperature controlControl system

The invention discloses a method for controlling the speed regulation of the isothermal extrusion of industrial aluminum profiles for transportation, wherein a control system host machine, an isothermal extrusion PLC (Programmable Logic Controller) and an industrial aluminum profile outlet temperature thermodetector are used. The isothermal extrusion curves of the industrial aluminum profiles and profile outlet temperature control information are saved in the control system host machine. The method comprises the steps of: continuously monitoring and acquiring extruded profile outlet temperature by the thermodetector, importing temperature data into the isothermal extrusion PLC, issuing an extrusion speed regulation instruction by the isothermal extrusion PLC and a control system according to the detected temperature, transmitting the extrusion speed regulation instruction to an extruder PLC through the isothermal extrusion PLC, and regulating the increment / decrement of the extrusion speed of an extruder; and meanwhile, feeding back the real-time extrusion speed of the extruder to the isothermal extrusion PLC by the extruder PLC, and carrying out the processes in cycle. The method disclosed by the invention obviously improves the automation degree and production and manufacture efficiency of the extrusion production procedure of the industrial aluminum profiles and solves the technical problems of huge quality fluctuation and low production efficiency caused by controlling on the basis of manual experience for a long time.

Owner:GUANGDONG XINGFA ALUMINUM

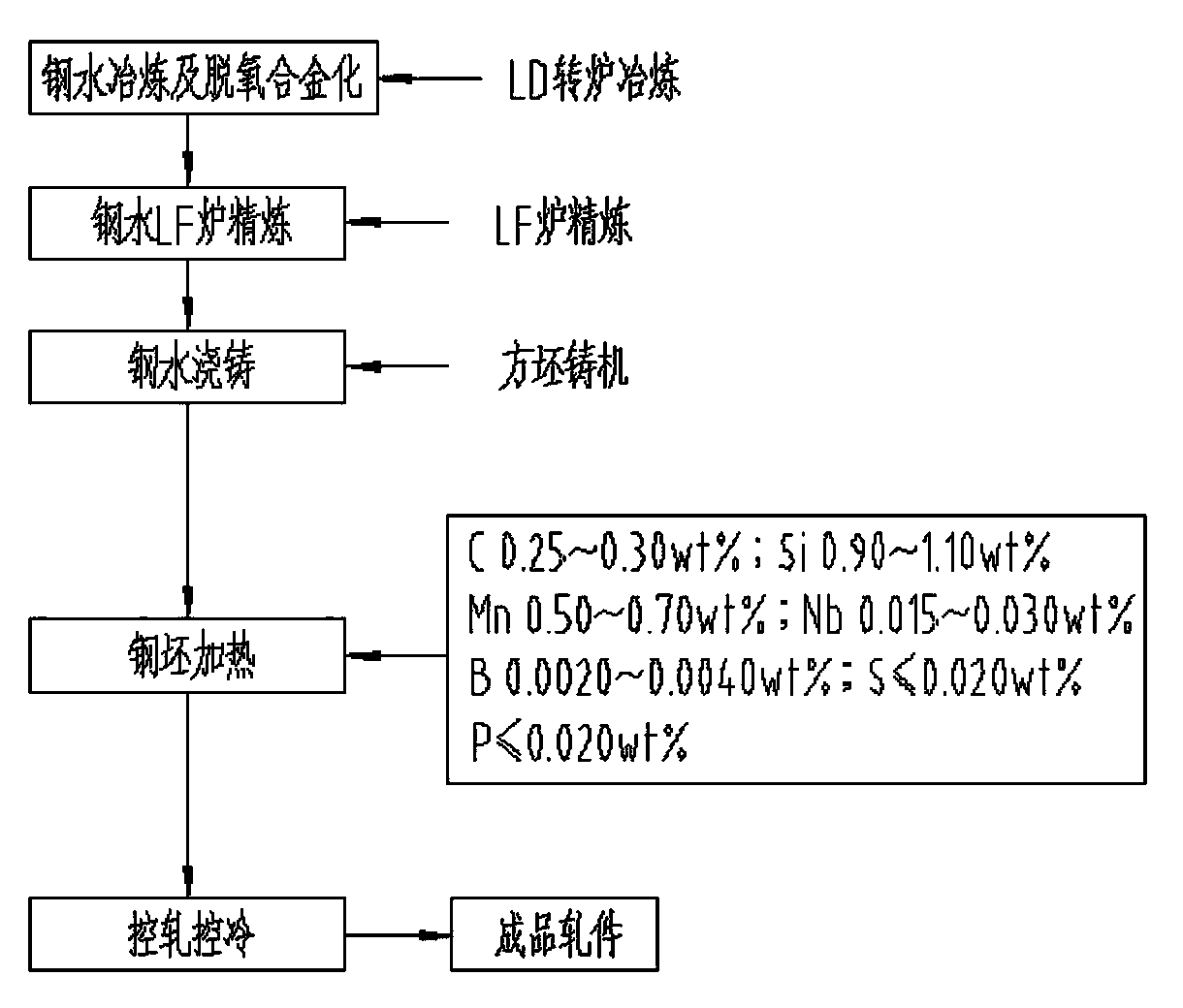

Optical round wire rod reinforcement bar for producing prestressed concrete steel rod and processing method

The invention discloses an optical round wire rod reinforcement bar for producing a prestressed concrete steel rod and a processing method. A steel blank comprises in percentage by weight: 0.25-0.30% of C, 0.90-1.10% of Si, 0.50-0.70% of Mn, 0.015-0.030% of Nb, 0.0020-0.0040% of B, no more than 0.020% of S, no more than 0.020% of P and the balance of Fe and inevitable impurities; the optical round wire rod reinforcement bar with the nominal diameter of 8.0-14.0mm is produced by heating and performing controlled rolling and controlled cooling to the steel blank, and has the following characteristics that the tensile strength (Rm) is 630-660MPa, the percentage reduction of area is more than or equal to 65%, and the ferrite grain size is 10.0-11.5 level. Through integration and creation of converter melting, LF melting, steel blank heading and multiple technology of standard and delay type controlled rolling and controlling cooling and the like, the invention provides a production method of the optical round wire rod reinforcement bar for producing the prestressed concrete steel rod, and the product is high in hardenability, and uniform in microscopic structure. The method has the advantages of excellent quality, low production cost, good processability, strong popularization and the like.

Owner:WUKUN STEEL

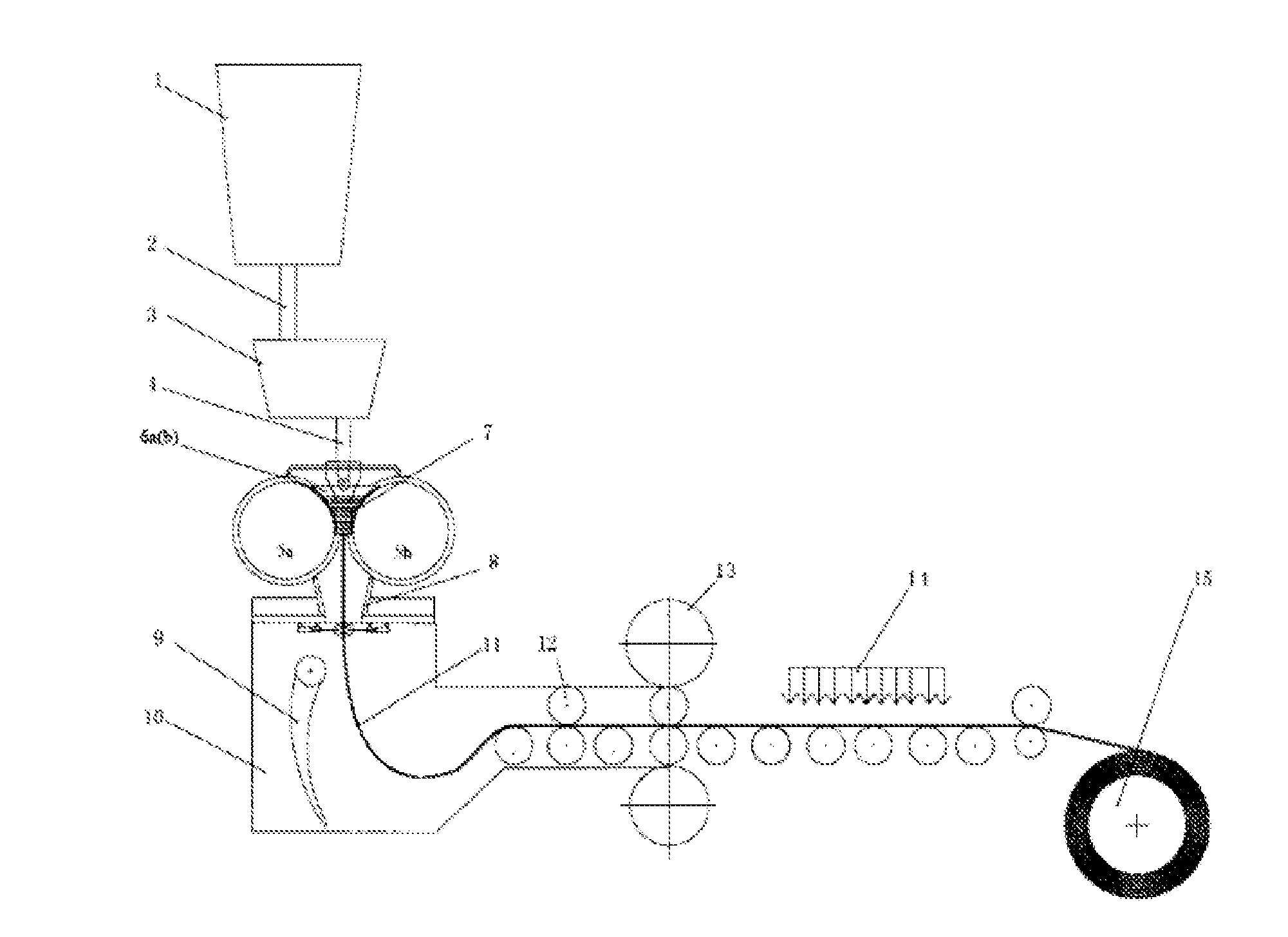

Method for Manufaturing Thin Strip Continuously Cast 700MPa-Grade High Strength Weather-Resistant Steel

ActiveUS20140366602A1High elongationUniform microstructureFurnace typesRollsMicrostructureReduction rate

A method for manufacturing thin strip continuously cast 700 Mpa grade high strength weather-resistant steel, the method comprising the following steps: 1) casting a 1-5 mm thick cast strip in a double roller continuous casting machine, the cast strip comprising the following chemical compositions by weight percent: C 0.03-0.1%, Si≦0.4%, Mn 0.75-2.0%, P 0.07-0.22%, S≦0.01%, N≦0.012%, and Cu 0.25-0.8%, further comprising more than one of Nb, V, Ti and Mo: Nb 0.01-0.1%, V 0.01-0.1%, Ti 0.01-0.1%, and Mo 0.1-0.5%, and the balance being Fe and unavoidable impurities; 2) cooling the cast strip at a rate greater than 20° C. / s; 3) hot rolling the cast strip under a temperature of 1050-1250° C. at a reduction rate of 20-50% and a deformation rate greater than 20 s-1; then conducting austenite online recrystallization, the thickness of the hot rolled strip being 0.5-3.0 mm; 4) cooling at a rate of 10-80° C. / s; and 5) rolling up under a temperature of 500-650° C. The obtained steel strip microstructure mainly consists of uniformly distributed bainites and needle-shaped ferrites.

Owner:BAOSHAN IRON & STEEL CO LTD

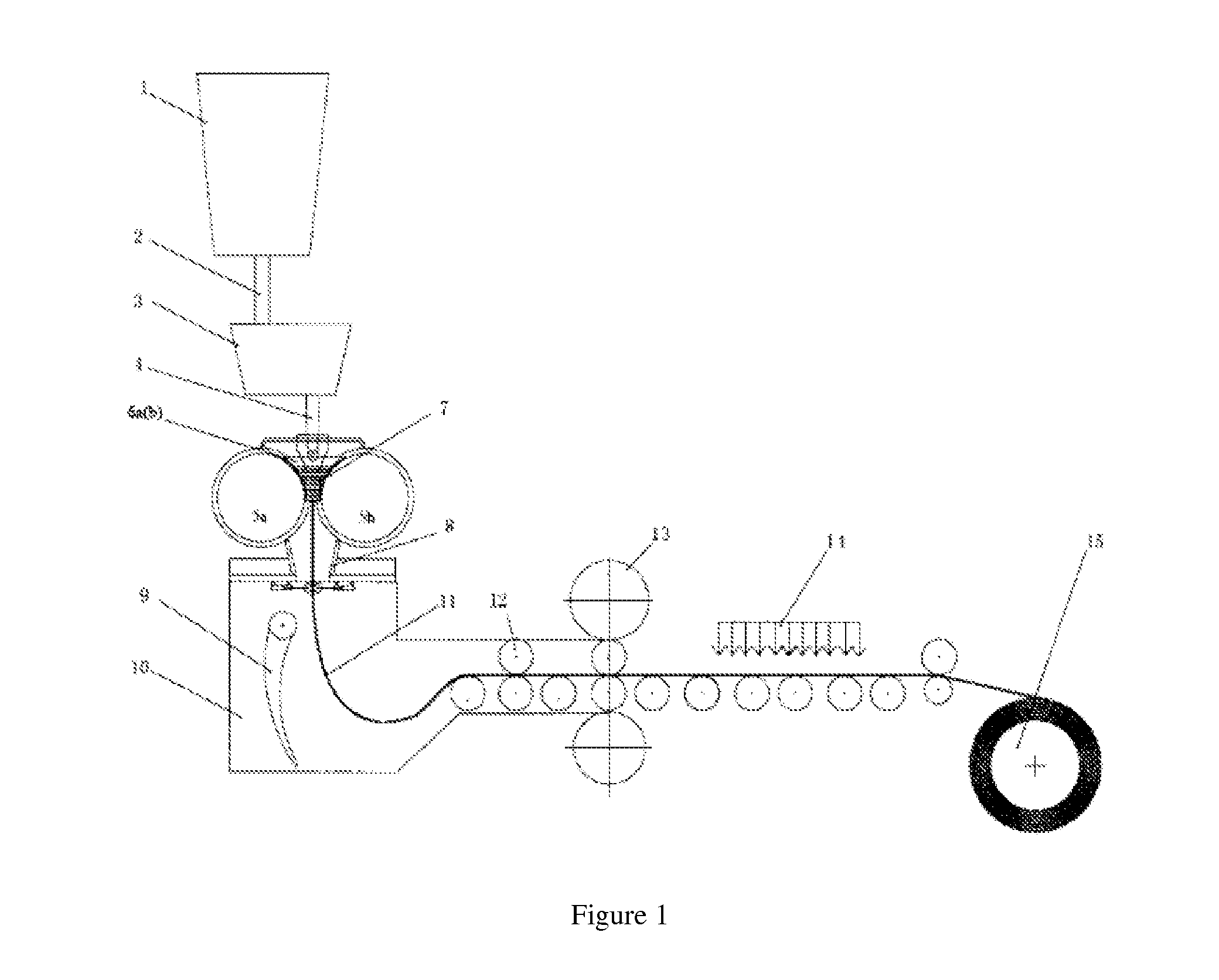

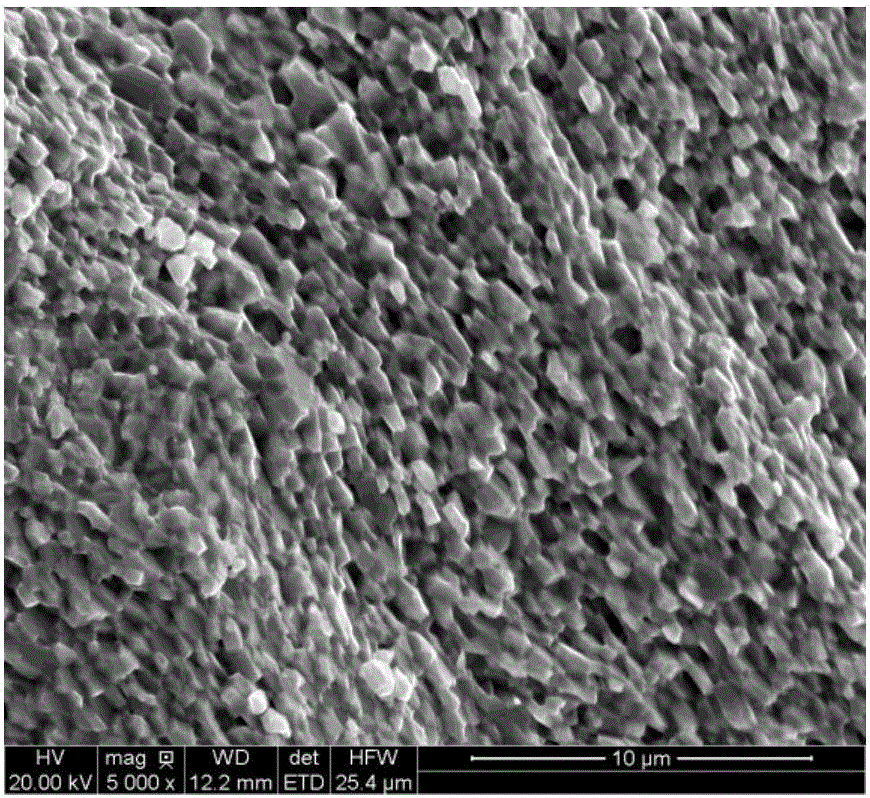

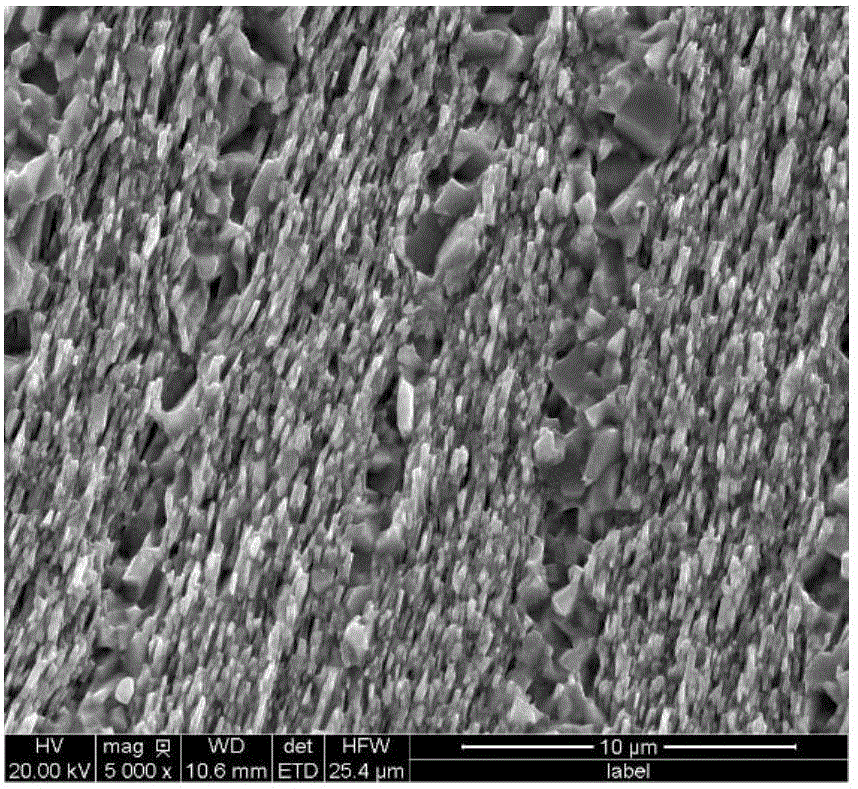

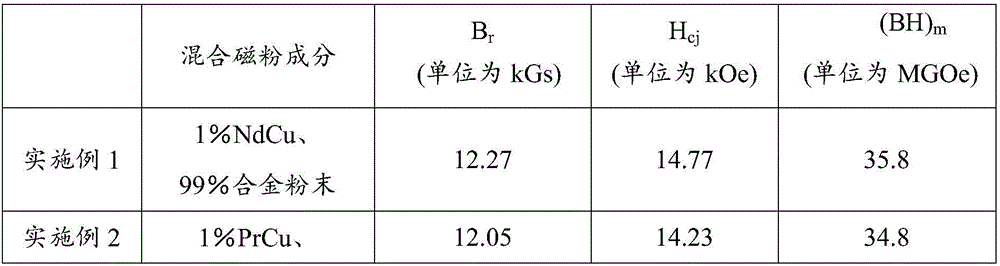

Thermal deformation rare-earth permanent magnet material and preparation method thereof

ActiveCN106548844APromote formationEasy to optimizeInductances/transformers/magnets manufactureMagnetic materialsMass ratioRare earth

The invention relates to a preparation method of a thermal deformation rare-earth permanent magnet material. The method comprises the following steps of (1) providing main magnetic powder and low-melting-point alloy powder separately, wherein a chemical formula of the main magnetic powder is Re<x>Fe<100-x-y-z>M<y>B<z> according to the mass percent, the chemical formula of the low-melting-point alloy powder is ReCu<100-a>, Re is one or more of Nd, Pr, Dy, Tb, La and Ce and a is smaller than or equal to 90 and greater than or equal to 60; (2) mixing the main magnetic powder with the low-melting-point alloy powder evenly to obtain mixed magnetic powder, wherein the mass ratio of the low-melting-point alloy powder in the mixed magnetic powder is greater than 0 and smaller than or equal to 10%; (3) carrying out hydrogenation-disproportionation-dehydrogenation-recombination treatment on the mixed magnetic powder and diffusing a low-melting-point alloy in the treatment process to obtain HDDR magnetic powder; and (4) sequentially carrying out hot-press molding and deformation molding on the HDDR magnetic powder to obtain the thermal deformation rare-earth permanent magnet material. The invention further provides the thermal deformation rare-earth permanent magnet material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Nanocrystalline tungsten-based alloy block body material and preparation method thereof

The invention relates to a plastic forming technique and a powder metallurgical technique, in particular to a nano crystal tungsten based alloy block material and a method for preparing the same. The block material comprises the following components in weight percentage: 86 to 88 percent of W, 6.5 to 7.5 percent of Ni, 2.5 to 3.5 percent of Fe, 2 to 4 percent of Mo and 1 to 2 percent of Co. The preparation method comprises the following steps: Fe-Co-Ni and W-Mo after dry mixing are ball milled in advance respectively until the Fe, Co and Ni completely form solid solution, and tungsten phase crystal grain is thinned to below 100nm; the Fe-Co-Ni and W-Mo are subjected to high energy ball milling until the Fe-Co-Ni is evenly distributed around the W-Mo crystal grain; and the discharge plasma rapid sintering is adopted. The nano crystal tungsten based alloy block material has the advantages of reasonable formula, even and thin microstructure, nearly full compact, higher hardness and tensile strength and good specific elongation, and the method for preparing the block material effectively improves the mechanical performances of the sintering material.

Owner:SOUTH CHINA UNIV OF TECH

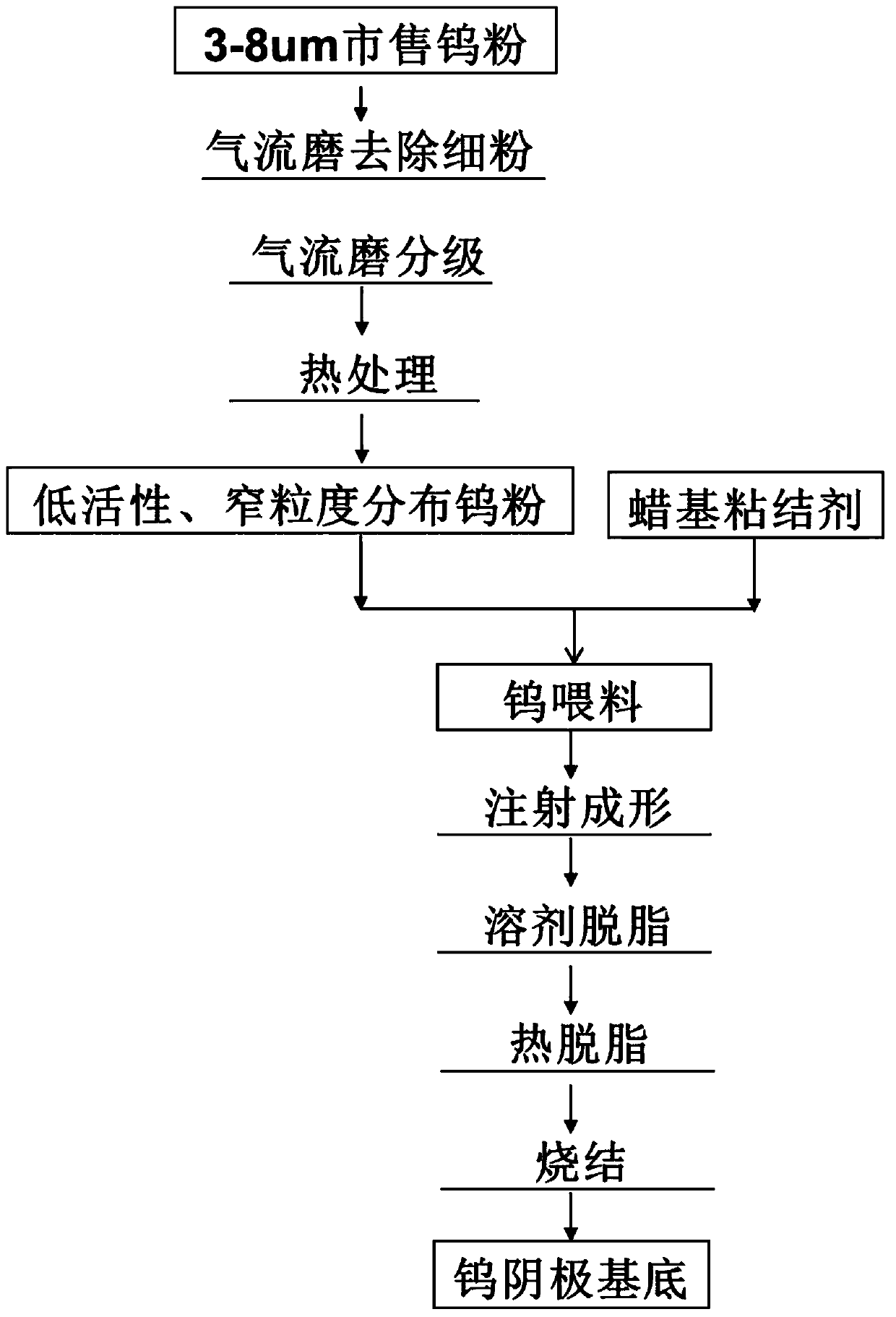

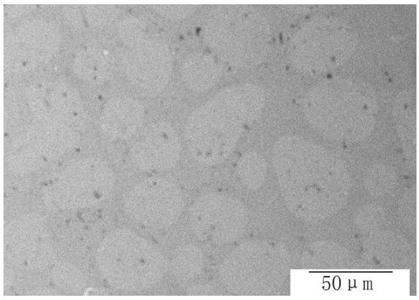

Method for preparing specially-shaped porous tungsten product with uniform pores

ActiveCN105499574AIncrease profitLow costTransportation and packagingMetal-working apparatusPore distributionAlloy

The invention provides a method for preparing a specially-shaped porous tungsten product with uniform pores, and belongs to the technical field of preparation of porous high-temperature alloy. After high-purity tungsten powder is dispersed, aggregates of the tungsten can be opened, and ultrafine particles (particle size being smaller than 2 mum) in original tungsten powder are collected and removed; after stage treatment is carried out, tungsten powder with narrow size distribution can be obtained; after thermal treatment is carried out, the tungsten powder can be purified, and the activity of the tungsten powder can be reduced to obtain nearly spherical powder with narrow size distribution, so that liquidity and tap density of the powder are improved, the loading amount of injection-molded powder is correspondingly improved, shrinkage deformation of a product in a sintering process is reduced, and a porous cathode substrate with high dimension precision is obtained; and the powder size distribution is narrow, and ultrafine powder is absent, so that the obtained cathode substrate is uniform in pore distribution. The porous tungsten product with a complex shape and high dimension precision can be directly prepared by combining jet-milling multi-time treatment with an injection molding process.

Owner:UNIV OF SCI & TECH BEIJING

Soil firming agent

InactiveCN1442465AAdaptableStrong soil effectOrganic fertilisersSoil conditioning compositionsFirming agentMaterials science

A soil solidifying agent is prepared from calcium carbide dregs (25-90 portions), granualr slags (10-75 portions) of blast furnace and chemical trigger (0.1-5 portions) through grinding, and proportional mixing. Its advantages are broad spectrum, and high effect and durability.

Owner:TIANZHUJIE SPECIAL BUILDING MATERIAL TECH DEV BEIJING

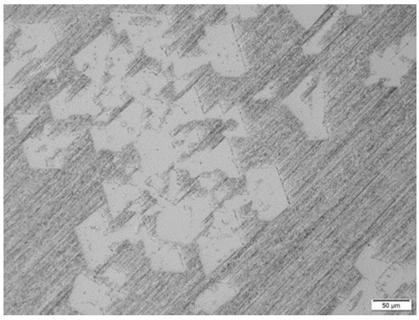

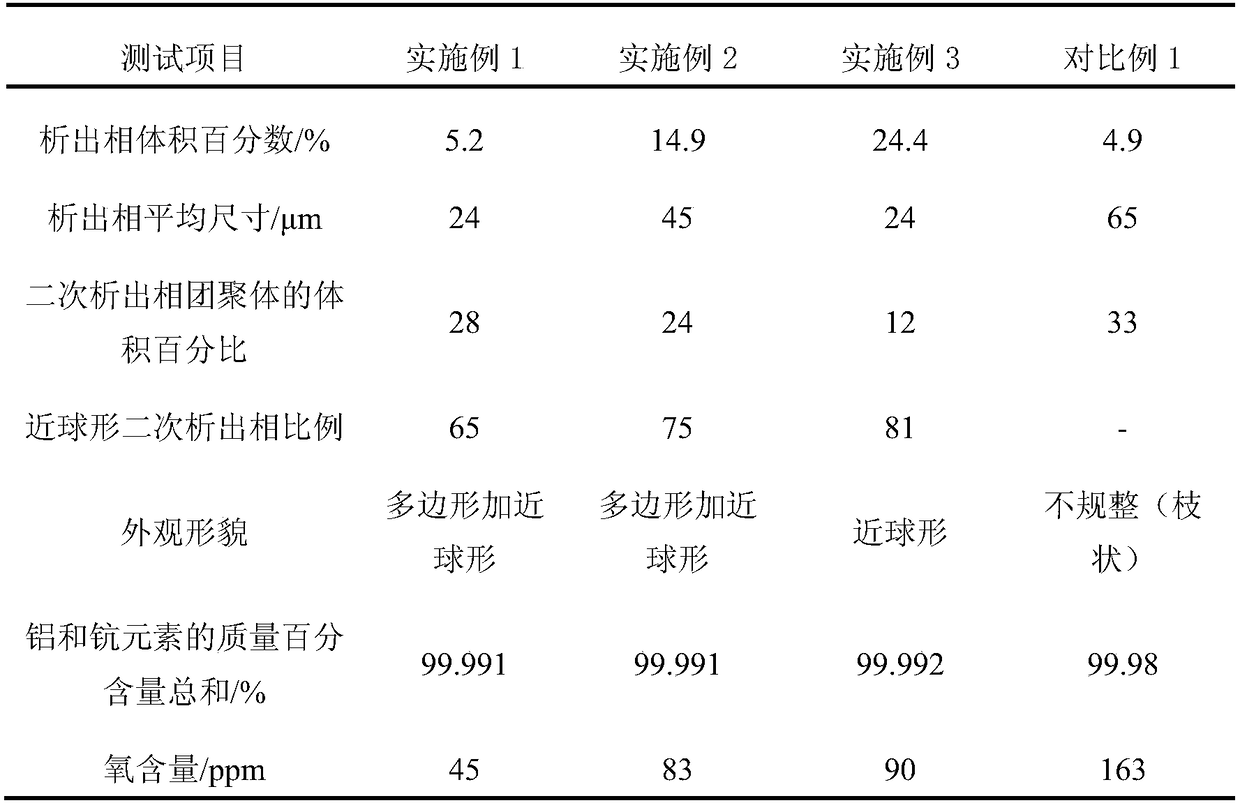

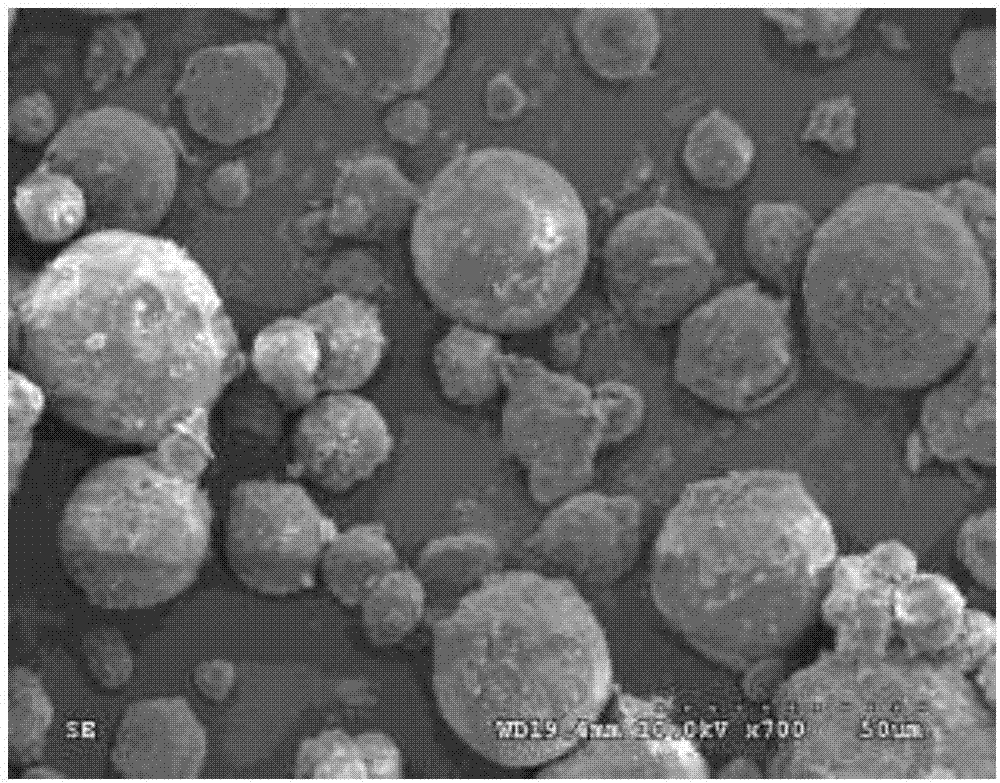

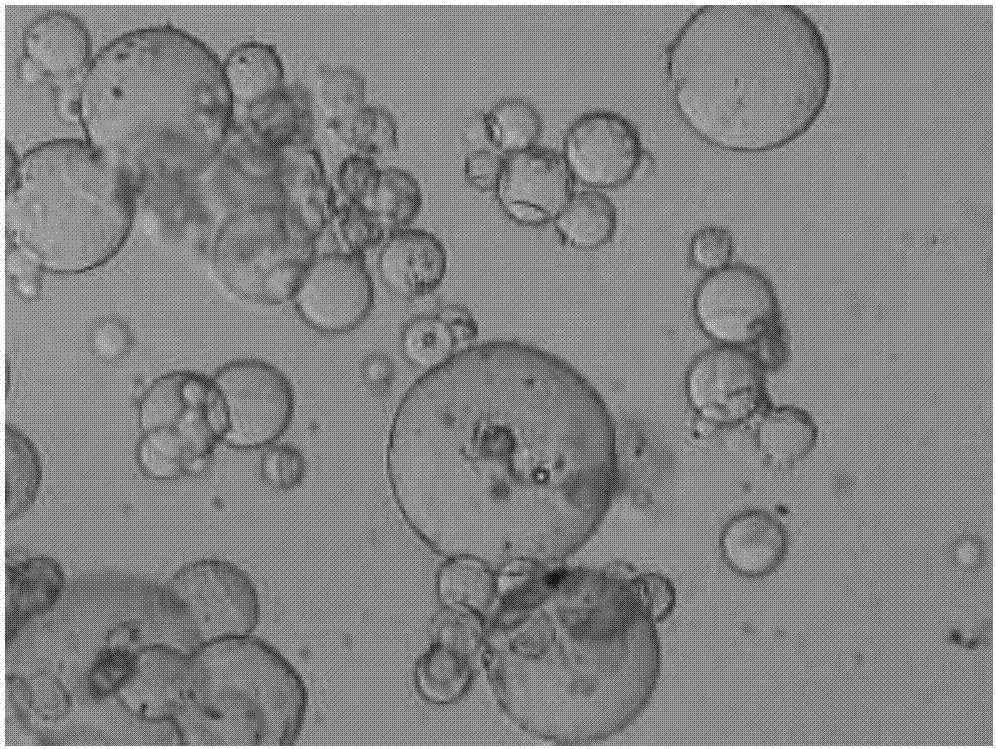

Aluminum-scandium alloy target blank, and preparation method and application thereof

InactiveCN109252142AHigh purityLow oxygenVacuum evaporation coatingSputtering coatingSpherical shapedAlloy

The invention discloses an aluminum-scandium alloy target blank, and a preparation method and an application thereof, and belongs to the technical field of aluminum-scandium alloys. The aluminum-scandium alloy target blank prepared by combination of cold crucible levitation melting and variable-frequency electromagnetic stirring has an oxygen content of below 100 ppm and a total aluminum and scandium element content of 99.95 mass%, and has a high purity and a low oxygen content, so later high-quality film formation is facilitated; the volume percentage of a secondary precipitated phase in thealuminum-scandium alloy target blank is 5-25%, the average size is 20-45 [mu]m, and the blank has polygonal and nearly spherical shapes, a uniform microstructure and a significantly improved density,so micro-cracks and other internal defects in the ingot casting and deformation processing processes are effectively avoided, and the quality and yield of a target are significantly improved.

Owner:有研新材料股份有限公司

Method for preparing ZTA multi-phase ceramic through 3D printing based on stereo lithography appearance

InactiveCN106699137ASolve uneven structureImprove molding efficiencyAdditive manufacturing apparatusSlurryDimensional precision

The invention belongs to the technical field of 3D printing, and particularly relates to a method for preparing ZTA multi-phase ceramic through 3D printing based on stereo lithography appearance. The invention provides a composition. The raw materials of the composition comprise a ceramic powder, a premixed liquid, a photoinitiator, a dispersing agent, a surfactant, zirconium salt and titanium salt. The invention also provides a method for preparing ZTA ceramic by using the composition. The method comprises the steps of preparing slurry, forming, drying and degreasing, performing impregnation and performing aftertreatment. In the technical scheme provided by the invention, a ceramic green body is prepared by a stereo lithography appearance method, so the forming efficiency is high and the dimensional precision of the product is high; the parameters in the degreasing step are optimized, so deformation and cracking of the green body in the degreasing process are avoided; through the impregnation step, the sintering temperature of the toughed ZTA ceramic material is reduced under the condition that the additive has minute quantity. Moreover, the microstructure of the product is uniform after the product structure is observed by an electronic speculum, and the defect that the sintering temperature of the ZTA ceramic is high in the prior art is overcome.

Owner:GUANGDONG UNIV OF TECH

Production of polyvinyl alcohol/sericin blended gel thin film

InactiveCN101028536AImprove performanceGood biological propertiesAbsorbent padsBandagesFreeze thawingPolymer science

A gel film of polyvinyl alcohol and sericin mixture with uniform microstructure, high mechanical performance and high bioactivity is prepared through respectively preparing polyvinyl alcohol solution and sericin solution, proportional mixing, stirring, pouring in a container with flat bottom, sealing, and freezing-thawing several times.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing microorganism immobilization embedded particles

InactiveCN101177677AUniform microstructureIncrease resistanceContaminated soil reclamationOn/in organic carrierBrickPeat

The invention relates to microorganism immobilization technology, in particular to a method for preparing immobilized granules for remediation of polycyclic aromatic hydrocarbons (PAHs) polluted soil. Mix the glue evenly, and pass through a granulator with a diameter of 1-4.00mm under natural conditions of 25-40°C and pH to prepare immobilized granules at a dripping speed of 20-30 drops / min. Chemically cross-link, then stand in the fixative for 23-58 hours, and finally soak in sterile water for 24-72 hours, rinse off the residual liquid, multiply and cultivate, and set aside; the mass ratio of the gel solution is: alginic acid Sodium (Na·Alg) 2-3%, (150 mesh) activated carbon, red brick powder, peat soil and / or fly ash 0.3-0.6%, and the balance is water. The invention can greatly improve the mechanical strength, elasticity and slow-release performance of the immobilized particles.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

Preparation method of polyvinyl alcohol/hydroxyapatite (PVA/HA) composite microspheres

InactiveCN107376795AGood dispersionUniform internal structureCosmetic preparationsOther chemical processesFood additiveMicrosphere

A preparation method of polyvinyl alcohol / hydroxyapatite (PVA / HA) composite microspheres belongs to preparation methods of composite water-in-oil emulsion system microspheres. PVA and HA precursors are used as raw materials to prepare a clear and transparent mixed solution; the clear and transparent mixed solution is dispersed into an oil phase containing a surfactant to form a homogeneous water-in-oil microemulsion; and the PVA / HA composite microspheres can be finally obtained by successive crosslinking reaction under acid-catalyzed conditions, HA deposition under alkaline conditions, product centrifugation, washing, drying and other processes. The method has the advantages of simple process, good repeatability, low energy consumption and low cost, and effectively solves the problems that inorganic nanoparticles are easy to agglomerate in the microspheres to cause uneven structures and poor comprehensive performances and the like. The composite microspheres prepared by the method have the advantages of regular morphology, high dispersibility, uniform microstructure, good biocompatibility, biological activity and adsorption performance, and can be used as drug carrier materials, bone repair materials, environmental water treatment materials, cosmetics or food additives and the like.

Owner:CHINA UNIV OF MINING & TECH

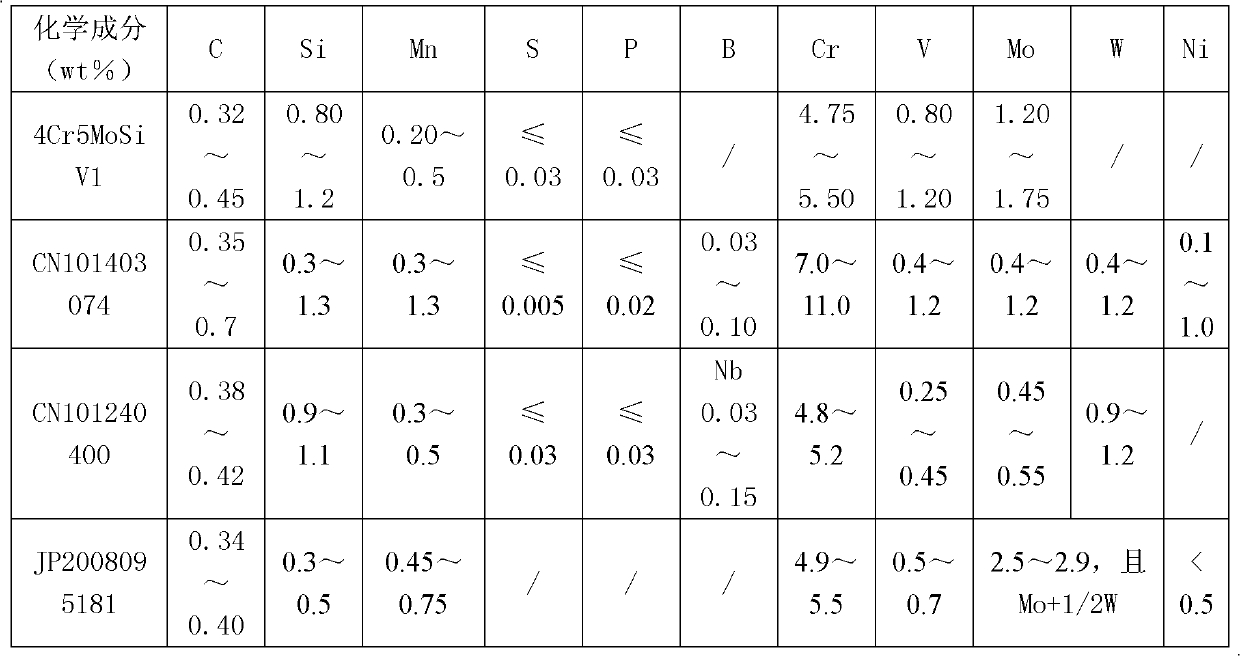

Hot stamping mould steel and method for manufacturing same

The invention discloses a hot stamping mould steel which comprises the following chemical elements in percent by weight: 0.43-0.48% of C, 0.3-0.5% Si, 0.5-0.8% of Mn, 2.3-2.7% of Cr, 1.9-2.4% of Mo, 0.7-1.0% of V, 0.03% of P or less, 0.03% of S or less and the balance of Fe and other inevitable impurities. In addition, the invention further discloses a method for manufacturing the hot stamping mould steel, which adopts the electroslag remelting process and the high-temperature homogenization and ultrafining heat-treatment process to control the material tissue so as to strengthen the material and improve the performance index of the material. Compared with the prior material, the thermal conductivity coefficient of the hot stamping mould steel is improved by more than 29.5%, the tempering hardness is improved by more than 7.5%, and impact toughness is improved by more than 16.7%. In addition, the hot stamping mould steel has the advantages of low-cost and high comprehensive performance.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

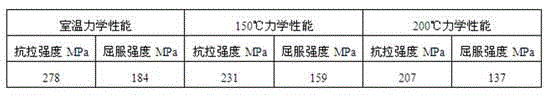

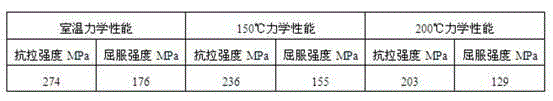

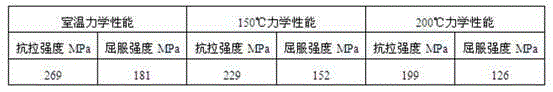

Low-cost multi-component heat-resistant magnesium alloy and preparation method of magnesium alloy

InactiveCN104694805AImprove plasticityImprove high temperature performanceHeat resistanceRoom temperature

The invention provides a low-cost multi-component heat-resistant magnesium alloy and a preparation method of the magnesium alloy. The low-cost multi-component heat-resistant magnesium alloy comprises the following components in percentage by weight: 4.2-6.7% of Al, 0.5-1.2% of Zn, 0.7-0.9% of Sr, 0.2-0.8% of Ca, 1.1-1.5% of Sn, 0.8-1.3% of Sb, 0.05-0.4% of Mn, 0.2-0.6% of Bi, 0.4-0.9% of Si and the balance of Mg. According to the low-cost multi-component heat-resistant magnesium alloy, a right amount of low-cost alloy elements such as Sr, Ca, Sn, Sb, Mn, Bi and Si are introduced; the high-temperature performance of the magnesium alloy can be remarkable improved; the application range of the magnesium alloy can be expanded; the magnesium alloy is low in cost, simple in smelting and heat treatment process and uniform in microscopic structure; the mechanical performance and the heat resistance of the alloy can be remarkably improved; after the alloy is solidified and aged, the maximum room-temperature tensile strength reaches 278MPa; the maximum tensile strength at 150 DEG C reaches 236MPa; the maximum tensile strength at 200 DEG C reaches 207MPa.

Owner:HENAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com