Patents

Literature

152results about How to "No microcracks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spraying liquid bunch electrolysis-laser composite processing method and apparatus thereof

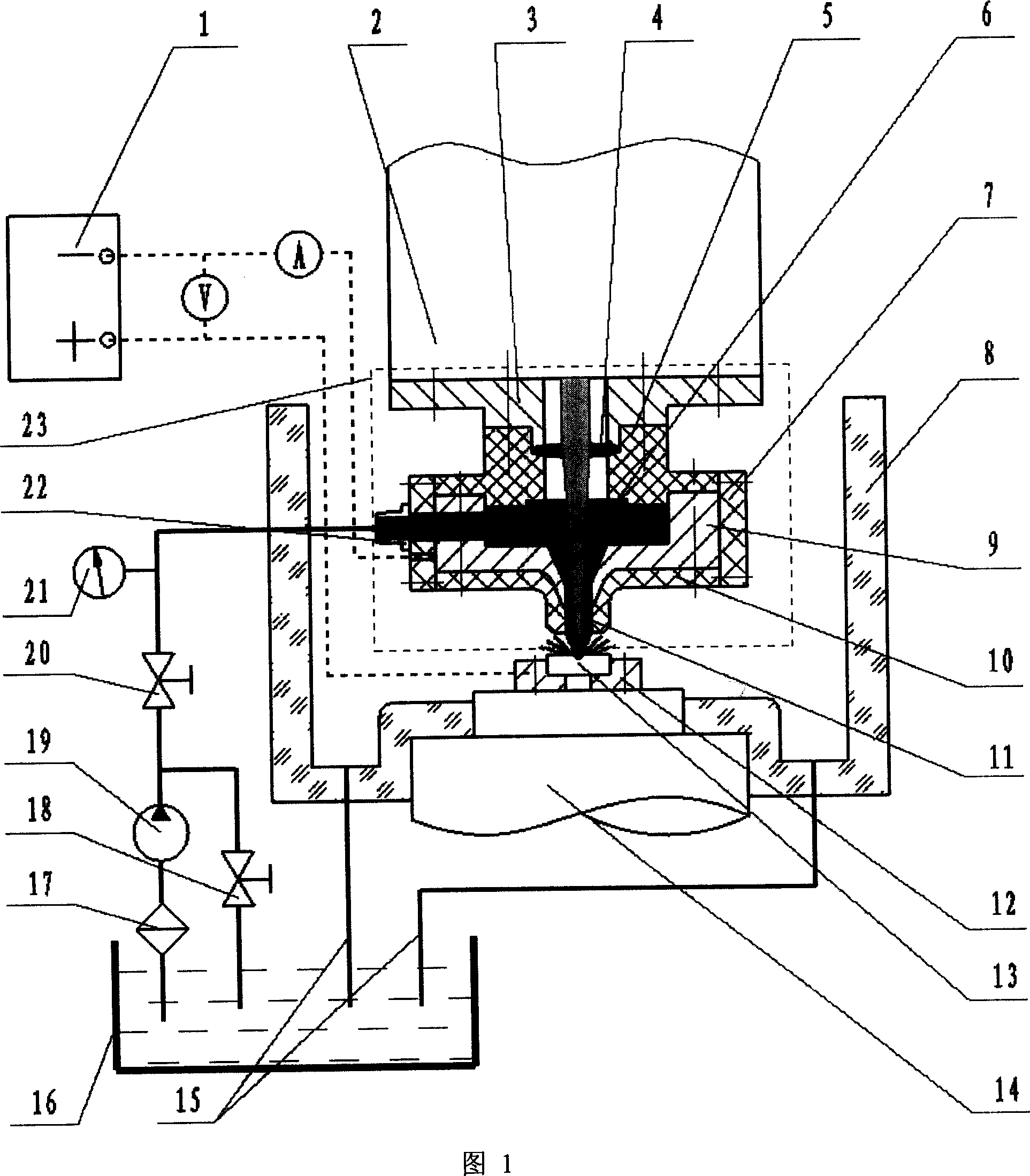

InactiveCN1919514ASolve processing problemsEfficient removalLaser beam welding apparatusElectrolysisLaser processing

The invention discloses a spraying liquid beam electrolytic-laser compound manufacturing method and device, which comprises the following steps: utilizing layer generating device to produce laser beam on the working piece, manufacturing hole, seam and groove, generating high-speed spraying liquid removing material with the same shaft of laser beam through spraying liquid beam device. The device contains layer, working piece assembling chuck, power and spraying liquid beam device, wherein the spraying liquid beam device concludes assembling seat of spraying device, insulating switching seat, cathode, focal lens, protective lens, insulating sleeve and sprayer.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

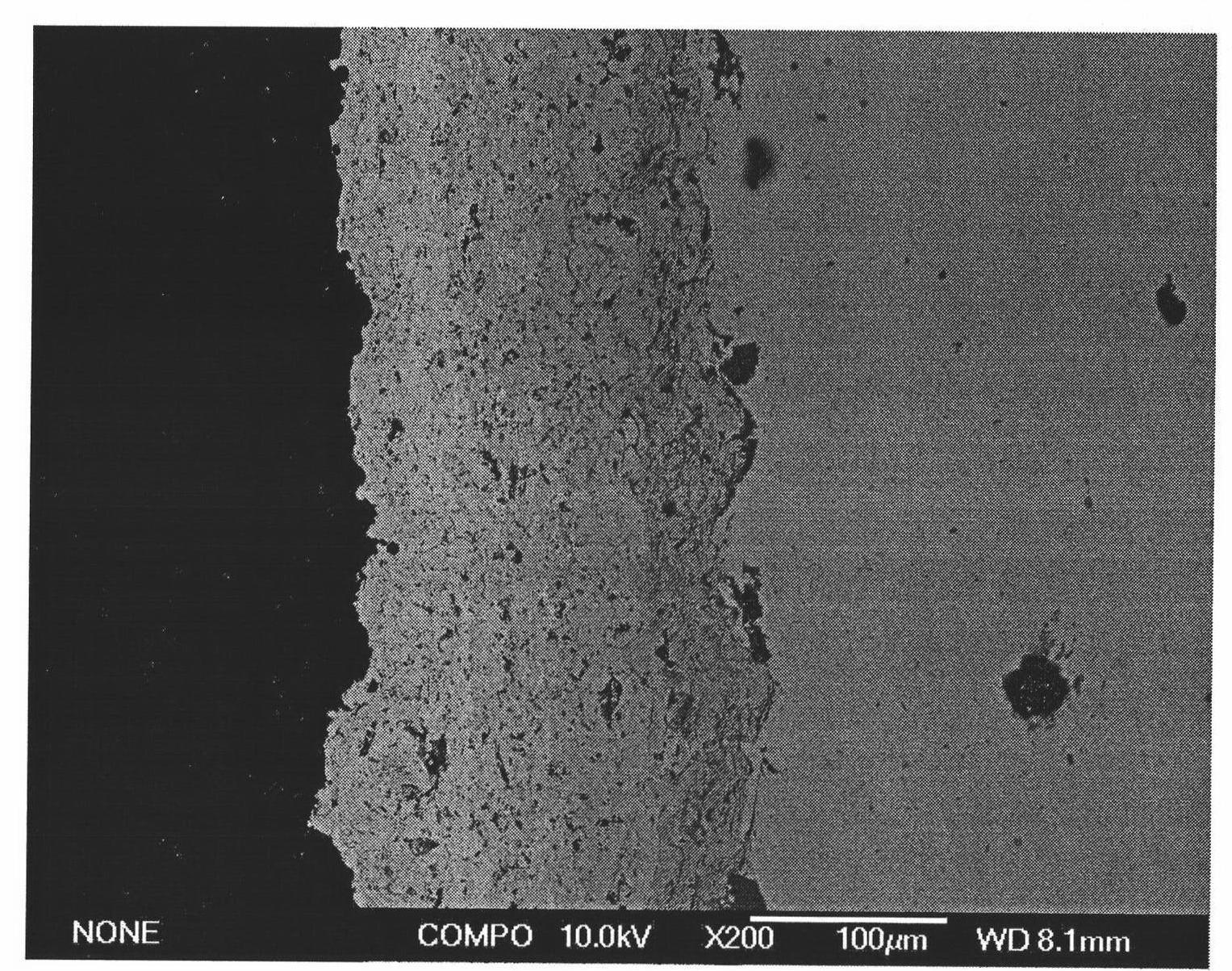

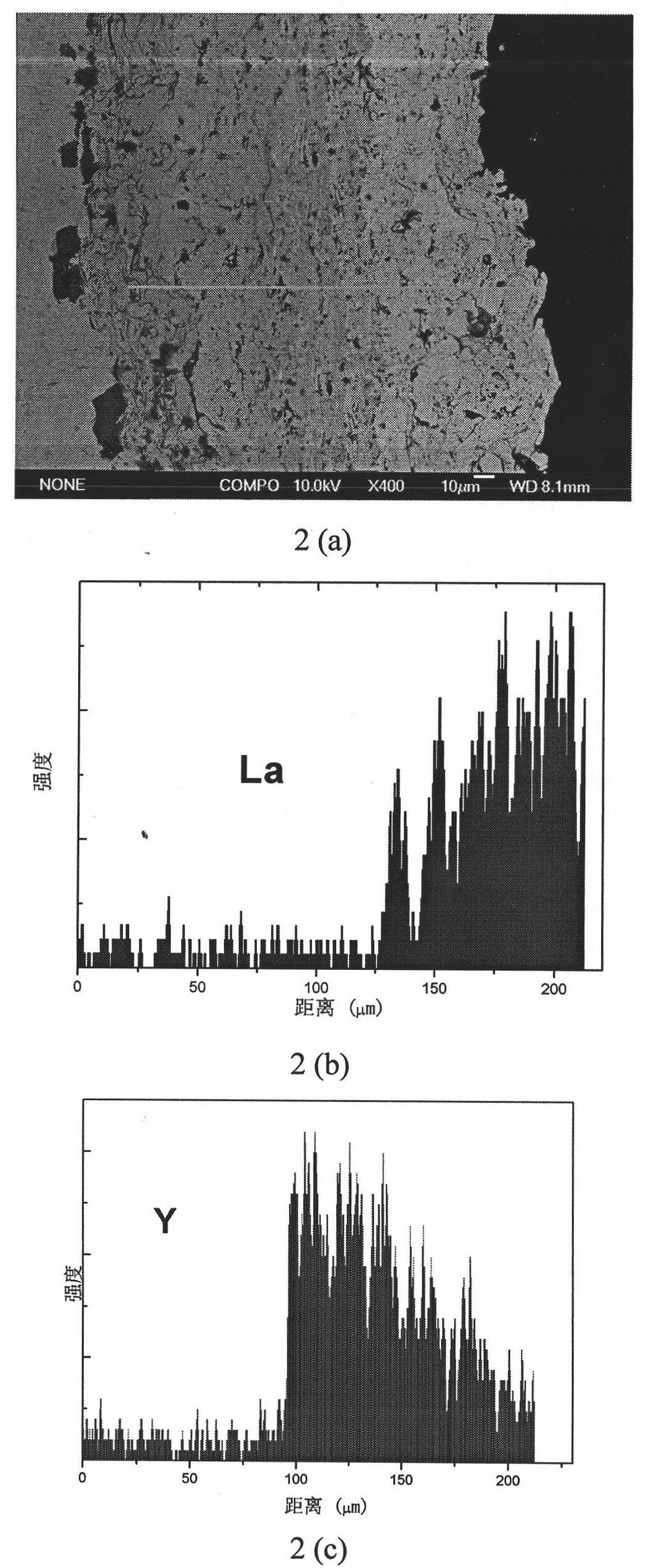

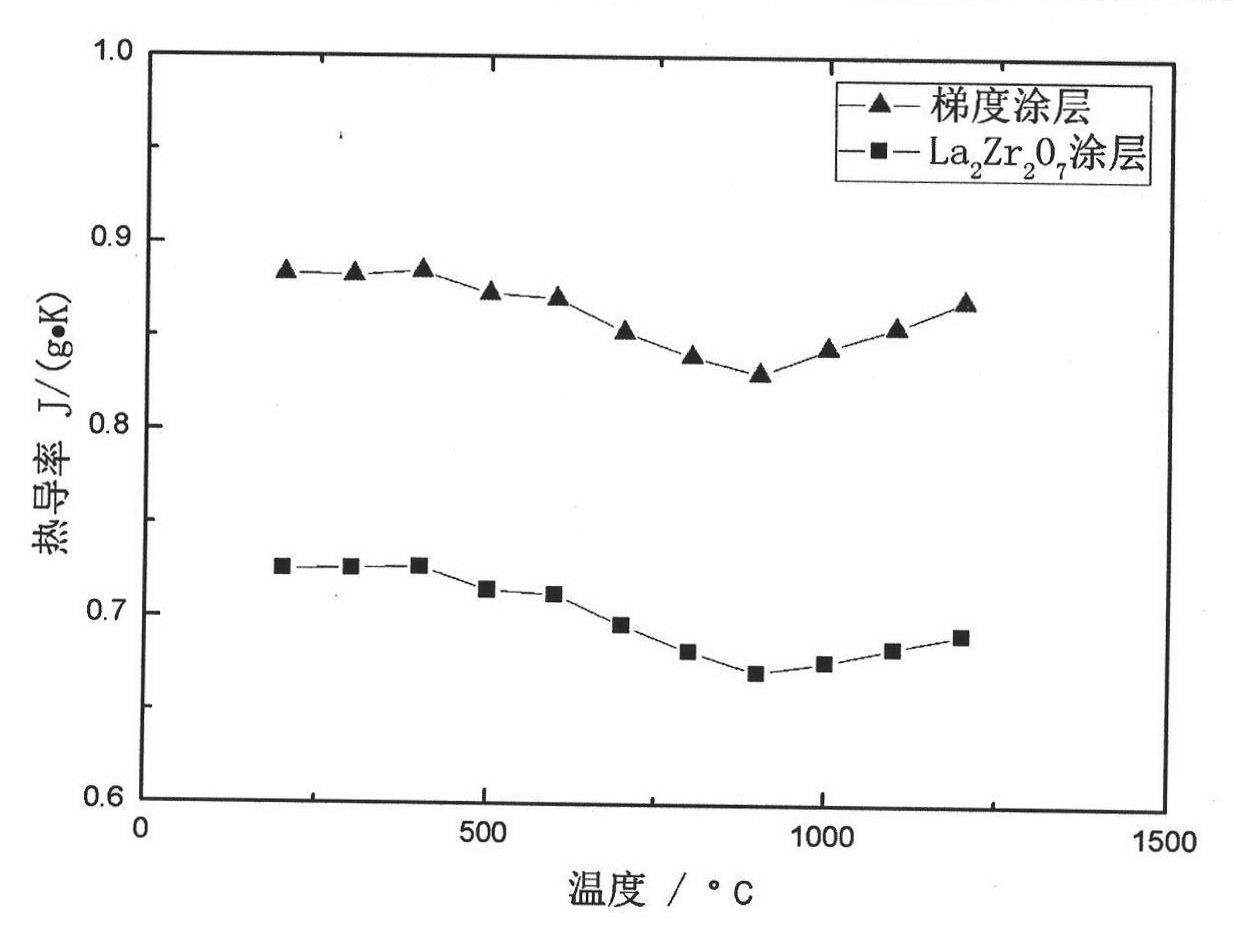

Thermal protection coating with component gradient change and preparation method

InactiveCN101768380AReduce heat stress concentrationImprove thermal shock resistanceMolten spray coatingRare-earth elementLanthanum aluminate

The invention belongs to the field of inorganic materials, particularly relates to a thermal protection coating with component gradient change and a preparation method. The thermal protection coating comprises two components of M1 and M2, wherein the M1 is selected from one of YSZ, lanthanum aluminate, mulite or BSAS, the M2 is selected from one of Ln2Zr2O7, Ln2Ce2O7, Ln2SiO5, Ln2Si2O7 or MoSi2, and Ln is selected from rare earth elements the atom coefficients of which are 57-71, Y or Sc. The thermal protection coating has the characteristics of good coating compactness, high bonding strength with a substrate, low thermal conductivity and the like and has favorable thermal shock resistance.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

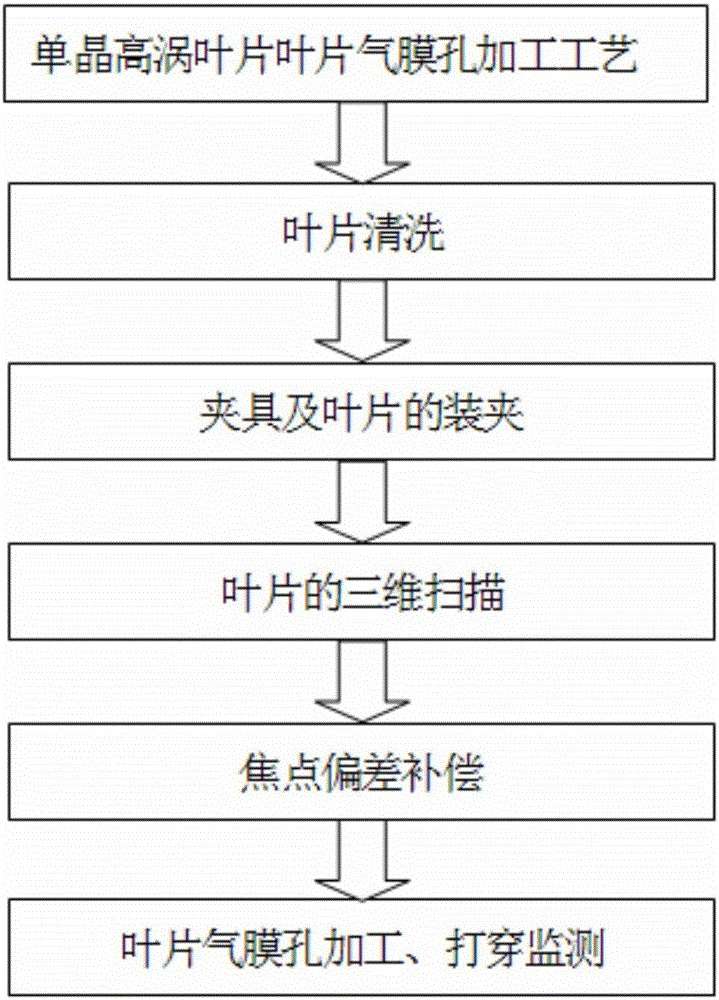

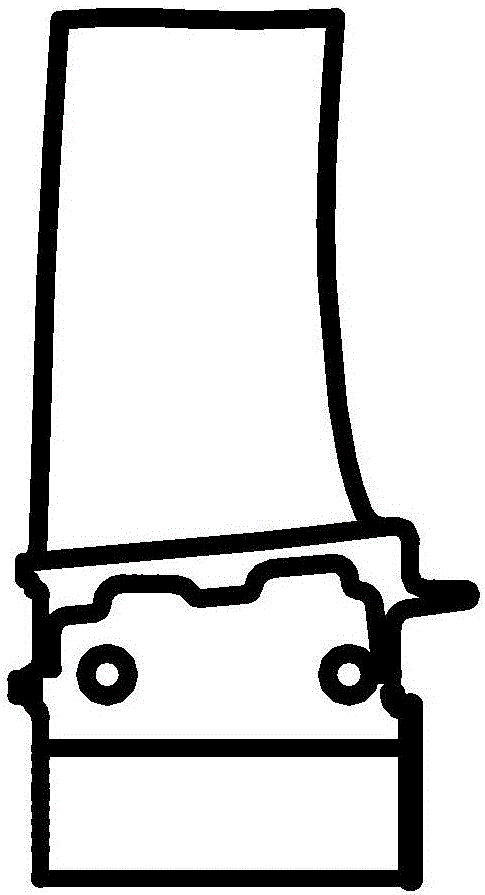

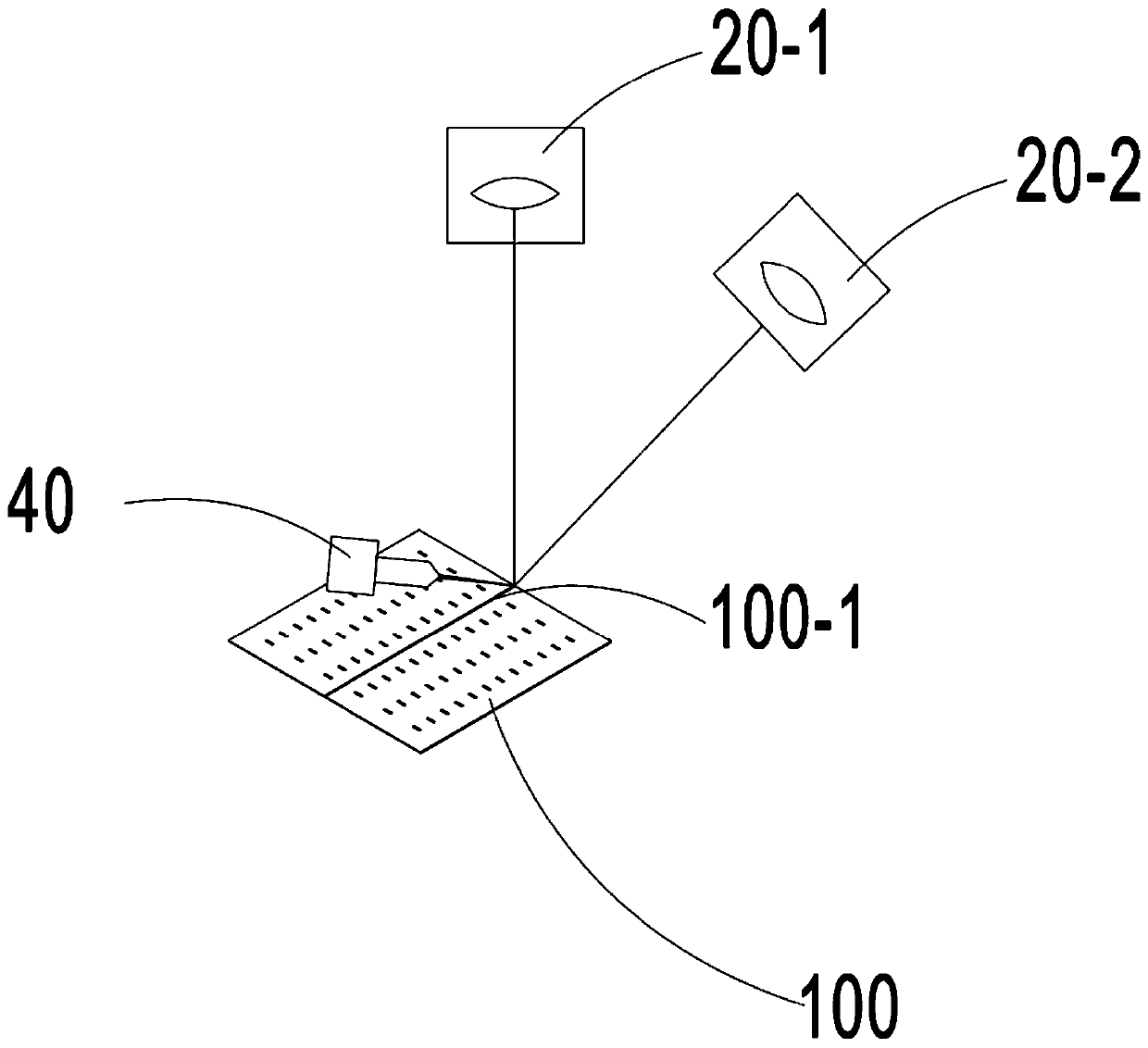

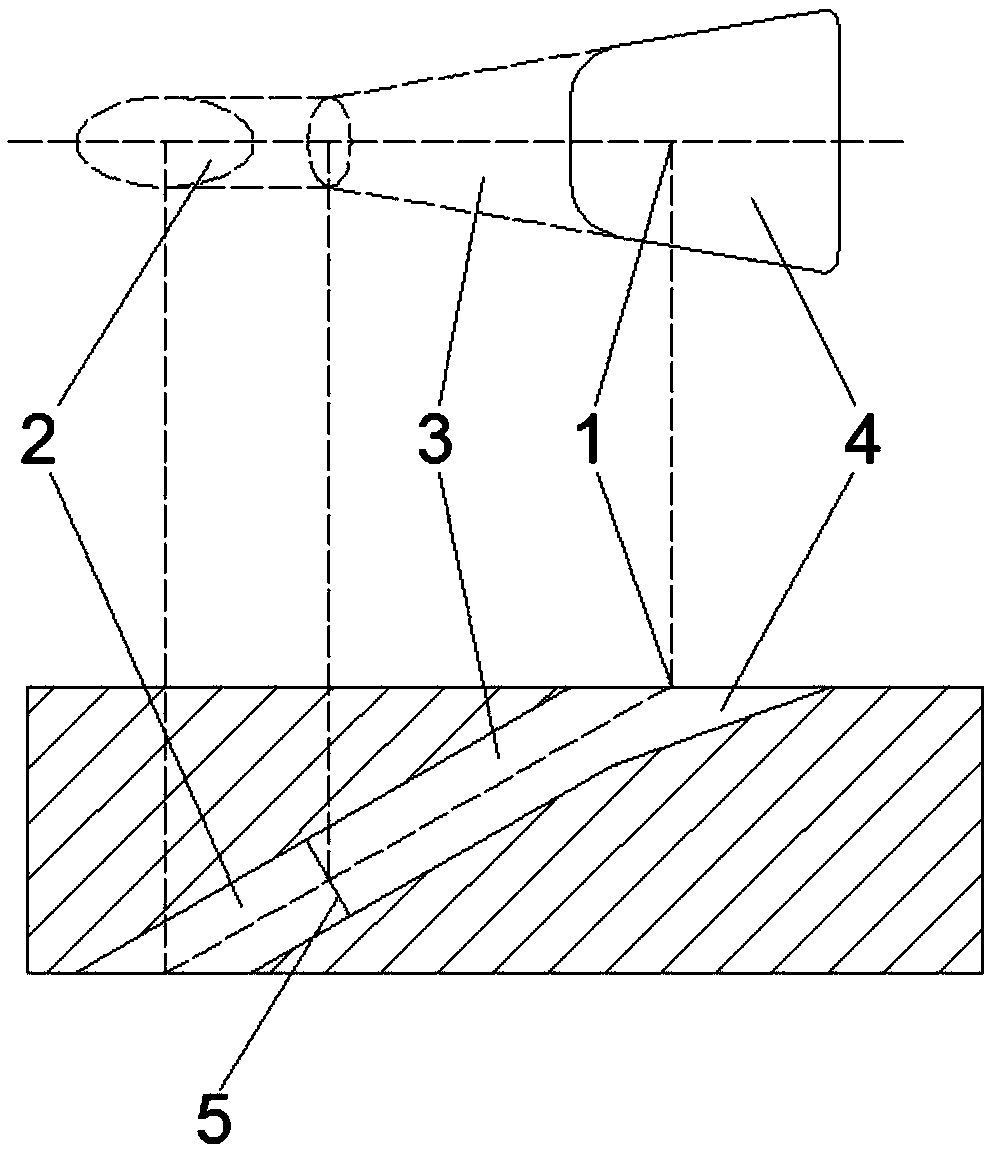

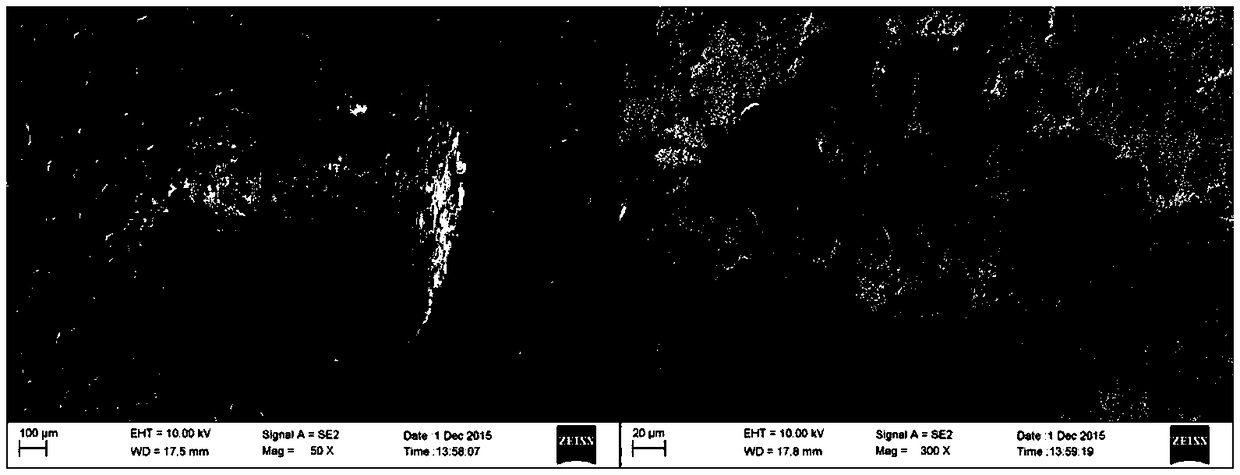

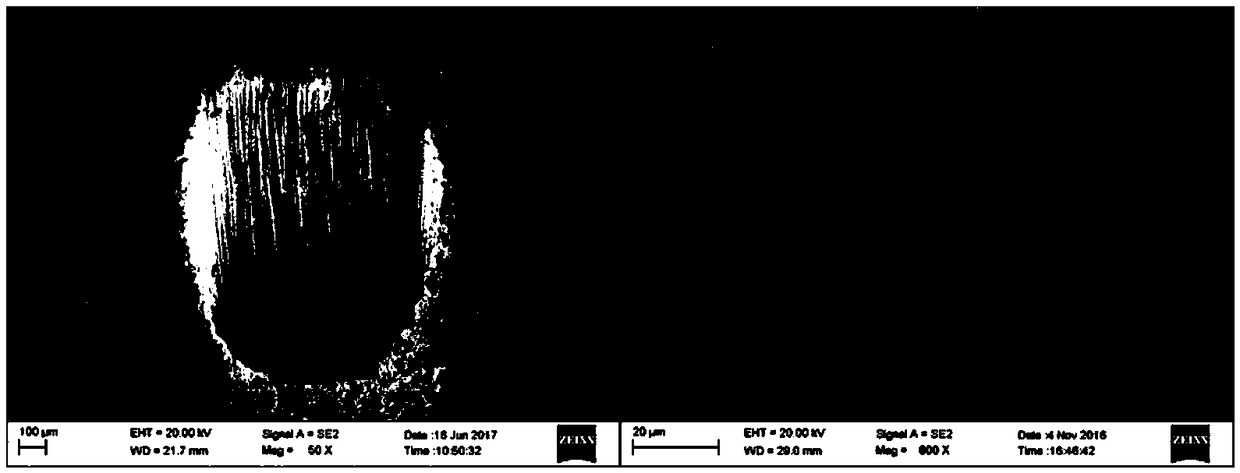

Low-damage processing method of film holes in single crystal high-pressure-turbine hollow blade of aircraft engine

ActiveCN106583949AExtend the life cycleExtended processing cycleLaser beam welding apparatusAviationEngineering

The invention provides a low-damage processing method of film holes in a single crystal high-pressure-turbine hollow blade of an aircraft engine. The low-damage processing method comprises the following steps: wiping the surface of the blade through degreasing cotton with absolute alcohol; transferring into a drying box to dry; arranging a clamp on a machine table, and aligning; assembling the dried blade on the clamp and locking; presetting scanning system parameters; scanning the blade; saving axis moving coordinate value of each hole to be processed under an automatically-generated machine coordinate system as a *.xls file; importing and generating a hole position file; performing compensative correction on the deviation value of a focus position of the hole to be processed; and setting the optimized laser processing technological parameters through a main processing interface. With the adoption of the low-damage processing method, the processed hole is outstanding in quality; a remelting layer, microcacks and recrystallization can be avoided after the single crystal material is processed, so that subsequent processing can be saved, and as a result, the fatigue life and the processing cycle of the blade can be prolonged and improved; the ablation threshold of the single crystal material can be effectively reduced; the recrystallization of the single crystal material can be avoided.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Aluminum oxide electric porcelain

InactiveCN1990420ALittle dispersion of strengthImprove reliabilityPlasticizerUltimate tensile strength

The invention relates to alumina oxide electric porcelain, belonging to transmission and distribution device, which in detail is an insulator for transmission line. The proportioning by weight comprises: industrial alumina oxide 20-40%, feldspar 12-28%, clay 45-55%, and alumina silicate-magnesium plasticizer 1-3%. The produced disc suspended ceramic insulator is characterized by strong strength, long durability and good pollution resistance and so on.

Owner:叶胜平

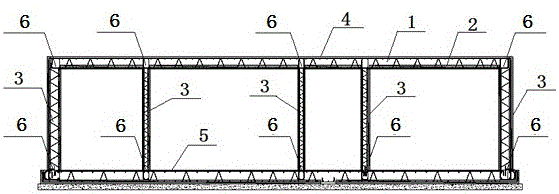

Construction and manufacturing process of total-prefabricated superimposed assembly type underground pipe gallery

ActiveCN105839667AOutstanding FeaturesHighlight significant effectArtificial islandsUnderwater structuresPrefabricationBuilding construction

Owner:CHANGSHA BROAD HOMES IND GRP CO LED

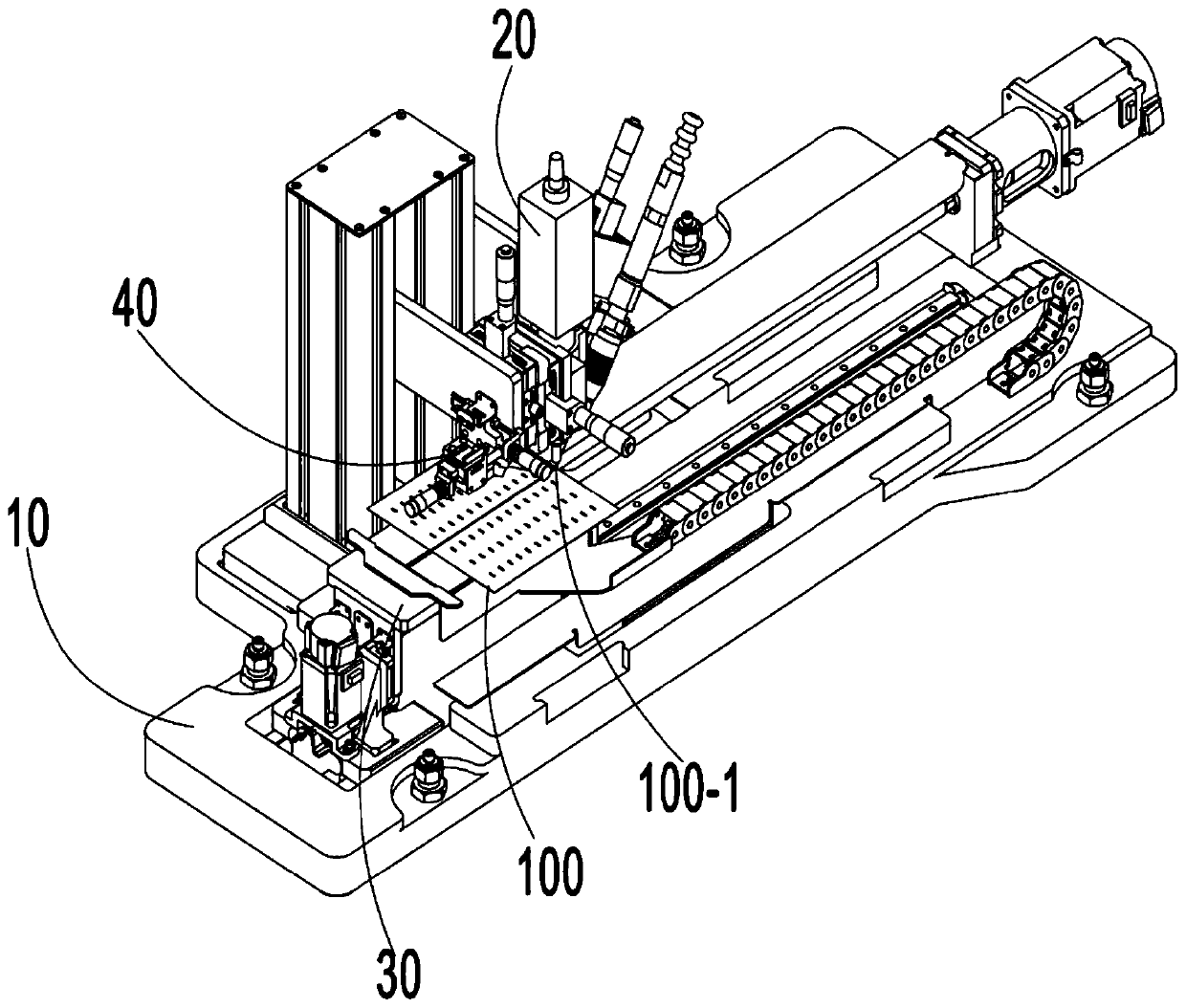

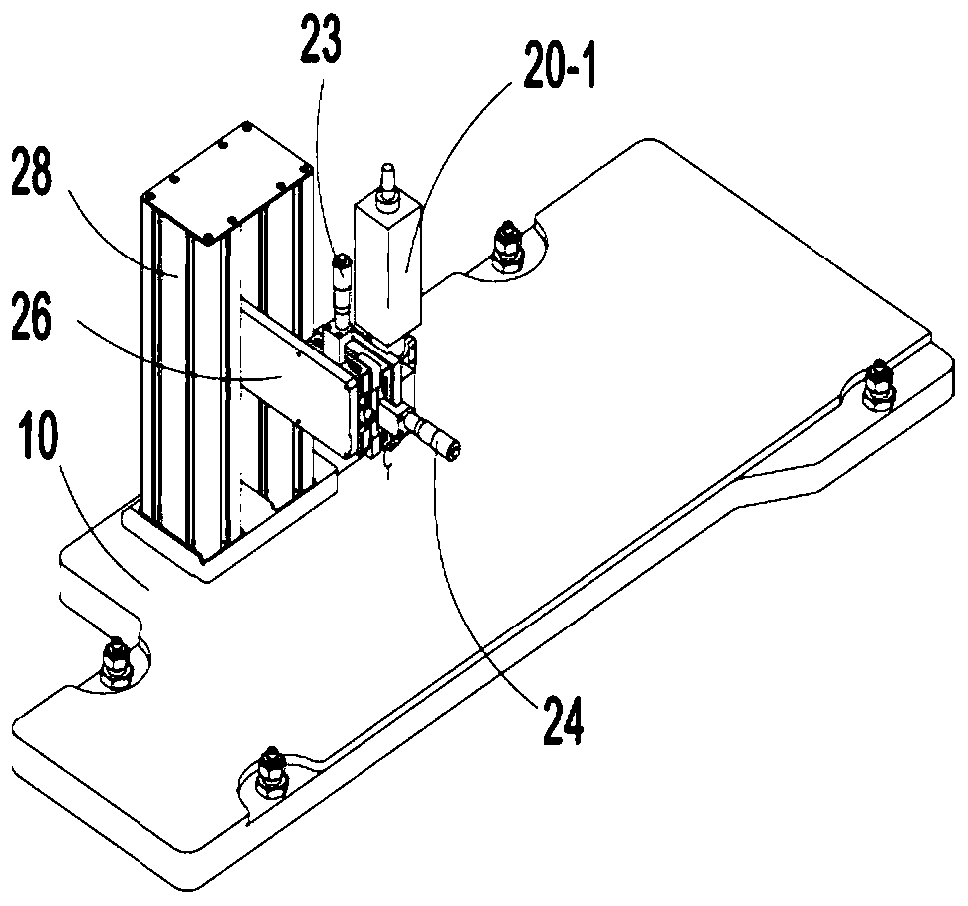

Cutting method and cutting equipment for solar battery pieces

The invention provides a cutting method and cutting equipment for solar battery pieces. In the method, two beams of lasers are mainly adopted to be aligned to to-be-split lines of battery pieces to achieve cutting, meanwhile, a cooling portion sprays a cooling medium to the split lines, so that the battery pieces are cut under small internal stress, and no accumulated object is formed at the splitlines. The equipment adopting the method mainly comprises a fixe frame used for mounting of components, a battery piece transporting portion used for conveying the battery pieces so as to enable thesolar battery pieces to move relative to the focusing point of the first laser beam and the second laser beam, a laser assembly used for generating the first laser beam and the second laser beam and the cooling portion used for spraying the cooling medium to the split lines or points of the battery pieces.

Owner:NINGXIA XN AUTOMATION EQUIP CO LTD

Preparation method of high-temperature-resistant SiBN(C) carbon fiber coating

InactiveCN103243548ANo special equipment requiredHigh implementabilityCarbon fibresCarbon fibersNitrogen

The invention relates to a preparation method of high-temperature-resistant SiBN(C) carbon fiber coating. The preparation method comprises the following steps of: (1) preparing polyborosilazane anhydrous toluene solution; (2) performing glue-removing treatment on the carbon fiber at 100 to 600 DEG C and soaking the carbon fiber into 40 to 70 percent nitric acid to obtain the treated carbon fiber; (3) under the protection of nitrogen, soaking the treated carbon fiber into the polyborosilazane anhydrous toluene solution for 0.1 to 5 hours and standing; and (4) under the atmosphere of nitrogen flow, crosslinking the soaked carbon fiber obtained in the step (3), heating to 1,000 to 1,600 DEG C at the rate of 0.05 to 5 DEG C / min, cracking and cooling to obtain the high-temperature-resistant SiBN(C) carbon fiber coating. The preparation method is simple and has strong actionability; and the surface of the obtained SiBN(C) carbon fiber coating is uniform and compact, the original mechanical property of the carbon fiber is maintained, and the high-temperature oxidation resistance is improved.

Owner:DONGHUA UNIV

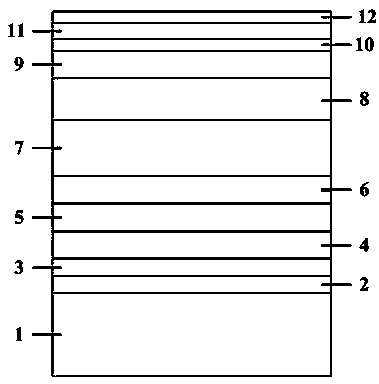

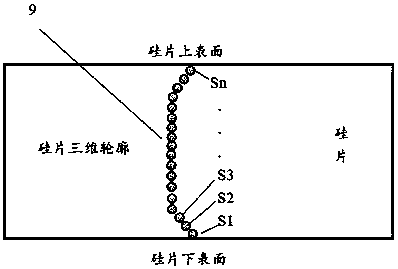

Si (Silicon)-base III nitride epitaxial wafer without microcracks in surface

ActiveCN104201196AImprove crystal qualityIncrease growth ratePolycrystalline material growthSemiconductor/solid-state device manufacturingHeterojunctionSilicon

The invention discloses a Si (Silicon)-base III nitride epitaxial wafer without microcracks in surface. The Si-base III nitride epitaxial wafer is characterized by comprising an Si substrate, two AlN (aluminium nitride) nucleating layers, three Al<x>Ga<1-x>N intermediate layers with Al components degreased progressively, an AlGa<1-a>N / AlGa<1-b>N superlattice intermediate layer, two GaN channel layers and three barrier layers sequentially from down to up. The Si-base III nitride epitaxial wafer has the advantages that an Si-base III nitride heterojunction is high in surface quality and does not have micro cracks in comparison with an existing technology; furthermore, the AlGaN intermediate layers with progressively-degreased components of which an average Al component is low in an epitaxial layer structure provided by the invention is adopted to achieve an aim of improving surface appearance, therefore, the influence of a pre-reaction between a metal organic source and an ammonia gas can be reduced beneficially, the crystalline quality of the epitaxial wafer can be improved, and the growth rate of the epitaxial wafer can be improved.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

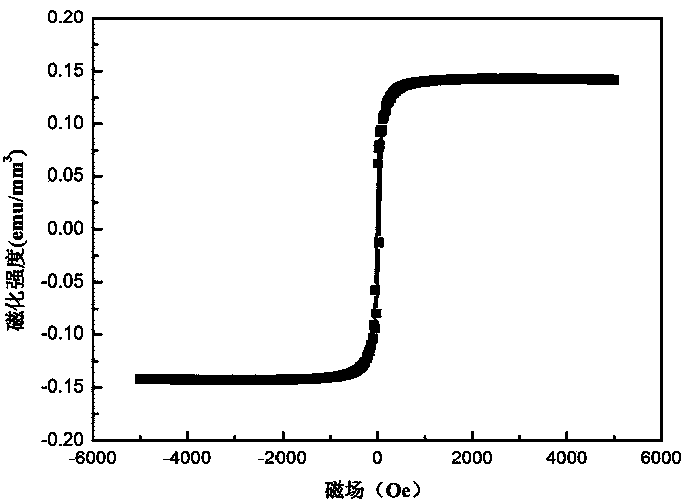

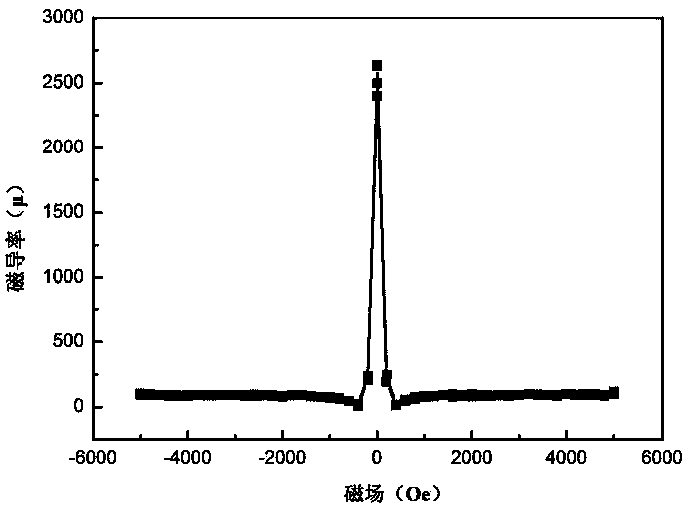

Magnetic nano composite film and its method for preparing sol-gel

InactiveCN1588593ACounteract internal stressNo microcracksNanostructure manufactureMagnetic film to substrate applicationComposite filmElectromagnetic shielding

The invention is a nano complex film and its sol-gel preparing method, firstly making a TiO2 sol and a barium ferrite precursor sol, respectively, then mixing them to make stable mixed sols in different mass proportions, adopting a rotating method to coat a substrate (like a quartz glass plate), making drying and thermal treatment to obtain a microcrack-free complex film. It belongs to a nano complex film and a crystal particle size less than 100 nm; it also belongs to an inorganic film and has a wide range of use temperature. It has higher magnetic property and has a wide application prospect in the fields of magnetic recording, electromagnetic screening, wave absorption coating, etc.

Owner:SHANGHAI JIAO TONG UNIV

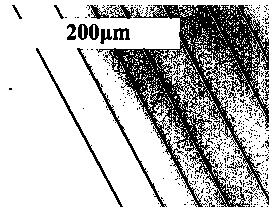

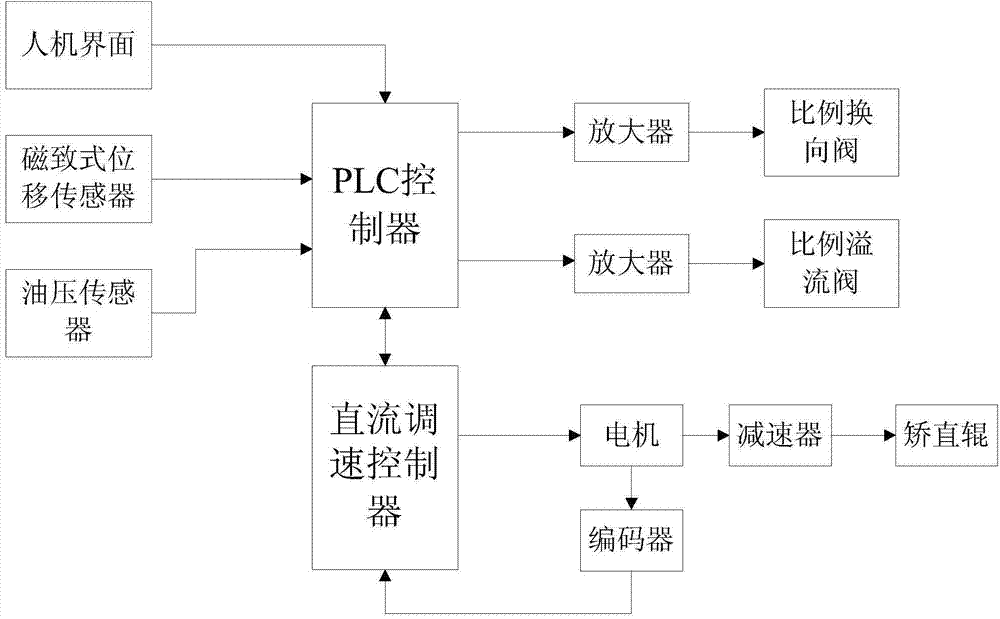

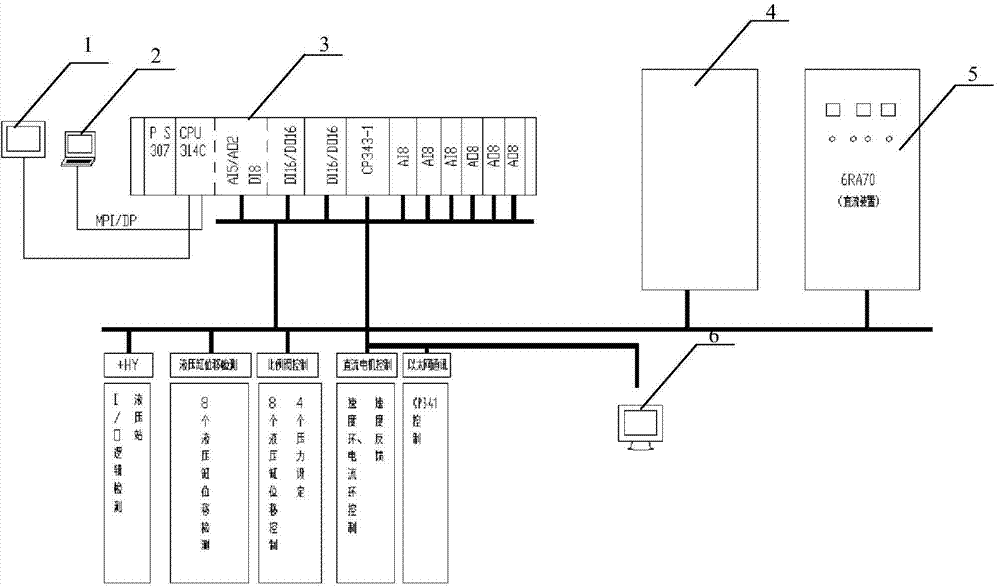

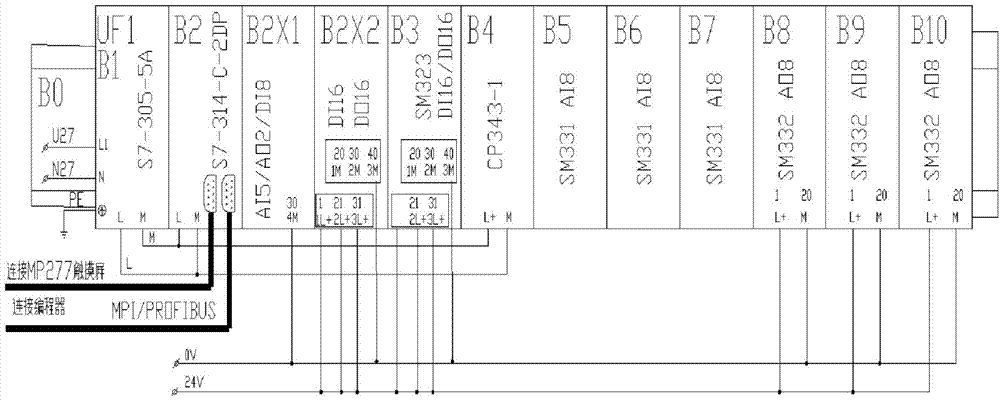

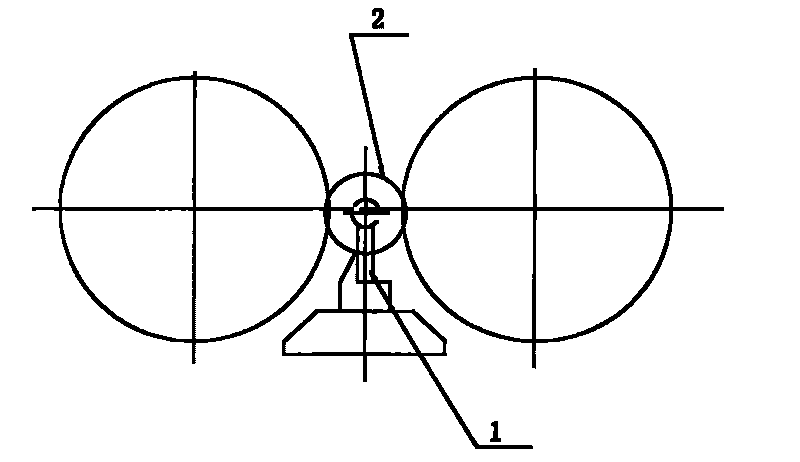

Automatic control system and method for high-precision straightening machine

ActiveCN104117554AEnsure consistencyNo dead zoneProgramme control in sequence/logic controllersPistonAutomatic control

The invention relates to an automatic control system and method for a high-precision straightening machine and belongs to the field of automatic control. Through the automatic control system and method, the straightness (curvature) reaches over 0.3 mm / m according to the straightening precision of the high-precision straightening machine; a hardware structure and a software method of the automatic control system for the high-precision straightening machine are designed considering closed-loop control of oil source pressure and oil cylinder piston displacement of a hydraulic system of the high-precision straightening machine, continuous detection of straightening operation process data, stepless speed regulation control for calibrating transmission of all sets of straightening rollers and the like, the international advanced level of three-dimensional rotation straightening under high-precision automatic control is reached, consistency of roller gap precision in the straightening process, stability of evenly distributed and balanced straightening force and reliability of nonlinear variable gain automatic compensation can be guaranteed, the straightness is improved to 0.2 mm / m from 0.3 mm / m according to the straightening precision of the high-precision straightening machine, and the straightening target that straightened materials have no blind area or tiny crack or scratch or oval or bounce is achieved.

Owner:辽宁银捷装备科技股份有限公司

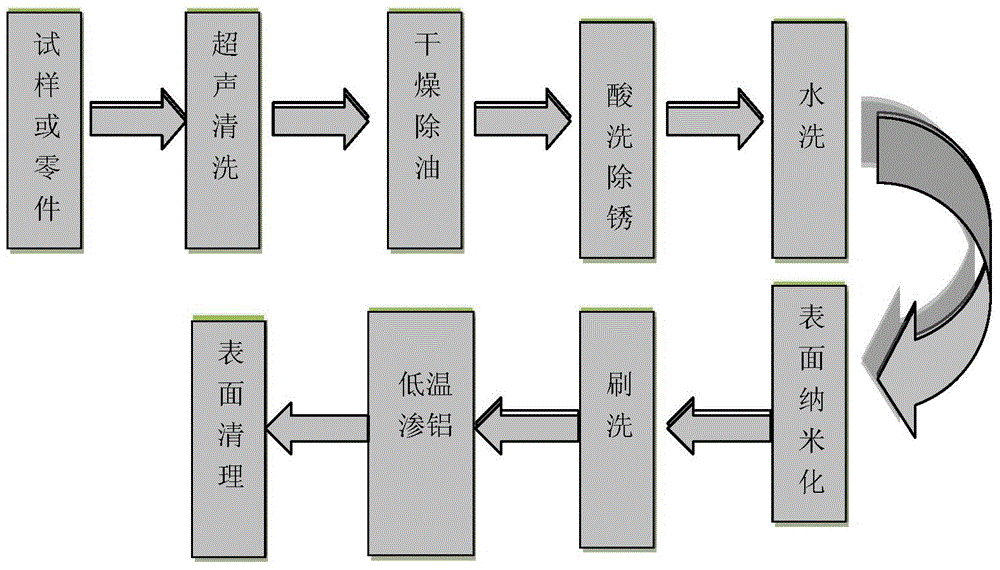

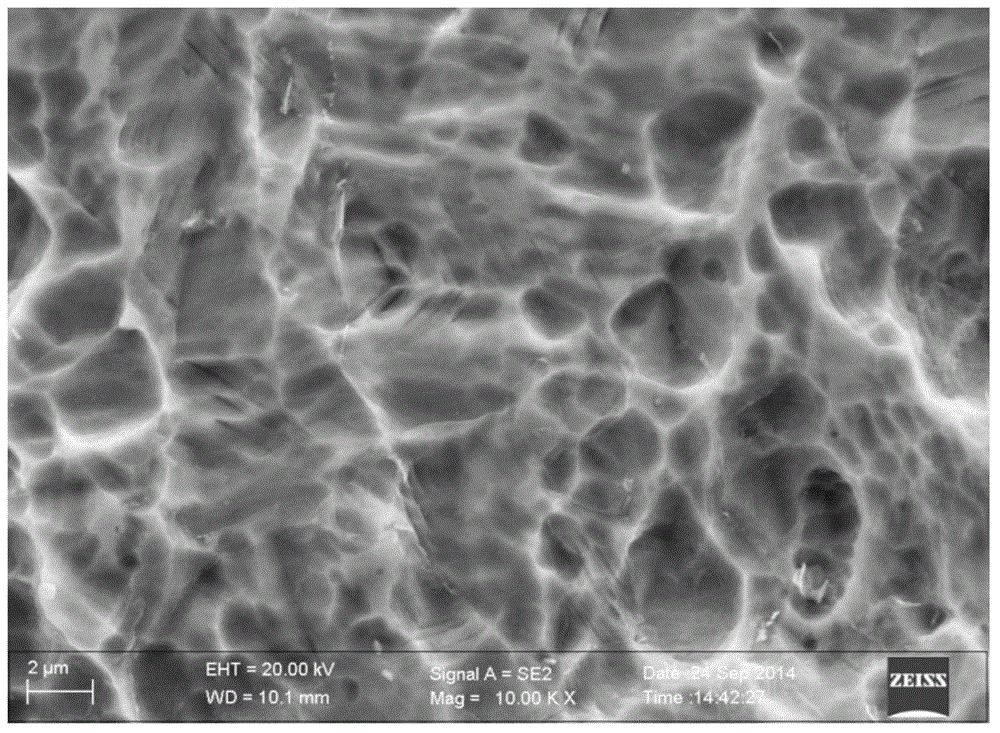

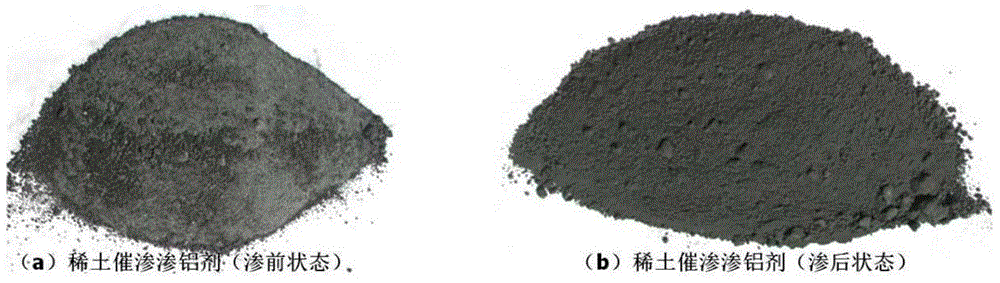

Surface-nanocrystallization low-temperature aluminizing treatment method for steel products

InactiveCN104911536AIncrease nucleation rateAchieve low temperature diffusionSolid state diffusion coatingCorrosion resistantAl element

The invention relates to a surface-nanocrystallization low-temperature aluminizing treatment method for steel products. According to the method, uniform nanocrystallines are obtained on the surface of a material substrate by virtue of mechanical grinding, and then the steel products are subjected to low-temperature aluminizing by virtue of a rare-earth-catalyzed solid aluminizing method, so as to form a high-performance aluminized layer; the steel products and grinding balls different in particle size and quantity are put into a vibration mill together and are subjected to vibration grinding, and the impact energies of the grinding balls of different particle sizes to the surfaces of the steel products are different, so that the surface nanocrystallization treatment of the steel products is easily realized; the problems in a traditional aluminizing process that the aluminizing temperature is high, the temperature preservation time is long, the obtained aluminized layer is not compact, and the use effect is poor are solved to some degree, and a workpiece produced by virtue of the method has relatively high temperature oxidation resistance and corrosion resistance; the obtained aluminized layer is relatively uniform and compact, an aluminide coating with a single-layer structure is well combined with the substrate, a microscopic crack is avoided, the middle of the aluminized layer is a relatively narrow transition region, and Fe and Al elements are uniformly distributed.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

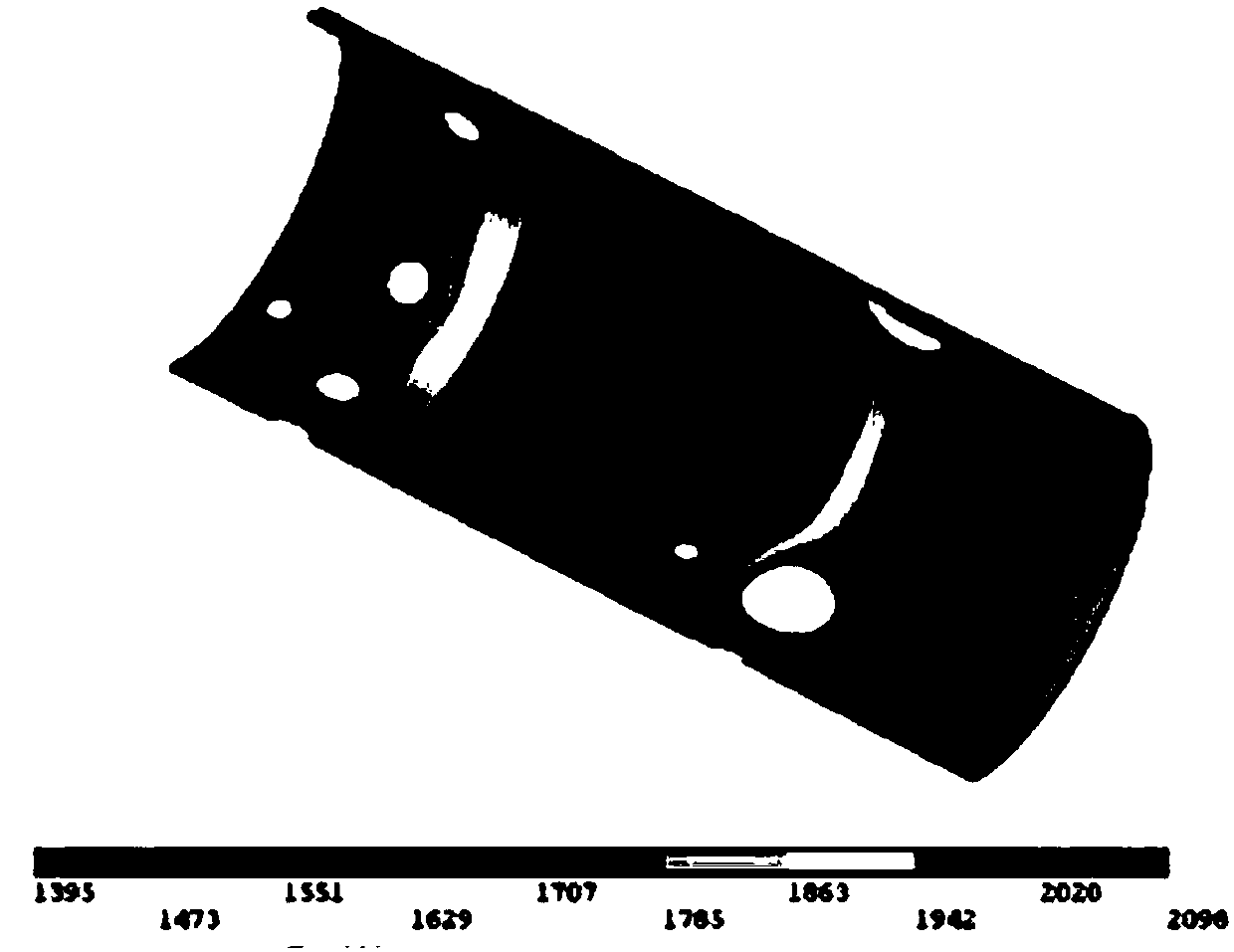

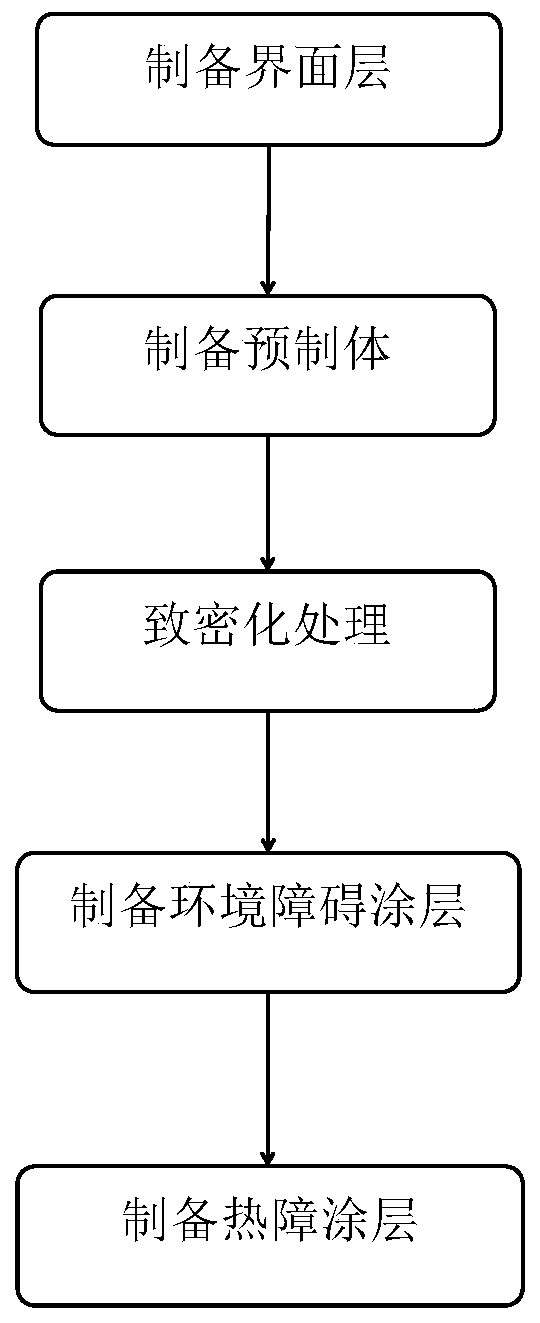

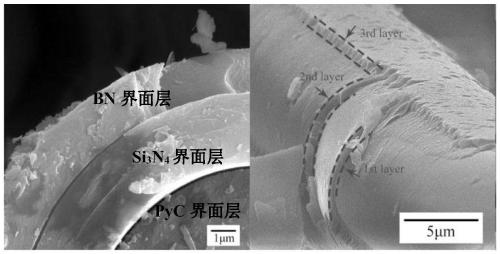

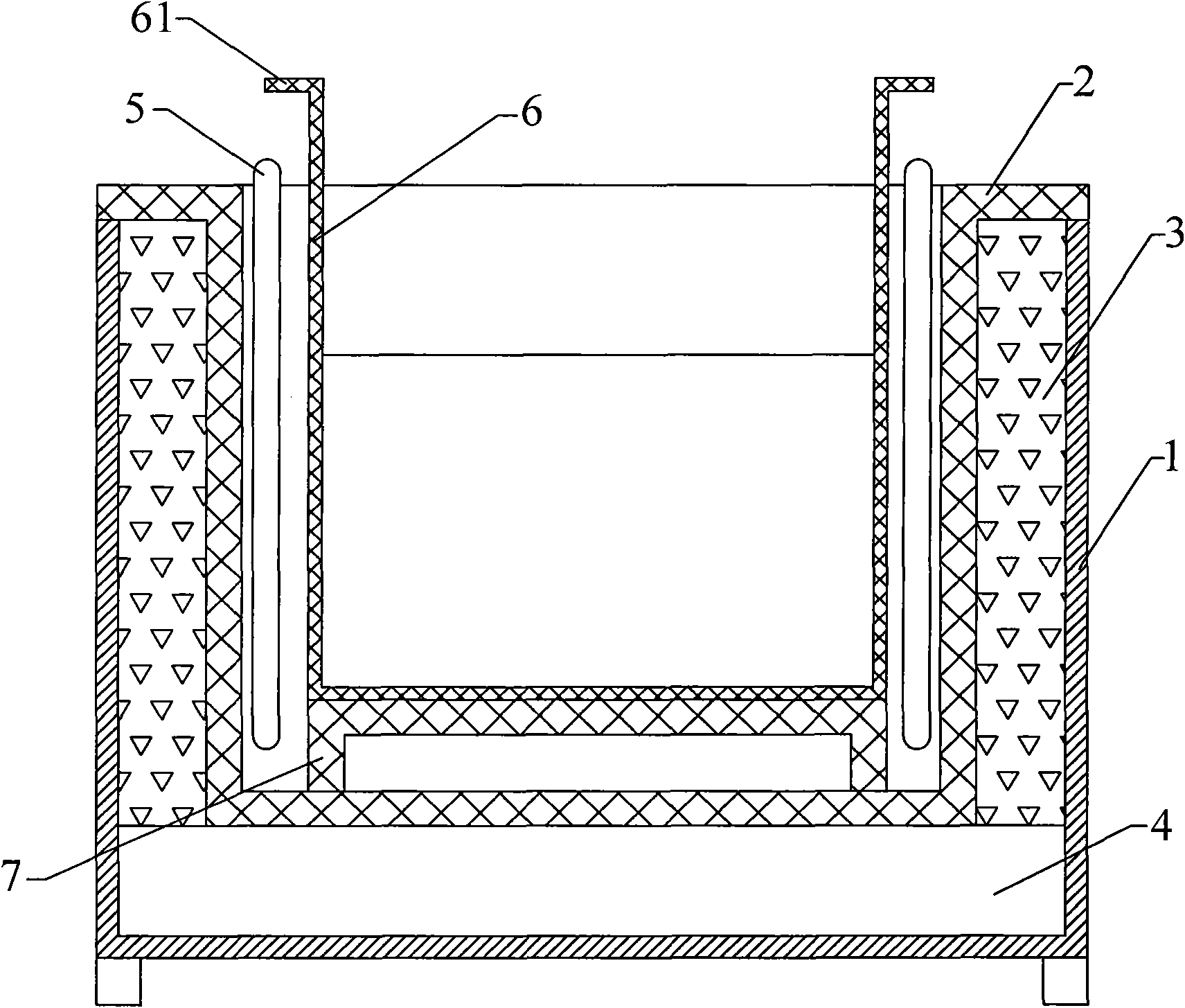

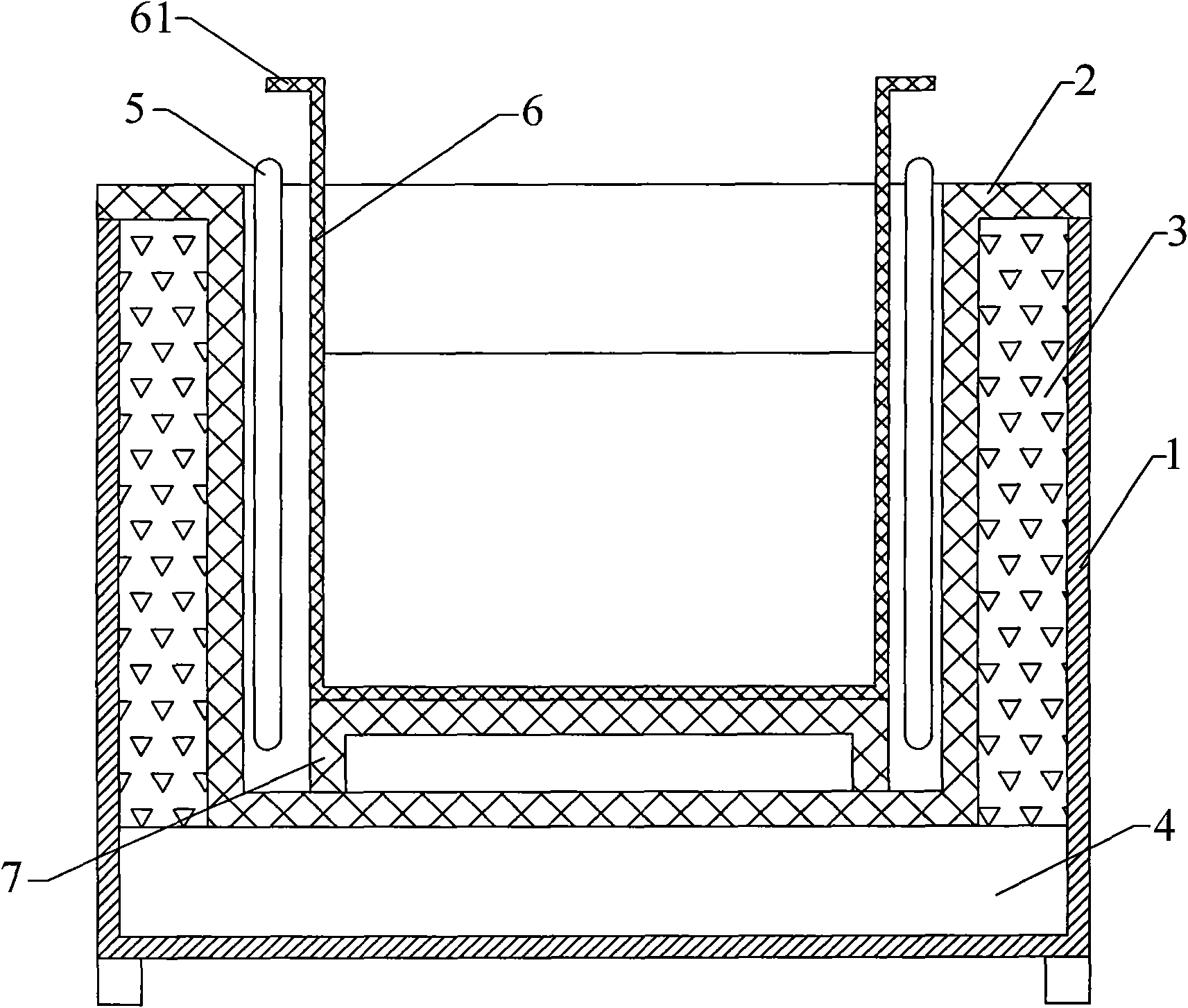

SiCf/SiC composite material flame tube and automatic preparation method thereof

ActiveCN110330353AHigh mechanical strengthCorrosion protectionContinuous combustion chamberCeramic layered productsPolymer scienceGas phase

The invention discloses an automatic preparation method of a SiCf / SiC composite material flame tube. The preparation method comprises the following steps: preparing an interface layer from SiC fibersby adopting chemical vapor deposition, so as to obtain SiC fibers with a continuous interface layer; performing unidirectional tape laying and filament winding on the SiC fibers with the continuous interface layer according to the fiber volume and fiber orientation obtained by simulation calculation, so as to obtain net size forming preform; performing densifying treatment on the obtained preformby adopting a reactive melt infiltration process and the chemical vapor deposition process; preparing an environmental barrier coating on the surface of the obtained preform; finally, continuously preparing a thermal barrier coating on the surface, thereby fully intelligently obtaining the high-density SiCf / SiC composite material flame tube. The SiCf / SiC composite material flame tube prepared withthe method disclosed by the invention has the characteristics of high temperature resistance and long service life and also has the advantages such as low thermal expansion coefficient, high thermalconductivity, high thermal shock resistance and excellent mechanical property. Meanwhile, the preparation method is high in degree of automation, short in production cycle, low in cost and controllable in quality.

Owner:CENT SOUTH UNIV

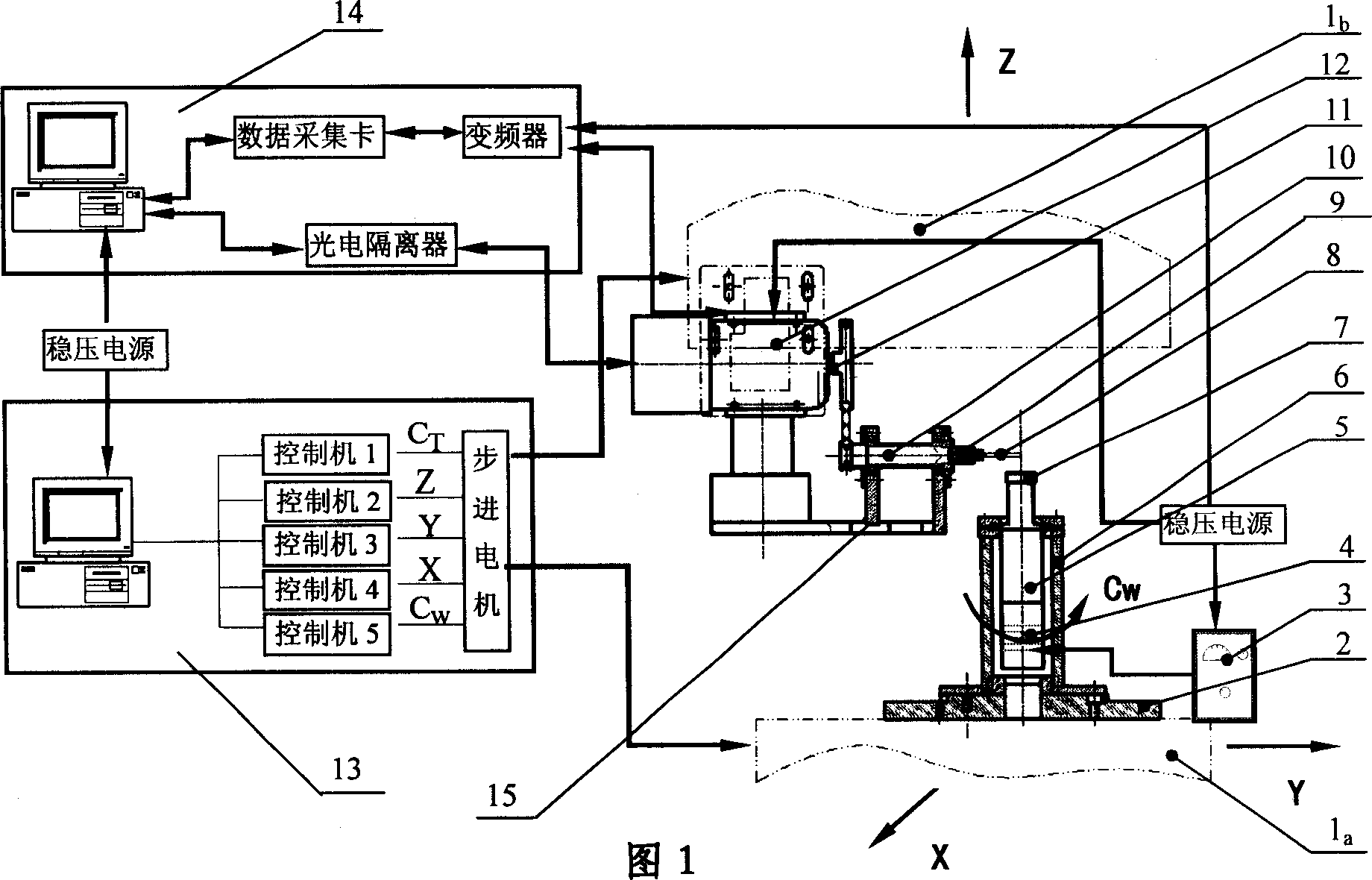

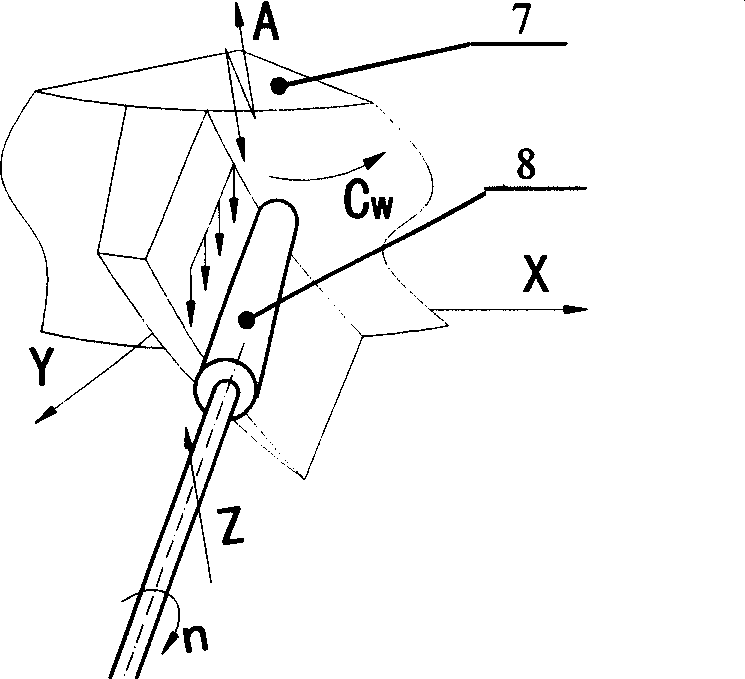

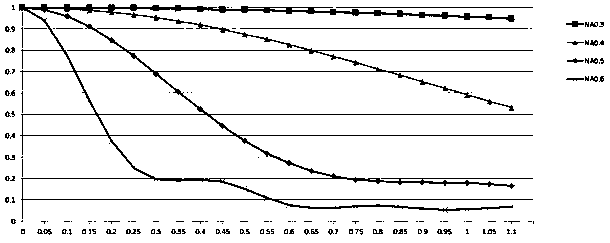

Digital controlled development and creep ultrasonic grinding process and apparatus for engineer ceramic blade profiles

InactiveCN1745966AHigh processing flexibilityImprove surface qualityControl systemUltrasonic vibration

A technology for machining the shaped surface of engineered ceramic blade by numerally controlled developing, creep advance and ultrasonic grinding features that the ceramic work piece is ultrasonically vibrating in Z axis, the grinding disc is rotating around main shaft perpendicular-to Z axis at high speed, and under the control of numeral control system, the grinding disc and work piece are relatively moving in X, Y, Z directions and rotating around Z axis. Its apparatus is composed of a numerally controlled 5-axle machine tool, numeral control system, grinding disc and its main shaft, frequency-regulatable motor and its control system and ultrasonic vibrating system.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Bridging particle for shallow casing blind hole

The invention discloses a bridging particle for a shallow casing blind hole. The bridging particle is suitable for the leakage stoppage of a shallow casing blind hole in an oil field, and comprises 1 to 3% of nano-zirconia, 10 to 20% of silica micropowder, 10 to 15% of light calcium carbonate, 25 to 40% of superfine cement, 0.2 to 2% of glass fiber, 1 to 2% of drag reducer, 0.5 to 2% of early strength agent and 30 to 45% of water. The slurry of the bridging particle has good thixotropy; the multiviscosity time is adjustable; the strength is high and the volume does not shrink after solidification; and no micro-cracks are generated. The invention can effectively solve technical problems of oil field leakage stoppage, such as severe casing leakage after a casing of an oil-water well is corroded and holed, while improving construction safety.

Owner:CHINA PETROLEUM & CHEM CORP +1

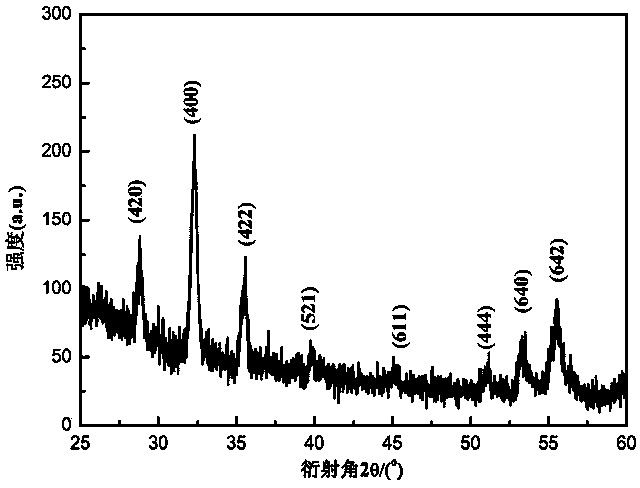

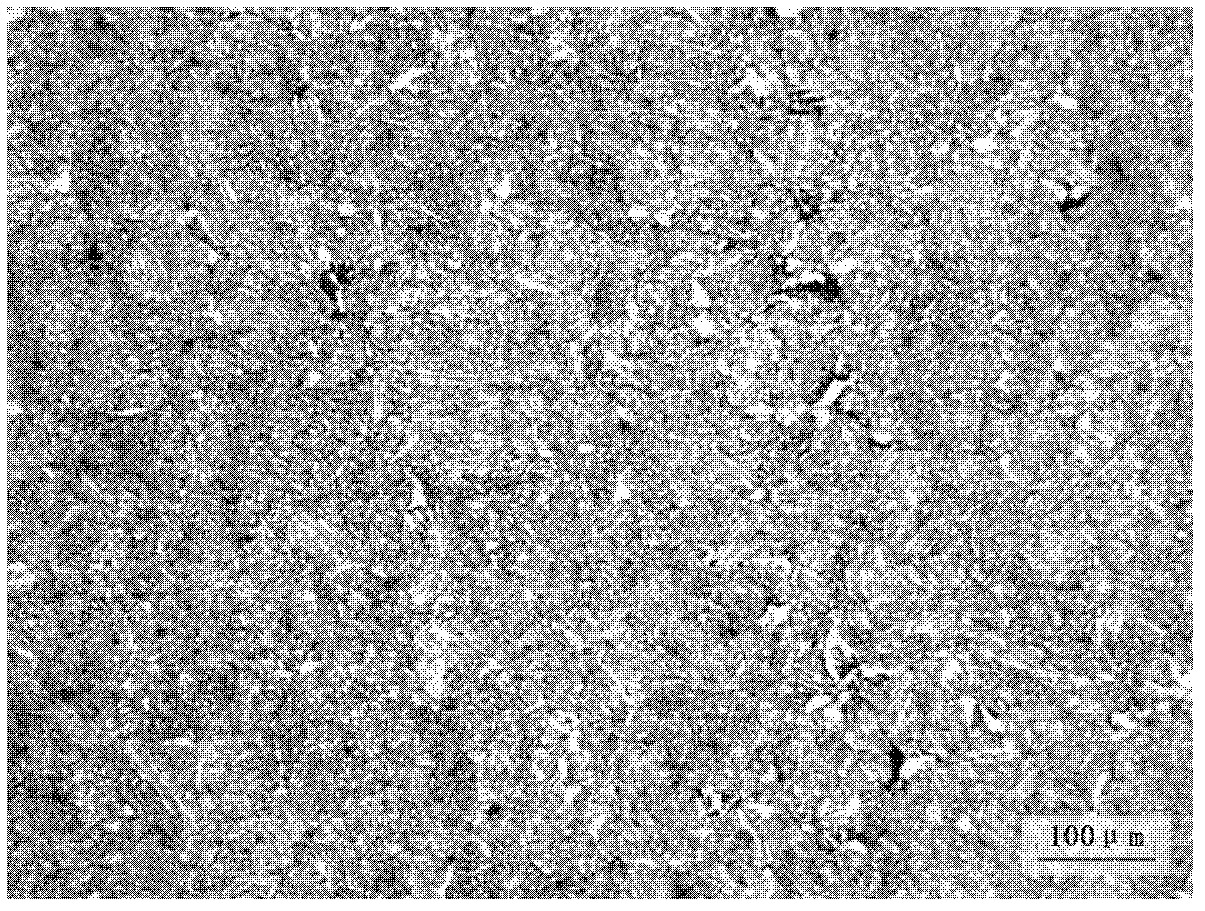

Yttrium iron garnet film and preparation method thereof

The invention discloses a yttrium iron garnet film and a preparation method thereof. The method comprises the following steps: 1) dissolving yttrium oxide and ferric nitrate in a mixed solvent consisting of acetic acid and water to obtain a mixed solution; 2) adding acetylacetone into the mixed solution to react; 3) after standing the mixed solution, filtering out precipitates by virtue of a microfiltration membrane to obtain a yttrium iron garnet precursor solution; 4) dropwise adding the yttrium iron garnet precursor solution on a substrate to form a gel film; 5) firstly, preserving heat for the gel film and then carrying out pyrolysis treatment; and 6) annealing the gel film subjected to pyrolysis treatment.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Wear-resistant steel plate and its production device and production method

The invention discloses a wear-resistant steel plate. The composition of the steel plate includes: 0.19-0.25% of C, 0.70-1.10% of Si, 1.50-1.80% of Mn, 0.20-0.80% of Ti, ≥0.0020 % B, < 0.020% P, and < 0.015% S. On the other hand, the present invention also provides a production device for producing the above-mentioned wear-resistant steel plate, including a smelting device, a slab continuous casting device, a rolling device, and a cooling device. In another aspect, the present invention also provides a production method of the above-mentioned wear-resistant steel plate. The present invention effectively improves the hardenability of the steel plate due to the adoption of an appropriate ferroboron adding device and adding method; in addition, the steel plate has excellent strength, toughness and weldability after heat treatment, and the steel quality is pure, which is beneficial to improving the hardness of the workpiece after heat treatment. service life.

Owner:LIUZHOU IRON & STEEL

Ceramic and resin composite grinding wheel

InactiveCN103753411AHigh tensile strengthHigh bonding strengthAbrasion apparatusHeat resistanceGrinding wheel

The invention relates to a ceramic and resin composite grinding wheel. The ceramic and resin composite grinding wheel is prepared by a method which comprises the following steps of (1) uniformly mixing ceramic bond and grinding materials proportionally, and preparing a ceramic grinding wheel according a ceramic grinding wheel producing method; (2) smashing the ceramic grinding wheel obtained in the step (1) so as to obtain ceramic grinding wheel powder; and (3) preparing a grinding wheel by using the ceramic grinding wheel powder obtained in the step (2) as raw materials so as to obtain the ceramic and resin composite grinding wheel. The macrostructure of the ceramic and resin composite grinding wheel is a resin grinding wheel, the microstructure of the ceramic and resin composite grinding wheel is a ceramic grinding wheel, the heat resistance of the ceramic and resin composite grinding wheel can be equal to that of the ceramic grinding wheel, the bonding strength of the grinding materials is greatly enhanced, the bending strength reaches 60MPa, the tensile strength reaches 16MPa, the ceramic bond can be safely used under the condition that the revolving speed is 80-100m / s owing to the high strength of the ceramic bond, and the yield is higher than 95%.

Owner:袁德禄

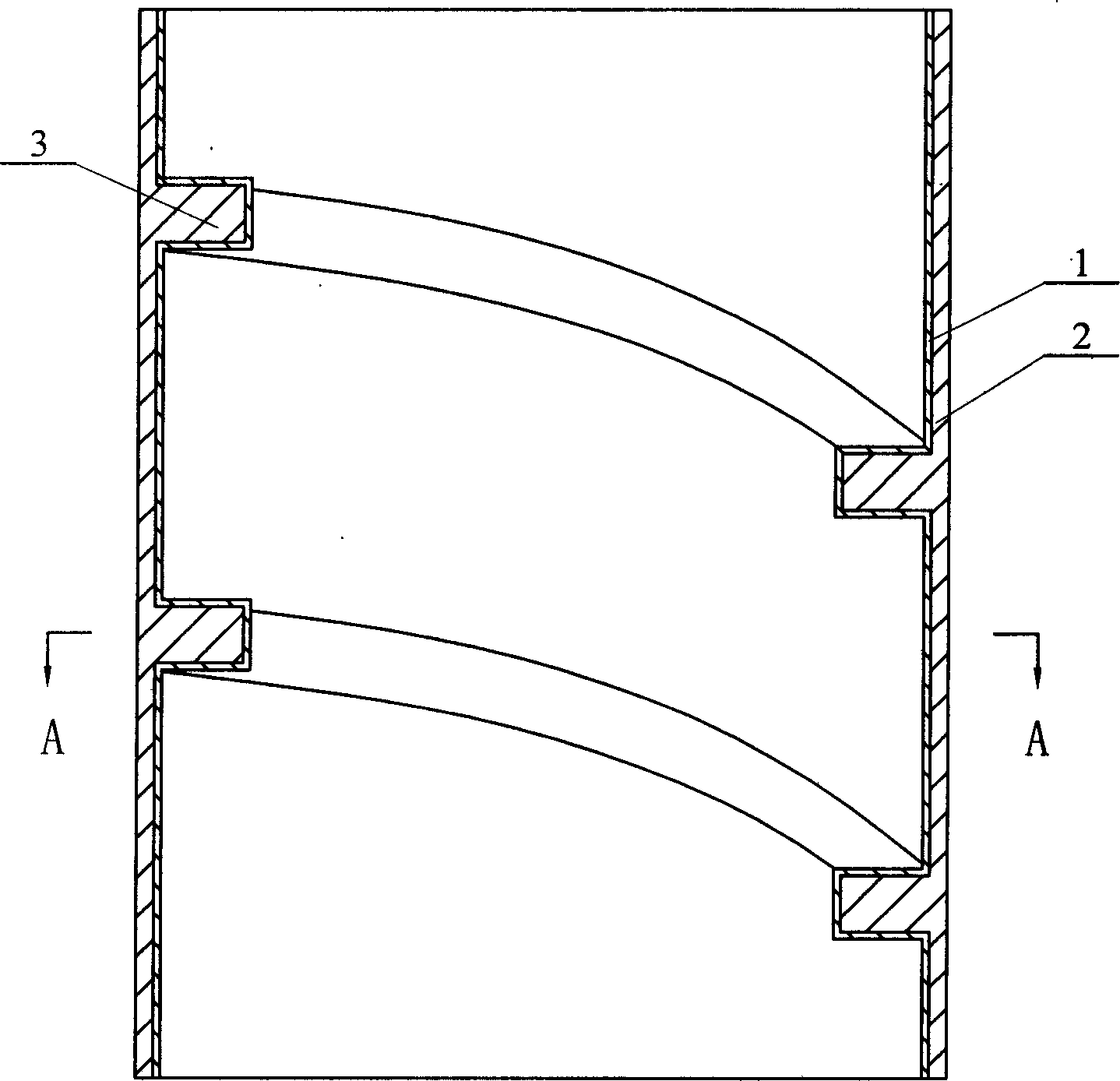

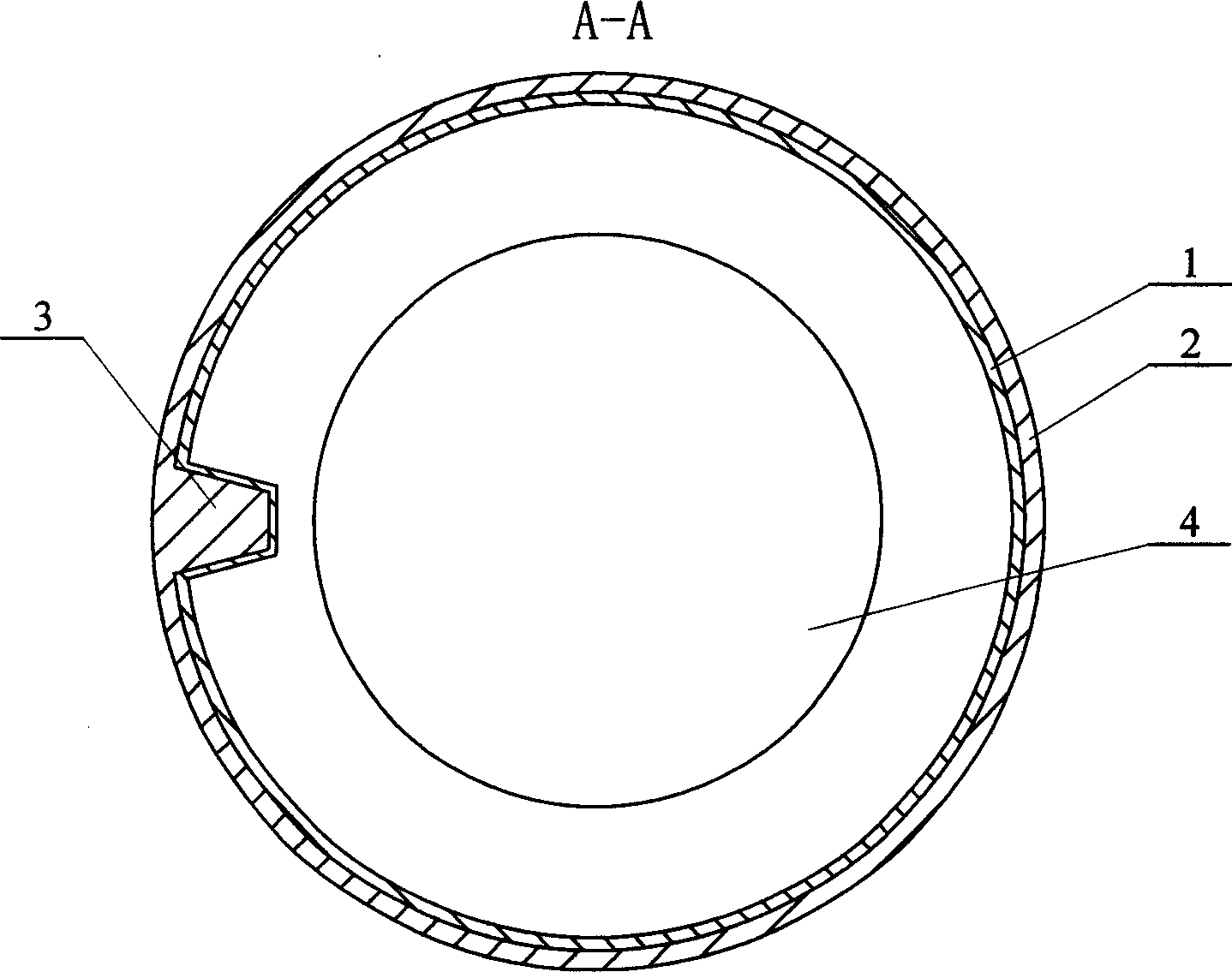

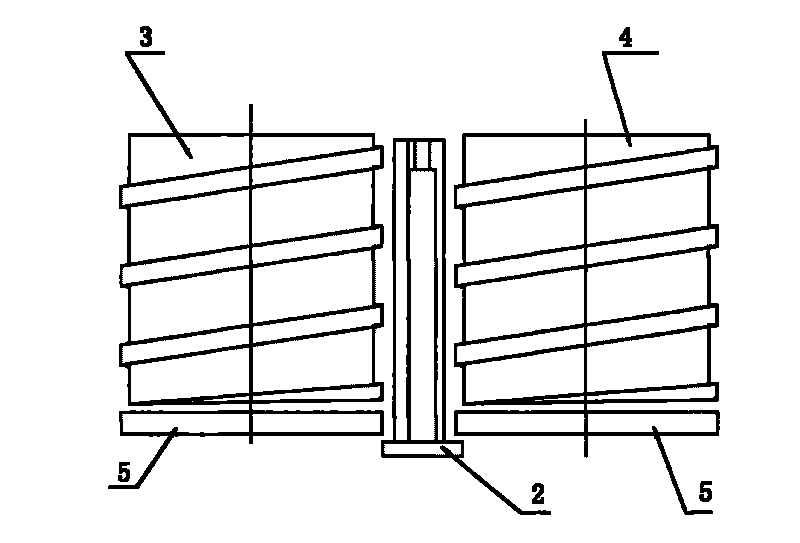

Fiber reinforced plastic cylinder with interior spiral reinforcing bar and method for manufacturing the same

The invention relates to a fiber strengthen plastic cylinder with inner screw strength bar. Wherein, the liner layer (1) has at least one screw groove; the strength bar (3) is fixed inside the groove whose length is at least 1 / 3 of the cylinder length; the outer layer (2) of cylinder is fixed on the outer surface of liner layer (1) and the strength bar (3). The producing method comprises: treating the outer surface of mould; laying and coiling the liner layer (1), cylinder outer layer (2) and the strength bar (3) to be put into solidify furnace to be molded; then treating the outer surface. The invention has short producing time, high efficiency and simple process. And the inventive cylinder has high strength, smooth inner surface without crack, etc.

Owner:HARBIN FRP INST +1

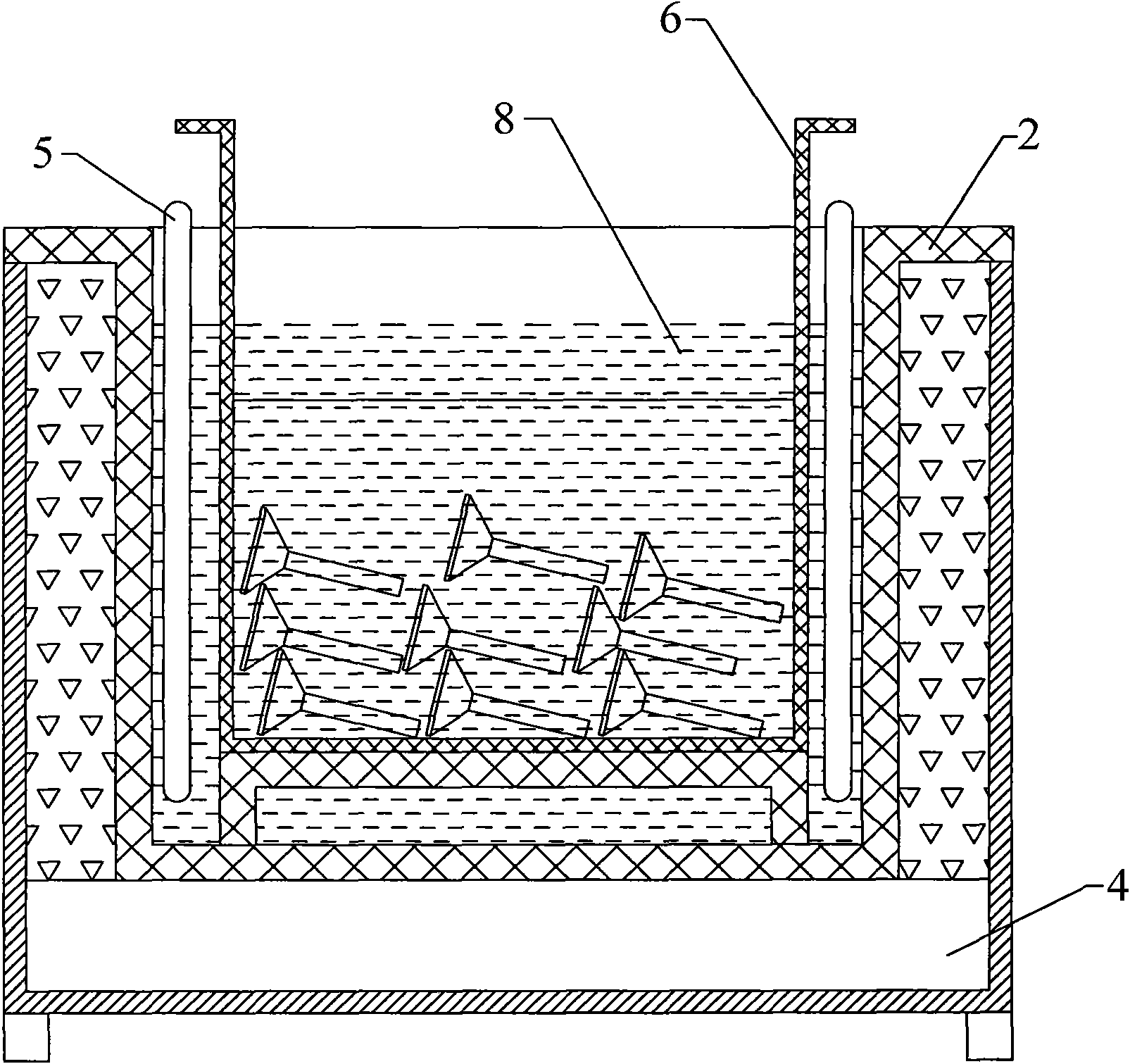

Rapid descaling device and descaling treatment method thereof

The invention discloses a rapid descaling device and a descaling treatment method thereof, and the descaling device comprises a pallial chute and a lining chute, wherein the lining chute is arranged in the pallial chute; the bottom end inside the pallial chute is provided with an ultrasonic sound board which is in contact fit with the bottom part of the lining chute; and the lining chute is internally provided with at least one heating pipe. The using method is as follows: a, injecting a proper amount of descaling solution in the lining chute, controlling the heat temperature of the heat pipe and setting the descaling time; b, placing a workpiece shelf loaded with workpieces in the lining chute, starting the ultrasonic sound board, and rapidly descaling the workpieces under the jointed action of descaling solution chemical etching and ultrasonic vibration; and c, taking the workpiece shelf out when the set descaling time is over, and stopping the descaling operation. The invention can effectively and rapidly remove oxide layers after valve thermal treatment with the descaling efficiency 2-3 times quicker than that of shot blast, and the processed valve surface has no cracks; the intrinsic defect on the valve surface is not covered after descaling treatment, so that the valve with the intrinsic defect can be selected to discard as soon as possible to avoid waste of subsequent machining.

Owner:HUAI JI DENG YUE VALVE CO LTD

Special-shaped hole machining method and special-shaped hole

InactiveCN109175732AHigh shape accuracyHigh dimensional accuracyLaser beam welding apparatusGalvanometerNanosecond pulse

The invention discloses a special-shaped hole machining method and a special-shaped hole and relates to the technical field of laser machining. According to the method, femtosecond or picosecond or nanosecond pulse laser is adopted, and a mode completely based on scanning galvanometer filling machining is provided. The method comprises the steps that firstly, a through hole smaller than the hole diameter requirement is machined so that gasification objects and fusion objects formed in the machining process can be discharged and re-coagulation objects are prevented from depositing; then, roughmachining of a special-shaped hole diffusion section is conducted; then, the laser focusing position is adjusted, broaching is conducted on the basis of a dust discharge through hole, and a cylindrical through hole meeting the hole diameter requirement is machined; and finally, the focus position is precisely adjusted, and the diffusion section is machined layer by layer. By means of the special-shaped hole machining method and the special-shaped hole, heat-induced defects such as recasting layers, microcracks, coating collapse and the like generated in the process that in the prior art, a special-shaped hole is machined, and in particular, the special-shaped hole is machined in a workpiece with the surface coated with a thermal barrier coating are avoided; and in addition, the shape and dimension precision of the special-shaped hole are improved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Nickel-tungsten-silicon carbide-aluminum oxide composite electroplate liquid as well as preparation method and application thereof

InactiveCN104313656AOvercome the phenomenon of cakingImprove current efficiencyElectrolytic coatingsSulfateSodium tungstate

The invention relates to nickel-tungsten-silicon carbide-aluminum oxide composite electroplate liquid as well as a preparation method and application thereof, and belongs to the technical field of material surface treatment. Each liter of the composite electroplate liquid comprises the following raw materials: 10-30 g of sodium tungstate, 140-200 g of nickel sulfate, 10-40 g of silicon carbide, 5-20 g of aluminum oxide, 60-100 g of a complexing agent, 1-2 mL of a surfactant and the balance of de-ionized water. According to the composite electroplate liquid provided by the invention, the raw materials are easily available, the environmental harm is little, and the composite electroplate liquid can be stored for a long term after being prepared; the preparation method provided by the invention is simple, feasible and favorable for industrialization; the invention further provides a method for electroplating petroleum machinery by the composite electroplate liquid, an obtained composite coating is uniform in particle distribution, does not have microcracks on the surface and is remarkably improved in both corrosion resistance and wear resistance.

Owner:ZIBO SHENGFENG IND & TRADE

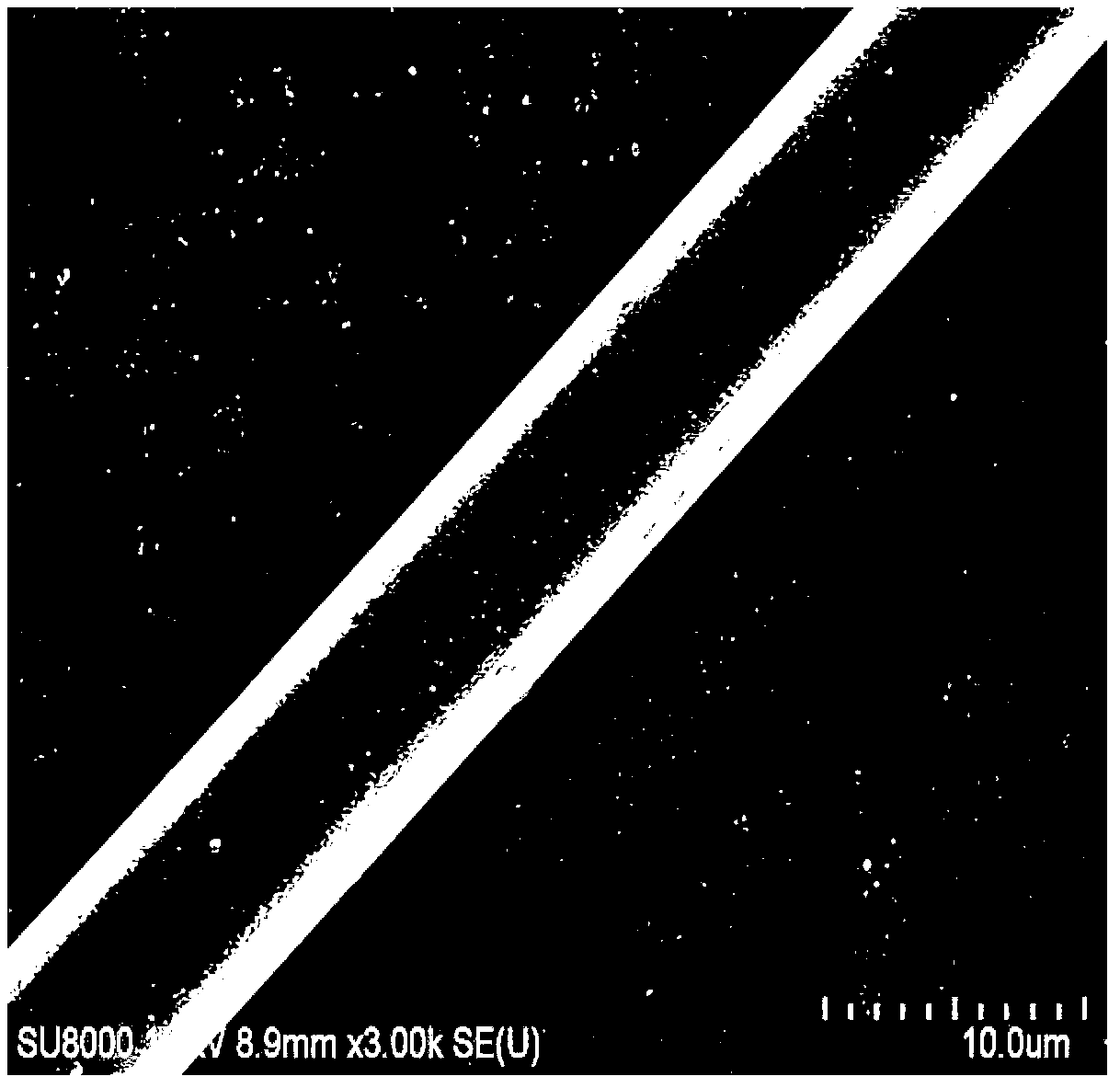

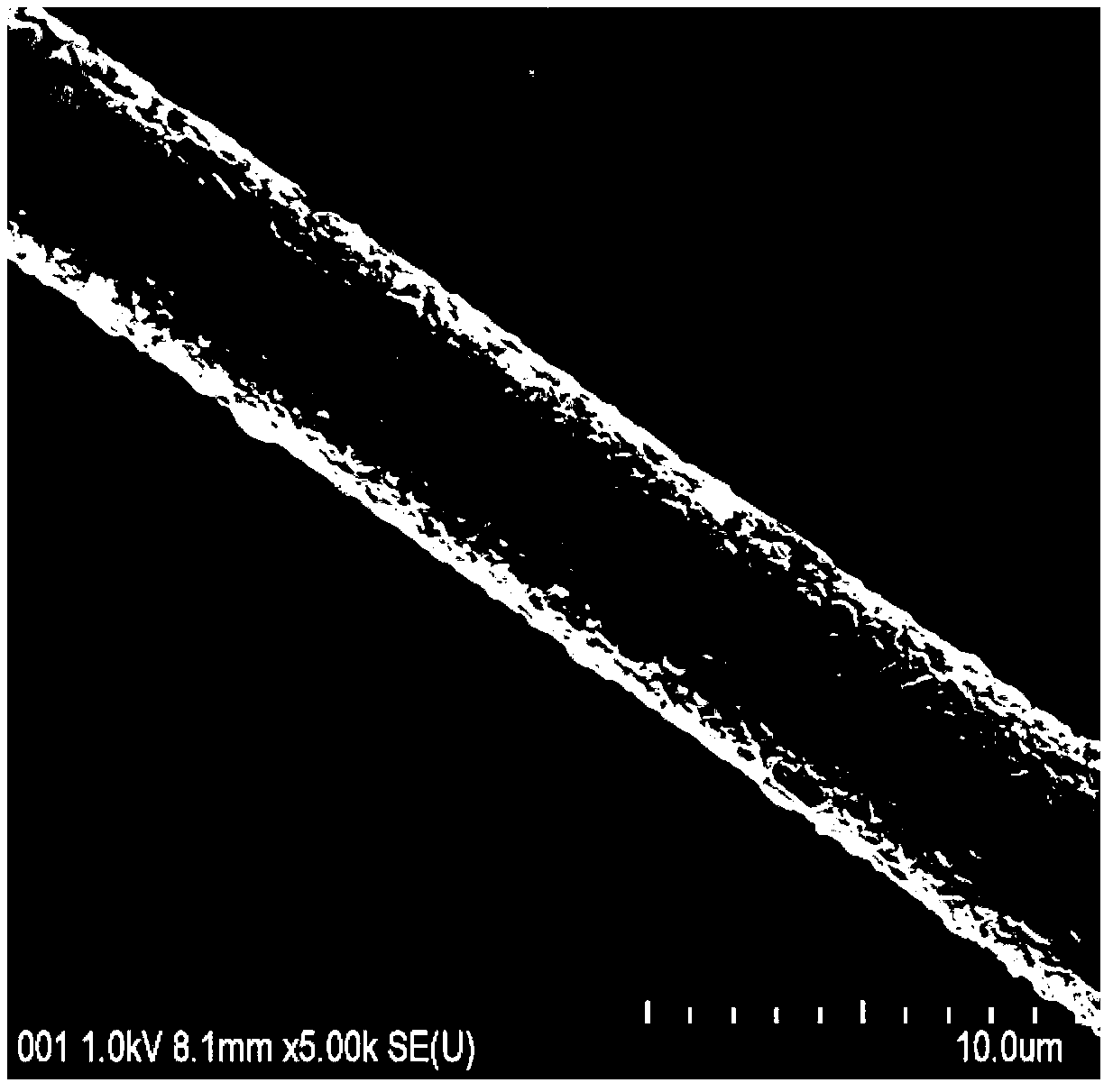

Method and equipment for utilizing ultrafast lasers for frequency modulation of quartz crystals

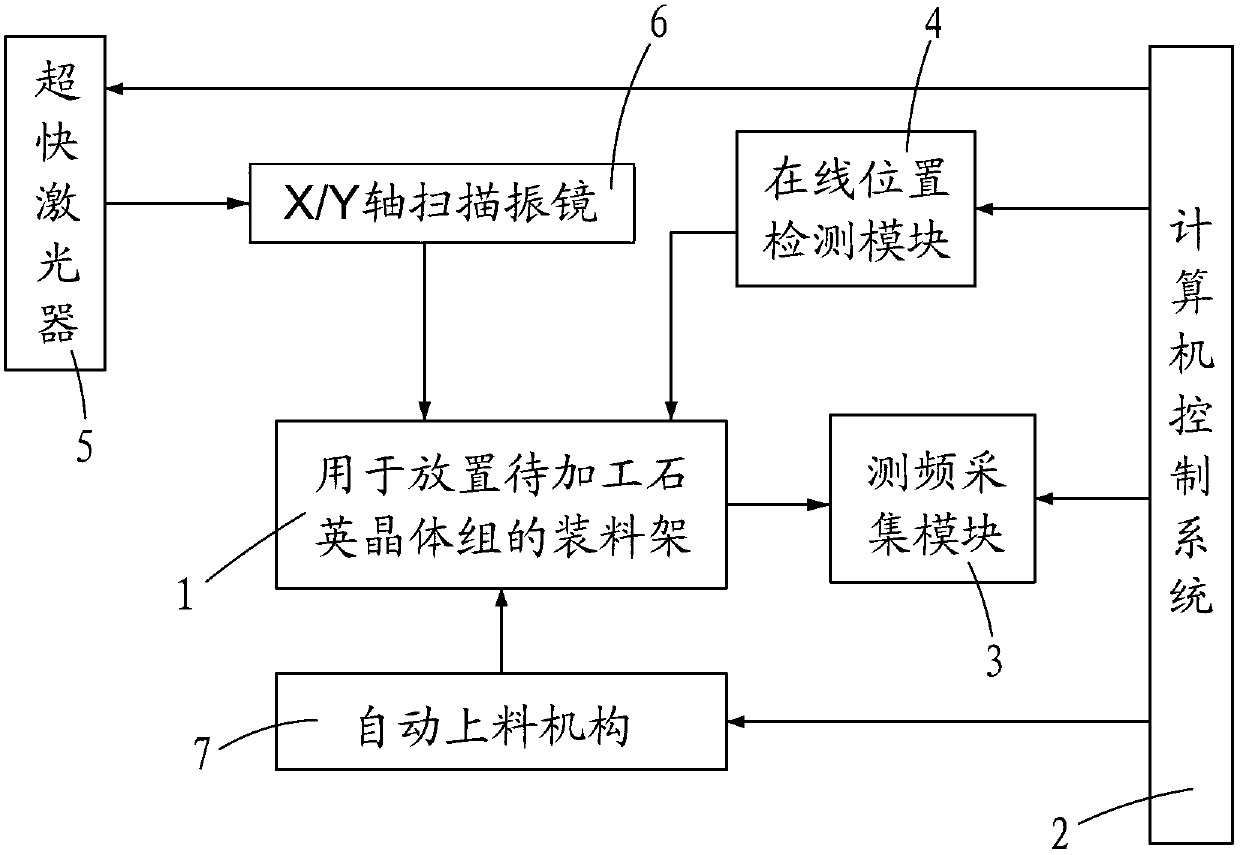

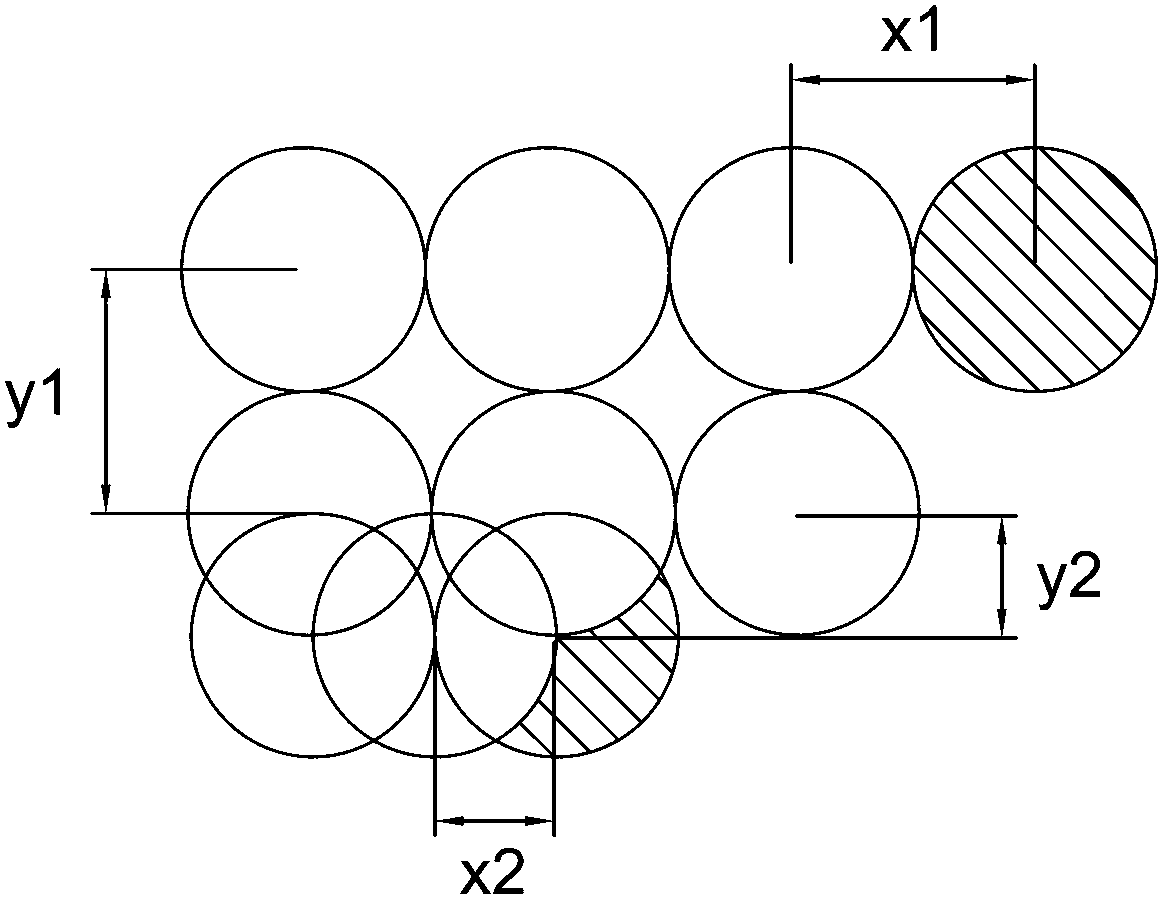

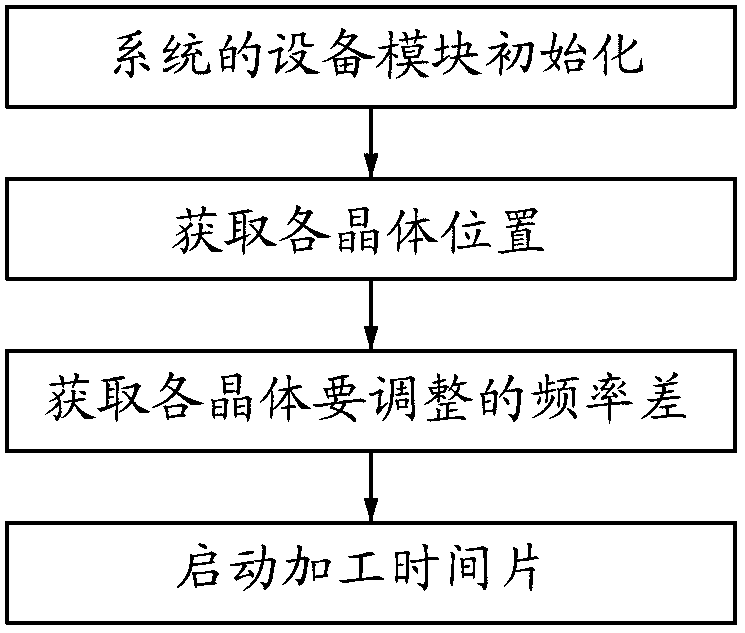

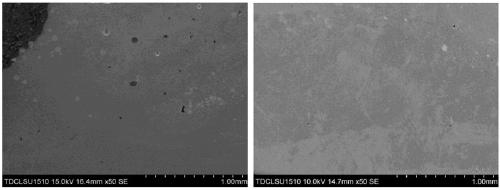

InactiveCN103128451AHigh peak powerIncrease the electric field strengthImpedence networksLaser beam welding apparatusFrequency stabilizationElectricity

The invention provides equipment for utilizing ultrafast lasers for frequency modulation of quartz crystals. The equipment comprises a feeding frame used for placement of quartz crystals to be processed, a computer control system, a frequency measuring collection module used for measuring resonance frequency of the quartz crystals and arranged on the feeding frame, an online position detection module arranged on the feeding frame, an ultrafast laser which realizes etching by casting lasers generated by an X / Y-axis scanning galvanometer to the quartz crystals, and an automatic loading mechanism which is electrically connected with the computer control system. The invention further provides a method for utilizing the ultrafast lasers for frequency modulation of the quartz crystals, and surface quality of the quartz crystals is changed by etching sliver-coated layers on surfaces of the quartz crystals and quartz crystal materials under the silver-coated layers by the ultrafast laser, so that large-range accurate frequency modulation of frequency of the quartz crystals is realized, and frequency stability of finished crystal products is improved.

Owner:PUTIAN UNIV

Microwave curing method for block

ActiveCN110936485AUniform temperatureDimensionally stable materialCeramic shaping apparatusChemistryMicrowave frequency

The invention provides a microwave curing method for a block. The method includes steps that (1) slurry is injected into a test mold, covered by a film, and is subjected to standing and pre curing for2-4 hours, and the temperature is controlled at 30-45 DEG C; (2) after pre curing, a steel wire is used to cut an uncured block, and then the film is utilized to re-cover and transferred to a microwave reaction chamber for 1-2 hours, the temperature is controlled at 50-70 DEG C, and the microwave frequency is 433-2450 MHz; and (3) after microwave heating and curing, the block is naturally cooledto room temperature, and curing is completed. The method is advantaged in that a microwave source with the specific frequency of 433-2450 MHz has the characteristics of deep acting depth, which can realize synchronous heating of the whole block inside and outside so that the temperature of each part of the block is uniform, and the stress damage caused by temperature difference is avoided, and themethod can realize fast curing of the block, improve production efficiency, and realize energy conservation and environmental protection.

Owner:GUANGXI ACAD OF SCI +2

In-situ preparation method for manufacturing high-entropy alloy by gradient powder feeding laser additive material

ActiveCN109079137AImprove molding efficiencyReduce manufacturing costAdditive manufacturing apparatusIncreasing energy efficiencyMaterials preparationMetallurgy

The invention discloses an in-situ preparation method for manufacturing high-entropy alloy by gradient powder feeding laser additive materials. The in-situ preparation method comprises the following steps of raw material preparation and gradient powder feeding laser additive material preparation. The material forming efficiency prepared by the in-situ preparation method is high, and a part model is not subjected to technological constraints, so the in-situ preparation method can be used to prepare parts with complex shapes, and the near-net forming of the materials can be realized, the production cost of the parts is greatly reduced. Samples have good forming effect, no air holes and macroscopic cracks, no micro-air holes and micro-cracks, good density, uniform organization and coexistenceof three phase structures. Composition detecting is carried out by using an energy disperse spectroscopy, and the definition of high-entropy alloy is met from the composition. The boundary between aprinting layer and two sides of base is fuzzy, the combination is better, and the crack tendency is low. It can be concluded that the gradient powder feeding mode greatly reduces the crack tendency atthe joint.

Owner:TIANJIN UNIV

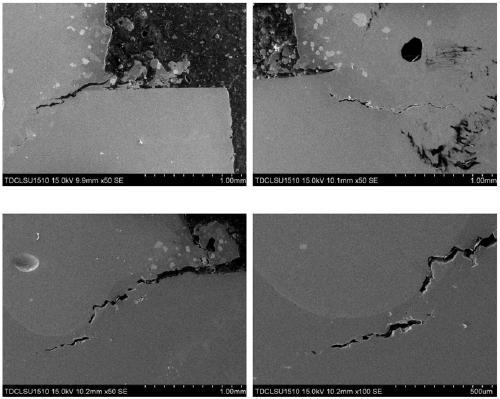

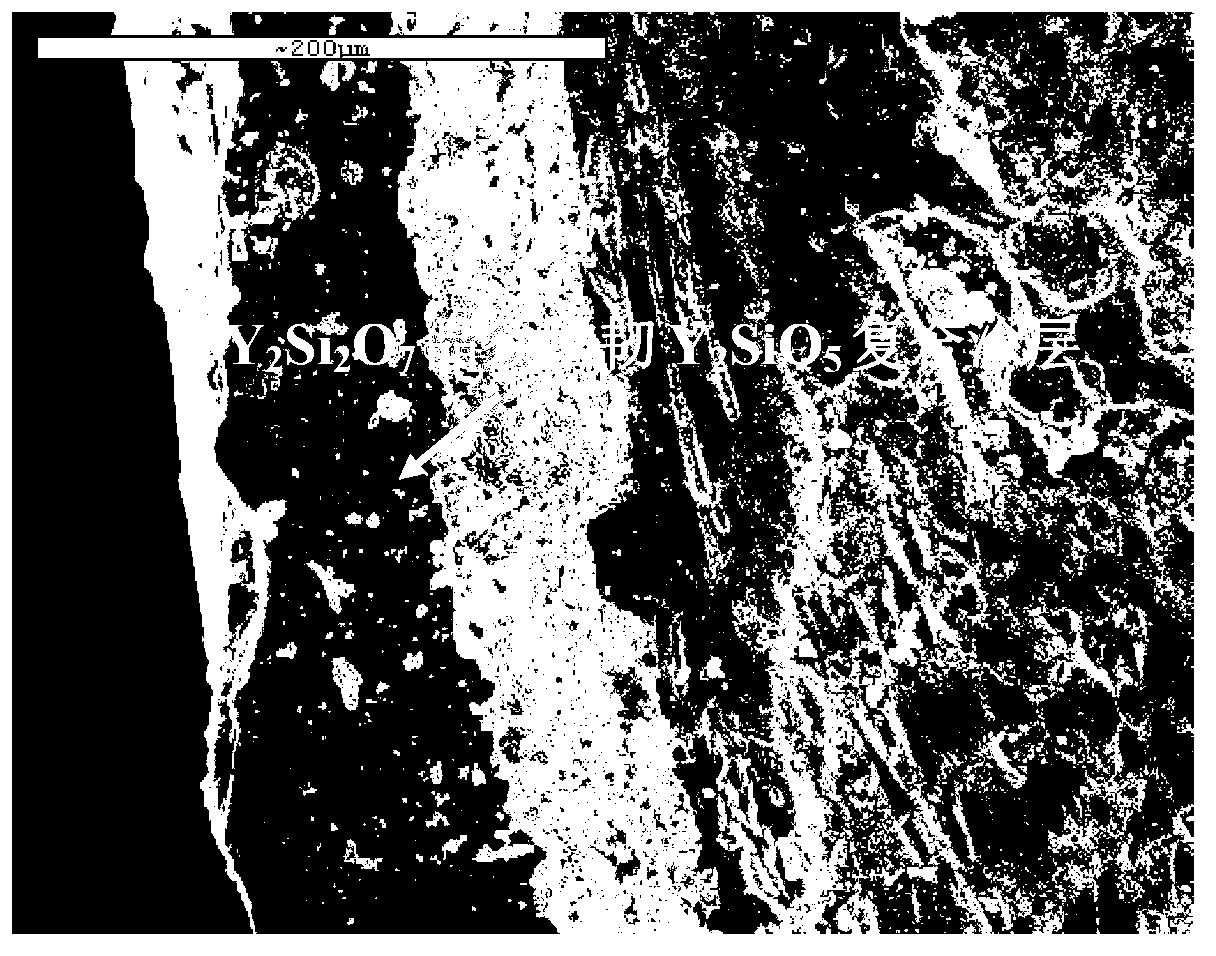

Preparation method of Y2Si2O7 whisker toughened Y2SiO5 composite coating

Provided is a preparation method of a Y2Si2O7 whisker toughened Y2SiO5 composite coating. The method includes that first, a SiC porous inner coating is prepared on the surface of a C / C composite material substrate through an embedding method, and then Y2Si2O7 whisker is prepared, surface modification is conducted on the Y2Si2O7 whisker by using a composite surface active agent to obtain mixed liquid; the C / C composite material with SiC porous inner coating prepared on the surface and the mixed liquid are adopted for ultrasonic electrophoresis selectively assembling and depositing to obtain a Y2Si2O7 whisker pinning layer, and finally the Y2Si2O7 whisker toughened Y2SiO5 composite coating is prepared through hydrothermal electrophoretic deposition method. The Y2Si2O7 whisker toughened Y2SiO5 composite coating is even, compact, free of microscopic cracks, and binding force between the substrate and the inner coating and between the inner coating and an outer coating is remarkably improved. The Y2Si2O7 whisker toughened Y2SiO5 composite coating can conduct effective anti-oxidation protection on the C / C composite material for 300h in static air at the temperature of 1800 DEG C, and oxidization weightless rate is smaller than 0.45%.

Owner:鄢三元

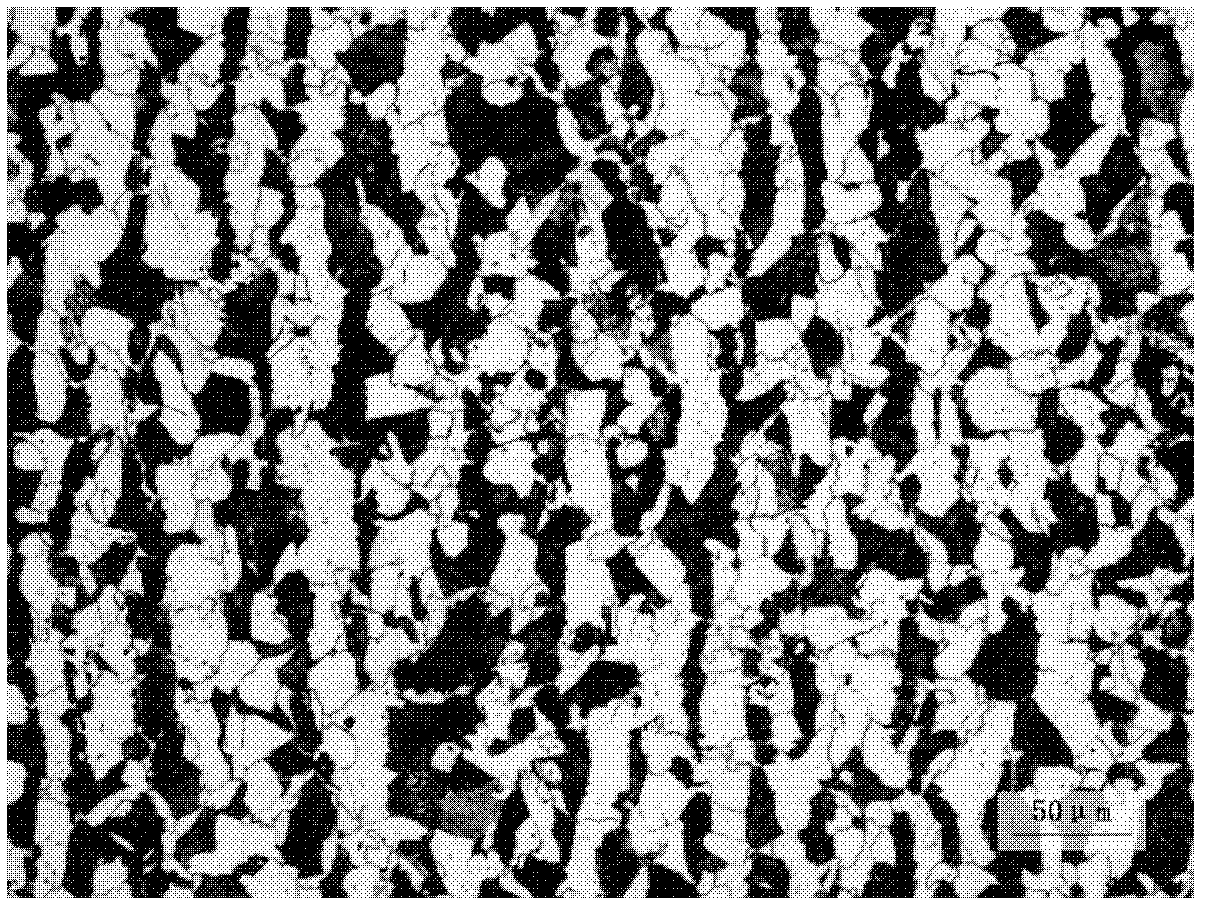

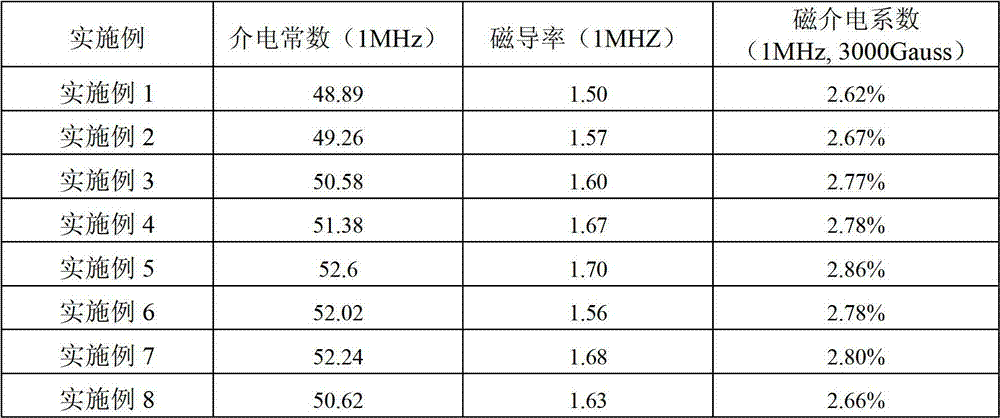

Multiferroic composite material with magneto-dielectric effect and preparation method thereof

The invention discloses a multiferroic composite ceramic material with a magneto-dielectric effect, the chemical formula of the material is NaNbO3-NiFe2O4, and the molar ratio is 1:1. The material is prepared by taking Na2CO3, Nb2O5, NiO and Fe2O3 as raw materials through adopting a solid phase method, carrying out material preparing and ball milling on the raw materials, burning an obtained object at a temperature of 900-1150 DEG C, carrying out compression moulding on the obtained object, and sintering the obtained object at a temperature of 1100-1200 DEG C. The multiferroic composite ceramic material disclosed by the invention has the advantages of good uniformity, small roughness, no micro-crack, stable performance, good electrical properties, magnetic properties, magneto-dielectric effect, and the like, and can be used for manufacturing integrated multifunctional magnetic / electrical parts; and the multiferroic composite ceramic material is simple in preparation process, non-toxic, small in pollution, and wide in application range.

Owner:TIANJIN UNIV

Lightweight high heat conductive composite material and preparation method thereof

The lightweight high heat conductive composite material disclosed in the present invention comprises the following components in weight percentages of: graphite powder 71-99%, and Al powder 1-29%. The preparation method comprises the steps of: weighing the graphite powder and the Al powder according to the weight percentages; putting into an enclosed container, mixing, and standing for 0.5-24 hours; hot compacting with the pressure over 10 MPa, at temperature above 600 degrees centigrade, in vacuum or under protection of argon or nitrogen. The invention has the advantages of simple preparation process, one-shot forming, short production cycle, wide raw material source, and low cost; the obtained composite material finished product has low density, high mechanical strength, high thermal conductivity and no micro-crack inside material.

Owner:ZHEJIANG UNIV

Screw-type straightening method for tap bolt of slender rod

ActiveCN101708516AEven by forceThe surface of the shank of the part is smoothStress concentrationFriction force

The invention relates to a screw-type straightening method for a tap bolt of a slender rod, which comprises a single spiral curve straightening roller wheel, an auxiliary roller wheel and a supporting block, wherein the straightening roller wheel is in a single spiral curve type, the straightening roller wheel and the auxiliary roller wheel are arranged on a parallel rotating shaft in turn, and the supporting block is arranged between the straightening roller wheel and the auxiliary roller wheel. During the straightening process, only a rod part of the tap bolt of the slender rod is placed on the supporting block and the rod part of the tap bolt of the slender rod rotates in a negative direction under the action of frictional force, the rod part is straightened by rolling, and until the surface of the rod part of a component is polished and spotless, only slight visible uniform spiral traces exist. The screw-type straightening method can straighten the rod part of the tap bolt of the slender rod comprehensively without blind spots, has no stress concentration in the straightening process, cannot generate potential safety hazards such as micro cracks, and has a good straightening effect.

Owner:DONGFENG MOTOR FASTENER CO LTD

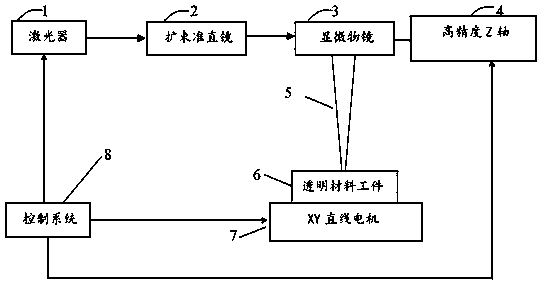

Method for processing three-dimensional contour of transparent material

ActiveCN111558785ANo crackNo damageGlass severing apparatusWelding/soldering/cutting articlesLaser processingCrack free

The invention discloses a method for processing a three-dimensional contour of a transparent material. The whole transparent material is processed according to a preset path through a laser beam, laser processing energy is continuously adjusted according to different processing depths, the Z axis height and a corresponding processing track are changed, and the three-dimensional contour of the transparent material is formed; after the three-dimensional contour of the transparent material is formed, a forming method is used for treatment, and the three-dimensional contour of the transparent material is separated from waste to be formed finally. The laser beam acts in the thickness direction of the whole transparent material, the transparent material is modified through ultra-short pulse width, the transparent material is formed and separated through a special treatment method, a crack-free damage-free workpiece is obtained, generation of small debris is avoided, and the product yield isimproved.

Owner:WUHAN HGLASER ENG CO LTD

Liquid rubber modified nitrile rubber cable material

The invention discloses a liquid rubber modified nitrile rubber cable material. The liquid rubber modified nitrile rubber cable material comprises raw materials as follows: nitrile rubber, liquid isoprene rubber, benzoxazine resin, superfine acrylate rubber powder, an organic silicon polyurethane oligomer, silica, hydrotalcite, tetrapod-shaped zinc oxide whiskers, nanosilicon dioxide, zinc oxide, zinc methacrylate, zinc gluconate, stearic acid, sulfur, N, N'-M-phenylene dimaleimide, triallyl isocyanurate, styreneic bock copolymers, propanediol sebacate polyester, glycerol distearates, zinc stearate, calcium stearate, ethenyl triethoxysilane, an accelerant and an anti-aging agent. The liquid rubber modified nitrile rubber cable material has high strength, excellent elasticity and rigidity, good ageing resistance and long service life.

Owner:无为县茂林电缆材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com