Digital controlled development and creep ultrasonic grinding process and apparatus for engineer ceramic blade profiles

An engineering ceramics and ultrasonic technology, which is applied in the field of engineering ceramic blade surface numerical control generating creeping ultrasonic grinding technology and device, to achieve the effects of improving processing flexibility, shortening production preparation period, and high surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

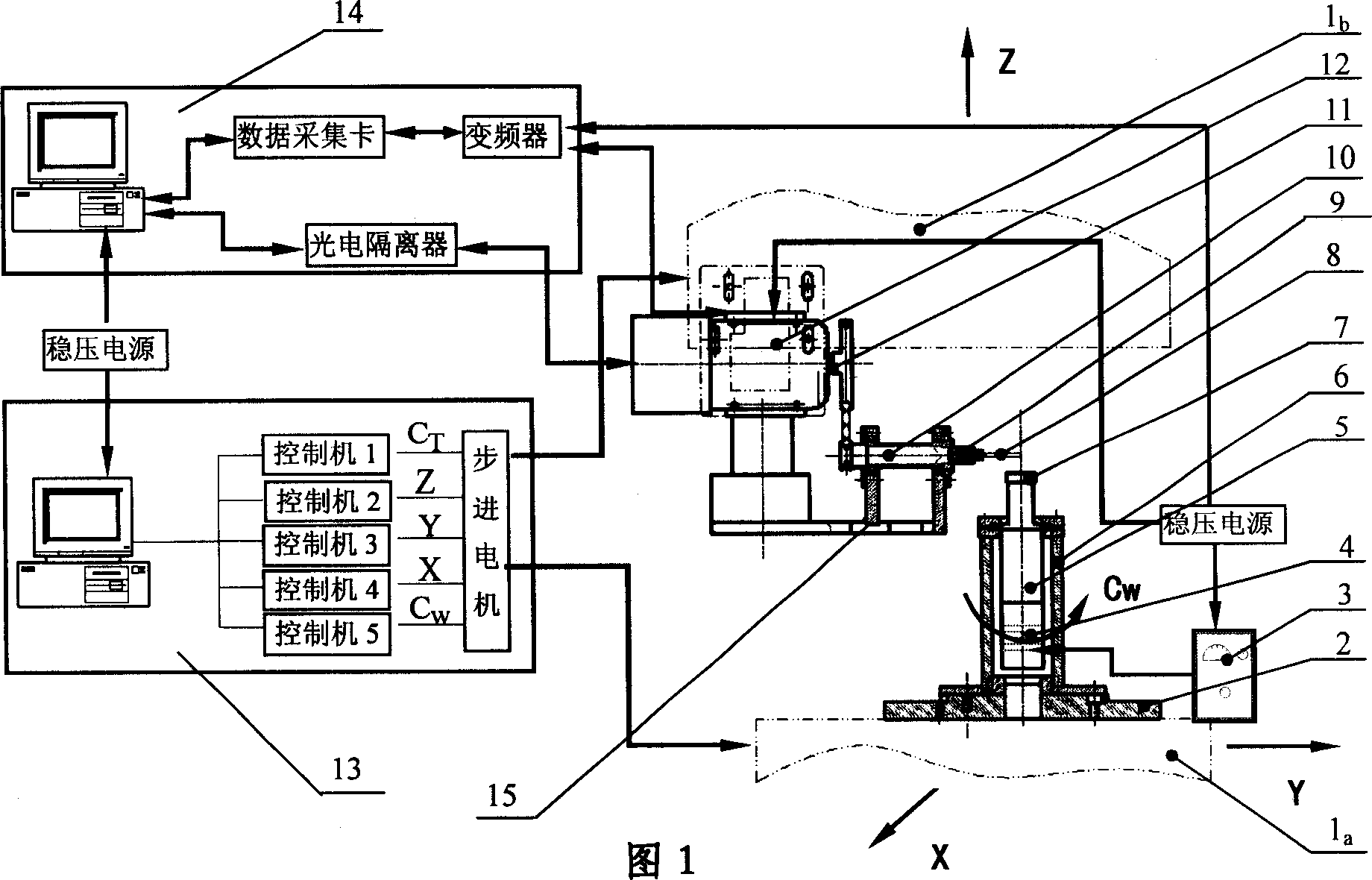

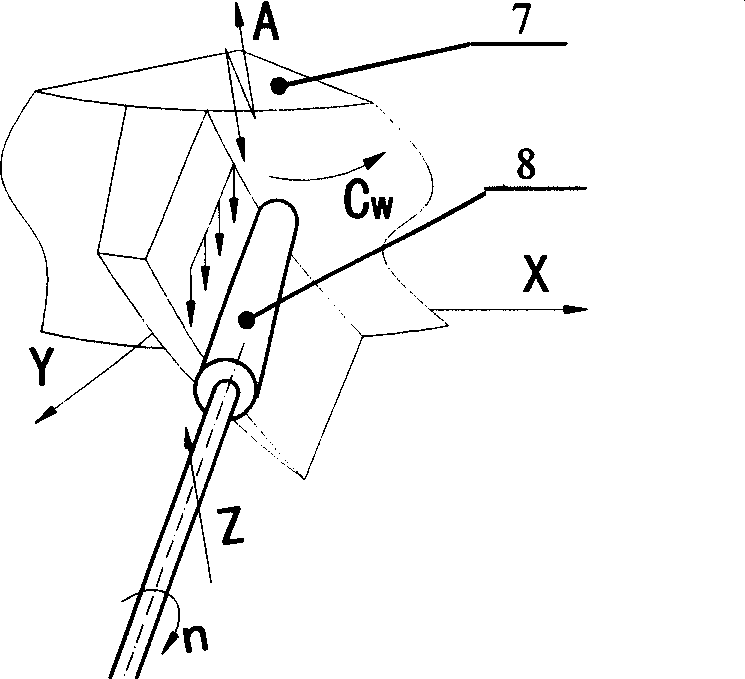

[0012] The device for implementing the "engineering ceramic blade surface numerical control generating creeping ultrasonic grinding process" of the present invention is shown in Fig. 1 . The device includes a five-axis CNC machine tool 1 (utility model patent: ZL 96 2 31072.7), a corresponding five-axis linkage CNC system 13 (invention patent: ZL 96 1 156810.2), and a grinding wheel spindle installed on the Z-direction sliding seat 1b of the vertical axis of the machine tool. Seat 15, grinding wheel 8, frequency modulation motor 12, motor frequency conversion speed regulation control system 14, ultrasonic vibration system installed on the machine tool rotary table 1a.

[0013] The grinding wheel 8 is fixed and clamped on the grinding wheel main shaft 10 through the collet 9, and the frequency modulation motor 12 is connected with the grinding wheel main shaft 10 through the belt pulley 11, and speeds up to drive the grinding wheel main shaft 10 and the grinding wheel 8 mounted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com