Patents

Literature

153 results about "Engineering ceramics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Engineering ceramics are ceramic products that are used to make other products. Examples of their applications are the space shuttle tiles, car parts and computer parts.

High-instantaneous-energy-density electric spark high-speed milling method

InactiveCN103008802AGood removal effectEfficient processingElectrical-based machining electrodesWorking fluidCombined method

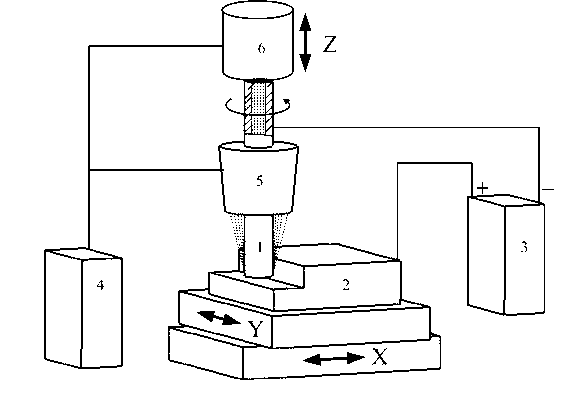

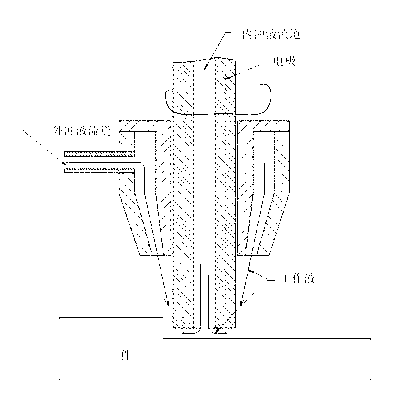

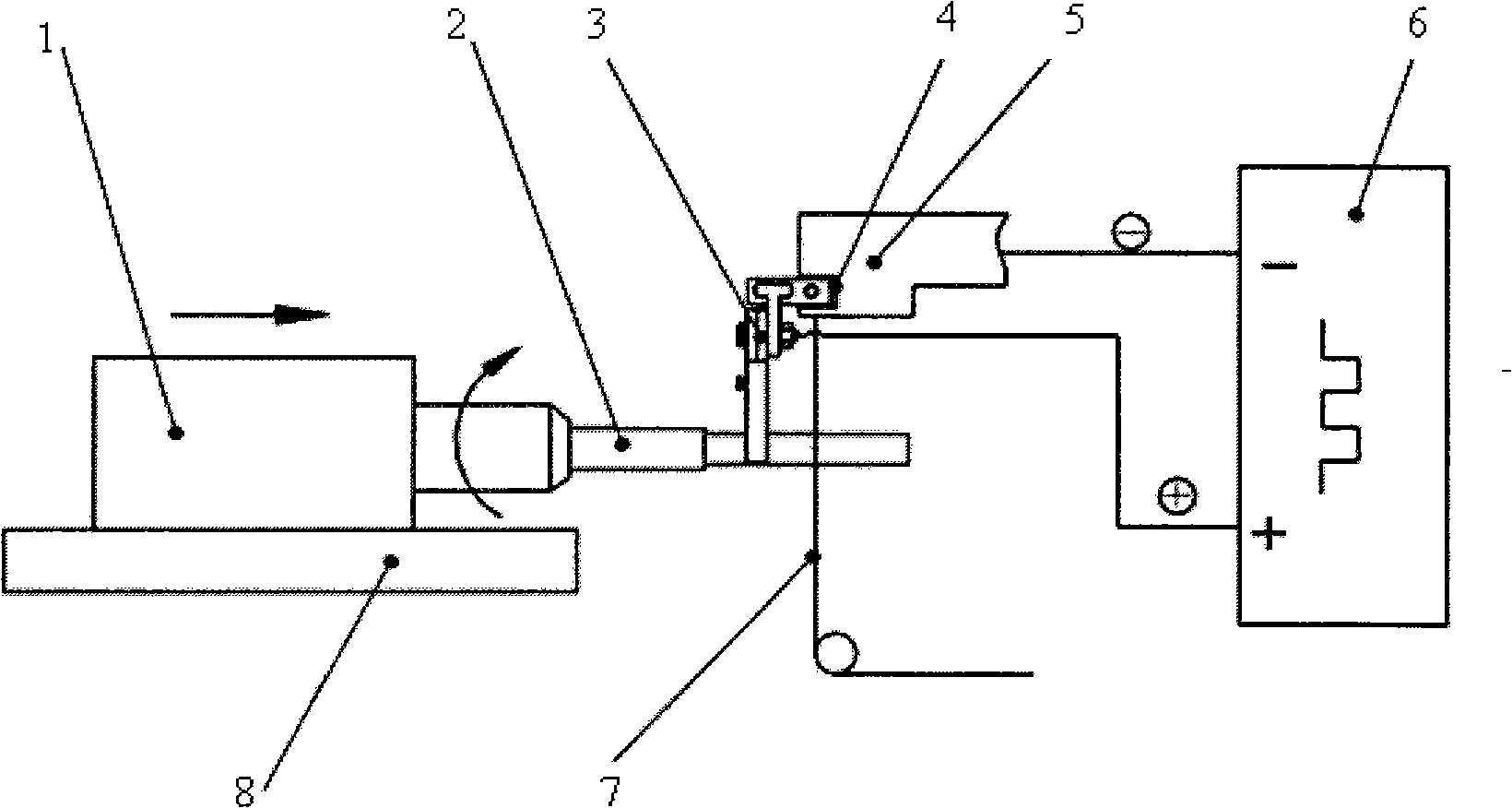

The invention relates to a high-instantaneous-energy-density electric spark high-speed milling method, which belongs to the field of machining. The method comprises the following steps of: connecting a rotary rod-like electrode with an inner flushing fluid hole with a negative electrode of a power supply, connecting a to-be-machined workpiece with a positive electrode of the power supply and melting to remove the workpiece material by utilizing high-instantaneous-energy-density spark discharge between the electrodes and the workpiece in a machining process; discharging molten material out of a discharge gap by working fluid which flows at a high speed; and cooling the machined workpiece. According to the method, by utilizing high-instantaneous-energy-density spark discharge and a high-pressure forced inner flushing fluid and low-pressure outer flushing fluid combined method, the stability and the high efficiency of machining are realized, and high-efficiency machining on any conductive material, including conventional difficult-to-machine materials such as engineering ceramic with weak conductivity and high-temperature alloy, can be realized.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Ceramic binder for steel ball grinding wheel

The invention relates to a structure of a grinding material composited with a novel high-shrinkage engineering ceramic binder for the preparation of a grinding wheel and a preparation method thereof. The preparation method is characterized in that: the high-strength high-shrinkage engineering ceramic binder which is prepared from clay, feldspar, boracic glass, bentonite and manganite is composited with the mixed grinding material, the opacifying effect of the boracic glass promotes the glass nucleation, fluxing agents bentonite and manganite powder promote the preparation of the high-strengthhigh-shrinkage engineering ceramic structure, and the ceramic binder for the steel ball grinding wheel is prepared through carrying out cold-press high-pressure molding, and sintering at a certain temperature. Compared with market products, the strength, the combination degree, the elastic modulus and the linear velocity in usage of the steel ball grinding wheel are greatly improved, the geometric dimension of the steel ball grinding wheel is stable, the steel ball grinding wheel which has a high strength, a high hardness and a uniform tissue density and has the advantages of large grinding ratio, high fineness and no workpiece burning under high speed grinding conditions is a special grinding wheel for a novel high efficiency steel ball. So the steel ball grinding wheel can be widely applied to the mechanical steel ball manufacturing industry and is easy to be automated in the industry.

Owner:江苏华东砂轮有限公司

High-strength silicon carbide ceramic pipe and manufacturing method thereof

The invention discloses a high-strength silicon carbide ceramic pipe and manufacturing method thereof, and belongs to the technical field of engineering ceramic materials. Silicon carbide ceramic powders with different granularities are used as the main raw materials, graphite powder and carbon black are used as binders, and resin is used as a binder. The materials are uniformly mixed by a spray granulation process; an organic plasticizer of cellulose and a lubrication agent are added into the mixture; and vacuum pugging, decaying and extrusion molding are conducted to obtain a pipe base substrate; and the base substrate is subjected to drying solidification, high temperature sintering reaction, sandblast and heat treatment to obtain the high strength silicon carbide ceramic pipe. The pipe biscuit manufactured by the process has high strength and length of more than 4000mm; after sintering, the pipe has strength of 300MPa or more, and has the advantages of moderate density, high thermal conductivity, high fracture toughness, good thermal shock resistance and low cost, and can be widely applied to chemical and metallurgy fields, such as acid and alkaline corrosion and high temperature erosion.

Owner:NANTONG SANZER PRECISION CERAMICS CO LTD

Steel blank grinding abrasion wheel adopting microcrystal ceramic bonding agents

ActiveCN102363286AImprove the speed of useExtended service lifeAbrasion apparatusCeramic compositeTissue density

The invention relates to a steel blank grinding abrasion wheel adopting microcrystal ceramic bonding agents, which is in a structure made of polycrystalline solid materials with the coexistence of glass and crystals and adopts the bonding agents of clay, feldspar, boron-containing microcrystal glass, pyrophyllite and soapstone to be made into high-intensity and low-shrinkage engineering ceramic bonding agents, good performance of the glass and the ceramics such as high mechnical intensity, wear resistance, corrosion resistance and the like are integrated, then, the glass and the ceramics are combined with mixed grinding materials, a molding pressing method is adopted for the high-pressure double-side pressing process forming, the low-temperature firing is adopted, the positive pressure reducing atmosphere heat simulation crystallization is adopted at the 800 DEG C heat insulation section, and the mixed grinding material and micro porous glass phase high-intensity microcrystal engineering ceramic composite structure is formed, so the intensity and the bonding degree of the steel blank grinding abrasion wheel are greatly improved, the use linear speed of the abrasion wheel is accelerated, and the safety factor is high. The steel blank grinding abrasion wheel belongs to the novel efficient special steel blank grinding abrasion wheel with the characteristics that the intensity andthe hardness are high, the tissue density is uniform, the grinding ratio is great under the condition of high-speed grinding, workpieces can not be damaged through firing, and the automation of iron and steel industries is easy to realize.

Owner:江苏华东砂轮有限公司

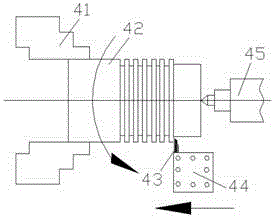

Circular turning tool for ceramic excircle processing and axial processing method thereof

InactiveCN101774139ASimple application maintenanceLow investment costRevolution surface grinding machinesStone-like material working toolsMachiningMaterials science

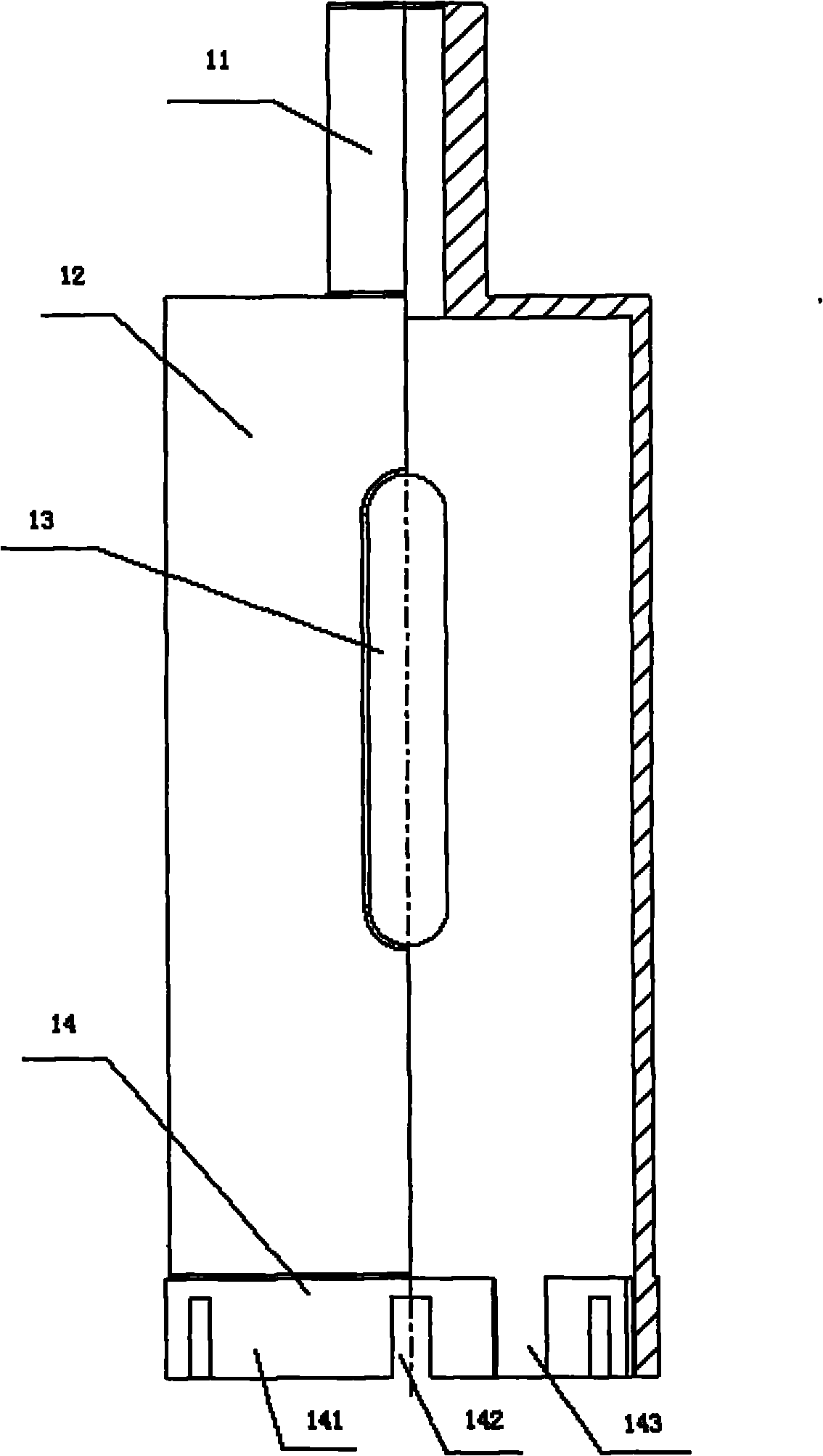

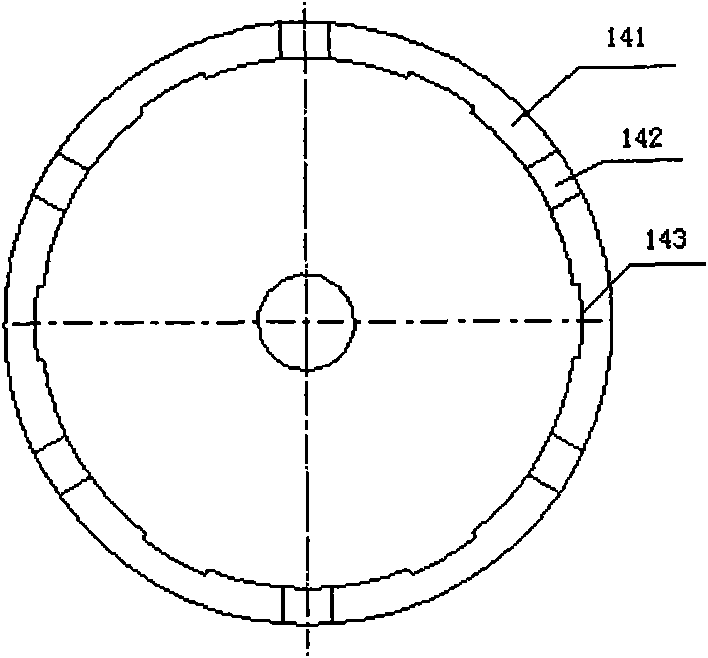

The invention relates to a circular turning tool for ceramic excircle processing and an axial processing method thereof, which belong to the field of the non-traditional processing in machining. The tool mainly comprises a tool handle, a tool body and a tool head which are sequentially and coaxially connected; the tool handle, the tool body and the tool body are hollow round pipes, and the tool body wall is provided with a balance groove; and the tool head comprises tool teeth, through slots formed between every two tool teeth and tooth sockets processed on the inner surface of the tool teeth. The method axially turns the excircle to cylindrical ceramic material through the high-speed rotation of the circular tool; the tool head bottom end surface of the circular tool serves as the main cutting surface removing material, and the inner surface of the tool head of the circular tool serves as an auxiliary cutting surface and grinds the excircle surface of processed work piece; and the rotating speed of the tool is 4000 to 20000r / min, and the rotating speed of the work piece is 0 to 5000r / min. The invention can process the excircle of engineering ceramic material with high efficiency, and has the advantages of simple process, easy operation and lower cost.

Owner:田欣利 +1

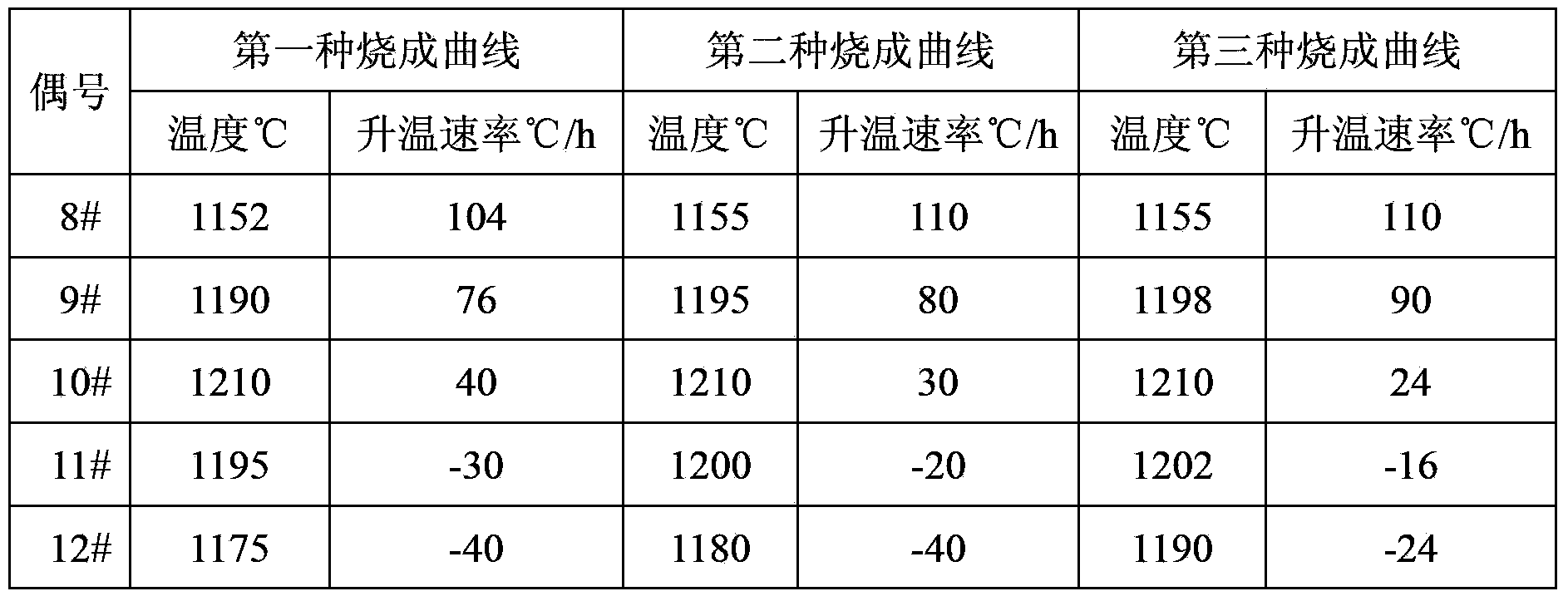

High-strength deformation-resistant engineering ceramic product and preparation method thereof

The invention belongs to the field of ceramic preparation, and particularly relates to a high-strength deformation-resistant engineering ceramic product and a preparation method thereof. The preparation method comprises the following steps: proportioning washed kaolin, Changxing white clay, calcined quartz, feldspar, pyrauxite, wollastonite and spodumene used as raw material, carrying out ball milling, iron removal, aging, pressure filtration and pulping by stirring to obtain a formed blank, carrying out injection forming to prepare a billet, carrying out bisque firing, drying, and carrying out glaze firing. According to the preparation method, the wollastonite, spodumene and other materials are used instead of partial materials in the traditional ceramic blank formula, and a reasonable firing regime is adopted, thereby promoting the generation of the mullite and the generation of the high-strength corundum phase during firing, and reducing the generation of the liquid glass phase and bubbles. The tight coupling of the billet and glaze and the prolonging of the holding time are beneficial to the growth of the crystal, and the volume density becomes higher. The prepared high-strength deformation-resistant engineering ceramic product has the characteristics of high mechanical strength, small thermal expansion coefficient, deformation resistance and the like.

Owner:江苏省宜兴彩陶工艺厂

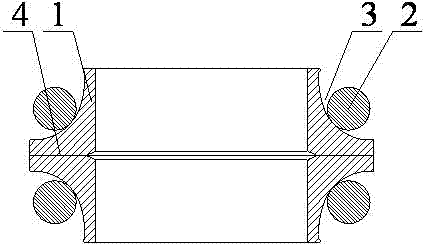

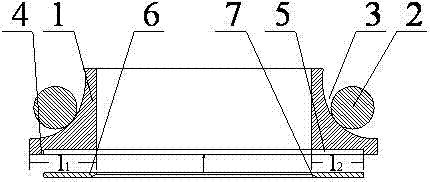

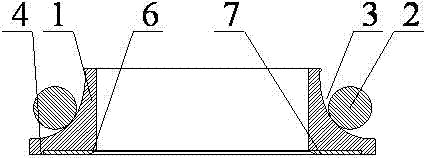

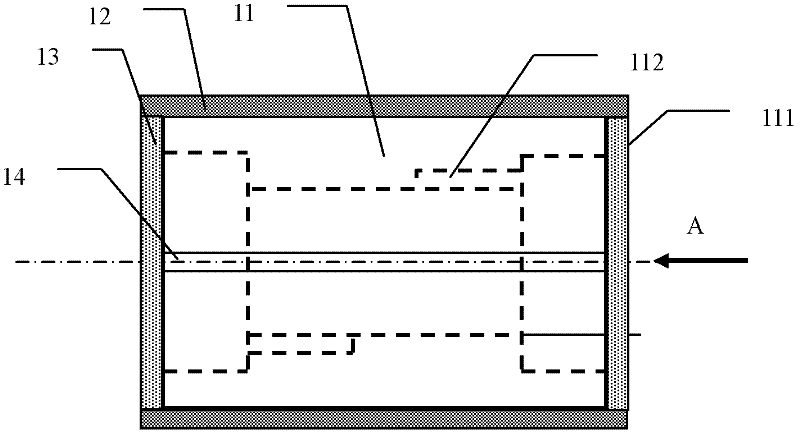

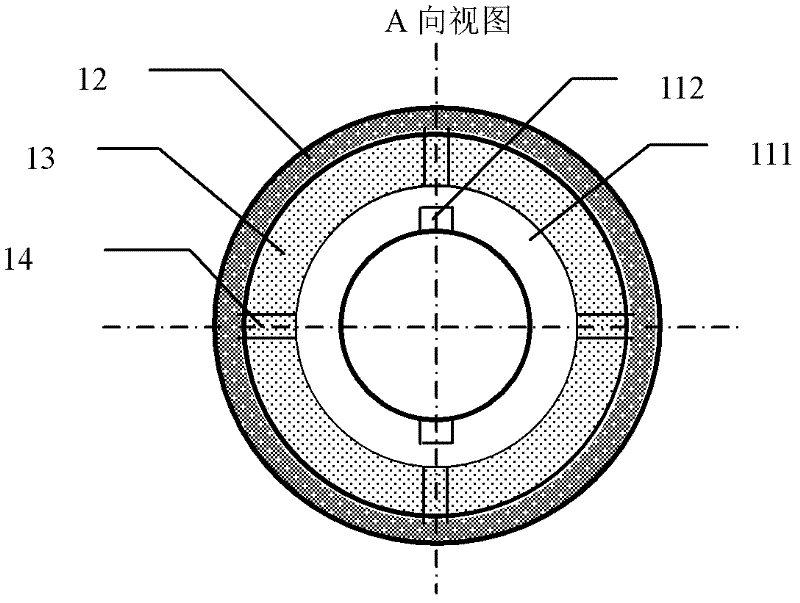

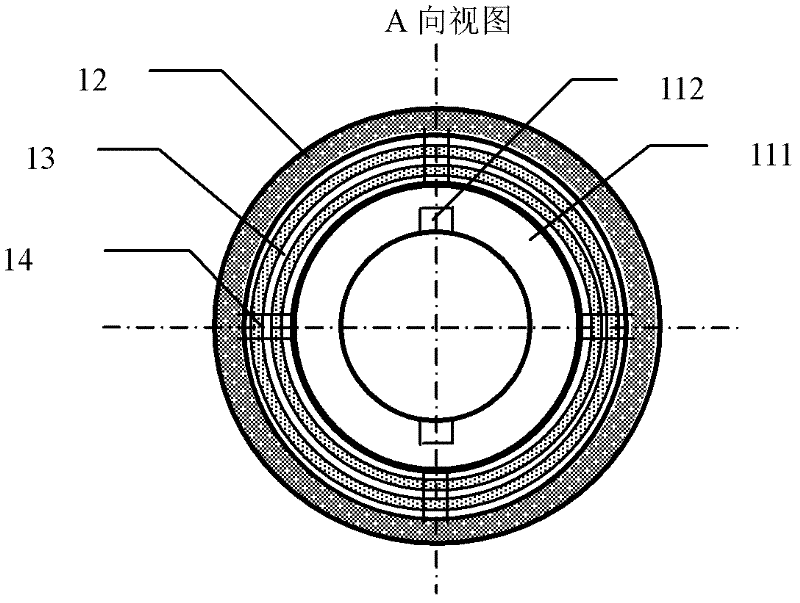

Floating seal ring with composite working face

InactiveCN104728444AHigh hardnessImprove wear resistanceEngine sealsWear resistantMetallic materials

The invention provides a floating seal ring with a composite working face. The floating seal ring with the composite working face comprises an upper sealing ring body and a lower sealing ring body which are symmetrical in structure. The sealing ring bodies are made of metal materials, a circle of groove for arranging a sealing ring is formed in the outer side of each sealing ring body, a circle of wear-resistant belt assembling groove is formed in the working face of each sealing ring body, the width 12 of the wear-resistant belt assembling groove is 25%-75% of the total width 11 of the working face, a wear-resistant belt is fixedly assembled in the wear-resistant belt assembling groove, the wear-resistant belt is made of aluminum oxide ceramic materials or other engineering ceramic materials, the friction surface of the wear-resistant belt and the working faces of the sealing ring bodies are located on the same plane, or the friction surface of the wear-resistant belt protrudes out of the working faces of the sealing ring bodies. The floating seal ring with the composite working face can effectively improve the wear resistant degree of the working face, prolong the service life, and is easy to machine and low in production cost.

Owner:武汉盛普林斯陶瓷有限公司

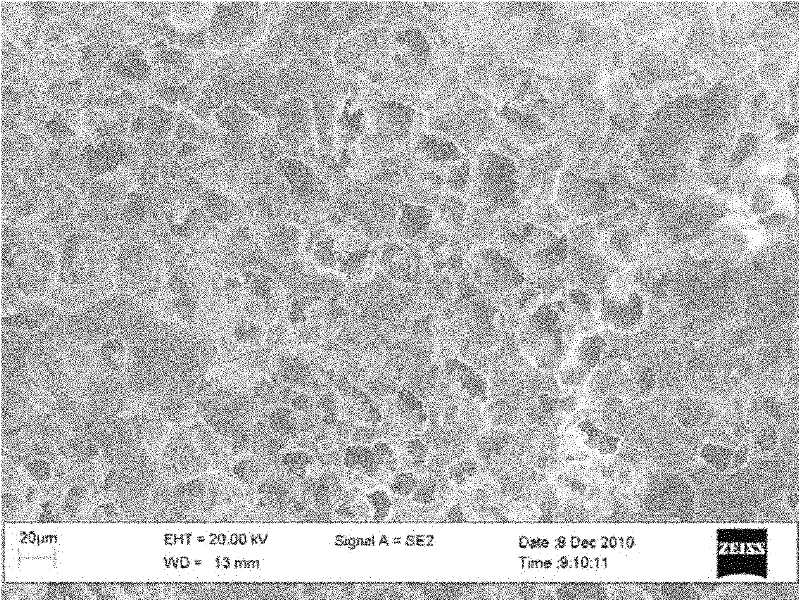

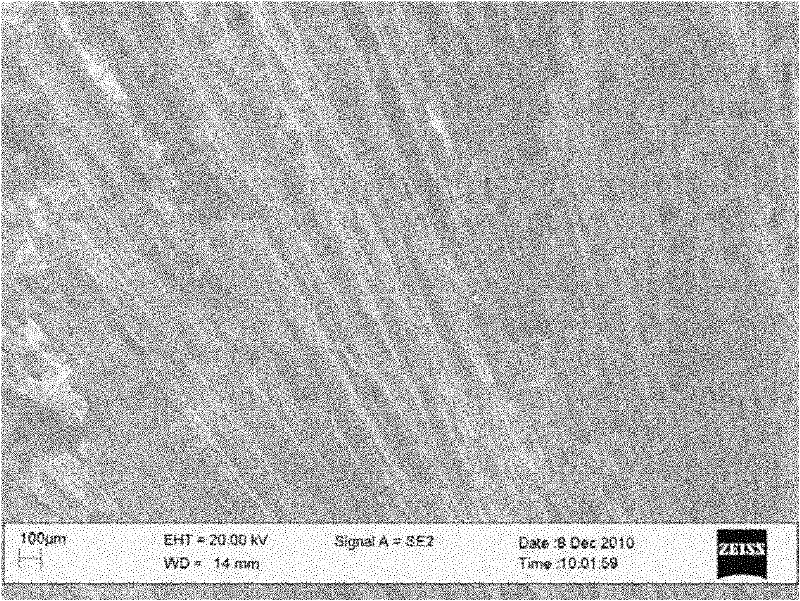

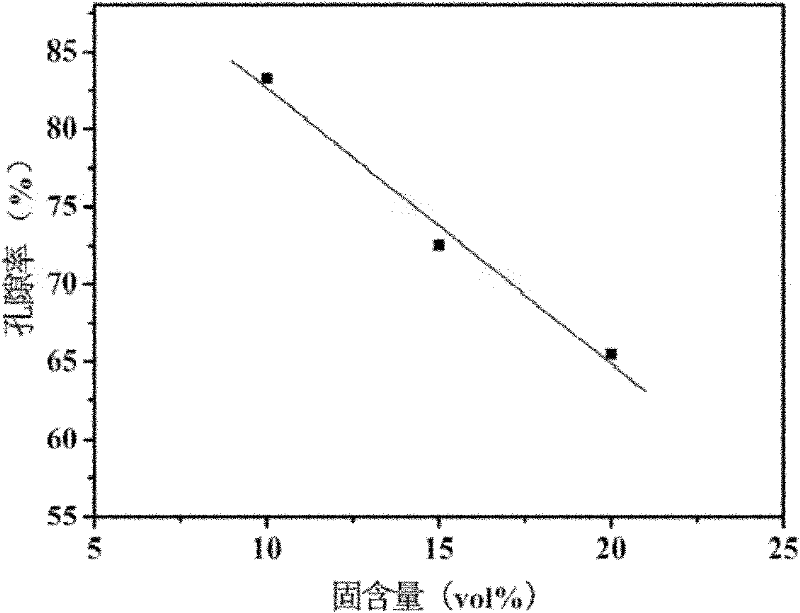

Method for preparing porous ceramic by using tertiary butanol-based freezing sublimation method

InactiveCN102531660ASimple selection of raw materialsSimple processCeramicwareOxide ceramicPolyvinyl butyral

The invention relates to the field of porous ceramics, in particular to a method for preparing a porous ceramic by using a tertiary butanol-based freezing sublimation method. The method disclosed by the invention basically has no restriction to an oxide material system and is generally suitable for engineering ceramics. The method comprises the following steps of: with oxide ceramic powder as a raw material, tertiary butanol as a solvent, citric acid as a dispersing agent and polyvinyl butyral as a binding agent, carrying out ball grinding on the raw material for 5-50h, pouring the uniformly-dispersed raw material into a polyethylene mold of which the bottom temperature is above 0 DEG C and the top temperature is room temperature, and cooling for 5min-2h; and demolding, then sublimating for 24-27h by using a water circulating pump under the condition of suction filtering, and heating to 1200-1600 DEG C in an air furnace and preserving the temperature for 5min-2h. According to the method disclosed by the invention, slurry of an organic system is prepared under the room temperature; and the obtained porous ceramic is distributed with directional holes, wherein the directional holes are polygonal holes and have the size distribution of below 100 microns and the longitudinal lengths of reaching millimeter-scale. According to the method disclosed by the invention, the porosity can be controlled by adjusting the solid content, and the porous ceramic material with ultrahigh porosity (more than 80 percent) can be prepared.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

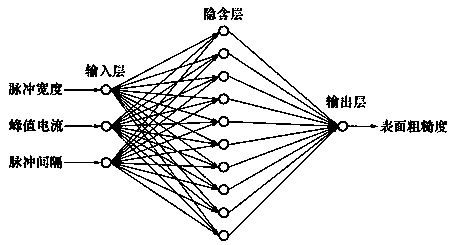

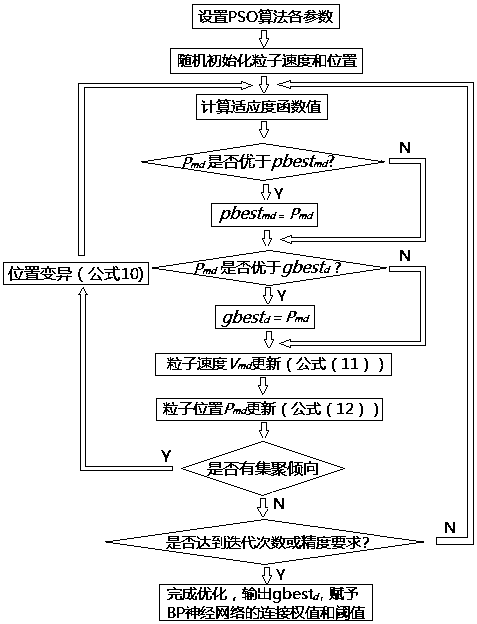

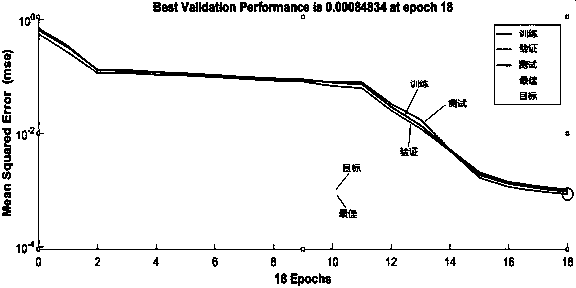

PSO neural network-based engineering ceramic electrospark machining effect prediction method

InactiveCN108388702AOptimize weightAvoid the problem of being prone to getting stuck in local minimaDesign optimisation/simulationMulti-objective optimisationNerve networkParticle swarm algorithm

The invention provides a PSO neural network-based engineering ceramic electrospark machining effect prediction method. The method comprises the steps of building a three-layer BP neural network prediction model of an insulated engineering ceramic line electrode discharge grinding process effect by utilizing a BP neural network; in combination with an adaptive variation particle swarm algorithm, optimizing connection weight and threshold of the BP neural network; building a particle swarm neural network-based engineering ceramic line electrode discharge grinding process effect prediction modelby utilizing Matlab programming; and verifying the reliability of the engineering ceramic line electrode discharge grinding process effect prediction model built by optimizing the BP neural network bythe adaptive position variation particle swarm algorithm. The method remarkably reduces an iterative frequency, has relatively high prediction precision, reliability and validity, has a certain practical value, and can be used for optimizing engineering ceramic line electrode discharge grinding process electric parameters to further improve surface quality of workpieces.

Owner:HENAN INST OF ENG

Silica sol solidification method for forming ceramic component

The present invention relates to a method for producing ceramic component by utilizing silica sol coagulation forming process. Said method includes the following steps: mixing ethyl orthosilicate and sodium hydroxide solution, mechanically-stirring to make the ethyl orthosilicate be hydrolyzed to obtain silica sol, then adding the engineering ceramic powder into said silica sol solution, stirring and mixing then to obtain ceramic pulp material, injuecting said ceramic pulp material into a hole-free mould, coagulating at 25-10 deg.C and forming so as to obtain the ceramic blank body with required shape.

Owner:TSINGHUA UNIV

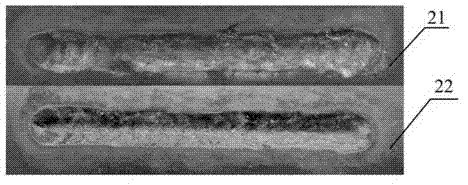

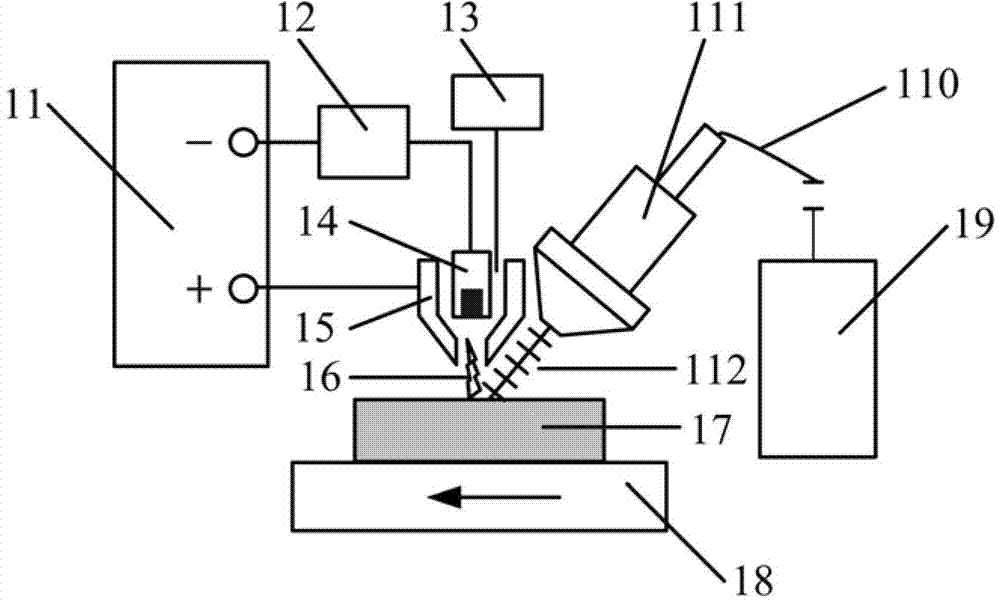

Laser heating auxiliary arc striking micro-explosion processing method and device for engineering ceramic material

InactiveCN102950387AControl outputImprove quality and efficiencyLaser beam welding apparatusMaterial removalSpray nozzle

The invention relates to a laser heating auxiliary arc striking micro-explosion processing method and a laser heating auxiliary arc striking micro-explosion processing device for an engineering ceramic material, and belongs to the technical field of the processing of hard and brittle materials. The method comprises the following steps of: focusing a laser beam, and then, obliquely irradiating the laser beam on the surface of a work piece to be processed; vertically aligning a jet nozzle of an arc striking micro-explosion generator with the surface of the work piece downwards; and enabling the work piece to continuously perform a feed movement along with a working platform, carrying out laser preheating first, raising the temperature of a micro cell to the softening temperature of the ceramic material, and then, carrying out arc striking micro-explosion processing until the processing of the engineering ceramic work piece to be processed is finished. The system mainly comprises a special pulse power supply, a pulse controller, a numeric control three-dimensional working platform, a micro-explosion generator, a gas supply device, a medium-low power laser apparatus, an optical fiber and a laser head. By using the laser heating auxiliary arc striking micro-explosion processing method and the laser heating auxiliary arc striking micro-explosion processing device, the material removal efficiency of the arc striking micro-explosion processing method is improved; the processing damage is reduced; and the practical application of the arc striking micro-explosion processing method in the processing of the engineering ceramic material is further promoted.

Owner:田欣利 +1

Method for preparing spherical nanometer zirconium dioxide

InactiveCN102249304ASmall granularityGood crystal formNanostructure manufactureZirconium oxidesIon exchangeSpherical shaped

The invention relates to the technical field of advanced nanometer materials, and in particular relates to a method for preparing spherical nanometer zirconium dioxide. The invention aims at adopting a system, in which zirconium oxychloride is taken as a raw material, ammonia water is taken as a precipitator and quadrol is taken as an assistant, to provide a constant-temperature hydrothermal preparation method for the spherical nanometer zirconium dioxide. The method provided by the invention has the advantages that the production method is simple, the cost is low and the response speed is high. The method provided by the invention is widely applied in various fields, such as ceramic pigments, engineering ceramics, jewel industry, piezoelectric elements, ion exchangers, solid electrolytes, and the like.

Owner:张永昶

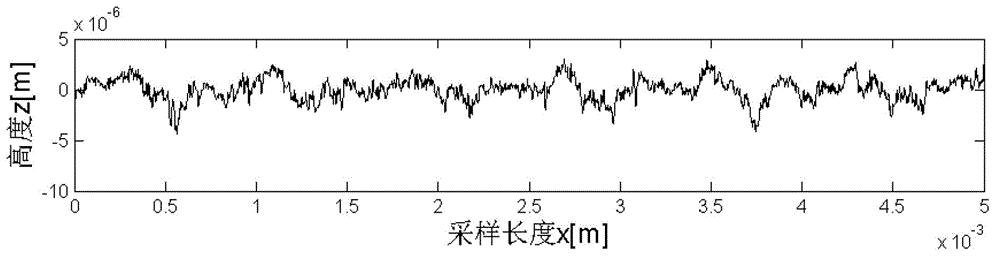

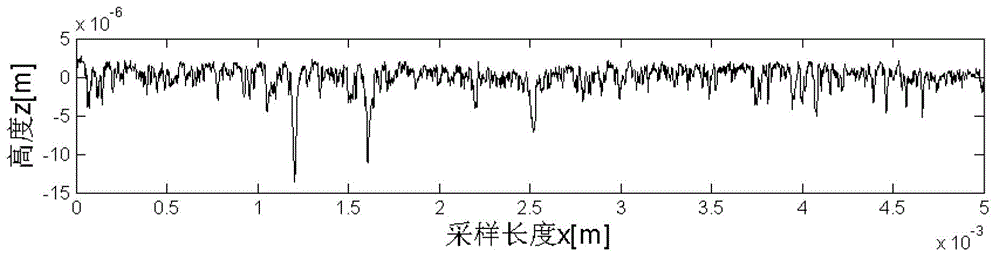

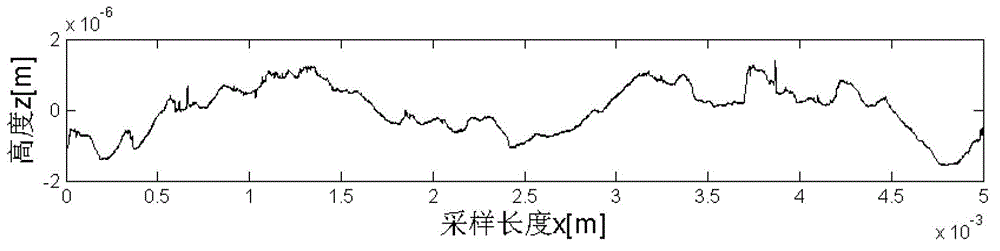

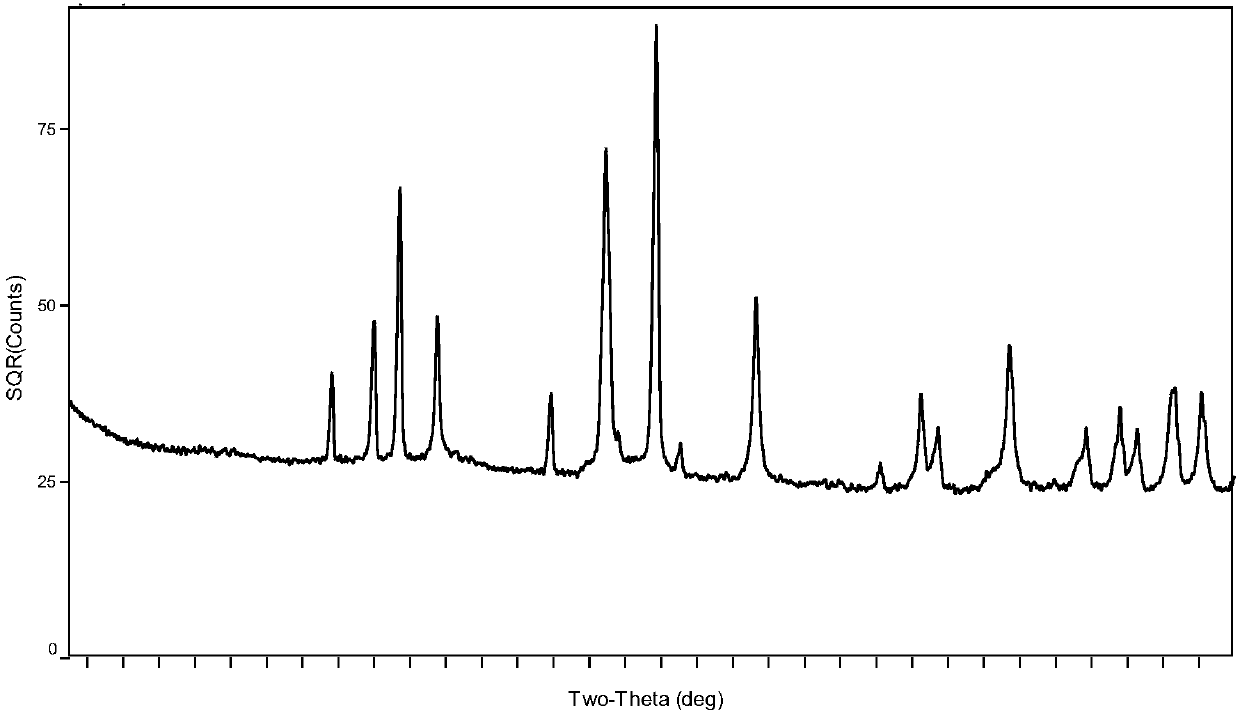

Method for evaluating damage of grinding surface of advanced ceramics based on wavelet multi-scale analysis

InactiveCN103149348AAccurate extractionAccurate evaluationMaterial testing goodsMultiscale decompositionDecomposition

The invention provides a method for evaluating damage of the grinding surface of advanced ceramics based on wavelet multi-scale analysis. The method comprises the steps of collecting original outline data of a sample, and selecting an optimal wavelet basis by combining the mathematical characteristics of the wavelet basis with a principle that a reconstruction error of the grinding surface of engineering ceramics is minimum; carrying out multi-scale decomposition by using the optimal wavelet basis, and extracting damage information by reconstructing a high-frequency coefficient; drawing a damage rate curve according to a reconstruction outline and calculating a mean damage distance; directly reading out a maximum damage depth and a maximum damage rate according to the damage rate curve; and judging a damage distribution condition. The method for evaluating the damage of the grinding surface of the advanced ceramics based on the wavelet multi-scale analysis provided by the invention has the advantages of simple steps and strong operability, can be used for accurately extracting and estimating the damage characteristics of the grinding surface of the advanced ceramics, and meets the using requirements of the quality estimation of the grinding surface of the advanced ceramics in actual engineering.

Owner:TIANJIN UNIV

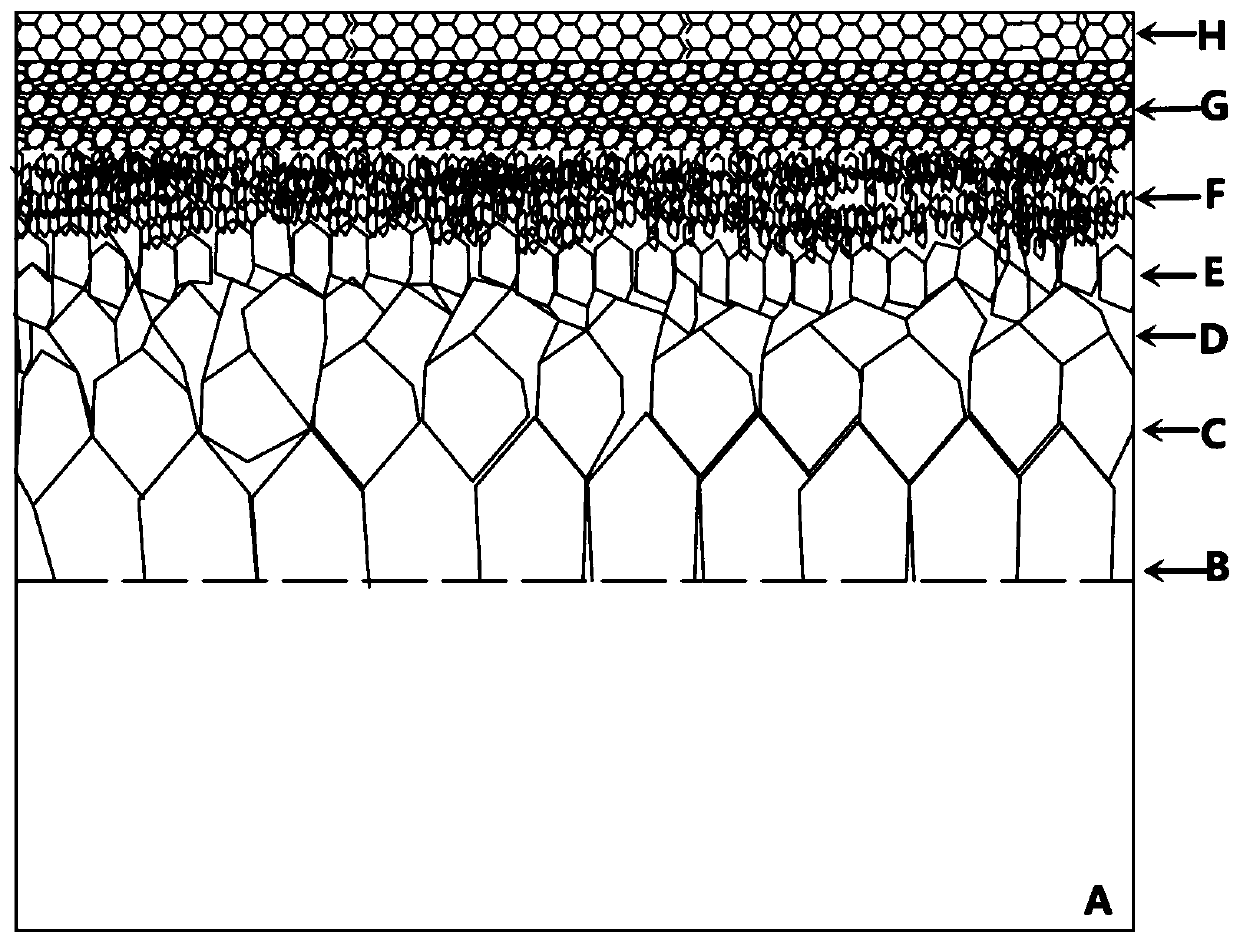

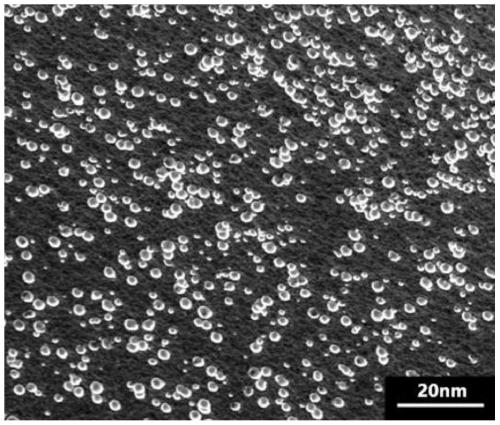

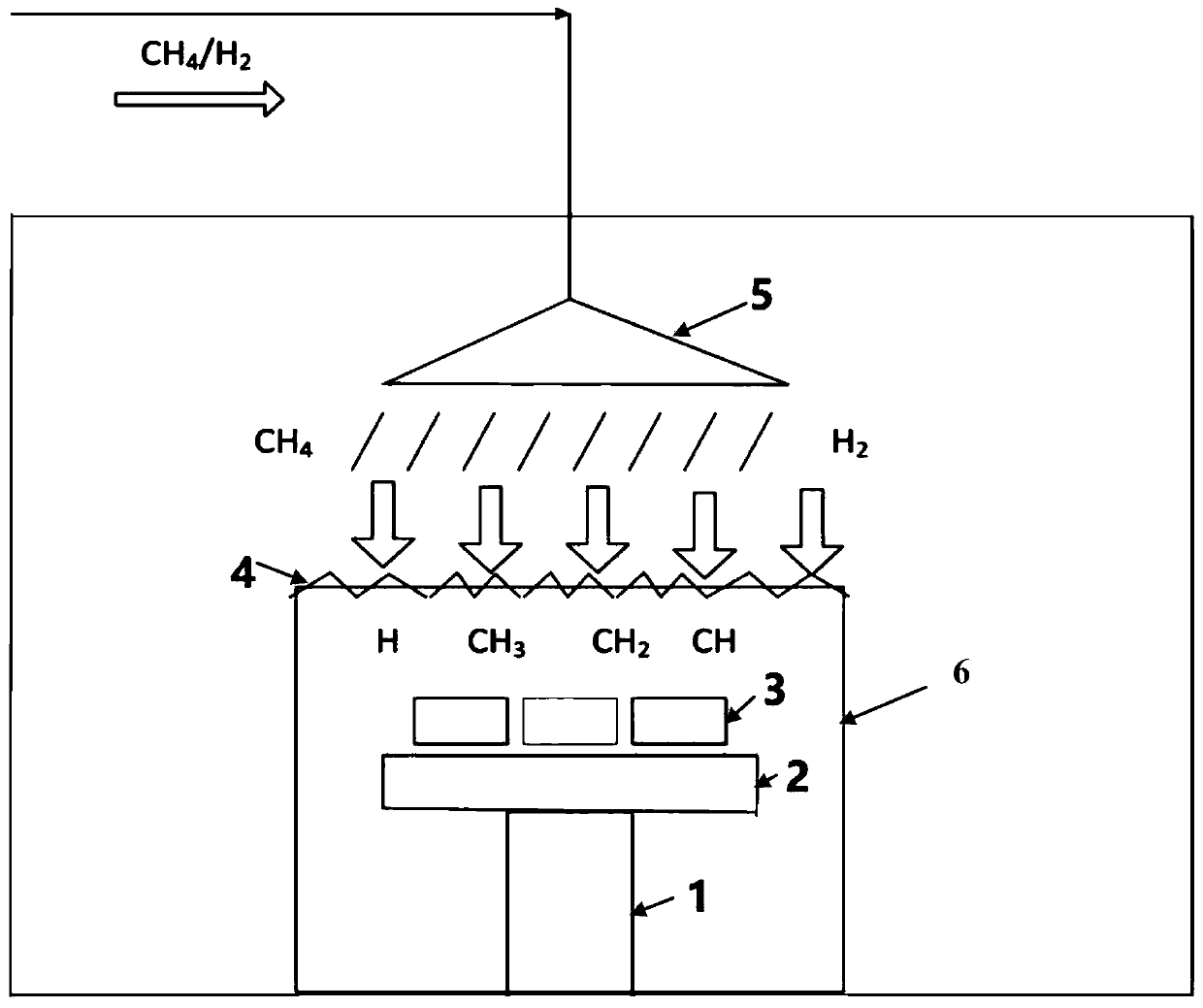

Gradient diamond and graphite composite self-lubricating antifriction engineering ceramic coating and preparation method thereof

ActiveCN110205604AGood internal stepped growth structureImprove toughnessChemical vapor deposition coatingCeramic coatingWear resistant

The invention provides a gradient diamond and graphite composite self-lubricating antifriction engineering ceramic coating and a preparation method thereof, and belongs to the field of full-ceramic bearing self-lubricating wear-resistant coatings. The coating is sequentially composed of multiple stages of size-progressive diamond coatings and multiple graphite coatings from the surface of an engineering ceramic substrate to the outside; each stage of the size-progressive diamond coating comprises multiple micro-crystal diamond coatings, multiple sub-micron-crystal diamond coatings and multiplenanocrystal diamond coatings; and the diameters of crystal grains of diamonds in every two adjacent diamond coatings are stepwise decreased from the surface of the engineering ceramic substrate to the outside. The gradient diamond and graphite composite self-lubricating antifriction engineering ceramic coating is prepared through a hot filament chemical vapor deposition method. The coating is a first-stage stepwise-changed or multistage stepwise-changed micron / submicron / nano-diamond and graphite coating, the internal toughness and the surface hardness of the coating are improved, and the bonding strength of graphite and diamond coatings or the diamond coatings and the engineering ceramic substrate is enhanced. Under the limiting conditions, the durability is good, and the self-lubricatingproperty is stable.

Owner:SHENYANG JIANZHU UNIVERSITY

Preparation method for engineering ceramic acid and alkali resistant container

ActiveCN103641447AGood acid and alkali resistanceHigh mechanical strengthClaywaresEconomic benefitsPerformance index

The invention discloses a preparation method for an engineering ceramic acid and alkali resistant container. The preparation method comprises steps of batching of blank material raw materials, forming of the blank material, batching of glaze material raw materials, preparation of the glaze material, biscuiting, glaze application and sintering. The engineering ceramic acid and alkali resistant container has advantages of high acid resistance, high alkali resistance, particularly being free from pollution of media, high mechanical strength, high compactness, high dimensional precision, low water absorption, good heat stability, small thermal expansion coefficients, leak resistance and the like. The carcass is compact, the glaze is bright and clean, and there are no defects of pin holes, glaze shrinkage, thin glaze and the like. The defective percentage is lowered, and the production efficiency is raised. Temperature-resistant requirements to a kiln device are eliminated, and the production cost is lowered. The novel engineering ceramic acid and alkali resistant container has good appearance quality and performance indexes, and is an ideal product raising economic benefits.

Owner:江苏省宜兴彩陶工艺厂

Highly effective deep-grinding process for engineering ceramic material

InactiveCN1788931AIncreased Plastic Removal RatioSlow down the feed rateAbrasion apparatusGrinding machinesWater basedUltra high speed

The technological process of deeply grinding engineering ceramic material in high efficiency includes: 1. trimming with resin combined super high speed diamond grinding wheel to outer circle jitter not greater than 5 microns and dressing with a dynamic balance system to make the grinding wheel possess dynamic unbalance amount less than 0.1 micron; 2. adopting water base cooling liquid with liquid pressure of 6-10 MPa; 3. grinding in the technological conditions of grinding off rate per unit grinding wheel width 20-120 cu mm / mm.s, grinding wheel linear speed 40-160 m / s, grinding depth 1-6 mm and workpiece feeding speed 0.5-6 mmin. The present invention has high structure ceramic machining efficiency, low ceramic part cost, improved ceramic part surface quality and greatly raised part reliability.

Owner:HUNAN UNIV

Single hydraulic prop hydraulic pressure three-purpose valve

The invention discloses a single hydraulic prop hydraulic pressure three-purpose valve, and belongs to the technical field of single hydraulic prop control valves. The single hydraulic prop hydraulic pressure three-purpose valve comprises a left valve cylinder, a right valve cylinder, a one-way valve part and a safety valve part. The one-way valve part comprises a cone valve element, the safety valve part comprises a safety valve needle, the cone valve element and the safety valve needle are provided with evenly-distributed micron-level tiny pits or grooves, the cone valve element is of a two-stage throttling structure, a high-pressure flow guiding through hole is formed in the center of the cone valve element, the one-way valve part further comprises a one-way valve seat, the safety valve part further comprises a safety valve seat and a hexagonal guiding sleeve, the one-way valve seat, the safety valve needle, the safety valve seat and the hexagonal guiding sleeve are all made of Cr-Ni-series cast steel ZG0Cr18Ni9, and meanwhile thermal spraying processing is carried out on engineering ceramics on the surfaces of the one-way valve seat, the safety valve needle, the safety valve seat and the hexagonal guiding sleeve. According to the single hydraulic prop hydraulic pressure three-purpose valve, water can be used as media, pollution resistance and abrasion resistance are good, gas etching can be effectively eliminated, vibration and noise can be reduced, and the single hydraulic prop hydraulic pressure three-purpose valve is safe, environmentally friendly and high in adaptability.

Owner:ANHUI UNIV OF SCI & TECH

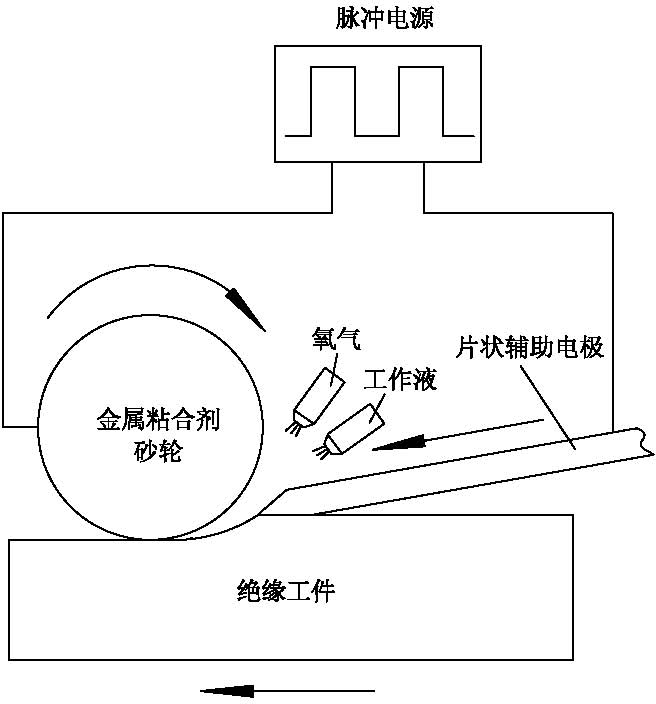

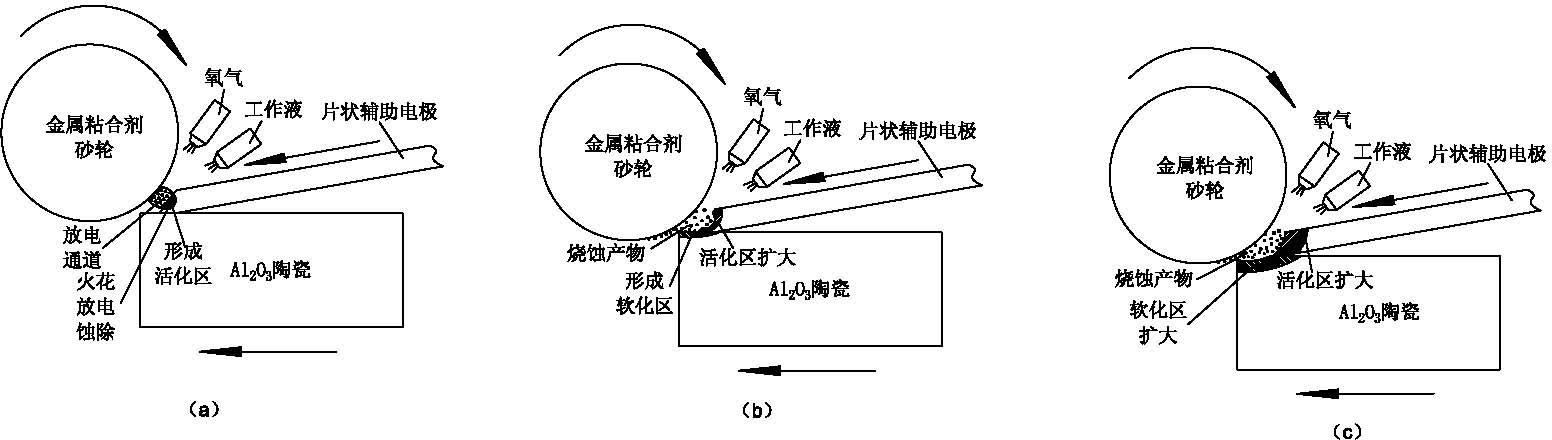

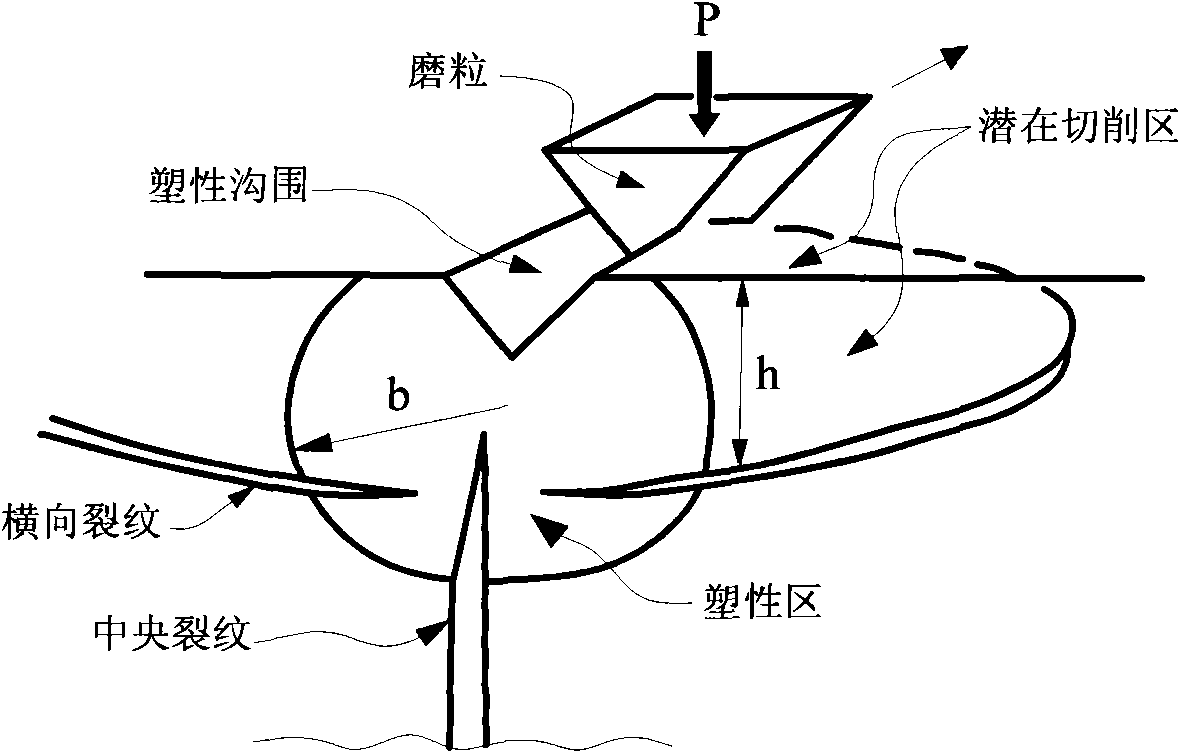

Controllable and ablated non-conductive engineering ceramic grinding method based on discharge induction

InactiveCN102172833AKeep sharpSmall grinding forceOther manufacturing equipments/toolsAdhesiveAuxiliary electrode

The invention discloses a controllable and ablated non-conductive engineering ceramic grinding method based on discharge induction, and is characterized in that a conductive metal adhesive grinding wheel is adopted as a grinding wheel, conductive auxiliary electrodes are continuously fed between the grinding wheel and the non-conductive engineering ceramic, electric sparkle discharge is generated between the grinding wheel and the conductive auxiliary electrodes under the action of pulse voltage, and a combustion-supporting gas capable of generating ablation exothermic reaction with the platy conductive auxiliary electrodes is led into a machining area continuously or intermittently during the process, thus leading machining to be in a state of discharge induced by electric sparkle-ablating of auxiliary electrodes-grinding of the grinding wheel on the non-conductive engineering ceramic; the grinding wheel and the conductive auxiliary electrodes generate discharge under the action of the electric sparkle discharge, the conductive auxiliary electrode materials reach over ignition temperature and are in a melting or even gasification state to generate ablating reaction with the combustion-supporting gas capable of generating ablation exothermic reaction, thus producing ablation product, releasing a large amount of heat acted on the surface of the non-conductive engineering ceramic material, and further leading the surface of the non-conductive engineering ceramic to be heated in a softening or even melting state, and removing the grinding under the grinding action of the grinding wheel. The method has the advantages of high machining efficiency, greening and environment friendliness.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

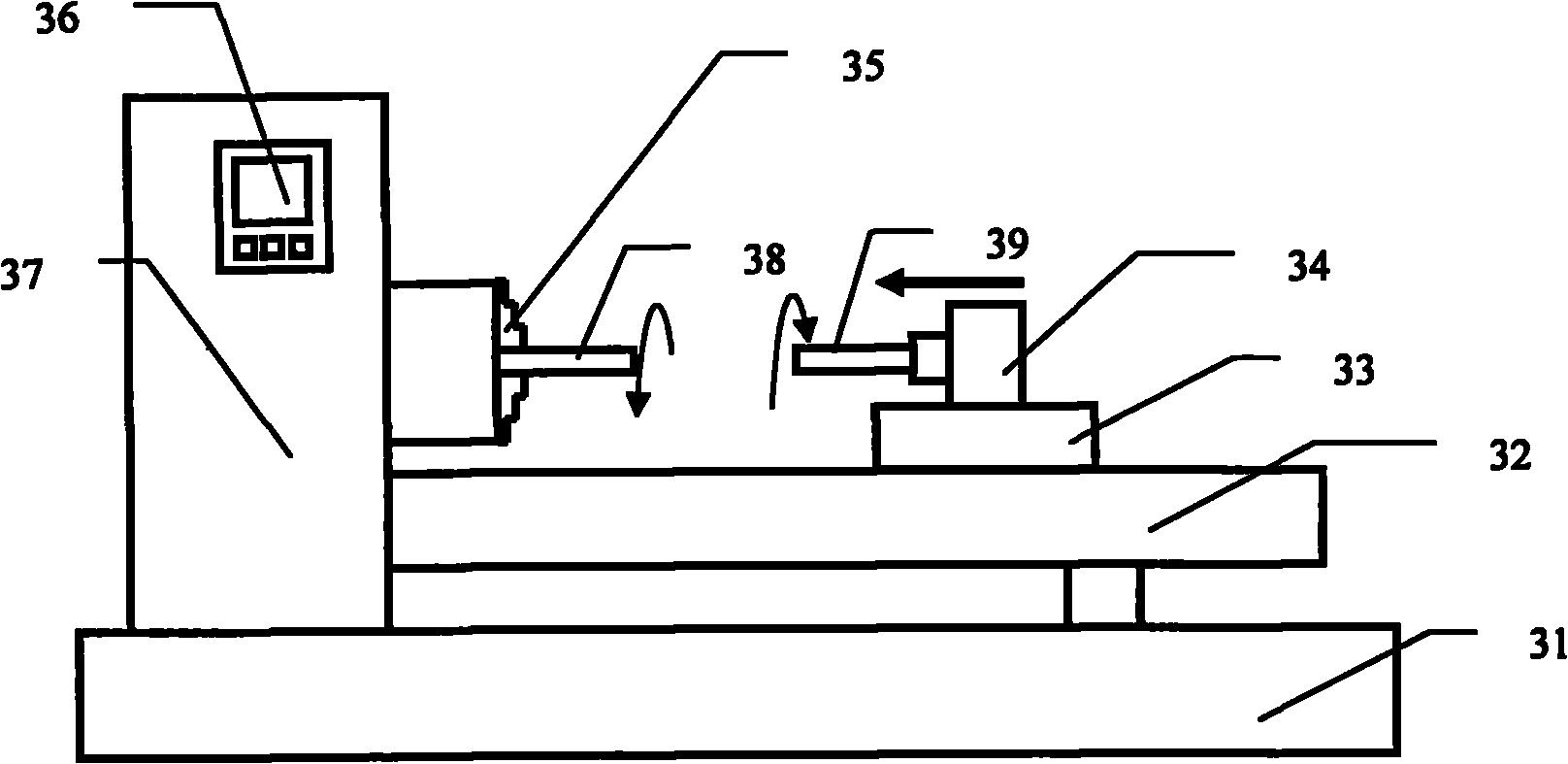

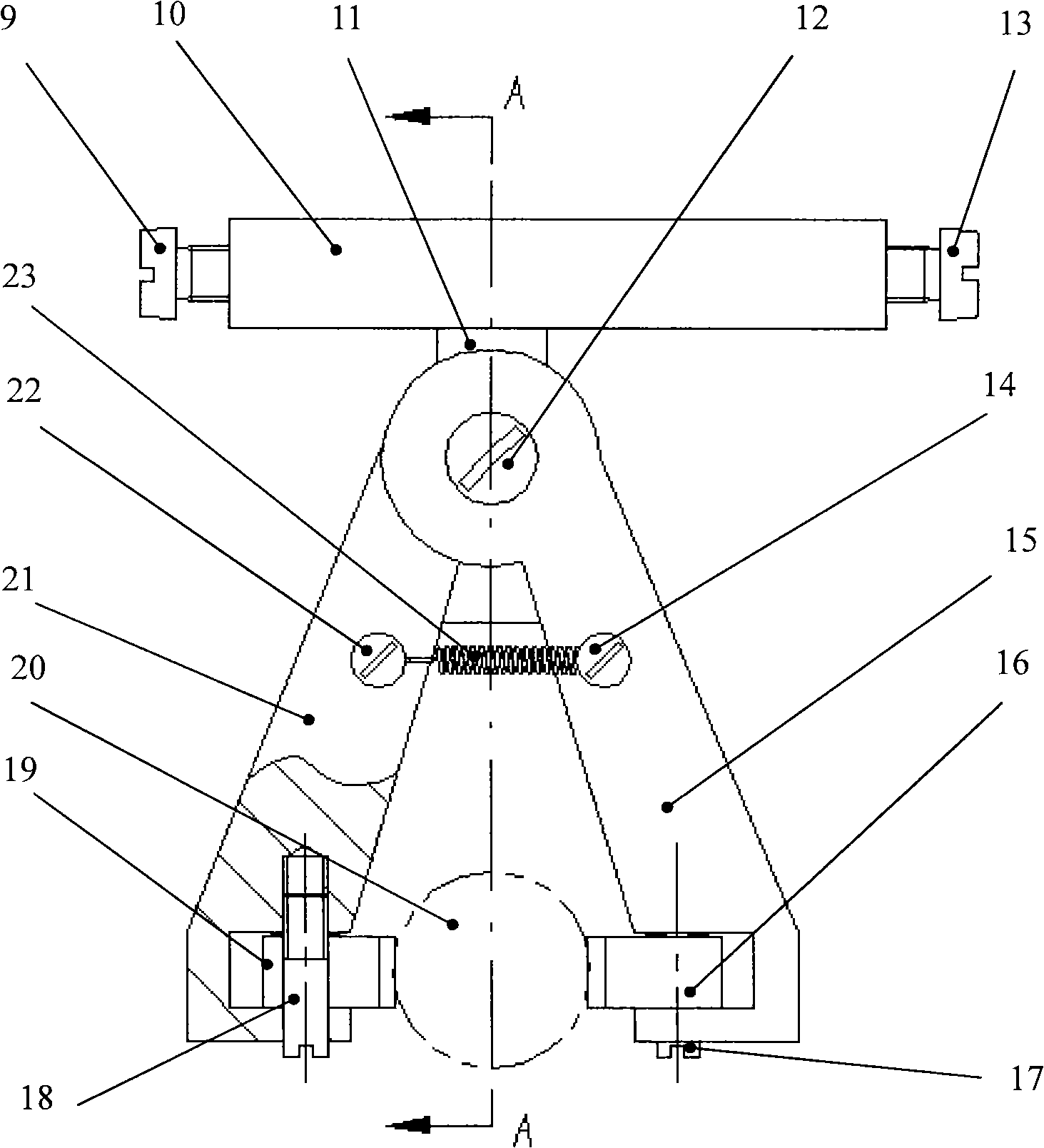

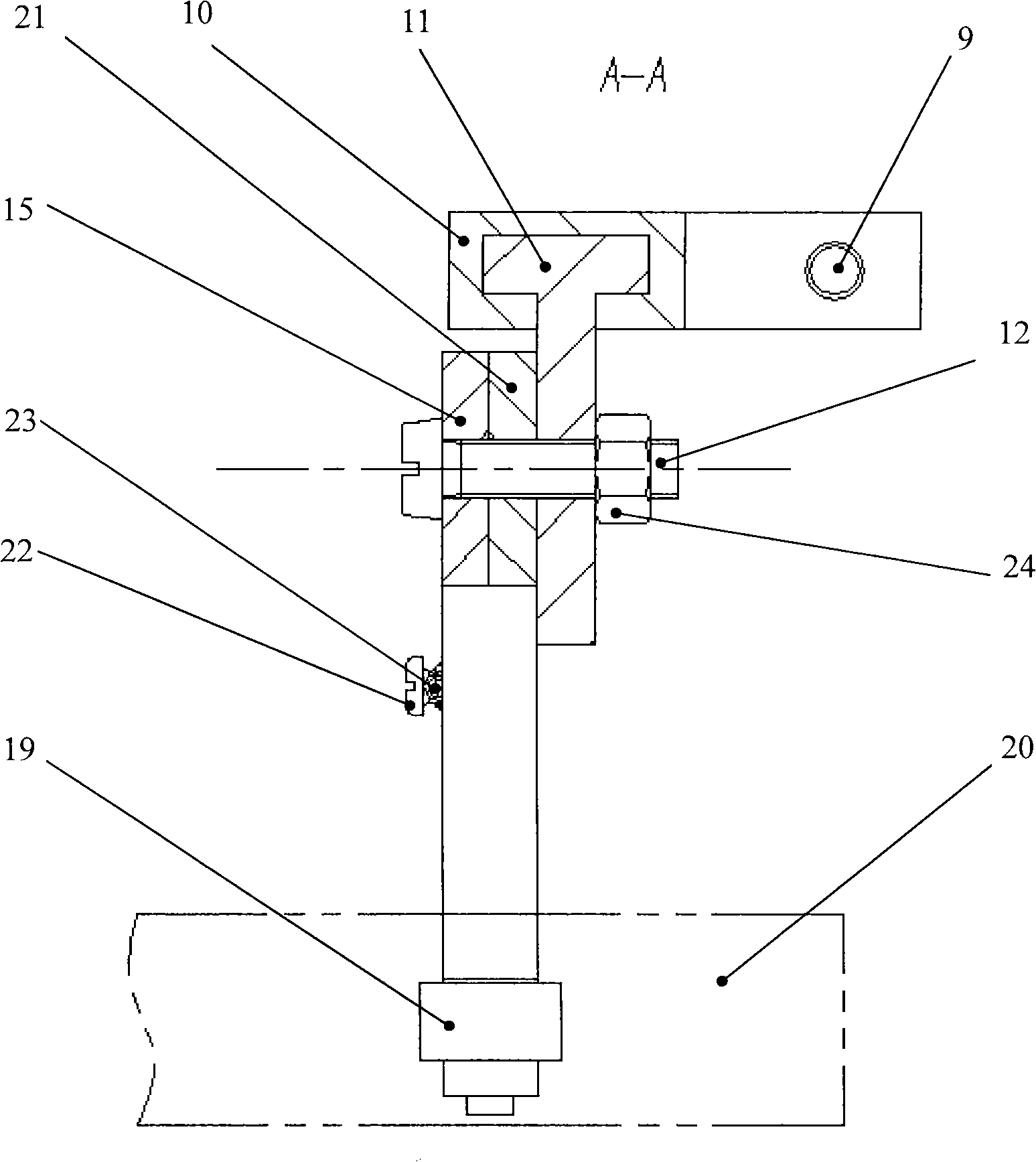

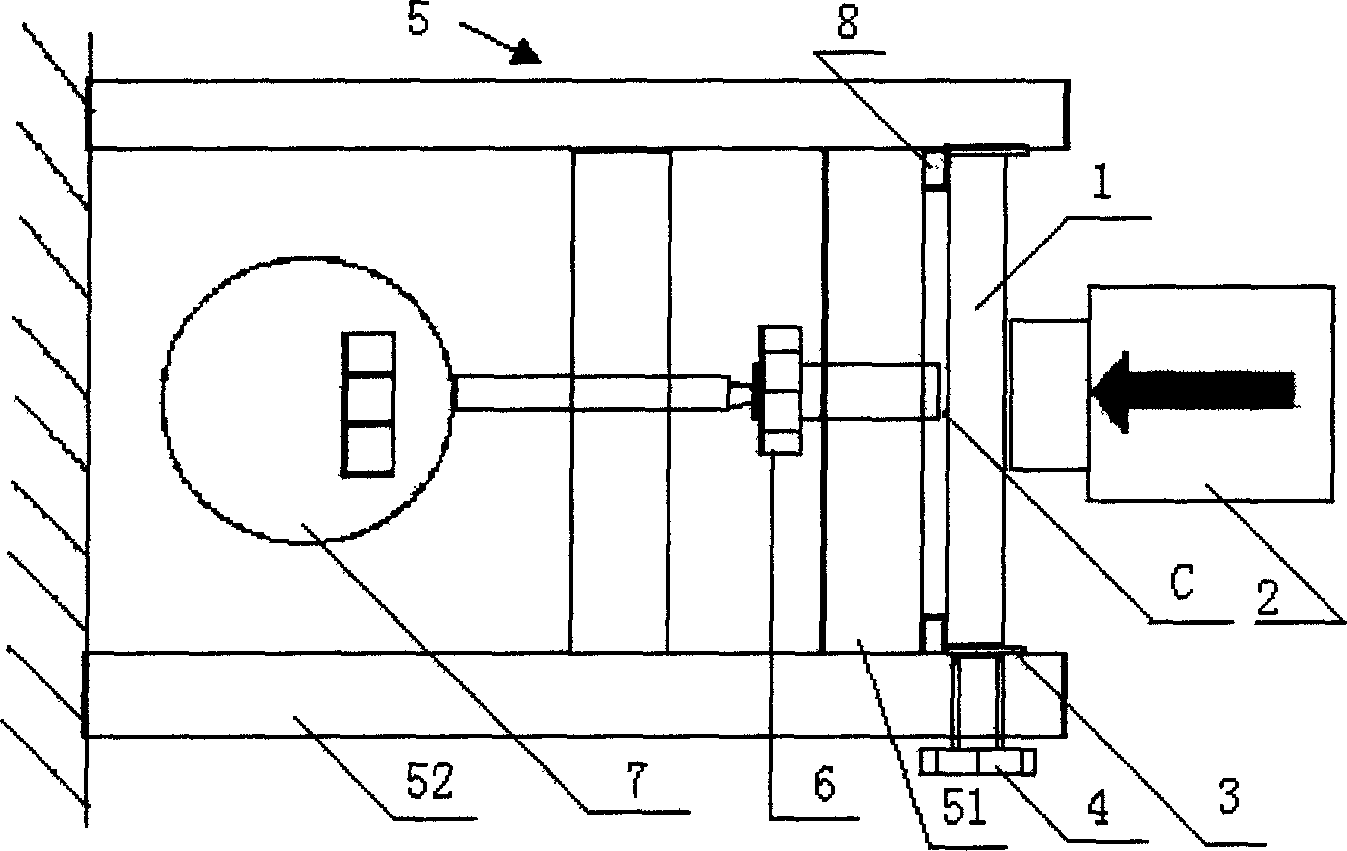

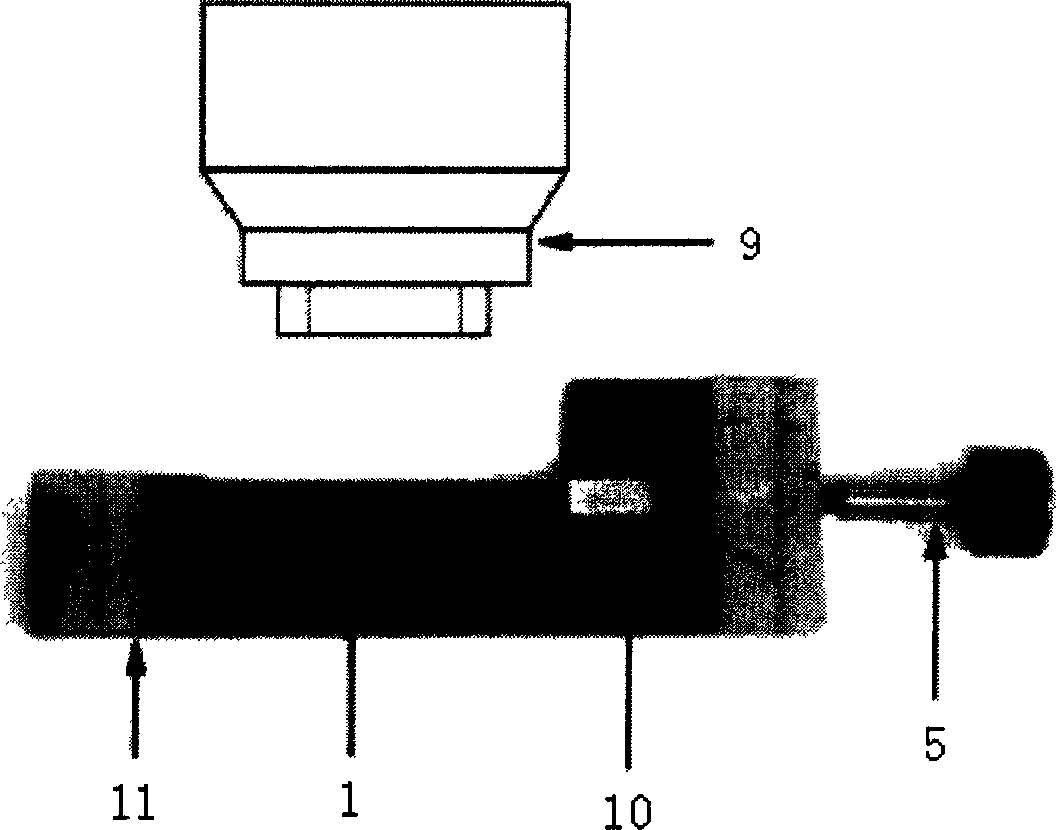

Electrical discharge grinding device for semiconducting ceramic rotating surface with tracking-electrode

The invention relates to an electrical machining device of engineering ceramic materials, in particular to a semiconducting ceramic rotary surface discharge grinding machining device with a tracking electrode. The device aims at eliminating the phenomenon that the resistance of a work piece in a discharge channel is changed along with the change of the electric discharge machining part, thus ensuring the consistency of the pulse discharge energy during the machining process and further ensuring the consistency of the discharge erosion amount and the machining quality. The device connects a cathode of a pulse power supply of a wire cutting machine with an electrode wire, an anode is connected with a ceramic work piece by the self-adaptive variable diameter tracking electrode, the tracking electrode device is utilized to lead the electrodes of the pulse power supply of the wire cutting machine to slide correspondingly to the work piece, thus maintaining the resistance of the work piece between a feeding end and a discharge point constant. The invention changes the machining mode that the electrodes of the original pulse power supply are connected on a work bench, and the power supply is just carried out at the clamping position of the work piece.

Owner:JILIN UNIV

Method for machining outer circles of ceramics in squeezing manner by aid of edge cracking and horn effects

InactiveCN103551949AFull play of stressMake full use of the broken edge effectRevolution surface grinding machinesStone-like material working toolsAlloyGrinding wheel

The invention discloses a method for machining outer circles by the aid of edge cracking and horn effects, and belongs to the field of technologies for machining hard and brittle materials. The method includes machining spiral grooves or annular grooves on the surface of an outer circle of cylindrical engineering ceramics on a grinding machine by the aid of a diamond grinding wheel disc; clamping the ceramics on a lathe by the aid of a chuck and an apex, and axially feeding the engineering ceramics at a low speed to complete squeezing and machining on the surface of the outer circle of the engineering ceramics by the aid of a lathe tool clamped on a tool rest or a ceramic or hard alloy cylindrical squeezing tool which is turned by the aid of a high-speed motor; repeating the procedure, and feeding the tool repeatedly until the diameter of an axial section of the engineering ceramics meets dimensional requirements; buffing the surface of the outer circle of the engineering ceramics by the aid of a diamond grinding wheel so that quality requirements on the surface of the engineering ceramics can be met. The method has the advantages that consumed power for removing materials in a workpiece rough machining stage is low while the outer circle of the ceramics can be machined, loss of tools is low, and accordingly the machining cost can be reduced.

Owner:田欣利 +1

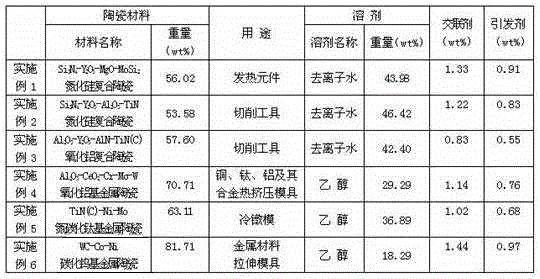

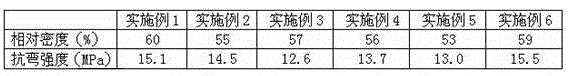

Gel injection molding method of engineering ceramic

The invention relates to a gel injection molding method of engineering ceramic, which comprises the following steps: (1) adding mixed engineering ceramic powder and a crosslinking agent carbomer accounting for 0.8-1.5 wt% of the mixed engineering ceramic powder into a solvent, and carrying out mixing and ball milling for 3-5 hours to obtain a stable suspension slurry; (2) adding an initiator accounting for 0.5-1.0 wt% of the mixed engineering ceramic powder into the slurry, carrying out ball milling for 7-9 minutes, and defoaming in a vacuum for 6-8 minutes; and (3) injecting into a mold, carrying out in-situ solidification colloid molding, drying, demolding, and drying in a constant temperature oven to obtain the engineering ceramic. The method is simple to operate, has the advantages of stable technique, controllable molding process, low production cost and high production efficiency, and is suitable for near-net size molding of various engineering ceramic powders.

Owner:冷水江市明玉陶瓷工具有限责任公司

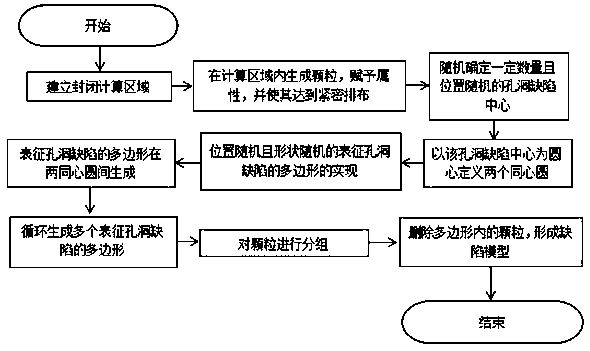

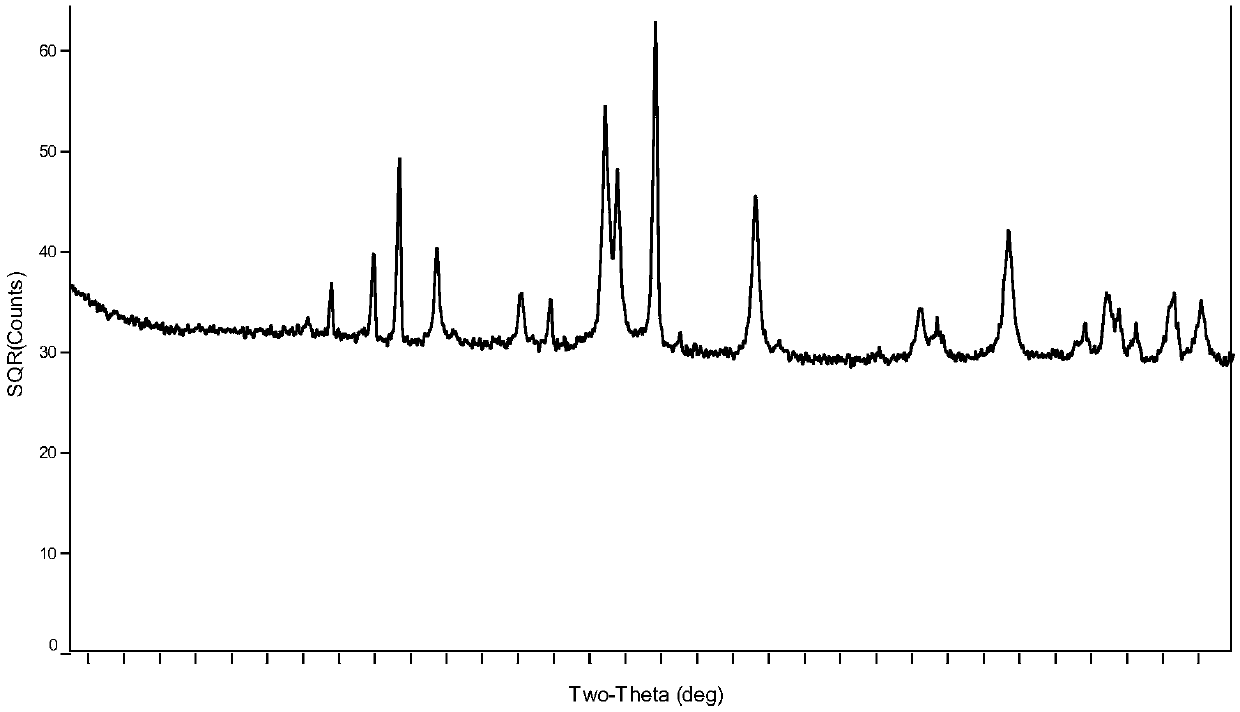

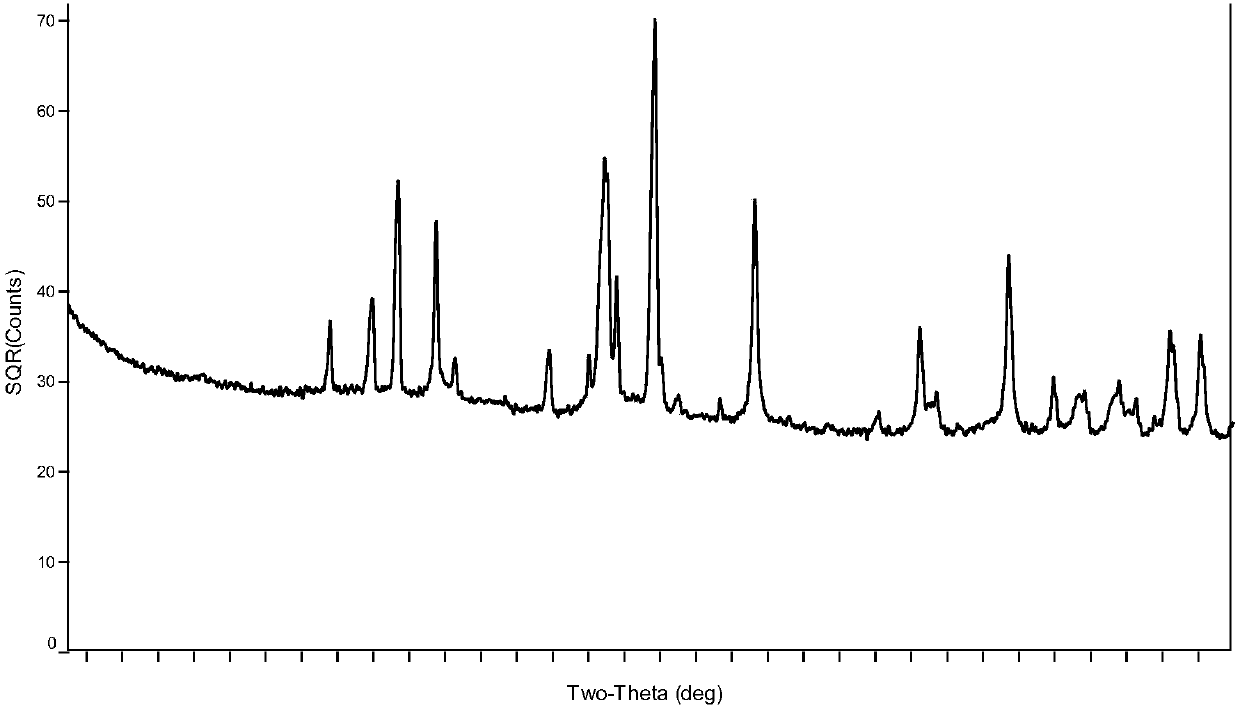

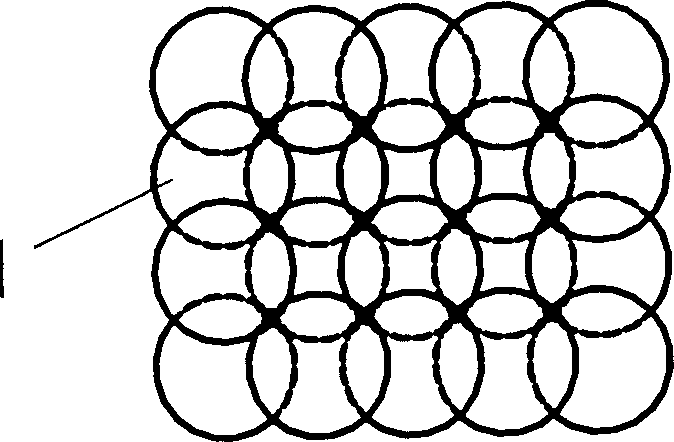

Brittle material discrete element modeling method considering shape of hole defect and distribution randomness thereof

ActiveCN108846186ADesign optimisation/simulationSpecial data processing applicationsMaterial defectDiscrete element simulation

The invention discloses a brittle material discrete element modeling method for considering a shape of a hole defect and the distribution randomness thereof, which is mainly used for the discrete element simulation research of brittle materials such as engineering ceramics. The method includes: creating a closed area, and adding a certain number of particles with uniformly or normally distributedradiuses into the closed area to achieve tight arrangement of the particles; selecting an appropriate contact model to give the particles a certain strength of connection keys; determining a certain number of randomly located hole defect centers through a position random function, and constructing each hole defect polygon with shape randomness; and finally deleting a closed area wall, and deletingthe particles in the polygon to form a hole defect. The method is easy to program, is simple to debug, conforms to the existence state of the actual brittle material defects, can make the simulationexperiment result more accurate, more in line with the actual situation, and can improve the effectiveness of the simulation experiment.

Owner:XIANGTAN UNIV

Preparation method of boron carbide superfine powder

ActiveCN107758670ADifficult to operateLarge controllable difficultyCarbon compoundsBrickBoron carbide

The invention discloses a preparation method of boron carbide superfine powder. The preparation method is based on a boron carbide smelting device which comprises a smelting furnace body built with refractory bricks and a sunken cover plate buckled at a top opening of the smelting furnace body, wherein a positive pole and a negative pole communicating a power supply are inserted into the side wallof the smelting furnace body. The preparation method comprises the following steps: S1, mixing a boron source with a carbon source fully to obtain a smelting raw material; S2, fully filling the smelting furnace body with the smelting raw material and covering the furnace with the sunken cover plate; and S3, applying a voltage to heat the smelting raw material to 1500-1900 DEG C and keeping the temperature for 24-48h to obtain the boron carbide superfine powder. Boron carbide is prepared by means of a nearly closed high-temperature treatment method according to the preparation method disclosedby the invention, so that impurity pollution is reduced, the product is good in crystallinity, the primary content of the obtained boron carbide superfine powder is greater than 96%, and the productgraded meets the demand of an abrasive material, and meets the quality demand on boron carbide powder in the field of grinding industry or engineering ceramics.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

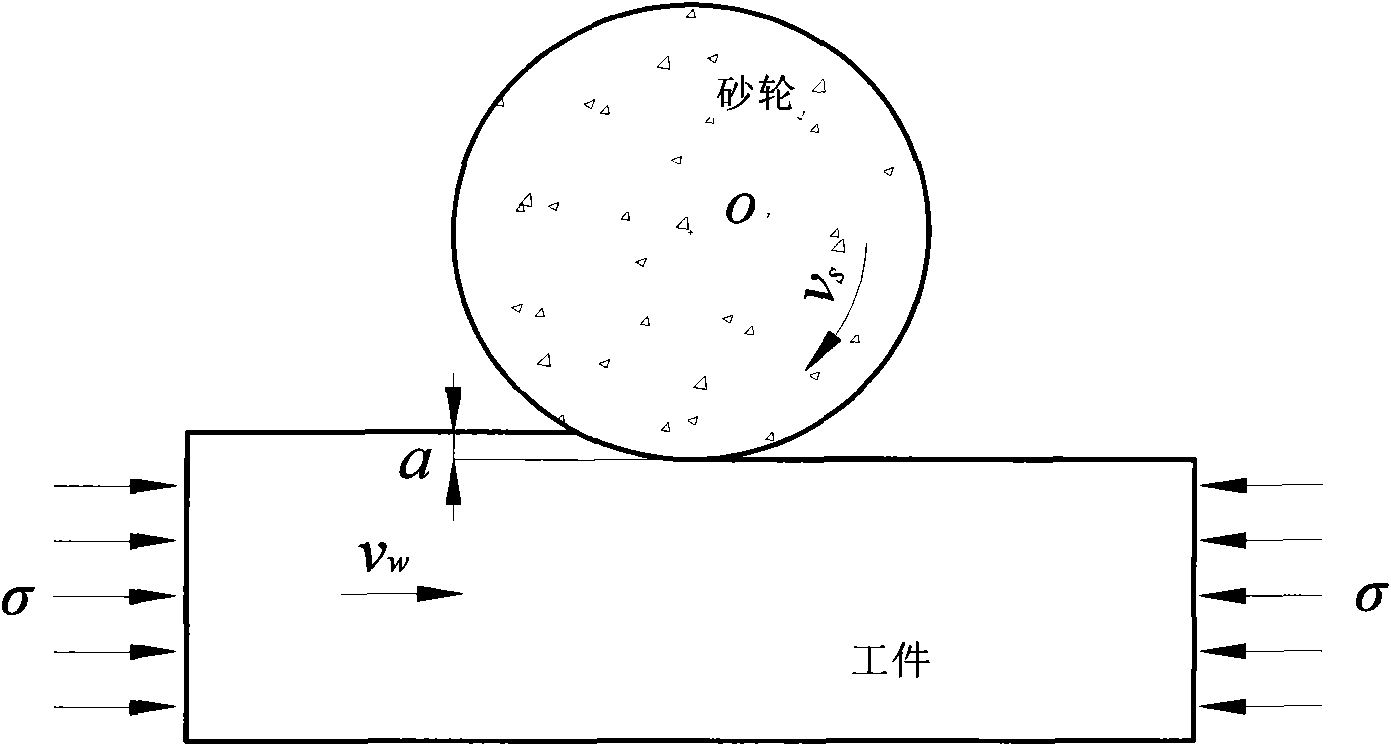

Prestress grinding processing method of ceramic material

InactiveCN101564826AImprove stabilityImprove reliabilityGrinding machinesCompressive strengthProcessing cost

The invention discloses a prestress grinding processing method of a ceramic material. The method comprises the following steps of: firstly, testing to obtain compression strength of processed ceramic material work pieces; secondly, using a prestress applying device to applying prestress to the ceramic material work pieces; and then arranging the ceramic material work pieces with the prestress applying device on a grinding machine for grinding and processing. The prestress grinding processing method has the following beneficial effects that 1. from the damage caused to the surface / subsurface, the processing method improves the stability and reliability of processing quality of the ceramic work pieces; 2. in the coarse grinding process of the work pieces, the grinding depth can be increased, thus improving the production efficiency without generating deeper processing damage; 3. not only high-efficiency low-damage grinding processing can be conducted on the common grinding machine, the processing cost is reduced, but also a new processing technique route is provided for high-precision low-damage processing of the ceramic work pieces; and 4. the new technology of ceramic grinding and processing is improved and developed, a new technique for high-efficiency ultraprecision ductile-regime grinding processing is found and the engineering practical application of engineering ceramic is further promoted.

Owner:XIANGTAN UNIV

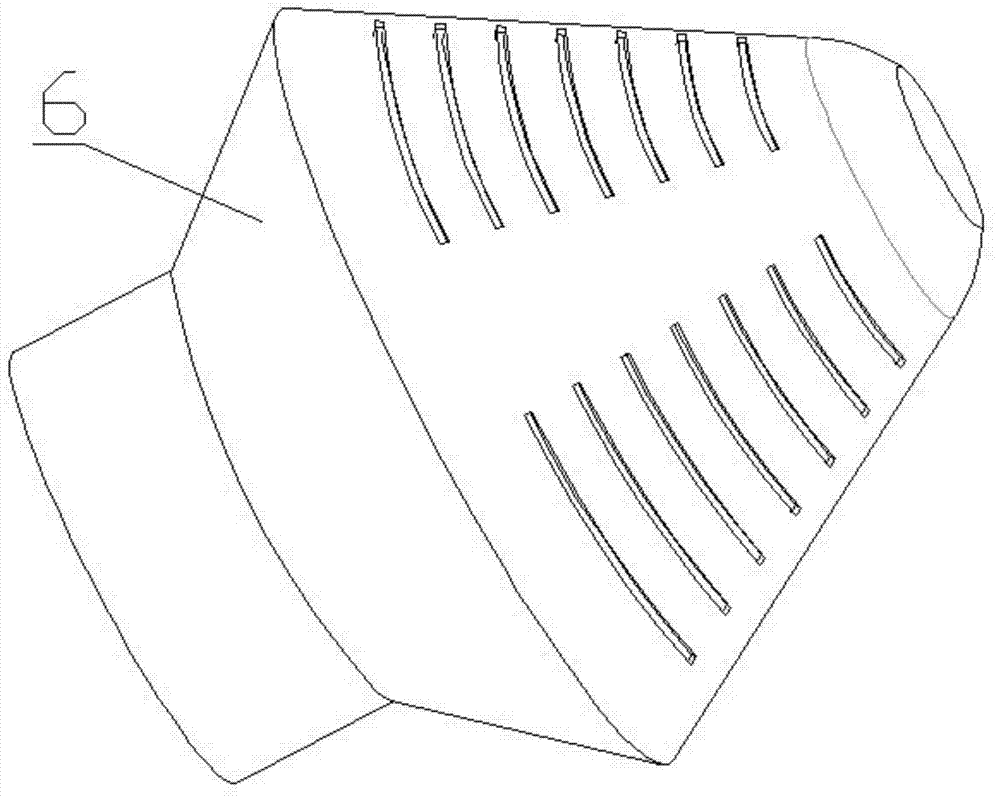

Dual-abrasive diamond grinding wheel for machining external round surface of engineering ceramic

InactiveCN102513945AGuaranteed processing efficiencyGuarantee processing qualityBonded abrasive wheelsDual effectMachining

The invention relates to a dual-abrasive diamond grinding wheel for machining an external round surface of engineering ceramics and belongs to the technical field of machining tools for the engineering ceramics. The grinding wheel comprises a base body, an auxiliary grinding zone, a primary grinding zone and abrasive dust discharging slots, wherein the auxiliary grinding zone is combined with the circumferential surface of the base body and consists of a diamond fine abrasive layer, and the primary grinding zone is combined with the end face of the base body and consists of a diamond coarse abrasive layer; or the auxiliary grinding zone is combined with the end face of the base body and consists of the diamond fine abrasive layer, and the primary grinding zone is combined with the circumferential surface of the base body and consists of the diamond coarse abrasive layer; the primary grinding zone is used for removing workpiece materials, and the auxiliary grinding zone is used for grinding ground surfaces of workpieces; and the abrasive dust discharging slots are uniformly distributed on the end face and the circumferential surface of the grinding wheel. According to the grinding wheel, dual effects of removing materials and grinding machined surfaces are achieved through once machining, the machining efficiency is high, the structure is simple, and the production process is not complicated.

Owner:田欣利 +1

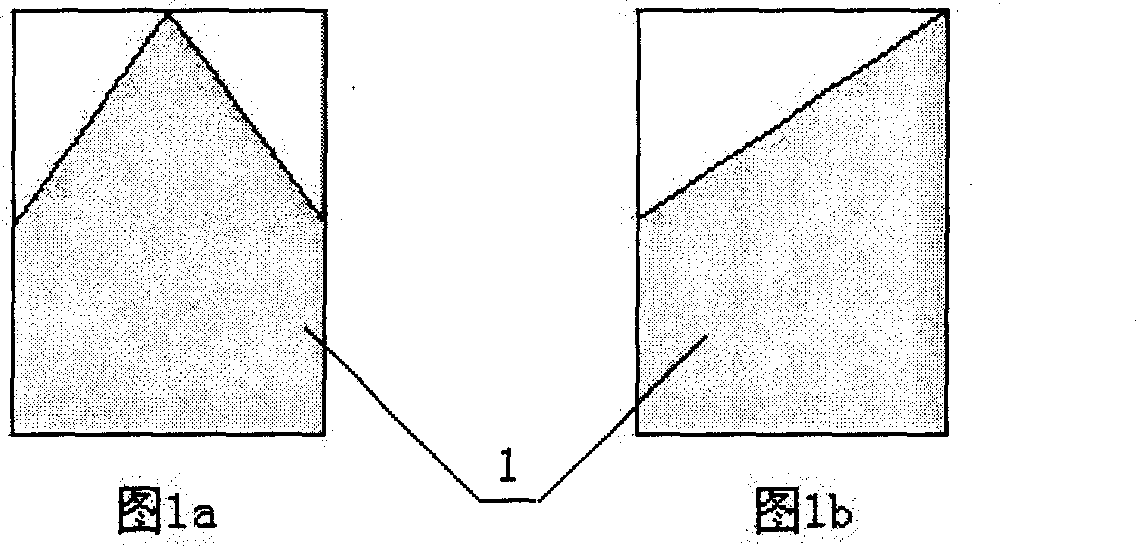

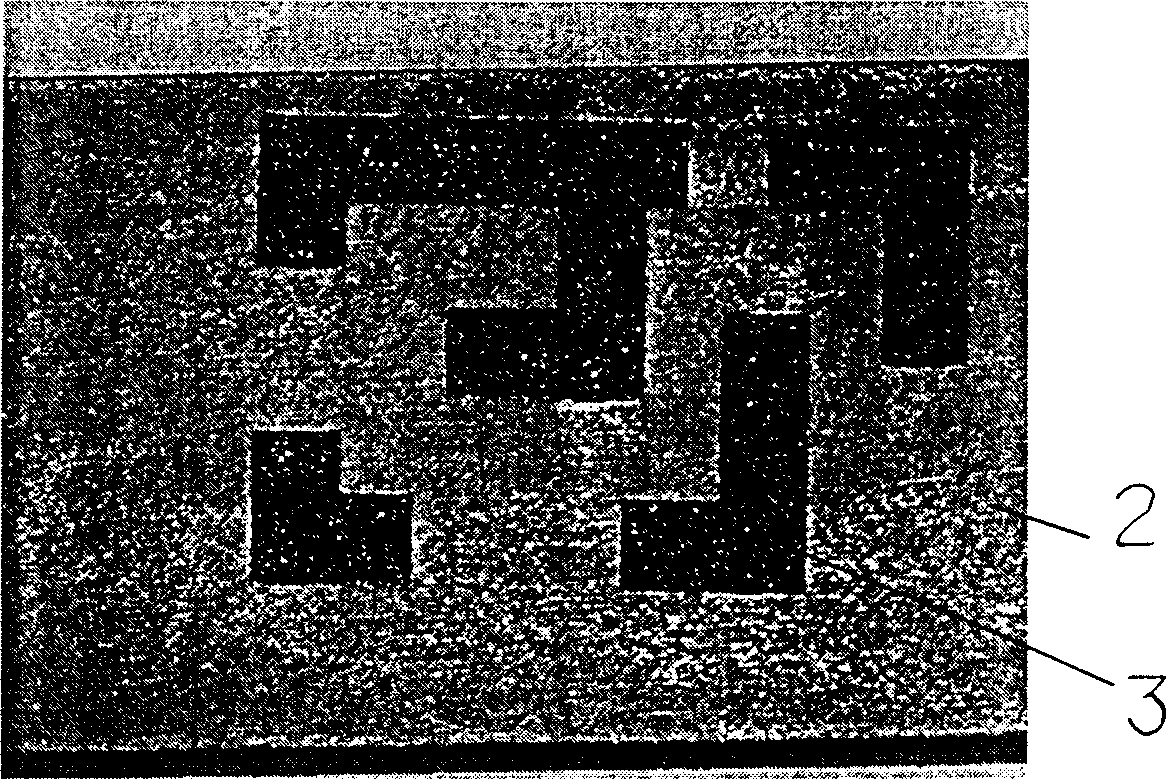

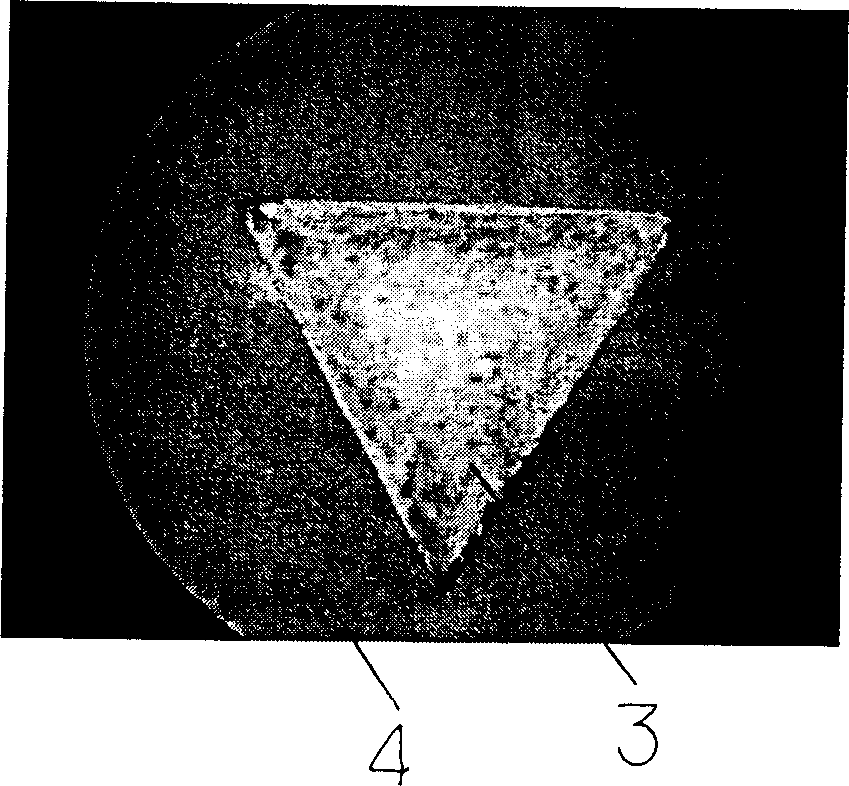

Method for prefabricating straight through crack and dedicated device therefor

InactiveCN1632508APrevent instability and fractureThe experimental method is simplePreparing sample for investigationCeramicMaterial Crack

This invention discloses a pre-process straight crack of engineer ceramics material and rigid material and its special device. The method is to use the strain rule of the ceramics material crack expansion; first to cut a •¢ shape cut or triangle cut in the outer round shear machine in the specimen; to make the strain of the crack top end under control through one limit deflection degree and vertical constrains bending load. The device comprises rigid rack, clock gage, adjustable top pillar, and tight screw. The parallel beam forms rigid rack through vertical beam. There fixed with clamping beam specimen tight screw. The clock gage test part is connected with the adjustable top pillar on the back of the beam specimen.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Laser milling method for hard brittle material

InactiveCN1730227AAchieve the purpose of formingSimple methodLaser beam welding apparatusHigh power densityLaser milling

The laser milling method for hard fragile material uses solid pulse laser for manufacture. Compared with common methods, this invention needs not to prepare electrode and mould, easy to manufacture for single piece and small scale; the laser device has simple structure and well reliable to spread in industry, which has high power density and fit to material of high melting point, such as high alloy steel, semiconductor silicon slice, engineering ceramics, and diamond.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

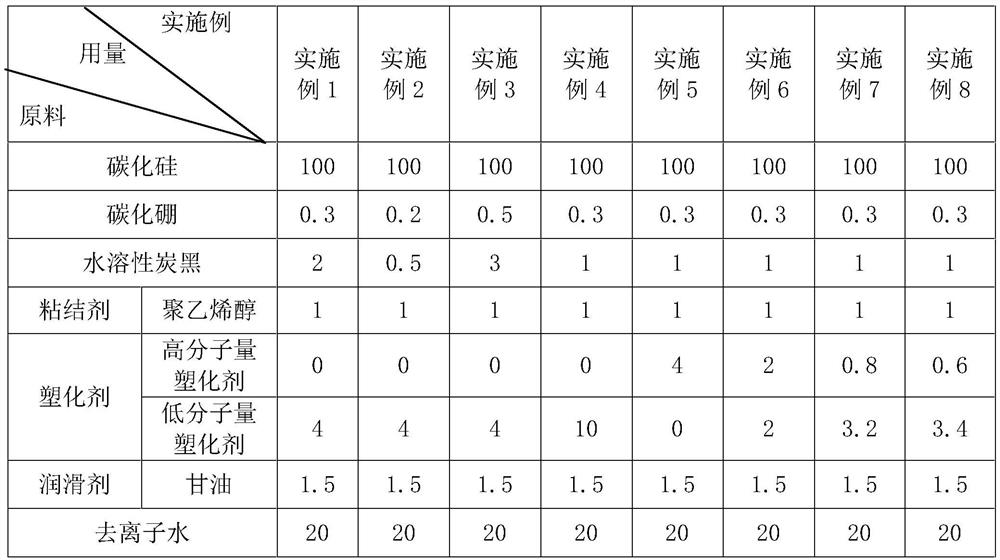

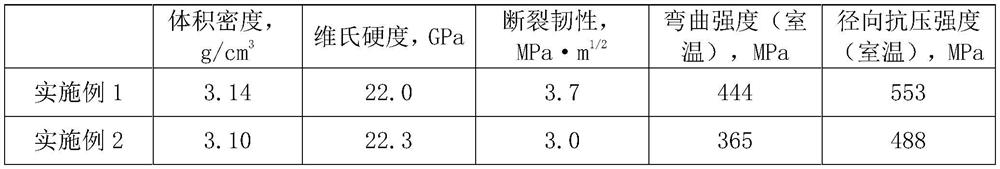

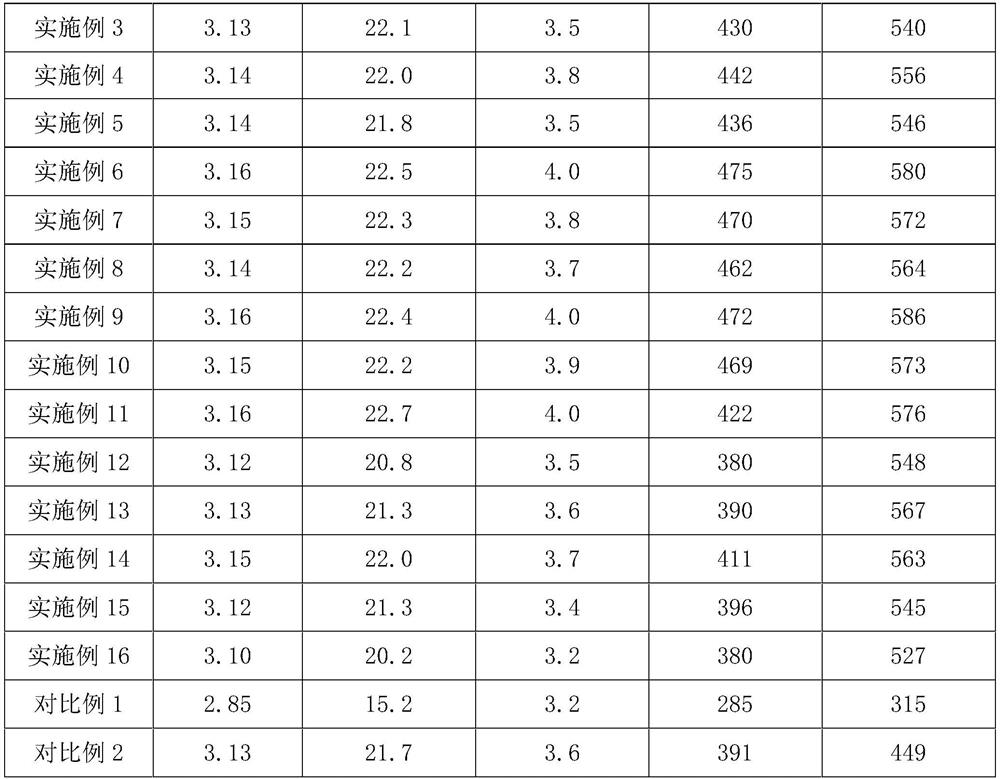

Solid-phase sintered silicon carbide product and preparation method thereof

The invention relates to the field of engineering ceramic materials, and particularly discloses a solid-phase sintered silicon carbide product and a preparation method thereof. The preparation method of the solid-phase sintered silicon carbide product comprises the following steps: grinding raw materials: mixing micron-sized silicon carbide powder with a boron-containing sintering aid, and performing wet grinding to obtain slurry; performing spray granulation: adding water-soluble carbon black and a binder into the slurry, uniformly stirring, and carrying out spray granulation to obtain silicon carbide granulation powder; mixing the materials; aging: aging the wet powder obtained by mixing to obtain an aged material; and performing post-treatment: performing pugging, extrusion, drying and heat treatment on the aged material. The silicon carbide product prepared by the preparation method can be used as a heat exchange tube, a roller rod, a square beam, a micro reaction tube and the like, and has the advantages of high sintering density, high compressive strength and high toughness; in addition, the preparation method has the advantages of low production cost and high production efficiency.

Owner:NANTONG SANZER PRECISION CERAMICS CO LTD

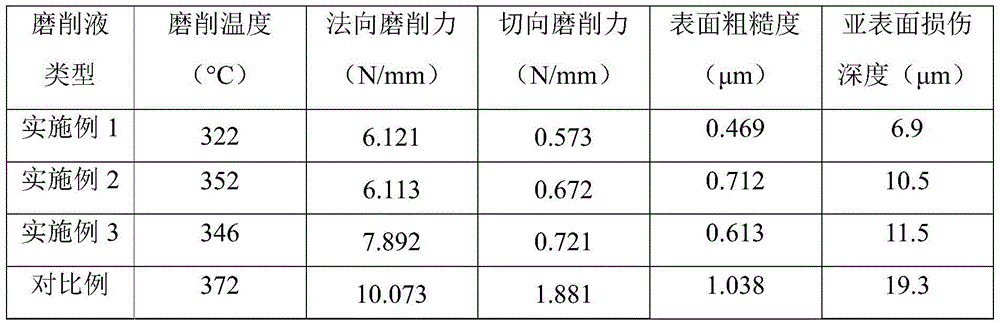

Special grinding fluid for grinding of silicon carbide ceramic by diamond grinding wheels and preparation method of special grinding fluid

ActiveCN105586142AImprove the lubrication effectImprove cooling effectAdditivesBase-materialsDimethyl siloxaneMachining process

The invention relates to a special grinding fluid for grinding of silicon carbide ceramic by diamond grinding wheels. The special grinding fluid comprises 4.8%-6.2% of fatty acid methyl ester polyoxyethylene ether, 2.5%-2.9% of an alkyl synthol alkoxy compound, 2.2%-2.5% of tungsten disulfide, 4.2%-4.4% of cyclopentasiloxane, 3.5%-3.7% of an anti-wear reagent at extreme pressure, 2.3%-3% of a corrosion inhibitor, 2.5%-3.5% of a friction modifier and the balance of deionized water. The special grinding fluid for grinding of the silicon carbide ceramic by the diamond grinding wheels has excellent lubricating, cooling and cleaning effects, has the long service cycle and can substantially reduce the grinding temperature, the normal grinding force and the tangential grinding force in the machining process of the silicon carbide ceramic, reduce abrasions of the grinding wheels, effectively improve surface quality and precision of ground surfaces of the silicon carbide engineering ceramic and the like.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

Laser-induced heat-cracking grinding method for aluminum oxide engineering ceramics

InactiveCN103831674AImprove processing efficiencyImprove surface qualityWelding/soldering/cutting articlesLaser beam welding apparatusWater basedCrack free

The invention relates to a laser-induced heat-cracking grinding method for aluminum oxide engineering ceramics. The laser-induced heat-cracking grinding method for the aluminum oxide engineering ceramics is characterized by comprising the following steps of 1 using Nd: YAG laser as a heat source to heat aluminum oxide engineering ceramic part surfaces, using Ar gas to perform cooling and inducing initial cracks in advance; 2 performing precise wet-type grinding after the initial cracks are produced on the aluminum oxide engineering ceramic part surfaces, wherein water-based cooling liquid is selected, liquid supply pressure is 6MPa, the grinding wheel linear speed is 80m / s, the grinding depth is 2mm, and the feeding speed is 2.2m / min. By applying the laser-induced heat-cracking grinding method, crack-free fused-metamorphic-layer low-roughness and high-quality machined surfaces can be obtained, and the machinability of ceramic materials can be remarkably improved. Compared with traditional aluminum oxide engineering ceramic grinding methods, large grinding depth can be adopted to perform machining. The laser-induced heat-cracking grinding method is a novel machining method for engineering ceramics and other hard, crisp and difficultly-machined materials.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com