Patents

Literature

98results about How to "Small grinding force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diamond resin grinder

The invention relates to a diamond resin grinding tool in the field of grinding tool technology. The working layer is formed by diamond grinding material, catalyst, and filler; the diamond grinding material adopts self-sharpening diamond grinding material which has working layer volume rate 12.5-31.25úÑ.The working layer also comprises: hardening carbonizable substance with volume rate 5-15úÑ and admixture formed by carbite 0-3úÑ.The hardening carbonizable substance comprises: one or two combines of silicon carbide, boron carbide, titanium carbide, and tungsten carbide; the hardening oxide substance comprises: aluminum oxide or / and silicon oxide. The catalyst chooses phenol resin or polyimide resin which has working layer volume rate 40-50úÑ; the filler chooses copper, chromic oxide, zinc oxide and iron oxide which have working layer volume rate 8-15úÑ, 5-15úÑ, 0-8úÑ, 0-8úÑ.

Owner:ZHENGZHOU ARTIFICIAL DIAMOND & PROD ENG TECH RES CENT

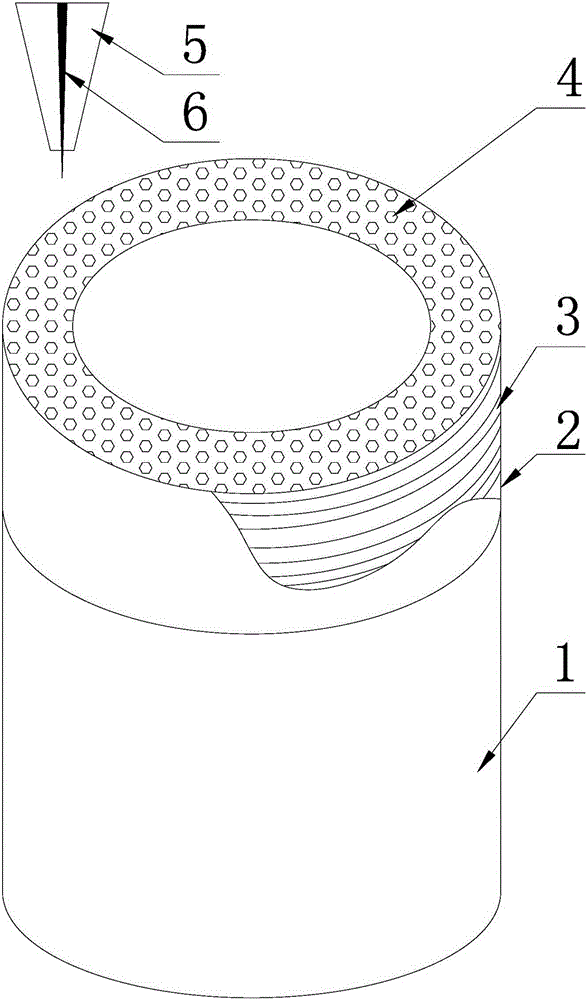

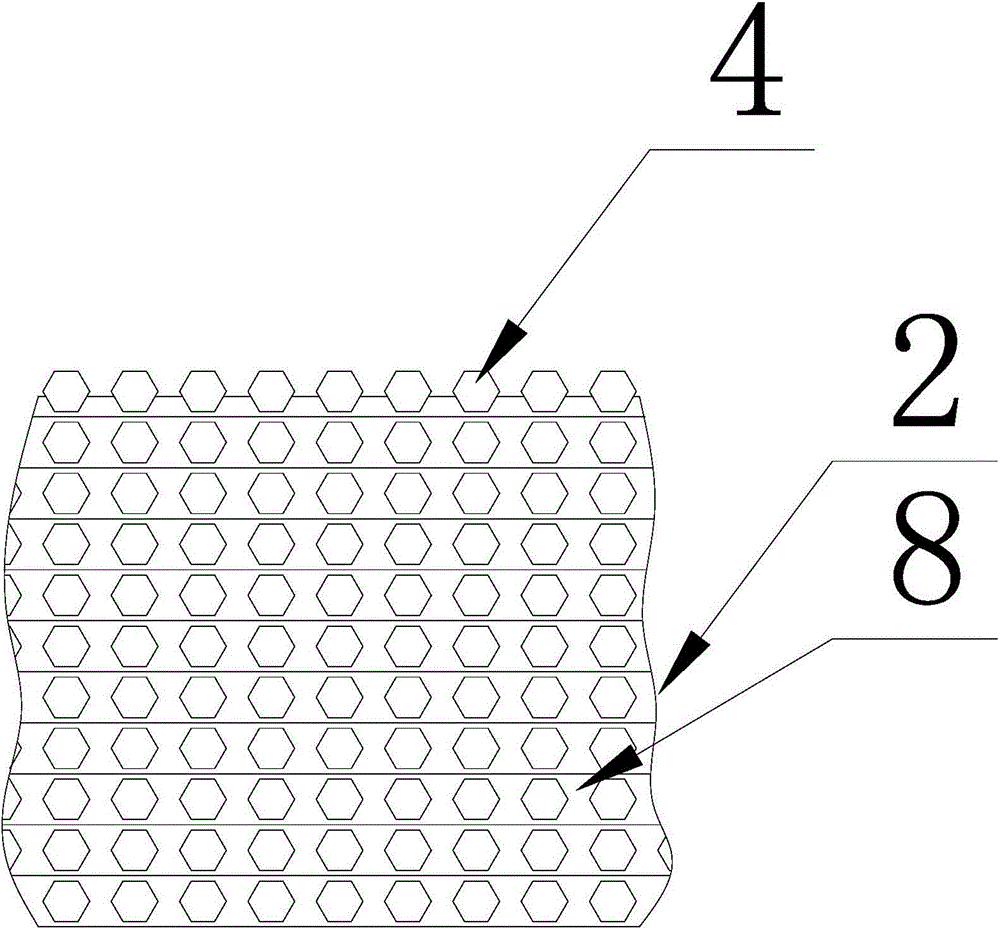

Diamond grinding wheel and production method thereof

InactiveCN106312843AAvoid graphitizationConsistent blade heightBonded abrasive wheelsGrinding devicesDiamond grindingBonding strength

The invention discloses a diamond grinding wheel, which has multi-layer abrasive particle orderly arrangement, is high in bonding strength and is convenient to repair after being worn, and a production method thereof. The production method comprises steps of processing a grinding wheel basal body, cleaning and the like. According to the diamond grinding wheel and the production method thereof disclosed by the invention, a laser material increasing technology is adopted to accurately process, so that processing precision and processing quality are improved; a sandwich structure is adopted for sintering, so that the abrasive particles are prevented from moving, protruding height of the abrasive particles is guaranteed to be consistent, orderly arrangement of the diamond abrasive particles is realized, a chip space during grinding is great, grinding force is reduced, a grinding temperature is reduced, grinding efficiency is improved, and grinding surface quality is improved; power of a laser unit is controlled for controlling a sintering temperature, so that the diamond abrasive particles are prevented from graphitizing, and a metal bonder is combined with the diamond abrasive particles in a high-strength metallurgical mode; a manufacturing process further can be simplified; and the diamond grinding wheel is finished layer by layer after being worn, and then is continuously used, so that finishing is convenient, and the service life of the diamond grinding wheel is long.

Owner:HUNAN CITY UNIV

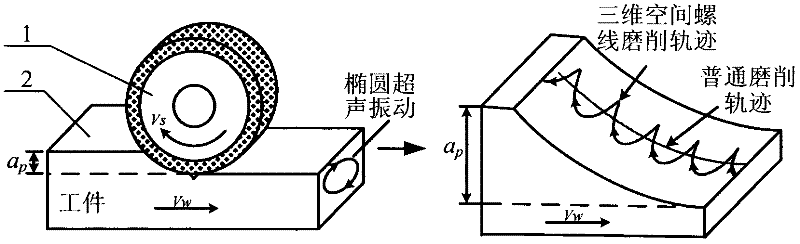

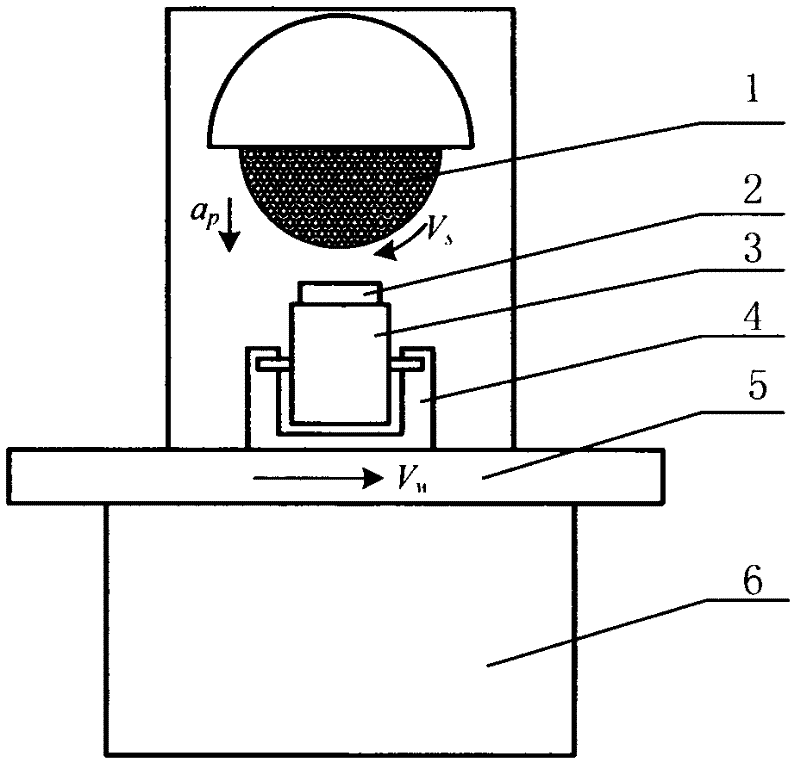

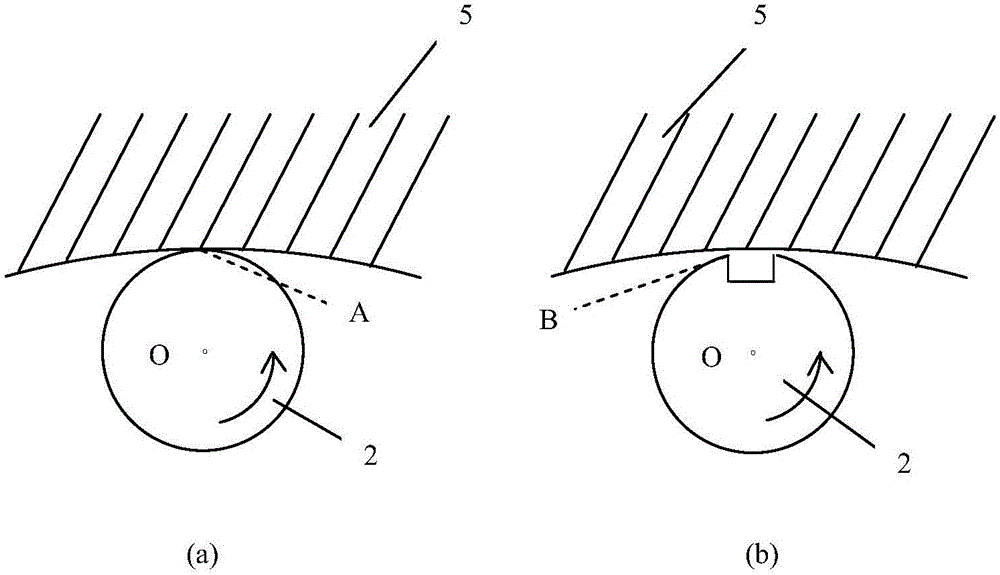

Three-dimensional spiral line grinding method through ultrasonic vibration

The invention provides a three-dimensional spiral line grinding method through ultrasonic vibration, which is applicable to high-efficiency precision machining of difficult-to-cut materials. Two-dimensional ultrasonic vibration is applied to a workpiece in the axial direction of a grinding wheel and in the radial direction of the grinding wheel on a common grinder by an ultrasonic transducer, so that the workpiece is in ultrasonic elliptic vibration. As the grinding direction is perpendicular to a plane of ultrasonic elliptic vibration, cutting tracks of abrasive particles relative to the workpiece are three-dimensional spiral lines. The tracks of the abrasive particles on the surface of the workpiece interfere with each other by the aid of the ultrasonic vibration in the axial direction of the grinding wheel, so that roughness is reduced. Besides, the maximum cutting depth of the abrasive particles is increased by the aid of the ultrasonic vibration in the radial direction of the grinding wheel, and the abrasive particles function in intermittent cutting, so that grinding force is reduced, and material removing rate is increased. The method can be used for improving machining surface quality, decreasing surface damage and improving production efficiency, thereby being applicable to high-efficiency precision machining of the difficult-to-cut materials.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

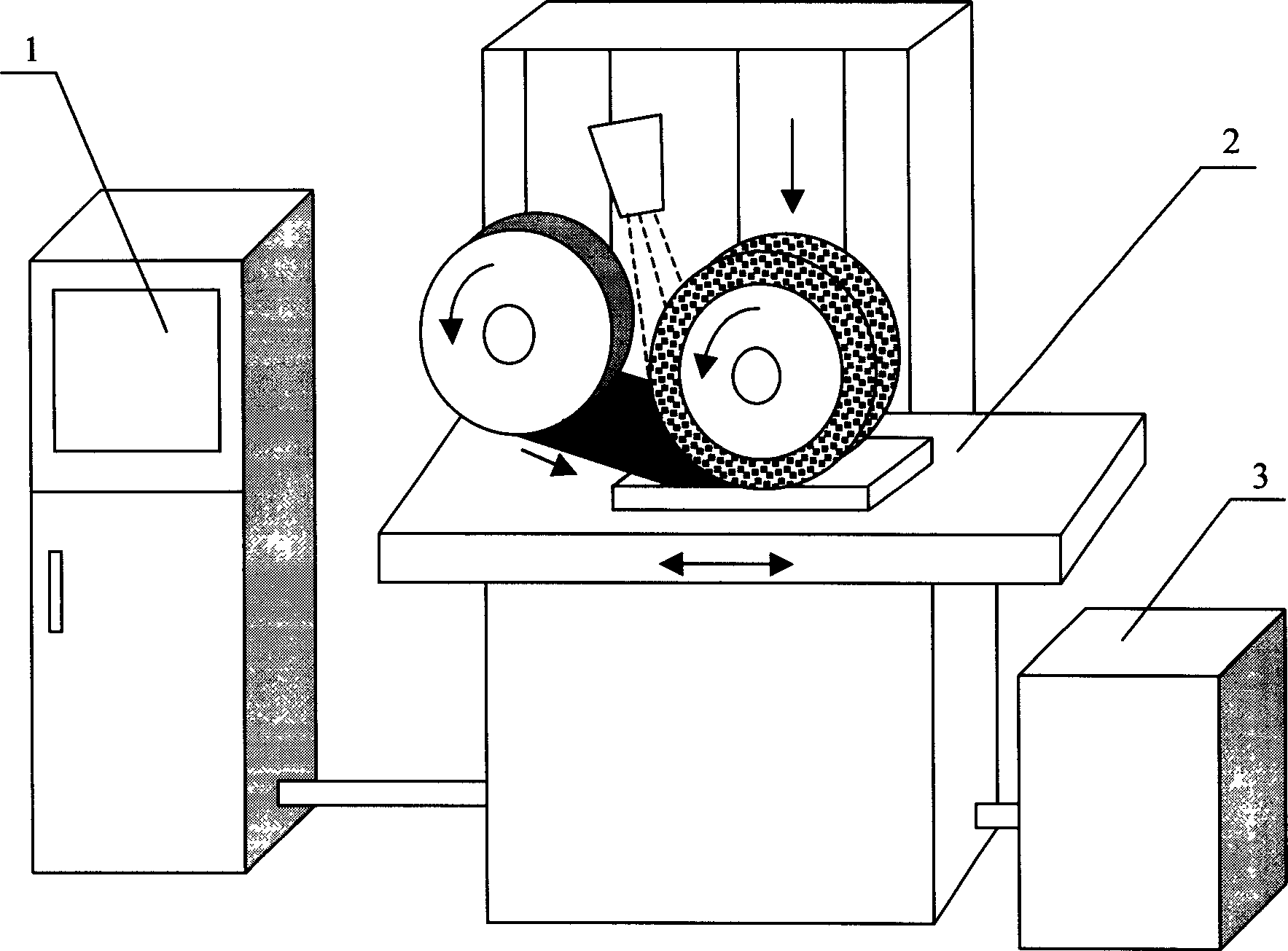

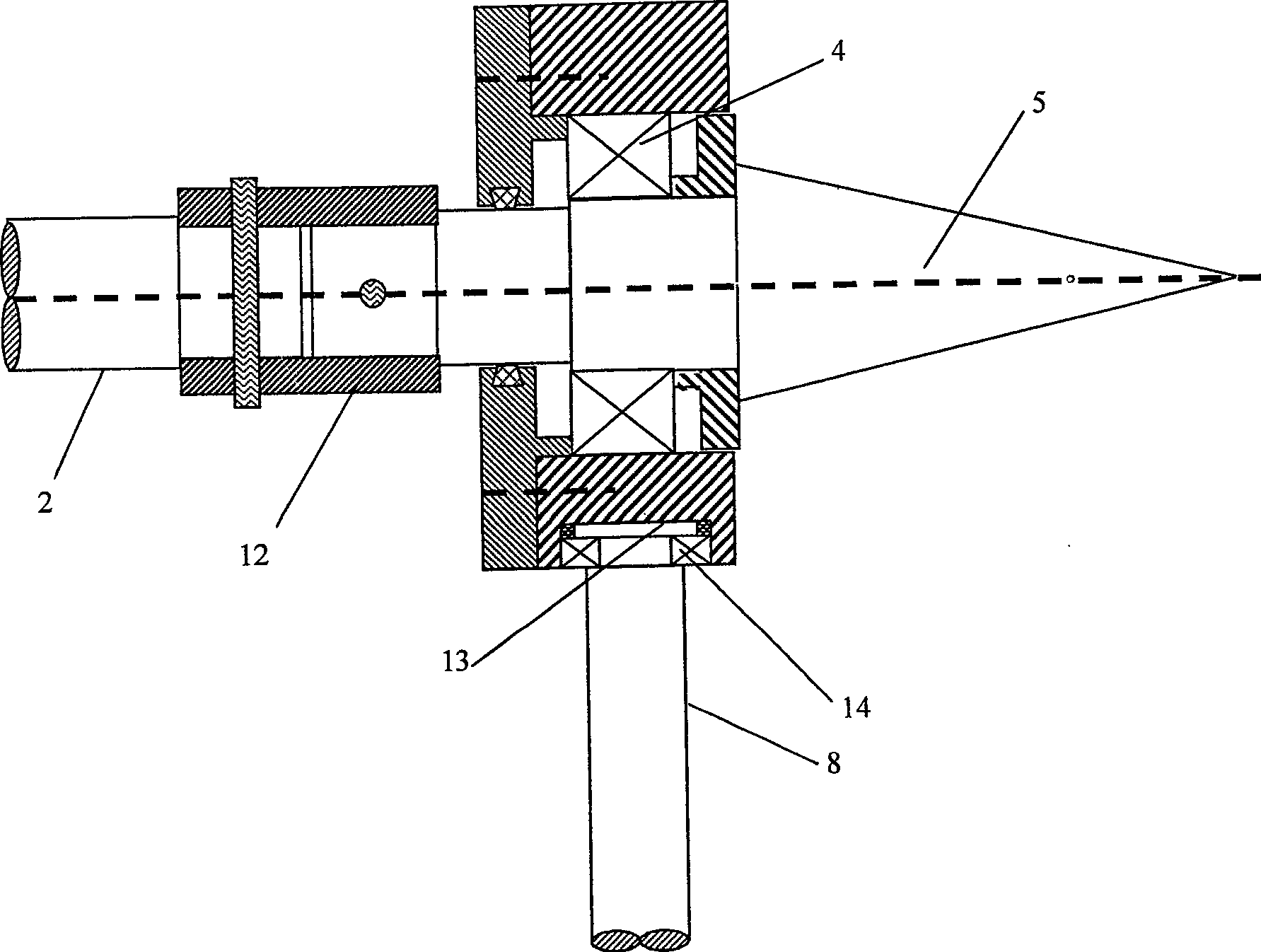

Electric spark mechanical composite grinding method and machine for non-conductive superhard material

ActiveCN1557606AImprove processing efficiencyLow costOther manufacturing equipments/toolsSuperhard materialControl system

The present invention is composite electric spark machine grinding method and machine apparatus for machining non-conductive super-hard material. During the machine, the rotary conducting grinding wheel is used as one electrode for electron spark grinding, electrode sheet feeding along the surface of the workpiece as the other electrode, and the spark discharge in the surface of workpiece between the conducting grinding wheel and the sheet electrode makes the surface of the workpiece of non-conductive super-hard material carbonized and denatured for being eliminated via mechanical grinding. The machine apparatus includes machining unit, pulse power source, control system and liquid supplying system. The sheet for machining is wound onto a barrel, which is driven by a DC motor for servo motion. The present invention has high machining efficiency on non-conductive super-hard material, high surface quality and low machining cost.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

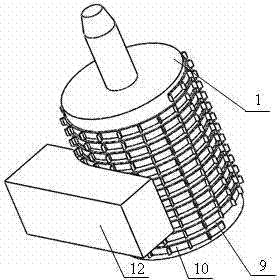

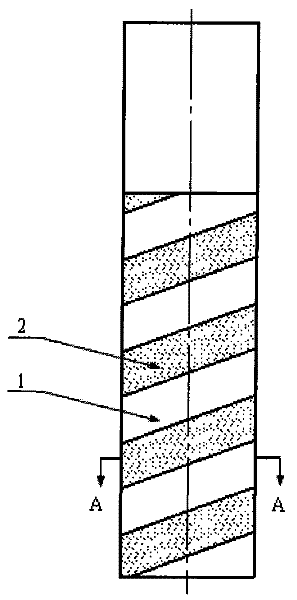

Method for machining narrow groove system impeller, grinding head and preparation method of grinding head

The invention provides a method for machining a narrow groove system impeller, a grinding head and a preparation method of the grinding head. The grinding head is a cylinder. The top end of the grinding head is in the shape of a spherical surface, and a spiral groove is formed in the side wall of the grinding head. The preparation method includes the steps that materials for use are calculated; ingredients are weighed; wetting and material mixing are performed; pressing of grinding head sand blocks is performed; drying is performed; the firing link is performed; and the grinding head sand blocks which are qualified through checking are selected and enter an adhesion processing procedure of a cutter handle, the cutter handle is bonded, after adhesives are cured and stabilized, laser dressing is performed, grooving is performed, and acceptance check of the grinding head is performed, and therefore preparation of the grinding head is completed. The method for machining the narrow groove system impeller through the grinding head includes the steps that fluttering stability analysis is performed, and a stable lobe graph of a grinding system is established; the technological parameter selecting range of stable grinding is determined; and technological parameters of stable grinding are selected, and the grinding head is installed for grinding machining. By means of the grinding head, the grinding temperature is effectively lowered, the adhesion and abrasion effects of cuttings on the grinding head are reduced, the machining surface burning problem is reduced, and better machining surface quality is acquired.

Owner:NORTHEASTERN UNIV

Combined precise trimming device and trimming method for ultrahard grinding sand wheel

ActiveCN106392885AImprove profile accuracySmall grinding forceAbrasive surface conditioning devicesEngineeringContact type

The invention discloses a combined precise trimming device and trimming method for an ultrahard grinding sand wheel. The method comprises a first step: grinding water jet rough trimming, specifically, an ultrahard grinding sand wheel and a trimming wheel are enabled to rotate at a certain speed, and the grinding sand wheel is enabled to feed in a reciprocation manner at a constant speed along an axial direction, meanwhile, the grinding water jet trimming device jets a grinding water jet into a gap formed by the ultrahard grinding sand wheel and the trimming wheel along a direction vertical to an axis of the grinding sand wheel, and the grinding water jet impacts the surface of the ultrahard grinding sand wheel, such that a finished sand wheel bonding agent is crushed and abrasive particles fall off; a second step: contact type fine trimming, specifically, when circle run-out of the sand wheel is reduced to certain extent, the circle run-out cannot be continuously reduced effectively by using the grinding water jet purely, and the trimmed ultrahard grinding sand wheel is used to perform fine trimming on stainless steel or cast iron. The abrasive particles with inconsistent heights are removed or ground off, such that the abrasive particles on the surface of the sand wheel tend to be consistent; and a third step: grinding water jet sharpening, specifically, performing final sharpening on the sand wheel by adopting low-pressure large-jet target distance grinding water jet.

Owner:SHANDONG UNIV

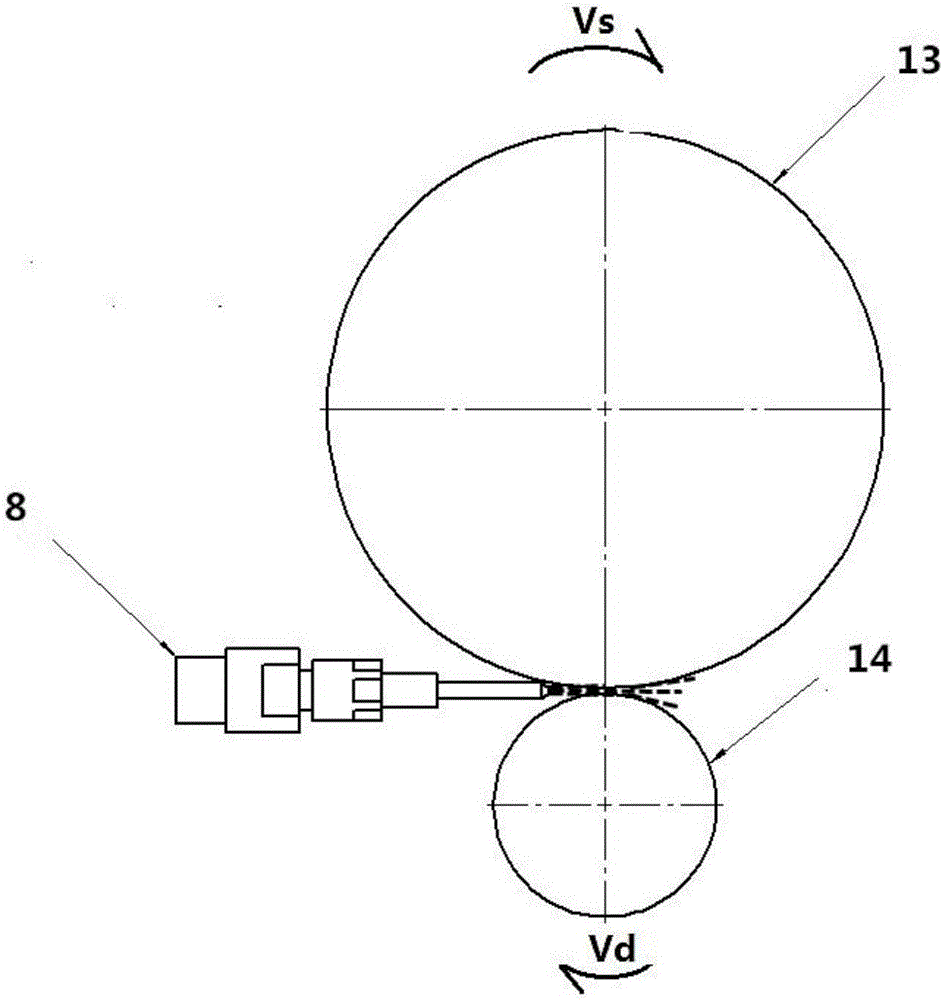

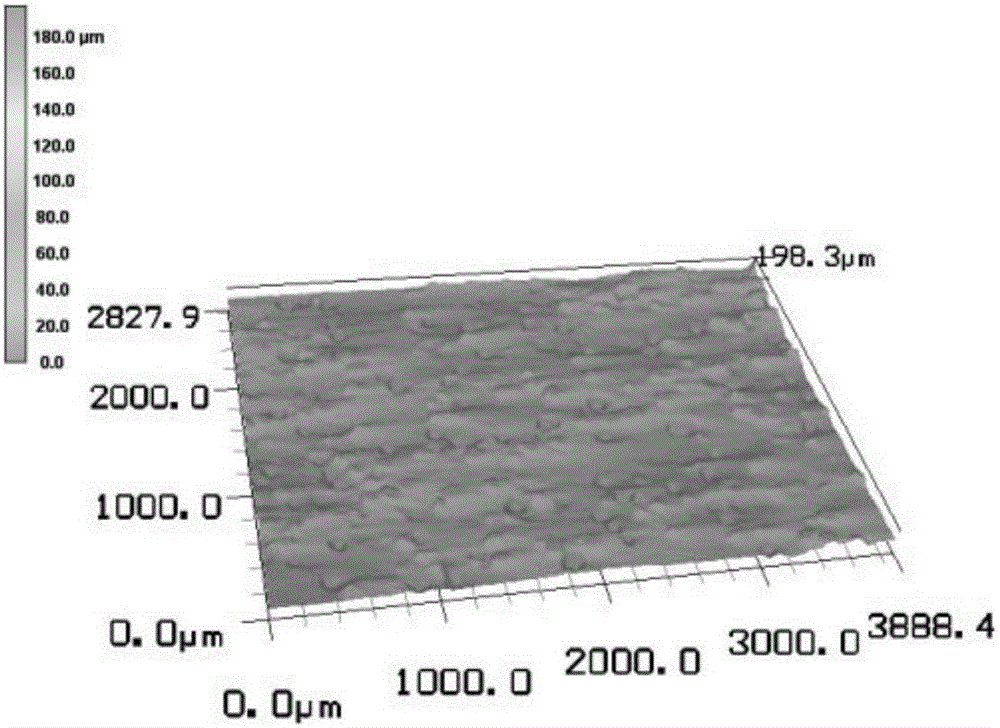

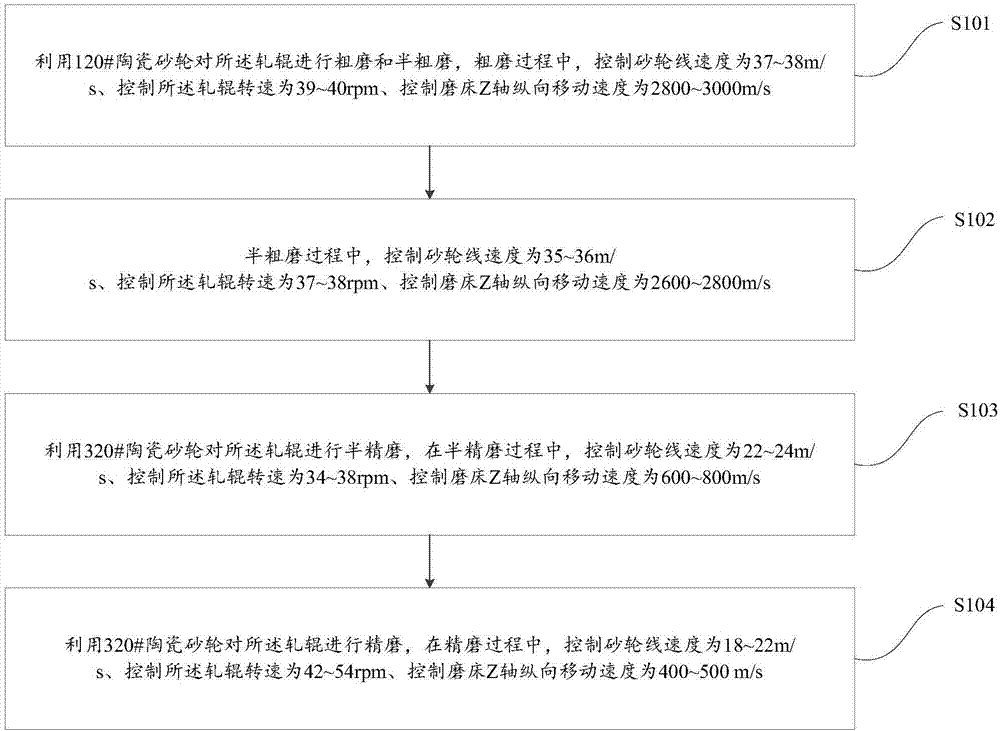

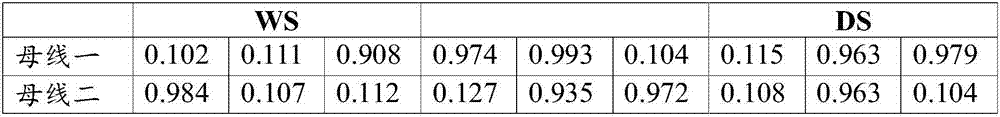

Process for grinding roller

InactiveCN107199507AImprove grinding efficiencySmall grinding forceGrinding headsEngineeringGrinding wheel

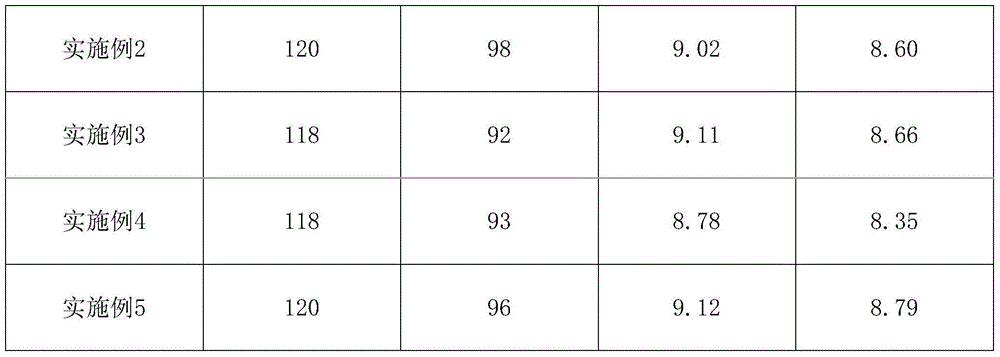

The invention provides a process for grinding rolls, comprising: using a 120# ceramic grinding wheel to perform rough grinding and semi-rough grinding on the rolls, during the rough grinding process, the linear velocity of the grinding wheel is controlled to be 37-38m / s, and the rotational speed of the rolls is controlled to be 39~40rpm, control the Z-axis longitudinal movement speed of the grinding machine to 2800~3000m / s; in the semi-coarse grinding process, control the grinding wheel linear speed to 35~36m / s, control the roll speed to 37~38rpm, control the Z-axis longitudinal movement speed of the grinding machine 2600~2800m / s; 320# ceramic grinding wheel is used for semi-fine grinding of the roll. During the semi-fine grinding process, the linear speed of the grinding wheel is controlled to be 22-24m / s, the speed of the roll is controlled to be 34-38rpm, and the Z-axis longitudinal direction of the grinder is controlled. The moving speed is 600-800m / s; use 320# ceramic grinding wheel to fine-grind the roller. During the fine-grinding process, control the linear speed of the grinding wheel to 18-22m / s, control the speed of the roller to 42-54rpm, and control the Z-axis longitudinal direction of the grinding machine. The moving speed is 400-500m / s; among them, the semi-fine grinding includes: the first semi-fine grinding and the second semi-fine grinding; the fine grinding includes: the first fine grinding, the second fine grinding and the third fine grinding Grinding; the concentration of grinding fluid is 3.5-4.0%.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Modified diamond abrasive tool and manufacturing method thereof

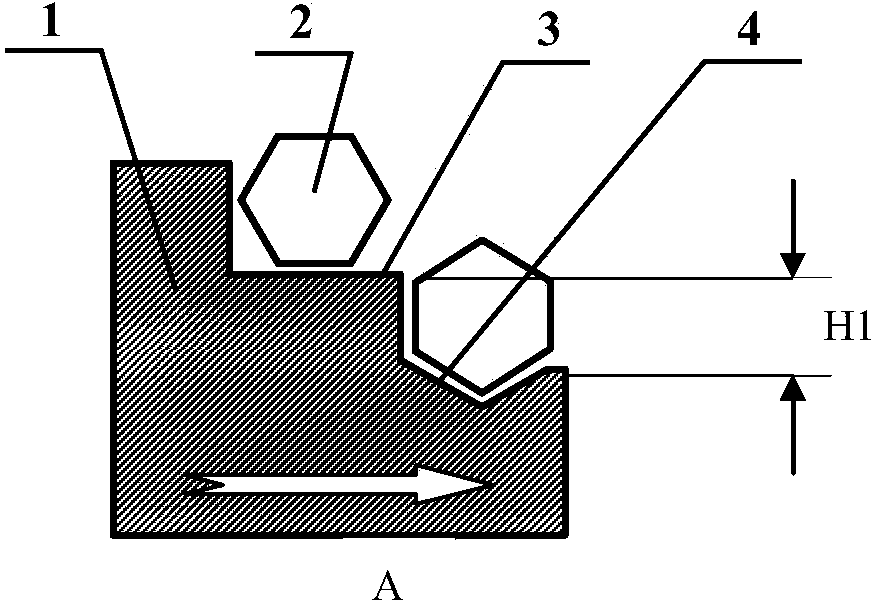

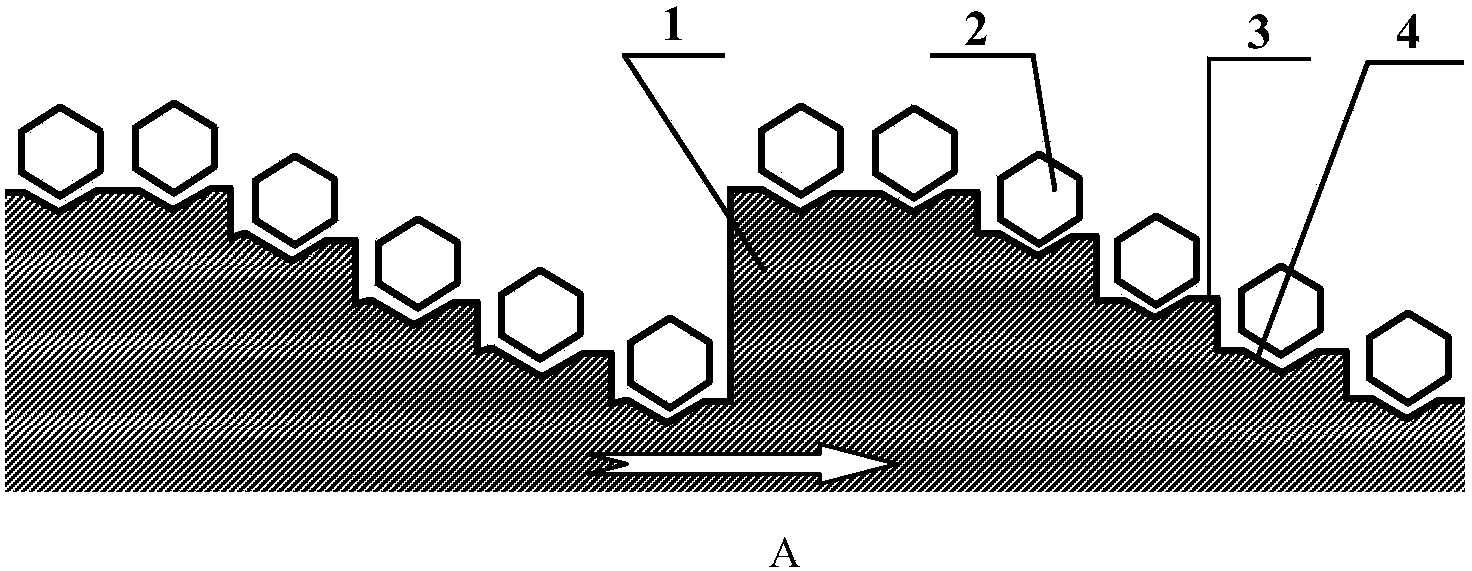

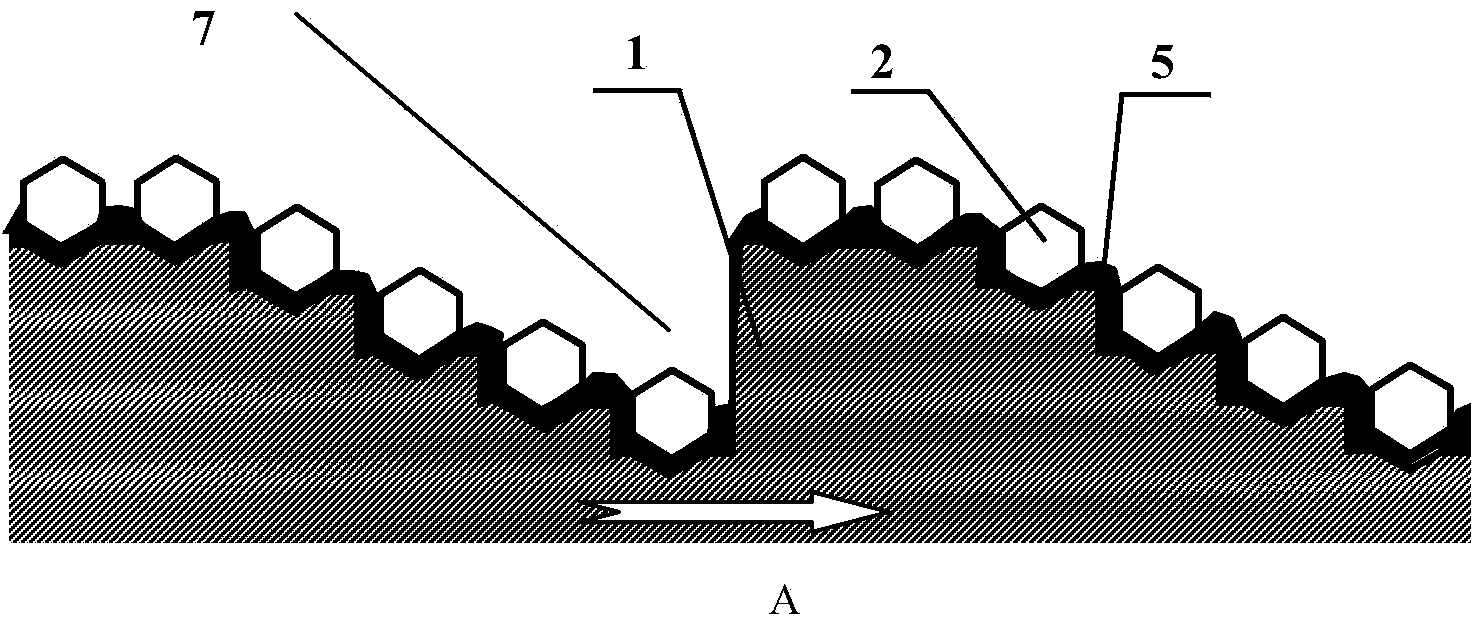

InactiveCN103506964AReduce contact areaExtended service lifeGrinding devicesGrinding/polishing hand toolsDiamondAbrasive

The invention discloses a modified diamond abrasive tool and a manufacturing method of the modified diamond abrasive tool. The modified diamond abrasive tool comprises a base body and diamond abrasive materials arranged in a work area on the surface of the base body, wherein the work area on the surface of the base body is a step surface provided with a plurality of steps, each step is composed of a vertical surface and a horizontal surface, the step surfaces gradually decrease from the working direction, the horizontal surface of each step is provided with at least one installation groove used for containing the lower portions of the diamond abrasive materials, the diamond abrasive materials are embedded in the installation grooves and sequentially distributed on the step surfaces, the topmost end of each diamond abrasive material is a sharp end or an edge, the diamond abrasive material at the topmost part of the step surfaces works firstly, and after the diamond abrasive material at the topmost part of the step surfaces is blunt, the diamond abrasive materials at the other parts gradually work. The sharp end or the edge of each diamond abrasive material is the topmost end of the diamond abrasive material, so that the diamond abrasive materials are used in an optimized mode. The contacting area between the diamond abrasive materials and a machined object is reduced, the grinding force is small, machining efficiency is high, and the service life of the modified diamond abrasive tool is prolonged.

Owner:广东省电力线路器材厂有限公司

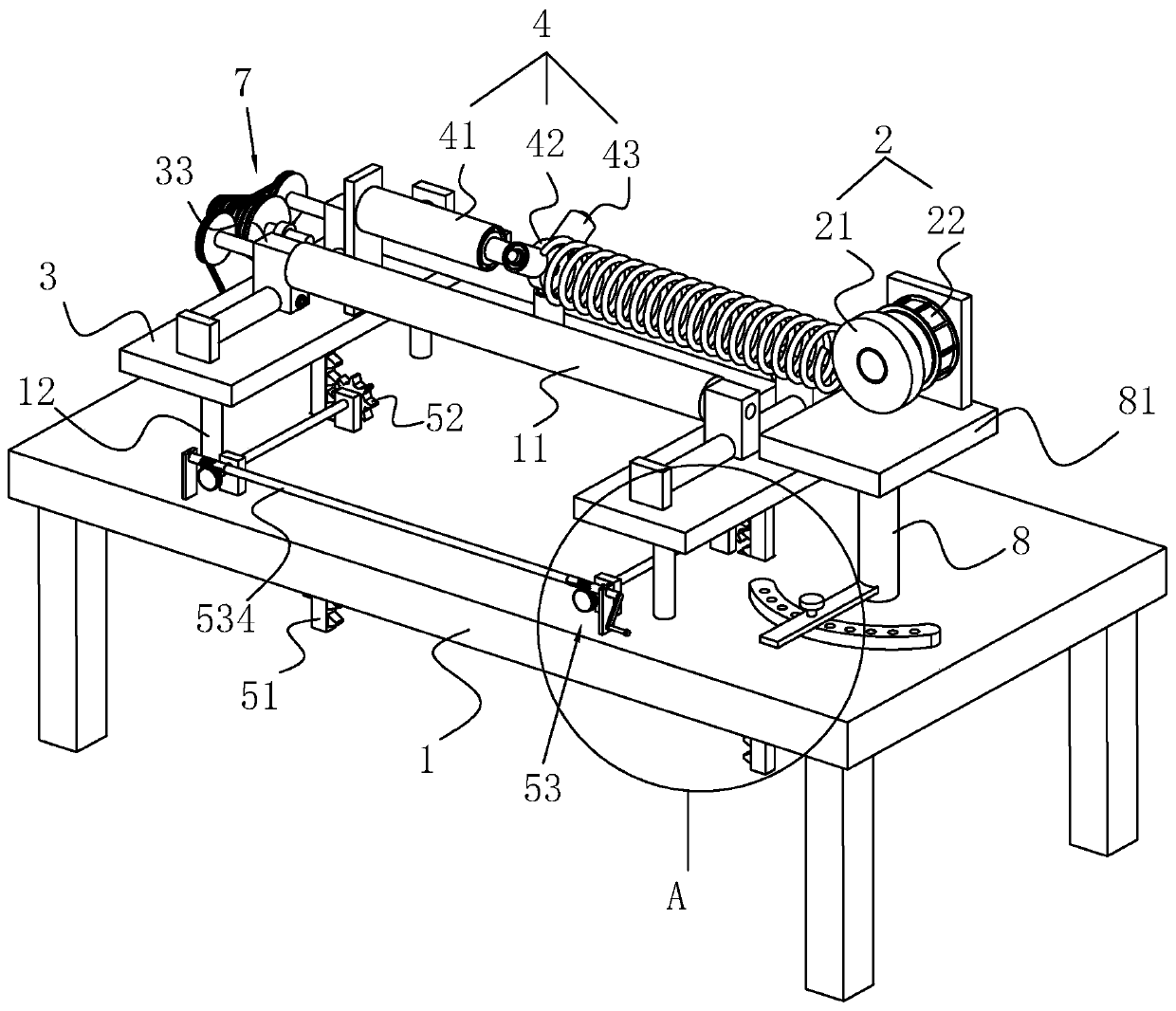

Spring end face grinding device and grinding method thereof

InactiveCN111037389ALower the altitudeImprove grinding performanceGrinding carriagesGrinding drivesElectric machineryEngineering

The invention relates to a spring end face grinding device and a grinding method thereof, and belongs to the technical field of spring grinding. The spring end face grinding device comprises a bottomplate, wherein a grinding assembly used for grinding a spring is arranged on the bottom plate, and the grinding assembly comprises a grinding wheel and a rotating motor; a mounting plate is arranged on the bottom plate, an abutting assembly used for abutting against one end, away from the grinding assembly, of the spring is arranged on the mounting plate, two rotating rollers are horizontally arranged on the mounting plate, and a driving source for driving the rotating rollers to rotate is arranged on the mounting plate; and a lifting assembly used for driving the mounting plate to ascend anddescend is arranged on the bottom plate. When a larger spring is polished, the mounting plate is driven to move downwards through the lifting assembly to reduce the height of the spring, and then theabutting assembly abuts against the spring; and the height of the spring is adjusted, so that the grinding position of the spring and the center of the grinding wheel are on the same horizontal line,the grinding effect of the grinding wheel on the spring is improved, radial jumping of the spring in the grinding process is reduced, and the grinding quality is effectively improved.

Owner:CHENGDU CHENHUI SPRING MFG

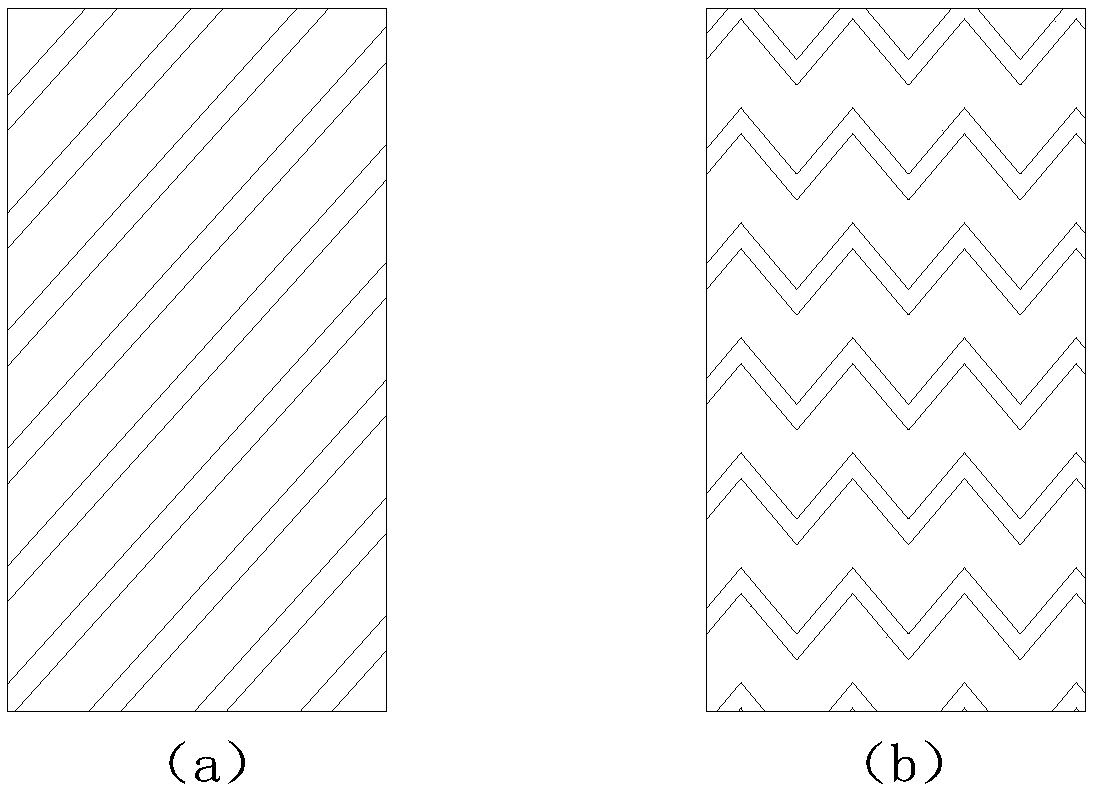

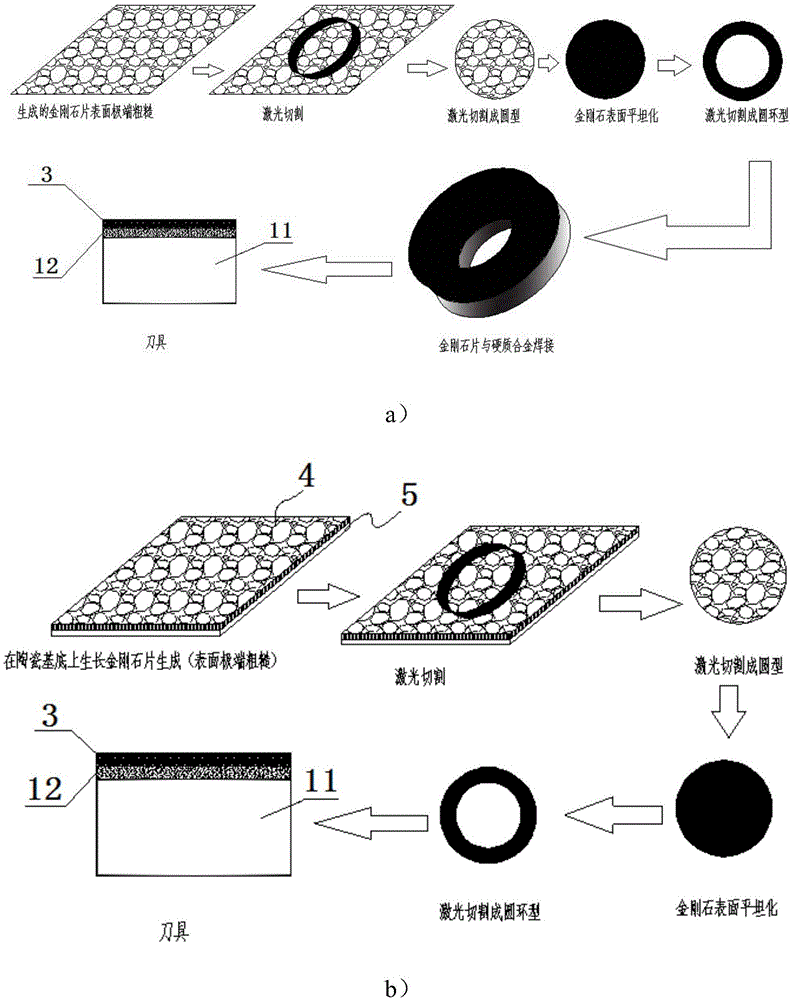

Diamond grinding wheel with micro structure and manufacturing method for diamond grinding wheel

ActiveCN109333385AImprove manufacturing precisionGuaranteed Surface AccuracyBonded abrasive wheelsGrinding devicesMicro structureChemical vapor deposition

The invention discloses a diamond grinding wheel with a micro structure and a manufacturing method for the diamond grinding wheel, and relates to the technical field of ultra-precision machining. Thediamond grinding wheel can solve the problems that existing diamond grinding wheel abrasive particles limit grinding quality, and reduce grinding efficiency, a chip space of the diamond grinding wheelis small, and the like. The diamond grinding wheel utilizes a chemical vapour-phase deposition method to manufacture a diamond abrasive material layer, and the micro structure is manufactured on thediamond abrasive material layer surface. The diamond grinding wheel with the micro structure and the manufacturing method for the diamond grinding wheel disclosed by the invention can be mainly applied to the ultra-precision machining field of hard and brittle material optical surfaces.

Owner:HARBIN INST OF TECH

Processing method of straws and manufacturing method of straw fiber plate

InactiveCN102431072AReduce contentImprove bonding performanceFlat articlesDomestic articlesHydrofluoric acidFiber

The invention discloses a processing method of straws, which comprises the steps of: (1) cutting off straws which are harvested just now into segments of 5-15 mm in length, then removing iron by a magnetic drum, and then crushing the segments into straw blocks of 5-10 in length, width and height; (2) performing microwave radiation on the straw blocks; and (3) immerging the straw blocks in water, adding hydrofluoric acid, mixing until pH is 5-6 and washing with water until the pH is 6.5-7, and then centrifuging and separating. The invention has the beneficial effects as follows: by processing the straws with microwaves, partial or all the silicon cells and suberisation cells are damaged so that the hydrofluoric acid in the acidifying step immerges into the cells to dissolve SiO2, thereby reducing content of the SiO2 in the straw fiber, improving bonding performance of the straw fiber and further improving intensity of a straw fiber plate. The straw fiber plate in the invention has dense texture; and after a saw cutting process, the straw fiber plate compared with the normal shaving board has an even, bright and clean surface and has an internal bonding intensity of 0.56-0.65 MPa, a static bending strength of 30-60 MPa, an elastic modulus of 3000-4000 MPa and a screw holding capability of the plate surface of 1600-1750 N.

Owner:张文生

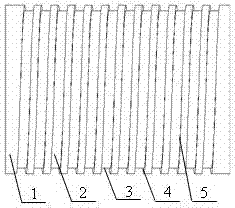

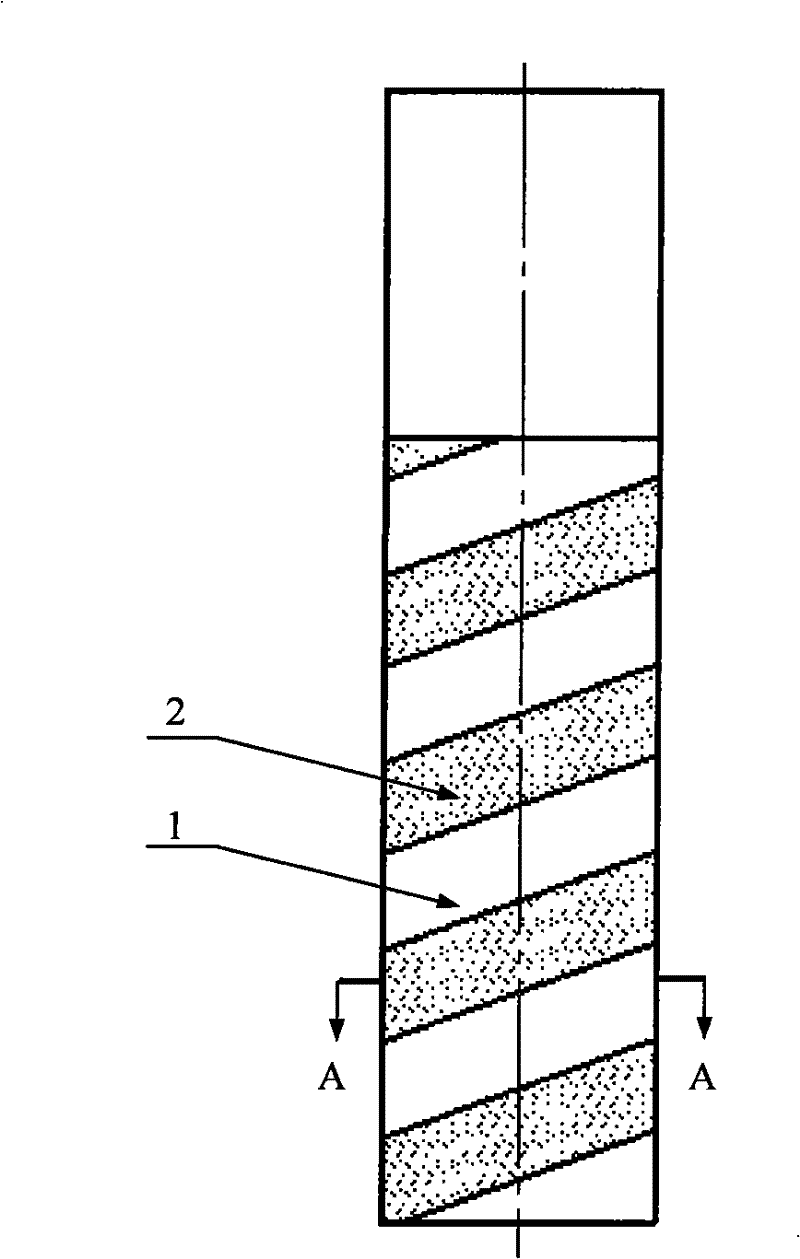

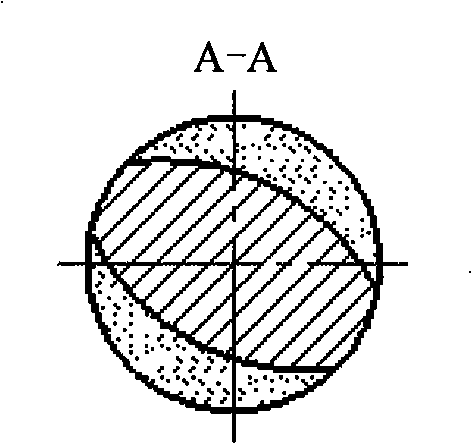

Spiral grinding wheel with composite material fiber micro blade

The invention discloses a spiral grinding wheel with a composite material fiber micro blade. The spiral grinding wheel comprises fiber micro blades, grinding belts, a thin-strip-shaped metal sheet, a blade grinding layer and a grinding wheel base body, each fiber micro blade has a zero anterior angle through blade grinding, the grinding belts are fixedly bonded on the thin-strip-shaped metal sheet by the fiber micro blades at equal intervals through electroplating orientation, and the blade grinding layer of the spiral grinding wheel is formed by a plurality of grinding belts which are bonded in a spiral groove of the grinding wheel base body and distributed in a spiral-belt-shaped manner. Zero anterior angle grinding processing is realized by utilizing the fiber micro blades, and generation of grinding heat is reduced; the grinding belts are distributed in a spiral-belt-shaped manner, so that chip containing space and chip discharging capability of the grinding wheel are increased, blockage of the grinding wheel is reduced, and grinding liquid is facilitated to enter a grinding area for lubricating and cooling. The spiral grinding wheel has the advantages that the spiral grinding wheel generates little grinding heat and is excellent in lubricating and cooling performance, a grinding blade is good in wearing-resistant performance, high in hardness, good in tenacity, reproducible and repairable and the like, and the spiral grinding wheel is suitable for high-efficiency precise processing of difficult-to-process materials such as hard and brittle materials.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Device and method for polishing special-shaped metal tube inner wall

ActiveCN110480425AHigh polishing precisionNo tool wearEdge grinding machinesPolishing machinesMetalAbrasive

The invention discloses a device and method for polishing a special-shaped metal tube inner wall, and belongs to the technical field of precision tube inner wall polishing and grinding machining. Themethod comprises the steps that magnetorheological fluid is injected into a gap formed by a special-shaped metal tube and a mandrel; through applying magnetic fields with different intensities to different areas inside the special-shaped metal tube, a polishing film is formed by the magnetorheological fluid inside the special-shaped metal tube on the inner wall of the special-shaped metal tube under the action of the magnetic fields; and through controlling the magnetorheological fluid to move in the special-shaped metal tube, the omni-directional high-efficiency polishing treatment on the inner wall of the special-shaped metal tube is carried out by the abrasive in the magnetorheological fluid. Compared with a conventional polishing method, the method has the advantages that the machiningefficiency is high, the use amount of the magnetorheological fluid is small, the machining purposes of different roughness degrees of different parts of the inner wall of the special-shaped metal tube can be realized, the personalized requirements are met, the polishing precision is high, the phenomenon of tool wear and blockage is avoided, the removal rate is high, and no sub-surface damage is introduced.

Owner:SHAANXI UNIV OF SCI & TECH

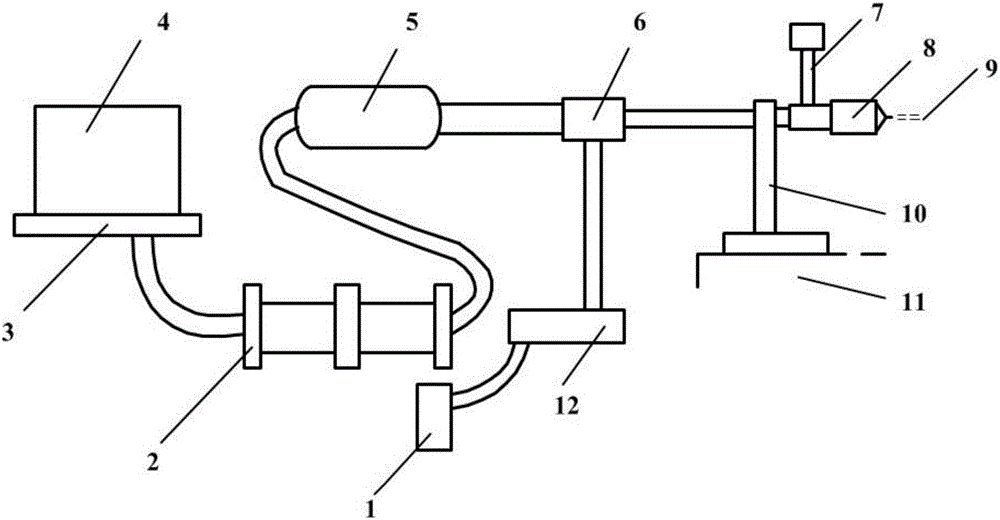

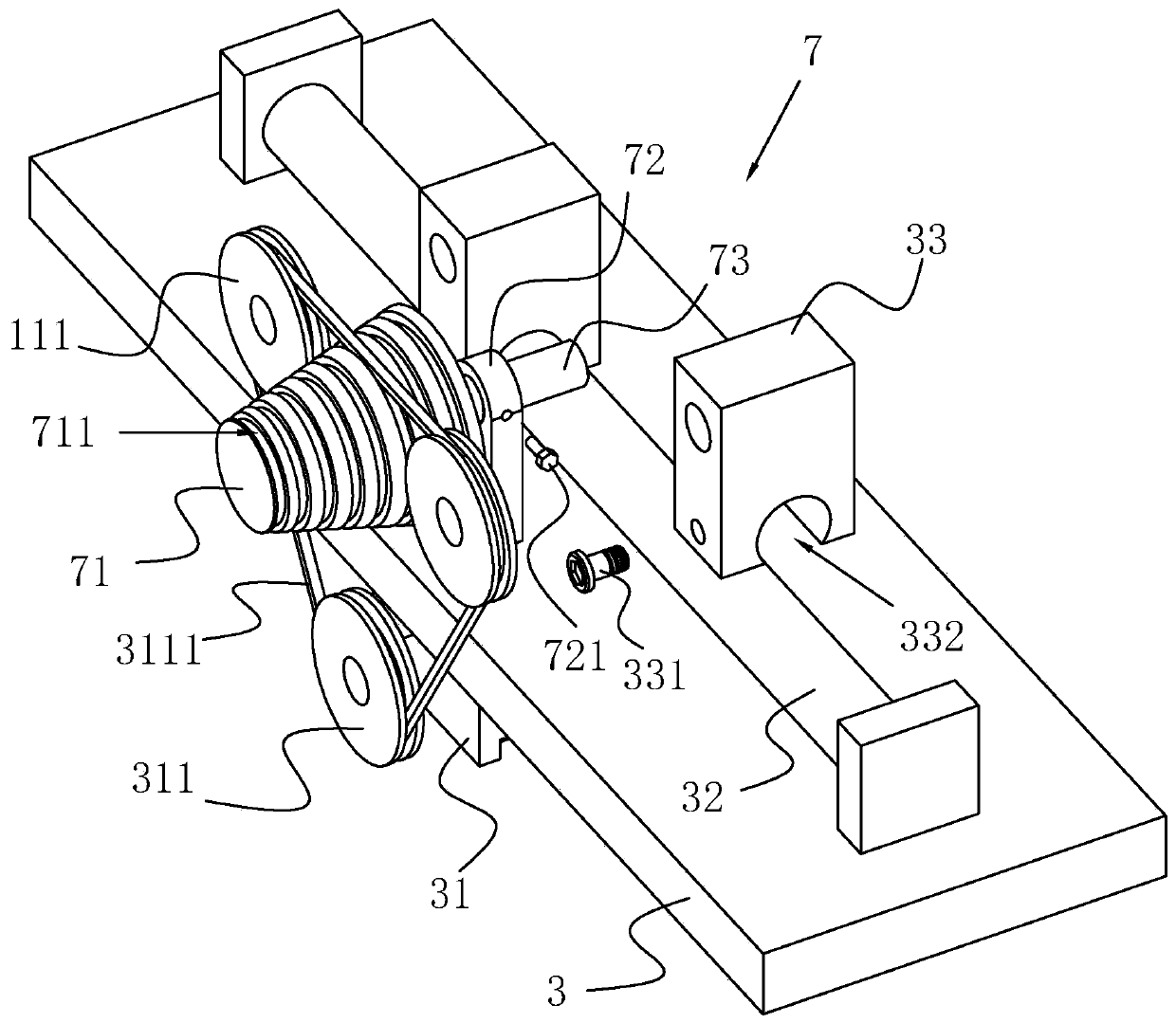

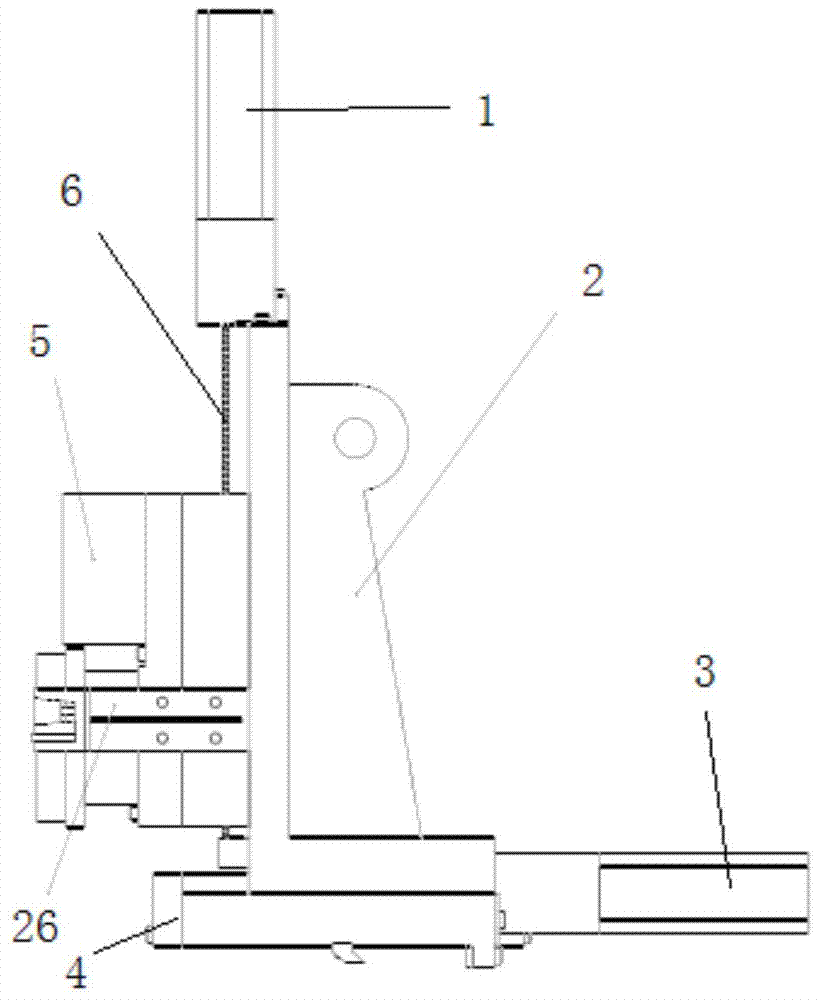

Rotary ultrasonic grinding machine tool and application

InactiveCN113118882AExtend your lifeImprove processing qualityGrinding drivesGrinding work supportsCouplingEngineering

The invention belongs to the technical field of hard and brittle material ultrasonic precision machining, and particularly relates to a rotary ultrasonic grinding machine tool. The rotary ultrasonic grinding machine tool comprises a rotary ultrasonic grinding main shaft, an ultrasonic wave power transmission device, a main shaft clamping and lifting device and a part clamping and feeding device. The rotary ultrasonic grinding main shaft comprises a grinding wheel, wherein the grinding wheel is installed at the output end of an amplitude-change pole, an amplitude-change pole flange is arranged in the middle of the amplitude-change pole and connected with the end face of a hollow sleeve, and a large-end mandrel of the amplitude-change pole stretches into the hollow sleeve and is connected with the output end face of an energy converter. A copper sheet is arranged on the energy converter, a positioning flange is arranged in the middle of the outer surface of the energy converter, the energy converter is connected with the inner surface of the hollow sleeve in a transition fit mode through the positioning flange, the hollow sleeve is installed in a support, and the tail end of the hollow sleeve is connected with an electric main shaft through a coupling. According to the rotary ultrasonic grinding machine tool, the grinding main shaft is directly driven by the electric main shaft, so that the grinding efficiency is improved, the grinding force and the grinding heat are reduced, and the part machining quality is improved.

Owner:ZHONGBEI UNIV +1

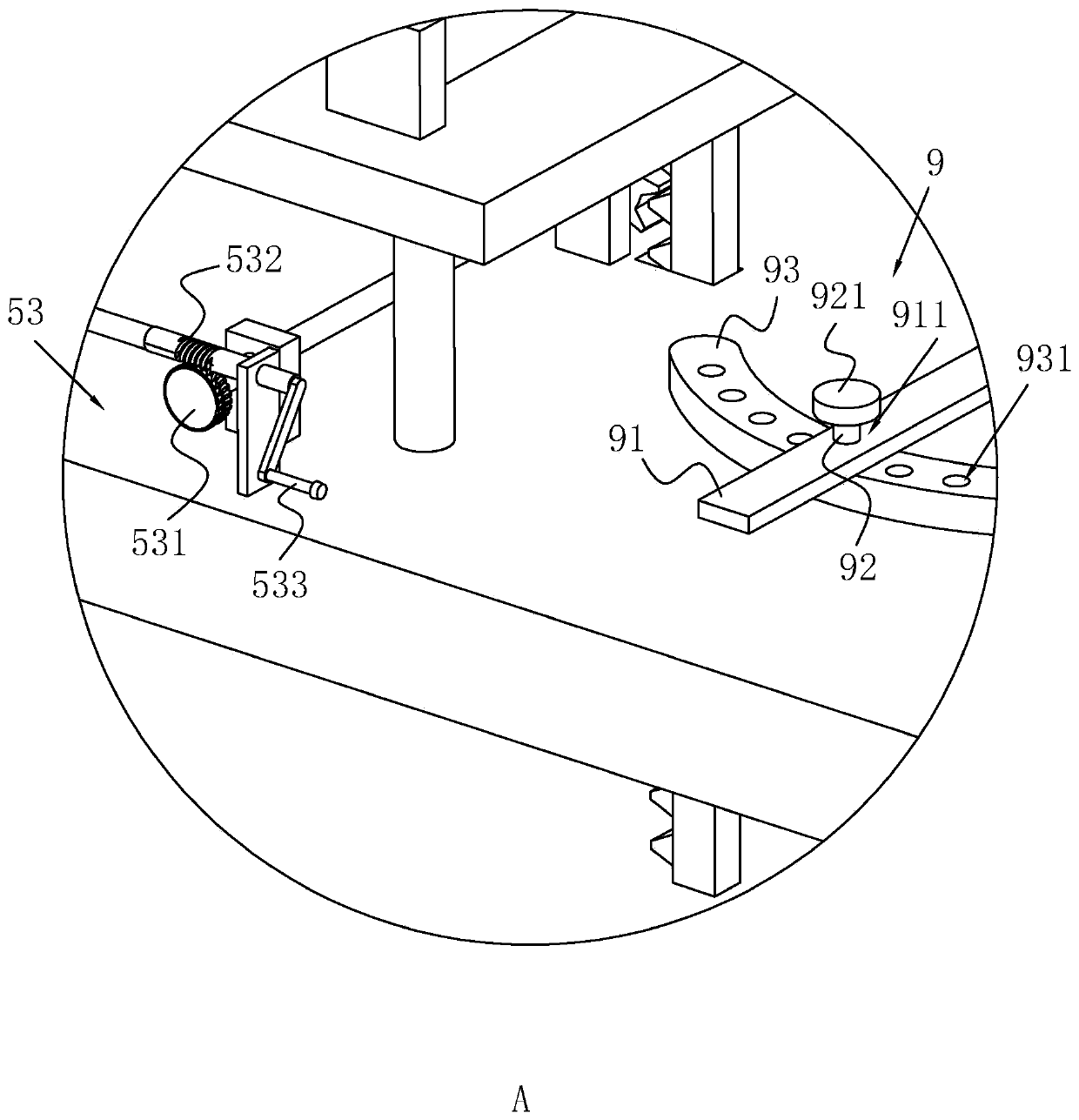

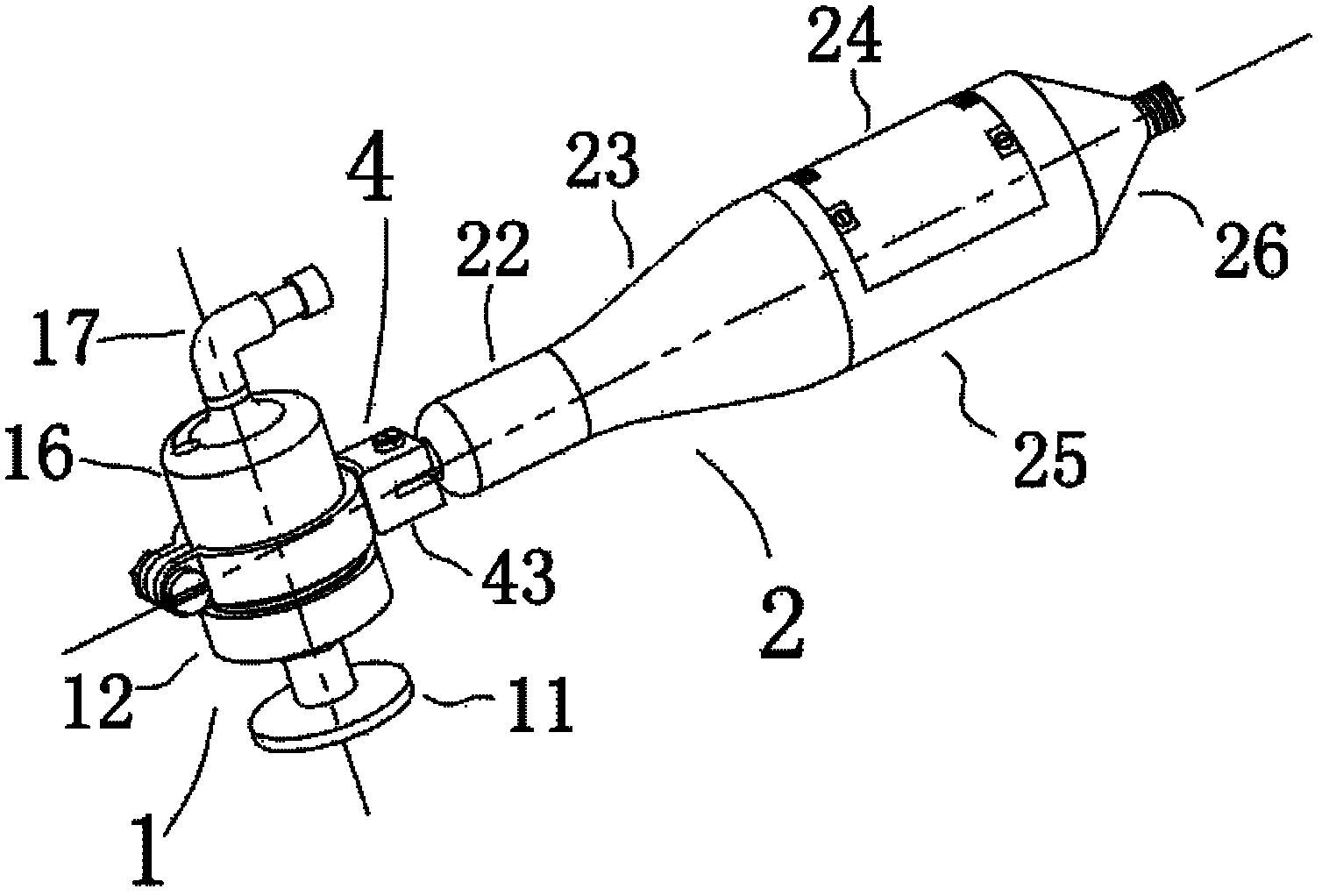

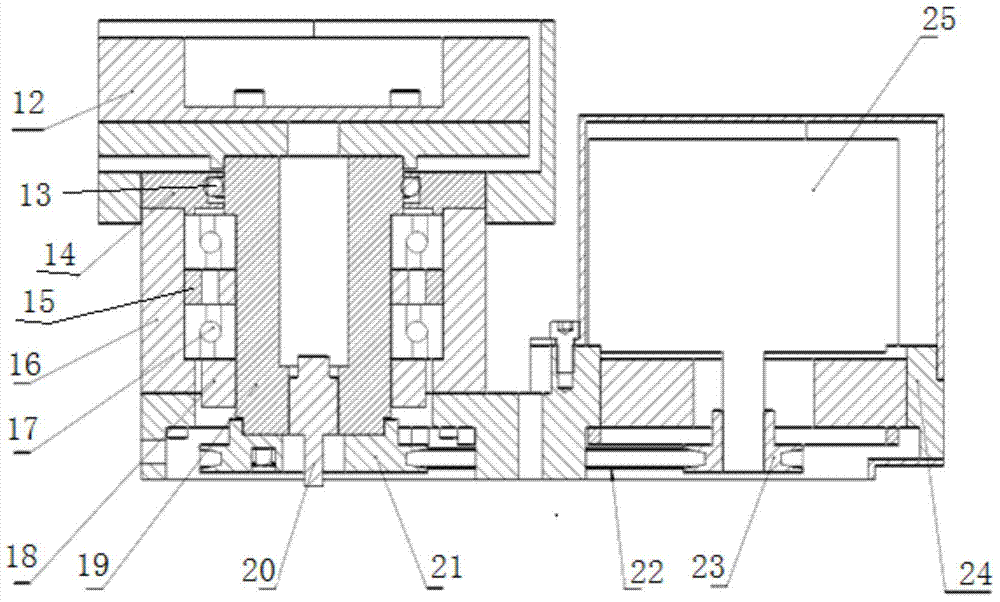

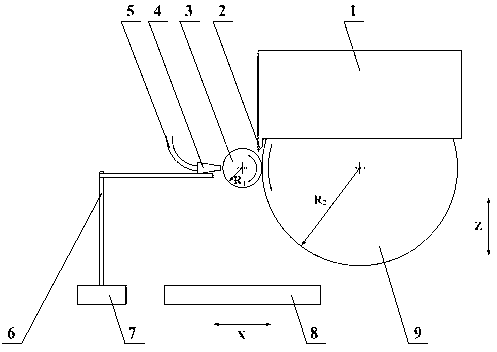

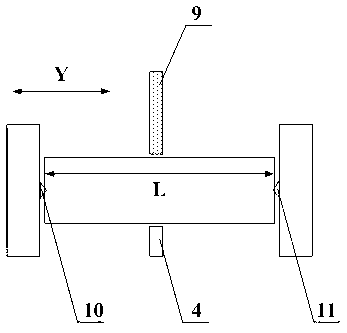

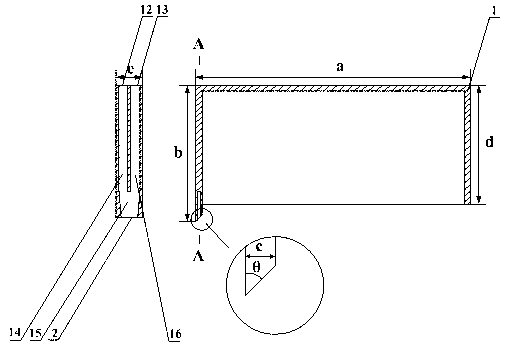

Method and device for composite vibration grinding based on ultrasonic high frequency and pneumatic low frequency

The invention relates to a method and device for composite vibration grinding based on an ultrasonic high frequency and a pneumatic low frequency. The device consists of an ultrasonic high-frequency vibration subassembly, a low-frequency vibration outer shell subassembly, a low-frequency vibration excitation subassembly and a connecting subassembly. The ultrasonic high-frequency vibration subassembly is arranged on a main shaft of the low-frequency vibration excitation subassembly through the connecting subassembly; and the low-frequency vibration excitation subassembly is connected with bearing mounting grooves of the low- frequency vibration outer shell subassembly through supporting bearings of the low-frequency vibration excitation subassembly, wherein the low-frequency vibration excitation subassembly is arranged in a shell of the low-frequency vibration outer shell subassembly. The grinding method comprises eight steps. According to the method and the device disclosed by the invention, the composite vibration grinding of the ultrasonic vibration and low-frequency vibration of coating materials is realized, the cost is low, the efficiency is high, the practicability is high, and the composite vibration is stable and reliable. The invention has a better practical value and a broad application prospect in the technical fields of coating material cutting machining process and coating machining equipment components.

Owner:BEIHANG UNIV

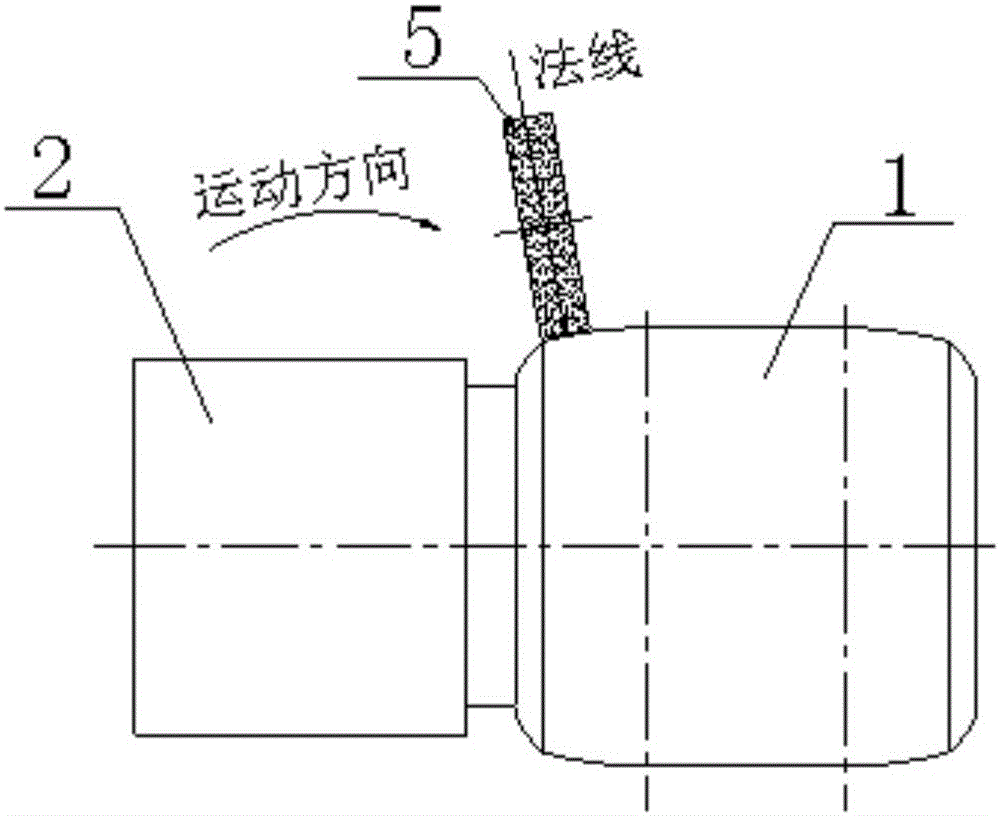

Machining method for aviation high-precision bearing roller

InactiveCN106181678AEasy to tilt and swivelImprove balanceGrinding drivesGrinding machinesAviationStress conditions

The invention discloses a method for processing aviation high-precision bearing rollers, which is characterized in that a clamping position is set at the end of the roller, a swinging part is set on the workbench, the roller is installed on the swinging part through the clamping position, and the swinging part The rotation makes the roller axially inclined, and the rotation direction of the grinding wheel always coincides with the normal direction at the grinding point of the sinking contour of the roller, ensuring that the grinding wheel and the roller are always in point contact. In the method for processing aviation high-precision bearing rollers described in the present invention, a clamping position is set at the end of the roller, which is convenient for clamping the roller to make it tilt and rotate, and the grinding wheel and the surface of the roller are ground by point contact, and the grinding force And the grinding heat is small, the force of the grinding wheel is consistent, the deformation is consistent, the machining accuracy is effectively improved, and the error distribution on the surface of the roller is evenly distributed to ensure that the roller has a good balance when it rotates at a high speed.

Owner:成都芬尼克兹机电设备有限公司

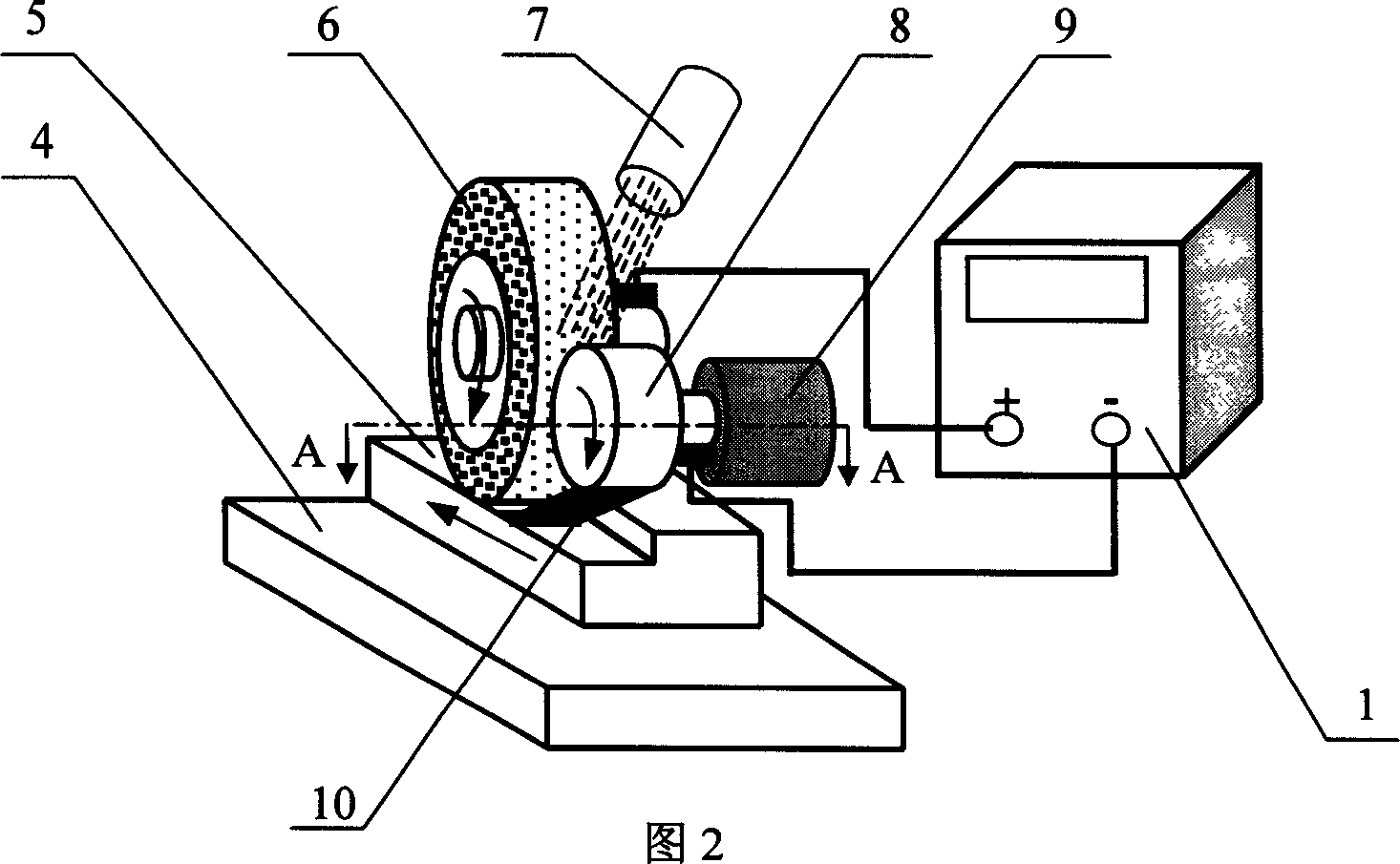

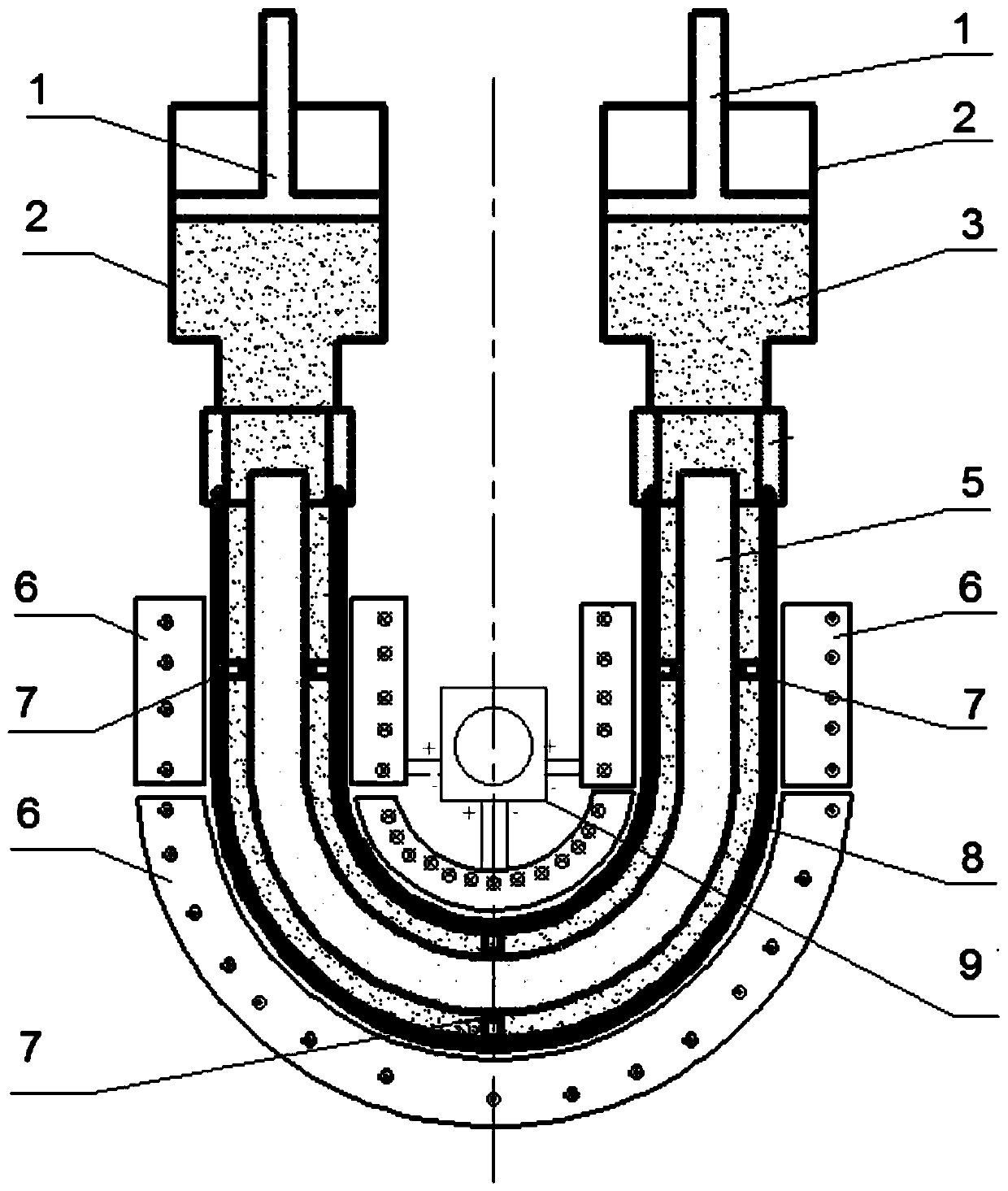

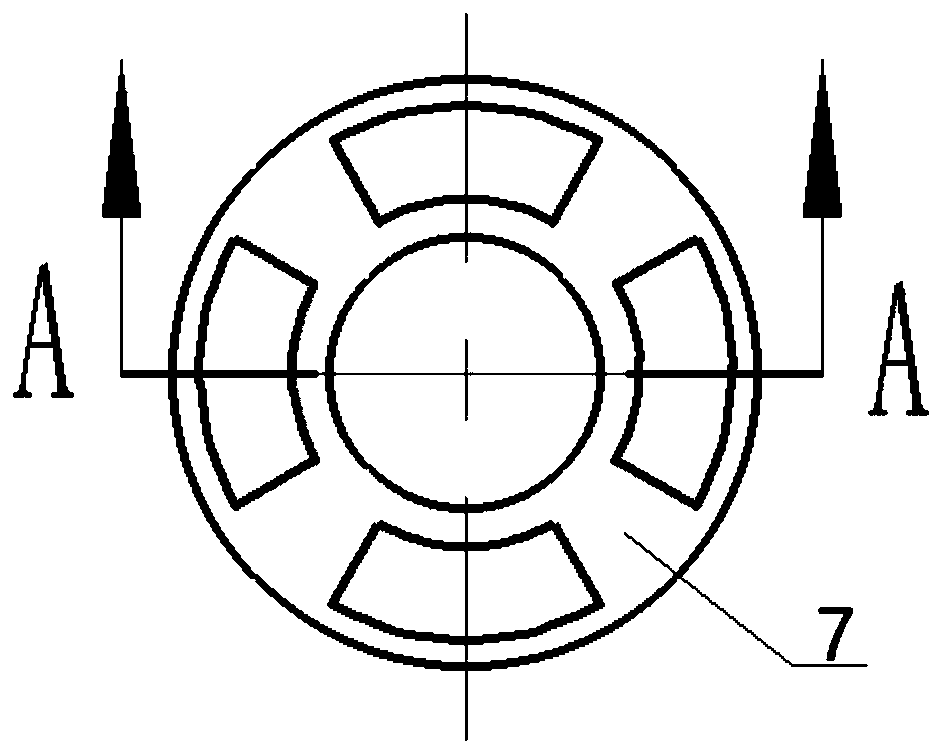

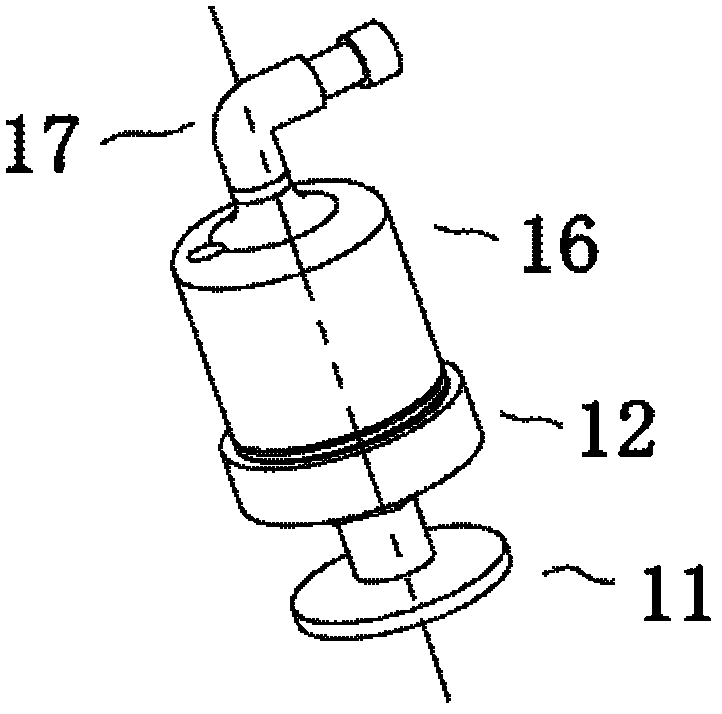

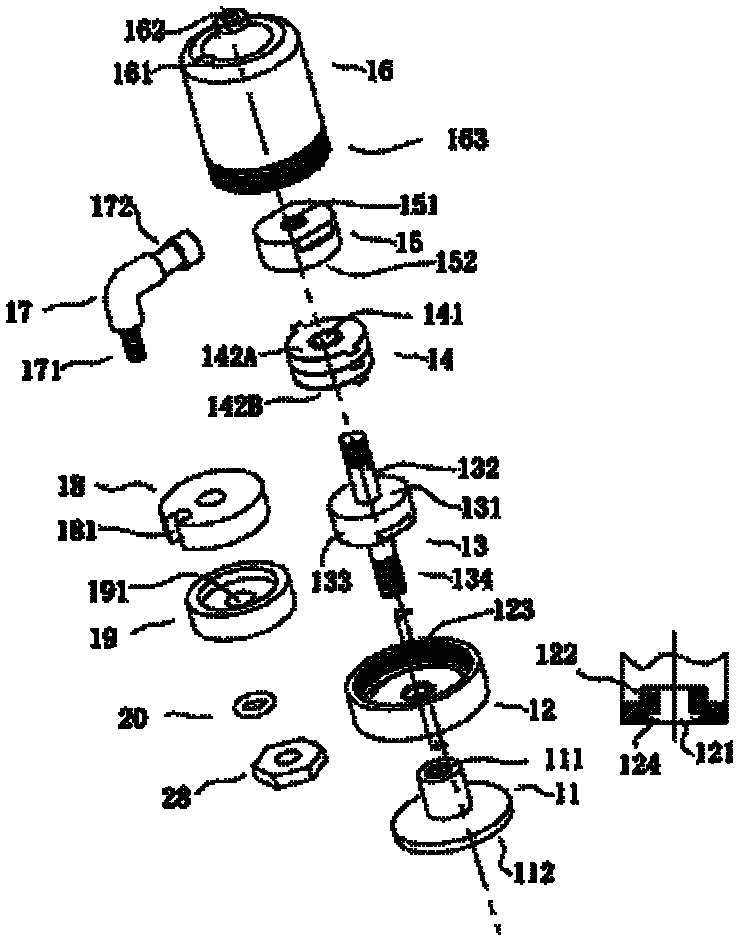

Cathode device suitable for high speed on line electrolysis grinding

InactiveCN1785597AImprove grinding surface qualitySmall grinding forceAbrasive surface conditioning devicesElectrolysisGrinding wheel

A cathode device for the in-line high-speed electrolytic grinding for sharpening has a cathode cavity with terminal and insulating cover on its top, electrolyte feeding inlet, and the lower open arc part which is composed of 3 strip holes, front and back baffle plates, and a flexible shielding plate with an open slot. It can generate a continuous and compact oxidized film on the surface of abrasive disc.

Owner:HUNAN UNIV

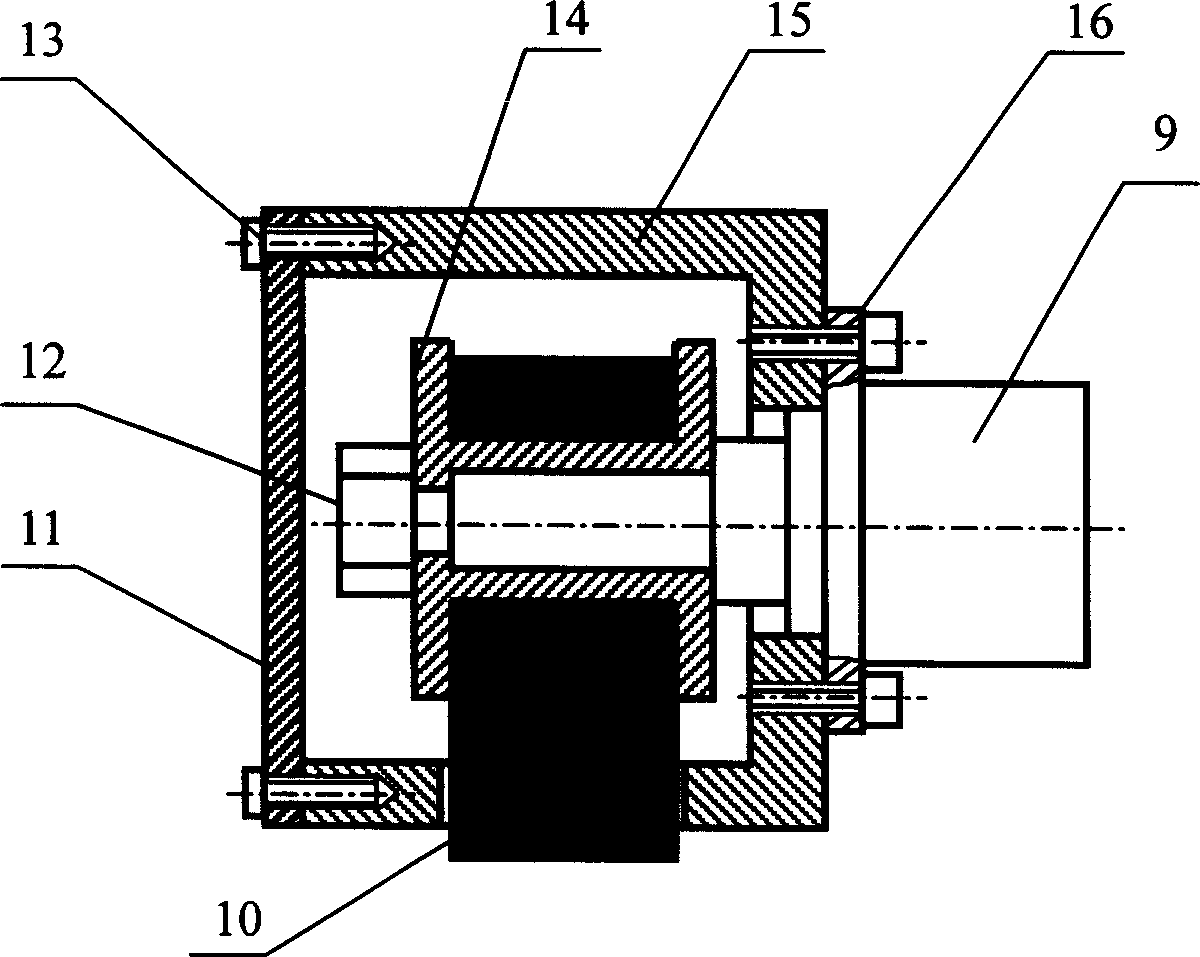

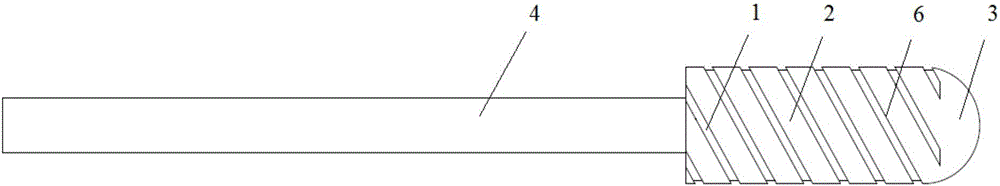

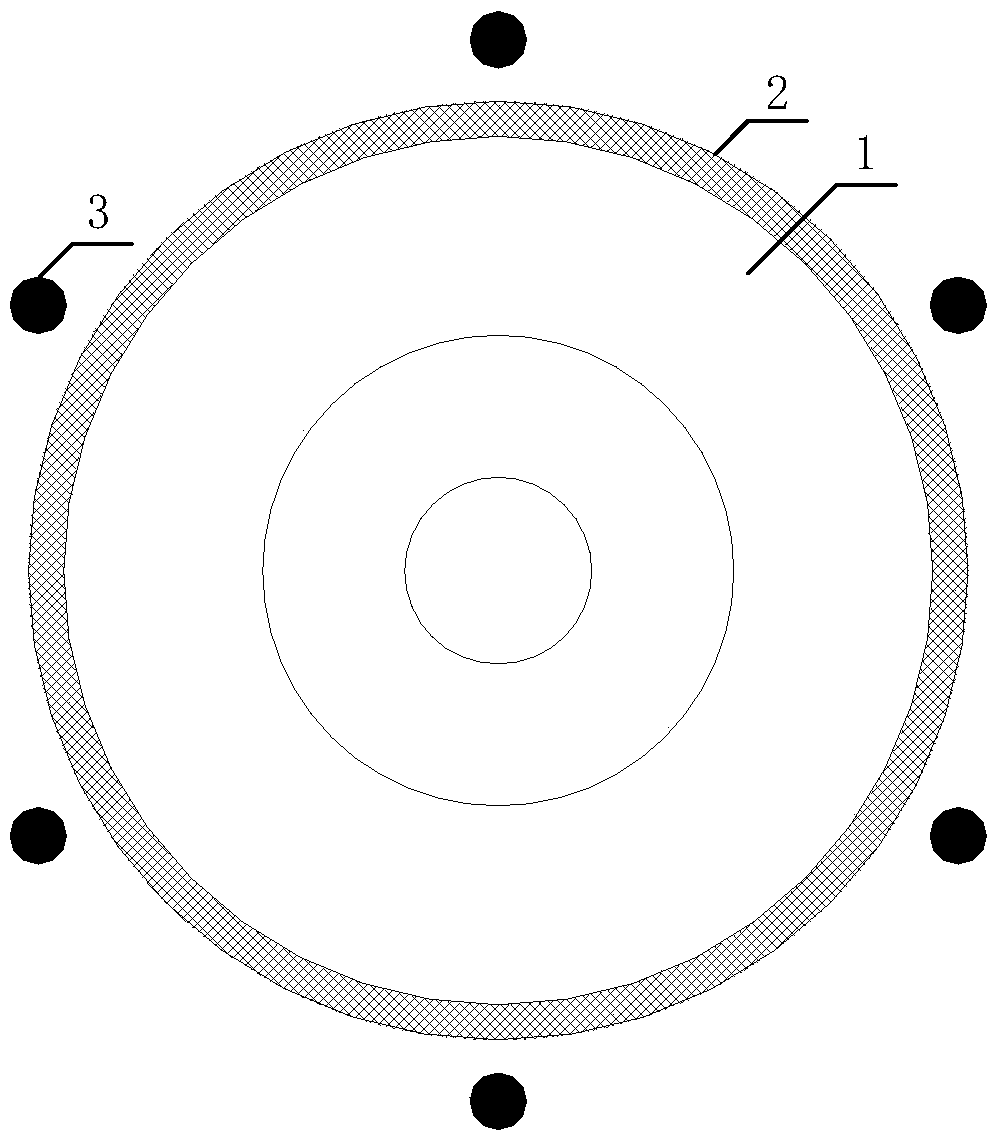

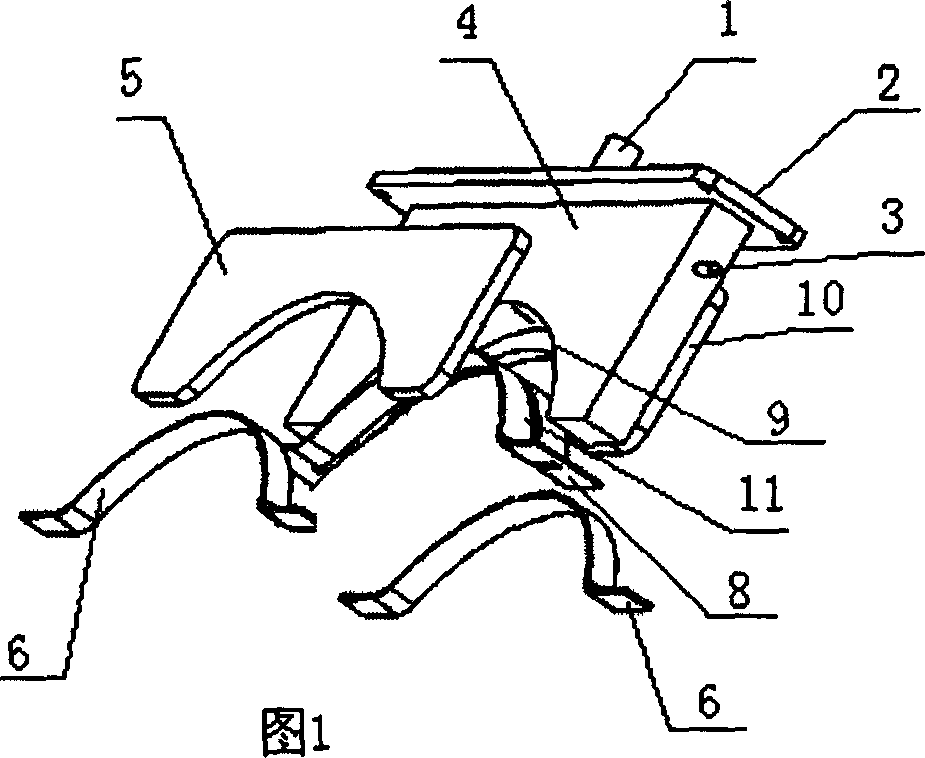

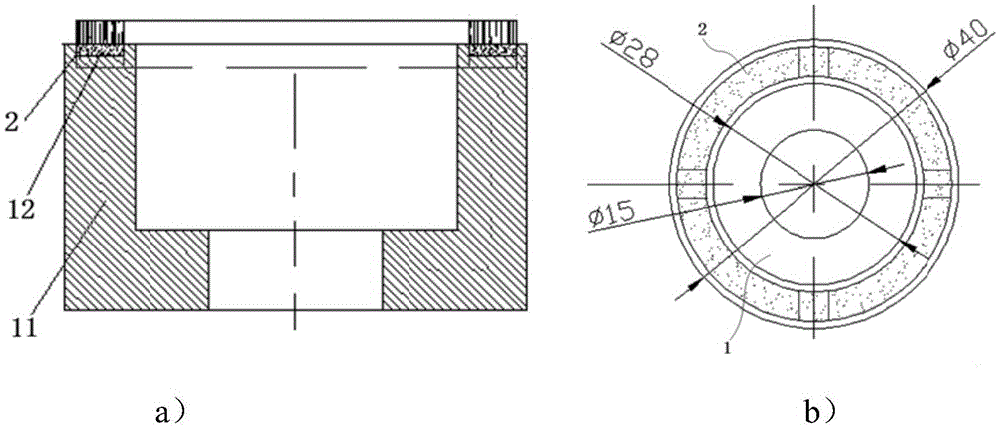

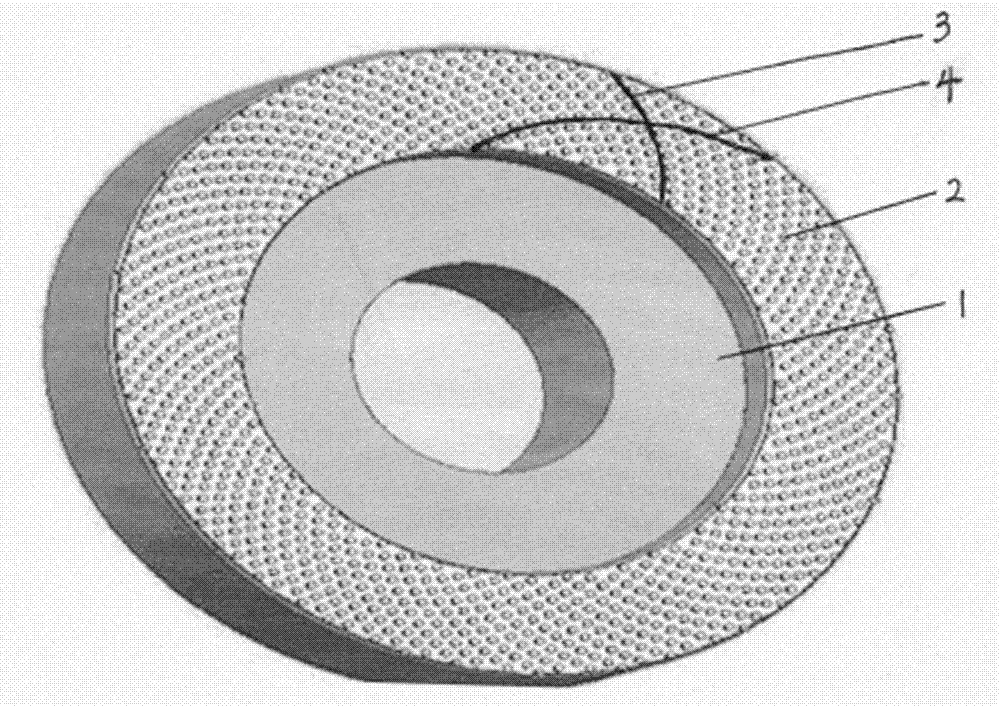

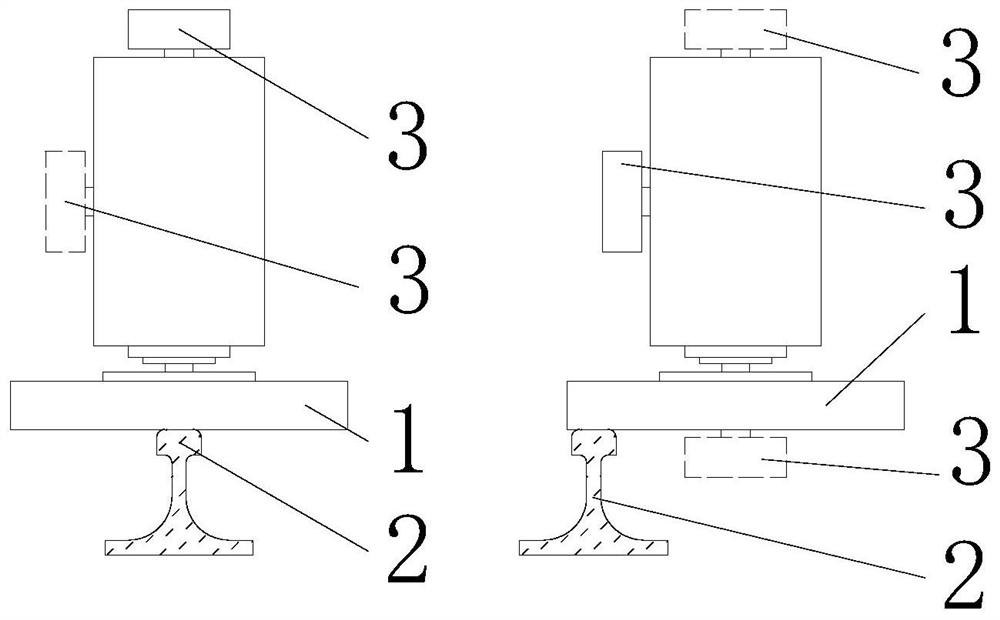

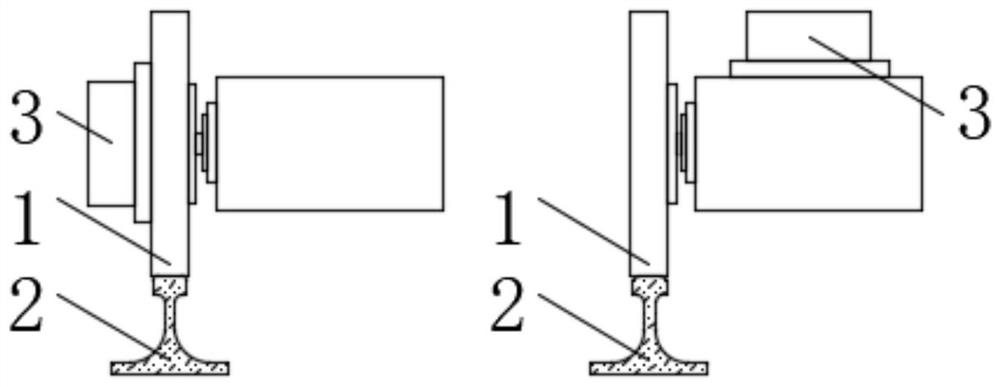

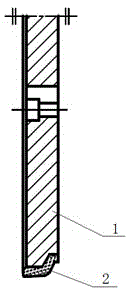

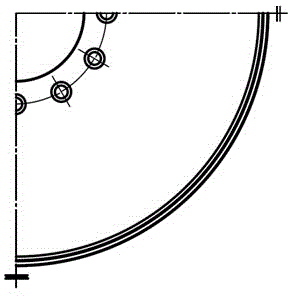

Electric spark milling and mechanical grinding composite machining tool electrode

ActiveCN101497142BImprove stabilityAvoid stable arcingElectrical-based machining electrodesEngineeringPulse power supply

The invention relates to an electric spark milling and mechanical grinding combined machining tool electrode, and belongs to the field of non conventional machining. The tool electrode consists of two parts, namely a metal tool electrode 1 and a grinding body 2, wherein the metal tool electrode 1 is cylindrical, and the periphery of the metal tool electrode 1 is provided with a spiral groove; thegrinding body 2 is an insulated sand-containing rubbing block; and the grinding body 2 is filled and consolidated in the spiral groove of the metal tool electrode 1, and the diameter of the grinding body 2 is the same as that of the metal tool electrode 1. When the tool electrode performs processing, the tool electrode of the invention and a workpiece are connected with two poles of a pulse powersource, and the tool electrode realizes electric spark milling and mechanical grinding combined machining for the workpiece through electric spark milling of the metal tool electrode 1 and the mechanical grinding of the grinding body 2. The electric spark milling and mechanical grinding combined machining tool electrode has the advantages of simple structure, high processing efficiency and precision, low cost, and the like.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

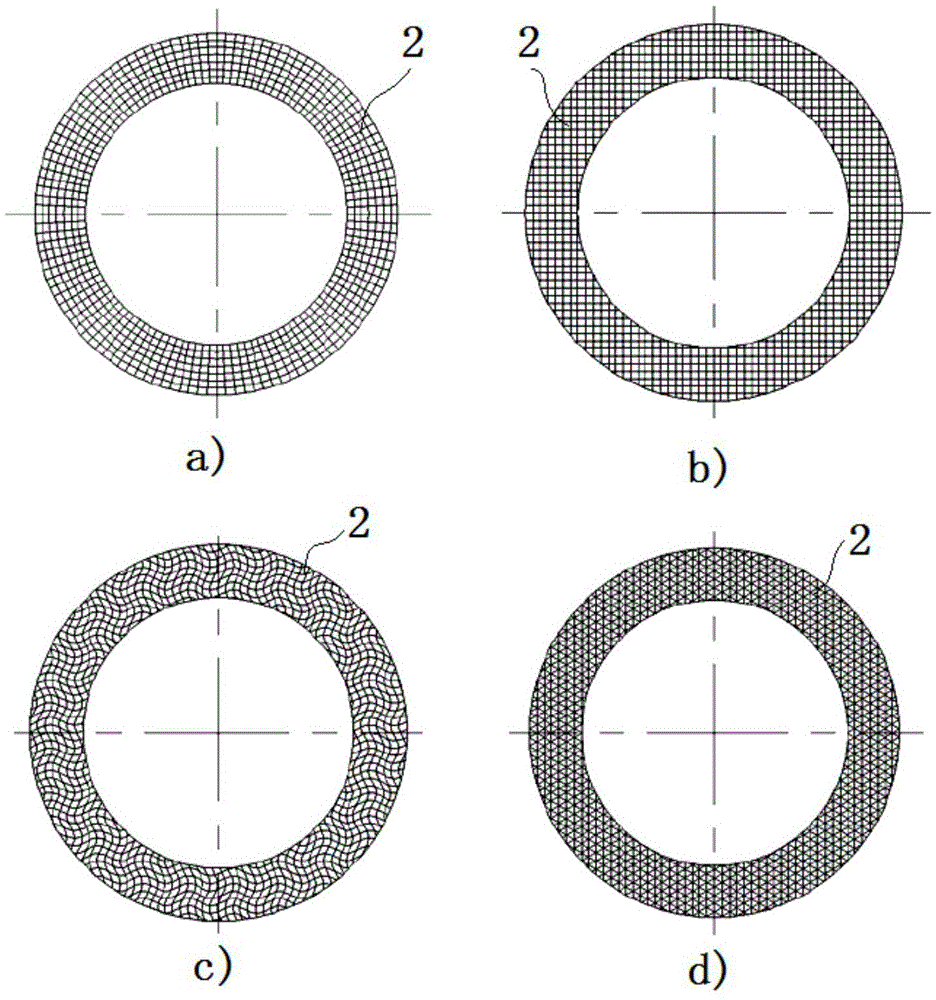

Ultra-hard diamond grinding wheel free of binding agent and manufacturing method of ultra-hard diamond grinding wheel

ActiveCN105538173AHigh strengthEvenly distributedBonded abrasive wheelsGrinding devicesUltimate tensile strengthChemical vapors

The invention discloses an ultra-hard diamond grinding wheel free of a binding agent and manufacturing method of the ultra-hard diamond grinding wheel. The ultra-hard diamond grinding wheel free of the binding agent comprises a metal base body and a grinding material layer fixed to the metal base body. The grinding material layer is a polycrystalline chemical vapor deposited (CVD) diamond piece free of the binding agent. Grinding particles and chip grooves are machined in the working surface of the grinding material layer. In this way, the ultra-hard grinding wheel free of the binding agent is manufactured by machining the grinding particles and the chip grooves manually, and the strength of the grinding wheel is improved. The grinding particles and chip grooves of the grinding wheel are evenly distributed and are highly consistent, and thus the grinding force can be effectively reduced and the grinding temperature is decreased during grinding.

Owner:HUNAN UNIV

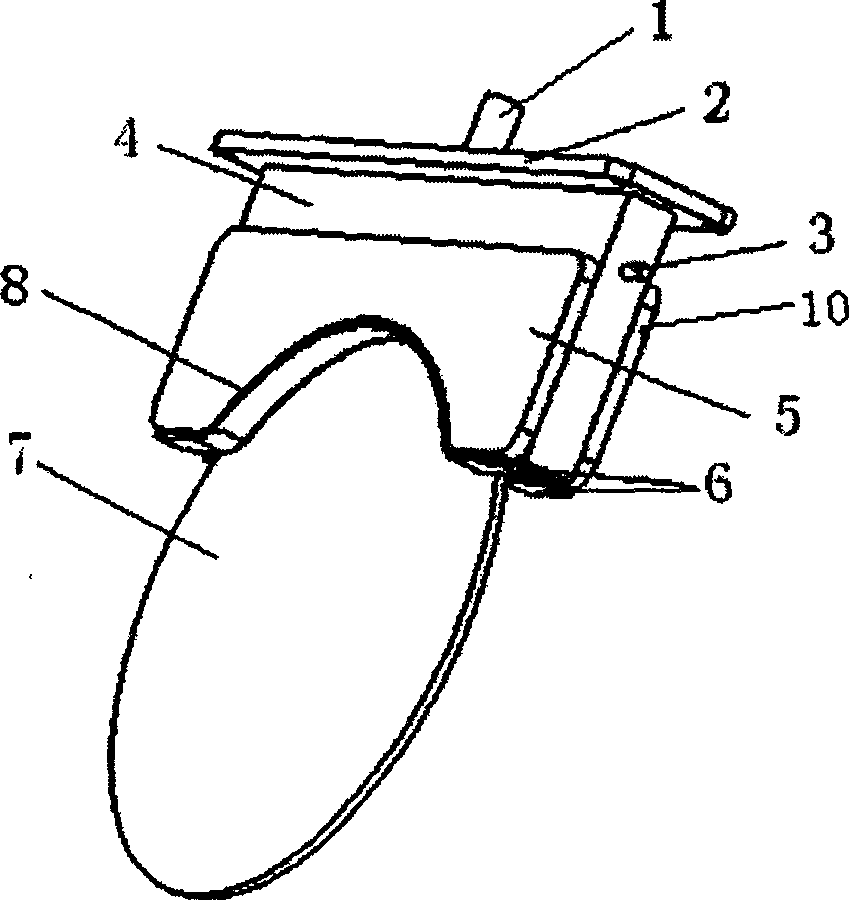

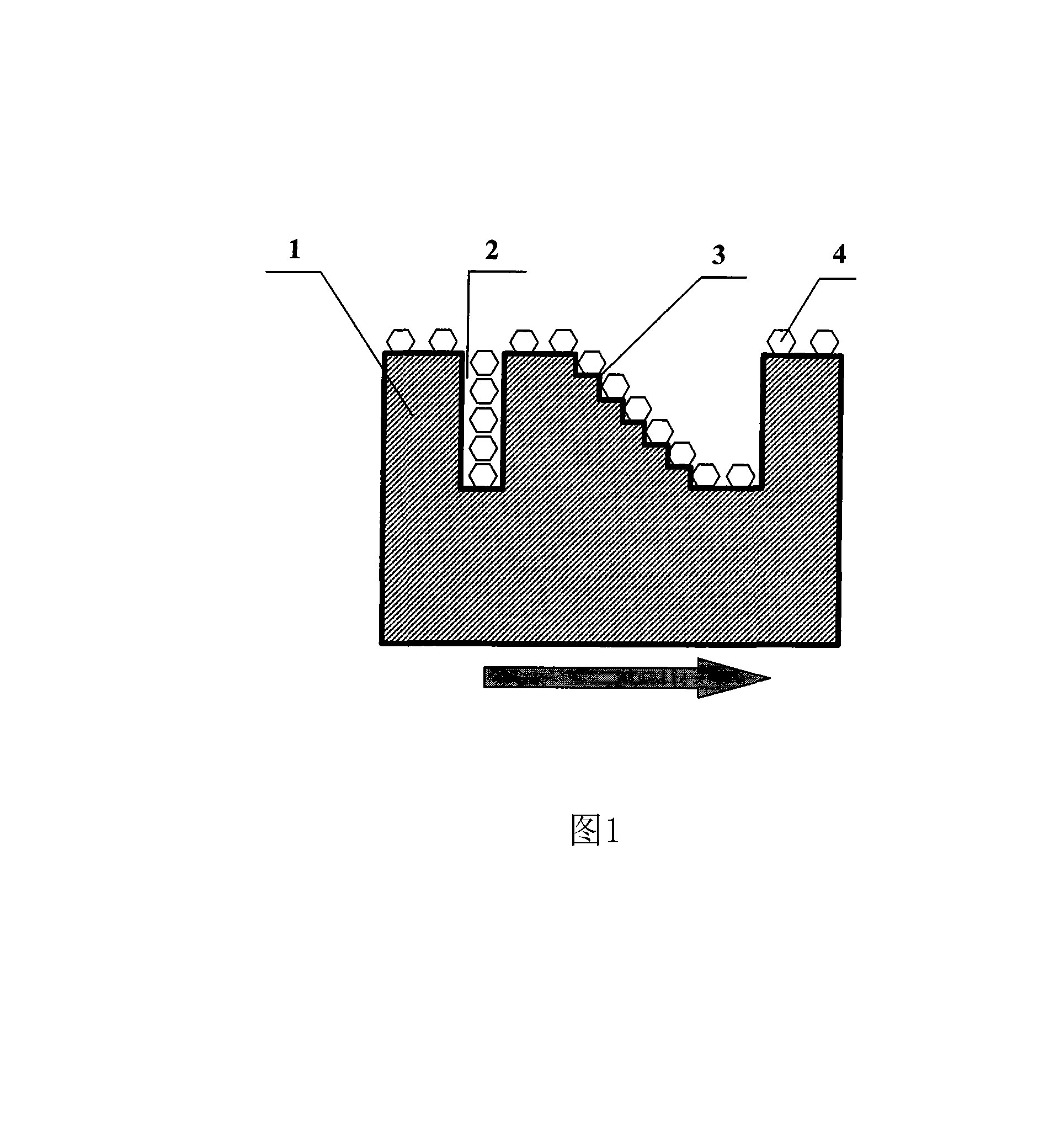

Diamond soldering appliance

InactiveCN101195257ASolution to short lifeMeet flowBonded abrasive wheelsStone-like material working toolsMaterials processingSoldering

The invention relates to the manufacturing field of hard brittle materials, in particular to a diamond brazing tool which is in the combining structure of joint and staircase-like steps. The invention comprises a bit, a saw blade and a grinding wheel, and is mainly used for the drilling, cutting, grinding and polishing of stone materials, concrete, glass, ceramics, crystal, hard alloy and the like materials. The matrix structure of the working area of the diamond brazing bit, the saw blade and the grinding wheel is designed to a combining structure of joint and staircase-like steps, diamond abrasive is brazed on the step surface and in the joint, and the diamond abrasive is put into use step by step when in the process of drilling, cutting, grinding and polishing, thereby the contact surface with the processing object is reduced, the grinding force is small and the cutting efficiency is high.

Owner:江苏华昌工具制造有限公司

Can conveying device

The invention provides a can conveying device which is applicable to conveying various ring-pull cans between a filling machine and a capping machine. The can conveying device comprises a can conveying table support and a can conveying guide rail. A conveying chain guide rail with a conveying chain is arranged in the can conveying table support. A conveying chain is connected with a shifting pawl, a ring-pull can is driven by the shifting pawl to move along the upper surface of the can conveying guide rail, can protection plates are arranged on the two sides of the ring-pull can, and the can conveying guide rail comprises a supporting plate and a plurality of round steel guide rails fixed to the supporting plate. According to the can conveying device, the round steel guide rails replace traditional nylon plates or stainless steel plates, the contact face between the can bottom and the guide rails is small, the friction force is small, the phenomenon that materials are spilled is reduced, the round steel guide rails rotating by an angle can be used again after one sides of the round steel guide rails are abraded, and the service life is long; the height and interval of the round steel guide rails can be adjusted, and requirement for filling and conveying different ring-pull cans can be met, and applicability is good.

Owner:南京轻机包装机械有限公司

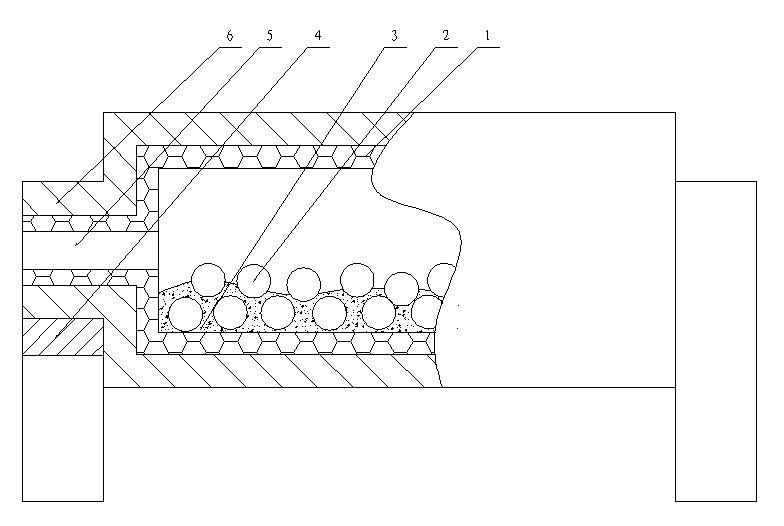

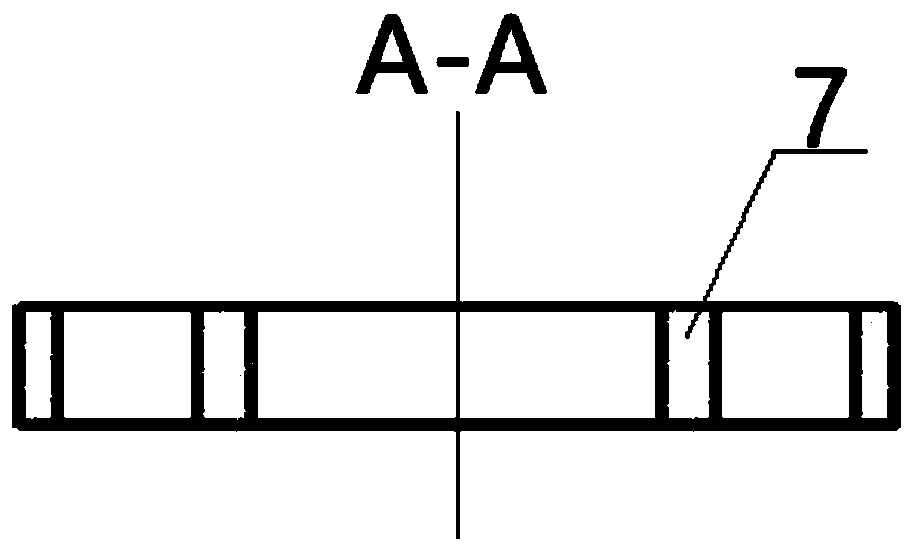

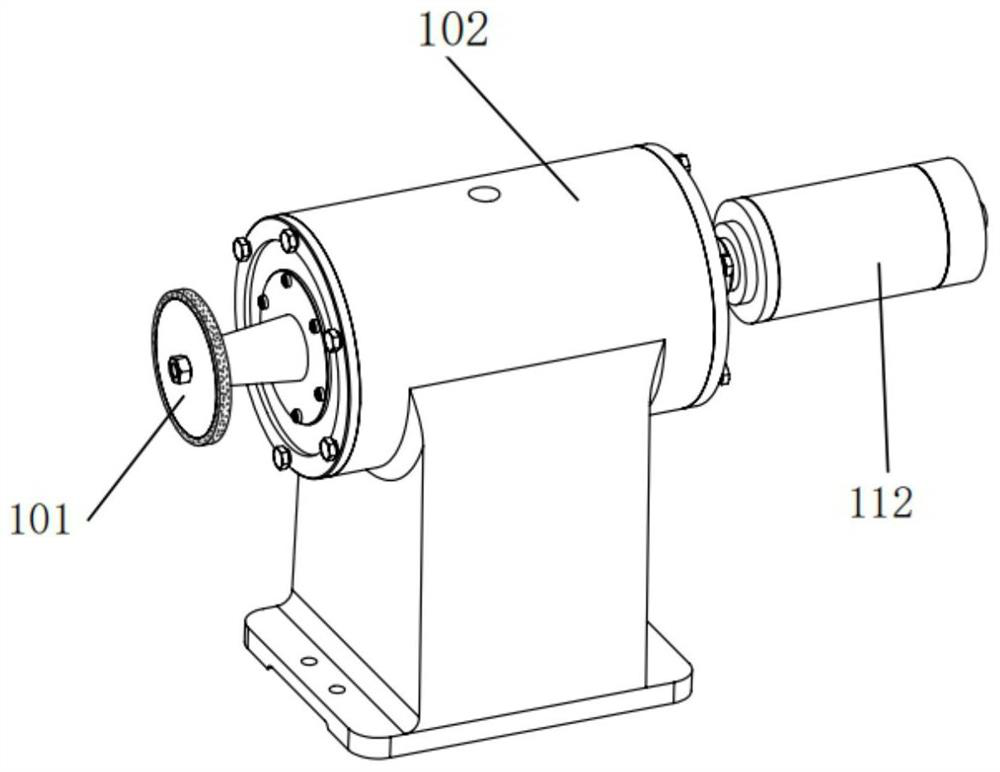

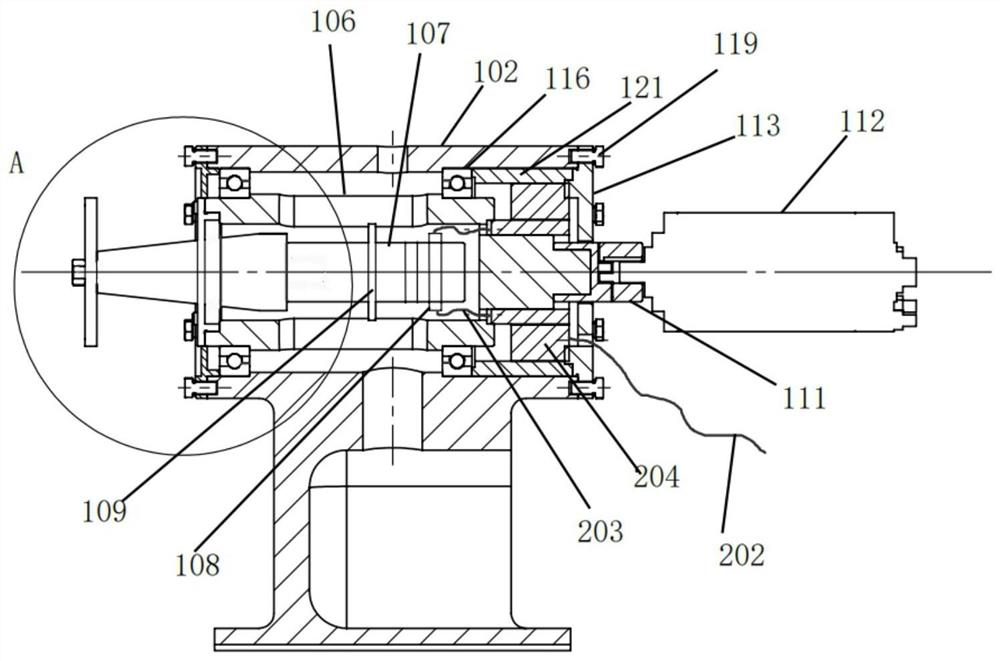

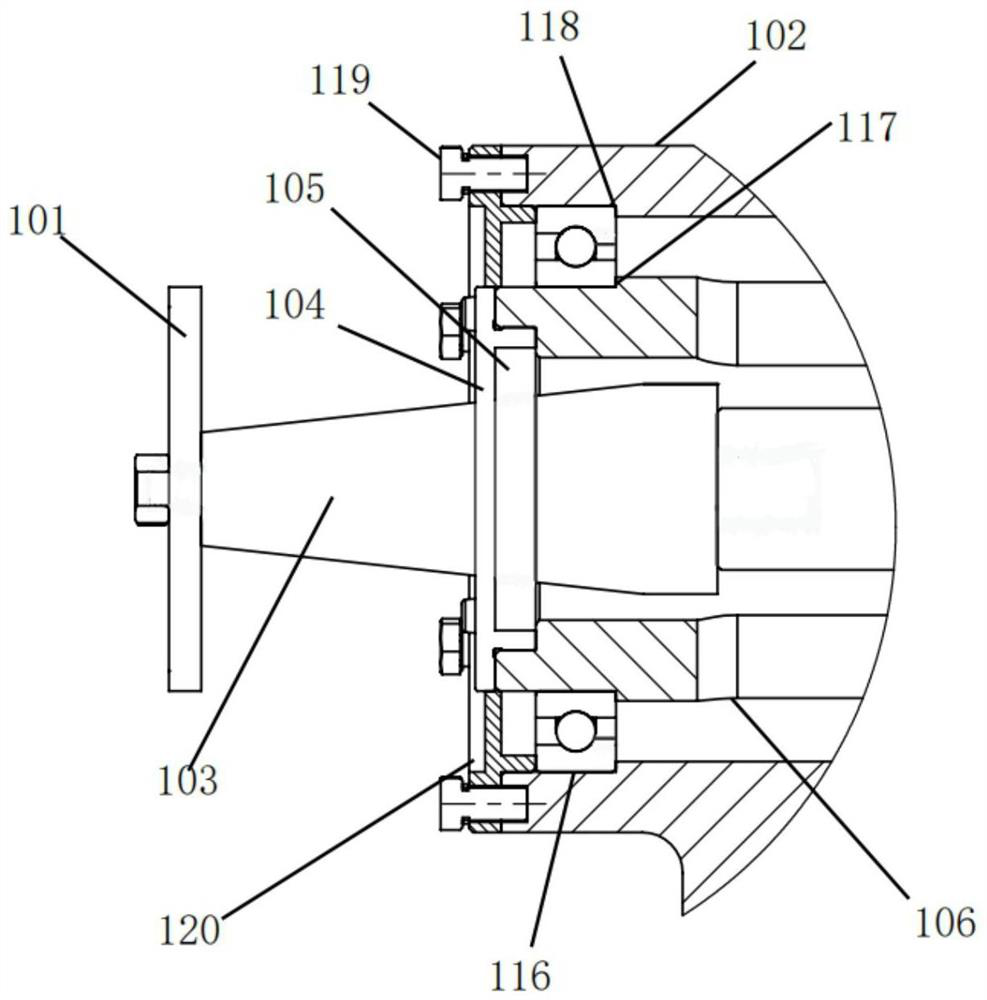

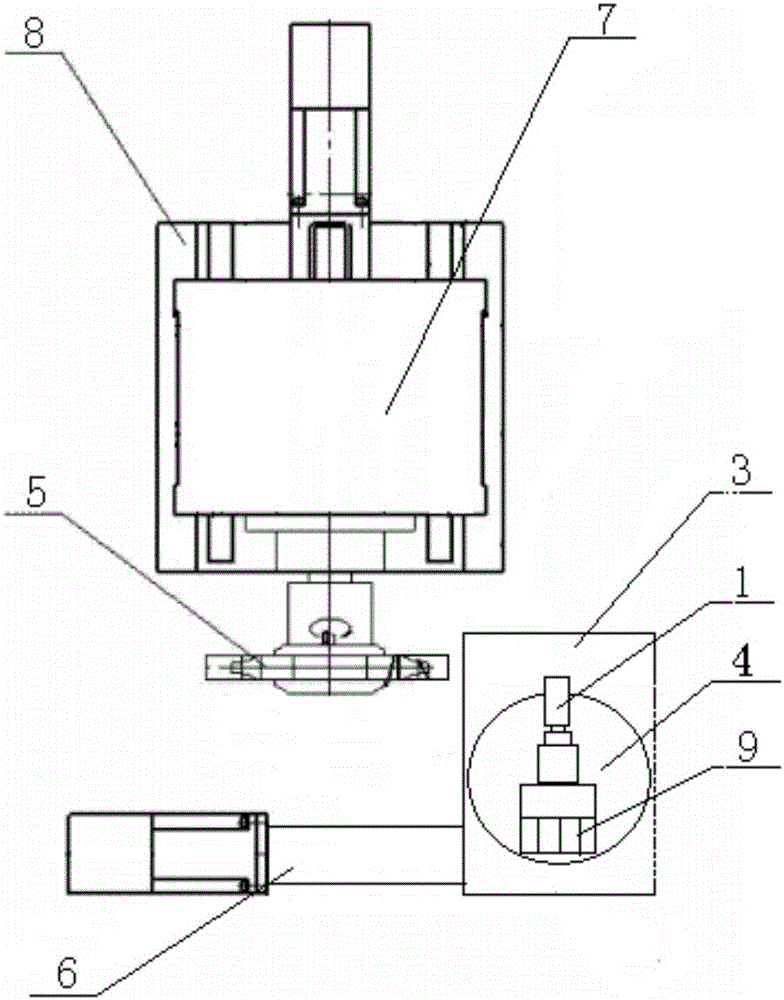

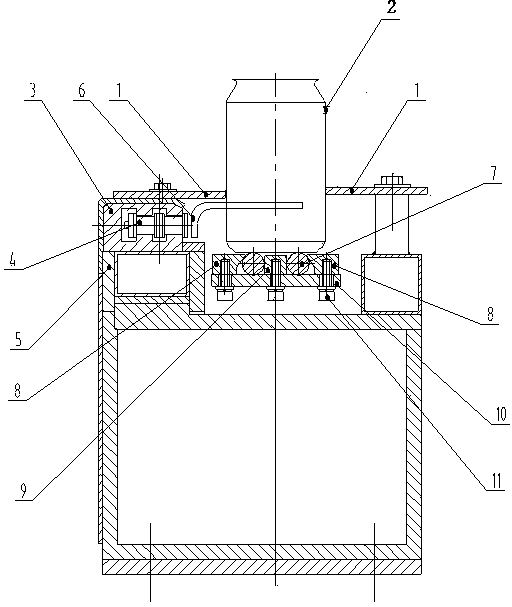

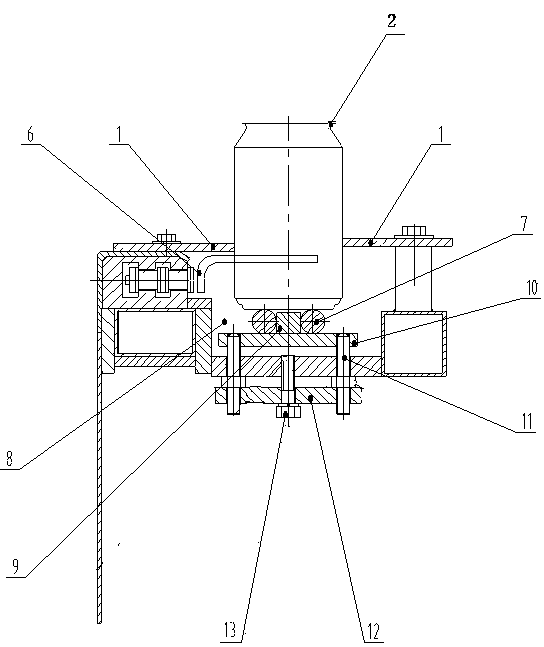

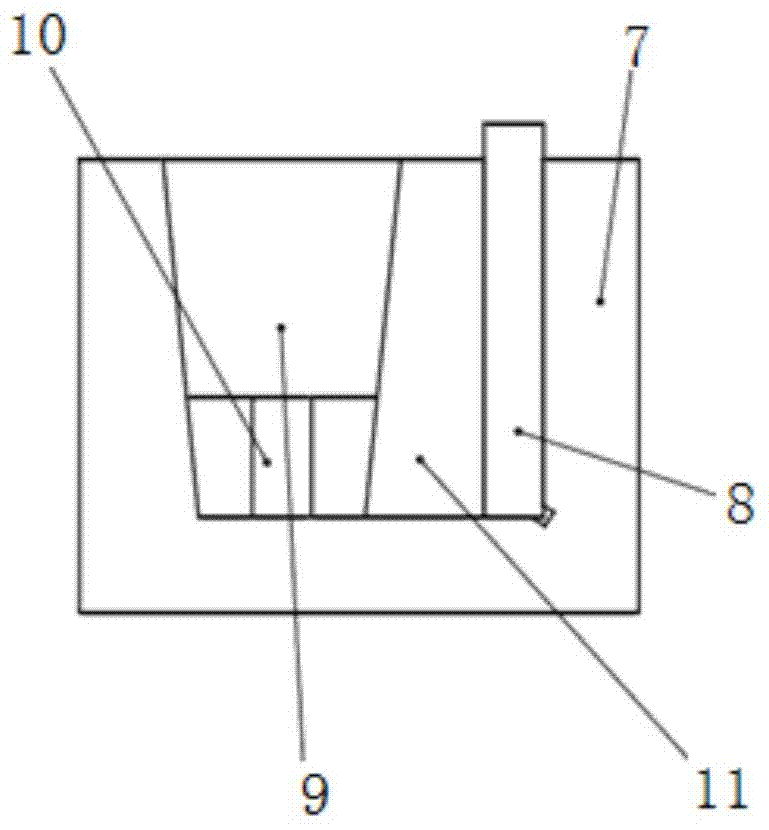

Cup grinding wheel-electric spark composite trimmer for superhard abrasive grinding wheel

ActiveCN104842274AImprove trimming abilitySmall grinding forceAbrasive surface conditioning devicesEngineeringCopper electrode

The invention discloses a cup grinding wheel-electric spark composite trimmer for a superhard abrasive grinding wheel. The cup grinding wheel-electric spark composite trimmer comprises the grinding wheel, a hollow spindle, a conducting slip ring and a motor. The grinding wheel is connected with the hollow spindle, and the conducting slip ring is fixed into the hollow spindle. In shaping, the grinding wheel is fixedly arranged on a fixing disc located at one end of the hollow spindle and used for shaping a target object. After shaping is completed, in sharpening, the abrasive wheel is replaced by a red copper electrode, and the red copper electrode is connected with the conducting slip ring and conducts electric spark trimming on the target object. The motor is connected with the hollow spindle and drives the hollow spindle to rotate. The cup grinding wheel-electric spark composite trimmer integrates a cup grinding wheel trimming method and an electric spark trimming method, and overcomes the defects that shaping and sharpening can not be conducted at the same time in a common trimming method and abrasive particles are passivated after trimming. The trimmer is provided with a pipe screw hole, and the pipe screw hole is connected with a quick coupling. Air is led to the trimmer through an M6 air pipe in work, and the blowing and cooling effect and the waterproof effect are achieved.

Owner:北京兴华机械厂有限公司

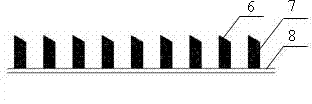

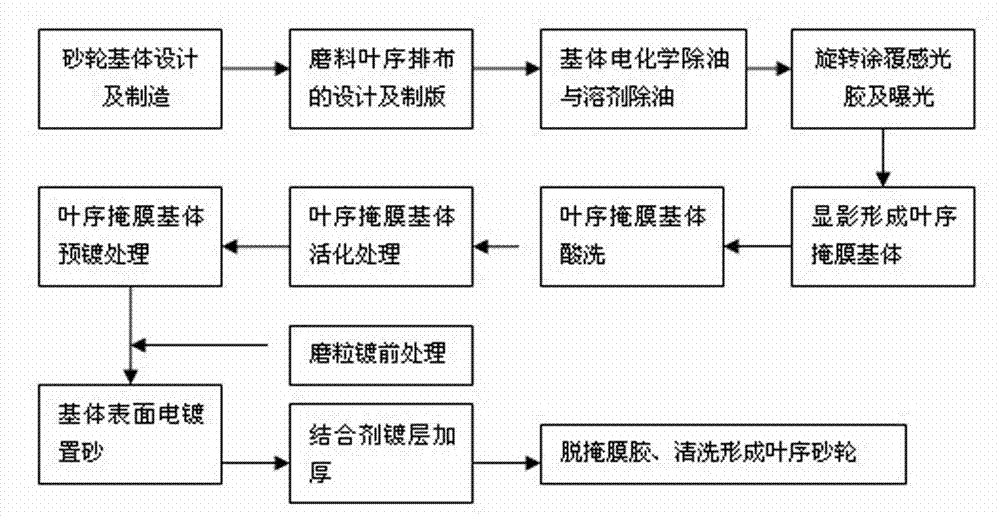

Super-hard abrasive grinding wheel with head face having abrasives in phyllotaxis arrangement and production method thereof

InactiveCN102198641BReduce wearAchieving landform controllabilityBonded abrasive wheelsWear particleWheel wear

The invention discloses a super-hard abrasive grinding wheel with a head face having abrasives in a phyllotaxis arrangement, comprising a grinding wheel basal body. The working surface of the grinding wheel basal body is provided with a plurality of abrasive particles or abrasive particle groups fitting with the biological phyllotaxis theory. The plurality of abrasive particles or abrasive particle groups are fixed on the grinding wheel basal body through a metal bonding agent. According to the biological phyllotaxis theory, the plurality of abrasive particles or abrasive particle groups forma plurality of anticlockwise leaf column line grooves and a plurality of clockwise leaf column line grooves. By means of the invention, the arrangement of the abrasive particles or the abrasive particle groups on the working surface of the grinding wheel fits with the H.Vogel model of the phyllotaxis theory so as to realize the physiographic controllability of the working surface of the grinding wheel. Nickel or nickel-cobalt alloy is adopted to serve as the bonding agent so as to fixedly bond the abrasives. The grinding wheel is capable of controlling the cutting state of the abrasive particles in a grinding region, the cooling liquid distribution and the grinding temperature distribution, and achieving lowest grinding force and specific energy consumption, lowest grinding temperature and burn, lowest abrasion of the grinding wheel, optimal work-surface surface integrity, and the like. The comprehensive grinding performance of the head face grinding of the super-hard abrasive grinding wheel is improved.

Owner:SHENYANG LIGONG UNIV

Preparation method of carbon fiber reinforced high-porosity ceramic bonding agent CBN grinding wheel

The invention discloses a preparation method of a carbon fiber reinforced high-porosity ceramic bonding agent CBN grinding wheel. The method comprises the steps that CBN grinding materials, borosilicate glass powder, GG17 glass powder, T400 short carbon fiber and quartz powder are weighed according to weights, the materials are subjected to ball milling and mixed to be uniform, the mixed powder and molten paraffin are stirred and mixed according to the proportion, and CBN grinding wheel molding slurry is prepared; the slurry is injected into a molding die at 80 DEG C, demolding is carried out after cooling, and a CBN grinding wheel blank is obtained; and the grinding wheel blank is subjected to buried sanding through white corundum and then is dewaxed and sintered through a certain heat treatment process under nitrogen atmosphere, the sintered grinding wheel blank is subjected to outer circle, inner circle and plane machining, and the carbon fiber reinforced high-porosity ceramic bonding agent CBN grinding wheel with the porosity higher than 40% and carbon fibers evenly distributed in a grinding wheel base body is prepared.

Owner:江苏华东砂轮有限公司

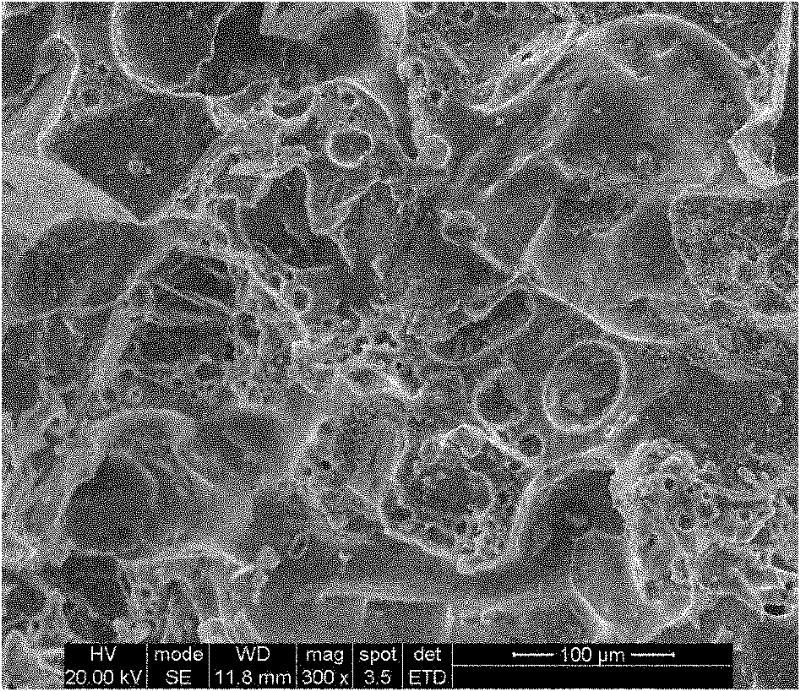

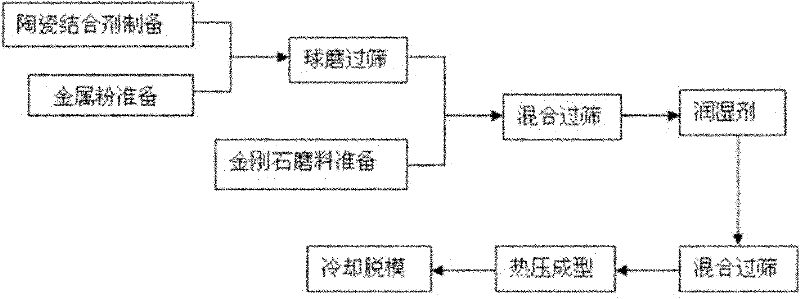

Diamond grinding tool of ceramic-metallic bond and preparation method of grinding tool

ActiveCN102152248BImprove toughnessHigh strengthAbrasion apparatusGrinding devicesLithium oxideMixed materials

The invention discloses a diamond grinding tool of a ceramic-metallic bond and a preparation method of the grinding tool. The preparation method comprises the following steps of: firstly, preparing the ceramic-metallic bond by ball milling the following components in percentage by weight: 40 to 50 percent of silicon dioxide (SiO2), 8 to 15 percent of aluminium oxide (Al2O3), 12 to 20 percent of diboron trioxide (B2O3), 3 to 6 percent of lithium oxide (Li2O), 6 to 12 percent of sodium oxide (Na2O), 3 to 6 percent of potassium oxide (K2O), 2 to 8 percent of zinc oxide (ZnO), 1 to 10 percent of titanium (Ti) and 1 to 5 percent of aluminium (Al); secondly, mixing the ceramic-metallic bond with a diamond abrasive to obtain a mixed material, and then adding 3 to 5 mass percent of wetting agent into the mixed material to obtain a raw material of the grinding tool; and finally, carrying out hot-forming and cooling de-moulding on the raw material of the grinding tool respectively to obtain thediamond grinding tool of the ceramic-metallic bond. The diamond grinding tool of the ceramic-metallic bond provided by the invention has the advantages of the diamond grinding tool of a metallic bondand the grinding tool of a ceramic bond.

Owner:长沙百通新材料科技有限公司

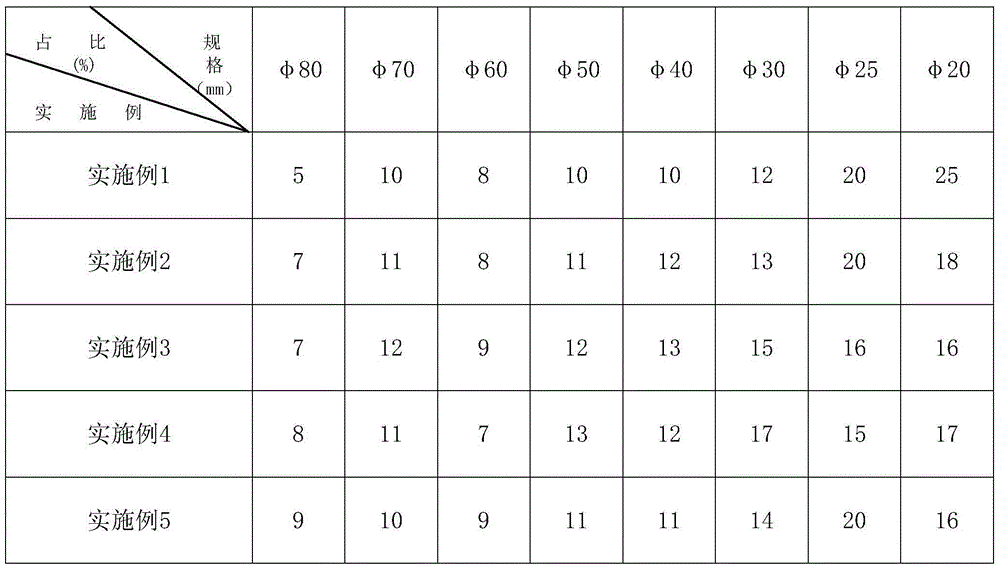

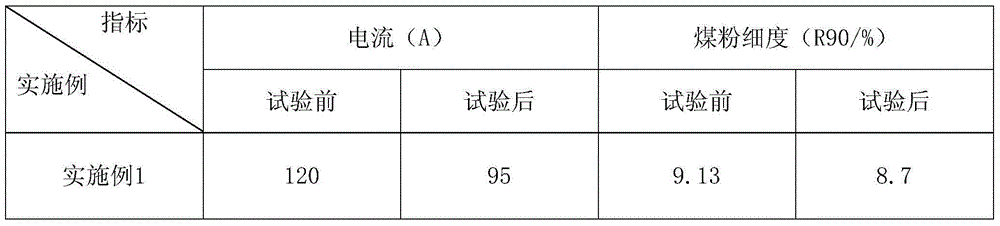

Grading method of coal mill steel balls and application thereof

The invention discloses a grading method of coal mill steel balls. The method comprises the step of filling steel balls with different sphere diameters in a ball mill according to the following weight ratios: 5-10% of steel balls with sphere diameters of 80mm, 10-15% of steel balls with sphere diameters of 70mm, 8-10% of steel balls with sphere diameters of 60mm; 10-15% of steel balls with sphere diameters of 50mm, 10-18% of steel balls with sphere diameters of 40mm, 12-18% of steel balls with sphere diameters of 30mm, 15-30% of steel balls with sphere diameters of 25mm, and 15-30% of steel balls with sphere diameters of 20mm. The grading method disclosed by the invention is used for reasonably grading the steel balls to reduce the energy consumption of a coal mill while ensuring the output of the coal mill, and meanwhile since the attrition of the steel balls is small, the production cost of the coal mill is reduced.

Owner:QINGDAO CHUTIAN ENERGY SAVING TECH

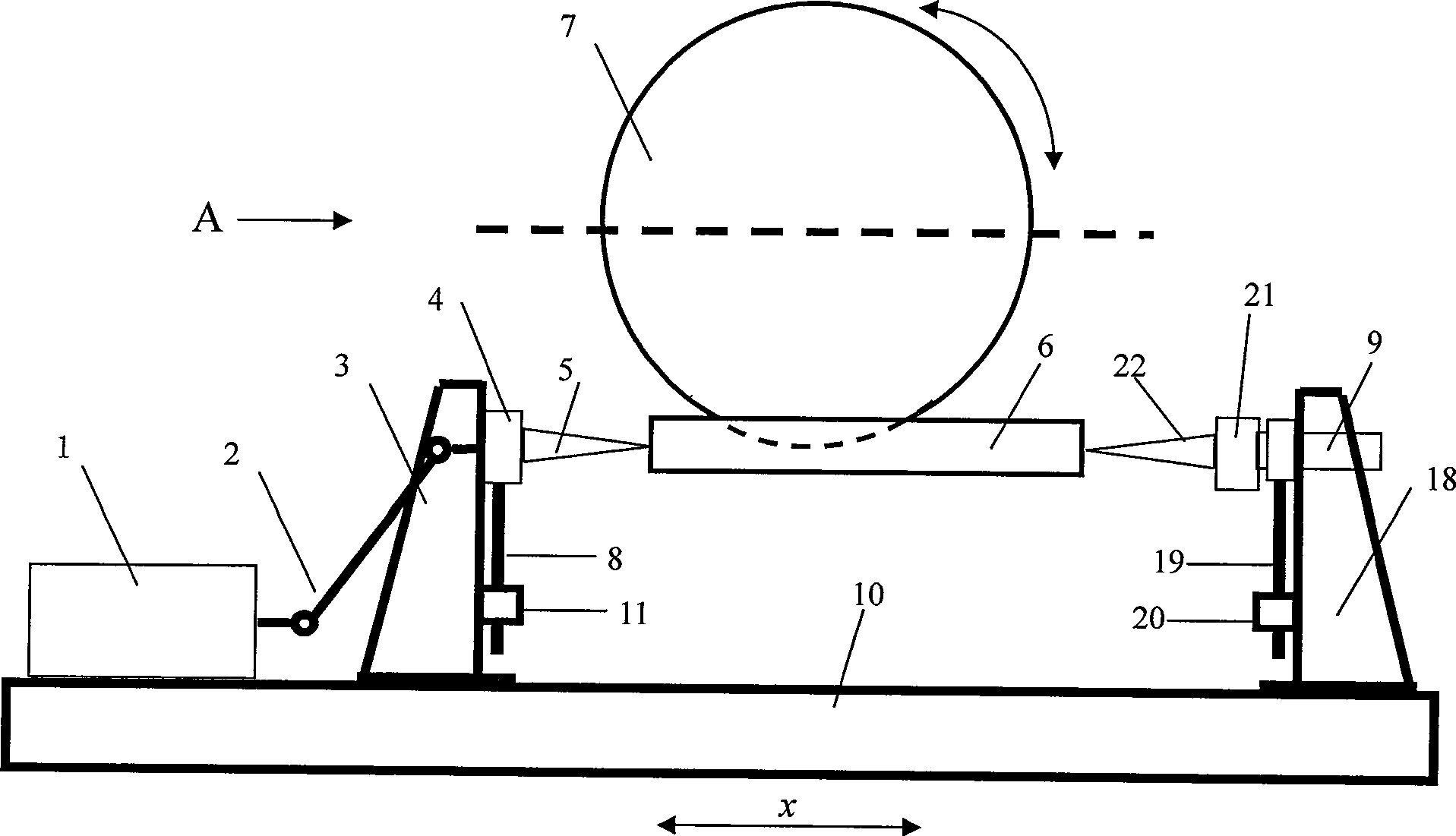

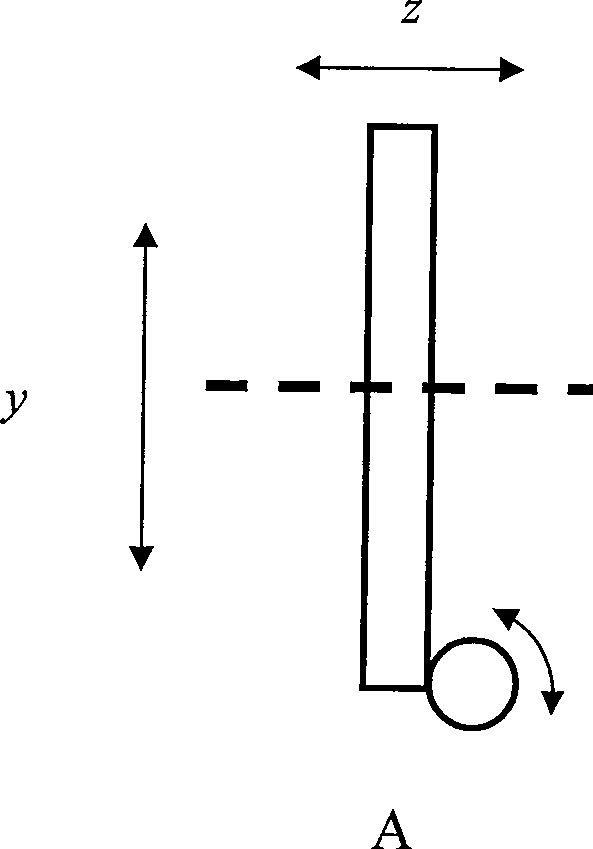

Excircle grinding type planar grinding machine

InactiveCN100488718CExpand the scope of processingLower acquisition costsRevolution surface grinding machinesPlane surface grinding machinesEngineeringMechanical engineering

The present invention discloses one kind of plain grinding machine capable of grinding both plate and shaft and with widened application range. Structurally, the plain grinding machine includes one grinding machine body, one workbench capable of moving in X-direction, two racks set on the workbench, one fixture set on the racks for longitudinal motion for installing shaft workpiece and connected via a driving set to the power set, and one grinding set capable of moving in both Y-direction and Z-direction set over the shaft workpiece.

Owner:SHANDONG UNIV

Processing method for ultra-high strength steel axis parts

InactiveCN103072053AImprove brittlenessEasy to processRevolution surface grinding machinesGrinding work supportsMachined surfaceCylindrical grinder

The invention relates to a processing method for ultra-high strength steel axis parts. According to the method, the ultra-high strength steel axis parts are clamped on a high speed cylindrical grinder; in the four process flows of device setting and parts clamping, coarse grinding, semi-grinding and accurate grinding, the parts are cooled intensely after and before the process flows of coarse grinding, semi-grinding and accurate grinding; high-pressure gas and liquid mixed fluid is sprayed into a grinding area from top to bottom in the three process flows of coarse grinding, semi-grinding and accurate grinding. The processing method for the ultra-high strength steel axis parts has the advantages of small grinding force, high grinding efficiency, improving the fragility of a material, improving the processability of the material, reducing the generation of grinding heat and temperature rising, reducing burning and hardening of a processed surface, reducing clamping errors, improving processing precision and processing efficiency and no need of secondary clamping.

Owner:唐昆

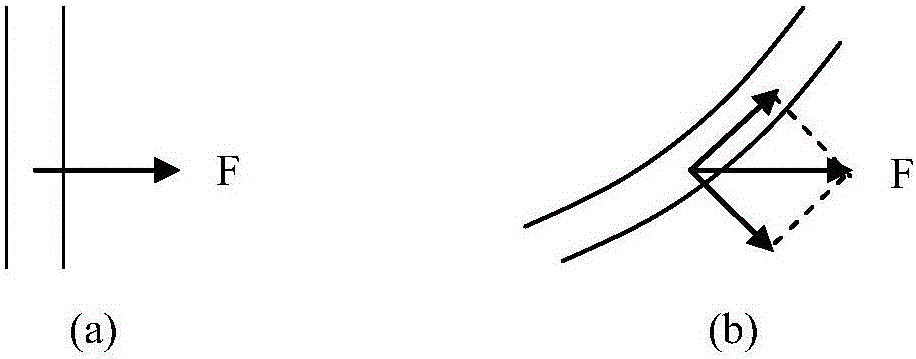

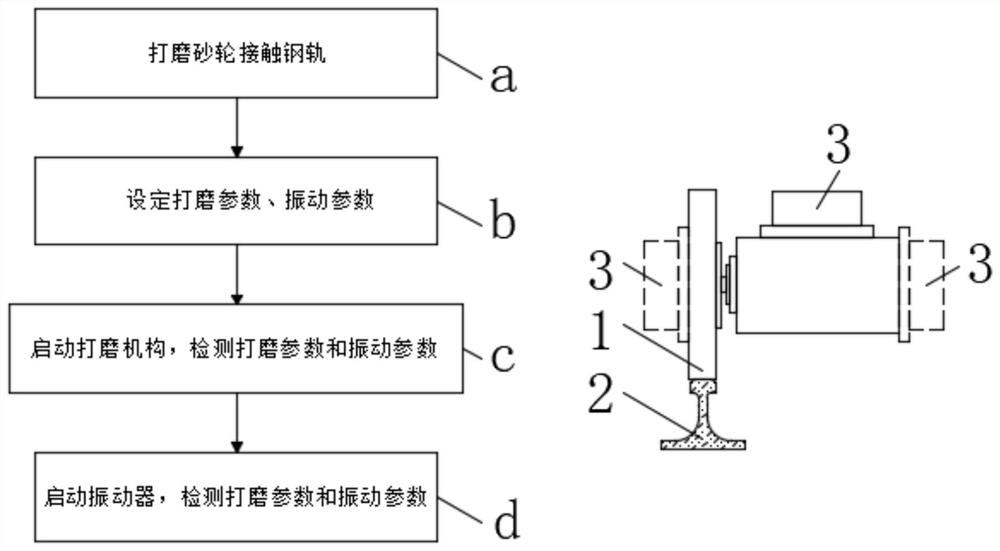

Vibration grinding steel rail grinding method

InactiveCN112647375AImprove grinding efficiencyIncrease feed rateRailway track constructionStructural engineeringGrinding wheel

The invention discloses a vibration grinding steel rail grinding method, and belongs to the technical field of grinding. The method comprises the following steps that a, vibration is generated when a grinding wheel grinds a steel rail to form vibration grinding; b, a vibration generator is arranged at any position of a grinding wheel-main shaft system, and the vibration form, the vibration power, the amplitude frequency and the like are adjusted according to the grinding process requirements; and c, the vibration direction can be any direction such as the longitudinal direction, the transverse direction, the vertical direction and the inclined direction of the steel rail or the composite disordered vibration direction. According to the vibration grinding method, vibration is provided for the grinding wheel, the grinding efficiency and the feeding speed of the steel rail are improved, and the grinding depth is increased, so that the grinding efficiency is improved, the maintenance time is shortened, the grinding vibration effect is achieved, the grinding force is reduced, meanwhile, the residual stress of the grinding surface is reduced, grinding burn is avoided, the surface quality of the steel rail is improved, and the service life of the steel rail is prolonged.

Owner:HUNAN UNIV

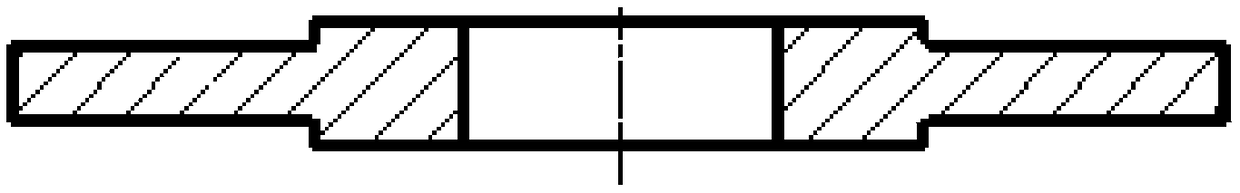

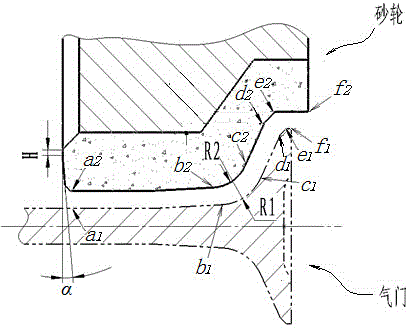

Grinding wheel for grinding air valve and method for grinding air valve

ActiveCN104526585AImprove processing efficiencyHigh precisionBonded abrasive wheelsEngineeringGrinding wheel

The invention discloses a grinding wheel for grinding an air valve and a method for grinding the air valve. The grinding wheel for grinding the air valve has an outer contour line which is adapted to the outer contour line, in the axial direction, of the air valve, the outer contour line of the grinding wheel is composed of a first line segment corresponding to the contour of an outer circle of an air valve disc, a second line segment corresponding to the contour of the outer conical surface of the air valve disc, a third line segment corresponding to the contour of the inner conical surface of the air valve disc, an arc-shaped line segment corresponding to the arc-shaped contour of the neck of the air valve and a fourth line segment corresponding to the contour of the neck of the air valve, the radius of the arc-shaped line segment of the outer contour line of the grinding wheel is smaller than that of the arc-shaped contour of the neck of the air valve, and the length of the second line segment of the outer contour line of the grinding wheel is larger than that of the contour of the outer conical surface of the air valve disc. When the grinding wheel is used for grinding the air valve, grinding of the air valve can be achieved through one-time clamping and one-time grinding, and thus both air valve machining efficiency and air valve machining quality are improved.

Owner:YUHUAN CNC MACHINE TOOL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com