Spiral grinding wheel with composite material fiber micro blade

A composite material fiber and spiral grinding wheel technology, applied in the field of grinding tools, can solve the problems of complex structure of the grinding wheel and liquid supply device, easy wear of the edge of the grinding wheel groove, difficult regenerative repair, etc., to reduce the probability of micro-blade falling off, The effect of improving processing quality and processing efficiency, improving processing accuracy and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

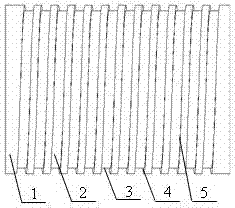

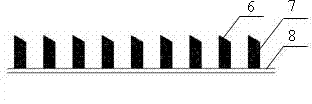

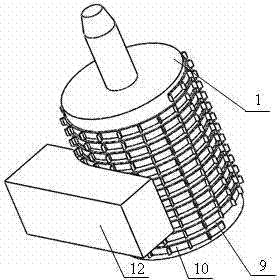

[0023] see figure 1 , figure 2 , image 3 with Figure 4 , the spiral grinding wheel includes: fiber micro blade 7, grinding belt 8, thin strip metal sheet 13, grinding layer 11, grinding wheel base 1, grinding wheel base 1 is cast into a rough body with aluminum alloy or other materials in advance, and then processed on the surface of the base Spiral groove 2. The fiber microblade 7 of the spiral grinding wheel is a heat-resistant, high-strength composite material. The composite material is sintered with nano-tungsten carbide composite powder and micron-sized diamond particles using pulse plasma technology to prepare a cemented carbide / diamond composite material, and then used It is cut into fiber strips by electric discharge cutting technology, and then sharpened to obtain zero rake angle 6, and then the fiber micro-blade 7 is oriented a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com