Patents

Literature

118results about How to "Reduce grinding temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

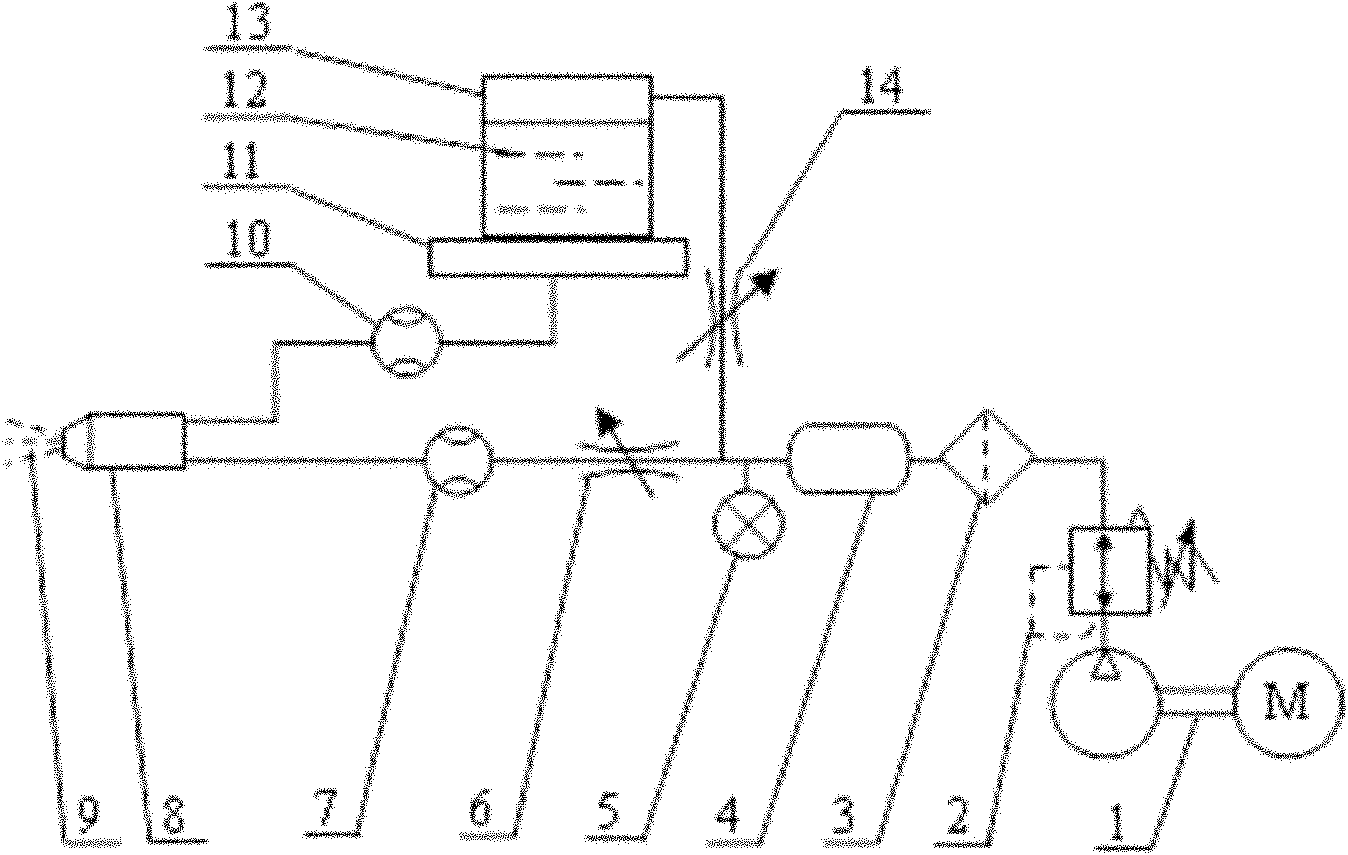

Lubricating and cooling method for cutting process and device thereof

InactiveCN102029551AImprove the lubrication effectReduce coefficient of frictionMaintainance and safety accessoriesLubricant compositionIonNanoparticle

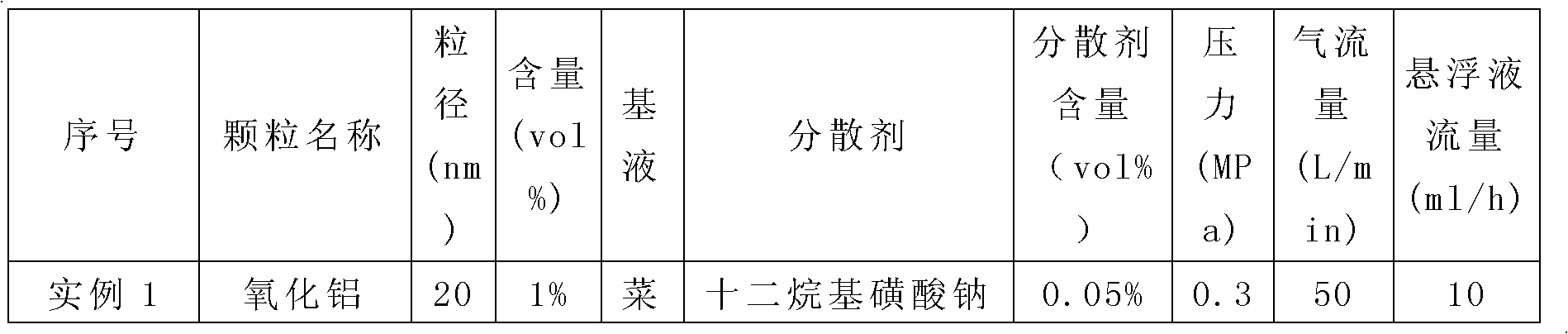

The invention discloses a lubricating and cooling method for cutting process and a device thereof. The method comprises the following steps: adding nano-particles with particle size of 20-40 nm at a volume ratio of 1-5% into vegetable oil or deionized water; adding dispersant at a volume ratio of 0.05-0.15% while conducting ultrasonic vibration at a frequency of 10-40 kHz so as to obtain uniform oil-based or water-based nano-particle suspension with high dispersibility; and under the effect of compressed air with pressure of 0.3-1 MPa, sufficiently atomizing the nano-particle suspension into atomized particles with micron-level diameter, wherein the high-pressure atomized particles break through a cutter through a nozzle and an air barrier layer on the workpiece surface and then are ejected to a cutting area so as to lubricate and cool the cutting area. Through the lubricating and cooling method for cutting process and the device thereof which are disclosed by the invention, the cooling medium with high lubricating performance and heat conducting performance can be effectively injected into the cutting area so as to improve the lubricating state of the cutting area and reduce friction and heat emission; and the generated heat is taking away in real time.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

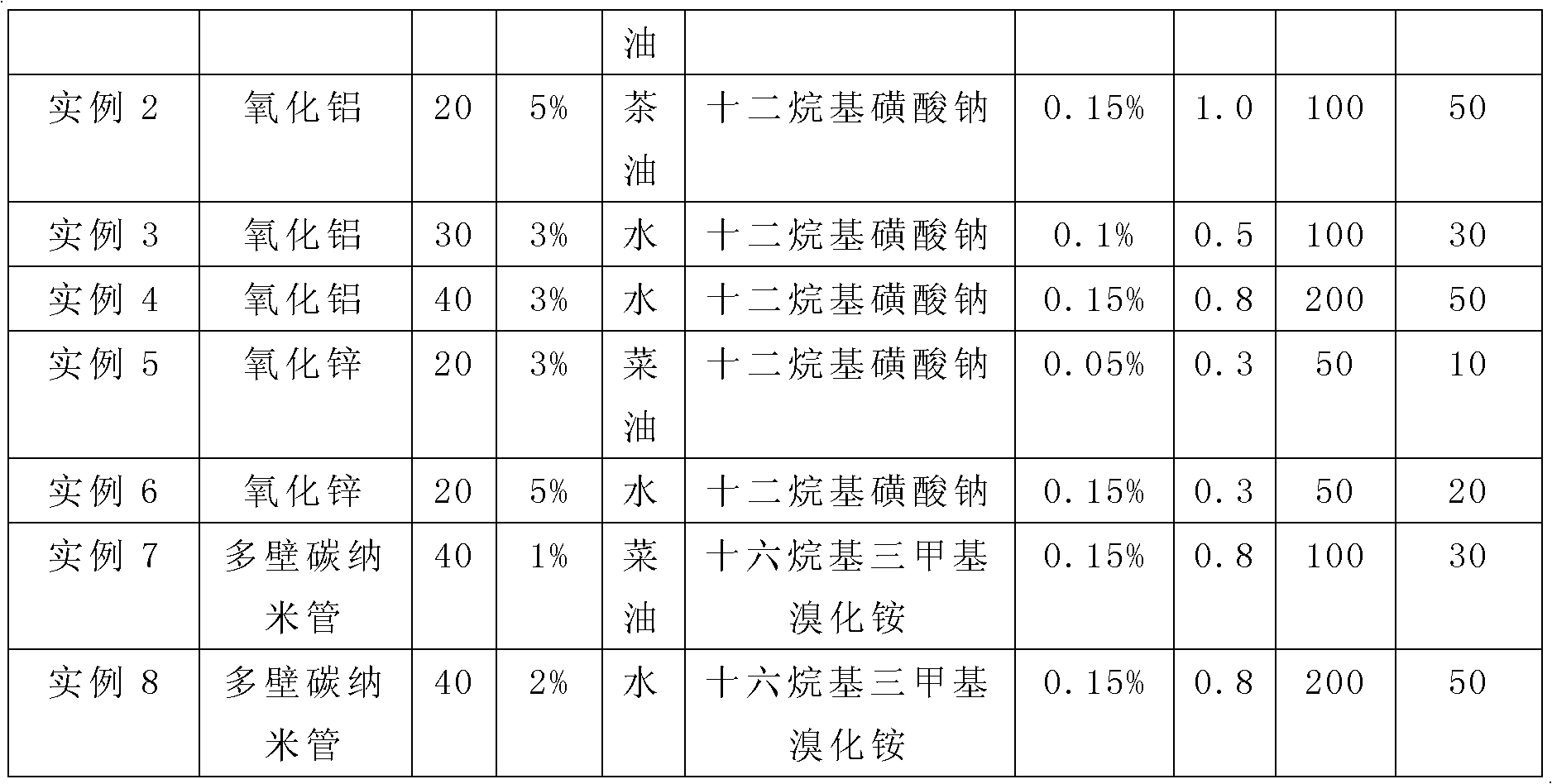

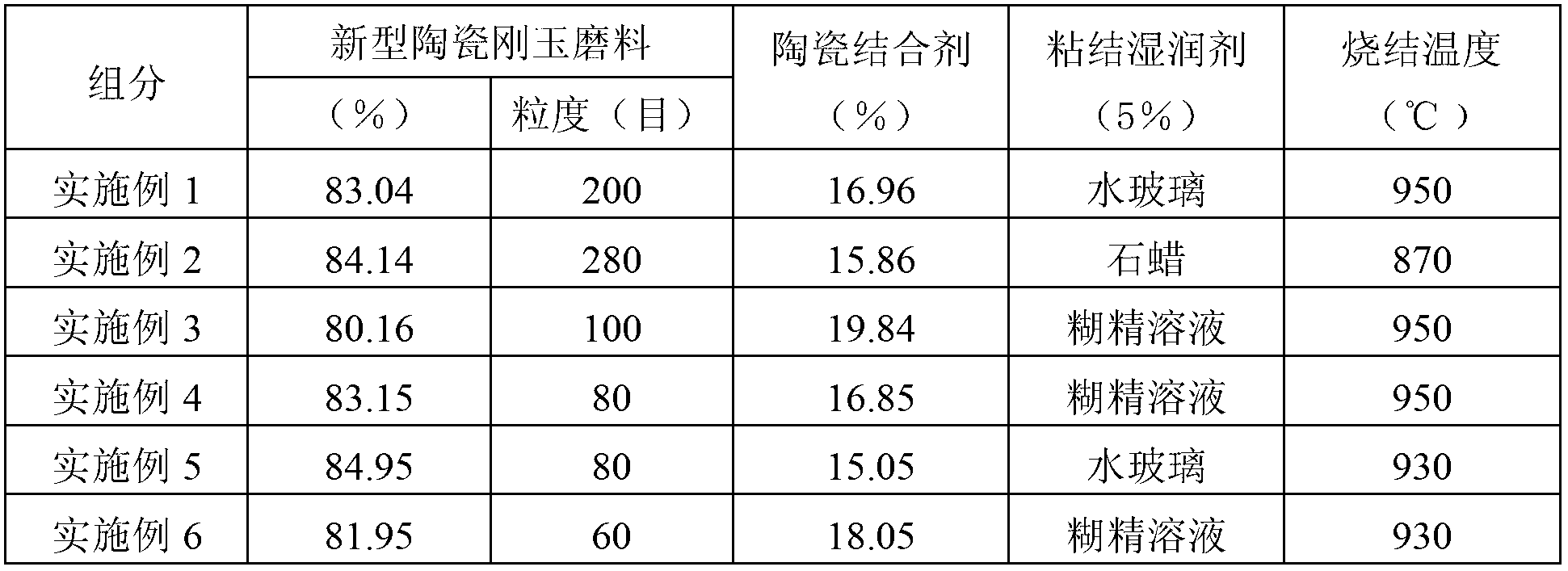

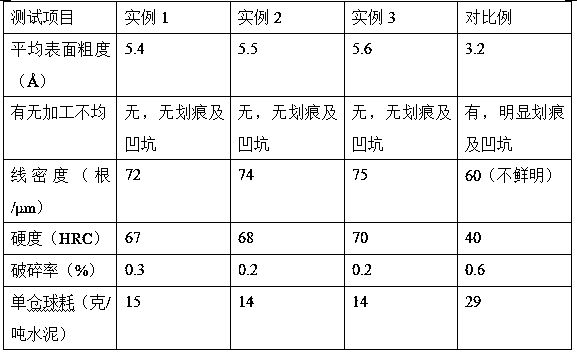

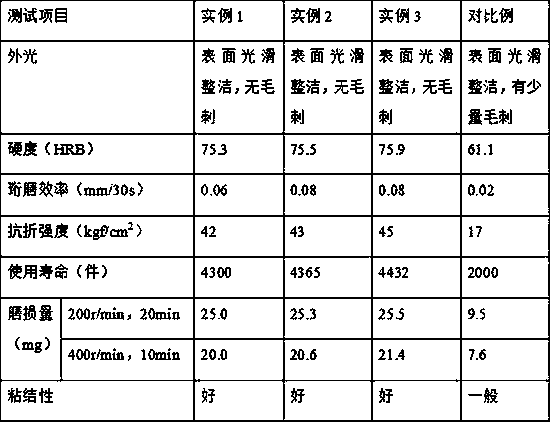

Novel ceramic corundum grinding tool of low-temperature and high-strength ceramic bonding agent and preparation method thereof

InactiveCN102699825ASharp abrasiveStrong cutting forceAbrasion apparatusGrinding devicesGrinding wheelBorosilicate glass

The invention discloses a novel ceramic corundum grinding tool of a low-temperature and high-strength ceramic bonding agent. The grinding tool consists of the following components in percentage by mass: 15 to 20 percent of ceramic bonding agent, 80 to 85 percent of novel ceramic corundum grinding material and 5 percent of bonding wetting agent, wherein the bonding agent consists of the following components in percentage by mass: 10 to 30 percent of clay, 10 to 30 percent of feldspar, 45 to 70 percent of borosilicate glass, 0 to 15 percent of kryocide, 0 to 5 percent of quartz and 0 to 5 percent of magnesium oxide. The novel ceramic corundum grinding tool can be sintered at the sintering temperature of 850 to 980 DEG C, and by the grinding tool, a grinding wheel can be safely used at the rotation speed of 80 to 100m / s. The single-travel feeding amount of the grinding tool can be over 0.3mm, the metal removing rate is over 3 times that of an ordinary corundum grinding wheel, the grinding interval time is 3 to 5 times that of the ordinary corundum grinding wheel, the service life is 5 to 10 times that of the ordinary corundum grinding tool, and the novel ceramic corundum grinding tool is superior to a super-hard grinding tool and the ordinary grinding tool in performance and price.

Owner:TIANJIN UNIV

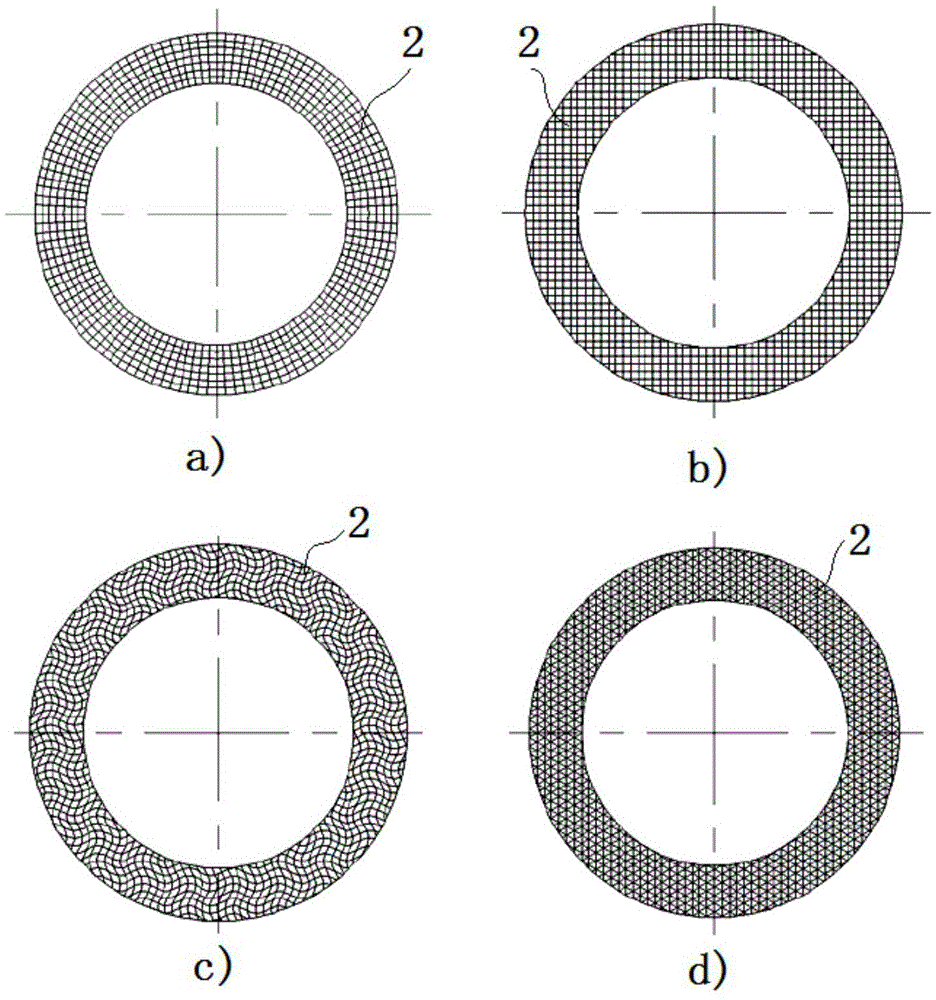

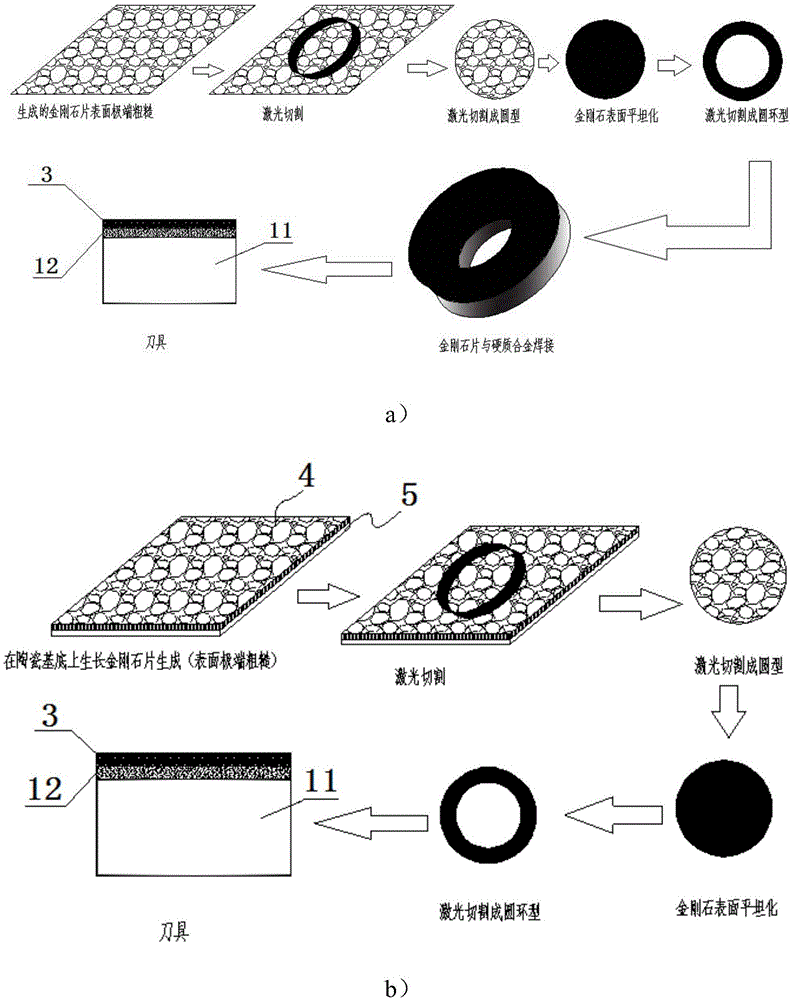

Diamond grinding wheel and production method thereof

InactiveCN106312843AAvoid graphitizationConsistent blade heightBonded abrasive wheelsGrinding devicesDiamond grindingBonding strength

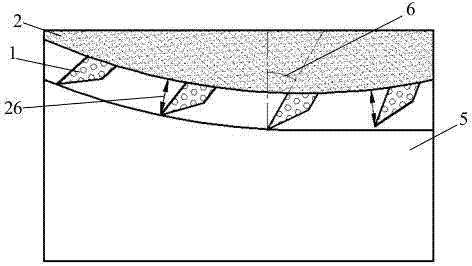

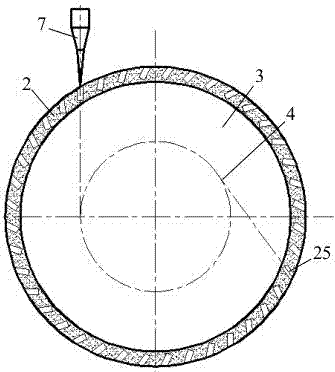

The invention discloses a diamond grinding wheel, which has multi-layer abrasive particle orderly arrangement, is high in bonding strength and is convenient to repair after being worn, and a production method thereof. The production method comprises steps of processing a grinding wheel basal body, cleaning and the like. According to the diamond grinding wheel and the production method thereof disclosed by the invention, a laser material increasing technology is adopted to accurately process, so that processing precision and processing quality are improved; a sandwich structure is adopted for sintering, so that the abrasive particles are prevented from moving, protruding height of the abrasive particles is guaranteed to be consistent, orderly arrangement of the diamond abrasive particles is realized, a chip space during grinding is great, grinding force is reduced, a grinding temperature is reduced, grinding efficiency is improved, and grinding surface quality is improved; power of a laser unit is controlled for controlling a sintering temperature, so that the diamond abrasive particles are prevented from graphitizing, and a metal bonder is combined with the diamond abrasive particles in a high-strength metallurgical mode; a manufacturing process further can be simplified; and the diamond grinding wheel is finished layer by layer after being worn, and then is continuously used, so that finishing is convenient, and the service life of the diamond grinding wheel is long.

Owner:HUNAN CITY UNIV

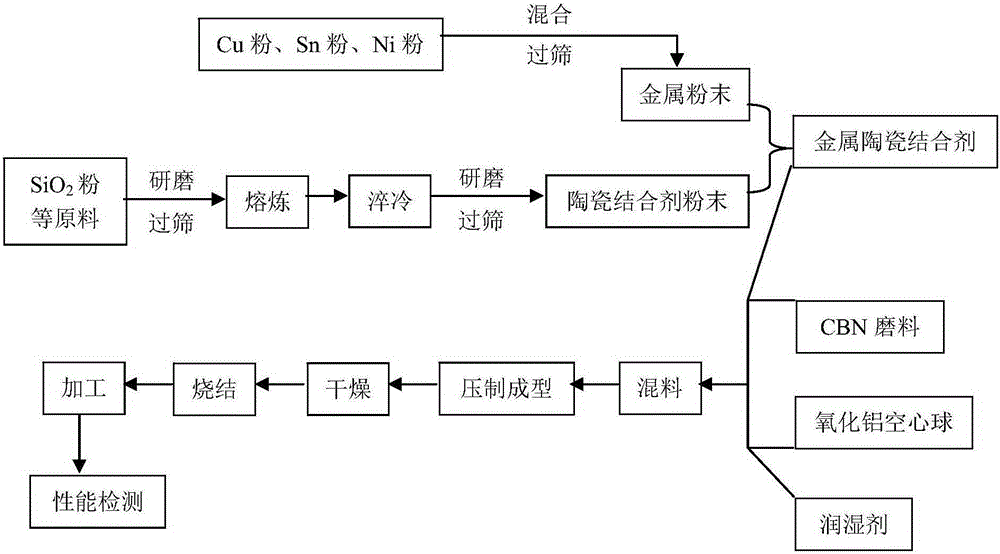

Metal and ceramic bonding agent and preparation method of metal and ceramic bonding agent, CBN grinding wheel and manufacturing method of CBN grinding wheel

ActiveCN105349868AImprove sharpnessGood self-sharpeningAbrasion apparatusGrinding devicesSurface roughnessGrinding wheel

The invention discloses a metal and ceramic bonding agent and a preparation method of the metal and ceramic bonding agent, a CBN grinding wheel and a manufacturing method of the CBN grinding wheel. The metal and ceramic bonding agent is composed of, by mass fraction, 75%-92% of ceramic and 8%-25% of metal. The ceramic is composed of, by mass fraction, 40%-65% of SiO2, 8%-35% of B2O3, 6%-20% of Al2O3, 5%-18% of Na2O5, 0.5%-5% of CaO, 3%-10% K2O, 0.5%-2% of MgO and 2%-6% of TiO2. The metal is composed of, by mass fraction, 55%-80% of Cu, 15%-30% of Sn and 5%-20% of Ni. The metal and ceramic bonding agent can be used as a CBN grinding wheel bonding agent and overcomes the defects that in the grinding process of the ceramic CBN grinding wheel, the surface roughness of a workpiece is large, chatter marks are generated easily, and impact resistance is poor.

Owner:白鸽磨料磨具有限公司

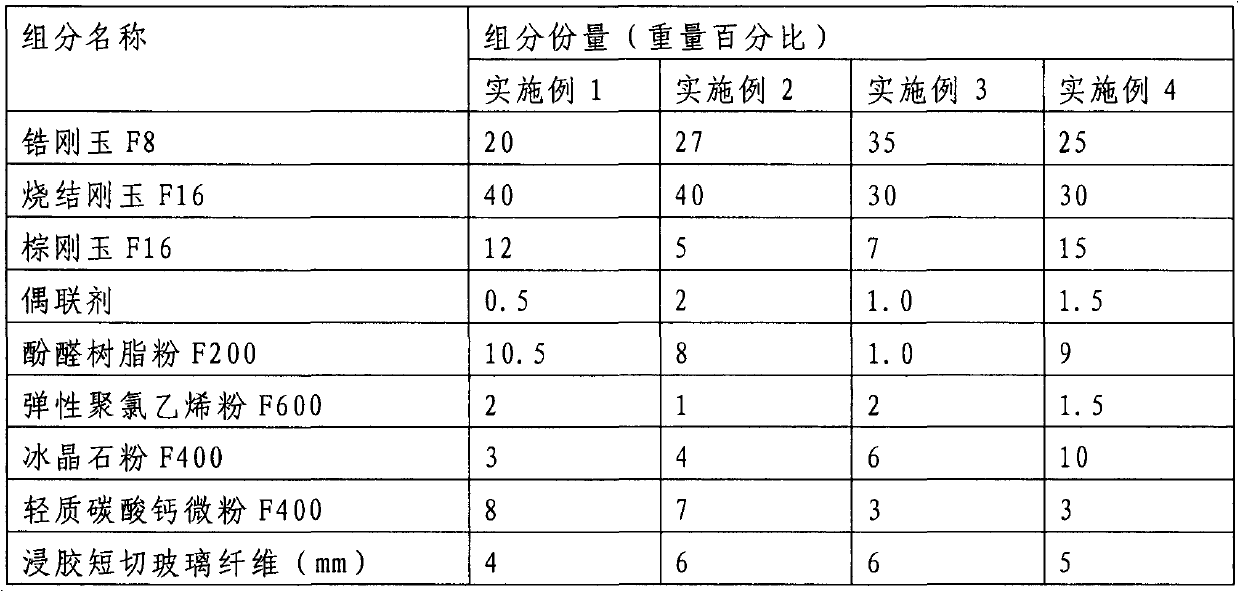

Heavy-load grinding wheel and preparation method thereof

InactiveCN103144047APlay the role of cushioning and dampingImprove flame retardant performanceAbrasion apparatusGrinding devicesPolyvinyl chlorideGrinding wheel

The invention discloses a heavy-load grinding wheel. The heavy-load grinding wheel comprises the following components in percentage by weight: sintered corundum, fused alumina zirconia, brown fused alumina, a coupler, phenol-formaldehyde resin powder, elastic polyvinyl chloride powder, cryolite powder, light calcium carbonate micro powder and impregnation chopped glass fibers and is prepared by a hot pressing molding process. The elastic polyvinyl chloride resin powder is mixed in a grinding material, so that the tenacity and the shock absorbing effect of the grinding wheel are improved, and the probability of sheet blasting is greatly reduced. On the other hand, elastic polyvinyl chloride has excellent flame resistance, so that burning of grinding heat to phenol-formaldehyde resin is reduced, the bonding ability of the phenol-formaldehyde resin to the grinding material is improved, and the grinding ratio of the grinding wheel is improved. The coupler is used for modifying the surface of the phenol-formaldehyde resin, so that the interface bonding force between the organic resin and the inorganic grinding material is stronger, and the rotation strength of the grinding wheel is improved. Furthermore, due to the adoption of the impregnation chopped glass fibers, the dissolving ability of the phenol-formaldehyde resin is favorably enhanced, and the rotation strength of the grinding wheel is further improved.

Owner:泰州苏蒙砂轮有限公司

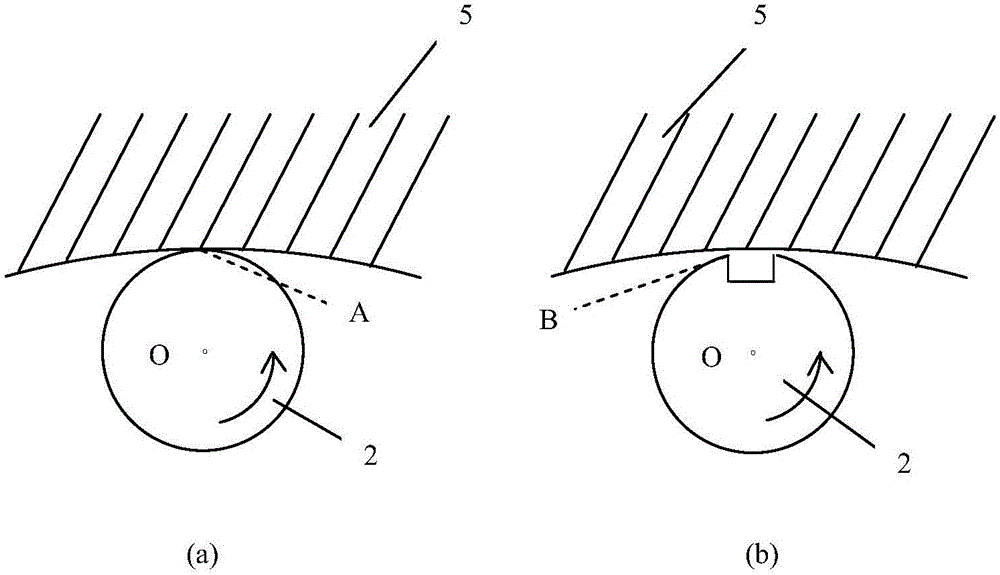

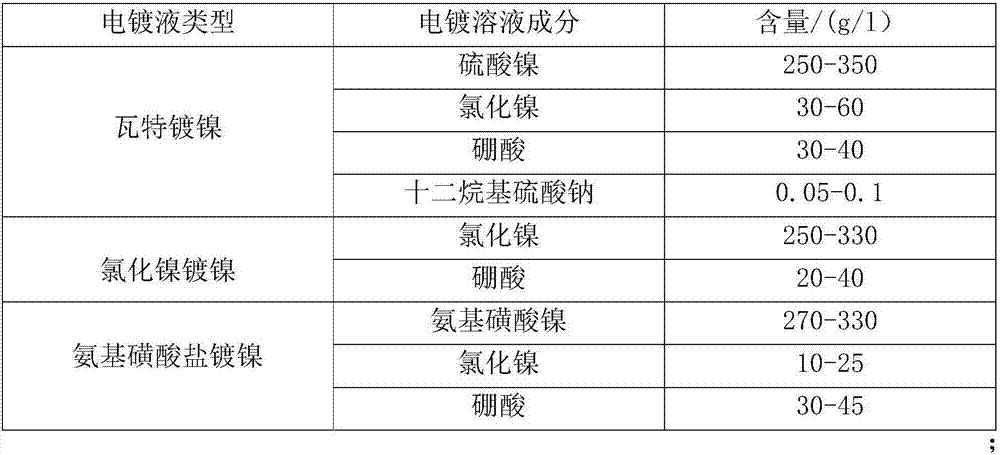

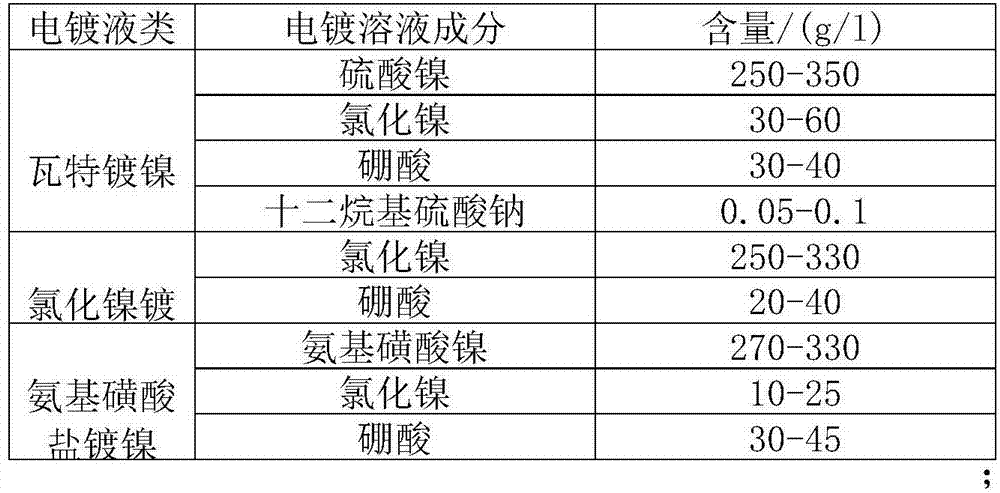

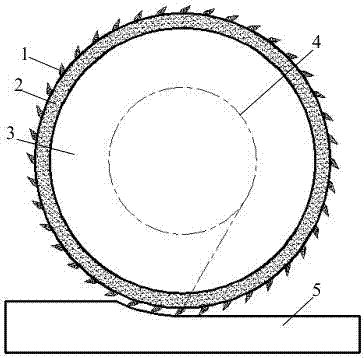

Manufacturing method of electroplated grinding wheel of ordered structure

The invention discloses a manufacturing method of an electroplated grinding wheel of an ordered structure. The method includes: adopting a pulse laser beam to process a fine spiral groove with the pitch of hundreds of micrometers and the notch size of dozens of micrometers in the working surface of the outer annulus of a grinding wheel base body made of metal, filling the groove with epoxy resin, and enabling the metal and the epoxy resin on the working surface of the outer annulus of the grinding wheel base body to be in spiral regularly-spaced layout; then electroplating the working surface of the outer annulus of the grinding wheel base body with abrasive grains by adopting an electroplating method. Since the groove is filled with the non-conductive epoxy resin, the region cannot be electroplated with the abrasive grains. By the steps, the electroplated grinding wheel with the abrasive grain layer and the epoxy resin being in spiral regularly-spaced layout can be obtained. The manufactured electroplated grinding wheel of the ordered structure is in favor of solving the problems that the grinding wheel is blocked easily during grinding and grinding fluid cannot enter the grinding region easily, workpieces can be prevented from being burnt, and the grinding quality is improved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

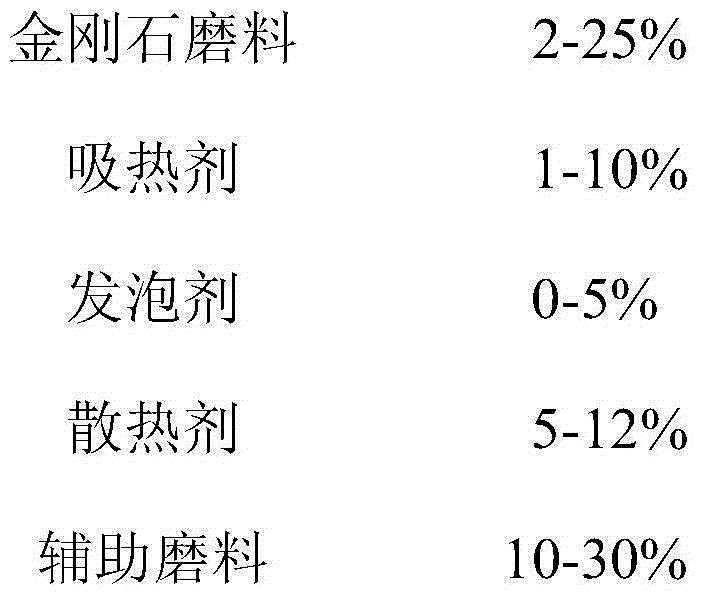

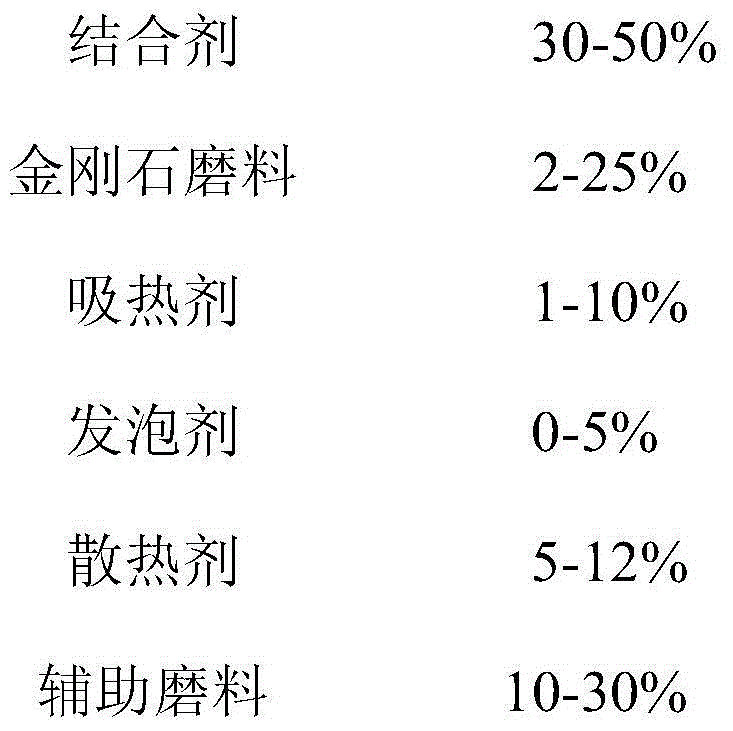

Screen printing type casting diamond dry grinding sheet and manufacturing process thereof

ActiveCN104816257AReduce the temperatureImprove protectionAbrasion apparatusGrinding devicesScreen printingPolymer adhesive

The invention provides a screen printing type casting diamond dry grinding sheet and a manufacturing process thereof. The manufacturing process comprises placing the following materials of, by volume, 30 to 50% of binding agent, 2 to 25% of diamond grinding materials, 1 to 10% of endothermic agent, 0 to 5% of foaming agent, 5 to 12% of cooling agent and 10 to 30% of grinding materials into a mixer to be mixed for 1 to 4 hours; brushing mixed paste on a textile base layer through a screen printing die; lifting up the die to be naturally solidified for 3 to 36 hours at the room temperature or placing the die into an oven to be solidified for 1 to 42 hours under the condition of 60 to 300 DEG C; adhering a layer of nylon buckle wool surface or nylon buckle hook surface onto the bottom surface of the textile base layer through a polymer adhesive; trimming the edge to obtain a dry grinding sheet finished product. According to the screen printing type casting diamond dry grinding sheet and the manufacturing process thereof, devices are simple, the process is advanced, the heat resistance of the dry grinding is improved, most of the heat generated in the grinding process can be absorbed, and the grinding temperature is directly reduced.

Owner:HUBEI LITTLE ANT DIAMOND TOOLS CO LTD

CBN (Cubic Boron Nitride) grinding wheel

ActiveCN106625297AReduce grinding temperatureReduce power lossAbrasion apparatusGrinding devicesProcessing accuracyThermal conductivity

The invention relates to the field of superhard materials, and concretely relates to a CBN (Cubic Boron Nitride) grinding wheel. The invention provides the CBN grinding wheel, which has favorable shock resistance and shape retention, and can bear a larger load during a high-speed grinding process. The CBN grinding wheel comprises a steel core and an abrasive ring. The steel core and the abrasive ring are combined through a binding agent. The CBN grinding wheel is characterized in that the abrasive ring is prepared from the following raw materials in percentage by mass: 30 to 70 percent of CBN abrasive, 20 to 60 percent of metal binding agent, and 2 to 10 percent of auxiliary adhesion agent. The CBN grinding wheel provided by the invention has favorable heat conductivity and is beneficial for reducing the grinding temperature, so that the power loss is reduced, and the grinding speed is improved; the auxiliary adhesion agent in a formula is beneficial for forming pores, and the characteristic of high holding force of the metal binding agent is combined, so that a chip space can be effectively enlarged, and abrasives are more sufficiently utilized; and the grinding wheel has the characteristics of high grinding efficiency, low grinding temperature, low power loss, good processing accuracy, long service life and the like.

Owner:磐维科技(青岛)有限公司

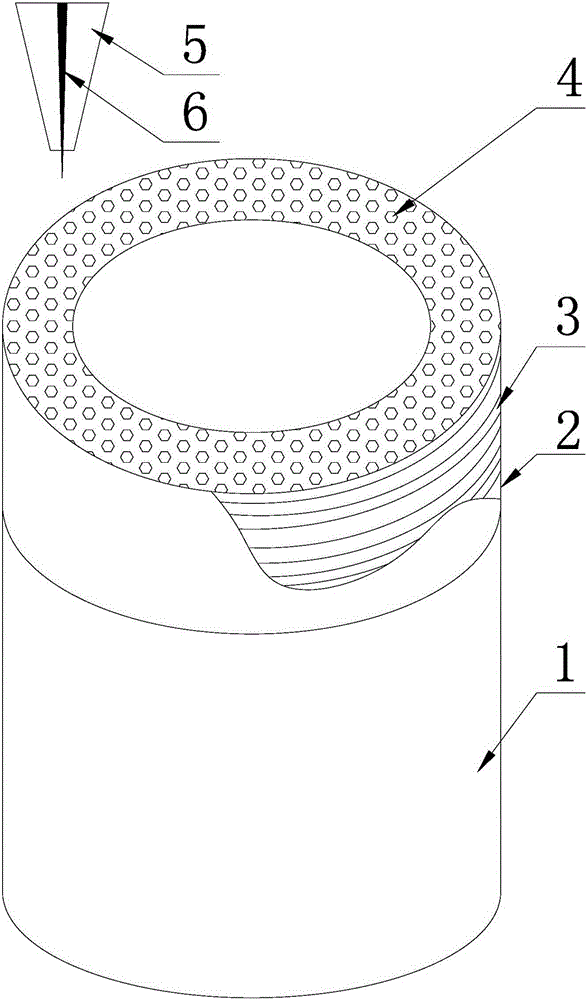

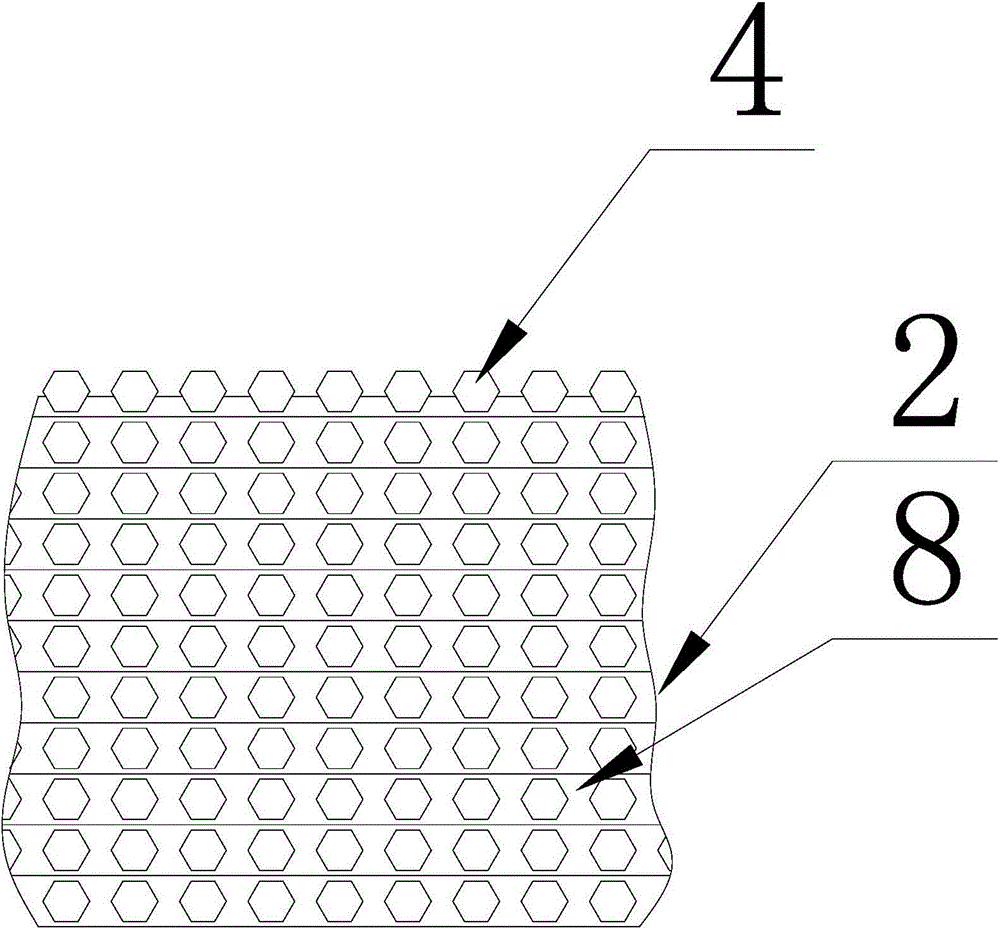

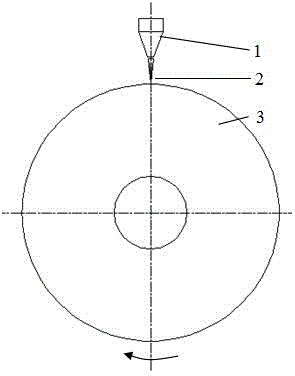

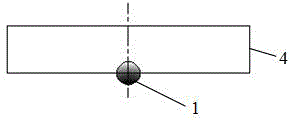

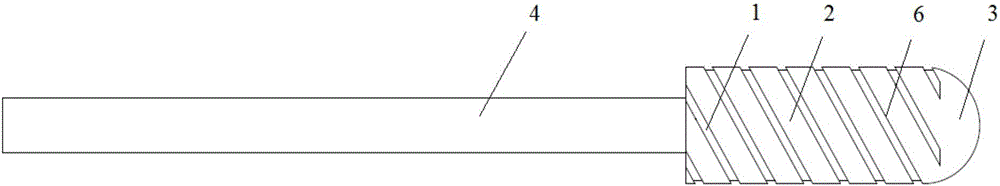

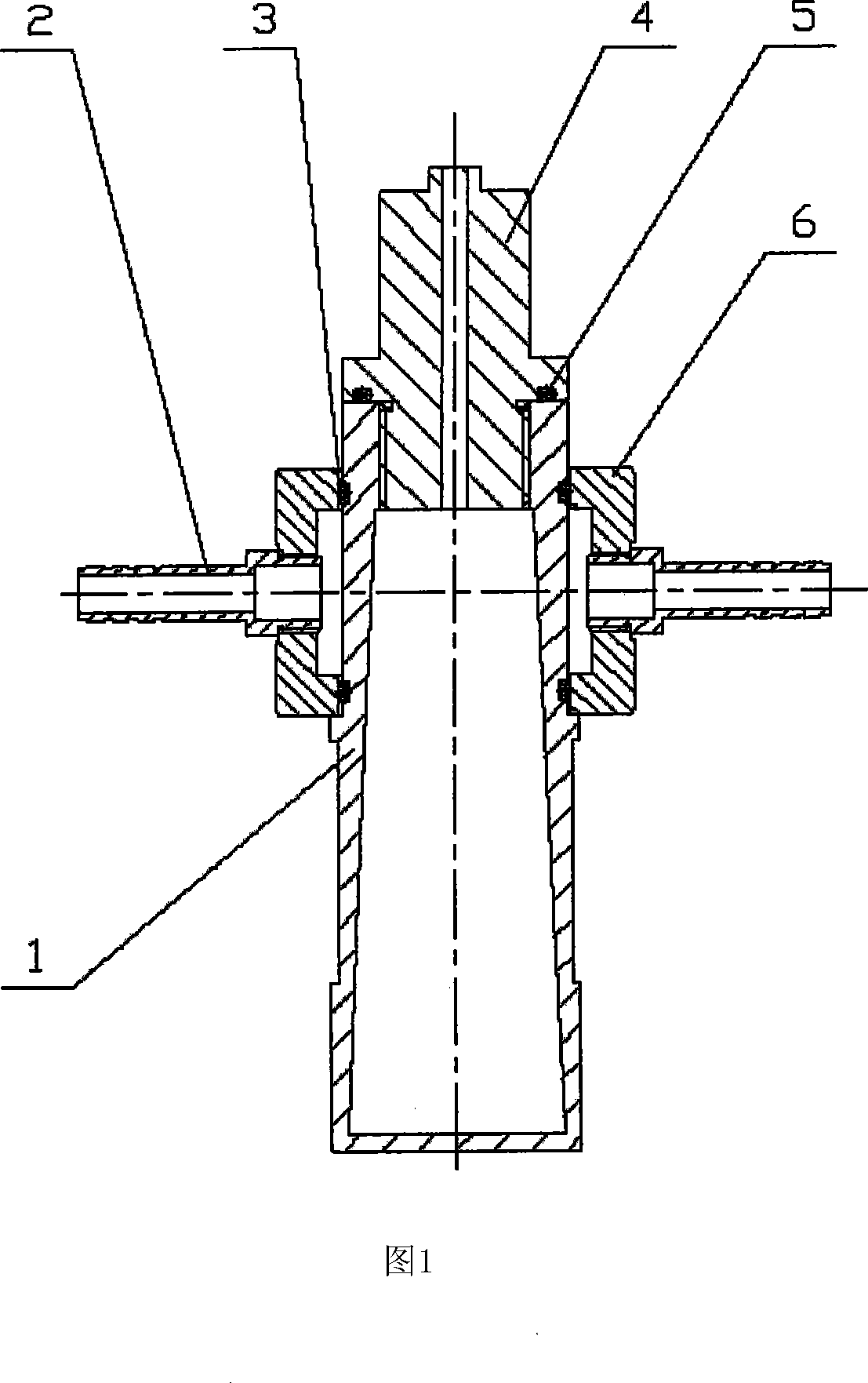

Method for machining narrow groove system impeller, grinding head and preparation method of grinding head

The invention provides a method for machining a narrow groove system impeller, a grinding head and a preparation method of the grinding head. The grinding head is a cylinder. The top end of the grinding head is in the shape of a spherical surface, and a spiral groove is formed in the side wall of the grinding head. The preparation method includes the steps that materials for use are calculated; ingredients are weighed; wetting and material mixing are performed; pressing of grinding head sand blocks is performed; drying is performed; the firing link is performed; and the grinding head sand blocks which are qualified through checking are selected and enter an adhesion processing procedure of a cutter handle, the cutter handle is bonded, after adhesives are cured and stabilized, laser dressing is performed, grooving is performed, and acceptance check of the grinding head is performed, and therefore preparation of the grinding head is completed. The method for machining the narrow groove system impeller through the grinding head includes the steps that fluttering stability analysis is performed, and a stable lobe graph of a grinding system is established; the technological parameter selecting range of stable grinding is determined; and technological parameters of stable grinding are selected, and the grinding head is installed for grinding machining. By means of the grinding head, the grinding temperature is effectively lowered, the adhesion and abrasion effects of cuttings on the grinding head are reduced, the machining surface burning problem is reduced, and better machining surface quality is acquired.

Owner:NORTHEASTERN UNIV

Method for manufacturing metal binder cubic boron nitride grinding wheel with self-lubricating function

InactiveCN101148037AEnhanced Lubricating BehaviorGrinding potential fully exploitedAbrasion apparatusMetal working apparatusChemical reactionHexagonal boron nitride

The process for producing cubic boron nitride (CBN) grinding wheel with self-lubricating metal binding agent belongs to the field of super hard grinding tool making technology. Through addition of hexagonal boron nitride (HBN) grains in 5-15 wt% to Ag-Cu-Ti alloy or Cu-Sn-Ti alloy to form the mixture to constitute the grinding wheel binding agent layer and the subsequent vacuum liquid phase activating and sintering process including heating to 900-1000 deg.c and maintaining for 5-20 min for the alloy and the HBN grains and CBN grains to produce chemical reaction to make the CBN grinding wheel with self-lubricating metal binding.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Metal material composite electrodeposition diamond grinding pad and manufacturing method thereof

InactiveCN107042477AImprove heat resistanceImprove cooling effectAbrasion apparatusGrinding devicesAdhesiveAlloy

The invention provides a metal material composite electrodeposition diamond grinding pad. One or more than one metal and diamond are electronically deposited on a flexible conductive matrix together in an electroplating mode, and a metal-diamond composite layer is formed on the matrix. The metal or alloy which wraps the diamond is fixed on the matrix, so that a grinding function is fulfilled; a loop surface or a hook surface of a hook-and-loop tape is adhered to the other surface of the matrix by an adhesive, so that the matrix can be connected with corresponding using equipment conveniently. According to the metal material composite electrodeposition diamond grinding pad, a metal material is used as a binding agent and replaces a high polymer material binding agent, strength, wear resistance, heat resistance and heat dissipation performance of the binder are improved, the grinding temperature is directly reduced, deadly defects such as high polymer material burning and dyeing are overcome, the metal material composite electrodeposition diamond grinding pad not only can be used for water grinding, but also can be used for dry grinding, meanwhile, the service life of the grinding pad can be greatly prolonged, and the grinding efficiency is greatly improved.

Owner:江西中核智能机械技术有限公司

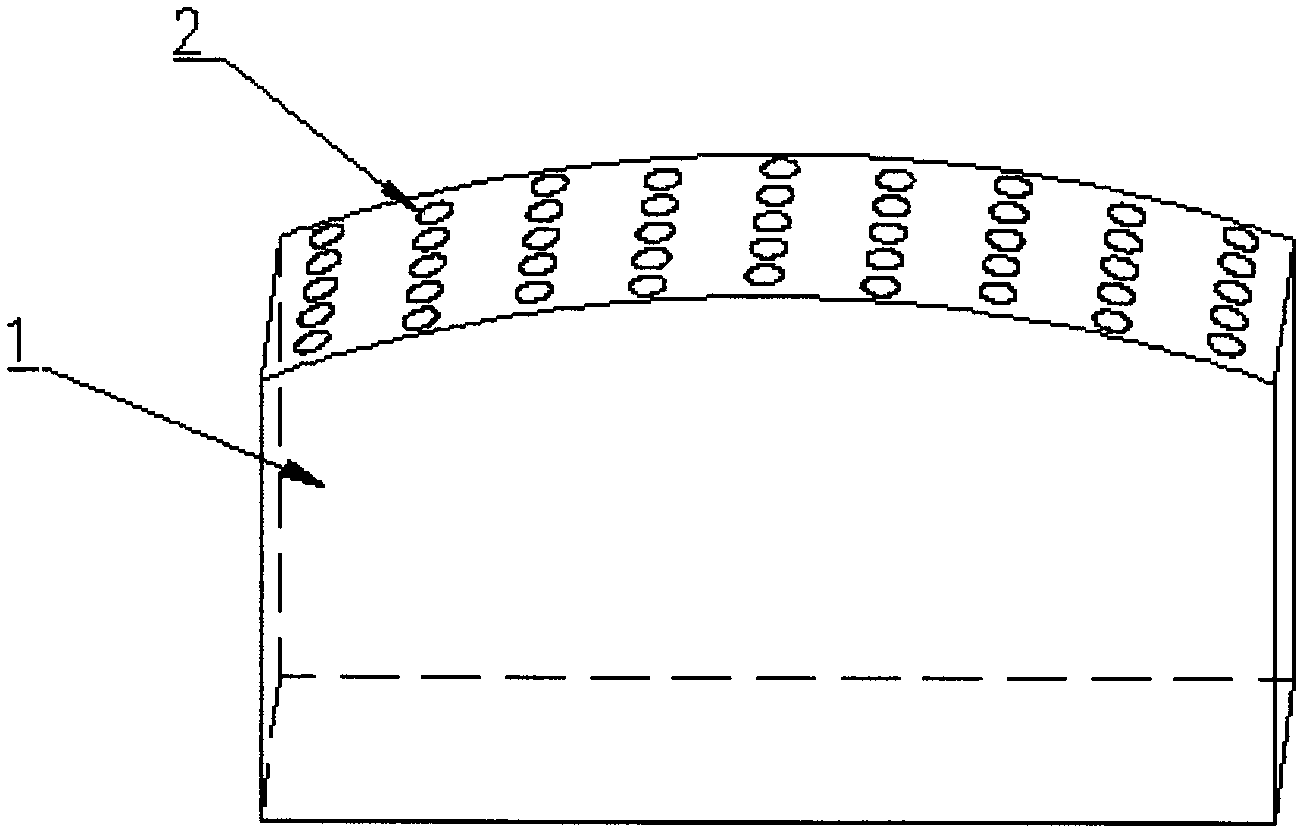

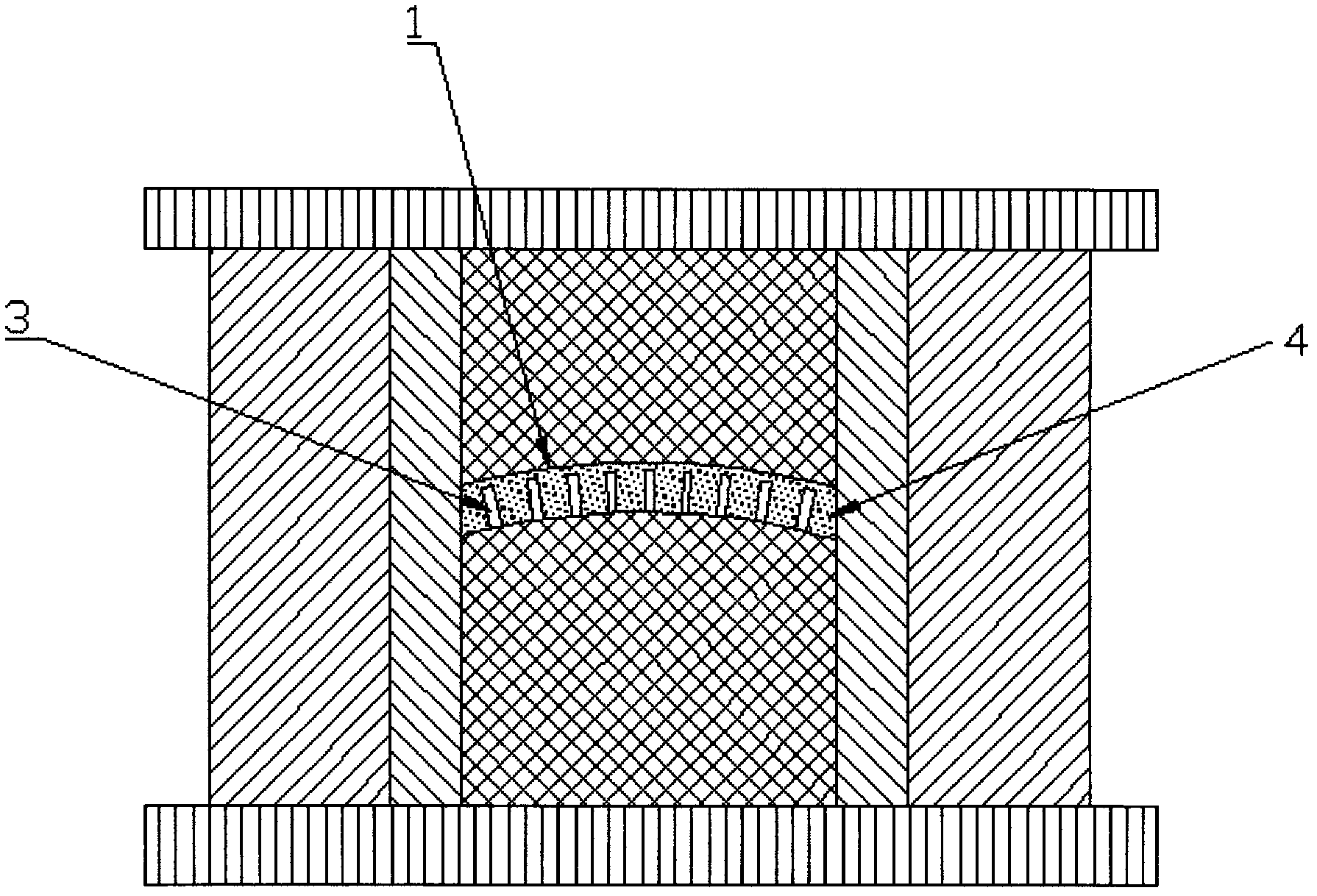

Preparation method for diamond fiber grinding wheel and section mold

InactiveCN103381577AExtended service lifeNot easy to fall offAbrasion apparatusGrinding devicesFiberSmall hole

The invention discloses a preparation method for a diamond fiber grinding wheel and a section mold. The preparation method for the diamond fiber grinding wheel comprises the following steps: step 1, preparing a grinding wheel section: uniformly fixing strip-shaped diamond fiber to the periphery of the designed section mold, wherein one end of the diamond fiber points to the center of the section mold in radiation arrangement, then adding section mold to the carcass material to perform hot press formation, so that the grinding wheel section is prepared; step 2, performing overall hot press formation for the grinding wheel section: performing hot press formation for a plurality of grinding wheel sections and grinding wheel base material to obtain the diamond fiber grinding wheel. A plurality of rows of small holes are formed in the periphery of the section mold provided by the invention; the prepared diamond grinding wheel has a long service life, the diamond cannot fall off easily, the scrap containing capacity and dissipation capacity are increased, and heat damage of the workpiece can be effectively avoided or reduced.

Owner:HUNAN UNIV OF SCI & TECH

Metal nano material composite binder and composite binder diamond grinding wheel

The invention discloses a metal nano material composite binder and a composite binder diamond grinding wheel which is produced by using the metal nano material composite binder. The metal nano material composite binder comprises, by weight percentage, 20-40% of nano materials, 20-75% of tin powder, 10-25% of copper powder, 5-20% of zinc powder, 5-10% of phosphorus powder, 3-10% of tungsten powder, 1-7% of lead powder and 1-5% of zinc borate. The grinding wheel produced by using the metal nano material composite binder is good in elasticity and polishing effect, good in self-sharpening performance, less prone to blocking, little in trimming, high in grinding efficiency and low in grinding temperature. In addition, the surface ground by the grinding wheel is high in smoothness.

Owner:GUILIN CHAMPION UNION DIAMOND CO LTD

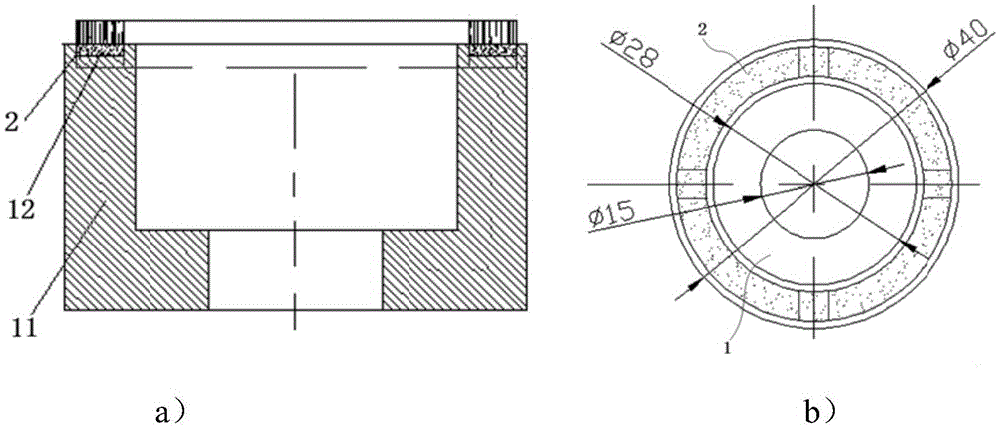

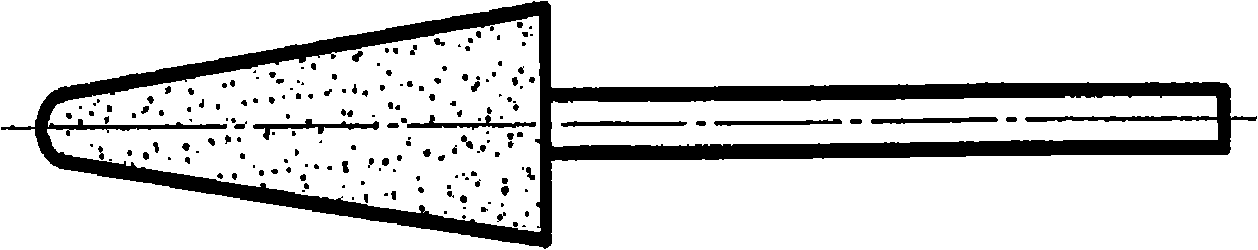

Heat pipe type superhard abrasive material grinding tool

ActiveCN101134304AExtended service lifeReduce grinding temperatureMetal working apparatusHeat flowHeat conducting

The heat pipe type superhard abrasive tool as one kind of abrasive tool includes one grinding head, one pipe union, one grinding head handle and one water jacket. The grinding head serving as the casing of heat pipe has one conic hole as the work cavity of the heat pipe and possesses high heat transferring efficiency. The abrasive tool adopts diamond or CBN with very high heat conducting capacity as the abrasive material has reduced heat resistance between the grinding arc area and the wall of the heat pipe. The cold end of the heat pipe is cooled with the water jacket, so that the work fluid may be liquefied fast, and this is favorable to grinding refractory material with high heat flow density. Adopting heat pipe as the heat conducting element can dissipate heat directly, avoid the heat damage of the superhard abrasive tool and the refractory material, and omit grinding fluid for protecting environment.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

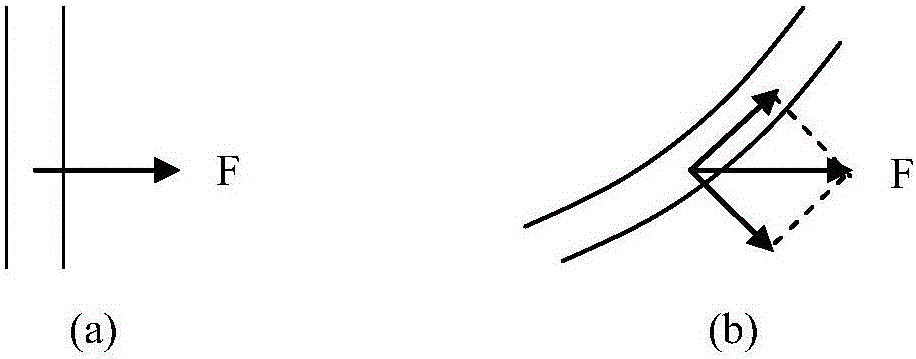

Spiral and orderly arranging fiber tool capable of conducting positive rake angle machining and preparation method thereof

InactiveCN107243848AImprove efficiencyImprove processing efficiencyBonded abrasive wheelsGrinding devicesFiberHelical line

The invention discloses a helically and orderly arranged fiber cutter capable of positive rake angle processing and a preparation method thereof. The fiber cutter includes fiber, carcass and steel matrix; the fiber is tangent to the base circle in the steel matrix, and the fiber can process the workpiece with a positive rake angle during cutting; Arranged in an orderly manner. The preparation method is as follows: the fiber is prepared by wire electric discharge cutting technology; the series of fibers are clamped and sharpened by special clamps; the matrix is prepared on the prefabricated steel base by pressing and sintering technology; A series of small holes arranged in a helical line are processed on the body; epoxy resin is injected into the small holes, the fibers are inserted into the small holes, and the embracing device is used to ensure that the blade height of the fibers is consistent; the fiber cutter is prepared by heating and curing. The helical and orderly arranged fiber cutter prepared by the invention can realize positive rake angle processing, significantly reduce cutting force and cutting temperature, and improve cutting performance.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

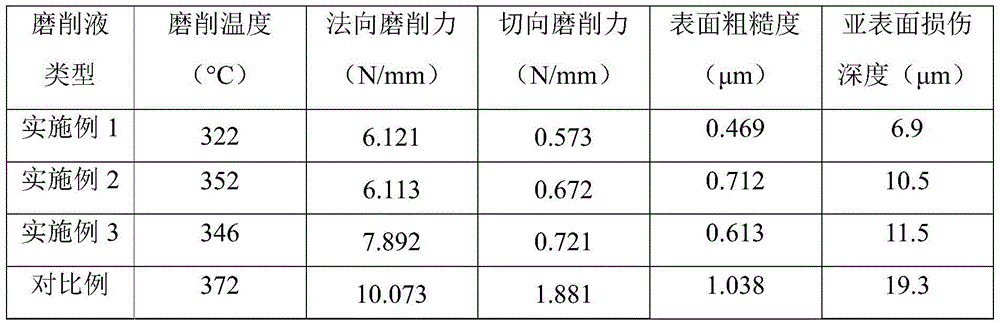

Special grinding fluid for grinding of silicon carbide ceramic by diamond grinding wheels and preparation method of special grinding fluid

ActiveCN105586142AImprove the lubrication effectImprove cooling effectAdditivesBase-materialsDimethyl siloxaneMachining process

The invention relates to a special grinding fluid for grinding of silicon carbide ceramic by diamond grinding wheels. The special grinding fluid comprises 4.8%-6.2% of fatty acid methyl ester polyoxyethylene ether, 2.5%-2.9% of an alkyl synthol alkoxy compound, 2.2%-2.5% of tungsten disulfide, 4.2%-4.4% of cyclopentasiloxane, 3.5%-3.7% of an anti-wear reagent at extreme pressure, 2.3%-3% of a corrosion inhibitor, 2.5%-3.5% of a friction modifier and the balance of deionized water. The special grinding fluid for grinding of the silicon carbide ceramic by the diamond grinding wheels has excellent lubricating, cooling and cleaning effects, has the long service cycle and can substantially reduce the grinding temperature, the normal grinding force and the tangential grinding force in the machining process of the silicon carbide ceramic, reduce abrasions of the grinding wheels, effectively improve surface quality and precision of ground surfaces of the silicon carbide engineering ceramic and the like.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

Preparing method for toughening-wear-proof abrasive material

The invention discloses a preparing method for a toughening-wear-proof abrasive material, and belongs to the technical field of abrasive material preparation. According to the preparing method, in thefermentation process of rice hull ash, nitrogen in ammonia gas is fixed in fermentation filter residues through the micro-corrosion effect of microorganisms in pericarp, and nitrogen-containing composite powder and boron-containing ceramic bond are mixed to be subjected to hot pressing sintering to form a hexagonal boron nitride crystal. In the process of preparing diamond-silicon carbide composite powder, the rice-hull-ash-containing fermentation filter residues are reduced and carbonized on the surface of diamond, compact silicon carbide is formed on the surface of the diamond, air holes can contain abrasive scraps, the exposure rate of the abrasive material in the abrasive process is higher, crystal whiskers can be generated through magnesium mine powder and boric acid in the sinteringreaction process, and can prevent the air holes from being oversize, and the toughness of the abrasive material is improved. According to the preparing method for the toughening-wear-proof abrasive material, the holding force of the bond in a man-made abrasive material for the abrasive material is improved at suitable air hole rate, the wear-proof performance of the man-made abrasive material isimproved accordingly, abrasion is reduced, and application prospects are broad.

Owner:史茜赟

MC (Monomer Casting) nylon glass polishing disc and manufacturing method thereof

InactiveCN103072097AHigh porosityLong lasting glossFlexible-parts wheelsGrinding devicesPorosityHeat conducting

The invention relates to an MC (Monomer Casting) nylon glass polishing disc and a manufacturing method thereof. The MC nylon glass polishing disc is characterized in that the raw materials of the polishing disc consist of abrasive particles, filling materials, caprolactam monomers, a catalyst and a cocatalyst, wherein the abrasive particles are aluminum oxide-cerium oxide nuclear shell composite abrasive particles, and the filling materials consist of heat conducting filling materials, active filling materials and a water-soluble pore forming agent. The MC nylon glass polishing disc has the advantages that 1, the porosity of an abrasive tool is high and the chip holding is facilitated; 2, the temperature of a grinding area is low and a workpiece is not ruptured; and 3, the wear resistance of a bonding agent is high and the service life of the abrasive tool is long.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

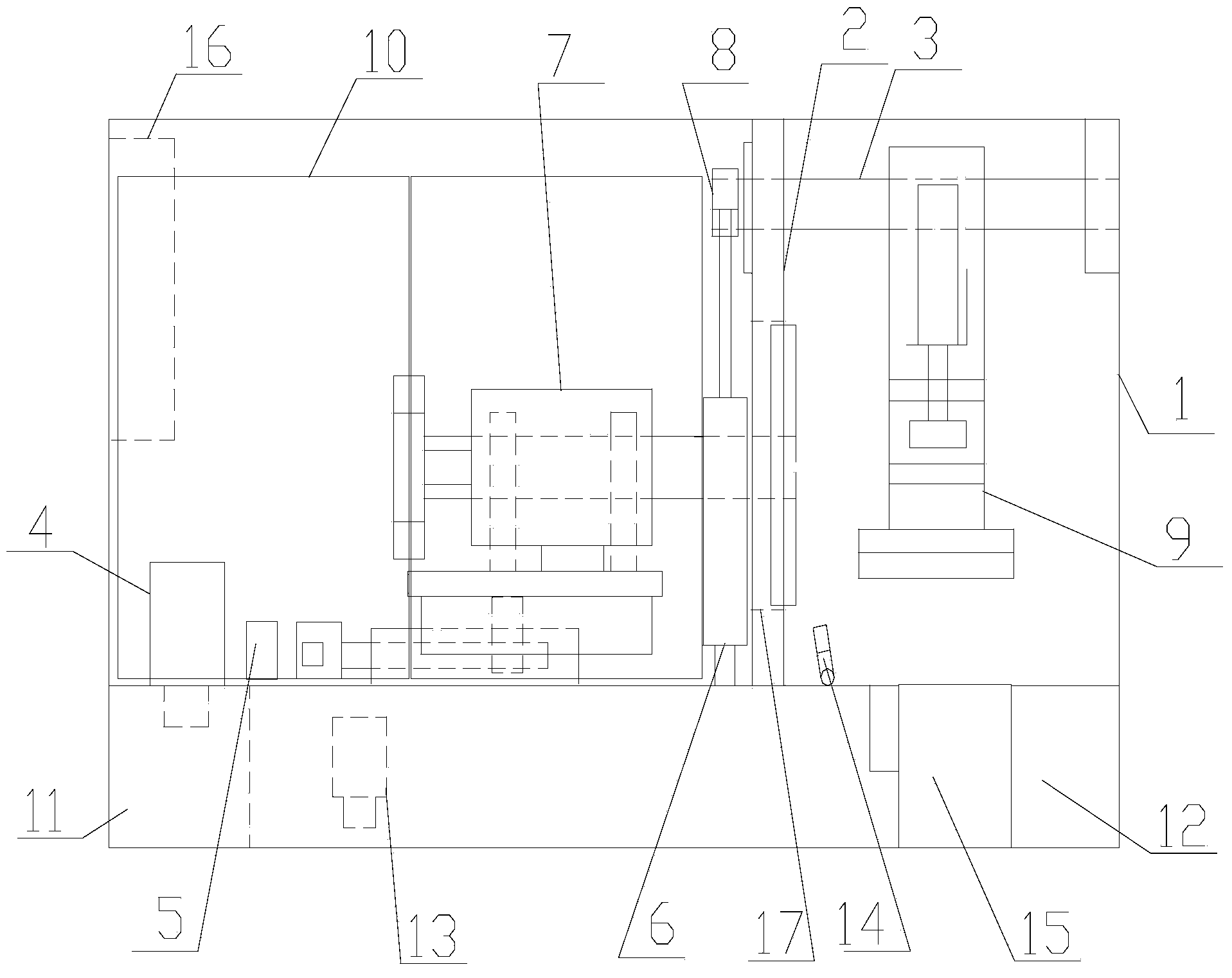

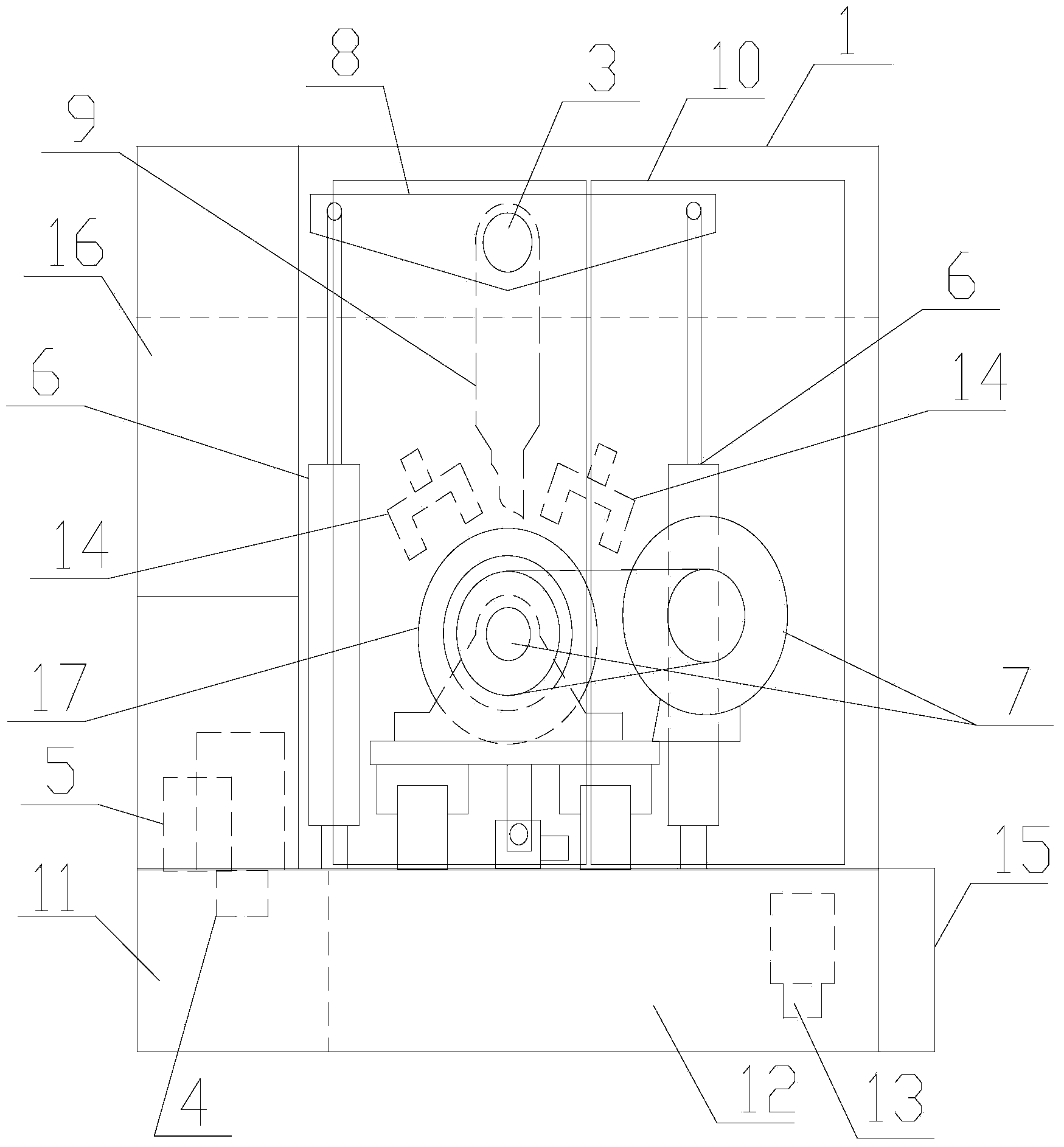

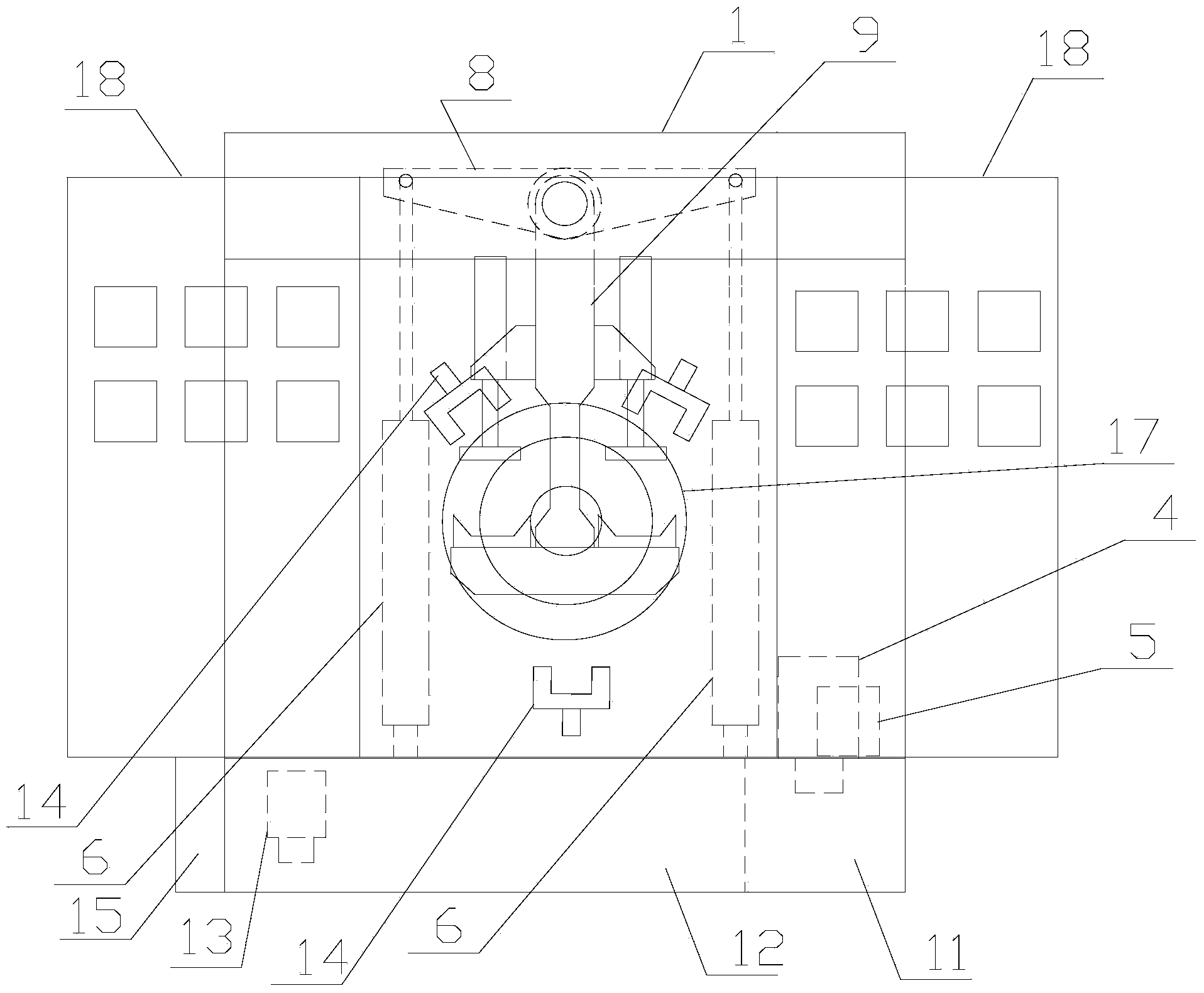

Spring grinding machine

InactiveCN103639862AReduce usageLow investment costPlane surface grinding machinesGrinding/polishing safety devicesHydraulic cylinderFuel tank

The invention discloses a spring grinding machine. The spring grinding machine comprises a first frame body, a partition board, a connecting shaft, a first motor pump set, a valve set, a first hydraulic cylinder, a grinding machine device, a connecting arm, a support base, a protection door, an oil tank, a water tank, a second motor pump set, a water injection nozzle, an abrasive dust separating device, an electric appliance cabinet and a through hole, wherein the input end of the first motor pump set is connected with the oil tank, the output end of the first motor pump set is connected with the input end of the valve set, the output end of the valve set is connected to the first hydraulic cylinder, the input end of the second motor pump is connected with the water tank, the output end of the second motor pump set is connected with the water injection nozzle, the first frame body is supported by the oil tank and the water tank, the abrasive dust separating device is arranged on the side face of the water tank, the partition board, the grinding machine device and the water injection nozzle are arranged inside the first frame body, the partition board is provided with the connecting shaft, the through hole and the water injection nozzle, the connecting arm and the support base are arranged on the connecting shaft, a piston rod of the first hydraulic cylinder is connected with the connecting arm in a rotary mode, and the protection door and the electric appliance cabinet are arranged on the first frame body.

Owner:ZHUJI GUANGXIN AUTOMATION EQUIP

High-durability ceramic grinding tool

The invention discloses a high-durability ceramic grinding tool which is characterized by comprising the following components in parts by weight: 11-27 parts of zirconite, 31-50 parts of calcite, 3-14 parts of ethylene copolymer elastomer, 1-9 parts of closed-cell perlite, 15-45 parts of borate glass, 5-17 parts of solid paraffin, 11-25 parts of tourmaline concentrate micropowder, 3-4 parts of molybdenum disilicide, 34-61 parts of spodumene, 11-31 parts of mica, 3-5 parts of zinc oxide, 5-12 parts of ferric sodium pyrophosphate, 1-3 parts of calcium hydrogen phosphate and 5-9 parts of cryolite. The high-durability ceramic grinding tool has the advantages of sharp grinding grains, low trimming frequency, favorable sharpness, low grinding temperature, favorable toughness, low abrasion, high durability and long service life, and can be used for high depth, roughing feed, heavy load and high efficiency grinding.

Owner:QINGDAO XIANGHAI ELECTRONICS

Preparation method for wear-resisting man-made oilstone

ActiveCN108247553APromote densificationImprove cooling effectAbrasion apparatusGrinding devicesSilicon dioxideFermentation

The invention relates to a manufacturing method of grinding materials and grinding tools, in particular to a preparation method for wear-resisting man-made oilstone. According to the preparation method, silicon dioxide, aluminum oxide, zirconium oxide and boric acid serve as main raw materials, ball milling powder is processed to obtain ceramic binder fragments, the ceramic binder fragments are subject to ball milling, drying and screening to obtain ceramic binder powder, rice hull ash is used as a raw material, palm wax and pericarp are added, fermentation is carried out under the ammonia atmosphere to obtain fermentation filter residues, the fermentation filter residues and diamond particles are mixed to obtain rigid powder, diamond-silicon carbide composite powder is obtained through roasting, and then the diamond-silicon carbide composite powder and additives such as magnesia powder and white corundum are mixed to obtain a to-be-sintered material; and finally, the to-be-sintered material is placed into a graphite jig, the wear-resisting man-made oilstone is obtained through processing, in the rice hull ash fermentation process, the micro rotting effect of microorganisms in thepericarp is used for fixing nitrogen in ammonia gas into the fermentation filter residues, the wear-resisting property of the man-made oilstone and the grinding effect on the high-hardness materials are improved, and the application prospect is wide.

Owner:义乌市安航科技有限公司

Glass polishing disk and manufacturing technique thereof

InactiveCN104759995ALong continuous grinding timeGrinding speed is fastAbrasion apparatusGrinding devicesSodium phosphatesMetallurgy

The invention discloses a glass polishing disk and a manufacturing technique thereof and belongs to the technical field of abrasive substance. The polishing disk comprises curing agent, pore forming agent, padding, initiating agent, cleaning agent and abrasive particles, the abrasive particles are Fe2O3 / SiO2 nanometer composite particles, and the padding comprises heat absorbent composed of sodium acetate trihydrate and sodium phosphate dibasic dodecahydrate. The manufacturing technique includes steps that 1, adding initiating agent-cobalt naphthenate, pore forming agent and heat absorbent to the curing agent; 2, adding the abrasive particles, initiating agent-cyclohexanone peroxied and cleaning agent; 3, pouring mixed slurry into a die, curing, and slicking the slurry. According to the glass polishing disk, the gap distribution in the polishing disk is uniform, the abrasive particle distribution is uniform, the workpiece polishing precision is high, the raw material cost is low, and the production technique is simple.

Owner:ANYANG INST OF TECH

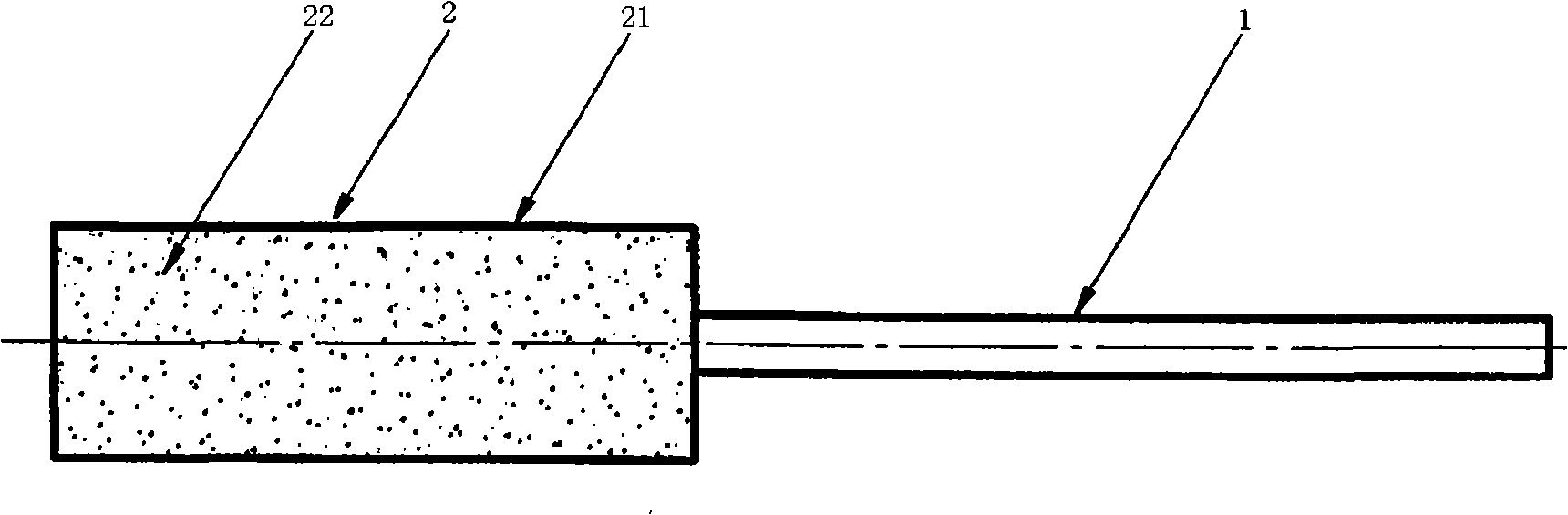

Ultra-hard diamond grinding wheel free of binding agent and manufacturing method of ultra-hard diamond grinding wheel

ActiveCN105538173AHigh strengthEvenly distributedBonded abrasive wheelsGrinding devicesUltimate tensile strengthChemical vapors

The invention discloses an ultra-hard diamond grinding wheel free of a binding agent and manufacturing method of the ultra-hard diamond grinding wheel. The ultra-hard diamond grinding wheel free of the binding agent comprises a metal base body and a grinding material layer fixed to the metal base body. The grinding material layer is a polycrystalline chemical vapor deposited (CVD) diamond piece free of the binding agent. Grinding particles and chip grooves are machined in the working surface of the grinding material layer. In this way, the ultra-hard grinding wheel free of the binding agent is manufactured by machining the grinding particles and the chip grooves manually, and the strength of the grinding wheel is improved. The grinding particles and chip grooves of the grinding wheel are evenly distributed and are highly consistent, and thus the grinding force can be effectively reduced and the grinding temperature is decreased during grinding.

Owner:HUNAN UNIV

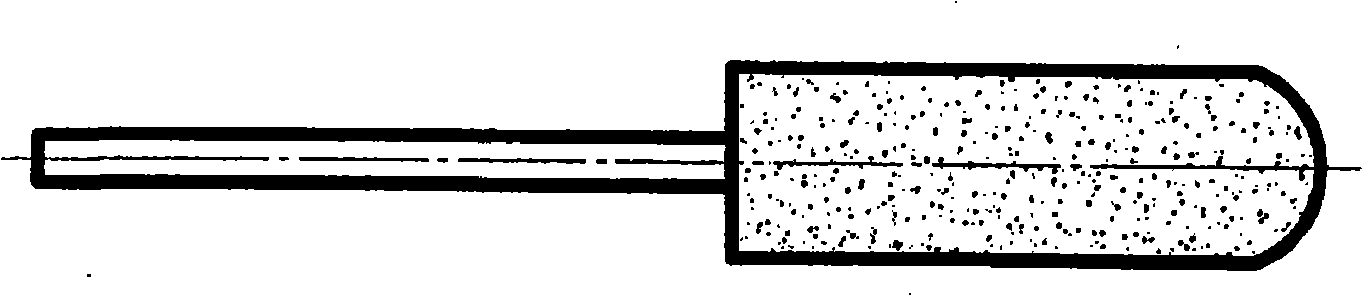

Soft projectile body polishing grinding head

InactiveCN101274420AGood flexibilityImprove flexibilityGrinding machine componentsTwist drillsElastomerEngineering

The invention relates to a soft elastomer polishing head which comprises a rotor shaft connected with a motor and a polishing head arranged on the other end of the rotor shaft, and is characterized in that: the polishing head consists of an abrasive core fixedly arranged on the rotor shaft and abrasive particles evenly embedded into the surface of the abrasive core; the material of the abrasive core is elastic rubber plastic; the abrasive particles are acicular and acicular blades thereof face outwards; the abrasive core adopts the material of EVA rubber plastic and the abrasive particles are evenly embedded into the surface of the abrasive core by adopting an electrostatic sand-planting method.

Owner:SHANGHAI MARITIME UNIVERSITY

Self-lubricating wheel

InactiveCN103419142AEnhanced Lubrication BehaviorAvoid heat damageAbrasion apparatusGrinding wheelLubrication

The present invention relates to a self-lubricating wheel, comprising: a substrate, a binding agent, an abrasive and an additive, wherein the total content of the substrate is at least 55 weight percent by weight, and the binding agent, the abrasive and the content of the additive is less than 45 weight percent of the total weight. Thus, self-lubricating wheel of the invention can be mixed with additives to provide lubrication between the grinding wheel and the workpiece, and improve the flatness of the surface of the workpiece.

Owner:RITEDIA CORPORATION

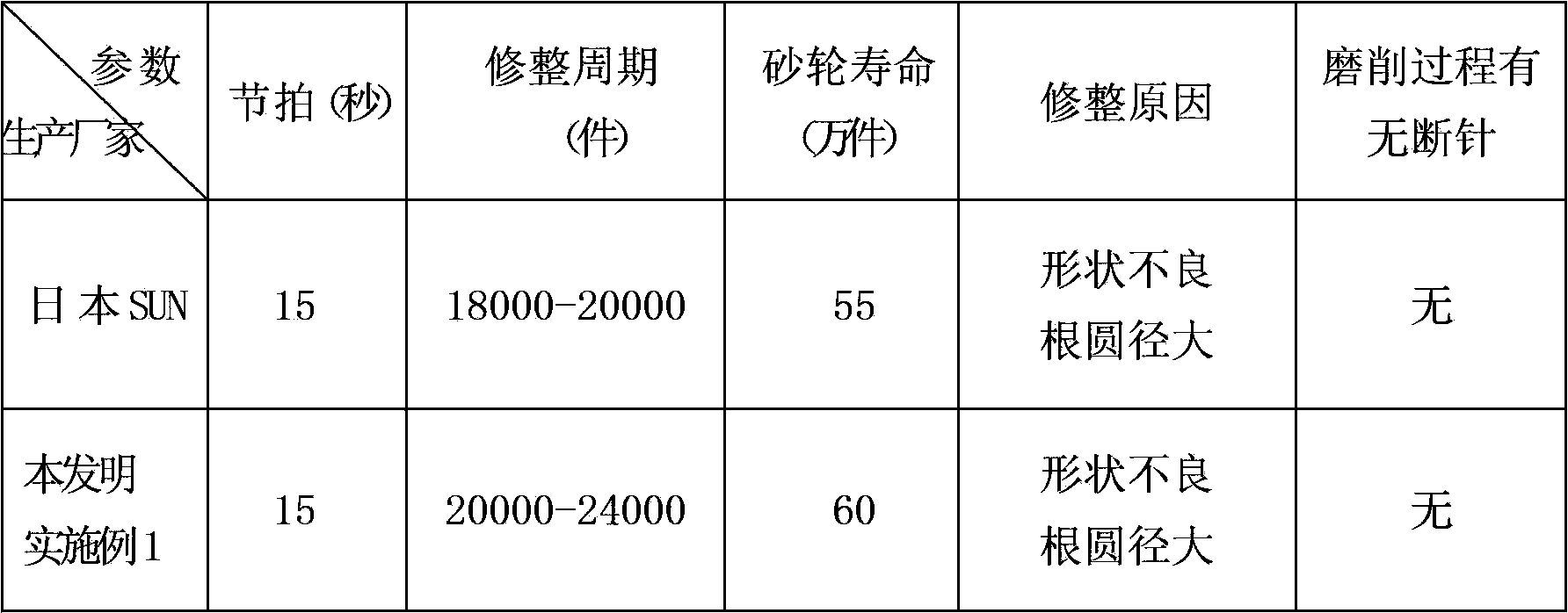

High-precision resin diamond micro-drilling excircle grinding wheel and application

ActiveCN103567889AImprove toughnessReduce needle breakageAbrasion apparatusDrilling toolsEngineeringGrinding wheel

The invention discloses a high-precision resin diamond micro-drilling excircle grinding wheel and an application. By means of the grinding wheel and the application, the problem that product machining efficiency is low, rejection rate is high, a cutting edge is not sharp and the like due to the fact that a printed circuit board (PCB) drill material is high in hardness, abrasion resistance and brittleness and small in drill edge diameter (0.10-6.50mm) and the like is solved. The grinding wheel is composed of a base body and a work grinding material layer. The work grinding material layer comprises, by weight, 50-70% of resin binder, 10-20% of white corundum, 1-5% of nanoscale MgO, 5-15% of copper powder, 1-10% of nanoscale TiO2, 10-20% of diamond and 5-10% of CBN. The grinding wheel has the advantages of being high in grinding efficiency; being good in grinding wheel shape retention and high in abrasion resistance; being low in grinding temperature and good in heat conduction; being high in ground workpiece precision and sharp in cutting edge; greatly reducing rejection rate caused by needle breaking.

Owner:沈阳中科超硬磨具磨削研究所

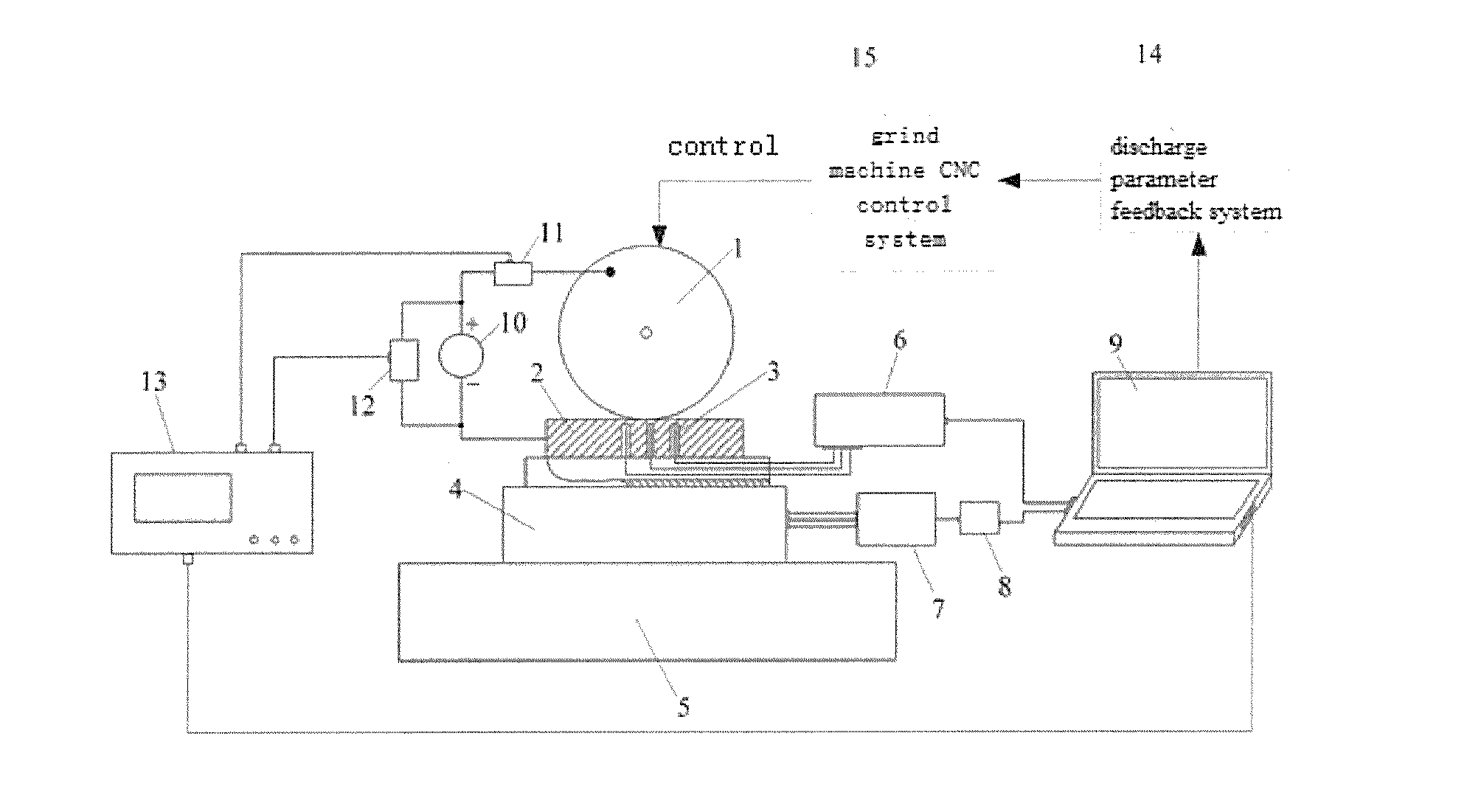

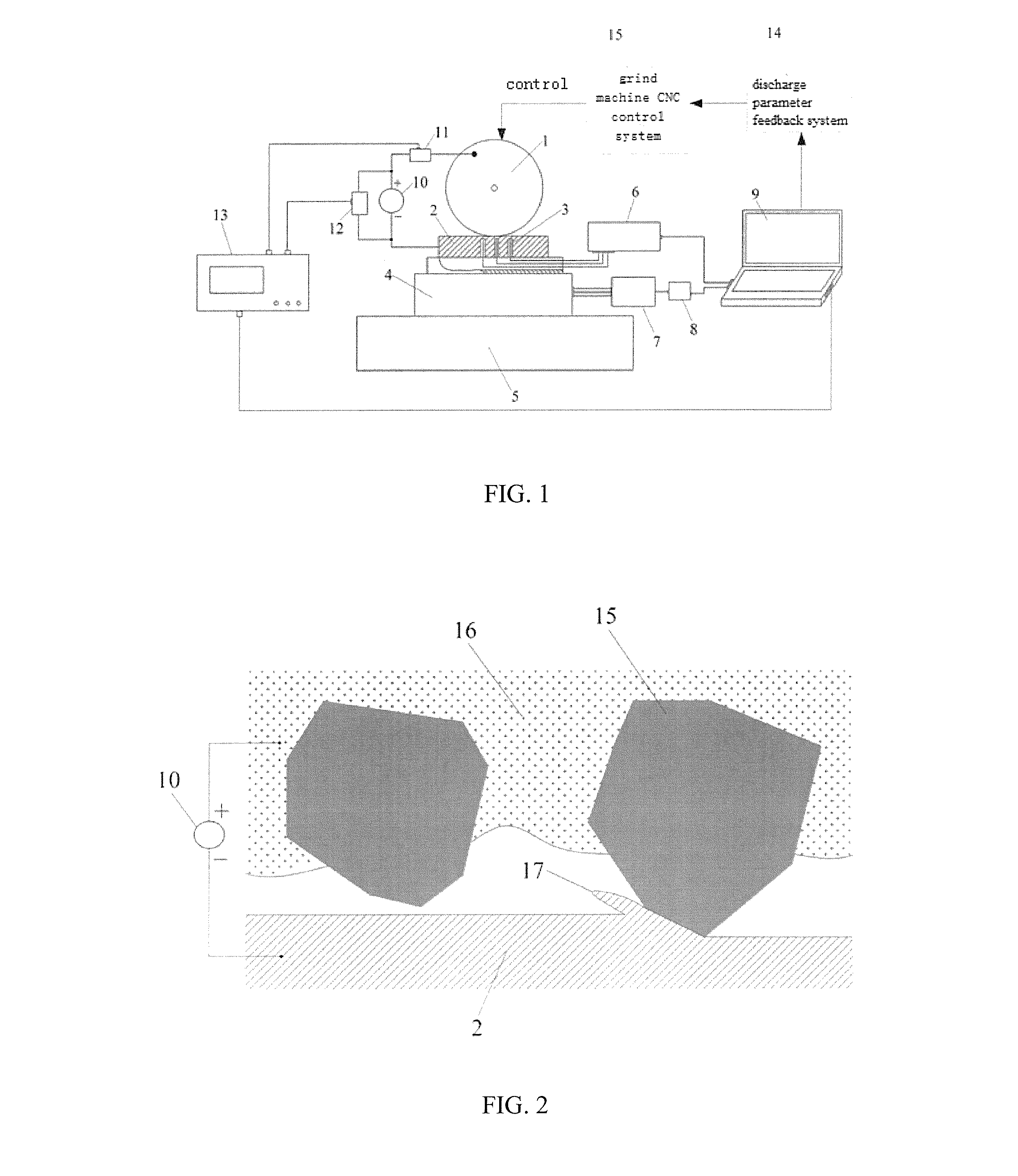

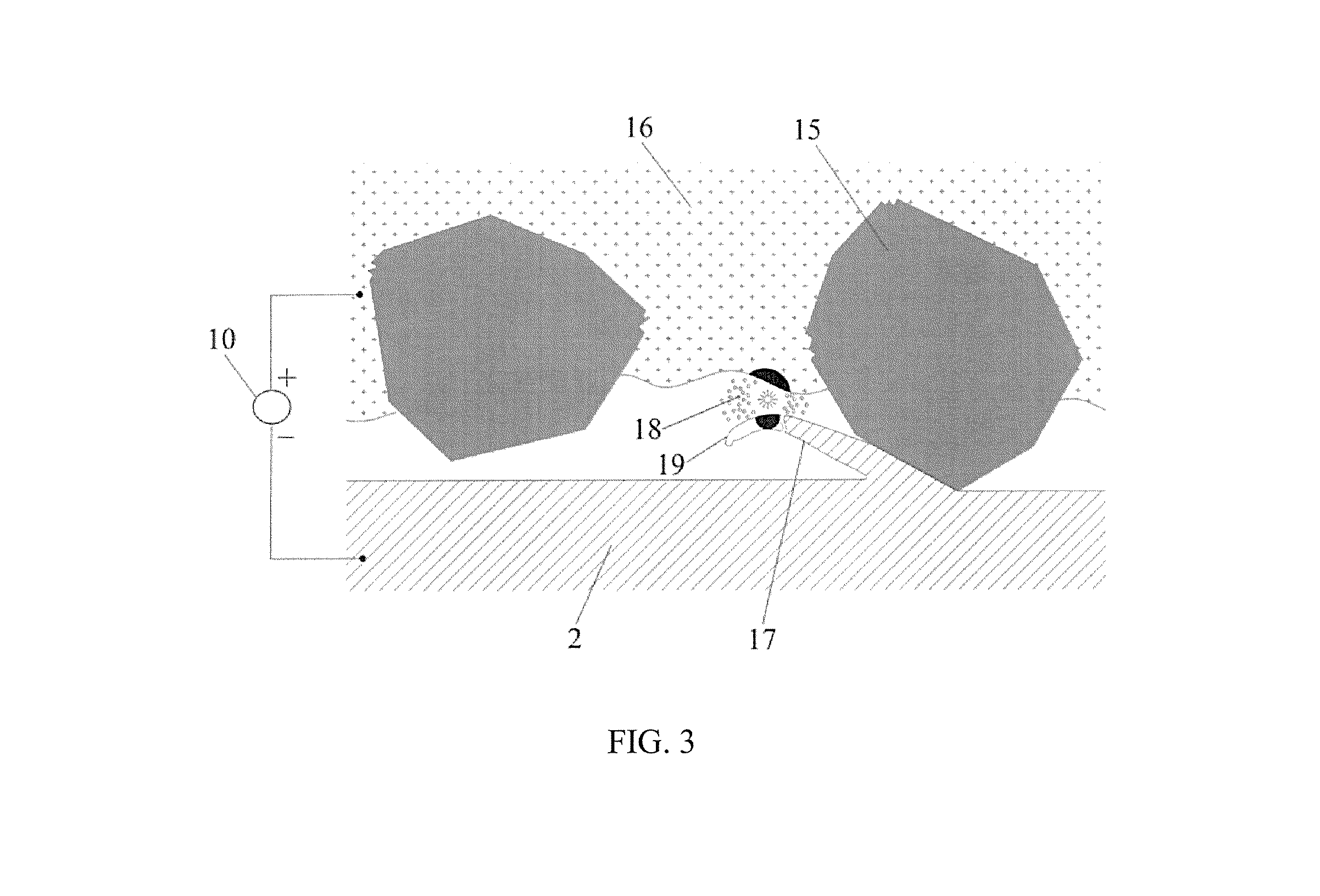

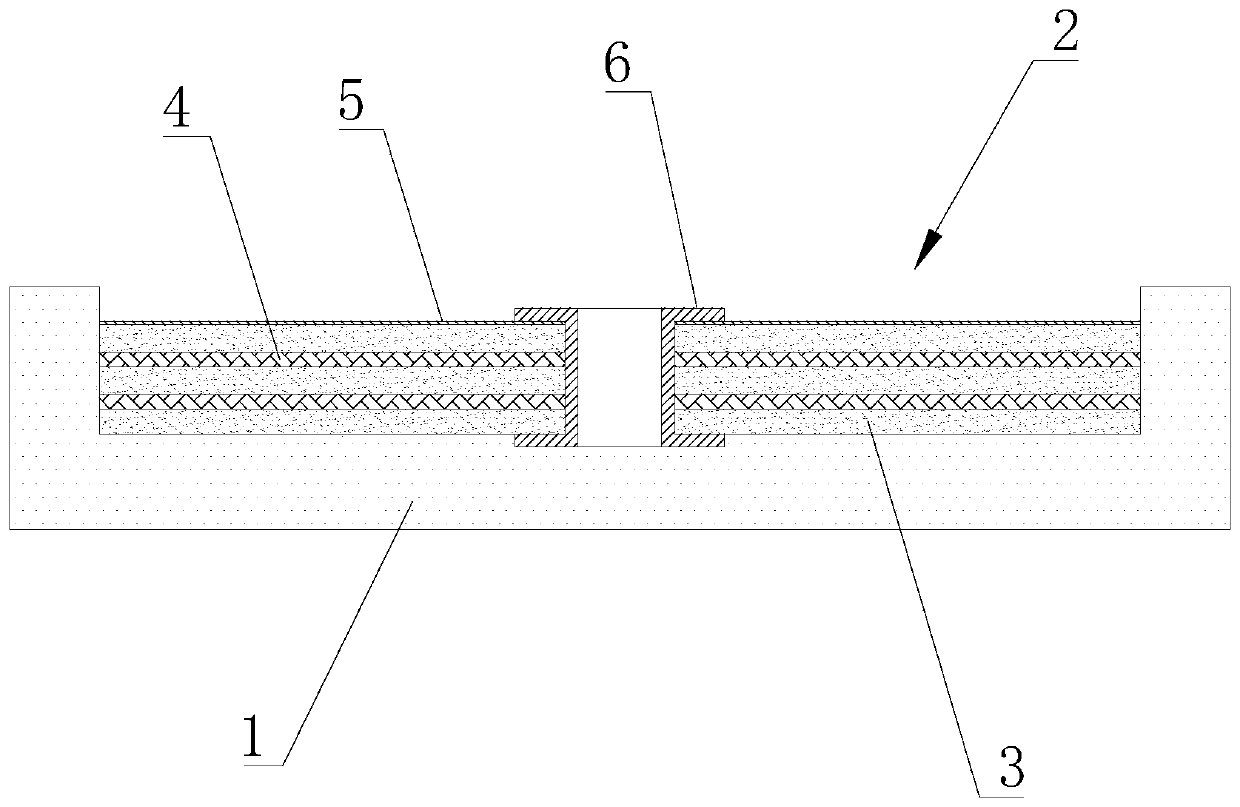

Intelligent Grinding Device for Short Pulse Electrical Melt Chip Removal Cooling

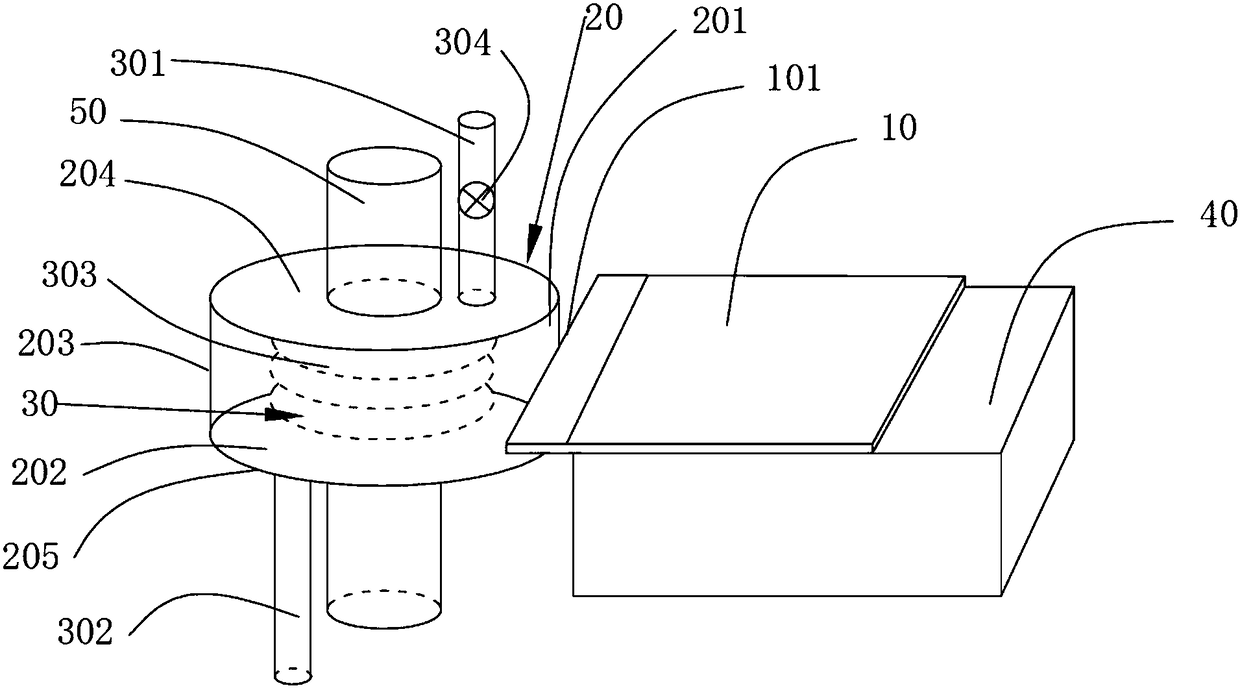

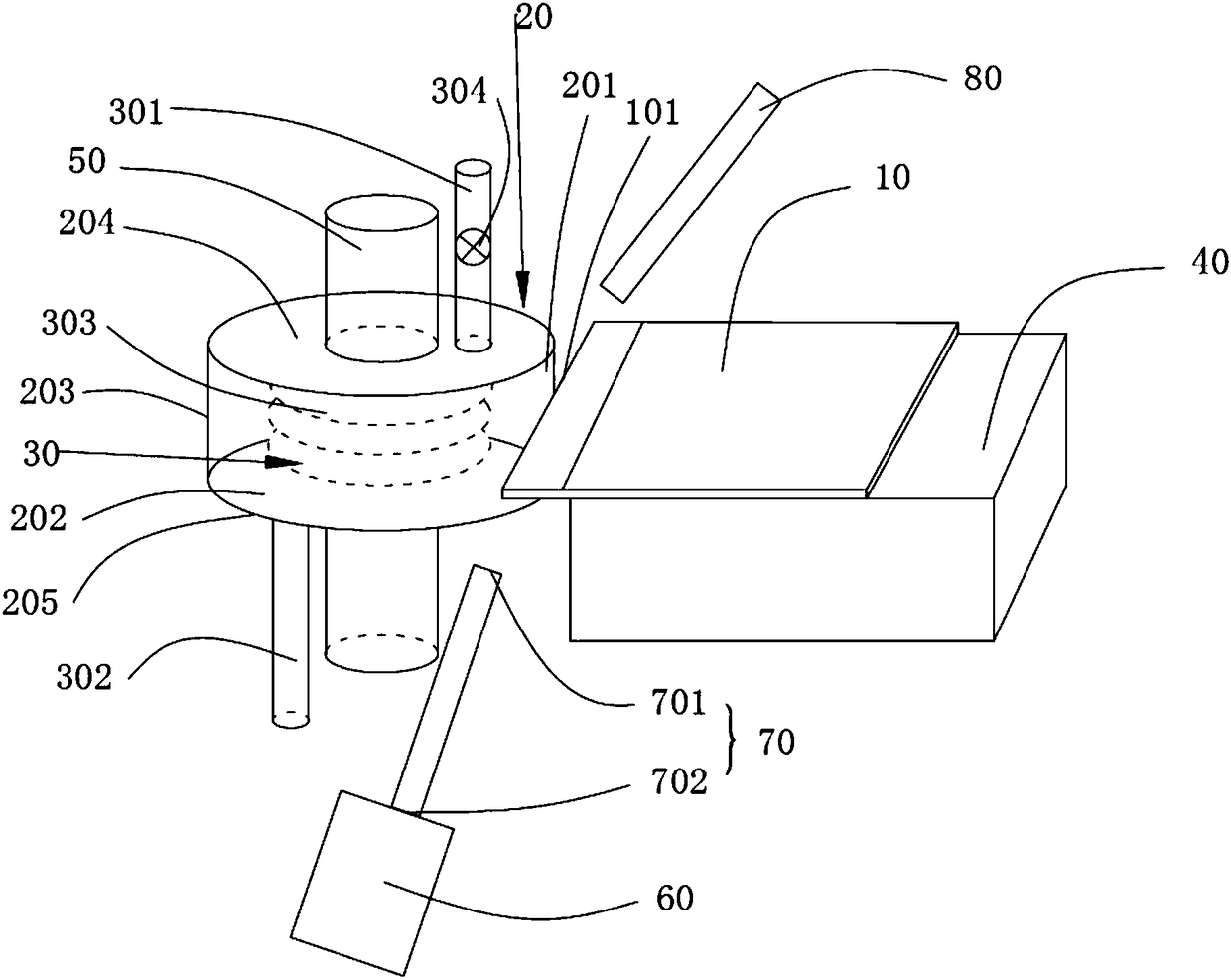

ActiveUS20170014967A1Reducing grinding forceReduce grinding temperatureGrinding feed controlGrinding machinesEngineeringPulse power supply

An intelligent grinding device for short pulse electrical melt chip removal cooling, includes a diamond grinding wheel, a pulse power supply, a force meter sensor, thermocouple in a hole of work piece for measuring machining temperature, a voltage sensor, a current sensor, a temperature collecting card, a charge amplifier, a force meter, a digital oscilloscope and a discharge parameter feedback adjustment system. The pulse power supply has a positive pole connecting with the grinding wheel, and a negative pole connecting with the work piece. The voltage sensor and the current sensor respectively put collected discharge voltage and current wave of the discharge circuit to be stored in a display terminal through the digital oscilloscope. The thermocouple connects with the display terminal by the temperature collecting card.

Owner:SOUTH CHINA UNIV OF TECH

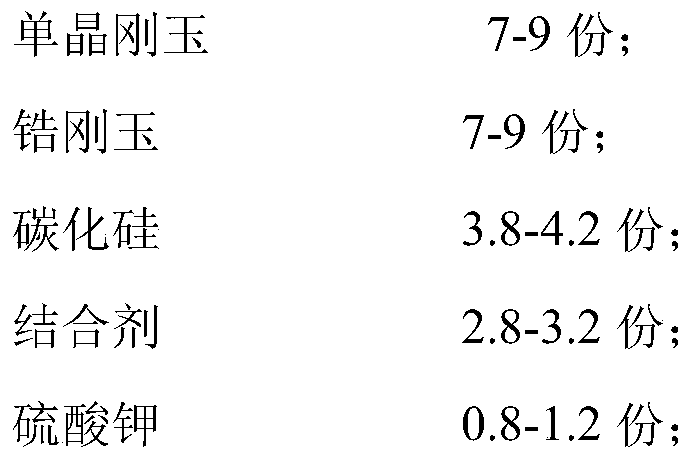

Resin grinding wheel for steel rail cutting and manufacturing method of resin grinding wheel

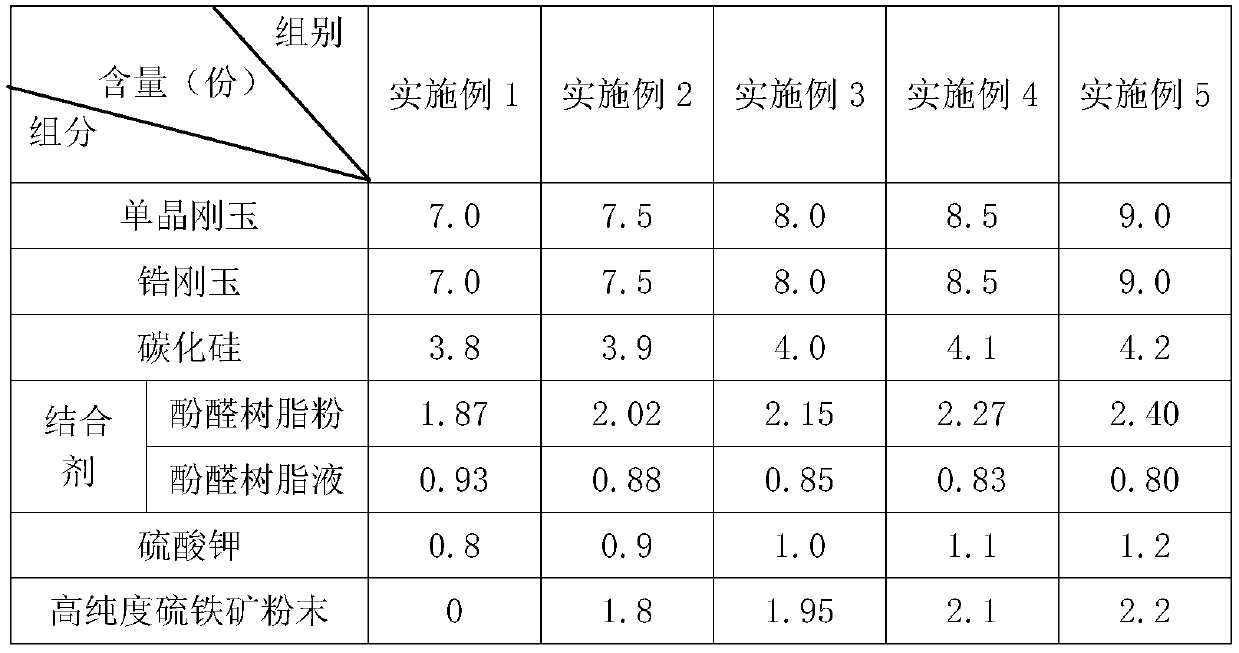

InactiveCN110497326AHigh hardnessImprove toughnessBonded abrasive wheelsGrinding devicesZirconia aluminaPotassium sulfate

The invention discloses a resin grinding wheel for steel rail cutting and a manufacturing method of the resin grinding wheel, and relates to the technical field of grinding wheel manufacturing and production. The formula includes the following components of, in parts by weight, 7 - 9 parts of monocrystalline fused alumina, 7 - 9 parts of fused zirconia alumina, 3.8 - 4.2 parts of silicon carbide,2.8 - 3.2 parts of a binding agent and 0.8 - 1.2 parts of potassium sulfate, wherein the binding agent comprises phenolic resin powder and phenolic resin liquid, and the weight part ratio of the phenolic resin powder to the phenolic resin liquid is 2 : 1 - 3 : 1. The manufacturing method of the resin grinding wheel for steel rail cutting comprises a material mixing process and a forming process, wherein the material mixing process comprises the following steps of A1, mixing and preparing a pre-mixing material; A2, mixing a coarse grinding material; and A3, screening the coarse grinding material; and the forming process comprises the following steps of B1, paving a forming material; B2, carrying out pressurizing and forming; and B3, carrying out drying and hardening. The resin grinding wheel for the steel rail cutting has the technical effects that the cutting efficiency is high, the resin grinding wheel is not easy to wear, so that the service life is long.

Owner:NO 2 GRIND WHEELS FACTORY & SHENZHEN UNION CO

Grinding device

ActiveCN108145600AExtend your lifeImprove yieldEdge grinding machinesGrinding feed controlEngineeringGrinding wheel

The invention provides a grinding device for grinding a glass substrate. The grinding device includes a fixedly disposed grinding wheel, a cooling tube and a movable platform deck; the glass substrateis disposed on the platform deck, and the grinding wheel is provided with a peripheral grinding surface; the glass substrate is driven by the platform deck to move, so that the peripheral grinding surface of the grinding wheel grinds the surface to be ground of the glass substrate; and the grinding wheel is further provided with a cavity, and the cooling tube containing cooling liquid is disposedin the cavity to reduce a temperature of the cavity, so that the temperature of the peripheral grinding surface of the grinding wheel and the surface to be ground of the glass substrate is lower thana preset temperature during grinding. According to the grinding device, the technical problem that the grinding temperature of the grinding wheel and the glass substrate is higher is solved, and theservice life of the grinding wheel and the yield rate of the glass substrate are improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Reactive type water-based metal grinding fluid and preparation method thereof

InactiveCN101812366ANo pollution in the processNo pollution, no harm to human bodyLubricant compositionWater basedMetal working fluid

The invention relates to a water-based metal grinding fluid and a preparation method thereof. The water-based metal grinding fluid comprises the components of sodium tetraborate, boric acid, a solvent, triethanolamine, a sodium salt with slow release function, a corrosion inhibitor, a water-based defoamer, preservative and deionized water. The grinding fluid greatly improves the machining precision and the surface finish quality of a workpiece, and effectively eliminates surface sewages of the workpiece. Through practical application tests by many enterprises, the use effect of the grinding fluid achieves the engineering level of an imported fully synthetic water-based grinding fluid, and the water-based metal grinding fluid can be used for effectively replacing an imported high-grade fully synthetic water-based metal grinding fluid, thereby greatly lowering the production cost of grinding machining.

Owner:BEIJING CARL RES INST FOR CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com