Lubricating and cooling method for cutting process and device thereof

A cutting and cutting fluid technology, used in lubricating compositions, metal processing equipment, metal processing machinery parts, etc., can solve the problems of accelerated metal workpiece rusting, high cost of liquid nitrogen cooling, and unsatisfactory cooling effect. , to achieve the effect of improving the lubrication state, reducing the processing cost and reducing the friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

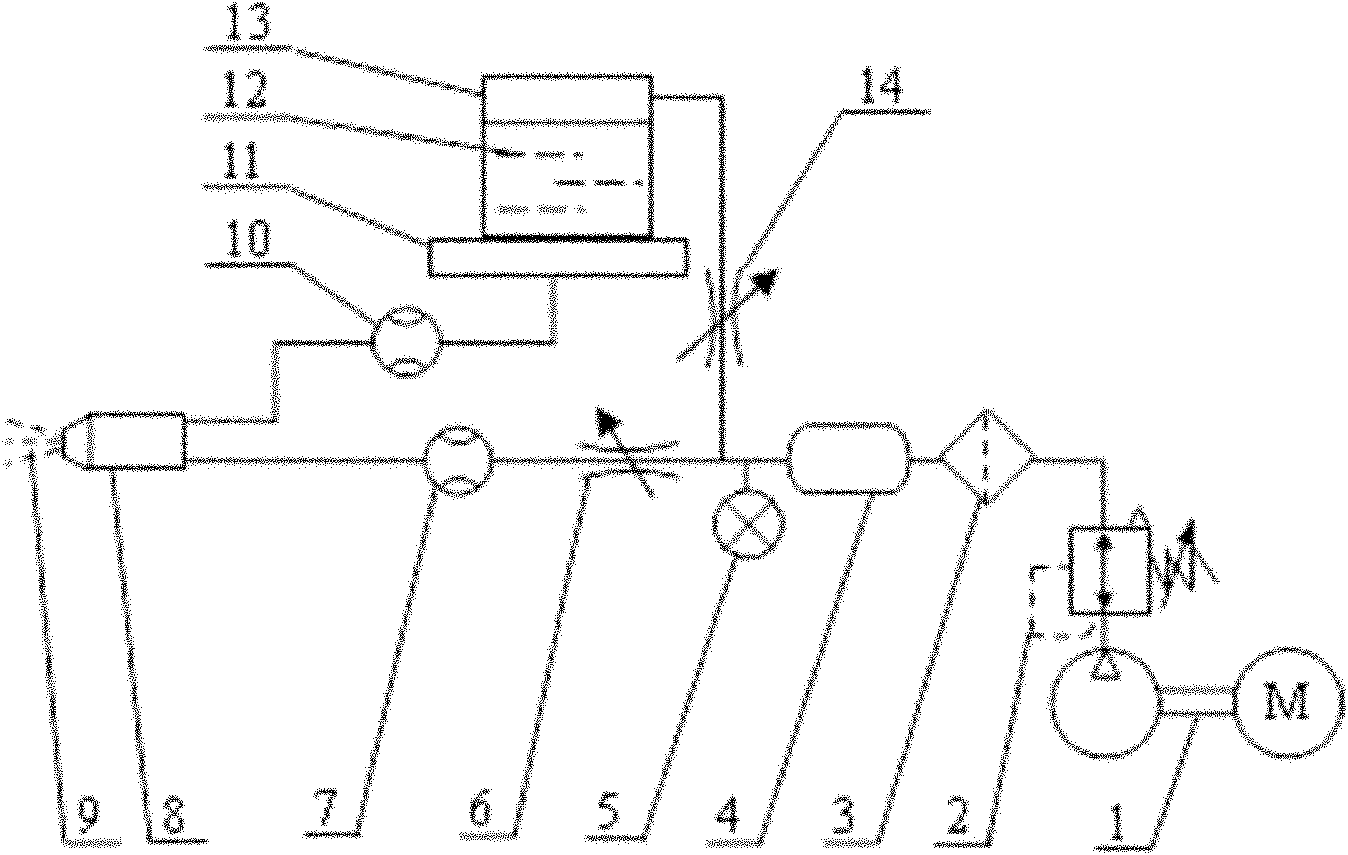

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

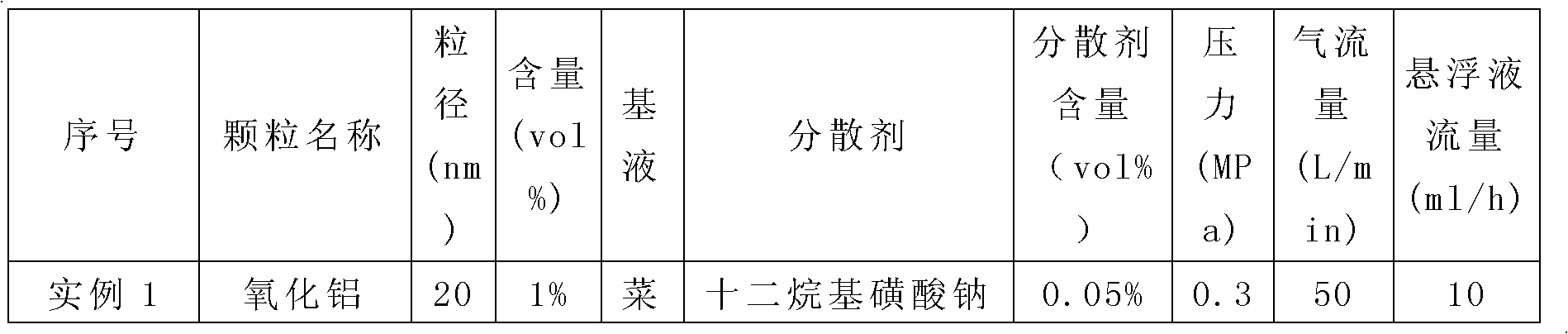

[0021] The method for lubricating and cooling the cutting process that the present invention adopts is; adding vegetable oil (such as rape oil, camellia oleifera oil or castor oil) or deionized water with a volume ratio of 1 to 5% and a particle diameter of 20-40 nanometers Nanoparticles (such as aluminum oxide Al 2 o 3 , multi-walled carbon nanotubes or zinc oxide ZnO), and then add a dispersant (such as sodium dodecylsulfonate SDBS, chemically pure, anionic; or hexadecyltrimethyl bromide) with a volume ratio of 0.05 to 0.15%. Ammonium chloride CTAB, chemically pure, cationic) and ultrasonic vibration with a frequency of 10-40KHz to obtain a uniform and well-dispersed oil-based (or water-based) nanoparticle suspension, compressed at a pressure of 0.3-1MPa Under the action of air, the nano-particle suspension is fully atomized into mist parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com