Patents

Literature

88results about How to "Increase jet velocity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

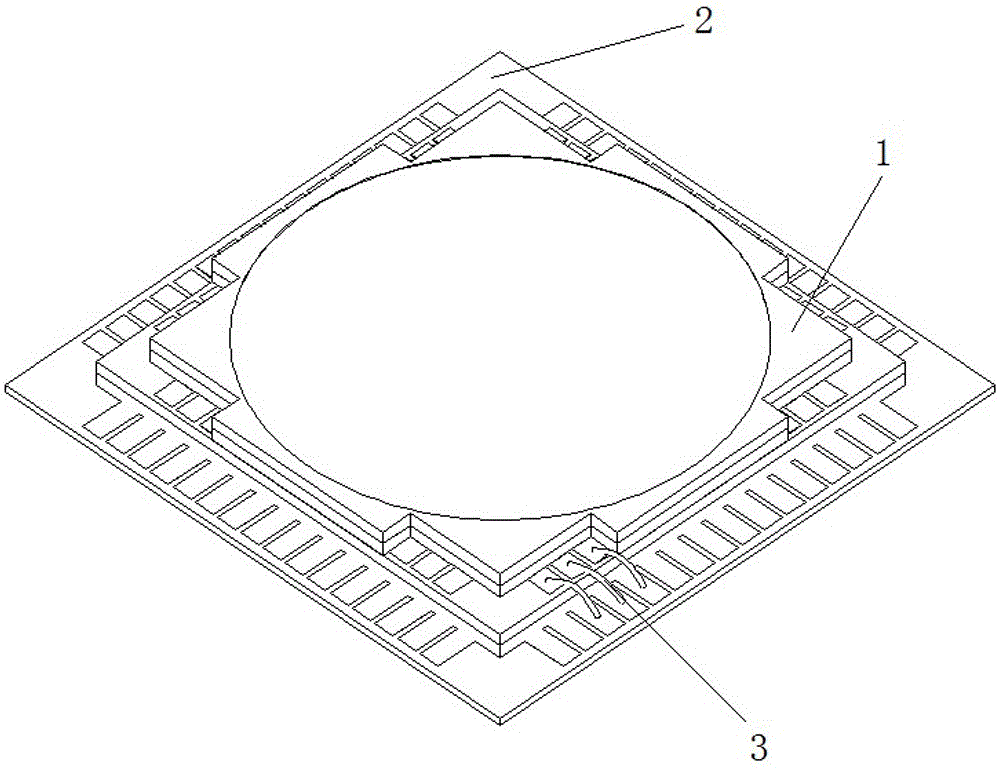

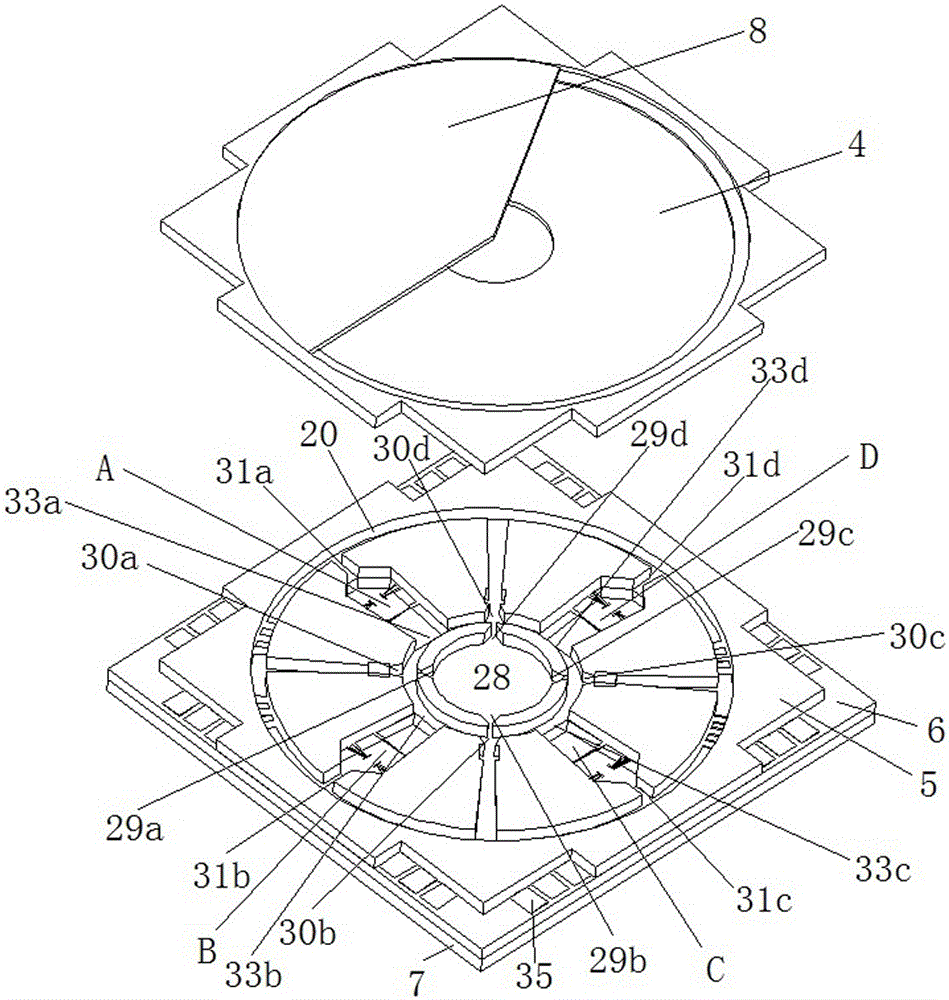

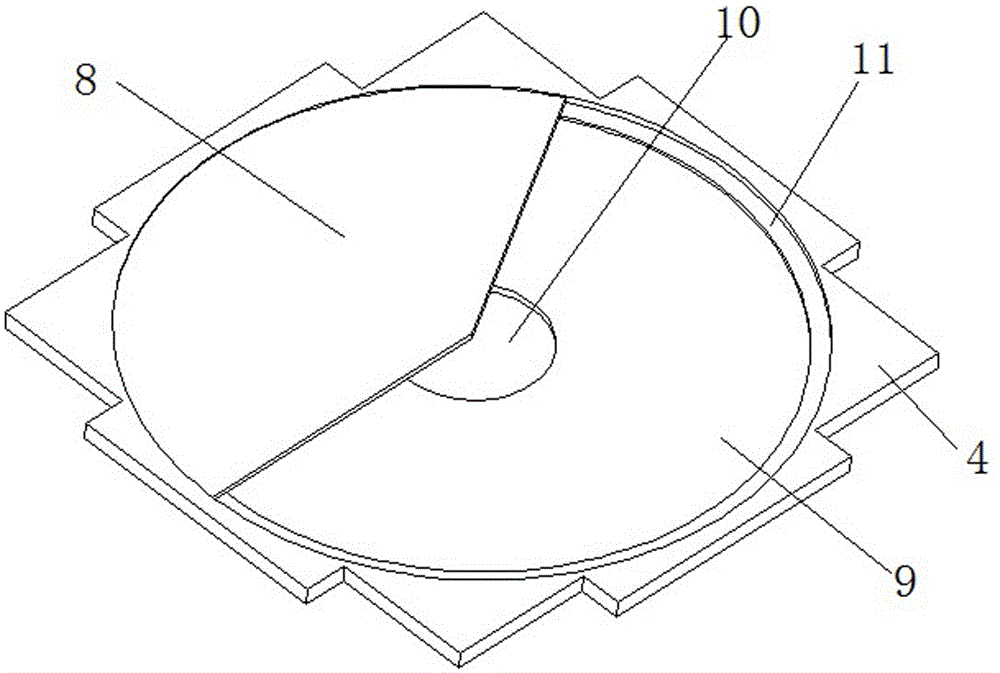

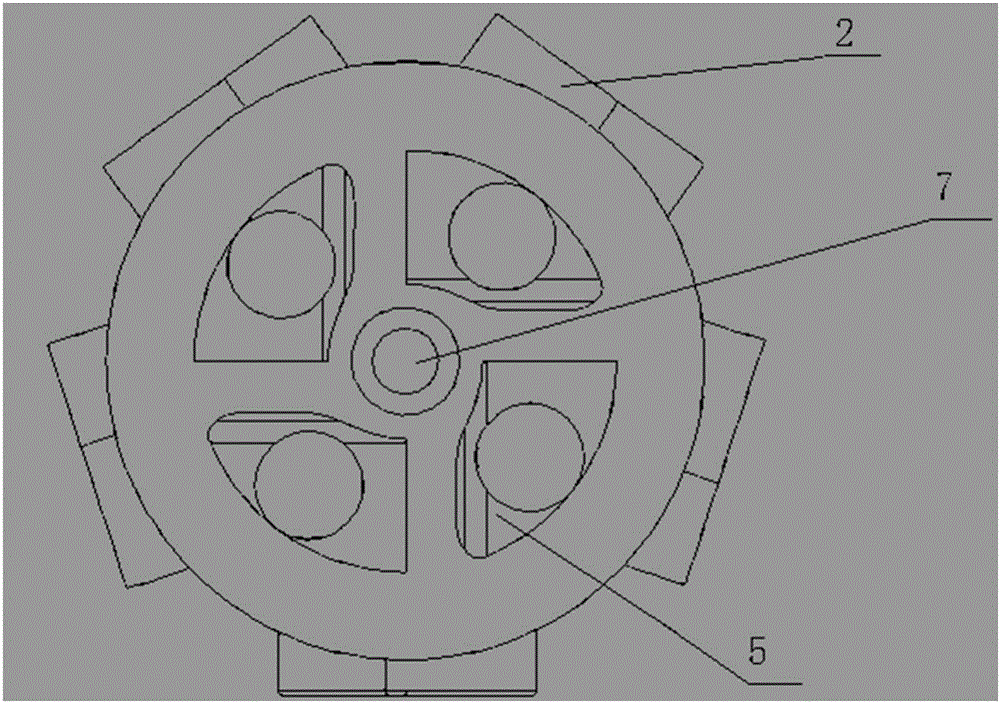

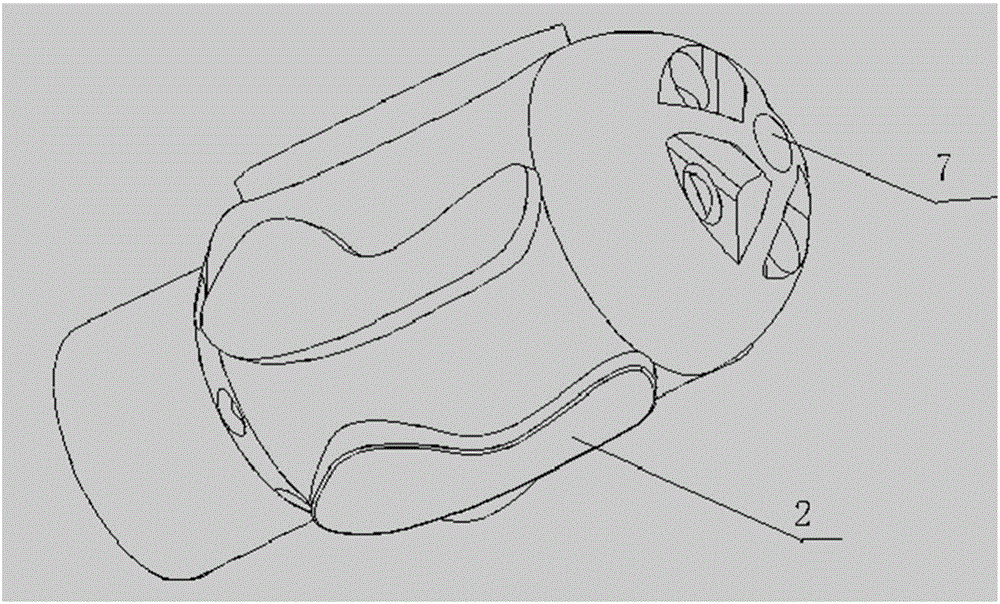

Miniature four-channel circular flow type triaxial silicon jet gyro

InactiveCN105091876AIncrease the areaImprove driving abilityTurn-sensitive devicesElectricityJet flow

The application exposes a miniature four-channel circular flow type triaxial silicon jet gyro; the jet gyro comprises a four-channel circular flow type triaxial angular velocity sensitive element and a PCB, and the sensitive element is electrically connected with the PCB, wherein the sensitive element comprises a PMMA upper cover, an upper silicon board, a lower silicon board, a PMMA bottom cover and a piezoelectric ceramic round oscillator; the piezoelectric ceramic round oscillator is embedded in the PMMA upper cover; the upper silicon board is provided with a jet network; the lower silicon board is provided with a jet network and a hot line; the PMMA upper cover, the upper silicon board, the lower silicon board and the PMMA bottom cover are successively bonded to form the sensitive element. The jet gyro adopts one piezoelectric ceramic round oscillator to drive four-channel circular flow, not only is simple in structure, long in life and low in power consumption, and implements deformation direction of the piezoelectric ceramic round oscillator and direction turning of jet flow network planes; the area of the piezoelectric ceramic round oscillator is large, the driving ability is strong, the jet velocity is high, and the jet gyro sensitivity is high; and angular velocities of three orthogonal directions can be sensitive at the same time, and multi-axis integration is achieved.

Owner:BEIJING INFORMATION SCI & TECH UNIV

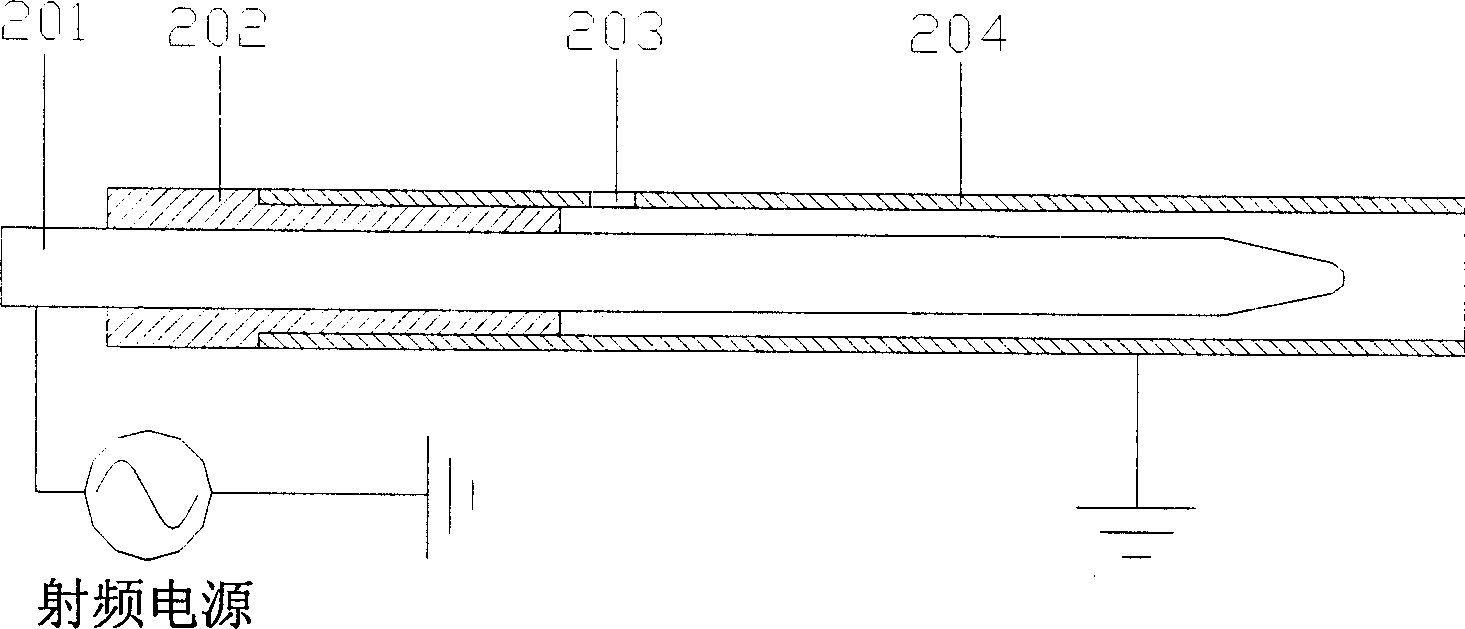

Atmospheric radio-frequency discharging high-speed cold plasma array generator

InactiveCN1812687AImprove work efficiencyRealize large area applicationElectric discharge tubesSemiconductor/solid-state device manufacturingPlasma generatorEngineering

A high velocity cold plasma array generator of atmosphere radio frequency discharge consists of cylindrical shell and generator array formed by multiple single coaxial type of cold plasma generator .It featured as building generator array in cylindrical shell, setting a switching in hole of radio frequency power supply and inlet of cold plasma operation air on said shell, connecting internal electrodes of said generator to radio frequency power supply after they are parallel-connected and external electrodes to earthing after they are parallel-connected ,setting side director or axial direction operation air inlet on said generator and setting a cooling media inlet and outlet on said shell .

Owner:TSINGHUA UNIV

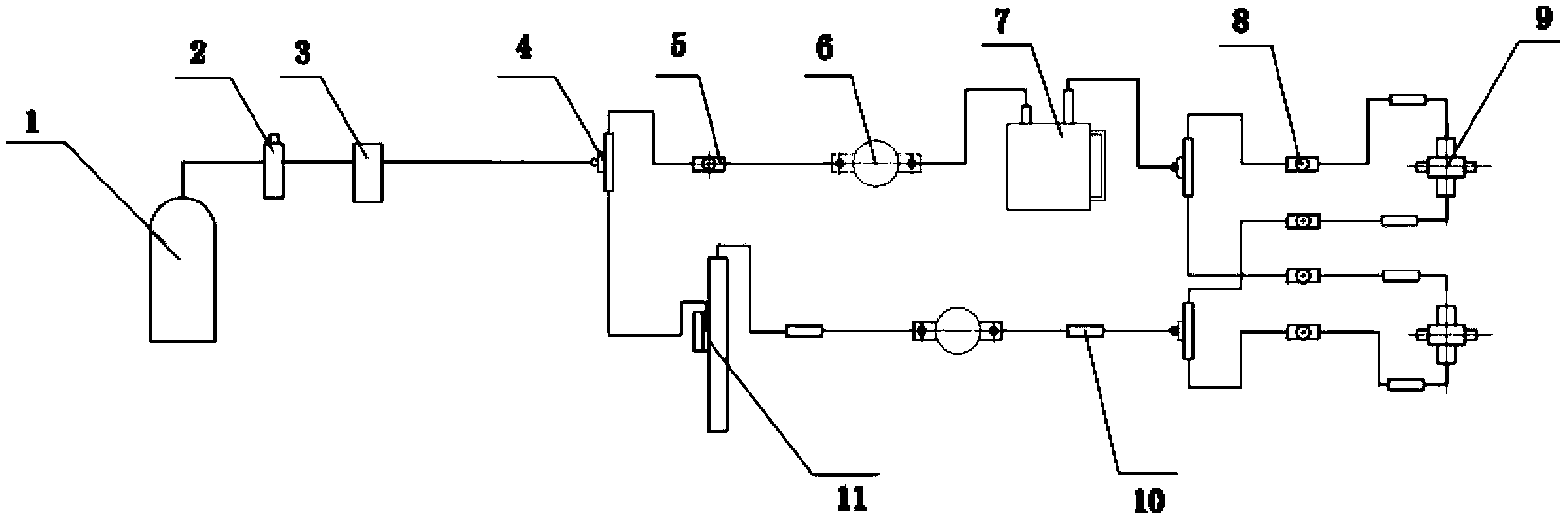

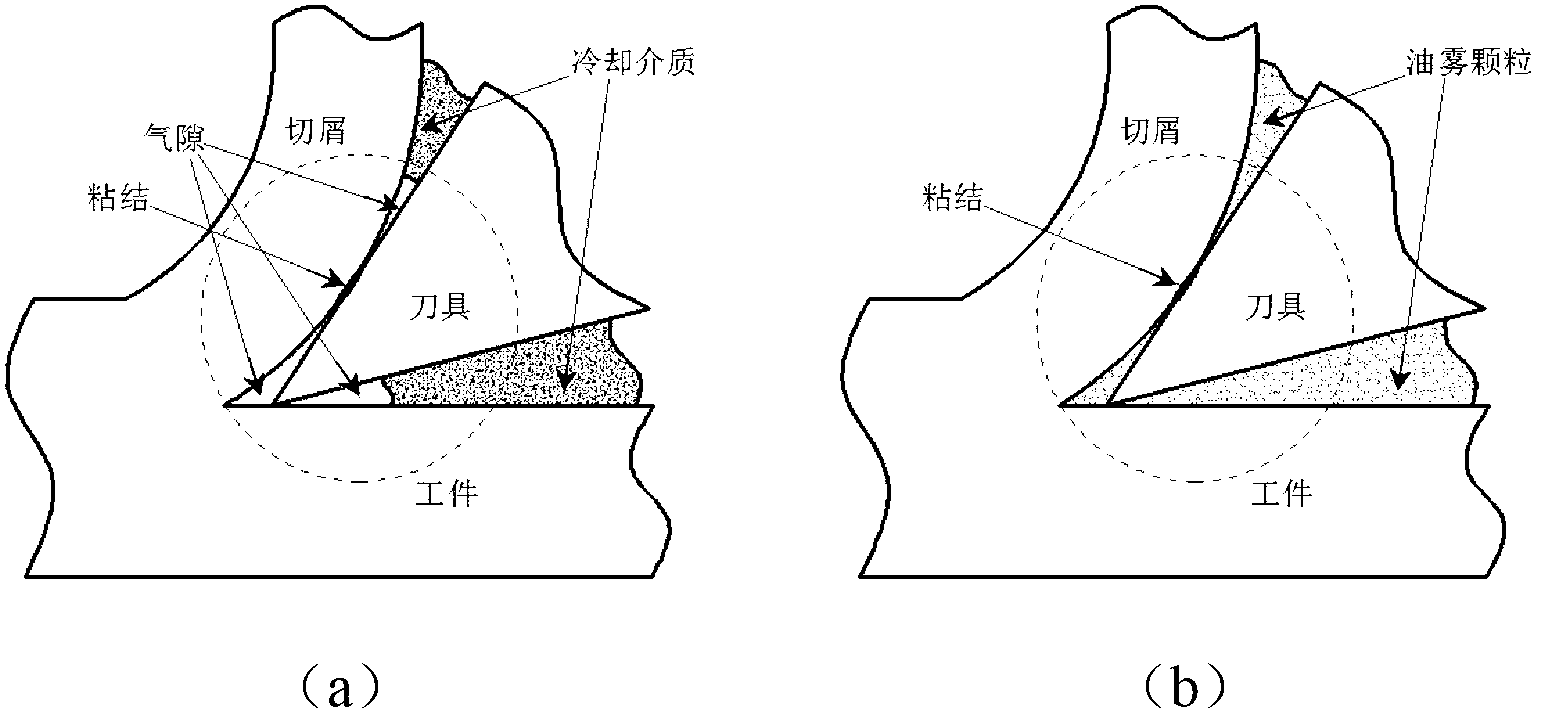

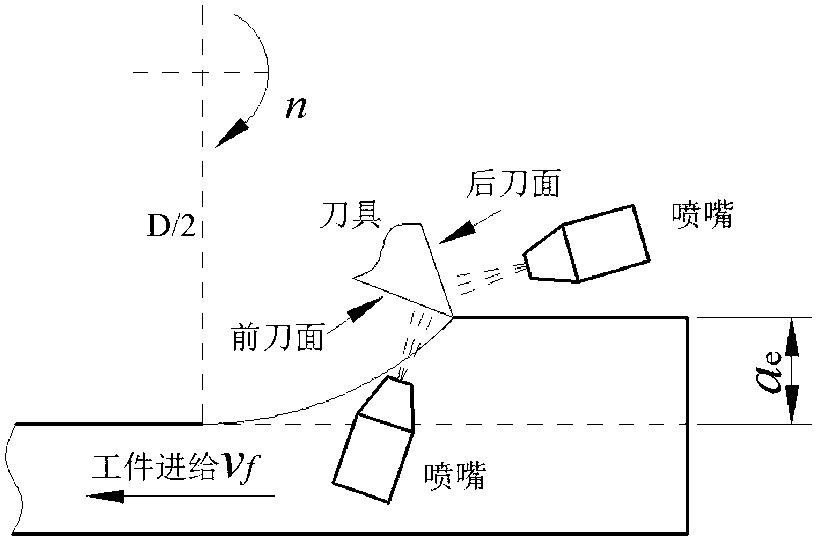

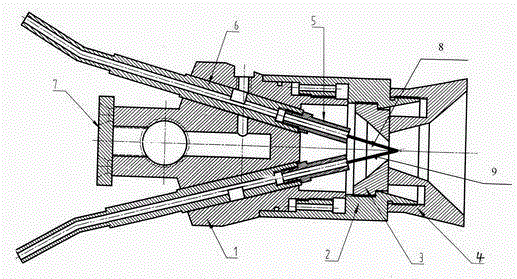

Method and device for forming high-pressure and low-temperature jet flow by cutting coolant

ActiveCN103286629AIncreased durabilityReduce cutting temperatureMaintainance and safety accessoriesJet flowSpray nozzle

The method discloses a method and device for forming high-pressure and low-temperature jet flow by cutting coolant. The method includes that compressed air stored inside an air storage tank is filtered and dried and connected to a tee joint through a hose to divide an output pipe into two branches, air in one branch is cooled by a cooling device to become low-temperature high-pressure air, and inputted into an air inlet end of a pneumatic spray nozzle after being connected with one or more than one tee joint, the air in the other branch is inputted into a well-sealed cutting fluid storage container after pressure in the air is regulated by a pressure regulating valve, the cutting fluid is pressed out, and connected into liquid inlet ends of a plurality of pneumatic spray nozzles after passing one or more than one tee joint prior through the hose, the air and the liquid are mixed outside a jet nozzle to produce high-speed jet flow. By the method, usage amount of cooling lubricating liquid is reduced, cooling and lubricating functions of fluid medium are fully performed, cutting temperature is greatly lowered, and tool durability is conspicuously improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

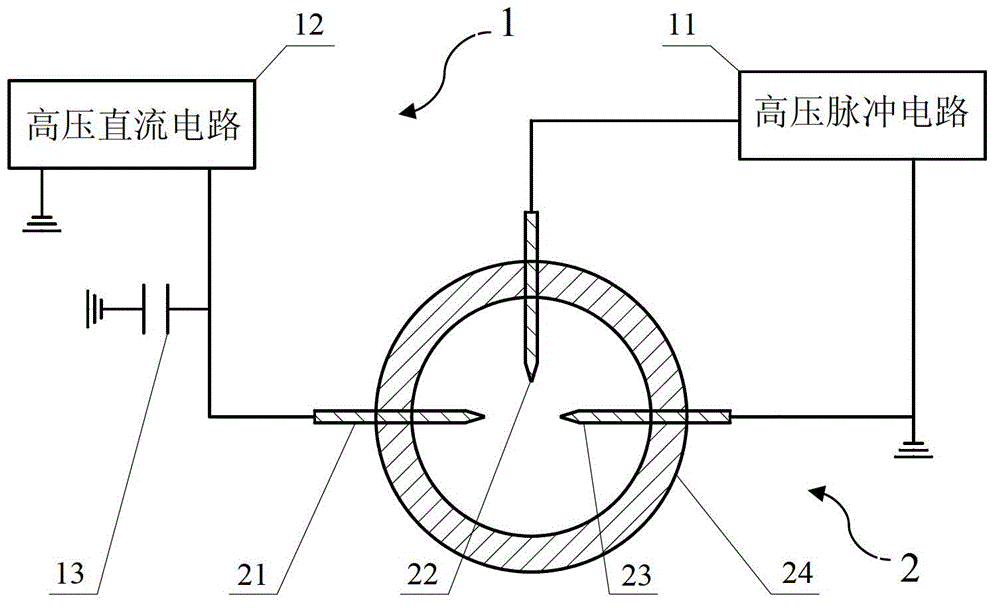

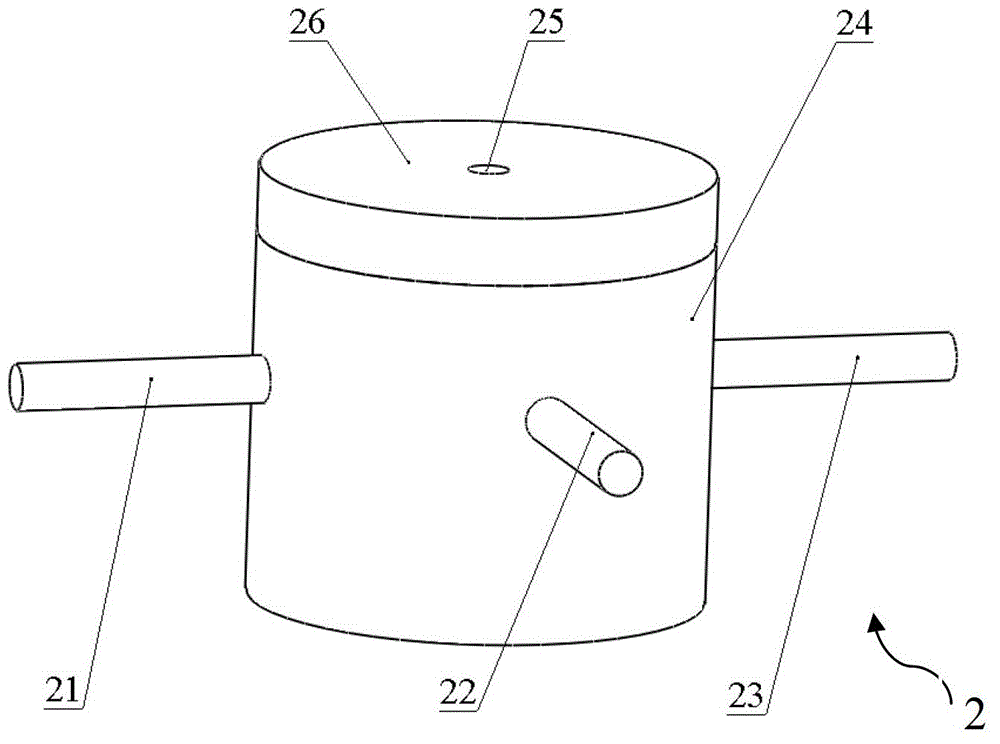

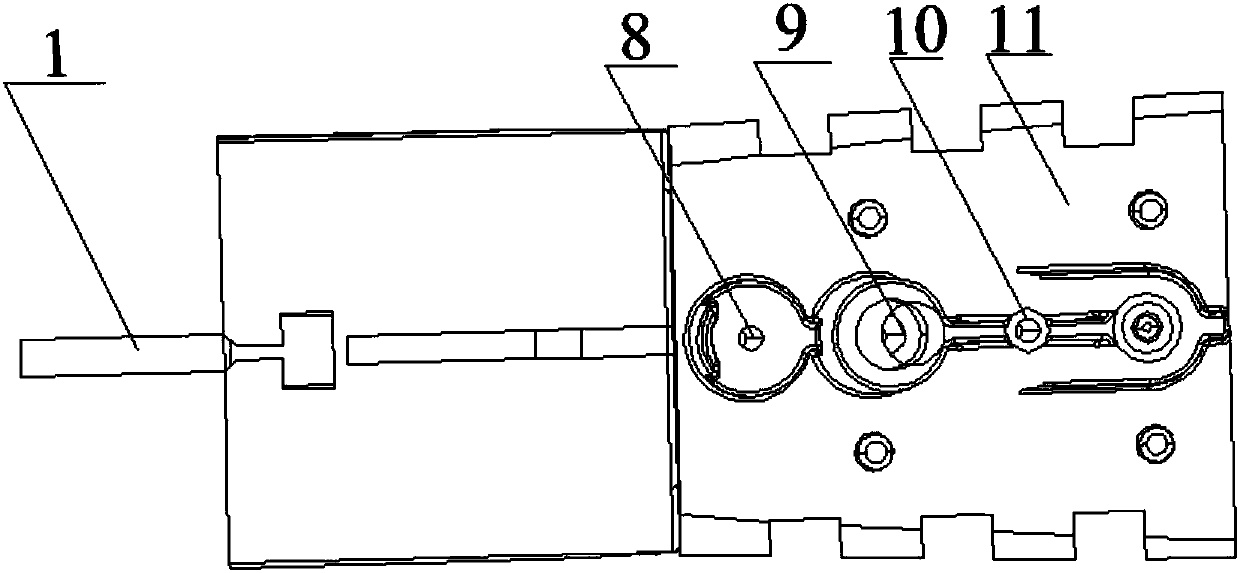

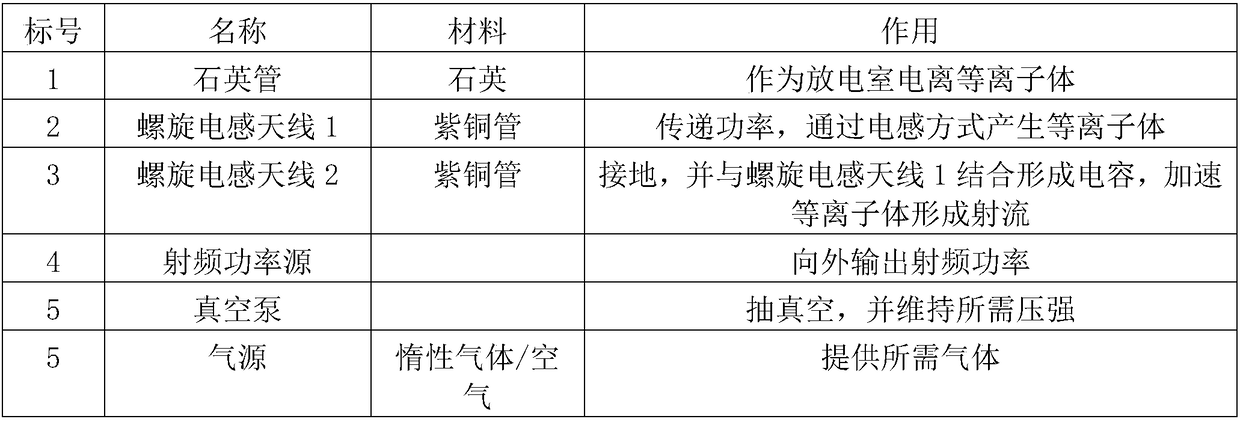

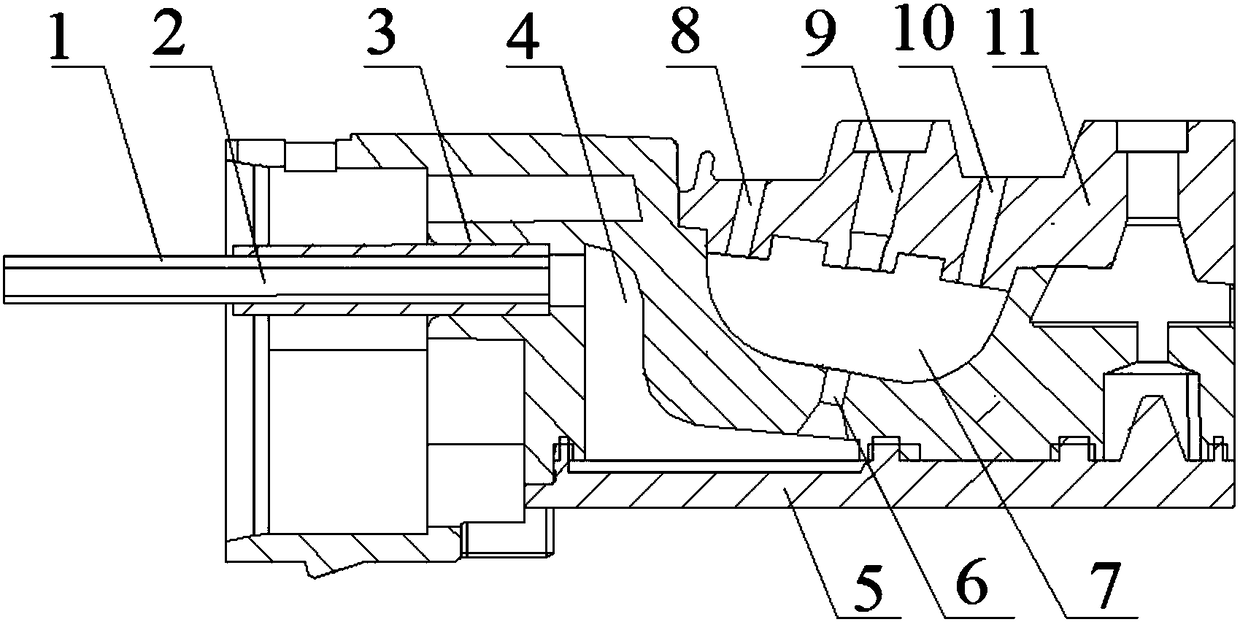

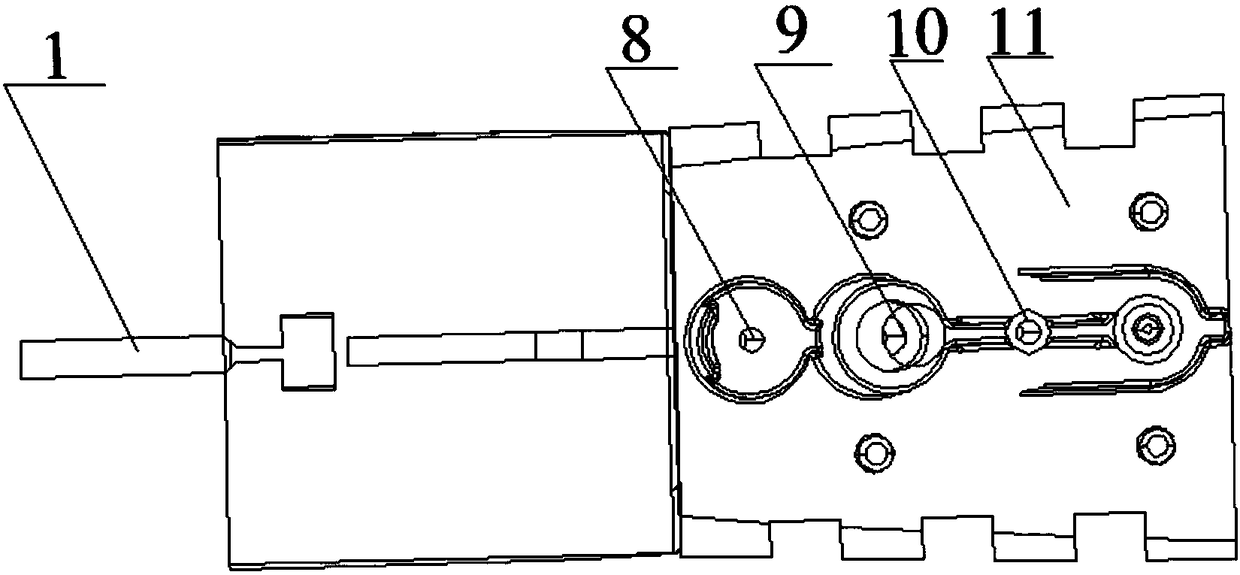

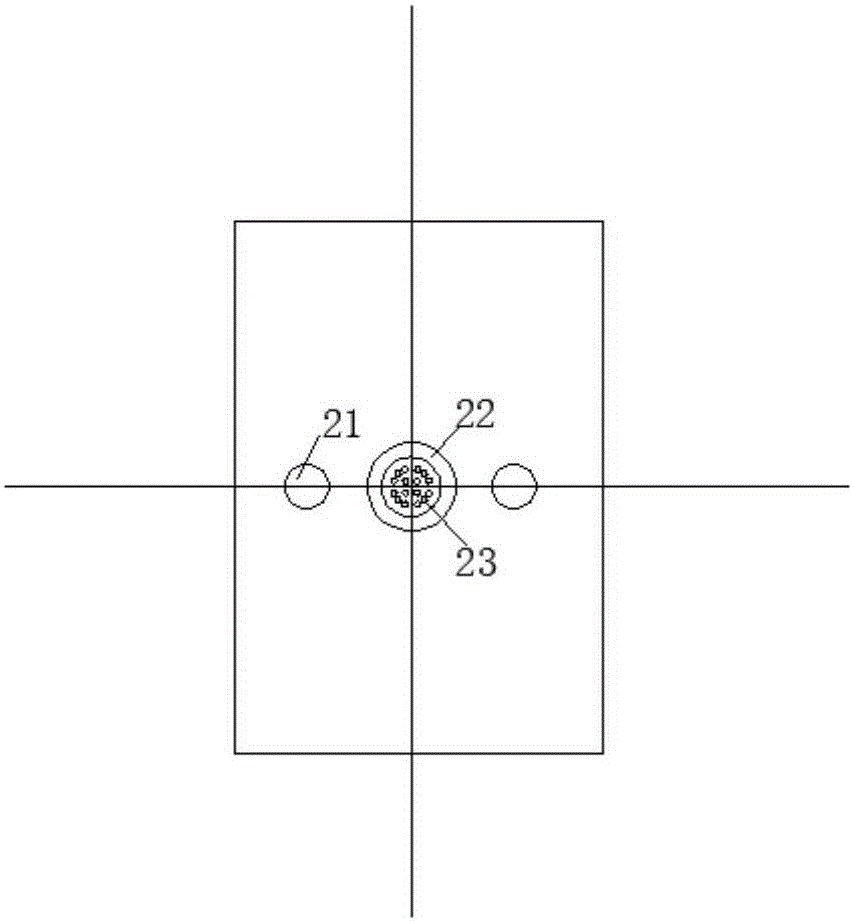

Quick-response direct force generating device

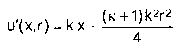

ActiveCN102943751AHigh Synthetic Jet VelocityIncrease jet velocityMachines/enginesUsing plasmaCapacitanceHigh-voltage direct current

The invention discloses a quick-response direct force generating device. A power supply system (1) comprises a high-voltage pulse circuit (11), a high-voltage direct-current circuit (12) and a charging and discharging capacitor (13). A spark discharge plasma synthetic jet actuator (2) of the device comprises an actuator body (24) provided with a cover plate (26), and a main discharge electrode (21), an ignition positive electrode (22) and an ignition negative electrode (23) which are inserted in the actuator body (24) at intervals. A jet outlet (25) is opened in the cover plate (26). The main discharge electrode (21) is connected with the high-voltage direct-current circuit (12), and the ignition positive electrode (22) and the ignition negative electrode (23) are connected in parallel with the high-voltage pulse circuit (11). According to the device, the pulse jet frequency and the jet energy can be adjusted according to needs, a novel generating mode is provided for controlling quick-response direct force of a high-speed air vehicle, and the device can be used an actuator in active flow control in high-speed internal and external flow fields.

Owner:NAT UNIV OF DEFENSE TECH

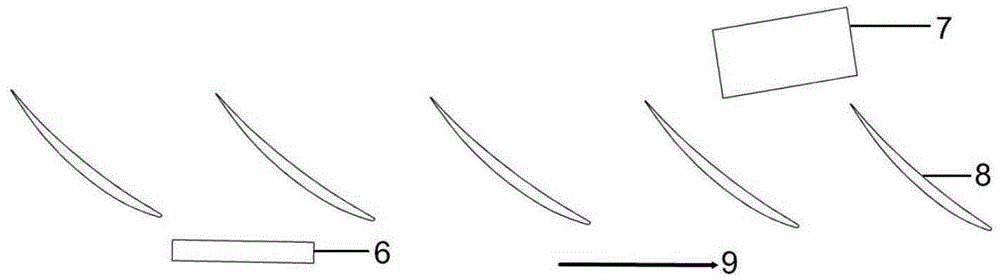

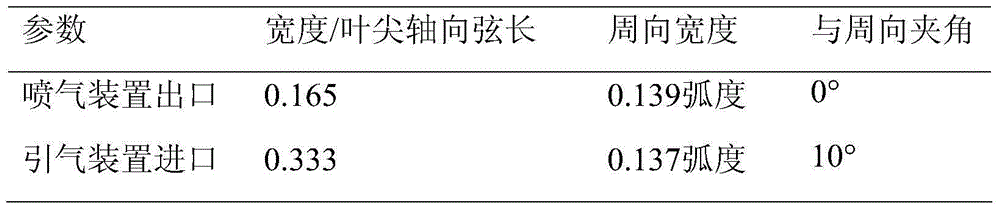

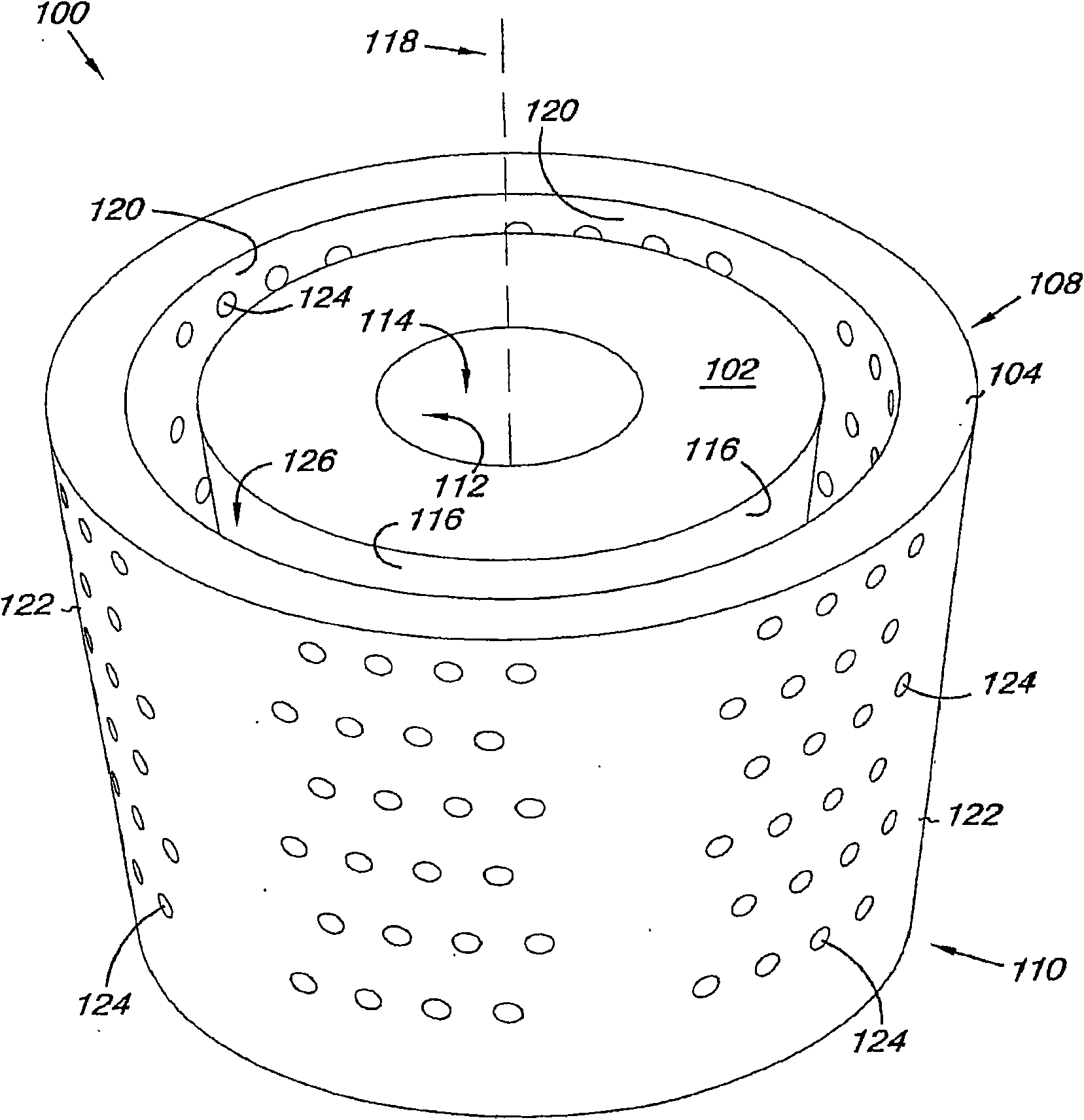

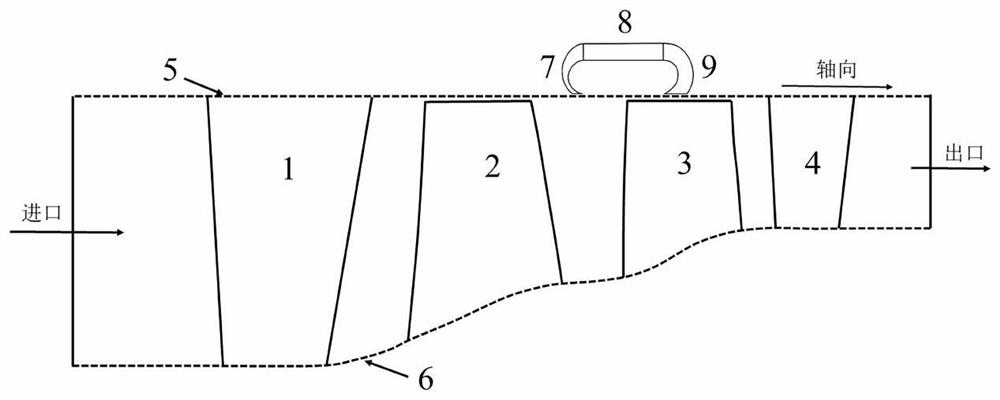

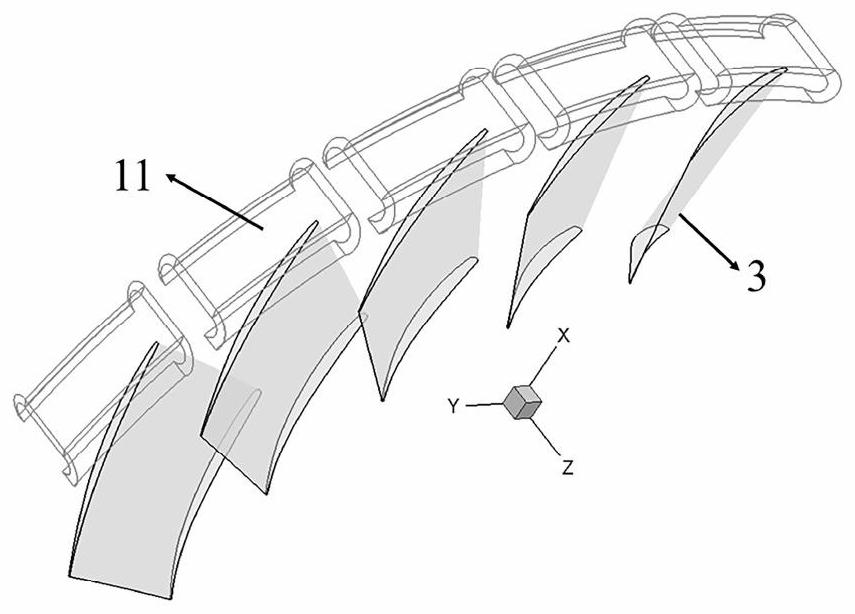

Circumferential staggered self-circulating casing treating method for axial-flow compressor

InactiveCN104675755AImprove stabilitySolve the problem of weak ability to stabilize the working rangePump componentsPumpsIndustrial engineeringInjector

The invention discloses a circumferential staggered self-circulating casing treating method for an axial-flow compressor and aims to solve the technical problem that an existing self-circulating casing treating method is poor in stability extension capacity. The technical scheme includes that a bridge and an air entraining device are provided, and the air entraining device is rotated circumferentially to fit in the flowing direction of absolute air flows of outlets of rotor blade tops and to be staggered in the circumferential direction of an air injector, so that air entraining amount is increased, and the problem that a self-circulating treated casing is poor in stable axial-flow compressor working range extending capability due to the fact that the air entraining device cannot fit in the air flowing direction of the outlets of the rotor blade tops is solved. By circumferentially rotating the air entraining device by a certain angle, the direction of an inlet, on the casing side, of the air entraining device is enabled to fit in the flowing direction of the absolute air flows of the outlets of the rotor blade tops, namely the air flowing direction of the outlets of the rotor blade tops is in alignment with the inlet of the air entraining device, so that air entraining amount is increased, air injecting speed is increased, and the problem that self-circulating treated casing is poor in stable axial-flow compressor working range extending capability is solved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

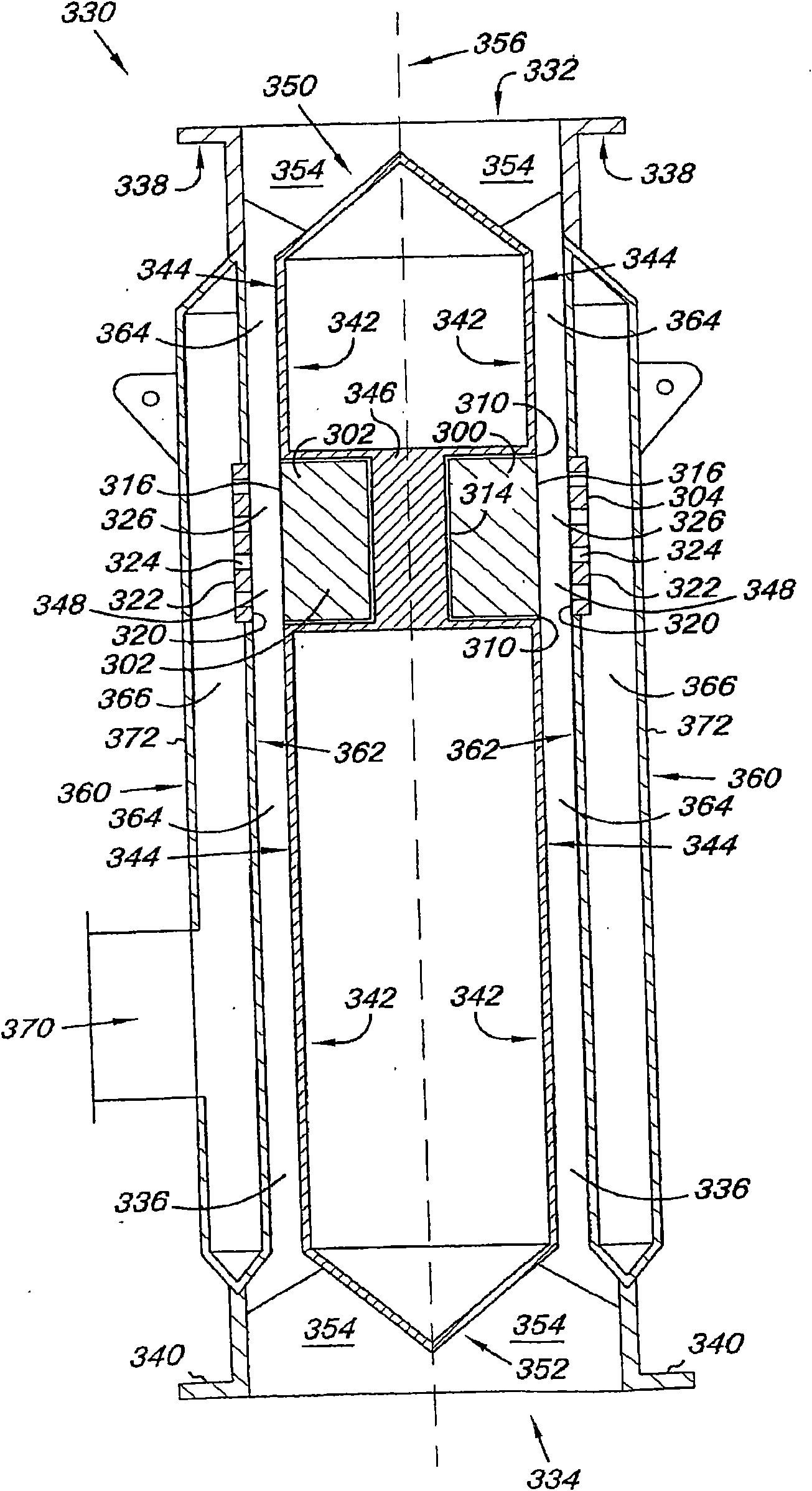

Mixer for a continuous flow reactor, method of forming such a mixer, and method of operating such a reactor

ActiveCN101663084AHigh degree of separationIncrease jet velocityFlow mixersTransportation and packagingInjection pointContinuous flow

A mixer (100) for a continuous flow reactor (330) and methods for forming the mixer and the operation thereof. The mixer allows for segmentation of a primary reactant flow through a plurality of ports (124) into many smaller flows that are injected as jets into a secondary reactant flow in channels of the mixer. The channel (126) has a constant width dimension to enhance even flow distribution and local, turbulence of the primary and secondary reactant flows. The constant width dimension of the channel and the size and number of the ports of the mixer can be configured to ensure the primary reactant flow injected into the channel directly impinges on a surface (116) of the channel that is opposite the injection point at normal operating conditions.

Owner:DOW GLOBAL TECH LLC

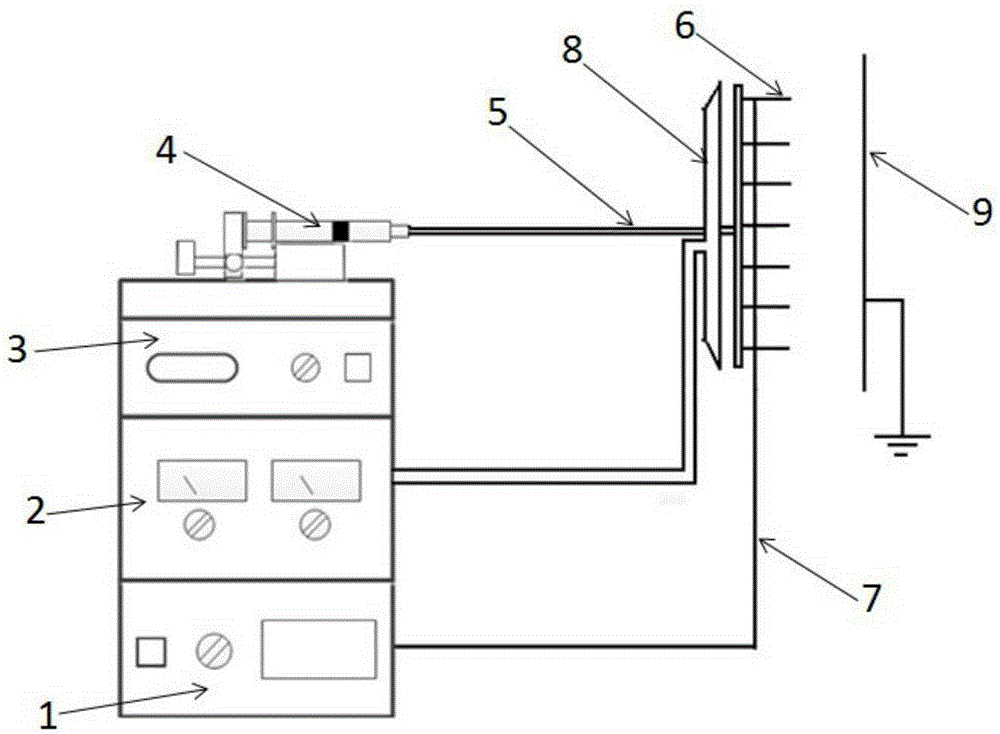

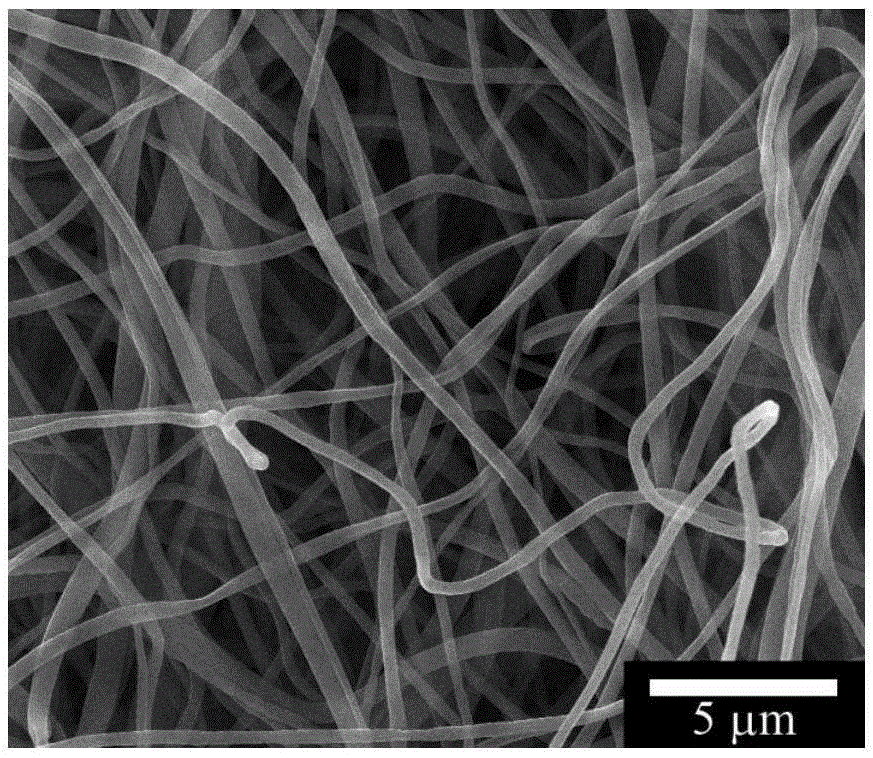

Sodium alginate nanofiber as well as large-scale electrospinning preparation method and application thereof

InactiveCN106480517ALarge specific surface areaPromote healingFilament/thread formingAlginate artificial filamentsCross-linkElectrospinning

The invention discloses a sodium alginate nanofiber as well as a large-scale electrospinning preparation method and application thereof. A sodium alginate micro-nanofiber is prepared by an airflow-assisted electrospinning method, wherein the content of sodium alginate in the micro-nanofiber is 75% or higher; the fiber diameter is 50-900 nm; the sodium alginate nanofiber is prepared according to the air-assisted electrospinning method; airflow same as a spinning jet direction is provided by a gas producing mechanism in the spinning process, so as to accelerate the evaporation of a solvent and promote the formation of spun silk; the sodium alginate nanofiber is simple in preparation method, low in requirement on spinning conditions, high in yield, and suitable for large-scale production; spinning precursor liquid is simple in formula, without adding a cross-linking agent and an irritant or toxic solvent; the content of sodium alginate in the obtained nanofiber is high, so that the sodium alginate nanofiber has significant advantage in application in fields of biological tissue engineering materials, wound repair materials or beauty and cosmetics.

Owner:QINGDAO XINZHIYUAN HEALTH TECH

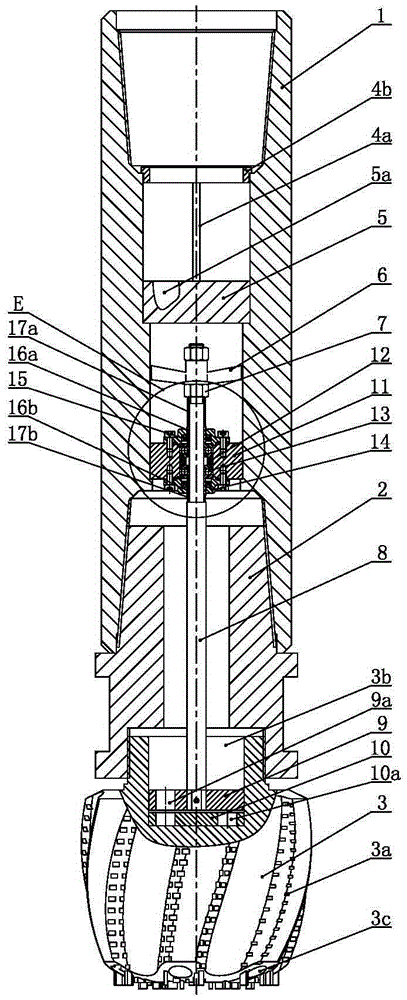

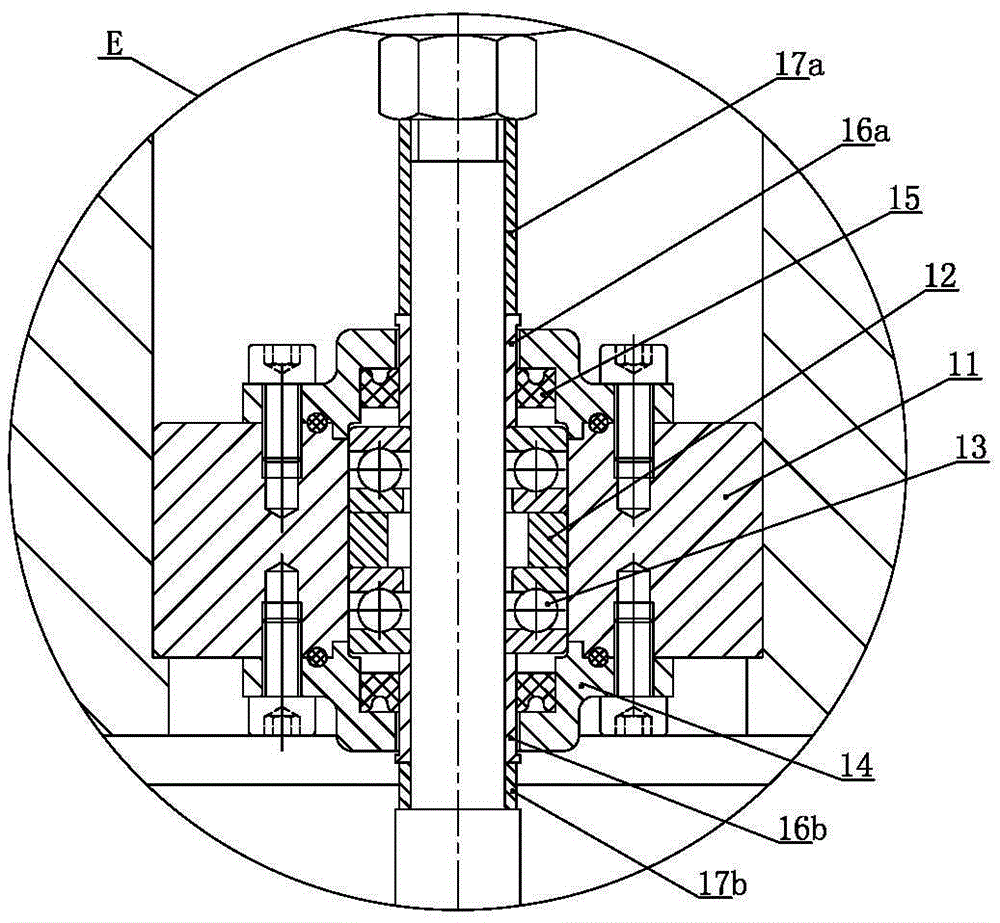

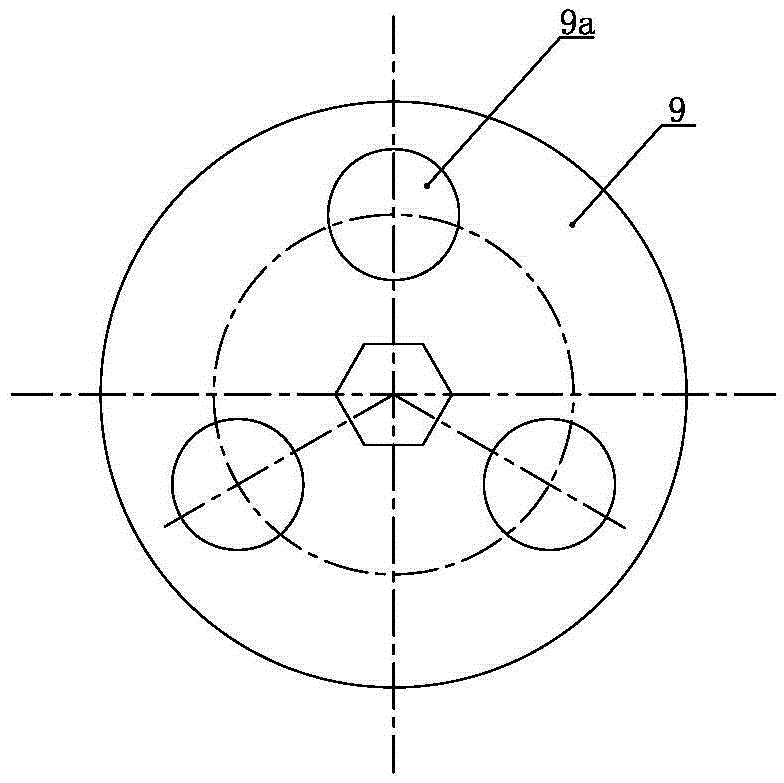

Underground pulsing jet drill bit device

The invention relates to an underground pulsing jet drill bit device. A double-end sleeve, a drill bit connector and a drill bit body are sequentially screwed; the upper end of the drill bit body is provided with a drill bit water cavity; a plurality of drill bit water holes are distributed in the bottom wall of the drill bit water cavity; all of the drill bit water holes are uniformly distributed by using the axial line as the center; each drill bit water hole downwards extends and is communicated with a corresponding spray hole formed in the lower end surface of the drill bit body; the center of the double-end sleeve and the center of the drill bit connector are provided with a center water passage communicated with the drill bit water cavity; a static valve disc is arranged on the bottom wall of the drill bit water cavity; static valve disc water holes are formed in the static valve disc; each static valve water hole has the same hole diameter as the drill bit water hole and is in one-to-one corresponding communication with the corresponding drill bit water hole; a movable valve disc capable of rotating around the axial line covers the static valve disc; at least one movable valve disc water hole is formed in the movable valve disc; and the movable valve disc water hole has the same hole diameter as the static valve disc water hole, and is positioned on the same circumference as the static valve disc water hole. The drill bit device has the advantages that the shaft bottom cleaning effect can be improved; and the hydraulic rock breaking capability can be improved.

Owner:CHINA PETROCHEMICAL CORP +2

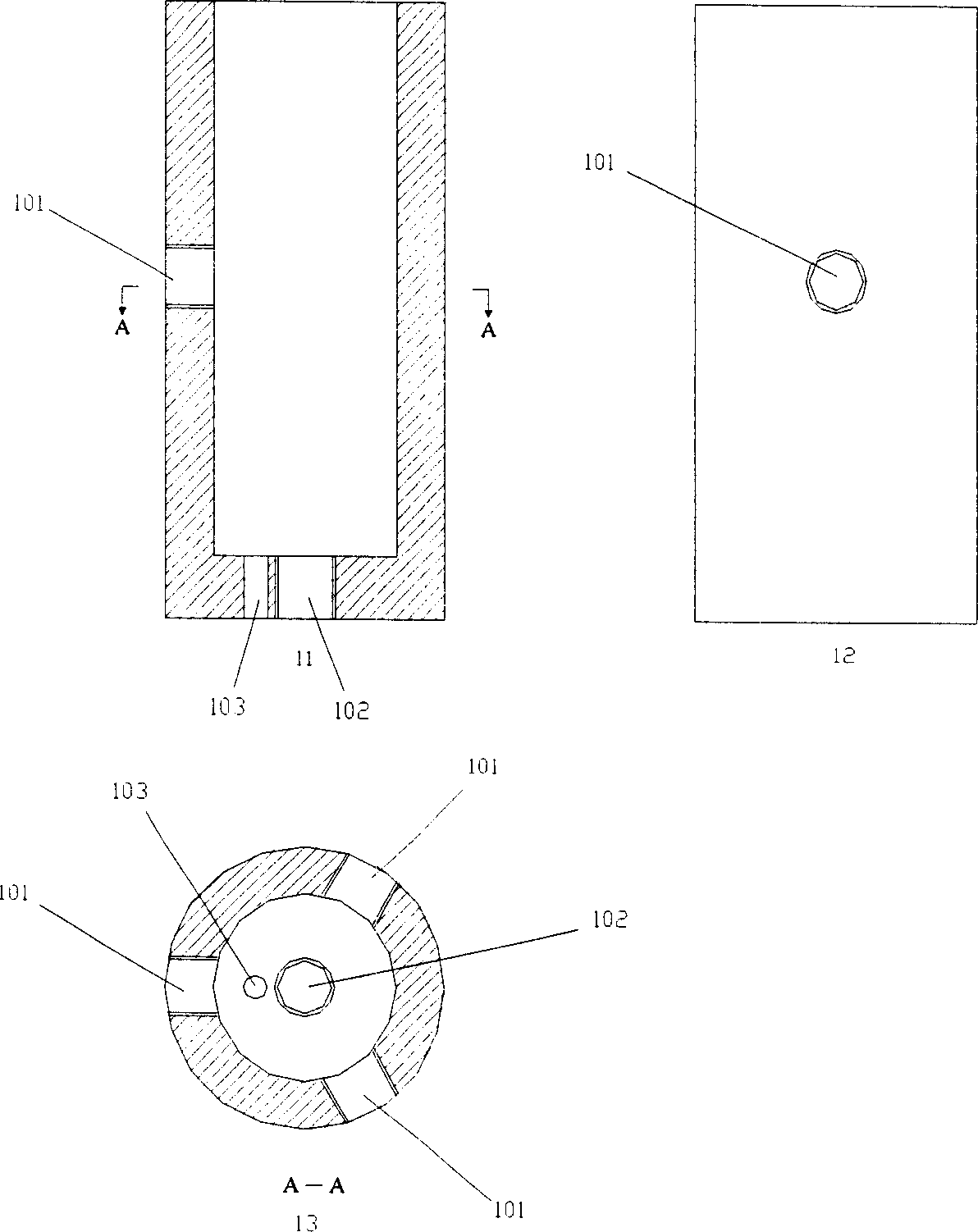

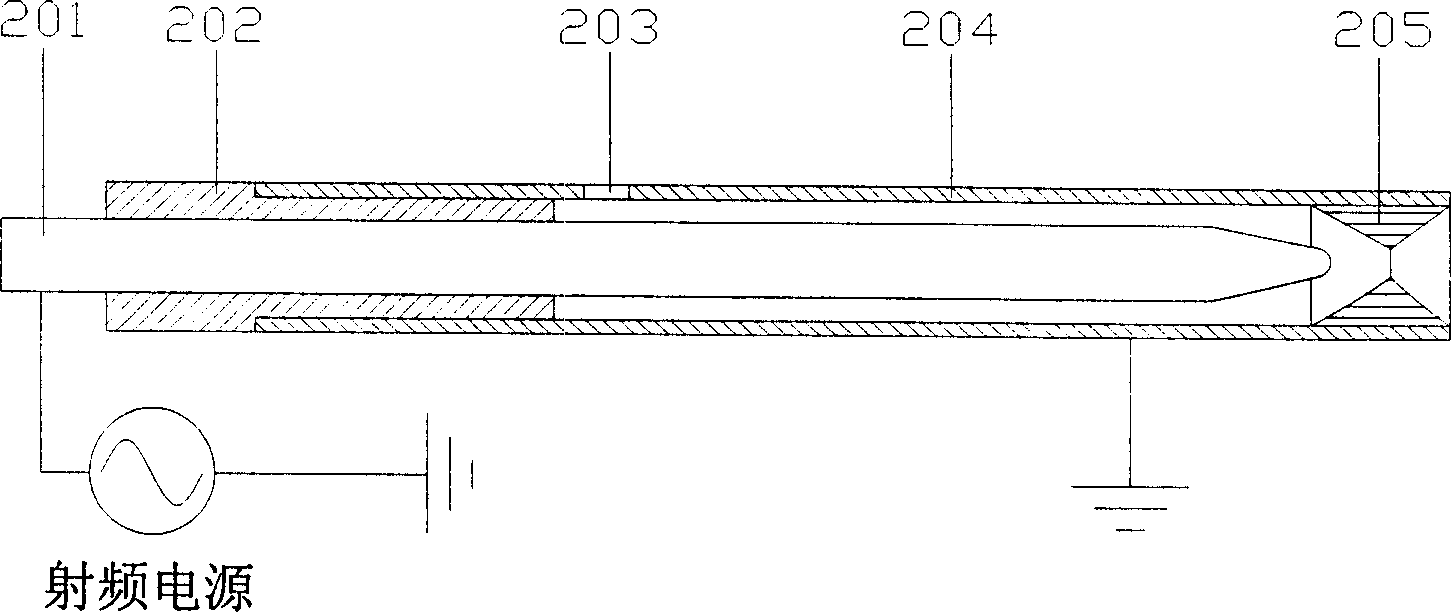

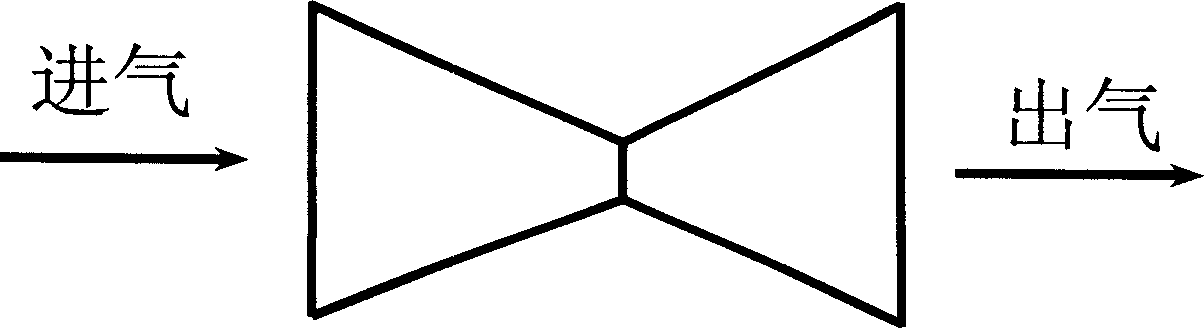

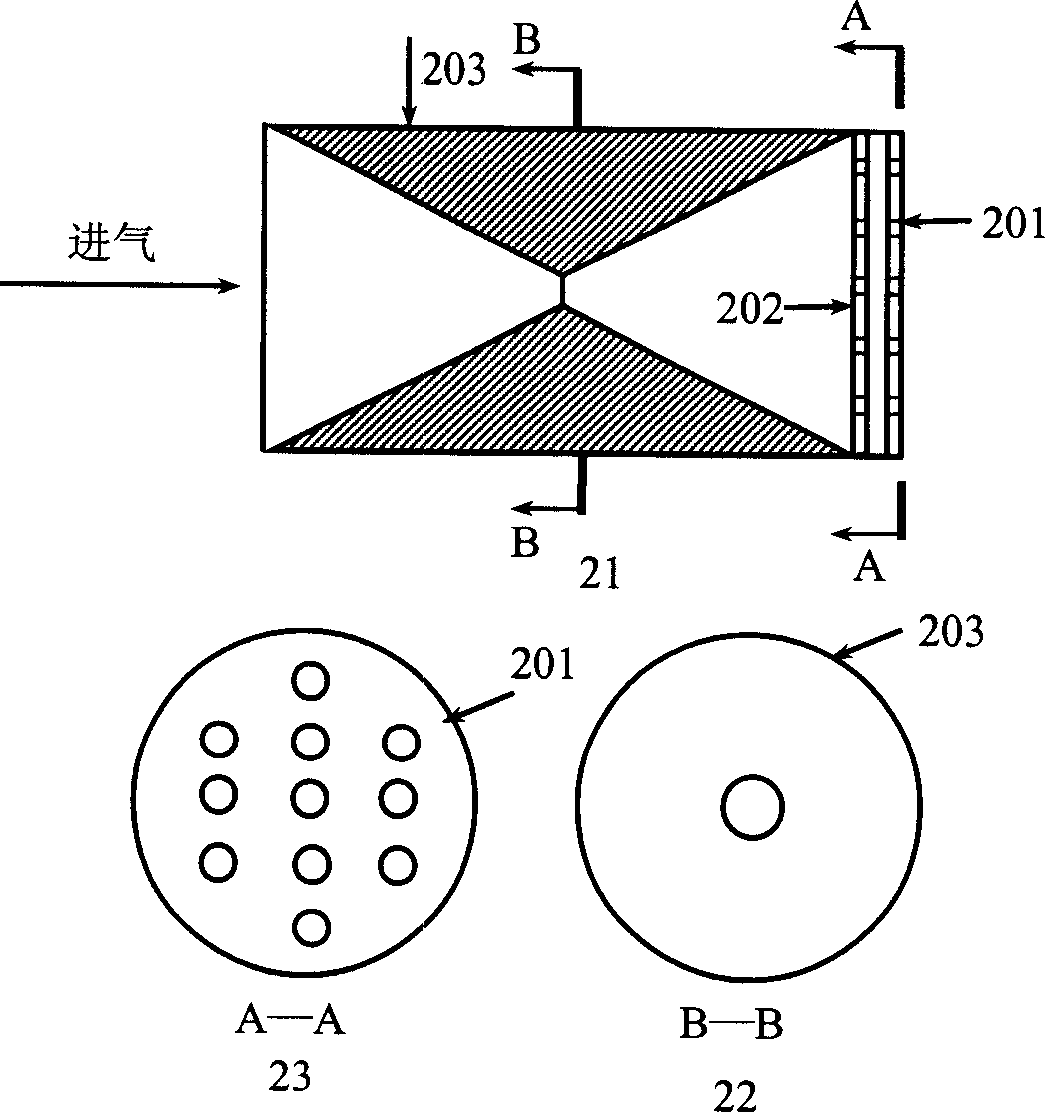

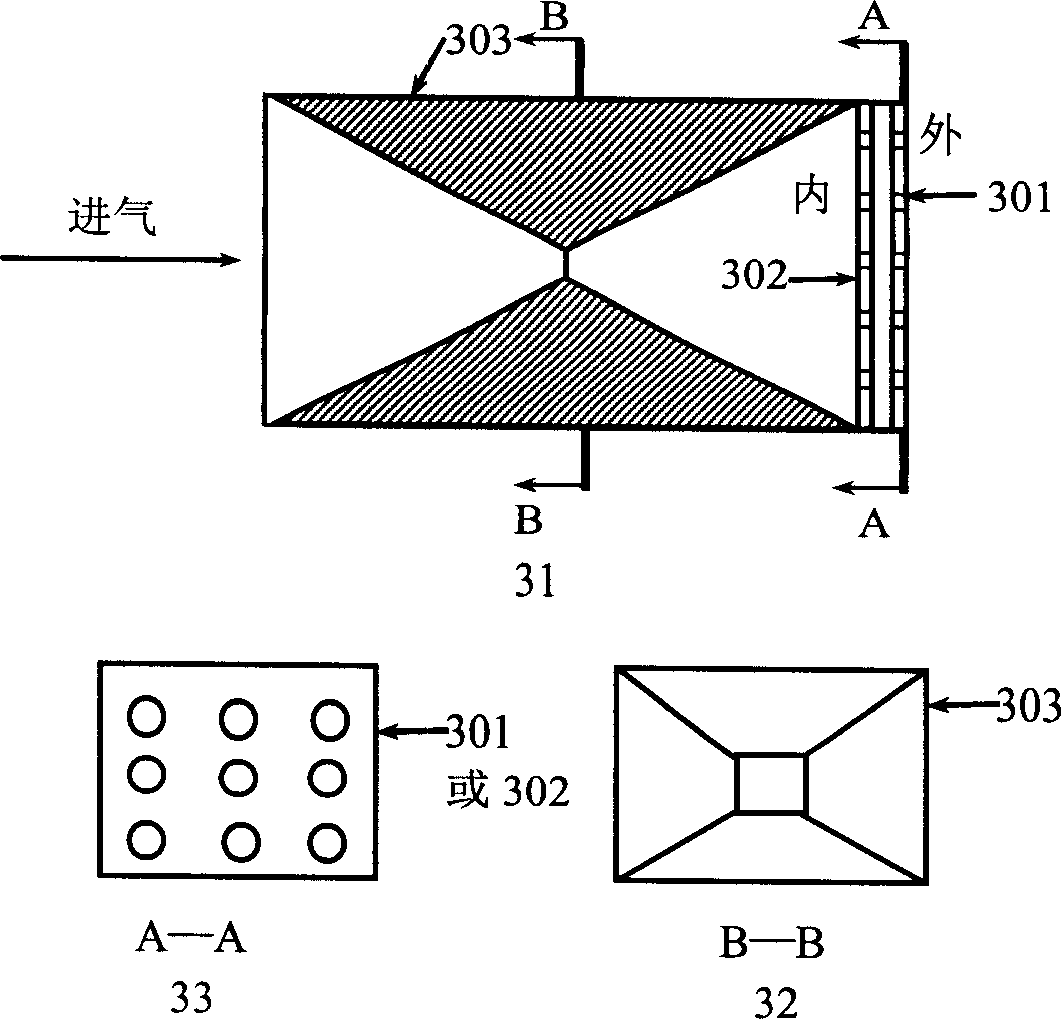

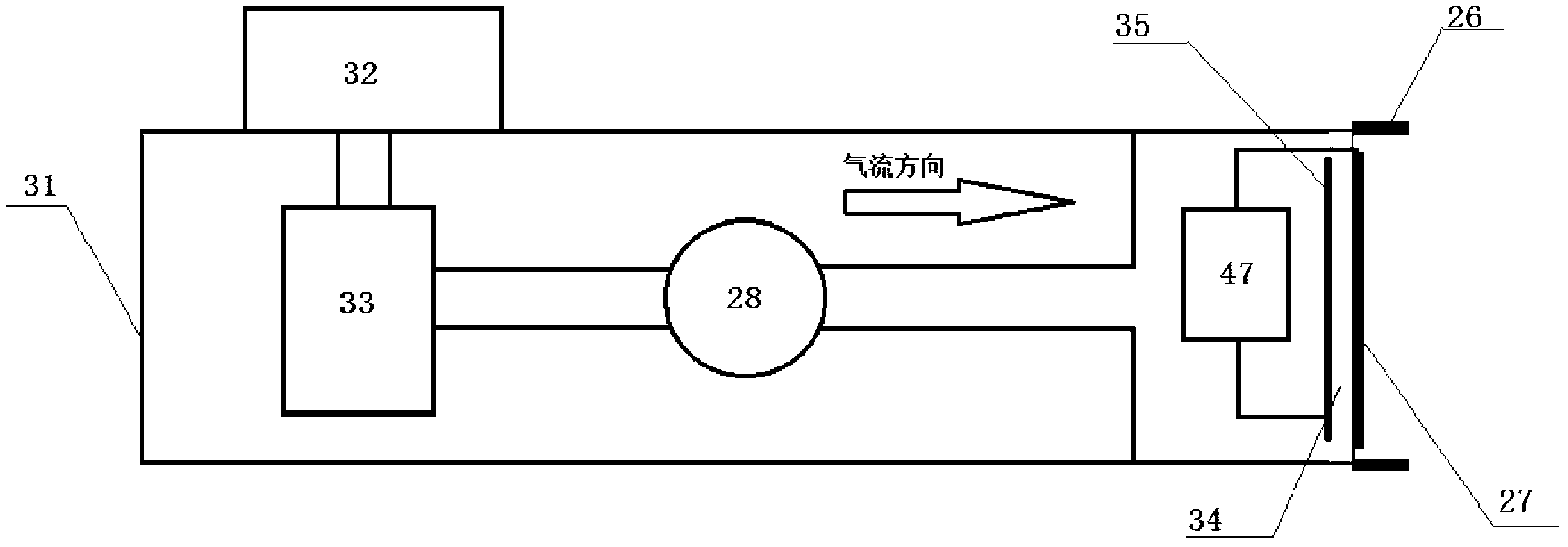

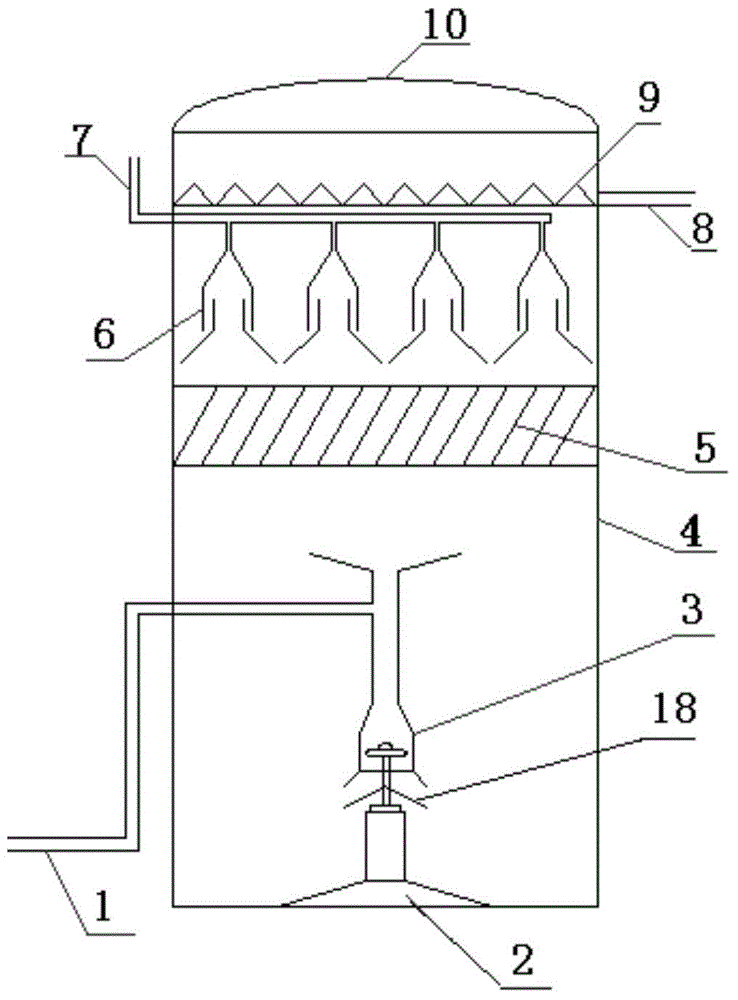

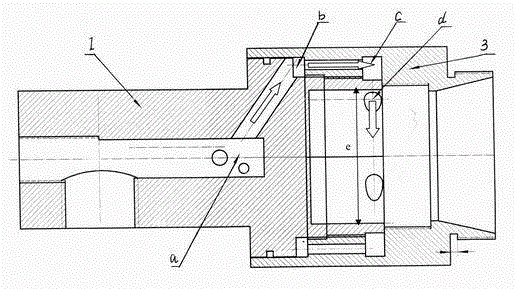

Atmospheric discharging cold plasma generator and array based on contraction and enlargement channel structure

ActiveCN1812686AIncrease jet velocityElectric discharge tubesSemiconductor/solid-state device manufacturingThroatAtmospheric pressure discharge

A cold plasma generator of atmosphere discharge is featured as setting flat-plate type or rotation type of contraction and enlargement channel structure at air inlet or air outlet or discharge region of generator to form flat-plate type or coaxial type cold plasma generator of atmosphere discharge and furthermore to form generator array .The said contraction and enlargement channel structure is formed by compression unit, throat unit and expansion unit to raise efflux velocity of cold plasma at outlet of said generator .

Owner:WUXI RES INST OF APPLIED TECH TSINGHUA UNIV

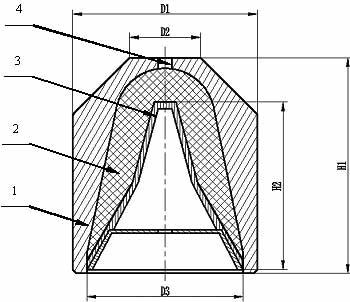

Perforating bullet

The invention belongs to the petroleum production field and in particular relates to a novel perforating bullet. The perforating bullet is based on the prior perforating bullet; the bullet is inside provided with a detonation wave reshaper which effectively blocks the transmission of a detonation wave, delays the time for transmitting the detonation wave to the bottom of the reshaper and ensures that the detonation wave in a booster explosive channel can firstly reach a main interface in order that the detonation wave generated in main explosive can effectively act on a shaped charge liner, thereby improving the utilization rate of explosive energy, increasing the speed, quality and kinetic energy of the shooting flow, strengthening perforation capacity so that the perforating depth of the oil well is deeper.

Owner:INST OF APPLIED PHYSICS & COMPUTATIONAL MATHEMATICS

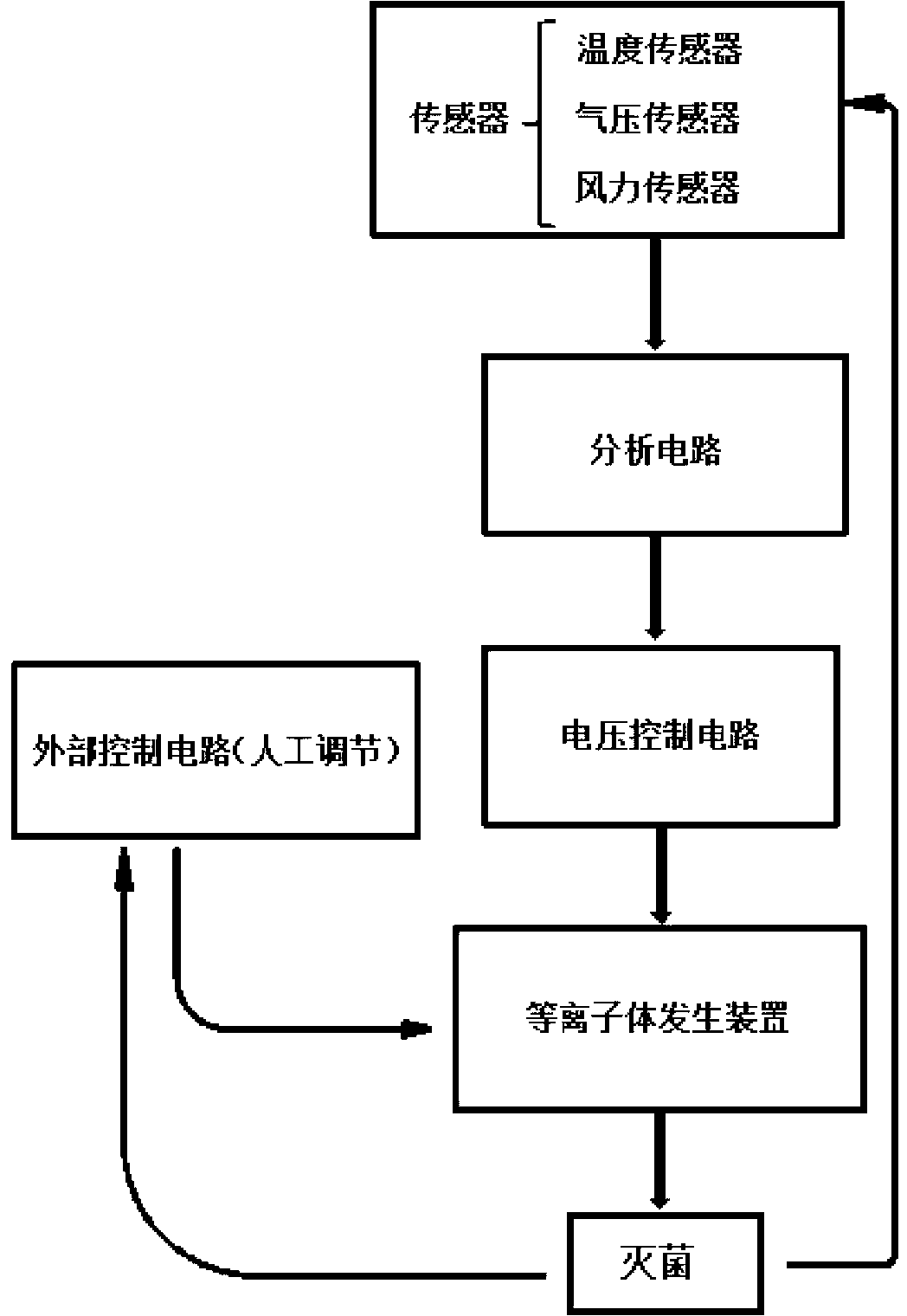

Atmospheric dielectric barrier discharge plasma sterilization device

ActiveCN103055332AUniform densityReduce power consumptionLavatory sanitoryDeodrantsEngineering plasticEngineering

The invention provides an atmospheric dielectric barrier discharge plasma sterilization device. The device comprises sensors (a temperature sensor, an air pressure sensor and a wind power sensor), an analysis circuit, a power supply control circuit, a plasma generation device and the like. The device adopts the principles of dielectric barrier discharge, preionization and self-inductance, so that the needed power supply voltage can be effectively reduced, the device volume is decreased, and the actual use of the sterilization device is convenient. And above all, breakdown voltage is reduced to more easily ionize gas, that is, plasma is more easily generated under the atmospheric condition, so that the density of the plasma is increased, and the sterilization efficiency of the device is improved. As thin needle tubing is adopted, the jet speed of the plasma is quickened, and the sterilization range of the plasma sterilization device is improved. In addition, the appearance design is more humanized, so that more convenience is brought to the actual operation; and for materials, heat-resistant and insulative engineering plastics with antibacterial effect after the plasma injection treatment are adopted.

Owner:YUNNAN AEROSPACE IND

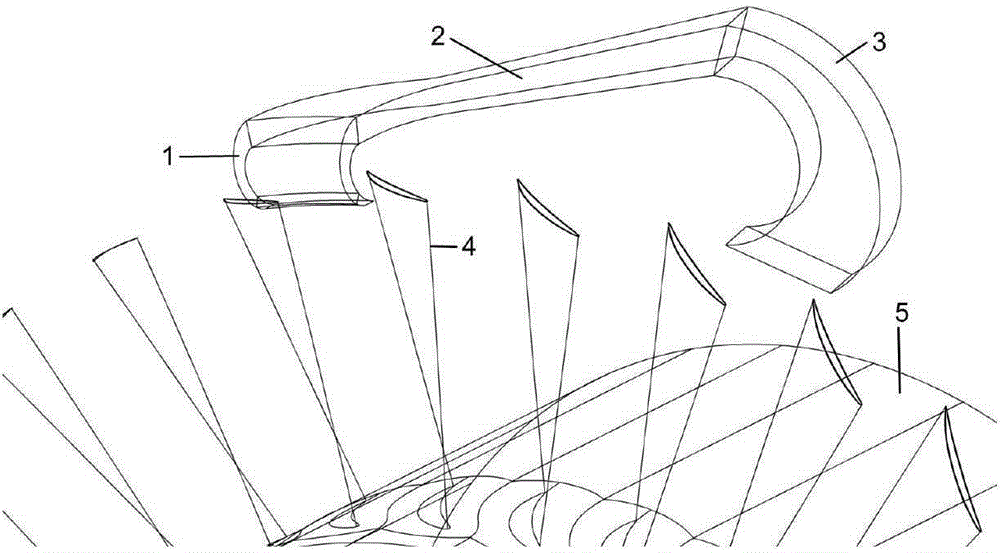

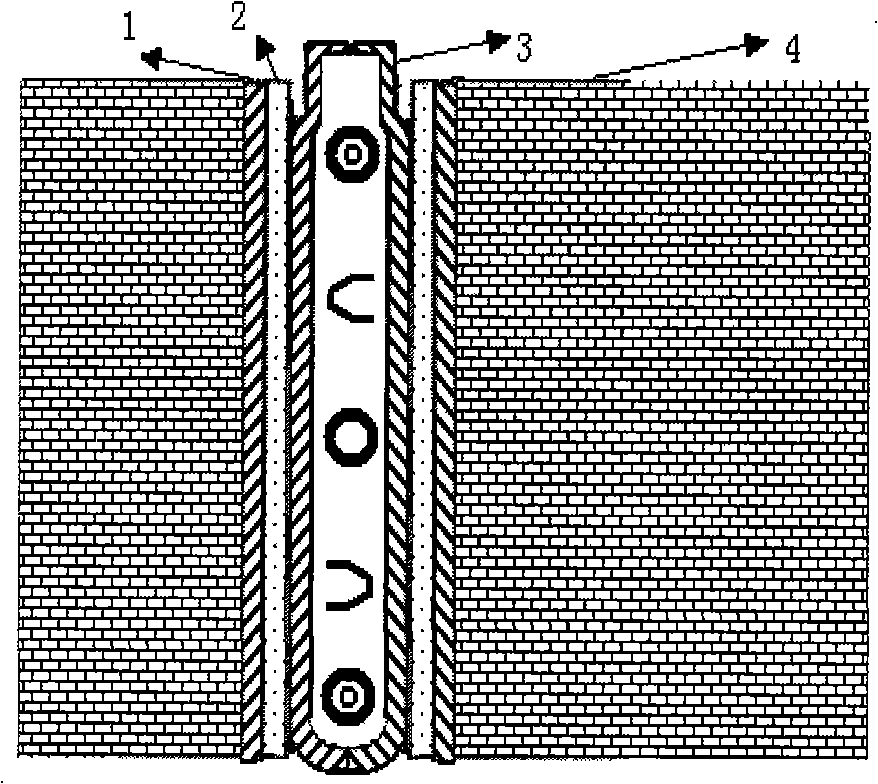

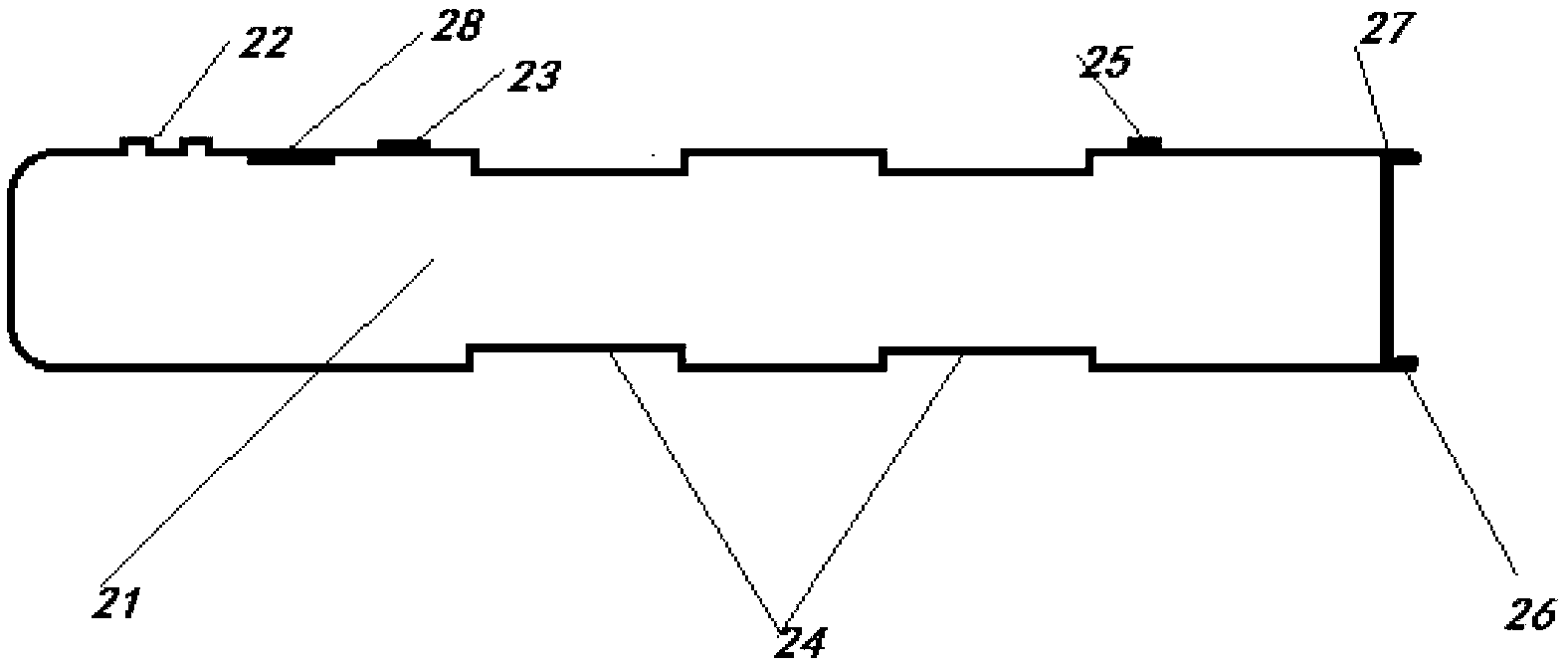

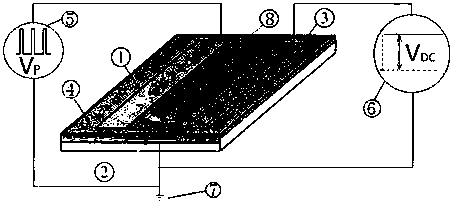

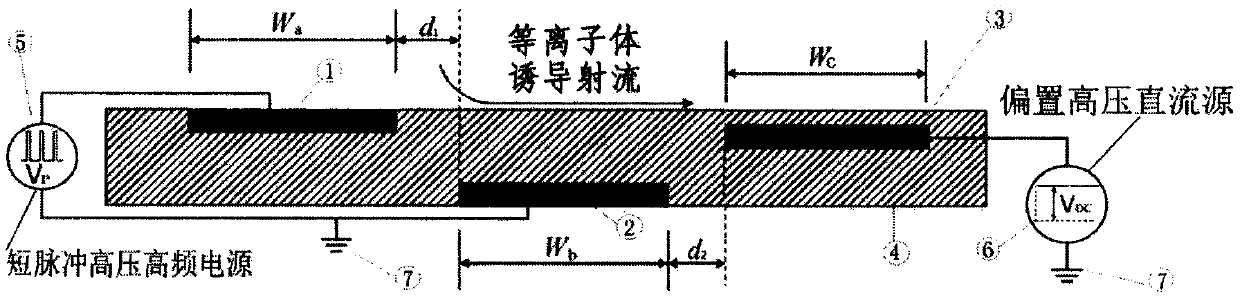

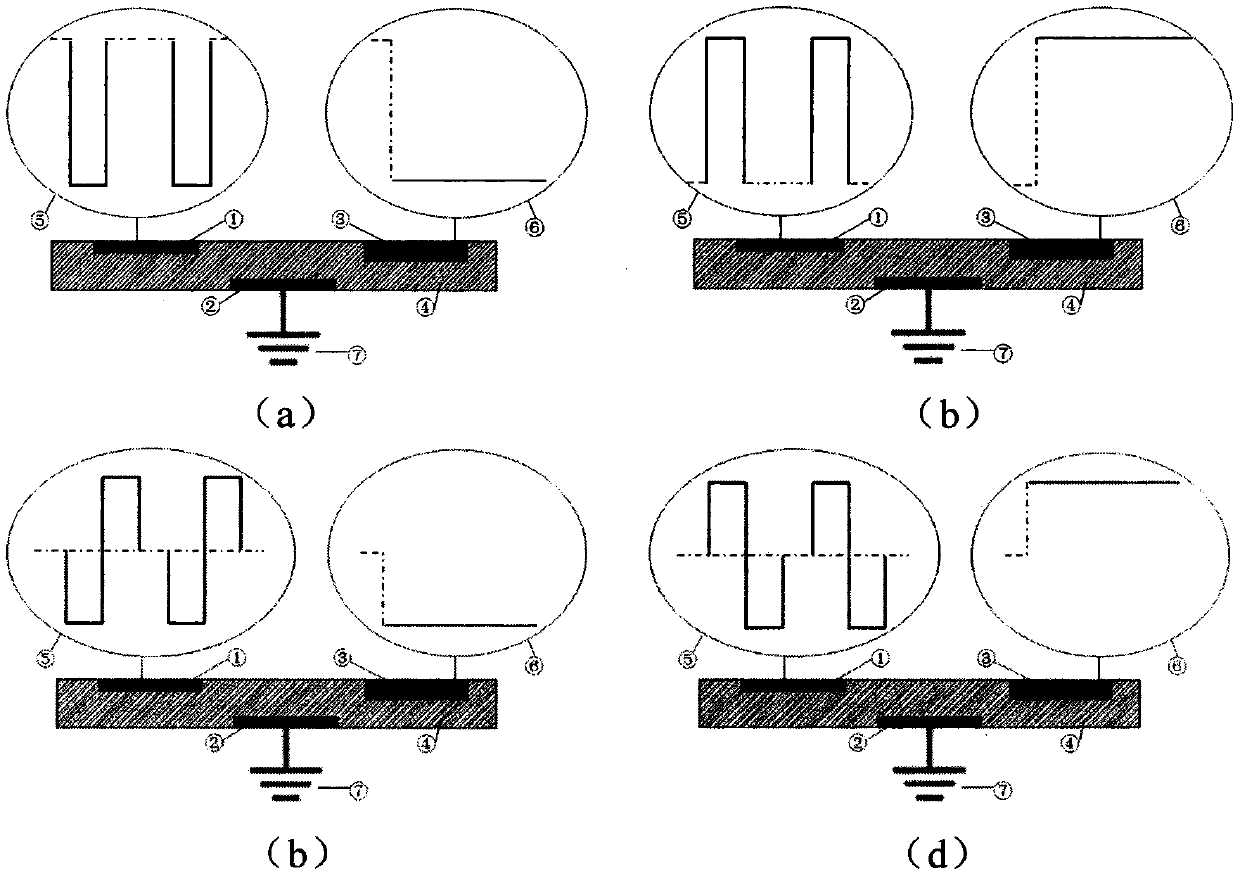

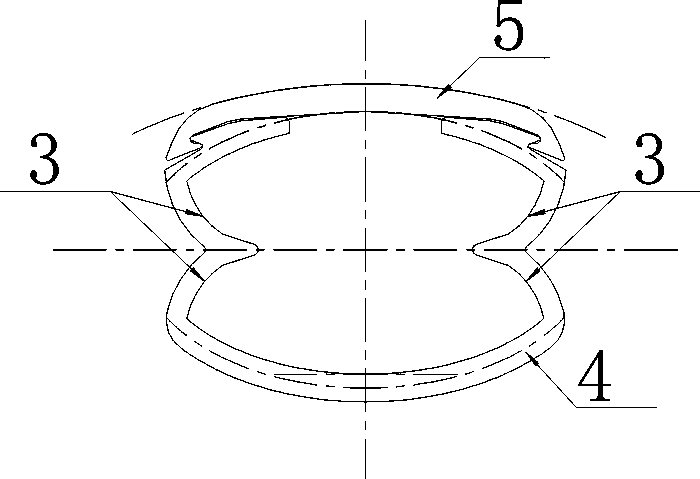

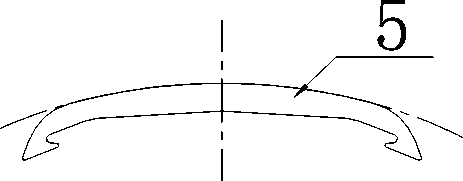

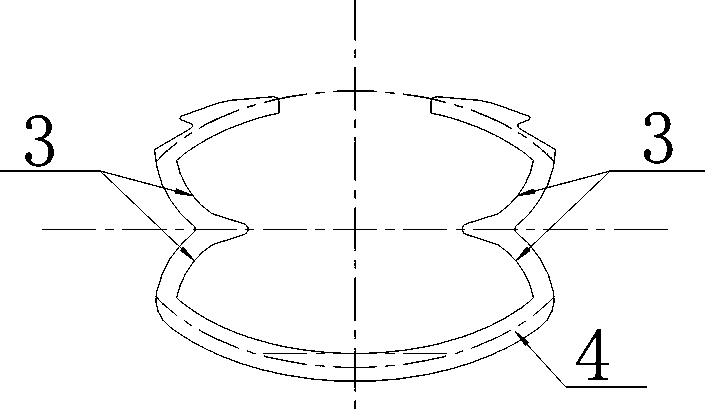

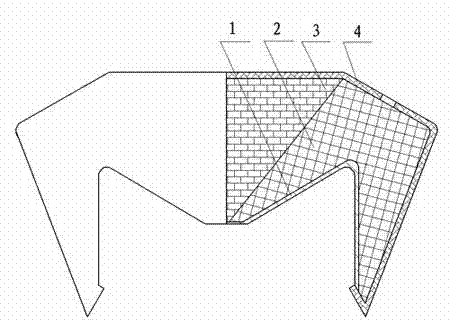

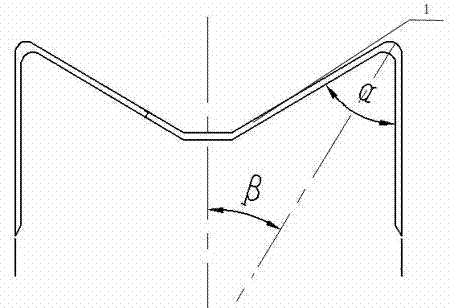

Device and method for increasing induced jet velocity of surface DBD exciter

InactiveCN110225639AHigh densityIncreased persistencePlasma techniqueHigh-voltage direct currentHigh pressure

The invention provides a three-electrode-layout DBD exciter. The three-electrode-layout DBD exciter is composed of a high-voltage electrode (1), a ground electrode (2), a third electrode (3) and a blocking dielectric layer (4). Based on this, the invention provides a device for increasing an induced jet velocity of a surface DBD exciter. The device comprises a short pulse high-voltage high-frequency plasma power supply (5), the three-electrode-layout DBD exciter and a bias high-voltage direct-current power (6). The invention further provides a method for increasing the induced jet velocity ofthe surface DBD exciter. According to the method, the plasma induced jet velocity is remarkably increased, and the discharge induced near wall jet can reach more than 10m / s.

Owner:AIR FORCE UNIV PLA

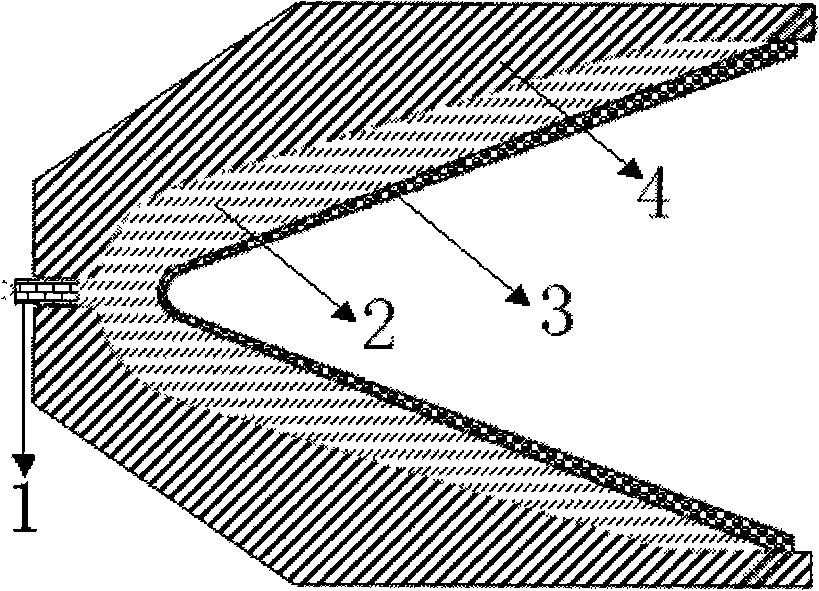

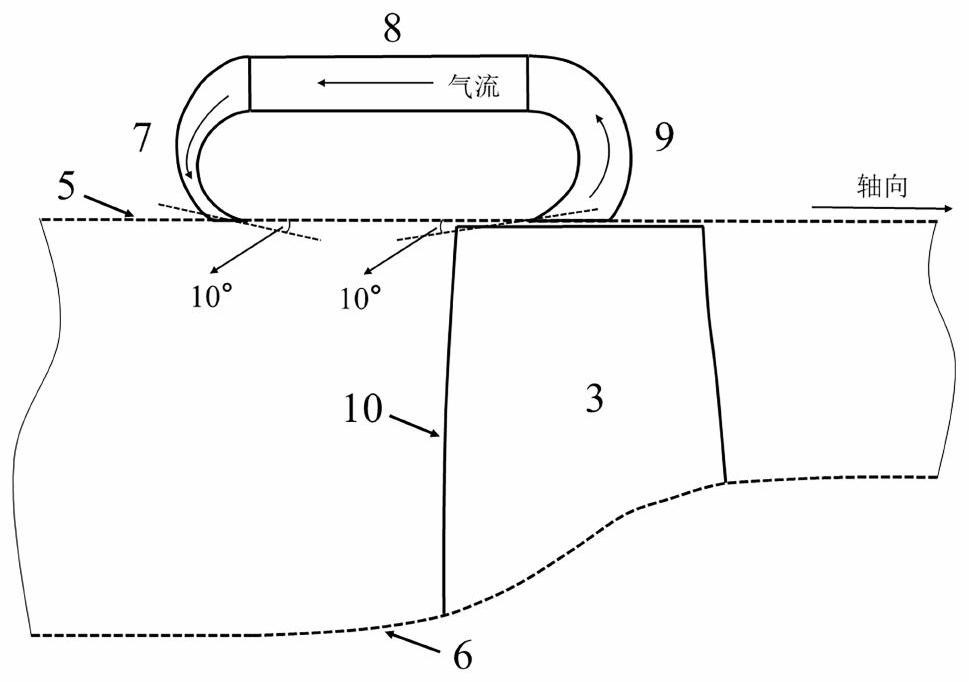

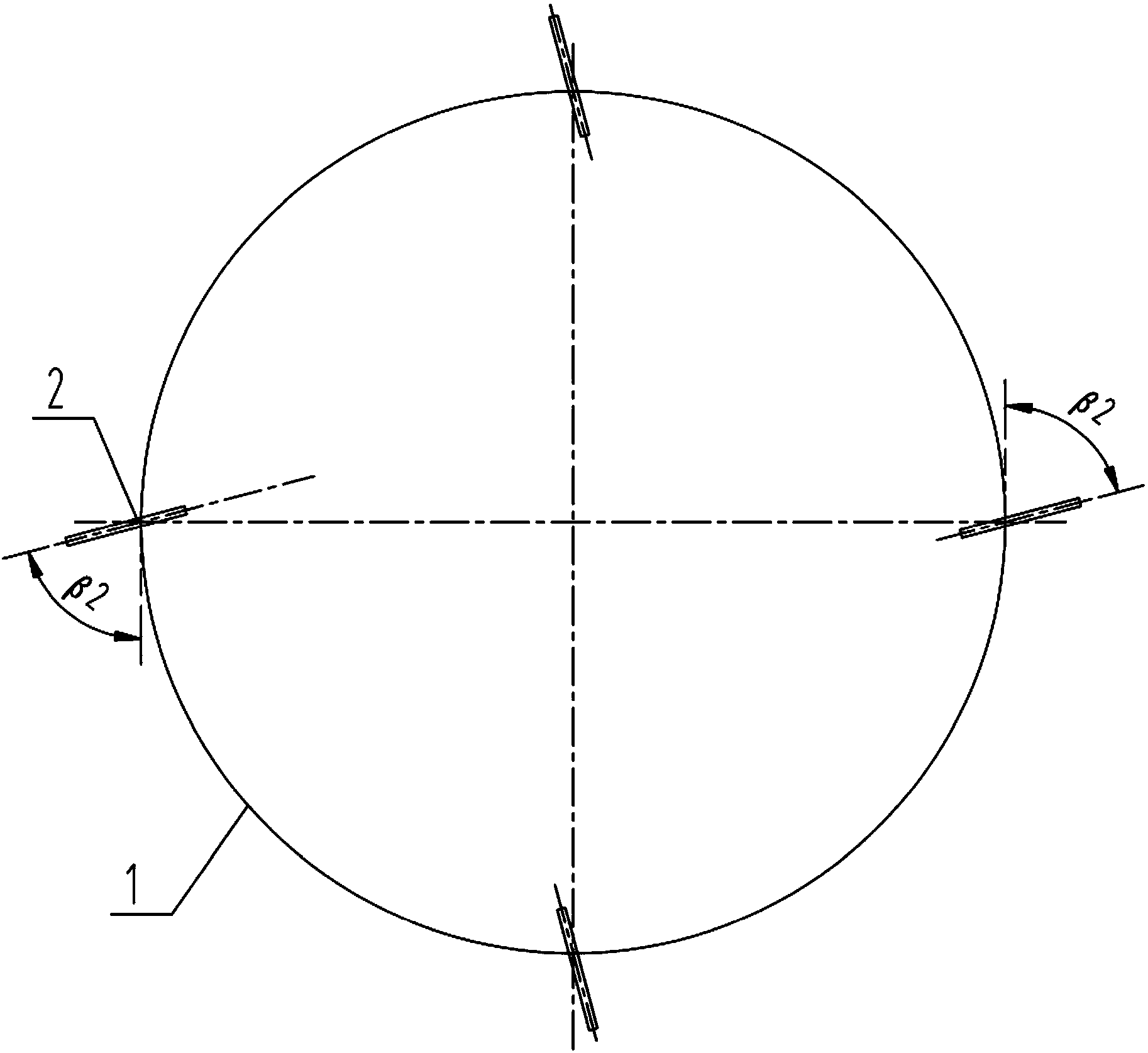

Circumferential-deflecting self-circulation casing treatment device for contra-rotating gas compressor

The invention relates to a circumferential-deflecting self-circulation casing treatment for a contra-rotating gas compressor, and belongs to the technical field of internal flow control of turbomachinery. The circumferential-deflecting self-circulation casing treatment for the contra-rotating gas compressor comprises an air suction section, a bridge road and an air injection section. The two-dimensional molded line of the air suction section is composed of two semicircular arc lines, and the two-dimensional molded line of the air injection section is formed by NURBS fitting. The stall margin of a contra-rotating compressor rotor R2 can be remarkably improved through self-circulation casing treatment. Compared with casing treatment of other forms, the self-circulation casing treatment of the design can reduce efficiency loss. The stability expansion effect of the self-circulation casing treatment on a certain two-stage contra-rotating gas compressor is examined. A self-circulation casing treatment air suction port is spaced from the downstream of the front edge of the blade top of the rear-row rotor R2 by 25% of the axial chord length, an air jet port is spaced from the upstream of the front edge of the blade top of the rear-row rotor R2 by 40% of the axial chord length, the air jet angle and the air suction angle are 10 degrees, and the throat area ratio is 4.0. Researches show that the stall margin of the contra-rotating gas compressor can be obviously improved through self-circulation casing treatment at the designed rotating speed of 70%-100%.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Deep penetration large-aperture perforating bullet

The invention belongs to the field of oil production, and particularly relates to a deep penetration large-aperture perforating bullet which is composed of a casing, a charging portion, a metal powder composite chemical cover and a detonating device. The deep penetration large-aperture perforating bullet mainly solves the problem that a deep penetration perforating bullet and a large-aperture perforating bullet cannot form large apertures on sleeves simultaneously and the problem of deep penetration of an oil and gas well stratum. After the charging portion detonates, the metal powder composite chemical cover generates high-speed jet flow to fly to the end face of a perforating bullet hole. After the jet flow formed on the inner surface of the chemical cover penetrates through a center hole of a truncated-cone-shaped lower cover body, the high-speed jet flow which is good in continuity and even in diameter and has a certain velocity gradient is formed so as to carry out deep penetration to the oil and gas well stratum.

Owner:ZHONGBEI UNIV

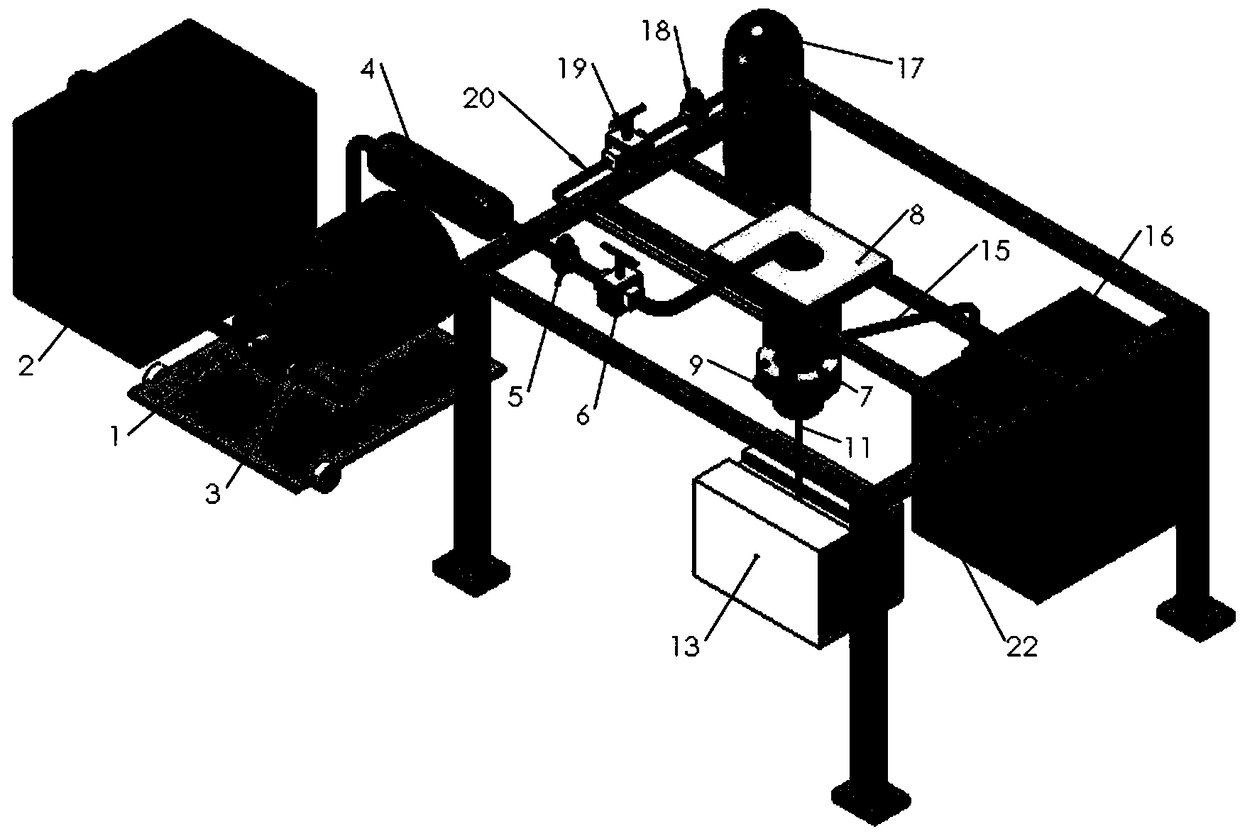

Underwater ventilation cavity assisted high-pressure water jet cutting device

InactiveCN109290958AEnsure safetyImprove cutting accuracyBlast gunsAbrasive feedersNumerical controlChemical reaction

The invention belongs to the field of underwater cold cutting, and particularly relates to an underwater ventilation cavity assisted high-pressure water jet cutting device. A high-pressure water tank,a high-pressure water pump, an energy accumulator, a pressure regulating valve, a flowmeter, a water pipe connector, a water cutter generator and a ruby nozzle are sequentially connected through a high-pressure water pipe; water in the high-pressure water tank forms a high-speed water jet flow at the ruby nozzle through the high-pressure water pipe; grinding sand is located on a water cutter numerical control guide rail installation frame and is connected with the water pipe connector through a grinding sand conveying pipe and a grinding and mixing pipe sequentially; a high-pressure gas cylinder, a gas pressure regulating valve, a gas flowmeter, a gas pipe, a gas cavity and an air bubble are sequentially connected through a pipeline; gas and the high-speed water jet flow are ejected ontoa workpiece to be cut so as to cut the workpiece; and the air bubble packs the jet flow at the position close to an outlet. According to the underwater ventilation cavity assisted high-pressure waterjet cutting device provided by the invention, the workpiece cannot be locally heated so as to be prevented from being deformed, no molten slags and chemical reaction is generated to cause toxic substances, the cutting accuracy is high, the cutting surfaces are in order, and the equipment performance and the service life are improved.

Owner:HARBIN ENG UNIV

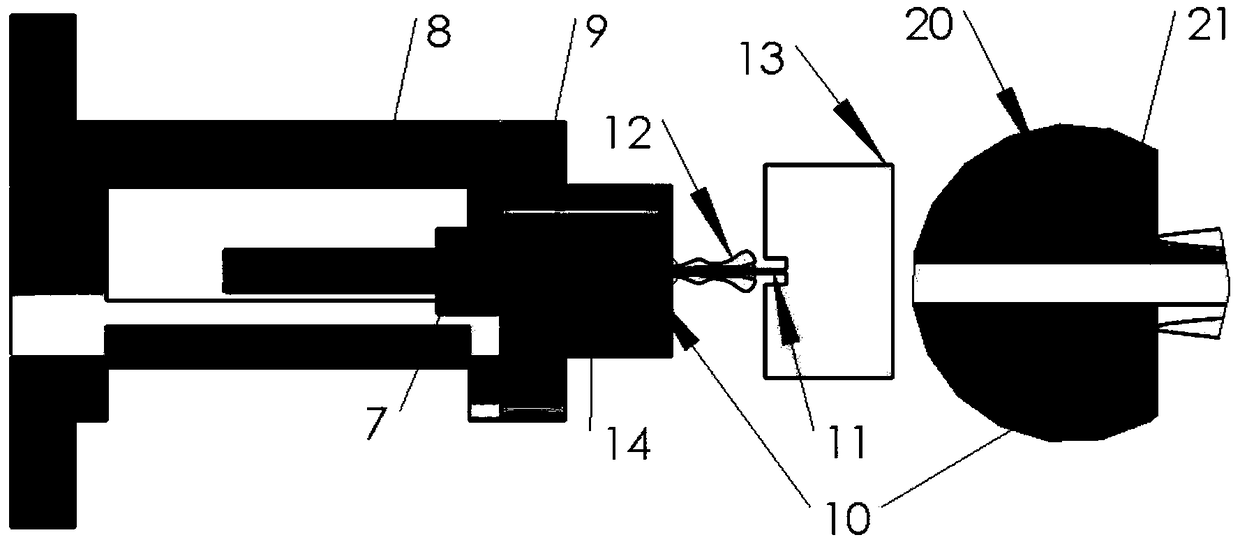

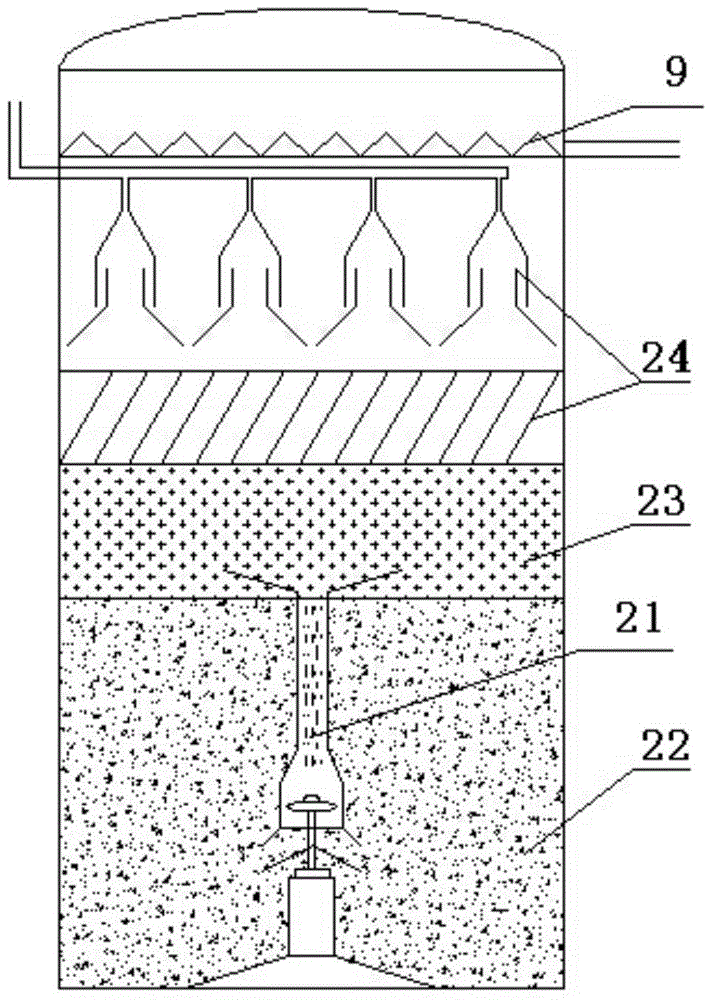

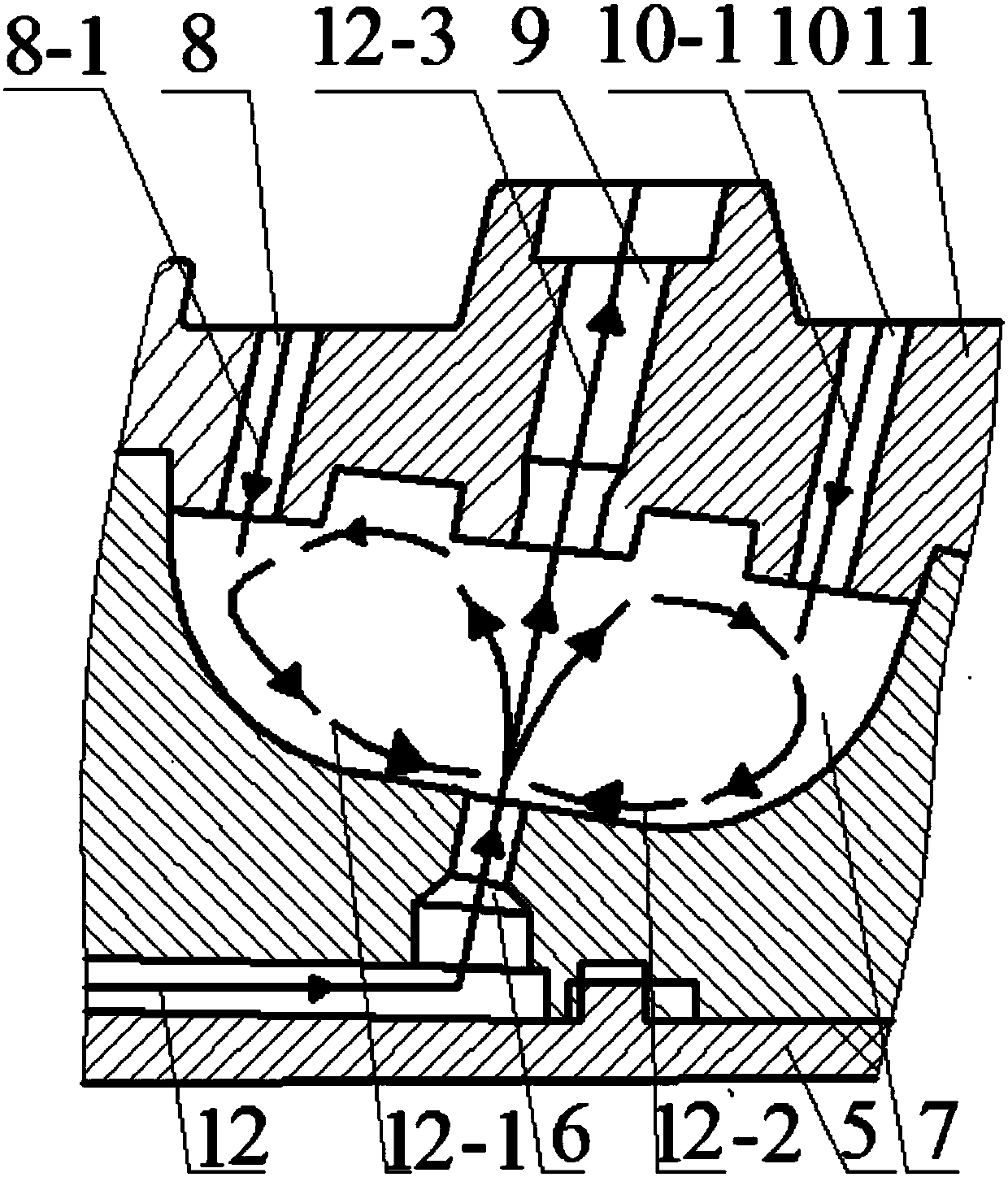

Mechanical internal circulation jet-flow anaerobic reactor and wastewater treatment method thereof

ActiveCN104445605AChange cloth waterChange the way of beingTreatment with anaerobic digestion processesHigh concentrationFluidized bed

The invention discloses a mechanical internal circulation jet-flow anaerobic reactor and a wastewater treatment method thereof, and belongs to the technical field of biological sewage treatment. The mechanical internal circulation jet-flow anaerobic reactor comprises a reactor tank body, a multi-phase separator, a water outlet weir and an internal circulation jet-flow device, wherein the internal circulation jet-flow device comprises an upper part and a lower part; the upper part comprises a jet-flow hole, a diffusion hole, a flow guide pipe and a flow stabilization hole; the lower part comprises a motor, a rotary shaft and high-speed blades. The wastewater treatment method comprises the following steps: forming a fluidized bed layer, forming a suspended bed layer, separating a separation region and discharging water from the water outlet weir. Due to the use of the internal circulation jet-flow device, the difficult problems of low treatment load, instable effect and relatively narrow application range in the treatment process of an existing conventional anaerobic reactor are solved; the mechanical internal circulation jet-flow anaerobic reactor has the advantages of high treatment load, good water impact resistance, high concentration of biological toxicity resistance matters, quick starting and the like.

Owner:NANJING UNIV

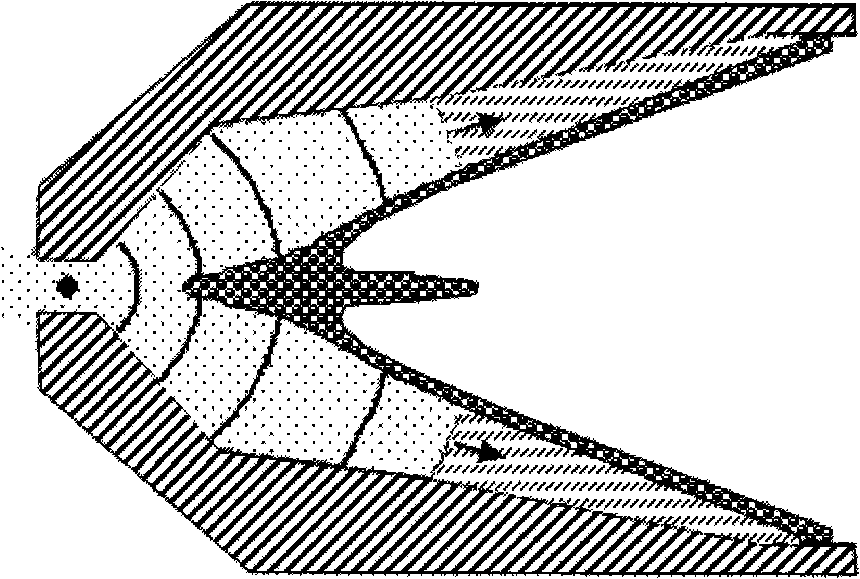

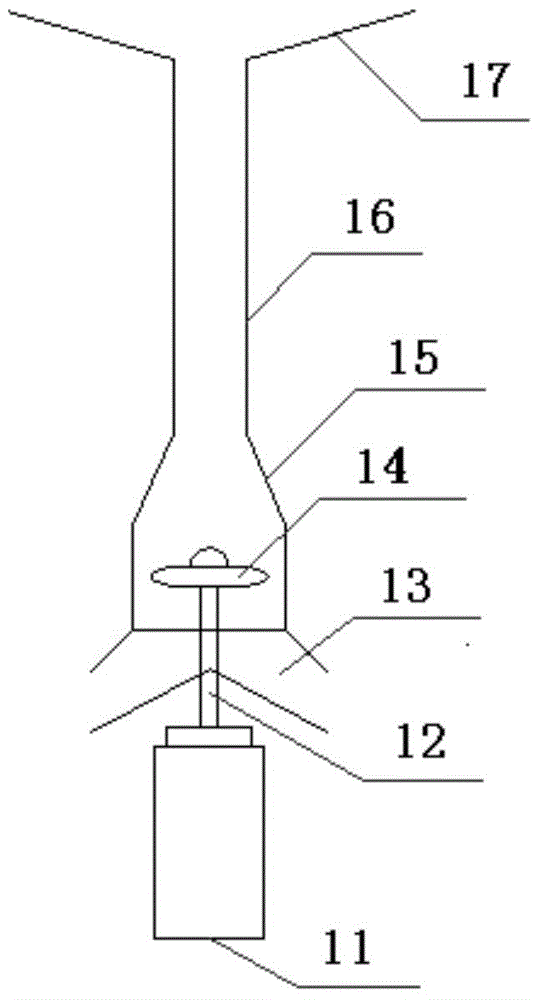

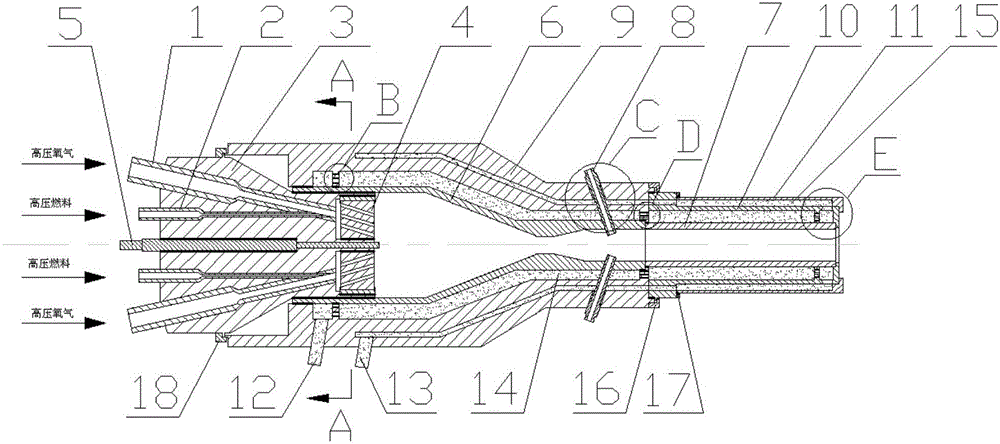

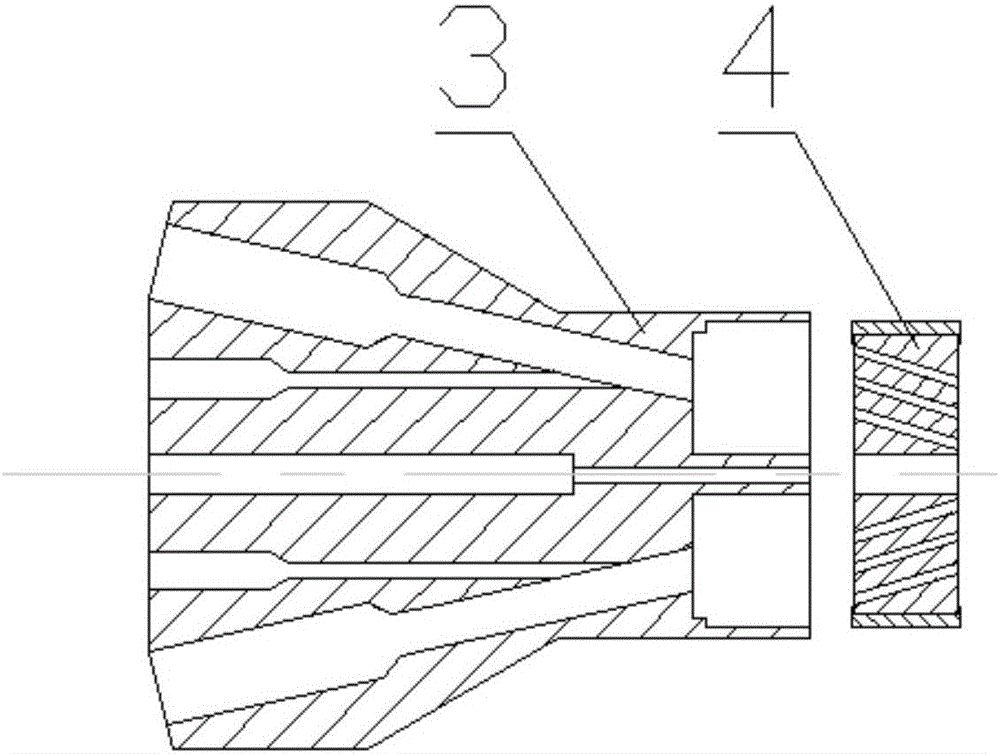

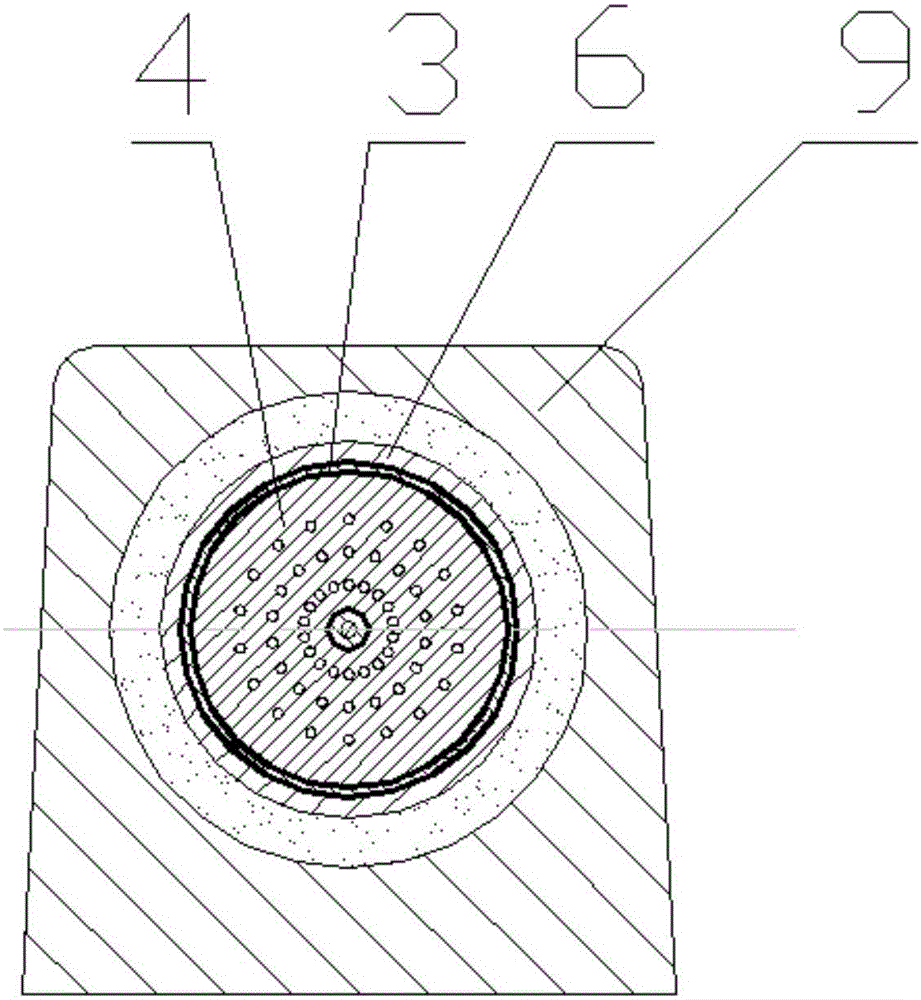

Novel hypersonic flame spraying gun

ActiveCN106016258AIncrease jet velocityParticle speed increasedBurnersBurner safety arrangementsCombustion chamberCombustor

The invention relates to a novel hypersonic flame spraying gun. The novel hypersonic flame spraying gun mainly comprises a combustor shell body, a gun barrel shell body, a coaxial tail base, a combustor, a gun barrel, two high-pressure oxygen input pipes, two high-pressure liquid fuel input pipes, a catalysis ceramic chip, an ignition needle, power feeding needles, a water cooling sleeve and the like, wherein the gun barrel shell body and the coaxial tail base are coaxially fixed to the front end and the back end of the combustor shell body correspondingly; the combustor is arranged in the combustor shell body; and the gun barrel is arranged in the gun barrel shell body. Compared with traditional hypersonic flame spraying guns, the jet speed and the particle speed are significantly increased through the unique structural design of the novel hypersonic flame spraying gun, jetting of eleven mach cones can be achieved, the jet speed reaches 3500 m / s, and the particle speed reaches 1500 m / s.

Owner:MIN OF WATER RESOURCES HANGZHOU MACHINERY DESIGN INST

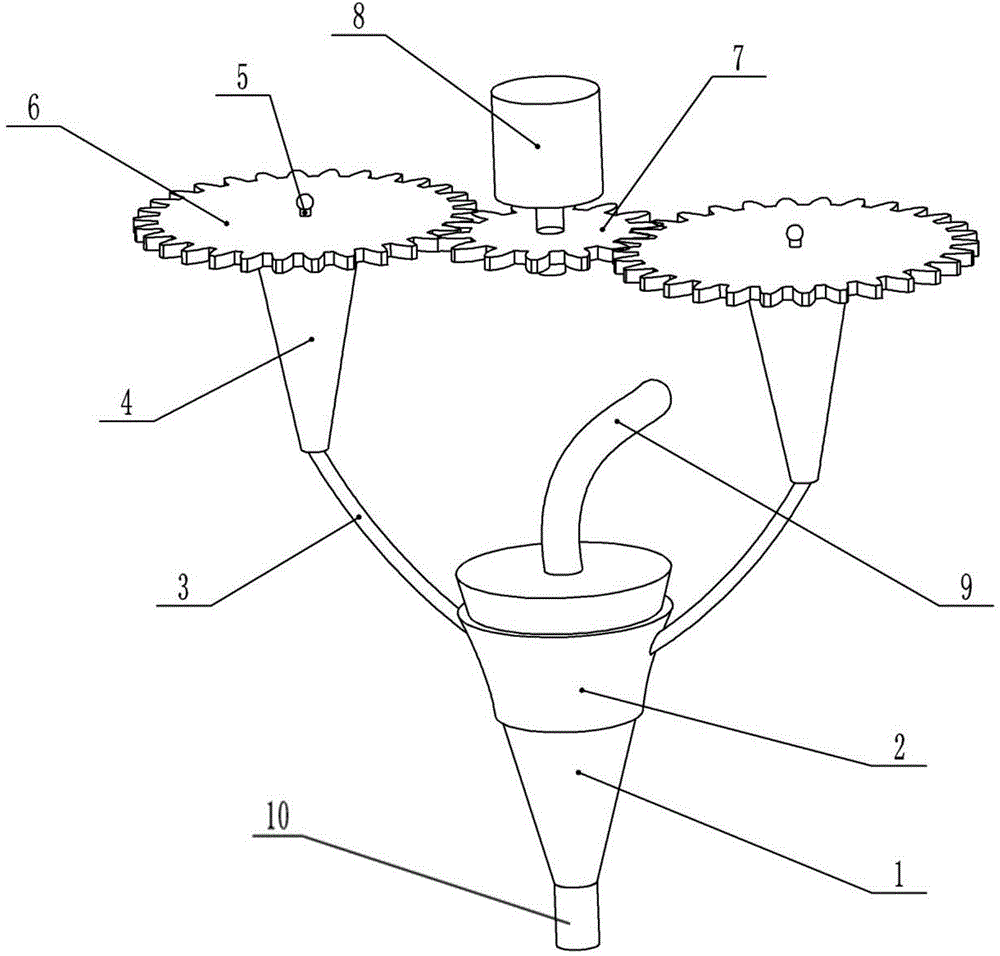

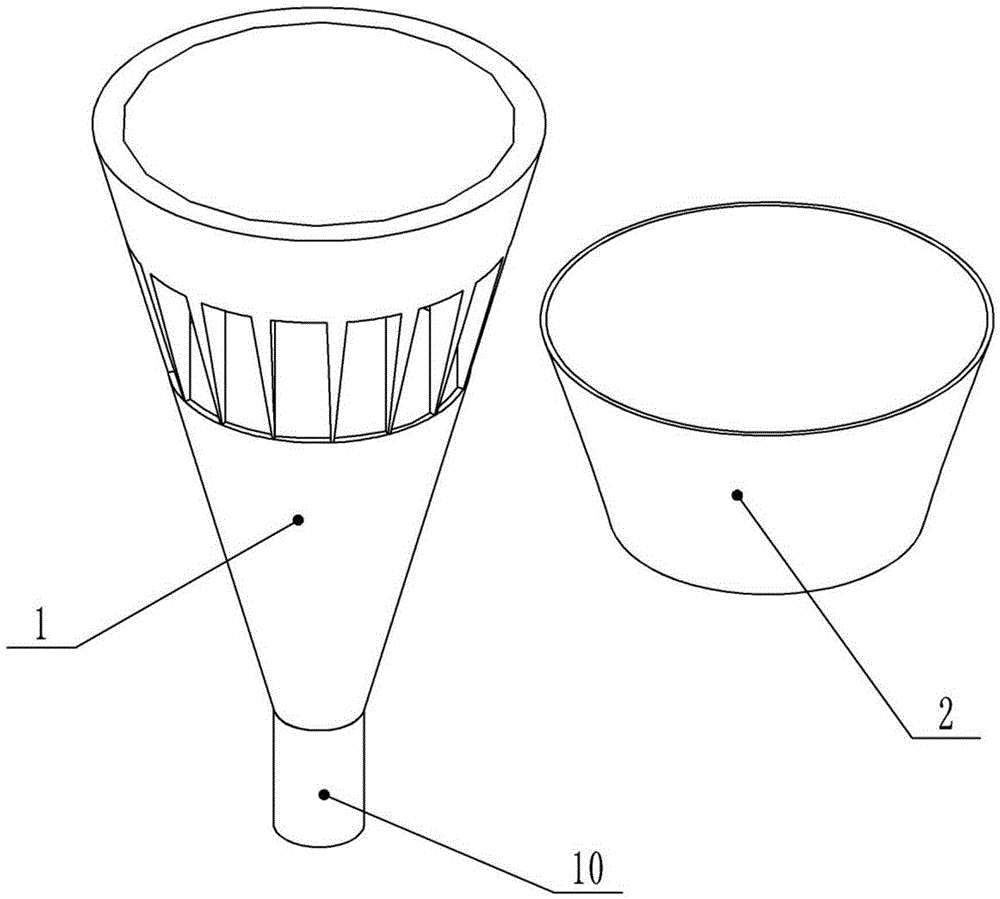

Ultrahigh-pressure water jet cutting machine nozzle

The invention belongs to the technical field of high-pressure water jet cutting machines, and particularly discloses an ultrahigh-pressure water jet cutting machine nozzle. The ultrahigh-pressure water jet cutting machine nozzle comprises a conical hollow nozzle body and a material grinding device, wherein the material grinding device is used for transporting a grinding material and comprises a spiral reamer, a drive gear and a conical hollow cylinder body; the hollow cylinder body is provided with a material inlet and a discharge pipe communicated with a nozzle body; the spiral reamer is arranged in the hollow cylinder body; one end of the drive shaft is fixedly connected with a material receiving end of the spiral reamer, and the other end of the drive shaft is provided with the drive gear; an output end of a driving motor is provided with a driving gear which is meshed with drive gears on the first drive shaft and the second drive shaft; a guide channel is communicated with a liquid outlet of the nozzle body; the pore diameter of the guide channel is equal to the pore diameter of a liquid outlet of the nozzle body; the length of the guide channel is equal to 2-3 times of the pore diameter. Compared with the traditional ultrahigh-pressure water jet cutting machine, the cutting machine is used for mixing grinding materials with high-pressure water skillfully, and water and the grinding materials act as the cutting media together, so that the cutting efficiency is enhanced.

Owner:重庆新锐科技服务有限公司

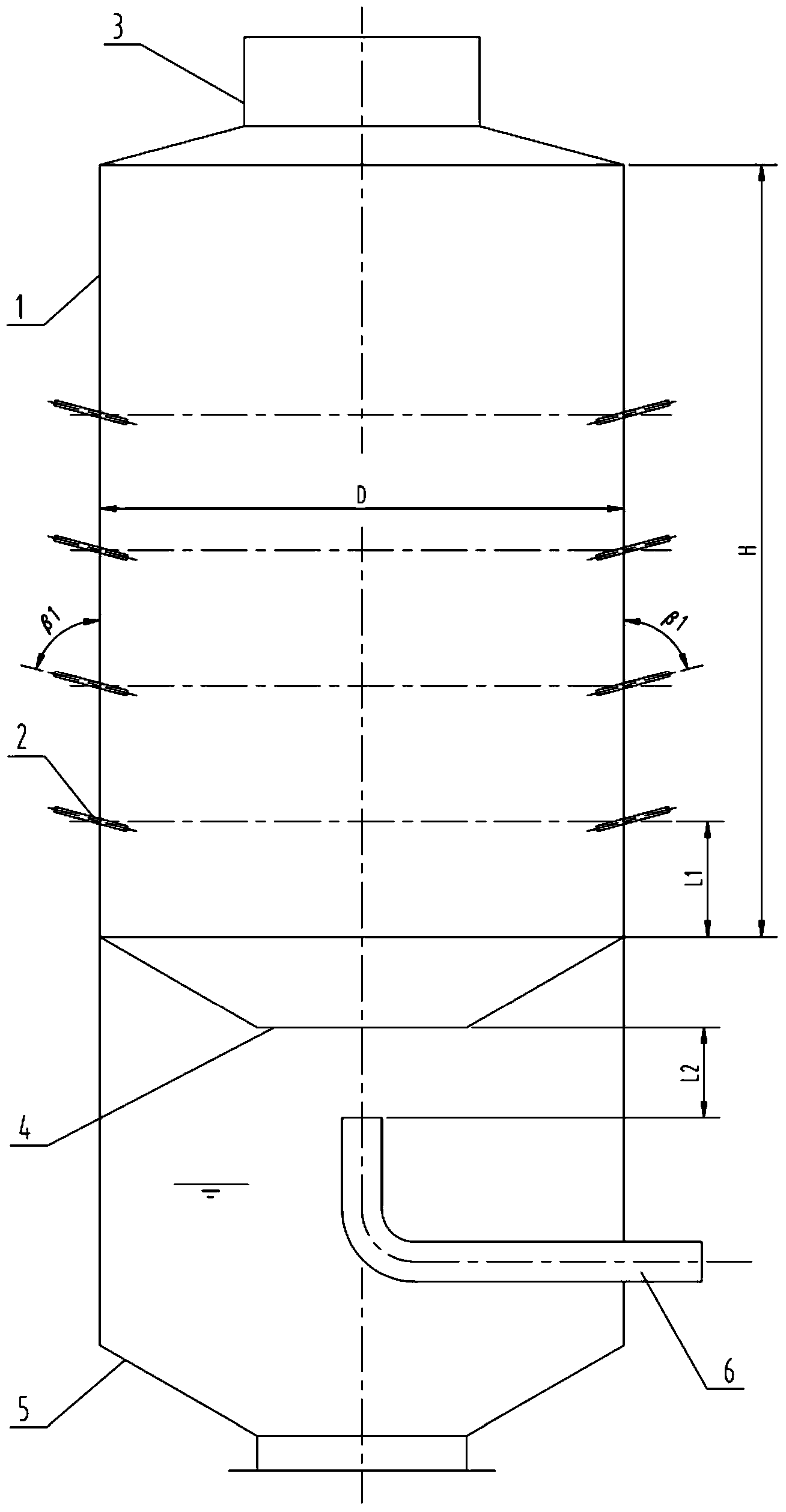

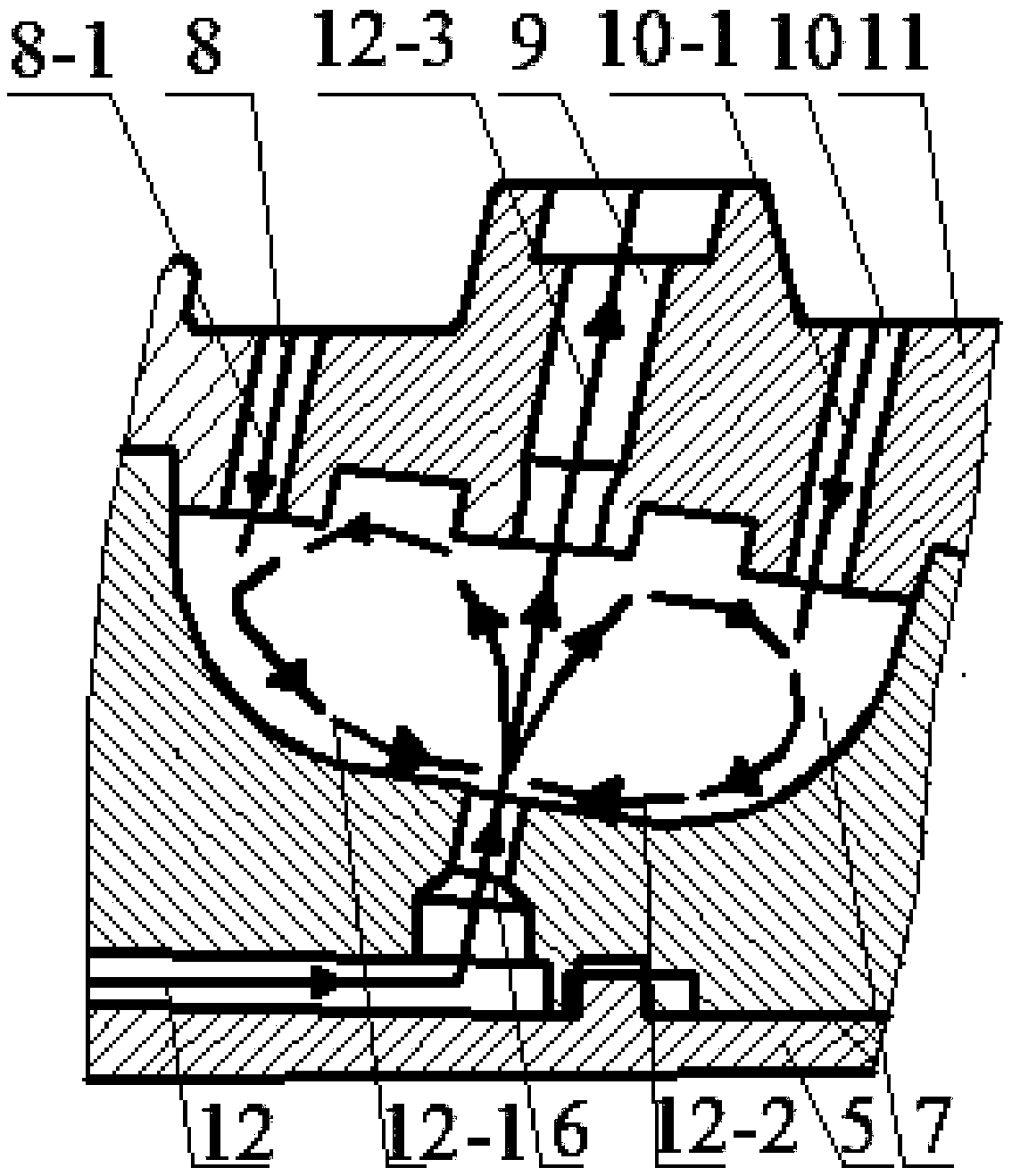

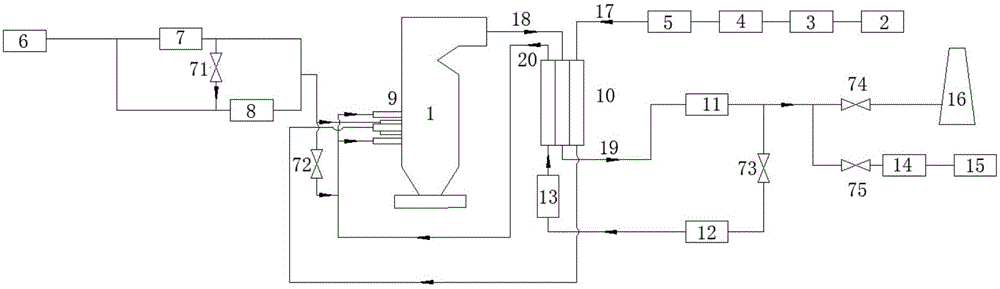

Gasification entrained-flow bed coal powder gasification furnace and gasification method of micro-positive pressure air

ActiveCN103725327AFully contactedAdequate responseGranular/pulverulent flues gasificationPositive pressureSlag

The invention discloses a gasification entrained-flow bed coal powder gasification furnace and a gasification method of micro-positive pressure air. At present, a normal-pressure fixed bed gasification furnace is commonly applied in an industrial fuel gas preparation industry and an efficient powdered coal entrained-flow bed gasification technology has some difficulties on preparing industrial fuel gas under the condition that the micro-positive pressure air is used as a gasifying agent. The gasification entrained-flow bed coal powder gasification furnace is characterized in that a gasification furnace body is provided with at least one row of wall surface burners; each row of the wall surface burners comprise a plurality of wall surface burners which are arranged along the peripheral direction of the gasification furnace body at intervals; the gasification agent which is sprayed into the gasification furnace by all the wall surface burners accounts for 80%-97% of the use amount of all the gasification agent; a furnace bottom nozzle is arranged below the bottom face of a gasification furnace slag opening; the gasification agent which is sprayed into the gasification furnace by the furnace bottom nozzle accounts for 3%-20% of the use amount of all the gasification agent. According to the gasification furnace, the gasification intensity of a unit volume is high; the quantity of in-furnace coal powder falling into a dreg tank is effectively reduced; the gasification entrained-flow bed coal powder gasification furnace is very suitable for producing the industrial fuel gas by taking the micro-positive pressure air as the gasification agent.

Owner:ZHEJIANG ASROAD HIGHWAY CONSTR & MAINTENANCE MACHINERY

Blasting cutting device with composite charging structure and construction method of blasting cutting device

The invention discloses a blasting cutting device with a composite charging structure and a construction method of the blasting cutting device. The blasting cutting device is composed of a shaped blasting tube, a tail connector, explosives, a detonating cord and a reverse detonating cartridge, wherein the shaped blasting tube comprises an explosive groove with a horn-shaped groove and an outer buckling explosive groove cover; a tube is filled with the explosives and is provided with the detonating cord; the reverse detonating cartridge can be connected with the tail of the tube through the tail connector, and therefore the blasting cutting device is formed; and the blasting cutting device is fixed in a blasting hole by a positioning block. According to the horn-shaped groove in the shapedexplosive tube, the charging structure of the horn-shaped groove can generate higher jet velocity than the charging structure of a cone-angle-shaped groove, and the cutting ability on rock mass is higher. The shaped blasting tube has two types including a common type and a reinforced type. A groove of the common type shaped blasting tube is an opening, a groove notch of the reinforced type shapedblasting tube is closed, a shaped cavity is formed in the groove, on the one hand, the rigidity of the structure can be enhanced, on the other hand, after water is injected into the shaped cavity, high-pressure jet water can be generated during blasting to form a water jet, the cutting ability on the rock mass can be enhanced, and the generated water mist can further play a role in dust removal.

Owner:四川路航建设工程有限责任公司

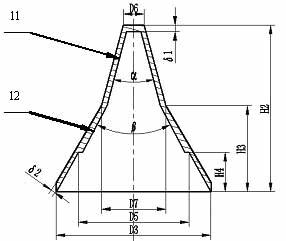

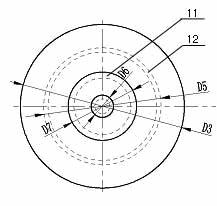

Double-focusing linear jet cutter

The invention belongs to the technical field of engineering blasting and relates to a double-focusing linear jet cutter. The double-focusing linear jet cutter consists of a liner, explosive, a waveform regulator and a shell. The liner with the structure can be viewed as two traditional wedge-shaped covers which are relatively combined. The way of initiation is to initiate from the central points of two edges of a charged top. After the explosive is charged and initiated, the two wedge-shaped covers respectively form two jet flows along respective axes. The two jet flows are converged again on the symmetrical surface of the two wedge-shaped covers to form one condensed jet to cut metal and other materials. Compared with the existing devices for cutting the metal and other materials, the double-focusing linear jet cutter has the beneficial effects that the jetting speed and the continuous jetting length of the linear cutter are effectively improved, the power of the linear cutter is improved and the application prospect is wide.

Owner:ZHONGBEI UNIV

Ultrasonic nozzle for use in metallurgical installations and method for dimensioning an ultrasonic nozzle

ActiveCN103069015AReduce weightImproved jet characteristicsGeometric CADCharge manipulationElectric arc furnaceUltrasonic nozzle

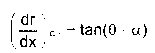

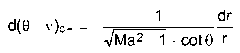

The invention relates to an ultrasonic nozzle for use in metallurgical installations, in particular for the top blowing of oxygen in a Basic Oxygen Furnace (BOF) or an electric arc furnace (EAF), comprising a convergent portion and a divergent portion, which are adjacent to each other at a nozzle throat (DK), wherein the ultrasonic nozzle is defined by the following group of nozzle forms in the respective design case thereof: (T1)

Owner:SMS DEMAG AG

Gas mixed pulse cleaning device for intelligent toilet bowl

The invention discloses a gas mixed pulse cleaning device for an intelligent toilet bowl, and relates to the field of water jet cleaning devices low in pressure and small in flow. The gas mixed pulsecleaning device comprises a hollow shaft, a water supply pipe, a nozzle fixing device, a water supply path, a bottom plate, a throttling pipe, a gas mixing chamber, a gas suction pipe A, a gas mixed pulse nozzle, a gas suction pipe B and an upper cover. The nozzle fixing device is arranged on the hollow shaft in a sleeving mode and can move leftward and rightward. The water supply pipe is placed in the hollow shaft. One end of the water supply path is connected with the water supply pipe, and the other end of the water supply path is connected with the throttling pipe. The water supply path isarranged on the bottom plate. The bottom plate is connected with the gas mixing chamber through laser welding. The throttling pipe is connected at the center of the gas mixing chamber. The center ofthe gas mixed pulse nozzle and the center of the throttling pipe coincide and are connected to the gas mixing chamber. The gas suction pipe A and the gas suction pipe B are arranged on the two sides of the gas mixed pulse nozzle, and the gas suction pipe A, the gas suction pipe B and the gas mixed pulse nozzle are arranged on the upper cover. The upper cover is connected with the gas mixing chamber through laser welding. Lots of water and electricity resources can be saved, the structure is simple, and the gas mixed pulse cleaning device is good in cleaning effect, water saving effect and energy saving effect through actual trial use.

Owner:JIANGSU UNIV

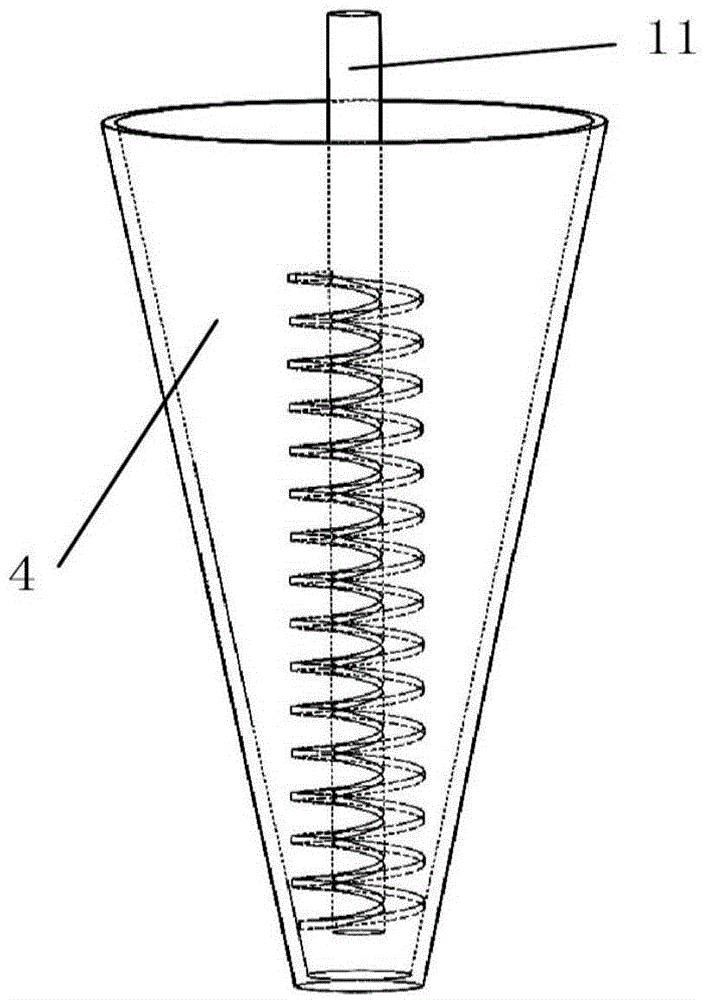

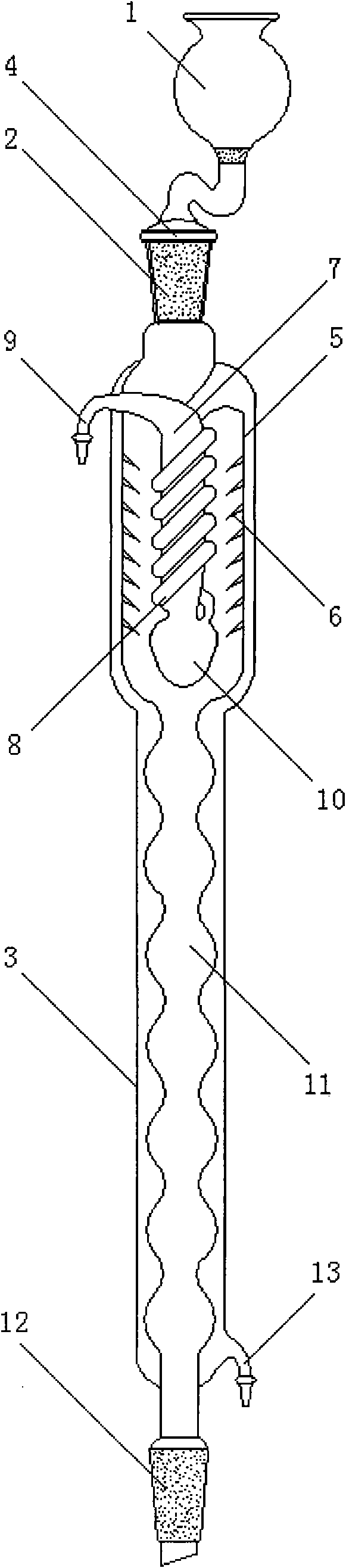

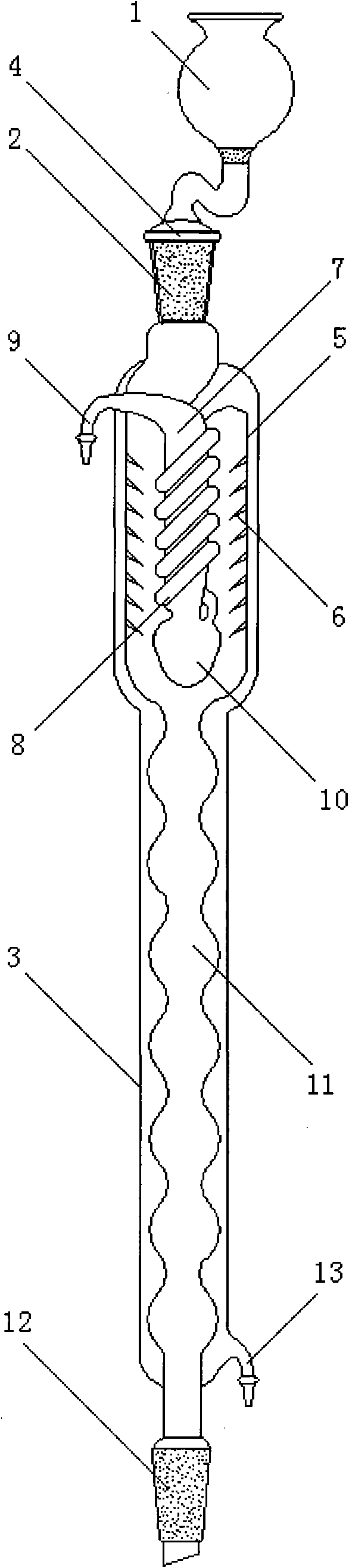

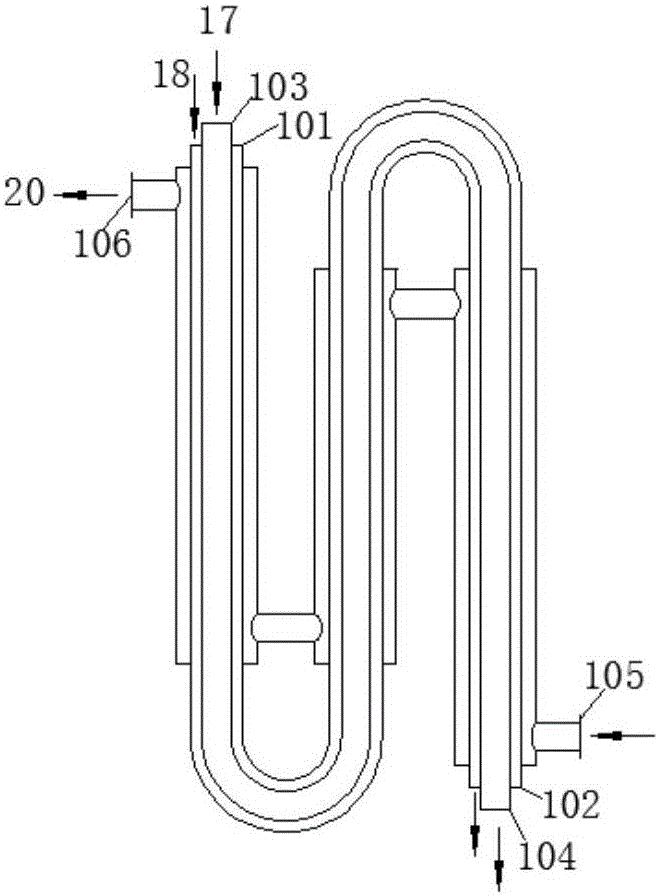

Reflux condenser pipe special for microwave chemistry

InactiveCN101780423AIncreased separation lossReduced separation lossSteam/vapor condensersLaboratory glasswaresRefluxOrganic solvent

The invention discloses a reflux condenser pipe special for microwave chemistry, which mainly comprises an external layer water sleeve (3), a standard ground (4), a barrel-shaped pipe (5), baffle stabs (6), an inner core pipe (7), a coil pipe (8), a water distribution head (10) and a serial ball pipe (11). The reflux condenser pipe special for the microwave chemistry is characterized in that: the standard ground (4) at the upper end of the external layer water sleeve (3) is welded with the barrel-shaped pipe (5) together; the baffle stabs (6) are uniformly distributed at the periphery of the inner wall of the barrel-shaped pipe (5); the lower end of the barrel-shaped pipe (5) is welded with the upper end of the serial ball pipe (11); the lower end of the inner core pipe (7) is connected with the water distribution head (10); and the coil pipe (8) is coiled outside the inner core pipe (7), and the lower end of the coil pipe (8) is connected with the water distribution head (10). Therefore, blasting explosion and high consumption of an organic solvent can be effectively prevented.

Owner:王锦化

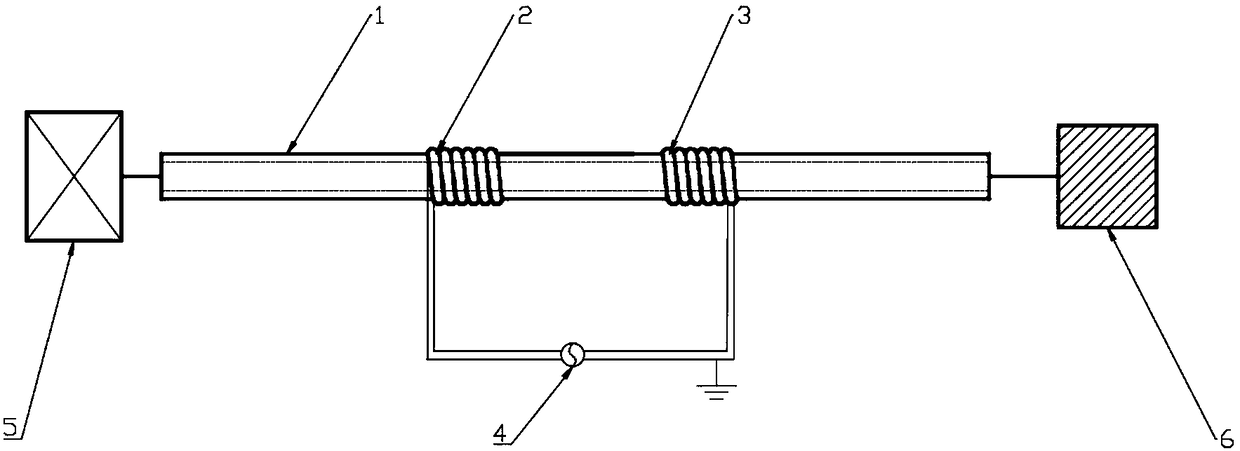

Blocked inductance-capacitance coupling helical plasma antenna

InactiveCN108631047AImprove ionization efficiencyIncrease jet velocityRadiating elements structural formsCapacitancePlasma jet

A blocked inductance-capacitance coupling helical plasma antenna is disclosed. The invention discloses a plasma antenna device capable of acquiring a stable plasma jet flow in a wide air pressure range. The antenna is formed by two helical inductor antennas which are wound on a quartz tube. A helical inductor antenna 1 is connected to the anode of a radio frequency power supply. A helical inductorantenna 2 is grounded. The two segments of antennas are separated by a certain distance. The antenna has air blocking and forms an axial voltage drop in a capacitance mode to accelerate plasmas so asto obtain a high-speed jet flow. The structure of the antenna is simple and compact. The ionization of the plasmas and acceleration are combined and ionization efficiency is high. The stable ionization can be realized in an air pressure range from 150Pa to 2500Pa. Technical guarantee is provided for realizing radio frequency plasma ionization under different air pressure conditions, and an application range is wide.

Owner:SICHUAN UNIV

Spiral-flow type supersonic speed electric arc spraying gun

InactiveCN102974486AGood effectImprove stabilityMolten spray coatingElectric arc sprayingSpray coatingSpray nozzle

The invention discloses a spiral-flow type supersonic speed electric arc spraying gun, which comprises a gun body, wherein a contact tip is connected onto a conducting wire; airflow holes are uniformly distributed on a radial airflow channel arranged in the gun body; a spiral-flow ring is connected with the gun body through screw threads; spiral-flow holes are uniformly distributed on the periphery of the spiral-flow ring; an air gathering hood is fixed with the spiral-flow ring through screw threads; a ceramic nozzle is pressed in the spiral-flow ring through the air gathering hood; and an inner cavity of the ceramic nozzle and an inner cavity of the air gathering hood are combined to form a Laval nozzle. According to the technical scheme, spiral-flow atomization and supersonic speed atomization are combined, the effect and the stability of jet flow atomization are enhanced through a spiral-flow structure and a Laval spray pipe, secondary acceleration of jet flow is realized, and the speed of jet flow is further improved, so that the spray coating particle hole atomization effect is stronger, nanometer refinement is achieved, flying speed achieves supersonic speed, and the prepared coating layer is obviously improved. The spiral-flow type supersonic speed electric arc spraying gun is not only suitable for coating equipment for precision parts, but also suitable for large-area coating preparation.

Owner:新乡市布瑞林特机械再制造有限责任公司

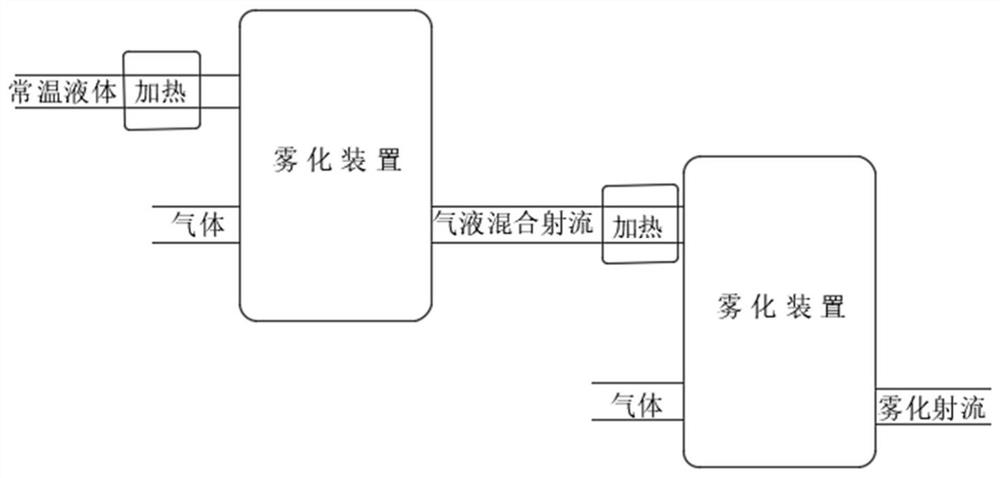

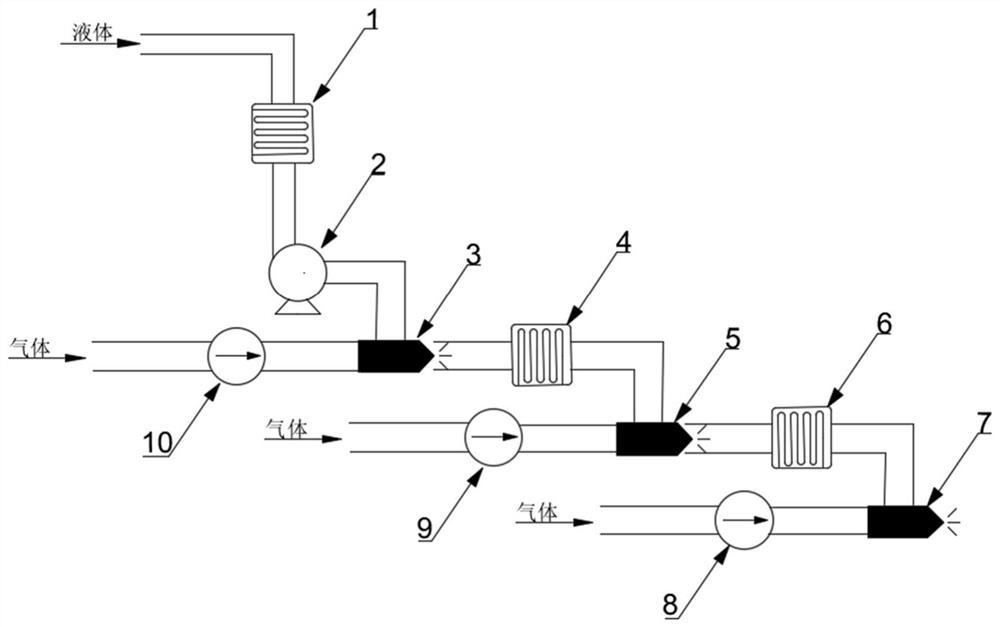

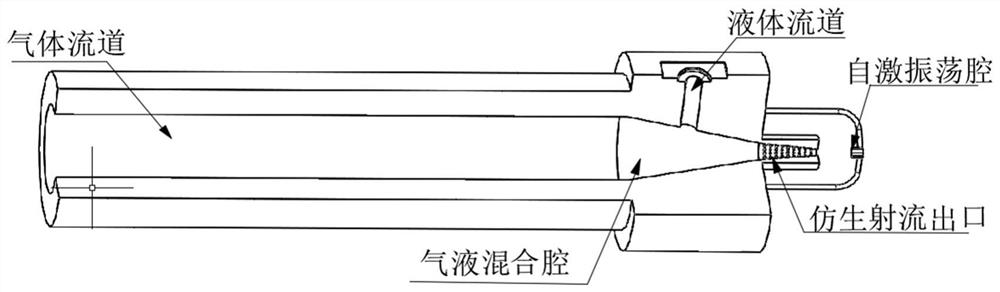

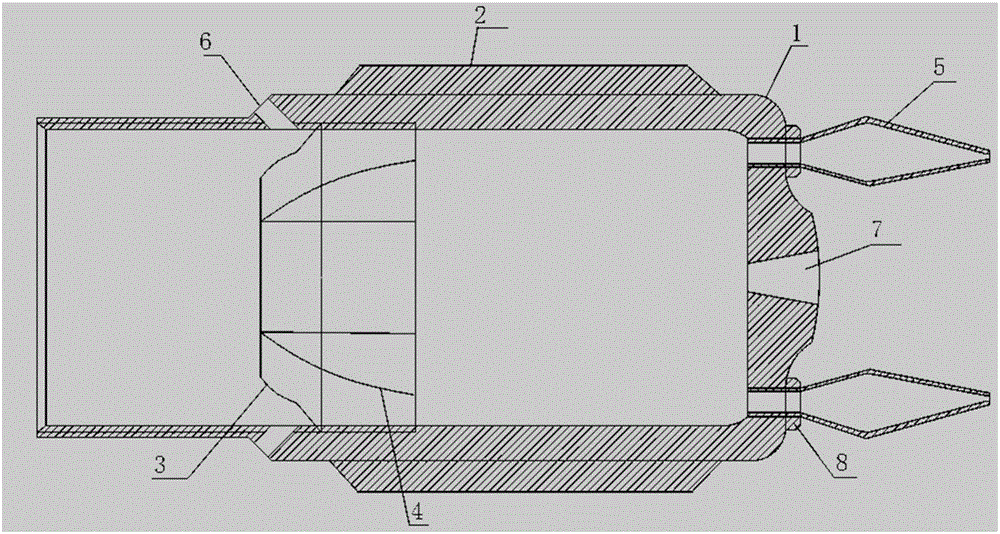

Device and method for synergistically enhancing two-fluid atomization performance

ActiveCN112808478APromote fragmentationReduce forceWatercraft hull designUsing liquid separation agentEngineeringMechanical engineering

The invention discloses a device and a method for synergistically enhancing a two-fluid atomization performance. The device is formed by connecting multiple stages of two-fluid atomization units in series, wherein the output of a gas-liquid mixing unit in the previous stage of two-fluid atomization unit is connected with the input of a liquid feeding unit in the next stage of two-fluid atomization unit; the output of the last stage of two-fluid atomization unit is used as the output of the whole device; and a heating device is further arranged in the liquid feeding unit. According to the device and the method for synergistically enhancing the two-fluid atomization performance provided by the invention, liquid or fog drops are heated, so that the acting force between liquid molecules is reduced, and the liquid drops can be broken easily. Through the multi-stage series connection mode, the flow of gas-liquid mixed liquid is greatly increased compared with the previous stage, the reaction in each two-fluid atomization device unit is more violent compared with the previous stage, the effect of generating high-speed jet flow with low energy consumption can be achieved, and the quality of generated fog drops is higher.

Owner:ZHEJIANG UNIV OF TECH

Self-feeding type composite rock breaking high-pressure sprayer for radial horizontal well

InactiveCN106246107AImprove self-improvementIncrease jet velocityLiquid/gas jet drillingDirectional drillingEngineeringRock breaking

The invention discloses a self-feeding type composite rock breaking high-pressure sprayer for a radial horizontal well. The self-feeding type composite rock breaking high-pressure sprayer is provided with a sprayer shell which is provided with a forward nozzle, a backward nozzle and spiral and special-shaped flow guiding grooves. The spiral and special-shaped flow guiding grooves are located between the forward nozzle and the backward nozzle. A fluid shock excitation device is arranged in the shell and connected with the sprayer shell through threads. Four extending composite rock breaking nozzles are mounted at the front end of the sprayer shell and connected with the sprayer shell through threads. Under the condition that hydraulic power energy of the forward nozzle is not lost, the jet speed of the backward nozzle is increased to the maximum extent, so that the self-feeding force of the sprayer is increased; direct-spiral mixed jetting is adopted by the central forward nozzle, a large impact area can be formed, forward impact force and circumferential cutting force can be exerted on rock in the rock breaking process, and thus the rock breaking speed is increased; and the self-feeding type composite rock breaking high-pressure sprayer is relatively simple and reliable in structure, and broad in application prospect.

Owner:SOUTHWEST PETROLEUM UNIV

Water spouting device for toilet

InactiveCN108240023ASimple structurePromote productionFlushing devicesLavatory sanitoryGas mixingToilet

The invention provides a water spouting device for a toilet. The water spouting device comprises a spray head fixing device, a chassis and an upper cover, wherein the chassis is arranged on the lowerend surface of the spray head fixing device, and a cavity formed between the spray head fixing device and the chassis is a water supply room; the upper cover is arranged on the upper end surface of the spray head fixing device, and a cavity between the spray head fixing device and the upper cover is a gas mixing room; the gas mixing room and the water supply room are communicated through a throttle pipe; the upper cover is provided with a first gas suction pipe, a second gas suction pipe and a gas mixing pulse nozzle penetrating through the gas mixing room; the spray head fixing device is provided with a water inlet channel; and the water inlet channel is communicated with the water supply room. In the invention, a gas mixing pulse jet flow can be generated perfectly, the same aim of cleaning can be achieved by using little water, and the electric quantity for heating water is reduced.

Owner:JIANGSU UNIV

Coal water slurry flame-free oxygen-enriched combustion system

ActiveCN105757651ASolve the problem of high capture costEmission reductionBurnersIndirect carbon-dioxide mitigationGas heaterOxygen tank

The invention discloses a coal water slurry flame-free oxygen-enriched combustion system. The system comprises a hearth, a high-speed atomization combustor, a slurry supply system, an oxygen supply system, a flue gas circulating system and a flue gas discharging and recycling system. The high-speed atomization combustor comprises a primary air nozzle, a secondary air nozzle and a coal water slurry atomization nozzle; the slurry supply system comprises a slurry storage tank, a slurry conveying pump, a stirring filter and a slurry supply pump; the oxygen supply system comprises an oxygen tank, a gas heater and a gas pressurizing pump; the flue gas circulating system comprises a flue gas heat exchanger, a dust remover, a circulating draught fan and a condenser; and the flue gas discharging and recycling system comprises a CO2 compression and storage device and a chimney. According to a coal water slurry flame-free oxygen-enriched combustion technology provided by the invention, oxygen is pressurized and heated and is mixed with circulating flue gas, and mixed gas is sprayed into a furnace to form volume combustion; coal water slurry is subjected to heat exchange through the flue gas heat exchanger, so that the initial temperature is improved and ignition heat is reduced; and the problems of a current coal water slurry boiler that the combustion efficiency is relatively low, the emission of NOx is high and the capturing cost of CO2 is high and the like can be solved.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com