Patents

Literature

346 results about "Feeding force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

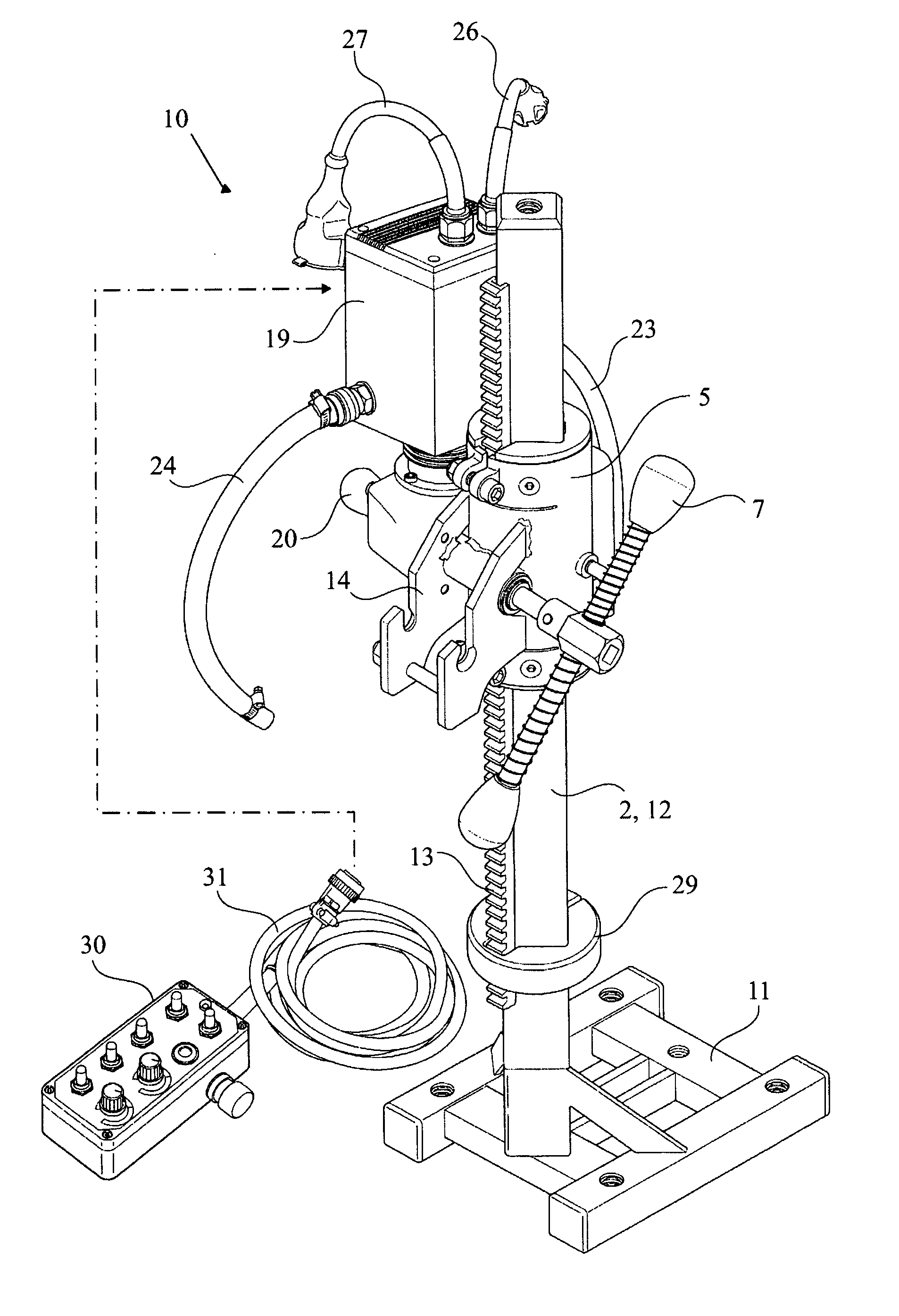

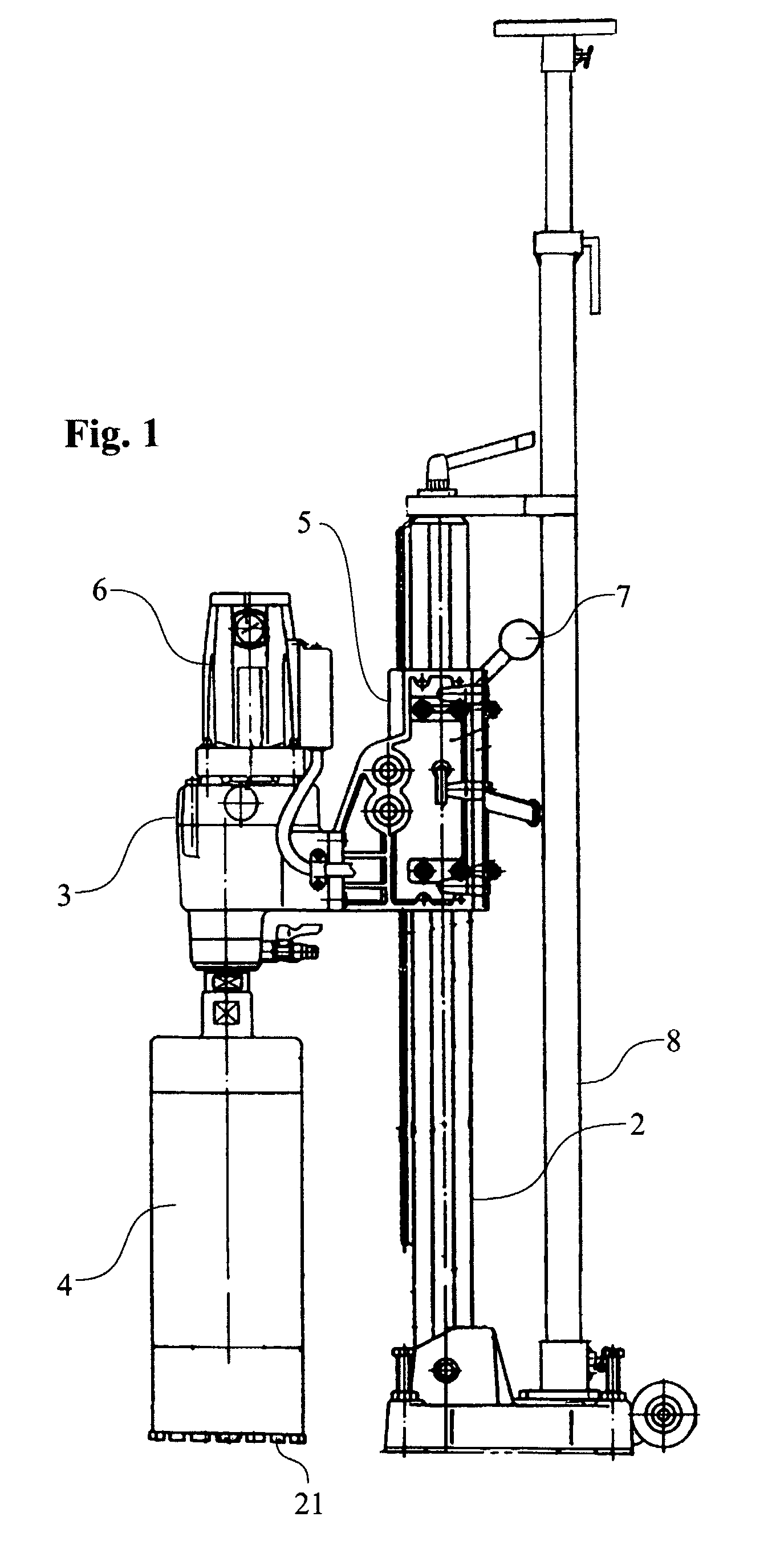

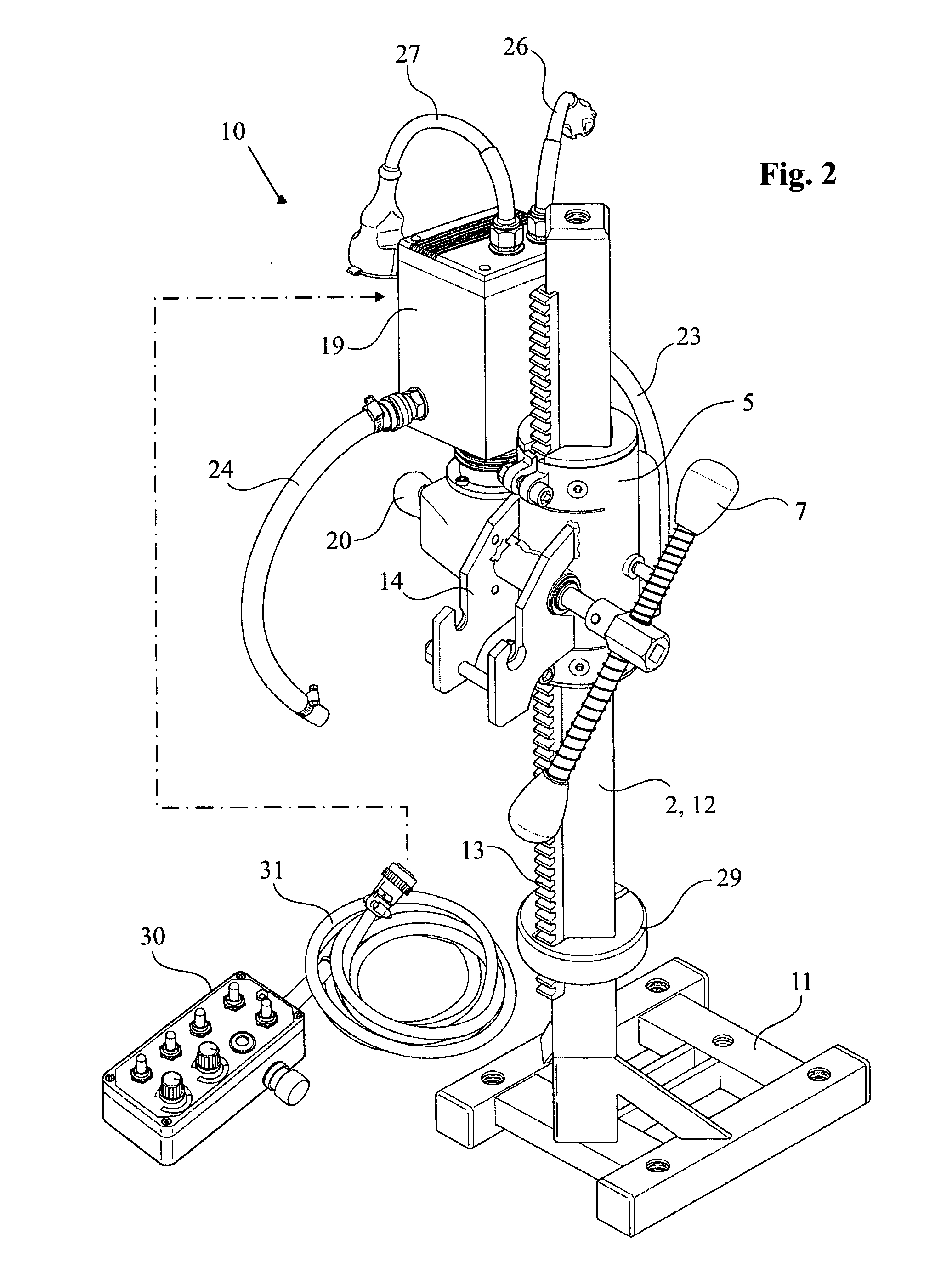

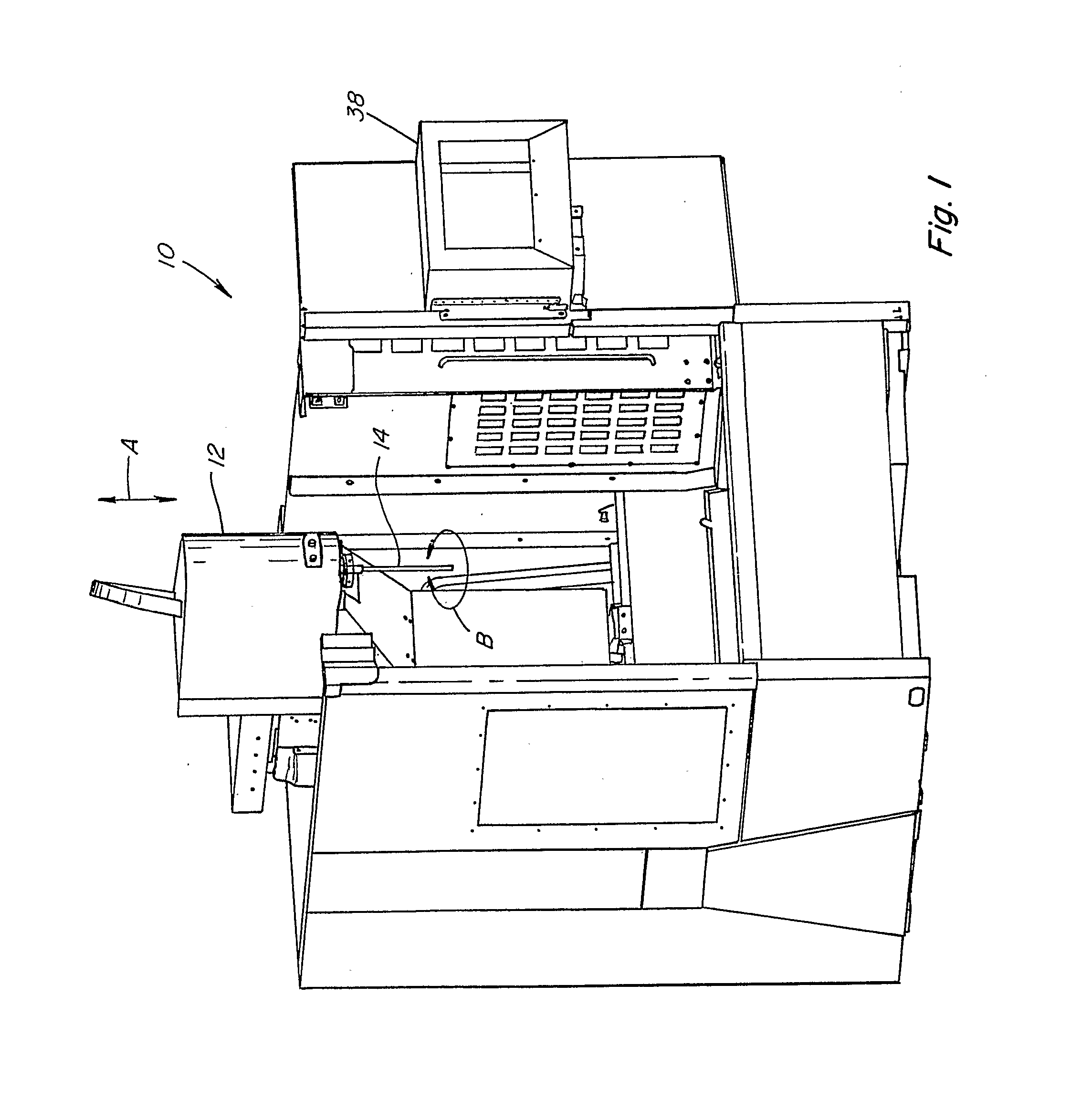

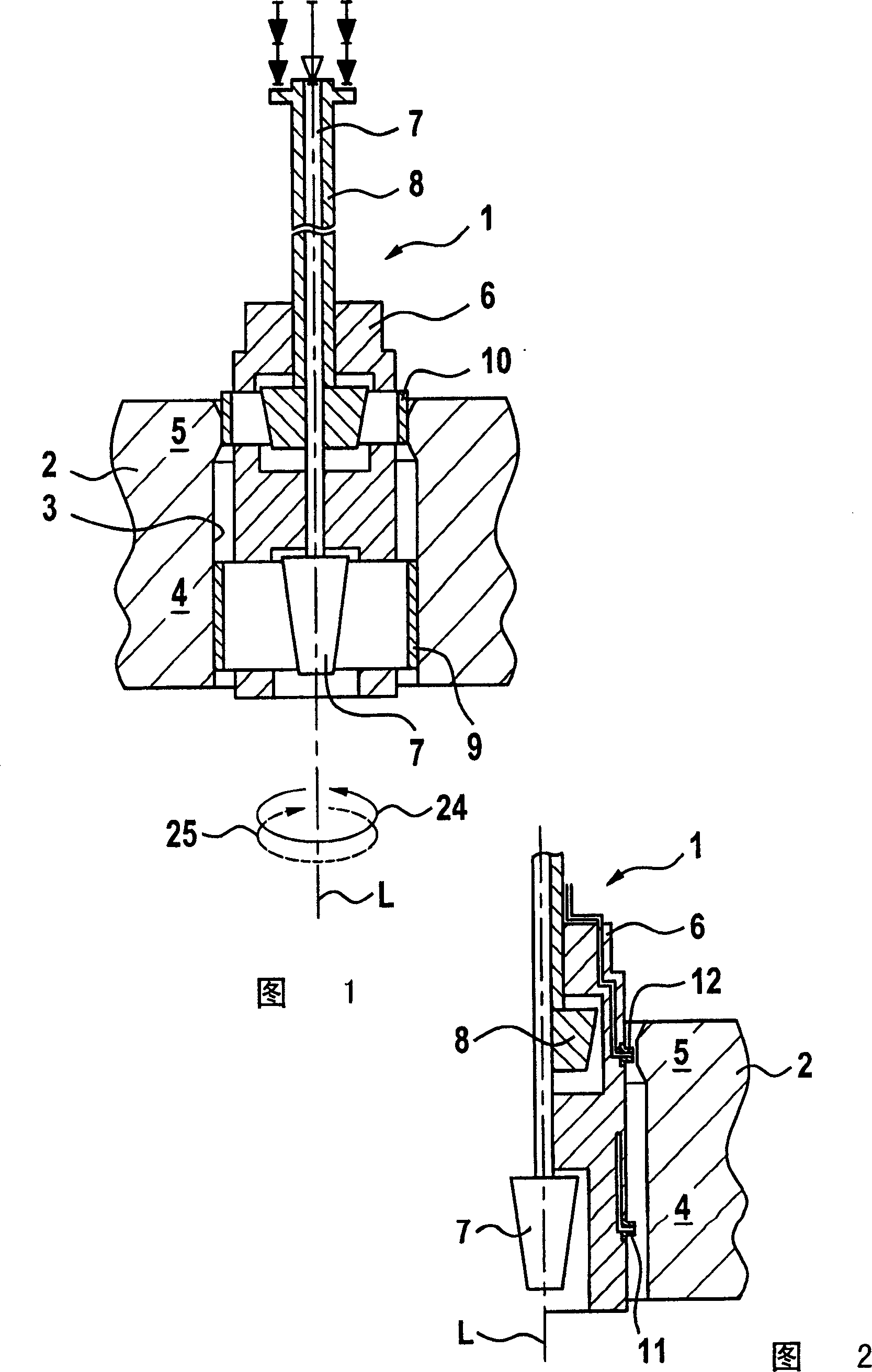

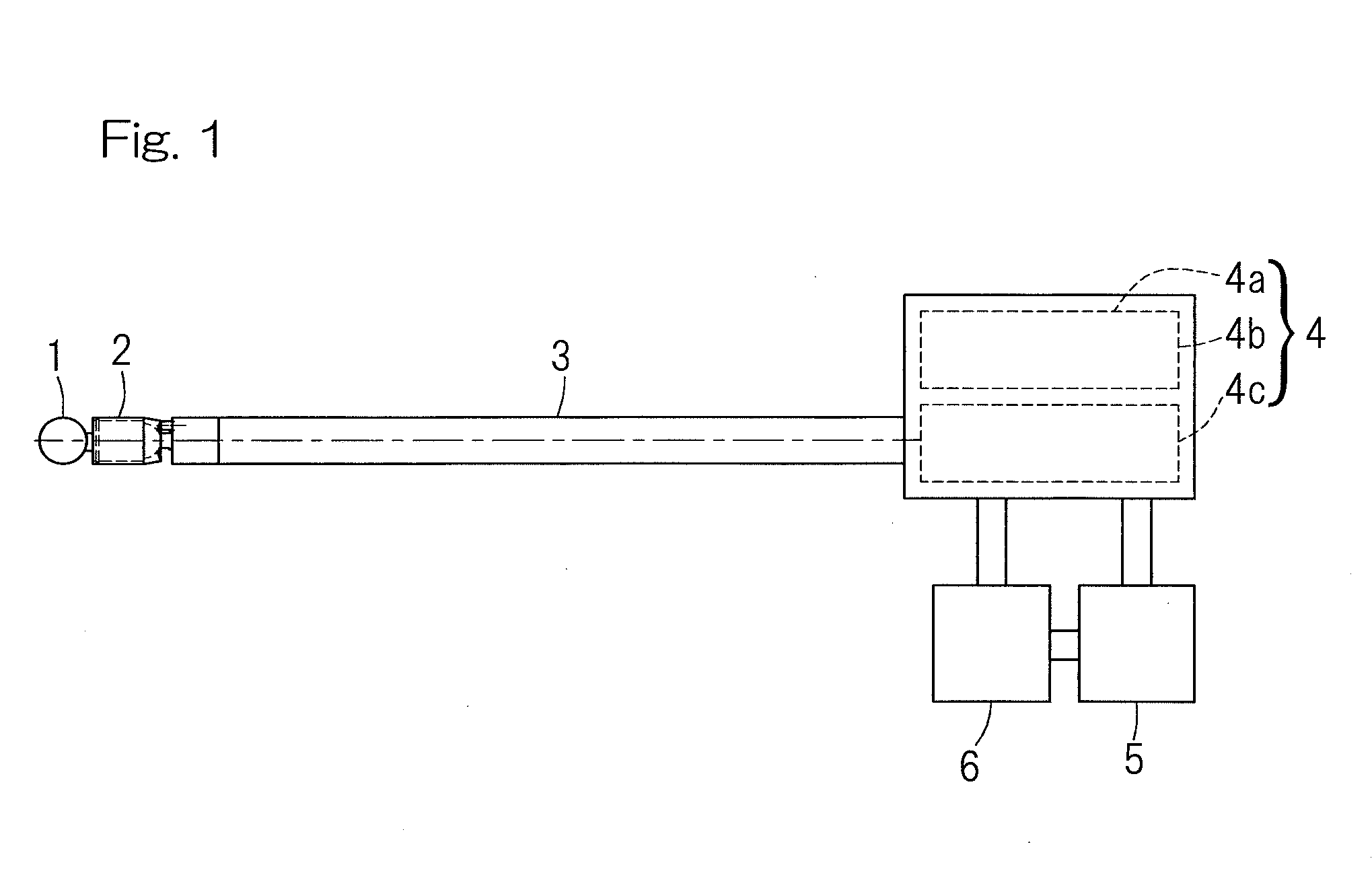

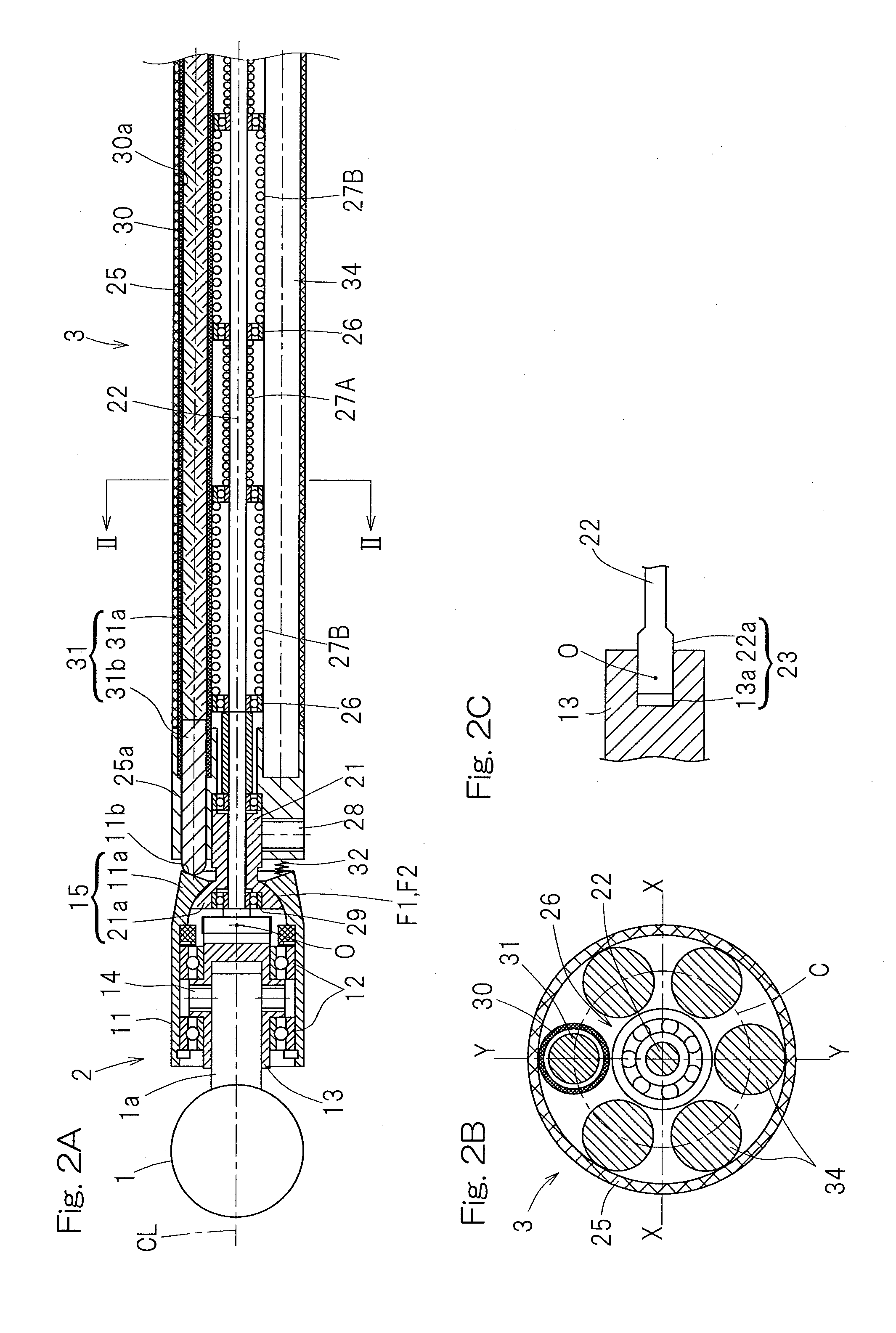

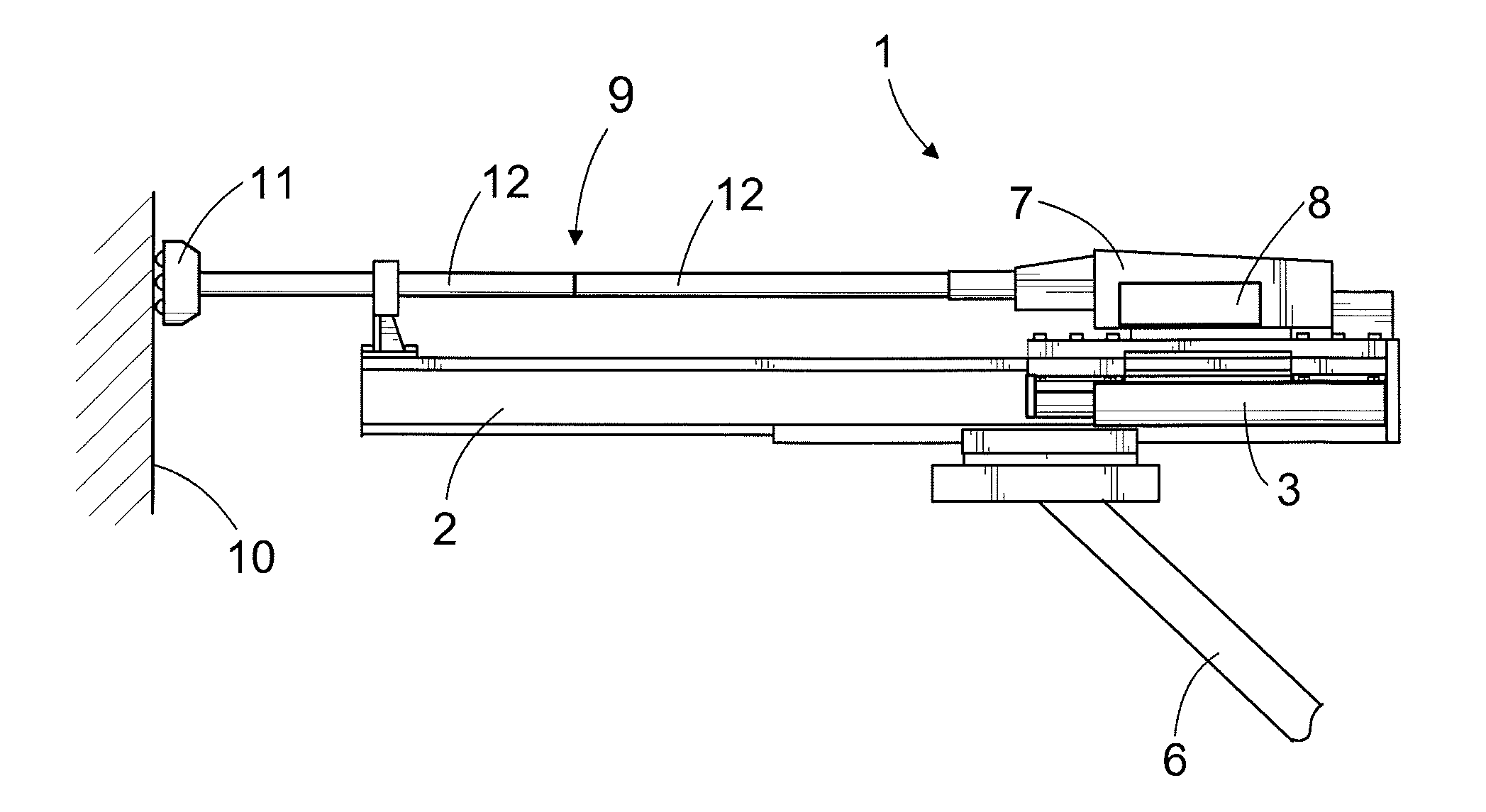

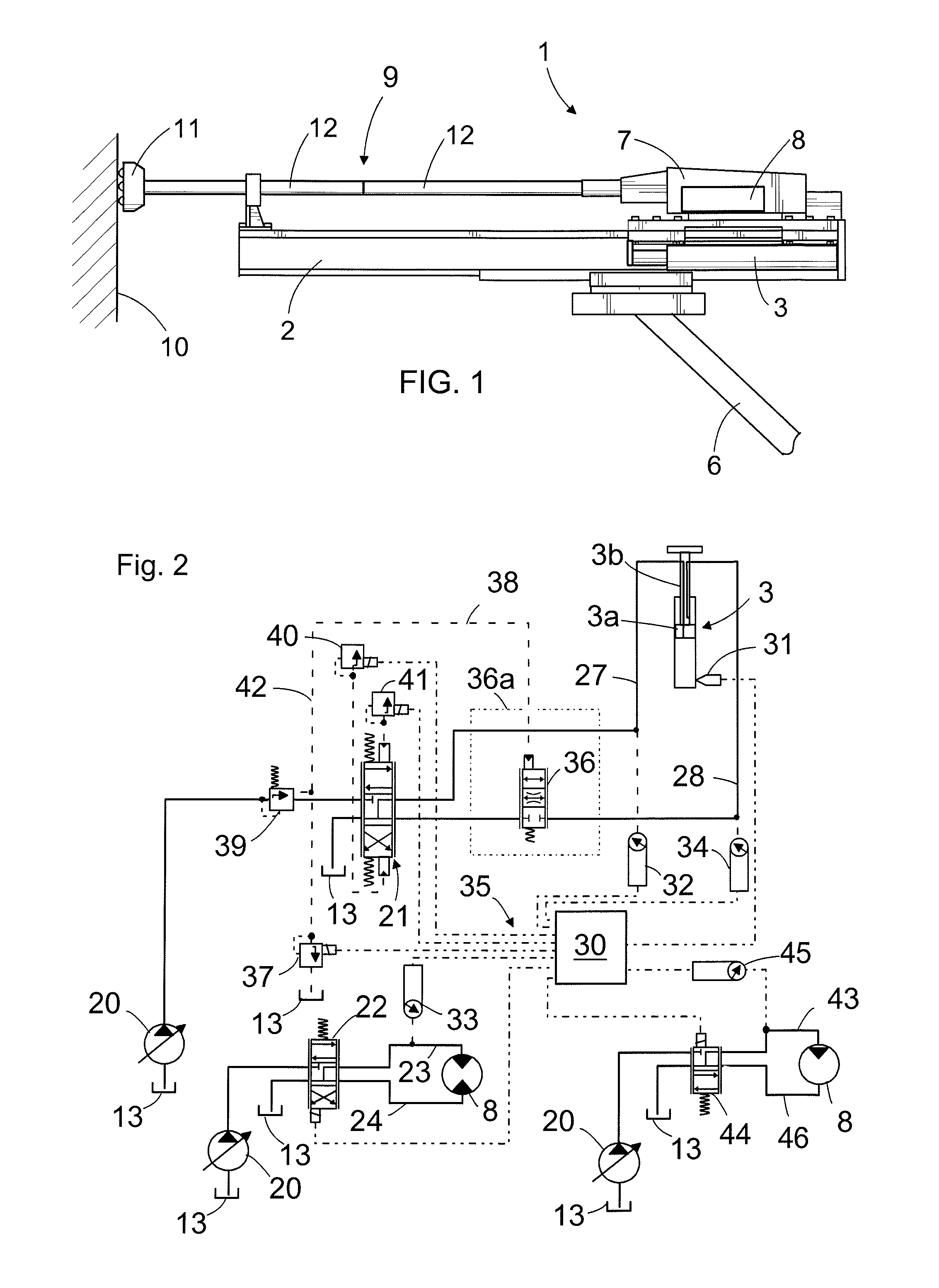

Core Drilling Device With Electrical Feeding That Is Manually Controlled

InactiveUS20070217879A1Thread cutting auxillary apparatusWorking accessoriesElectricityFeeding force

A core-drilling device (10) comprising a drilling machine (3) with a core drill (4), a drill stand (2), a feeding housing suspending the drilling machine and which is movable along the stand, an electric drilling motor for rotation of the core drill in the drilling machine and a feeding unit (19) with an electric feeding motor (17) for the feeding of the feeding housing along the stand. A control unit (30), which is electrically connected to the feeding unit, comprises at least a first control (33) for manual influence of the feeding motor's (17) feeding force.

Owner:HUSQVARNA AB

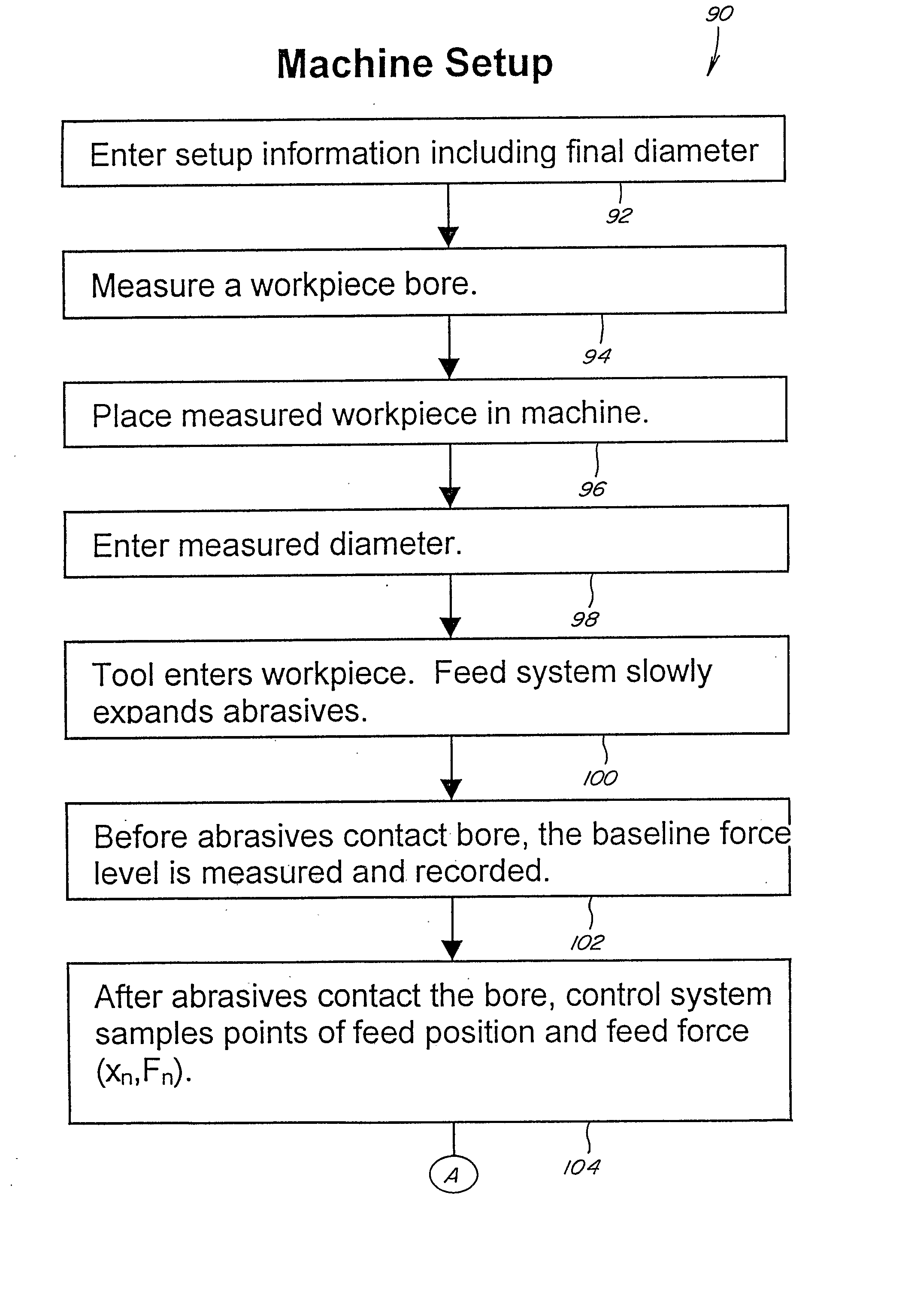

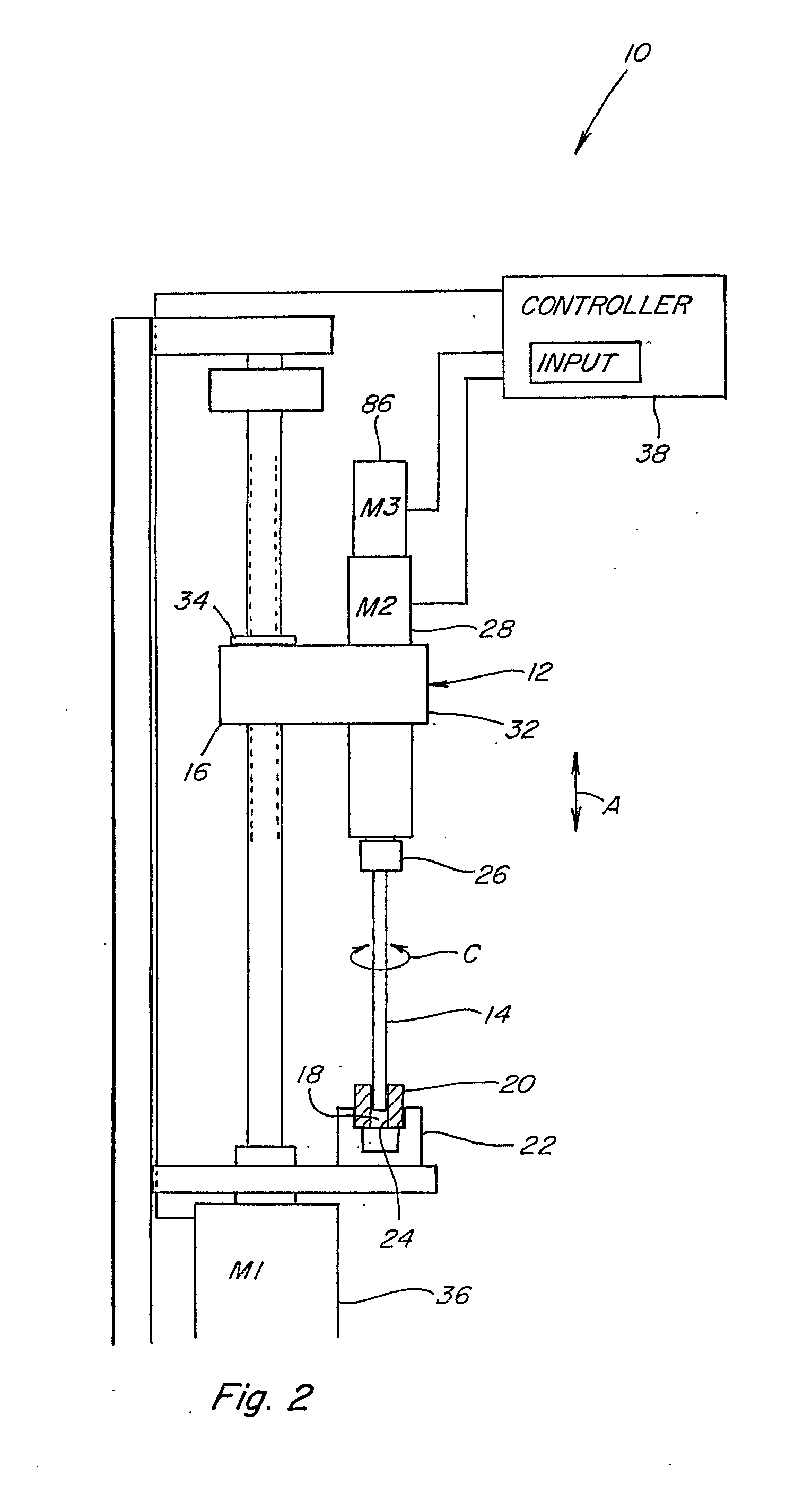

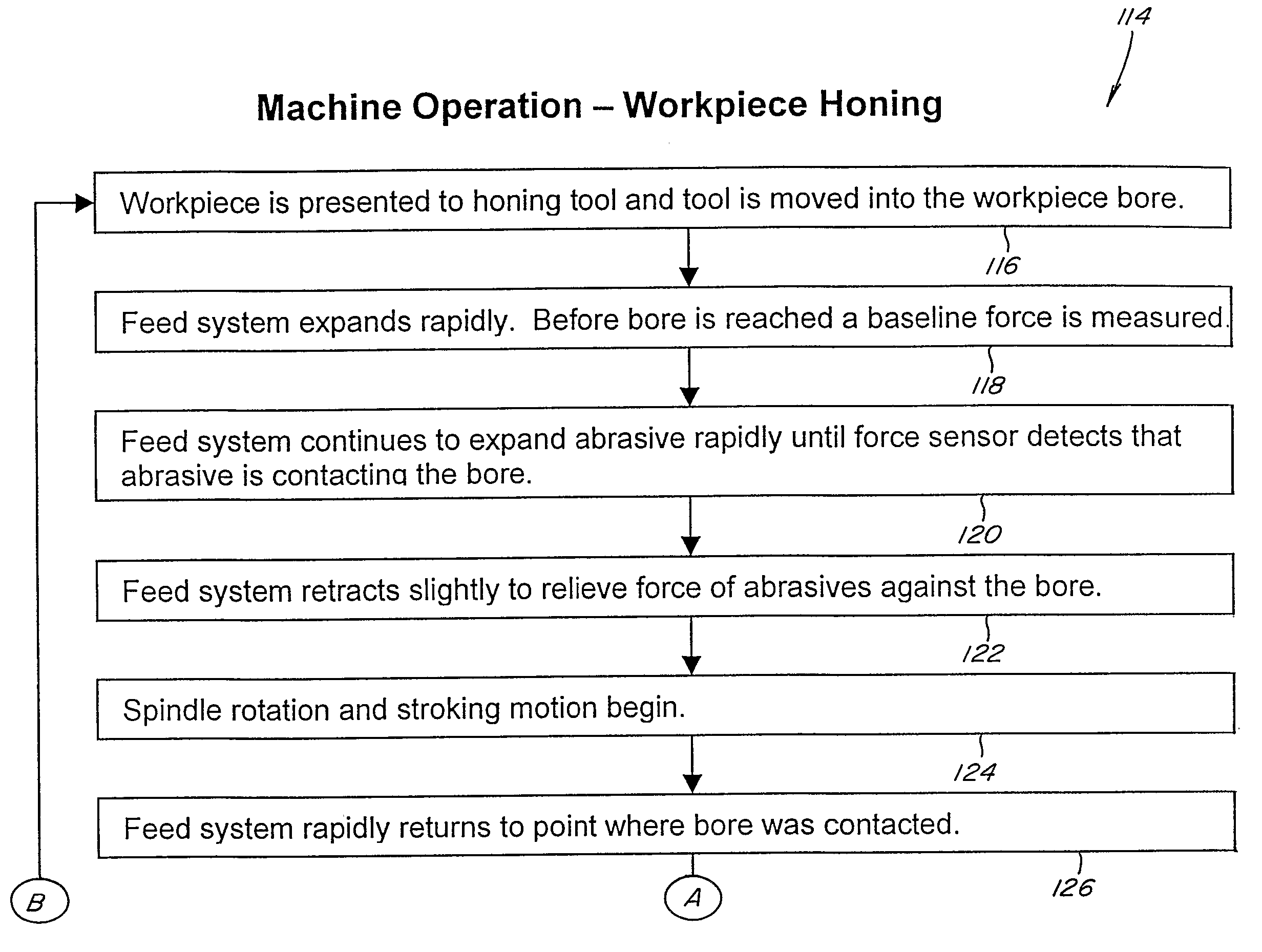

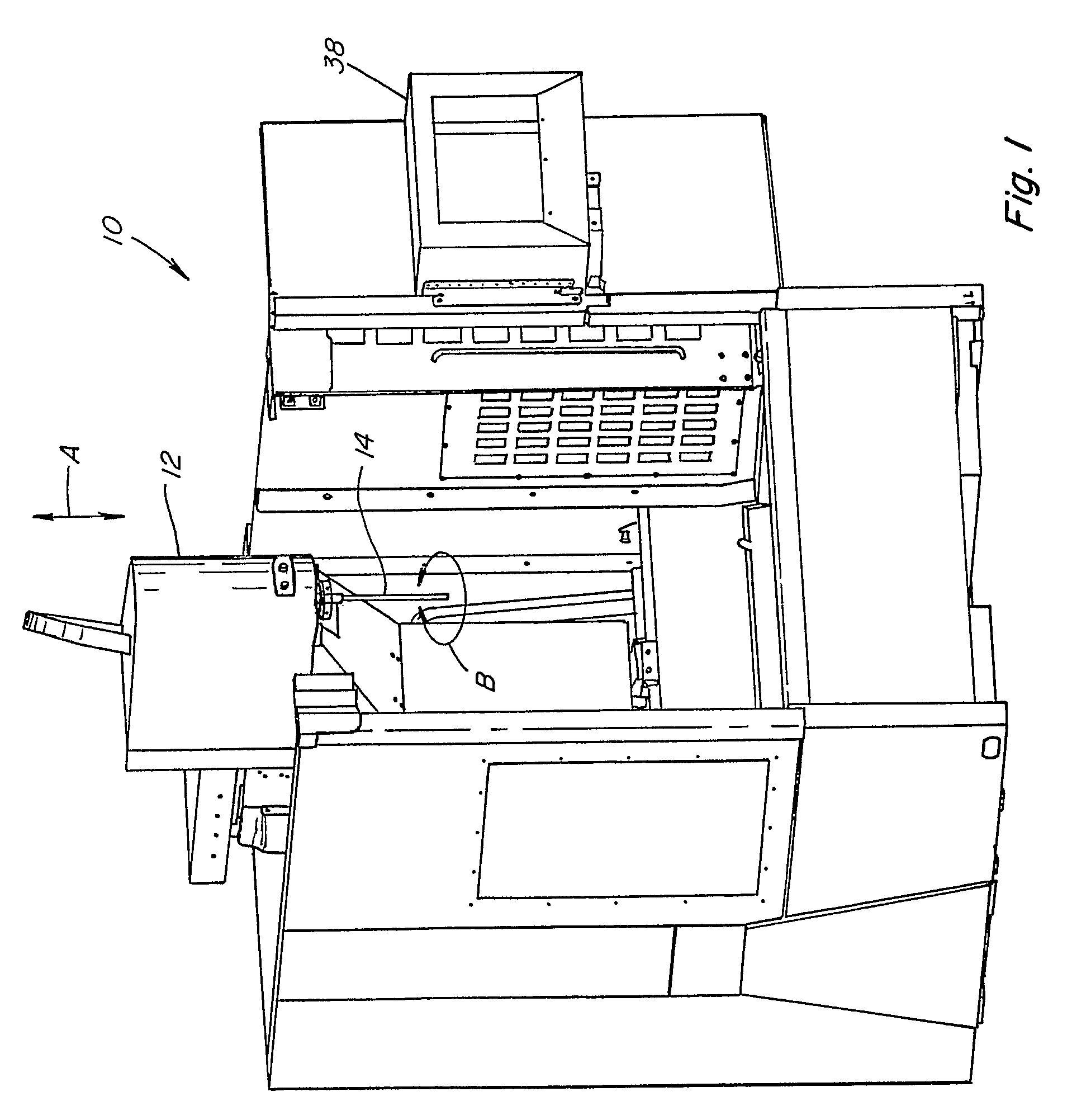

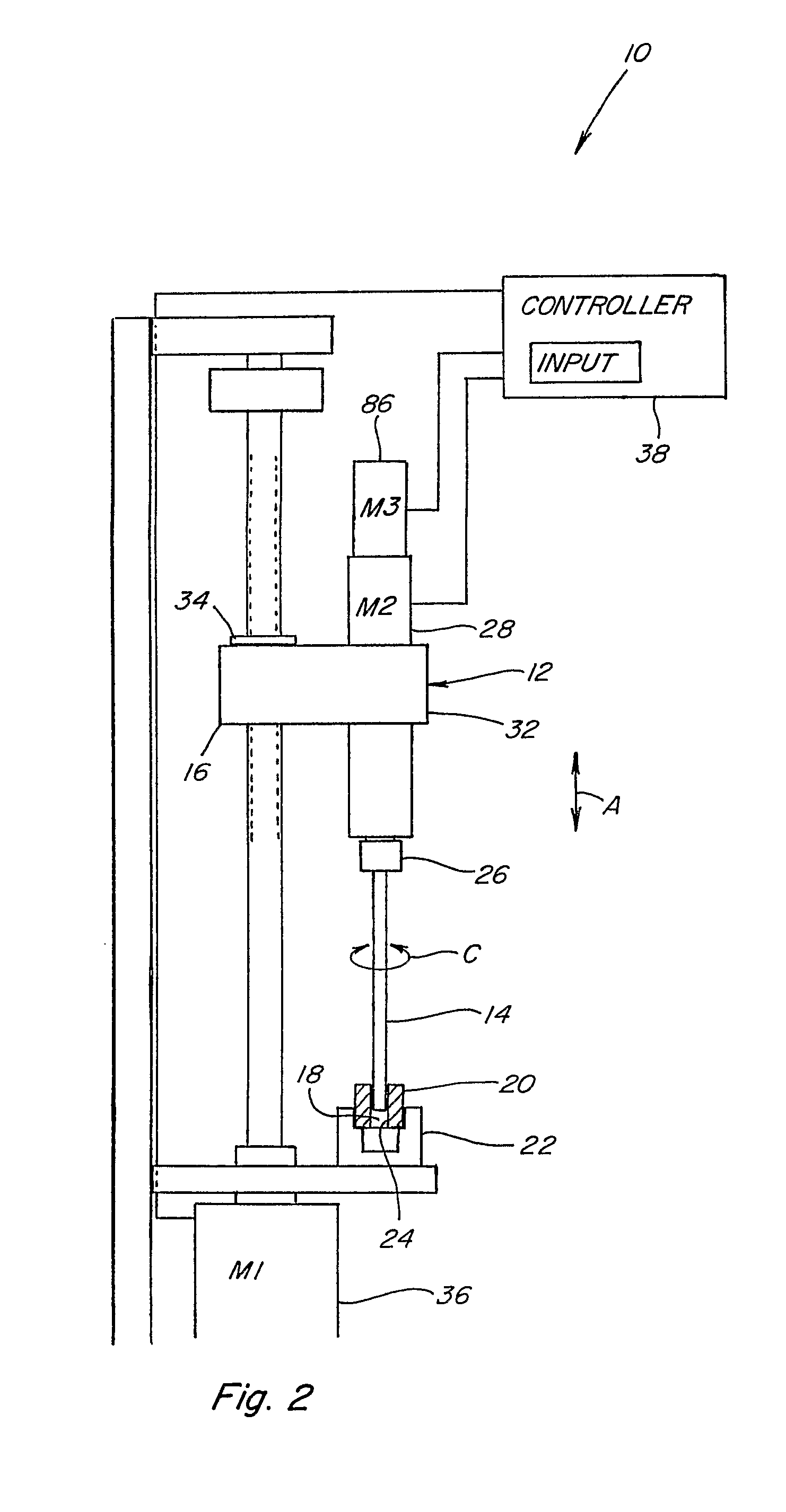

Honing Feed System Having Full Control of Feed Force, Rate, and Position and Method of Operation of the Same

ActiveUS20070298685A1Wide applicationImprove productivityProgramme controlEdge grinding machinesTime errorFeeding force

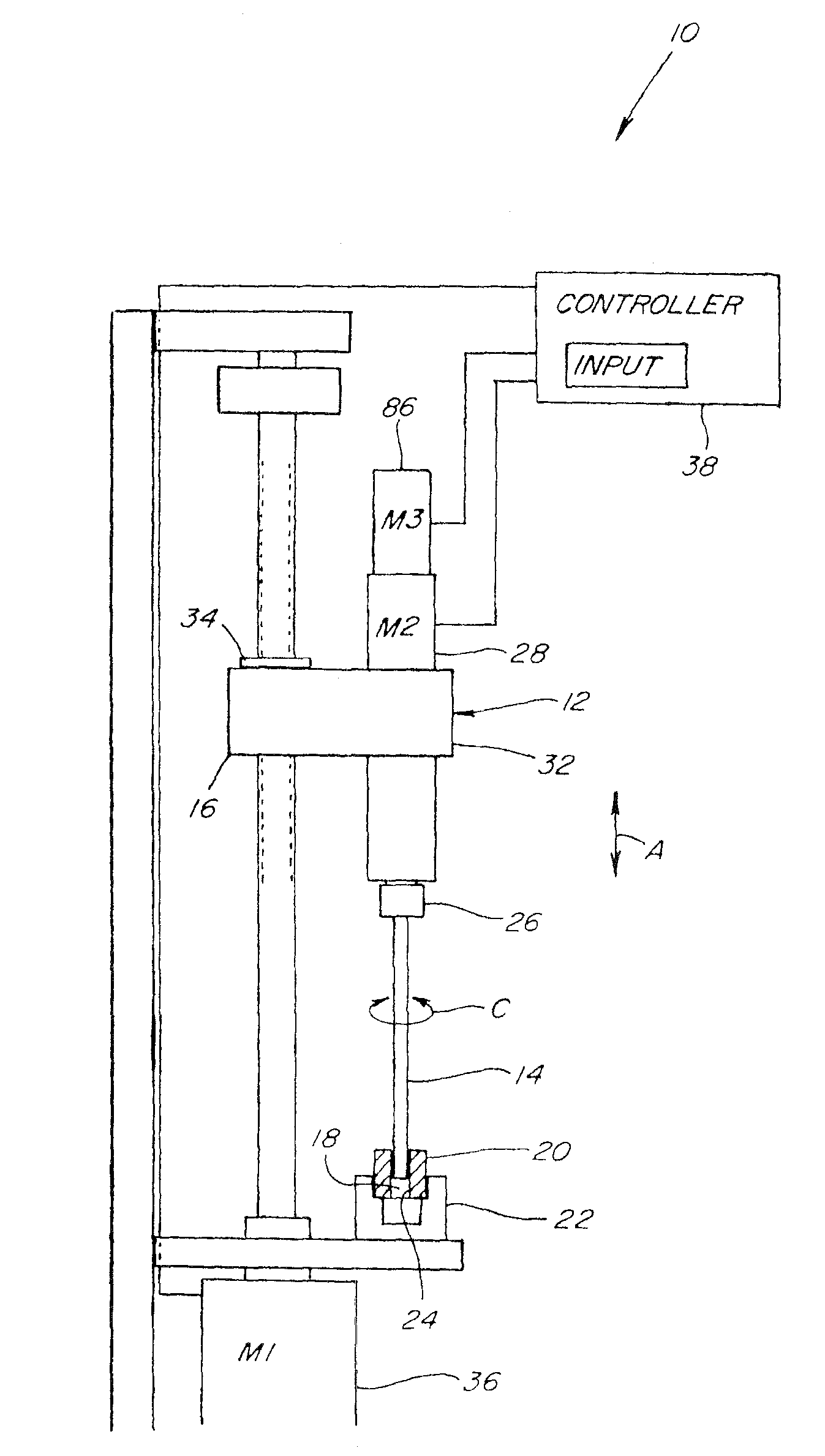

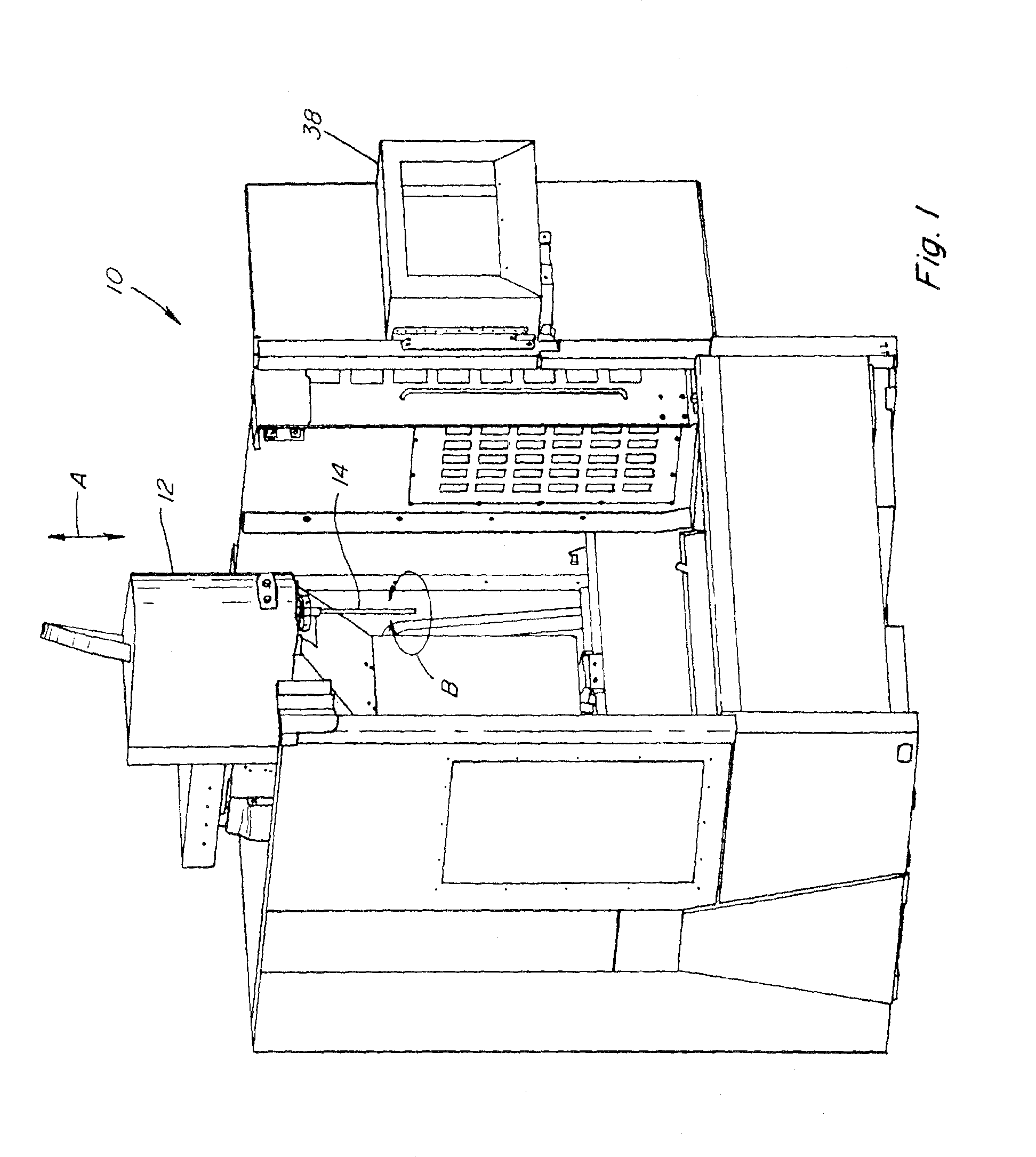

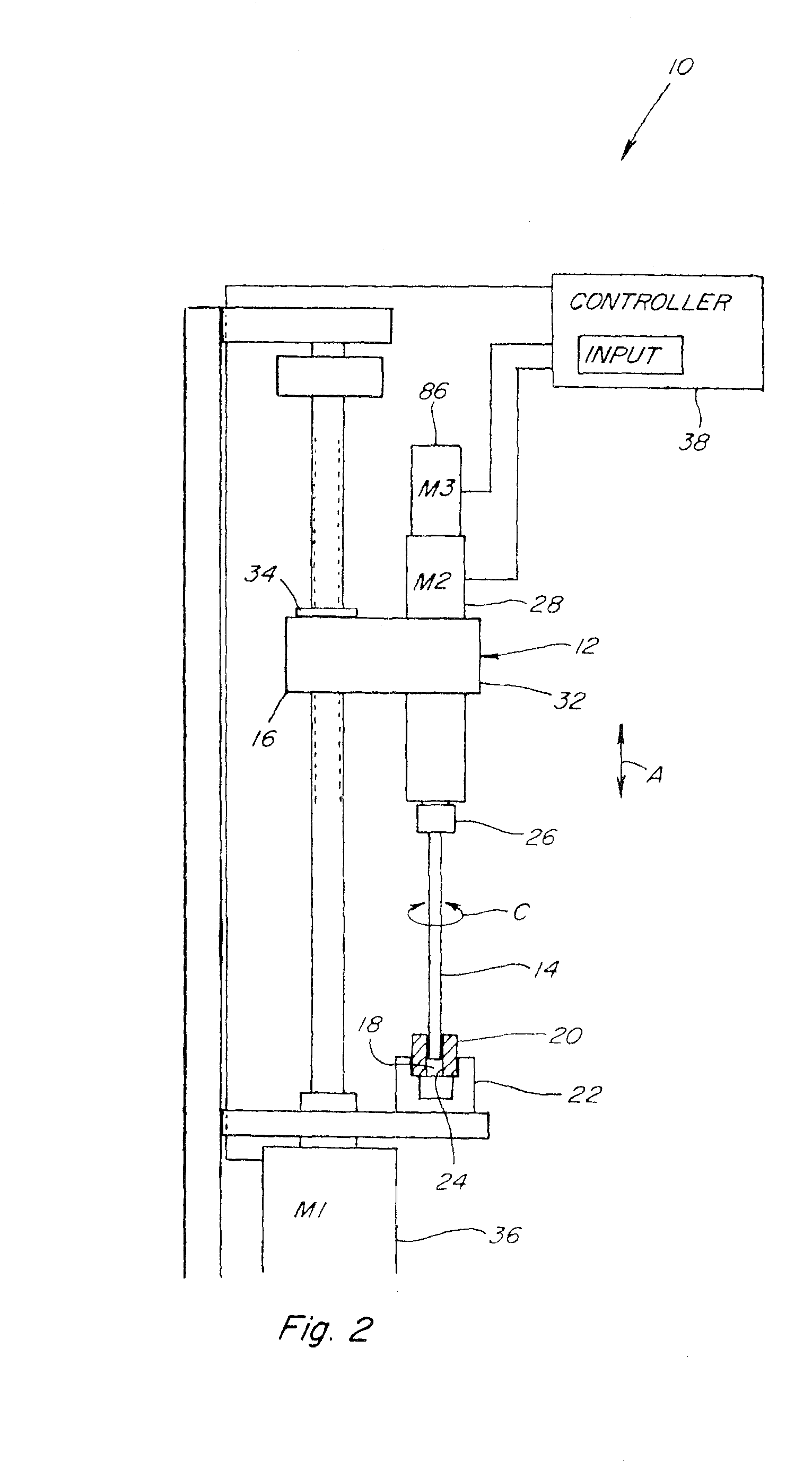

The feed system (30) for a honing machine (10) provides a capability to dynamically correct in real time errors in bore size inferred arising from variations in feed force, and a method of operation of the same. The system (10) allows a user to select between rate and force controlled honing modes, which provides one or more of the advantages of both modes. The system provides capabilities for automatic rapid automatic bore wall detection, compensation for elasticity of elements of the feed system (30) and honing tool (14), and automatic tool protection. The system is automatically operable using feed force, feed rate and positional information for honing a work piece (20) to one or more target parameters, such as one or more in-process sizes and a final size.

Owner:SUNNEN PROD

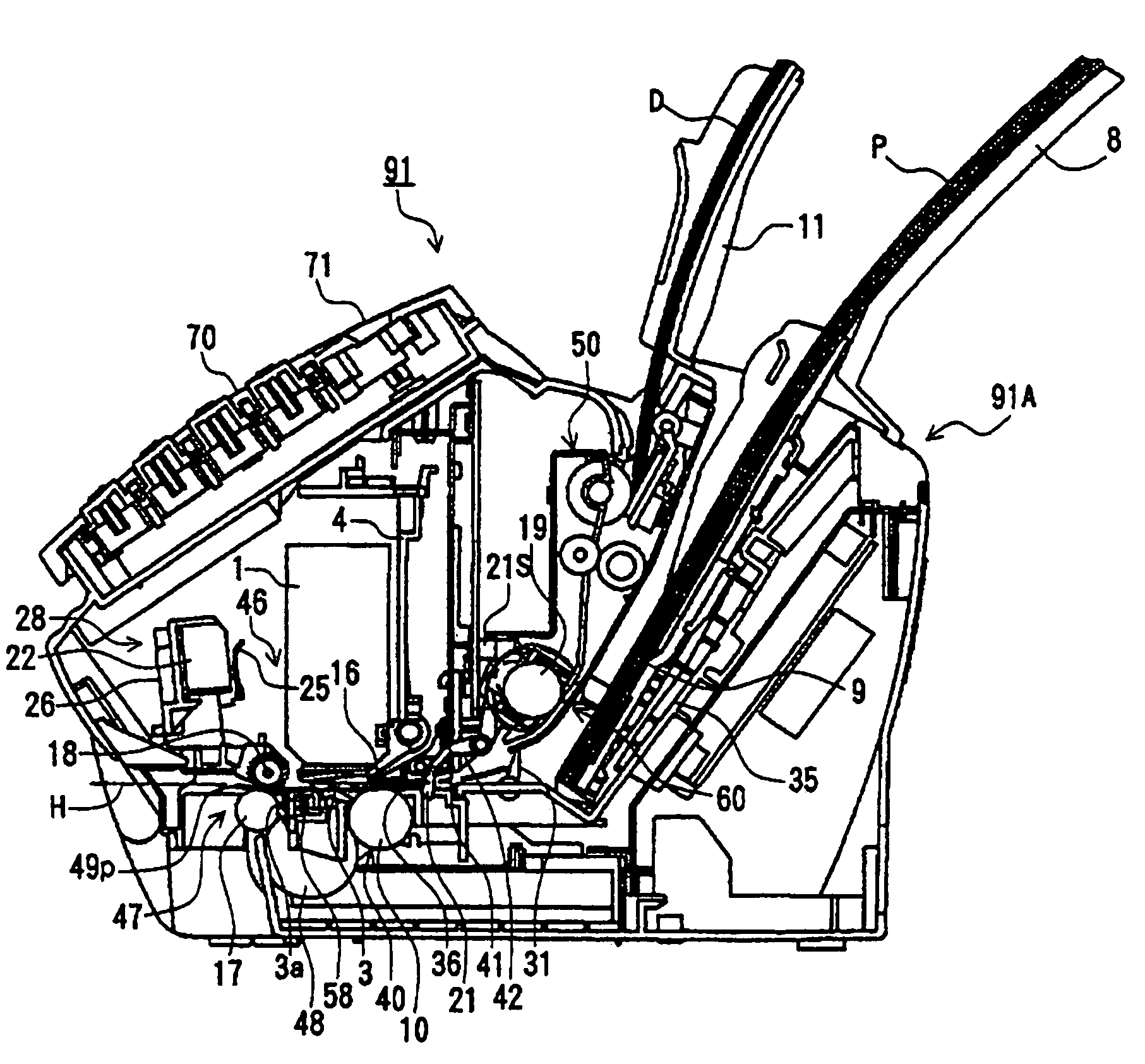

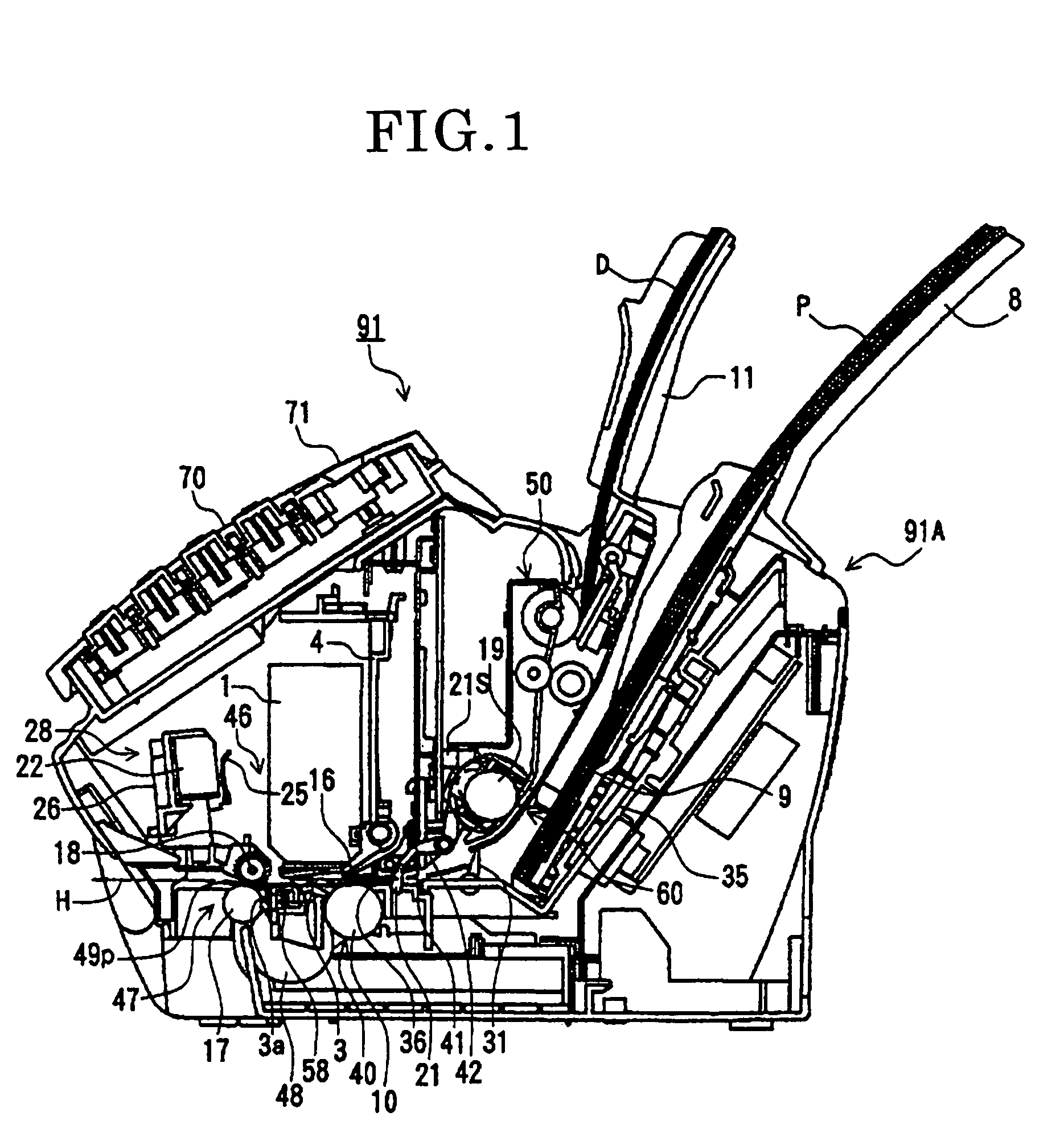

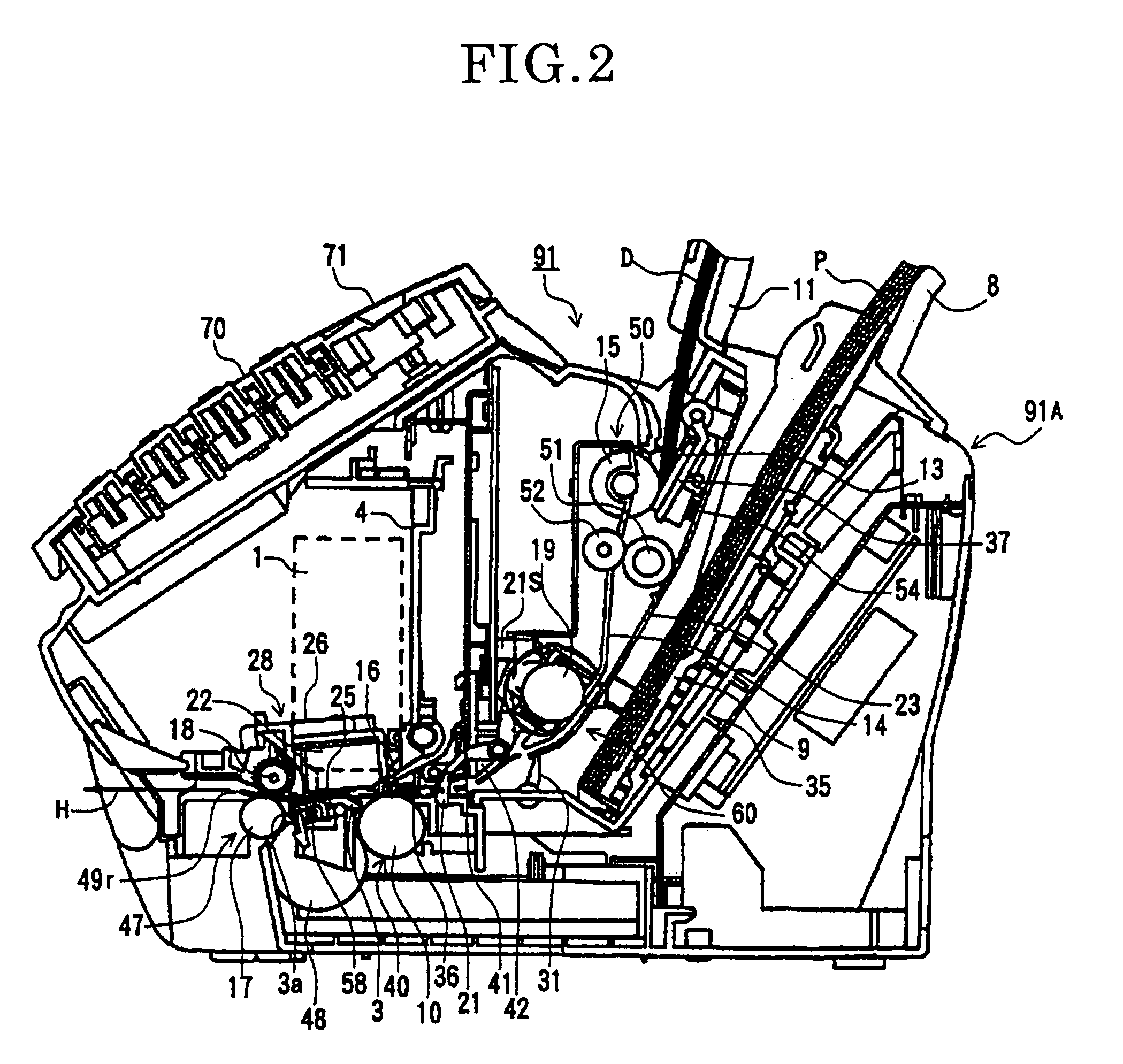

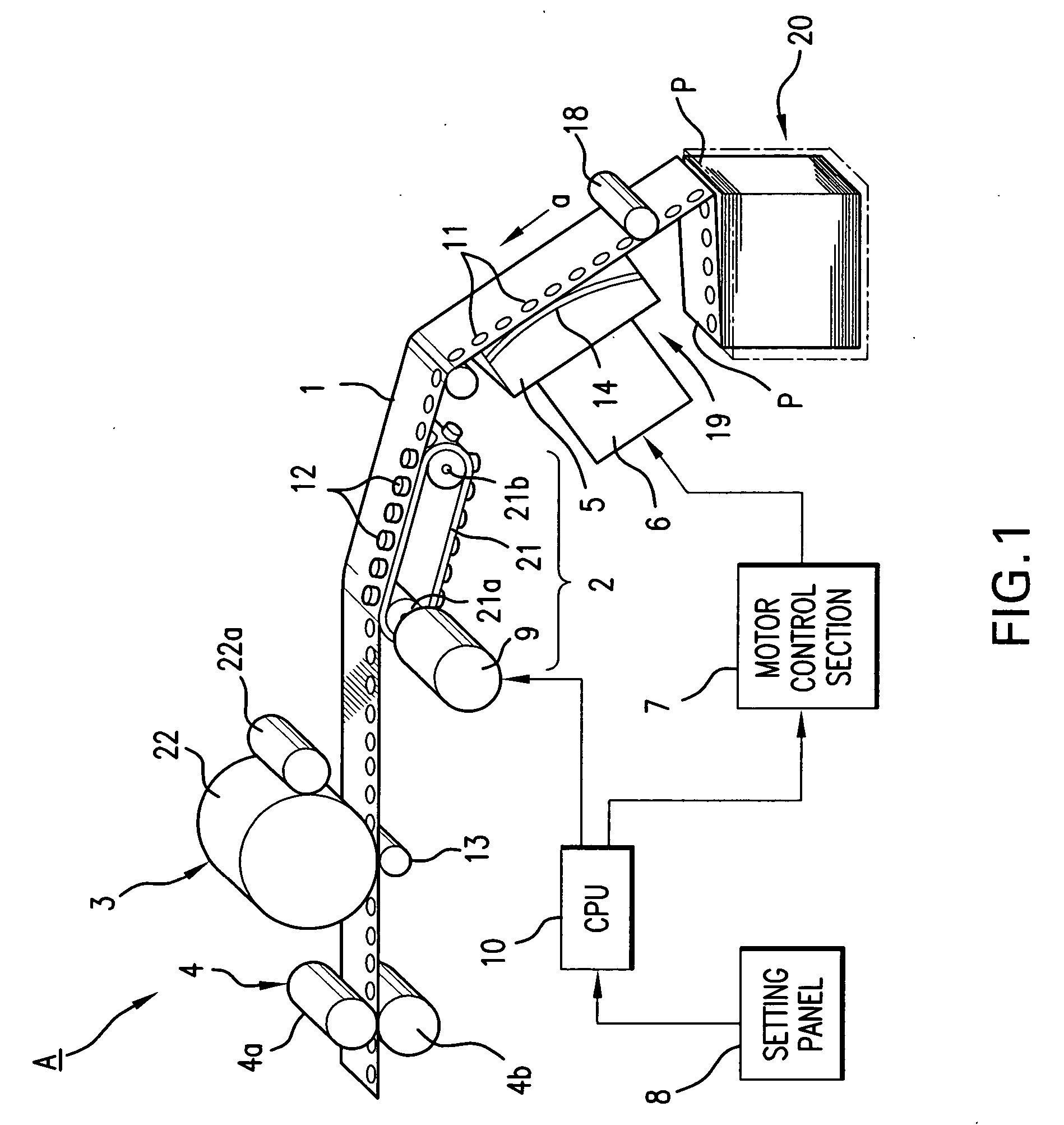

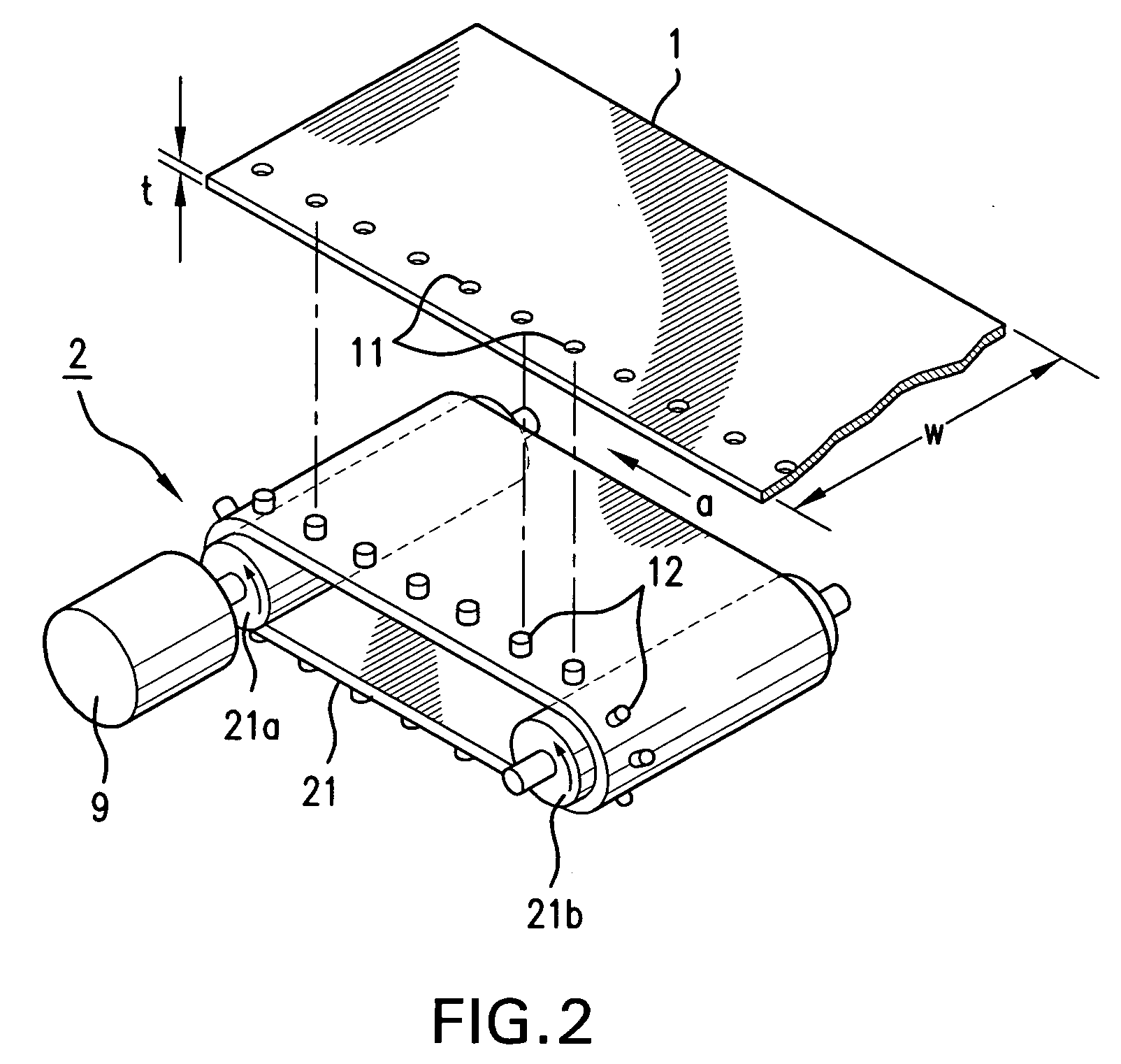

Image reading and recording apparatus

InactiveUS7077517B2Low costHighly image readingRecording apparatusOther printing apparatusFeeding forceComputer science

The present invention relates to an image reading and recording apparatus comprising: a driving source; a recording sheet feeding means for feeding a recording sheet; recording means for recording an image in a predetermined recording area on the recording sheet, supplied by the recording sheet feeding means, and movable to outside of the recording area; document feeding means for feeding a document; reading means movable between the reading position for reading an image on the document, fed by the document feeding means, and the stand by position withdrawn from the reading position; a document feeding force transmitting means for transmitting the driving force of the driving source to the document feeding means; and moving means for moving the reading means to the reading position by the driving force of the driving source at the time the recording means is moved to the outside of the recording area.

Owner:CANON KK

Honing feed system having full control of feed force, rate, and position and method of operation of the same

ActiveUS7371149B2Wide applicationImprove productivityEdge grinding machinesProgramme controlTime errorFeeding force

The feed system (30) for a honing machine (10) provides a capability to dynamically correct in real time errors in bore size inferred arising from variations in feed force, and a method of operation of the same. The system (10) allows a user to select between rate and force controlled honing modes, which provides one or more of the advantages of both modes. The system provides capabilities for automatic rapid automatic bore wall detection, compensation for elasticity of elements of the feed system (30) and honing tool (14), and automatic tool protection. The system is automatically operable using feed force, feed rate and positional information for honing a work piece (20) to one or more target parameters, such as one or more in-process sizes and a final size.

Owner:SUNNEN PROD

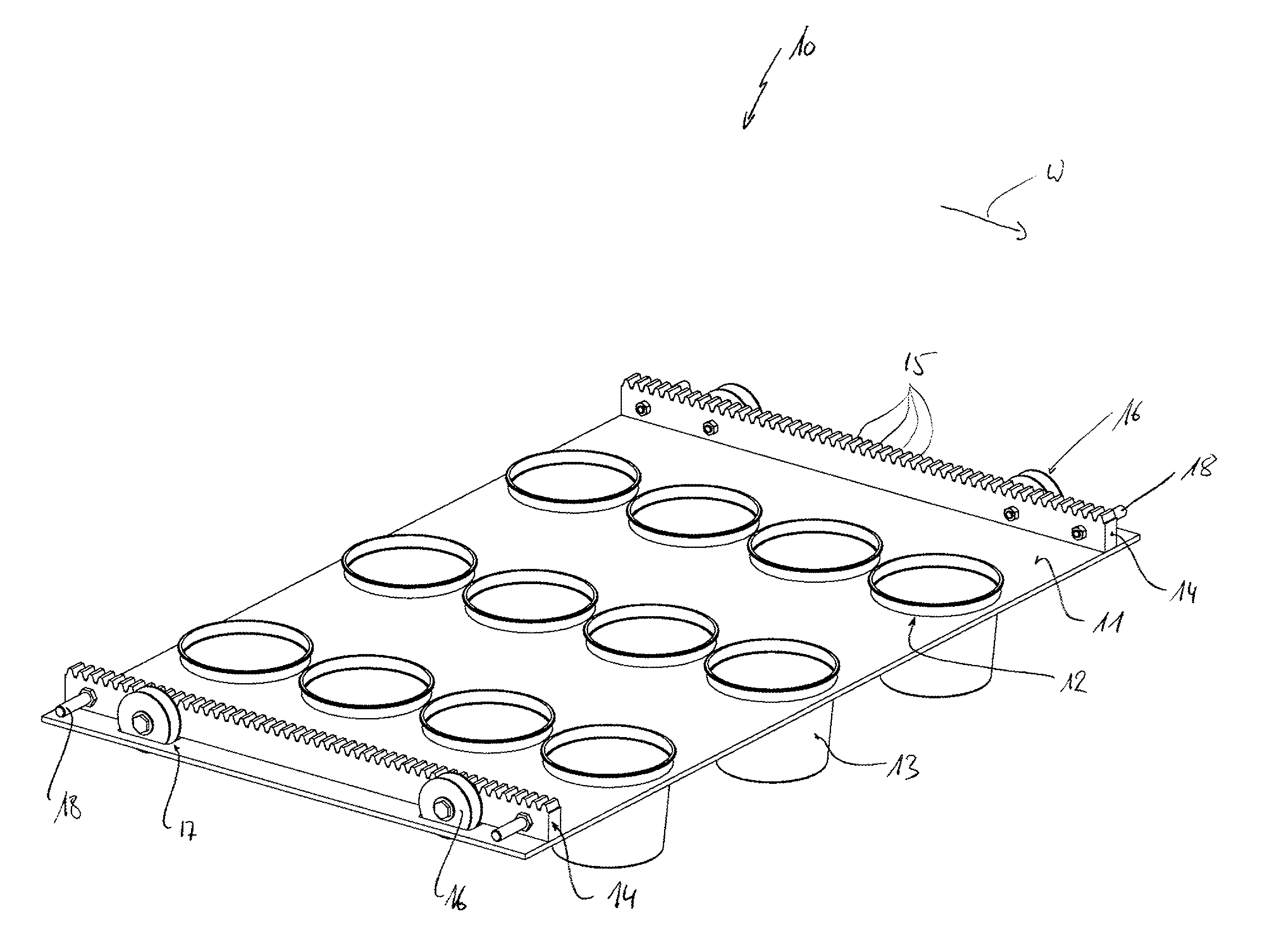

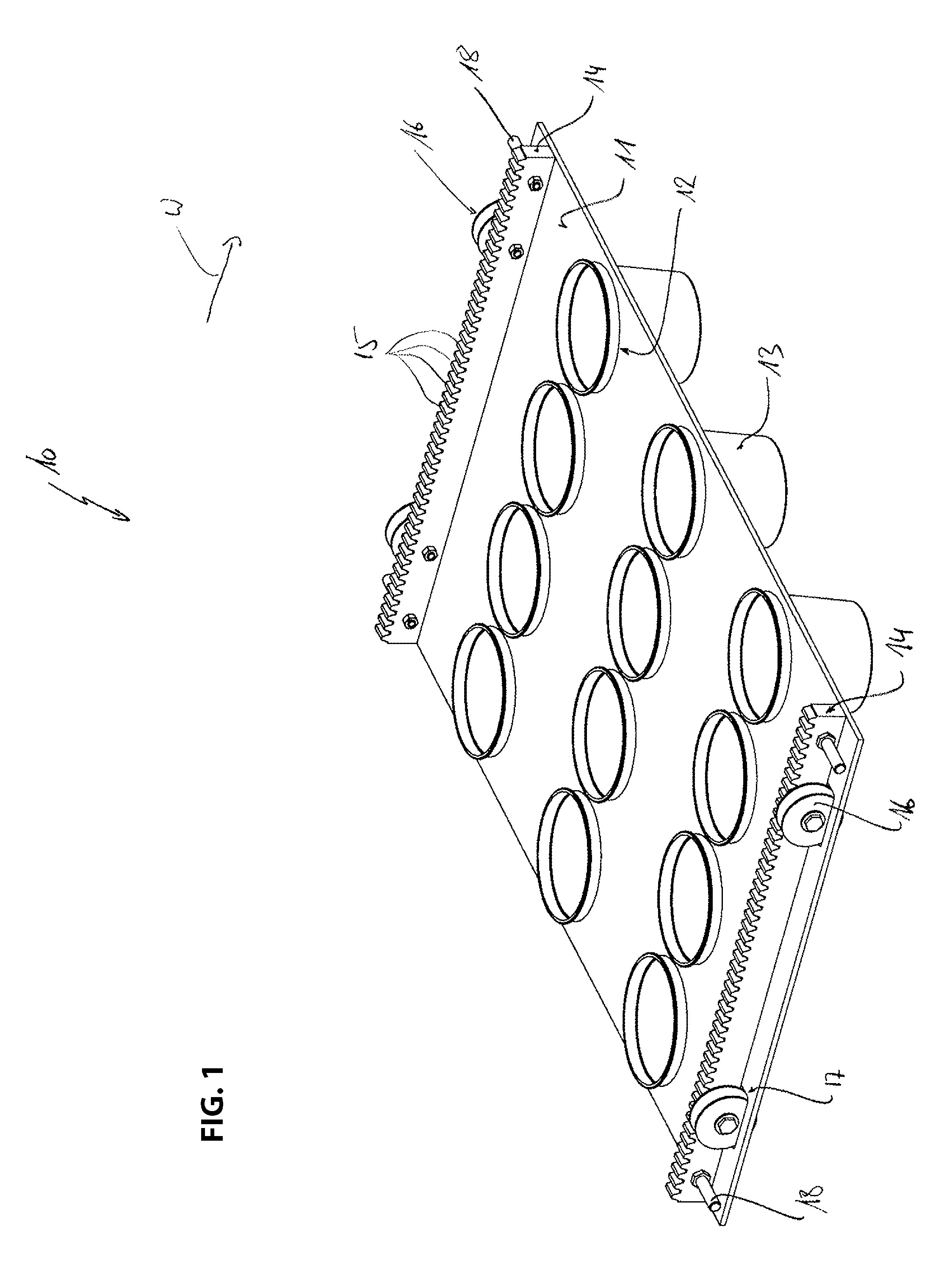

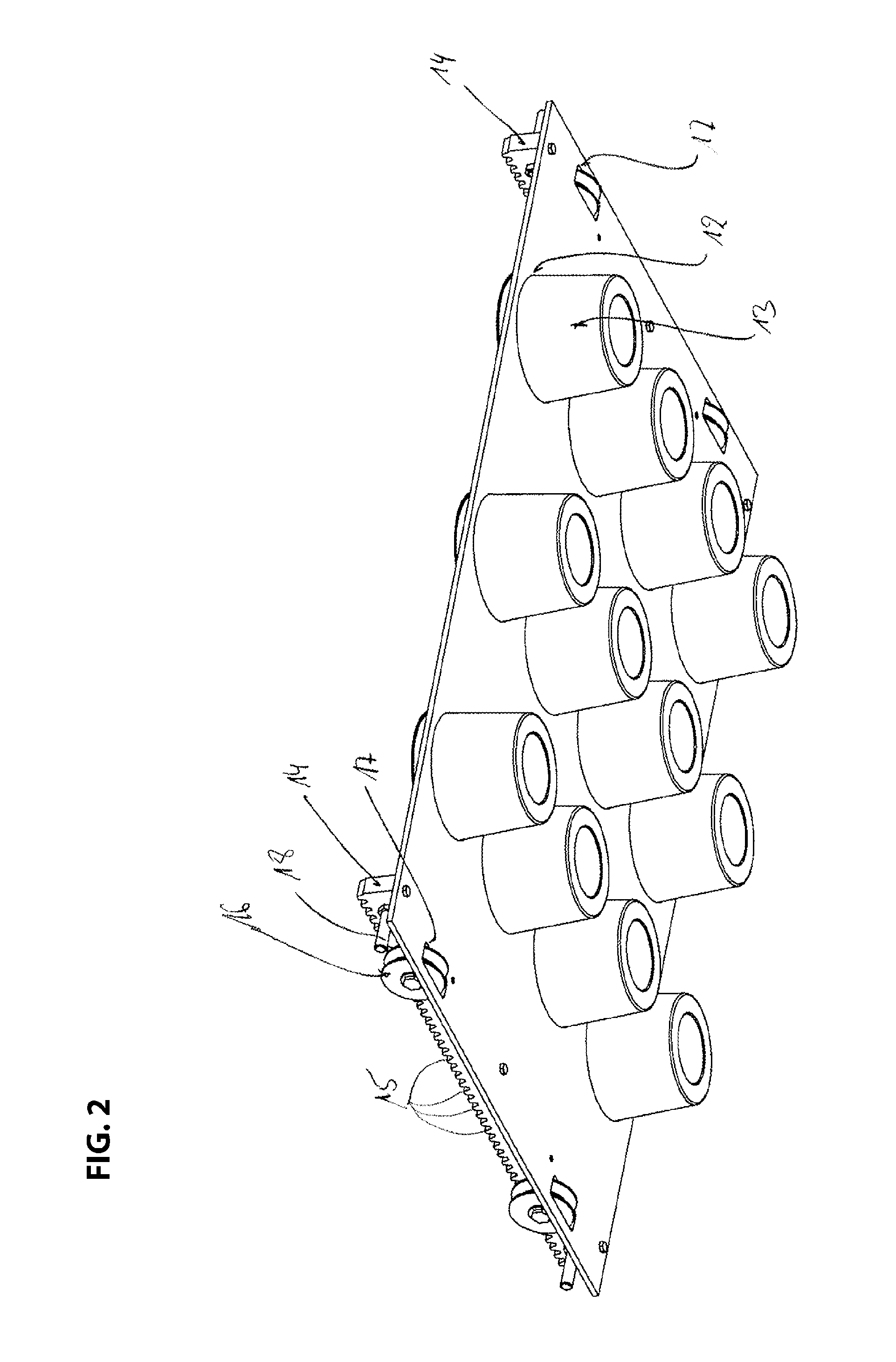

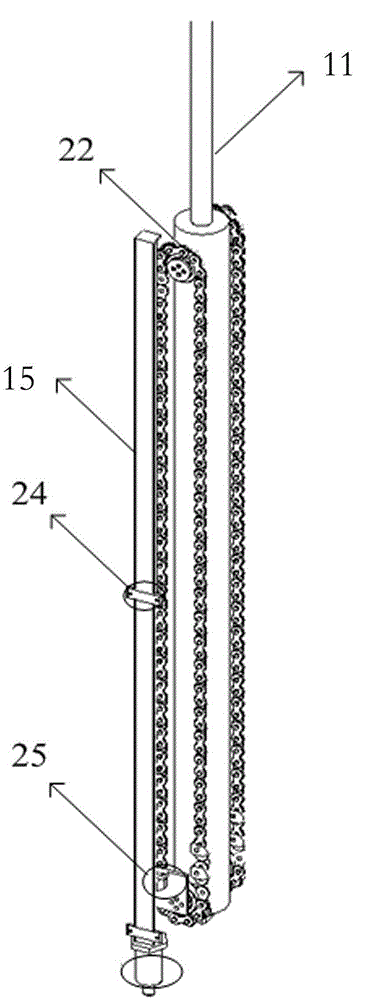

Container filling device

A device for filling containers including an upper main element, a lower main element and lateral main elements connecting the upper and the lower main element; support elements arranged at one another without a continuous drive device, which support elements are provided with receivers for the containers and are run in an endless manner through the device past operating stations and along the main elements; a drive which runs the support elements in a feed direction at least through the upper main element or the lower main element along the operating stations; and operating elements arranged at the support elements through which a feed force of the drive is introduced into the support elements, wherein the operating elements at the support elements are gear racks in which a drive side feed member with a complementary teething engages in order to introduce the feed force into the support elements.

Owner:HAMBA FILLTEC

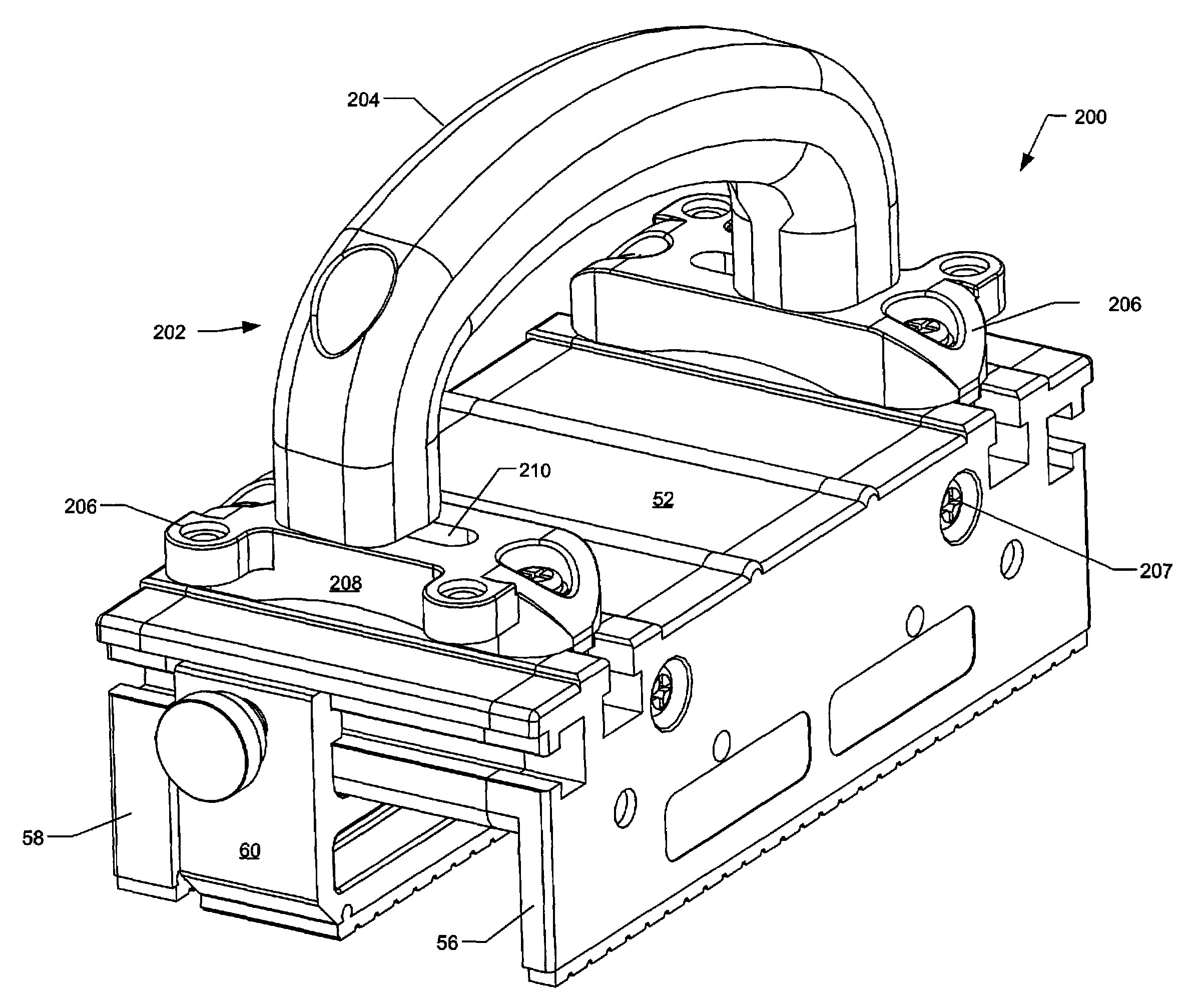

Straddle safety pusher system

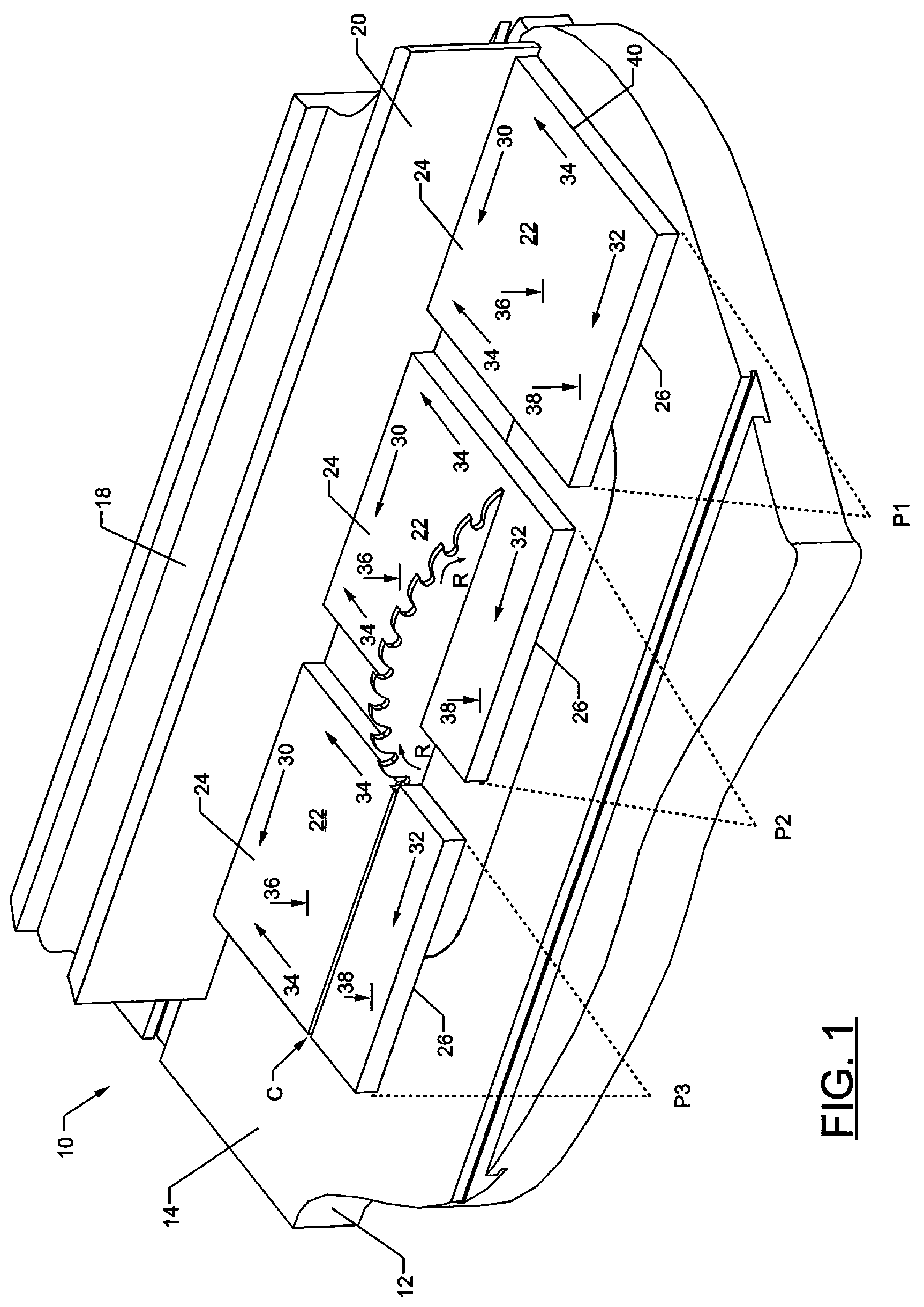

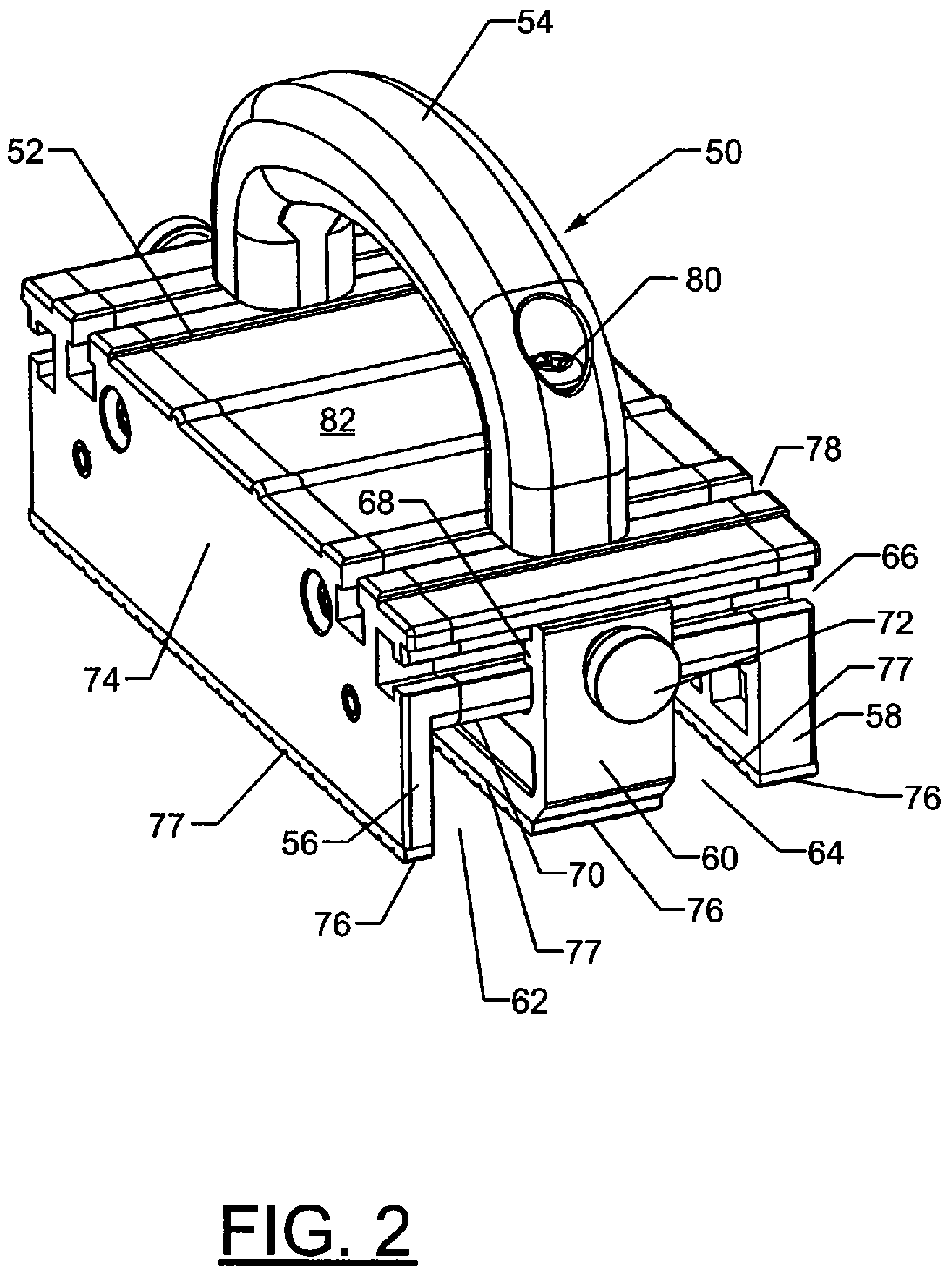

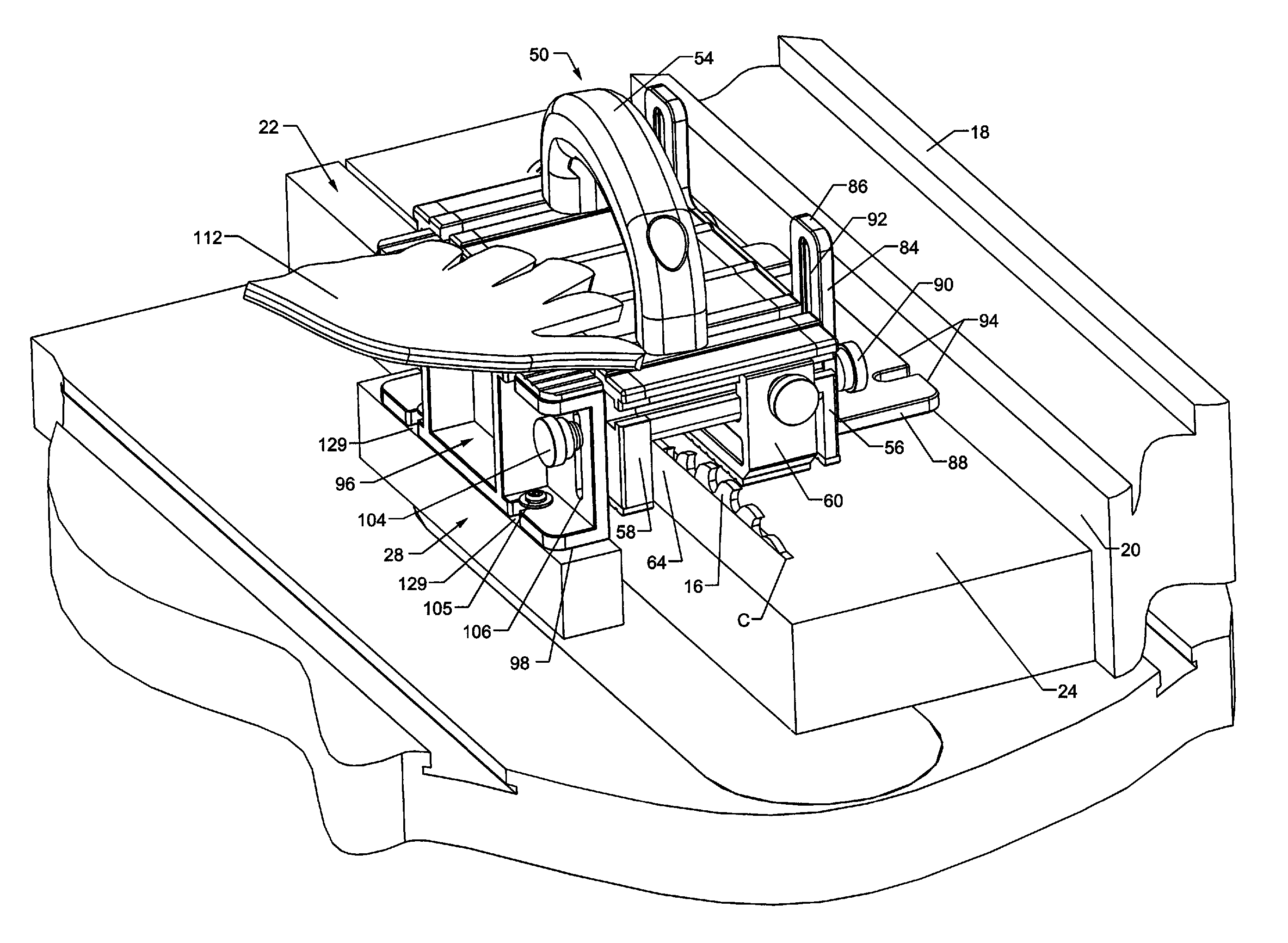

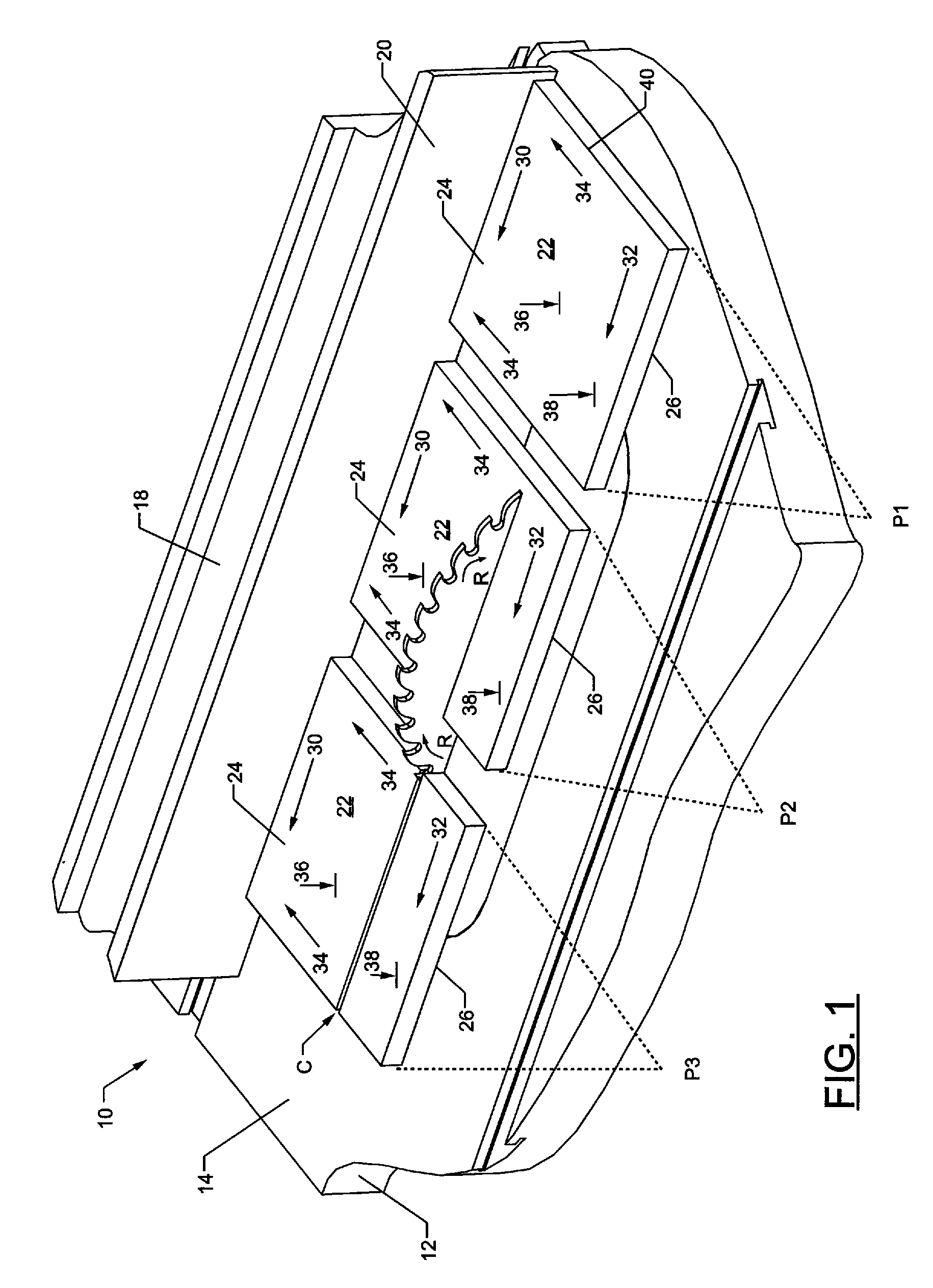

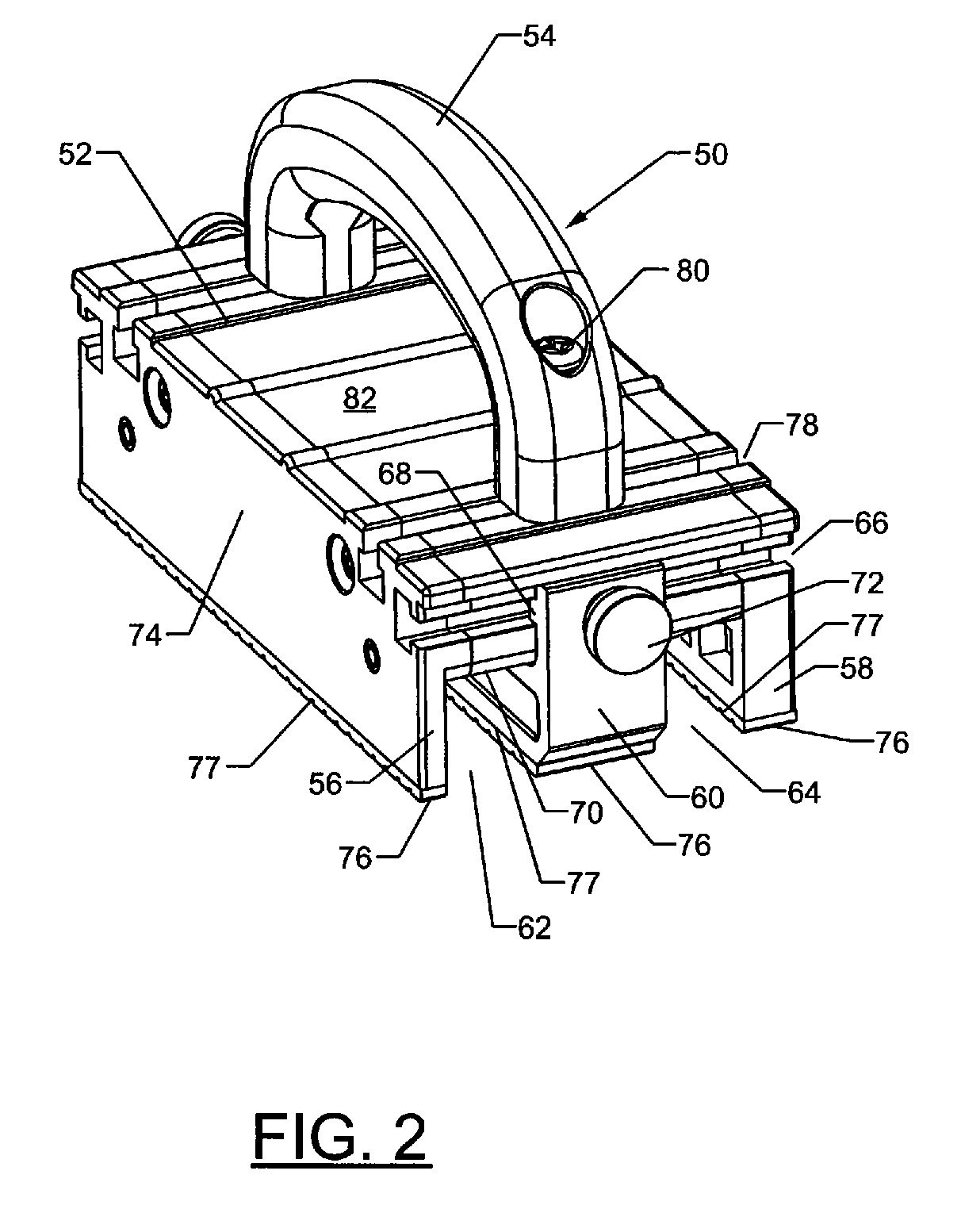

An adjustable pushing apparatus (50) for safely moving a work piece (22) past a cutting tool (16). The apparatus includes a body (52), a first leg (56), a second leg (58) and a moveable center leg (60) defining a leg side surface (74) and two adjustable-width tunnels (62, 64) through which a cutting tool may pass. A handle (54) is moveable along a top surface (82) of the body to provide a balance of forces on both the inside cut portion (24) and the outside cut portion (26) of the work piece. Non-slip work piece-contacting surfaces (76) provide positive engagement with the work piece. A balance support device (84) may be attached to either the first or second leg at a plurality of vertical heights to balance the apparatus when the work piece is too narrow to make contact with a work piece-contacting surface on both side of the cut line (C). In one embodiment (200) a bridge handle (202) is used to maintain balanced forces on both sides of the cut line. The handle portion (204) may be longitudinally angled relative to the cut line to provide a force vector keeping the pushing apparatus and work piece secured against the table saw fence (16). A trailing edge heel (212) may be attached to the pusher to minimize blowout of the rearmost edge of the work piece and to assist in applying additional feeding force to the work piece.

Owner:WANG HENRY

Honing feed system and method employing rapid tool advancement and feed force signal conditioning

ActiveUS20100029179A1Maintaining bore geometryRepeatable initial condition of the abrasiveEdge grinding machinesProgramme controlFeeding forceSignal conditioning

The honing feed system and method utilizes feedback from various sources during rapid feeding of the honing tool while rotating and stroking, to detect initial contact with a bore surface, to slow the feed to a normal honing rate, involving conditioning the feedback signals to eliminate noise factors such as the stroking movement and forces generated to rotate and feed the tool unopposed.

Owner:SUNNEN PROD

Straddle safety pusher system

An adjustable pushing apparatus (50) for safely moving a work piece (22) past a cutting tool (16). The apparatus includes a body (52), a first leg (56), a second leg (58) and a moveable center leg (60) defining a leg side surface (74) and two adjustable-width tunnels (62, 64) through which a cutting tool may pass. A handle (54) is moveable along a top surface (82) of the body to provide a balance of forces on both the inside cut portion (24) and the outside cut portion (26) of the work piece. Non-slip work piece-contacting surfaces (76) provide positive engagement with the work piece. A balance support device (84) may be attached to either the first or second leg at a plurality of vertical heights to balance the apparatus when the work piece is too narrow to make contact with a work piece-contacting surface on both side of the cut line (C). In one embodiment (200) a bridge handle (202) is used to maintain balanced forces on both sides of the cut line. The handle portion (204) may be longitudinally angled relative to the cut line to provide a force vector keeping the pushing apparatus and work piece secured against the table saw fence (16). A trailing edge heel (212) may be attached to the pusher to minimize blowout of the rearmost edge of the work piece and to assist in applying additional feeding force to the work piece.

Owner:WANG HENRY

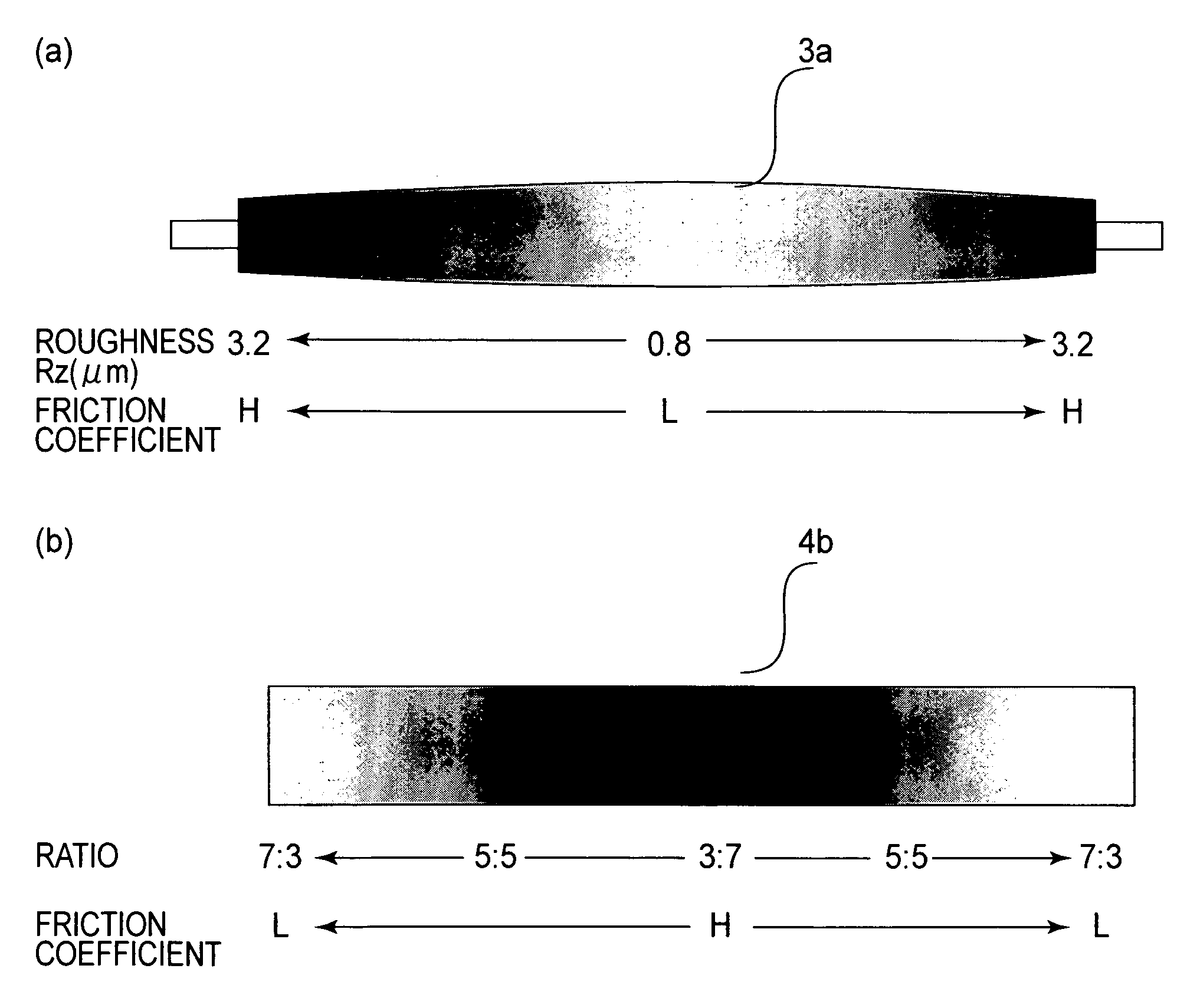

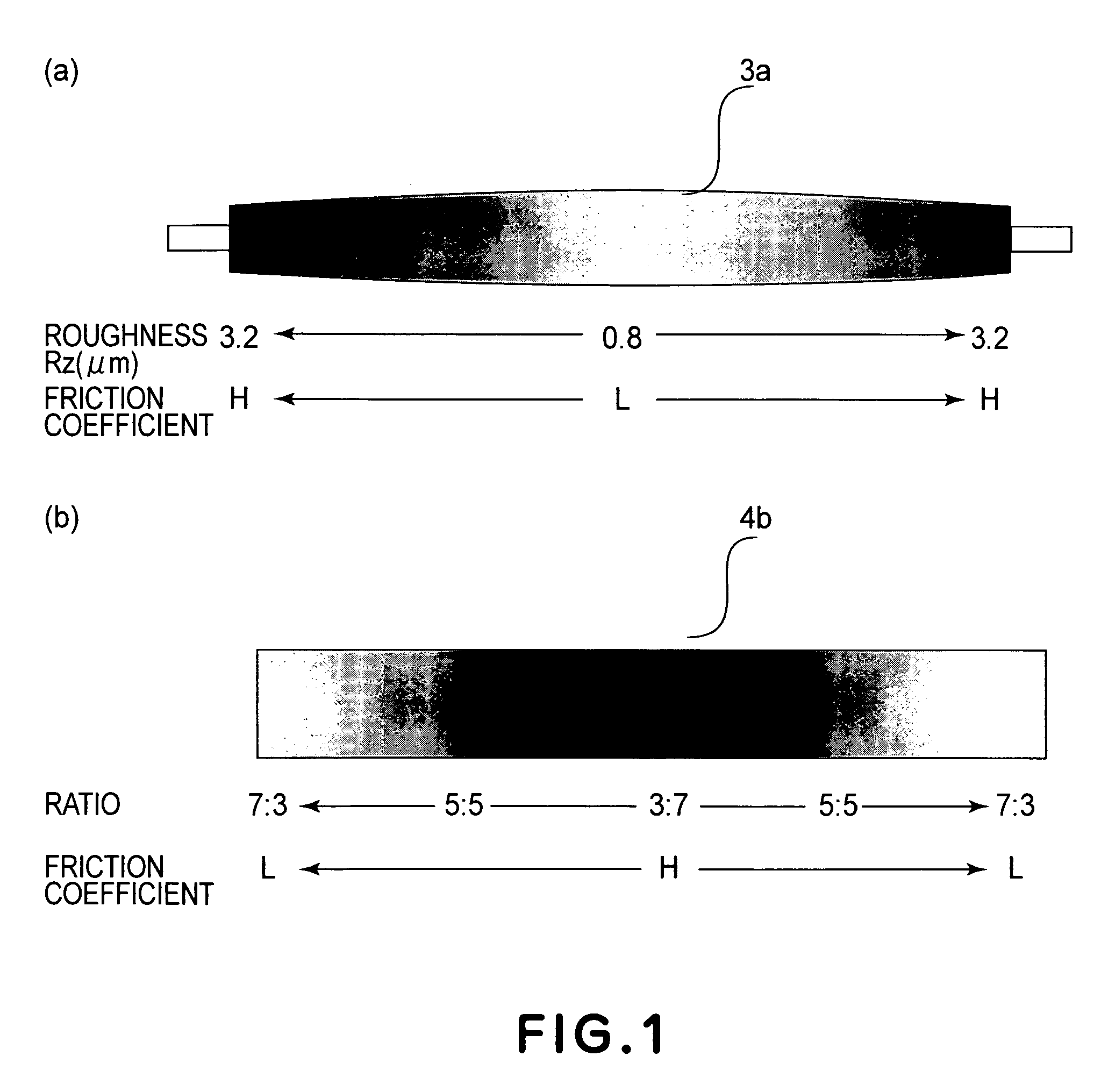

Image heating apparatus with adjusted feeding force to sheet with toner image

An image heating apparatus includes a heating rotatable member for forming a nip and heating an image on a recording material at the nip; an endless belt cooperative with the heating rotatable member to form the nip; and a pressing roller for pressing the belt toward the heating rotatable member at the nip, the roller having a diameter which is larger at an axially central portion thereof than at opposite end portions thereof and having a friction coefficient which is smaller at the axially central portion than at the opposite end portions.

Owner:CANON KK

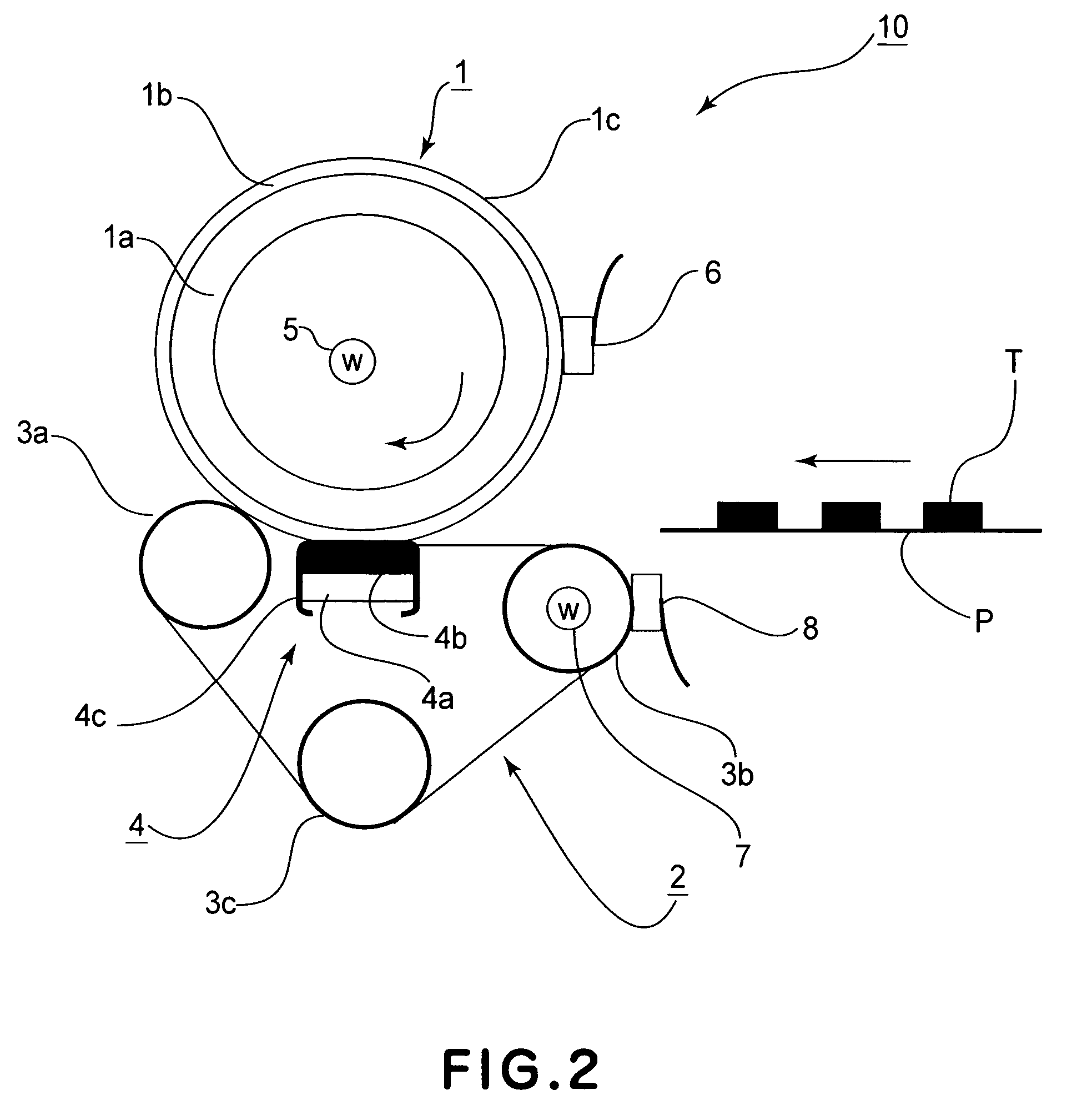

Processing technology for shaft parts

The invention relates to a processing technology for shaft parts. The processing technology is characterized by comprising the steps of material preparation, turning of two end faces, center hole drilling, rough turning of each outer circle, thermal refining, center hole polishing, nitrizing and semi-extractive turning of each outer circle, recessing, chamfering, threading, key groove processing line marking, key groove milling, center hole polishing, grinding and checking. The double-center method is adopted, a tailstock adopts an elastic center and positioning is accurate; reversing feed is adopted when cutting is conducted, and when a slender shaft is cut, a turning tool generally is made to do a feed movement towards the tailstock direction, in this way, the feed force applied on a work piece by the tool is in the direction towards to the tailstock, and therefore the work piece has a tendency to axial extension; a three-jaw chuck provided with three jaws can freely move and is convenient to clamp and firm in clamping, so that inconveniences brought to a worker due to different thicknesses of the work pieces are greatly reduced. In general, the processing technology has the advantages of being convenient in operation, improving the efficiency and improving the accuracy of the work piece.

Owner:徐玉明

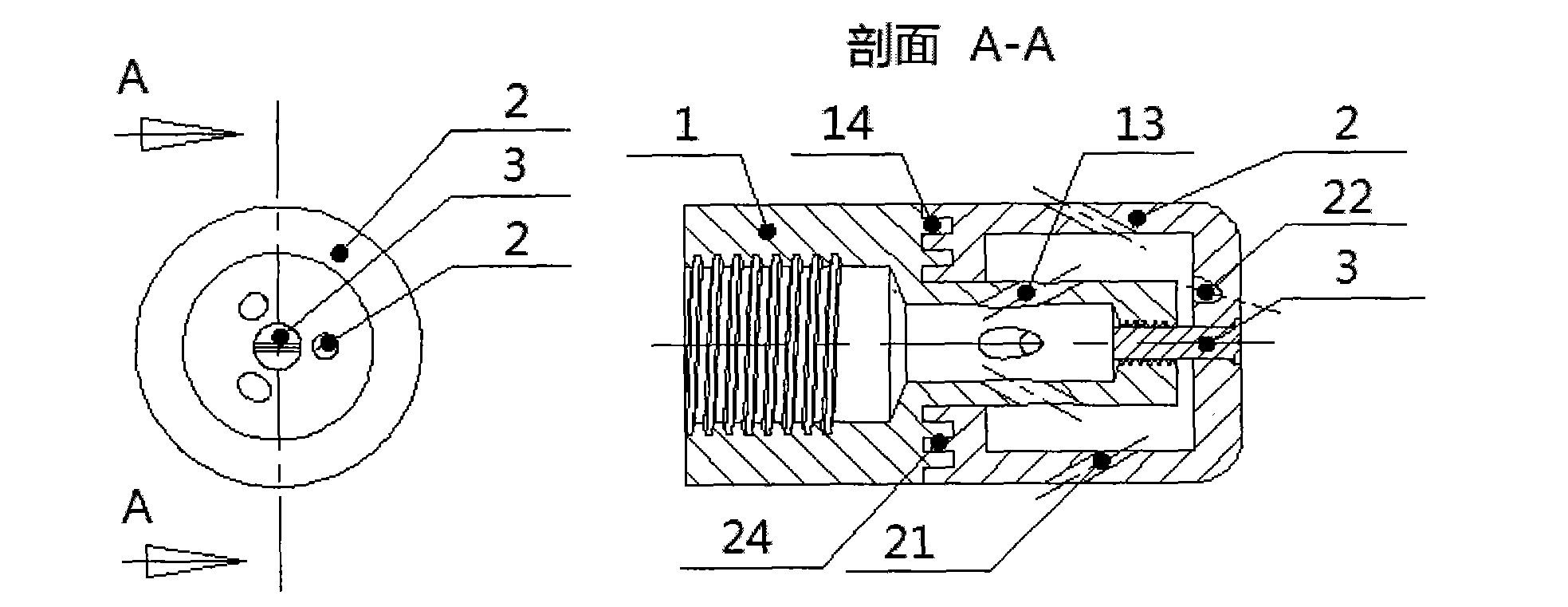

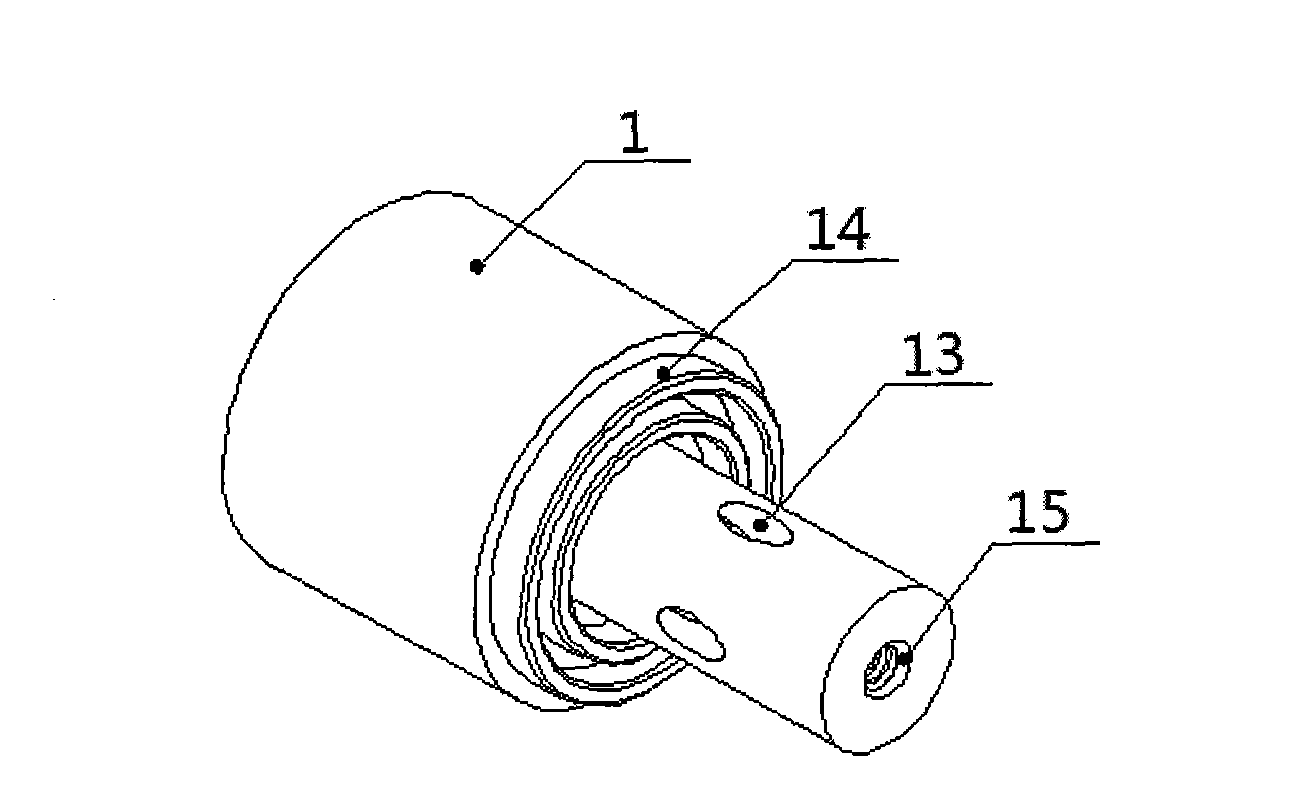

Self-feeding rotary jet flow multi-hole spray nozzle

ActiveCN103806836AGuaranteed reliabilitySimple structureLiquid/gas jet drillingFeeding forceJet flow

The invention relates to a self-feeding rotary jet flow multi-hole spray nozzle, which comprises a spray nozzle cap, a back end shaft, a screw and the like. The self-feeding rotary jet flow multi-hole spray nozzle has the basic work principle that a plurality of forward holes are uniformly formed in a certain circle, leaving away from the center for a certain distance, of the front end surface of the spray nozzle, a plurality of center axes of the holes are in the located plane of a certain tangent line of the circle and are distributed in a way of forming different angles with an axial line of the spray nozzle cap, and the projection of the axial lines of the holes in the front end surface is a tangent line of the same circle, so the jet flow has high tangential speed, and the efficient rock breaking is favorably realized; the jet flow dispersion is realized, the acting range is wide, and large-aperture holes are favorably formed; the spray nozzle cap realizes autorotation through the jet flow reaction, each hole is scanned along the self rail for completing the rock breaking, and the formed holes are more regular; the spray nozzle cap realizes the autorotation, and the self feeding of the spray nozzle is favorably realized. The backward spray nozzle provides the self-feeding force, and meanwhile, the autorotation of the spray nozzle cap can be controlled. The self-feeding rotary jet flow multi-hole spray nozzle has the advantages that the structure is simple, the efficient rock breaking can be realized, and large-diameter regular holes are formed.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

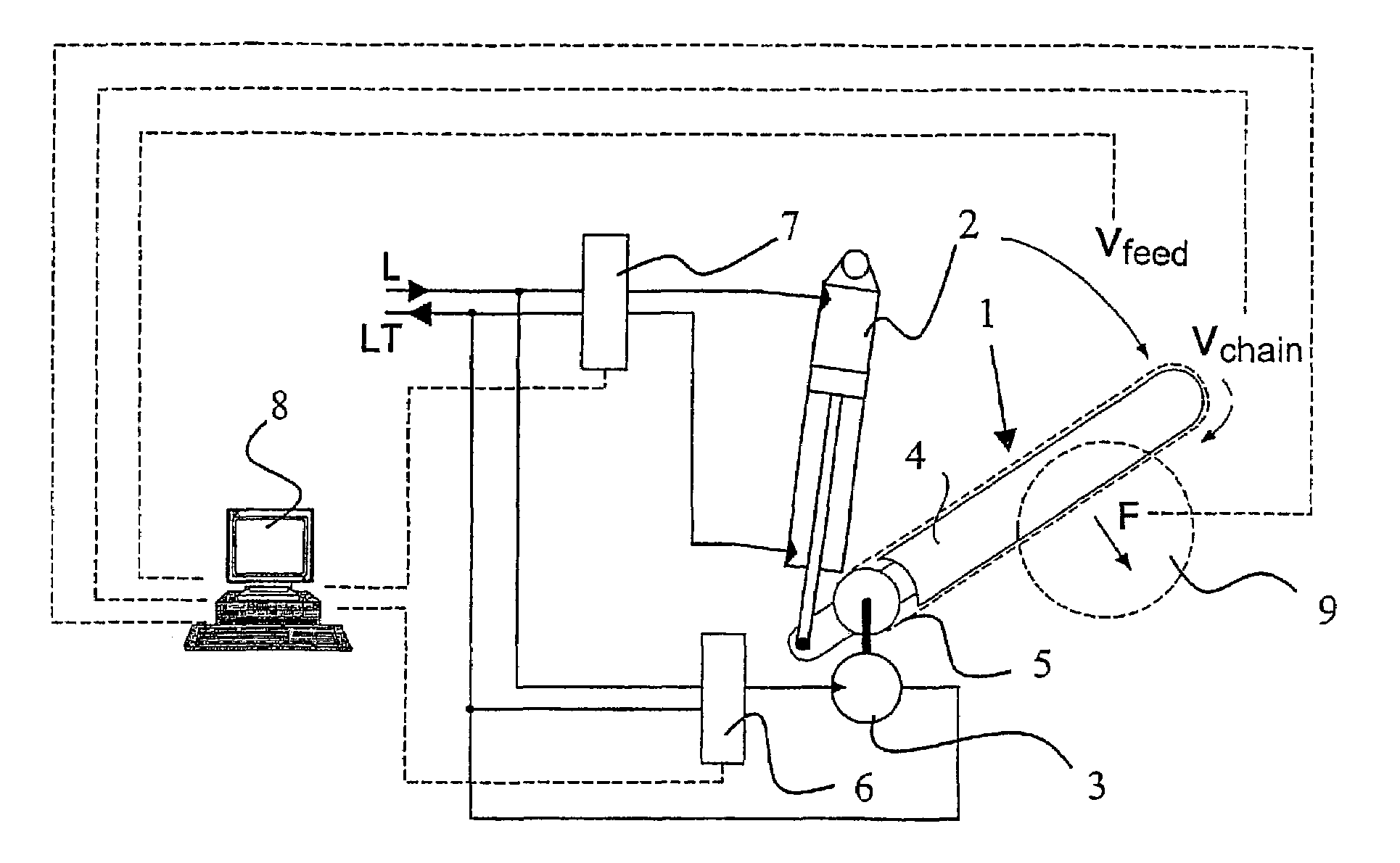

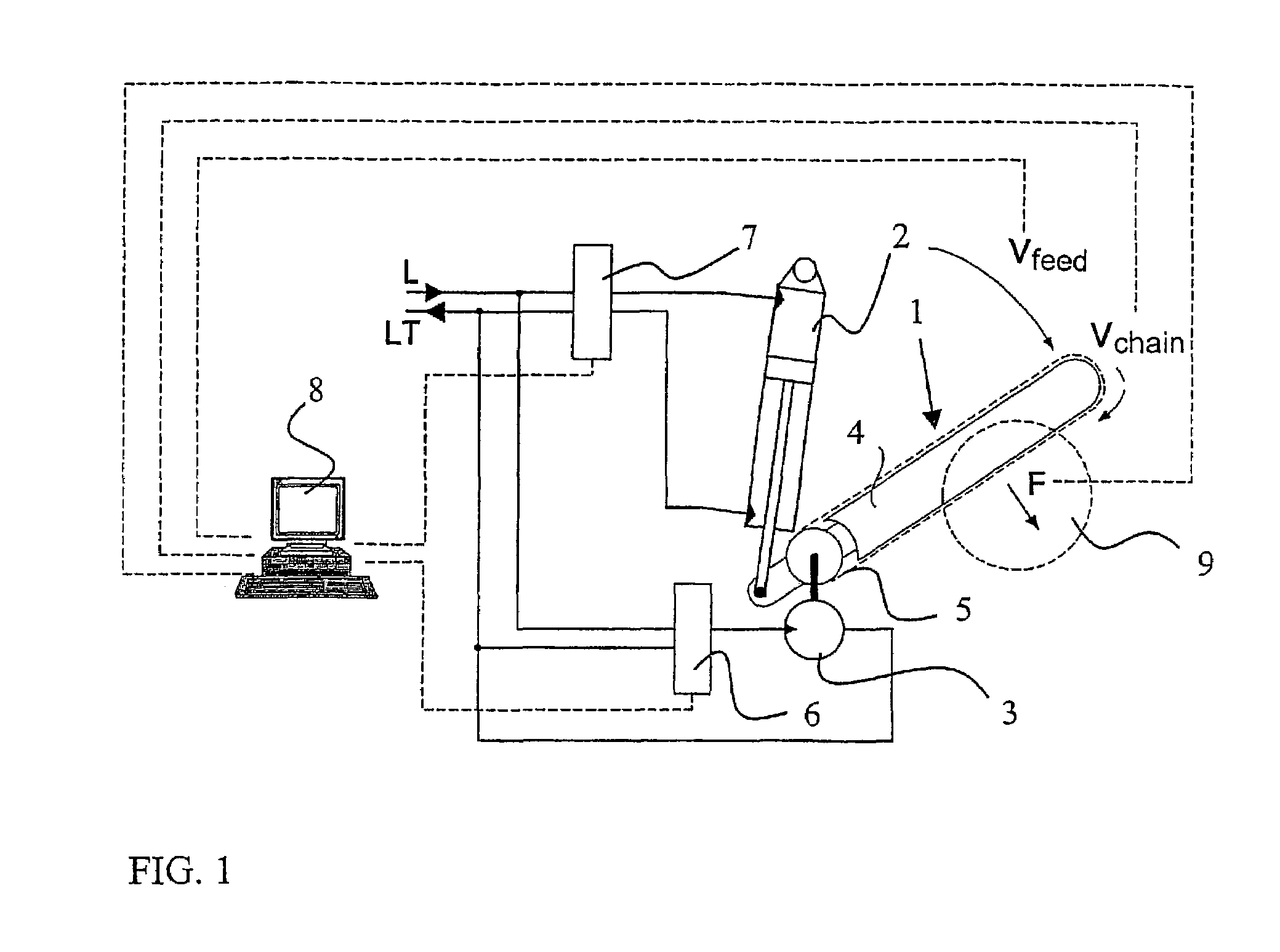

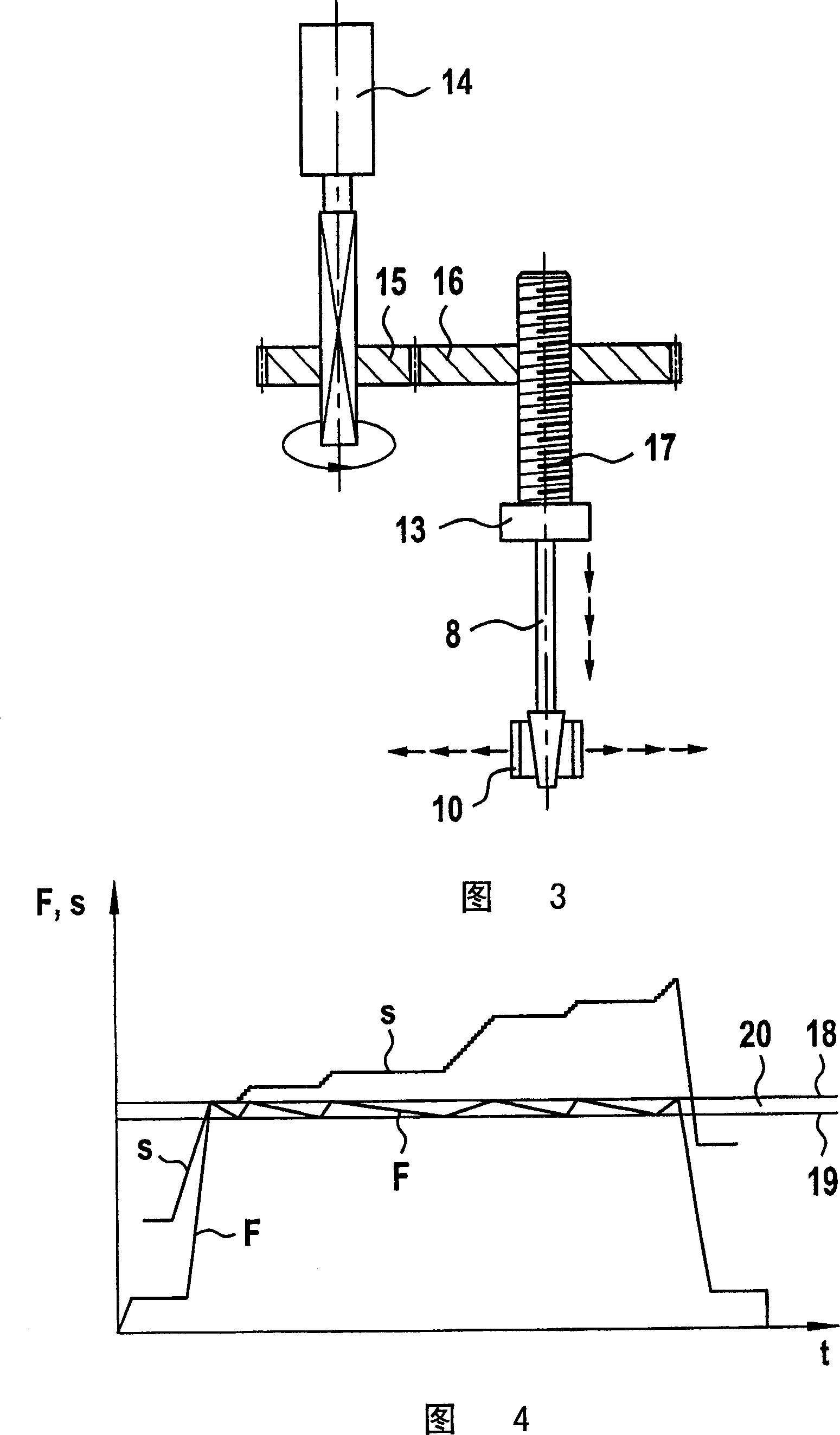

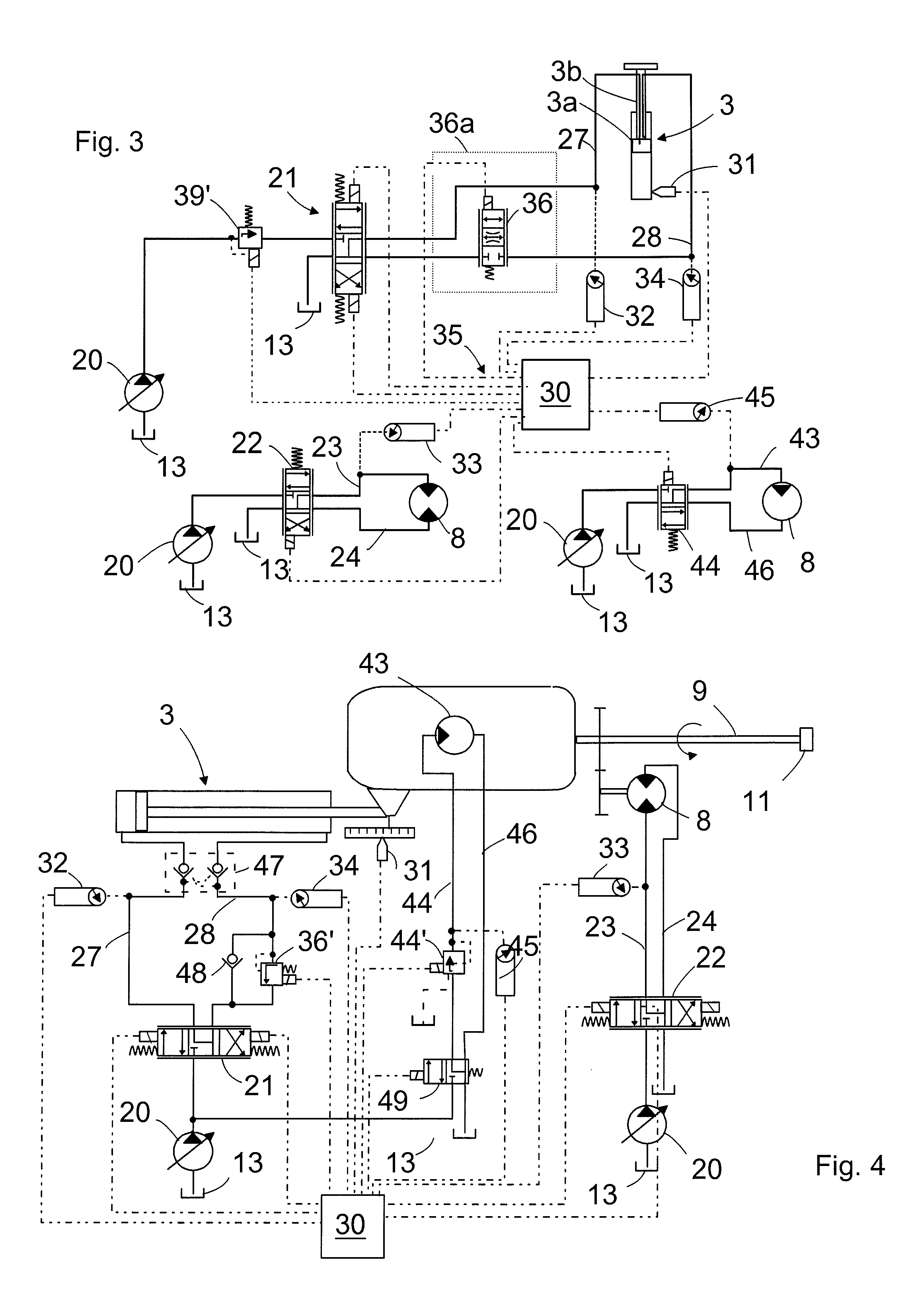

Method and arrangement for adjusting feed rate of a crosscut saw

InactiveUS7017460B2Limiting power neededImprove efficiencyMetal sawing devicesAutomatic control devicesFeeding forceActuator

A method and arrangement for adjusting a feed rate of a crosscut saw (1), in particular, in a harvesting head of a forest machine during the crosscutting of wood (9) in the apparatus. A feed force (F) of the crosscut saw and / or a rotating rate (vchain) of a cutter chain (5) revolving around a guide bar (4) are thus controlled. The control is implemented such that first the feed rate (vfeed) of the crosscut saw (1) is measured at given intervals. By adjusting thereafter the feed force of the actuator (2) controlling the crosscut saw and / or the rotating rate (vchain) of the cutter chain (5) and by determining the effect of the performed adjustment on the feed rate of the crosscut saw any change (δv) in the feed rate and the most advantageous adjustment measure to be performed next is concluded.

Owner:PONSSE

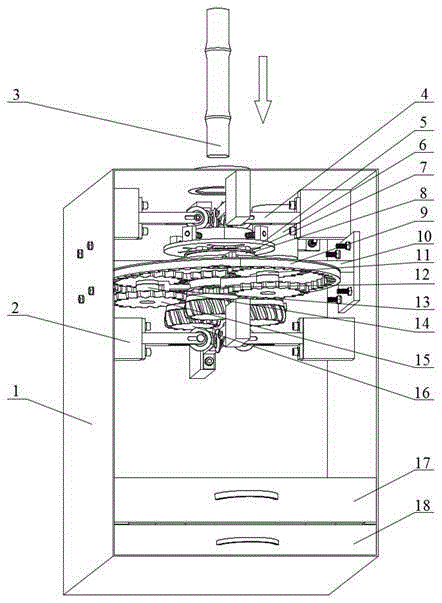

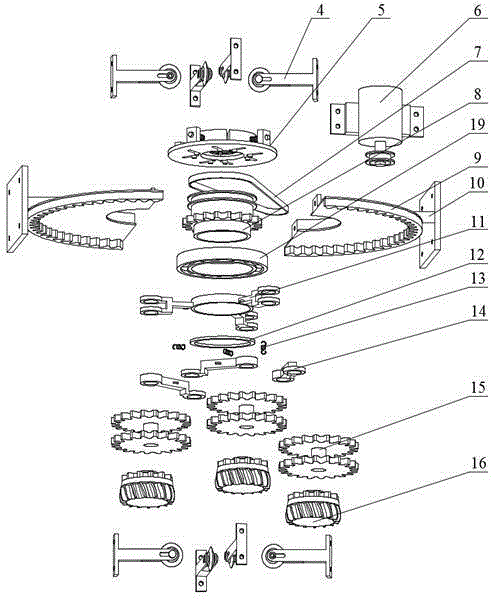

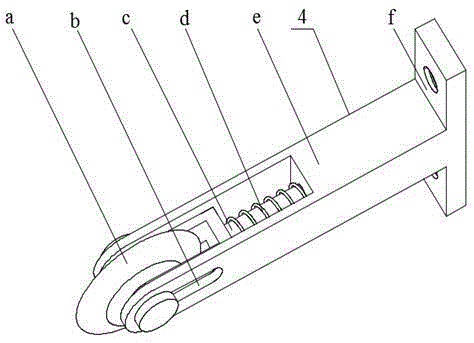

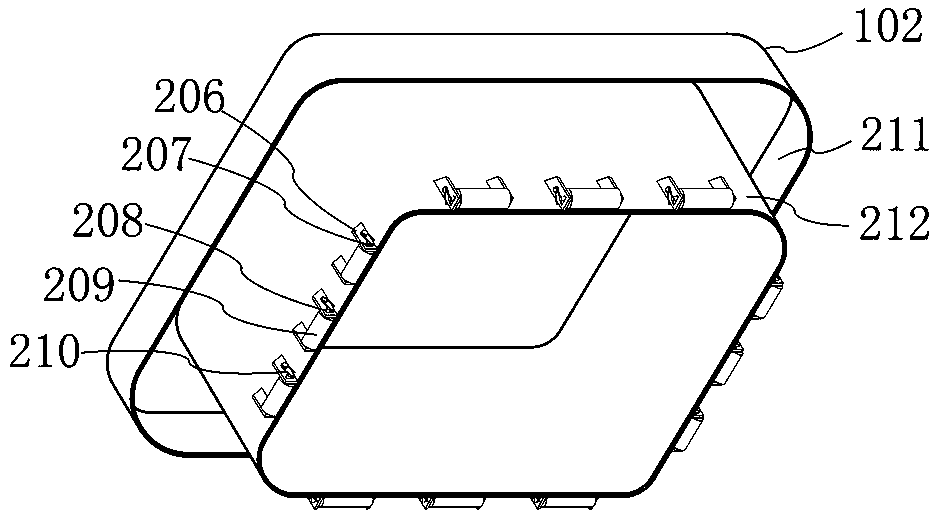

Sugarcane automatic peeler

The invention discloses a sugarcane automatic peeler; a power system is powered by an AC motor arranged on a frame; a hollow main shaft is driven to rotate through belt transmission; a feeding system and a cutting system are arranged on the same hollow main shaft; the feeding system is welded on the top of the hollow main shaft; a spiral block rotates to provide a downward feeding force, thus driving the sugarcane to move downwards; a clamp guide system is respectively arranged before spiral feeding and after cutting, thus preventing sugarcane from rotating; the cutting system is arranged on the bottom of the hollow main shaft, and uses three planetary gear train cutters to cut; a collection system is arranged on the bottom of the frame, and used for storing peeled sugarcanes and sugarcane chips; sugarcane deadweight can be fully utilized so as to realize feeding and cutting process of the sugarcane; the sugarcane automatic peeler is compact in whole structure, small in land occupation, suitable for peeling sugarcanes of different diameters, uniform in peeling thickness, thus solving the pulp waste problems caused by ununiform artificial peeling thickness; the sugarcane automatic peeler is convenient in operation, and suitable for usage in normal households.

Owner:JIANGSU UNIV

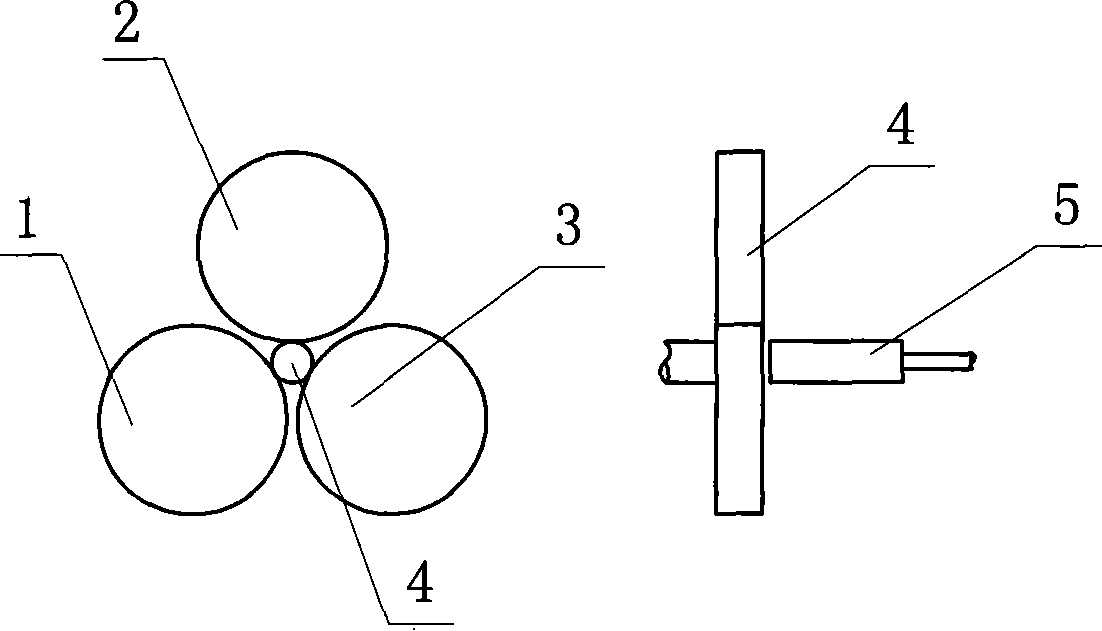

Method for processing stainless steel tube rolling thread

InactiveCN101209523ACorrect out of roundness problemsHigh precisionScrew-threads articlesPunchingFeeding force

The invention provides a stainless steel pipe thread rolling processing method. The pipe contraction disposal is carried out before the rolling processing, a three-shaft thread rolling processing process is carried out and conical pipe thread is rolled on the external surface of the pipe end. The invention aims at solving the forming problem of the conical pipe thread when the cold rolling processing is carried out, in order to improve the precision and strength of the conical pipe thread, implement the optimum thread type and correct the non-roundness of the steel pipe. The detailed operation flows comprise a pipeline cutting, a pipeline chamfering, pipe reduction disposal, pressing and fixing the pipe end by a hydraulic pressing device, processing the pipe end into the conical pipe shape by the reciprocating motion of a punching device on the pipe end, the three-shaft thread rolling processing which inserts the pipe end after the pipe reduction disposal into a revolution body chamber which is formed by the mutual inscribed three-shaft idler wheel which is symmetrically arranged, rolling the conical pipe thread on the external surface of the pipe end by the axial feeding force which is acted on the pipe end by the rotation of the three-shaft idler wheel, and the linear reciprocating extrusion feeding motion of the three-shaft idler wheel on the external surface of the pipe end.

Owner:CRRC QINGDAO SIFANG CO LTD

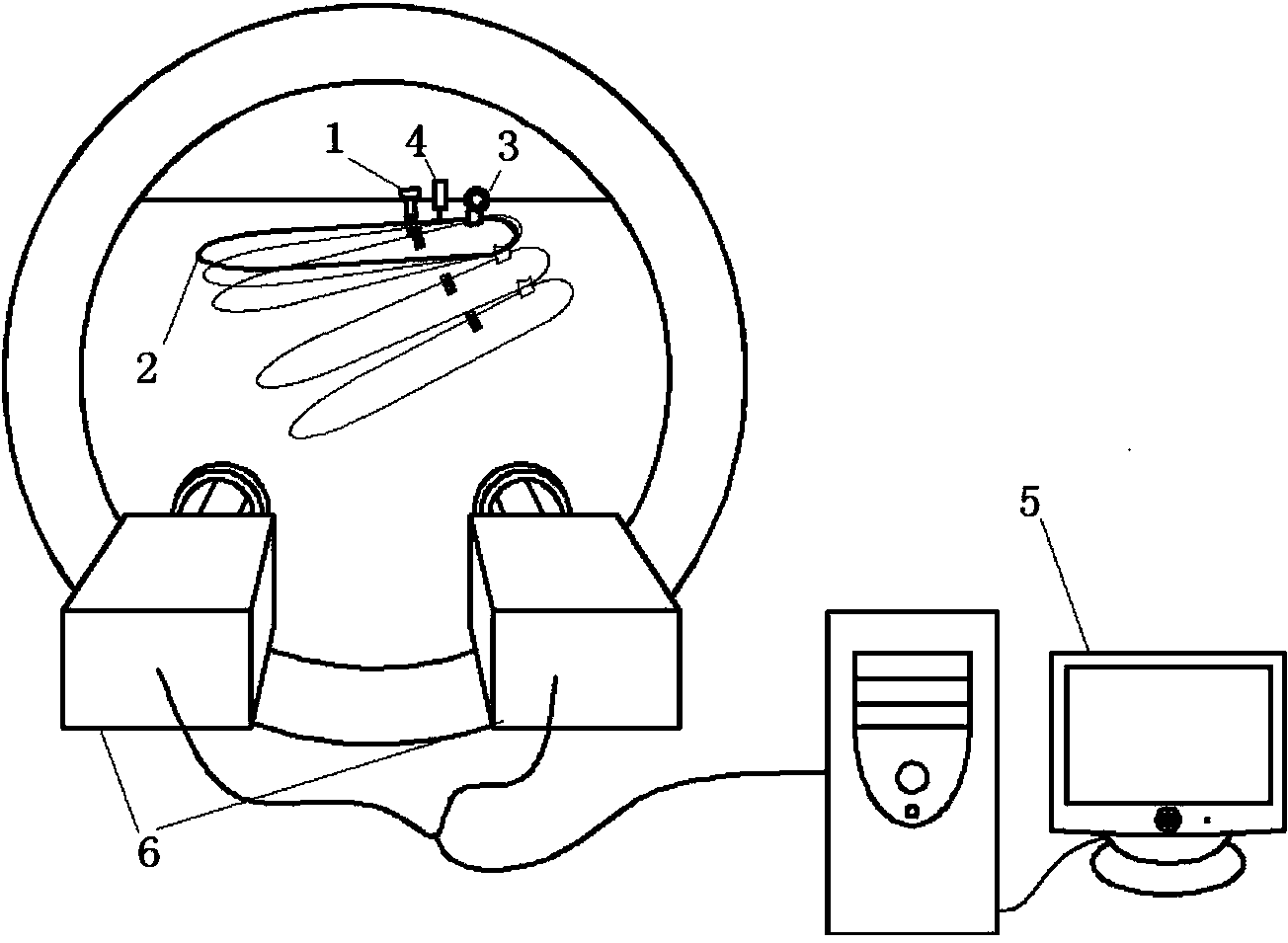

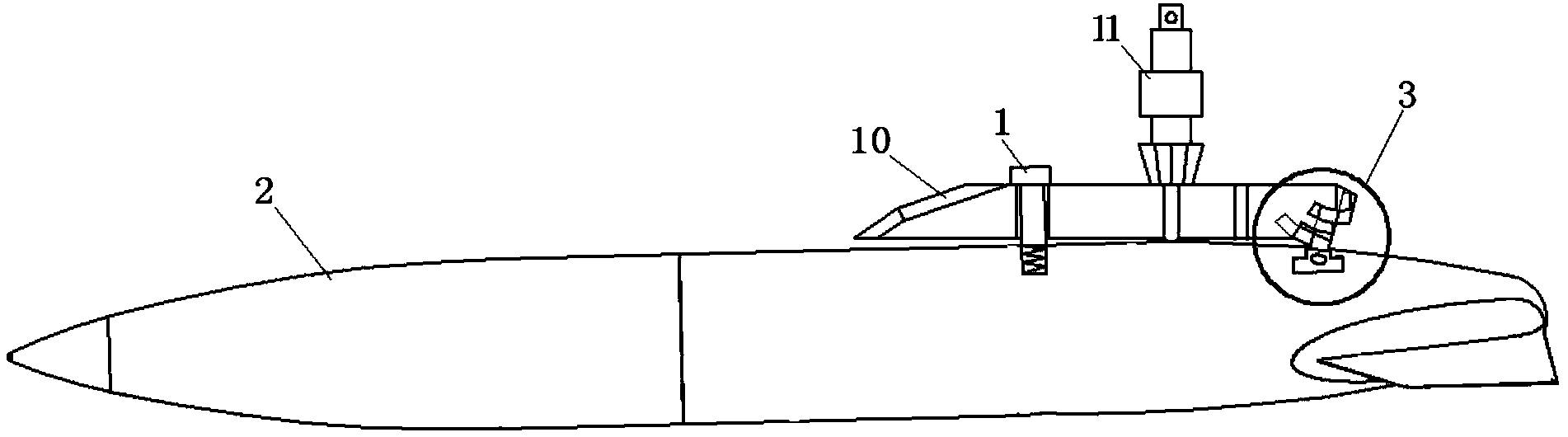

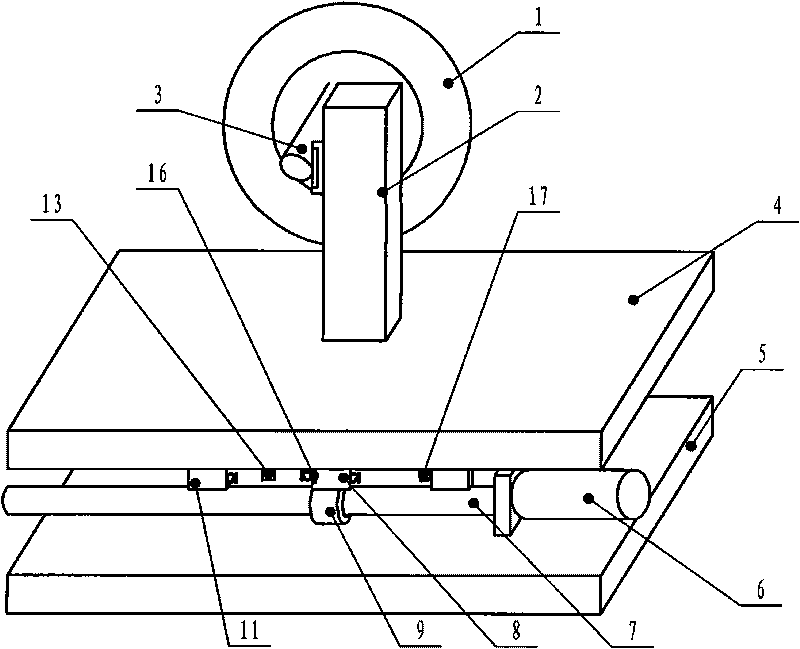

Wind tunnel separation simulation experiment system and method

InactiveCN104180965AImprove carrying capacityHigh precisionAerodynamic testingFeeding forceEngineering

The invention discloses a wind tunnel separation simulation experiment system, belongs to the technical field of wind tunnel experiments, and relates to a simulation experiment system suitable for measuring the separation process of an external carried object model in the wind tunnel environment. According to the simulation experiment system, an explosive bolt is matched with a mechanical concentric sliding rail device, acting force is exerted through a feeding assistant device to complete separation between an external carried object and a master, and the separation process is measured through a high-speed visual device. By means of the wind tunnel separation simulation experiment system, the explosive bolt is matched with the mechanical concentric sliding rail device, it is guaranteed that a wind tunnel separation body model separation system is safe and reliable, the high bearing capacity and the rapid triggering capacity are achieved, the feeding assistant device is introduced to exert the adjustable feeding force to the model, the separation initial angle, the separation angle, the separation speed and the separation angular speed of the wind tunnel separation model are controlled, high consistency of the separation model separation process and the true machine separation process is guaranteed, and the whole separation process parameter measurement requirement is met due to the fact that the binocular high-speed visual device has the advantages of being high in accuracy, high in frequency response and the like.

Owner:DALIAN UNIV OF TECH

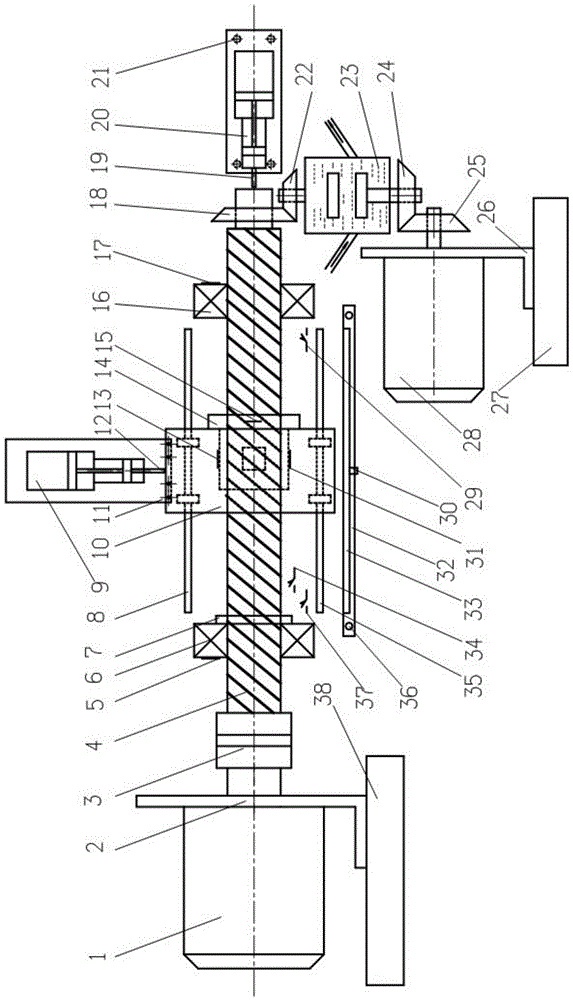

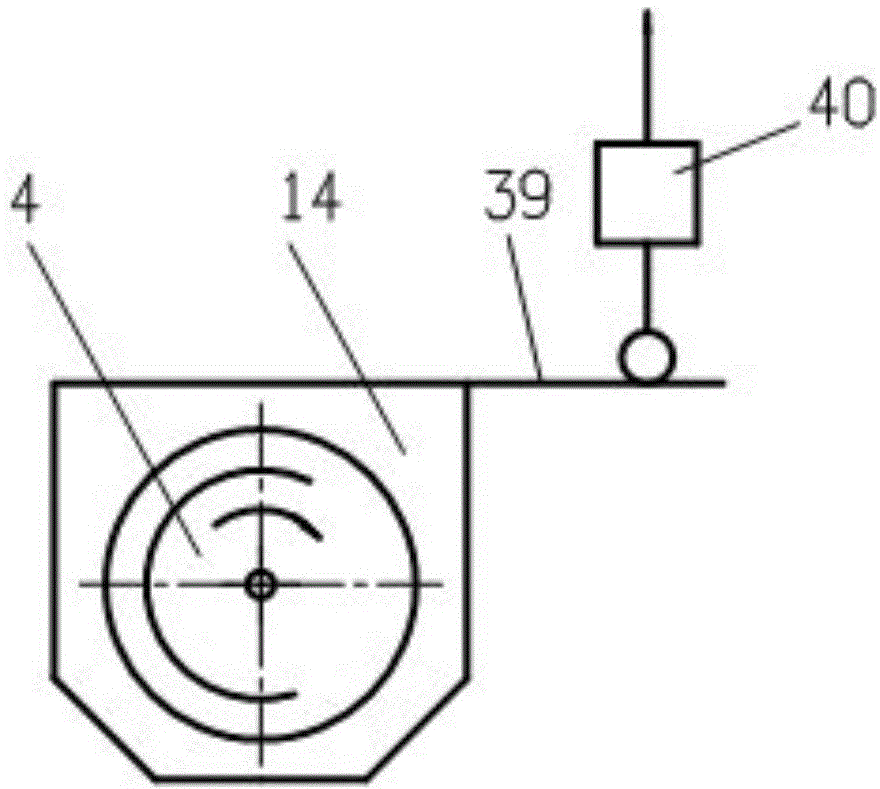

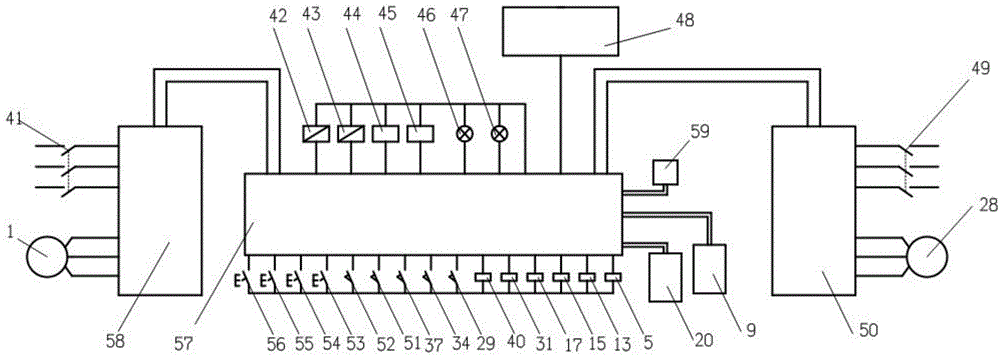

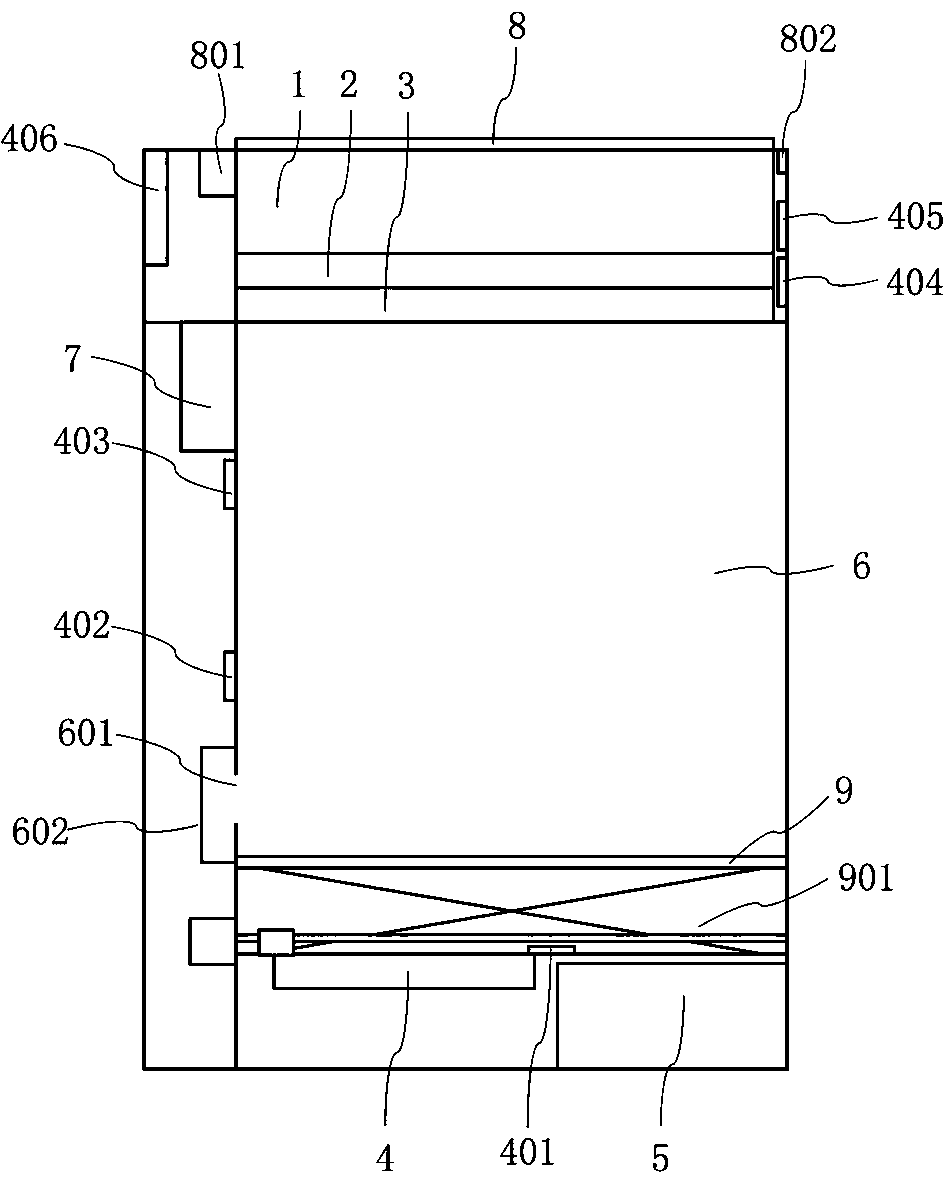

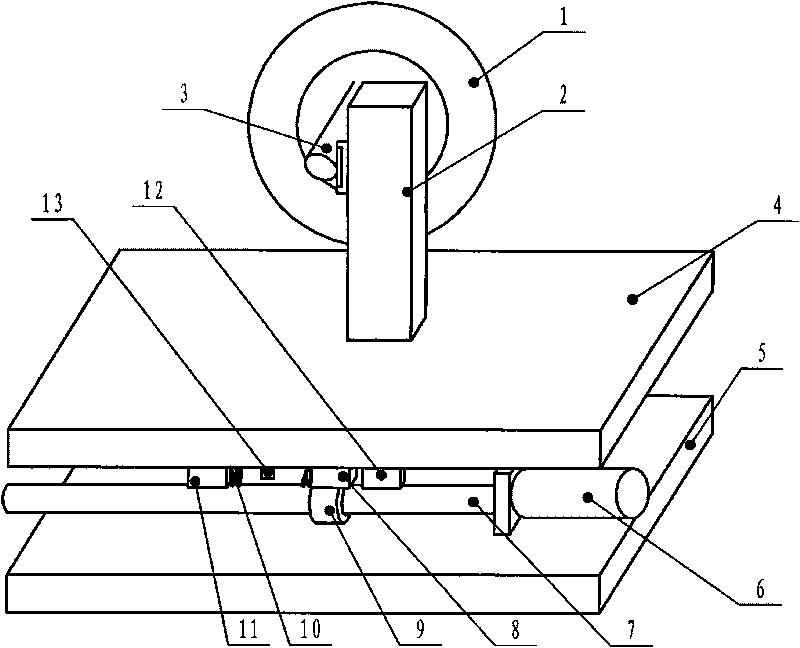

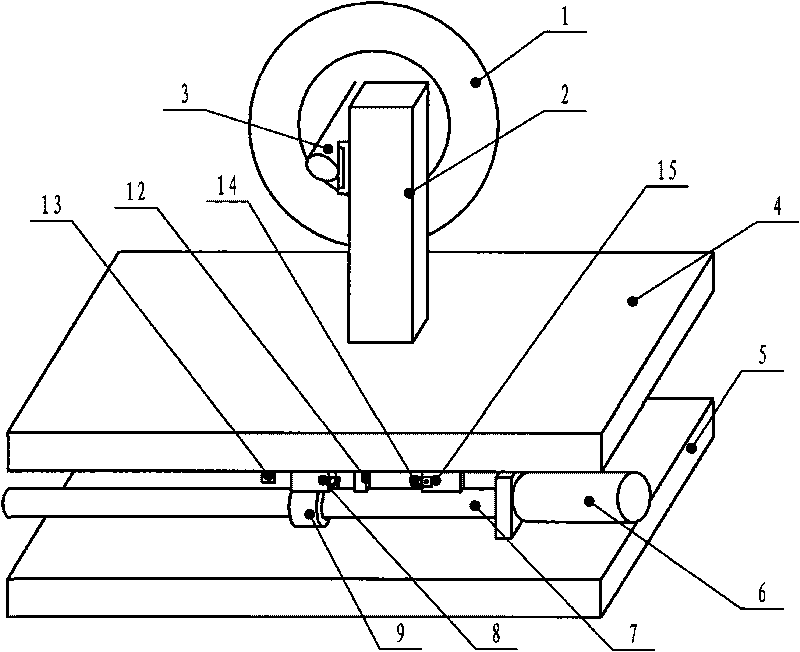

Reliability test device for CNC (Computer Numerical Control) grinding machine

The invention discloses a reliability test device for a CNC (Computer Numerical Control) grinding machine. The integral test device is controlled by a PLC (Programmable Logic Controller); axial grinding force is loaded at one end of a screw of a hydraulic cylinder extension cylinder; the axial grinding force is loaded at one end of the screw due to the fact that a servo motor drives a hydraulic coupler; loading of radial feed force is achieved due to the fact that the hydraulic cylinder extension cylinder acts on a workbench; the positioning accuracy of a feed unit is measured through element devices such as a high-accuracy encoder and an optical grating; friction moment of the screw is indirectly achieved due to the fact that a force transducer measures the bearing force of a force measuring rod which is installed on a nut; the temperature is measured through temperature sensors which are installed on a front bearing seat, a rear bearing seat and a screw nut; the vibration acceleration is measured through an acceleration sensor which is installed on the screw nut. The reliability test device for the CNC grinding machine can simulate working conditions of a feed system of the CNC grinding machine and collect reliability data of the feed system of the CNC grinding system to calculate the reliability level of the feed system of the CNC grinding machine.

Owner:BEIJING UNIV OF TECH

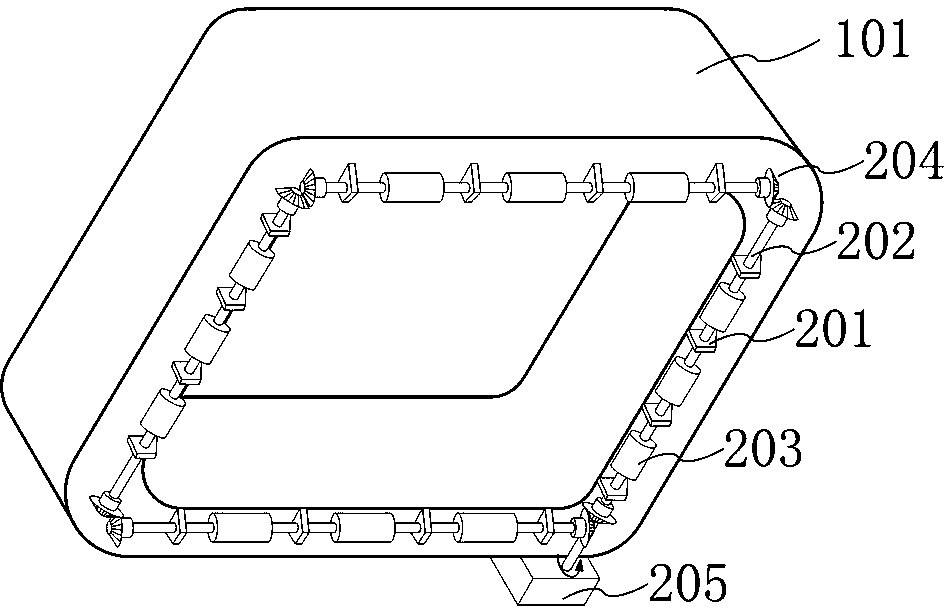

Fully automatic intelligent garbage can

The invention relates to a fully automatic intelligent garbage can, and solves the technical problems that the garbage can has a complex structure and bag feeding and bag changing are inconvenient inthe prior art. A garbage bag storage device and a garbage bag sealing device are arranged at the upper part of a main garbage can body, and a garbage bag feeding device is arranged on the garbage bagstorage device and comprises a rolling bag feeding element and a rolling clamping element which are mutually matched. A garbage bag is driven to move down from the garbage bag storage device into themain garbage can body by the matching of the rolling bag feeding element and the rolling clamping element. After garbage is put, the used garbage bag is sealed by the garbage bag sealing device, and the bag bottom of the unused garbage bag is sealed to form a new garbage bag. The fully automatic intelligent garbage can is strong in bag feeding force and stable in bag feeding. Cylinder materials inthe garbage bag storage device are more compact, and the capacity of the garbage bag storage device is increased. A plurality of sensors are arranged, therefore different bag feeding size requirements are met, and the universality is improved.

Owner:HANGZHOU CHEELE ELECTRONICS

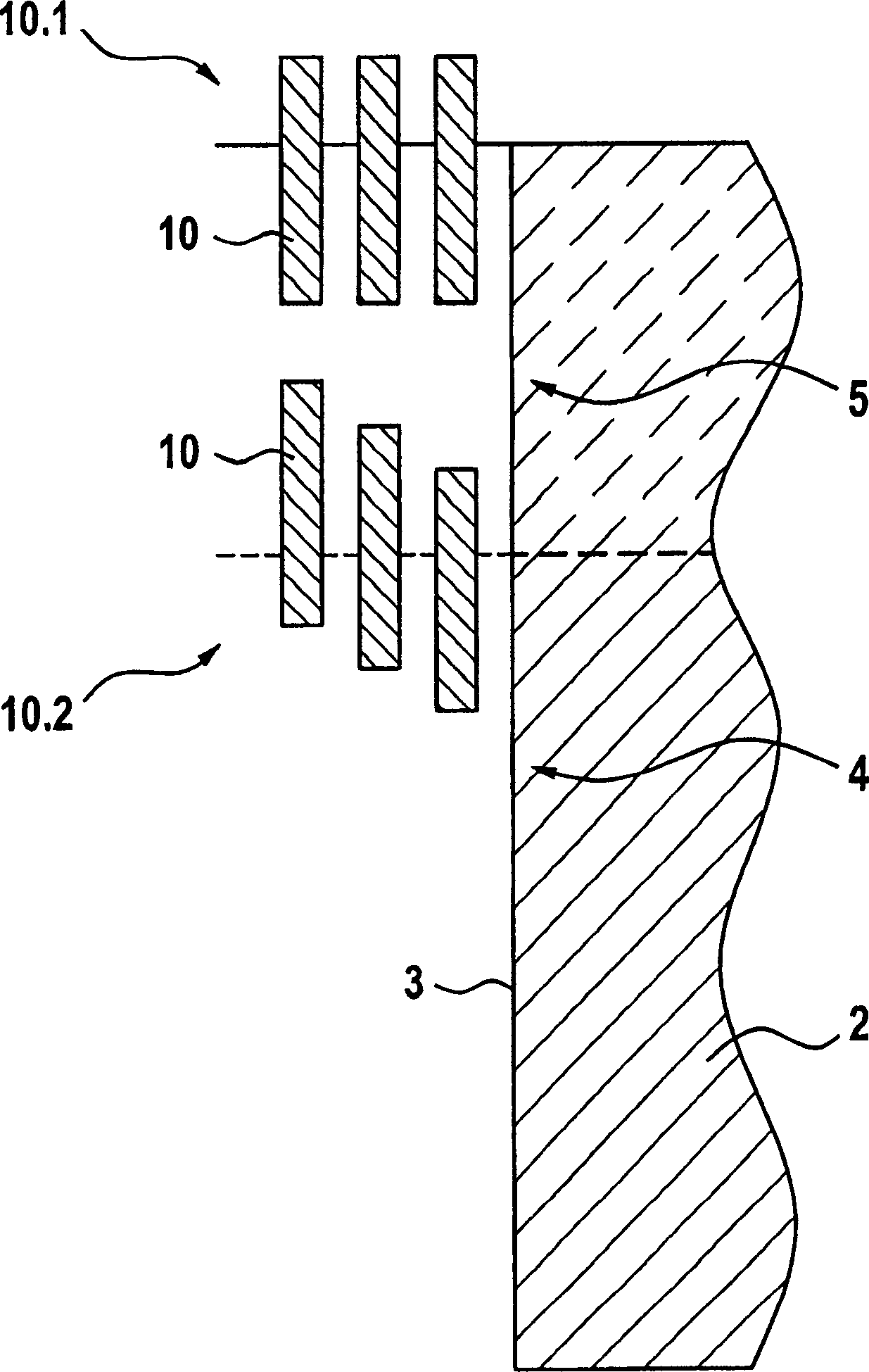

Method of honing bores

The invention describes a method for honing a hole (3) having two hole sections (4, 5) connected one behind the other in the axial direction of the hole (3), the surfaces to be machined of the hole sections having different hardnesses. The honing tool (1) is supported radially in the unhardened bore section (4), while the hardened bore section (5) is machined and thus ground with the honing stick (10) mounted on the honing tool (1). drop material. The feed adjustment of the honing stick (10) takes place in a force-controlled electromechanical feed and the working stroke of the honing tool is continuously varied at least towards the end of the honing process.

Owner:GEHRING GMBH & CO KG

Method for monitoring radial grinding force of grinder and realizing constant-force feeding

InactiveCN102059649AEasy to processAchieve the effect of full closed-loop CNC machiningGrinding feed controlNumerical controlFeeding force

The invention discloses a method for monitoring the radial grinding force of a grinder and realizing constant-force feeding, comprising the steps of: detecting the feeding force of a workpiece or a grinding wheel in the feeding process of the grinder; and controlling a driving mechanism which drives the workpiece or the grinding wheel according to the detected feeding force so as to apply constant feeding force on the workpiece or the grinding wheel. In the invention, through changing a method for applying the unknown radial force of the grinding wheel of the grinder into a method for applying the known radial force (controlling the force) or a method for detecting the radial force of the grinding wheel (detecting the force), the constant-pressure grinding of the grinder is realized and the purposes of achieving the grinding efficiency, ensuring the precision of the product and protecting the grinding wheel are achieved. By means of the invention, the problem that the machining effect after the automation and the numerical control of the grinder is bad is solved; and if the devices such as a workpiece online measuring instrument and the like are used, the effect in strict accordance with coarse-fine-finish grinding process requirements and fully closed-loop numerical control machining can be achieved.

Owner:河源富马硬质合金股份有限公司

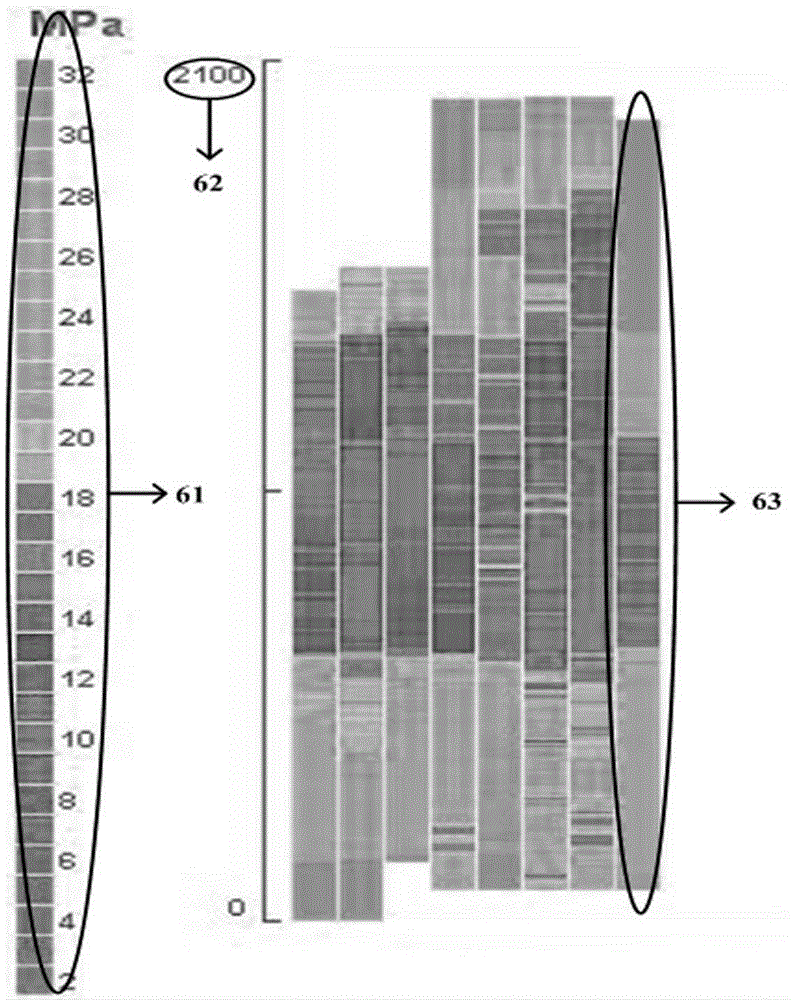

Coal mine roadway geological parameter on-line monitoring system

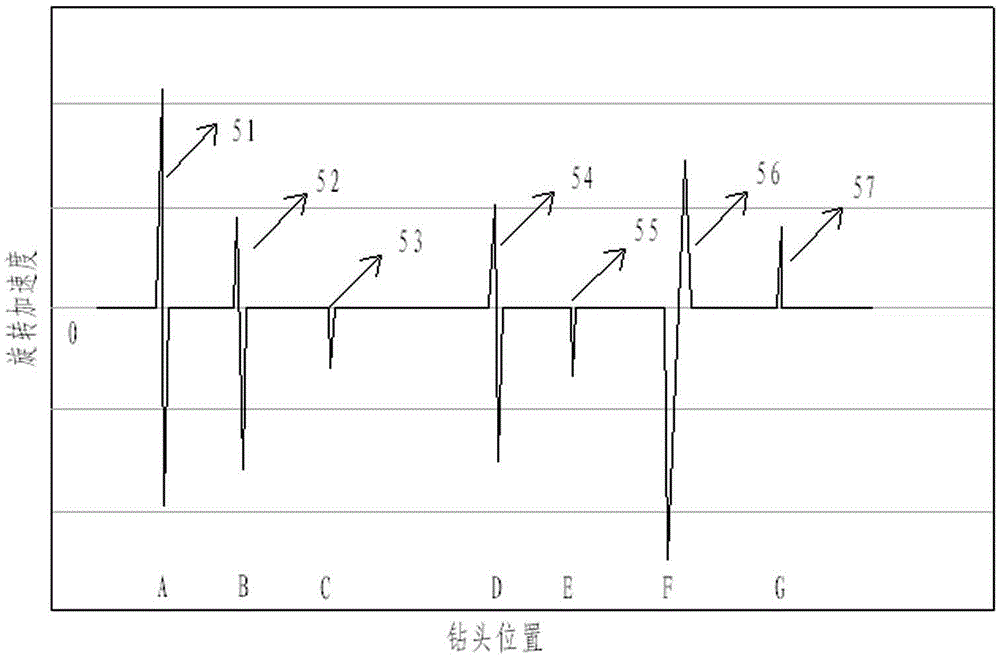

ActiveCN105422088AEasy to identifyAvoid security issuesSurveyMeasurement devices for drillingGeomorphologyFeeding force

The invention belongs to the technical field of geological parameter detection measurement, aims at overcoming the deficiency and limitation that existing anchor rod drilling machines adopting the rotation cutting method cannot conduct reasonable support according to the actual roadway geological conditions and provides a coal mine roadway geological parameter on-line monitoring system. The system comprises sensor detection elements, a data conversion module and a human-computer interface, roadway geological parameters such as a rock crack and the position and thickness thereof, a stratum surface limit and the position thereof and rock lateral-confinement-free compressive strength can be identified conveniently through four drilling parameters obtained by sensors, such as the oil cylinder feeding force and feeding speed and the drilling box motor rotating torque and rotating speed, hardness grading is further conducted on a back, the roadway geological parameters are judged so that anchoring protection parameters and drilling parameters can be adjusted and improved, and the deficiency and limitation that existing anchor rod drilling machines adopting the rotation cutting method can only conduct pure anchoring drilling operation and cannot conduct reasonable support according to the actual roadway geological conditions are overcome.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

Hydraulic system of horizontal buffer cylinder of forging and pressing operating machine

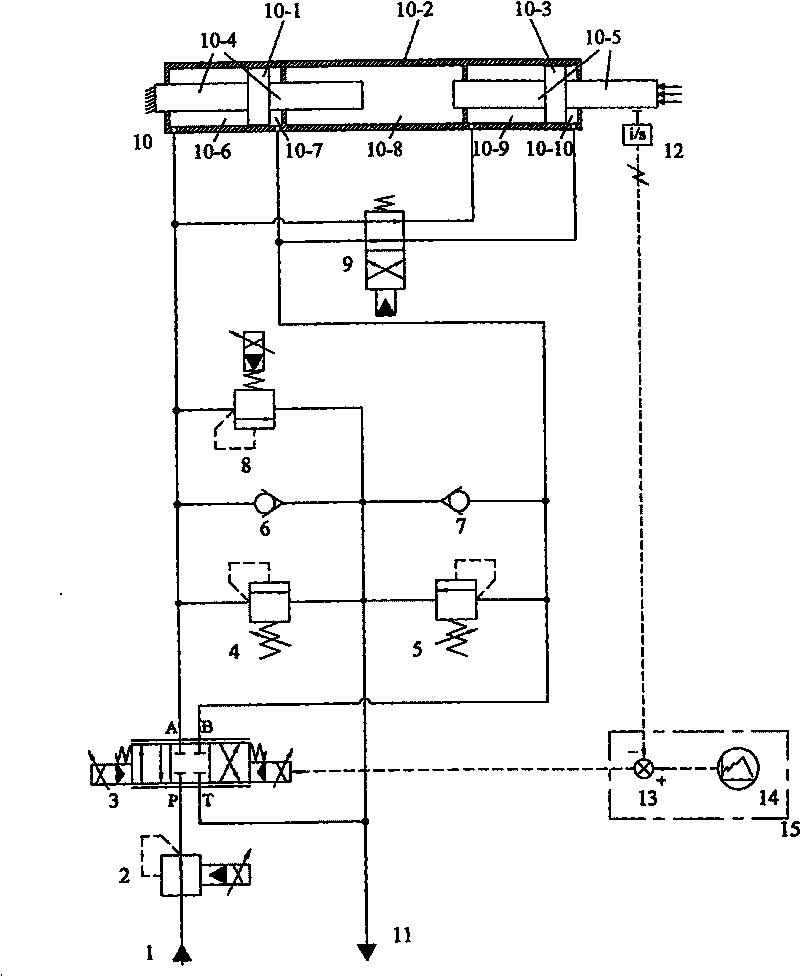

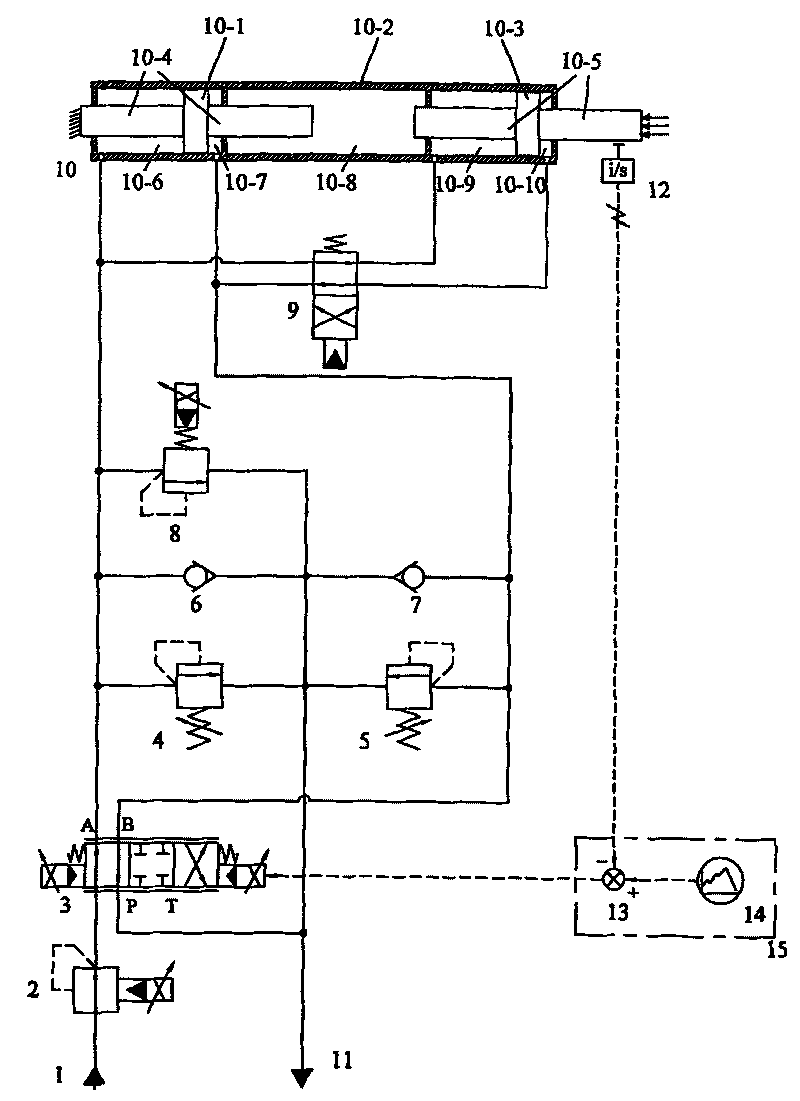

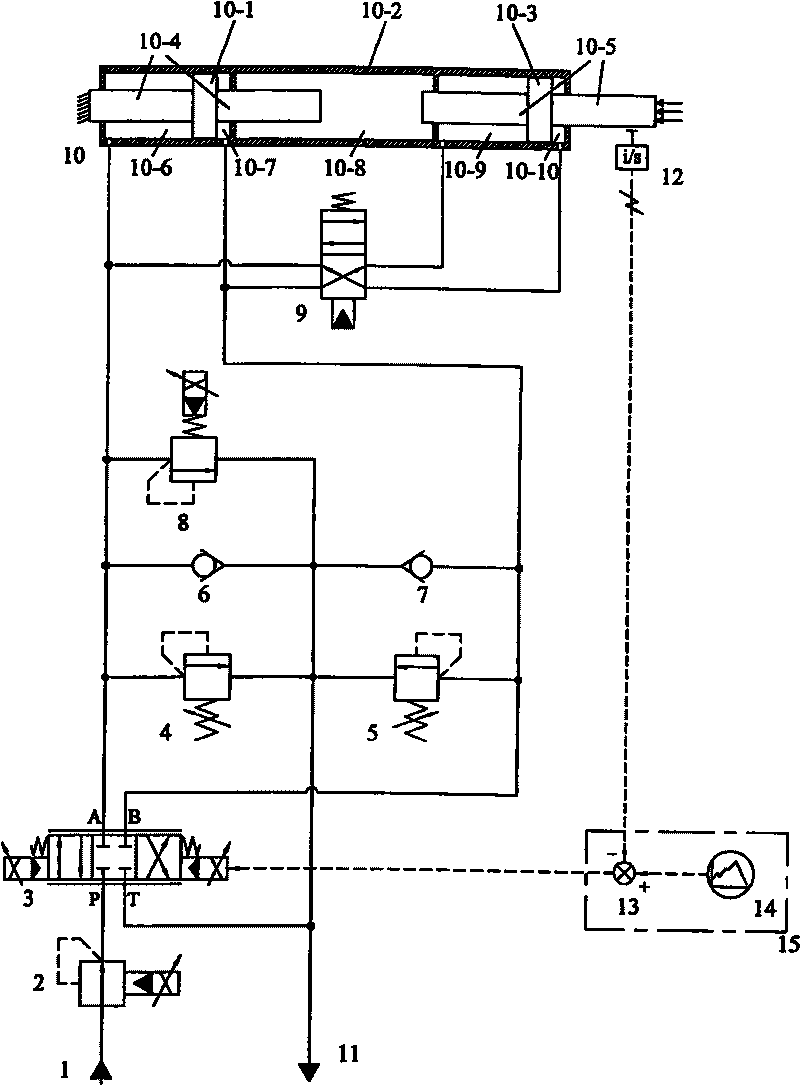

InactiveCN101704059AEasy to switchImprove reliabilityServomotor componentsForging press drivesFeeding forceProportional control

The invention discloses a hydraulic system of a horizontal buffer cylinder of a forging and pressing operating machine, which comprises an oil-feed port, a proportional pressure-reducing valve, a proportional directional valve, two safety valves, two check valves, a proportional overflow valve, an electromagnetic directional valve, a buffer cylinder, an oil return port, a displacement sensor and a displacement controller. The invention realizes the passive buffering of the buffer cylinder and the switching of an active feeding function through controlling the electromagnetic directional valve, realizes the control of passive buffering force through regulating the proportional overflow valve, realizes the control of active feeding force and buffering restoring force through regulating the proportional pressure-reducing valve, and realizes active feeding displacement and speed accurate control through the displacement closed-loop control of the proportional directional valve. The invention can finish the passive buffering and the active feeding function required by the horizontal buffering of the forging and pressing operating machine and realize the proportional control of force and displacement; and the hydraulic system has the advantages of simple structure and multiple functions.

Owner:ZHEJIANG UNIV

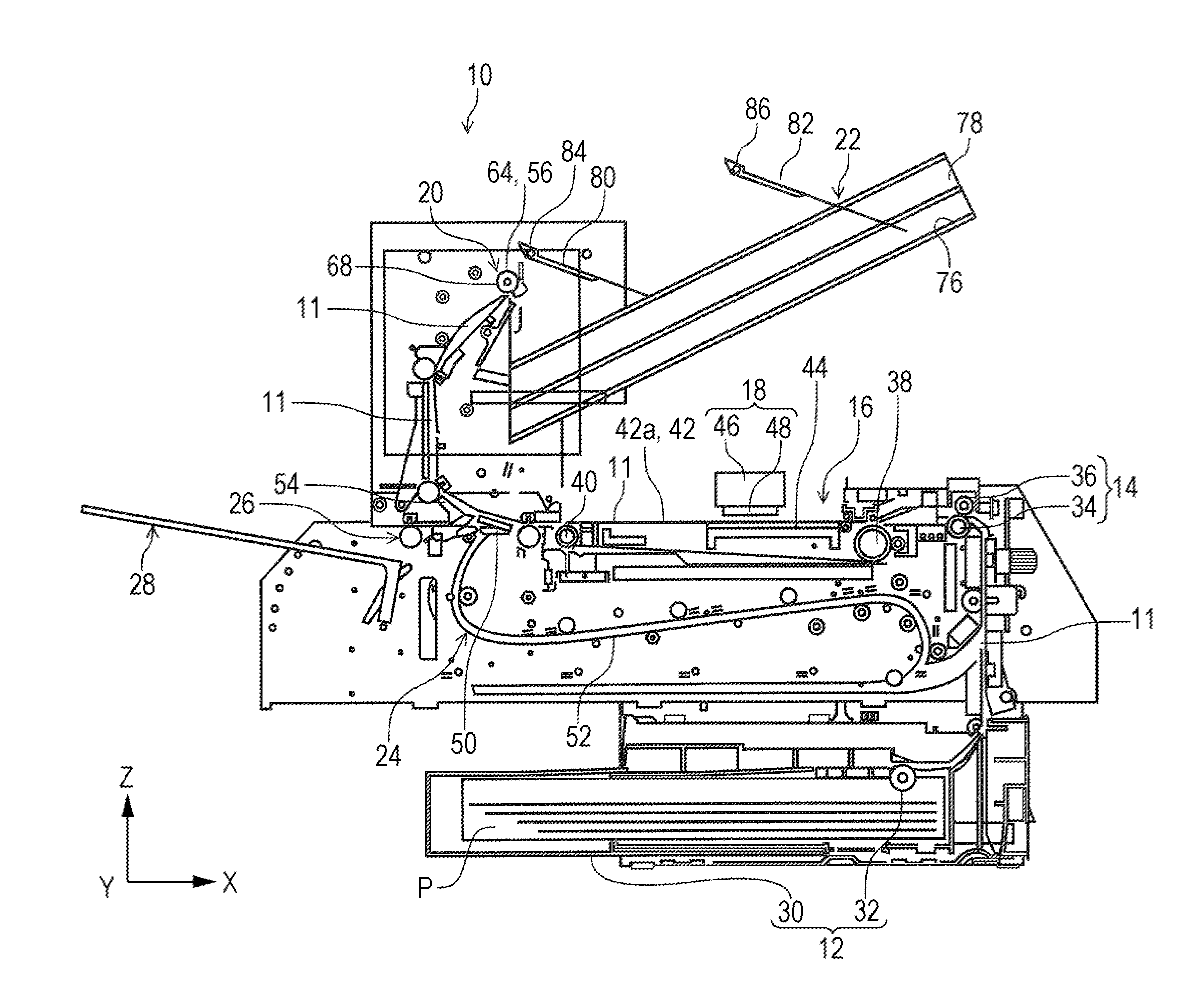

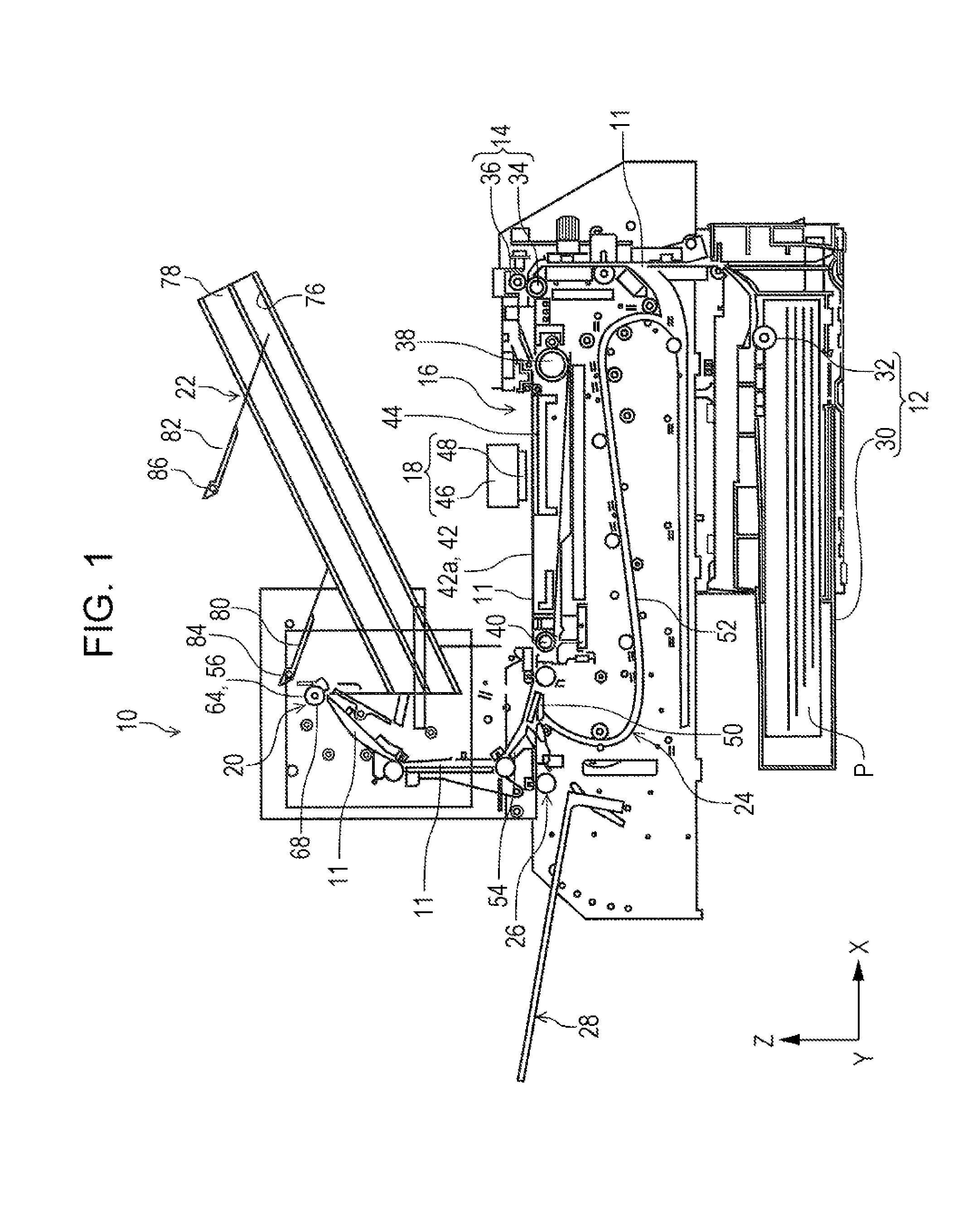

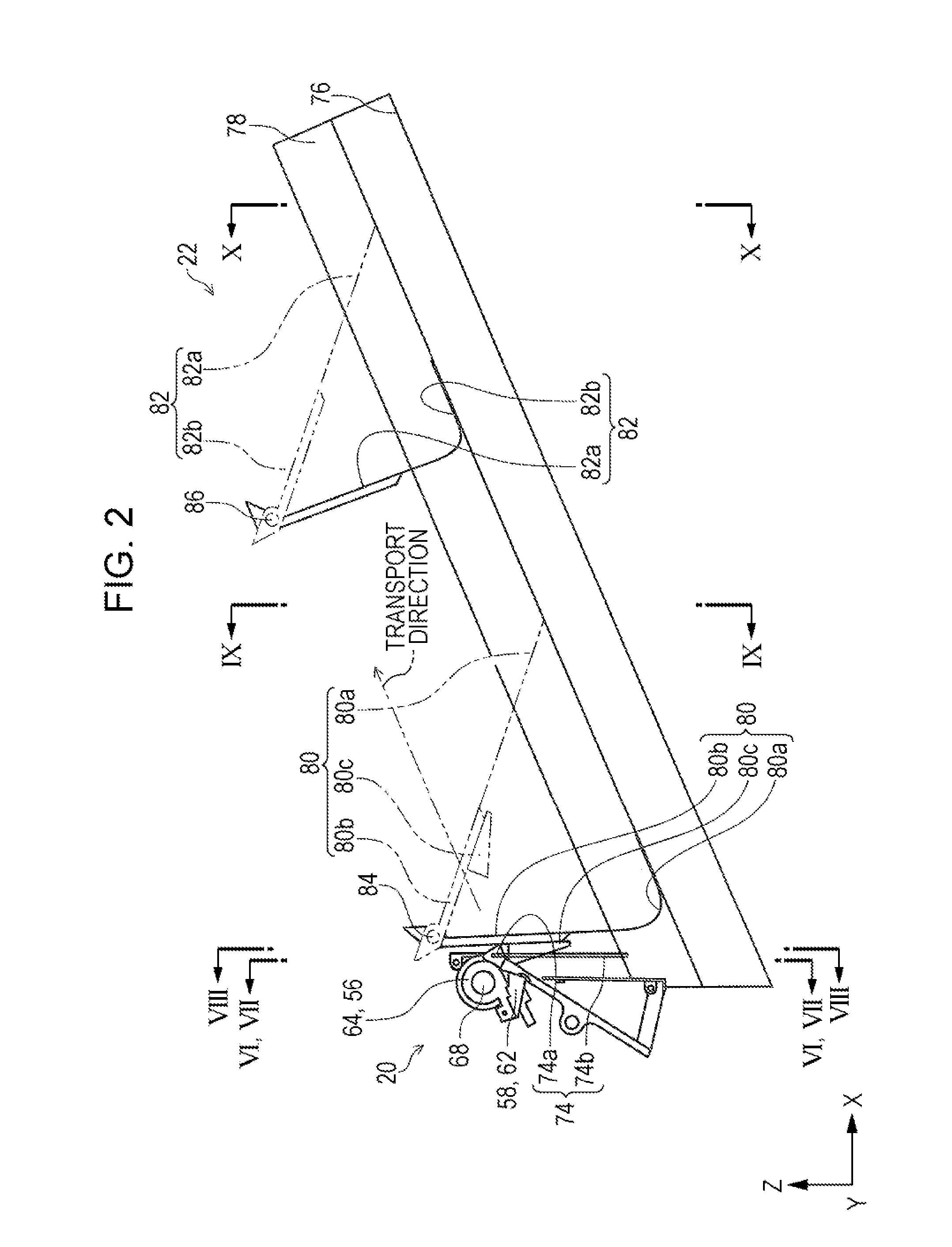

Recording apparatus

ActiveUS20140292979A1Increase flexibilityCurl suppressionOther printing apparatusArticle deliveryFeeding forceEngineering

A recording apparatus includes a recording unit that performs recording on a recording surface of a recording medium, a discharge section that discharges the recording medium, and a first bending member that is in contact with the recording medium which passes through the recording unit in the transport path and is transported toward the discharge section to bend the recording medium, in which the first bending member bends the recording medium in such a manner that the recording surface is directed inside by displacing both side portions of the recording medium in a width direction with respect to a central portion of the recording medium in the width direction of the recording medium at a position on a further upstream side in a direction of the transport than a contact position of the discharge section where a feeding force is applied to the recording medium.

Owner:SEIKO EPSON CORP

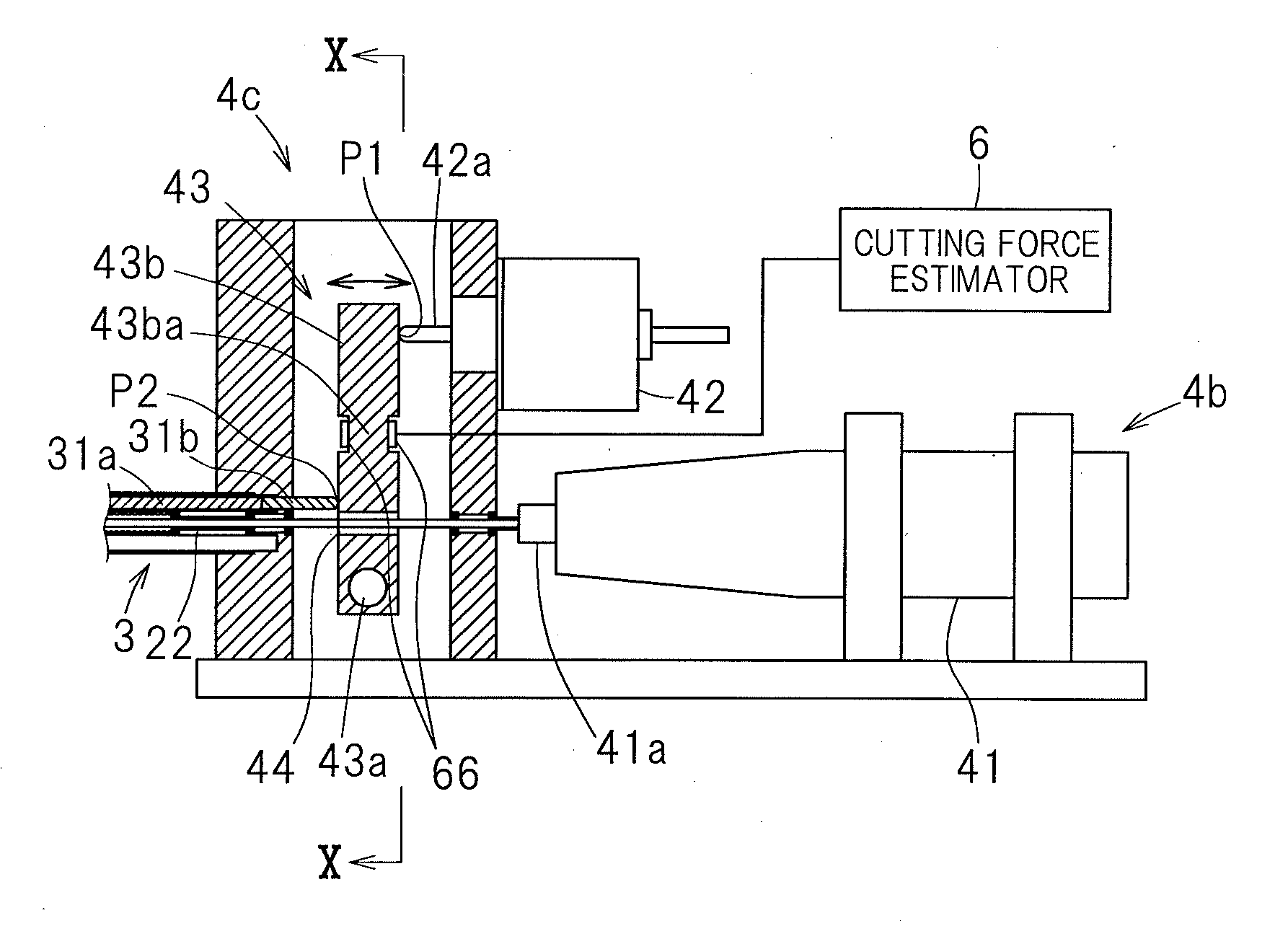

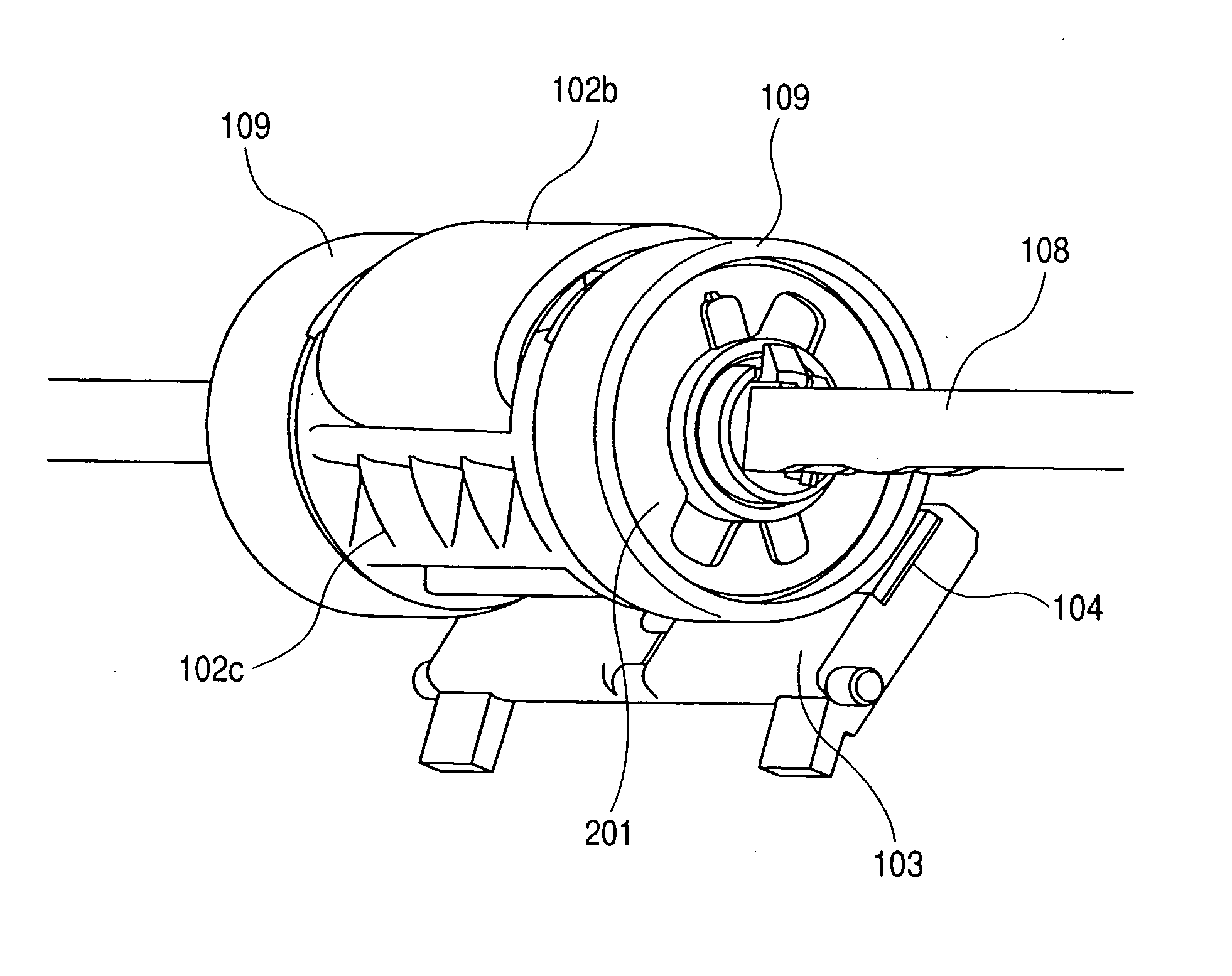

Remote-controlled actuator

InactiveUS20110230868A1Reduce pressureIncrease pressureDiagnosticsSurgeryFeeding forceRemote control

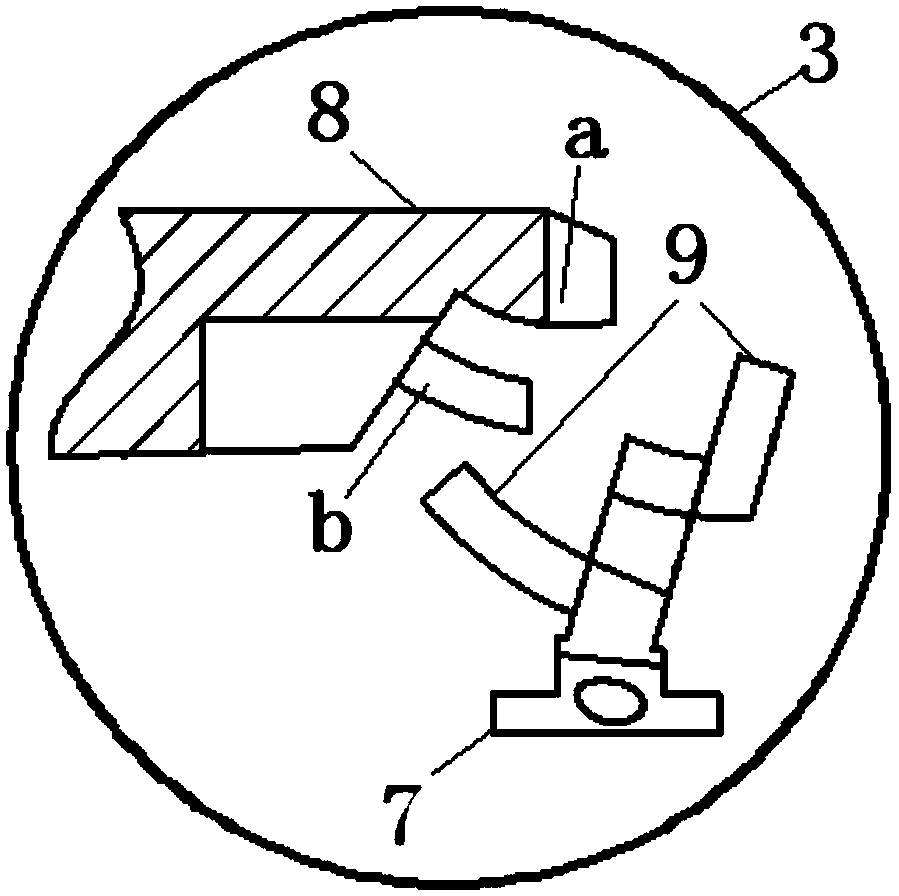

A remote-controlled actuator includes a spindle guide section of an elongated shape, a distal end member fitted to a distal end of the spindle guide section for alteration in attitude and rotatably supporting a tool, and a drive unit housing having a base end of the spindle guide section connected therewith. A rotary shaft for transmitting rotation of a tool rotation drive source within the drive unit housing to the tool and an attitude altering member for altering the attitude of the distal end member by the drive of an attitude altering drive source within the drive unit housing are accommodated within the spindle guide section. A cutting force estimator is provided for estimating the magnitude of at least one component force of a principle force, a radial force and a feed force in a cutting force which the tool applies to a work to be processed.

Owner:NTN CORP

Elastic buffering feeding device of inner diameter slicing machine and feeding method thereof

An elastic buffering feeding device of an inner diameter slicing machine belongs to the device of automatic inner diameter slicing machines. The feeding device comprises a cutting tool driven by a main shaft motor, an X axis travelling table driven by a stepping motor and a Y axis travelling table driven by the stepping motor. The X axis travelling table is arranged above the Y axis travelling table, and a frame for chucking materials is arranged on the X axis travelling table. The present invention is characterized in that an elastic part or an elastic assembly is arranged in a delivery connecting device for controlling shift and force, arranged between the X axis travelling table and the Y axis travelling table. Control feed instantly completed is absorbed by the elastic part or the elastic assembly, so the purpose in elastically buffering feeding force is achieved. The defect that the pulse feeding is directly forced is overcome, the influence of part rigidity variation of cutting materials on cutting quality and cutting efficiency is avoided, and the adoptability of processing parameters to the cutting possibility of materials cut is improved. Thus, cutting speed is improved.

Owner:杨潇

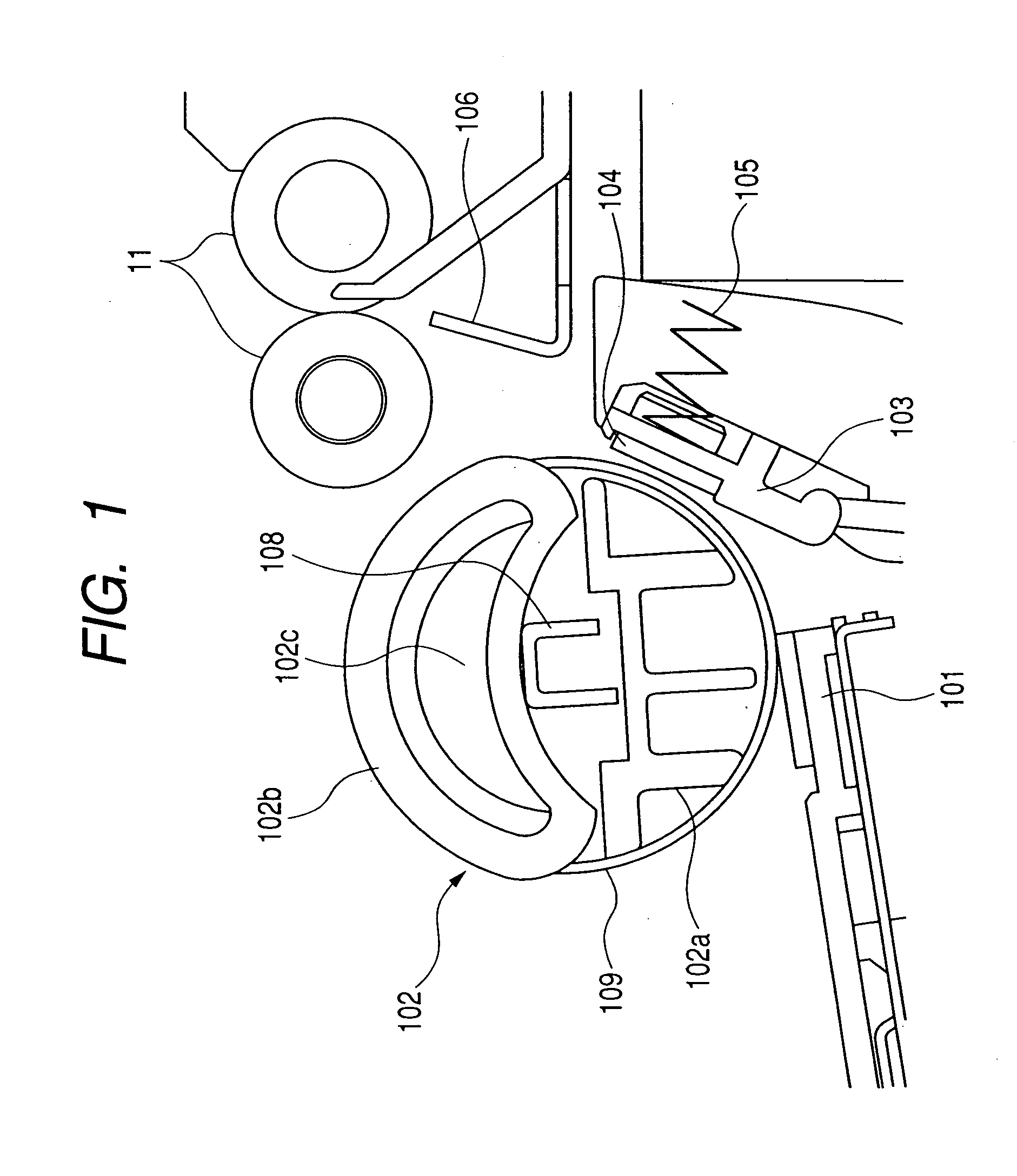

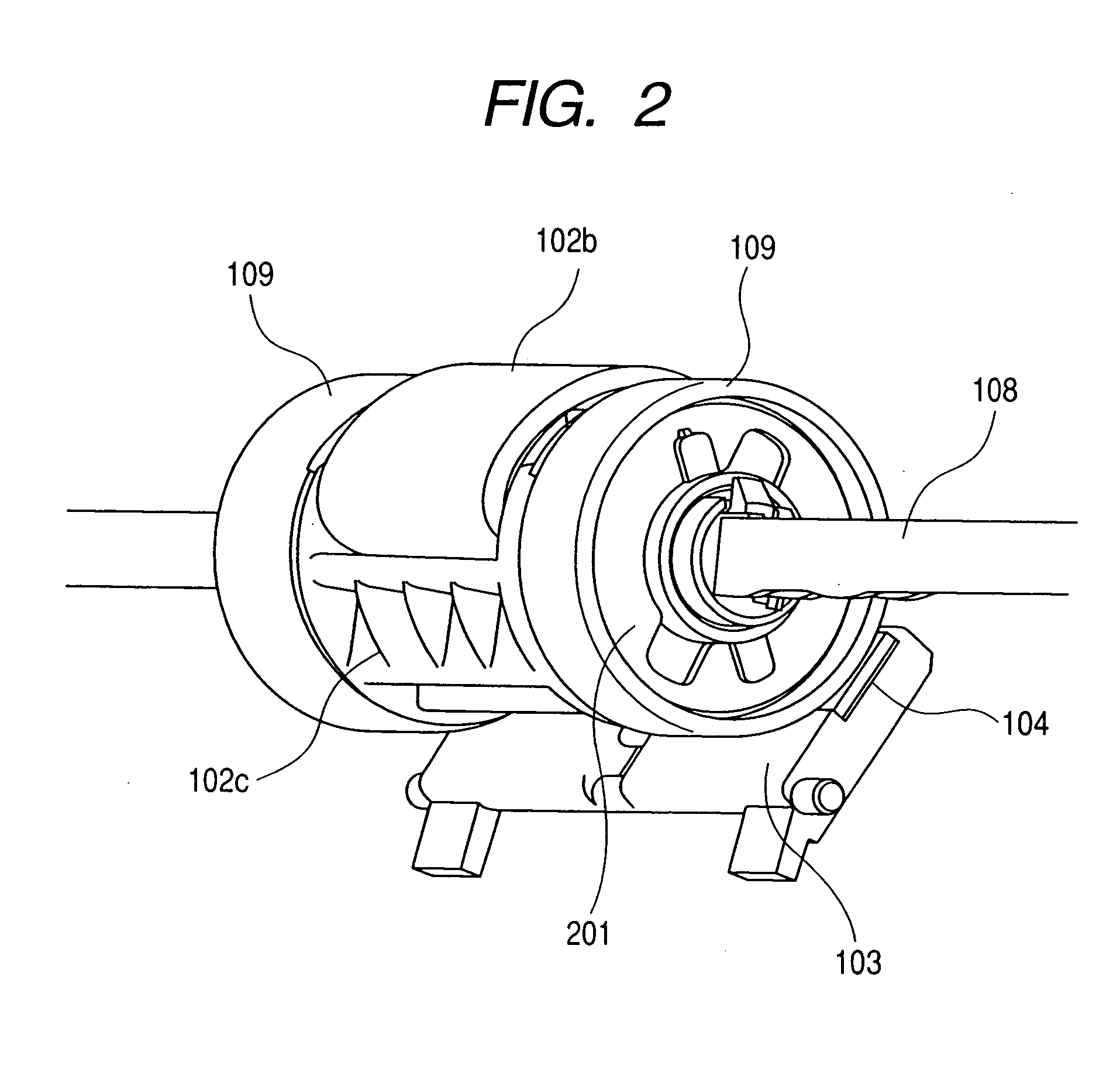

Sheet feeding apparatus and image forming apparatus

ActiveUS20060022396A1Without deteriorating sheet feeding performanceArticle separationFeeding forceEngineering

An apparatus is provided with a feed roller that is rotatable to apply a feeding force on a sheet, a separating pad for pressing the sheet against the feed roller and a roller portion provided coaxially with a support shaft of the feed roller to position the feed roller relative to the separating pad. A damping member for suppressing vibration of the sheet is provided on a side surface of the roller portion to prevent an unusual noise from being generated.

Owner:CANON KK

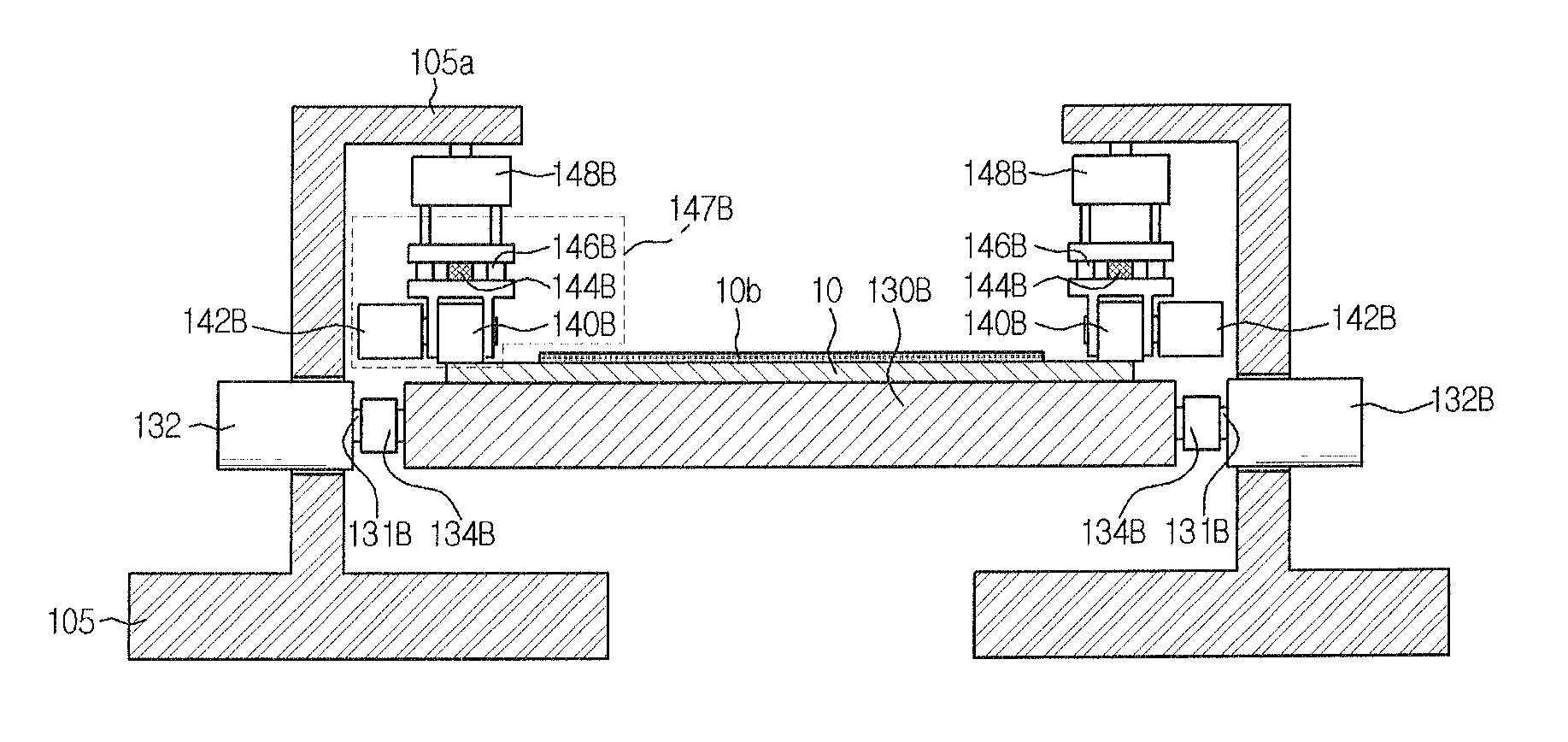

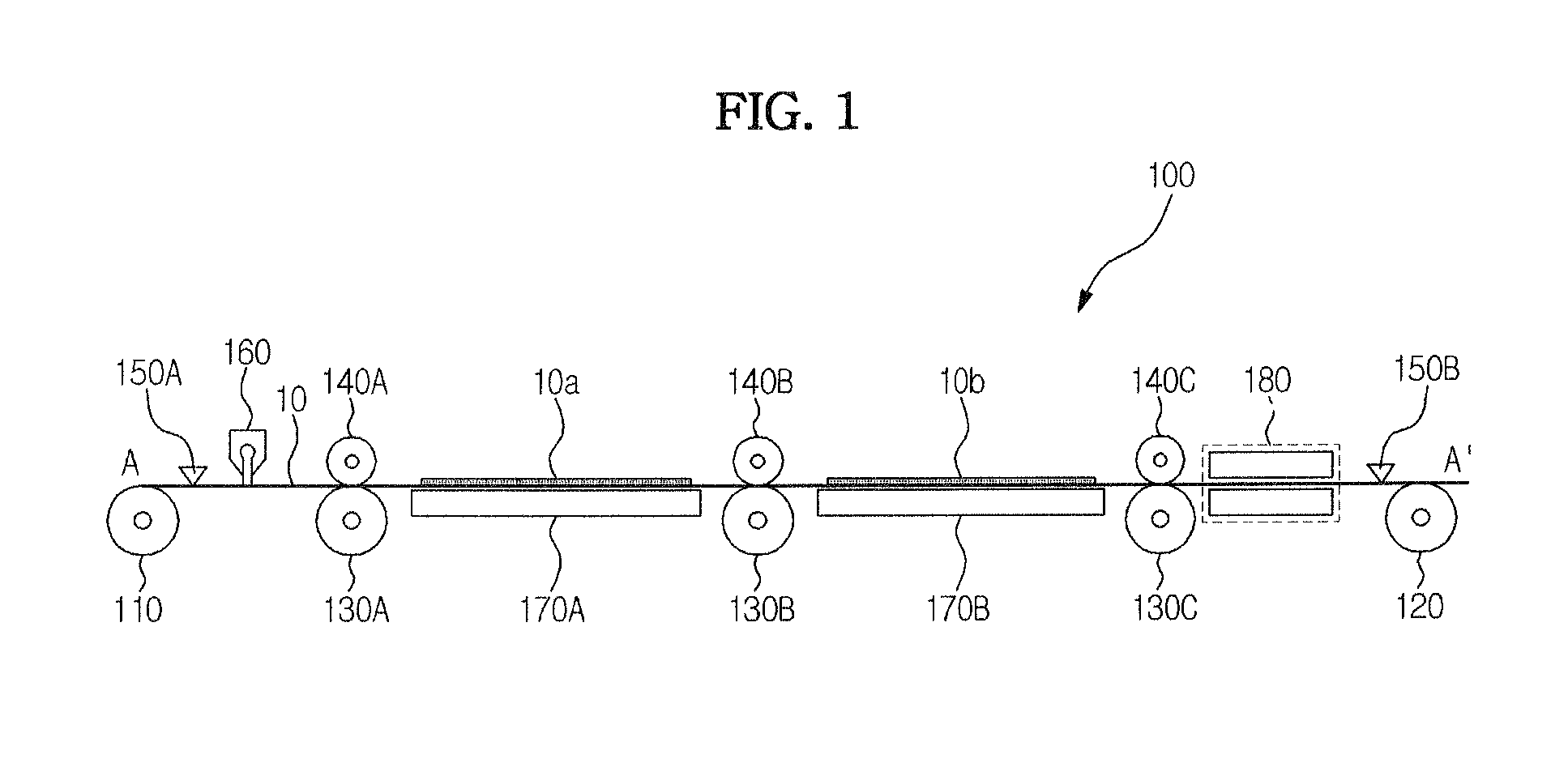

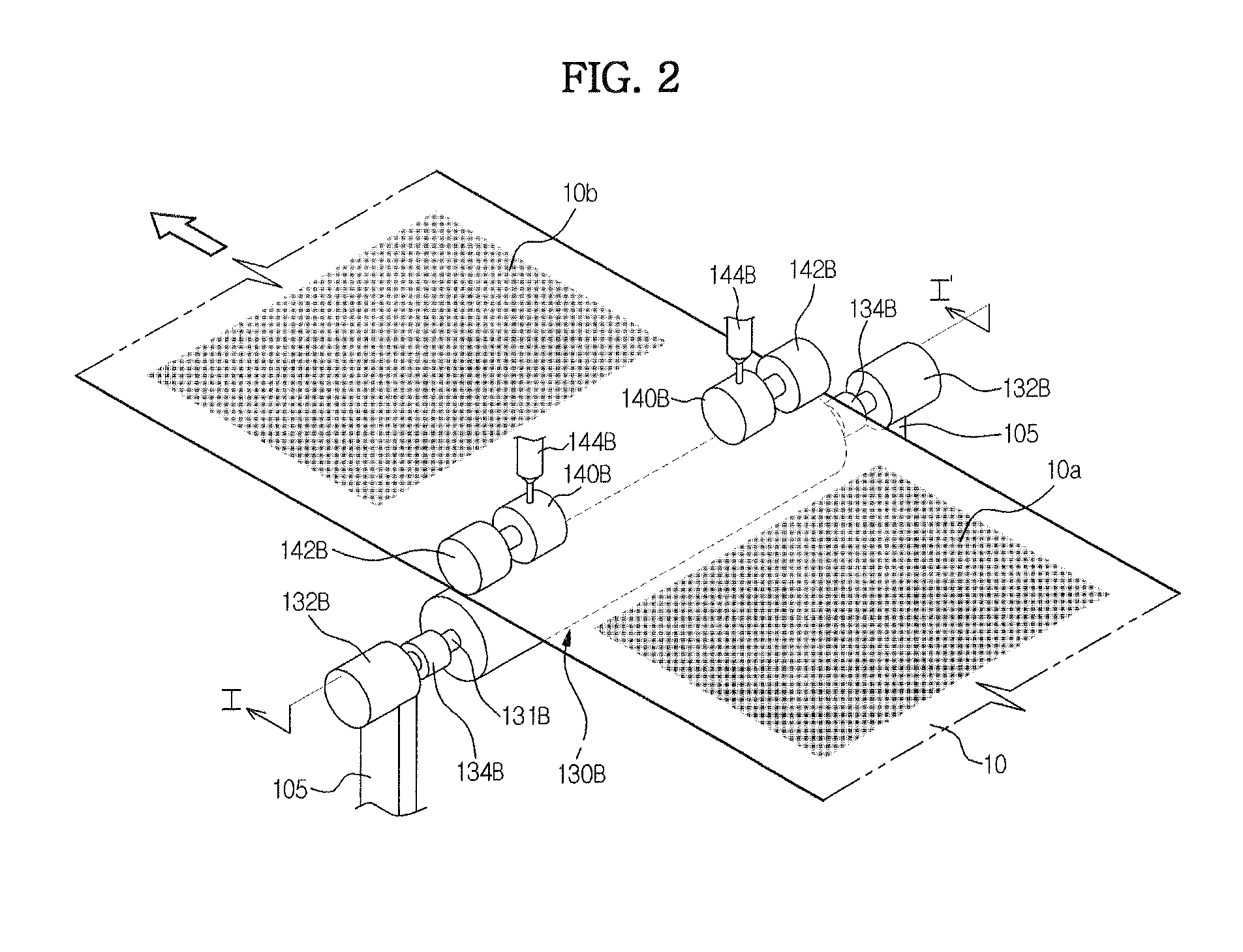

Roll-to-roll printing system

ActiveUS20130042774A1Control tensionFunction indicatorsConductive pattern formationFeeding forceEngineering

A roll-to-roll printing system includes driven rolls to apply a feeding force to a flexible substrate so that the flexible substrate is fed from an unwinder to a rewinder, nip rolls respectively disposed above two opposite end portions of each of the driven rolls to pressurize two opposite side portions of the flexible substrate, nip roll driving motors connected to the nip rolls to rotate the nip rolls, and a control unit to receive information regarding change of torque values of the nip roll driving motors and control tension of the flexible substrate based on the information.

Owner:SAMSUNG ELECTRONICS CO LTD

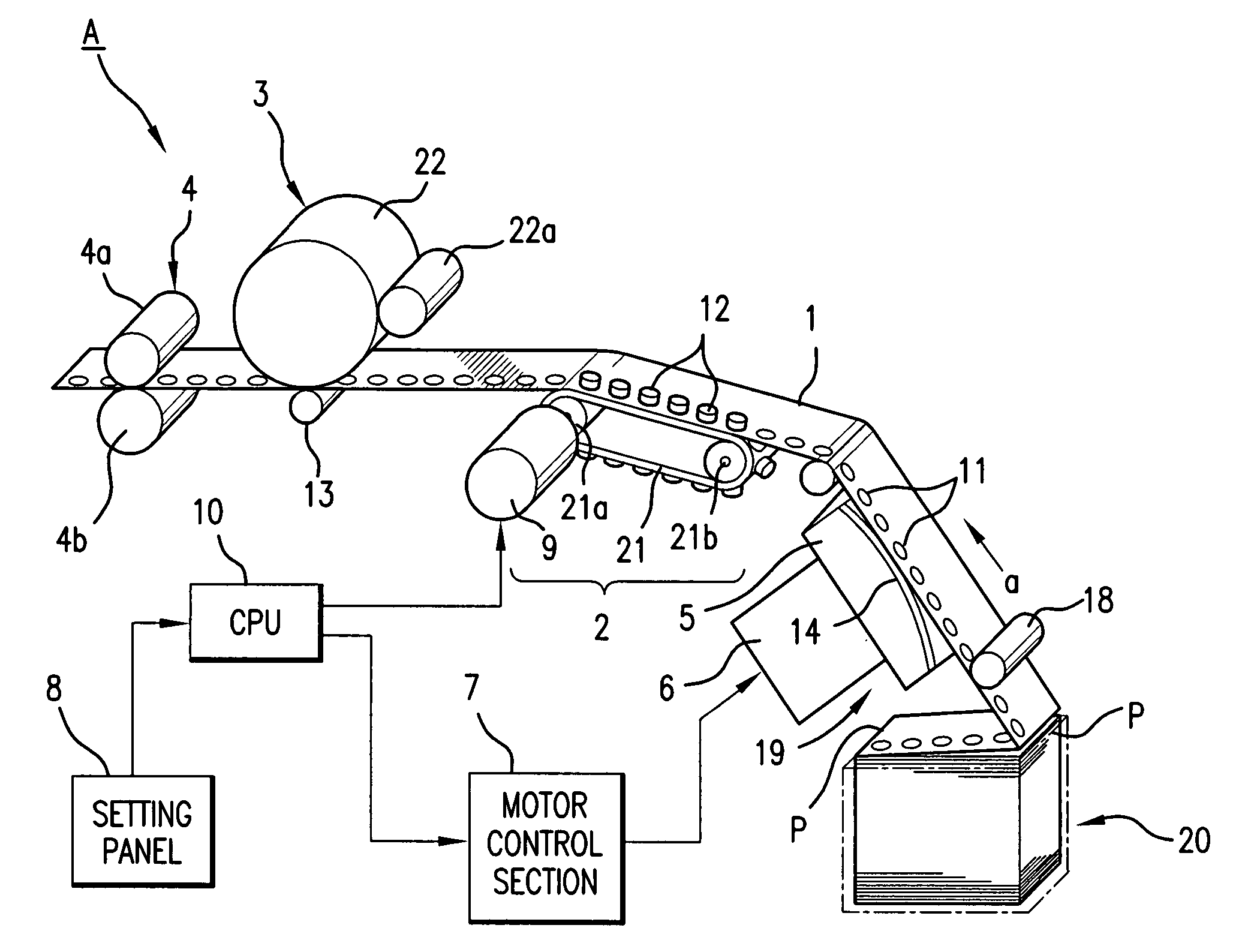

Continuous paper feeding device and printer incorporating the same

InactiveUS20050230448A1High feed accuracyBreakage problemFunction indicatorsOther printing apparatusFeeding forcePaper sheet

A tractor feeds a perforated continuous paper sheet to a printing position. The feeding force of a fusing device located downstream of the printing position is set larger than the feeding force of the tractor in order to apply tension to the continuous paper sheet at the printing position. A braking device located upstream of the tractor applies a braking force balancing with the feeding force of the fusing device to the continuous paper sheet. The braking force of the braking device is varied depending upon the properties of the paper sheet or the environmental conditions. This arrangement makes it possible to stabilize the feeding state even under situations where the sheet feeding force is likely to become unstable, thereby realizing printing without any deviation from the predetermined position. Further, this arrangement can also prevent hole breakage to occur.

Owner:MINOLTA CO LTD

Method And Apparatus For Controlling Rock Drilling

ActiveUS20120097449A1Controlling the drilling effectively and automaticallyDrilling rodsConstructionsFeeding forceControl valves

Method and apparatus for controlling rock drilling with a percussion device belonging to a rock drill to deliver stress waves to rock through a tool by pushing the tool against the rock by means of a feed motor and rotating simultaneously the tool by means of a rotation motor, whereby the maximum feed force is determined, pressure medium is supplied to the feed motor and to the rotation motor and the feed force is controlled according to the drilling conditions. The feed force is controlled on the basis of the feed speed and the rotation torque. The apparatus has a load control valve which controls the feed.

Owner:SANDVIK MINING & CONSTR OY

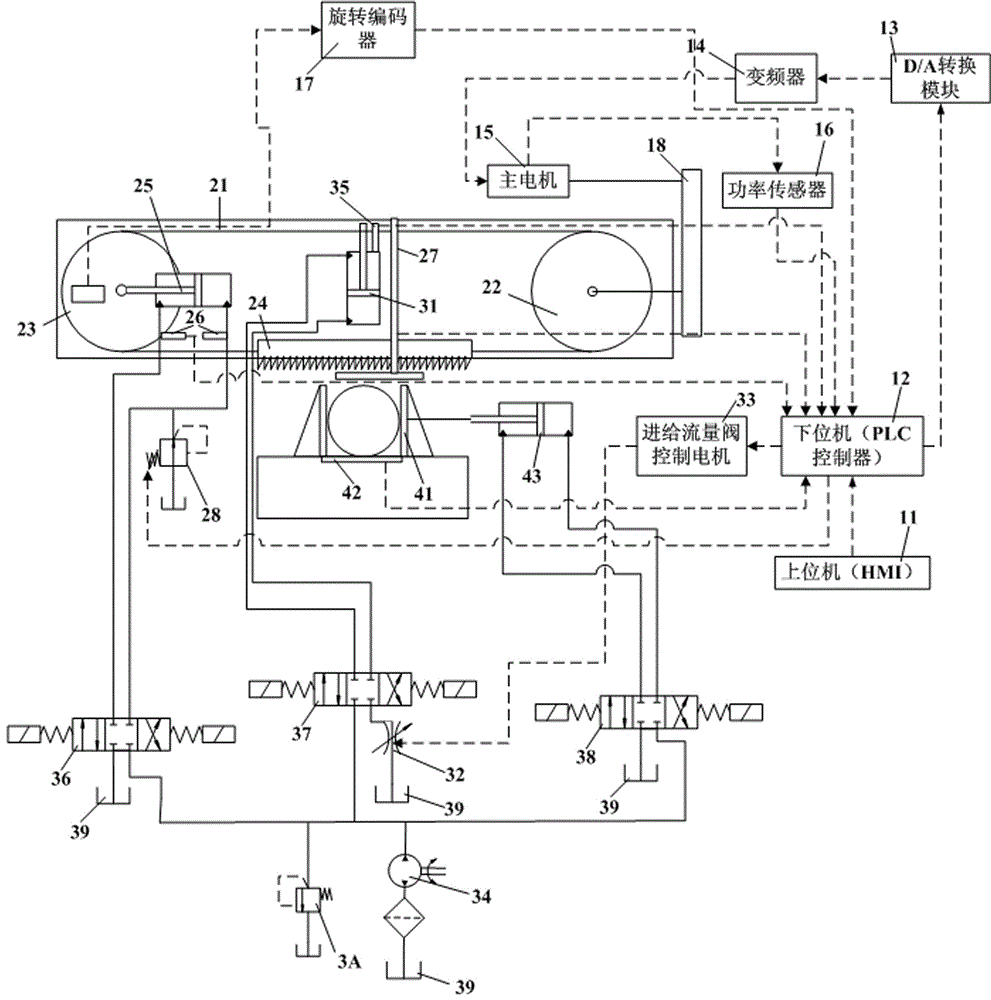

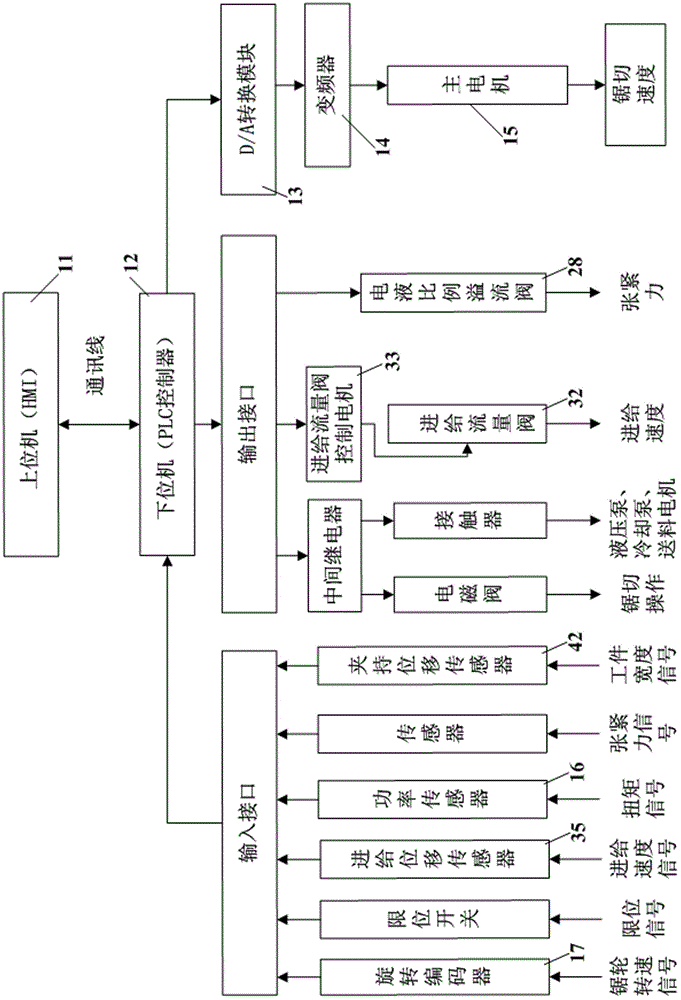

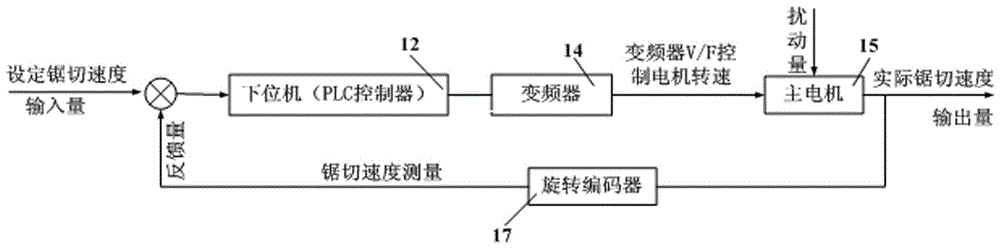

Band sawing machine constant power sawing control method and intelligent band sawing machine thereof

ActiveCN105033352ARealize intelligent sawingThe actual power used is constantMetal sawing devicesPower sensorFrequency changer

The invention relates to a band sawing machine constant power sawing control method and an intelligent band sawing machine thereof; the intelligent band sawing machine comprises a control system, a saw frame system, a feeding system and a clamp mechanism; a rotary encoder is arranged on a rotary shaft of a driven saw wheel, and rotary speed of the driven saw wheel is detected in real time; a power sensor detects a frequency converter feedback current, and the current value is sent to a lower computer through the rotary encoder; the lower computer collects the rotary speed and torque data of a main motor, uses a feeding flow valve control motor to adjust the opening of the feeding flow valve, thus changing lifting speed of an oil cylinder piston rod; the lower computer can adjust the pressure of an electric-hydraulic proportional overflow valve through sensor feedbacks, thus controlling tensile force of a tensioning oil cylinder. The power of the driving main motor is fully used, sawing condition influences on the saw blade life and different material feeding force limit conditions are considered, thus realizing intelligent sawing of the band sawing machine, and effectively prolonging fatigue life of the saw blade.

Owner:ZHE JIANG CHENLONG SAWING MACHINE CO LTD

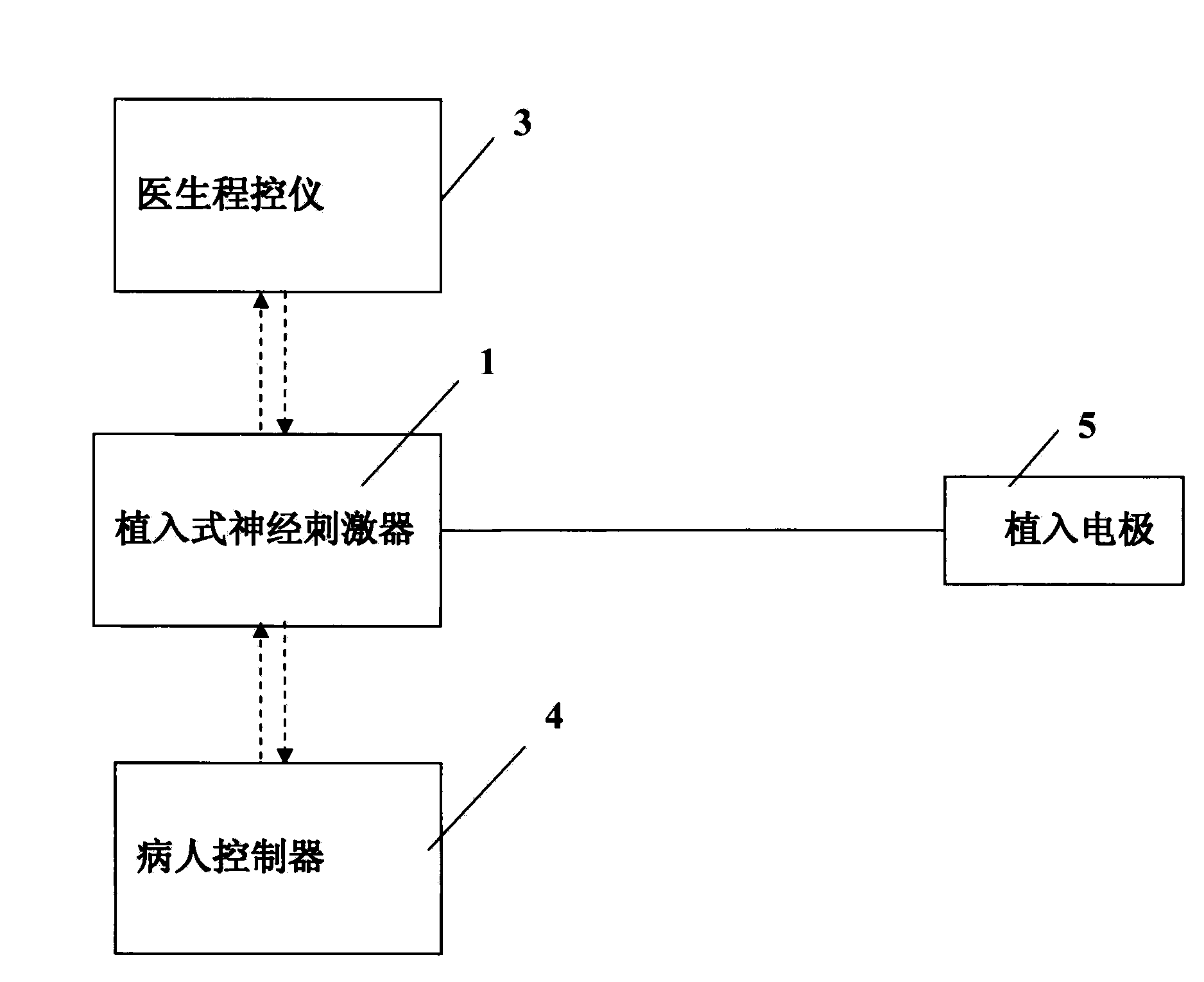

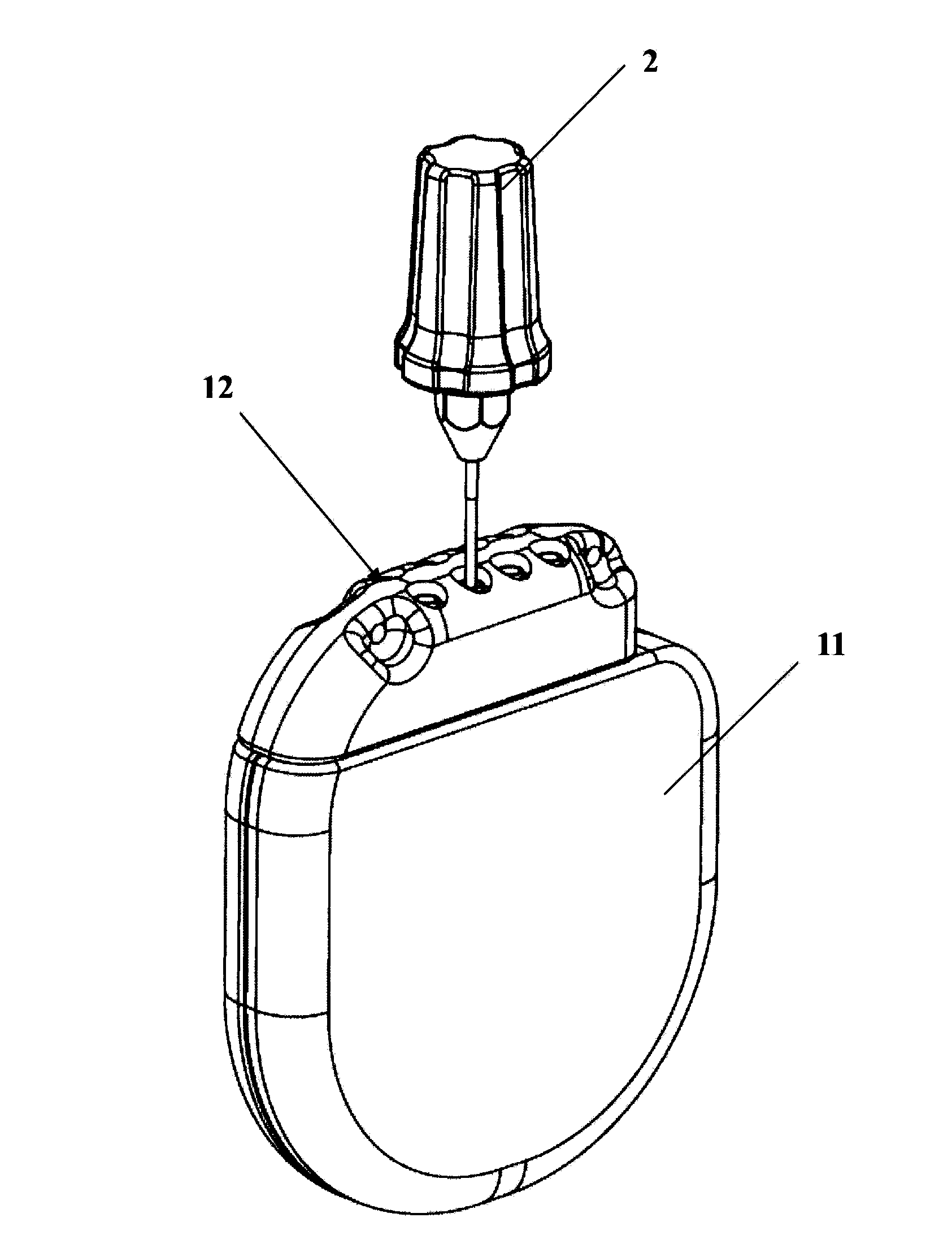

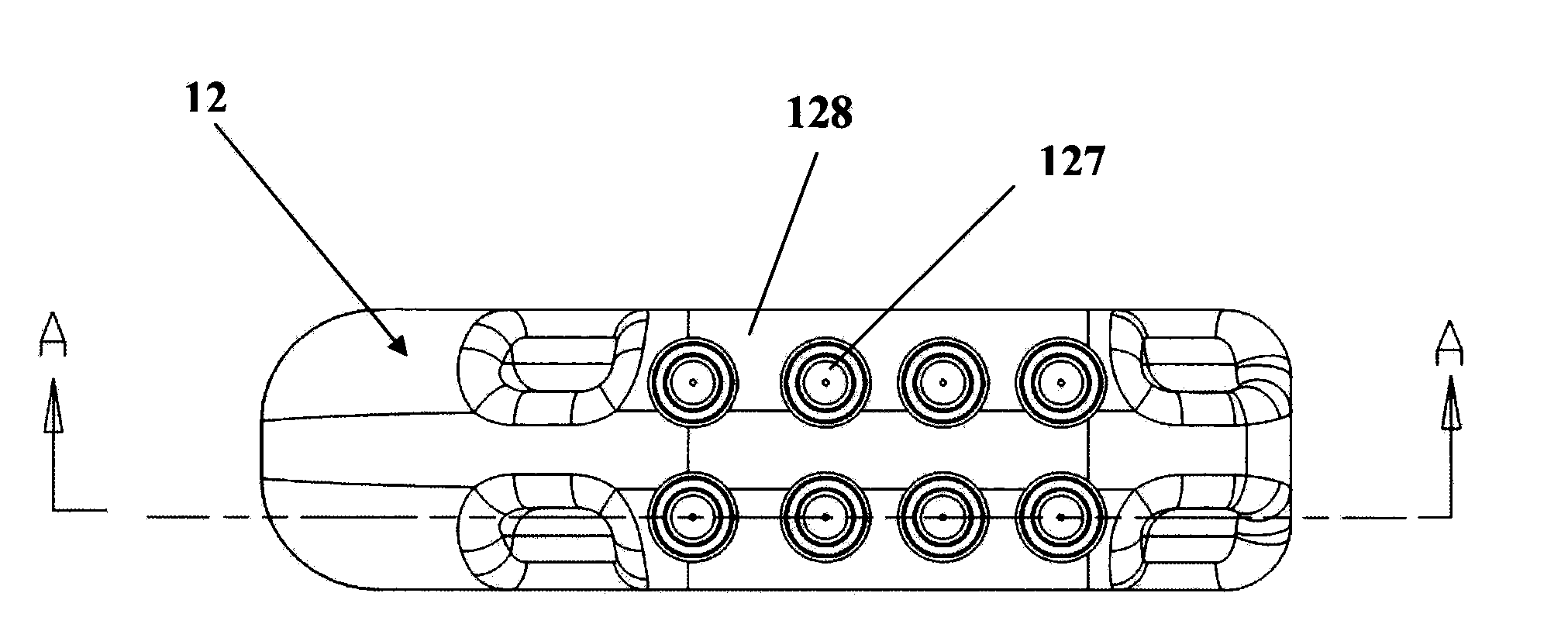

Implantable medical device and system with structure for preventing screw-out of screws

ActiveCN103893911AUnscrew will notThe reduce function is brokenElectrotherapyMedical devicesFeeding forceScrew thread

The invention discloses an implantable medical device with a structure for preventing screw-out of screws. The device includes a shell, a battery and a circuit board both arranged in the shell, and a connecting head hermetically connected with the shell. The connecting head includes a plurality of connecting blocks, a wireless communication antenna and a sealing filler. The connecting blocks are radially provided with screw holes which are in communication with connecting holes. Screws for pressing connection of conductive rings on line traps are arranged in the screw holes. A screw thread on an end part, close to a corresponding water seal part, of each screw, is filled with the filler covered by threads. When a doctor reversely operates, the screws only apply a downward push-out force to the water seal parts and do not apply any upward spiral feeding force. The lengths of joint cuttings arranged in the water seal parts are smaller than the outer diameters of the corresponding screws so that even if the screws are completely screwed out of the connecting blocks, the screws do not pass through the joint cuttings in the water seal parts. Therefore, the probability that the water seal parts are damaged in function because of misoperation of the doctor is reduced. The invention also discloses a medical system including the implantable medical device.

Owner:SCENERAY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com