Patents

Literature

4226results about "Recording apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Printer and ink cartridge attached thereto

InactiveUS6631967B1Low costExtra processingRecording apparatusPower drive mechanismsComputer printingEngineering

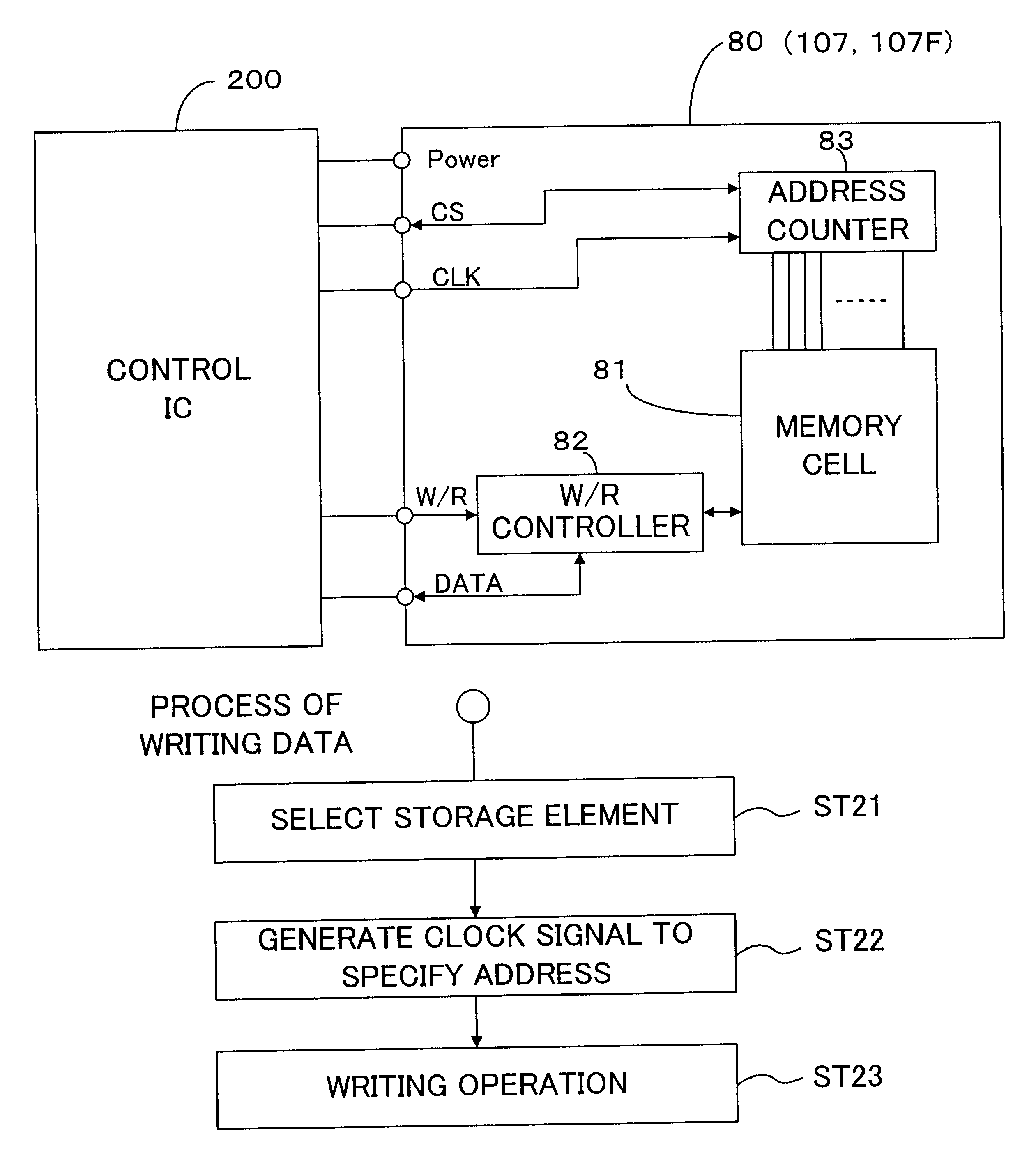

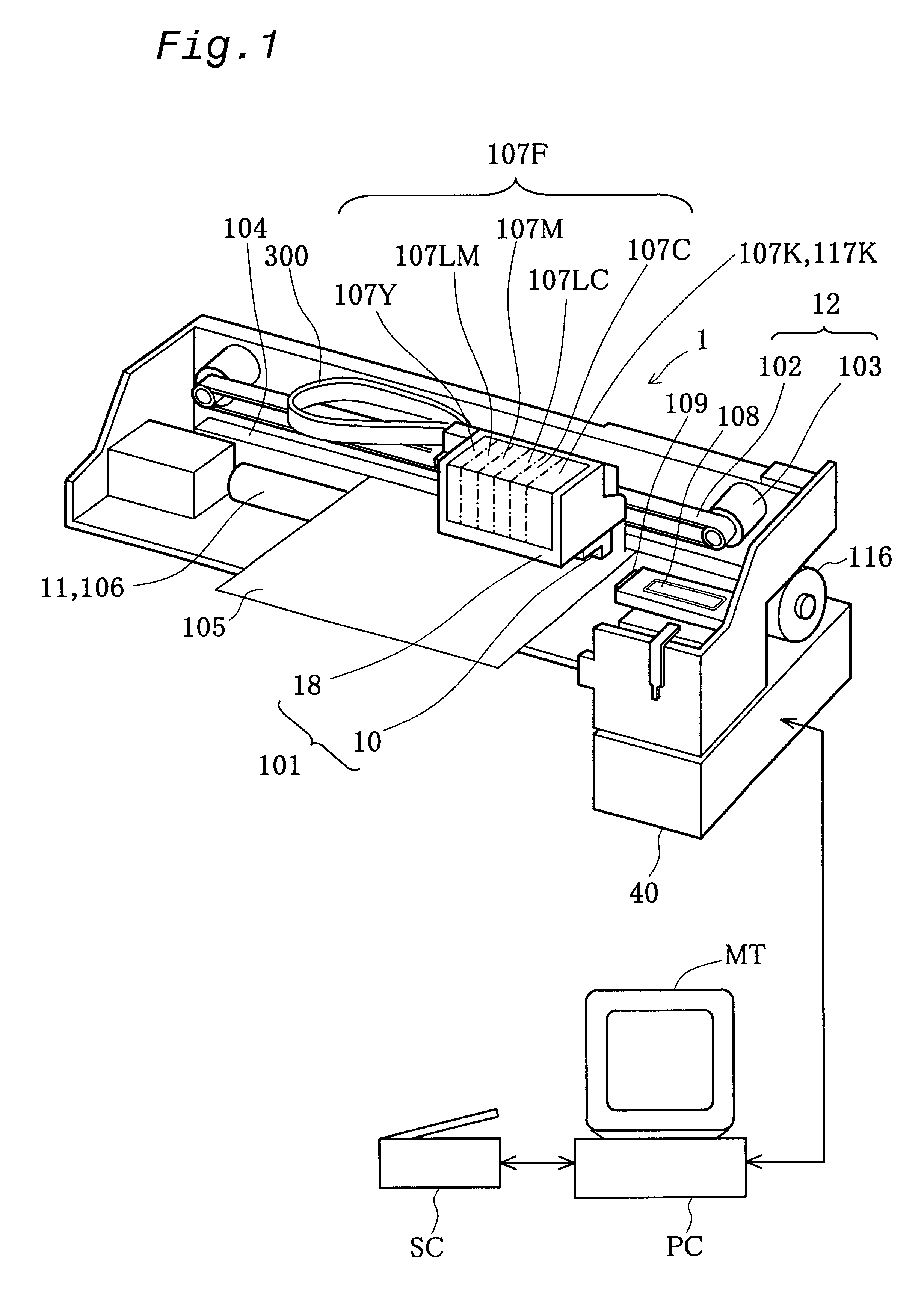

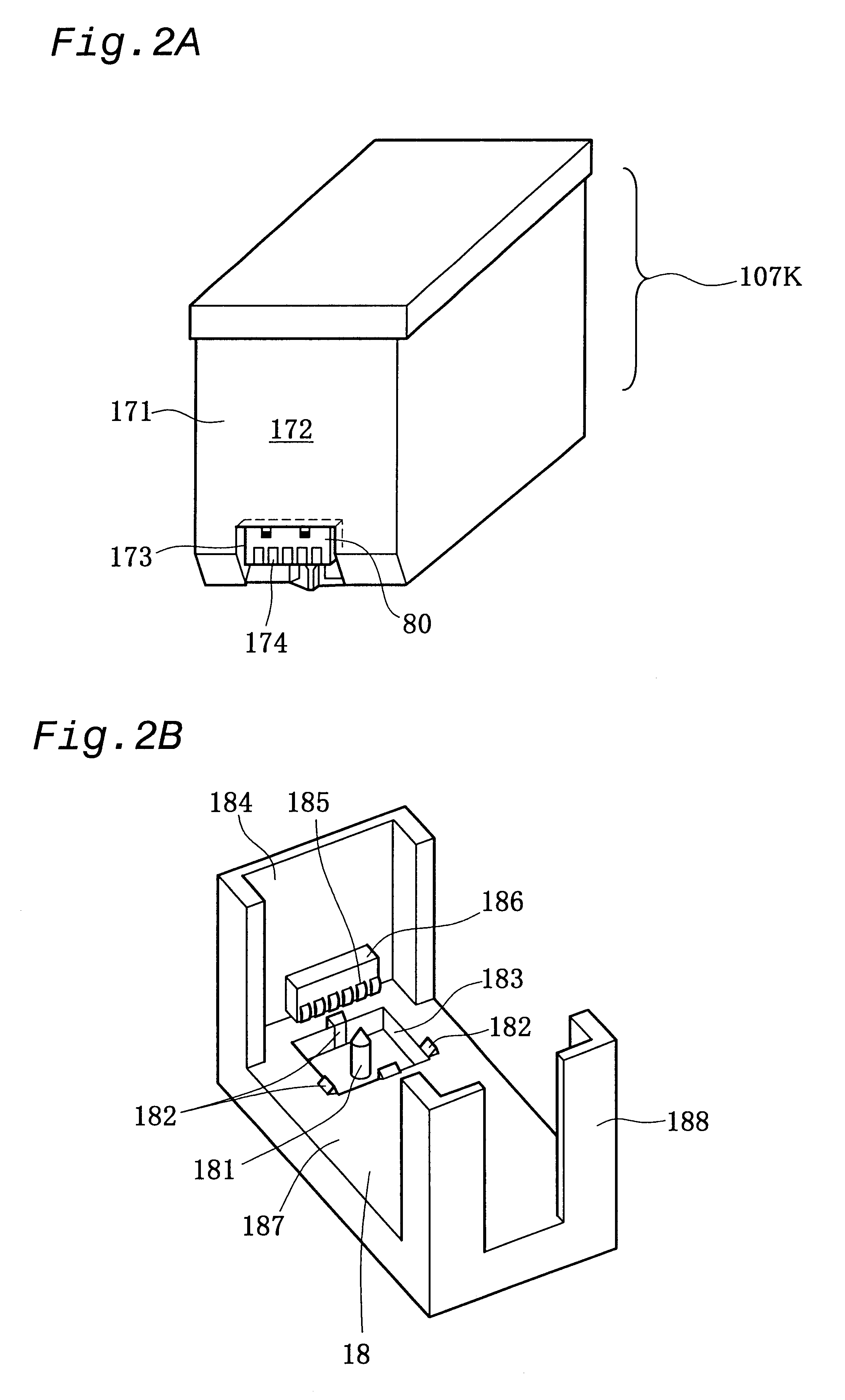

In a printer of the present invention, an EEPROM that carries out sequential access and has a relatively small storage capacity is applied for storage elements mounted on both black and color ink cartridges, which are detachably attached to the printer. Pieces of information relating to each ink cartridge, for example, pieces of information on remaining quantities of respective inks in the ink cartridge, are stored in the storage element of the ink cartridge. A format of addressing adopted in the storage elements of the ink cartridges Is different from that adopted in an EEPROM incorporated in a printer main body of the printer. A control IC provided in the printer accordingly converts the storage format of addressing, before writing the information into the storage elements of the ink cartridges. In the printer, a RAM is mounted with the control IC on a carriage, and the pieces of information to be written Into the storage elements of the ink cartridges are temporarily registered in the RAM. The pieces of information are then written into the respective storage elements of the black and color ink cartridges, for example, at a timing of a powe-off operation. The signal lines and the memory used in the course of writing the information into the storage elements are identical with the signal lines, through which print data are transmitted to a print head mounted on the carriage of the printer, and the memory, in which the print data are stored. The arrangement of the present invention reduces the manufacturing cost of the ink cartridge and also enables size reduction of the whole printer.< / PTEXT>

Owner:SEIKO EPSON CORP

Manufacturing method of ink jet head

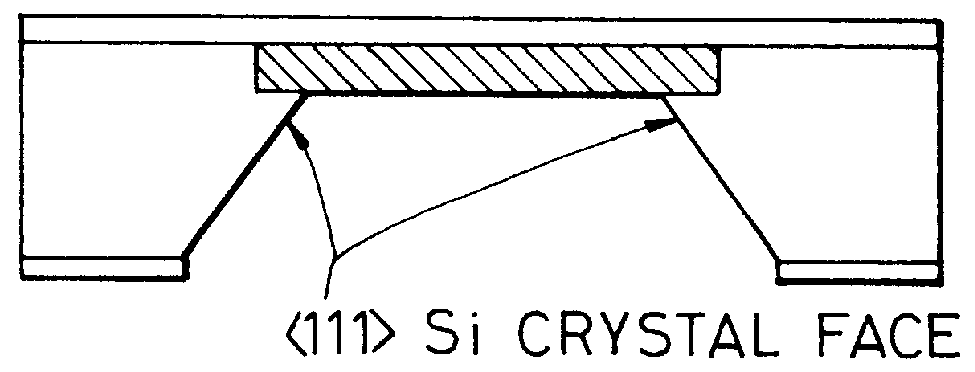

InactiveUS6139761ADistanceSimple processRecording apparatusSemiconductor/solid-state device manufacturingPressure generationSilicon oxide

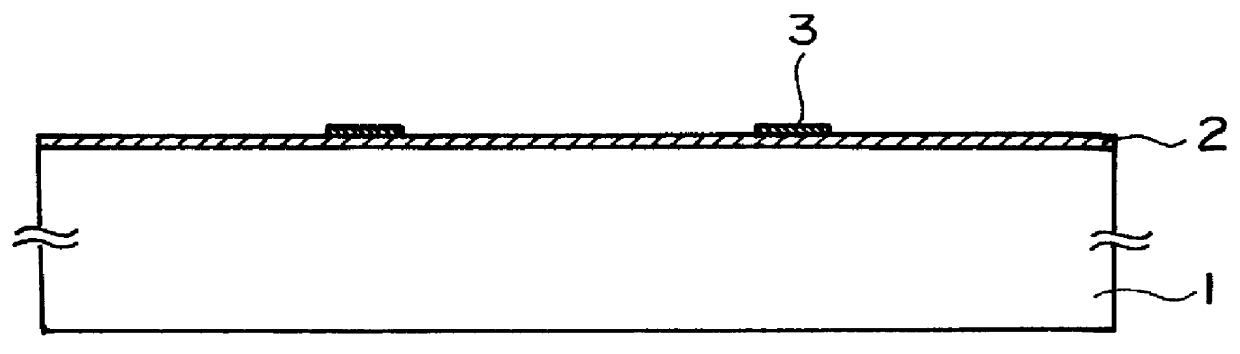

A manufacturing method for an ink jet head having an ink ejection pressure generation element for generating energy for ejecting ink, and an ink supply port for supplying the ink to an ink jet head, including the steps of preparing a silicon substrate; forming, on a surface of the silicon substrate, the ink ejection pressure generation element and silicon oxide film or silicon nitride film; forming anti-etching mask for forming an ink supply port on a back side of the silicon substrate; removing silicon on the back side of the silicon substrate at a position corresponding to the ink supply port portion through anisotropic etching; forming an ink ejection portion on a surface of the silicon substrate; and removing the silicon oxide film or silicon nitride film from the surface of the silicon substrate of the ink supply port portion.

Owner:CANON KK

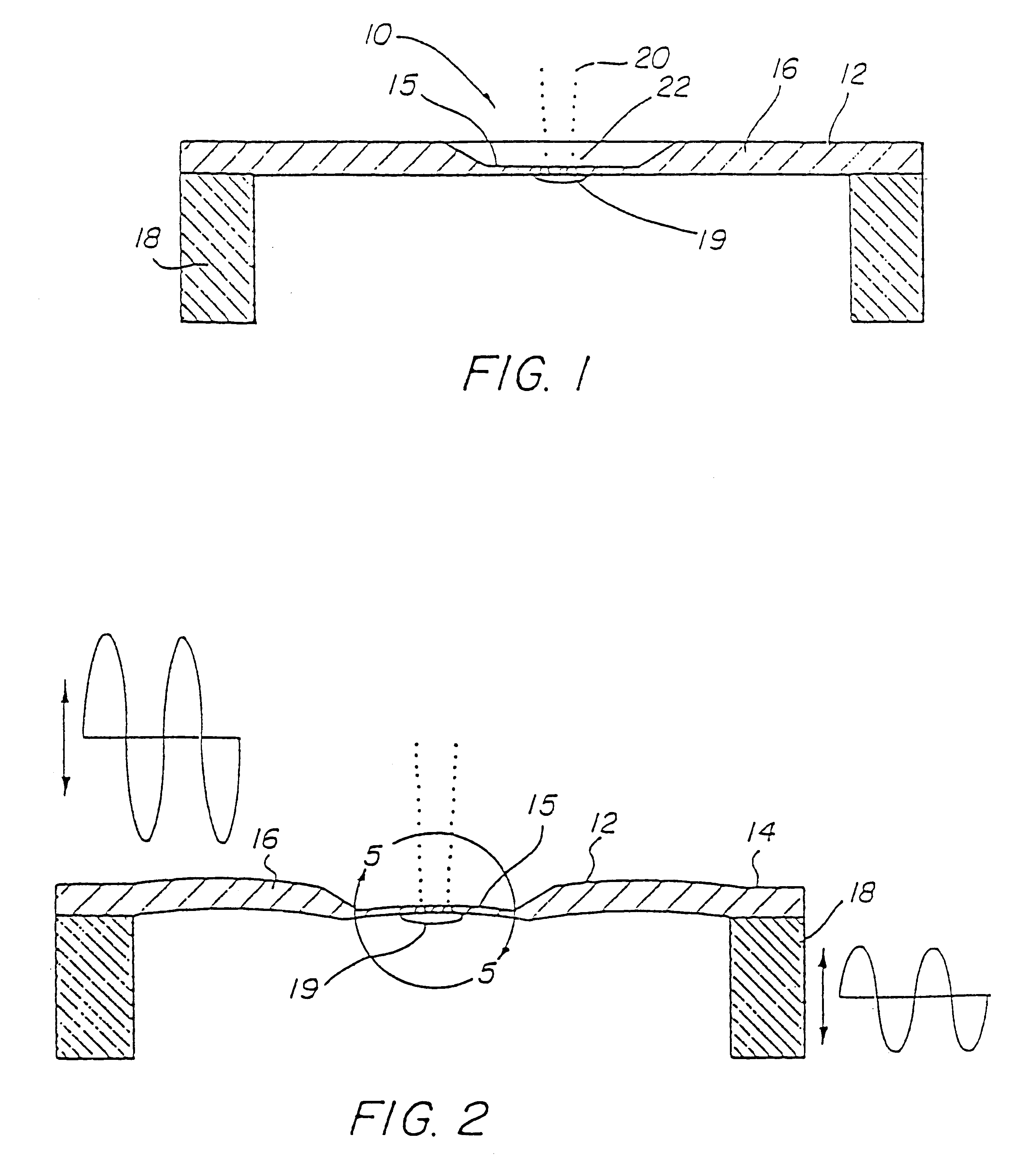

Method of producing a through-hole, silicon substrate having a through-hole, device using such a substrate, method of producing an ink-jet print head, and ink-jet print head

The invention provides a method of producing a through-hole, a substrate used to produce a through-hole, a substrate having a through-hole, and a device using such a through-hole or a substrate having such a through-hole, which are characterized in that: a through-hole can be produced only by etching a silicon substrate from its back side; the opening length d can be precisely controlled to a desired value regardless of the variations in the silicon wafer thickness, and the orientation flat angle, and also regardless of the type of a silicon crystal orientation-dependent anisotropic etchant employed; high productivity, high production reproducibility, and ease of production can be achieved; a high-liberality can be achieved in the shape of the opening end even if temperature treatment is performed at a high temperature for a long time; and a high-precision through-hole can be produced regardless of the shape of a device formed on the surface of a substrate.

Owner:CANON KK

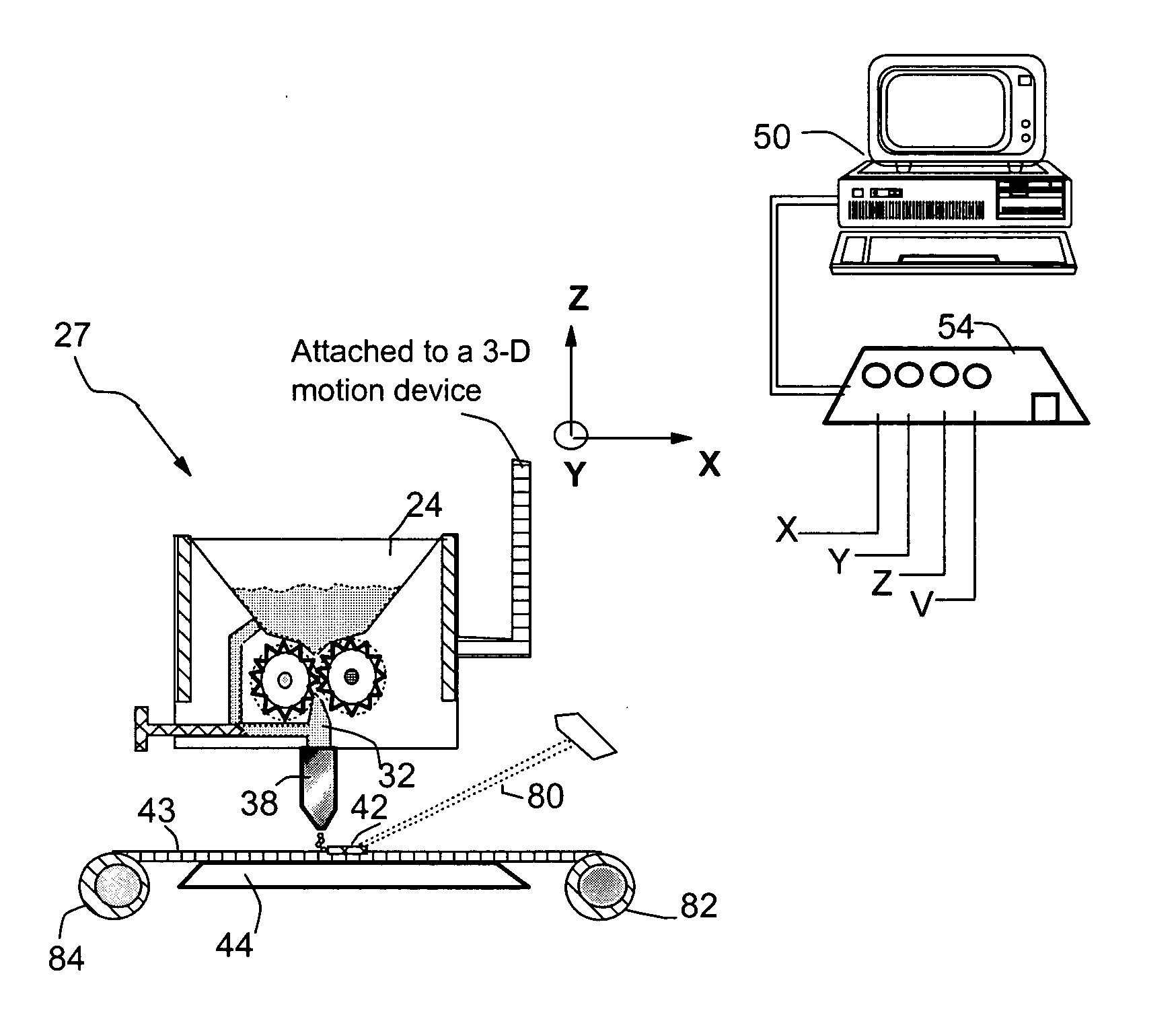

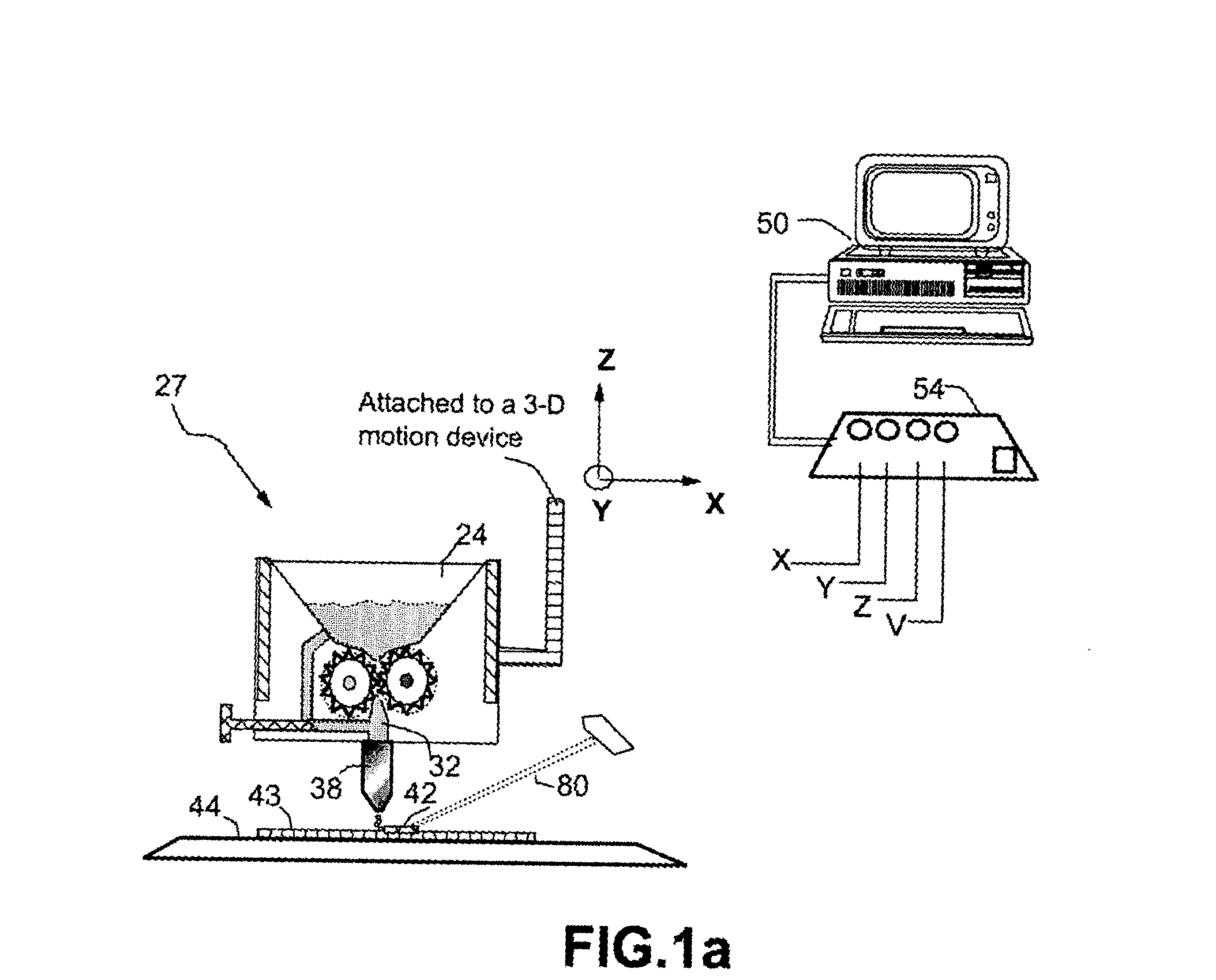

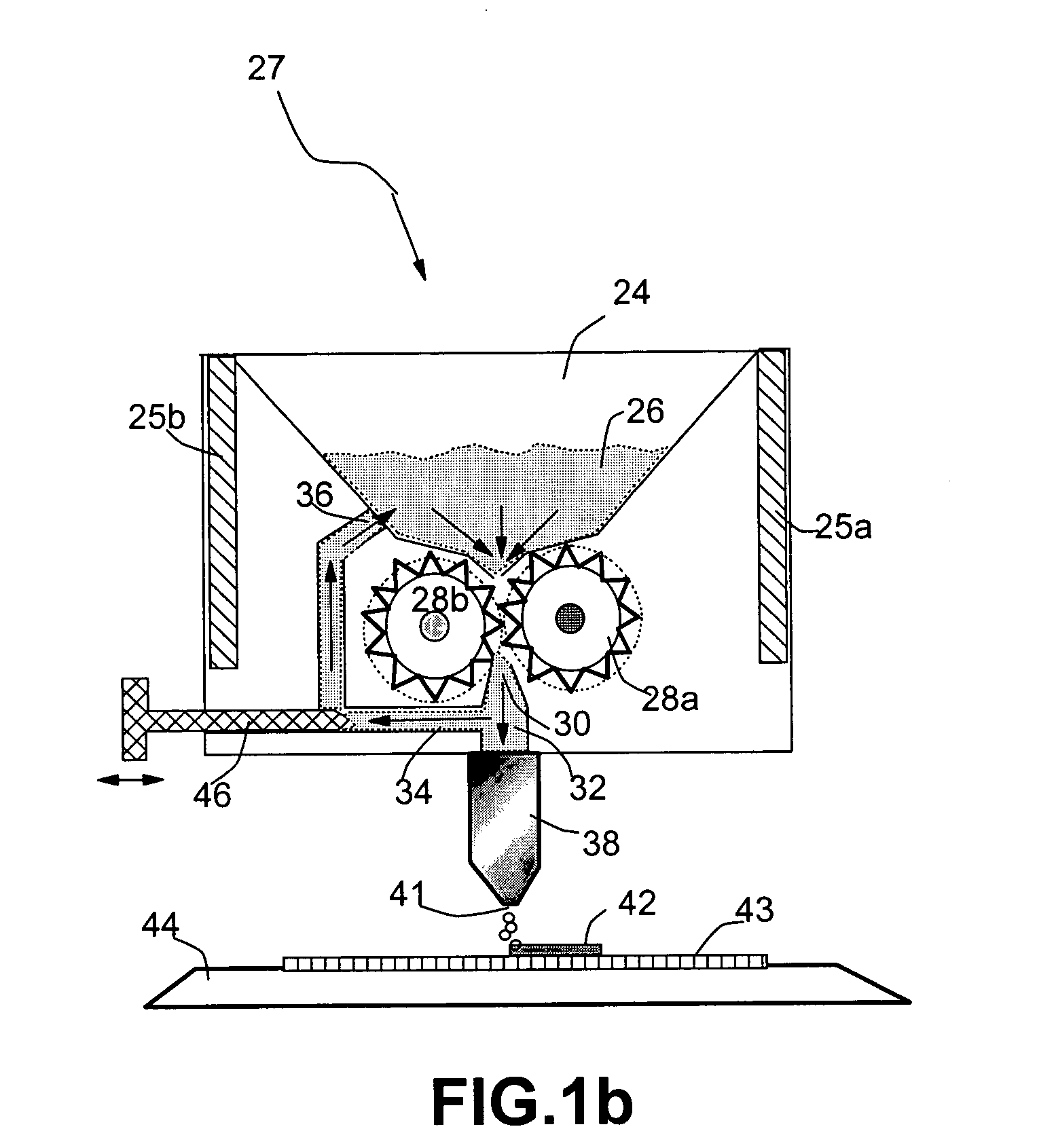

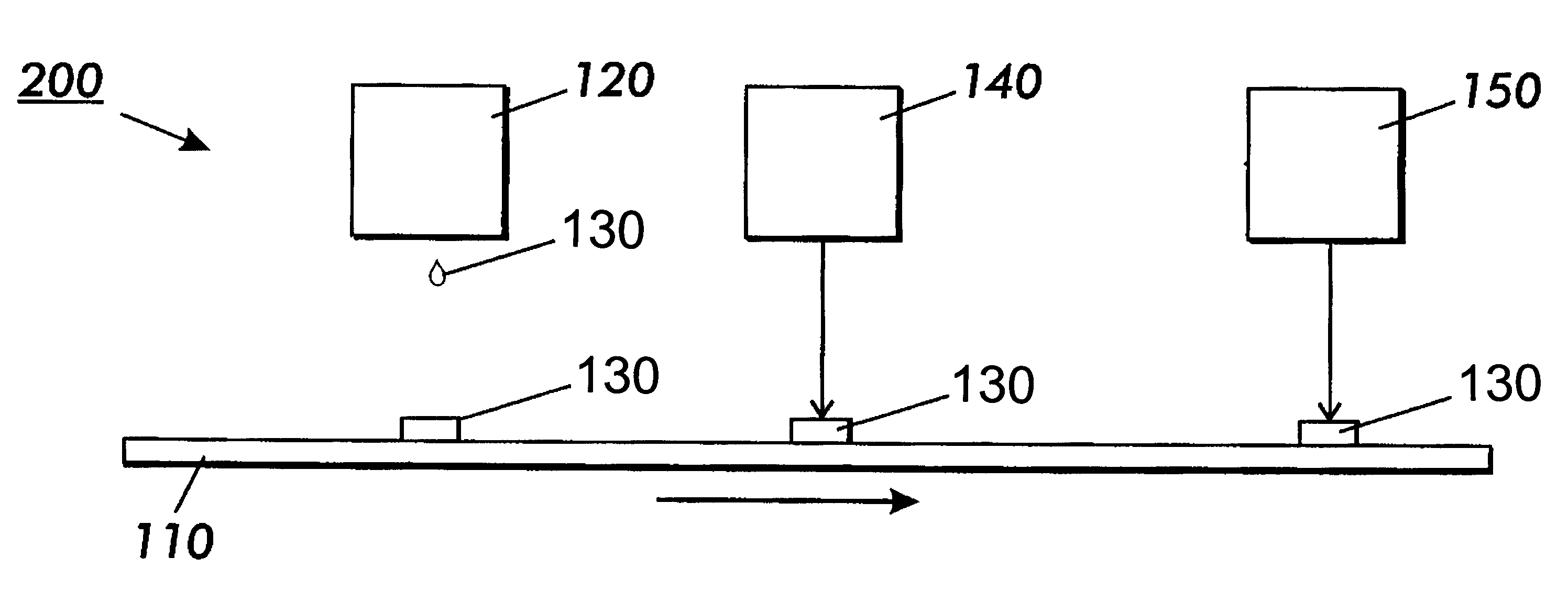

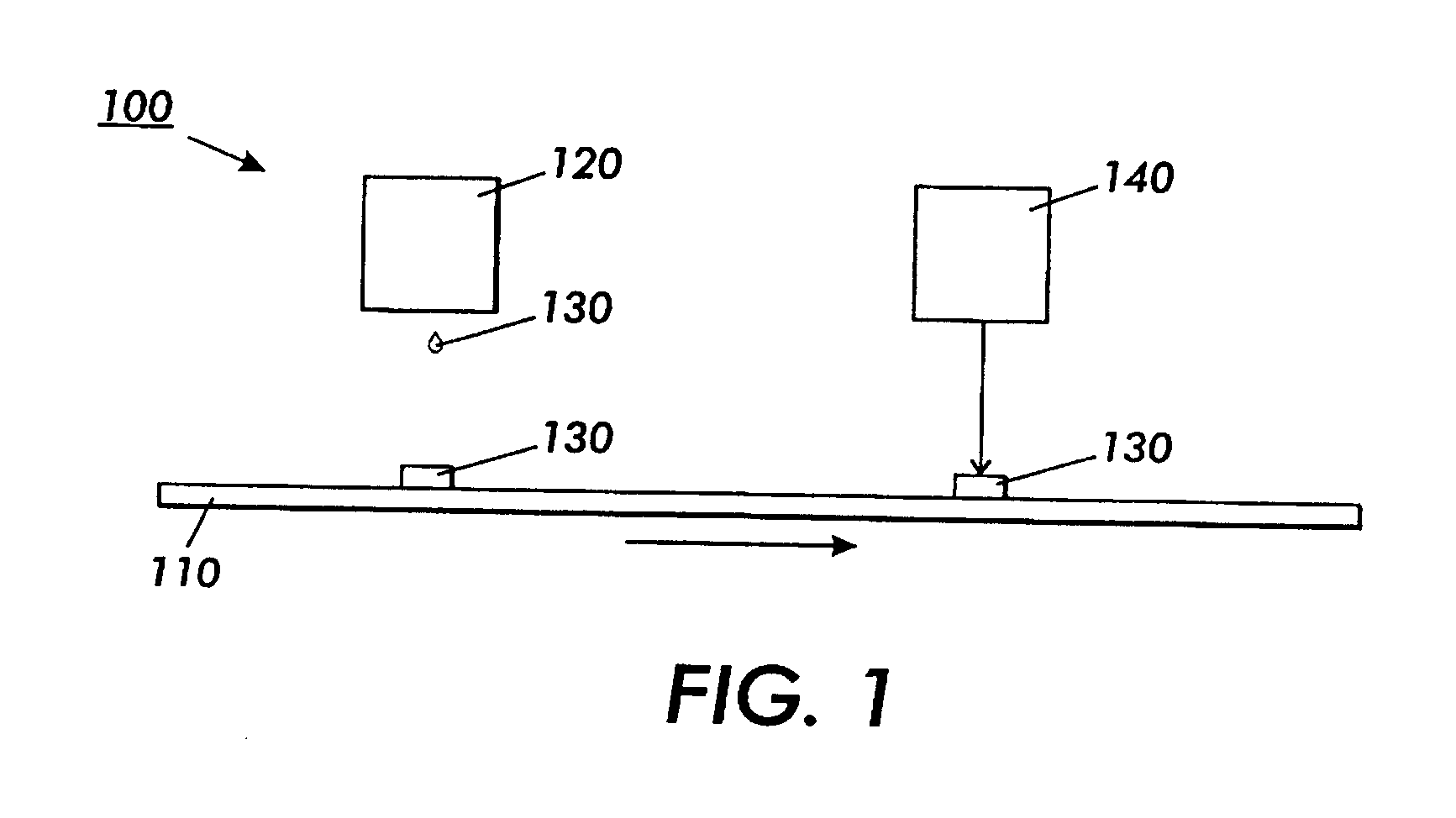

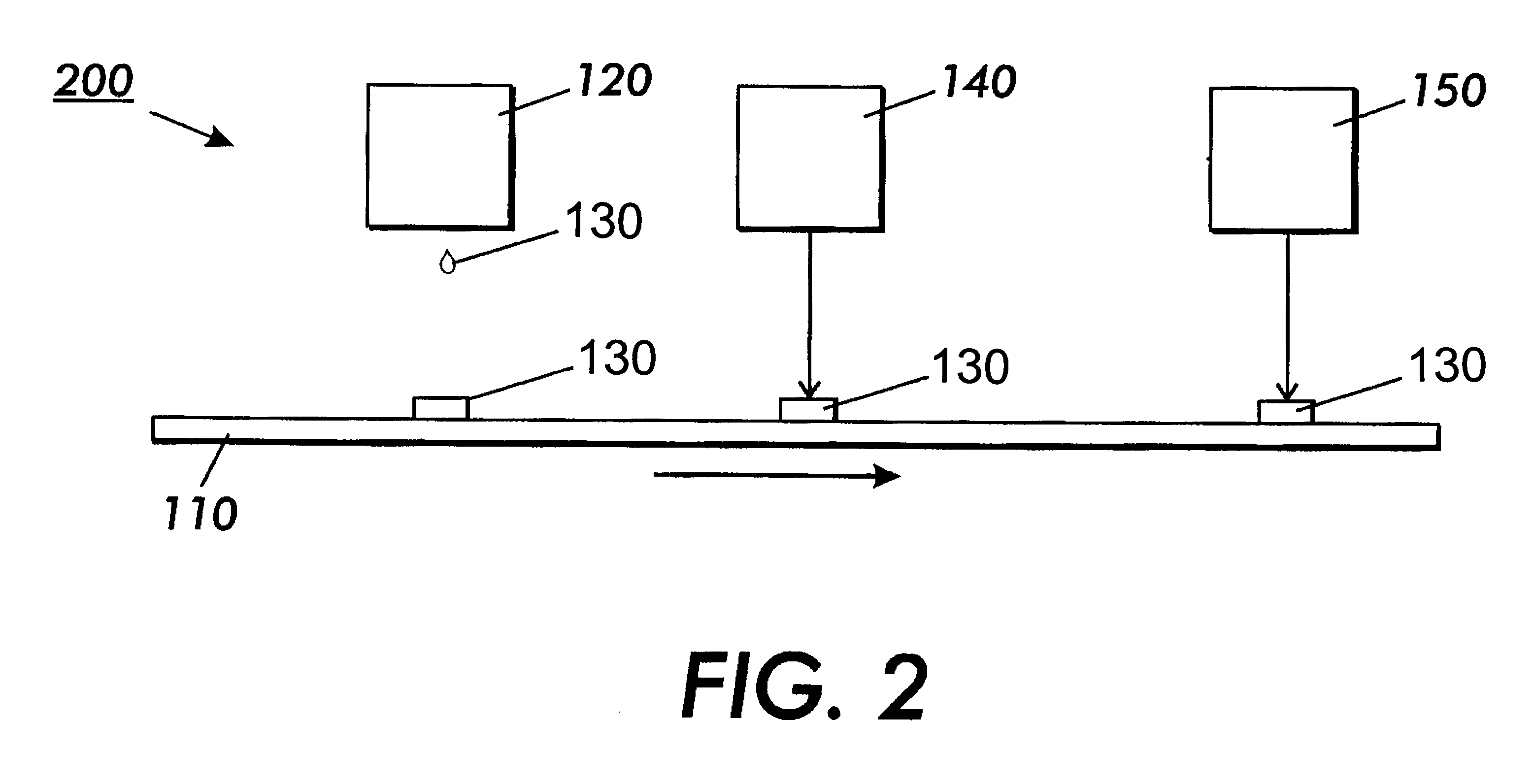

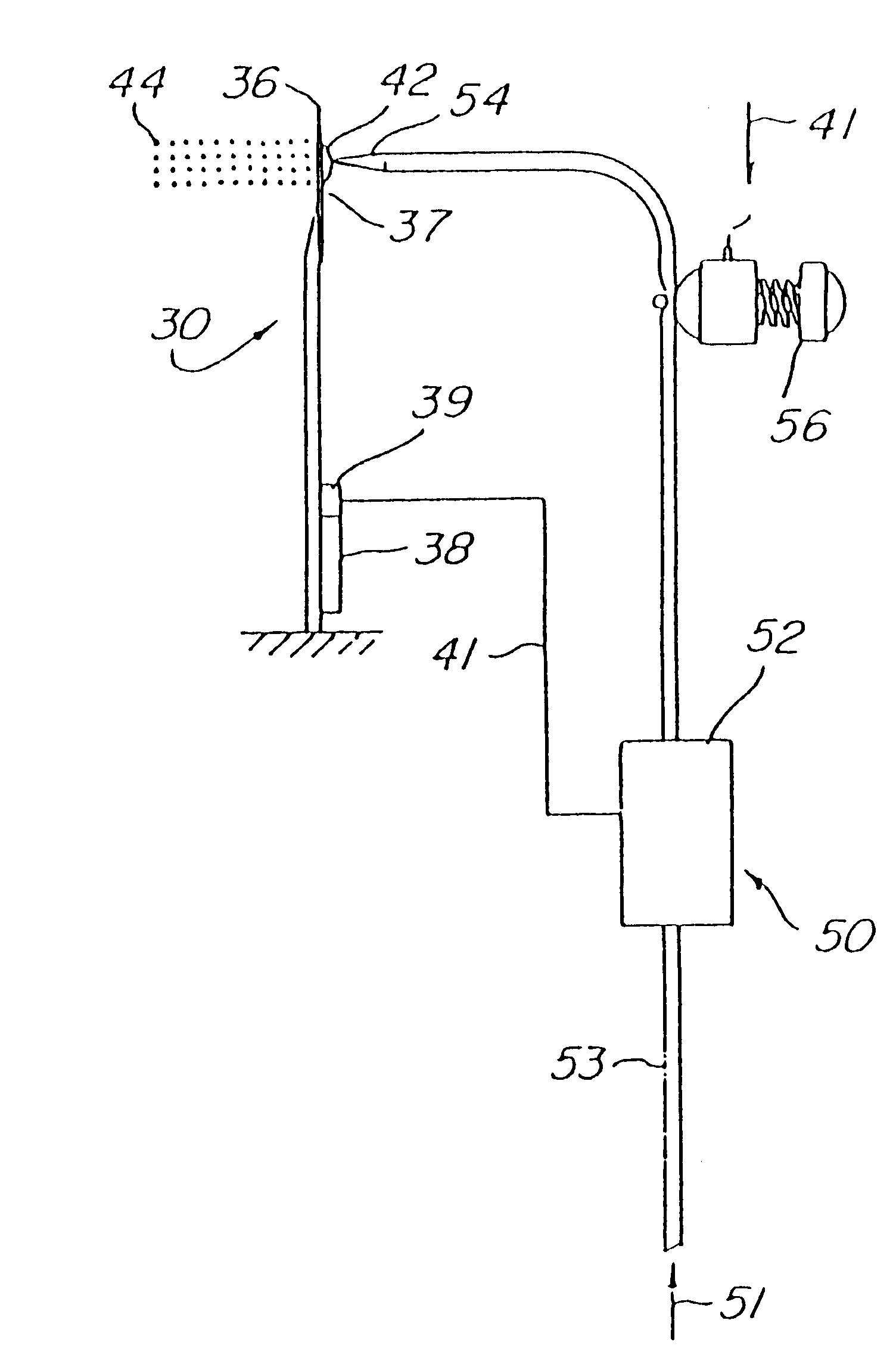

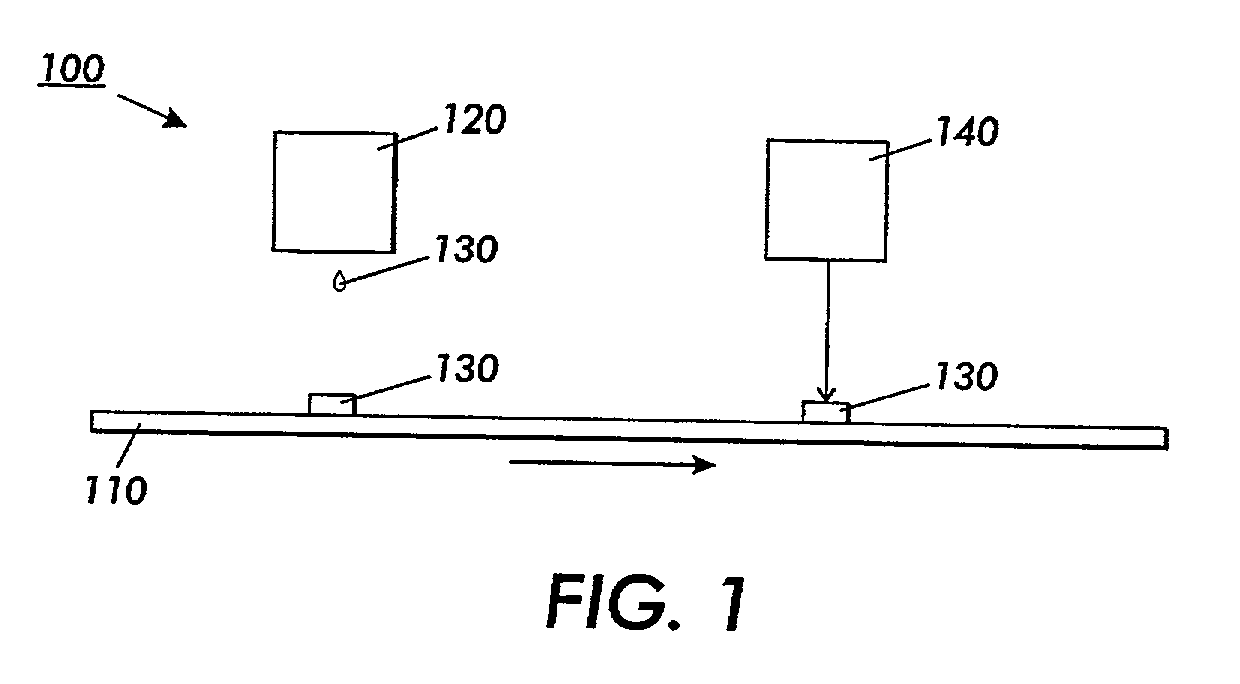

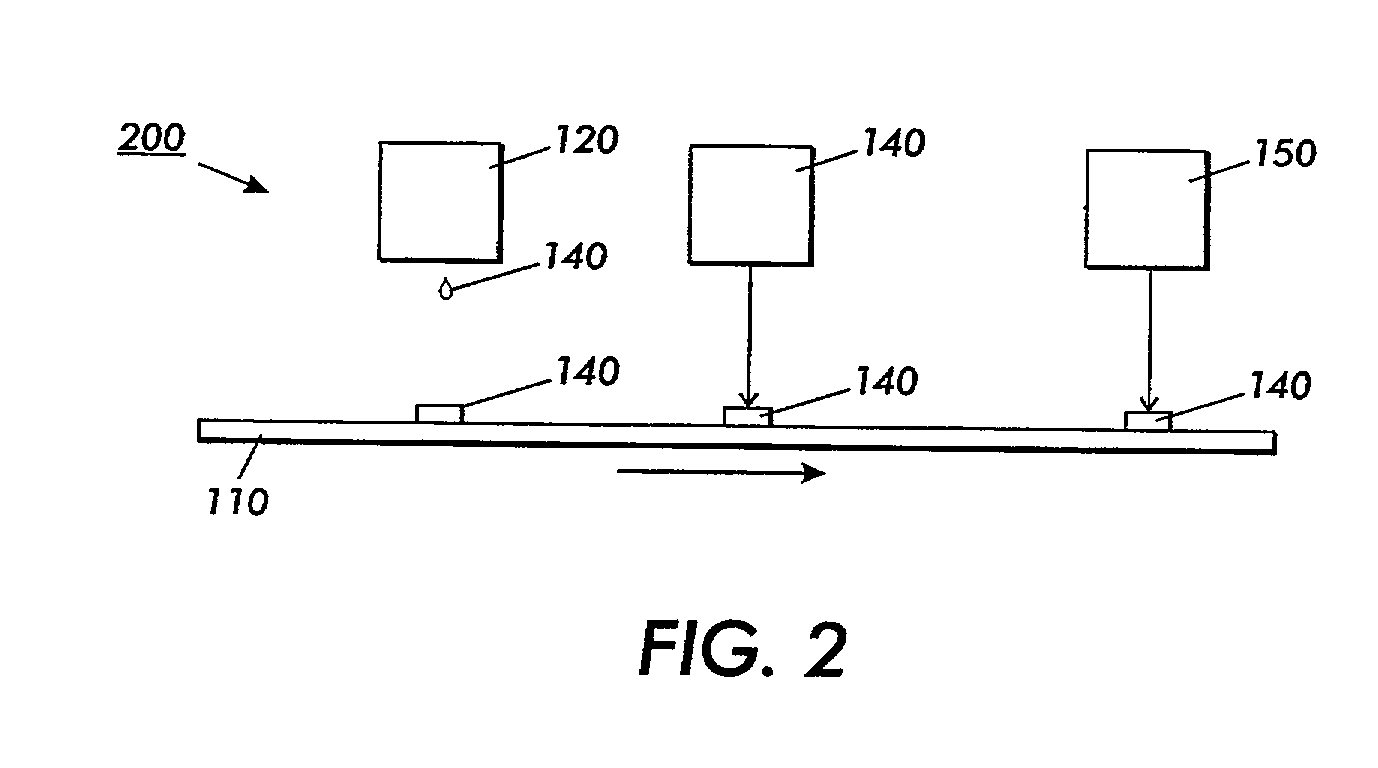

Direct write process and apparatus

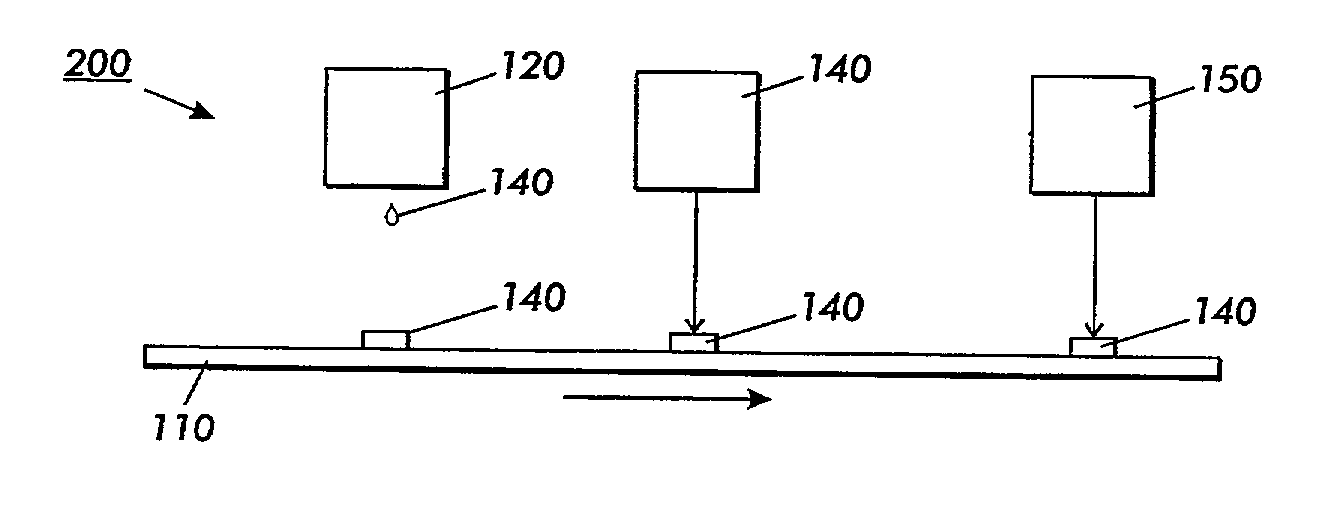

ActiveUS20050015175A1Fast preparationIncrease back pressureRecording apparatusAdditive manufacturing apparatusDielectricControl signal

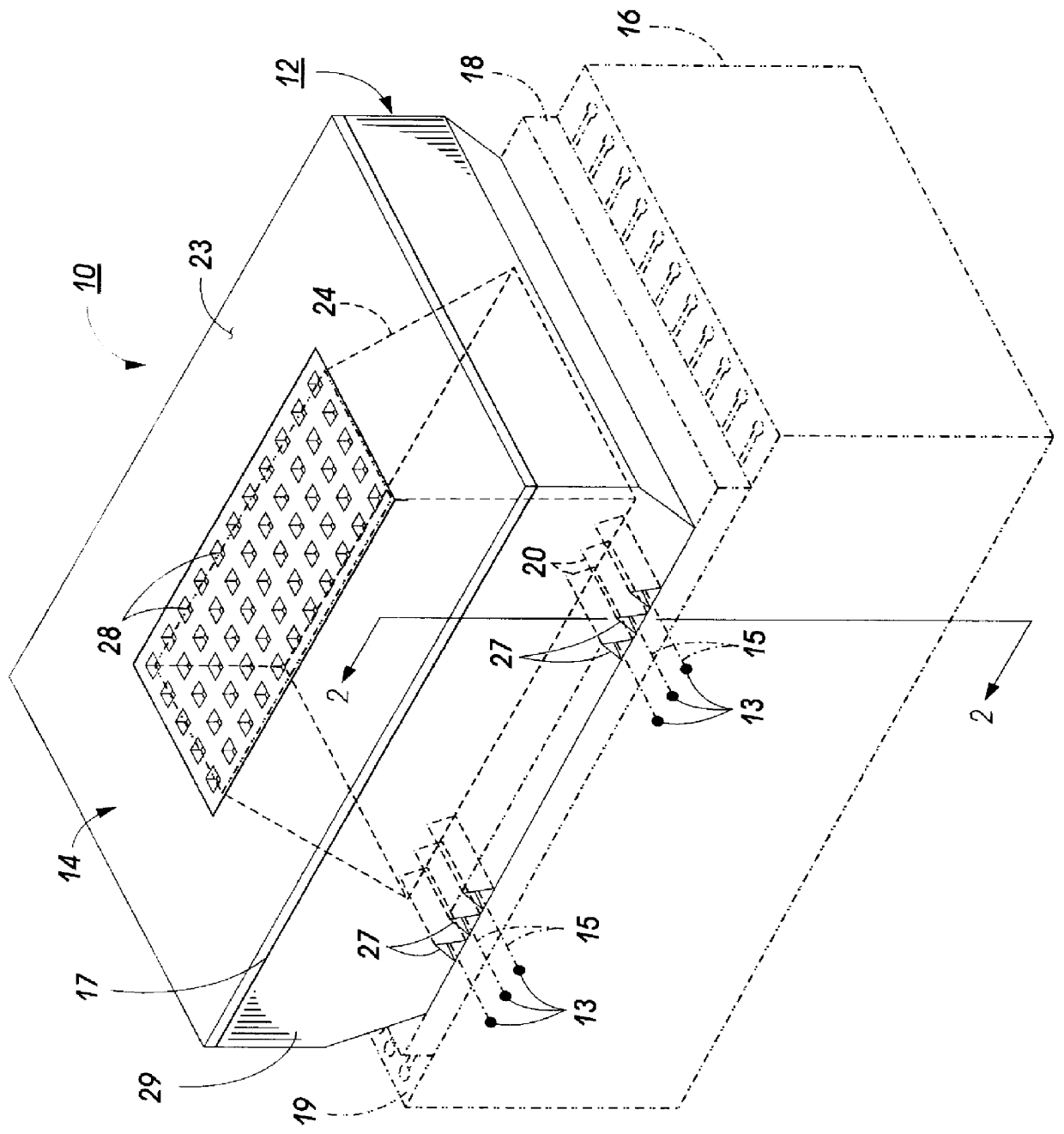

A direct write process and apparatus for fabricating a desired circuit component onto a substrate surface of a microelectronic device according to a computer-aided design (CAD). The process includes (a) providing a support member by which the device is supported while being fabricated; (b) providing a chamber for containing a precursor fluid material under a substantially constant pressure differential relative to the ambient pressure, with the precursor fluid material having a viscosity no less than 10 cps; (c) operating an inkjet-based dispensing head with a control valve or actuator for dispensing and depositing minute droplets of the precursor fluid material onto the substrate surface; (d) energy- or heat-treat the deposited precursor fluid material for converting it to the desired active or passive component; and (e) operating a machine controller for generating control signals in response to the CAD coordinates for controlling the position of the dispensing head relative to the support member in response to the control signals to control dispensing and depositing of the precursor material to form the desired component. The process is useful for depositing a wide range of component materials onto an electronic device, including conductor, resistor, capacitor, dielectric, inductor, antenna, solar cell electrode, battery electrode, interconnect, superconductor, sensor, and actuator element materials.

Owner:NANOTEK INSTR GRP LLC

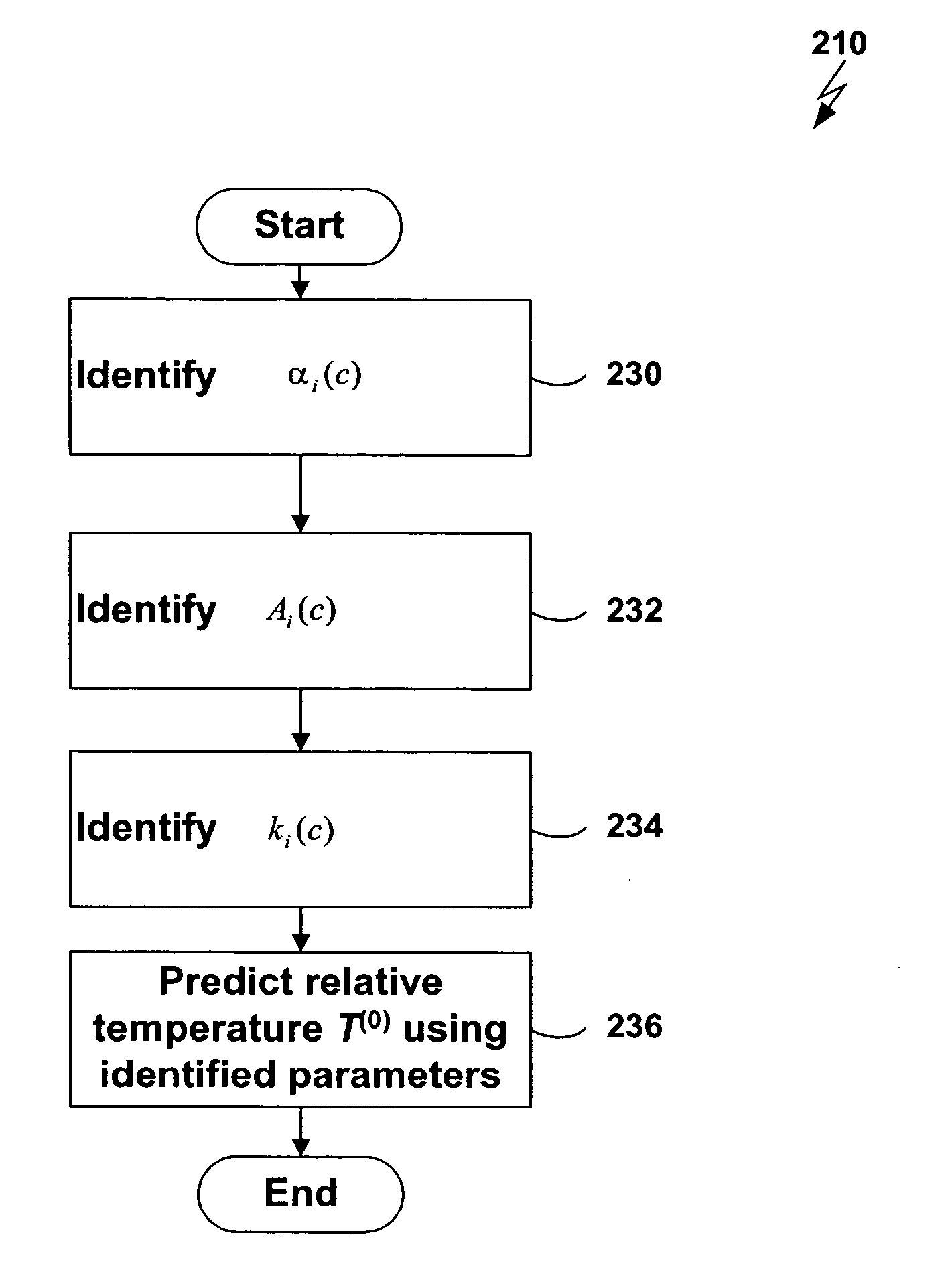

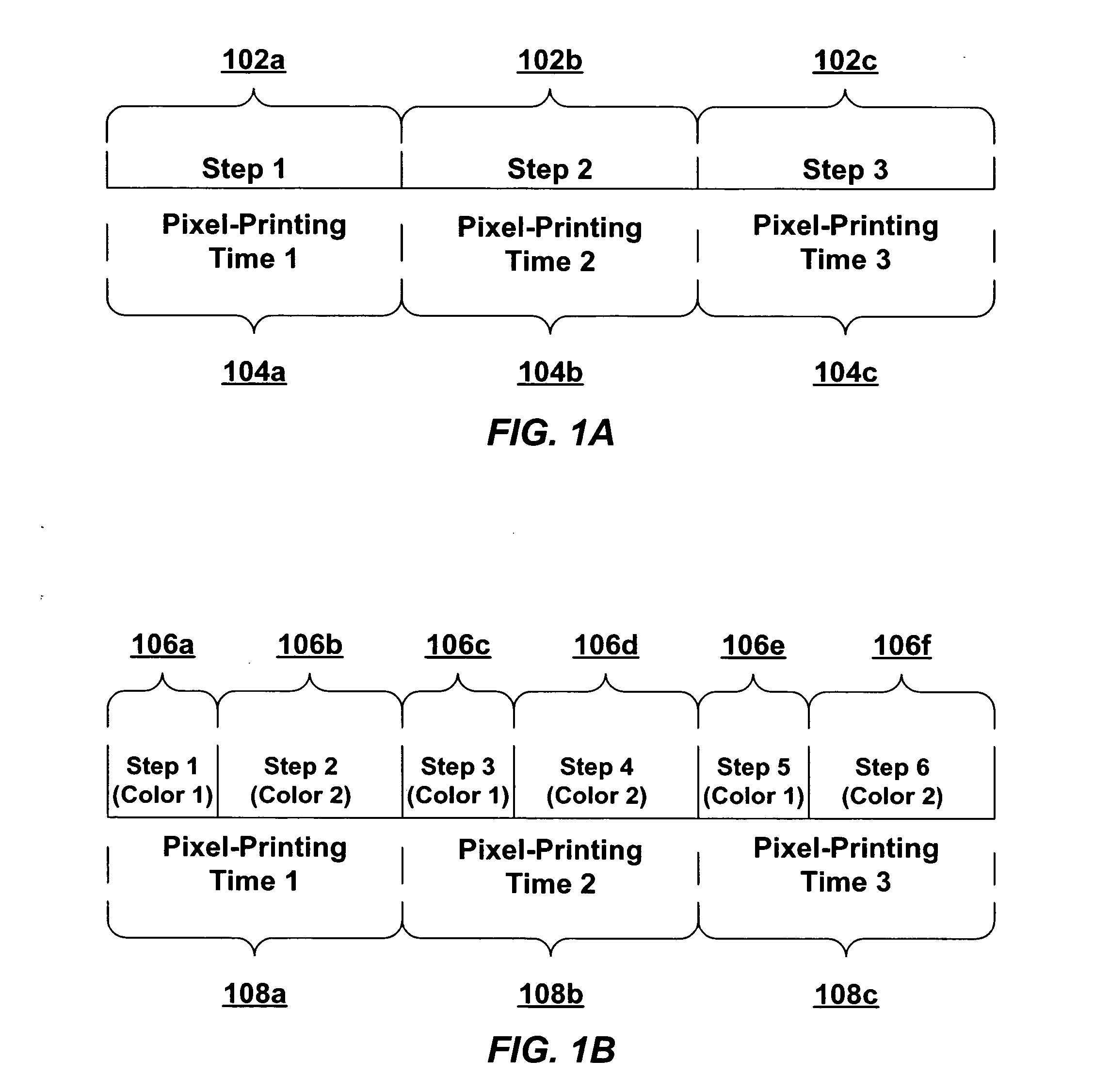

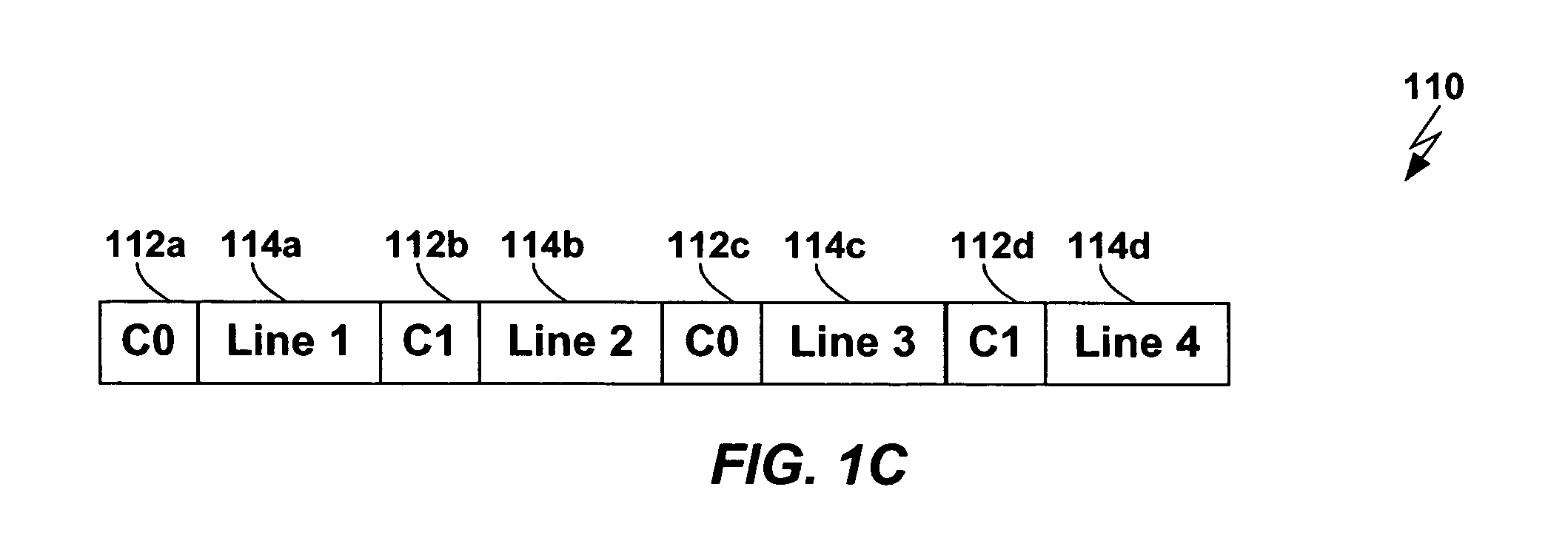

Thermal response correction system

Techniques are disclosed for performing thermal history control in a thermal printer in which a single thermal print head prints sequentially on multiple color-forming layers in a single pass. Each pixel-printing interval may be divided into subintervals, which may be of unequal duration. Each sub-interval may be used to print a different color. The manner in which the input energy to be provided to each print head element is selected may be varied for each of the subintervals. For example, although a single thermal model may be used to predict the temperature of the print head elements in each of the subintervals, different parameters may be used in the different subintervals. Similarly, different energy computation functions may be used to compute the energy to be provided to the print head in each of the subintervals based on the predicted print head temperature.

Owner:TPP TECH LLC

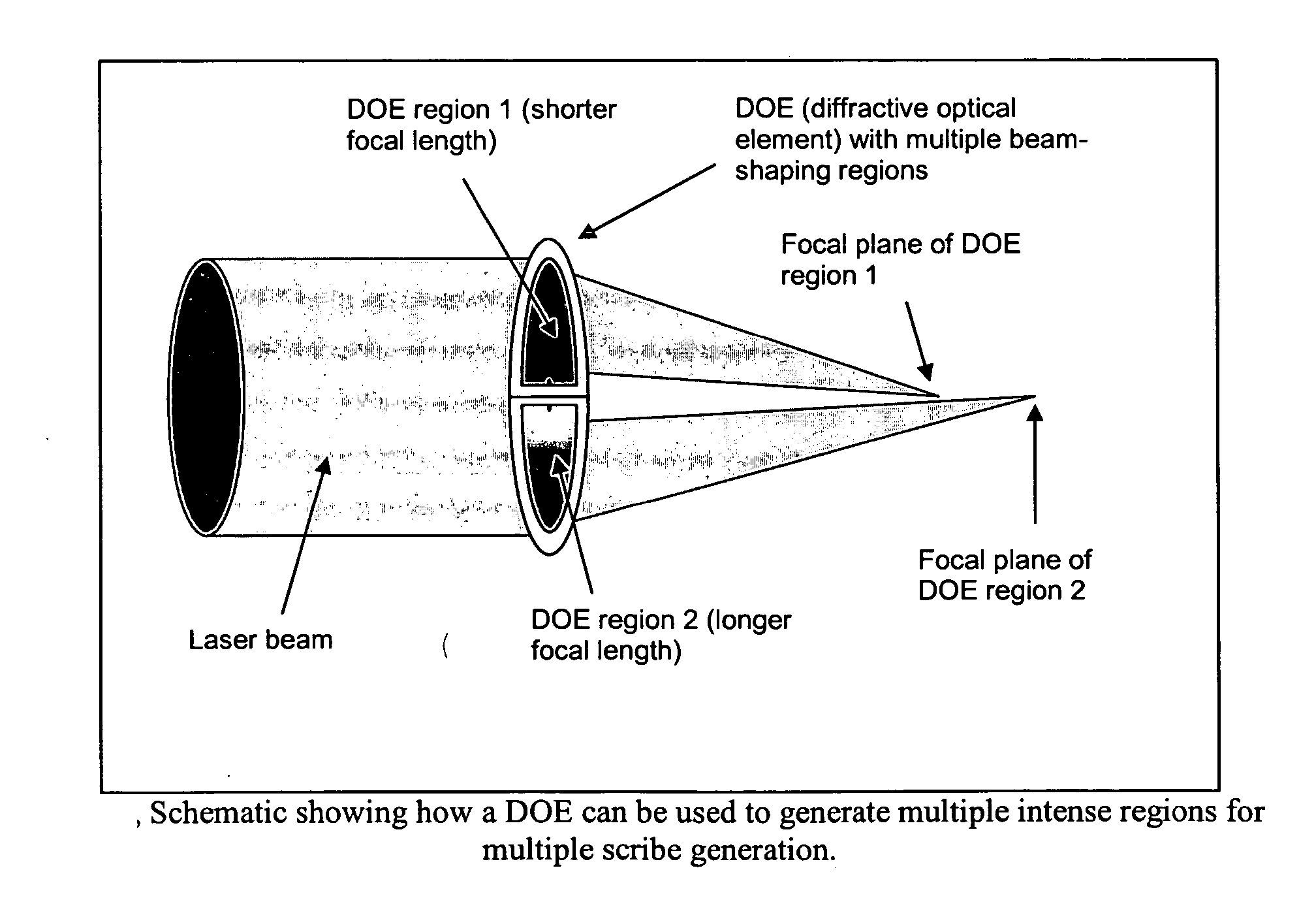

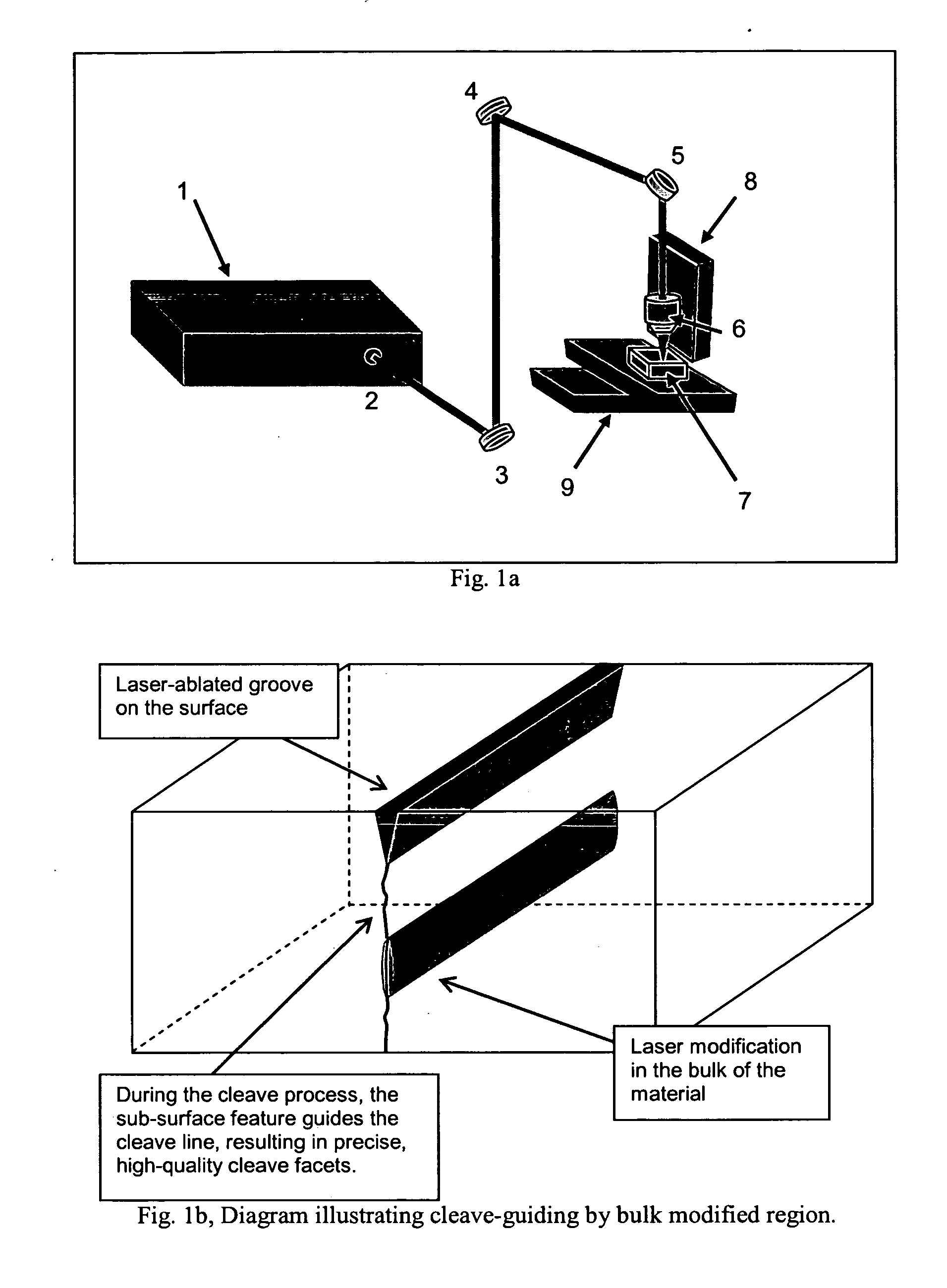

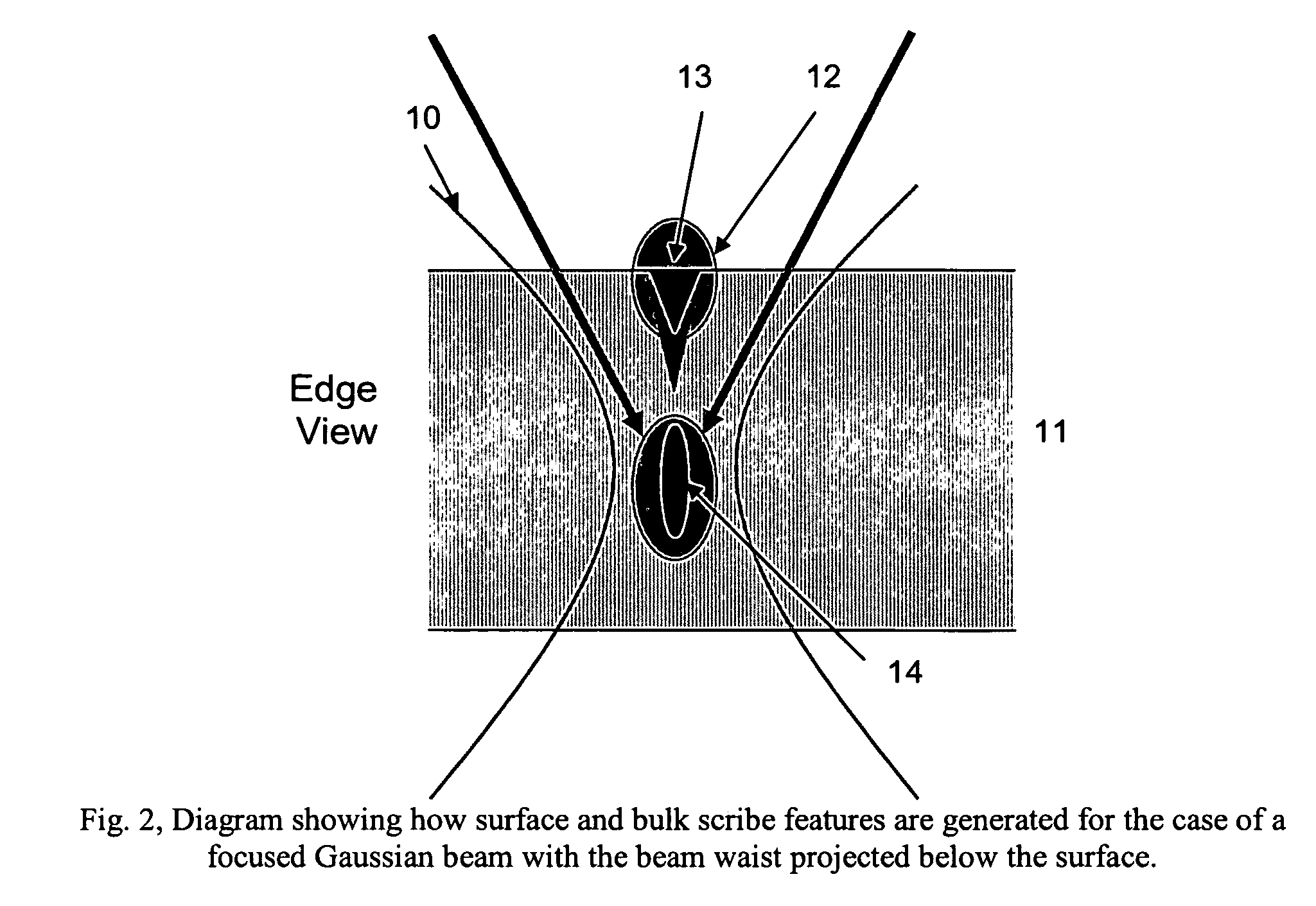

Transparent material processing with an ultrashort pulse laser

InactiveUS20070051706A1Reduce quality problemsPoor precisionFixed microstructural devicesThin material handlingHigh energyNonlinear absorption

Methods for ultrashort pulse laser processing of optically transparent materials. A method for scribing transparent materials uses ultrashort laser pulses to create multiple scribe features with a single pass of the laser beam across the material, with at least one of the scribe features being formed below the surface of the material. This enables clean breaking of transparent materials at a higher speed than conventional techniques. Slightly modifying the ultrashort pulse laser processing conditions produces sub-surface marks. When properly arranged, these marks are clearly visible with side-illumination and not clearly visible without side-illumination. In addition, a method for welding transparent materials uses ultrashort laser pulses to create a bond through localized heating. The ultrashort pulse duration causes nonlinear absorption of the laser radiation, and the high repetition rate of the laser causes pulse-to-pulse accumulation of heat within the materials. The laser is focused near the interface of the materials, generating a high energy fluence at the region to be welded. This minimizes damage to the rest of the material and enables fine weld lines.

Owner:IMRA AMERICA

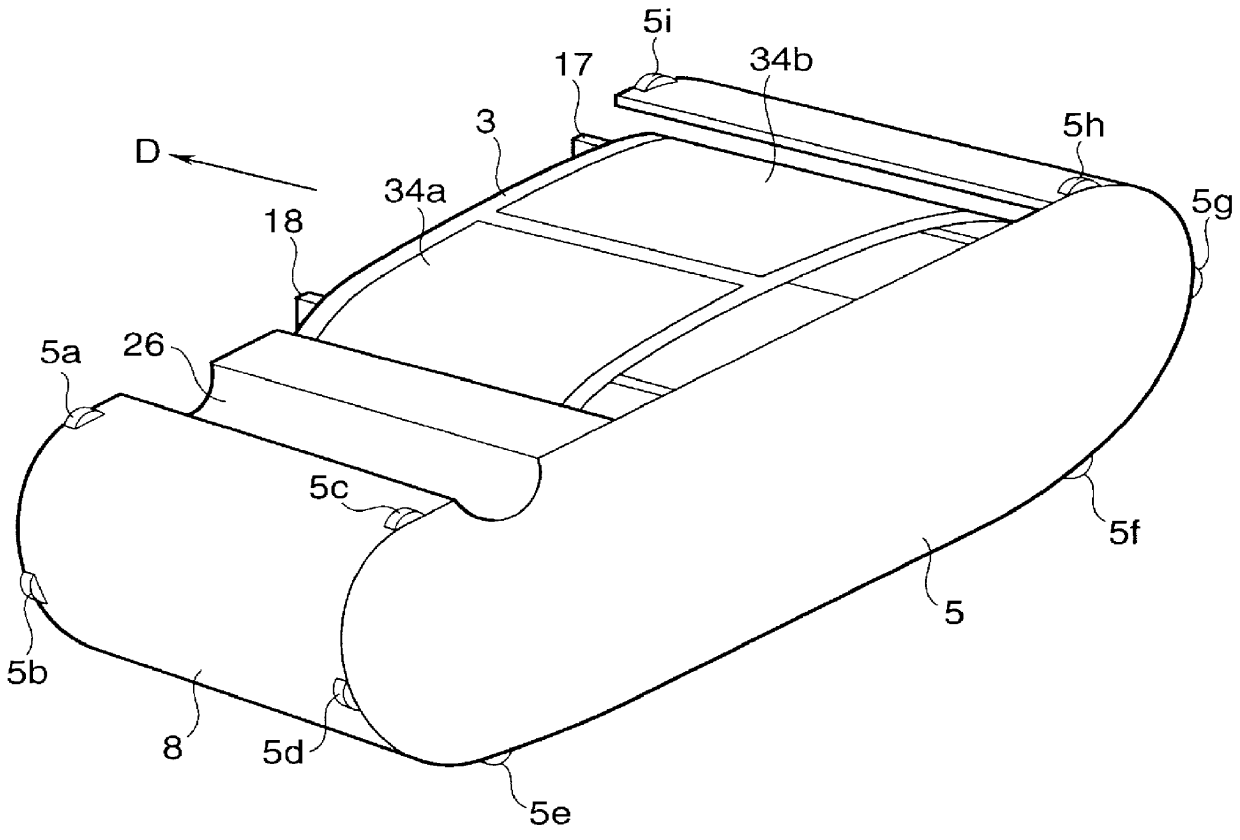

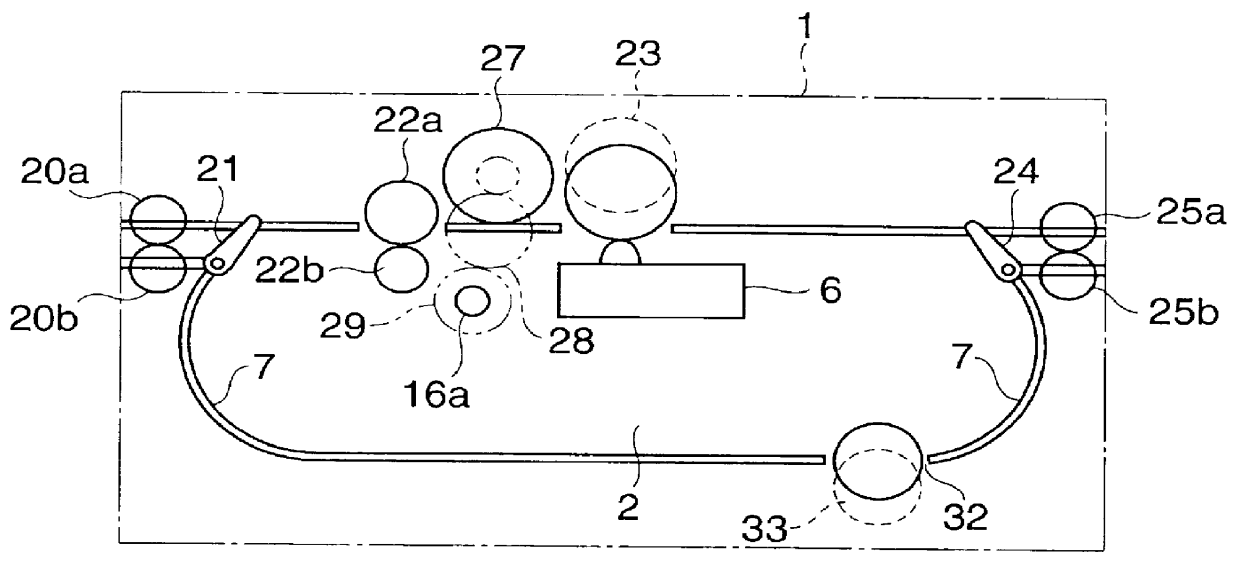

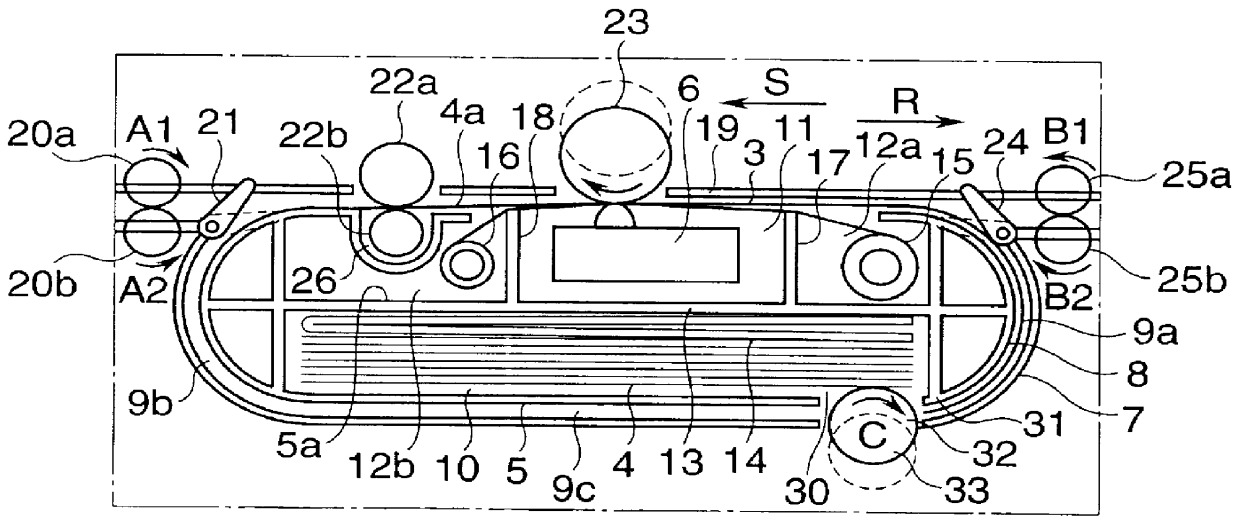

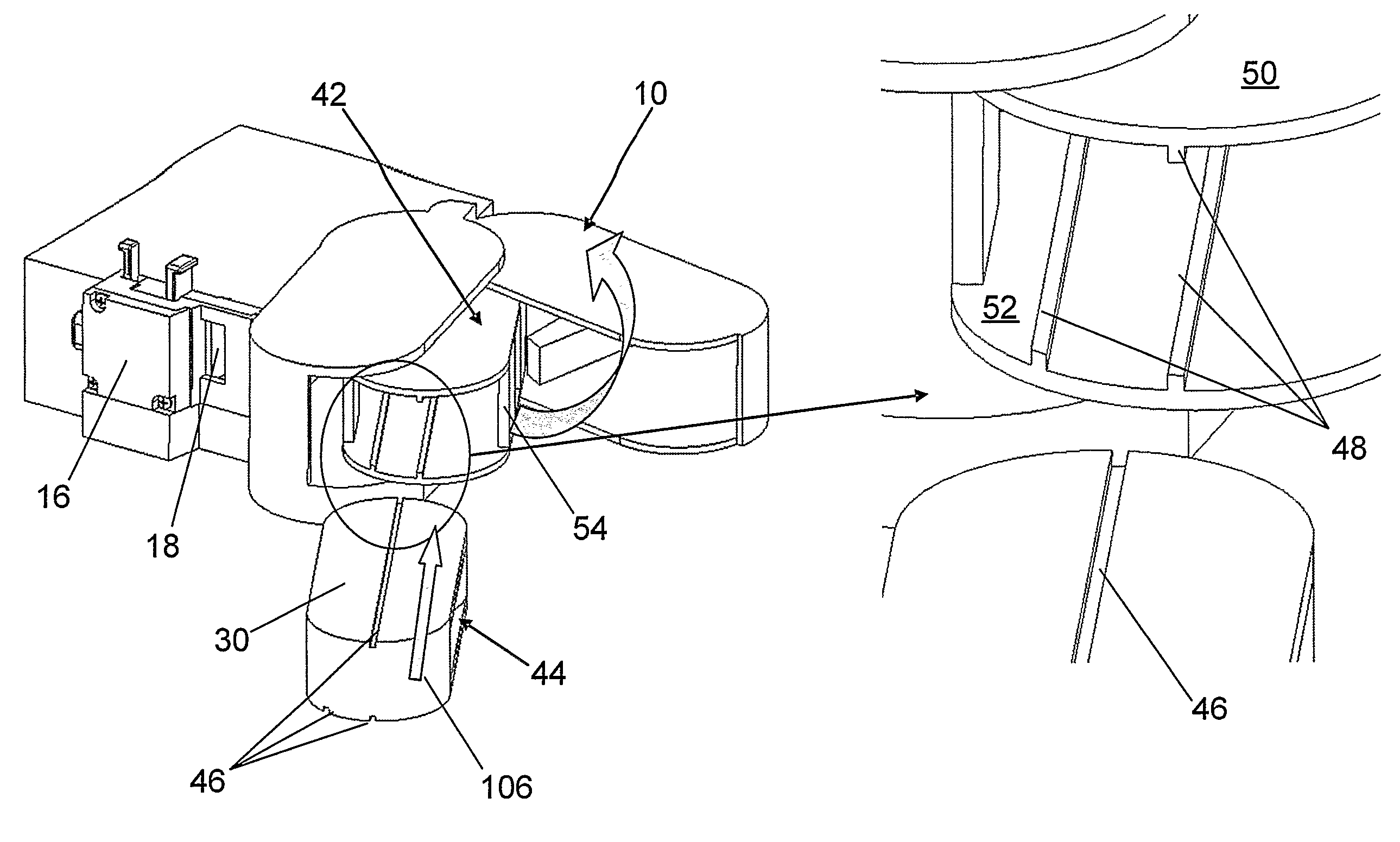

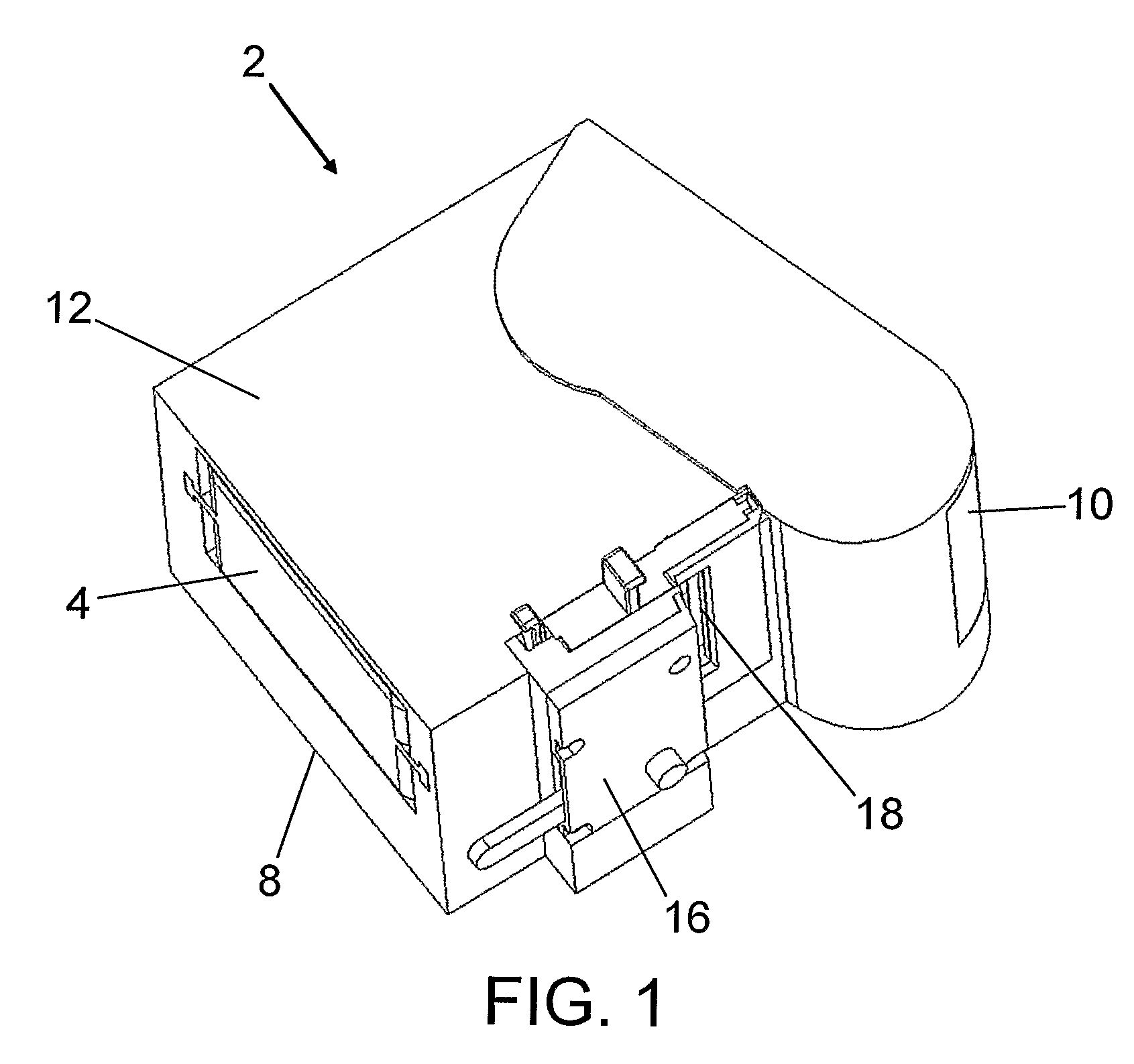

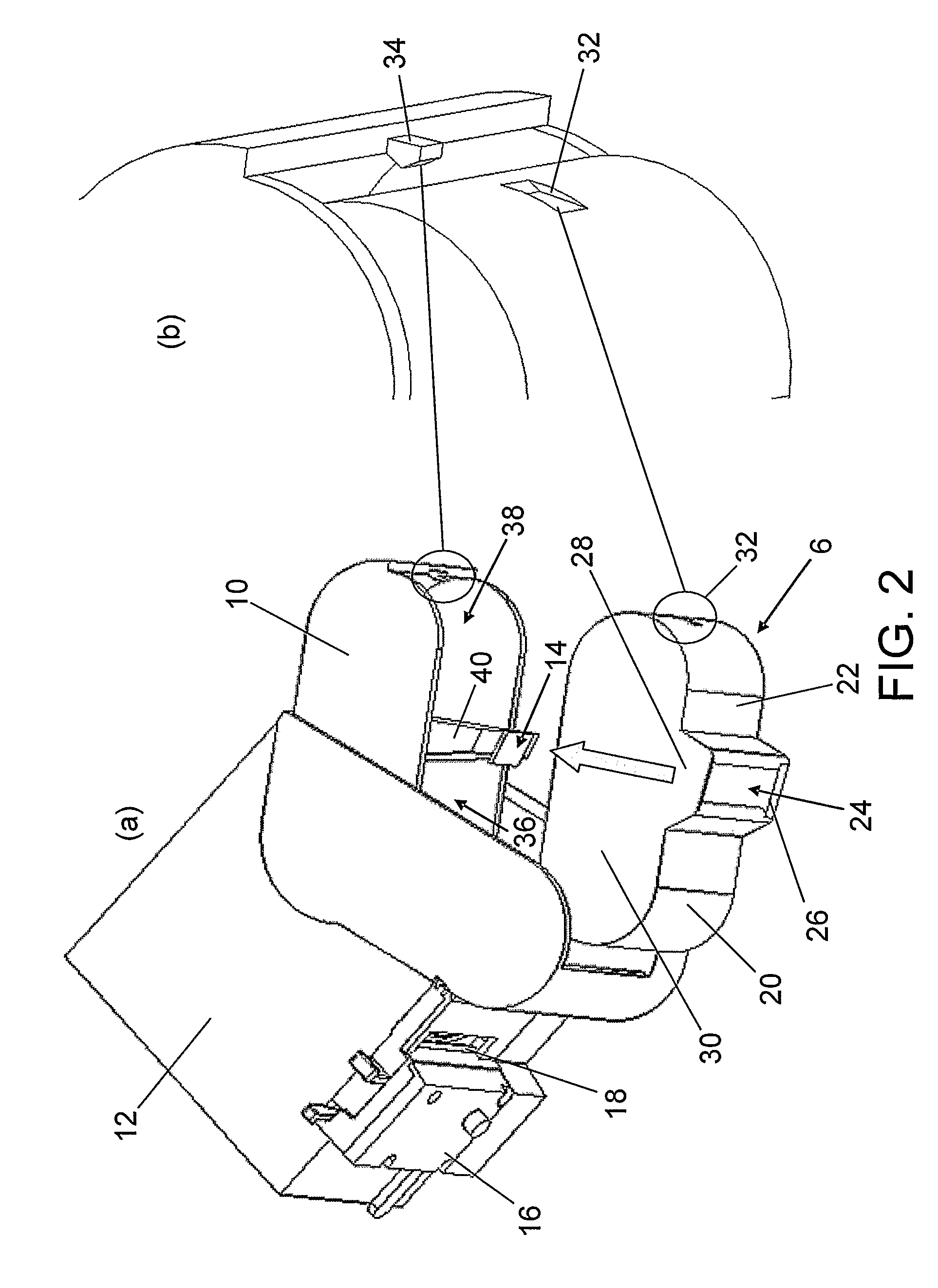

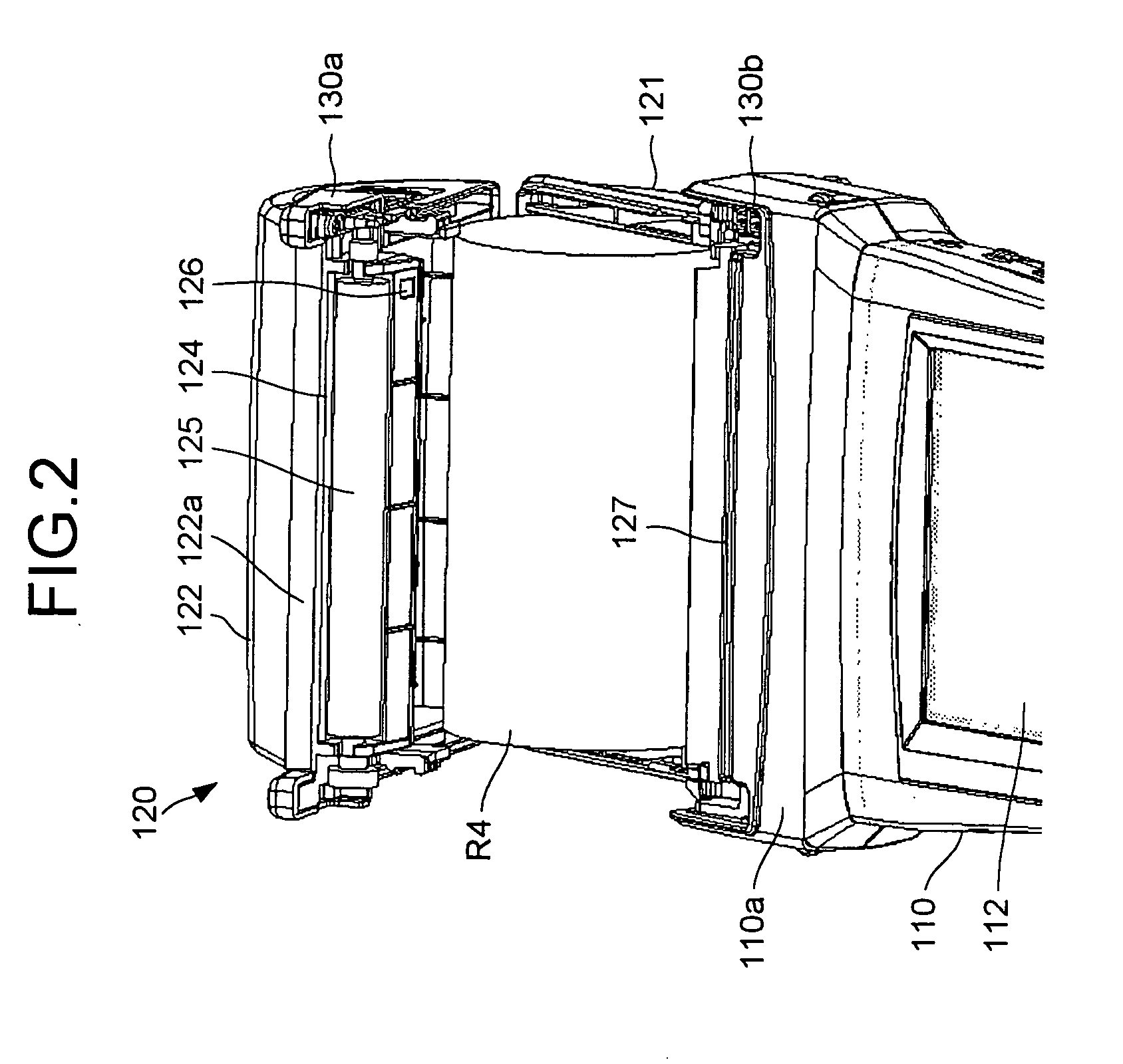

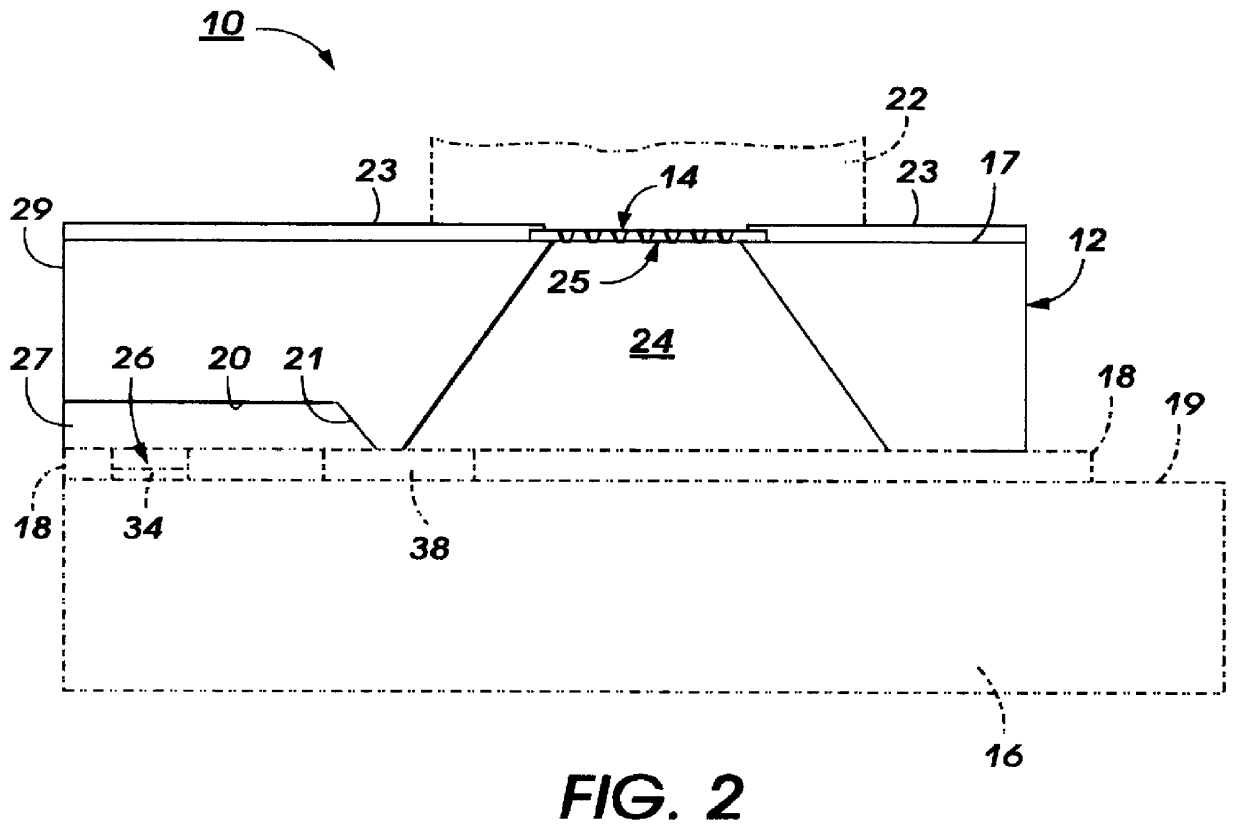

Cassette for holding ink ribbon and print paper therein and printer incorporating the cassette therein

An ink ribbon-print paper cassette is used in a thermal printer. A paper tray accommodates a stack of single sheets of print paper. The paper tray has an opening through which the print paper is fed into a paper path on a sheet-by-sheet basis. An ink ribbon for thermal printing runs over a thermal head located adjacent the paper tray. A housing accommodates the paper tray, thermal head, and ink ribbon therein. When the cassette is loaded into the thermal printer, the outer surface of the cassette and an inner wall of the thermal printer cooperate to form a paper path therebetween through which each of the sheets of print paper is advanced from the paper tray to the thermal head.

Owner:OKI DATA CORP

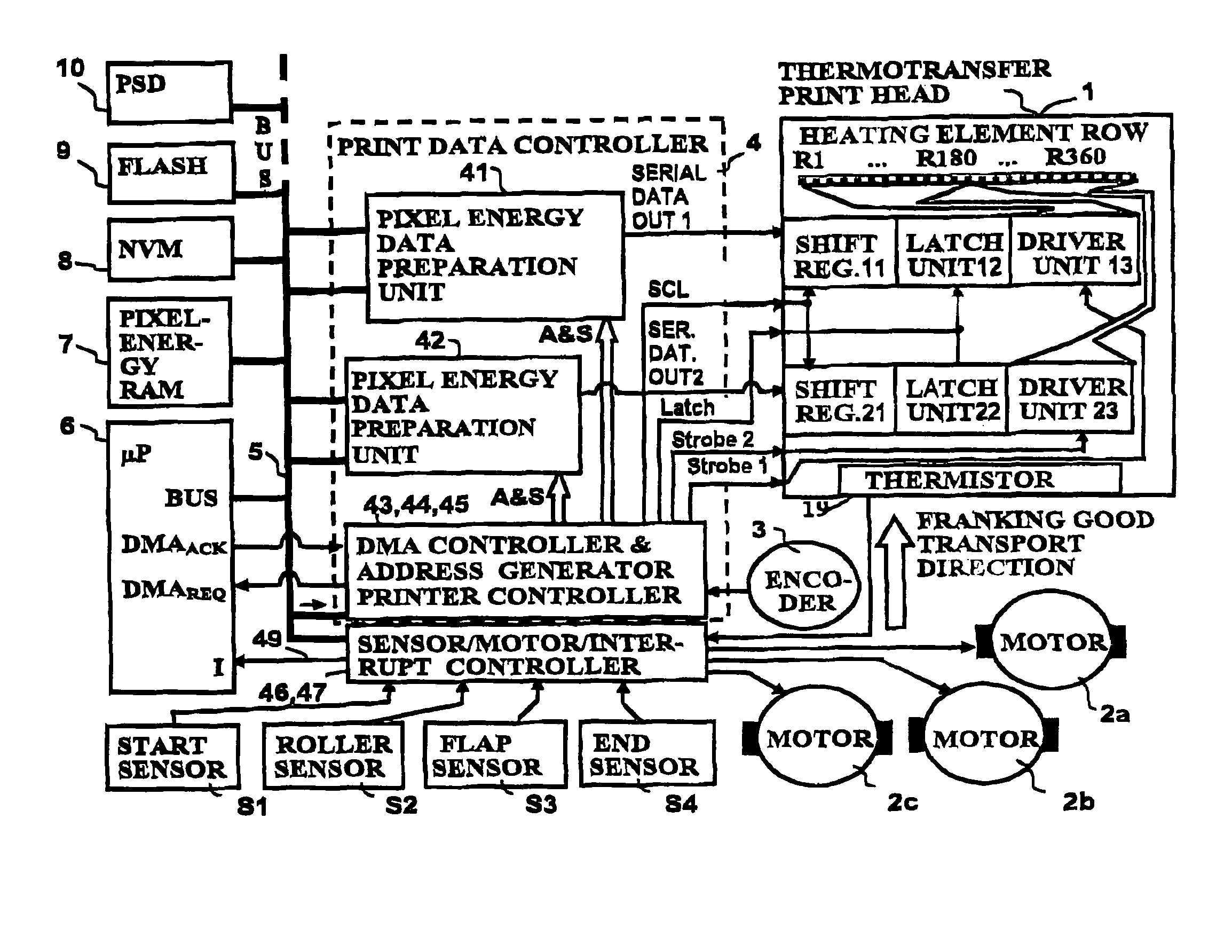

Systems and methods of printing with ultraviolet photosensitive resin-containing materials using light emitting devices

Method of printing with ultraviolet photosensitive resin-containing materials includes depositing at least one substance that includes an ultraviolet photosensitive resin on to a substrate, partially curing the substance by irradiating the substance with at least one ultraviolet light emitting device, and completely curing the substance. Substance curing system including a substrate, an applicator that deposits a substance that includes an ultraviolet photosensitive resin on to a substrate, and at least one ultraviolet light emitting device usable to irradiate the substance to partially cure and / or completely cure the substance.

Owner:XEROX CORP

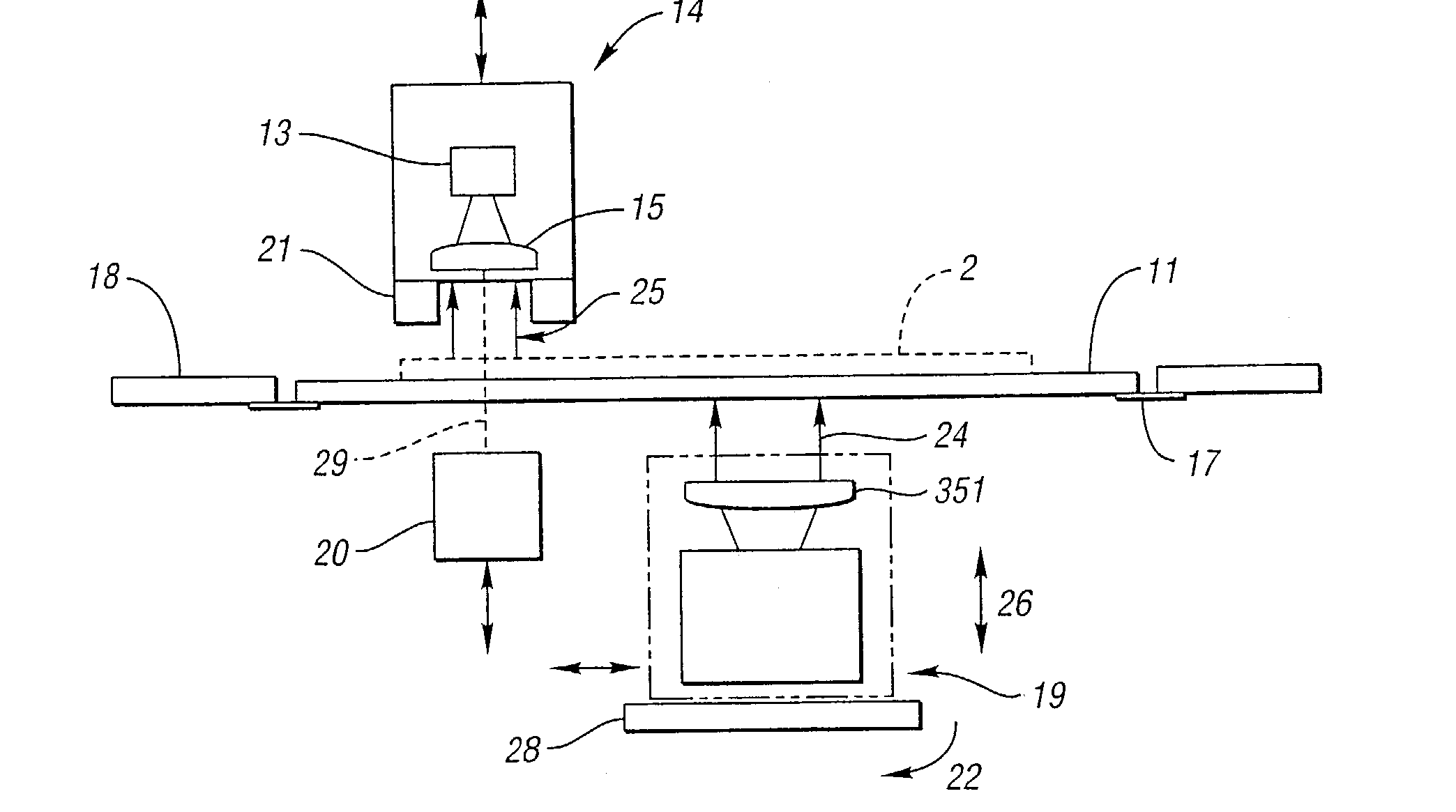

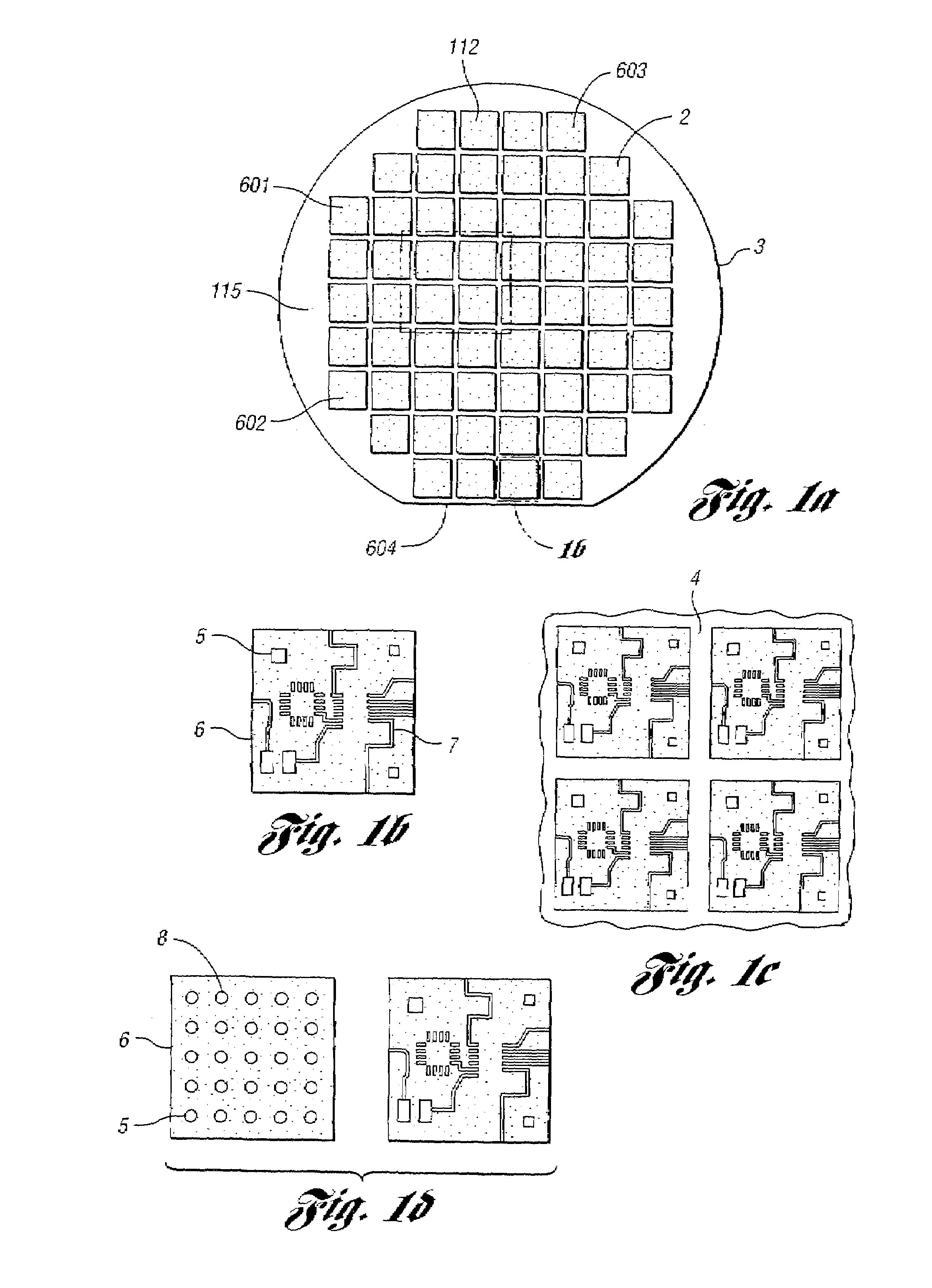

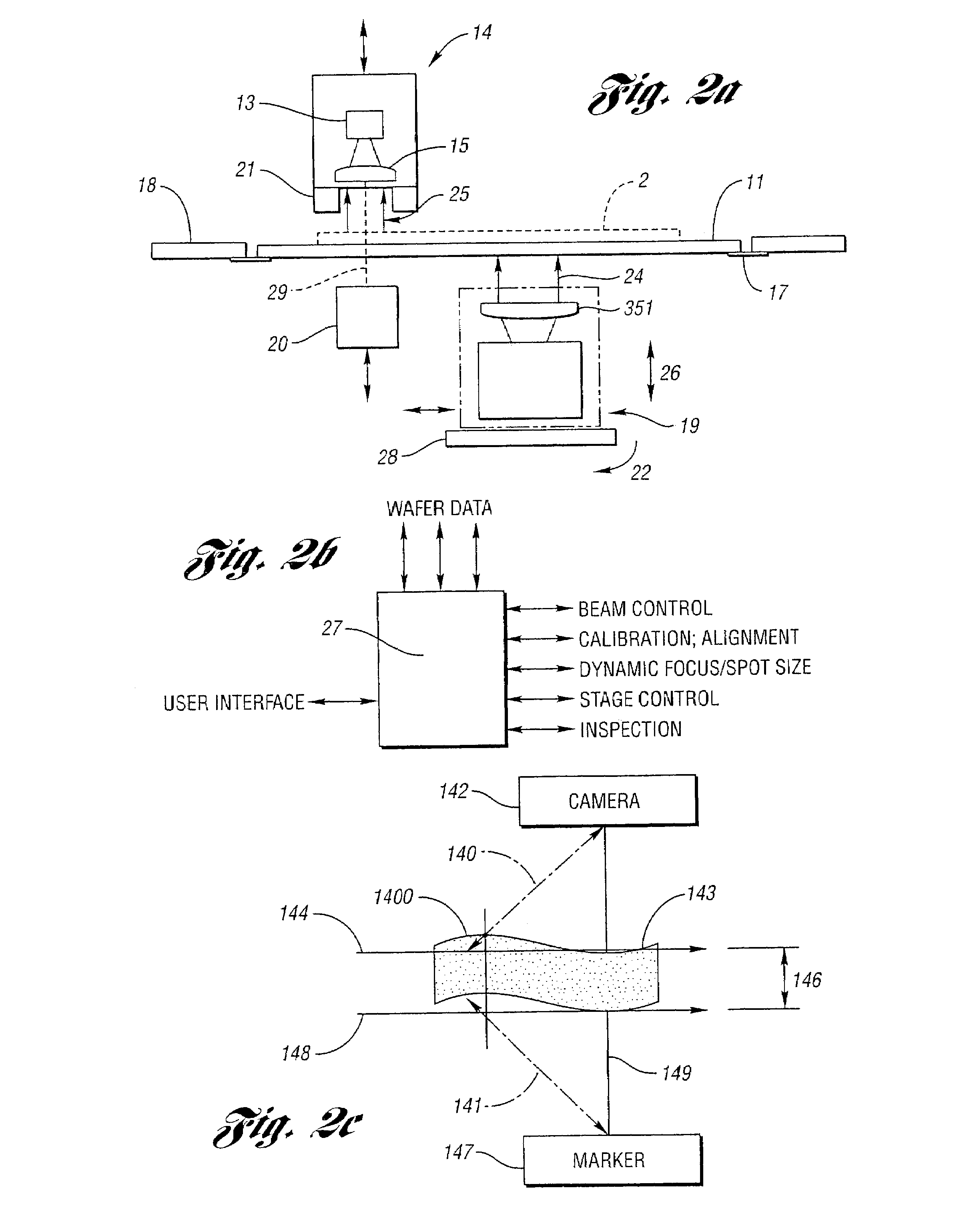

Method and system for calibrating a laser processing system and laser marking system utilizing same

InactiveUS7015418B2Mark accuratelyRecording apparatusSemiconductor/solid-state device detailsLaser processingThree degrees of freedom

A method of calibrating a laser marking system includes calibrating a laser marking system in three dimensions. The step of calibrating includes storing data corresponding to a plurality of heights. A position measurement of a workpiece is obtained to be marked. Stored calibration data is associated with the position measurement. A method and system for calibrating a laser processing or marking system is provided. The method includes: calibrating a laser marker over a marking field; obtaining a position measurement of a workpiece to be marked; associating stored calibration data with the position measurement; relatively positioning a marking beam and the workpiece based on at least the associated calibration data; and calibrating a laser marking system in at least three degrees of freedom. The step of calibrating includes storing data corresponding to a plurality of positions and controllably and relatively positioning a marking beam based on the stored data corresponding to the plurality of positions.

Owner:ELECTRO SCI IND INC

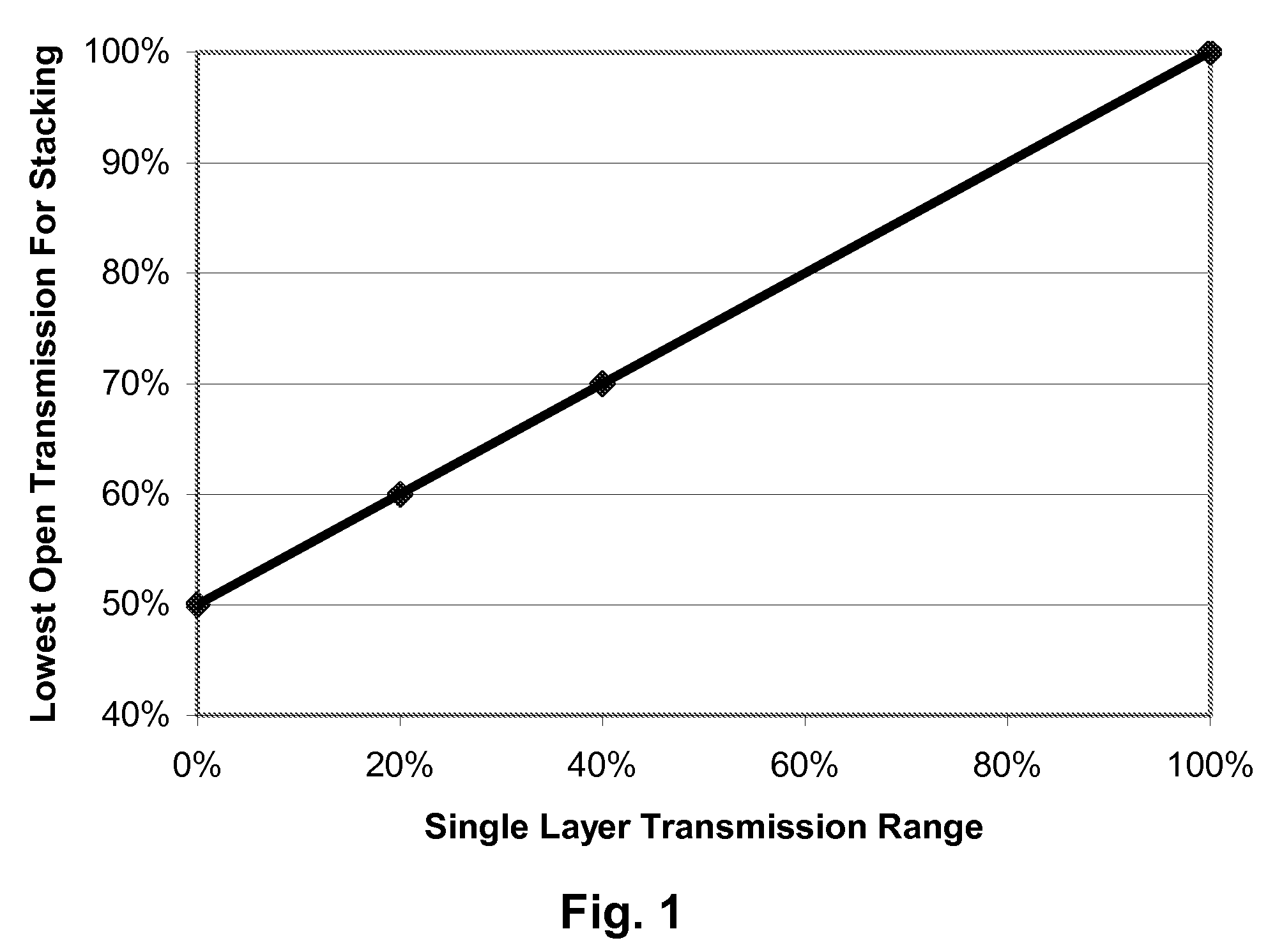

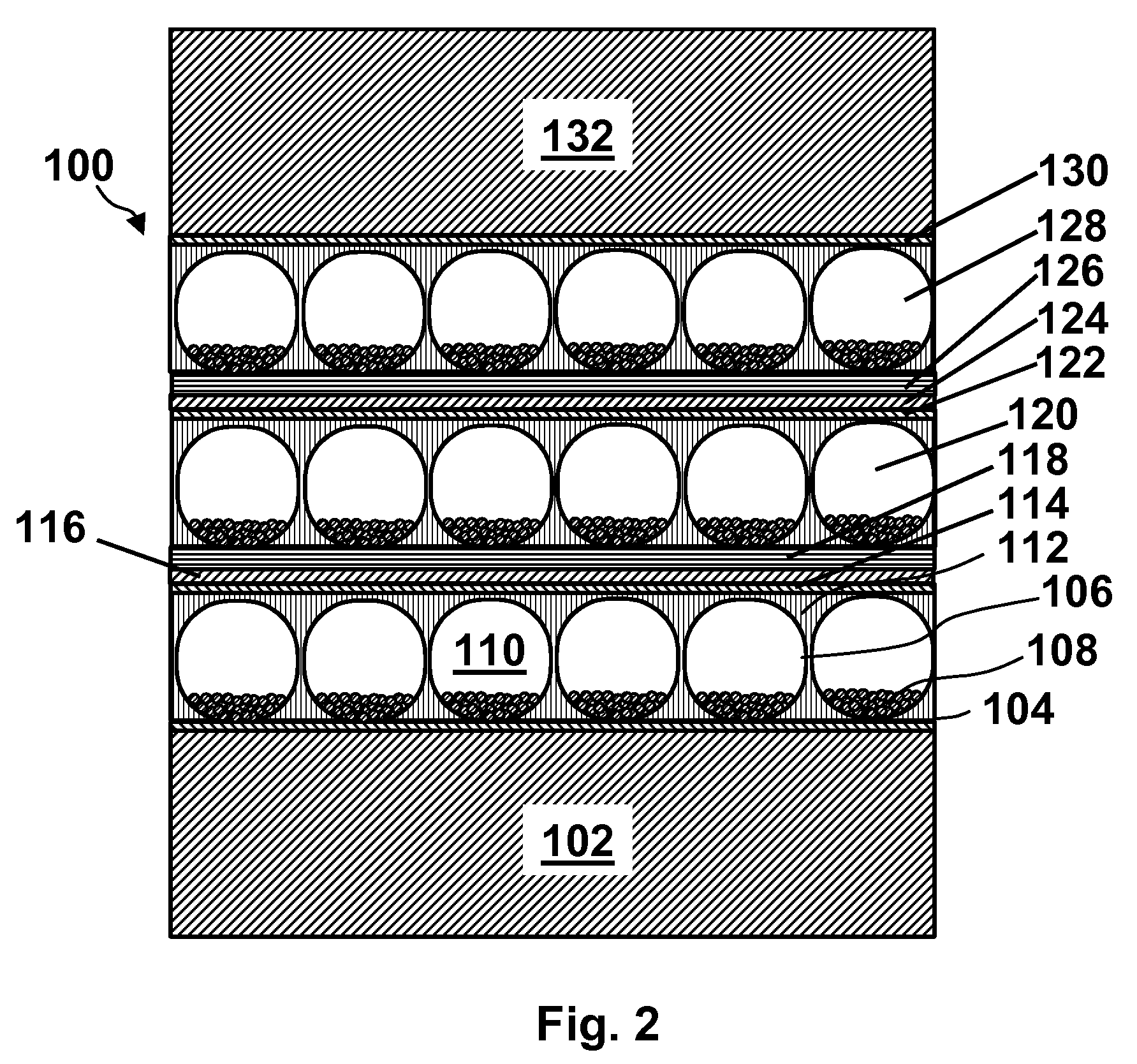

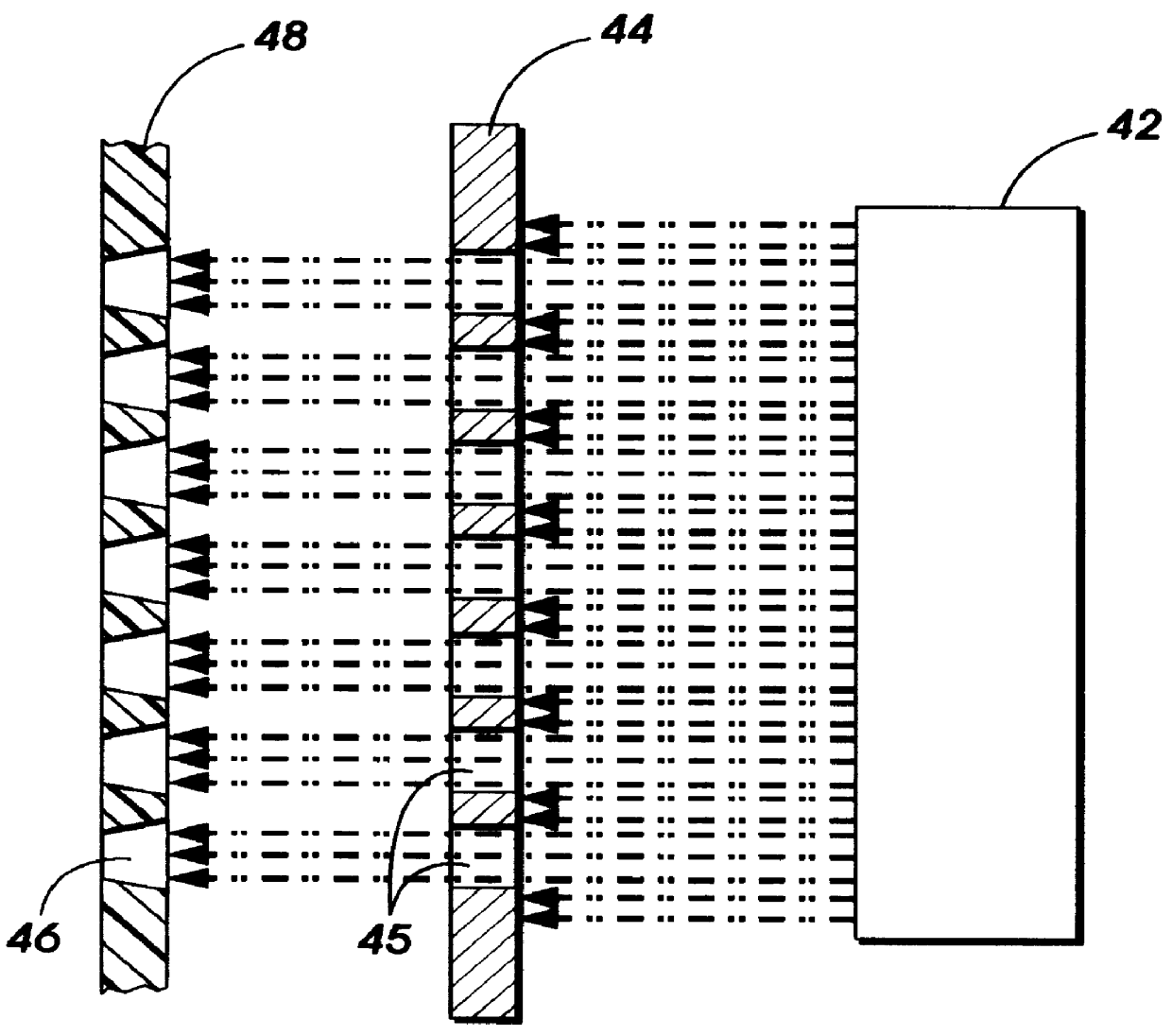

Multi-layer light modulator

ActiveUS7492497B2Reduce light lossRecording apparatusStatic indicating devicesOptic layerHigh transmission

A light modulator comprises a plurality of discrete variable transmission electro-optic layers arranged so that light will pass successively through the plurality of layers; the light modulator has a higher transmission range than any of the individual electro-optic layers separately.

Owner:E INK CORPORATION

Methods and apparatus for dispensing liquids as an atomized spray

InactiveUS6540153B1Sufficient volumeHigh trafficRespiratorsRecording apparatusEngineeringMechanical engineering

Owner:NOVARTIS FARMA

Method of manufacture of high Young's modulus thermoelastic inkjet printer

A method of manufacturing a thermally actuated ink jet printhead includes the step of initially providing a wafer having a circuitry layer including the electrical circuitry necessary for the operation of a thermal actuator. A first sacrificial layer is deposited on the wafer and is etched. A Young's modulus layer is deposited to form a first layer of a thermal actuator and a portion of a nozzle chamber wall. A conductive heater material layer is provided and has a portion interconnected to the circuitry layer. A second sacrificial layer is deposited and etched in preparation for nozzle chamber walls. A nozzle wall material layer is deposited to form the walls of the nozzle chamber. The nozzle wall material layer is etched to define a nozzle port for the ejection of ink. The sacrificial layers are etched away to release the thermal actuator. The nozzle chamber walls are formed to define a fulcrum for the thermal actuator.

Owner:SILVERBROOK RES PTY LTD +1

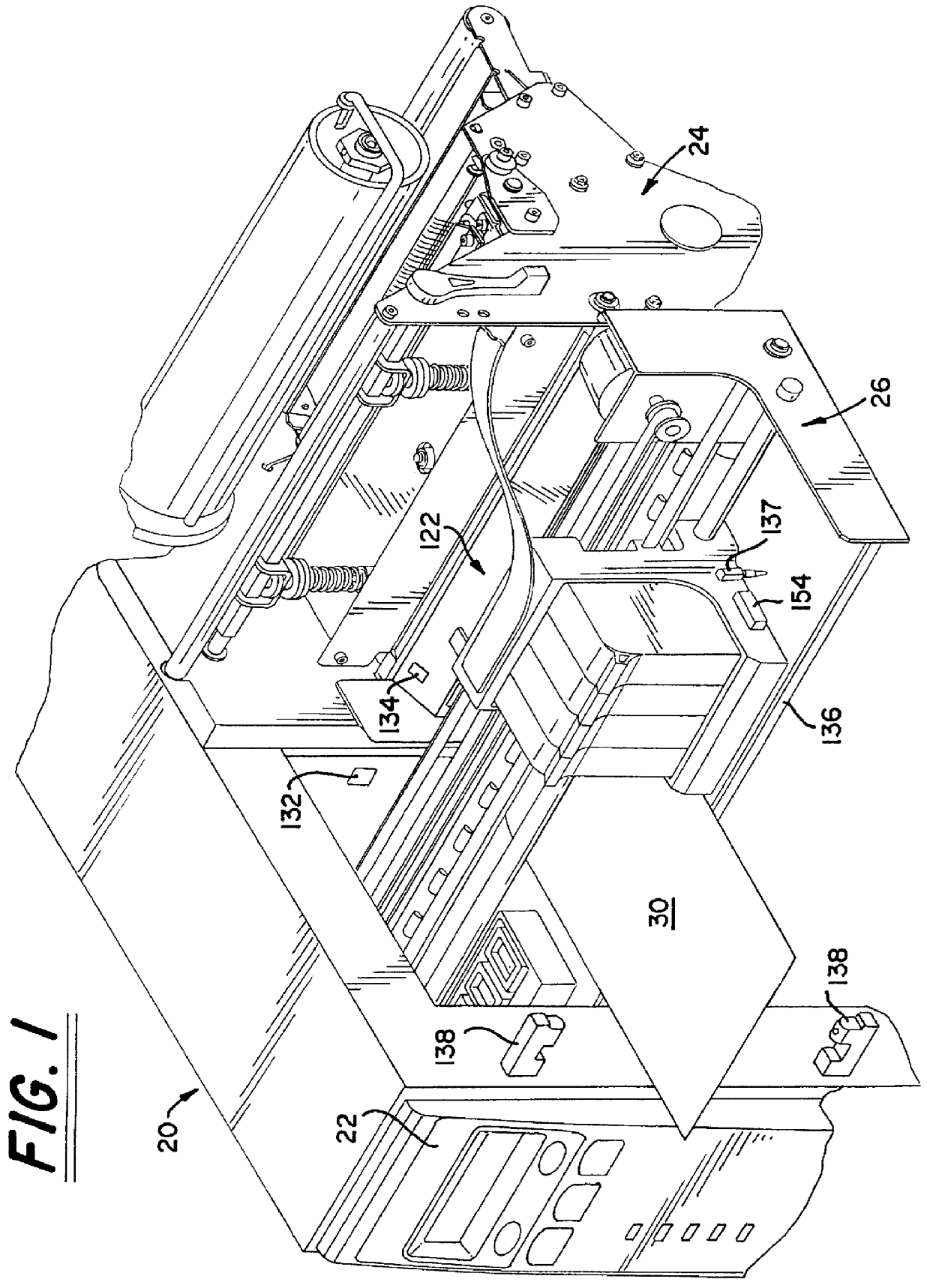

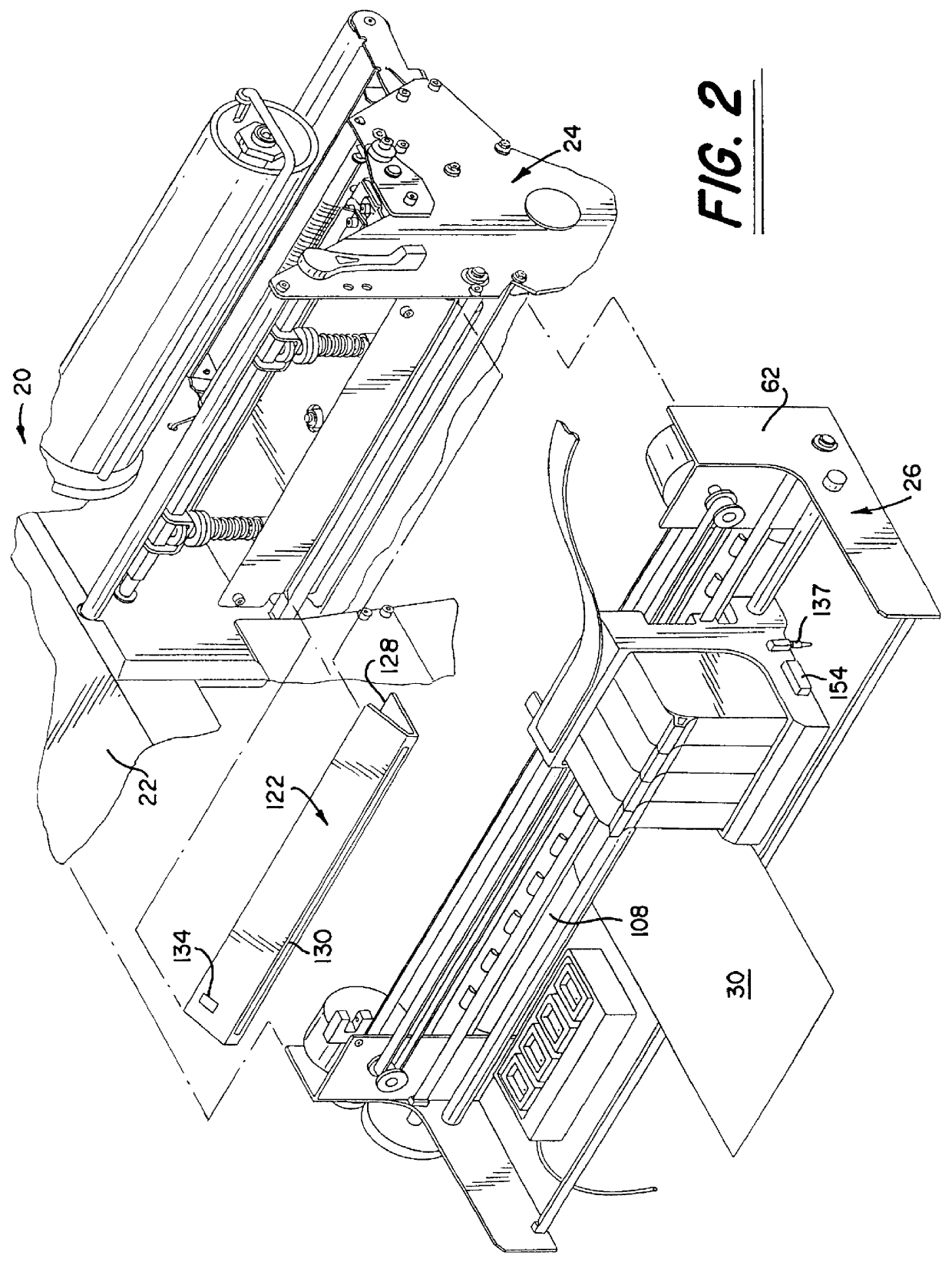

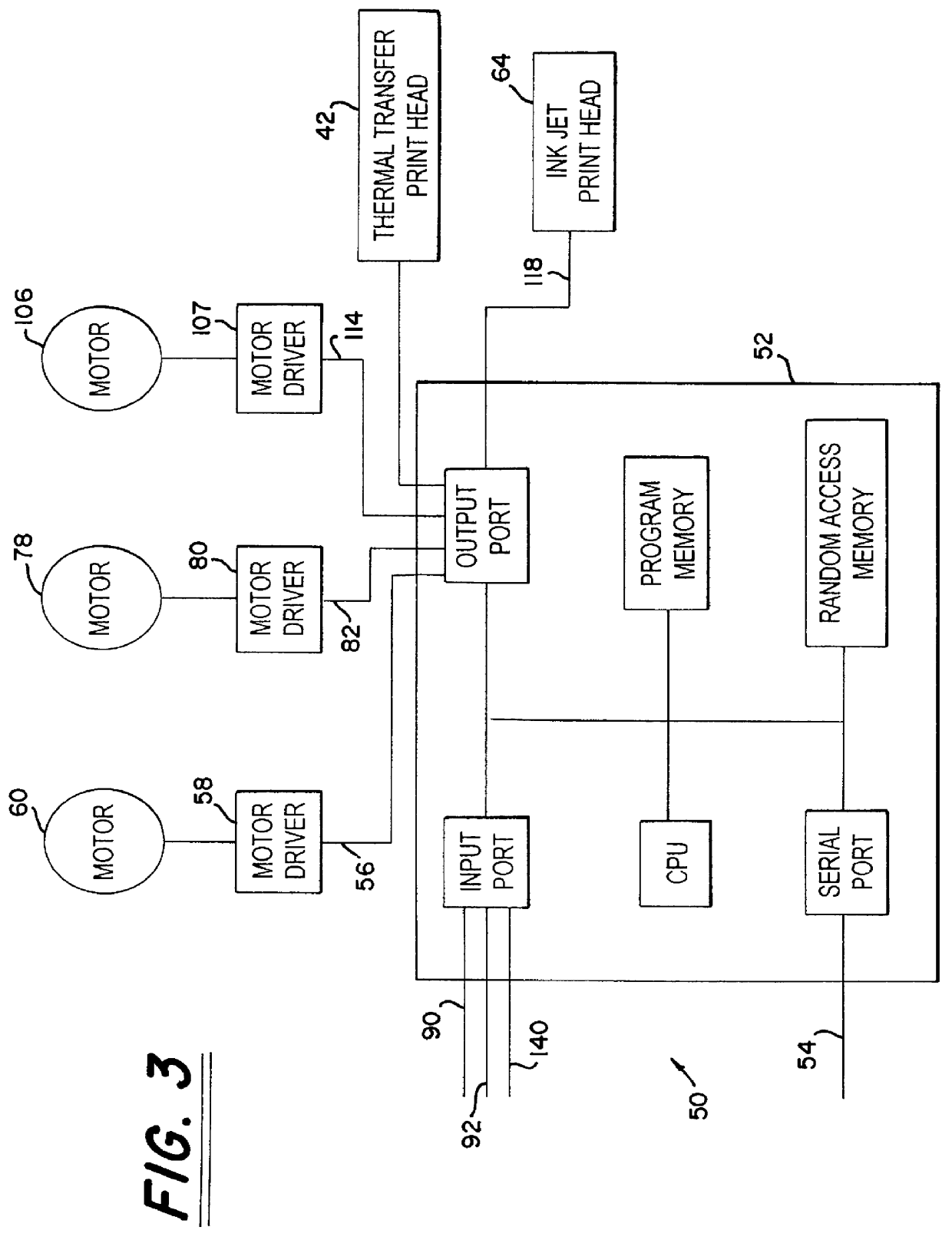

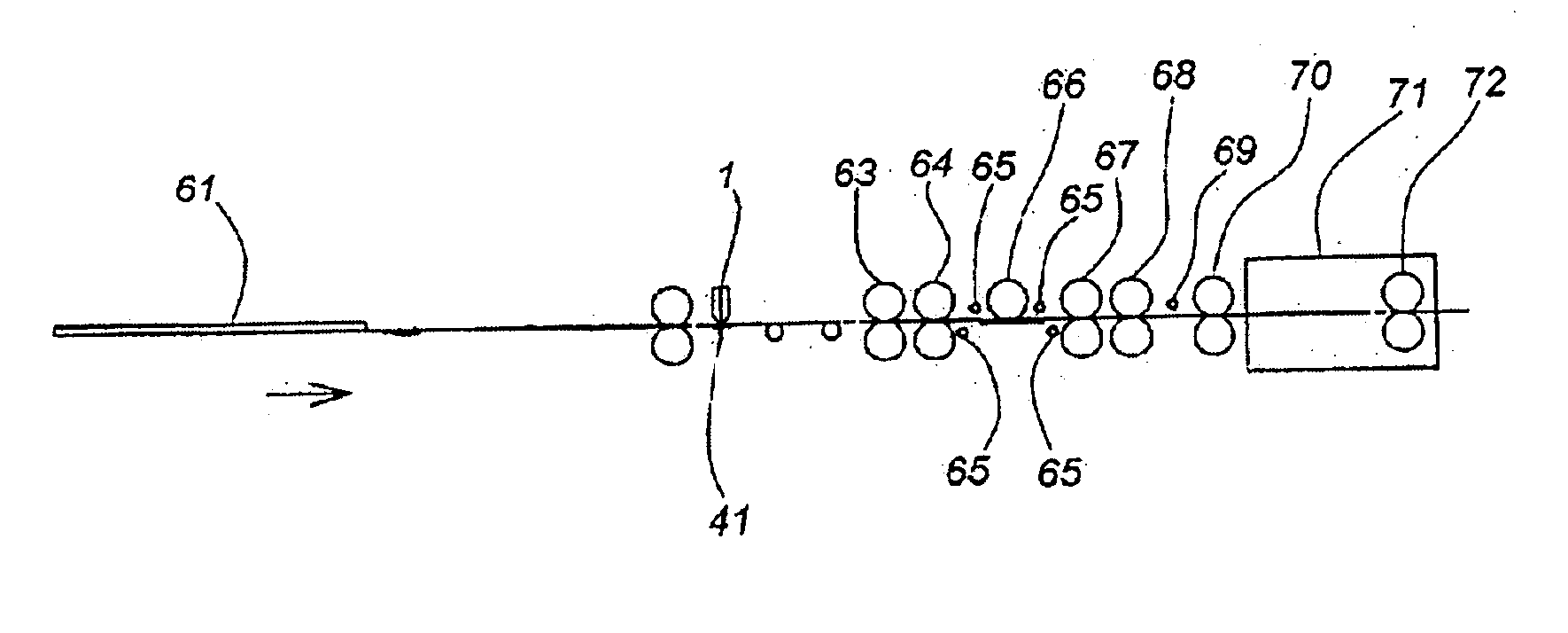

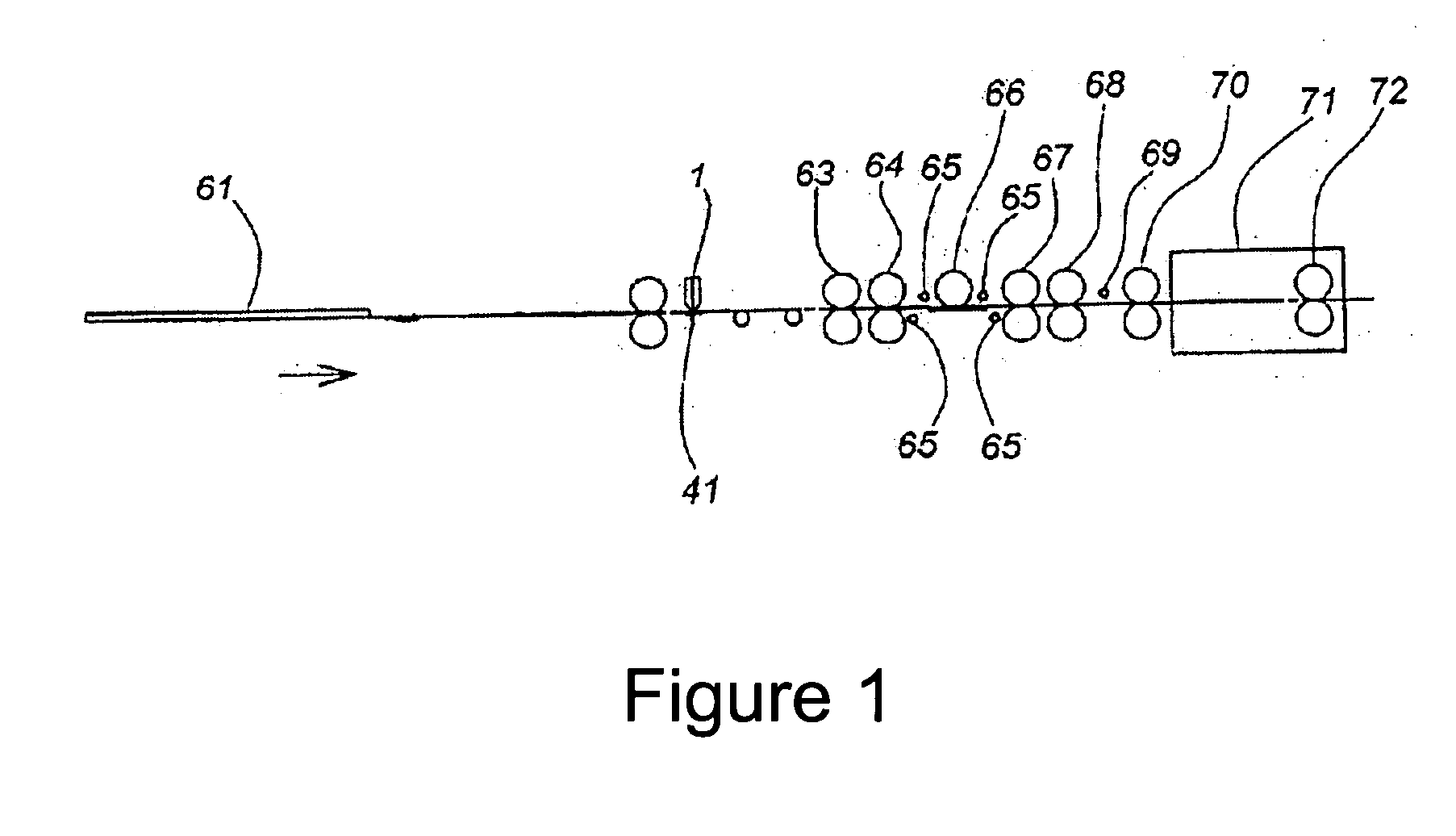

Printing apparatus

InactiveUS6151037ASimple structureAdditional operating advantageRecording apparatusTypewritersMonochromeElectrical and Electronics engineering

A printing apparatus, having a housing in which a thermal transfer printhead station and an ink jet printhead station are mounted, is used for printing indica on a medium, such as tickets, tags and the like. The thermal transfer printhead station is used for printing a monochrome colored indicia on the print medium and the ink jet printhead station is used for printing a single monochrome colored indicia or a plurality of monochrome colored indicia on the print medium. A decoupling station is mounted between the thermal transfer printhead station and the ink jet printhead station for accumulating print medium therein. A sensor is associated with the decoupling station for sensing the amount of print medium accumulated therein. In use, the print medium is passed through the thermal transfer printhead station and a monochrome colored indicia is printed thereon. Thereafter, the print medium is accumulated in the decoupling station and when a predetermined amount of print medium is accumulated therein, the print medium is passed to the ink jet printhead station and a plurality of monochrome colored indicia may be printed thereon or a single monochrome colored indicia is printed thereon. The printed-on medium is thereafter ejected from the printing apparatus. A die cutting or severing structure may be provided for die cutting or severing the print medium.

Owner:ZEBRA TECH CORP

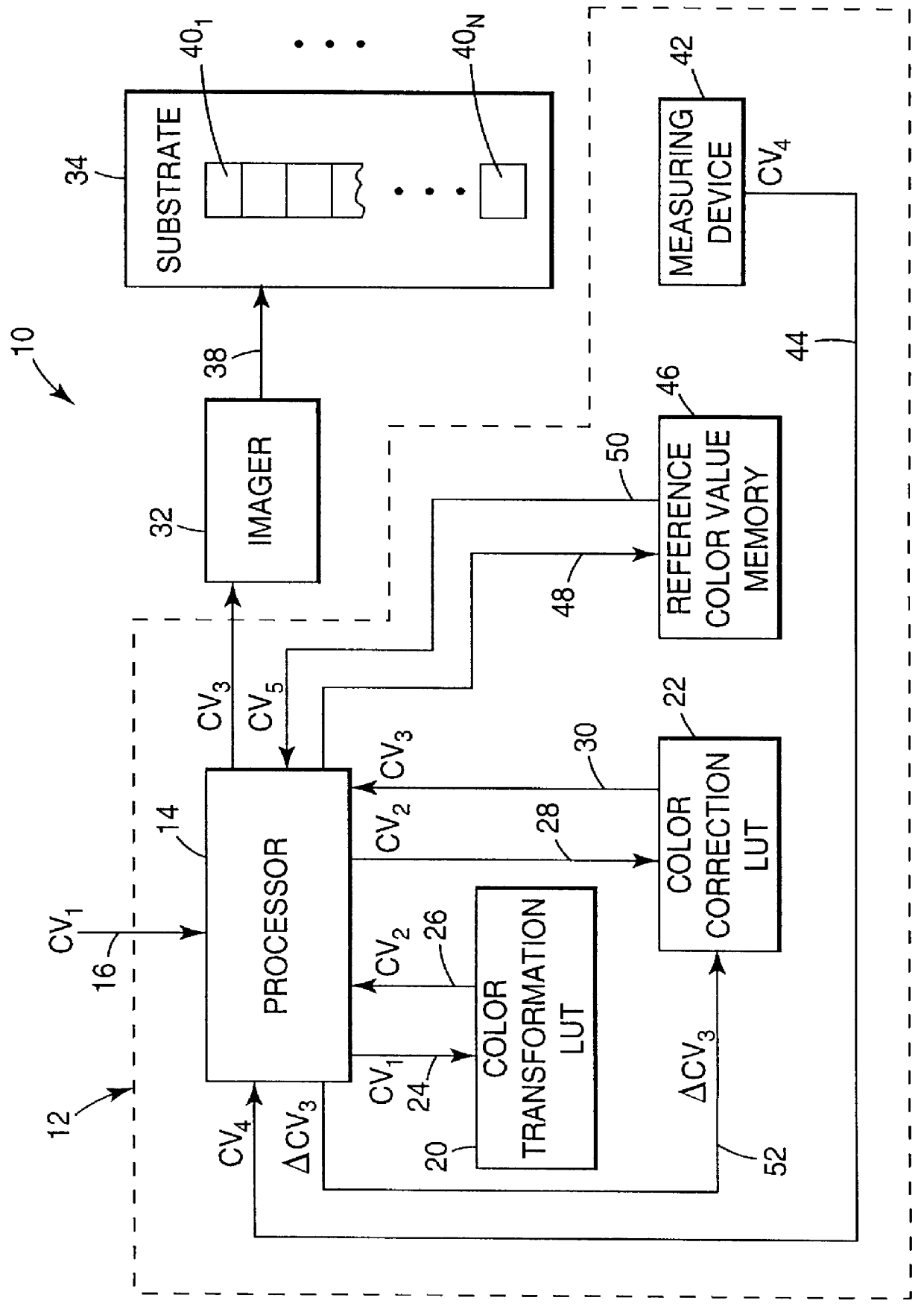

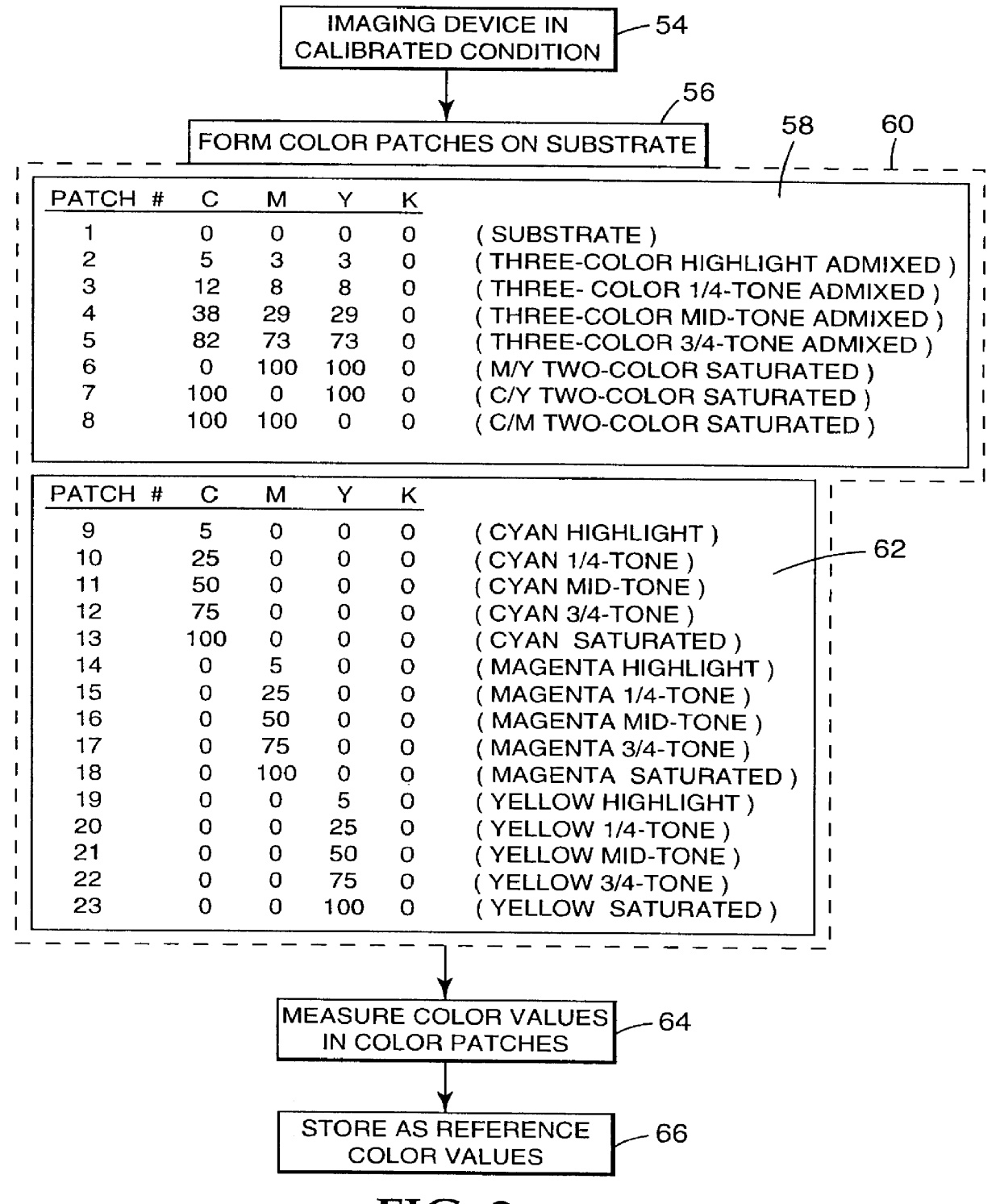

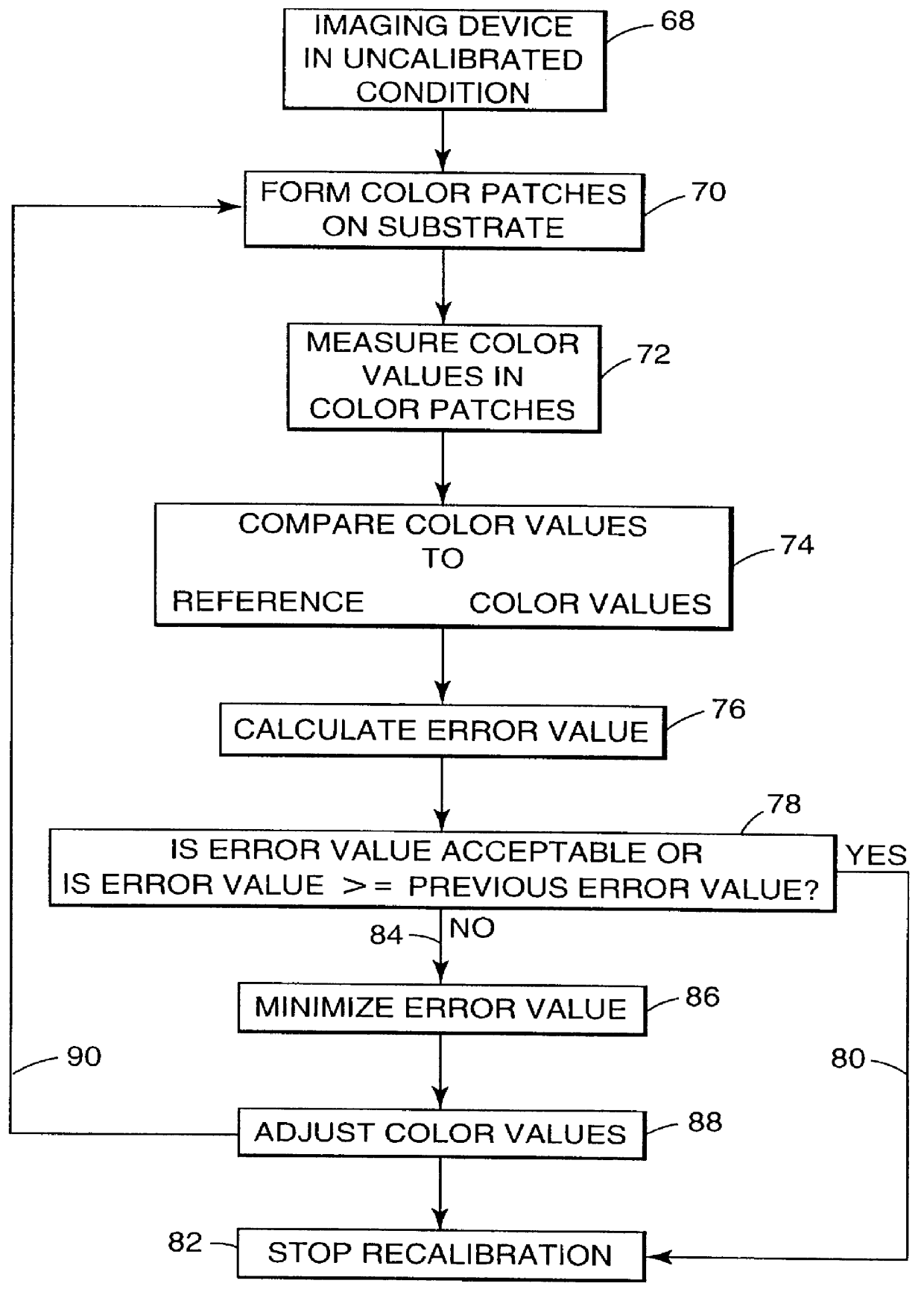

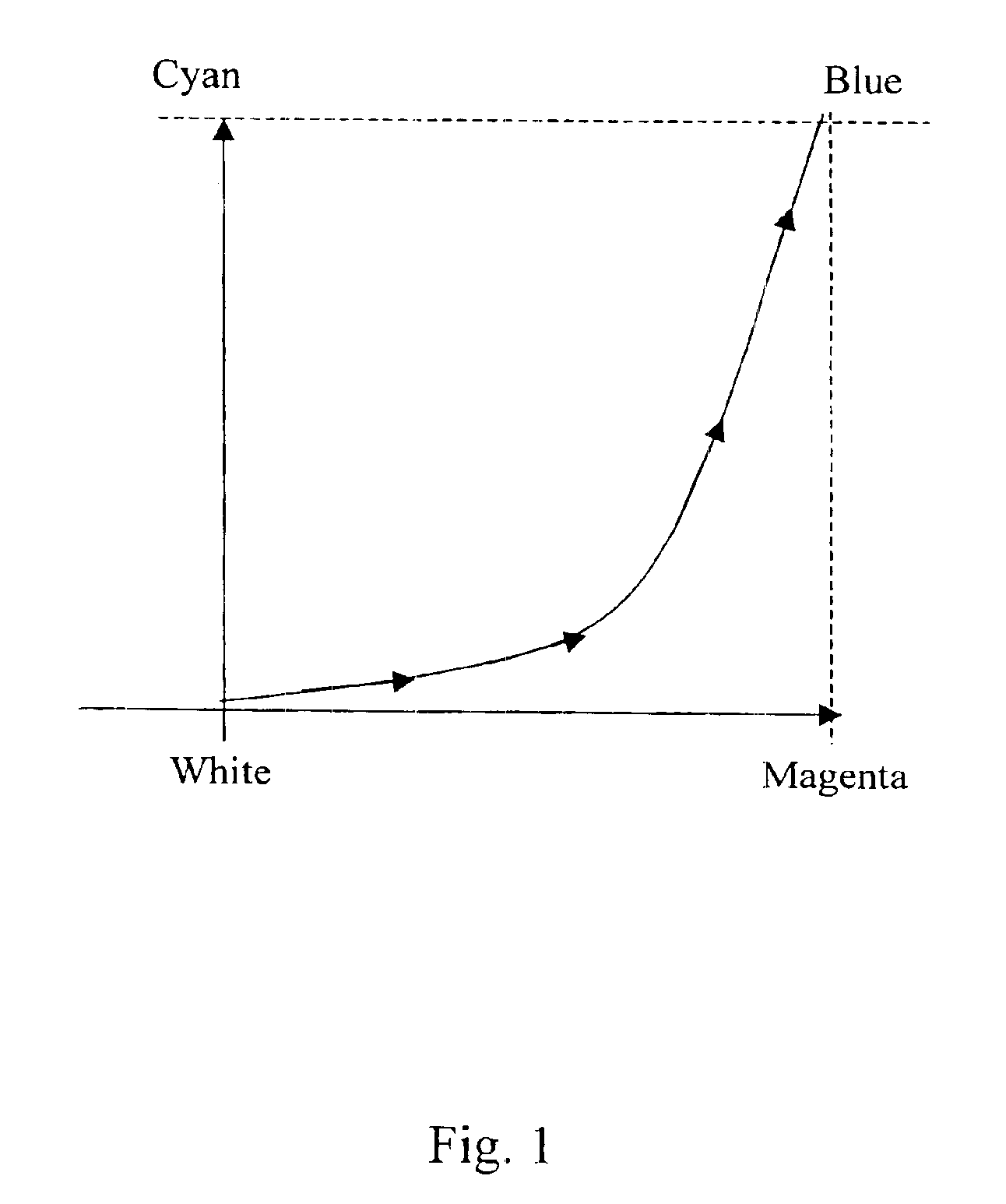

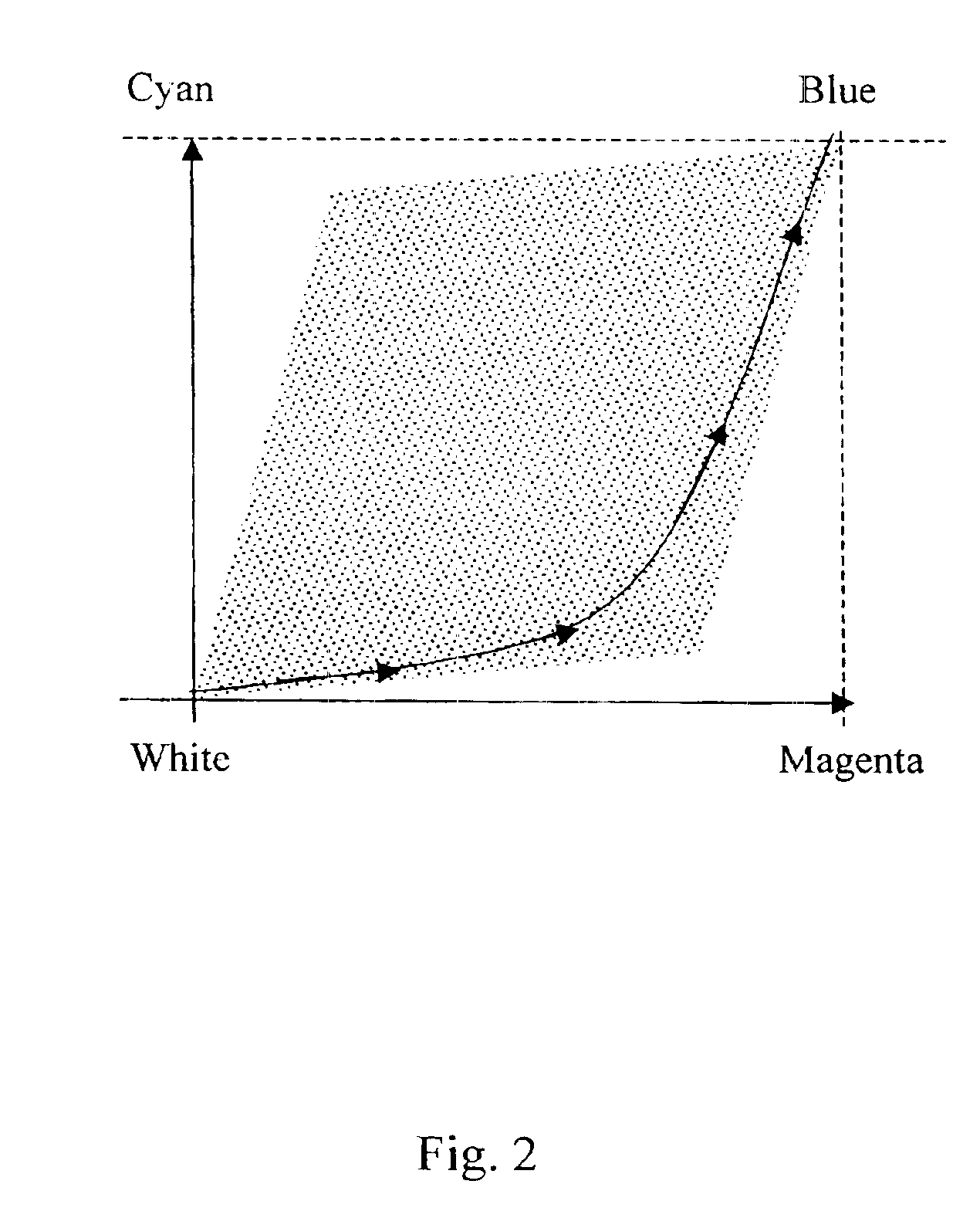

Recalibrating a multi-color imaging system

An apparatus and method for recalibrating a multi-color imaging system are provided. The multi-color imaging system is capable of applying different colorants to a substrate based on a plurality of input color values. The input color values control amounts of the colorants to be applied to the substrate by the imaging system. A subset of the input color values is selected and used to control the imaging system to apply one or more of the different colorants to the substrate, thereby forming a plurality of different color patches on the substrate. The subset of input color values is selected such that one or more of the different color patches is formed by application of a combination of at least two of the different colorants to the substrate. Color values are measured for each of the different color patches, and compared to reference color values, representing a calibrated condition of the imaging system. An error value is calculated. The error value represents a deviation of the measured color values from the reference color values. The input color values for each colorant then are independently adjusted to reduce the error value to a predetermined degree.

Owner:EASTMAN KODAK CO

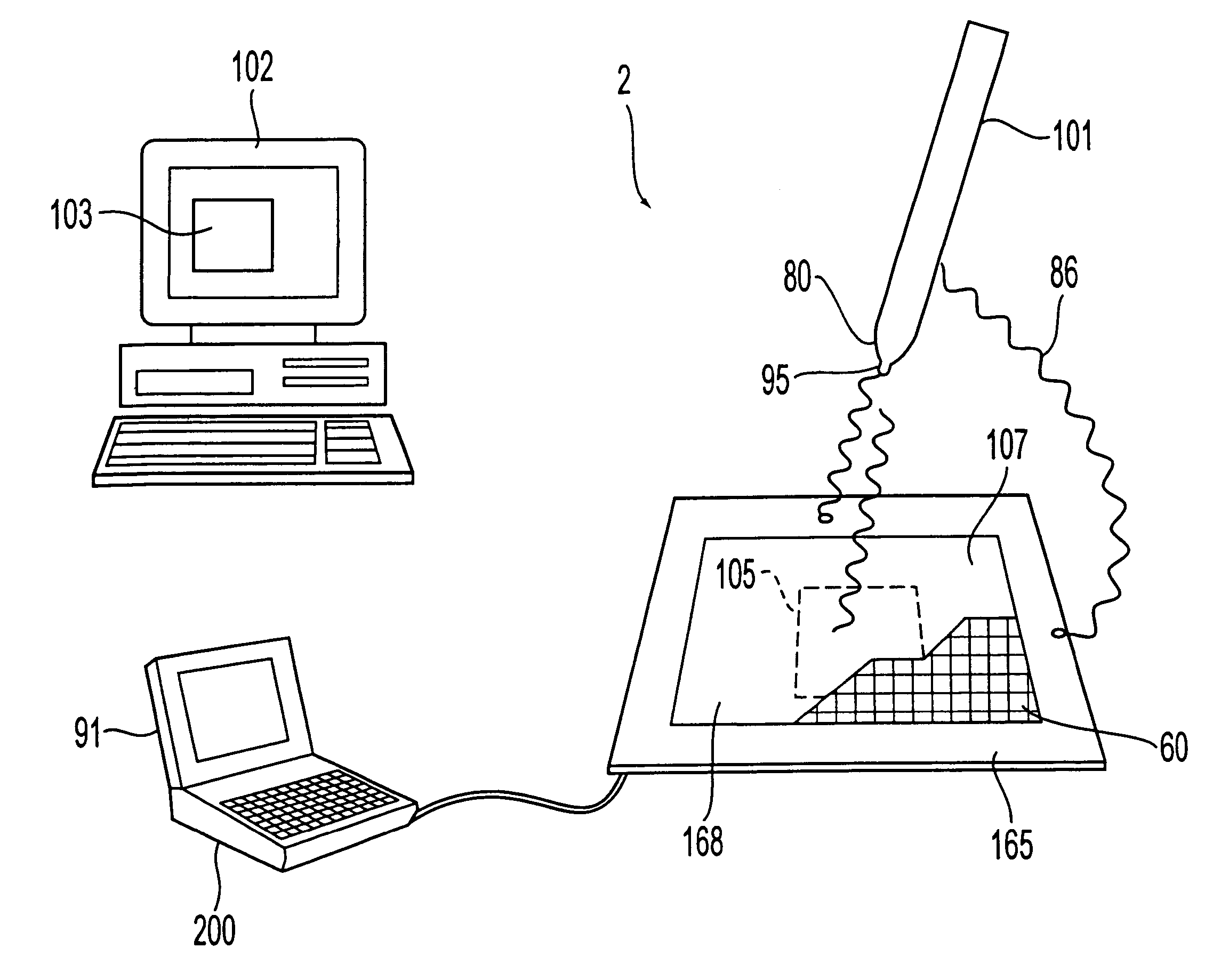

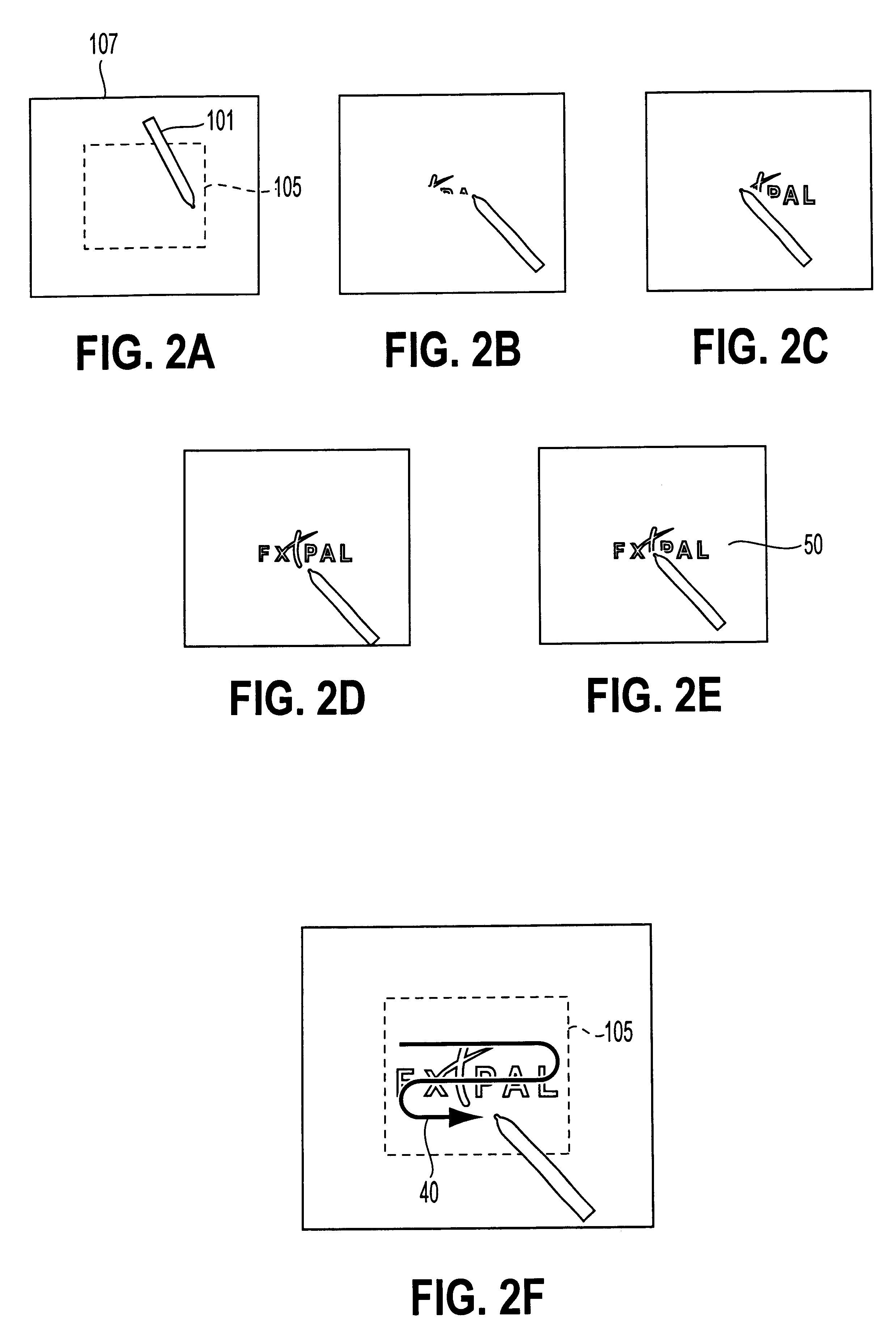

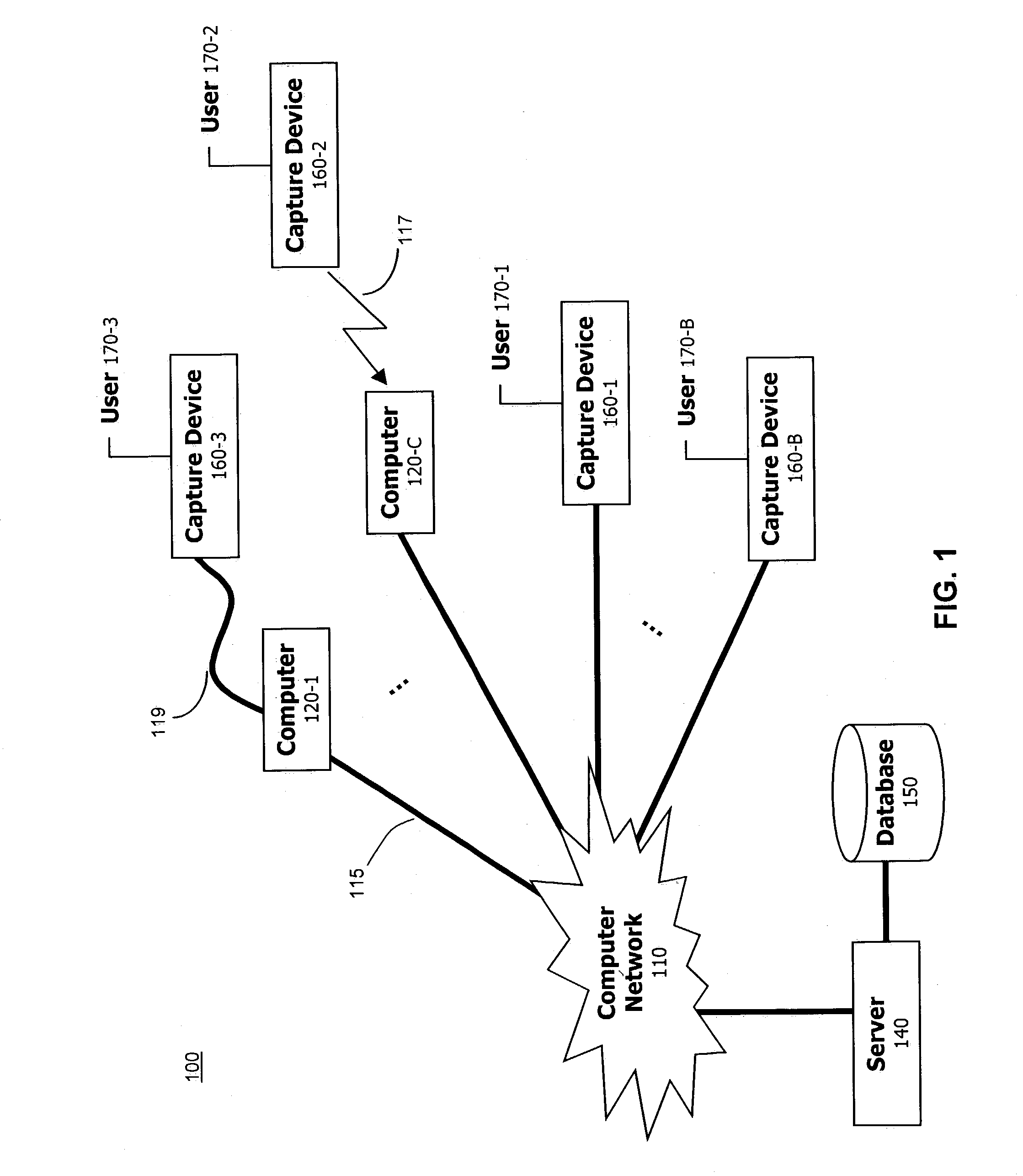

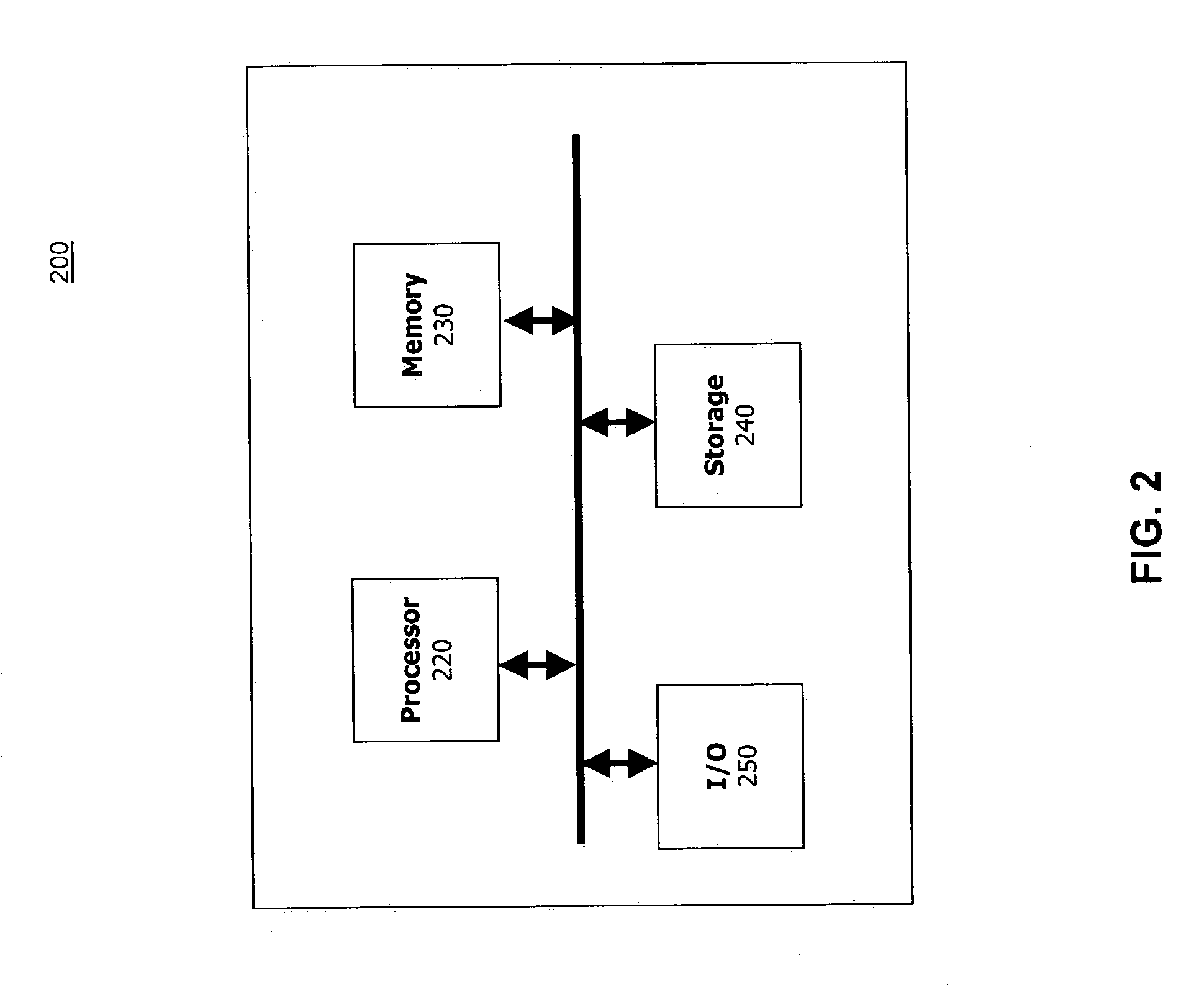

Method and system for position-aware freeform printing within a position-sensed area

Owner:FUJIFILM BUSINESS INNOVATION CORP

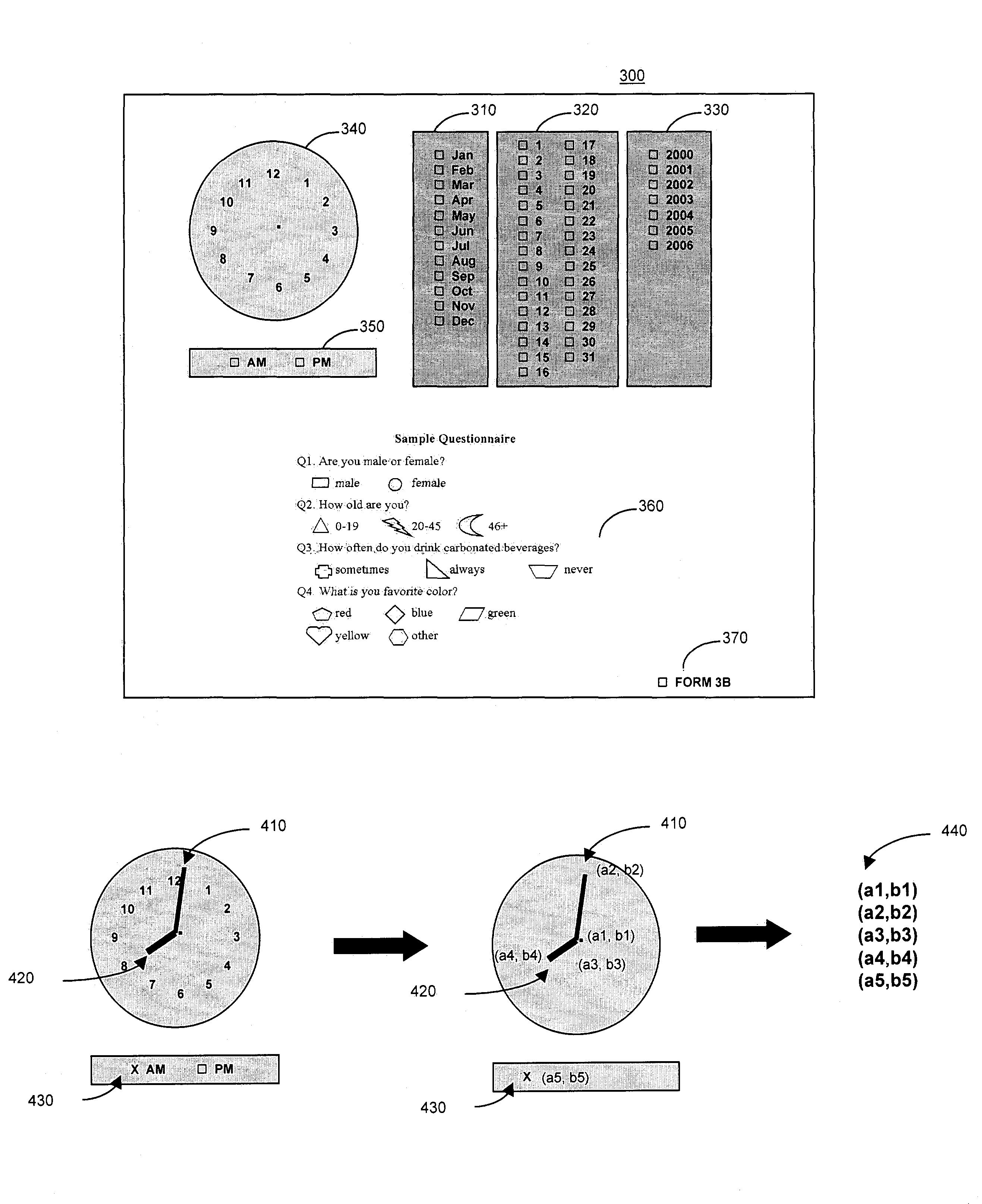

Method and system for recognizing time

ActiveUS7257254B2Easy to identifyPromote productionTelevision system detailsRecording apparatusGraphicsTime information

A method and system for recognizing time. An embodiment of a method for recognizing a time includes receiving a set of coordinates from a capture device, the set of coordinates indicating where a set of marks was made on a paper form without the use of a graphical user interface, and mapping the set of coordinates to a time. The method enables a processor to accurately and quickly determine time information entered on a piece of paper attached to the capture device, independent of the user who enters the time information. Exemplary applications include a field survey and inventory.

Owner:SAP AG

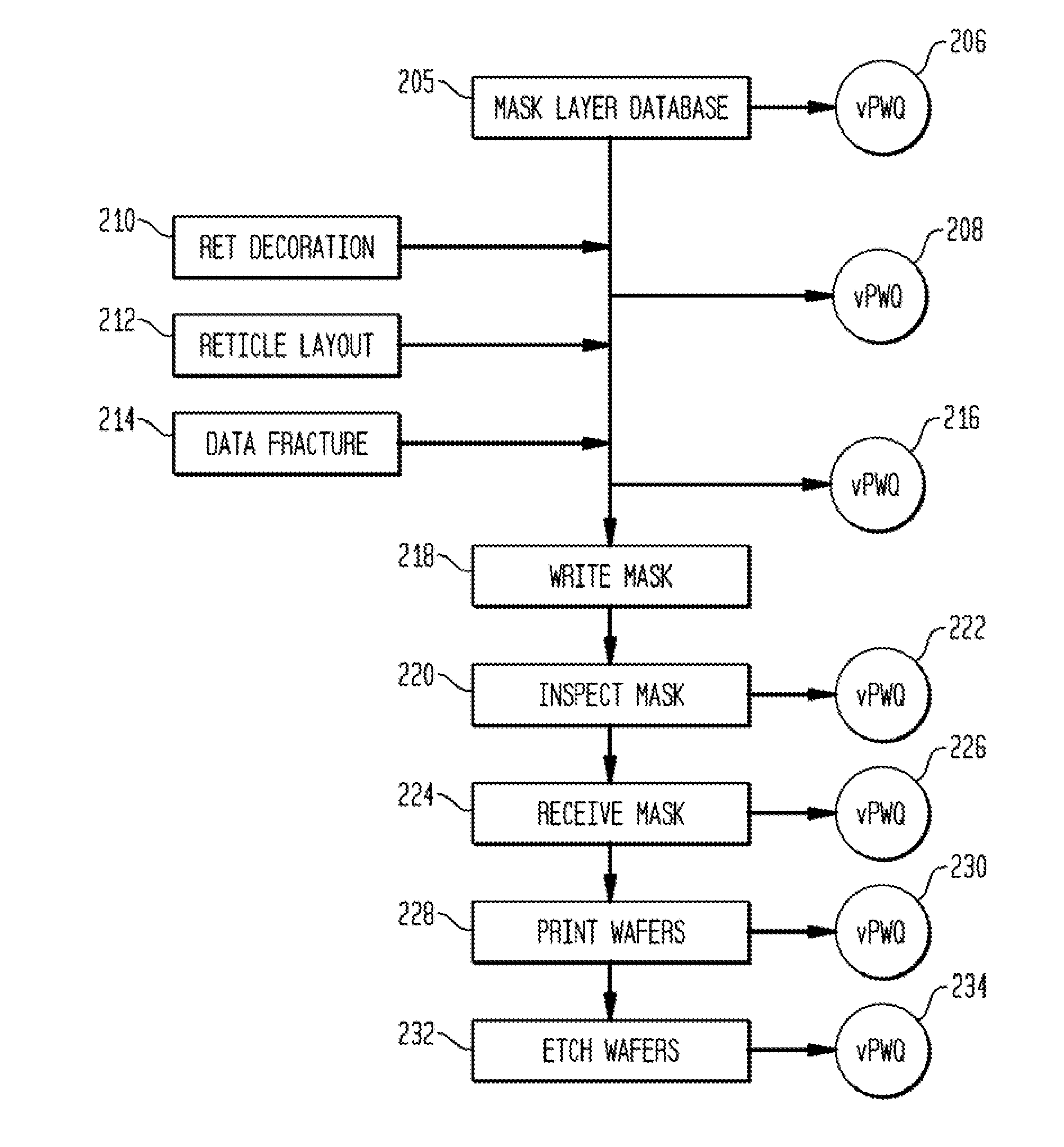

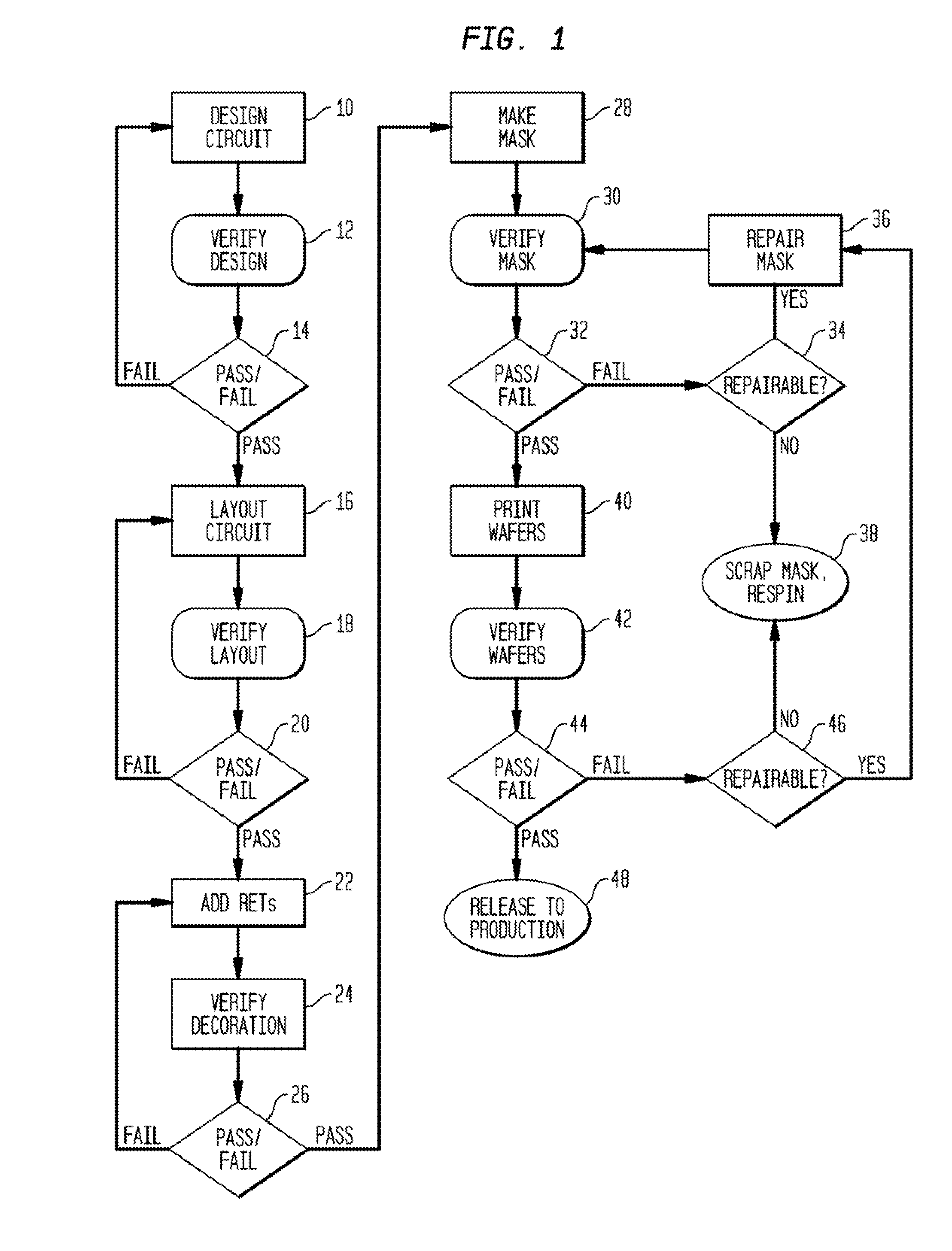

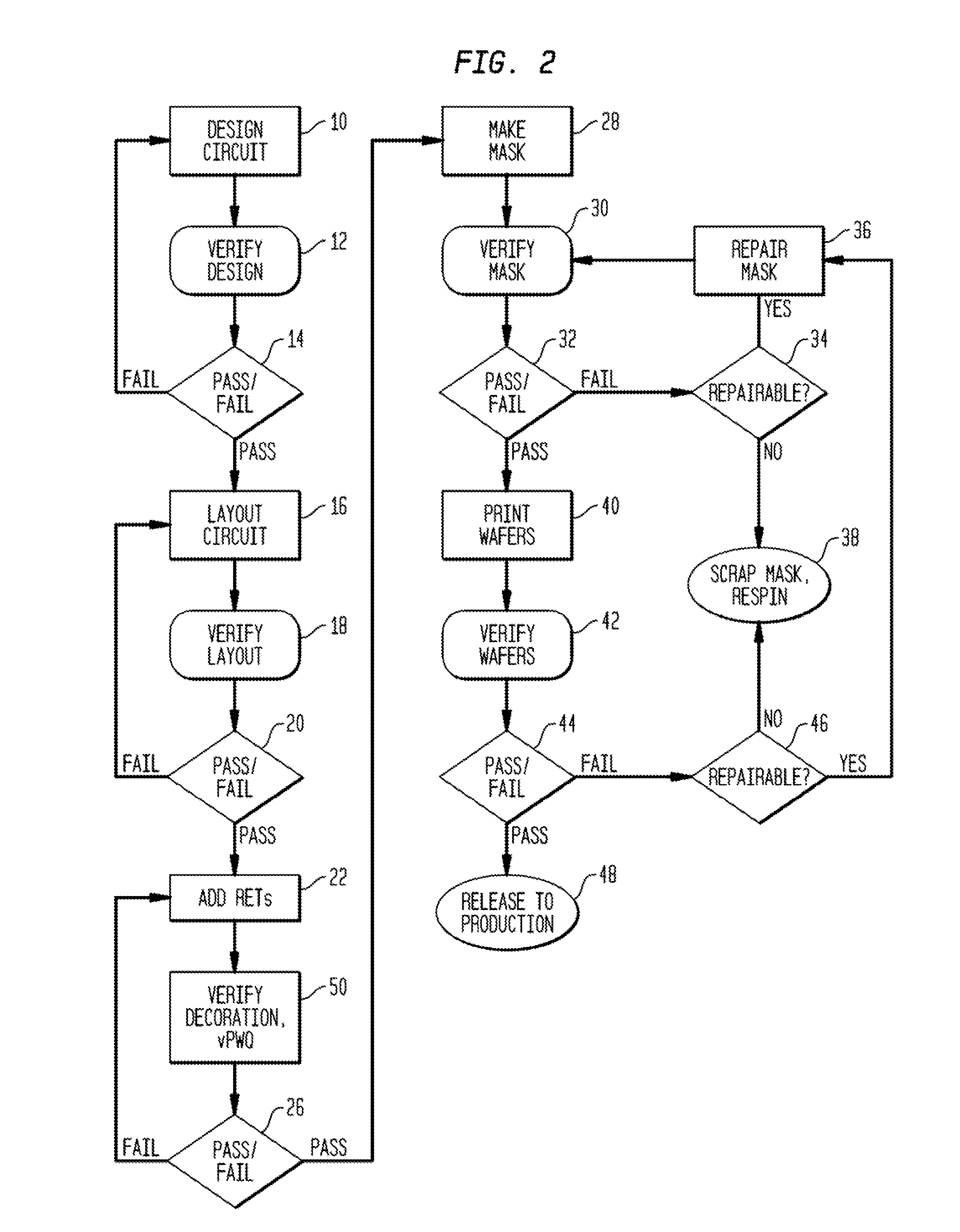

Computer-implemented methods and systems for determining different process windows for a wafer printing process for different reticle designs

ActiveUS20080072207A1Maximize distanceRecording apparatusOriginals for photomechanical treatmentEngineeringProcess window

Computer-implemented methods and systems for determining different process windows for a wafer printing process for different reticle designs are provided. One method includes generating simulated images illustrating how each of the different reticle designs will be printed on a wafer at different values of one or more parameters of the wafer printing process. The method also includes detecting defects in each of the different reticle designs using the simulated images. In addition, the method includes determining a process window for the wafer printing process for each of the different reticle designs based on results of the detecting step.

Owner:KLA TENCOR TECH CORP

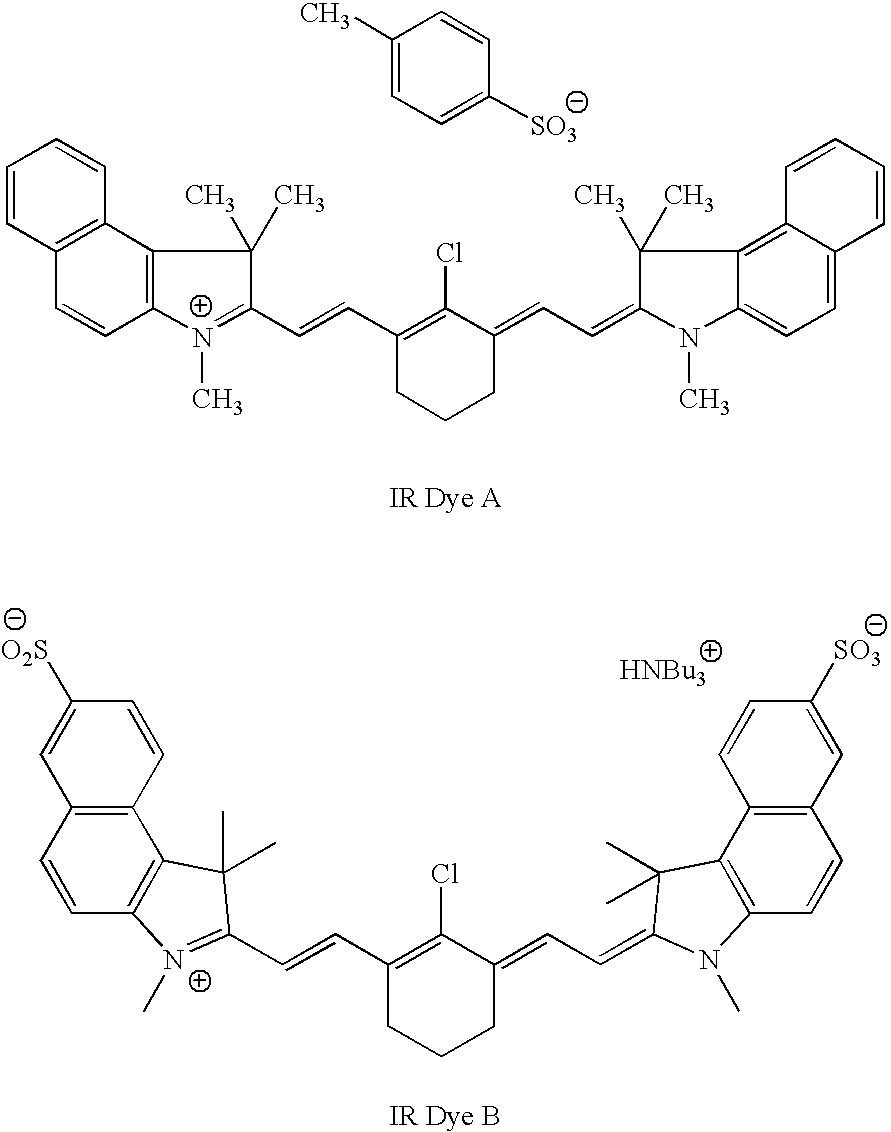

Method for developing multilayer imageable elements

InactiveUS20050162505A1Recording apparatusSemiconductor/solid-state device manufacturingEngineeringStochastic screening

A method for forming an image by imaging and developing a multi-layer imageable element, in which the developer is fresh developer and the developer is not reused, is disclosed. Much smaller variation in dot percentage is obtained when each imaged imageable element is developed in fresh developer than when the developer is reused to develop additional imaged imageable elements. The method is especially suited to the formation of images using stochastic screening. Either a solvent based developer or a high pH developer may be used.

Owner:KODAK POLYCHROME GRAPHICS

Electrical, Plating And Catalytic Uses Of Metal Nanomaterial Compositions

ActiveUS20080020304A1Improve absorption rateReduce reflectivityOptical radiation measurementMangetographic processBiological activationElectroplating

This invention relates generally to uses of novel nanomaterial composition and the systems in which they are used, and more particularly to nanomaterial compositions generally comprising carbon and a metal, which composition can be exposed to pulsed emissions to react, activate, combine, or sinter the nanomaterial composition. The nanomaterial compositions can alternatively be utilized at ambient temperature or under other means to cause such reaction, activation, combination, or sintering to occur.

Owner:NCC NANO LLC

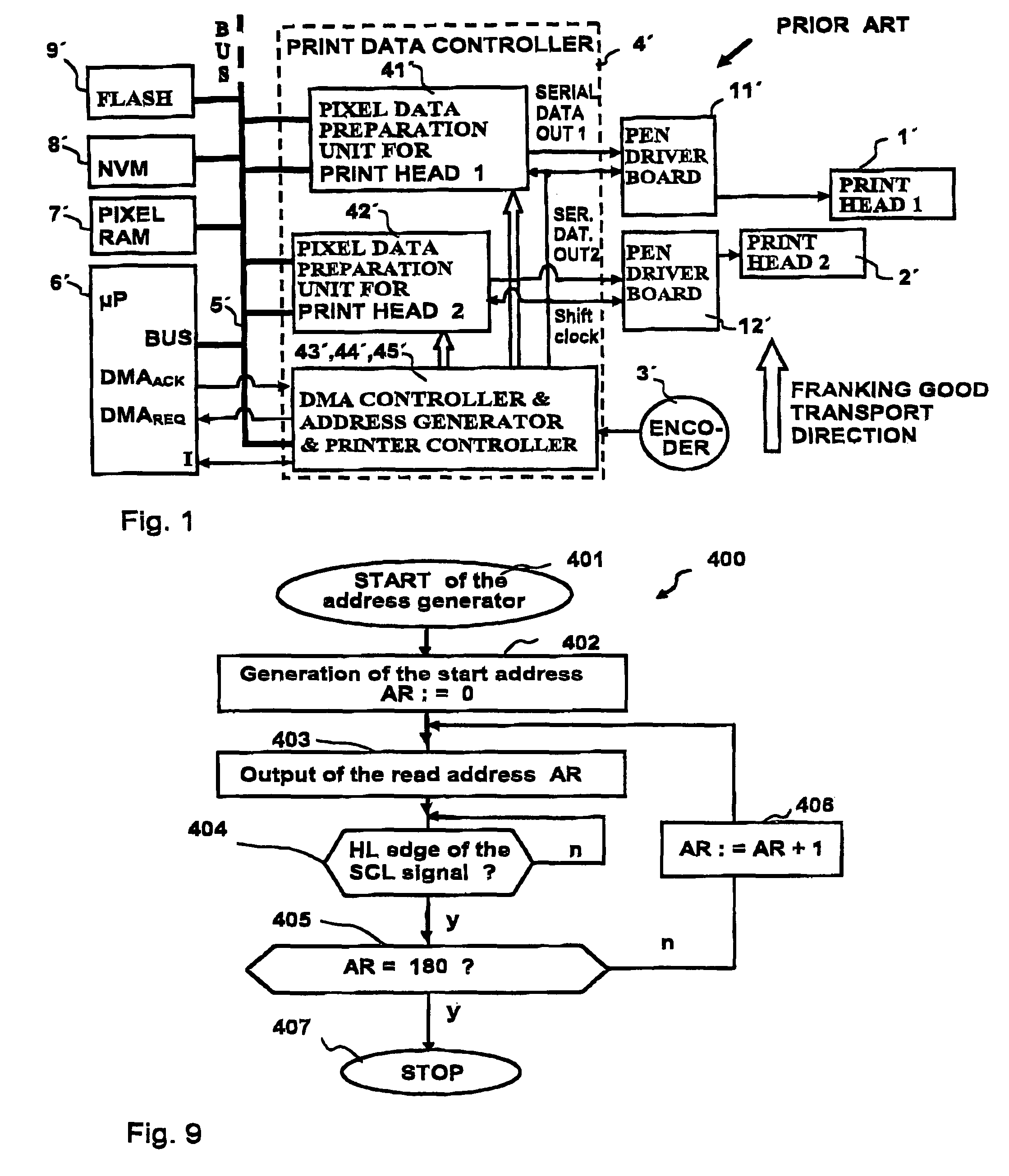

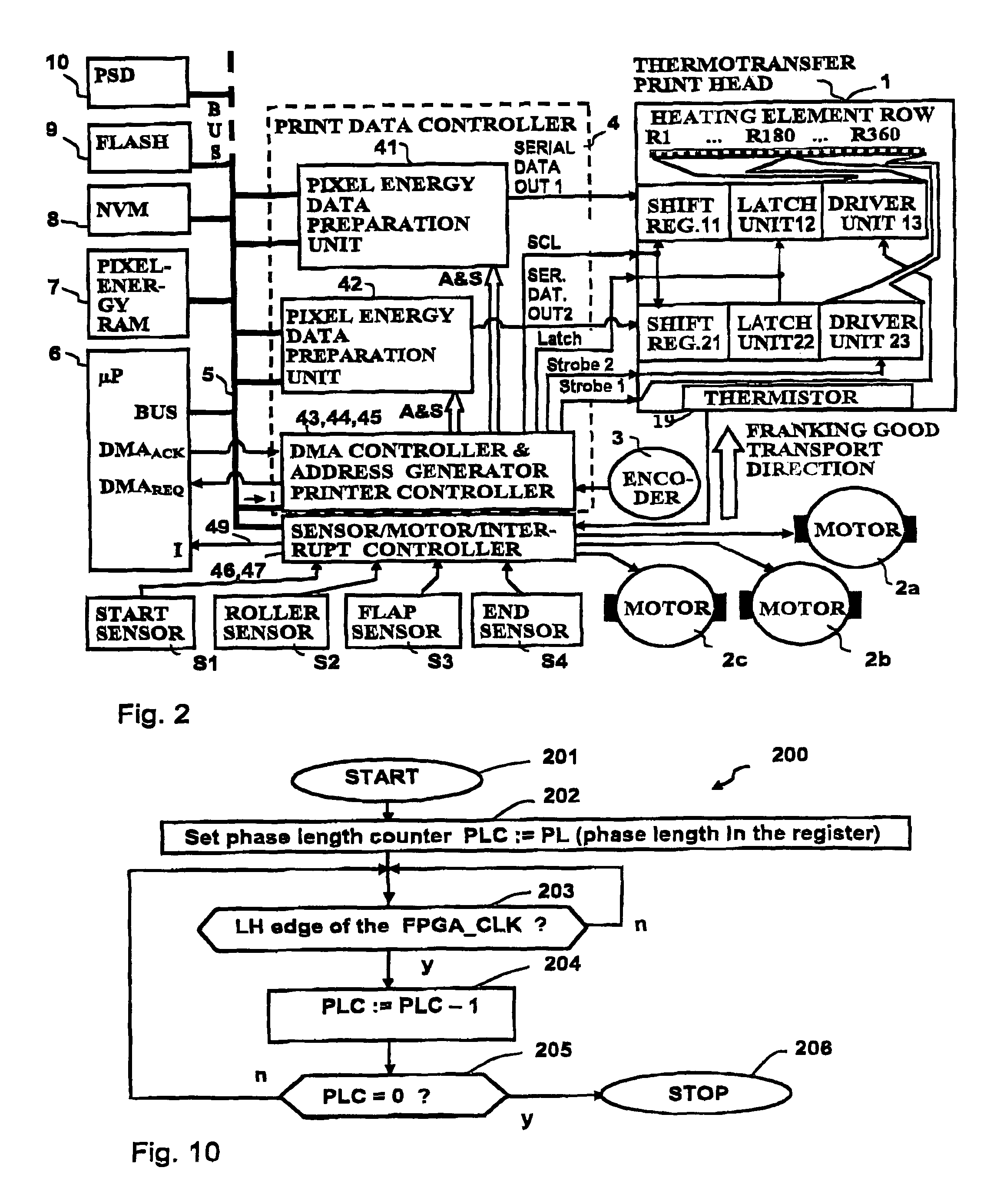

Method and arrangement for control of the printing of a thermotransfer printing device

InactiveUS7965308B2Improve throughputHigh resolutionRecording apparatusFranking apparatusShift registerData control

In a method and an arrangement for controlling printing by a thermotransfer printing apparatus with relative movement between a thermotransfer print head and a print medium, a microprocessor that provides pixel energy data to a pixel energy memory by making an energy value calculation and by coding, and a print data controller prepares the pixel energy data by decoding during the printing in a number (corresponding to the pixel energy value) of binary pixel data each with the same binary value. The print data controller includes at least one pixel energy data preparation unit, a DMA controller, an address generator, a printer controller and a phase counter. The DMA controller allows an access to the pixel energy data stored in the pixel energy memory as code in order to provide the pixel energy data in print columns to the at least one pixel energy data preparation unit. The address generator generates addresses for selection of the buffered code during each phase of a number of phases. The phase counter supplies a phase count value to a phase data preparation unit in which the code value A and phase count value B are compared in order to generated binary pixel data, which are serially supplied from the output D to at least one shift register of the thermotransfer print head.

Owner:FRANCOTYP POSTALIA

Tape printer

InactiveUS20070172293A1Loading and unloadingBetter quality printingInk ribbon cartridgesRecording apparatusMagnetic tape

Owner:DYMO (BVBA)

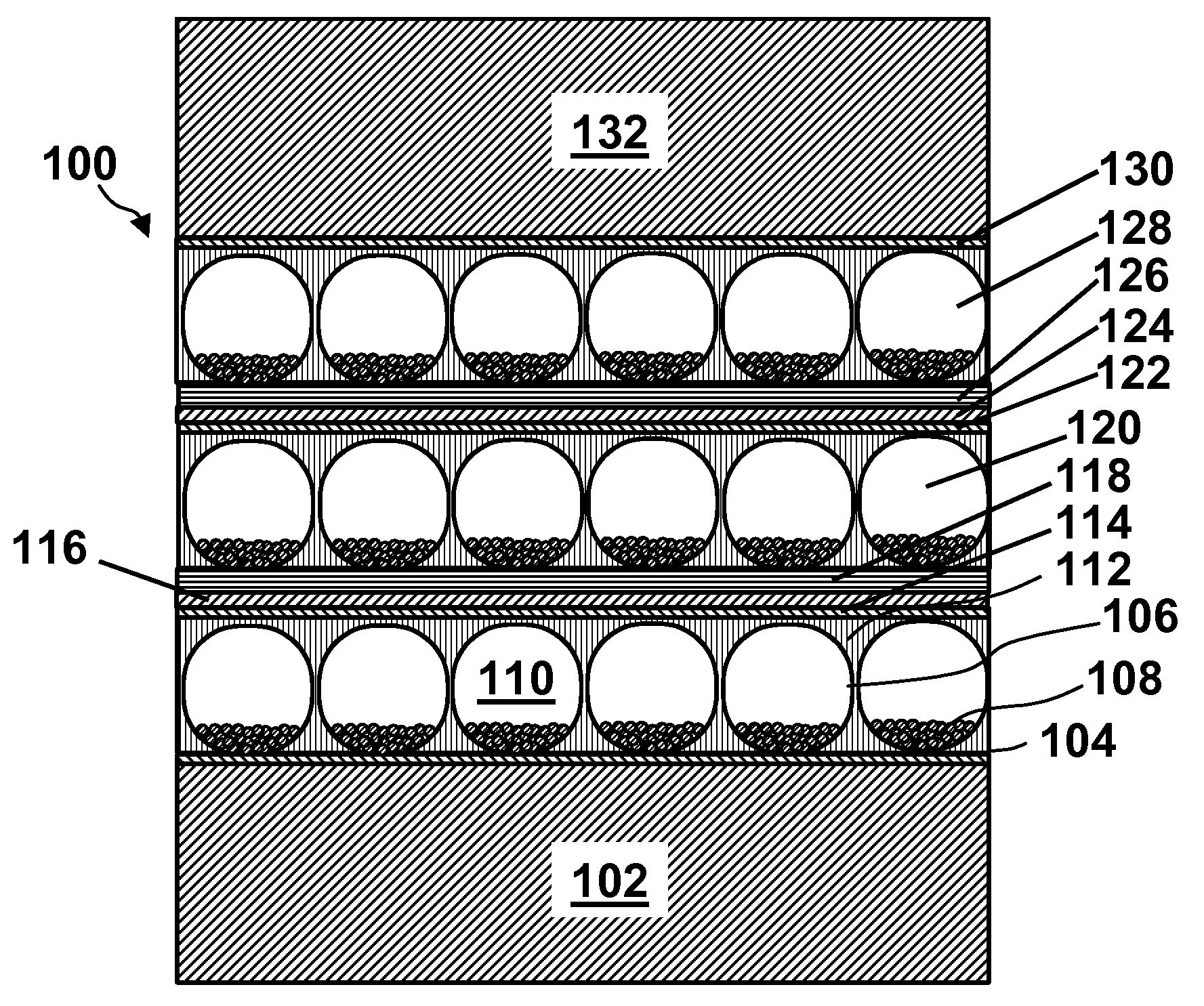

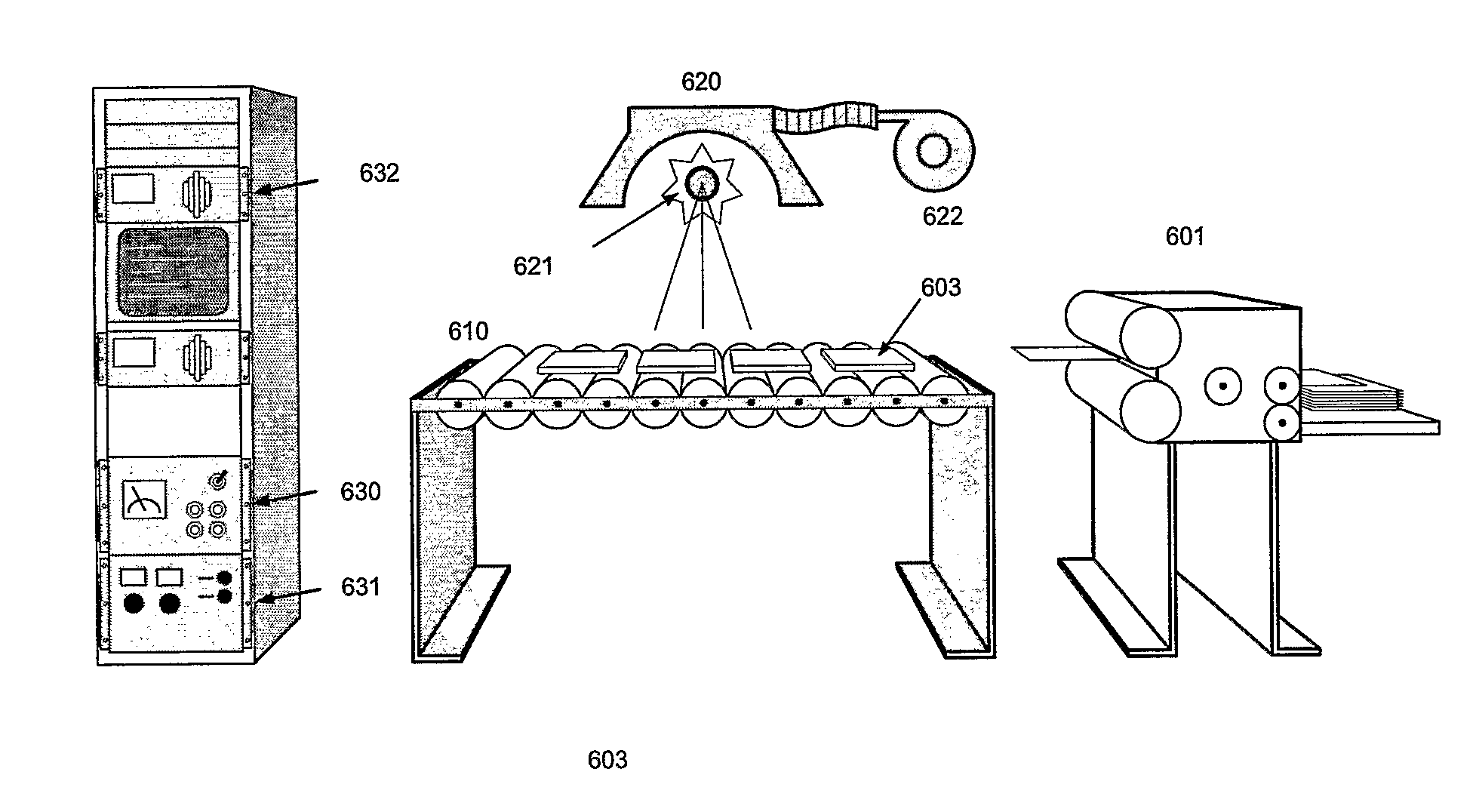

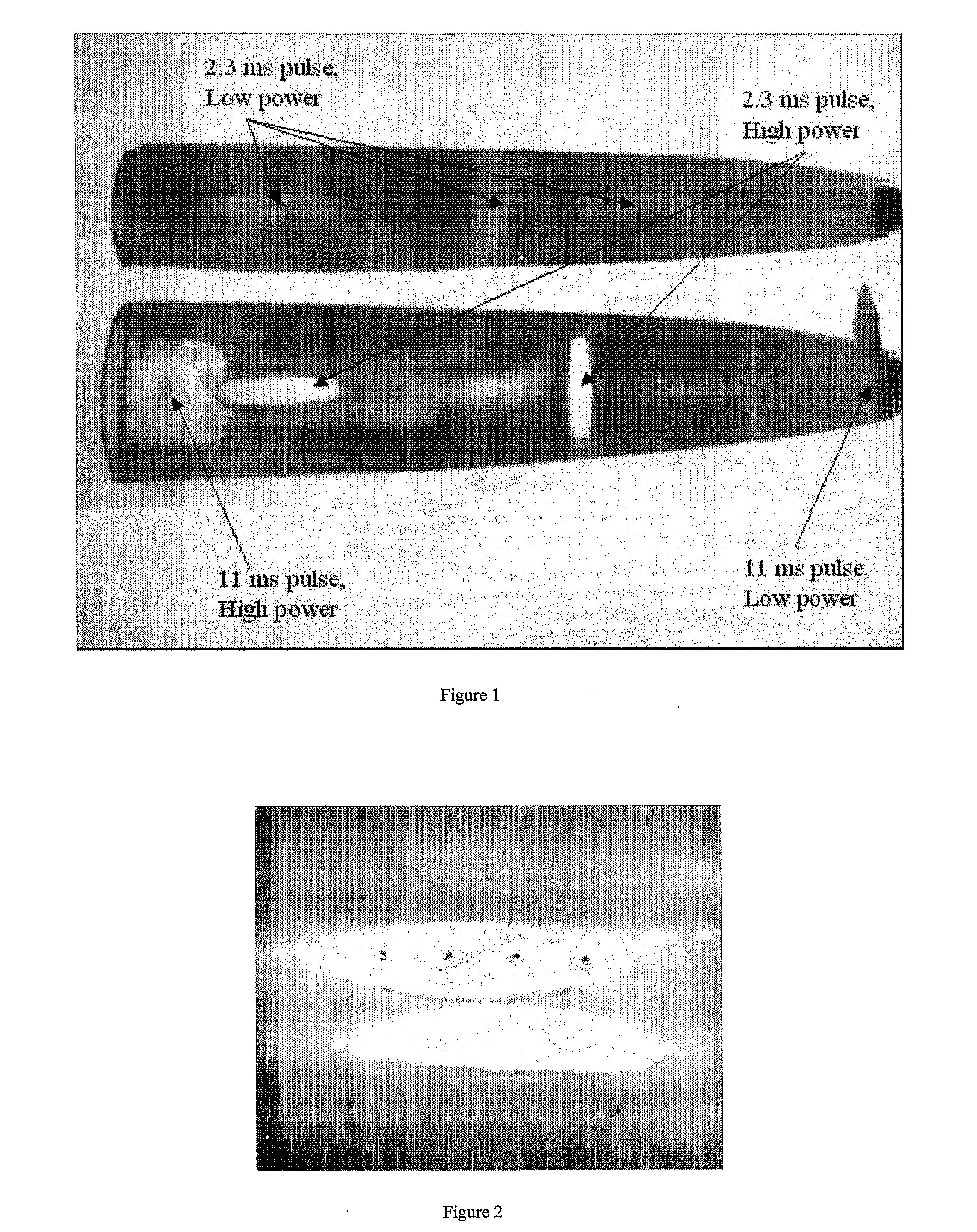

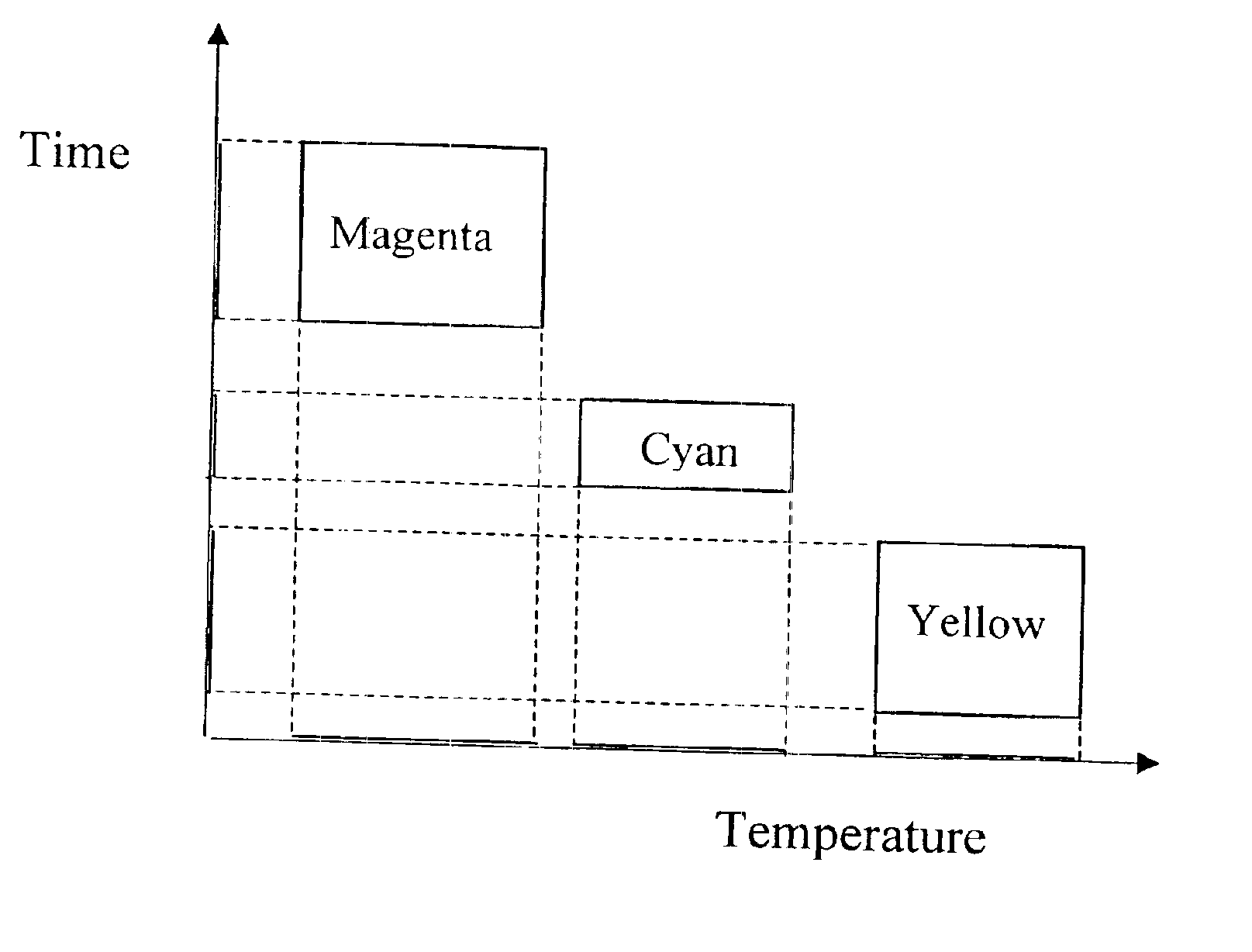

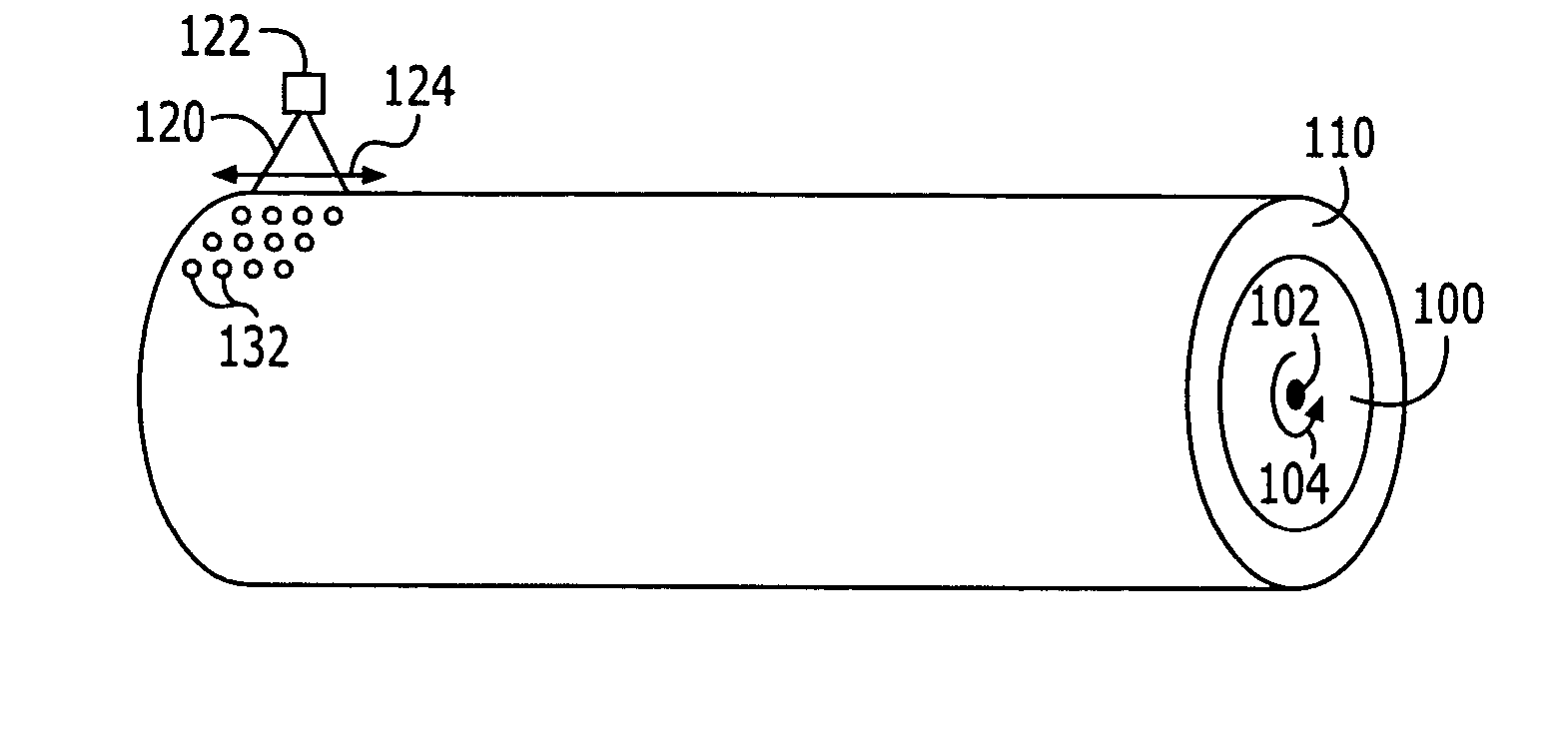

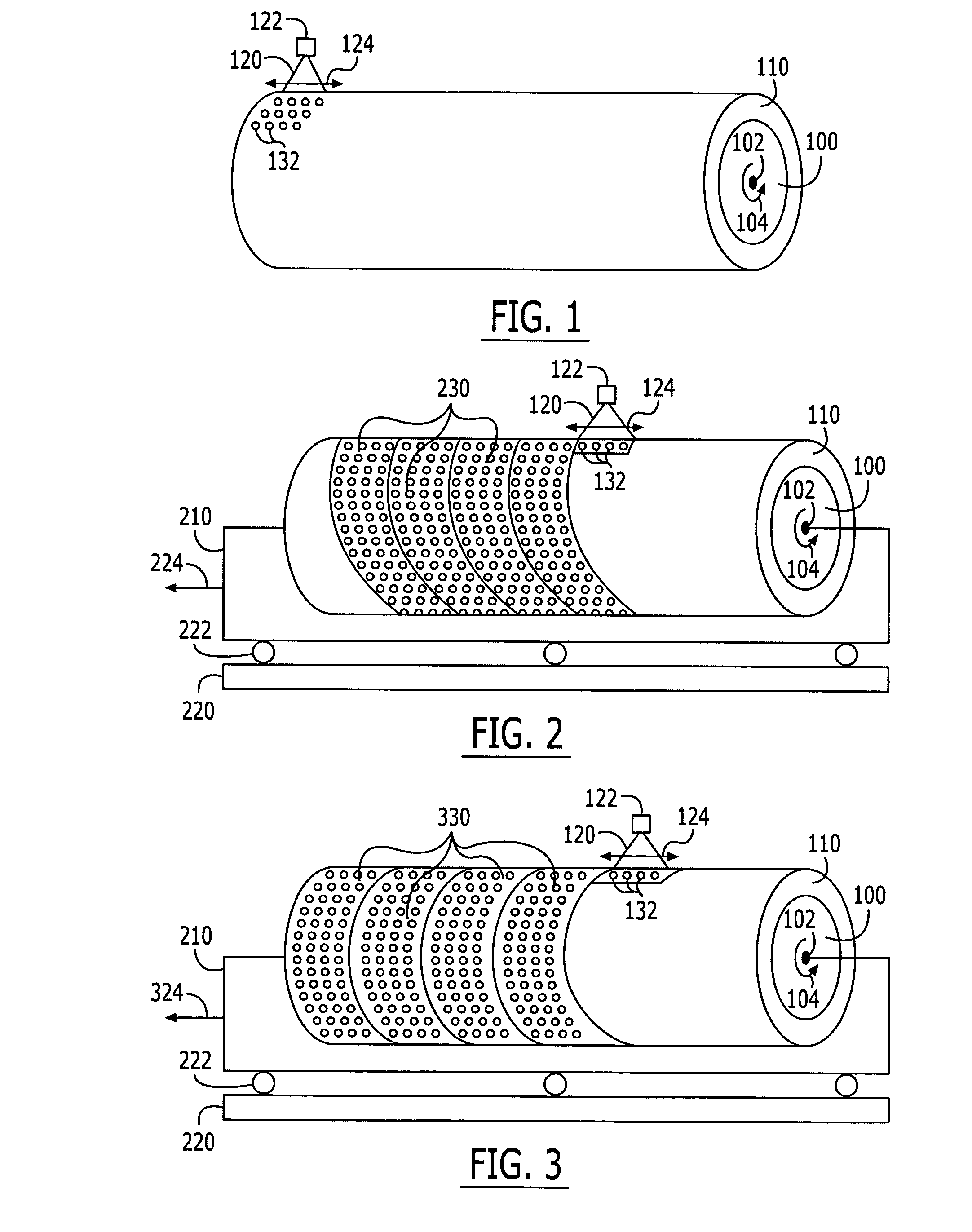

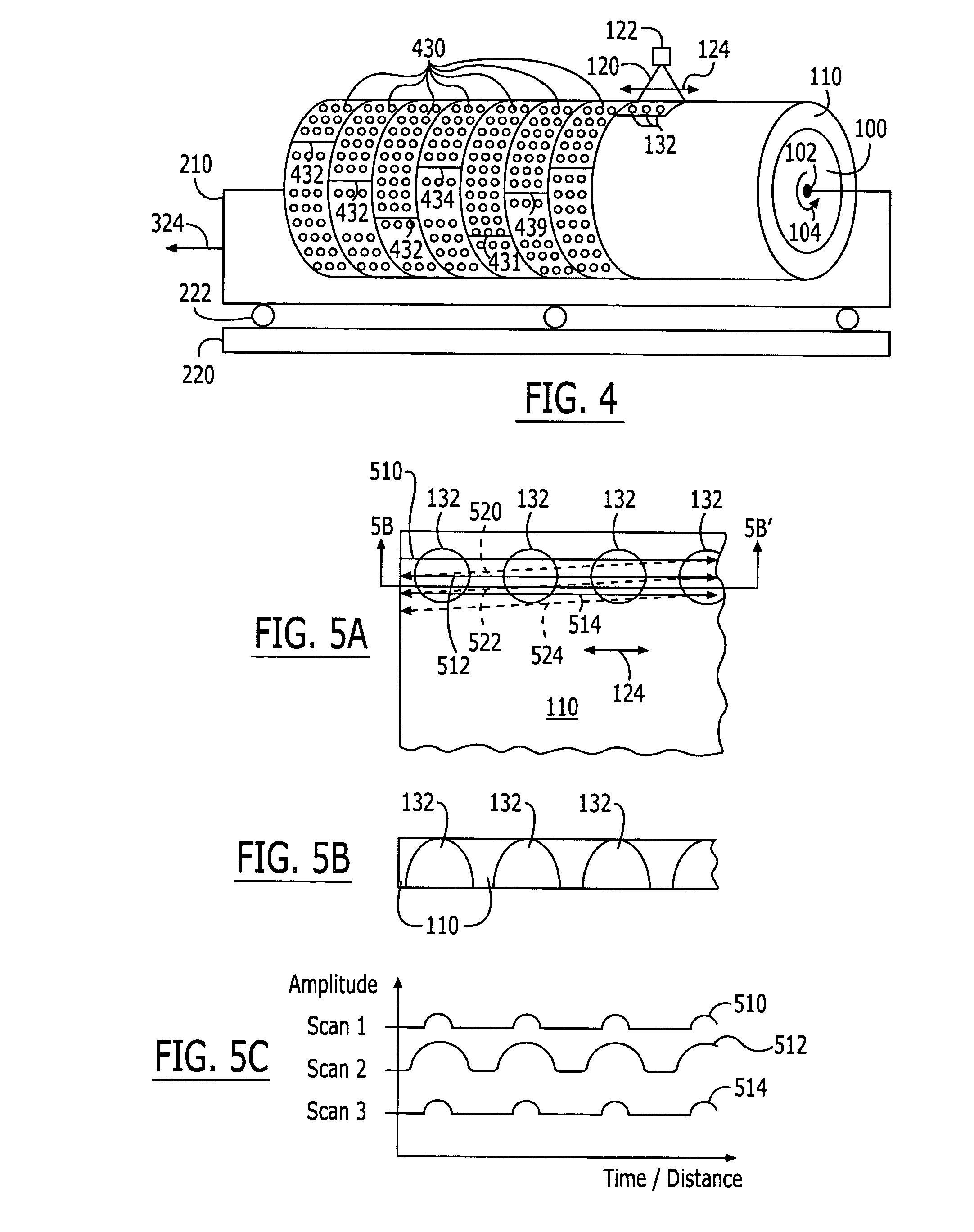

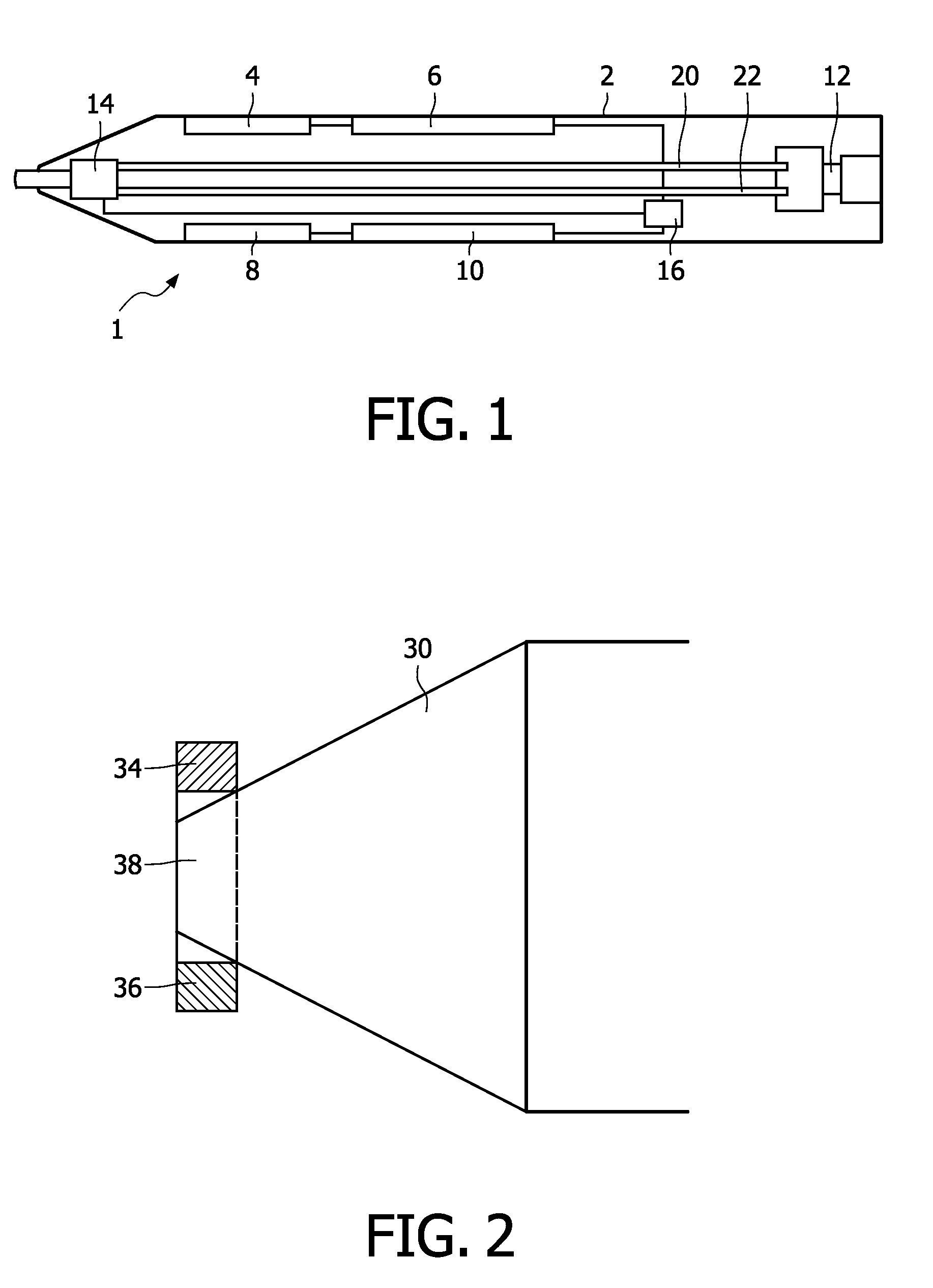

Thermal imaging system

A multicolor imaging system is described wherein at least two, and preferably three, different image-fonning layers of a thermal imaging member are addressed at least partially independently by a thermal printhead or printheads from the same surface of the imaging member by controlling the temperature of the thermal printhead(s) and the time thermal energy is applied to the image-forming layers. Each color of the thermal imaging member can be printed alone or in selectable proportion to the other color(s). Novel thermal imaging members are also described.

Owner:ZINK IMAGING

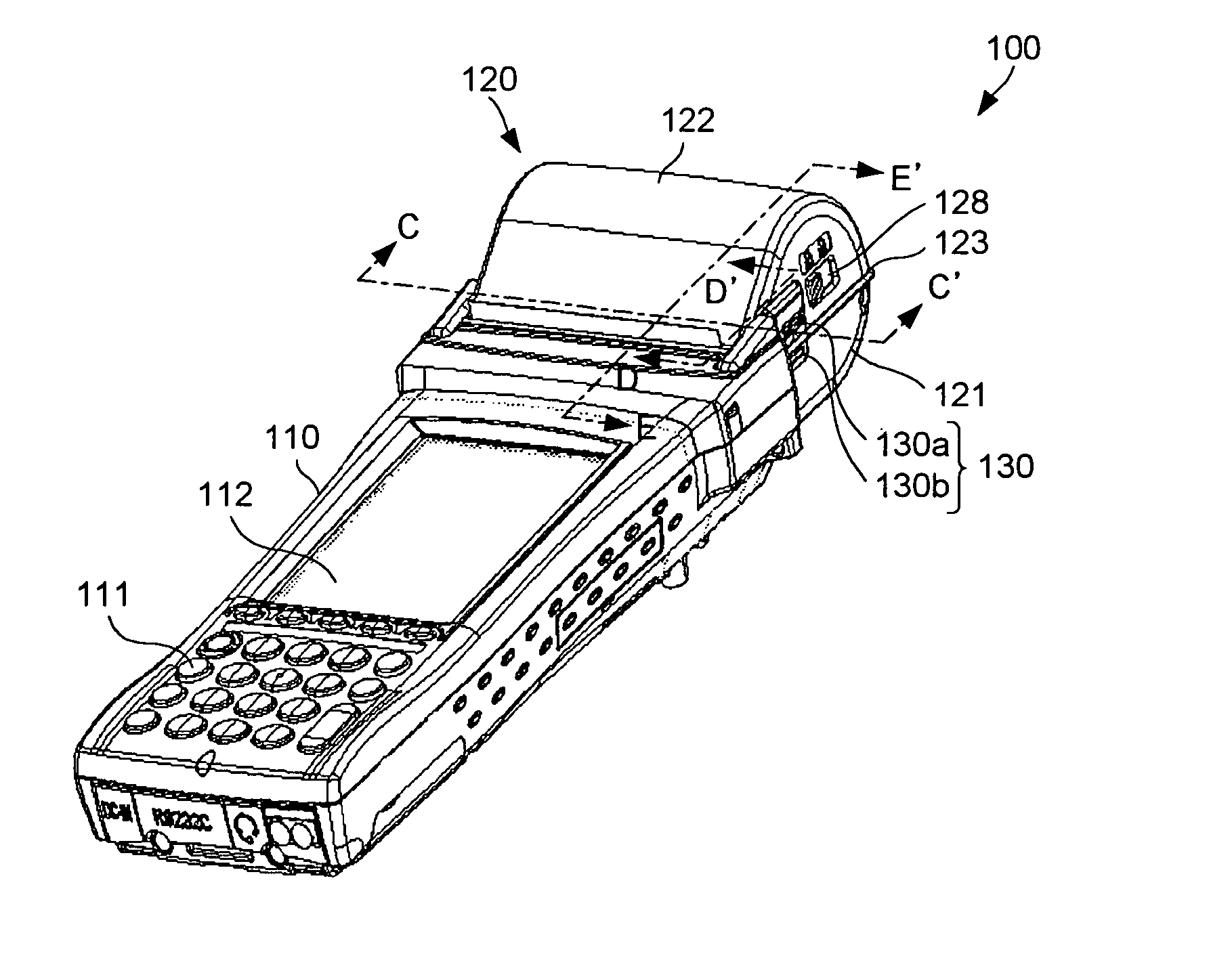

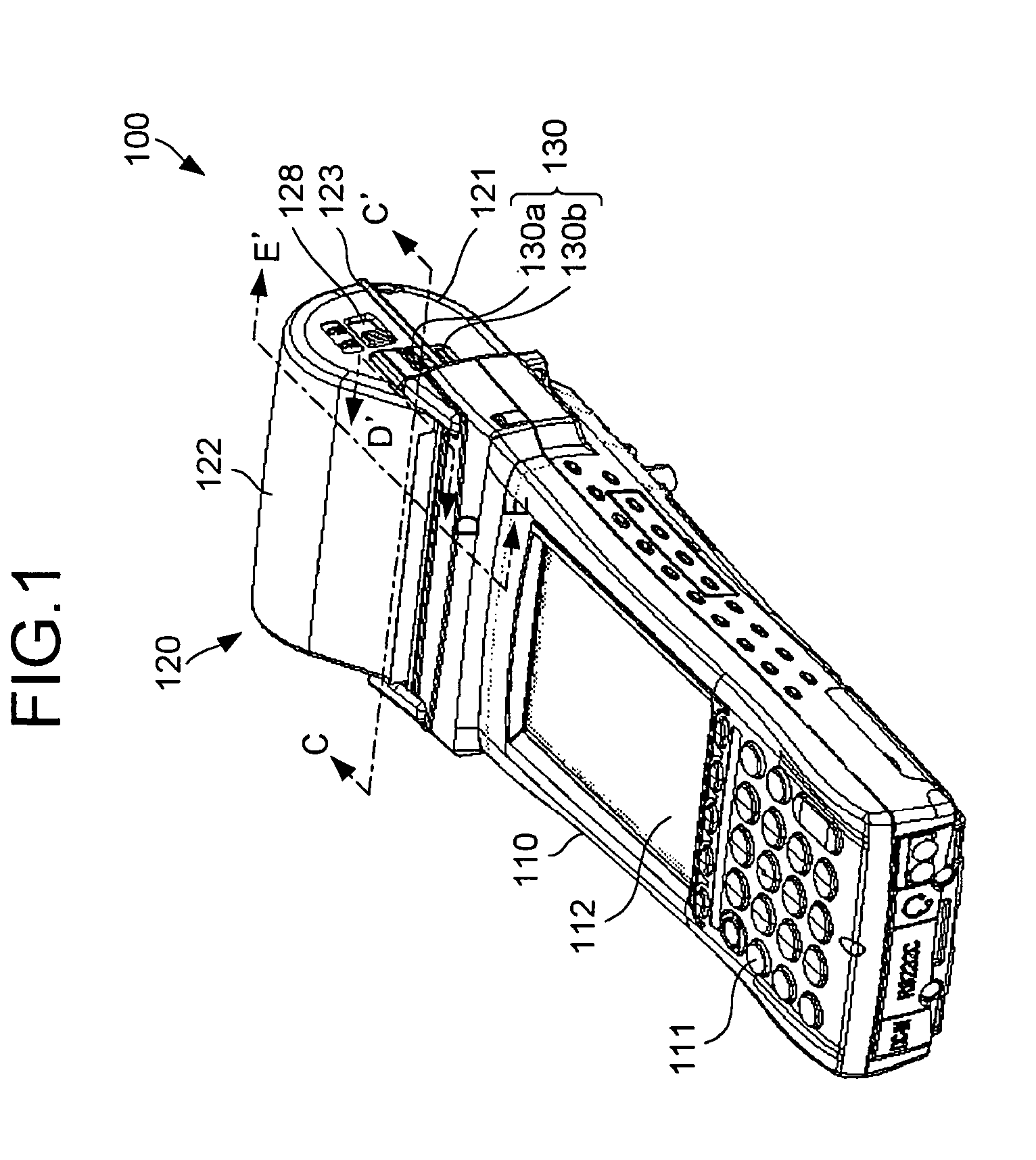

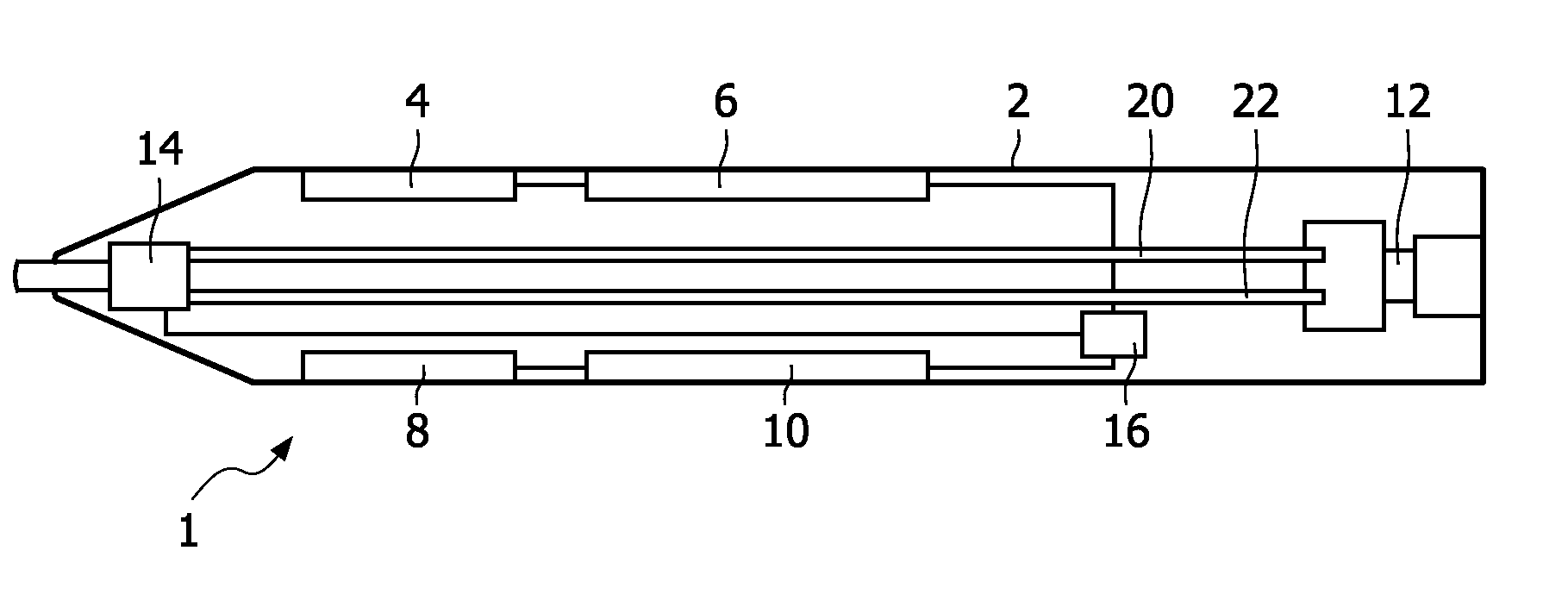

Handy thermal head printer

A printer has a main body and a printer unit that is fixed to the main body. The printer unit has an upper cover and a lower cover. The lower cover is attached to the main body and the upper cover is fixed to the lower cover. A hollow space is formed between the upper and lower covers and a printing paper is set in this space. A sensor is provided in the upper cover and it detects a mark on the non-printable surface of the printing paper. One protrusion is provided in each of the upper and lower covers such that the protrusions make an electrical contact when the upper and lower covers are closed. A control unit is provided in the main body and it is electrically connected to the mark detection unit through the protrusions on the upper and lower covers and it controls various operations of the printer.

Owner:FUJITSU FRONTECH LTD

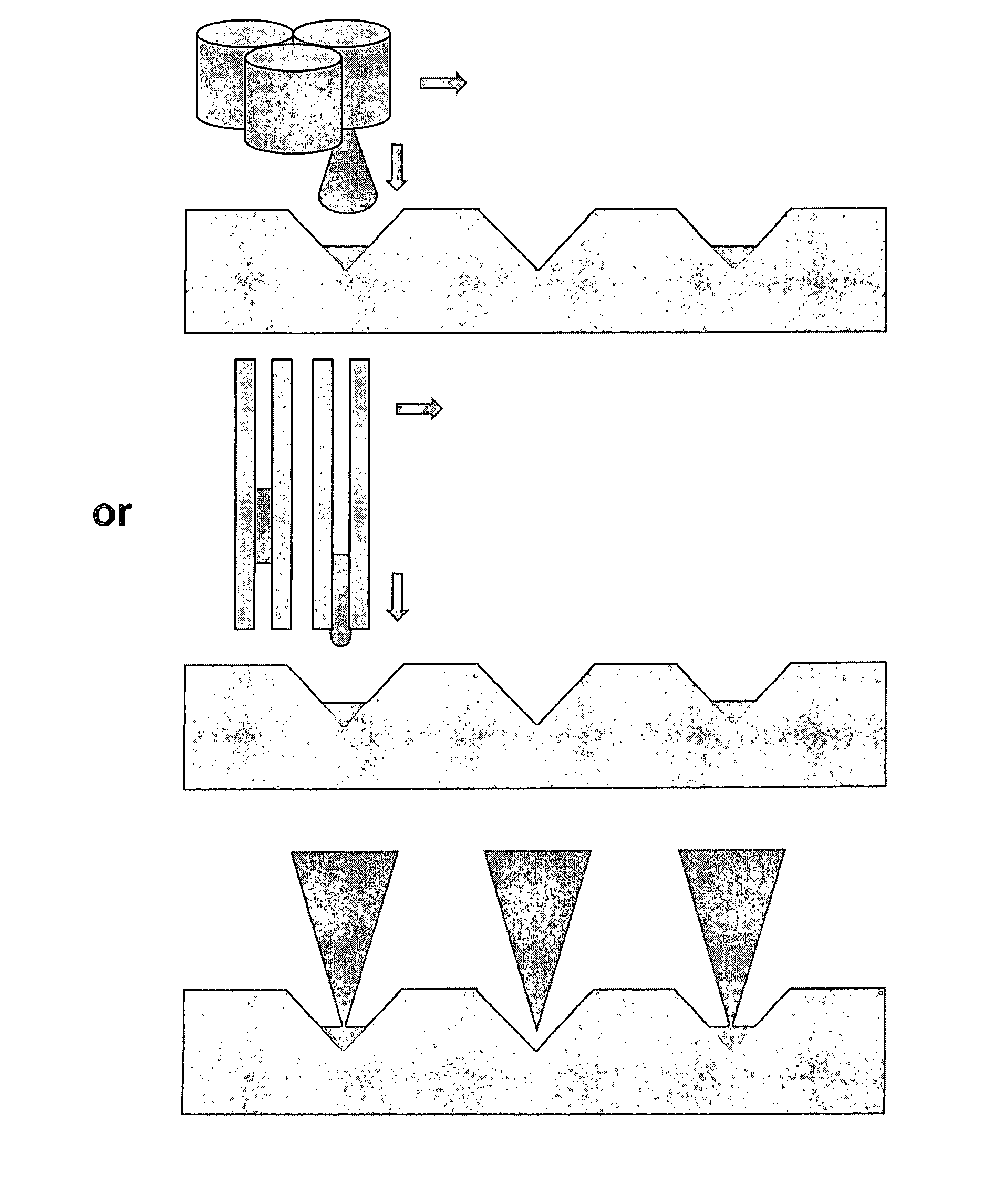

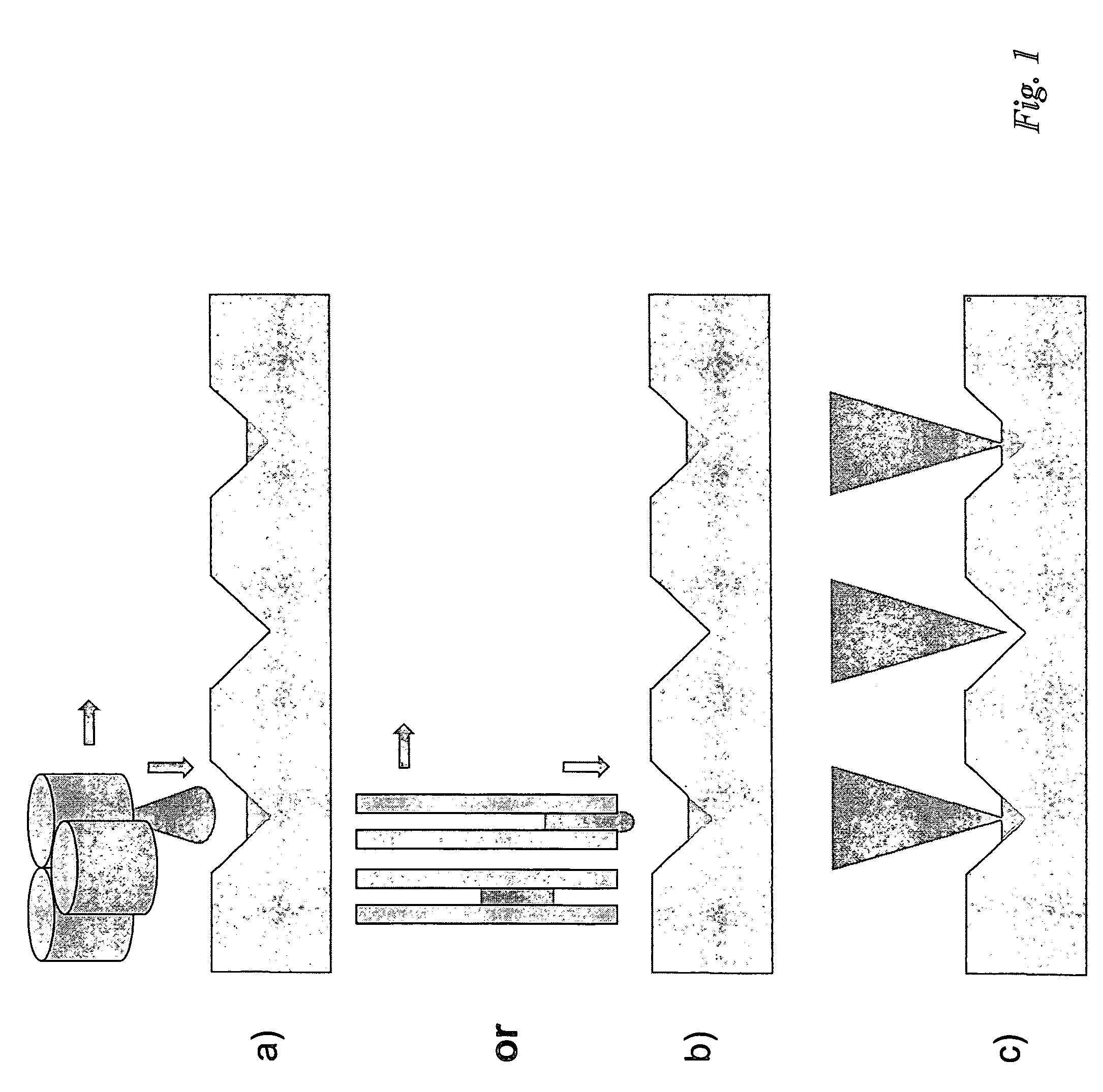

Methods and apparatus for ink delivery to nanolithographic probe systems

InactiveUS7034854B2Improve the level ofEasy to printRecording apparatusMaterial nanotechnologyNanolithographyEngineering

Inkwells adapted for use in direct-write nanolithography and other applications including use of wells, channels, and posts. The wells can possess a geometry which matches the geometry of tips which are dipped into the inkwells. The channels can be open or closed. Hydrophilicity and hydrophobicity can be used to control ink flow. SEM can be used to characterize the inkwells. Ink flow can be monitored with video. Hydrophobic material layers can be used to prevent cross contamination. Microsyringes can be used to fill reservoirs. Satellite reservoirs can be used to prevent bubble formation.

Owner:NANOINK INC

Systems and methods for mastering microstructures through a substrate using negative photoresist and microstructure masters so produced

Microstructures are fabricated by impinging a radiation beam, such as a laser beam, through a substrate that is transparent to the laser beam, into a negative photoresist layer on the substrate. The negative photoresist layer may be subsequently developed to provide a master for optical and / or mechanical microstructures. Related systems, microstructure products and microstructure masters also are disclosed.

Owner:BRIGHT VIEW TECHNOLOGIES CORPORATION

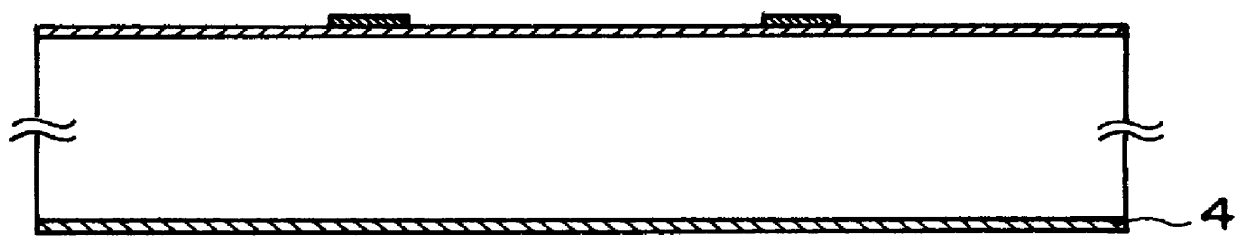

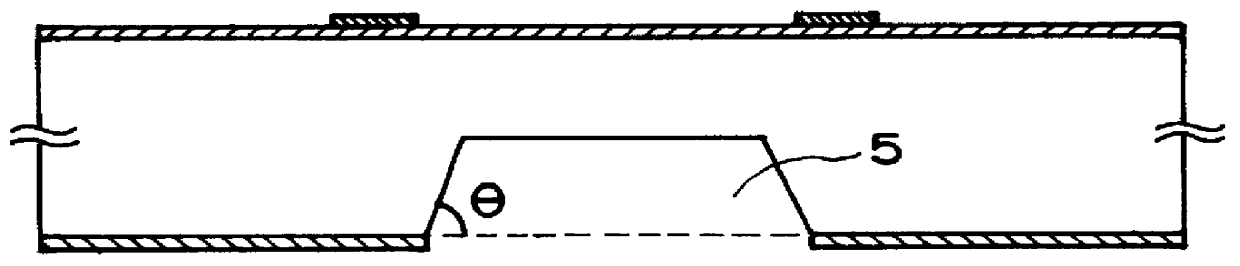

Method of making an ink jet printhead filter by laser ablation

InactiveUS6139674AImprove ink droplet directionalityHigh strengthPaper/cardboard articlesDecorative surface effectsEngineeringLaser ablation

A method for fabricating a filter element to prevent contaminants from entering an ink supply inlet of an ink jet printhead. The filter is formed by laser ablation process in which output laser radiation is directed through a mask system or light transmitting system to create a filter hole pattern in a thin film. Slightly tapered holes are formed in the film, and the formed filter element is laminated to the ink supply inlet. The tapered holes provide improved flow / impedance and add increased structural strength.

Owner:XEROX CORP

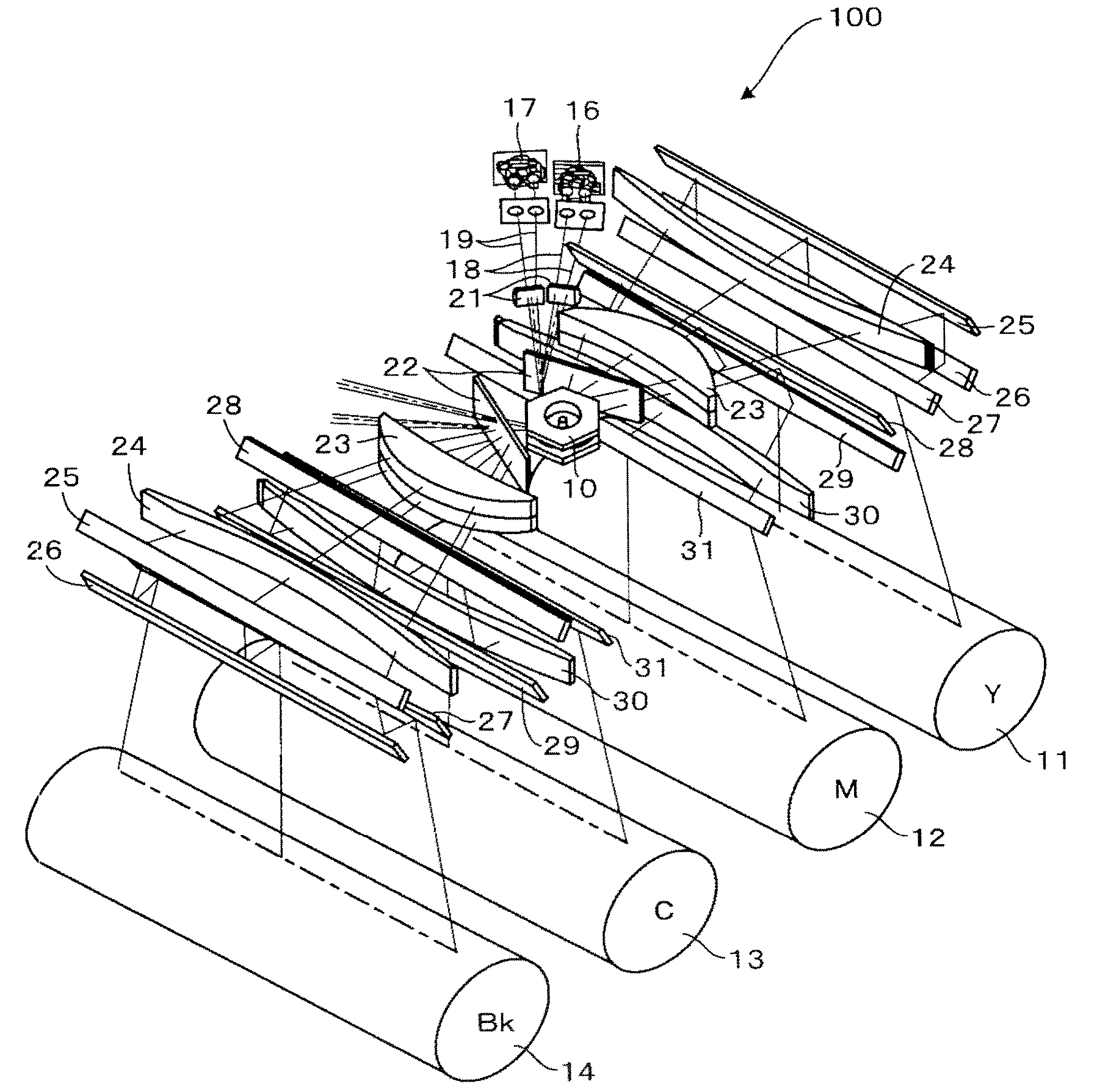

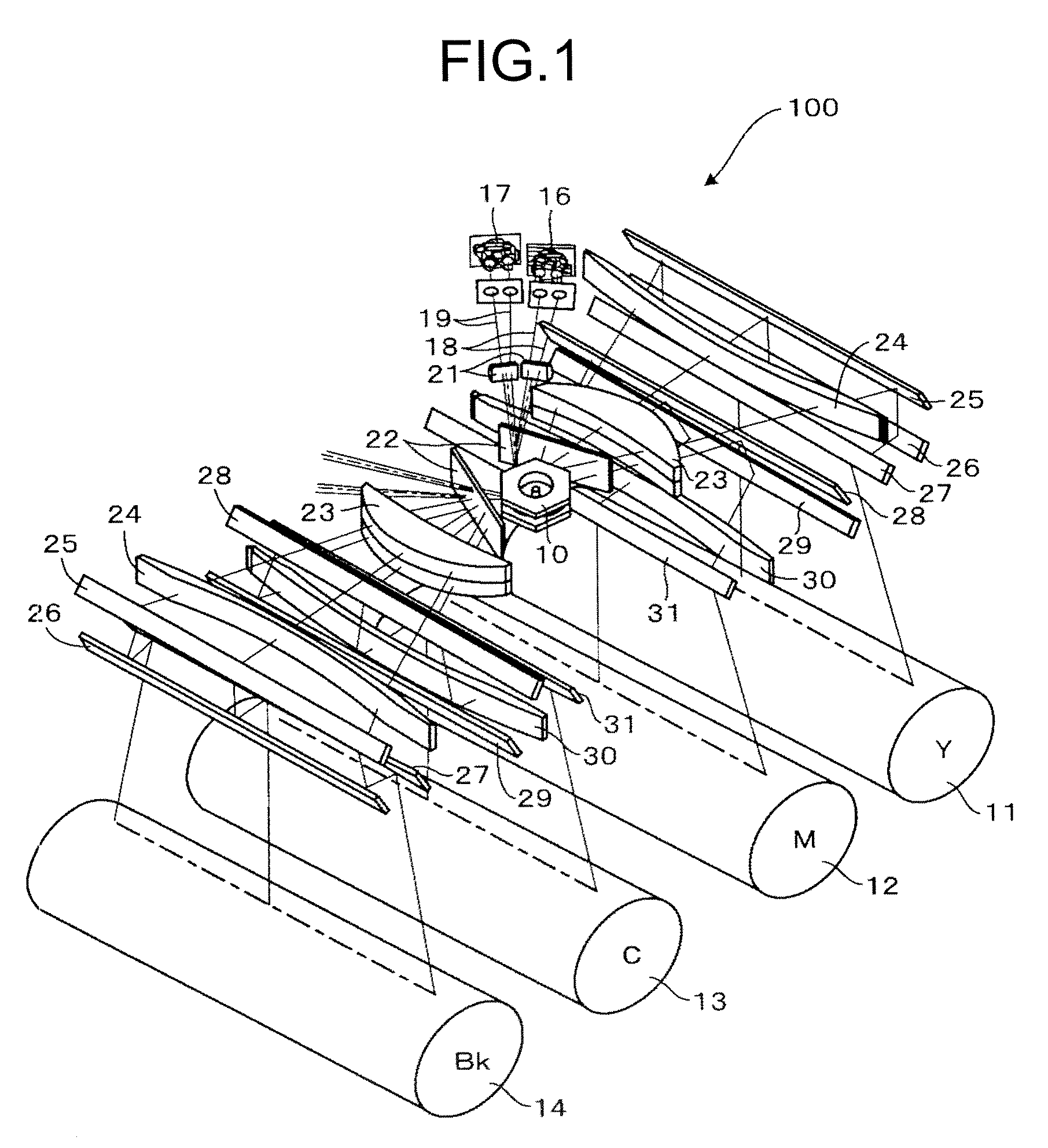

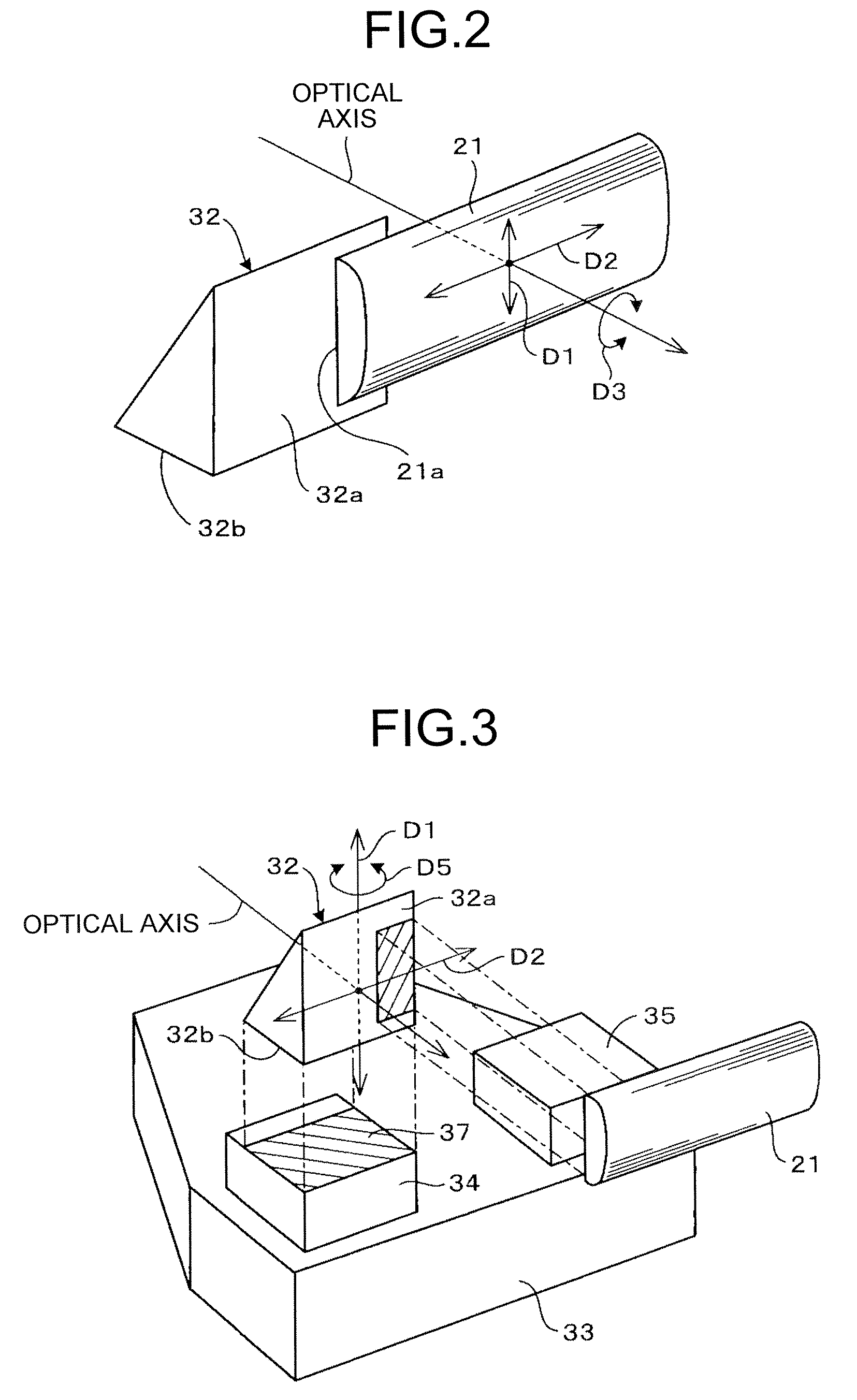

Optical scanning device and image forming apparatus

An optical scanning device includes a light source, a deflector that deflects a light beam from the light source, a first optical system that guides the light beam to the deflector, a second optical system that guides the light beam from the deflector to a surface to be scanned, and a housing that holds the light source and the deflector. At least one optical element included in the first optical system or the second optical system is attached to the housing via an intermediate member. The optical element is adjustable with respect to the intermediate member. The number of directions in which the optical element can be adjusted is two or more.

Owner:RICOH KK

Expressive pen

In this disclosure a new type of pen is described which is able to modulate the trace of the pen in response to a sensory signal of the user, such as for example skin conductance or respiration. As is known, these types of sensory signals represent the mood of the user. By changing the trace of the pen from for example blue to red, a change in mood of the user can be expressed.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

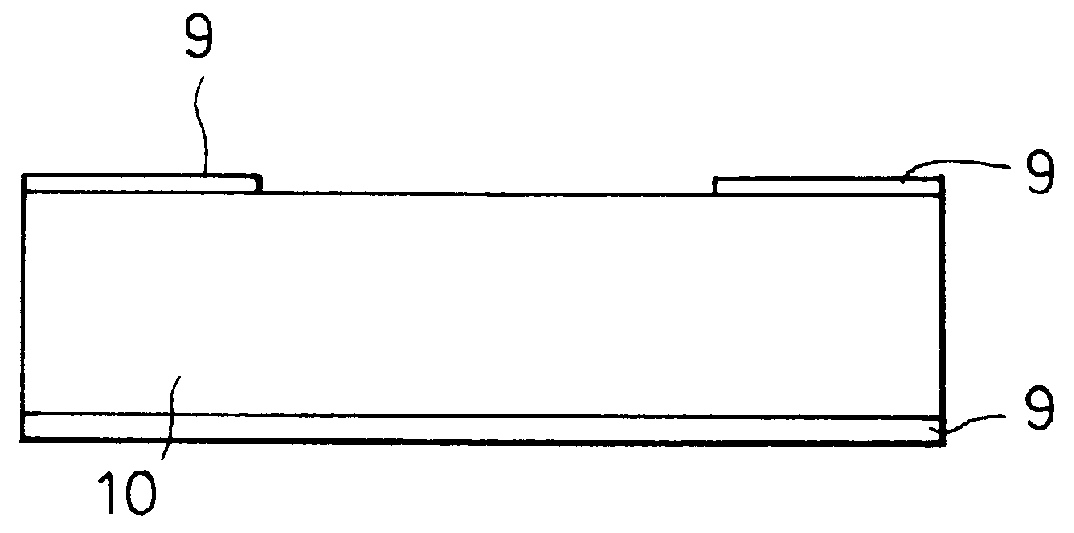

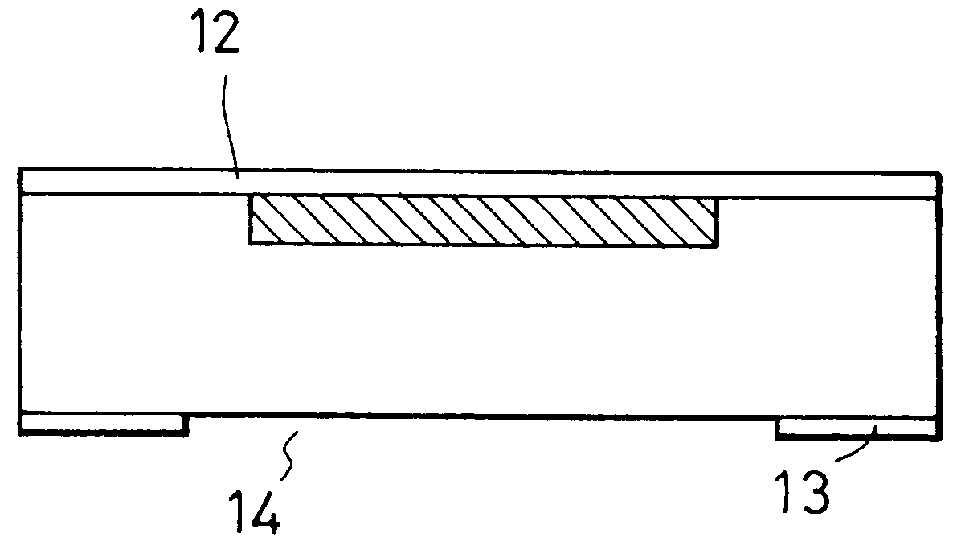

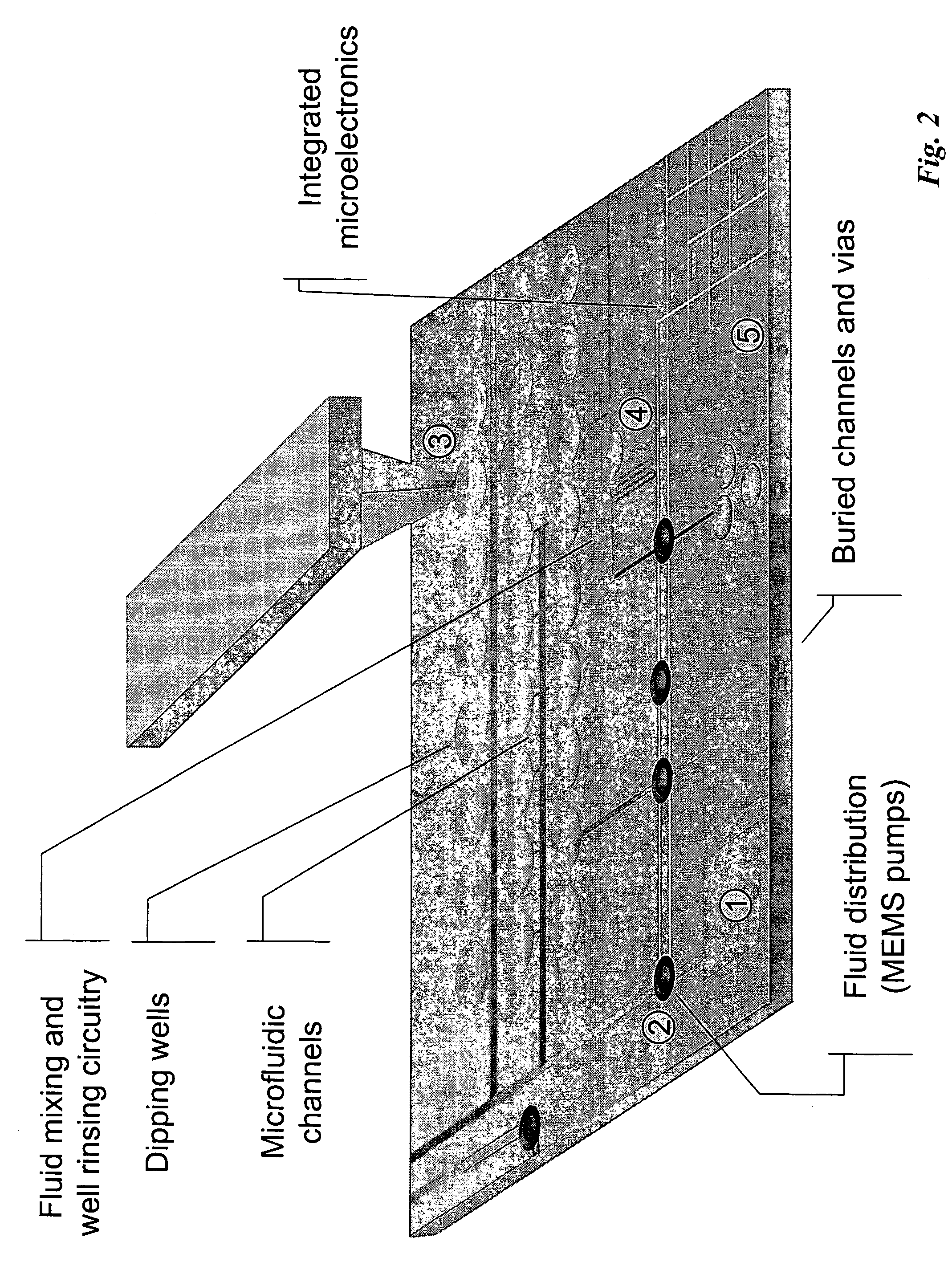

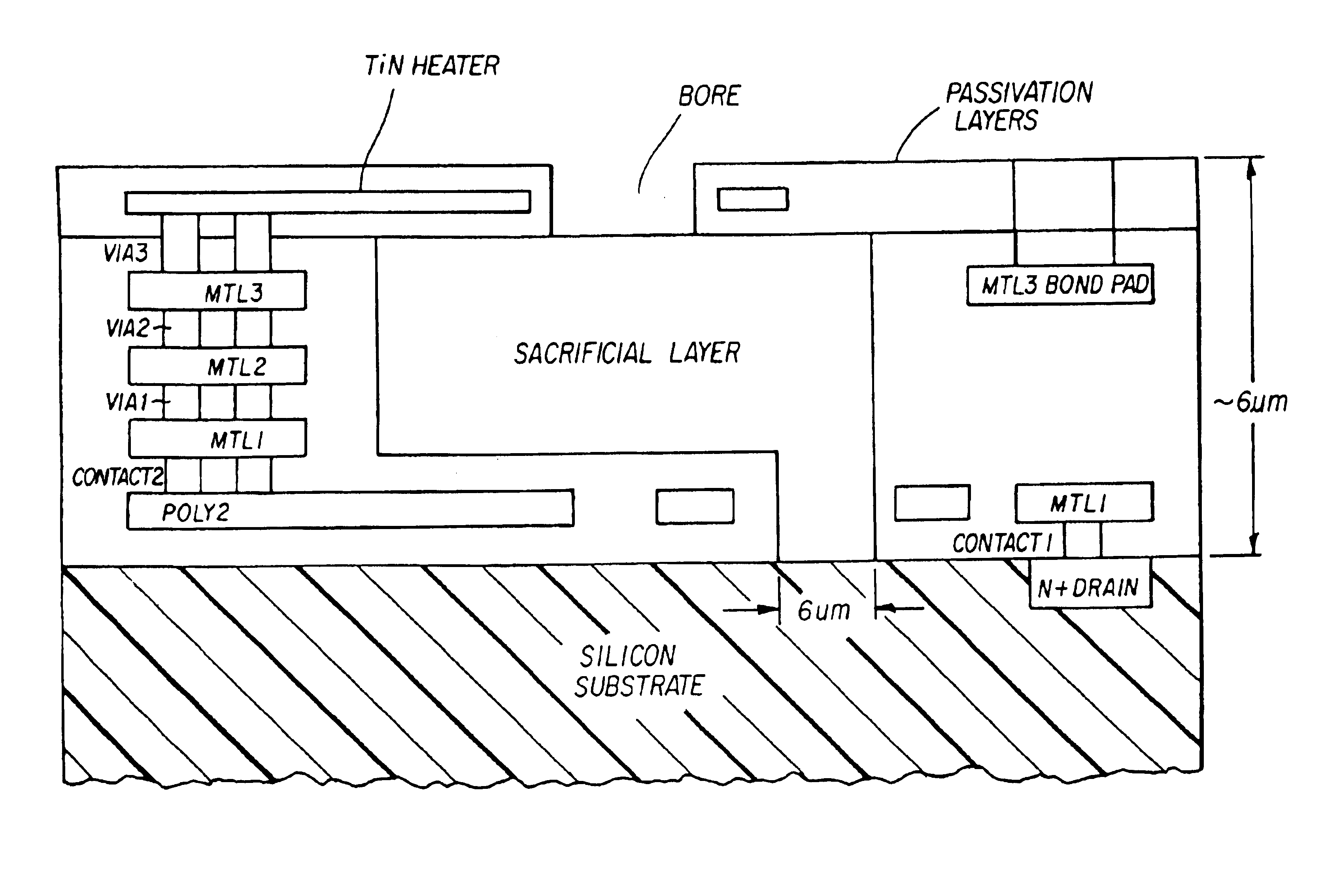

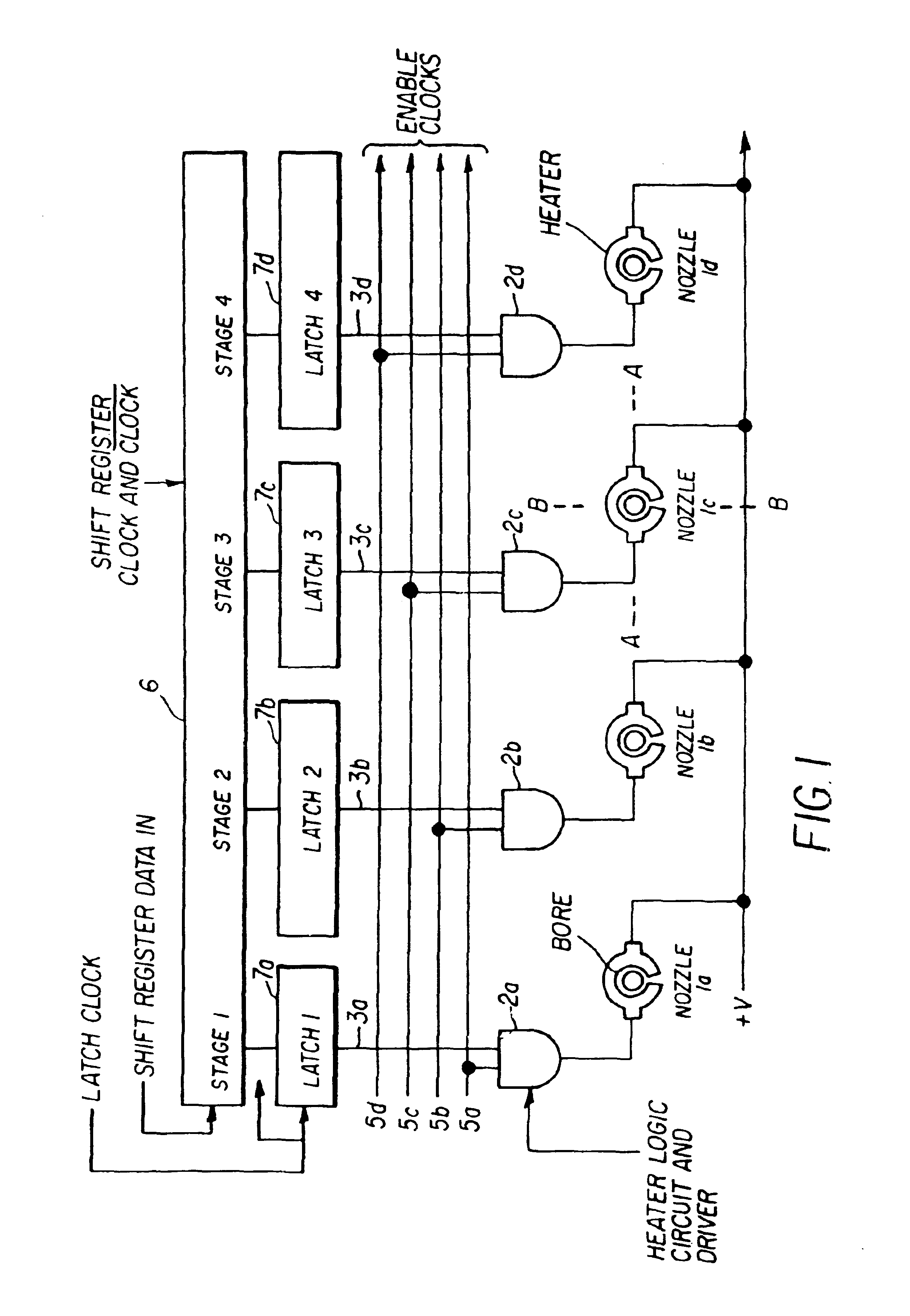

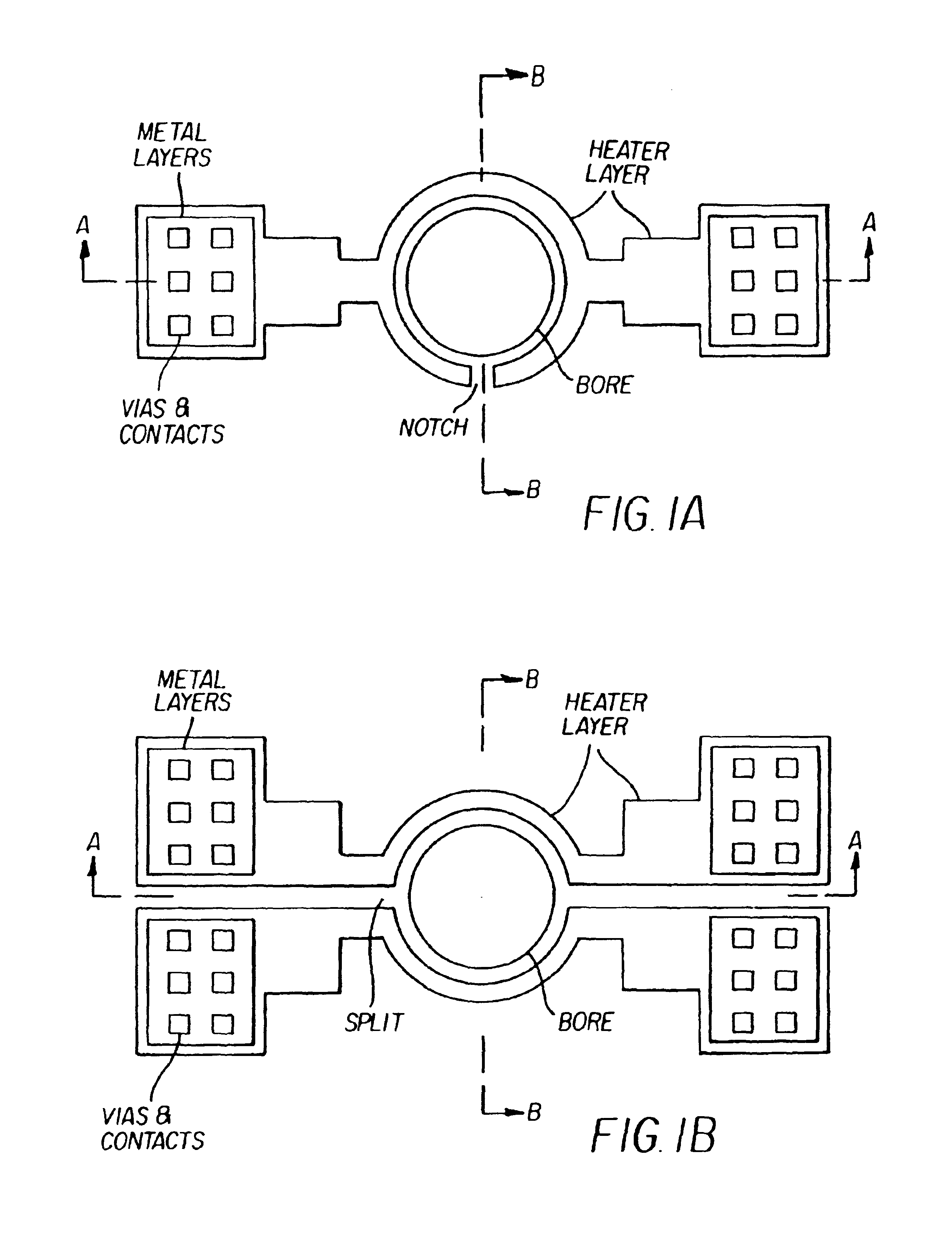

CMOS/MEMS integrated ink jet print head and method of forming same

InactiveUS6943037B2Low costImprove manufacturabilityRecording apparatusInking apparatusCMOSEngineering

An ink jet print head is formed of a silicon substrate that includes an integrated circuit formed therein for controlling operation of the print head. The silicon substrate has one or more ink channels formed therein along the longitudinal direction of the noble array. An insulating layer or layers overlie the silicon substrate and has a series or an array of nozzle openings or bores formed therein along the length of the substrate and each nozzle opening communicates with an ink channel. The area comprising the nozzle openings forms a generally planar surface to facilitate maintenance of the printhead. A heater element is associated with each nozzle opening or bore for asymmetrically heating ink as ink passes through the nozzle opening or bore.

Owner:EASTMAN KODAK CO

Systems and methods of printing with ultra violet photosensitive resin-containing materials using light emitting devices

Method of printing with ultraviolet photosensitive resin-containing materials includes depositing at least one substance that includes an ultraviolet photosensitive resin on to a substrate, partially curing the substance by irradiating the substance with at least one ultraviolet light emitting device, and completely curing the substance. Substance curing system including a substrate, an applicator that deposits a substance that includes an ultraviolet photosensitive resin on to a substrate, and at least one ultraviolet light emitting device usable to irradiate the substance to partially cure and / or completely cure the substance.

Owner:XEROX CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com