Patents

Literature

4300 results about "Wall material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The construction materials of the Great Wall were mainly earth, stone, brick, lime, and wood. The materials used depended on the local resources available. When building the Great Wall on mountains, stones were used from the mountains; when building it across the plains, the materials used were earth, bricks, and lime.

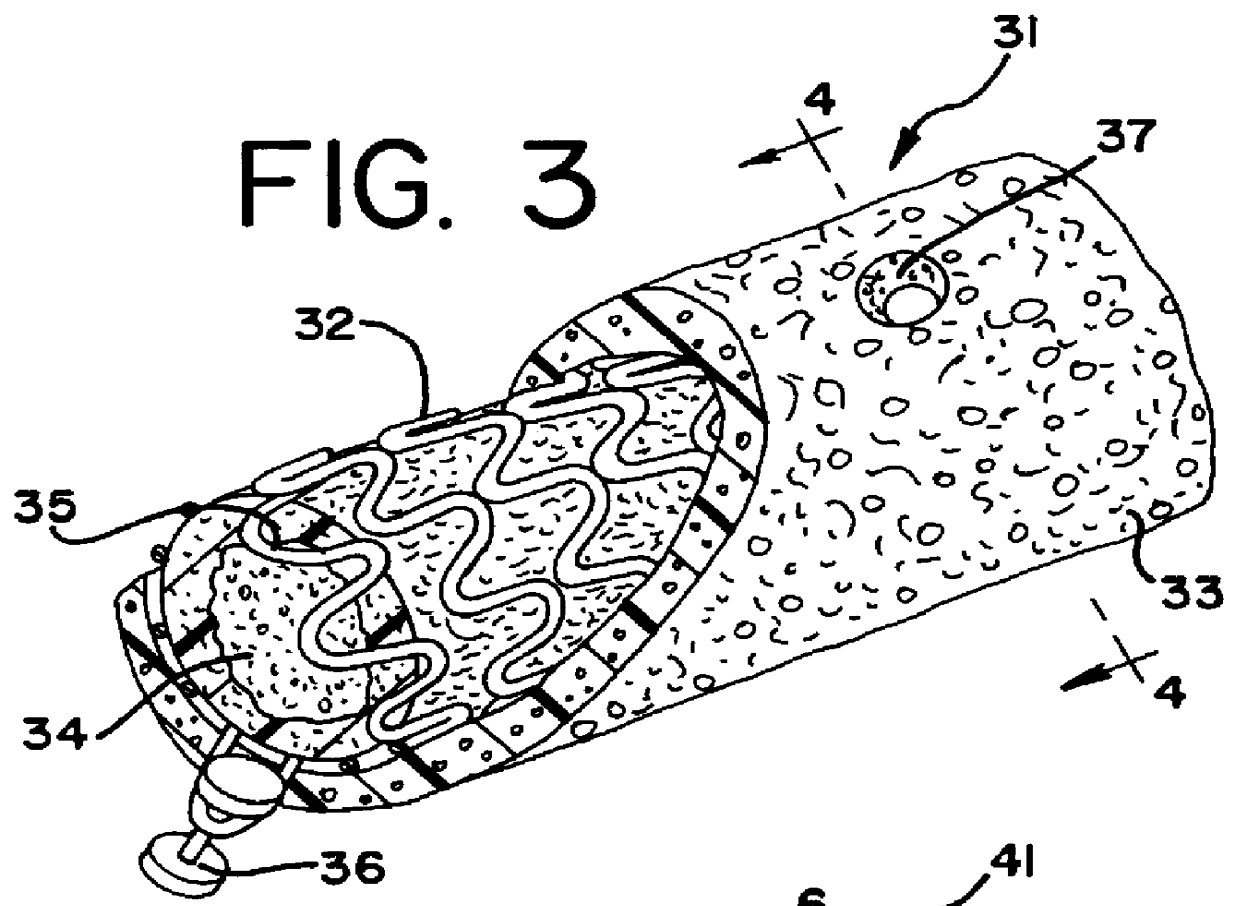

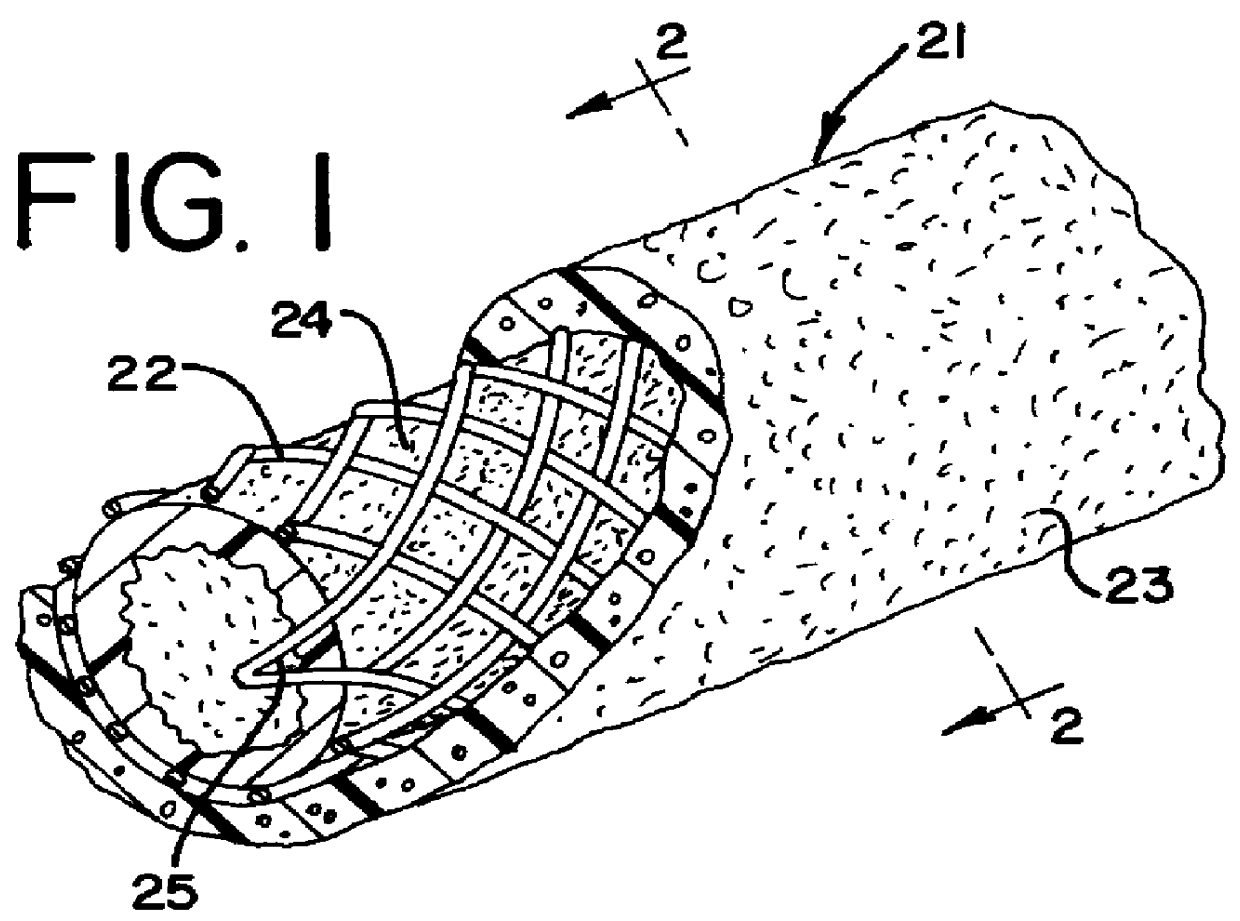

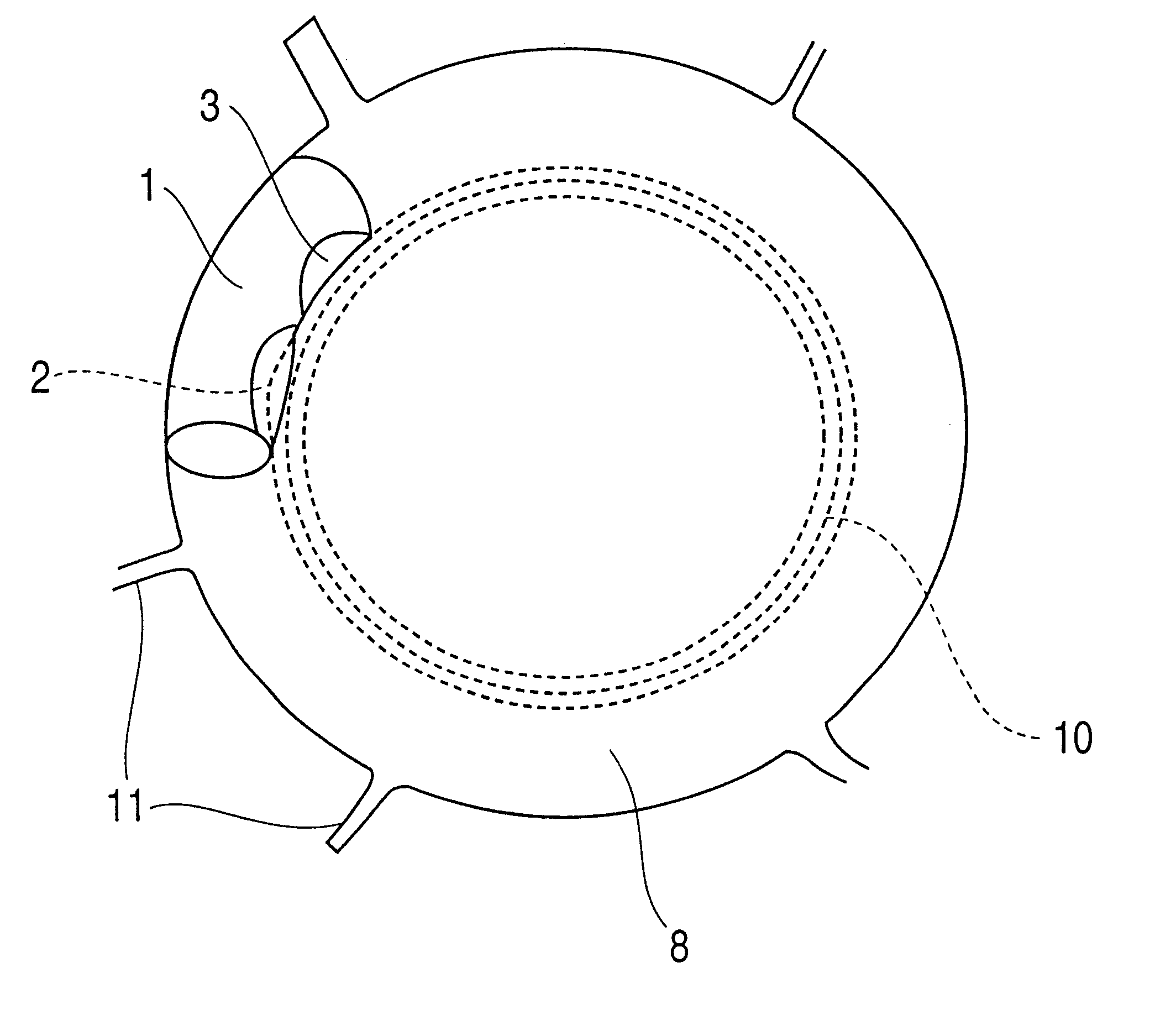

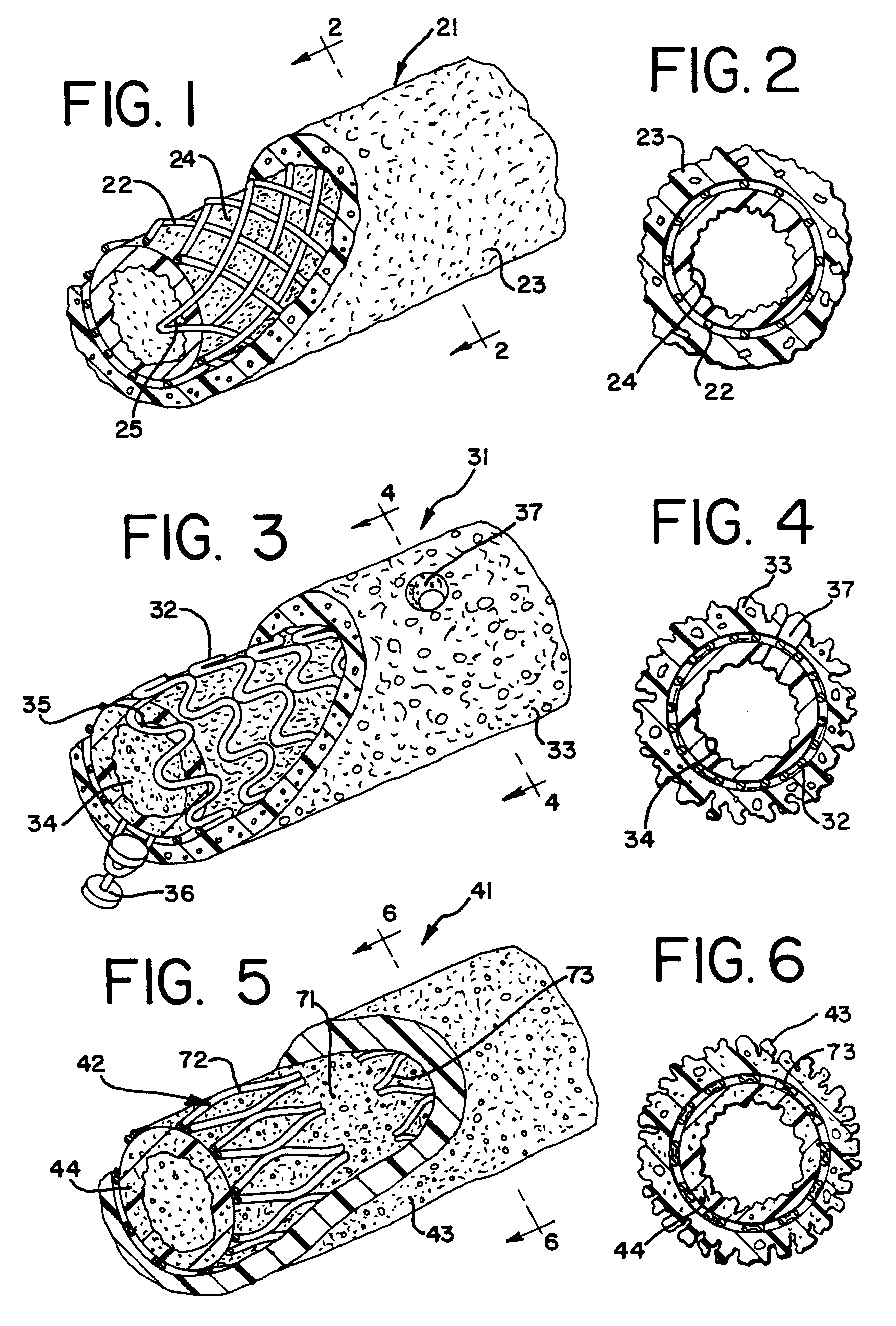

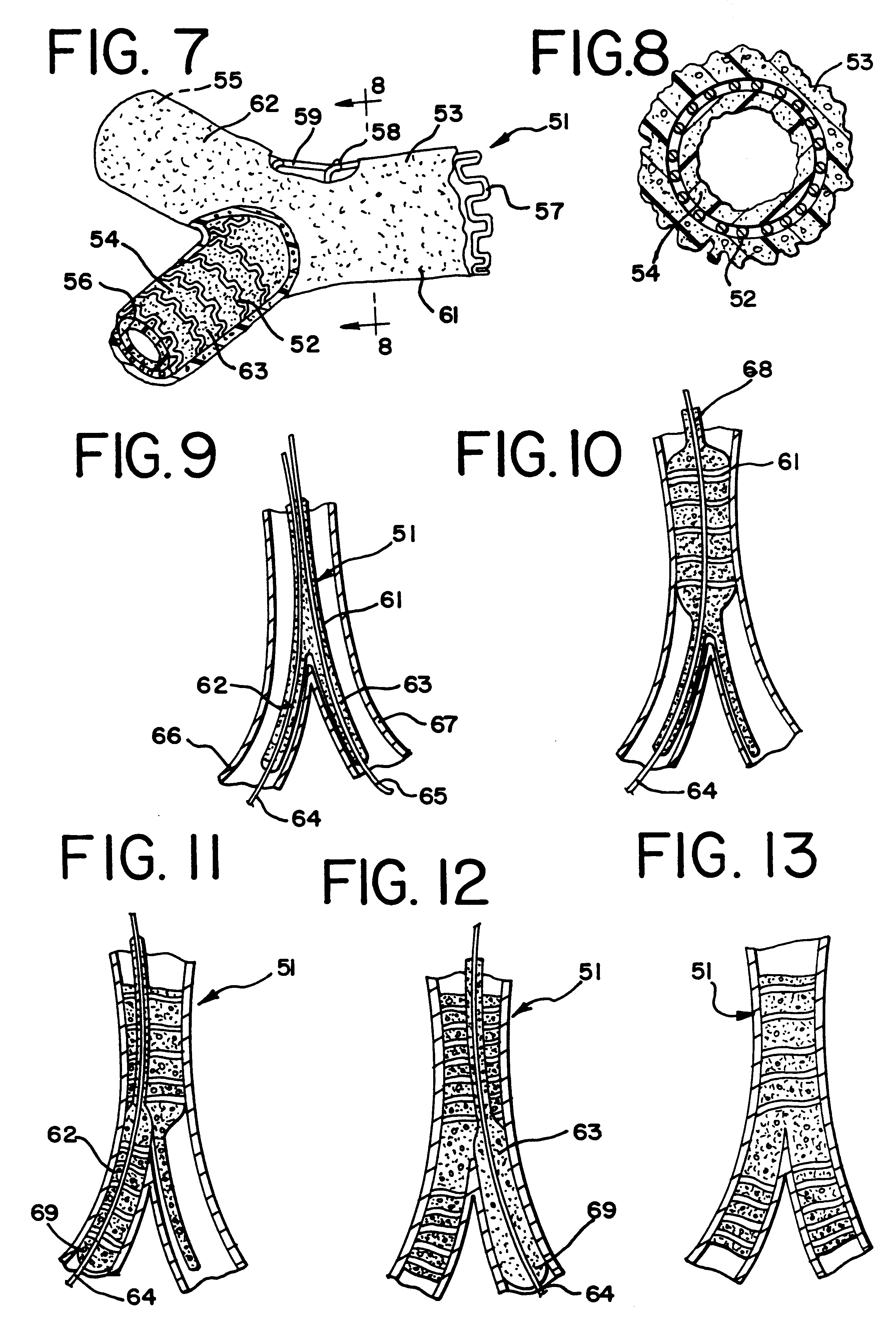

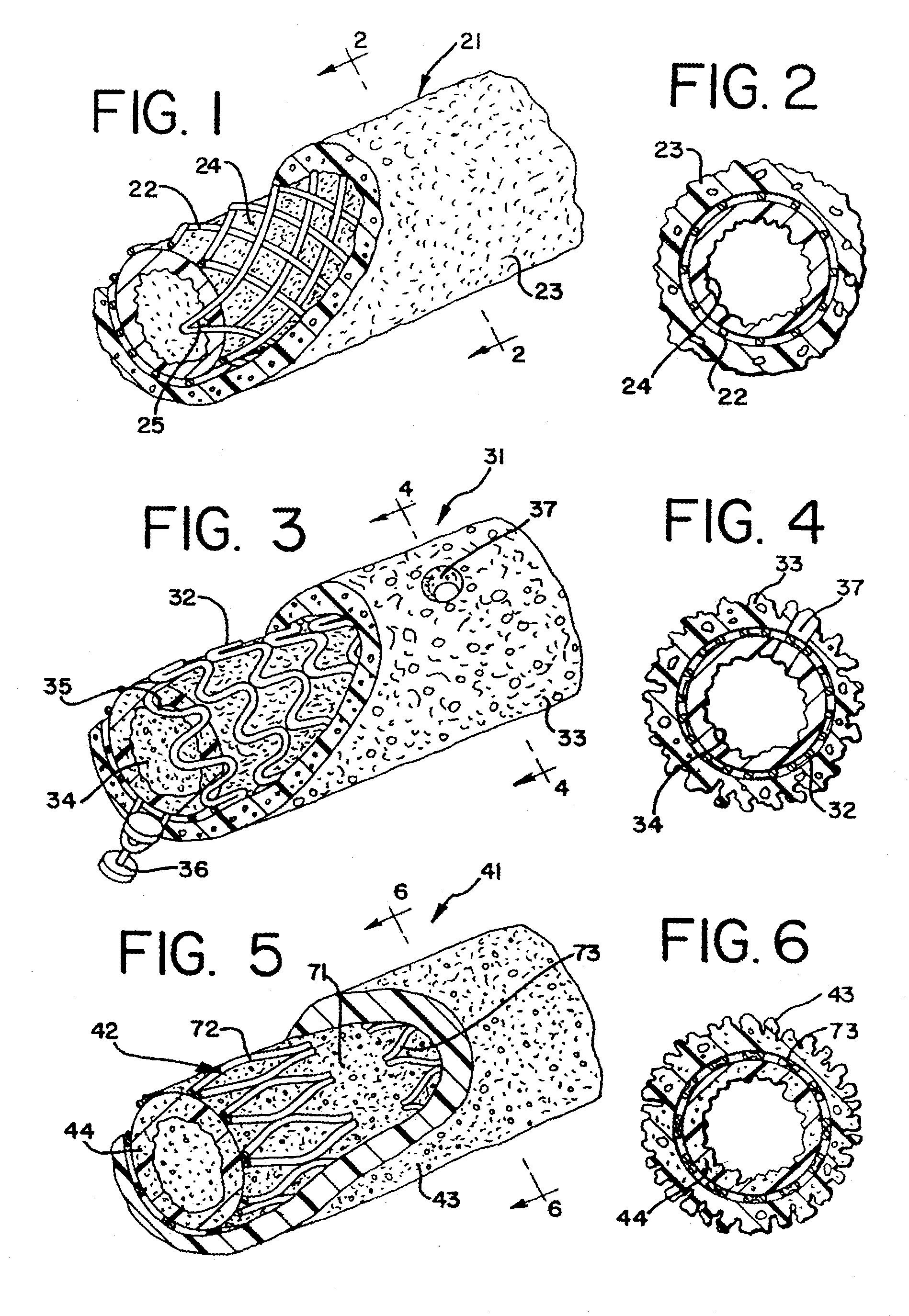

Expandable supportive endoluminal grafts

An endoluminal graft which is both expandable and supportive is provided either in a longitudinal form or in a bifurcated form. The graft expands between a first diameter and a second, larger diameter. The support component is an expandable stent endoprosthesis. A cover, liner, or a liner, or both a cover and a liner are applied to the endoprosthesis in the form of a stretchable wall material that is porous, elastomeric and biocompatible in order to allow normal cellular invasion upon implantation, without stenosis, when the expandable and supportive graft is at its second diameter. Preferably, the elastomeric wall material is a polycarbonate urethane.

Owner:LIFEPORT SCI

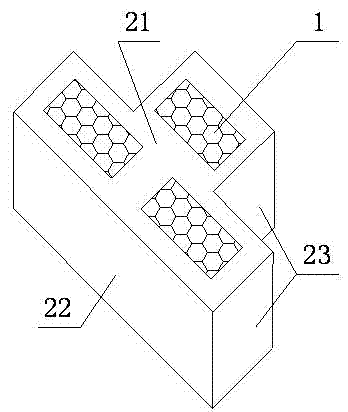

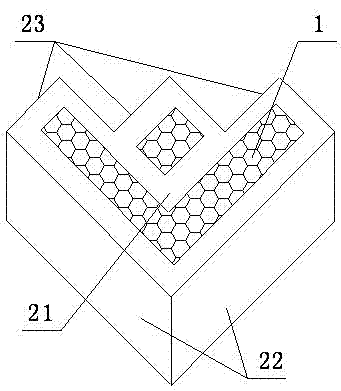

Self-insulation wall with high energy conservation property

The invention discloses a self-insulation wall with a high energy conservation property, and belongs to the field of building wall materials. The self-insulation wall with the high energy conservation property is mainly characterized in that building blocks of a self-insulation wall body are shaped like a T, building blocks of a self-insulation right-angle wall corner are in a flower shape and a scissor shape, building blocks of a self-insulation T-shaped wall corner are provided with either a T-shaped top with a handle or a T-shaped bottom with a handle, when the wall body is built, one of every two horizontally adjacent self-insulation wall bricks is placed in a T shape, the other one is placed in a reverse T shape, when the right-angle wall corner is built, the flower-shaped and scissor-shaped building blocks of the self-insulation right-angle wall corner are alternatively placed, and when the T-shaped wall corner is built, the building blocks, provided with either the T-shaped top with the handle or the T-shaped bottom with the handle, of the self-insulation T-shaped wall corner are alternatively placed. The self-insulation wall with the high energy conservation property has the advantage of improving the energy conservation property.

Owner:SHANDONG UNIV OF SCI & TECH

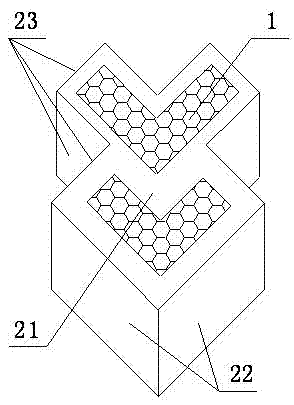

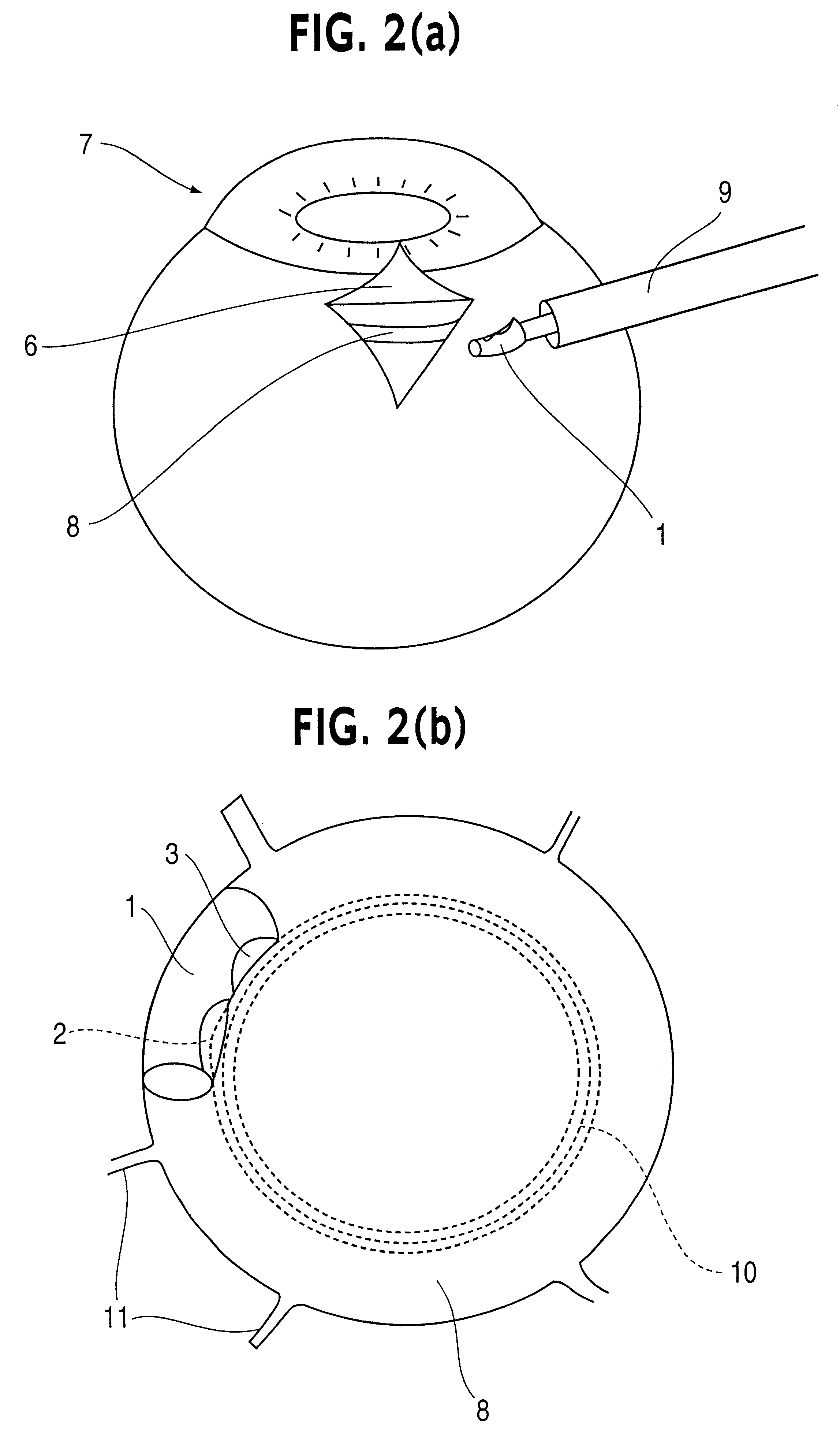

Device for improving in a targeted manner and/or permanently ensuring the ability of the aqueous humor to pass through the trabecular meshwork

A device is disclosed for selectively improving and / or permanently ensuring the permeability for ocular aqueous humour through the trabecular formations into Schlemm's canal. A small tubular element is provided, whose wall material encloses a hollow duct that presents an open configuration on both ends along the longitudinal extension of the hollow duct, so that the size and the shape of the small tubular element correspond approximately to the internal contour of Schlemm's canal, and the wall material as well as the wall thickness are so selected that upon introduction into Schlemm's canal the small tubular element keeps the canal open and dilates adjacent trabecular formations.

Owner:NEUHANN THOMAS

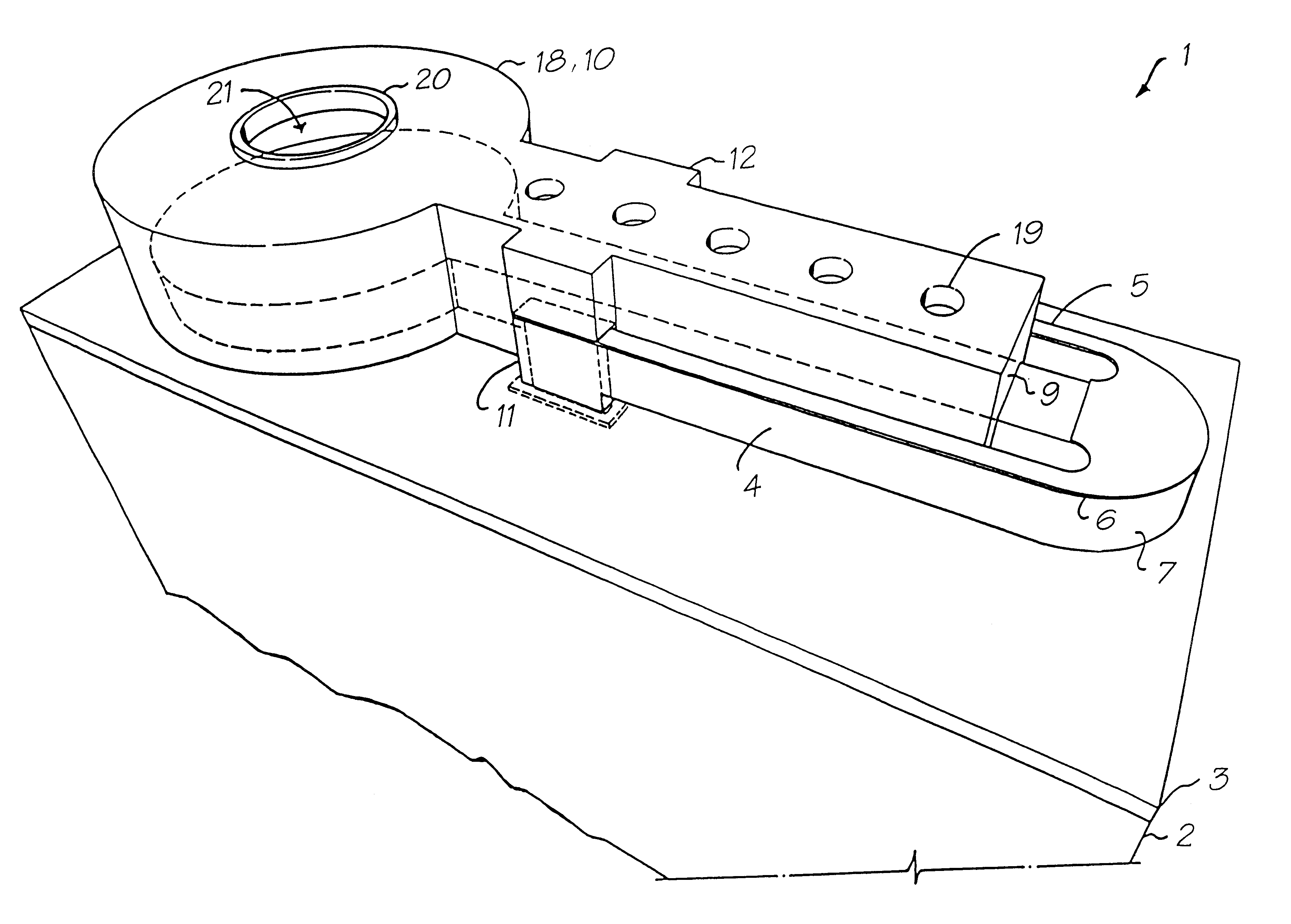

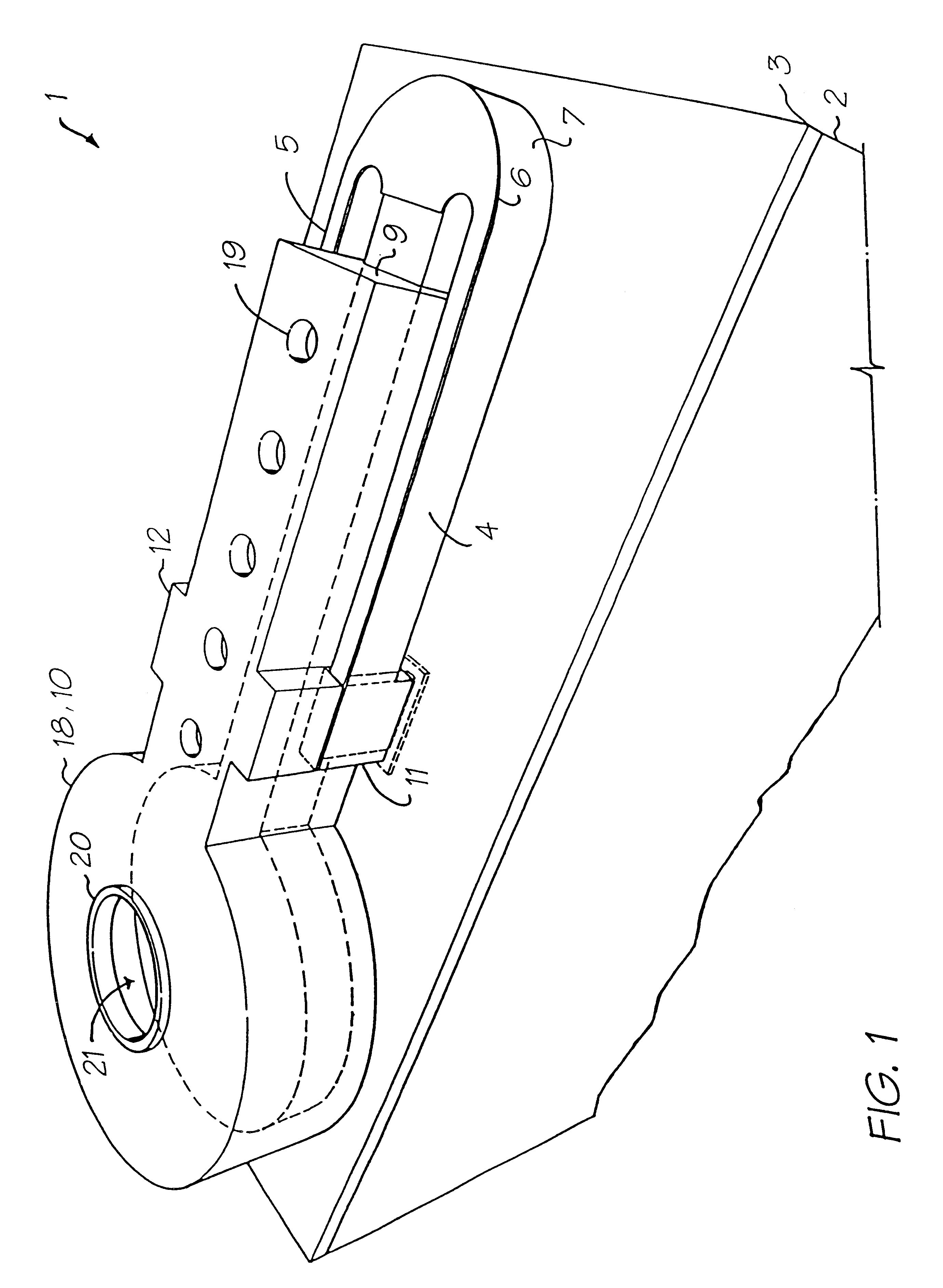

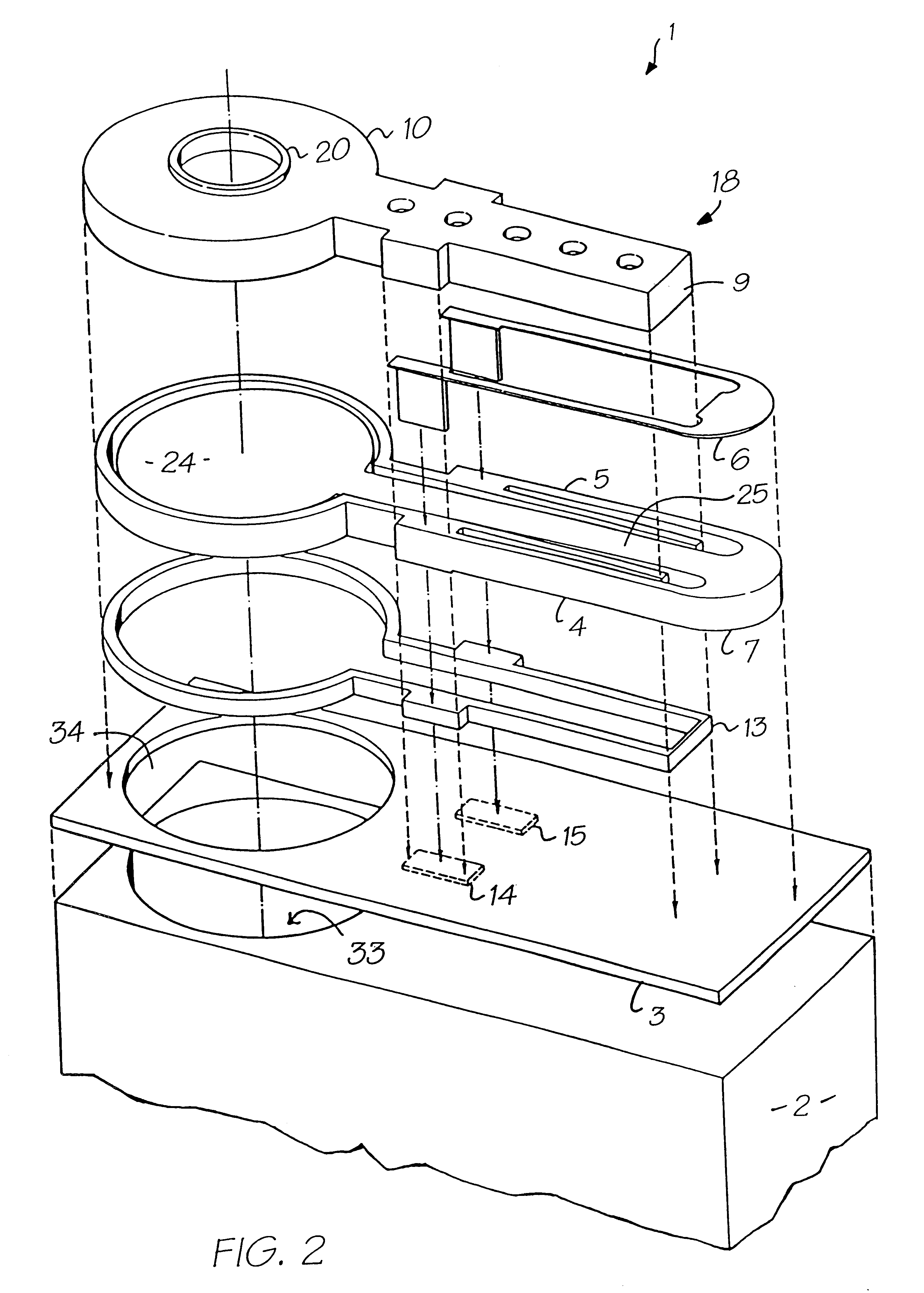

Method of manufacture of high Young's modulus thermoelastic inkjet printer

A method of manufacturing a thermally actuated ink jet printhead includes the step of initially providing a wafer having a circuitry layer including the electrical circuitry necessary for the operation of a thermal actuator. A first sacrificial layer is deposited on the wafer and is etched. A Young's modulus layer is deposited to form a first layer of a thermal actuator and a portion of a nozzle chamber wall. A conductive heater material layer is provided and has a portion interconnected to the circuitry layer. A second sacrificial layer is deposited and etched in preparation for nozzle chamber walls. A nozzle wall material layer is deposited to form the walls of the nozzle chamber. The nozzle wall material layer is etched to define a nozzle port for the ejection of ink. The sacrificial layers are etched away to release the thermal actuator. The nozzle chamber walls are formed to define a fulcrum for the thermal actuator.

Owner:SILVERBROOK RES PTY LTD +1

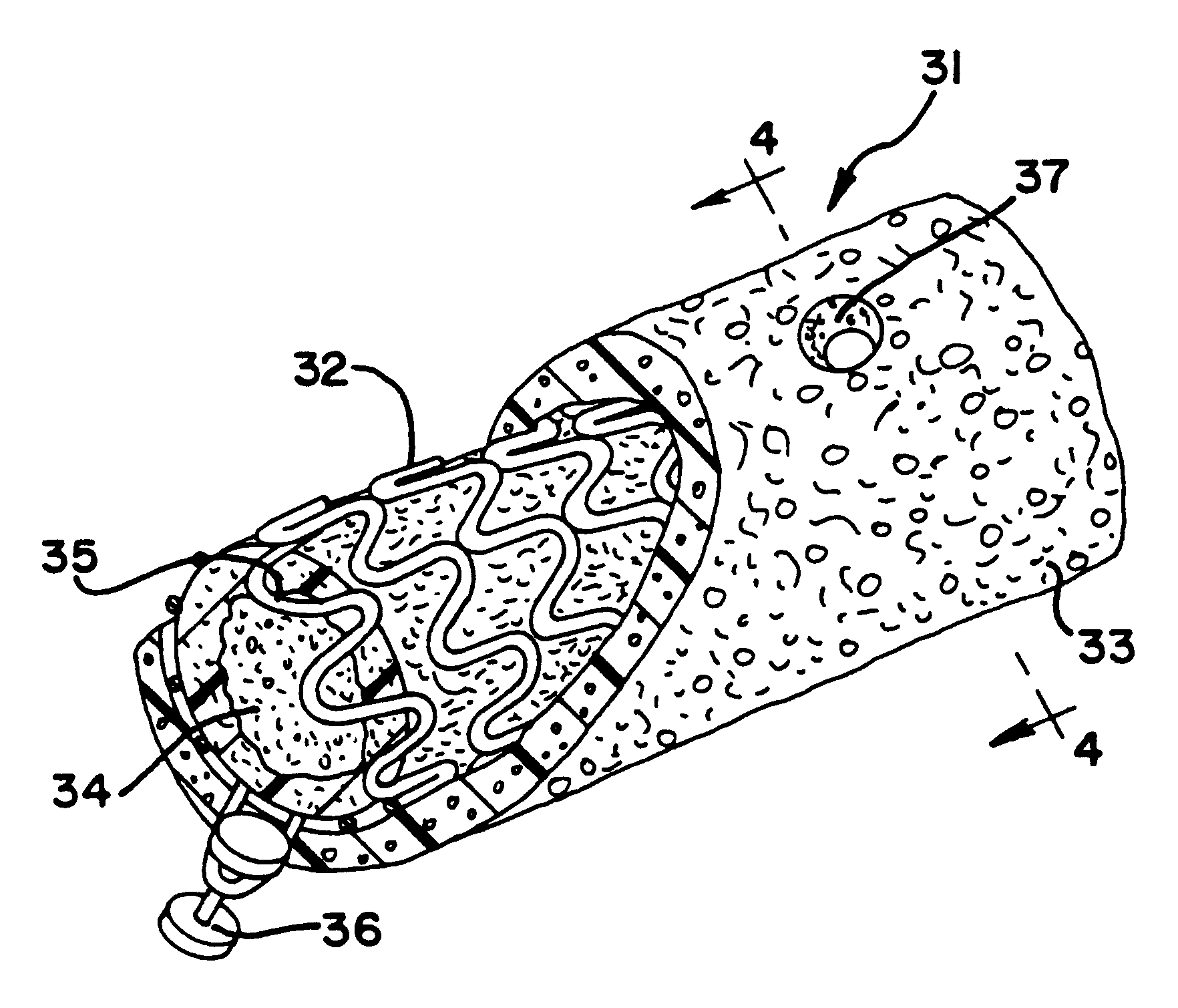

Expandable supportive endoluminal grafts

Owner:LIFEPORT SCI

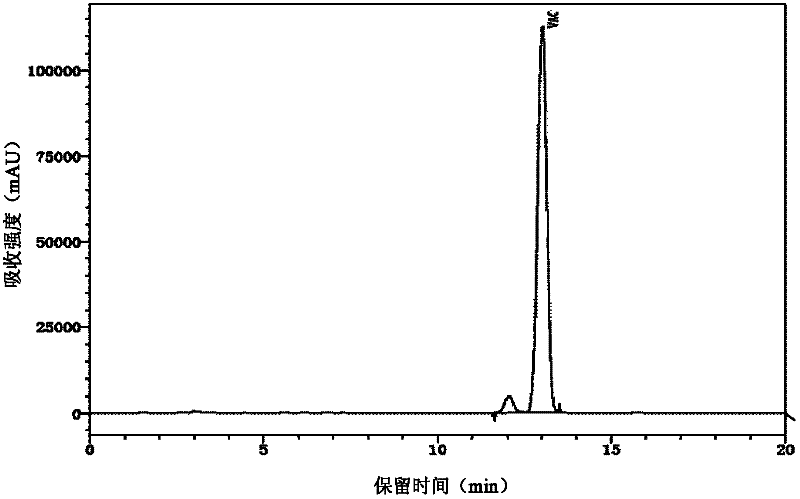

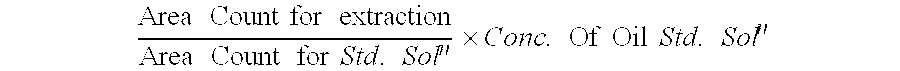

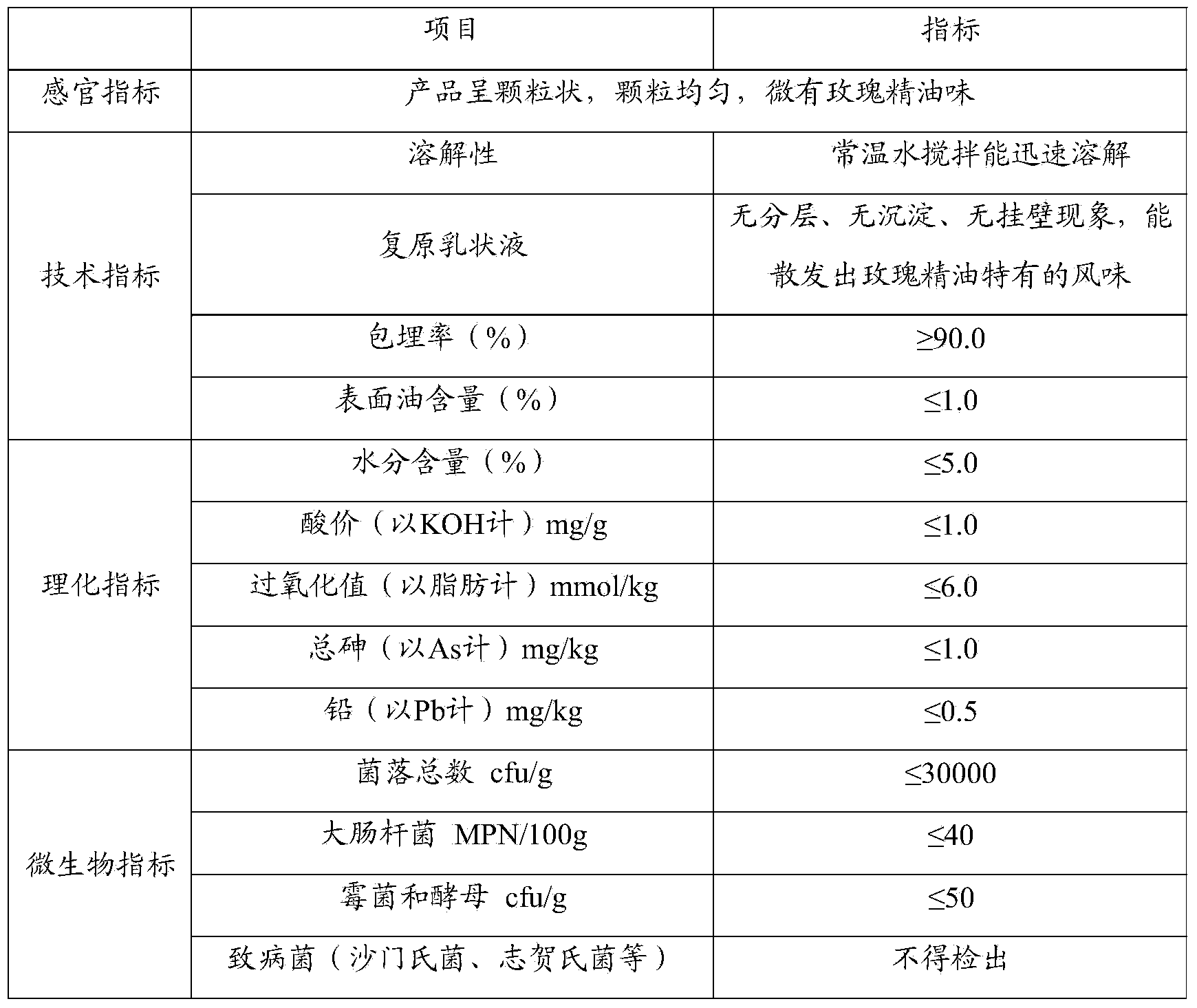

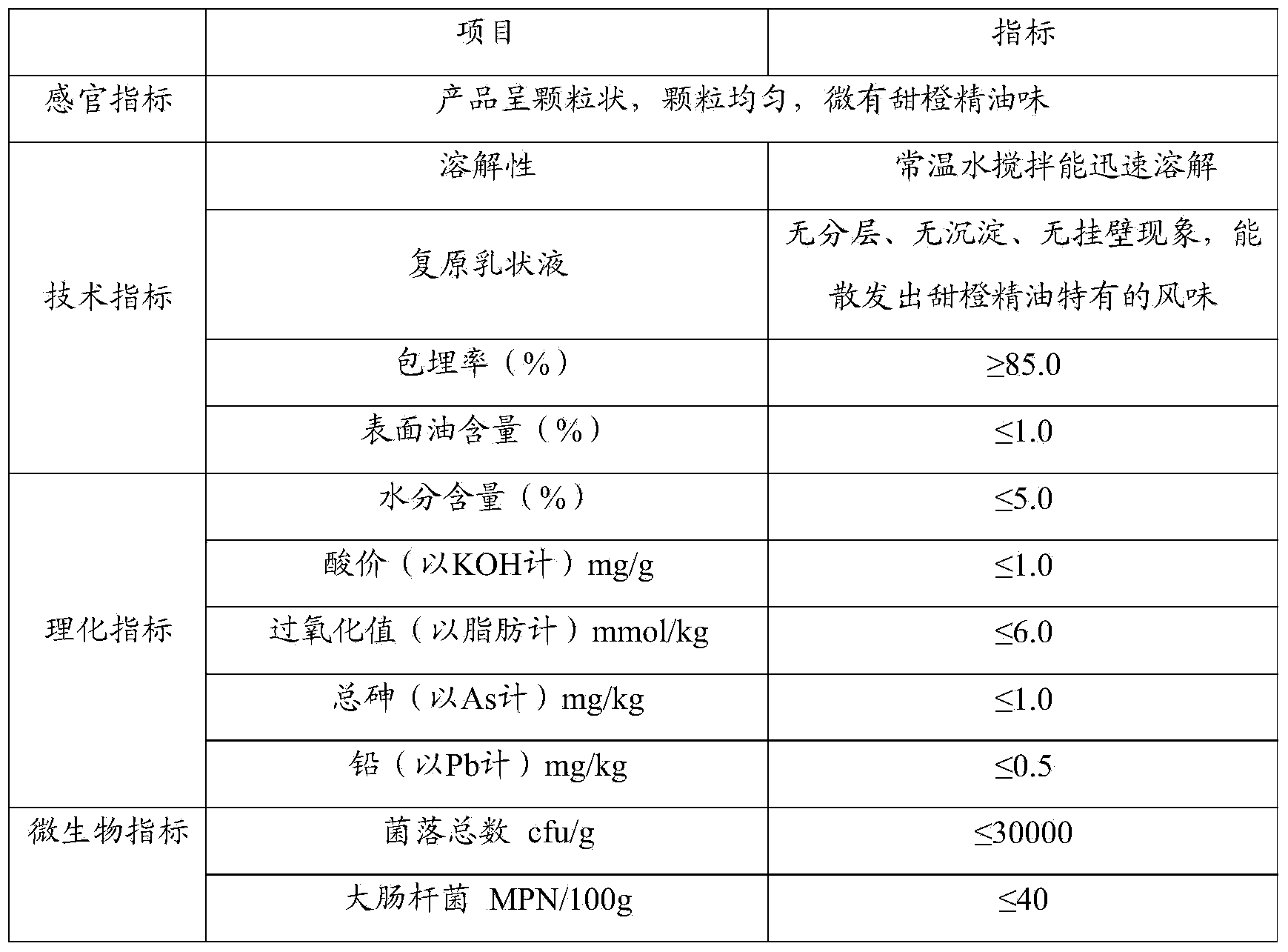

Functional oil microencapsulation and manufacturing method thereof

ActiveCN102550817AGood water solubilityImprove antioxidant capacityMetabolism disorderAlgae medical ingredientsOil and greaseWater baths

The invention provides a functional oil microencapsulation and a manufacturing method thereof and relates to a microencapsulation, and the functional oil microencapsulation has the advantages of high stability and immobilized proteinaceous pellicle. The oil microencapsulation is prepared from the following raw materials: functional oil, plant oil, an antioxidant, aqueous-phase main-wall materials, aqueous-phase auxiliary-wall materials, bio-enzyme protein and water. The plant oil serving as a carrier is mixed with the functional oil, then the antioxidant is added, and then the materials are heated and dissolved in water bath, thus obtaining an oil-phase core material solution; the aqueous-phase main-wall materials and the aqueous-phase auxiliary-wall materials are added into deionized water, and then the materials are heated and dissolved in water bath, thus obtaining an aqueous-phase wall material solution; the oil-phase core material solution is added in the aqueous-phase wall material solution, the mixture is sheared and emulsified by a shearing machine, and then is homogenized by a homogenizer, thus obtaining a nanometer-level solution with uniform oil drop diameter; and bio-enzyme is added into the nanometer-level solution, the mixture is placed in hot-water bath for heating and stirring reaction, temperature is raised after the reaction so as to enable the bio-enzyme to be inactivated, and drying is carried out, thus obtaining the functional oil microencapsulation.

Owner:XIAMEN KINGDOMWAY BIOTECH CO LTD +1

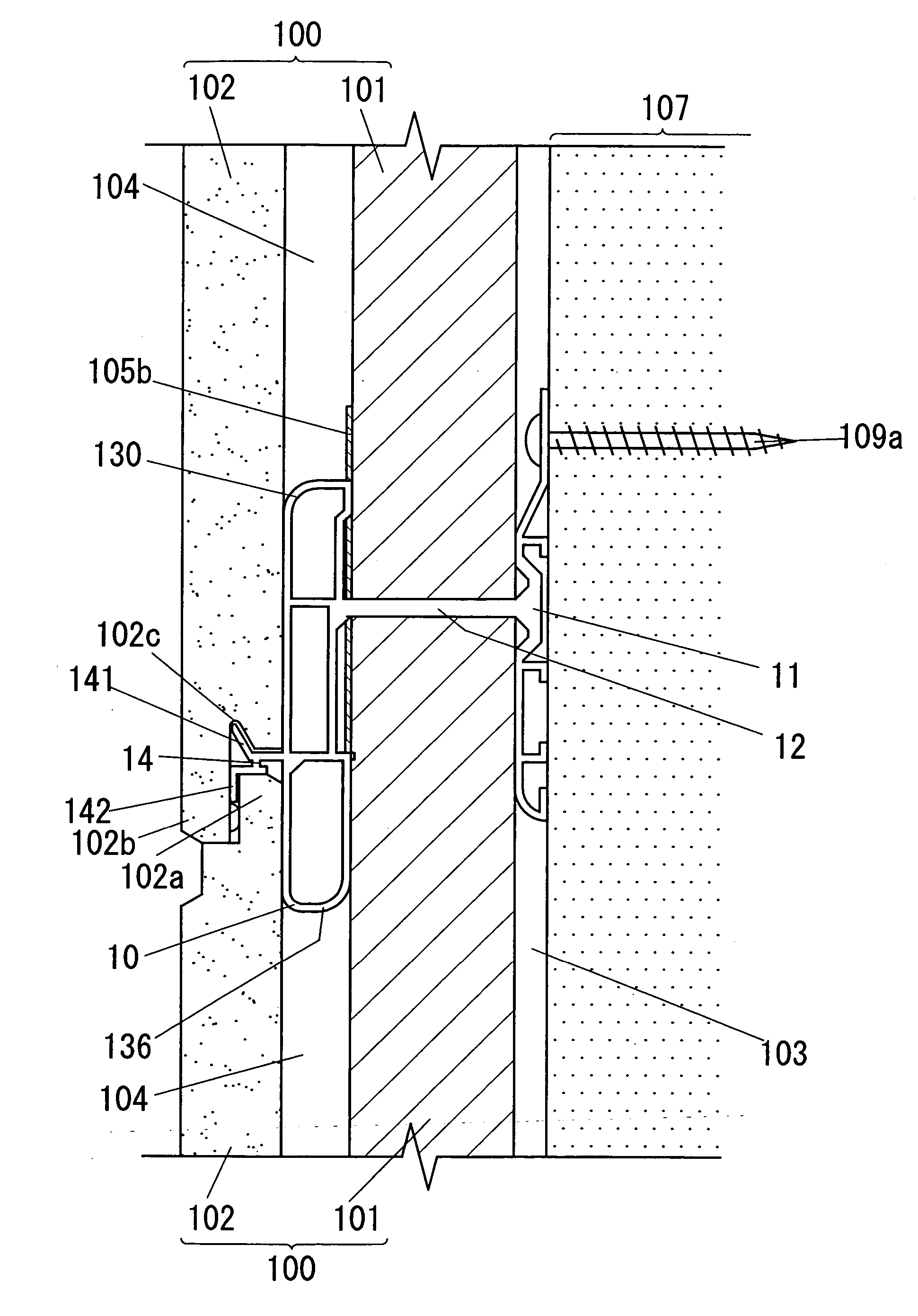

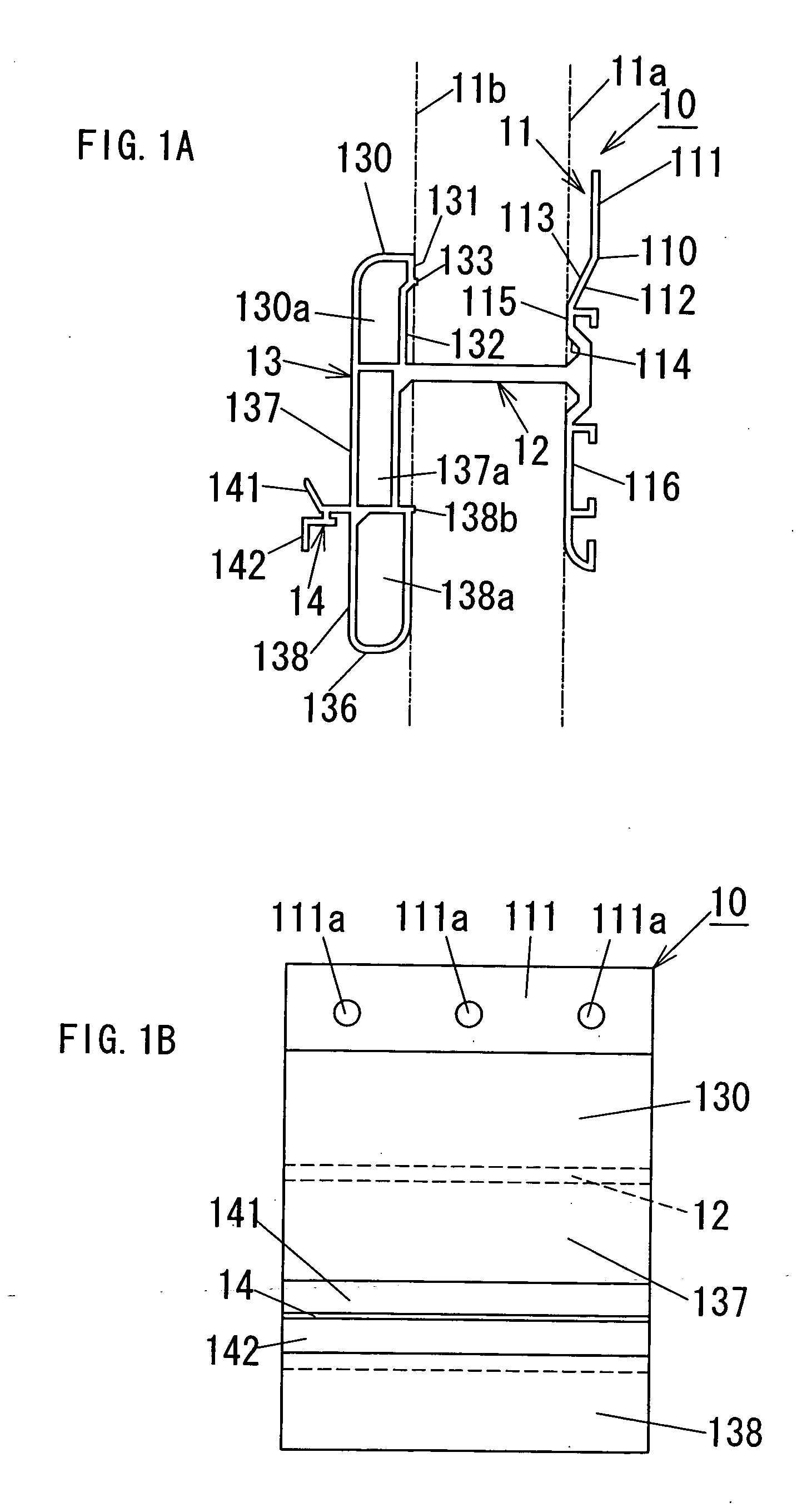

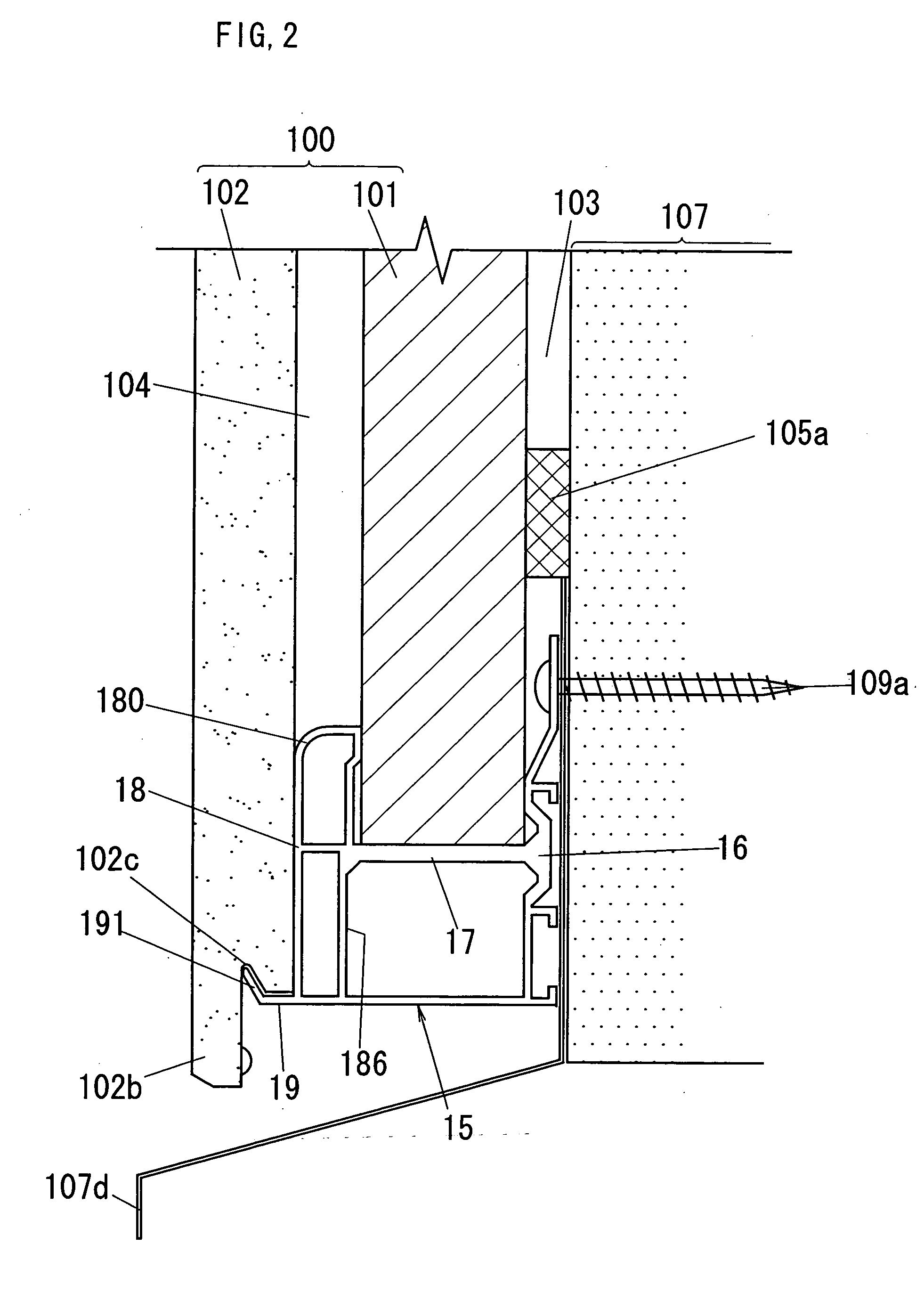

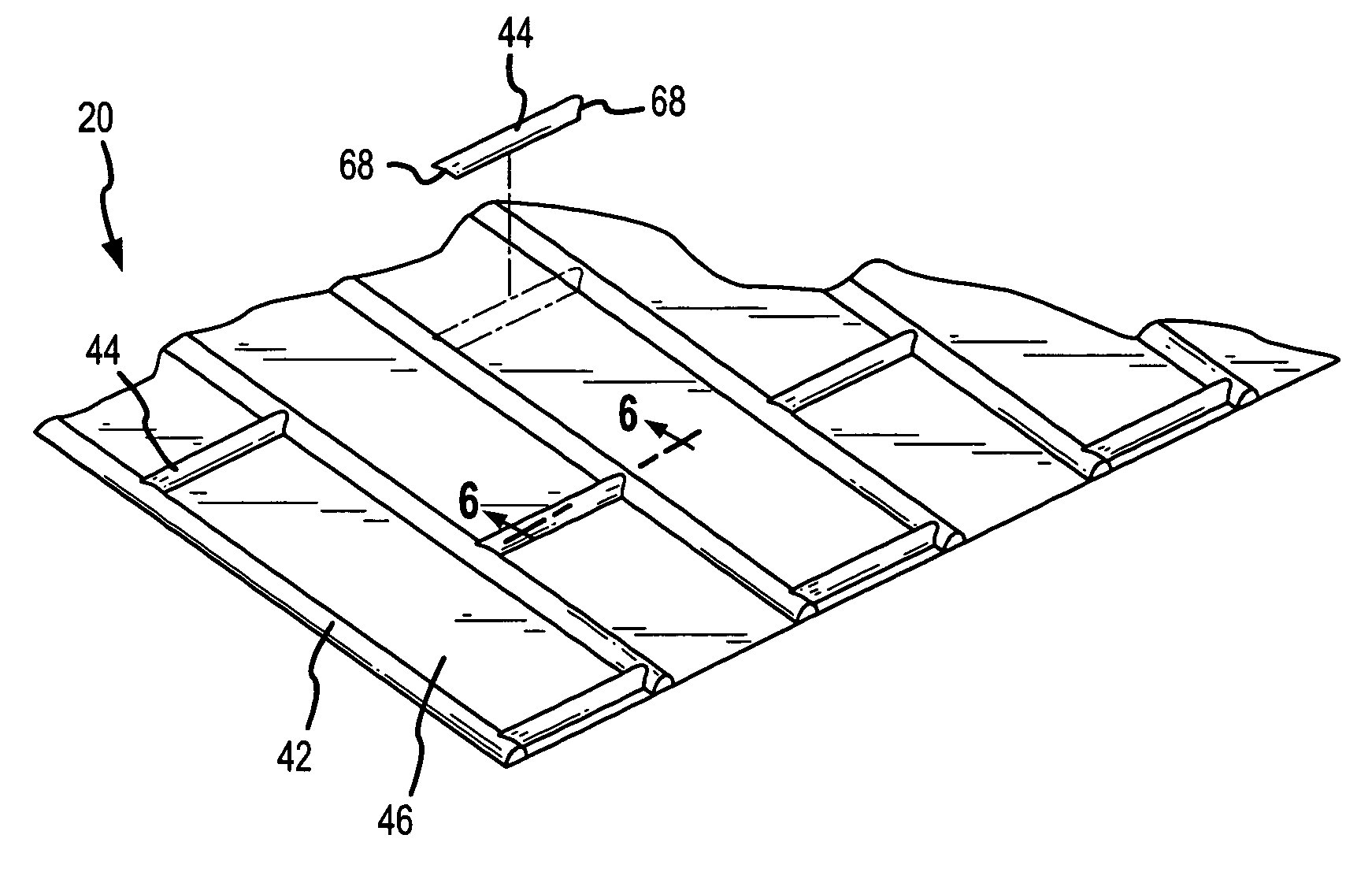

Wall materials bracket and insulating wall structure

A wall materials bracket comprises a base piece 11, a catching piece 12, a spacing piece 13 and a holding piece 14, and further includes a leaning means for leaning an insulation put on the catching piece 12 against a wall substrate. For example, the leaning means is constructed with the upper half 111 of the upper part 110 of the base piece 11, a slope 113 in the lower half 112 of the upper part 110, and a cavity 132 and bosses (133) in the upper part 130 of the spacing piece 13.

Owner:KMEW CO LTD

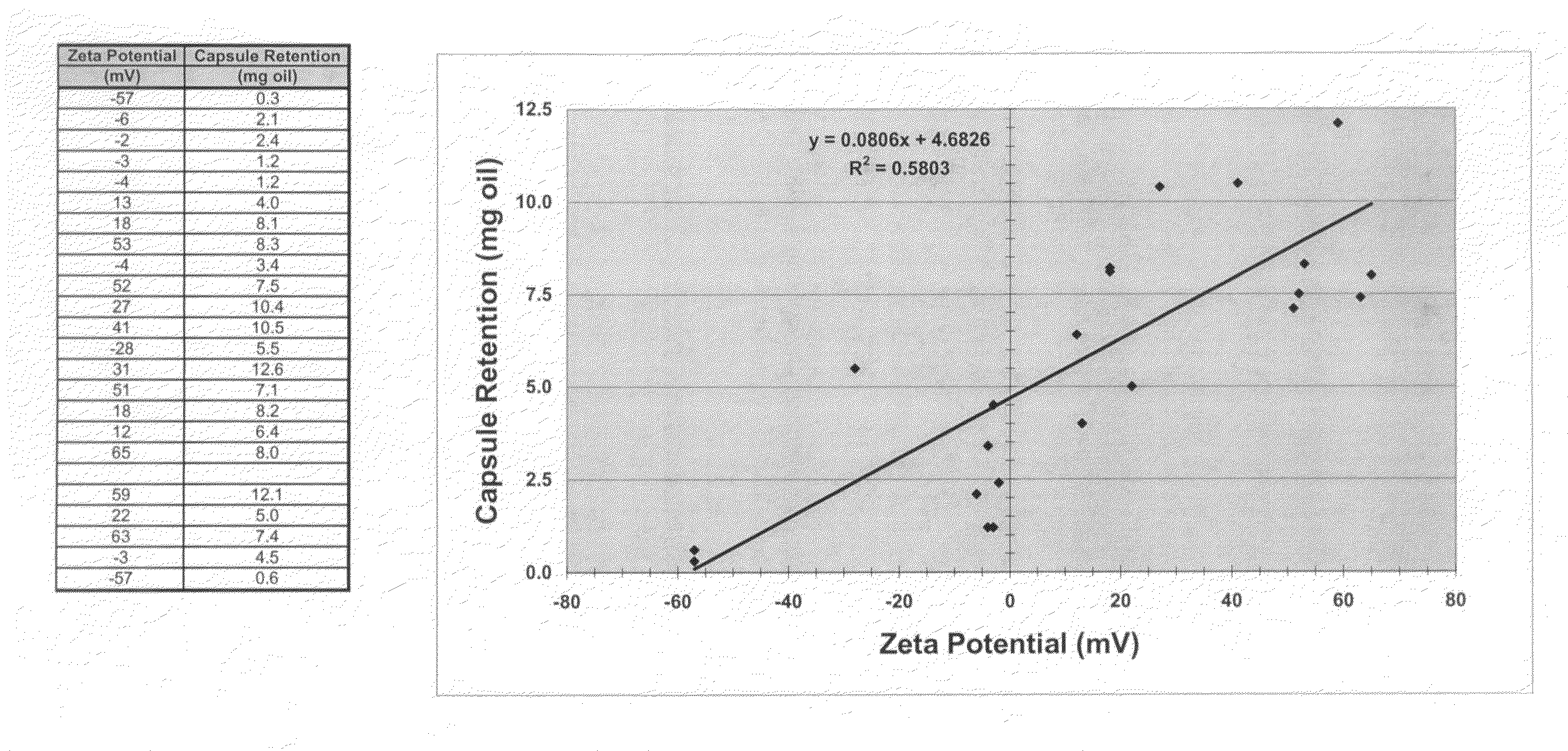

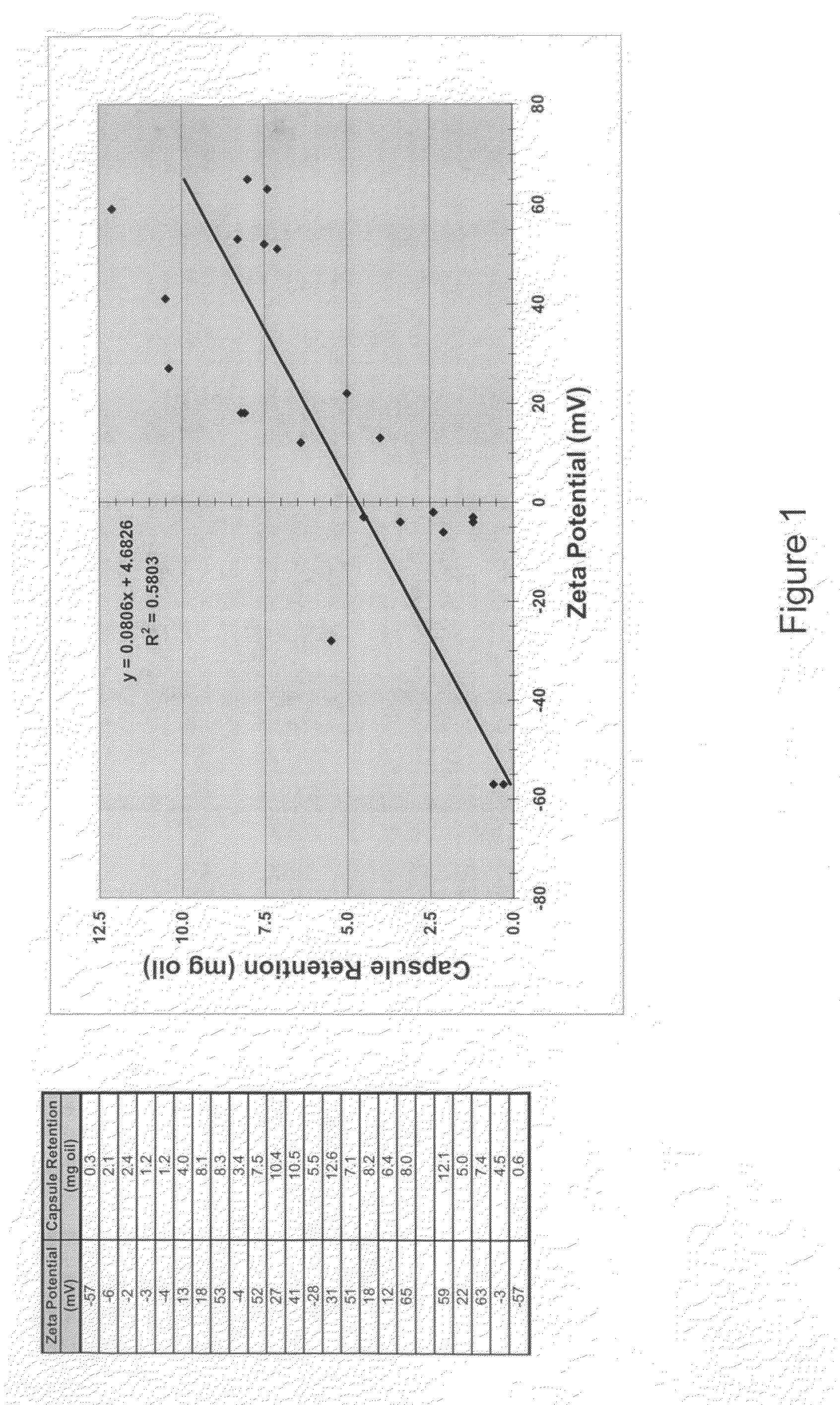

Cationic microcapsule particles

ActiveUS20090274905A1Strong adhesionReduce permeabilityCosmetic preparationsLiquid surface applicatorsZeta potentialMethacrylate

The present invention teaches a cationically charged or neutral microcapsule particle comprising an oil soluble or dispersible core material and a wall material at least partially surrounding the core material, the microcapsule wall material comprising the reaction product of a first composition in the presence of a second composition comprising an emulsifier which is cationic or nonionic, the first composition comprising a reaction product of i) an oil soluble or dispersible amine with ii) a multifunctional acrylate or methacrylate monomer or oligomer, an oil soluble acid and an initiator. The cationic or nonionic emulsifier comprises a water soluble or water dispersible material and optionally a water phase initiator. The first composition initiator and the water phase initiator is an energy-activated initiator. The reaction product of the first composition and second composition results in the formation of a population of microcapsules having a microcapsule wall of low permeance to the core material and having a zeta potential of−5 millivolts or greater. The resulting microcapsules have adherence to anionic surfaces.

Owner:ENCAPSYS LLC

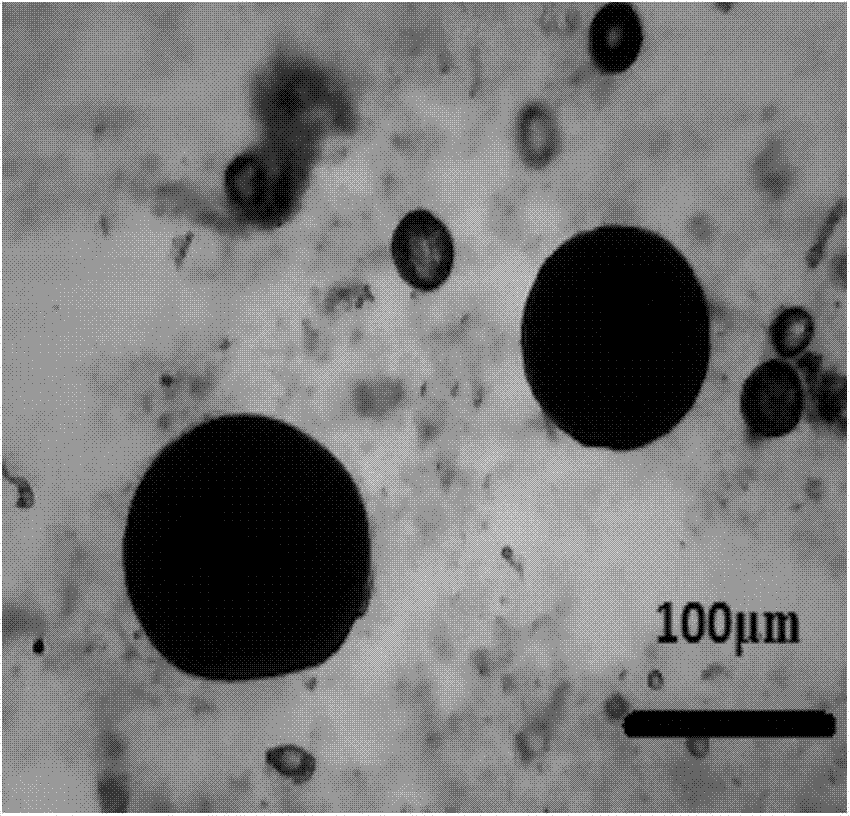

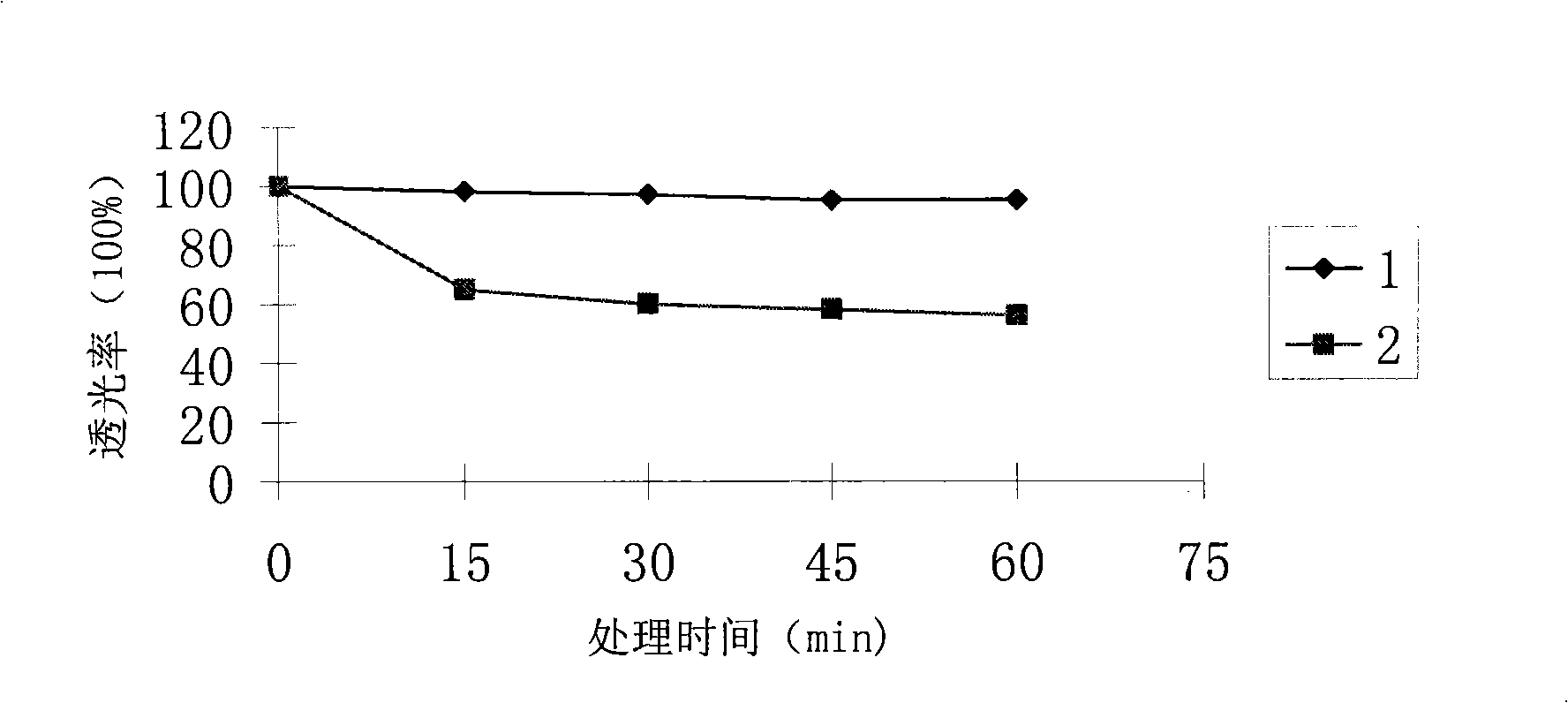

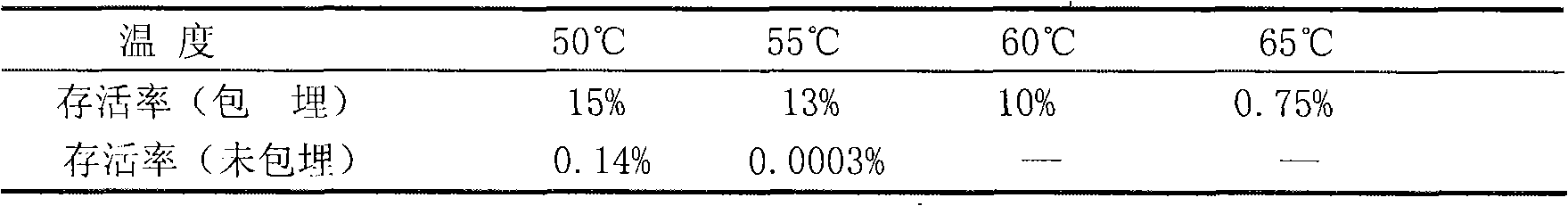

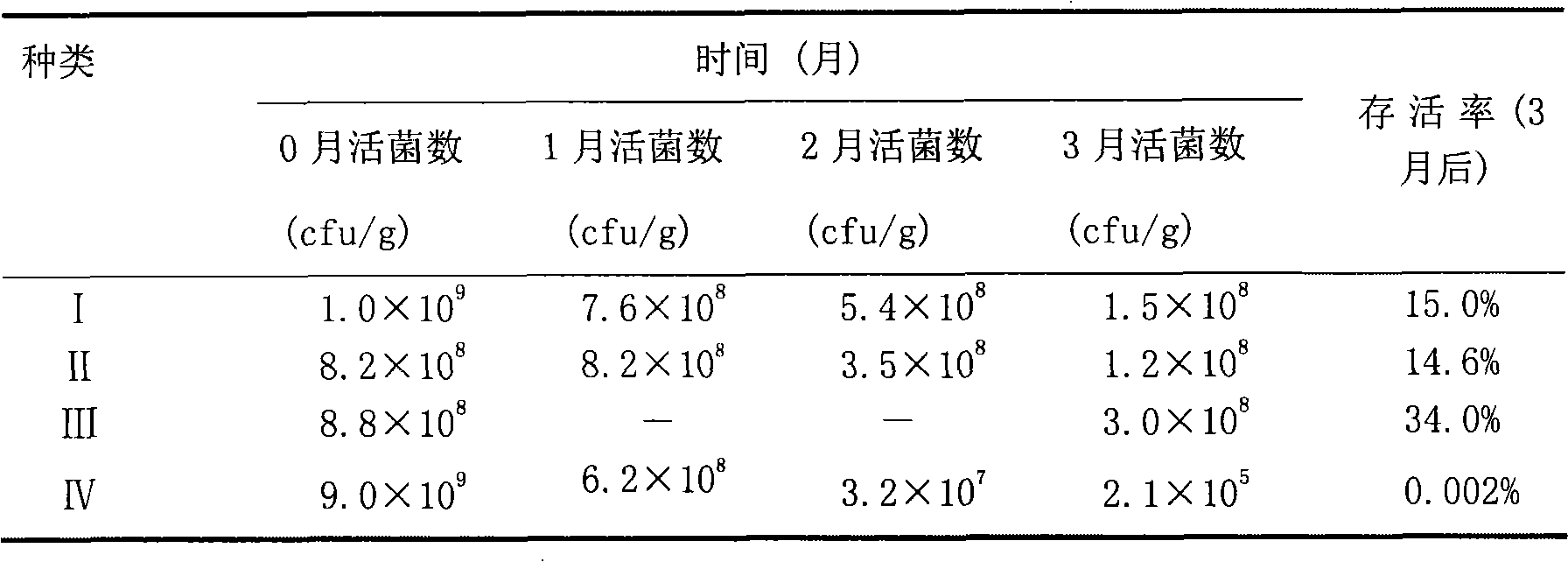

Lactobacillus micro-capsule as well as preparation method and use

ActiveCN101496555AReduce harmHigh viable countBacteria material medical ingredientsAnimal feeding stuffEcological environmentFreeze-drying

The invention relates to a lactobacillus microcapsule, a method for preparing the same, and the use of the same. The lactobacillus microcapsule consists of an outer layer of wall material, a freeze dried protective agent and lactobacilli. The invention also provides the method for preparing the lactobacillus microcapsule and the use of the lactobacillus microcapsule as a feed additive. The lactobacillus microcapsule can effectively protect the lactobacilli in a core material, prolong the survival time of the lactobacilli at room temperature and improve the tolerance of the lactobacilli to the metal ions in the feed; in addition, the lactobacillus microcapsule has good gastric acid resistance and can disintegrate in the intestinal canal quickly to release the lactobacilli, thereby improving the utilization rate of the lactobacilli, balancing the micro-ecological environment in the intestinal canal, suppressing the growth of pathogenic bacteria, protecting the health of the intestinal canals of animals, reducing the incidence rate of the intestinal canals of the animals and the like.

Owner:BEIJING DABEINONG TECH GRP CO LTD +1

Method for treating and regenerating reuse building waste

ActiveCN101099974AAvoid excessive cement slurry contentAvoid Excessive Water DemandSolid waste managementSolid waste disposalPrillBrick

The present invention discloses building waste treating and reusing process, which includes the following steps: classifying building wastes into waste concrete, waste stone material, waste ceramic, waste sintered brick and waste lime-sand brick; crushing separately into coarse grains and eliminating metal, timber and other impurity; milling into 5 mm below regenerated fine aggregate; sorting 0.15 mm below high quality fine aggregate and milling into regenerated fine powder material of 250-600 sq m / kg specific surface area; and preparing mortar, concrete, asphalt concrete and other building material with the regenerated fine aggregate and the regenerated fine powder.

Owner:SOUTH CHINA UNIV OF TECH

Blumea oil microcapsule textile composite finishing agent and use thereof

InactiveCN101591859AStir wellSmall particle sizeFibre treatmentMicroballoon preparationCross-linkChemical Linkage

The invention discloses a blumea oil microcapsule textile composite finishing agent and use thereof. Gelatin or acacia of natural polymers is used the main ingredient of a wall material, the blumea oil serving as a Chinese medicinal material is used as a core material, and complex coacervation is adopted to prepare an blumea oil microcapsule aqueous emulsion; a shrink-resistance crosslinker and a catalyst are added to be combined with the blumea oil microcapsule aqueous emulsion into a multifunctional blumea oil microcapsule textile composite finishing agent; researches on the use of blumea oil microcapsules in textile finishing are carried out; and a novel cross linked graft method is used to perform the microcapsule finishing of textiles to form chemical bonds between the microcapsules and the textiles though the shrink-resistance crosslinker and free formaldehyde molecules in 2D resin further participate in a cross-linking and curing reaction as a microcapsule curing agent, so the textiles achieve a long lasting antibacterial and health-care function, a shrink-resistance function and low formaldehyde release content performance.

Owner:SOUTH CHINA AGRI UNIV

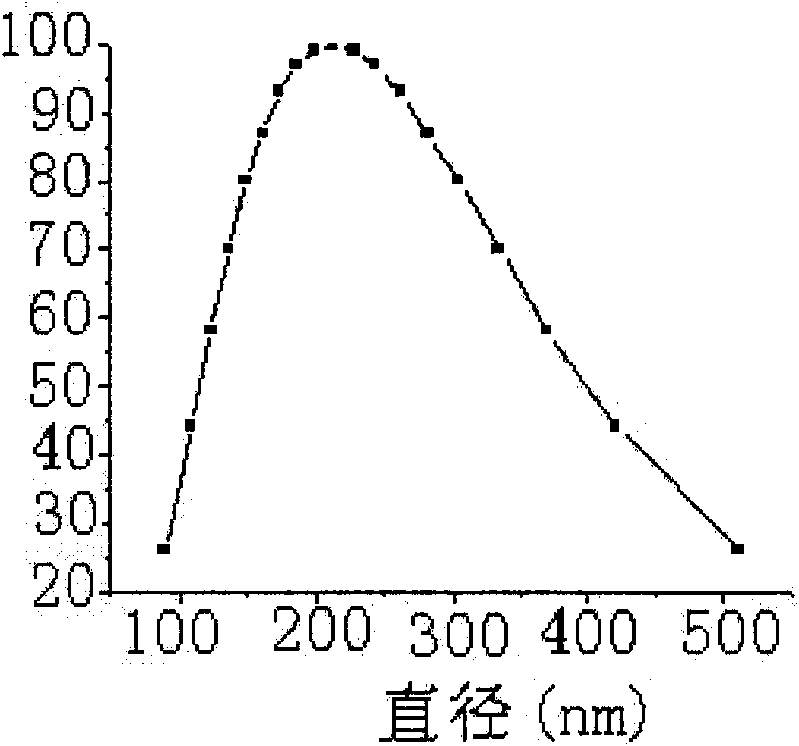

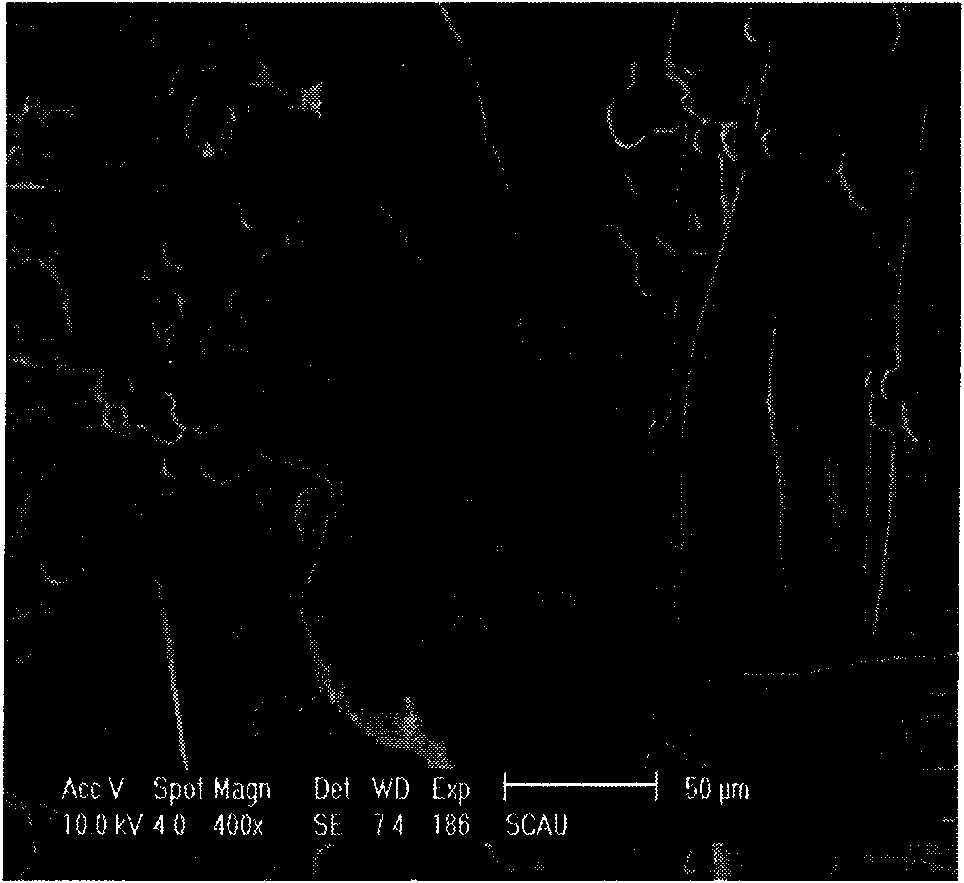

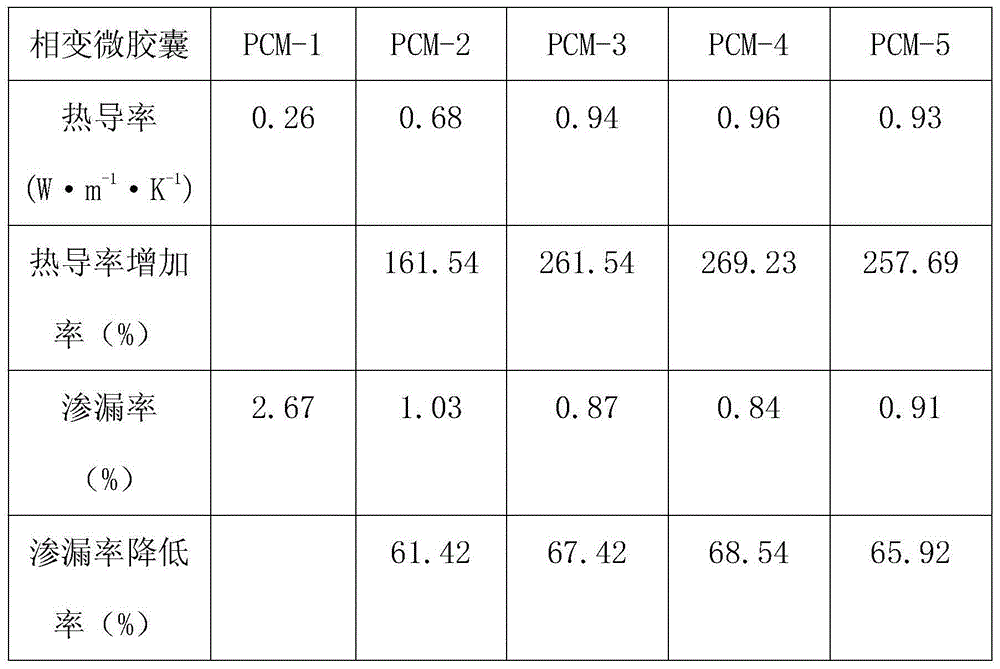

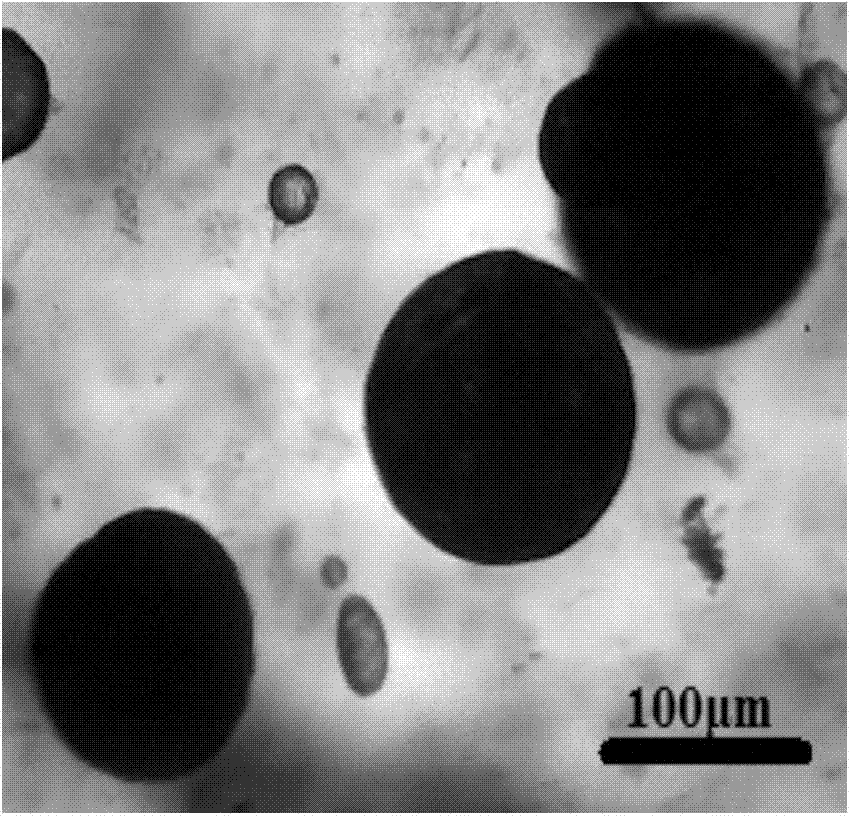

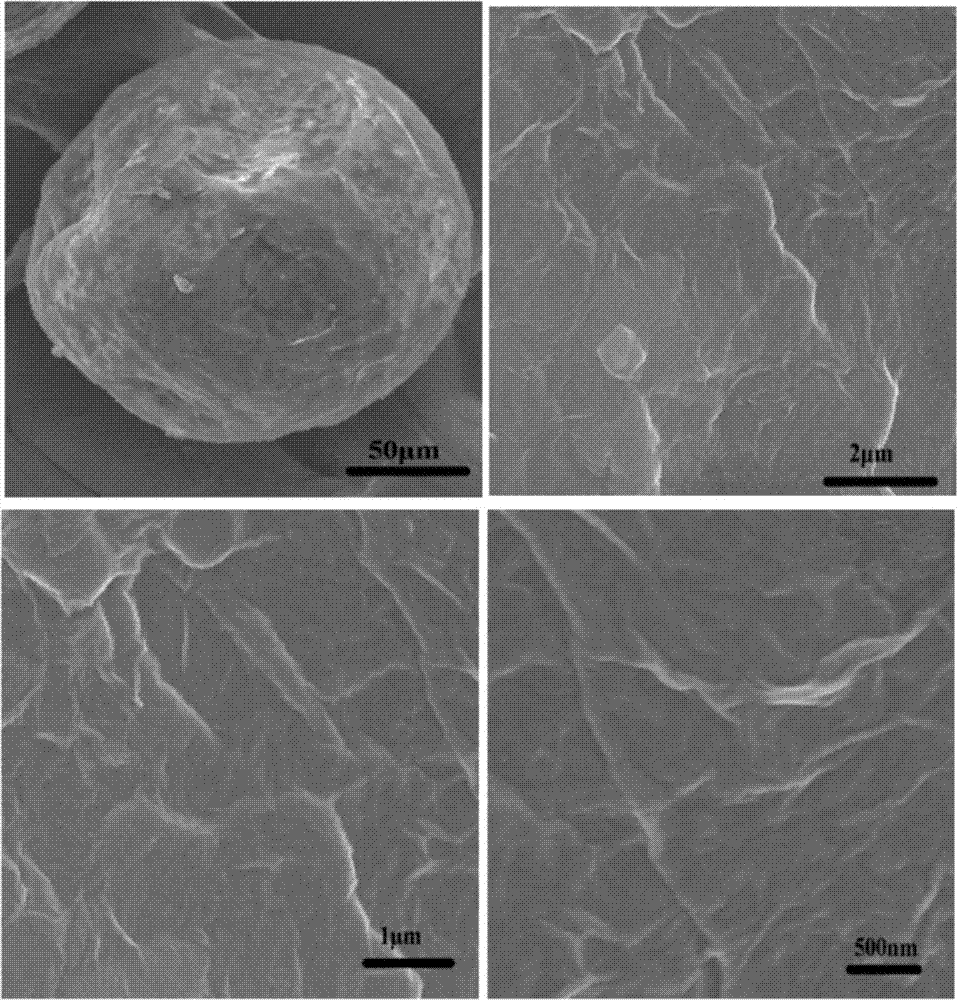

Preparation method of phase change microcapsule with graphene-modified wall material

InactiveCN104861934AImprove thermal conductivityReduce leak rateHeat-exchange elementsMicroballoon preparationState of artIn situ polymerization

The invention discloses a preparation method of a phase change microcapsule with a graphene-modified wall material. The preparation method comprises the following steps: preparing a graphene oxide solution; preparing a graphene-modified wall material pre-polymer; emulsifying a phase change material; preparing the phase change microcapsule with the graphene-modified wall material. A solid-liquid phase change material serves as a core material of the phase change microcapsule prepared by using an in-situ polymerization method, and a graphene-modified polymer serves as the wall material. Compared with the prior art in which graphene is not added for modification, the preparation method in which the graphene is added into the wall material has the advantages that the heat conductivity of the phase change microcapsule is improved, and the leakage rate is lower.

Owner:SOUTHWEAT UNIV OF SCI & TECH +1

Washable ecologic wall material capable of decomposing formaldehyde

ActiveCN101935190BStrong water absorptionHigh decolorizing powerOther chemical processesDispersed particle separationFiberSodium Bentonite

The invention relates to a washable ecologic wall material capable of decomposing formaldehyde. The invention not only can be used for decomposing and absorbing the formaldehyde, improving indoor moisture and absorbing indoor water content, but also is very convenient to wash and brings great convenience for people to clean the wall. The washable ecologic wall material capable of decomposing the formaldehyde is characterized by being prepared from the following components in percentage by weight: 18-29 percent of diatomite, 25-30 percent of quartz sand, 0.1 percent of fiber, 15-18 percent of bentonite, 1-3 percent of adhesive, 12-17 percent of ash calcium, 13-18 percent of water retention agent, 5-8 percent of formaldehyde purifier, 3-6.1 percent of titanium dioxide and 3-7 percent of anion powder. The invention further improves a traditional original wall material to satisfy the market needs and bring convenience and benefits to the life of people.

Owner:氧宜多硅藻新材料(宜昌)有限责任公司

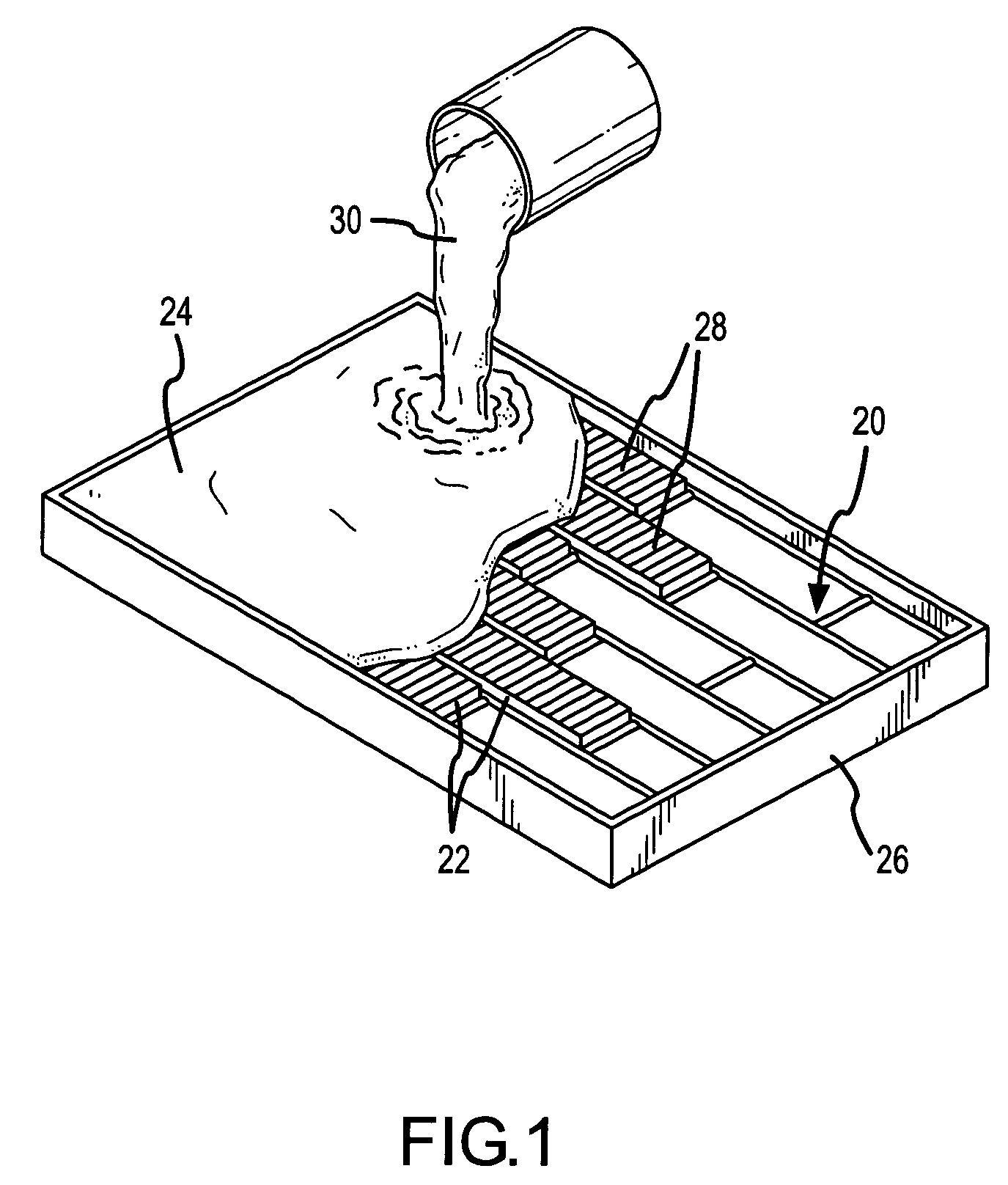

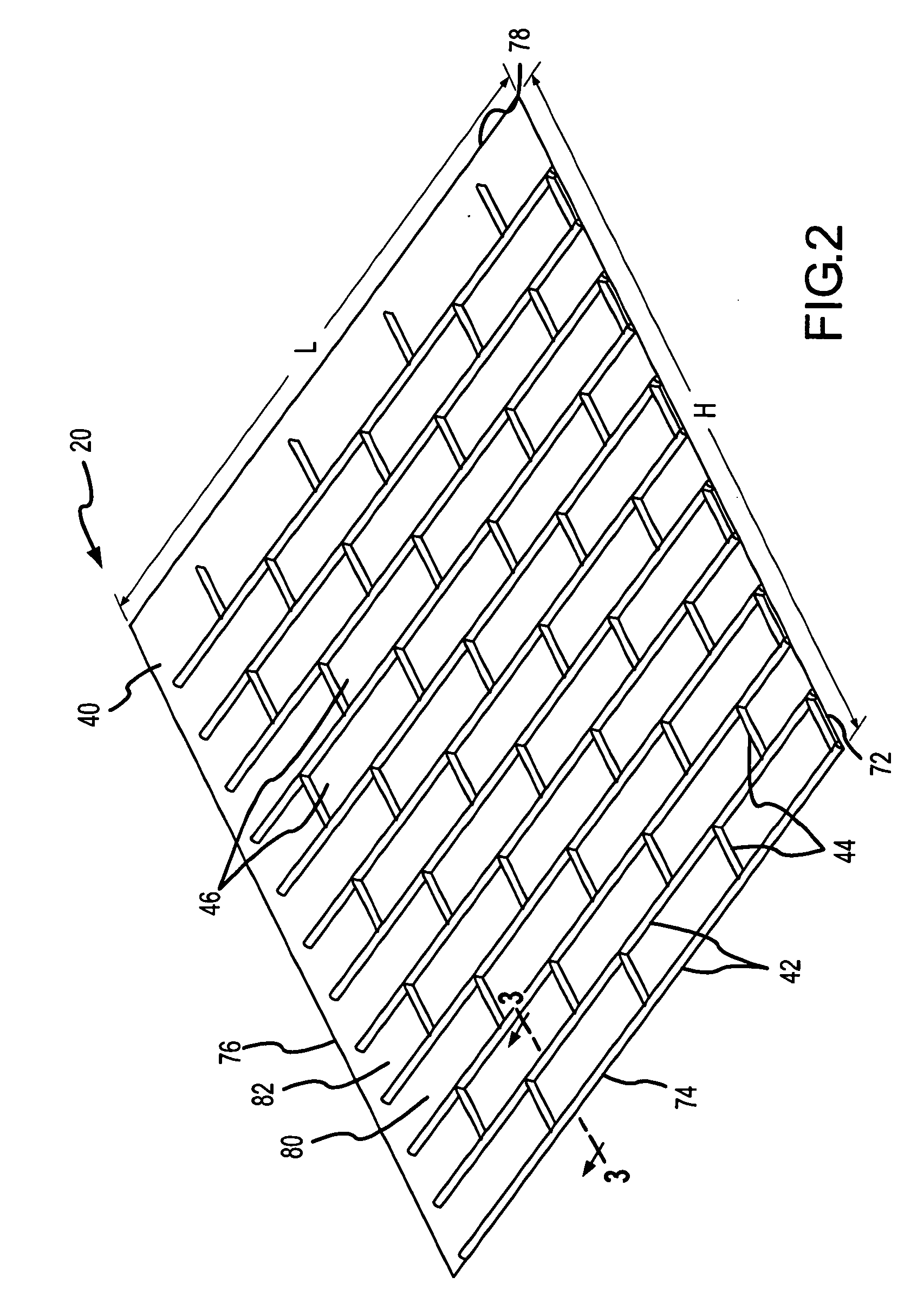

Foam liner for casting objects in poured walls

A liner holds objects in place within a form for a poured wall. The liner includes a backing sheet and a plurality of foam bed joints arranged in a substantially parallel fashion along a length dimension. A plurality of separate foam head joints are attached along a height dimension, wherein opposing ends of the foam head joints engage adjacent bed joints to define a plurality of regions on the backing sheet for receiving the objects to be cast in the poured wall. Each foam joint has a rounded cross section to form a curved grout line between the objects cast in the poured wall. The foam joints include an outer protective skin to prevent the poured wall material from bonding with the foam cells. A method of forming the liner includes aligning the separate foam bed joints and head joints in a grid and then pressing an adhesive-backed paper sheet against the foam joints.

Owner:SCOTT WILLIAM CLARE +1

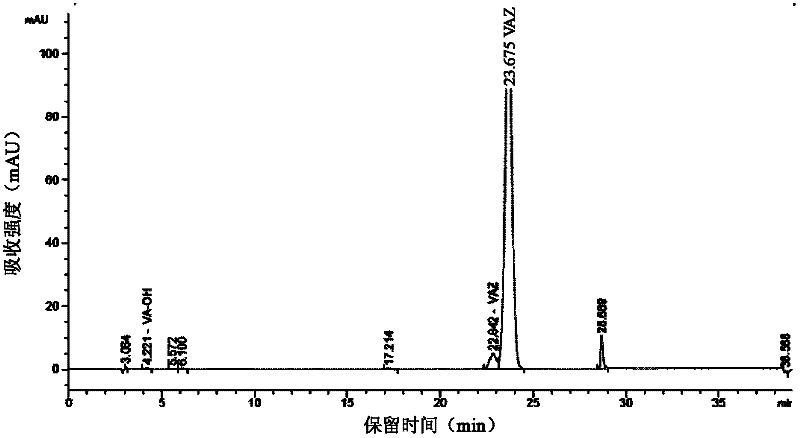

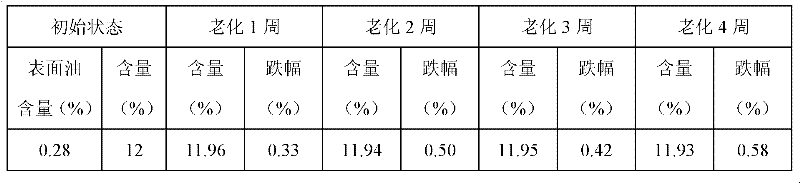

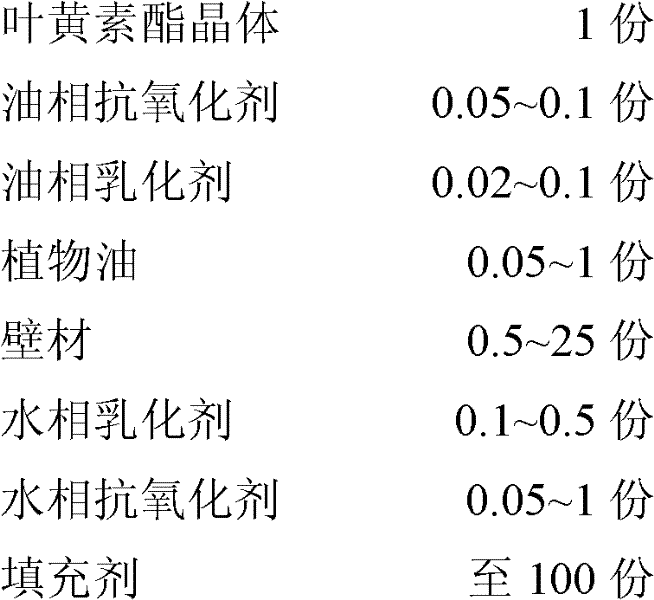

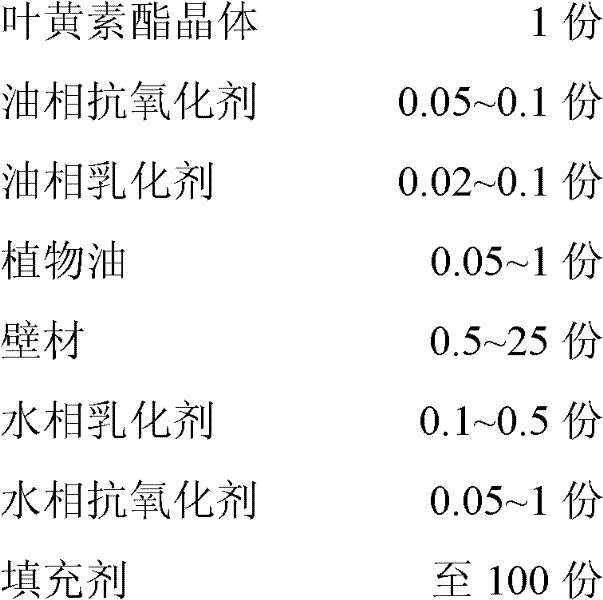

Lutein ester microcapsule powder and preparation method thereof

ActiveCN102389108AInstant highGood self-emulsifying performanceFood preparationAntioxidantFiller Excipient

The invention discloses lutein ester microcapsule powder and a preparation method thereof. The preparation method comprises the following steps of: preparing an oil phase solution and a water phase solution respectively, and mixing and emulsifying the oil phase solution and the water phase solution; and non-water raw materials comprise the following components in part by weight: 1 part of lutein ester crystal, 0.05 to 0.1 part of oil phase antioxidant, 0.02 to 0.1 part of oil phase emulsifying agent, 0.05 to 1 part of plant oil, 0.5 to 25 parts of wall material, 0.1 to 0.5 part of water phaseemulsifying agent, 0.05 to 1 part of water phase antioxidant, and the balance of filler. In the preparation method for the lutein ester microcapsule powder, the oil-soluble lutein ester is fully dispersed in cold water in the form of sub nanometer particles, and the product can be self-emulsified in water, and is good in instant capacity and self-emulsification capacity, and high in stability, and has uniform and durable color; and the phenomena of oil floating, precipitation, adhesion to a bottle wall and the like are avoided during application. Organic solvents are not introduced in the powder, so solvent residues are avoided in the product. The production process is environment-friendly, simple and practicable, expensive equipment is not needed, and the microcapsule powder can be industrially produced easily and conveniently.

Owner:INNOBIO CORP LTD

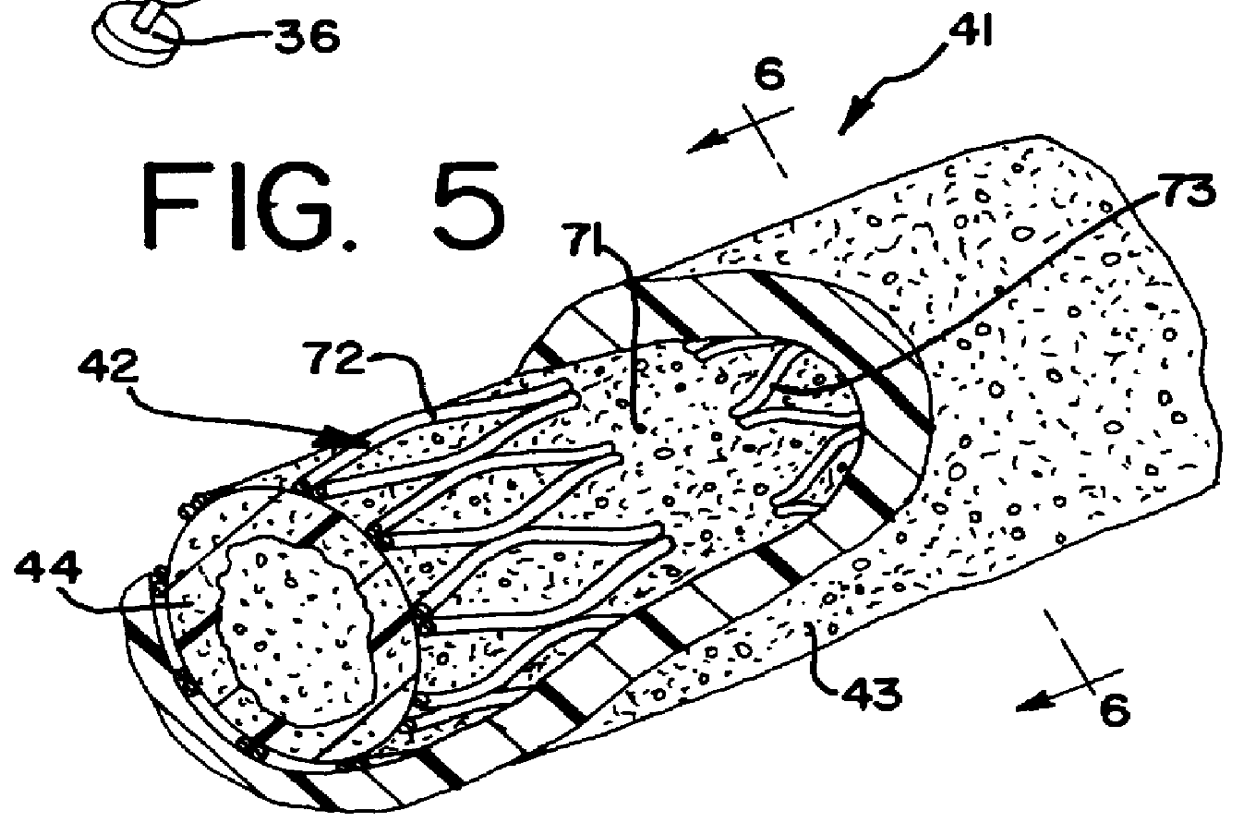

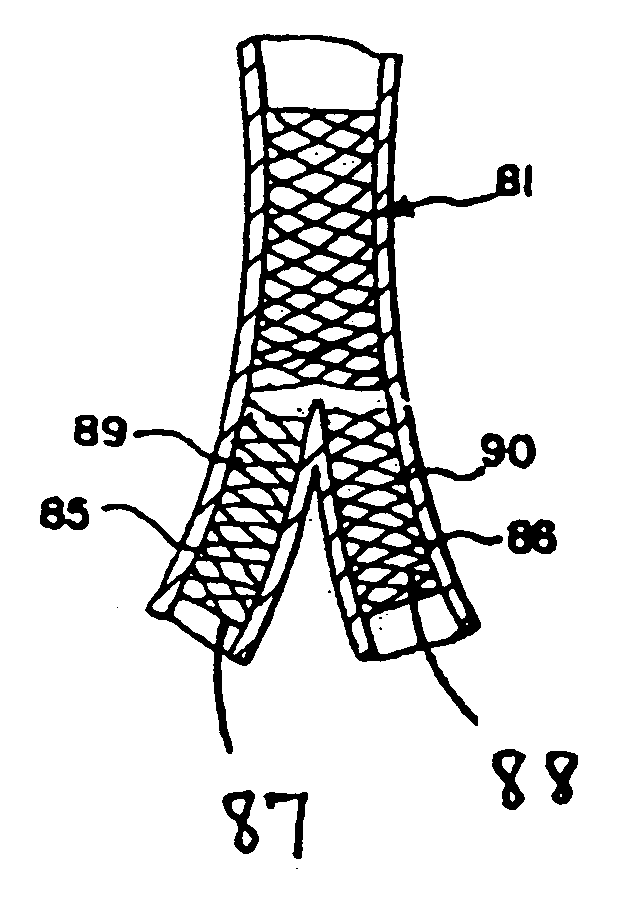

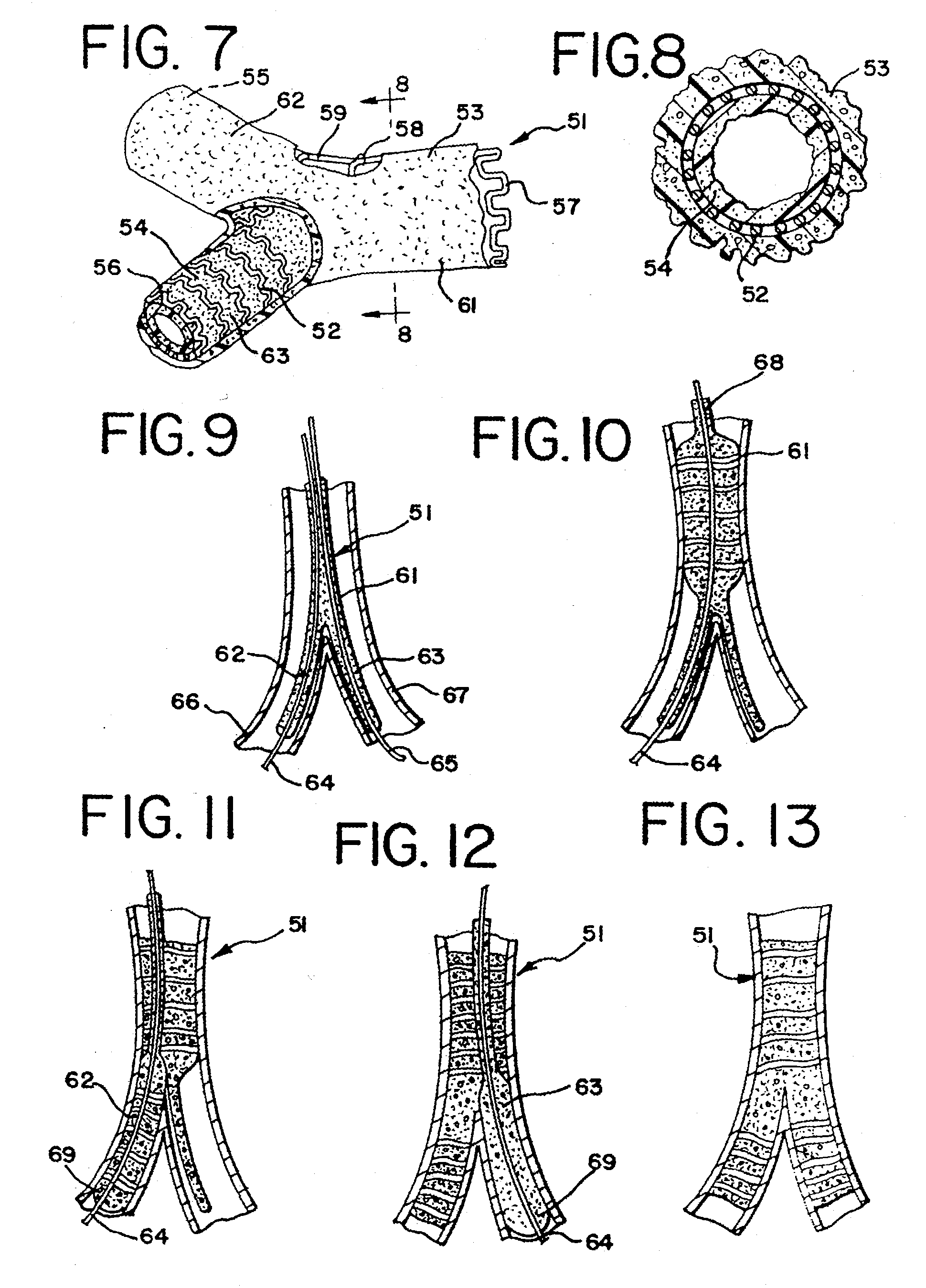

Expandable supportive branched endoluminal grafts

InactiveUS20090138067A1Facilitates good tissue ingrowthFully coveredStentsBlood vesselsProsthesisTubular stenosis

An endoluminal graft which is both expandable and supportive is provided in a form suitable for use in a branched body vessel location. The graft expands between a first diameter and a second, larger diameter. The support component is an expandable stent endoprosthesis. A liner is applied to the endoprosthesis in the form of a compliant wall material that is porous and biocompatible in order to allow normal cellular invasion upon implantation, without stenosis, when the expandable and supportive graft is at its second diameter. The supportive endoluminal graft is preferably provided as a plurality of components that are deployed separately at the branching body vessel location, one of which has a longitudinal seam defining leg portions within which the other components fit in a telescoping manner.

Owner:LIFEPORT SCI

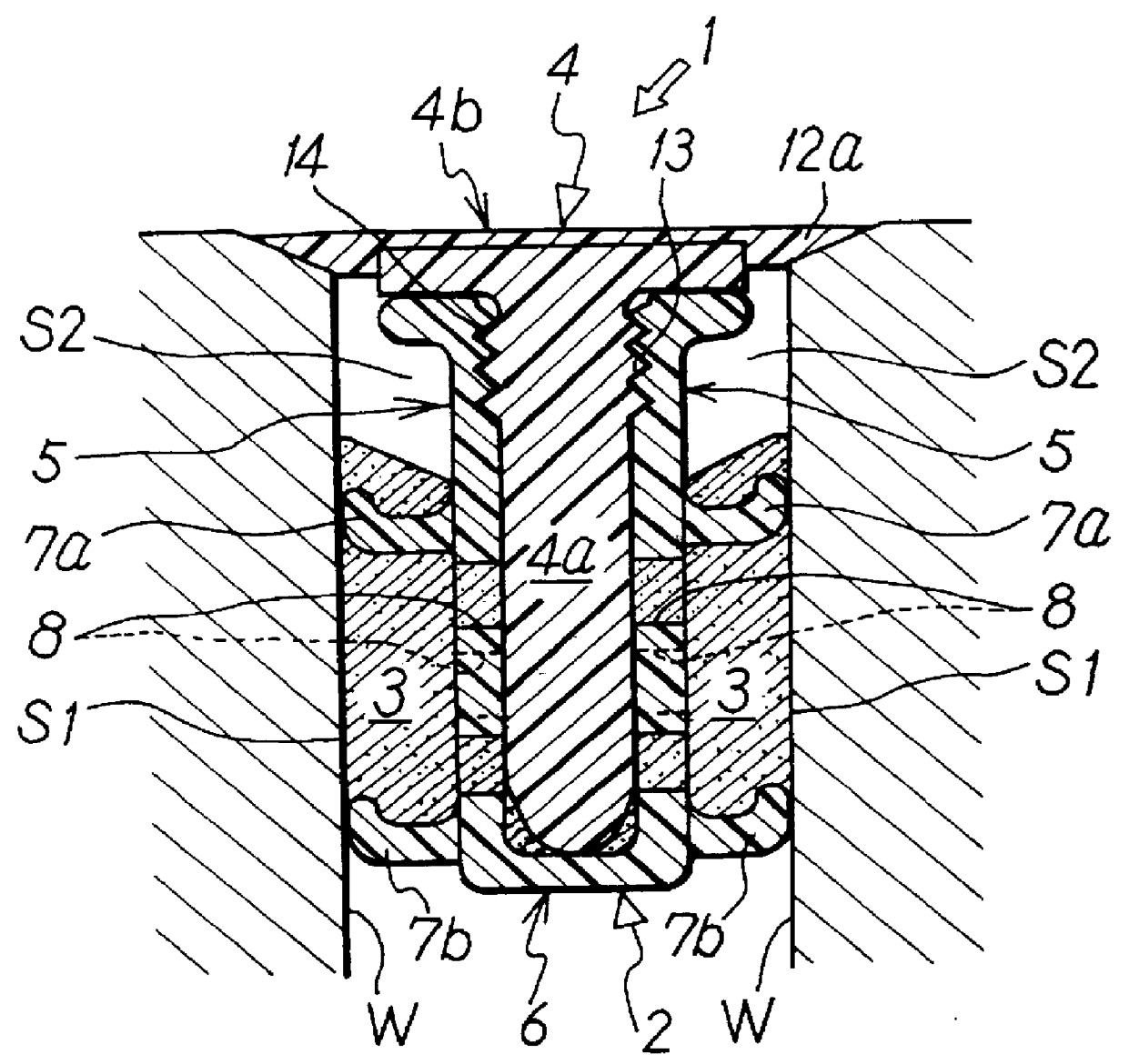

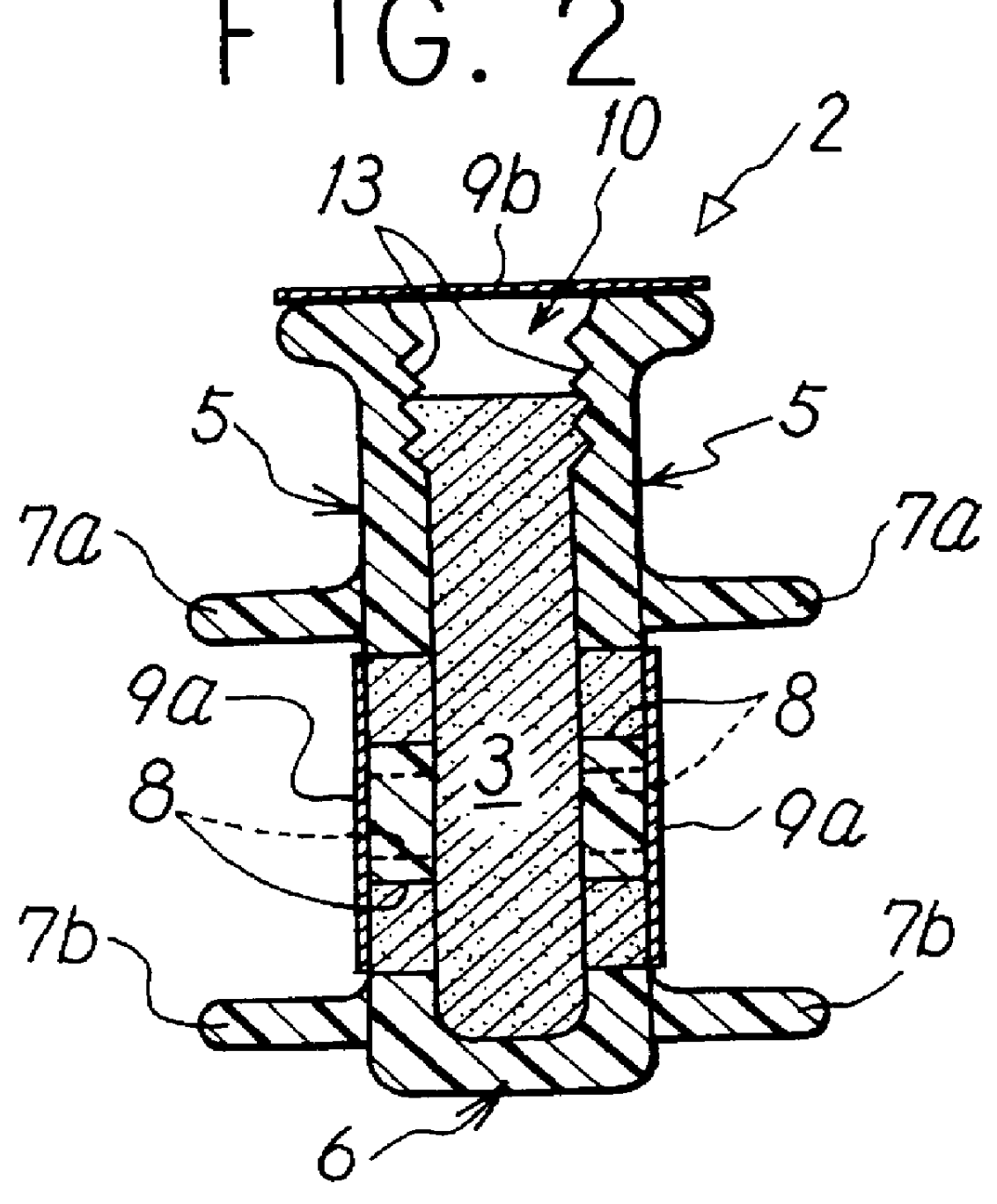

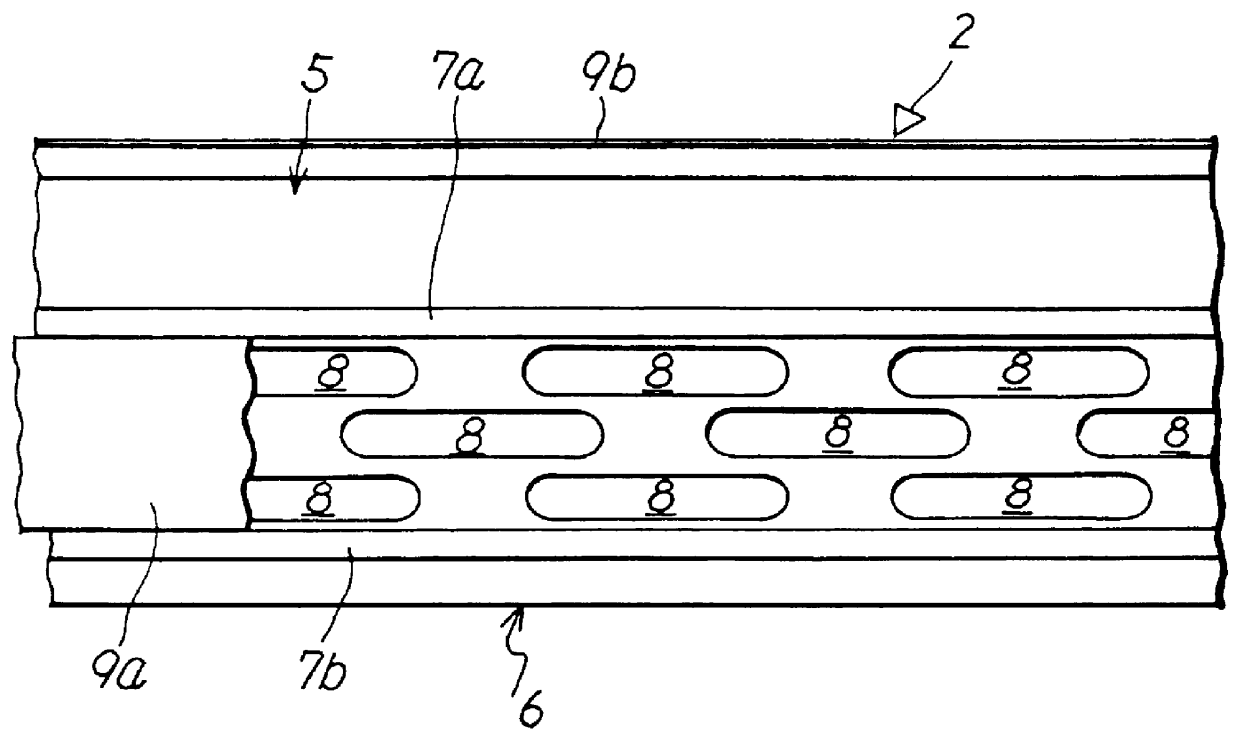

Joint seal and assembly method thereof

InactiveUS6102407APreventing excessive insertion of the joint base materialImprove sealingCovering/liningsWallsMechanical engineeringWall material

A joint seal is designed to maintain its proper position in the joint groove opening port to create an effective seal between the inner walls of the joint groove and to resist peeling or damage, even in an event, such as an earthquake, during which the adjacent outer wall materials shift; and to have a joint base material 2, a sealing material 3 and a heart wood 8. The joint base material 2 has at least two seal tongue pieces 14a and 14b projecting from the outer face of side plates 5, 5. A number of small openings 8 to allow sealing material to be pressed out at the insertion of heart wood 8 is punched between the seal tongue pieces 14a and 14b, and release mold sheets 18a and 18b are attached to joint base material 2 as a cap member covering the small openings 8 and the opening ports of side plates 5, 5.

Owner:SEIKI IND

Xanthophyll micro-capsule and its preparation method

InactiveCN101288662AHydroxy compound active ingredientsAntinoxious agentsAntioxidantMagnesium stearate

The invention relates to a xanthophylls microcapsule and a preparation method thereof. The core material of the microcapsule is xanthophylls and the wall material is natural macromolecule chitosan or glutin, gum acacia and antioxidant. The technique has the following steps: the xanthophylls is dissolved in an organic solvent, which is added into a gum acacia solution containing emulsifier and antioxidant for uniform emulsion; the well emulsified gum acacia is added into the chitosan or glutin solution for being condensed into capsules, and the capsules are processed with magnesium stearate after solidification; the microcapsules with excellent dispersivity are obtained after drying. The microcapsule prepared by the technique has the grain diameter of 1-200 Mum. The preparation technique has simple process, mild preparation condition and easy popularization; the microcapsule prepared has good dispersivity and high stability and is suitable for industries such as food, health care products, feed, etc.

Owner:UNIV OF JINAN

Coated micro capsule of lactic acid bacteria and its preparation

InactiveCN1569043AEnhance gastric protection effectAvoid damageBacteria material medical ingredientsAnimal feeding stuffCelluloseCarrageenan

The invention discloses a micro capsule of lactic acid bacteria and its preparation, wherein the micro capsule includes a core material of lactic acid bacterium particles, the bolus making auxiliary material being one or more selected from cane sugar, maltose dextrin, crystalline cellulose, maize starch, glucose or protein sugar, and the wall material comprises sodium acetylide and CaCl2, carrageenan, soybean separated albumen powder, and water-insoluble plant oil.

Owner:CHINA AGRI UNIV

Microcapsule essence perfume for cigarettes as well as preparation method of microcapsule essence perfume

InactiveCN103451019AChemically stableNo pollution in the processTobacco treatmentEssential-oils/perfumesFlavorGlycerol

The invention discloses a microcapsule essence perfume for cigarettes as well as a preparation method of the microcapsule essence perfume. The microcapsule essence perfume contains the following raw materials in parts by weight: 1-3 parts of essence, 0.05-0.2 part of glycerinum or / and propylene glycol, 1-5 parts of wall materials and 0.01-0.03 part of emulsifier. The preparation method comprises the steps of: mixing essence, glycerinum or / and propylene glycol to obtain a mixture, evenly stirring the mixture, adding 95% ethanol with 1-10 times weight of the mixture, and mixing and evenly mixing to obtain a mixed solution; adding wall materials and emulsifier in the mixed solution and stirring for homogenization; and sealing, standing for 1-2 hours at normal temperature, refrigerating for 15-60 minutes at the temperature of minus 20 DEG C to minus 80 DEG C, drying for 8-24 hours at the vacuum degree of 30-80MPa and the temperature of 40-80 DEG C, grinding dried products, sieving the ground products to prepare microcapsule particles, thereby obtaining the microcapsule essence perfume for cigarettes. The perfume for cigarettes is made to microcapsules, so that perfume is free from being affected by external factors, and loss and fragrance distortion caused by volatile components in the perfume for cigarettes are effectively reduced.

Owner:HUBEI CHINA TOBACCO IND +1

Thermo-sensitive discoloration material microcapsule and preparation method thereof

InactiveCN102477290AGood chemical stabilityGood solvent resistanceTenebresent compositionsMicroballoon preparationEmulsionChange color

The invention discloses a thermo-sensitive discoloration material microcapsule and a preparation method thereof. The microcapsule is composed of a core material and a wall material for covering the core material, wherein the core material comprises a thermo-sensitive discoloration compound composed of a chromogenic reagent, a color-developing agent and a solvent; the wall material is a melamine resin pre-polymer; the mass ratio of the thermo-sensitive discoloration compound to the melamine resin pre-polymer is 1:(1-2). The preparation method comprises the following steps of: mixing the chromogenic reagent, the color-developing agent and the solvent to form a thermo-sensitive discoloration solution under the heating condition; adding an emulsifying agent solution into the thermo-sensitive discoloration solution and emulsifying a commixed solution to obtain an emulsion; adjusting the pH value to 3-6 and adding the melamine resin pre-polymer into the emulsion; reacting at a temperature for 60-70 DEG C for 1-1.5 hours and then cooling to 30-40 DEG C; then adding a dispersant; and washing and drying to obtain the thermo-sensitive discoloration microcapsule. According to the method provided by the invention, the influences on human bodies and environments are greatly reduced; the operation is simple, the prepared microcapsule products can fast change color and fade and the effect is obvious, so that the thermo-sensitive discoloration material microcapsule can be widely applied in the fields of anti-counterfeiting textile and printing and the like.

Owner:BEIJING CTA TEX CHEM

Fruit and vegetable micro encapsulated fresh-keeping agent and preparation method thereof

ActiveCN101965863ADoes not affect flavorGuaranteed qualityFruit and vegetables preservationPropolisGlycerol

The invention discloses a fruit and vegetable micro encapsulated fresh-keeping agent, which is prepared from chitosan, propolis and beta-cyclodextrin which are used as wall materials and cassia oil, rosemary oil and lemon oil which are used as core materials. The fruit and vegetable micro encapsulated fresh-keeping agent is prepared by the following steps of: adding the beta-cyclodextrin and water in a three-port bottle; electrically stirring and heating to 60-70DEG C for dissolving the beta-cyclodextrin into the water; continuously stirring and cooling to 40-45DEG C; adding the core materials of the cassia oil, the rosemary oil and the lemon oil to ensure that the mixed essential oil is uniformly dispersed in solution; then slowly cooling to the room temperature to obtain a beta-cyclodextrin-essential oil microcapsule; adding the mixed wall material of the chitosan and the propolis; adding glycerol and tween-80; and continuously stirring for 30 minutes to form the micro encapsulated fresh-keeping agent. in the invention, the beta-cyclodextrin-essential oil microcapsule is smeared on the surface of the fruit and vegetable by the film forming characteristics of the chitosan and the propolis and an essential oil fresh-keeping agent is continuously released under the action of the microcapsule, so that the aim of keeping the quality of the fruit and vegetable can be achieved.

Owner:大有作为(天津)冷链技术研究院

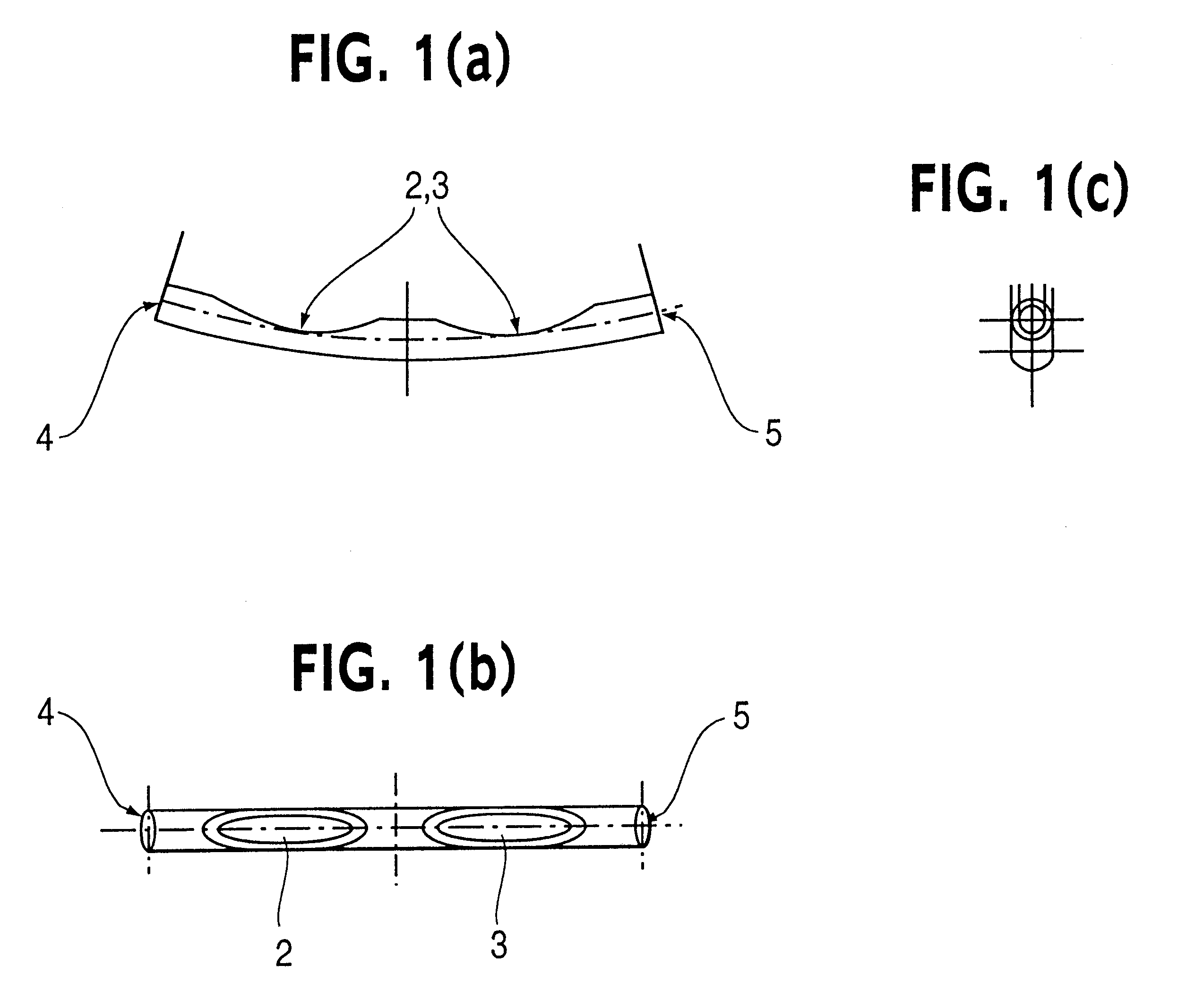

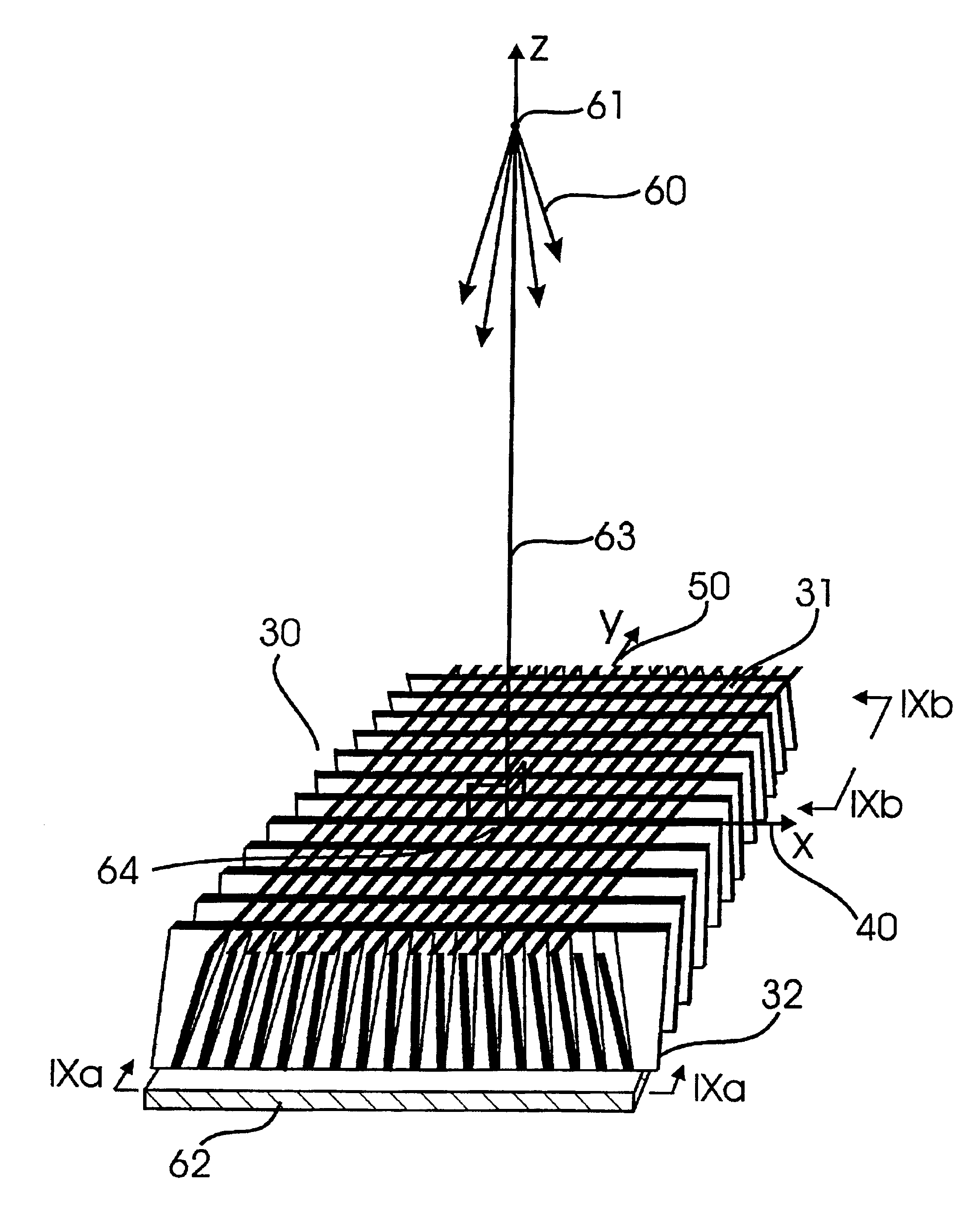

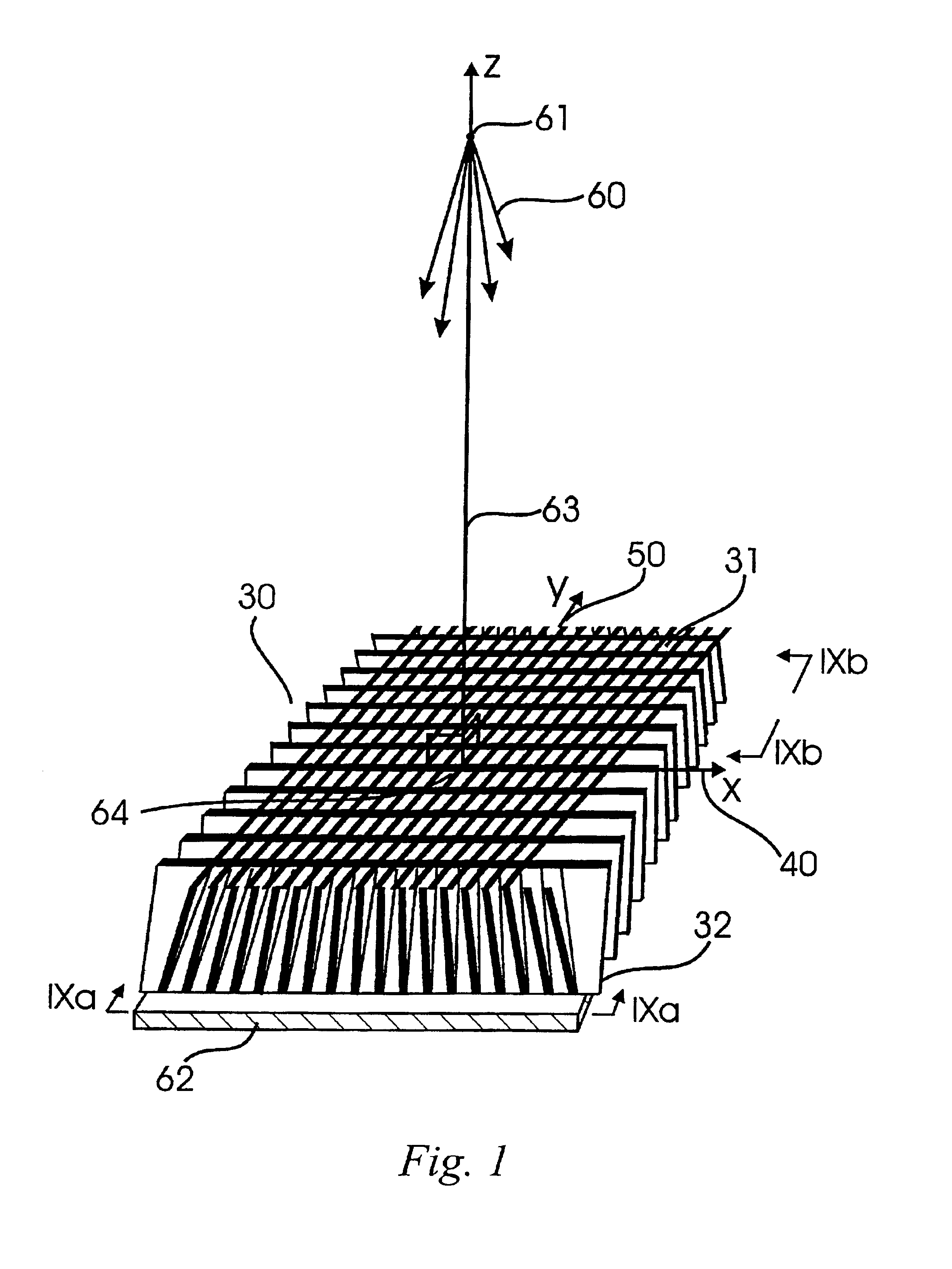

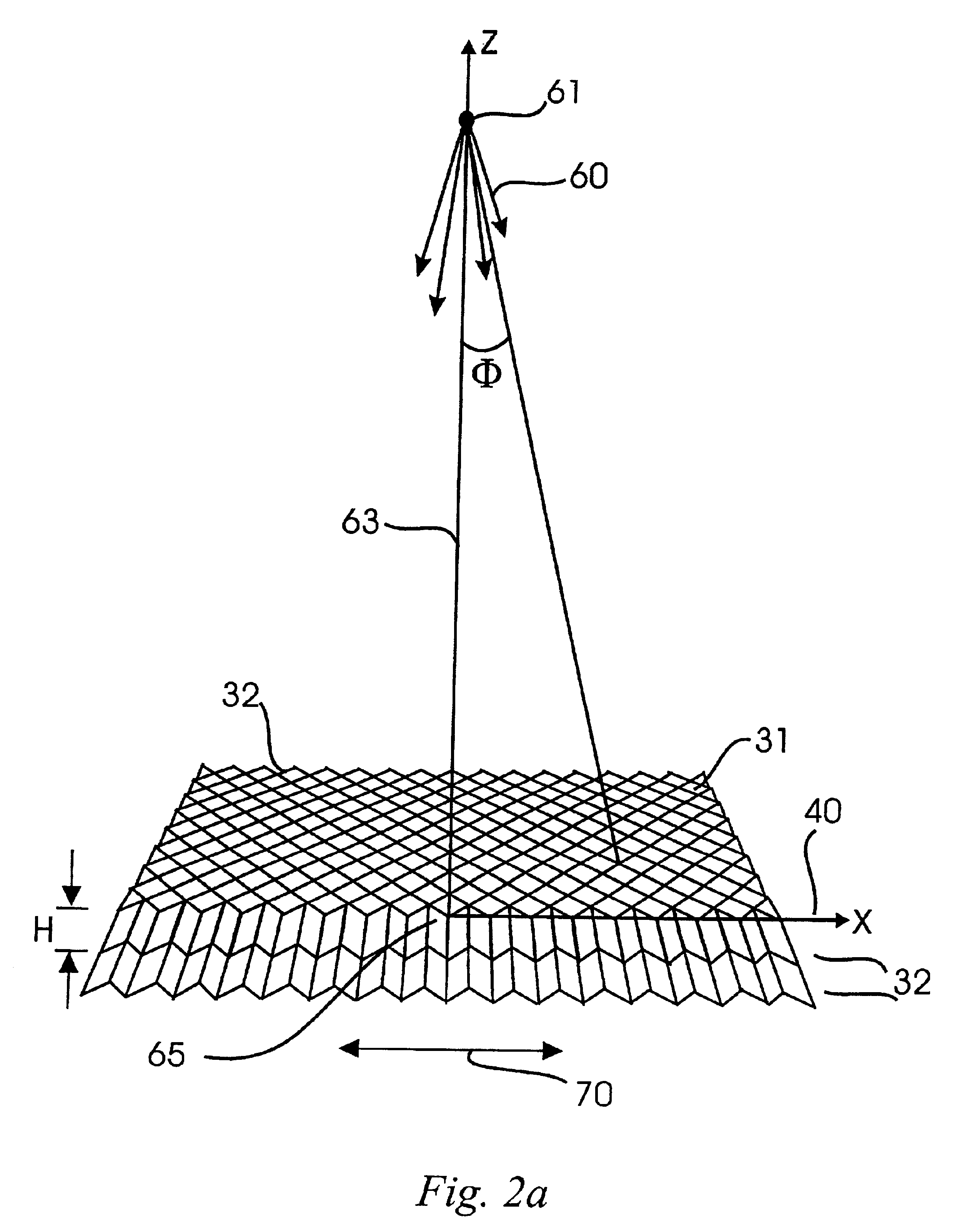

Anti-scatter grids and collimator designs, and their motion, fabrication and assembly

InactiveUS6987836B2Minimize shadowsMinimize overexposureHandling using diaphragms/collimetersCopperMechanical engineering

Grids and collimators, for use with electromagnetic energy emitting devices, include at least a metal layer that is formed, for example, by electroplating / electroforming or casting. The metal layer includes top and bottom surfaces, and a plurality of solid integrated walls. Each of the solid integrated walls extends from the top to bottom surface and has a plurality of side surfaces. The side surfaces of the solid integrated walls are arranged to define a plurality of openings extending entirely through the layer. At least some of the walls also can include projections extending into the respective openings formed by the walls. The projections can be of various shapes and sizes, and are arranged so that a total amount of wall material intersected by a line propagating in a direction along an edge of the grid is substantially the same as another total amount of wall material intersected by another line propagating in another direction substantially parallel to the edge of the grid at any distance from the edge. Methods to fabricate these grids using copper, lead, nickel, gold, any other electroplating / electroforming materials or low melting temperature metals are described.

Owner:CREATV MICROTECH

Preparation method of essential oil microcapsule

ActiveCN103861537AWell mixedOvercome volatilityEssential-oils/perfumesMicroballoon preparationSolubilityEmbedding rate

The invention discloses a preparation method of an essential oil microcapsule. The preparation method of the essential oil microcapsule comprises the following steps: preparing a wall material water phase, preparing a core material oil phase, mixing the two phases, emulsifying and homogenizing, carrying out spray drying through a fluidized bed and screening materials. Through the method, the defects of volatilization and loss of the essential oil which are easily caused due to high spraying temperature in a conventional spray drying method can be avoided; a whole preparation process can be carried out at low temperature, thus retaining components of the essential oil maximally; the prepared essential oil microcapsule is high in embedding rate, low in water content, good in solubility and durable in fragrance retention, so that the application of the essential oil is improved and expanded; meanwhile, a novel technical manner guidance is provided for preparation and development of other microcapsule products prepared from thermosensitive core materials. The essential oil microcapsule prepared by the preparation method can be widely applied in the fields such as food, tobacco and household chemicals.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

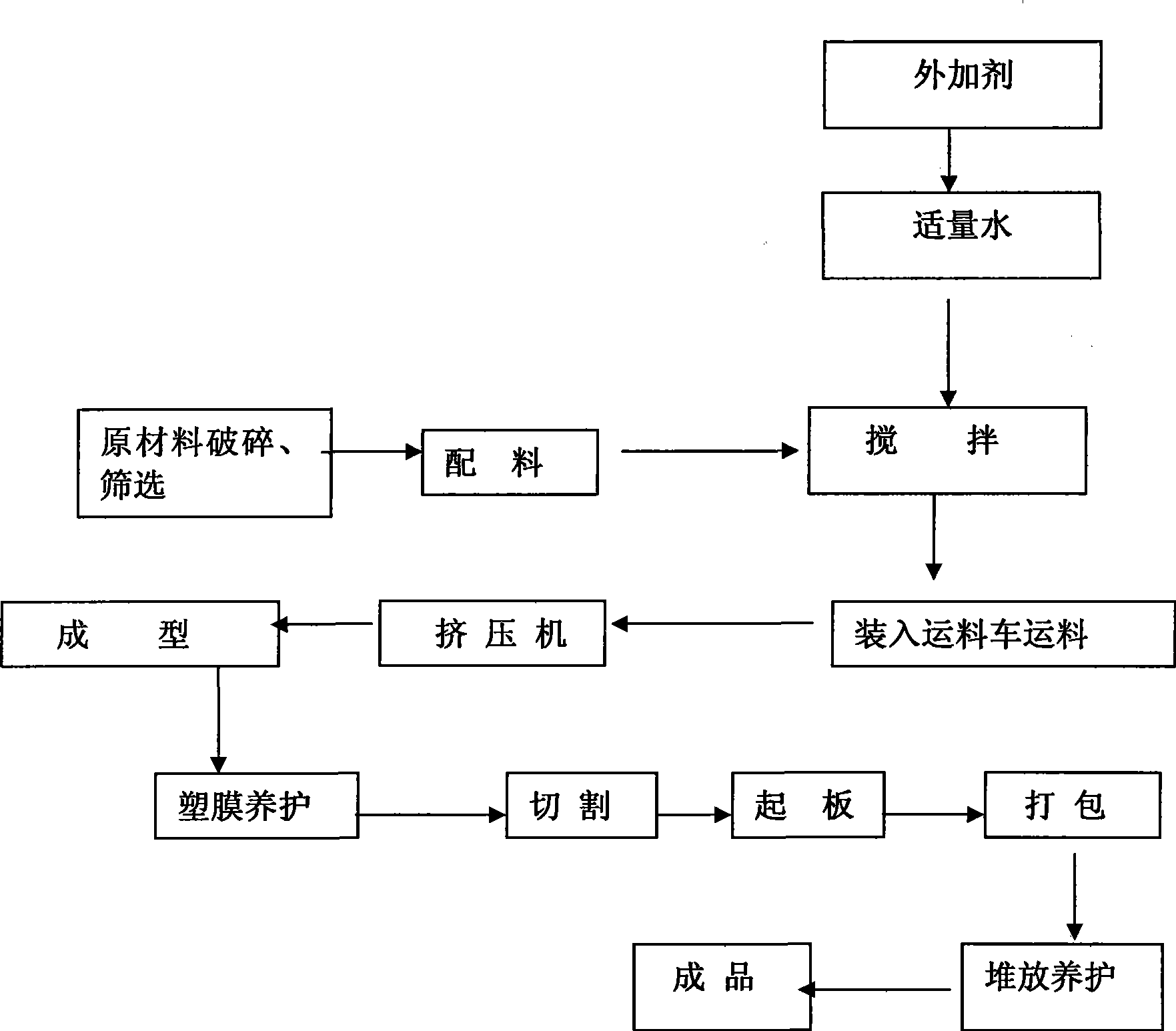

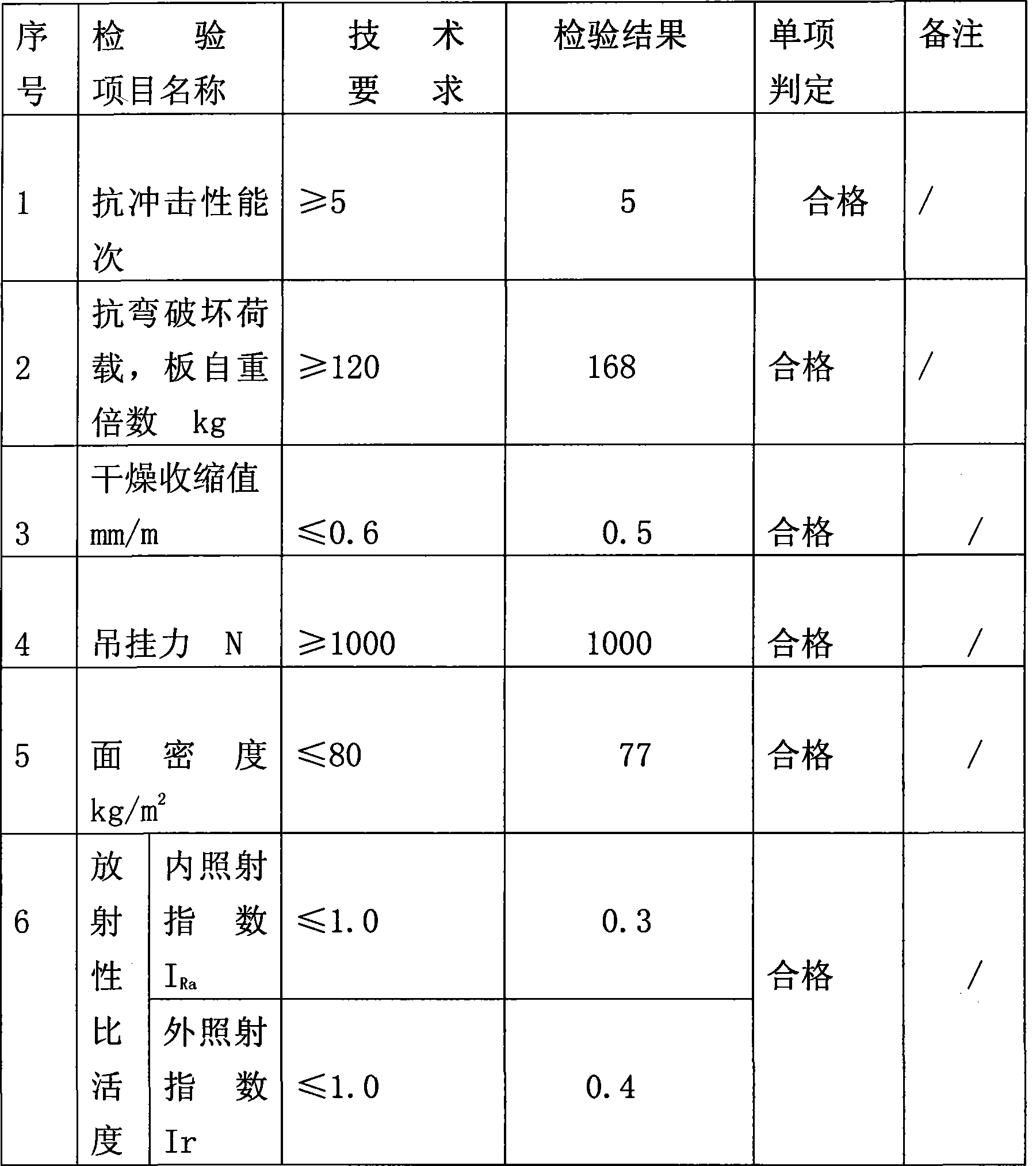

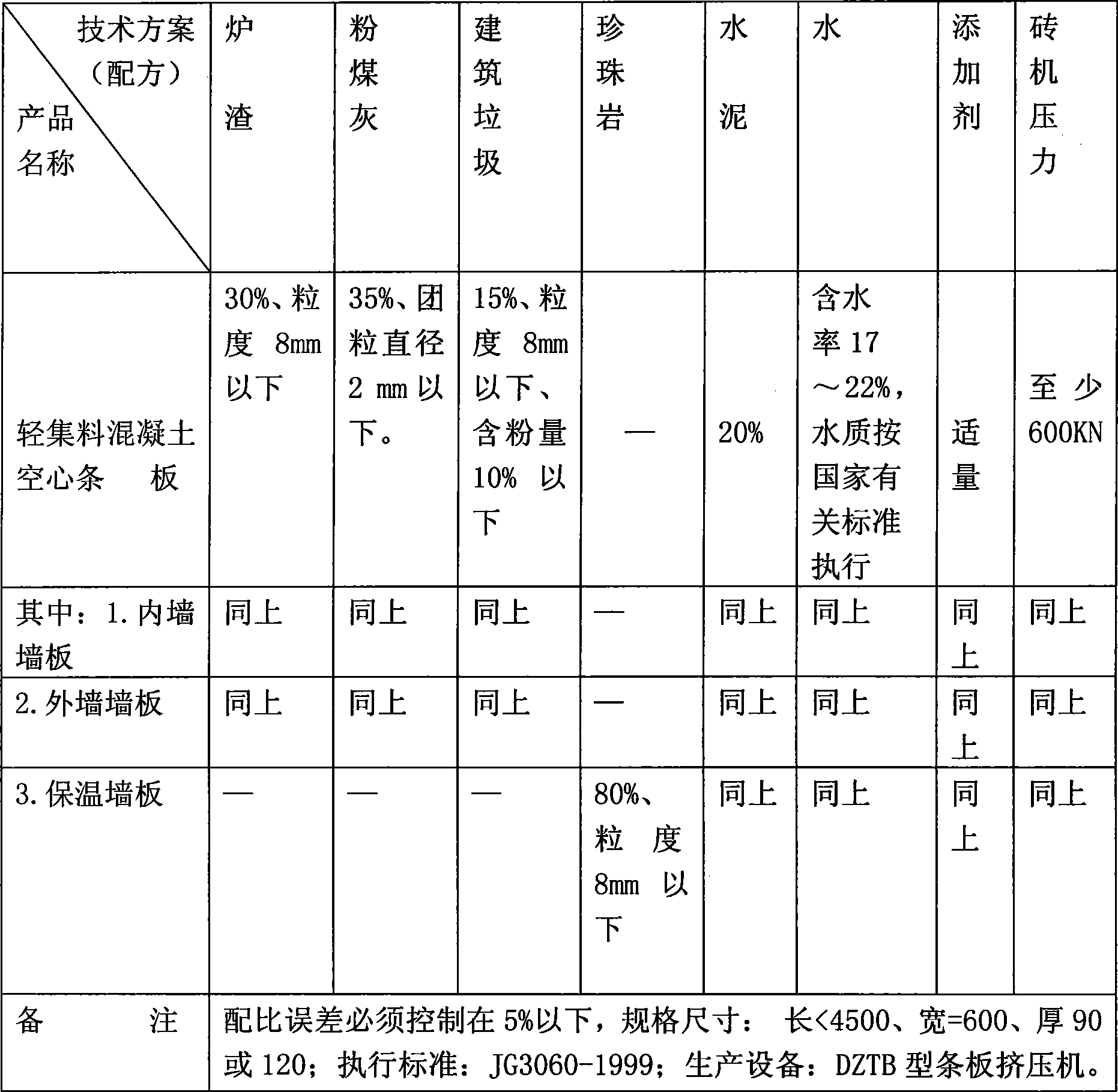

Light wall board and manufacturing technology thereof

InactiveCN101423368AFast constructionIncrease typeSolid waste managementManufacturing technologySlag

The invention provides a light wall slab, which is producing by the following materials in weight percentage: 30 percent of slag with the grain size of less than 8mm, 35 percent of fly ash with the pellet diameter of less than 2mm, 15 percent of construction waste with the grain size of less than 8mm and the power content of less than 10 percent, and 20 percent of cement; moreover, a water reducing agent, a water repellent and an accelerating agent are added into the materials, and water of which the weight accounts for the total weight of the slag, the fly ash, the construction waste and the cement dry material is between 17 and 22 percent is added into the mixture; and the production process comprises the following: crushing raw materials, screening, preparing materials, mixing and stirring the materials, extruding by a slat extruder, curing, cutting, lifting the slab and pile-curing. The light wall slab has the advantages of improving the construction speed of single buildings, saving energy, increasing usable floor areas, meeting building requirements on various levels and prompting the wall material to develop towards industrialization and modernization of the housing industry. The light wall slab can promote the development of internal wall slabs and external wall slabs, and increase types of heat preservation wall slabs. Compared with expanded perlite, the sound insulation property of the industrial residue light aggregate wall slab is improved by more than 30 percent.

Owner:丁志强

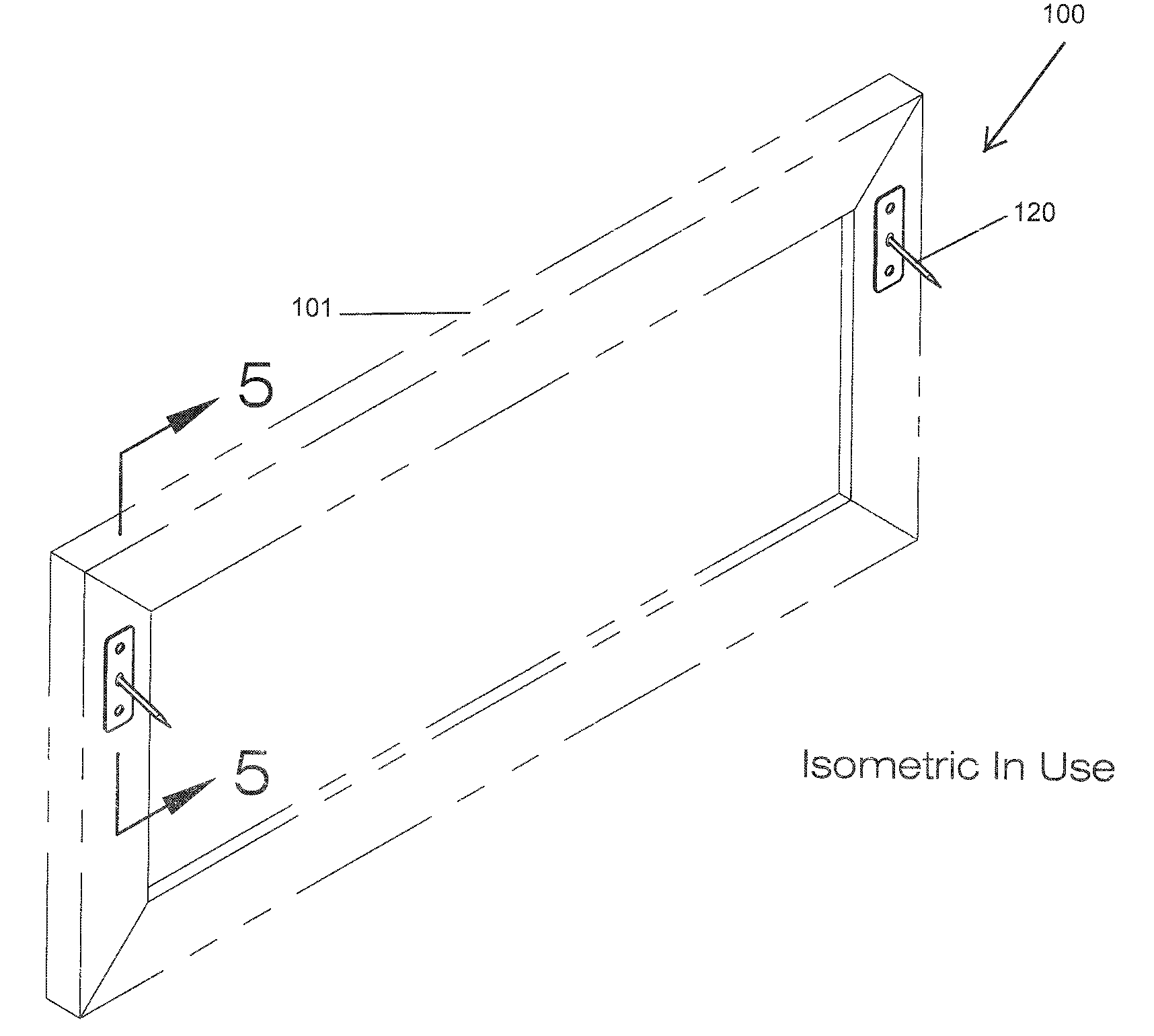

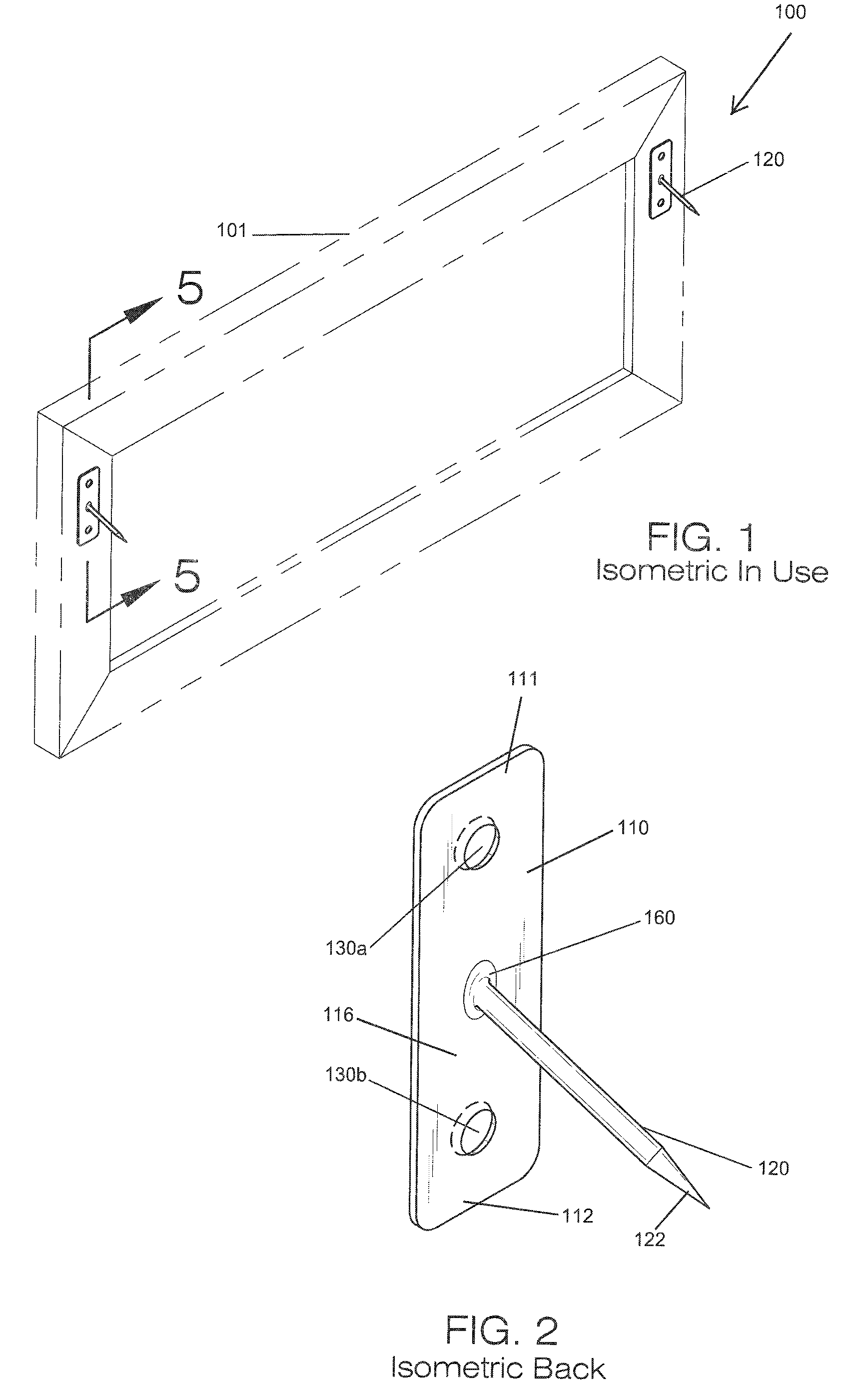

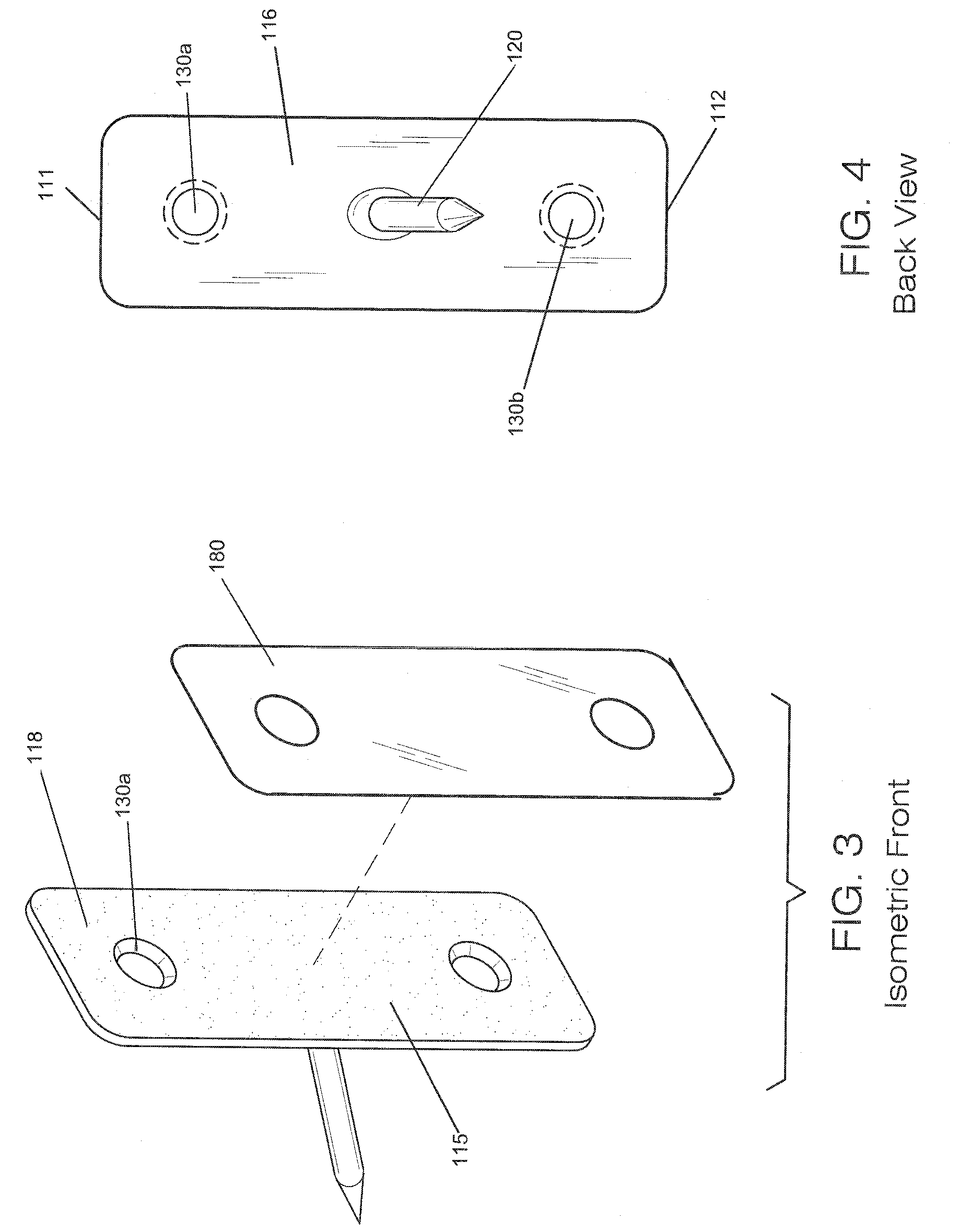

Hanging system for pictures or objects

A hanging system having a panel with a front and back surface, wherein an adhesive component is on the front surface, and a pin on the back surface, the pin extends outwardly from the back surface at an angle with respect to the back surface, the angle being between about 50 to 80 degrees, the pin has an outer end, wherein the outer end is pointed so as to allow for a puncturing effect when pressed into a wall material.

Owner:CRESCENZO PHILIP J

Preparation method of oxidized graphene phase change microcapsule

InactiveCN103752234APerformance impactSimple ingredientsHeat-exchange elementsMicroballoon preparationHeat conductingPickering emulsion

The invention relates to a preparation method of an oxidized graphene phase change microcapsule. The preparation method comprises the following steps: dissolving oxidized graphene in water, stirring, performing ultrasound treatment, preparing an oxidized graphene solution; adding a phase change material in the oxidized graphene solution, heating at a temperature higher than a melting point of the phase change material to ensure that the phase change material is melted, stirring to obtain a stable Pickering emulsion of the phase change material wrapped with the oxidized graphene; adding acid in the Pickering emulsion, adjusting the pH value of a system to be 2-3, completing emulsion drops of the phase change material by the oxidized graphene by using an acting force between functional groups to form an oxidized graphene capsule wall; and cooling into a capsule to separate out to obtain the oxidized graphene phase change microcapsule. Compared with the prior art, the oxidized graphene phase change microcapsule has the advantages that the oxidized graphene is used as an emulsifying agent and a heat conducting reinforced wall material, other emulsifying agents need not to be added so that the oxidized graphene phase change microcapsule with better heat conducting material can be obtained. The oxidized graphene phase change microcapsule has the characteristics of high heat conducting coefficient, high heat storage amount, and the like. The preparation method has the advantages of simplicity and convenience in operation, low cost and the like.

Owner:TONGJI UNIV

Lactobacillus helveticus microcapsule, preparation and use thereof

InactiveCN101323850AOvercoming the problem of low survival rate of freeze-dryingImprove efficiencyMilk preparationMetabolism disorderFreeze-dryingDietary supplement

The invention provides a lactobacillus helveticus microcapsule as well as the preparation and application thereof, pertaining to the embedding technology of lactobacillus helveticus and aiming at microencapsulating the lactobacillus helveticus so as to solve the problems of low embedding efficiency and embedding yield in single-layer or double-layer embedment. The technical proposal adopted by the invention is that isolated soy protein, microporous starch and sodium alginate are respectively taken as the first, the second and the third layers of wall materials for microencapsulation; the three-layer embedment is carried out to the lactobacillus helveticus for the first time, wherein, in the process of preparing bacterial suspension, an orthogonal optimization protective agent is adopted to improve the livability after freeze drying. The microcapsule of the invention has strong heat resistance and acid resistance, solves the inactivation problem caused by gastric acid, digestive enzyme and antibiotic, etc. to active bacillus, is capable of releasing when reaching large intestine, and balances intestinal flora. The reusability of fermented milk is good. The lactobacillus helveticus used by the invention enriches the variety of probiotic bacteria microcapsule and is a good dietary supplement.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Environment-friendly diatom ooze wall material powder and wall material and preparation method thereof

InactiveCN101700965AImprove adsorption capacityAdequate adsorptionMoisture absorptionAir purification

The invention discloses environment-friendly diatom ooze wall material powder and a wall material as well as a preparation method and application thereof. The diatom ooze wall material with macromolecule sieve structure is prepared by taking a plurality of natural environment-friendly non-metal material having strong adsorbability and good plasticity as main materials through a simple process. The environment-friendly diatom ooze wall material powder has the advantages of low cost, air purification, moisture absorption, deodorization, inflaming retarding, heat insulation, easy popularization,and the like.

Owner:QINGDAO CHUANSHAN NEW MATERIALS

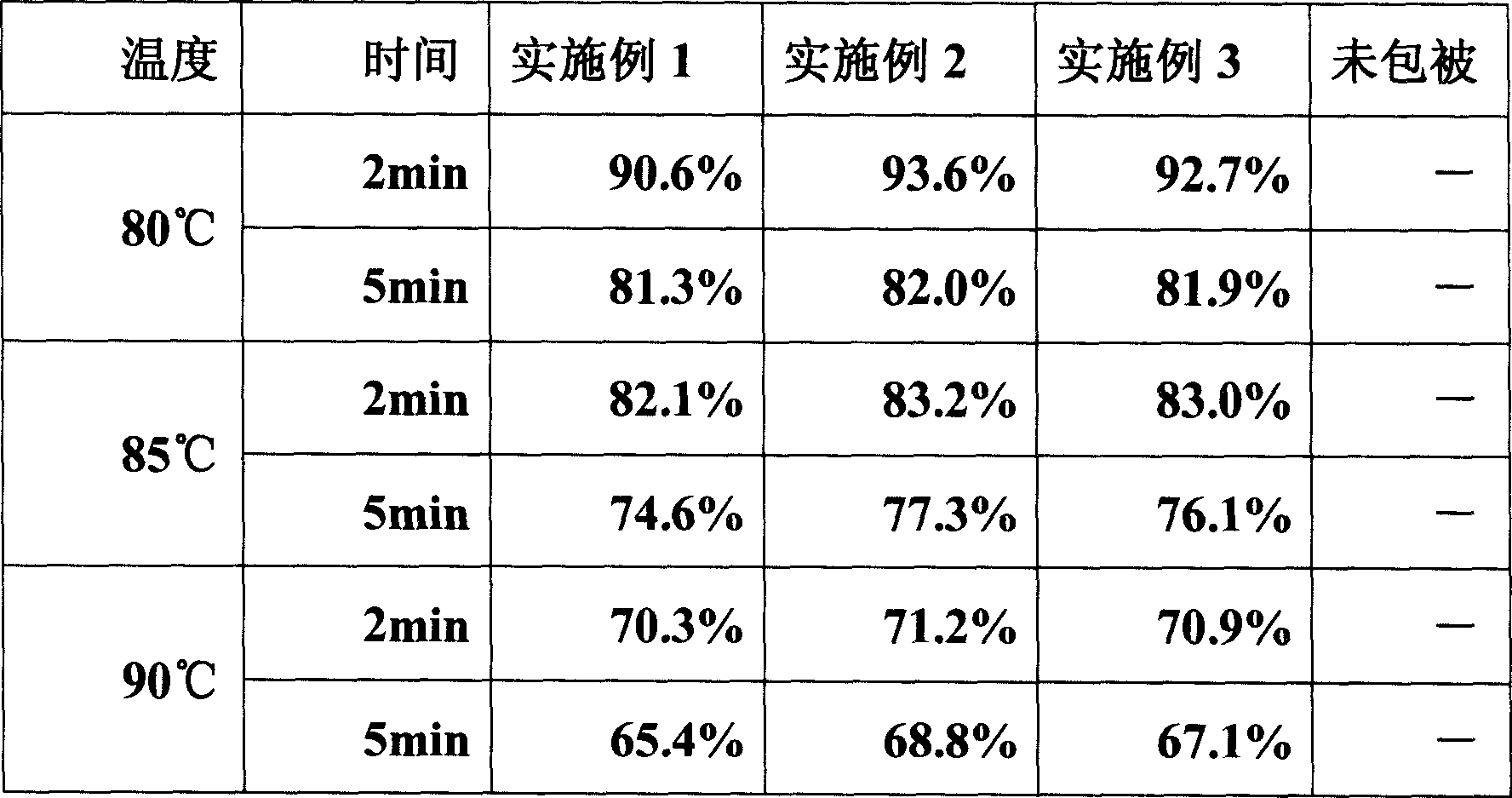

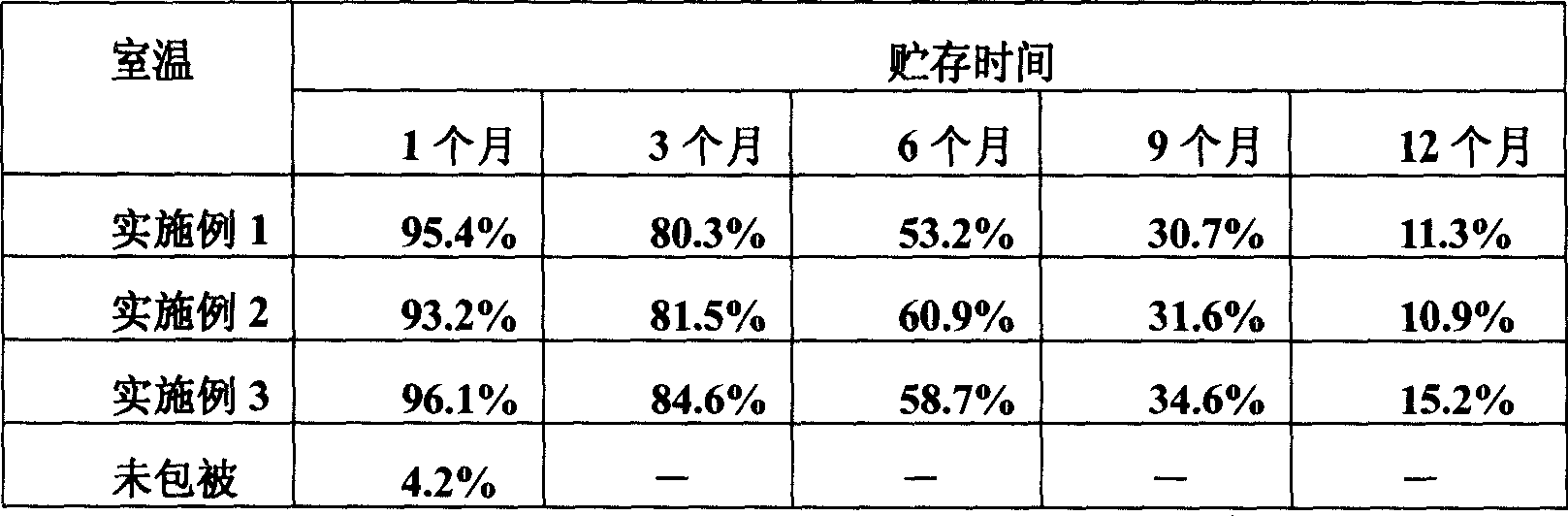

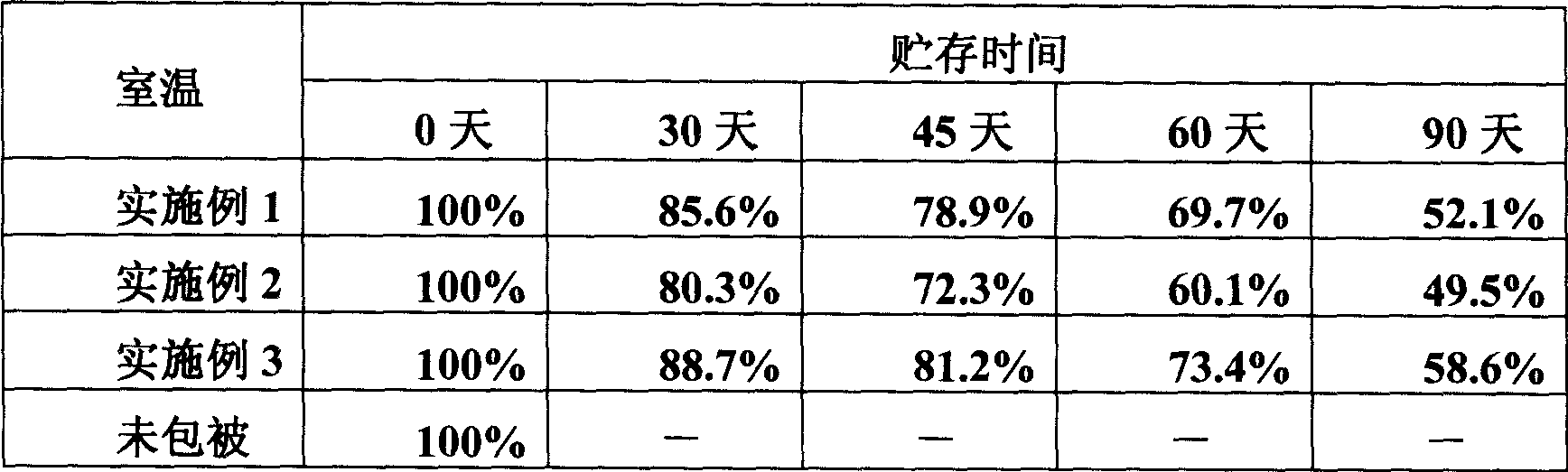

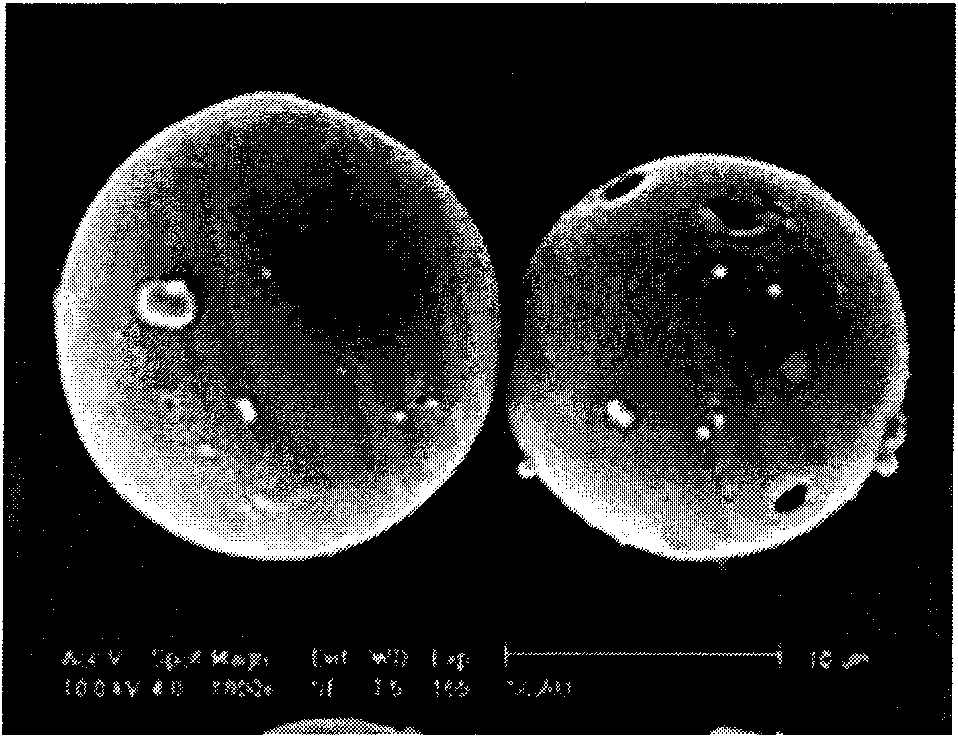

Efficient probiotics microcapsule as well as preparation method and application thereof

The invention discloses an efficient probiotics microcapsule which comprises a core material and a wall material, wherein the core material comprises 90-95wt% of probiotics and 5-10wt% of a protector; the wall material is of a double-layer structure, wherein the inner layer is made from sodium alginate and the outer layer is made from whey protein or gelatin. The invention also discloses a preparation method and application of the efficient probiotics microcapsule. The microcapsule is coated by double layers of the sodium alginate and the gelatin or whey protein, so that the acid resistance, cholate resistance and storage resistance of the probiotics are improved. The microcapsule disclosed by the invention is added into the feed, so that the host intestinal microenvironment equilibrium can be regulated, the harmful bacteria can be restrained and the disease resistance of the host can be improved.

Owner:NANJING YOUFAN BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com