Patents

Literature

1561 results about "Gastric acid" patented technology

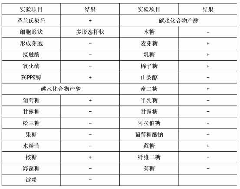

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gastric acid, gastric juice, or stomach acid, is a digestive fluid formed in the stomach and is composed of hydrochloric acid (HCl), potassium chloride (KCl), and sodium chloride (NaCl). The acid plays a key role in digestion of proteins, by activating digestive enzymes, and making ingested proteins unravel so that digestive enzymes break down the long chains of amino acids. Gastric acid is produced by cells in the lining of the stomach, which are coupled in feedback systems to increase acid production when needed. Other cells in the stomach produce bicarbonate, a base, to buffer the fluid, ensuring that it does not become too acidic. These cells also produce mucus, which forms a viscous physical barrier to prevent gastric acid from damaging the stomach. The pancreas further produces large amounts of bicarbonate and secretes bicarbonate through the pancreatic duct to the duodenum to completely neutralize any gastric acid that passes further down into the digestive tract.

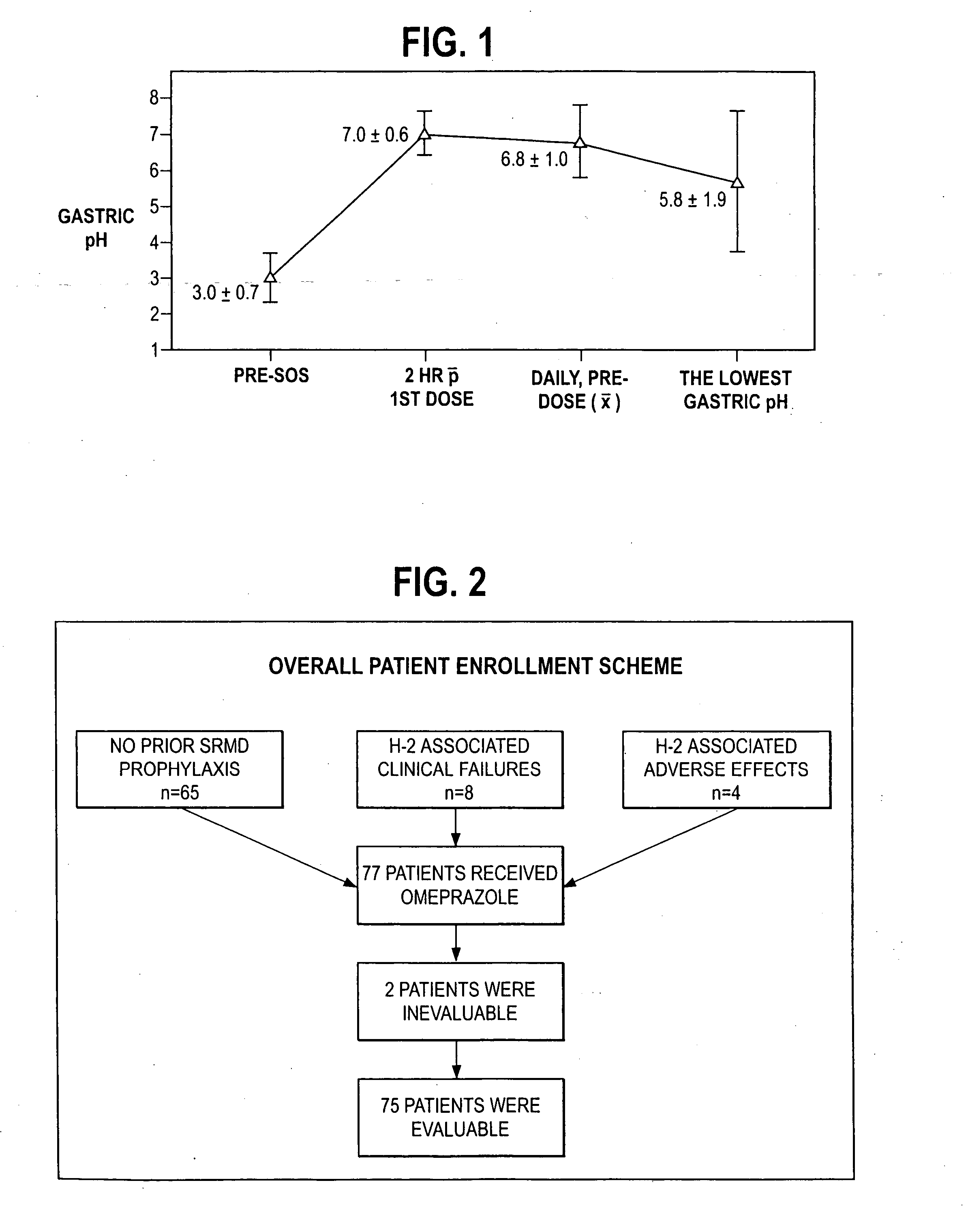

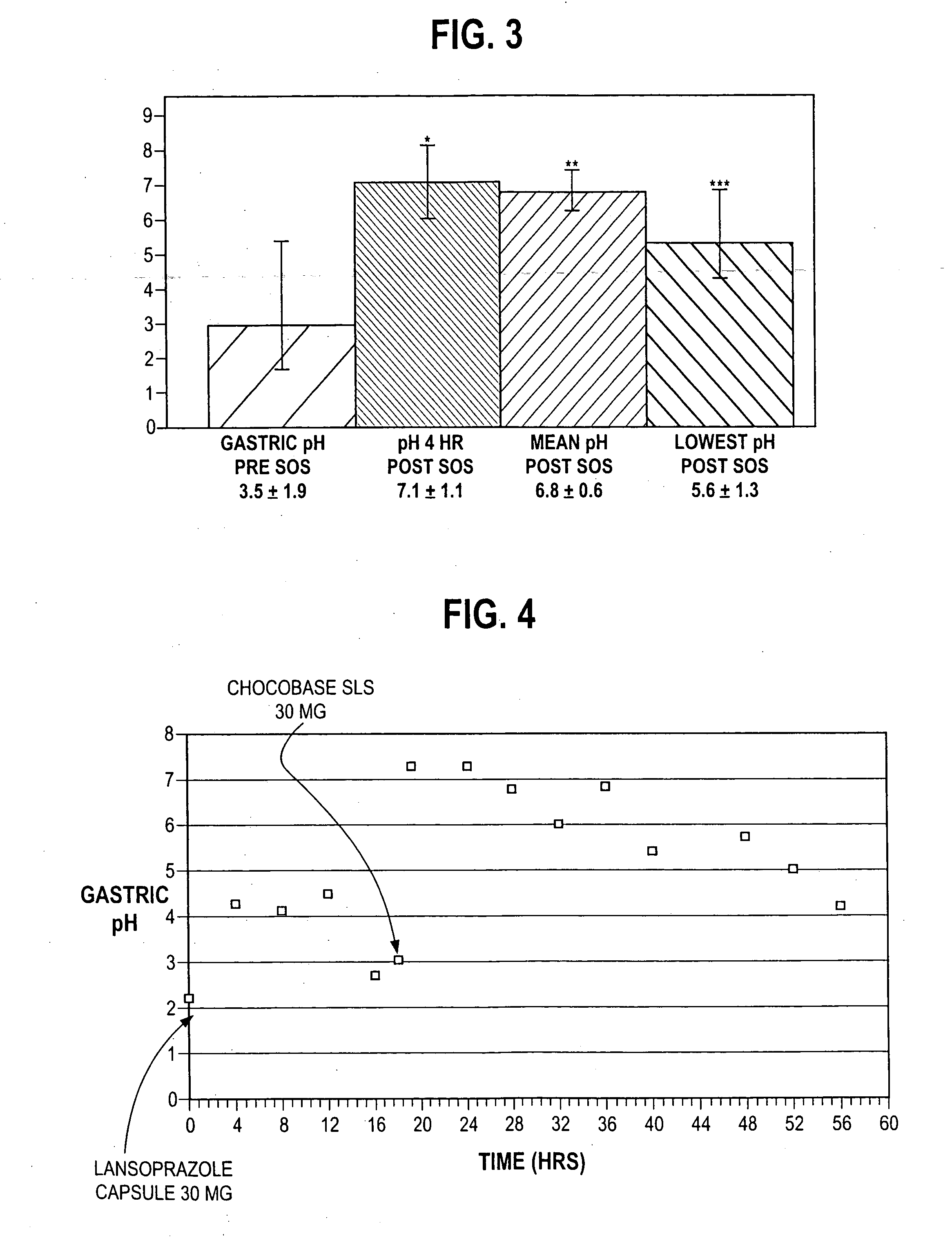

Combination of proton pump inhibitor, buffering agent, and nonsteroidal anti-inflammatory drug

InactiveUS20050249806A1Preventing gastric acid related disorderReduce riskBiocideSenses disorderNonsteroidal Antiinflammatory Drugs/NSAIDsBuffering agent

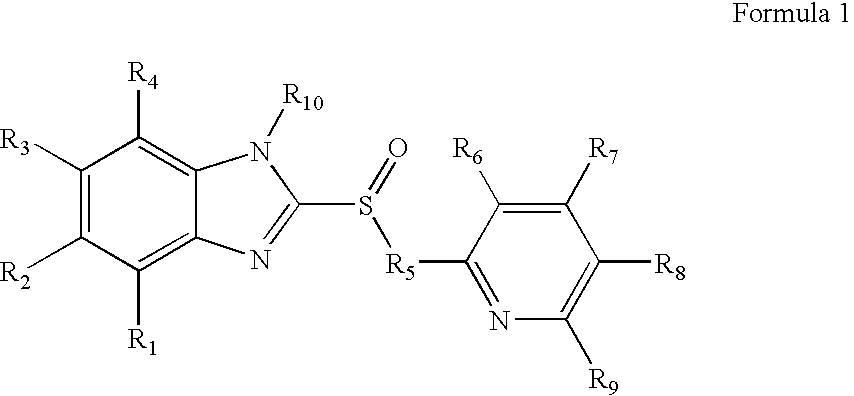

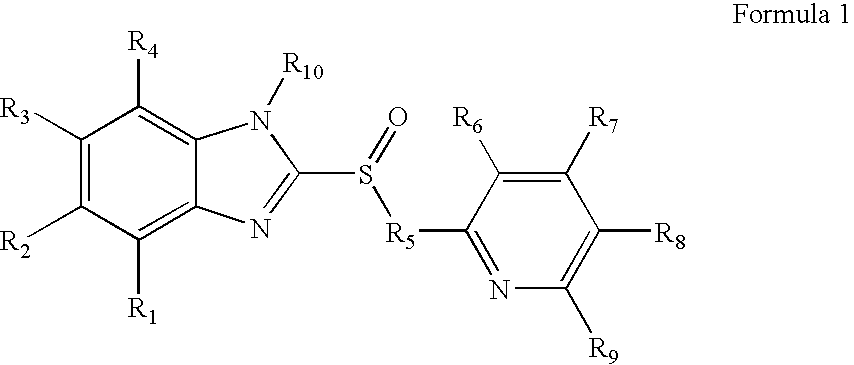

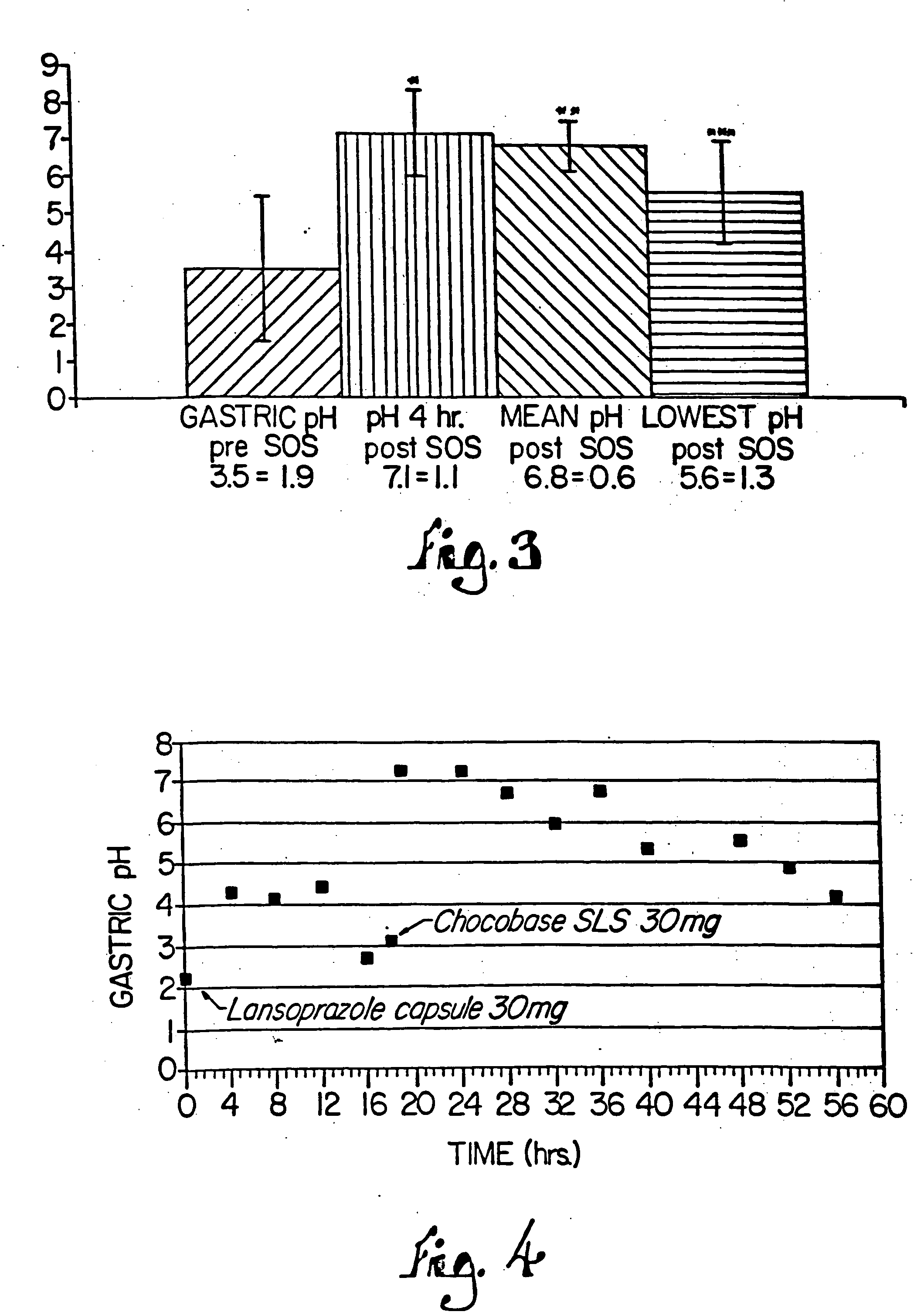

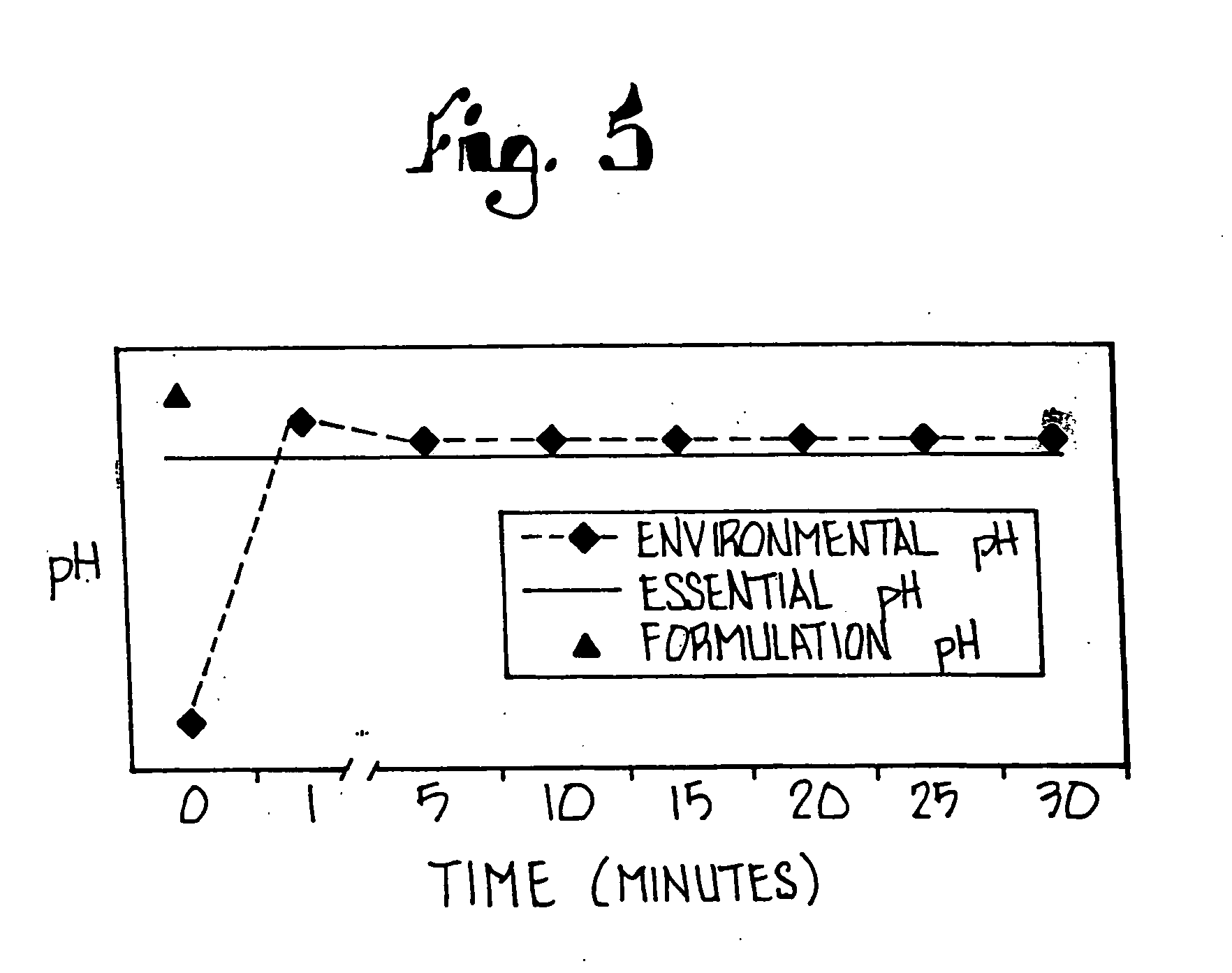

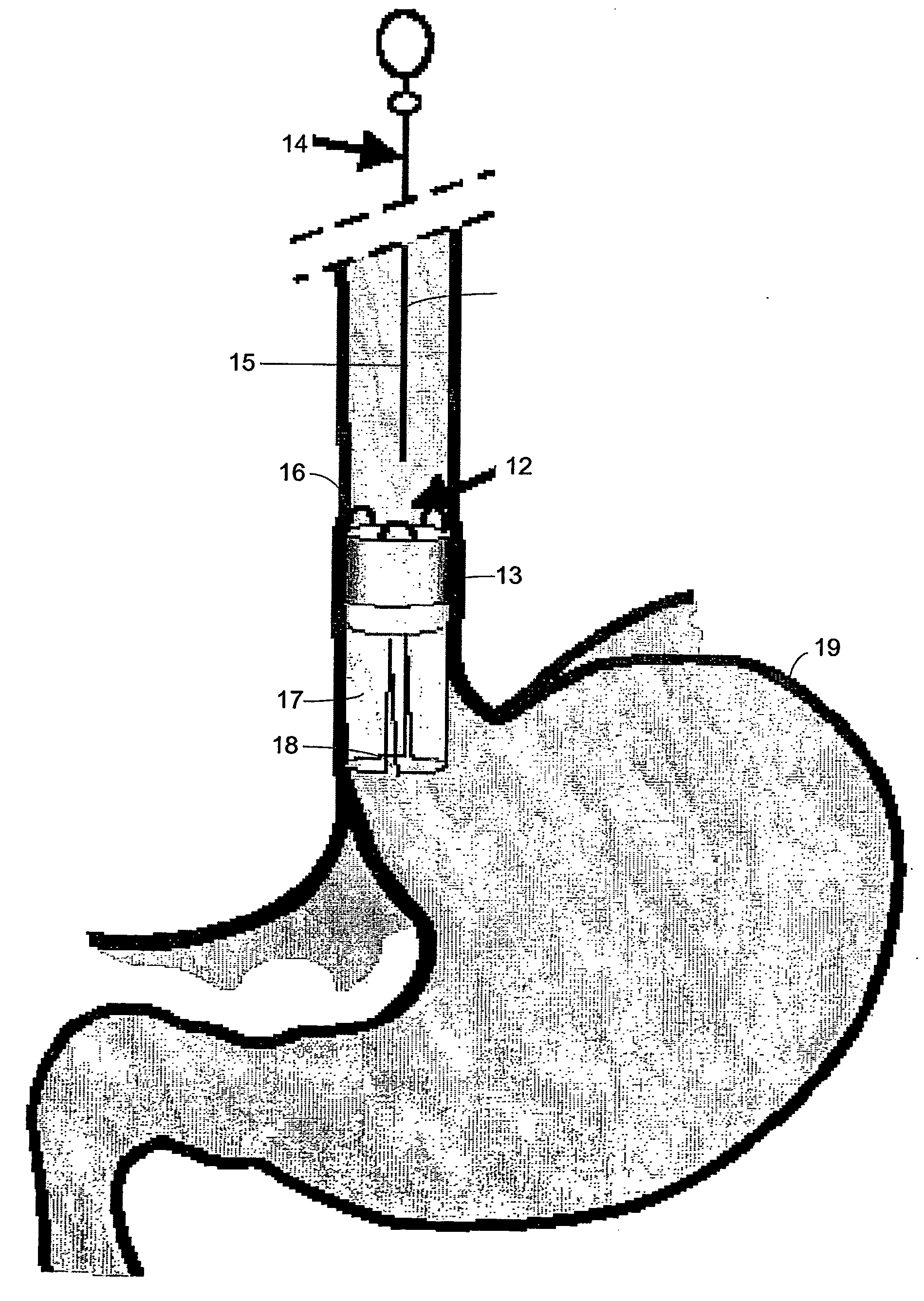

Pharmaceutical compositions comprising a proton pump inhibitor, one or more buffering agent and a nonsteroidal anti-inflammatory drug are described. Methods are described for treating gastric acid related disorders and treating inflammatory disorders, using pharmaceutical compositions comprising a proton pump inhibitor, a buffering agent, and a nonsteroidal anti-inflammatory drug.

Owner:SANTARUS

Method of reducing ecologically adverse changes of the gastro intestinal microbial flora in patients under treatment with medicaments

InactiveUS20020022019A1Reduce generationBiocideOrganic active ingredientsMicroorganismPresent method

A method for reducing ecologically adverse changes of the gastrointestinal micro-flora in patients under treatment with medicaments (which may also be referred to herein as the therapeutic compounds or medications) such as gastric acid reducing medicaments or antibiotics. A pharmaceutical product useful in the present method comprising a medicament and a probiotically active organism as a combined preparation presented in a commercial package unit.

Owner:CHR HANSEN AS

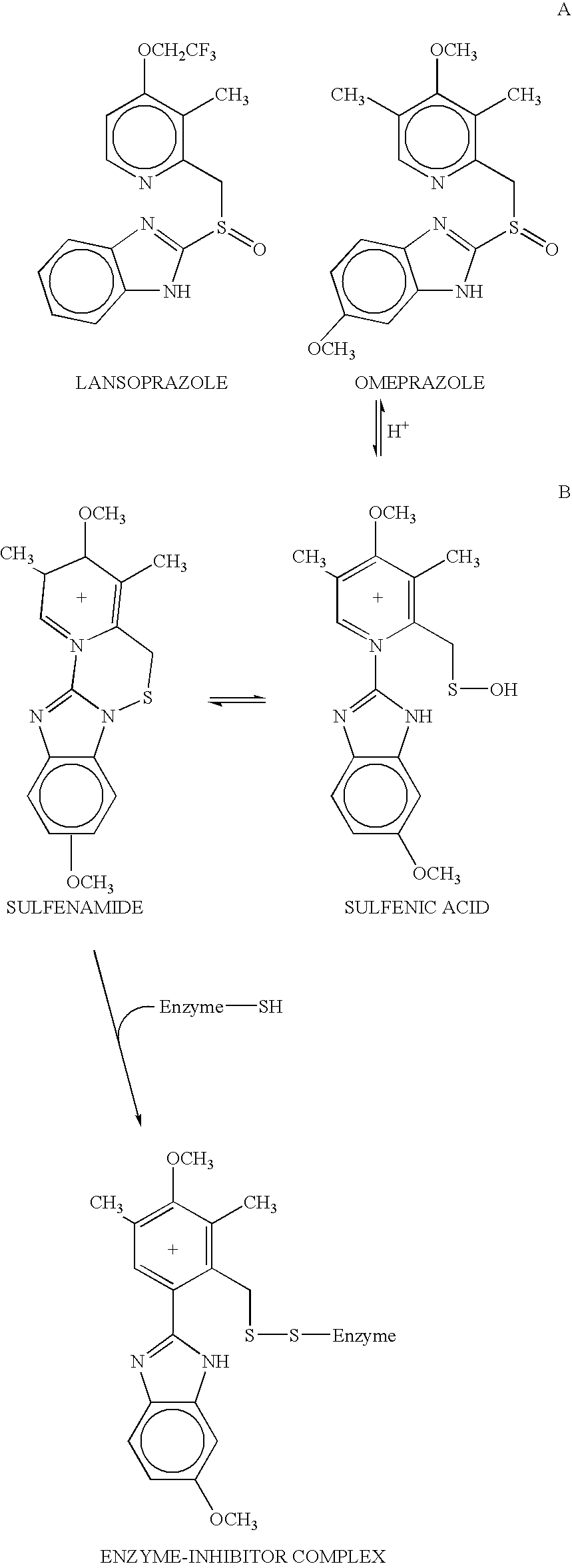

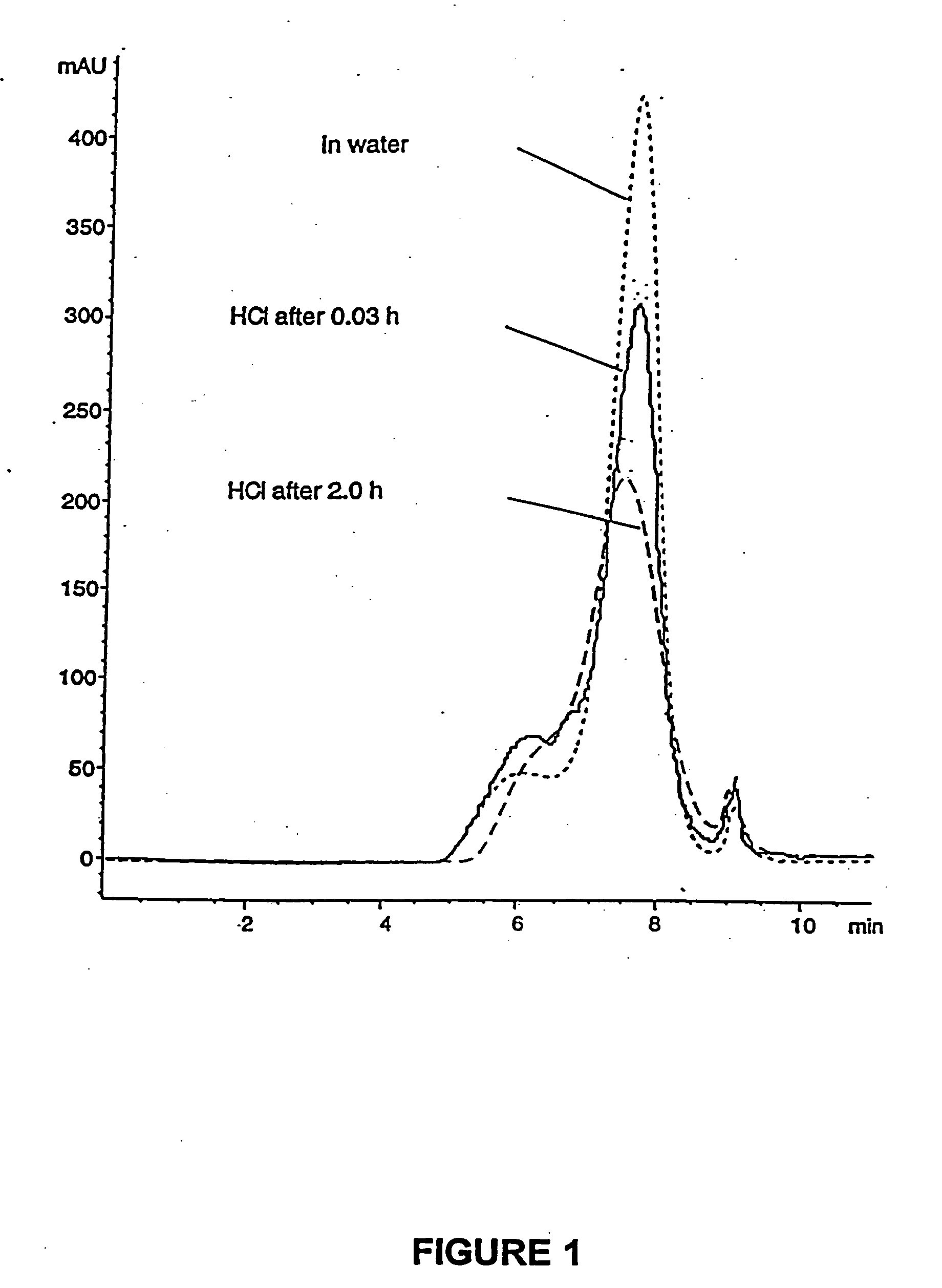

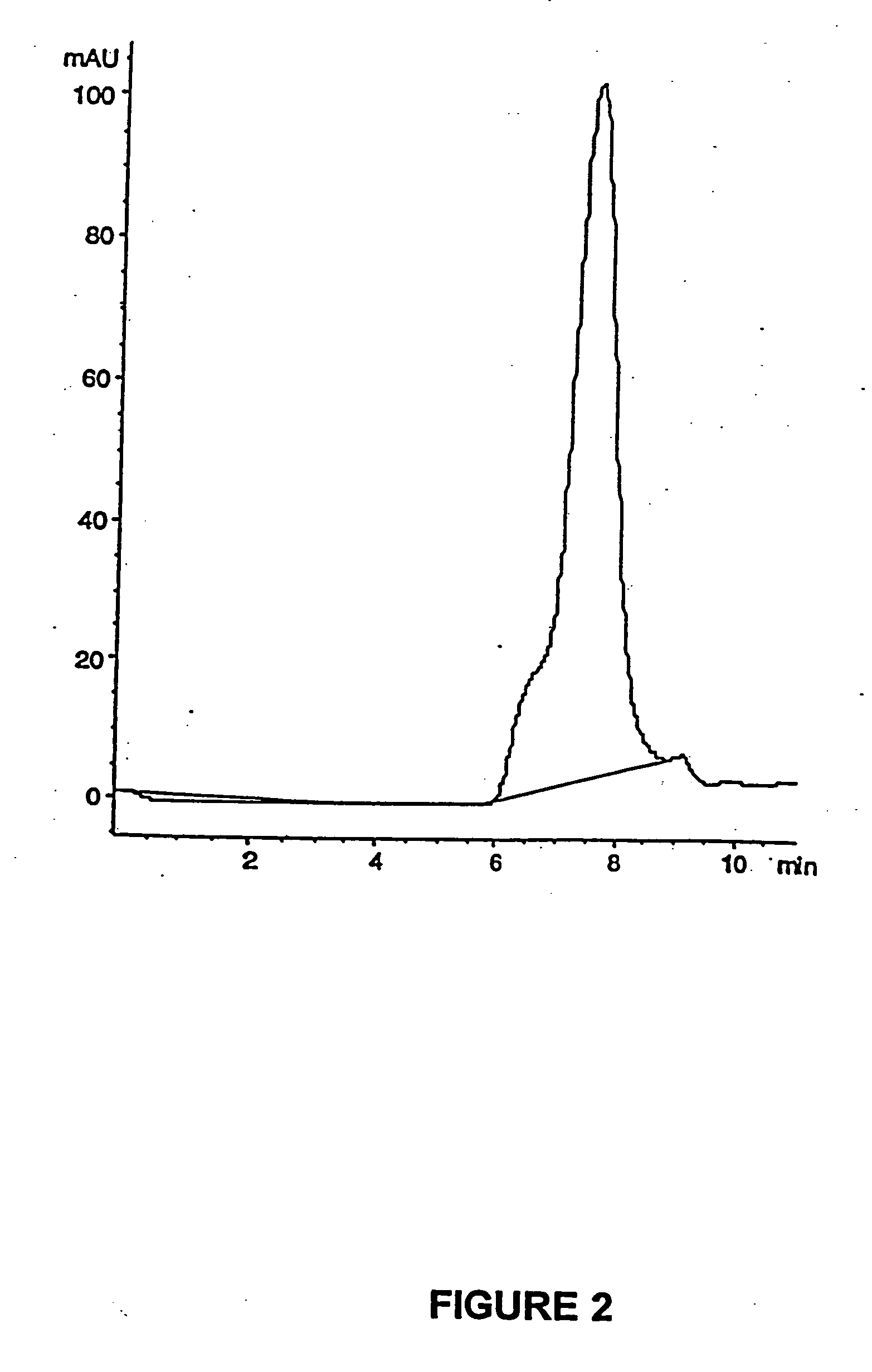

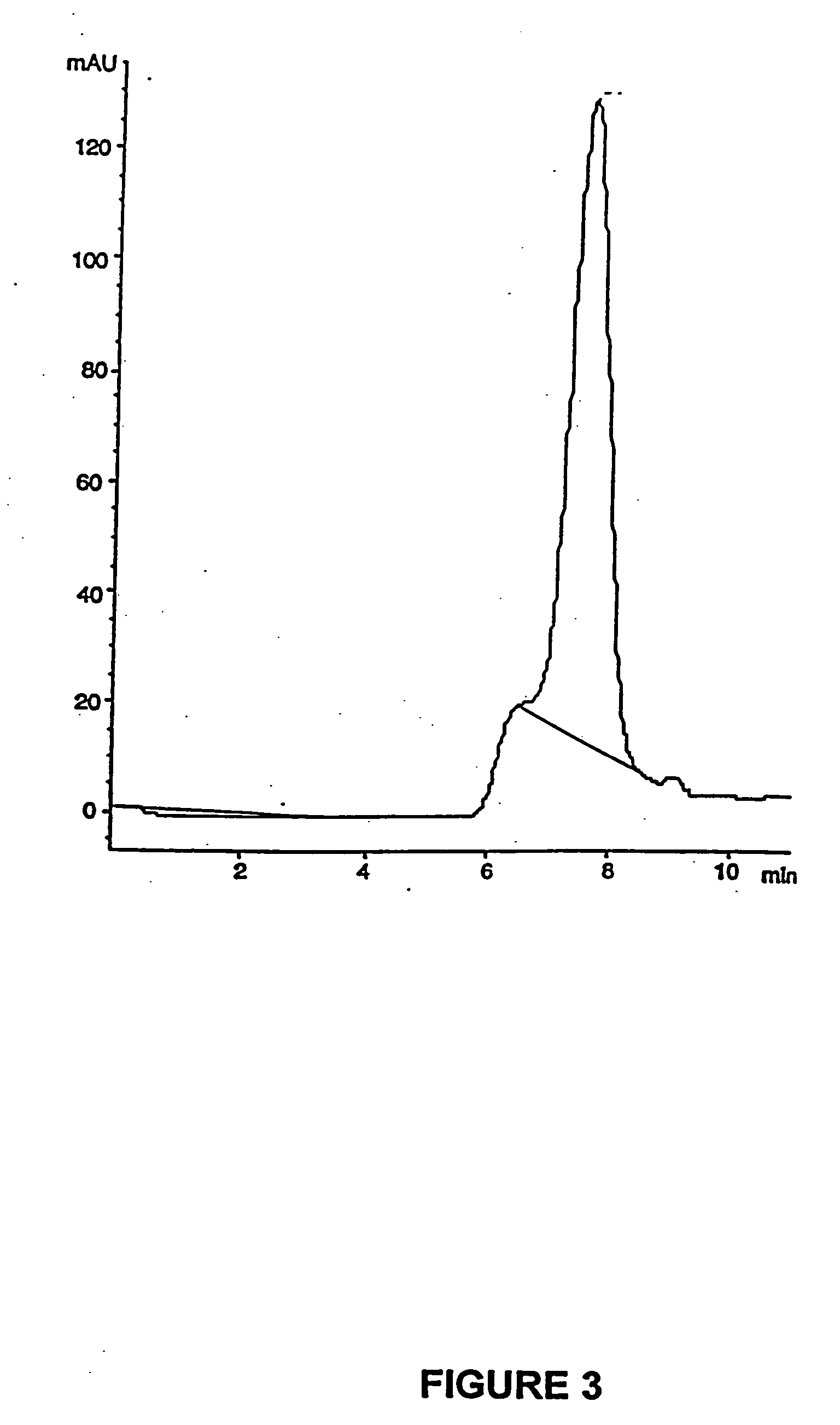

Pharmaceutical compositions comprising substituted benzimidazoles and methods of using same

InactiveUS20050054682A1Improve stabilityDecreased time to therapeutic effectBiocideDispersion deliveryBuffering agentPharmacology

The present invention is directed to, inter alia, pharmaceutical compositions comprising at least one proton pump inhibitor and at least one buffering agent. Compositions of the invention are useful in treating, inter alia, gastric acid related disorders.

Owner:UNIVERSITY OF MISSOURI

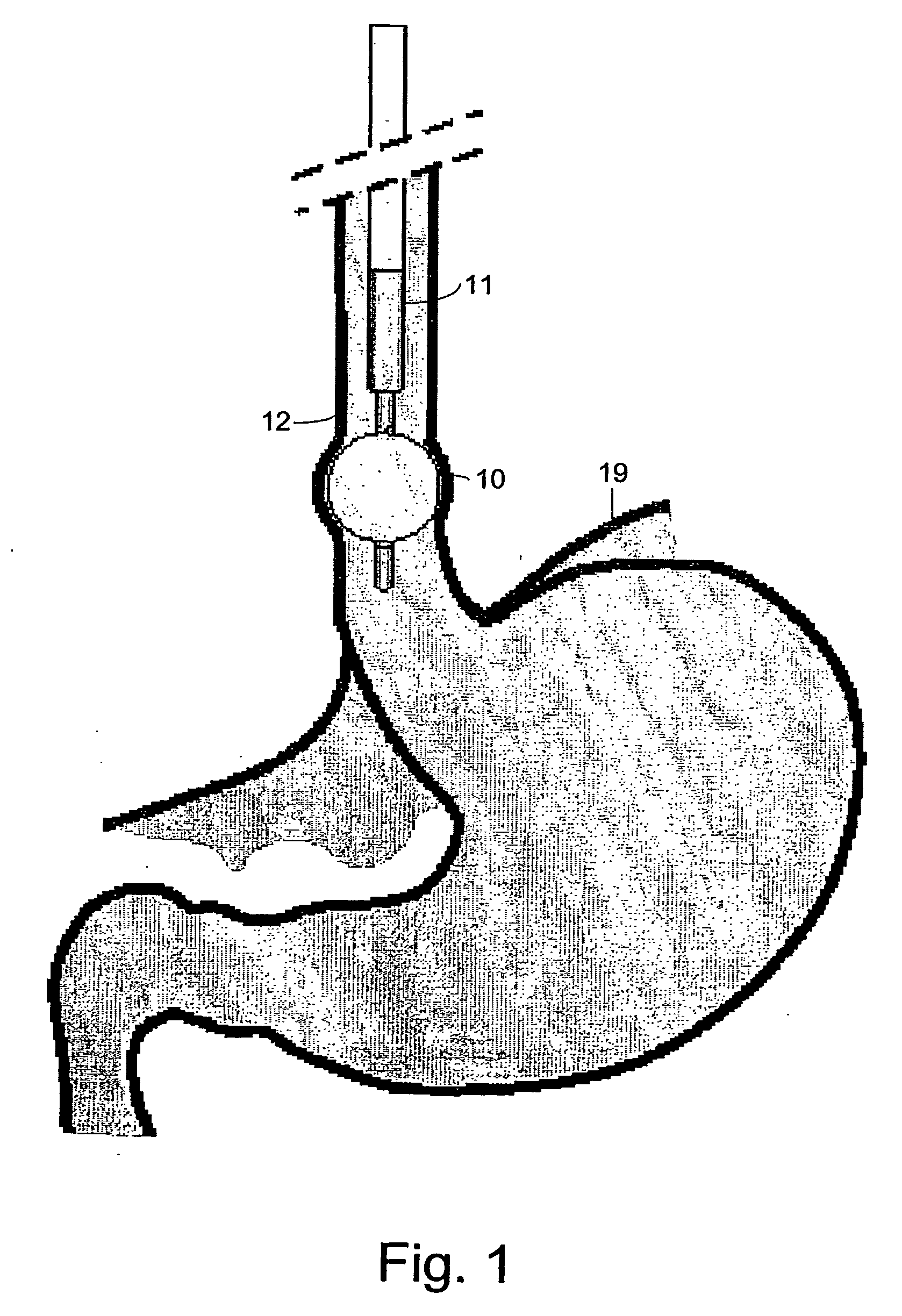

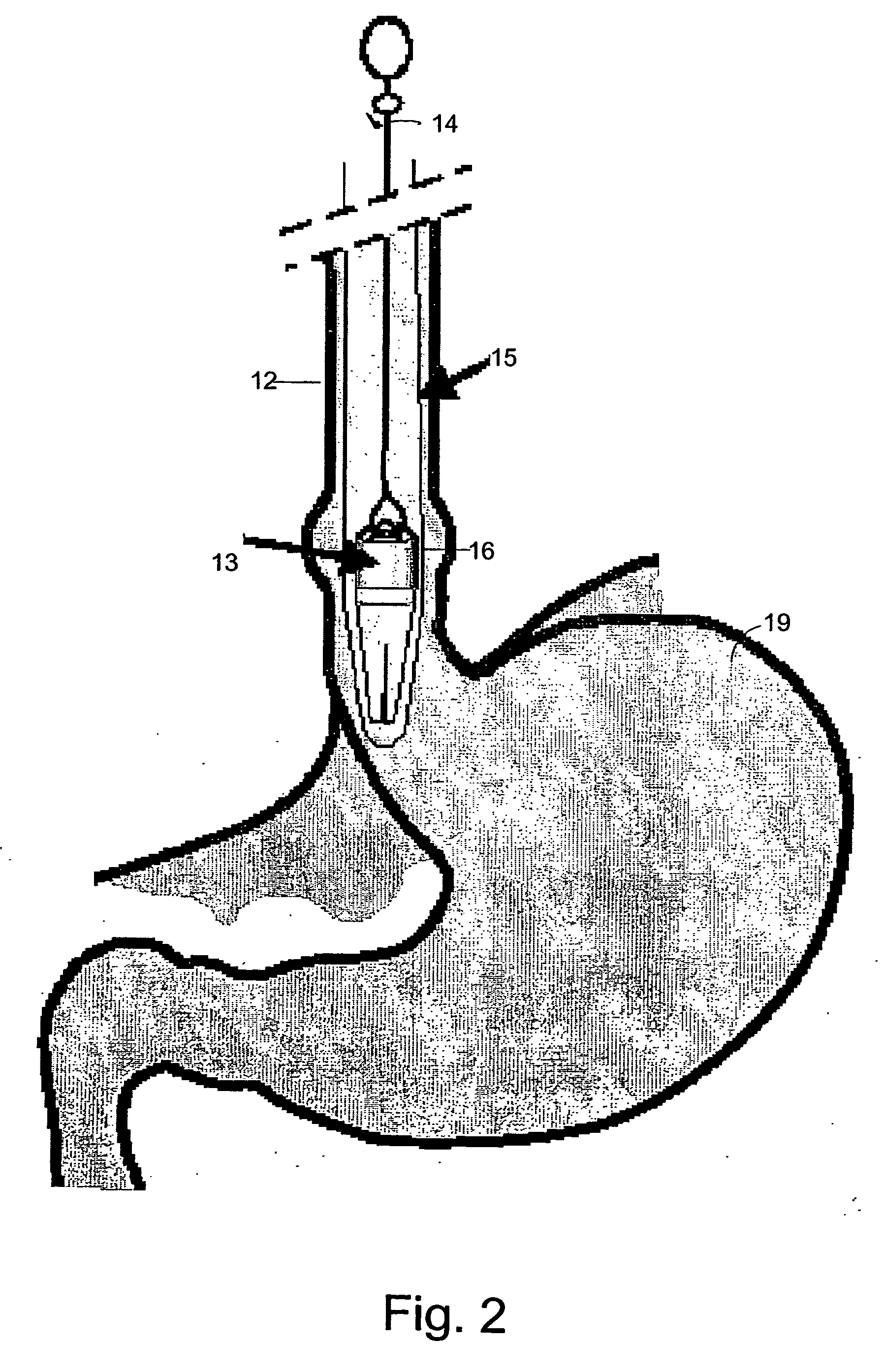

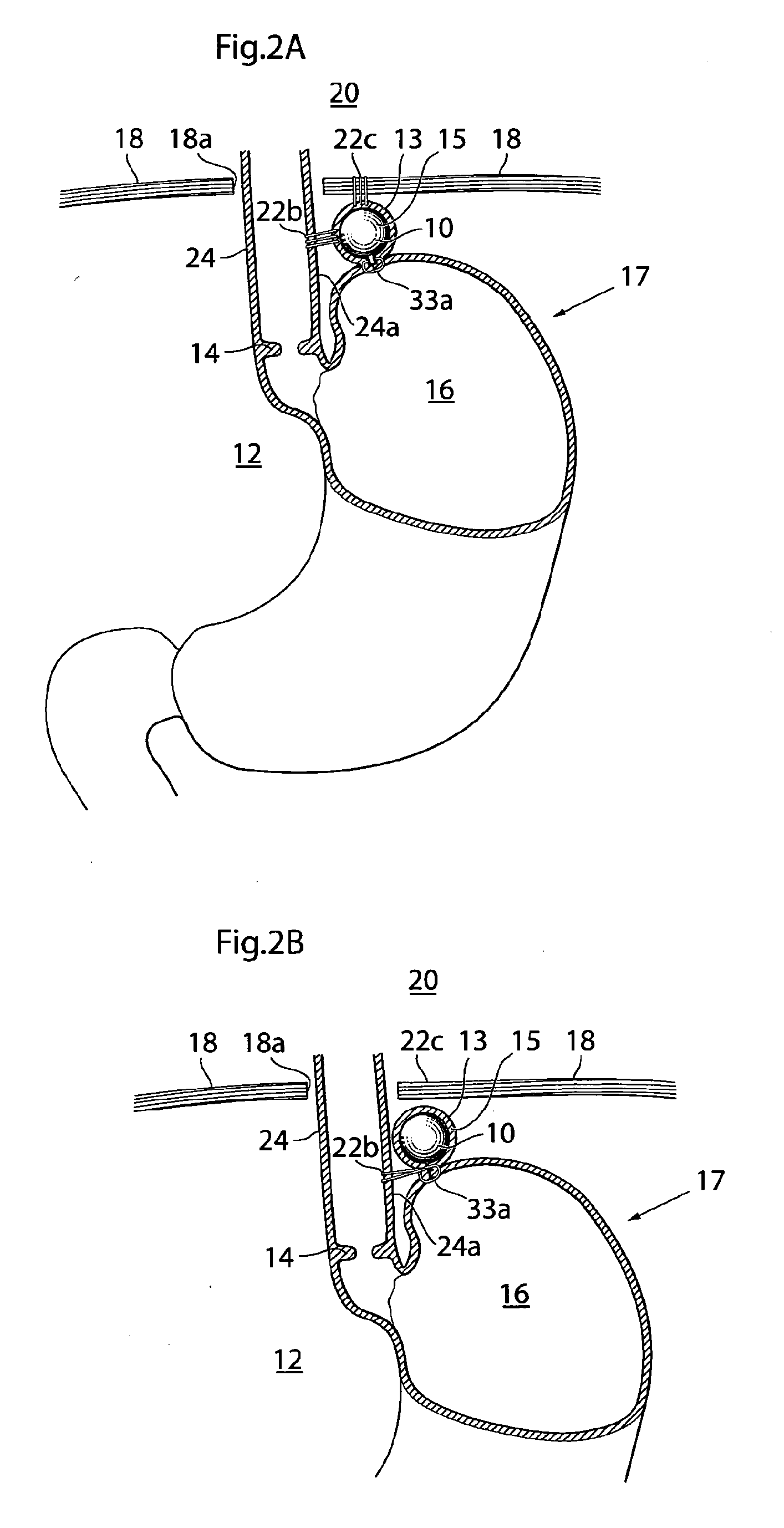

Gastrointestinal anti-reflux prosthesis apparatus and method

InactiveUS20070027549A1Prevent gastric refluxFacilitating inversionHeart valvesOesophagiGastric refluxProsthesis

A prosthesis (13) for implanting in an upper stomach to prevent gastric reflux in an esophagus comprising a tube (17) made of a biocompatible polymer that is resistant to gastric acid, the tube having an upper end and a lower end, a length, and a generally constant diameter along the entire length thereof, the upper end having means (16) for securing to the upper stomach, the lower end having at least one slit (18) to facilitate inversion of the tube during vomiting but to facilitate collapsing of the tube under pressure generated by gastric reflux.

Owner:GODIN NORMAN

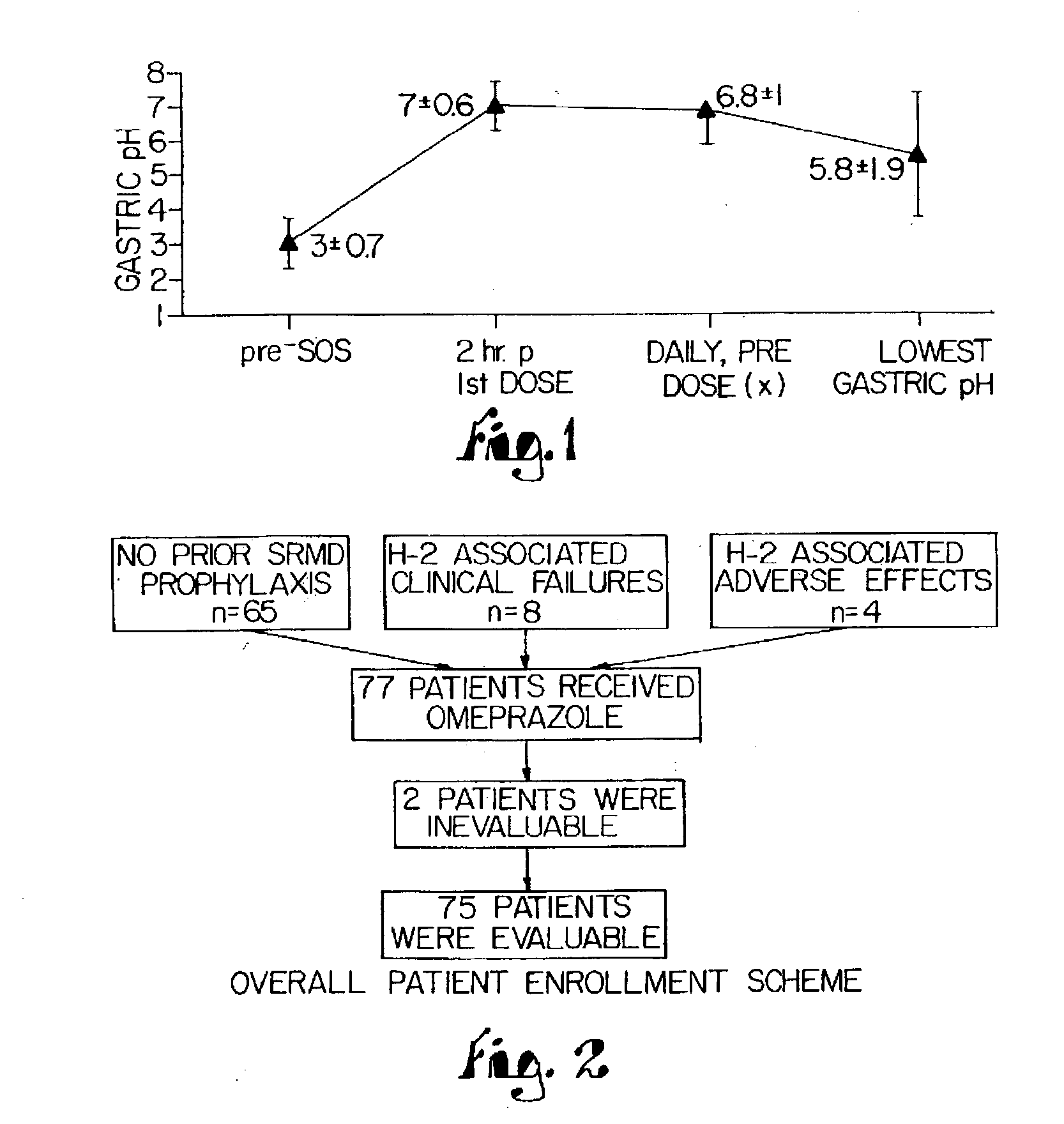

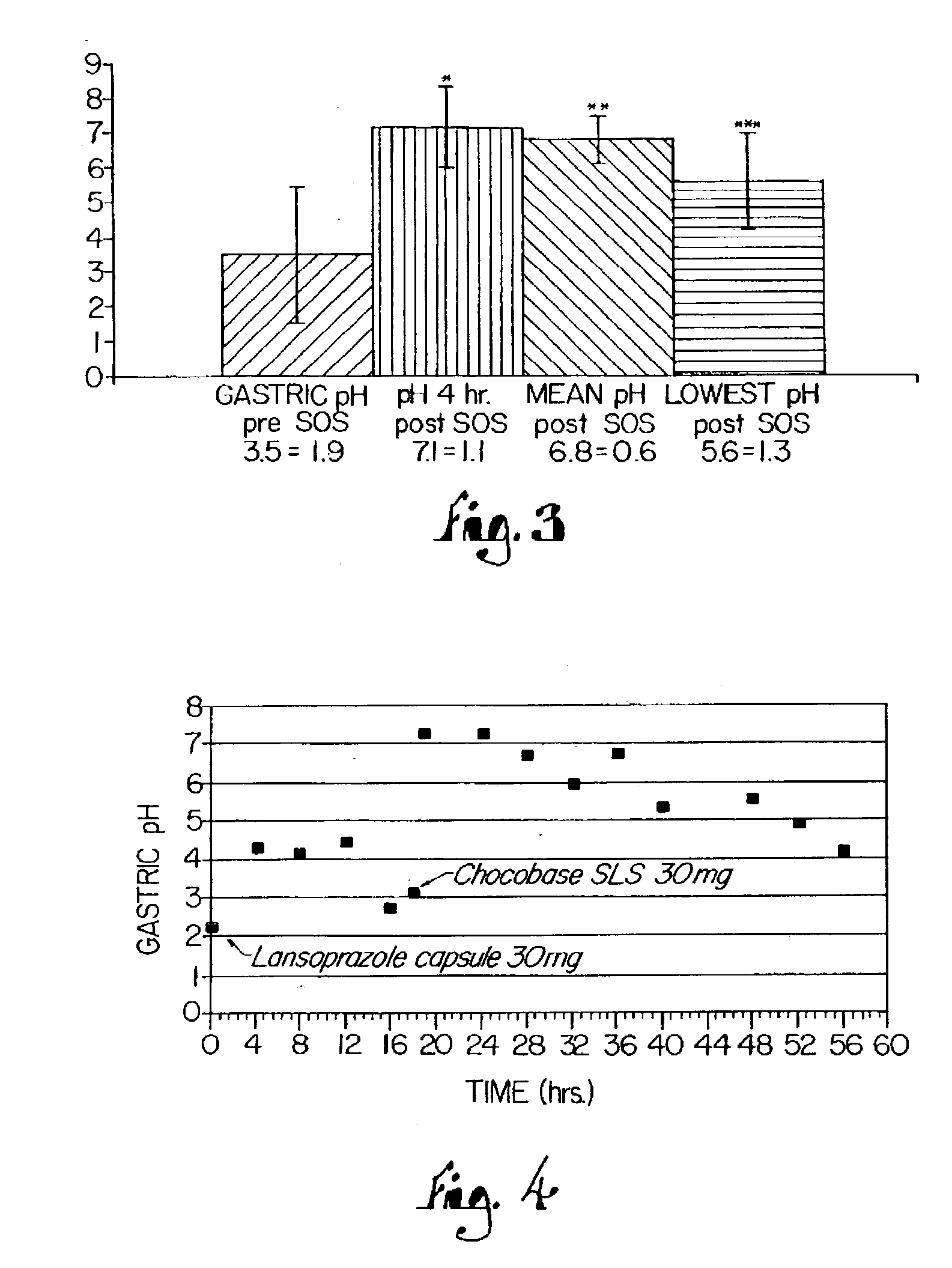

Novel substituted benzimidazole dosage forms and method of using same

InactiveUS20040048896A1Improve pharmacological activityGood effectBiocideOrganic chemistryDosage formBenzimidazole

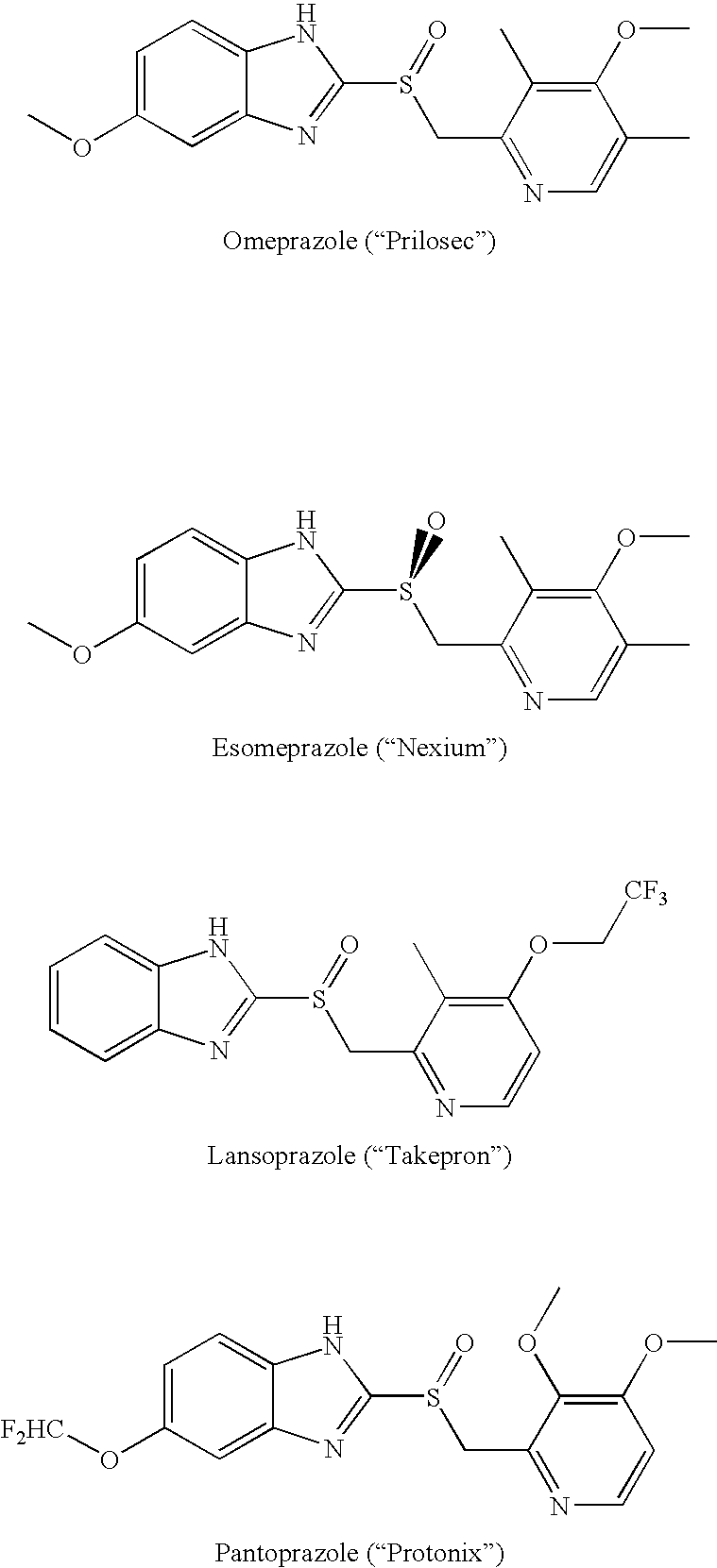

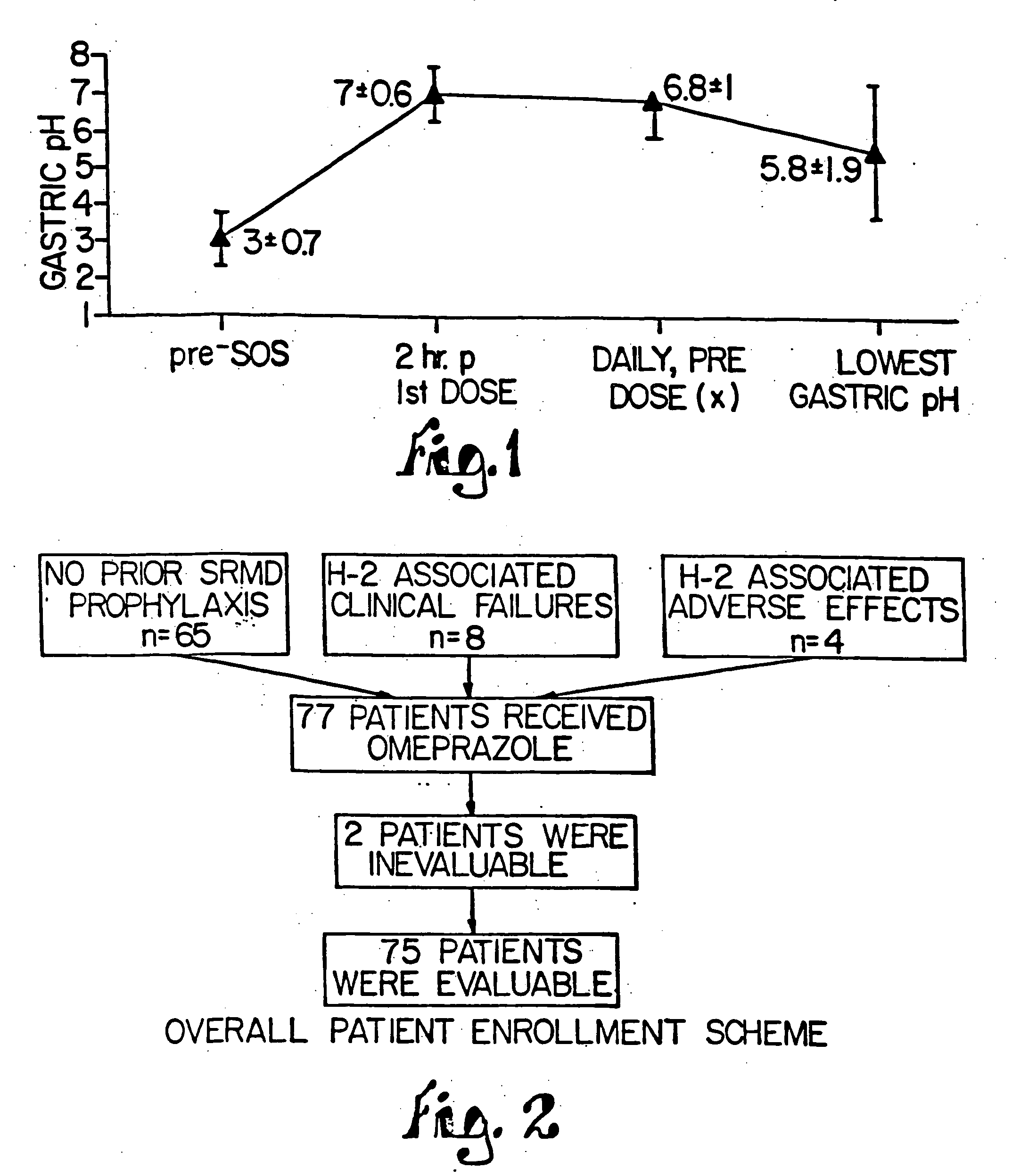

Disclosed herein are compositions and methods for treating gastric acid disorders employing pharmaceutical compositions comprising a proton pump inhibitor (PPI) in a pharmaceutically acceptable carrier.

Owner:UNIVERSITY OF MISSOURI

Sulfonamide and carboxamide derivatives and drugs containing the same as the active ingredient

InactiveUS6448290B1Low toxicityEasy to useBiocideOrganic chemistryBULK ACTIVE INGREDIENTAnalgesic agents

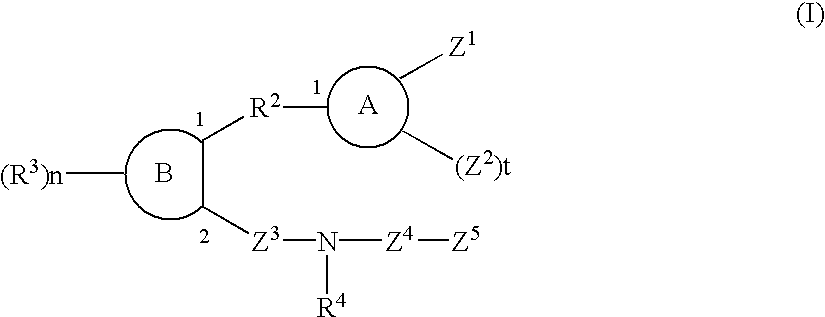

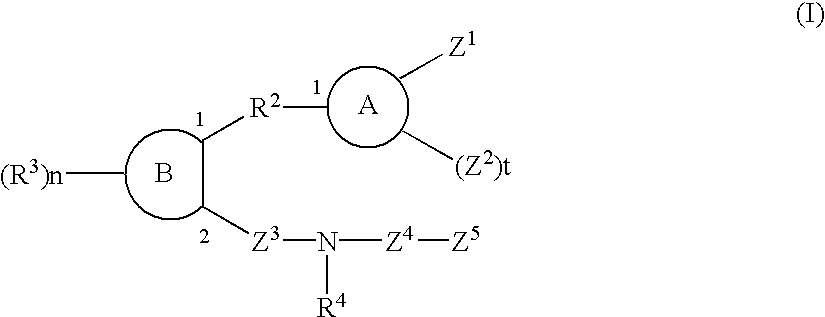

The sulfonamide or carboamide derivatives of the formula (I) and a pharmaceutical composition which comprise them as an active ingredient:(wherein A ring, B ring is carbocyclic ring, heterocyclic ring; Z1 is -COR1, -CH=CH-COR1 etc.; Z2 is H, alkyl etc.; Z3 is single bond, alkylene; Z4 is SO2, CO; Z5 is alkyl, phenyl, heterocyclic ring etc.; R2 is CONR8, O, S, NZ6, Z7-alkylene, alkylene etc.; R3 is H, alkyl, halogen, CF3 etc.; R4 is H, (substituted) alkyl etc.; n, t is 1-4).The compounds of the formula (I) can bind to receptors of PGE2 and show antagonistic activity against the action thereof or agonistic activity. Therefore, they are considered to be useful as medicine for inhibition of uterine contraction, analgesics, antidiarrheals, sleep inducers, medicine for increase of vesical capacity or medicine for uterine contraction, cathartic, suppression of gastric acid secretion, antihypertensive or diuretic agents.

Owner:ONO PHARMA CO LTD

Irreversible electroporation (IRE) for esophageal disease

InactiveUS20100256630A1Function increaseSurgical instruments for heatingEsophageal diseaseIrreversible electroporation

A method for treating Barrett's esophagus and esophageal cancer by using non-thermal electroporation energy to ablate diseased portions of the esophagus which, in effect, prevents stomach acids and other fluids from entering the esophagus thereby alleviating continued deterioration of the esophagus and allows the columnar cells in the lining of the esophagus to assume their normal physical characteristics and functions and.

Owner:ANGIODYNAMICS INC

Long-acting sour milk containing beneficial bacteria factor and its producing method

The invention discloses a long-effect yoghourt and process for preparation, wherein the yoghourt is prepared from the following raw materials (by weight portions): milk 50-100, isomaltose hypgather 0. 01-20. 00 and stabilizing agent 0. 2-8. 0. The nourishing constituents in the yoghourt can be preserved, and the storage period of the product can reach longer than six months.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

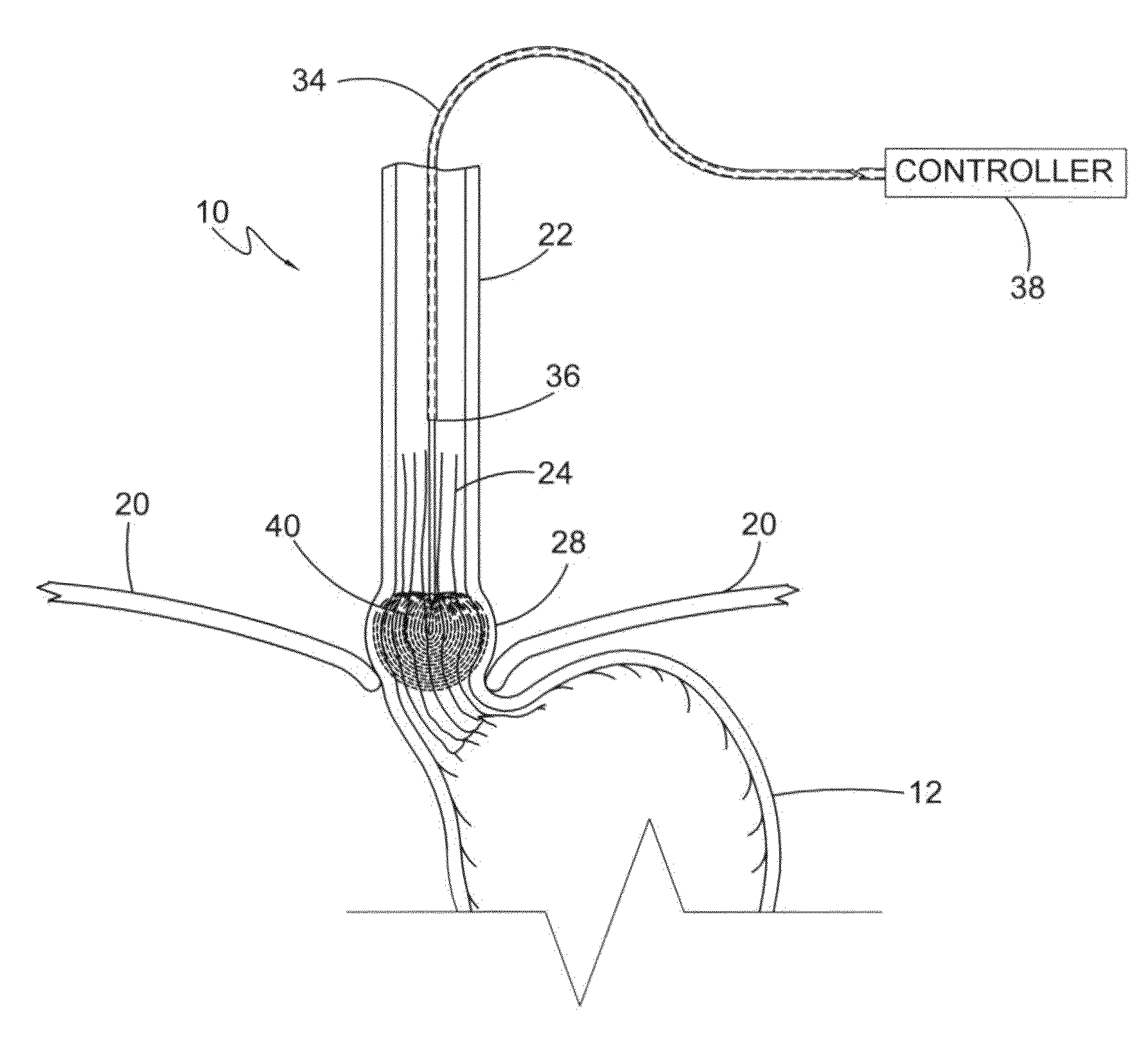

Gastro-electric stimulation for increasing the acidity of gastric secretions or increasing the amounts thereof

InactiveUS7742818B2Low costTherapy is simpleInternal electrodesExternal electrodesMedicineGastric secretions

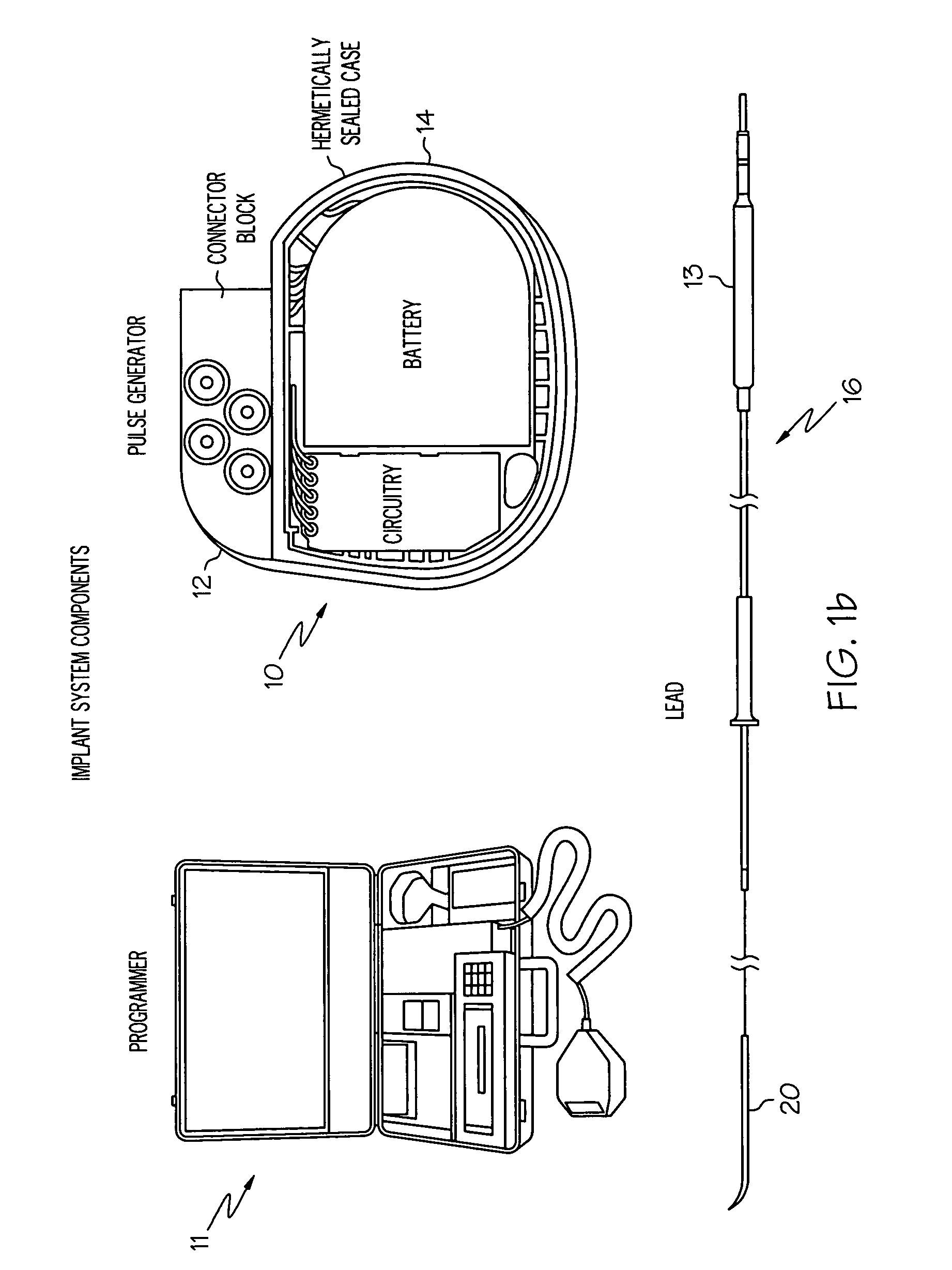

A gastro-electric stimulation system includes an INS for producing an electrical stimulation signal, at least one medical electrical lead, and at least two electrical contacts. The medical electrical lead has a proximal end and a distal end, the proximal end being connected to the INS and the distal end being adapted for placement in or near a patient's stomach or appropriate nerve or nerve portion. The electrodes are disposed near the distal end of the medical electrical lead, and the electrodes are electrically connected through the medical electrical lead to the INS to receive the electrical stimulation signal and convey such signal to the selected electrode implant position. The electrical stimulation signal is provided in an amount and manner adapted to decrease the pH of the gastric acid in the patient's stomach and / or to increase the amount of gastric acid produced thereby.

Owner:MEDTRONIC INC

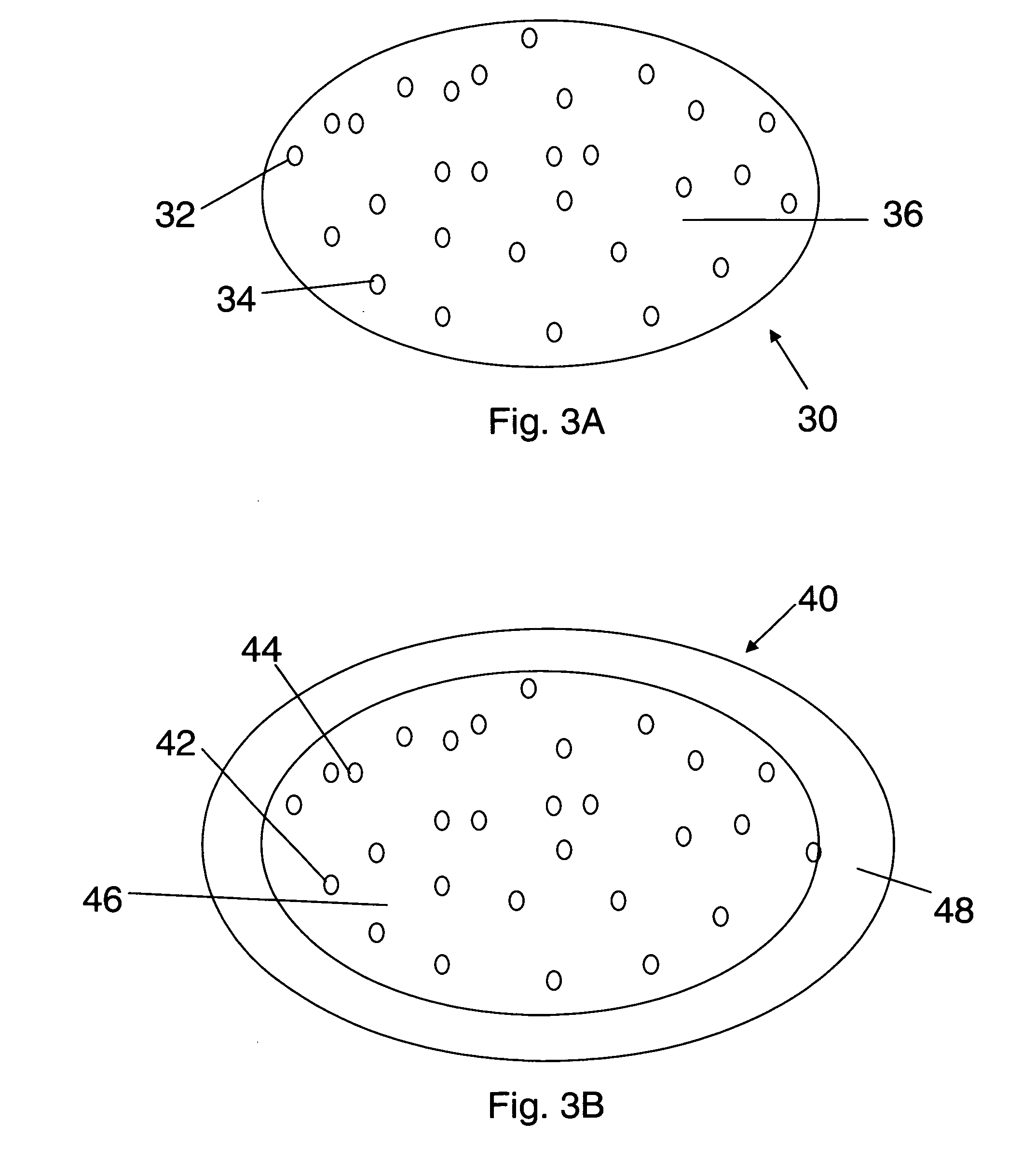

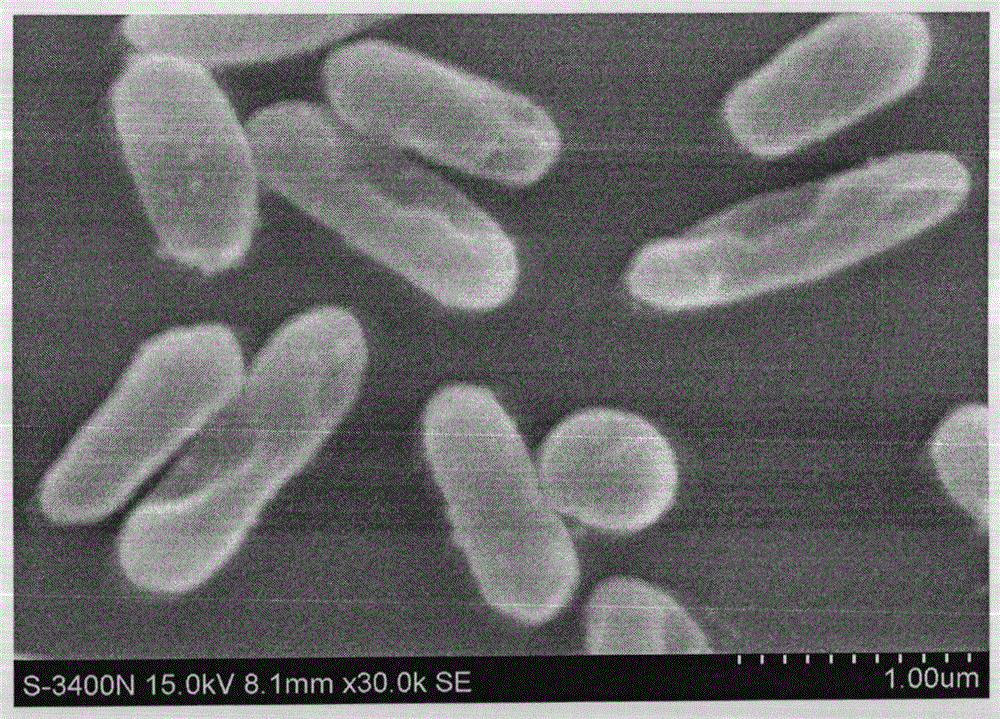

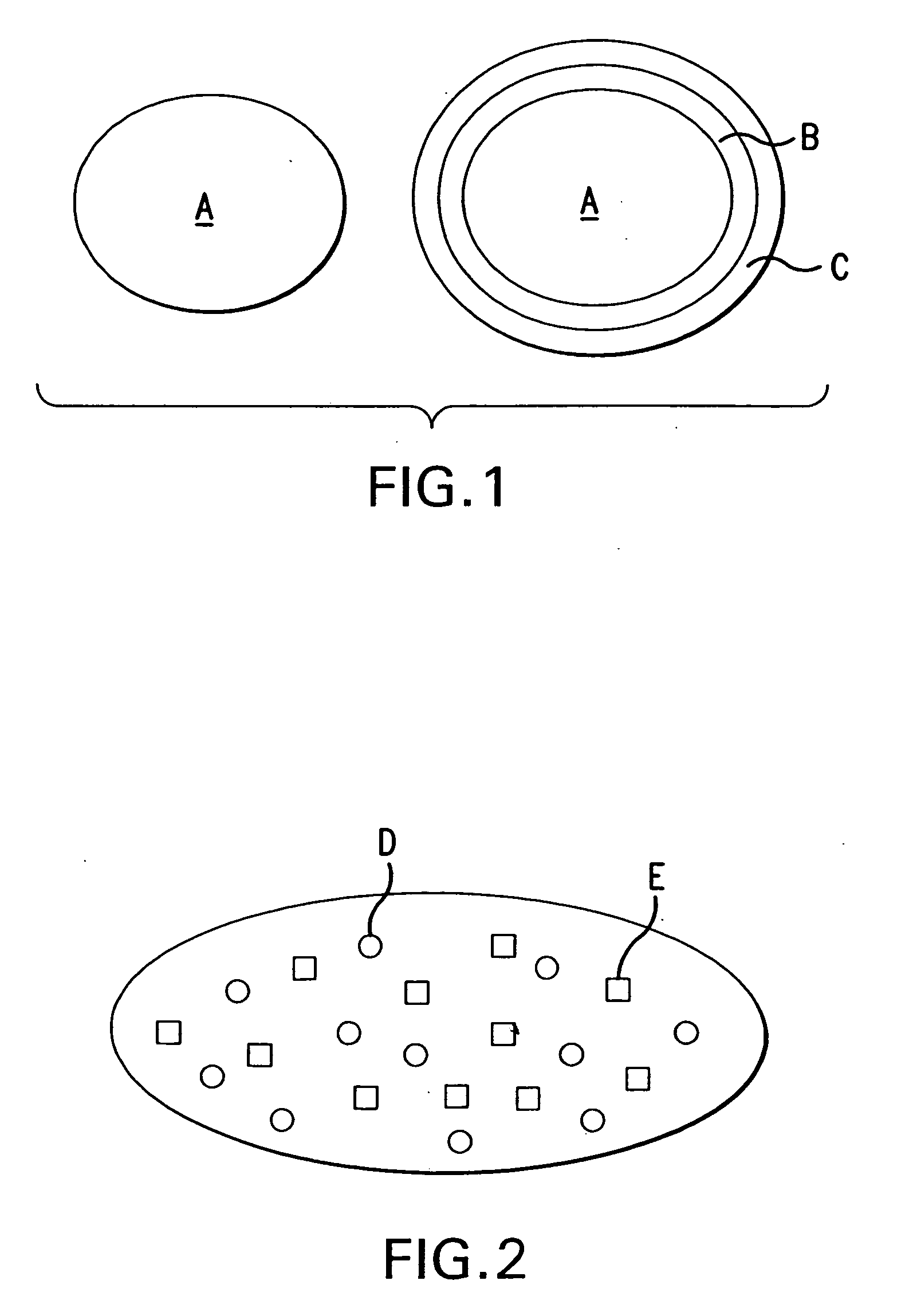

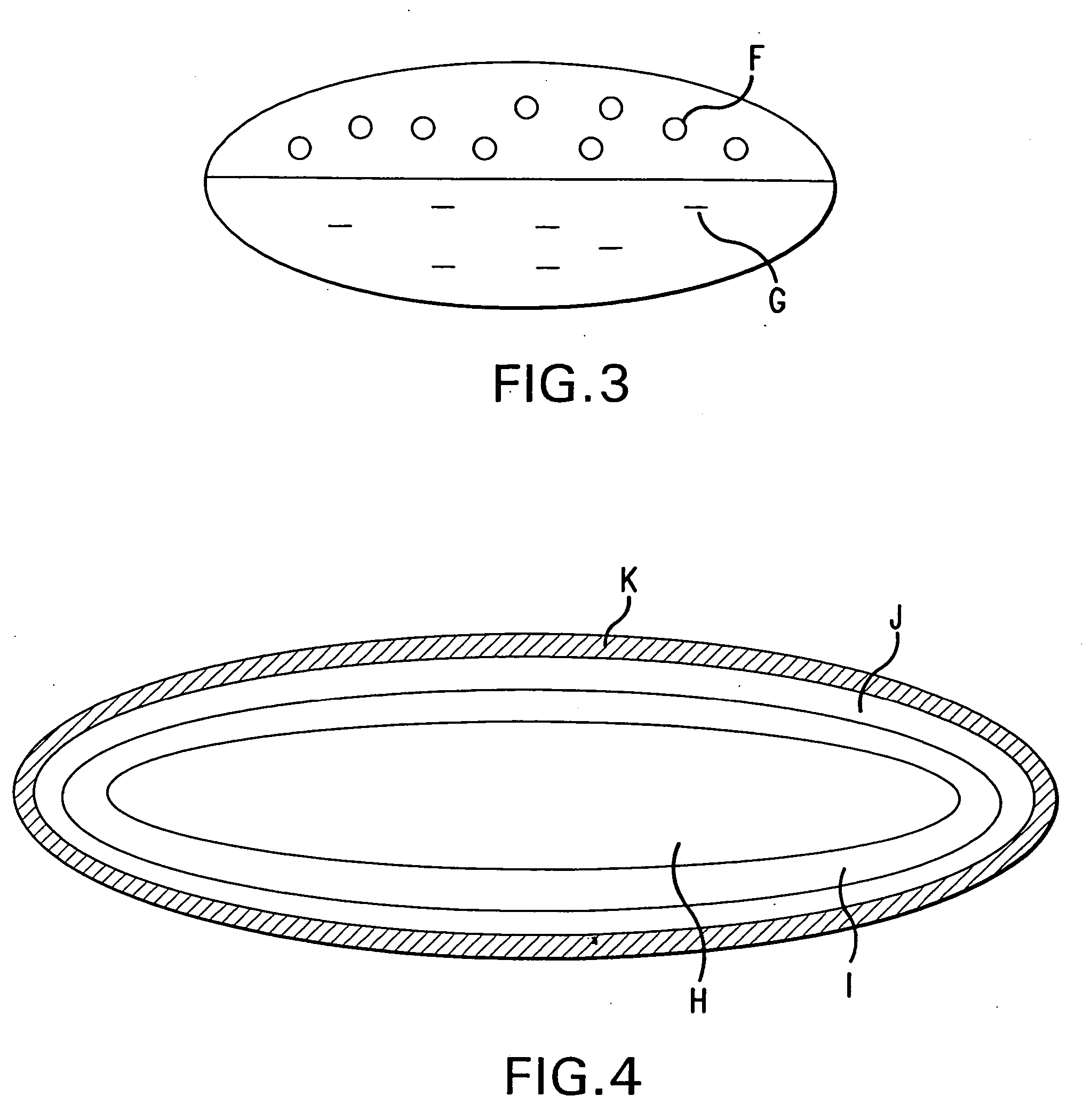

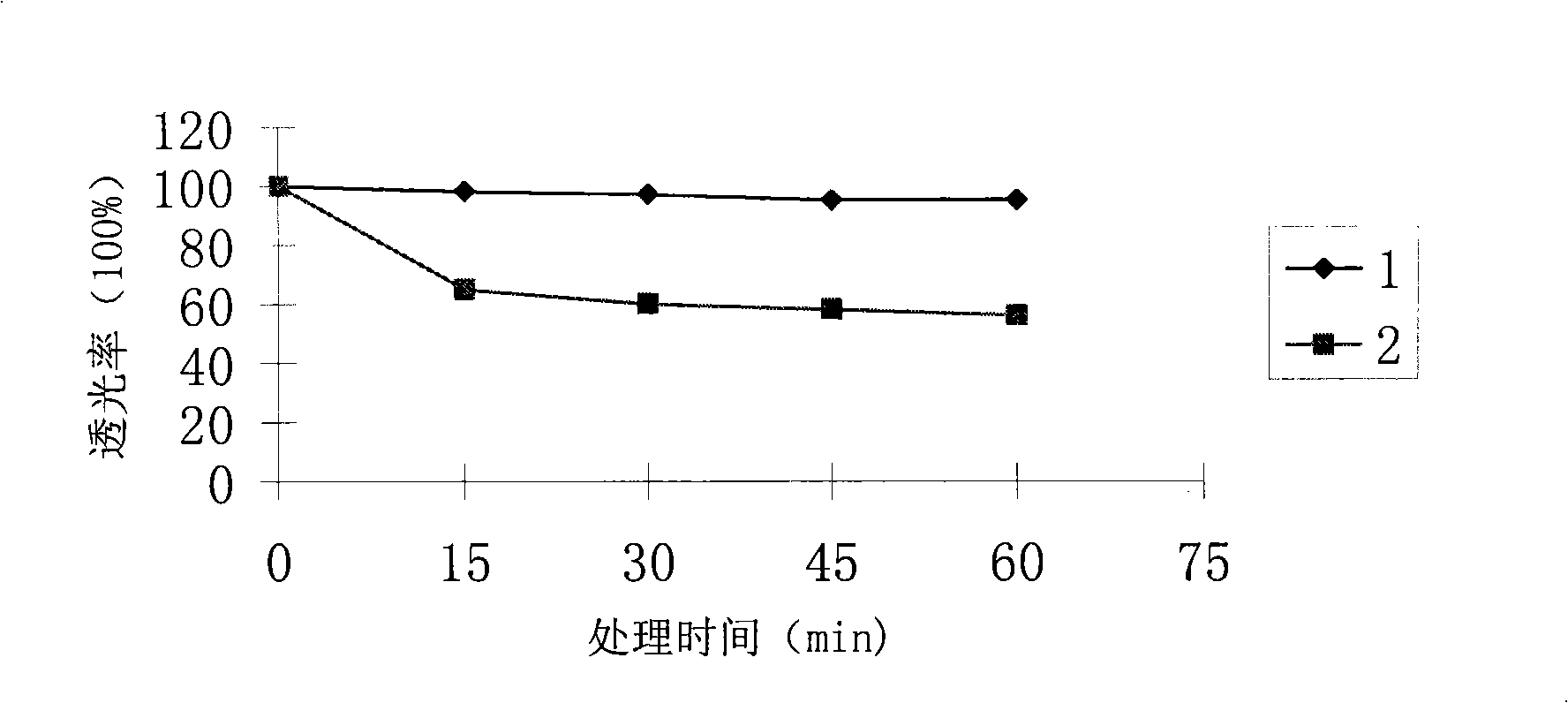

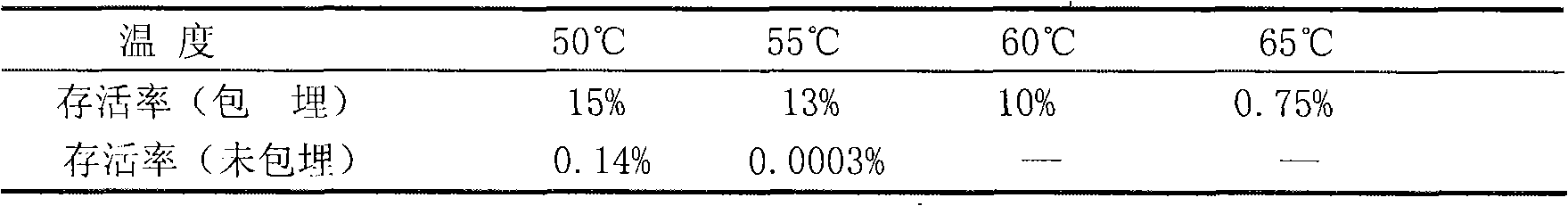

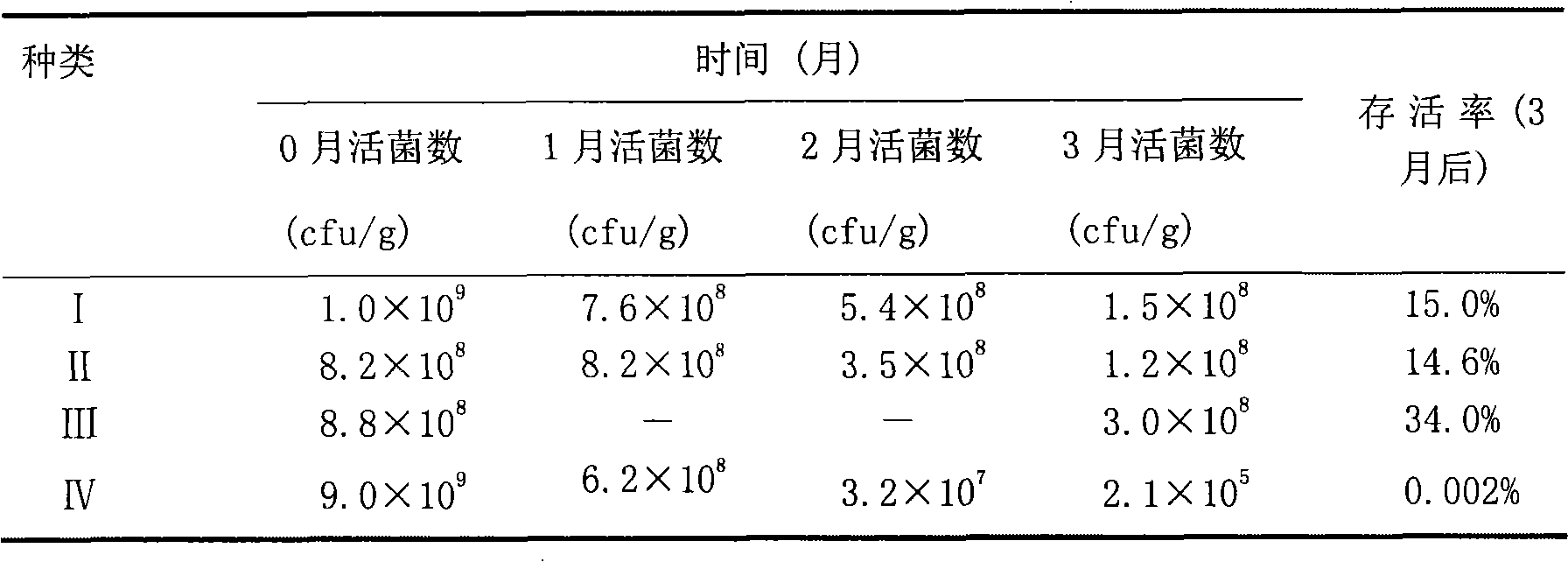

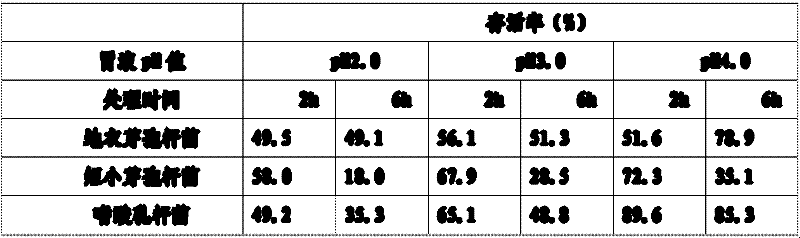

Lactobacillus micro-capsule as well as preparation method and use

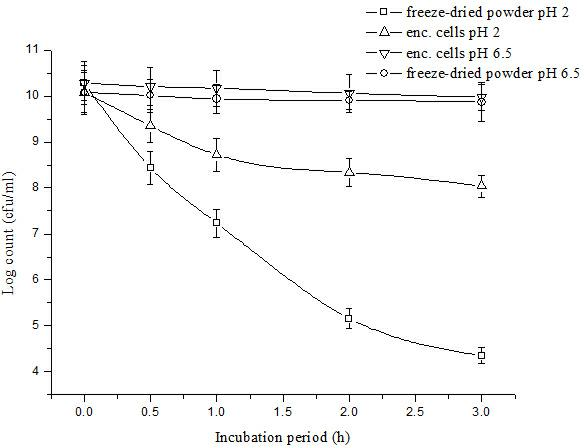

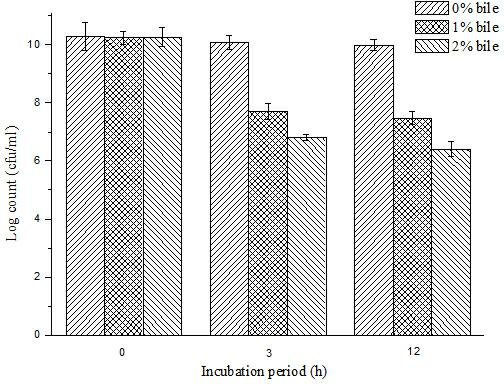

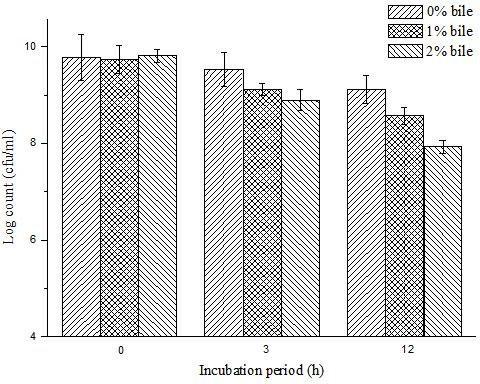

ActiveCN101496555AReduce harmHigh viable countBacteria material medical ingredientsAnimal feeding stuffEcological environmentFreeze-drying

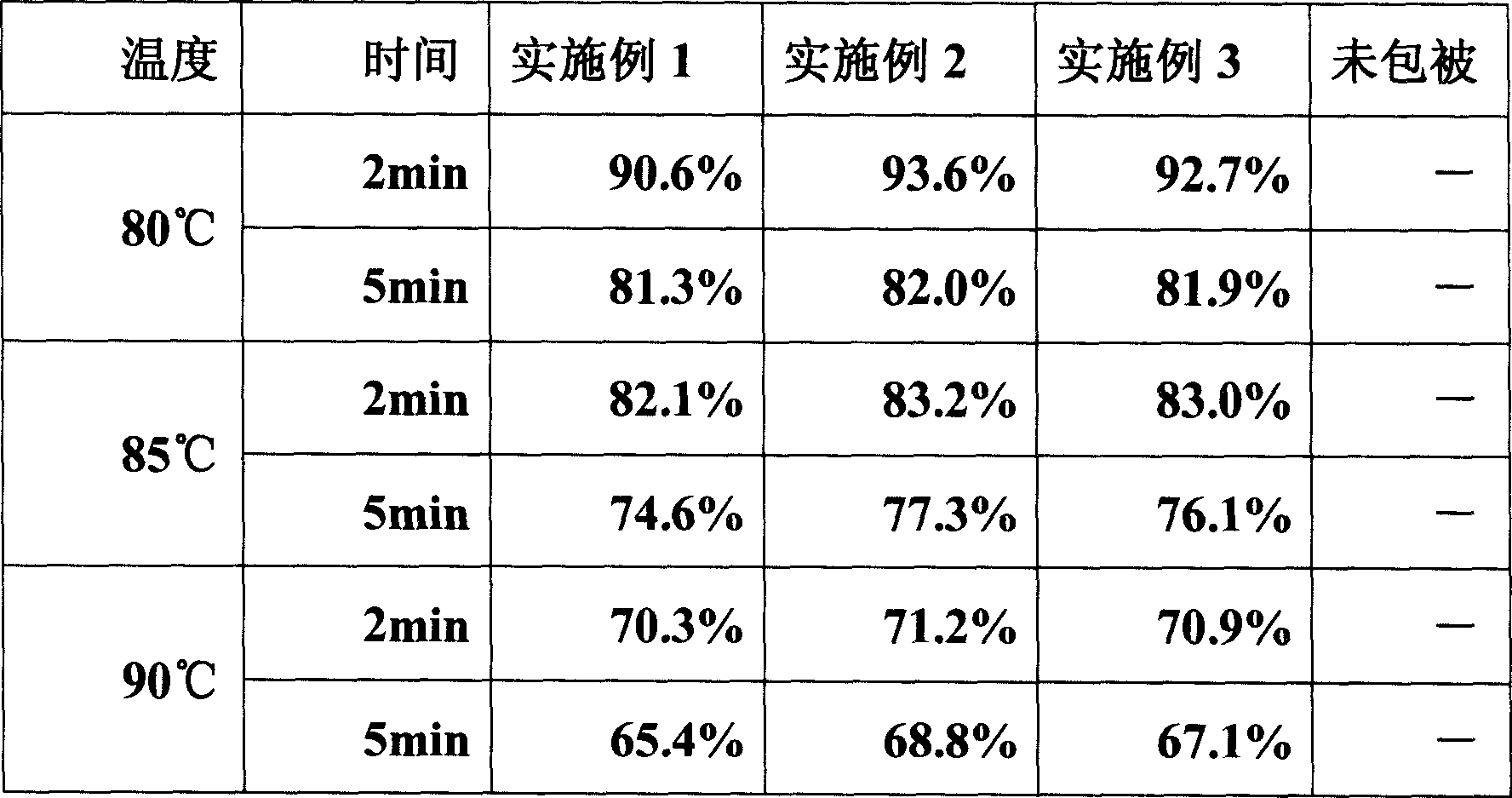

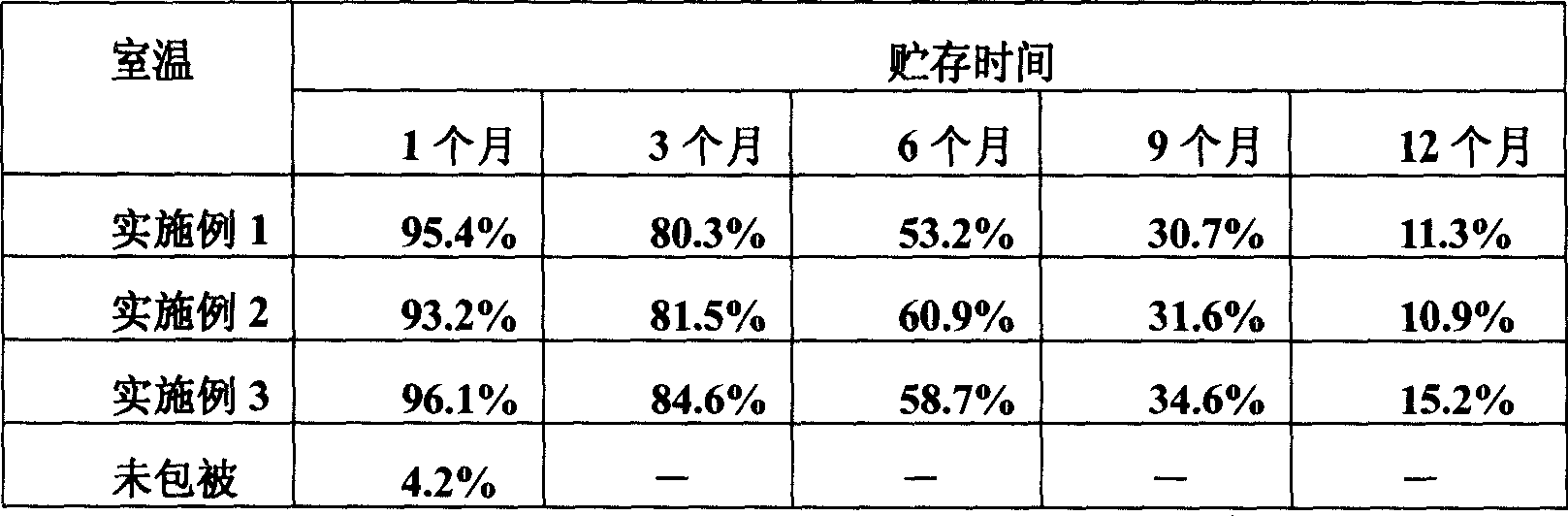

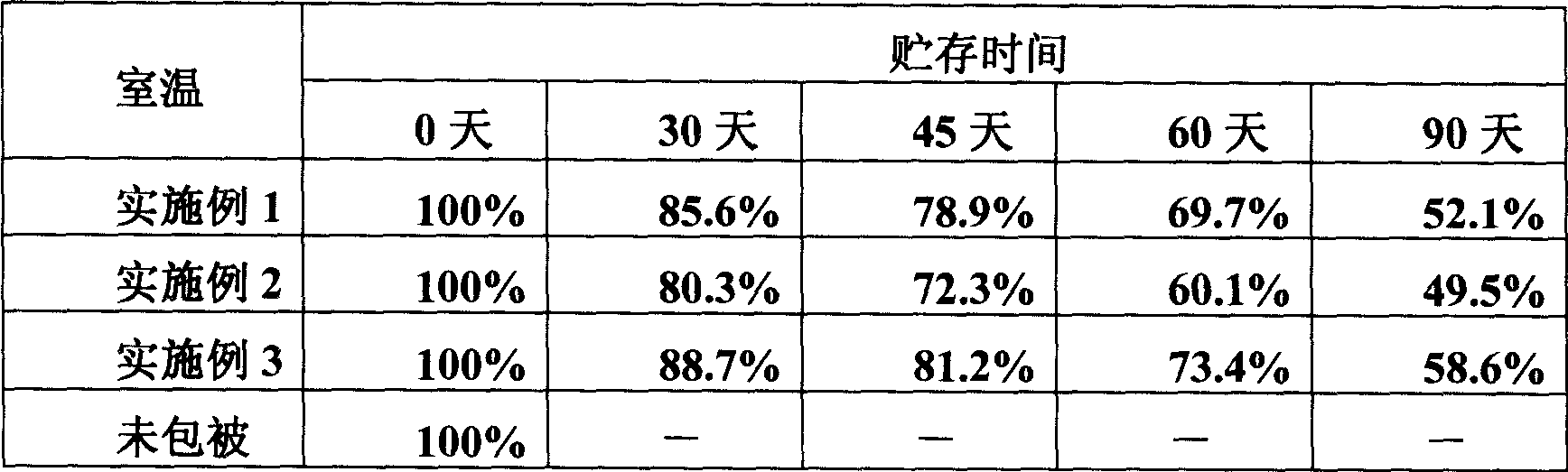

The invention relates to a lactobacillus microcapsule, a method for preparing the same, and the use of the same. The lactobacillus microcapsule consists of an outer layer of wall material, a freeze dried protective agent and lactobacilli. The invention also provides the method for preparing the lactobacillus microcapsule and the use of the lactobacillus microcapsule as a feed additive. The lactobacillus microcapsule can effectively protect the lactobacilli in a core material, prolong the survival time of the lactobacilli at room temperature and improve the tolerance of the lactobacilli to the metal ions in the feed; in addition, the lactobacillus microcapsule has good gastric acid resistance and can disintegrate in the intestinal canal quickly to release the lactobacilli, thereby improving the utilization rate of the lactobacilli, balancing the micro-ecological environment in the intestinal canal, suppressing the growth of pathogenic bacteria, protecting the health of the intestinal canals of animals, reducing the incidence rate of the intestinal canals of the animals and the like.

Owner:BEIJING DABEINONG TECH GRP CO LTD +1

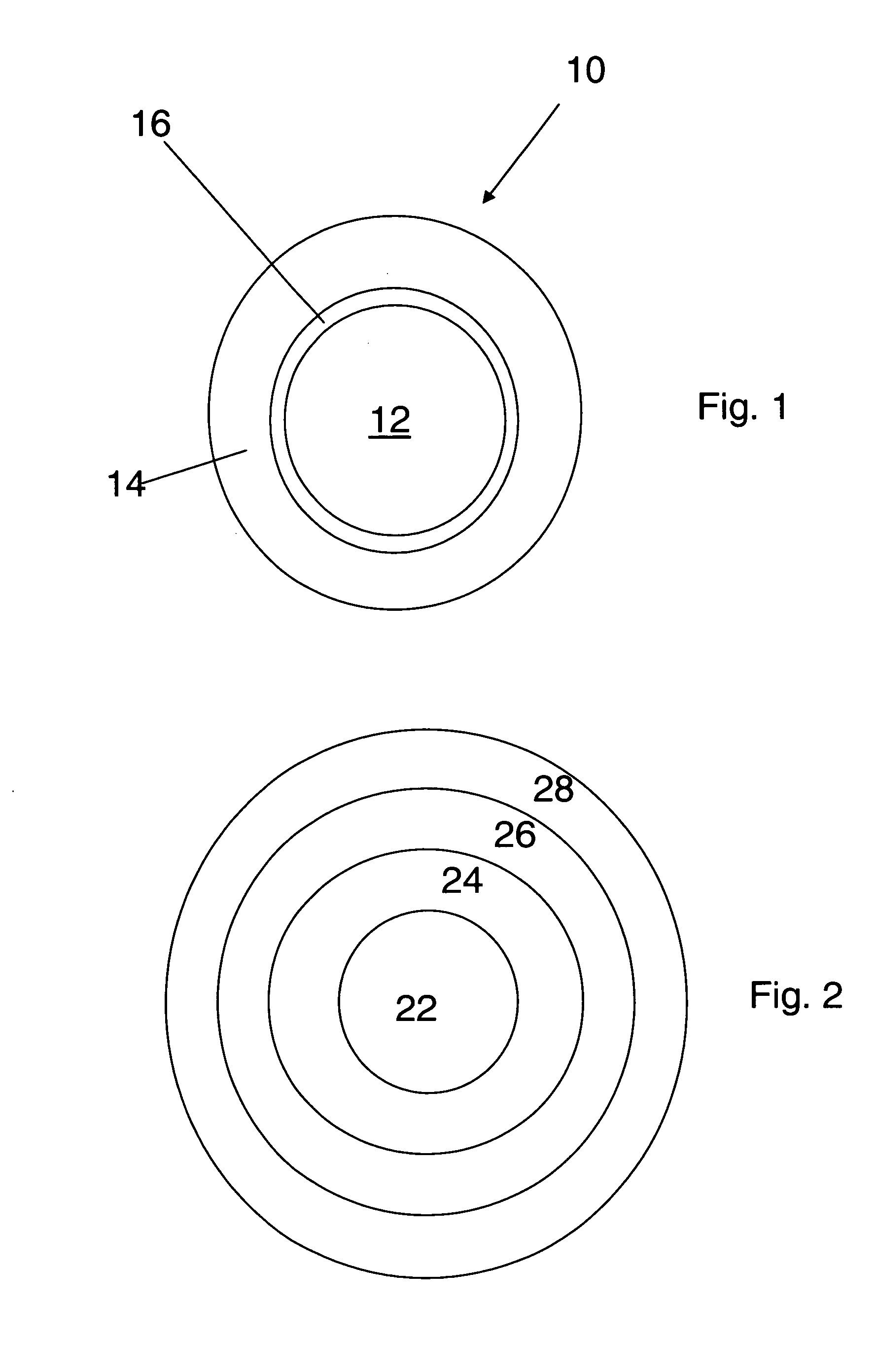

Pulsatile gastric retentive dosage forms

Dosage forms for delayed and pulsed release of therapeutic agents into the stomach are described. The dosage forms are gastric retentive dosage forms that achieve release of the therapeutic agent into the stomach and upper gastrointestinal tract subsequent to administration of the dosage form. The dosage forms find particular use in administration of acid-labile active agents such as proton pump inhibitors, and in treating gastric acid secretion such as gastro-esophageal reflux disease (GERD) and nocturnal acid breakthrough (NAB).

Owner:DEPOMED SYST INC

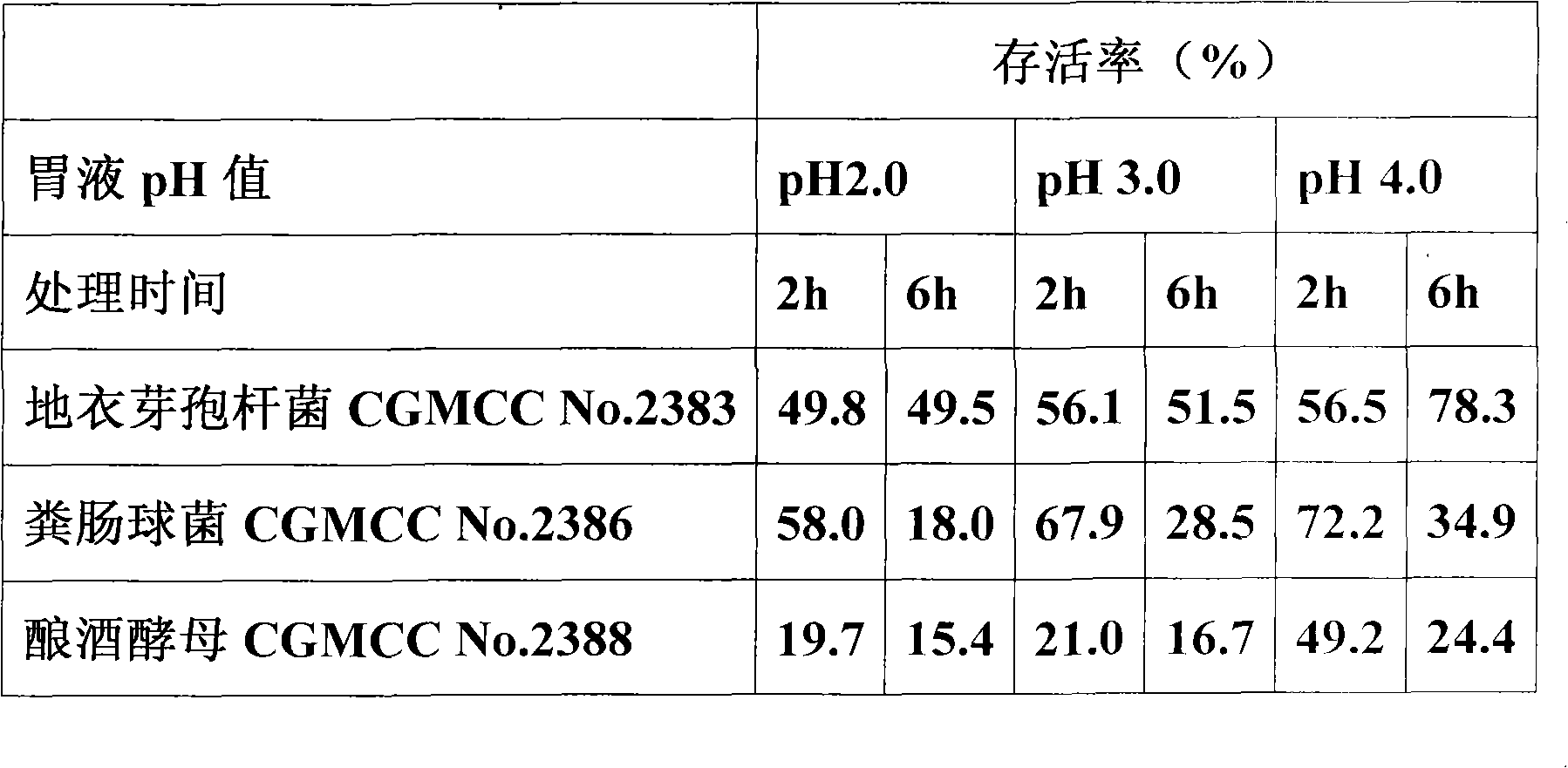

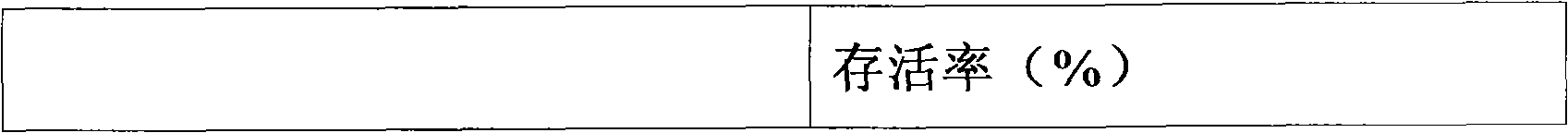

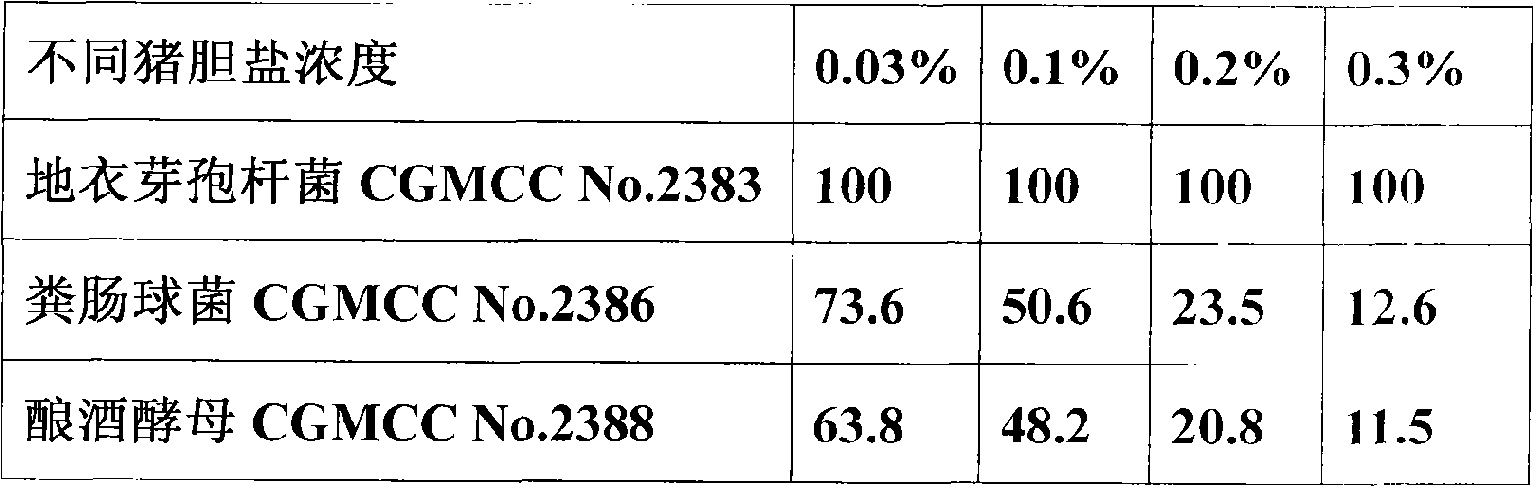

Micro-ecological preparation and application thereof

The invention relates to a micro-ecological preparation and the application thereof, in particular to a micro-ecological preparation containing a variety of probiotics and the application thereof. The micro-ecological preparation contains any three or four of the components including CGMCC No. 2383 bacillus licheniformis powder, bacillus subtilis powder, CGMCC No. 2386 enterococcus faecalis powder, lactobacillus acidophilus powder, and CGMCC No. 2388 saccharomyces cerevisiae. The micro-ecological preparation has content of live bacteria, has the adversity resistance such as gastric acid resistance, bile salt resistance, high-temperature resistance, common antibiotic resistance, and the like and the probiotic functions of producing acid and enzyme and resisting pathogenic bacteria. The variety and the proportion of the probiotics and carrier can be determined according to different kinds of animals and different animal growth phase. The micro-ecological preparation can improve the feed utilization efficiency, increase the yield of meat, eggs and milk, promote the growth of the animal, improve the immunity and the disease resistance of the animal, replace the antibiotic and improve the quality of the animal product.

Owner:BEIJING DABEINONG TECH GRP CO LTD +1

Bacteroides fragilis and applications thereof

ActiveCN106399141AEffective for diarrheaGood probiotic propertiesBacteriaBacteria material medical ingredientsAntibiotic-associated diarrhoeaFood additive

The invention relates to Bacteroides fragilis and applications thereof, particularly to Bacteroides fragilis ZY-312 having the preservation number of CGMCC No.10685, and applications of the Bacteroides fragilis ZY-312 in preparation of medicines, pharmaceutical compositions, foods, health products and food additives for prevention and / or treatment of antibiotic-associated diarrhea, wherein the Bacteroides fragilis ZY-312 is preserved in the China general microbiological culture collection center on April 2, 2015, has the preservation number of CGMCC No.10685, does not contain enterotoxin gene bft, has characteristics of significantly-improved cholate resistance and significantly-improved gastric acid resistance compared to the existing Bacteroides fragilis, and can effectively prevent and / or treat antibiotic-associated diarrhea.

Owner:GUANGZHOU ZHIYI PHARMA INC

Dosage form for treating gastrointestinal disorders

InactiveUS20060165797A1Quick reliefPrevent relapseBiocideDigestive systemGastrointestinal disorderSecreted substance

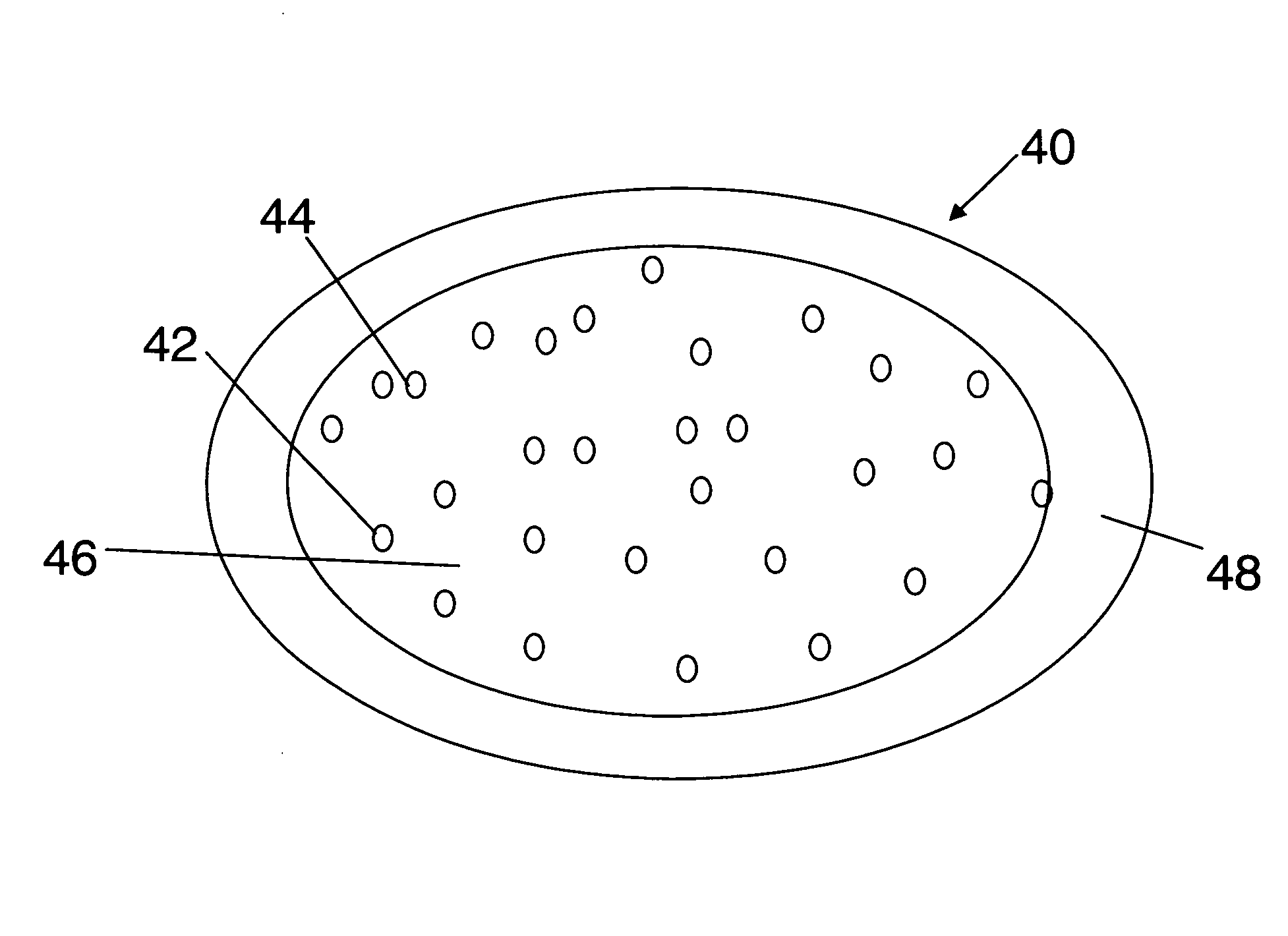

The present invention is directed to drug dosage forms that can be used to treat diseases characterized by abnormal gastric acid secretion. The dosage forms have a core containing a proton pump inhibitor surrounded by an enteric coating or multiple particles containing proton pump inhibitor, each particle being surrounded by an enteric coating. The enteric coating delays the release of drug until the surrounding pH has risen. The tablets also include an outer coating that contains either a proton pump inhibitor or an H2 blocker. The outer coating is designed to rapidly dissolve in a patient's stomach.

Owner:POZEN INC

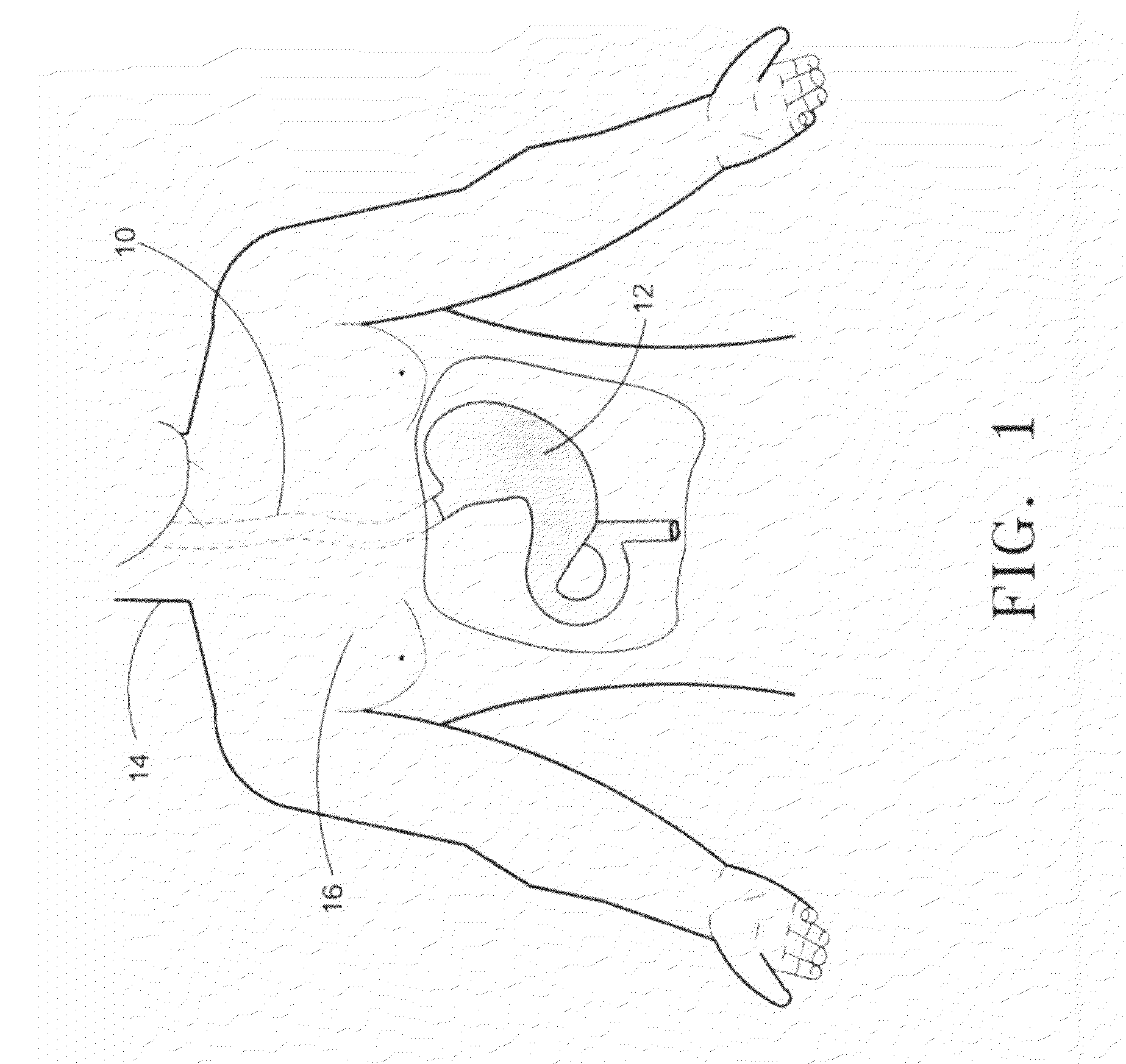

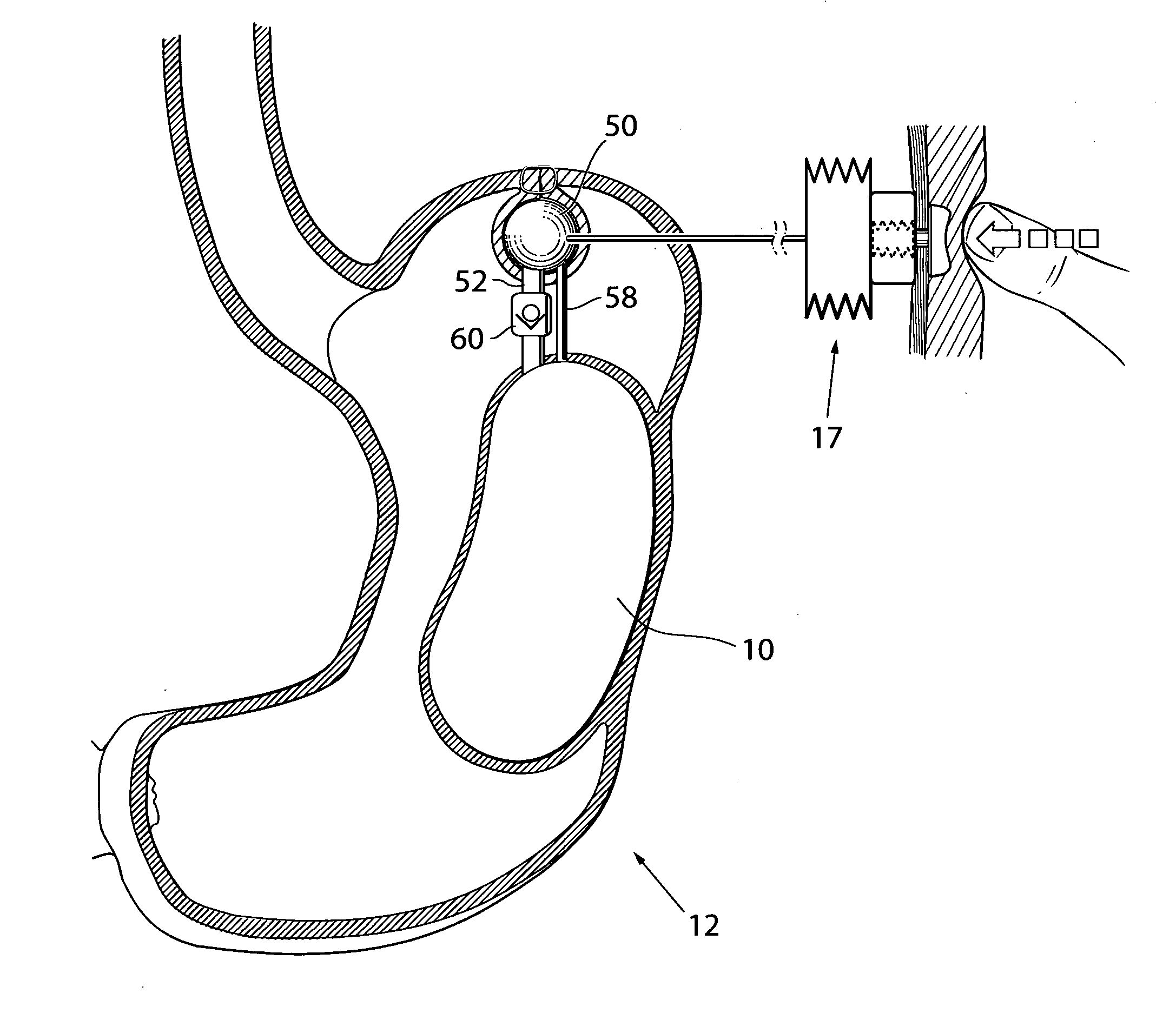

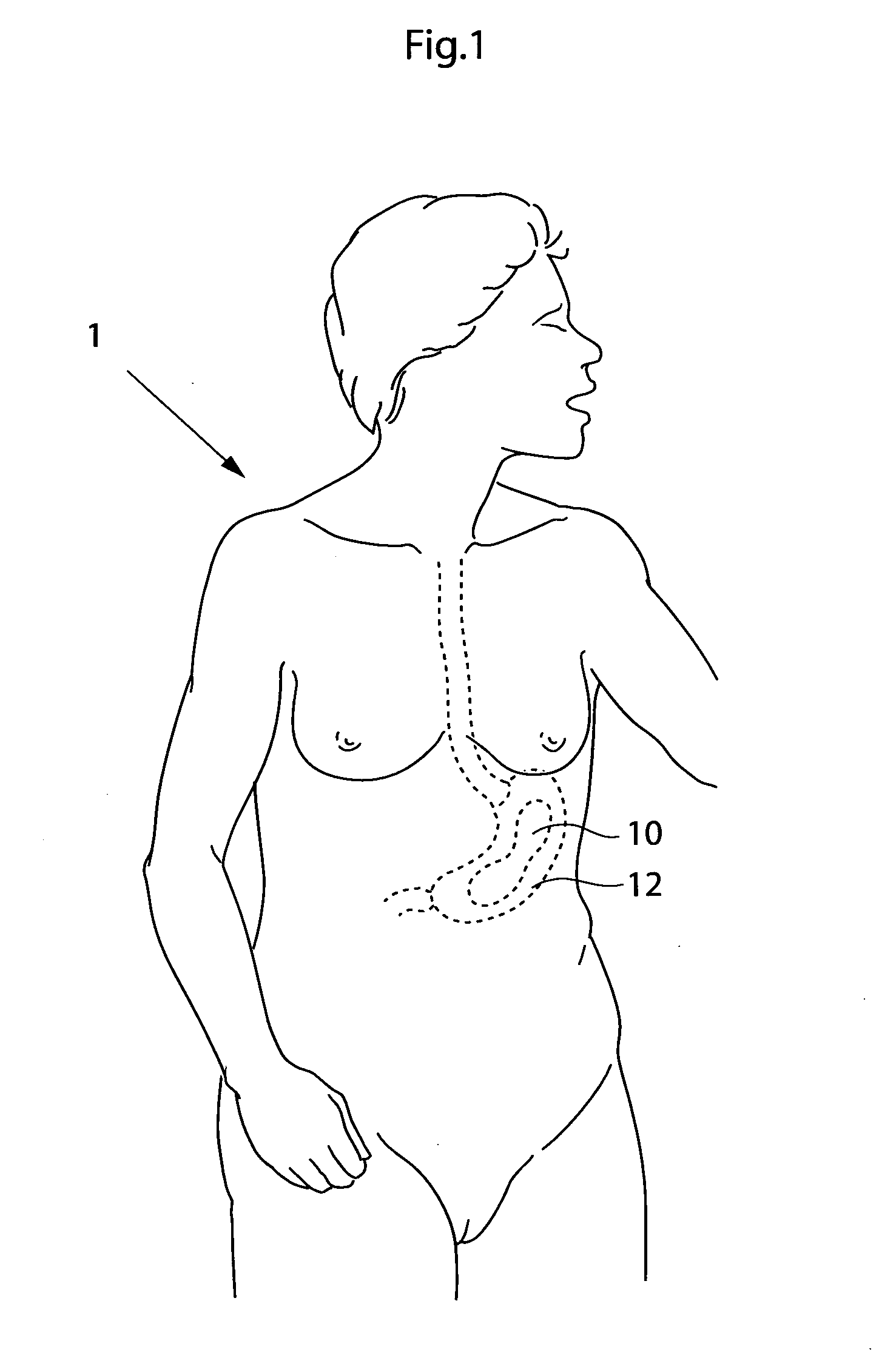

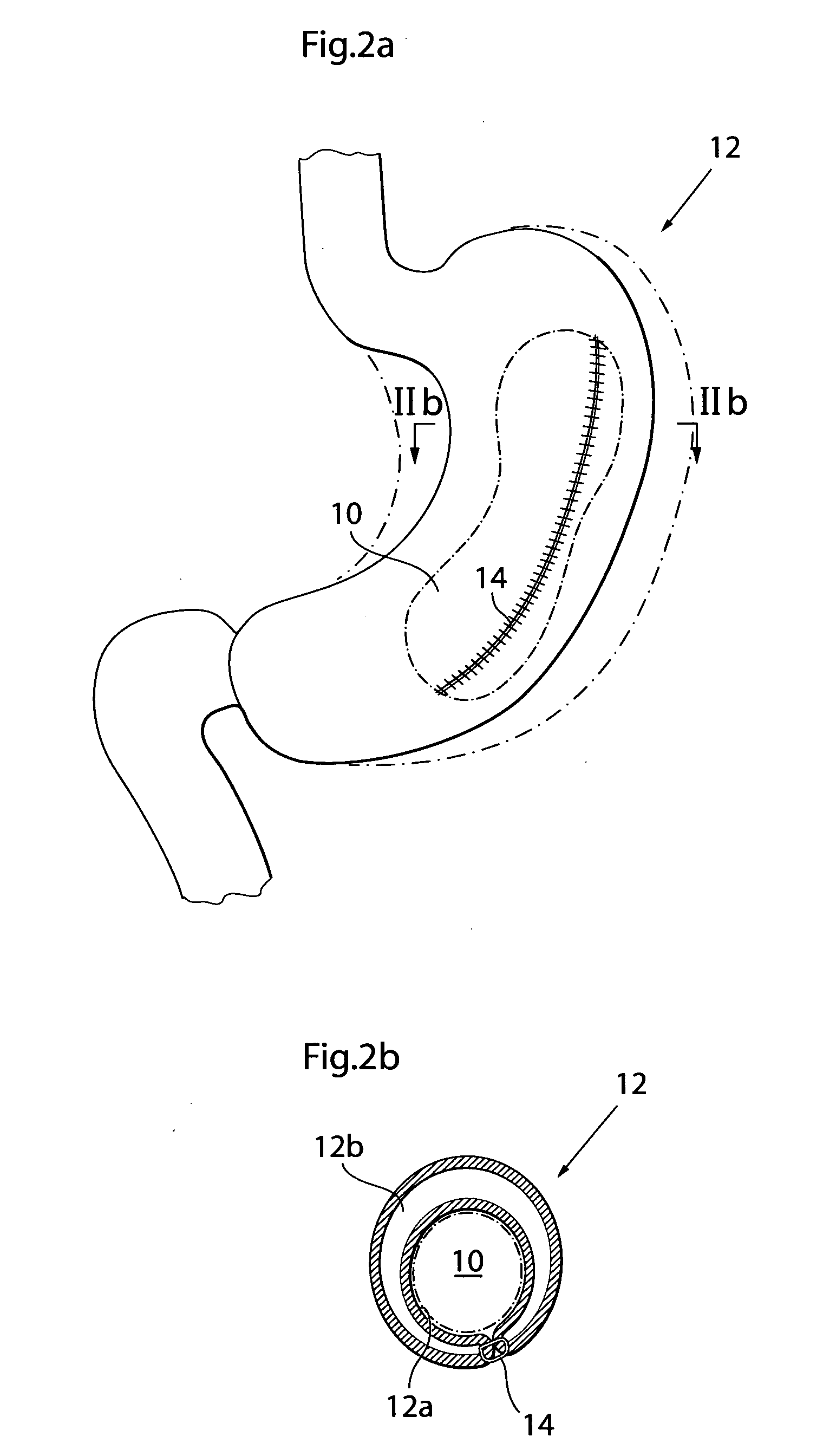

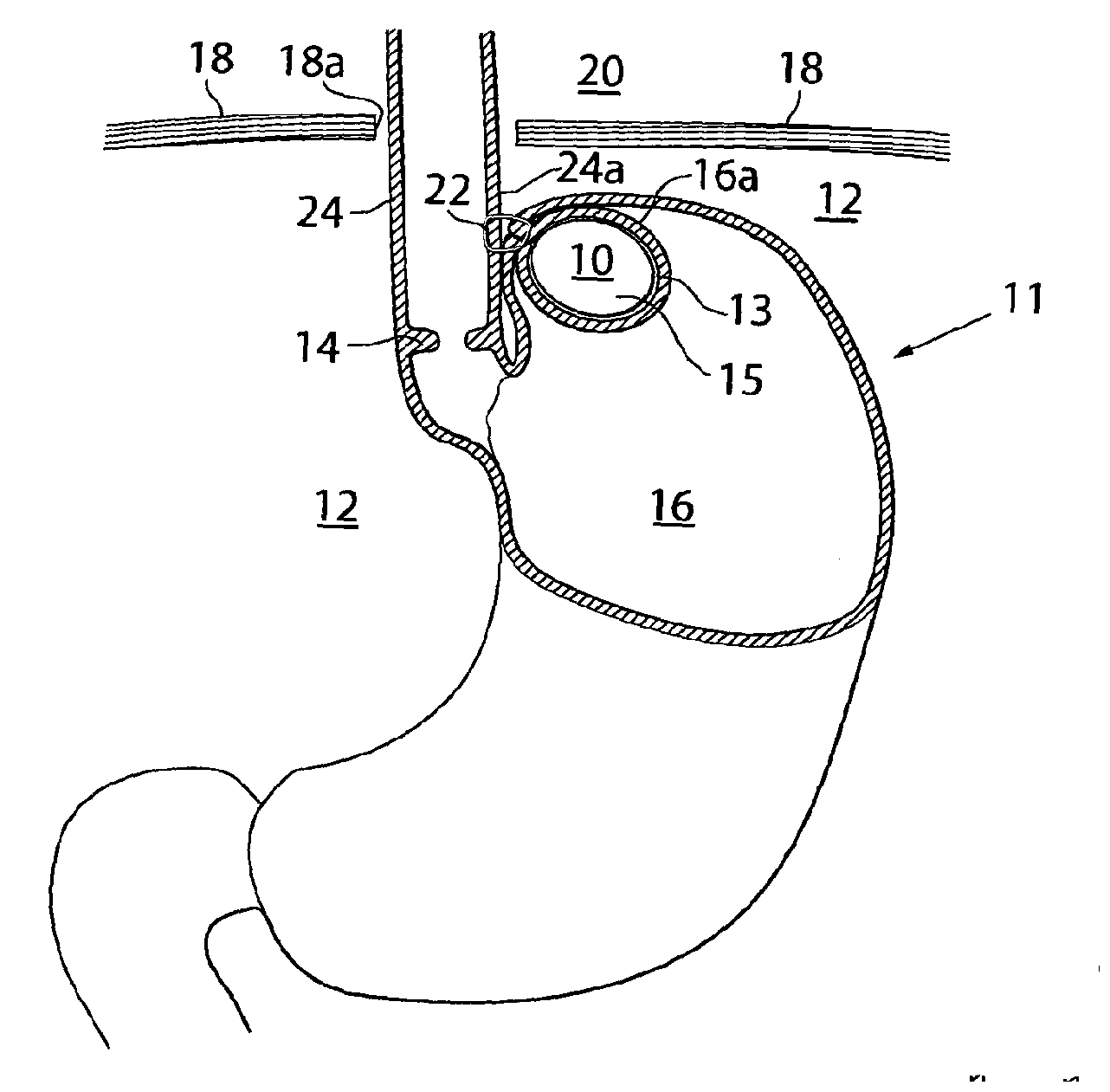

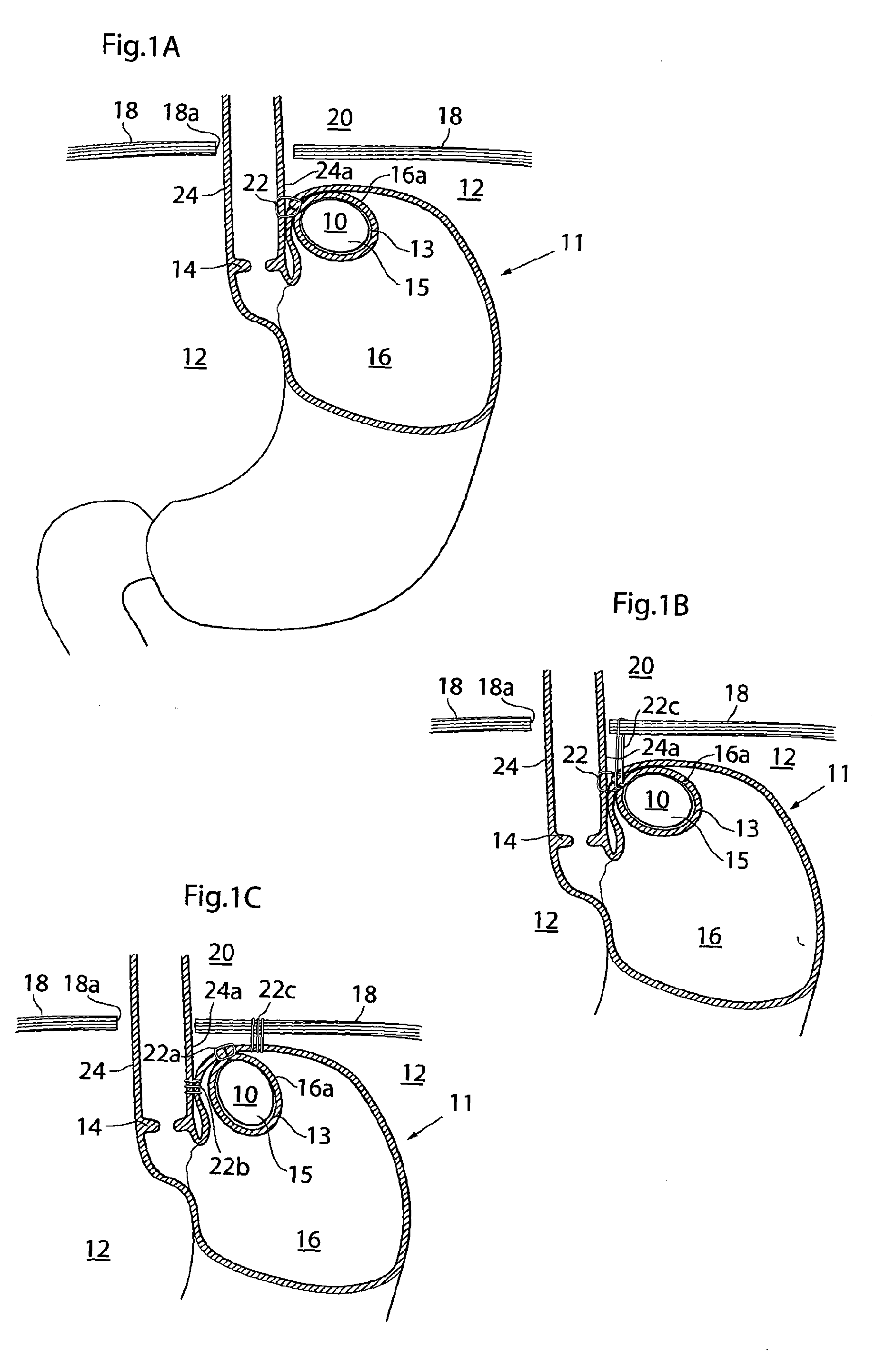

Apparatus for treating obesity

ActiveUS20100312049A1Improved long-term propertyLower the volumeSuture equipmentsElectrotherapyStomach wallsVolume filling

An volume filling device for treatment of obesity is placed outside the stomach wall of the patient to reduce the inner volume of the stomach, thereby affecting the patient's appetite. By providing the volume filling device outside the stomach wall, contact with stomach acids is avoided, thereby increasing the life of the device.

Owner:FORSELL PETER

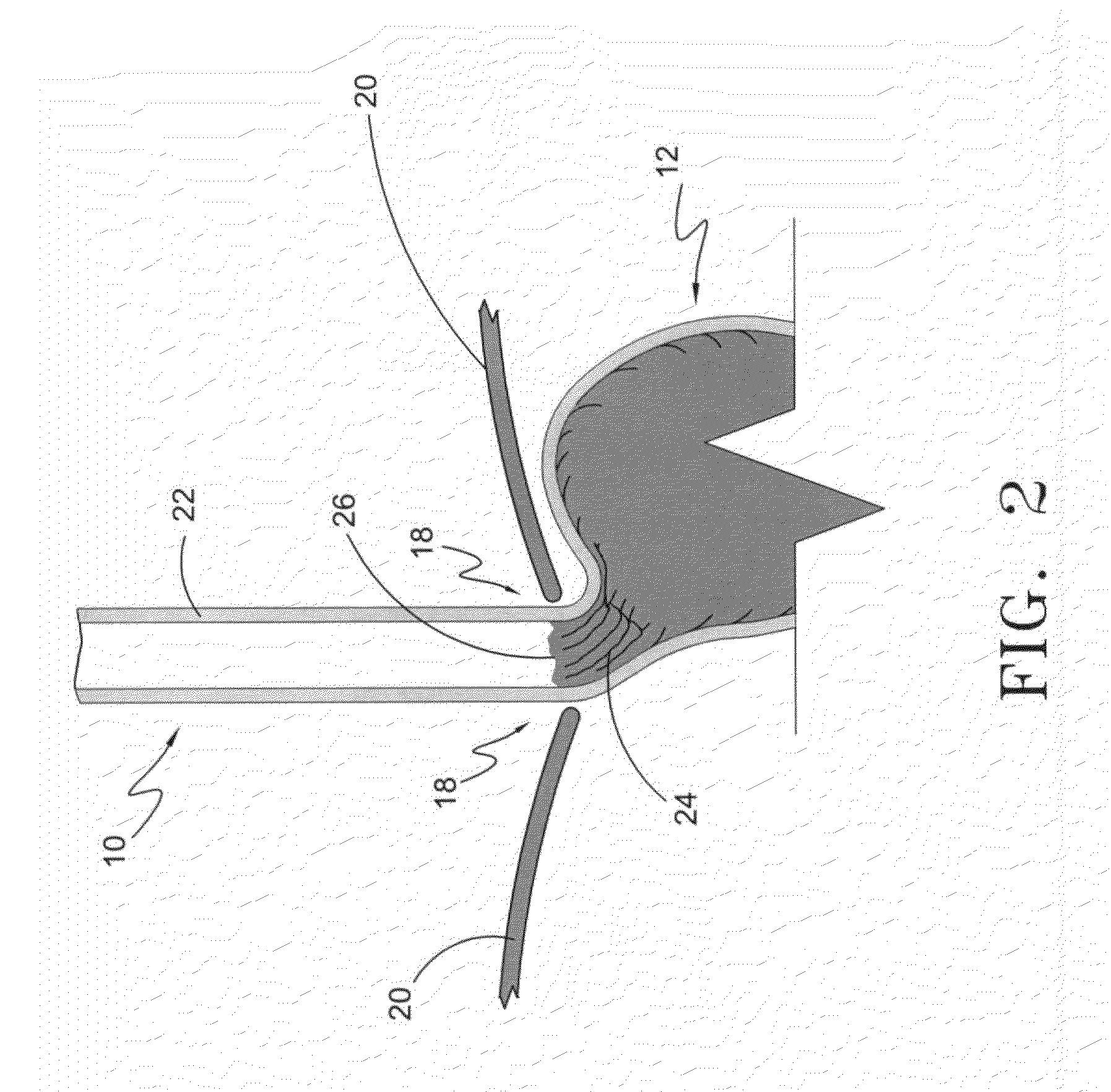

Apparatus for treating gerd

An implantable device for the treatment of acid reflux disease has a body including an outer surface adapted to rest against a patient's fundus wall. The device, when implanted in a patient, fills a volume in the patient's abdomen in the cardia area and above the cardia of the patient, when standing. The body prevents the cardia from moving through the diaphragm opening into the thorax, thereby preventing reflux by keeping the abdominal pressure supporting the cardia sphincter muscle. The device may be affixed to stomach tissue. The device may also be invaginated or otherwise indirectly secured in position.

Owner:FORSELL PETER

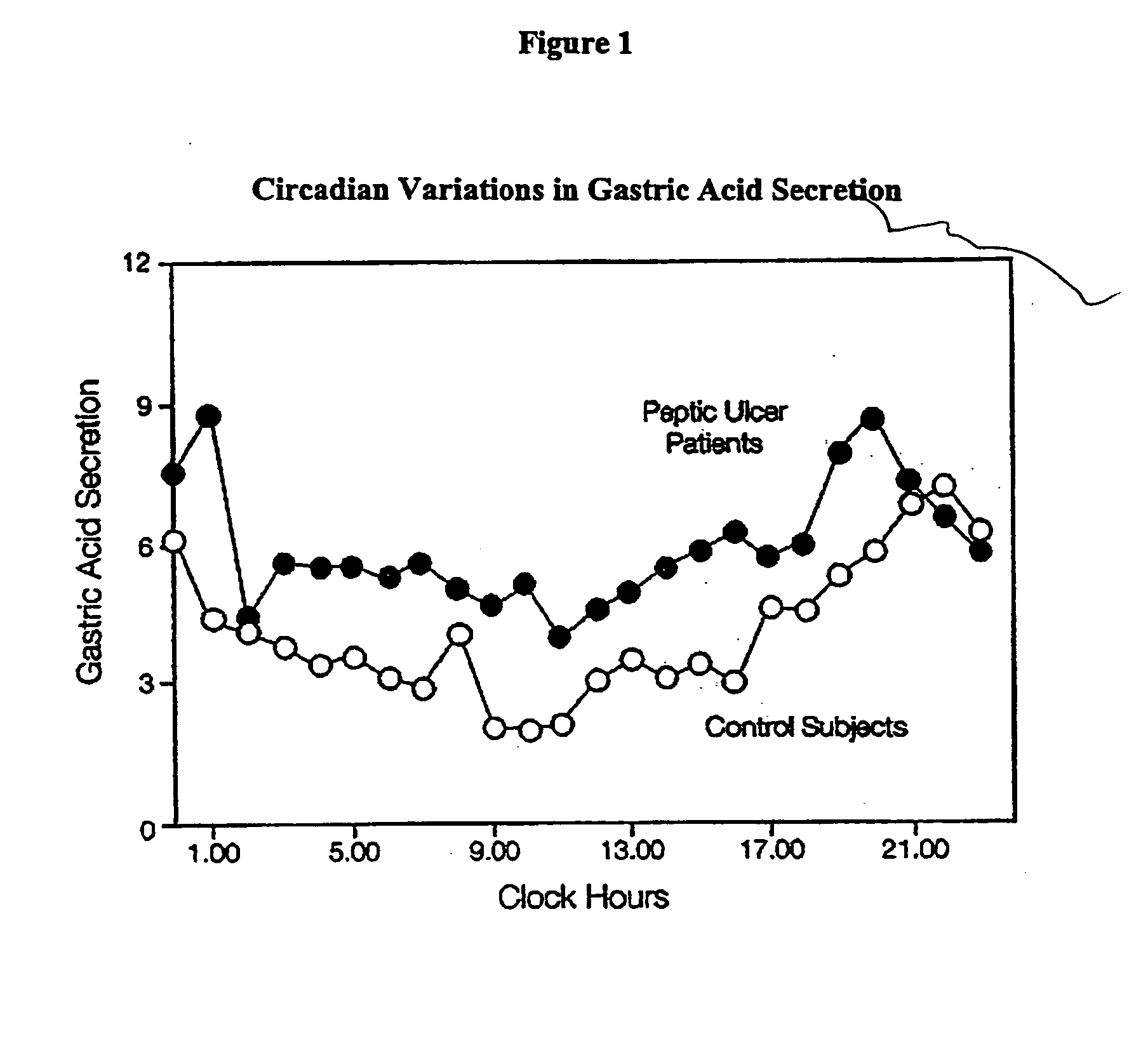

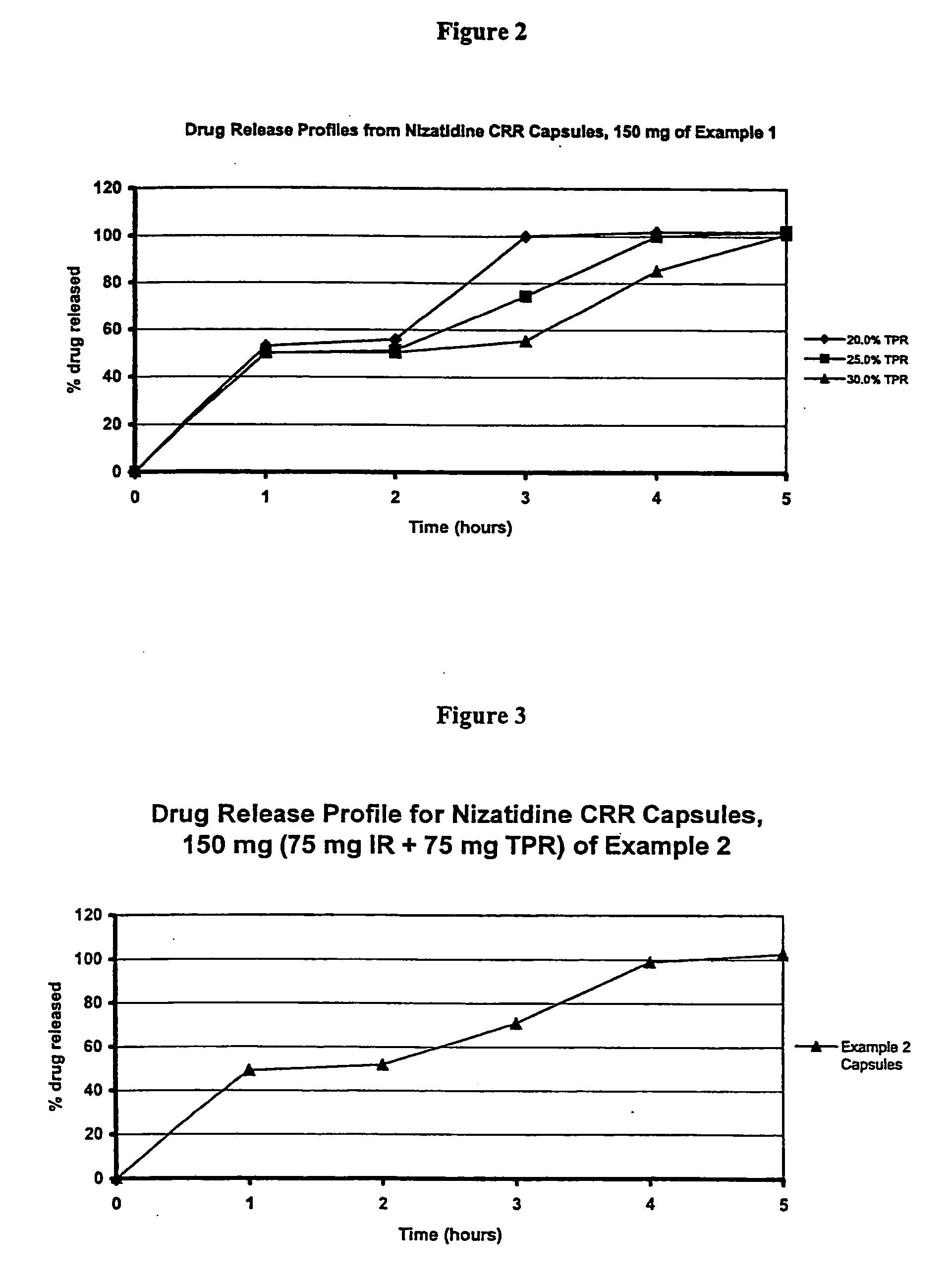

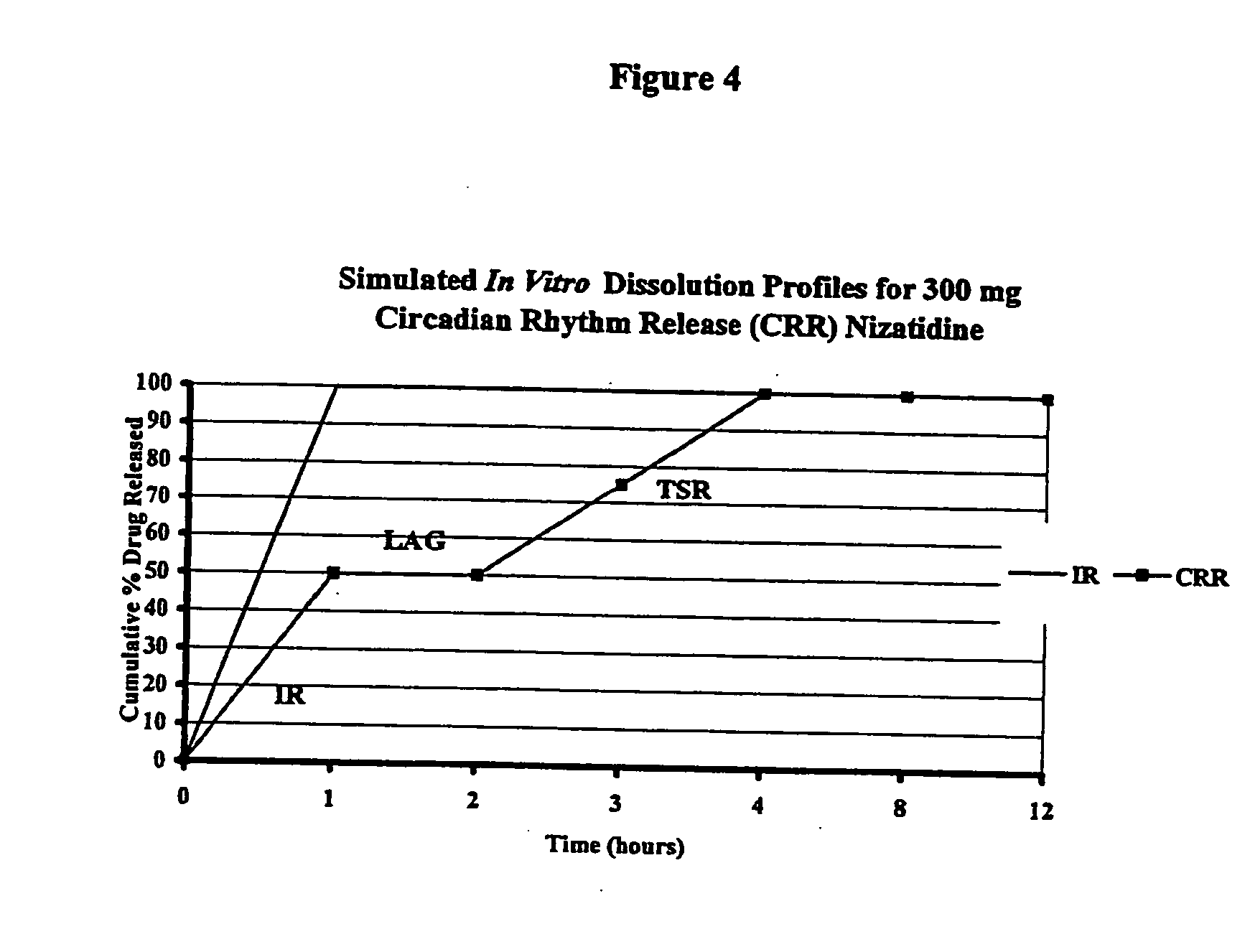

Pulsatile release histamine H2 antagonist dosage form

A unit dosage form, such as a capsule or the like, for delivering drugs into the body in a circadian release fashion comprising one or more populations of drug-containing particles (beads, pellets, granules, etc.) is disclosed. Each bead population exhibits a pre-designed rapid or sustained release profile with or without a predetermined lag time of 3 to 5 hours. Such a circadian rhythm release drug delivery system is designed to provide a plasma concentration-time profile, which varies according to physiological need at different times during the dosing period, i.e., mimicking the circadian rhythm and severity / manifestation of gastric acid secretion (and / or midnight gerd), predicted based on pharmaco-kinetic and pharmaco-dynamic considerations and in vitro / in vivo correlations.

Owner:APTALIS PHARMATECH

Enteric formulations of proanthocyanidin polymer antidiarrheal compositions

InactiveUS20050019389A1Reduce secretionReduce acidityAntibacterial agentsBiocideSecretory diarrheaPharmaceutical formulation

Pharmaceutical compositions containing a proanthocyanidin polymer composition which are useful for the treatment and prevention of secretory diarrhea are provided. The invention specifically relates to pharmaceutical formulations of a proanthocyanidin polymer composition which has been isolated from a Croton spp. or a Calophyllum spp. In particular, the invention relates to a formulation of a proanthocyanidin polymer composition which protects the composition from the effects of stomach acid after oral administration, particularly to those formulations which are enteric coated. The invention also relates to methods of producing a directly compressible proanthocyanidin polymer composition, as well as compositions containing the directly compressible proanthocyanidin polymer composition.

Owner:NAPO PHARMA INC

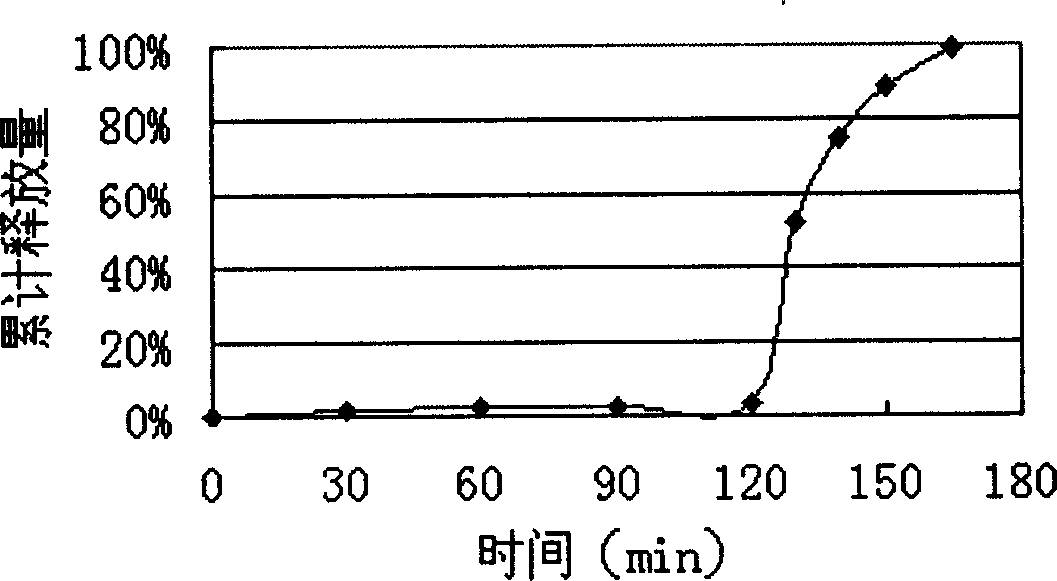

Lactobacillus helveticus microcapsule, preparation and use thereof

InactiveCN101323850AOvercoming the problem of low survival rate of freeze-dryingImprove efficiencyMilk preparationMetabolism disorderFreeze-dryingDietary supplement

The invention provides a lactobacillus helveticus microcapsule as well as the preparation and application thereof, pertaining to the embedding technology of lactobacillus helveticus and aiming at microencapsulating the lactobacillus helveticus so as to solve the problems of low embedding efficiency and embedding yield in single-layer or double-layer embedment. The technical proposal adopted by the invention is that isolated soy protein, microporous starch and sodium alginate are respectively taken as the first, the second and the third layers of wall materials for microencapsulation; the three-layer embedment is carried out to the lactobacillus helveticus for the first time, wherein, in the process of preparing bacterial suspension, an orthogonal optimization protective agent is adopted to improve the livability after freeze drying. The microcapsule of the invention has strong heat resistance and acid resistance, solves the inactivation problem caused by gastric acid, digestive enzyme and antibiotic, etc. to active bacillus, is capable of releasing when reaching large intestine, and balances intestinal flora. The reusability of fermented milk is good. The lactobacillus helveticus used by the invention enriches the variety of probiotic bacteria microcapsule and is a good dietary supplement.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Novel substituted benzimidazole dosage forms and method of using same

Disclosed herein are methods, kits, combinations, and compositions for treating gastric acid disorders employing pharmaceutical compositions comprising a proton pump inhibiting agent (PPI) and a buffering agent in a pharmaceutically acceptable carrier.

Owner:UNIVERSITY OF MISSOURI

Chinese medicine composition for treating gastritis, gastric ulcer and duodenal ulcer

InactiveCN1739783ACompatibility with strict scienceAppropriate dosageDigestive systemBird material medical ingredientsDiseasePinellia

The Chinese medicine composition for treating gastritis, gastric ulcer and duodenal ulcer is prepared with pinellia tuber, skullcap root, dry ginger, ginseng, corydalis tuber and other 14 kinds of Chinese medicinal materials in certain weight proportion. It is used mainly in treating chronic atrophic gastritis, gastric ulcer, duodenal ulcer, hyperchlorhydria and other gastrointestinal diseases. The Chinese medicine composition of the present invention has the advantages of scientific recipe, high curative effect, simple preparation process, etc.

Owner:王俊

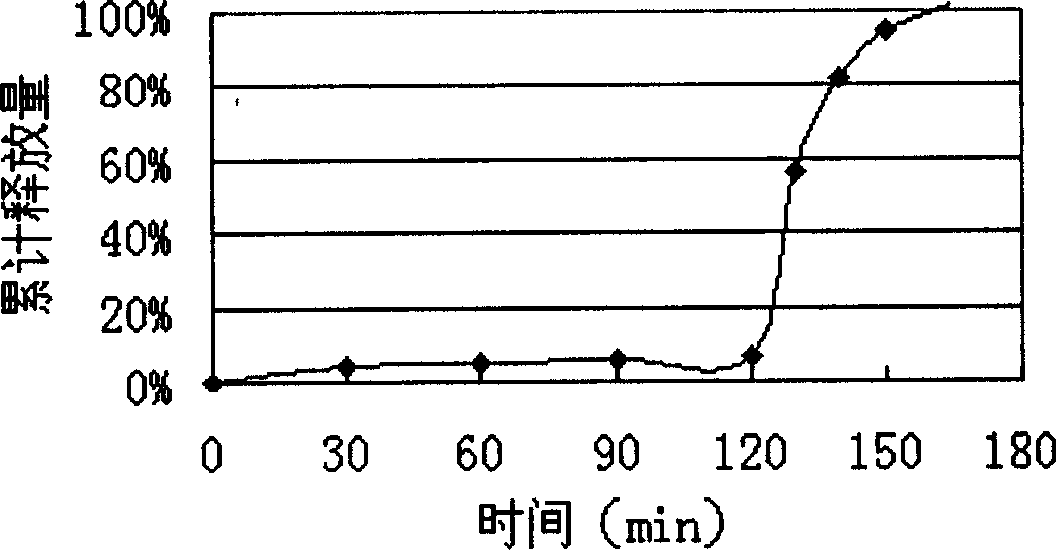

Bifidobacterium microcapsule and preparing method thereof

ActiveCN102210659AResistant to gastric acidBile salt resistantMetabolism disorderBacteria material medical ingredientsFreeze-dryingHigh survival rate

The invention specifically relates to a bifidobacterium microcapsule and a preparing method thereof. The bifidobacterium is obligatorily anaerobic and very sensitive to oxygen, PH, temperature, humidity, and other adverse external environment, thereby being very hard to remain activity during production, storage and transport; besides, if taken orally in a form of dry bifidobacterium powder, the bifidobacterium cannot tolerate low-pH value gastric acid, bile salt, and other environments, so a purpose that massive survived bifidobacteria arrive at an intestinal tract and colonise on the intestinal mucosa is hard to be guaranteed. The preparing method disclosed by the invention comprises the following steps of: adding freeze-dried bifidobacterium powder into a sodium alginate solution and then mixing in soybean oil, emulsifying the mixed solution and standing; centrifugally collecting micro-capsules; and drying the micro-capsules by using a vacuum freeze-drying technology. The bifidobacterium microcapsule disclosed by the invention has the advantages of gastric acid resistance, bile salt resistance and entericsolubility, high survival rate of bifidobacterium, simple preparation method, strong practicality, convenience for industrial production, and excellent storage stability and solves the problem of short storage period of probiotics preparations.

Owner:SHAANXI GIANT BIOTECHNOLOGY CO LTD

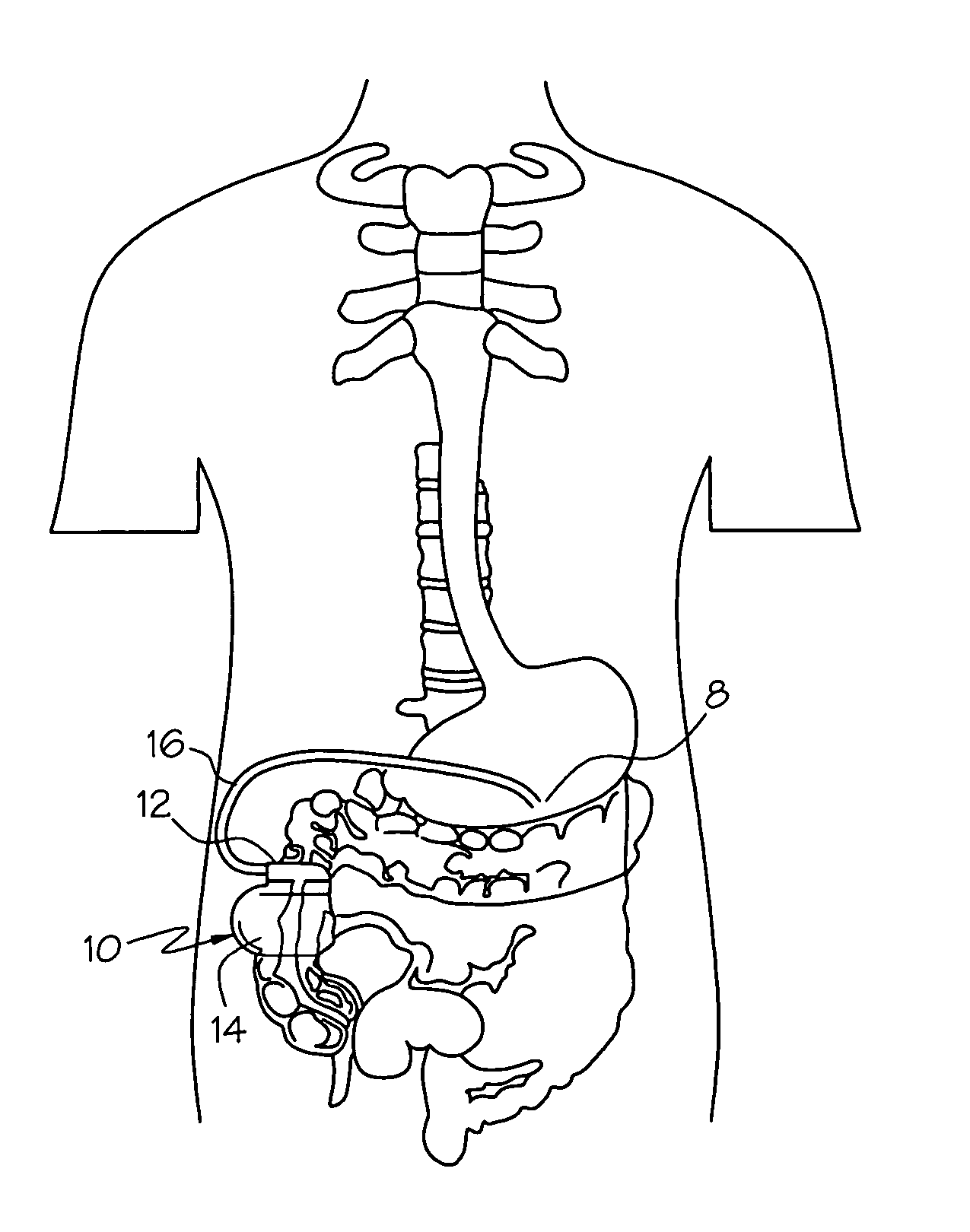

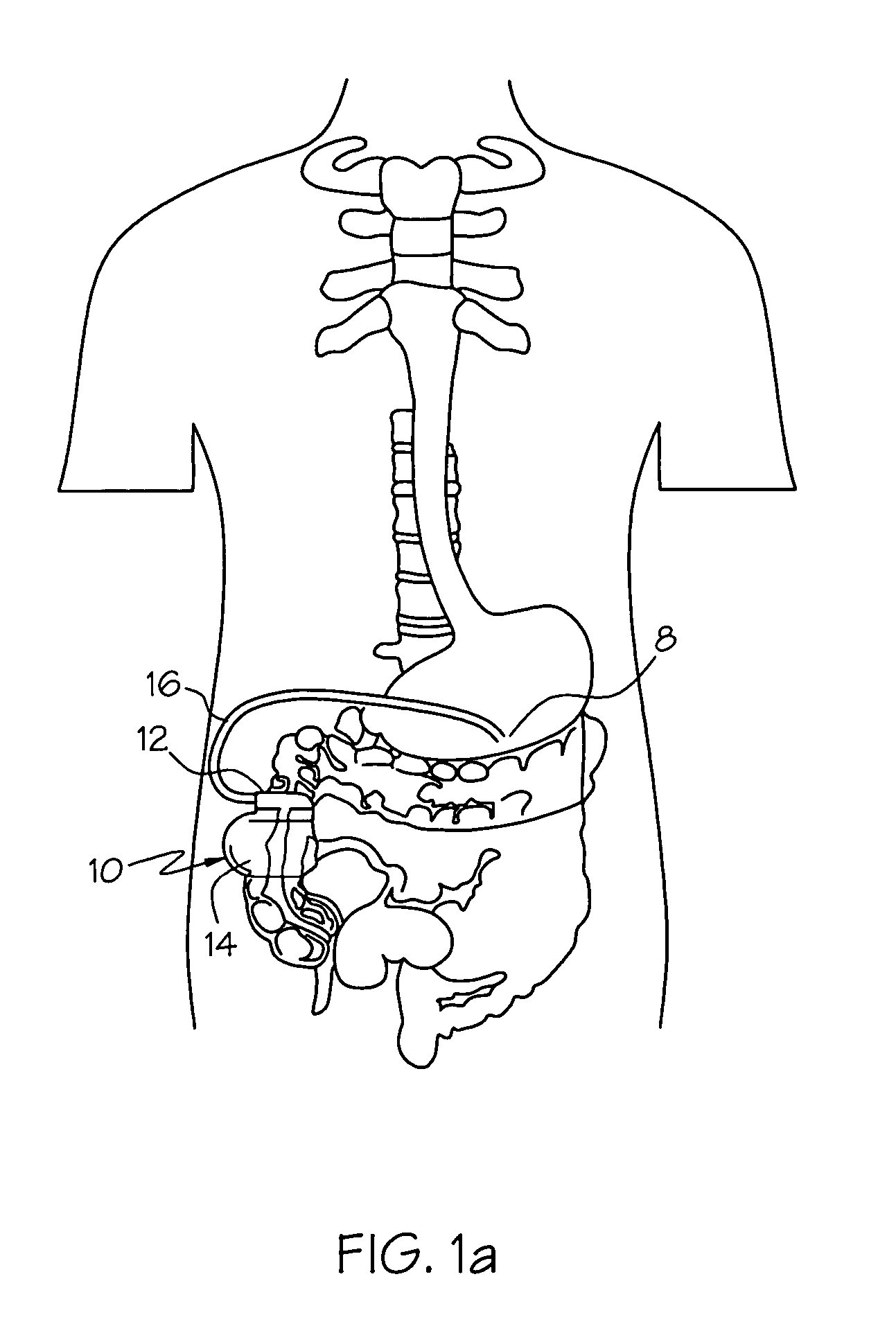

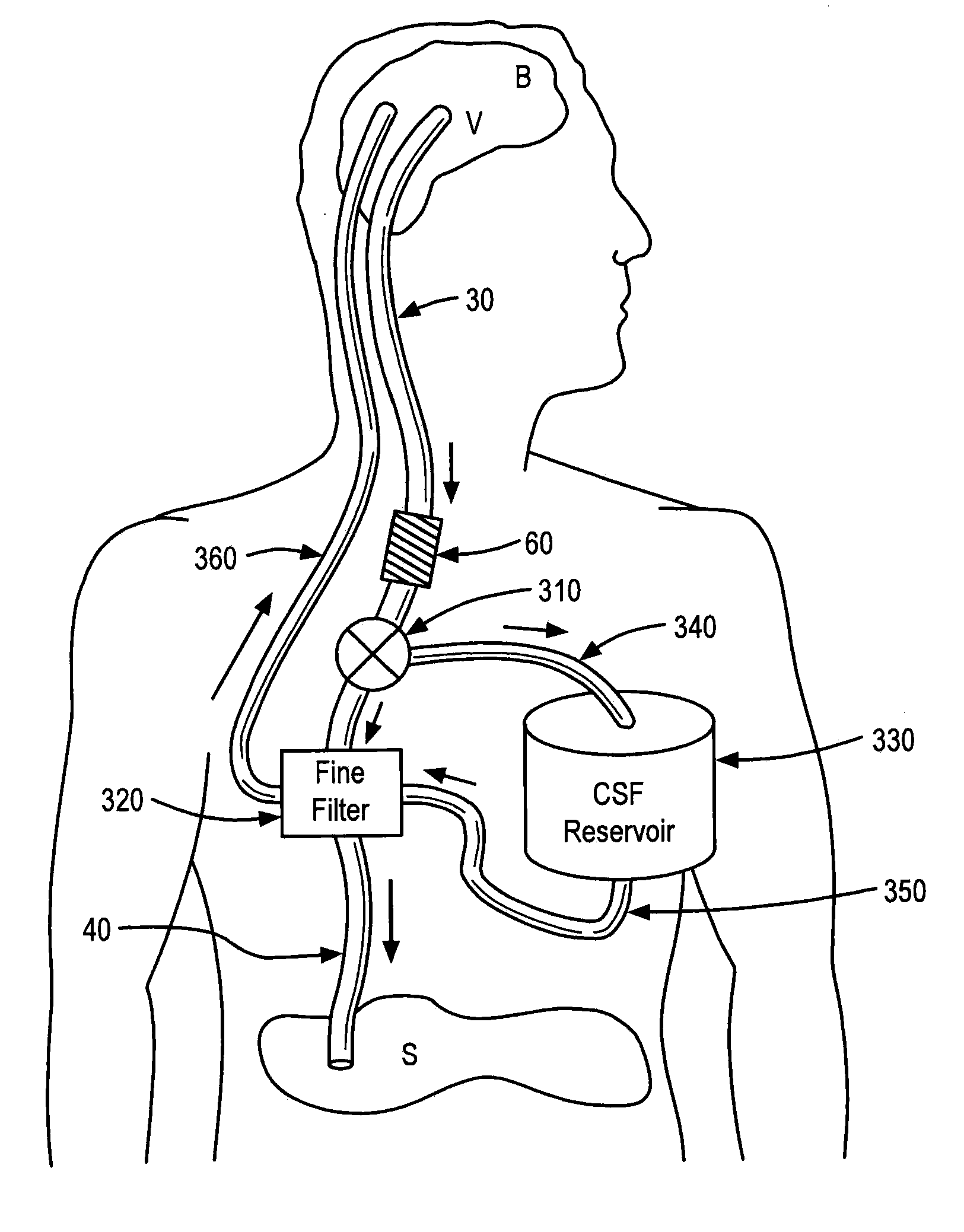

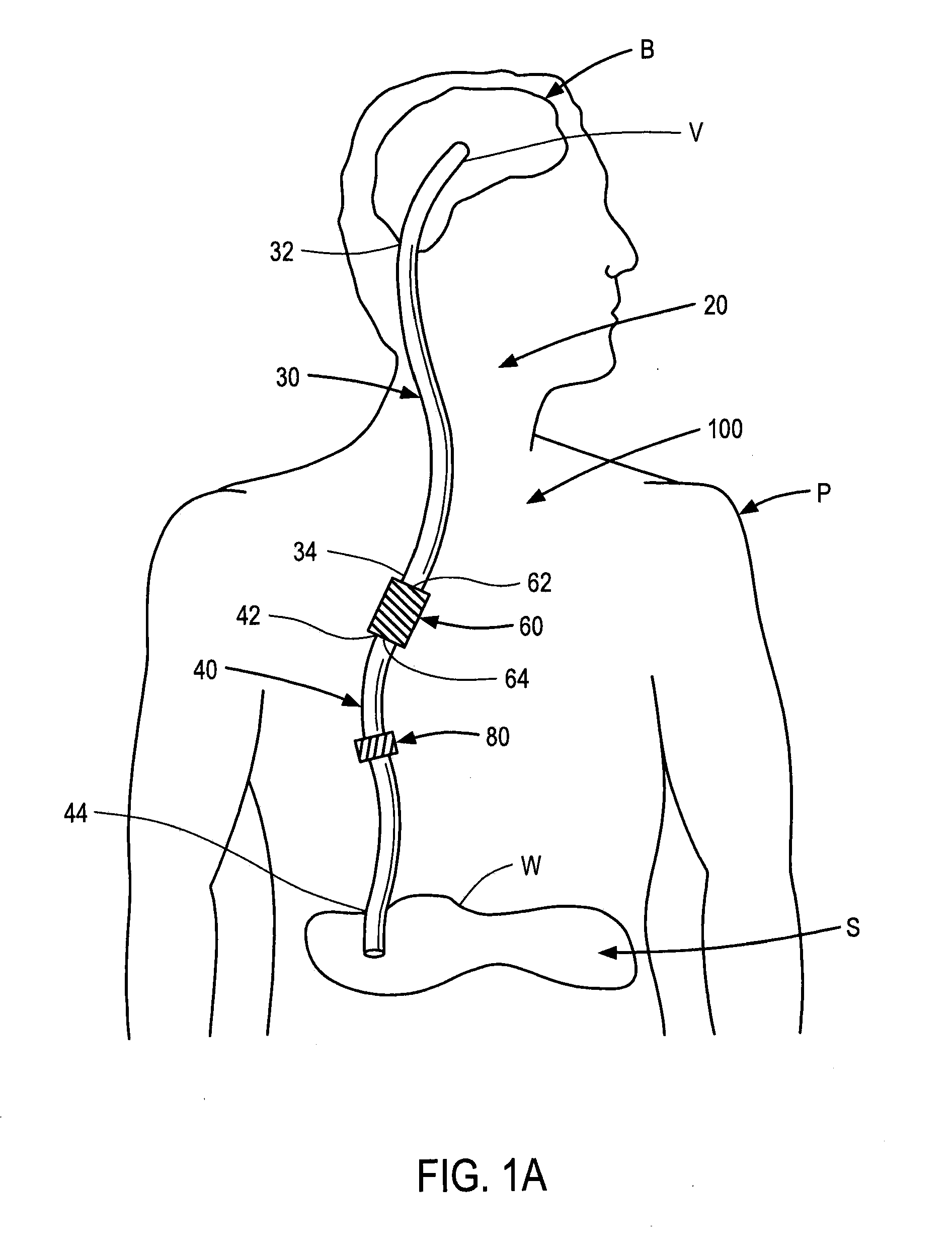

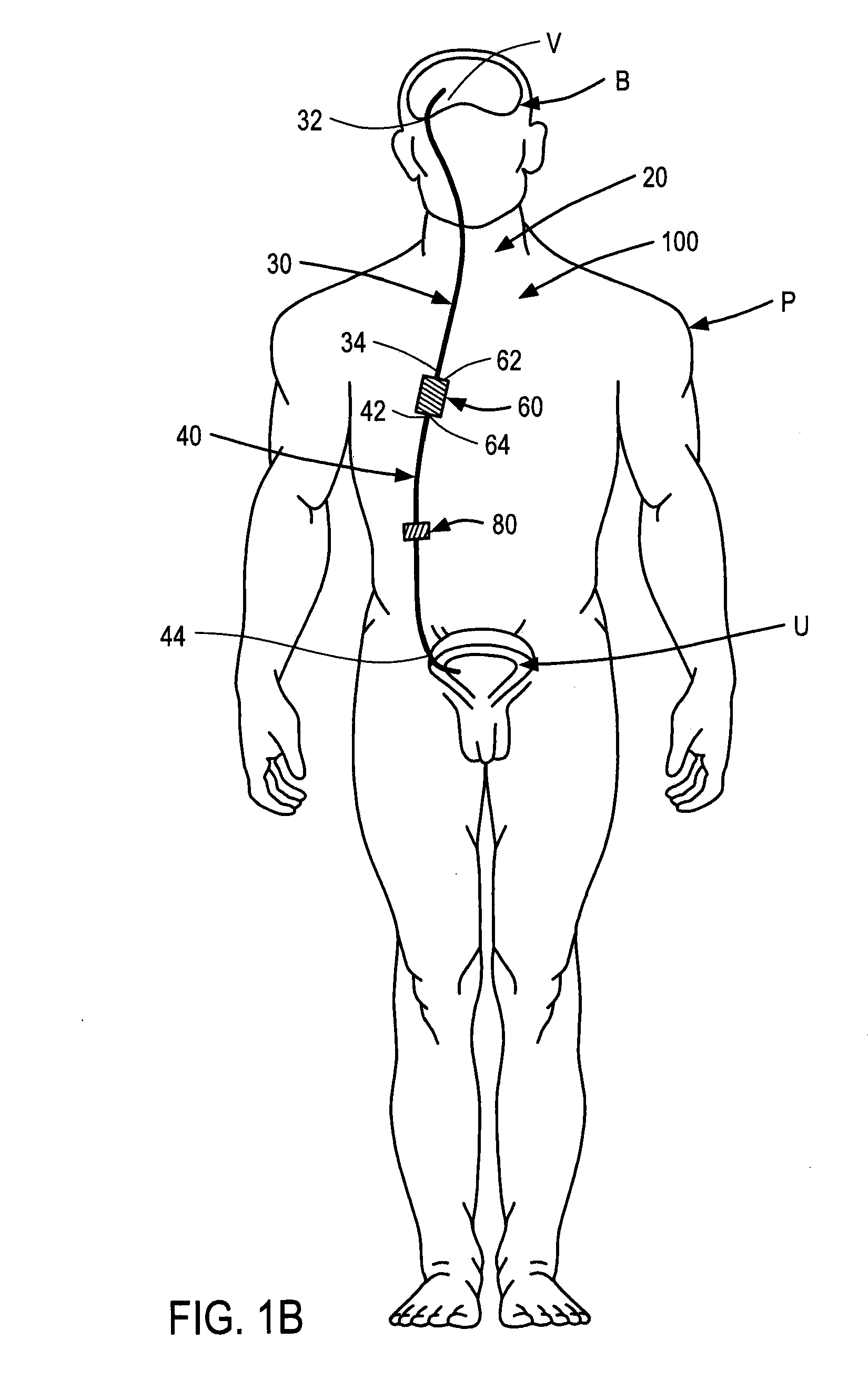

Systems and methods for moving and circulating fluid to treat alzheimer's disease

ActiveUS20150094644A1Reduce concentrationOvercomes drawbackWound drainsMedical devicesDiseaseCatheter device

A system for the treatment of Alzheimer's disease is provided by moving cerebrospinal fluid containing particles know to contribute to onset of Alzheimer's disease from a source of cerebrospinal fluid to the stomach or bladder, where the particles are safely digested by gastric acid or excreted, the system including an implantable pump, an inlet catheter, an outlet catheter, and a one-way valve. The system further includes at least one filter to filter harmful particles from the cerebrospinal fluid and return the filtered cerebrospinal fluid back to the source of cerebrospinal fluid, where the harmful particles blocked by the filter may be rinsed off the filter and transported to the stomach or bladder.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

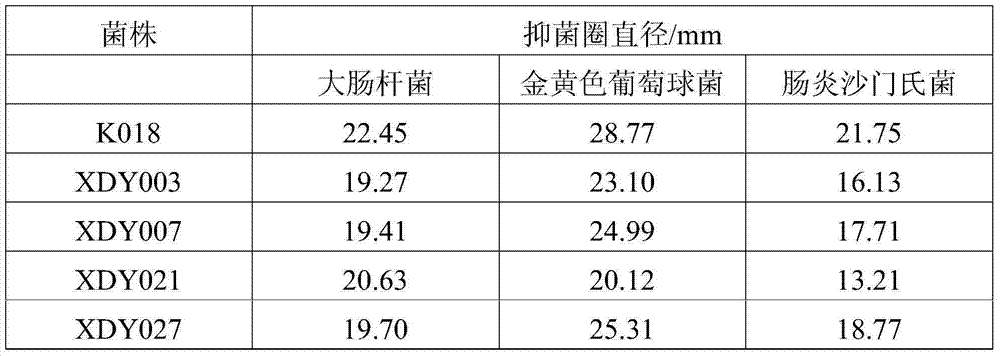

Bacillus subtilis and use thereof

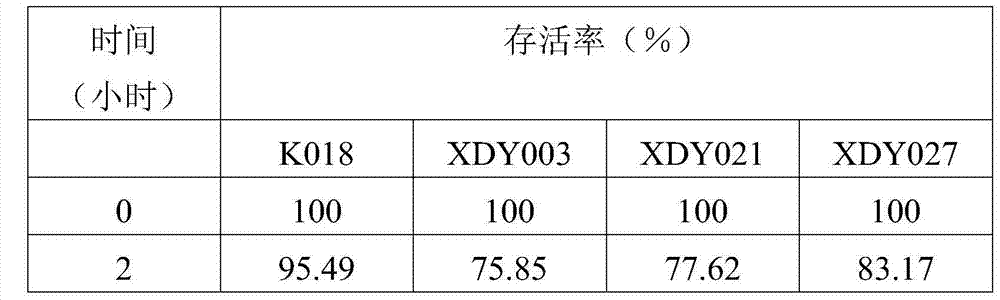

ActiveCN103614327AEnhanced inhibitory effectStrong amylase production abilityBacteriaMicroorganism based processesEscherichia coliStaphylococcus aureus

The invention provides bacillus subtilis K018 which is strong in stress resistance, excellent in probiotics function and safe and reliable, a biological feed additive containing the bacillus subtilis K018 and use thereof. The bacillus subtilis K018 provided by the invention can resist artificial gastric acid, cholate, artificial intestinal juice and high temperature, has stronger inhibiting effects to pathogenic staphylococcus aureus, escherichia coli, salmonella enteritidis and the like in the intestinal tract, is stronger in amylase and cellulase generating capacity, and can degrade starch and cellulose.

Owner:北京昕大洋科技发展有限公司

Combination of proton pump inhibitor and sleep aid

InactiveUS20050244517A1Extended shelf lifeSimple compositionBiocideDigestive systemDiseaseBuffering agent

Pharmaceutical compositions comprising a proton pump inhibitor, one or more buffering agent and a sleep aid are described. Methods are described for treating gastric acid related disorders and inducing sleep, using pharmaceutical compositions comprising a proton pump inhibitor, a buffering agent, and a sleep aid.

Owner:SANTARUS

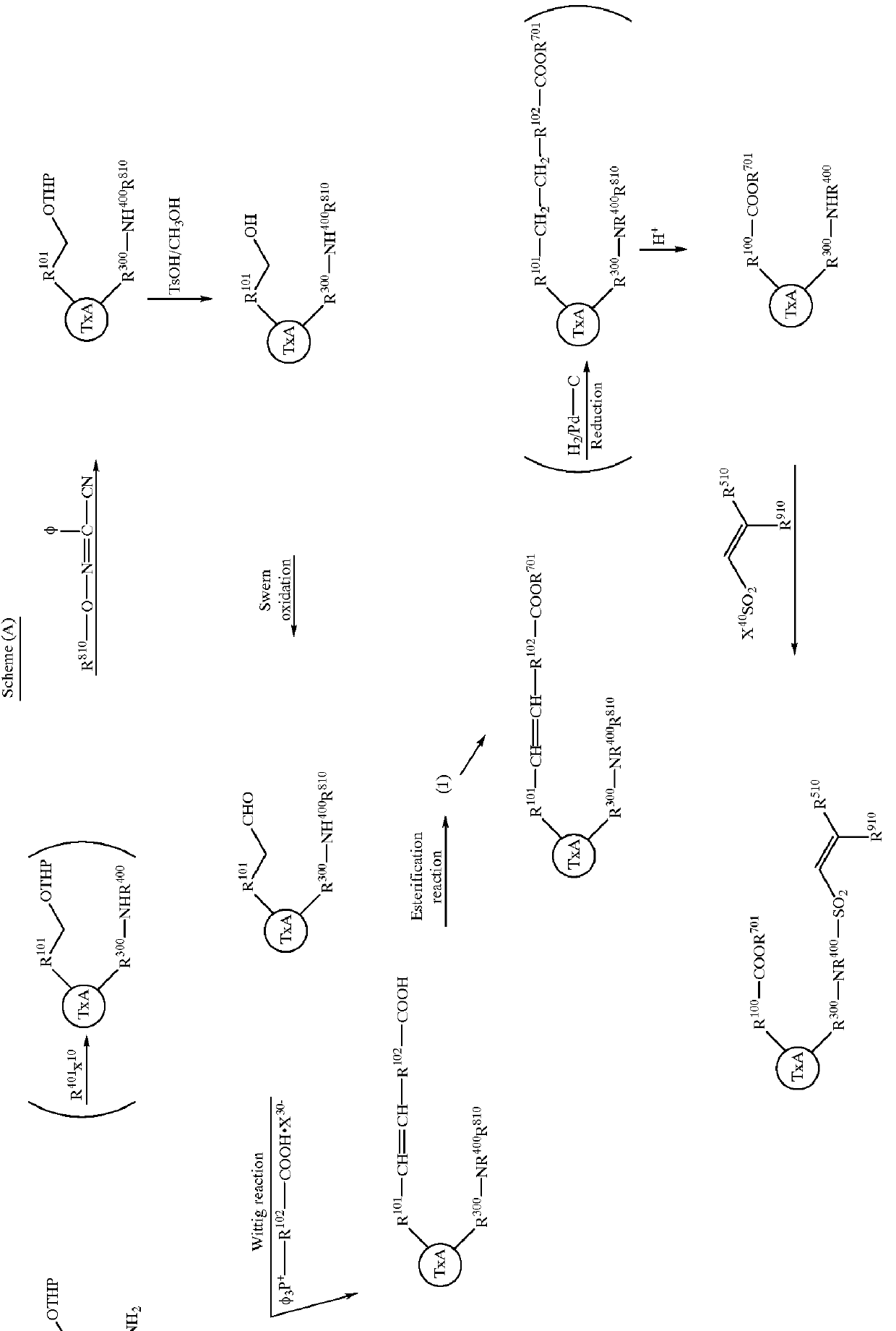

Carbocyclic sulfonamides

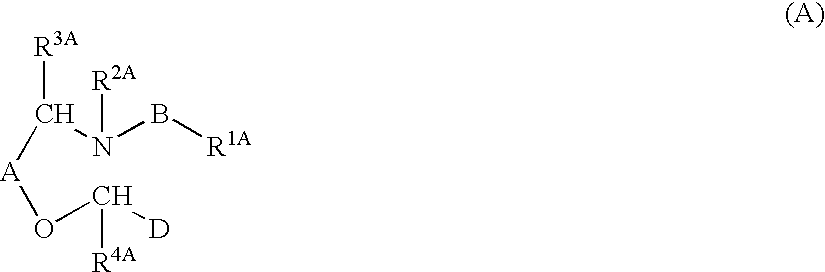

(1) Prostaglandin (PG) E2 antagonist or agonist containing carbocyclic sulfonamides represented by the compound of the formula (I): cyclodextrin clathrates thereof, non-toxic salts thereof as active ingredient, (2) carbocyclic sulfonamides represented by the compound of the formula (II): cyclodextrin clathrates thereof, non-toxic salts thereof, (3) process for the preparation of the compound represented by the compound of the formula (II) described hereinbefore, (4) PGE2 antagonist or agonist containing the compound represented by the compound of the formula (II) as active ingredient. The compounds represented by the compounds of the formula (I) and (II) can be adapted to medicines which possess an inhibitory effect of uterine contraction, an analgetic action, an inhibitory effect of digestive peristalsis, a sleep-inducing effect as PGE2 antagonists, and an uterine contractile activity, a promoting effect of digestive peristalsis, a suppressive effect of gastric acid secretion, a hypotensive activity as PGE2 agonists, because they bind onto PGE2 receptor and have an activity of antagonist or agonist against the action thereof.

Owner:ONO PHARMA CO LTD

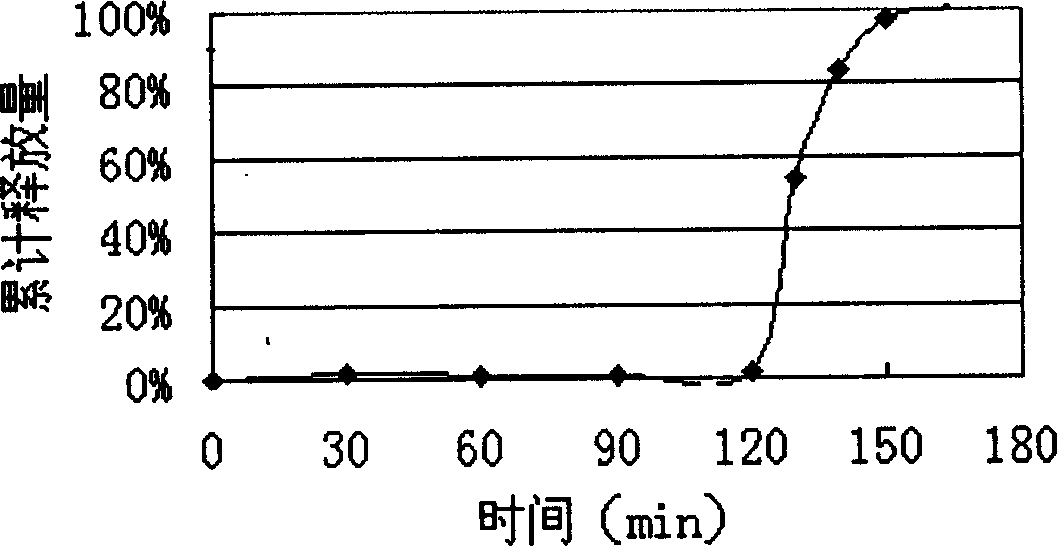

Composite micro-ecological preparation as well as premixed material and application of preparation in feed additive

ActiveCN102409015AHigh content of live bacteriaReduce moisture contentBacteriaAnimal feeding stuffFood additiveAntibiotic Y

The invention belongs to the technical field of feed micro-ecology and relates to a composite micro-ecological preparation as well as a premixed material and an application of the preparation in a feed additive. The preparation contains Lactobacillus acidophilus powder and any two, three or four bacterium powders selected from Bacillus licheniformis, Bcillus pumilus, enteroccus and Bcillus subtilis; the preparation has high live bacteria content and low moisture content, has stress tolerance properties such as gastric acid resistance, cholate resistance, high temperature resistance, common antibiotics tolerance and the like and has the probiotic functions of producing acid and enzyme, inhibiting pathogenic bacteria and the like. By using the composite micro-ecological preparation of the invention, the utilization rate of the feed can be improved, the yields of meat, eggs, milk and the like are increased, the growth of animals is promoted, the immunity and disease-resistant capability of an animal organism are improved, and partial preparation can be used for replacing antibiotics, thereby changing the quality of an animal product.

Owner:BEIJING DABEINONG TECH GRP CO LTD +2

Duloxetine enteric coated tiny pill capsule, and preparation method

ActiveCN1759829AImprove solubilityReduced bioavailabilityNervous disorderGranular deliveryDuloxetineMedicine

An enteric micropill (microsoftgel) of Duluoxiting and its preparing process are disclosed. Said micropill is composed of an empty core pill and a coated external layer consisting of a principal medicine layer, an isolating layer and an enteric layer. It features that its principal medicine can be quickly released only in small intestine.

Owner:SHANGHAI INST OF PHARMA IND CO LTD

Animal Bifidobacterium and use method thereof

ActiveCN102191192AGood synergistic growthGood recombinationMilk preparationBacteriaEscherichia coliMicrobiological culture

The invention relates to an animal Bifidobacterium and a use method thereof. The animal Bifidobacterium is the Bifidobactrium amimalis Subsp Lactis B174, the CGMCC No. is 4182, the conservation date is September 16, 2010 and the conservation unit is the China General Microbiological Culture Collection Center. The Bifidobactrium amimalis Subsp Lactis B174 can colonize in human body and resist the gastric acid and cholate of human body. Meanwhile, the strain has better inhibitory action on Escherichia coli and can survive for 30 days at the room temperature. The strain and other lactic acid bacteria have better synergic action for growth; the strain has better combination effect with lactic acid bacteria; the product has better flavor, can be used to prepare fermented yoghurt, animal feed additives and antibacterial solution and can be widely used in the fields of other foods and biological products.

Owner:BEIJING BOJINYUAN BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com