Patents

Literature

99 results about "Volume filling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

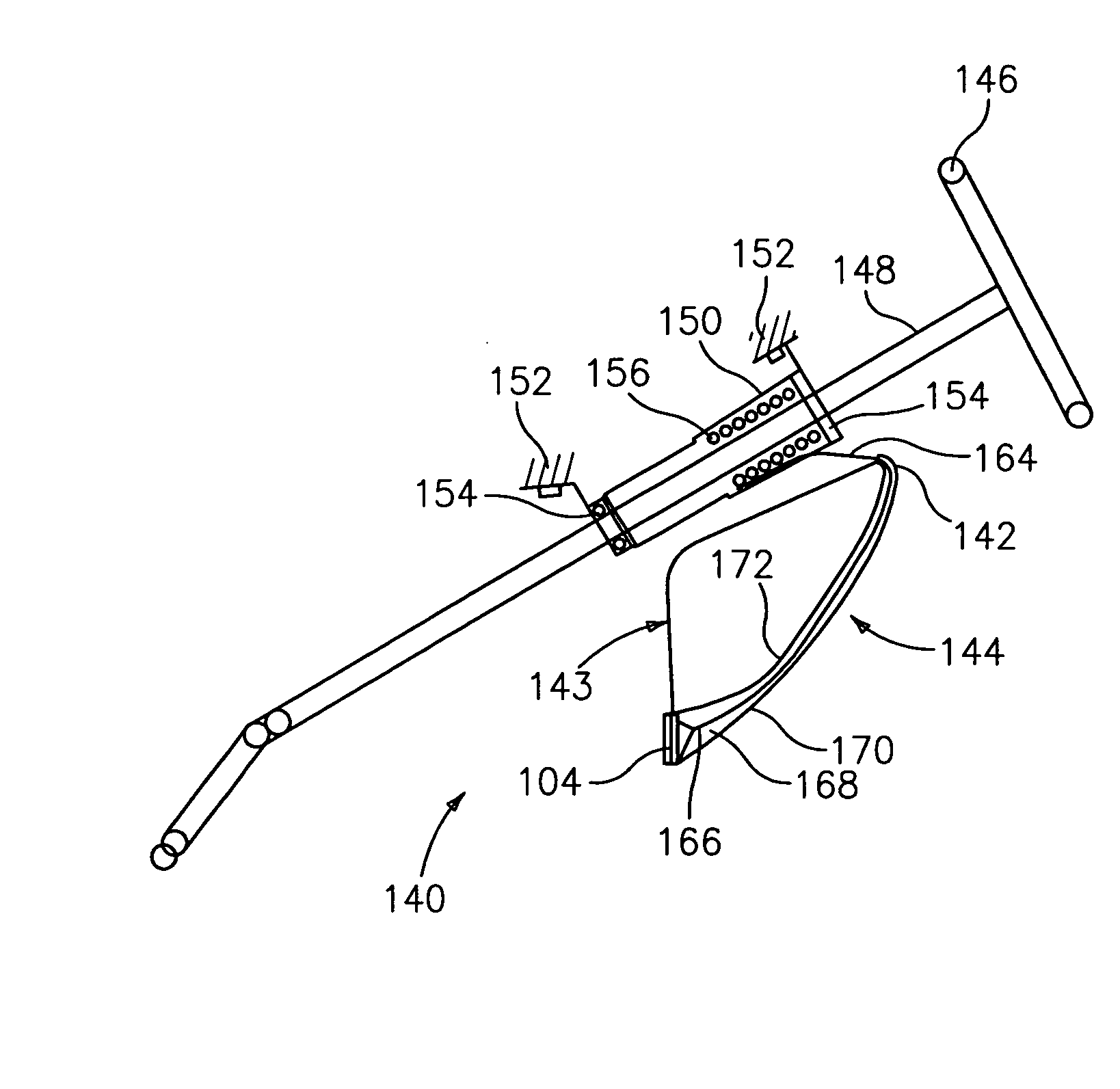

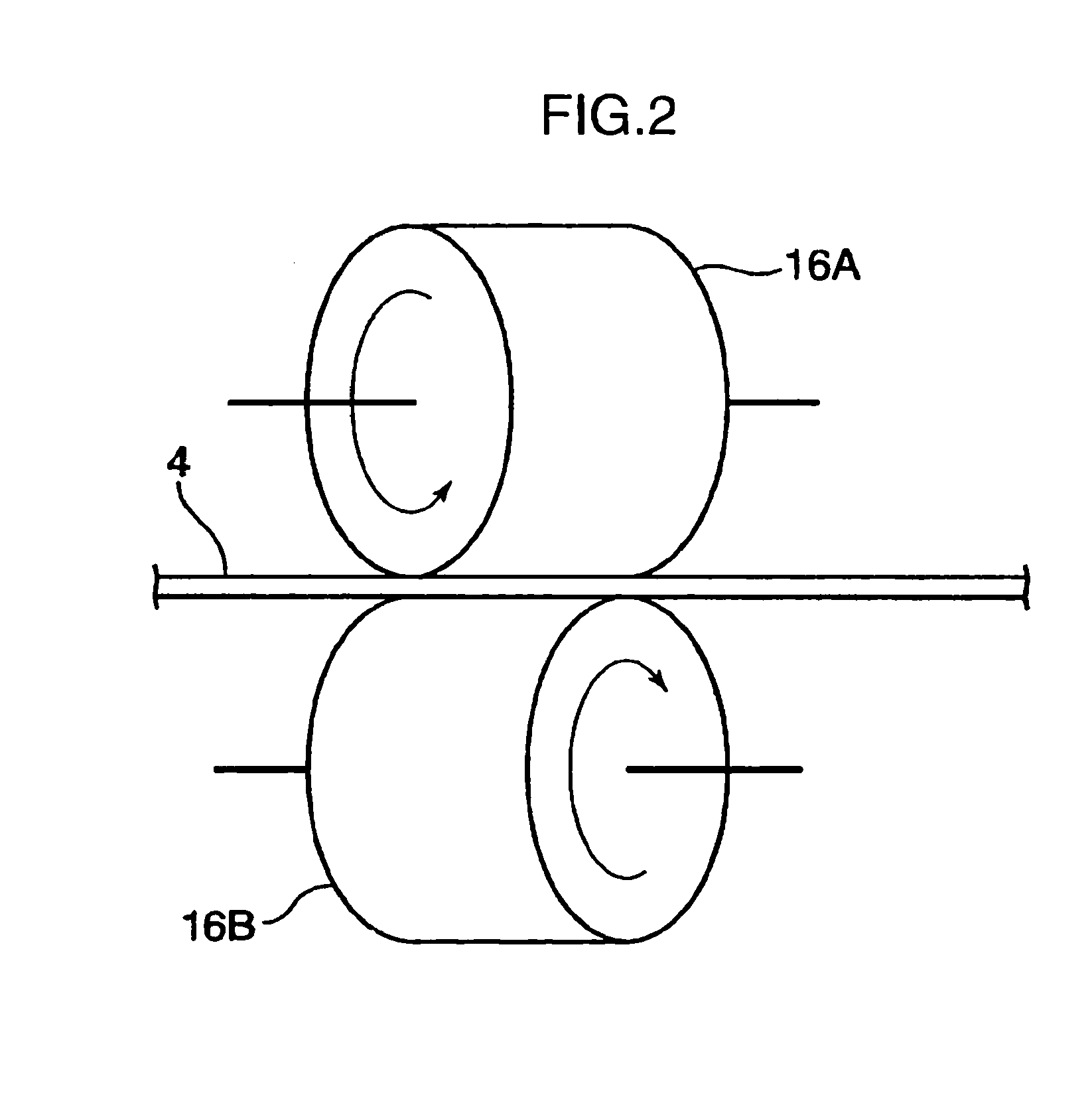

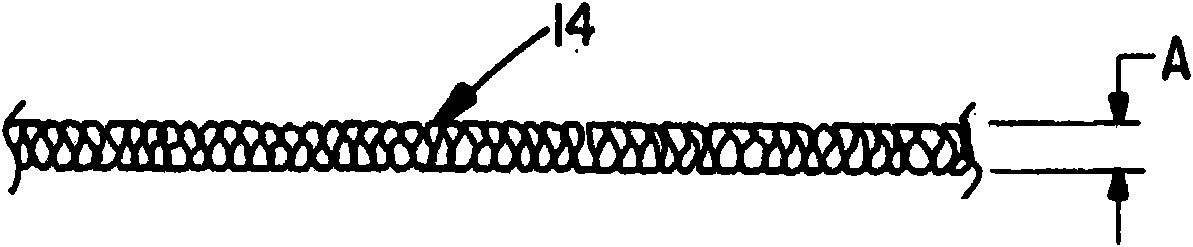

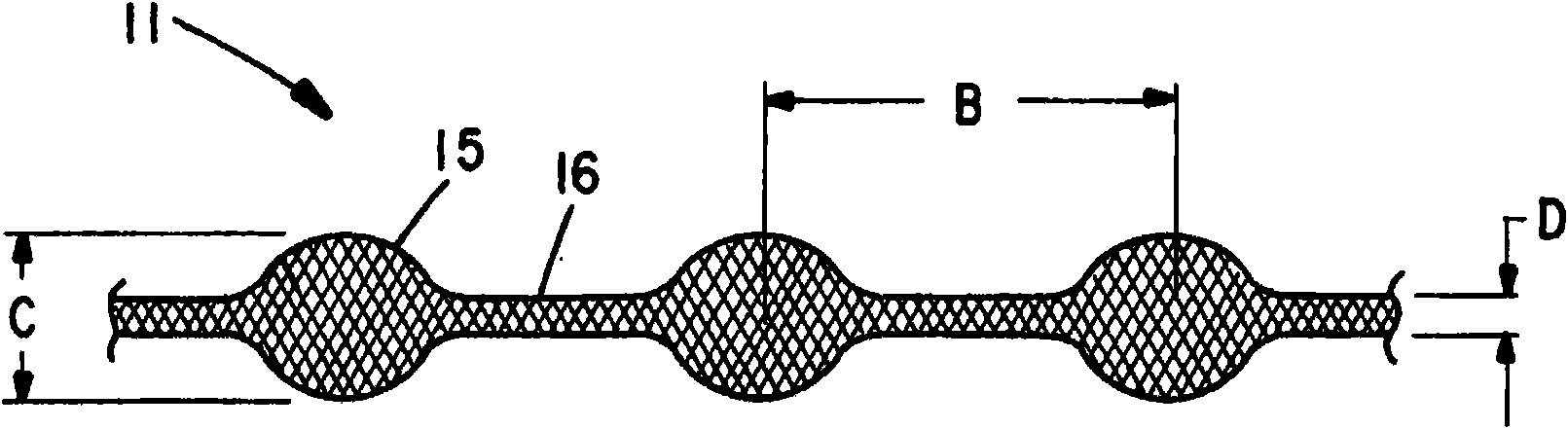

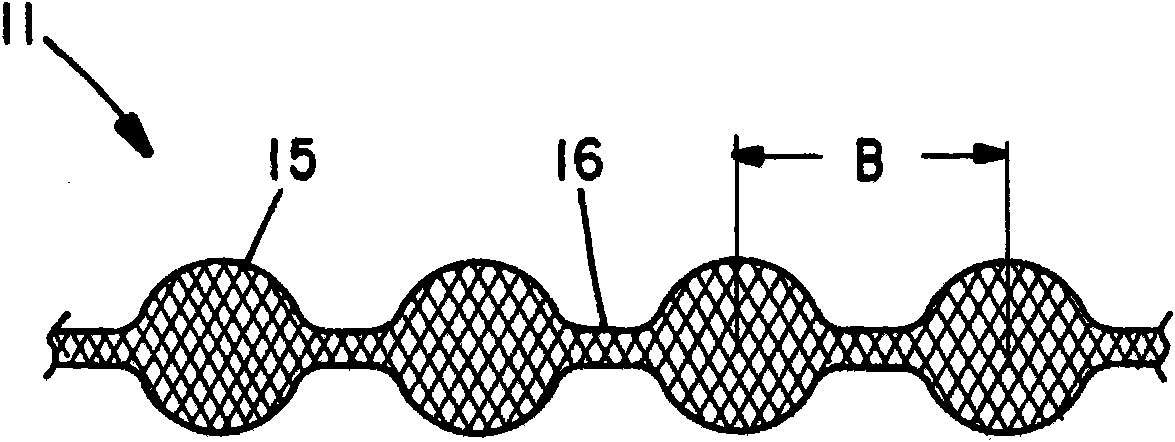

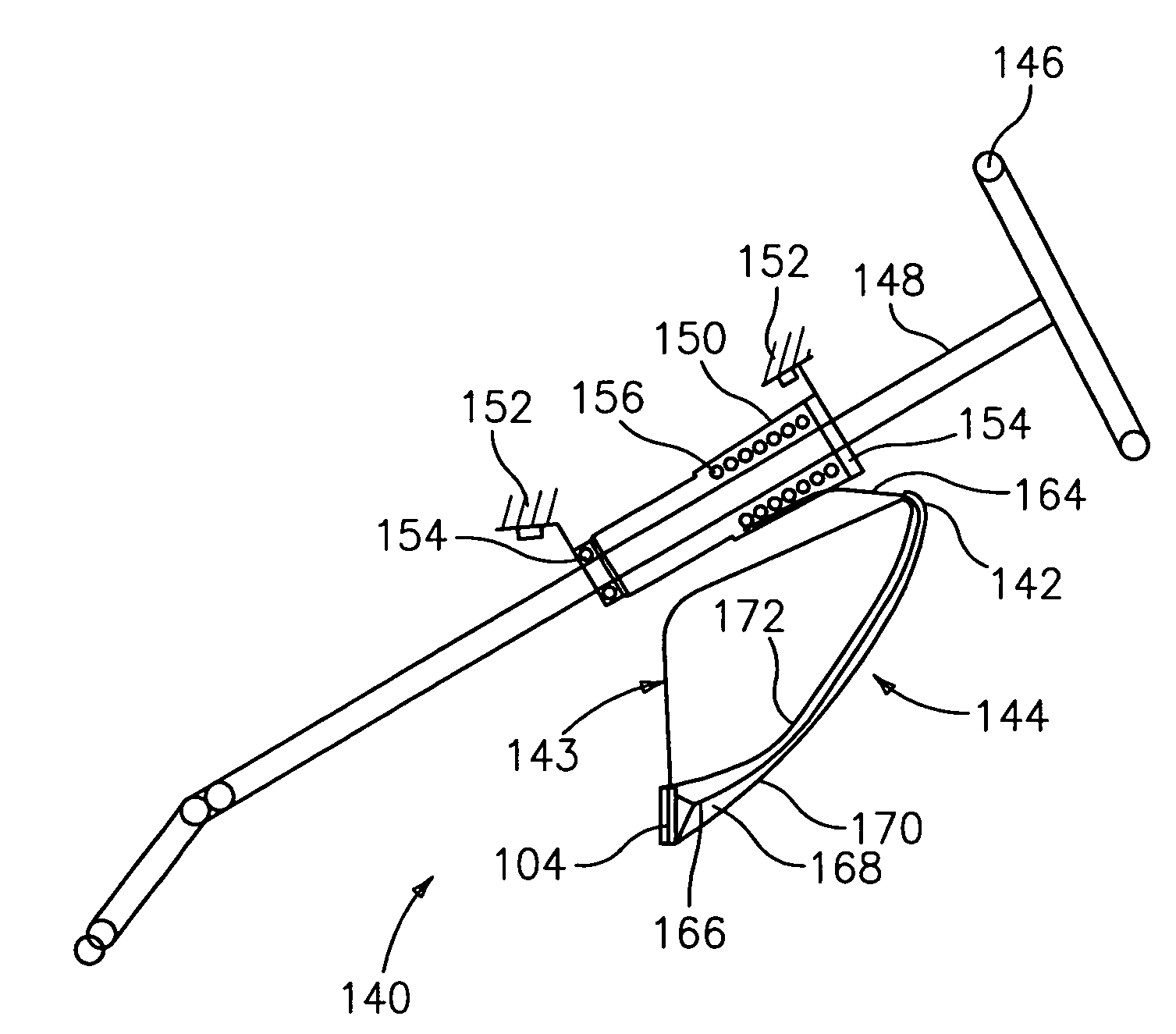

Braided occlusion device having repeating expanded volume segments separated by articulation segments

InactiveUS20090025820A1Occlude a vessel, channel, lumen, or cavity quicklyMeet high volumeWire articlesDilatorsBody organsVolume filling

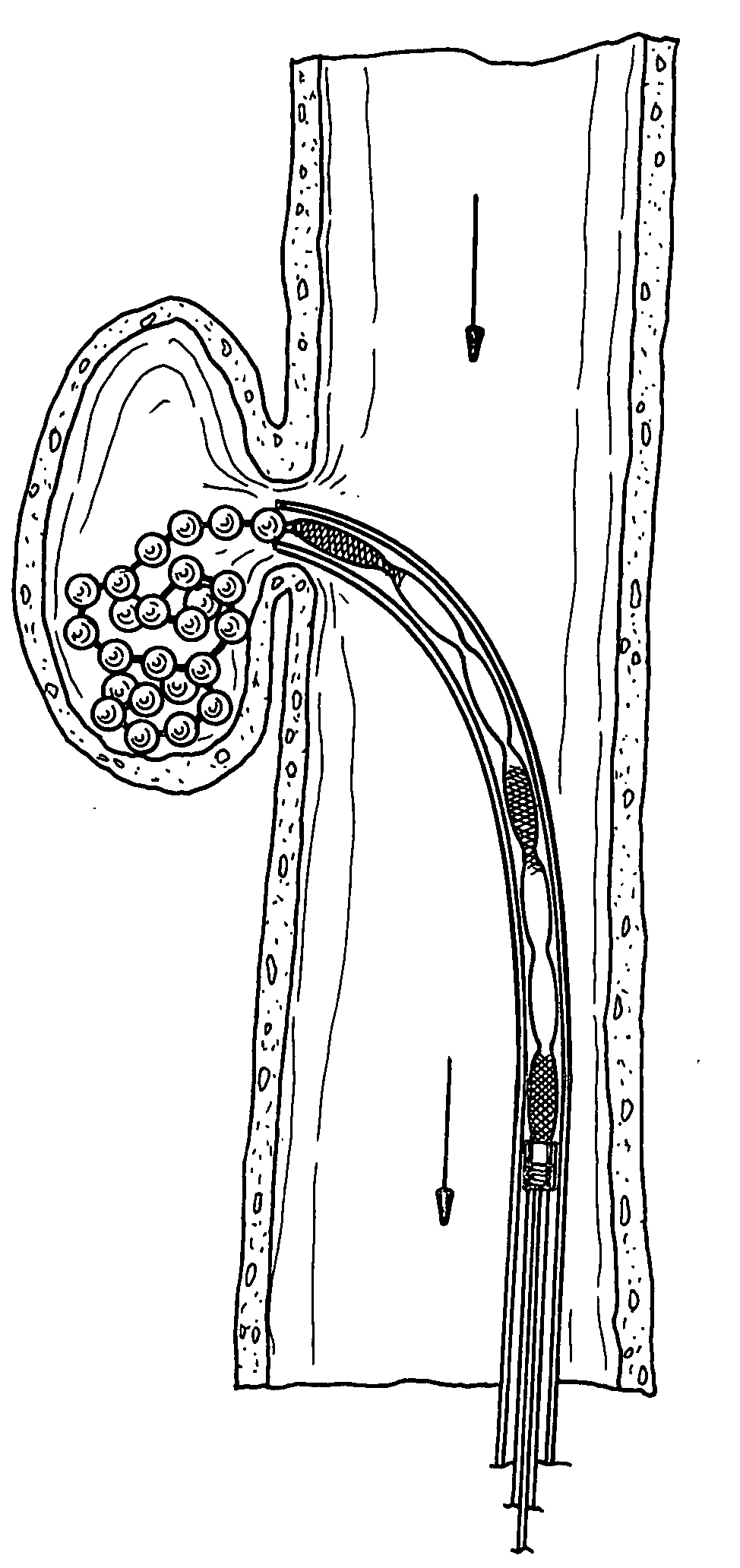

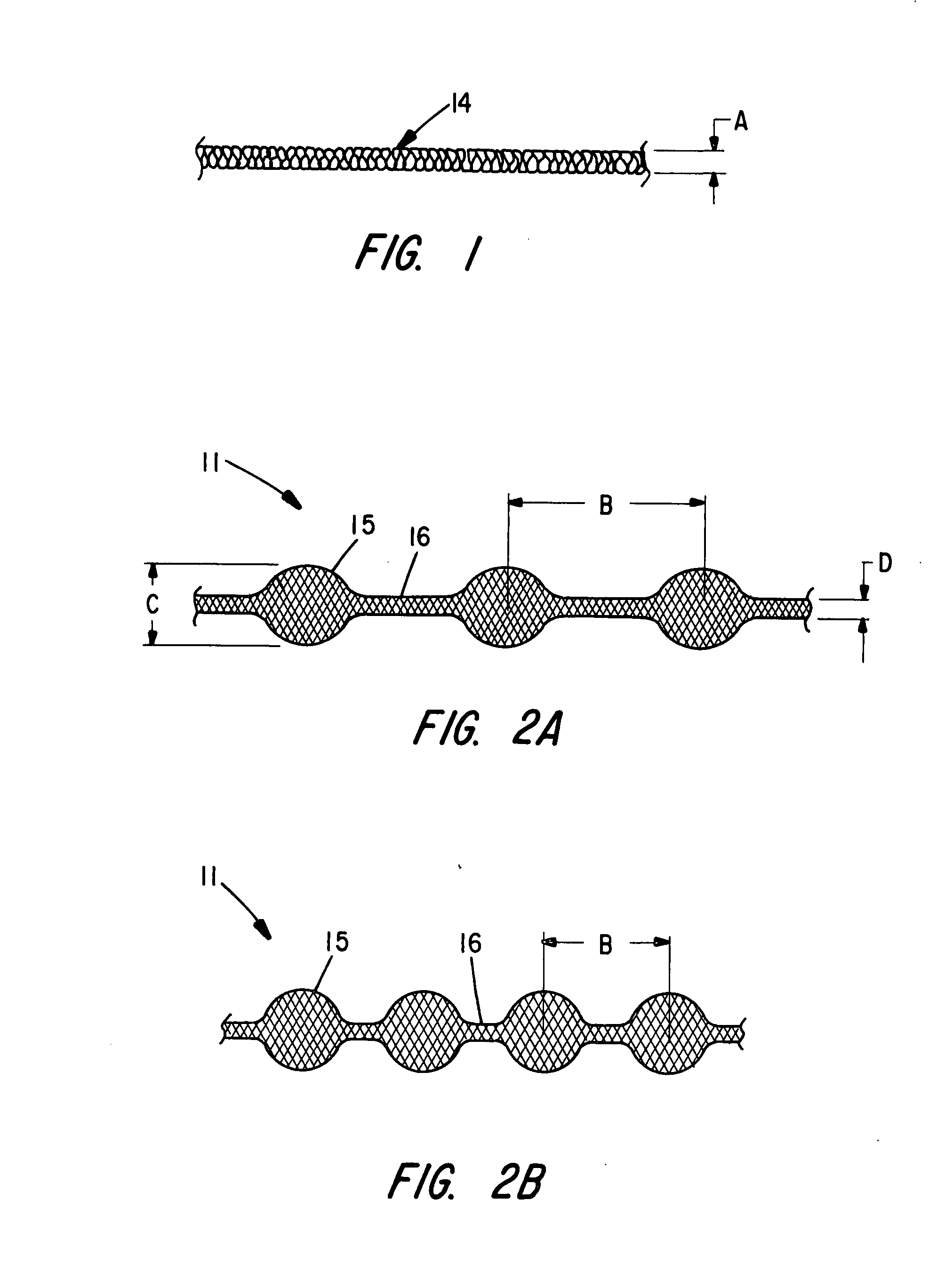

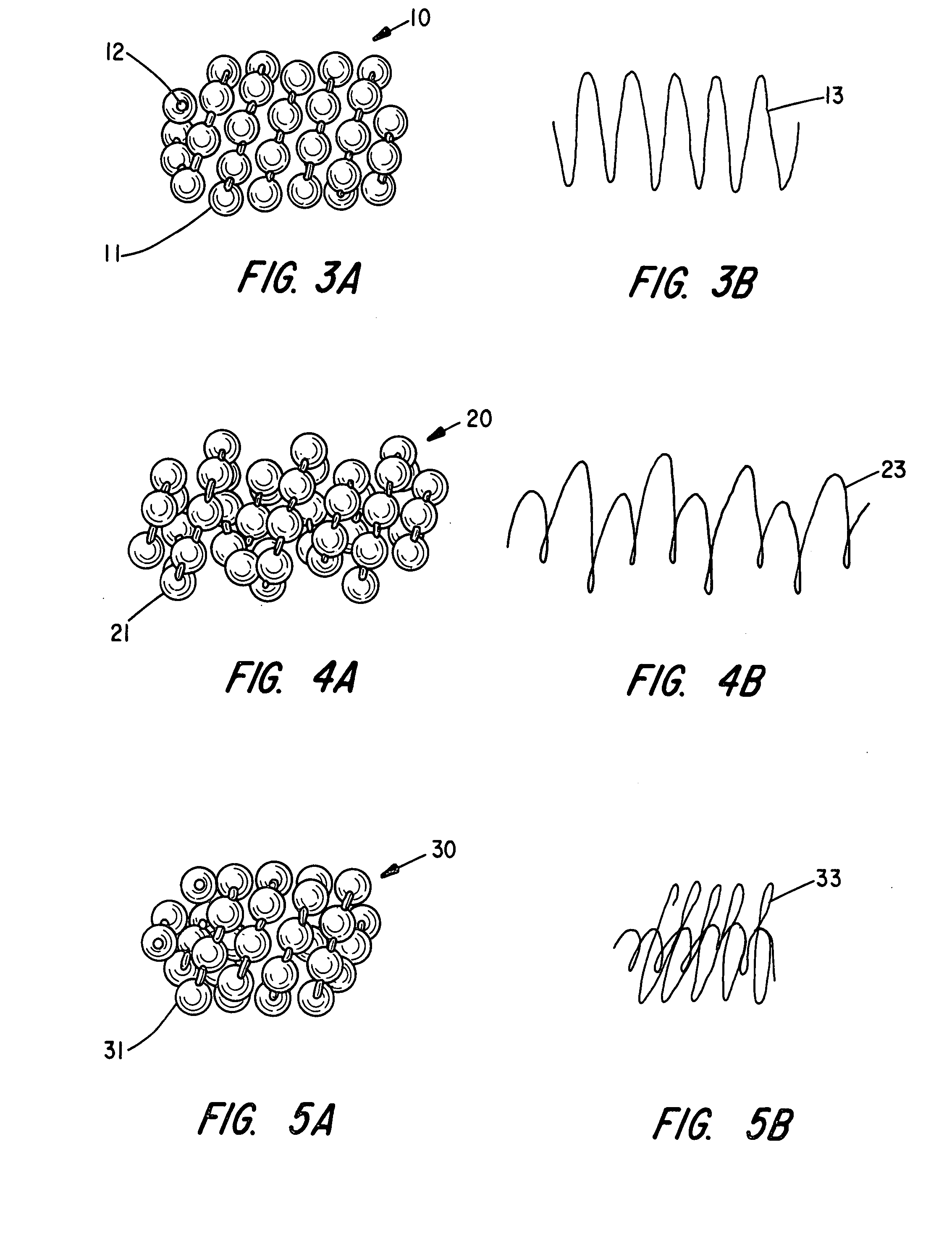

The present invention provides a flexible, low profile vascular occlusion device having large volume filling capability and high metal content for fast occlusion, of the type fabricated from braided tubular metal fabric having an expanded preset configuration and an elongated collapsed reduced diameter configuration for delivery through a catheter to a treatment site and shaped to create an occlusion of an abnormal opening in a body organ or vessel, the woven metal fabric having a memory property whereby the medical device tends to return to said expanded preset configuration when unconstrained. The device further includes a first shape formed from the braided tubular fabric consisting of a repeating pattern of expanded volume segments separated by small diameter articulation segments and a second overall device shape comprised of the first shape formed about itself in various shapes to occlude a vessel. In one embodiment a shaping wire contained coaxially within the tubular braid, provides or assists in the formation of the second overall device shape.

Owner:ST JUDE MEDICAL CARDILOGY DIV INC

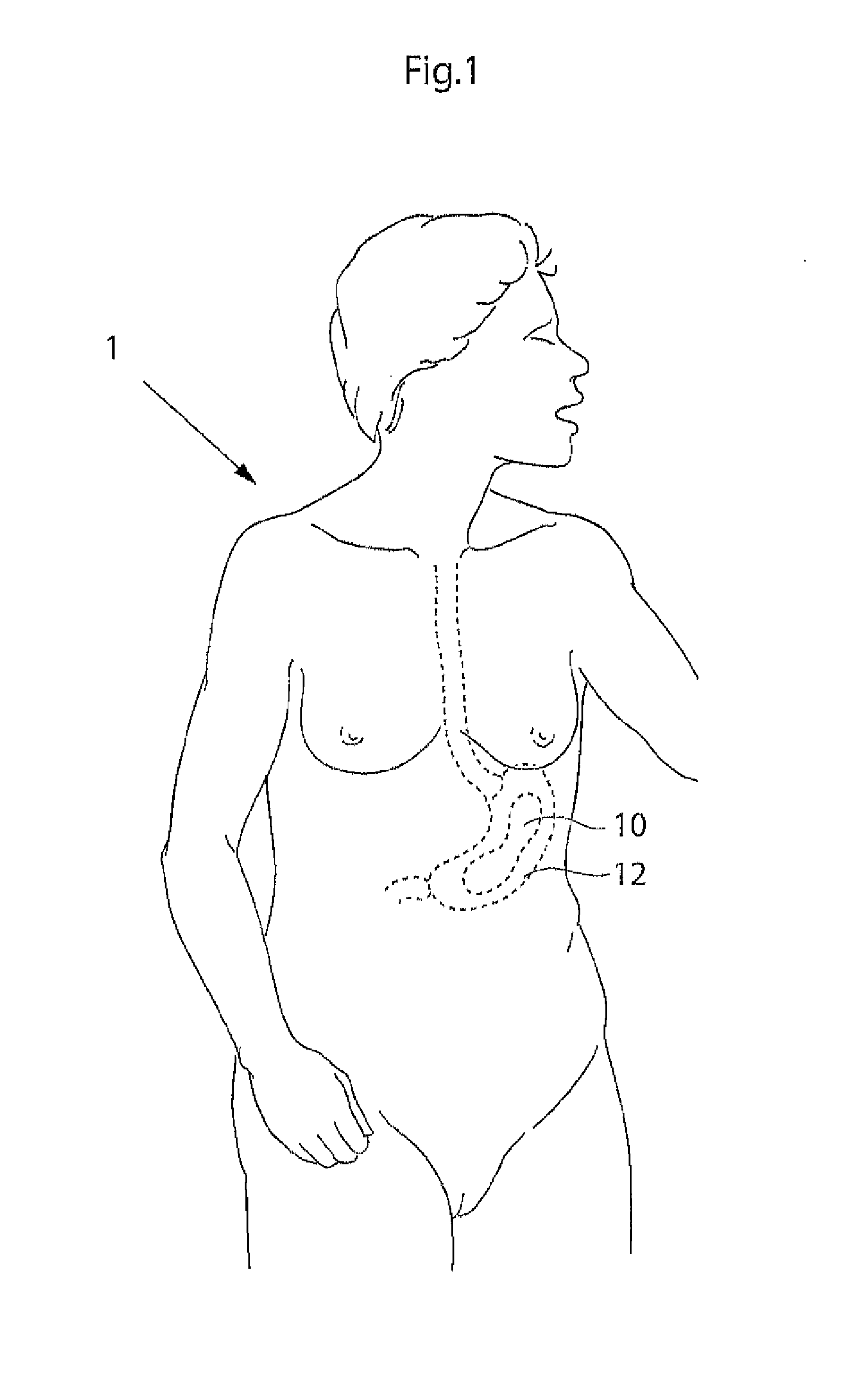

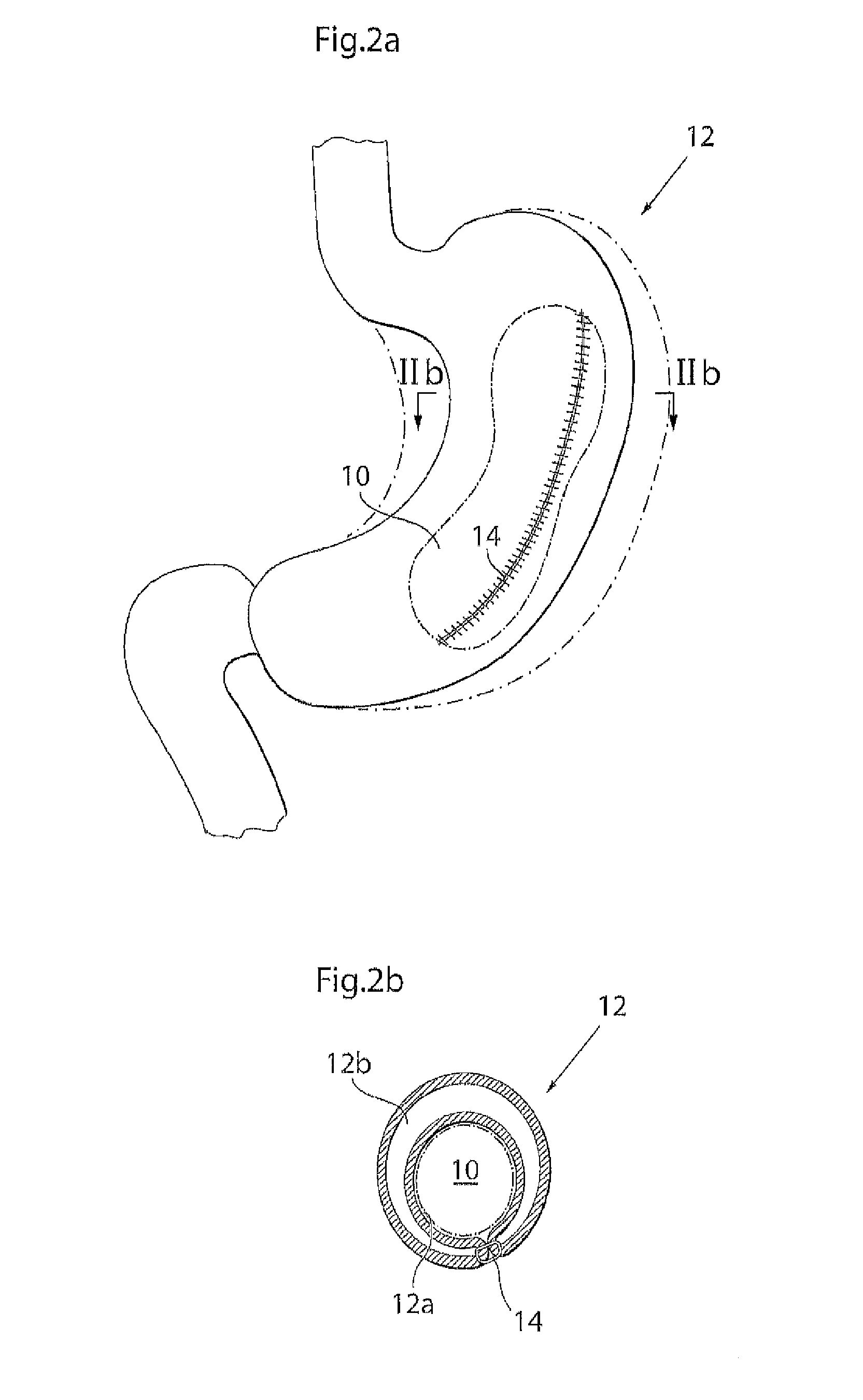

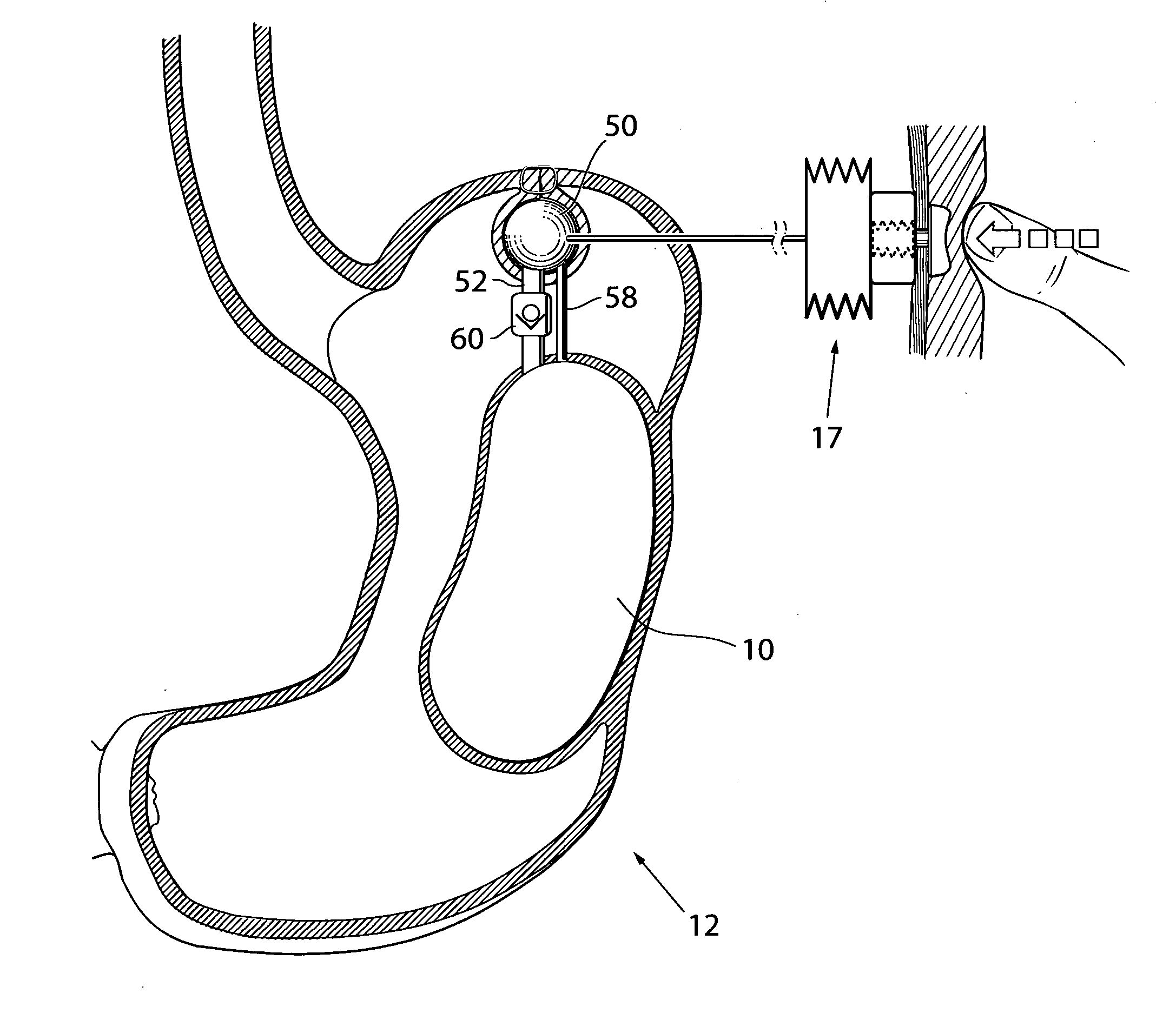

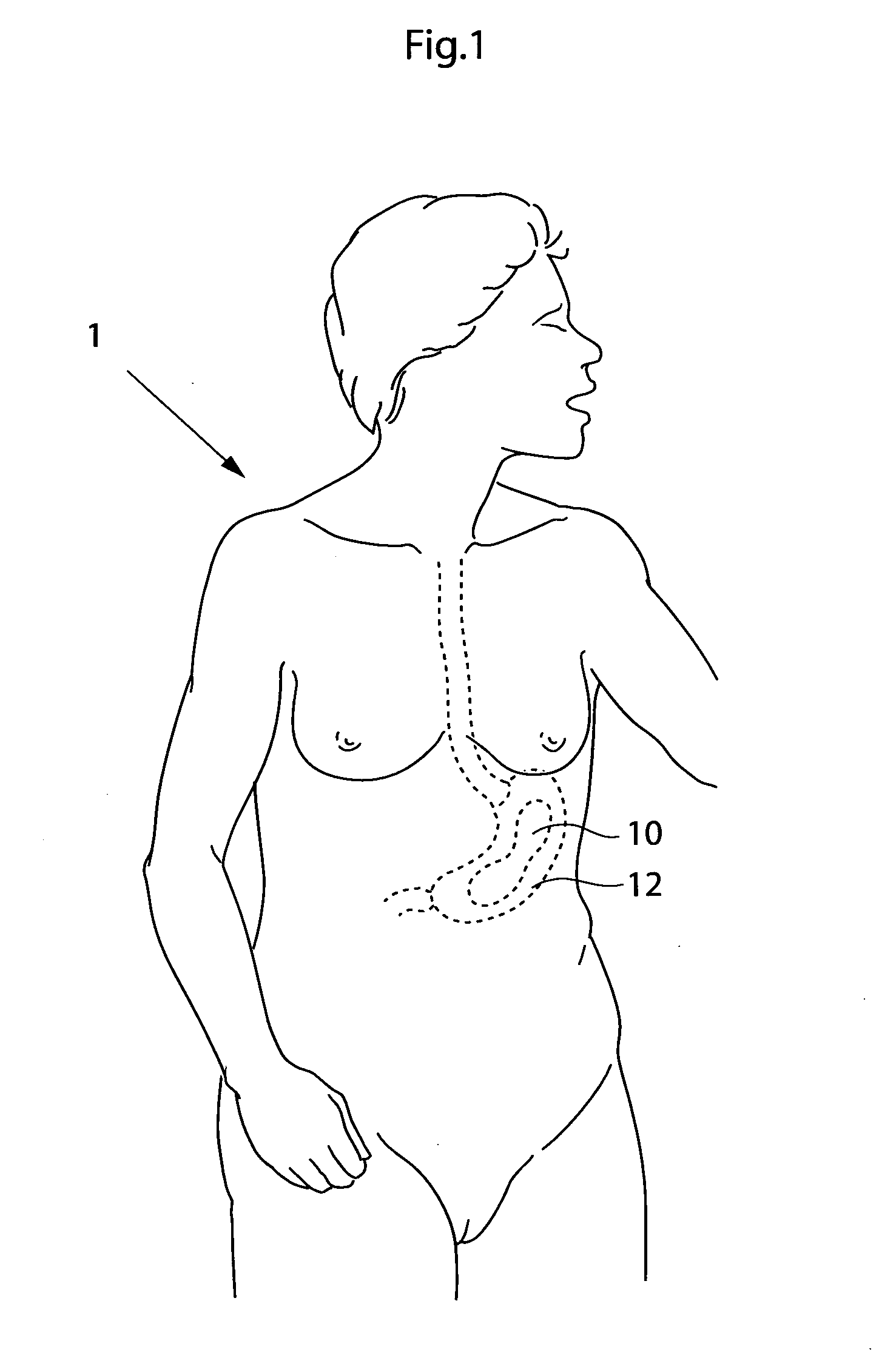

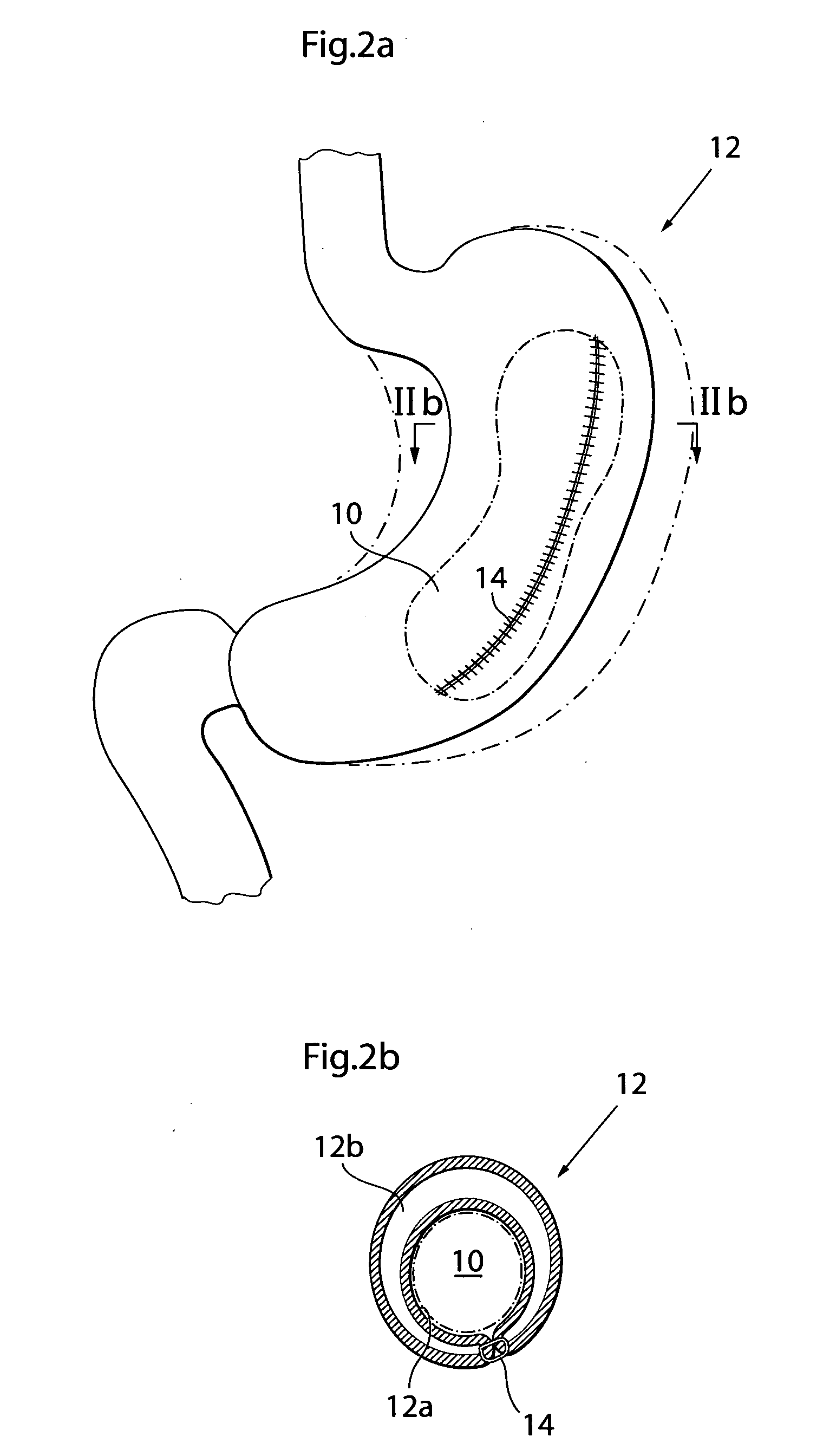

Obesity treatment

ActiveUS20120029550A1Improved long-term propertyLower the volumeSuture equipmentsBatteries circuit arrangementsStomach wallsVolume filling

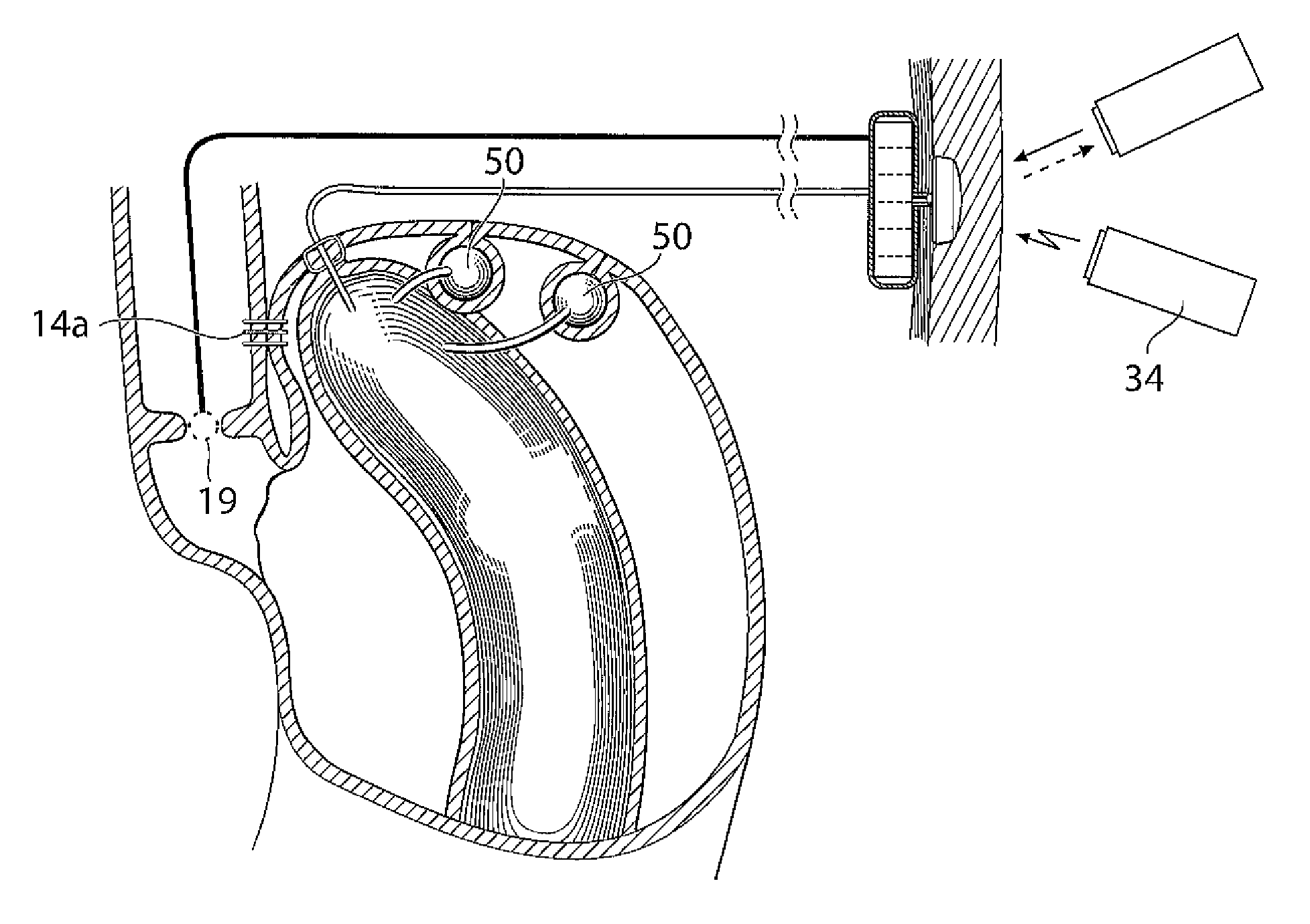

An apparatus for treating obesity comprises a volume filling device formed by at least two segments and is provided and following implantation, the device is placed resting against the stomach wall of the patient to reduce the inner volume of the stomach, thereby affecting the patients appetite.

Owner:FORSELL PETER

Apparatus for treating obesity

ActiveUS20100312049A1Improved long-term propertyLower the volumeSuture equipmentsElectrotherapyStomach wallsVolume filling

An volume filling device for treatment of obesity is placed outside the stomach wall of the patient to reduce the inner volume of the stomach, thereby affecting the patient's appetite. By providing the volume filling device outside the stomach wall, contact with stomach acids is avoided, thereby increasing the life of the device.

Owner:FORSELL PETER

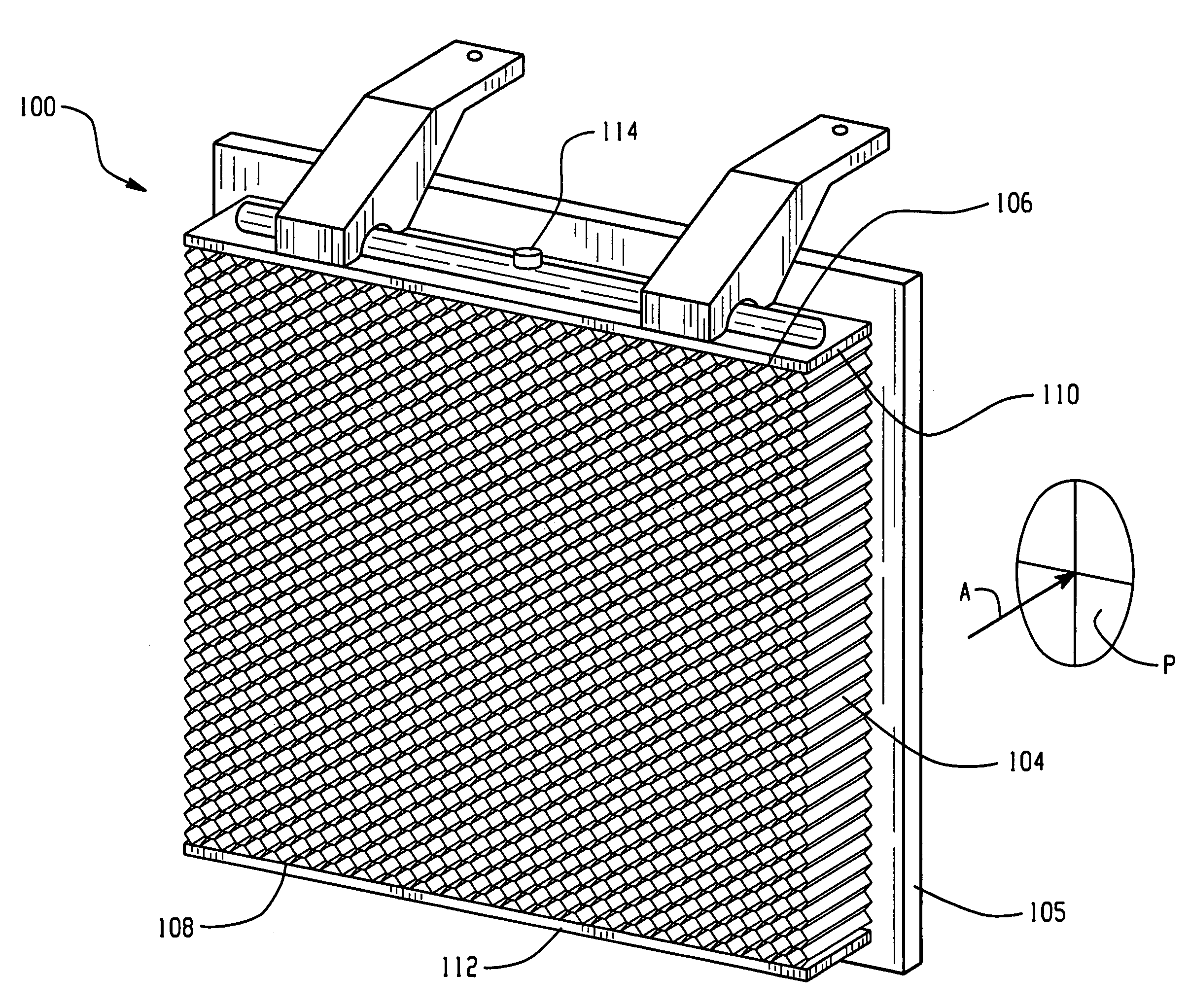

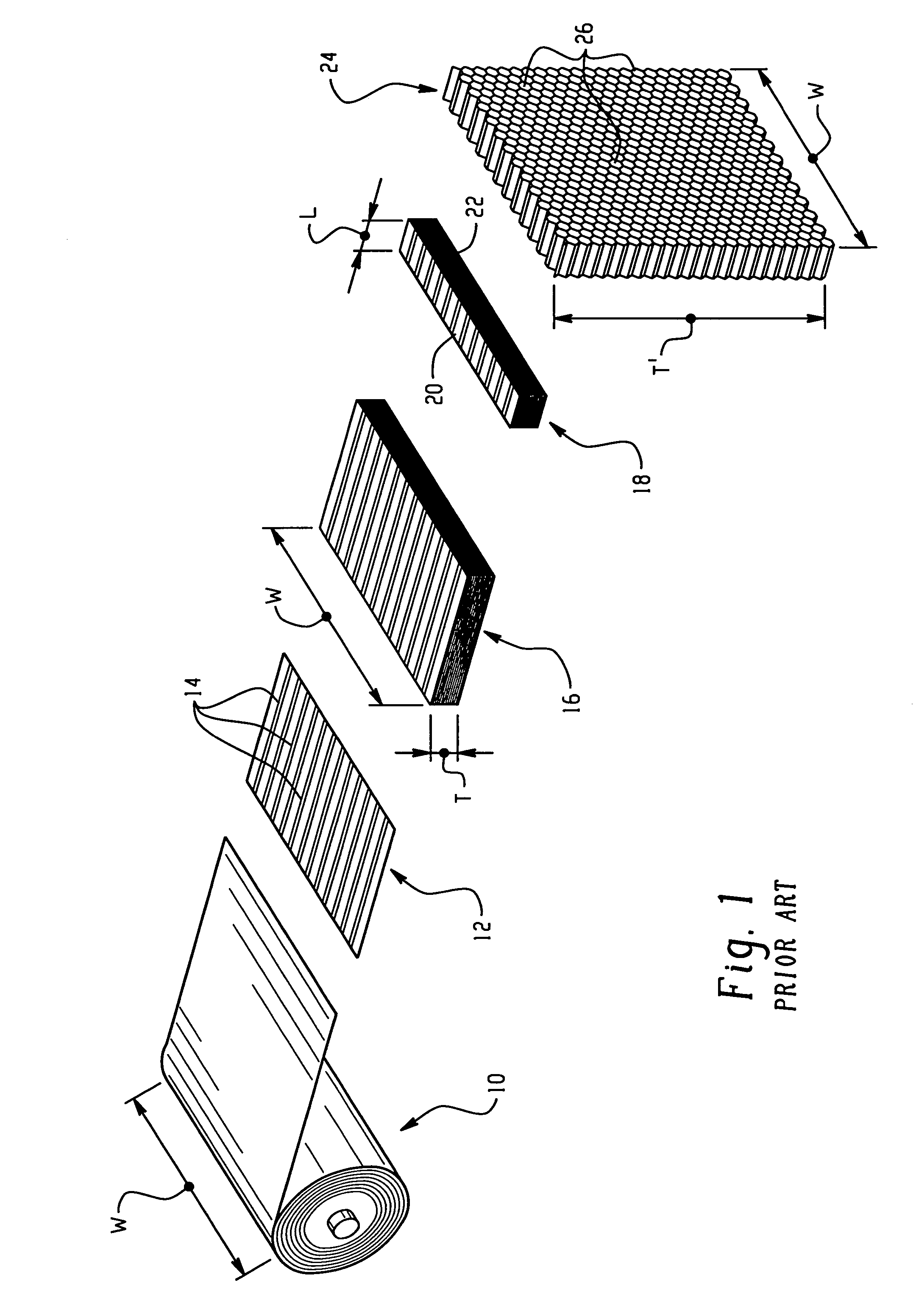

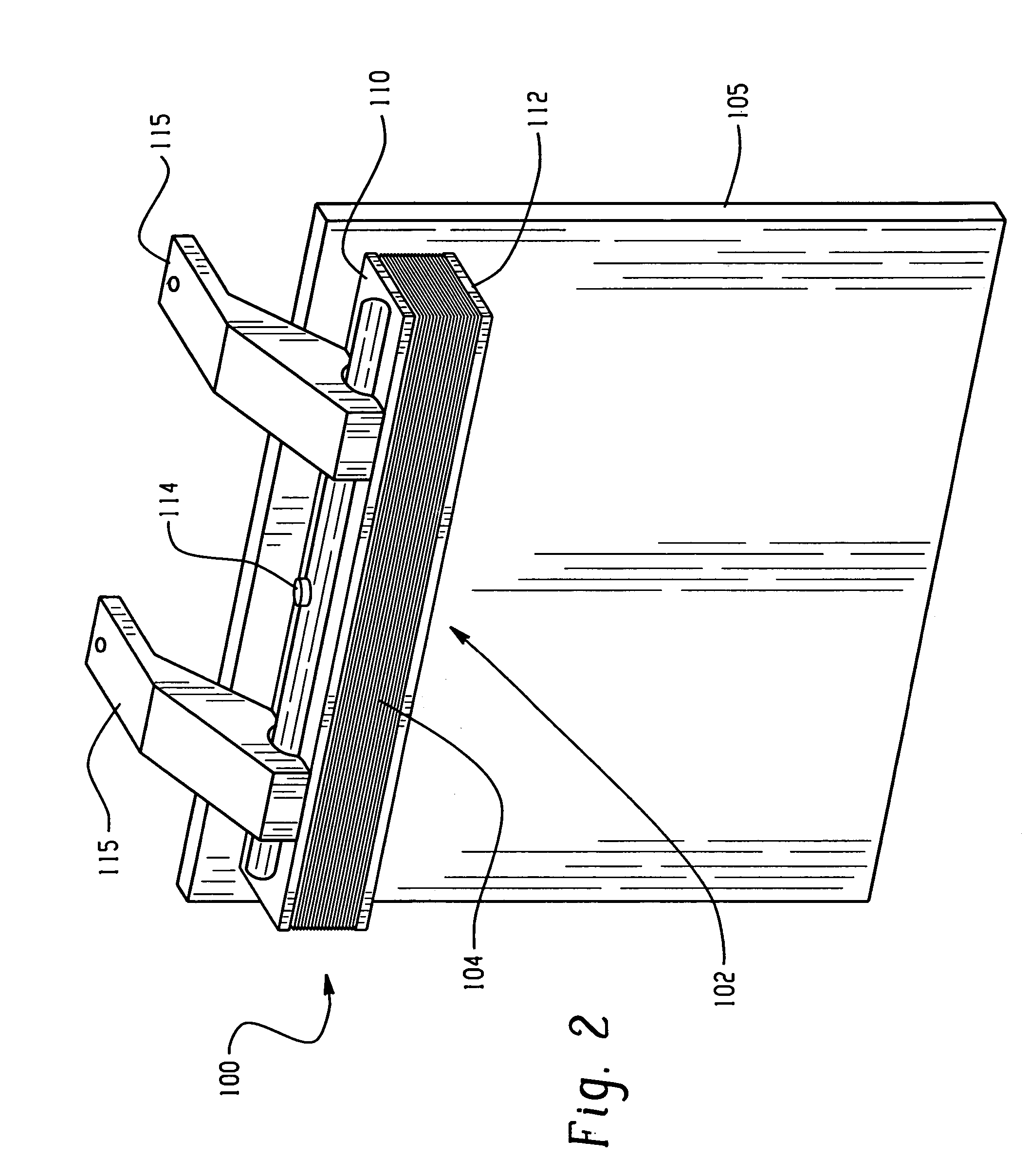

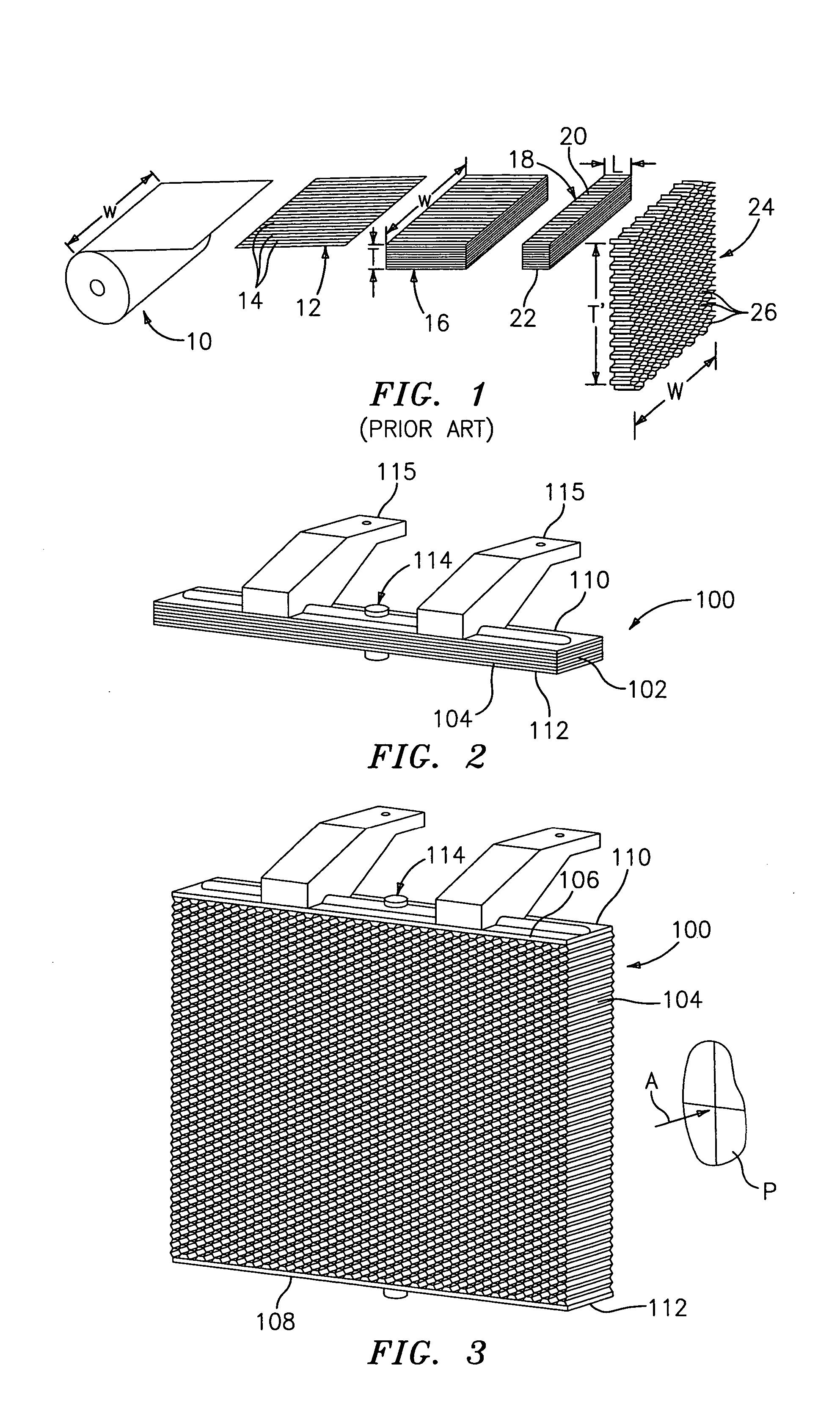

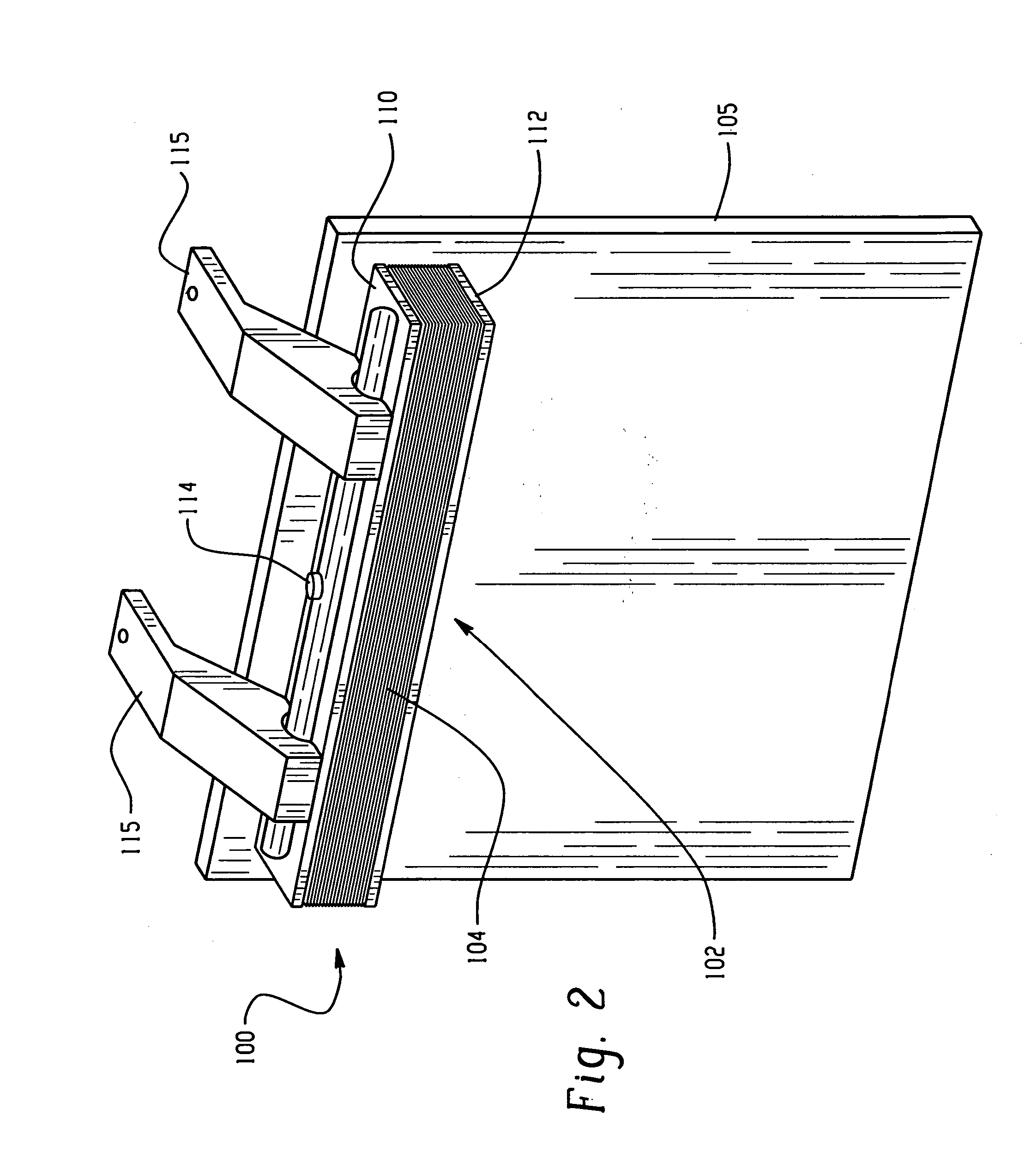

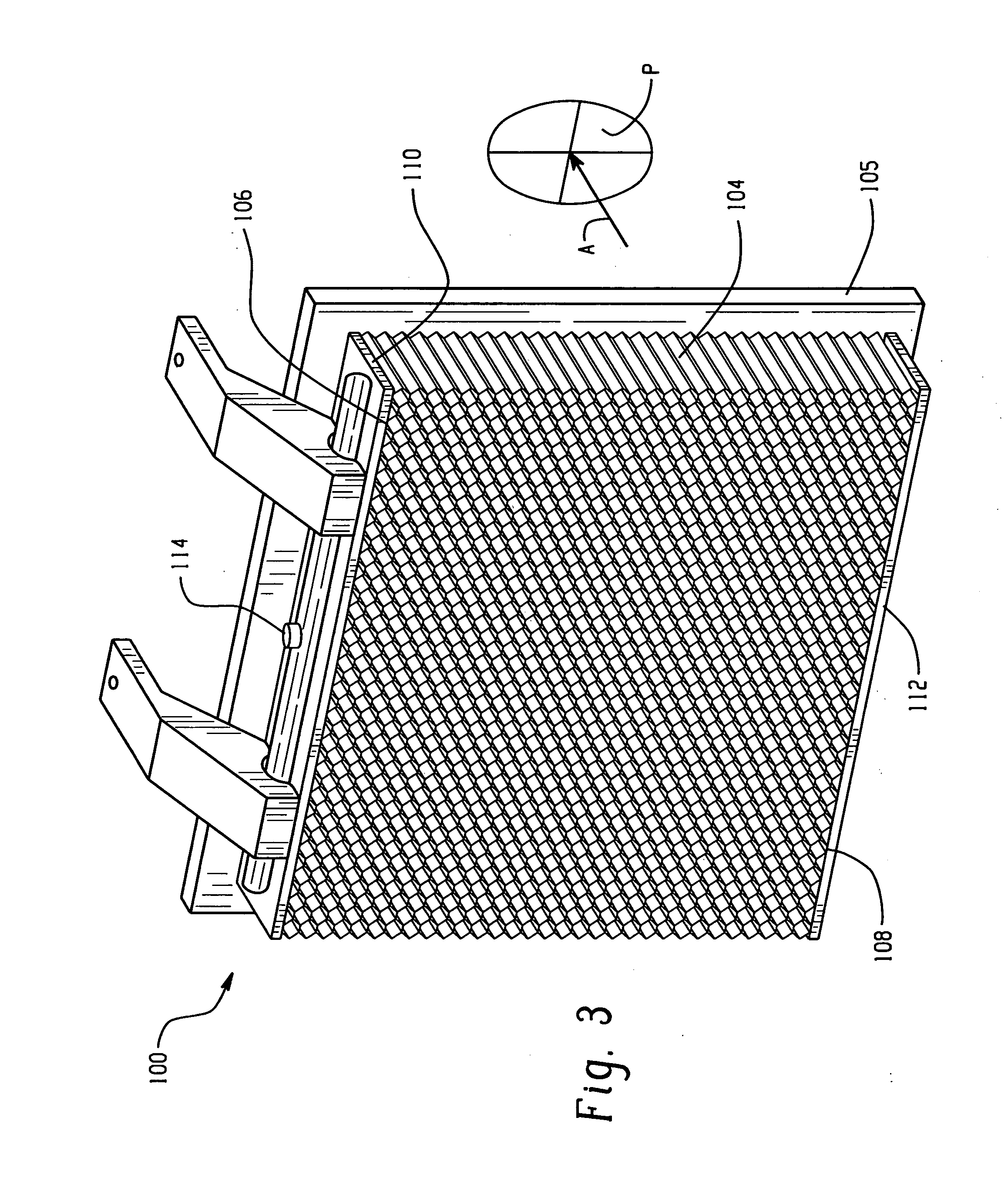

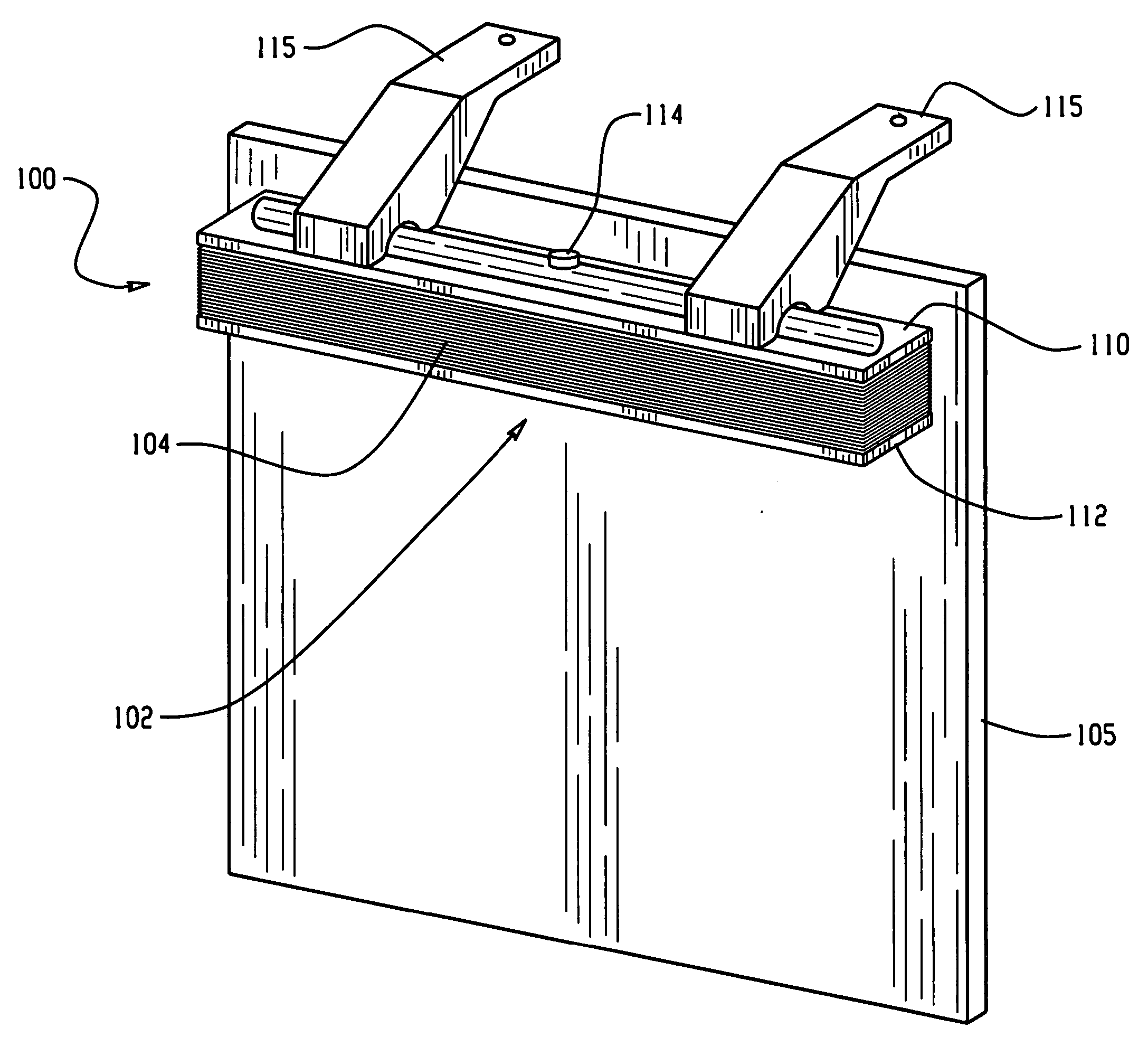

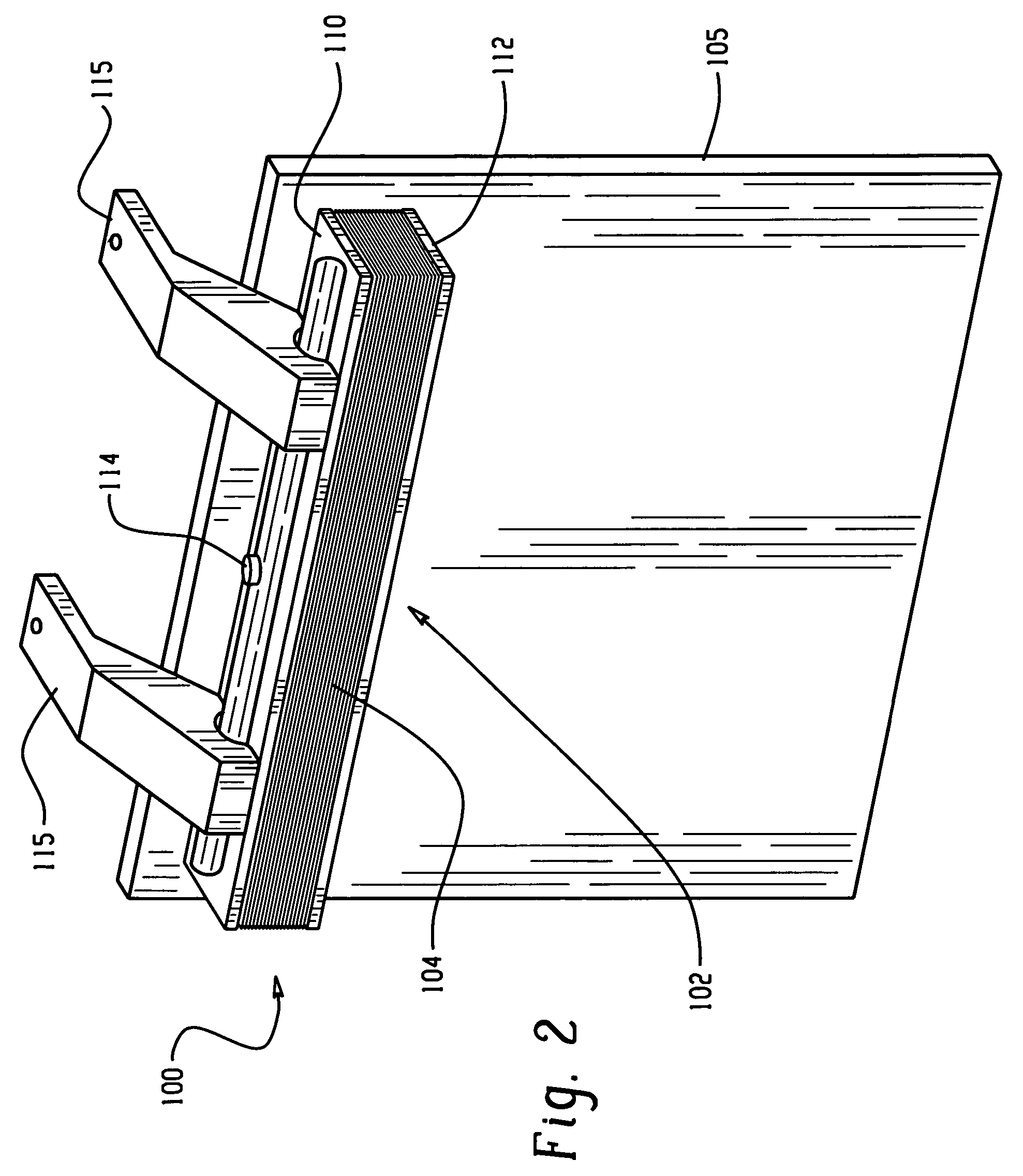

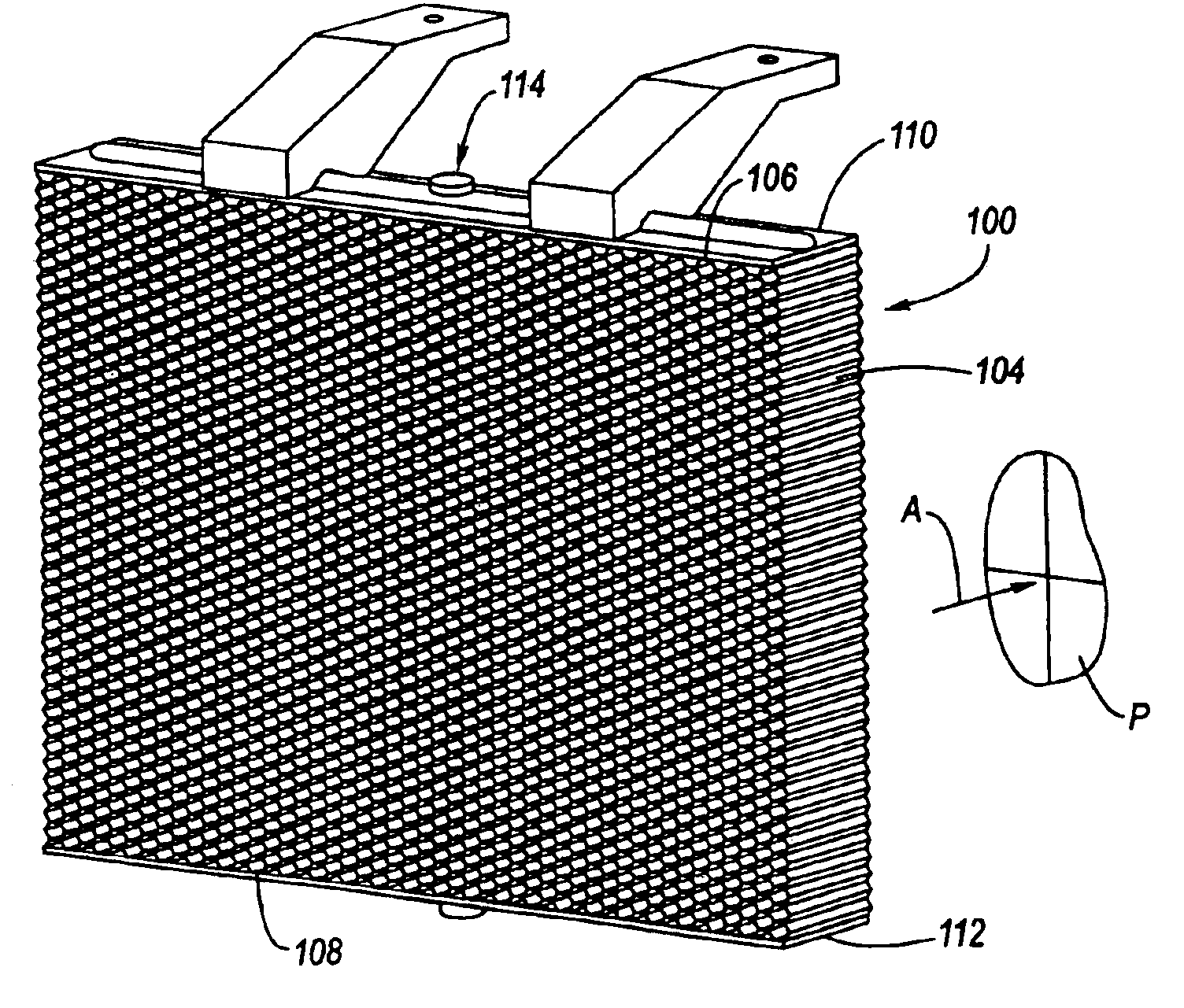

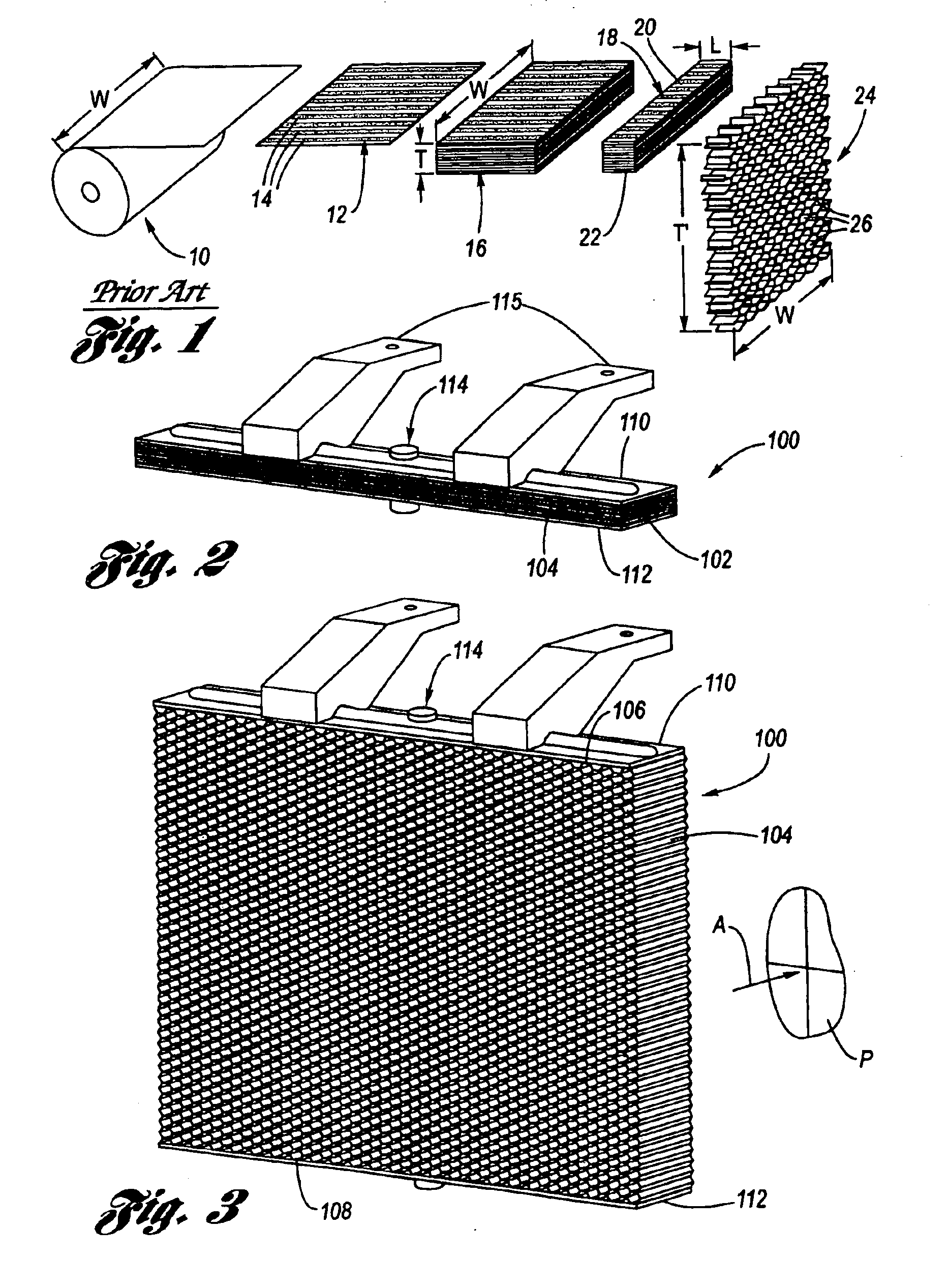

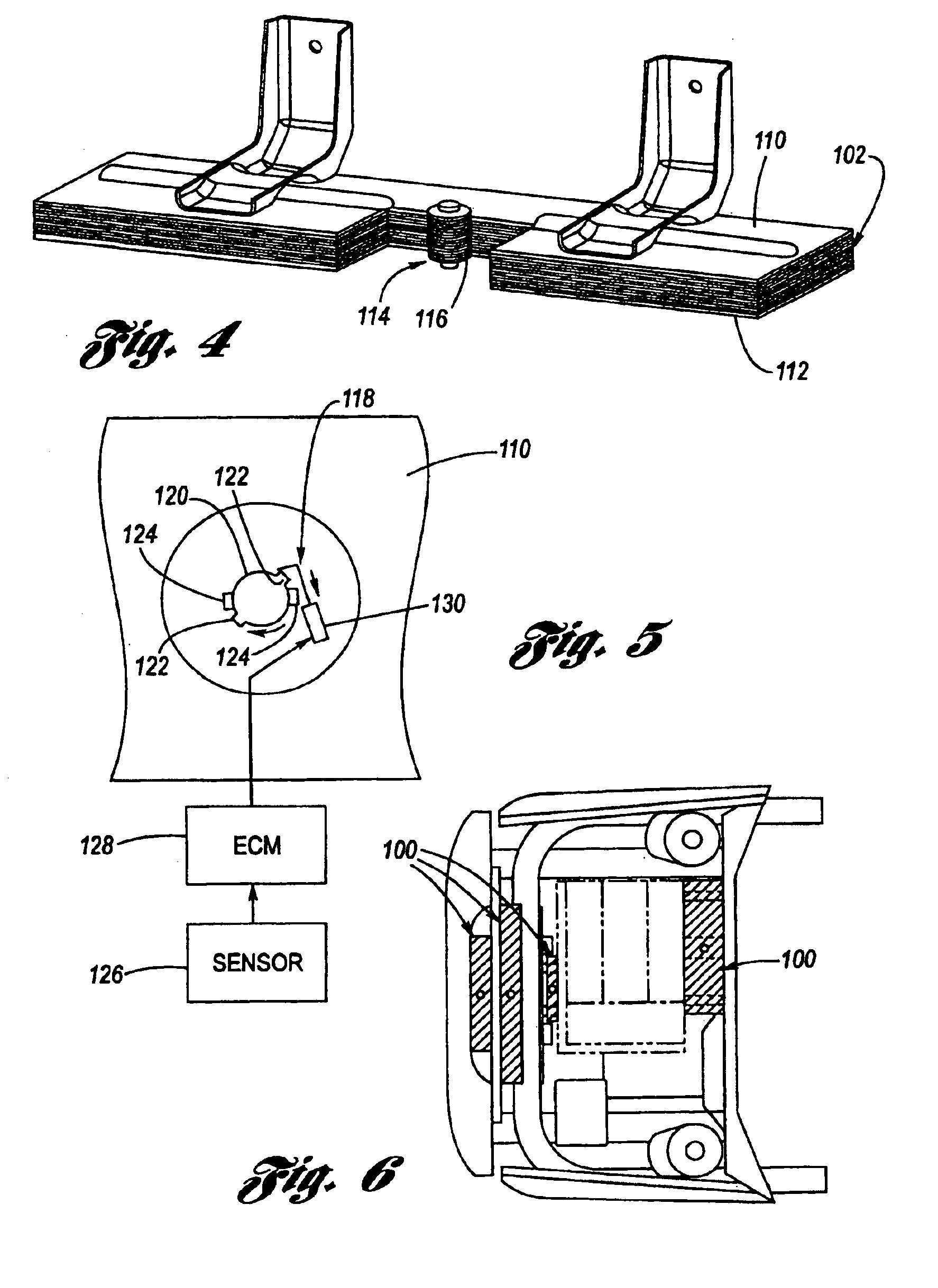

Volume-filling mechanical assemblies and methods of operating the same

Owner:GM GLOBAL TECH OPERATIONS LLC

Volume-filling mechanical structures with means for deploying same in a bolster system

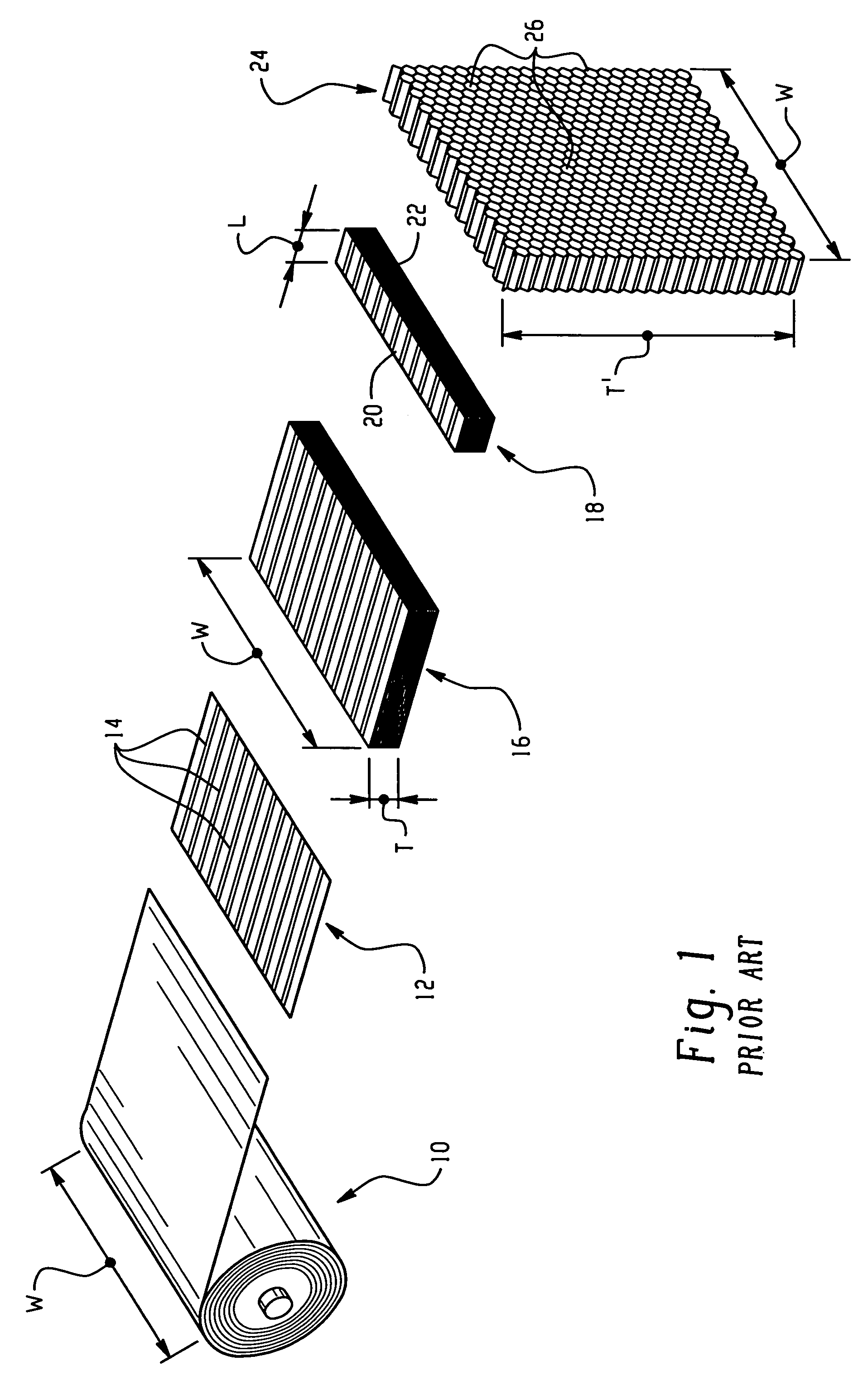

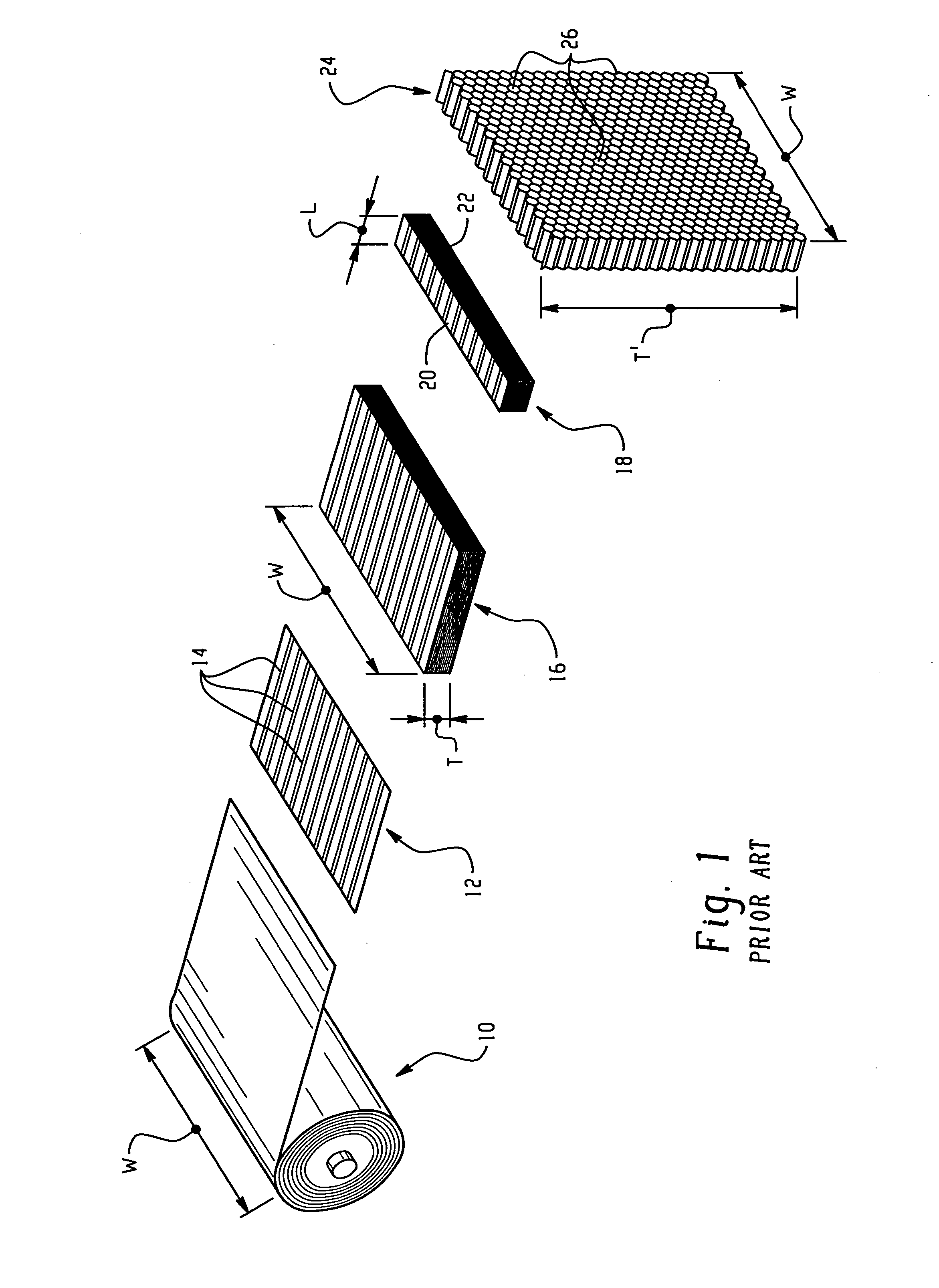

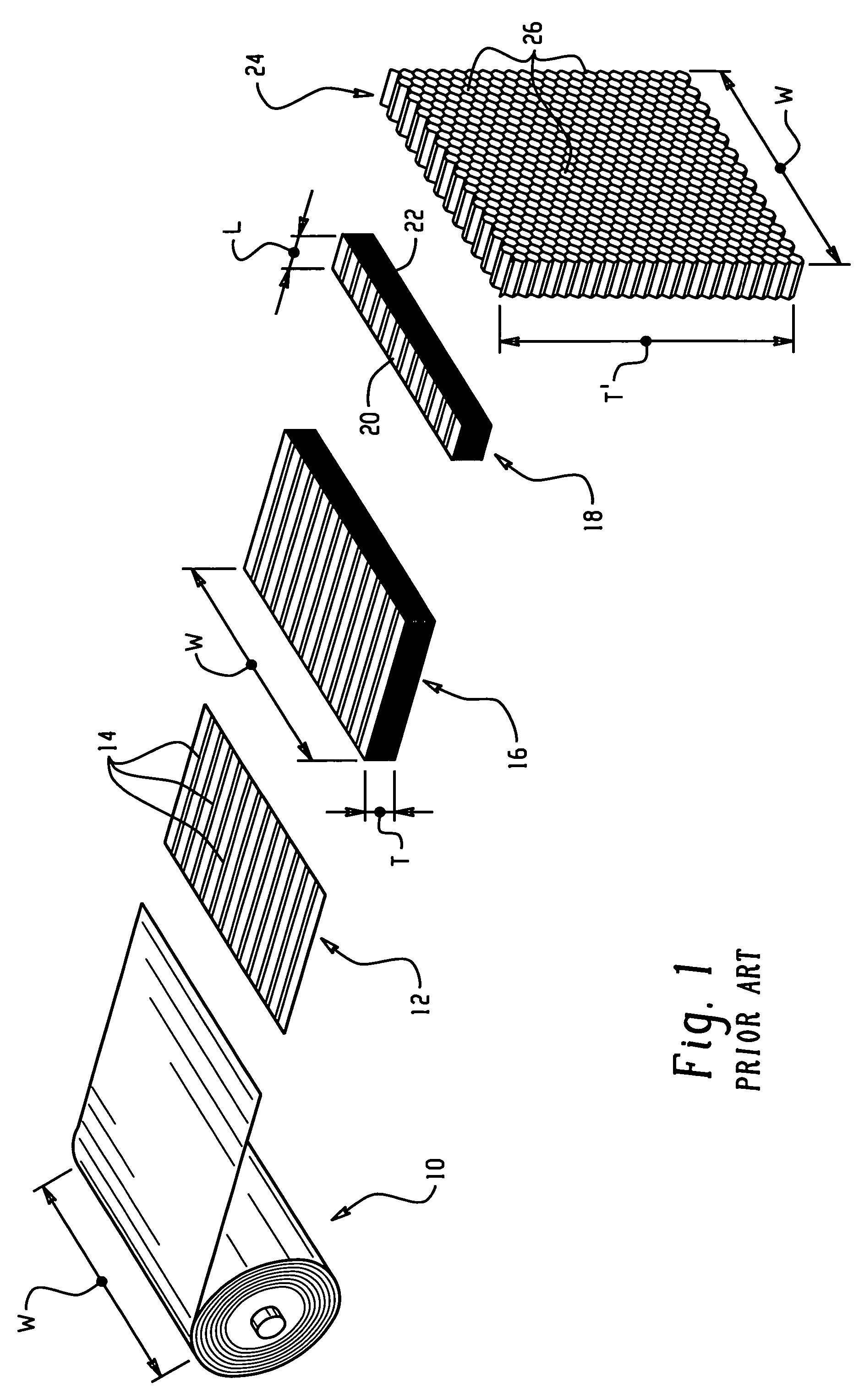

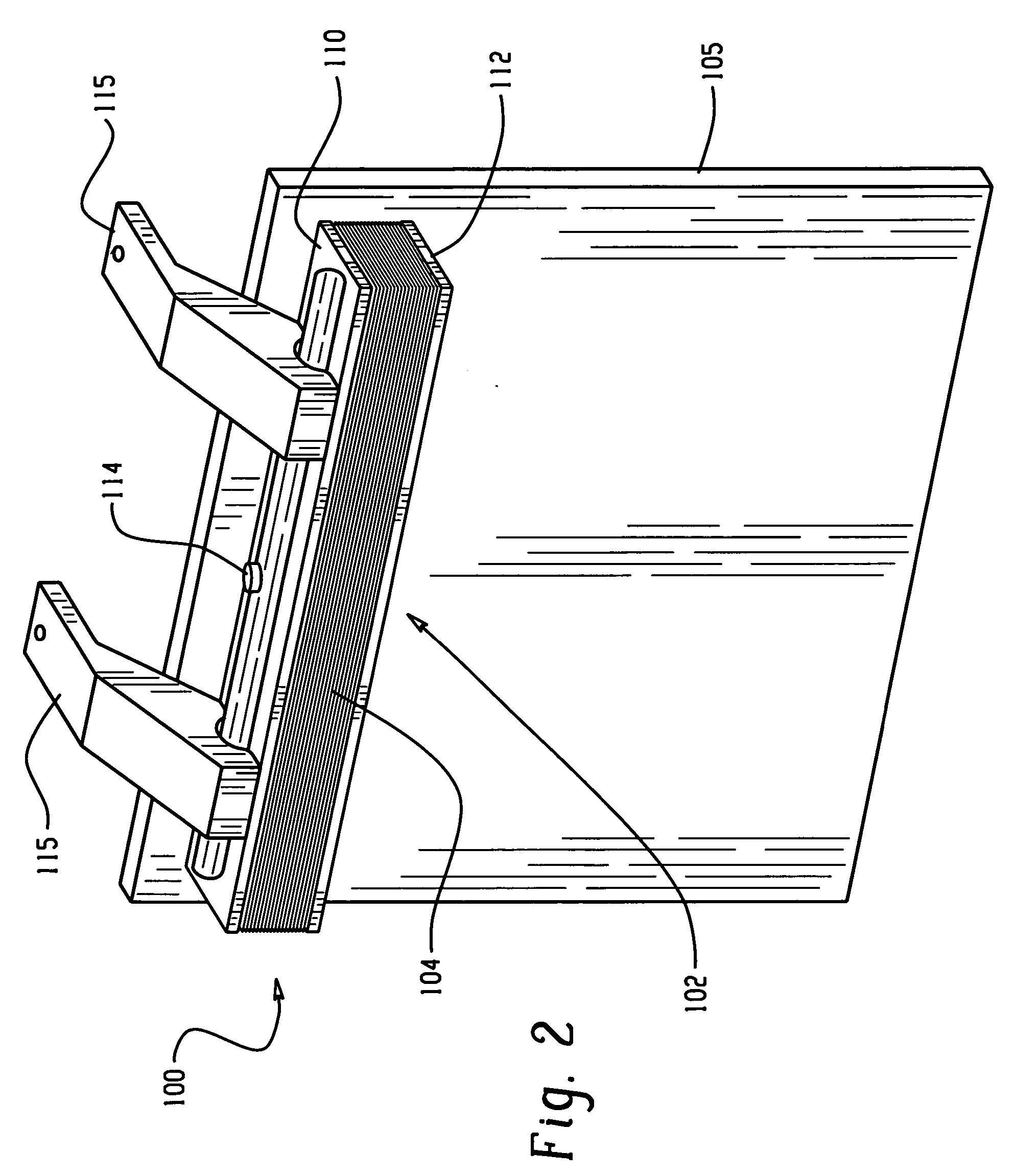

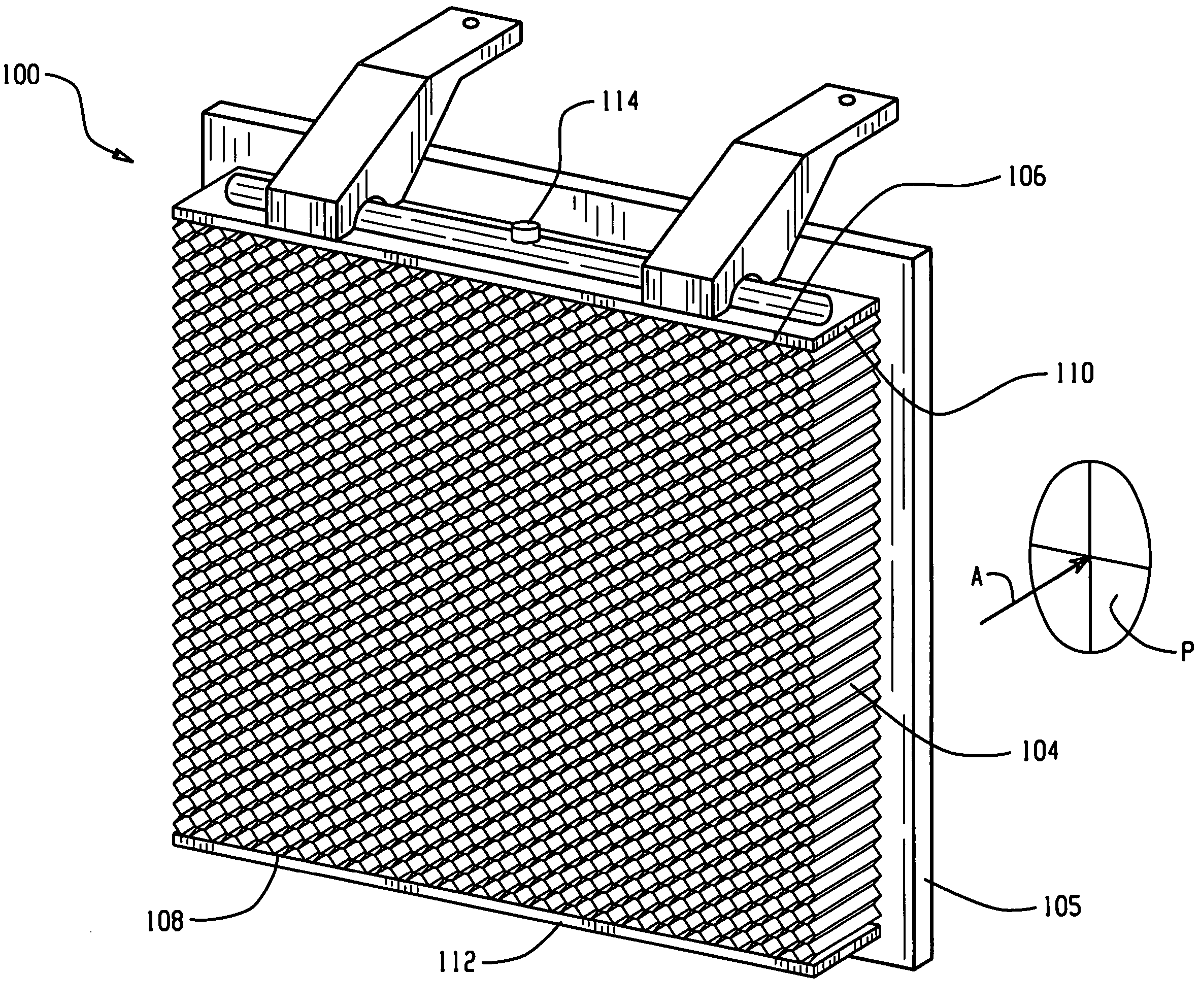

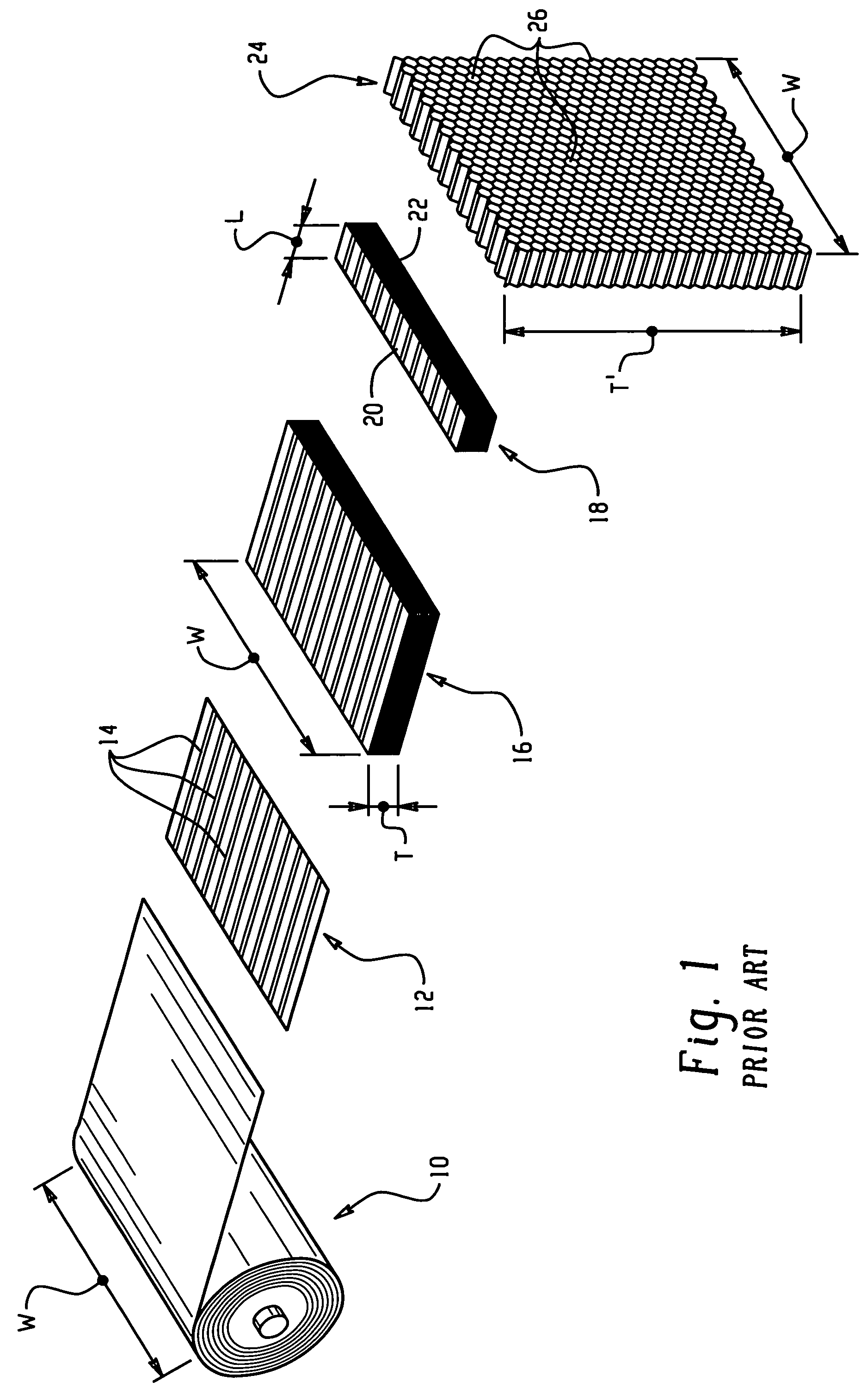

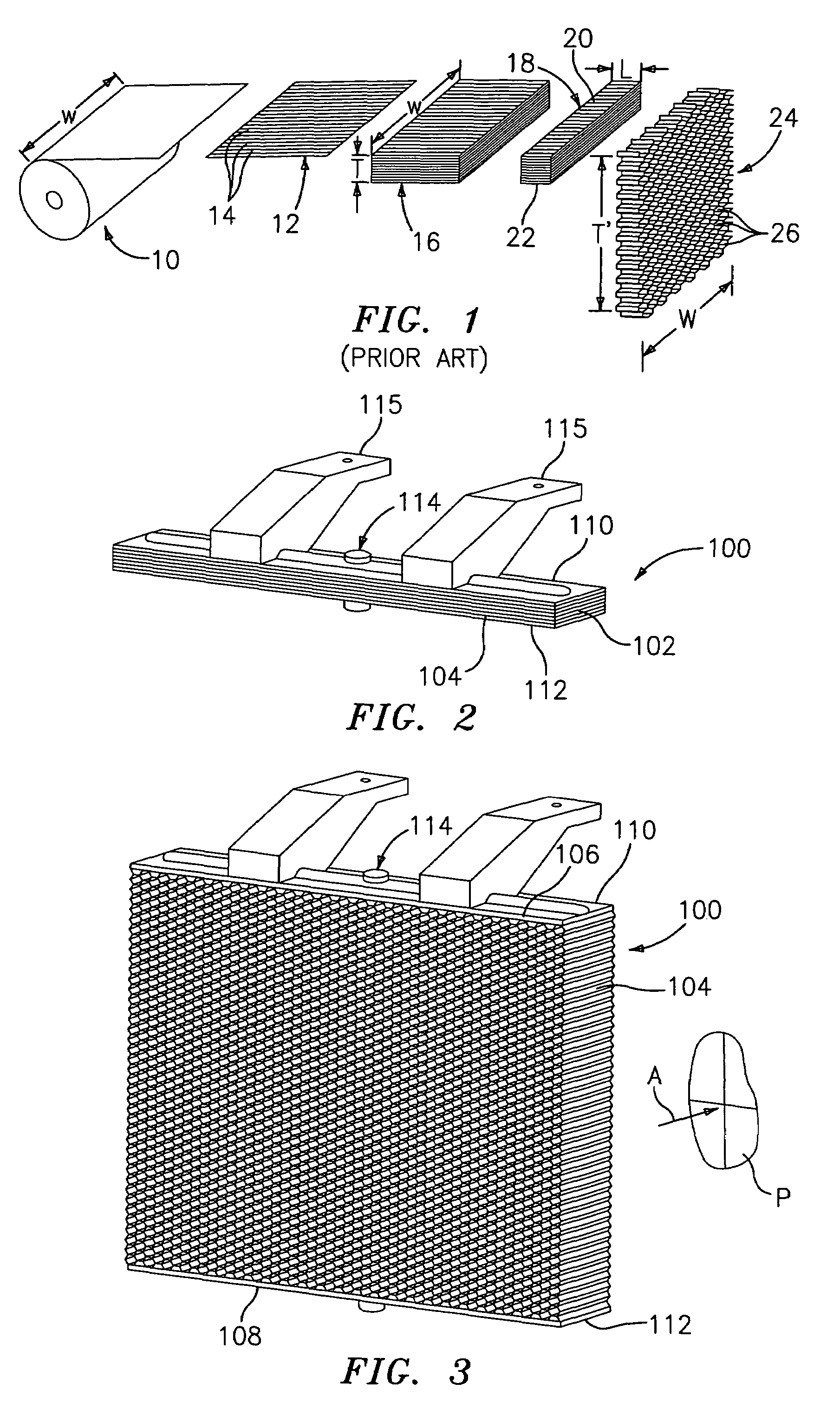

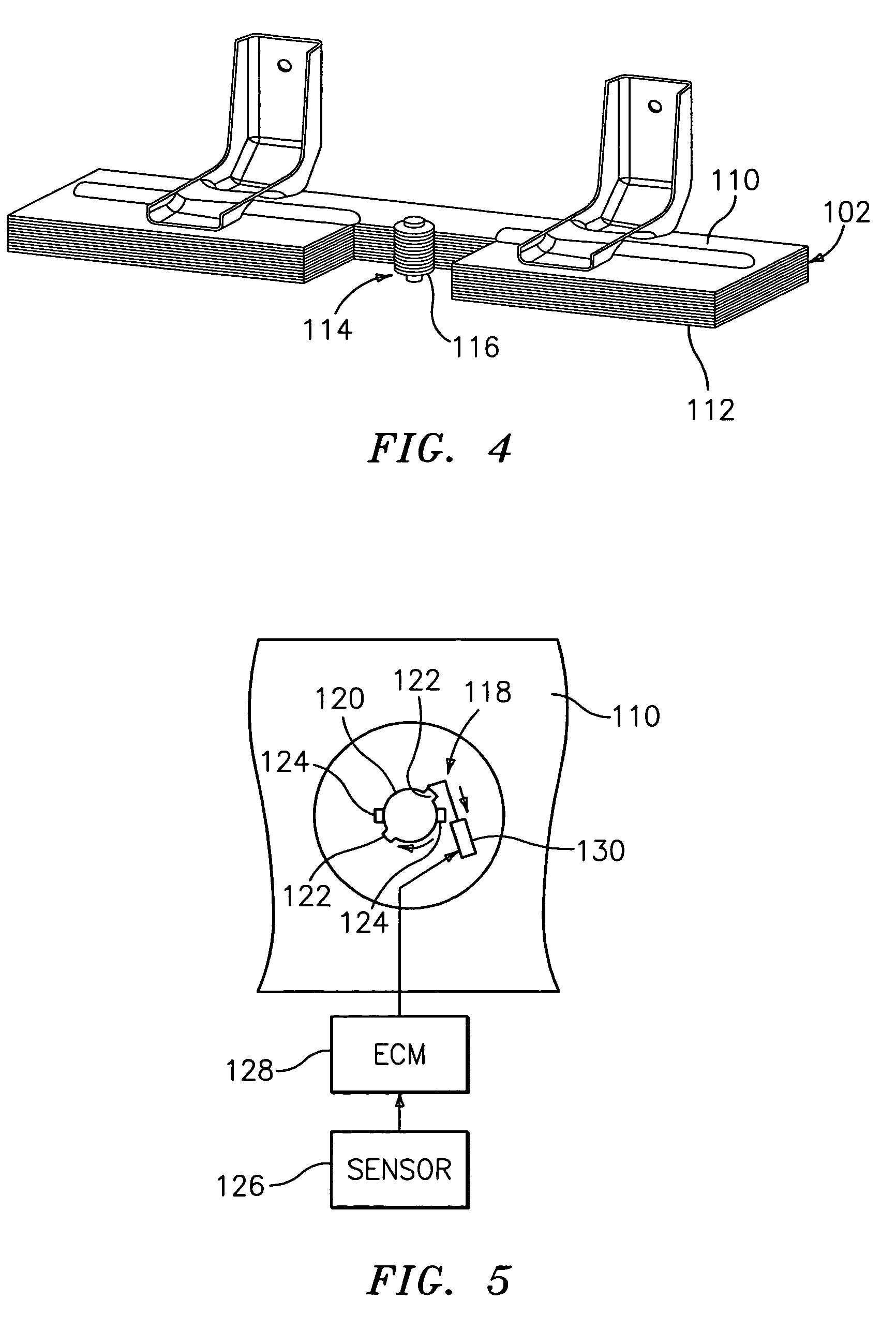

InactiveUS20060232051A1Excellent crash energy management capabilityLarge crush forcePedestrian/occupant safety arrangementVehicle safety beltsHoneycombEngineering

A volume-filling mechanical structure for modifying a crash including: a bolster system defined by an outer bolster and an inner bolster; a honeycomb celled material expandable from a dormant state to a deployed state, the honeycomb celled material disposed intermediate the outer and inner bolsters cooperatively positioned with the honeycomb celled material to cover surfaces defining the honeycomb celled material in the deployed and dormant states; a means for deploying the honeycomb celled material from the dormant state to the deployed state causing the outer bolster to translate away from the inner bolster; and a tether operably connecting one end of the honeycomb celled material to the means for deploying the honeycomb celled material from the dormant state to the deployed state.

Owner:GM GLOBAL TECH OPERATIONS LLC

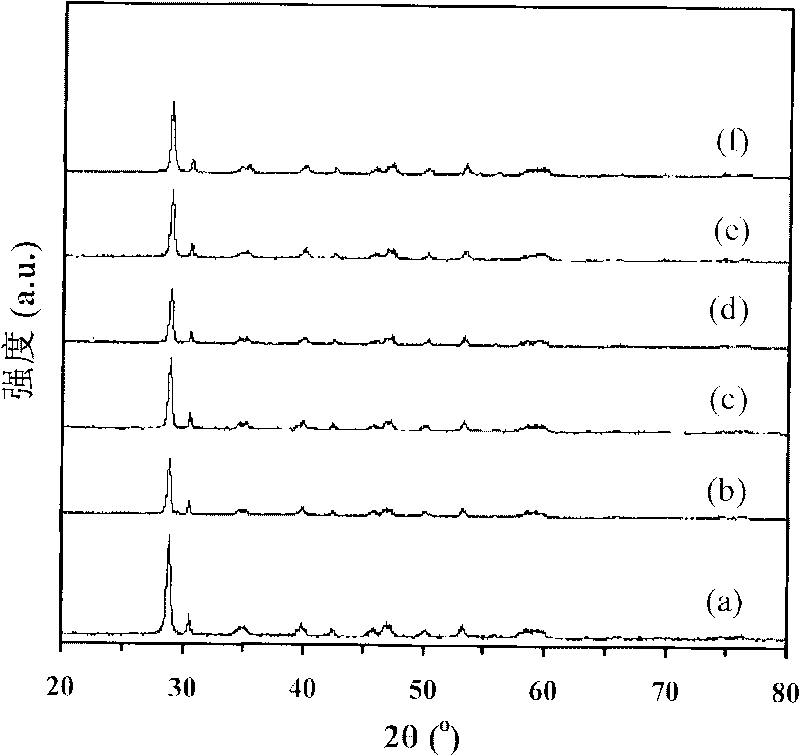

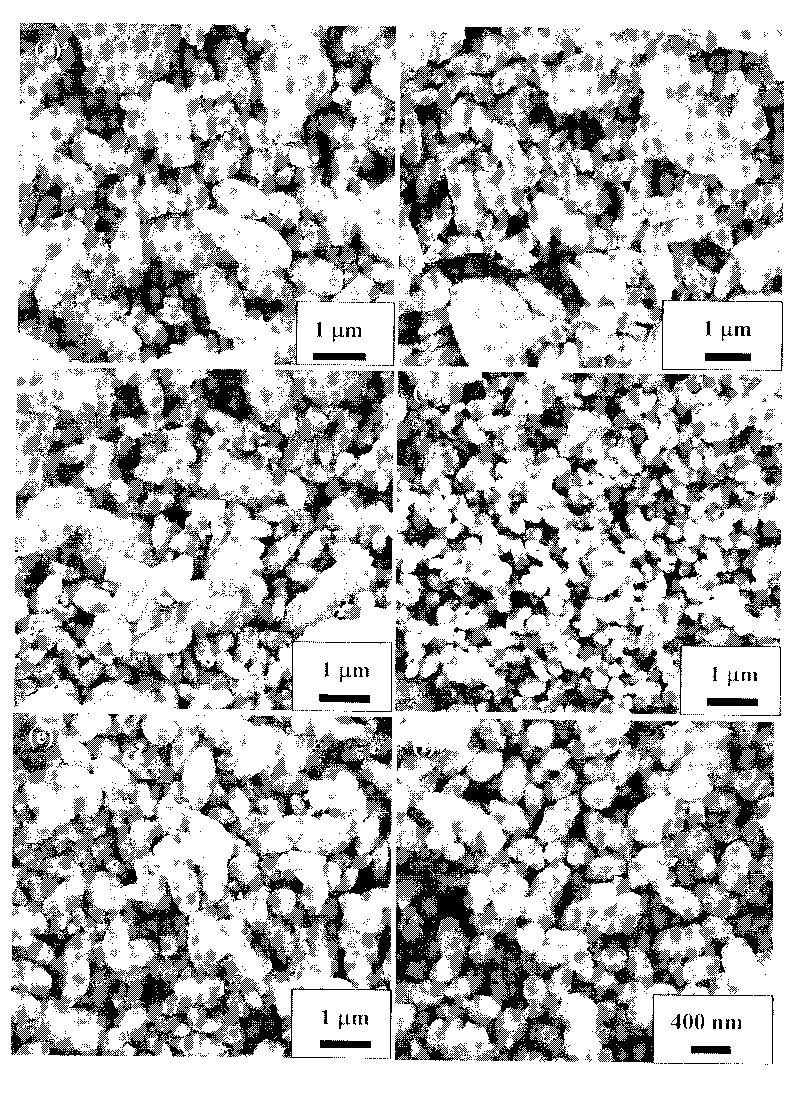

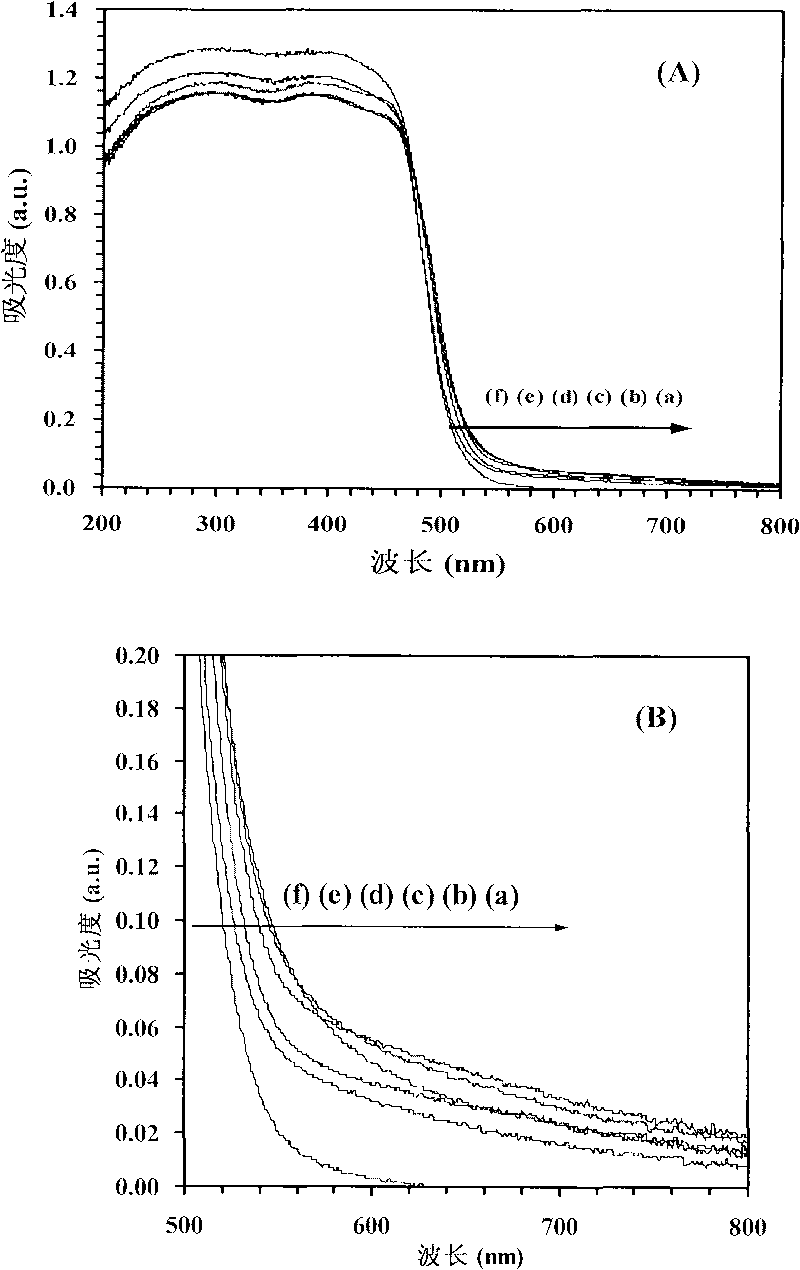

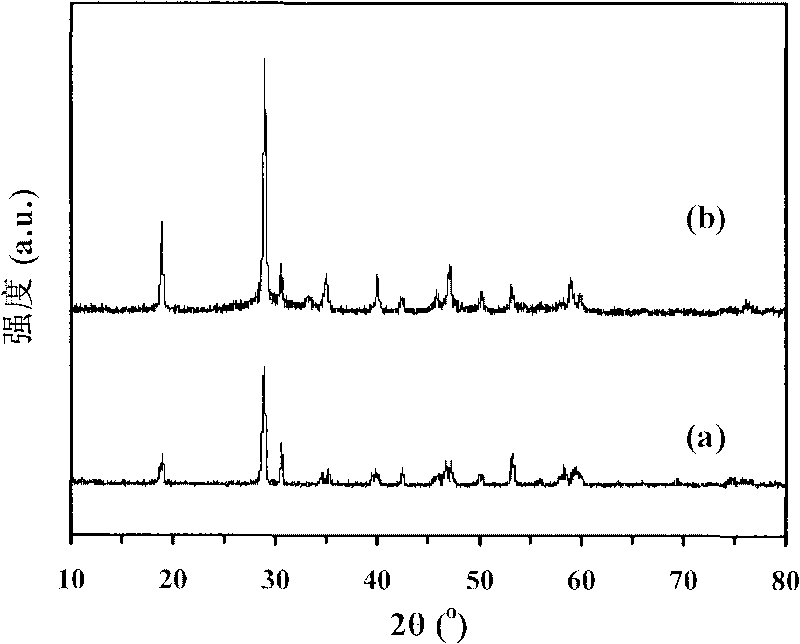

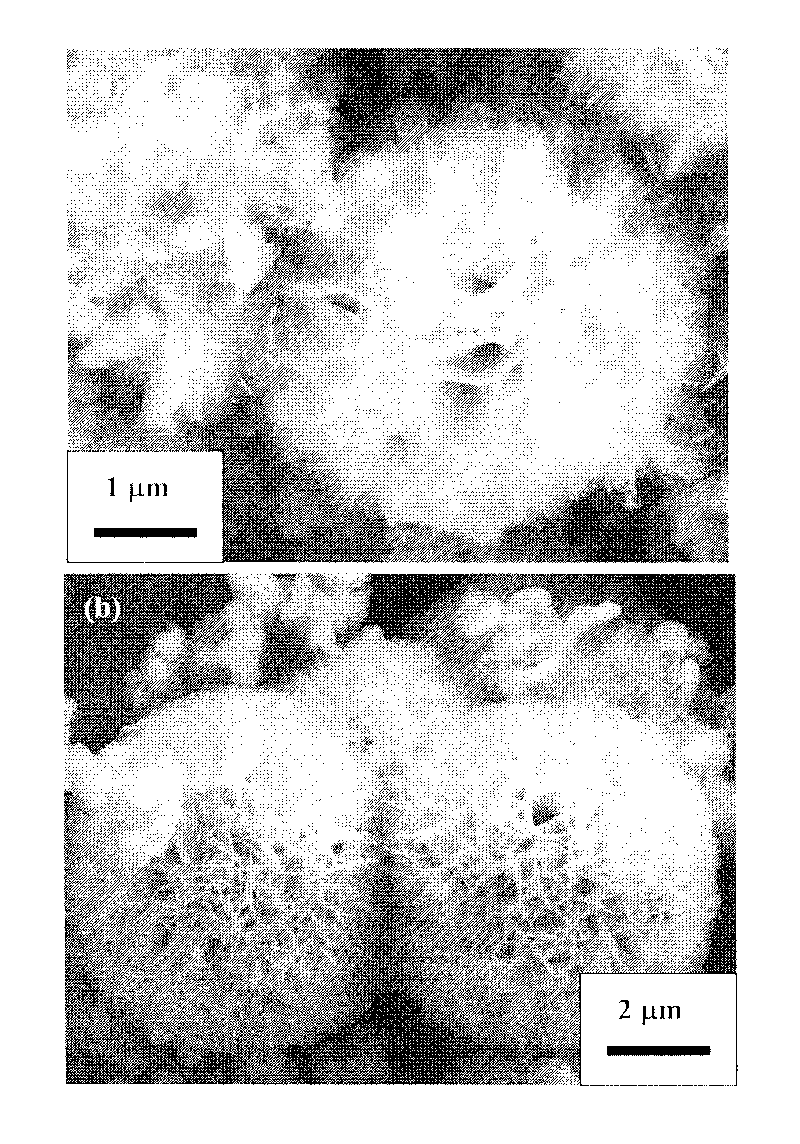

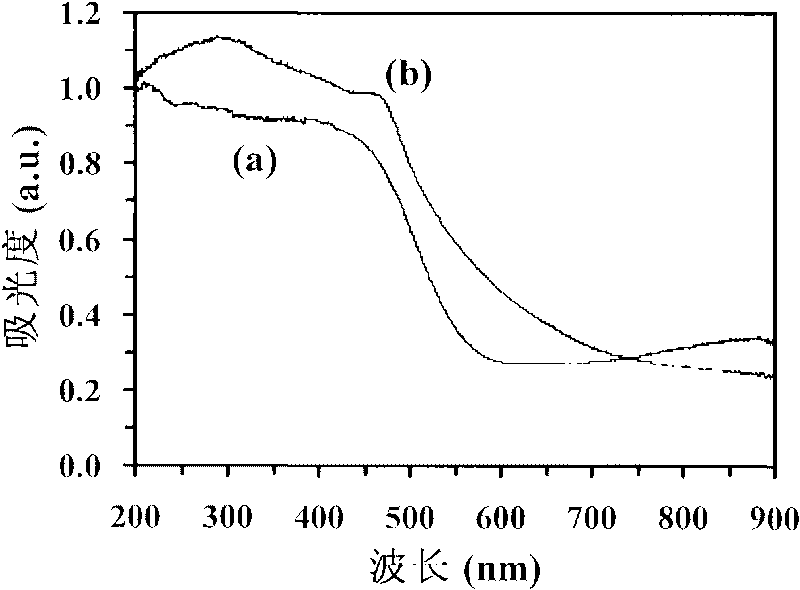

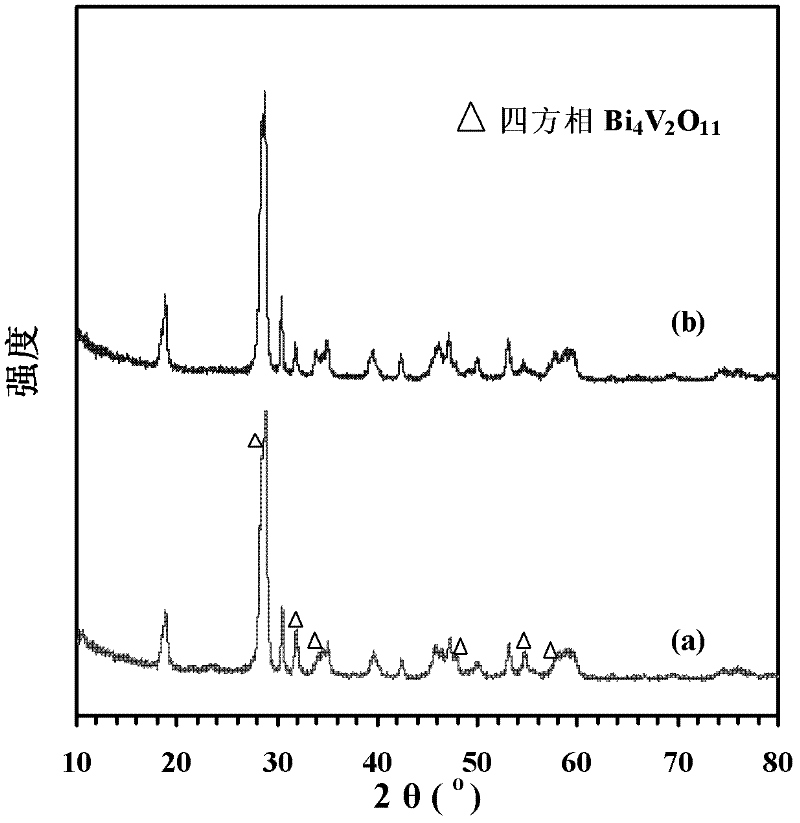

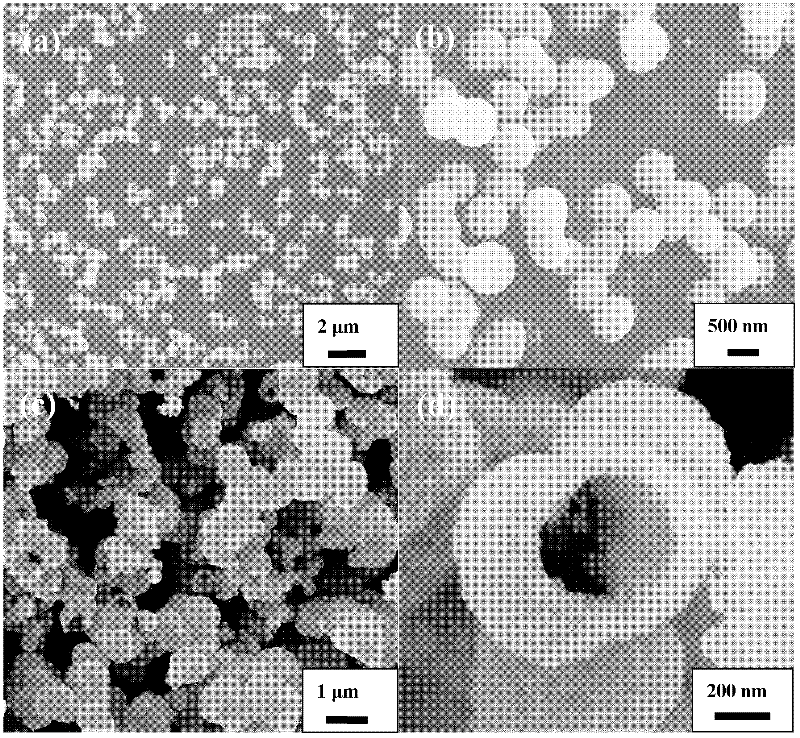

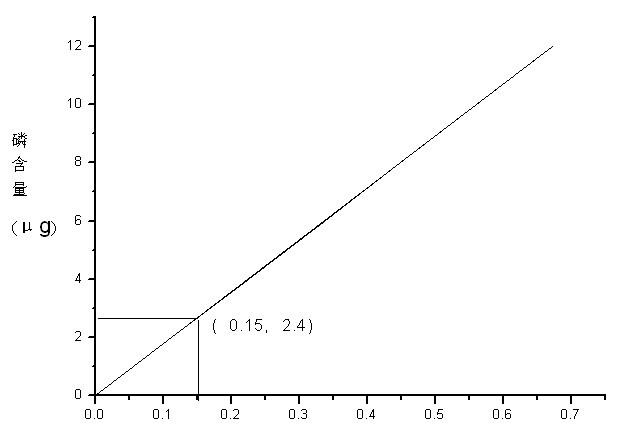

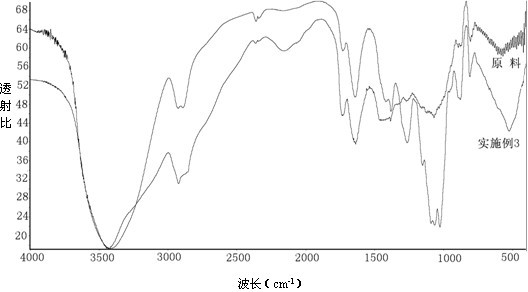

Organic solvent-water heating method for preparing football-shaped mesoporous BiVO4

InactiveCN101746825ASave raw materialsSimple processVanadium compoundsBismuth vanadateAmmonium metavanadate

The invention discloses an organic solvent-water heating method for preparing football-shaped mesoporous BiVO4, comprising the following experimental steps: under the condition of stirring, bismuth nitrate and ammonium metavanadate are dissolved in a mixed solution of ethanol, ethylene glycol, nitric acid and laurylamine (oleylamine or mixed liquid of oleylamine and oleic acid); a sodium hydroxide (2mol / L) alcohol solution of ethanol and ethylene glycol with the volume ratio of 1 to 1 is used to regulate the pH of the solution to be equal to 1.5-3; the mixed solution is transferred in a stainless steel self-pressing vessel (the volume filling degree is about 70%) with a Teflon inner liner and is put in an incubator to carry out organic solvent - water heating treatment for 12h in constant temperature of 100 DEG C; and the mixed solution is naturally cooled to room temperature after taking out. The obtained product after the organic solvent - water heating treatment is filtered, is washed with deionized water and absolute ethanol and is dried for 12h at the temperature of 60 DEG C, and then football-shaped mesoporous BiVO4 micron particles with a monoclinic scheelite structure is obtained. The porous bismuth vanadate obtained by the method has good application prospects in the fields of photocatalysis, electrode materials, pigments, ion conductive ceramic, and the like.

Owner:BEIJING UNIV OF TECH

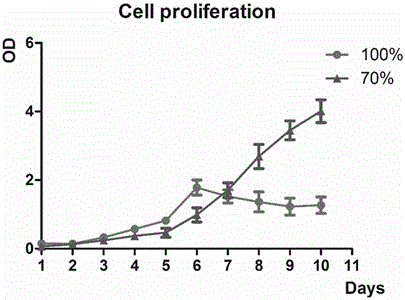

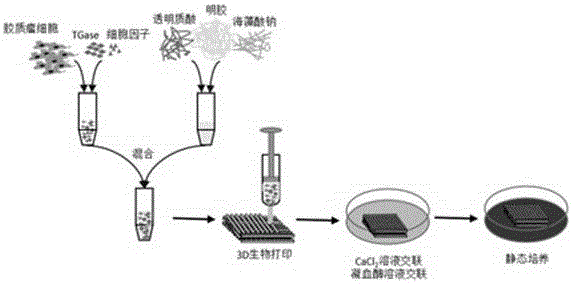

Three-dimensional (3D) bio-printed brain tumor in vitro model and construction method thereof

ActiveCN106434562AAddress nutritional deficienciesSolve the characteristicsCell culture supports/coatingCell culture active agentsFiberMedicine

The invention relates to a three-dimensional (3D) bio-printed brain tumor in vitro model and a construction method thereof. The brain tumor in vitro model is obtained from a brain tumor cell-containing hydrogel system by preparing hydrogel fibers and constructing with a 3D bio-printer, wherein the hydrogel fibers has a diameter of 0.16-0.75mm, and has a volume filling percentage in the brain tumor in vitro model of 40-90 percent; the brain tumor cell-containing hydrogel system is prepared from the following raw materials: hyaluronic acid, sodium alginate, gelatin, glutamine transaminase and brain tumor cells. According to the brain tumor in vitro model, the 3D structure can be well maintained in the later culturing process, the problems of insufficient nutrition supply for cells inside large-sized hydrogel and biological characteristic and function loss of brain tumor cells when an existing brain tumor model is subjected to in vitro two-dimensional (2d) culture can be effectively solved.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

Surface active agent assisting alcohol-hydrothermal method for preparing anthoid BiVO4

The invention discloses an alcohol-hydrothermal method for preparing anthoid BiVO4. The method comprises the following steps of: under a stirring condition, adding cetylpyridinium chloride as a surface active agent to a mixed solution, wherein the volume ratio of ethanol to glycol to concentrated HNO3 (the concentration is 67 percent) in the mixed solution is 12:12:1, the concentration of the cetylpyridinium chloride is 0.48mol / L; adding Bi(NO3)3.5H2O and NH4VO3 according to the molar ratio of Bi(NO3)3 to NH4VO3 to nitric acid is 1:1:4 after dissolving; adding NaOH powder to control the pH value of the solution to 3-7; transferring the mixed solution into a stainless steel self compression kettle (the volume filling degree is 63 percent) with a polytetrafluoroethylene lining and putting the stainless steel self compression kettle in a thermostat for treating for 12h at a temperature of 100 DEG C; taking out the stainless steel self compression kettle and cooling to room temperature; and after drying an obtained product for 12h at a temperature of 60 DEG C, obtaining BiVO4 micron particles with monoclinic scheelite structures. Bismuth orthovanadate crystals with specific appearances obtained by the method have good application prospects in the field of photocatalysis, electrode materials, pigment, ionic conductive ceramics, and the like.

Owner:BEIJING UNIV OF TECH

Methods for modifying a crash deceleration pulse

A volume-filling mechanical structure for modifying a crash comprising a honeycomb celled material expandable from a dormant state to a deployed state; a support surface cooperatively positioned with the honeycomb celled material to cover a surface of the honeycomb celled material in the deployed and dormant states; and a means for deploying said volume-filling mechanical structure from said dormant state to said deployed state.

Owner:GM GLOBAL TECH OPERATIONS LLC

Volume-filling mechanical assemblies and methods of operating the same

ActiveUS20050234139A1Simple structurePedestrian/occupant safety arrangementBumpersHoneycombVolume filling

Owner:GM GLOBAL TECH OPERATIONS LLC

Calcium chloride-active carbon mixed adsorbent

InactiveCN1569324AImprove permeabilityIncrease in sizeOther chemical processesActivated carbonHeat conducting

The invention is a calcium chloride-active carbon compound sorbent. The sorbent can be divided into bulk and solid. The component and weight percentage of the sorbent with bulk type is: calcium chloride 60%-78%, active carbon 22%-40, the solid sorbent: calcium chloride 49%-60.2%, active carbon 17.2-32.7%, water 12.2%-15.1%, cement 6.1%-7.5%. The invention uses active carbon as base material, it upgrades the gas penetration performance and its volume filling quantity greatly. At the same time, because the filling density is large, it improves the heat conducting performance of the sorbent.

Owner:SHANGHAI JIAO TONG UNIV

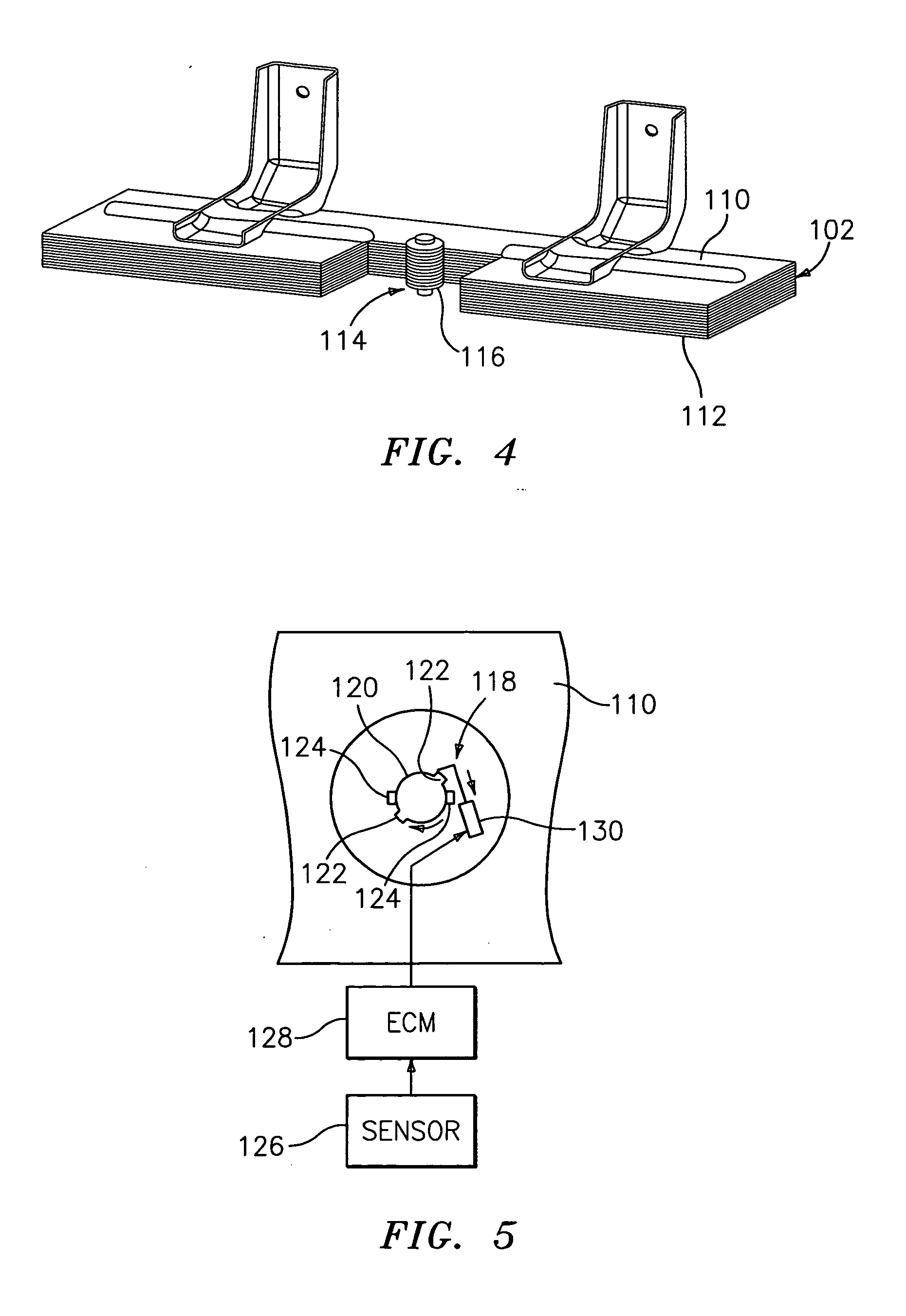

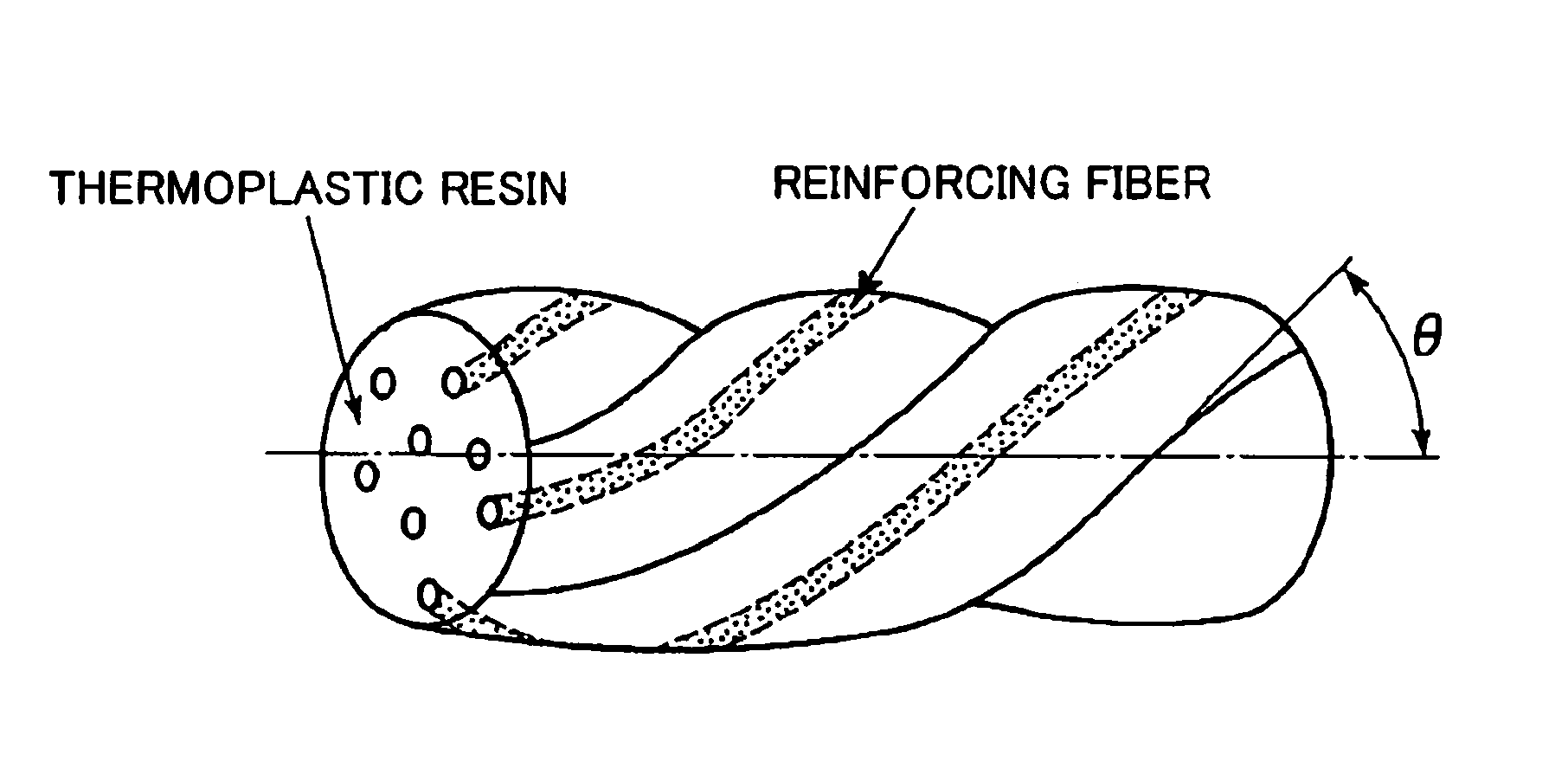

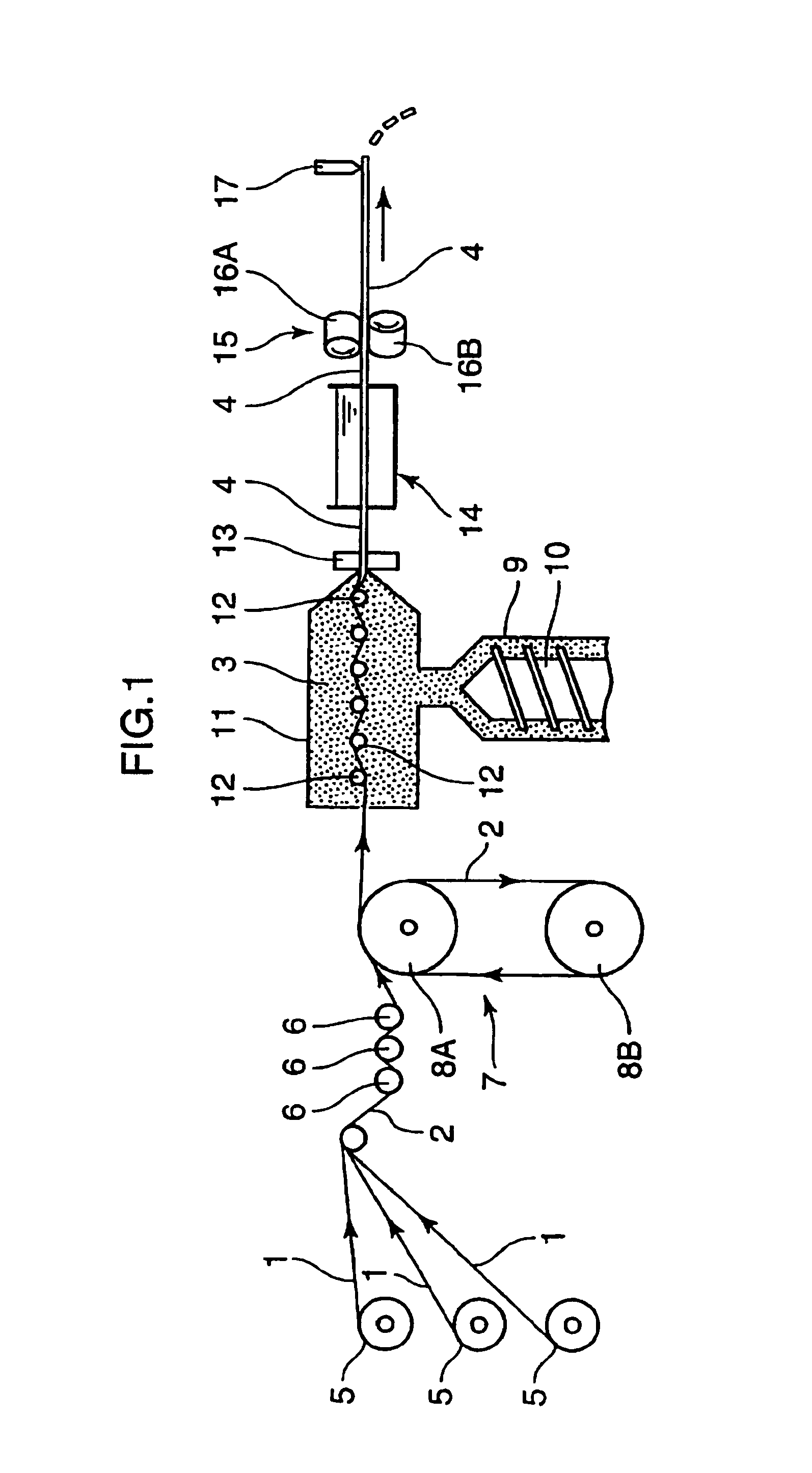

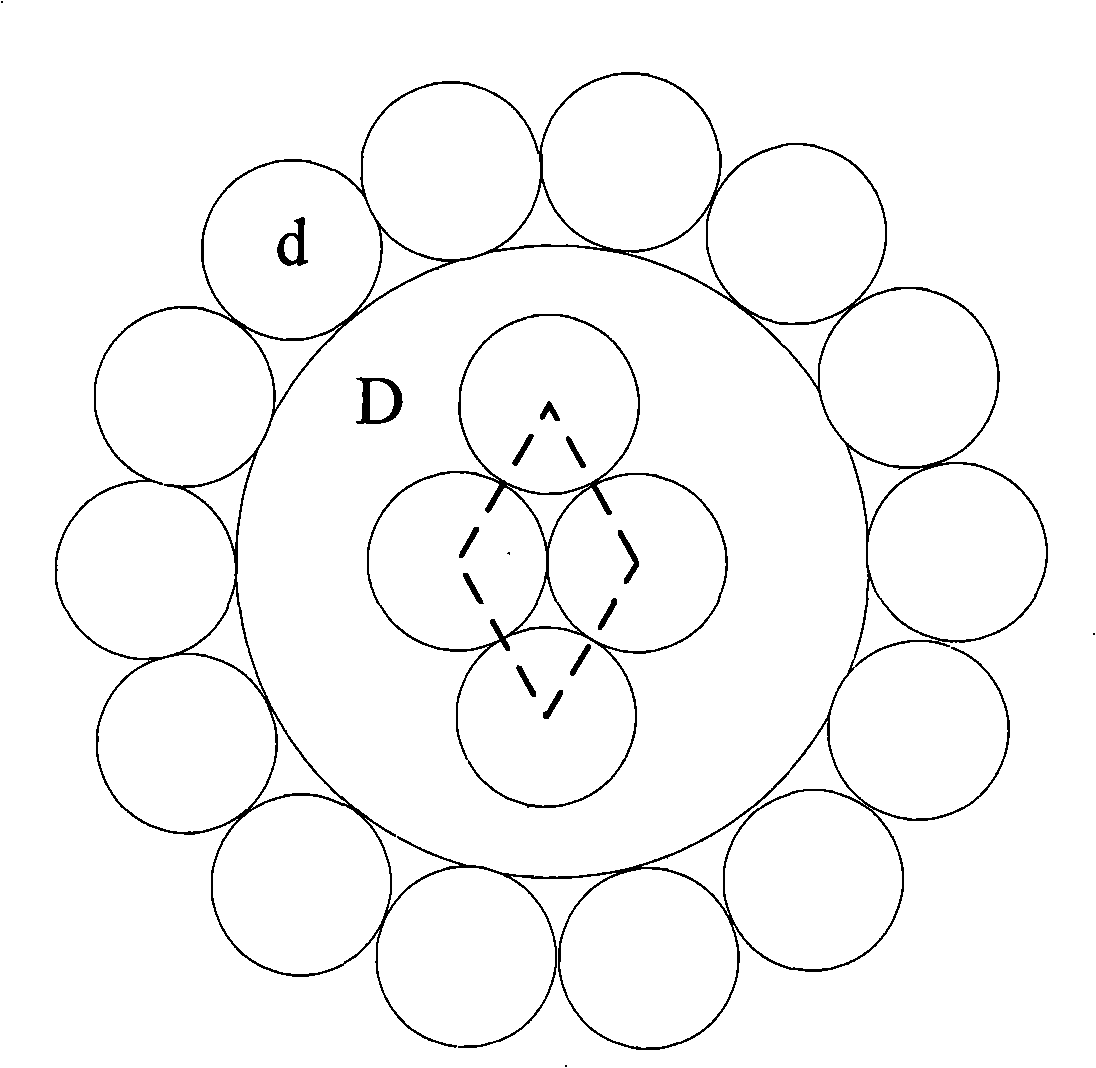

Continuous fiber-reinforced thermoplastic resin pellets and manufacturing method of the same

ActiveUS20100098946A1Good dispersionSatisfactory outward appearanceSynthetic resin layered productsCoatingsFiber bundleVolume filling

To provide continuous fiber-reinforced thermoplastic pellets having a good dispersion property of a reinforcing fiber bundle in injection molded articles and capable of achieving a satisfactory outward appearance of the injection molded articles and satisfying a mechanical strength of the injection molded articles by fully exerting the reinforcing effect, and a manufacturing method of the same.In continuous fiber-reinforced thermoplastic resin pellets manufactured by letting a long reinforcing fiber bundle be impregnated with molten thermoplastic resin and pultruding the resin-impregnated reinforcing fiber bundle with twisting, followed by the cutting of a rod-shaped composition formed of the twisted resin-impregnated reinforcing fiber bundle into pellets, a volume filling ratio Vf, which is a proportion of a cross section area of the reinforcing fiber bundle in a cross section area of a pellet cross section in a direction perpendicular to a pellet longitudinal direction, is in a range of 70% to 20%, and a twisting pitch P given by P=L / d (where L is a traveling length of a twist in a rod-shaped composition longitudinal direction per rotation of the rod-shaped composition, and d is a diameter of a circle comparable to an area of a rod-shaped composition cross section) is in a range of 2.5 to 36 (m / rev·m).

Owner:KOBE STEEL LTD

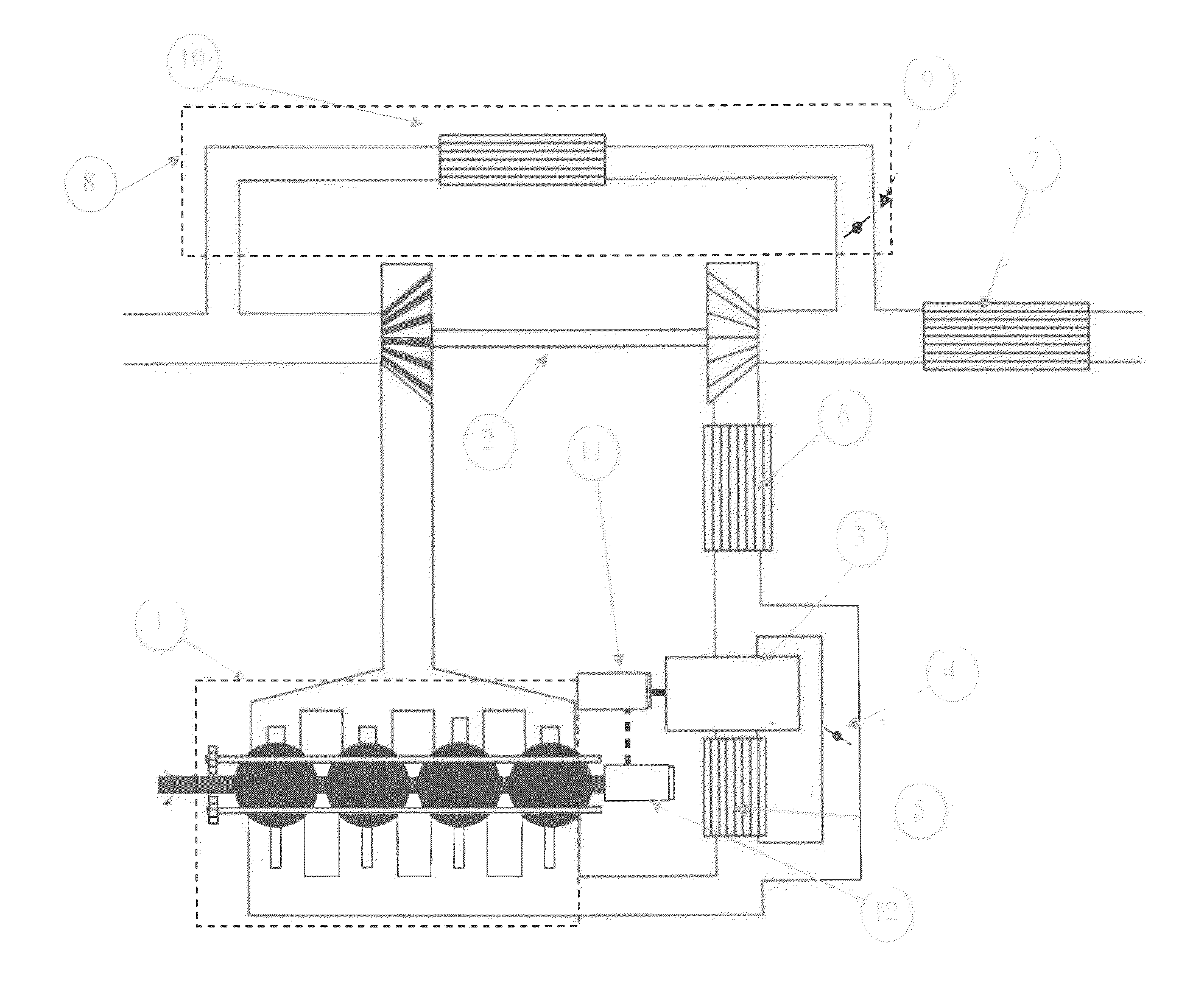

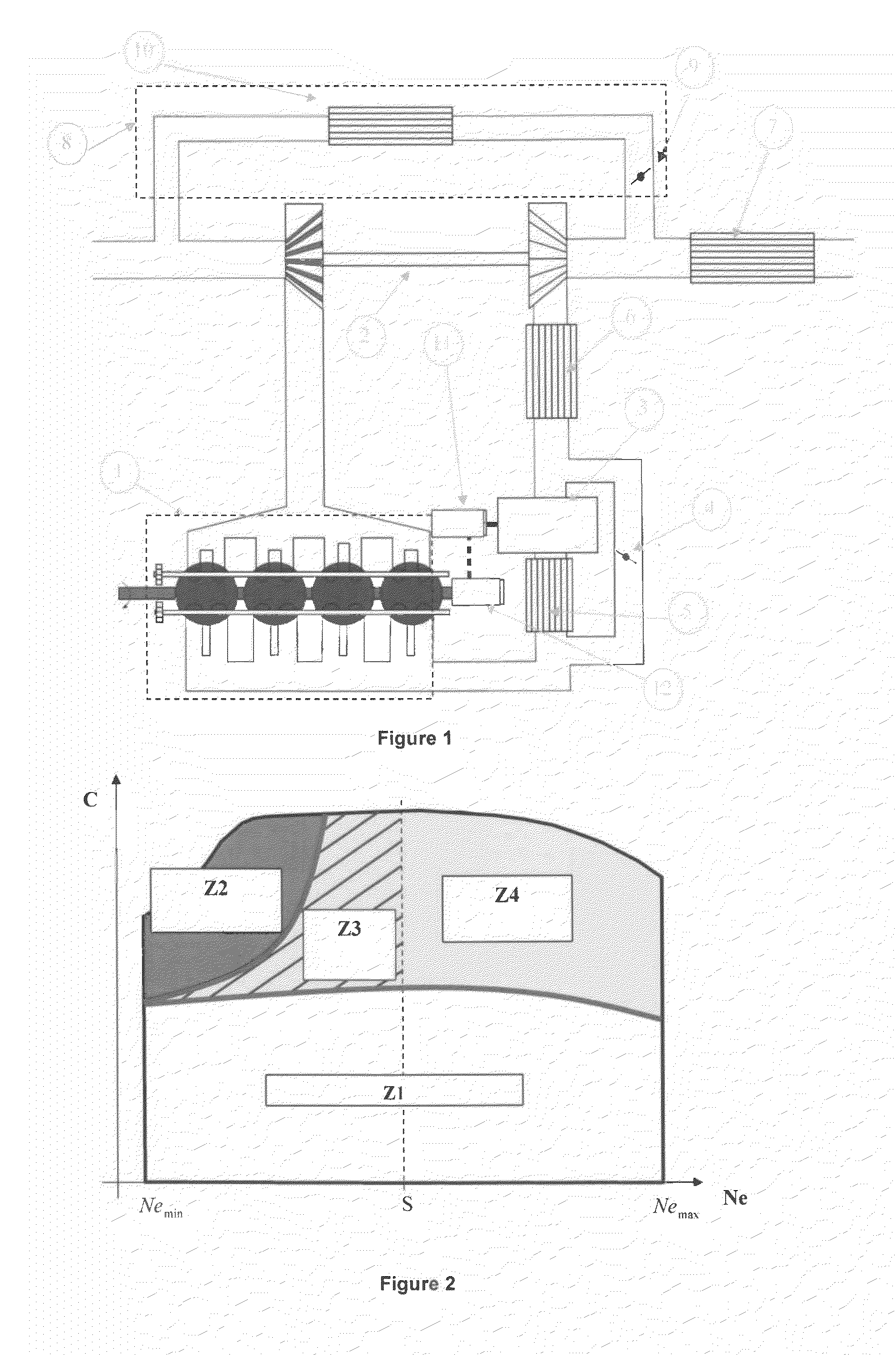

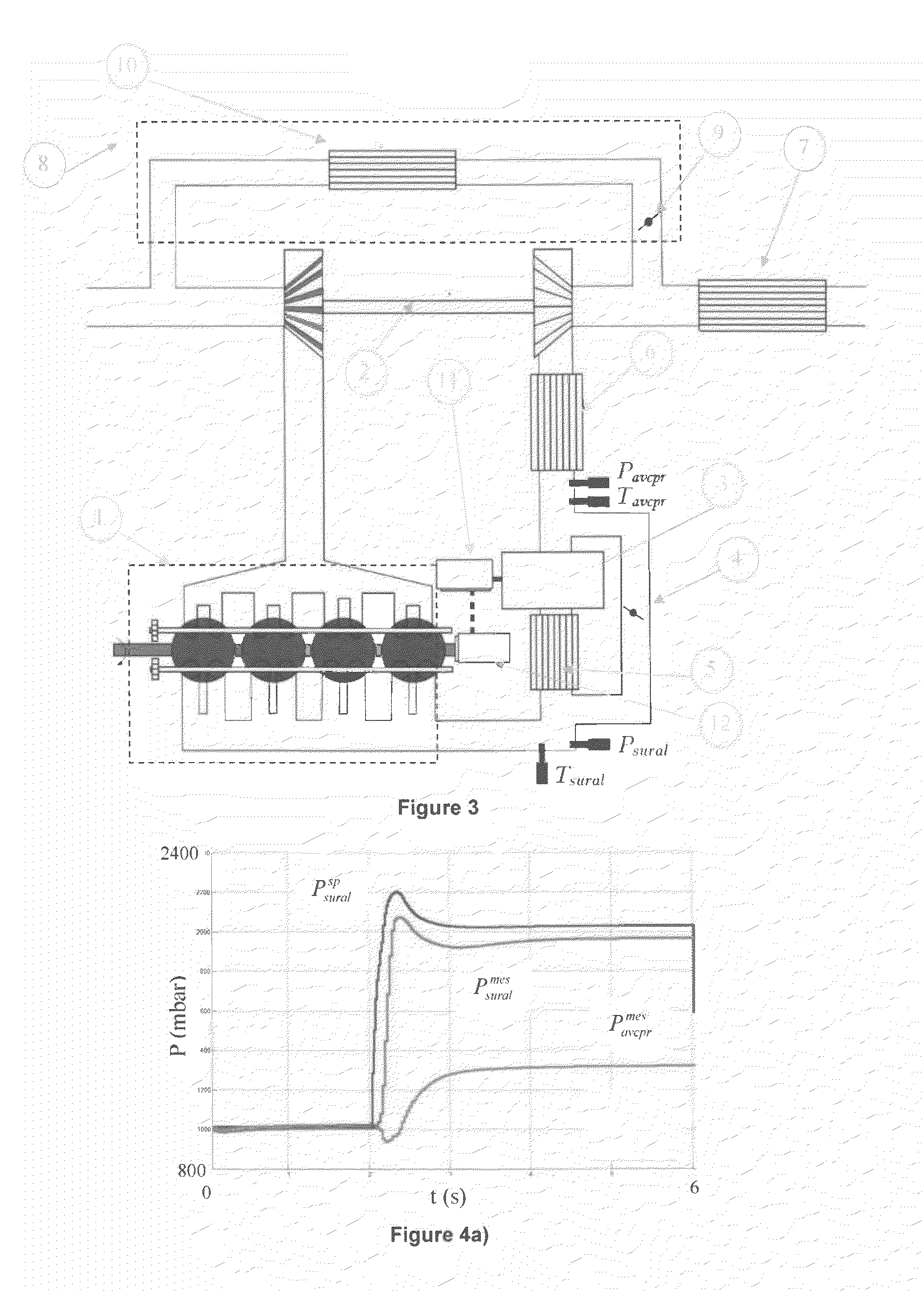

Method for controlling a dual-supercharged combustion engine

The invention relates to a combustion engine equipped with a dual supercharging system in which a mechanical compressor is driven by an electric motor. The method controls a combustion engine with the electric motor being controlled by determining a rotational speed setpoint for positive-displacement compressor using a supercharge volume filling model.

Owner:INST FR DU PETROLE

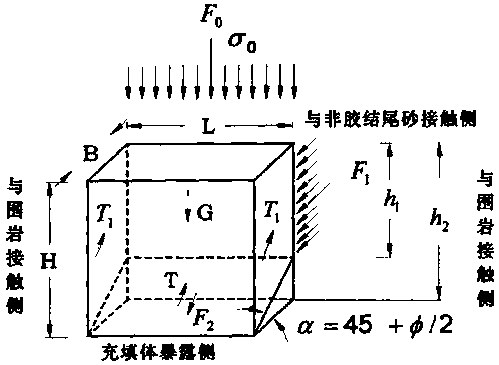

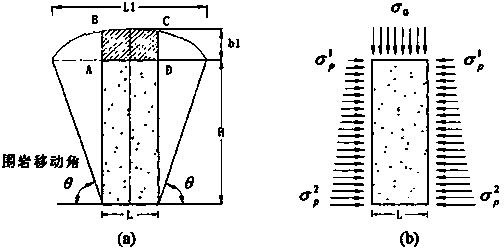

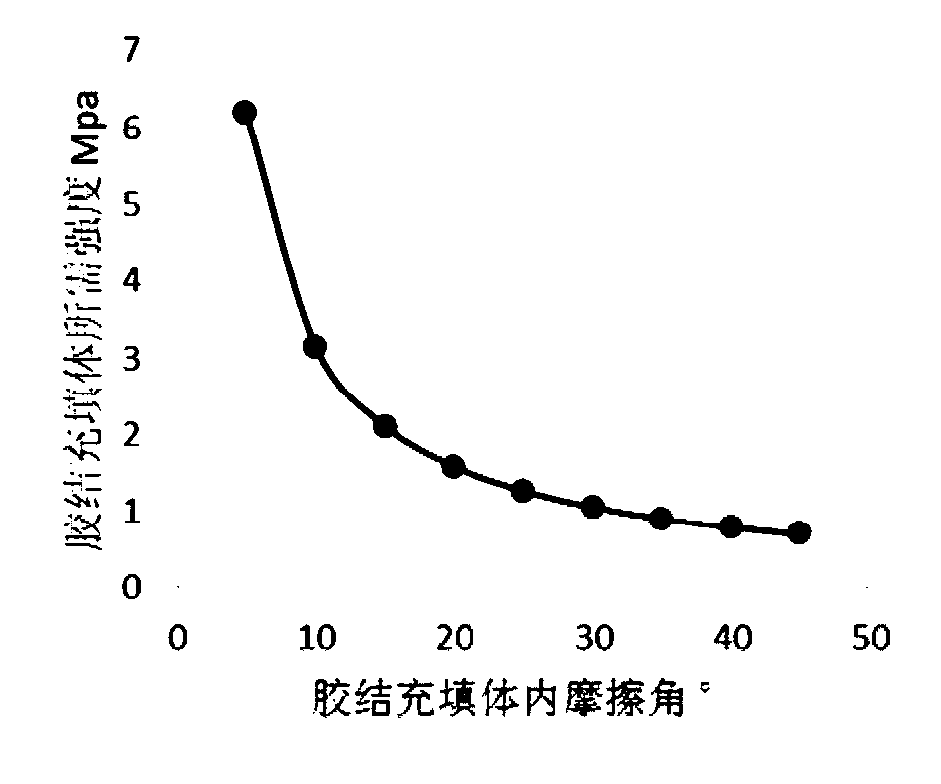

Construction method of large-volume-filling-body strength model of two-step open-stope subsequent-filling

ActiveCN107918712AHigh strengthSolve the disadvantages of solving the required strength of cemented filling bodyDesign optimisation/simulationSpecial data processing applicationsMineral SourcesVolume filling

Owner:YUXI MINING +1

Volume-filling mechanical assemblies and methods of operating the same

A volume-filling mechanical structure comprising a honeycomb celled material expandable from a compact state to an expanded state and methods for operating the same.

Owner:GM GLOBAL TECH OPERATIONS LLC

Volume-filling mechanical assemblies and methods of operating the same

A volume-filling mechanical structure comprising a honeycomb celled material expandable from a compact state to an expanded state and methods for operating the same.

Owner:GM GLOBAL TECH OPERATIONS LLC

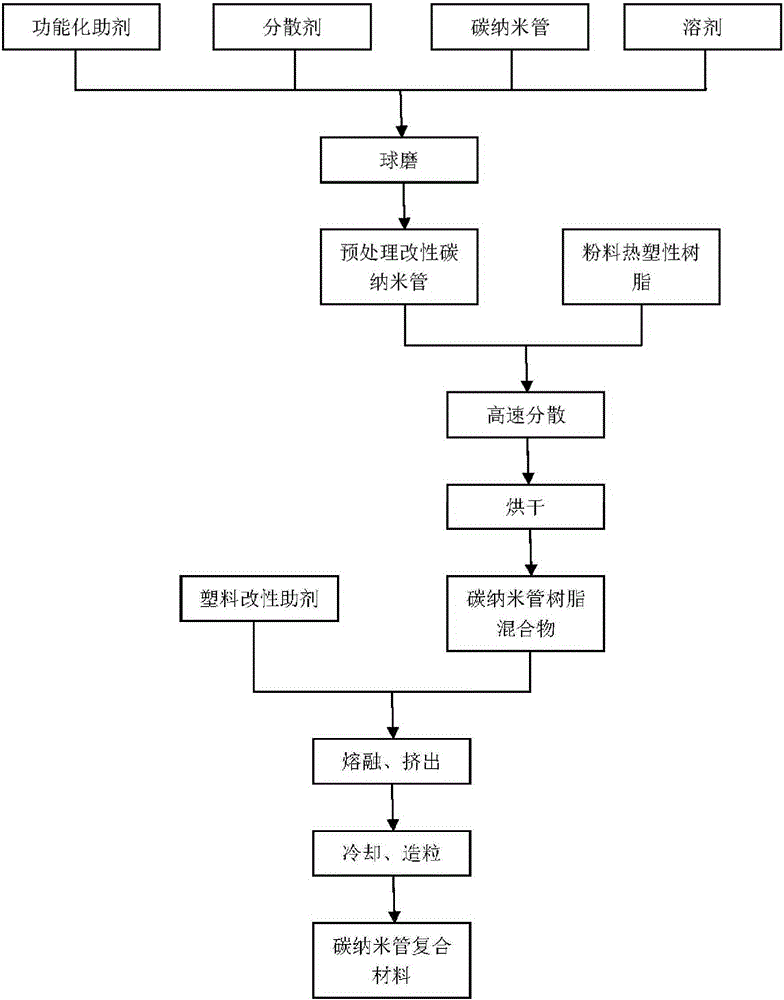

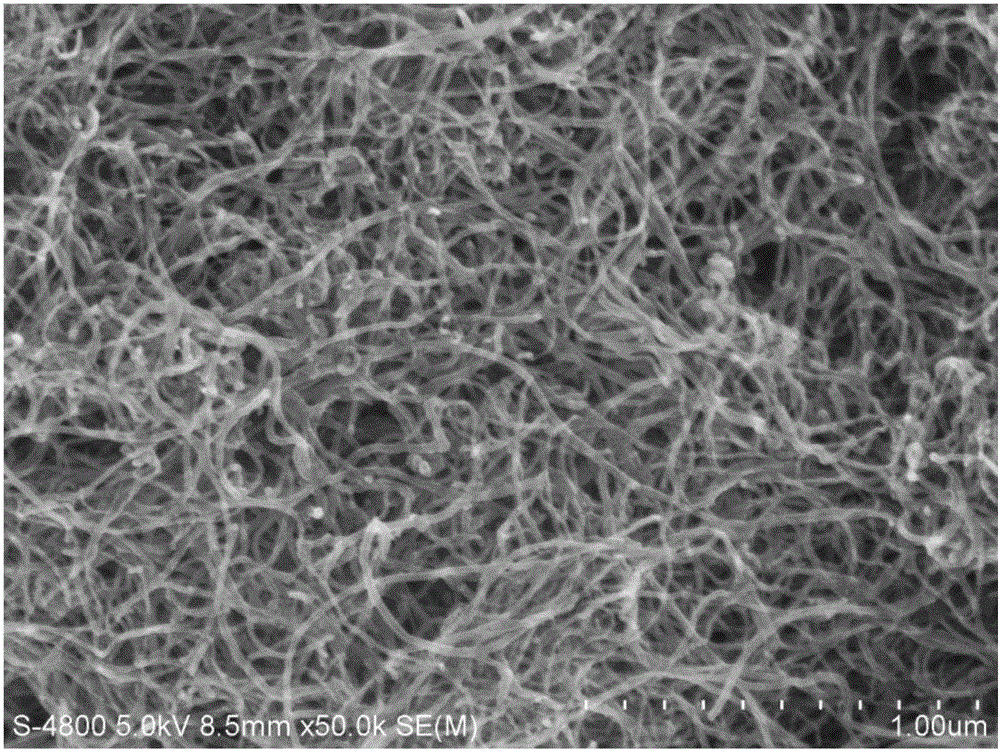

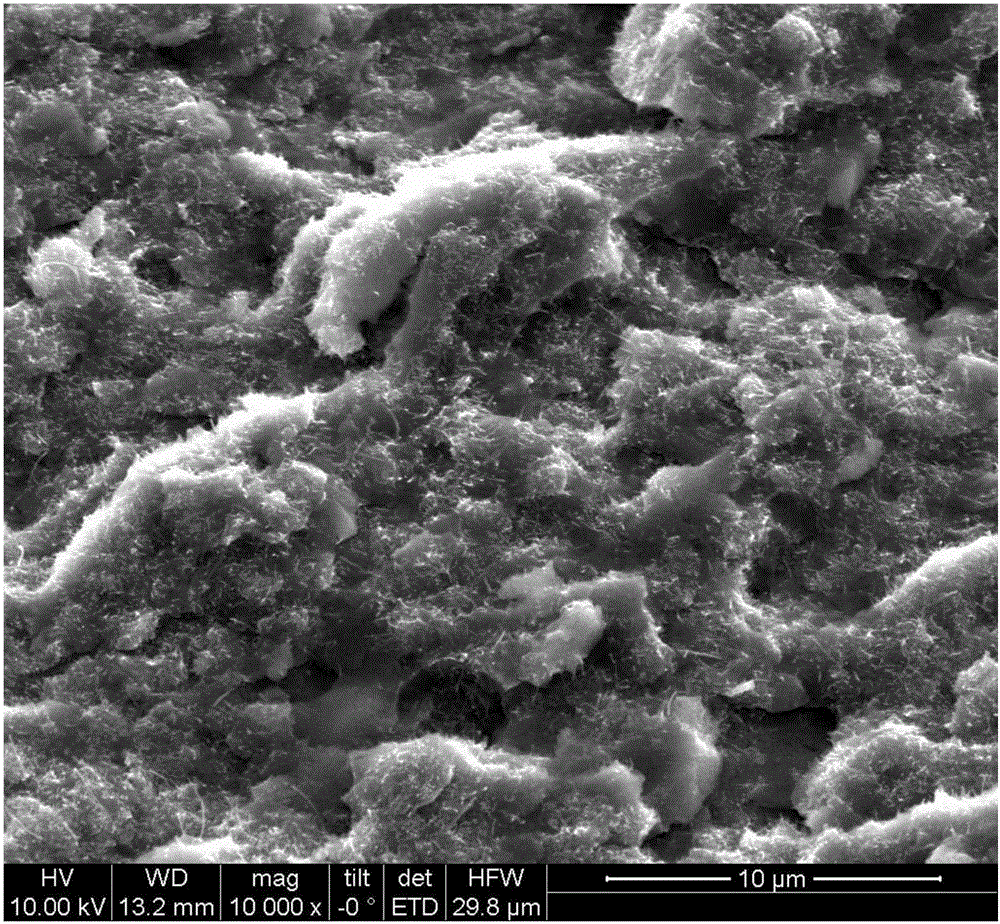

Carbon nanotube modified thermoplastic resin and preparation method thereof

The invention discloses carbon nanotube modified thermoplastic resin and a preparation method thereof. The preparation method is as follows: mixing carbon nanotubes, a functional agent, a dispersing agent and a solvent for ball milling to obtain pretreated modified carbon nanotubes; using a high speed dispersion process for fully stirring and mixing the pretreated modified carbon nanotubes and thermoplastic resin powder to obtain a stably-dispersed carbon nanotube / resin mixture; drying the carbon nanotube / resin mixture, adding a plastic modified additive, and using a double screw extruder for melt extrusion and cooling granulation to obtain the target product. Through use of carbon nanotube functionalization and pre dispersion one-step treatment process, the process is greatly simplified; at the same time, the thermoplastic resin powder is used as a raw material to obtain effective mixing and dispersion of pretreated carbon nanotube powder, and then carbon nanotube high volume filling can be realized. The preparation method has the obvious advantages of simple process, environmental protection, low cost and the like, and is an effective preparation technology of a carbon nano tube functional master batch.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Volume filling mechanical structures for modifying crash deceleration pulse

InactiveUS6877795B2Large crush forceImprove rendering capabilitiesVehicle seatsPedestrian/occupant safety arrangementBrickHoneycomb

A mechanical, active crash pulse management structure for providing modification of crash pulse, wherein the structure has a dormant (initial) state volume, but then in the event of a crash, timely expands into a much larger deployed volume for providing management of an expectant crash energy. The preferred crash energy management structure is a before expansion honeycomb celled material brick, wherein expansion of the honeycomb brick is in a plane transverse to the cellular axis of the cells thereof, and crash crush is intended to be parallel to the cellular axis. In the event of a crash, either an active or passive activation mechanism is provided for causing expansion of honeycomb celled material.

Owner:GM GLOBAL TECH OPERATIONS LLC

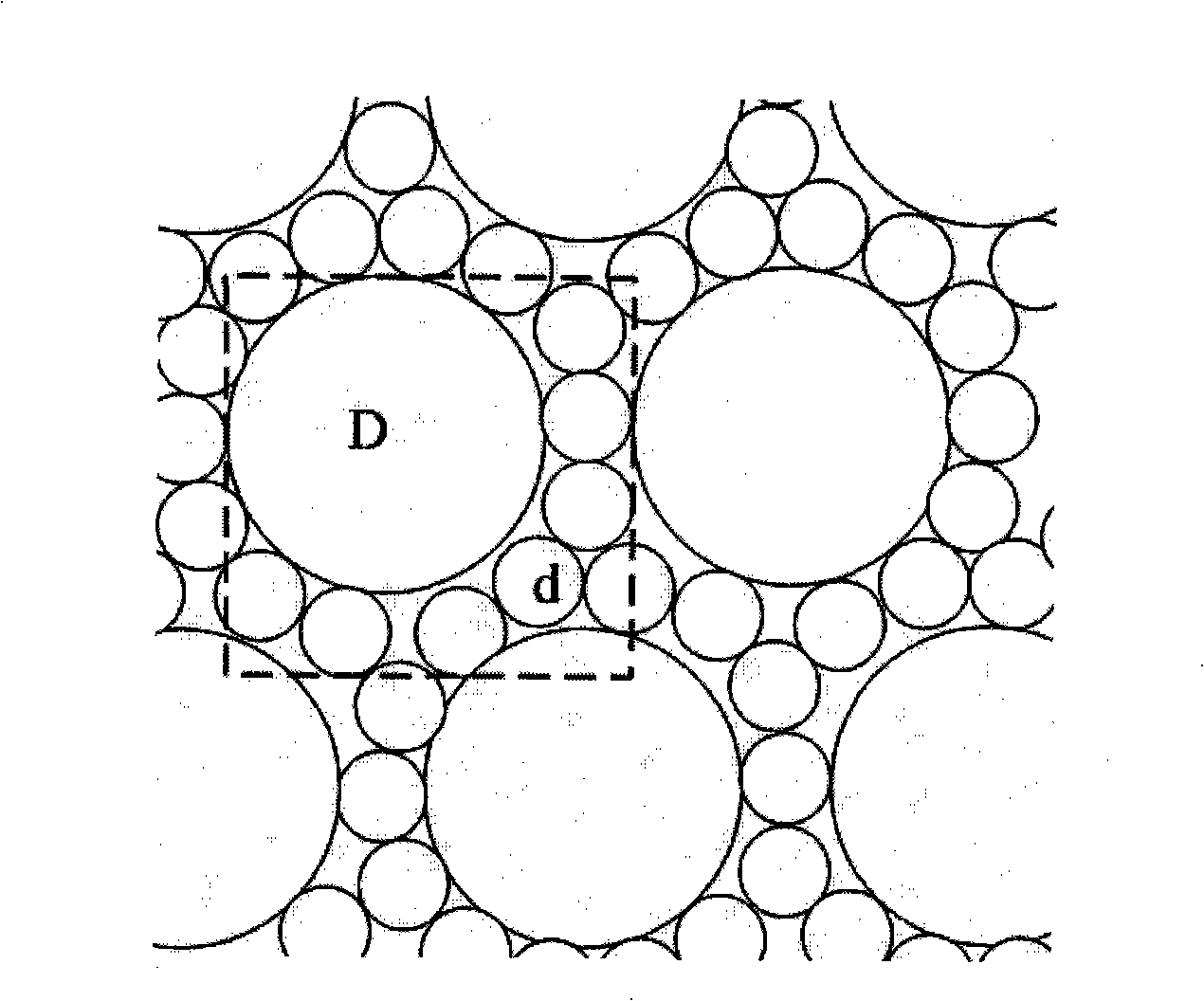

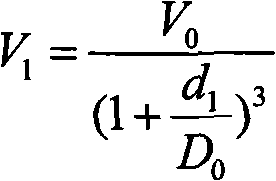

Framework type asphalt mixture gradation design method

InactiveCN101492270AOvercome the defect of not paying enough attention to gradation selectionEasy to acceptFill rateRoad surface

The invention relates to a method for designing graduation of a dense-framework type asphalt mixture, and belongs to a method for designing the graduation of a mixture. The method comprises the following: step one, determining the volume filling rate V0 of coarsest aggregate of which the diameter is D0 in the asphalt mixture when the coarsest aggregate solely forms the mixture; step two, after the sole filling rate of the coarsest aggregate is determined, according to V1=V0 / ((1+d1 / D0)), calculating the volume filling rate of the coarsest aggregate in a system of coarse and fine aggregates of which the diameters are D0 and d1; step three, according to the formula, after the V1 of the D0 is deducted, calculating the volume filling rate of the coarsest aggregate in the system of the coarse and fine aggregates of which the diameters are d1 and d2; and step four, repeating the step two and the step three till the last grade of the fine aggregate of the asphalt mixture. The method provides reasonable design steps for the graduation of the dense-framework type asphalt mixture, and is an important technical measure for improving the high-temperature property of asphalt pavement.

Owner:SOUTHEAST UNIV

Braided occlusion device having repeating expanded volume segments separated by articulation segments

The present invention provides a flexible, low profile vascular occlusion device having large volume filling capability and high metal content for fast occlusion, of the type fabricated from braided tubular metal fabric having an expanded preset configuration and an elongated collapsed reduced diameter configuration for delivery through a catheter to a treatment site and shaped to create an occlusion of an abnormal opening in a body organ or vessel, the woven metal fabric having a memory property whereby the medical device tends to return to said expanded preset configuration when unconstrained. The device further includes a first shape formed from the braided tubular fabric consisting of a repeating pattern of expanded volume segments separated by small diameter articulation segments and a second overall device shape comprised of the first shape formed about itself in various shapes to occlude a vessel. In one embodiment a shaping wire contained coaxially within the tubular braid, provides or assists in the formation of the second overall device shape.

Owner:AGA MEDICAL CORP MS US

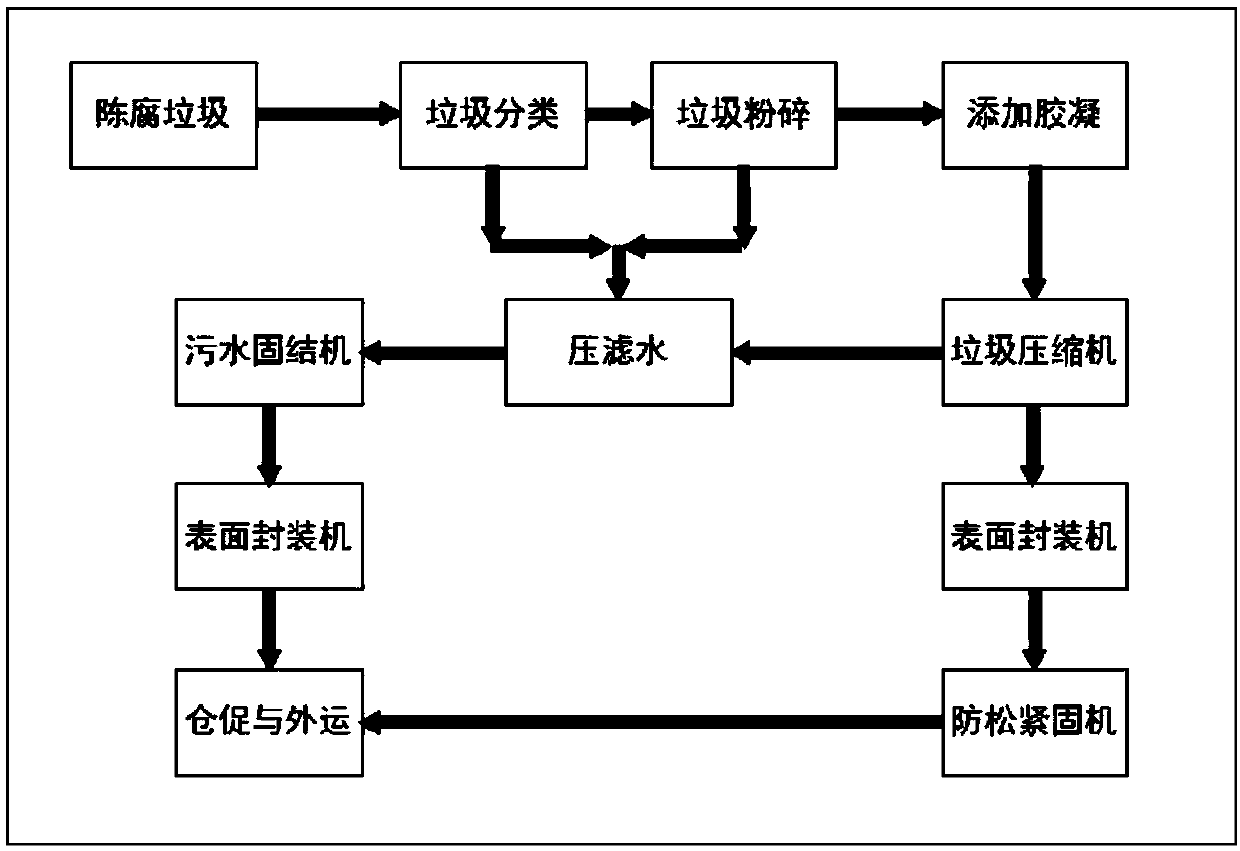

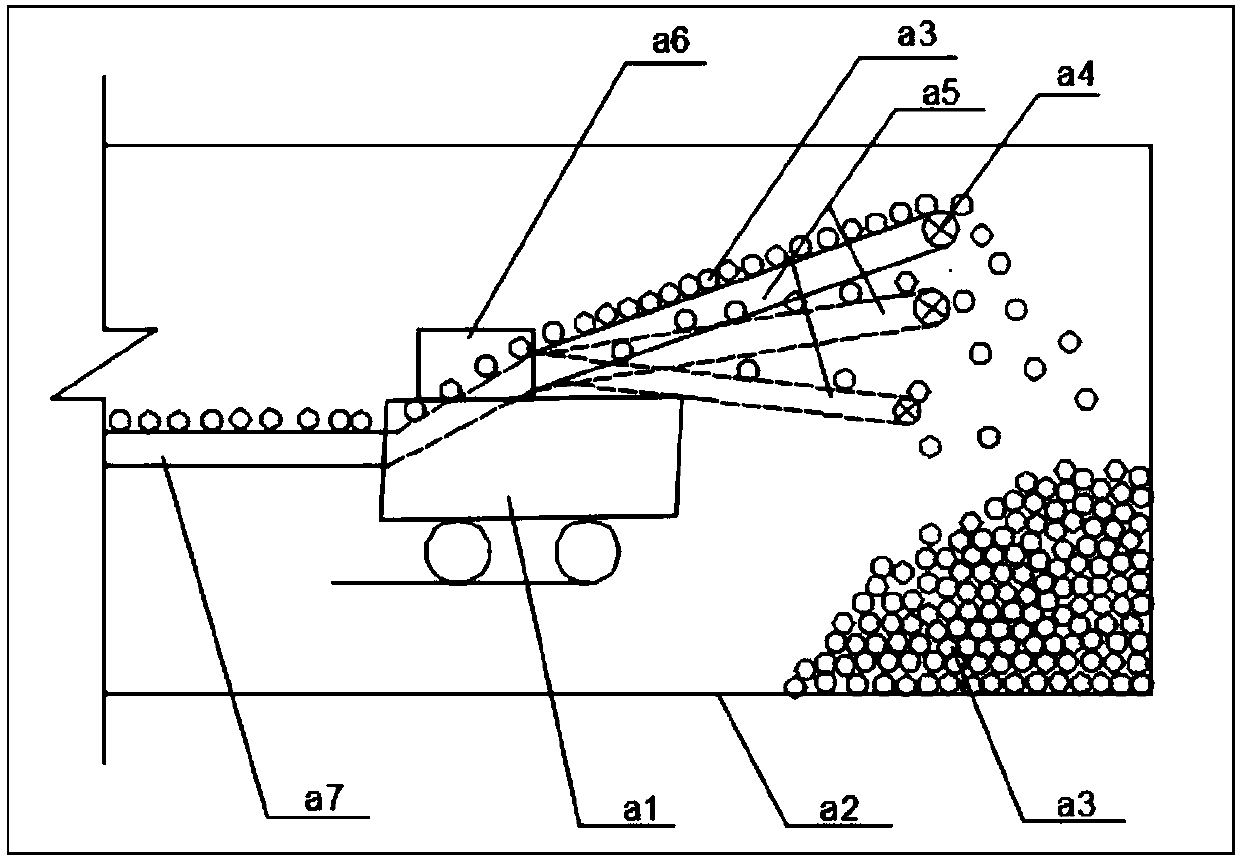

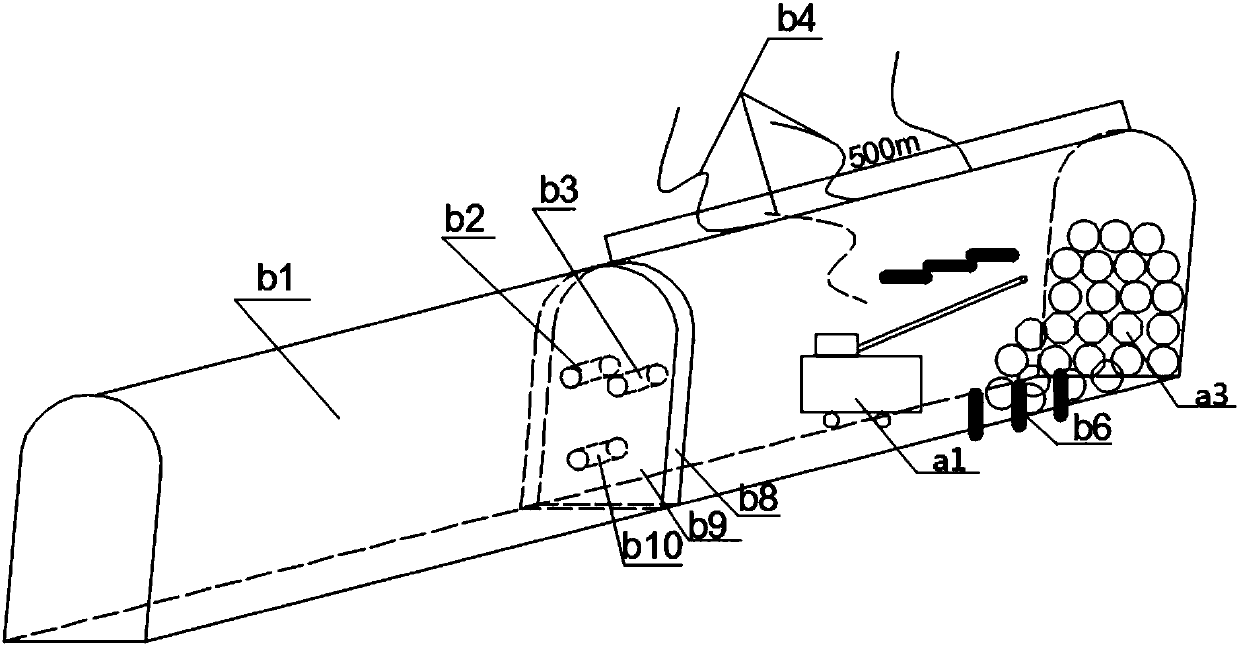

Municipal solid waste deep well sealing and filling mining method

ActiveCN107725051AReduce pollutionMitigation capacityUnderground miningLandfill technologiesMineral SourcesPipeflow

The invention provides a municipal solid waste deep well sealing and filling mining method and belongs to the technical field of mining engineering and environmental engineering. The municipal solid wastes are processed to form cubes or balls through a waste formation machine, the cubes or balls are transmitted to a mine enterprise from a treatment plant in peri-urban areas and then are conveyed to position under a well through a drilling pipe or an auxiliary shaft on the mine ground, then the cubes or balls are conveyed to a waste tunnel and a work surface through a flat car or a belt, closedtreatment on the municipal solid waste in a deep well waste tunnel is carried out through a volume filling technology according to different cases, and filling treatment on a replaced mine resource on a coalface through a strength filling process is carried out. The method solves the problem that the municipal waste treatment resource is limited and a mining waste space has a large space amount and a wide range, is a novel method for treatment on wastes with wastes and harm and disaster reduction for the city government and mine enterprise and is economic, environmentally friendly, safe and efficient.

Owner:UNIV OF SCI & TECH BEIJING

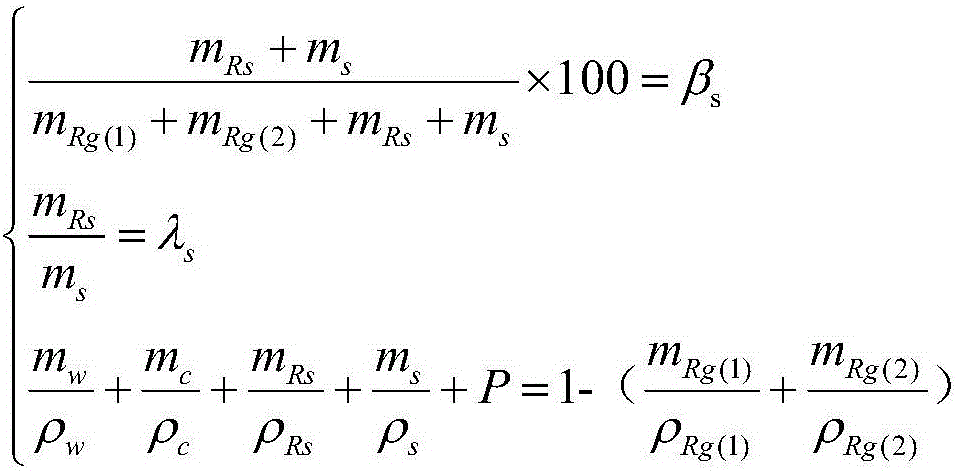

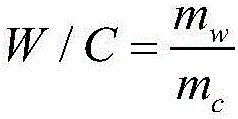

Laboratory mix proportion design method of permeable recycled aggregate concrete

ActiveCN106227976AReduce quality fluctuationsGeometric CADSpecial data processing applicationsVoid ratioCombined method

The invention provides a laboratory mix proportion design method of permeable recycled aggregate concrete. The laboratory mix proportion design method is adaptable to characteristics of more cracks, high water absorption rate and large design mix proportion experimental result volatility of building rubbish recycled aggregates. Compared with a common concrete mix proportion design method, by the aid of an experiment and calculation combined method and a framework volume filling method, double-control indexes design void ratio and compressive strength serve as a main design target, and a recycled coarse-fine aggregate and natural sand serve as design references of a surface dry state and an air drying state respectively. The design method is simple, practical, narrow in fluctuation range, less in cement content, high in recycling degree, economical and environmentally friendly, quality is easily controlled, and addition agents and admixtures are omitted.

Owner:SHANDONG JIAOTONG UNIV

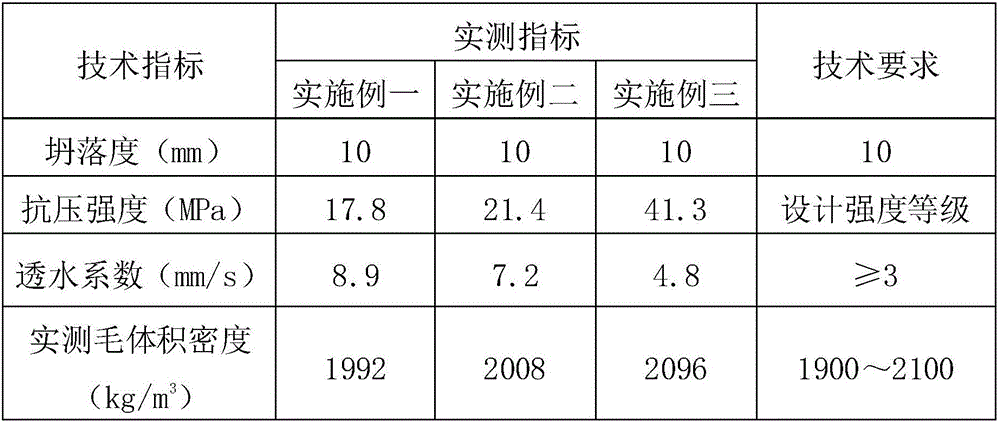

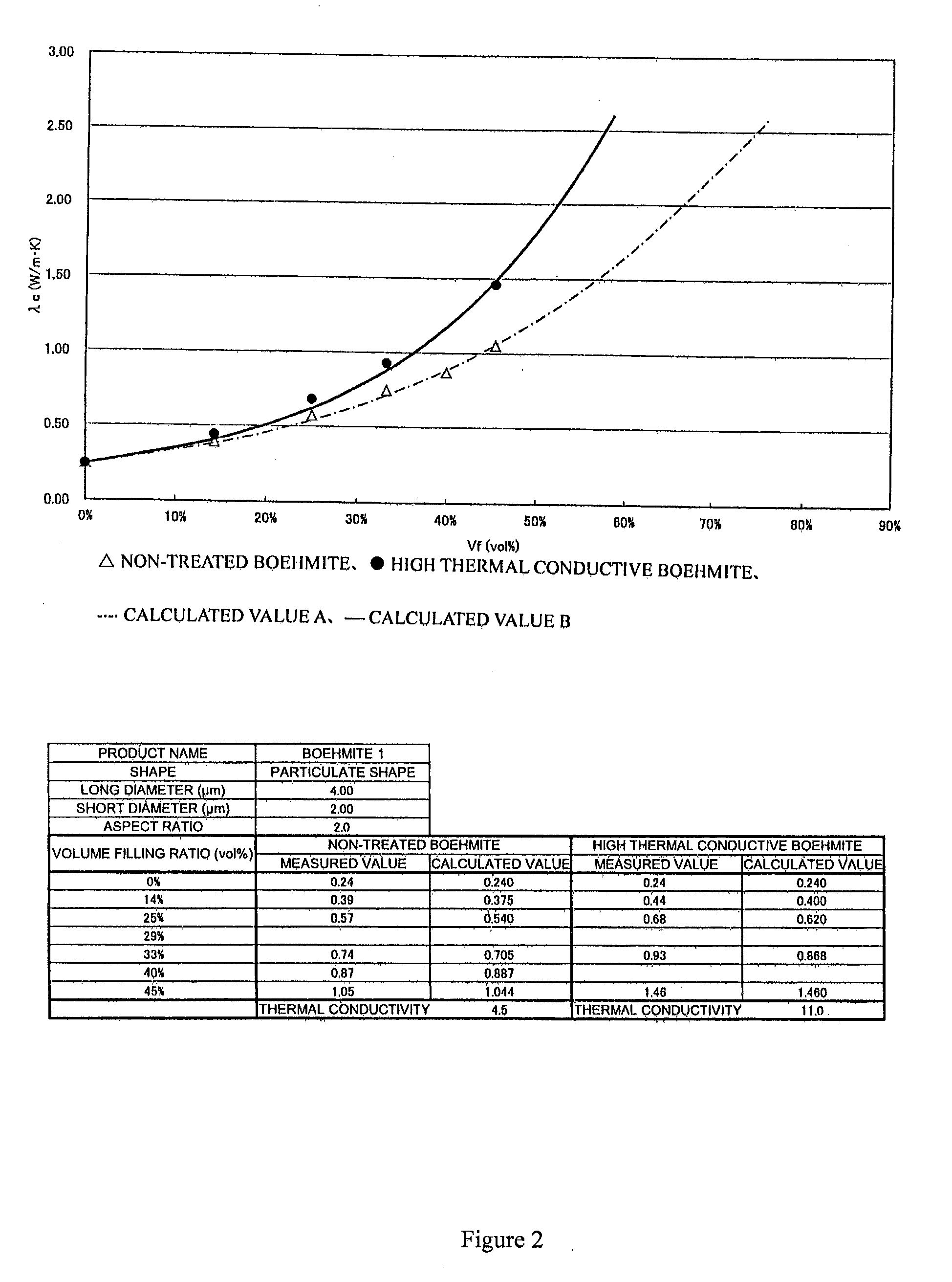

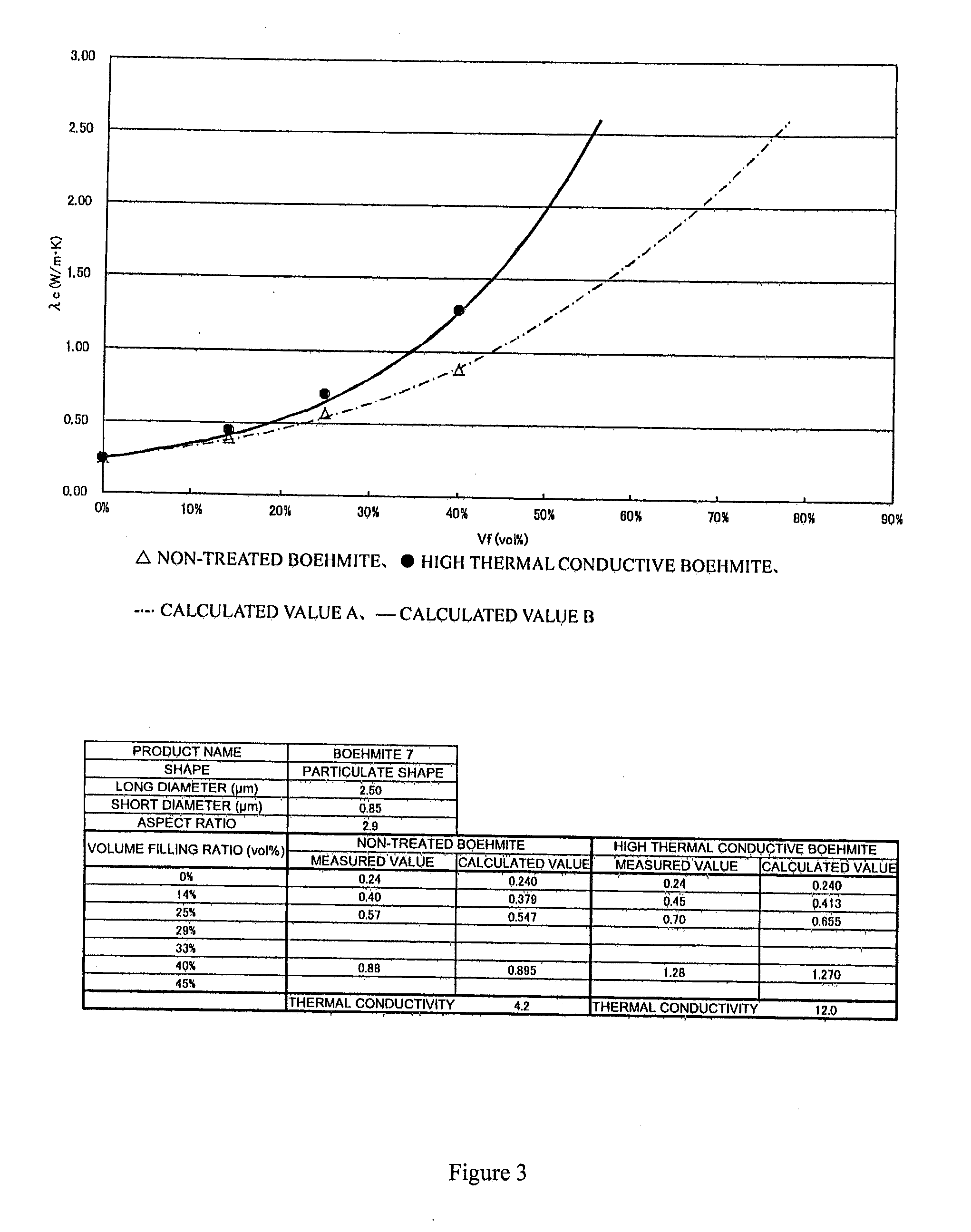

High thermal conductive boehmite and method for manufacturing same

InactiveUS20150299551A1Improve thermal conductivityEasy to fillAluminium compoundsHeat-exchange elementsVolume fillingFilling ratio

Provided are high thermal conductive boehmite, which has the characteristics of boehmite such as flame retardancy and high filling and yet has an improved thermal conductivity, and a method for manufacturing the high thermal conductive boehmite. The high thermal conductive boehmite is characterized by having thermal conductivity calculated in accordance with the following Mathematical Formula 1 of 11.0 W / m·K or greater;1−Vf=(λc−λf) / (λm−λf)×(λm / λc)̂(1 / n)n=3 / ψ [Mathematical Formula 1](with the proviso that, Vf represents the volume filling ratio of boehmite, λc represents the thermal conductivity (W / m·K) of a boehmite-resin composite, λf represents the thermal conductivity (W / m·K) of boehmite, λm represents the thermal conductivity (W / m·K) of the resin, n represents the shape factor of filler particles proposed by Hamilton and Crosser, ψ represents a value calculated by dividing the surface area of a sphere that has the same volume of a boehmite particle volume by the surface area of an actual particle, and ̂ represents exponentiation).

Owner:KAWAI LIME IND

Mixed organic solvent-thermal method for preparing spherical or hollow spherical BiVO4

InactiveCN102502821ARaw materials are cheap and easy to getSimple processVanadium compoundsVolume fillingThermal methods

The invention relates to a mixed organic solvent-thermal method for preparing spherical and hollow spherical BiVO4, and belongs to the technical field of BiVO4. The method comprises the steps of: adding Bi(NO3)3 and NH4VO3 at a stoichiometric ratio of 1:1 to a mixed liquid of ethanol, acetylacetone and concentrated HNO3 at a volume ratio of 9:1:1, sufficiently dissolving, adding oleyl amine at a molar ratio of oleyl amine to Bi(NO3)3 being 15.5:1, adjusting the pH of the solution to 1.5 or 5 with triethanolamine, transferring the solution to a stainless steel autogenous pressure kettle with apolytetrafluoroethylene inner lining at a volume filling degree of 80%, carrying out heat treatment at 100 DEG C for 12 hours, cooling, filtering the product, washing, drying, placing in a muffle furnace, heating to 400 DEG C at a heating rate of 1 DEG C / min and burning for 4 hours. According to the invention, the process is simple; and the target product has a controllable particle appearance and crystalline phase structure, and has excellent application prospects in photocatalysis, electrode materials, pigments, ionic conduction ceramics and other fields.

Owner:BEIJING UNIV OF TECH

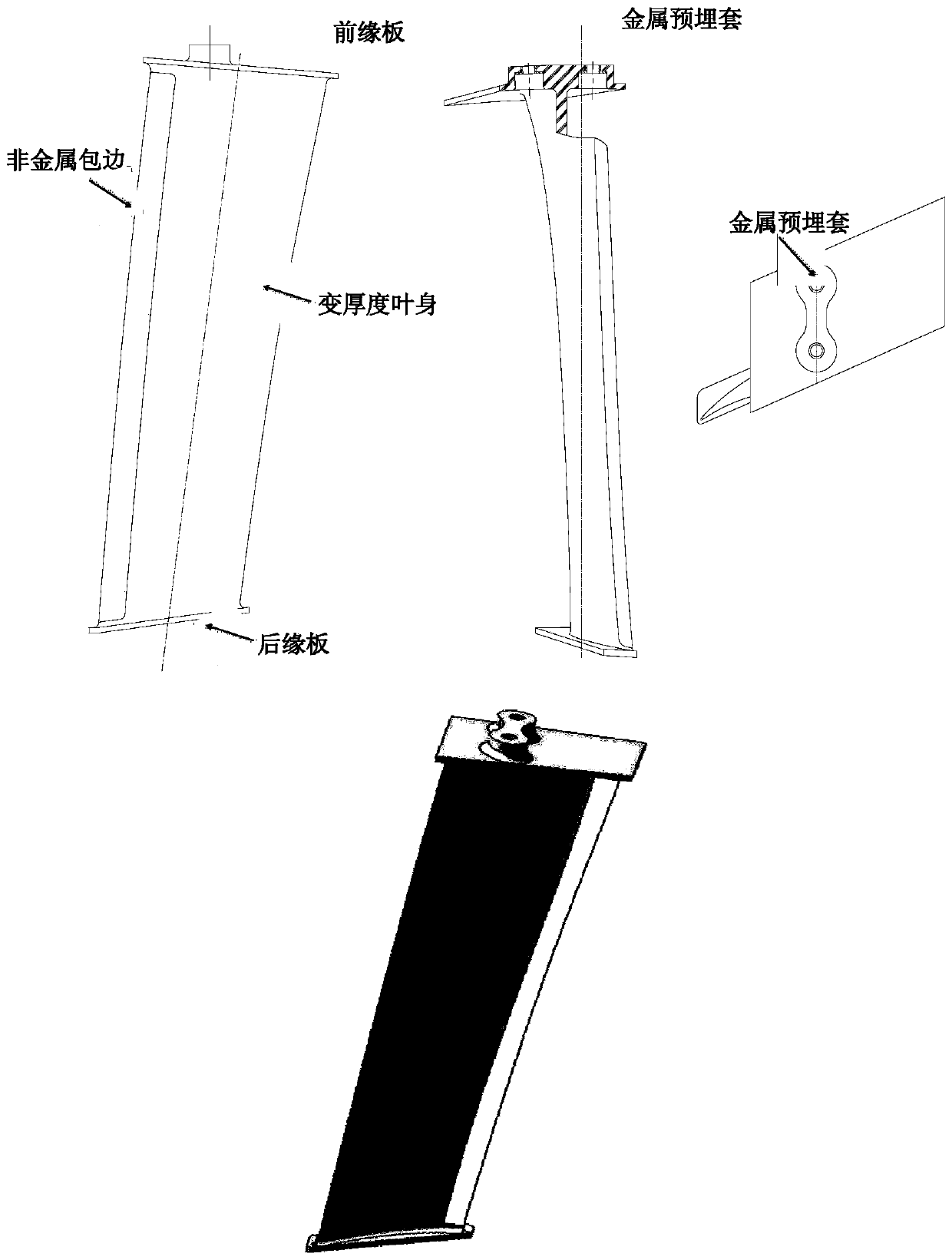

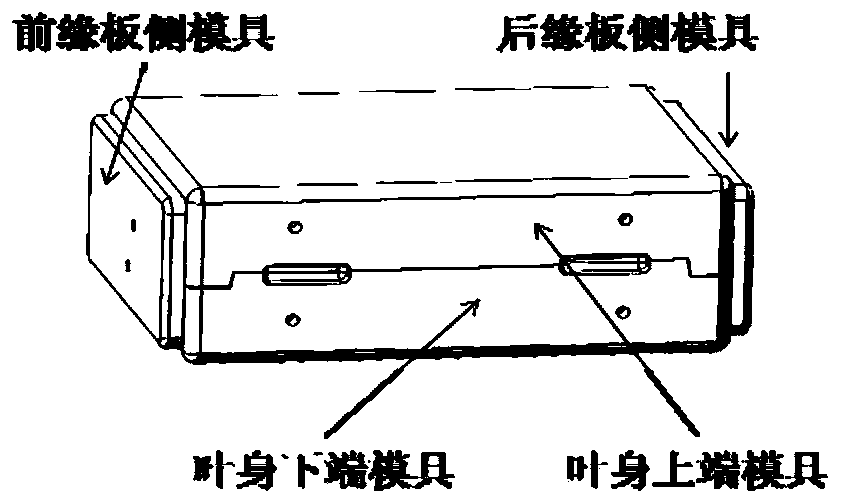

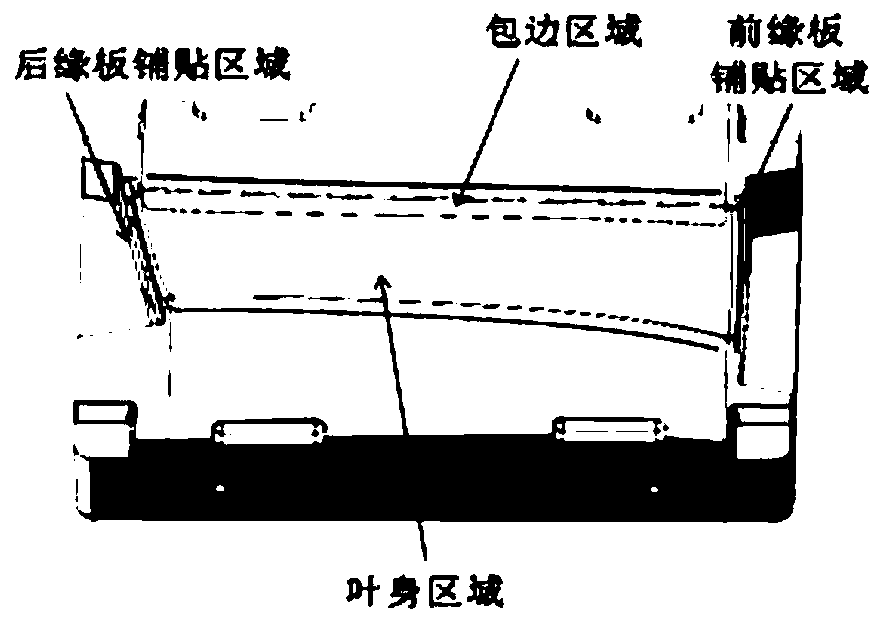

Variable thickness composite stator blade and molding method thereof

ActiveCN110439630AMeet structural strength and rigidity requirementsMeet the surface accuracy requirementsStatorsMachines/enginesTotal thicknessVolume filling

The invention relates to a variable thickness composite stator blade and a molding method thereof, in particular to the variable thickness stator blade integral molding technology and belongs to the technical field of advanced composites. The blade comprises a front edge plate, a variable thickness blade body and a rear edge plate which are integrally formed by the same material. The windward sideof the blade body is protected through a wear-resistant nonmetal edge wrapper. A forming mold is designed to a combined mold communicating four combined modules, and the forming mold is provided witha closed mold cavity. Tapered guiding and limiting matching surfaces are designed between the modules. Through combination of an extracted blade body neutral surface and a net volume filling method,a side line contour of laid prepreg layers conforming to the total thickness of different areas of the blade body is simulated and designed. A preform of the blade is manufactured from a continuous-filament woven fabric prepreg on four forming molds. Metal is embedded and inlaid in the corresponding position. The embedded part and the blade body are subjected to co-curing preparation through the hot pressing process. The molding method ensures that the stator blade can meet the requirements for the structural strength and stiffness and also meet the requirement for the precision of the moldedsurface of the aerodynamic configuration.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

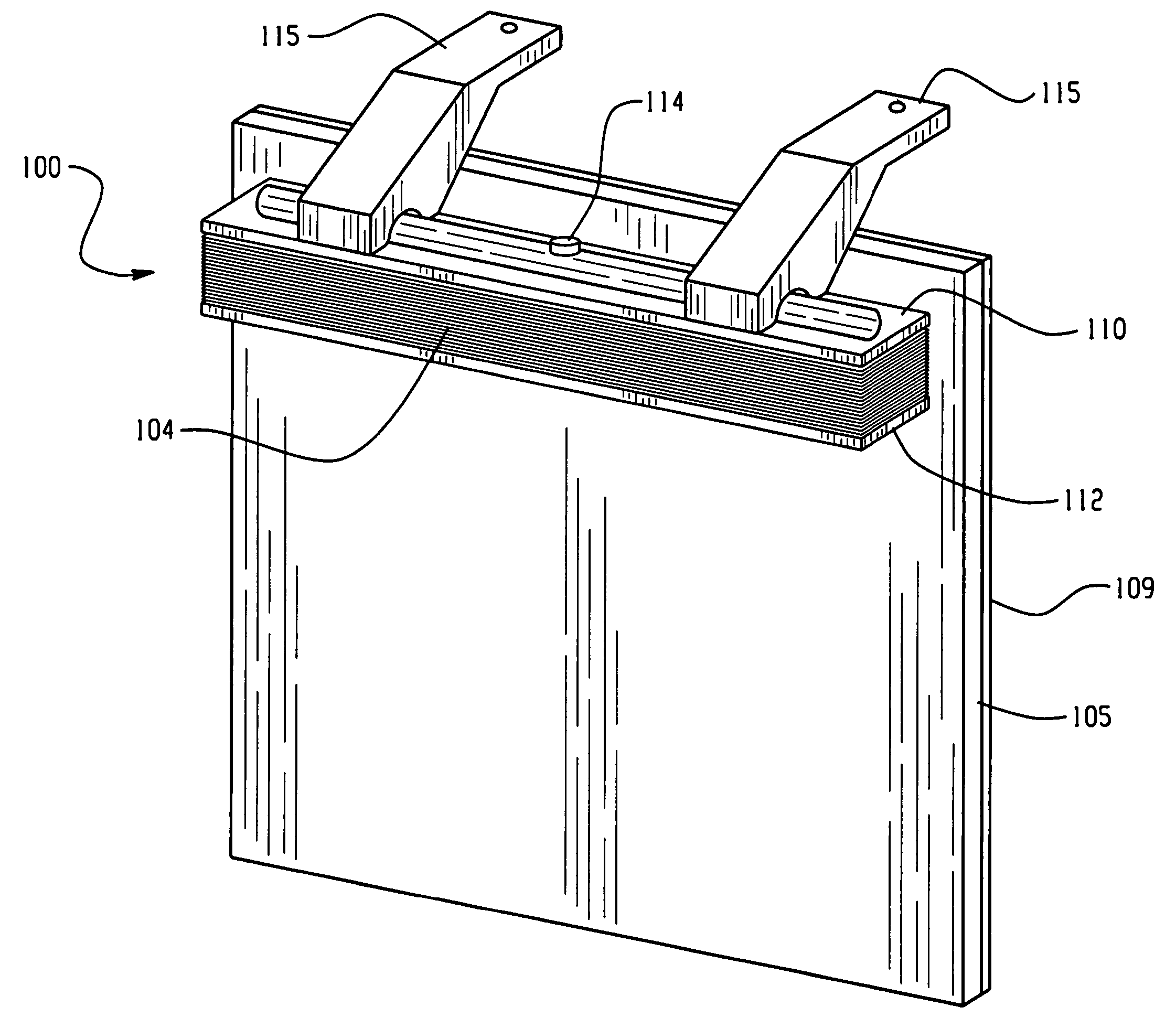

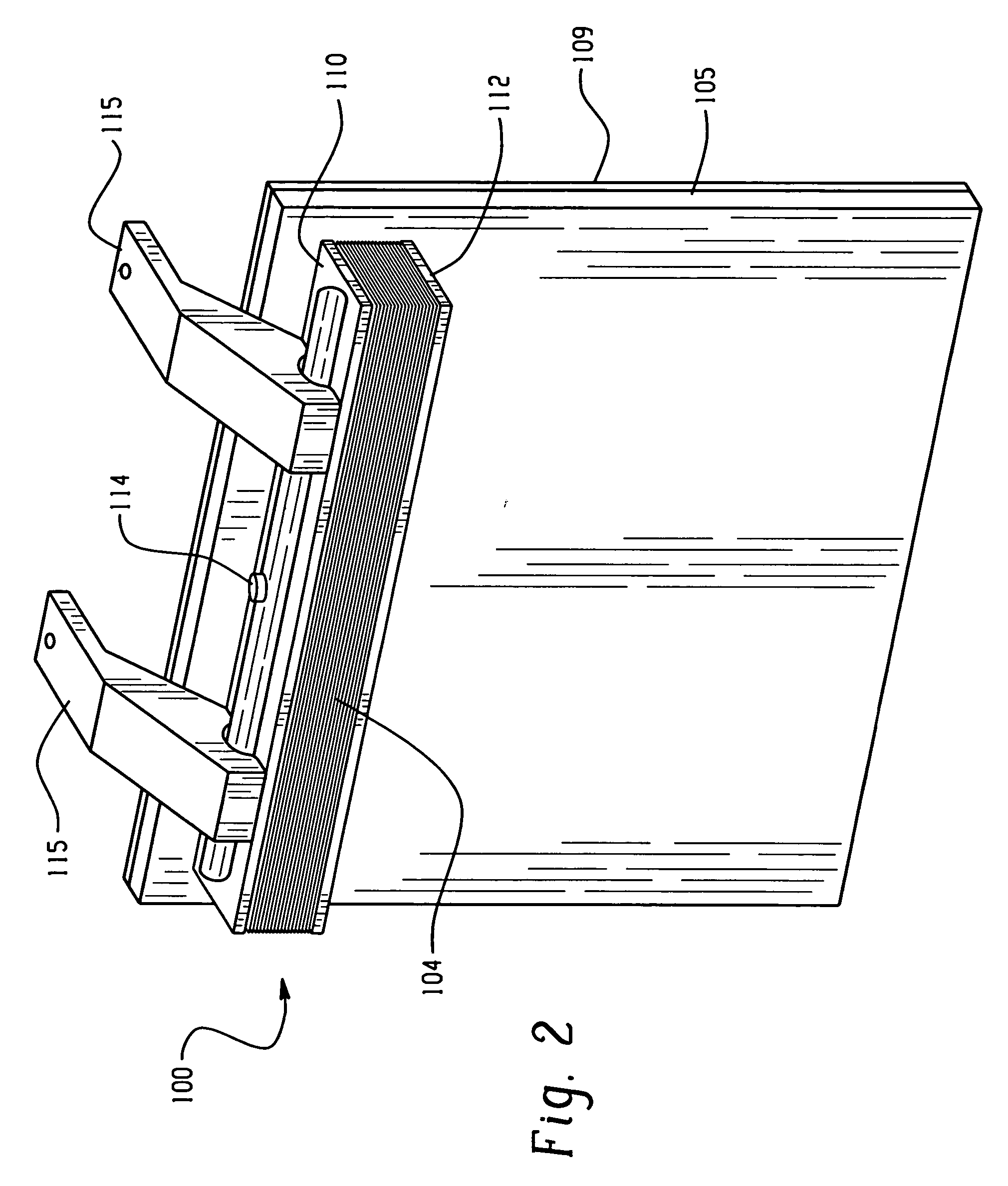

Volume-filling mechanical structures with means for deploying same in a bolster system

InactiveUS7364189B2Excellent crash energy management capabilityLarge crush forcePedestrian/occupant safety arrangementVehicle safety beltsHoneycombEngineering

A volume-filling mechanical structure for modifying a crash including: a bolster system defined by an outer bolster and an inner bolster; a honeycomb celled material expandable from a dormant state to a deployed state, the honeycomb celled material disposed intermediate the outer and inner bolsters cooperatively positioned with the honeycomb celled material to cover surfaces defining the honeycomb celled material in the deployed and dormant states; a means for deploying the honeycomb celled material from the dormant state to the deployed state causing the outer bolster to translate away from the inner bolster; and a tether operably connecting one end of the honeycomb celled material to the means for deploying the honeycomb celled material from the dormant state to the deployed state.

Owner:GM GLOBAL TECH OPERATIONS LLC

Porous concrete mix proportion design method

InactiveCN106874692AEasy to meet engineering needsClear design stepsInformaticsSpecial data processing applicationsWater useFilling rate

The invention belongs to the technical field of construction materials, and particularly relates to a porous concrete mix proportion design method. The method includes the following steps that firstly, the composition of a cementitious material is determined; secondly, a compacting molding test is conducted on a to-be-prepared specimen, and the water-binder ratio is determined through the test and visual inspection; thirdly, aggregate gradation and the volume amount are determined through trial mixing; fourthly, an estimated cement use amount serves as the mid-value, five different cement use amounts are selected at the interval of 25 Kg / m<3>, concrete is mixed with cement in the five use amounts respectively, then compressive strength is solved through testing, a cement use amount and strength relation curve is drawn, the minimum cement use amount required for achieving the needed strength is obtained by means of the interpolation method, and then the cement use amount per unit volume and the stirring water use amount are determined; fifthly, the aggregate composition and the cement use amount are slightly adjusted so that the workability of a porous concrete mixture and the volume filling rate of cement beyond aggregate can be reasonable, and trail mixing and forming are achieved.

Owner:CHONGQING UNIV

Quick starting process of biofilm reactor in oligotrophic habitat

ActiveCN101870516AStart fastEfficient enrichmentSustainable biological treatmentBiological water/sewage treatmentSludgeWater source

The invention discloses a quick starting process of a biofilm reactor in an oligotrophic habitat, which comprises the following steps: (1) distributing 5-7 strings of elastic three-dimensional filler with the volume filling rate of 2-3 percent in a 90L of biofilm reactor and distributing 2-4 aeration sand tables at the bottom of the biofilm reactor; (2) pretreating substrate sludge of riverways of three potable water sources, mixing the substrate sludge according to the volume ratio of 2.5:3.0:4.5 to form inoculated sludge and paving 3-5L of the inoculated sludge at the bottom of the reactor; (3) filling sewage into the reactor, tightly sealing and aerating at the aeration amount of 240-260L / h for 2-3 days and completely draining the inoculated substrate sludge along the effluent; and (4) under the condition of intermittent of aeration for 3h and aeration stop for 3h, increasing the water-feeding flow of the reactor from 15ml / min to 30ml / min every fiver days at the increase speed of 4-6ml and finally continuously operating at the flow speed of 25-35ml / min for 2-3months. Compared with the prior art, the invention has the beneficial effects that: (1) quick starting of an aquatic film repairing system in a micro-polluted water source can be realized; and (2) a biofilm system has high operation performance in a stable state.

Owner:ZHEJIANG UNIV

Fluorine nanometer composite modified anticorrosion paint

InactiveCN106398499AImprove compactnessImprove anti-corrosion performanceAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyPolymer science

The invention relates to a fluorine nanometer composite modified anticorrosion paint, comprising 32 to 55 parts of waterborne polyurethane emulsion, 28 to 43 parts of epoxy resin, 8 to 15 parts of modified nanometer titanium dioxide, 11 to 19 parts of fluorine polymer, 7 to 14 parts of pigment, 0.3 to 0.8 part of a catalyst triethylamine and 12 to 17 parts of an auxiliary agent. A preparation method for the paint comprises the following steps: step 1, preparing modified nanometer titanium dioxide; step 2, preparation of a fluorine polymer; and step 3, compounding of the anticorrosion paint. According to the invention, the volume-filling density of a carrier is improved through nanometer titanium dioxide, so capillary action is reduced and shielding density is greatly improved; a film structure can be filled with tiny particles of a nano-material, so the density of a film is enhanced, permeability of the film is reduced, and corrosion of water, oxygen and the like to a metal substrate is efficiently blocked; thus, the anticorrosion performance of the paint is improved.

Owner:中国人民解放军空军勤务学院

Method for esterification reaction of konjac glucomannan

InactiveCN101935360AMeet the performance requirements of different applicationsNo pollutionFilling rateVolume filling

The invention provides a method for an esterification reaction of konjac glucomannan. The method adopts a mechanical chemical method and comprises the following steps of: 1, drying the konjac glucomannan until the water content of the konjac glucomannan is less than 4 percent and adding an esterification modifier in an amount of 0.5 to 5 percent based on the total mass of the konjac glucomannan; 2, preparing a grinding medium according to the volume filling rate of 50 to 90 percent of a grinding tank of a vibrating mill; 3, uniformly mixing the konjac glucomannan and the grinding medium, adding the mixture into the grinding tank of the vibrating mill, sealing the grinding tank and starting the vibrating mill to grind for 20 to 60 minutes; and 4, separating the grinding medium from a sample by screening so as to obtain the konjac glucomannan prepared by the esterification reaction. The method for the esterification reaction of the konjac glucomannan provided by the invention adopts the mechanical chemical method and has the advantages of simple and convenient operation, low cost, no pollution and capability of possibly meeting the requirement of industrialized production on different application performance of the konjac glucomannan.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com