Construction method of large-volume-filling-body strength model of two-step open-stope subsequent-filling

A technology of strength model and construction method, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of neglecting anti-slip resistance, long exposure time of cemented backfill, and no physical and mechanical parameters of tailings.

Active Publication Date: 2018-04-17

YUXI MINING +1

View PDF0 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0009] (2) From the mining sequence, it can be seen that the cemented filling body is exposed for as many as 2-4 times during the stage mining process. At the same time, the blasting volume of the mine room is large at one time, and the mining time is long, which makes the cemented filling body exposed for a long time

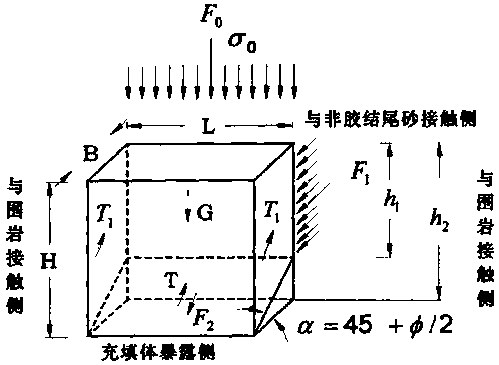

[0010] (3) One side of the cemented filling body is exposed, and the other side is a filling body with non-adhesive ending sand. Under the condition of bearing its own gravity, it also needs to bear the active pressure of non-adhesive ending sand, and the stress state is complicated

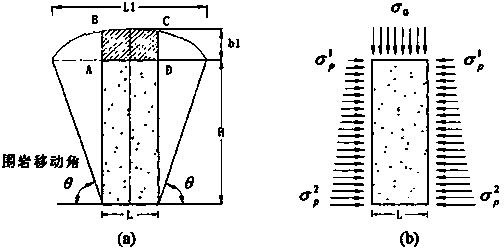

[0027] (2) Equation (1) is applicable to the condition that there is latera

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

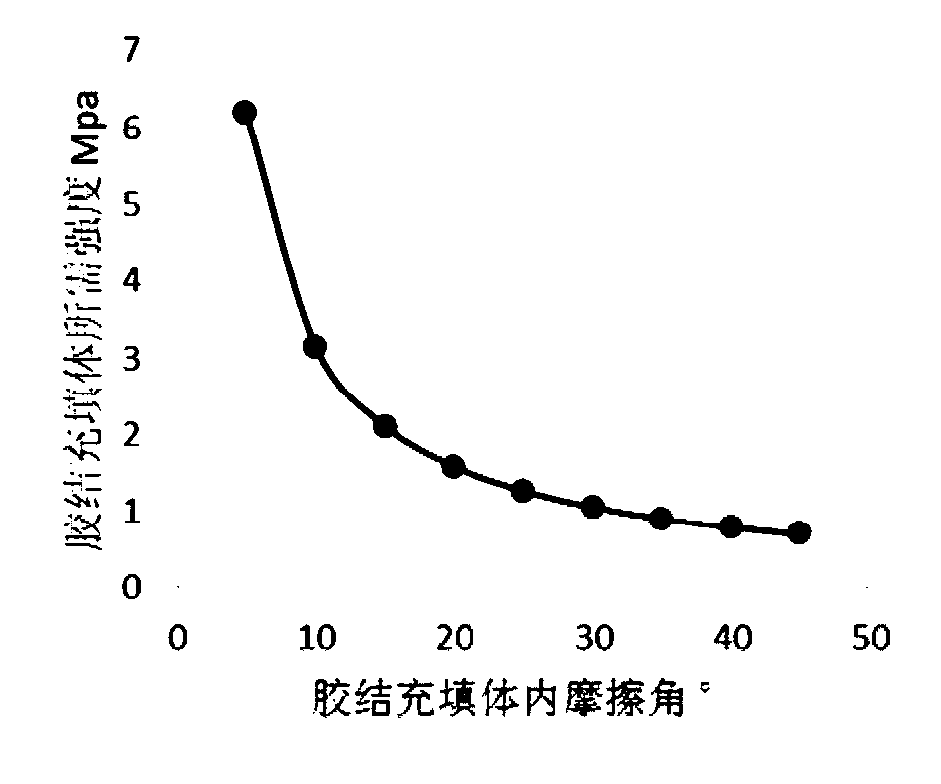

The invention relates to a construction method of a large-volume-filling-body strength model of two-step open-stope subsequent-filling, and belongs to the technical field of mining. A cohesive-force calculation formula of a cementation filling body, an uniaxial-compressive-strength calculation formula and a shear strength calculation formula provided by the method form a complete strength calculation system, the large-volume-filling-body strength model of two-step open-stope subsequent-filling, and required strength of the cementation filling body is comprehensively calculated. Stability of the cementation filling body can by ensured by the cementation-filling-body strength, which is obtained through the model of the method, to provide a safe and reliable operation environment for two-stepstoping, the cementation filling body is also designed as layered filling according to a relationship between the required strength of the cementation filling body and height and can reduce a cementconsumption amount, safe and highly efficient stoping of mineral resources is realized with minimal filling costs, no-waste or low-waste mine mining is realized, mine environment protection is promoted, and mine disaster control is facilitated.

Description

Technical field [0001] The invention belongs to the field of mining technology, and specifically relates to a method for constructing a two-step empty field subsequent filling of a large-volume filling body strength model. Background technique [0002] As the basic industry at the forefront of the production chain, the mining and utilization of mineral resources not only provide the necessary materials for human construction, but also provide a guarantee for the development of the national economy and society. With the rapid development of human society, the demand for mineral products has increased rapidly. In the face of the huge economic benefits brought by mining activities, the concept of coordinated development of mineral resource development and environmental protection has been ignored. As a result, the storage of solid waste occupies a large amount of land, which causes the deterioration of the ecological environment; the extensive mining mode of "mining the rich and aba...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G06F17/50

CPCG06F30/23G06F2119/06

Inventor 王俊李广涛乔登攀孙宏生张希廖庆永唐锐陈平季现伟

Owner YUXI MINING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com