Patents

Literature

213results about How to "Safe and Efficient Mining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low premeability high gas soft thick coal layer remote pressure relief gas exhausting method

ActiveCN1534164AEliminate the danger of coal and gas outburstSafe and efficient miningGas removalCoalEnvironmental geology

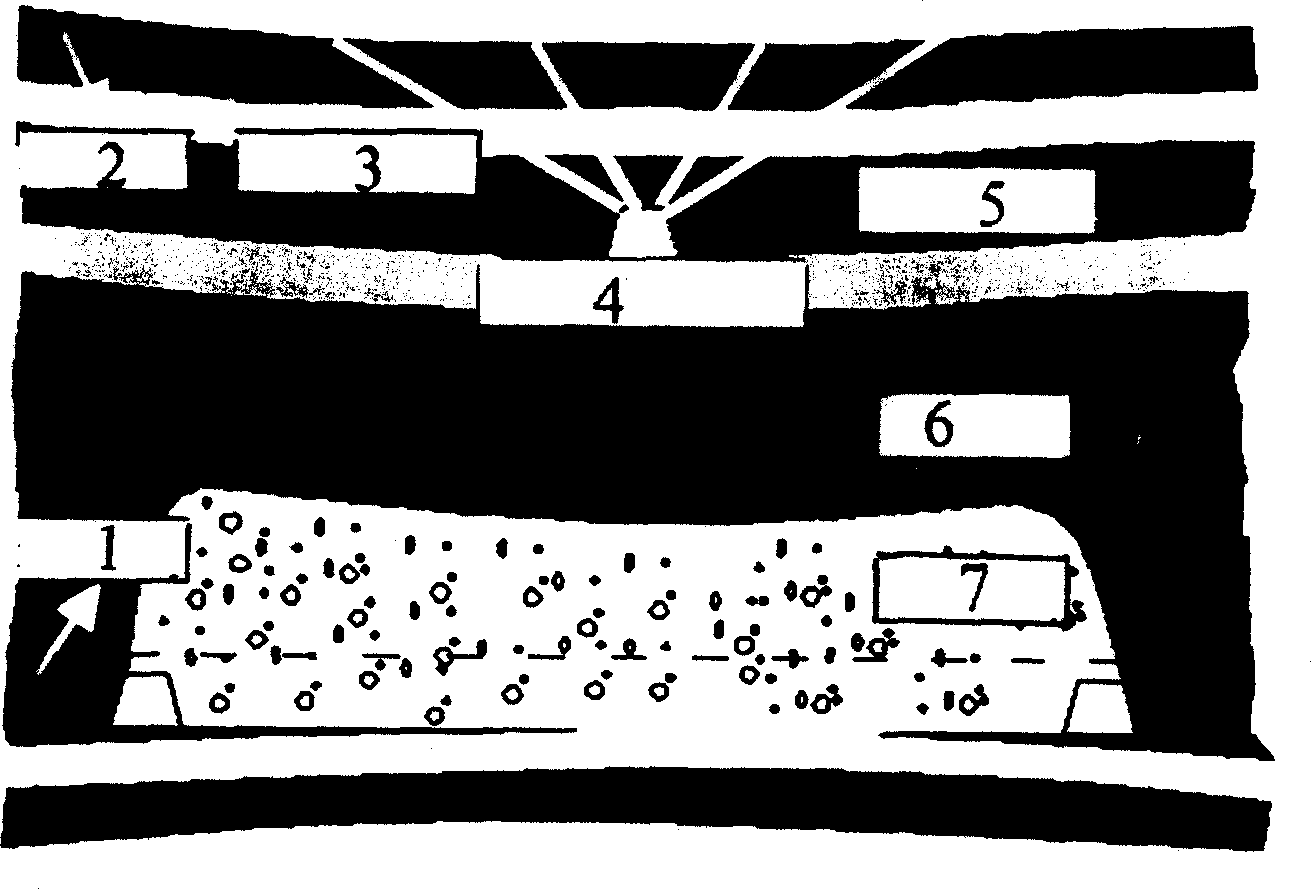

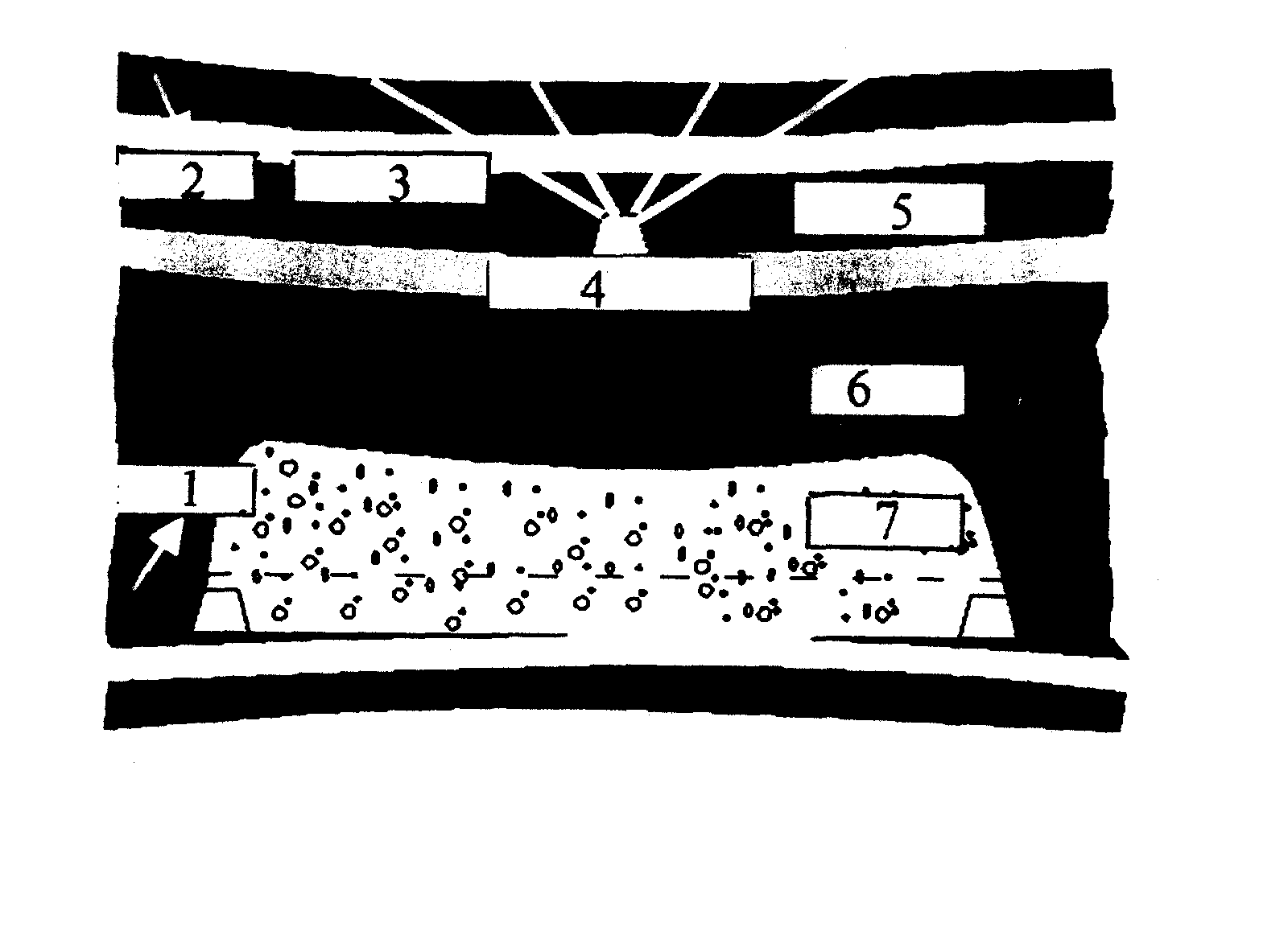

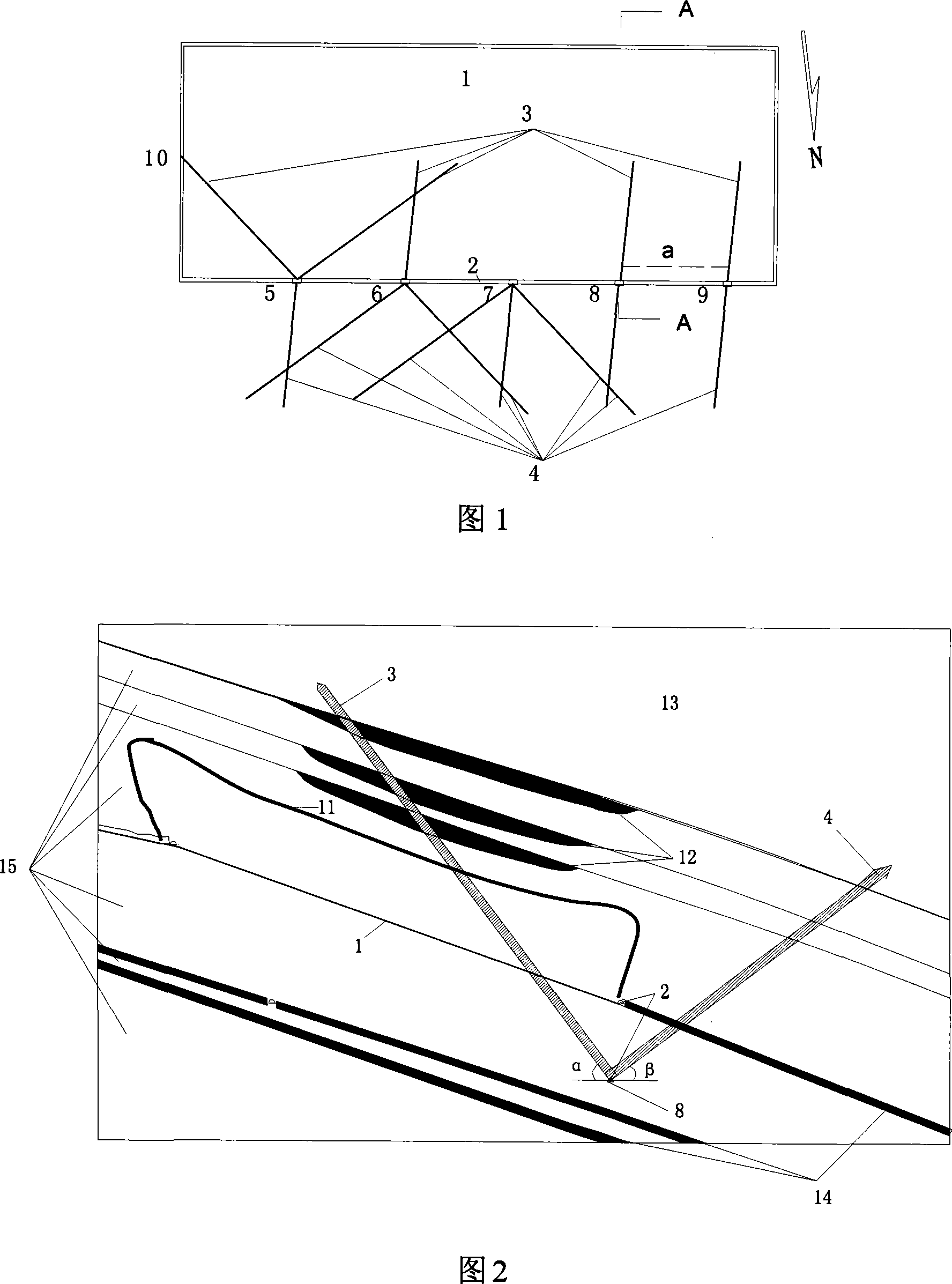

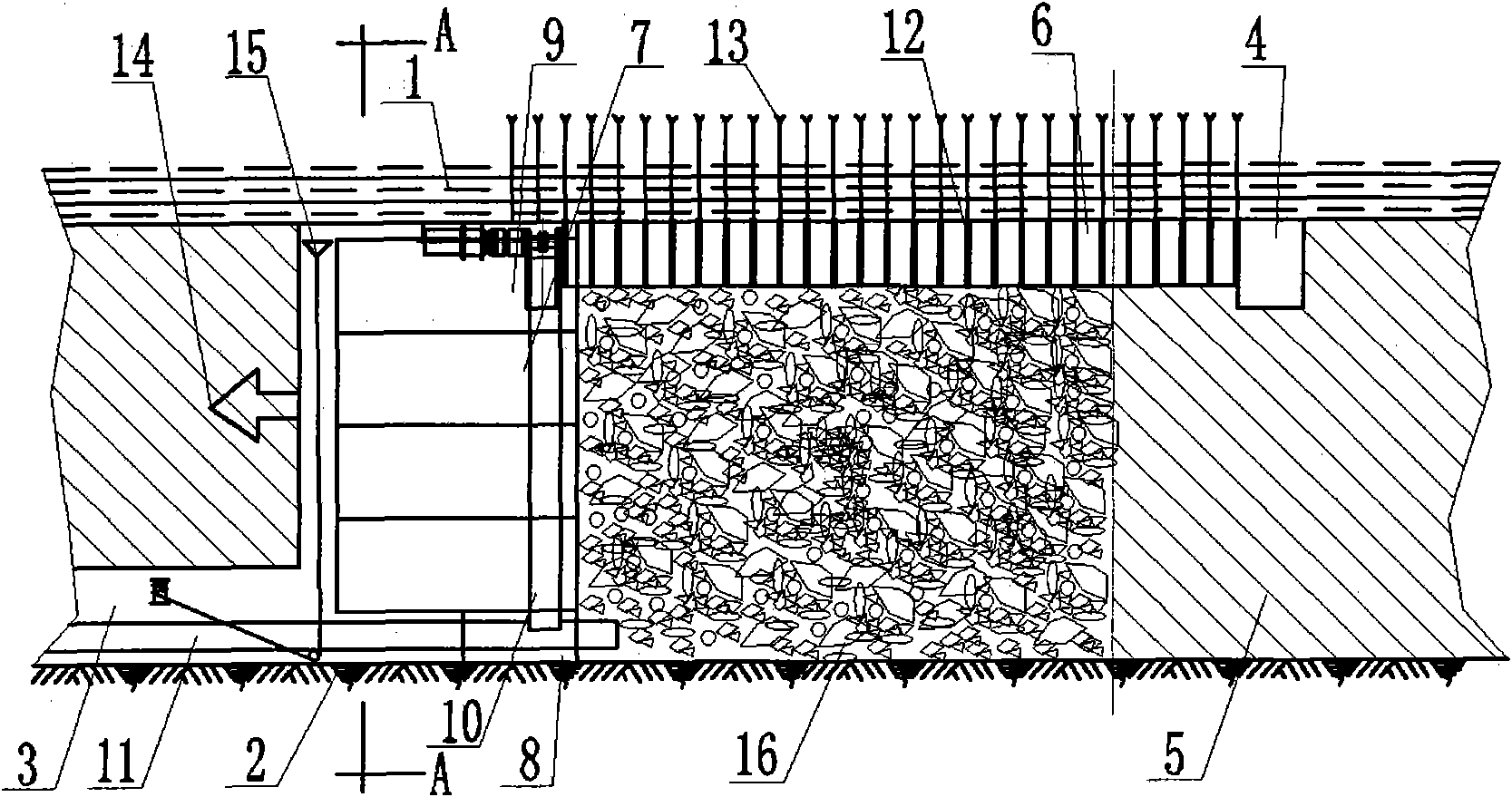

A remotely pressure-releasing method for sucking and exhausting gas from the low-air-permeability high-gas soft and thick coal seam is disclosed. The coal seam, which is 70m under the coal seam to be gas-exhausted and has relative interbeam distance of 30-70 times, is first mined. Under the action of pressure release and subsidence, the cracks are generated in the coal seam and the gas penetrates through the cracks and then is exhausted via predrilled holes. After the coal seam is mined, a great deal of gas is flowing along the seam and then is sucked by said predrilled holes.

Owner:HUAINAN MINING IND GRP +1

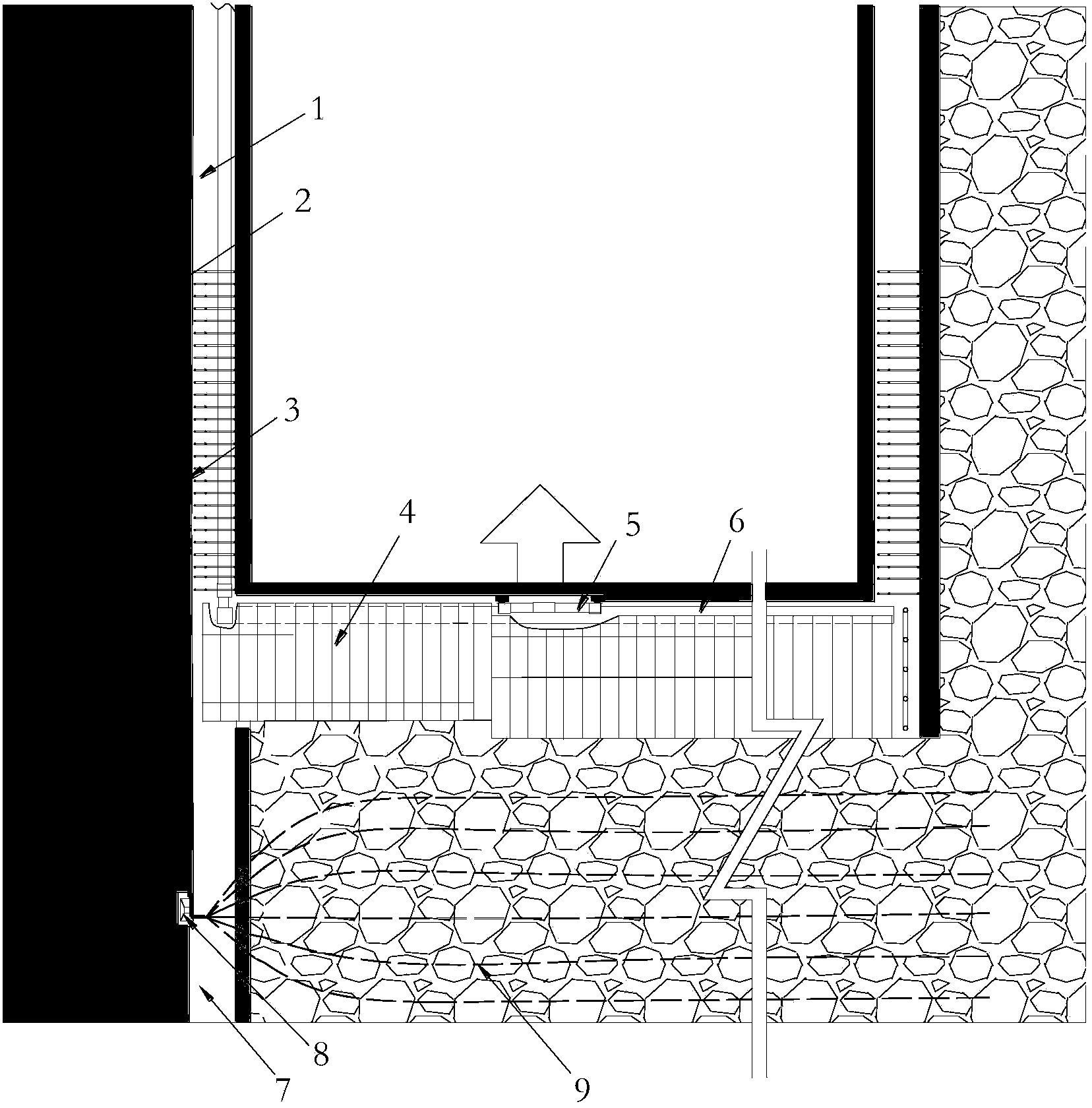

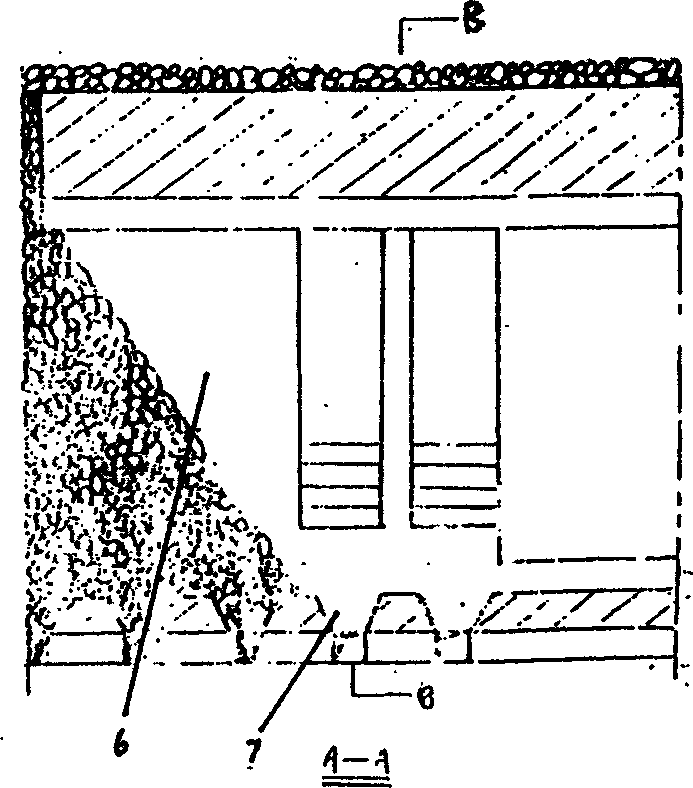

Aquifer preventing and controlling method for coal face roof plate separation layer

InactiveCN101196123ASafe and Efficient MiningAvoid delamination water damage accidentsDrainageWater diversionDrill hole

A prevention method for a water body at an abscission layer on a roof plate for a working face of mining is provided, which can be applied for the coal layer that has formed abscission seeper on the roof plate before the mining. Before the mining on the working face, making drilling hole groups in the upward and downward direction to the mountain along with the slot (rail track lane and mechanical lane) under the working face, so as to realize simplified water diversion and discharging of well before mining; during the mining on the working face, conduct the water diversion and discharge throughout the ''whole process'' of mining via the mountain descending drill hole outside the mining impact scope of the working face, so as to cut off the water source for the abscission seeper on the roof plate; conduct the dynamic monitoring, diversion and discharge of seeper on the roof plate by estimating the height for the cultivation of a water guidance gap via the exceeding degree of mountain ascending direction over the coal layer to be explored as well as by going through the drill hole at the expected layer of abscission seeper on the roof plate. Therefore, by dynamic monitoring of abscission seeper and the diversion and discharge of seeper throughout the whole process of mining, the invention is able to realize the working environment without water, thus preventing the accident caused by abscission seeper and ensuring the high efficient mining on the working face. With simple method and convenient application, this invention is able to realize excellent social and economic benefit.

Owner:HUABEI MINING GRP +1

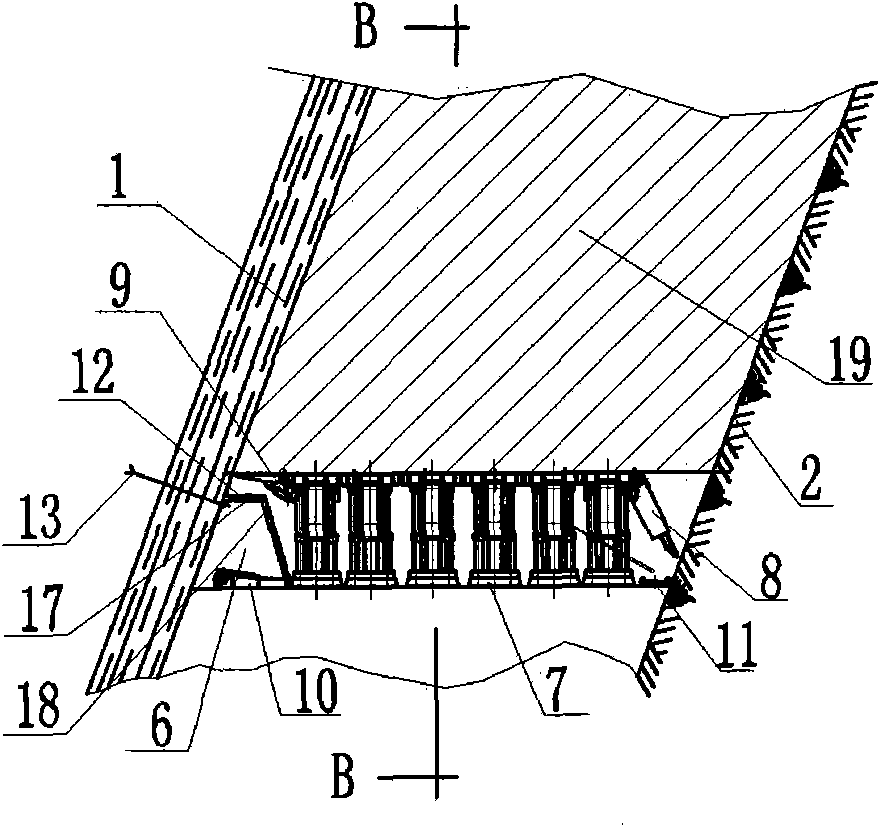

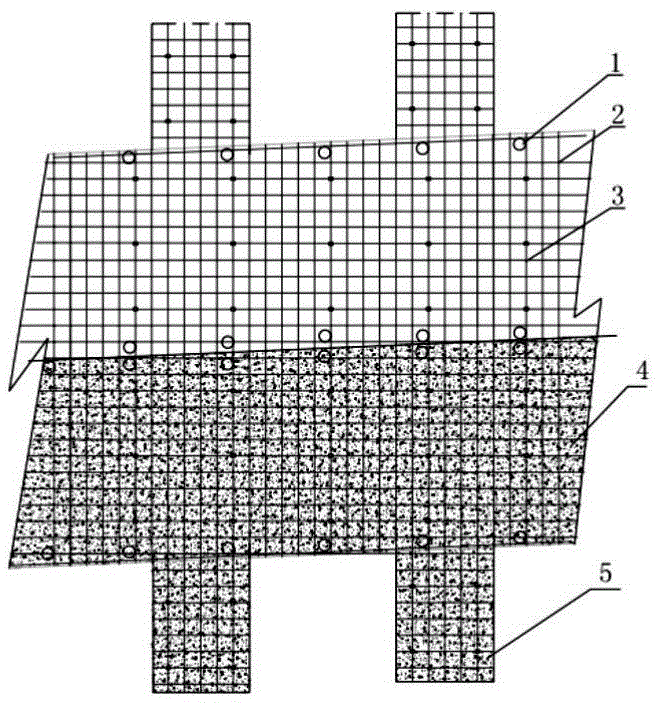

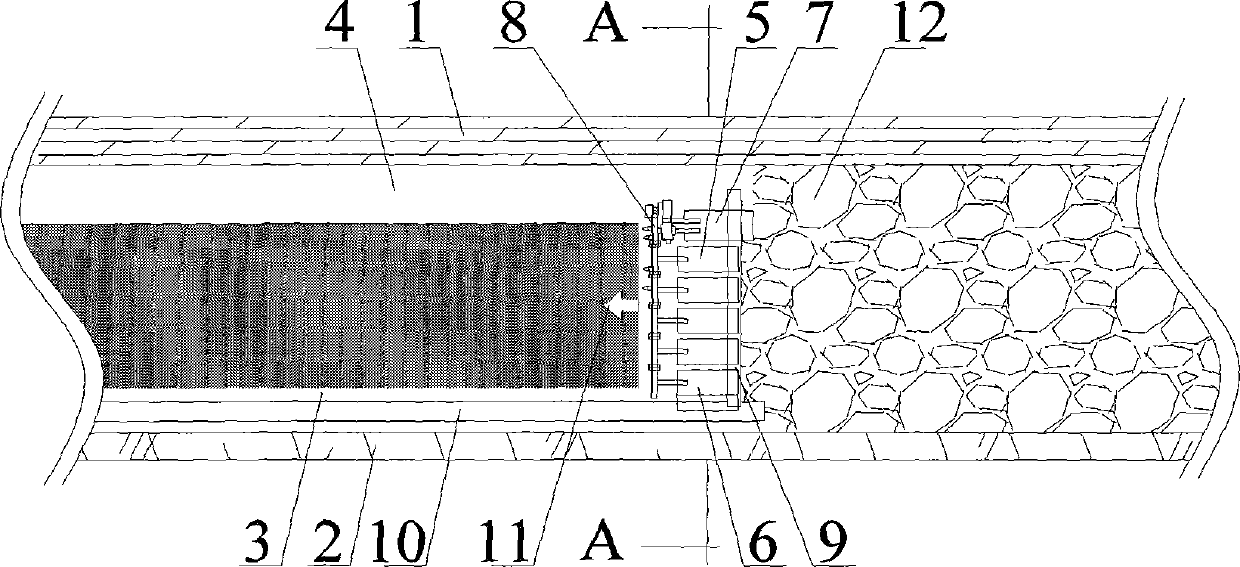

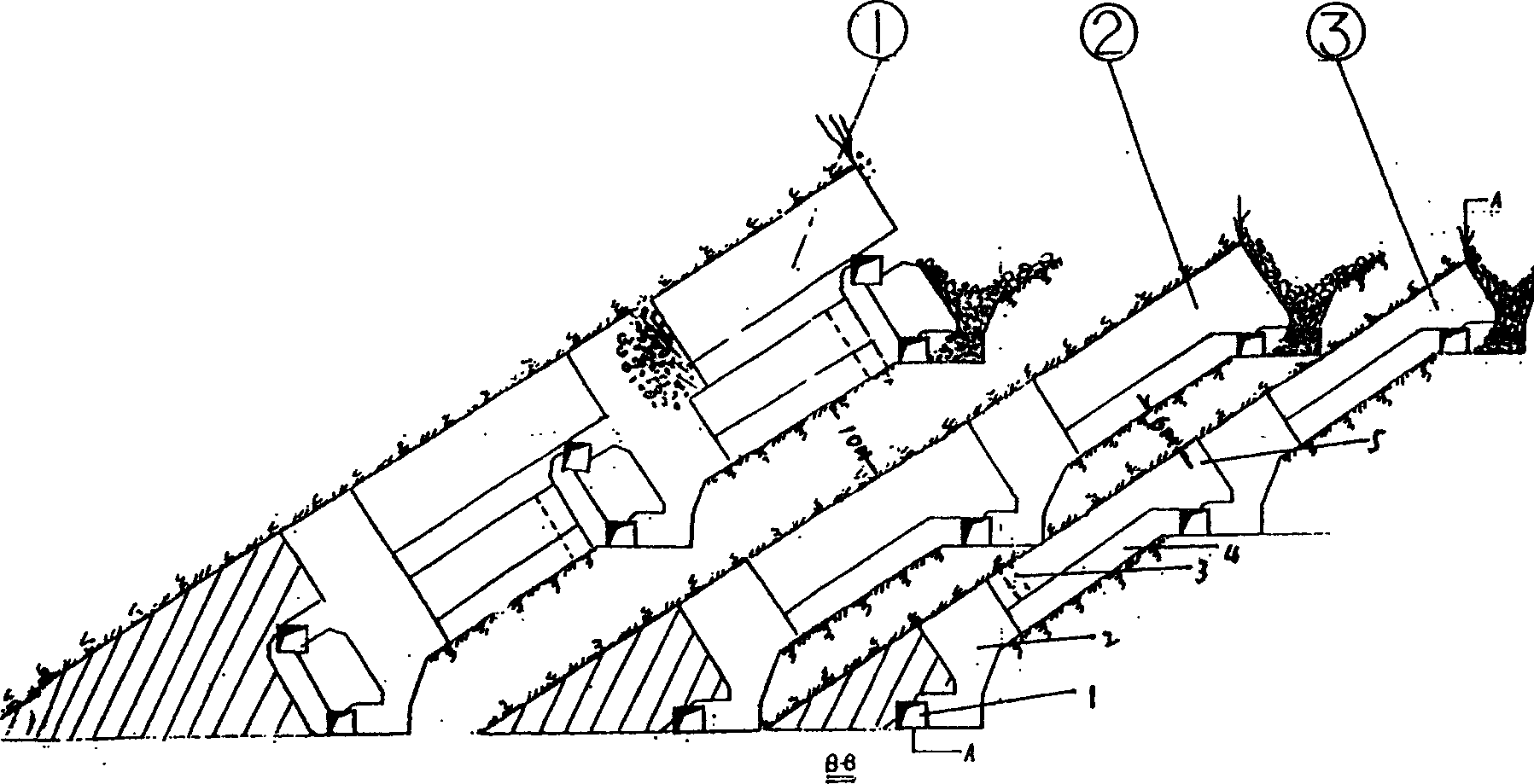

Method of mining coal from heavy pitch thick coal seam

ActiveCN101915101AIncrease productionImprove efficiencyUnderground miningSurface miningEngineeringCoal mining

The invention provides a method for mining coal from a heavy pitch thick coal seam in a horizontal and segmental short wall manner. The method comprises the following steps of: supporting and caving coal by using a top coal caving hydraulic support in a work surface; drilling holes, blasting coal, and conveying the coal with a scraper conveyor; performing gob-side entry retaining by using a prefabricated metal shed or a plastic bucket. The coal-mining method can realize mechanical mining of the heavy pitch thick coal seam, greatly improves yield and efficiency of the working face and ensures safe production.

Owner:TIANDI SCI & TECH CO LTD

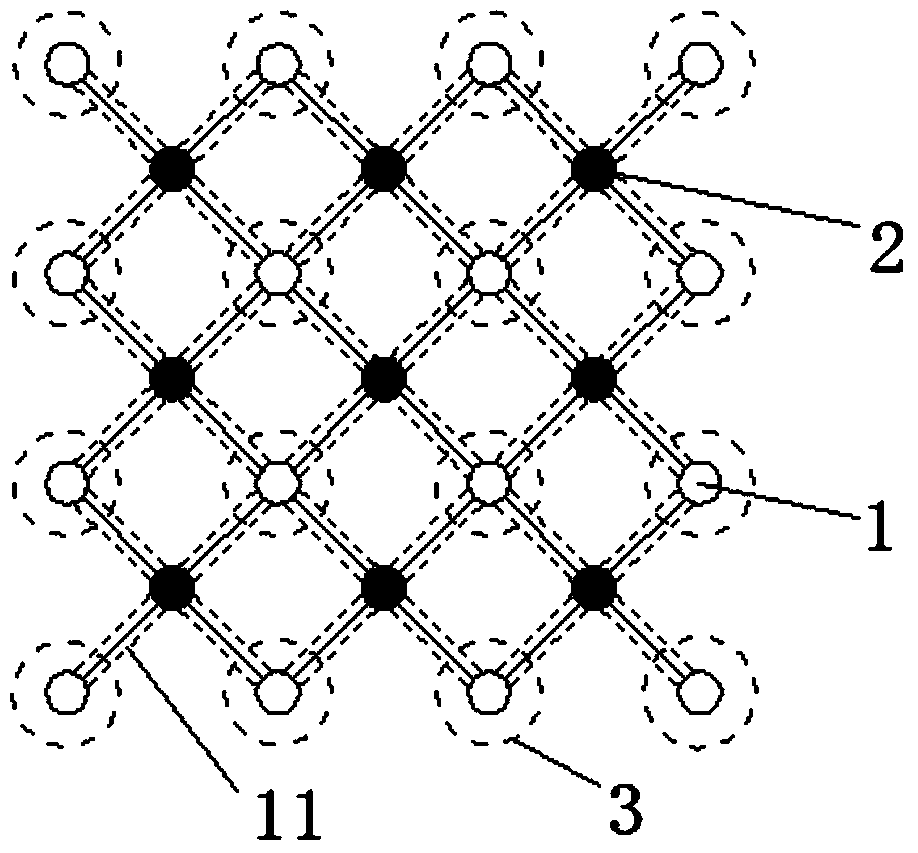

Slotting and fracturing cooperation networking permeability increasing method for low-permeability coal seam

ActiveCN104389631AImprove breathabilityIncreased air permeability coefficientFluid removalGas removalHigh pressure waterHigh pressure

The invention provides a slotting and fracturing cooperation networking permeability increasing method for a low-permeability coal seam, which is applicable to regional gas control for high-gas-content low-permeability coal seams. The permeability increasing method comprises the following steps that: firstly, hole positions of slotting drill holes and fracturing drill holes are arranged alternately at a floor suction roadway in a networking arrangement mode; each slotting drill hole is subjected to high-pressure water jet flow slotting to form an annular slotted hole; and then, each fracturing drill hole is subjected to segmented fracturing, and a fracture net is formed in the coal seam. The slotting drill holes and the fracturing drill holes are in cooperative arrangement; the slotted holes formed by slotting are used for controlling the expanding direction of fracturing cracks; the number of cracks in the coal seam can be effectively increased through segmented fracturing multiple times; and good conditions are created for the drill hole gas extraction and the gas flowing in the coal seam. After the fracturing cracks are communicated with the slotted holes, a crack network is formed in the coal seam; the permeability coefficient of a coal body around the drill holes can be improved by 150 to 400 times; the single-drill-hole gas extraction effective influence range can be expanded by 2 to 4 times; the drill hole gas extraction quantity can be increased by 3 to 6 times; and the gas pre-extraction time in the high-gas outburst coal seam can be effectively shortened.

Owner:CHINA UNIV OF MINING & TECH

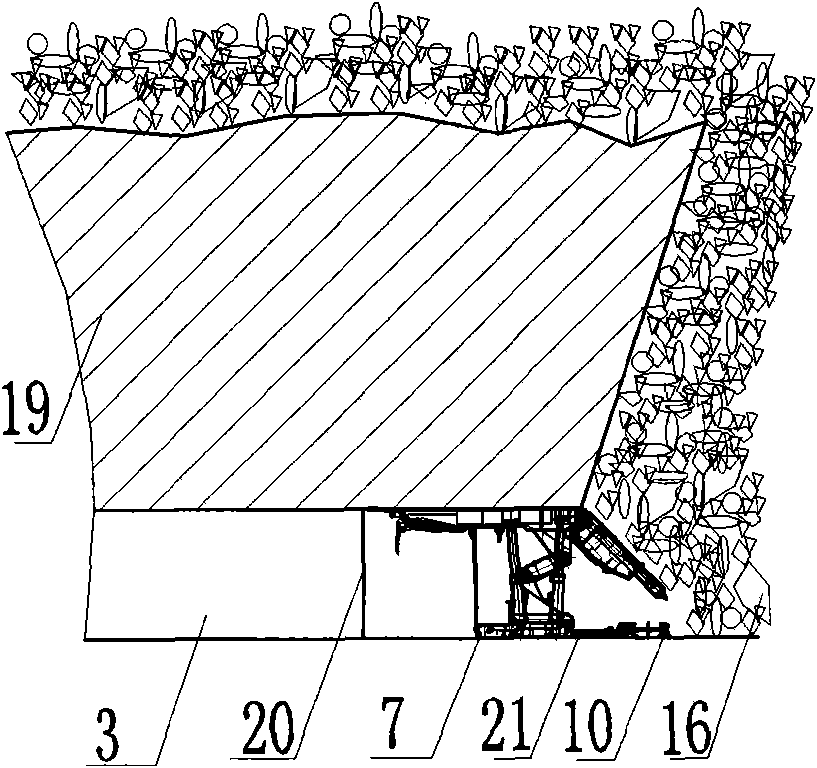

End slope coal bed remote control excavating mining method

InactiveCN104074521AImprove the recovery rate of coal resourcesSimple production processUnderground miningSlitting machinesMining engineeringMan machine

The invention provides an end slope coal bed remote control excavating mining method, which belongs to an end slope residue coal resource extraction method and is used for open pit coal mine end slope and hillside outcrop and shallow surface coal bed mining. A coal mining system adopts a remote control excavating machine system, which comprises an excavating machine and a remote operating and control room, wherein operating and control equipment consists of three parts including a mining flameproof excavating machine electric control box, an excavating machine electric control box and an operating table; the operation function of long-distance wired control is realized; the man-machine separation is realized; and during the coal mining, people operate in a safe operation room. The main mining flow process comprises the steps of cleaning preparation, initial stage mining roadway pit selection, excavating and coal cutting by the excavating machine, coal loading by the excavating machine, belt extending, outward coal conveying by a belt, pile pouring by a loading machine, laneway exiting after coal excavating to a preset position, equipment withdrawing, overhauling, and preparation again for next roadway pit extraction. The end slope coal bed remote control excavating mining method has the characteristics that the coal resource extraction rate improved; the production process is simple, safe and efficient; and the production cost is low, and the like. The safe and efficient mining of open pit coal mine end slope remained coal resources is favorably realized.

Owner:CHINA UNIV OF MINING & TECH

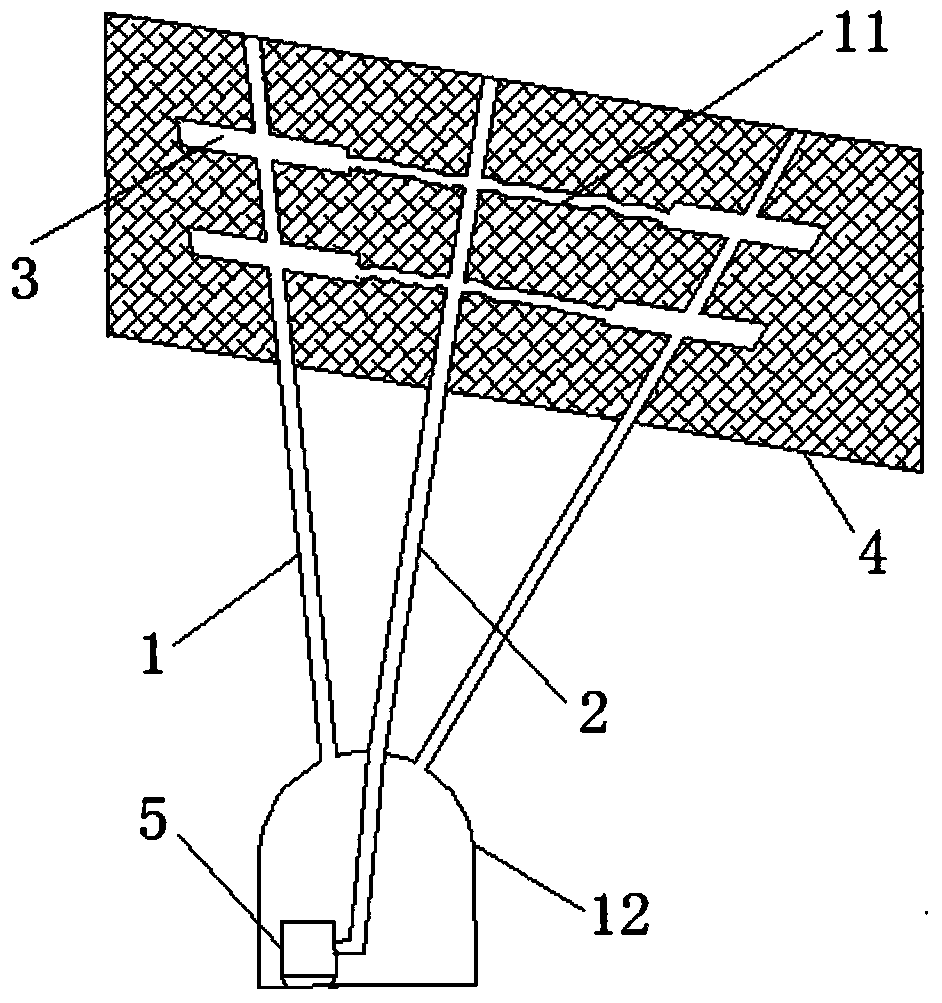

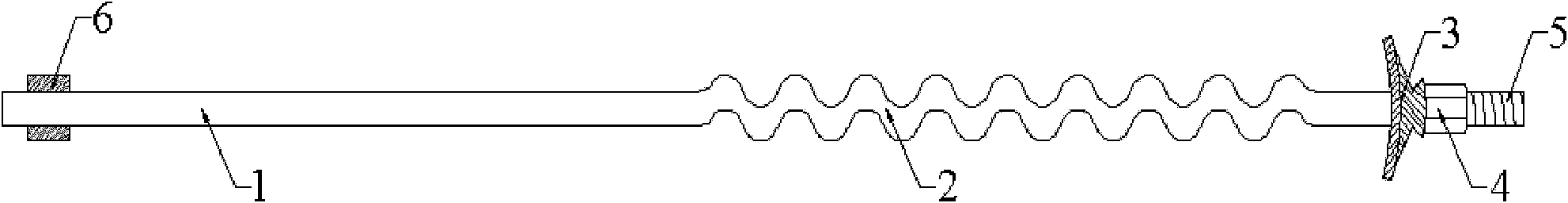

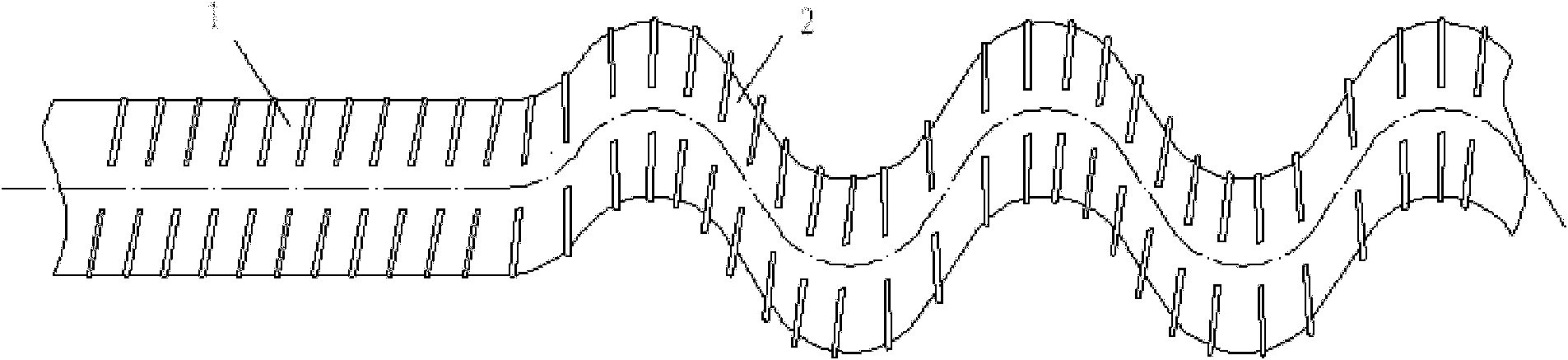

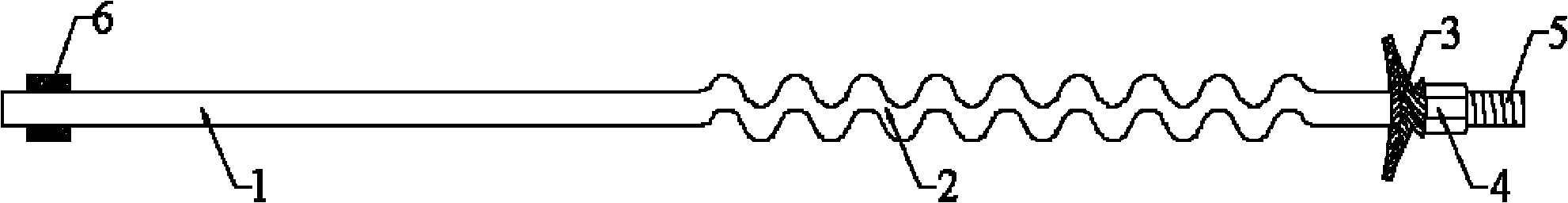

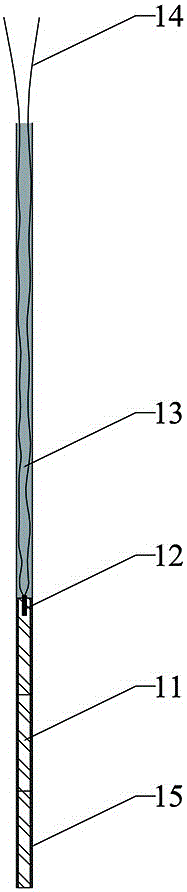

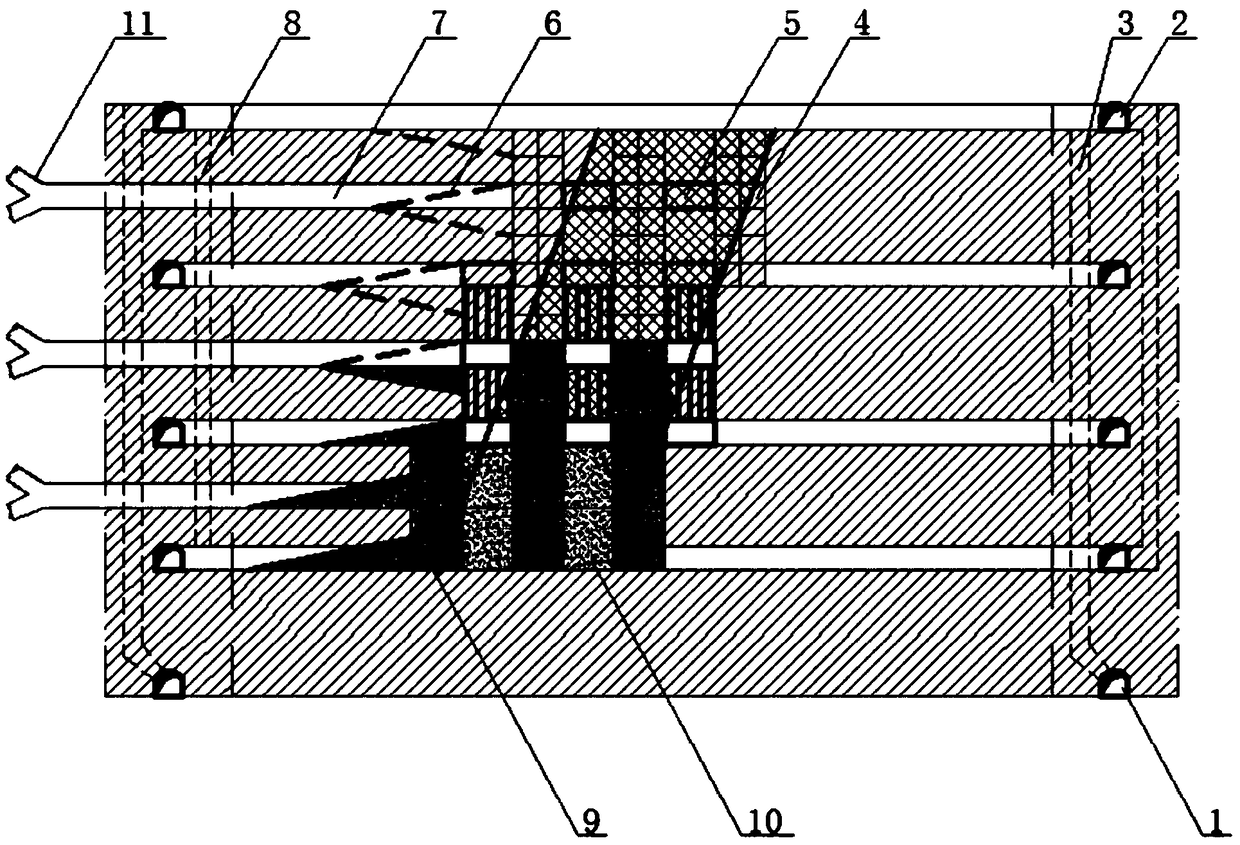

Coordinated-deformation energy-absorption anchor rod suitable for mining high-stress large-deformation rock mass

InactiveCN101929347ASimple structureEasy to process in large batchesAnchoring boltsGround pressureEnergy absorption

The invention discloses a coordinated-deformation energy-absorption anchor rod suitable for mining a high-stress large-deformation rock mass. The rod body of the anchor rod mainly comprises an elongated anchoring section straight rod body (1) and an energy-absorption section bending rod body (2), wherein one end, close to the energy-absorption section bending rod body, of the rod body is provided with a threaded section (5); a fastening nut (4) is screwed on the threaded section (5); and a steel pallet (3) is sleeved between the fastening nut (4) on the threaded section (5) and the energy-absorption section bending rod body. The anchor rod is mainly characterized in that: a wavelike bending energy-absorption section in a specific length and a specific shape is mechanized on a long straight threaded steel rod body in a heat treatment mode; the energy-adsorption section restrictively allows a wall rock to deform properly and simultaneously absorb the deformation energy of the rock mass until reaching total allowable deformation quantity meeting a design requirement. In the process, the supporting force of the anchor rod is increased gradually; and finally, after the bending section is completely straightened and a yielding effect controlled by a high-stress roadway ground pressure is achieved, the anchor rod becomes a high-strength rigid resin anchor rod for providing greater supporting force for a supported wall rock mass.

Owner:CENT SOUTH UNIV

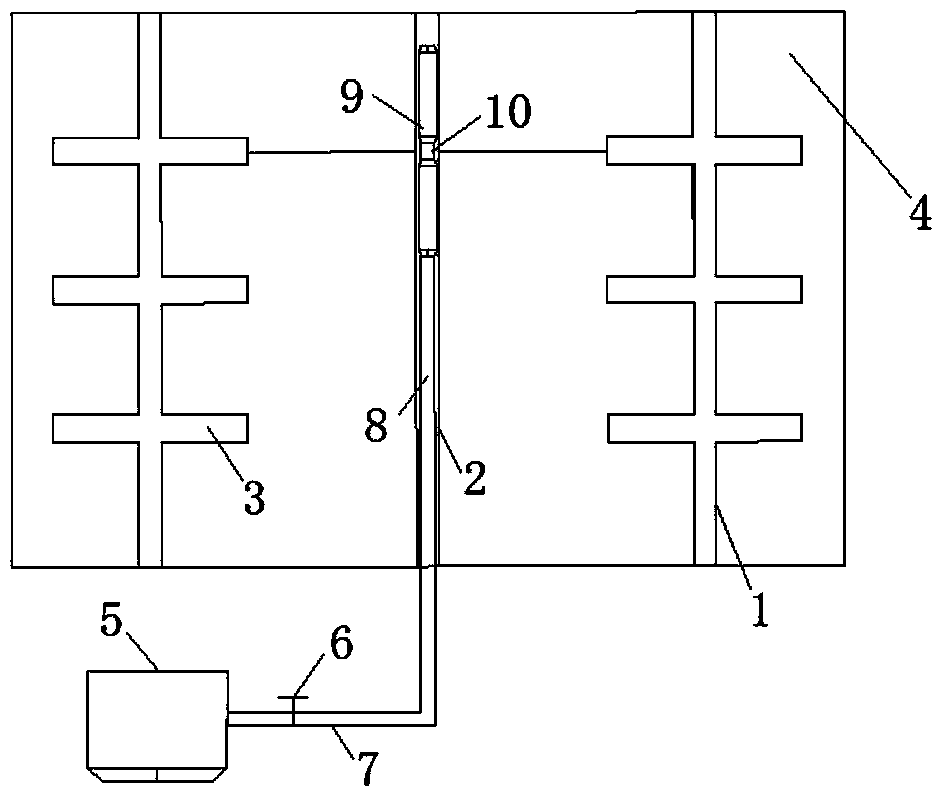

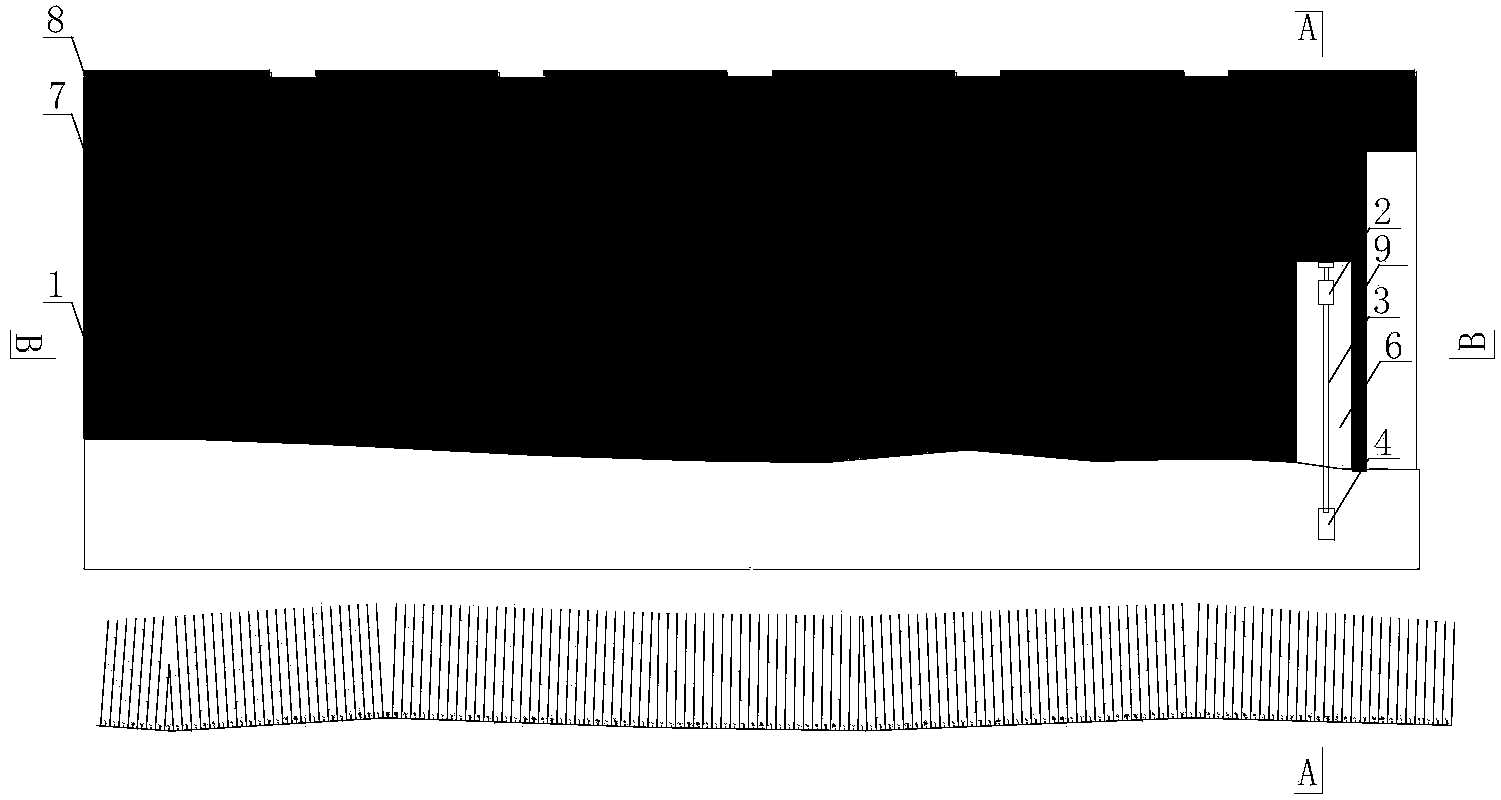

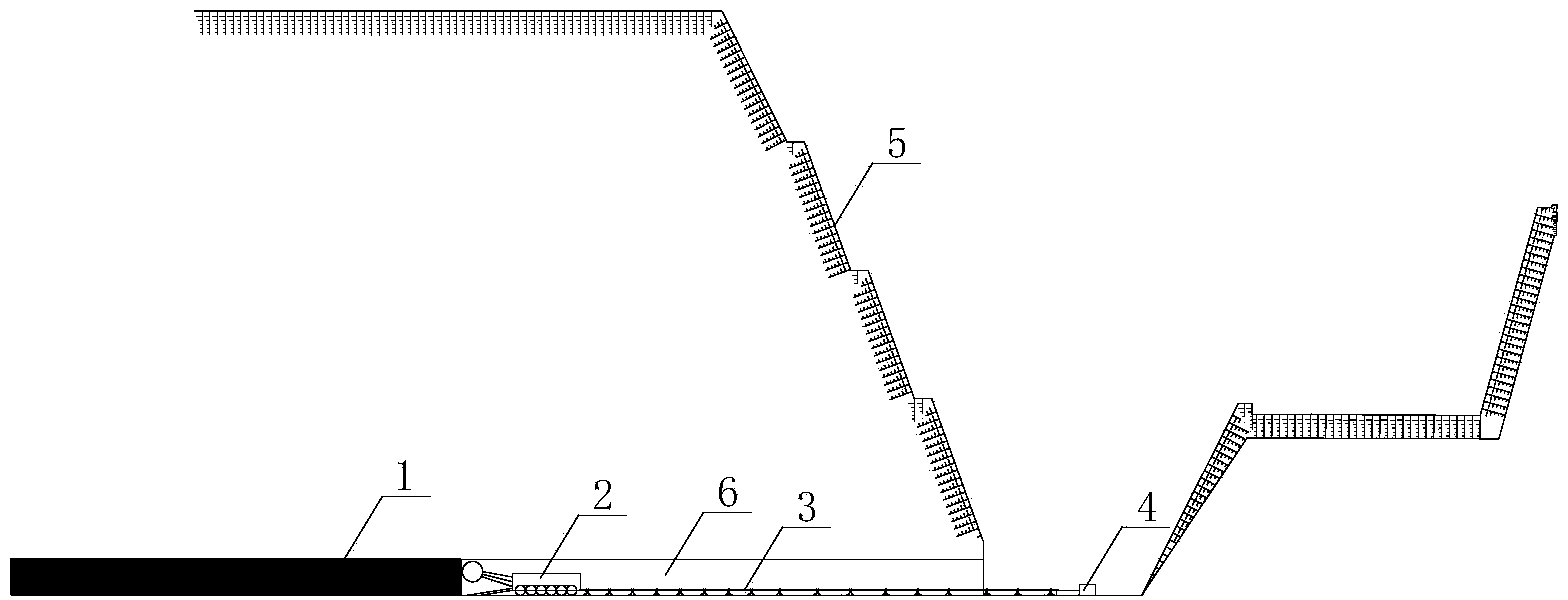

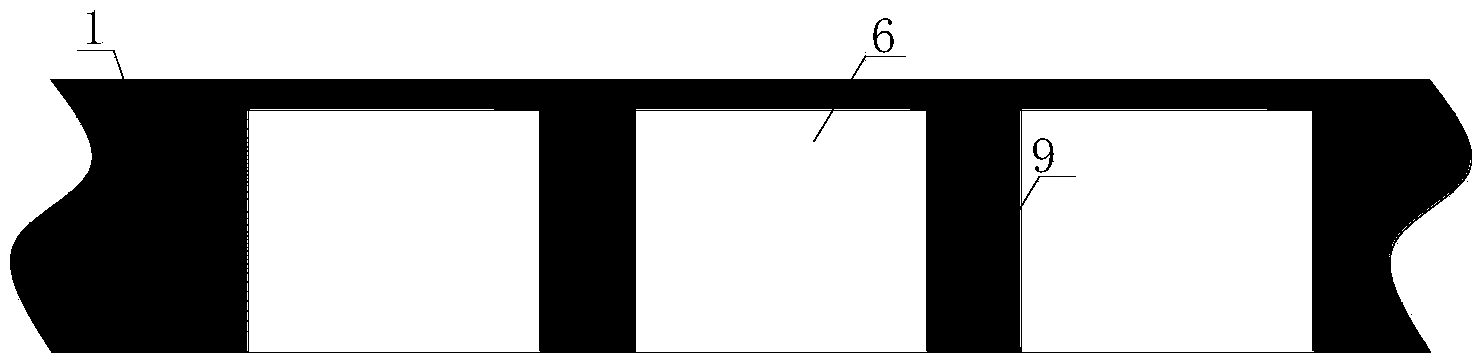

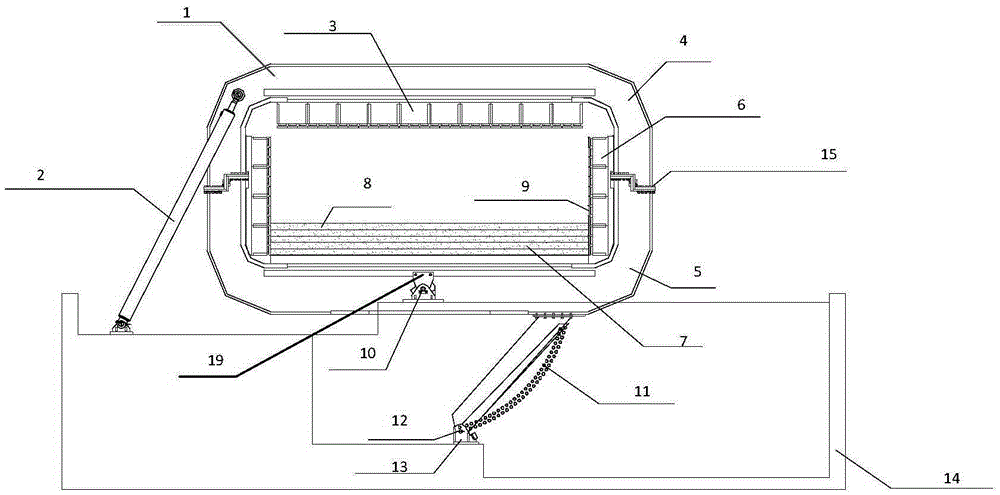

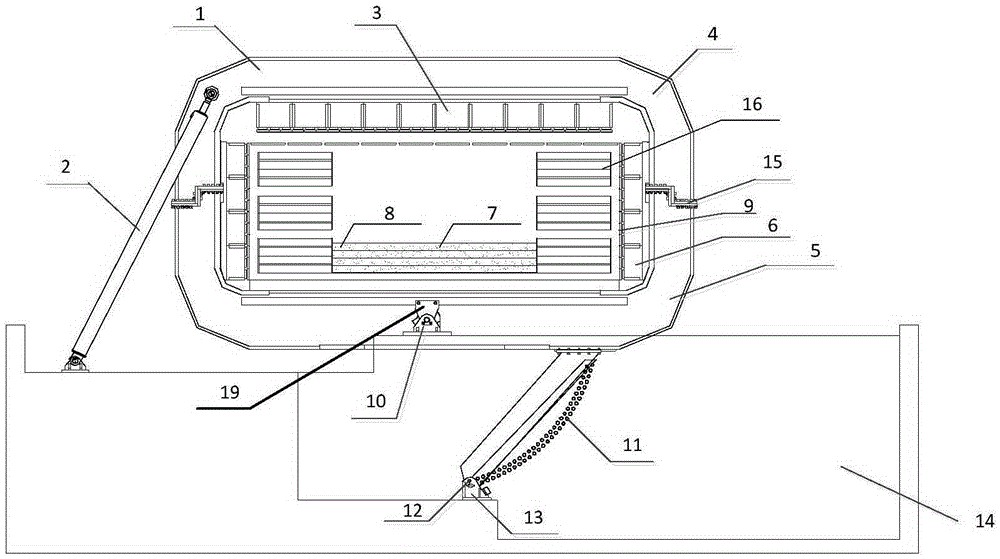

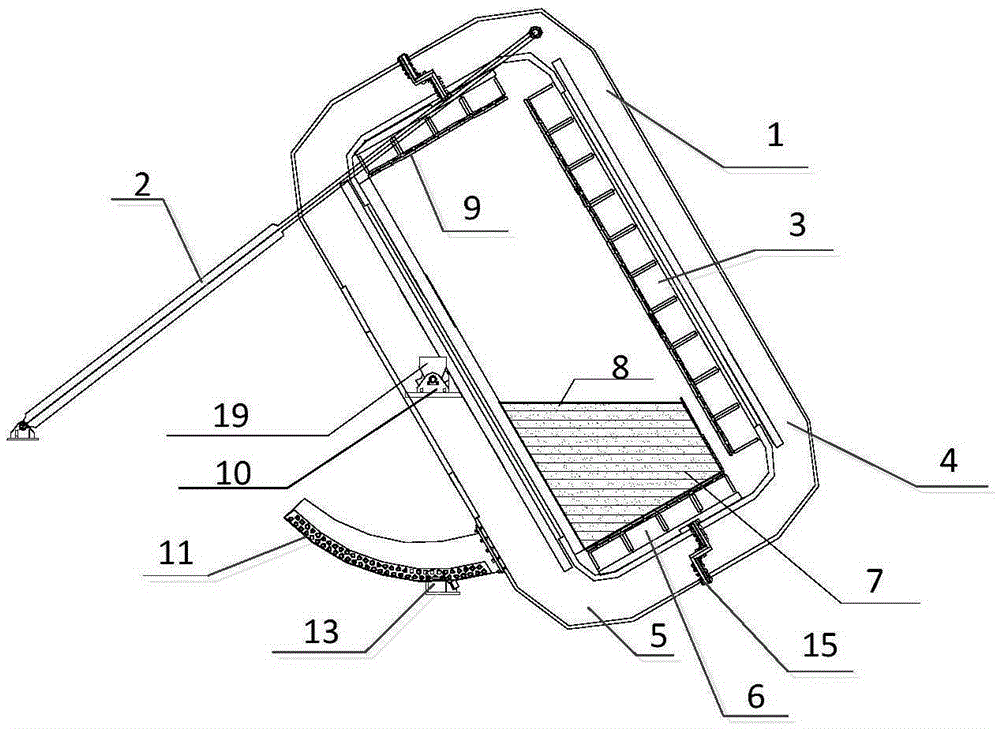

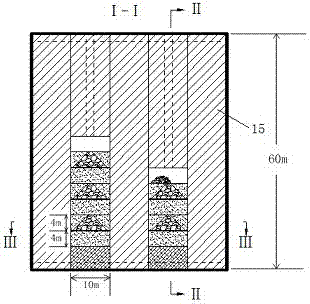

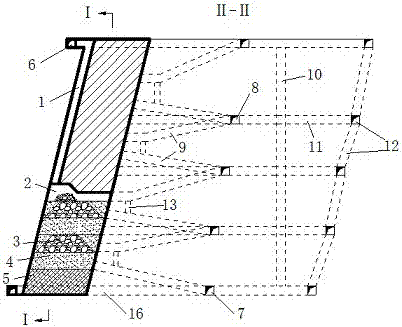

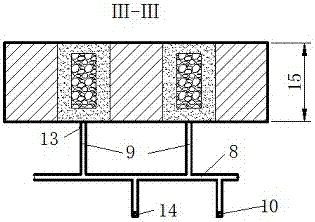

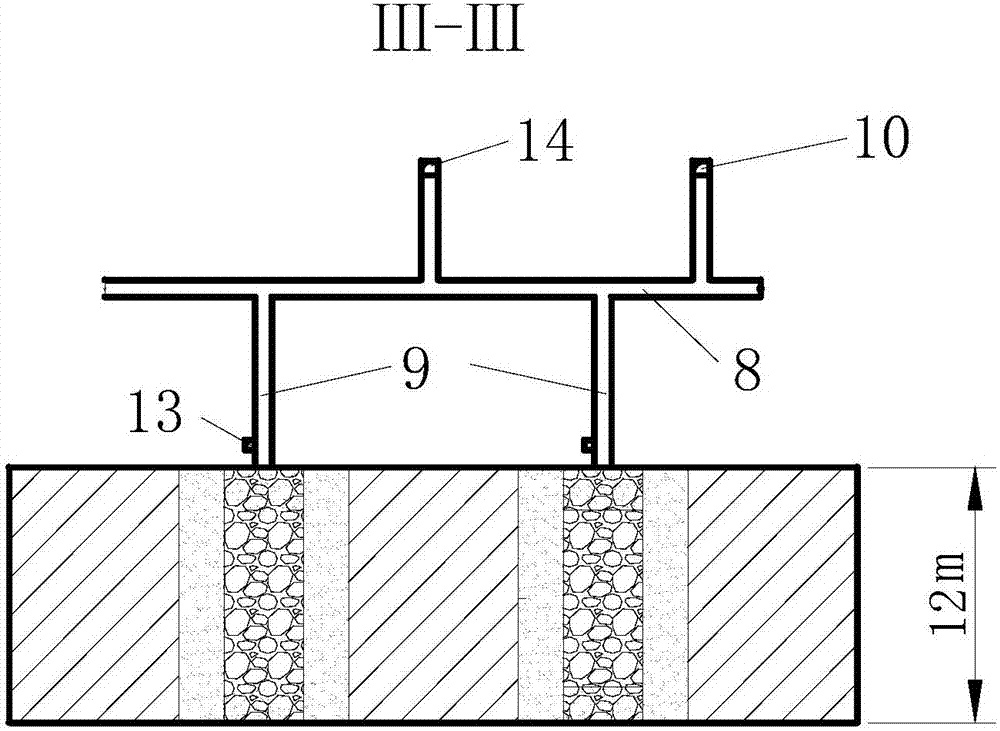

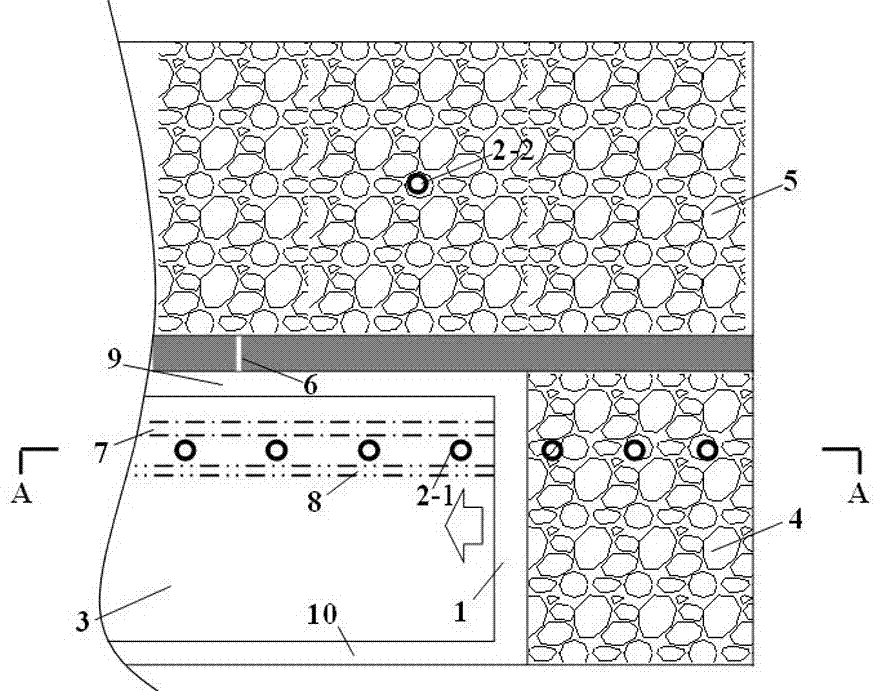

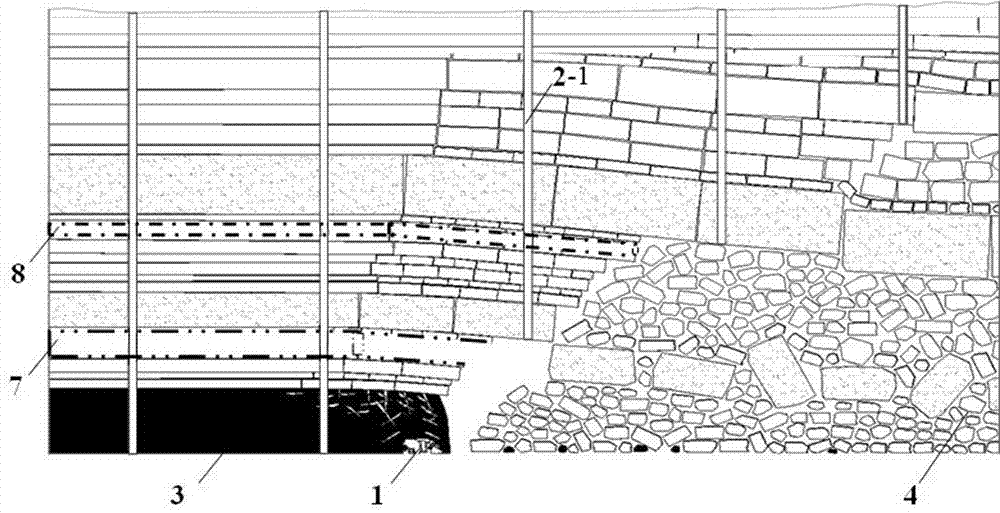

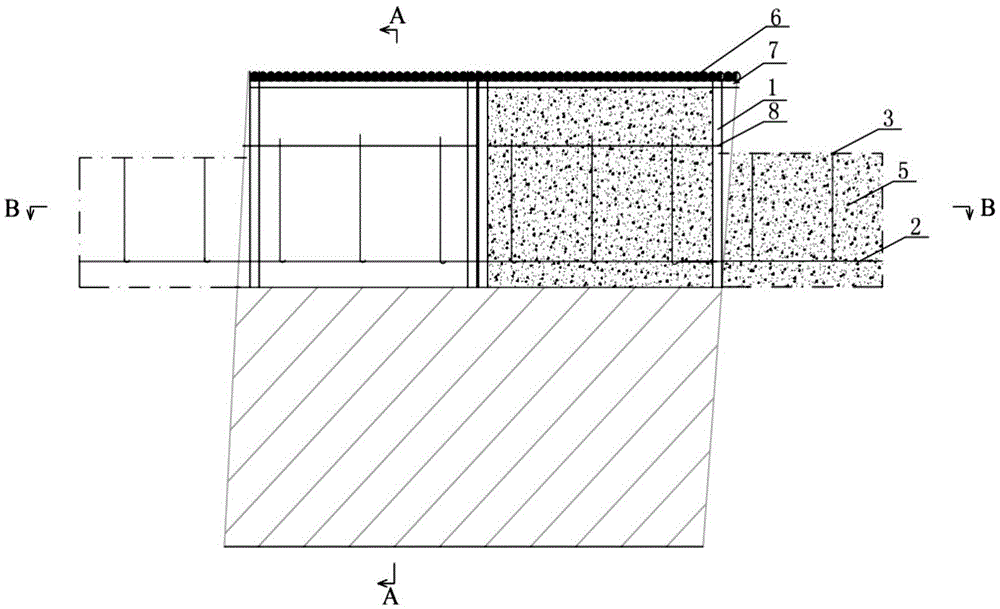

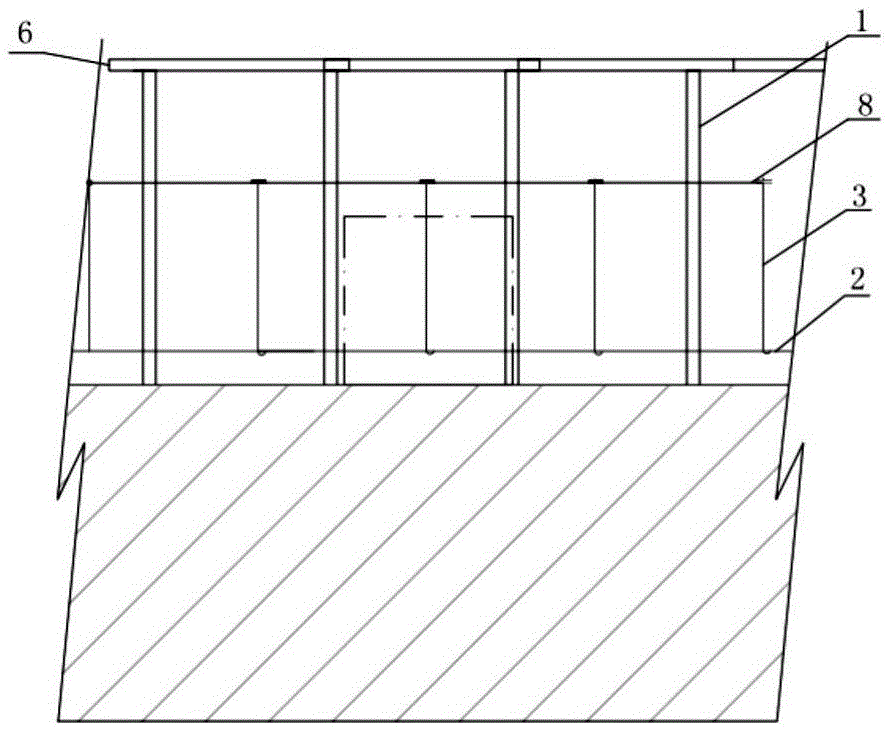

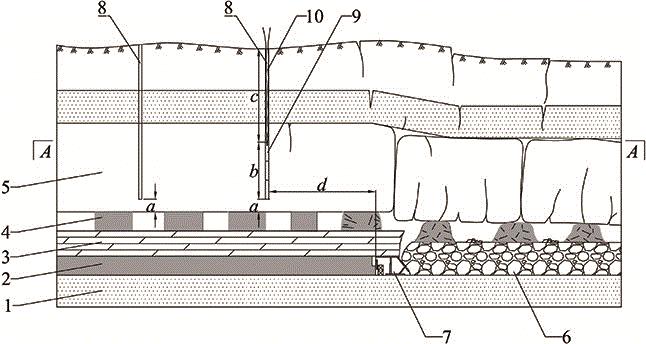

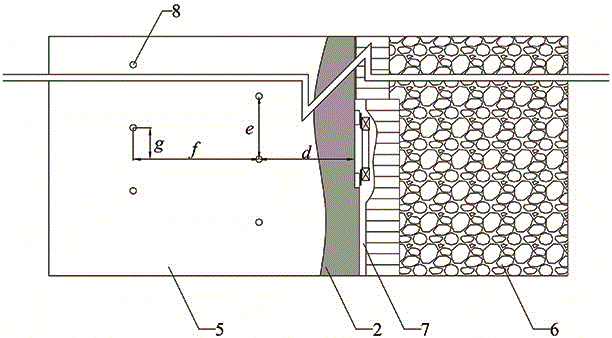

Dimension and dip angle adjustable type coal mine stope similar model test system and method

The invention relates to a dimension and dip angle adjustable type coal mine stope similar model test system and method. The system comprises a model bearing frame, a pressure loading device, a model frame rotating device, a centralized control device and a monitoring device, wherein the model bearing frame is used for laying a stope similar model; the centralized control device is used for sending a pressure application control instruction to the pressure loading device according to a pressure value set by the test and sending a rotation control instruction to the model frame rotating device according to a dip angle value set by the test; the pressure loading device is used for applying pressure to the model bearing frame according to the pressure application control instruction; the model frame rotating device is used for enabling the model bearing frame to rotate by the set dip angle according to the rotation control instruction; the monitoring device is used for monitoring the state of the stope similar model in an excavation process. With the adoption of the system provided by the invention, the pressure characteristics of a coal working face of different dip angles, different buried depths and different coal seam thicknesses of a coal mine site can be simulated in a laboratory.

Owner:CCTEG COAL MINING RES INST

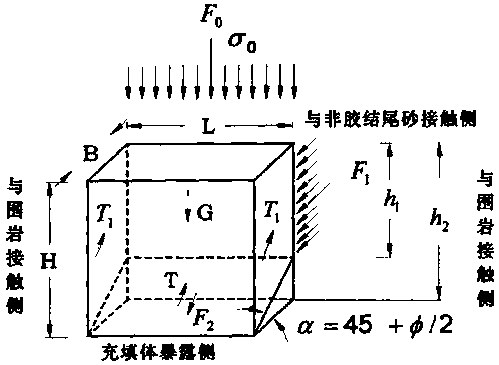

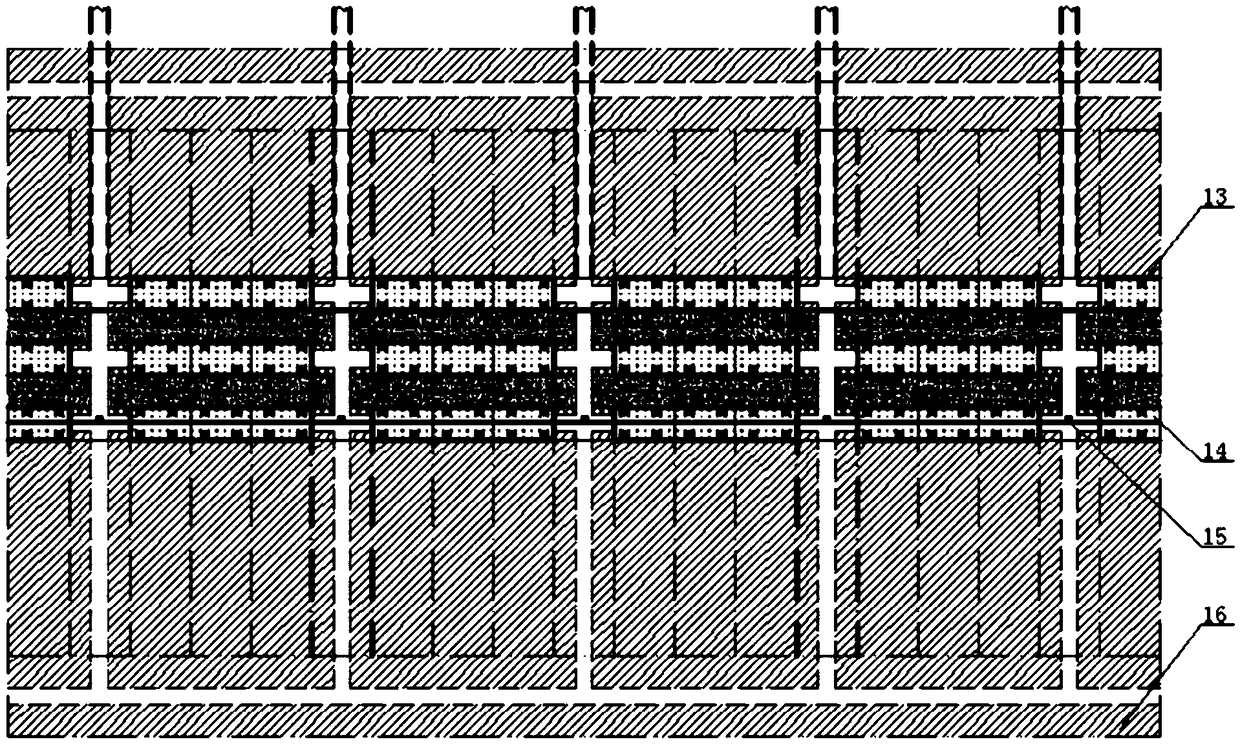

Waste rock and cementing layered wedge bonding filling mining technology and structure thereof

ActiveCN106869931AGuaranteed StrengthSafe and Efficient MiningUnderground miningSurface miningFilling materialsWedge bonding

The invention discloses a waste rock and cementing layered wedge bonding filling mining technology and a structure thereof. In the mining process through an upward horizontal cut and fill method, upward stoping and filling are conducted by adoption of layers with the depth being 3-4 m; three layers serve as a section; the first layer and the third layer are separately subjected to cementing filling through tailings; the second layer in the middle is filled with waste rock in a spaced and mixed mode; the bottom face pavement range is set according to the size of a stope, and a certain distance is kept from the periphery; and the periphery of a waste rock pile is still subjected to cementing filling through tailings, and the tailings are in contact and connection with cementing filling bodies of the upper layer and the lower layer. By adoption of the waste rock and cementing layered wedge bonding filling mining technology and the structure thereof, the problems that in the prior art, technologies are complex, the cost is high, the labor productivity and the ore block production capacity are relatively low, and waste rock cannot be reasonably applied are solved, and by adoption of a layered wedge bonding mixed filling method, the strength of the filling bodies is ensured, a large amount of downhole waste rock is consumed, cementing filling materials are saved, and the layered wedge bonding mixed filling method has the characteristics of being safe in operation, high in filling efficiency and low in cost.

Owner:GUANGXI GAOFENG MINE IND

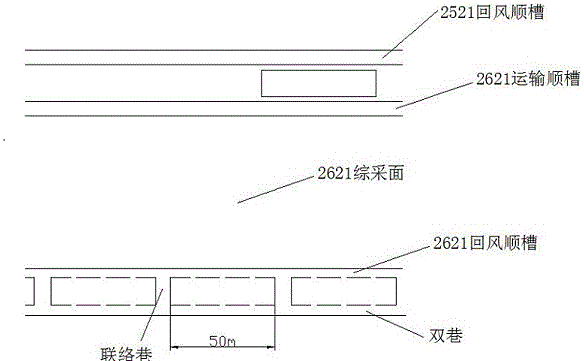

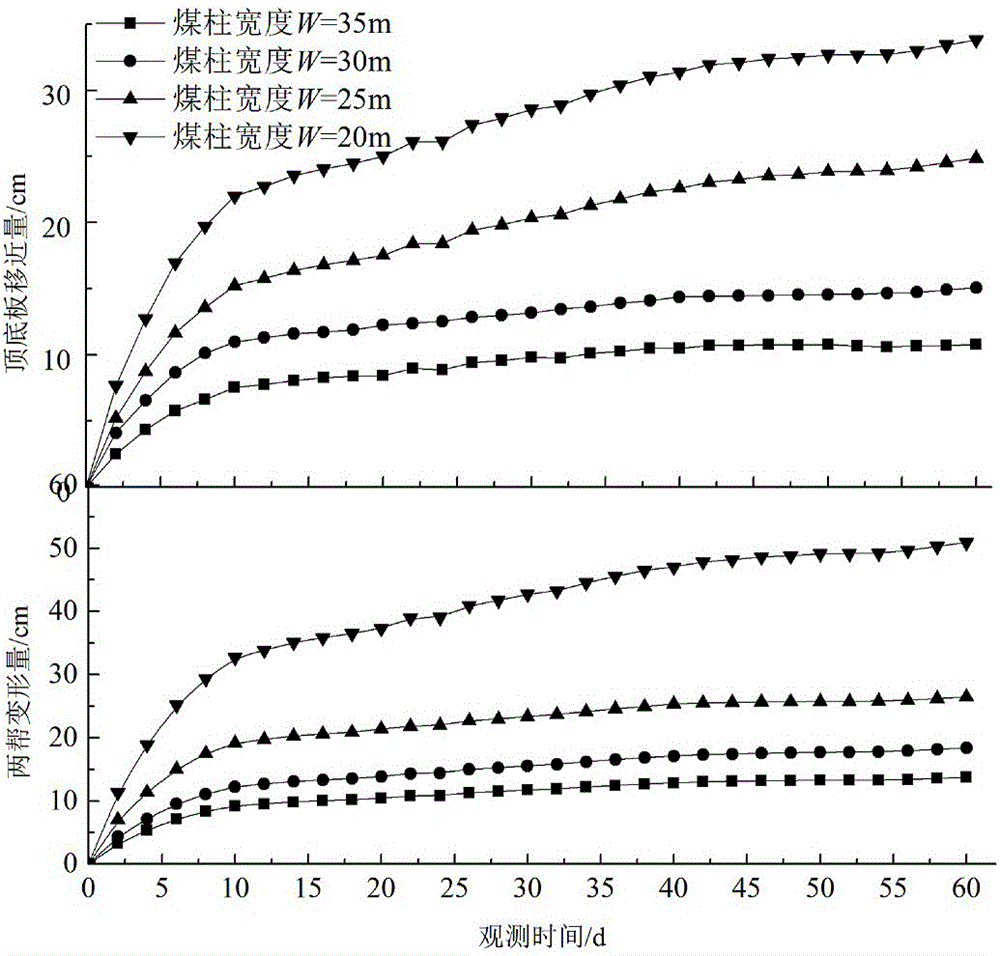

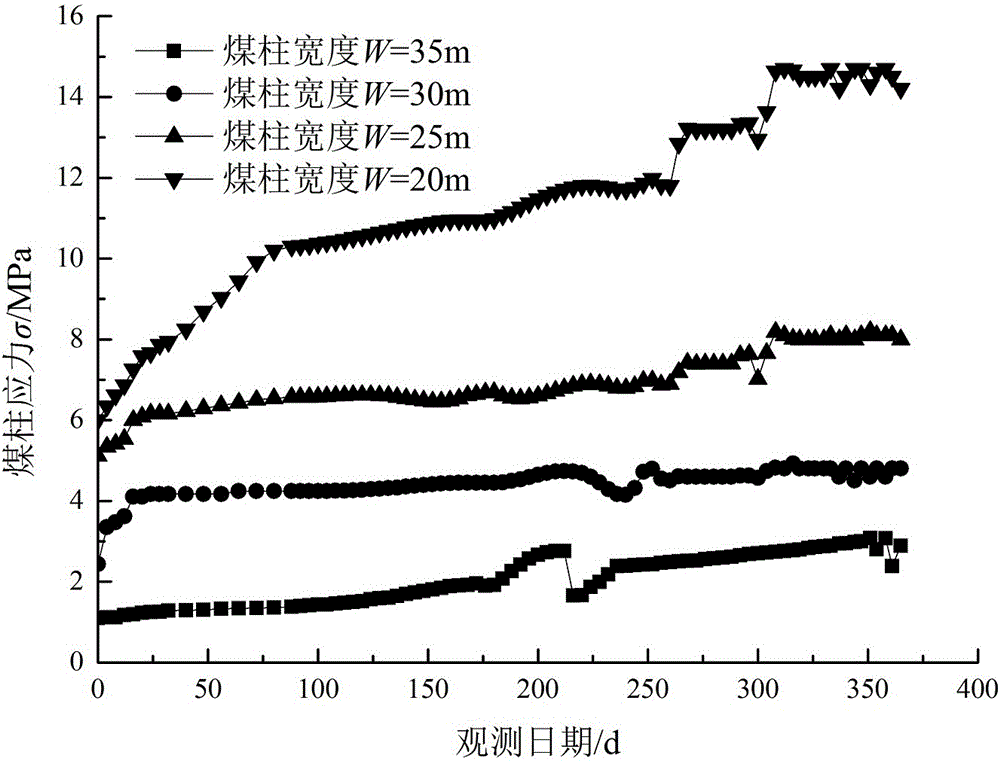

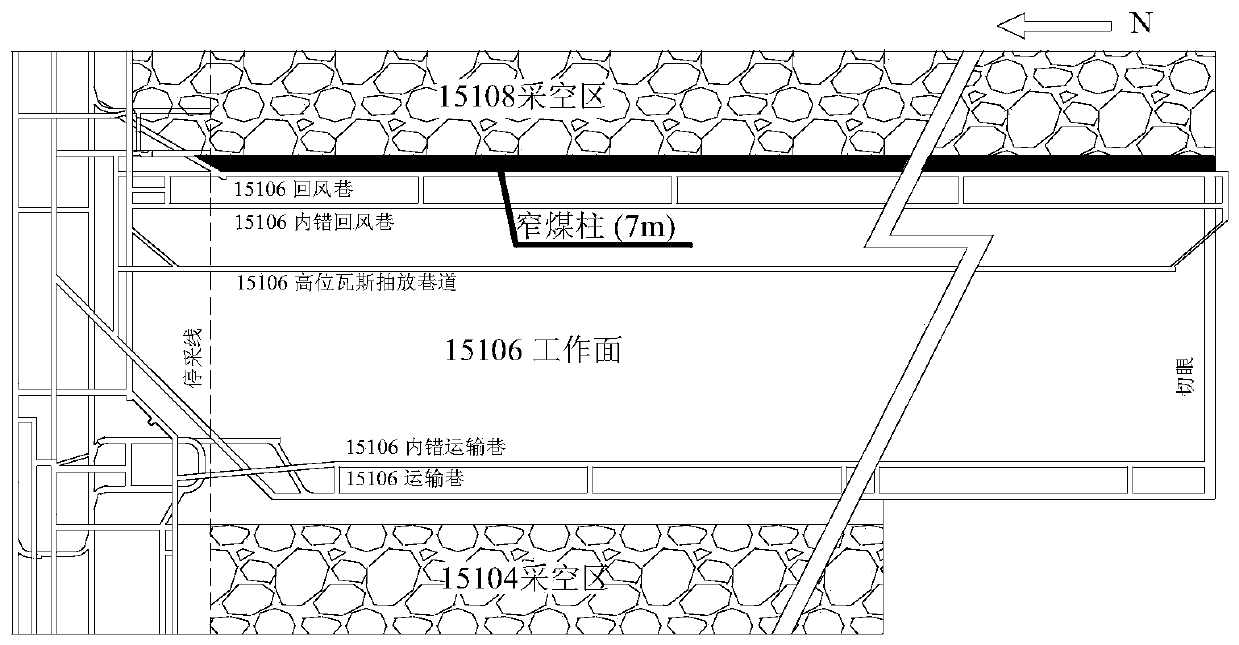

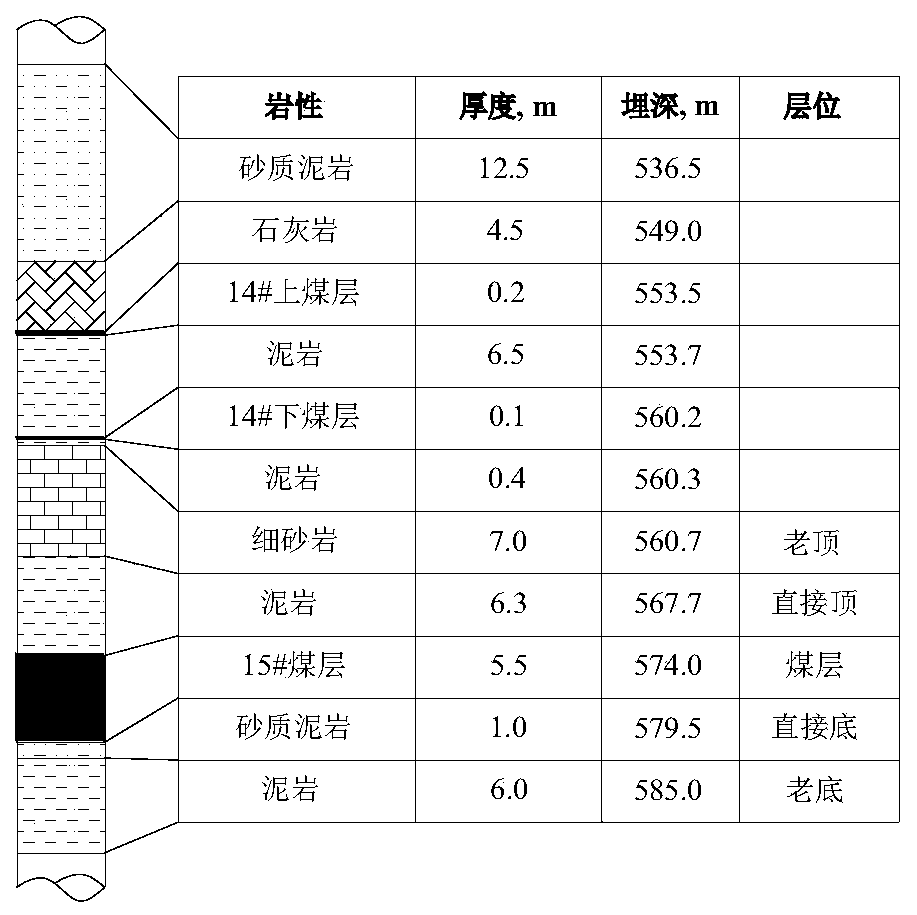

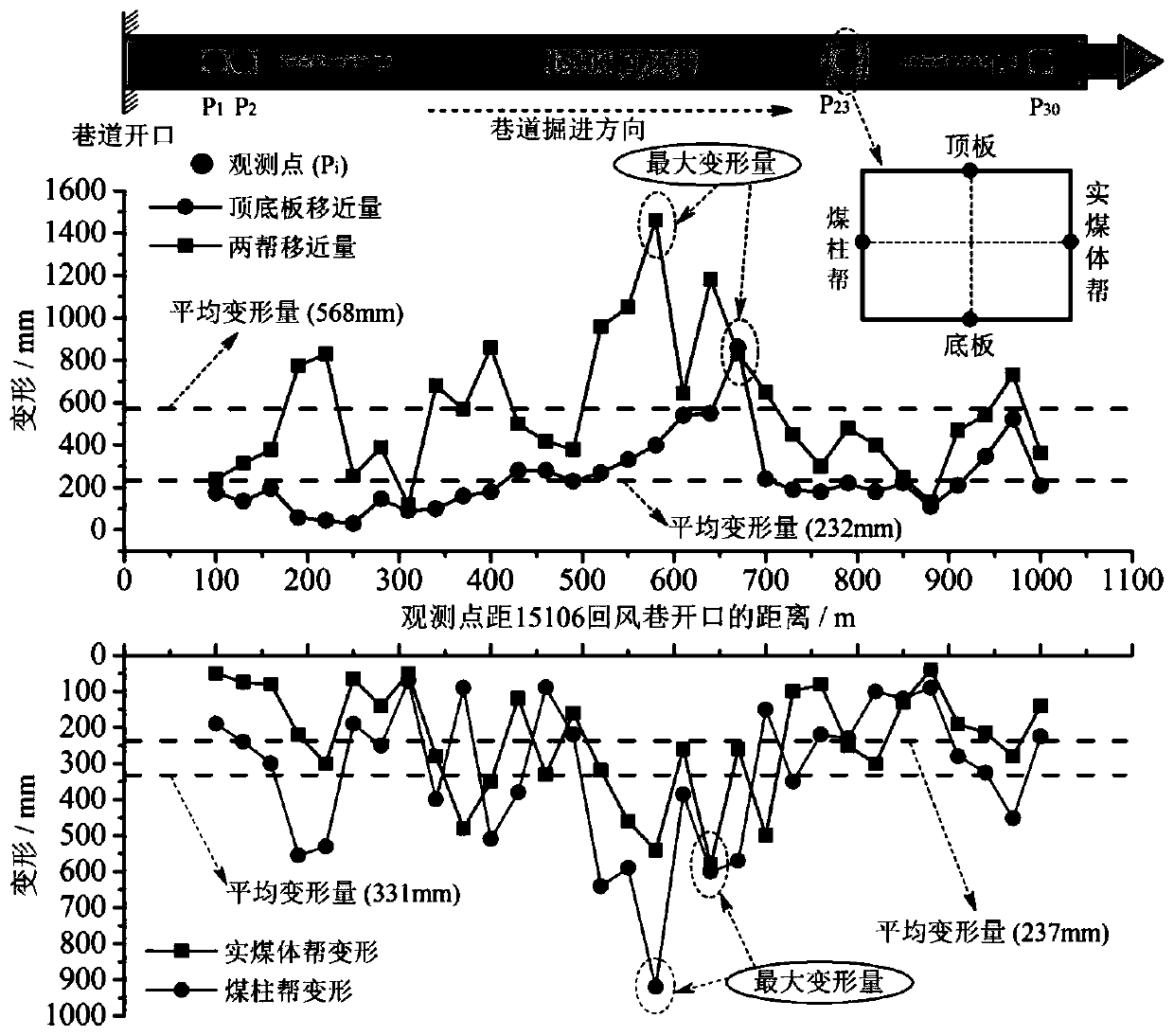

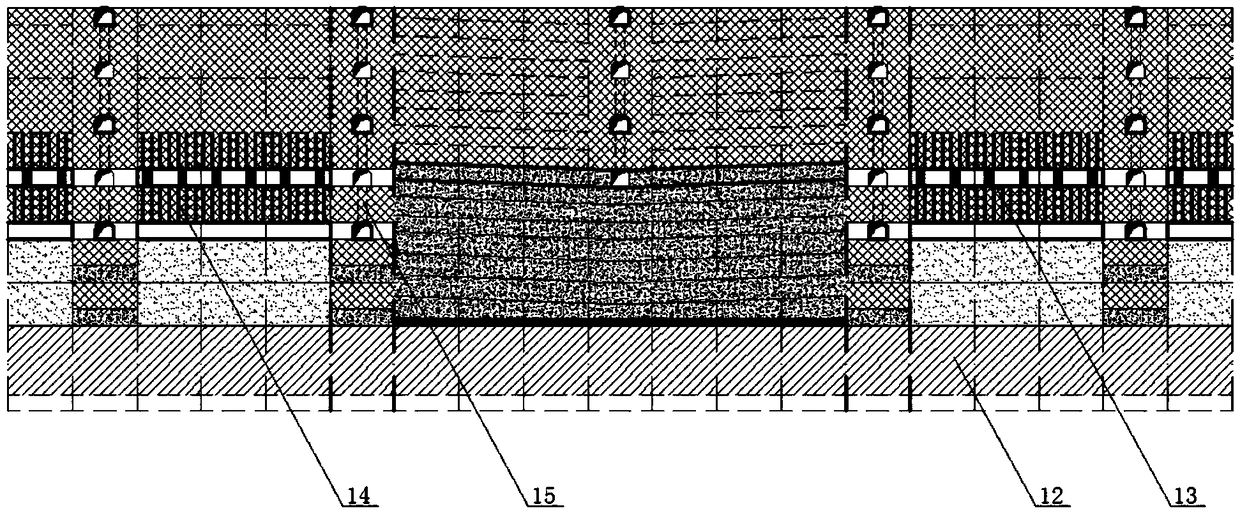

Method for determining setting size of coal columns in fully mechanized caving coal mine gob-side entrydriving

The invention discloses a method for determining the setting size of coal columns in fully mechanized caving coal mine gob-side entrydriving. Means such as indoor test, theoretical calculation, numerical simulation and field test are adopted; a strong constraining and reinforcing scheme for coal columns of 'anchor pole + metal mesh + concrete injection+ reinforcement of coal columns with hollow grouting anchor cable' is provided; the reasonable setting width of coal columns is determined and the long-term stability of coal columns and mining roadways is guaranteed. By means of the method, on one hand, the tunnel later maintenance engineering work load and the maintenance cost are greatly reduced, and on the other hand, the safe and efficient recovery of the working faces is guaranteed. Therefore, the provided method for determining setting size of coal columns in fully mechanized caving coal mine gob-side entrydriving is of great theoretical significance and has engineering practice value.

Owner:LIAONING TECHNICAL UNIVERSITY

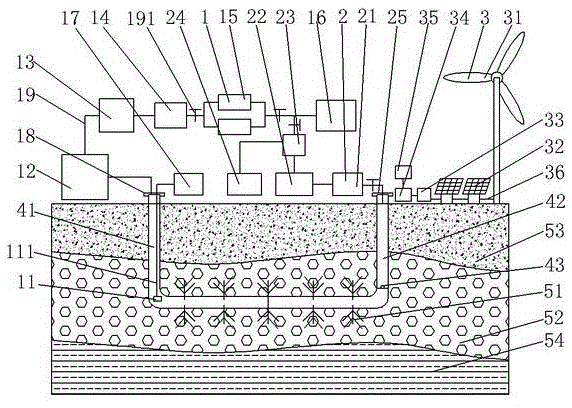

Device and method for exploiting terrestrial natural gas hydrates through CO2 fracturing and displacing

InactiveCN105545273AKeep abreast of the breakdownStay abreast of penetration ratesConstructionsFluid removalControl systemEngineering

The invention discloses a device and method for exploiting terrestrial natural gas hydrates through CO2 fracturing and displacing. The device is composed of a CO2 control system, a natural gas hydrate control system and a power generation control system; the power generation control system is connected to the CO2 control system and the natural gas hydrate control system, and the CO2 control system is connected with the natural gas hydrate control system. According to the device and method, by combining CO2 dry fracturing with CO2 displacing, the problems that when the hydrates are exploited only by adopting CO2 displacing, the speed and the efficiency are low are solved, hydrate exploiting and greenhouse gas burying and storing are integrated into a whole, and meanwhile the stability of a hydrate layer in the exploiting process is guaranteed. Information such as the pressure, the temperature and the permeability of the hydrate layer can be collected in real time in the fracturing and exploiting process, the exploiting speed of hydrate decomposition gas and improvement treatment on the reservoir permeability are adjusted and controlled according to the information, and therefore the purpose of efficient and safe exploiting is achieved.

Owner:JILIN UNIV

Method for extracting protruded coal-bed downward bedding long-borehole step-by-step covering area gas

InactiveCN101029575AReduce gas contentEliminate outstanding hazardsGas removalSealing/packingEngineeringGas concentration

This is a gas extraction method for a single burst coal bed of stable coal occurrence, angle less than 10o, and firm index over 0.5. Drill a hole from top working face downward along the coal bed from shallow bed to deep, from low gas concentration zone to high for pre-extraction to lower down the gas concentration.

Owner:淮北矿业股份有限公司祁南煤矿 +1

Deep inclined coal seam mining roadway mine pressure control mining method

InactiveCN104775819ASafe and efficient miningControl mine pressure displayUnderground miningSurface miningRetreat miningCoal pillar

The present invention relates to a deep inclined coal seam mining roadway mine pressure control mining method. According to the method, the filled mining strip and the fully mechanized mining work face are subjected to coordination arrangement, wherein the one fully mechanized mining work face is arranged between each two filled mining strips; and after the mining of the filled mining strip is completed, the mining roadway is adopted as the mining roadway of the middle fully mechanized mining work face by using the gob-side entry retaining method, the filled work face is arranged in a rising manner, the advancing mining is performed, the fully mechanized mining work face is arranged in a dip manner, the retreating mining is performed, the width of the filled mining strip is 35-45 m, and the width of the fully mechanized mining work face is 3-4 times the width of the filled strip. With the method of the present invention, the problem of the influence of the near goaf concentrated stress on the mining roadway is fundamentally solved, the mine pressure appearing of the gob-side entry retaining country rock is effectively controlled, the country rock deformation of the roadway is reduced, the safe mining of the mining area work face is ensured, the resource loss caused by the protection coal pillars between the work faces is reduced through the gob-side entry retaining technology, and the recovery rate of the mining area reduces is improved.

Owner:CHINA UNIV OF MINING & TECH

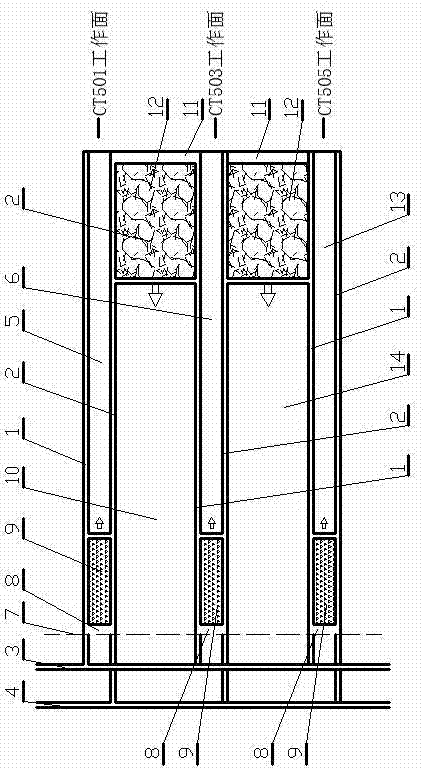

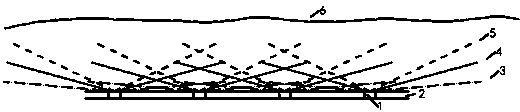

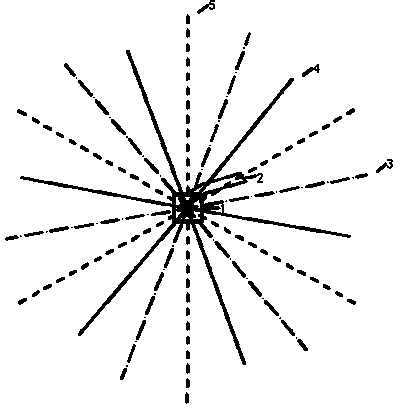

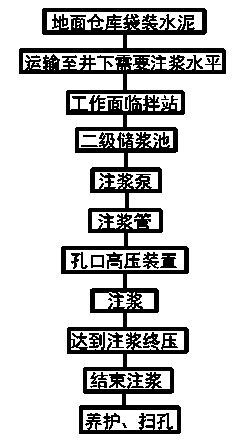

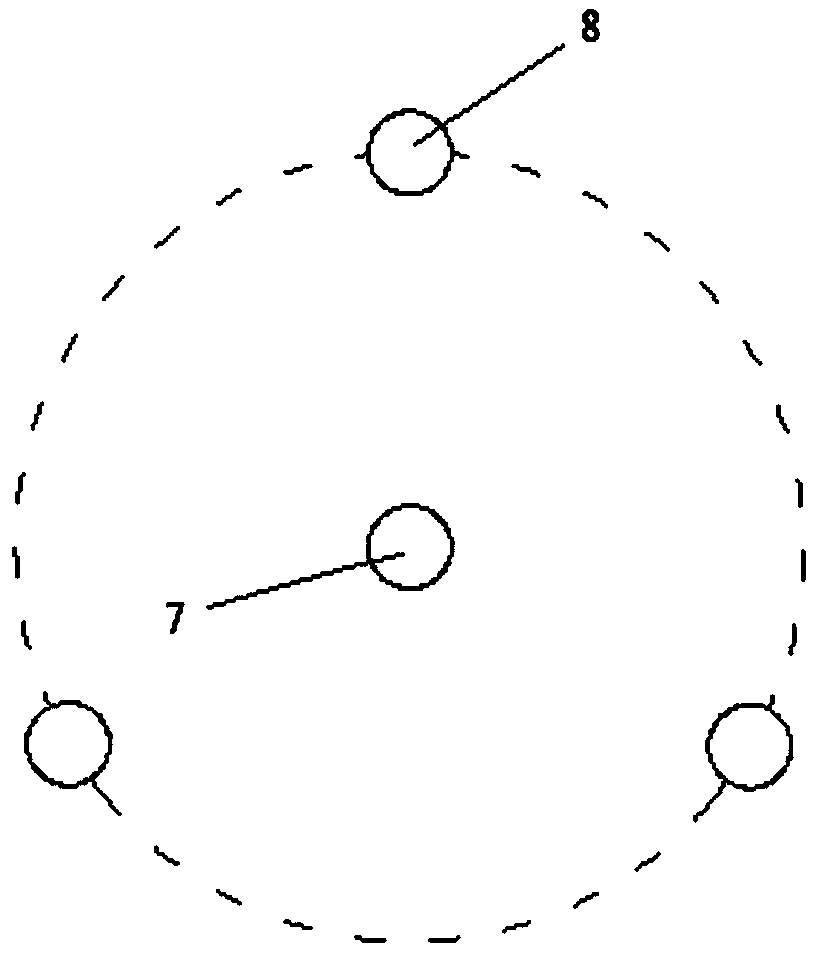

Curtain grouting process suitable for water-rich mine underground mining water plugging

ActiveCN103967507AStrong targetingLess ineffective drillingUnderground chambersTunnel liningKarstHigh pressure

The invention discloses a curtain grouting process suitable for water-rich mine underground mining water plugging. According to the arrangement method of grouting holes, six grouting holes facing upwards by 5 degrees, six grouting holes facing upwards by 15 degrees and six grouting holes facing upwards by 25 degrees are formed in each chamber, the grouting holes facing upwards by 5 degrees, the six grouting holes facing upwards by 15 degrees and the six grouting holes facing upwards by 25 degrees are evenly distributed in the plane in a 60-degree staggered mode, and grouting holes facing downwards by -5 degrees, grouting holes facing downward by -30 degrees and grouting holes facing downwards by -60 degrees are formed outward in the chambers at the ends. According to the grouting process, bagged cement in a ground warehouse is transported to underground positions where grouting and leveling are needed, grouting is conducted through a working face temporary stirring station, a two-level pulp storage pond, a grouting pump, a grouting pipe and a hole opening high pressure device, grouting is completed after the designed final grouting pressure is reached, and the whole curtain grouting work is completed after further maintenance and hole cleaning. A grouting curtain with a high water plugging rate is set up underground for roof karst cracks, the water isolation function and the reinforcing function can be achieved, an ore body is safely and efficiently freed under protection of the grouting curtain, technical guarantees are provided for safe and efficient mining of the mine, project input is small, and the construction period is short.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

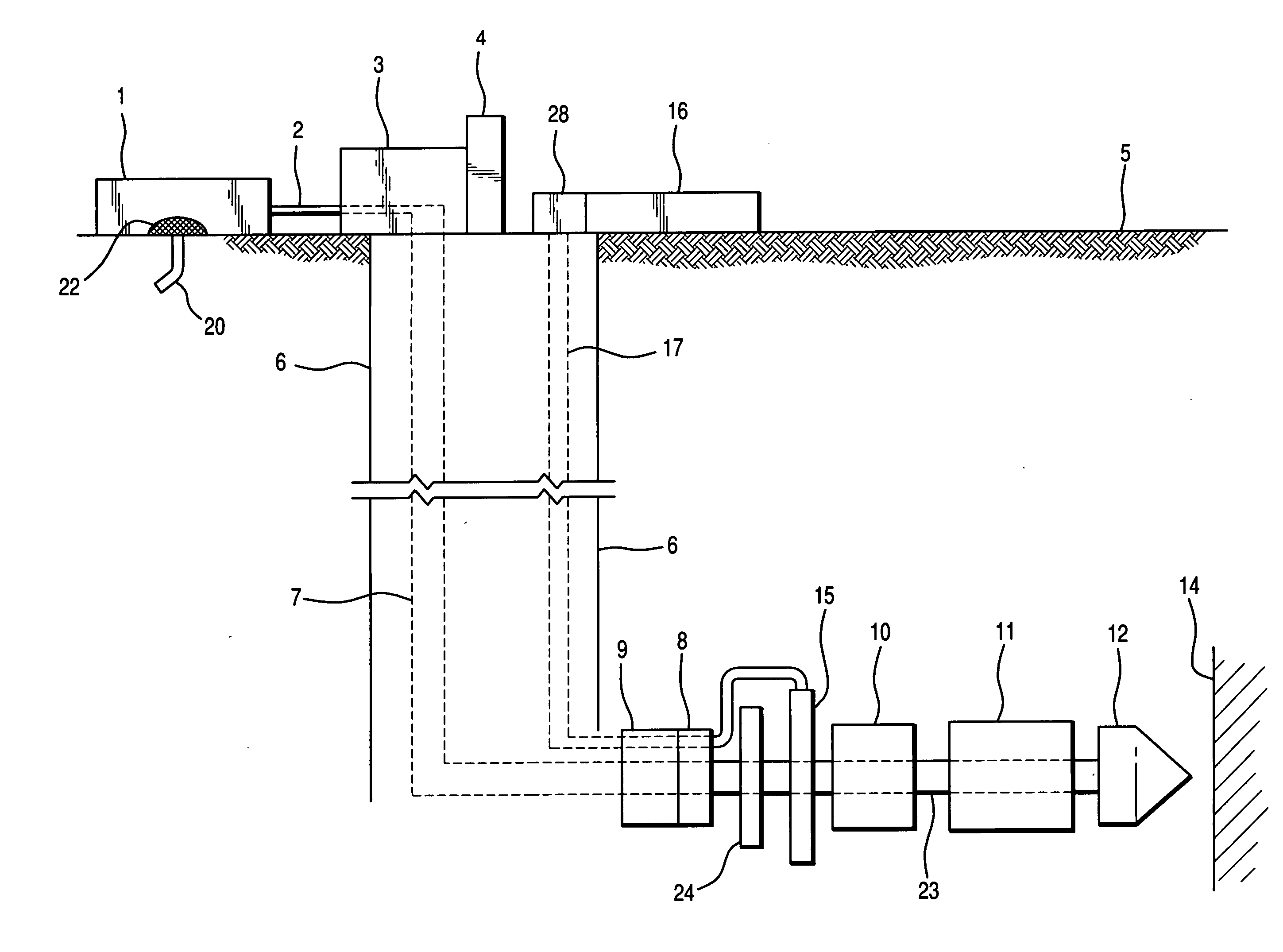

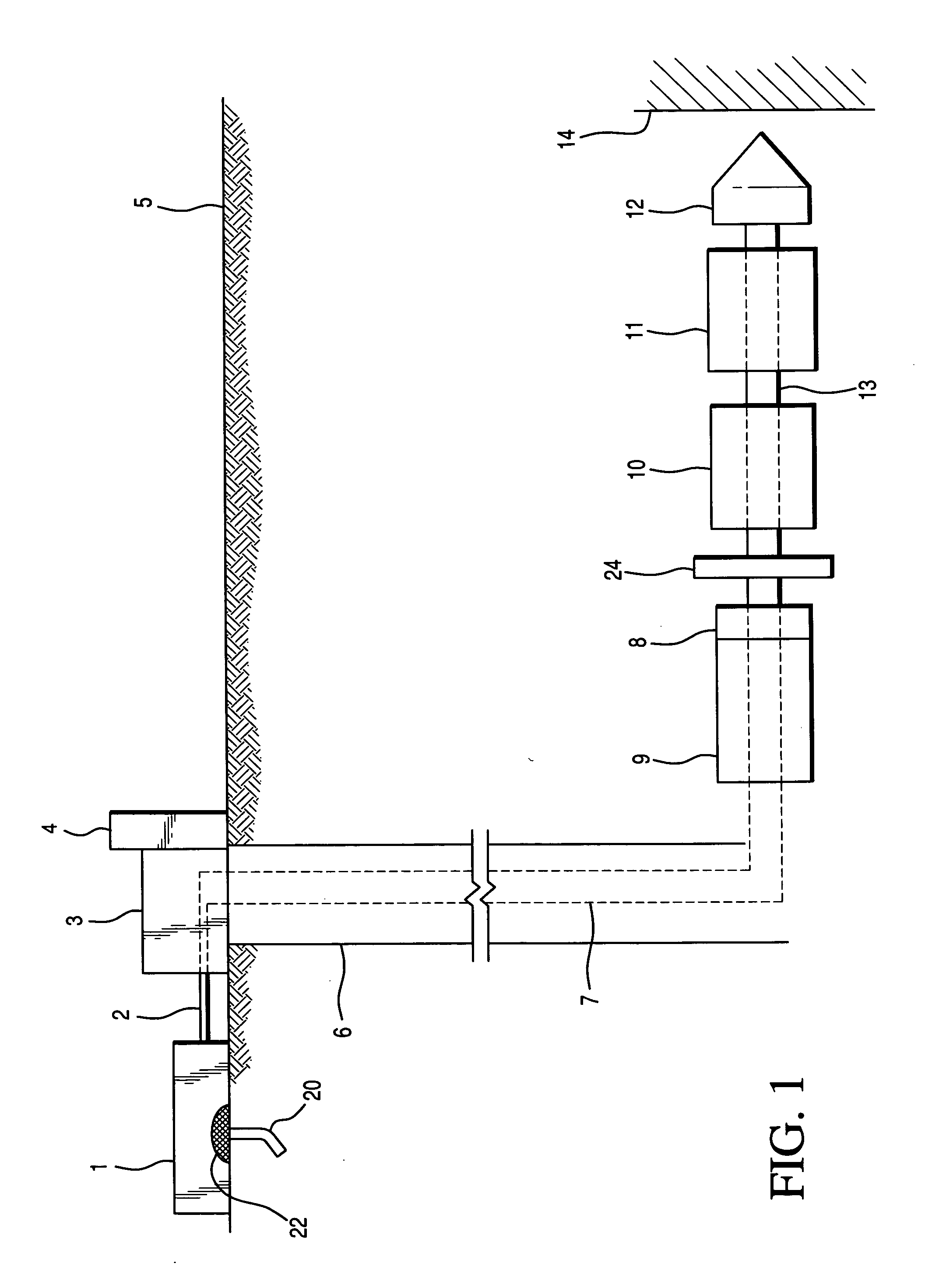

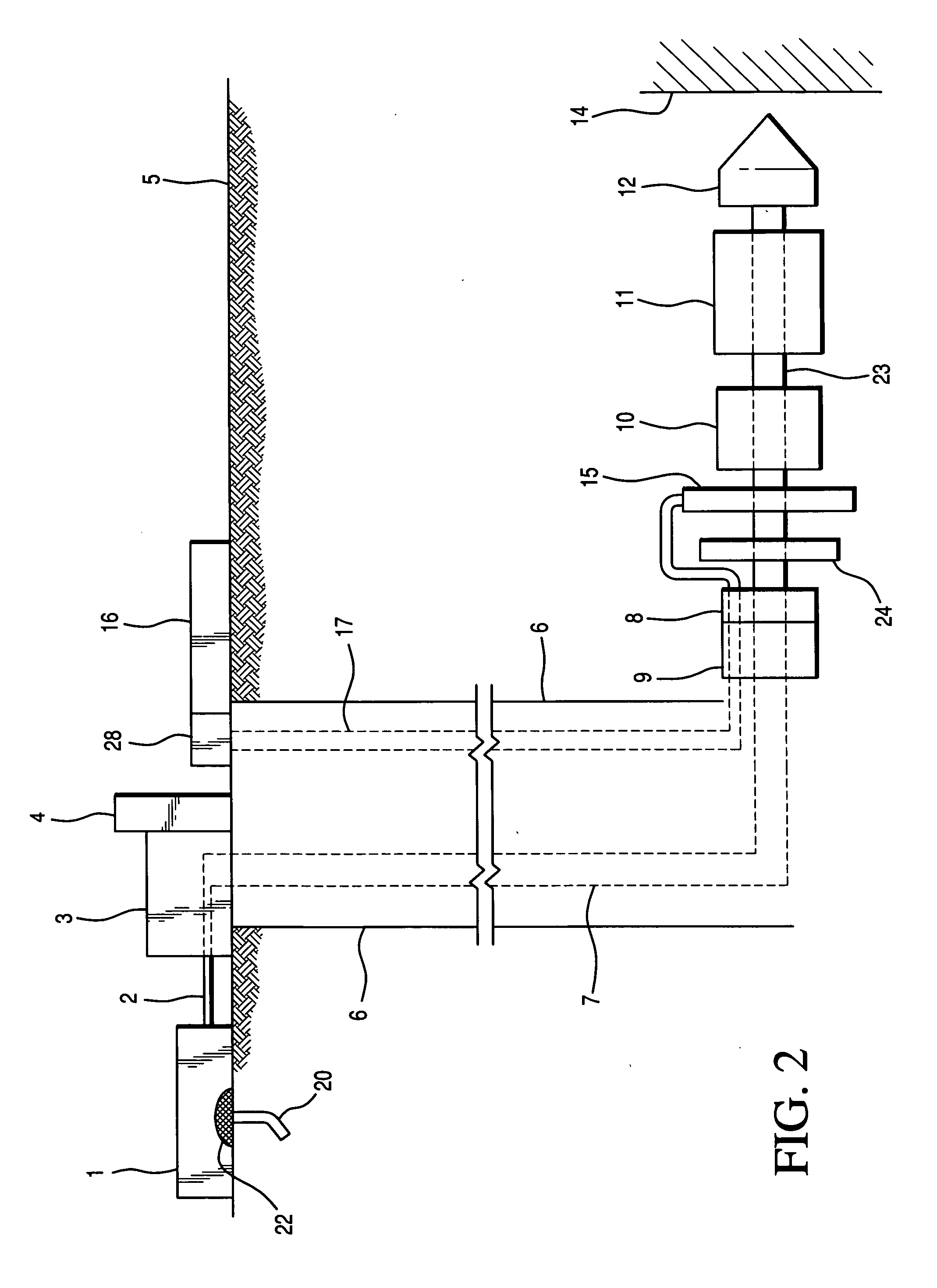

Apparatus and method for mining coal

ActiveUS20110049965A1Pump operationSafe and Efficient MiningUnderground miningSlitting machinesCoalEngineering

The present invention relates to a novel method of mining underground coal and recovering coal seam gas, the method including locating a seam of coal; digging a mine shaft to reach the seam of coal; constructing a ventilated underground control center which includes a computerized control panel, wherein the computerized control panel controls the movement of a drill head, a hollow drill shaft, a movable hydraulic shield, a movable resin roof bolting machine, and a movable waste extrusion device; providing mining personnel to the ventilated underground control center; and allowing the mining personnel to operate the computerized control panel wherein they perform the tasks of moving the drill head into the seam of coal to obtain aggregate coal and coal seam gas; extruding waste material into mined-out space of the coal seam; and transferring the aggregate coal and coal seam gas to the surface of the earth.

Owner:AULISIO GEORGE ANTHONY +1

Discrete element method for simulating roadway surrounding rock fracture evolution

ActiveCN110390152AStrong on-site guidanceAuthentic and reliable simulationEarth material testingMaterial strength using tensile/compressive forcesDiscrete element methodFinite element method

The invention discloses a discrete element method for simulating roadway surrounding rock fracture evolution. The discrete element method comprises the steps that on-site coal and rock stratum coringis conducted an RQD value is recorded, roadway deformation is observed, and coal seam fracture distribution characteristics are counted; mechanical parameters of coal rock samples are tested indoors,and the strength of the rock mass is calculated according to the RQD value; a UDEC-Trigon module is used for establishing a numerical model to adjust parameters, and parameters match with rock mass strength to correct model parameters; and a numerical model of the engineering scale is established to adjust the parameters to be matched with field deformation characteristics, and finally roadway surrounding rock fracture evolution is simulated. Accurate basic mechanical parameters are provided for discrete element numerical simulation roadway deformation, and it can be ensured that the simulation result is real and reliable.

Owner:CHINA UNIV OF MINING & TECH +1

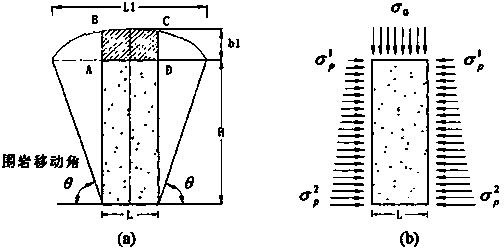

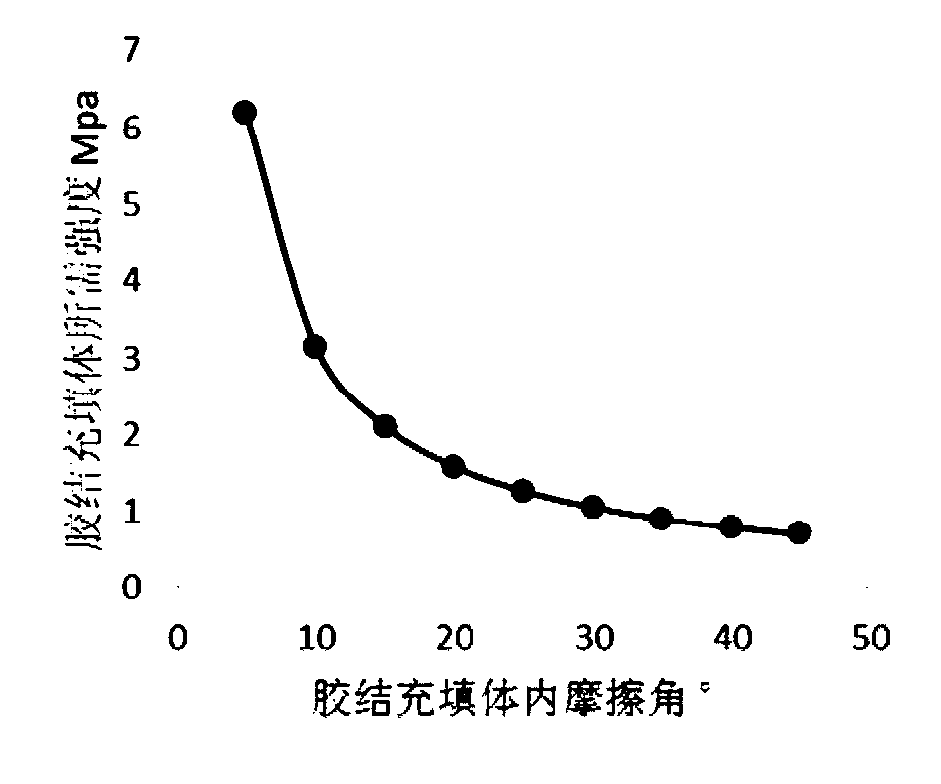

Construction method of large-volume-filling-body strength model of two-step open-stope subsequent-filling

ActiveCN107918712AHigh strengthSolve the disadvantages of solving the required strength of cemented filling bodyDesign optimisation/simulationSpecial data processing applicationsMineral SourcesVolume filling

Owner:YUXI MINING +1

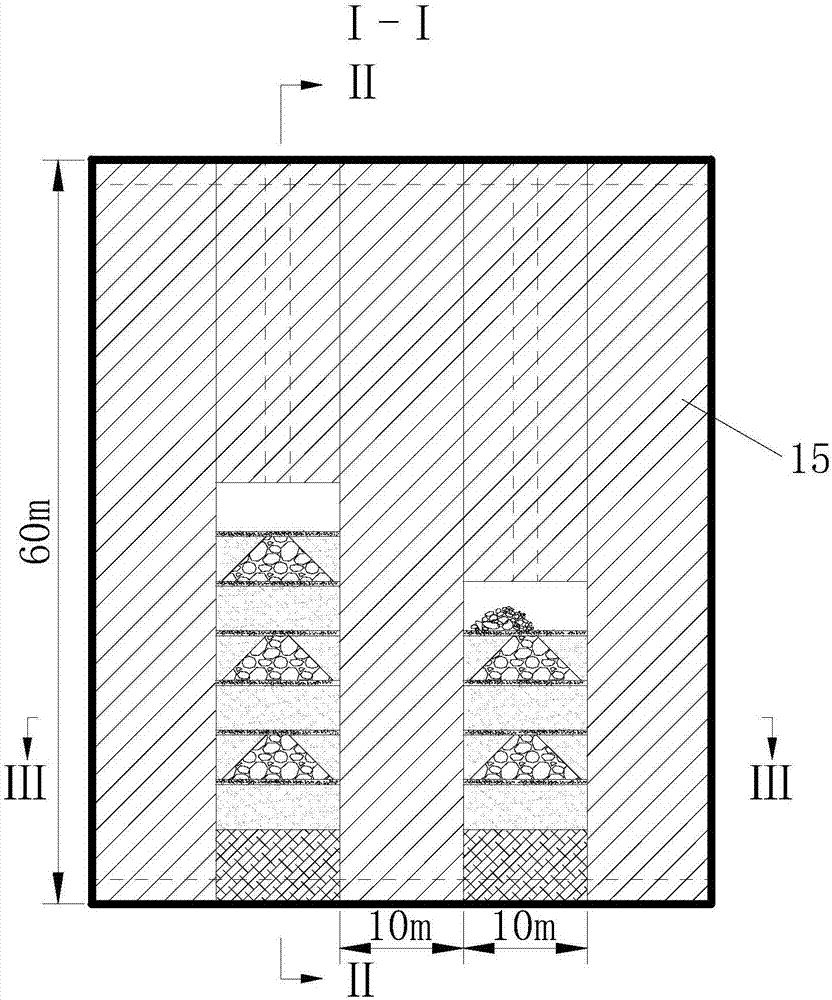

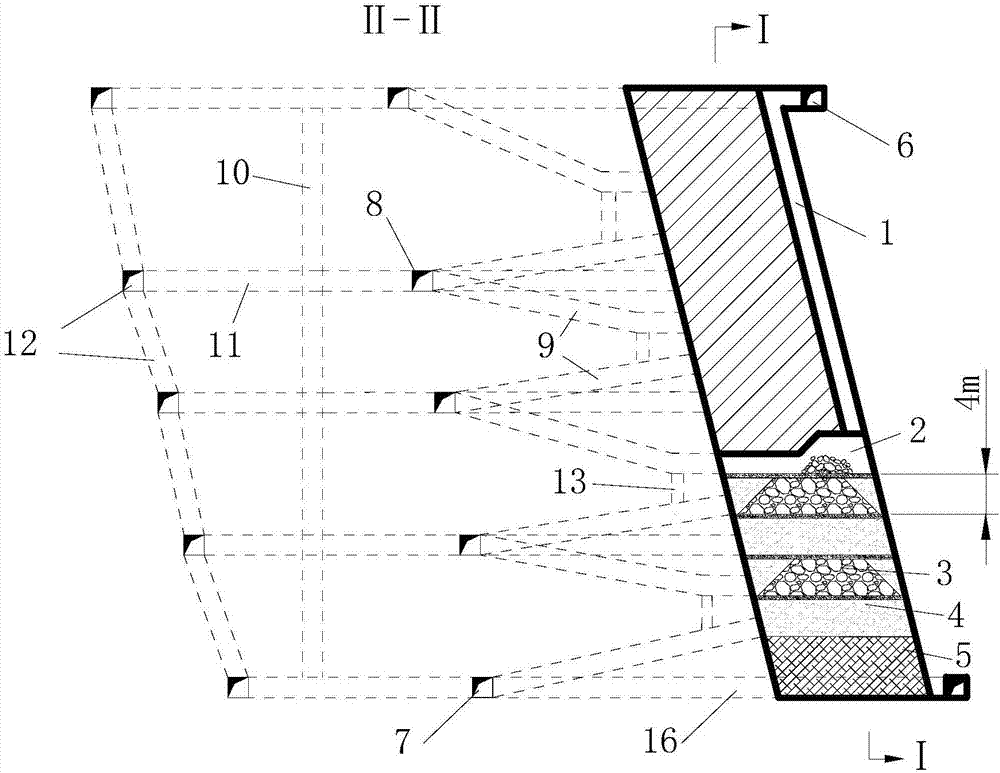

Mechanized upward-slicing wedging mixed filling mining method

ActiveCN106894817AIncrease profitGuaranteed StrengthUnderground miningSurface miningMining engineeringUltimate tensile strength

The invention discloses a mechanized upward-slicing wedging mixed filling mining method. When mining is conducted through the upward horizontal slicing filling process, upward stoping and filling are conducted with each slice being 3-4 m, and slices from bottom to top are alternately subjected to full tail sand cementing filling and waste stone wedging mixed filling. During wedging mixed filling, waste stone is stacked upward to form a quadrangular frustum pyramid. The laying range of the bottom waste stone is arranged according to the size of a stope, and certain spacing is kept with an adjacent stope. Tail sand cementing filling is still conducted on the two sides of a waste stone pile, and making contact with upper and lower layered tail sand cementing filling bodies is conducted, the whole strength of a mixed filling body is guaranteed, and dilution caused by caving of an ore body or surrounding rock at the time of being unstable is stopped. When the upward horizontal slicing filling process is adopted, the strength of the filling body can be guaranteed, and a large quantity of the downhole waste stone can be consumed, so that the waste stone is not out of a pit, and accordingly the cementing filling material is saved, and the filling cost is reduced effectively.

Owner:CENT SOUTH UNIV

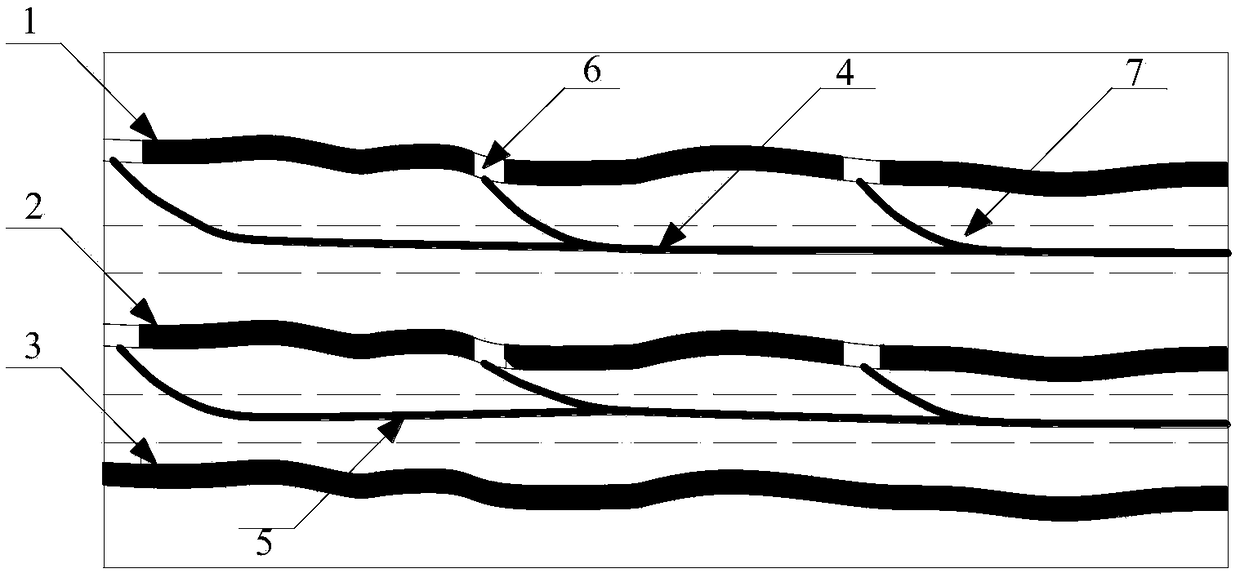

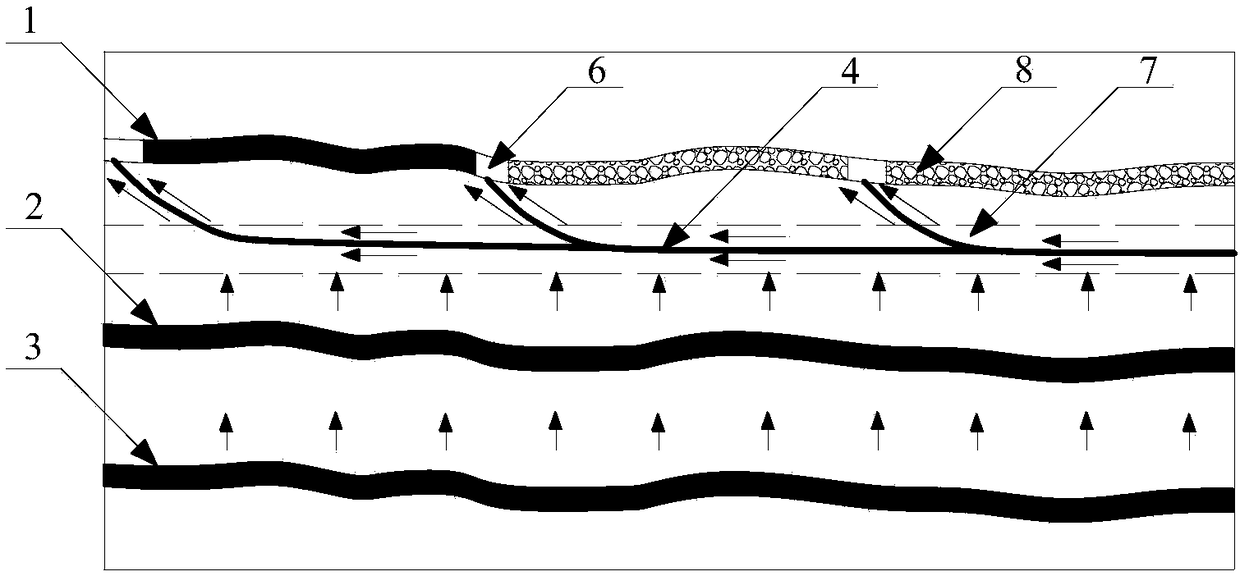

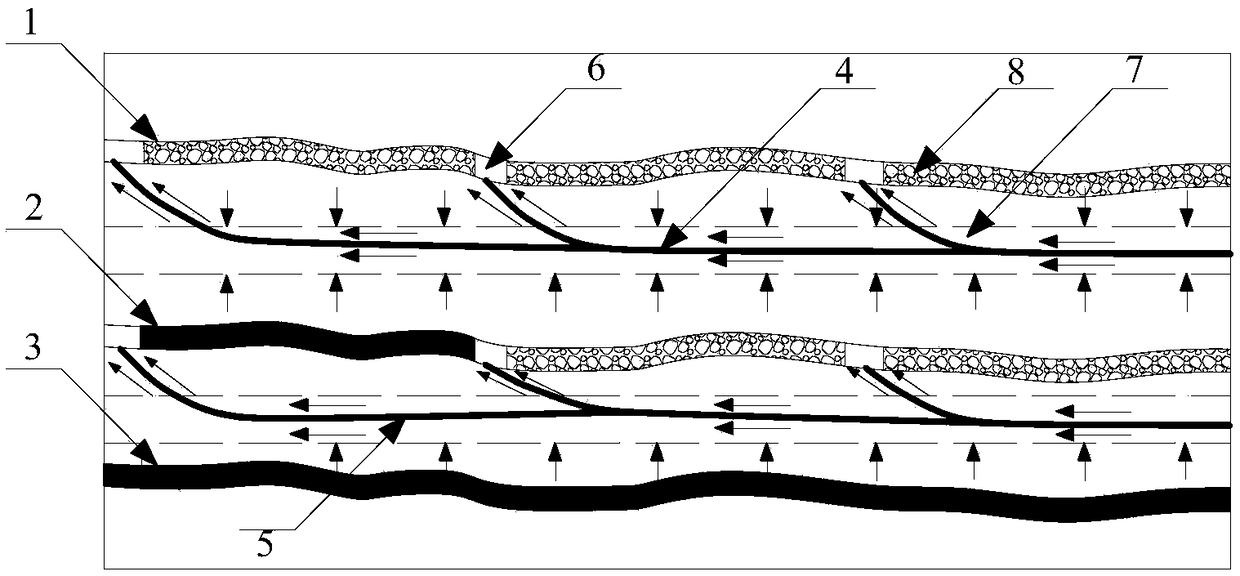

Stereo treatment method for low-occurrence and high-emission gas according to sources and zones

ActiveCN106988778ASafe and Efficient MiningImprove the extraction effectGas removalGas concentrationCoal

The invention relates to drainage methods for gas sources in different zones of a working face leading coal and rock mass fractured zone, a working face and a working face goaf, and a zone close to the working face goaf in the top-coal caving mining process of an extra-thick coal seam, in particular to a stereo treatment method for low-occurrence and high-emission gas according to sources and zones. The stereo treatment method for the low-occurrence and high-emission gas by sources and zones has the following advantages that (1) through a gas drainage drilling hole, a gas drainage roadway and a strike drainage drilling hole arranged continuously, gas in different zones of the working face leading coal and rock mass fractured zone, the working face and the working face goaf can be drained, and the gas concentration in the working face is minimized; and (2) gas in a working face deep goaf can be drained at any time, and the defects that the traditional drainage method cannot drain the gas in the working face deep goaf is overcome.

Owner:DATONG COAL MINE GRP

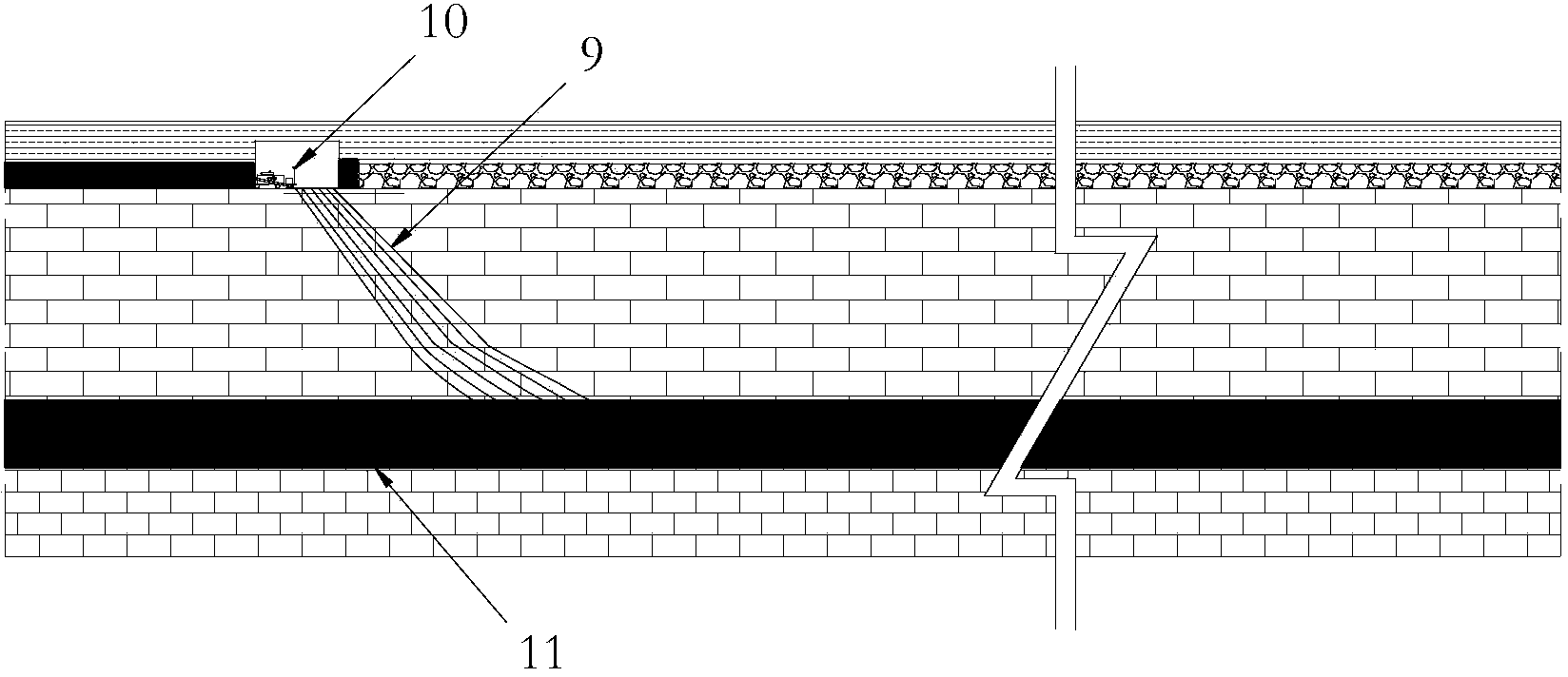

Method for extracting gas close to lower coal layer through directional drilling in thin coal seam fully-mechanized coal mining gob-side entry

ActiveCN104047629AIncrease gas areaReduce gas contentUnderground miningSurface miningMining engineeringDirectional drilling

The invention provides a method for extracting gas close to a lower coal layer through directional drilling in a thin coal seam fully-mechanized coal mining gob-side entry. For a thin coal seam fully-mechanized coal mining face, through the mode of the gob-side entry, directional drilling is carried out in the entry to extract the gas close to the high-gas coal layer. Due to the mode of the coal mining face gob-side entry, in the thin coal seam exploiting process, the situations that the digging ratio is large, and digging replacement is tense can be relieved, the preparation time of the coal mining face is shortened, and the digging amount of a semi-coal stone drift can be reduced; on the other hand, directional drilling holes are drilled in the gob-side entry and can be distributed in the lower coal layer in a large drilling hole range mode due to directional drilling, the area of extracting the gas in the coal layer through the drilling holes is greatly increased, by means of extraction of directional drilling, the content of the gas close to the high-gas coal layer is reduced, and conditions are provided for safe, high-yield and high-efficiency mining of the lower coal layer. The method solves the problems that the gas of the high-gas coal layer poor in gas permeability is difficult to extract, the digging ratio of mining of the thin coal seam layer is large, the drivage ratio is large, and digging replacement is tense.

Owner:CHINA UNIV OF MINING & TECH

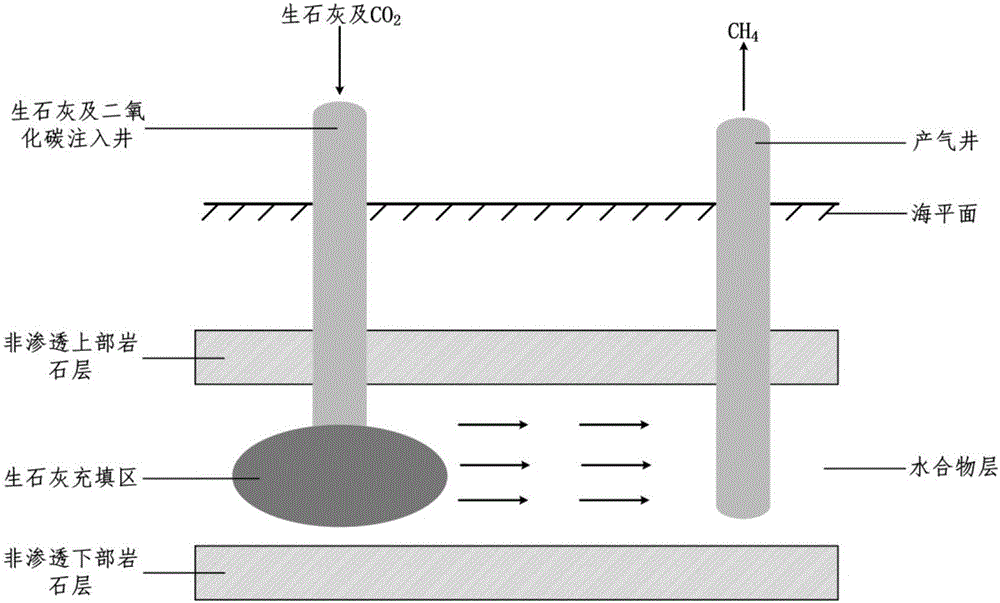

Method for jointly exploiting hydrates and hermetically storing carbon dioxide by aid of quicklime and carbon dioxide injection processes

ActiveCN106437653AIncrease temperatureBreak phase balanceGas treatmentMethane captureGreenhouseInstability

The invention provides a method for jointly exploiting hydrates and hermetically storing carbon dioxide by the aid of quicklime and carbon dioxide injection processes. The method includes selecting hydrate occurrence regions as target regions and drilling quicklime and carbon dioxide injection wells and gas production wells; injecting quicklime into hydrate layers from the quicklime and carbon dioxide injection wells to form quicklime filling regions; completely carrying out reaction on the quicklime and water in the hydrate layers and then injecting the carbon dioxide from the quicklime and carbon dioxide injection wells; controlling outlet pressures of the gas production wells to allow gas production pressures to be higher than carbon dioxide and hydrate phase-balance pressures corresponding to the temperatures of the hydrate layers and lower than methane and hydrate phase-balance pressures corresponding to the temperatures of the hydrate layers; collecting methane gas at well mouths of the gas production wells. The method has the advantages that the hydrates can be safely and efficiently exploited, environmental problems such as decrease of the strength of existing hydrate layers and instability of strata in natural gas hydrate exploitation procedures can be effectively solved, and the purposes of hermetically storing the carbon dioxide and abating greenhouse effects can be achieved.

Owner:DALIAN UNIV OF TECH

Artificial top construction method based on paste filling

ActiveCN105545353AImprove securitySafe and efficient miningMaterial fill-upEngineeringUltimate tensile strength

The invention provides an artificial top construction method based on paste filling and belongs to the technical field of mining engineering. The method comprises the steps of drift excavation, beam head excavation, hanging bar arrangement and paste filling. According to the method, artificial top filling drifts are excavated firstly, and a steel bracket and a timber support are erected; secondly, chambers are excavated on the two sides of a roadway every other 3 m, and each chamber is 150 cm wide, 150 cm height and 200 cm deep; thirdly, bar arrangement is conducted, bottom bars and hanging bars are arranged, and the bottom bars include horizontal bars and longitudinal bars; fourthly, paste filling is conducted, strength reaches 4-5 Mpa within 28 days, and the mass concentration of paste is 78-80%. According to the method, work amount is small, construction cost is low, construction is easy, risks caused by insufficient span or excessive span of a filled artificial top are avoided, drilling safety is improved for workers, and high-level large-diameter deep-hole safe and efficient recovery of weak broken ore bodies can be achieved. The method provides a new idea for large-scale mining of the ore bodies.

Owner:UNIV OF SCI & TECH BEIJING +1

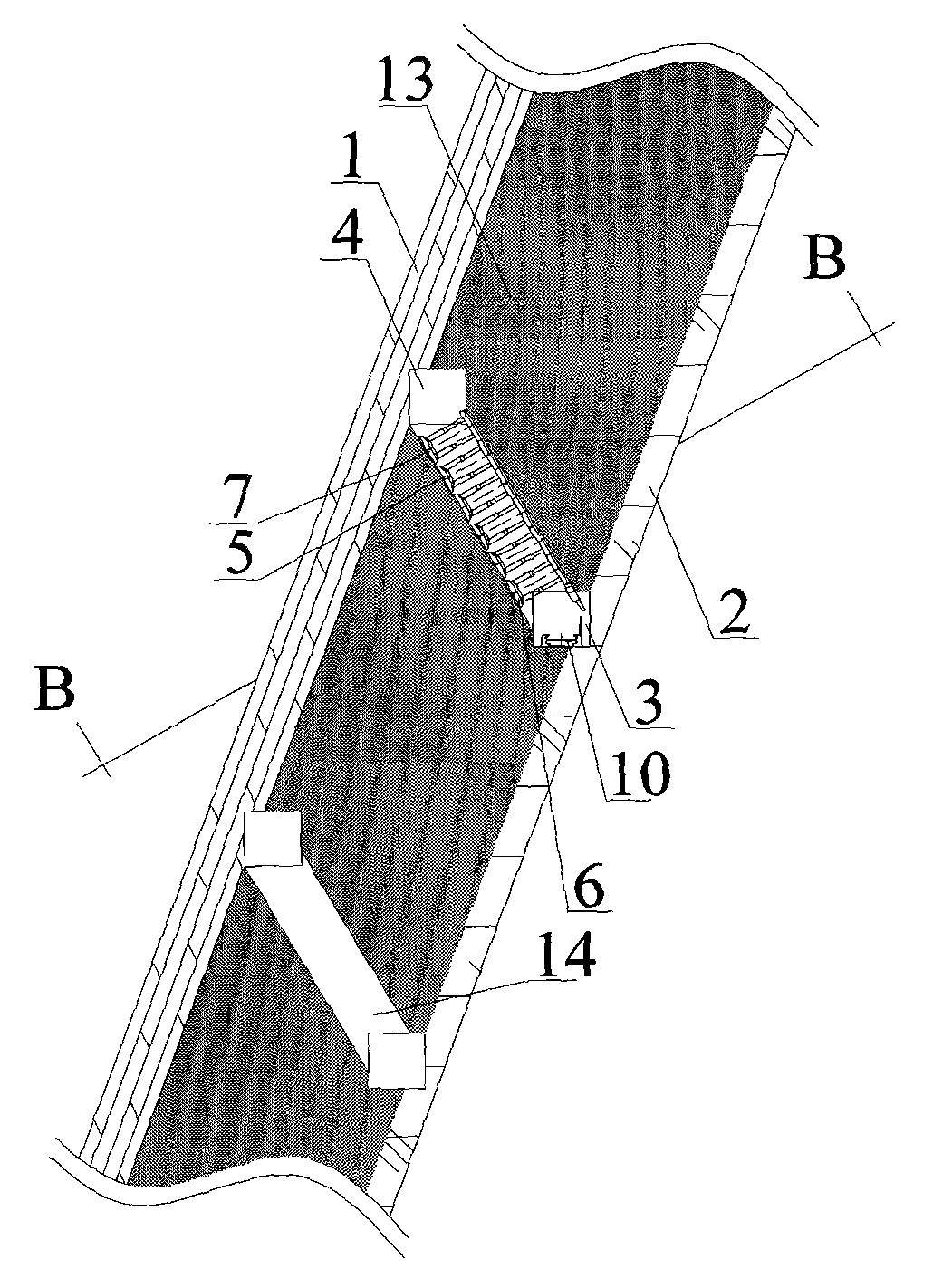

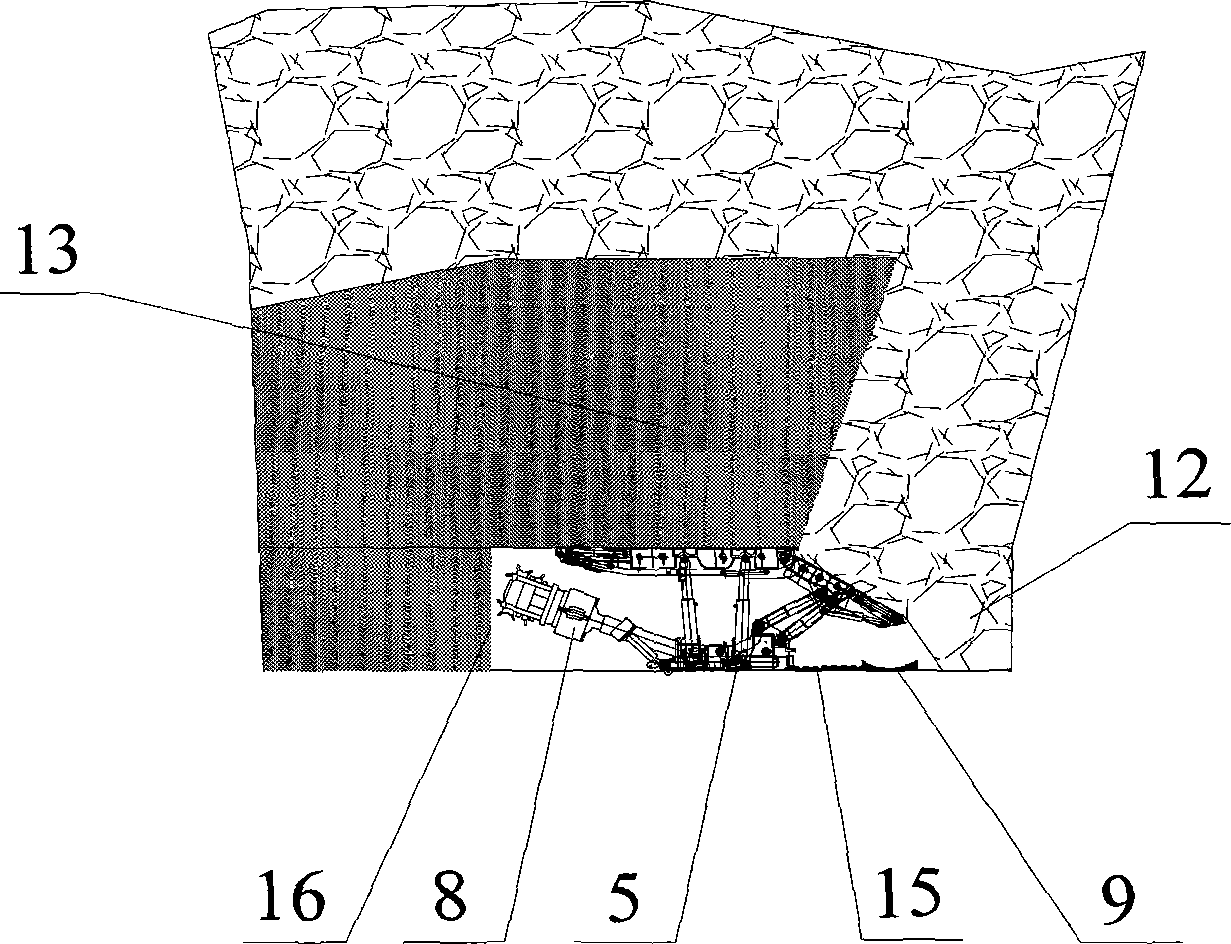

Comprehensive mechanized coal mining method of steeply inclined and extremely thick coal seam planing conveyor

InactiveCN104265291ASafe and Efficient MiningSolve coal mining method problemsUnderground miningSurface miningMineralogyCoal mining

The invention provides a comprehensive mechanized coal mining method of a steeply inclined and extremely thick coal seam planing conveyor, and relates to a coal mining method of an inclined cutting segmented trend short-wall mining steeply inclined and extremely thick coal seam (the coal seam thickness is 6 to 12m). The method is called as an inclined cutting segmented planing conveyor top coal caving coal mining method. According to the method, the planing conveyor is adopted for coal falling and conveying in a working face, a top coal caving hydraulic support frame is used for supporting a top plate, and an iron sheet chute is used for realizing self sliding of fallen top coal. Therefore the comprehensive mechanized coal mining of the steeply inclined and extremely thick coal seam (6 to 12m) is realized.

Owner:TIANDI SCI & TECH CO LTD

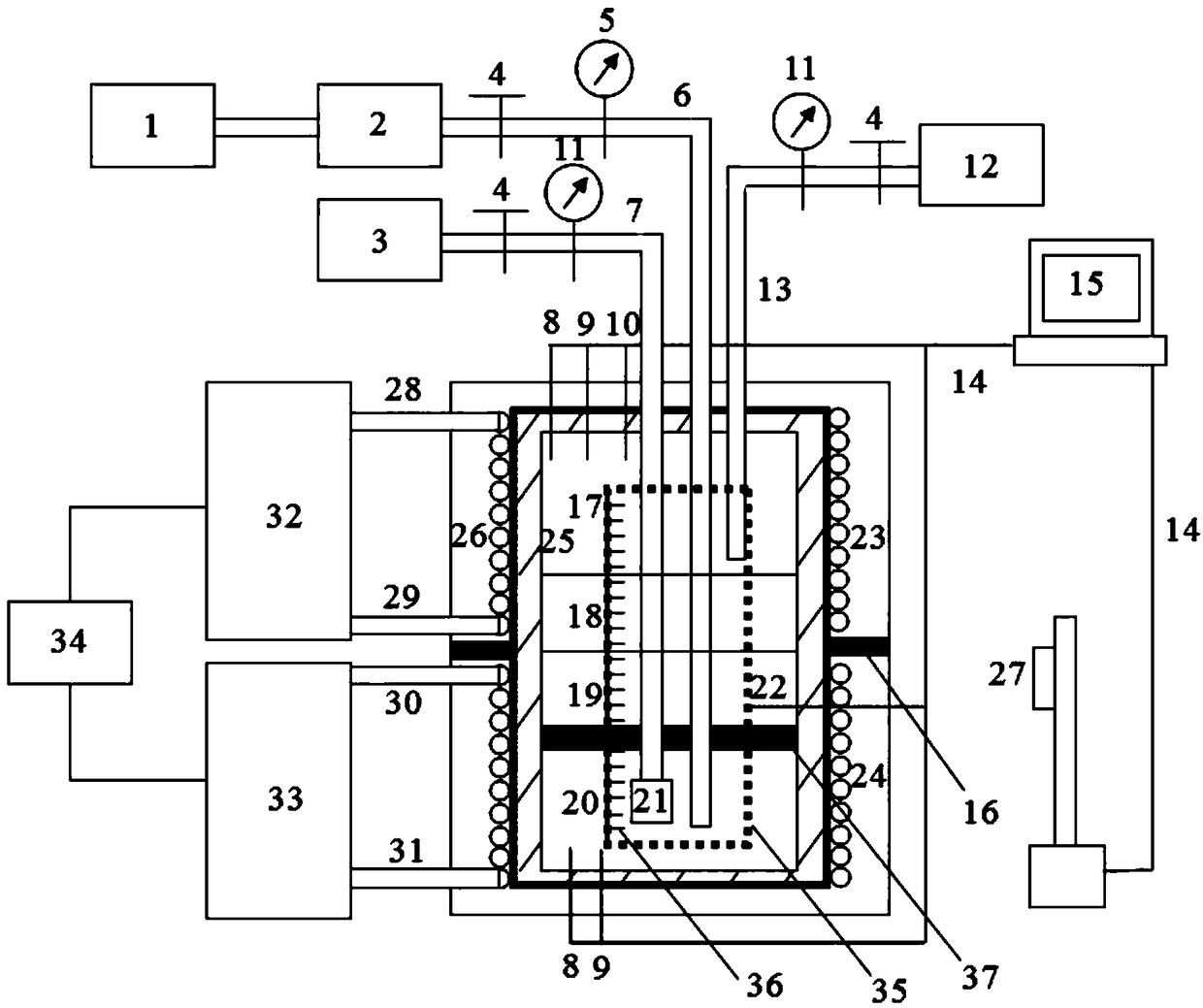

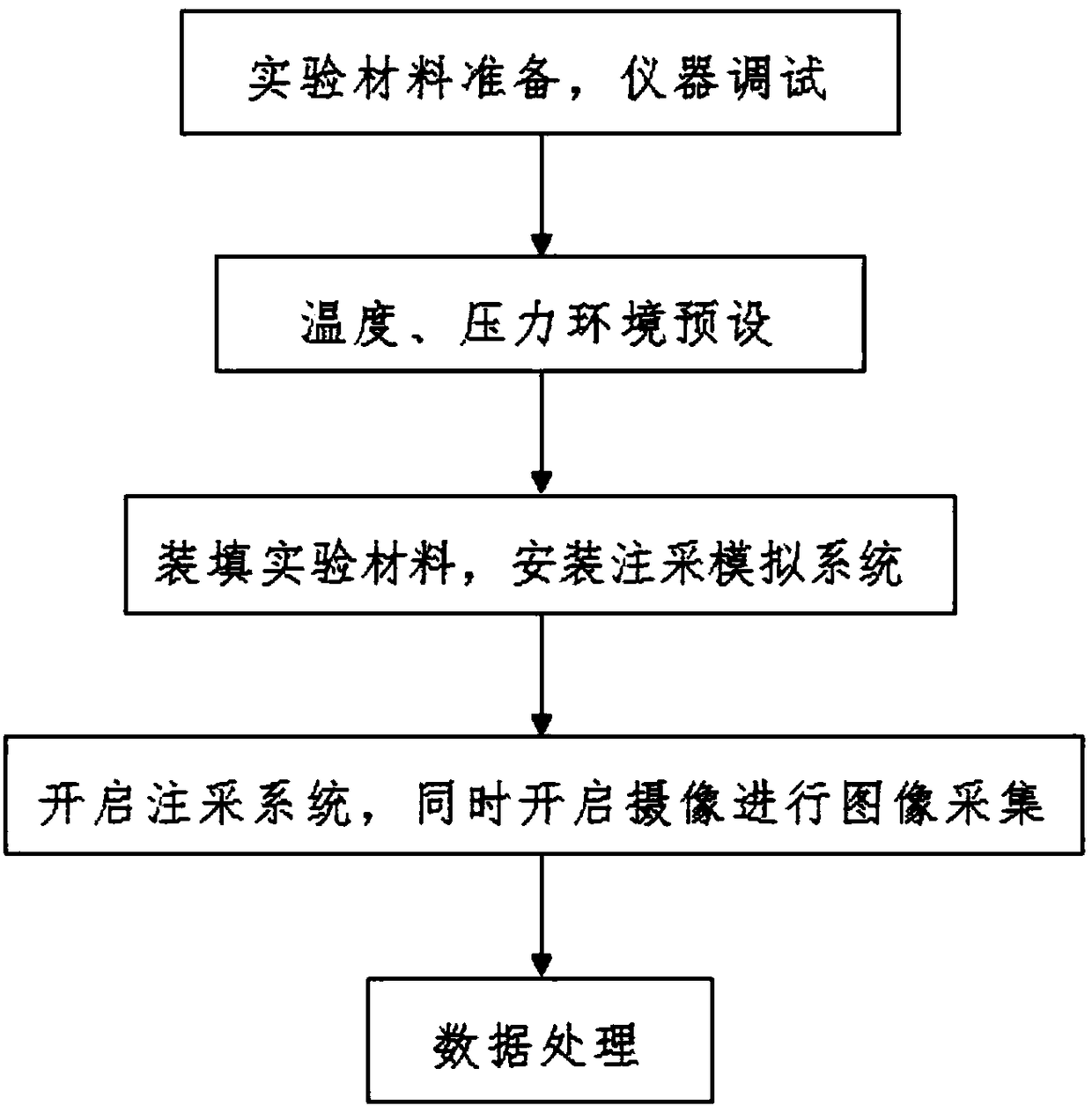

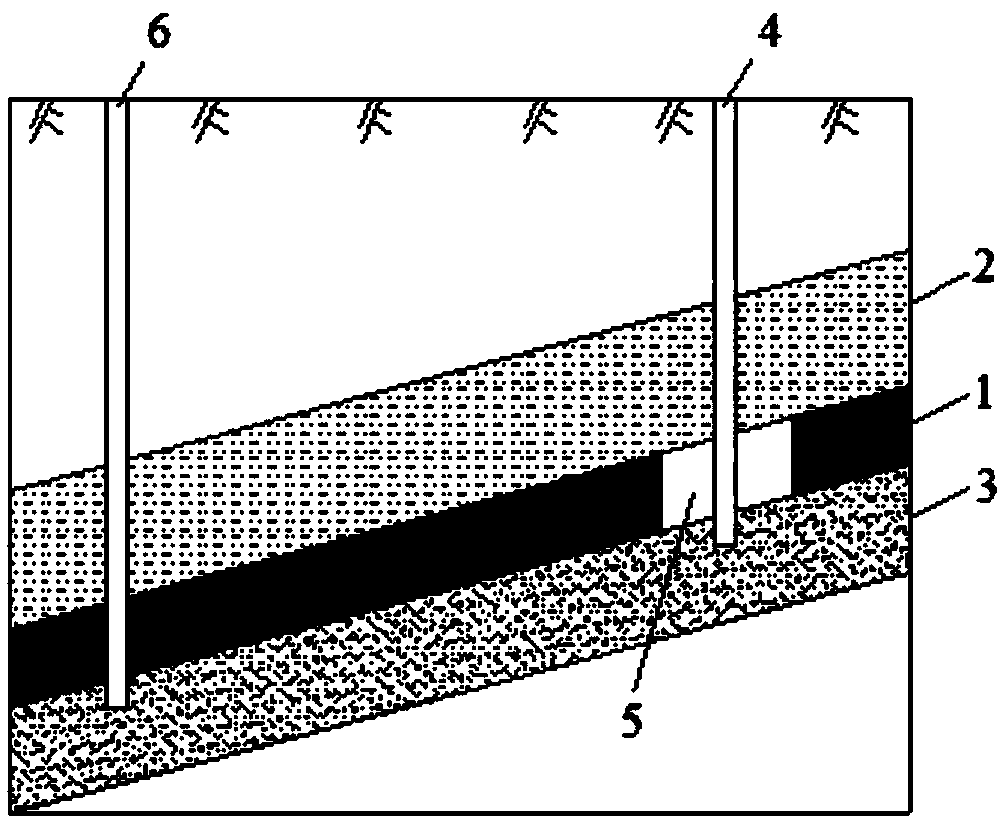

Experimental simulation researching device and experimental method of disaster induced by exploitation of undersea hydrate with compact overlying strata

PendingCN108344837AIngenious and reasonable structureSimple installation and layoutMaterial analysisOcean bottomCollection system

The invention relates to an experimental simulation researching device and experimental method of disasters induced by exploitation of undersea hydrate with compact overlying strata. The device comprises an atmosphere-deepwater-stratum natural environment visible simulation system, a natural gas hydrate injection-production simulation system, a temperature control system, a pressure control system, a data collection system, and an image collection system. The system has the advantages of being reasonable in design, complete in function and convenient to operate, by means of the method, effective simulation operation can be conducted on the disasters induced by the exploitation of the undersea hydrate with the compact overlying strata, real-time monitoring is conducted on related data in the simulation process through corresponding temperature, pressure and gas concentration sensors, and image collection is conducted on the simulation process by using photographing devices in the wholeprocess. The device and the method have a certain guiding meaning on safe and high-efficient exploitation of undersea natural gas hydrate and therefore have a significant meaning on the recognition and researching of a triggering mechanism of caused geological environmental disasters, and the device and the method have extensive popularization and application prospects.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Waterproof mining method with coal seam as main aquifer

InactiveCN109139011ASafe and efficient miningNormal miningUnderground chambersUnderground miningWater blockCoal

The invention provides a waterproof mining method with a coal seam as a main aquifer. A row of grouting boreholes are formed along the upper boundary of a mining area or well field through drilling, the coat seam is subjected to grouting, and a water-blocking curtain belt is formed in the coal seam; a row of drainage boreholes I parallel to the upper boundary of the mining area or well field is formed a certain distance away from the lower portion of the water-blocking curtain belt through drilling, several drainage boreholes II are formed uniformly in the periphery of the position of each pre-set shaft for drainage of coal-seam water, and well construction starts when the water pressure of the coal seam drops below the safety value; after well construction, the working area is arranged along the upper boundary of the mining area or well field, and a row of inclined drainage boreholes III are formed from an underground mining roadway to the coal seam through drilling to drain coal-seamfissure water; finally back production of coal is conducted. The method is an effective means to solve the mine water hazard prevention and control under the special mine hydrogeological condition inwhich the coal seam serves as the main aquifer, the targeted property is strong, the method is simple, the design is reasonable, the reliability is high, the cost is low, and the method has a good application and popularization prospect.

Owner:缪协兴

Mining method for inclined medium-thick bedded or thick-bedded orebody continuous stoping

InactiveCN1548702AReduce mining costsIncrease labor productivity andUnderground miningSurface miningStopingMineralogy

The present invention belongs to the field of underground mining method of various useful mineral, and is especially the mining of inclined layers of mediate thickness and thick mineral layer. The present invention features that by means of one increased rise heading and the explosion of columnar explosive, ore is thrown from the stope to preset chute opening. The said mining method has high safety, high efficiency, capacity of mining rock gangue layer, lowered lean ore loss and lowered mining cost. The present invention solves the difficult problem of mining inclined mine body.

Owner:CENT SOUTH UNIV

Surface drilling pre-splitting blasting shallow burying method for room type goaf roof

ActiveCN106705773APrevent crushingSafe miningUnderground miningBlastingLongwall miningShortest distance

The invention discloses a surface drilling pre-splitting blasting shallow burying method for a room type goaf roof and belongs to a roof disaster preventing and controlling method for mining of a short distance coal bed below a shallowly-buried goaf. During long wall mining of the short distance coal bed below the shallowly-buried room type goaf, main roof large-area pressure coming happens easily, the yielding damage happens to a small-size coal column under the fracture load of a main roof, a large-size coal column has an elastic kernel and acts the concentrated stress on a lower coal bed work face hydraulic support, and collapse of a work face inner roof, pushing down of a support, hurricane impacting and other disasters are caused. According to the method, drilling pre-splitting blasting of the roof is performed on the ground, the problems that construction is difficult and the effective distance of drilling is short during forced caving of room penetrating type drilling pre-splitting blasting of the goaf are solved, roof large-area pressure coming, roof collapse, pushing down of the support and other disasters can be effectively prevented, and the method is also applicable tomining of lower coal beds of concentrated coal columns of a shallowly-buried long-wall goaf. The method is simple in implementation process, safe and efficient and has wide applicability.

Owner:CHINA UNIV OF MINING & TECH

Reasonable width determination method for gob-side entrydriving narrow coal pillar based on fracture evolution

ActiveCN110397470AEffective isolationIncrease mining rateUnderground miningFluid removalPre stressDistribution characteristic

The invention discloses a reasonable width determination method for a gob-side entrydriving narrow coal pillar based on fracture evolution. The method comprises the following five steps: observing roadway deformation and coal pillar fracture distribution characteristics on site; establishing a UDEC-Trigon numerical model to match with on-site condition to determine model parameters; reversing an evolution rule of fractures in different coal pillar widths; determining the reasonable coal pillar width fracture evolution penetration; and finally providing a high pre-stressed anchor and anchor cable technology to control stability of the coal pillar. By adopting a damage factor for quantifying assessment of fracture evolution penetration to finally determine the optimum reasonable width of thegob-side entrydriving narrow coal pillar, inner fractures of the coal pillar in a service period are not penetrated, and gas in a goaf can be isolated effectively while the coal pillar is carried stably.

Owner:CHINA UNIV OF MINING & TECH +1

Layering and sectioning combined mining method for broken orebody interlayer

ActiveCN108894785ASafe and Efficient MiningSafe Mining ConditionsUnderground miningSurface miningStructural engineeringDeep hole

The invention discloses a layering and sectioning combined mining method for a broken orebody interlayer. According to the method, panel areas and panel interval columns are sequentially divided alongthe direction of the broken orebody interlayer, wherein step 1 room stopes and step 2 column stopes are sequentially divided in each panel area along the vertical direction, the horizontal directionof each step 1 room stope is formed by two parallel routes, the number of routes in the vertical direction is determined by the subsection height, filling is instantly performed after mining is finished, and cemented backfills are formed to replace columns; after mining and filling of the step 1 room stopes in the panel areas are completed, mining and filling are transformed into backstopping of step 2 column stopes, the step 1 cemented backfills are arranged on two sides of the step 2 stopes, and an efficient mining method for of long anchor rope pre-reinforced downward parallel deep hole segmented open stoping post-mining filling is adopted for the step 2 column stopes. The combined mining method mainly aims at backfilling of a broken orebody interlayer, which can be well joined with steady orebodies on two sides of the interlayer, so that the aim of safely and efficiently backfilling the broken orebody interlayer can be achieved.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD +1

Pressure relief gas directional drilling and blocking extraction method for mining adjacent layers in close-range coal seam group

ActiveCN108301866AWarranty extensionEffective hole lengthGas removalDirectional drillingTreatment costs

The invention relates to a pressure relief gas directional drilling and blocking extraction method for mining adjacent layers in a close-range coal seam group. An upper coal seam is a first mining layer, when the upper coal seam is mined, and pressure relief gas in a central coal seam is blocked and extracted by directional drilling in an upper bottom plate; when the central coal seam is mined, gas in a mined-out area of the upper coal seam and the pressure relief gas which is mined in the central coal seam are blocked and extracted by directional drilling in the upper bottom plate, and the pressure relief gas in a lower coal seam is blocked and extracted by directional drilling in a lower bottom plate; when the lower coal seam is mined, gas in a mined-out area of the central coal seam andthe pressure relief gas which is mined in the lower coal seam are blocked and extracted by directional drilling in the lower bottom plate. The pressure relief gas directional drilling and blocking extraction method solves the problems that in the mining process of the close-range coal seam group, the pressure relief gas in the adjacent layers mutually pours into each other, thereby causing the gas in a coal mining working face and the mined-out area easily exceed the limit, difficult to manage and the like. The pressure relief gas directional drilling and blocking extraction method has the advantages of long effective hole length, multi-purpose use of one hole, high extraction efficiency, low treatment cost and the like, and realizes safe and efficient mining of the close-range coal seamgroup.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Method for inclined normally closed stoping of too old roadway under complicated conditions

ActiveCN107542467ASafe and efficient miningLow failure rateUnderground miningSurface miningWater dischargeEngineering

The invention relates to a method for inclined normally closed stoping of a too old roadway under the complicated condition. The method is characterized by comprising the following steps of (1) a early stage preparation work step and (2) a later-stage construction step. The method has the advantages that under the complicated conditions, the statistic analysis is performed on the old roadway layerposition condition, the sealing condition in the old roadway, the slurry condition and the old material condition in the inclined long-wall too old roadway stoping period; potential safety hazards inaspects of layer position regulation, too old roadway technical schemes, fireproof and fire extinguishing measures, electromechanical device state control, lifting transportation management, water proofing and water discharge and the like in the working face stoping process are investigated in detail, so that the effective technical measures are made in a targeted way; and the working face reaches the safe and efficient stoping goal. The equipment fault rate is reduced; and the enterprise benefits are improved.

Owner:LONGKOU MINING GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com