Patents

Literature

103 results about "Rock mass strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In general, rock mass strength depends on the strength of intact rock and the strength of rock discontinuities. In general, compared to intact rock, a rock mass has reduced tensile strength (almost zero), and reduced shear strength especi ally along discontinuity planes.

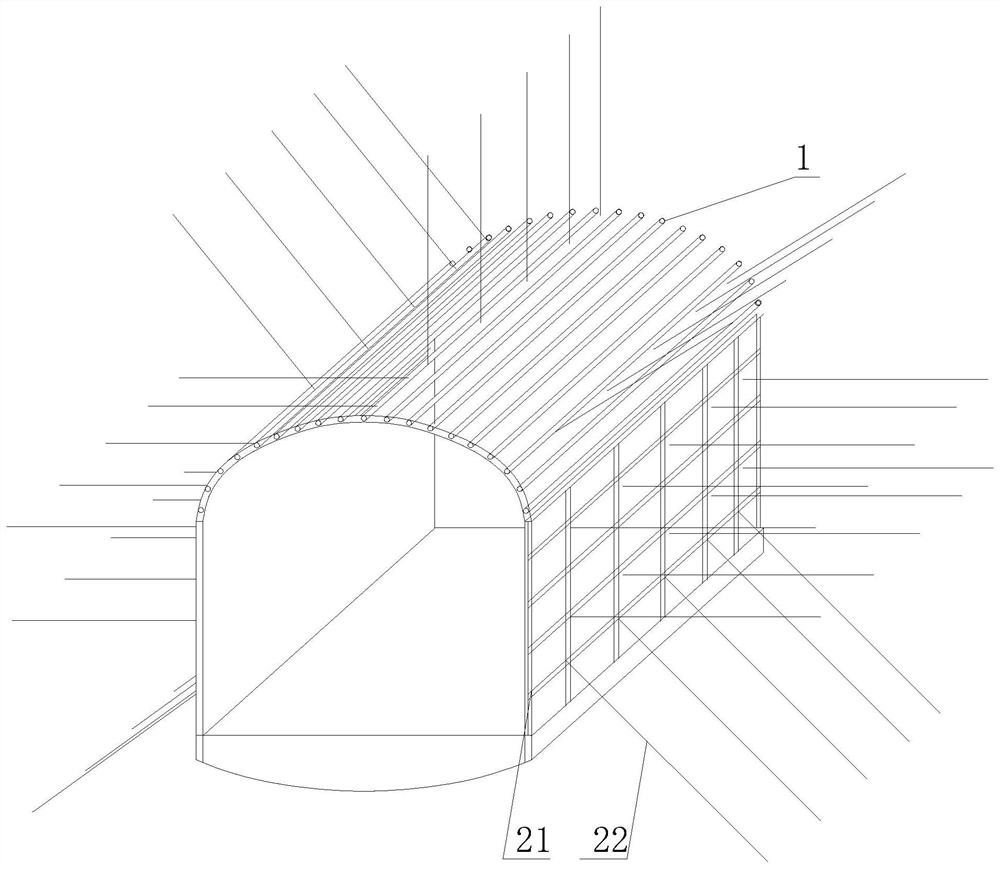

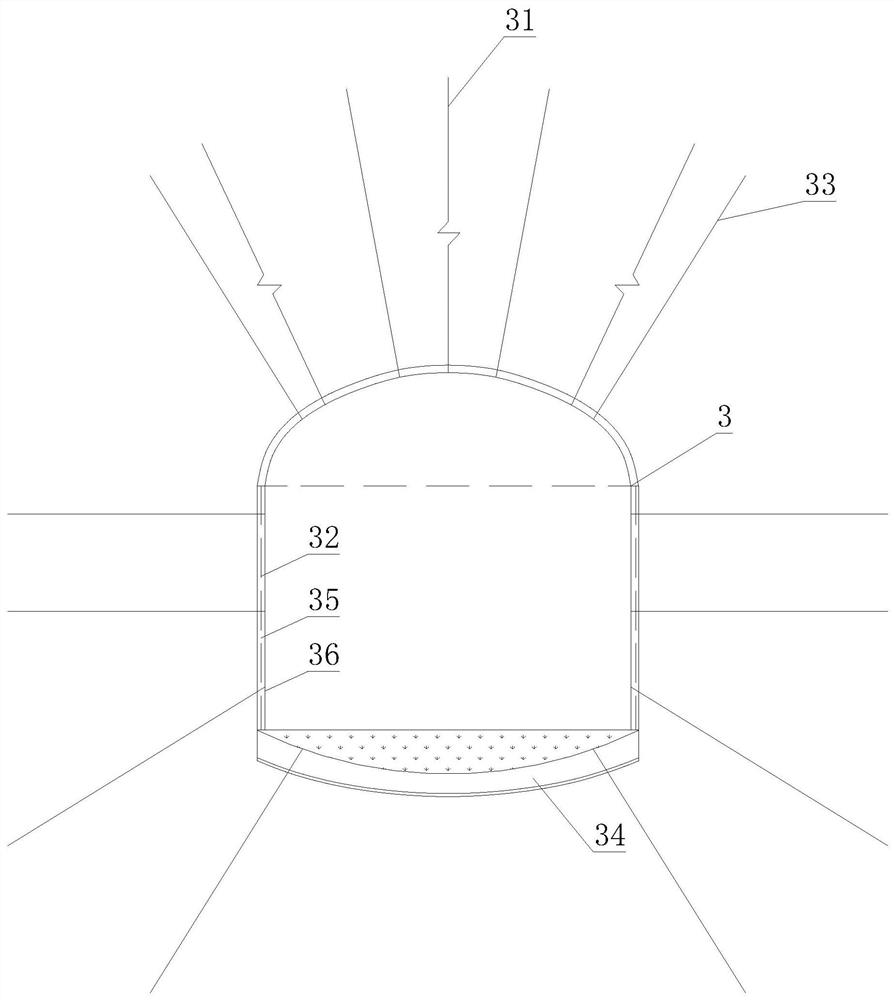

High ground stress weak surrounding rock tunnel excavation and support construction method

ActiveCN105156118AThe method steps are simpleReasonable designUnderground chambersTunnel liningSteel frameRock tunnel

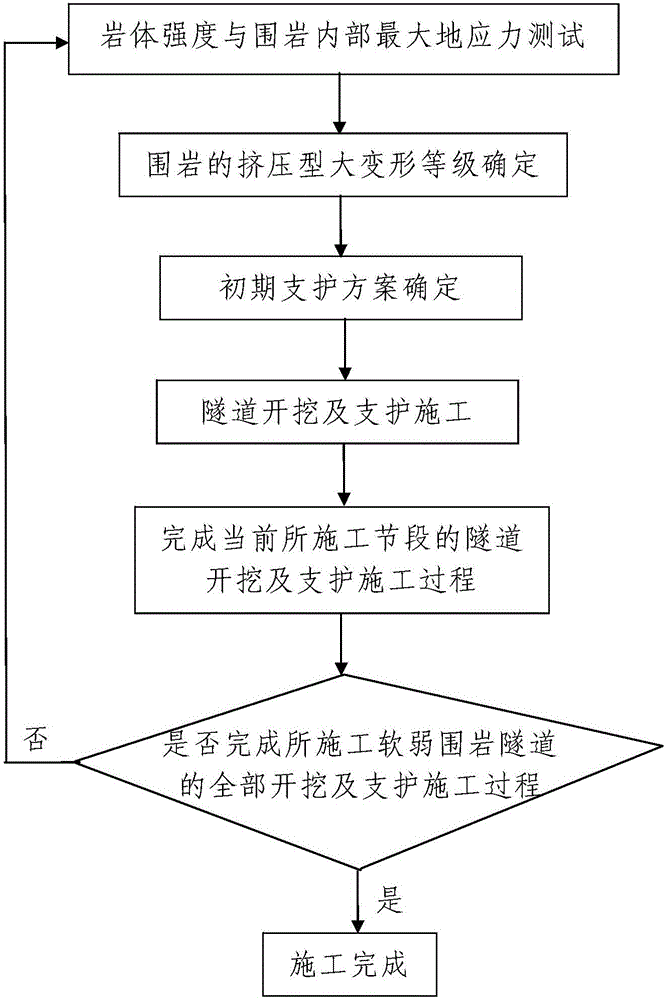

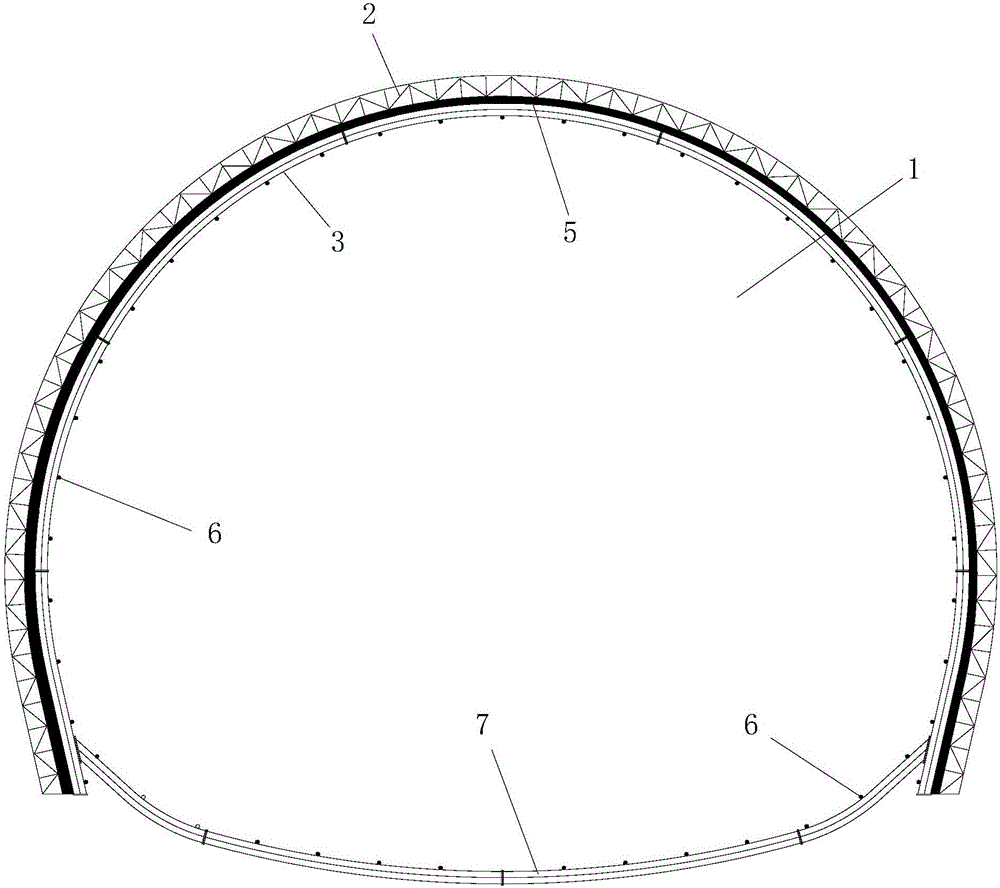

The invention discloses a high ground stress weak surrounding rock tunnel excavation and support construction method. Excavation and support construction are conducted on a weak surrounding rock tunnel to be constructed in multiple sections from rear to front in the longitudinal extension direction of the tunnel. The method comprises the steps that 1, rock body strength and the maximum ground stress inside surrounding rock are tested; 2, the extrusion-type large-deformation level of the surrounding rock is determined; 3, a primary support scheme is determined, wherein the primary support scheme is determined according to the determined extrusion-type large-deformation level, and the primary support scheme is a profile steel frame support scheme or a grid steel frame and cover arch combined support scheme; 4, tunnel excavation and support construction are conducted; 5, excavation and support construction of the next section are conducted; 6, the fifth step is repeated for many times till the whole excavation and support construction process of the weak surrounding rock tunnel to be constructed is completed. According to the high ground stress weak surrounding rock tunnel excavation and support construction method, the steps are simple, the design is reasonable, construction is convenient, the use effect is good, the tunnel excavation and support construction process of the high ground stress weak rock tunnel can be completed easily, conveniently and rapidly, and the construction process is safe and reliable.

Owner:CHINA RAILWAY 20 BUREAU GRP

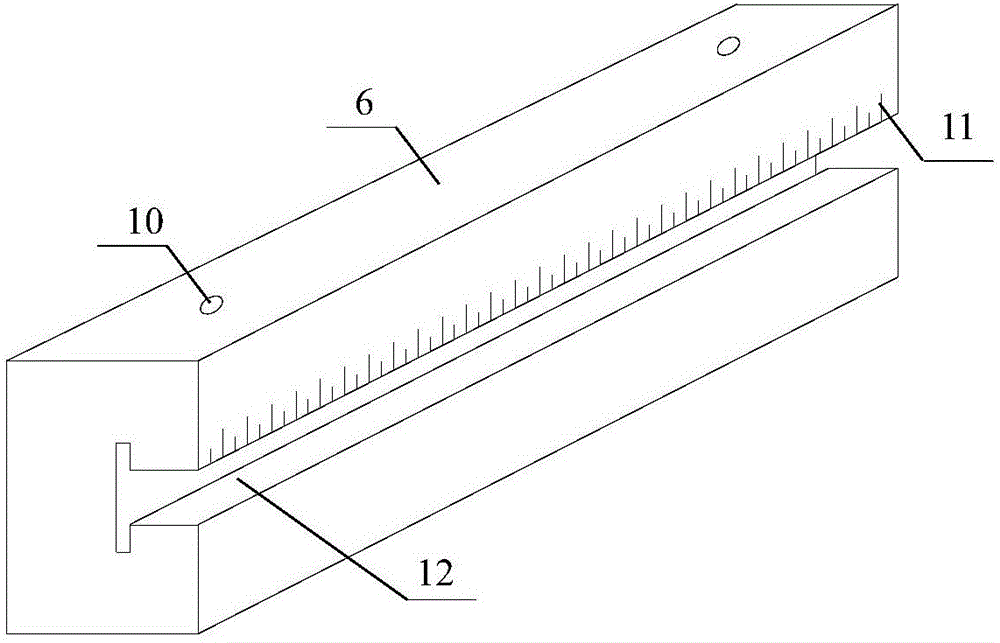

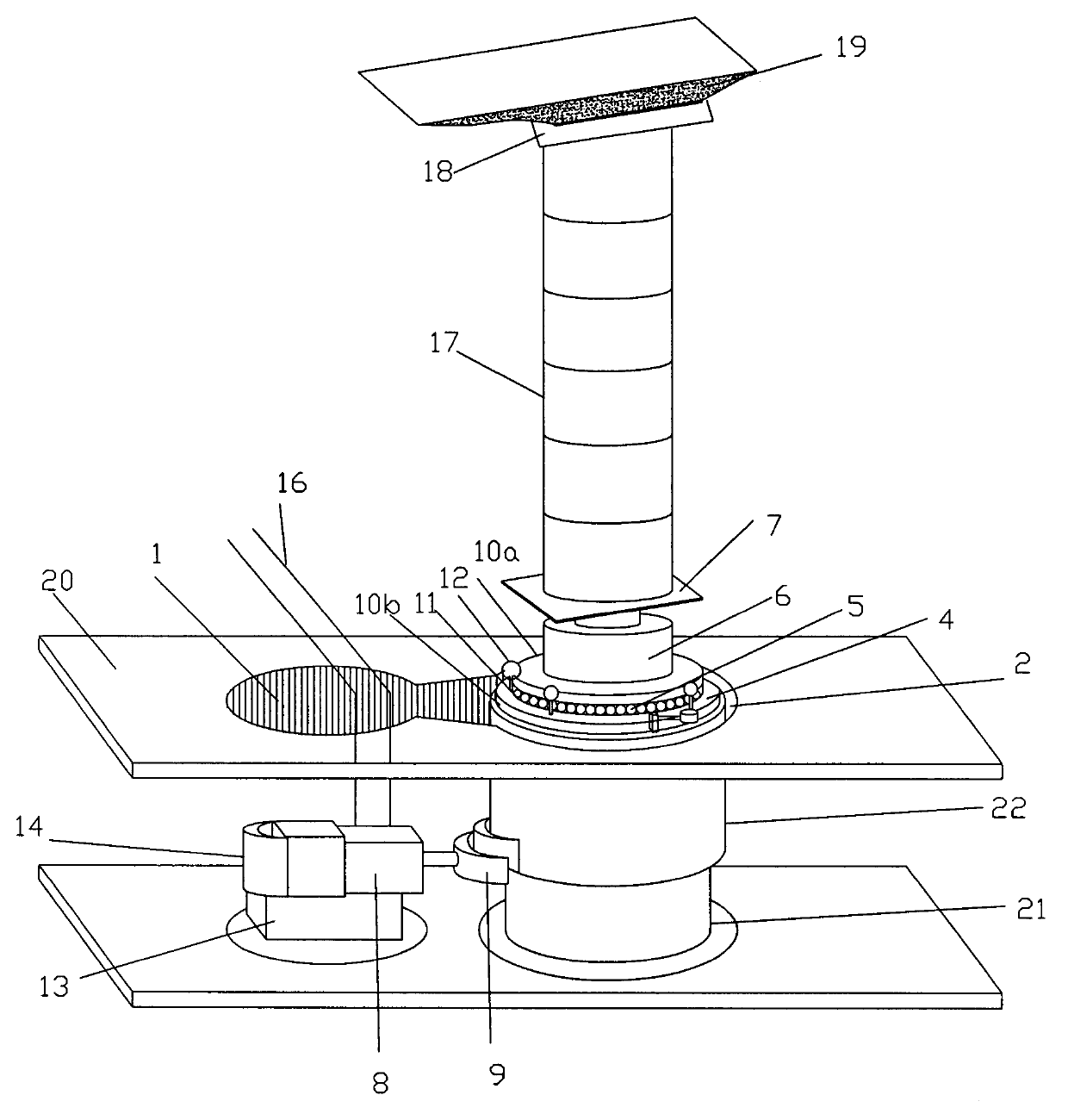

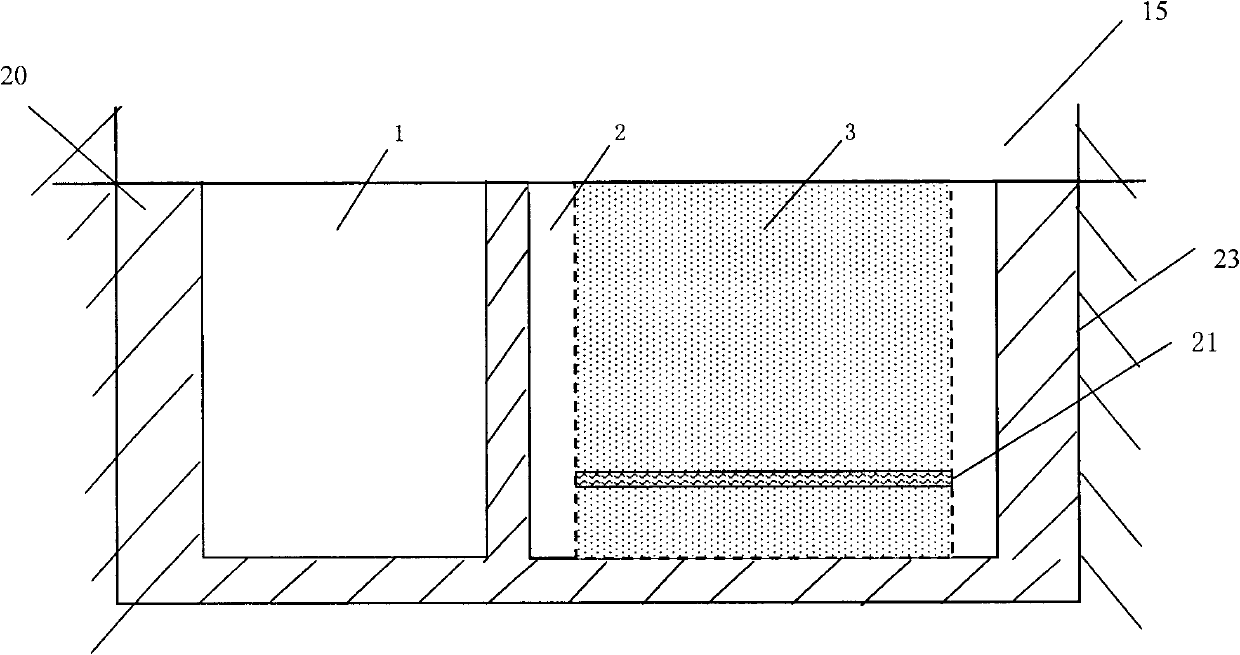

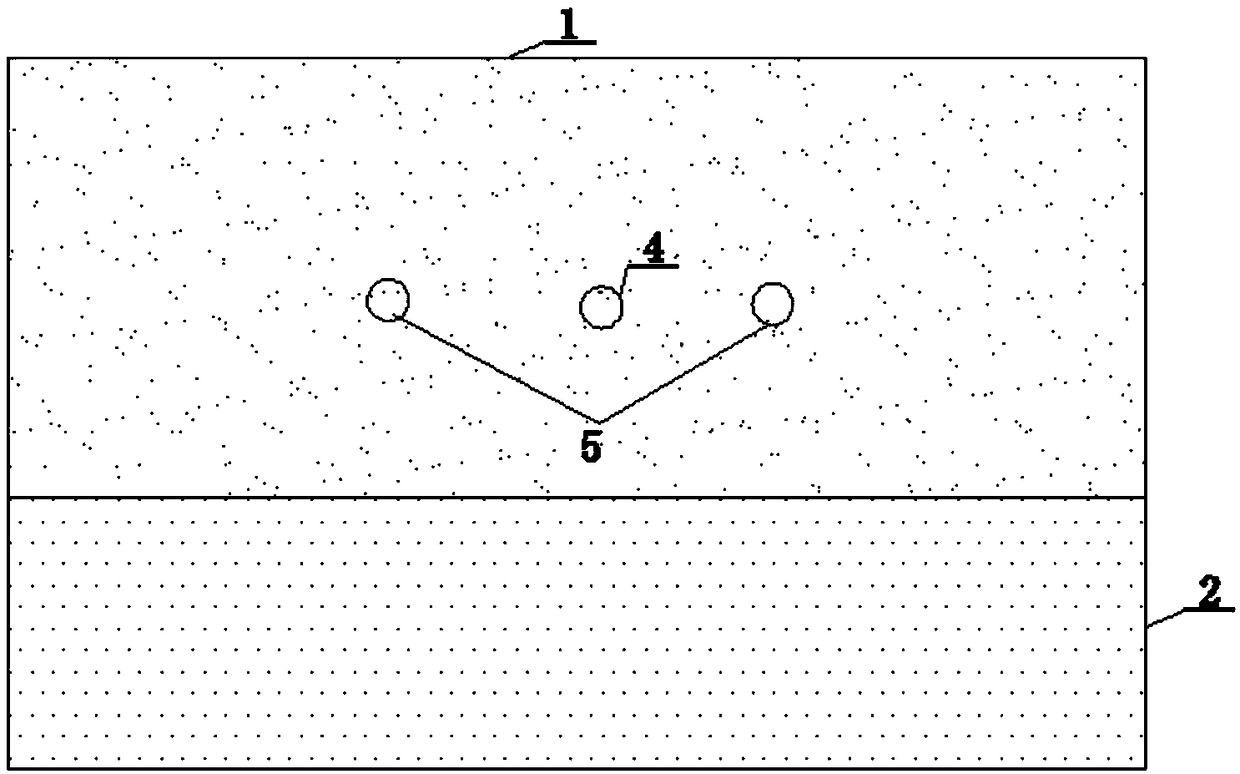

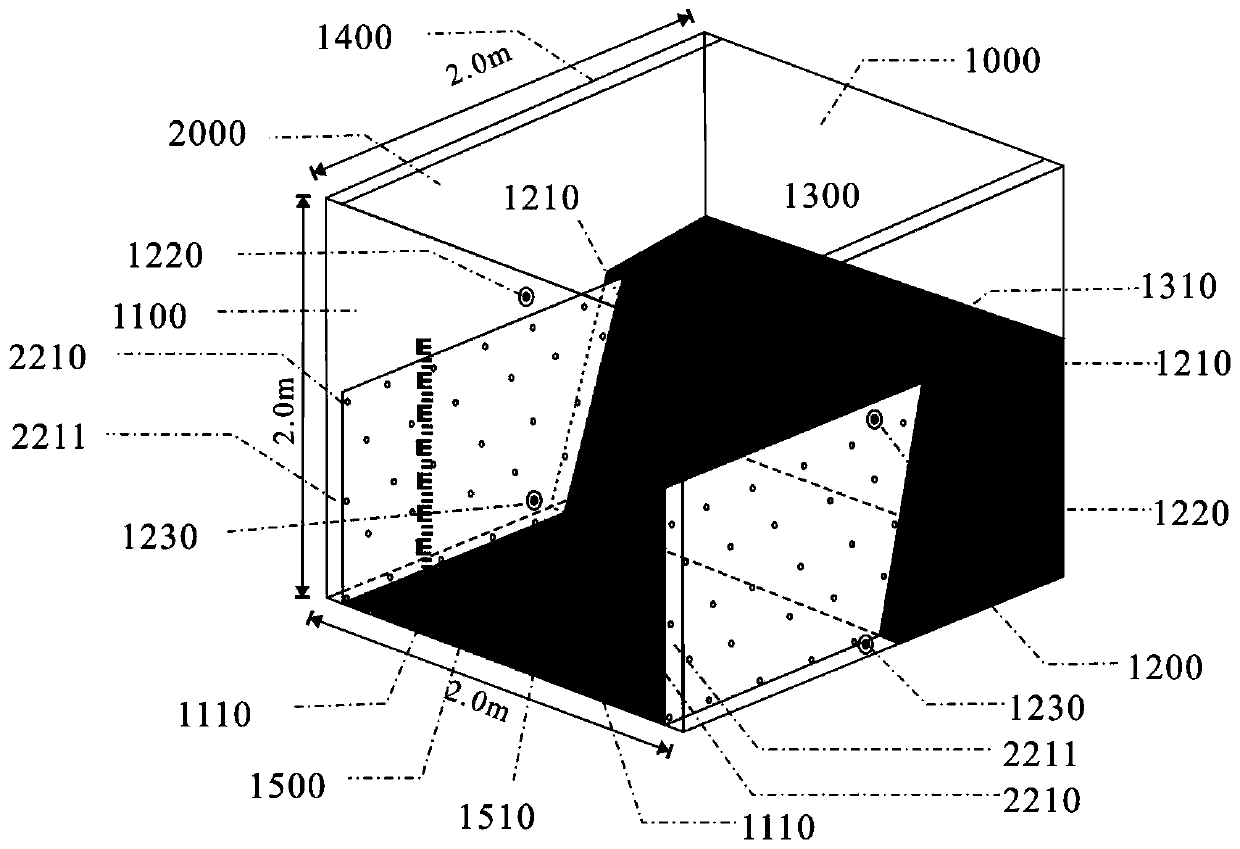

Accurate positioning and producing device for intermittent joints of similar-material rock mass samples

ActiveCN106124272AImprove stabilityMade in unisonPreparing sample for investigationTransverse fractureLongitudinal fracture

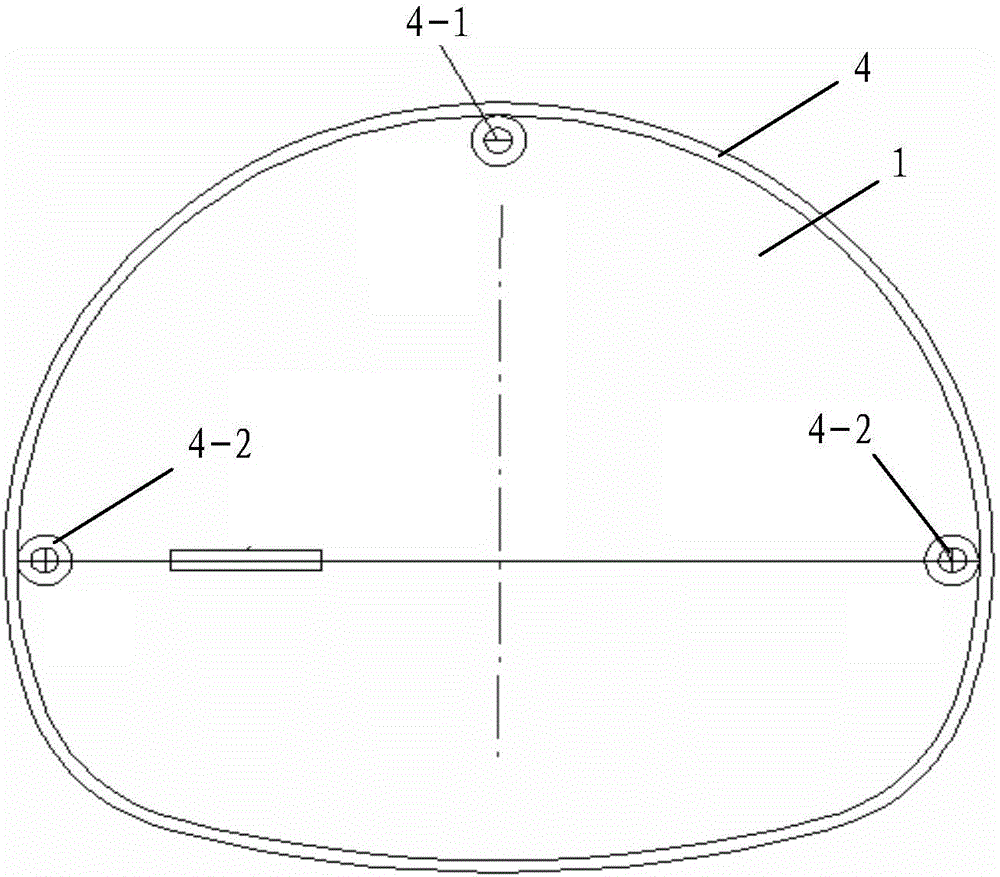

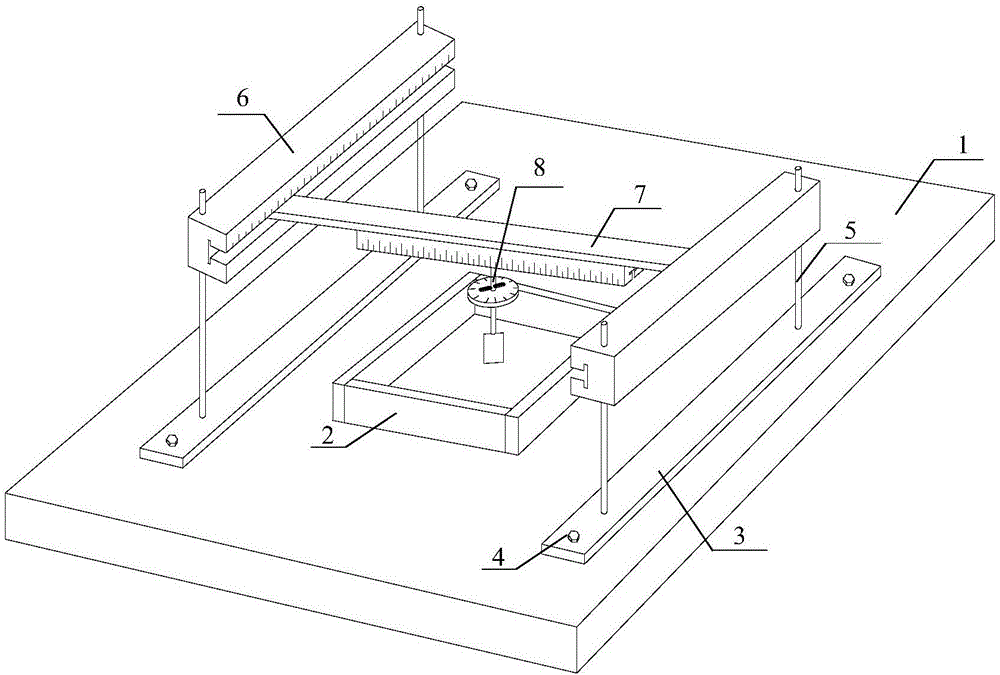

The invention discloses a device for accurately positioning intermittent joints of similar material rock mass samples. The bottom plate of the crack positioning bracket is arranged in parallel on both sides of the sample mold, and the anchor bolts of the crack positioning bracket are anchored on the sample preparation base plate. The crack positioning bracket It is connected with the bottom plate of the crack positioning bracket through threads, and the crack longitudinal positioning rods are respectively arranged parallel to the crack positioning bracket bottom plate and fixed on the four crack positioning brackets by screws. The slider of the horizontal positioning rod is stuck in the groove of the longitudinal positioning rod of the crack, and the angle positioning device is stuck in the groove at the lower end of the horizontal positioning rod of the crack through the square slider at the top, and the crack is made by the steel plate at the lower end of the angle positioning device. The structure is simple and the operation is convenient, which effectively guarantees the high-efficiency creation of fractures and the enrichment of fracture forms, which greatly facilitates the strength and deformation behavior tests of rock masses with different fractures, and quickly creates intermittent fractures with specified parameters.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

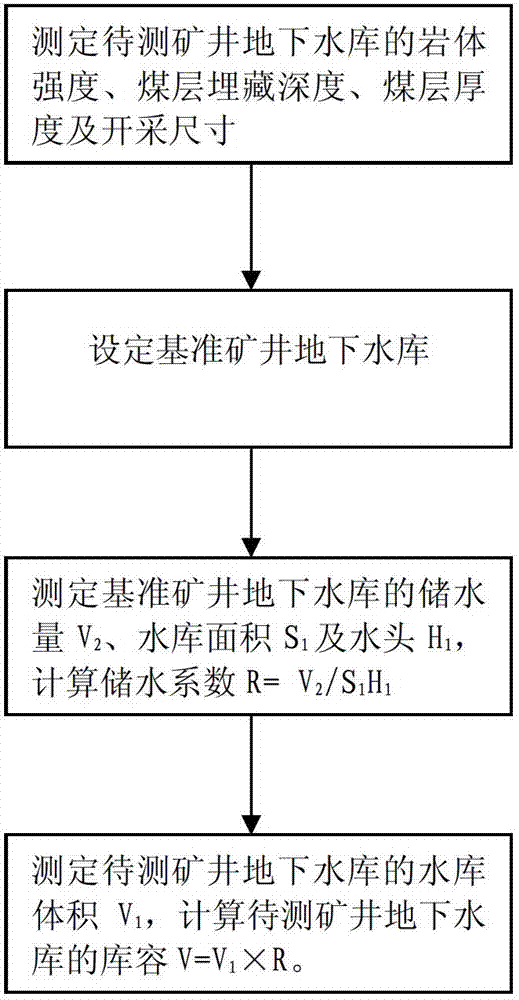

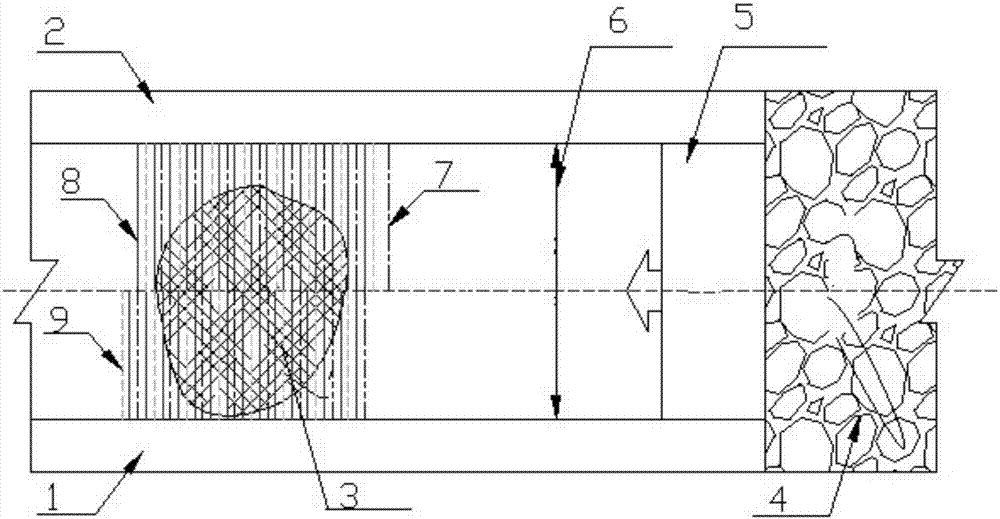

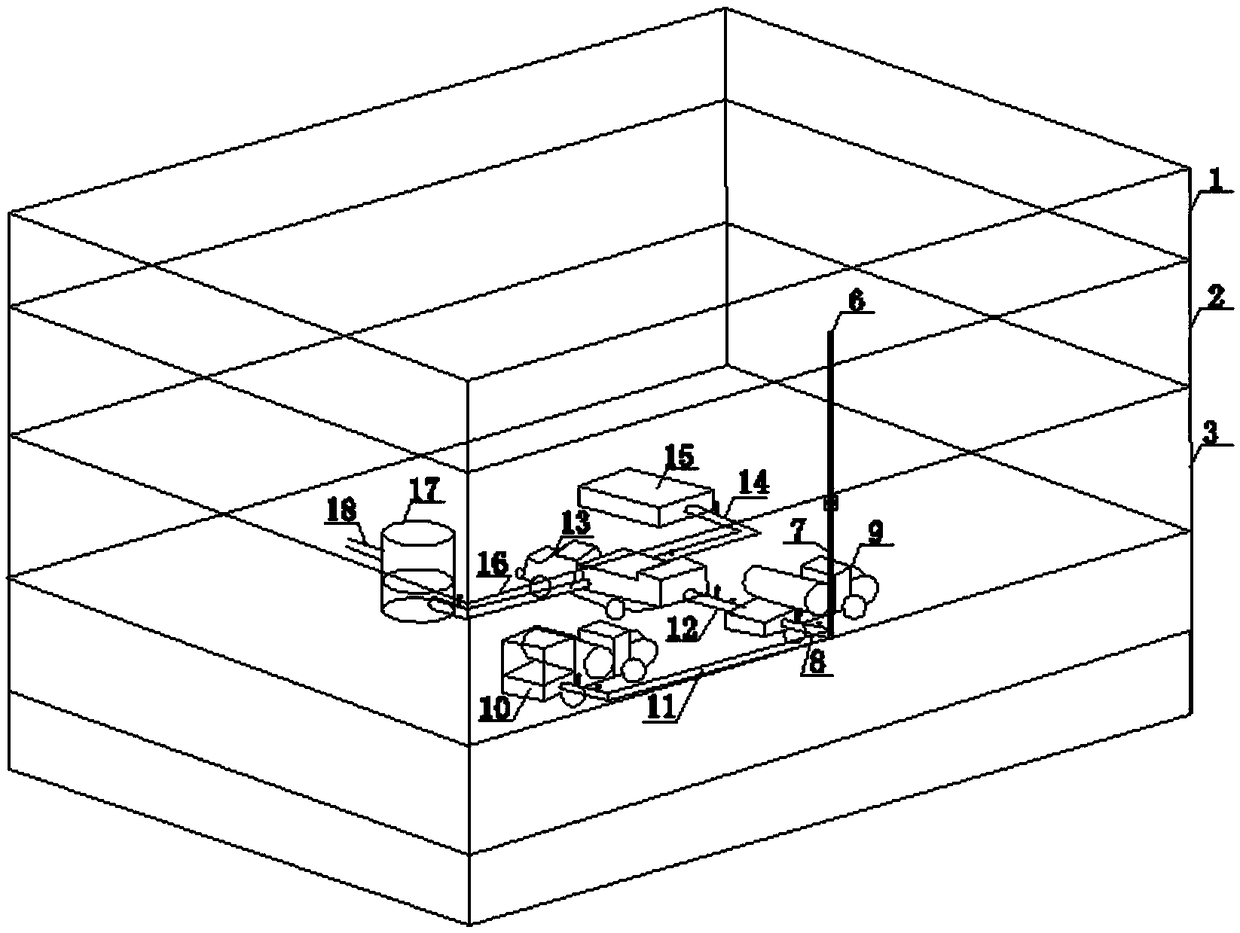

Method for determining capacity of underground reservoir of mine

ActiveCN102778215AEasy to know the water storage capacityAchieve reasonable protectionMeasurement devicesWater storageWater resources

The invention discloses a method for determining capacity of an underground reservoir of a mine. The method includes steps of 1, measuring rock mass strength, coal seam buried depth and exploitation dimensions of the underground reservoir of the mine; 2, setting a reference underground reservoir of the mine with rock mass strength, coal seam buried depth and exploitation dimensions which are consistent with those of the to-be-measured underground reservoir of the mine; 3, measuring water storage capacity V2, reservoir area S and water head H of the reference underground reservoir of the mine and computing a water storage coefficient R according to the equation of R=V2 / SXH; and 4, measuring reservoir volume V1 of the to-be-measured reservoir of the mine and computing the capacity of the to-be-measured reservoir of the mine according to the equation of V=V1XR. By the aid of the method, the capacity of the underground reservoir of the mine can be obtained, so that water resources of a mining area can be regulated.

Owner:CHINA SHENHUA ENERGY CO LTD +1

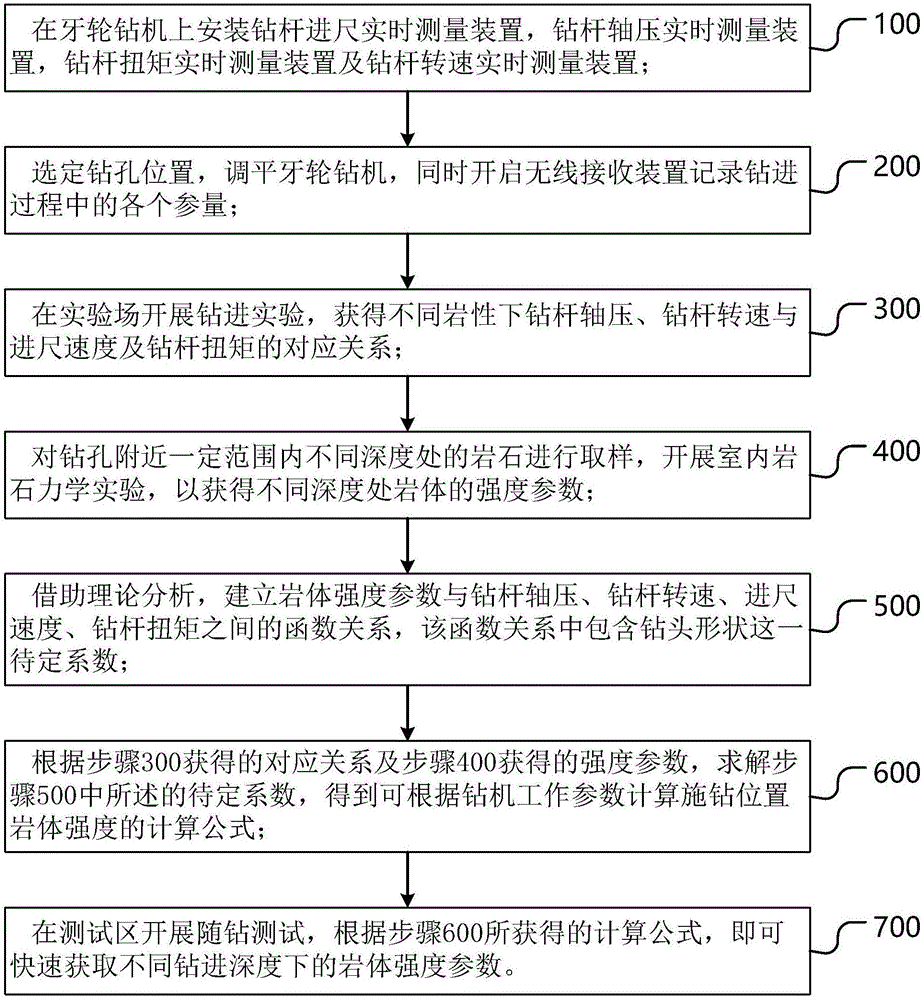

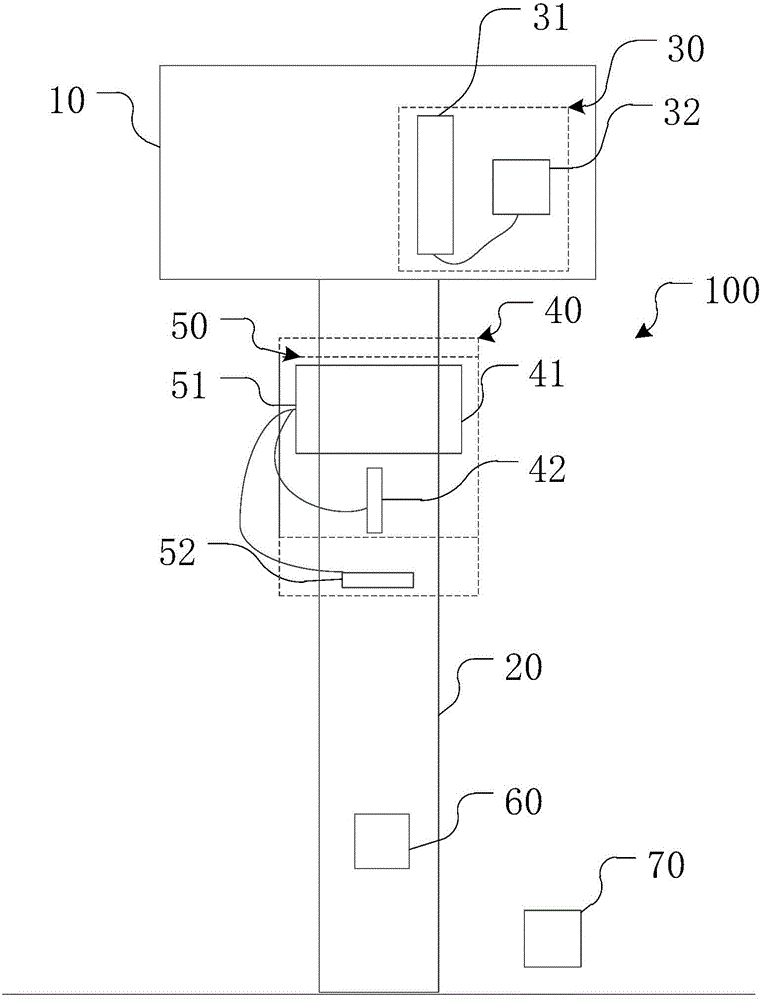

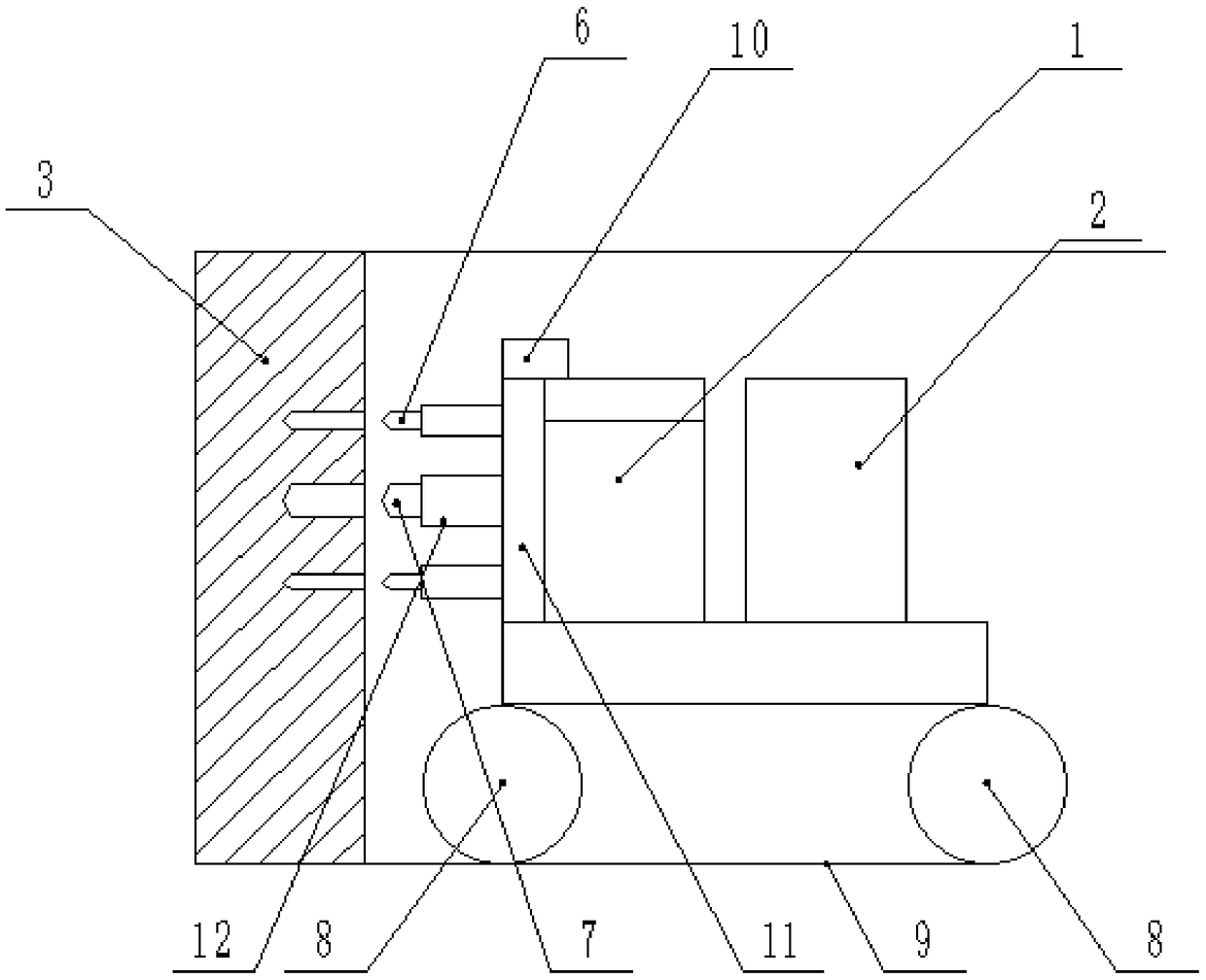

Method and device for testing rock mass strength through technology of monitoring during drilling

ActiveCN106321093AIntensity parameters are given in real timeCohesion given in real timeMaterial strength using tensile/compressive forcesBorehole/well accessoriesUltimate tensile strengthRock mass strength

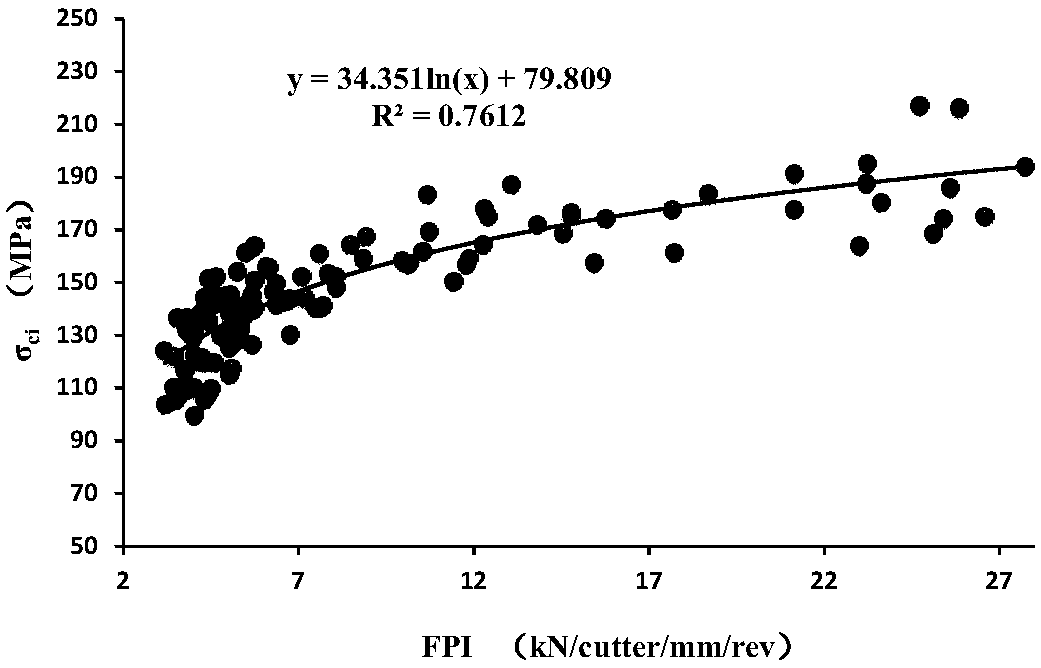

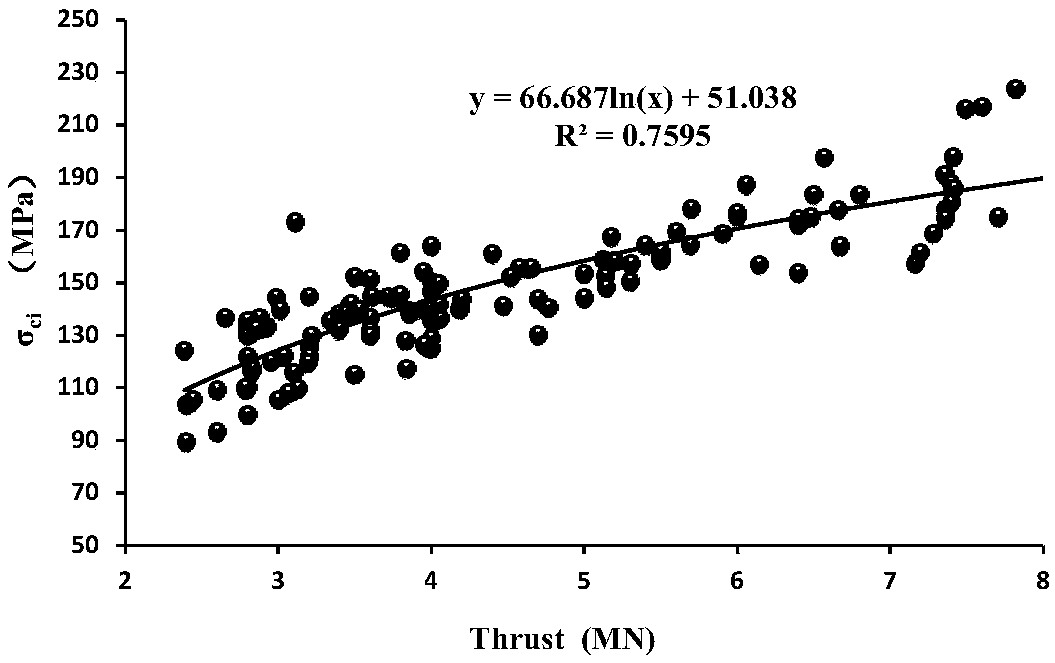

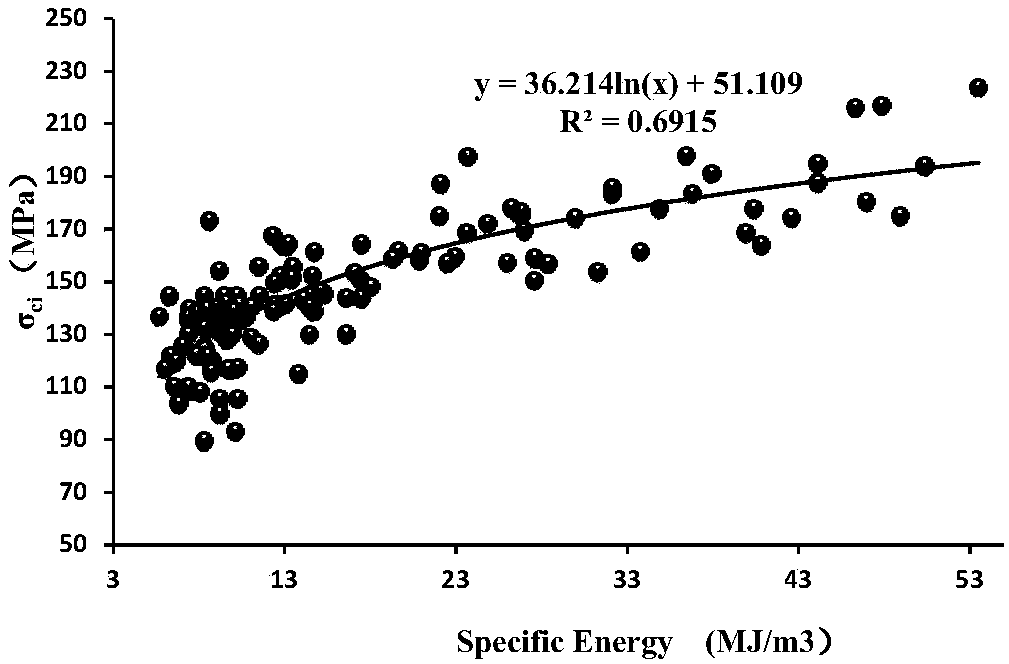

The invention provides a method and device for testing rock mass strength through the technology of monitoring during drilling. The method includes the steps that firstly, various measuring devices are installed on a rotary drilling rig; secondly, the rotary drilling rig is leveled; thirdly, a drilling experiment is conducted in an experimental field to obtain corresponding relationships between parameters of a drill pipe under different lithologic characters; fourthly, an indoor rock mechanic experiment is conducted to obtain rock mass strength parameters at different depths; fifthly, the function relationship between the rock mass strength parameters and the drill pipe is constructed; sixthly, according to the strength parameters, a computational formula capable of calculating the rock mass strengt at drilling positions according to work parameters of a drilling machine can be obtained; seventhly, testing during drilling is carried out in a testing area, and the rock mass strength parameters at different drilling depths are quickly obtained through the computational formula. By researching the quantitative relationship of shaft pressure of the drill pipe, torque of the drill pipe, rotation speed, drilling speed and rock mass strength, the aim of quickly and accurately obtaining the rock mass strength in the drilling process can be achieved. Compared with a traditional method, the method is simple and easy to implement.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

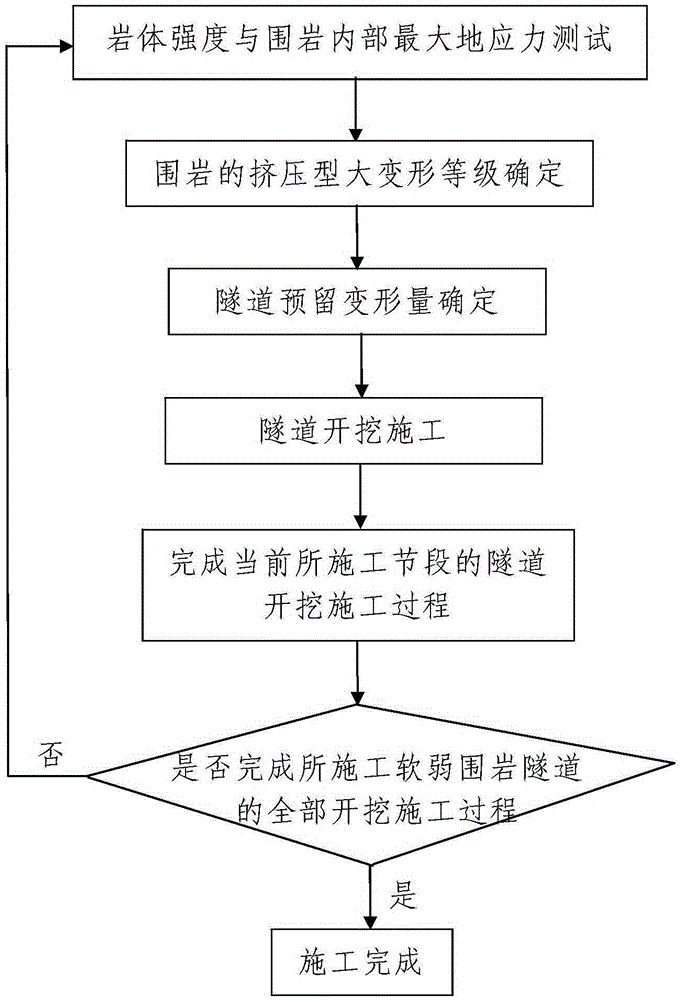

High-ground-stress weak surrounding rock tunnel excavation construction method

The present invention discloses a high-ground-stress weak surrounding rock tunnel excavation construction method. A weak surrounding rock tunnel under construction is excavated and constructed by multiple segments from back to front along a tunnel lengthwise extension direction. The method comprises a first step of rock mass strength and surrounding rock internal maximum ground stress testing; a second step of surrounding rock extrusion-type large deformation level determination; a third step of tunnel deformation allowance determination, determining the deformation allowance according to a determined extrusion-type large deformation level; a fourth step of tunnel excavation construction, carrying out excavation construction on the current constructed segment according to the determined deformation allowance; a fifth step of carrying out excavation construction on the following segment; and a sixth step of repeating the fifth step till a tunnel excavation construction process is completed. The method provided by the present invention is simple in procedure, reasonable in design, convenient to construct and excellent in using effect, the tunnel excavation deformation allowance is determined according to the high-ground-stress weak surrounding rock extrusion-type large deformation level, the tunnel excavation construction process can be conveniently and quickly completed, and the construction process is safe and reliable.

Owner:CHINA RAILWAY 20 BUREAU GRP +1

Method and device for predicting rock burst in tunnel, and storage medium and system

InactiveCN107748103AMaterial strength using tensile/compressive forcesUltimate tensile strengthRock mass strength

The application provides a method and a device for predicting rock burst in a tunnel, and a storage medium and a system. The method includes the steps of: acquiring Hoek-Brown rock mass strength of surrounding rocks at a to-be-tested depth and the maximum ground stress of an in-situ stress field in the direction being vertical to tunnel axis; calculating a predicted index of rock burst, wherein the threshold value of the predicted index of rock burst is the ratio of the Hoek-Brown rock mass strength to the maximum ground stress of the in-situ stress field in the direction being vertical to tunnel axis; and predicting rock burst level according to the threshold value of the predicted index of the rock burst.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

Discrete element method for simulating roadway surrounding rock fracture evolution

ActiveCN110390152AStrong on-site guidanceAuthentic and reliable simulationEarth material testingMaterial strength using tensile/compressive forcesDiscrete element methodFinite element method

The invention discloses a discrete element method for simulating roadway surrounding rock fracture evolution. The discrete element method comprises the steps that on-site coal and rock stratum coringis conducted an RQD value is recorded, roadway deformation is observed, and coal seam fracture distribution characteristics are counted; mechanical parameters of coal rock samples are tested indoors,and the strength of the rock mass is calculated according to the RQD value; a UDEC-Trigon module is used for establishing a numerical model to adjust parameters, and parameters match with rock mass strength to correct model parameters; and a numerical model of the engineering scale is established to adjust the parameters to be matched with field deformation characteristics, and finally roadway surrounding rock fracture evolution is simulated. Accurate basic mechanical parameters are provided for discrete element numerical simulation roadway deformation, and it can be ensured that the simulation result is real and reliable.

Owner:CHINA UNIV OF MINING & TECH +1

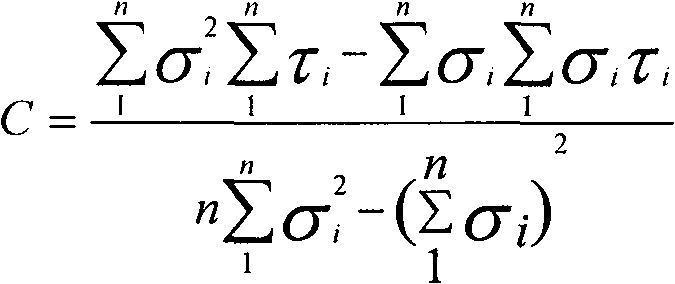

Side direction high stress cracking rock intensity determination method

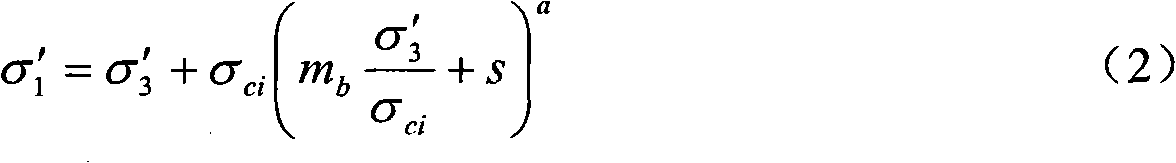

InactiveCN101216395AGet the shear strengthLow costMaterial strength using steady shearing forcesSpecial data processing applicationsSmall sampleHigh stress

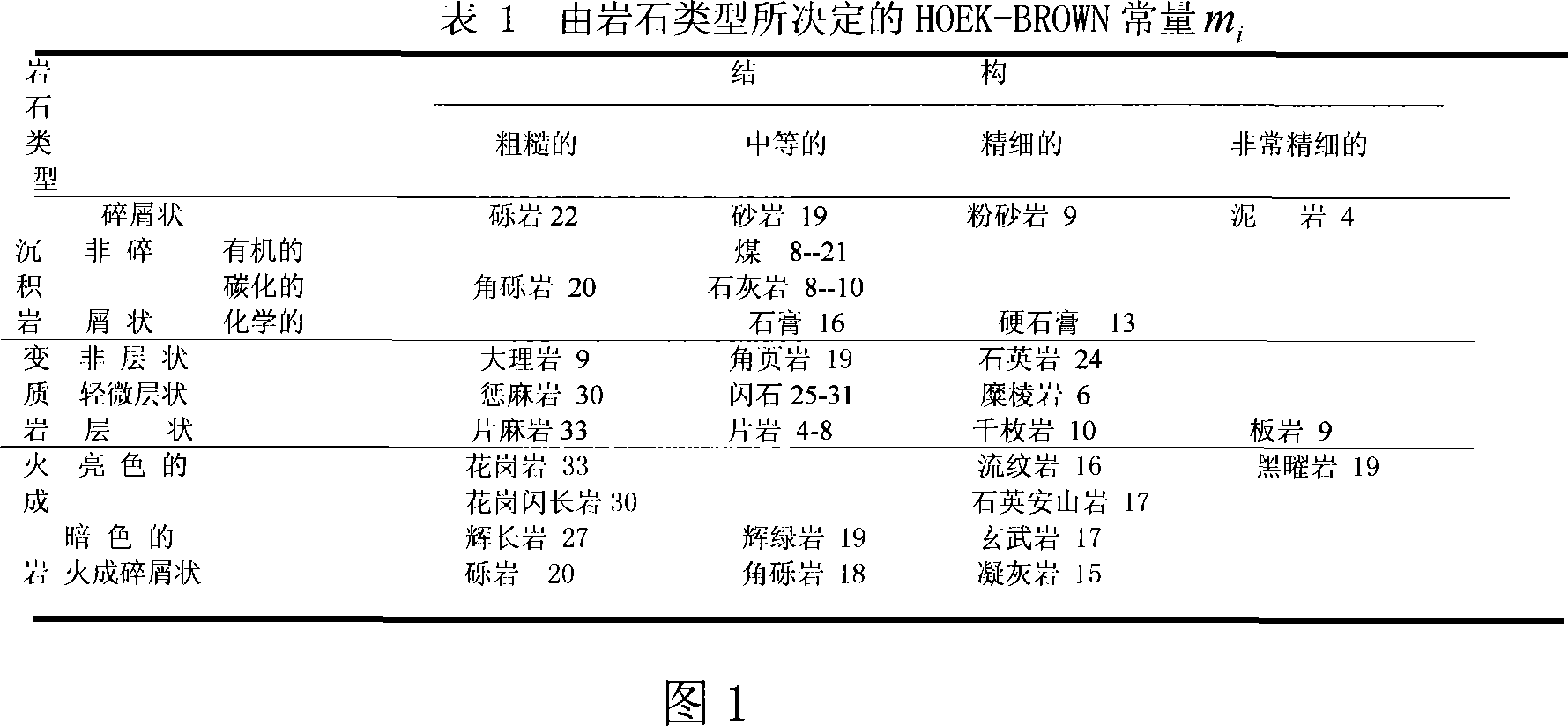

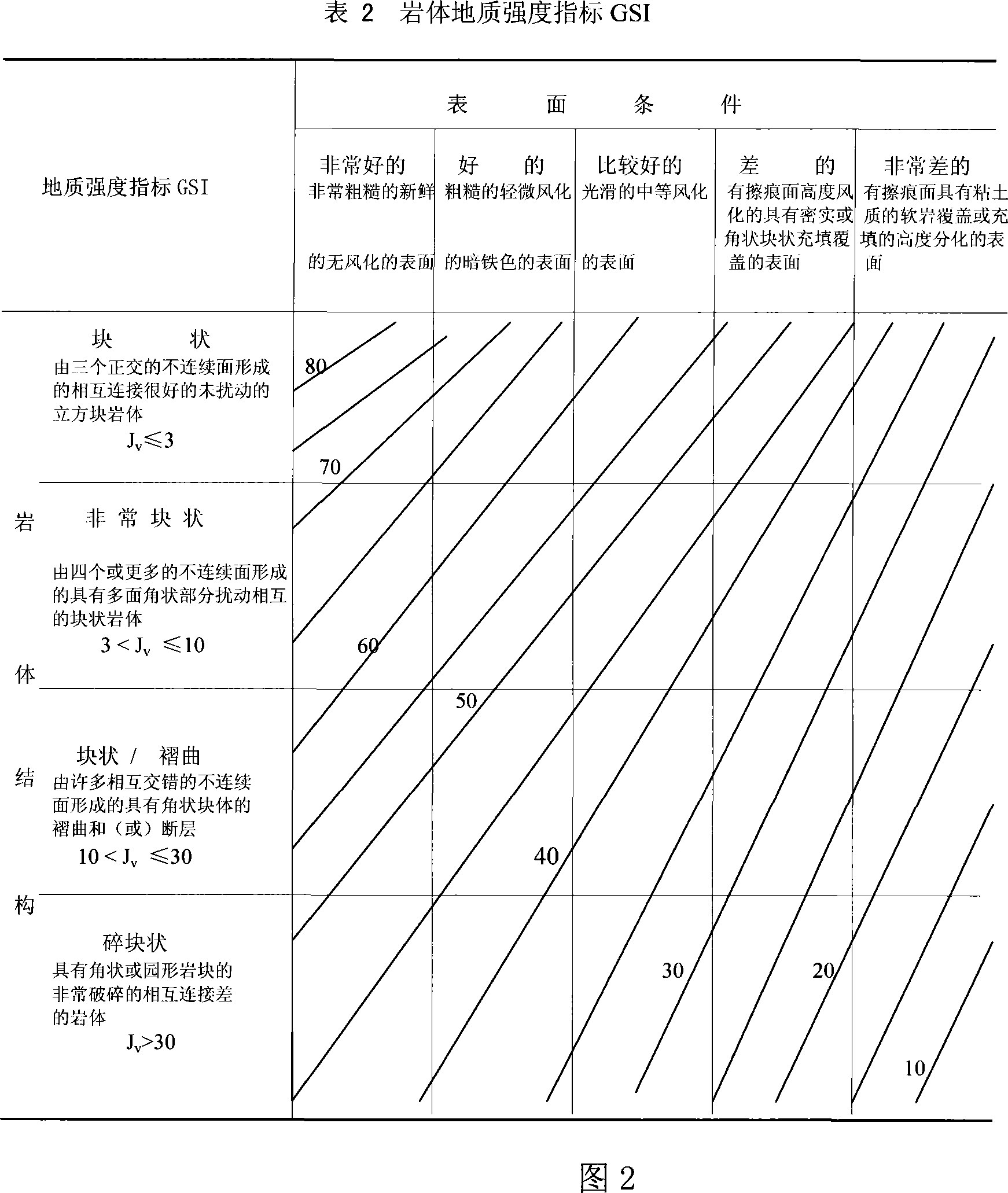

The invention relates to mining engineering, which belongs to a simple method for determining shear strength of large-size fractured rock under the action of lateral high stress and constant-confining-pressure triaxial compressive strength of fractured rock. The method is characterized in that the invention comprises the following steps of: testing the uniaxial compressive strength of a small sample block of an intact rock on a large-size fractured rock body, determining the type constant of the rock body to be detected, evaluating geological strength index of the rock body, constructing Hoek-Brown criterion and Mohr-Coulomb criterion of the rock body, and analyzing to obtain the shear strength under the action of lateral high stress and the constant-confining-pressure triaxial compressive strength of fractured rock. The invention can significantly reduce the in-situ strength test cost of large-size fractured rock and can obtain the shear resistance and the constant-confining-pressure triaxial compressive strength of large-size fractured rock without using special rock strength test equipment. The invention has the advantages of low cost, simple implementation method, and practical value in determining strength parameters of deep fractured rock.

Owner:DALIAN UNIV

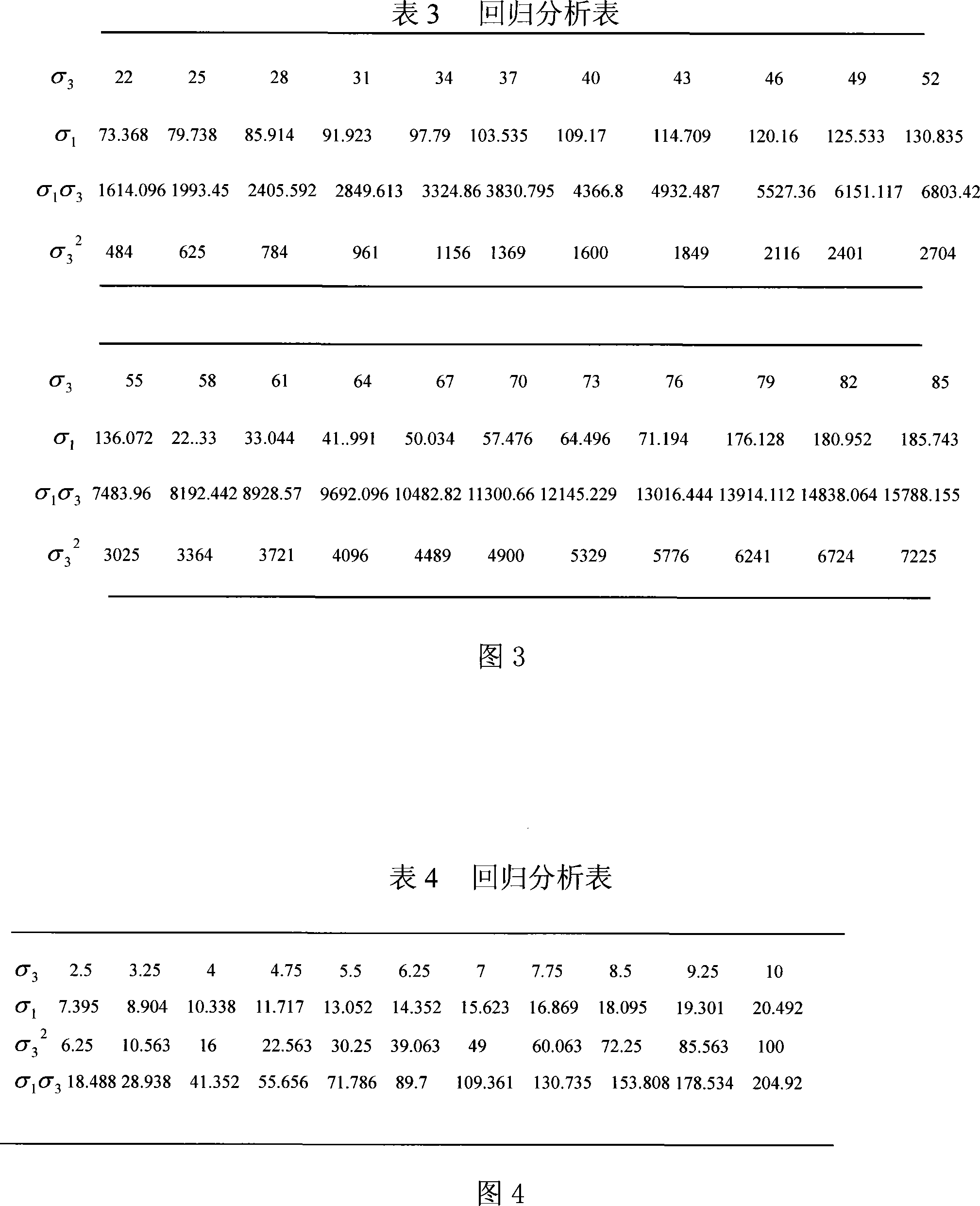

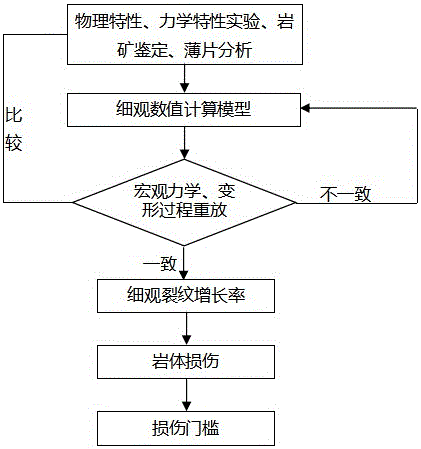

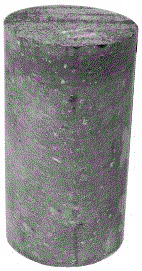

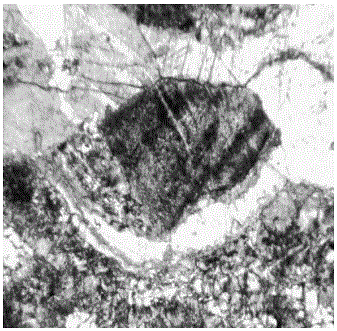

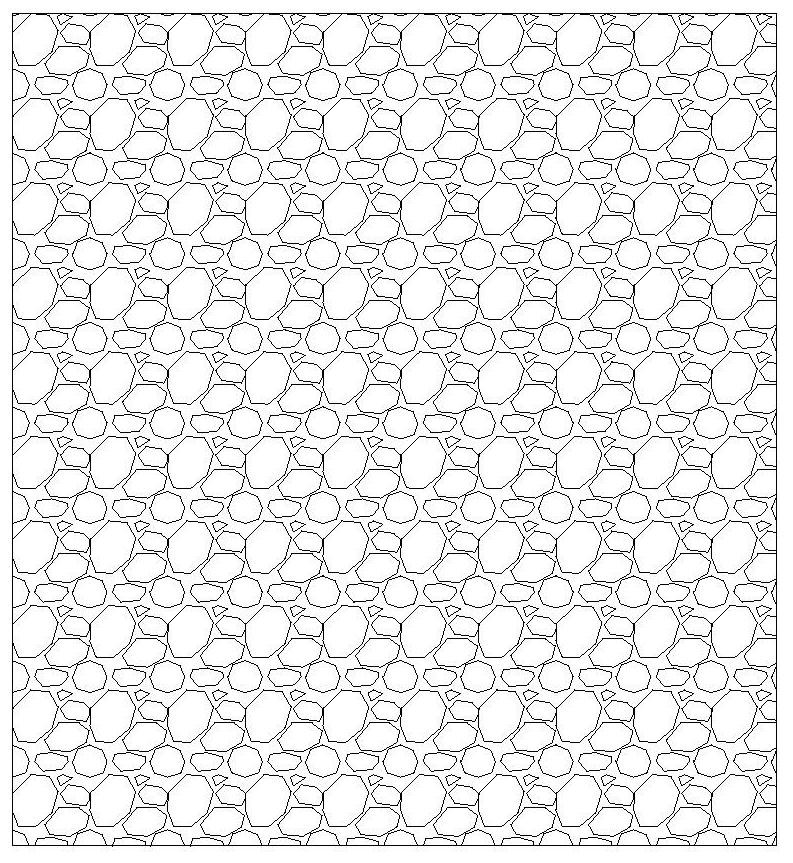

Meso-crack growth rate based rock mass damage threshold determination method

ActiveCN106294984AReduce workloadEasy to compareData processing applicationsDesign optimisation/simulationNuclear powerNumerical models

The present invention provides a meso-crack growth rate based rock mass damage threshold determination method. The method is characterized by comprising: carrying out an conventional physical mechanics property experiment and thin slice analysis on a target rock mass specimen; according to the obtained rock mass strength, deformation characteristics, and mesoscopic particle shape and cemented state, reconstructing a numerical model of the rock mass specimen by using a computer; carrying out numerical reproduction of the mechanical behavior and deformation process on the reality experiment process of the specimen; and investigating the change rule of the growth number of meso-cracks that change with the strain, introducing a parameter of the growth rate of the meso-cracks, and defining a damage threshold value through rock mass damage corresponding to the peak point. According to the method disclosed by the present invention, the growth rule of the rock meso-cracks under the loading condition is disclosed, and the concept of the growth rate of meso-cracks is introduced, and a new rock mass damage threshold determination method is provided; and by virtue of the analysis method of the present invention, the normalized damage threshold of the rock mass can be obtained, and a perfect foundation is laid for the threshold to be promoted and applied in water conservancy and hydropower, nuclear power and geotechnical engineering.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

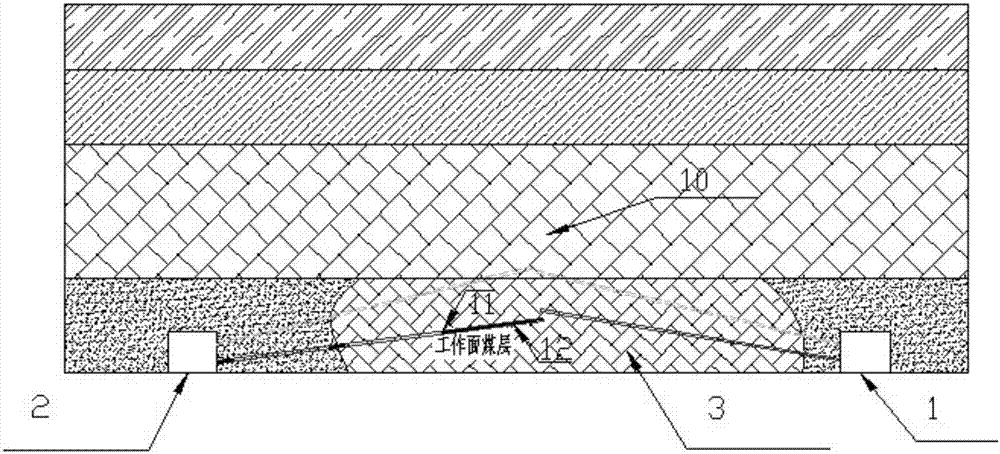

High-pressure two-alley pre-grouting method for super deep hole of large geologic structure crack coal-rock mass

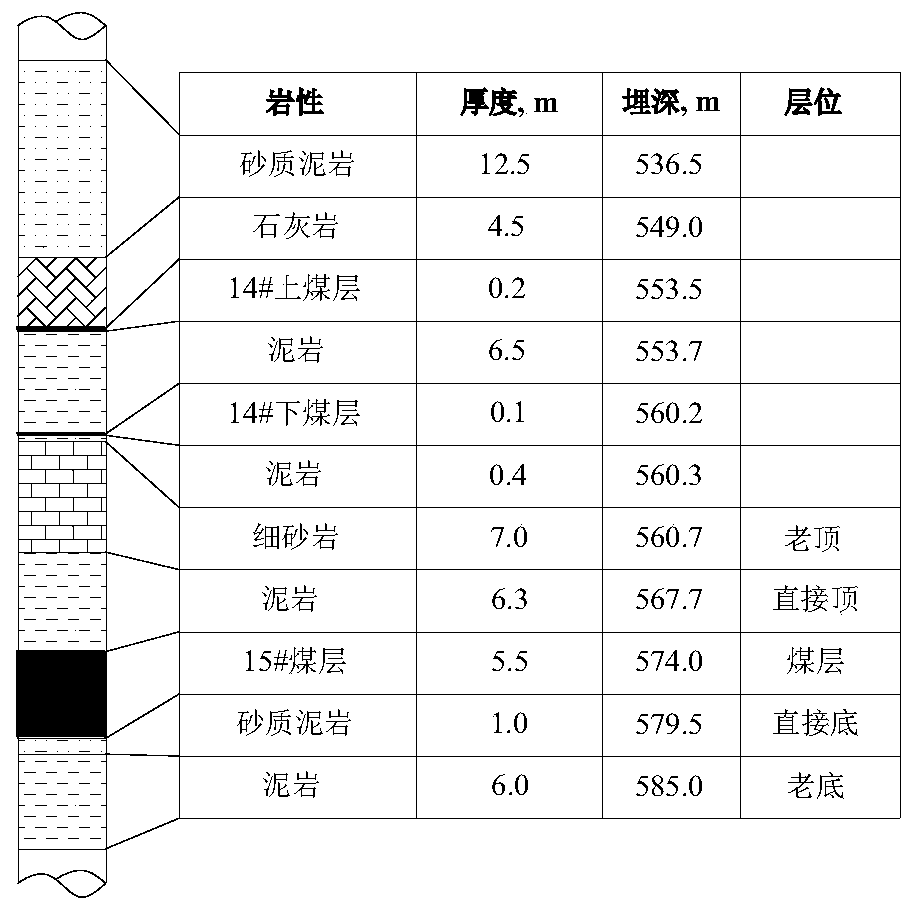

ActiveCN107448214AImprove physical and mechanical propertiesRestore wholenessUnderground chambersTunnel liningRock mass strengthGeomorphology

The invention relates to the field of coal mining and grouting, in particular to a high-pressure two-alley pre-grouting method for a super deep hole of large geologic structure crack coal-rock mass. The high-pressure two-alley pre-grouting method comprises the following steps of: obtaining a working face histogram, field drilling peeping sights and large geologic structure occurrence or a crack coal-rock mass range in a coal-mining working face; according to a coal-mining geological condition, determining a rock structure, lithology, coal-rock mass strength, geostress field type, a working face extraction process, an advance supporting pressure peak value, periodic weighting length and working face gas drainage layout; according to construction parameters, determining drilling height, a drilling angle, drilling depth, a hole sealing position, hole sealing section number, a hole sealing way and a grouting wall; and performing two-alley grouting according to high-pressure pre-grouting drilling parameters. The high-pressure two-alley pre-grouting method performs grouting reinforcing on coal-rack cracked bodies at different positions, restores integrity of crack coal-rock mass and the geologic structure, improves physical and mechanical properties of the coal-rock mass, improves stability of the crushed coal-rock mass, reduces influences on production, and increases a coal resource recovery rate.

Owner:TIANDI SCI & TECH CO LTD

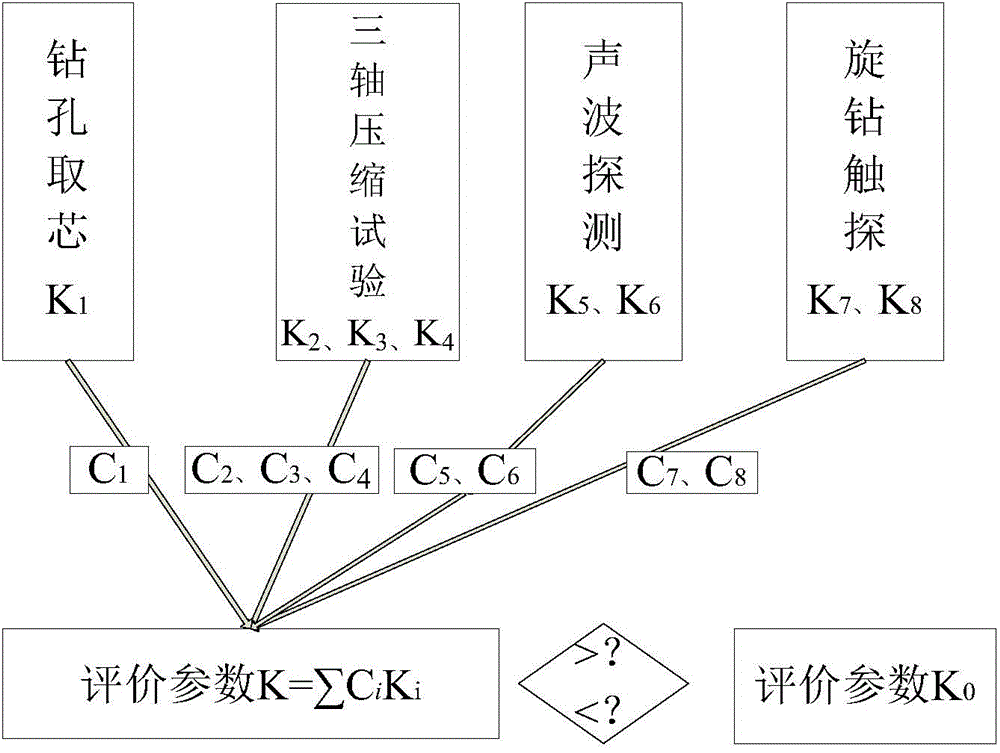

Bolting and injecting quality evaluation method for underground engineering

ActiveCN104866709AAvoid breakingAvoid uncorable defectsSpecial data processing applicationsAnchoring boltsRock mass strengthResidual strength

The invention discloses a bolting and injecting quality method for underground engineering. The evaluation method comprises the following steps: acquiring data before grouting; acquiring data after grouting; according to the data acquired before and after grouting, respectively calculating the borehole coring increasing rate K1, the internal friction angle increasing rate K2, the cohesive force increasing rate K3, the residual strength increasing rate K4, the wave velocity increasing rate K5, the releasing range reduction ratio K6, the drilling pressure increasing rate K7 and the torque increasing rate K8 before and after grouting; utilizing a weight analysis method to establish the quantitative evaluation indexes of the rock mass strength before and after grouting, so as to perform quantitative evaluation on the bolting and injecting quality of surrounding rock, and comparing the quantitative evaluation value with an on-site bolting and injecting quality statistic standard value. The bolting and injecting quality evaluation method for underground engineering has the benefits as follows: the method belongs to multi-factor comprehensive evaluation methods, overcomes the defect that the conventional single-factor method is low in accuracy, and enables the evaluating effect to be more comprehensive and reasonable.

Owner:SHANDONG UNIV +1

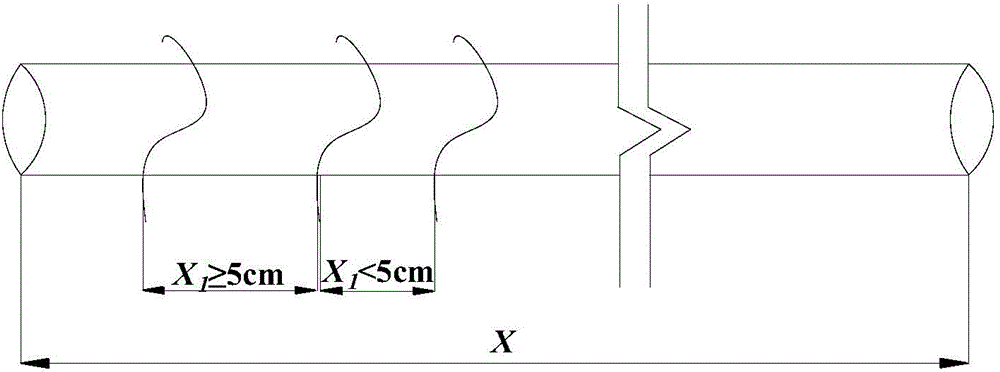

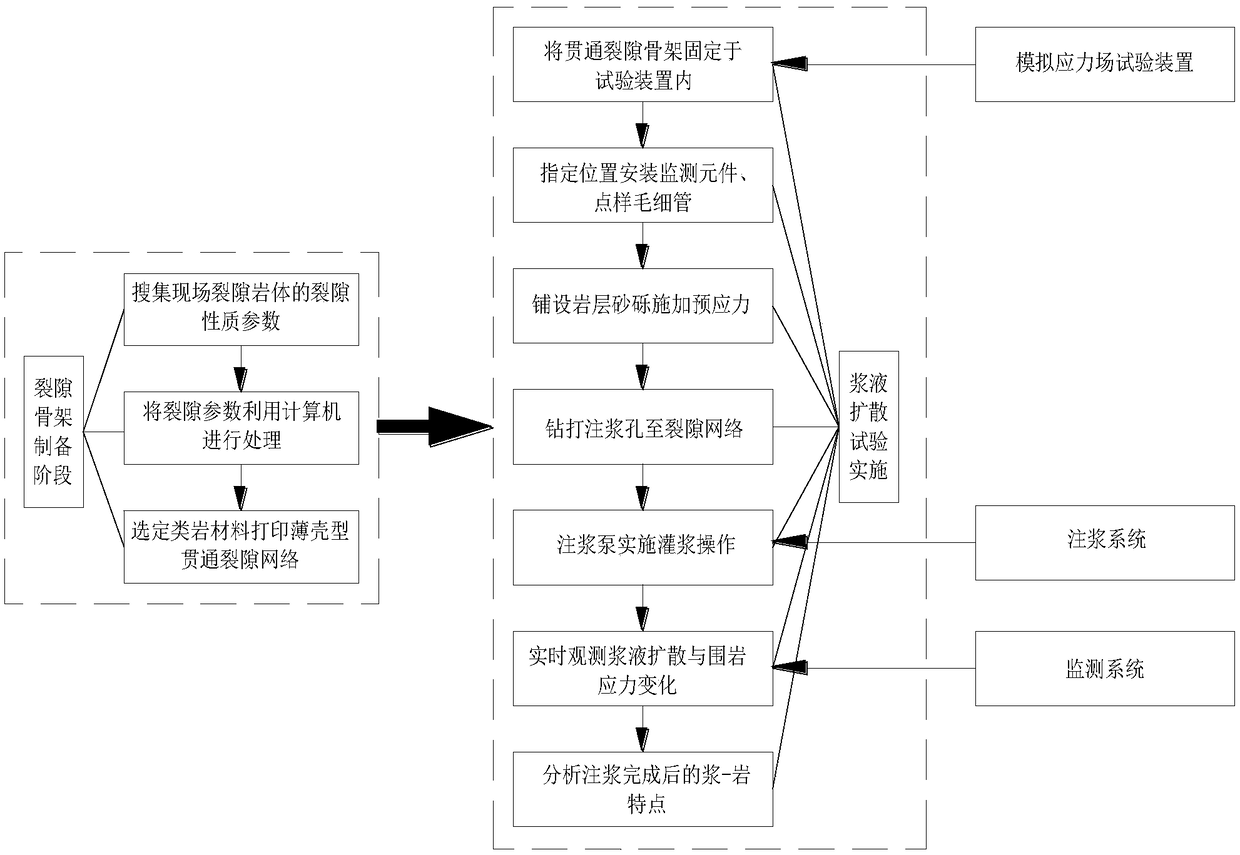

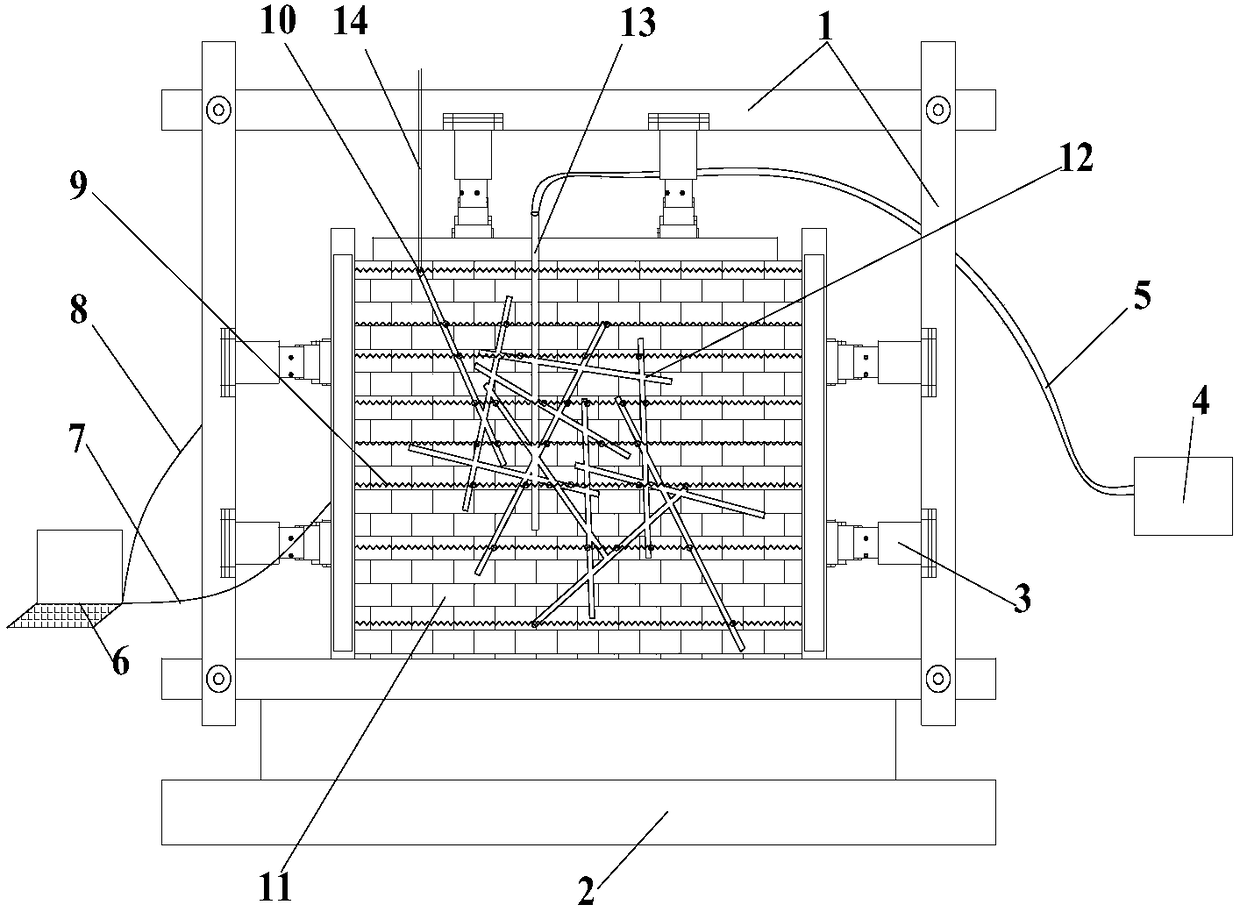

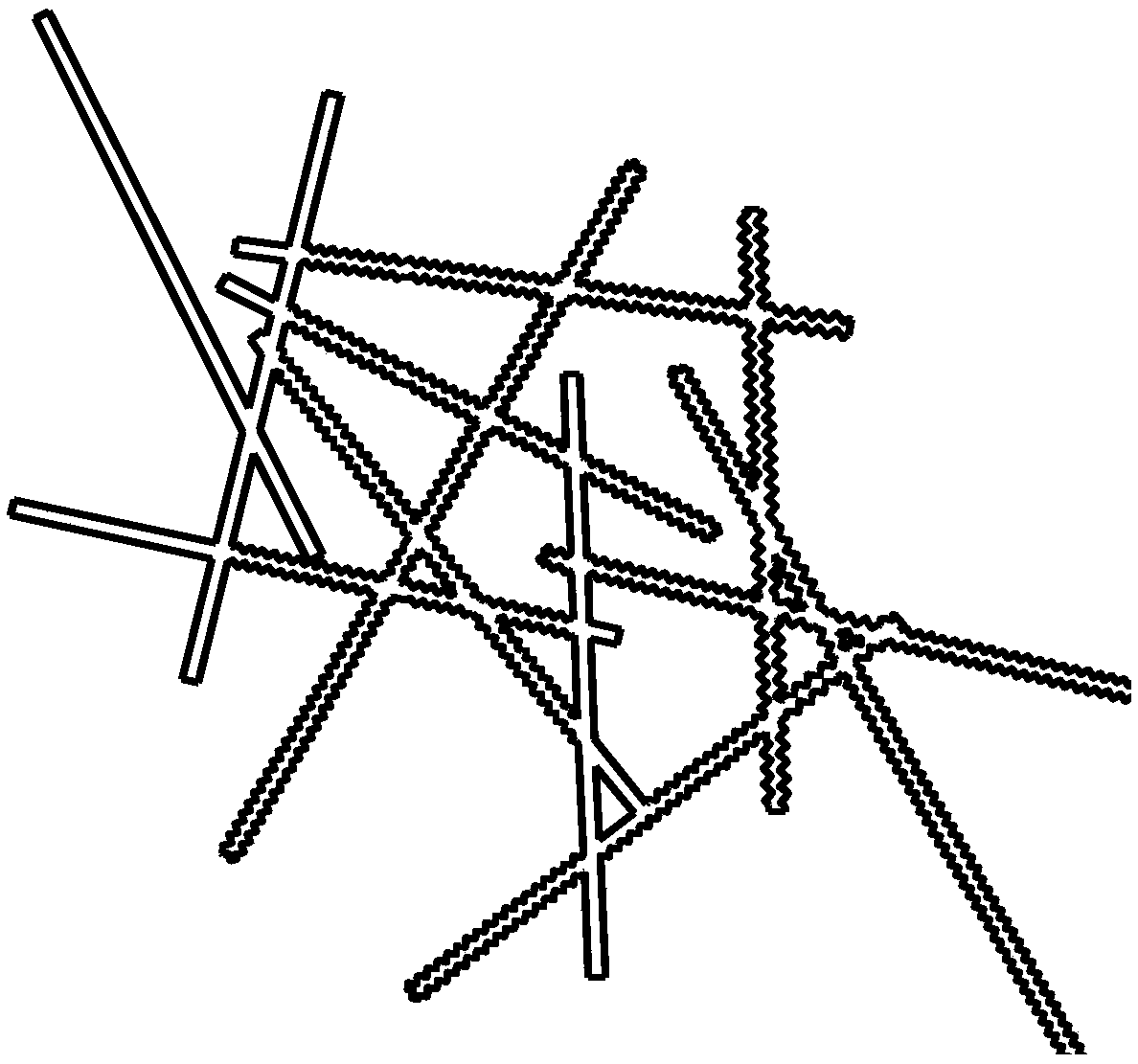

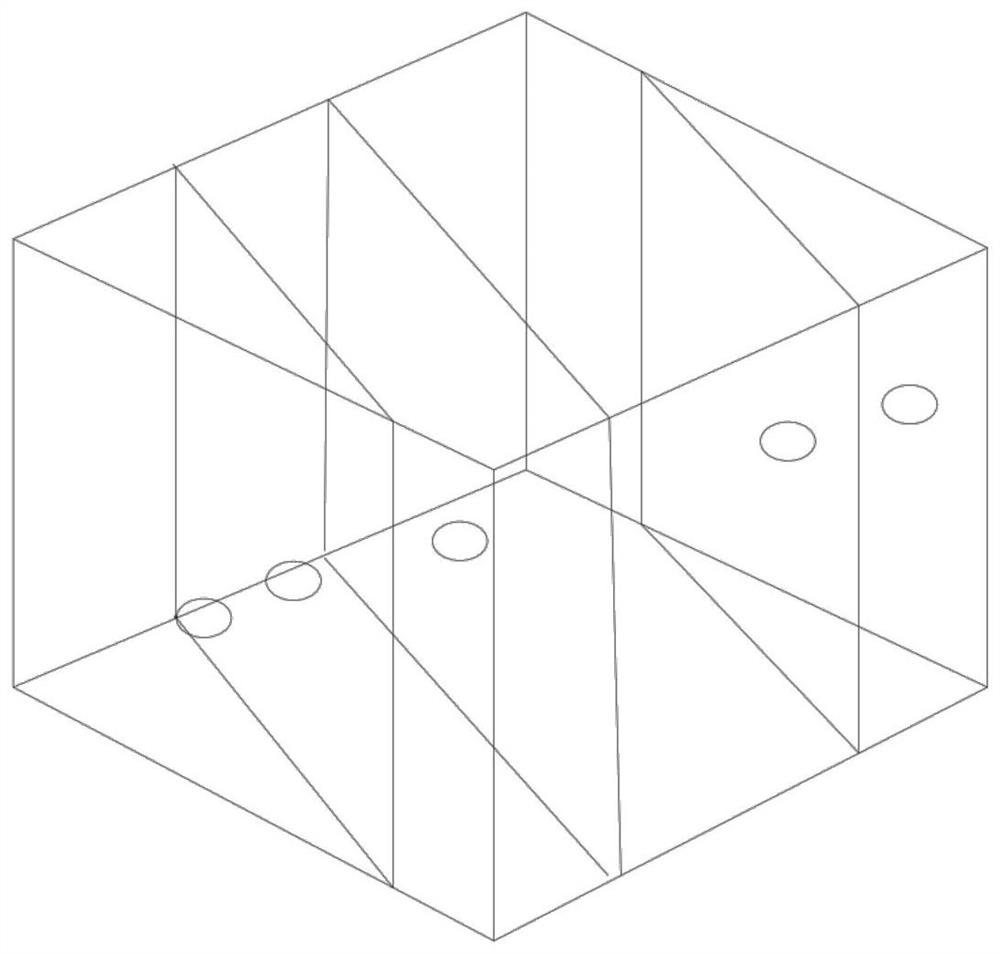

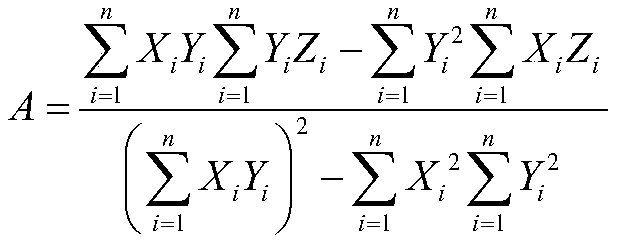

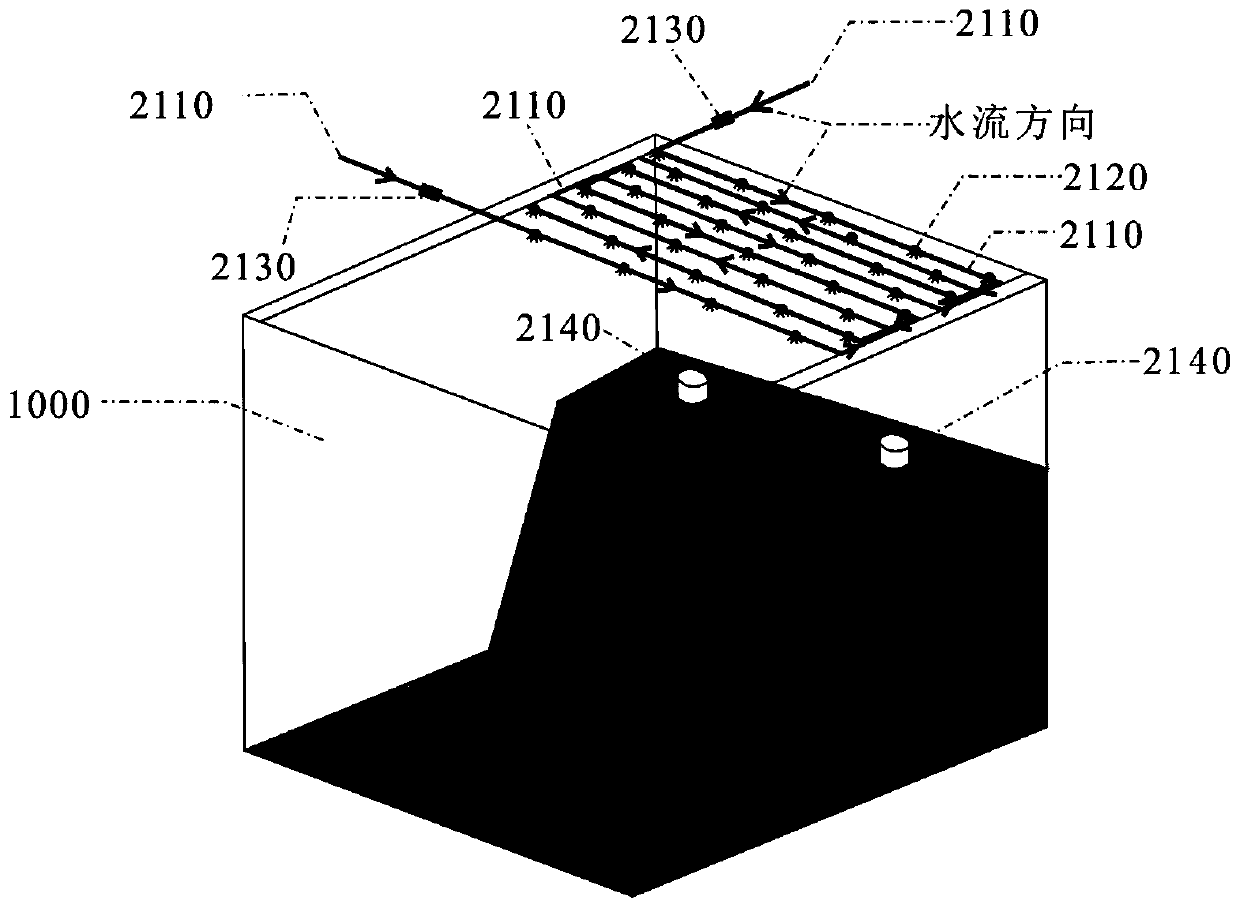

Penetrated crack rock mass grouting slurry diffusion test method

ActiveCN108519308AAchieve the correct representationAvoid damageDiffusion analysisSlurryRock mass strength

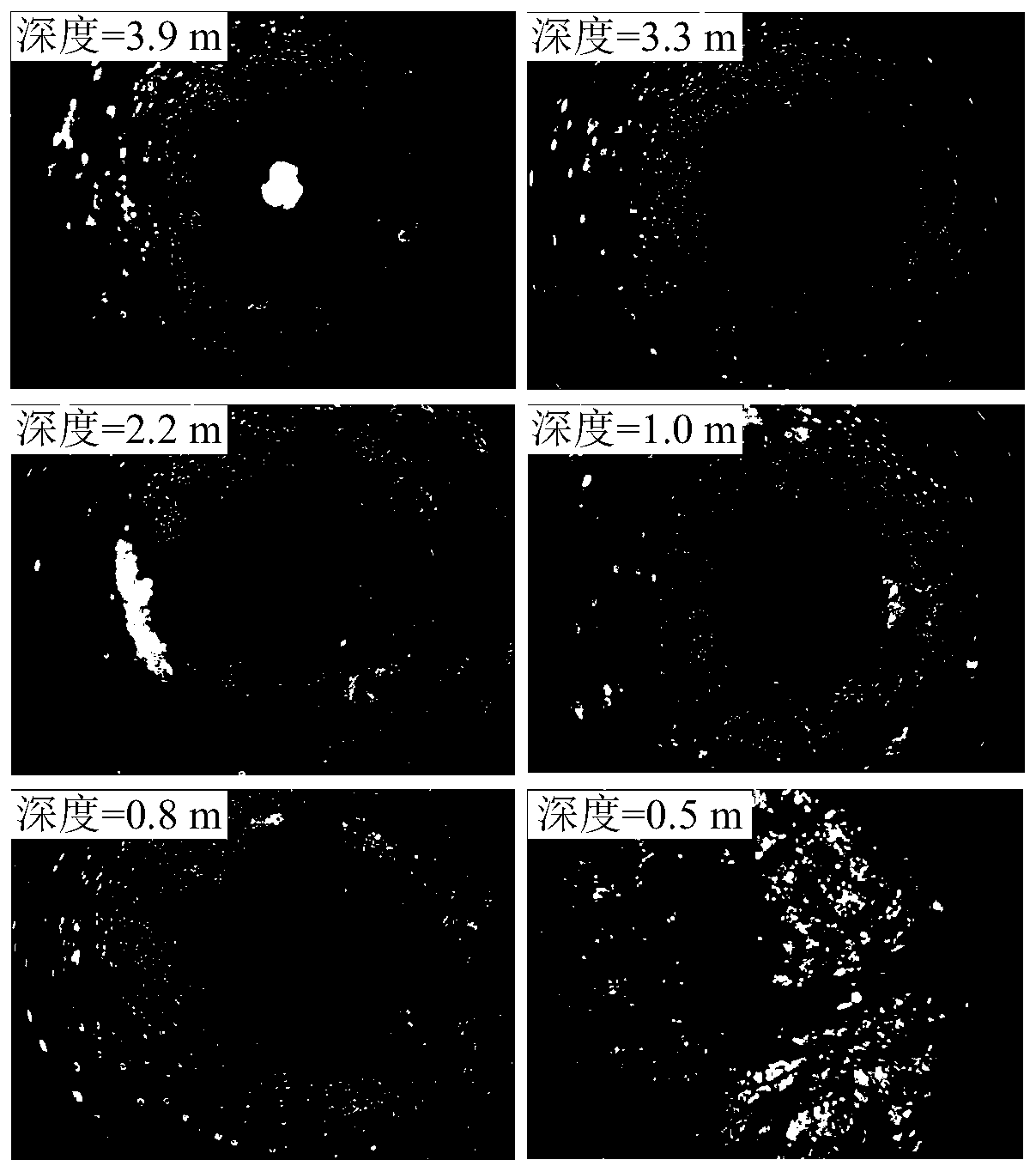

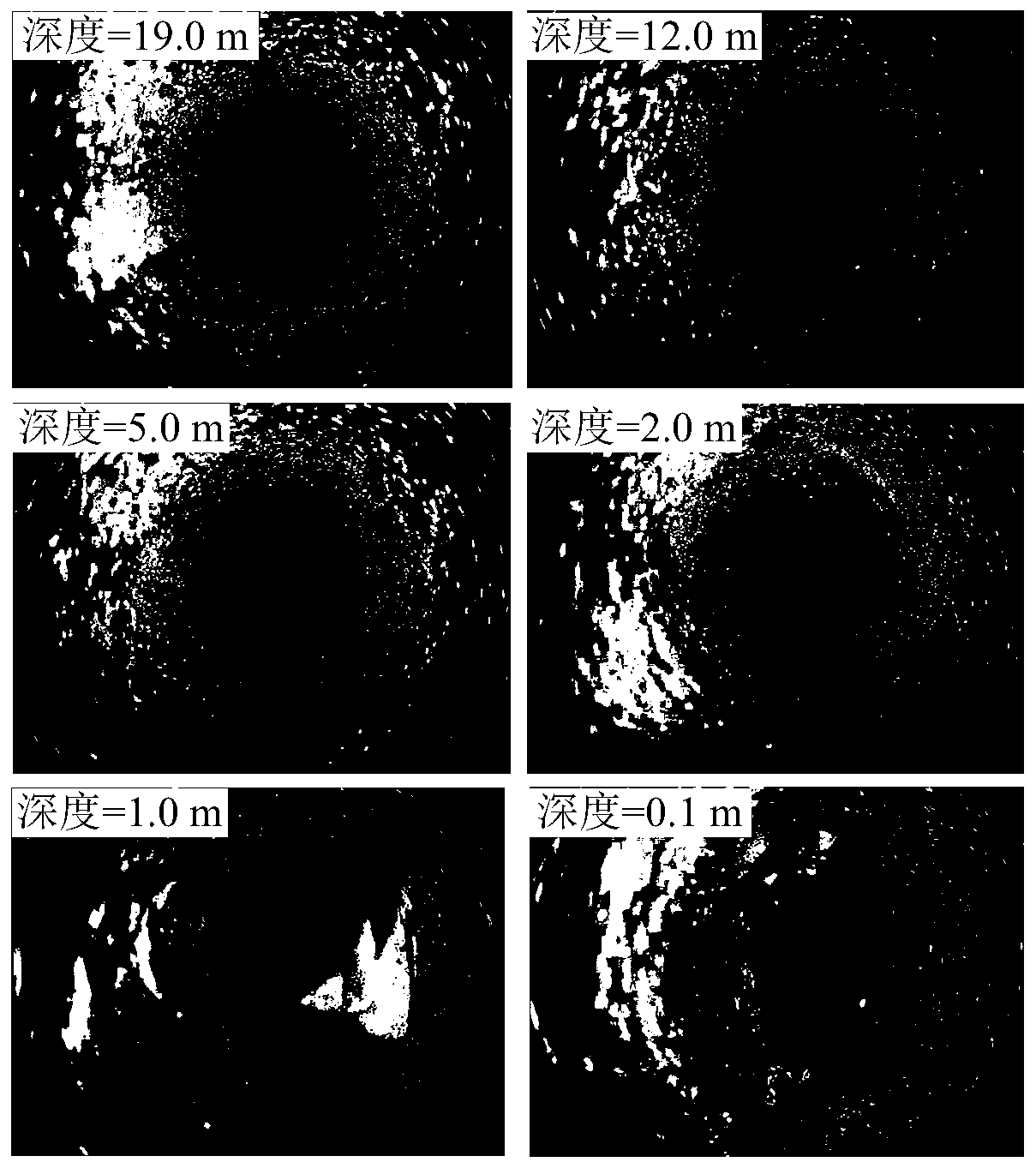

The invention discloses a penetrated crack rock mass grouting slurry diffusion test method. According to the method, based on site observation parameters, by means of the 3D printing technology, a hollow rock mass crack skeleton is constructed, monitoring elements are laid on the surface layer, the end portions and the joints of each crack, and the outer surface layer thickness of the skeleton meets similar rock mass strength attribute requirements; the hollow crack skeleton is connected with spotting capillary tubes, and thus the water saturation in the cracks is controlled; based on the skeleton, rock mass gravel similar to the rock mass gravel in a site is laid and subjected to cooling treatment, prestress corresponding to ground stress is applied on the two sides for compaction, drilling is conducted in proportion for going deep and then penetrating the cracks through perforation, and by means of a grouting pump, high temperature grouting is conducted on the interiors of the cracks; by means of a PC terminal and a thermal inductance instrument, the grouting process is observed, after grouting is completed, a device is detached, and the diffusion form of grouting in the cracks is observed. The method is simple to operate, real-time diffusion of the grouting in penetrated crack rock mass and stress distribution during grouting are easily and truly reflected, and thus the method is an efficient test method for studying a complex crack rock mass grouting technology.

Owner:NORTHEASTERN UNIV

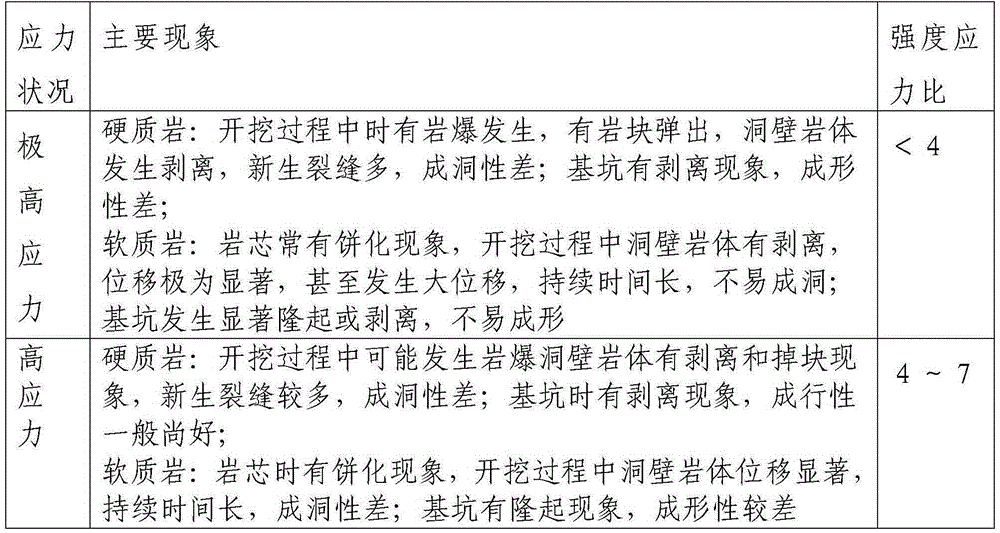

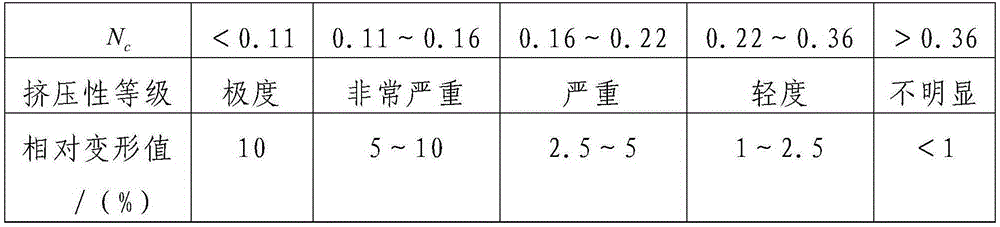

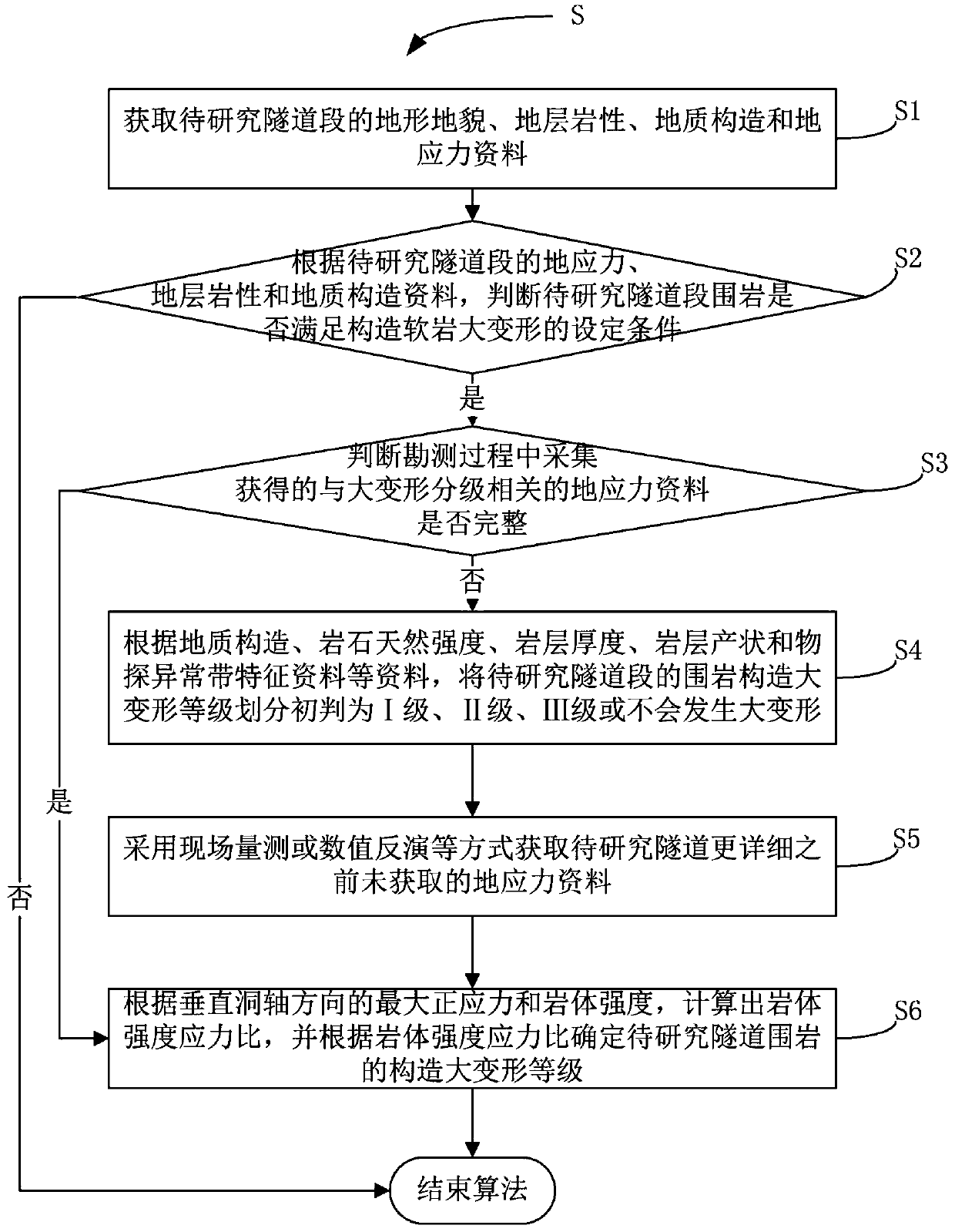

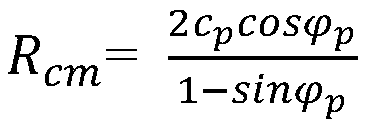

Tunnel structure soft rock large deformation grading method

ActiveCN111425252AReliable preparation for large deformation gradingImprove securityMining devicesBorehole/well accessoriesLithologyStress ratio

The invention discloses a tunnel structure soft rock large deformation grading method. The method comprises the following steps that topography and landform, stratum lithology, geological structure and ground stress data of a tunnel section to be researched are acquired; whether the to-be-researched tunnel section meets a set condition or not is judged, if the to-be-researched tunnel section meetsthe set condition, the next step is entered, and if the to-be-researched tunnel section does not meet the set condition, an algorithm is ended; whether the collected ground stress data are complete or not is judged, if the collected ground stress data are complete, the last step is entered, and if the collected ground stress data are not complete, the next step is entered; the large deformation level of a surrounding rock structure of the to-be-researched tunnel section is primarily judged to be level I, level II, level III or no large deformation; ground stress data, which are not acquired before, of the to-be-researched tunnel are acquired by adopting field measurement or numerical inversion; and a rock mass strength-stress ratio is calculated according to the maximum normal stress andthe rock mass strength in the direction perpendicular to the tunnel axis, and the large deformation level of the surrounding rock structure of the to-be-researched tunnel is judged in detail accordingto the rock mass strength-stress ratio.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD +1

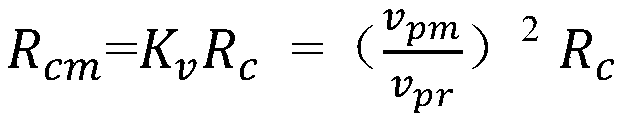

Technology for determining coal bed intensity by using coal ash

InactiveCN102102514AGood application effectBorehole/well accessoriesWell drillingGeological Strength Index

The invention relates to a technology for determining coal bed intensity by using coal ash, which is suitable for the technical field of well wall stabilization in well drilling for coal bed methane. The method comprises the following steps of: classifying, cleaning, baking and crushing coal rock debris obtained by logging, performing proximate analysis of coal according to the national standard, and determining the ratio of ash to volatile; judging the coal grade of the coal rock according to the volatile value; selecting the corresponding empirical formula of the relationship between the ash and the intensity according to the coal grade and calculating the intensity of coal rock blocks; and solving the coal reservoir intensity by combining a geological strength index (GSI) value and applying a Hoek-Brown rock mass strength empirical formula. The method is provided by combining the field on the basis of the Hoek-Brown rock mass strength empirical formula, and is suitable for the requirement for acquiring the parameters of the coal bed intensity in the well wall stabilization prediction of well drilling for the coal bed methane, and the prediction method is simple and has a good effect.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

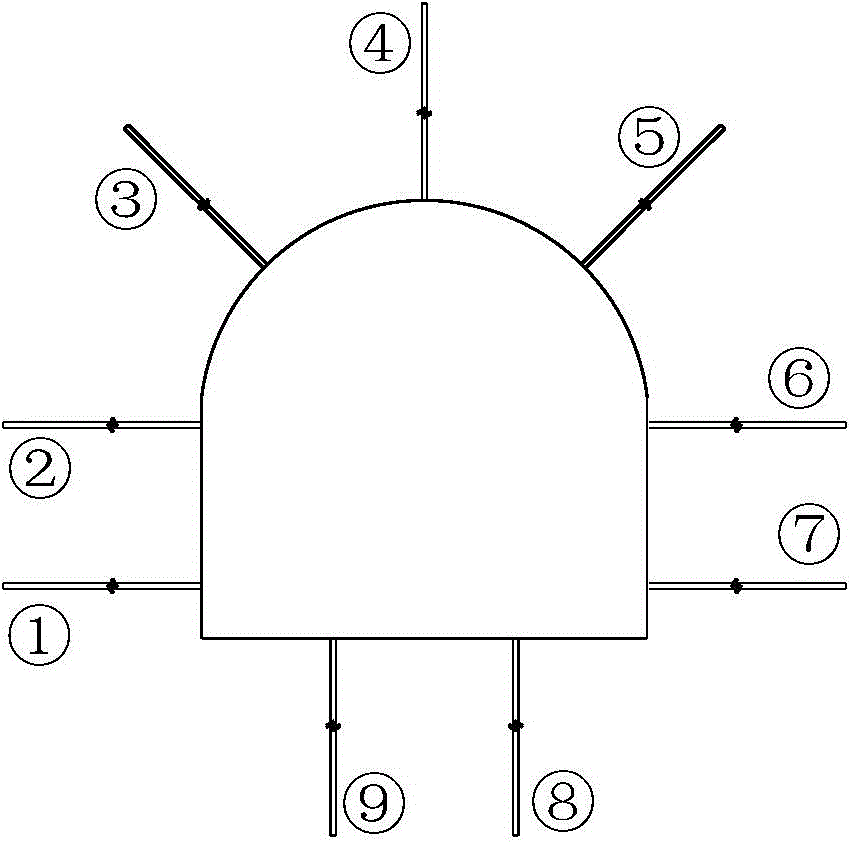

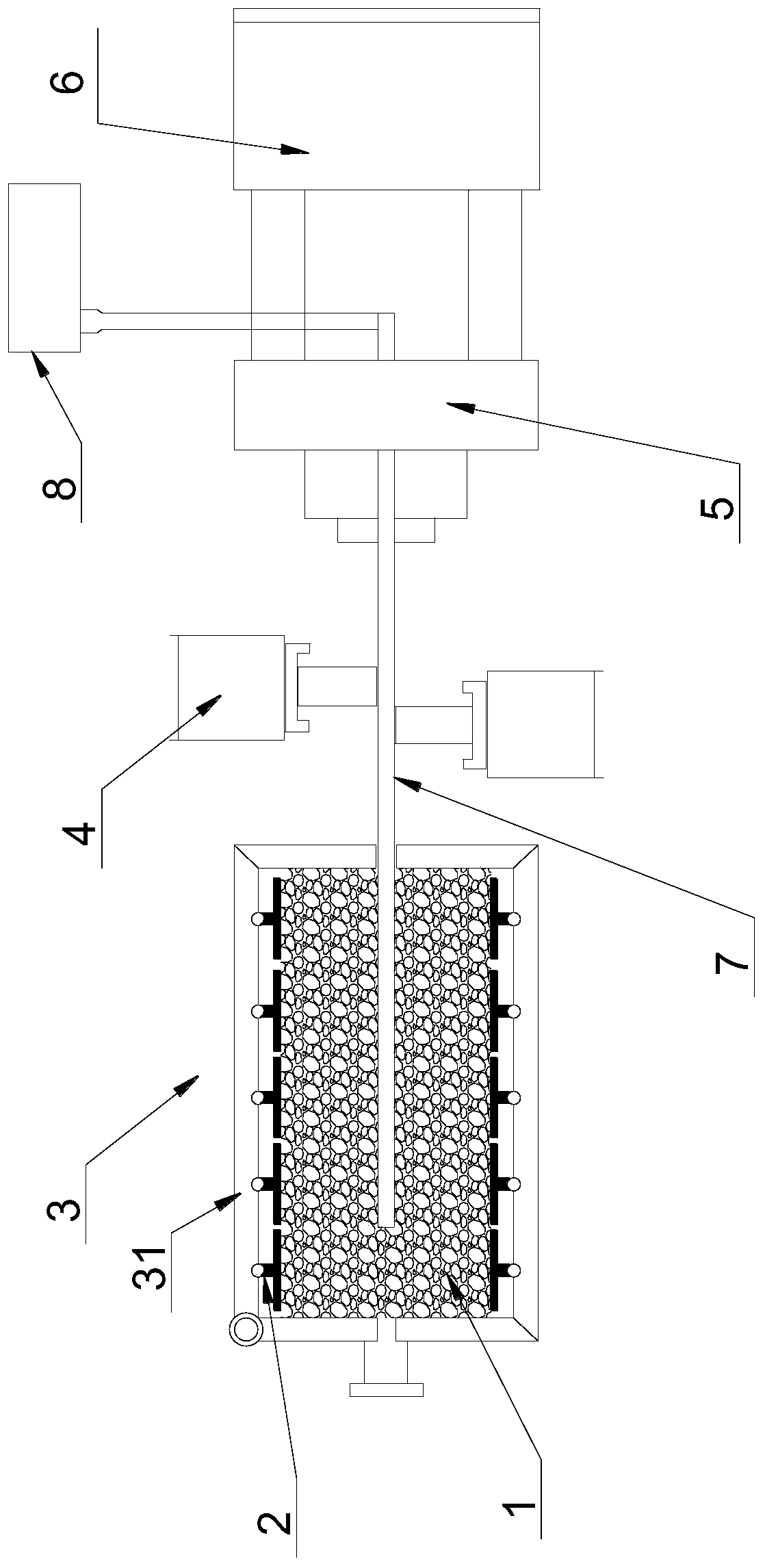

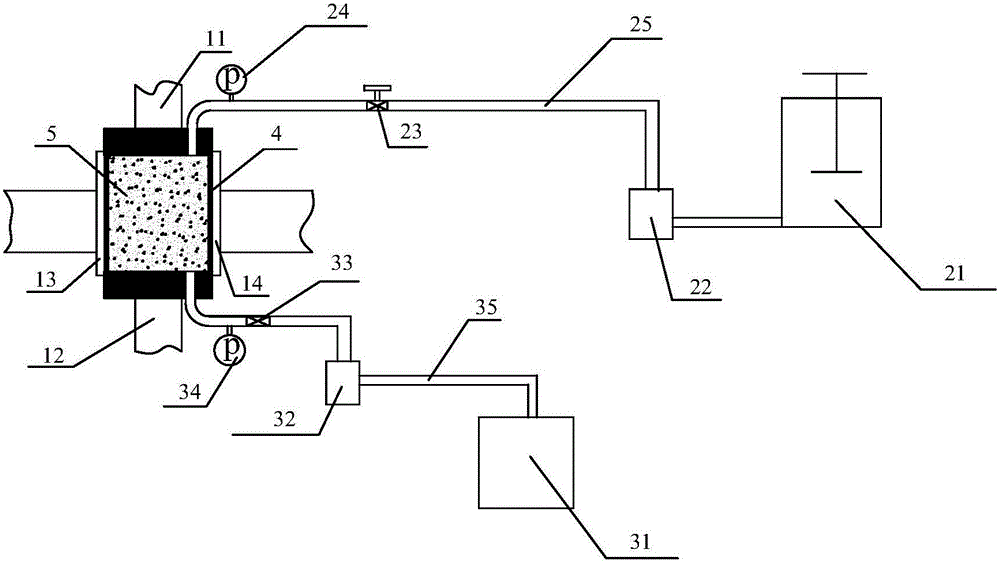

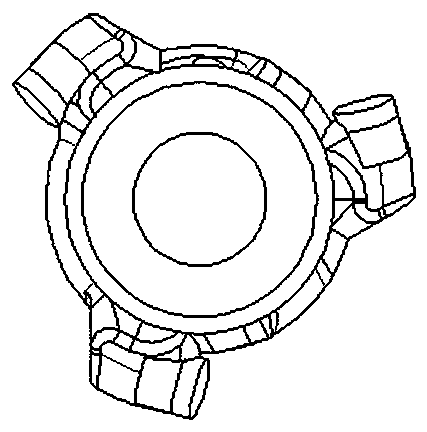

Large-scale complex surrounding rock condition bolt-grouting integrated coupling effect test system and method

PendingCN111595682AAchieve mechanical propertiesTest anchor strengthEarth material testingMaterial strength using tensile/compressive forcesEngineeringSlurry

The invention discloses a large-scale complex surrounding rock condition bolting-grouting integrated coupling effect test system and method, and the system mainly comprises a sealed box body, a plurality of side pressure units which independently provide side extrusion force are sequentially and uniformly arranged on the inner wall of the box body, and the box body is filled with a coal and rock mass or an analog simulation material; a plurality of transverse shearing units, and a twisting unit for twisting the grouting anchor rod and a stretching unit for controlling the twisting unit to stretch linearly are sequentially arranged in the linear direction of the embedded anchor rod or the grouting anchor rod of the test system. The free end of the grouting anchor rod embedded in the test system is detachably connected with the grouting device. Through the large-scale underground simulation test system, the mechanical properties of a common anchor rod and a grouting anchor rod under thesingle-factor or multi-factor coupling action of pulling, twisting, shearing, cutting and bending under complex geological conditions can be simulated; and deformation rules and mechanical propertiesof the underground rock mass and the grouting rock mass under complex conditions can be simulated, and seepage diffusion rules of different slurries and changes of rock mass strength are tested.

Owner:中国平煤神马控股集团有限公司 +1

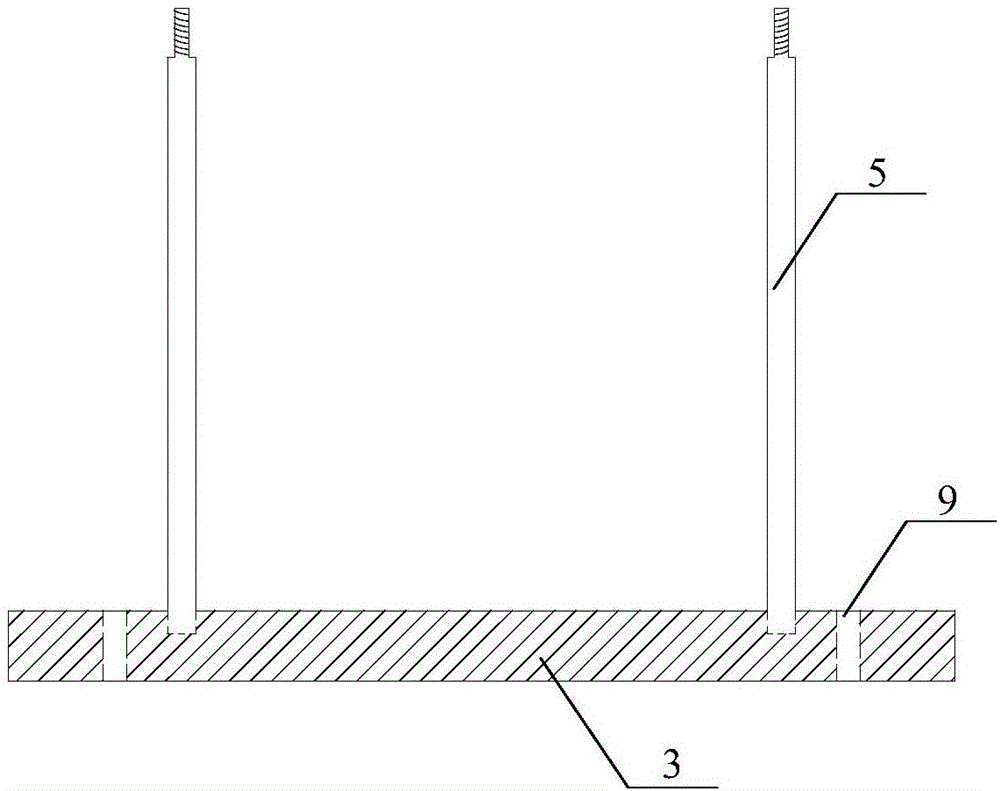

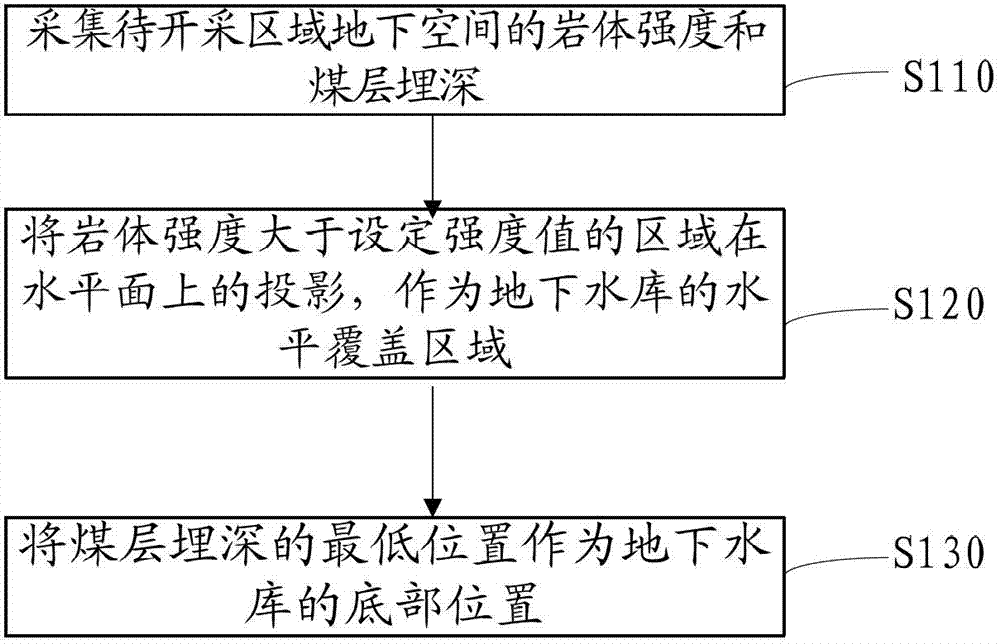

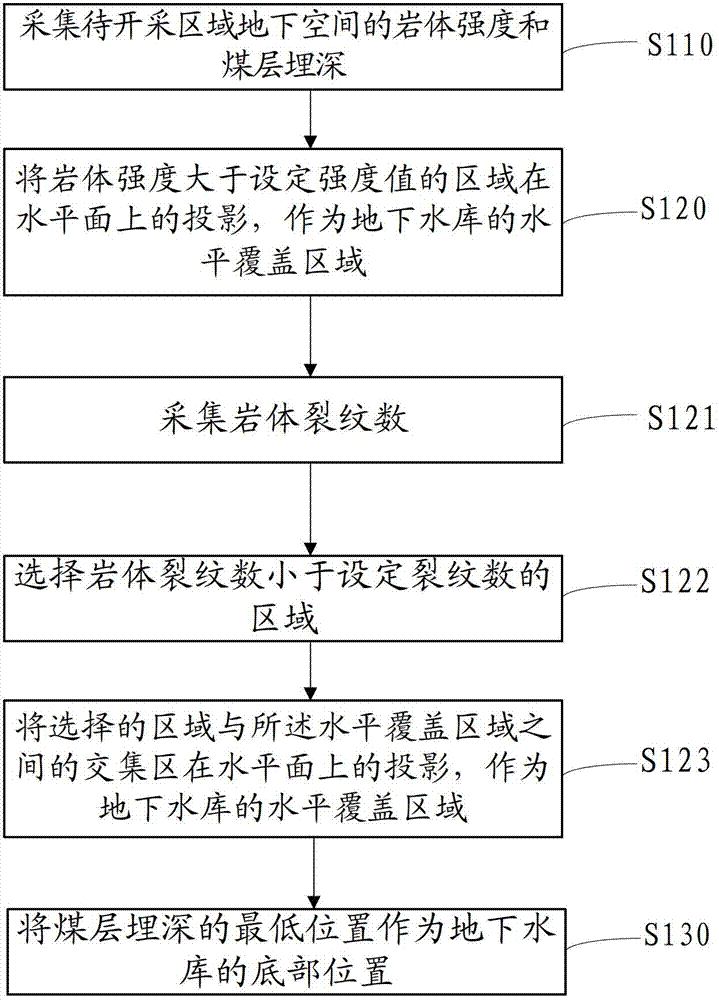

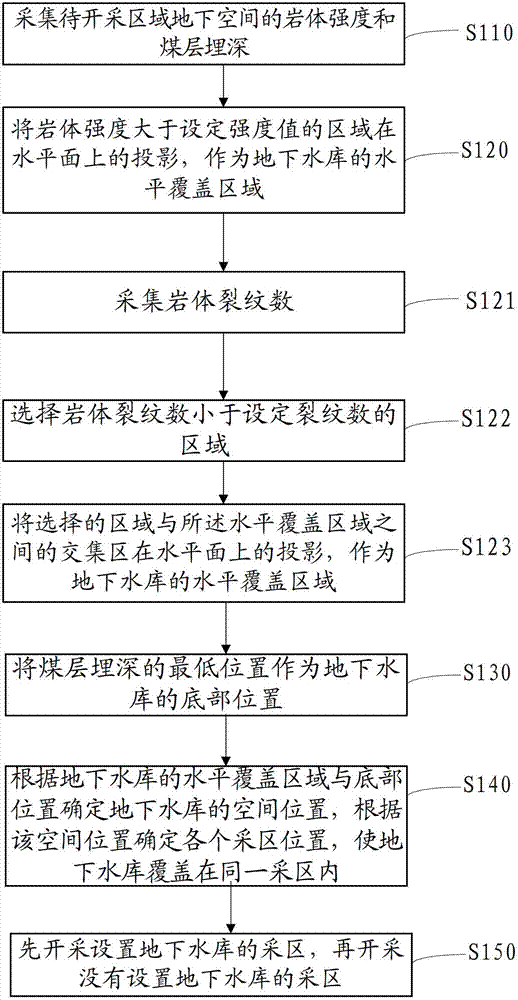

Position determining method for underground water reservoir

ActiveCN102809765AAvoid the defect of small water storageImprove water resource utilizationGeological measurementsWater storageGeomorphology

The invention discloses a position determining method for an underground water reservoir. The method comprises the following steps of: acquiring the rock mass strength and the coal bed burial depth in underground space of an area to be mined; taking the projection of the area with the rock mass strength greater than a set strength value on a horizontal plane as a horizontal coverage area of the underground water reservoir; and taking the lowest position of the coal bed burial depth as the bottom position of the underground water reservoir. According to the position determining method for the underground water reservoir provided by the embodiment of the invention, the spatial position of the underground water reservoir is determined by acquiring the rock mass strength and the lowest position of the coal bed burial depth and the underground water reservoir is subjected to overall layout before mining, so that the defect that the water storage amount is small caused by an improper position of the underground water reservoir is avoided, the utilization rate of water resources is improved, construction projects are reduced, and the construction cost is reduced.

Owner:CHINA SHENHUA ENERGY CO LTD +1

Three-dimensional stress fluid coupling grouting test system and method

The invention provides a three-dimensional stress fluid coupling grouting test system and method. An upper pressing head, a lower pressing head, a left pressing head, a right pressing head, a front pressing head and a rear pressing head are movably connected with the upper part, the lower part, the left part, the right part, the front part and the rear part of a support frame respectively; grouting flow passages are formed in the upper pressing head, the left pressing head, the right pressing head, the front pressing head and the rear pressing head; the grouting flow passages are assembled and connected with grouting units; a water injection flow passage is formed in the lower pressing head; the water injection flow passage is assembled and connected with a water injection unit; inner sides of the upper pressing head, the lower pressing head, the left pressing head, the right pressing head, the front pressing head and the rear pressing head are assembled and connected with sealing rings. The three-dimensional stress fluid coupling grouting test system and method have the following benefits: three-dimensional stress and water pressure seepage are carried out on test pieces so as to simulate the coupling of three-dimensional stress shearing and seepage for rock mass structure surfaces; grouting is carried out on damaged test pieces so as to simulate the broken rock mass grouting process, and after the grouting, loading is carried out on the test pieces until the test pieces are damaged, so as to simulate the rock mass damage process after the grouting and obtain the attributes such as rock mass strength and the like after the grouting.

Owner:SHANDONG UNIV OF SCI & TECH

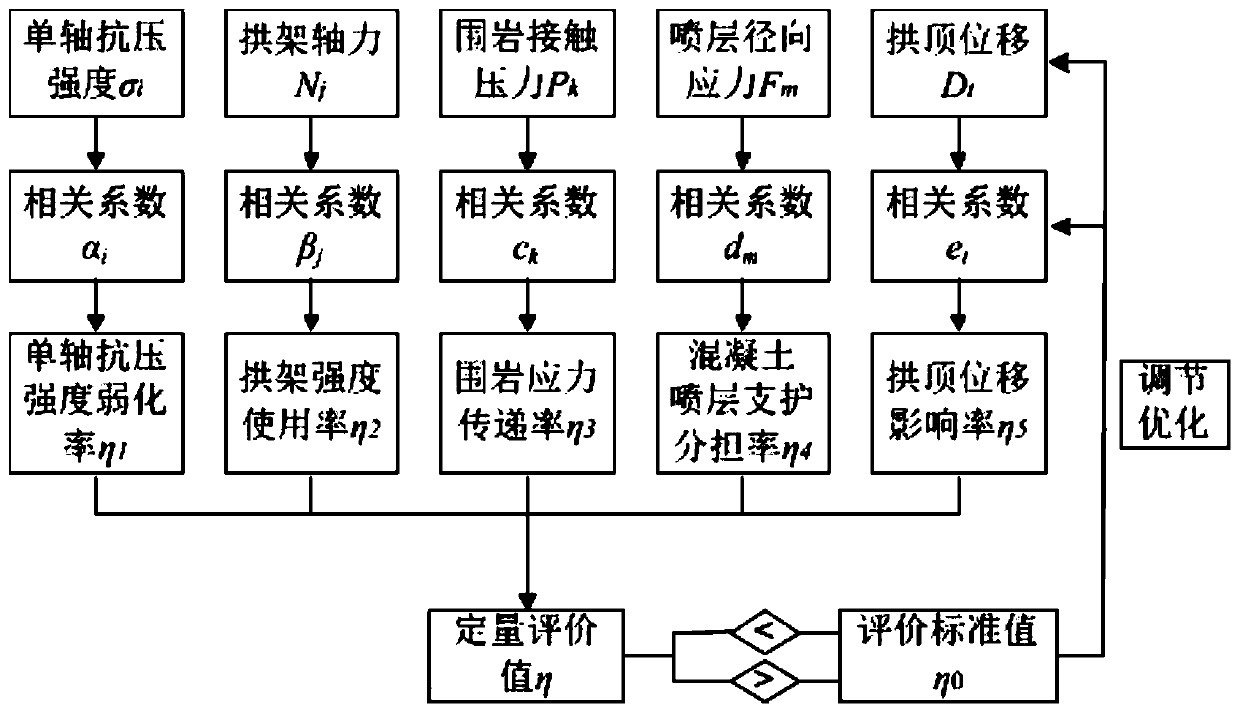

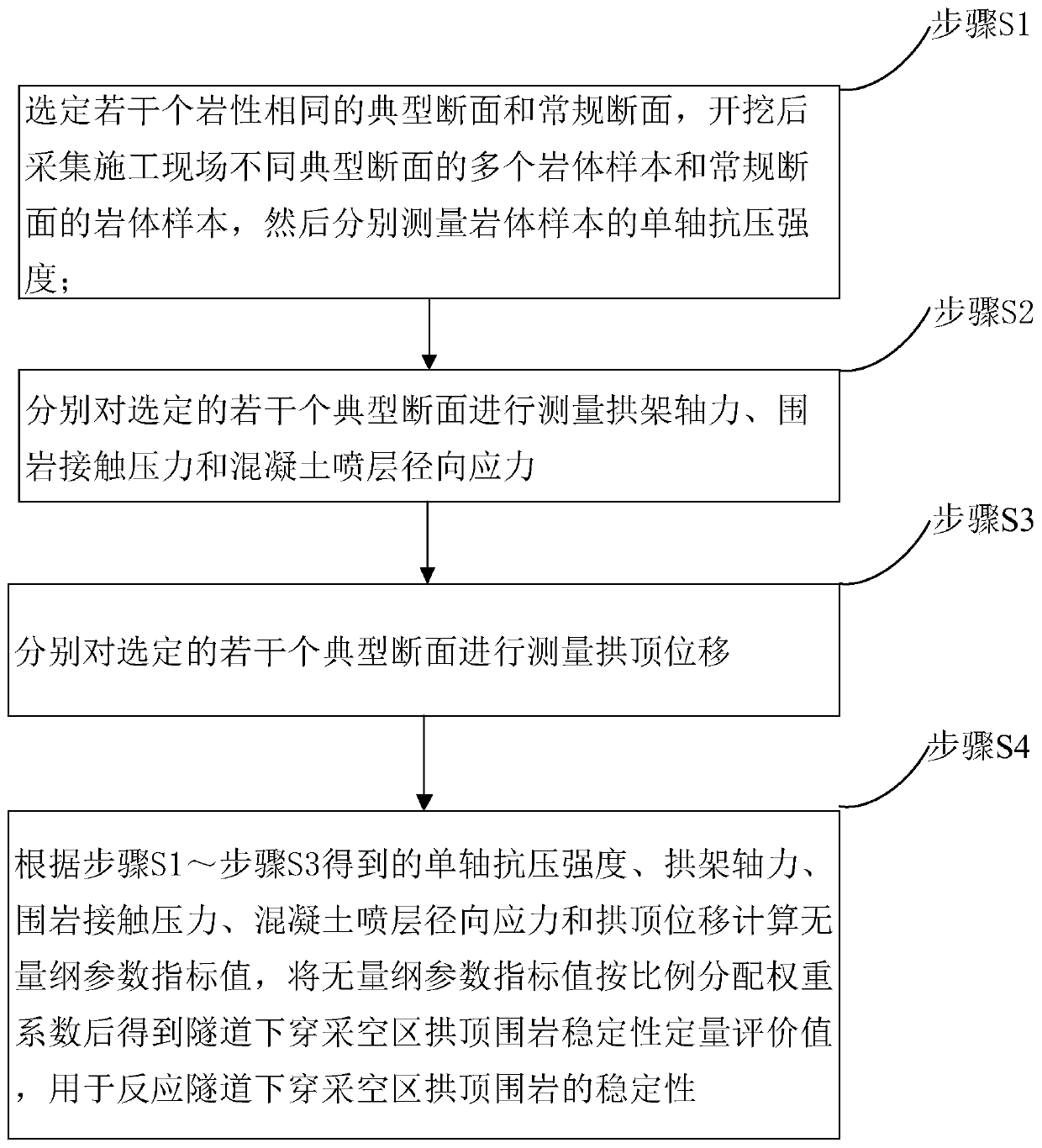

Surrounding rock stability evaluation method for tunnel down-traversing goaf

ActiveCN110346213AThe evaluation method is reasonableImprove the surrounding rock control evaluation systemMaterial strength using tensile/compressive forcesDesign optimisation/simulationLithologyContact pressure

The invention belongs to the technical field of tunnel construction, and particularly provides a surrounding rock stability evaluation method for a tunnel down-traversing goaf. The method comprises the following steps that: according to different heights between a tunnel vault and the goaf, selecting a plurality of typical fracture surfaces and conventional fracture surfaces with the same lithology, and utilizing a point load meter to measure the uniaxial compressive strength of a field rock mass; adopting a reinforcement stress meter, a pressure box and a concrete stress meter to collect archaxial force, surrounding rock contact pressure and concrete spray layer radial stress; collecting arch apex displacement; and calculating a dimensionless parameter index value for reflecting tunnel down-traversing goaf arch apex surrounding rock stability, distributing a weight coefficient according to a ratio, establishing the quantitative evaluation value of the tunnel down-traversing goaf archapex surrounding rock stability, and guiding field supporting and construction. By use of the method, testing under a situation of different field rock mass strengths is reinforced, so that the method is more reasonable when surrounding rock stability evaluation relates to field rock mass strength, the evaluation of a surrounding rock control effect can be carried out in the construction field, an indoor test does not need to be carried out, and construction efficiency is improved.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE +2

Direct-shear measuring method of drilling rock mass specimen preparation

ActiveCN101949288ASimple methodEasy to operateBorehole/well accessoriesCore removalRock coreTest sample

The invention relates to a direct-shear measuring method of drilling rock mass specimen preparation, which can solve the problems of high test expenses, long test period and low efficiency effectively and particularly can overcome the defect that specimen preparation is dependent on stonecutters. The method comprises the following steps of: excavating a test adit in a mountain by adopting a bursting method first, and drilling two holes upwards on a test adit bottom board by using a drilling machine, wherein one hole is a shear hole, the other hole is a specimen hole, the centers of the two holes are in the same straight line, the direction of the straight line is consistent with that of engineering stress, and the specimen hole is a test sample drill hole; reserving a rock core in the holes, taking the rock core from the shear hole for arranging a shearing test equipment, and cutting the rock mass on the middle part of the two holes for communicating; determining the drilling depth according to the position of a shear surface, and after completing a drilling workpiece, arranging a steel protective sleeve on a specimen; and arranging normal and shearing loading equipment respectively after the work is finished. The direct-shear measuring method has the advantages of simplicity, convenient operation, low cost, labor and time saving and high efficiency, and is the innovation of the direct-shear test of the site rock mass strength.

Owner:YELLOW RIVER ENG CONSULTING +1

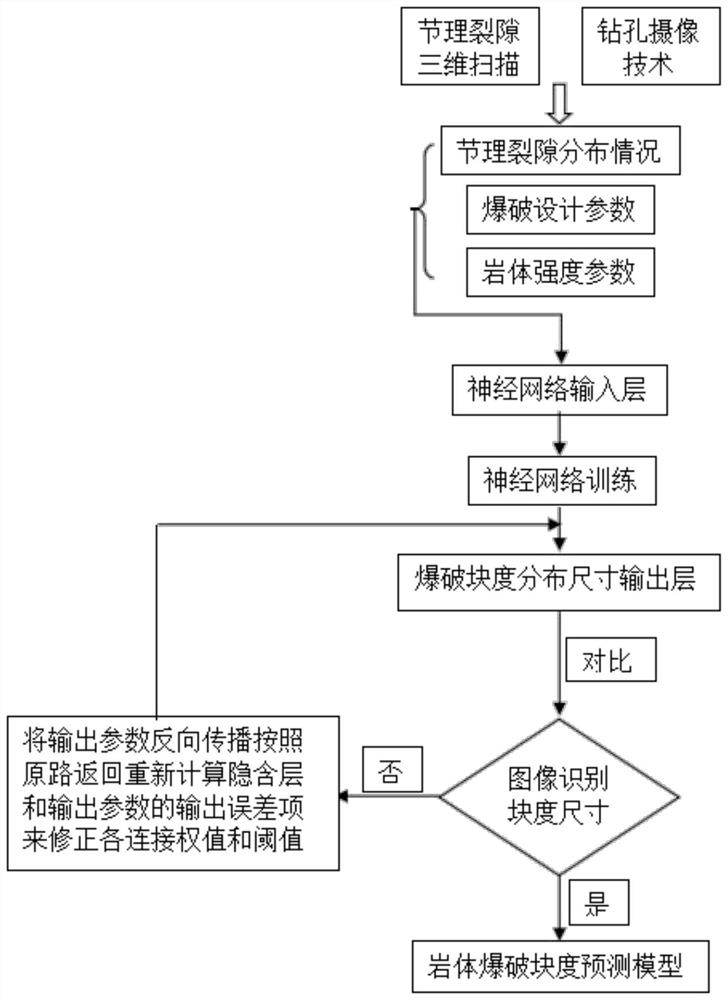

Method for predicting blasting lumpiness of rock mass

The invention discloses a method for predicting the blasting lumpiness of a rock mass, and relates to the field of prediction of the blasting lumpiness of the rock mass. The method comprises the following steps of: carrying out three-dimensional scanning on joint cracks of the rock mass to be blasted to obtain the distribution condition of the three-dimensional joint cracks of the rock mass; determining blasting design parameters; sampling the rock mass to be blasted to obtain rock mass strength parameters; determining the lumpiness size of the rock mass by applying an image recognition technology to a blasted blast heap; taking data obtained in the previous three steps as input parameters by applying a BP neural network, and correcting each connection weight and threshold value by continuously training the BP neural network to obtain an optimal rock mass blasting lumpiness prediction model; and inputting a test set into the optimal rock mass blasting lumpiness prediction model to obtain the blasting lumpiness size. According to the method, factors such as the distribution condition of the internal joint Jc and the surface joint Js of the rock mass, blasting design parameters and rock mass strength are comprehensively considered, the lumpiness size of the rock mass after blasting can be accurately predicted, and the prediction precision is high.

Owner:中铁十九局集团矿业投资有限公司

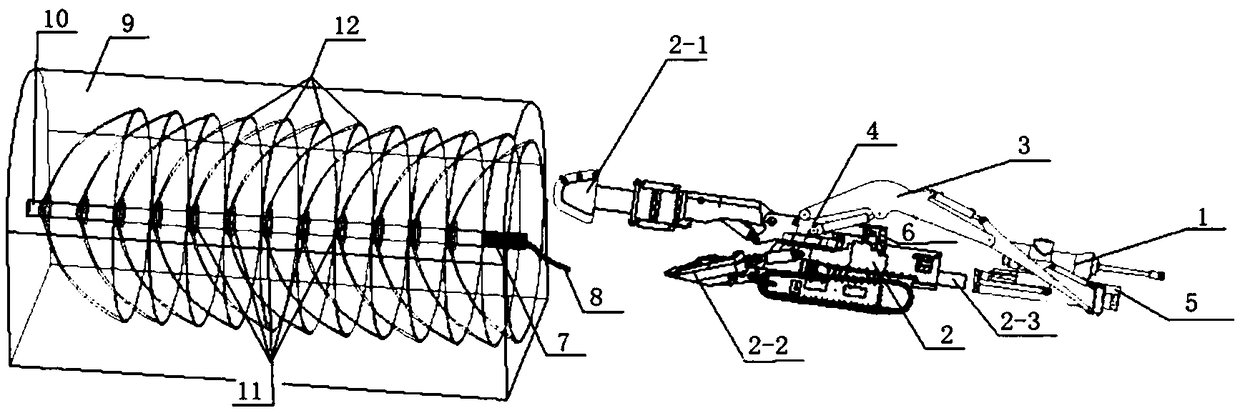

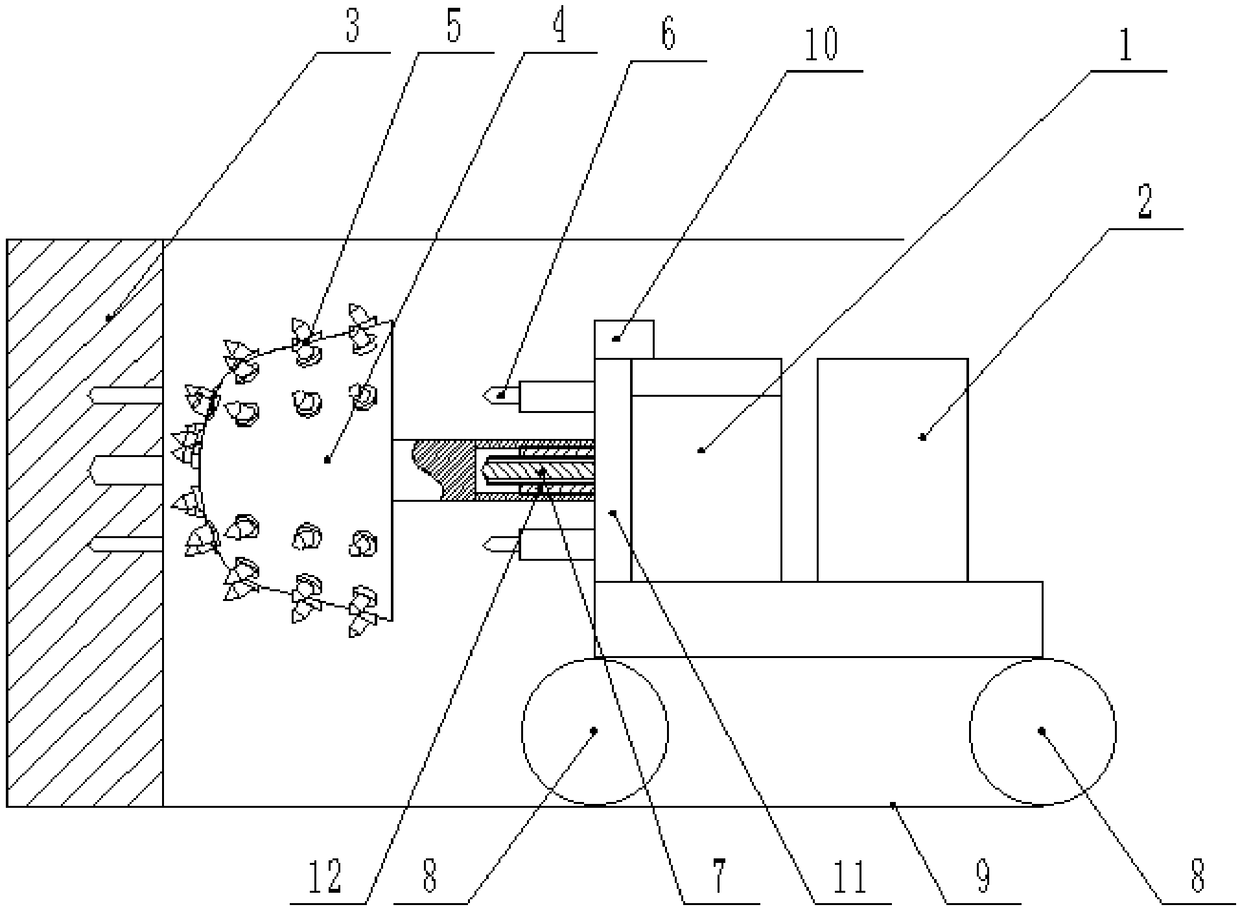

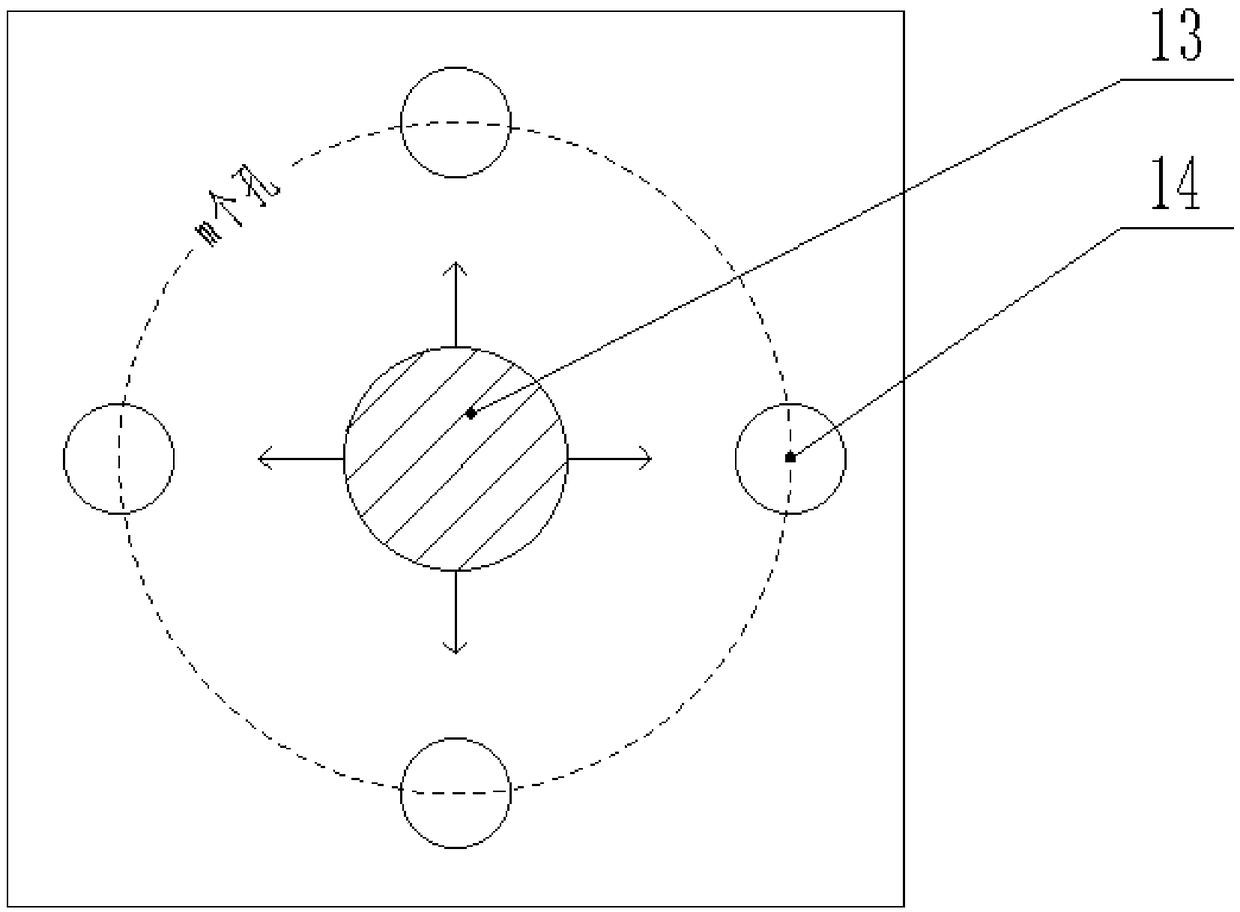

Tunneling method capable of weakening hard rock strength

ActiveCN108691508ADrilling heightImprove efficiencyLiquid/gas jet drillingSlitting machinesEngineeringHigh pressure water

The invention discloses a tunneling method capable of weakening hard rock strength. According to the method, a tunneling machine, an integrated grinding jetting drilling machine with the tunneling machine as a carrier, and a high-pressure water pump are arranged on a tunneling working surface; the integrated grinding jetting drilling machine is adopted to form drilled holes in a rock body, and a series of conical crack clusters are formed through cracking cutting on the basis of hole drilling; a high-pressure hole sealing device is used for sealing the tunneling surface for a distance, the high-pressure hole sealing device is communicated with a high-pressure water pump through a water inlet pipe, the characteristic that the rock body is resistant to pressure but not resistant to drawing is utilized, the conical crack clusters in the rock body are expanded to form a dense conical crack net, and therefore the rock strength is weakened; a tunneling machine cutting head is adopted to cutthe rock which has an internal conical crack net, the tunneling efficiency is greatly improved, the service life of the tunneling machine can be prolonged, and the tunneling cost is reduced.

Owner:CHINA UNIV OF MINING & TECH

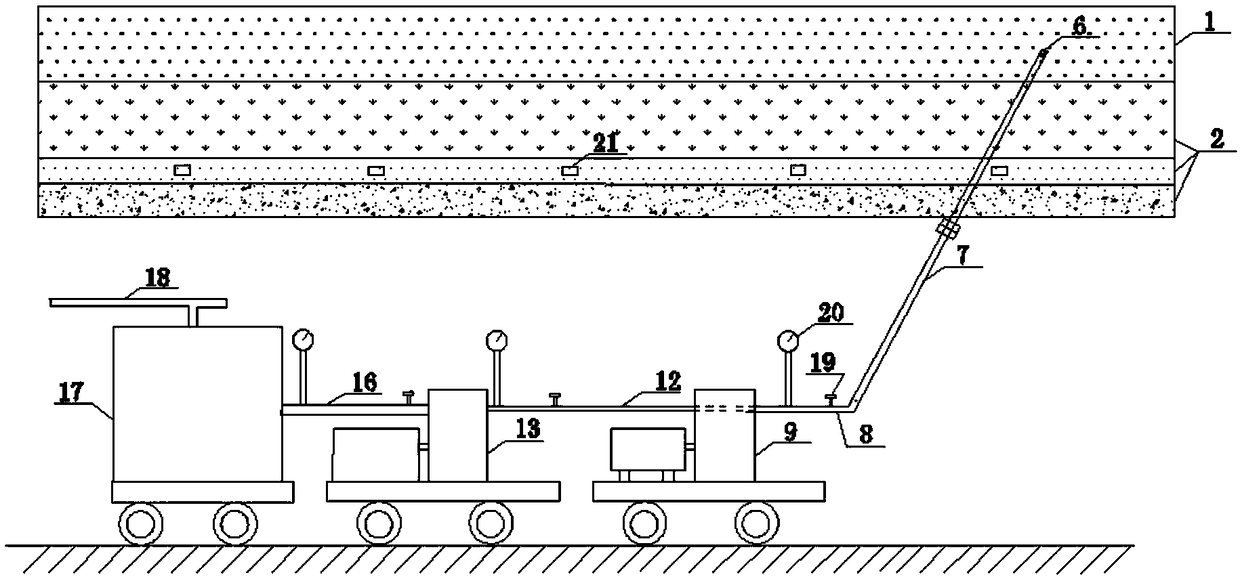

Construction device and method for fracturing and softening hard and difficultly-collapsing top plate in underground coal mine

InactiveCN108999636AAchieve chemical weakeningWeakened cementMining devicesAcid fracturingGeomorphology

The invention discloses a construction device and method for fracturing and softening a hard and difficultly-collapsing top plate in an underground coal mine. The construction method comprises the steps of S1, obtaining a hard and difficultly-collapsing top plate by using the combination of geological data and the key stratum theory, that is, determining a fracturing target stratum; S2, drilling aplurality of fracturing holes at intervals in the hard and difficultly-collapsing top plate, wherein the depth of the fracturing hole is matched with the position of the fracturing target stratum; S3, delivering high-pressure water into the fracturing holes through a fracturing device for hydraulic fracturing, wherein the fracture structure of the hard and difficultly-collapsing top plate is destroyed under the action of the high-pressure water so as to form cracks; S4, injecting quartz sand into the fracturing holes through the fracturing device; S5, injecting an acid liquor into the fracturing holes through the fracturing device; and S6, repeating the steps S3-S5 for each fracturing hole. The hard and difficultly-collapsing structure of the coal seam is destroyed through hydraulic fracturing and acid fracturing, the integrity and the rock mass strength are reduced, and the possible harms imposed on the normal mining of the working face, the personnel and the equipment by the hard and difficultly-collapsing top plate in the mining process are weakened or even avoided.

Owner:中铁十九局集团矿业投资有限公司

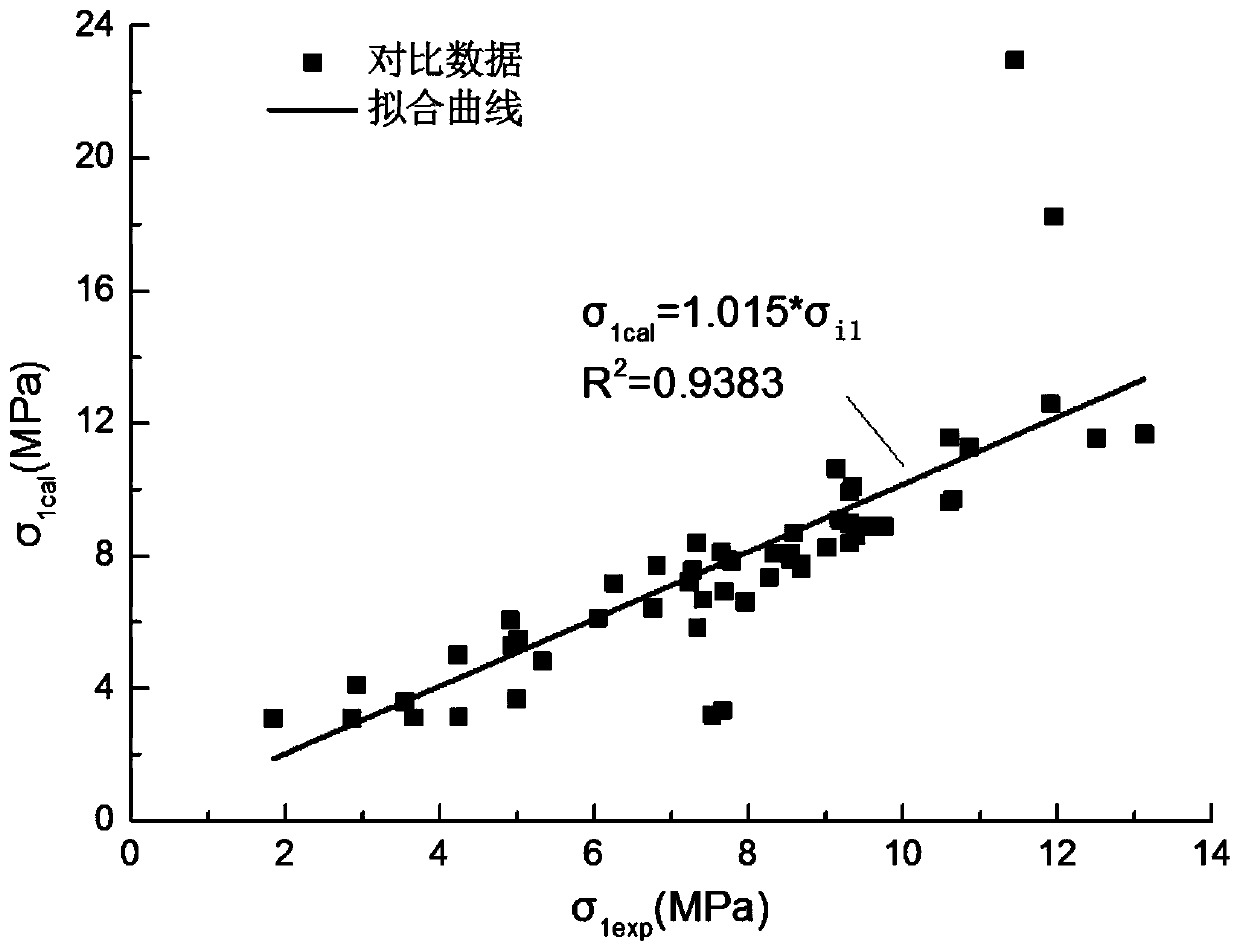

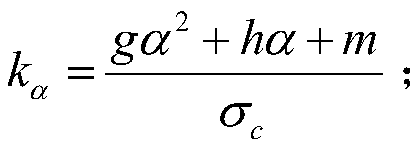

Method for analyzing and predicting strength of intermittent jointed rock mass under complex stress conditions

InactiveCN110823694AAccurate and detailed analysis and predictionConsider all factorsMaterial strength using tensile/compressive forcesInvestigating material hardnessUniaxial compressionPrincipal stress

The invention discloses a method for analyzing and predicting strength of intermittent jointed rock mass under complex stress conditions. The method comprises the following steps: acquiring the uniaxial compression strength of a rock mass sample; acquiring the uniaxial compression strength of single non-through jointed standard rock mass samples with different joint inclination angles; calculatingfitting parameters; calculating an angle correction coefficient; carrying out true triaxial compression tests on the single non-through jointed standard rock mass samples with different joint inclination angles, and acquiring the maximum principal stress, the intermediate principal stress and the minimum principal stress when the single non-through jointed standard rock mass samples are damaged;calculating a parameter A and a parameter B; and calculating the strength of the jointed rock mass. The method can effectively predict the strength of the jointed rock mass under different confining pressure combinations and joint inclination angle conditions. The prediction method has the advantages of many consideration factors, simplicity in operation, wide use range, high prediction precisionand important market application prospect.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

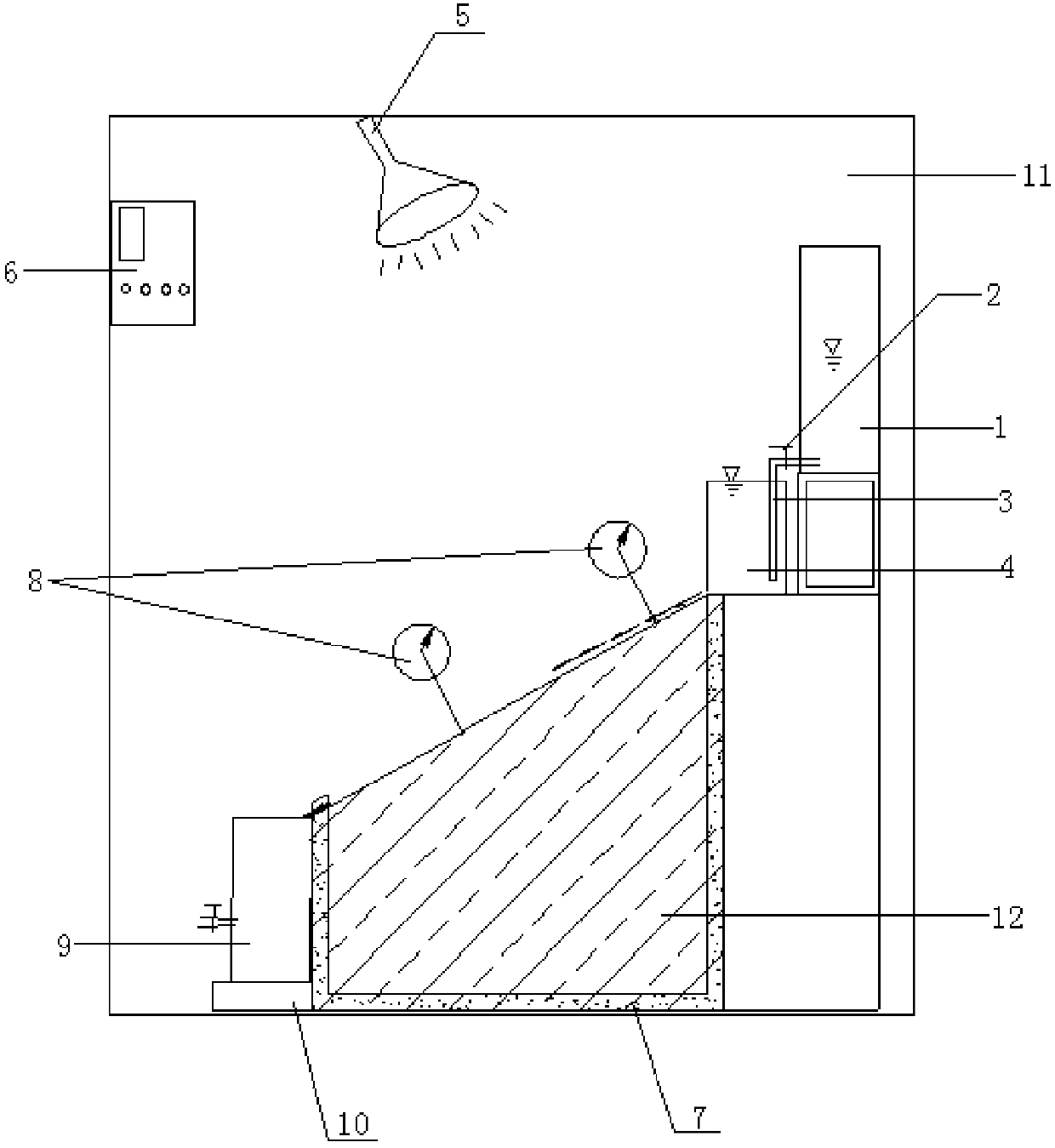

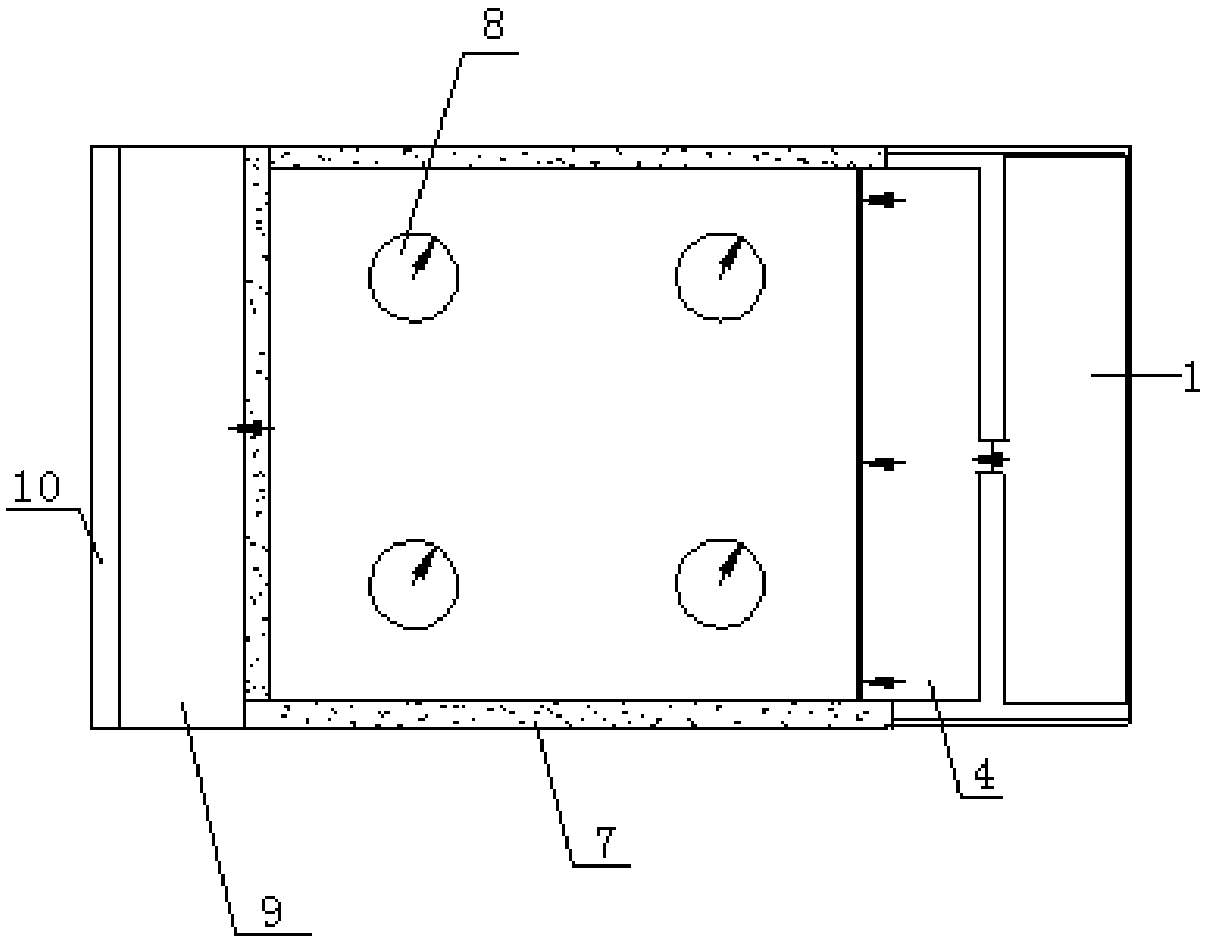

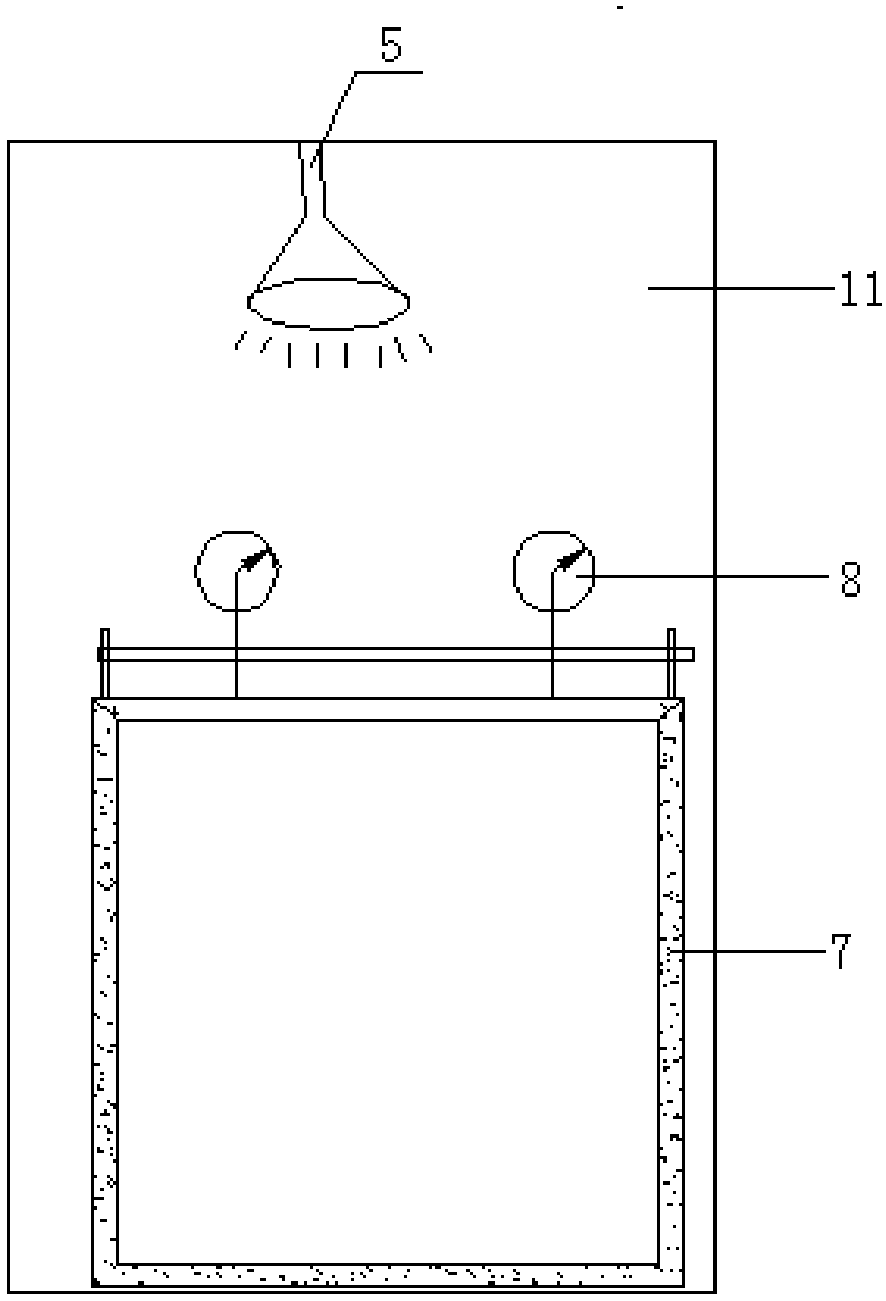

Rock mass experimental testing system and method under three-water coupling effect

PendingCN109826243ASolve the strength problemSolving Quantitative AssaysClimate change adaptationFoundation testingRock mass strengthReproduction

The invention provides a rock mass experimental testing method under a three-water coupling effect. The method comprises the steps of preparation of a rock slope model, arrangement of a test environment, collection of initial data, simulation of the test environment, collection of test data and data analysis. The invention also provides a rock mass experimental testing system under the three-watercoupling effect. The system comprises a test model box, a test environment simulation device and a test data collection device. Through the reproduction simulation of a real environment, by preciselyadjusting rainfall, reservoir water, fissure water and other factors, a rock mass strength test under the three-water coupling effect is completed, the test data is collected under different workingconditions, and parallel tests are performed many times; since the test process is non-destructive testing, the rock mass experimental testing method and system can be used for long-term monitoring simulation and strength inversion, and the method is an effective and reliable technical means for the quantitative research on rock mass strength of a bank slope under the three-water coupling effect.

Owner:INST OF GEOMECHANICS +1

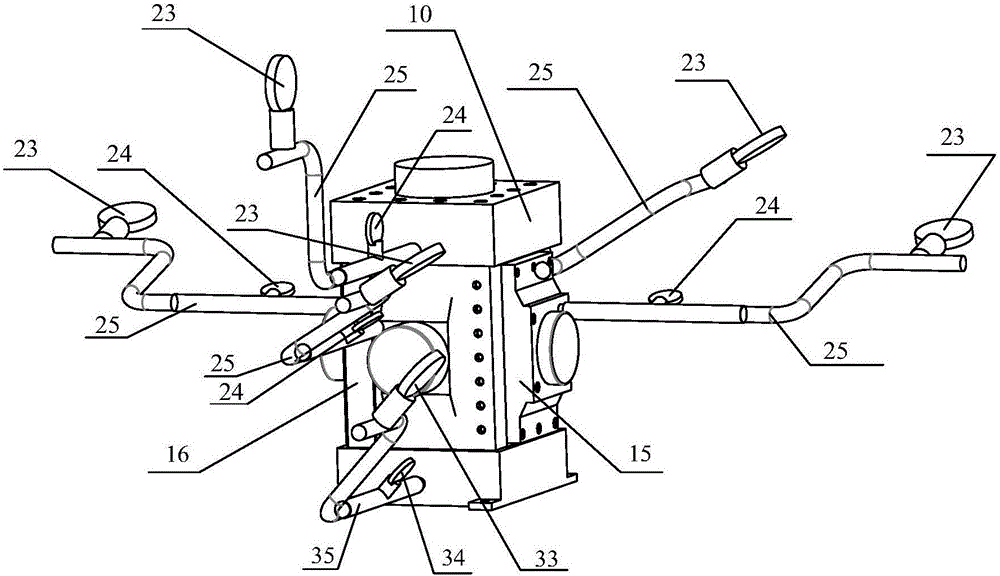

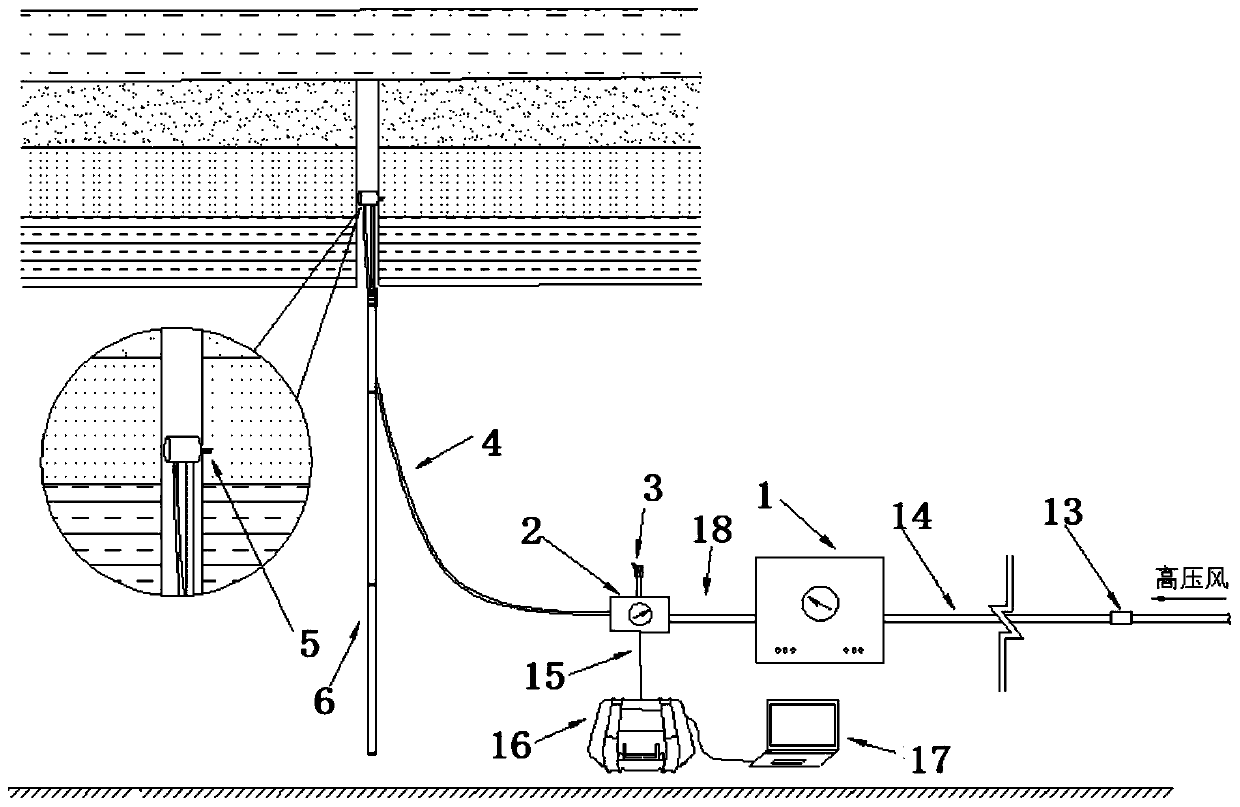

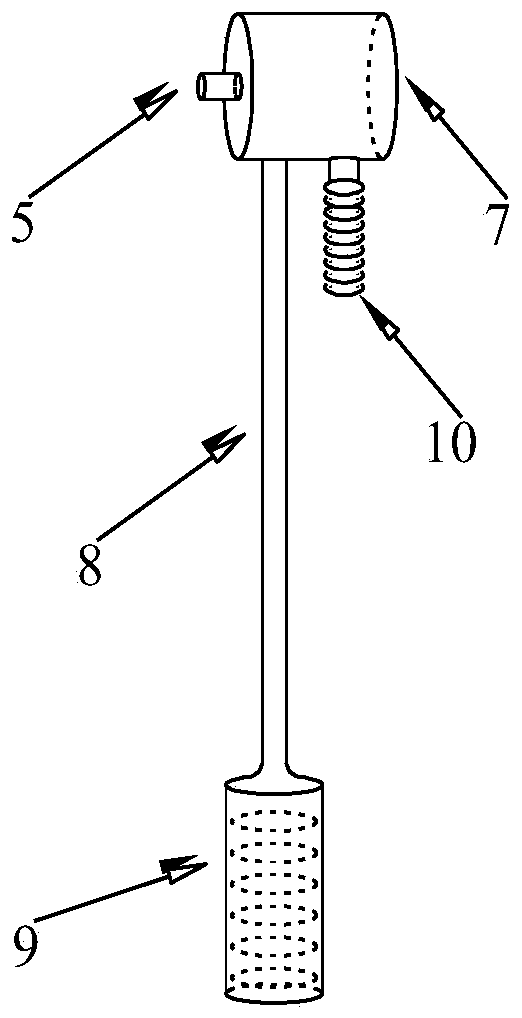

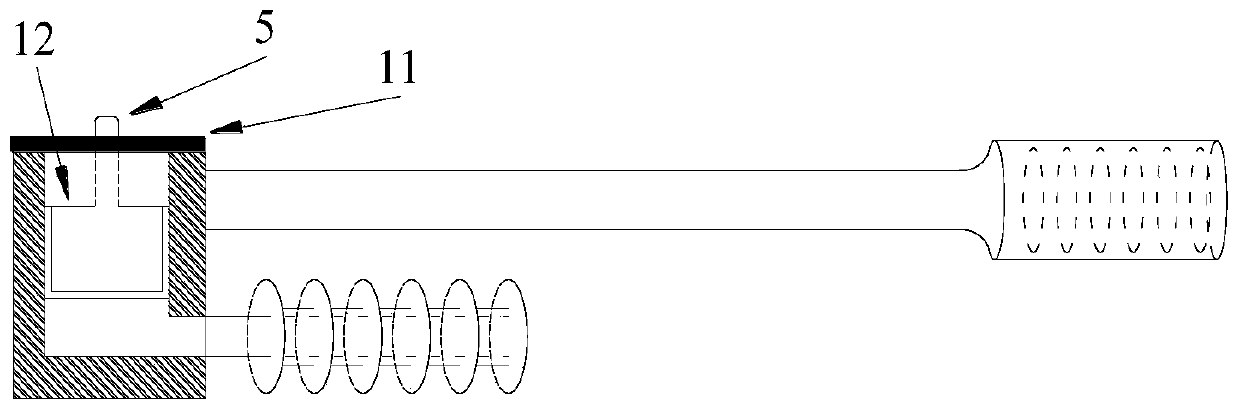

Testing device and testing method for uniaxial compressive strength of coal-rock mass

PendingCN110441160ARapid In Situ TestHigh feasibilityMaterial strength using tensile/compressive forcesLiquid mediumEngineering

The invention discloses a testing device and a testing method for uniaxial compressive strength of coal-rock mass, belongs to the field of coal-rock mass strength testing, and solves the problems thatin the prior art, the consumption is high, testing points are few, additional holing is needed, and a liquid medium is difficult to obtain. The testing device comprises a power supply device, a probe(7) and a mounting rod (6); the power supply device is used for providing power for the probe (7), and is connected with the probe (7) through a high-pressure pipe (4); the power supply device comprises a pneumatic booster pump (1) and a three-way valve (2); the pneumatic booster pump (1) is connected with a high-pressure air source; the first end of the three-way valve (2) is connected with thepneumatic booster pump (1) through a pressure-resistant pipe (18); and the second end of the three-way valve (2) is connected with the probe (7) through a high-pressure pipe (4). The testing device and the testing method provided by the invention are suitable for small-aperture in-situ testing of the uniaxial compressive strength of the coal-rock mass.

Owner:CHINA UNIV OF MINING & TECH

Test device for simulating slope site rock mass disintegration and test method of test device

ActiveCN107655771AGrasp the law of intensity changeTest reasonableWithdrawing sample devicesPreparing sample for investigationTemperature controlTest flow

The invention discloses a test device for simulating slope site rock mass disintegration. The test device comprises a humidifier, a test box, test equipment and disintegrating object collecting equipment, the test box is placed in a temperature control room, a temperature controller and a heating lamp are arranged in the temperature control room, the test box is enclosed by a plurality of steel plates to form a right trapezoid with a top opening, and the included angle between a bevel edge of the test box and a horizontal plane ranges from 33.3 degrees to 66.7 degrees. Scouring water flow flowing out of the humidifier flows down along the bevel edge of the test box, a plurality of through hole structures are arranged at the bottom of the test box, rock masses to be tested are placed into the test box, disintegrating objects of the rock masses to be tested flow into the collecting equipment along the bevel edge of the test box, the collecting equipment is positioned at the lower end ofthe bevel edge of the test box, and the test equipment acquires the disintegrating deformation amount of the rock masses to be tested through a dial indicator arranged on the test box. By the aid of the test device, slope site conditions can be effectively simulated, rock mass disintegration characteristics are more reasonably and accurately tested, and rock mass strength change rules are grasped.

Owner:HOHAI UNIV

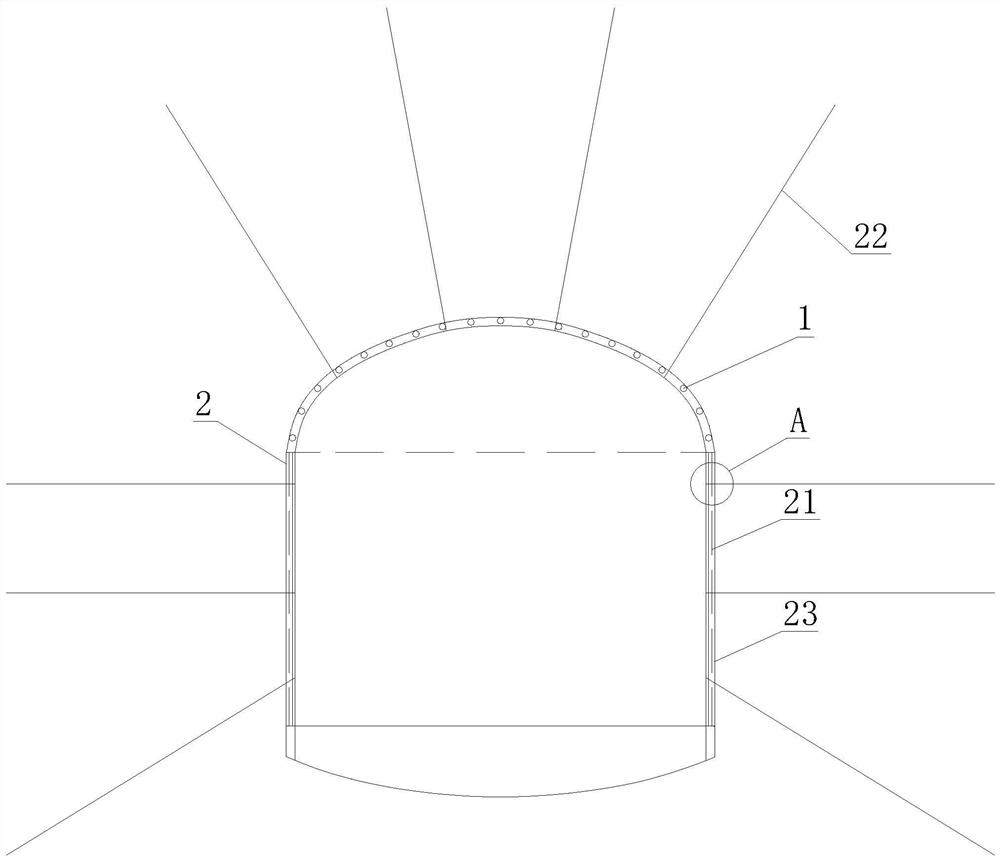

Roadway support method for soft broken rock masses of underground mine

ActiveCN113090284AImprove the support effectImprove construction qualityUnderground chambersHydro energy generationRock boltRock mass strength

The invention discloses a roadway support method for soft broken rock masses of an underground mine, which is suitable for roadway support engineering with weak rock mass weathering, hammer knocking hoarse sound and a rock mass strength value less than or equal to 10 Mpa. Advance supporting anchor rods are arranged along the arch part of a roadway, and additionally, pipe seam type anchor rods which are constructed at different footage driving cycles are mutually overlapped, so that the support effect on the soft rock masses is good; the section of the initial roadway is designed to be in the form of a three-centered arch and an inverted arch, then anchor rod advance support is performed, i.e. the pipe seam type anchor rods in the advance support anchor rods are inserted into the arch part of a roadway top plate by 1.5 m and are exposed by 1 m, each footage driving cycle does not exceed 1 m, the exposed part protects personnel to safely work below the support, then anchor net jet primary support is performed, and the interval between the primary support and the secondary support is 50 to 80 m; and according to the whole complete support method, the permanent stability of metal mine roadway engineering support can be realized, the roadway support construction quality is increased, and the roadway repair rate is reduced, so that the support cost is reduced.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +2

Rock roadway bursting and cutting united tunneling device and control method thereof

The invention discloses a rock roadway bursting and cutting united tunneling device and a control method thereof. The rock roadway bursting and cutting united tunneling device comprises a rock mass, an impact drill for drilling the rock mass, an injector for injecting a bursting agent into a drill hole formed in the rock mass through the impact drill and a tunneling machine for forward tunneling after the bursting agent acts in the drill hole for a period of time and the rock strength is reduced. The bursting agent is injected into a pre-processed expanding hole to reduce the rock strength byadopting a non-explosion tunneling method, and construction is performed by using a tunneling method to achieve the purpose of tunneling in a non-explosion way. An explosion way is not used in the tunneling process, the pollution is small, the cost is low, a construction period is short, the danger of landslide is effectively avoided, and lots of tunneling problems caused by the fact that the explosion way cannot be used in the cities are solved.

Owner:SHANDONG UNIV OF SCI & TECH

Pre-supporting technology used in tunnel engineering construction

The invention discloses a pre-supporting technology used in tunnel engineering construction. The pre-supporting technology comprises the steps of infusing binding materials into fragile flabby rocks through an advancing duct before the fragile flabby rock mass are excavated, and stabilizing the fragile flabby rocks. The binding materials comprise one of pitch and slurry or a mixture of the pitch and the slurry. The pre-supporting technology is aimed at overcoming the shortcomings of current supporting, and particularly, for fragile flabby rocks containing water, the weight of the rock mass can be increased because of the large infusion amount of the slurry in a current supporting technology, which can in turn bring potential safety hazard to the supporting of the steel frames. And if the infusing amount of the slurry is not enough, the rock mass strength will be lowered. To balance the situation, the pre-supporting technology used in tunnel engineering construction adopts a kind of pitch with high coagulability and light mass as the binding materials, wherein the pitch can be used independently or used through mixing with the slurry; meanwhile, the pitch can improve the rock mass strength and reduce cost.

Owner:TIBET HUATAILONG MINING DEV

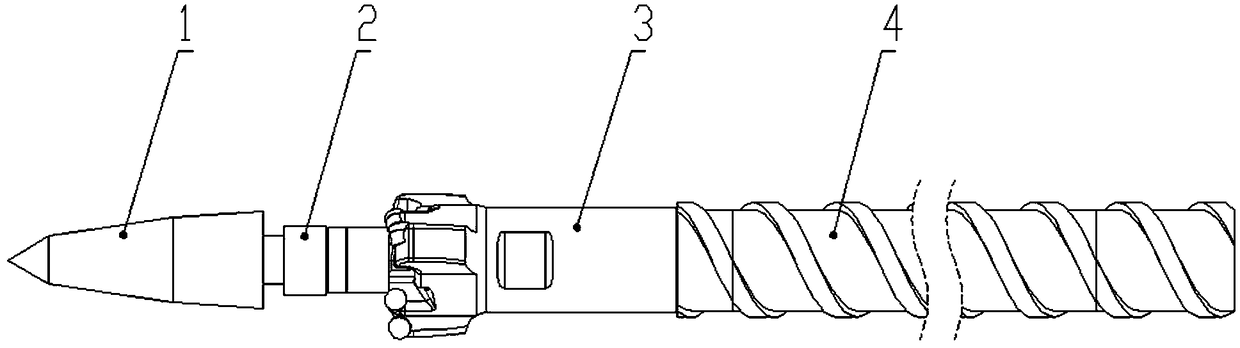

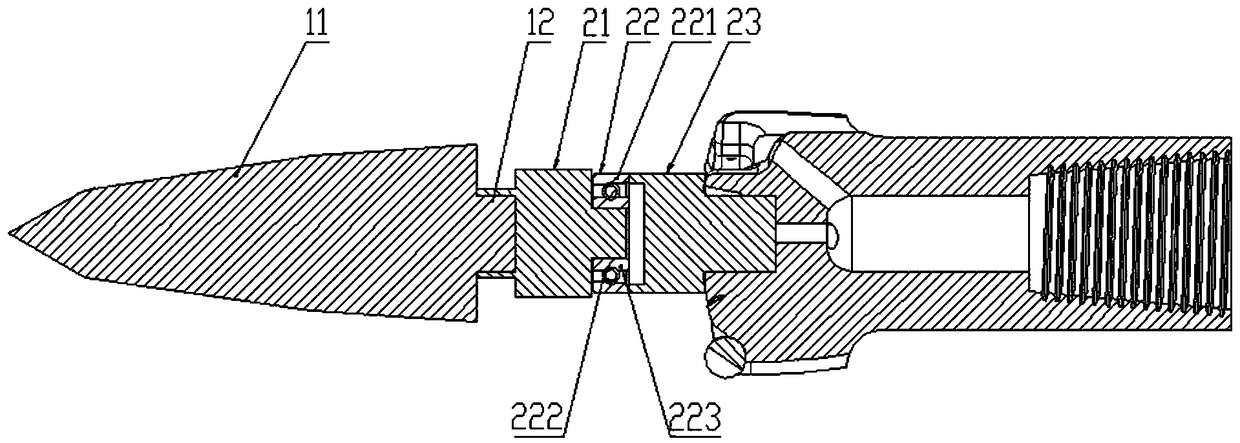

Drilling method and drilling tool for step-by-step strengthening soft coal rock strength

ActiveCN108316856AHigh strengthImprove acceleration performanceDrilling rodsDirectional drillingUltimate tensile strengthSolidity

The invention discloses a drilling method and a drilling tool for step-by-step strengthening soft coal rock strength. According to the drilling method for step-by-step strengthening the soft coal rockstrength, a coal-rock mass strength grade N, a graded strengthening length L<n>, a graded strengthening ratio d<q-n>, a coal rock bit rotational speed v<c> are determined based on a coal rock solidity coefficient f, a drilling speed v<d> and an air supply volume Q are determined based on the coal rock solidity coefficient f and gas pressure p, and a design form of the drilling tool for step-by-step strengthening the soft coal rock strength is determined. The drilling tool for step-by-step strengthening the soft coal rock strength includes a coal rock step-by-step strengthening drill bit, arotary sealing joint, a coal rock drill bit and a drill rod. In view of the technical difficulties of soft coal rock drilling, the geological conditions of coal seams are taken into consideration, and the invention discloses the drilling method for step-by-step strengthening the soft coal rock strength and the drilling tool; the drilling tool for step-by-step strengthening the soft coal rock strength is applied to the construction of drilling, and the synergistic drilling process scheme of ''first step-by-step strengthening-post drilling'' of soft coal rock is realized, and the drilling effect of soft coal rock formations can be effectively improved.

Owner:HENAN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com