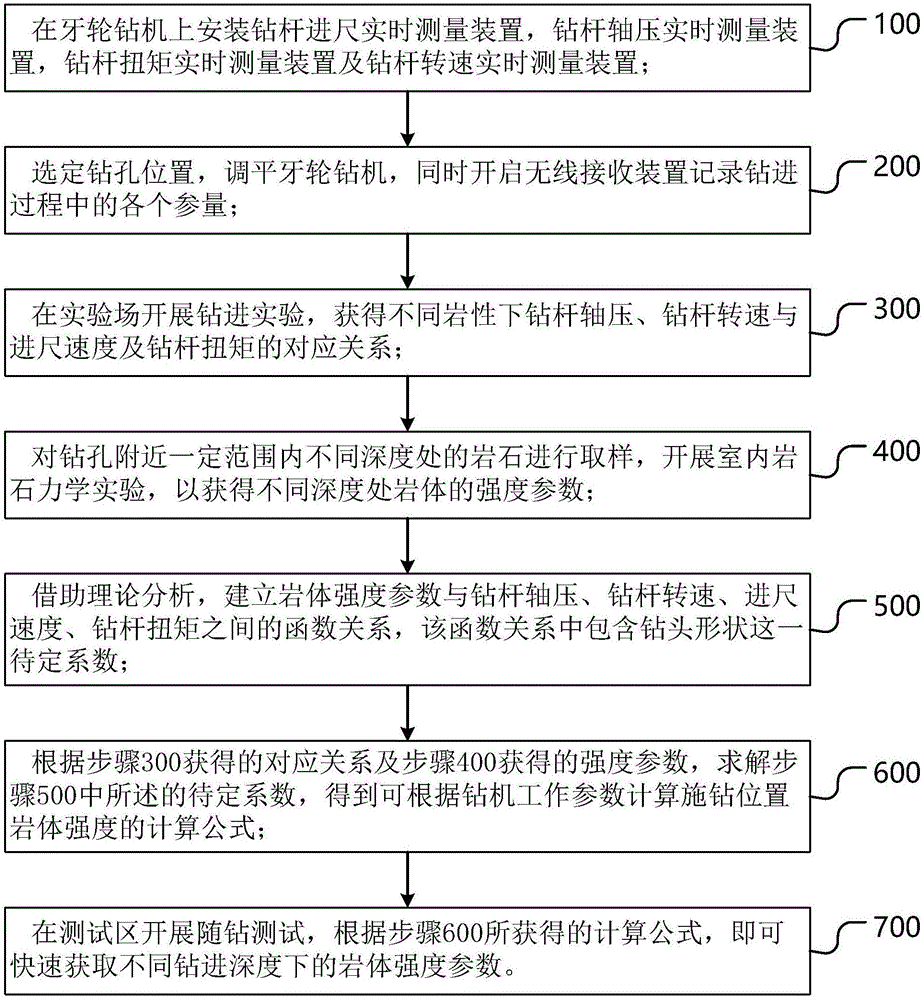

Method and device for testing rock mass strength through technology of monitoring during drilling

A rock mass strength, while drilling technology, applied in the direction of using stable tension/pressure to test material strength, measuring device, strength characteristics, etc., can solve the problem of not being able to give mechanical parameters such as elastic modulus and strength of different formations, etc. Achieve fast and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

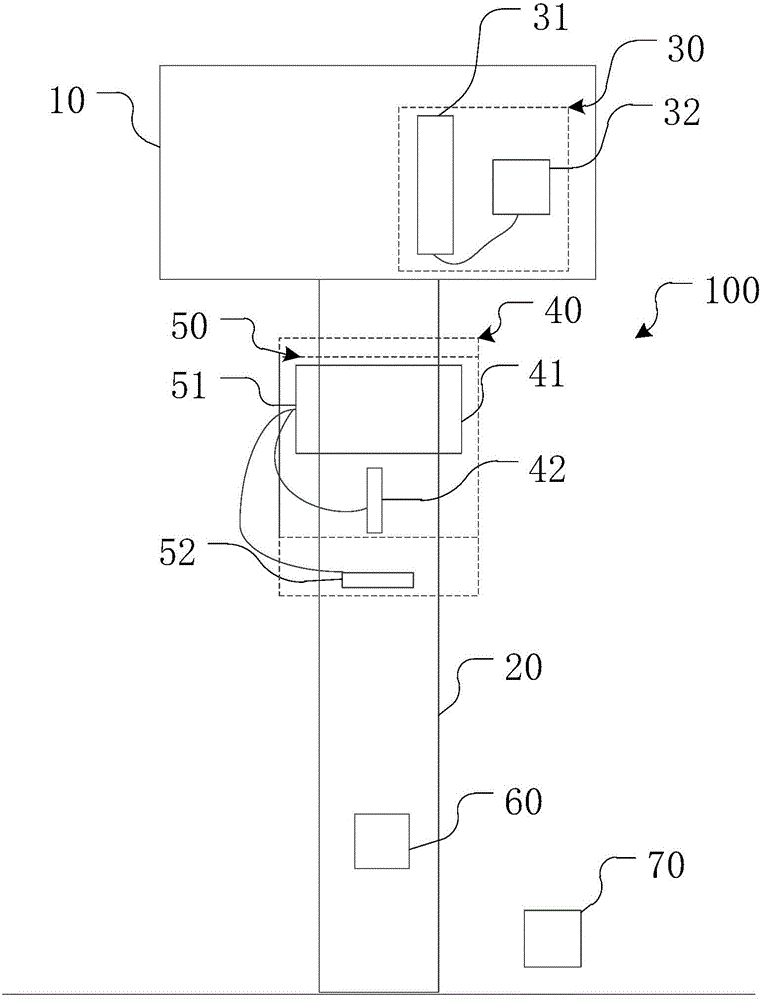

[0057] The strength of the rock mass was tested using the monitoring-while-drilling technology. The selected area was the platform behind the air-face in blasting mining. The distance from the drill hole to the air-face was 9m. The formation in this area was mainly limestone. The produced YZ35D roller cone drilling rig is drilling. When the previous drilling is completed, the rotary trolley is at the bottom to install the monitoring equipment.

[0058] Install the laser range finder and wireless transmitter on the rotary trolley. During the installation process, ensure the verticality between the laser range finder and the ground; paste the strain gauge on the drill pipe to test the axial pressure and torque of the drill pipe. The strain gauge adopts full Bridge connection, and connected with the INV3062T0 24-bit network synchronous acquisition instrument produced by Beijing Dongfang Vibration and Noise Technology Research Institute. Record the rotational speed by counting lap...

Embodiment 2

[0063] The strength of the rock mass was tested using the monitoring-while-drilling technology. The selected area was the platform behind the air face of blasting mining. The distance from the drill hole to the air face was 9m. The stratum in this area was mainly iron ore. The YZ35D roller cone drilling rig produced by the company is drilling. When the previous drilling is completed, the rotary trolley is at the bottom to install the monitoring equipment.

[0064] Install the laser range finder and wireless transmitter on the rotary trolley. During the installation process, ensure the verticality between the laser range finder and the ground; paste the strain gauge on the drill pipe to test the axial pressure and torque of the drill pipe. The strain gauge adopts full Bridge connection, and connected with the INV3062T0 24-bit network synchronous acquisition instrument produced by Beijing Dongfang Vibration and Noise Technology Research Institute. Record the rotational speed by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cohesion | aaaaa | aaaaa |

| Cohesion | aaaaa | aaaaa |

| Cohesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com