Patents

Literature

4877 results about "Rock body" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stability monitoring method for cold high-altitude steep slope

ActiveCN107067333AComprehensive monitoringComprehensive judgmentAnalysing solids using sonic/ultrasonic/infrasonic wavesData processing applicationsSlope stability analysisInstability

The invention relates to the technical field of mining safe engineering, and particularly to a stability monitoring method for a cold high-altitude steep slope. According to the stability monitoring method, through field engineering geology, hydrogeology survey, engineering geological rock quality evaluation and rock mechanical parameter determining, the lithologic condition, the rock structure, the hydrogeology condition, the slope shape, earthquake parameters, explosion parameters and the like of the slope are determined. Slope stability analysis and a treatment strategy measure are performed. Furthermore a comprehensive monitoring system and a slope instability criterion are established.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

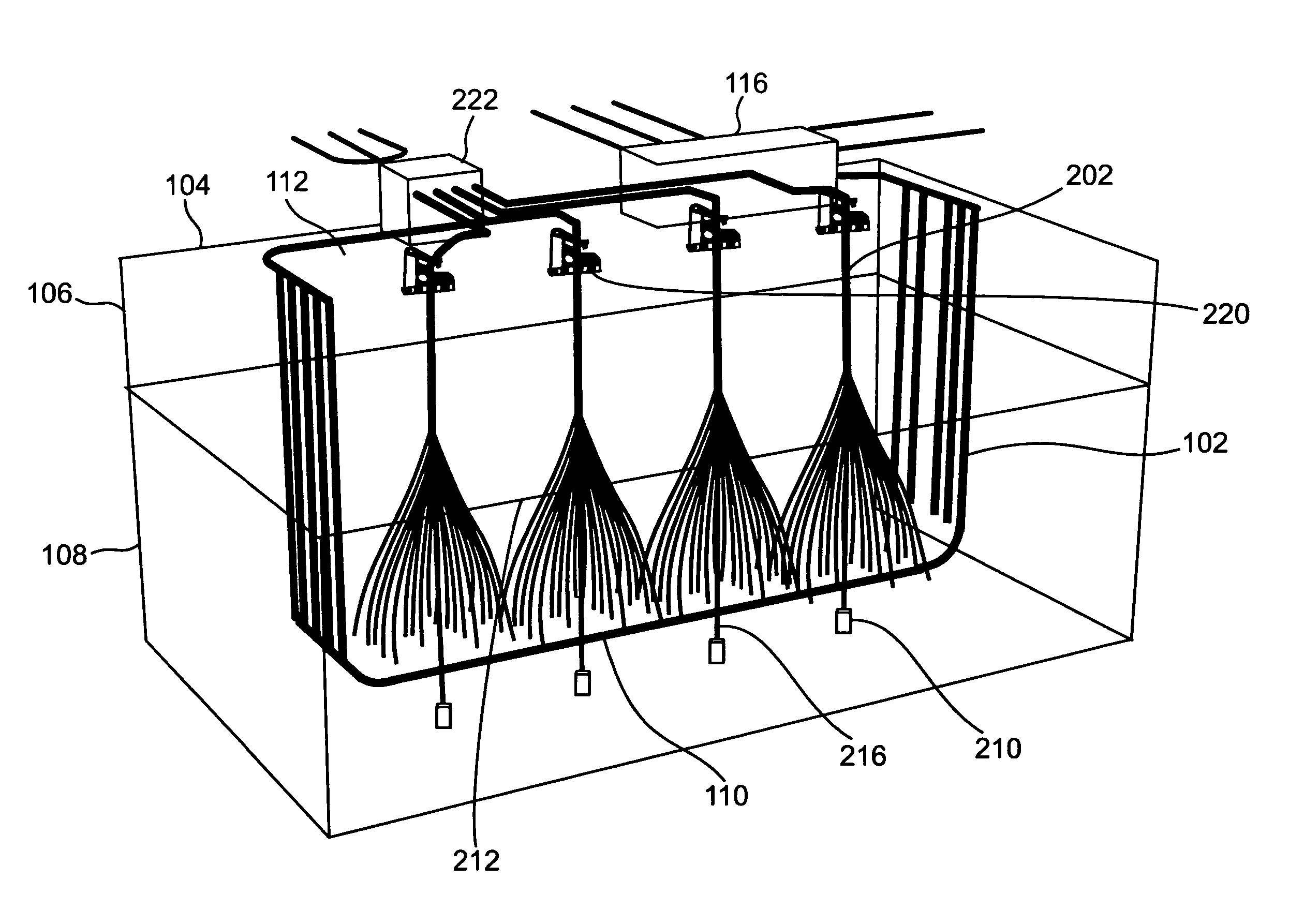

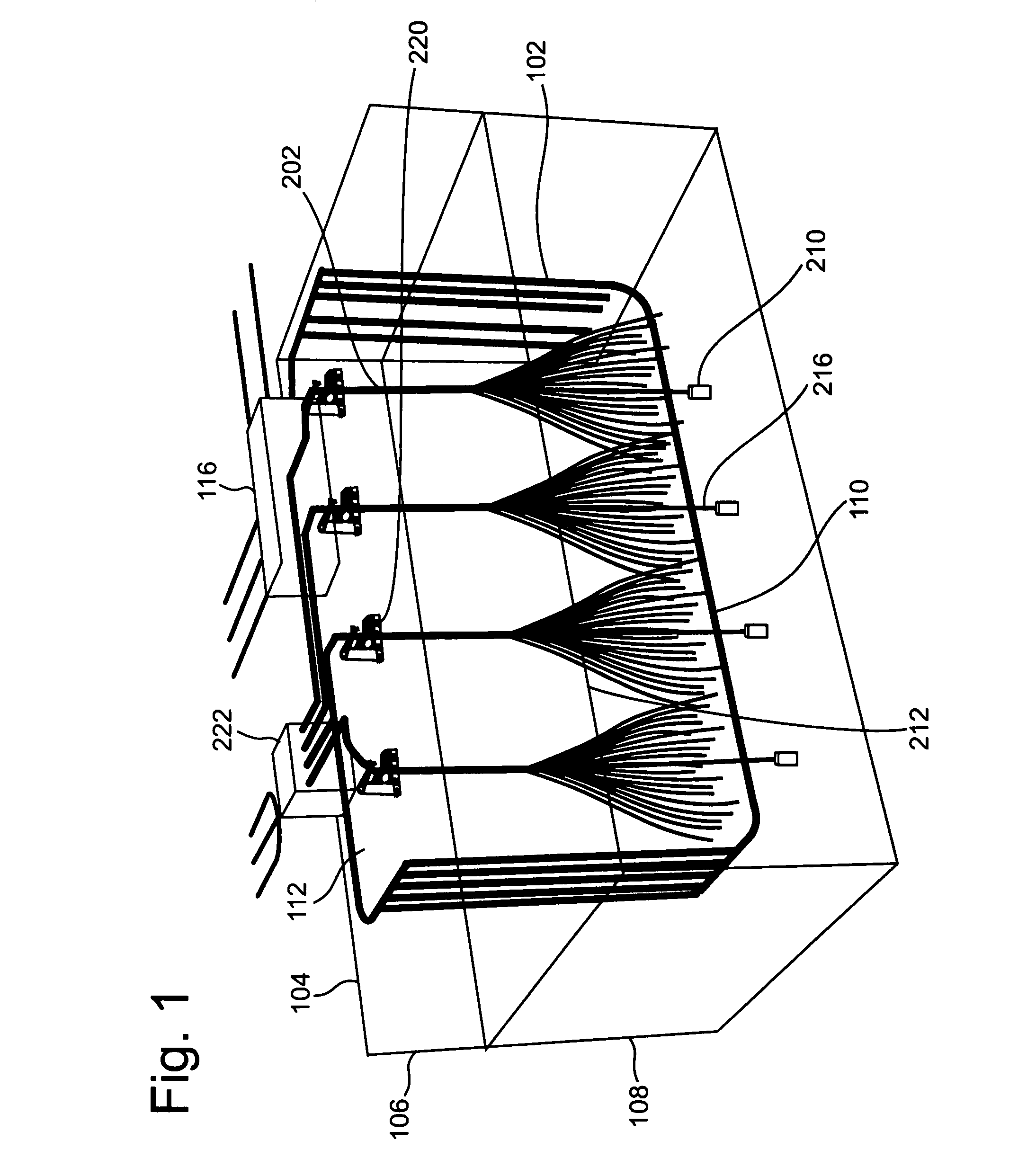

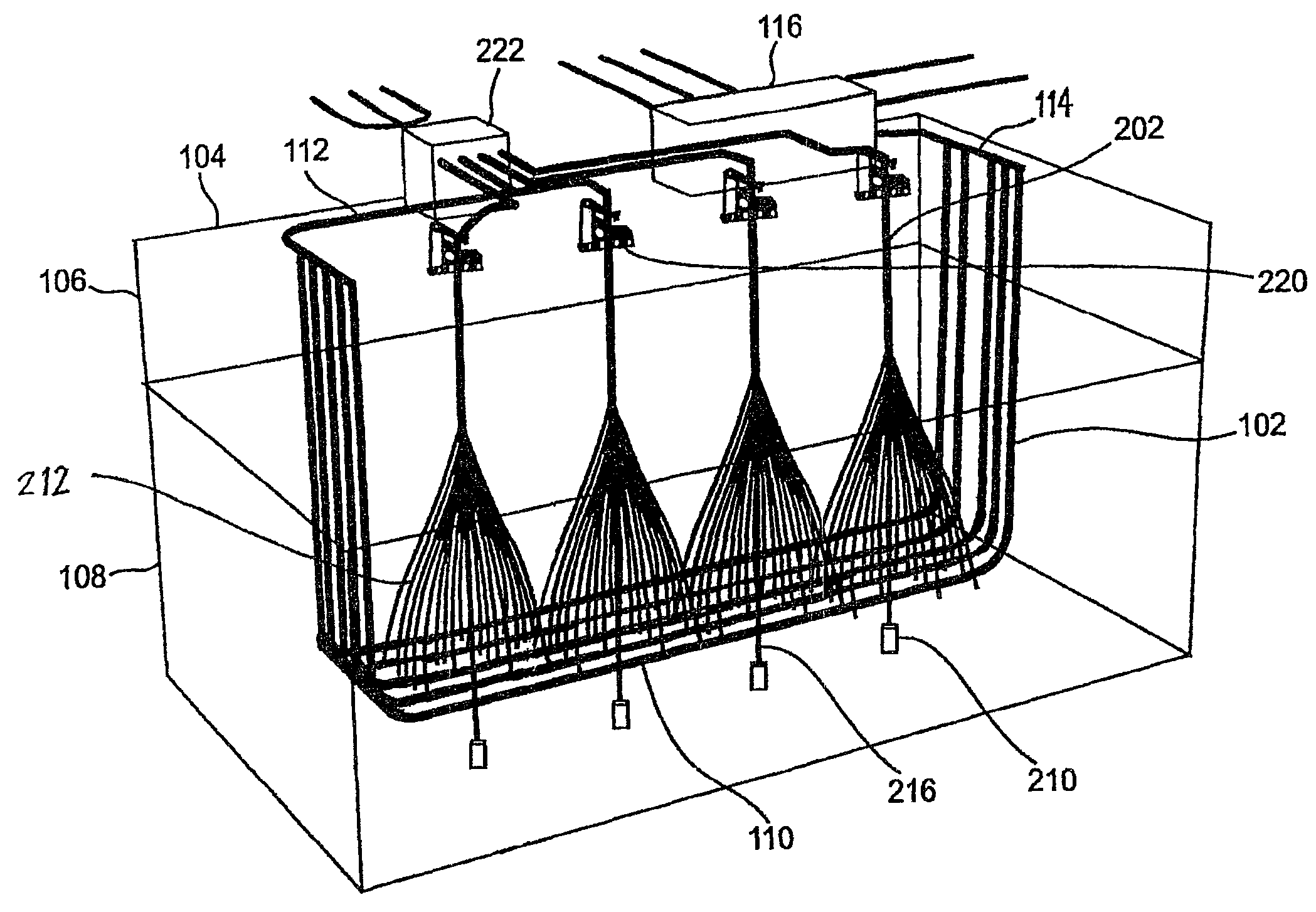

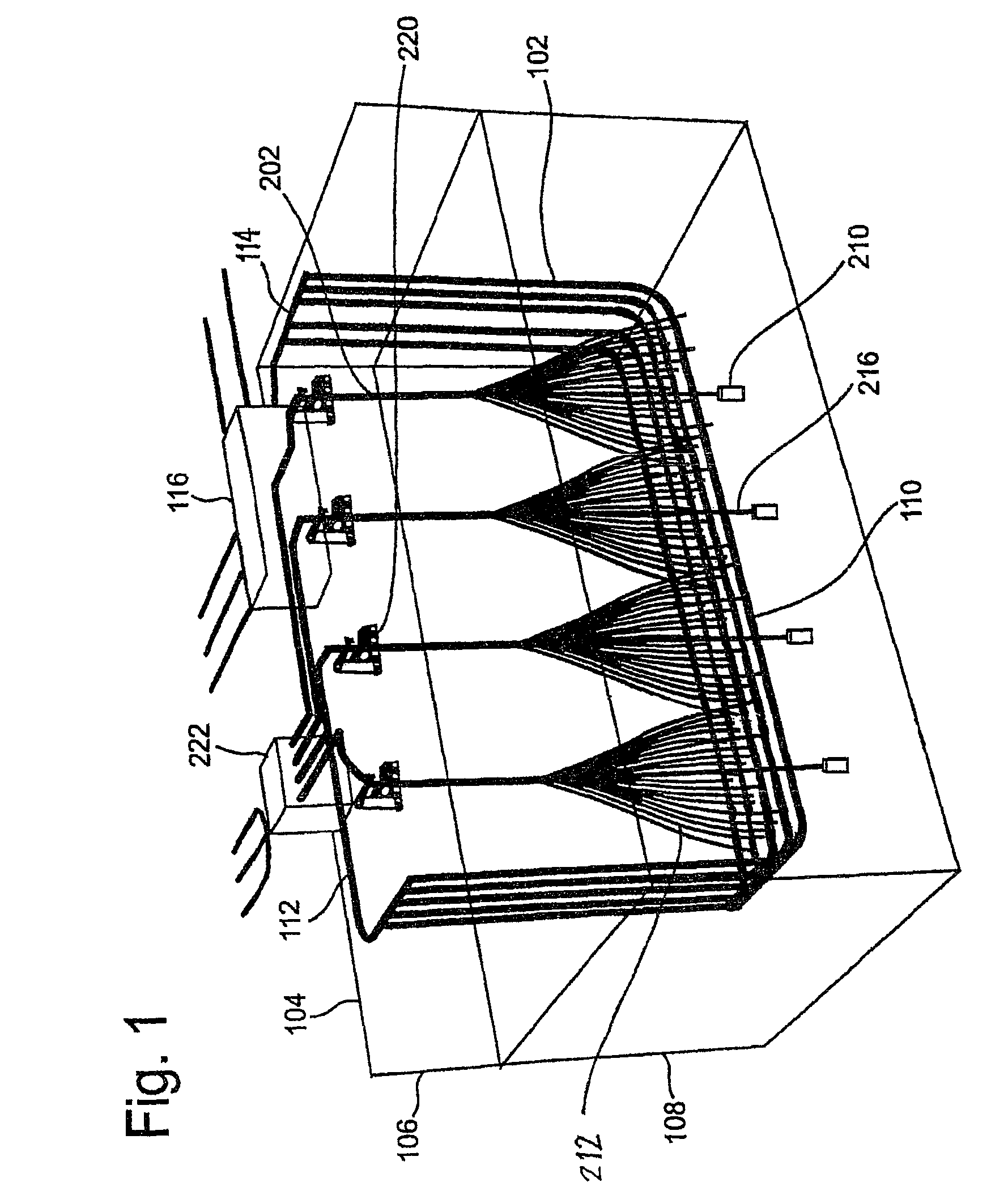

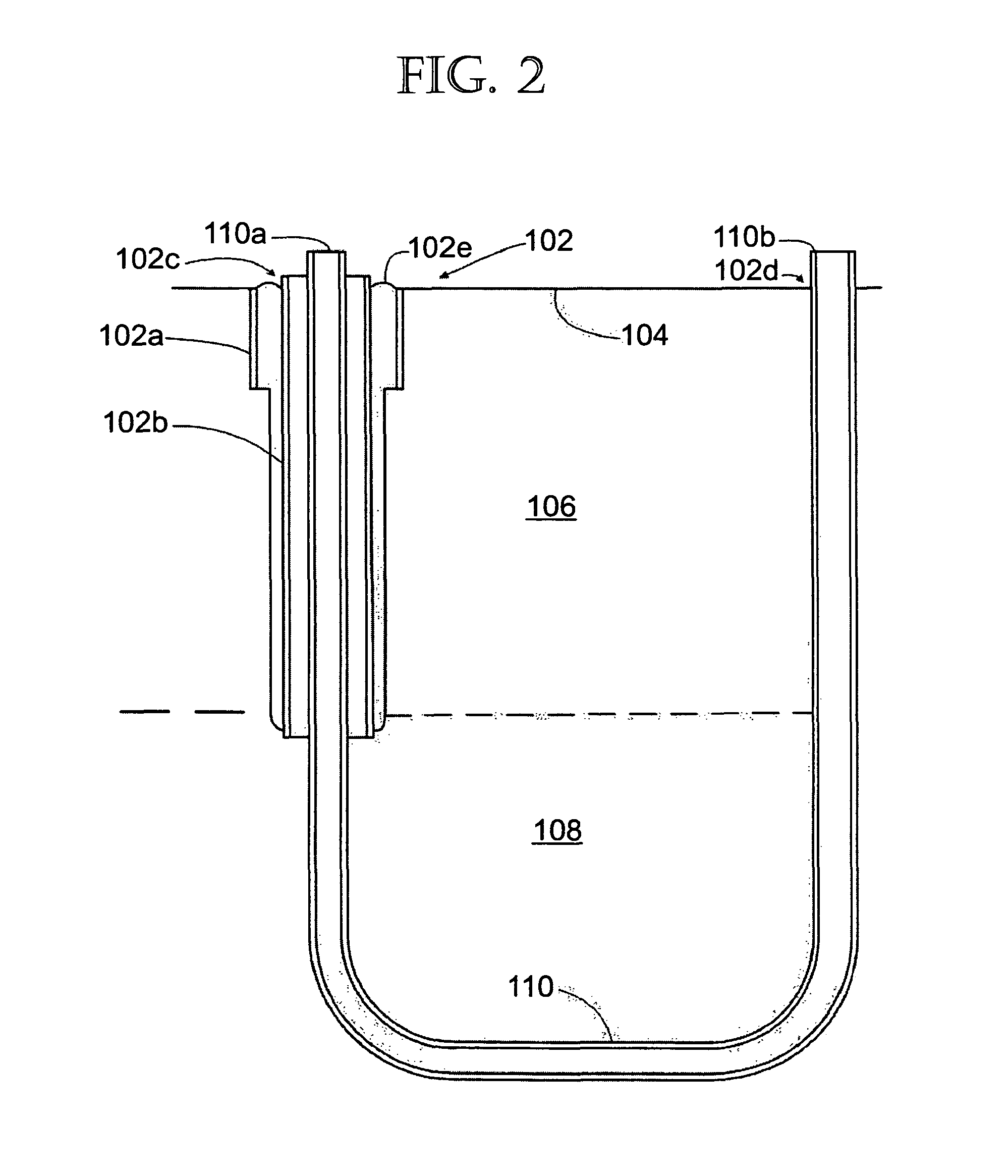

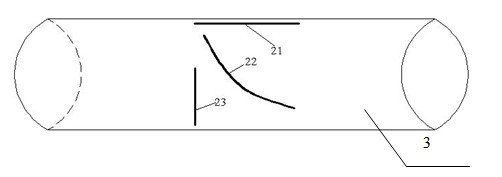

In situ method and system for extraction of oil from shale

ActiveUS20070193743A1Easy to moveAvoid insufficient temperatureInsulationFluid removalClosed loopEarth surface

A system and process is disclosed for retorting oil shale and extracting shale oil and other hydrocarbons therefrom, in which a cased heat delivery well is drilled generally vertically through an overburden and then through a body of oil shale to be retorted to the bottom thereof, generally horizontally under the body of oil shale to be retorted, and then back to the earth surface. Heat energy is transmitted conductively to the body of oil shale to be retorted from a closed loop heat delivery module in the well, the module comprising a fluid transmission pipe containing a heating fluid heated to at least a retorting temperature. Heat energy is also transmitted to the body of oil shale to be retorted above the fluid transmission pipe by vapor conduits that conduct retort vapors upward through the body of oil shale to be retorted; the ascending retort vapors condense and reflux, delivering their latent heat of vaporization to the body of oil shale to be retorted, and the condensed retort liquids descend. If not recycled, the retort liquids are collected in a sump at the bottom of a production well and are transmitted to the surface for processing. The vapor conduits communicate at upper ends thereof with the production well, so that vapors that do not reflux are collected in the production well and are transmitted to the surface for processing.

Owner:AMERICAN SHALE OIL

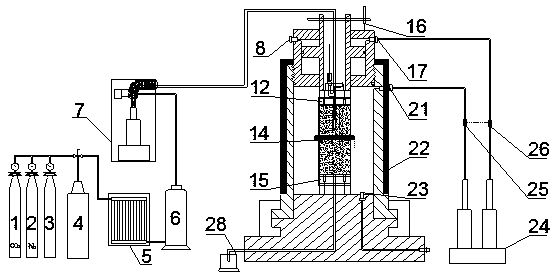

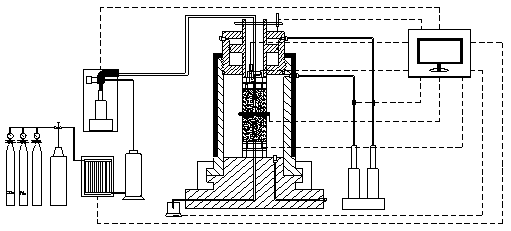

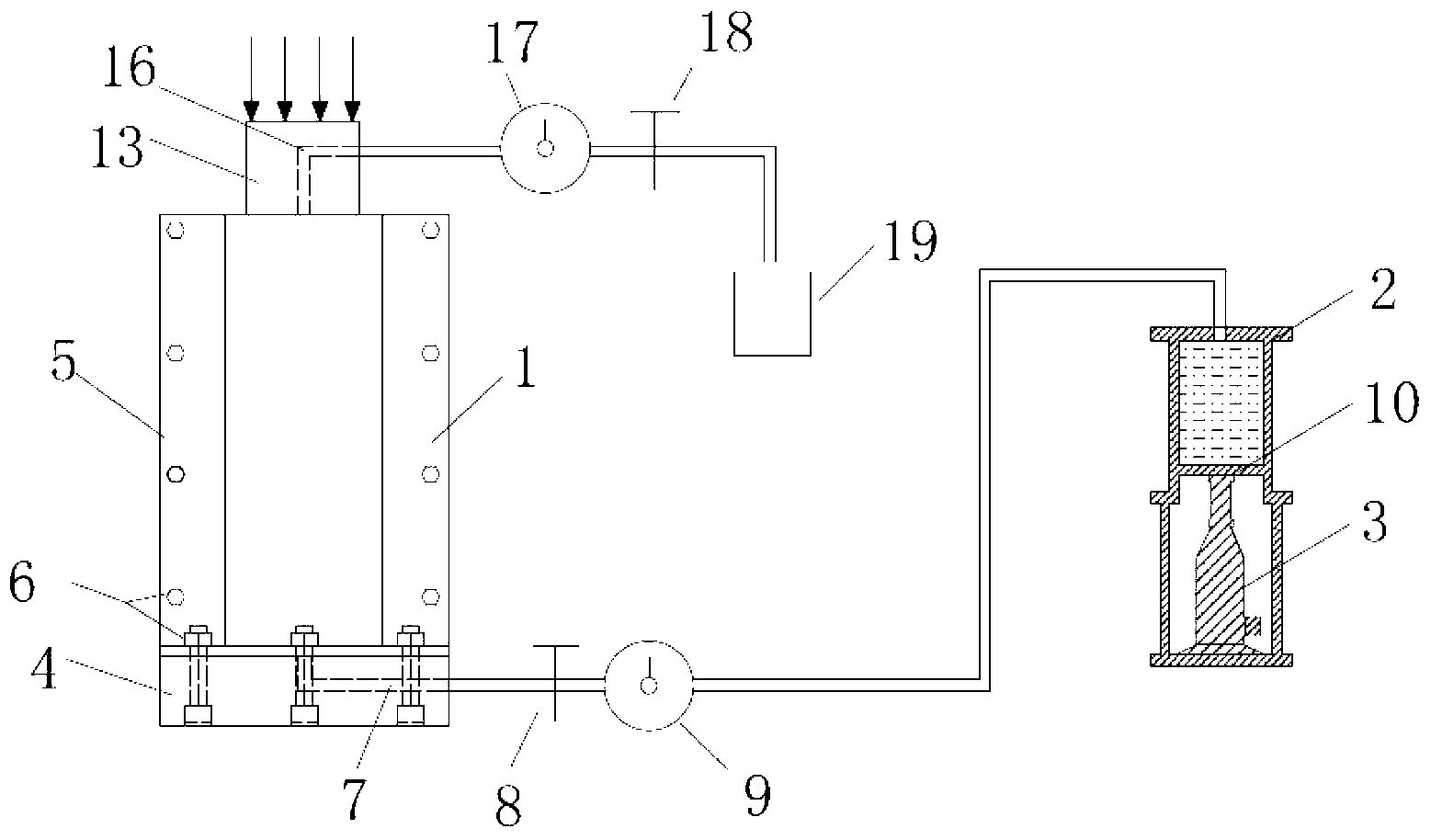

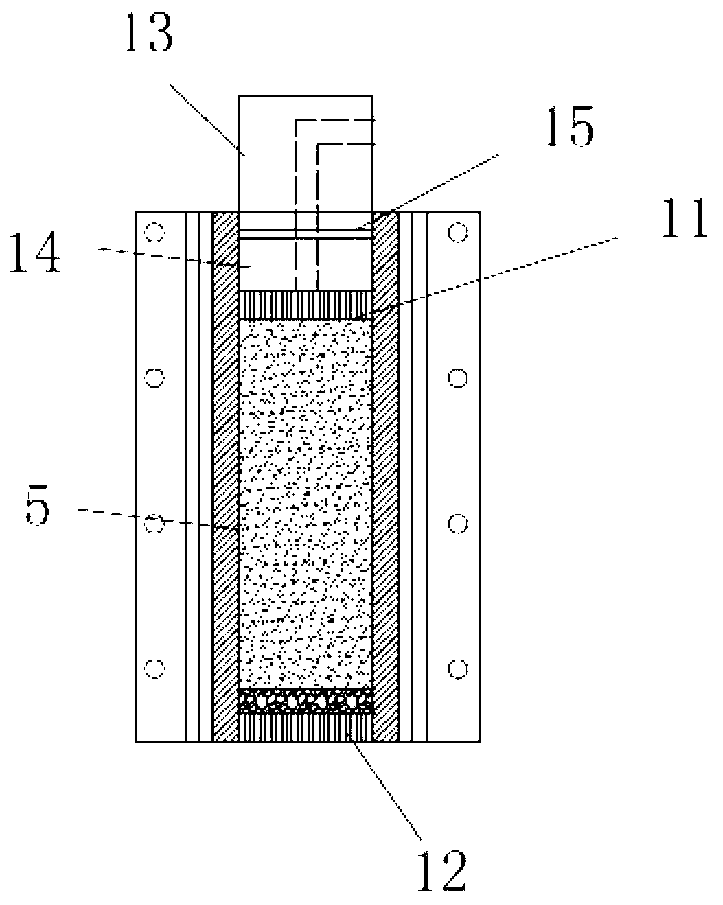

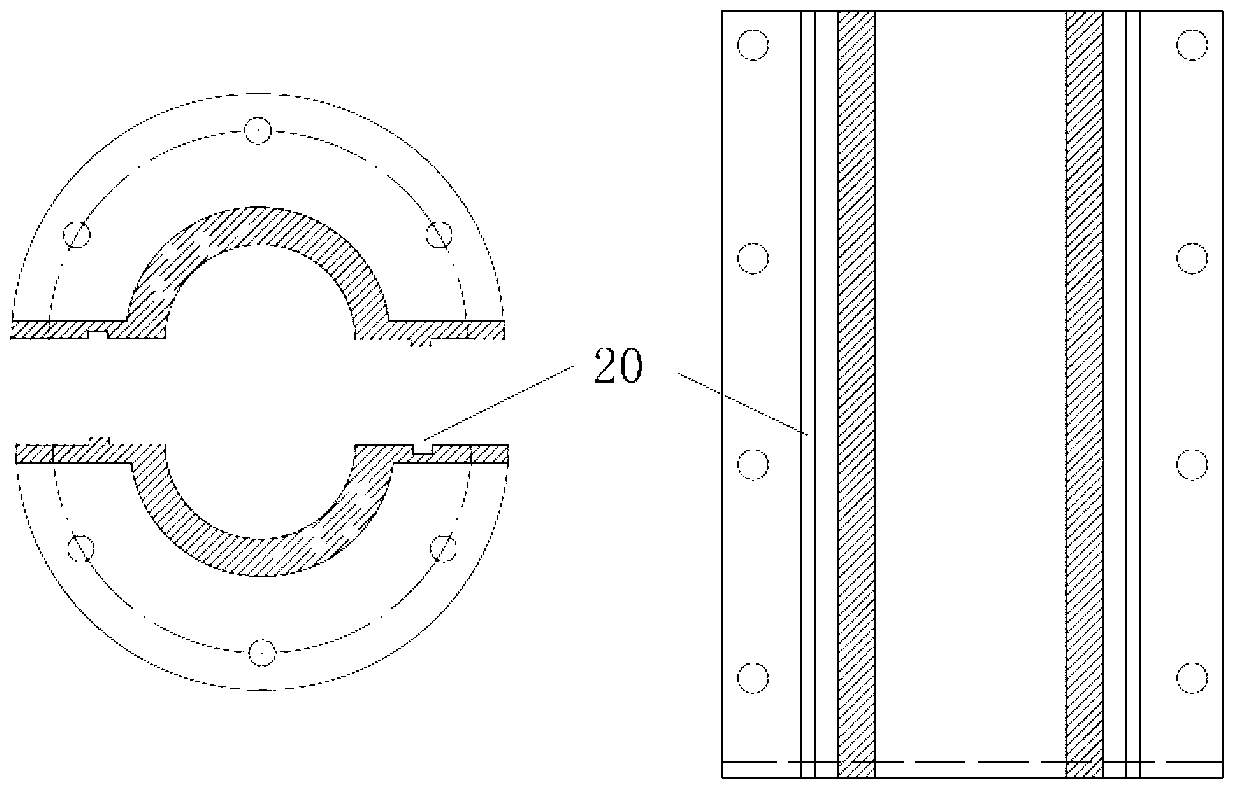

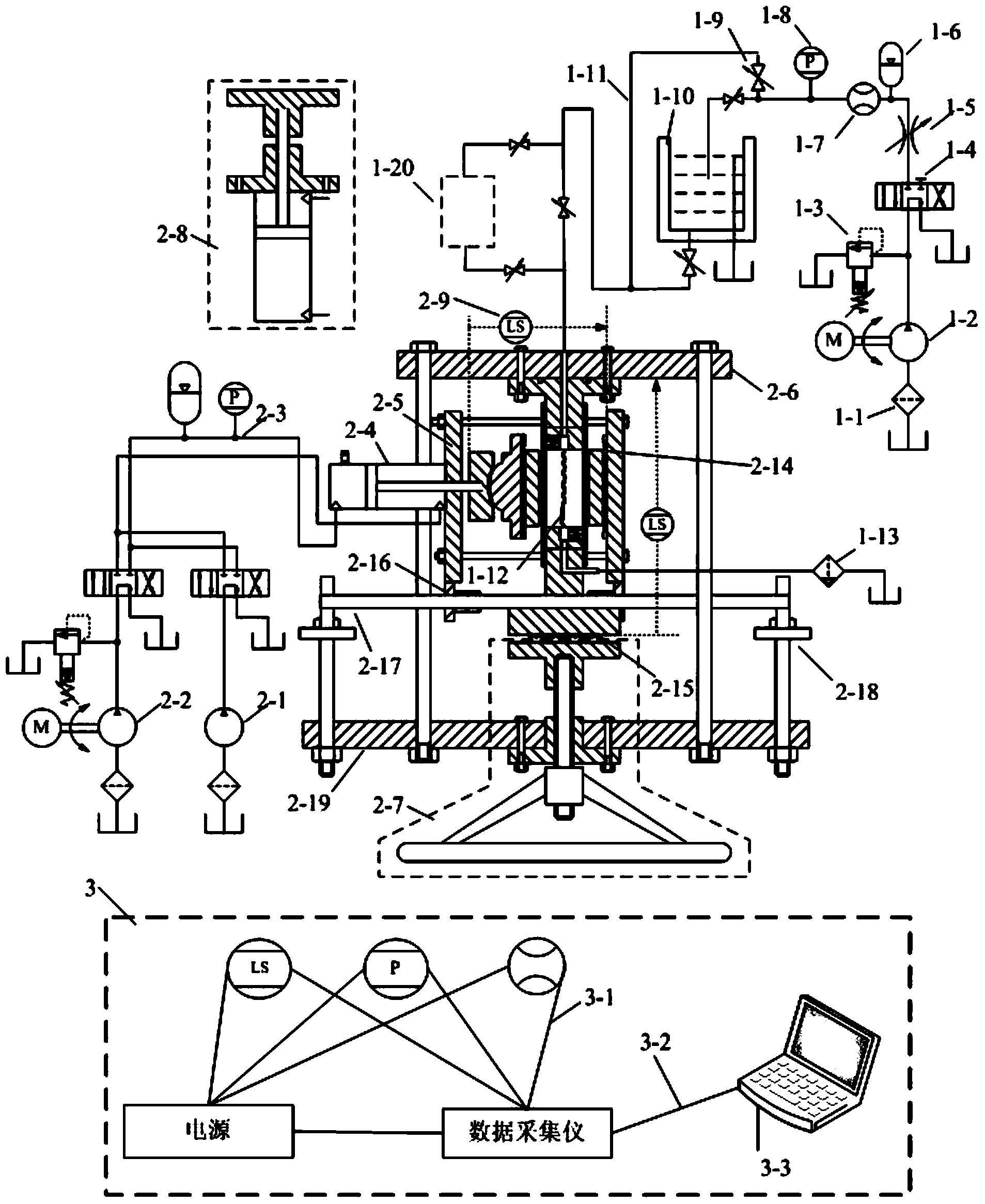

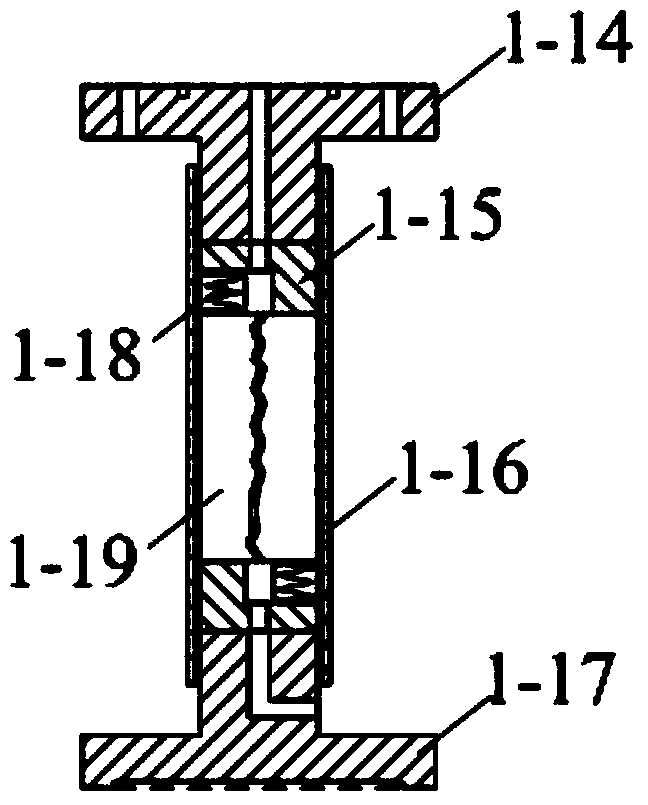

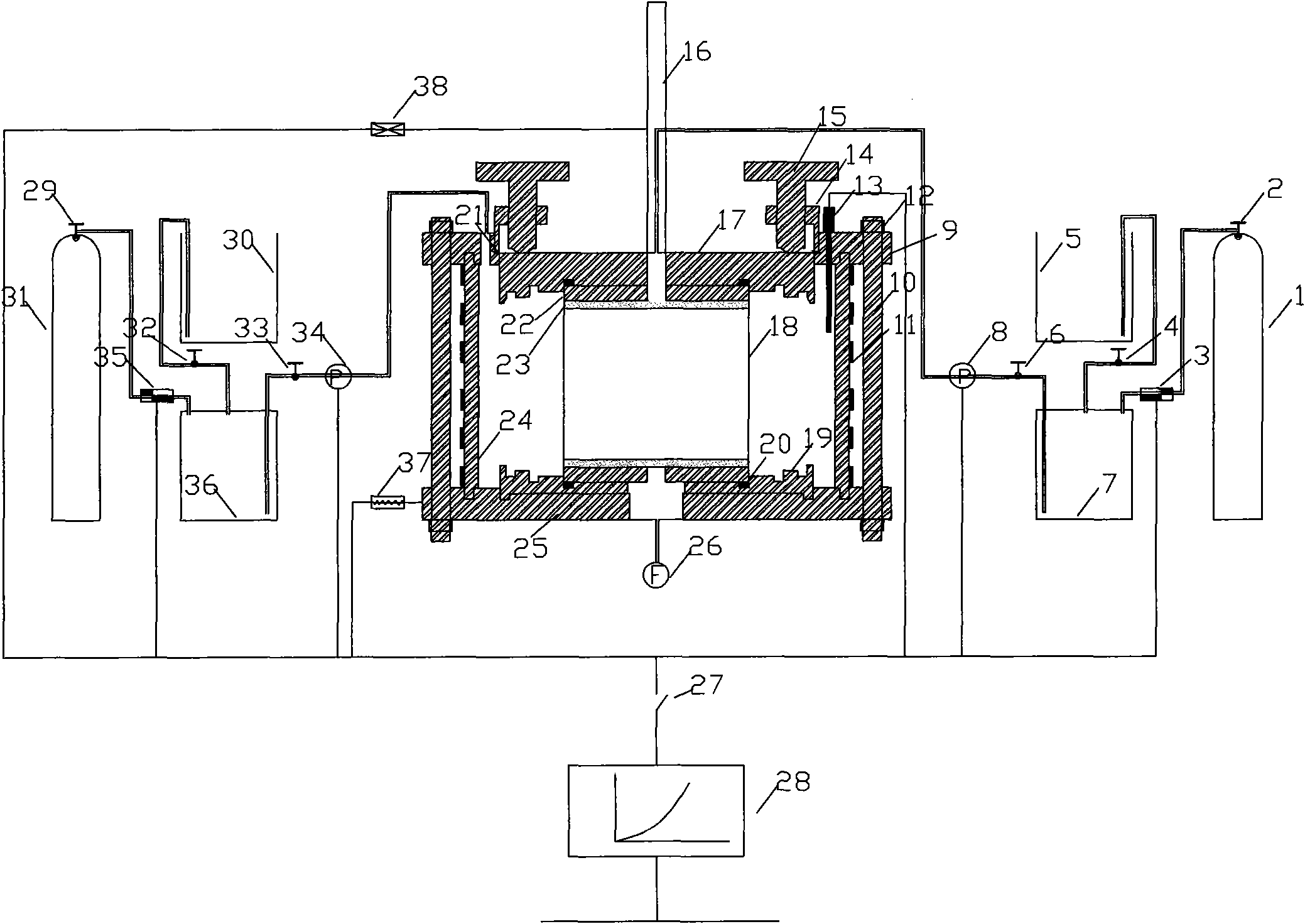

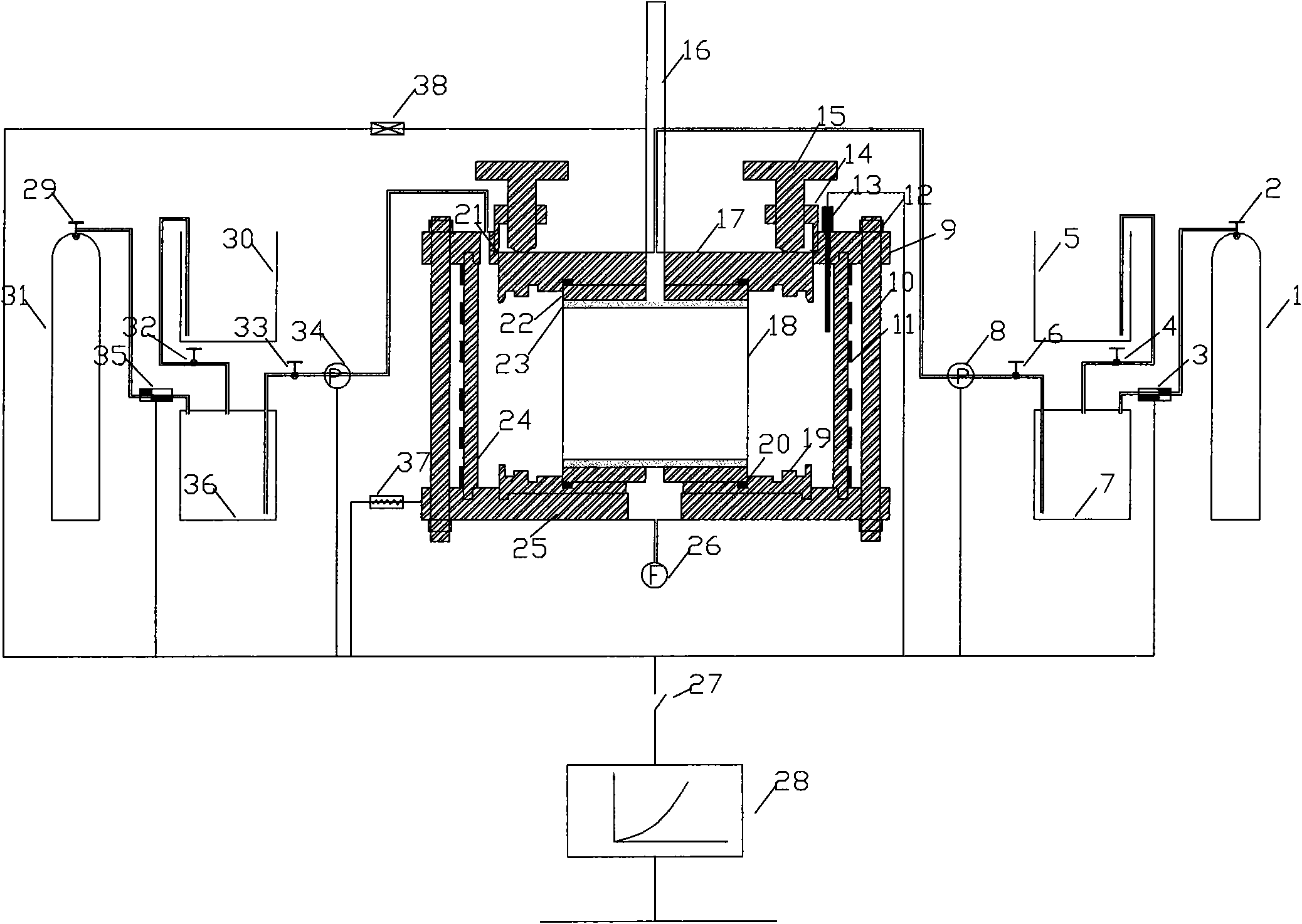

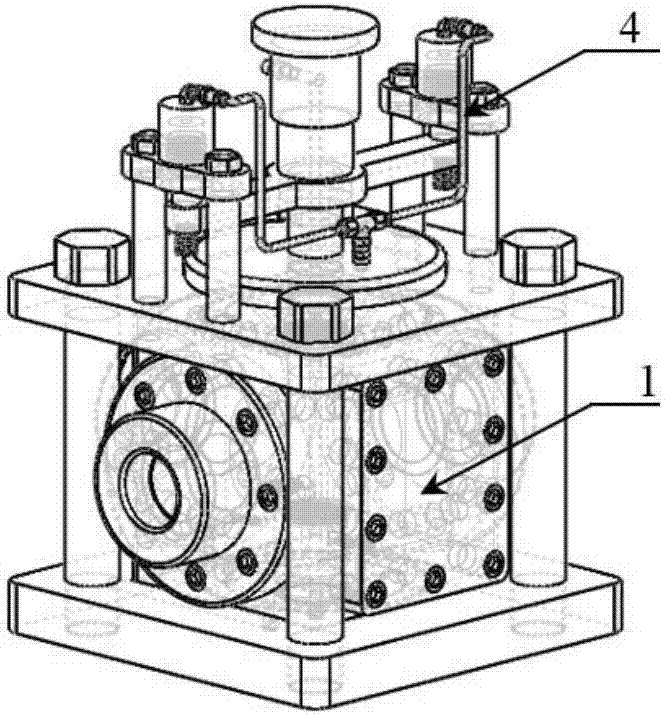

Coal petrography multiphase different fluid three-axis crushing test unit and method

ActiveCN105510142ARealize the effects of fracturingEnables research on the effects of fracturingMaterial strength using tensile/compressive forcesTest comparisonData acquisition

The invention discloses a coal petrography multiphase different fluid three-axis crushing test unit and method and belongs to the technical field of rock and rock mass mechanics and engineering. The unit is composed of a three-axis stress real-time loading system, a multiphase different fluid crushing system, a sealing system, a temperature control system, an acoustic emission monitoring system and a data acquisition system. Different fluid and multiphase crushing test comparison can be conducted on a coal petrography test piece, sensibility of parameters, such as fluid pressurization rate, fluid viscosity, fluid isothermal compressibility and fluid temperature, affecting crushing of the coal petrography test piece can be analyzed under multiple conditions, the change rule of the pressure and temperature of a crushing medium can be precisely recorded in a crushing experiment, acoustic emission events during test piece crushing can be recorded in real time through an assembled micro acoustic emission sensor, and multi-phase fluid seepage tests before and after crushing can also be conducted on the coal petrography test piece.

Owner:TAIYUAN UNIV OF TECH

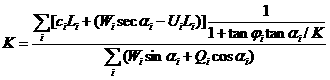

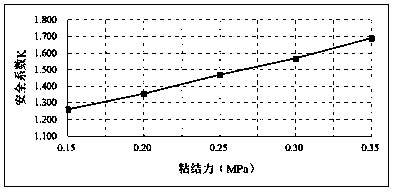

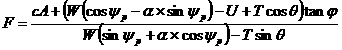

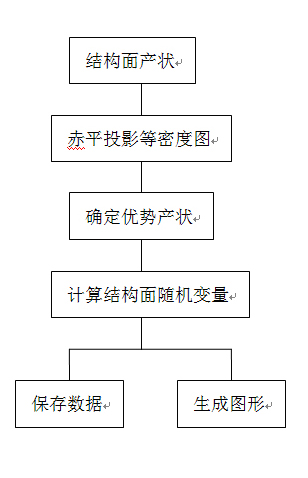

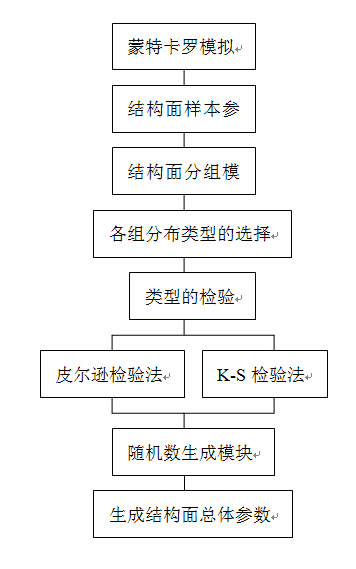

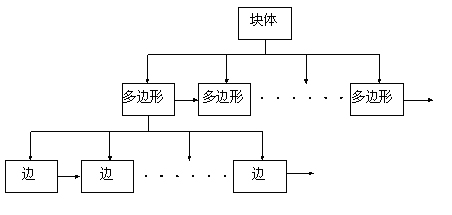

Rock slope three-dimensional model and block slide analysis method

The invention discloses a rock slope three-dimensional model and a block slide analysis method, and belongs to the entity structure space modeling and analysis field of rock engineering such as rock and earth engineering, mine exploitation, road engineering, water conservancy engineering and the like. The method comprises the following steps of: 1, acquiring engineering rock field structure initial data; 2, processing and extracting the engineering rock initial data; 3, constructing an engineering rock model; 4, identifying blocks and analyzing the stability; and 5, displaying the result. The method has the advantages that: the method realizes space modeling of the engineering rock slope and identification of key blocks, quickly identifies new structure surfaces in the engineering construction process, and can automatically search the key blocks, count the number and geometric information of the movable blocks and preliminarily calculate and analyze the mobility of the key blocks.

Owner:NORTHEASTERN UNIV

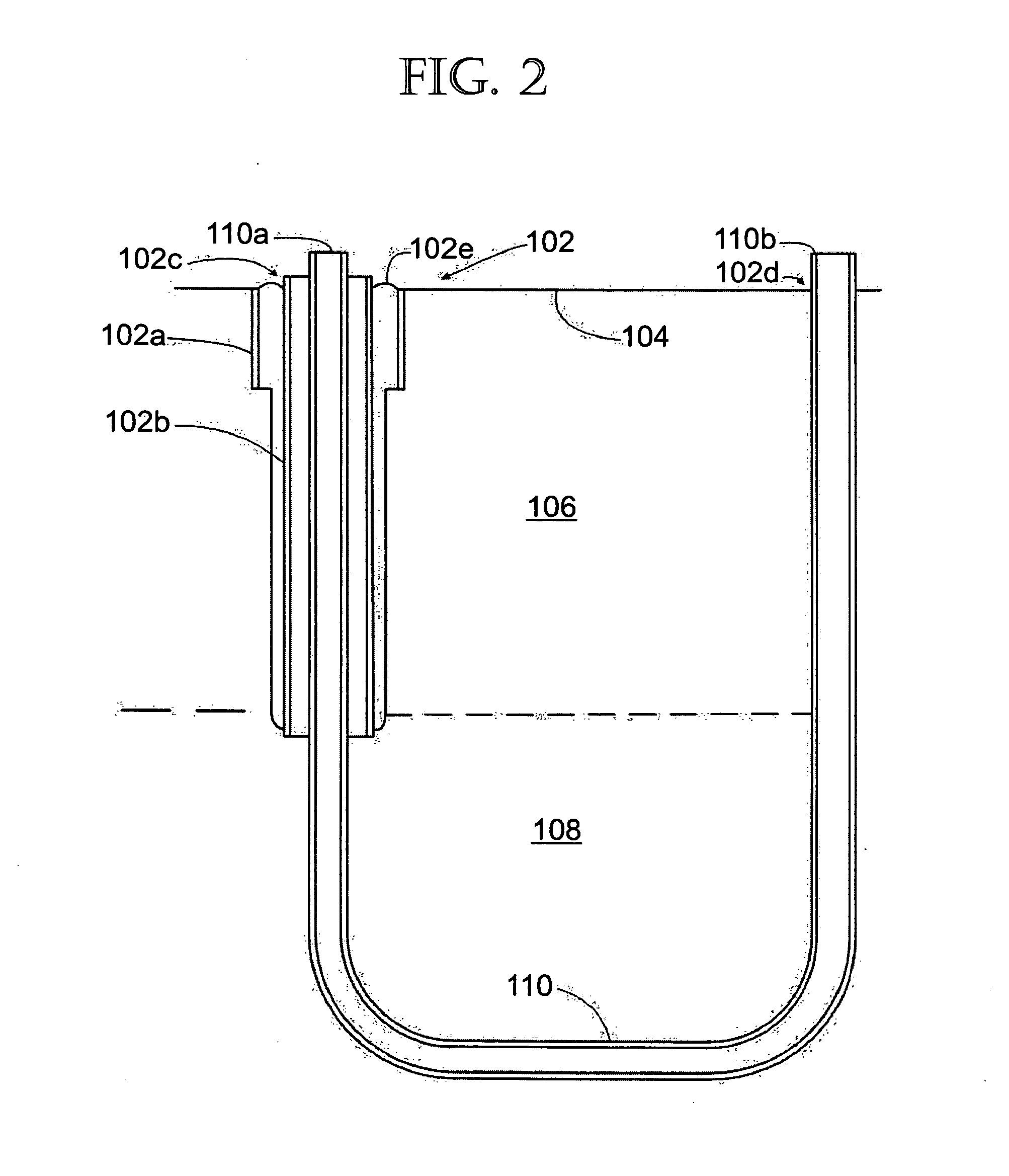

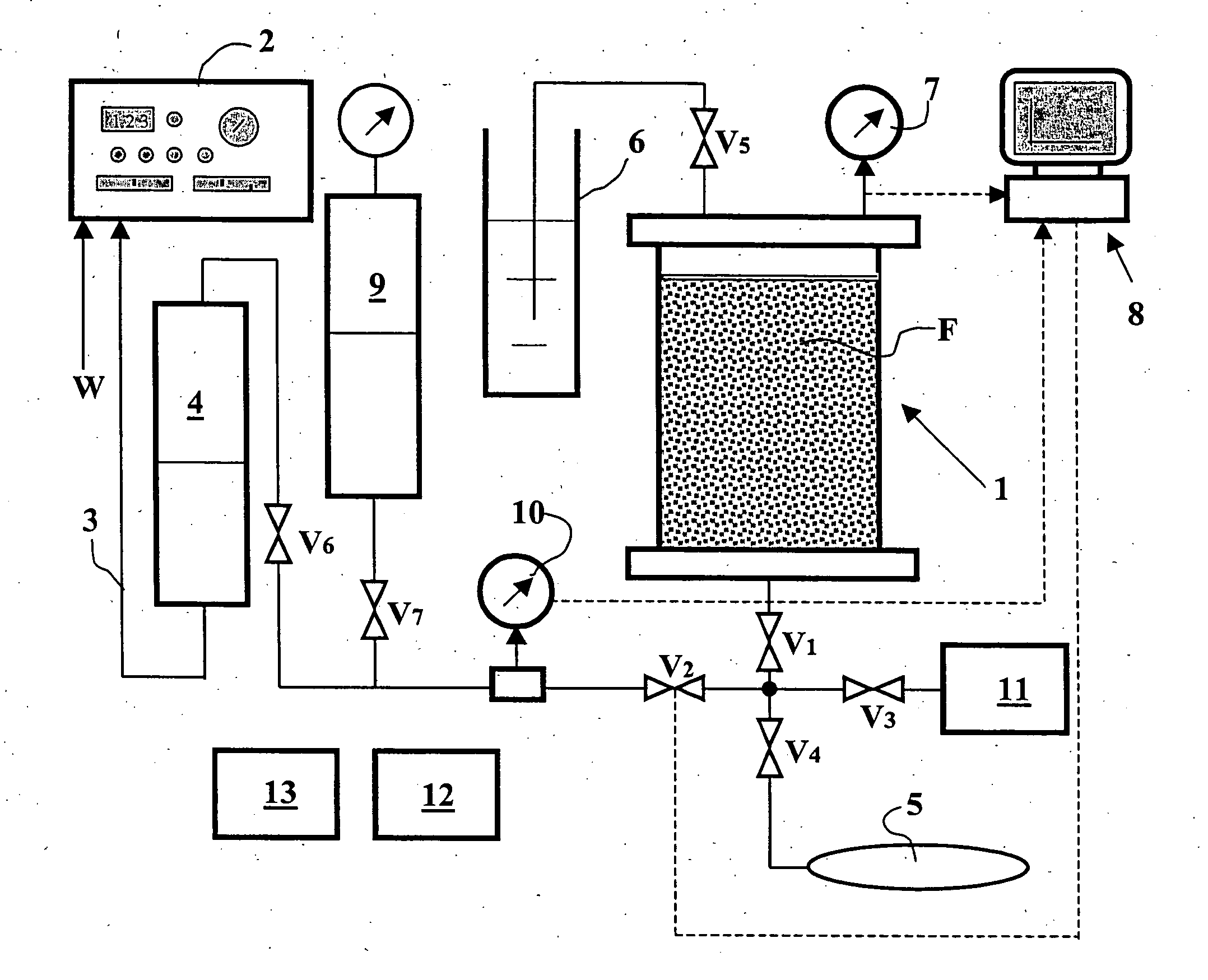

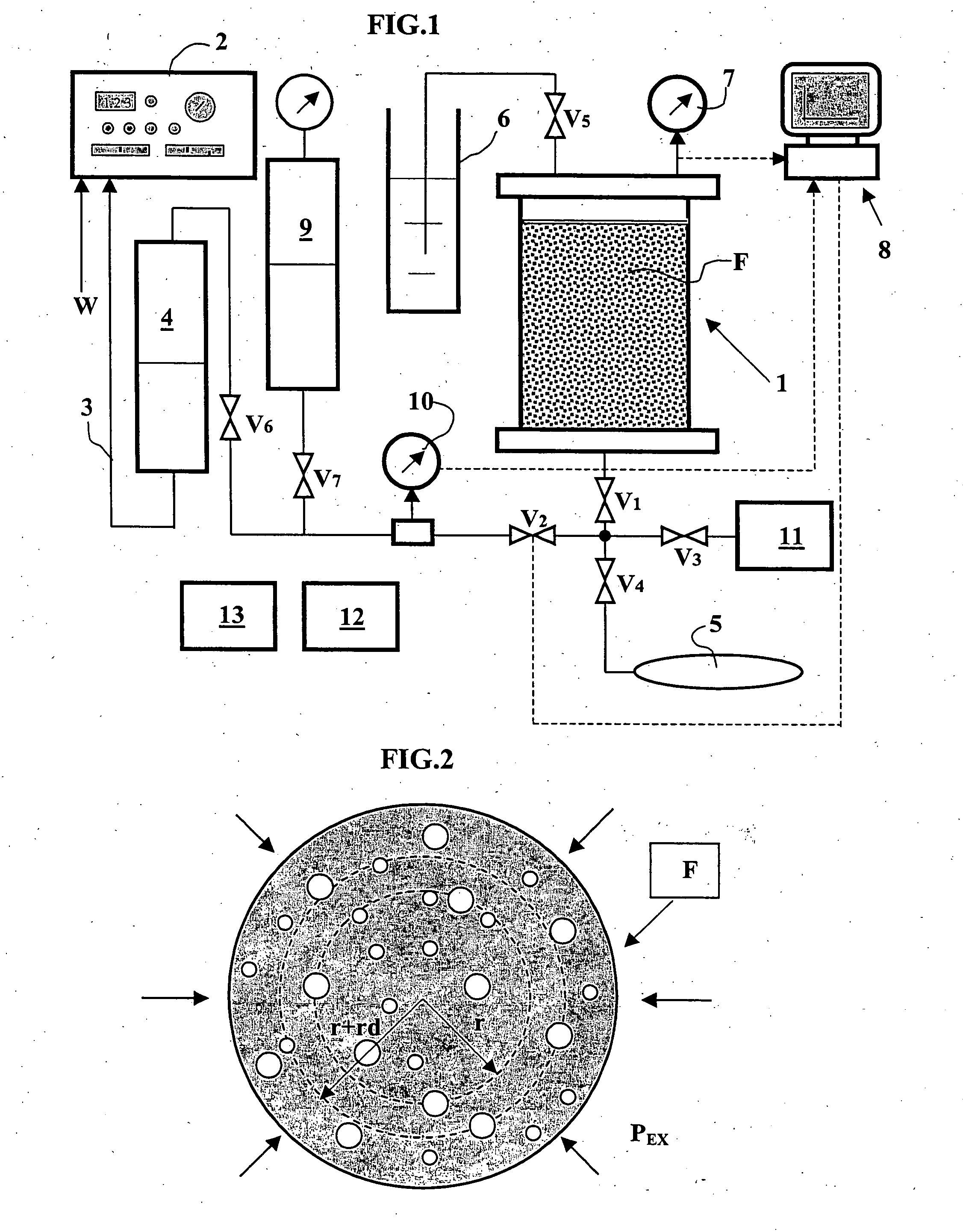

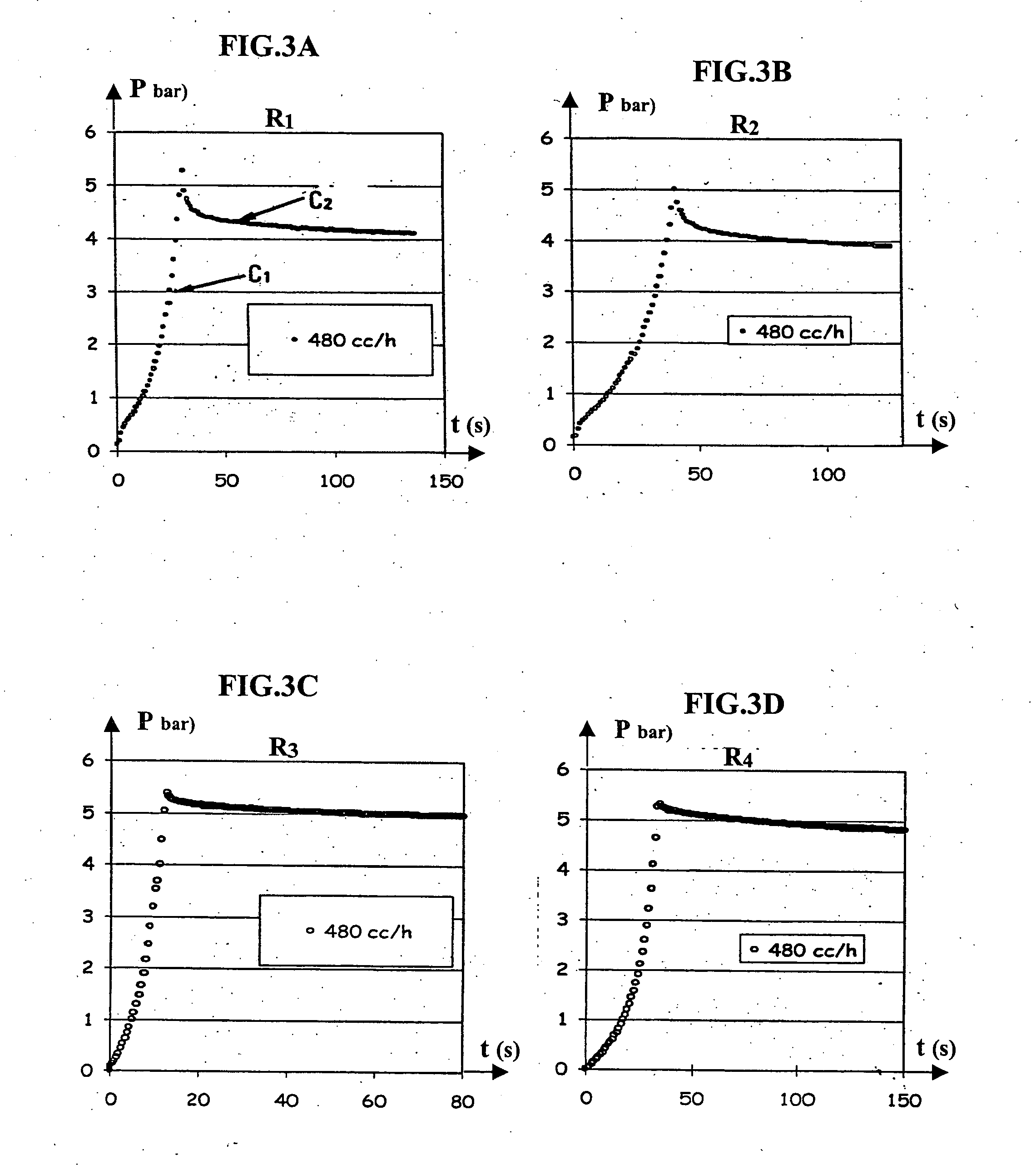

Method and device for evaluating physical parameters of an underground deposit from rock cuttings sampled therein

InactiveUS20050178189A1Short timeLimited spaceElectric/magnetic detection for well-loggingPermeability/surface area analysisMedicinePorous medium

Method and device for evaluating simultaneously, with the same equipment, physical parameters such as the absolute permeability and the porosity of fragments taken from a fragmented natural or artificial porous medium The porosity of the fragments is measured by means of helium pressure tests according to a protocol known in the art. The chamber (1) containing the fragments is communicated with a tank (11) whose volume is also known and containing helium at a known pressure. At pressure balance, the value of the solid volume can be deduced. The rock envelope volume and the fragments mass are also measured. Combining these measurements allows to determine the porosity of the samples and the density of the rock. Their permeability is then measured by immersing them in a viscous fluid and by communicating the chamber with viscous fluid at a determined pressure contained in a vessel (9) so as to compress the gas trapped in the pores of the rock, according to two different protocols. The values of the physical parameters are determined by modelling the evolution of the pressure or of the volume in the chamber and by means of an iterative adjustment. Applications: petrophysical measurements from drilling cuttings or crushed cores for example.

Owner:INST FR DU PETROLE

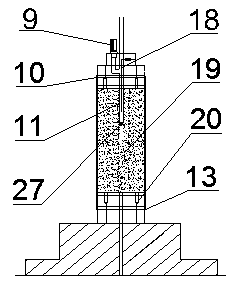

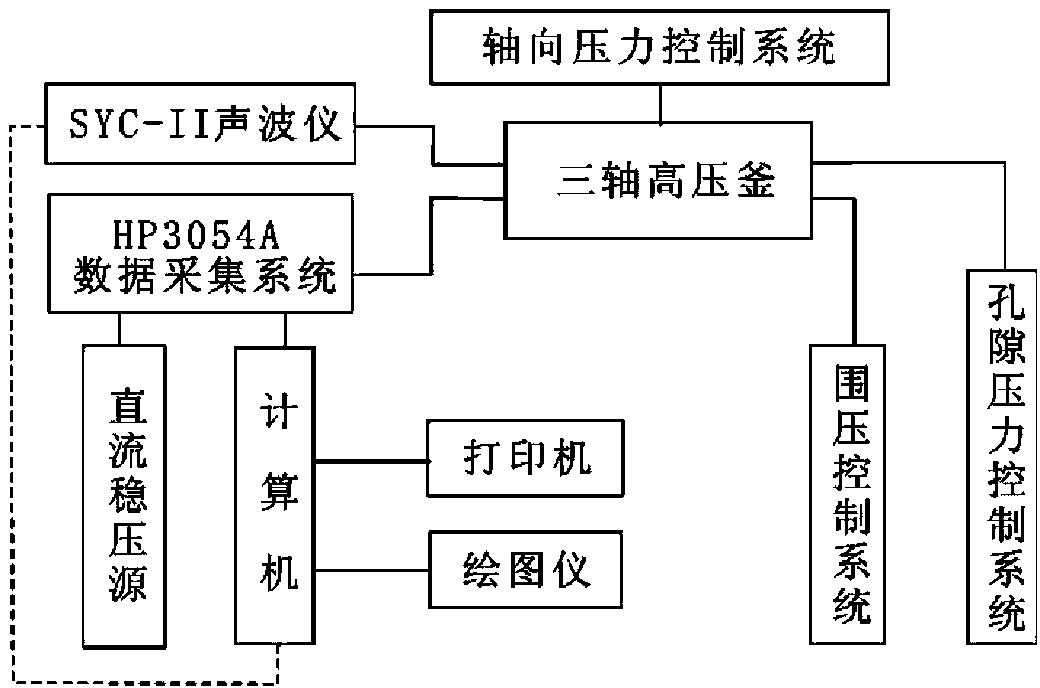

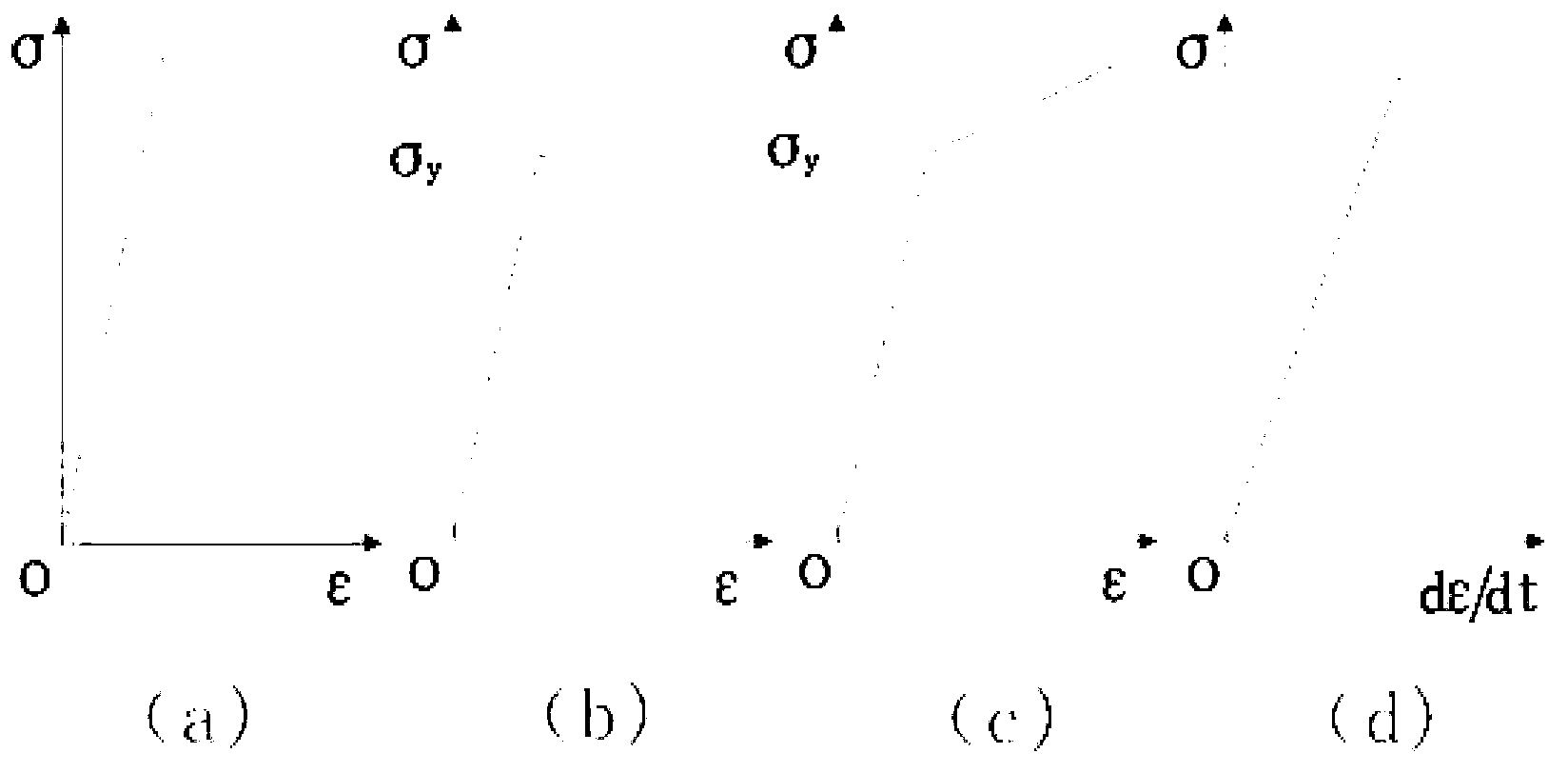

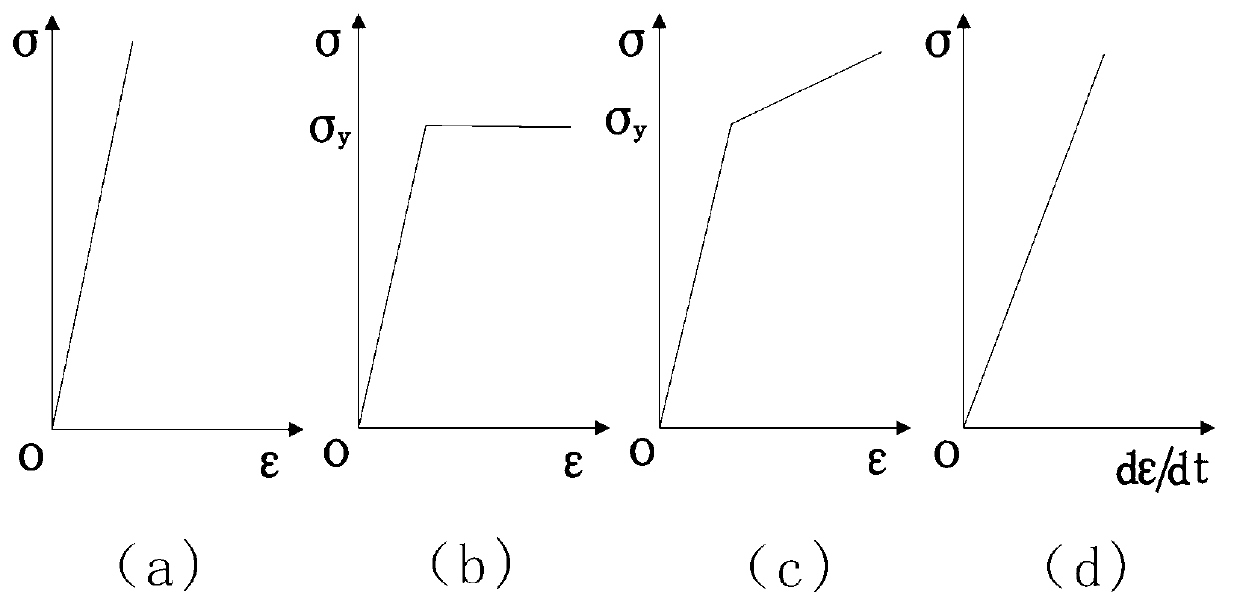

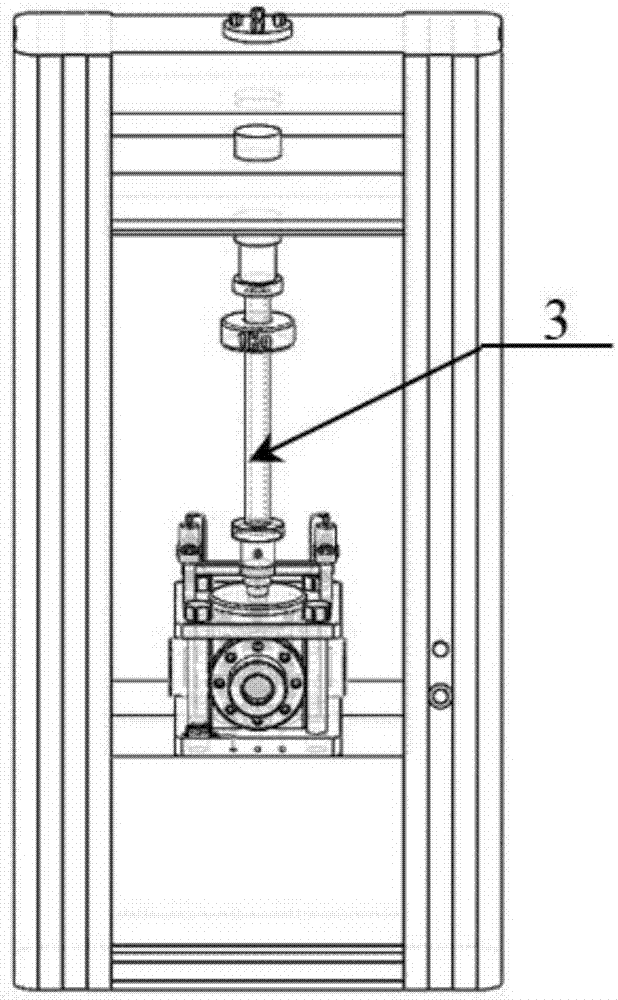

Method for synchronous measurements on dynamic and static elastic parameters of rocks

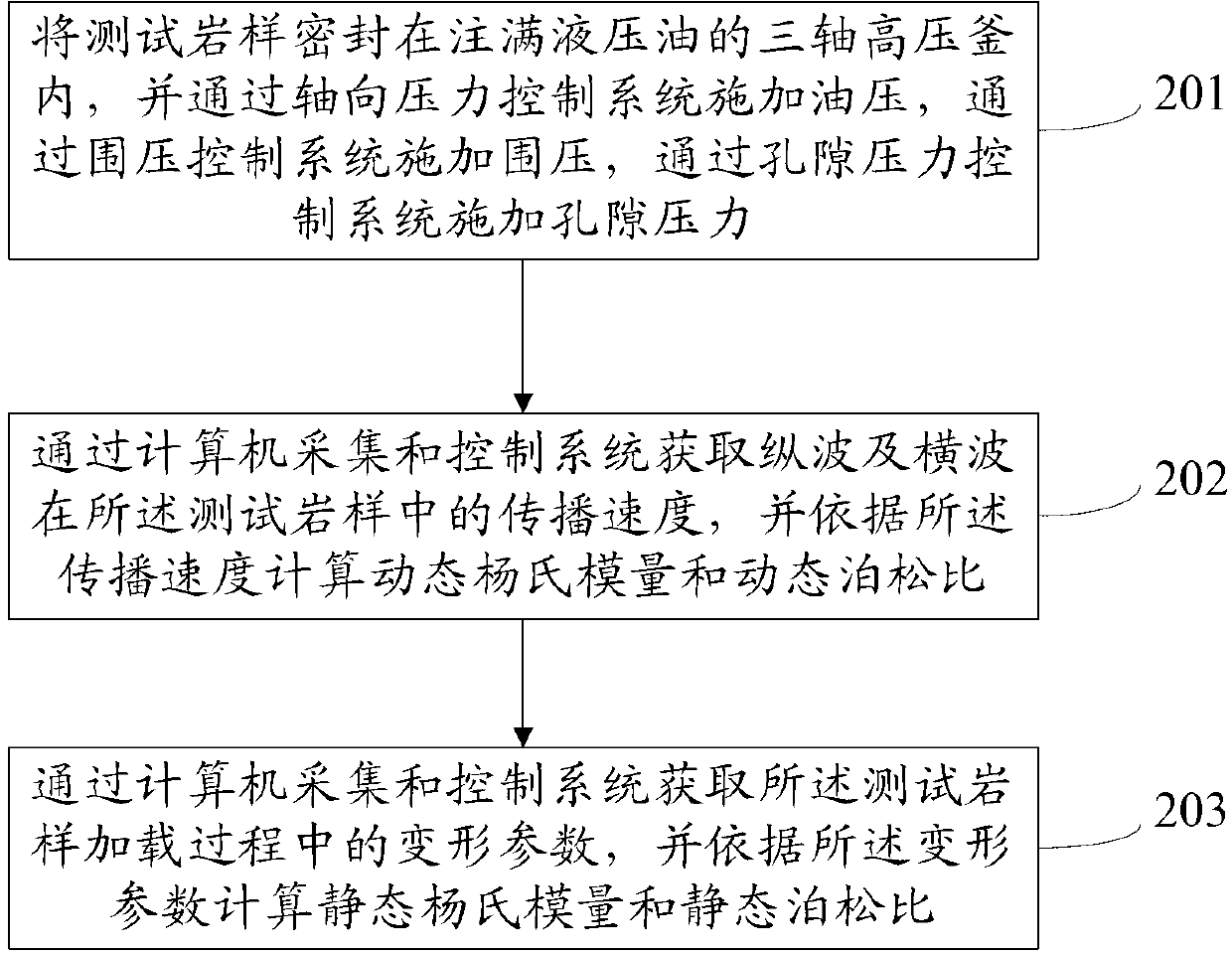

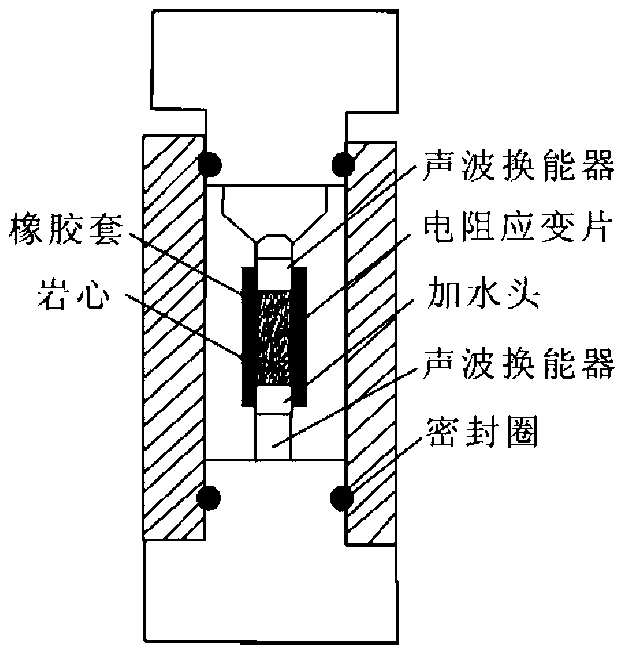

InactiveCN103278389AGuaranteed validityGuaranteed accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial strength using tensile/compressive forcesControl systemAxial pressure

The invention provides a method and a device for synchronous measurements on dynamic and static elastic parameters of rocks by using a rock triaxial anti-compression testing device. The method comprises: sealing a test rock sample in a triaxial autoclave filled with hydraulic oil, applying an oil pressure by an axial pressure control system, applying a confining pressure by a confining pressure control system, and applying a pore pressure by a pore pressure control system; acquiring propagation speeds of longitudinal waves and transverse waves in the test rock sample by a computer acquisition and control system, and calculating the dynamic Young modulus and the dynamic Poisson ratio according to the propagation speeds; and acquiring deformation parameters of the test rock sample during a loading process by the computer acquisition and control system, and calculating the static Young modulus and the static Poisson ratio according to the deformation parameters. The method and the device can ensure validity and accuracy of hydrocarbon reservoir rock mechanical parameter measurements in thousands of meters deep underground and under the conditions of complex confining pressure, high temperature, high pore pressure and polyphase fluid.

Owner:PEKING UNIV

In situ method and system for extraction of oil from shale

ActiveUS7743826B2Easy to moveAvoid insufficient temperatureInsulationFluid removalClosed loopEarth surface

A system and process is disclosed for retorting oil shale and extracting shale oil and other hydrocarbons therefrom, in which a cased heat delivery well is drilled generally vertically through an overburden and then through a body of oil shale to be retorted to the bottom thereof, generally horizontally under the body of oil shale to be retorted, and then back to the earth surface. Heat energy is transmitted conductively to the body of oil shale to be retorted from a closed loop heat delivery module in the well, the module comprising a fluid transmission pipe containing a heating fluid heated to at least a retorting temperature. Heat energy is also transmitted to the body of oil shale to be retorted above the fluid transmission pipe by vapor conduits that conduct retort vapors upward through the body of oil shale to be retorted; the ascending retort vapors condense and reflux, delivering their latent heat of vaporization to the body of oil shale to be retorted, and the condensed retort liquids descend. If not recycled, the retort liquids are collected in a sump at the bottom of a production well and are transmitted to the surface for processing. The vapor conduits communicate at upper ends thereof with the production well, so that vapors that do not reflux are collected in the production well and are transmitted to the surface for processing.

Owner:AMERICAN SHALE OIL

Pressure bearing permeation grouting strengthening test apparatus and method

InactiveCN103267722AEasy to manufactureSimple structurePreparing sample for investigationPermeability/surface area analysisAxial pressureMicro fracture

The present invention relates to a pressure bearing permeation grouting strengthening test apparatus and a method. The apparatus mainly comprises a grouting bucket, a slurry storage device and a manual grouting pressurization device, wherein the grouting bucket comprises a base, a bucket body and a pressing head, a grouting hole is arranged in the base, and is connected with the slurry storage device through a high pressure soft pipe, the slurry storage device is provided with a piston, and the manual grouting pressurization device is placed below the piston. With the test apparatus, influence of axial pressure, confining pressure and other factors of the upper portion of the micro fracture (pores) geology on the grouting can be simulated; the grouting conditions of the geological bodies with different physical and mechanical properties under different grouting parameters and different grouting process conditions can be simulated so as to analyze a mechanism and an effect of grouting strengthening; and with the test apparatus, broken coal rock bodies, soil samples and sand samples can be made into complete samples, can be processed into standard samples through a cutting machine, and then are subjected to related uniaxial and triaxial tests. In addition, the test apparatus has characteristics of simple structure, easy manufacturing, low cost, easy operation, and reliable use.

Owner:CHINA UNIV OF MINING & TECH

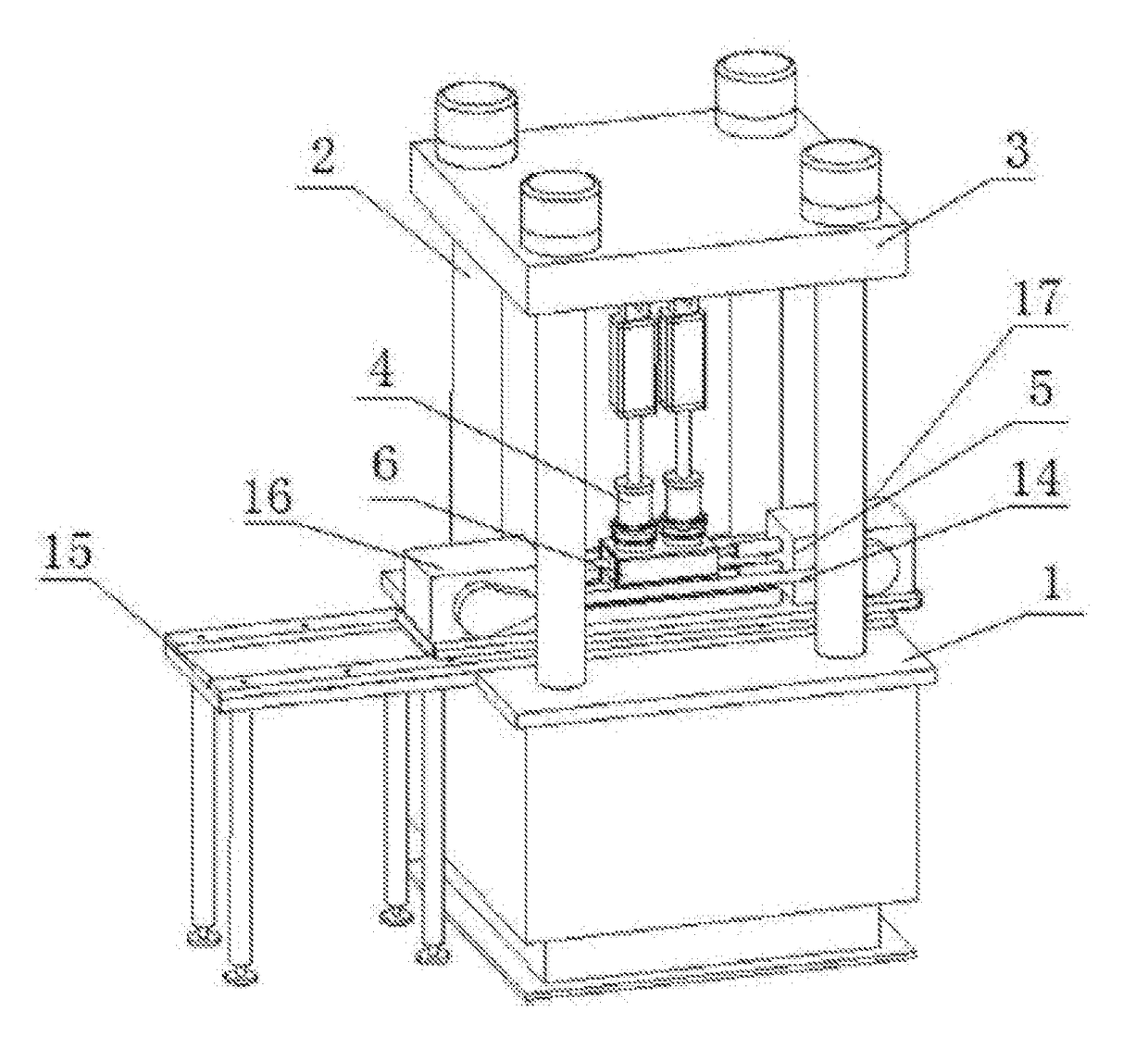

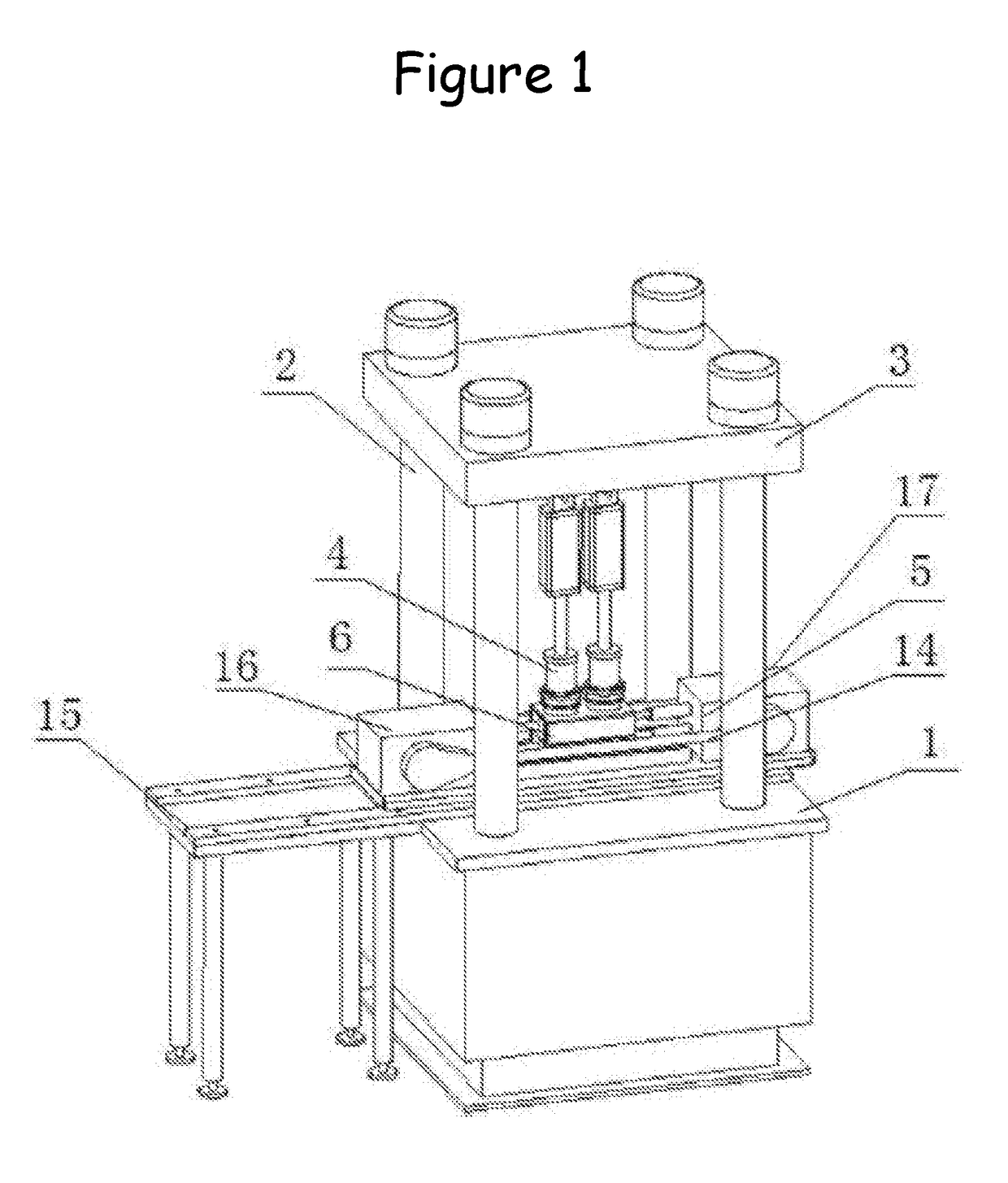

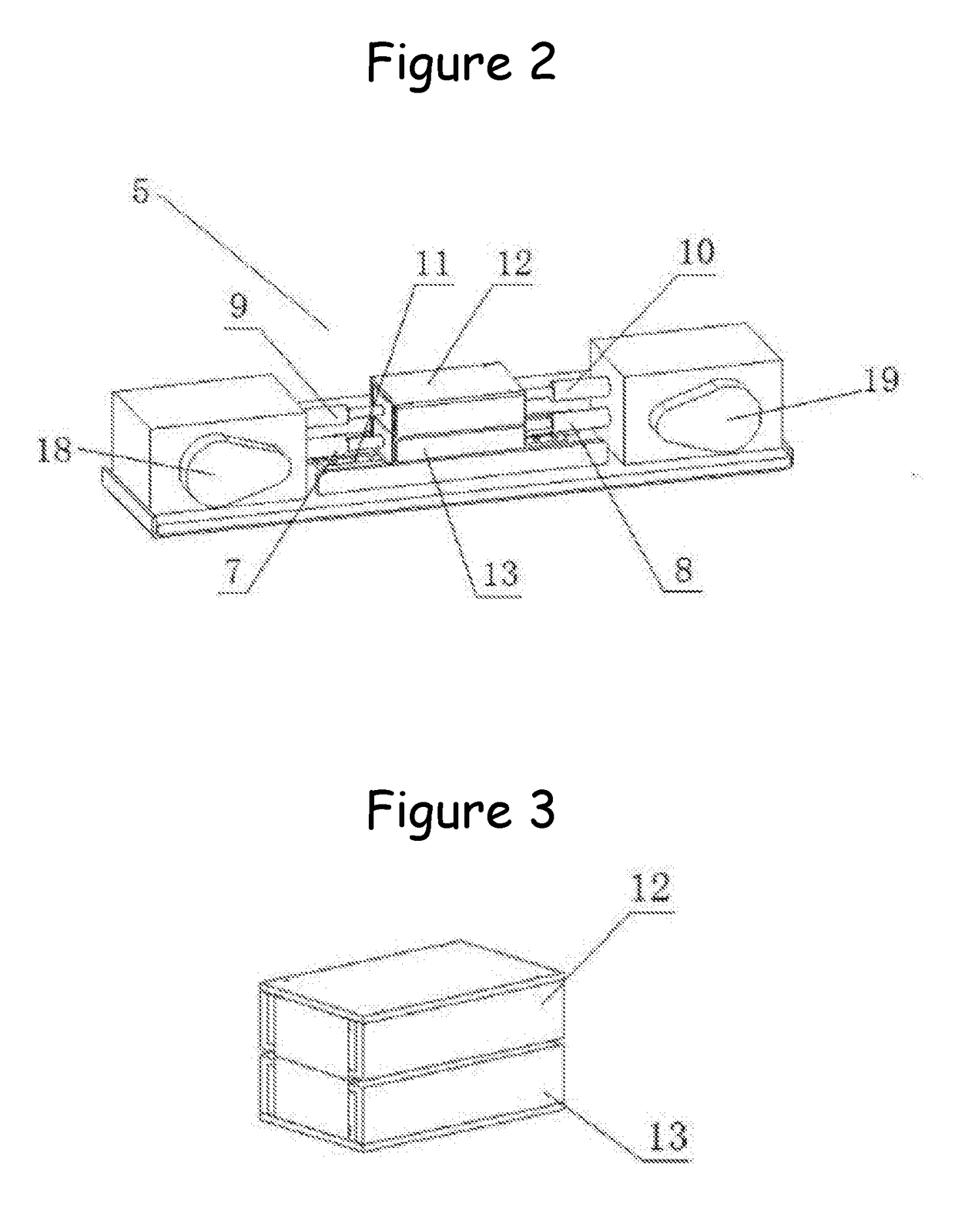

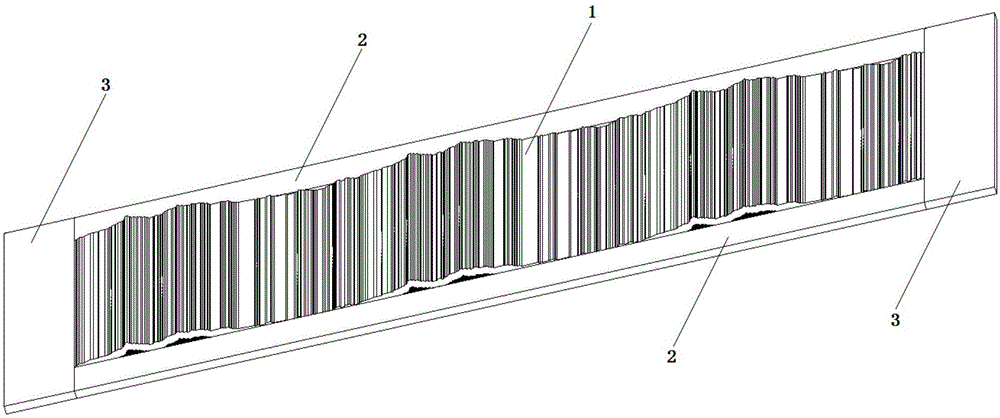

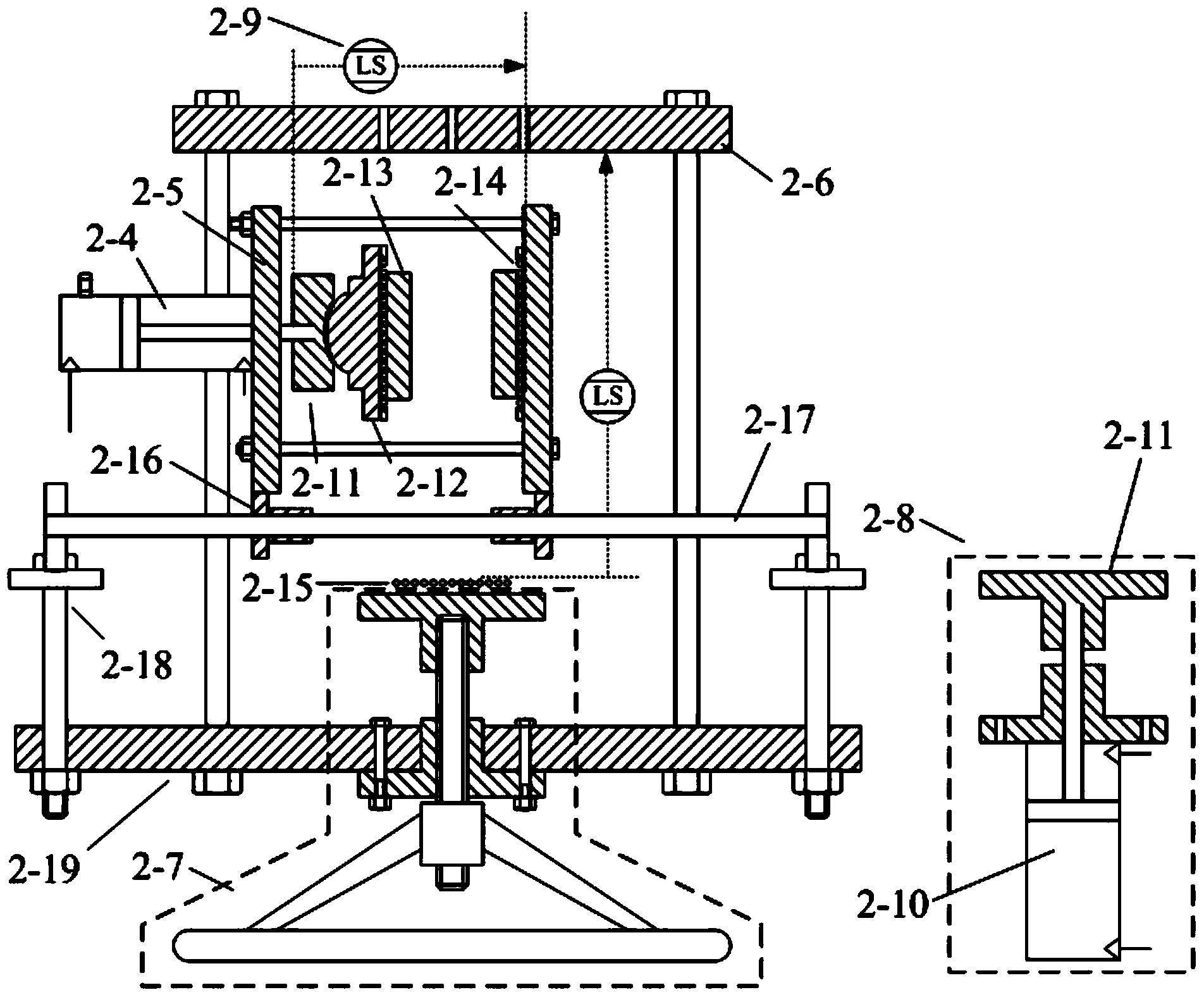

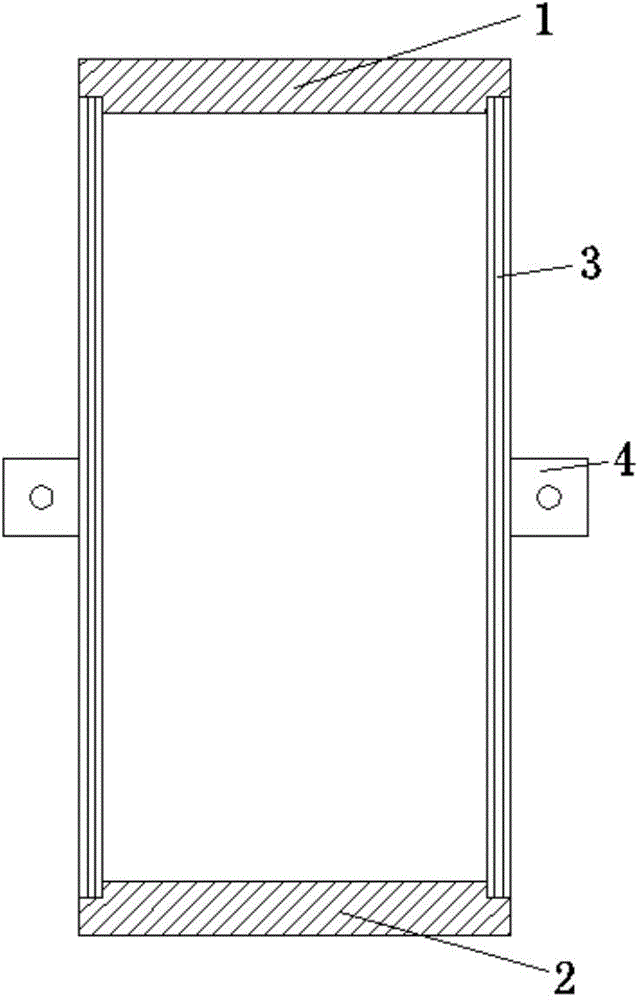

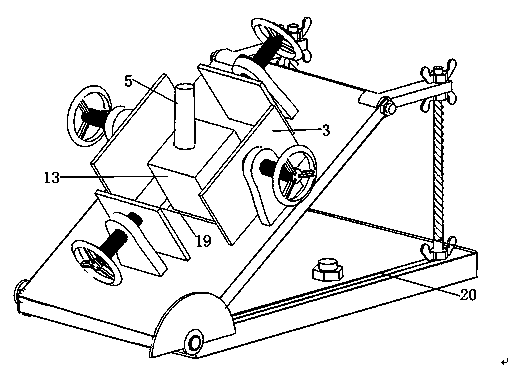

Shear test device and test method of rock mass discontinuities under constant normal stiffness condition

ActiveUS20180031457A1Overcomes shortcomingMaterial strength using tensile/compressive forcesEarth material testingComputer control systemMonitoring system

The present invention relates to a shear test device and test method of rock mass discontinuities under constant normal stiffness condition. The device includes: a base used for placing a test piece; a loading framework fixedly connected with the base; a shear loading system used for applying a shear force to the test piece; a normal loading system used for applying a normal pressure to the test piece; a normal displacement monitoring system used for measuring the magnitude of normal displacement of the test piece in real time; and a computer control system used for receiving the data of the normal displacement of the test piece in real time, and constantly adjusting the normal pressure applied by the normal loading system to the test piece according to the principle that the normal stiffness of the test piece is unchanged.

Owner:SHANDONG UNIV OF SCI & TECH

Method for weakening coal-rock mass by hydraulic blasting and fracturing

ActiveCN101644156AImprove fraudIncreased range of cracking fissuresDisloding machinesFluid removalSpelunkingHydraulic fracturing

The invention discloses a method for weakening coal-rock mass by hydraulic blasting and fracturing. The structure of coal-rock mass can be changed by adopting hydraulic blasting and fracturing. The method comprises the following steps: drilling a hole in a coal layer, and placing water-gel explosive in the hole; and then sealing the hole and injecting water into the hole to a set pressure; stopping water injection based on the standard that no hydraulic fracture is generated; detonating the explosive and carrying out hydraulic blasting to lead the wall rock of the drilling hole to burst; generating a great number of fractures on the periphery of the drilling hole; and then carrying out hydraulic fracturing; expanding along exploding fracture under the action of hydraulic pressure of the fracture, and forming a great number of hydraulic pressure fractures. The method of the invention not only can effectively weaken the strength of the coal-rock mass, can reduce wall rock stress of the weakening area, but also can improve ventilation property of the coal layer; is an effective technical way of improving the top coal caving, preventing impact mine pressure, preventing coal and gas burst, and improving efficiency of gas extraction in coal mine. The method has simple process, convenient construction, reliable safety, easy operation and good control.

Owner:CHINA UNIV OF MINING & TECH

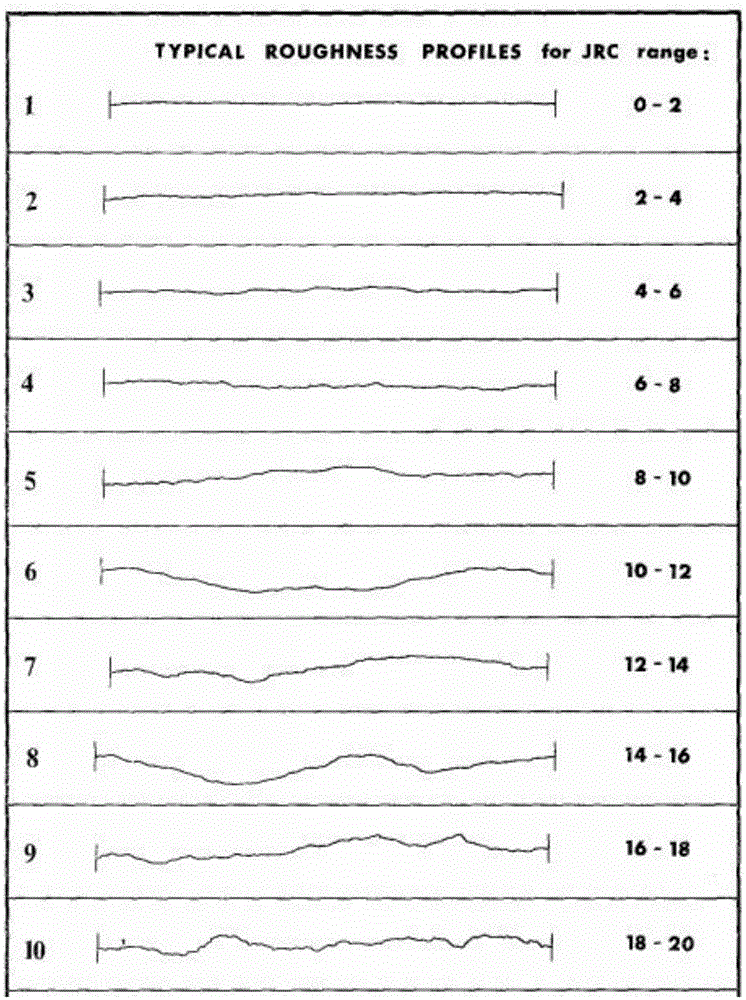

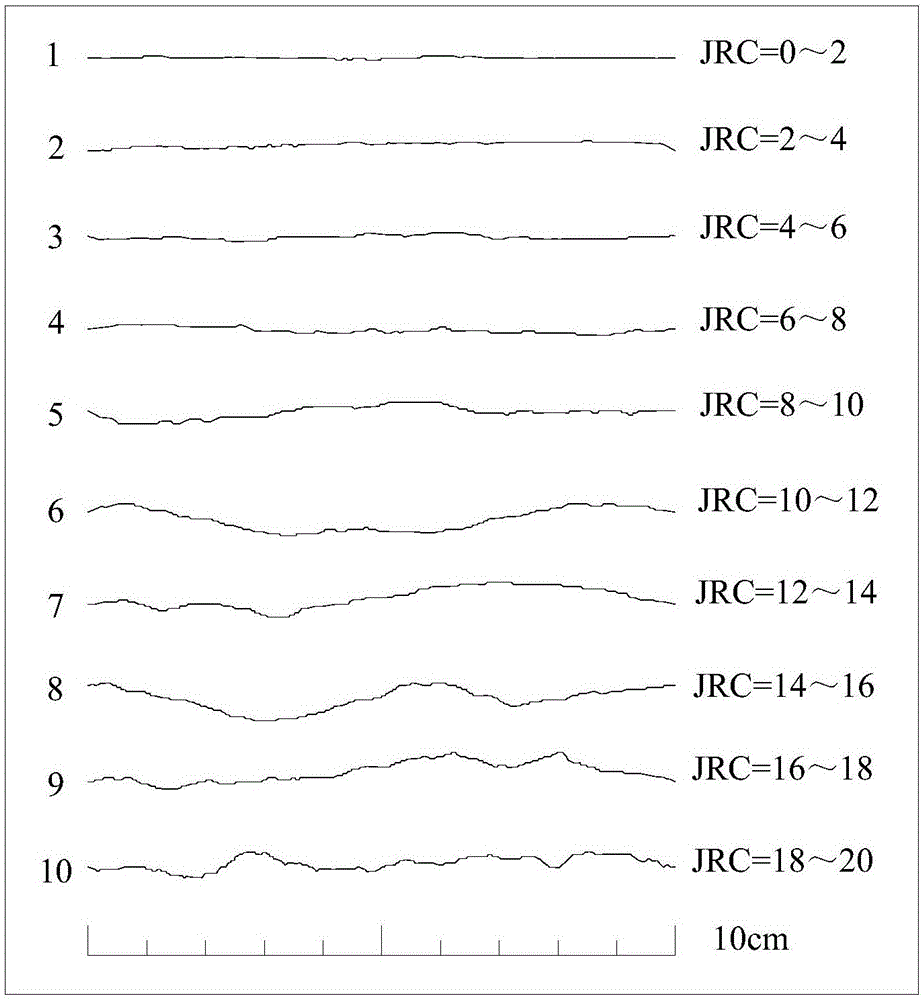

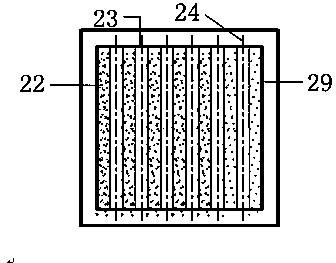

Manufacturing method of simulation fracture for fractured rock mass seepage test

InactiveCN105158039AOvercome limitationsHigh precisionPreparing sample for investigationPermeability/surface area analysisComputer Aided DesignSurface roughness

The invention discloses a manufacturing method of a simulation fracture for a fractured rock mass seepage test. The manufacturing method comprises the steps of drawing a fracture digitized profile curve, constructing a fracture three-dimensional model, making a fracture plate through 3D (three-dimensional) printing, making a fracture test piece casting model and performing casting and maintenance of a fracture test piece, specifically, through digitizing a rock structural surface joint roughness profile curve, drawing the fracture three-dimensional model on the basis of CAD (Computer Aided Design) software, making the fracture plate satisfying JRC value fluctuation by adopting a 3D printing technology, making the fracture test piece casting model by combining the fracture test piece, forming by using cement mortar to cast, and making the fracture test piece by performing maintenance in a cement test piece maintenance box for 28 days. The manufacturing method has the beneficial effects: the manufacturing method of rock rough fracture analogue simulation which is easy in observing, simple in manufacturing, convenient in testing, convenient for adjusting fracture opening, and capable of truly and accurately reflect rock mass fracture structural surface roughness is provided, the working procedures are simple and clear, the manufacturing duration is short, economy and efficiency are realized, the accuracy is high, and the adaptability is good.

Owner:HOHAI UNIV

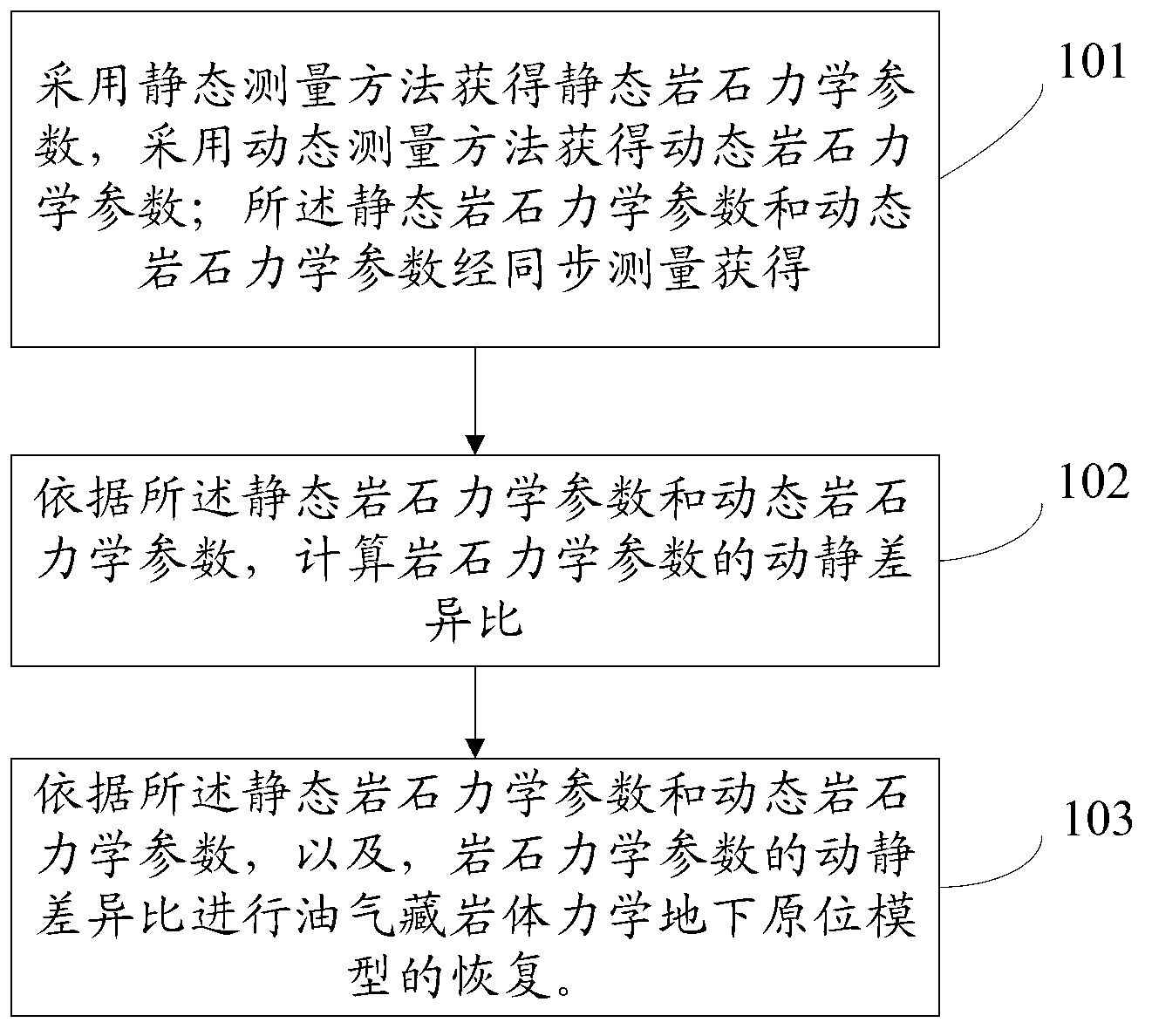

Synchronous measurement method and apparatus for dynamic and static rock mechanical parameters

InactiveCN103267678AImprove forecast accuracyGuaranteed accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial strength using tensile/compressive forcesGeomorphologyRock mechanics

Owner:PEKING UNIV

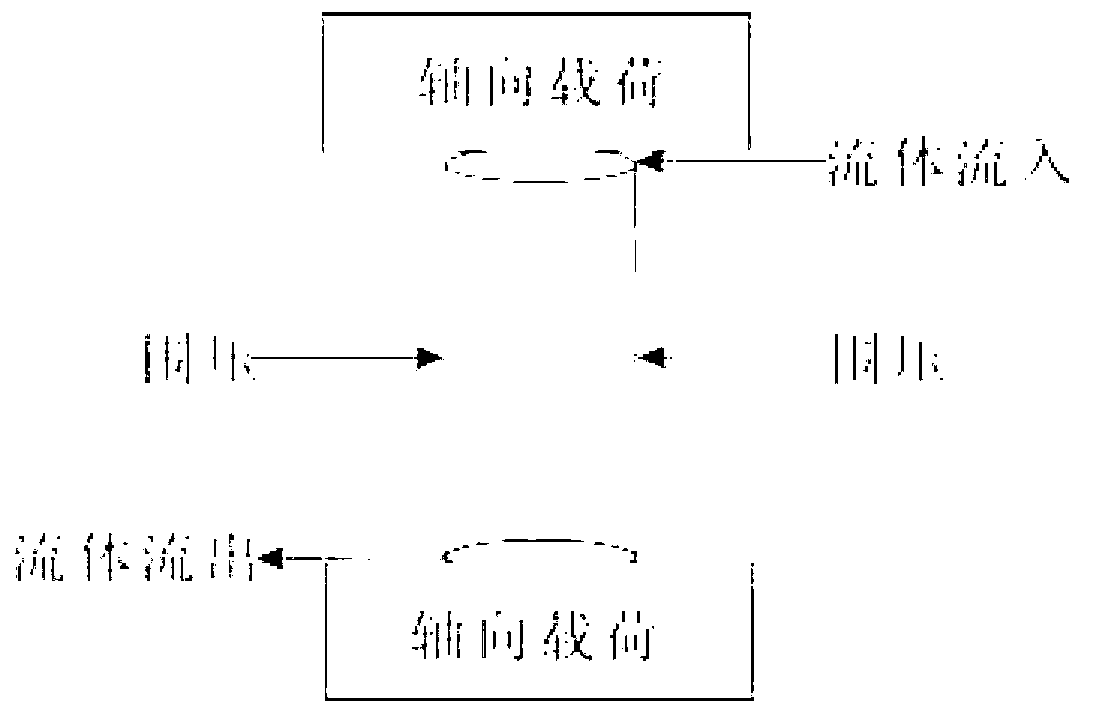

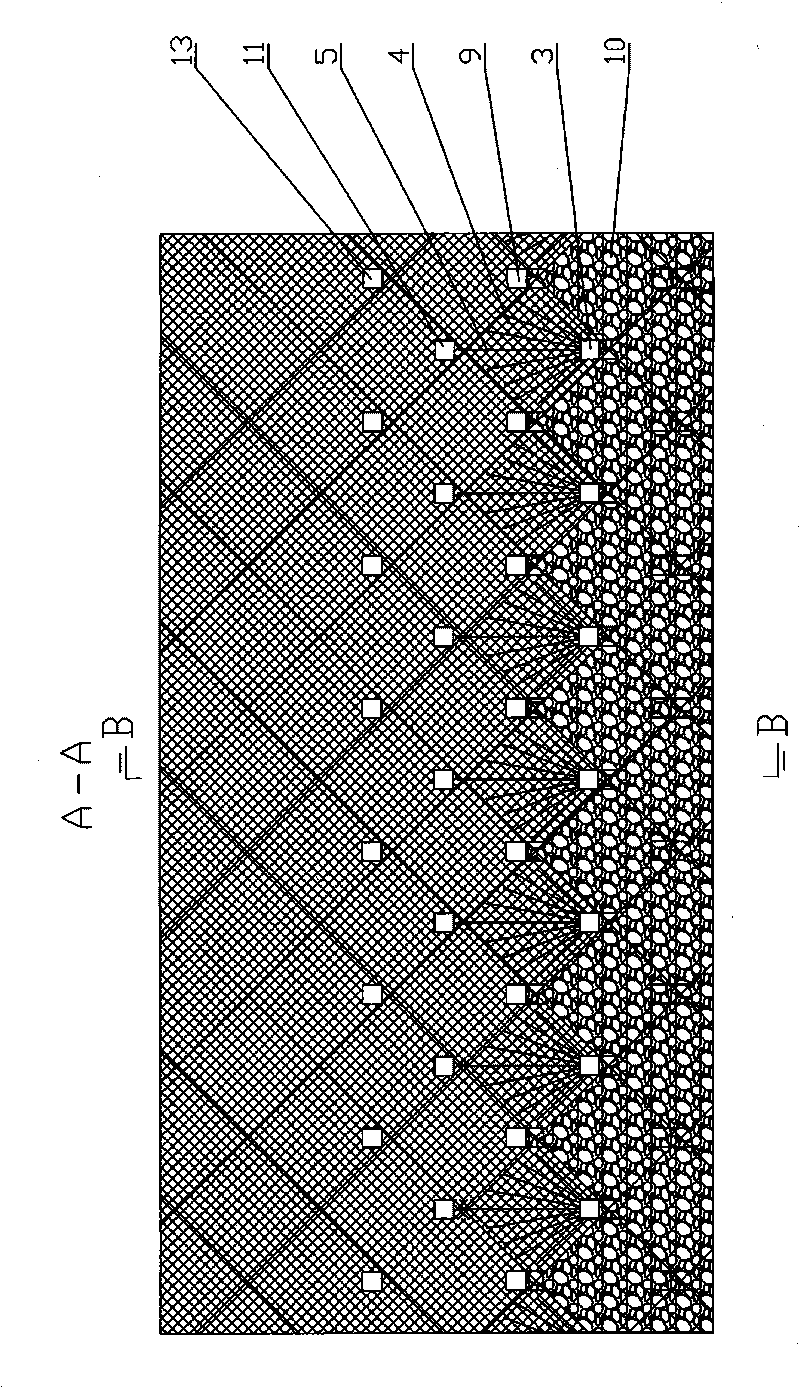

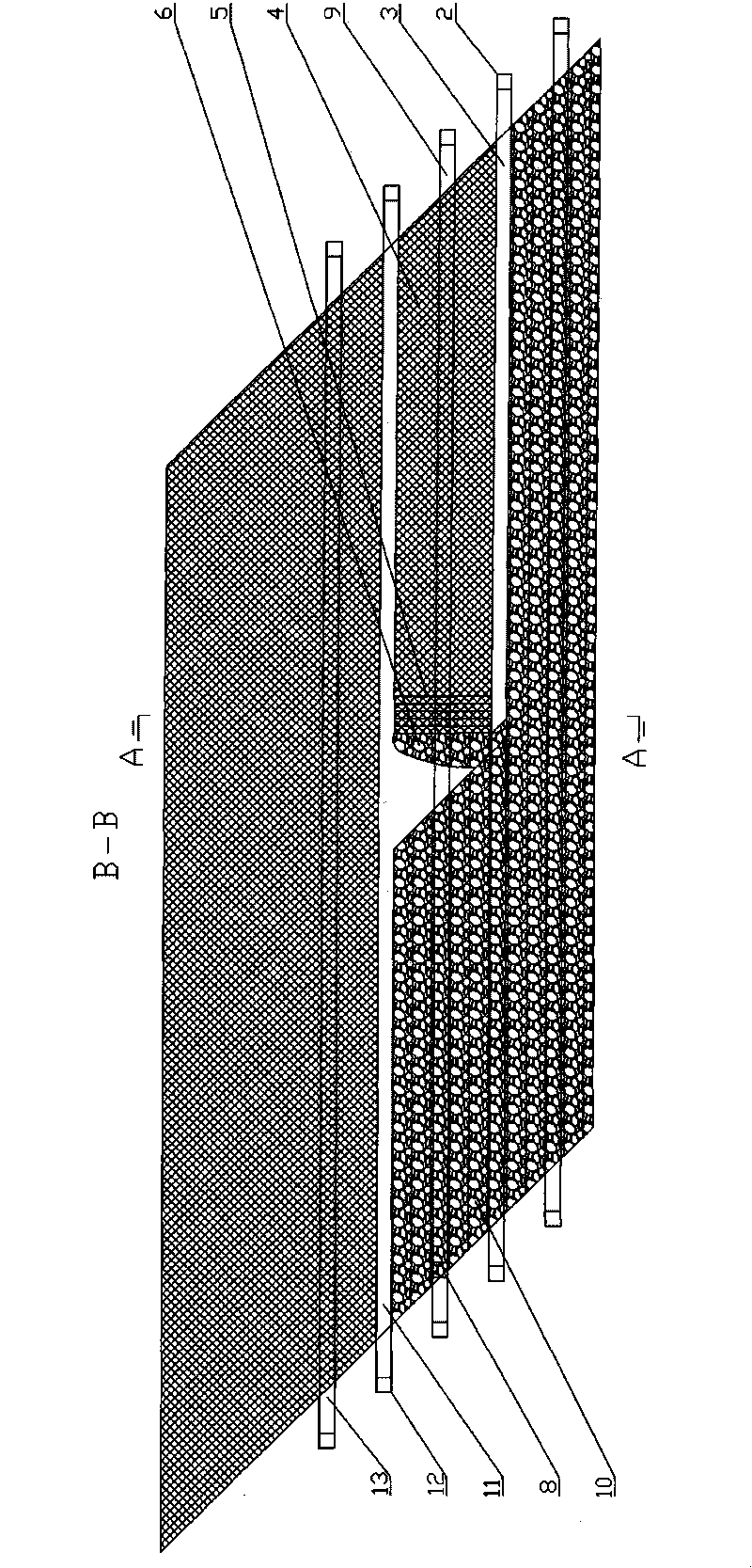

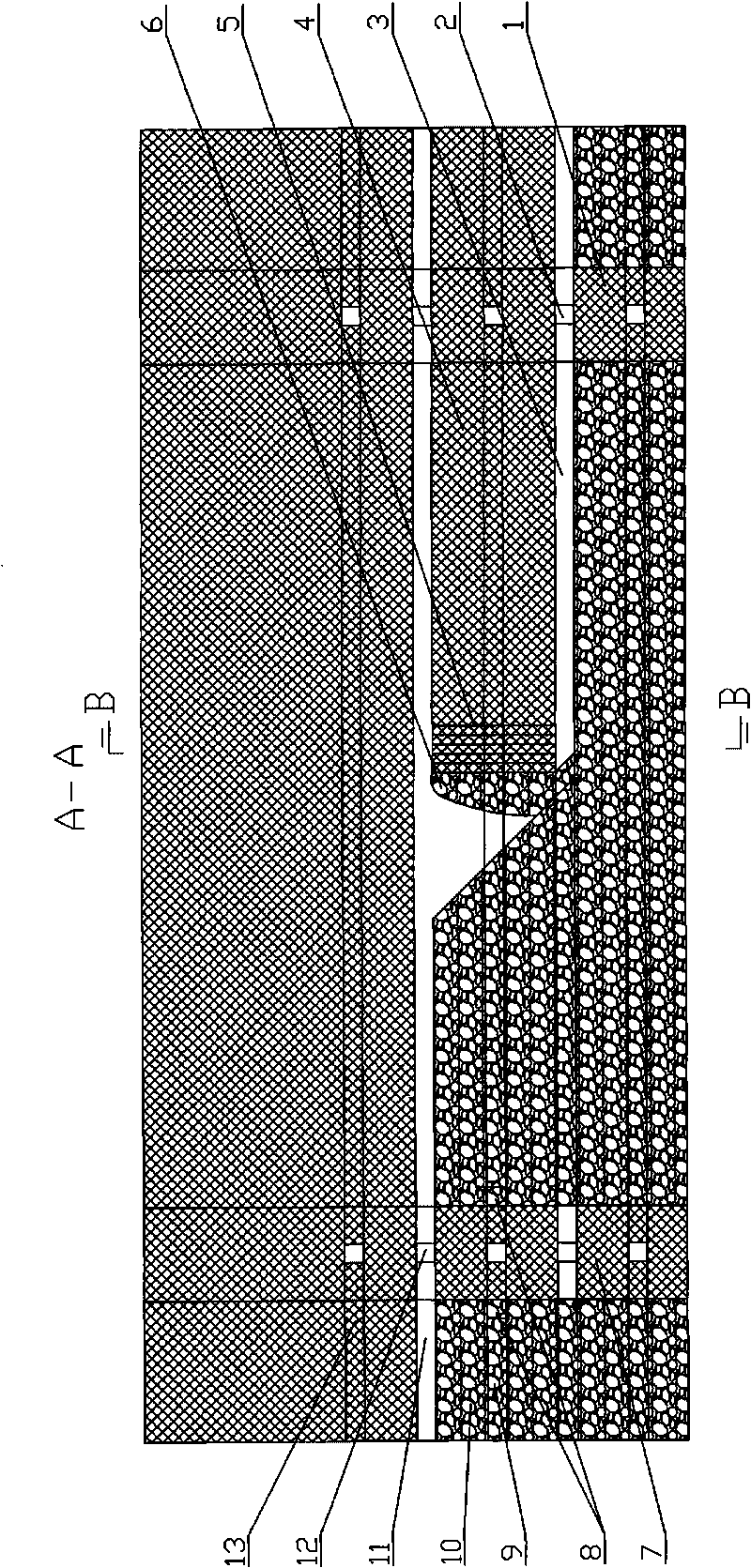

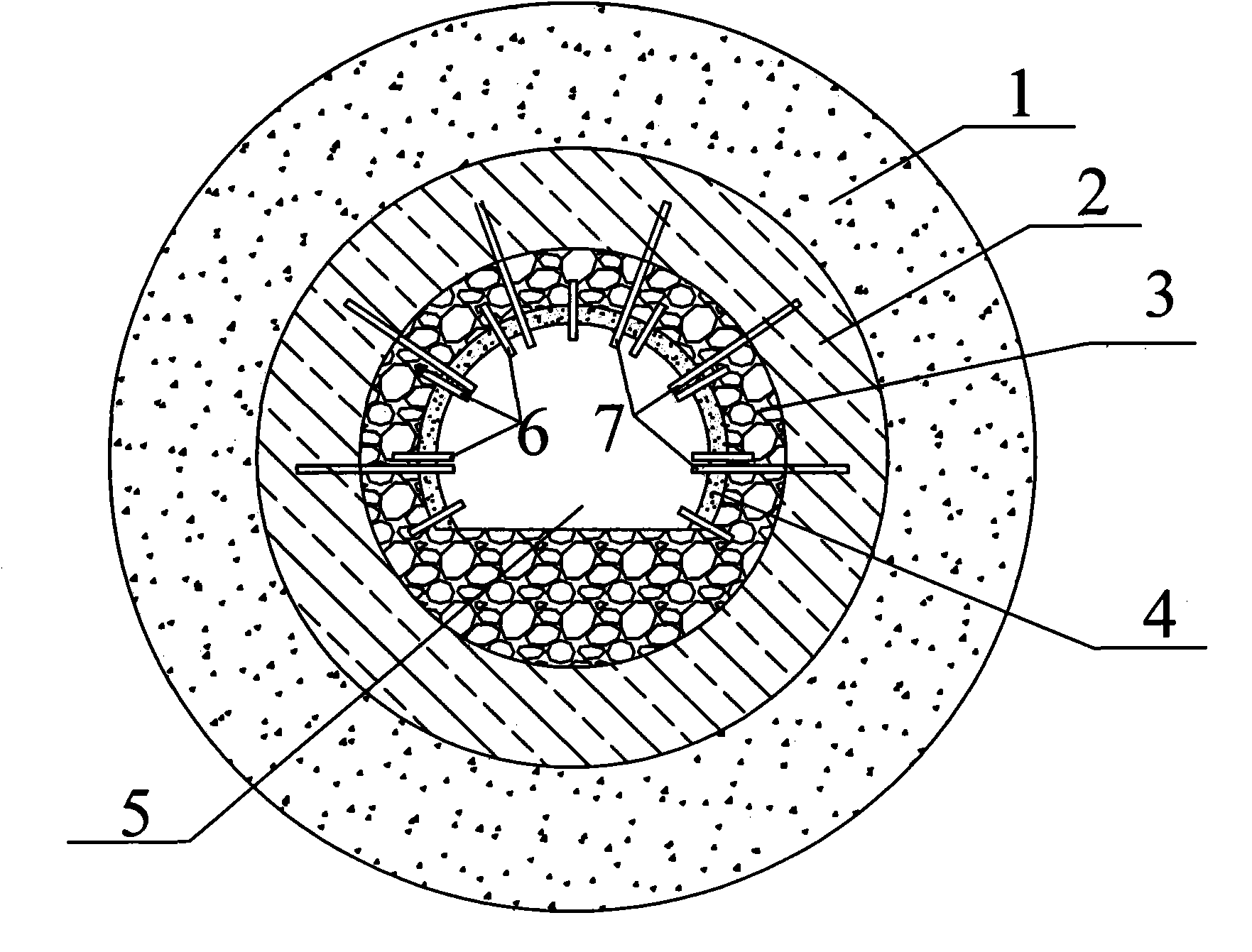

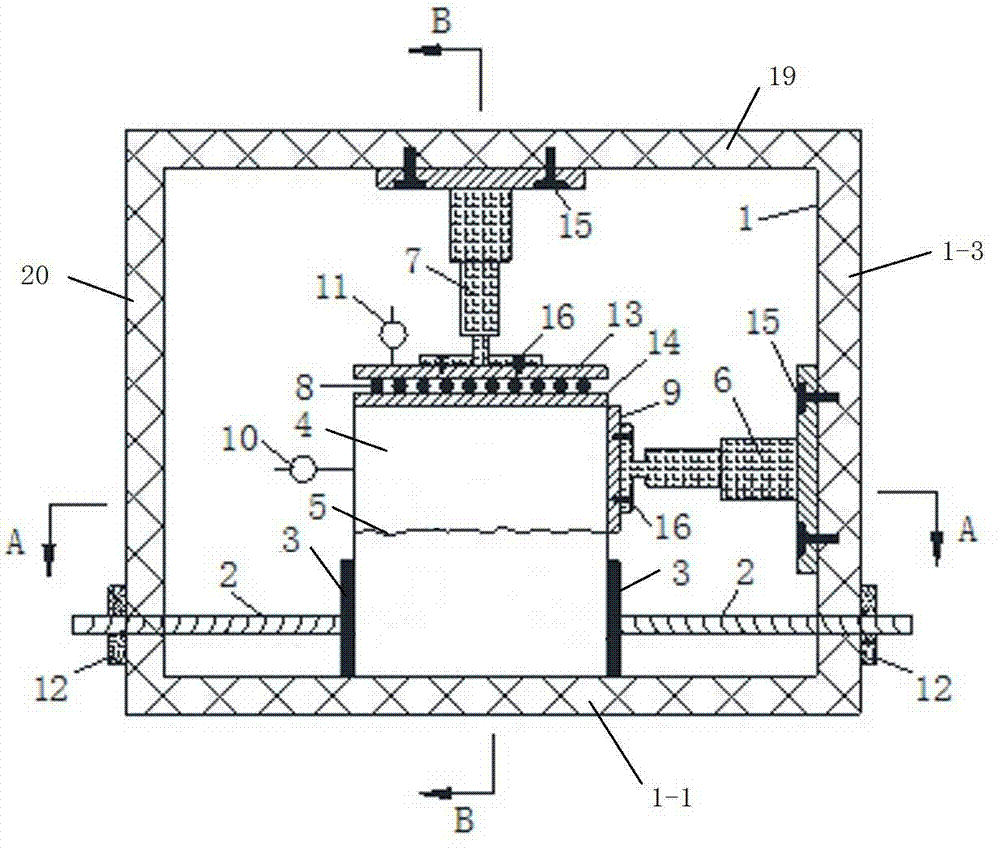

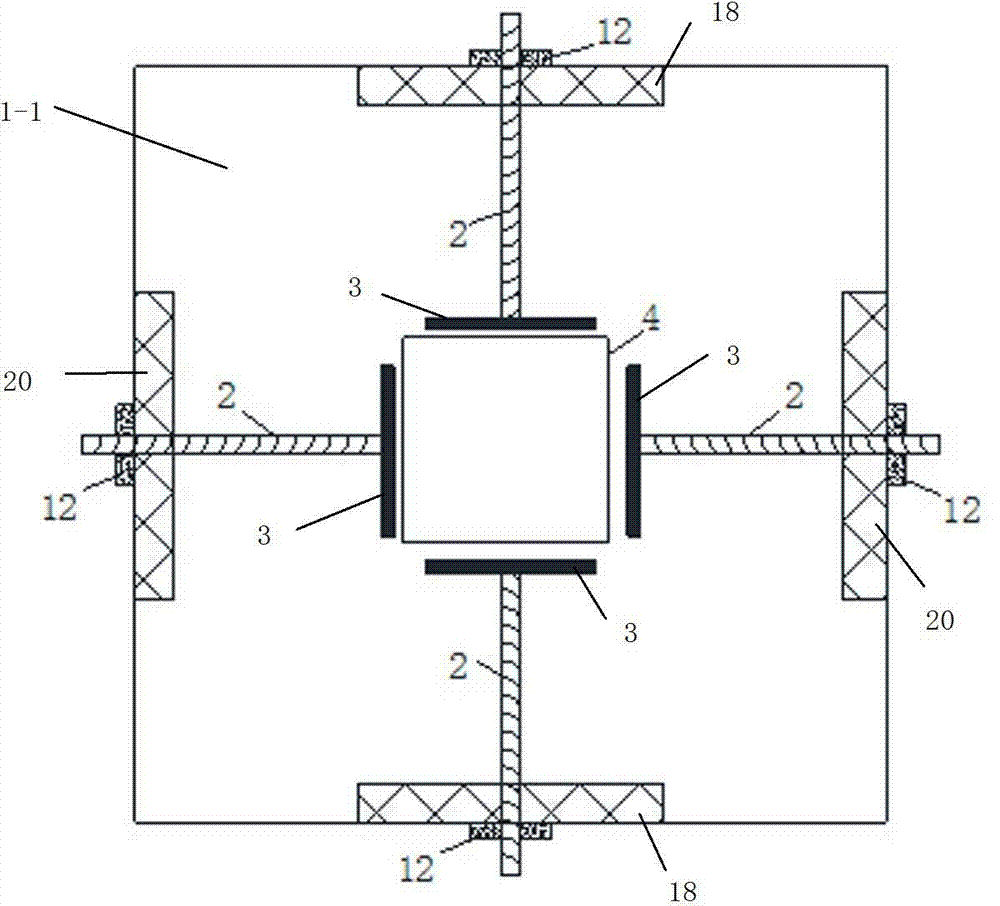

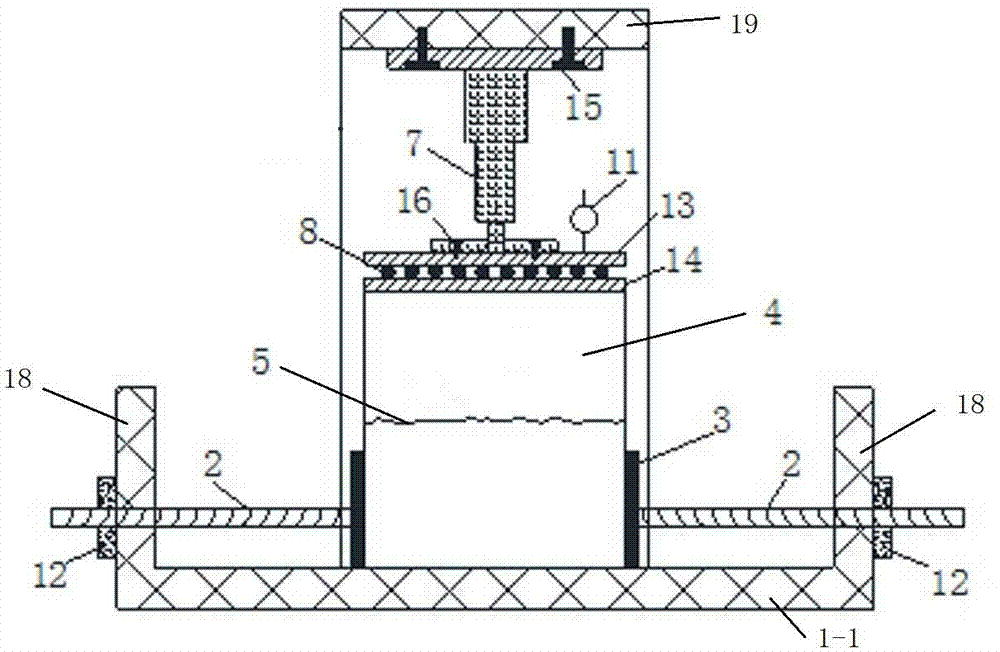

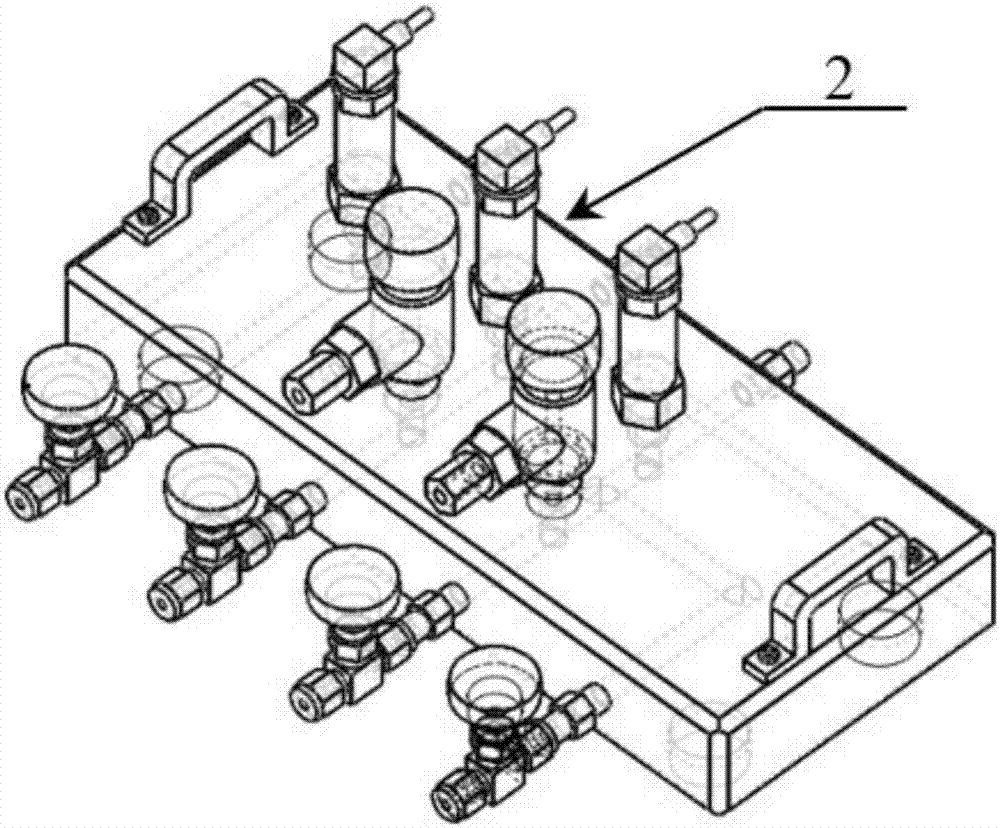

Fractured rock mass stress and seepage coupled testing system and method

InactiveCN104316447AEffective testing methodChange stress statePermeability/surface area analysisHydraulic cylinderThree degrees of freedom

The invention discloses a fractured rock mass stress and seepage coupled testing system and a fractured rock mass stress and seepage coupled testing method, belonging to testing systems and methods for fractured rock mass or pore medium seepage of rock and soil and geology. The system is divided into three parts, namely a seepage experiment device, a stress and displacement loading system and a data acquisition system, wherein the seepage experiment device can load square fractured rock mass or precast concrete crack samples, and a water pump provides power to form a test loop seepage channel; a control valve, an energy accumulator, a filtering device and a pressure and flow sensor are arranged on a water inlet / outlet pipe connected with the seepage experiment device; the stress and displacement loading system is equipped with a hydraulic cylinder driven by an oil pump and a trapezoidal screw; the hydraulic cylinder and the trapezoidal screw are matched with the pressure and flow sensor, so that the pressure and displacement can be accurately regulated and controlled; an unrelated three-degree-of-freedom sliding system is formed by a flange bearing, a cylindrical pin and a small ball, so that loading is not interfered by friction and other adverse factors; and moreover, all data in the experimental process is acquired and recorded by the data acquisition system in real time.

Owner:CHINA UNIV OF MINING & TECH

Sublevel fill-mining method

The invention discloses a sublevel fill-mining method. By utilizing the natural angle of repose characteristics of caving ores and dry mine fill and according to medium hole drilling device-adapted height and the ore-permitted exposed area, space and time at present, sublevel mining is carried out from the bottom to the top in the open-field state and the dry mine fill is adopted for filling in time. The sublevel fill-mining method has the advantages of an open-field method and a dry fill and sublevel caving method without sill pillar, thereby forming a novel sublevel dry fill-mining method without sill pillar, and is particularly applied to ore mines with large-scale ore body and high yield requirement. The top filling of a filling body is realized by the self-weight of the filling body; a vibratory roller or a device special for underground tamping is adopted to apply pressure to the filling body through a lane top plate to tamp the filling body in a vibration mode, so that the filling body generates a certain bearing force to the above ore body or the rock mass. The sublevel fill-mining method is a mining method which has the advantages of safety, high efficiency, high mining capacity, low loss and dilution, and low production cost.

Owner:HEBEI HAN XING INST OF MINE & METALLURGY DESIGN

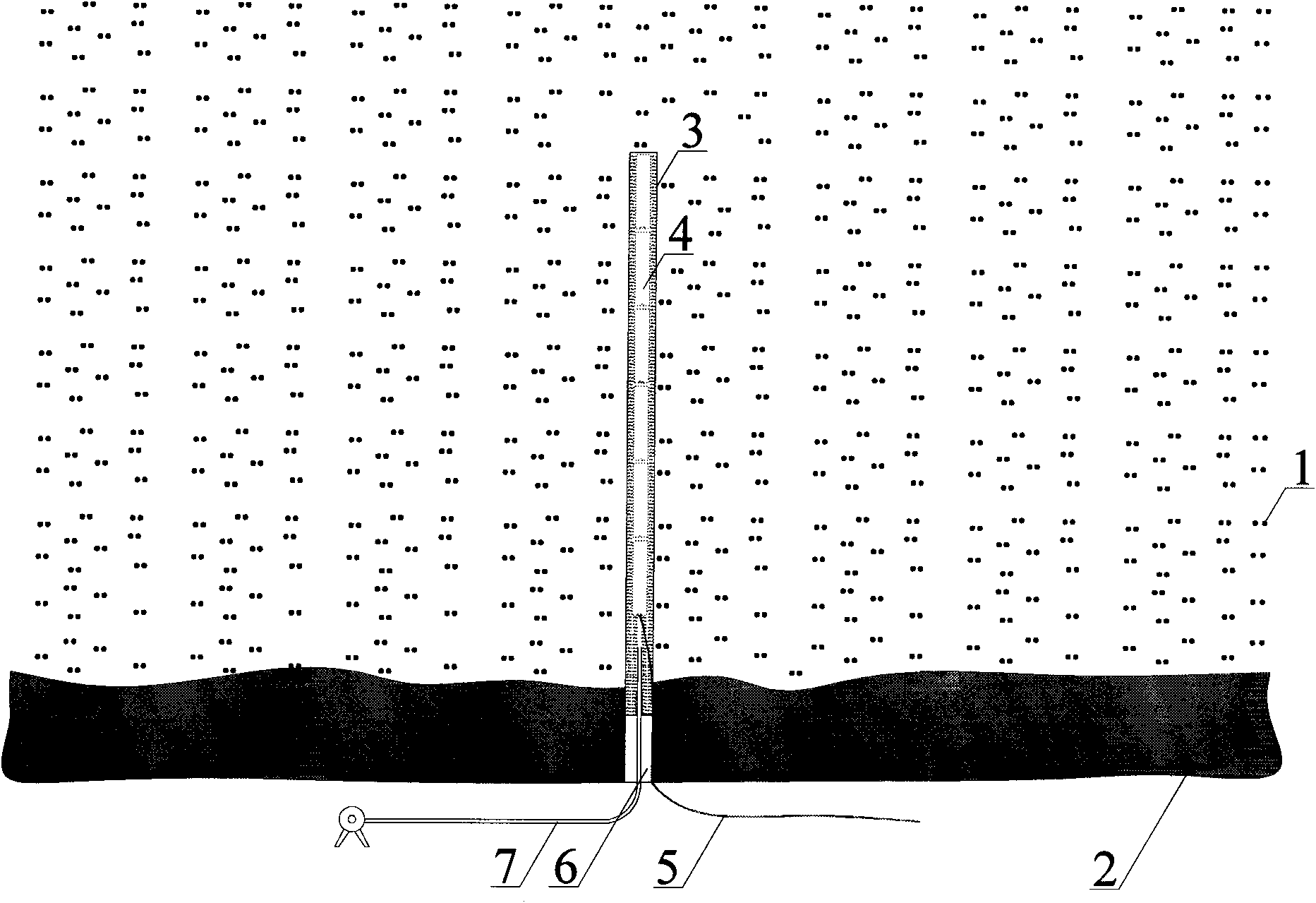

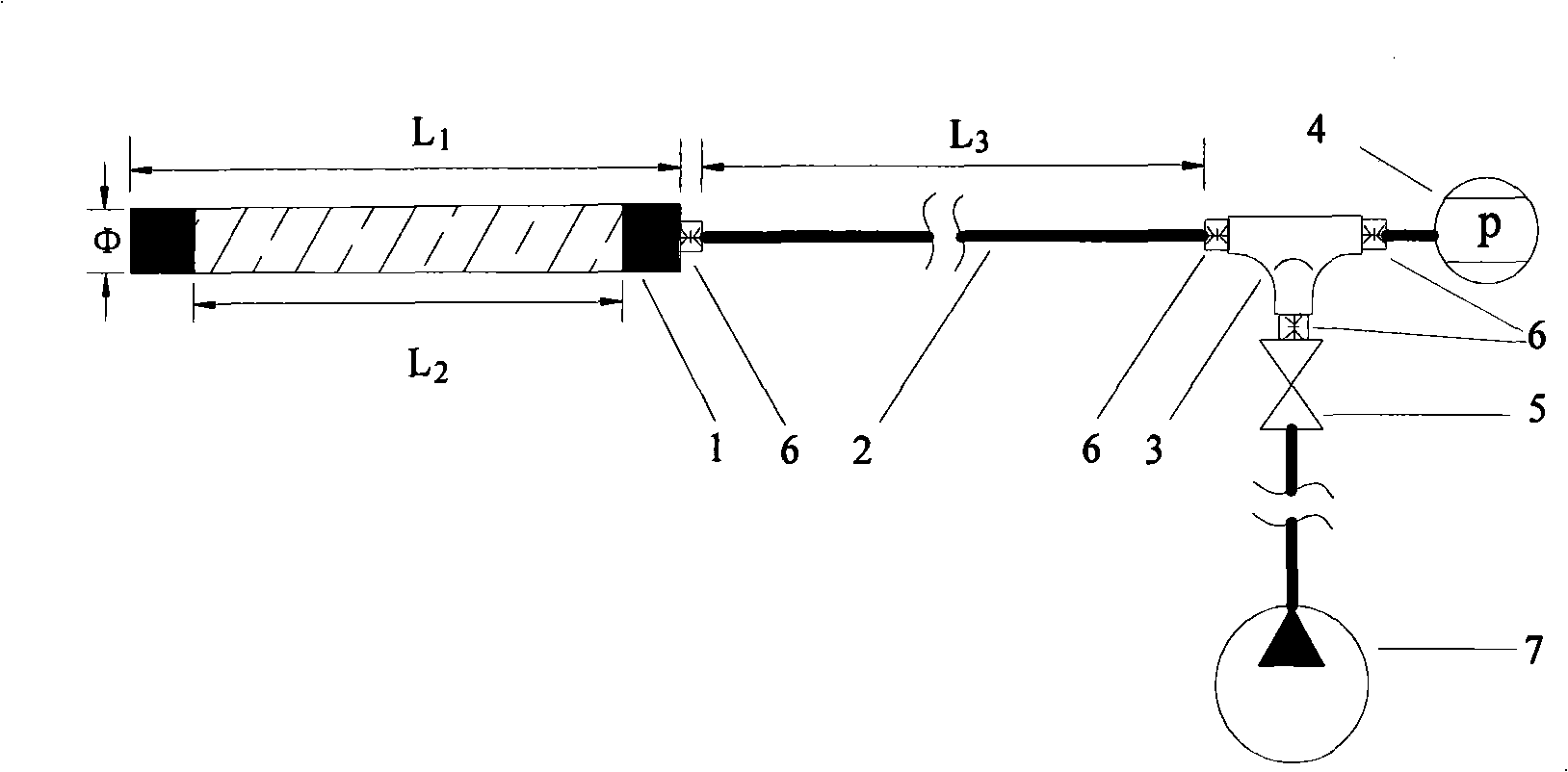

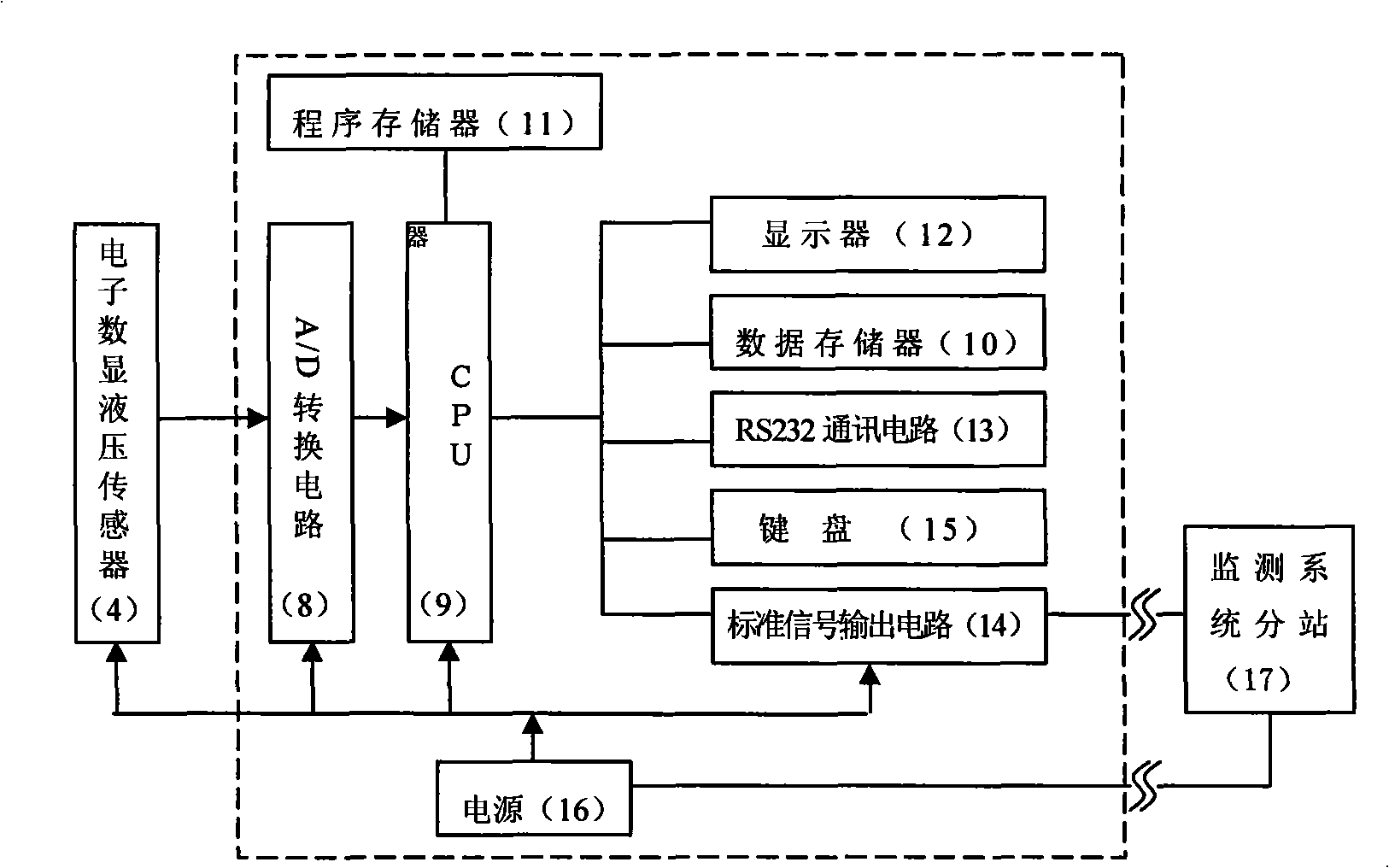

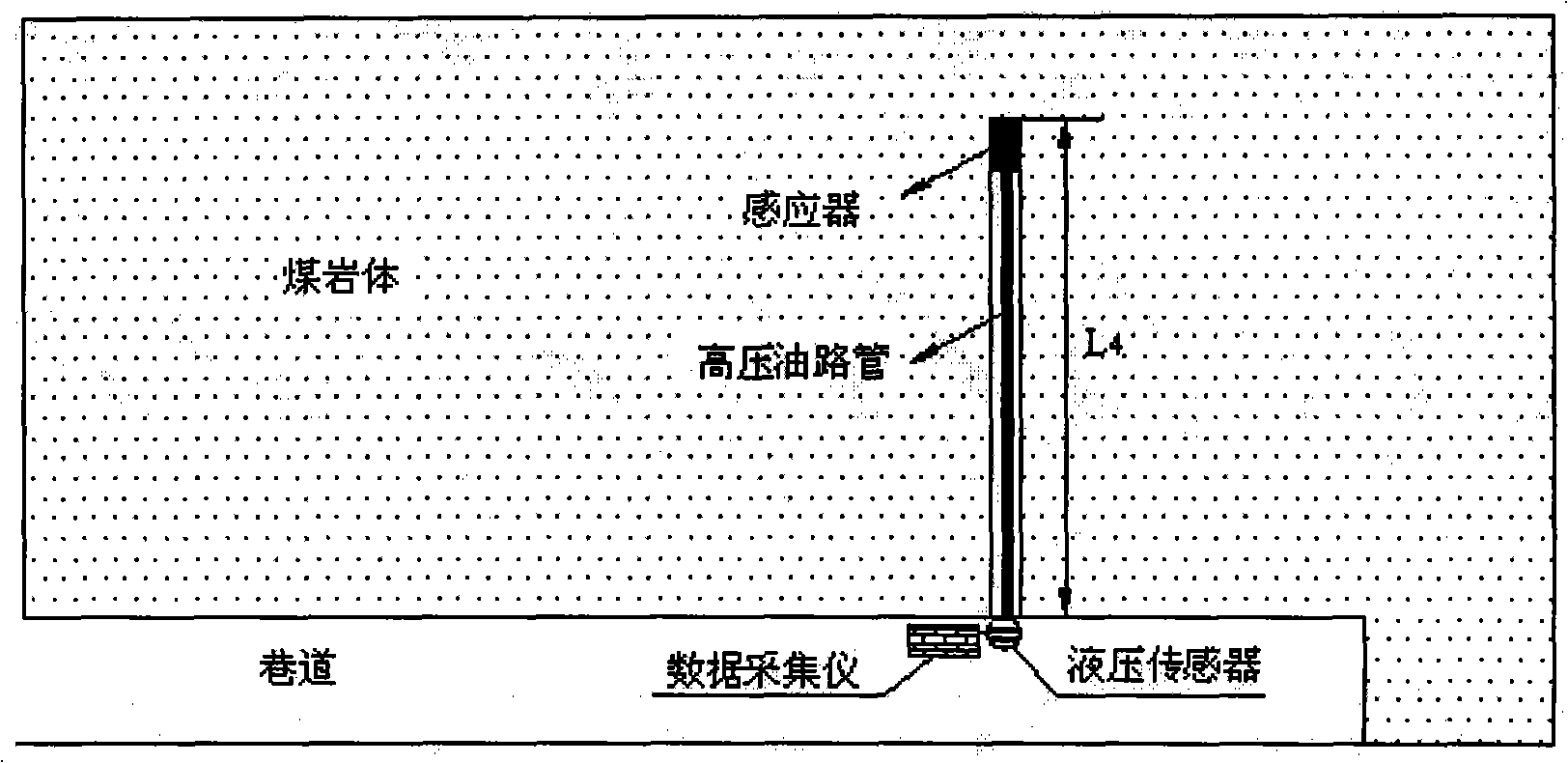

Coal-rock mass ground stress continuous testing device and method thereof

ActiveCN101514926AGood active couplingContinuous testingHydraulic/pneumatic force measurementModem deviceData acquisition

The invention relates to a coal-rock mass ground stress continuous testing device and a method thereof which are mainly used for testing the stress and change regularity of rock in place or crushed coal-rock mass. The device consists of a ground stress sensor, a data acquisition instrument and a high pressure oil pump, which can work separately and can be connected with the data acquisition instrument to work. The ground stress sensor consists of a preposing capsule pressure sensor (1), a high-pressure oil tube (2), a tee (3), an electronic digital display hydraulic sensor (4), a valve (5) and a quick change coupler (6); wherein, the capsule pressure sensor is arranged inside a borehole, and can be well coupled with the coal-rock mass by injecting oil liquid; the ground stress testing results can be directly displayed on a pressure gauge; the sensor can be directly connected with a coal mine safety monitoring system, or the data can be acquired by the data acquisition instrument for remote data transmission, or telephone wires can be used for the communication between the sensor and ground modem as well as a computer; in ground-based computer software, the ground stress data and the change regularity thereof can be looked over.

Owner:CHINA UNIV OF MINING & TECH +1

Device for testing durability of water pressure resistant grouted rock

InactiveCN101813604APrecise temperature controlAccurate measurementPermeability/surface area analysisAxial pressureEngineering

The invention discloses a device for testing the durability of a water pressure resistant grouted rock, which comprises a pressure chamber, a control cabinet, heating equipment, pressurizing equipment, measuring equipment and accessory equipment, wherein the heating equipment can supply a stable heat source for the pressure chamber; the pressurizing equipment can provide confining pressure and osmotic pressure for the pressure chamber; the pressure chamber can apply an axial pressure by means of a universal test, is corrosion resistant and can realize annular and vertical penetration tests of three kinds of standard samples of different dimensions at different temperatures and pressures; the measuring equipment can realize accurate measurement of temperature, pressure and flow rate; and the control cabinet can realize the accurate control of pressure and temperature. The device can be used for indoor researches on the durability of tunnel water pressure resistant grouted rock or dam impervious curtain in an environment of high-water-pressure and corrosive environment, and at the same time, realizes the researches on the change rule of the permeability of a rock sample under the coupled actions of a temperature field, a seepage field, a stress field and a chemical field.

Owner:TONGJI UNIV

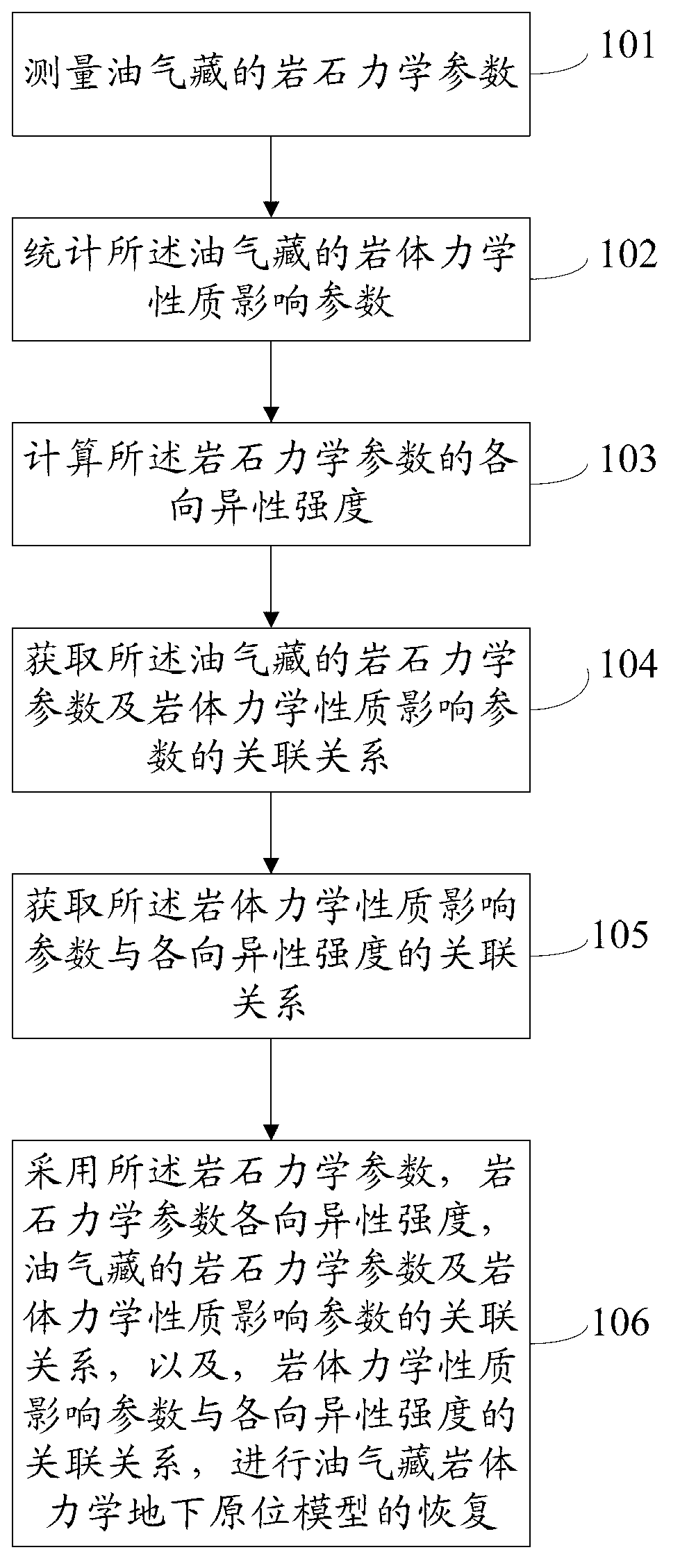

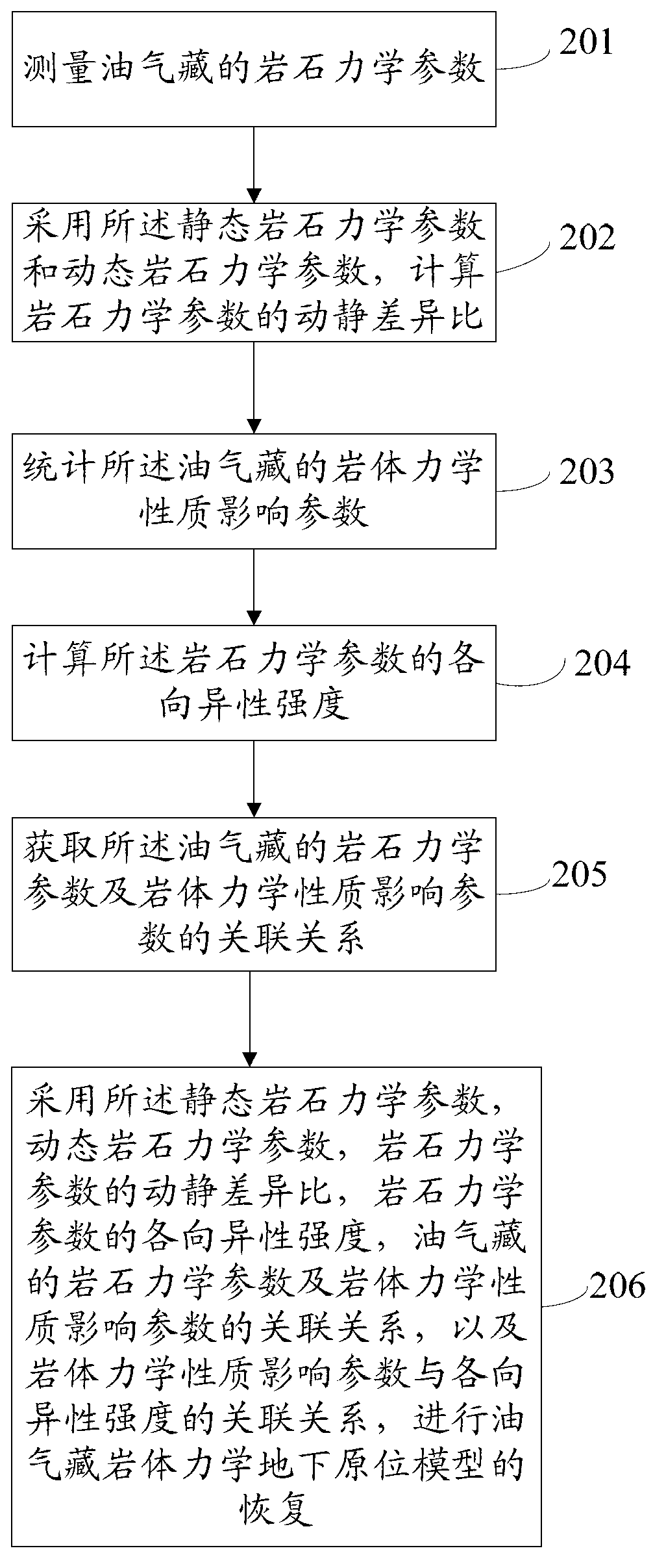

Method and device for recovering oil and gas reservoir rock mechanics underground in-situ model

InactiveCN103257081ARestoration of mechanical propertiesImprove exploration efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial strength using tensile/compressive forcesUltimate tensile strengthPetrology

The invention provides a method and a device for recovering an oil and gas reservoir rock mechanics underground in-situ model. The method comprises the following steps of: measuring rock mechanics parameters of an oil and gas reservoir; counting rock mechanics property influence parameters of the oil and gas reservoir; calculating the anisotropy strength of the rock mechanics parameters; obtaining a correlation between the rock mechanics parameters and the rock mechanics property influence parameters of the oil and gas reservoir; obtaining a correlation between the rock mechanics property influence parameters and the anisotropy strength; and recovering the oil and gas reservoir rock mechanics underground in-situ model by adopting the rock mechanics parameters, the anisotropy strength of the rock mechanics parameters, the correlation between the rock mechanics parameters and the rock mechanics property influence parameters of the oil and gas reservoir and the correlation of the rock mechanics property influence parameters and the anisotropy strength. By the method, the effectiveness and the accuracy for recovering the oil and gas reservoir rock mechanics underground in-situ model can be improved.

Owner:PEKING UNIV

Strengthening and reinforcing method of high-ground-pressure soft rock laneway by hierarchical grouting

InactiveCN101864967AImprove the strengthening effectWill not blockUnderground chambersTunnel liningSlurryHigh pressure

The invention relates to a strengthening and reinforcing method of a high-ground-pressure soft rock laneway by hierarchical grouting. Aiming at the deformation damage and crack distribution rules of laneway wall rock of high-ground-pressure soft rock, a hierarchical grouting mode for a shallow layer and a deep layer is adopted to hierarchically and emphatically strengthen and reinforce the shallow layer and the deep layer by grouting. The method comprises the following steps of: firstly, carrying out shallow-hole low-pressure grouting to a laneway shallow-layer gap development zone and then carrying out deep-hole high-pressure grouting to deep rock bodies; constructing shallow-hole grouting with small grouting pressure so that grout is scarcely diffused into the deep part, and grouting passages, such as a deep gap of the deep part and the like, are well preserved without blockage; and adopting a double-component chemical grout malisan with easy dispersion and strong permeability in constructing deep-hole grouting to realize deep high-pressure grouting on the basis of a formed grout-stopping shielding shell formed by former-period shallow-hole grouting so that the distribution compactness and the dispersion evenness of the grout in the deep grouting are improved, and the strengthening effect of the deep grouting on the wall rock is effectively improved. The method is simple and easy to implement.

Owner:CHINA UNIV OF MINING & TECH

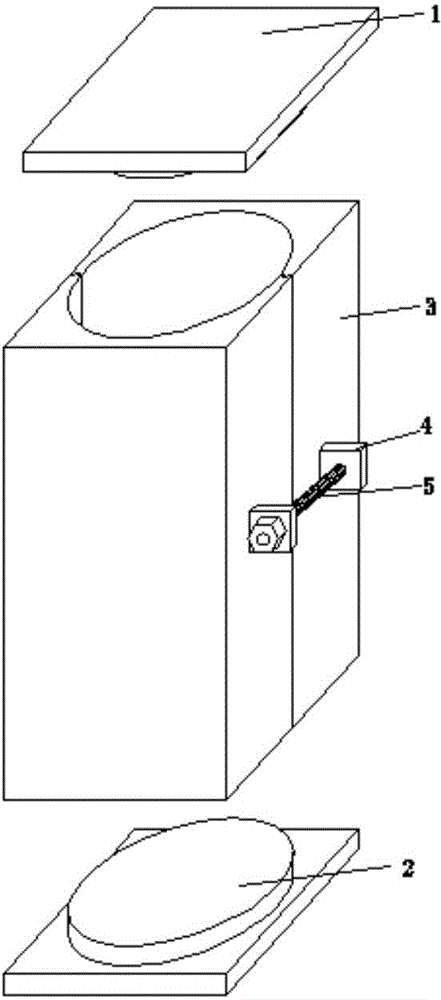

Joint test specimen method using 3D (three-dimensional) printing for making structure surface containing specific geometrical characteristics

ActiveCN104807685AThe sample preparation process is simple and fastOperational securityPreparing sample for investigationEngineeringModel test

The invention provides a joint test specimen method using 3D (three-dimensional) printing for making a structure surface containing specific geometrical characteristics, and belongs to a specimen making method of model test specimens similar to joint rock bodies. According to the method, the structure surface is independently designed according to study requirements, or the actual rock body structure surface appearance is obtained through a surface outline scanning technology; the designed structure surface penetrates through a complete cylinder model in 3D graphics software, two parts of complementary test block models obtained through separation are obtained through Boolean operation, and a 3D printer is used for respectively printing and forming the two parts of test block models; printing molds are respectively put into two specimen making boxes and are assembled, similar materials are cast into the specimen making boxes, and the mold dismounting maintenance is carried out after the materials are solidified and formed; the two parts of test blocks are correctly combined to obtain the standard test specimens containing the designed structure surface. The method has the advantages that (1) the operation of the method is safe, simple and convenient; (2) the complicated and variable structure surface is embedded in the standard test specimens, the actual rock body structural surface can be reproduced through being matched with the surface outline scanning technology, and the reasonable test result is obtained.

Owner:CHINA UNIV OF MINING & TECH

Drilling and sealing method and sealing device for ultra-high pressure fracturing holes in underground coal mines

The invention discloses a drilling-sealing method and a sealing device of a coal mine underground ultrahigh pressure fracturing hole. The drilling-sealing method comprises the following steps: drilling a plugging hole on coal rock body; going on drilling a fracturing hole forward in the plugging hole; transmitting the sealing device into the plugging hole, enabling a water outlet hole of a fracturing pipe to stretch into the fracturing hole and enabling a taper sleeve sleeved on the fracturing pipe and made of soft material to plug on a hole opening of the fracturing hole; sealing by using polyurethane and solidifying for 30 minutes for 1 m length section at the hole opening of the plugging hole; and grouting cement slurry greater than 425 into the plugging hole with pressure by a grouting pipe, and solidifying for 48 hours after finishing grouting. The device comprises a grouting pipe and a slurry returning pipe and a fracturing pipe. The grouting pipe and the slurry returning pipe are arranged in the plugging hole. The grouting pipe, the slurry returning pipe and the fracturing pipe are connected integrally. A soft taper sleeve is arranged on the fracturing pipe. The soft taper sleeve is plugged at the hole opening of the fracturing hole. The invention has the advantages that the sealing method has high sealing success rate, good effect and wide application range; and the sealing device has simple structure and convenient operation.

Owner:重庆市能源投资集团科技有限责任公司 +1

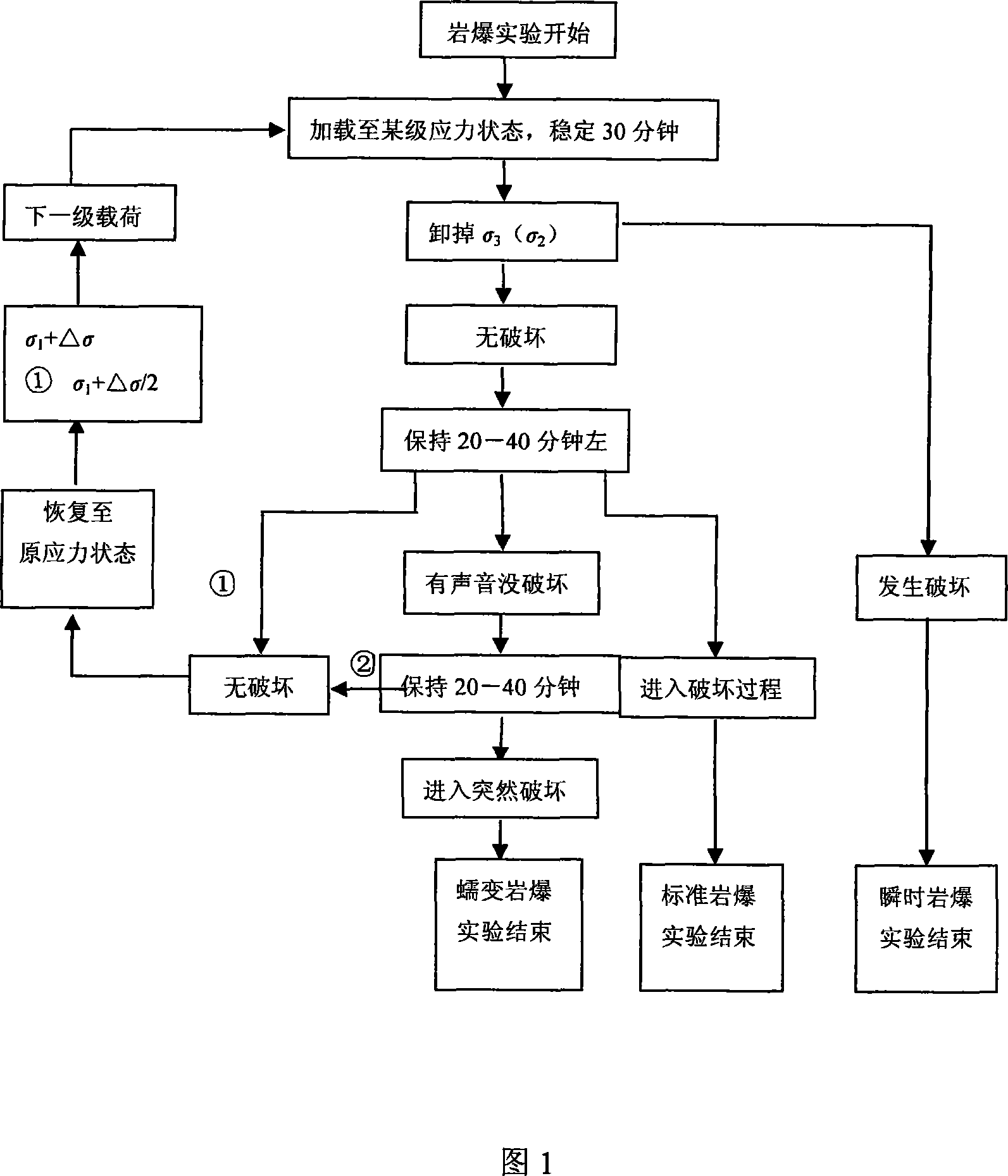

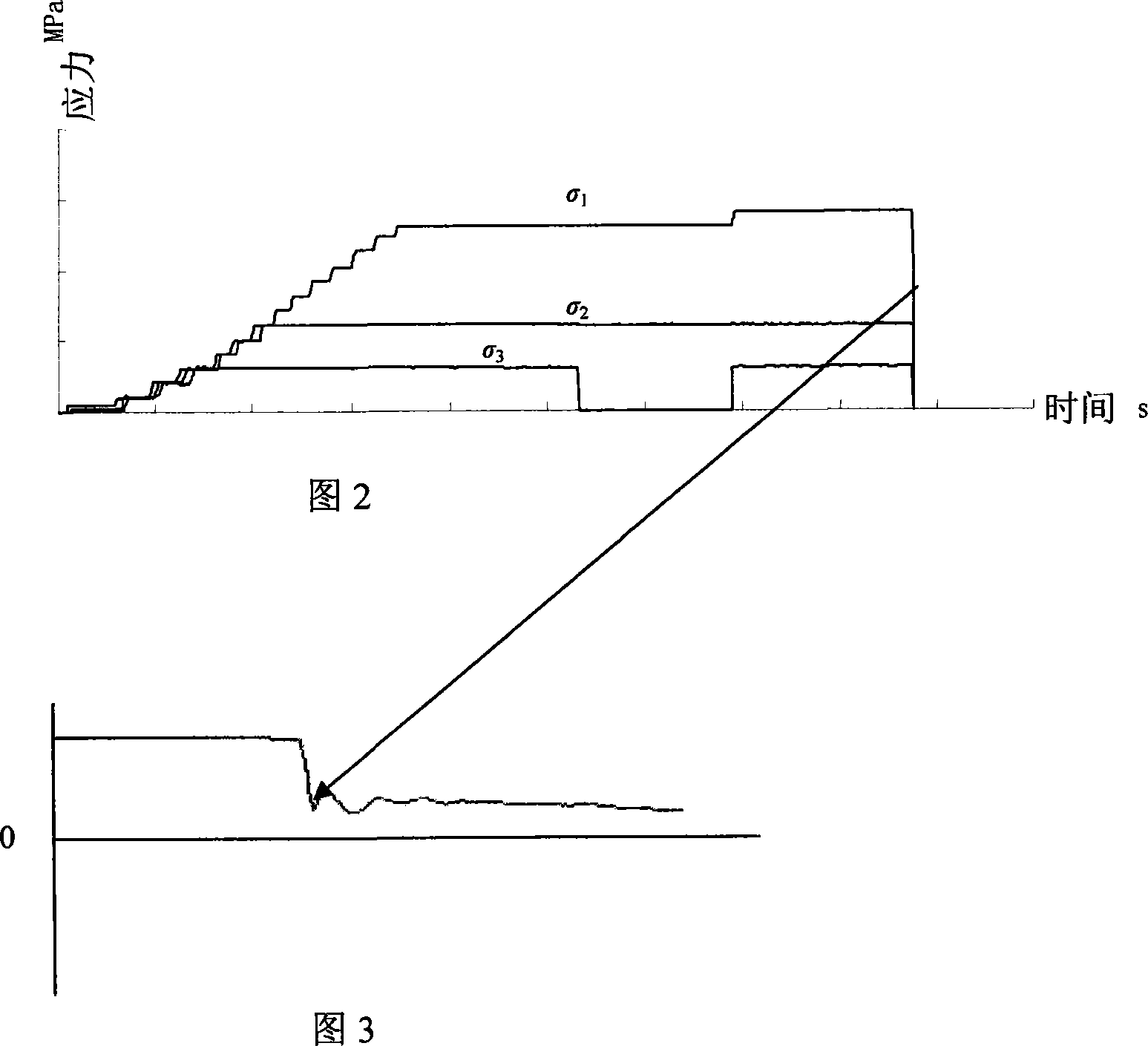

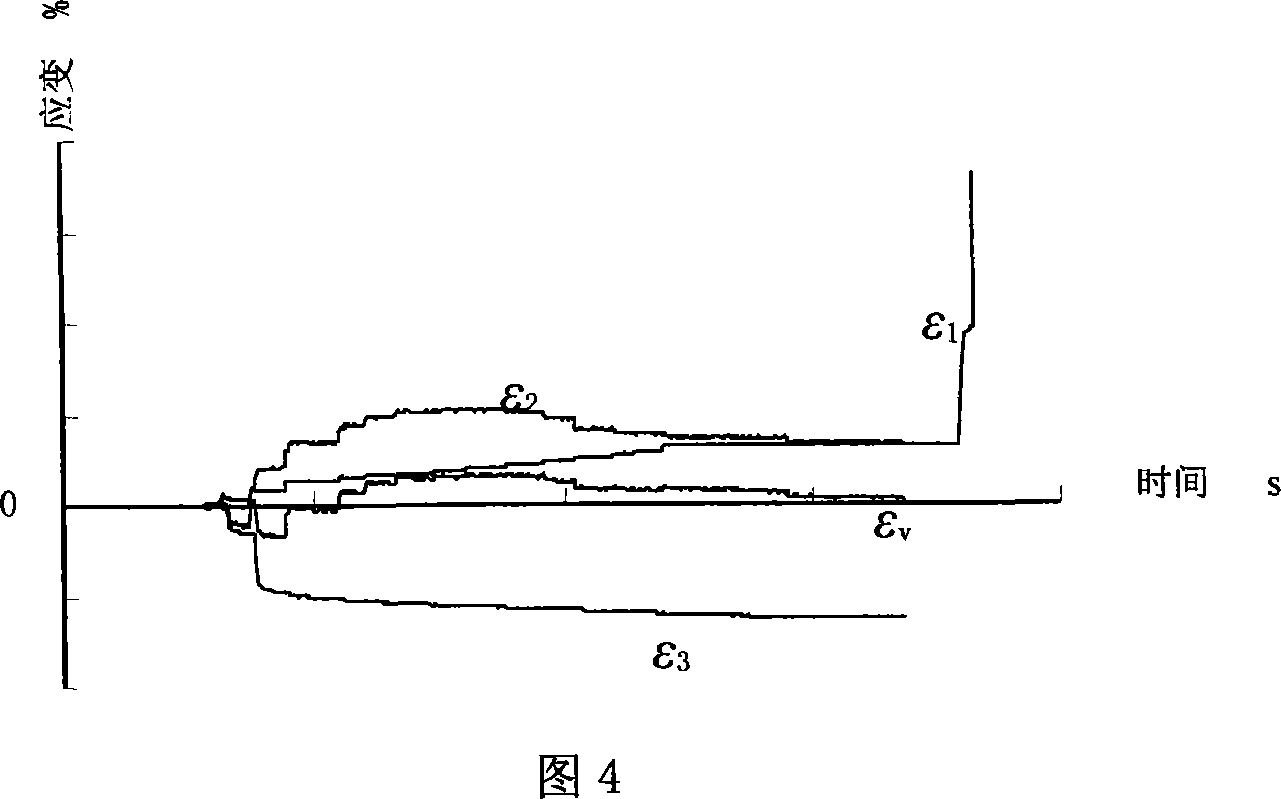

Test method for deep rock explosion process model

ActiveCN101051011ARock Burst Prevention and ControlMaterial strength using tensile/compressive forcesExperimental researchExperimental methods

A model testing method of deep rock burst includes carrying out true three shafts loading on rock burst simulation unit then applying unload at single surface, carrying out rock burst test on rock body when load is charged and discharged for realizing rock burst model test in laboratory.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

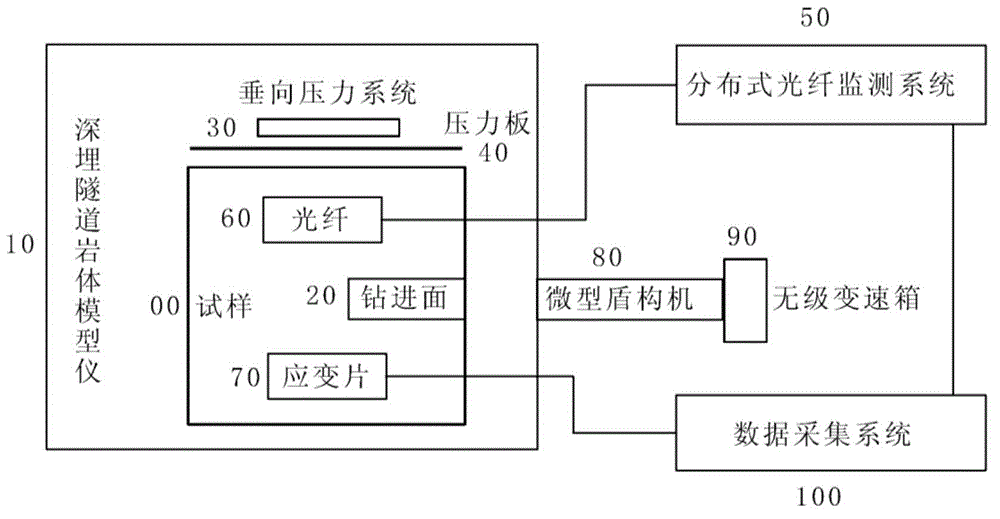

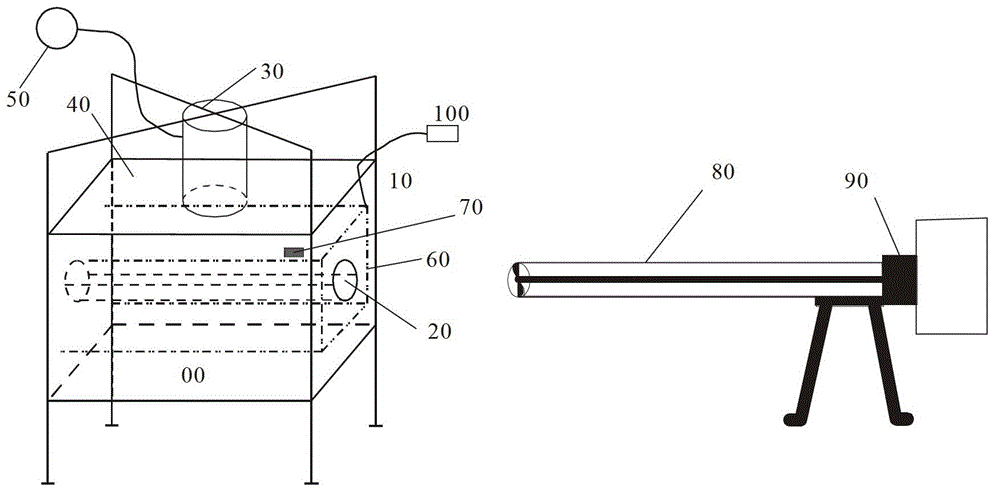

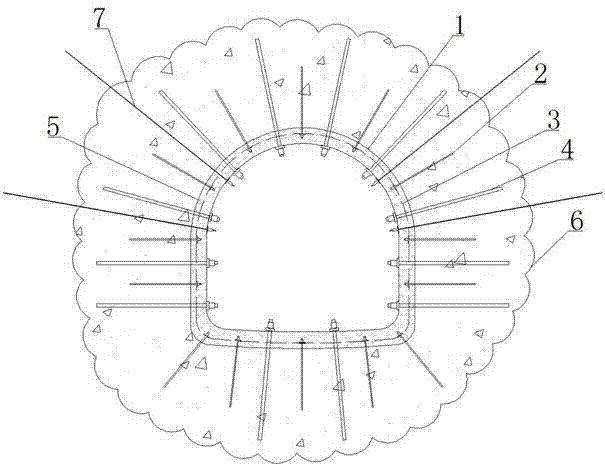

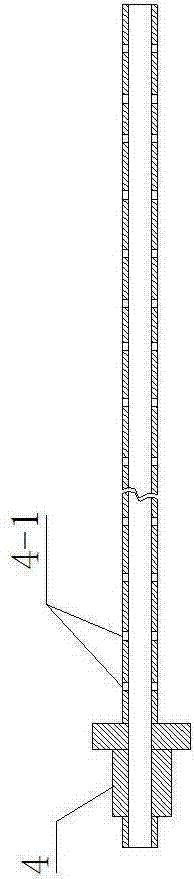

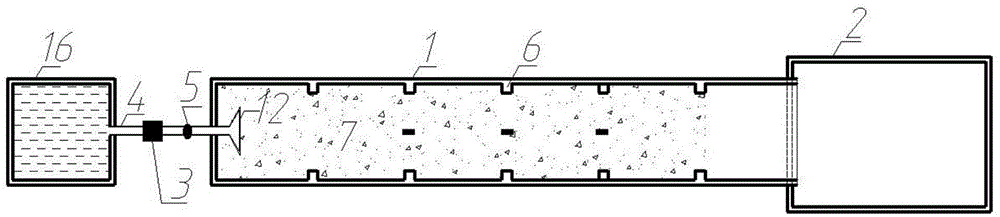

Device and method for physical simulation test of stability of deep tunnel surrounding rock

InactiveCN102721604ASafe Tunnel Construction SpeedEfficient tunnel construction speedStrength propertiesSoil mechanicsData acquisition

The invention discloses a device and a method for a physical simulation test of the stability of a deep tunnel surrounding rock and relates to a rock-soil mechanic technology. A structure of the device is that a pressure plate is covered on a sample in a deep tunnel rock body model instrument, and a vertical pressure system is arranged on the pressure plate and used for loading so as to simulate and exert gravity stress. A miniature shield machine drills into the sample from a drilling surface, and the miniature shield machine, a stepless speed changing box and a motor are sequentially connected to achieve drilling. Eight optical fibers and six strain gauges are distributed in the sample, the optical fibers are connected with a distributed optical fiber monitoring system, and the distributed optical fiber monitoring system and the strain gauges are respectively connected with a data acquiring system so as to achieve detection and recording. By means of the device and the method for the physical simulation test of the stability of the deep tunnel surrounding rock, a development and change law of stress strain when a deep tunnel rock body is excavated in tunnel construction can reappear accurately, and a novel solving path for researching the stability of the grotto surrounding rock and forming mechanism of rock burst in the tunnel construction.

Owner:INST OF GEOMECHANICS

Supporting and reinforcing structure of coal mine tunnel and construction technology thereof

InactiveCN103195441AEven by forcePrevent weatheringUnderground chambersTunnel liningPre stressArchitectural engineering

The invention discloses a supporting and reinforcing structure of a coal mine tunnel and a construction technology thereof. The supporting and reinforcing structure of the coal mine tunnel comprises a lane, wherein a grid-shaped reinforced layer is arranged on the inner wall of the lane, an anchor rod is arranged on the grid node portion of the reinforced layer, the inner end of the anchor rod is anchored in surrounding rock of the lane, and an anchor plate and a nut of the anchor reinforced layer are arranged at the outer end of the anchor rod. A concrete spraying layer covered on the reinforced layer and arranged at the outer end of the anchor rod is further arranged on the inner wall of the lane, a grouting anchor rod is arranged in the surrounding rock of the lane, an anchor cable is further arranged in the surrounding rock of the lane, the inner end of the anchor cable is anchored in the surrounding rock of the lane, and the outer end of the anchor cable is anchored on the outer side of the concrete spraying layer through a tray and a tensioning lock. The supporting and reinforcing structure of the coal mine tunnel integrates the surrounding rock of the lane in cementing mode with the initiative supporting theory as the guidance, prestress is reserved in the rock body, and stress is released and superimposed slowly, so that self integral strength and stability of soft rock and coal body are improved, the surrounding rock in a release ring of the lane can form a structure relatively homogenous and stable, and the aim of reinforcing and protecting the soft rock lane can be achieved within a long time.

Owner:PINGDINGSHAN TIANAN COAL MINING

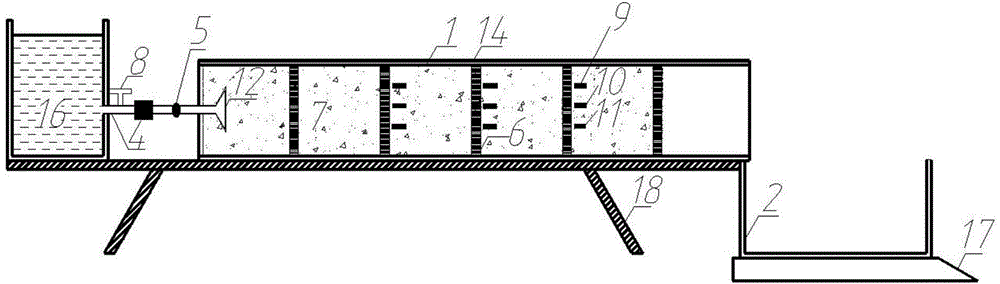

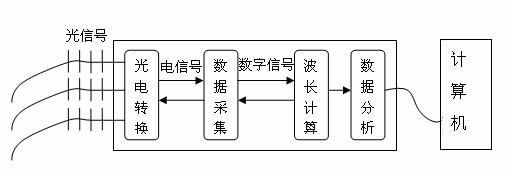

Visual model testing device and method for simulating water gushing in tunnel

ActiveCN104807960AObserving the Progressive Destruction ProcessEasy to fillMaterial analysisModel testingMonitoring system

The invention discloses a visual model testing device and method for simulating water gushing in a tunnel. The device comprises a model test box, a water tank, a high-pressure water pump, a flow meter, a runoff flow and filling collecting device, a digital photographing non-contact measuring system, an osmotic pressure monitoring system, a fiber grating displacement monitoring system and the like. The testing device is characterized in that the catastrophe evolution process of water gushing in the tunnel is simulated, and anti-gushing rock mass crack growth and water gushing channel formation during water gushing can be directly observed. The device can quantitatively research water gushing behavior of the tunnel under different water pressure, different lithological characters and different thicknesses of anti-gushing rock masses, acquire coupling information of multiple fields such as stress fields, displacement fields, seepage fields and the like during water gushing of the tunnel, determine formation processes and forms of water gushing channels under the effect of different factors, disclose mechanical characteristics and evolution laws in anti-gushing rock mass structure progressive failure processes and provide an effective basis for the tunnel water gushing disaster incoming criterion and the minimum safe thickness analysis method.

Owner:CHINA UNIV OF MINING & TECH

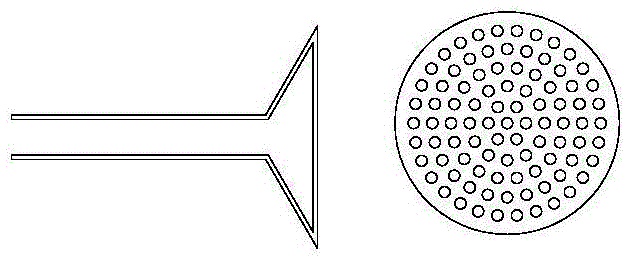

Fiber bragg grating (FBG) testing device and testing method for rock three-dimensional stress state

InactiveCN102175366AImprove test accuracyHigh precision measurementForce measurement by measuring optical property variationFbg sensorGeophysics

The invention discloses a fiber bragg grating (FBG) testing device and a testing method for rock three-dimensional stress state. The testing device comprises a data processing module consisting of an FBG network demodulator and a computer, three FBG sensors and a substrate for mounting the FBG sensors; the substrate can be deformed with the deformation of rocks; the three FBG sensors are respectively fixed in three-dimensional directions on the surface of the substrate; and the signal output ends of the three FBG sensors are connected with the signal input ends of the FBG network demodulator. The invention can measure the deformation amount of microstrain, so responses can be made in time before rock masses are damaged; the high-precision measurement of three-dimensional stress in rocks can be realized, so that the long-term and effective monitoring for large project rock masses can be realized, and disasters are prevented.

Owner:HENAN POLYTECHNIC UNIV

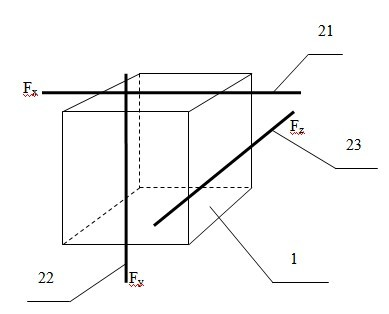

Rock mass structural surface shear test method and device

InactiveCN104749049AGuaranteed shear strengthGuaranteed StrengthMaterial strength using steady shearing forcesHorizontal axisSurface shear

The invention discloses a rock mass structural surface shear test method, which comprises the following steps of firstly, cutting a rock mass test piece into a cuboid and marking a vertical axis line and a horizontal axis line; then adjusting an adjusting rod, fixing the rock mass test piece by a movable steel baffle, enabling the vertical axis line of the rock mass test piece to coincide with the vertical axis line of a normal loading mechanism, enabling the horizontal axis line of the rock mass test piece to coincide with the horizontal axis line of a shear loading mechanism, and enabling the structural surface of the rock mass test piece to be located above the movable steel baffle; carrying out grading force application on the rock mass test piece by the normal loading mechanism from the vertical direction, and carrying out grading force application on the rock mass test piece by the shear loading mechanism from the horizontal direction; receiving the force application data of the normal loading mechanism and the shear loading mechanism and the displacement values of a normal displacement sensor and a horizontal displacement sensor by a computer, and analyzing and calculating the data. The invention also provides a rock mass structural surface shear test device. According to the invention, the stress bearing condition of a rock mass in the reality can be simulated, and test data are accurate and reliable.

Owner:WUHAN UNIV OF TECH

Method for manufacturing direct shear test structural plane model

ActiveCN101718644ALong sampling costLow efficiencyPreparing sample for investigationFeeding arrangmentsSize determinationOperability

The invention relates to a method for manufacturing a direct shear test structural plane model. The method comprises the following steps of: (1) the selection and the processing of a virgin rock structural plane: selecting a virgin rock structural plane to be used as a sample, and leveling an original structural plane of the rock mass; then coating a mould release agent at a selected position determined according to the specific size of a structural plane model, and spreading an isolating membrane; (2) putting a lower mould on the selected position of the original structural plane, and pouring a uniformly stirred mixed material into the lower mould; after carrying out water retention maintenance on the sample, turning over a lower disk structural plane sample together with the lower mould, and removing the used isolating membrane on the lower disk structural plane; (3) coating the mould release agent on the prepared lower disk structural plane, and spreading the isolating membrane; centering and putting an upper mould on a lower mould, and then pouring a uniformly stirred mixed material of weighed raw materials into the upper mould again; and (4) demoulding. The method has specific principle, strong maneuverability, low cost and good use effect.

Owner:GUANGZHOU FULI CONSTR & INSTALLATION ENG

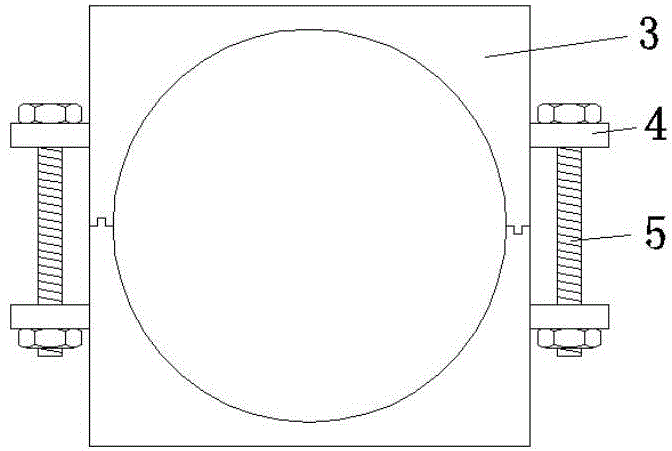

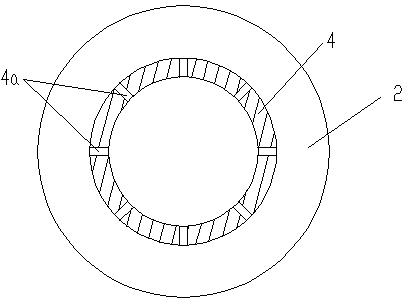

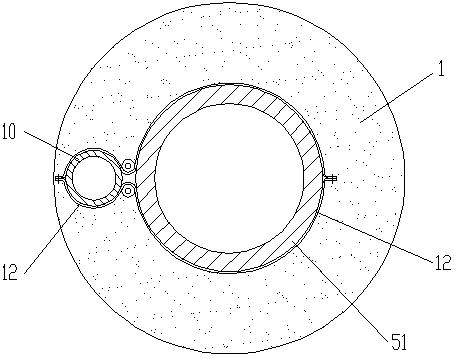

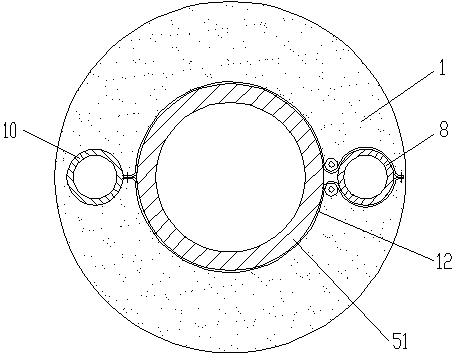

Dynamic and static combined loading rock test machine and test method used for multiphase coupling

ActiveCN106918531AModule division of labor is clearWith a clear purposeMaterial strength using tensile/compressive forcesEngineeringCoal

The invention discloses a dynamic and static combined loading rock test machine and test method used for multiphase coupling. The machine comprises a visual confining pressure loading chamber module, air pressure control modules, a dynamic loading module and constant volume modules; and the loading chamber of the visual confining pressure loading chamber module is a steel cylinder structure with a square outside and a circular inside, three surfaces of the loading chamber has windows, high borosilicate glass is embedded in every window to realize the visualization of the test process, an opening in one surface of the loading chamber is provided with a rear door which is convenient to replace and take a test piece, and various monitoring devices are arranged in the loading chamber and are led out through sensor lead wires of a baseboard to realize real-time monitoring of all physical-mechanical parameters of the test piece in the test process. The machine has the advantages of small size, simple structure, convenience in dismounting, and realization of accurate, quantitative and visual monitoring of the adsorption-desorption characteristic of a coal rock standard test piece in different load forms and coupling form and the permeability and the damage dilatancy process of gas-containing coal body in different loading stages.

Owner:SHANDONG UNIV

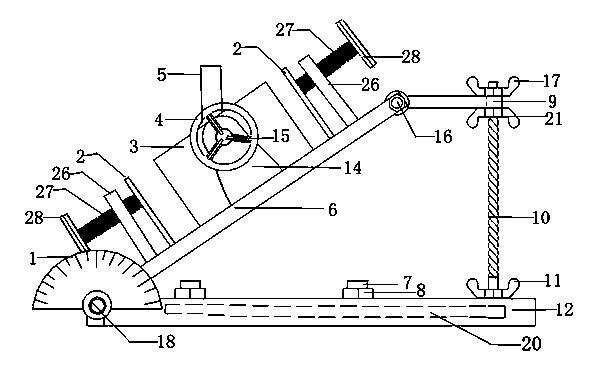

Test device of model for manufacturing rock masses containing interlayers and test method thereof

InactiveCN103983494ASimple structureEasy to operatePreparing sample for investigationUsing mechanical meansTest efficiencyDiameter ratio

The invention discloses a test device of a model for manufacturing rock masses containing interlayers and a test method thereof. The test device of the model for manufacturing the rock masses containing interlayers comprises a semicircular angle device, an upper baffle, a lower baffle, a left side plate, a right side plate, a circular turntable, a core-drilling machine drill bit, a flat plate, a flat plate angle control rod, a fixed screw rod, a base plate, an interlayer model test piece, a U-shaped plate and a guide slot. The test method comprises the following test steps: arranging the rock masses according to an outline central line and fixing the rock masses; manufacturing interlayer materials and casting the model, fastening the test piece, drilling the core, replacing the core-drilling machine drill bit, changing the position of the test piece to drill repeatedly and cutting to obtain the test pieces with different height-diameter ratios or obtain the test pieces with different interlayer inclination angles; then carrying out mechanical test. The test device is simple in structure and suitable for manufacturing the test pieces with different interlayer thicknesses, inclination angles and height-diameter ratios; according to a core-drilling and cutting machining device, by making full use of the existing device, the influence on the mechanical properties of the test pieces caused by different conditions can be analyzed, coring of irregular rock samples taken in the site can be carried out directly, so that the test efficiency is improved and the test time is shortened.

Owner:CENT SOUTH UNIV

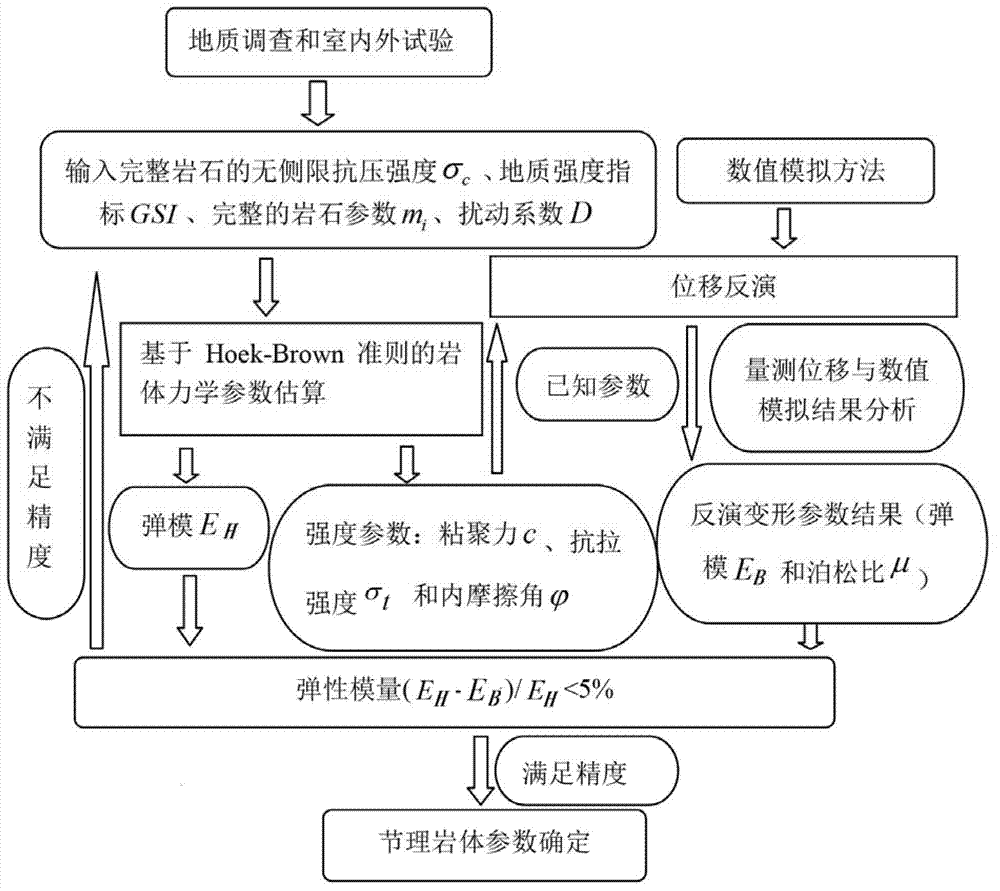

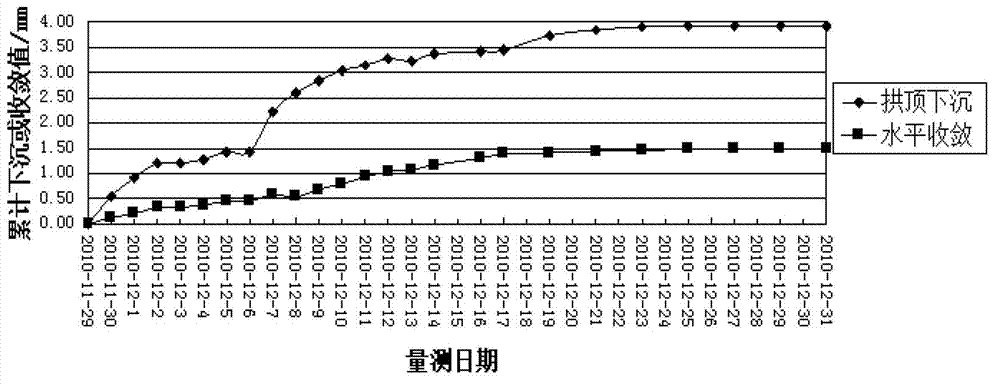

Method for determining jointed rock mechanical parameters

InactiveCN103175730AVerify reliabilityVerify uniquenessStrength propertiesGeomorphologyCompressive strength

The invention discloses a method for determining jointed rock mechanical parameters. Aiming at solving the problem that the existing jointed rock mechanical parameters have low reliability, the method comprises the following steps of: 1) measuring the uniaxial compressive strength sigmac of a rock, the flexibility mi of the rock, the GSI (geographical strength index) and the disturbance factor D; 2) estimating the mechanical parameters of rock, such as mass C, phi, sigmat and EH, by Hoek-Brown strength criterion; 3) establishing a numerical calculation model so as to obtain the calculated displacement, comparing with the site displacement so as to obtain a comparison result, and determining whether the strength of the GSI is regulated nor not according to the comparison result; and 4) comparing EH and EB, wherein when (EH-EB) / EH is less than 5%, the deformation parameter E of elasticity modulus is estimated as the deformation parameter EH of the elasticity modulus, then the jointed rock parameter is determined, if not, returning to step 1) and reregulating the strength of the GSI. By combining two theories, the method can determine the reliable jointed rock parameters, and is applicable to rocks with very good quality or cracked rocks or anisotropy rocks.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com