Patents

Literature

44results about How to "Restoration of mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

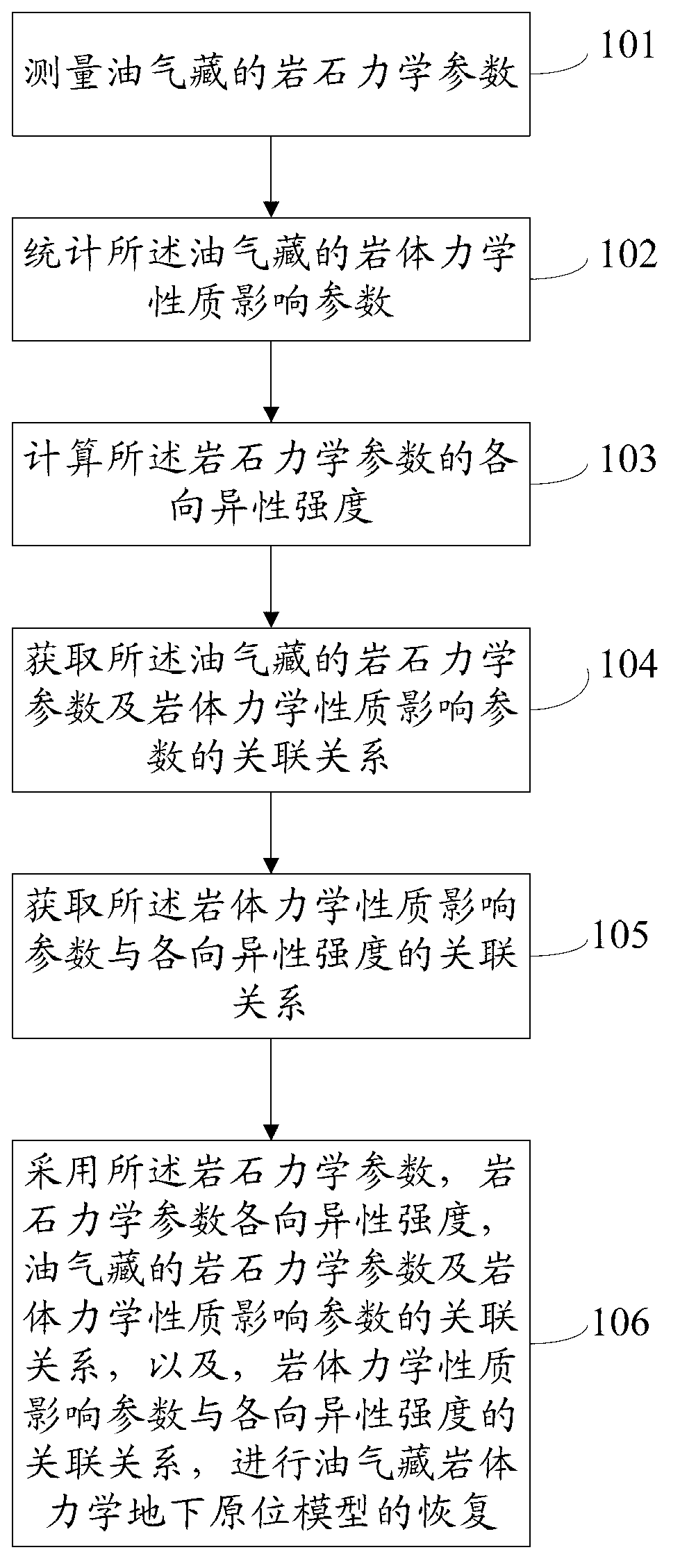

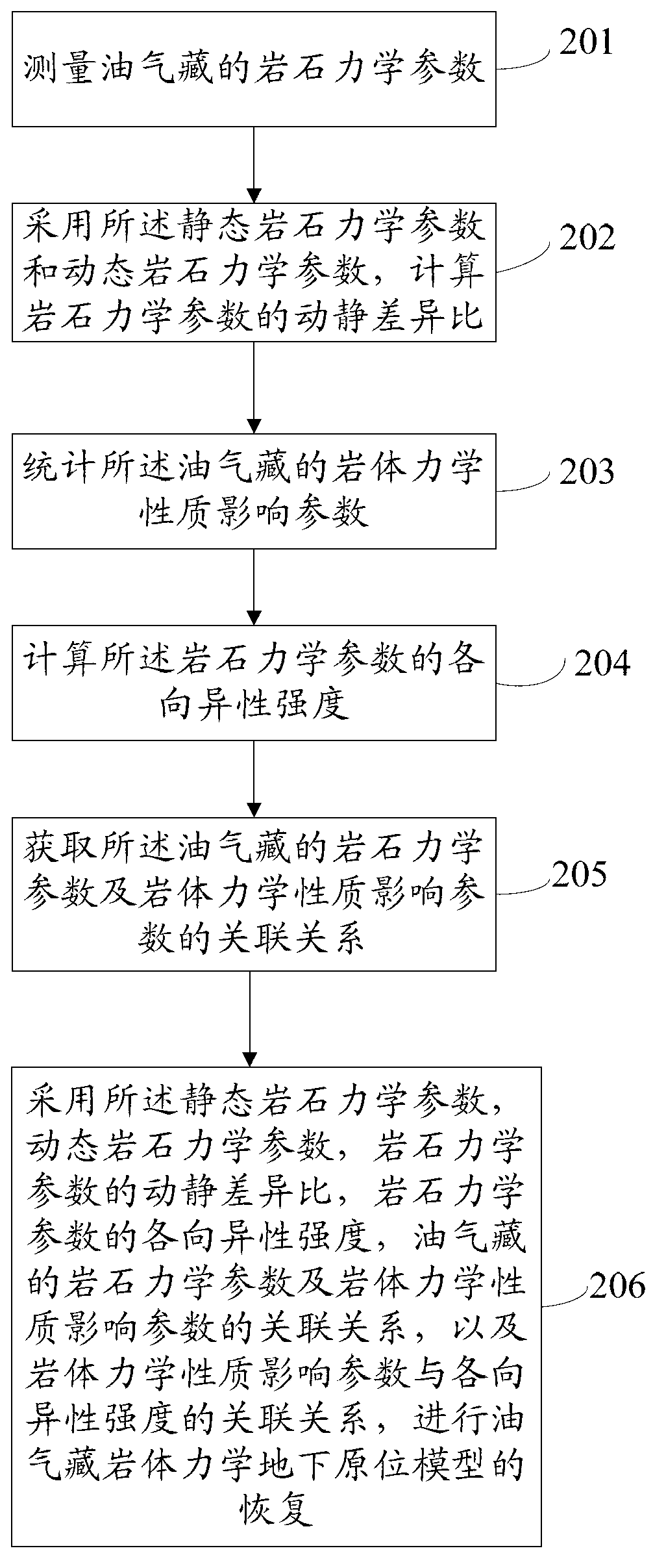

Method and device for recovering oil and gas reservoir rock mechanics underground in-situ model

InactiveCN103257081ARestoration of mechanical propertiesImprove exploration efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial strength using tensile/compressive forcesUltimate tensile strengthPetrology

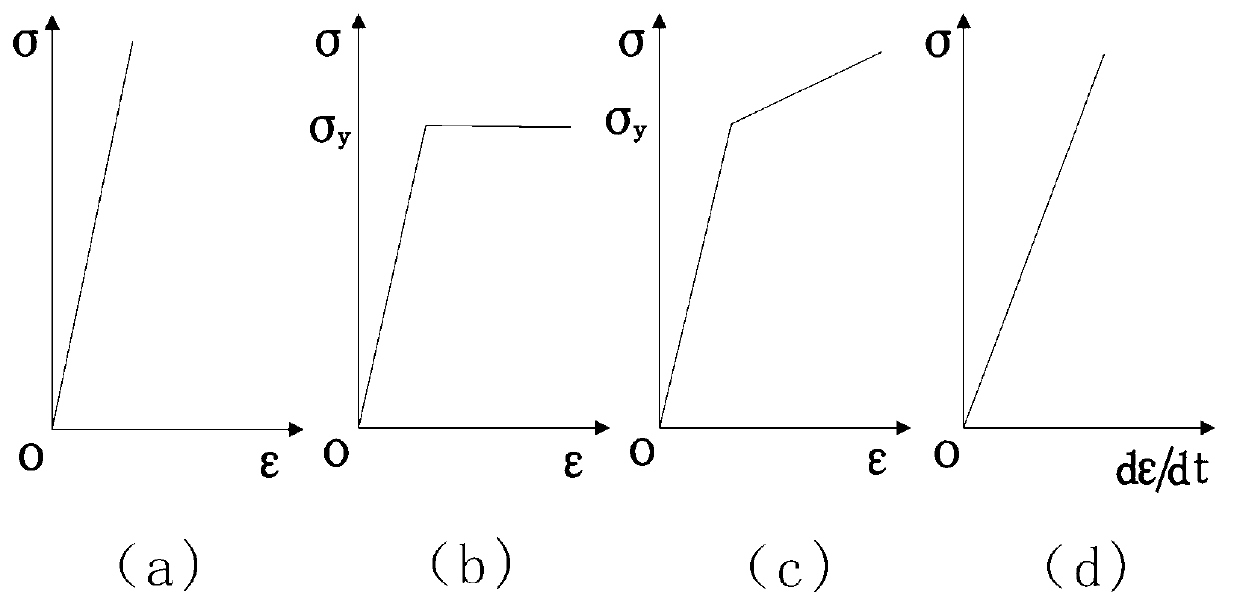

The invention provides a method and a device for recovering an oil and gas reservoir rock mechanics underground in-situ model. The method comprises the following steps of: measuring rock mechanics parameters of an oil and gas reservoir; counting rock mechanics property influence parameters of the oil and gas reservoir; calculating the anisotropy strength of the rock mechanics parameters; obtaining a correlation between the rock mechanics parameters and the rock mechanics property influence parameters of the oil and gas reservoir; obtaining a correlation between the rock mechanics property influence parameters and the anisotropy strength; and recovering the oil and gas reservoir rock mechanics underground in-situ model by adopting the rock mechanics parameters, the anisotropy strength of the rock mechanics parameters, the correlation between the rock mechanics parameters and the rock mechanics property influence parameters of the oil and gas reservoir and the correlation of the rock mechanics property influence parameters and the anisotropy strength. By the method, the effectiveness and the accuracy for recovering the oil and gas reservoir rock mechanics underground in-situ model can be improved.

Owner:PEKING UNIV

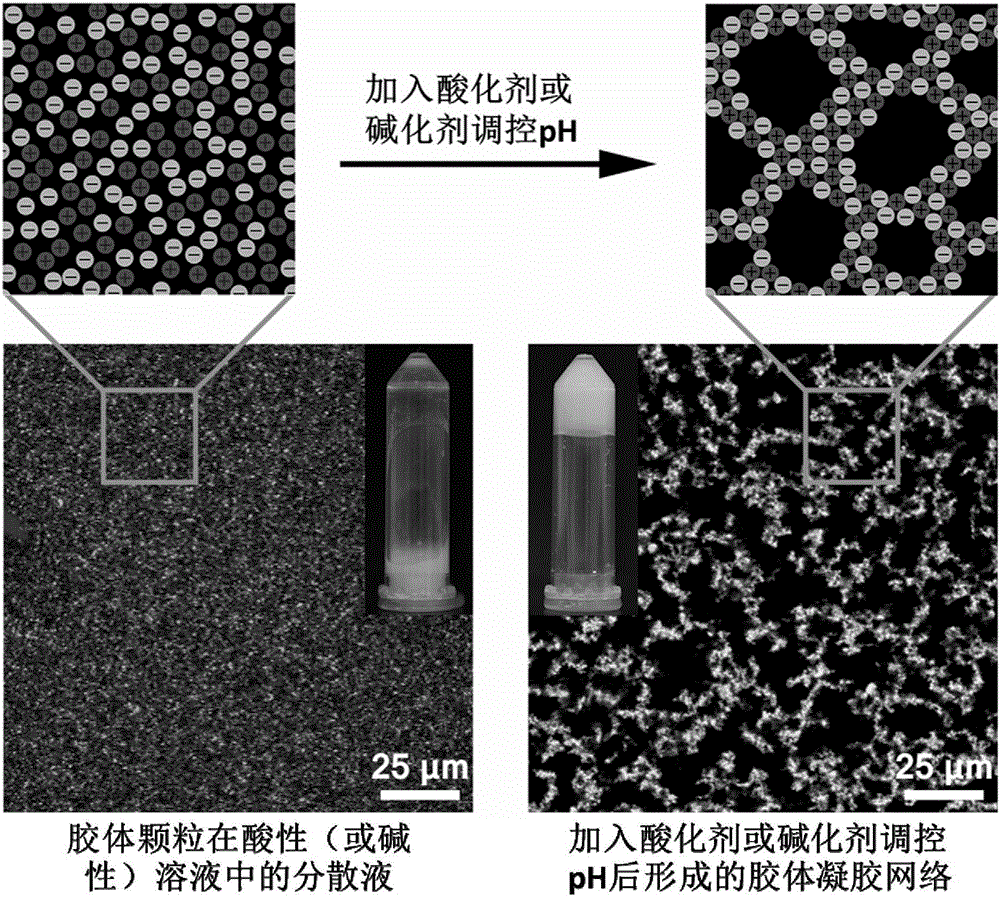

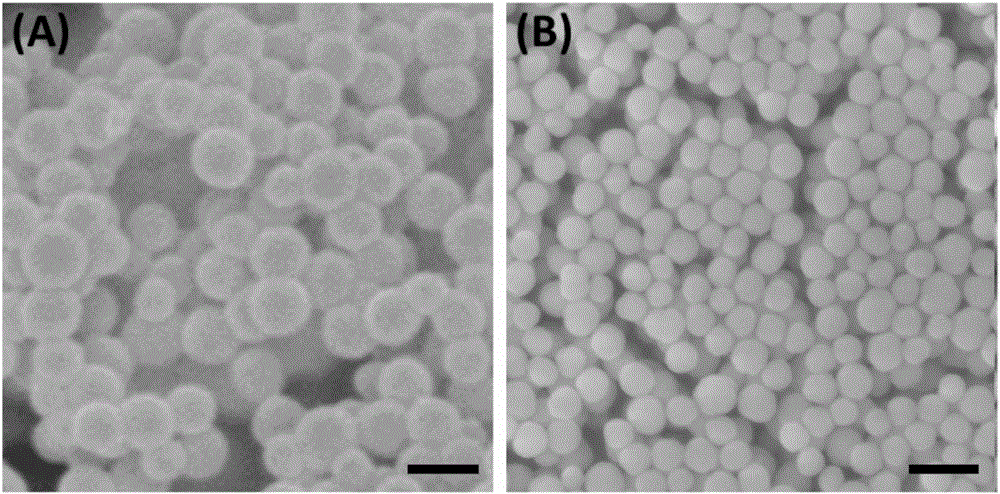

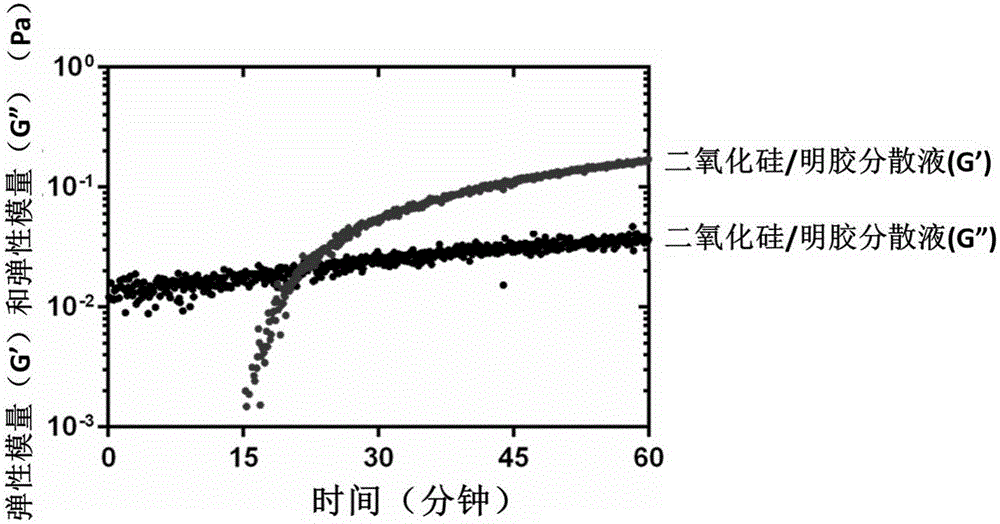

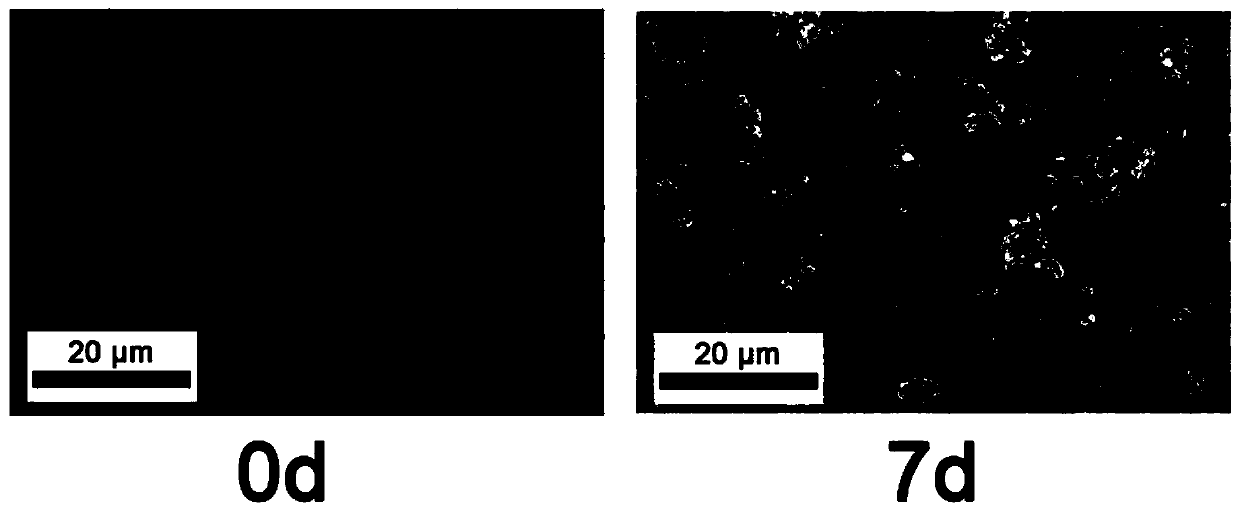

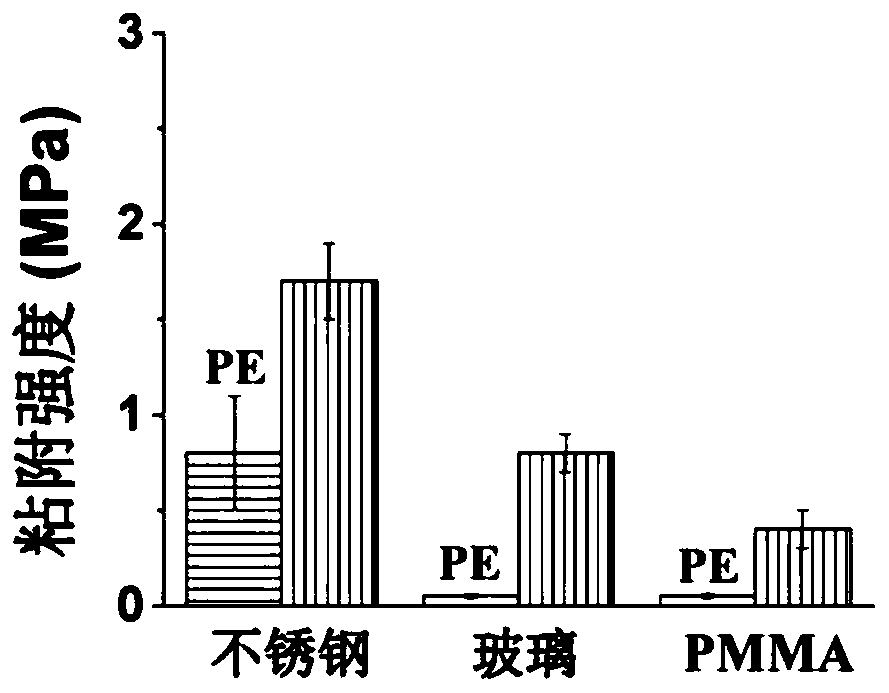

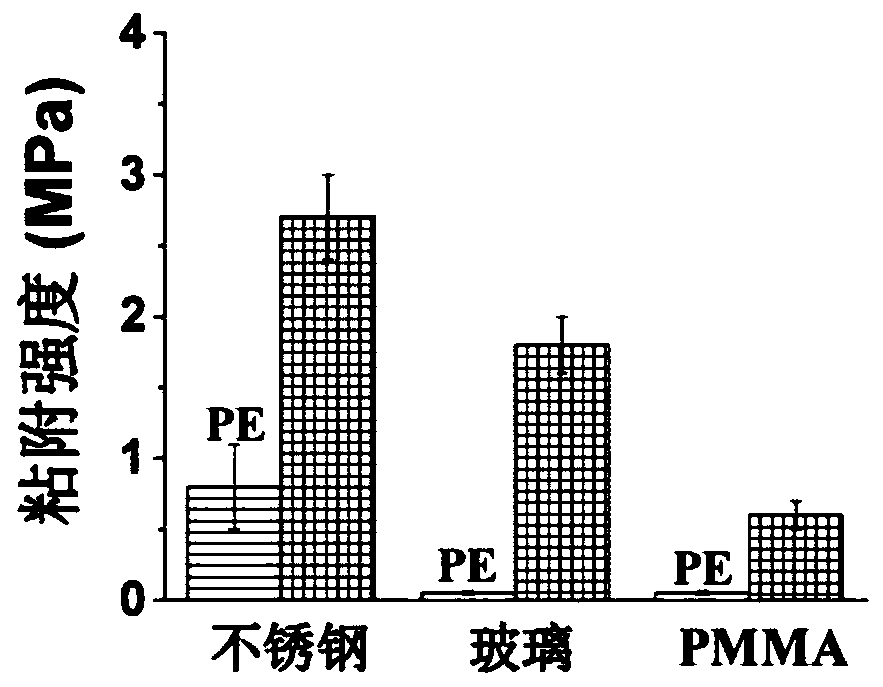

Nanometer colloid particle-assembled high-strength self-repairing injectable composite colloid gel material and preparation method and application thereof

InactiveCN105796478AHigh strengthImprove self-healing abilityAerosol deliveryInorganic non-active ingredientsBiological materialsSilicon dioxide

The invention discloses a nanometer colloid particle-assembled high-strength self-repairing injectable composite colloid gel material and a preparation method and application thereof. According to the preparation method, two-phase colloid particles with opposite electric charges are uniformly blended in an alkaline or acidic environment, an acidifying agent or alkalizing agent is added to induce the pH of the solution to recover the neutrality, electrostatic self-assembly among the two-phase colloid particles is initiated, and a uniformly-dispersed composite gel network is formed, wherein the gel is high in mechanical strength and wide in regulation and control range, the elasticity modulus of the gel can be regulated and controlled within the range of 10 Pa-100 kPa, and the self-repairing efficiency of the gel is higher than or equal to 100%. The silicon dioxide-gelatin composite colloid gel which has both the high mechanical strength and the self-repairing performance is finally and successfully prepared, and it is verified that the composite gel still can quickly recover the mechanical strength after being broken by shear force many times; in addition, the composite gel has the excellent injectable property and plasticity and can be used for an in-vitro cell culture matrix material by serving as an injectable biological material.

Owner:SHENZHEN HUA NOVA BIOTECH LTD

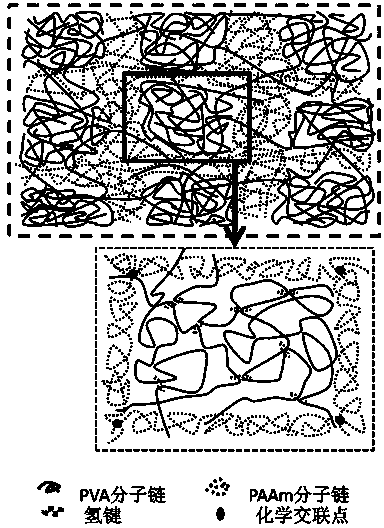

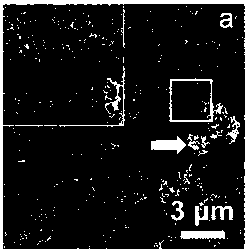

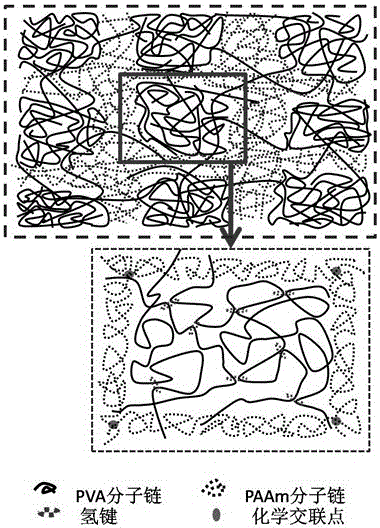

Preparation method of high-strength double-layer network hydrogel capable of being subjected to fatigue repair

The invention discloses a preparation method of high-strength double-layer network hydrogel capable of being subjected to fatigue repair. The preparation method comprises the following steps: firstly preparing a mixed solution of a first layer of network polymers PVA (Polyvinyl Acetate) and a second layer of network monomers, generating hydrogen bonds between PVA molecular chains by adopting a freezing-melting method so as to form a first layer of physical cross-linked networks, and then polymerizing and crosslinking the second layer of network monomers by adopting an ultraviolet-irradiation method so as to form a covalent cross-linking network, thus obtaining the double-layer network hydrogel, the two layers of networks of which are crosslinked in different ways. The preparation method of the high-strength double-layer network hydrogel, disclosed by the invention, has the advantages that the component range of the two layers of networks of the double-layer network hydrogel is expanded; after the obtained hydrogel is subjected to low temperature circulation, physical crosslinking points are capable of being subjected to fatigue repair and meanwhile the double-layer network hydrogel has the characteristic of high strength.

Owner:HUBEI UNIV OF TECH

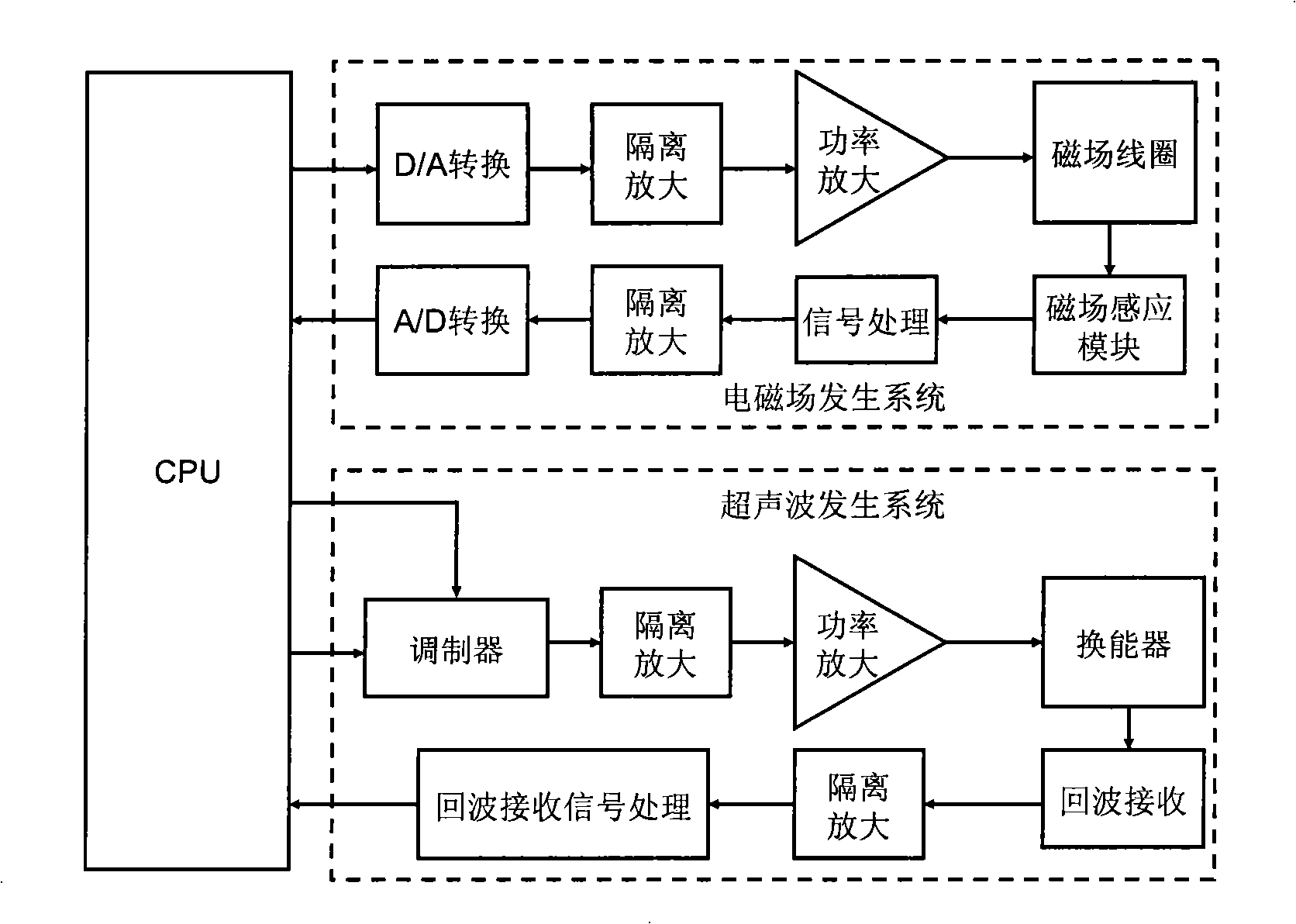

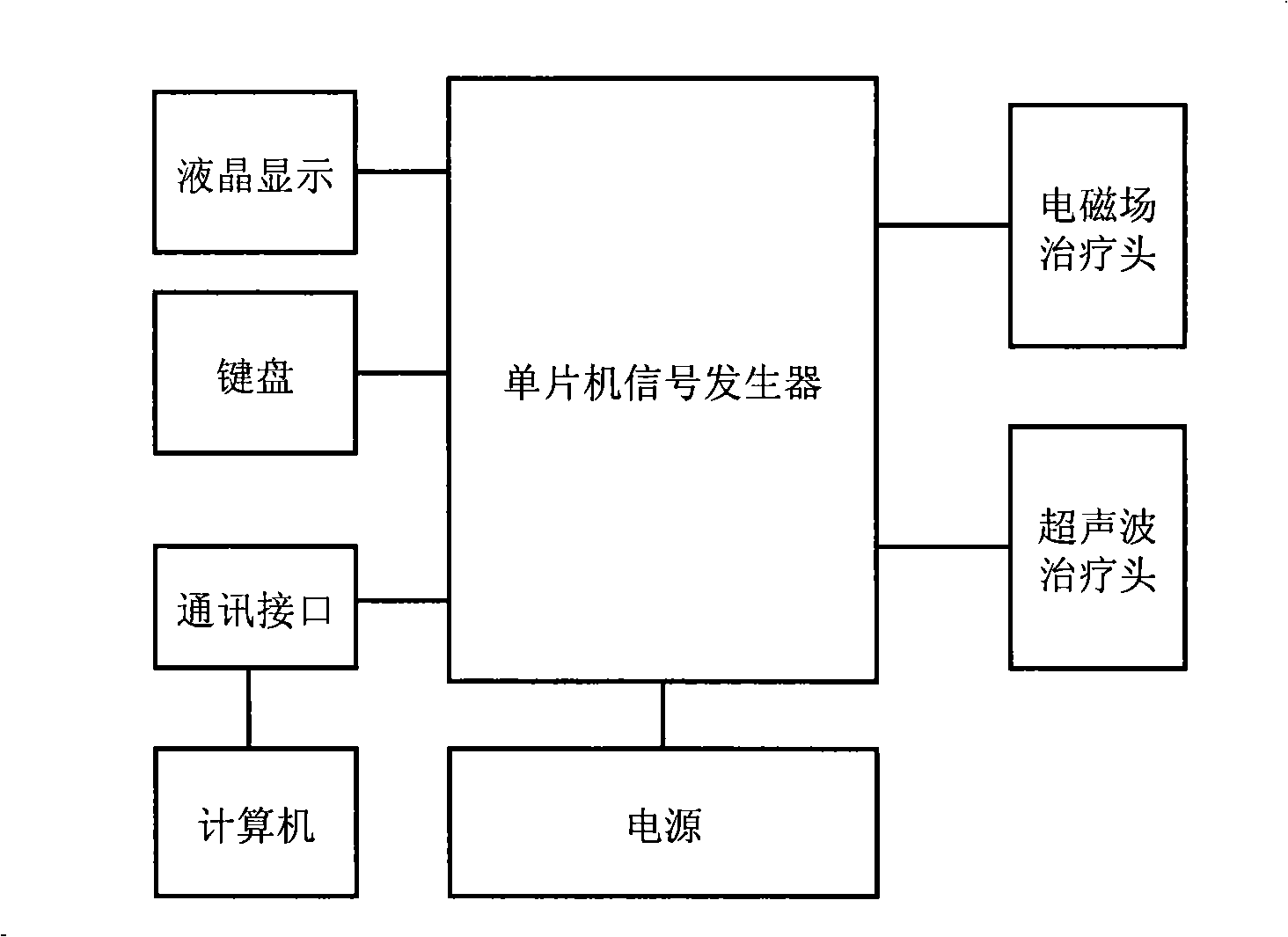

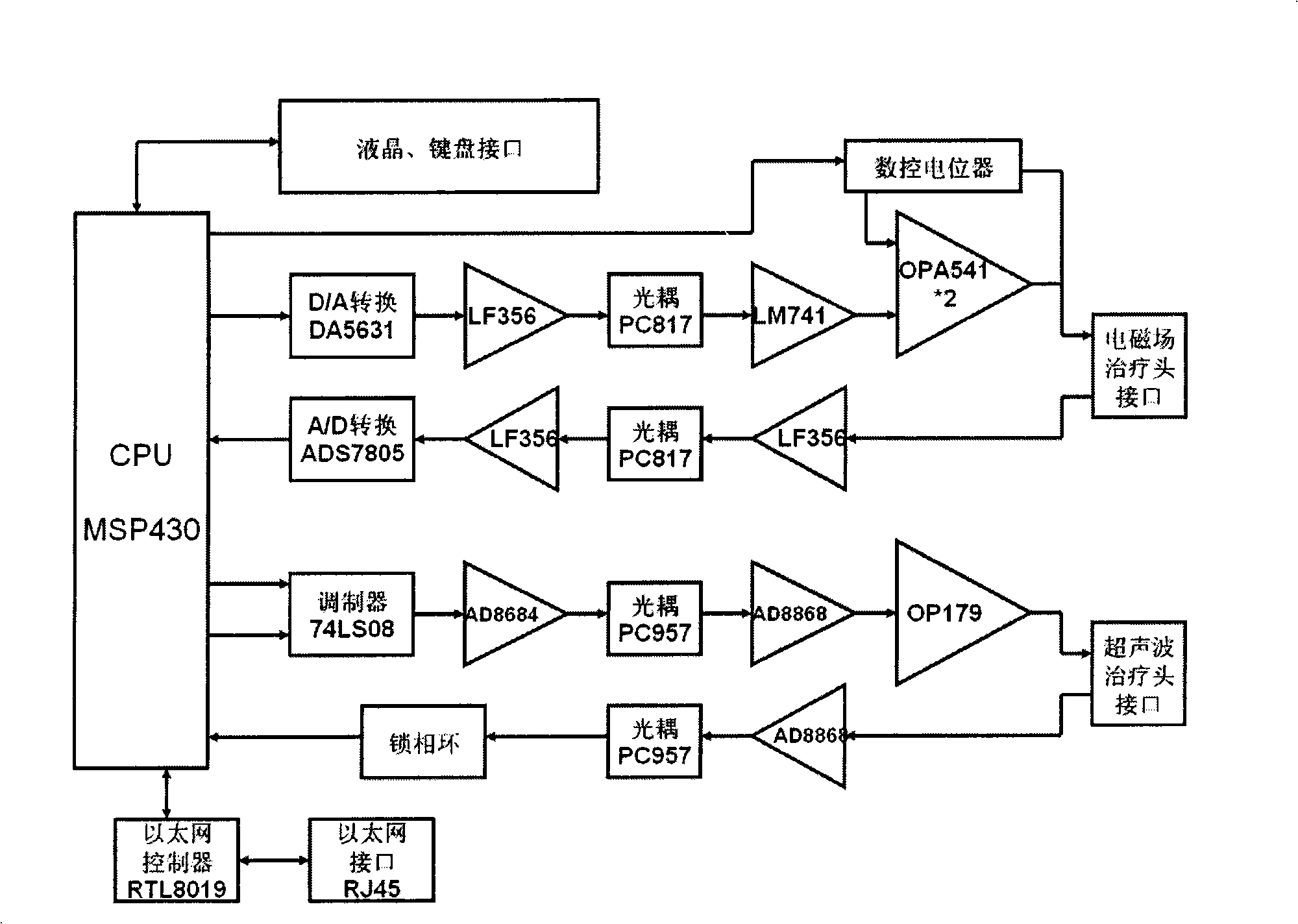

Electromagnetic field and ultrasonic wave composite therapy device for osteoporosis

InactiveCN101306228ARelieve muscle crampsPain reliefUltrasound therapyMagnetotherapy using coils/electromagnetsHealing rateUltrasound treatment

The invention provides an electromagnet field and ultrasonic wave combined device for remedying osteoprosis. The device comprises a power system, a signal generator powered by the power system, at least an electromagnet field treatment head and an ultrasonic wave treatment head driven by the signal generator. The electromagnet field generating device of the invention can wholly remedy the osteoprosis, enhance the density of human body bones, change the electric and chemical environment of a bone tissue, and influence and correct the growth, the restoration and the maintenance of the bone tissue; the ultrasonic wave emitting device has low density of a radiation bone or a fracture part, can promote the growth of the bone tissue, shorten the healing time of bone injury caused by the osteoprosis, and improve the curative ratio of bone disconnection. The above comprehensive treatment proposal from the whole to the part is applied in remedying the osteoprosis and promoting the rehabilitation of the osteoporosis bone injury. The device of the invention has the advantages that the operation is convenient, and the comprehensive remedy effect is good, and the device is suitable for various constituents and crowds.

Owner:才秀君

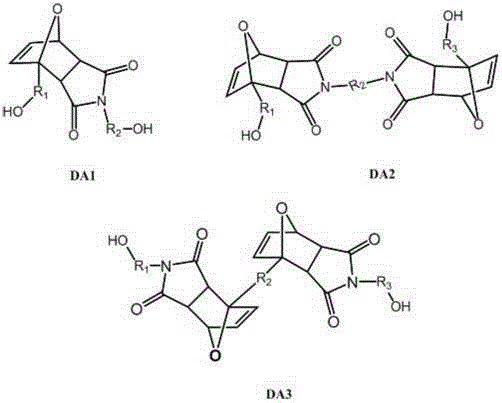

Self-repairing aqueous polyurethane prepolymer, and dispersion liquid and application thereof

InactiveCN106632957ARestore appearanceRestoration of mechanical propertiesTissue regenerationProsthesisPolyurethane dispersionAlcohol

The invention discloses a self-repairing aqueous polyurethane prepolymer, and a dispersion liquid and application thereof. A preparation method comprises the following steps: adding a prepolymer with good self-emulsifying properties into water, wherein the prepolymer is polymerized from diisocyanate, macromolecular polyol, a hydrophilic chain extender, and diatomic alcohol containing Diels-Alder dynamic bonds; and dispersing the mixture with high speed stirring by an emulsifier to obtain an aqueous polyurethane dispersion liquid with a solid content of 10-60%wt. The introduction of the diatomic alcohol containing the Diels-Alder dynamic bonds allows self-repairing of cracks and damages of the material by cracking and recombination of the Diels-Alder bonds during an application process, thus improving the service life and safety of the material.

Owner:SICHUAN UNIV

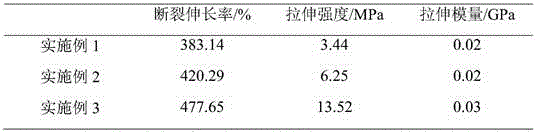

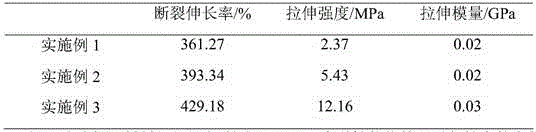

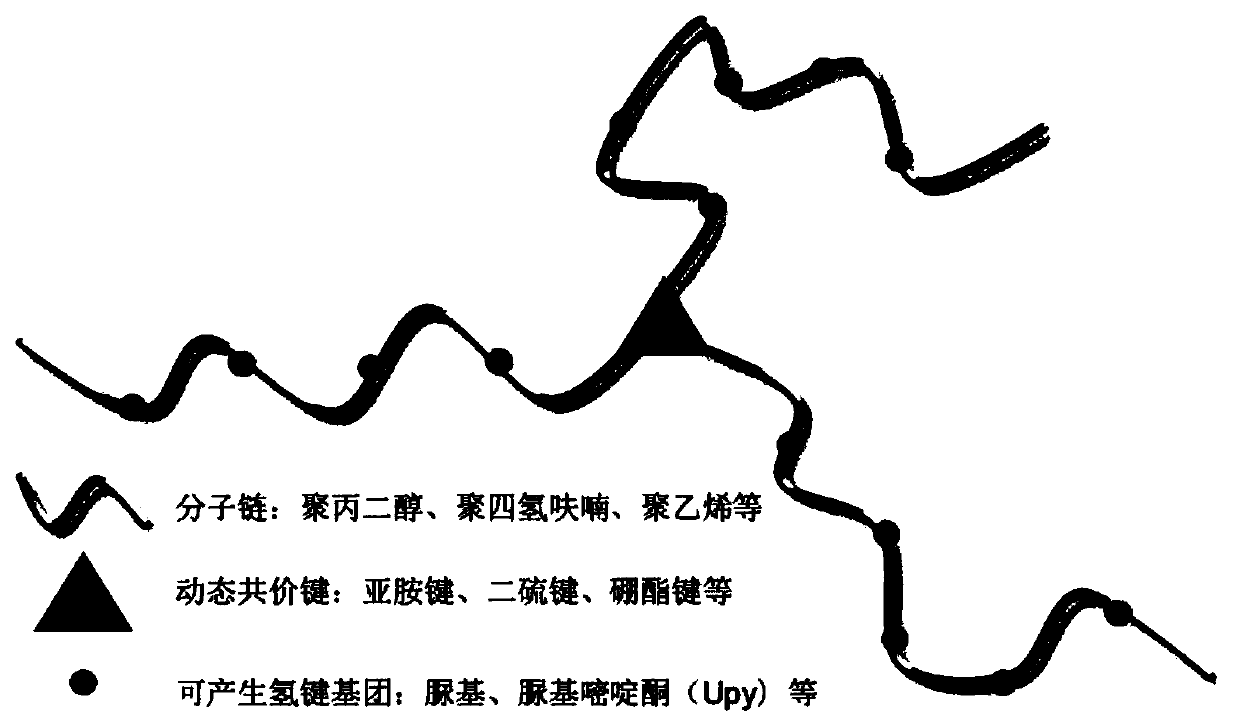

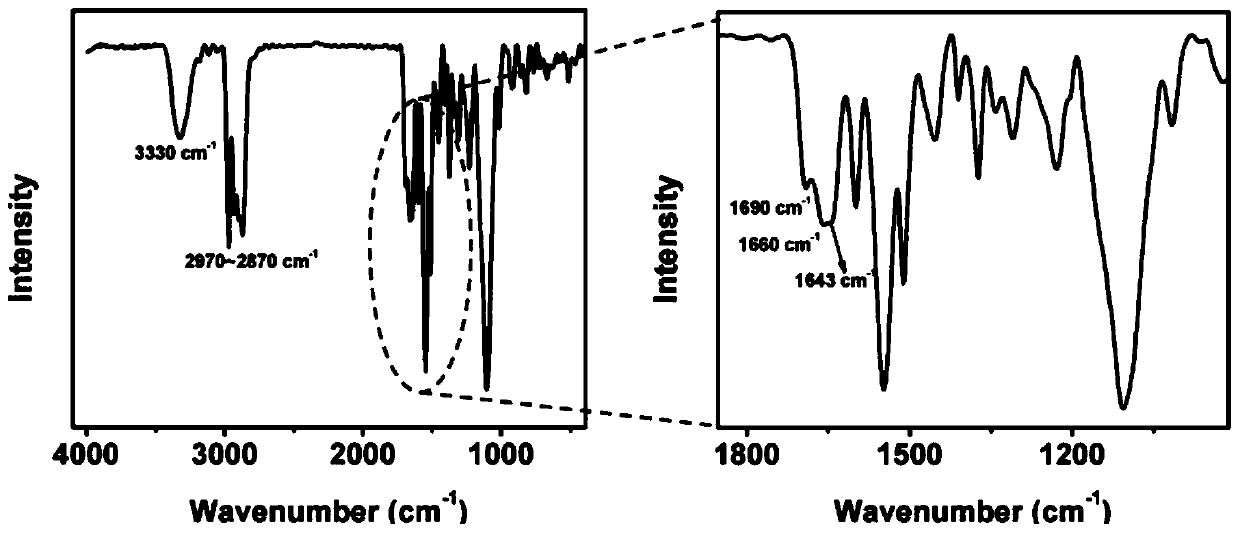

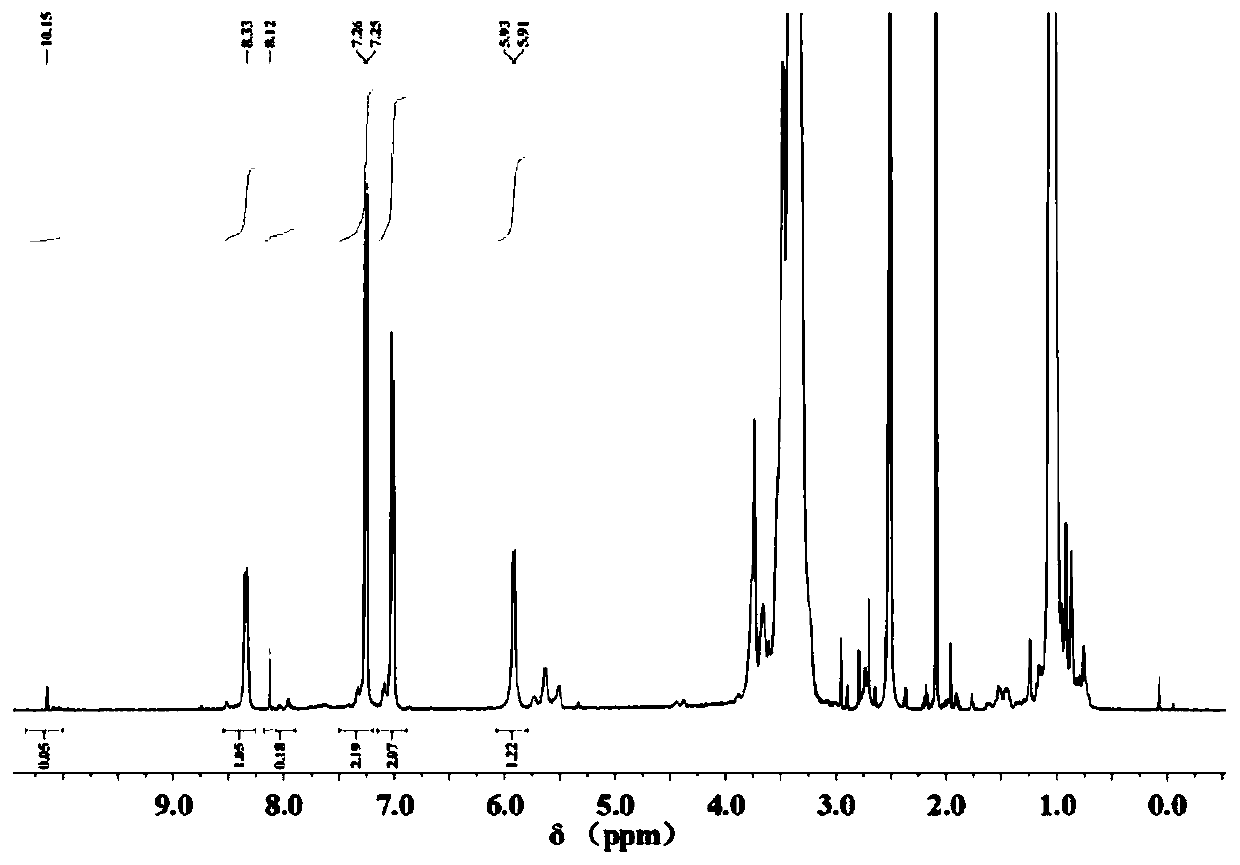

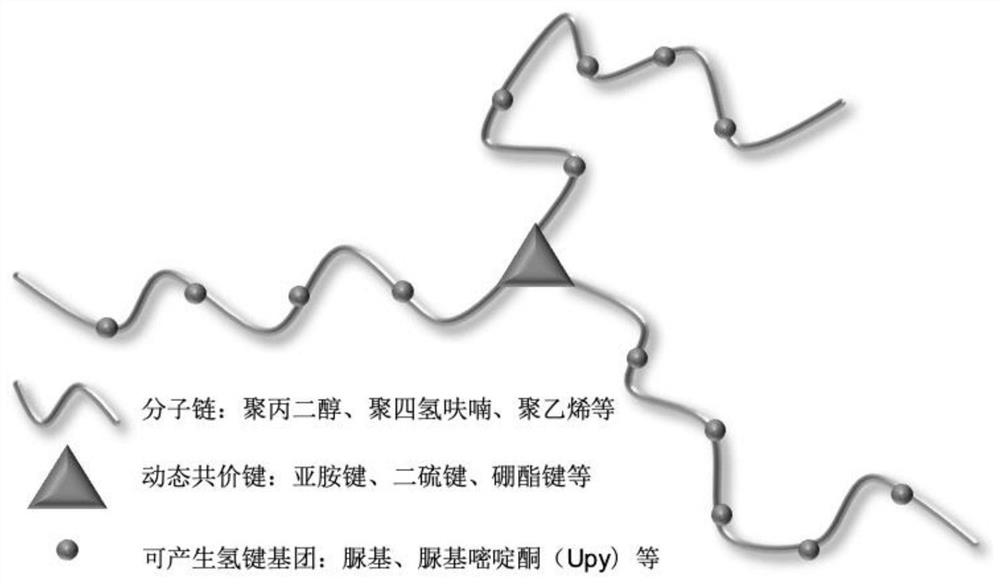

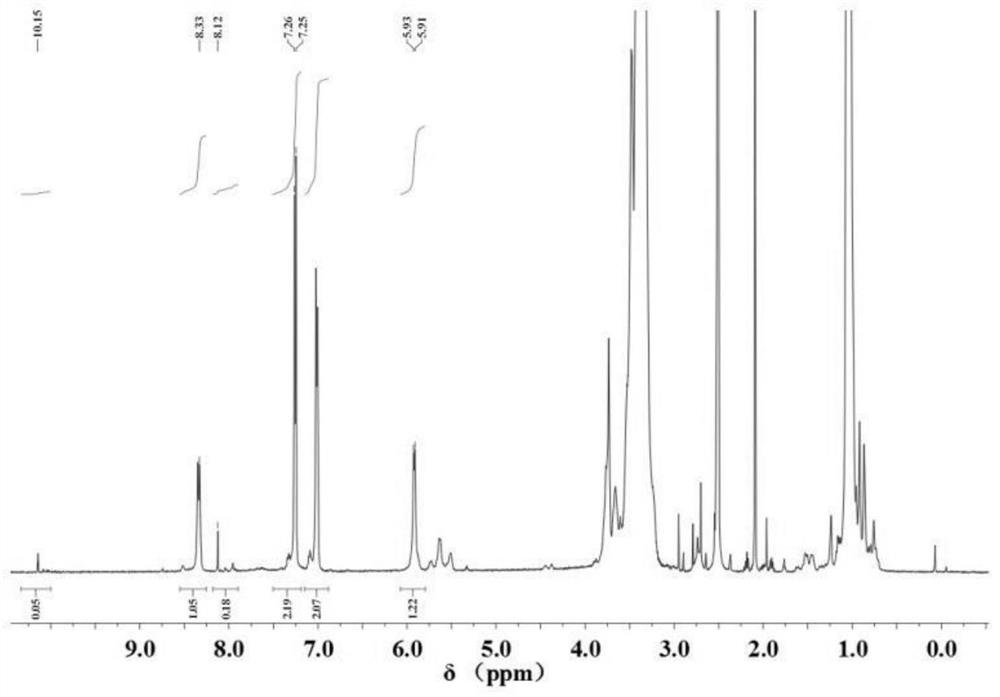

Polymer damping material capable of being repaired at room temperature and preparation method and application thereof

The invention provides a polymer damping material capable of being repaired at room temperature and a preparation method and application thereof, and belongs to the technical field of polymer materials. The polymer damping material capable of being repaired at room temperature is prepared from the following preparation raw materials: polyhydric alcohol, isocyanate, a chain extension cross-linkingagent and a solvent. The polyhydric alcohol comprises amino-terminated polyhydric alcohol or hydroxyl-terminated polyhydric alcohol, a molar ratio of the polyhydric alcohol to the isocyanate is (1.1-1.3): 1, and the crosslinking degree of the polymer damping material capable of being repaired at room temperature is 5-30%. The polymer damping material capable of being repaired at room temperature is high in transparency and excellent in mechanical property, spontaneous wound repair can be carried out at the room temperature after mechanical damage, the safety and durability of the material aregreatly improved, the service life of the material is greatly prolonged, and a good damping effect is achieved at the room temperature. Meanwhile, the damping material can be reshaped and recycled when being seriously damaged.

Owner:JILIN UNIV

Asynchronous cold rolling forming process of aluminum alloy stainless steel composite plate

ActiveCN110883093AIncrease rolling capacityImprove rolling precisionTemperature control deviceWork cooling devicesComposite plateLine heating

The invention discloses an asynchronous cold rolling forming process of an aluminum alloy stainless steel composite plate. The process comprises the following process steps: 1, rolling and compoundinga stainless steel plate and an aluminum alloy plate in an asynchronous rolling mode, and 2, after asynchronous rolling, diffusing and annealing the composite plate, specifically, in the step 1, online heating is carried out on the opposite surface of the composite plate surface of the stainless steel plate, online cooling is carried out on the opposite surface of the composite plate surface of the aluminum alloy plate online, and the heating temperature is 350 DEG C-850 DEG C; the temperature of the composite plate surface of the stainless steel plate from which the composite plate is rolledis lower than 650 DEG C, and the temperature of the composite plate surface of the aluminum alloy plate from which the composite plate is rolled is lower than 300 DEG C; the rolling reduction rate is20%-90%; the different speed ratio of a roller for asynchronous cold rolling is 1.05-1.50; the thickness ratio of the aluminum alloy plate to the stainless steel plate is 1.5-4.0; and in the step 2, the annealing temperature is 250 DEG C-500 DEG C and the annealing time is 15-120 min. The single-side online heating process for rolling the composite plate is creatively provided so as to improve theinterface bonding strength of the composite plate and realize rolling compounding in an interface semi-melting state.

Owner:JIANGYIN KANGRUI MOLDING TECH CO LTD

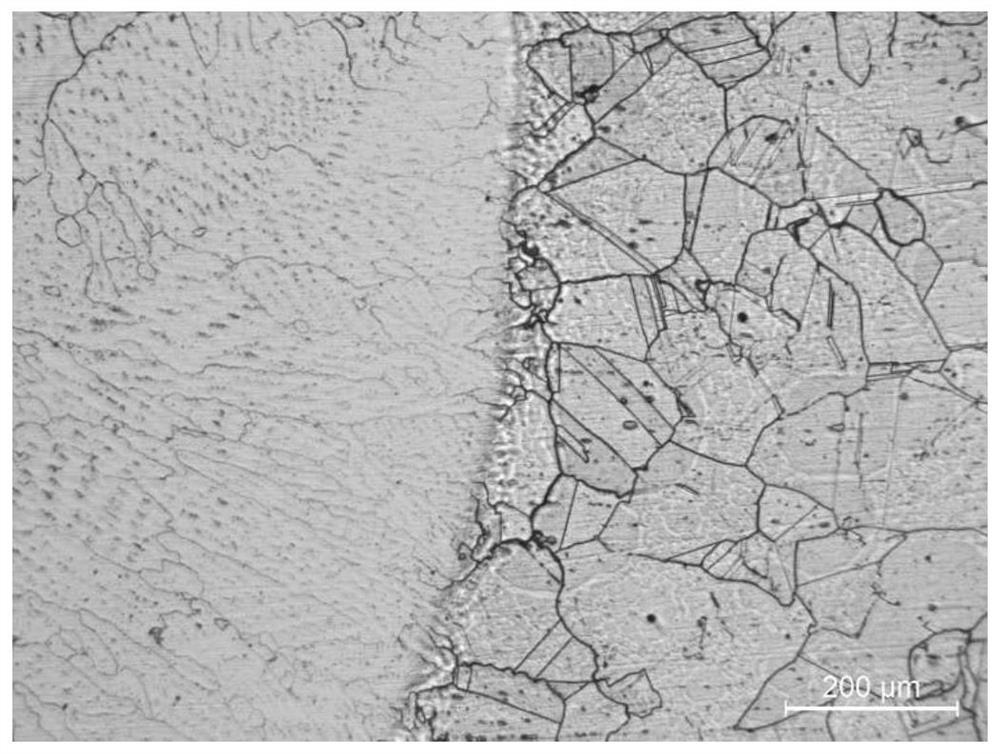

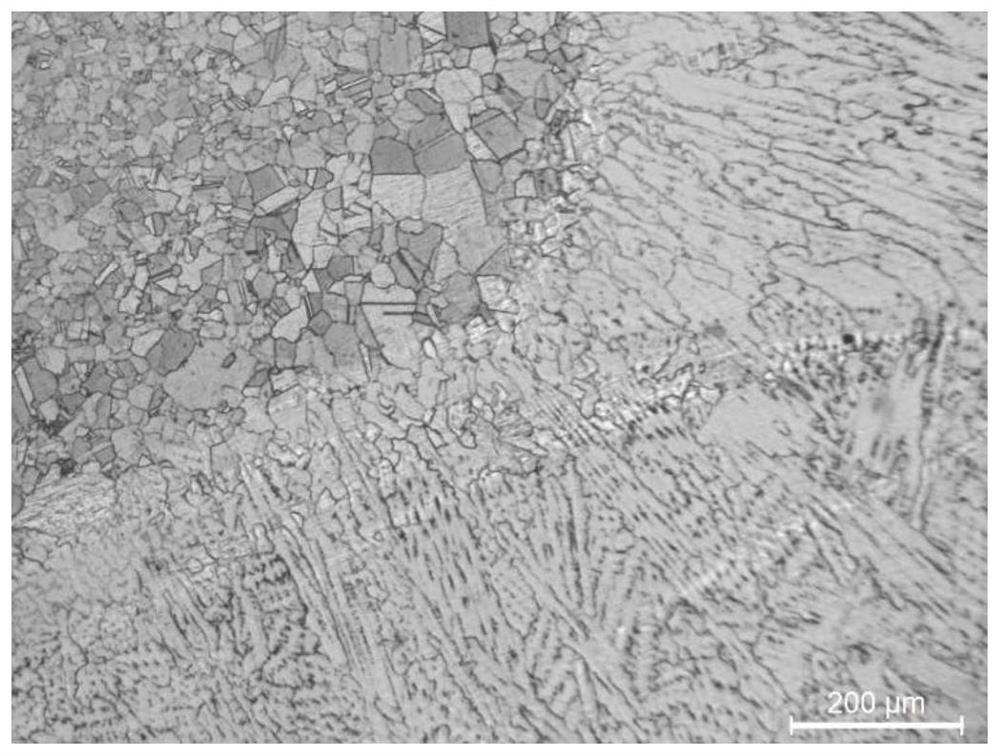

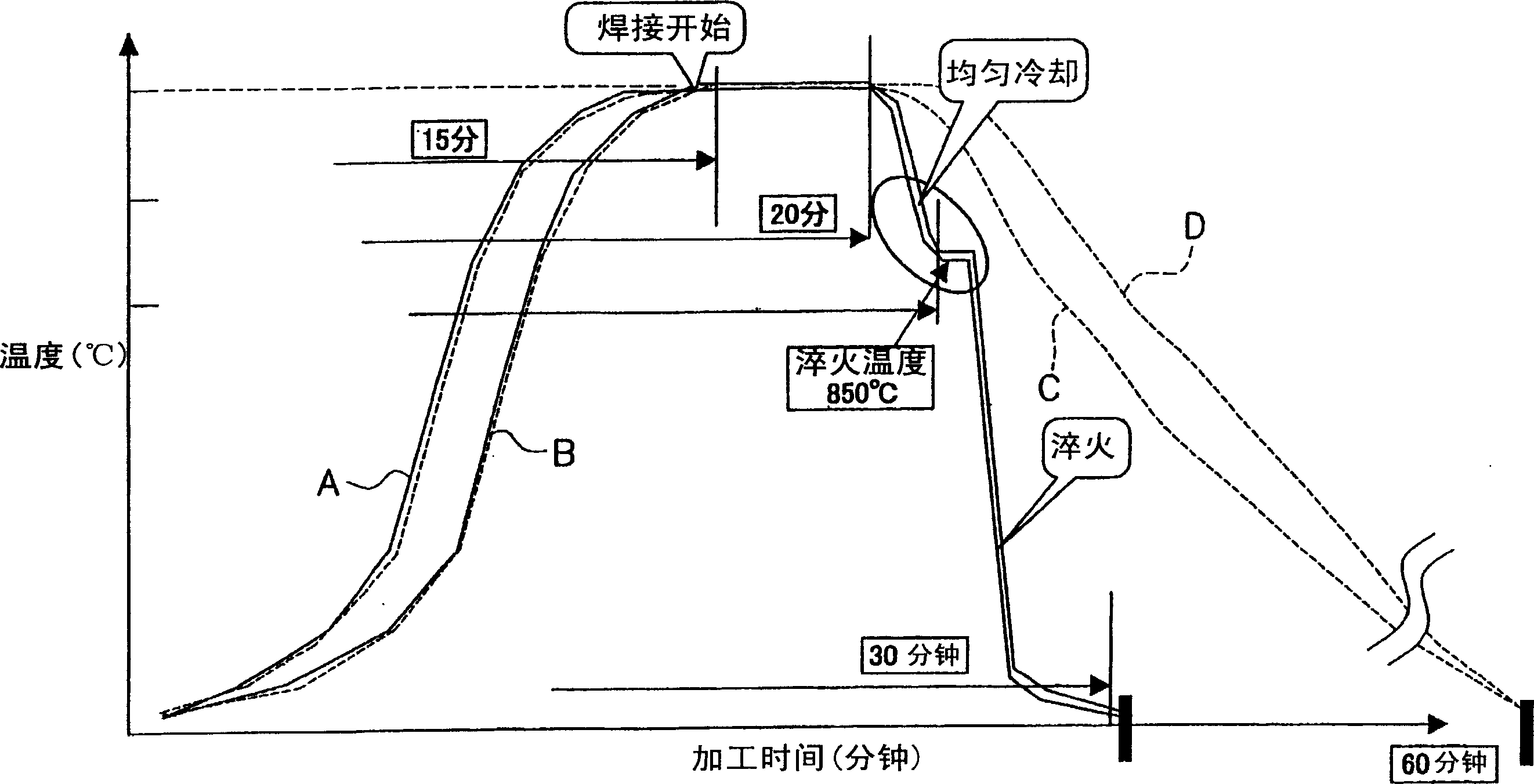

Post-weld heat treatment method for high-temperature alloy

InactiveCN112941436APrevent agingRestoration of mechanical propertiesFurnace typesHeat treatment furnacesHeat-affected zoneWelding residual stress

The invention discloses a post-weld heat treatment method for a high-temperature alloy, belongs to the field of material heat treatment, and particularly relates to a post-weld heat treatment method for a precipitation strengthening type high-temperature alloy for a high-temperature component of an advanced ultra-supercritical (A-USC) power station. The post-weld heat treatment method comprises the following steps of 1) low-temperature solid solution, specifically, keeping the temperature of 20-40 DEG C above the gamma' phase precipitation temperature or the recrystallization temperature (the higher temperature is selected) for 1-2 hours, and then performing air cooling to the aging temperature; and 2) aging, specifically, keeping the temperature for 4-16 hours in a gamma' phase precipitation temperature range, and then air-cooling to room temperature. According to the high-temperature alloy welding joint obtained through the post-weld heat treatment method, the welding residual stress is eliminated to the maximum extent, gamma' strengthening phases are evenly distributed in crystals, strain aging cracks of a welding heat affected zone are effectively avoided, and the mechanical property of the heat affected zone is recovered to the base metal level.

Owner:XIAN THERMAL POWER RES INST CO LTD

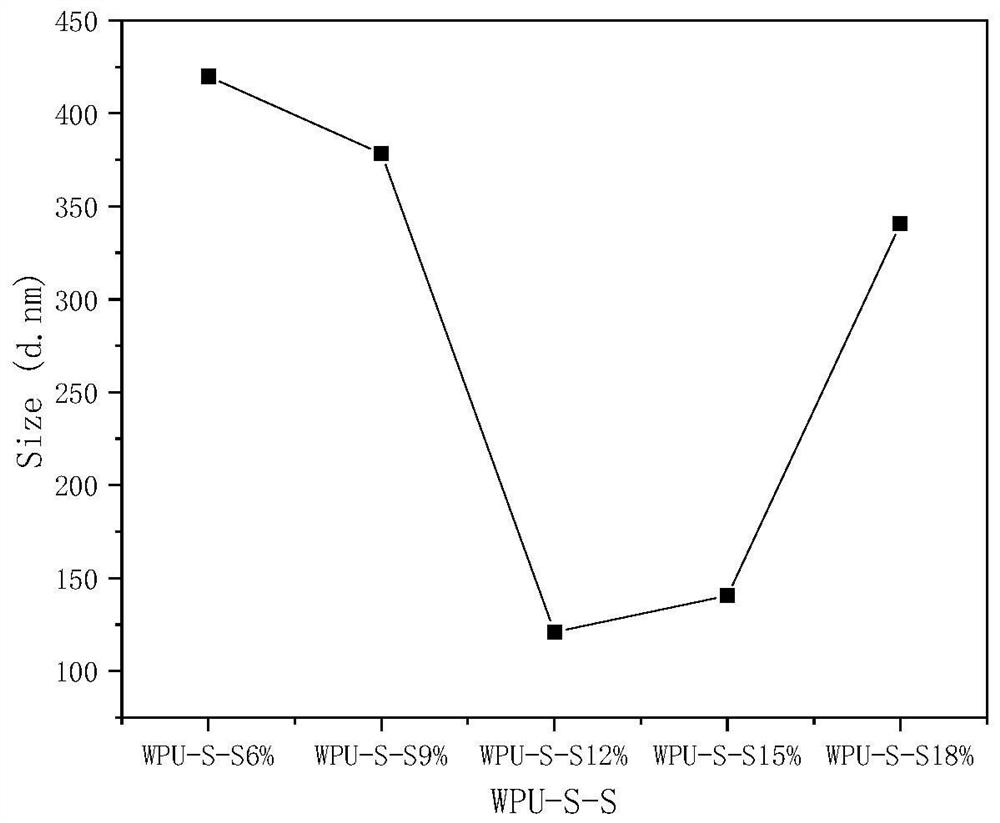

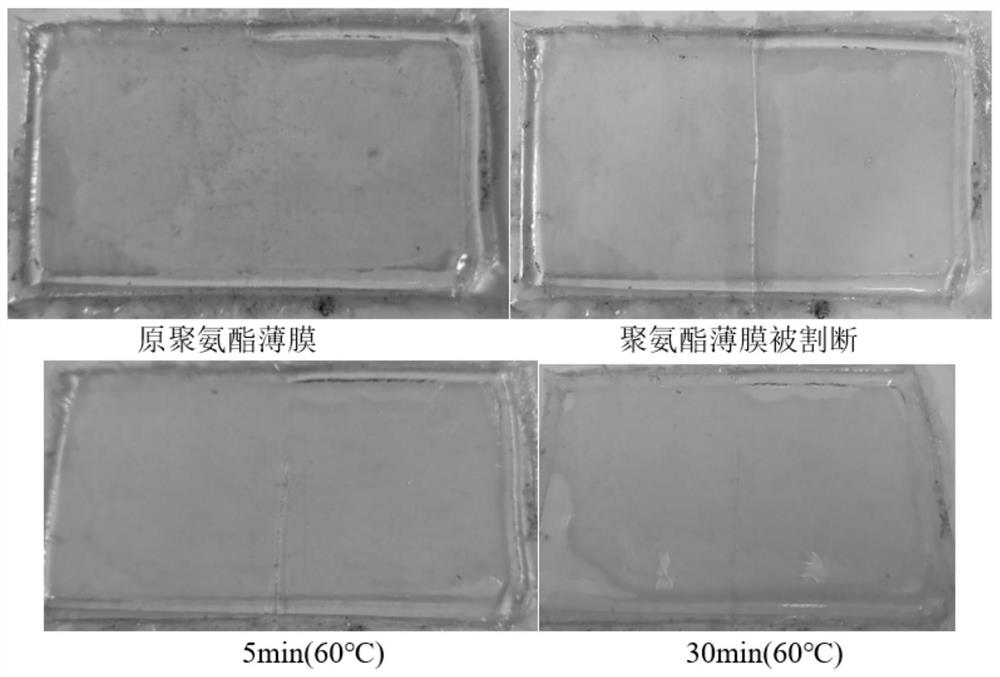

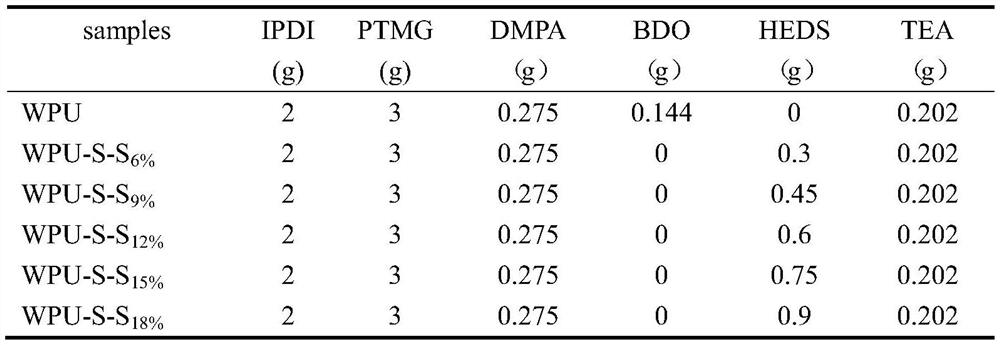

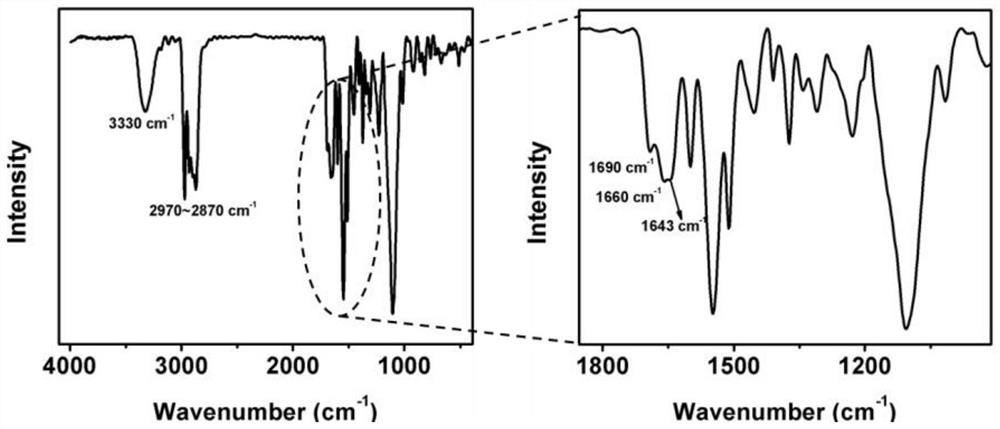

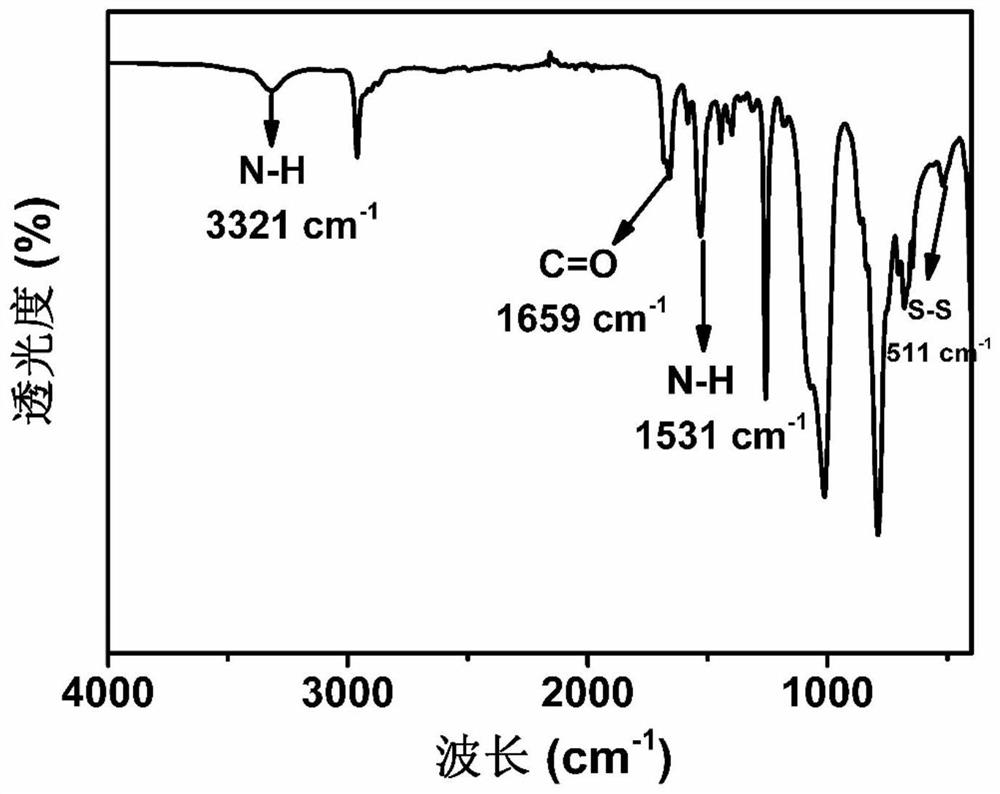

Self-repairing waterborne polyurethane film and preparation method thereof

InactiveCN112794966AExcellent self-healing performanceImprove stabilityDisulfide bondingPolymer science

The invention belongs to the technical field of preparation of self-repairing materials, and provides a preparation method of a self-repairing waterborne polyurethane film, wherein the preparation method comprises the following steps: 1) dissolving polytetrahydrofuran glycol in acetone, adding isophorone diisocyanate and a catalyst, and reacting to generate a polyurethane prepolymer; (2) sequentially adding N-methyl pyrrolidone, 2,2-dimethylolpropionic acid, 2-hydroxyethyl disulfide and triethylamine into the polyurethane prepolymer, and carrying out stirring reaction, so as to obtain a self-repairing waterborne polyurethane emulsion; and 3) pouring the self-repairing waterborne polyurethane emulsion on a polyfluortetraethylene plate, and drying to obtain the self-repairing waterborne polyurethane film. The reversible disulfide bond is introduced, based on the instability of the disulfide bond, a covalent bond of the disulfide bond is easy to break and recombine with other sulfur atoms, and self-repairing can be realized by utilizing an oxidation-reduction reaction between the disulfide bond and sulfydryl, so that the prepared waterborne polyurethane film has good self-repairing performance.

Owner:HUBEI UNIV

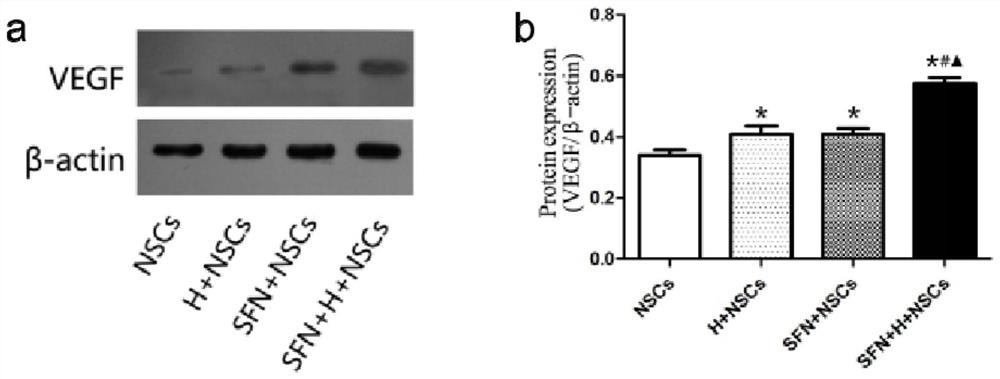

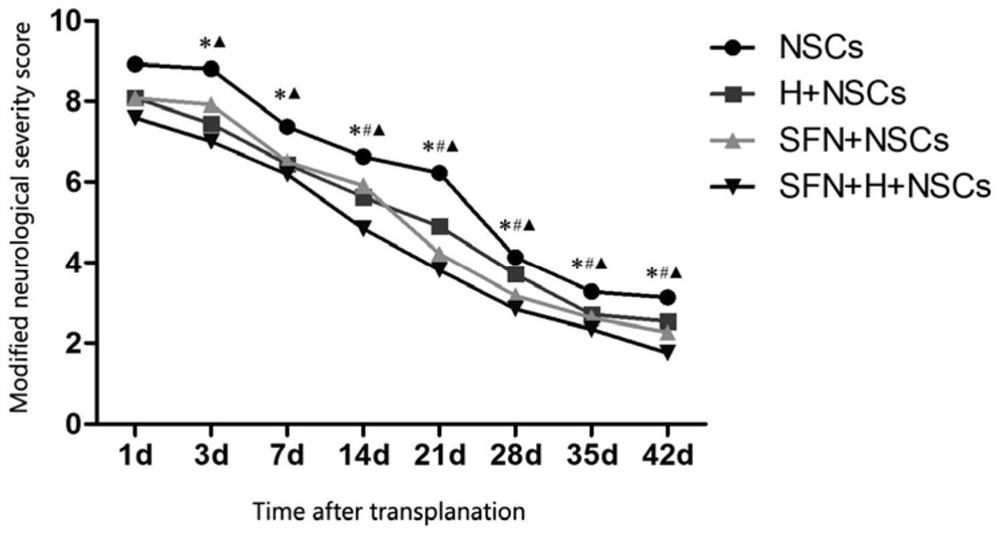

Hydrogel/fibroin nanofiber/neural stem cell integrated transplant for promoting VEGF secretion as well as preparation method and application thereof

ActiveCN112494727AReturn to normal structureRestoration of mechanical propertiesPharmaceutical delivery mechanismTissue regenerationDirected differentiationCerebral ischaemia

The invention discloses a hydrogel / fibroin nanofiber / neural stem cell integrated transplant capable of promoting VEGF secretion as well as a preparation method and application thereof, and belongs tothe technical field of biological tissue medical engineering. The method comprises the following step: polysaccharide-based hydrogel / neural stem cell gel are adhered to a fibroin nanofiber scaffold through dopamine to form a polysaccharide-based hydrogel / fibroin nanofiber / neural stem cell integrated transplant, wherein the polysaccharide-based hydrogel is a self-healing injectable polysaccharide-based hydrogel. According to the invention, the polysaccharide-based hydrogel embedded with the neural stem cells is adhered to a gap between fibroin nanofiber scaffolds through dopamine to construct the polysaccharide-based hydrogel / fibroin nanofiber / neural stem cells integrated transplant, so that the cells can be promoted to secrete VEGF and fill the defect part, and provide required microenvironment for adhesion, proliferation and directional differentiation of the neural stem cells into neurons, and the neural stem cells can be applied to the field of treatment of cerebral ischemia injuryand promotion of neural stem cell amplification and differentiation.

Owner:SHAANXI UNIV OF SCI & TECH +1

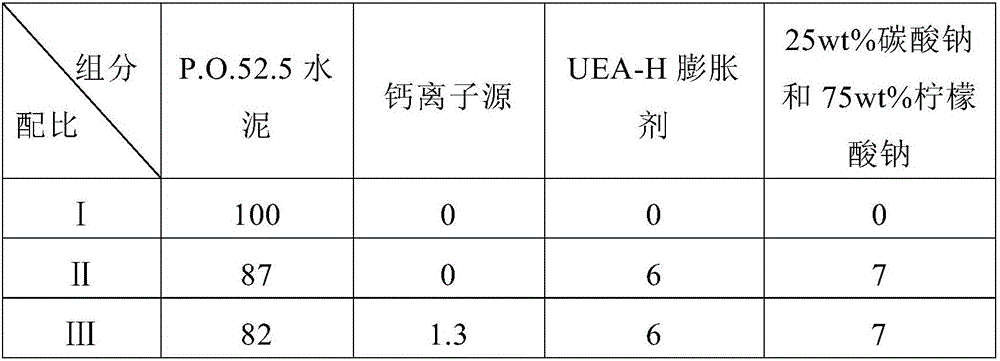

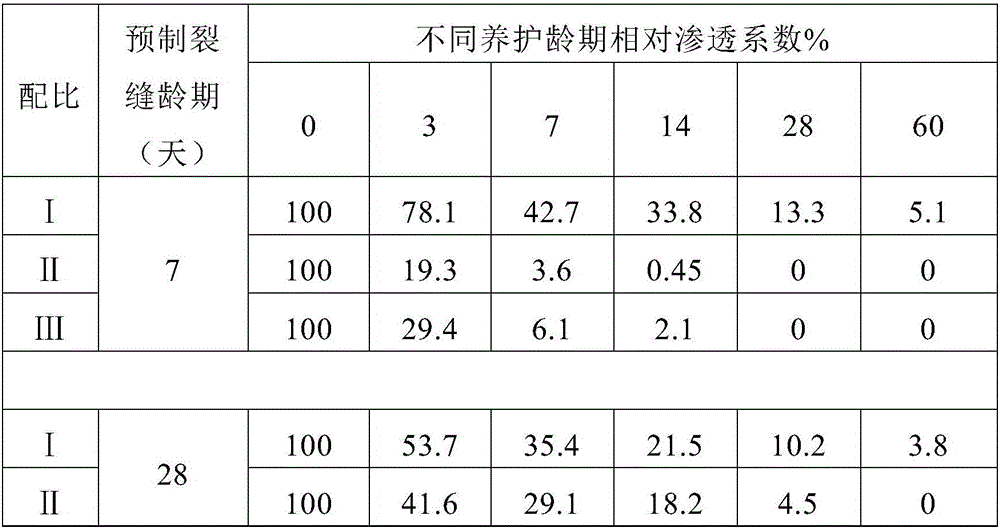

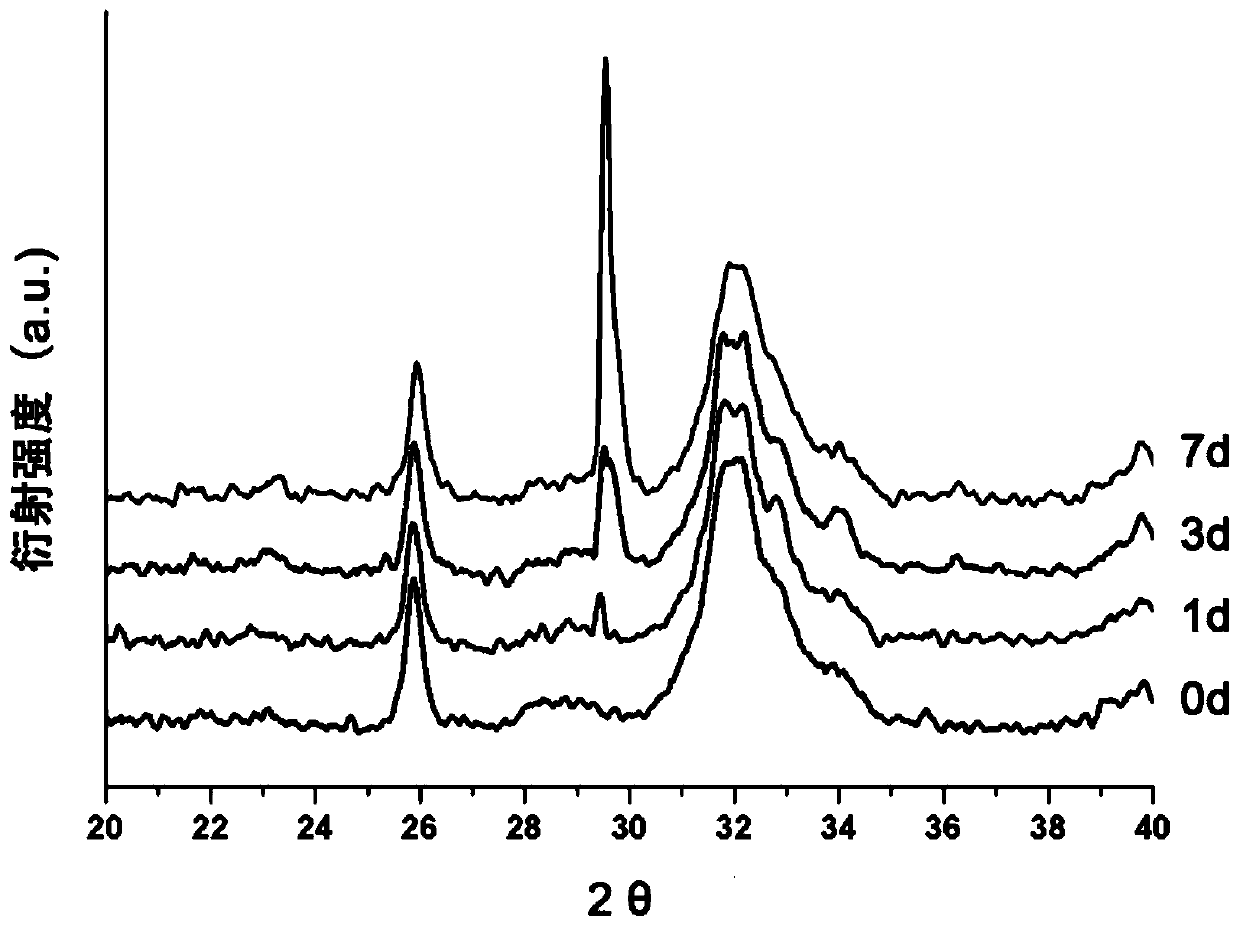

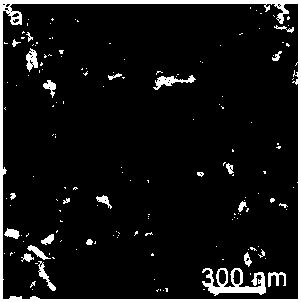

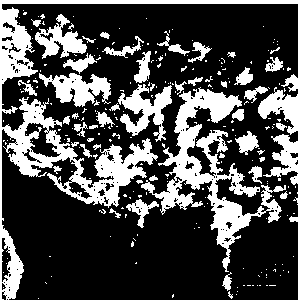

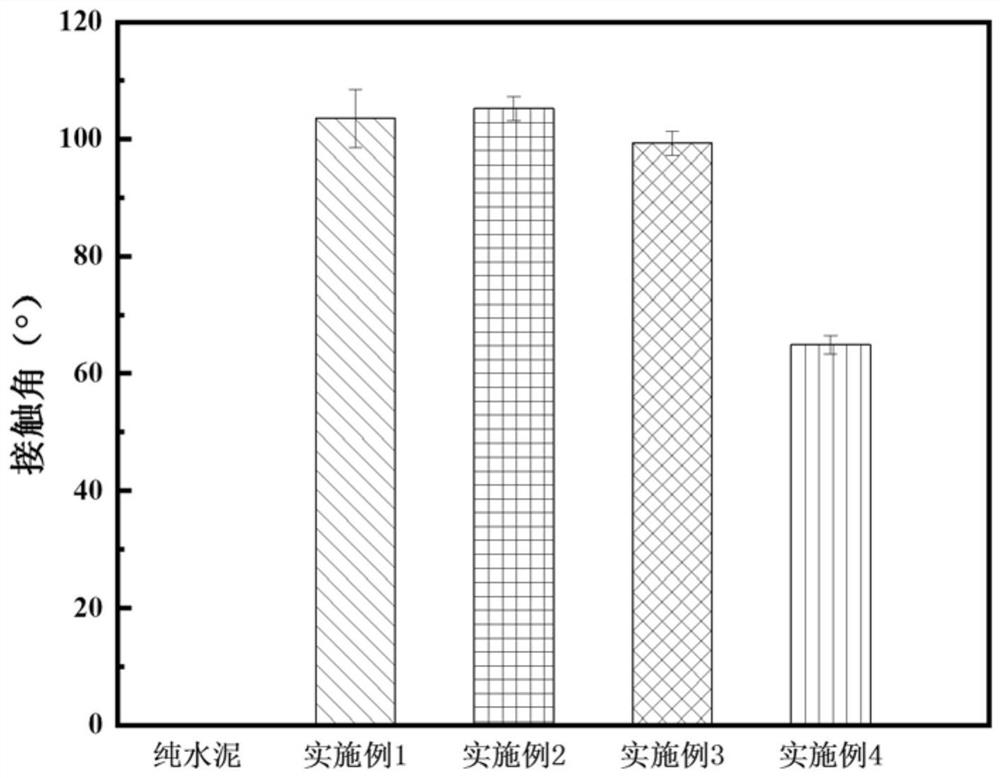

Mineral admixture for crack self-healing of steam-cured cement-based material and preparation of mineral admixture

ActiveCN106007442AGenerated in large quantities and stableImprove self-healing abilitySelf-healingMaterials science

The invention relates to a mineral admixture for crack self-healing of a steam-cured cement-based material and preparation of the mineral admixture. The mineral admixture is prepared from the following components in percentage by weight: 35%-50% of an expanding mineral component, 40%-55% of a crystalline mineral component and 5%-10% of a calcium ion source mineral component. The mineral components are weighed in proportion and uniformly mixed, and the mineral admixture is prepared. The mineral admixture has the advantages that the self-healing effect is remarkable, the cost is low, the durability of the steam-cured cement-based material is effectively improved and the like.

Owner:TONGJI UNIV

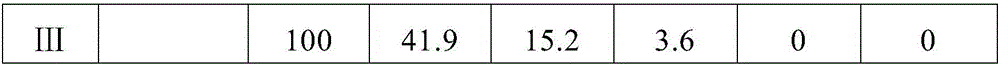

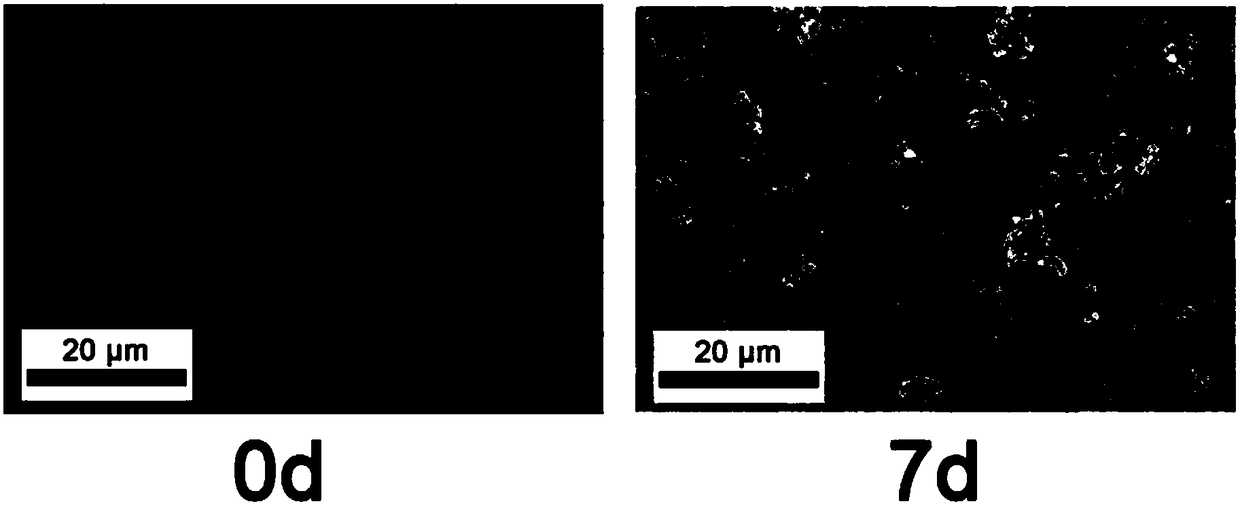

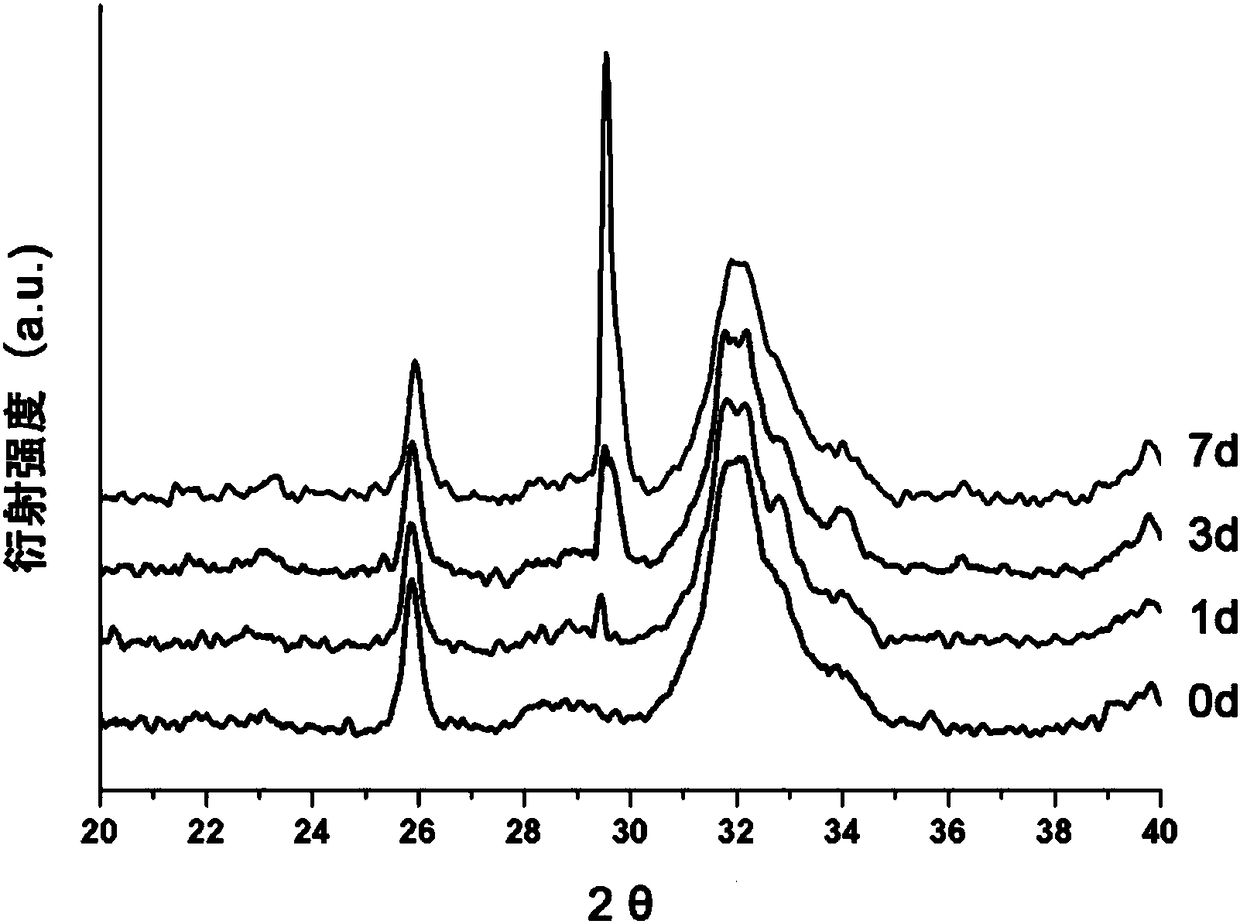

Liquid-phase mineralizing precursor and method of repairing demineralized dentine

ActiveCN108324578AAchieve a sensitive effectAchieve deep biomimetic mineralizationImpression capsDentistry preparationsDistilled waterRoom temperature

The invention discloses a liquid-phase mineralizing precursor and a method of repairing demineralized dentine and belongs to the technical field of biomaterials. The liquid-phase mineralizing precursor can repair the demineralized dentine and is a calcium carbonate mineralizing precursor solution containing a polymer and magnesium ions, wherein the concentration of the polymer is 5-100 [mu]g / mL, concentration of Ca<2+> is 1-15 mM, and molar ratio of Mg<2+> to Ca<2+> is 1-6:1. A preparation method of the liquid-phase mineralizing precursor includes steps of: suspending CaCO3 powder in distilledwater and feeding CO2 gas for 1-4 h at room temperature; filtering away residual CaCO3 and feeding CO2 gas for 15-60 min at room temperature; measuring the concentration of Ca<2+> and adding distilled water to regulate the concentration of Ca<2+>; adding the polymer and MgCl2 powder and uniformly mixing the mixture. The liquid-phase mineralizing precursor employs easy-to-obtained raw material andhas simple system, and is a creative break for therapy on oversensitive dentine.

Owner:WUHAN UNIV

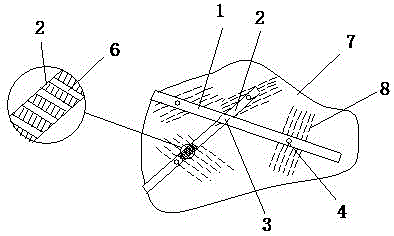

Bionic fixing device for treating calcaneal fractures

InactiveCN105877828AAchieve reconstructionRestore continuityInternal osteosythesisCalcaneusCross connection

The invention discloses a bionic fixing device for treating calcaneal fractures and belongs to the technical field of medical apparatus and instruments for orthopedics. The bionic fixing device is used for treating the calcaneal fractures. The technical scheme provided by the invention is that two intramedullary nails are embedded into calcaneus and are connected in a cross way for resetting the injured calcaneus; bionic pores are respectively formed in the two intramedullary nails; the directions of the pores are consistent with that of bone trabecula at the pore positions; the pores can guide the bone trabecula to be grown into; the intramedullary nails are made of degradable medical magnesium alloys, do not need to perform secondary surgery to be taken out after being planted, and can be autonomously degraded. The bionic fixing device disclosed by the invention is an initiation in calcaneal surgery of the orthopedics; by adopting a bionic principle, the reconstruction of the bone trabecula is realized and the continuousness of the bone trabecula is restored according to the anatomy and biomechanics characteristics of the bone trabecula as well as the degradability of the intramedullary nails, thereby achieving the aim of effectively restoring local normal structures and mechanical conductivity of bone. The bionic fixing device also has the characteristics of improving a fixing effect, facilitating surgical procedures and the like, and is beneficial for restoration of normal functions of patients; an ideal therapeutic effect is realized.

Owner:陈卫 +1

A liquid phase mineralization precursor and method for repairing demineralized dentin

ActiveCN108324578BAchieve long-term stabilityRestoration of mechanical propertiesImpression capsDentistry preparationsFluid phaseDistilled water

The invention discloses a liquid-phase mineralizing precursor and a method of repairing demineralized dentine and belongs to the technical field of biomaterials. The liquid-phase mineralizing precursor can repair the demineralized dentine and is a calcium carbonate mineralizing precursor solution containing a polymer and magnesium ions, wherein the concentration of the polymer is 5-100 [mu]g / mL, concentration of Ca<2+> is 1-15 mM, and molar ratio of Mg<2+> to Ca<2+> is 1-6:1. A preparation method of the liquid-phase mineralizing precursor includes steps of: suspending CaCO3 powder in distilledwater and feeding CO2 gas for 1-4 h at room temperature; filtering away residual CaCO3 and feeding CO2 gas for 15-60 min at room temperature; measuring the concentration of Ca<2+> and adding distilled water to regulate the concentration of Ca<2+>; adding the polymer and MgCl2 powder and uniformly mixing the mixture. The liquid-phase mineralizing precursor employs easy-to-obtained raw material andhas simple system, and is a creative break for therapy on oversensitive dentine.

Owner:WUHAN UNIV

A method for rapid restoration of demineralized dentin

ActiveCN105267046BRestoring the HierarchyRestoration of mechanical propertiesImpression capsDentistry preparationsPortland cementALLYL SUCROSE

The invention relates to a method of quickly repairing demineralized dentine. An existing method of repairing demineralized dentine uses two dentine non-collagen analogs, repairing is implemented by the aid of a Portland cement slow-release system, but this method is too complex and takes as long as four months to achieve full mineralization. According to the method of the invention, polyacrylic acid simple and easy to obtain is used as a regulator, calcium ions and phosphorus ions are used as raw materials, and fluidic amorphous calcium phosphate particles 15-20 nm in size are synthesized; glutamic acid is then used as a mineralization accelerator to mineralize the demineralized dentine again within 2 days, the natural hierarchical structure of the demineralized dentine is repaired, and the mechanical properties of the re-mineralized dentine also close to those of natural dentin. Compared with existing re-mineralization techniques, the method has the advantages that on the basis of achieving equivalent repaired hierarchical structure and mechanical properties, an apparatus is simple, time consumption is low, and the problem of re-mineralizing the demineralized dentine is more effectively solved.

Owner:ZHEJIANG UNIV

A kind of preparation method of fatigue-repairable high-strength bilayer network hydrogel

The invention discloses a preparation method of high-strength double-layer network hydrogel capable of being subjected to fatigue repair. The preparation method comprises the following steps: firstly preparing a mixed solution of a first layer of network polymers PVA (Polyvinyl Acetate) and a second layer of network monomers, generating hydrogen bonds between PVA molecular chains by adopting a freezing-melting method so as to form a first layer of physical cross-linked networks, and then polymerizing and crosslinking the second layer of network monomers by adopting an ultraviolet-irradiation method so as to form a covalent cross-linking network, thus obtaining the double-layer network hydrogel, the two layers of networks of which are crosslinked in different ways. The preparation method of the high-strength double-layer network hydrogel, disclosed by the invention, has the advantages that the component range of the two layers of networks of the double-layer network hydrogel is expanded; after the obtained hydrogel is subjected to low temperature circulation, physical crosslinking points are capable of being subjected to fatigue repair and meanwhile the double-layer network hydrogel has the characteristic of high strength.

Owner:HUBEI UNIV OF TECH

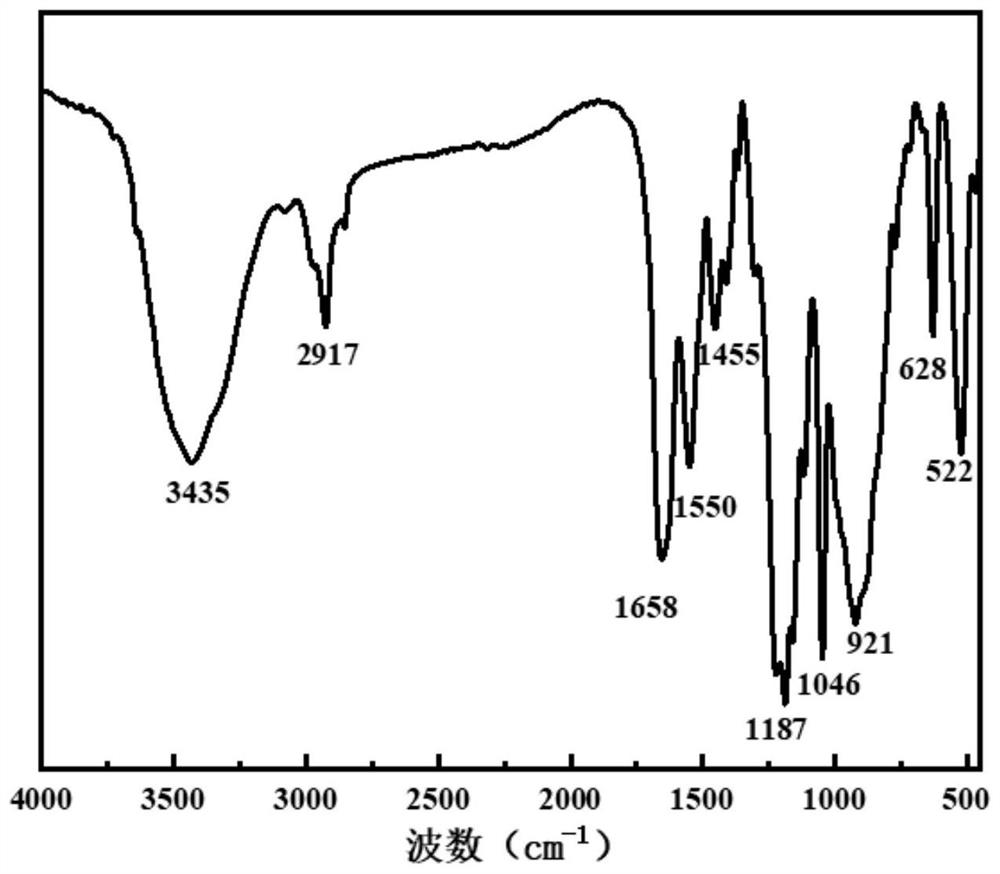

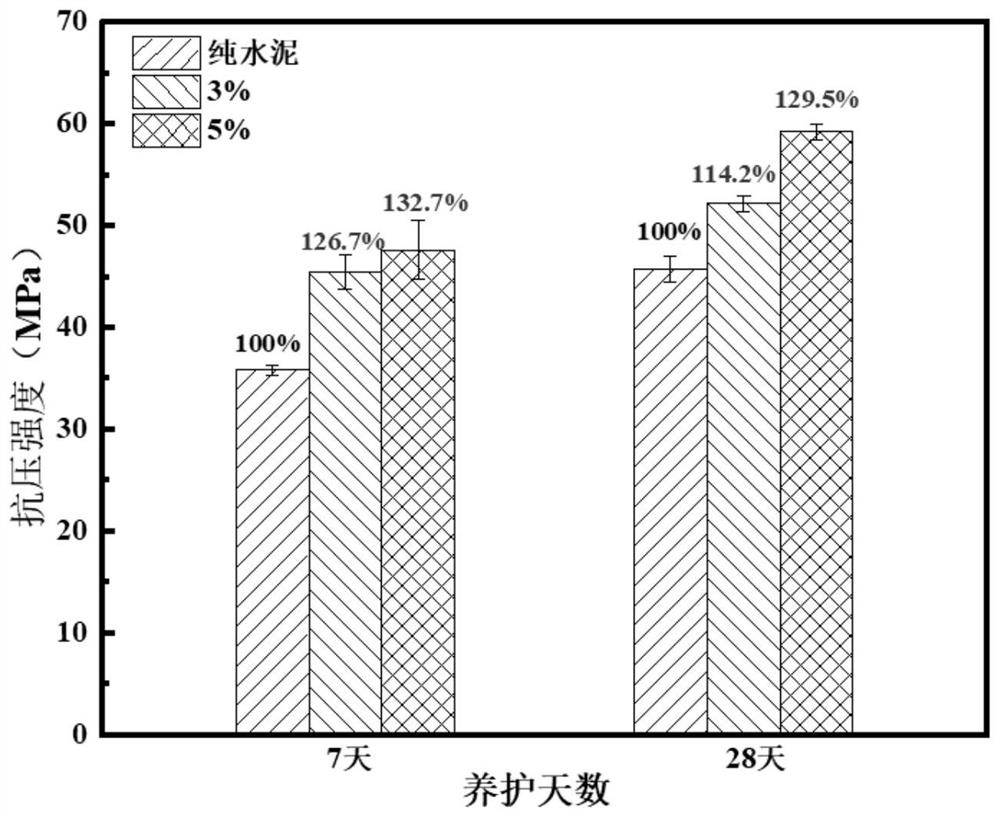

Organic-inorganic composite cement-based self-healing agent based on authigenic healing as well as preparation method and application thereof

The invention discloses an organic-inorganic composite cement-based self-healing agent based on authigenic healing and a preparation method and an application thereof. The preparation method comprises the following steps: dissloving 2-acrylamido-2-methylpropanesulfonic acid and carboxylic acid monomers in distilled water, adjusting pH, then adding acrylamide monomers, increasing the temperature to 50-60 DEG C, and obtaining a mixed solution; adding a silane coupling agent into absolute ethyl alcohol to obtain a silane coupling agent solution; adding an initiator into distilled water, and uniformly stirring to obtain an initiator solution; under stirring, dropwise adding the silane coupling agent solution and the initiator solution into the mixed solution at the same time; reacting to obtain a faint yellow viscous liquid; and adding cement into the faint yellow viscous liquid, stirring, performing vacuum freeze drying, grinding or crushing to obtain the organic-inorganic composite cement-based self-healing agent based on authigenic healing. The method is low in production cost, simple in process, easy for industrial production, high in autogenous healing efficiency and capable of realizing effective repair of cracks.

Owner:TIANJIN UNIV

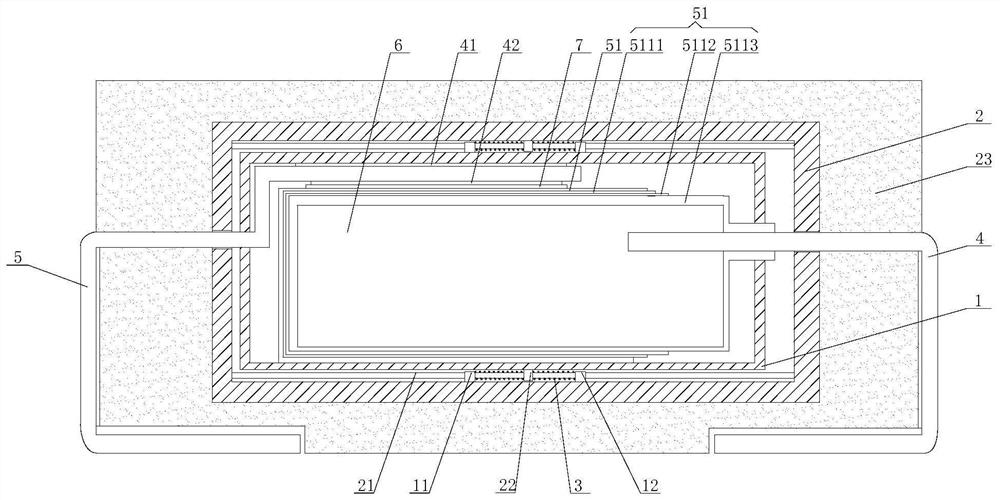

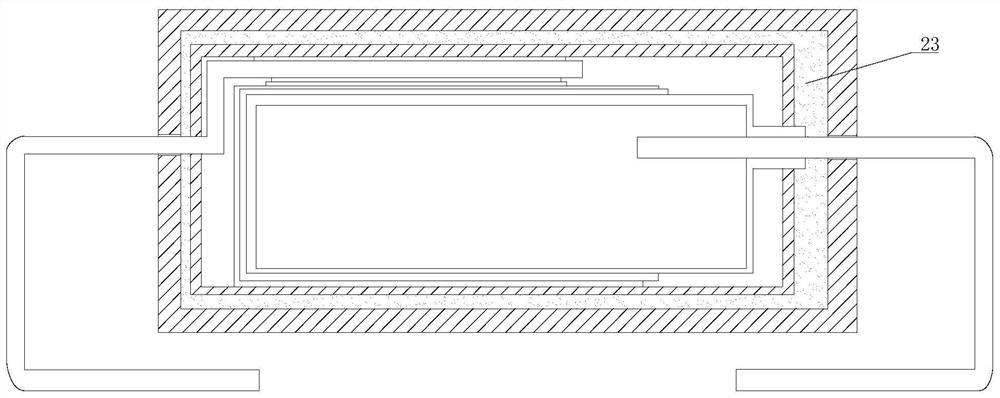

Tantalum and aluminum capacitor and preparation method thereof

ActiveCN111613444AImprove securityExtend your lifeCapacitor electrodesCapacitor dielectric layersEpoxyCapacitance

The invention discloses a tantalum and aluminum capacitor and a preparation method thereof. The tantalum and aluminum capacitor comprises an internal shell and an outer shell, the outer part of the inner shell is covered by the outer shell, and four side walls of the inner shell are respectively provided with a group of front plate and rear plate which are symmetrical to each other. A limiting rodpenetrating through the front plate and the rear plate is arranged on the inner wall of the outer shell, the outer part of the outer shell is also coated with epoxy resin, and a middle plate connected with the outer shell is fixed to the outer wall, located between the front plate and the rear plate, of the limiting rod. According to the present invention, springs sleeving the limiting rods are connected between the middle plate and the front plate and between the middle plate and the rear plate; the inner shell and the outer shell can be connected in an elastic connection mode through the springs additionally arranged on the tantalum capacitor; with the absorption effect between the springs, the vibration kinetic energy is absorbed; a conduction polymer based on bisamide bond hydrogen bond enhancement is added into an aluminum capacitor and covers the surface of an oxide film, the hydrogen bonds can be damaged and recombined in the heating and cooling process, and the mechanical property and the electrical property of the capacitor are recovered, so that the safety of the capacitor is improved, and the service life of the capacitor is prolonged.

Owner:朴力氏(浙江)半导体材料有限公司

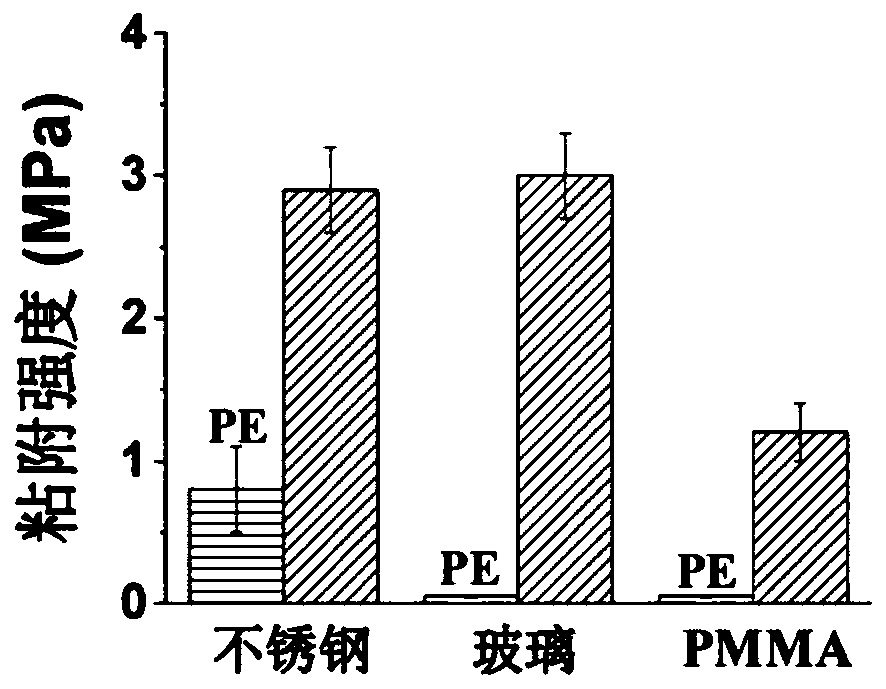

Multifunctional polar polyolefin material as well as metal complex material, preparation method and application thereof

The invention relates to a novel multifunctional polar polyolefin material as well as a metal complex material, a preparation method and an application thereof. The multifunctional polar polyolefin material is a random copolymer formed by copolymerizing an ethylene monomer represented by a formula CH2 = CH2, an alpha-olefin comonomer represented by a formula CH2 = CH-(CH2) m-CH3 and an eugenol comonomer represented by the formula, wherein m, X and Y are as defined herein, the multifunctional polar polyolefin material can be simply and effectively prepared under mild conditions, and can be usedas a compatible agent and an adhesive, and a multifunctional polar polyolefin metal complex material with significantly improved mechanical properties and a self-repairing function can be obtained after transition metal modification.

Owner:UNIV OF SCI & TECH OF CHINA

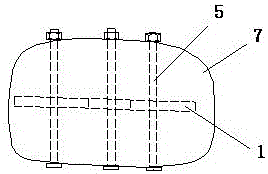

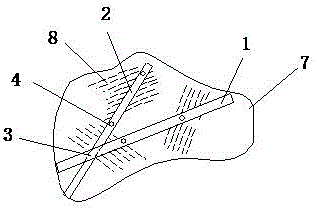

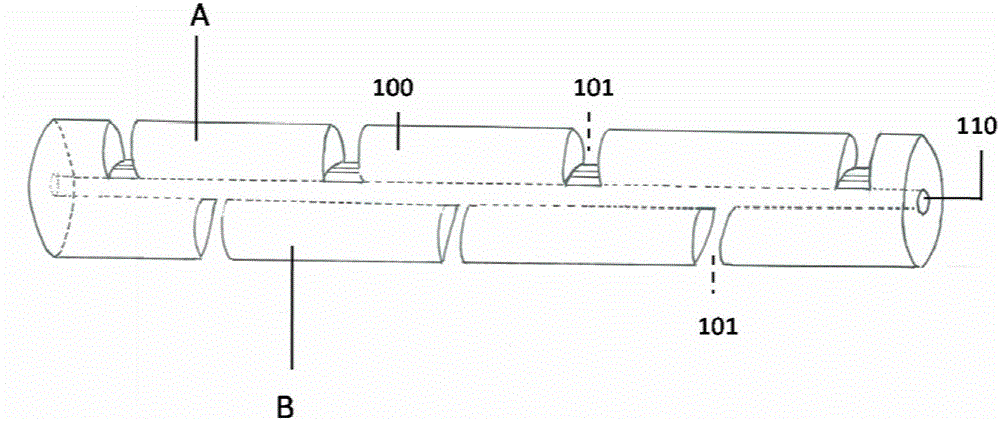

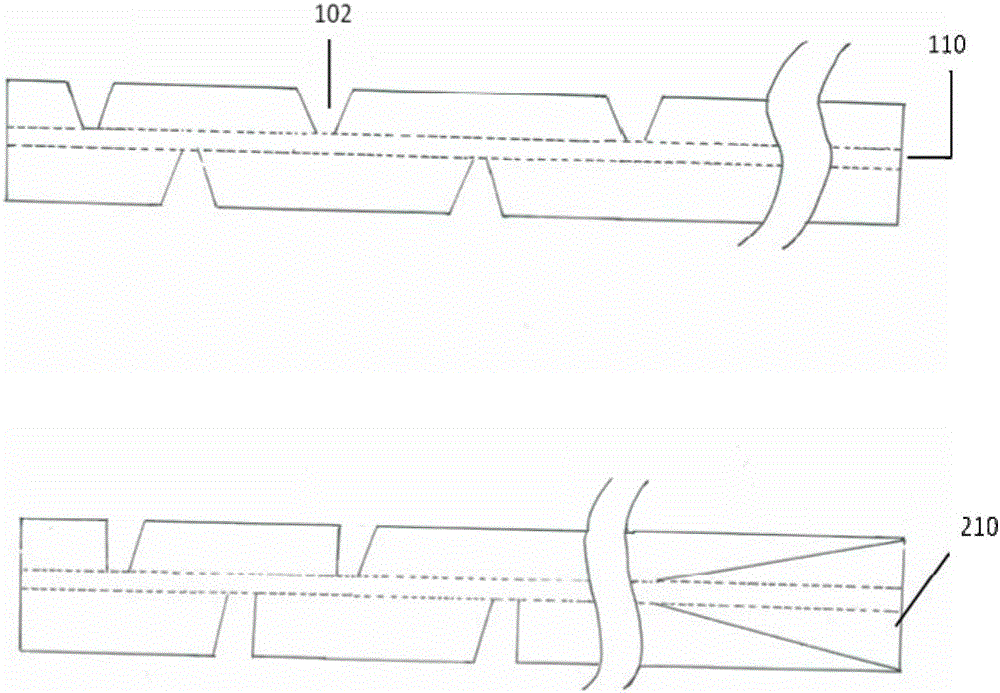

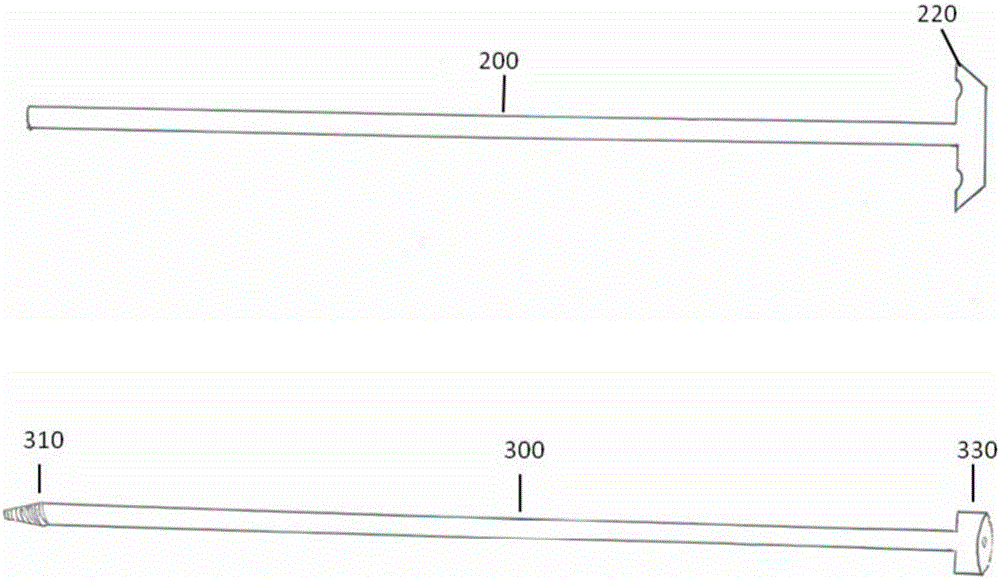

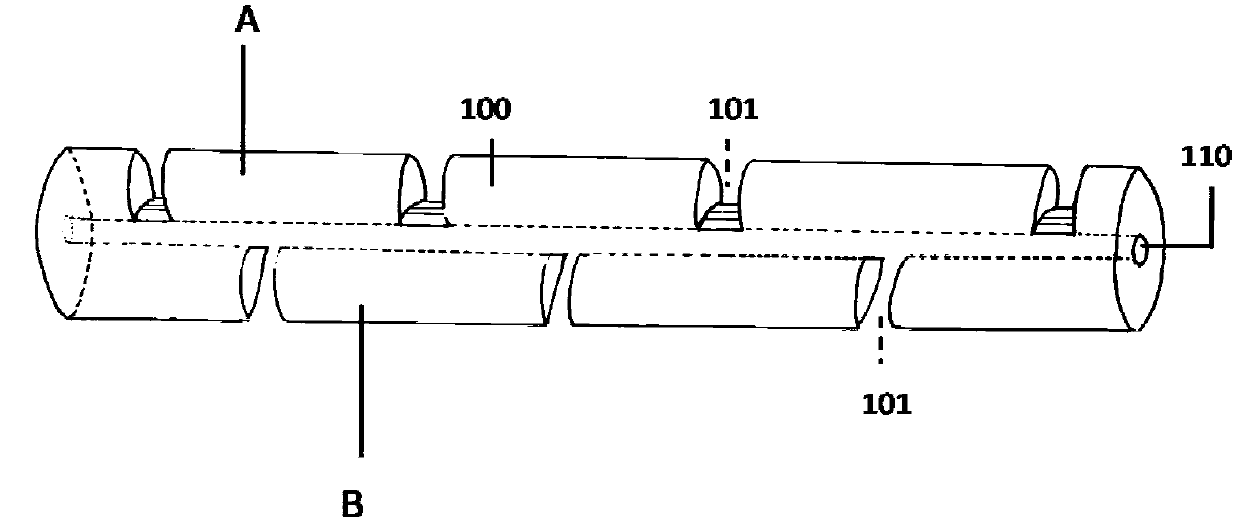

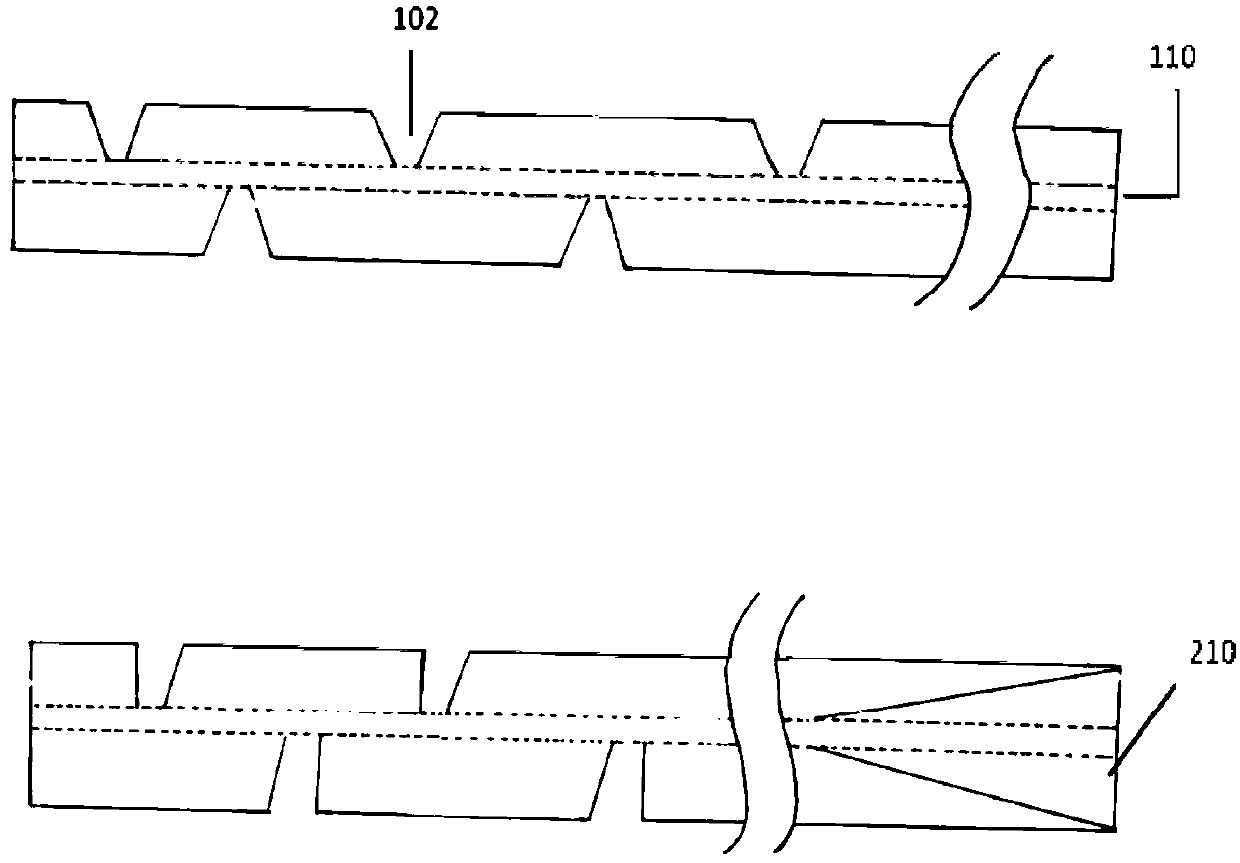

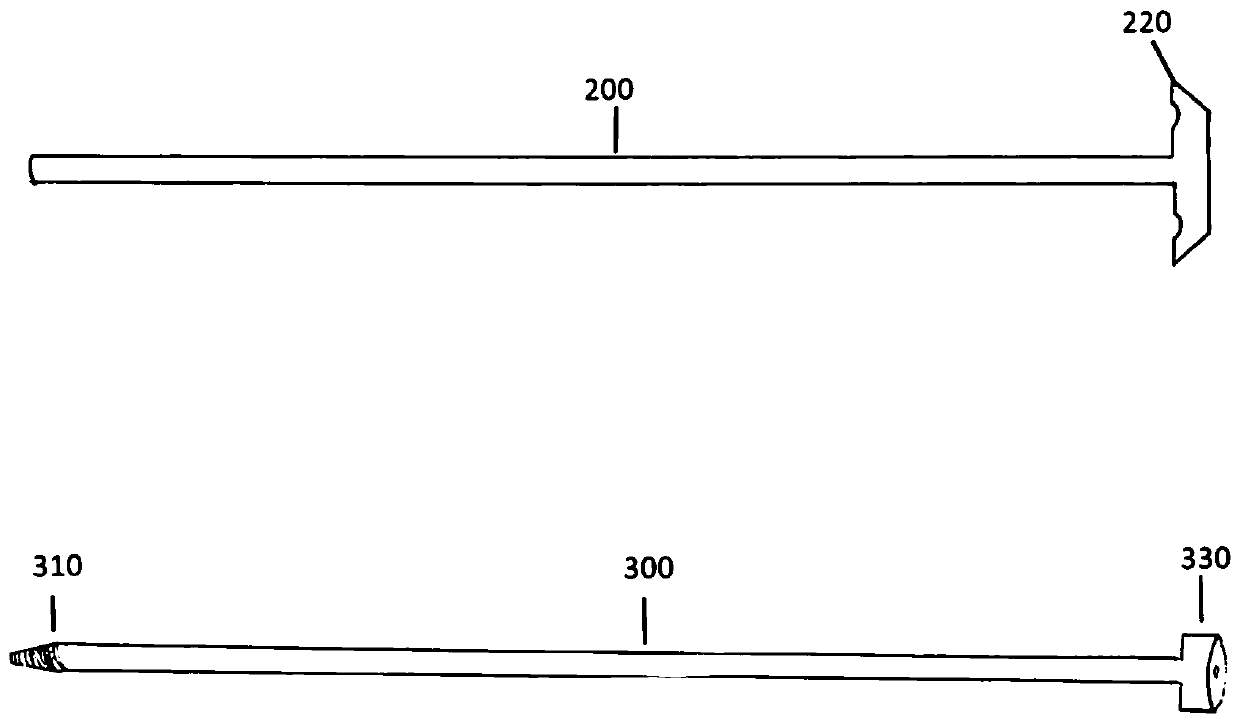

Injectable vertebra repairing device

ActiveCN105769324AMaintain normal biomechanical propertiesEvenly distributedOsteosynthesis devicesSpinal columnLesion site

The invention relates to an injectable vertebra repairing device for treating a spinal vertebral fracture.The injectable vertebra repairing device comprises an injectable chain and a filling tool; the injectable chain is in the shape of a cylinder with the rough surface, a central through hole is formed in the injectable chain, multiple grooves are formed in the upper portion and the lower portion of the chain, and the grooves are communicated with the central through hole; the filling tool comprises a filling casing pipe and a push rod casing pipe, and the tail end of the filling casing pipe and the tail end of the push rod casing pipe are provided with grab handles respectively; the front end of the push rod casing pipe and the near end of the injectable chain are designed to be of a tapper thread structure.When the device is operated, the top end of the filling casing pipe stretches into the lesion part, and the chain is filled into the damaged vertebra through the push rod casing pipe; bone cement is injected into the central through hole of the chain through the push rod casing pipe; the central through hole and the grooves are sequentially fully filled with the bone cement, solidification is performed to complete repairing, pressure exerting on the lesion part can be uniform and be reduced, and therefore the effect of effectively repairing the vertebra is achieved.The injectable vertebra repairing device is applied to the field of medical instruments and mainly used for achieving the purposes of stabilizing the fracture, recovering the vertebral mechanical strength and relieving pain.

Owner:山东明德生物医学工程有限公司

A room temperature repairable polymer damping material and its preparation method and application

The invention provides a polymer damping material capable of being repaired at room temperature and a preparation method and application thereof, and belongs to the technical field of polymer materials. The polymer damping material capable of being repaired at room temperature is prepared from the following preparation raw materials: polyhydric alcohol, isocyanate, a chain extension cross-linkingagent and a solvent. The polyhydric alcohol comprises amino-terminated polyhydric alcohol or hydroxyl-terminated polyhydric alcohol, a molar ratio of the polyhydric alcohol to the isocyanate is (1.1-1.3): 1, and the crosslinking degree of the polymer damping material capable of being repaired at room temperature is 5-30%. The polymer damping material capable of being repaired at room temperature is high in transparency and excellent in mechanical property, spontaneous wound repair can be carried out at the room temperature after mechanical damage, the safety and durability of the material aregreatly improved, the service life of the material is greatly prolonged, and a good damping effect is achieved at the room temperature. Meanwhile, the damping material can be reshaped and recycled when being seriously damaged.

Owner:JILIN UNIV

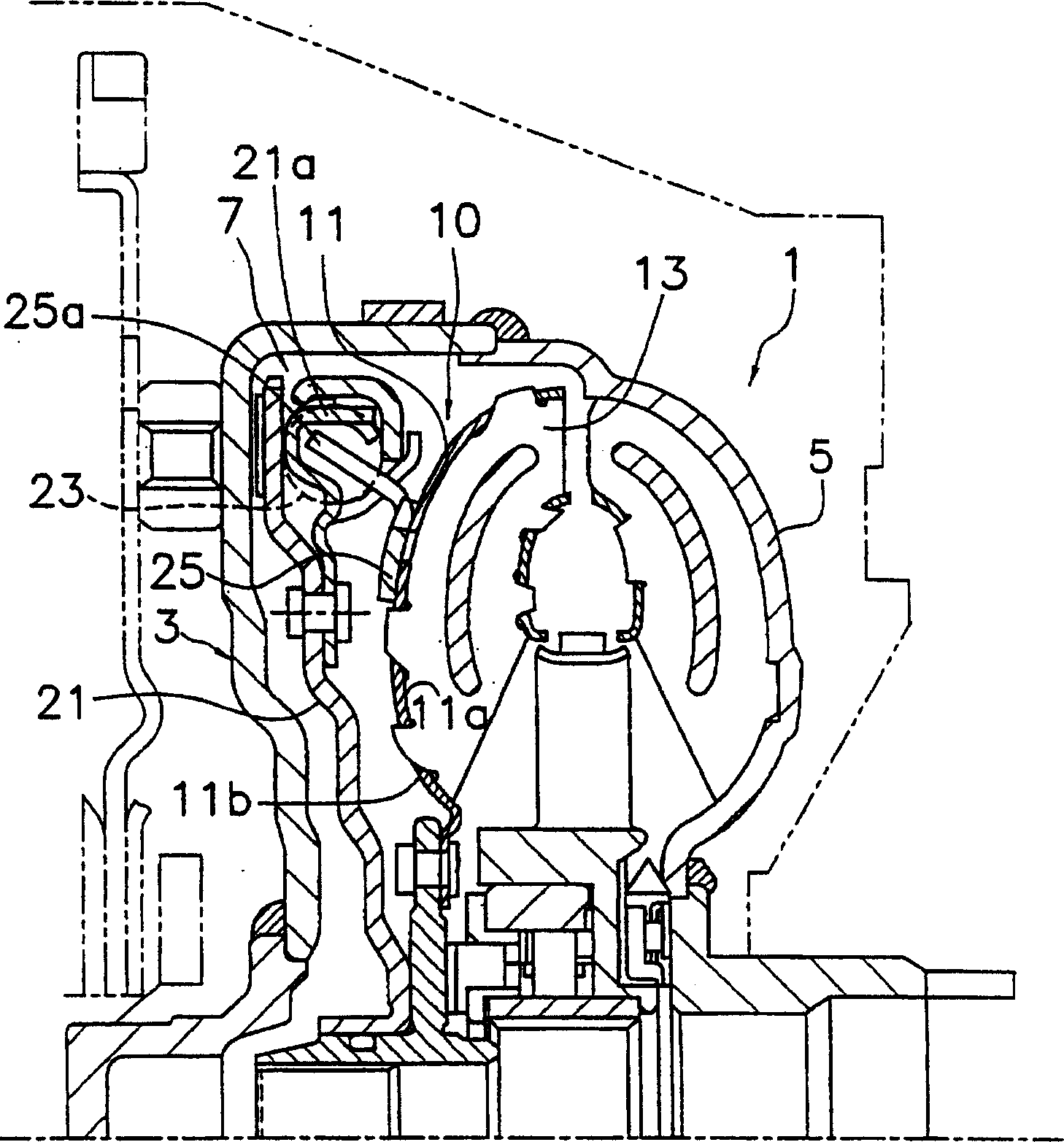

Method of manufacturing rotating body of torque converter and rotating body of torque converter manufactured by the manufacturing method

InactiveCN1878971ALow costRestoration of mechanical propertiesSoldering apparatusGearing controlTurbine bladeHeat treated

Owner:EXEDY CORP

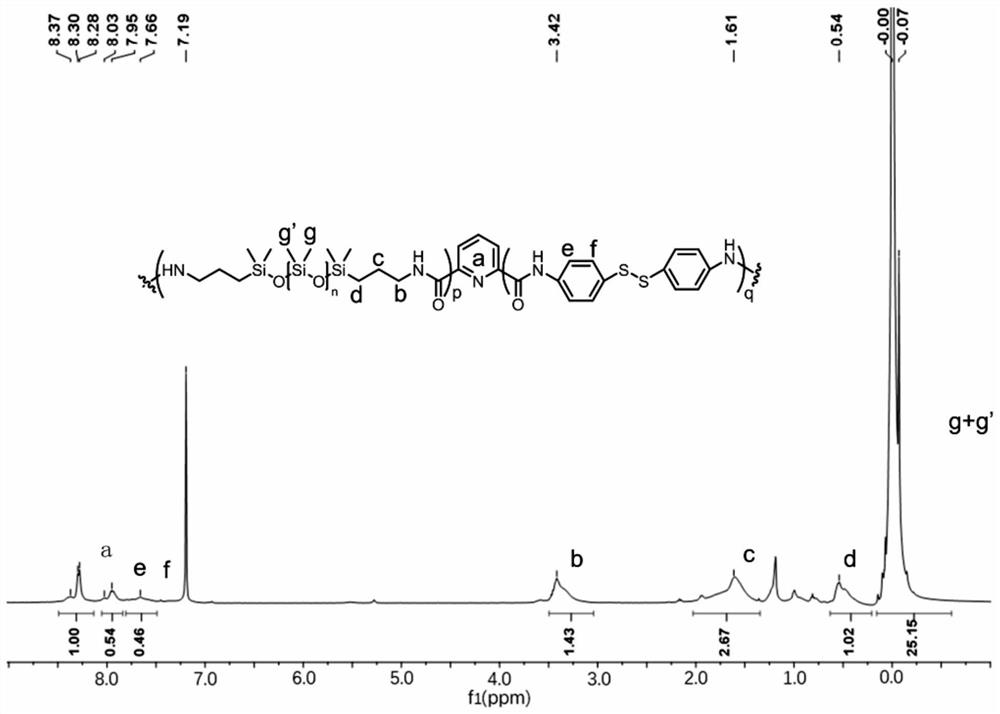

A kind of polysiloxane based on aromatic disulfide bond and its application

ActiveCN111518279BImprove flexibilityEasy to stretchSecondary cellsPositive electrodesDisulfide bondingCapacitance

The invention discloses a polysiloxane based on an aromatic disulfide bond, which is composed of an amino-terminated polysiloxane and a substituted or unsubstituted 4,4'-diaminodiphenyl disulfide reacted with a crosslinking agent Formation of amide bonds, polycondensation. The polysiloxane of the present invention not only has good flexibility, but also has a large number of reversible dynamic bonds, abundant hydrogen bonds and disulfide bonds, and can spontaneously repair damage at room temperature or under heating conditions, and is more capable of The repair material adapts to the physical environment of the positive electrode material of the lithium battery, has good bonding performance and stability, and can alleviate the specific capacitance attenuation caused by the expansion of the battery during charging and discharging, thereby repairing the micro-cracks of the battery, increasing the cycle times of the battery, and prolonging the life of the battery. The service life of the battery can be used as a self-healing binder to prepare positive electrode materials in lithium batteries.

Owner:NANJING UNIV

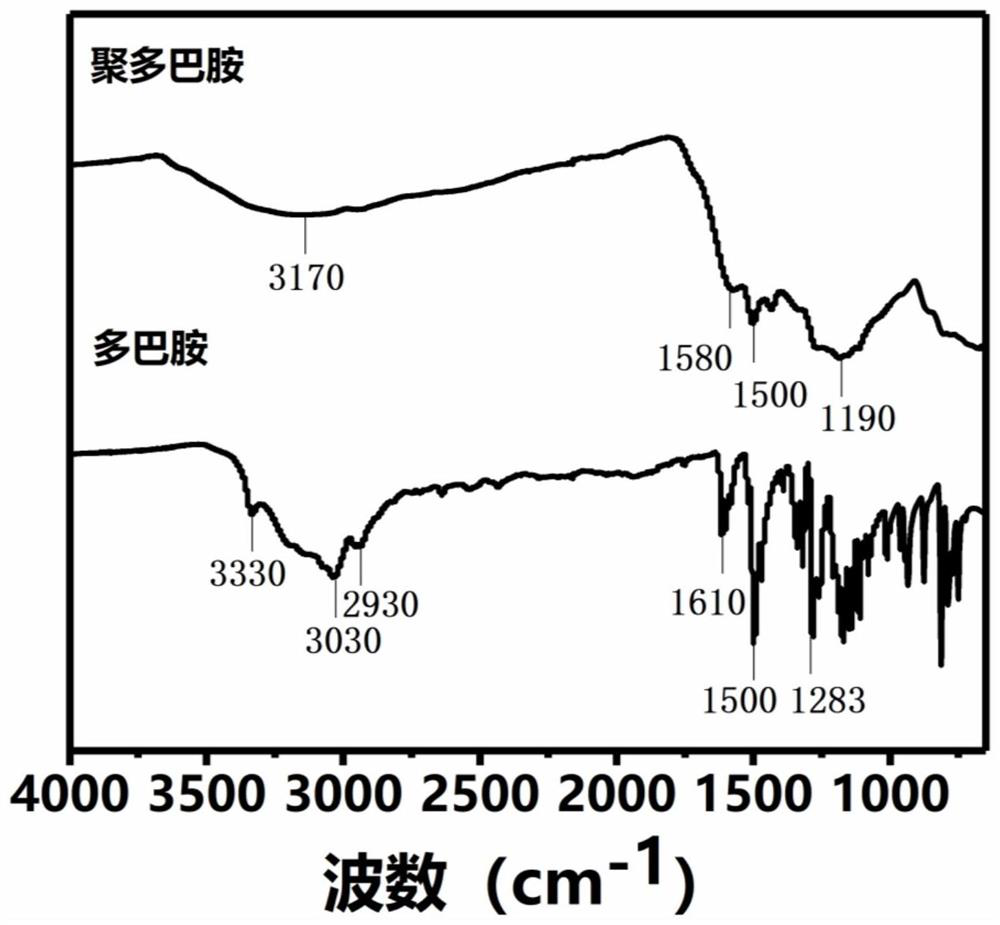

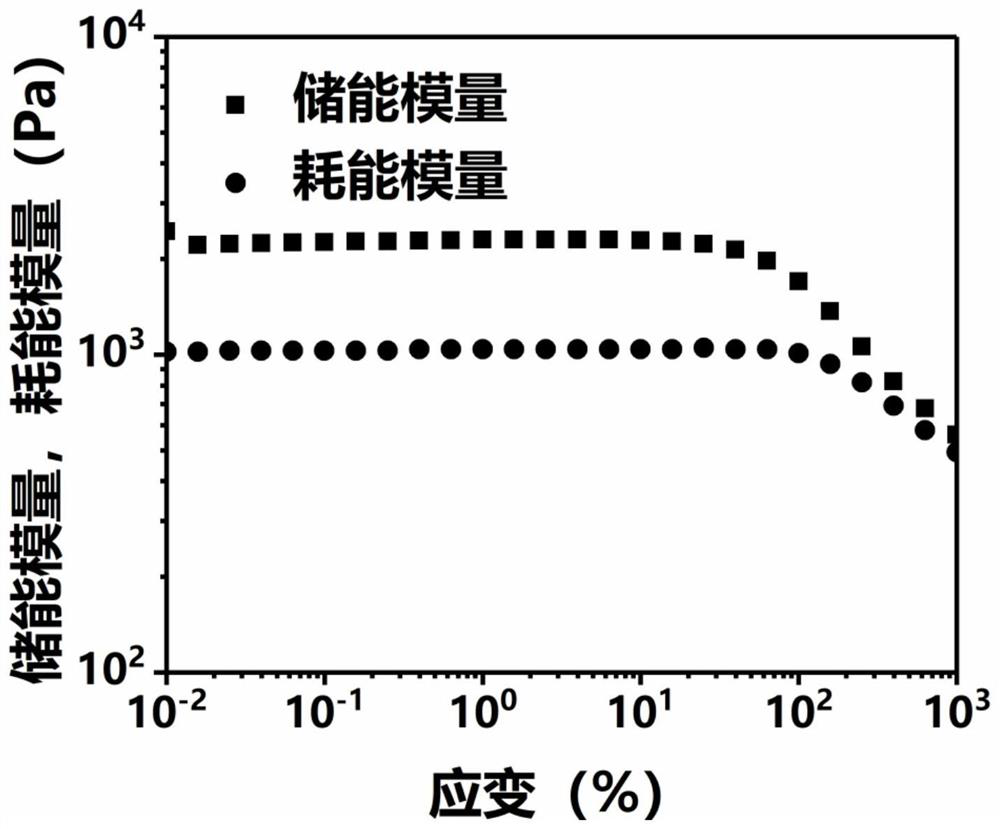

A preparation method of a hydrogel electrode with high mechanical properties and self-healing properties

InactiveCN106008799BImprove self-healing abilityConductivity recoveryDiagnostic recording/measuringSensorsSelf-healingBiocompatibility Testing

The invention discloses a preparation method of a hydrogel electrode with high mechanical properties and self-healing property, belonging to the technical field of biomaterials. In the present invention, polydopamine-modified conductive nanomaterials are firstly prepared in a solution, and then water-soluble monomers are added to the solution, and then an initiator, a cross-linking agent and an auxiliary agent are added to mix evenly, and the hydrogel is formed by free radical polymerization. electrode. The hydrogel electrode prepared by the invention does not have good electrical conductivity and mechanical properties; and due to the non-covalent bond between polydopamine chains, the hydrogel electrode has good self-healing performance. The hydrogel electrode prepared by the invention has the ability to heal spontaneously in a short period of time after accidental damage; combined with its good biocompatibility, the self-healing hydrogel electrode prepared by the invention It is expected to be applied to modern clinical detection and biomedical measurement.

Owner:SOUTHWEST JIAOTONG UNIV

Asynchronous cold rolling forming process of aluminum alloy and stainless steel clad plate

ActiveCN110883093BIncrease rolling capacityImprove rolling precisionTemperature control deviceWork cooling devicesLine heatingComposite plate

The invention discloses an asynchronous cold rolling forming process of an aluminum alloy stainless steel clad plate, which comprises the following process steps: adopting an asynchronous rolling method to roll and clad the stainless steel plate and the aluminum alloy plate; after the asynchronous rolling, diffusion annealing the clad plate; In the S1 step, the opposite surface of the composite plate surface of the stainless steel plate is heated online, and the opposite surface of the composite plate surface of the aluminum alloy plate is cooled online, and the heating temperature is 350 ° C to 850 ° C; The temperature of the clad plate surface of the stainless steel plate of the clad plate is lower than 650°C, and the temperature of the clad plate surface of the aluminum alloy plate rolled out of the clad plate is lower than 300°C; the rolling reduction rate is 20% to 90%; the roll of the asynchronous cold rolling The speed ratio is 1.05-1.50; the thickness ratio of the aluminum alloy plate and the stainless steel plate is 1.5-4.0; in the S2 step, the annealing temperature is 250°C-500°C, and the annealing time is 15-120min. The invention creatively proposes a one-side online heating process for rolling a composite plate to improve the bond strength of the interface of the composite plate and realize rolling and compounding in a semi-molten state of the interface.

Owner:JIANGYIN KANGRUI MOLDING TECH CO LTD

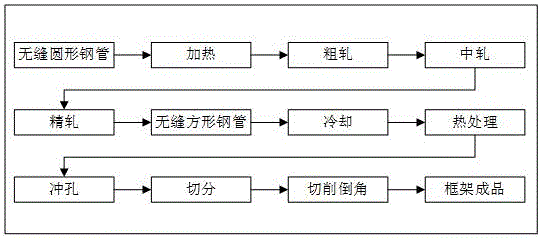

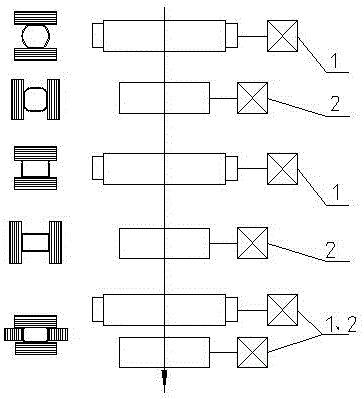

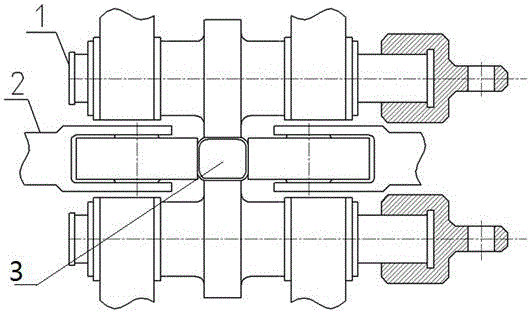

Manufacturing method of seamless frame of steel wire rope fastening device

The invention relates to the technical field of preparation of steel wire rope fastening equipment, in particular to a manufacturing method of a seamless frame of a steel wire rope fastening device. The method comprises steps including preheating treatment, rolling treatment, cooling treatment, heat treatment, punching treatment and cutting treatment. The finished product frame prepared through the manufacturing method adopts a seamless integrated structure, the whole frame is evenly stressed, stress concentration is avoided during stressing, and the whole frame is firmer in structure and safer and more reliable to use. A seamless steel pipe is used as a raw material directly and is a common standard part. The raw material is cheap and easy to obtain, and the machining cost is low. The manufacturing method adopts the multi-stage graded rolling technology and is simple to operate and low in implementation difficulty, the frame can be machined to the designed size conveniently and is not welded by a welding machine, and the energy consumption is substantially reduced. Meanwhile, damage of welding to material properties is also reduced.

Owner:甘肃酒钢集团西部重工股份有限公司

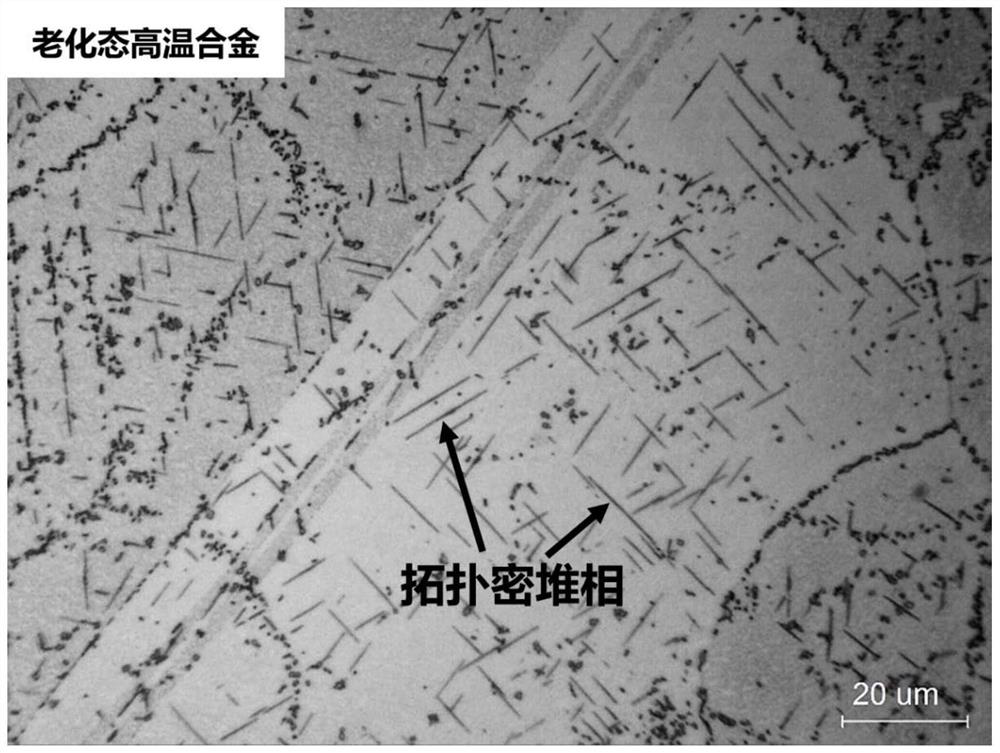

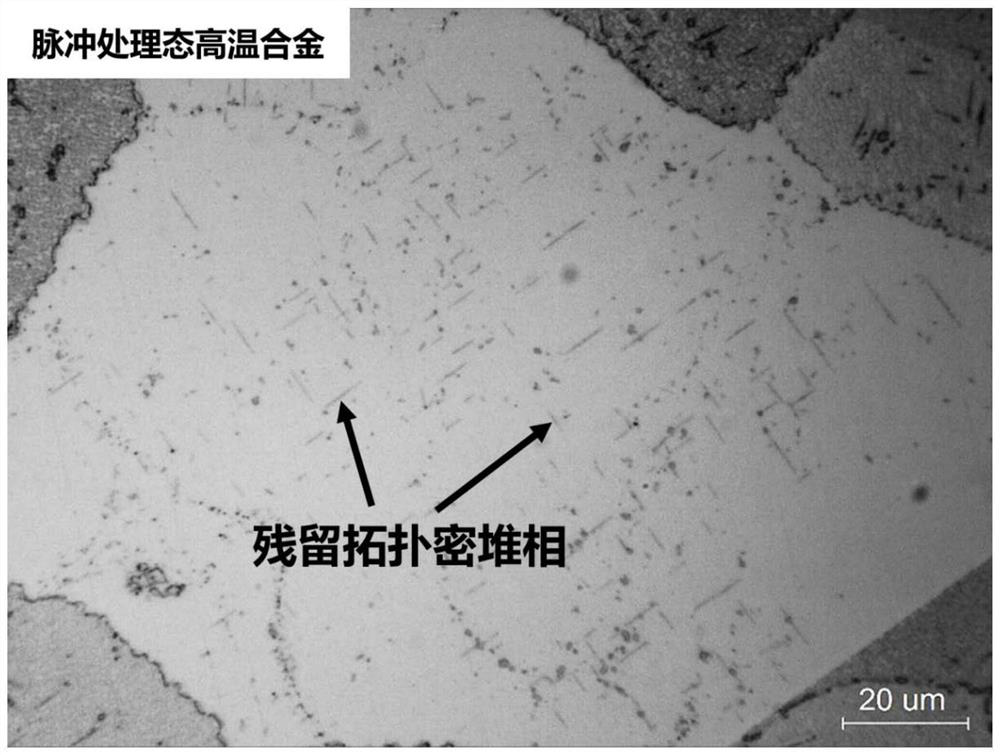

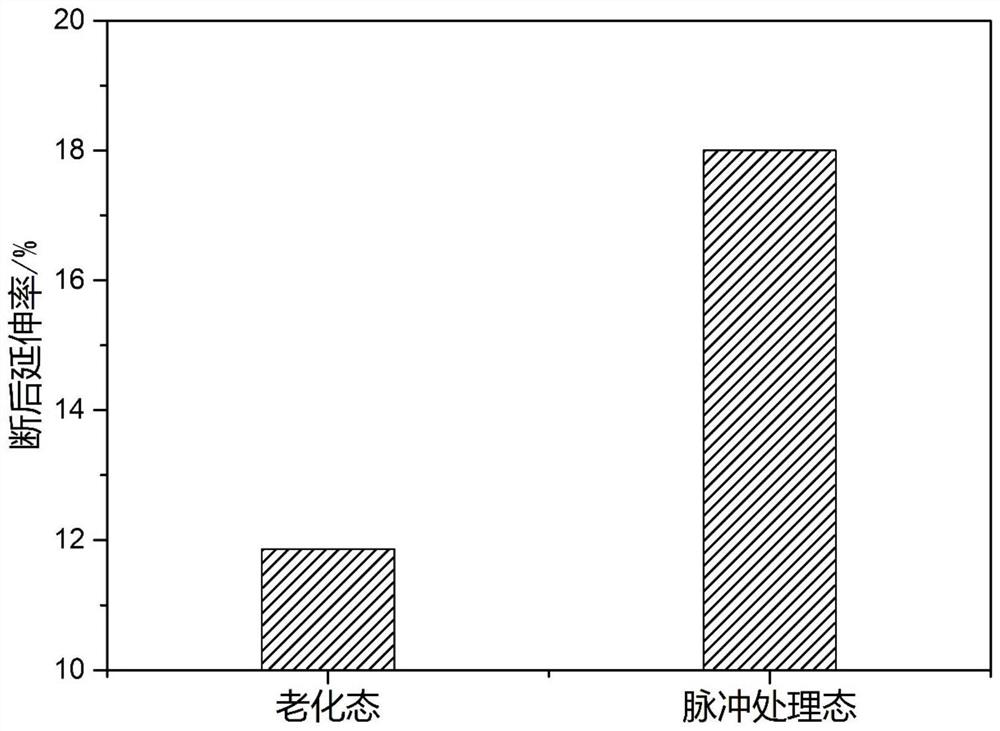

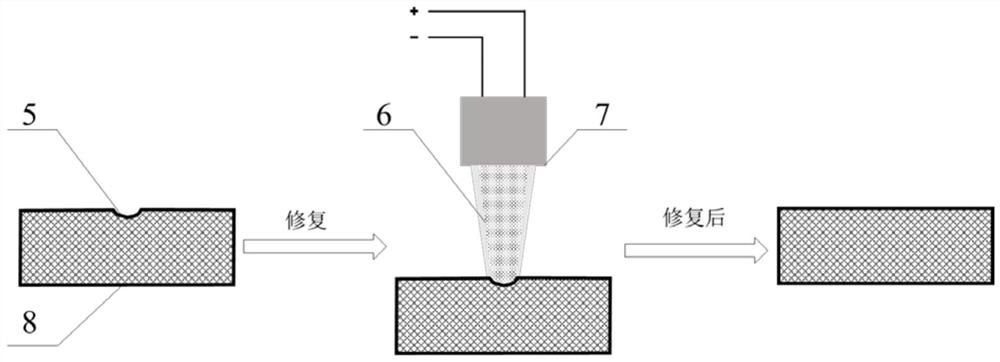

Method for quick repair of nickel-base superalloy turbine disk at the end of service

The invention relate to the technical field of advanced aviation engine turbine disc service life prolonging, and provides a method for rapidly repairing a nickel-base high-temperature alloy turbine disc at the last phase of service. Pulse current treatment is performed on the performance-deteriorated high-temperature alloy turbine disc at the last phase of service at a certain temperature. The method remarkably improves the microscopic structure and mechanical property of the alloy turbine disc. The parameter range of pulse treatment includes the frequency of 10-30000 Hz, the pulse width of 10-500 [mu]s, the current of 10-5000 A and the acting time of 1 minute to 10 hours. Treatment can be performed on the turbine disc at the last phase of service at a low temperature, the number densityof a brittle topological dense heap phase in a material is reduced, and the mechanical property of the aged high-temperature alloy turbine disc is restored to the maximum extent; and the method is short in treatment time and low in temperature, can greatly reduce energy consumption, meets the requirement of the current industrial green development program, provides a new method for prolonging theservice life of the high-temperature alloy turbine disc, and has broad application prospects.

Owner:UNIV OF SCI & TECH BEIJING

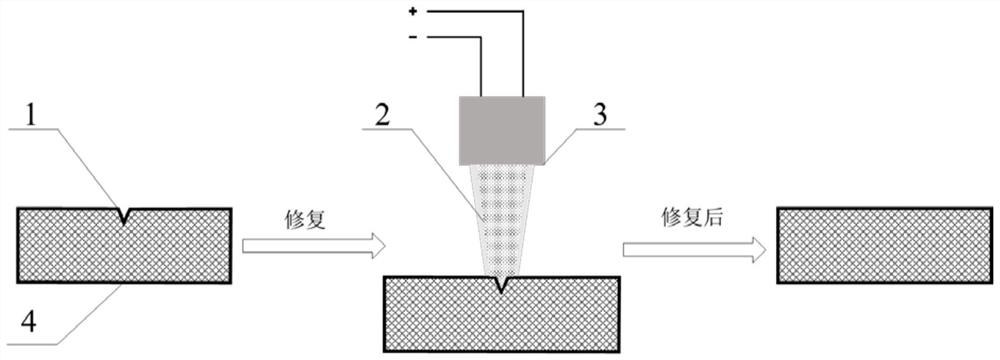

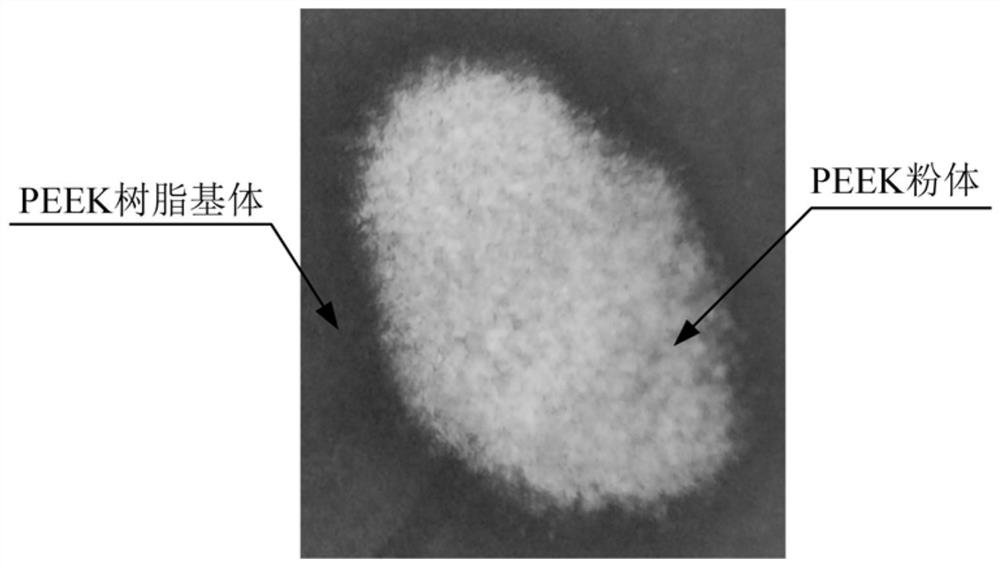

Method for repairing fiber-reinforced resin-based composite material

The invention discloses a method for repairing a fiber-reinforced resin-based composite material. The method comprises the following steps of: 1, preparing corresponding powder according to damage and defect types of the fiber-reinforced resin-based composite material; 2, cleaning and removing dust, chippings, dirt and other impurities in damage and defect areas of the fiber-reinforced resin-based composite material; 3, carrying out texturing treatment on the damage and defect areas of the fiber-reinforced resin-based composite material; and 4, spraying the prepared powder to the damage and defect areas through a supersonic cold spraying technology, depositing the powder to form a surface repairing layer, and completing repairing of the damage and defect areas. The method has the advantages of high efficiency, low energy consumption, environmental friendliness and the like, the surface of a repaired part is smooth, and the mechanical property is restored to a certain extent.

Owner:NANJING INST OF TECH

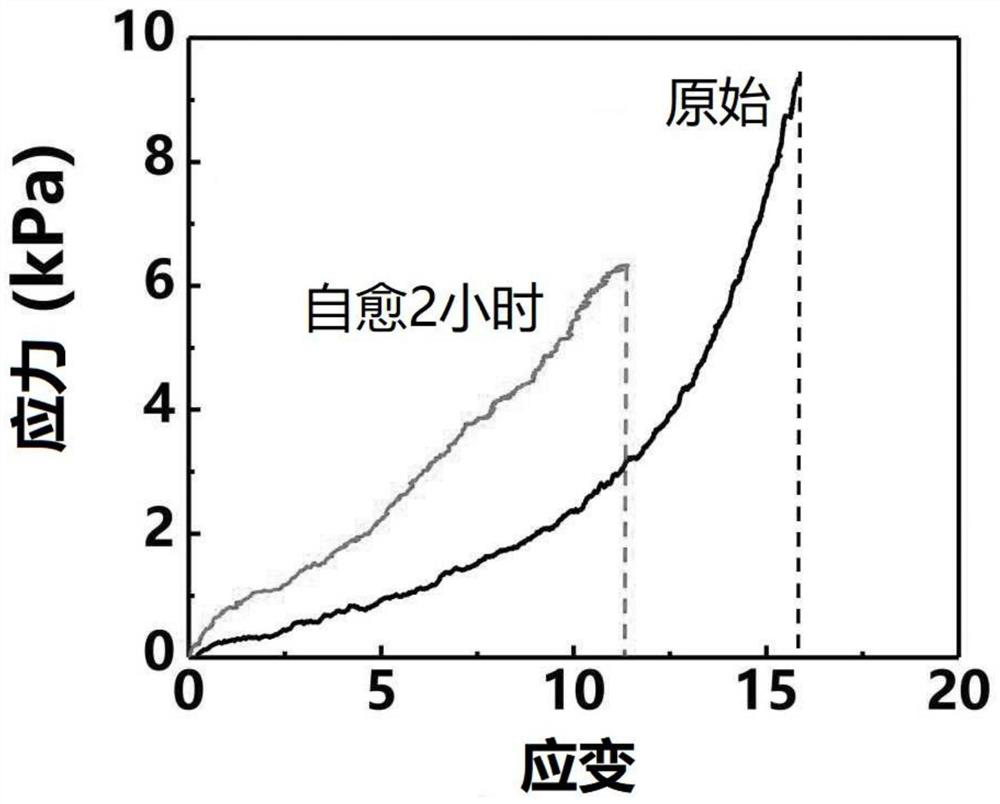

A high-strength autonomous self-healing hydrogel based on dopamine and its preparation method

A dopamine-based high-strength autonomous self-healing hydrogel and a preparation method thereof belong to the field of biomaterials. The mass of the high-strength autonomous self-healing hydrogel is based on 100wt%, and the components and their mass percentages are: the content of polydopamine is 0.15wt% to 0.88wt%, the content of acrylamide is 17.56wt% to 18.18wt%, and the rest is Deionized water. The dopamine is dissolved in the alkaline aqueous solution, the pH is adjusted to 8-14, and the mixture is fully stirred to prepolymerize the dopamine to form polydopamine, thereby obtaining a polydopamine solution. At room temperature, mix acrylamide, N,N'-methylenebisacrylamide and ammonium persulfate with polydopamine solution, stir and mix well, then add auxiliary agent tetramethylethylenediamine to polymerize acrylamide to form Polydopamine-polyacrylamide hydrogel. The present invention adopts a simple two-step method to successfully prepare the polydopamine-polyacrylamide hydrogel. The high-strength hydrogel has good self-healing performance, and the hydrogel can be recovered without external stimuli after being damaged and broken. Quickly restore its mechanical properties.

Owner:DALIAN UNIV OF TECH

An injectable vertebral body repair device

ActiveCN105769324BMaintain normal biomechanical propertiesEvenly distributedOsteosynthesis devicesSpinal columnLesion site

The invention relates to an injectable vertebra repairing device for treating a spinal vertebral fracture.The injectable vertebra repairing device comprises an injectable chain and a filling tool; the injectable chain is in the shape of a cylinder with the rough surface, a central through hole is formed in the injectable chain, multiple grooves are formed in the upper portion and the lower portion of the chain, and the grooves are communicated with the central through hole; the filling tool comprises a filling casing pipe and a push rod casing pipe, and the tail end of the filling casing pipe and the tail end of the push rod casing pipe are provided with grab handles respectively; the front end of the push rod casing pipe and the near end of the injectable chain are designed to be of a tapper thread structure.When the device is operated, the top end of the filling casing pipe stretches into the lesion part, and the chain is filled into the damaged vertebra through the push rod casing pipe; bone cement is injected into the central through hole of the chain through the push rod casing pipe; the central through hole and the grooves are sequentially fully filled with the bone cement, solidification is performed to complete repairing, pressure exerting on the lesion part can be uniform and be reduced, and therefore the effect of effectively repairing the vertebra is achieved.The injectable vertebra repairing device is applied to the field of medical instruments and mainly used for achieving the purposes of stabilizing the fracture, recovering the vertebral mechanical strength and relieving pain.

Owner:山东明德生物医学工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com