Self-repairing aqueous polyurethane prepolymer, and dispersion liquid and application thereof

A water-based polyurethane and prepolymer technology, which is applied in medical science, prosthesis, tissue regeneration, etc., can solve problems that have not been seen, and achieve the effect of restoring the mechanical properties of materials and the appearance of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

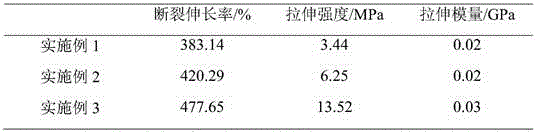

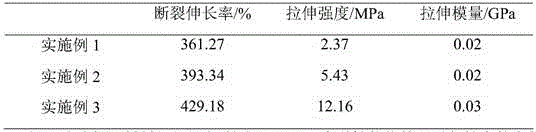

Embodiment 1

[0028] (1) Melt 62.5g of MDI100 and add it to 200g of PPG2000. After mixing evenly, add 0.25g of dibutyltin dilaurate as a catalyst, raise the temperature to 75°C, and stir the reaction for 1.5h under the protection of nitrogen. Determination of R value by amine titration;

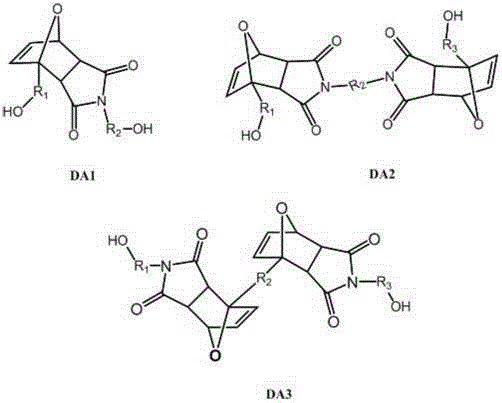

[0029] (2), add 18.4g of hydrophilic chain extender DMAP to the product of step (1), under the protection of inert gas, after reacting at 80°C for 0.5-2h, add 9g of the diol containing Diels-Alder bond to extend the chain Agent DA1, continue to react at 80°C for 2 hours, cool down to 30-50°C, add triethylamine, react for 40 minutes to neutralize to pH=8-9, and obtain self-repairing waterborne polyurethane prepolymer;

[0030] (3), after dissolving the water-based polyurethane prepolymer prepared in step (2) with 30ml of acetone, slowly add 540g of deionized water at a temperature of 20 to 40°C and an emulsifier rotating speed of 4000 rpm. After dispersing and dispersing, extract and remove the organic sol...

Embodiment 2

[0032] (1) Melt 109g of TDI and add it to 200g of PPG2000. After mixing evenly, add 0.22g of dibutyltin dilaurate as a catalyst, raise the temperature to 85°C, and stir the reaction for 1h under the protection of nitrogen. Titrate with acetone-di-n-butylamine Determination of R value by method;

[0033] (2), add 16g of hydrophilic chain extender DMAP to the product of step (1), under the protection of inert gas, after reacting at 75°C for 2h, add 16g of diol chain extender DA2 containing Diels-Alder bond, Continue to react at 80°C for 2-4 hours, cool down to 45°C, add ammonia water, react for 30 minutes to neutralize to pH=8-9, and obtain self-healing water-based polyurethane prepolymer;

[0034] (3) After diluting the water-based polyurethane prepolymer prepared in step (2) with 40ml of acetone, slowly add 820g of deionized water at a temperature of 35°C and an emulsifier speed of 3500 rpm for shear dispersion After that, the organic solvent is removed by extraction under re...

Embodiment 3

[0036] (1) After melting 109g of MDI, add it to 180g of PTMEG2000, mix it evenly, add 0.3g of stannous octoate as a catalyst, heat up to 85°C, under the protection of argon, stir and react for 1h, use acetone-di-n-butylamine titration method Determination of R value;

[0037](2), add 16g of hydrophilic chain extender DMAP to the product of step (1), under the protection of inert gas, after reacting for 2h at 75°C, add 23g of diol chain extender DA2 containing Diels-Alder bond, Continue to react at 80°C for 2.5h, cool down to 30°C, add triethylamine, react for 30min to neutralize to pH=8-9, and obtain self-healing waterborne polyurethane prepolymer;

[0038] (3) After dissolving the water-based polyurethane prepolymer prepared in step (2) with 60ml of methyl ethyl ketone, slowly add 600g of deionized water at a temperature of 45°C and an emulsifier speed of 4000 rpm for shear dispersion After dispersion, the organic solvent is removed by vacuum extraction to obtain the corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com