Patents

Literature

323 results about "Diels alder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

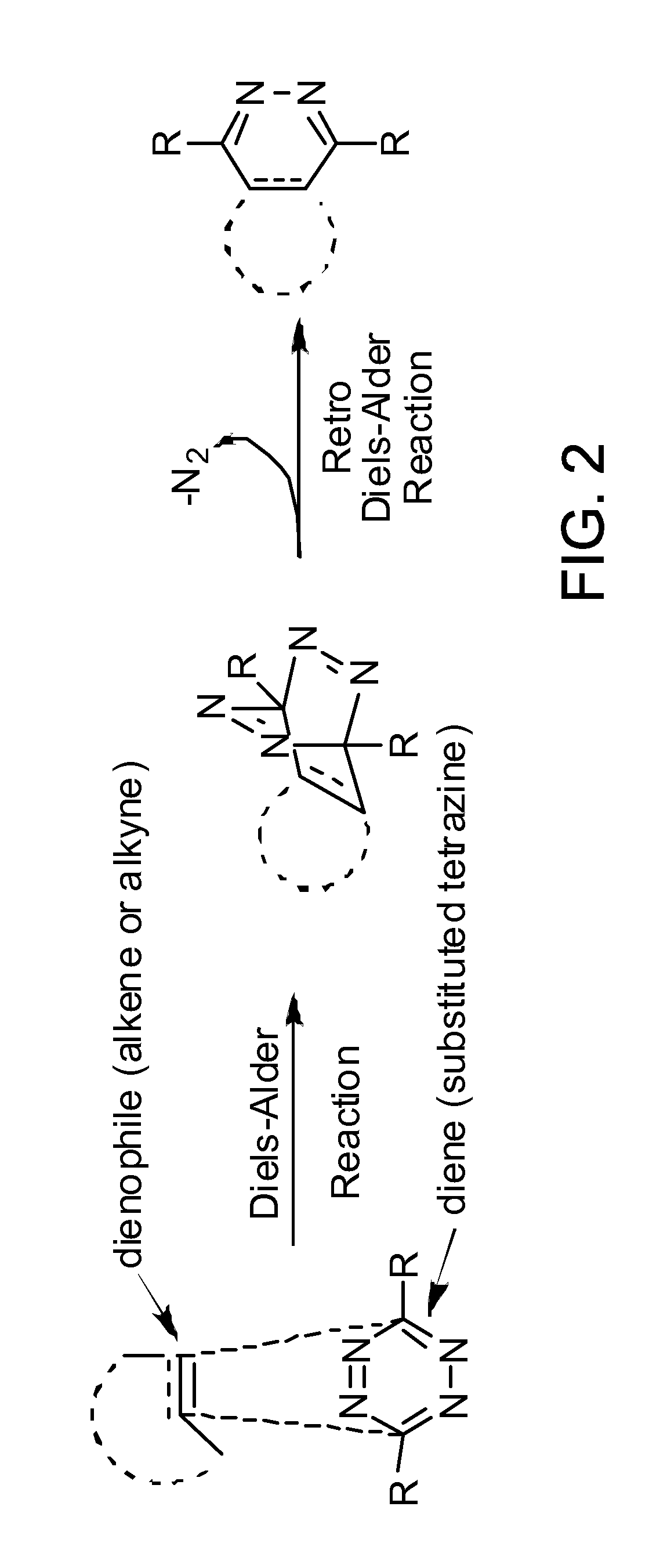

In organic chemistry, the Diels–Alder reaction is a chemical reaction between a conjugated diene and a substituted alkene, commonly termed the dienophile (also spelled dieneophile), to form a substituted cyclohexene derivative. It is the prototypical example of a pericyclic reaction with a concerted mechanism.More specifically, it is classified as a thermally-allowed [4+2] cycloaddition with ...

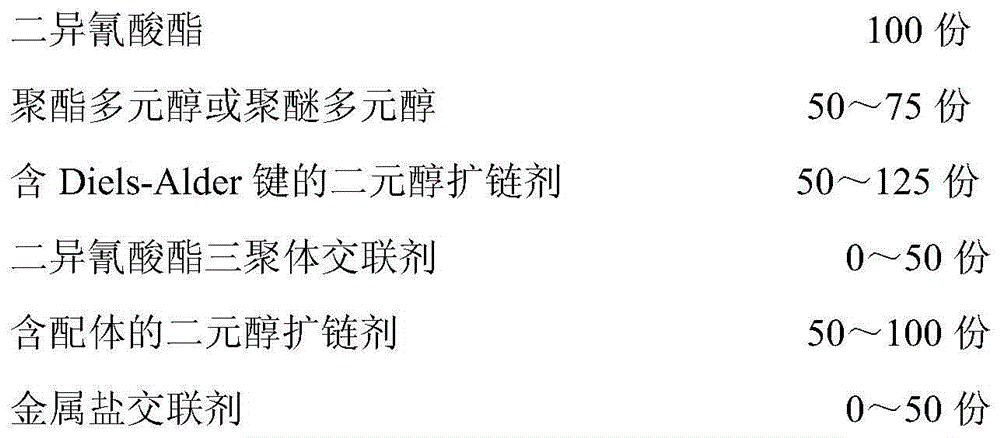

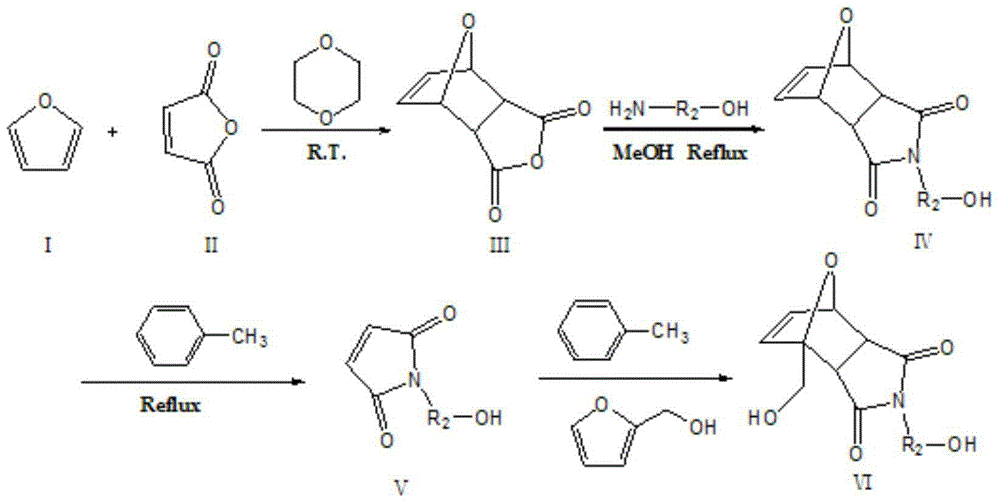

Dynamic bond-containing polyurethane material for 3D printing and its preparation method and use

ActiveCN104961881ALow viscosity3D printing process facilitatesAdditive manufacturing apparatusOrganic chemistryPolyesterAlcohol

Owner:SICHUAN UNIV

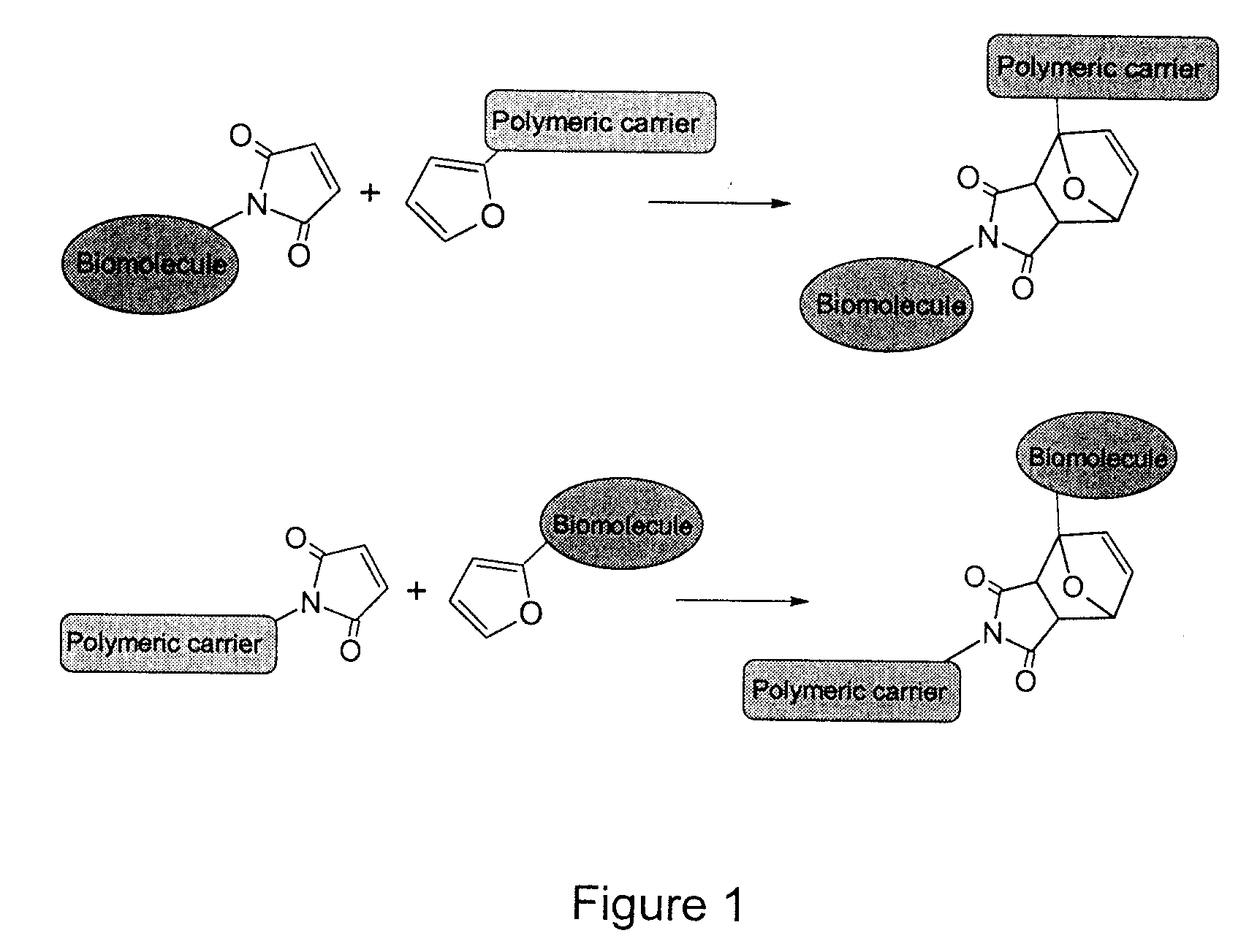

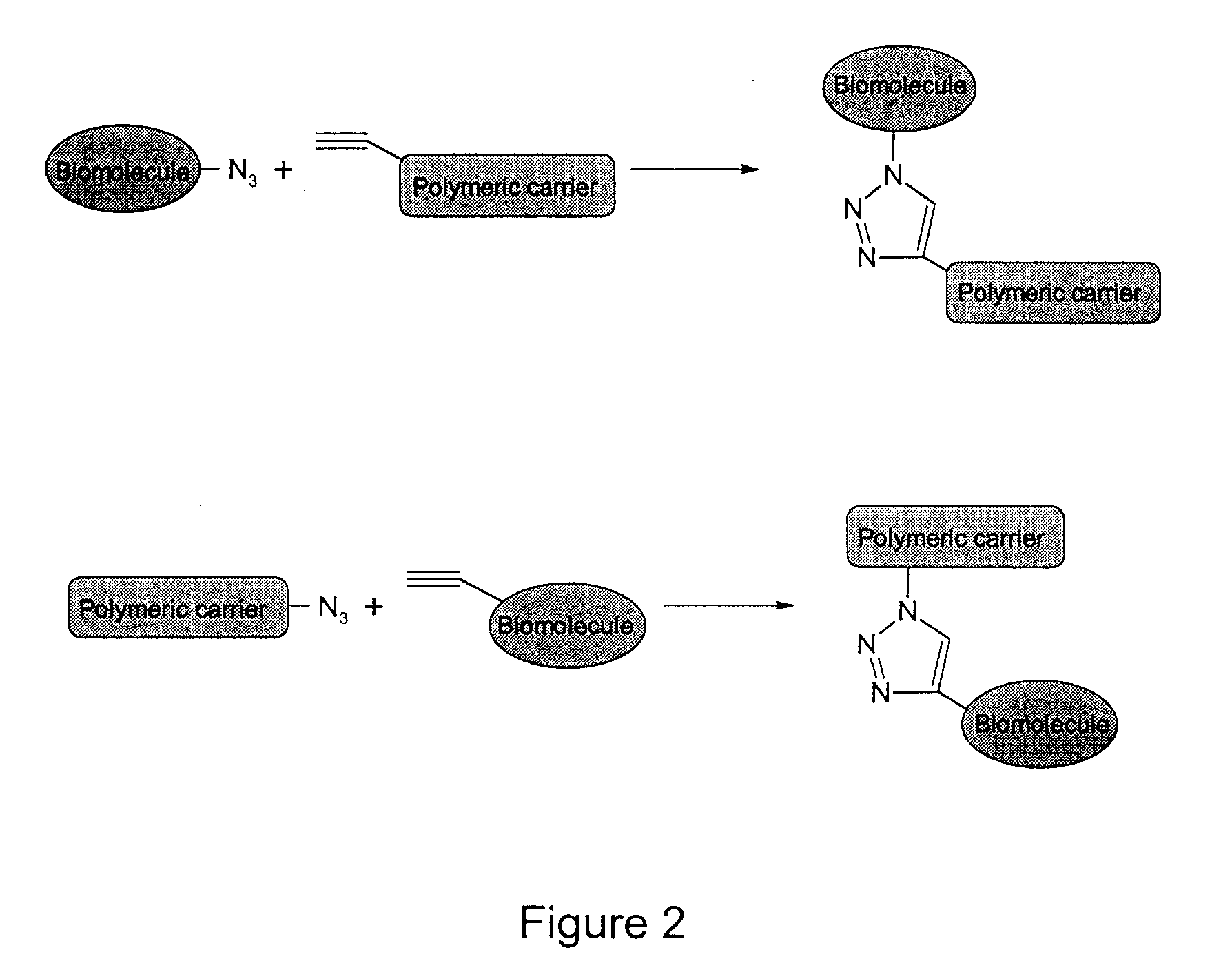

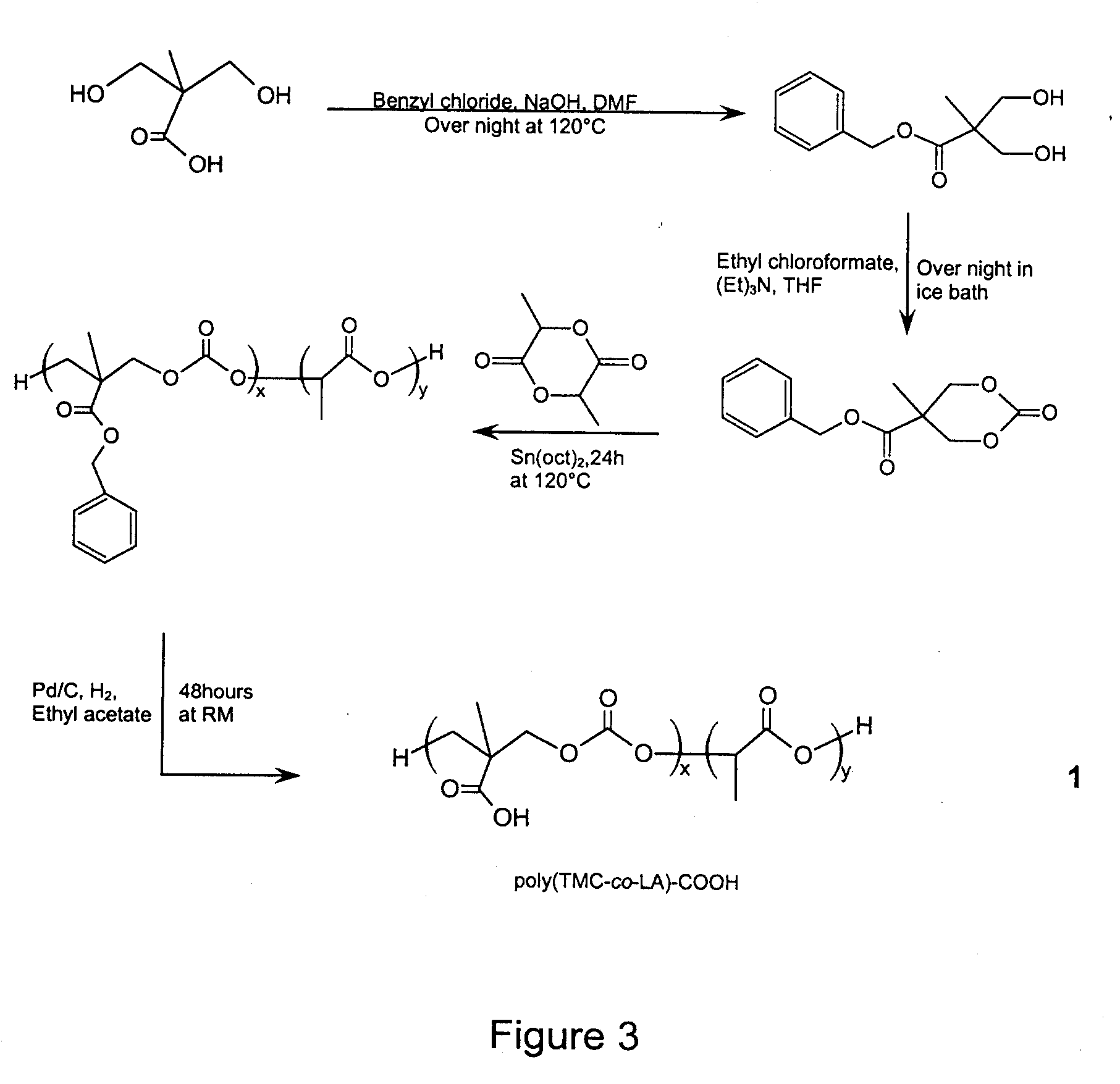

Method of Biomolecule Immobilization On Polymers Using Click-Type Chemistry

ActiveUS20090297609A1Improve efficiencyProcess environmental protectionBiocideOrganic active ingredientsFuranAlkyne

The present invention provides a method for the covalent immobilization of biomolecules on polymers for delivery of the biomolecules, which has the advantage of being simple, highly efficient, environmentally friendly and free of side products relative to traditional immobilization techniques. The invention provides a modified micro / nanoparticle system, which uses a functionalized polymer formed into micro or nanoparticles to bind a molecule to the particles using uses facile chemistry, the Diels-Alder cycloaddition between a diene and a dienophile with the polymer being functionalized with one of them and the molecule with the other, or the Huisgen 1,3-dipolar cycloaddition between a terminal alkyne and an azide to bind the molecule to the particle. The molecules and / or other therapeutic agents may be encapsulated within the polymer particles for intravenous therapeutic delivery. The invention also provides a novel synthetic biodegradable polymer, a furan / alkyne-functionalized poly(trimethylene carbonate) (PTMC)-based polymer, whose composition can be designed to meet the defined physical and chemical property requirements. In one example, the particle system self-aggregates from functionalized PTMC-based copolymers containing poly(ethylene glycol) (PEG) segments. The composition of the copolymers can be designed to meet various particle system requirements, including size, thermodynamic stability, surface PEG density, drug encapsulation capacity and biomolecule immobilization capacity.

Owner:SHOICHET MOLLY S +2

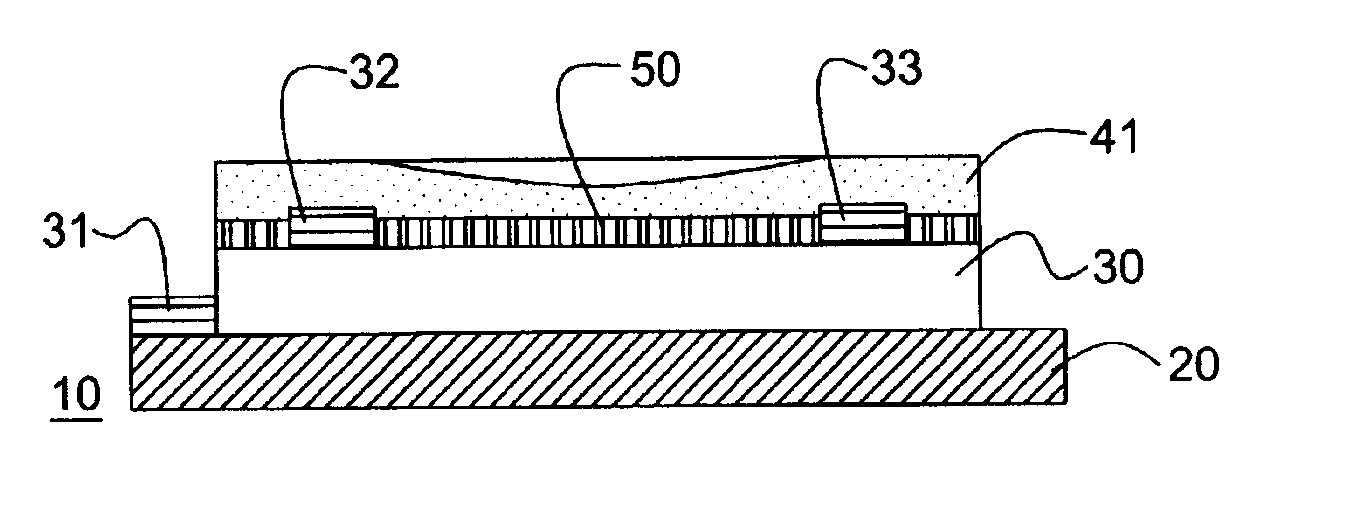

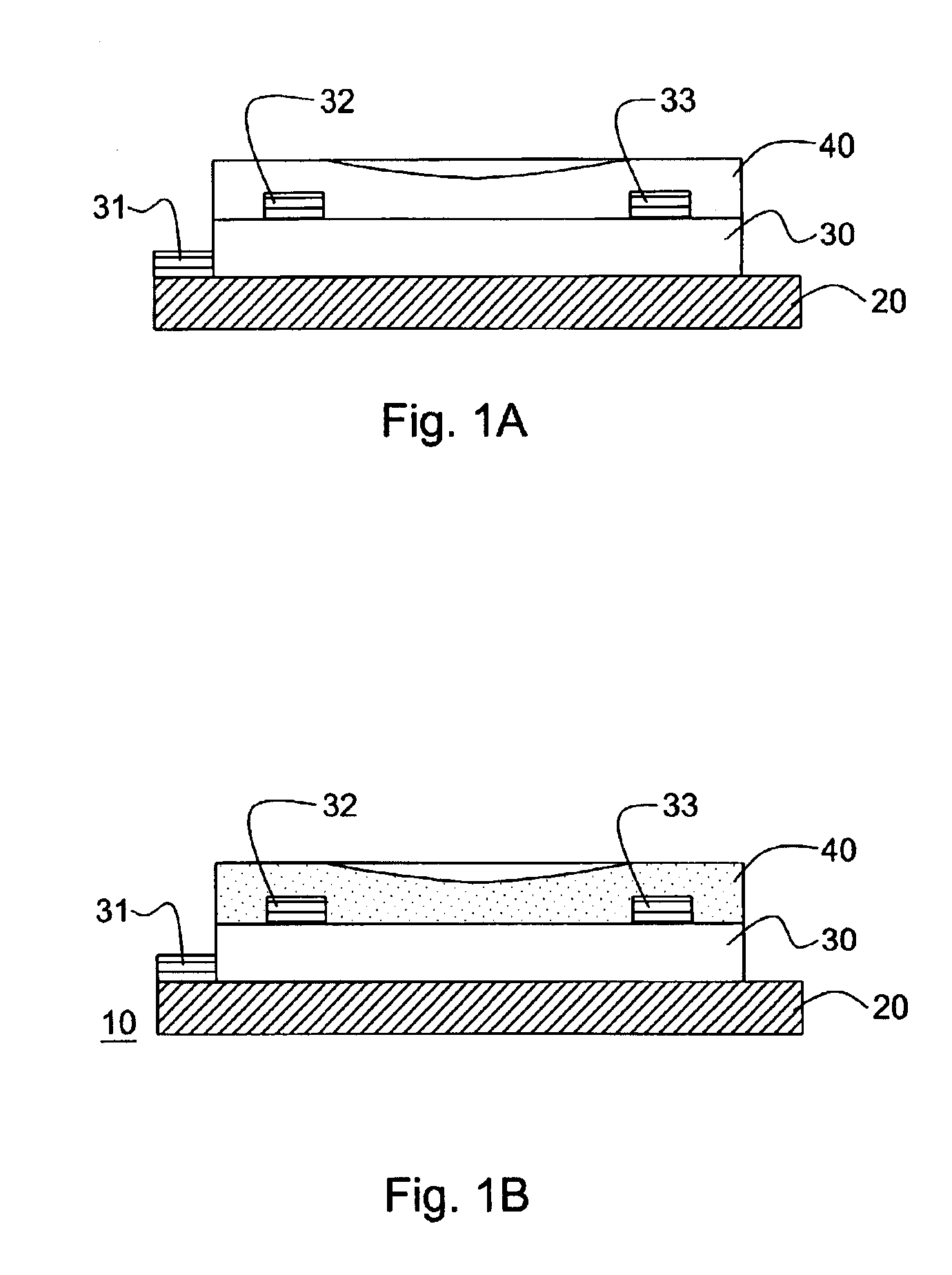

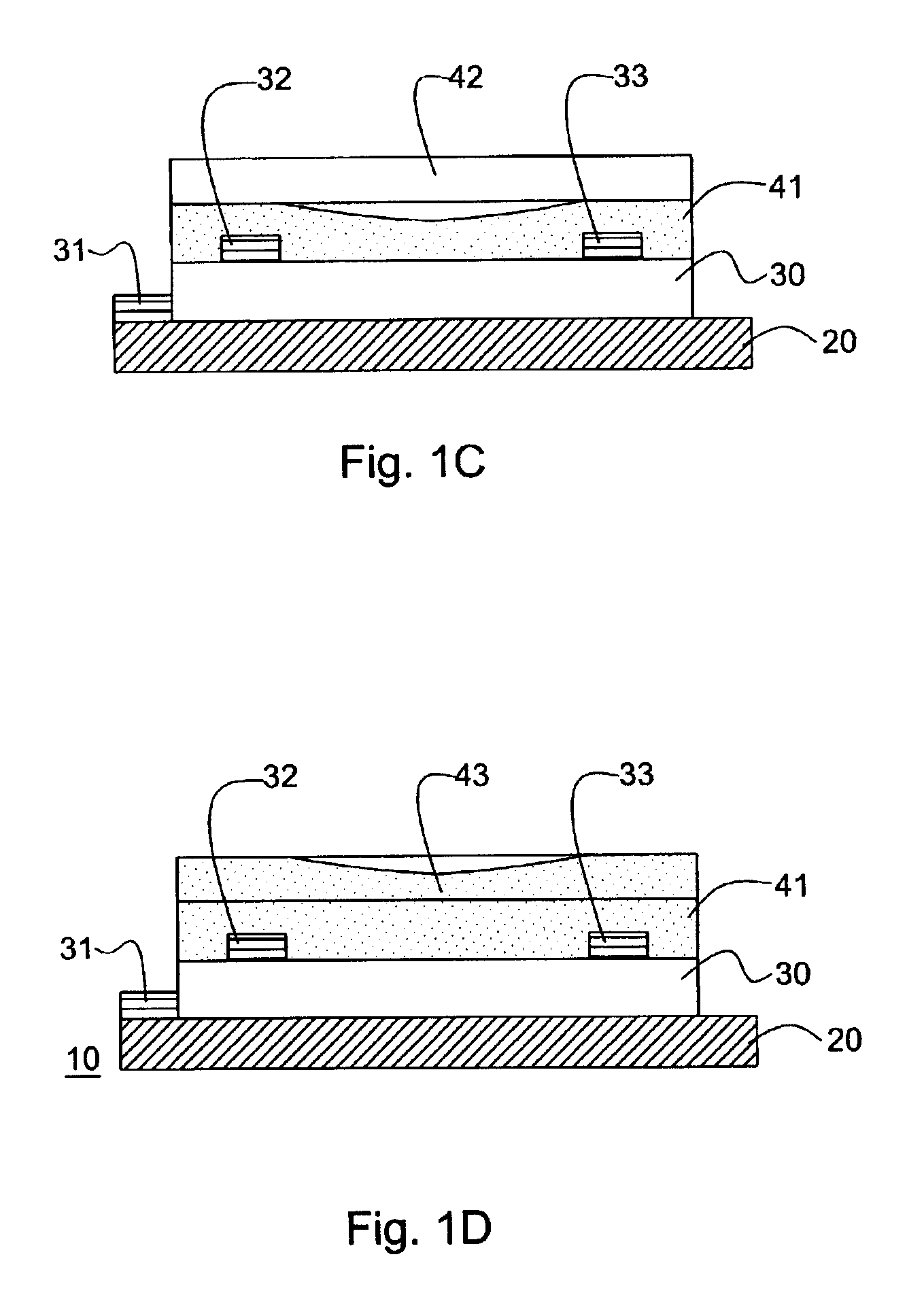

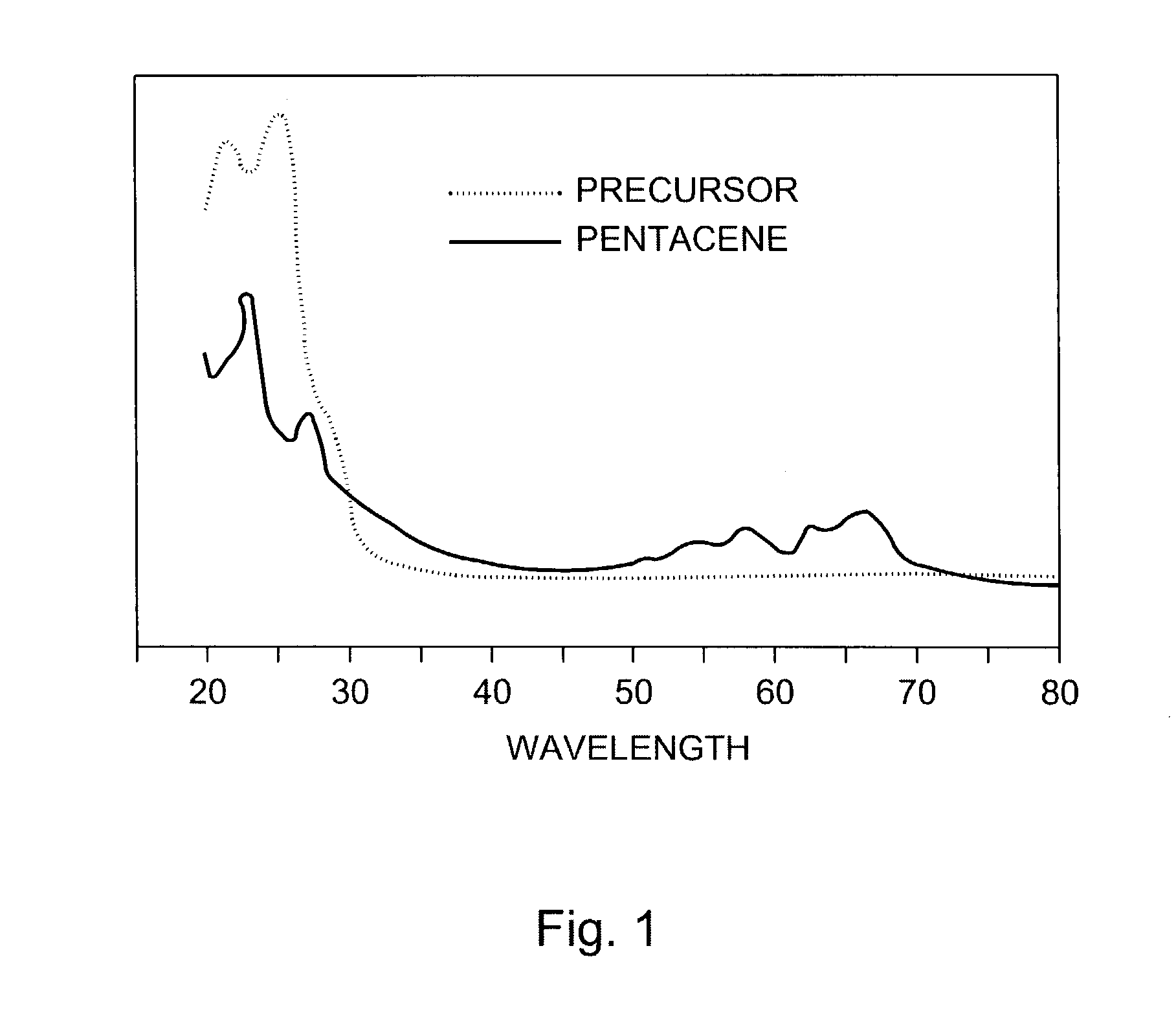

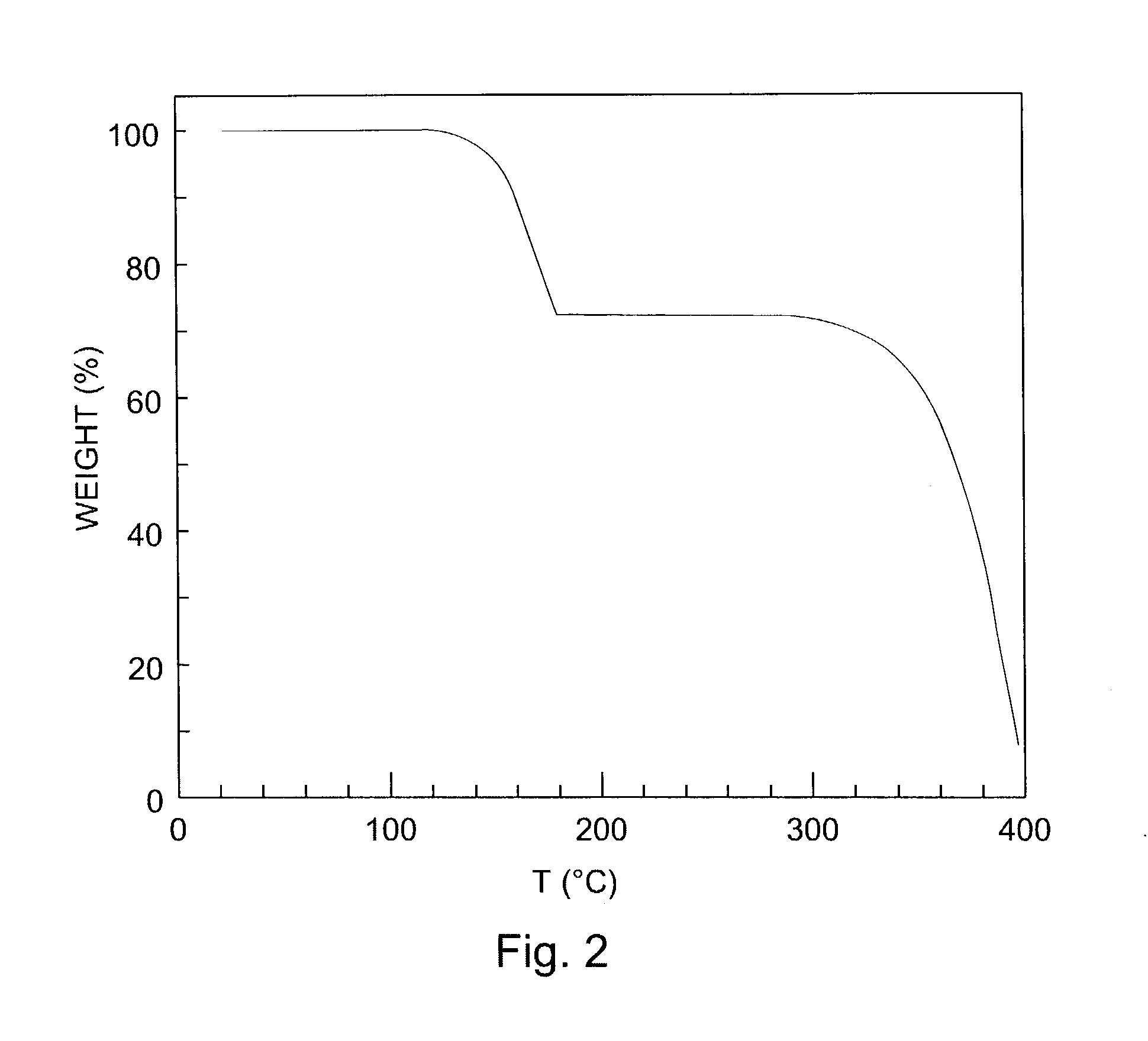

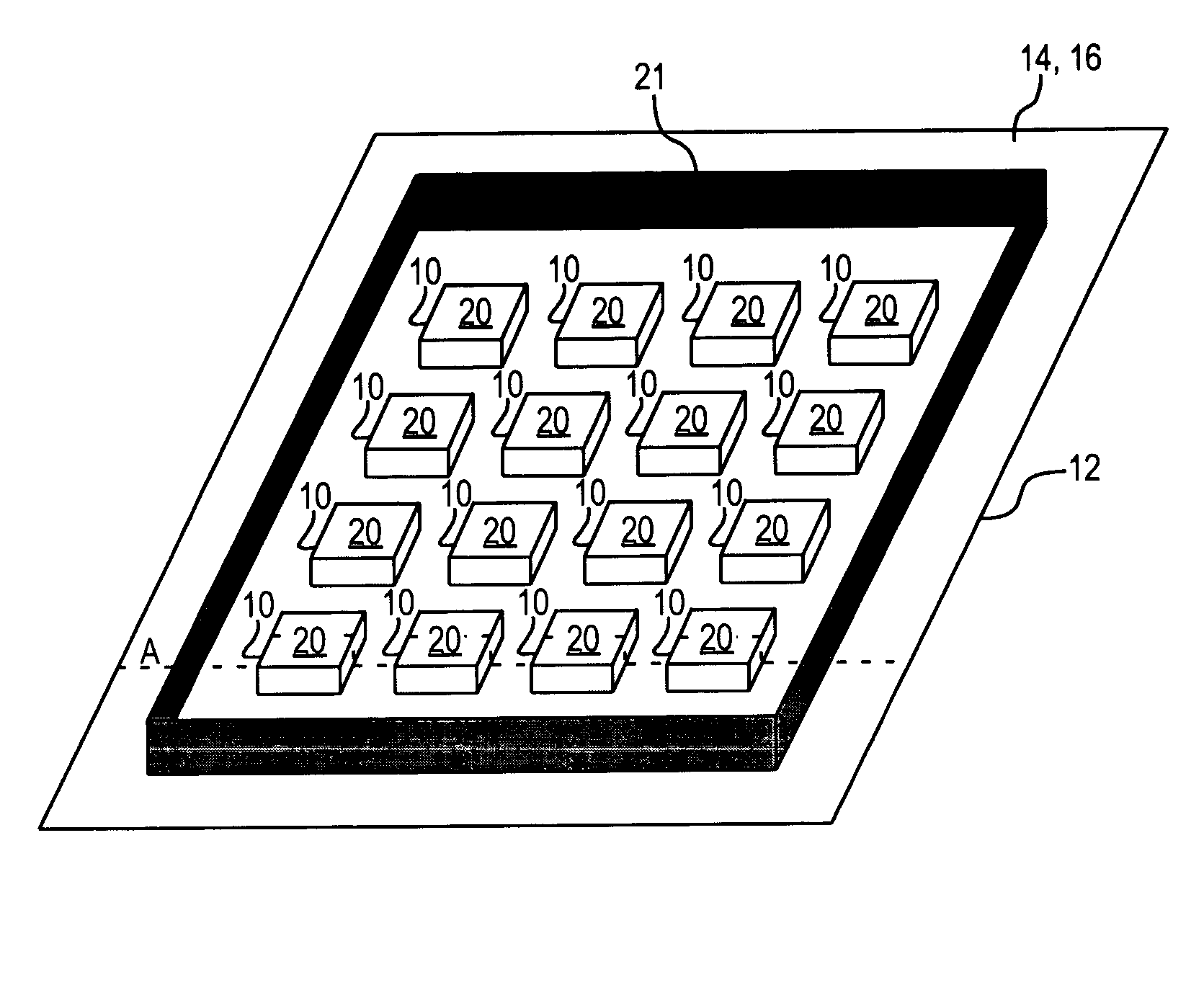

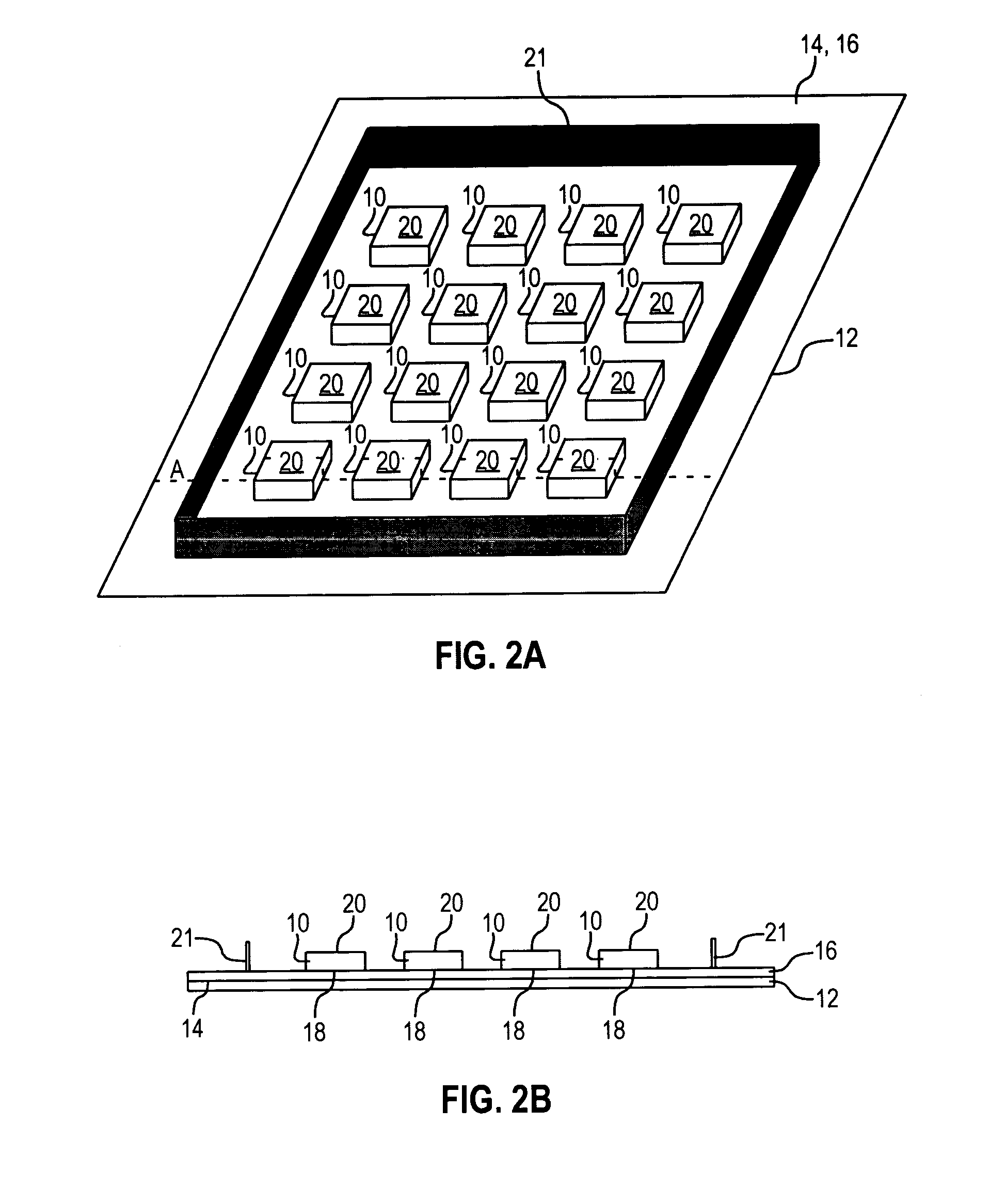

Thin film transistors using solution processed pentacene precursor as organic semiconductor

InactiveUS6963080B2Inexpensive approachLight weightMaterial nanotechnologyOrganic chemistryCoroneneArame

The present invention describes thin film transistors in which the active channel layer is a thin film of a polycyclic aromatic compound, such as, pentacene, prepared by solution processing a soluble precursor of the polycyclic aromatic compound on a substrate followed by heating to a moderate temperature to convert the precursor back to the polycyclic aromatic compound. The soluble precursors of the polycyclic aromatic compounds are organic solvent-soluble Diels-Alder adducts of polycyclic aromatic compounds, such as, oligothiophene, perylene, benzo[ghi]perylene, coronene and a polyacene with a variety of dienophiles that contain at least one heteroatom. The Diels-Alder adducts can be converted back to pentacene by retro-Diels-Alder reaction at moderate (60-250° C.) temperatures both in bulk, in solution or as thin-films.

Owner:GLOBALFOUNDRIES US INC

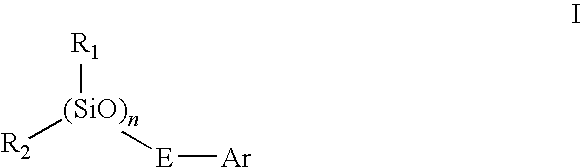

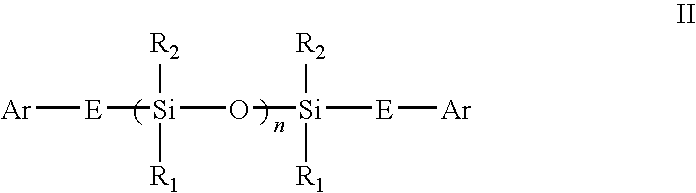

Novel siloxane monomers and methods for use thereof

The invention provides novel siloxane monomers useful in a variety of adhesive applications. In one aspect, the siloxane compounds described herein can be used as Diels-Alder type curatives for bismaleimide or poly-maleimide monomers. The unsaturated resins shown here are attractive for use as maleimide curatives due to their poly-functionality. Each substituted styrenyl reside can react with two maleimide functional groups. Thus, an invention adhesive composition typically contains an excess of bismaleimide monomers.

Owner:DESIGNER MOLECULES

Compositions and methods for delivering a substance to a biological target

ActiveUS20110268654A1Ultrasonic/sonic/infrasonic diagnosticsOrganic active ingredientsBiological targetCycloaddition

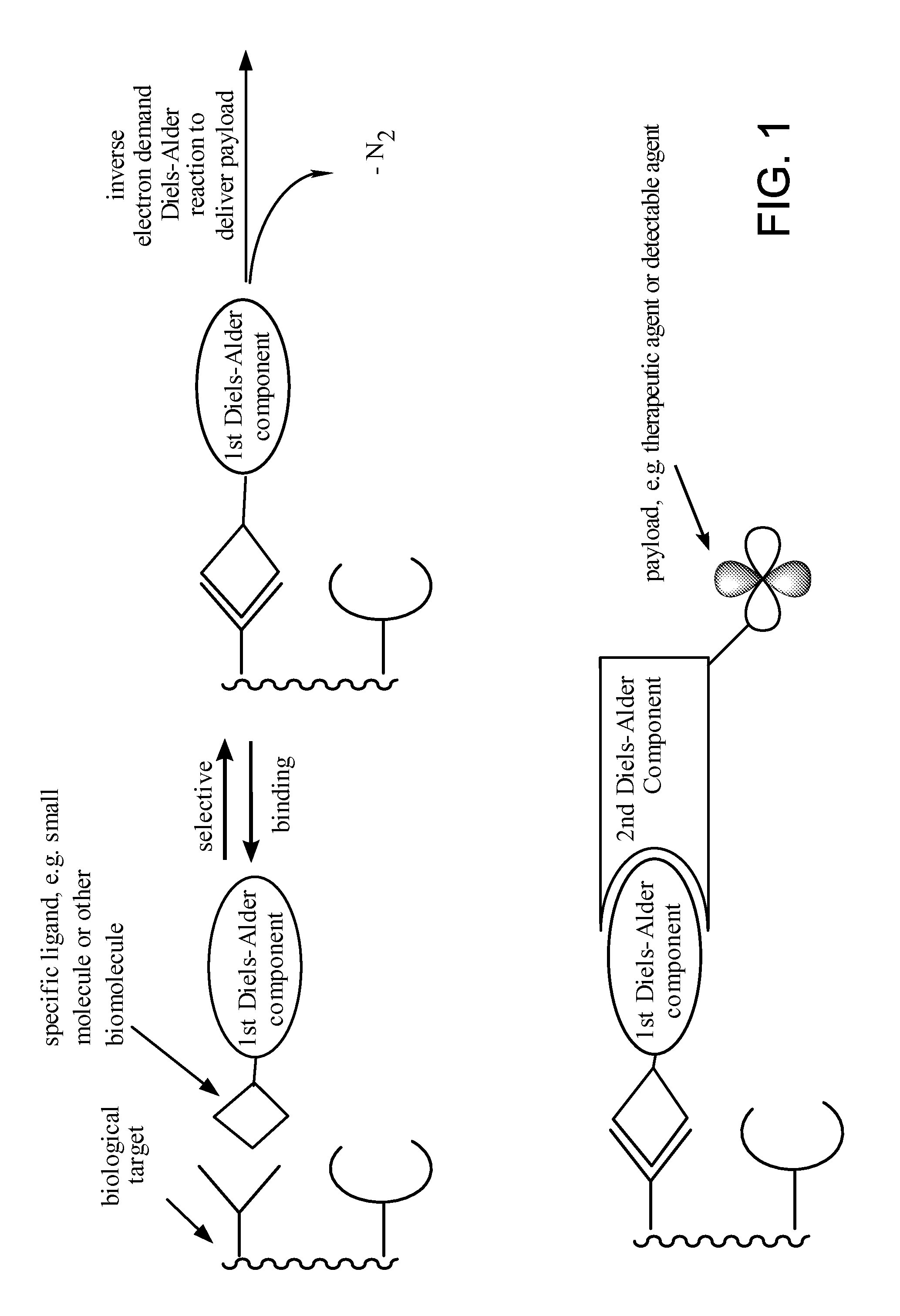

The present application provides compositions and methods using bioorthogonal inverse electron demand Diels-Alder cycloaddition reaction for rapid and specific covalent delivery of a “payload” to a ligand bound to a biological target.

Owner:THE GENERAL HOSPITAL CORP

Polymer powder for producing three-dimensional objects

InactiveUS20140121327A1Improve stabilityLow viscosityAdditive manufacturing apparatusAdditive manufacturing with solidsPowder mixtureMetallurgy

The invention relates to the use of a powder made of a polymer, which of two or more components with functionalities suitable for Diels-Alder reactions, or of a powder mixture (dry blend) made of powders respectively of at least one of the reactive components, where these together enter into the Diels-Alder reaction with one another and are capable of a retro-Diels-Alder reaction, in a rapid-prototyping process.The invention further relates to moldings produced with use of said polymer powder through a layer-by-layer shaping process in which regions of a powder layer are melted selectively. The molding here can be removed from the powder bed after cooling and hardening of the regions previously melted layer-by-layer.

Owner:EVONIK OPERATIONS GMBH

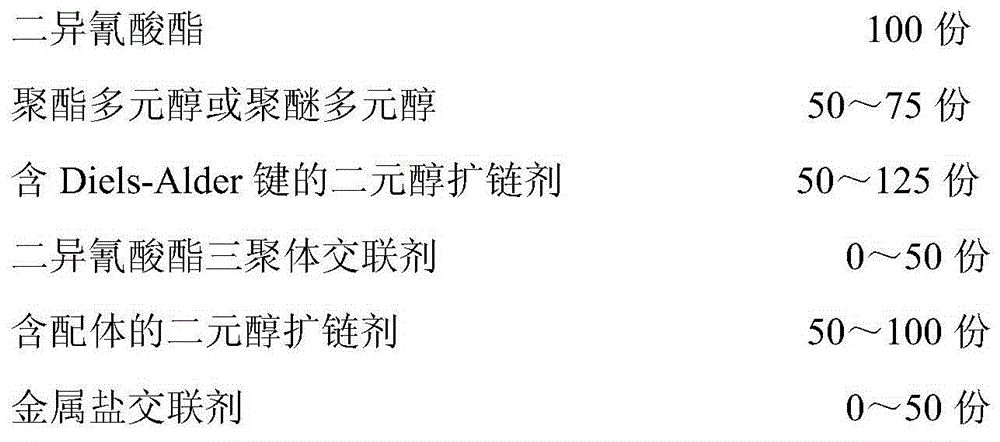

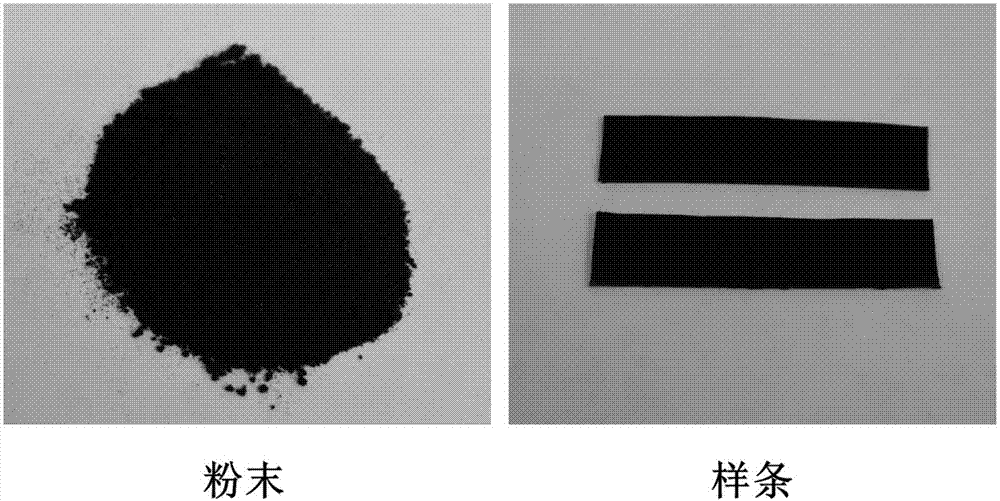

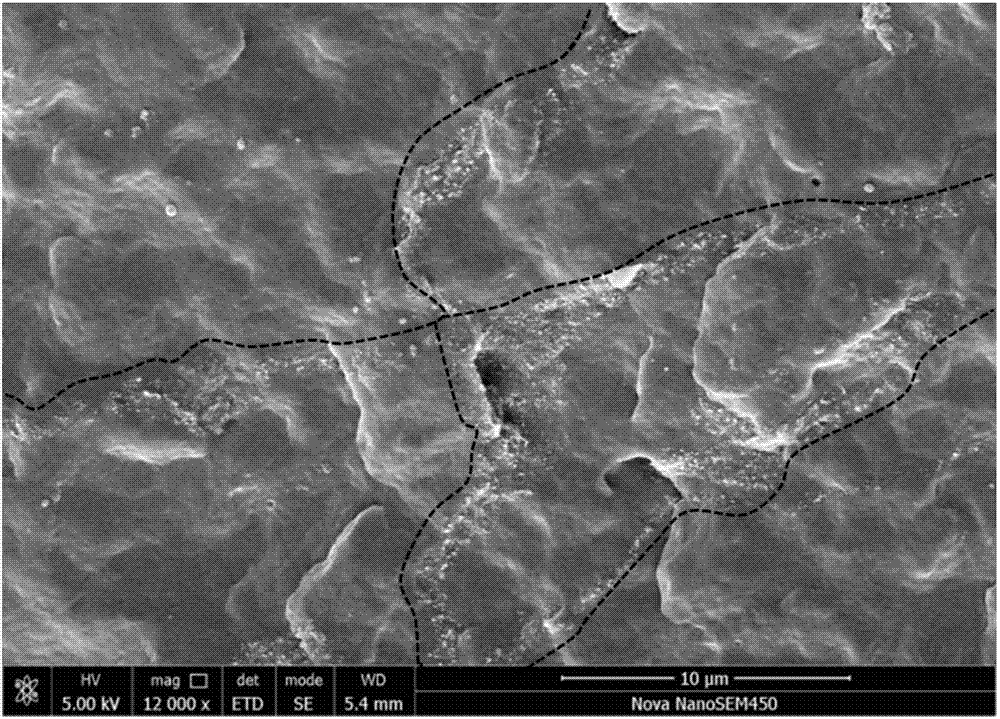

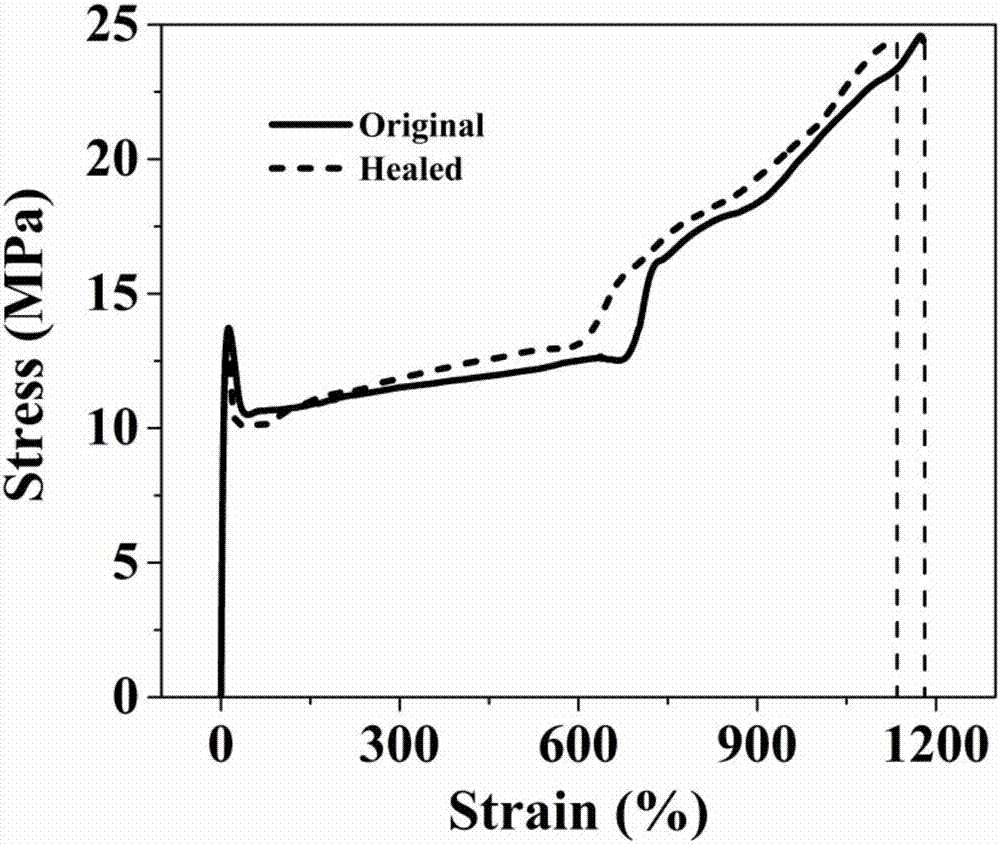

Self-repairing polyurethane nano-composite material and preparation method and application thereof

The invention discloses a self-repairing polyurethane nano-composite material and a preparation method and application thereof. The preparation method comprises the following steps: firstly, adding a surfactant and a conductive nano-filler into excessive absolute ethanol to obtain dispersion liquid containing the conductive nano-filler; then, adding a prepared self-repairing polyurethane powder material containing a Diels-Alder bond into the dispersion liquid, and performing suction filtration and drying to obtain a polyurethane powder material which is coated with the conducive nano-filler and contains the Diels-Alder bond; lastly, performing machine shaping to obtain a Diels-Alder bond-based multiple self-repairing polyurethane nano-composite material. The self-repairing polyurethane nano-composite material prepared by the method has the advantages that: (1) the material has excellent mechanical performance, excellent electric performance, an excellent photothermal effect and an excellent electromagnetic effect; (2) the material has excellent self-repairing performance; (3) the material has a plurality of repairing manners; (4) in a power-on state, sensing of cracking of the material can be realized, and self-repairing is performed.

Owner:SICHUAN UNIV

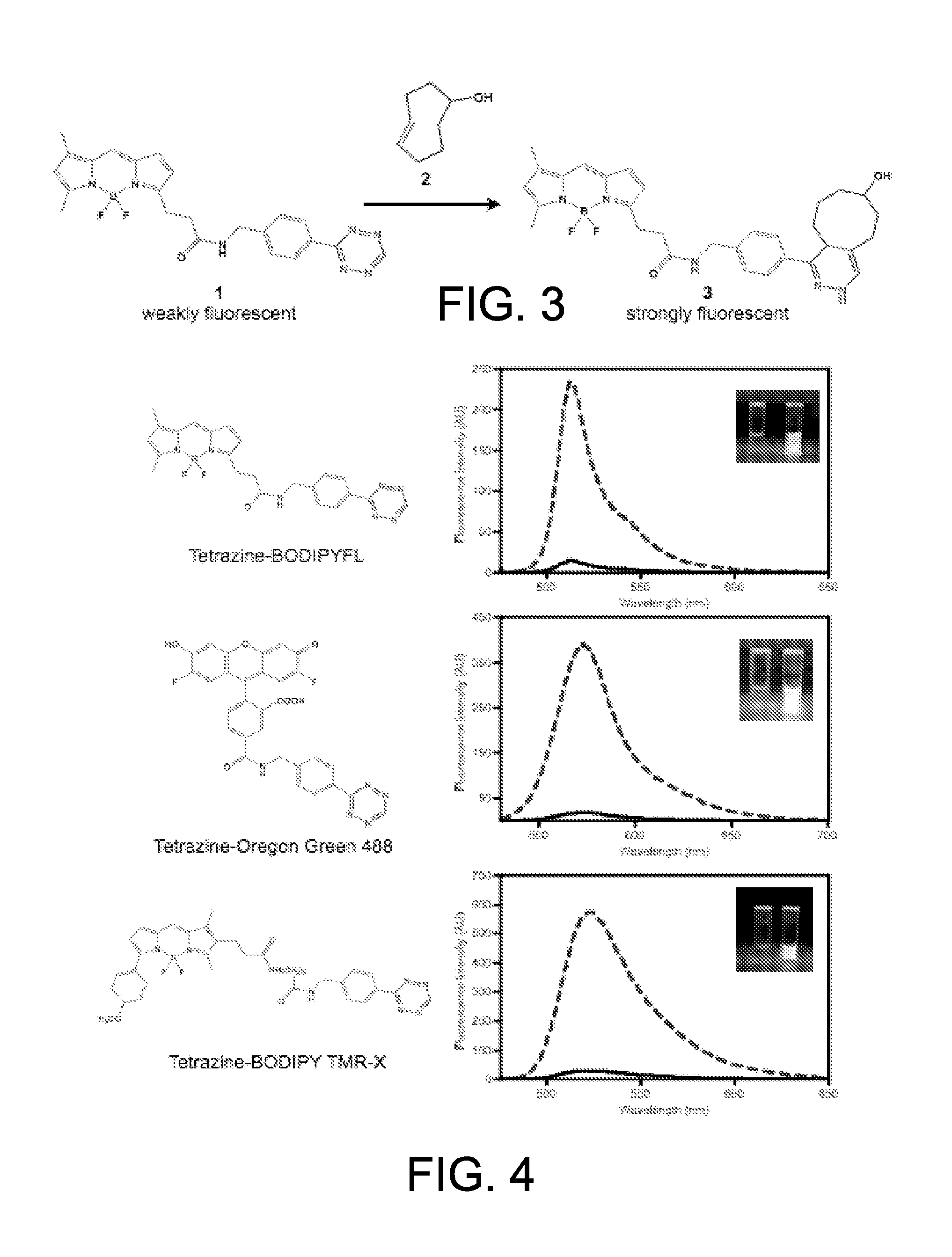

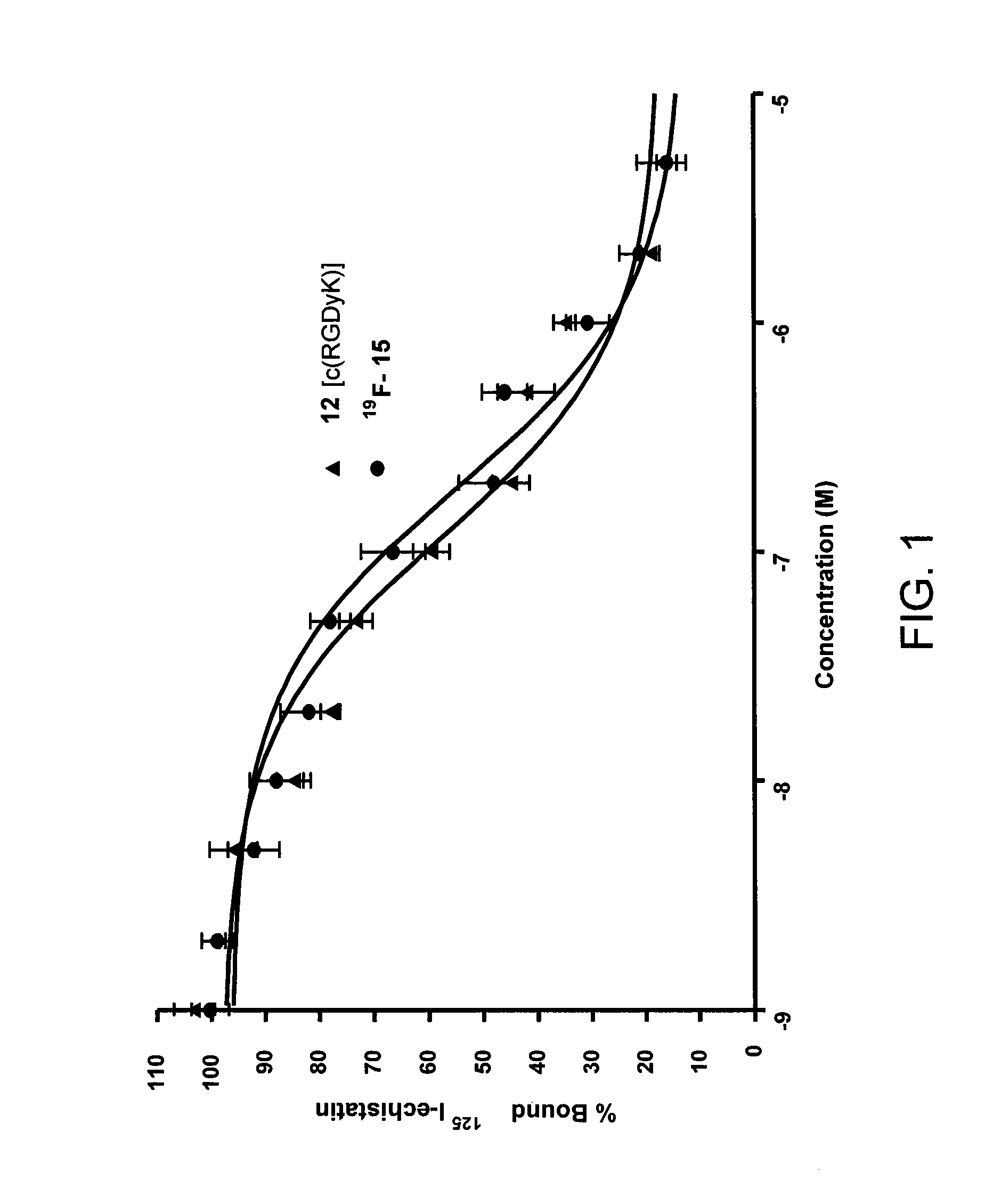

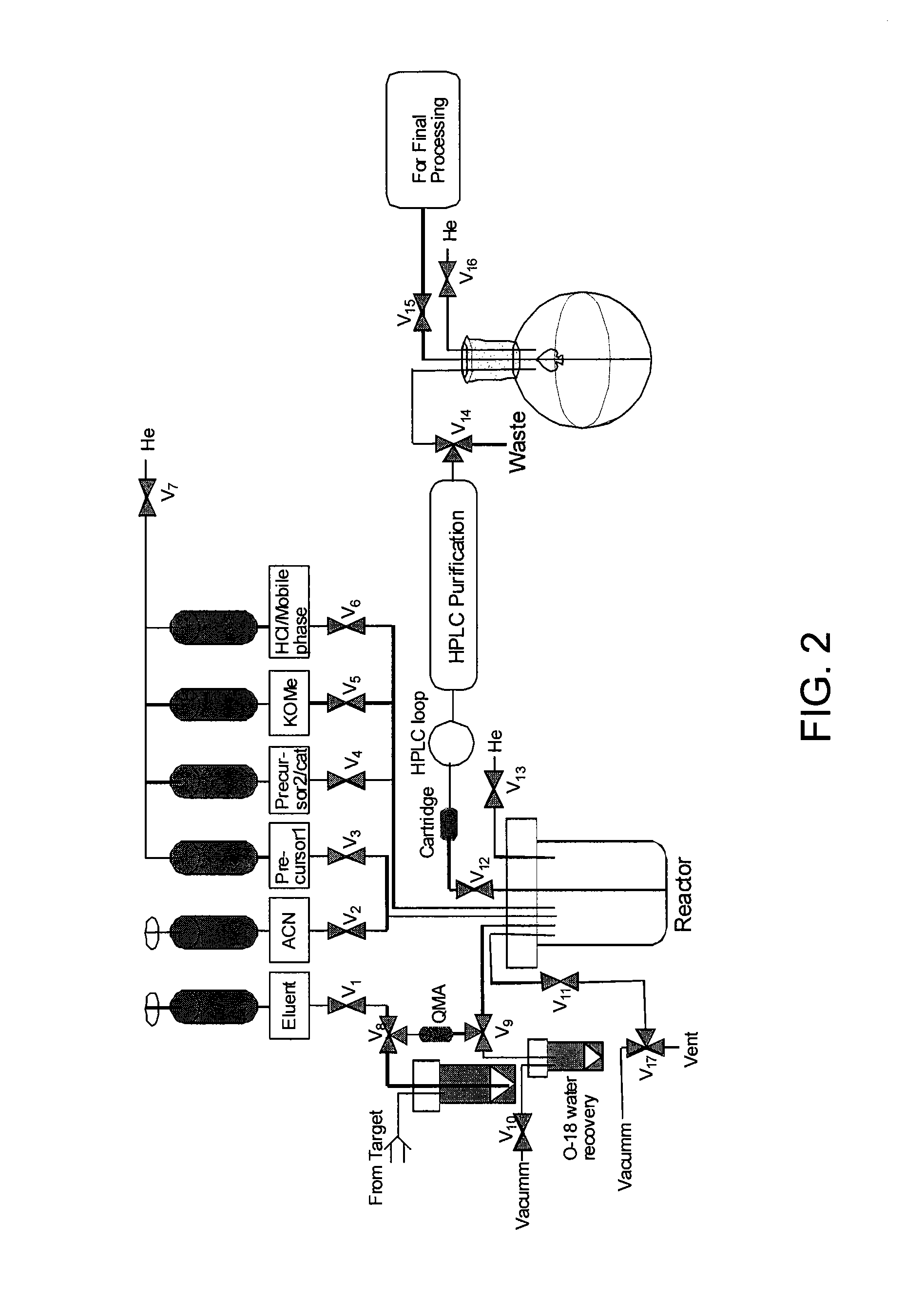

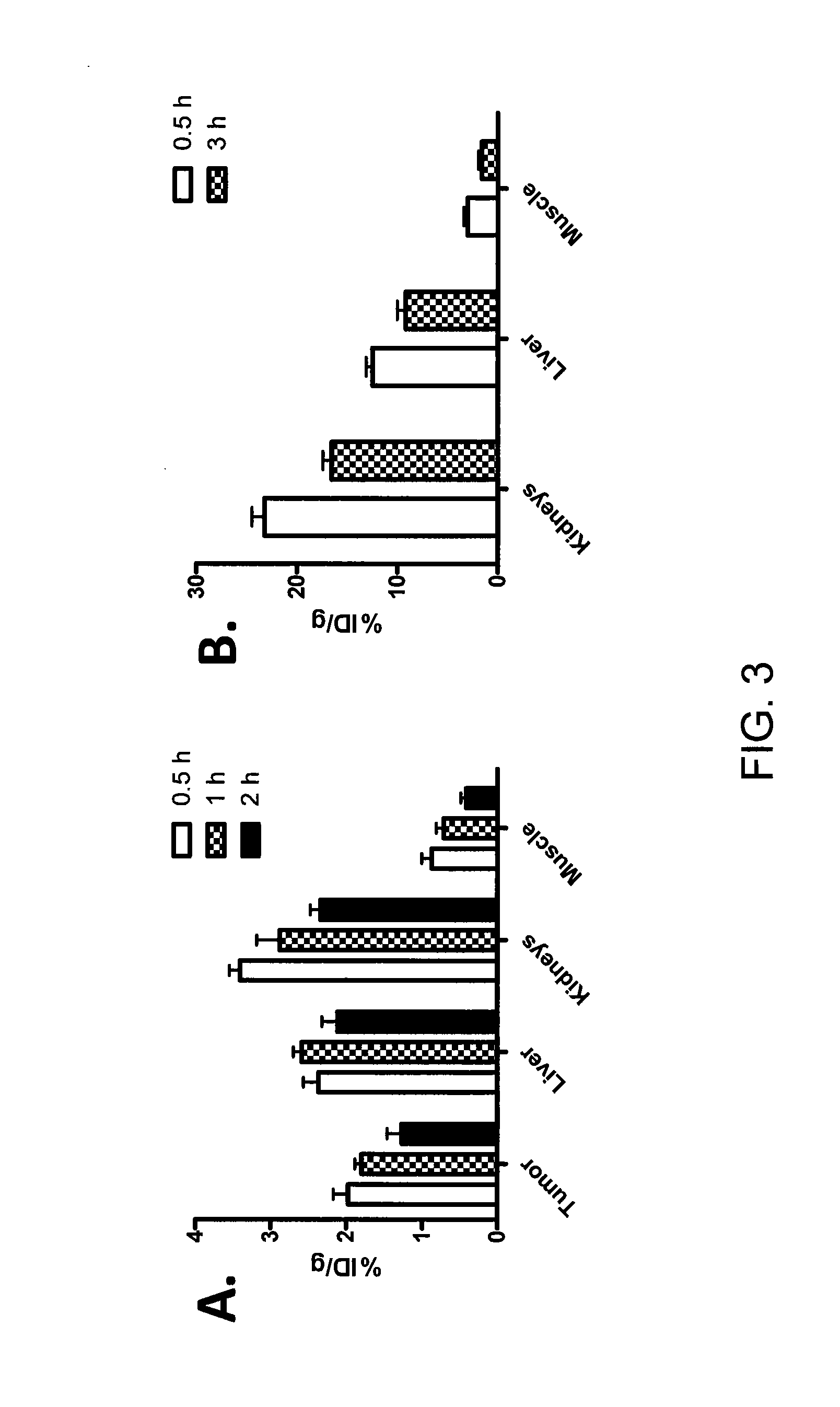

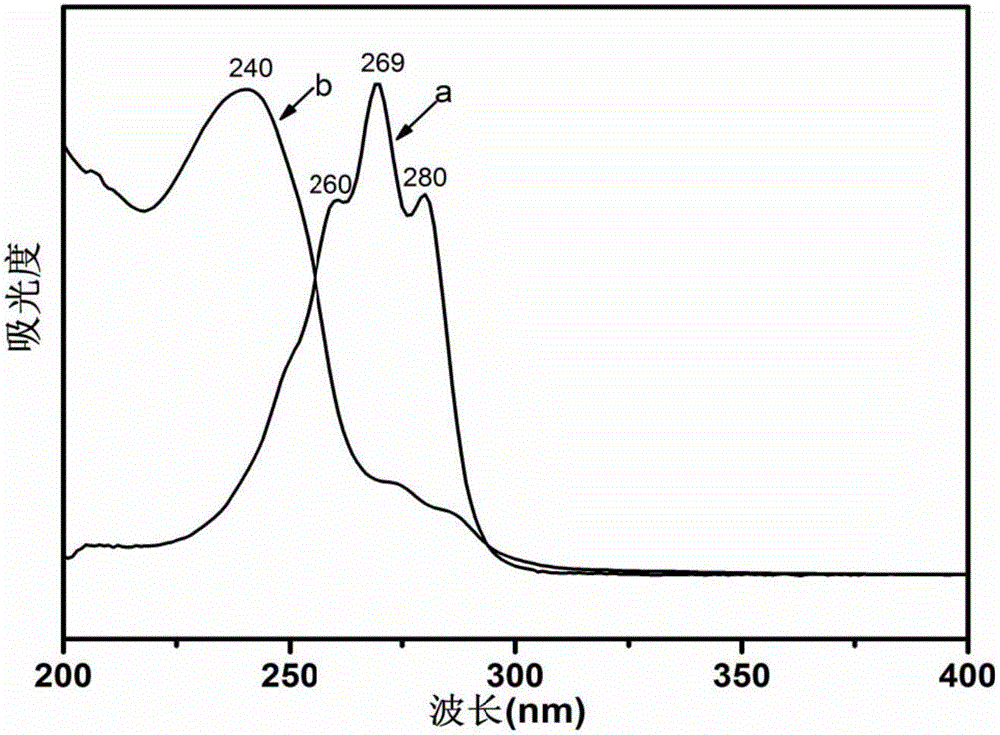

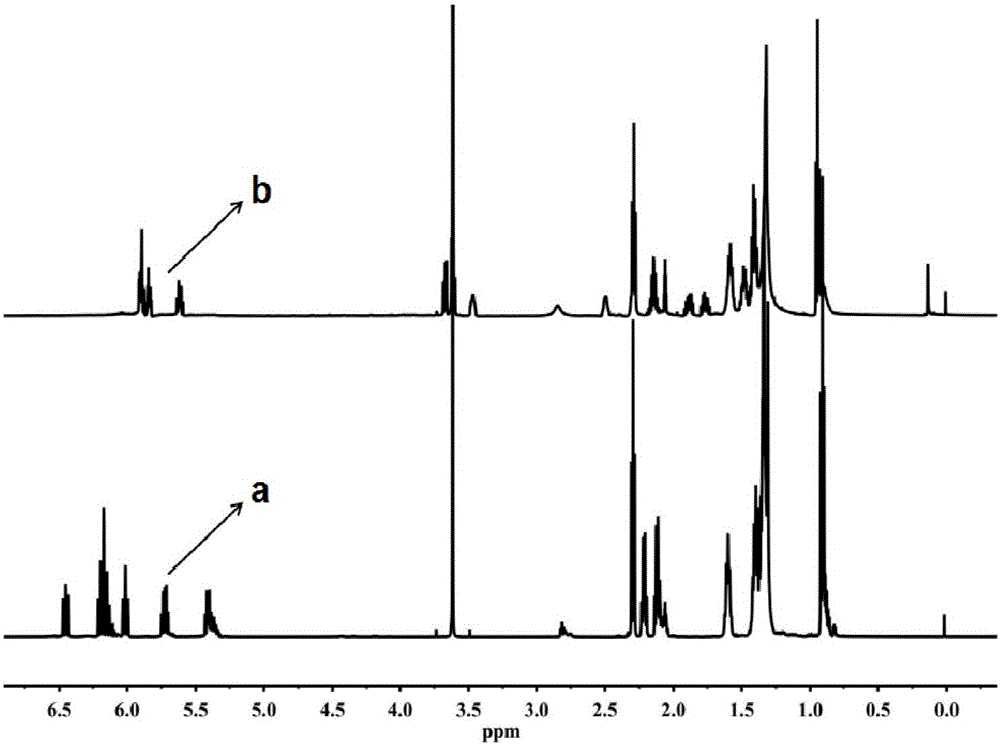

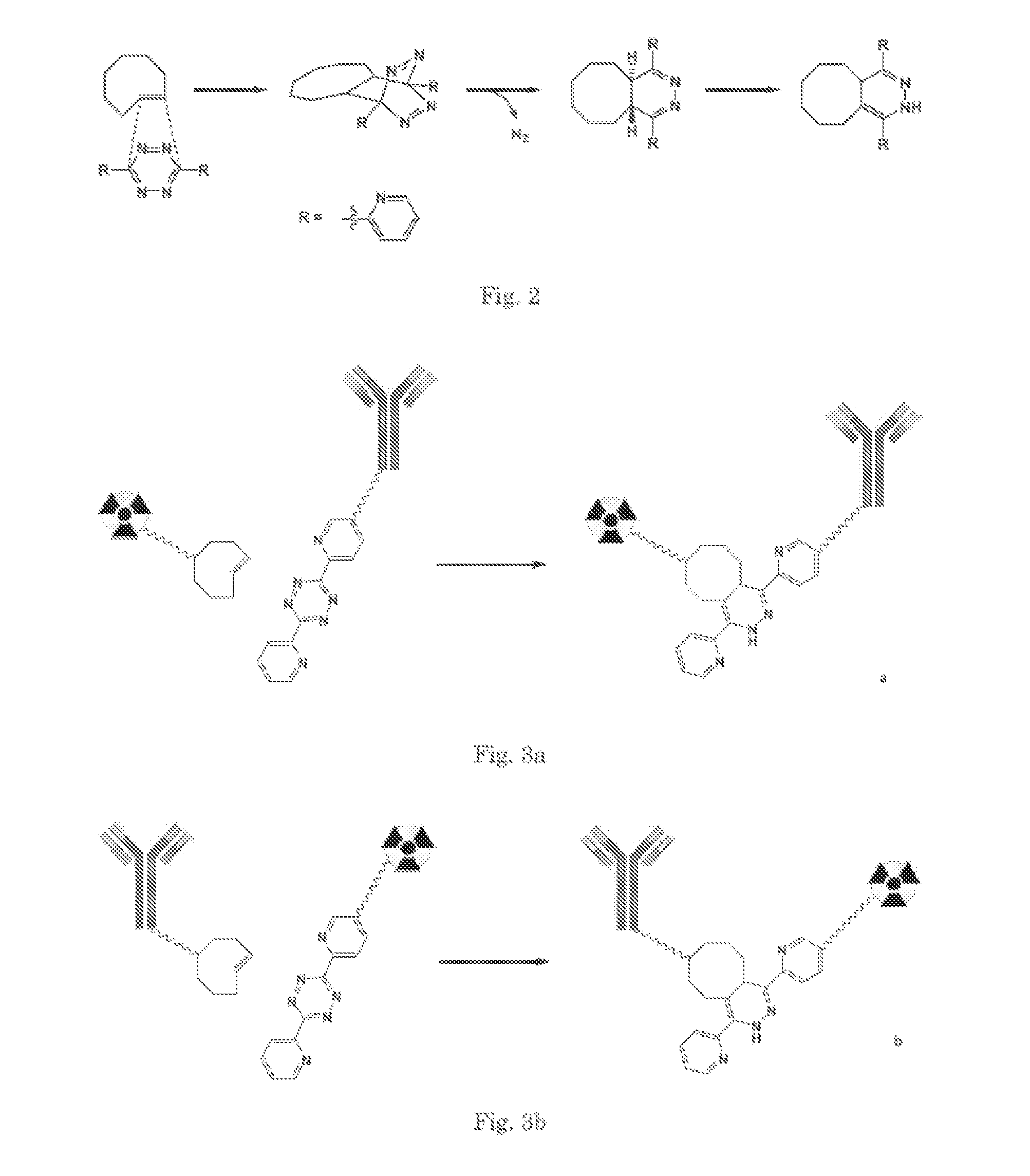

Tetrazine-trans-cyclooctene Ligation for the Rapid Construction of Radionuclide Labeled Probes

A Diels-Alder adduct of a trans-cyclooctene with a tetrazine is provided, wherein the adduct bears a substituent labeled with a radionuclide. A method of producing a PET or other image of an organ in an animal or human includes forming the Diels-Alder adduct in the animal or human. Trans-cyclooctenes and tetrazines suitable for preparing the adducts are provided.

Owner:UNIV OF SOUTHERN CALIFORNIA +1

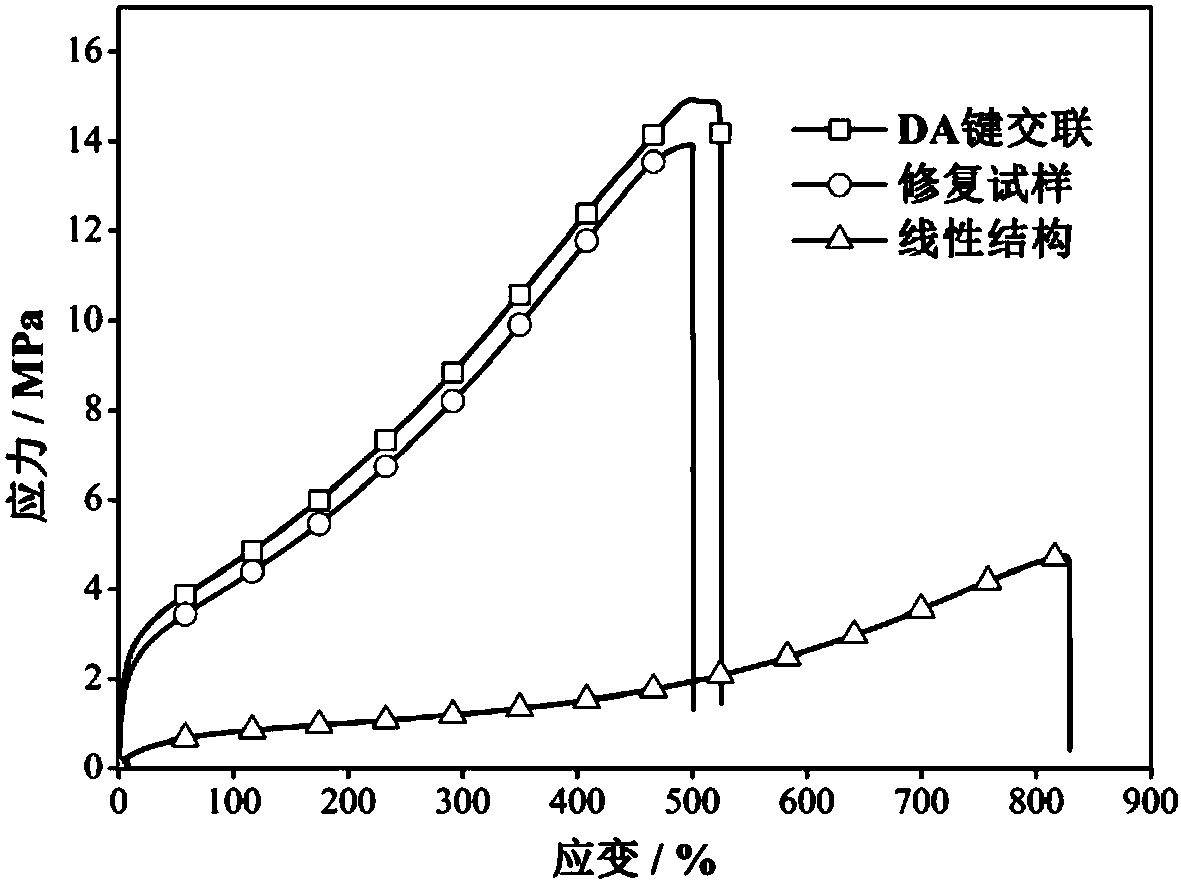

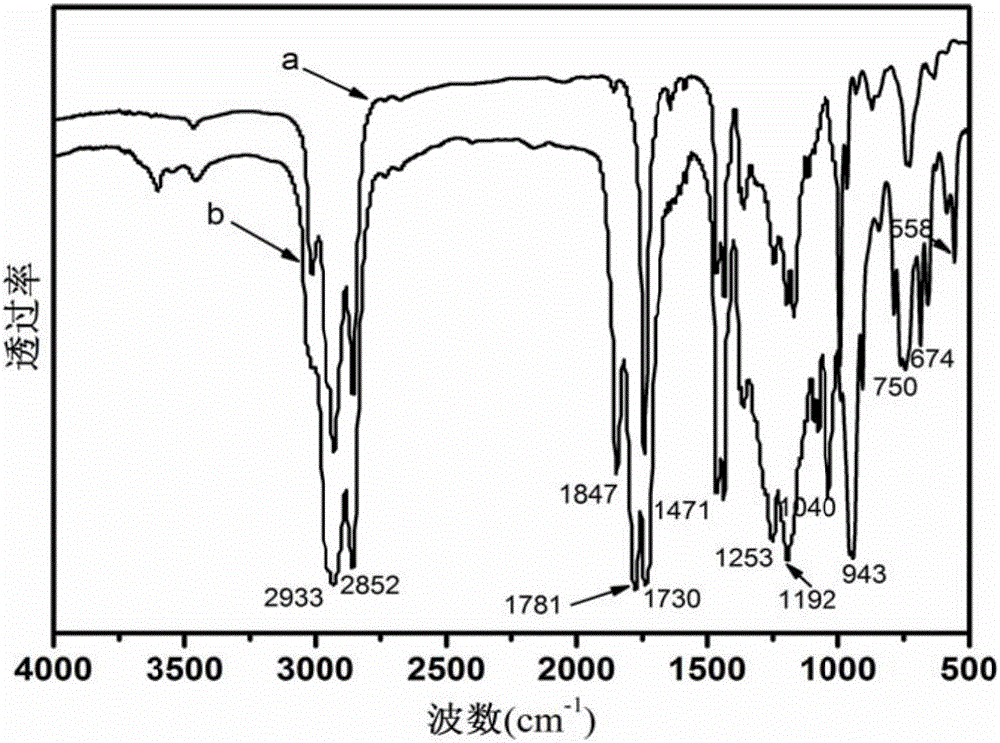

Polysiloxane-carbamate elastomer containing Diels-Alder bond and preparation method of polysiloxane-carbamate elastomer

InactiveCN105949422AHigh tensile strengthHigh elongation at breakOrganic chemistryElastomerPolyester

The invention relates to the field of materials, in particular to a polysiloxane-carbamate elastomer containing a Diels-Alder bond and a preparation method of the polysiloxane-carbamate elastomer. The polysiloxane-carbamate elastomer is prepared from a cross-linking agent, isocyanato-terminated polydimethylsiloxane, isocyanato-terminated polyester or polyether, diol containing the Diels-Alder bond as well as a catalyst dibutyltin dilaurate through curing after a reaction in anhydrous 1,4-dioxane under the protection of nitrogen. The elastomer has a microphase separation structure, multiple plastic micro-areas are formed in the elastomer, and on one hand, the micro-areas are taken as physical crossing points to improve tensile strength; on the other hand, the plastic micro-areas generate plastic deformation in a stretching process to increase elongation at break. The method adopts easily available raw materials, a synthesis process requires no special conditions or equipment, a synthesis technology is simple and easy to control, and the yield is high.

Owner:SICHUAN UNIV

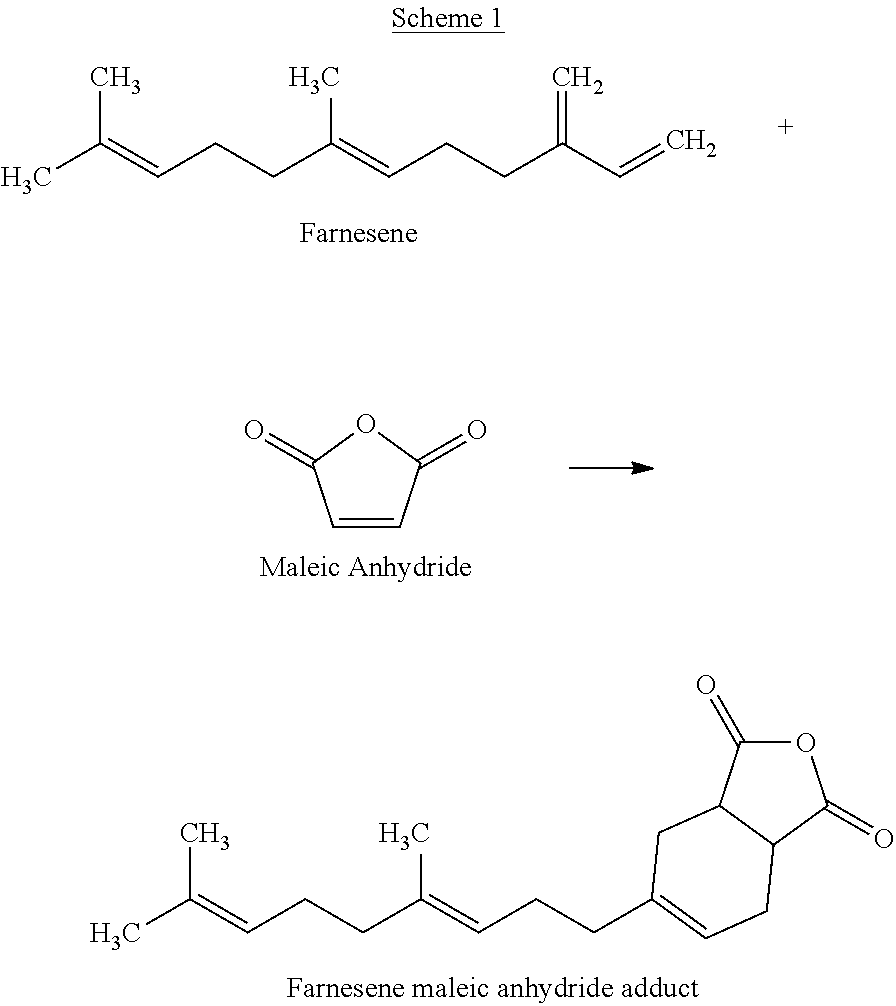

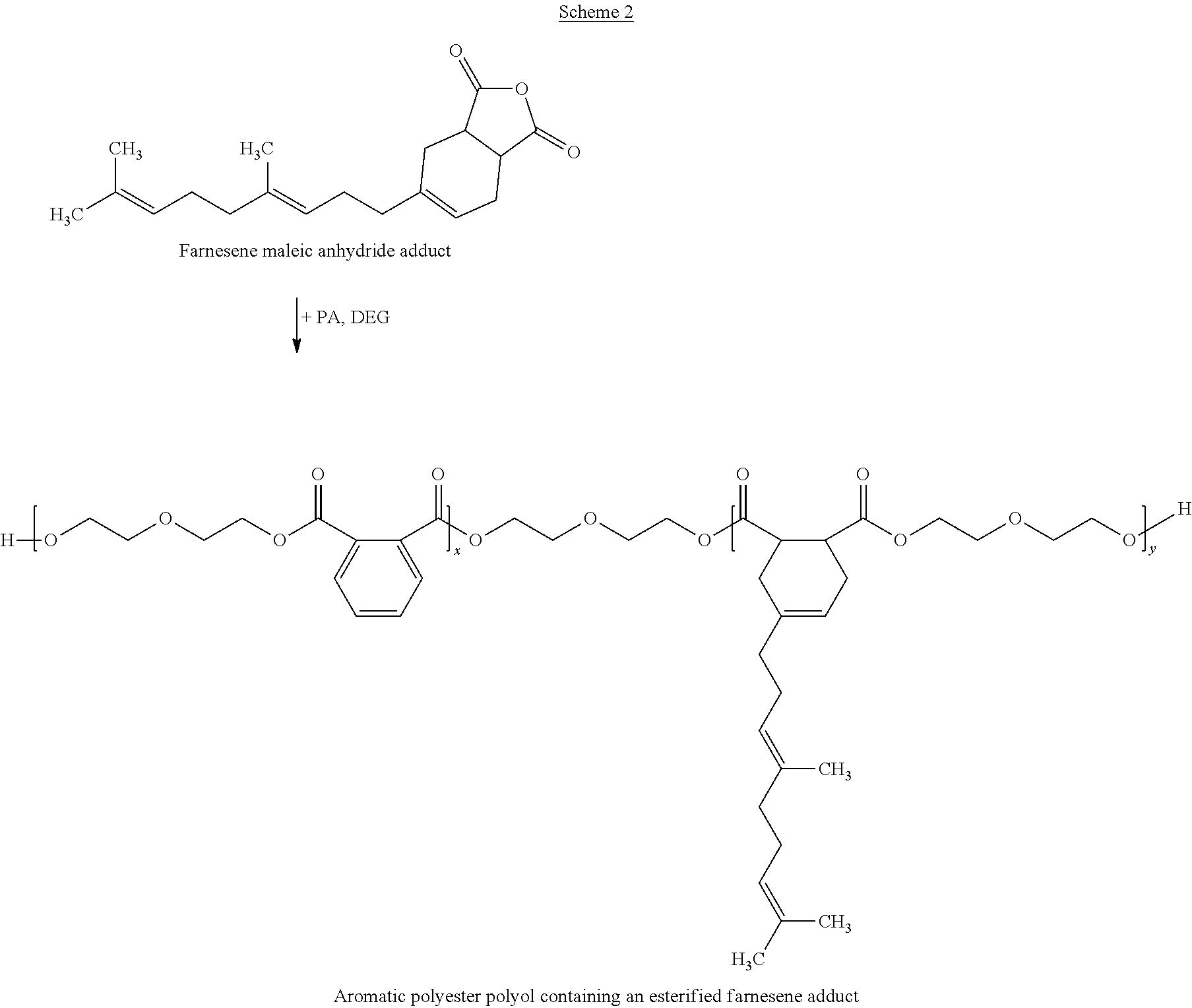

Polyester Polyols Containing Diels-Alder or Ene Adducts

Polyester polyols containing adducts formed from Diels-Alder and Ene reactions are disclosed. Processes for making the polyester polyols and uses of the polyester polyols as polyurethane coatings, adhesives, sealants, elastomers, and foams are also disclosed. In some embodiments, the polyester polyols contain biorenewable adducts based on maleic anhydride and farnesene and have particular application in making rigid and flexible polyurethane or polyisocyanurate foams.

Owner:STEPAN COMPANY

Hetero diels-alder adducts of pentacene as soluble precursors of pentacene

The present invention describes organic solvent-soluble Diels-Alder adducts of polycyclic aromatic compounds, such as, oligothiophene, perylene, benzo[ghi]perylene, coronene and polyacenes, with variety of dienophiles containing at least one heteroatom and in some cases two heteroatoms bonded to aromatic moiety, such as, thioxomalonates, azodicarboxylates, thialdehyde, acylnitroso and N-sulfinylamides. The Diels-Alder adducts are prepared by a simple, one step cycloaddition reaction of the polycyclic aromatic compounds, such as, pentacene, or other fused aromatic compounds, with heterodienophiles. The Diels-Alder adducts according to the present invention all form soluble adducts with pentacene and can be converted back to pentacene by retro-Diels-Alder reaction at moderate (60–250° C.) temperatures both in bulk, in solution or as thin-films.

Owner:GLOBALFOUNDRIES INC

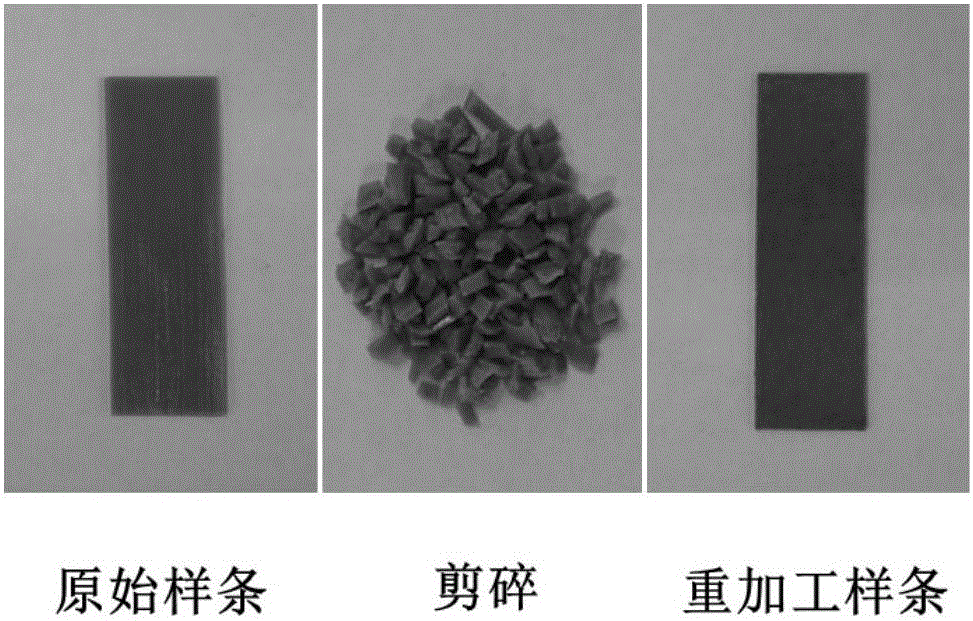

Reprocessed polyurethane with dual-dynamic covalent bond crosslinking and preparation method of reprocessed polyurethane

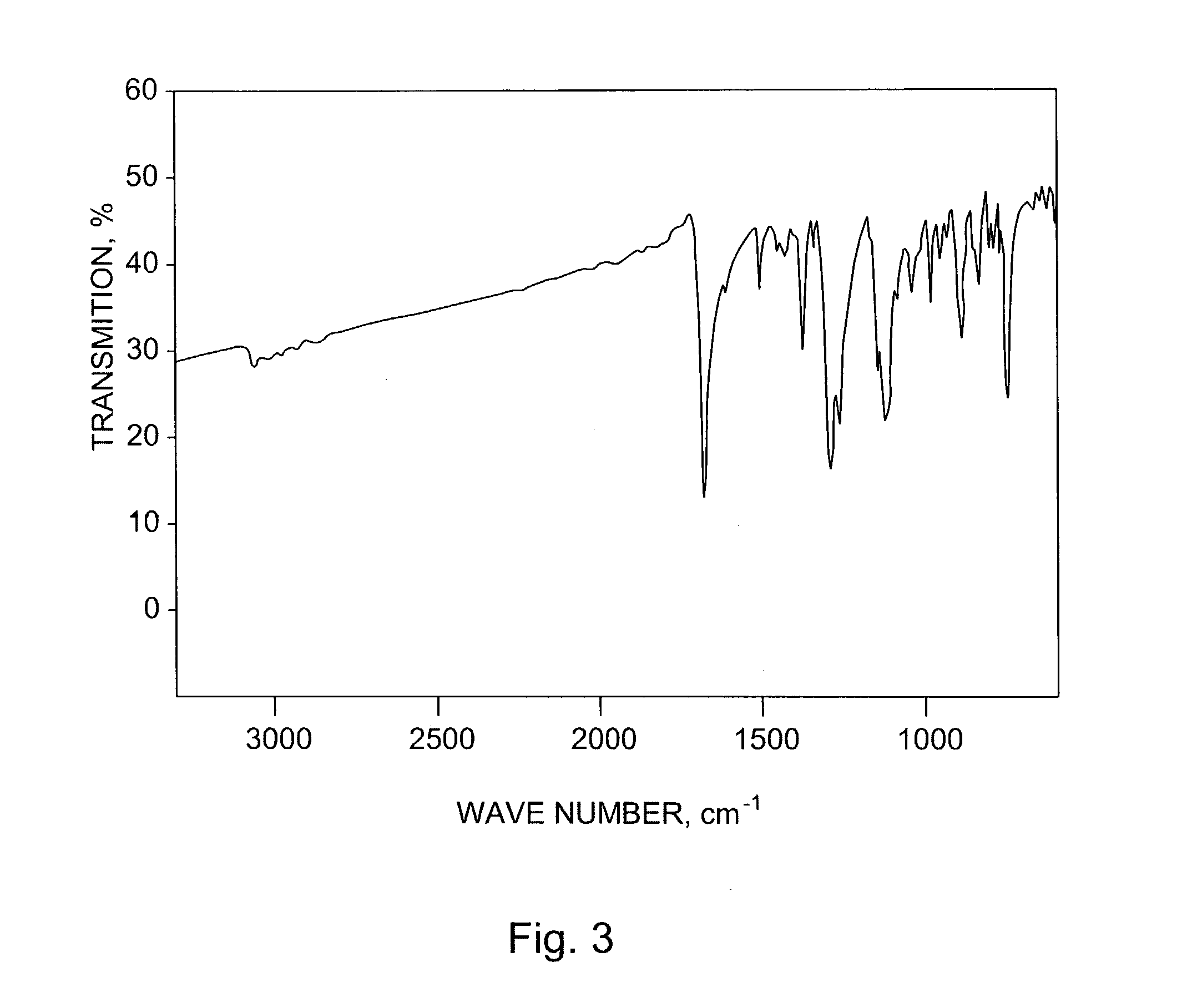

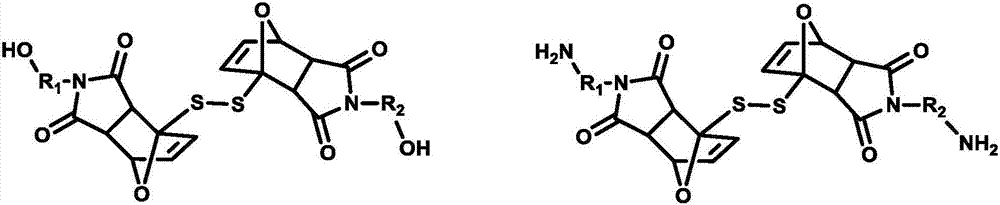

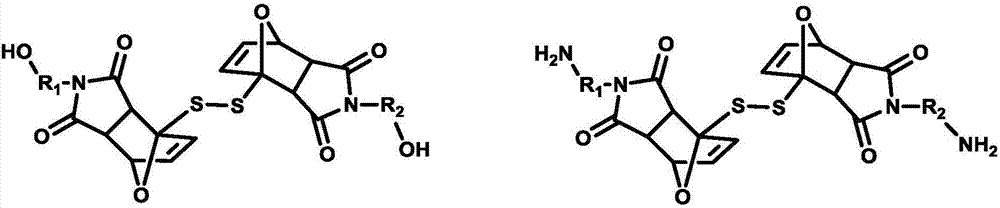

The invention relates to reprocessed polyurethane with dual-dynamic covalent bond crosslinking and a preparation method of the reprocessed polyurethane, and belongs to the field of high-molecular materials. Diisocyanate, triisocyanate or tetraisocyanate, macromolecular polyol / amine and dihydric alcohol / amine chain extenders with dynamically reversible Diels-Alder bonds and disulfide bonds are melted and commixed under the action of a catalyst or polymerized after addition of solvent to obtain the reprocessed polyurethane. Dual-dynamic bonds are introduced, so that the requirements of materials for mechanical properties are met, the materials have excellent reprocessing and self-repairing properties in different application environments, and the chain extenders with dynamically reversible Diels-Alder bonds and disulfide bonds can fracture and recombine at a certain temperature, so that the polyurethane materials have reprocessing performance and self-repairing functions on cracks or damage generated in the use process. Material viscosity obviously reduces after the dynamic bonds fracture, and melt viscosity is remarkably improved, so that processing performance is improved.

Owner:SICHUAN UNIV

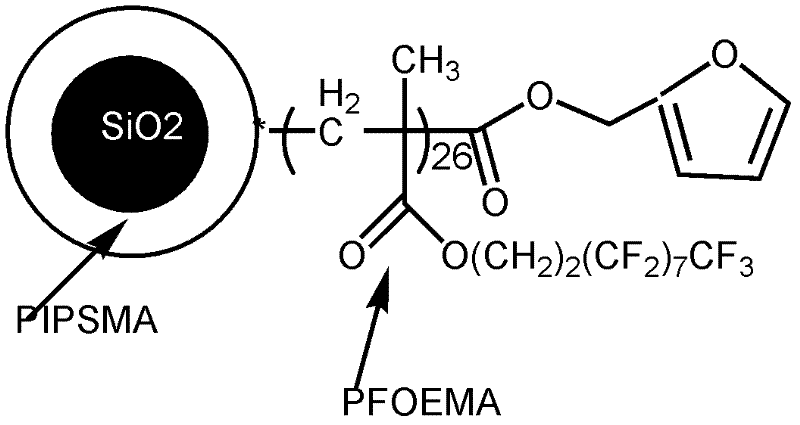

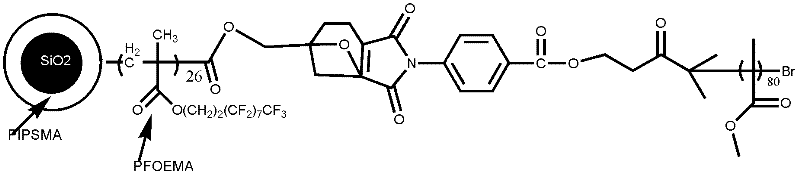

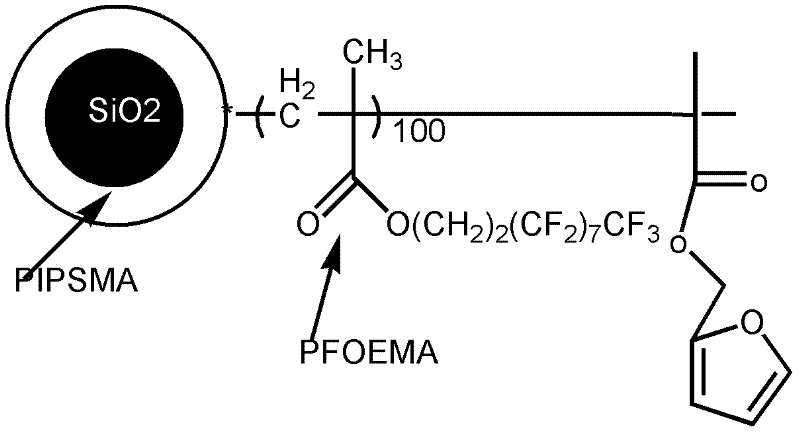

High-dispersion fluorine-containing nanosphere and epoxy resin super-amphiphobic surface

InactiveCN102604467AImprove hydrophobicity and oleophobicityReduce usagePigment treatment with macromolecular organic compoundsEpoxy resin coatingsEpoxyMicrosphere

The invention discloses a high-dispersion fluorine-containing nanosphere and an epoxy resin super-amphiphobic surface. The high-dispersion fluorine-containing nanosphere is obtained by grafting a fluorine-containing polymer with an end group of a compound D on the surface of the nanosphere and connecting a high-dispersion polymer with an end group of a compound A with the fluorine-containing polymer through a Diels-Alder reaction. The super-amphiphobic surface is prepared by the following steps that: the high-dispersion fluorine-containing nanosphere is dispersed in a low-boiling solvent, and then a liquid epoxy resin and an epoxy resin curing agent are added to obtain an epoxy resin coating with a super-amphiphobic effect; and then the epoxy resin coating is sprayed on a base material, and then is dried to obtain the super-amphiphobic surface. The poxy resin super-amphiphobic surface provided by the invention has excellent hydrophobic and oleophobic properties, the hydrophobic and oleophobic contact angle is greater than 150 degrees, and the rolling angle is less than 5 degrees. In the process of preparing the super-amphiphobic surface, a toxic fluorine-containing solvent is avoided being used, and the super-amphiphobic surface can be built on the surfaces of most materials by utilizing the excellent adhesive property of the epoxy resin coating.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

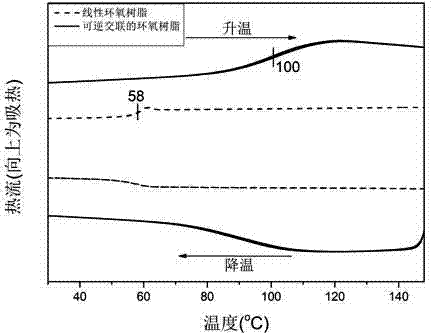

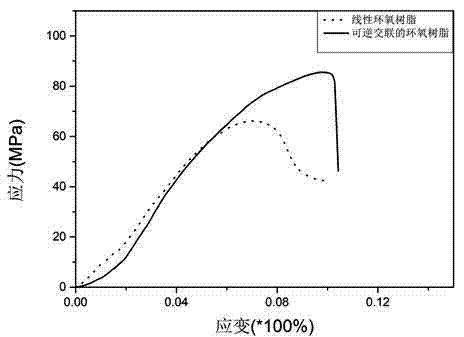

Reversible covalent cross-linked epoxy resin and preparation method thereof

The invention discloses a reversible covalent cross-linked epoxy resin. The reaction between diene monoamine and an epoxy resin monomer is adopted for obtaining a linear epoxy resin with a diene on a side chain, the linear epoxy resin and a dienophile cross-linking agent form a Diels-Alder reversible reaction cross-linked point on the side chain, the reversible covalent cross-linked bond of the cross-linked epoxy resin breaks at a temperature of 100 to 150 DEG C, and can be restored again when the temperature is lowered to below 90 DEG C, so that the crosslink reversibility can be achieved. The reversible covalent cross-linked epoxy resin and the preparation method, provided by the invention, have the advantages that: (1), the reversible covalent cross-linked point is introduced to the side chain of the linear epoxy resin, so that the thermostability, solvent corrosion resistance and mechanical property of the material are improved, and by changing the cross-linking density, the material performance can be adjusted within a larger range; (2), both structures of the diene and the dienophile in the cross-linked epoxy resin have reversible reaction properties, so that recycling and reprocessing under certain conditions can be conducted; (3), the preparation method is simple and convenient, and is easy to implement, the relative cost is low, and raw material sources are wide.

Owner:NANKAI UNIV

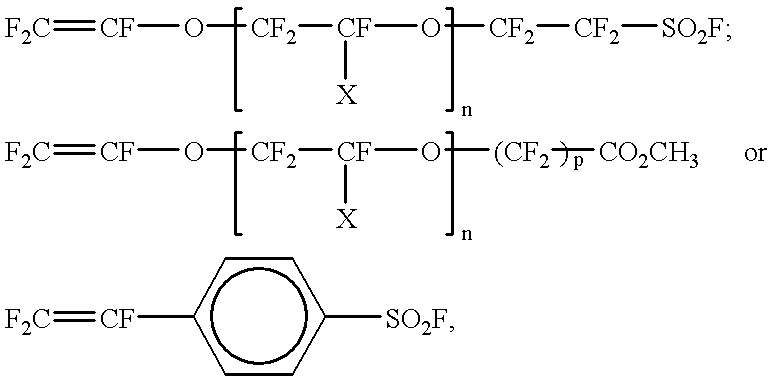

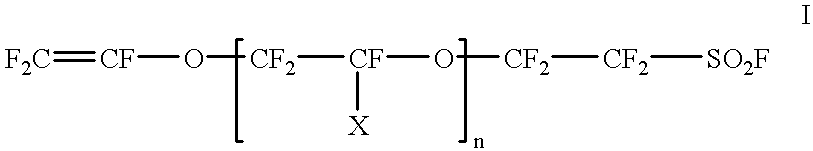

Cross-linked sulphonated polymers and method for preparing same

InactiveUS20020002240A1Improve mechanical propertiesFine surfaceSemi-permeable membranesOrganic diaphragmsCross-linkElectrolysis

The present invention is concerned with cross-linked sulfonated polymers, eventually perfluorinated, and their preparation process. When molded in the form of membranes, the polymers are useful in electrochemical cells, in a chlorine-sodium electrolysis process, as separator in an electrochemical preparation or organic and inorganic compounds, as separators between an aqueous phase and an organic phase, or as catalyst for Diels-Alder additions, Friedel-Craft reactions, aldol concentrations, cationic polymerisation, esterification, and acetal formation.

Owner:MICHOT CHRISTOPHE +1

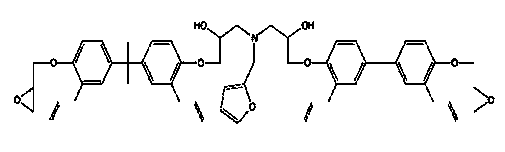

Reversible repair functional matrix resin for pultrusion and preparation method of matrix resin

InactiveCN104194269AMeet the requirements of pultrusion processImprove axial tensile strengthEpoxyDiphenylmethane

The invention discloses a reversible repair functional matrix resin for pultrusion and a preparation method of the matrix resin. The matrix resin is prepared from the following raw materials in parts by weight: 30-60 parts of 4,4'-diallylbisphenol A diglycidyl ether epoxy resin, 20-35 parts of furfuryl amine, 15-30 parts of 4,4'-bismaleimide diphenylmethane, 0-25 parts of liquid epoxy resin and 5-15 parts of curing agent. The preparation method comprises the following steps: dissolving the 4,4'-diallylbisphenol A diglycidyl ether epoxy resin in a formula amount into a solvent, slowly adding the furfuryl amine into a reaction container for reacting, adding the 4,4'-bismaleimide diphenylmethane, liquid epoxy resin and curing agent, reacting and mixing for a hour, performing reduced pressure distillation to remove the solvent, and cooling. The reversible repair functional matrix resin for pultrusion and the preparation method of the matrix resin disclosed by the invention have the beneficial effects that the matrix resin has good molding manufacturability, the molecular structure contains furan and imide structures, the heating and repairing functions of the prepared composite material can be realized by virtue of a Diels-Alder reversible reaction, and the matrix resin also has the advantages of high strength and high heat resistance.

Owner:HAIAN INST OF HIGH TECH RES NANJING UNIV

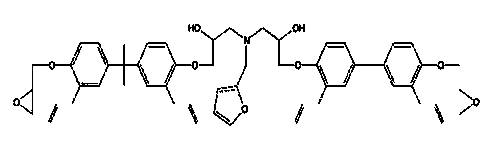

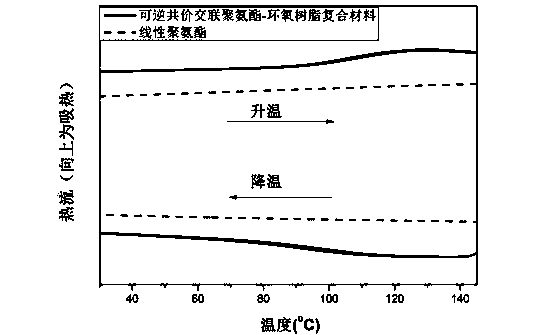

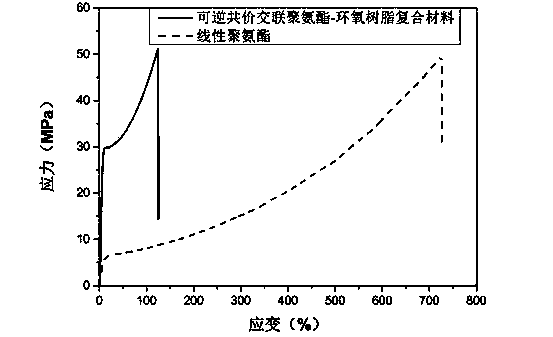

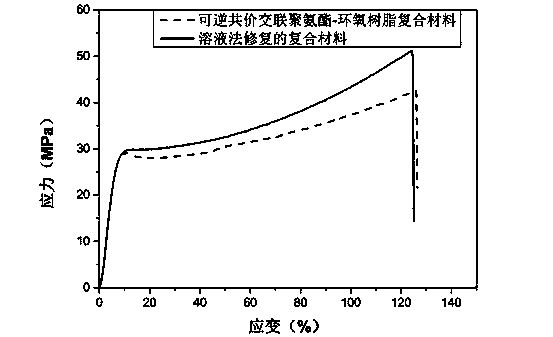

Reversible covalent crosslinked polyurethane and epoxy resin composite and preparation method thereof

InactiveCN103642199AImprove mechanical propertiesThe preparation method is simple and controllableEpoxySide chain

The invention discloses a reversible covalent crosslinked polyurethane and epoxy resin composite comprising two components: linear polyurethane and linear epoxy resin, wherein side chains of the reversible covalent crosslinked polyurethane and epoxy resin composite are respectively provided with a dienophile functional group and a diene functional group; the composite is a material with a crosslinked network structure, which is formed by connecting linear polyurethane and linear epoxy resin through a Diels-Alder reversible covalent bond; the Diels-Alder reversible covalent bond can be reversibly broken and bonded through temperature adjustment, so that the composite conversion between a linear polymer and the material with the crosslinked network structure has the characteristic of reversible covalent crosslinking. The reversible covalent crosslinked polyurethane and epoxy resin composite has the advantages that the mechanical and thermodynamic properties are excellent, and the mechanics can be adjusted within a relatively wide range; the preparation method is simple, convenient and controllable, the reversible covalent crosslinked polyurethane and epoxy resin composite is high in yield, good in quality and wide in application range, and the performance of the composite can be optimized through being re-modified by using filler.

Owner:NANKAI UNIV

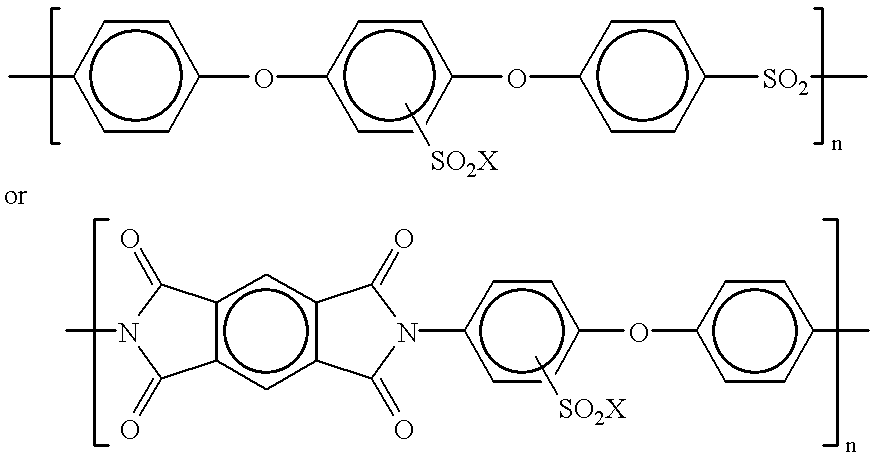

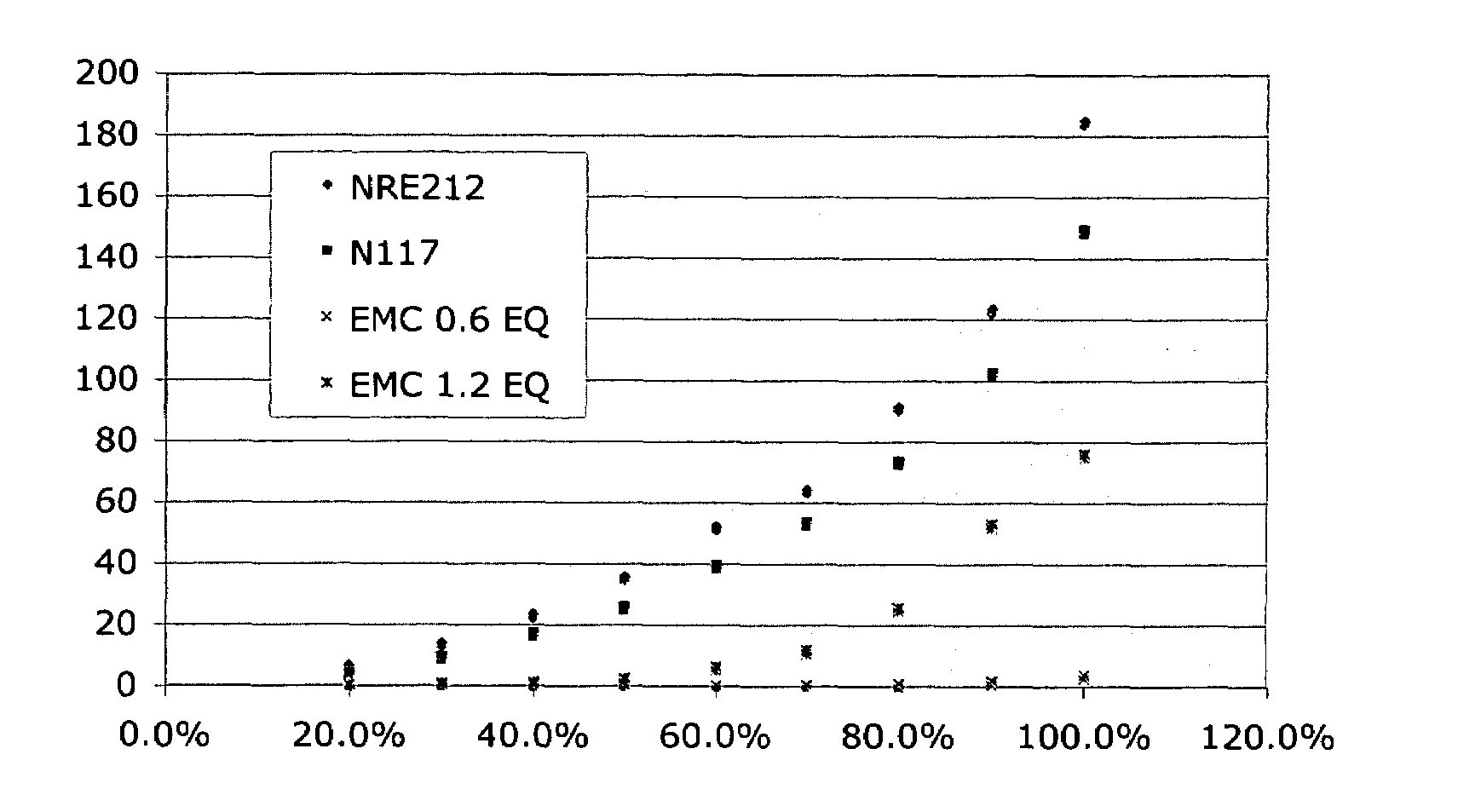

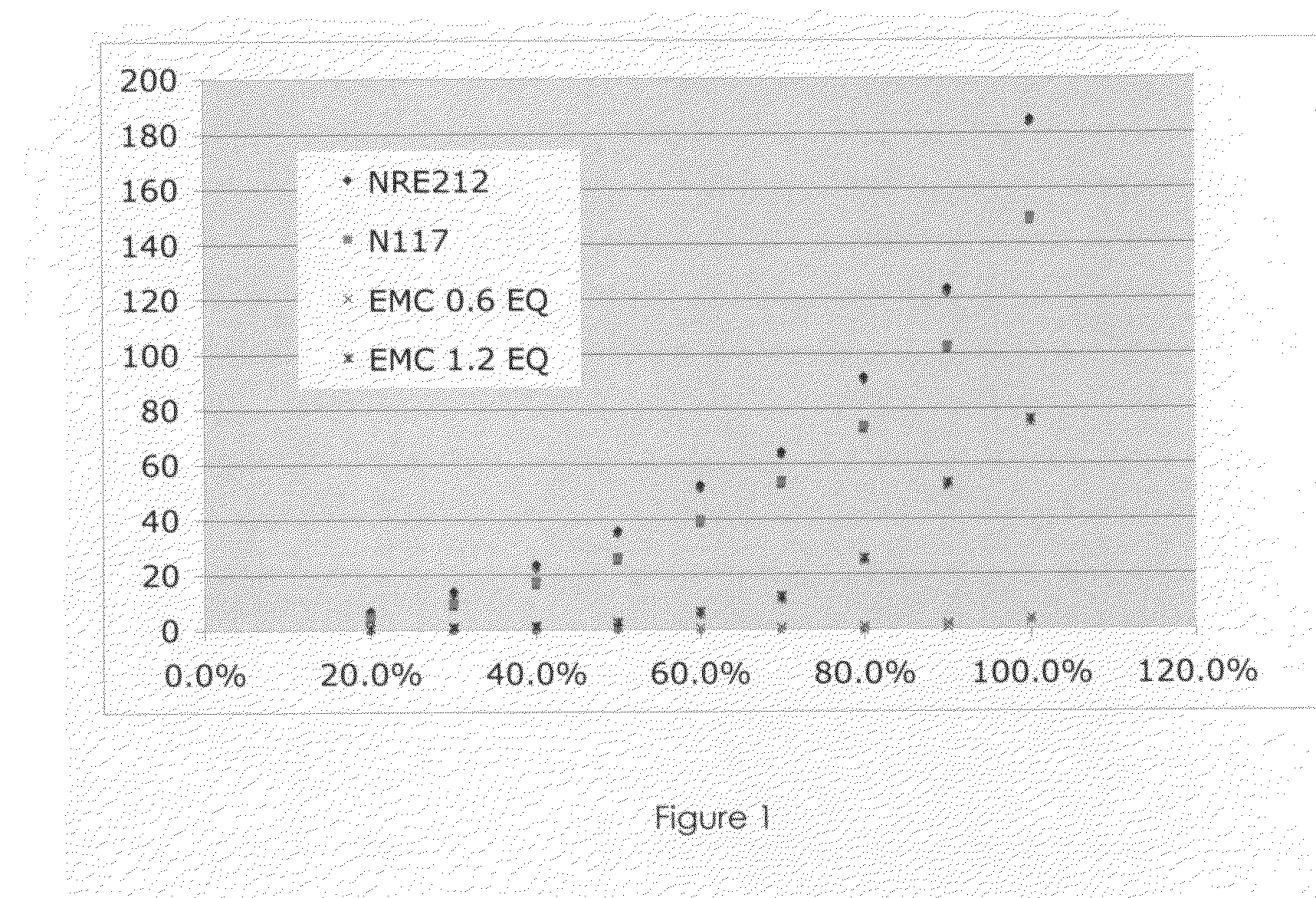

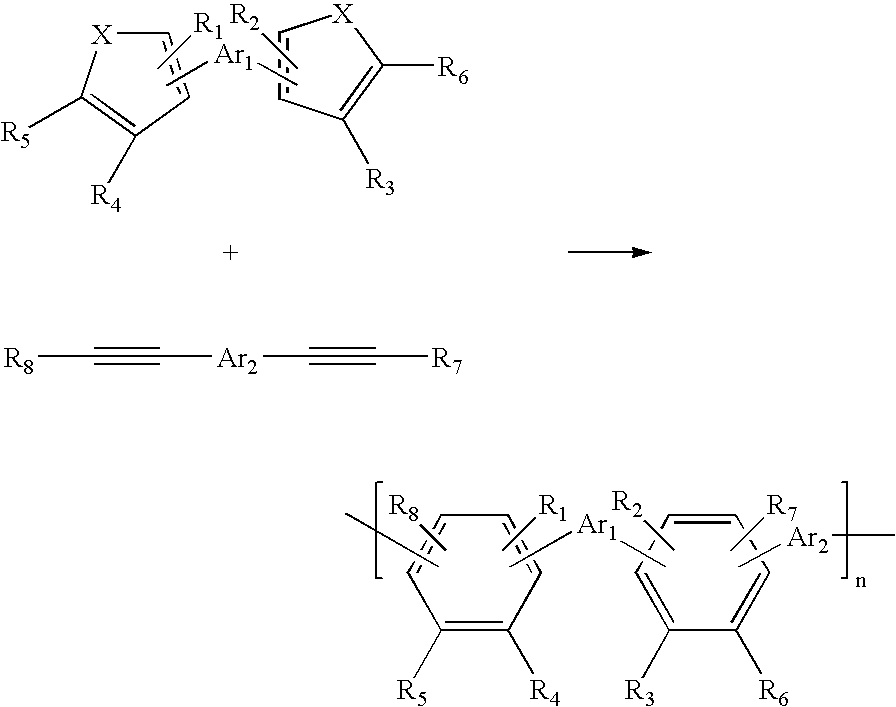

Polyarylene polymers and ion conducting functionalized polyarylene polymers resulting from pairing bis-diene arylenes and bis-dienophile arylenes via a diels-alder reaction

InactiveUS20090264544A1Improve antioxidant capacityLong life-timeSolid electrolytesIon-exchanger regenerationIonDiels alder

The invention discloses a group of novel and functionalized arylene polymers that comprise repeat units from a group consisting of polyarylene, polybenzimidazolene, polybenzimidazole, and poly(arylene-co-cyclohexadiene). The compositions are created via Diels-Alder polymerization and result in a polymer that is chemically and thermally stable. The polyarylene polymers can be used to create improved polymer electrolyte membranes that overcome the limitations of Nafion® membranes for use in fuel cells.

Owner:ENERGY MATERIALS

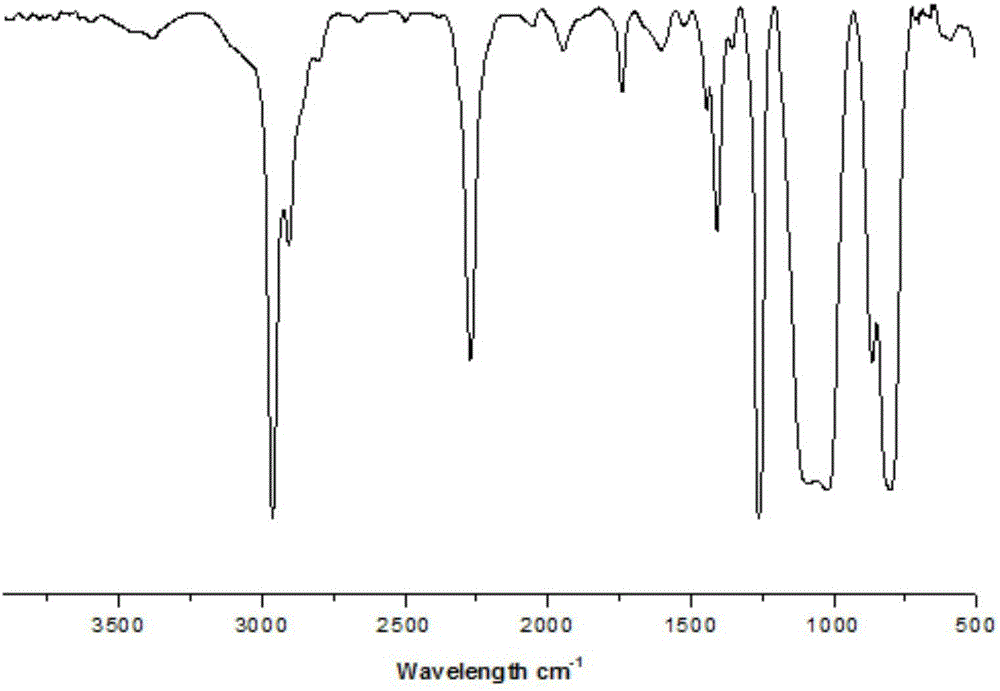

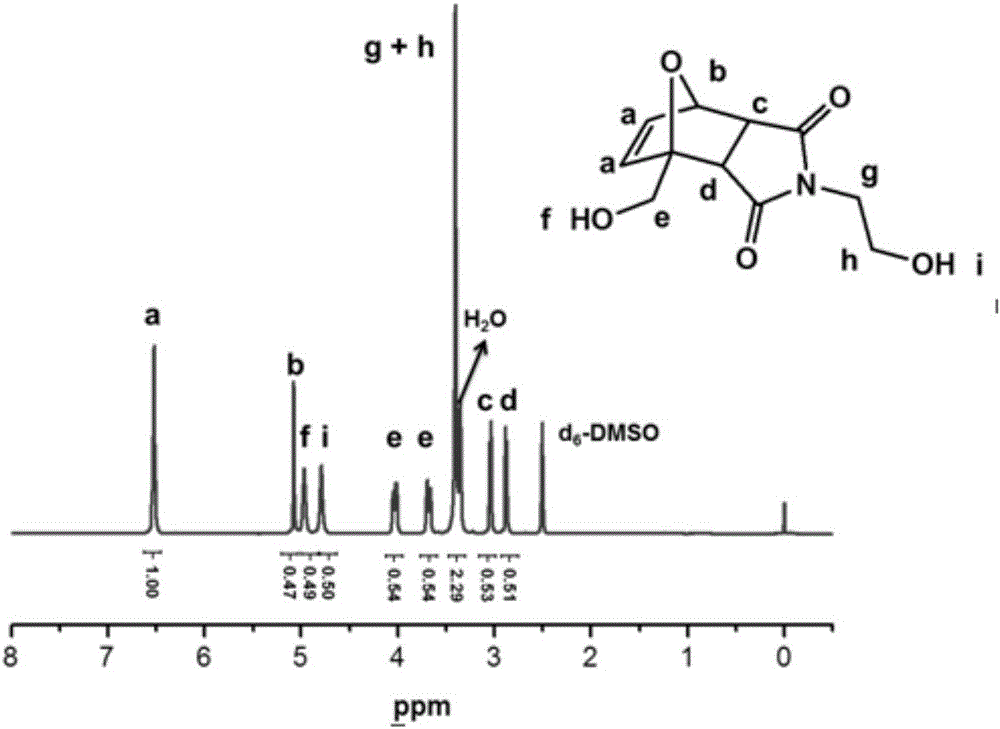

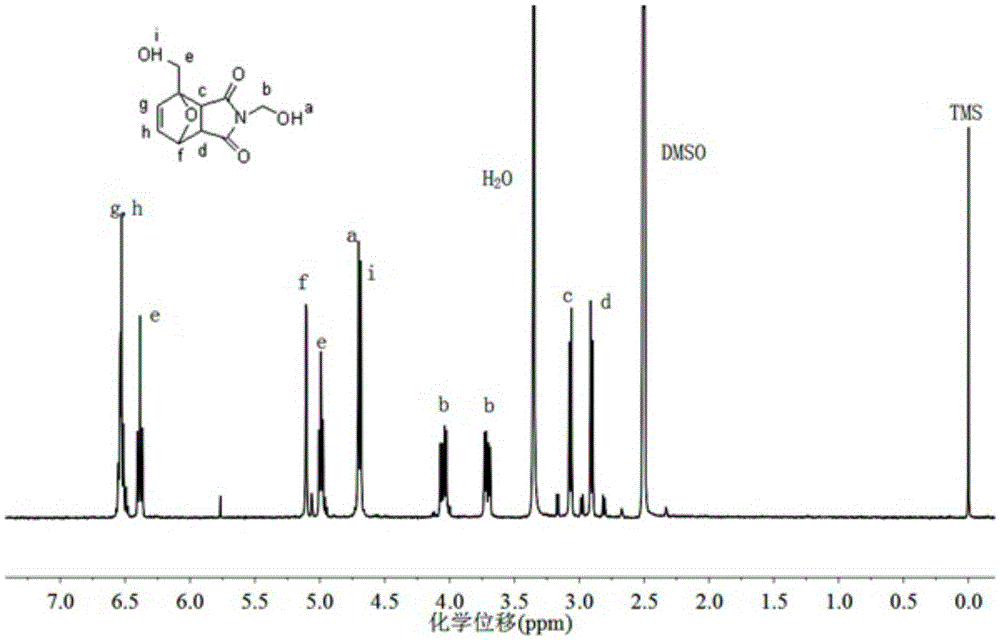

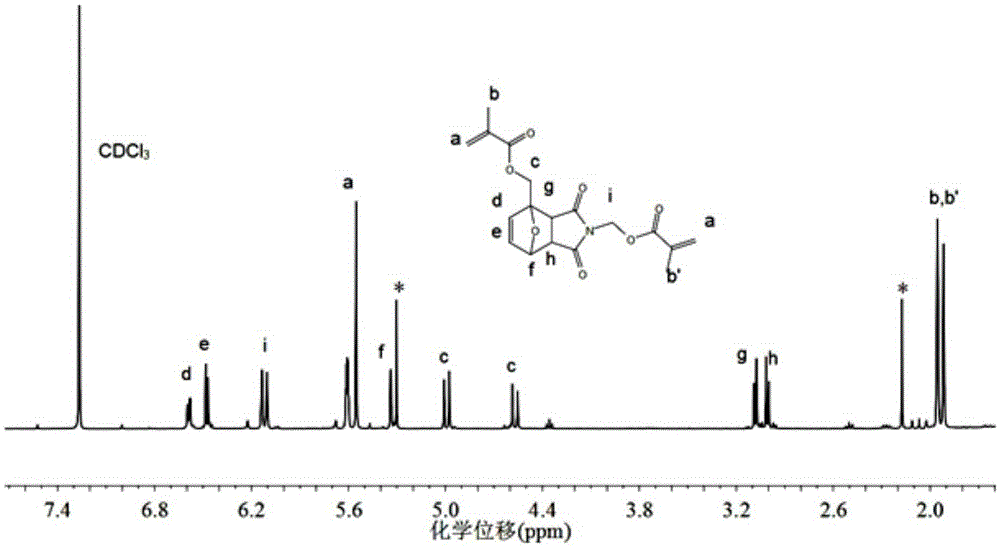

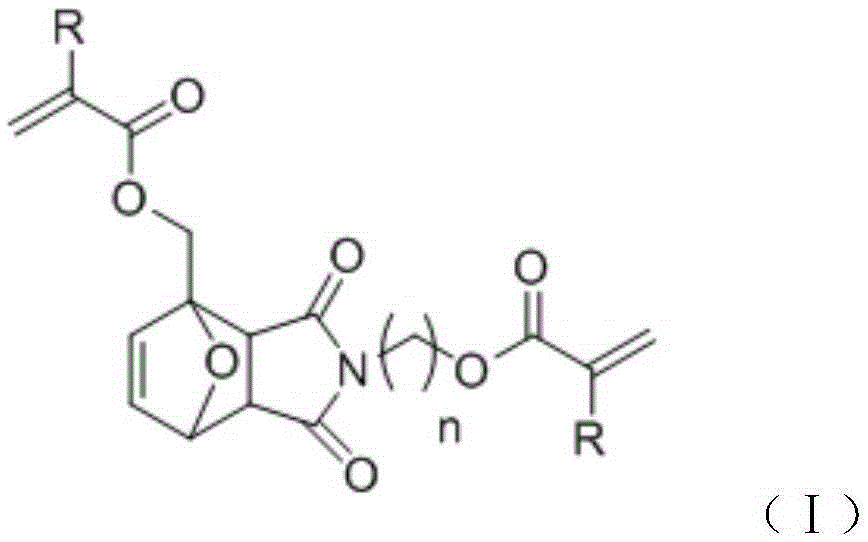

Bi-functionality-degree acrylic ester cross-linking agent and application thereof to 3D printing

The invention relates to the field of high molecular materials for photocuring 3D printing fast forming equipment and aims to provide a bi-functionality-degree acrylic ester cross-linking agent and application thereof to 3D printing. According to the preparation steps, under protection of nitrogen, furfuryl alcohol, N-hydroxyalkyl maleimide and solvent react, and suction filtration, washing and vacuum drying are carried out on the reaction product to obtain a dihydroxy-terminated Diels-Alder addition product; the addition product is dissolved into the solvent, a pyridine catalyst and acid anhydride are added, the mixture reacts, methyl alcohol is added, the mixture continues to react, methylene chloride is used for dissolving the product, and organic phases are collected to obtain a final product. The initial raw materials are wide in source, the preparation process and purification are simple, and the cross-linking agent is suitable for industrial production process; the product has universality, and the prepared vinyl polymer has excellent mechanical performance and solvent resistant performance of a thermosetting material at normal temperature, and has a recovery processing characteristic of thermoplastic at high temperature; use performance of the product is met, and the application is important breakthrough of the 3D printing material equipment technology.

Owner:殷若瑜

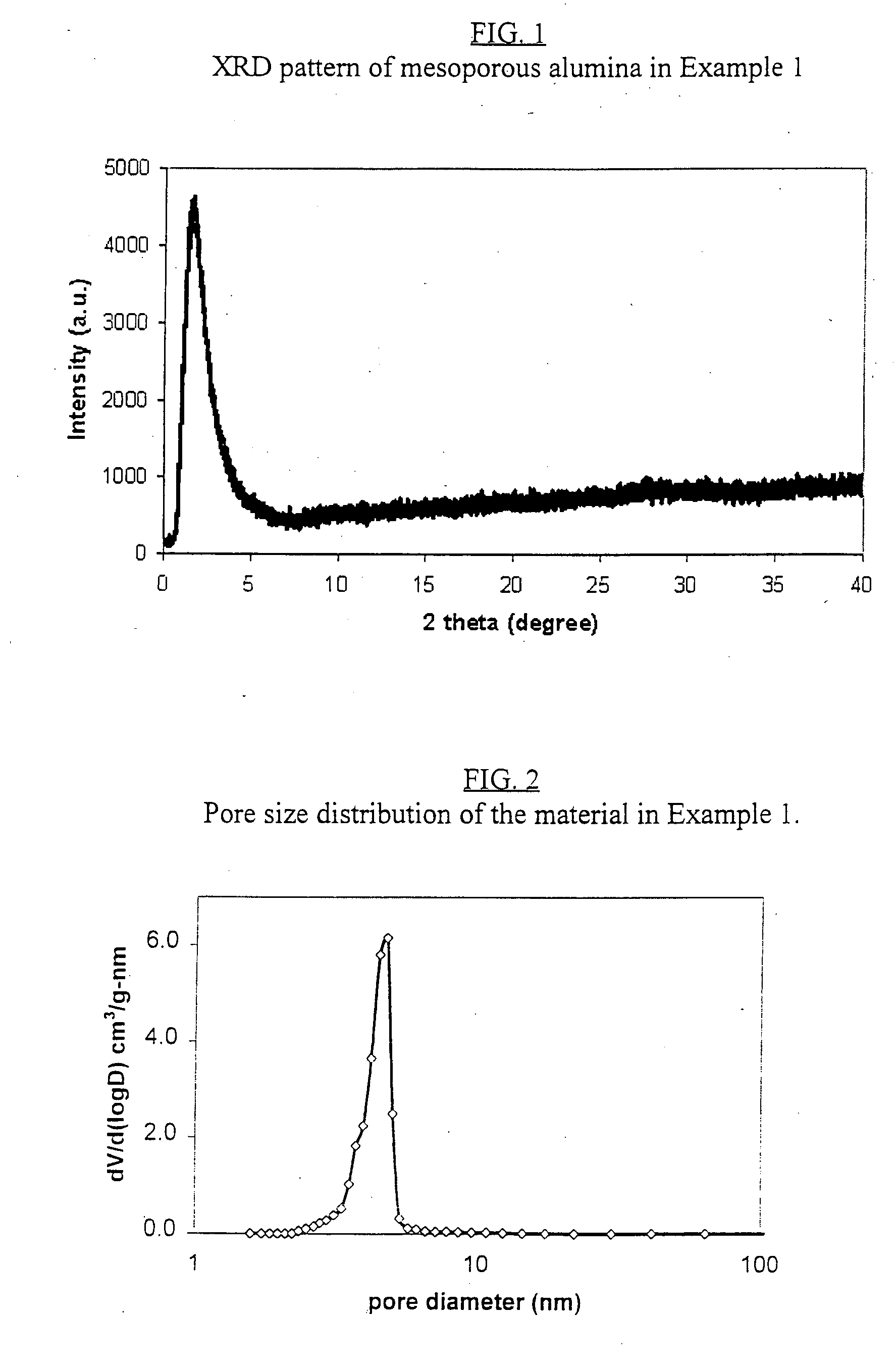

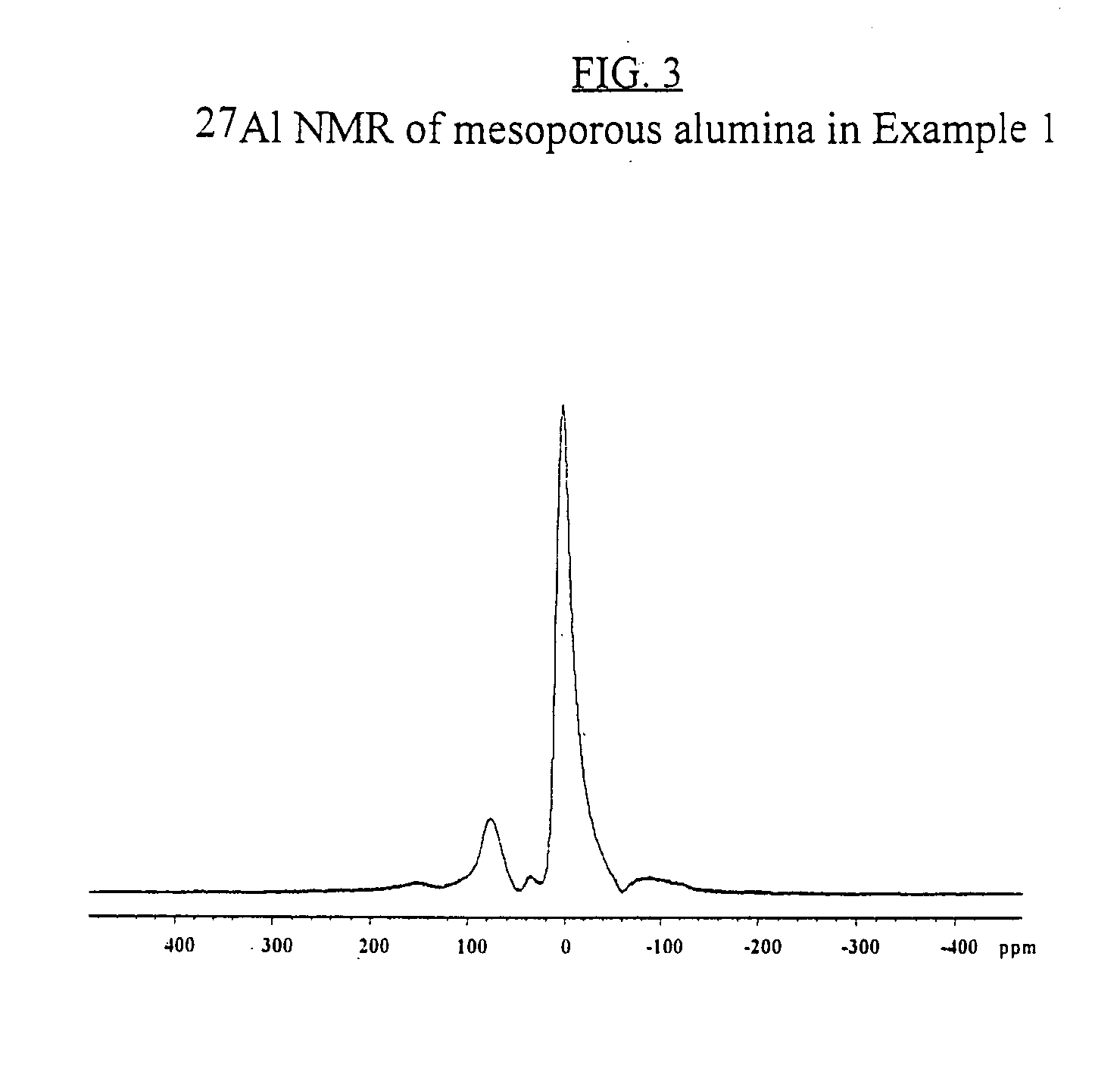

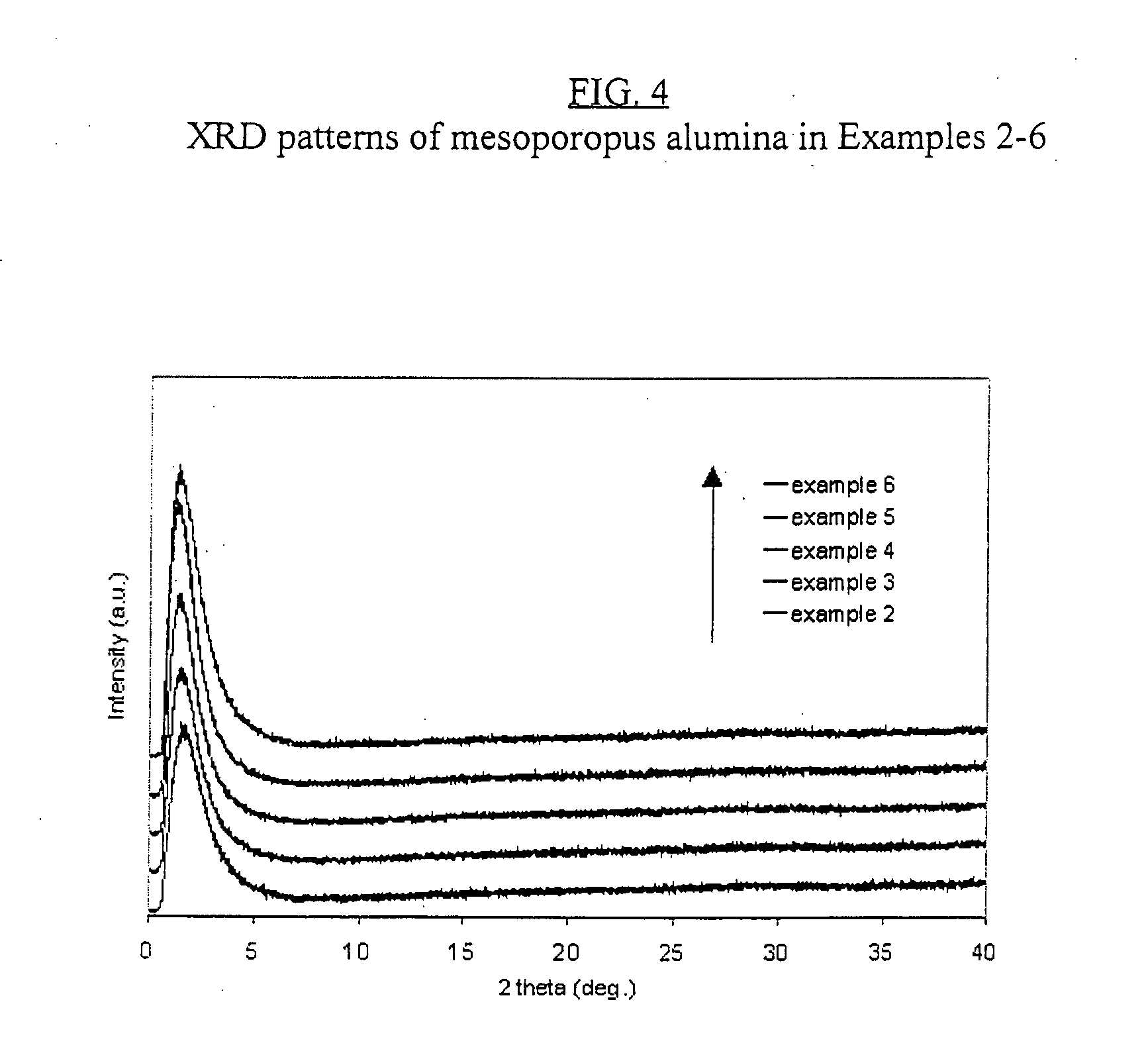

Mesoporous aluminum oxide, preparation and use thereof

InactiveUS20070170096A1Cost-effectiveEasy to operateHydrogenCatalytic naphtha reformingSteam reformingCatalytic reforming

Mesoporous aluminum oxides with high surface areas have been synthesized using inexpensive, small organic templating agents instead of surfactants. Option-ally, some of the aluminum can be framework-substituted by one or more other elements. The material has high thermal stability and possesses a three-dimensionally randomly connected mesopore network with continuously tunable pore sizes. This material can be used as catalysts for dehydration, hydrotreating, hydrogenation, catalytic reforming, steam reforming, amination, Fischer-Tropsch synthesis and Diels-Alder synthesis, etc.

Owner:LUMMUS TECH INC

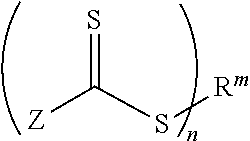

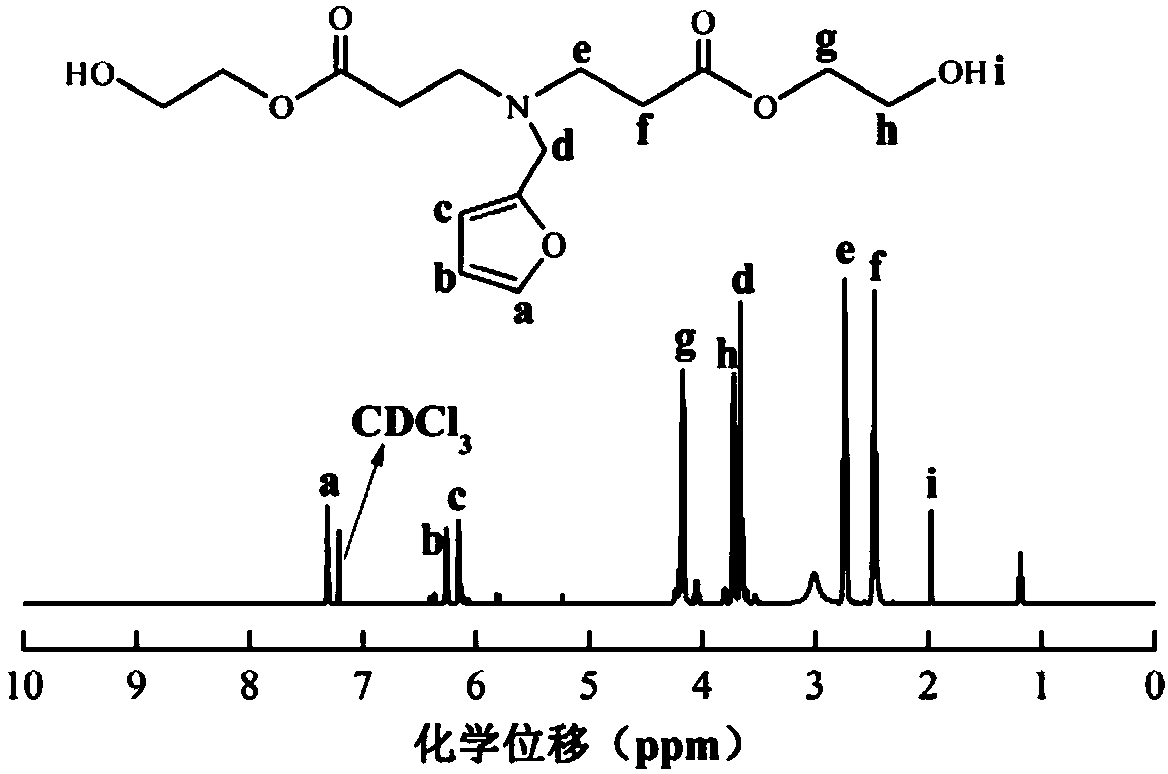

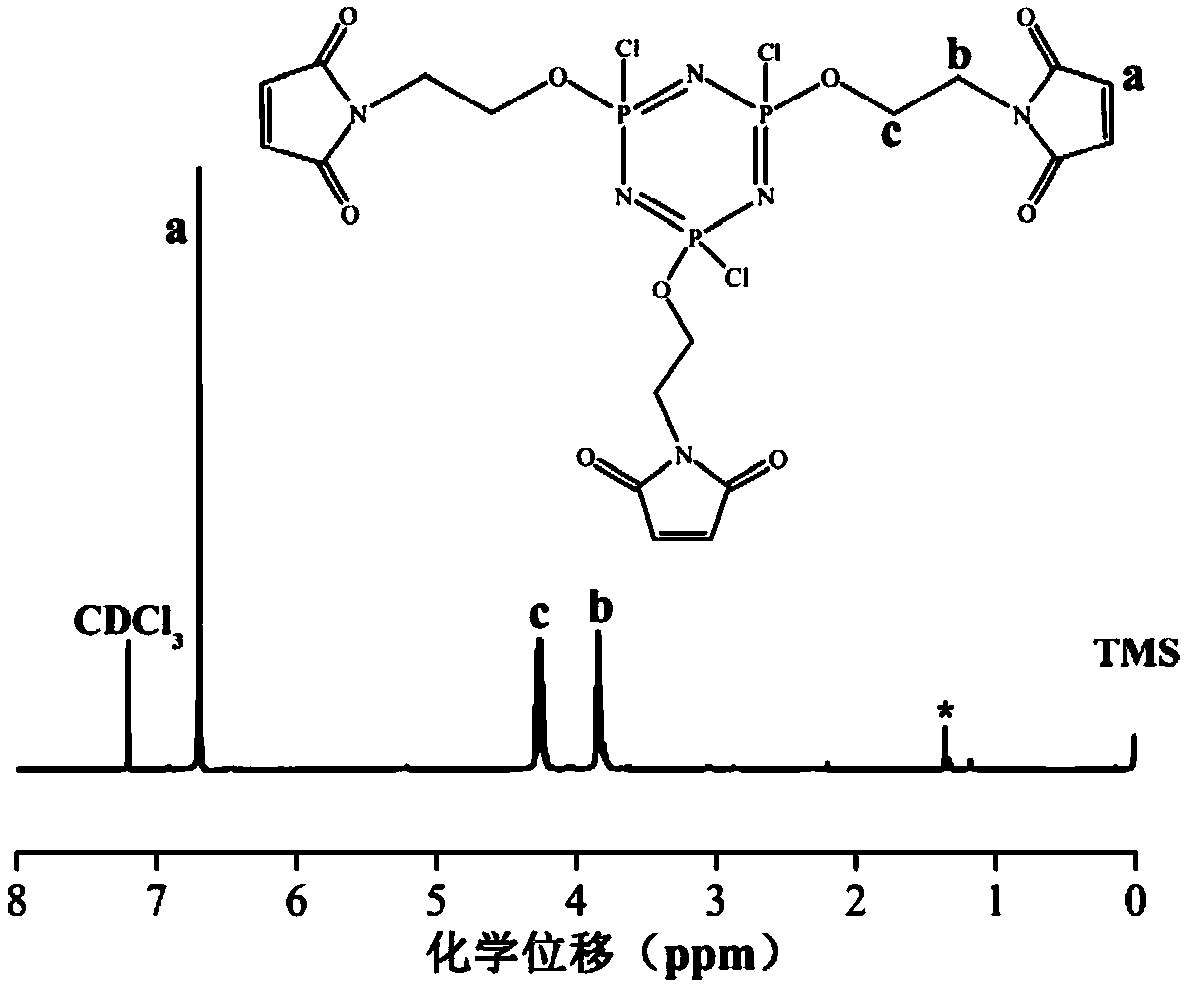

Diels-Alder bond containing self-repairing flame retardant polyurethane elastomer and preparation method thereof

The invention provides a Diels-Alder bond containing self-repairing flame retardant polyurethane elastomer and a preparation method of the Diels-Alder bond containing self-repairing flame retardant polyurethane elastomer. The structural formula of the polyurethane elastomer is shown in the specification. The preparation method of the polyurethane elastomer is as follows: (1) preparing dihydric alcohol having a furan functional group; (2) preparing a linear-structure polyurethane solution comprising a furan functional group on a side chain; (3) preparing a maleimide modified phosphonitrilic chloride trimer flame retardant; and (4) preparing the Diels-Alder bond containing self-repairing flame retardant polyurethane elastomer.

Owner:SICHUAN UNIV

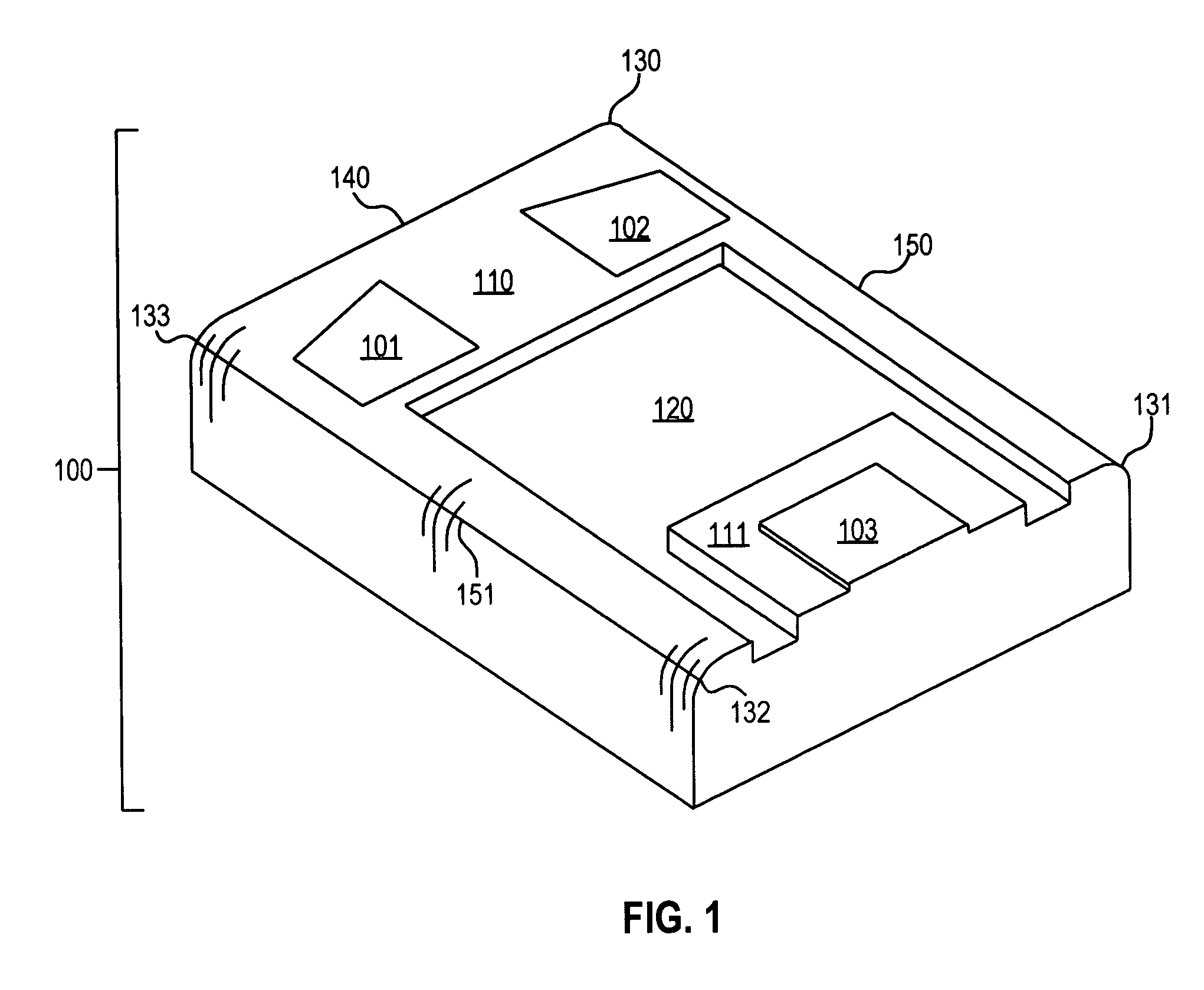

Stable encapsulant fluid capable of undergoing reversible diels-alder polymerization

An encapsulant fluid is provided comprising a mixture of a diene-containing compound and a dienophilic compound. At least one of the diene-containing and the dienophilic compounds is protected so that the compounds do not substantially react with each other at room temperature. The diene-containing and the dienophilic compounds undergo a reversible Diels-Alder polymerization reaction at a polymerization temperature above room temperature to form a solid debondable polymeric encapsulant. Also provided are methods for forming slider assemblies and methods for patterning a slider surface using the encapsulant.

Owner:WESTERN DIGITAL TECH INC

Preparation method and application of UV (Ultraviolet) photocatalysis-based unsaturated vegetable oil D-A (Diels-Alder) reaction product

The invention belongs to the field of a UV (Ultraviolet) photocatalysis biomass chemical reaction and in particular discloses a preparation method and an application of a UV photocatalysis-based unsaturated vegetable oil Diels-Alder (D-A) reaction product. The preparation method comprises the steps of: preparing vegetable oleate with unsaturated natural vegetable oil as a raw material; then carrying out the D-A addition reaction on the vegetable oleate and maleic anhydride or a derivative thereof under the condition of UV light irradiation and a catalyst; and finally preparing the UV photocatalysis-based unsaturated vegetable oil D-A reaction product. A UV photochemical reaction process and a UV photochemical reaction mechanism of the unsaturated vegetable oil series are researched, the preparation of an ideal target product is further regulated and controlled, thus the research thought is creative. The UV photocatalysis-initiated unsaturated vegetable oil D-A addition reaction is researched and is applied to prepare a vegetable oil derivative so as to optimize the UV reaction activity and the solidification property.

Owner:SOUTH CHINA AGRI UNIV

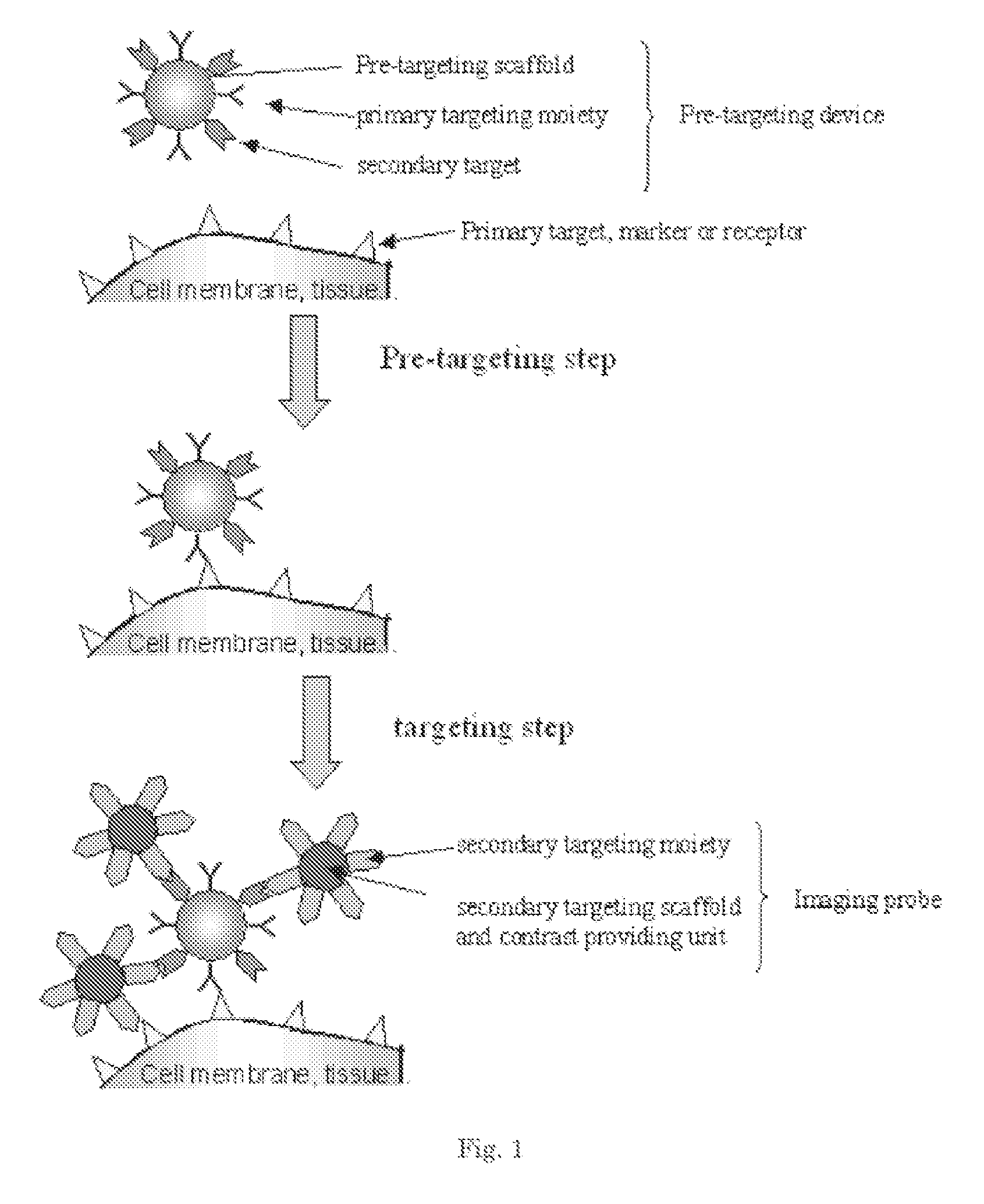

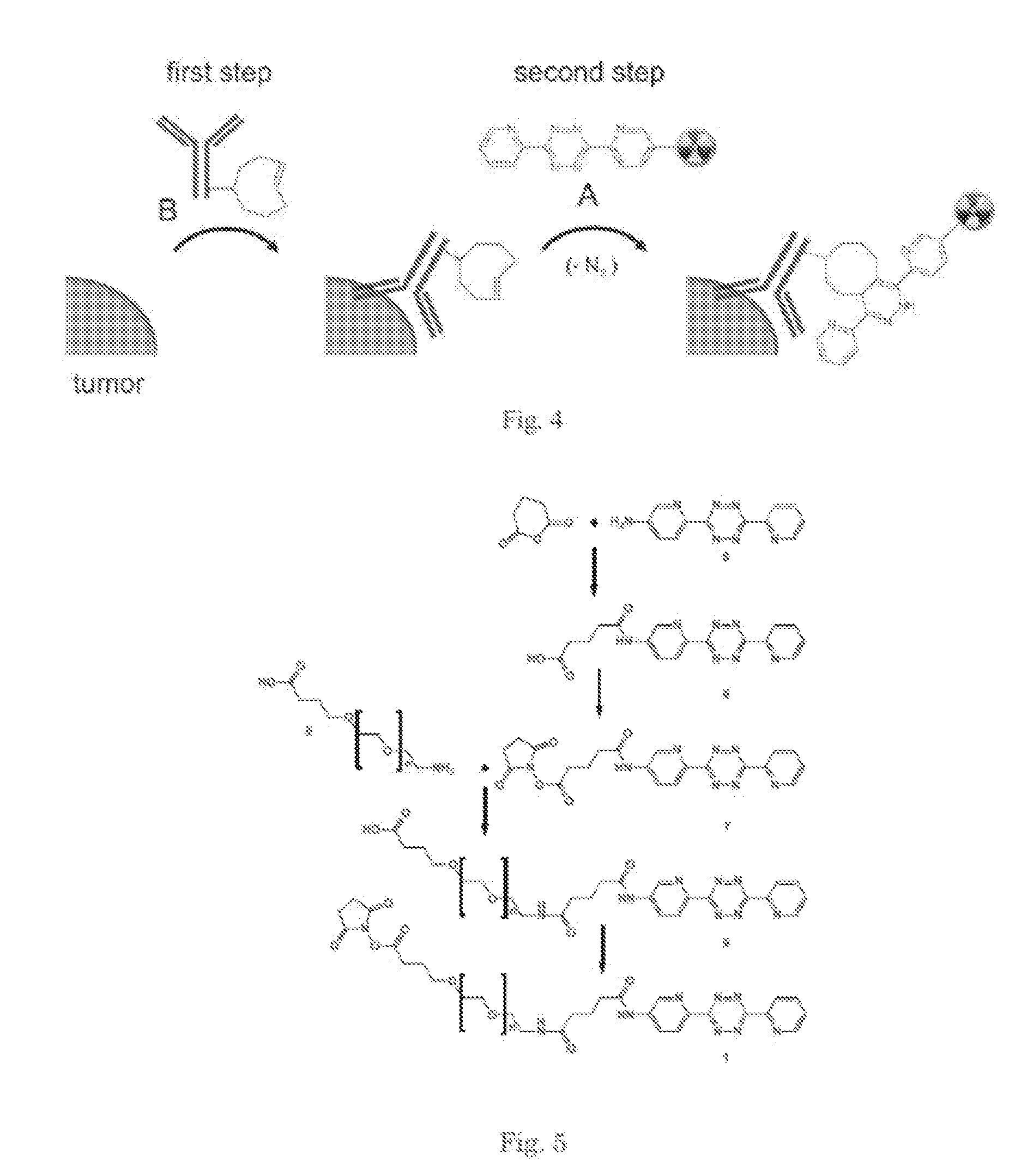

Pretargeting kit, method and agents used therein

Described is a pretargeting method, and related kits, for targeted medical imaging and / or therapeutics, wherein use is made of abiotic reactive chemical groups that exhibit bio-orthogonal reactivity towards each other. The invention involves the use of [4+2] inverse electron demand (retro) Diels-Alder chemistry in providing the coupling between a Pre-targeting Probe and an Effector Probe. To this end one of these probes comprises an electron-deficient tetrazine or other suitable diene, and the other an E-cyclooctene which has one or more axial substituents.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Method for preparing solid homogenous metallocene cataloyst carried by poly phenylethylene

A homogeneous solid metallocene catalyst carried by polystyrene for the polymerization of olefin is prepared through introducing the cyclopentadienyl to linear polystyrene chain and loading the metallocene into the cross-linked polystyrene network by the Diels-Alder cross-linking reaction under existance of metallocene. It features that when it is used for the polymerization of olefin, the cross-linked network of carrier can be gradually opened, resulting in smooth dynamic performance.

Owner:ZHEJIANG UNIV

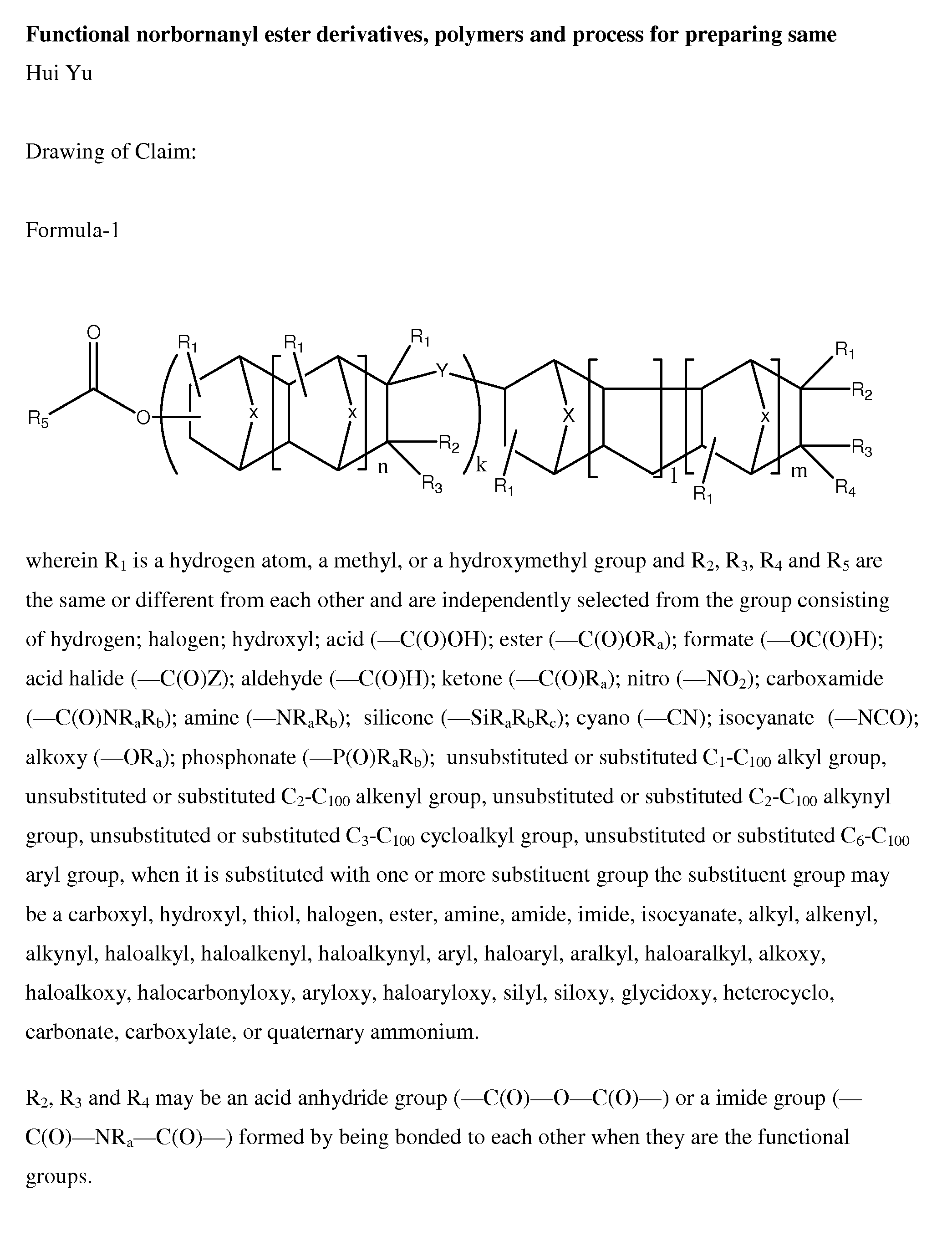

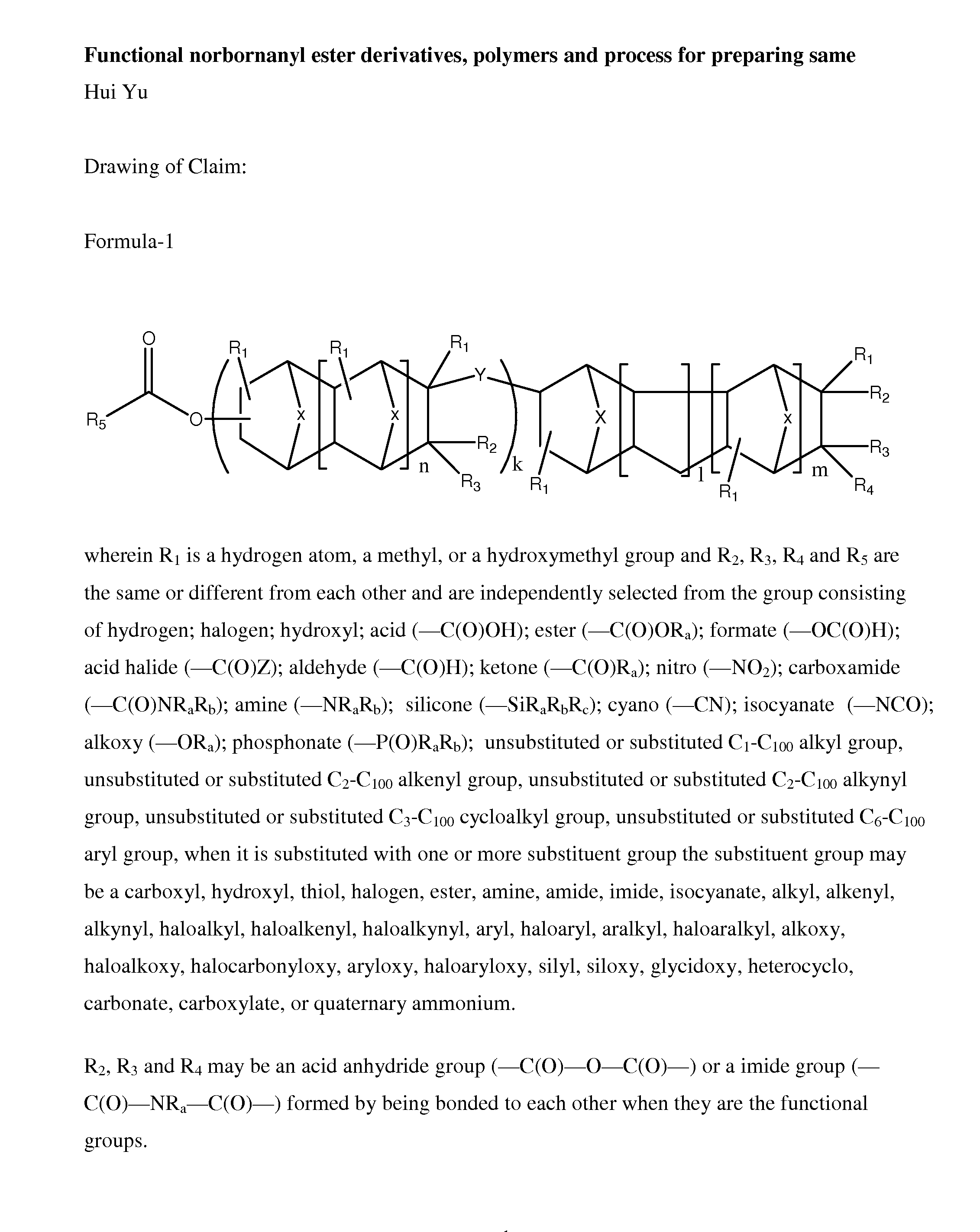

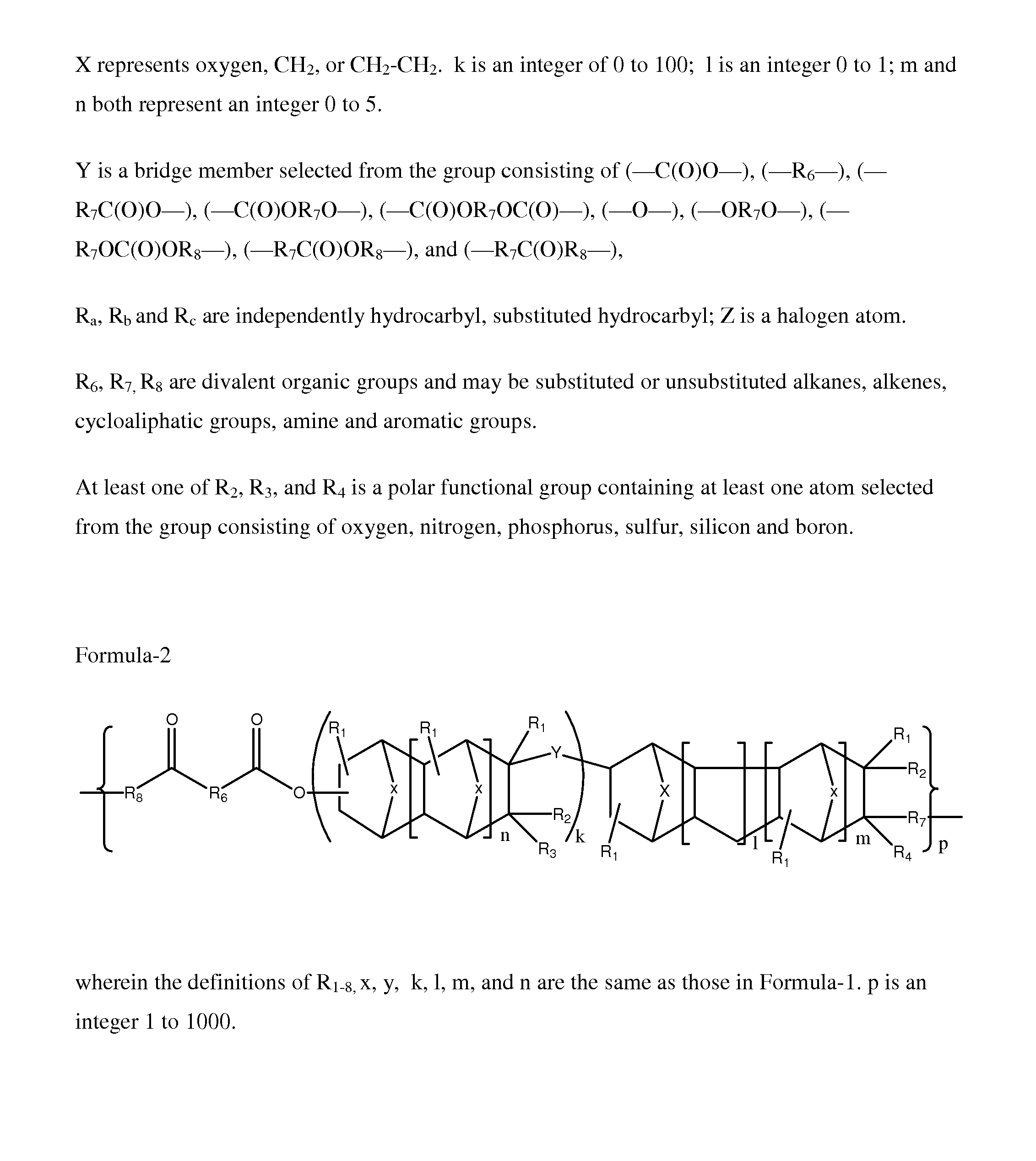

Functional norbornanyl ester derivatives, polymers and process for preparing same

This invention relates to the new functional norbornanyl ester derivative and / or polymer compositions which are easily obtainable by reacting the Diels-Alder adduct of appropriate dienes and dienophiles with carboxylic acids. In particular, this invention relates to a new process for making cyclic chemical raw materials suitable for production coating, ink, adhesive, plasticizer, thermoplastic or thermosetting plastic and functional polymers.

Owner:NEW FUNCTIONAL POLYMERS

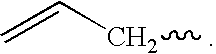

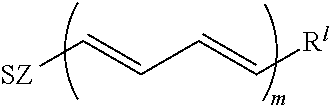

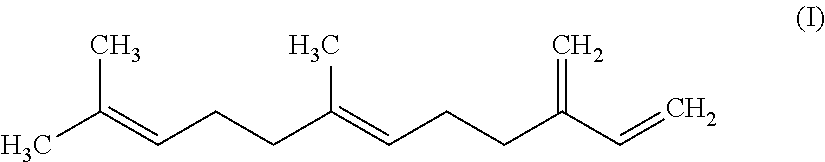

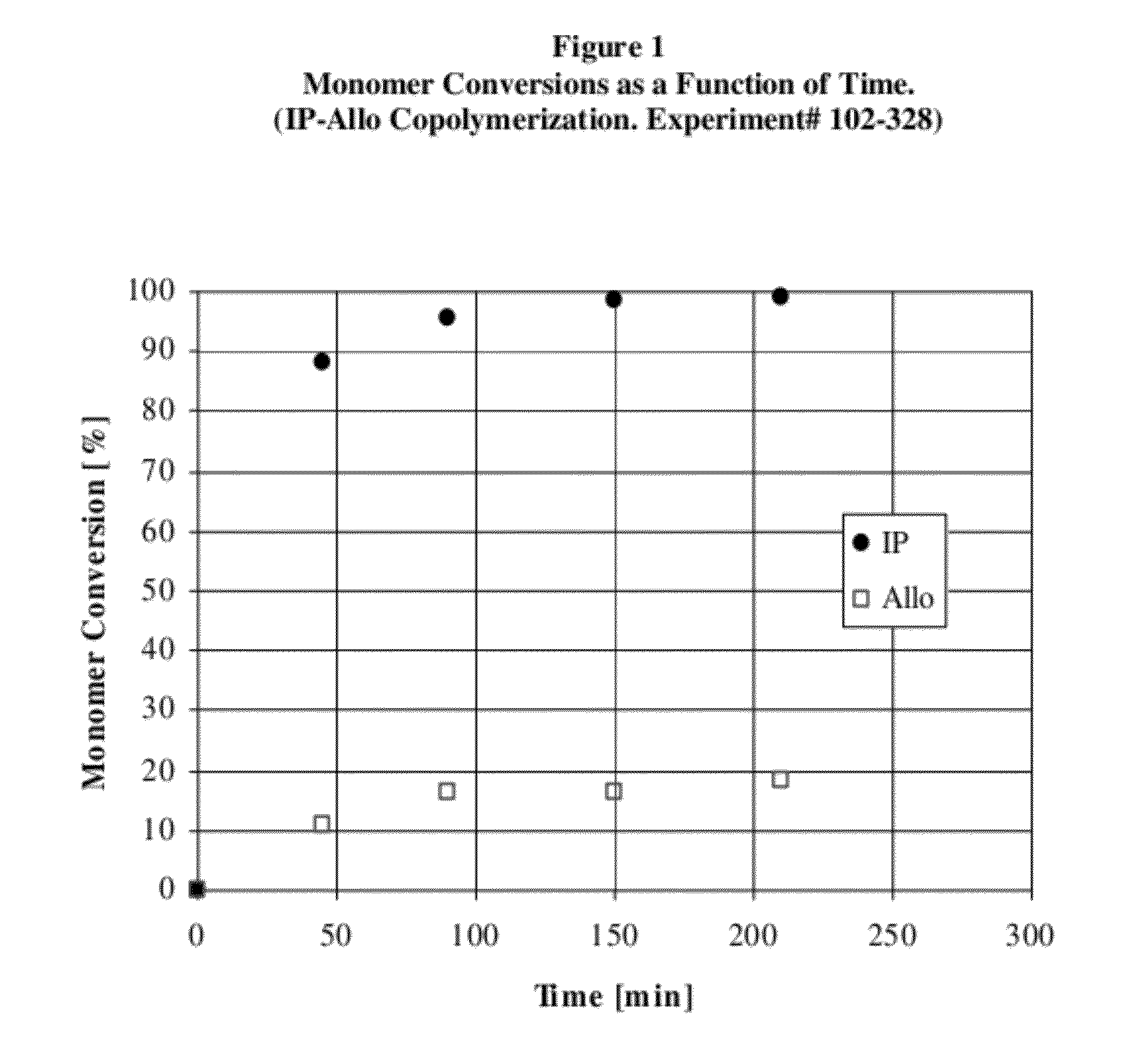

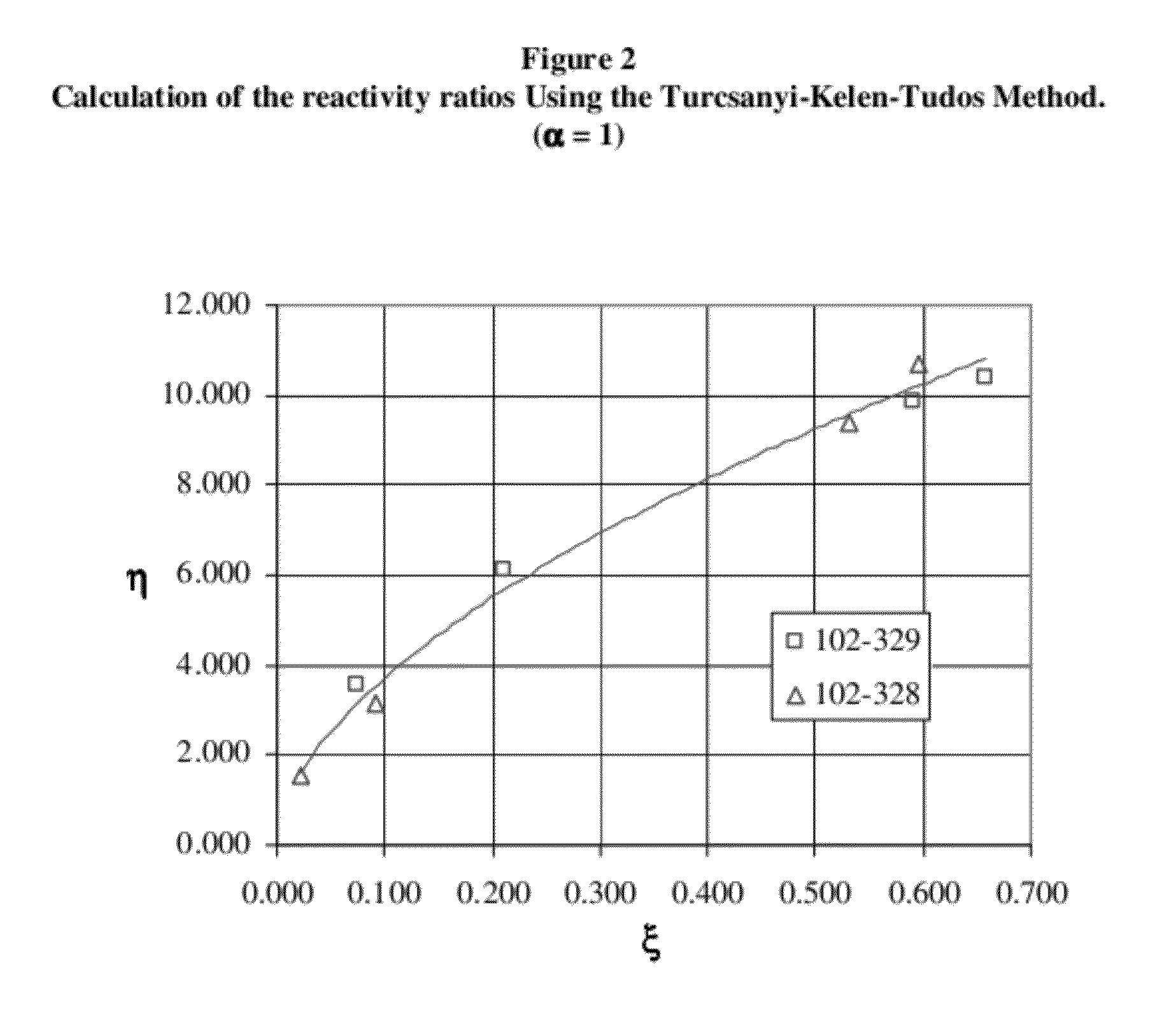

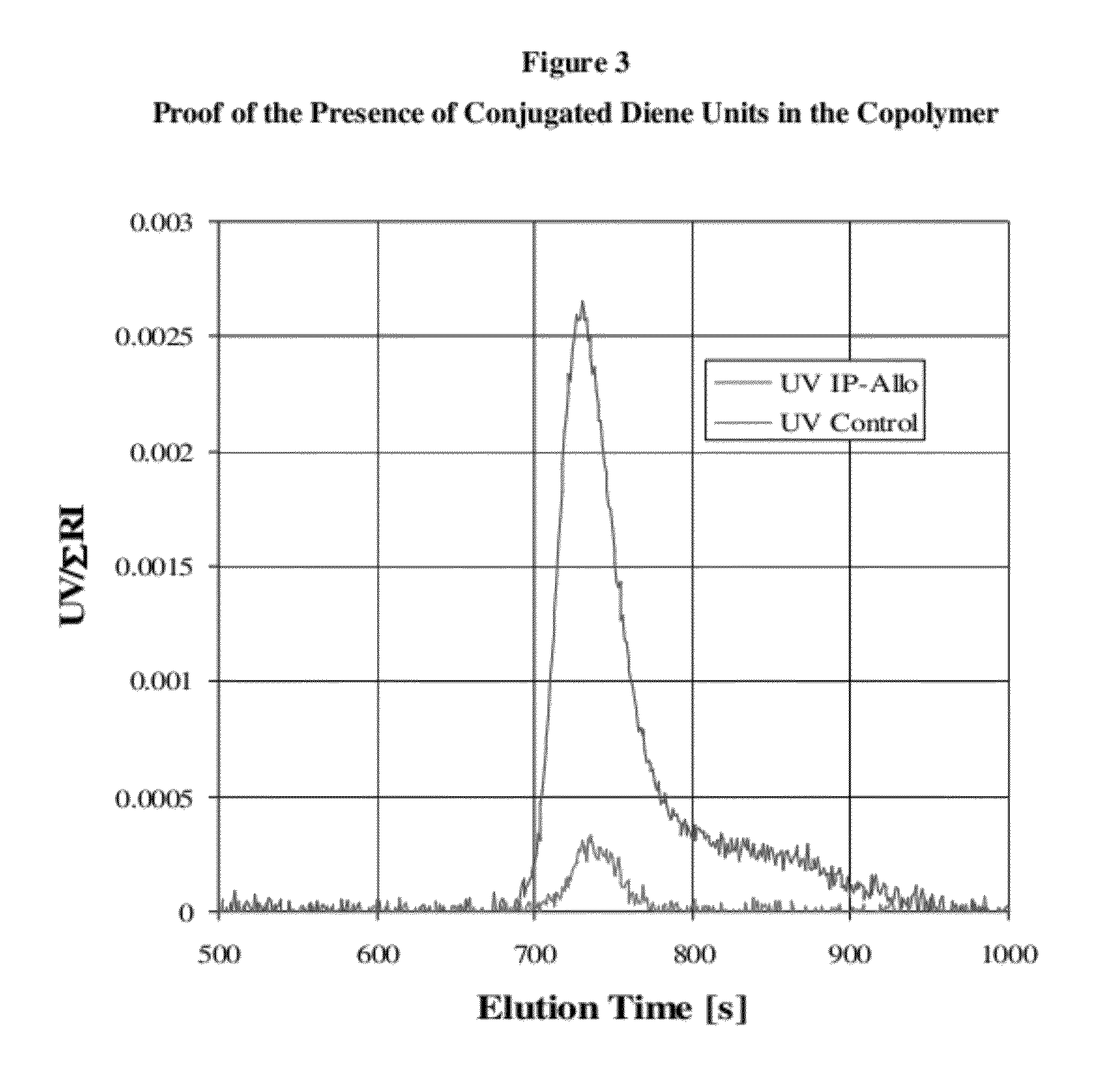

Copolymers of conjugated triene monomers for improved filler interaction

InactiveUS20120048446A1Increased filler interactionEasy to reinforceSpecial tyresPneumatic tyre reinforcementsCelluloseSilicon dioxide

The present invention achieves increased filler interaction by incorporating a small amount (a few units per chain of rubbery polymer) of a conjugated triene monomer, such as alloocimene, randomly throughout the polymer chain of a rubbery polymer or at the chain ends of the rubbery polymer. The incorporation of the conjugated triene monomer leads to the formation of a polymer containing highly reactive conjugated diene units. These conjugated diene units can chemically react with carbon black leading to superior reinforcement. Alternatively, these conjugated diene units can be used for functionalization of the polymer with silica interactive / reactive groups using Diels Alder reactions. This functionalization of the rubbery polymer can conveniently be conducted in a mixer, such as a Banbury mixer, a mill mixer, or the like. The present invention more specifically discloses a rubbery polymer having repeat units which are comprised of (1) an olefin monomer selected from the group consisting of conjugated diolefin monomers and monoolefin monomers and (2) a conjugated triene monomer. The subject invention further reveals a rubbery composition which is comprised of the reaction product of (I) a rubbery polymer having repeat units which are comprised of (1) an olefin monomer selected from the group consisting of conjugated diolefin monomers and monoolefin monomers and (2) a conjugated triene monomer and (II) a dienophile and / or dienophile which is functionalized with a group which is capable of reacting with a filler selected from the group consisting of carbon black, silica, starch, and cellulose.

Owner:THE GOODYEAR TIRE & RUBBER CO

Compound and method for synthesizing the same, ink, ink cartridge, recording unit, ink-jet recording apparatus, recording method, liquid composition, pattern generating method, article, environmental history-detecting method

InactiveUS7090719B2Quality improvementFunction increaseOrganic chemistryMeasurement apparatus componentsSolubilityRetro-Diels–Alder reaction

Provided is a solubility-controallable compound being soluble in a solvent due to a solvent-philic group thereof, of which solubility in the solvent is irreversibly lowered when the group is removed by retro-Diels-Alder reaction.

Owner:CANON KK

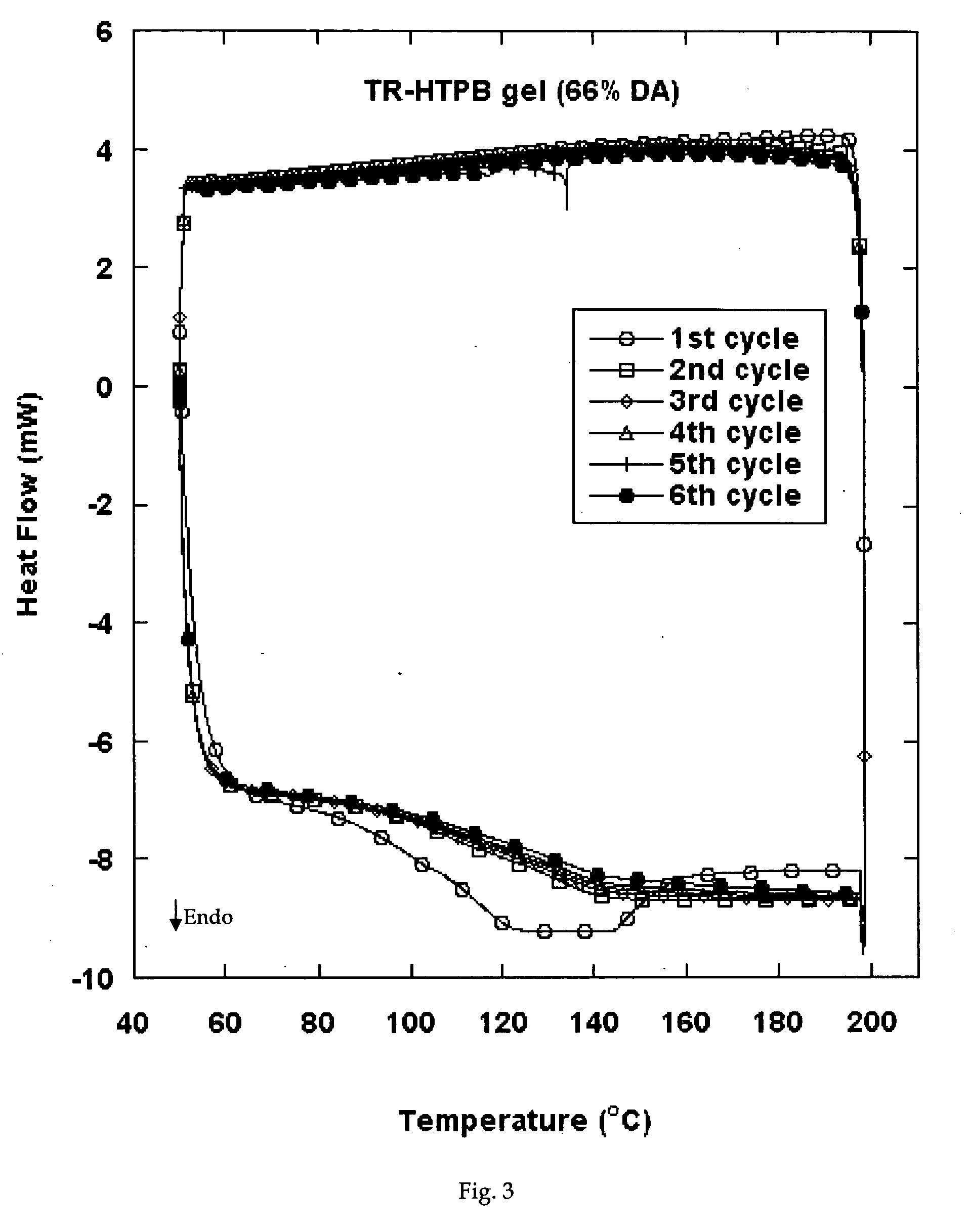

Reversible viscosity reducing polymer

InactiveUS20100099798A1Easily substitutedIncrease heat flowNon-explosive/non-thermic compositionsEndcappingDiels alder

A reversible viscosity reducing polymer is provided that has a crosslinkage between subunits inclusive of a single Diels-Alder Such a reversible viscosity reducing polymer is particularly well suited as a matrix material for a heterogeneous propellant. A process for forming a reversible viscosity reducing polymer inclusive of a single Diels-Alder linkage includes reacting a native crosslinkable moiety with a crosslinker moiety having a Diels-Alder reactive moiety of a diene or dienophile to form a Diels-Alder reactive moiety capped polymer subunit. The Diels-Alder reactive moiety capped polymer subunit is then exposed to a Diels-Alder reactant inclusive of a complementary Diels-Alder reactive moiety where the reactant also includes at least one conventional crosslinkable moiety to form a crosslinkable moiety capped polymer subunit. Reaction of the crosslinkable moiety capped polymer subunit is then reacted with a conventional multifunctional crosslinking agent.

Owner:US SEC THE ARMY THE

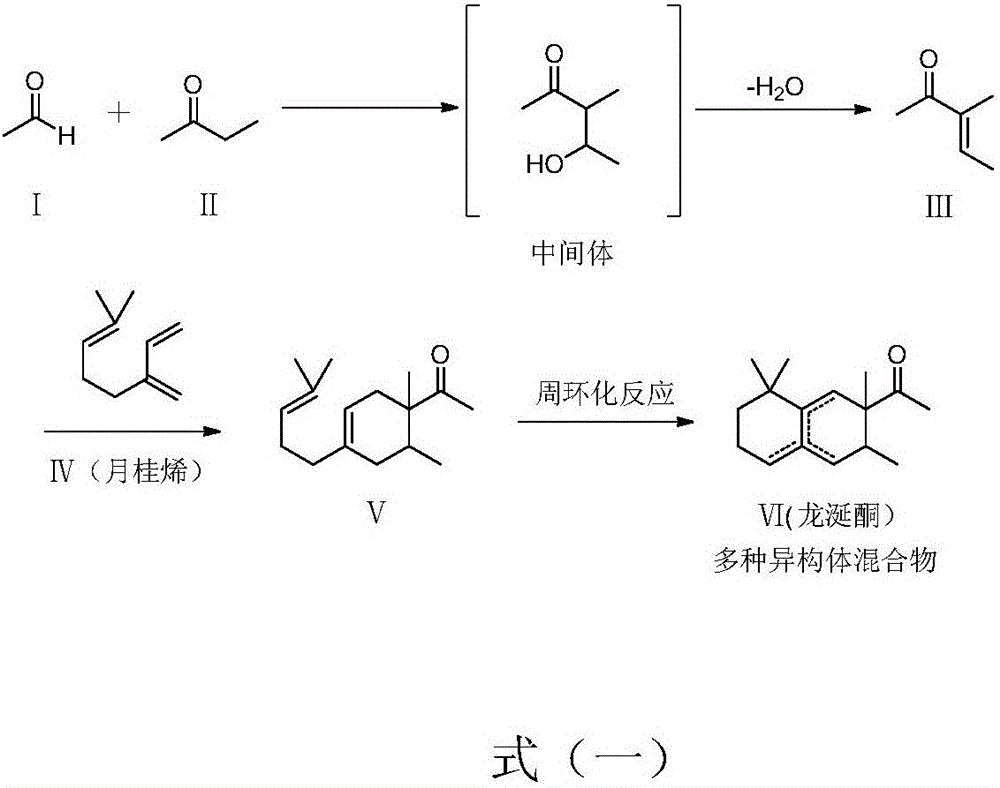

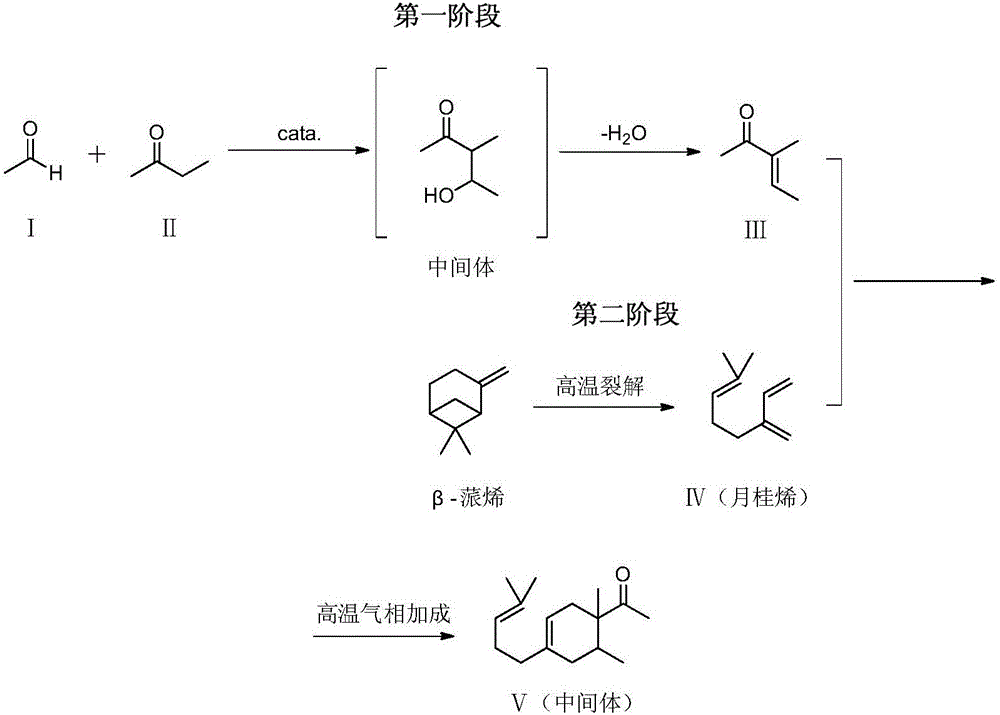

Method for preparing ambrotone

ActiveCN106045834AImprove pollutionHigh carcinogenOrganic compound preparationCarbonyl compound preparationCarcinogenGas phase

The invention relates to a method for preparing ambrotone. The method includes steps of 1, synthesizing 3-methyl-3-pentene-2-ketone; 2, carrying out diene addition for preparing ambrotone intermediates; 3, carrying out cyclization reaction to prepare the ambrotone. Diene addition for preparing the ambrotone intermediates is carried out without catalysts by the aid of high-temperature gas-phase reaction. The method has the advantages that the ambrotone is prepared from raw materials beta-pinene, butanone and acetaldehyde, other organic solvents are omitted, high-pollution and high-carcinogenesis substances such as benzene and toluene are omitted, accordingly, the cost can be lowered, the quality of products can be effectively improved, the application range of the products can be effectively expanded, and Diels-Alder condensation reaction is carried out by the aid of the high-temperature gas-phase reaction; the Diels-Alder condensation reaction is carried out by the aid of the high-temperature gas-phase reaction or atomized small-molecule water drop and gas phases, catalysts such as Lewis acid or proton acid are omitted at reaction steps, accordingly, the production cost can be lowered, technological equipment can be simplified, post-reaction treatment working procedures can be shortened, and the purpose of zero sewage discharge can be truly achieved.

Owner:福建南平青松化工有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com