Patents

Literature

517 results about "Chemical groups" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Articles having localized molecules disposed thereon and methods of producing same

ActiveUS20080032301A1Prevent intra-observation region diffusionMaterial nanotechnologySequential/parallel process reactionsChemical groupsBiological activation

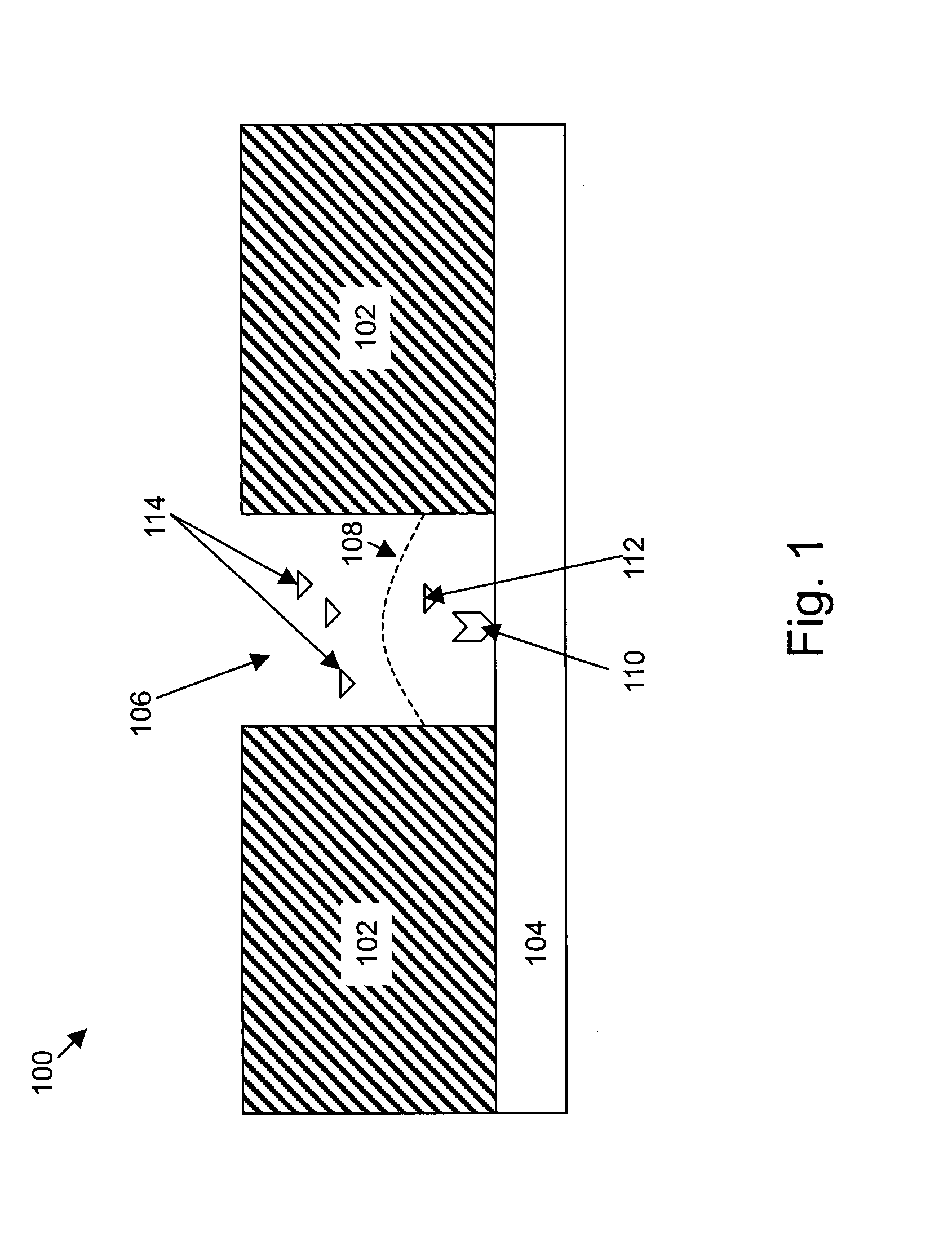

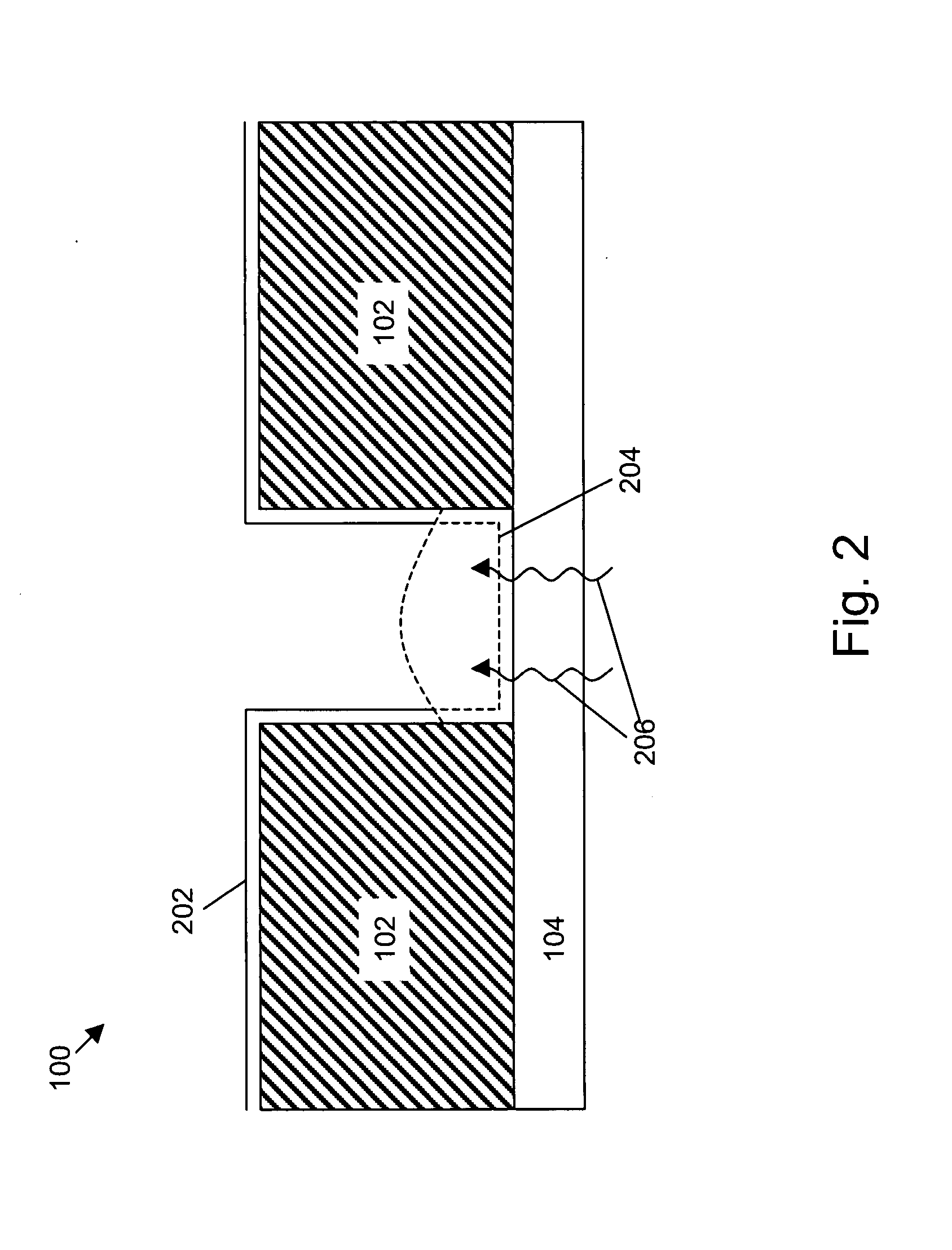

Methods of producing substrates having selected active chemical regions by employing elements of the substrates in assisting the localization of active chemical groups in desired regions of the substrate. The methods may include optical, chemical and / or mechanical processes for the deposition, removal, activation and / or deactivation of chemical groups in selected regions of the substrate to provide selective active regions of the substrate.

Owner:PACIFIC BIOSCIENCES

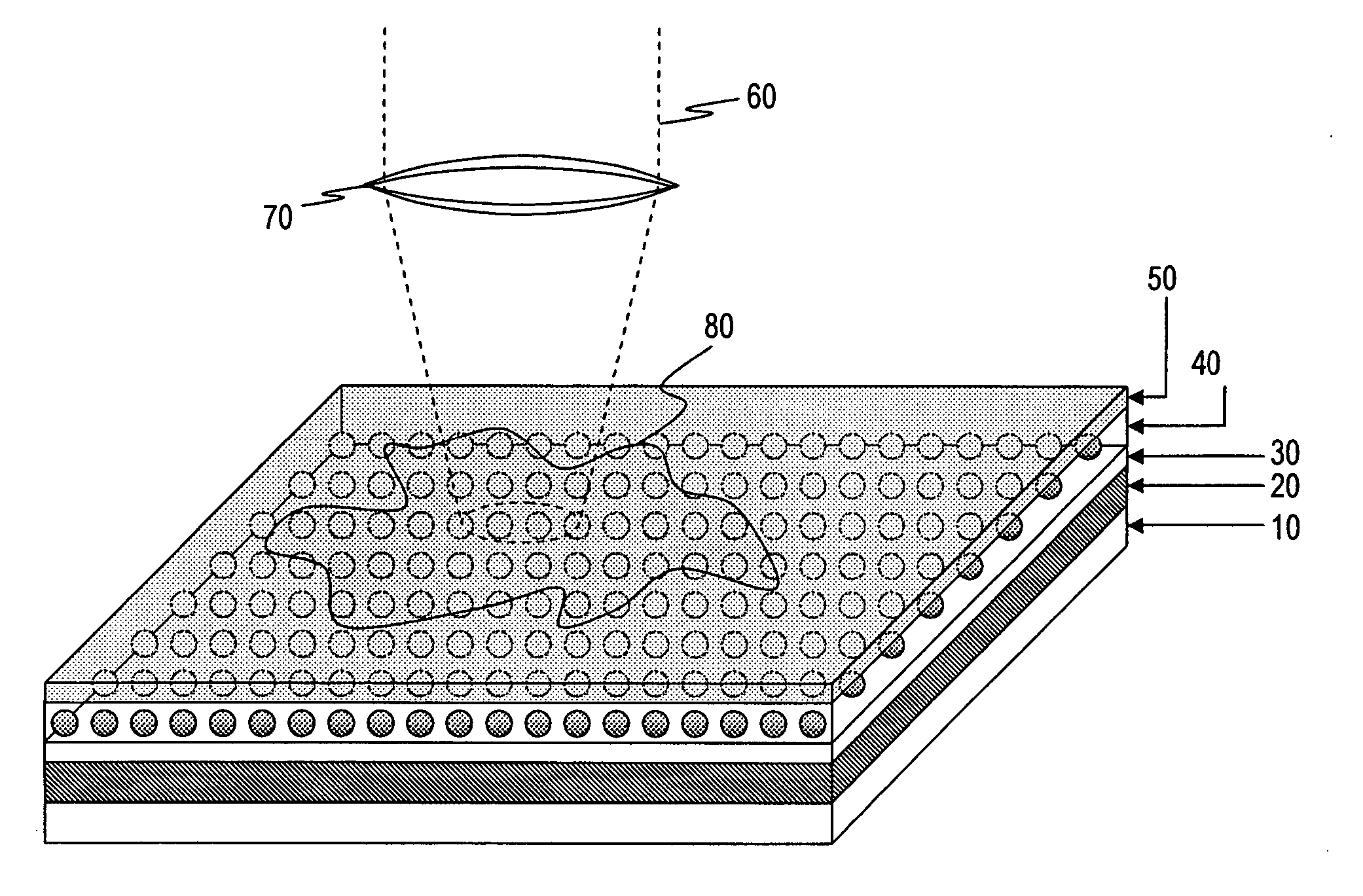

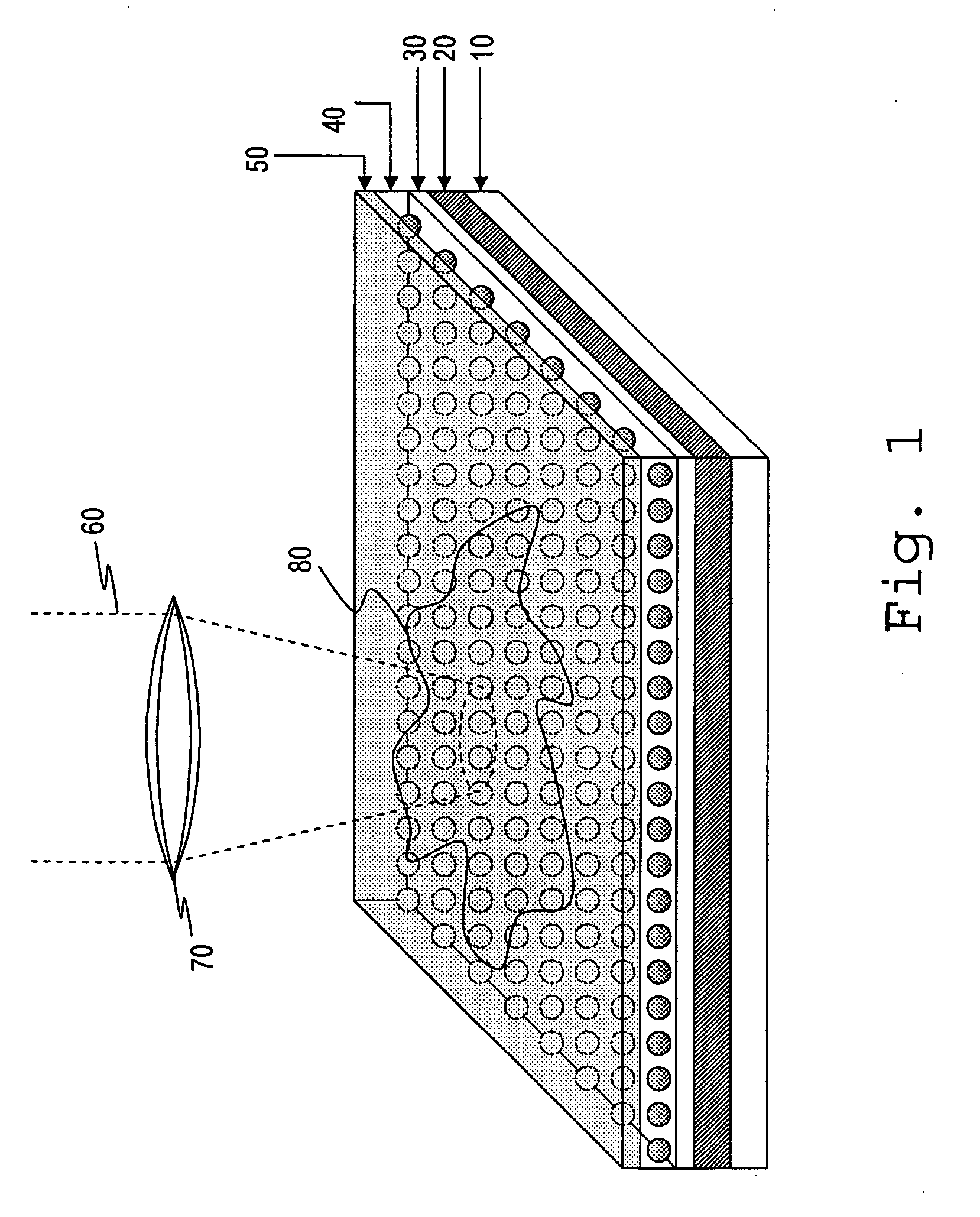

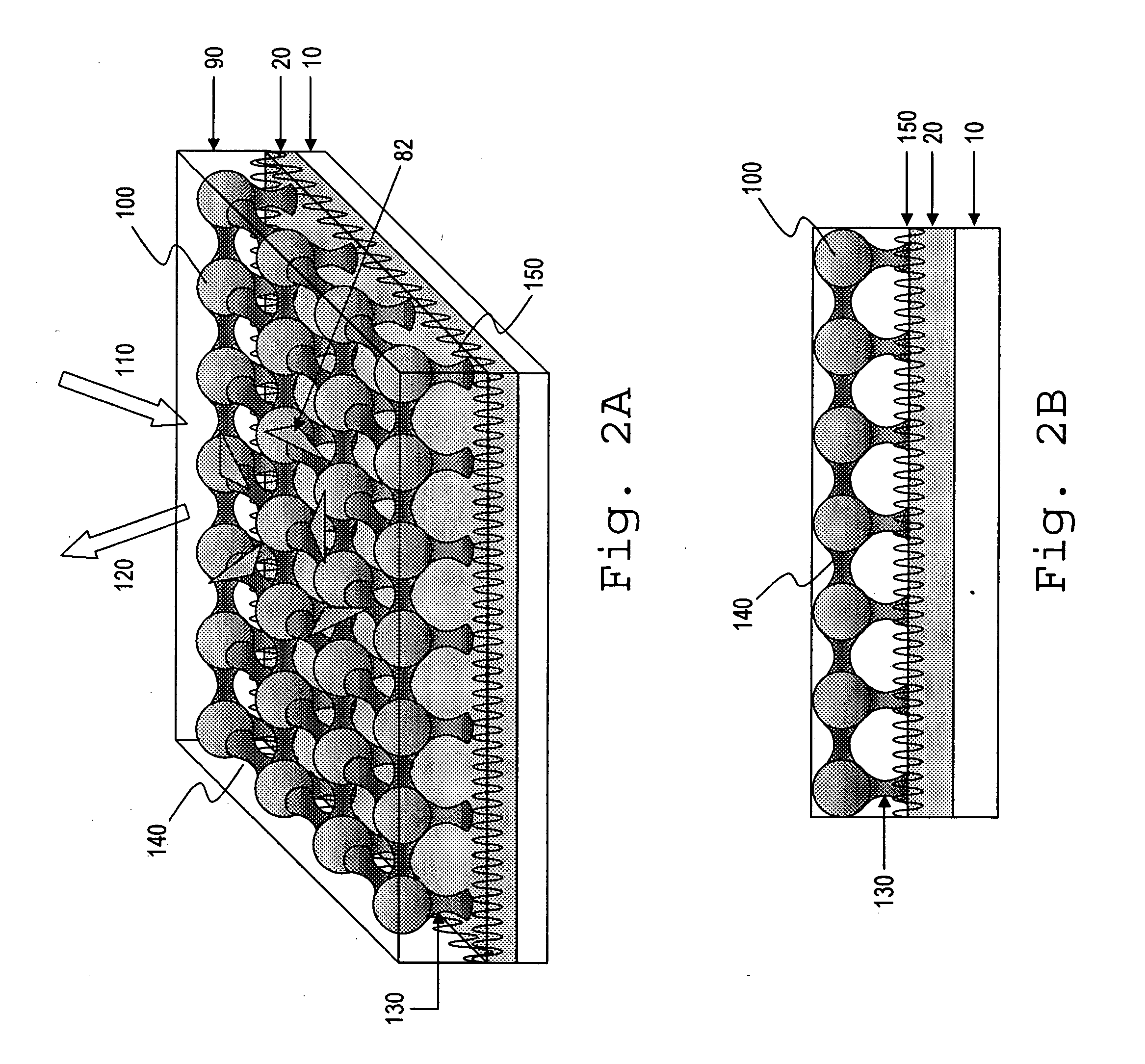

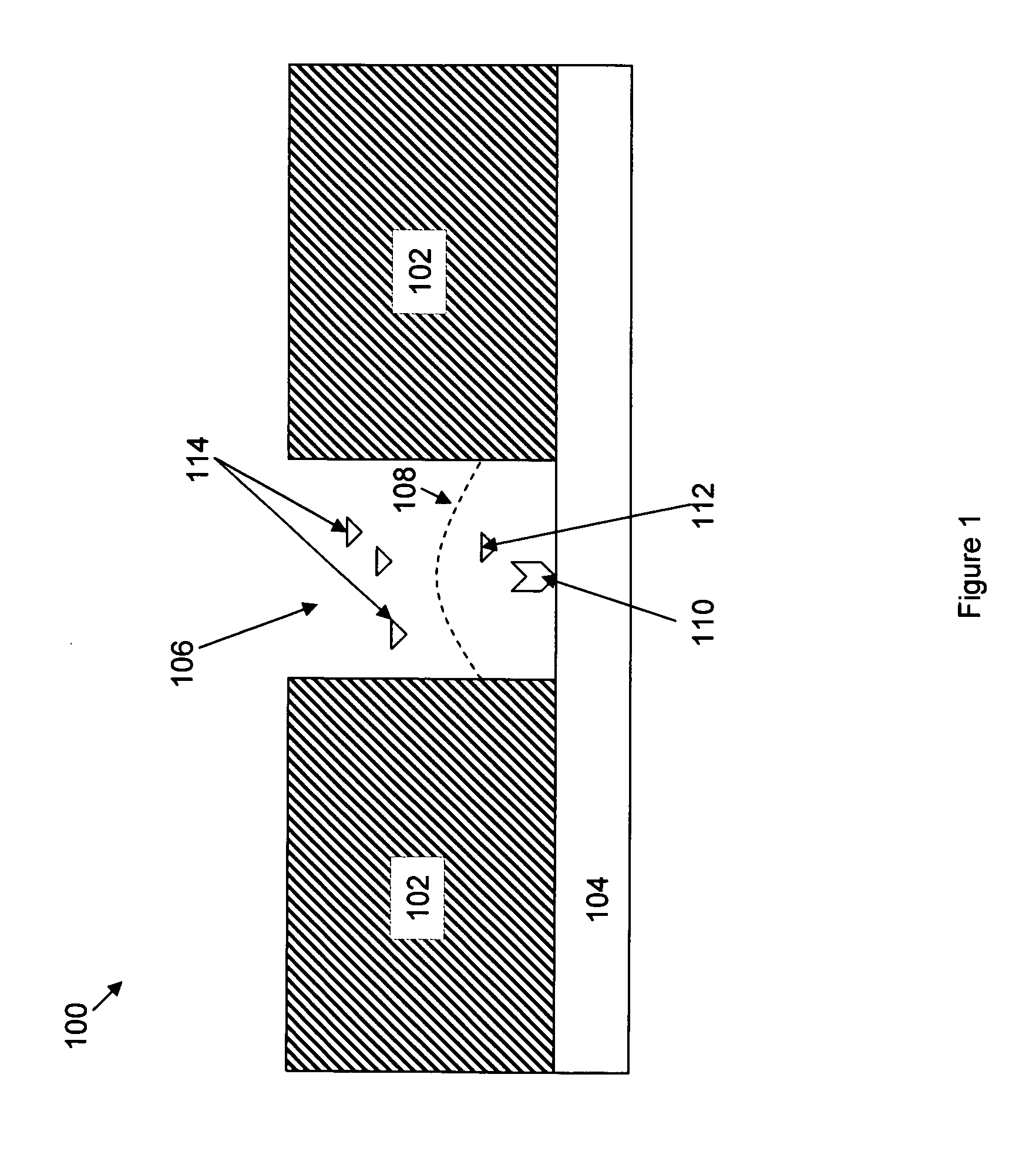

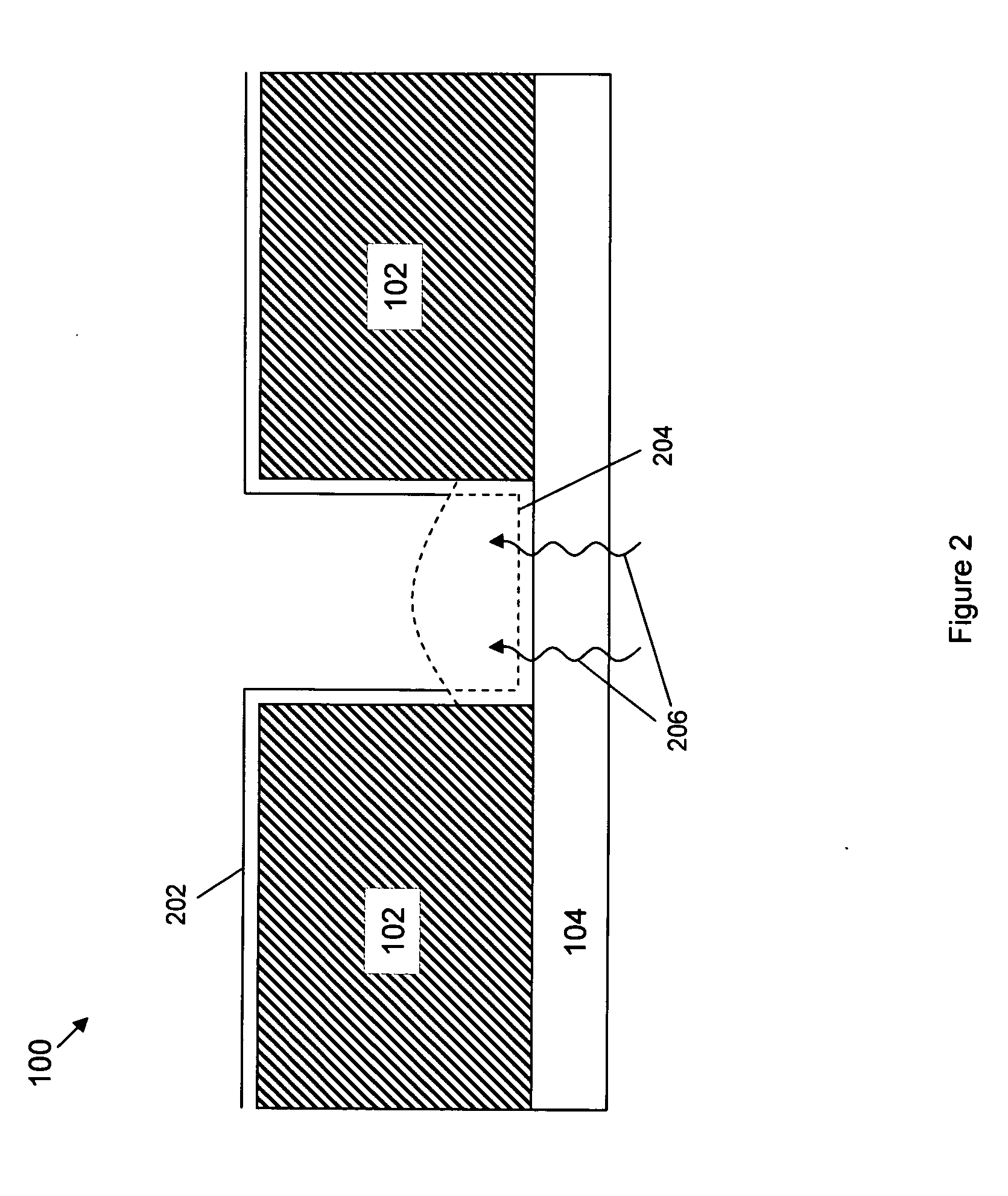

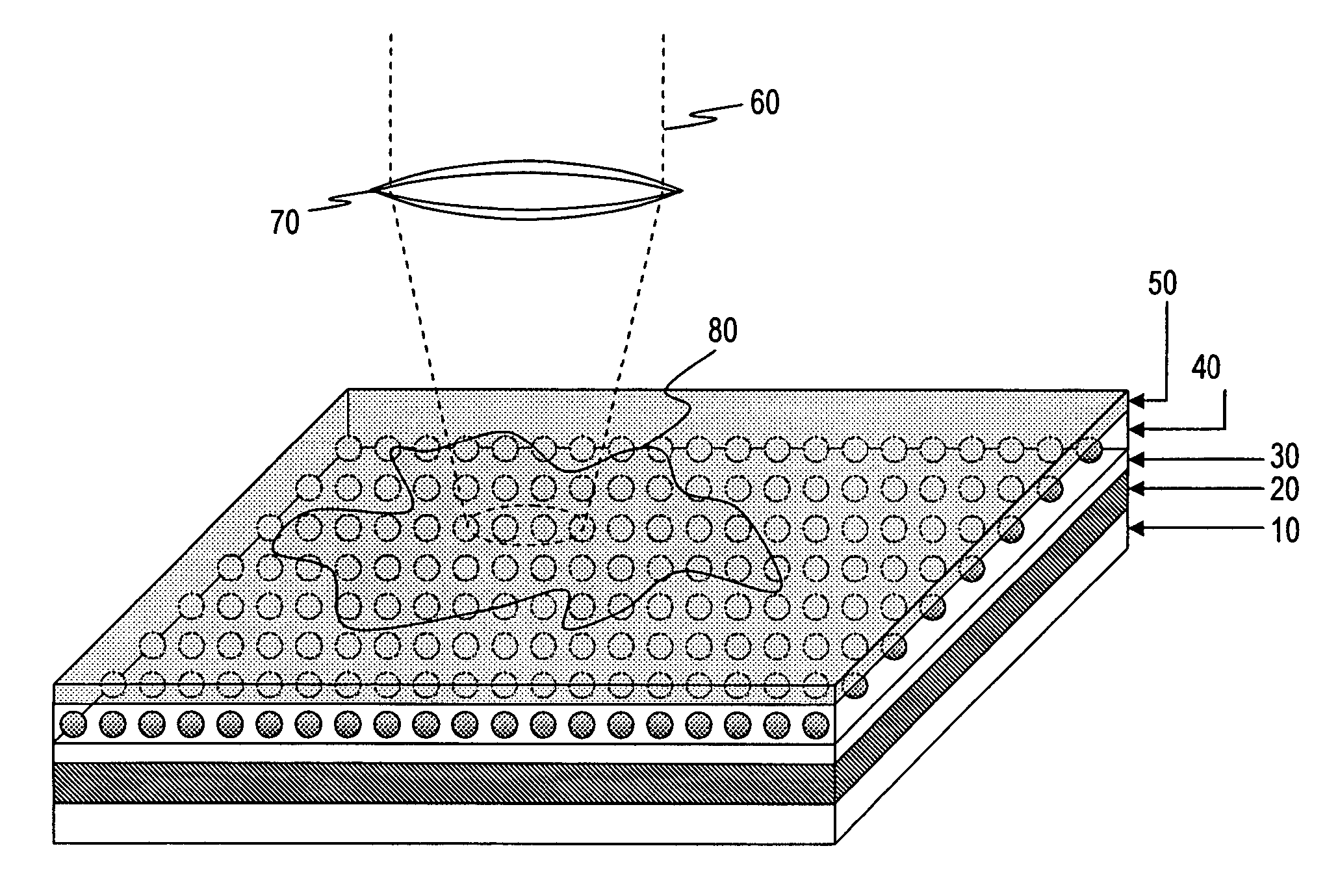

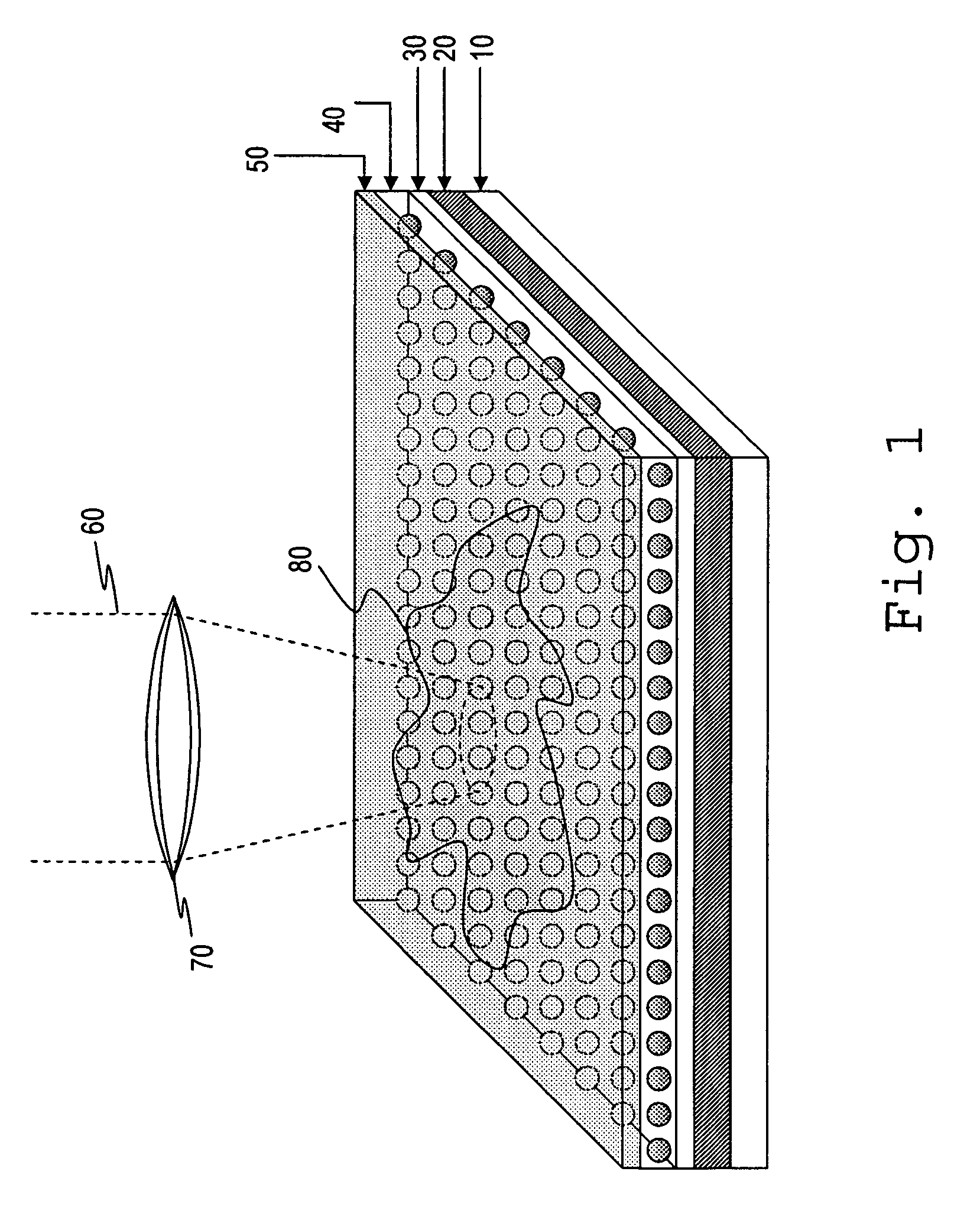

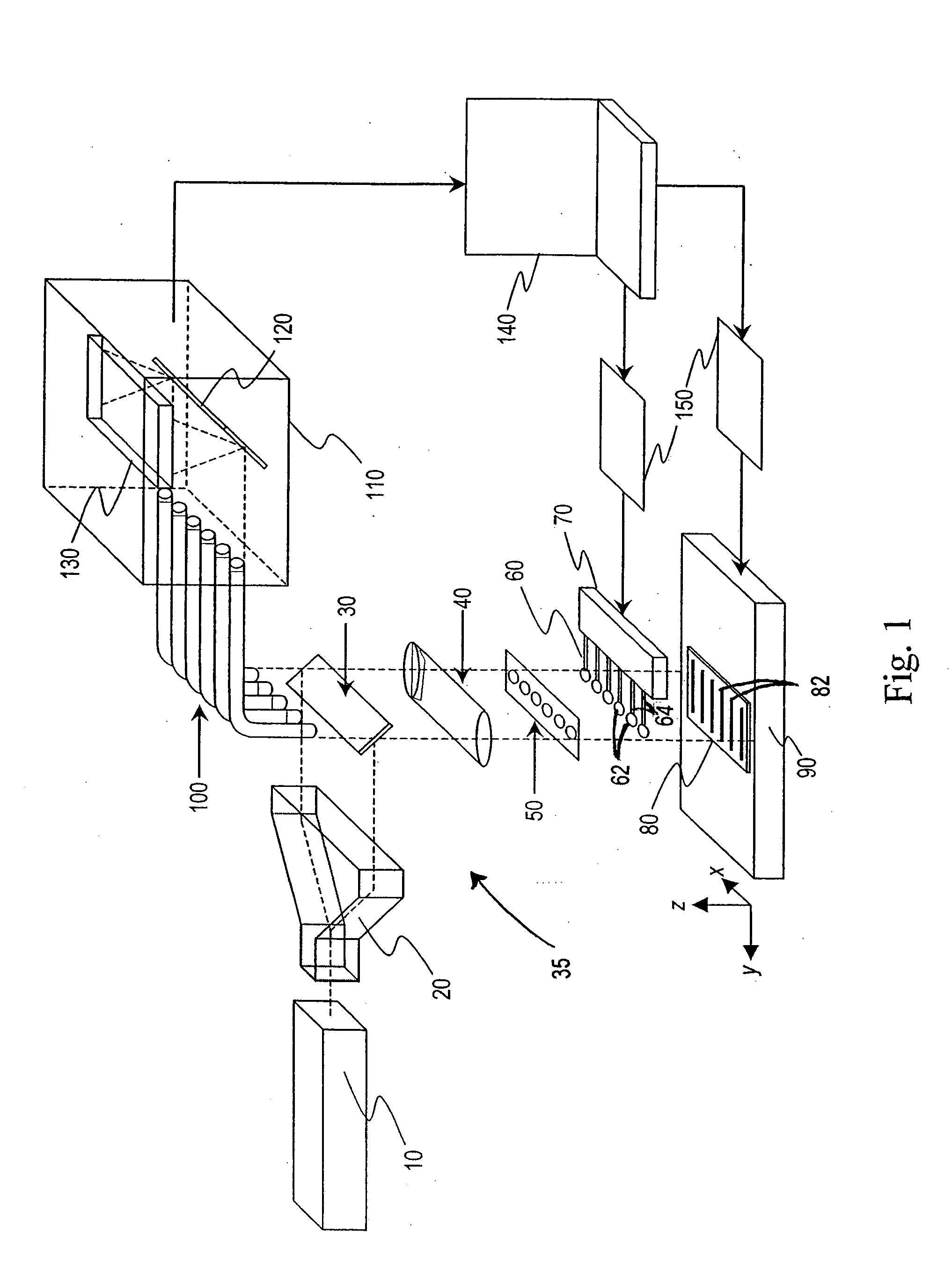

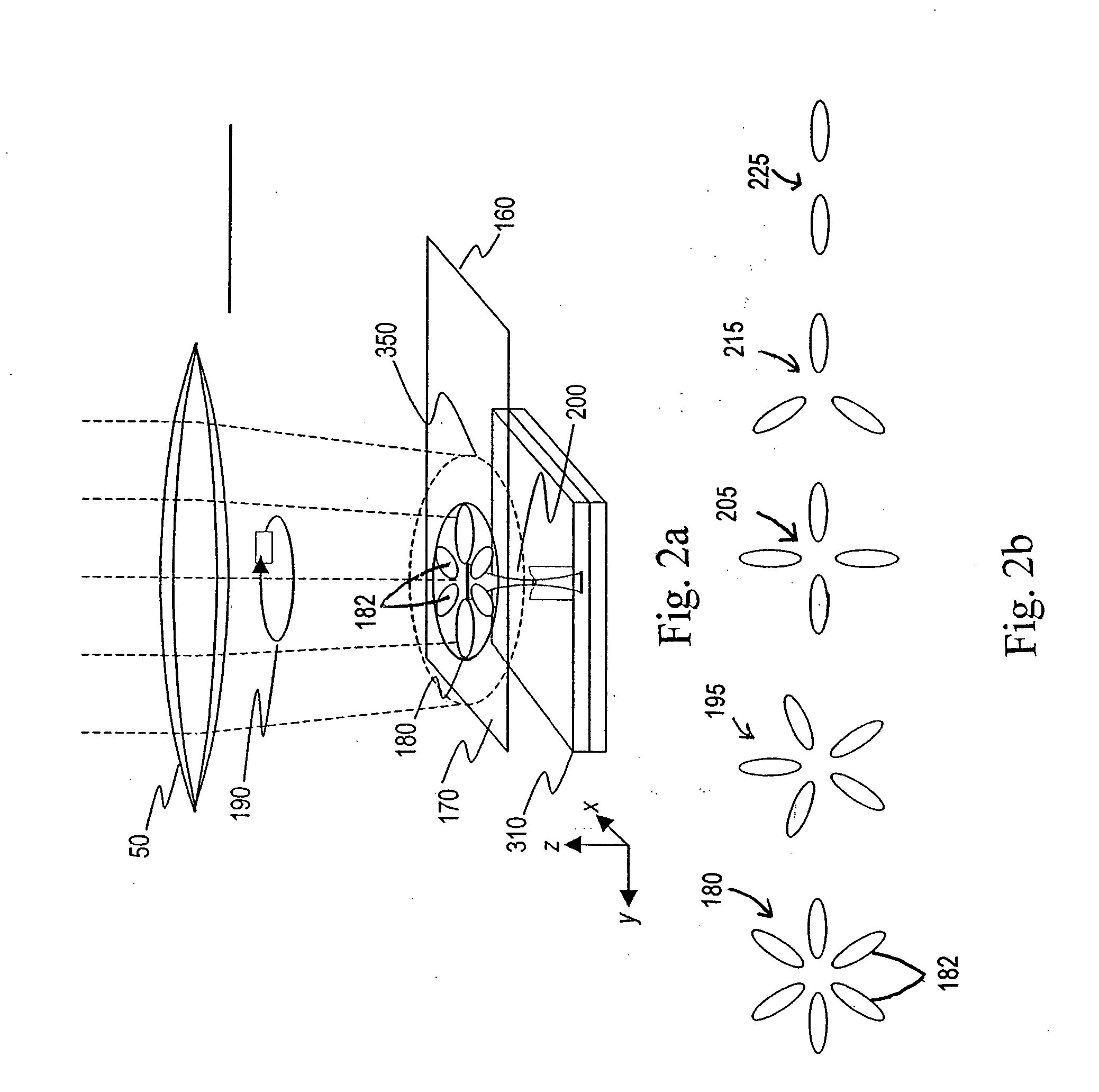

Optical sensor with layered plasmon structure for enhanced detection of chemical groups by SERS

InactiveUS20060034729A1Produced in advanceRadiation pyrometryMicrobiological testing/measurementExcitation beamLight excitation

An optical sensor and method for use with a visible-light laser excitation beam and a Raman spectroscopy detector, for detecting the presence chemical groups in an analyte applied to the sensor are disclosed. The sensor includes a substrate, a plasmon resonance mirror formed on a sensor surface of the substrate, a plasmon resonance particle layer disposed over the mirror, and an optically transparent dielectric layer about 2-40 nm thick separating the mirror and particle layer. The particle layer is composed of a periodic array of plasmon resonance particles having (i) a coating effective to binding analyte molecules, (ii) substantially uniform particle sizes and shapes in a selected size range between 50-200 nm (ii) a regular periodic particle-to-particle spacing less than the wavelength of the laser excitation beam. The device is capable of detecting analyte with an amplification factor of up to 1012-1014, allowing detection of single analyte molecules.

Owner:POPONIN VLADIMIR

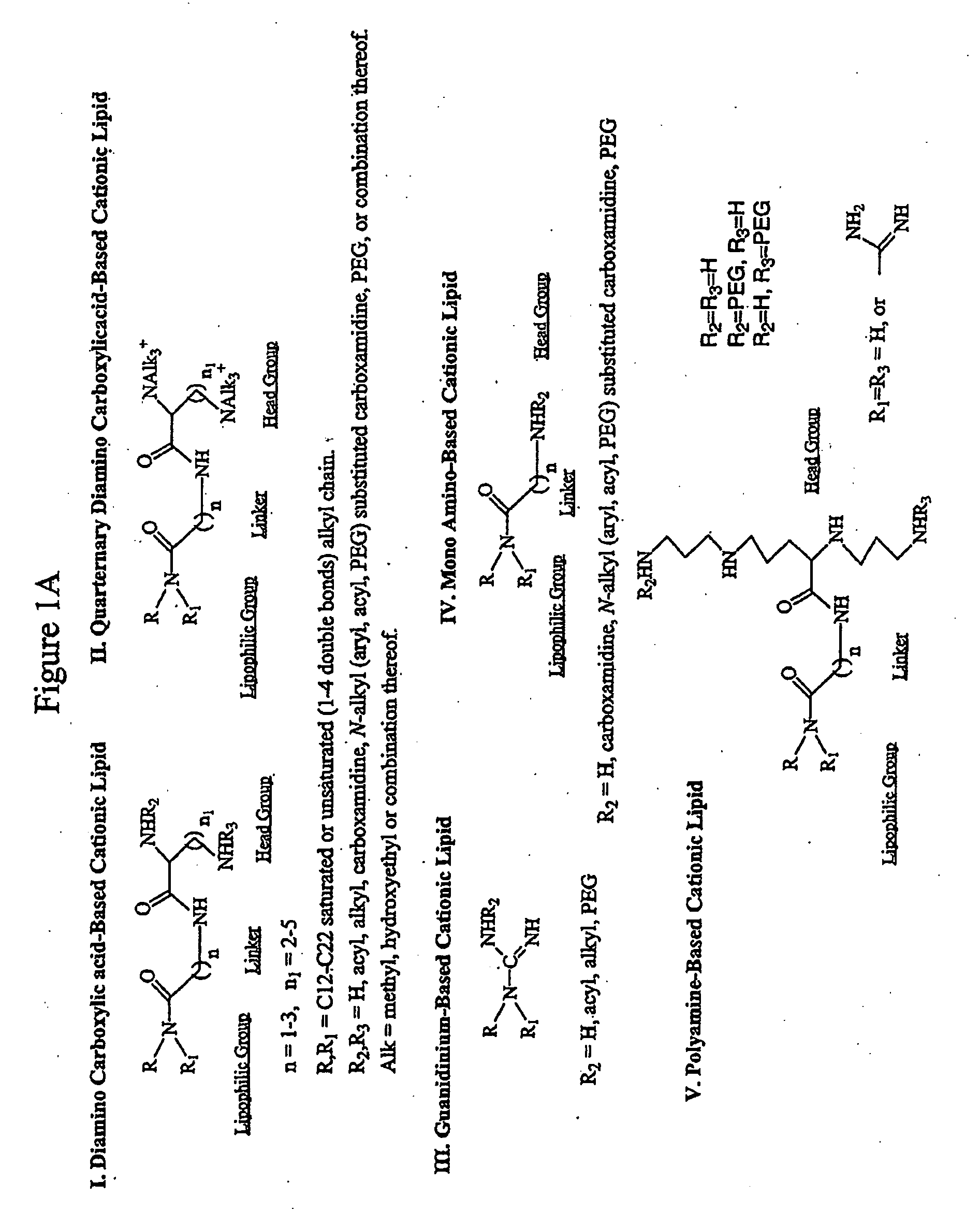

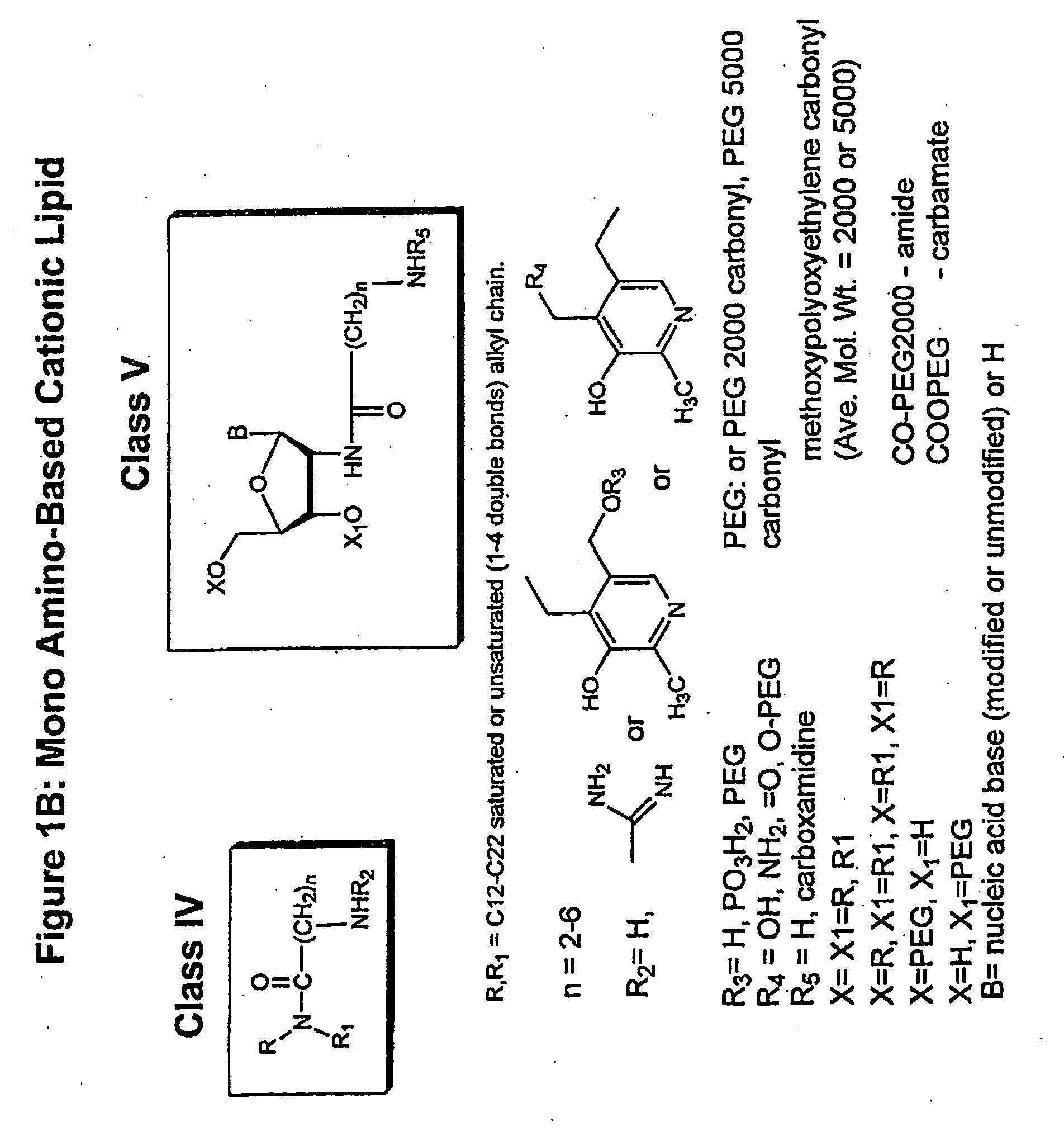

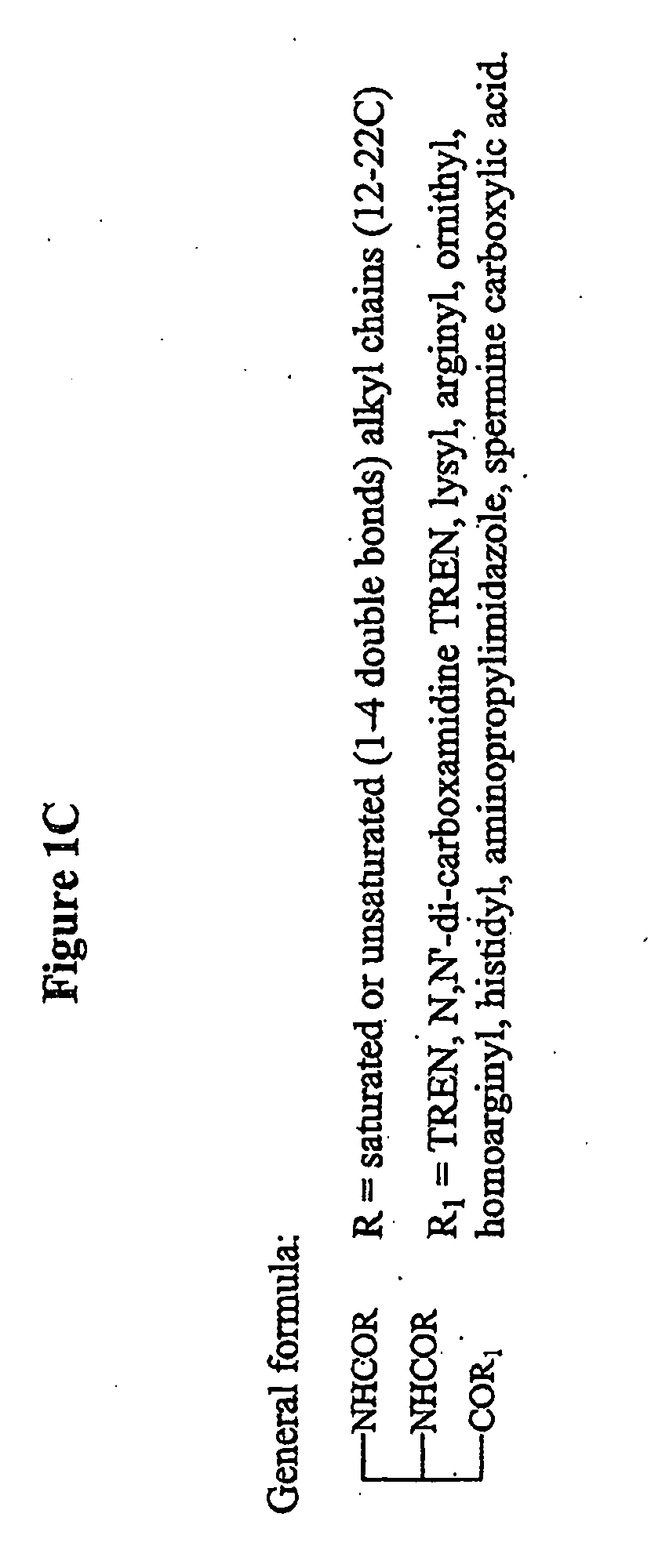

Novel Compositions for the Delivery of Negatively Charged Molecules

InactiveUS20100036115A1Facilitated DiffusionReduce deliverySugar derivativesDipeptide ingredientsMembrane permeabilityAntisense nucleic acid

This invention features permeability enhancer molecules, and methods, to increase membrane permeability of various molecules, such as nucleic acids, polynucleotides, oligonucleotides, enzymatic nucleic acid molecules, antisense nucleic acid molecules, 2-5A antisense chimeras, triplex forming oligonucleotides, decoy RNAs, dsRNAs, siRNAs, aptamers, or antisense nucleic acids containing nucleic acid cleaving chemical groups, peptides, polypeptides, proteins, carbohydrates, steroids, metals and small molecules, thereby facilitating cellular uptake of such molecules.

Owner:SIRNA THERAPEUTICS INC

Articles having localized molecules disposed thereon and methods of producing same

ActiveUS20070238679A1Prevent intra-observation region diffusionMaterial nanotechnologySequential/parallel process reactionsChemical groupsOrganic chemistry

Methods of producing substrates having selected active chemical regions by employing elements of the substrates in assisting the localization of active chemical groups in desired regions of the substrate. The methods may include optical, chemical and / or mechanical processes for the deposition, removal, activation and / or deactivation of chemical groups in selected regions of the substrate to provide selective active regions of the substrate.

Owner:PACIFIC BIOSCIENCES

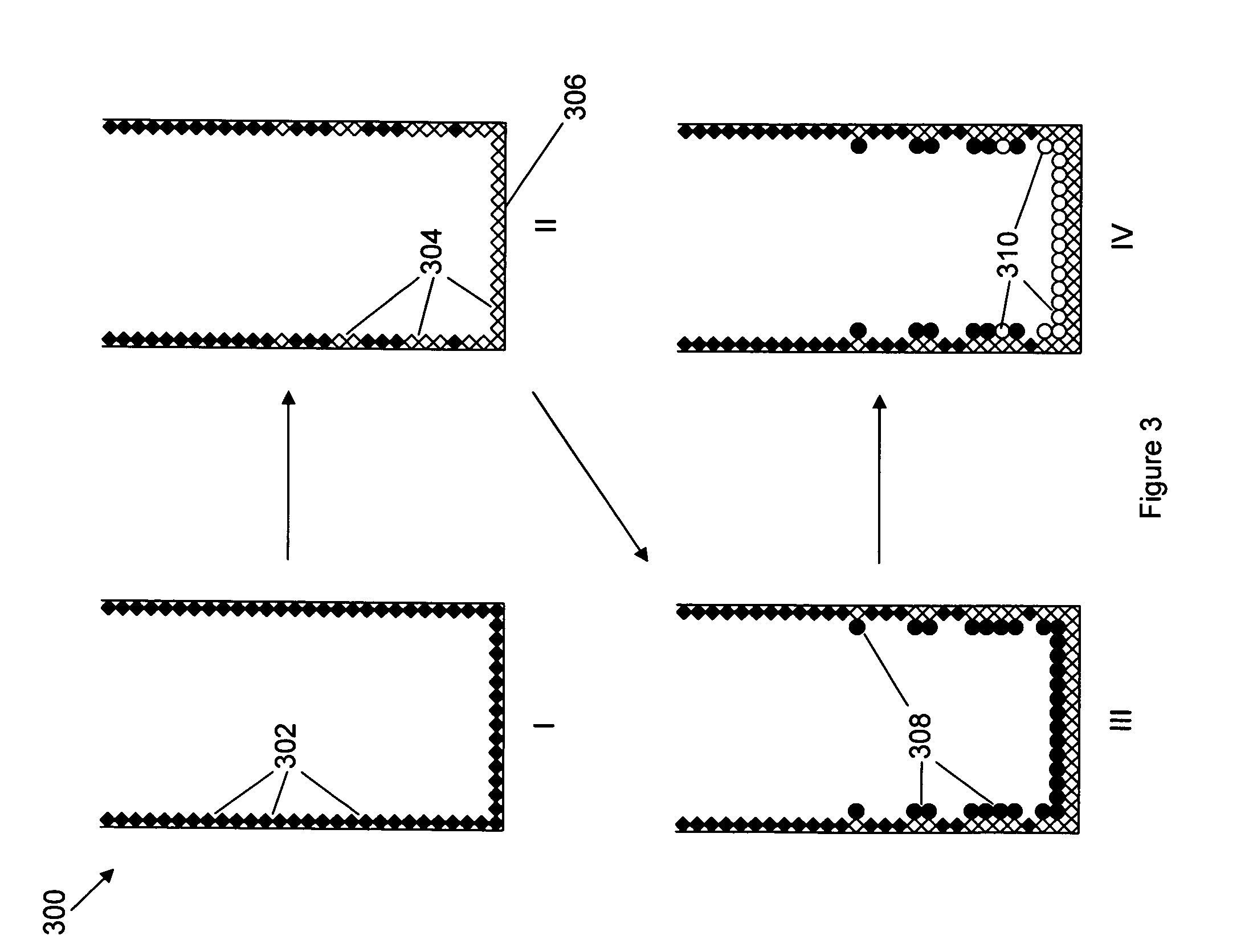

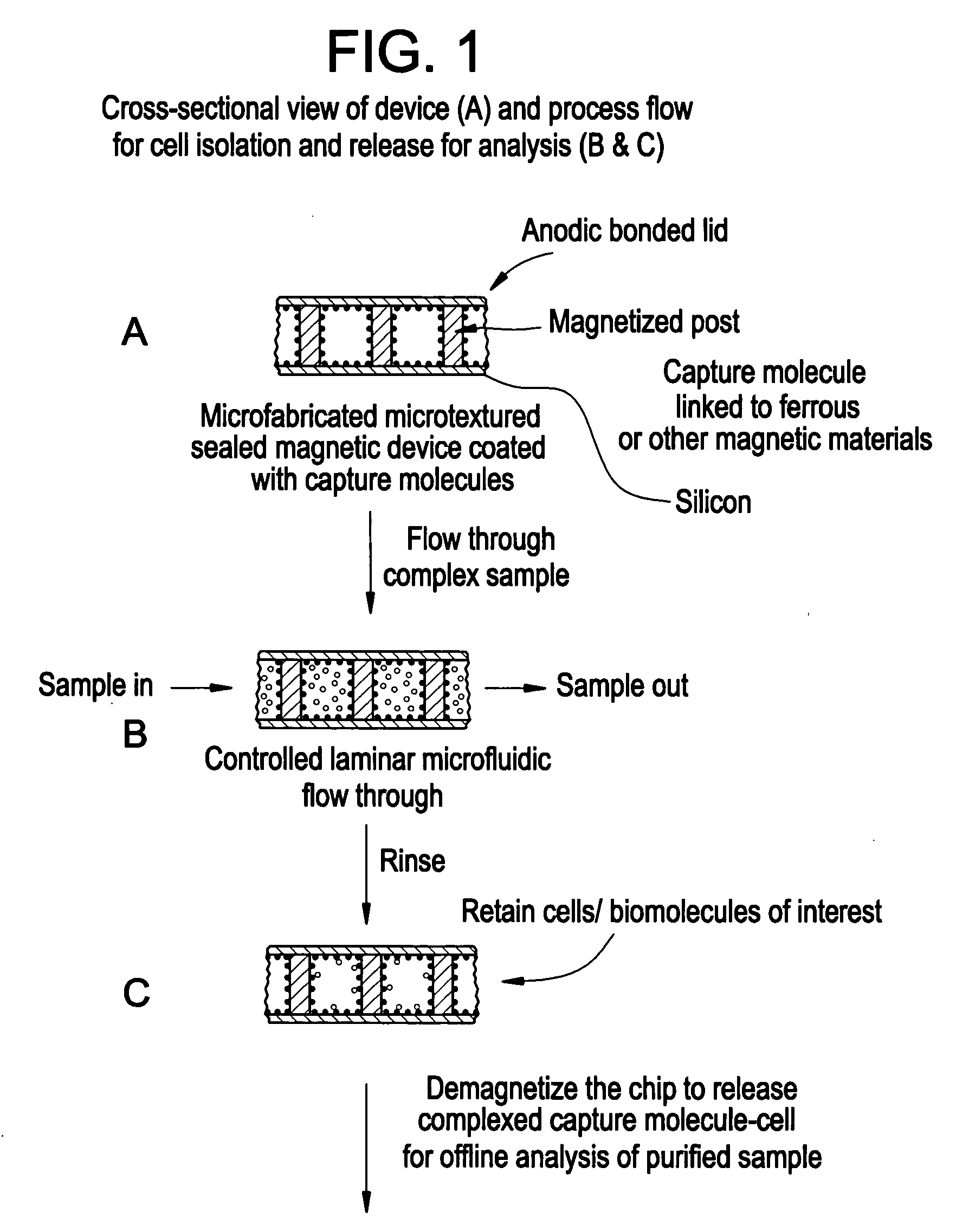

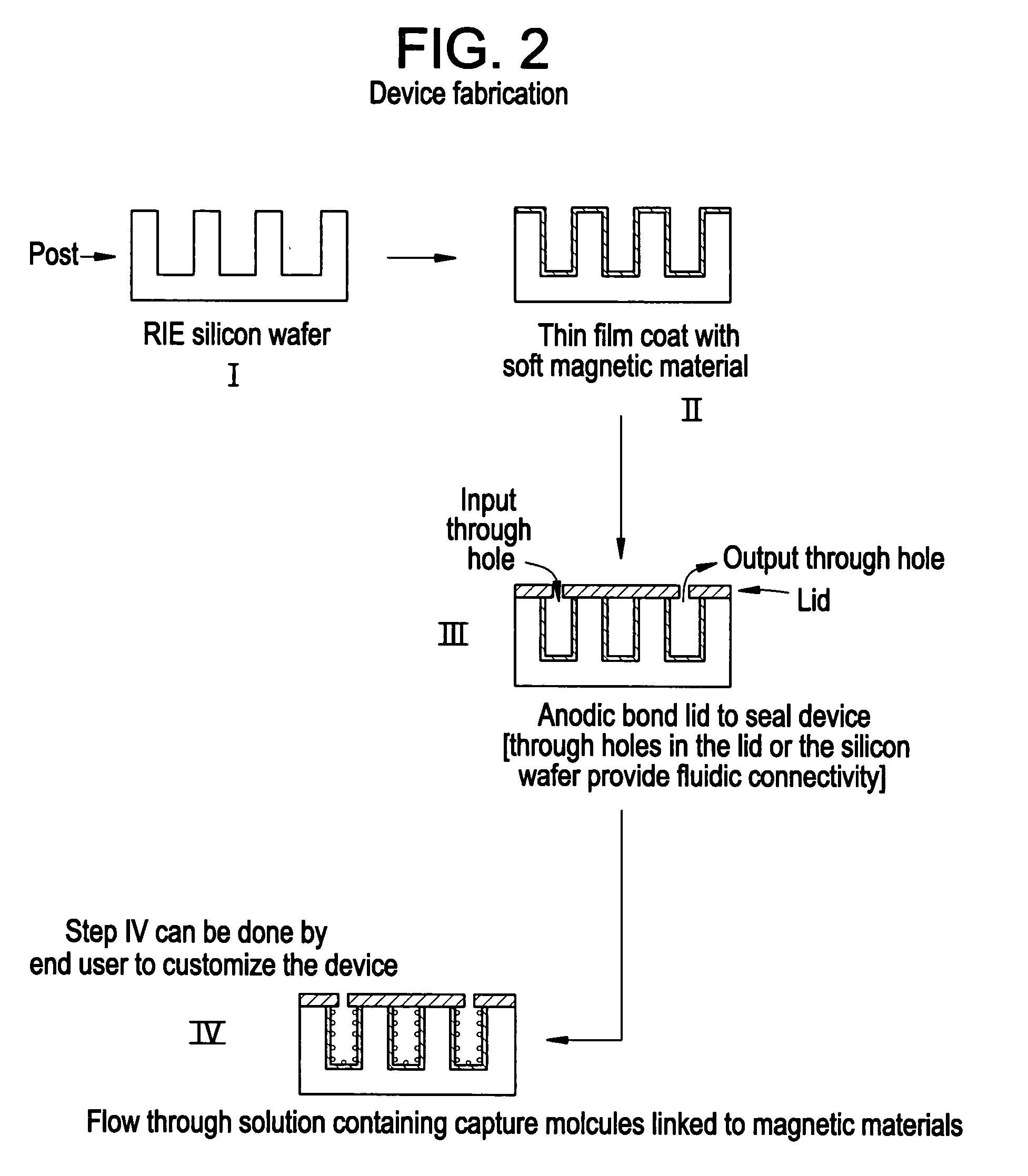

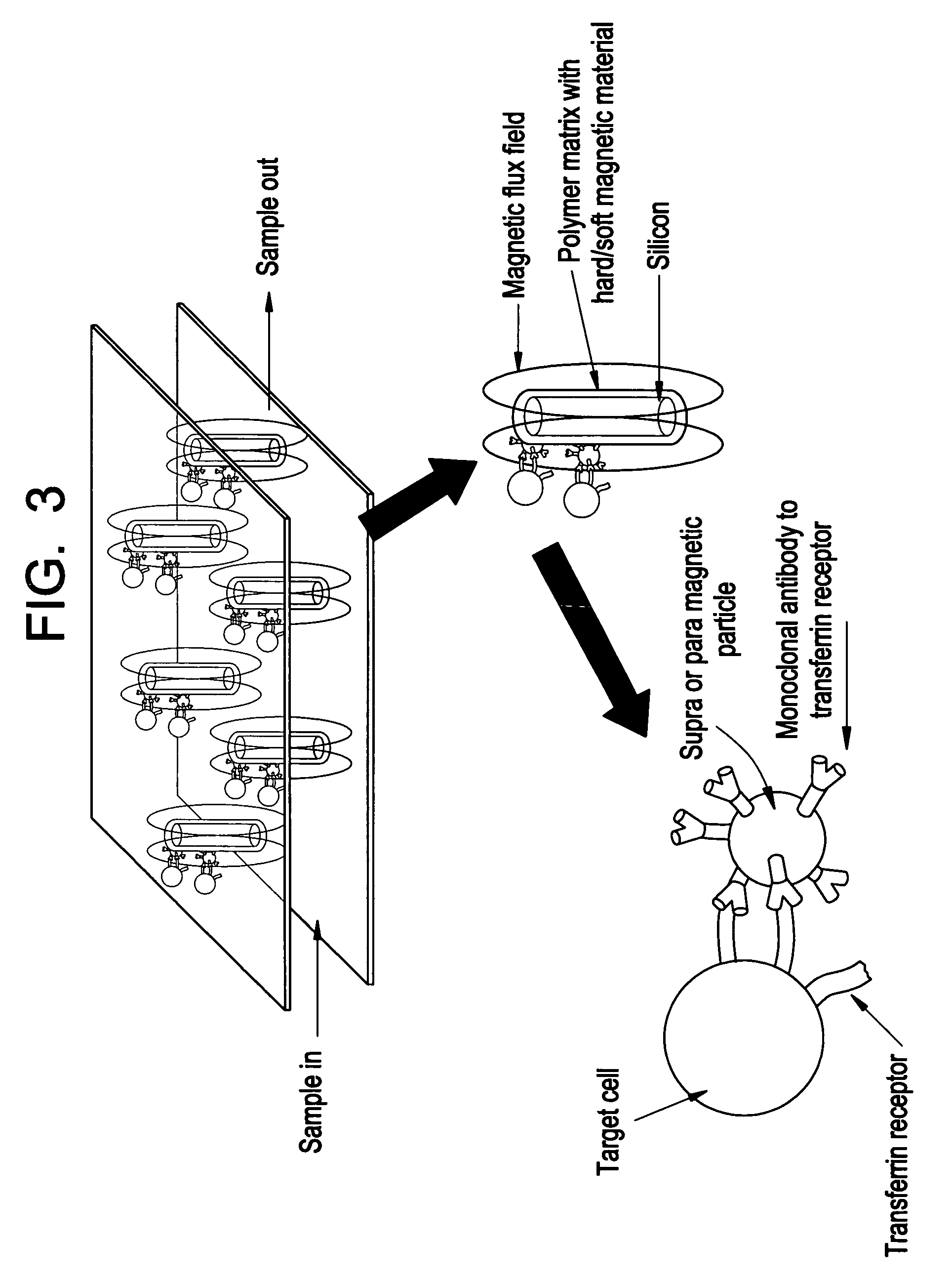

Magnetic device for isolation of cells and biomolecules in a microfluidic environment

InactiveUS20050266433A1Prevent disengagementHigh bandwidthBioreactor/fermenter combinationsBiological substance pretreatmentsChemical groupsDNA

The present invention features a new and useful magnetic device and methods of its use for isolation, enrichment, and purification of cells, proteins, DNA, and other molecules. In general the device includes magnetic regions or obstacles to which magnetic particles can bind. The chemical groups, i.e., capture moieties, on the surface of the magnetic particles may then be used to bind particles, e.g., cells, or molecules of interest from complex samples, and the bound species may then be selectively released for downstream collection or further analysis.

Owner:THE GENERAL HOSPITAL CORP +2

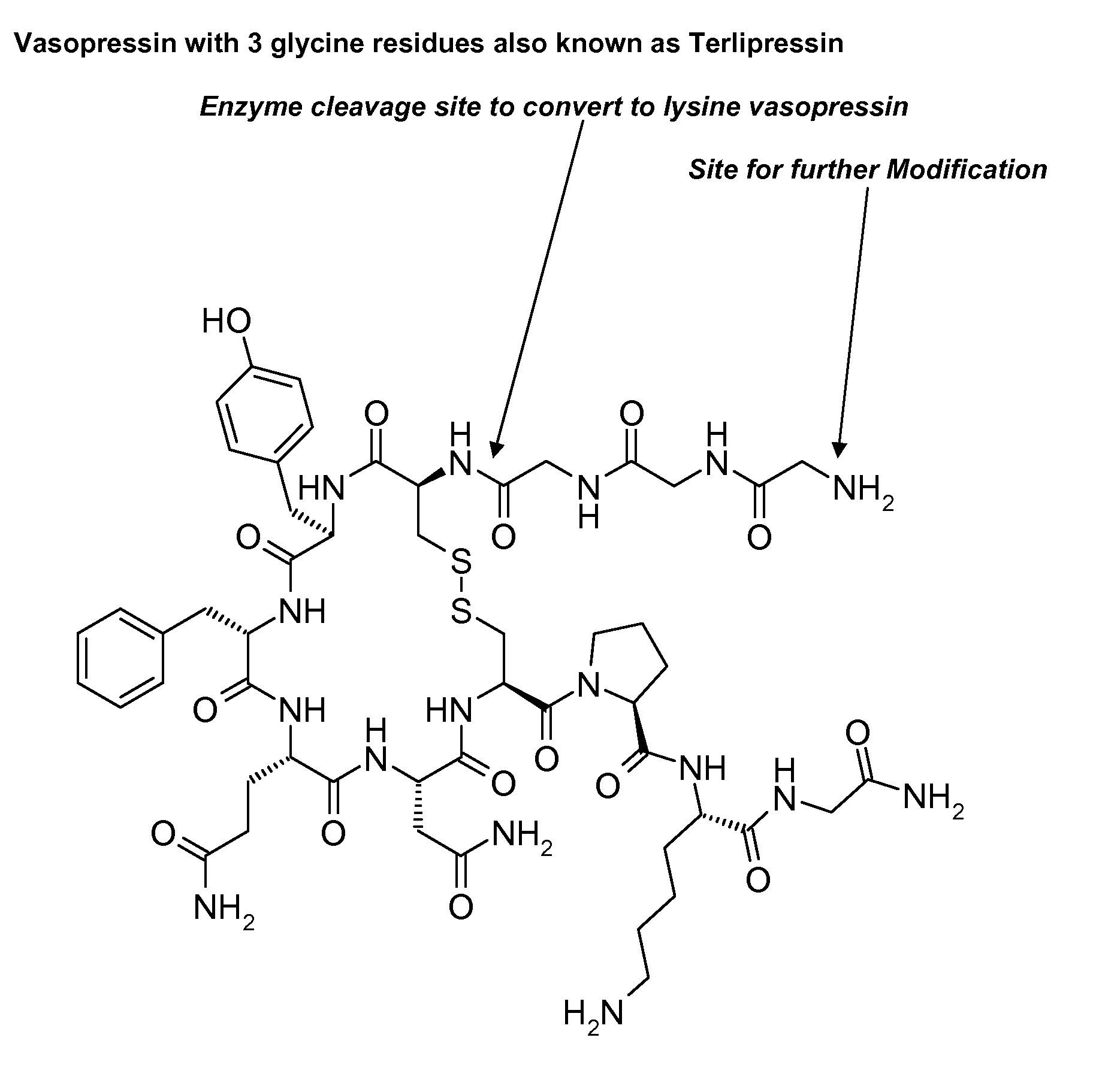

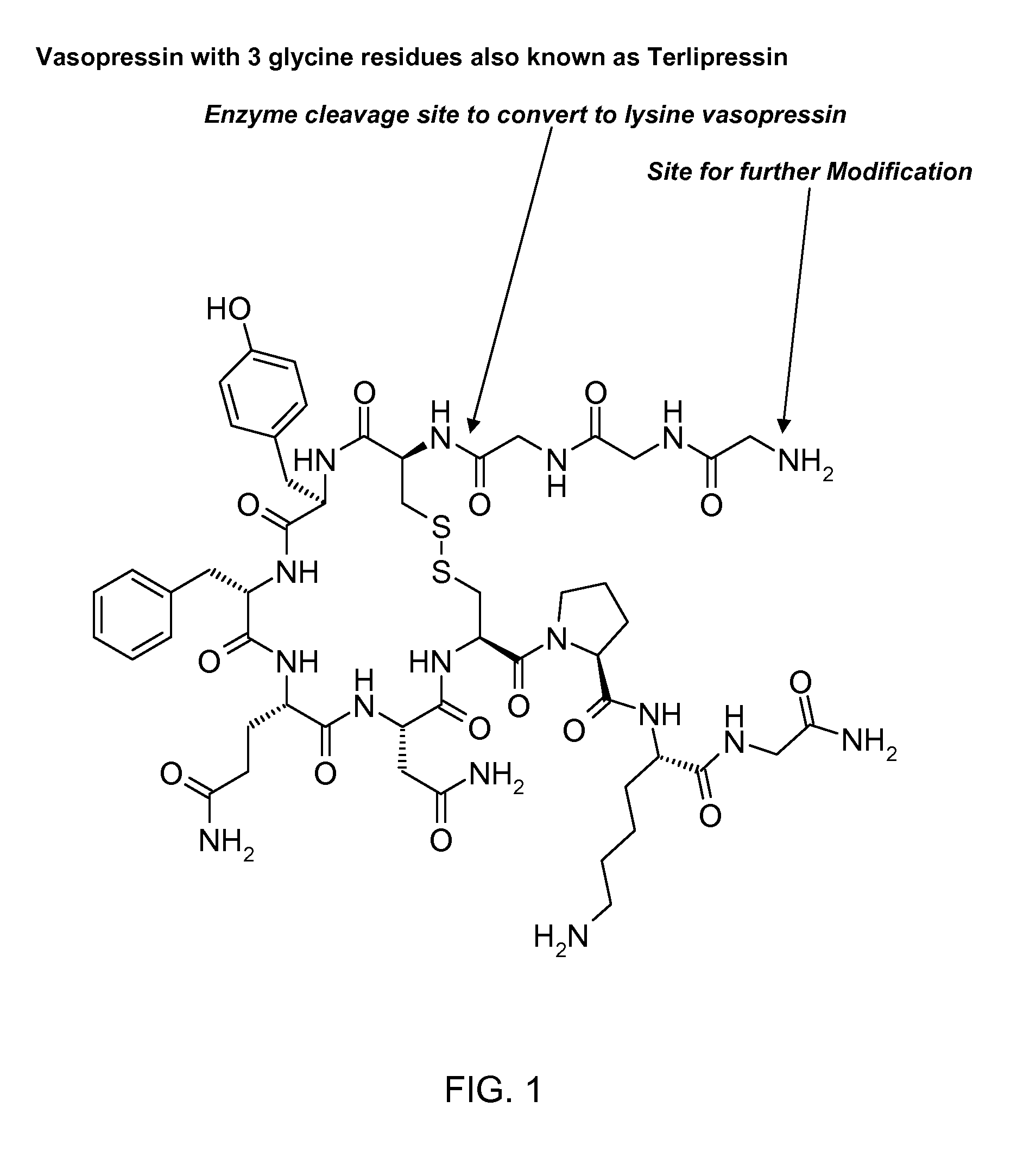

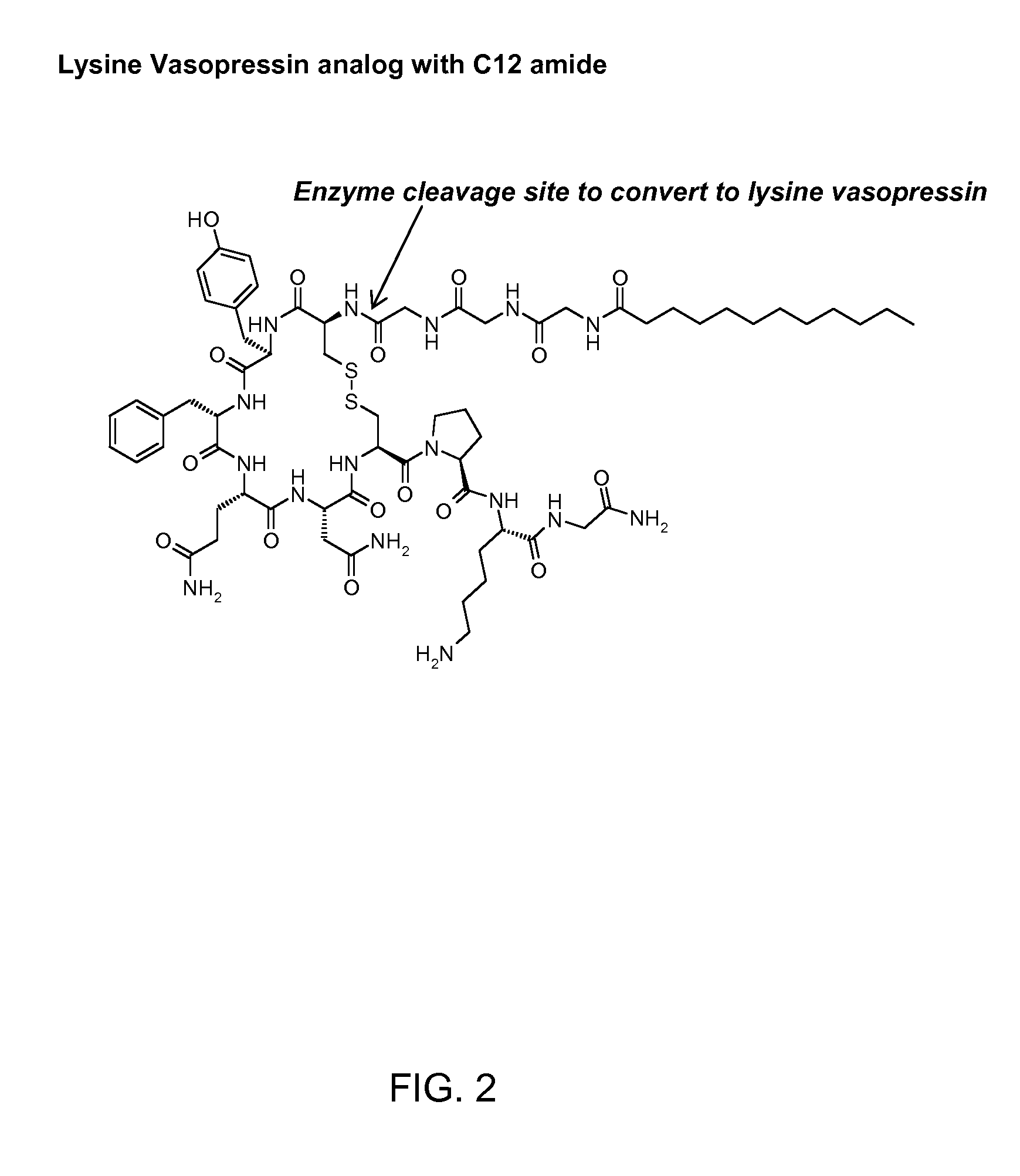

Composition for long-acting peptide analogs

ActiveUS20090088387A1Increase perfusionImprove the level ofAntibacterial agentsPeptide/protein ingredientsHalf-lifeArginine

The invention describes compositions of peptide analogs that are active in blood or cleavable in blood to release an active peptide. The peptide analogs have a general formula: A-(Cm)x-Peptide, wherein A is hydrophobic moiety or a metal binding moiety, e.g., a chemical group or moiety containing 1) an alkyl group having 6 to 36 carbon units, 2) a nitrilotriacetic acid group, 3) an imidodiacetic acid group, or 4) a moiety of formula (ZyHisw)p, wherein Z is any amino acid residue other than histidine, His is histidine, y is an integer from 0-6; w is an integer from 1-6; and p is an integer from 1-6; wherein if A has alkyl group with 6 to 36 carbon units x is greater than 0; and Cm is a cleavable moiety consisting of glycine or alanine or lysine or arginine or N-Arginine or N-lysine, wherein x is an integer between 0-6 and N may be any amino acid or none. The peptide analogs are complexed with polymeric carrier to provide enhanced half-life.

Owner:PHARMAIN CORP

Optical sensor with layered plasmon structure for enhanced detection of chemical groups by SERS

InactiveUS7351588B2Produced in advanceRadiation pyrometryMicrobiological testing/measurementAmplification factorPhysics

An optical sensor and method for use with a visible-light laser excitation beam and a Raman spectroscopy detector, for detecting the presence chemical groups in an analyte applied to the sensor are disclosed. The sensor includes a substrate, a plasmon resonance mirror formed on a sensor surface of the substrate, a plasmon resonance particle layer disposed over the mirror, and an optically transparent dielectric layer about 2-40 nm thick separating the mirror and particle layer. The particle layer is composed of a periodic array of plasmon resonance particles having (i) a coating effective to binding analyte molecules, (ii) substantially uniform particle sizes and shapes in a selected size range between 50-200 nm (ii) a regular periodic particle-to-particle spacing less than the wavelength of the laser excitation beam. The device is capable of detecting analyte with an amplification factor of up to 1012-1014, allowing detection of single analyte molecules.

Owner:POPONIN VLADIMIR

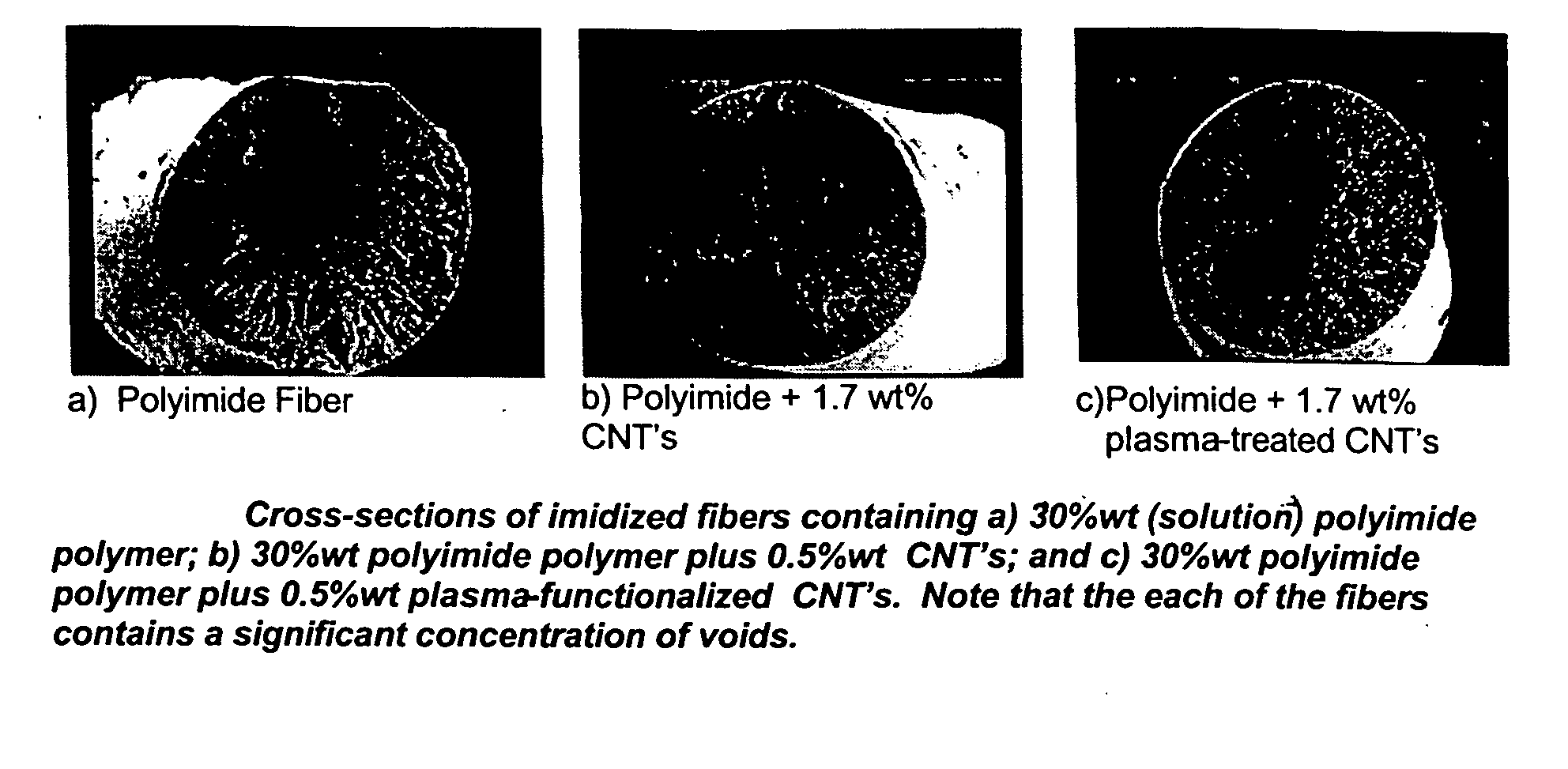

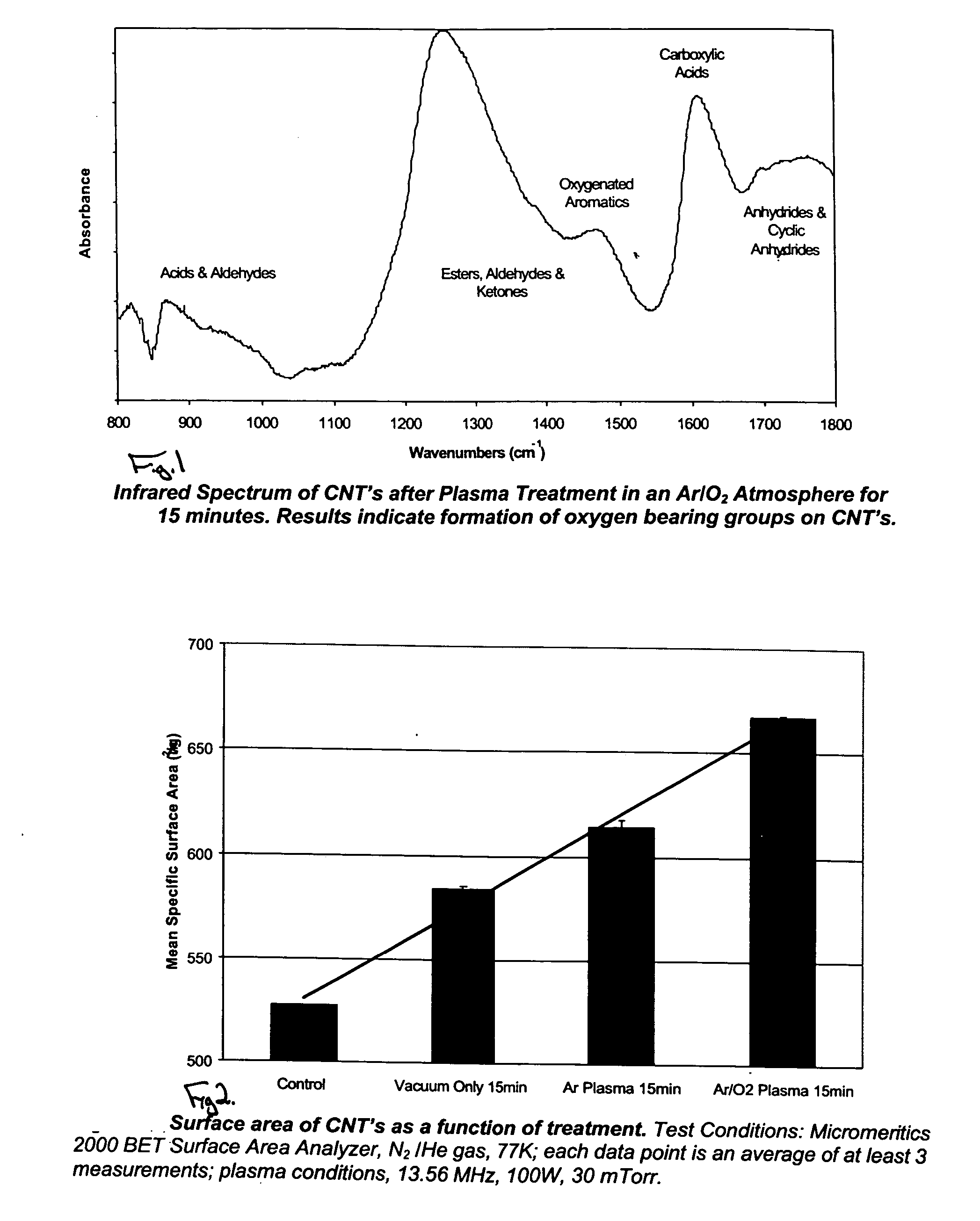

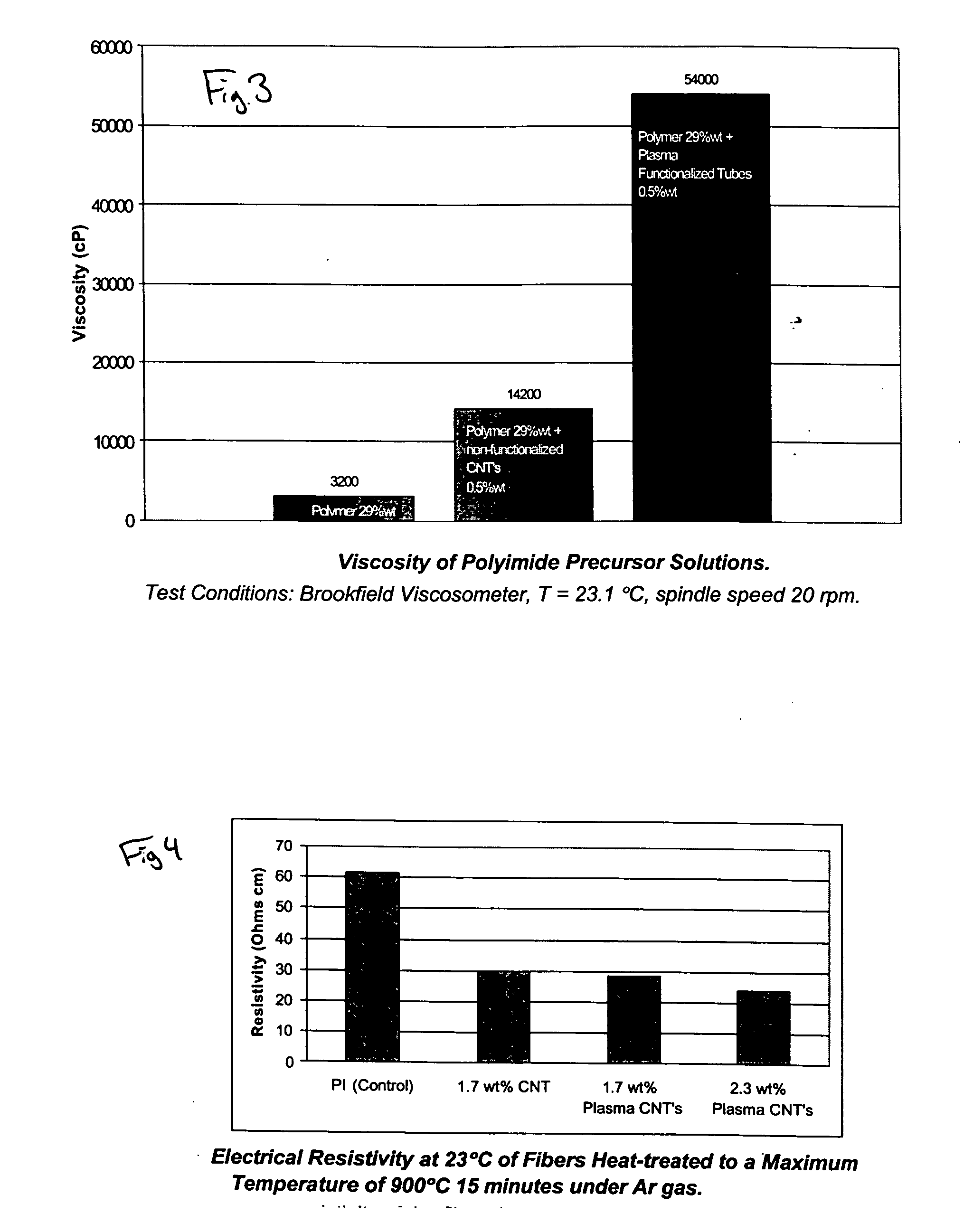

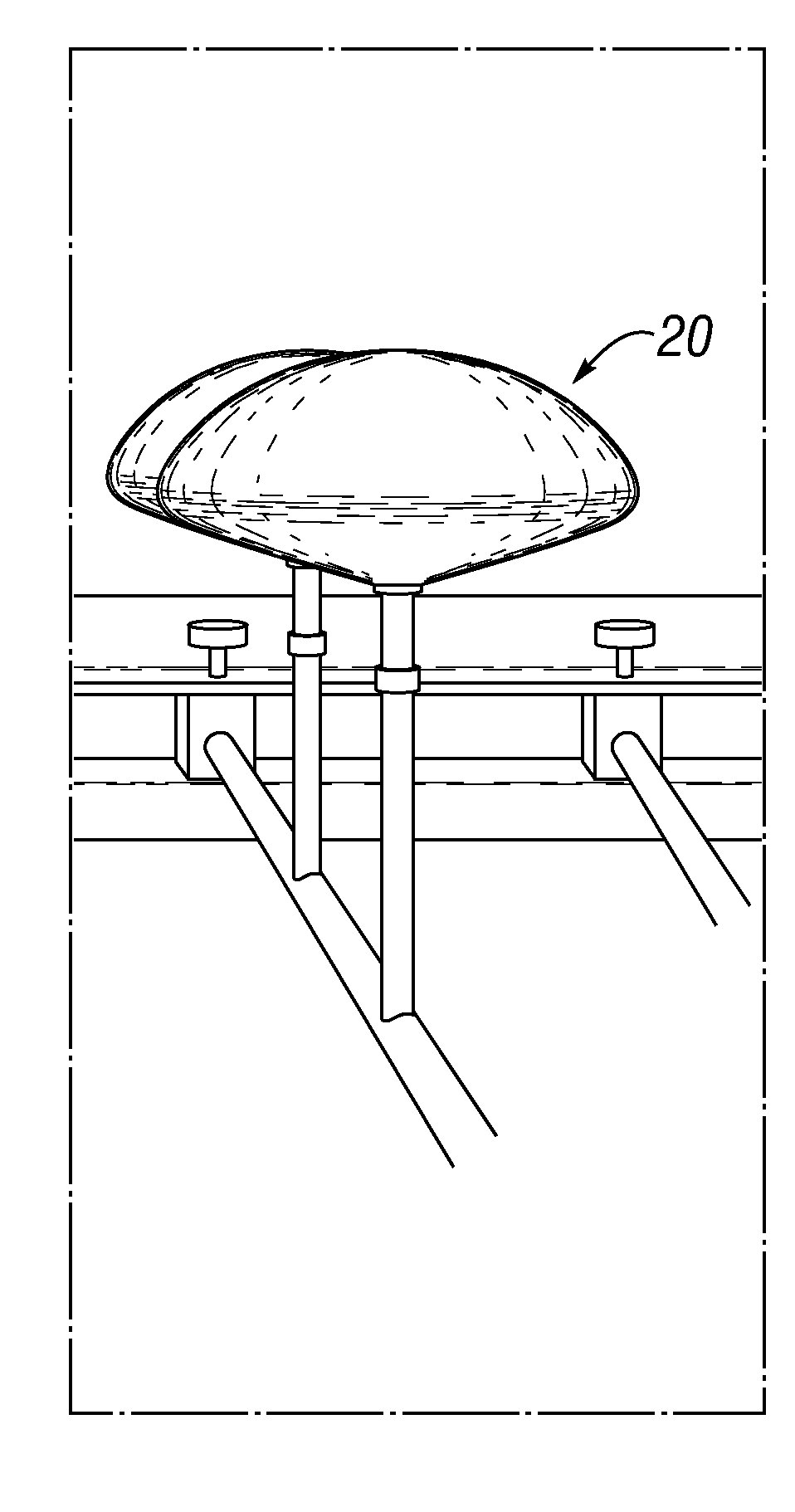

Photoresponsive polyimide based fiber

InactiveUS20070116422A1Improved electrical and mechanical and morphological propertyImprove mechanical propertiesMaterial nanotechnologyCarbon compoundsFiberChemical groups

The present invention provides a novel method for functionalizing the surfaces (and interior) of nanotube like materials using a plasma source. These plasma-functionalized carbon nanotubes (CNTs) are useful for preparing a variety of different composite fibers having improved characteristics, such as conductivity and mechanical strength. The key innovation being pursued is the development of plasma-based methods for plasma-functionalizing the surfaces of CNTs with reactive chemical groups that covalently bind to polymers and prepolymers.

Owner:REYNOLDS THOMAS A

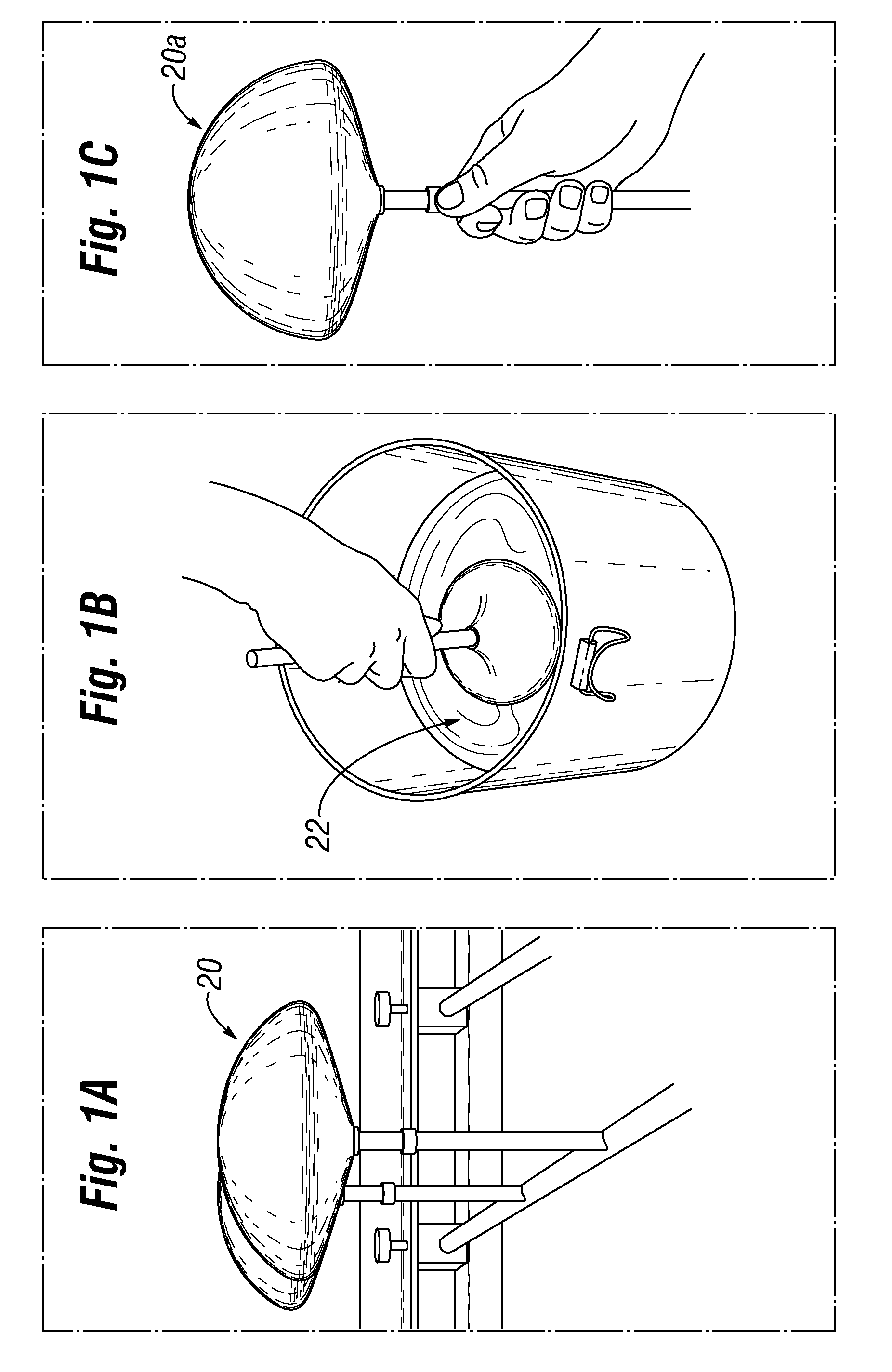

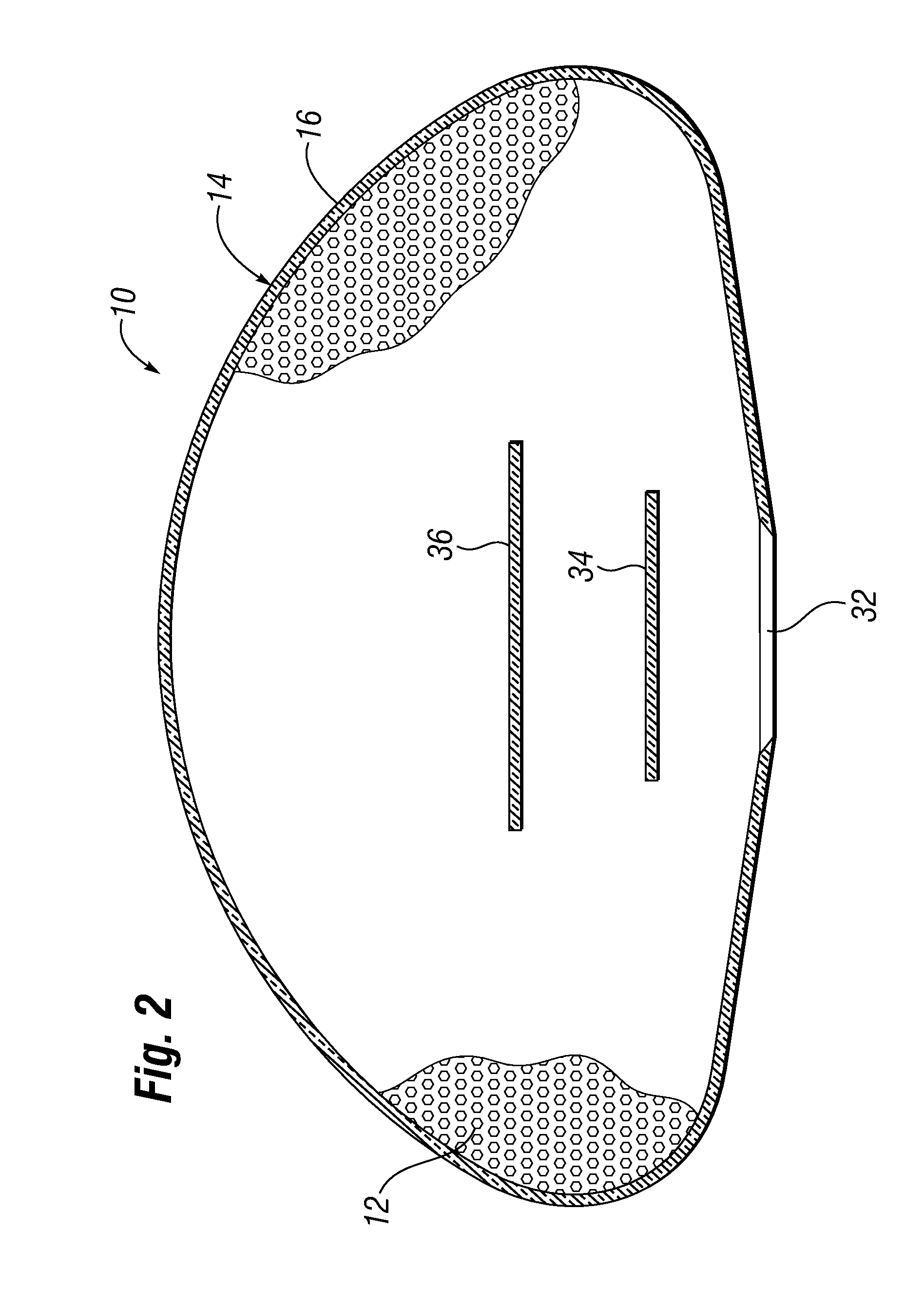

All-barrier elastomeric gel-filled breast prosthesis

An elastomeric gel-filled prosthetic implant having a shell made of a single gel barrier layer. The barrier layer is formed of a homogeneous silicone elastomer capable of sterically retarding permeation of the silicone gel through the shell and having a bleed rate that is less than about 40% of the bleed rate of current shells which use a sandwiched construction with an internal barrier layer. Further, the barrier layer shell is made of a material that exhibits a wet strength that is comparable to or greater than current shells. The silicone elastomer may be a polydimethyl siloxane, and the substituted chemical group is a diphenyl group with a minimum mole percent of at least 13%. The implant may be designed for breast reconstruction or augmentation such that the shell is accordingly shaped. The shell wall thickness is at least 0.254 mm (0.010 inches), and desirably about 0.456 mm (0.018 inches). The implant shell may be made by dip-forming, spray-forming, or rotational molding. The exterior may be smooth or textured.

Owner:ALLERGAN INC

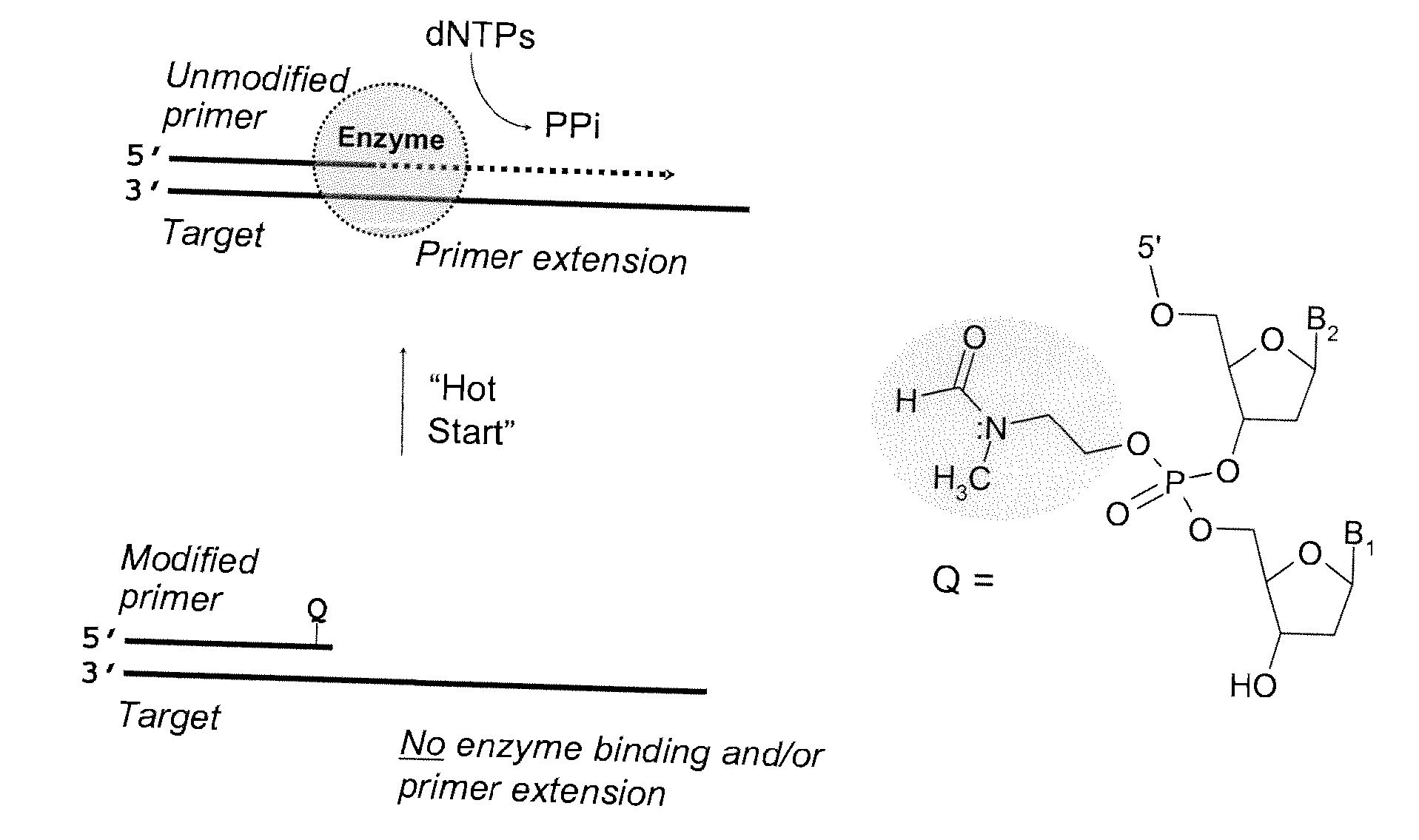

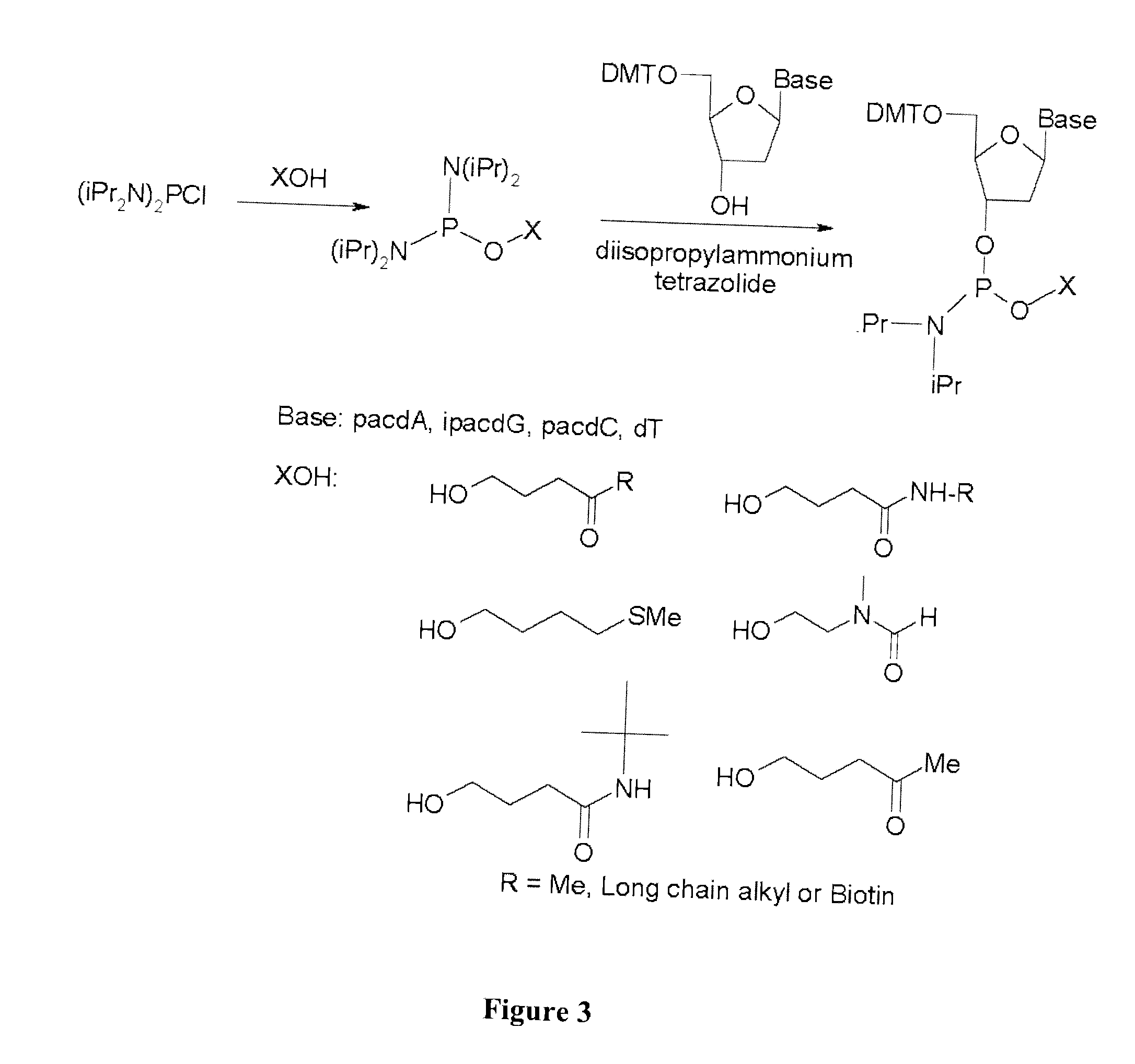

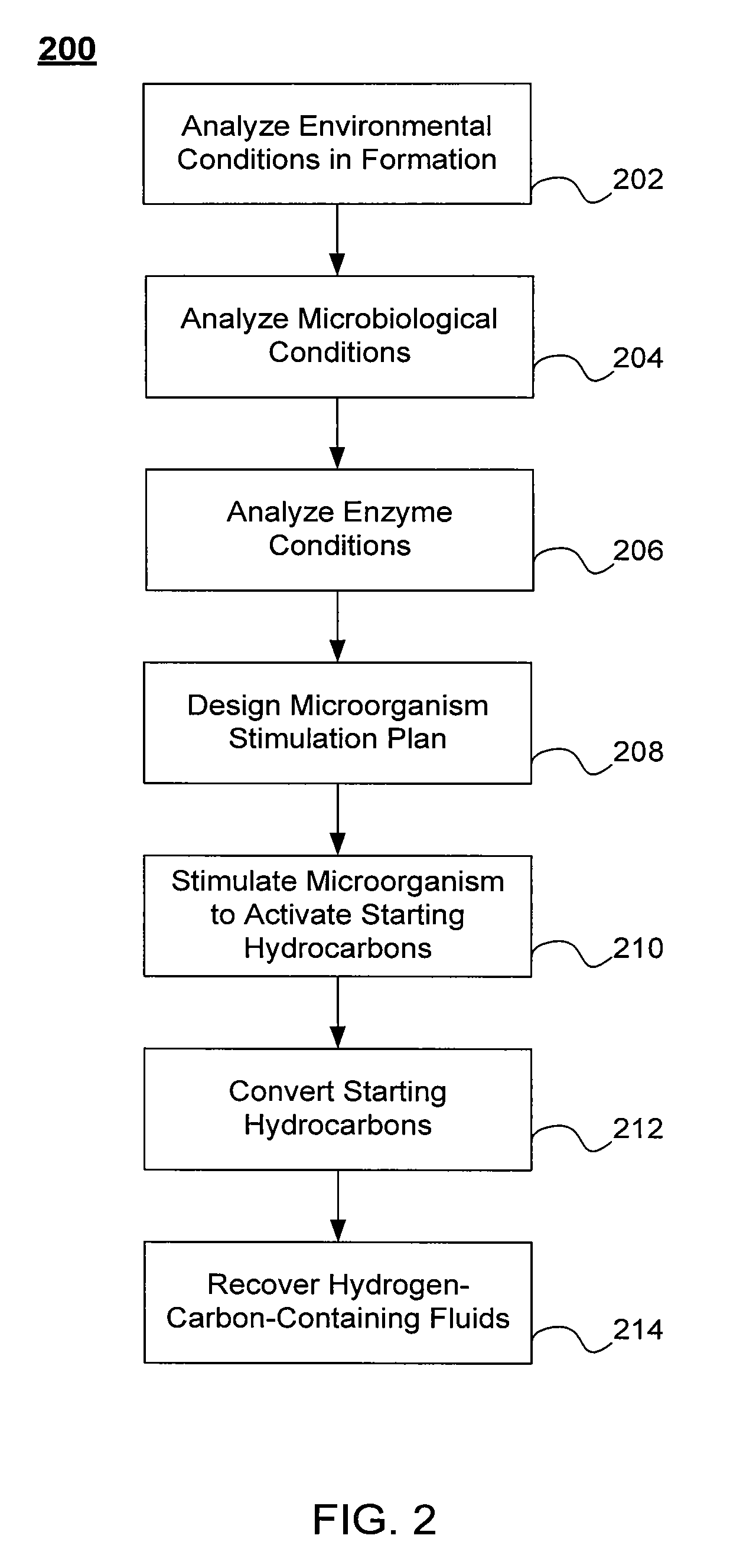

Chemically modified oligonucleotide primers for nucleic acid amplification

ActiveUS20070281308A1Impairs DNA polymerase mediated oligonucleotide primer extensionMicrobiological testing/measurementPhosphorus organic compoundsOligonucleotide primersBiology

The present invention provides methods and compositions for nucleic acid amplification. These methods involve the use of oligonucleotide primers in temperature dependent nucleic acid amplification reactions. In certain aspects, the methods are accomplished by use of certain modified oligonucleotide primers which provide utility in nucleic acid amplification. In preferred embodiments, the oligonucleotide primers are modified with particular chemical groups such as esters.

Owner:TRILINK BIOTECH LLC

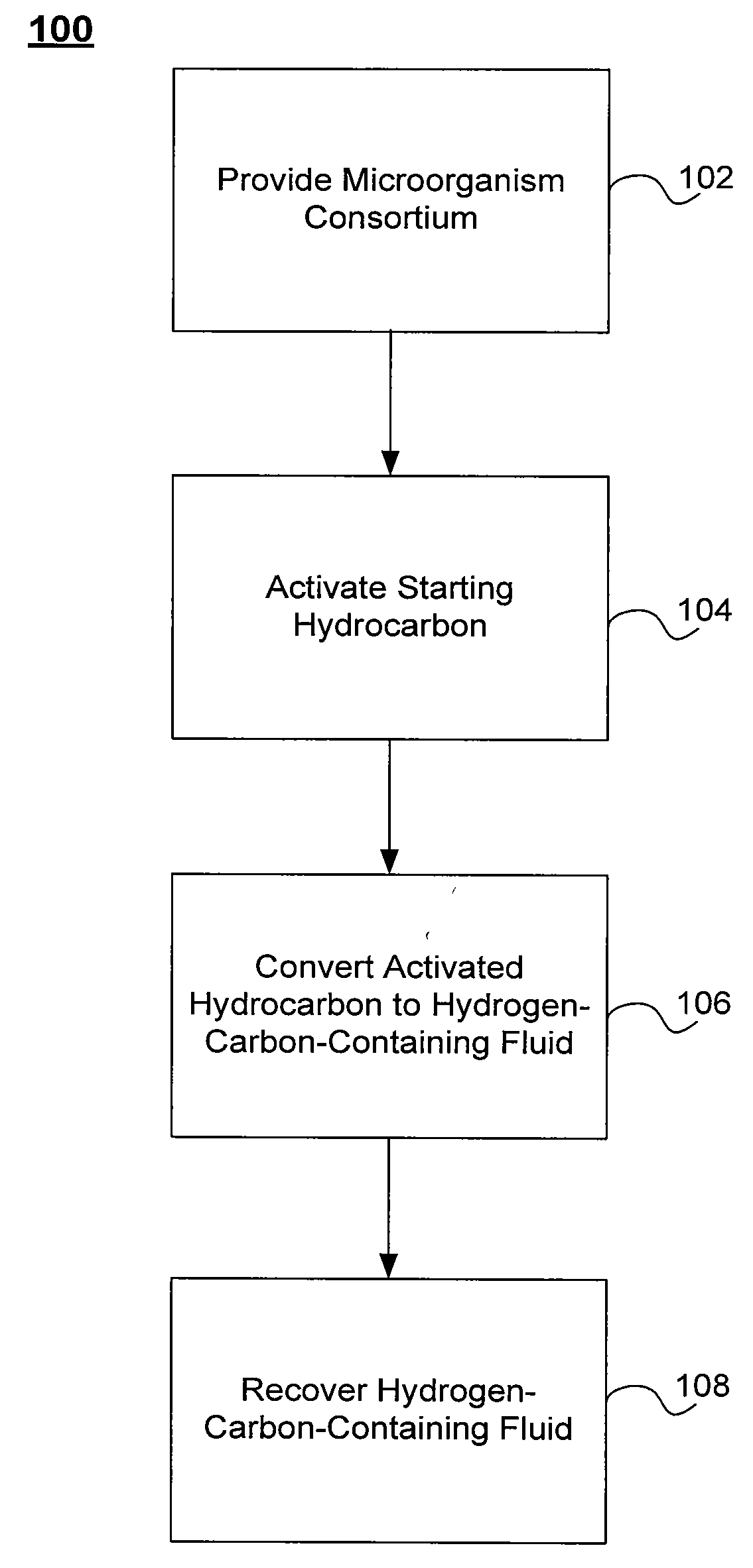

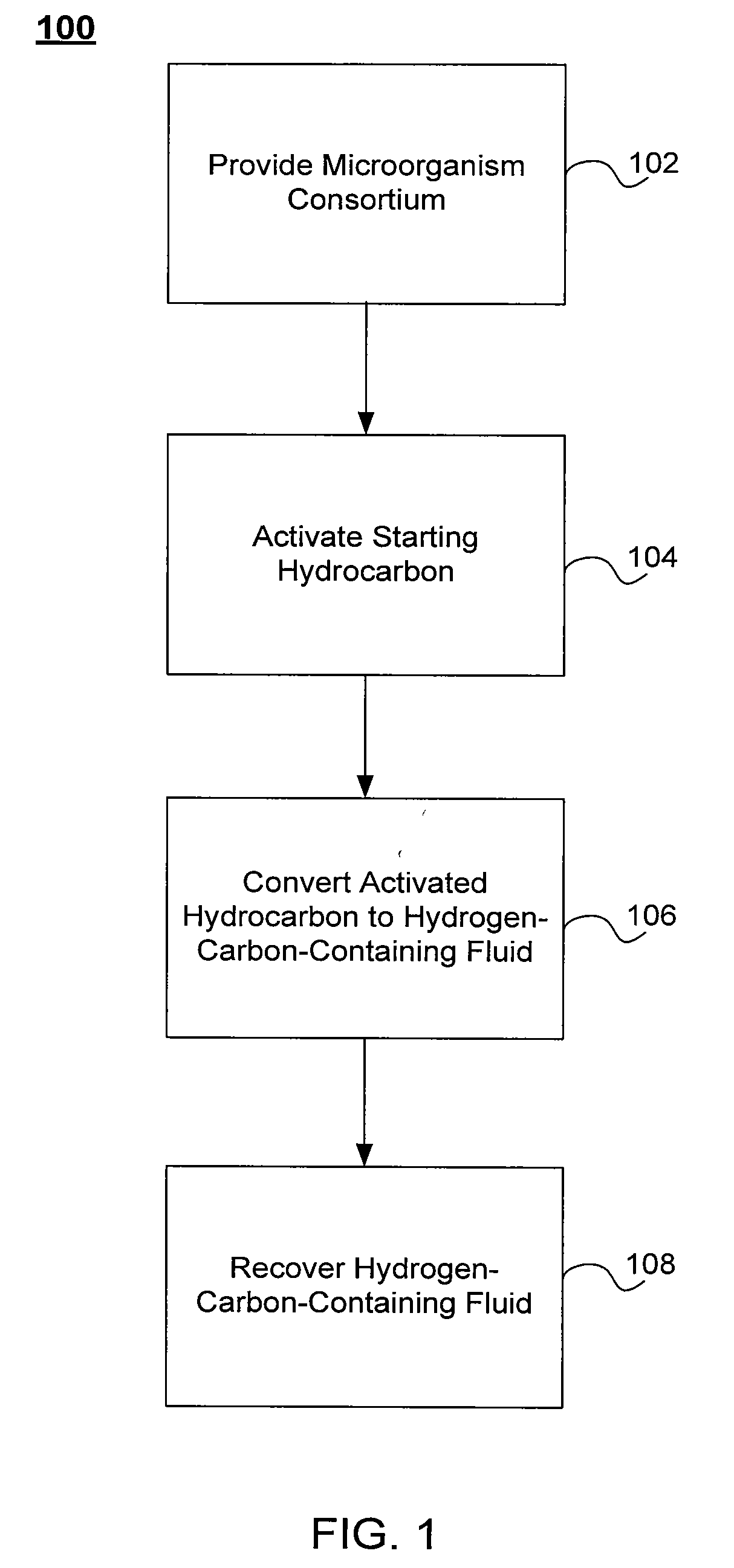

Analysis and enhancement of metabolic pathways for methanogenesis

InactiveUS20100035309A1Enhancing biogenic productionReliable informationWaste based fuelFermentationHydrogenMethanogenesis

Processes for biogenic production of a hydrogen-carbon-containing fluid from a hydrocarbon containing formation are described. The processes may include providing in the formation an anaerobic microorganism consortium containing one or more enzymes to activate a starting hydrocarbon by an addition of a chemical group to the hydrocarbon. The processes may further include converting the activated hydrocarbon into the hydrogen-carbon-containing fluid through one or more intermediate hydrocarbons, and recovering the hydrogen-carbon-containing fluid from the formation.

Owner:LUCA TECH

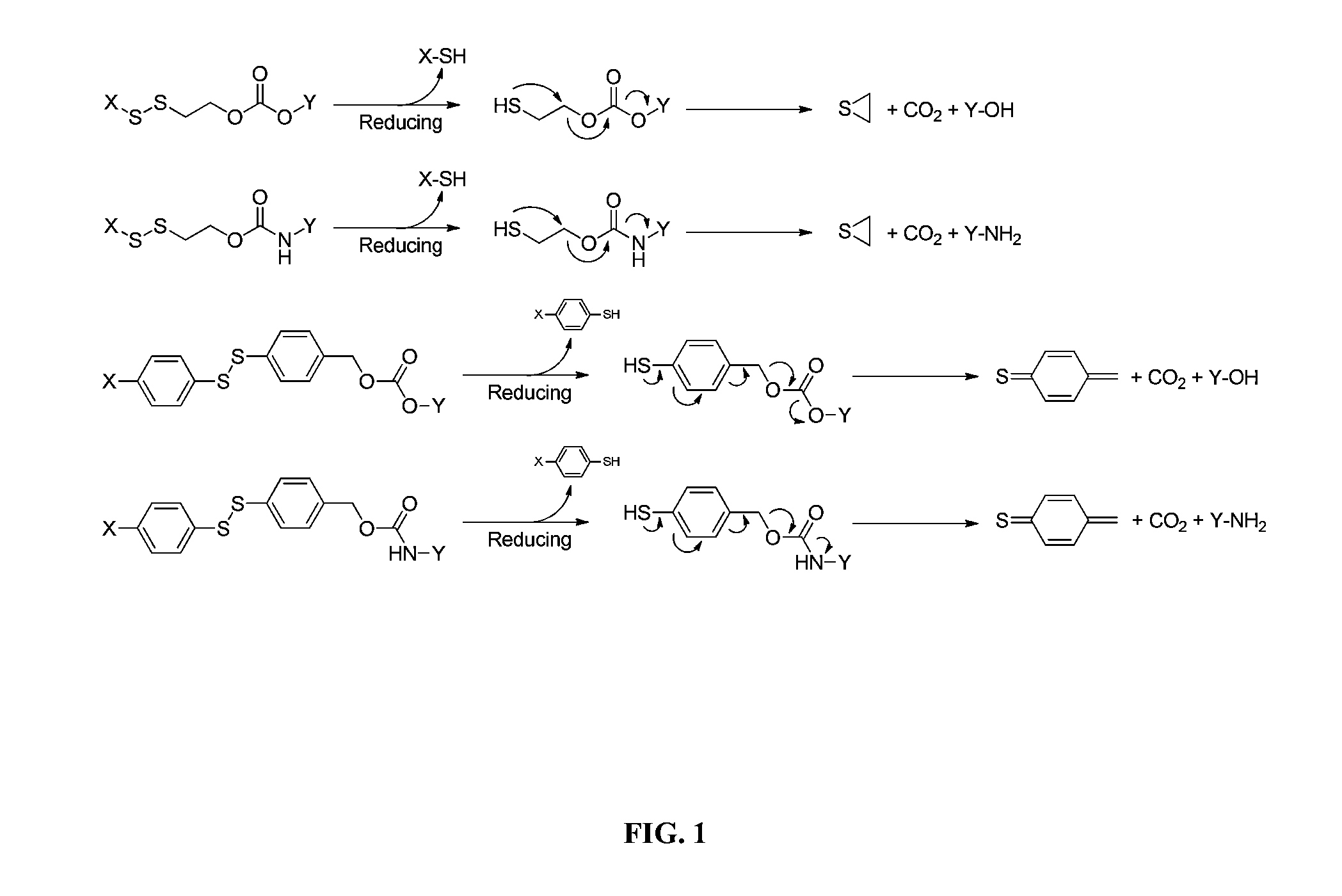

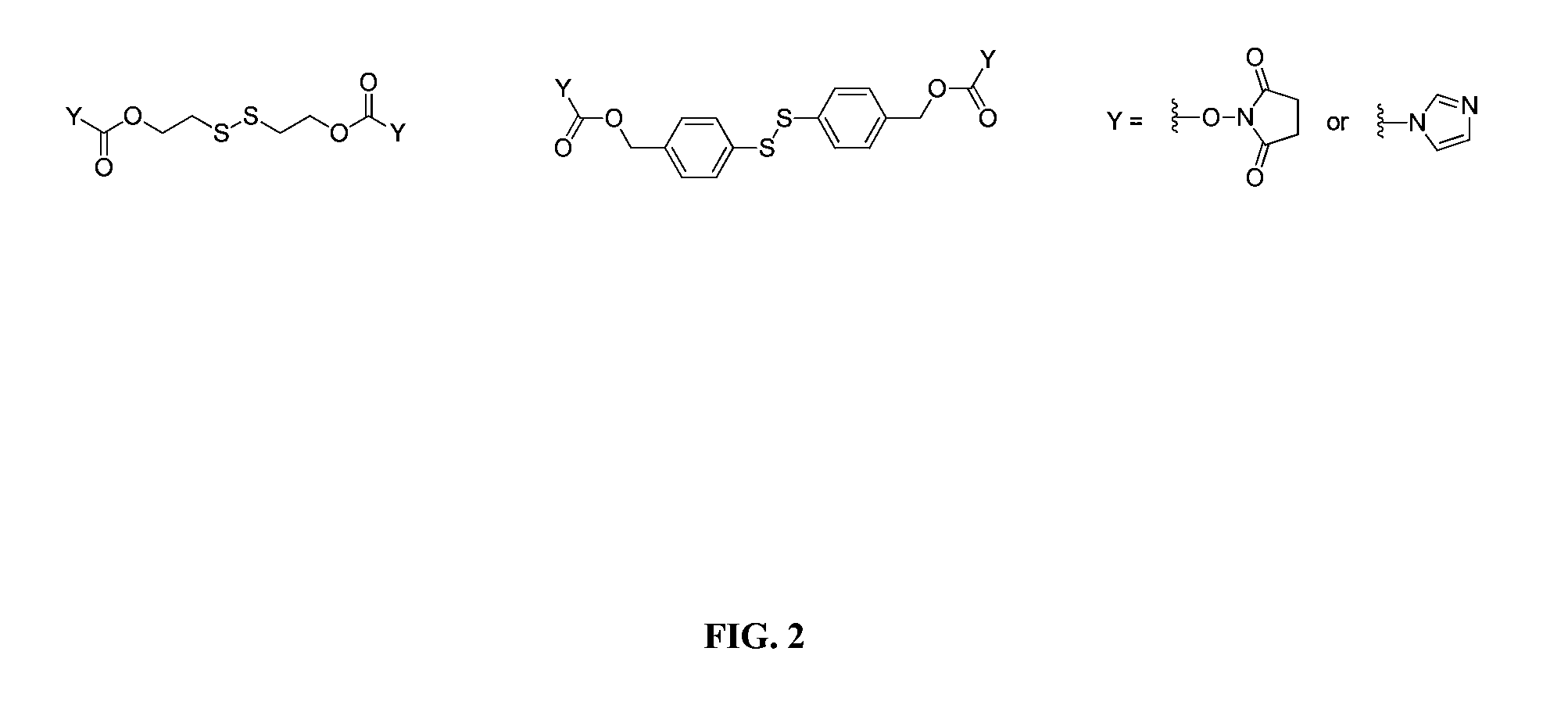

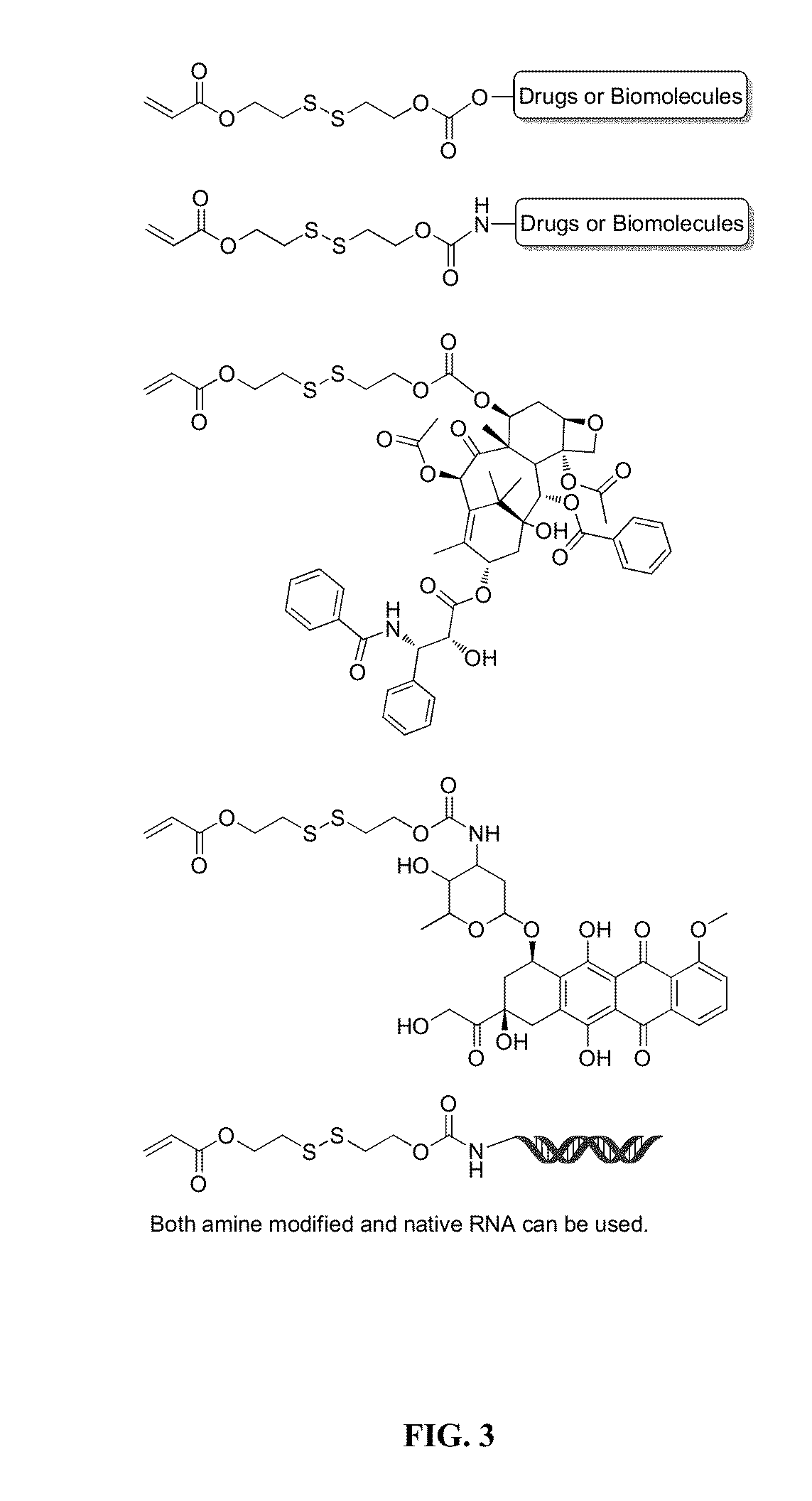

Nanoparticle, liposomes, polymers, agents and proteins modified with reversible linkers

Pharmaceutical, chemical and biological agents containing a reversible disulfide linker are described. These agents can also be covalently bound or contained in delivery vehicles for delivering the agents to desired targets or areas. Also described are delivery vehicles which contain an agent having a reversible disulfide linker and to vehicles that are covalently linked to the agent containing a reversible disulfide linker. The modifications described herein can modify properties of the agents and vehicles, thereby providing desired solubility, stability, hydrophobicity and targeting while the reversibility of the linker can leave the agent to which it is attached free from residual chemical groups after being reduced.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

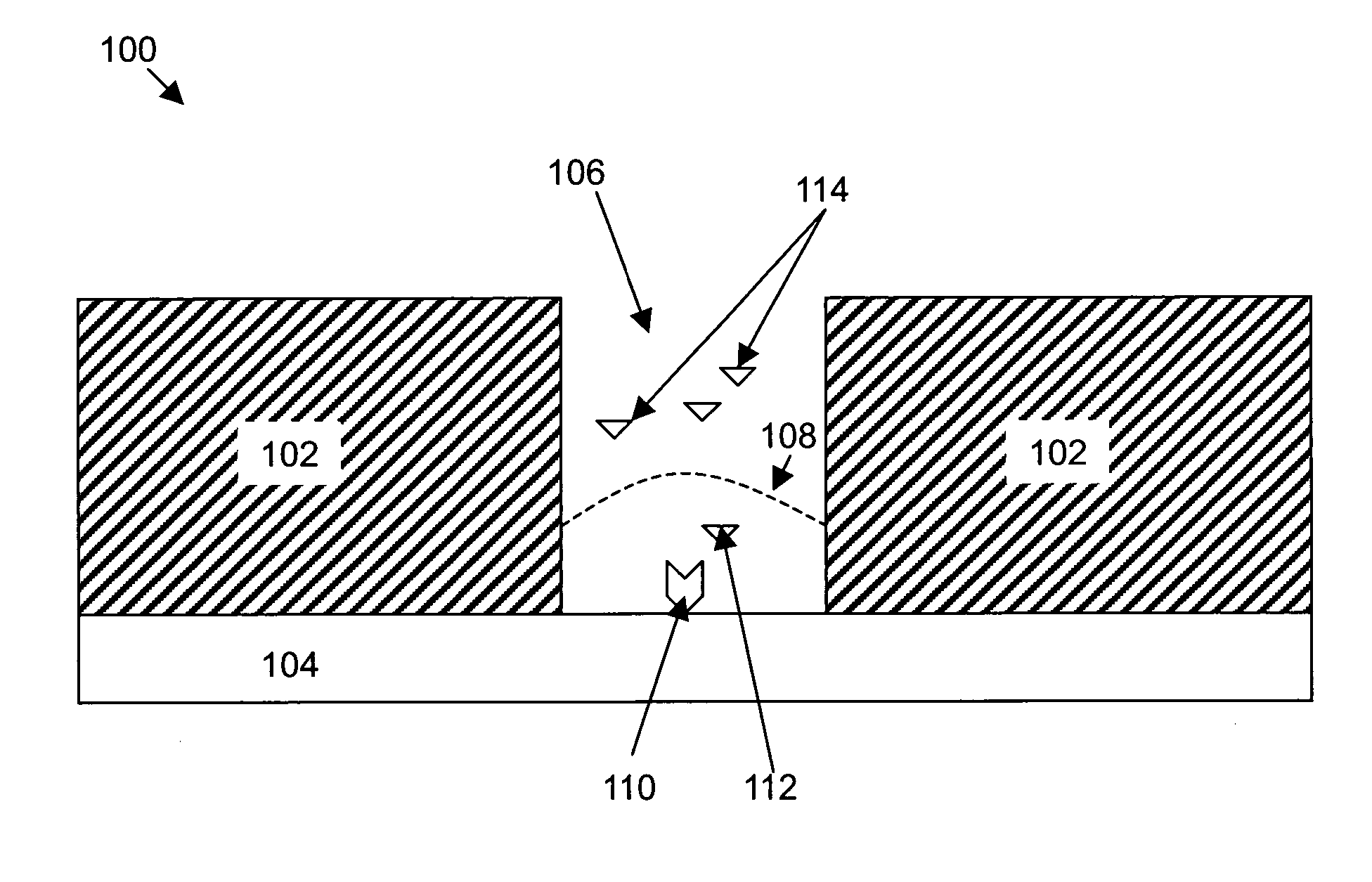

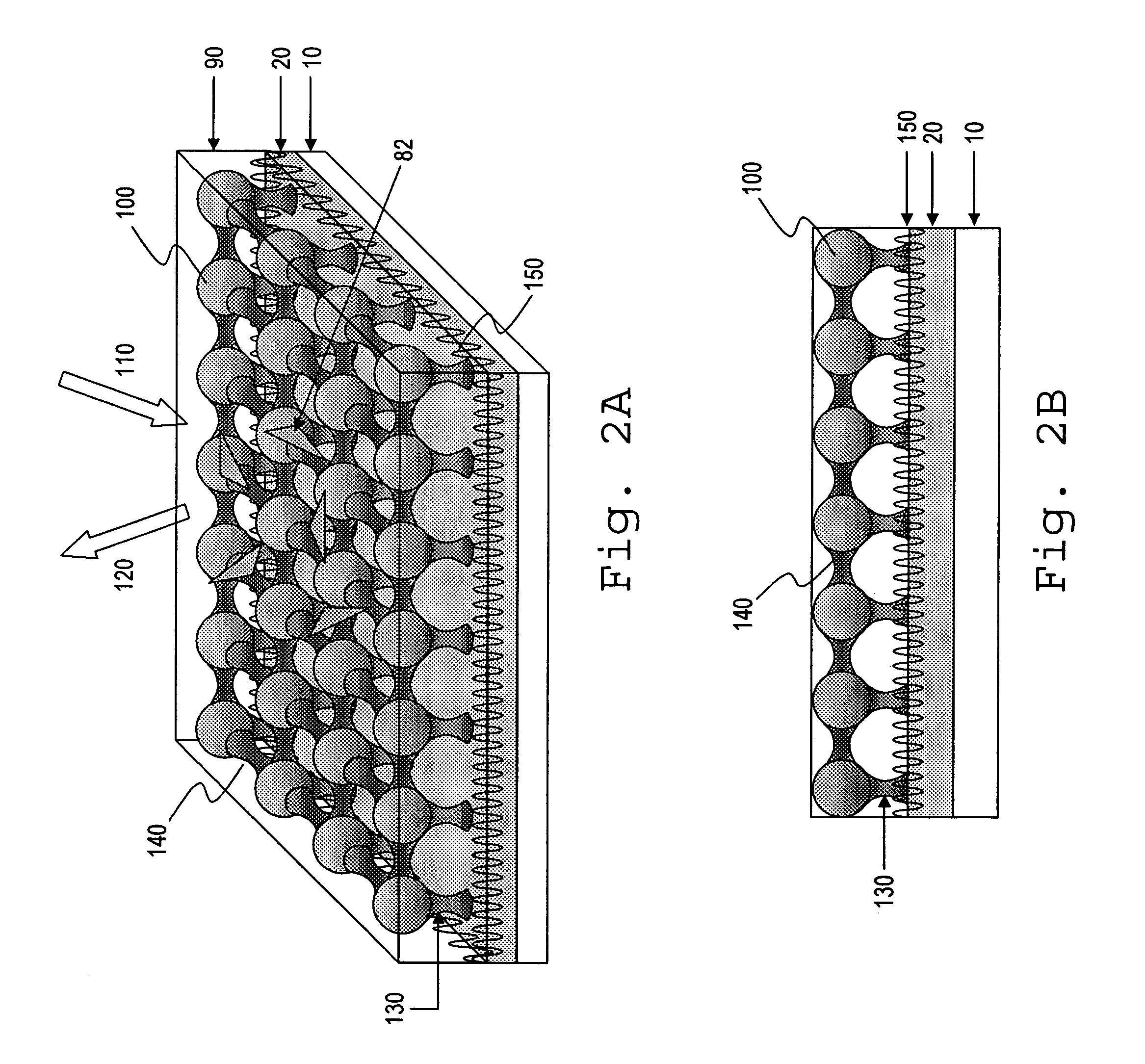

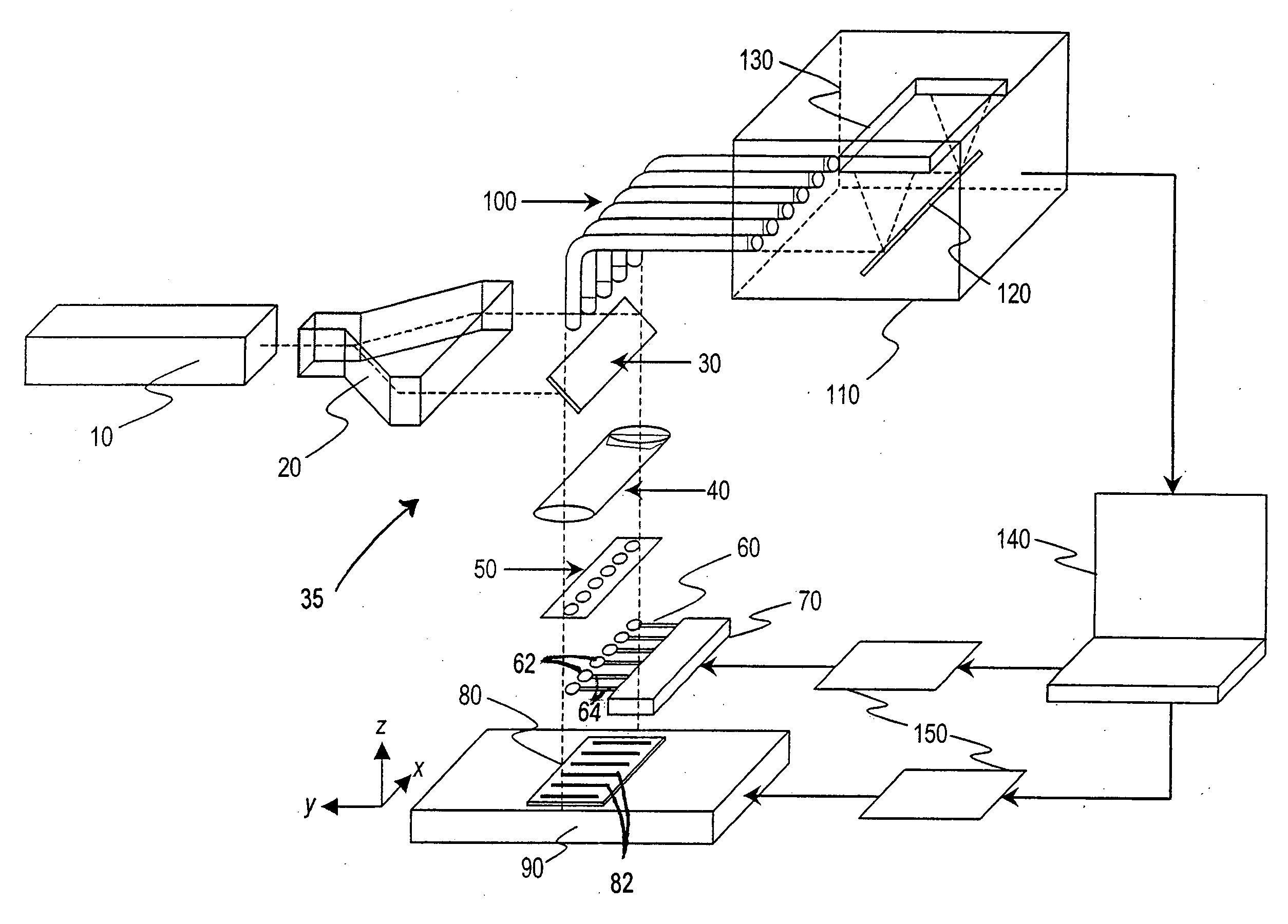

Method and apparatus for enhanced nano-spectroscopic scanning

InactiveUS20050084912A1Bioreactor/fermenter combinationsBiological substance pretreatmentsResonanceLight beam

Apparatus and method for examining the identity of chemical groups in a sample are disclosed. The apparatus has a substrate having a plasmon resonant surface on which the sample is supported, a source of a beam of light, and a lens assembly having a tip region and a nanolens composed of one or more plasmon resonance particles (PRPs) on the tip region. The PRPs are arranged to produce near-field electromagnetic gap modes in a space between the nanolens and a confronting detection region on the substrate surface when the gap between the nanolens and substrate is 30 nm or less. A focusing mechanism in the apparatus operates to move the lens assembly toward and away from the substrate surface, with a gap of less than 30 nm, to produce electromagnetic gap modes that enhance the Raman spectroscopy signals produced by the sample in the detection region. The apparatus and method are useful, for example, in identifying successive bases in a single DNA strand, for direct DNA sequencing. In one embodiment, the nanolens is positioned adjacent a nanopore opening for use in identifying successive bases of DNA, as the individual DNA bases are translocated through the nanopore.

Owner:POPONIN VLADIMIR

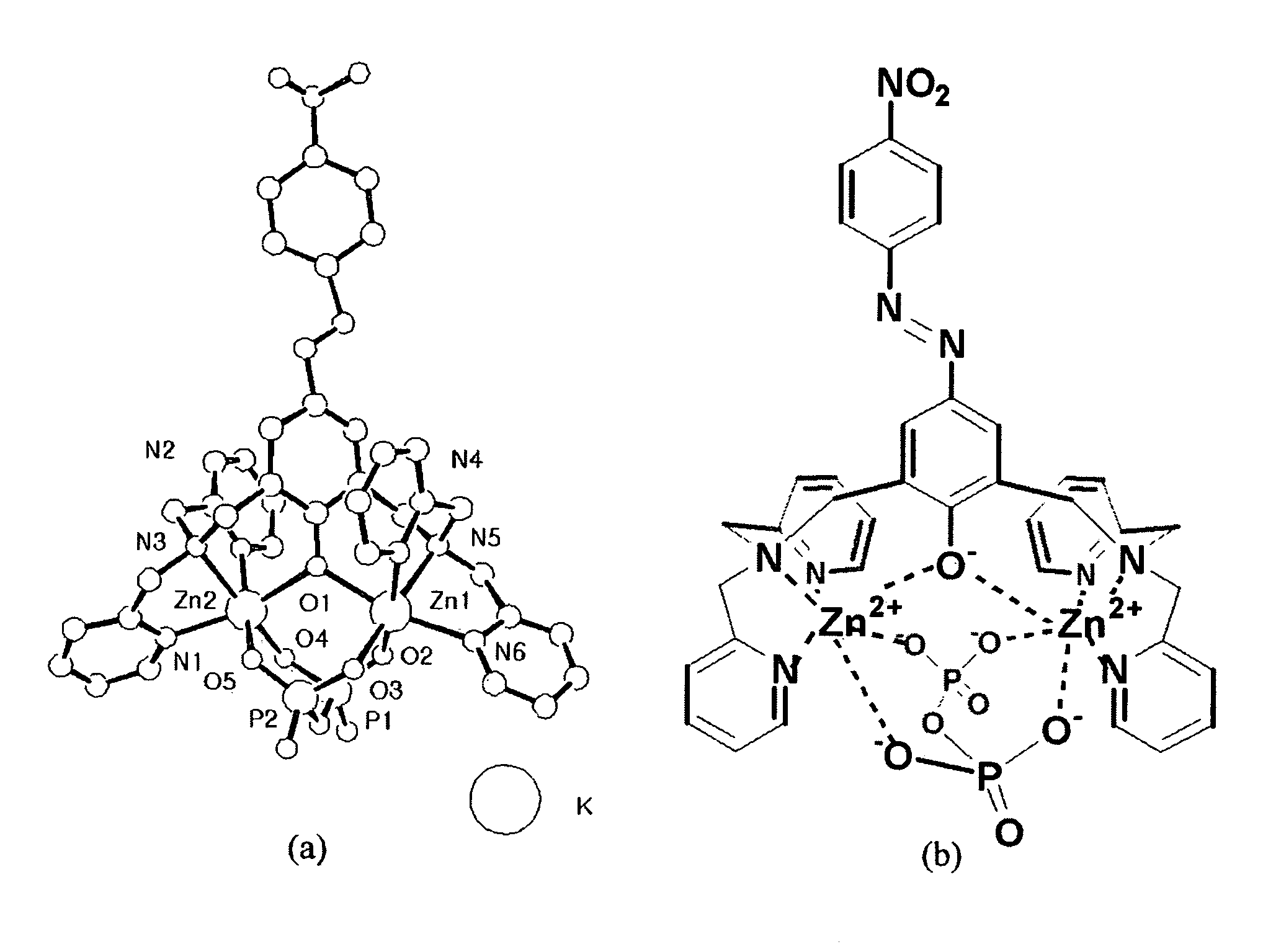

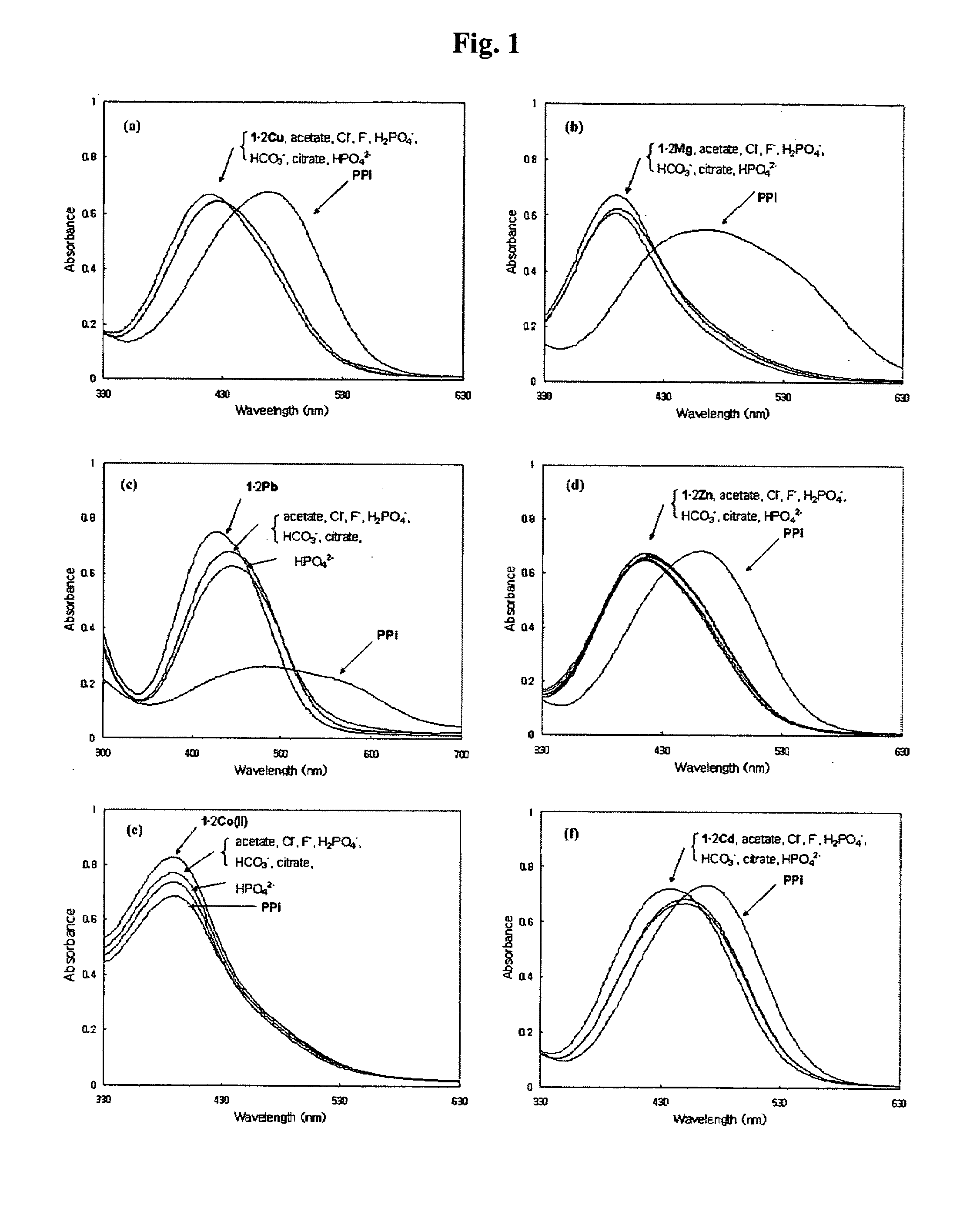

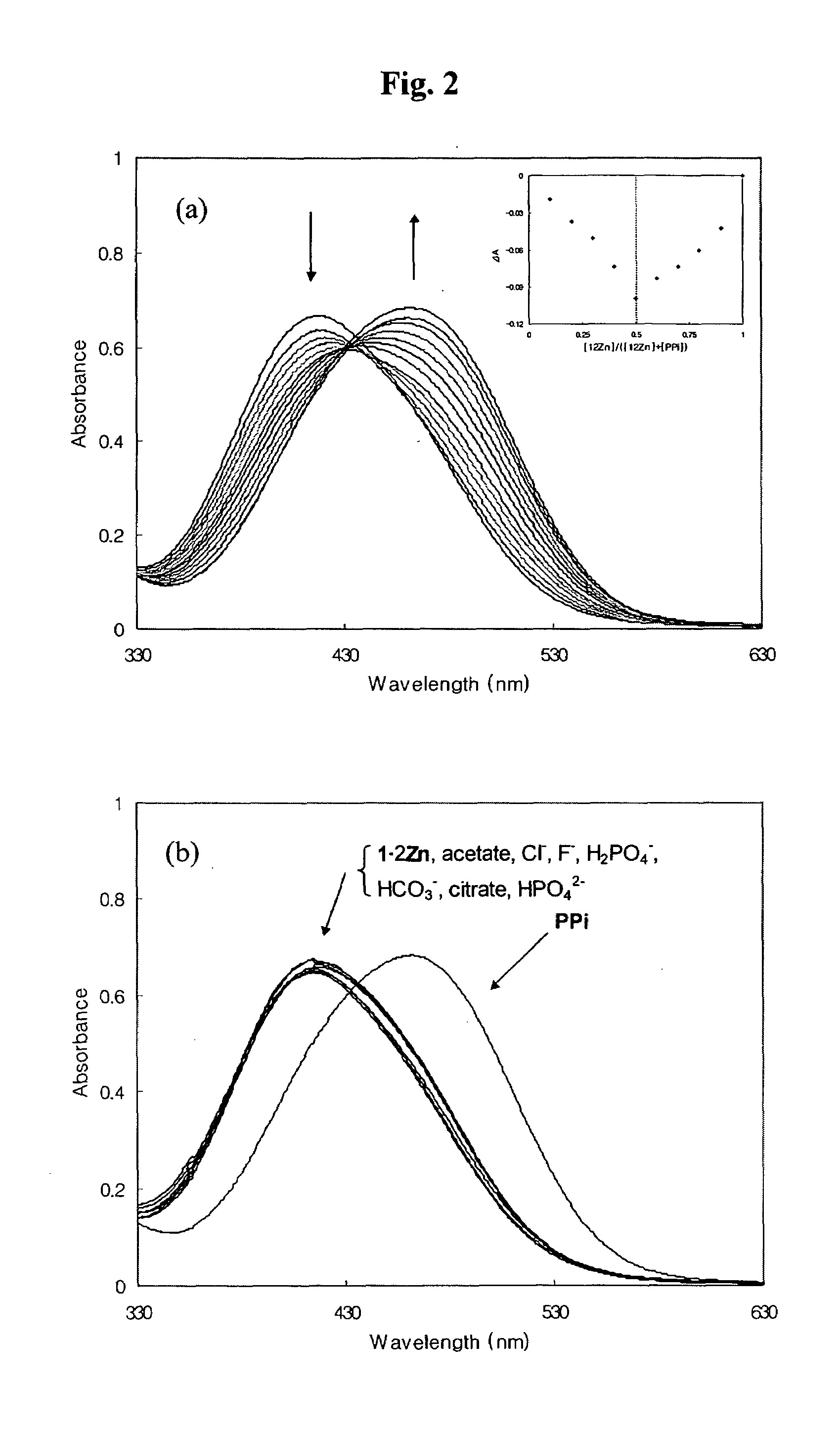

Dinuclear metal complex and pyrophosphate assay using the same

InactiveUS7279588B2Ultrasonic/sonic/infrasonic diagnosticsGroup 8/9/10/18 element organic compoundsElectronic densityPyrophosphate

A novel coordination complex formed by dinuclear metal complexation is provided. The complex is a dinuclear metal complex of a compound, wherein the compound comprises a conjugation ring system substituted with: a) an electron donating group selected from —OH, —SH and —NH2; b) an indicating group selected from a chromogenic group, a fluorescent group and an electrochemical group; and c) two binding auxiliary groups, in combination with the electron donating group each of which being coordinated with the metal to provide an anion bonding site, wherein as the complex binds to a anion, the coordination of the electron donating group with the metal is weakened and electron donation of the electron donating group to the conjugation ring system is reinforced such that the reinforced electron donation by the electron donating group is transferred through the conjugation ring system to the indicating group to produce an indicating signal concomitant with the change of its electronic density. The coordination complex shows high sensitivity and high selectivity for pyrophosphate over other anions in an aqueous solvent over a wide pH range. Therefore, the complex is useful for pyrophosphate assay as a pyrophosphate sensor.

Owner:SEOUL NAT UNIV FOUND

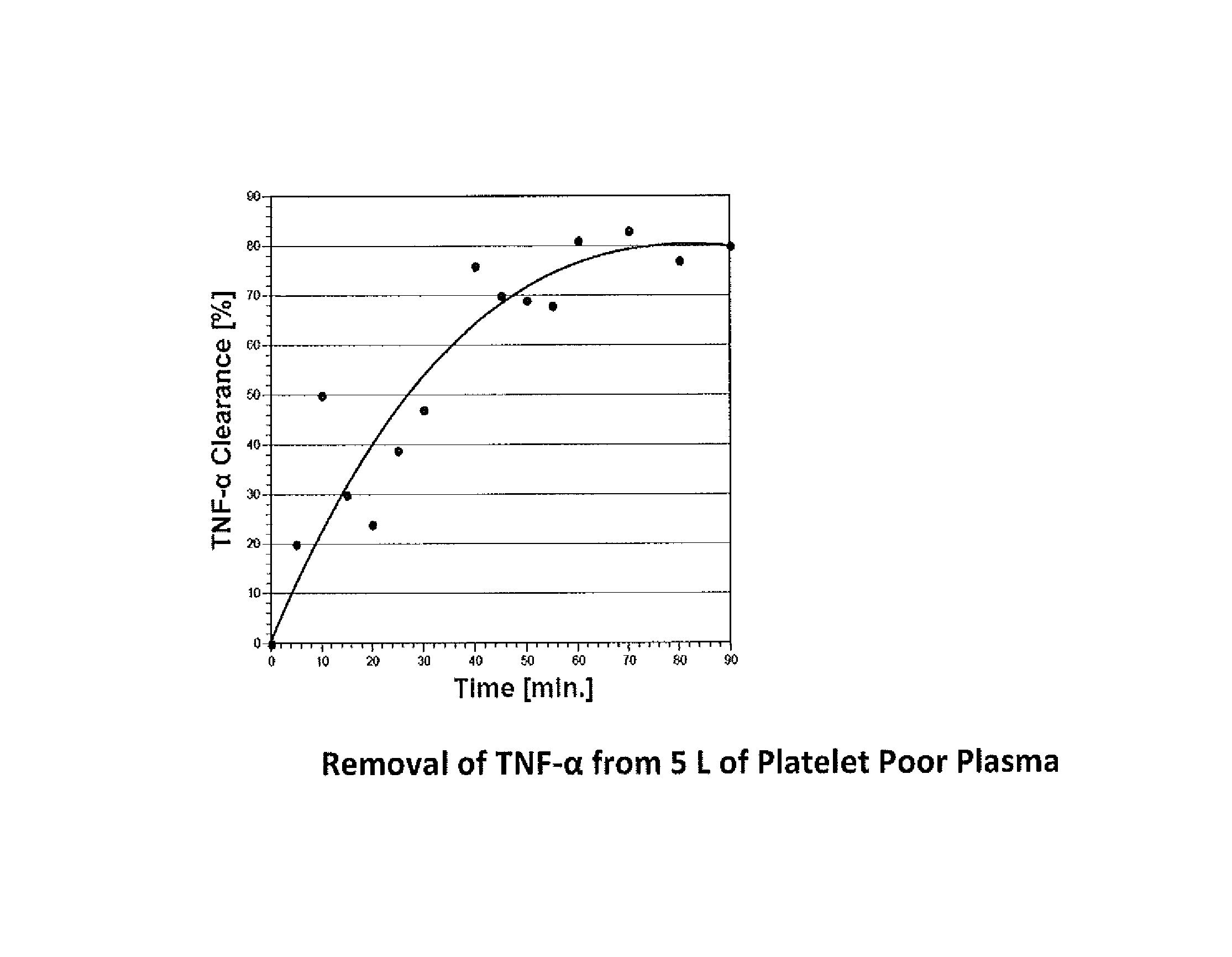

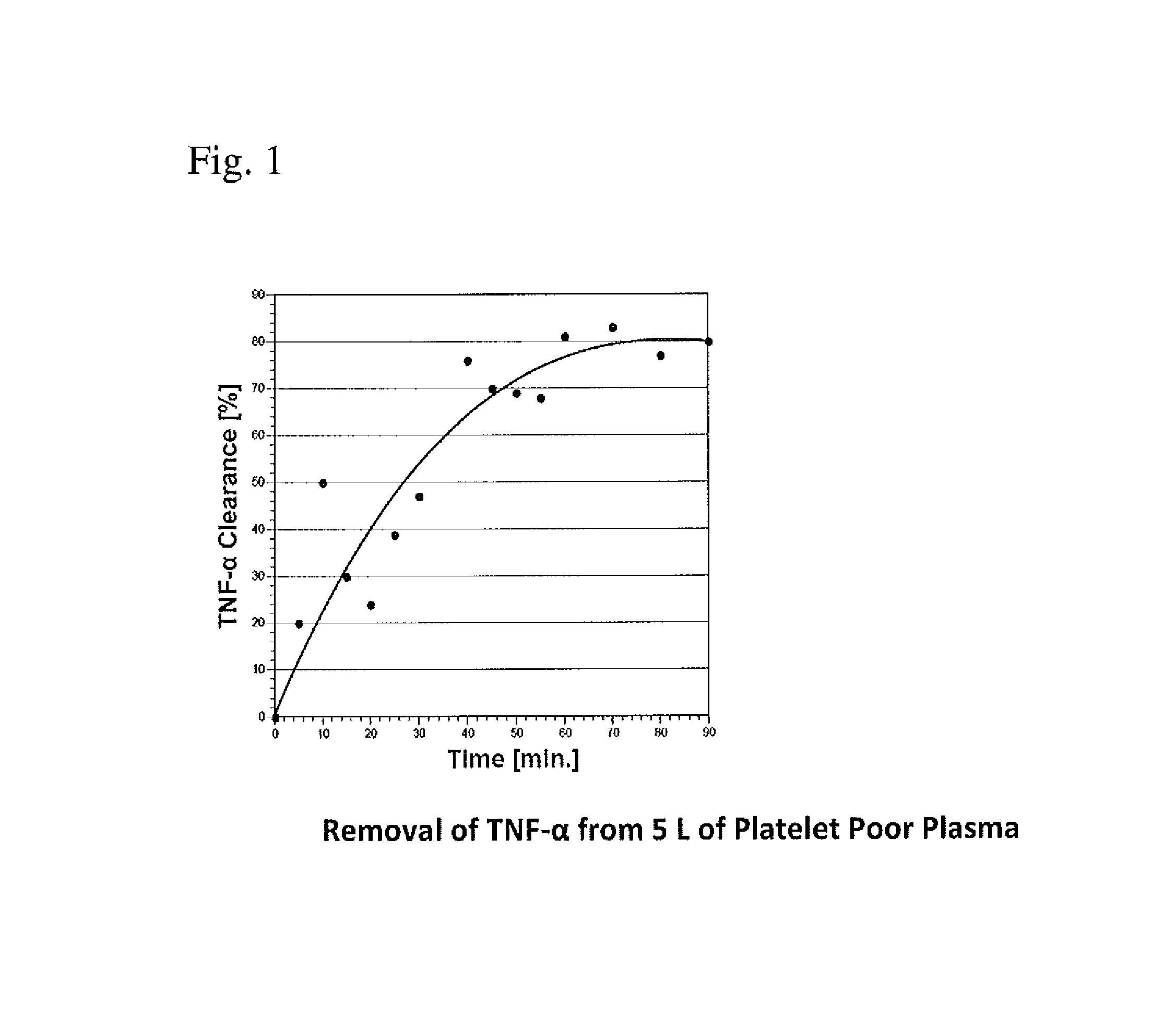

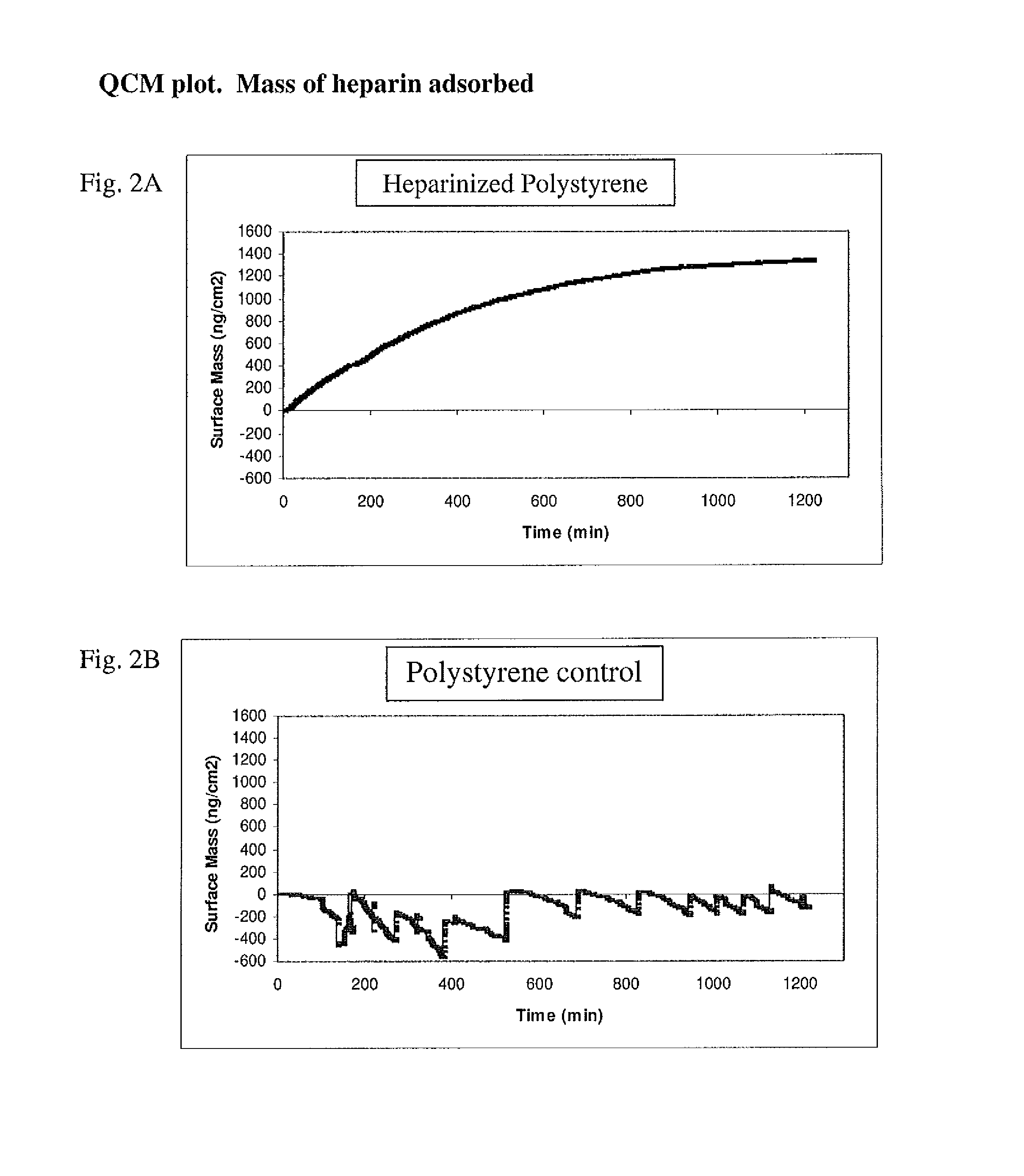

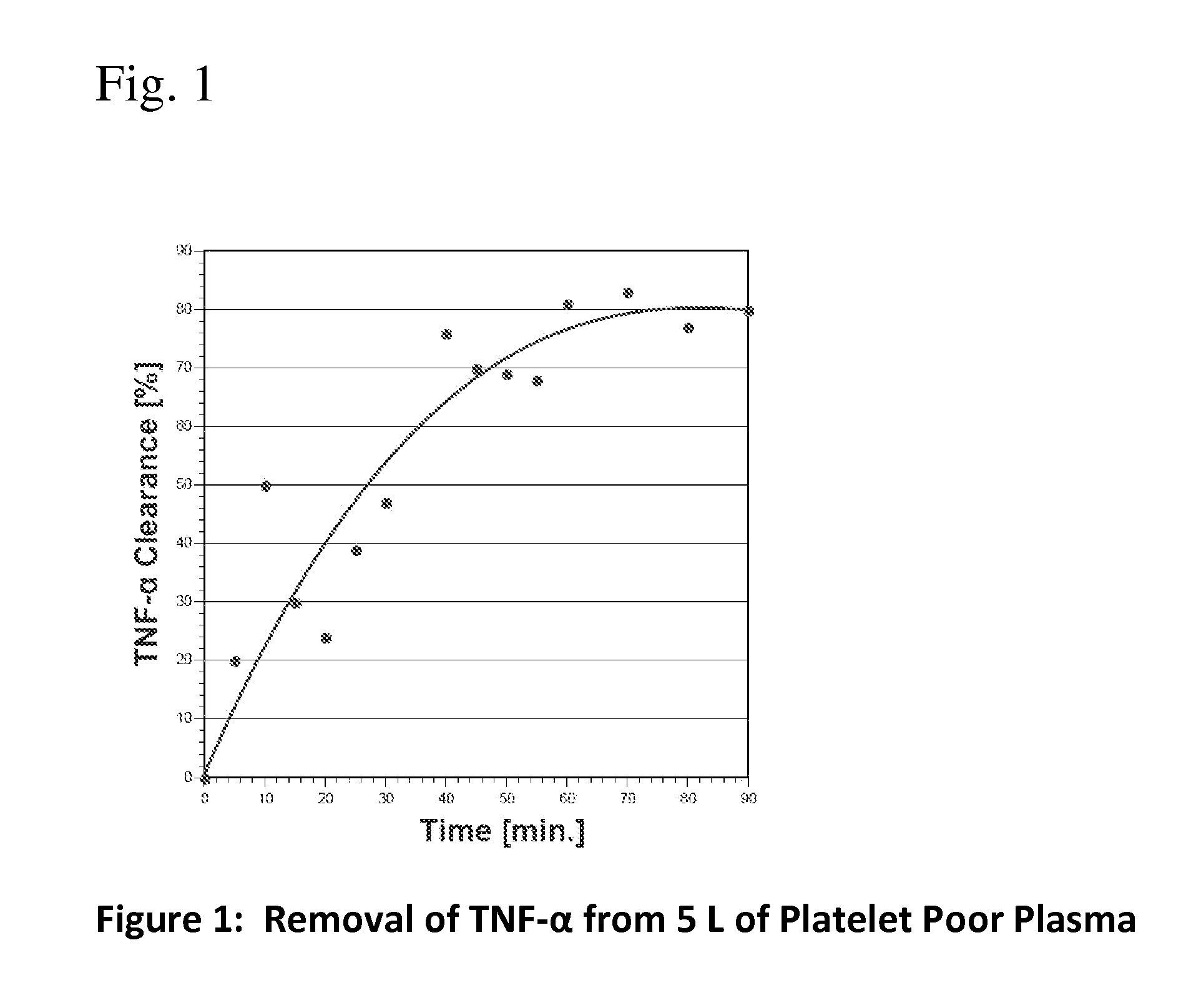

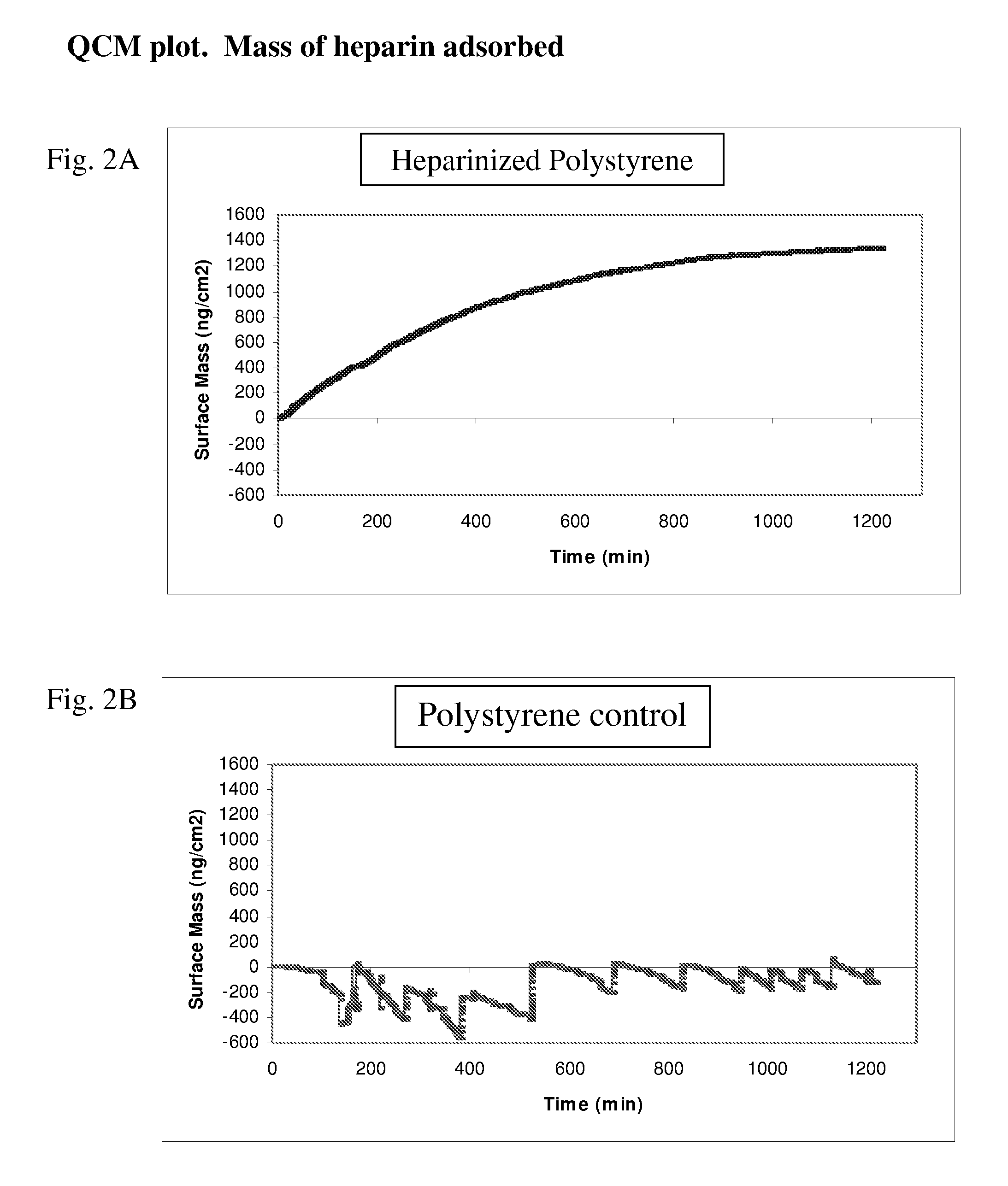

Method for removing cytokines from blood with surface immobilized polysaccharides

ActiveUS20110184377A1Lessen and eliminate spreadPrevent diseaseAntibacterial agentsSalicyclic acid active ingredientsPorous substrateSurface concentration

The present invention is directed to a method for removing cytokines and / or pathogens from blood or blood serum (blood) by contacting the blood with a solid, essentially non micro-porous substrate which has been surface treated with heparin, heparan sulfate and / or other molecules or chemical groups (the adsorbent media or media) having a binding affinity for the cytokine or pathogen(s) to be removed (the adsorbates), and wherein the size of the interstitial channels within said media is balanced with the amount of media surface area and the surface concentration of binding sites on the media in order to provide adequate adsorptive capacity while also allowing relatively high flow rates of blood through the adsorbent media.

Owner:EXTHERA MEDICAL

Prolonged FIX Analogues and Derivatives

InactiveUS20090252720A1Extended half-lifeHigh molecular weightPeptide/protein ingredientsEnzyme stabilisationChemical groupsPeak value

The invention is related to FIX analogues which have an increased circulation time in the blood stream before activation compared to that that of native FIX (and a week after injection to a patient retains at least about 5% of the FIX activity compared to the initial activity peak value reached after injection). The claimed FIX analogues comprise an inserted cysteine residue which has been further modified by conjugation with a chemical group increasing the molecular weight of the FIX analogue.

Owner:NOVO NORDISK AS

Modified Fillers And Elastomeric Composites Comprising Same

ActiveUS20130165560A1Improve hysteresisExcellent abrasion resistanceSilicon organic compoundsSpecial tyresElastomerHysteresis

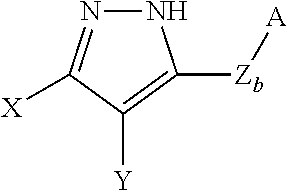

Modified fillers are described which have adsorbed and / or attached chemical groups, such as a triazole and / or pyrazole thereon. Other modified fillers are also described. Elastomeric compositions containing the modified filler are further described, as well as methods to improve hysteresis and / or abrasion resistance in elastomeric compositions using the modified fillers of the present invention.

Owner:CABOT CORP

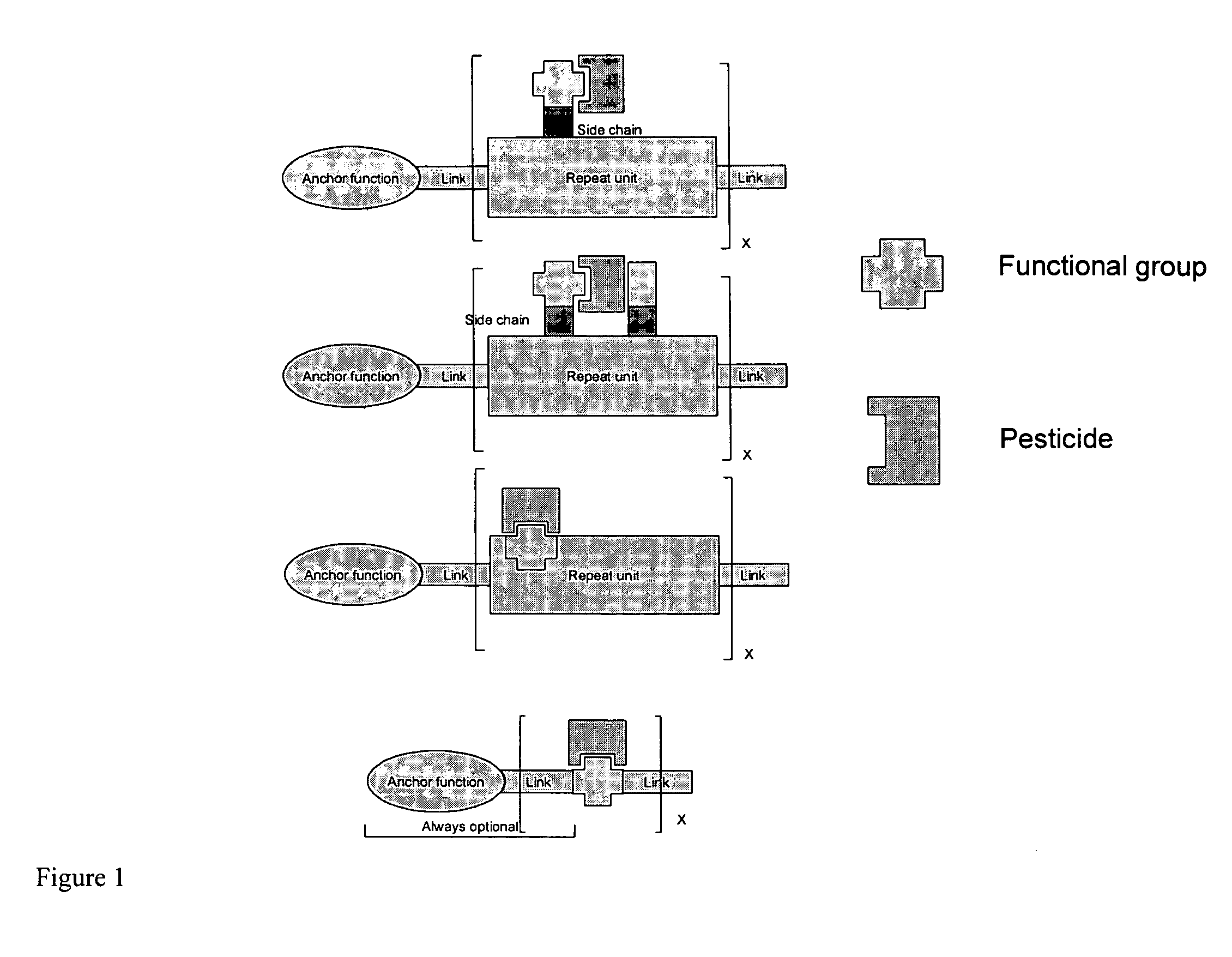

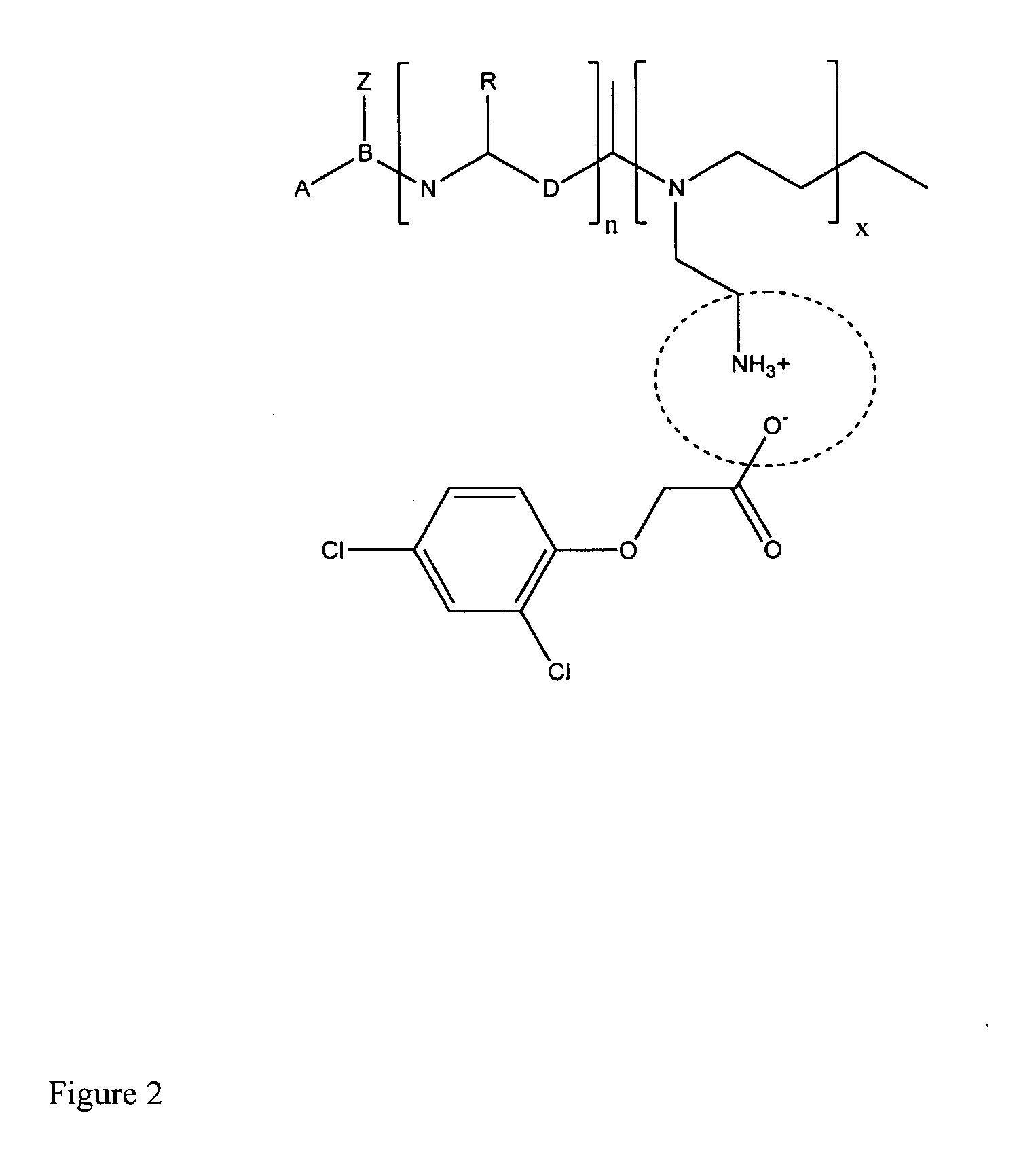

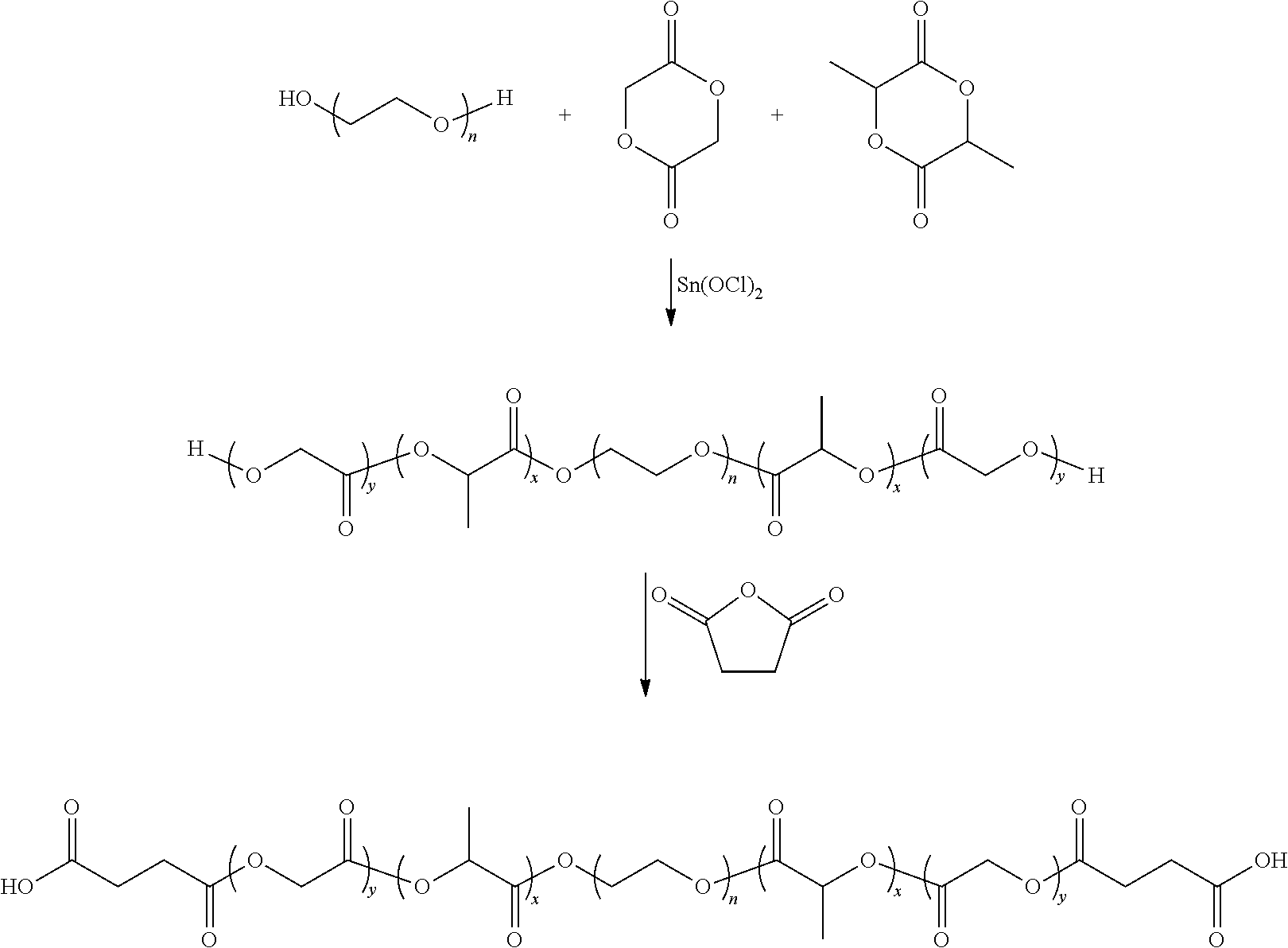

Pesticide formulations with substituted biopolymers and organic polymers for improving residual activity, droplet size, adherence and rainfastness on leaves and reduction in soil leaching

Functionalized polymers are mixed with pesticides to form semi-stable complexes with desirable field properties: reduced leaching in soil, improved leaf retention (rainfastness), selective unloading to roots and convenient packaging and application. Pesticides that may be so complexed include herbicides, insecticides (including compounds controlling non-insect arthropods and nematodes), bacteriocides, rodenticides, and fungicides. Polymers with which they may be complexed include derivatives of carbohydrates, amides, imines, alkanes, vinyls, styrenes or glycols. The polymers may be functionalized with chemical groups that exhibit ionic (amines, carboxyls), hydrophobic, complexing (e.g. metal chelating) and ligand binding interactions. The variously functionalized polymers may be mixed, grafted, or fused to obtain optimal properties. The polymer / pesticide formulations may be applied as granules, as suspensions or solutions in sprays, as foams, or as coats for seeds and fertilizers. The formulations may be applied to foliage, soil, irrigation water, construction materials (plastics, wood), seeding materials, grains, and buildings.

Owner:HI CAP FORMULATIONS

Microparticles and nanoparticles having negative surface charges

This invention provides methods for producing a polymer particle which contains unusually high negative charges on the surface of the particle. Preferably, the polymer is pharmaceutically acceptable. The negative charges can be conferred by chemical groups such as carboxyl, sulfonate, nitrate, fluorate, chloride, iodide, persulfate, and many others, with carboxyl group being preferred. The invention also provides polymer particle produced by the methods of the invention.

Owner:CYTODIGM INC

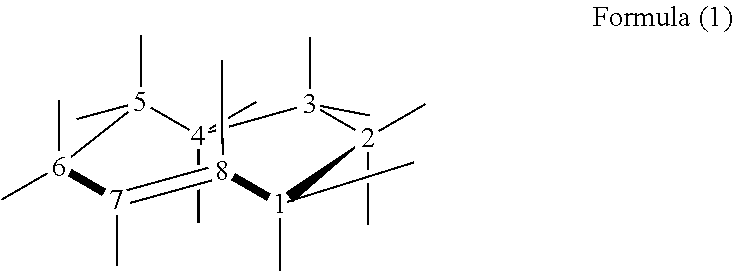

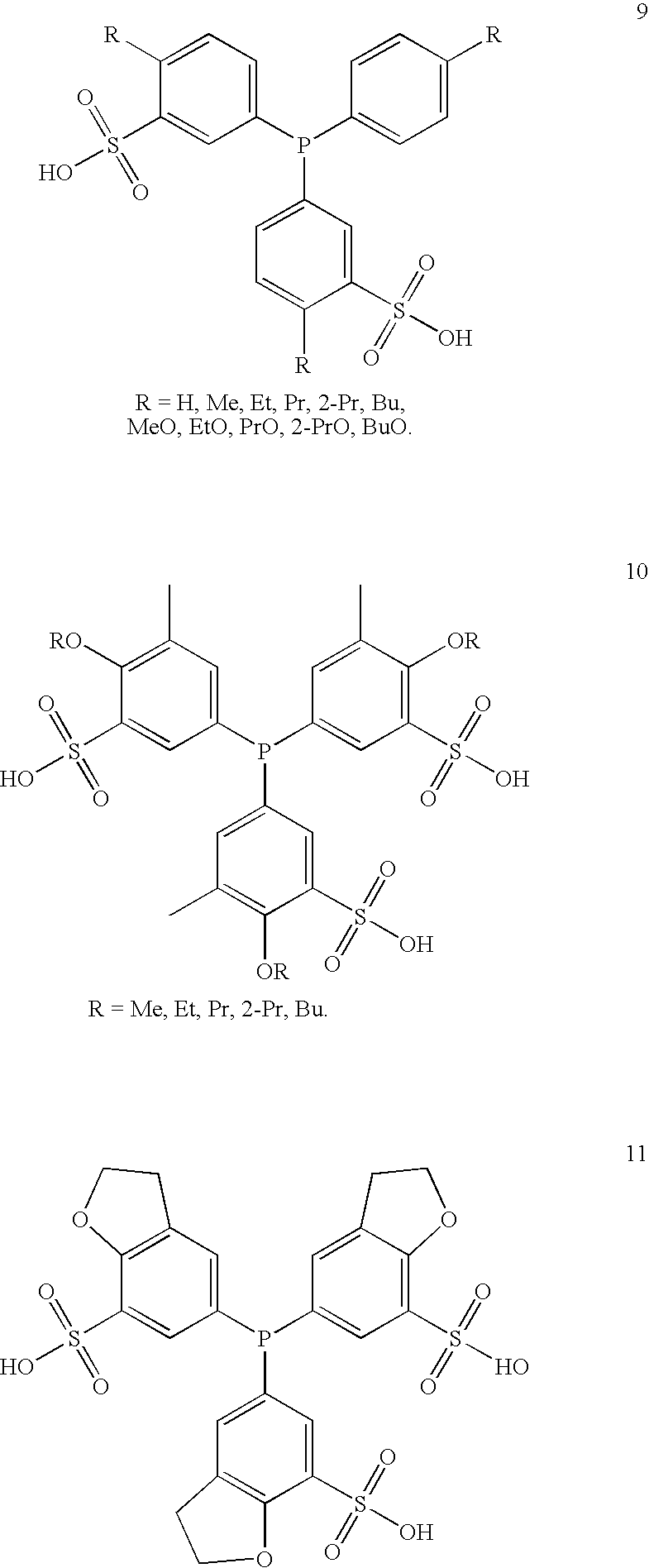

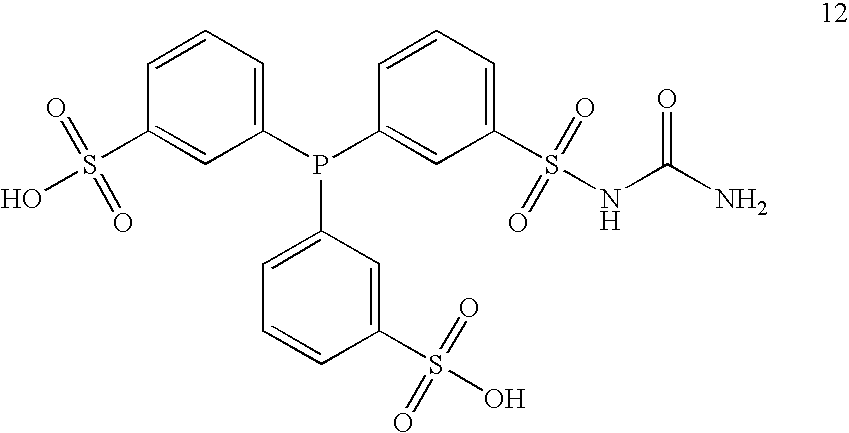

Organic semiconductor material containing naphthalene [1, 2-c: 5, 6-c] di [1, 2, 5] thiadiazole and application thereof

ActiveCN102060982AEasy to manufactureEquilibrium SolubilitySolid-state devicesSemiconductor/solid-state device manufacturingMetal catalystChemical groups

The invention relates to an organic semiconductor material containing naphthalene [1, 2-c: 5, 6-c] di [1, 2, 5] thiadiazole and application thereof, wherein the organic semiconductor material is prepared by reacting the halogenated derivatives with the monomer containing an aromatic group structure under the metal catalyst, wherein the halogenated derivatives are obtained by halogenating the naphthalene [1, 2-c: 5, 6-c] di [1, 2, 5] thiadiazole; the aromatic group is connected with a naphthalene [1, 2-c:5, 6-c] di [1, 2, 5] thiadiazole unit in a conjugate manner. The organic semiconductor material is characterized by containing 3, 7 substituted decorative[1, 2-c: 5, 6-c] di [1, 2, 5] thiadiazole chemical groups; as the naphthalene [1, 2-c:5, 6-c] di [1, 2, 5] thiadiazole has excellent electron-withdrawing ability and planarity, the organic semiconductor material can excellently adjust the photoelectric property, has excellent photoelectric performance, and is applied to the field of organic photoelectric components.

Owner:SOUTH CHINA UNIV OF TECH

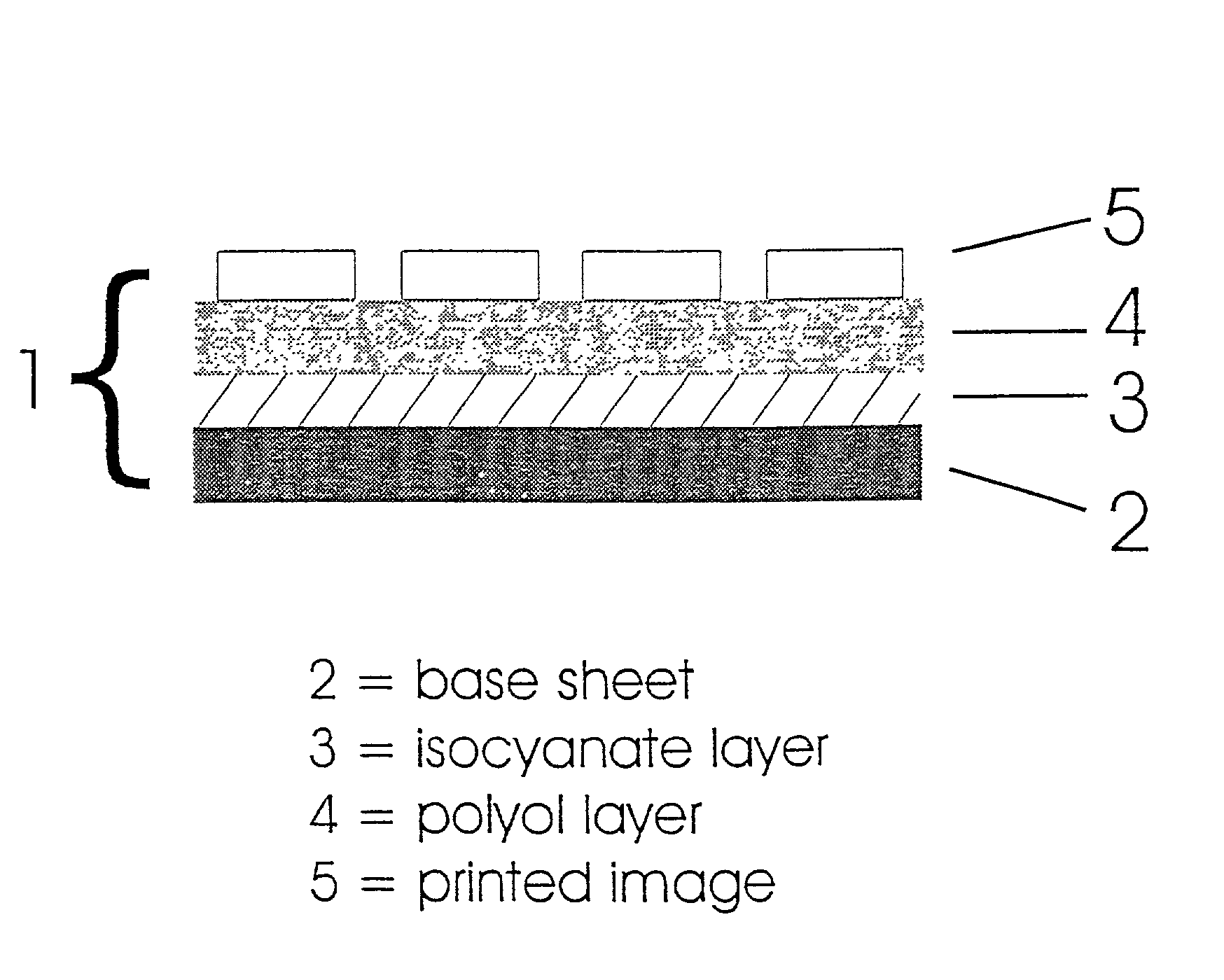

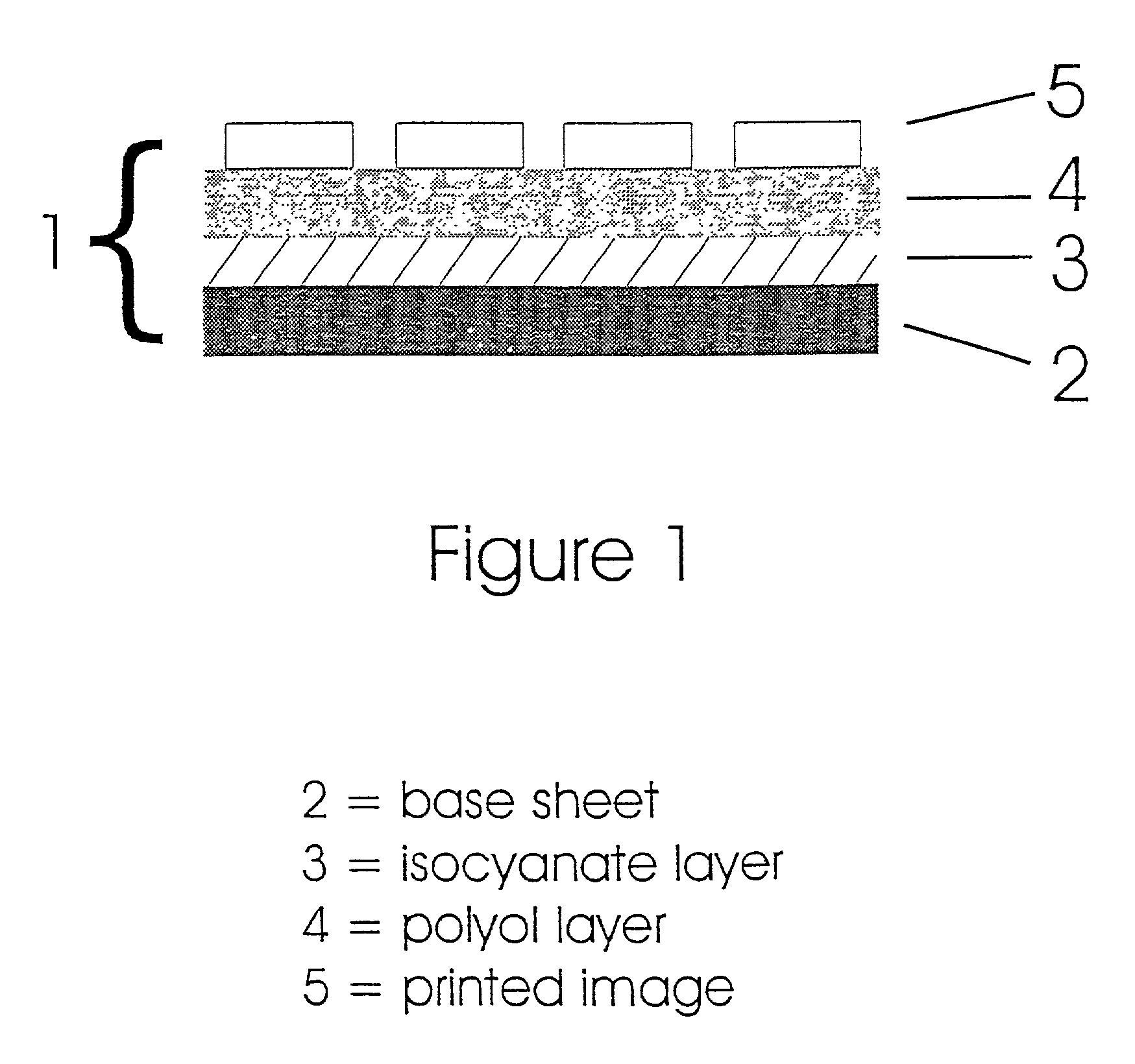

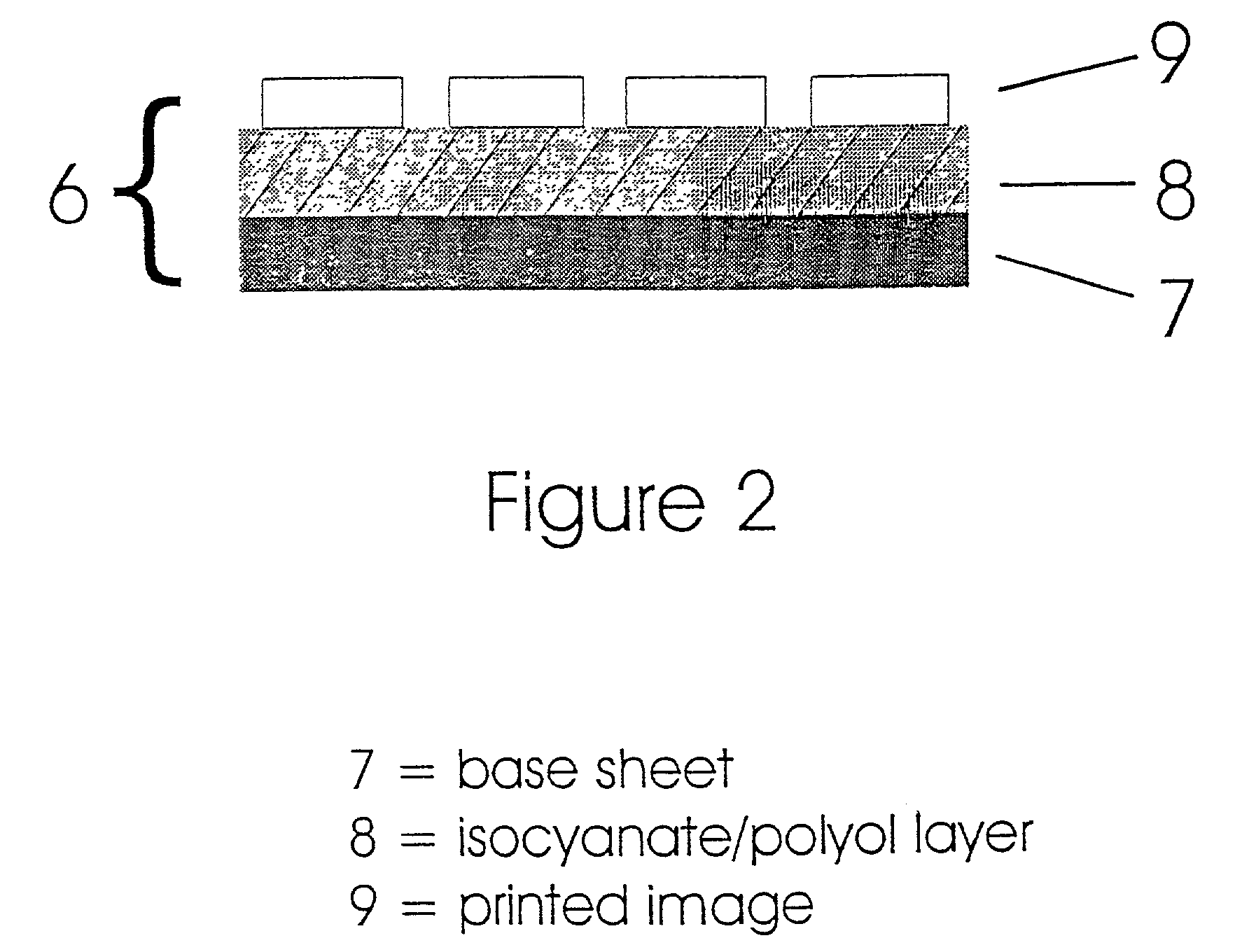

Intermediate transfer recording medium

InactiveUS7001649B2Avoid premature reactionExcellent abrasion resistanceDecorative surface effectsTransfer printing processColor imageHydrogen

A color image is digitally printed onto an intermediate transfer medium. The image is subsequently transferred from the intermediate transfer medium to a final substrate, which may be a cellulosic textile, such as cotton. Bonding of the color images is provided by the reaction between compounds selected from each of two chemical groups contained in the intermediate transfer medium. The first groups comprises compounds with functional groups capable of reacting with active hydrogen, such as isocyanate or epoxy groups. The second group comprises compounds with functional groups containing active hydrogen, or compounds with functional groups containing active hydrogen after a conversion process. The functional groups of one or both reactive chemical groups may be protected either by blocking with internal or external blocking agents or by a physical barrier such as encapsulating agents. The blocking agents are removed by the application of energy, such as heat, during the transfer of the image from the intermediate transfer medium to the final substrate. The intermediate transfer medium may be comprised of additional components which may be combined with either or both of the above two chemical groups, or applied as separate layers. Examples of such components are a thermally expandable material, an exothermic chemical, a release agent, and / or absorbent material. Transferred images so produced have a soft hand, particularly when applied to a textile, and excellent fade and abrasion resistance.

Owner:SAWGRASS TECH INC

Aqueous acrylic emulsion, aqueous adhesive for plastic-plastic composite materials and preparation method thereof

InactiveCN101717468AGood adhesionHigh molecular weightEster polymer adhesivesFunctional monomerMetal foil

The invention discloses an aqueous acrylic emulsion, an aqueous adhesive for plastic-plastic composite materials and a preparation method thereof, and belongs to the field of preparation of adhesive. The acrylic emulsion is polymerized from 30-50 wt% of acrylic acid hard monomer, 40-60 wt% of acrylic acid soft monomer and 5-10 wt% of acrylic acid functional monomer under the action of water, an emulsifying agent, an initiator, a buffering agent and a pH regulator. The invention also provides an aqueous adhesive and a preparation method thereof. The molecule segment of the film forming matter (acrylate copolymer) in the aqueous acrylic emulsion has various chemical groups, such as -OH, -COOH, -NH and the like; and the chemical groups can form various chemical bonds and hydrogen bonding acting force, and thereby having favorable adhering force for various composite substrates (plastic films, aluminum plating films, metal foils and the like). By properly matching the soft monomer and the hard monomer and adopting the corresponding functional monomer to participate in the copolymerization, the invention enhances the adhesive affinity to the plastic films with low surface tension, thereby enhancing the wetting property of the adhesive on the surface of the plastic films and the combined strength.

Owner:BEIJING COMENS NEW MATERIALS

Aqueous acrylic emulsion, aqueous adhesive for pearlized film composite materials and preparation method thereof

InactiveCN101717467AGood adhesionImprove the level ofEster polymer adhesivesFunctional monomerMetal foil

The invention discloses an aqueous acrylic emulsion, an aqueous adhesive for pearlized film composite materials and a preparation method thereof, and belongs to the field of preparation of adhesive. The acrylic emulsion is polymerized from 20-40 wt% of acrylic acid hard monomer and 55-70 wt% of acrylic acid soft monomer and 1-5 wt% of acrylic acid functional monomer under the action of water, an emulsifying agent, an initiator, a buffering agent and a pH regulator. The invention also provides an aqueous adhesive and a preparation method thereof. The molecule segment of the film forming matter (acrylate copolymer) in the aqueous acrylic emulsion has various chemical groups, such as -OH, -COOH, -NH and the like; and the chemical groups can form various chemical bonds and hydrogen bonding acting force, and thereby having favorable adhering force for various composite substrates (plastic films, aluminum plating films, metal foils and the like). The polymer obtained by polymerization has higher molecular weight, lower coating viscosity and favorable levelling property; and thus, the polymer has high shear strength and initial strength and can achieve the best bonding strength without curing for a long time.

Owner:BEIJING COMENS NEW MATERIALS

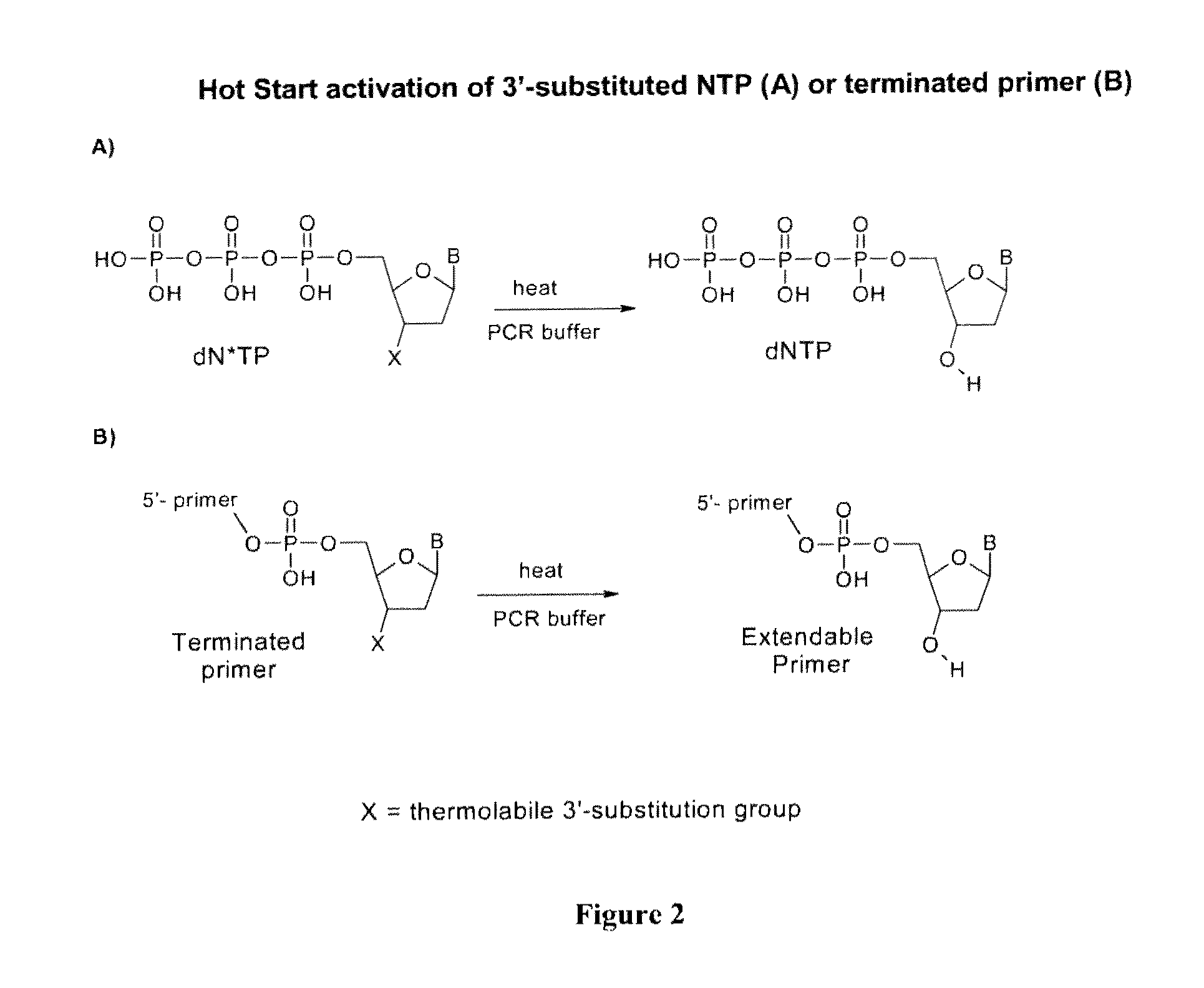

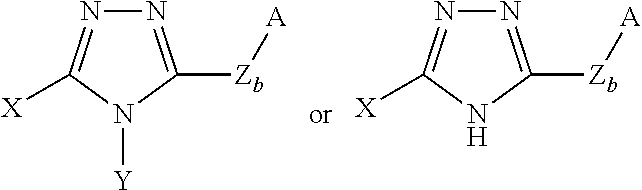

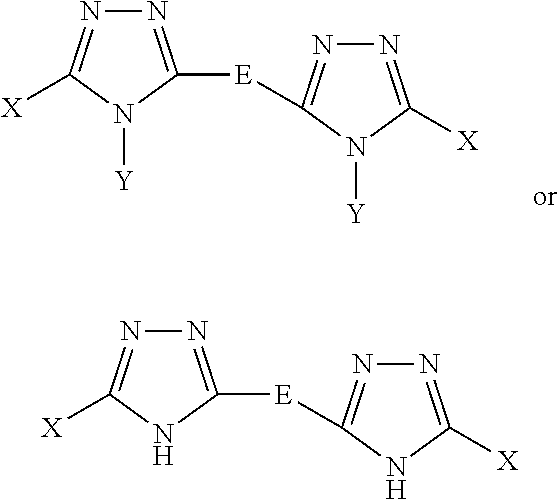

Organic semiconductor material containing 6-R group- [1, 2, 5] thiazole [3, 4-g] benzotriazole and application thereof

ActiveCN102050940AIdeal electron deficient materialEasy to processSolid-state devicesSemiconductor/solid-state device manufacturingSolubilityAlkyl transfer

The invention provides an organic semiconductor material containing 6-R group-[1, 2, 5] thiazole [3, 4-g] benzotriazole and an application thereof. Diazosulfide is used as parent, benzotriazole derivatives are formed by reduction and ring closure of nitrated diazosulfide, and finally, a halogenated 6-R group-[1, 2, 5] thiazole [3, 4-g] benzotriazole monomer is synthesized by performing alkylation reaction on an H of an N atom; and the monomer is reacted with a monomer containing an aromatic group under effect of metal catalyst to prepare the organic semiconductor material. Positions 1, 2, 5 and 6 of a benzene ring of the organic semiconductor material are respectively connected with alkyl triazole and thiazole, the two kinds of chemical groups have excellent electron attracting performance, and a formed ternary condensed ring has better planarity and conjugated bonds, and also has good dissolubility. The organic semiconductor material provided by the invention can be used as an active layer having application foreground to be applied in organic photoelectric devices.

Owner:SOUTH CHINA UNIV OF TECH

Blood Coagulation FVIII Analogues

InactiveUS20080227691A1High molecular weightFactor VIIPeptide/protein ingredientsTargeted disruptionChemical groups

The invention is related to a FVIII analogue which has a circulation time in the blood stream before activation of at least about two times of that of native FVIII and a week after injection to a patient retains at least about 5% of the FVIII activity compared to the initial activity peak value reached after injection. The claimed FVIII analogues comprise a targeted disruption of one or more of the clearance sites in the FVIII molecule by introduction of at least one N-glycosylation site or by introduction of at least one Cys residue within or spatially close to the clearance site in the A2 domain or a combination thereof. The inserted cysteine residues may be further modified by conjugation with a chemical group increasing the molecular weight of the FVIII analogue.

Owner:NOVO NORDISK AS

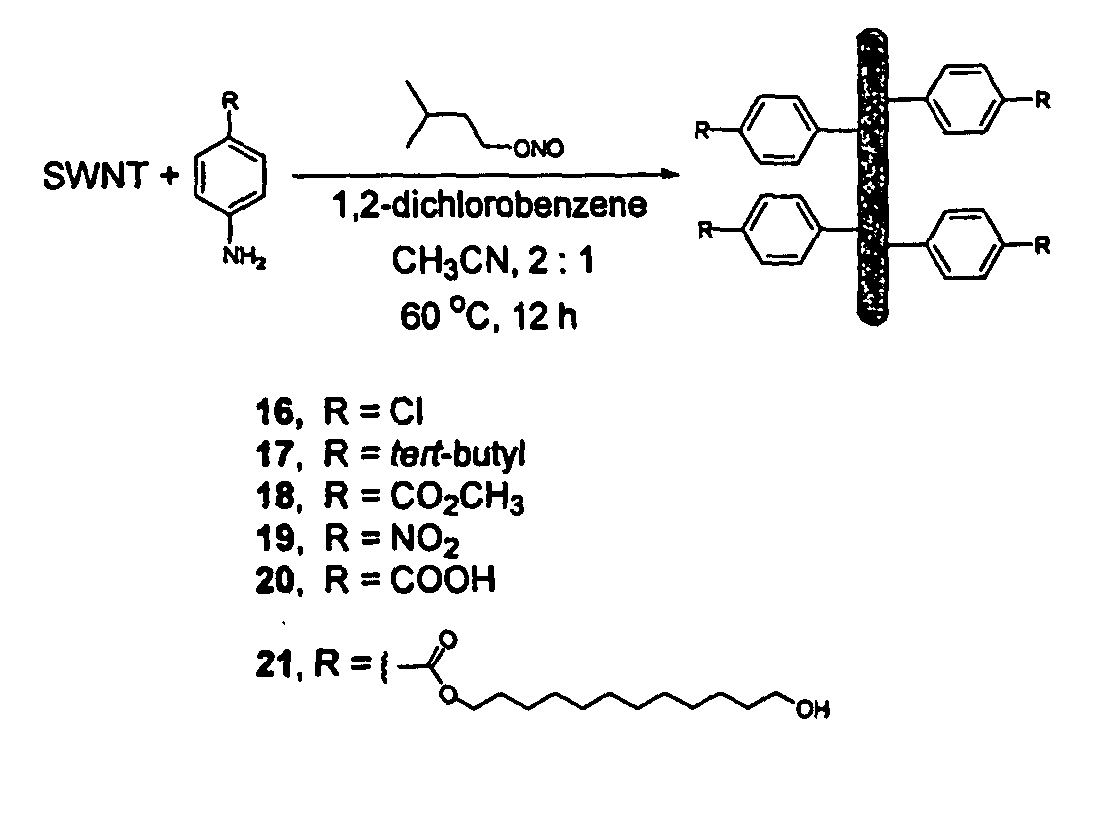

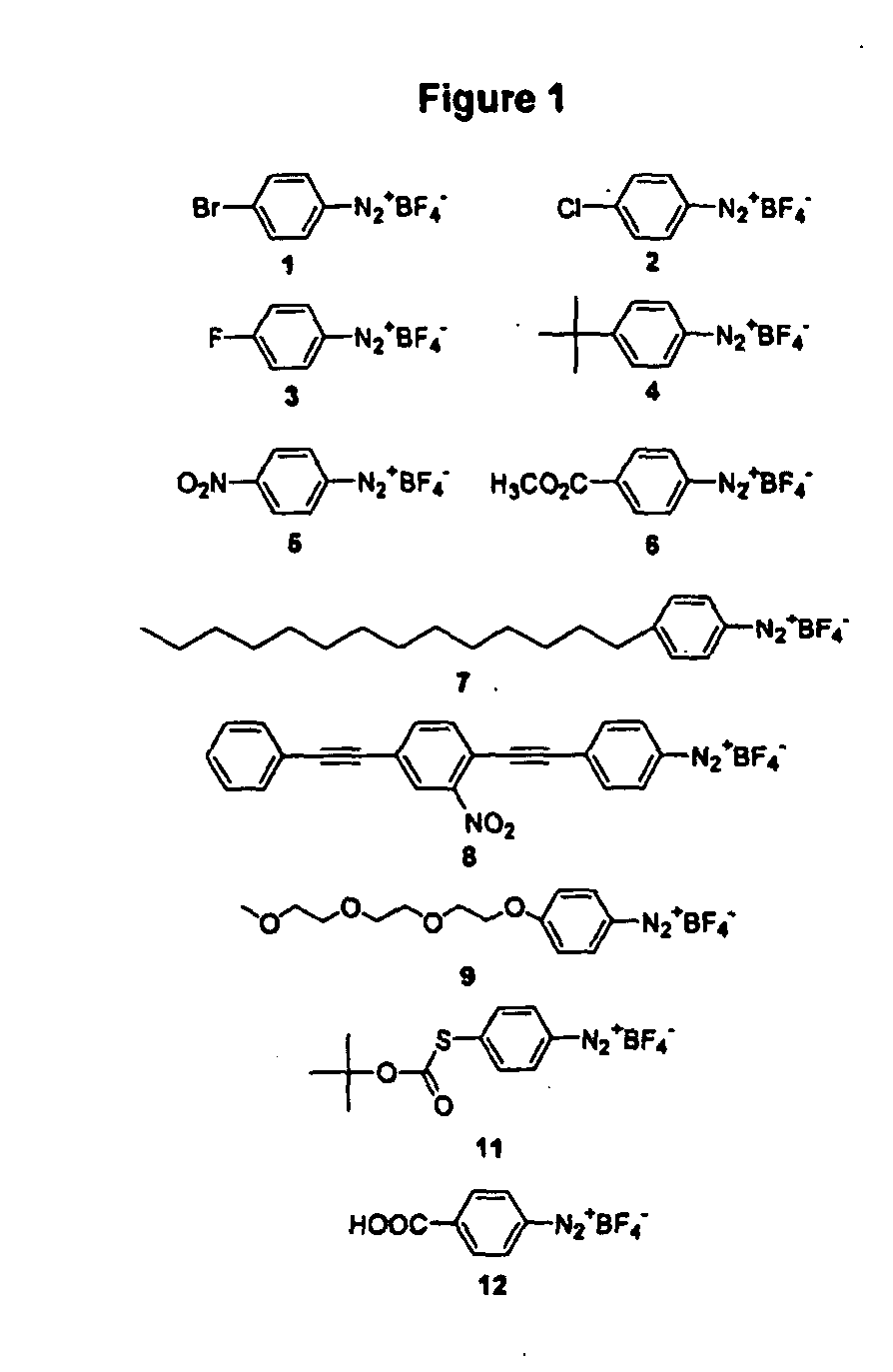

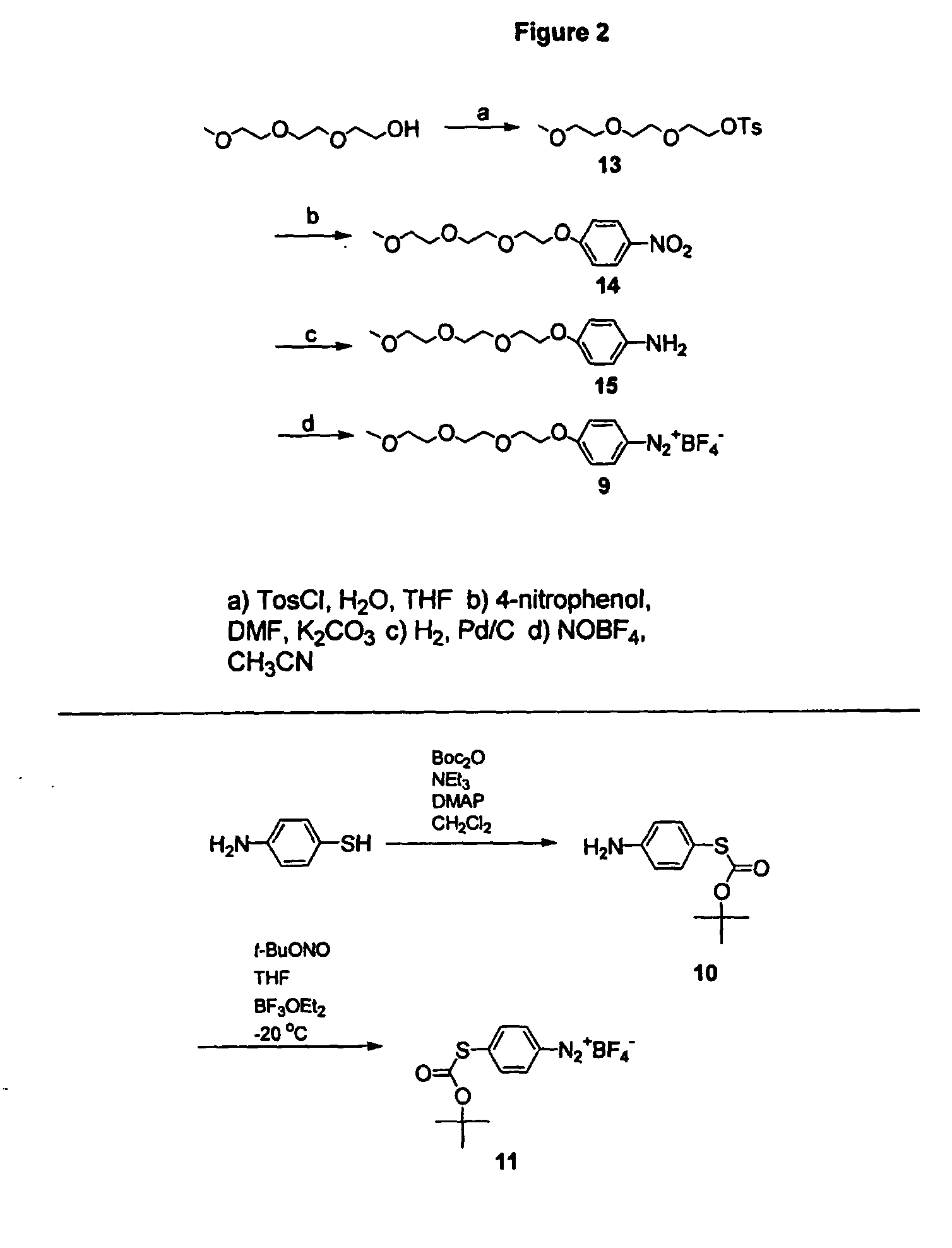

Carbon nanotubes derivatized with diazonium species

InactiveUS20050207963A1Advantage of scalabilityMaterial nanotechnologyPigmenting treatmentElectrochemistryOrganic compound

Owner:RICE UNIV

Method for removing cytokines from blood with surface immobilized polysaccharides

ActiveUS8758286B2Lessen and eliminate spreadAntibacterial agentsSalicyclic acid active ingredientsPorous substratePolysaccharide

The present invention is directed to a method for removing cytokines and / or pathogens from blood or blood serum (blood) by contacting the blood with a solid, essentially non micro-porous substrate which has been surface treated with heparin, heparan sulfate and / or other molecules or chemical groups (the adsorbent media or media) having a binding affinity for the cytokine or pathogen(s) to be removed (the adsorbates), and wherein the size of the interstitial channels within said media is balanced with the amount of media surface area and the surface concentration of binding sites on the media in order to provide adequate adsorptive capacity while also allowing relatively high flow rates of blood through the adsorbent media.

Owner:EXTHERA MEDICAL

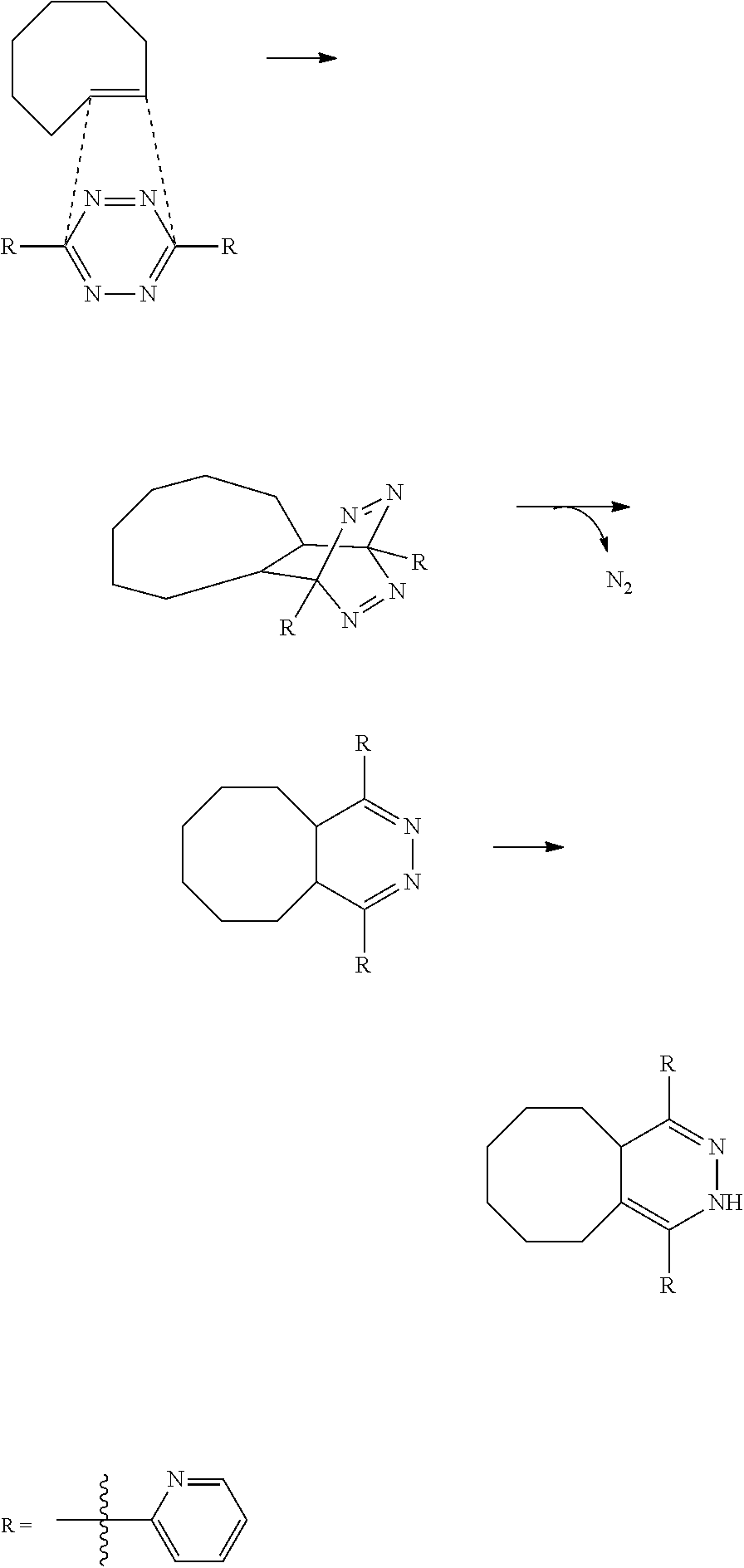

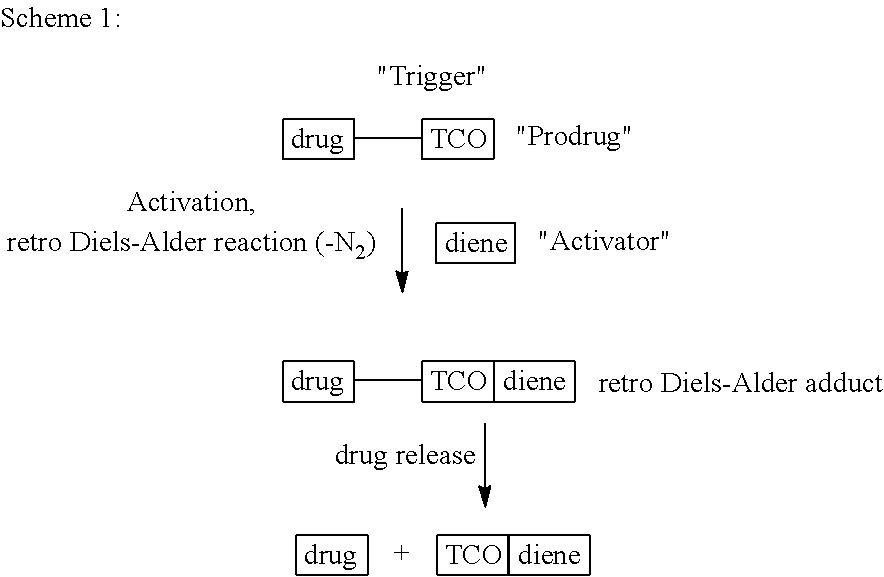

Bio-orthogonal drug activation

ActiveUS20140199331A1Organic active ingredientsDipeptide ingredientsDrug conjugationAntiendomysial antibodies

The invention relates to a Prodrug activation method, for therapeutics, wherein use is made of abiotic reactive chemical groups that exhibit bio-orthogonal reactivity towards each other. The invention also relates to a Prodrug kit comprising at least one Prodrug and at least one Activator, wherein the Prodrug comprises a Drug and a first Bio-orthogonal Reactive Group (the Trigger), and wherein the Activator comprises a second Bio-orthogonal Reactive Group. The invention also relates to targeted therapeutics used in the above-mentioned method and kit. The invention particularly pertains to antibody-drug conjugates and to bi- and trispecific antibody derivatives.

Owner:KONINK PHILIPS ELECTRONICS NV

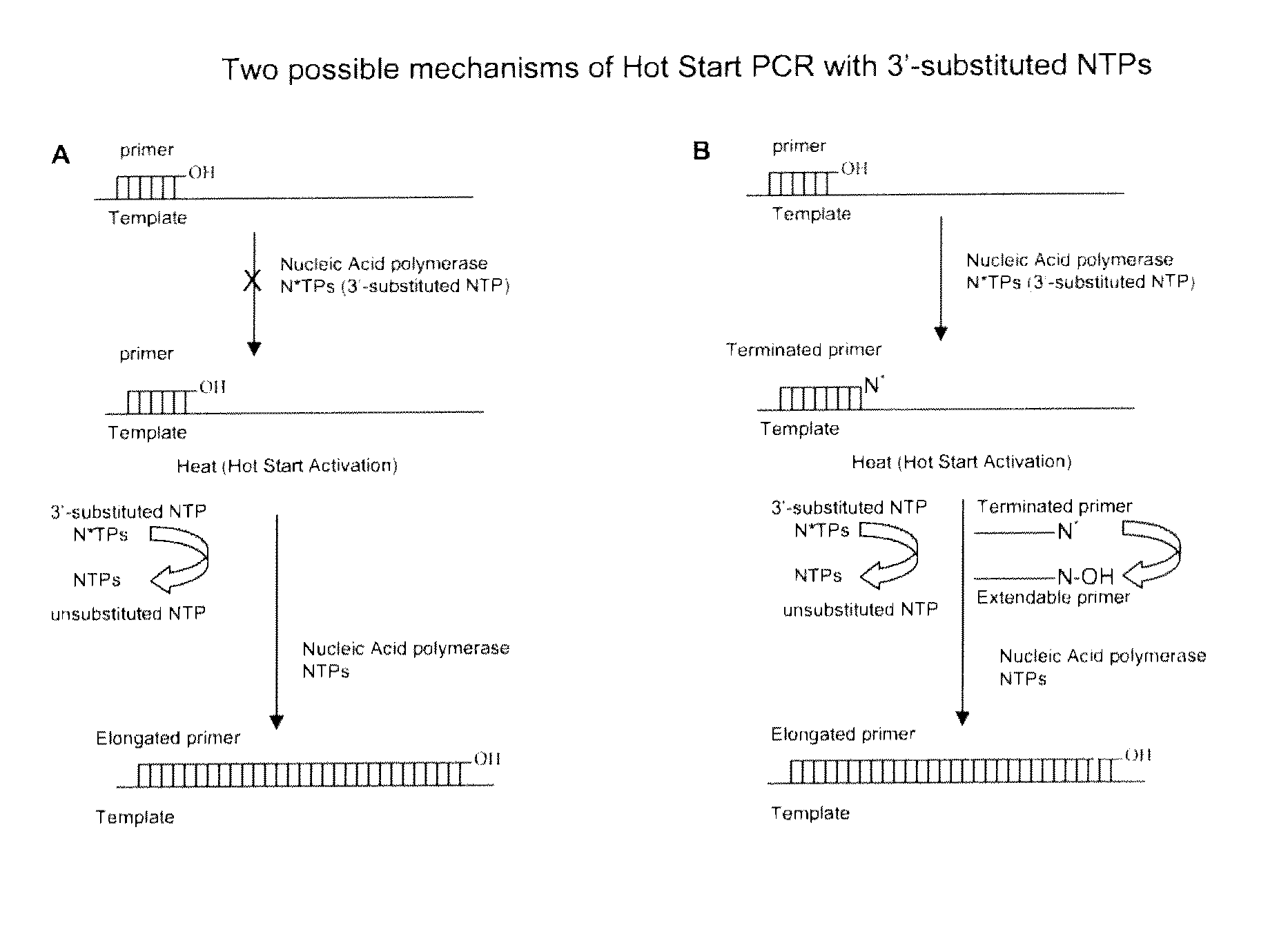

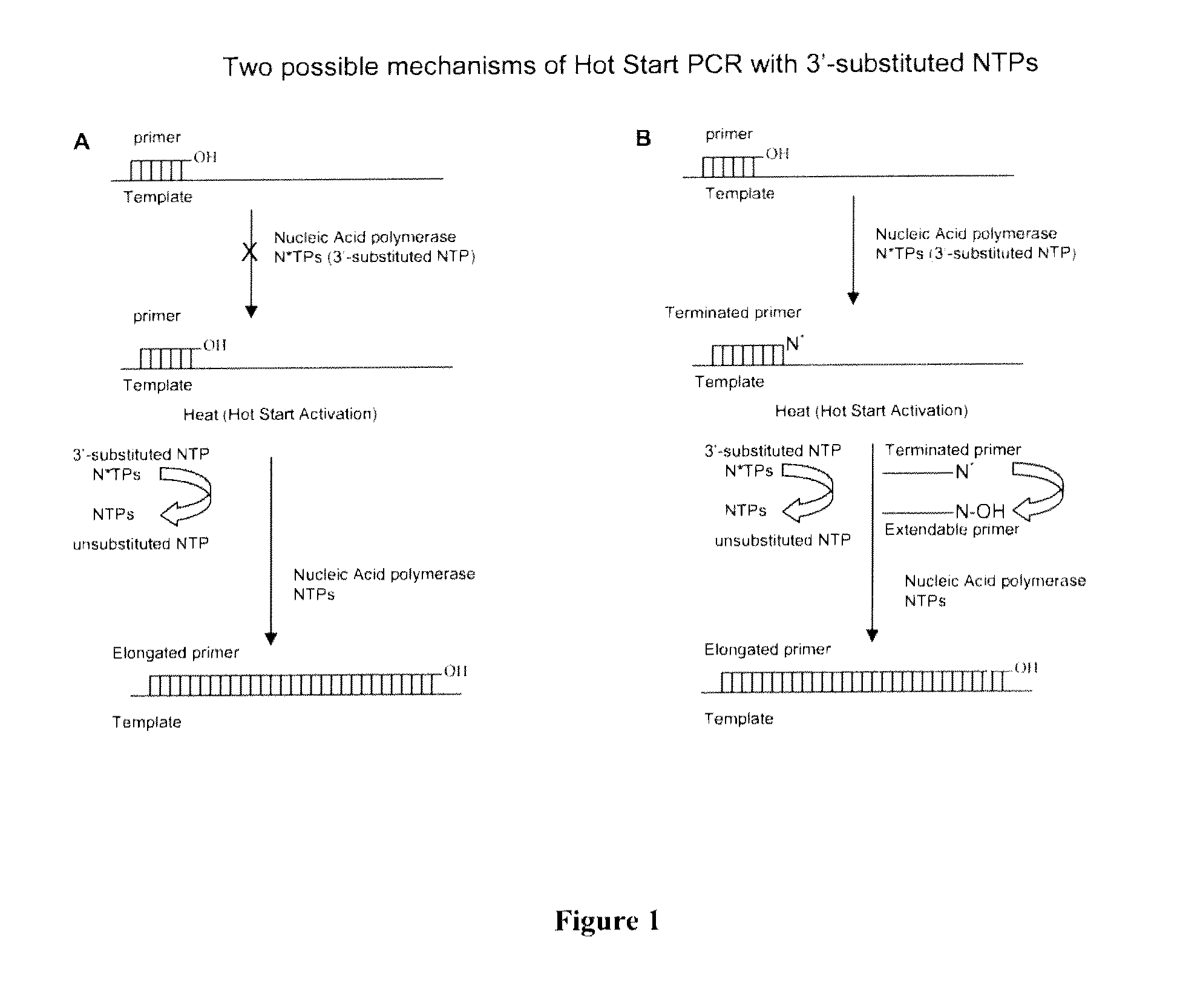

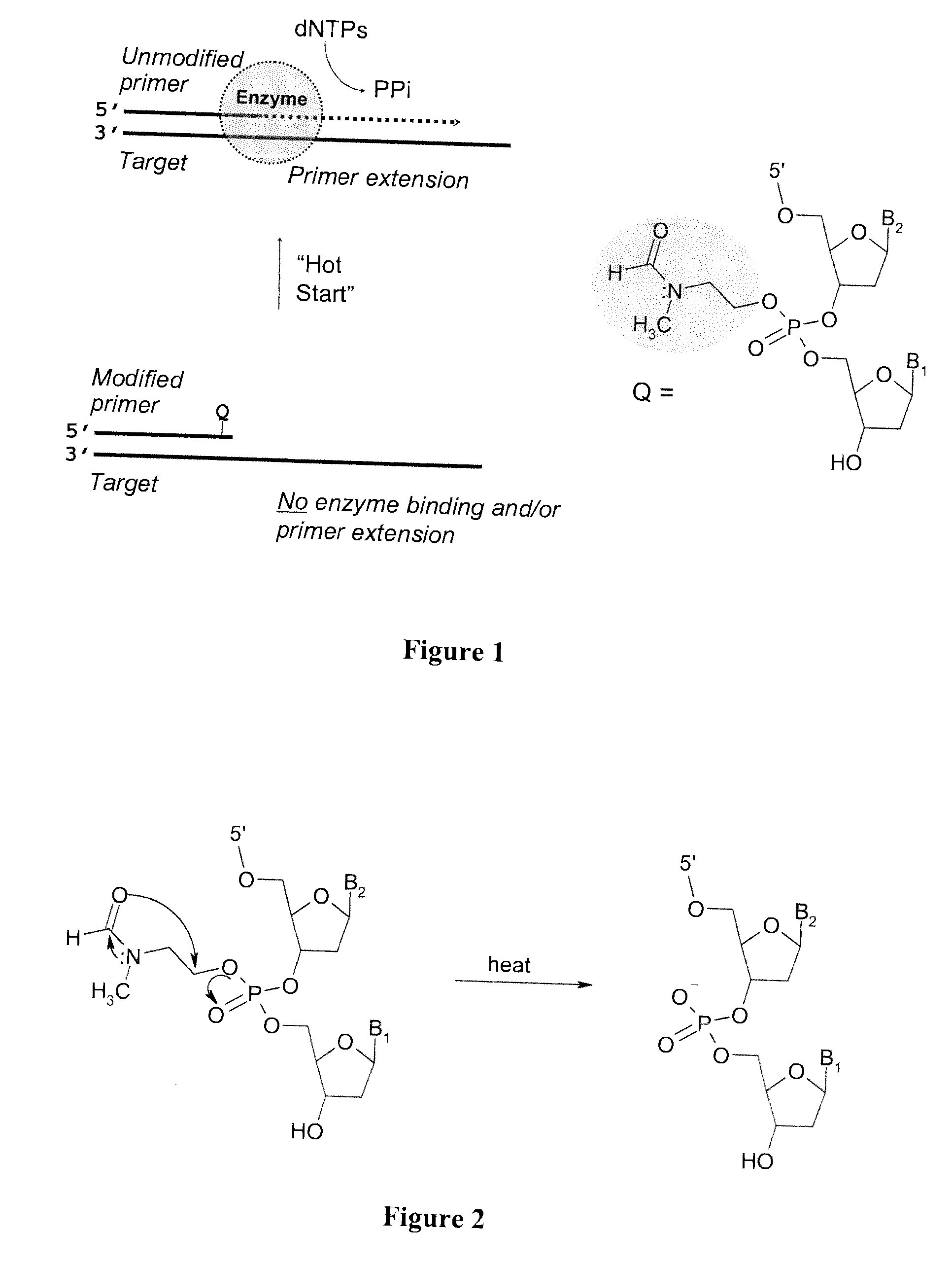

Chemically modified nucleoside 5′-triphosphates for thermally initiated amplification of nucleic acid

ActiveUS8133669B2Improve efficacyLess efficaciousAnalysis using chemical indicatorsSugar derivativesCarbonate esterEther

Provided herein are methods and compositions for nucleic acid replication. These methods involve the use of 3′-substituted nucleoside 5′-triphosphates or 3′-substituted terminated primers in nucleic acid replication reactions. In certain aspects, the methods are accomplished by use of 3′-substituted NTPs and / or 3′-substituted terminated primers which provide utility in nucleic acid replication. In preferred embodiments, the NTPs and / or primers are substituted at the 3′-position with particular heat labile chemical groups such as ethers, esters or carbonate esters.

Owner:TRILINK BIOTECH LLC

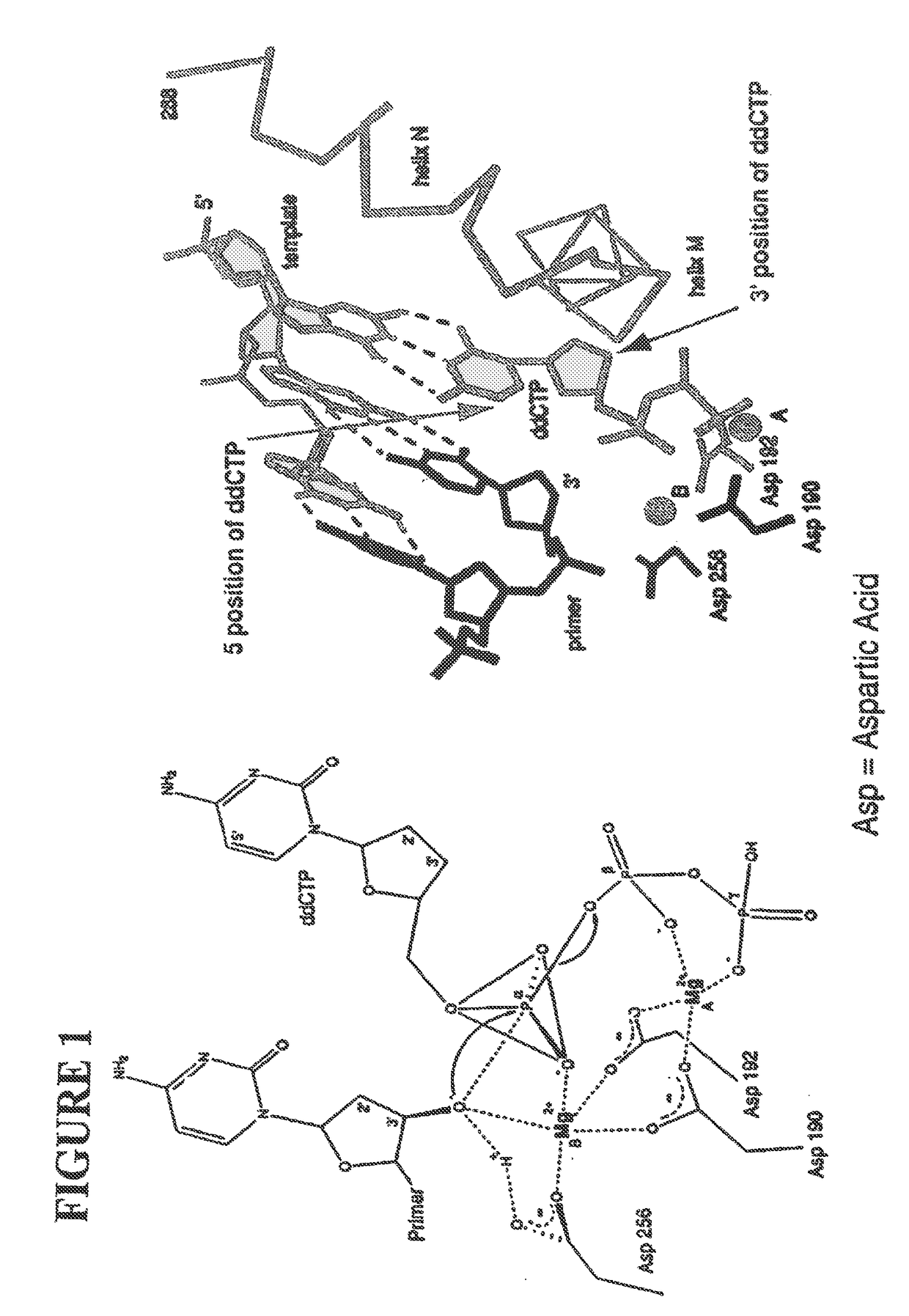

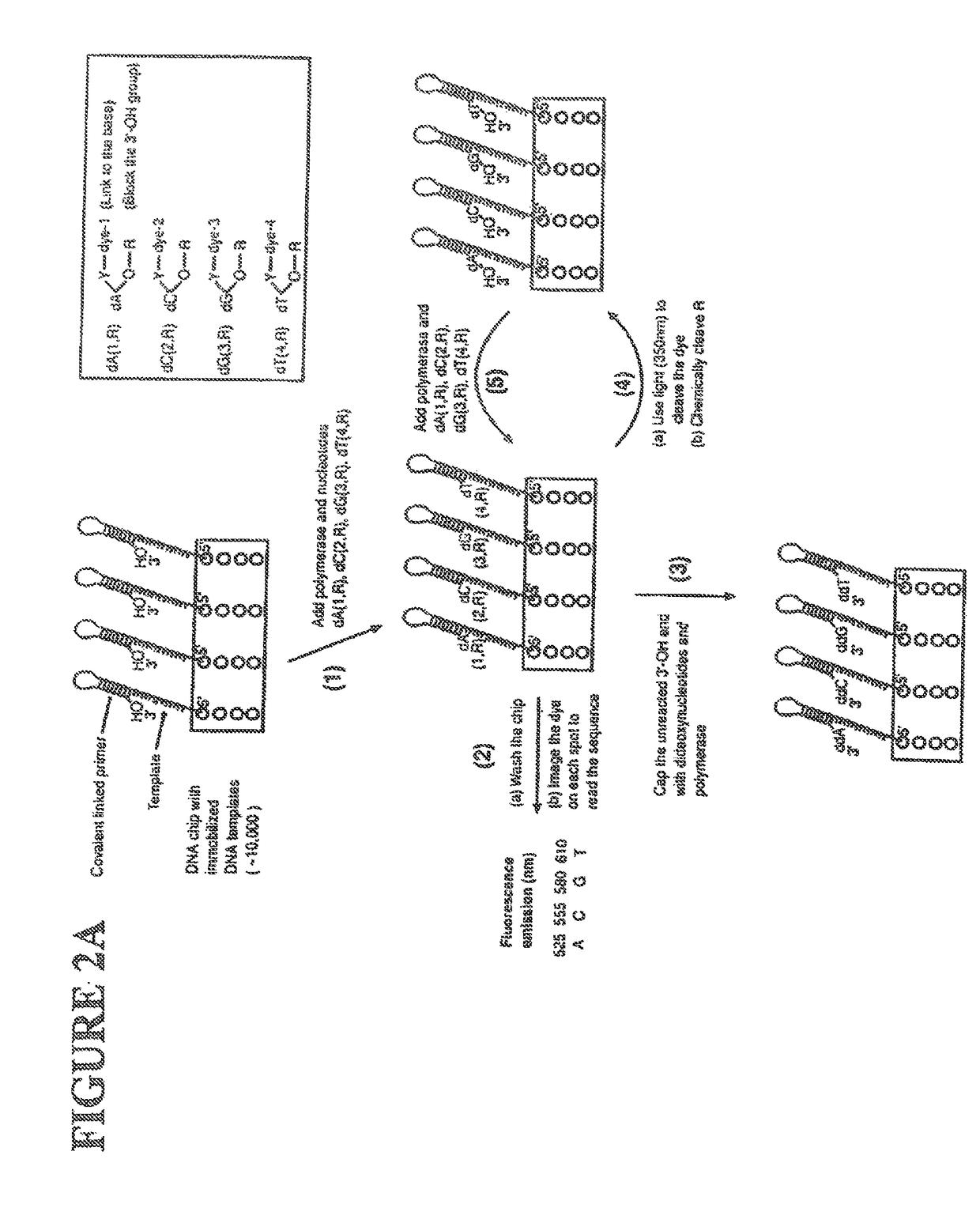

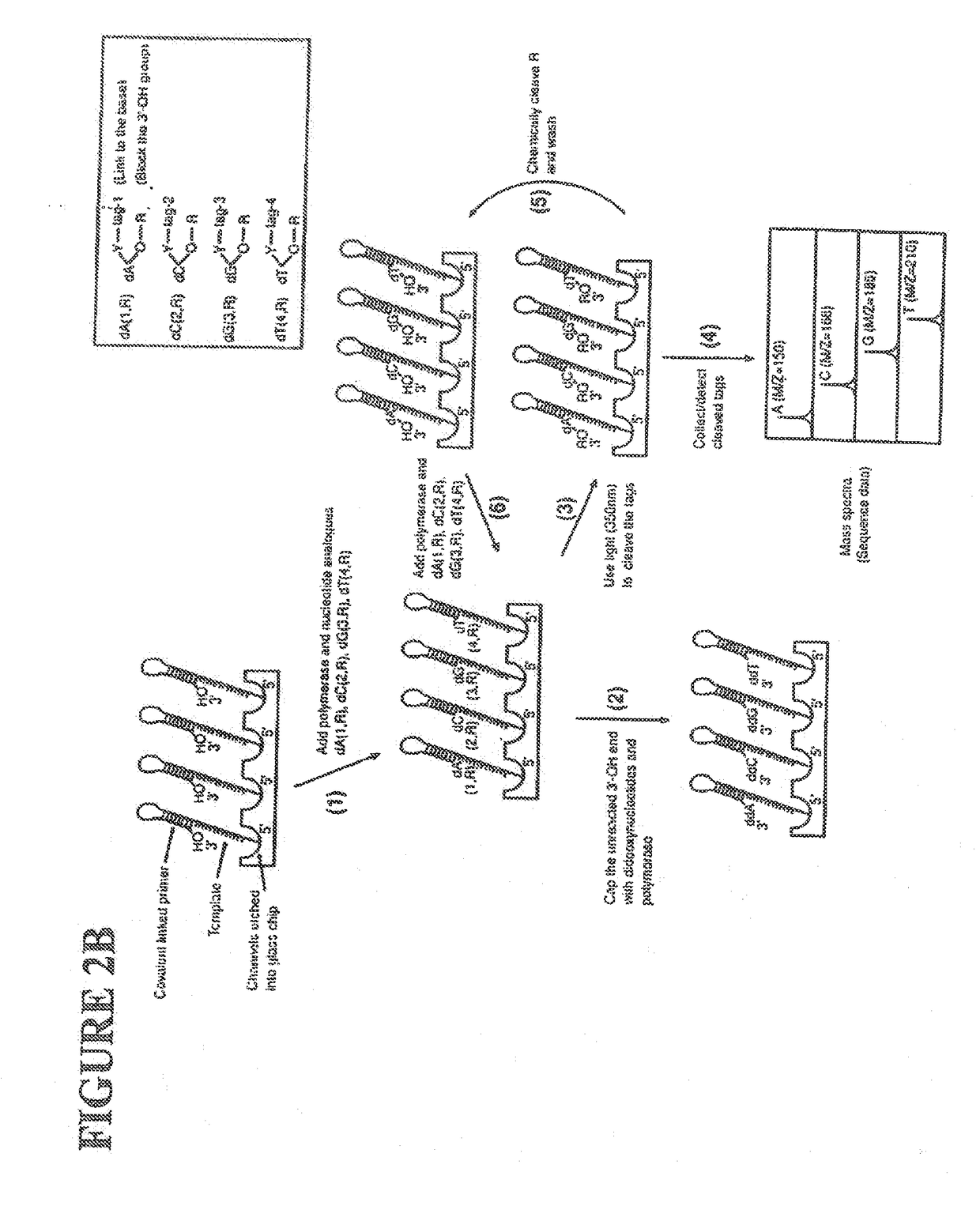

Massive parallel method for decoding DNA and RNA

This invention provides methods for attaching a nucleic acid to a solid surface and for sequencing nucleic acid by detecting the identity of each nucleotide analog after the nucleotide analog is incorporated into a growing strand of DNA in a polymerase reaction. The invention also provides nucleotide analogs which comprise unique labels attached to the nucleotide analog through a cleavable linker, and a cleavable chemical group to cap the —OH group at the 3′-position of the deoxyribose.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Organic semiconductor material containing naphthalene [1, 2-c: 5, 6-c] di [1, 2, 5] thiadiazole and application thereof Organic semiconductor material containing naphthalene [1, 2-c: 5, 6-c] di [1, 2, 5] thiadiazole and application thereof](https://images-eureka.patsnap.com/patent_img/60086426-a8d6-48fe-83a2-b88c7b9342e9/HSA00000374537600011.PNG)

![Organic semiconductor material containing naphthalene [1, 2-c: 5, 6-c] di [1, 2, 5] thiadiazole and application thereof Organic semiconductor material containing naphthalene [1, 2-c: 5, 6-c] di [1, 2, 5] thiadiazole and application thereof](https://images-eureka.patsnap.com/patent_img/60086426-a8d6-48fe-83a2-b88c7b9342e9/HSA00000374537600012.PNG)

![Organic semiconductor material containing naphthalene [1, 2-c: 5, 6-c] di [1, 2, 5] thiadiazole and application thereof Organic semiconductor material containing naphthalene [1, 2-c: 5, 6-c] di [1, 2, 5] thiadiazole and application thereof](https://images-eureka.patsnap.com/patent_img/60086426-a8d6-48fe-83a2-b88c7b9342e9/HSA00000374537600021.PNG)

![Organic semiconductor material containing 6-R group- [1, 2, 5] thiazole [3, 4-g] benzotriazole and application thereof Organic semiconductor material containing 6-R group- [1, 2, 5] thiazole [3, 4-g] benzotriazole and application thereof](https://images-eureka.patsnap.com/patent_img/63e990ec-e906-470a-909f-1f287dde0f0f/110128101030.PNG)

![Organic semiconductor material containing 6-R group- [1, 2, 5] thiazole [3, 4-g] benzotriazole and application thereof Organic semiconductor material containing 6-R group- [1, 2, 5] thiazole [3, 4-g] benzotriazole and application thereof](https://images-eureka.patsnap.com/patent_img/63e990ec-e906-470a-909f-1f287dde0f0f/110128101033.PNG)

![Organic semiconductor material containing 6-R group- [1, 2, 5] thiazole [3, 4-g] benzotriazole and application thereof Organic semiconductor material containing 6-R group- [1, 2, 5] thiazole [3, 4-g] benzotriazole and application thereof](https://images-eureka.patsnap.com/patent_img/63e990ec-e906-470a-909f-1f287dde0f0f/110128101036.PNG)