Patents

Literature

529 results about "Nitrilotriacetic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nitrilotriacetic acid (NTA) is the aminopolycarboxylic acid with the formula N(CH₂CO₂H)₃. It is a colourless solid that is used as a chelating agent, which forms coordination compounds with metal ions (chelates) such as Ca²⁺, Co²⁺ , Cu²⁺, and Fe³⁺.

Liver-targeting agents and their synthesis

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE +1

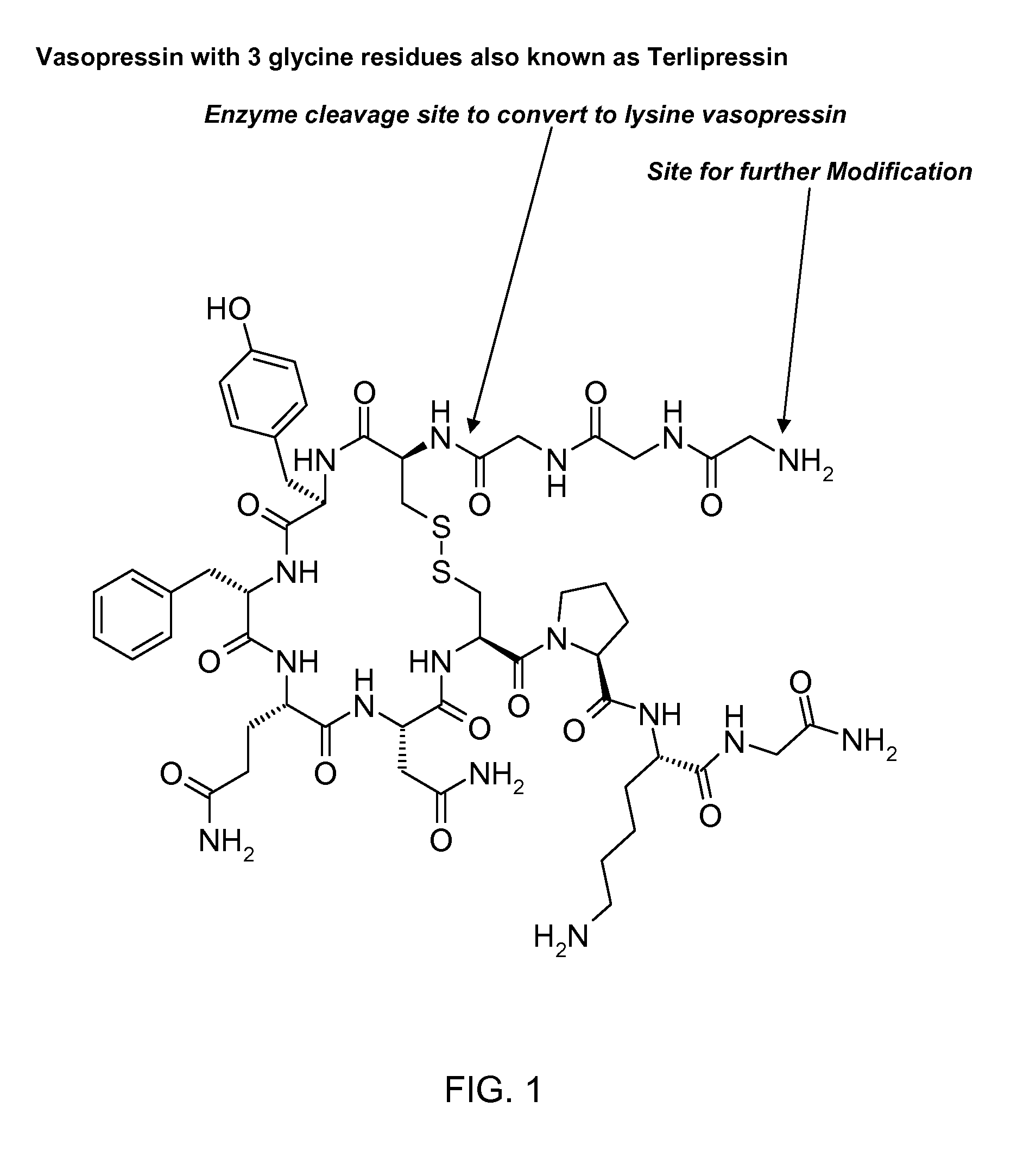

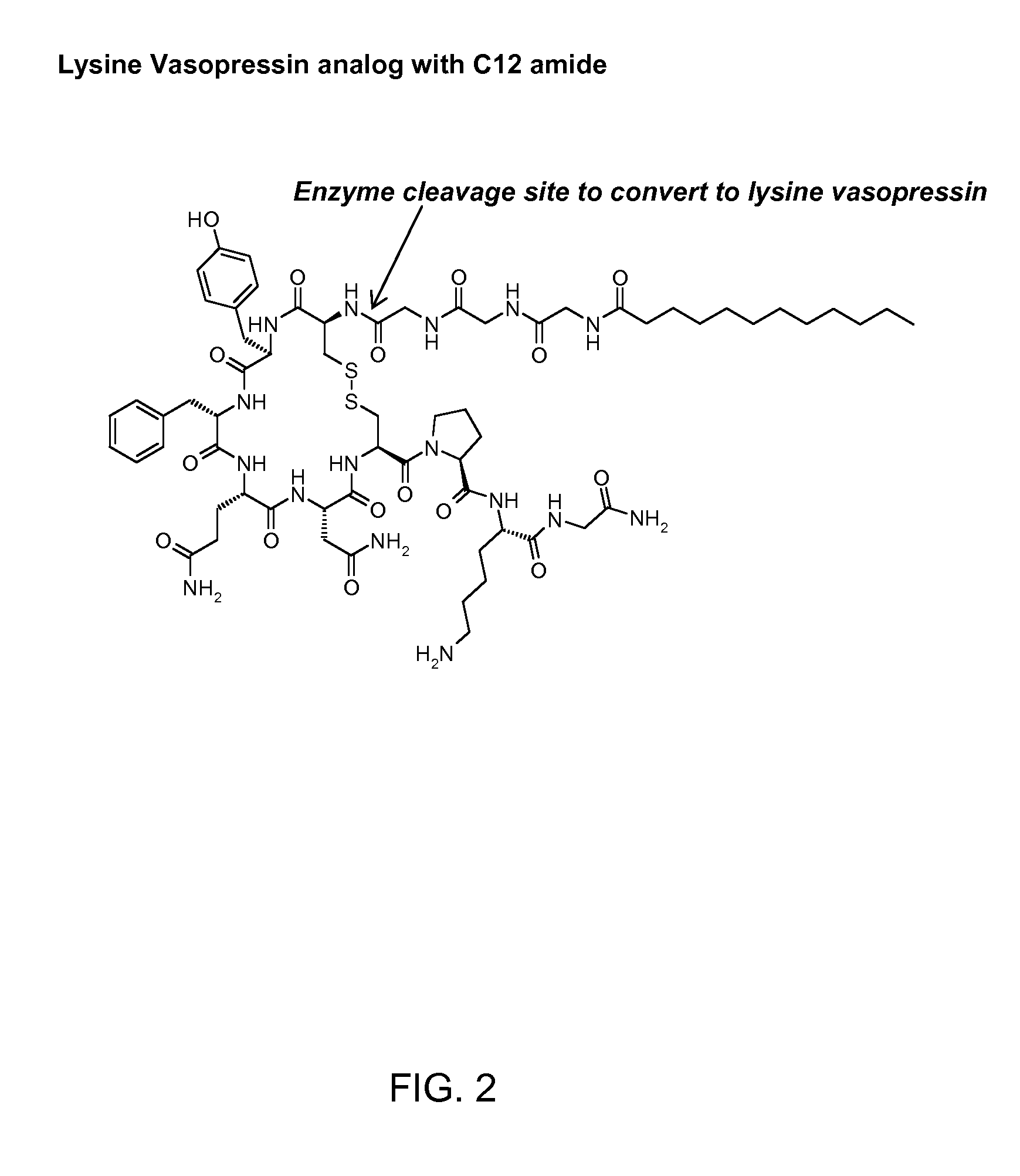

Composition for long-acting peptide analogs

ActiveUS20090088387A1Increase perfusionImprove the level ofAntibacterial agentsPeptide/protein ingredientsHalf-lifeArginine

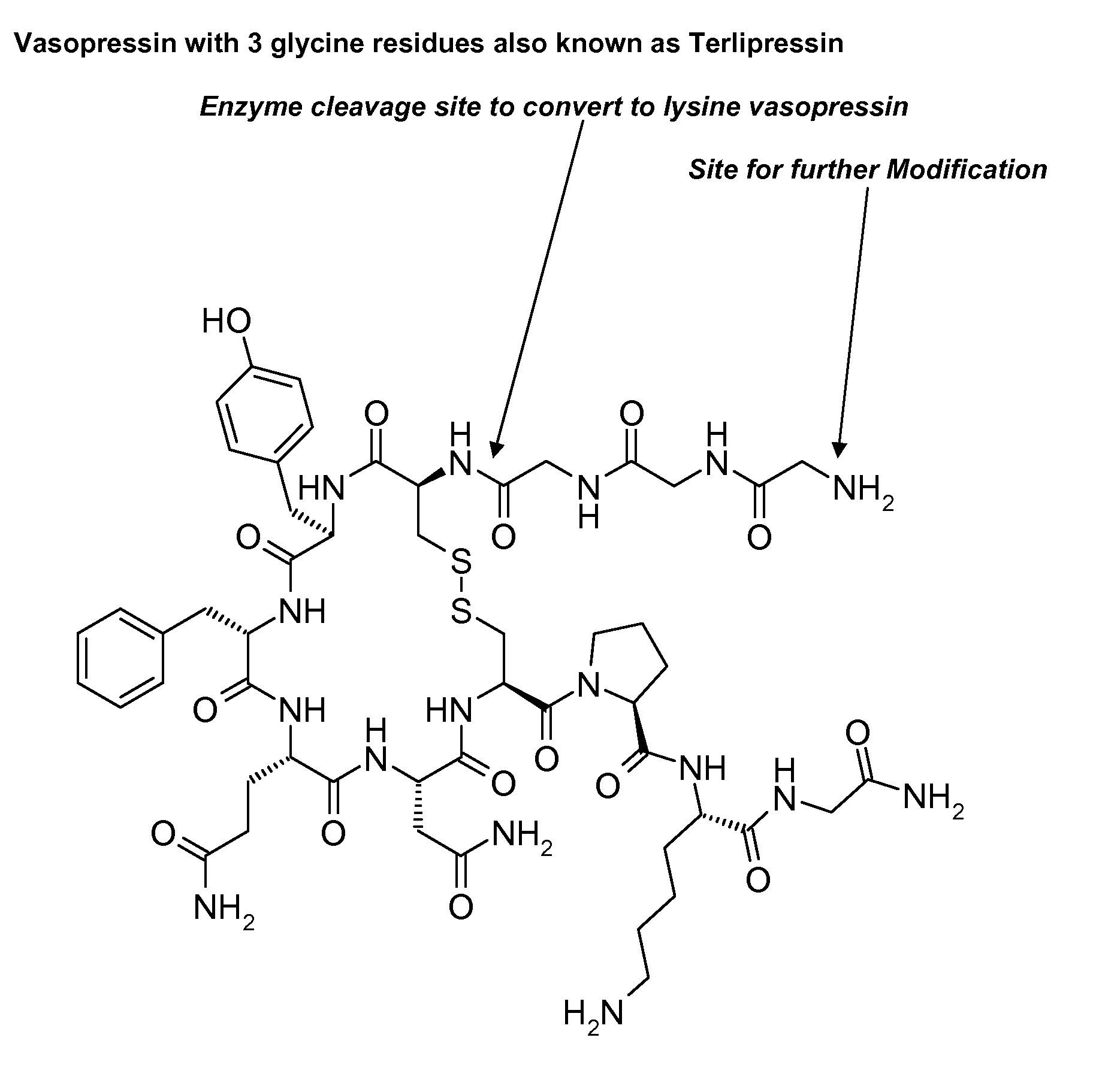

The invention describes compositions of peptide analogs that are active in blood or cleavable in blood to release an active peptide. The peptide analogs have a general formula: A-(Cm)x-Peptide, wherein A is hydrophobic moiety or a metal binding moiety, e.g., a chemical group or moiety containing 1) an alkyl group having 6 to 36 carbon units, 2) a nitrilotriacetic acid group, 3) an imidodiacetic acid group, or 4) a moiety of formula (ZyHisw)p, wherein Z is any amino acid residue other than histidine, His is histidine, y is an integer from 0-6; w is an integer from 1-6; and p is an integer from 1-6; wherein if A has alkyl group with 6 to 36 carbon units x is greater than 0; and Cm is a cleavable moiety consisting of glycine or alanine or lysine or arginine or N-Arginine or N-lysine, wherein x is an integer between 0-6 and N may be any amino acid or none. The peptide analogs are complexed with polymeric carrier to provide enhanced half-life.

Owner:PHARMAIN CORP

Anti-emulsification water-soluble metal washing agent

The invention relates to an anti-emulsification water-soluble metal washing agent. Every 100 parts of the anti-emulsification water-soluble metal washing agent include the following components according to parts by weight: 3-7 non-ionic surfactant, 3-7 bi-ion active agent, 1-5 chelator, 1-5 rust preventive, 5-10 inorganic builder and the balance water, wherein the non-ionic surfactant is any one of fatty amine polyoxypropylene ether, alkylphenol ether and fatty amine polyoxyethylene alkyl ether ammonium sulfate, the bi-ion active agent is any one of alkyl dimethylin acetic acid betaine, lauramidopropyl betaine and cocamidopropyl betaine, the chelator is any one of sodium citrate, ethylenediaminetetraacetic acid tetrasodium salt and nitrilotriacetic acid sodium salt, the rust preventive is any one of sodium borate, sodium nitrite, sodium benzoate and long carbon chain carboxylic acid amine, and the inorganic builder is any one of trisodium phosphate, sodium metasillcate, sodium carbonate, sodium bicarbonate and sodium hydroxide. The anti-emulsification water-soluble metal washing agent has the advantage of higher cleaning capacity and reutilization capacity.

Owner:NANJING KERUN LUBRICANTS

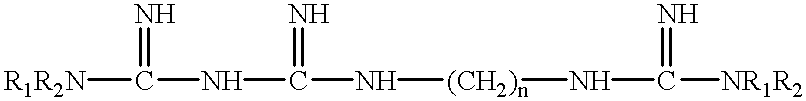

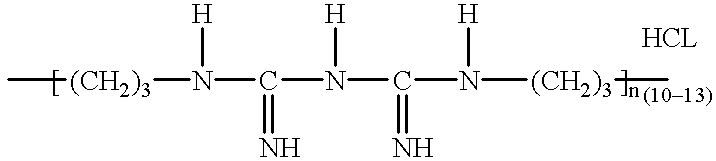

Fast acting disinfectant and cleaner containing a polymeric biguanide

InactiveUS6303557B1Improve effectivenessImprove efficiencyBiocideOrganic detergent compounding agentsSolventNon ionic

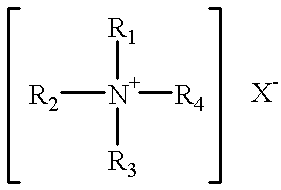

A cleaning and biocidal composition in liquid form comprising a solvent, a polymeric biguanide, a single quaternary ammonium salt, a sequestrant, and at least one surfactant. The composition comprising the solvent including water, the polymeric biguanide including a polyhexamethylene biguanide hydrochloride, the quaternary ammonium salt including a didecyldimethyl ammonium chloride, the sequestrant including an amino acid chelating agent selected from the group consisting of: ethylenediaminetetraacetic acid, nitrilotriacetic acid, tetrasodium ethylenediaminetetraacetic acid, or mixtures thereof, the surfactant including a non-ionic surfactant and an amphoteric surfactant.

Owner:JOHNSONDIVERSEY INC

Cleaning Composition

ActiveUS20090281017A1Improve abilitiesGood removal effectOrganic detergent compounding agentsNon-surface-active detergent compositionsIminodiacetic acidGlycine

The invention relates to compositions and methods for cleaning integrated circuit substrates. The compositions are in the form of an aqueous solution and include a quaternary ammonium hydroxide compound and a chelating compound. The chelating compound includes either boric acid or at least one N-substituted aminocarboxylate selected from the group consisting of N-bis(2-hydroxyethyl)glycine(bicine), N-tris(hydroxymethyl)methyl glycine (tricine) and mixtures thereof, and can optionally include glycine, Iminodiacetic acid (IDA), Nitrilo trizacetic acid (NTA), Ethylenediammine Tetraacetic acid (EDTA), or mixtures thereof.

Owner:EKC TECH

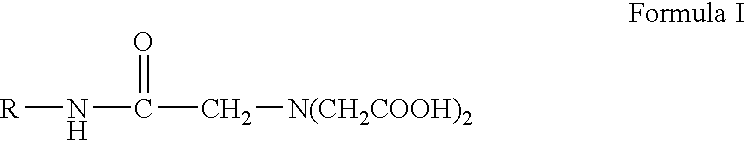

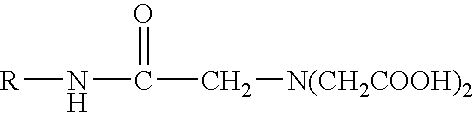

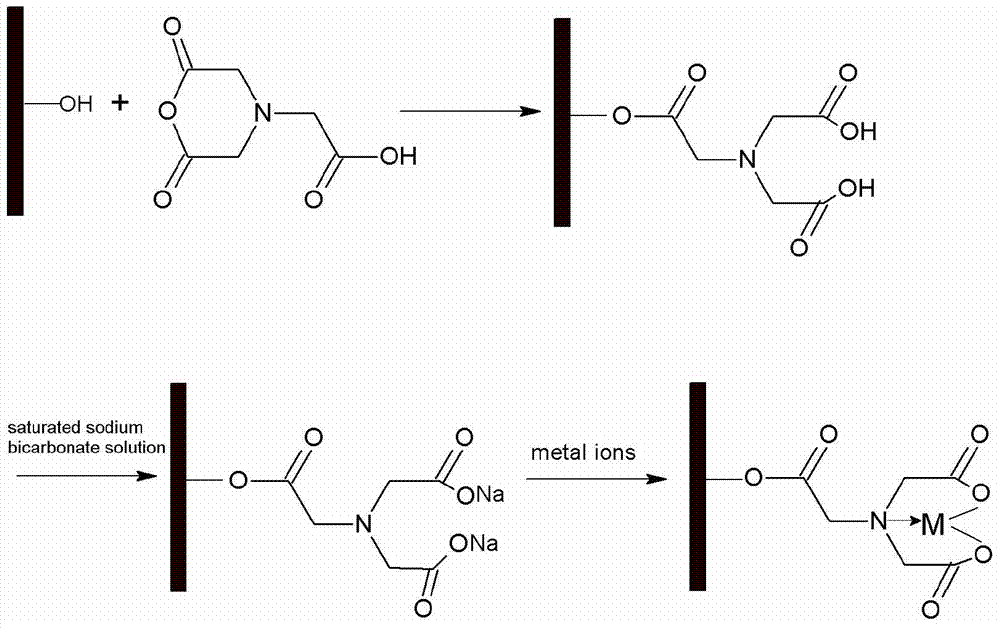

Preparing monomeric metal ion chelator containing diacetyl glycine group linked to proteinaceous molecule

A precursor for the construction of chelated metal conjugates which demonstrate improved assay performance and utility in minimizing non-specific binding while maintaining specificity for target molecules is disclosed. The precursor has tridentate functionality towards multivalent ions such as iron and nickel and contains a diacetyl glycine group covalently linked via an amide to a molecule such as a proteinaceous molecule providing a primary amide group for amide bond formation. The precursor is preferably prepared in monomeric form by reacting nitrilotriacetic acid or a salt thereof in an aqueous medium at an alkaline pH of at least 8 with a proteinaceous molecule containing a primary amine group in the presence of a carbodiimide. The proteinaceous molecule may be bovine serum albumin or an enzyme such as alkaline phosphatase or horseradish peroxidase.

Owner:PIERCE BIOTECHNOLOGY

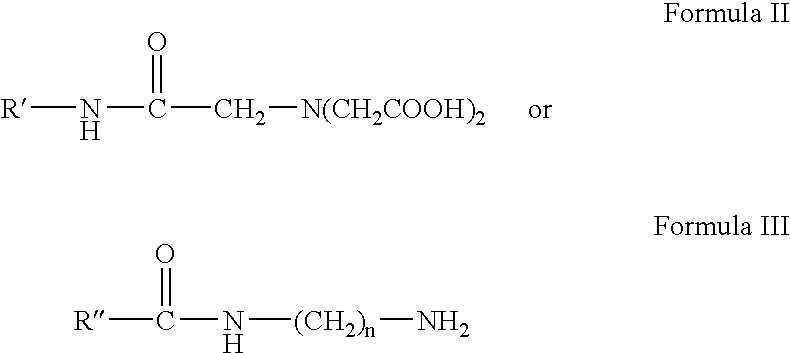

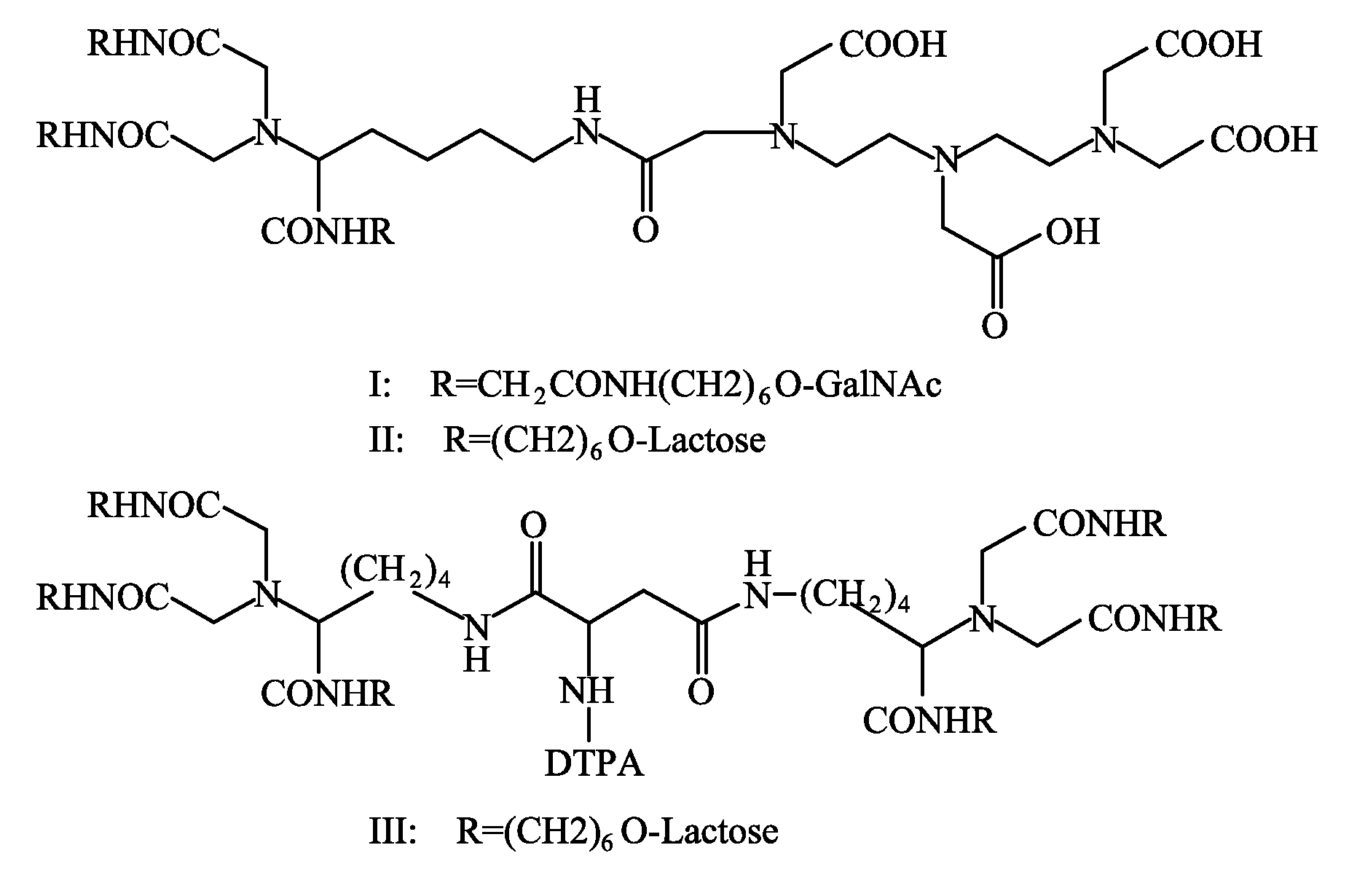

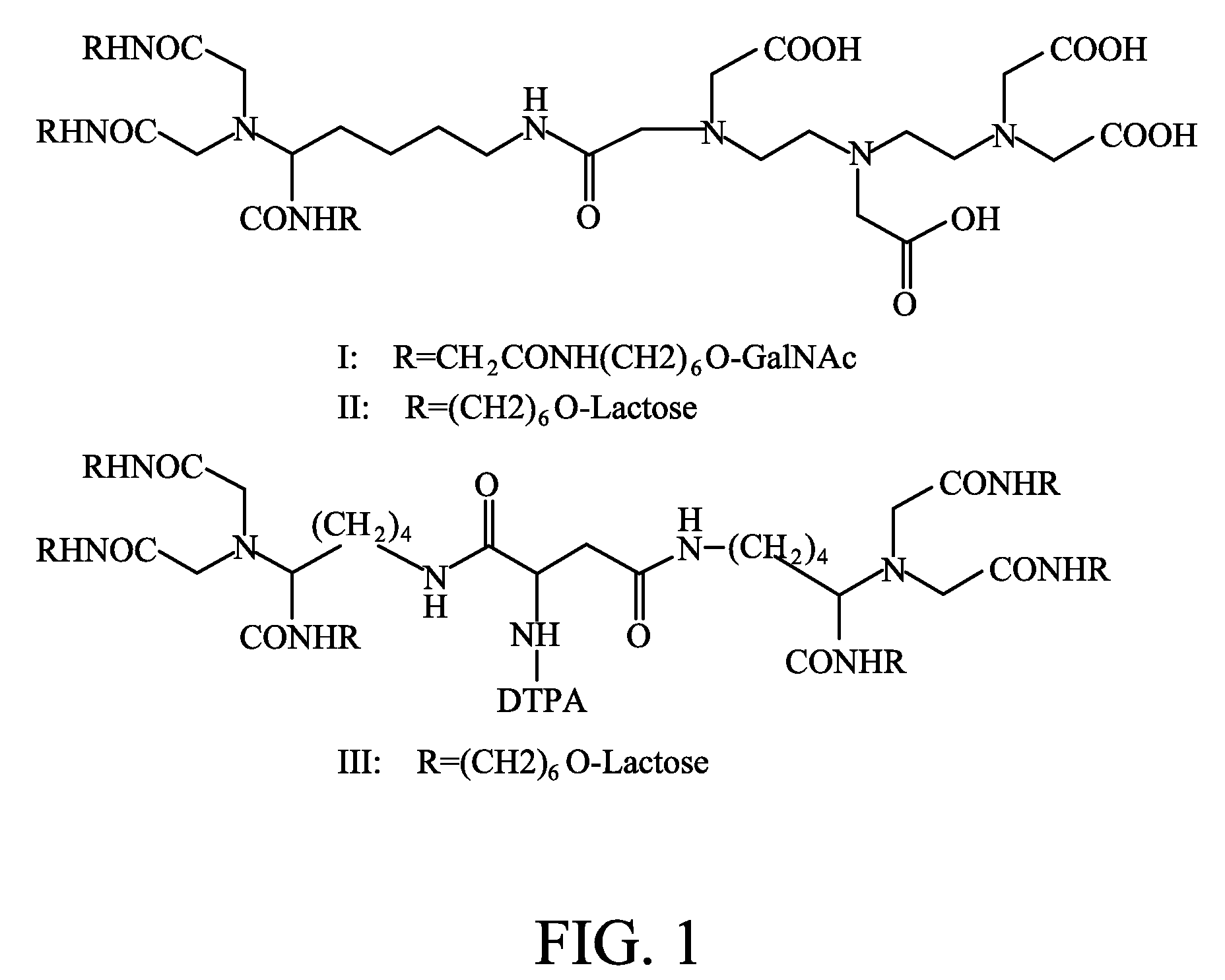

Novel liver-targeting agents and their synthesis

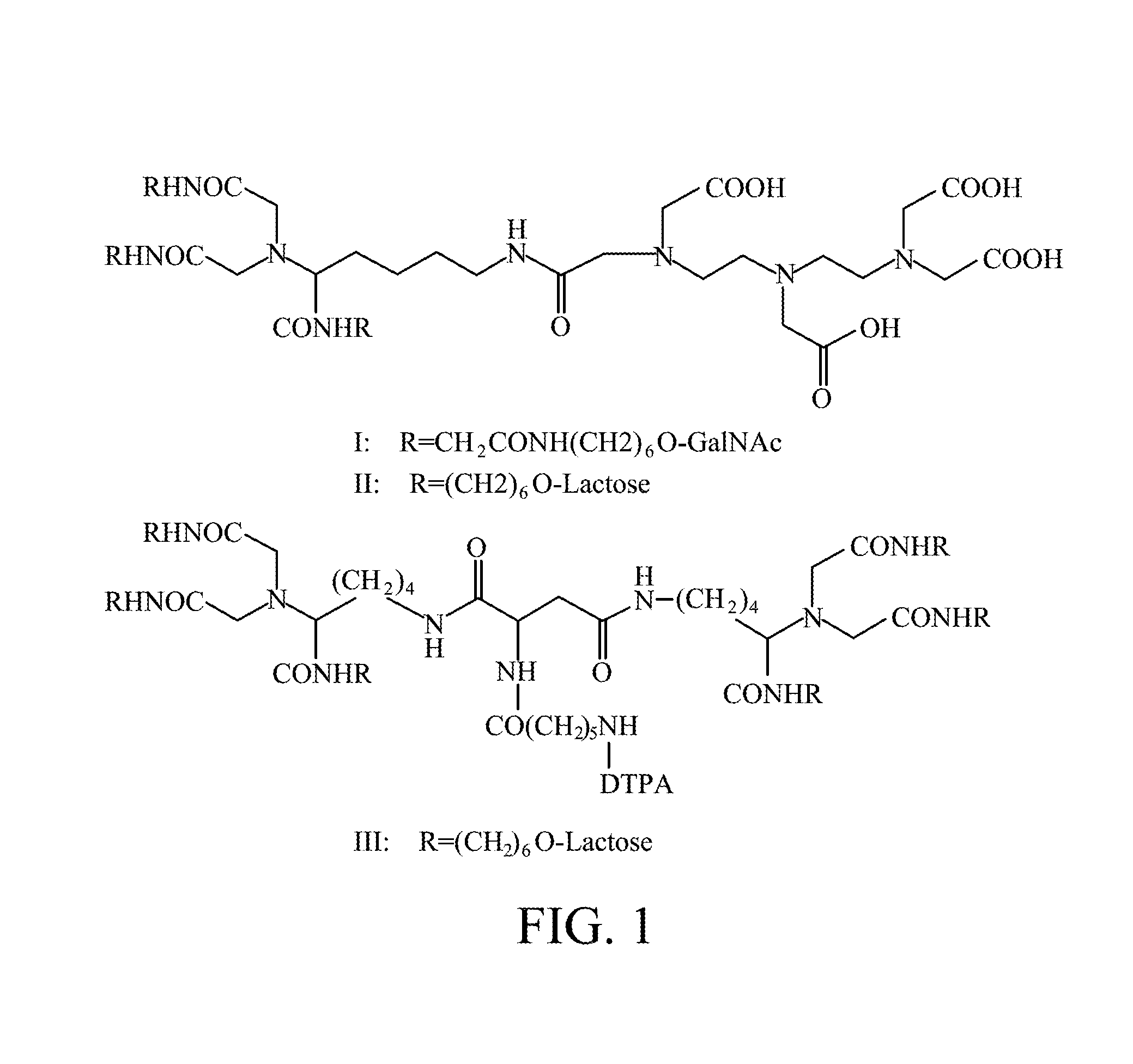

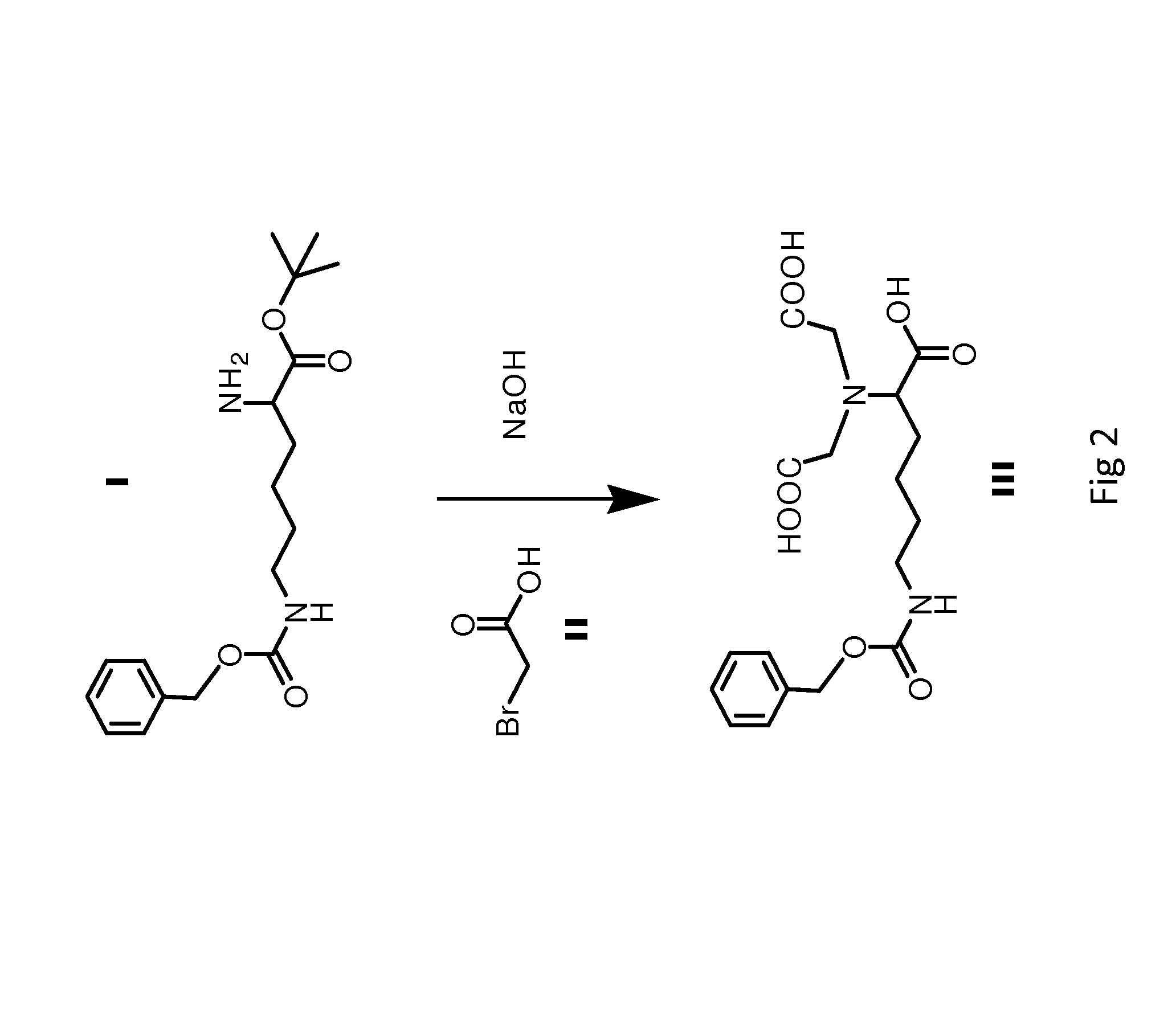

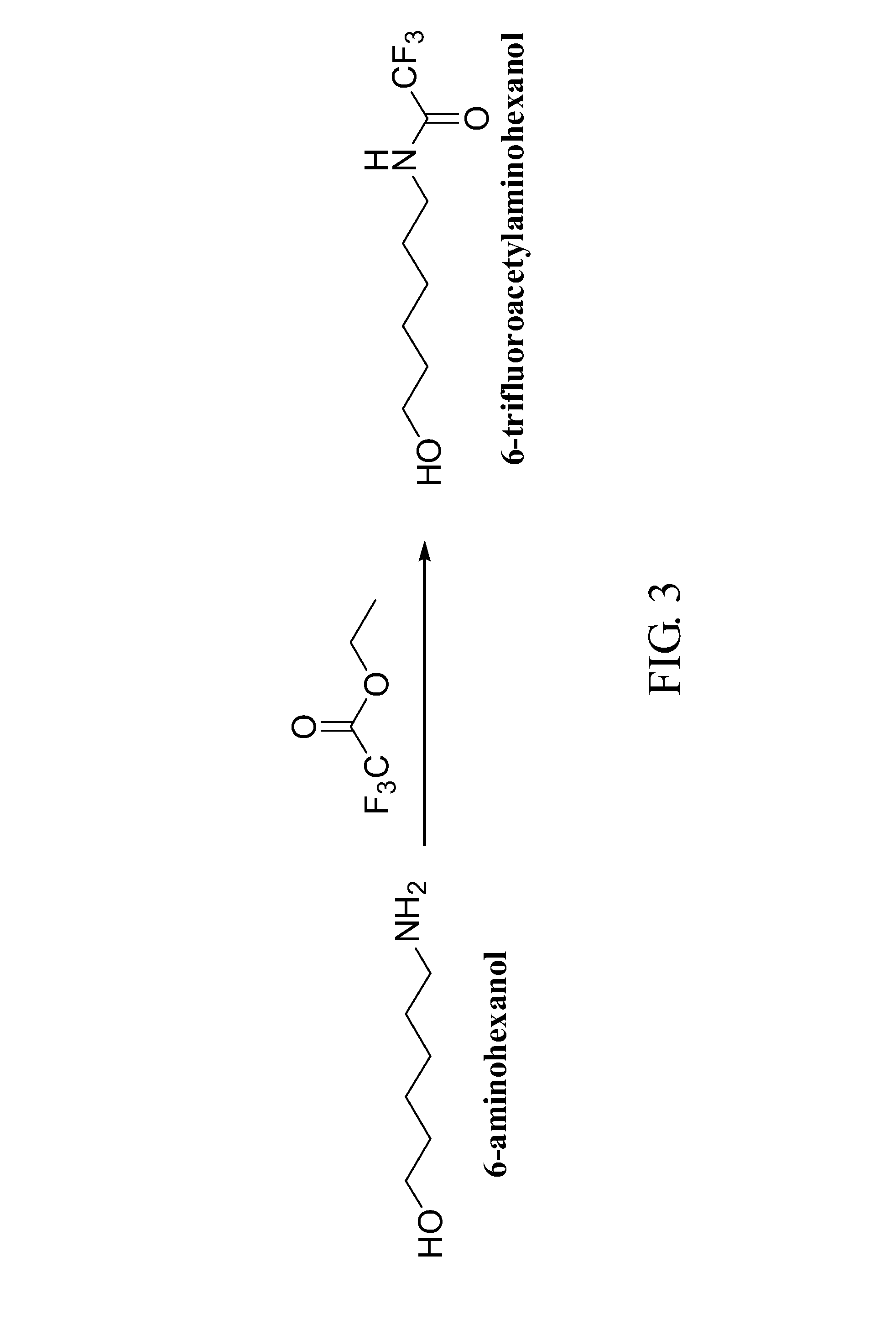

This invention provides novel liver targeting agents and their synthetic methods. A liver targeting agent, with a lysine based nitrilo triacetic acid structure as backbone which acquires multivalency with saccharide groups, to bind with a galactosamine chain or lactose chain is disclosed. In particular, only one amino acid L-lysine is involved to provide trivalency. All carboxyl groups in Nε-benzyloxycarbonyl-Nα-dicarboxymethyl-L-lysine can be conjugated with three glycosides of ahGalNAc or ahLac in one step. This invention also provides a hexa-lactoside. In particular, the TFA-AHA-Asp was used to conjugate 2 moles of NTA(ahLac)3. This invention also provides a method for adding a spacer between NTA and DTPA. The extended hepatocyte-specific glyco-ligand has higher 111In-radiolabelling yield than those non-extended.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE +1

Modified cellulose products

A modified cellulose product comprising cellulose ether, such as carboxymethyl cellulose, hydroxyethyl cellullose, carboxymethyl hydroxyethyl cellulose, methyl cellulose, hydroxyethyl methyl cellulose or ethyl hydroxyethyl cellulose, or xanthan gum product, characterized in that it further comprises salts of aluminium-, ferro-, ferri-, zinc-, nickel-, tin(2)- or tin(4)-cations, and nitrilo-tri-acetic acid, 1,2-cyclo-hexan-di-amin-N,N,N',N'-tetra-acetic acid, di-ethylen-tri-amine-penta-acetic acid, ethylen-di-oxy-bis(ethylen-nitrilo)-tetra-acetic acid, (N-(2-hydroxy-ethyl)-ethylen-diamin-N, N',N',tri-acetic acid, tri-ethylen-tetra-amine-hexa-acetic acid or N-(hydroxyethyl) ethylene-di-amine-tri-acetic acid as a ligand. The product can be used especially as a drilling mud additive.

Owner:METSA SPECIALTY CHEM

Heavy metal-contaminated soil remediation agent and preparation method thereof

InactiveCN105567247AHigh porosityHigh adsorption valueOther chemical processesOrganic fertilisersSodium BentoniteActivated Aluminum Oxide

The invention provides a heavy metal-contaminated soil remediation agent. The remediation agent is prepared from, by weight, 30%-45% of quick lime, 10%-25% of biomass charcoal, 10%-15% of kieselguhr, 10%-15% of sodium bentonite, 10%-15% of activated aluminum oxide, 5%-10% of nitrilotriacetic acid, 1%-5% of sodium lignin sulfonate and 1%-5% of sodium dodecyl sulfate. A preparation method comprises the steps that the quick lime, the biomass charcoal, the kieselguhr, the sodium bentonite, activated aluminum oxide, nitrilotriacetic acid, sodium lignin sulfonate and sodium dodecyl sulfate are stirred and mixed to be uniform according to the weight ratio, and then the soil remediation agent is prepared. The prepared soil remediation agent has the good effect when cadmium-lead-zinc-mercury compound contaminated soil is remedied.

Owner:CHANGSHA HUIJU ENVIRONMENTAL TECH CO LTD

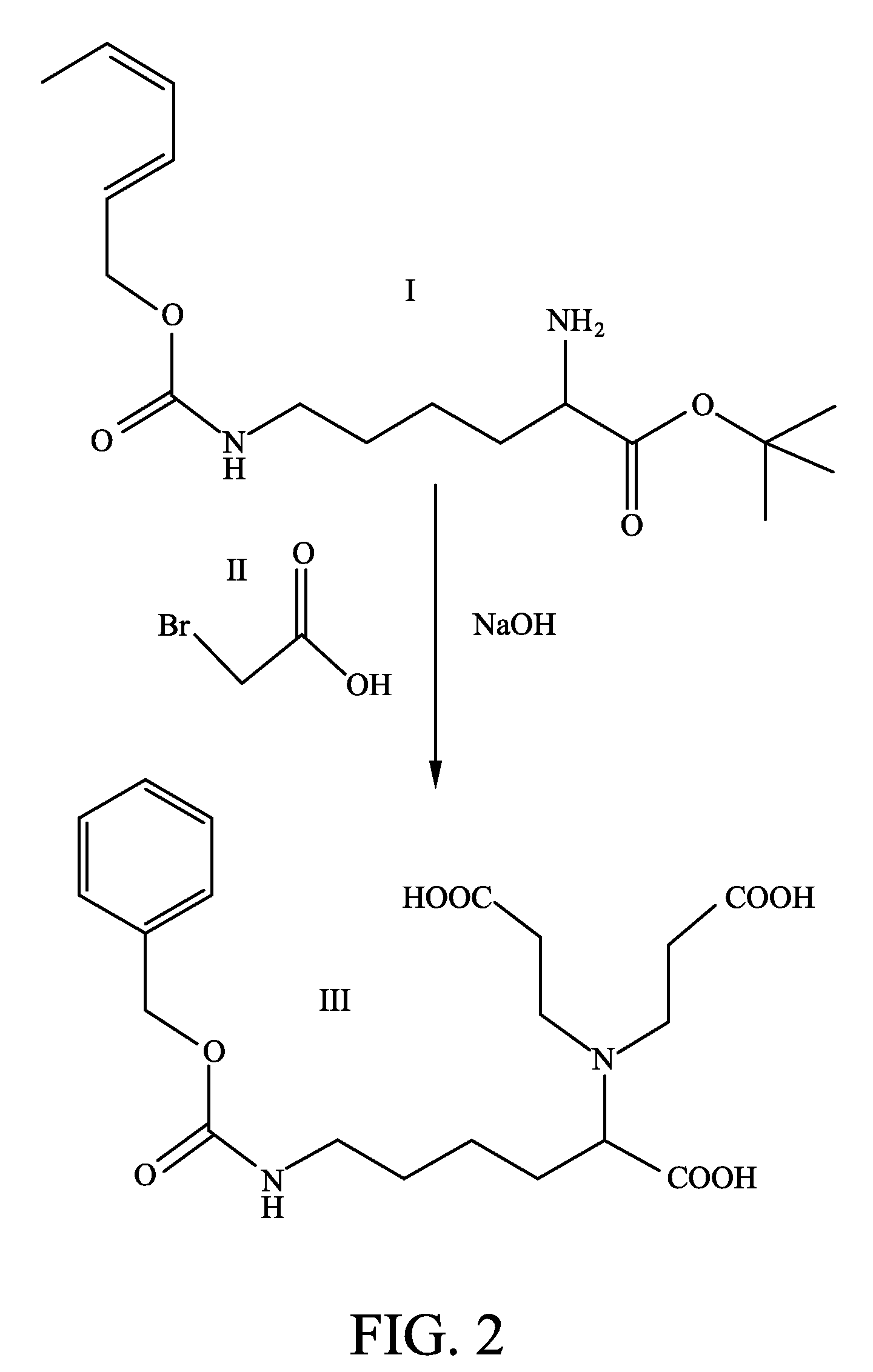

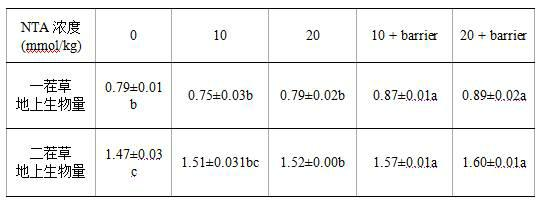

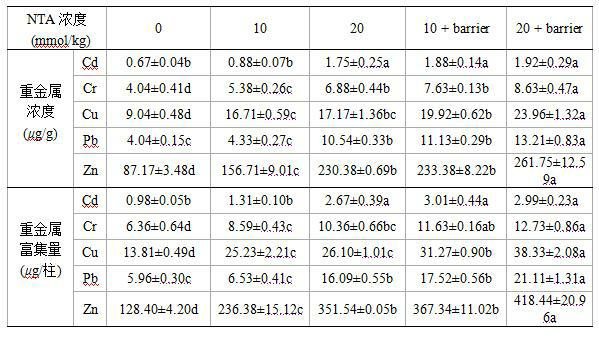

Method for repairing garbage compost heavy metal by adopting NTA (Nitrilotriacetic acid) of waste interlayer

InactiveCN102630474APromote chelationPromote absorptionHorticulture methodsFertilizer mixturesSoil scienceFestuca arundinacea

The invention discloses a method for repairing garbage compost heavy metal by adopting NTA (Nitrilotriacetic acid) of a waste interlayer. The method comprises the following steps of: filling 500g air-dried garden soil, 60g horizontal interlayer and 280g compost in a PVC (Poly Vinyl Chloride) pipe with the diameter of 7.5 cm and the length of 25 cm in turn; sowing 0.6g festuca arundinacea seeds in the pipe, applying 10-20 mmol / kg aqueous solution of NTA sodium salt of compost on the compost surface after sowing for 30 days; clipping grass after 10 days; and measuring the content changes of heavy metal Cd, Cr, Cu, Pb and Zn. A test result of the method provided by the invention shows that: the migration of harmful substances and heavy metal in the garbage compost to the soil can be reduced by paving the horizontal interlayer above the soil and under the compost, so as to increase the time of a lawn plant for absorbing heavy metal in the compost and the enrichment of heavy metal in the lawn plant under the induction of chelating agent and reduce the migration of heavy metal to deep soil.

Owner:TIANJIN NORMAL UNIVERSITY

Neutral blockage removing agent composition used for oilfield mechanical recovery well and preparation method thereof

ActiveCN104194757AGood compatibilityGood miscibilityDrilling compositionSodium acetateActivated attapulgite

The invention relates to a neutral blockage removing agent composition used for a mechanical recovery well in an oilfield. The neutral blockage removing agent composition is prepared from the following components in parts by weight: 16-20 parts of polyepoxysuccinic acid amine, 7-12 parts of hydroxyethylidene dipllosphate sodium, 21-25 parts of divinyl pentaacetic acid amine, 20-25 parts of hydroxyl ammonium acetate, 12-16 parts of activated attapulgite, 21-25 parts of ammonium persulfate, 9-12 parts ofdicyclohexyl sulfobutanedioate sodium, 7-9 parts of butyl lactate, 0.2-0.3 part of vanadium pentoxide, 5-8 parts of straight chain sodium dodecylbenzenesulfonate, 10-14 parts of nitrilotriacetic acid sodium salt, 4-7 parts of urotropin and 0.1-0.3 part of glycerin fatty acid ester. The neutral blockage removing agent composition is suitable for scale removal and blockage removal of an oil pumping unit well and a screw pump well, can effectively control the reaction speed of the blockage removing agent and the scale of the oil pumping unit well and the scaled screw pump well, and prevent the falling-off of big scale residues to result in the secondary blockage of the mechanical recovery well and an oil recovery pump thereof, has high blockage removal speed, is neutral and is free of corrosion; the waste liquid for blockage removal does not need to be discharged onto the ground to be subjected to sewage treatment, the blockage removal time does not exceed 24 hours, and the effect of safe and corrosion-free blockage removal is achieved.

Owner:GANSU HEIMA PETROCHEM ENG

Heavy metal polluted soil plant repair method

InactiveCN1640565ALarge biomassImprove enrichment capacityContaminated soil reclamationEthylenediaminePhytoremediation

The present invention discloses a method for repairing soil contaminated by heavy metal by utilizing plant. Said method is characterized by that in the soil contaminated by heavy metal the maize can be planted, before harvest at least two additives selected from editic acid or its sodium salt or its potassium salt (EDTA), nitrilotriacetic acid or its sodium salt or its potassium salt (NTA) and citric aid or its sodium salt or its potassium salt (CA) can be applied, and then the aerial part of maize can be harvested so as to attain the goal of repairing soil contaminated by heavy metal.

Owner:SOUTH CHINA UNIV OF TECH

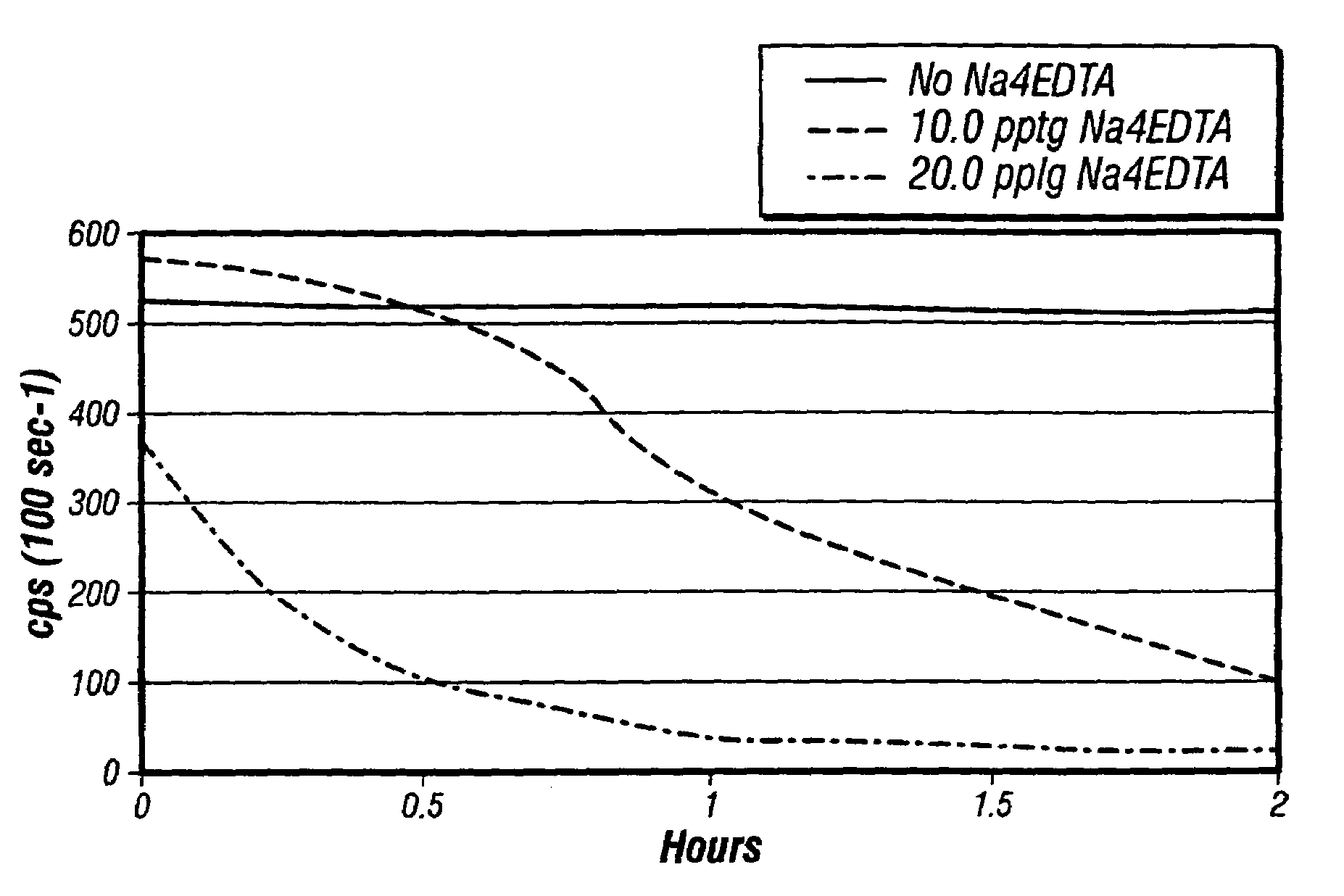

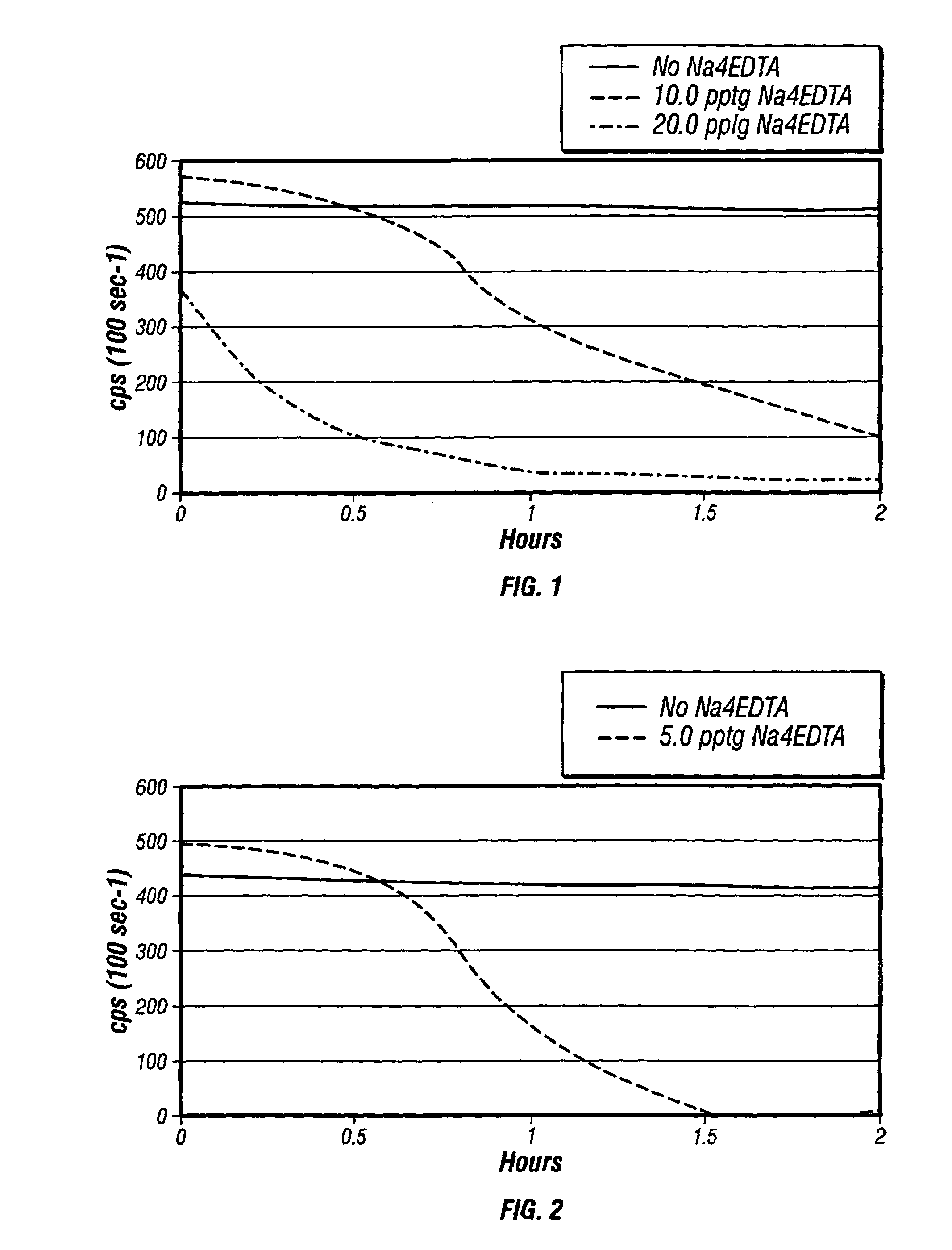

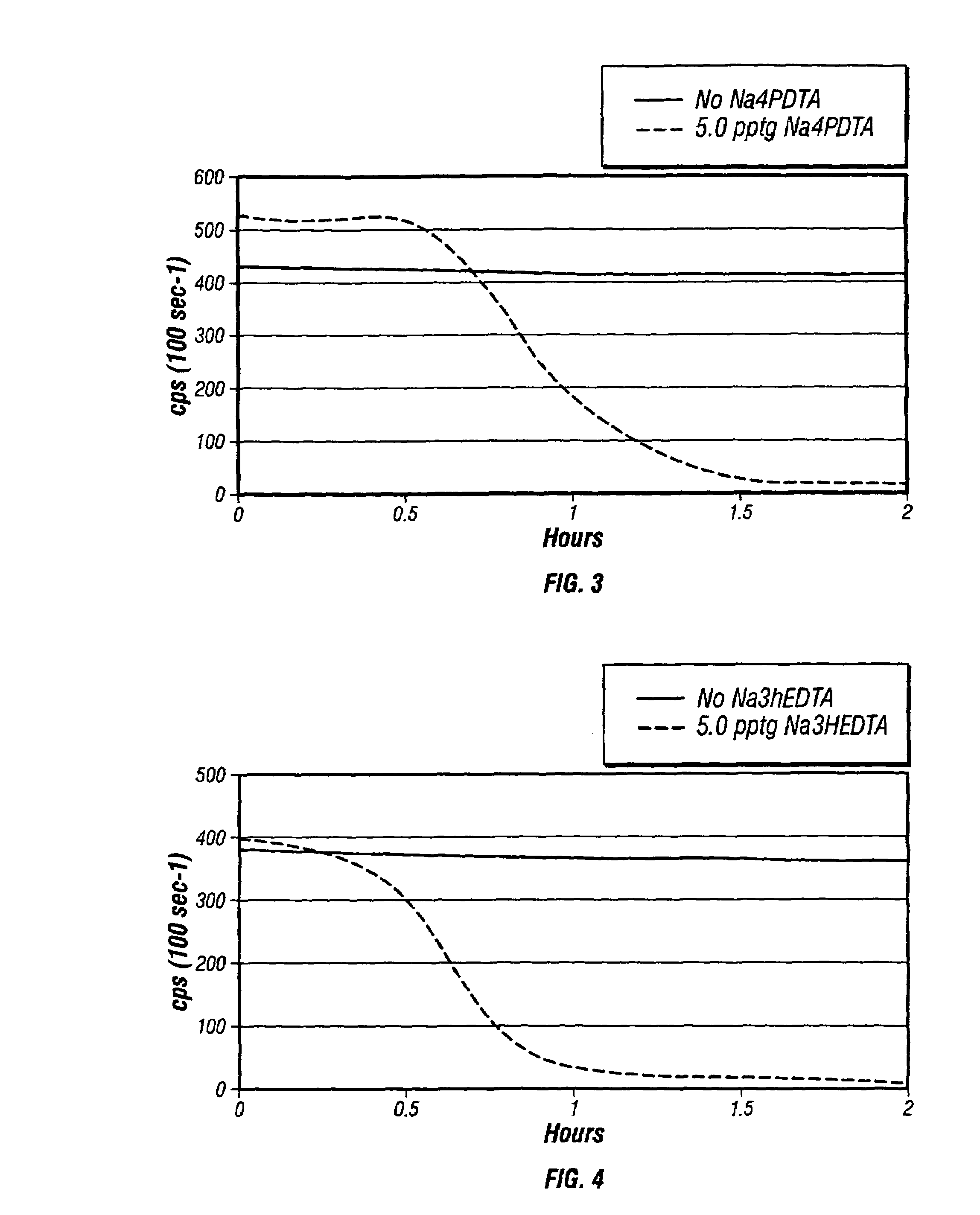

Aminocarboxylic acid breaker compositions for fracturing fluids

InactiveUS7208529B2Break viscosityOther chemical processesFluid removalFracturing fluidTRISODIUM NITRILOTRIACETATE

It has been discovered that aminocarboxylic acids are effective breakers for polymer-gelled aqueous fracturing fluids, particularly in the temperature range between about 120° F. (49° C.) and about 280° F. (138° C.). The aminocarboxylic acids are believed to act directly on the polymer and not to any great extent or not to as an effective extent on a crosslinking agent, if present. The polymer may be a polysaccharide, and the aminocarboxylic acid may be selected from the group including, but not necessarily limited to, tetrasodium ethylenediaminetetraacetic acid (Na4EDTA), tetrasodium propylenediaminetetraacetic acid (Na4PDTA), trisodium hydroxyethylenediaminetetraacetic acid (Na4HEDTA), trisodium nitrilotriacetic acid (Na3NTA), salts of these acids, and mixtures thereof.

Owner:SUPERIOR ENERGY SERVICES LLC

Preparation method of methyl-glycine diacetate tri-sodium

ActiveCN102993034AEliminate the refining processAchieve preparationOrganic compound preparationAmino-carboxyl compound preparationAcetic acidGlycinonitrile

The invention relates to a preparation method of methyl-glycine diacetate tri-sodium, successively comprising the following steps of: preparation of hydroxy acetonitrile solution, preparation of iminodiacetonitrile solution, preparation of methyl-flycine nitrile diacetonitrile crystal, preparation of methyl-glycine diacetate tri-sodium (MGDA-3Na) and preparation of solid product MGDA-3Na. In the method, the yield of methyl-flycine nitrile diacetonitrile crystal is higher than 92%, the total yield of MGDA-3Na can reach more than 86%, the content of NTA (nitrilotriacetic acid) is less than 0.08%; and the equipment investment and energy consumption in the hydrocyanic acid refining process are saved on the premise that high yield and low toxic side product content are met, and the hydrocyanic acid refining process is not required, so that the production cost is reduced and the environment pollution is reduced.

Owner:CHONGQING UNISPLENDOUR CHEM

Water-based ink

There is provided a water-based ink that gives good coloration and little blurring on regular paper, gives adequate coloration on specialist paper, and has good fixability, and further gives excellent discharge stability with ink jet recording, and moreover exhibits the effect of a chelating agent even in a small amount, and is not harmful due to evaporating, subliming or the like. The water-based ink of the present invention comprises a colorant, water, a water-soluble organic solvent, a surfactant, and a chelating agent, wherein the chelating agent is nitrilotriacetic acid (NTA) or a salt thereof, methylglycine diacetic acid (MGDA) or a salt thereof, L-glutamine diacetic acid (GLDA) or a salt thereof, L-aspartic acid diacetic acid (ASDA) or a salt thereof, diethylenetriamine pentaacetic acid (DTPA) or a salt thereof, gluconic acid (GA) or a salt thereof, citric acid (CA) or a salt thereof, nitrilotripropionic acid (NTP) or a salt thereof, nitrilotrisphosphonic acid (NTPO) or a salt thereof, dihydroxyethylglycine (DHEG) or a salt thereof, hydroxyethyliminodiacetic acid (HIDA) or a salt thereof, 1,3-diamino-2-hydroxypropane tetraacetic acid (DPTA-OH) or a salt thereof, hydroxyethylidene diphosphonic acid (HEDP) or a salt thereof, nitrilotrimethylene phosphonic acid (NTMP) or a salt thereof, or phosphonobutane tricarboxylic acid (PBTC) or a salt thereof.

Owner:SEIKO EPSON CORP

Deep treatment method for industrial wastewater through natural pyrite catalyzed H2O2 oxidation

ActiveCN103708647ASimple and fast operationHigh implementabilityMultistage water/sewage treatmentWater/sewage treatment by oxidationTreated water sampleWater quality

The invention relates to a deep treatment method for industrial wastewater through natural pyrite catalyzed H2O2 oxidation. The deep treatment method specifically comprises the following steps: pretreating natural pyrite, adding wastewater into a reactor, adjusting the pH value to be 8-10, adding the pretreated natural pyrite, adding nitrilotriacetic acid, fast stirring, adding a hydrogen peroxide solution, after reaction under stirring, adding a FeCl3 solution to control the mass ratio of pyrite and Fe (III) to be 10:1, adding hydrogen peroxide, continuing the reaction, and standing for precipitation, wherein residual mineral can be recycled; introducing air into supernatant separated through precipitation for secondary oxidation while keeping dissolved oxygen in the water to be above 3ppm, after sufficient aeration, adding polyacrylamide for coagulation treatment, and after standing for precipitation, discharging effluent; carrying out water quality analysis on a treated water sample to assess the treatment effect. By a simple way and various synergistic effects, the deep treatment method provided by the invention changes the generation way of Fenton reaction, significantly increases the reaction reactivity, expands the applicable pH range of the wastewater, improves the utilization efficiency of H2O2, and reduces the cost of technology, thus being an economical and efficient wastewater deep treatment technology.

Owner:TONGJI UNIV

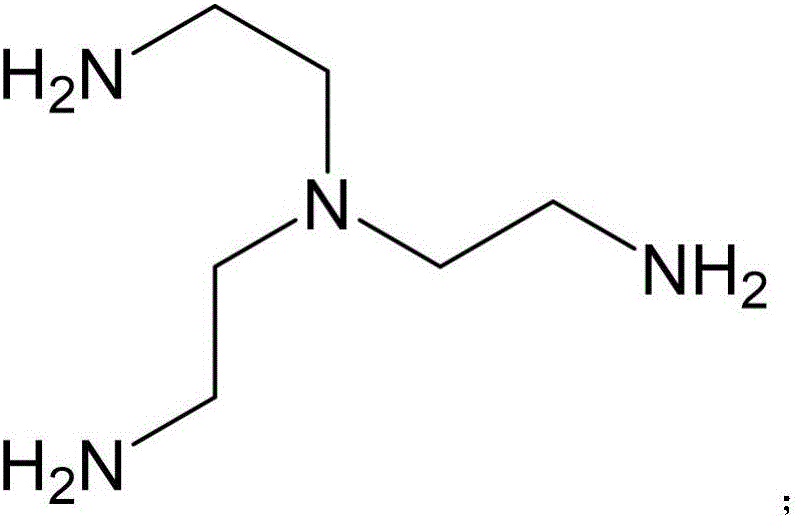

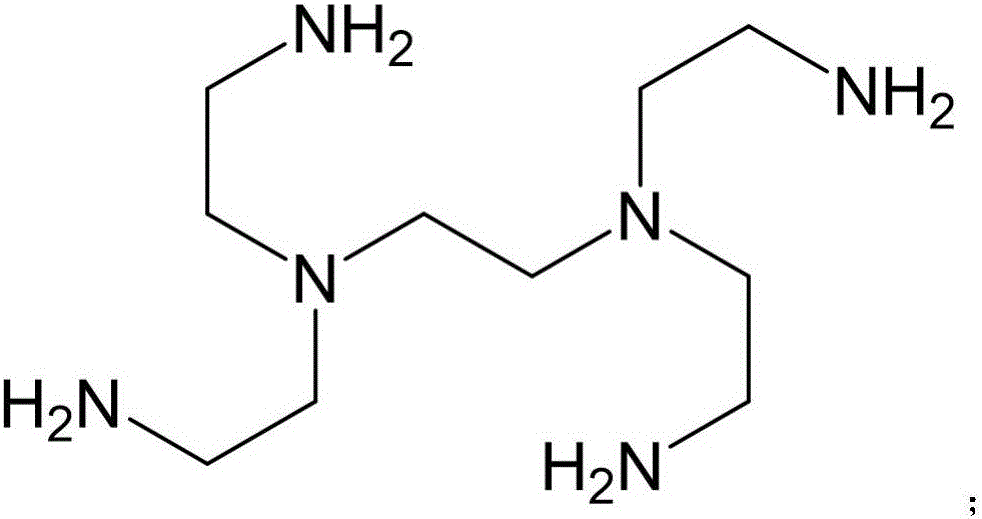

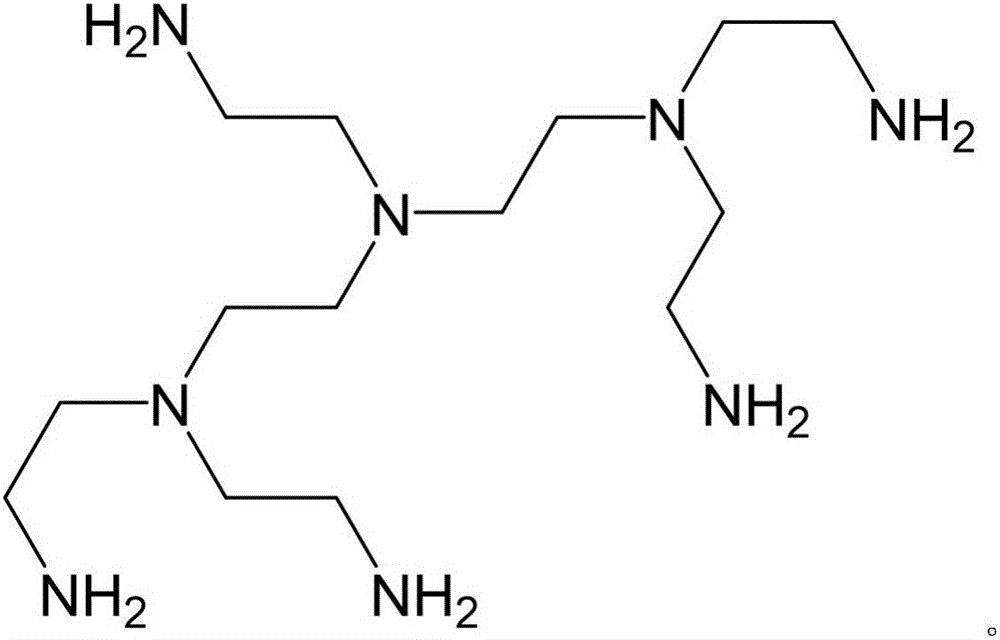

Ultralow-molecular weight intercalation inhibitor and preparation method thereof

ActiveCN106281263AReduce instabilityMeet the needs of useDrilling compositionNitrilotriacetic acidTetraethylammonium

The invention relates to an ultralow-molecular weight intercalation inhibitor and a preparation method thereof. The ultralow-molecular weight intercalation inhibitor contains any one or more of amino triethylamine, ethylenediamine tetraethylammonium and diethylenetriamine pentaethylamine and is prepared from the component and clear water in a ratio of 0.5-3%; the amino triethylamine is synthesized from nitrilotriacetic acid; the ethylenediamine tetraethylammonium is synthesized from ethylenediamine tetraacetic acid; and the diethylenetriamine pentaethylamine is synthesized from diethylenetriamine pentaacetic acid; and the preparation method comprises the following steps: adding the raw materials into absolute ethyl alcohol; adding concentrated sulfuric acid for reacting; adding an organic solvent and introducing ammonia water; and stirring and distilling to obtain the product. According to the invention, the inhibition performance of a drilling fluid system can be remarkably improved, the temperature resistance exceeds 240 DEG C, the needs of ultra-deep well drilling are completely met, and the problem of unstable well wall caused by shale hydration and dispersion is effectively reduced; and moreover, the synthesis technology is simple and environment-friendly, the yield is relatively high, the production cost is low, and the ultralow-molecular weight intercalation inhibitor is suitable for industrial production.

Owner:SOUTHWEST PETROLEUM UNIV

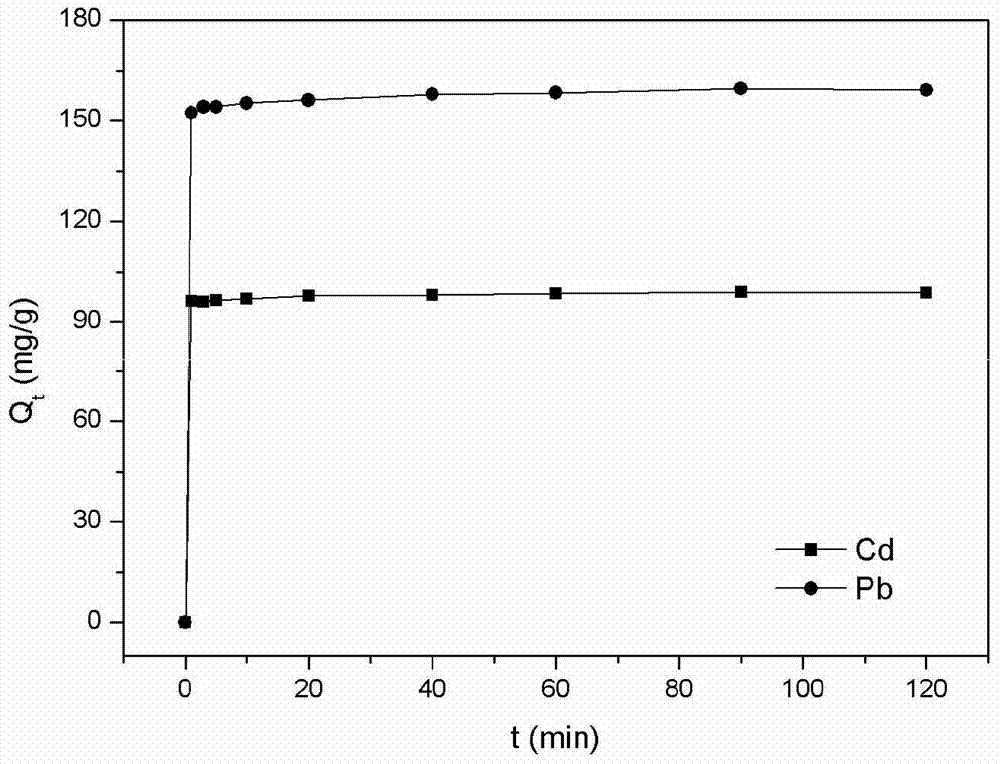

Preparation method and application of efficient corn straw adsorbent

InactiveCN103877947AWide variety of sourcesSimple production processOther chemical processesWater/sewage treatment by sorptionAcetic acidAcetic anhydride

The invention relates to a preparation method and application of an efficient corn straw adsorbent. The preparation method of the efficient corn straw adsorbent particularly comprises the following steps: cleaning corn straw, drying, crushing, sieving and dewaxing; then adding nitrilotriacetic acid into a mixed organic solution containing acetic anhydride and an activator, stirring at 60-70 DEG C, adding the corn straw after reaction, stirring at 70-80 DEG C, and separating, washing and drying after reaction so as to obtain the efficient modified corn straw adsorbent. The adsorbent can be used for removing heavy metal ions such as Cd<2+> and Pb<2+> in wastewater, has the absorbing capacity reaching up to 100mg / g and 160mg / g respectively for heavy metal ions of Cd<2+> and Pb<2+>, has the characteristics of simple preparation method, high absorbing capacity, reusability, adsorption stability and no secondary pollution, and also achieves resource utilization of biomass resources.

Owner:HUNAN UNIV

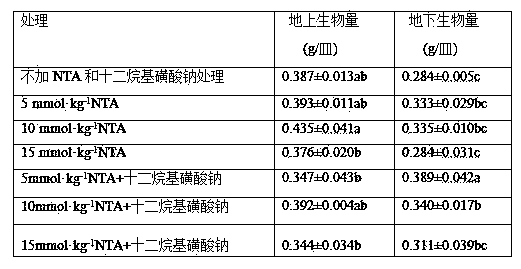

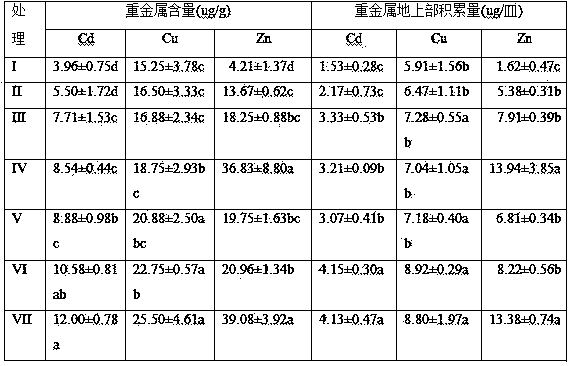

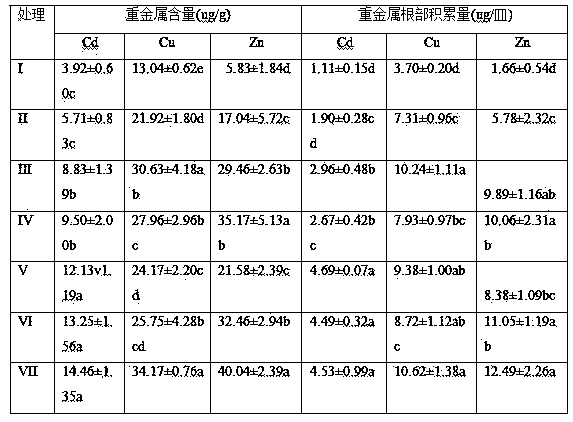

Method for concentrating soil heavy metals of sewage irrigation area by coalition of composite restoring agent and festuca arundinacea

InactiveCN103865545AIncrease contentPromote enrichmentOrganic fertilisersHorticultureSoil scienceFestuca arundinacea

The invention discloses a method for concentrating soil heavy metals of a sewage irrigation area by coalition of a composite restoring agent and festuca arundinacea, wherein the composite restoring agent consists of a chelating agent nitrilotriacetic acid (NTA) and a surfactant sodium dodecyl sulfate, wherein the mol ratio of the chelating agent nitrilotriacetic acid to the surfactant sodium dodecyl sulfate is (5-15) mmol.kg<-1>:1mmol.kg<-1>. Experimental results show that a most remarkable effect of increasing the content of Cd in the festuca arundinacea is achieved due to the addition of the surfactant and the chelating agent, the concentration of the heavy metals can be promoted through co-addition of the surfactant and the chelating agent, and especially the effect is more remarkable when 5 mmol.kg<-1> of the NTA and 1 mmol.kg<-1> of the chelating agent or 10 mmol.kg<-1> of the NTA and 1 mmol.kg<-1> of the chelating agent are used for restoring sewage irrigation soil.

Owner:TIANJIN NORMAL UNIVERSITY

Etching solution for high-transmittance anti-dazzle glass, and preparation method thereof

The invention discloses an etching solution for high-transmittance anti-dazzle glass, and a preparation method thereof. Raw materials of the etching solution comprise hydrofluoric acid, ammonium fluoride, ammonium bifluoride, magnesium fluoride, aluminum fluoride, calcium fluoride, calcium hydrogen fluoride, potassium hydrogen fluoride, ammonium chloride, zinc chloride, sodium acetate, barium sulfate, sodium fluoroborate, ammonium fluoroborate, sodium phosphate, ammonium biphosphate, potassium phosphate, ethylene diamine tetraacetic acid, nitrilotriacetic acid, a viscosity regulator, a surfactant, a sulfuric acid solution and water. The preparation method of the etching solution for high-transmittance anti-dazzle glass has the advantages of mild process and mild conditions, and the etching solution for high-transmittance anti-dazzle glass, prepared through the method, has the advantages of good stability, high transmittance and atomization rate, and good anti-dazzle effect.

Owner:广东金品科技有限公司

Cleaning composition comprising a chelant and quaternary ammonium hydroxide mixture

ActiveUS7825079B2Improve abilitiesGood removal effectOrganic detergent compounding agentsSemiconductor/solid-state device manufacturingGlycineIminodiacetic acid

Owner:EKC TECH

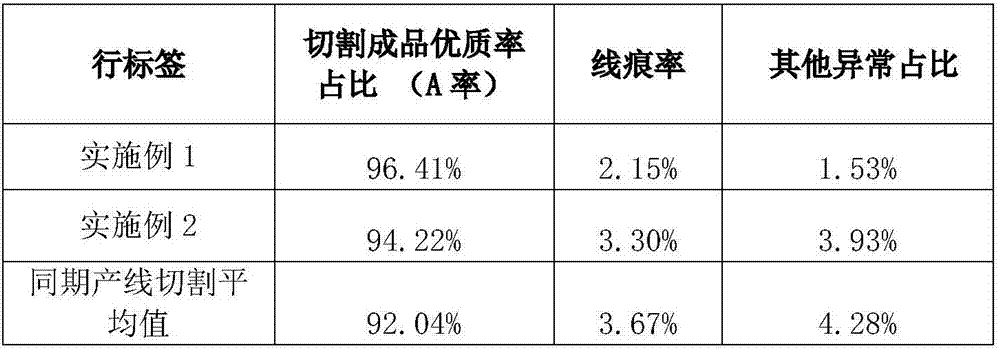

Low-foam water-based diamond wire cutting liquid

InactiveCN107011981AReduce stabilityReduce controllabilityLubricant compositionWater basedWire cutting

The invention provides low-foam water-based diamond wire cutting liquid which comprises the following components in percentage by weight: 3-15 percent of low-foam polyether with a molecular weight of 1500-2000, 2-10 percent of polyether modified polysiloxane with a silicone oil molecular weight of 220-20000 and a polyether molecular weight of 500-2000, 0.5-7 percent of an emulsifying agent, 0.5-5 percent of a PH regulating agent, 0.5-5 percent of a complexing agent, 0.2-1.5 percent of an extrusion agent and 70-95 percent of water, wherein the emulsifying agent uses one or more of isodecanol polyoxyethylene ether, iso-tridecanol polyoxyethylene ether, isooctyl alcohol polyoxyethylene ether, glyceryl monostearate, sorbitan polyethylene laurate and sorbitan stearate; the PH regulating agent is organic amine; the complexing agent is one of or a mixture of more of sodium gluconate, potassium gluconate, sodium nitrilotriacetate, sodium citrate, potassium citrate and sodium potassium tartrate; the extrusion agent preferably selects one or several of sodium carbonate, sodium silicate and sodium sulfate. The low-foam water-based diamond wire cutting liquid provided by the invention can realize a lubricating effect, the abrasion resistance, the cooling performance and the like required to be met in the cutting process.

Owner:ZHENJIANG RENDE NEW ENERGY TECH

Electrodeposition Material, Process for Providing a Corrosion-Protective Layer of TiO2 on an Electrically Conductive Substrate and Metal Substrate Coated with a Layer of TiO2

InactiveUS20080210567A1Improve protectionElectrolytic inorganic material coatingGluconic acidBuffering agent

The present invention relates to electrodeposition material for the electrochemical deposition of a corrosion-protective layer of TiO2 on an electrically conductive substrate comprising a titanium compound, a complexing agent, an accelerator, water and optionally organic solvents, buffering agents and one or more additives, characterized in that the titanium compound is titanyl sulfate and / or titanyl oxalate, the complexing agent is selected from the group consisting of citric acid, citrates, tartaric acid, tartrates, lactic acid, lactates, gluconic acid, gluconates, polyhydroxy-polycarbonic acids, ethylenediaminetetraacetate, methylglycinediacetate, iminodisuccinate, nitrilotriacetic acid and nitrilotriacetate, triethanolamine, phosphonic acid and phosphonates, polyaspartic acid and polyaspartates, polyacrylic acid and polyacrylates and the accelerator is selected from the group consisting of H2O2 and organic peroxides. The invention further relates to a process for providing a corrosion-protective layer of TiO2 on an electrically conductive substrate and to a metal substrate coated with a layer of TiO2.

Owner:HENKEL KGAA

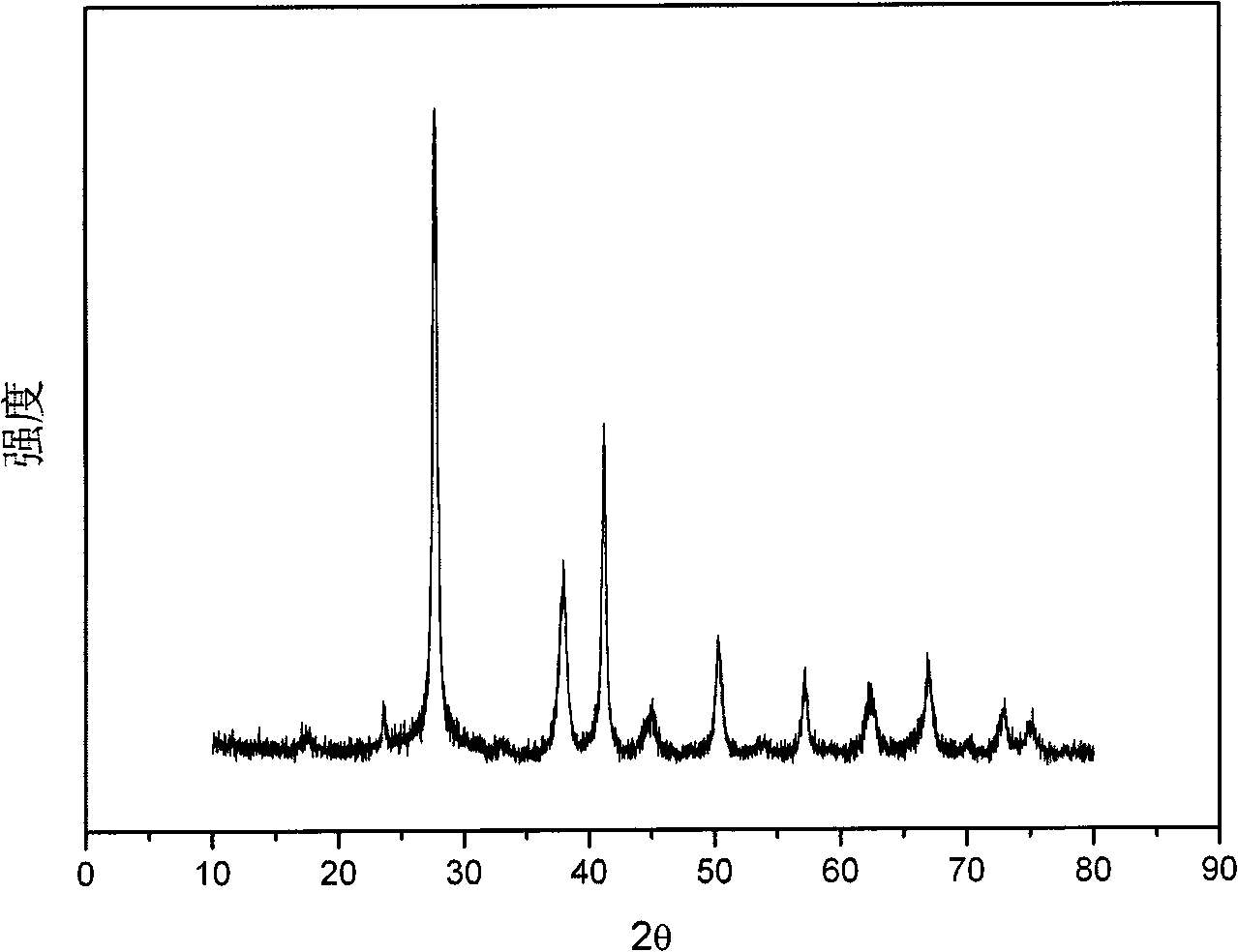

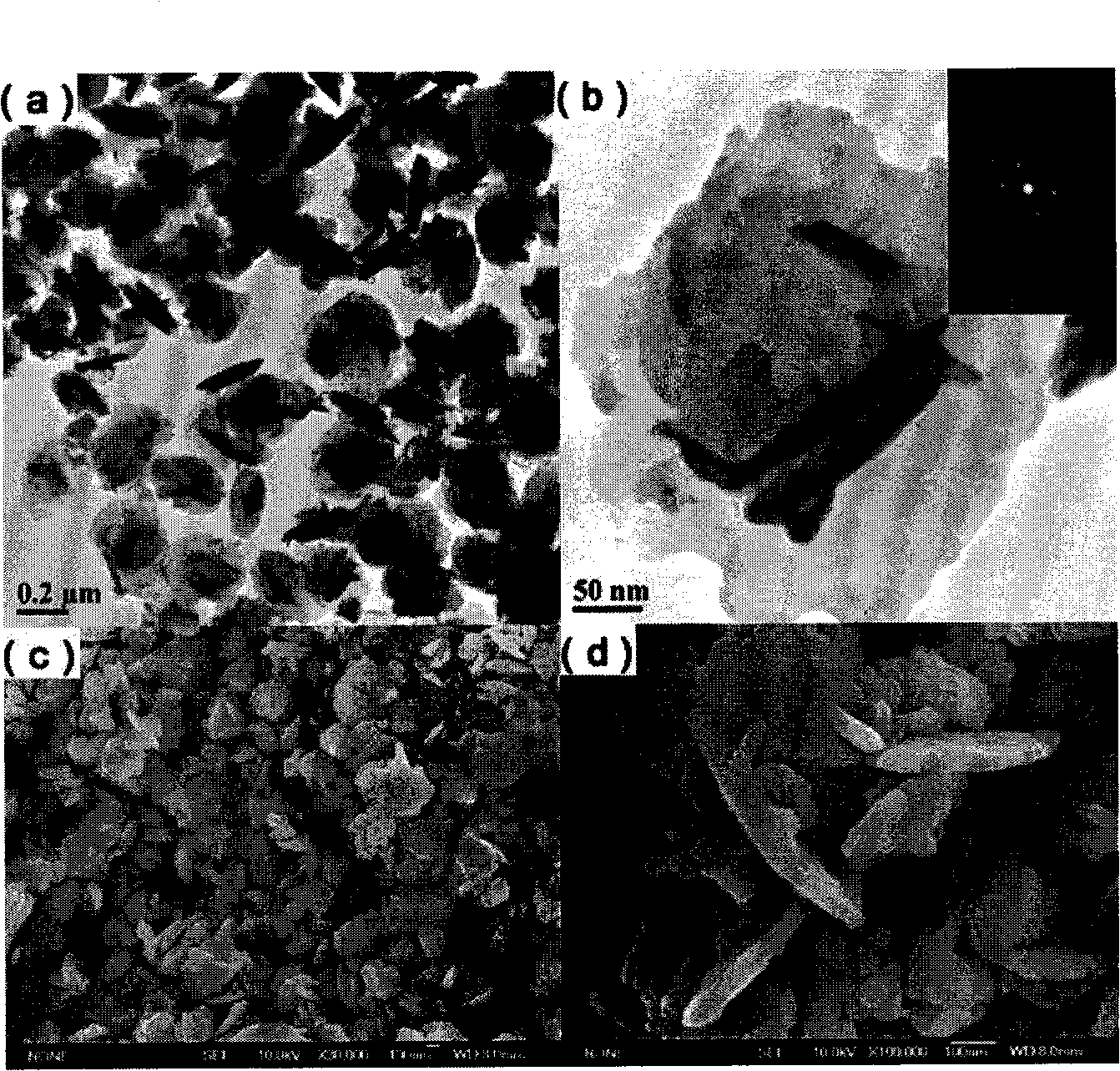

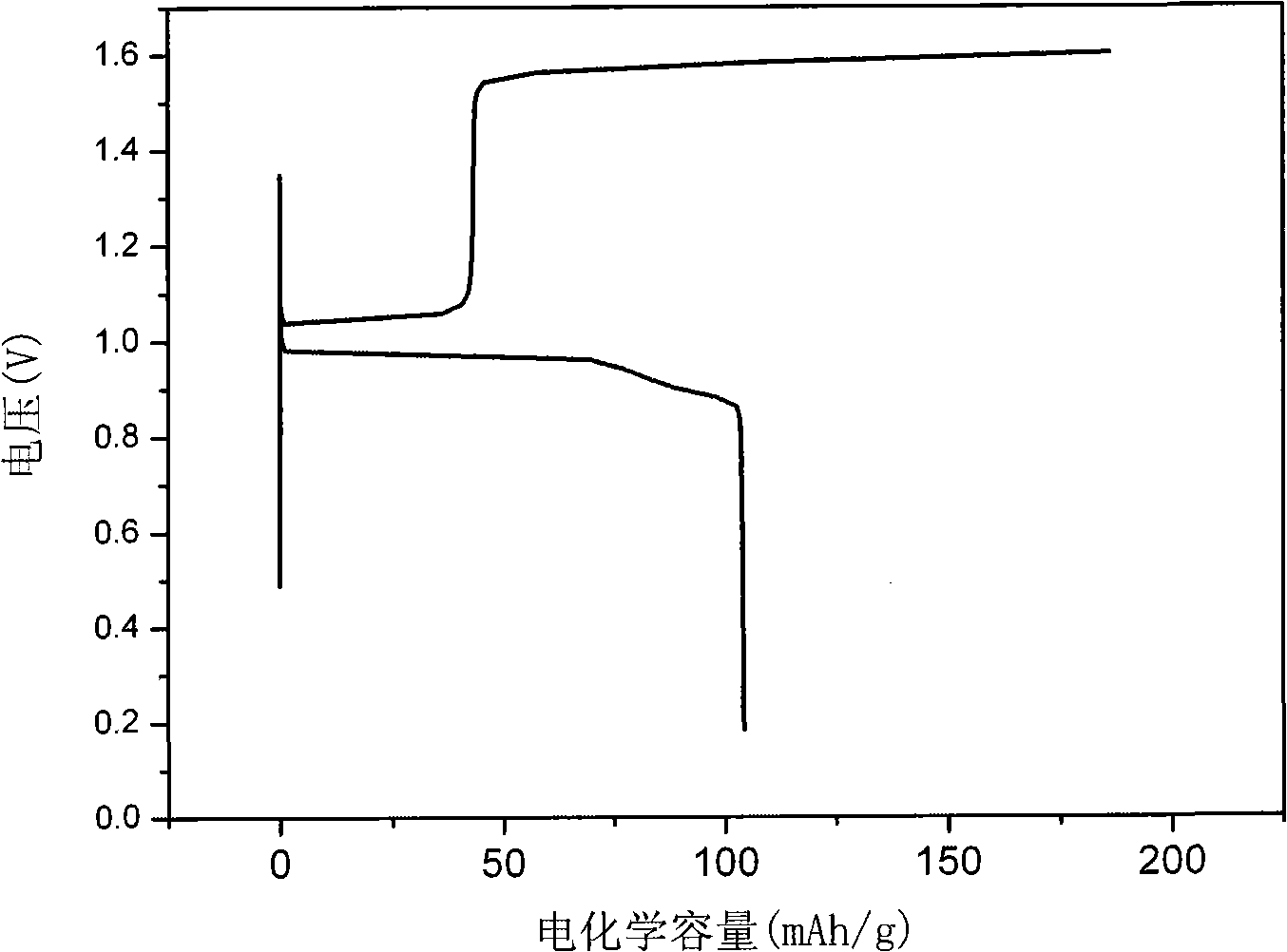

Bismuth base hydrogen storage material and preparation method thereof

ActiveCN101513994AUniform sizeSingle formCell electrodesBinary selenium/tellurium compoundsTe elementSolvent

The invention relates to a bismuth base (bismuth selenide, bismuth telluride) hydrogen storage material and a preparation method thereof, relating to low temperature liquid phase synthesis of bismuth base material and the application thereof on hydrogen storage, lithium storage and electrode material. The invention is characterized in that water is taken as solvent, bismuth salts such as bismuth nitrate, bismuth chloride and the like as a bismuth source, and water-soluble tellurium (selenium) acid salts (such as sodium tellurite, selenium substituted sodium sulfate, sodium selenite) or tellurium (selenium) acids (such as orthotelluric acid, tellurous acid and selenous acid) as a tellurium source (selenium) source; proper coordination agents (such as nitrilotriacetic acid, hexamethylene diamine tetraacethyl and the like) and reducing agents (such as vitamin C, sodium borohydride and the like) are added for liquid phase reaction synthesis at the low temperature of 60-80 DEG C. The bismuth selenide crystal grains prepared by the invention take on flower shapes with the sphere diameter of 1-6mum, and the bismuth telluride crystal grains take on sheet shapes with nanometer diameter; the hydrogen storage performance reaches over 100mAh.g. The method has the advantages of cheap raw material, simple technique, convenient operation, easy mass production, etc.

Owner:中国科学院上海硅酸盐研究所苏州研究院

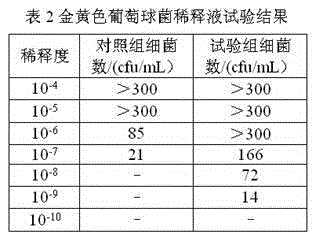

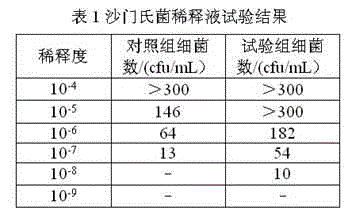

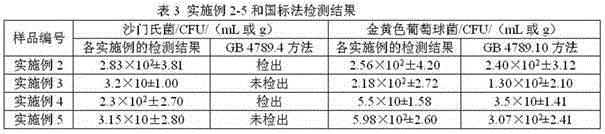

Method for detecting salmonella and staphylococcus aureus in food simultaneously

ActiveCN104894219AAvoid hindranceRapid enrichmentMicrobiological testing/measurementMaterial analysisBiotechnologyMagnetic bead

The invention discloses a method for detecting salmonella and staphylococcus aureus in food simultaneously. The method includes the following steps: 1), diluting a to-be-tested food sample according to GB4789 to obtain sample homogenate of 1:10, adding 50-65wt% of nitrilotriacetic acid solution into the sample homogenate according to the volume ratio of the sample homogenate to the nitrilotriacetic acid solution being (5-7):1, vibrating the mixture, adding phosphate buffer solution or 0.05% tween-20 contained phosphate buffer solution, performing centrifugal layering, and discarding an upper layer; 2), mixing a sample obtained after processing of the step 1) with immunomagnetic beads, vibrating the mixture, subjecting the mixture to standing and layering on a magnetic frame, discarding an upper layer, and washing a lower layer of the sample, wherein the immunomagnetic beads are obtained by modifying salmonella and staphylococcus aureus antibodies, which are labeled by magnetic bead coupled biotin, by streptavidin; 3), adding the phosphate buffer solution to the washed sample, vibrating the mixture, applying the mixture to an LB plate, and performing cultivation and observation. The method is simple and convenient to operate, accurate, efficient and low in cost, two target bacteria are enriched, and detection time can be shorten from 72h to 25h.

Owner:HENAN BUSINESS SCI RES INST

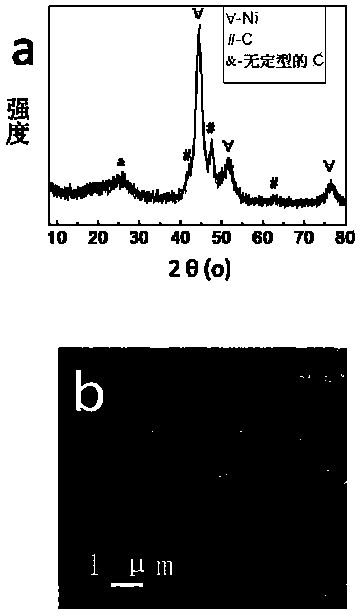

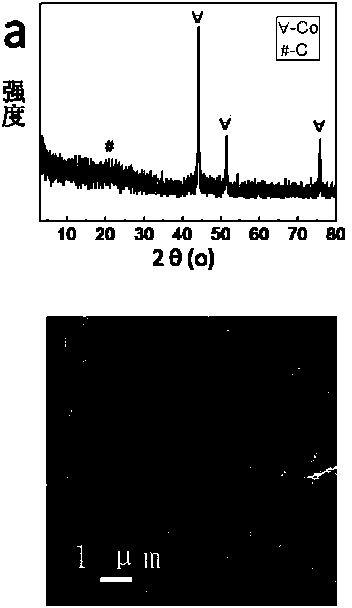

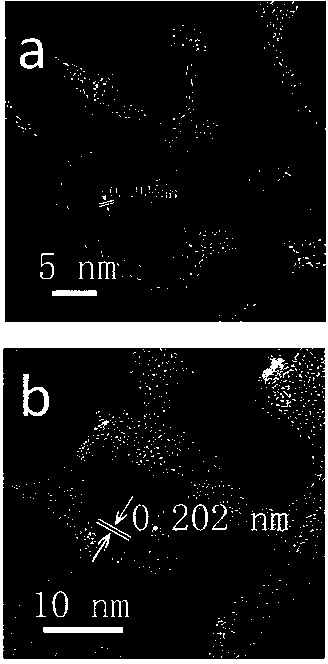

Method for preparing Ni@C or Co@C core-shell nanoparticles

InactiveCN104209514ALarge specific surface areaNarrow pore size distributionMaterial nanotechnologyPtru catalystHeat conservation

The invention relates to a method for preparing Ni@C or Co@C core-shell nanoparticles. The method comprises the steps: (1) adding nickel chloride or cobalt chloride into an isopropanol aqueous solution, adding nitrilotriacetic acid, and stirring for 1 hour at room temperature, so as to obtain a mixed solution; (2) transferring the mixed solution to a reactor, placing the reactor into an air-blasting drying oven, carrying out heat preservation for 6 hours at the temperature of 180 DEG C, cooling, then, separating a product, cleaning and drying in vacuum, so as to obtain a precursor; (3) putting the precursor into a tubular furnace, heating to the temperature of 500-600 DEG C at the heating rate of 2 DEG C / min, and carrying out heat preservation for 2 hours, thereby obtaining a black product, namely the Ni@C or Co@C core-shell nanoparticles. The method has the advantages that the method is simple in process, low in energy consumption, low in cost and free from environmental pollution, and the in-situ synthesis of the Ni@C or Co@C core-shell nanoparticles is realized; the prepared core-shell nanoparticles have porous structures and are larger in specific surface area and narrower in pore size distribution, thereby being a promising catalyst or energy storage material.

Owner:NANKAI UNIV

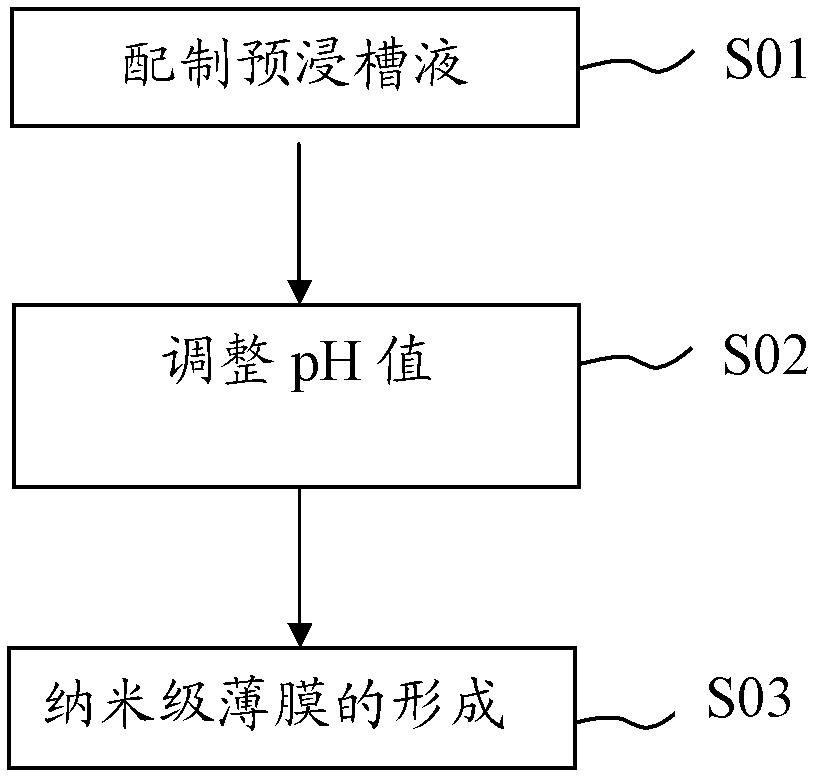

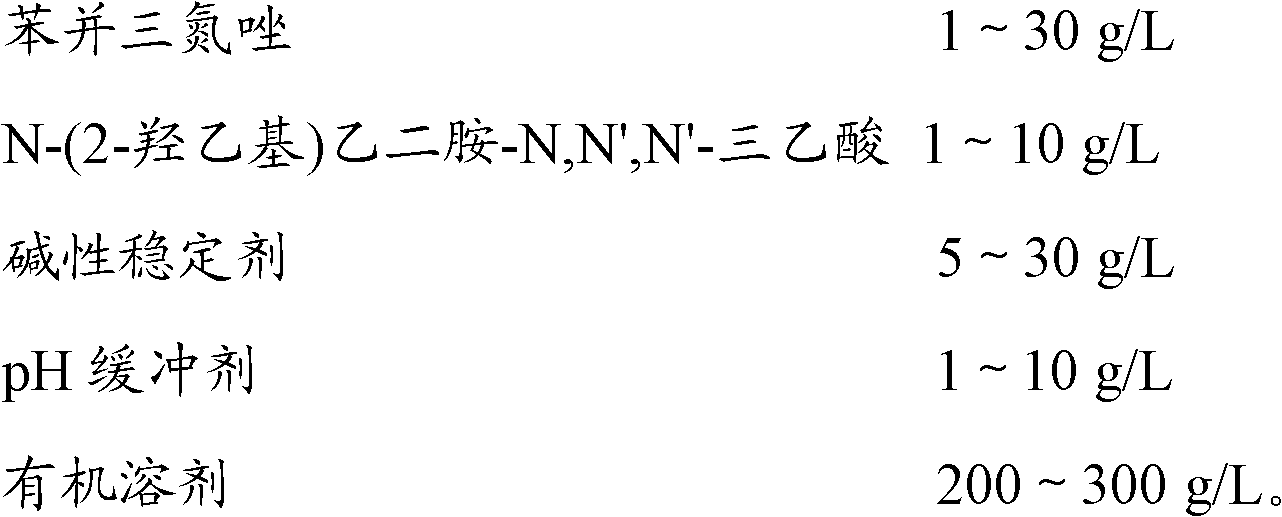

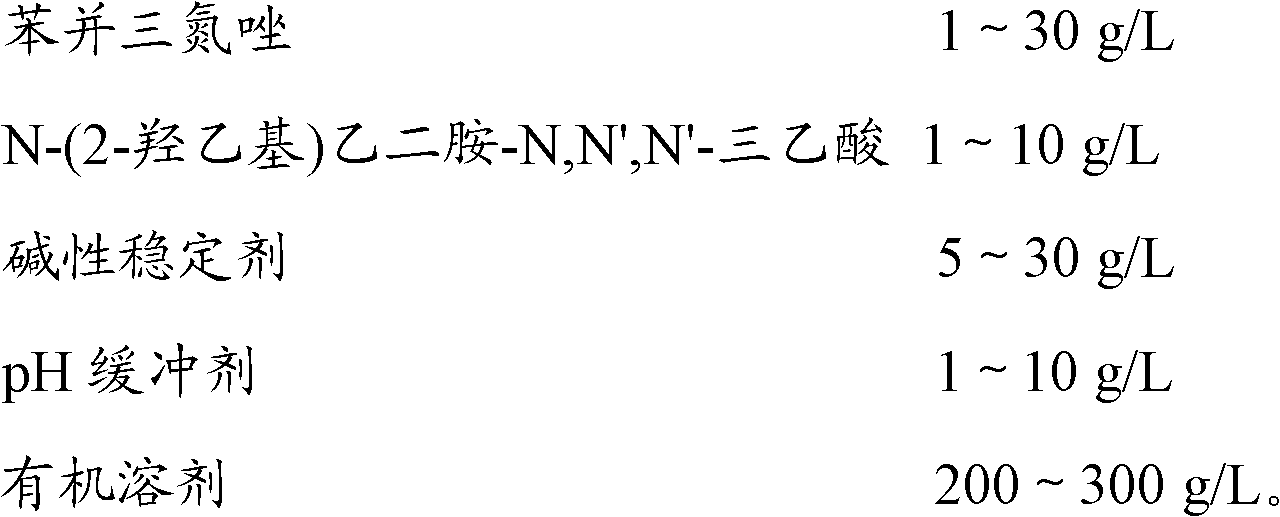

Organic solderability preservative (OSP) on surface of printed circuit board and presoaking stoste and method for manufacturing OSP

InactiveCN102523680AStrong adhesionImprove antioxidant capacityPrinted circuit detailsMetallic material coating processesPh bufferingOrganic solvent

The invention discloses an organic solderability preservative (OSP) on the surface of a printed circuit board and a presoaking stoste and a presoaking method for manufacturing the OSP. The presoaking stoste for manufacturing the OSP on the surface of the printed circuit board comprises the following components of: 1 to 30 g / L of benzotriazole, 1 to 10 g / L of N-(2-ethoxy)quadrol-N,N',N'-nitrilotriacetic-acid, 5 to 30 g / L of alkaline stabilizer, 1 to 10 g / L of pH buffering agent and 200 to 300 g / L organic solvent. The presoaking method for manufacturing the OSP on the surface of the printed circuit board comprises the following steps of: preparing a presoaking bath solution, adjusting the pH value and forming a nano thin film. The OSP on the surface of the printed circuit board is prepared by presoaking by the presoaking method for manufacturing the OSP on the surface of the printed circuit board, and then forming an OSP film. The presoaking stoste for manufacturing the OSP on the surface of the printed circuit board is high in stability and long in service life; the presoaking method for manufacturing the OSP on the surface of the printed circuit board is simple in process, and the conditions are easy to control; the obtained OSP has high adhesive force and high temperature resistance, and is uniform and compact, so that the solderability of the finished printed circuit board is improved.

Owner:深圳市华傲创表面技术有限公司

High-phosphorus chemical nickel-plating solution

InactiveCN106756904ALow costGood throwing abilityLiquid/solution decomposition chemical coatingSodium acetateSuccinic acid

The invention discloses a high-phosphorous chemical nickel-plating solution which comprises a cylinder opening solution and a supplement solution. The cylinder opening solution contains nickel sulfate, sodium hypophosphite, citric acid, lactic acid, sodium acetate, succinic acid, potassium iodate, potassium iodide, nitrilotriacetic acid, cerous sulfate, copper sulfate, benzotriazole, benzimidazole with the concentration being 2-10 mg / L, 5-25 mL / L of OP-10 with the concentration being 5-25 mL / L and the balance pure water. The nickel-plating solution has the advantages that cost is low, the excellent plating ability is achieved, the cylinder opening solution is stable, glossiness is achieved, the magnetism level requirement is met, and the service life reaches 11.0 MTO; during the service life, the average sedimentation rate is 12-14 [mu]m / h, the phosphorus content of a plating layer is 10%-14%, the time for neutral salt spraying is longer than or equal to 96 h (the thickness of the plating layer is 18-25 [mu]m), and the time for a purification resistant nitric-acid test is longer than or equal to 8 min (the thickness of the plating layer is 18-25 [mu]m); the magnetism level is lower than or equals to 200 gamma (specifically, 1 gamma is equal to 1 nT, and in general, remanence in the aerospace field takes gamma as a unit), the western country standard is met, and the magnetism is required to meet the NMB magnetism level; and the plating solution is free of lead and cadmium, conforms to the RoHS command and is an environment-friendly high-phosphorous chemical nickel-plating solution.

Owner:贵阳华科电镀有限公司

Method for adopting eluting solution to restore sewage irrigation area soil heavy metal

InactiveCN103918437AImprove acidificationHigh activityAgriculture tools and machinesOrganic fertilisersSoil scienceSoil heavy metals

The invention discloses a method for adopting an eluting solution to restore sewage irrigation area soil heavy metal. The eluting solution is composed of nitrilotriacetic acid which is a chelating agent and sodium dodecyl sulfate which is a surfactant, and mole ratio of nitrilotriacetic acid and sodium dodecyl sulfate is 5-15mmol kg-1:1mmol kg-1. On the basis of an optimal experiment, restored soil is eluted by using simulated acid rain, the objective of eluting restoration of lawn planting system sewage irrigation area soil heavy metal pollution is achieved, and the sewage irrigation area soil heavy metal after reaching the standard can continue to be applied to agricultural production.

Owner:TIANJIN NORMAL UNIVERSITY

Treatment Fluids Comprising Vitrified Shale and Methods of Using Such Fluids in Subterranean Formations

Owner:HALLIBURTON ENERGY SERVICES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com