Patents

Literature

1249 results about "Glyceryl monostearate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mosquito repelling and itching relieving toilet water and preparation method thereof

ActiveCN103432051ALong effective timeEasy to prepareCosmetic preparationsBiocideBiotechnologyPropolis

The present invention relates to a mosquito repelling and itching relieving toilet water and a preparation method thereof, and belongs to the field of daily chemicals. The mosquito repelling and itching relieving toilet water is characterized by comprising the following raw materials, by weight: 2-4 parts of lavender essential oil, 6-10 parts of argy wormwood leaf oil, 5-7 parts of robust eucalyptus leaf oil, 10-15 parts of peppermint, 12-18 parts of wild dendranthema flower, 5-8 parts of propolis, 80-100 parts of deionized water, and 1-4 parts of an emulsifying agent, wherein the emulsifying agent is one or a plurality of materials selected from modified soybean phospholipid, glyceryl monostearate and glycerol monolaurate. According to the present invention, the mosquito repelling and itching relieving toilet water is prepared from the pure nature raw materials, has characteristics of mosquito repelling, itching relieving, long acting time and good insect bite dermatitis treatment effect, and is an ideal daily care product. In addition, the finished production preparation method is simple and easy to popularize and apply.

Owner:中山榄菊日化实业有限公司

Preparation method of 3D printing rapid-prototyping precoated sand

InactiveCN105195667AStable in natureHigh surface glossFoundry mouldsFoundry coresStearic acidAmmonium bromide

The invention discloses a preparation method of 3D printing rapid-prototyping precoated sand. The method is characterized by comprising the steps that 1, fused ceramite is washed with water, soaked in a water solution with hexadecyl trimethyl ammonium bromide mass percentage concentration being 1-2%, filtered, washed with water to be neutral and dried to obtain pretreated fused ceramite; 2, by mass, 89-94% of pretreated fused ceramite, 2-5% of thermoplastic polyimide, 2-5% of phenolic resin, 0.4-1.0% of bisphenol A type dianhydride, 0.4-1.0% of glyceryl monostearate and acetone are added into a stirring machine, a grinding machine is started to rotate by 120 turns per minute, the mixture is ground for 30 min and then dried, and therefore the 3D printing rapid-prototyping precoated sand is obtained. The precoated sand can be directly molded under laser sintering, and has the advantages that the preparation process is simple, the conditions are easy to control, the production cost is low, and industrial production is easy to achieve.

Owner:UNIV OF JINAN

Eye shadow cream

InactiveCN103655411ANon-irritatingNo side effectsCosmetic preparationsMake-upMicrocrystalline waxEye shadow

The invention discloses an eye shadow cream, which is prepared from the following raw materials in parts by weight: 15-25 parts of microcrystalline wax, 6-12 parts of vaseline, 3-6 parts of squalane, 4-8 parts of beeswax, 12-20 parts of white oil, 2-6 parts of titanium dioxide, 2-4 parts of essence, 15-20 parts of almasilate, 3-6 parts of glyceryl monostearate, 2-5 parts of silicon wax, 3-7 parts of phenoxyethanol, 5-15 parts of pearl powder, 4-8 parts of glycerol and 3-7 parts of hydrogenated lanolin. The eye shadow cream provided by the invention is mild in texture, excellent in effect, convenient to use, nontoxic and harmless for human body.

Owner:QINGDAO CHENXUTONG COMMERCE & TRADE

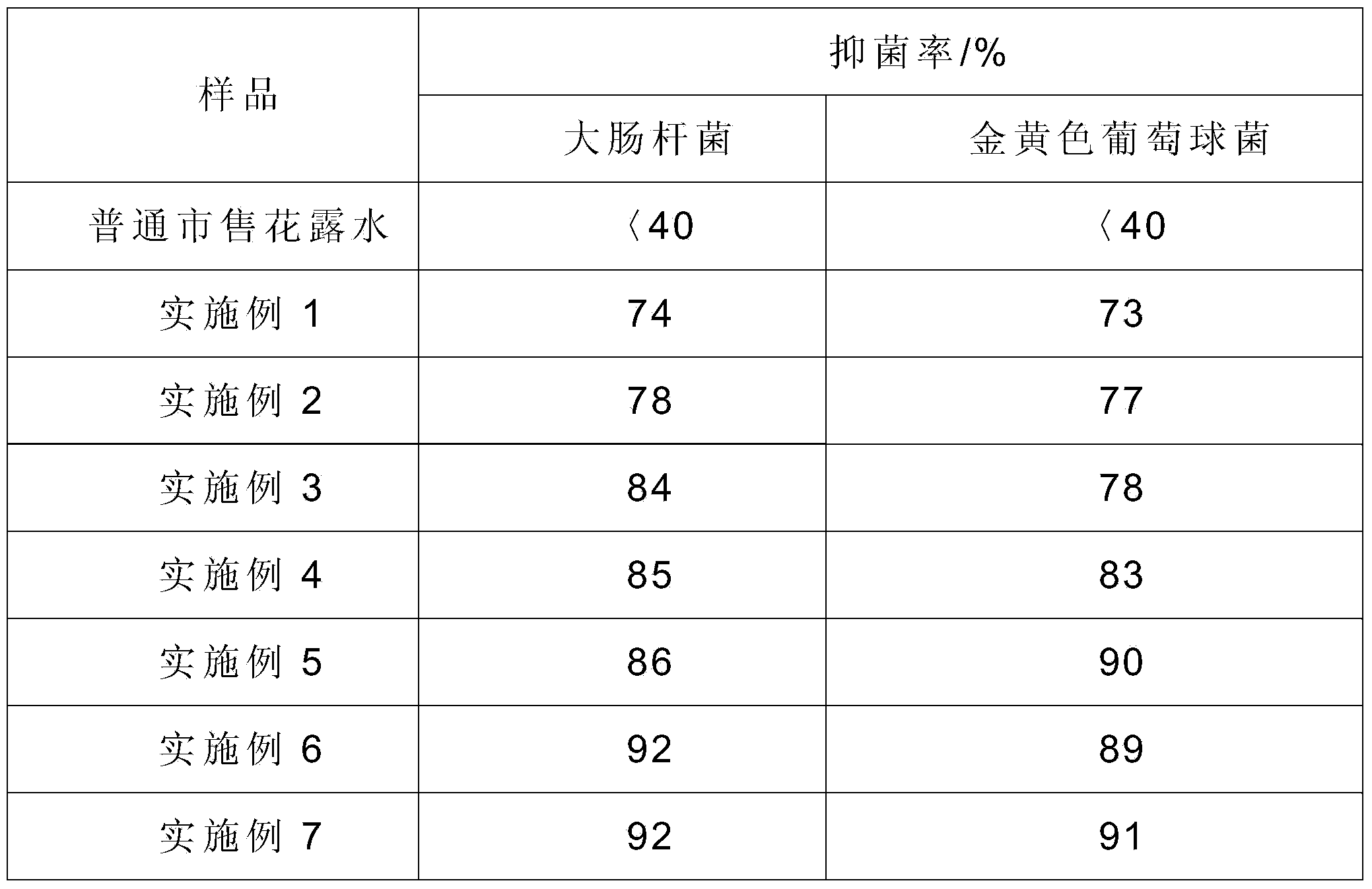

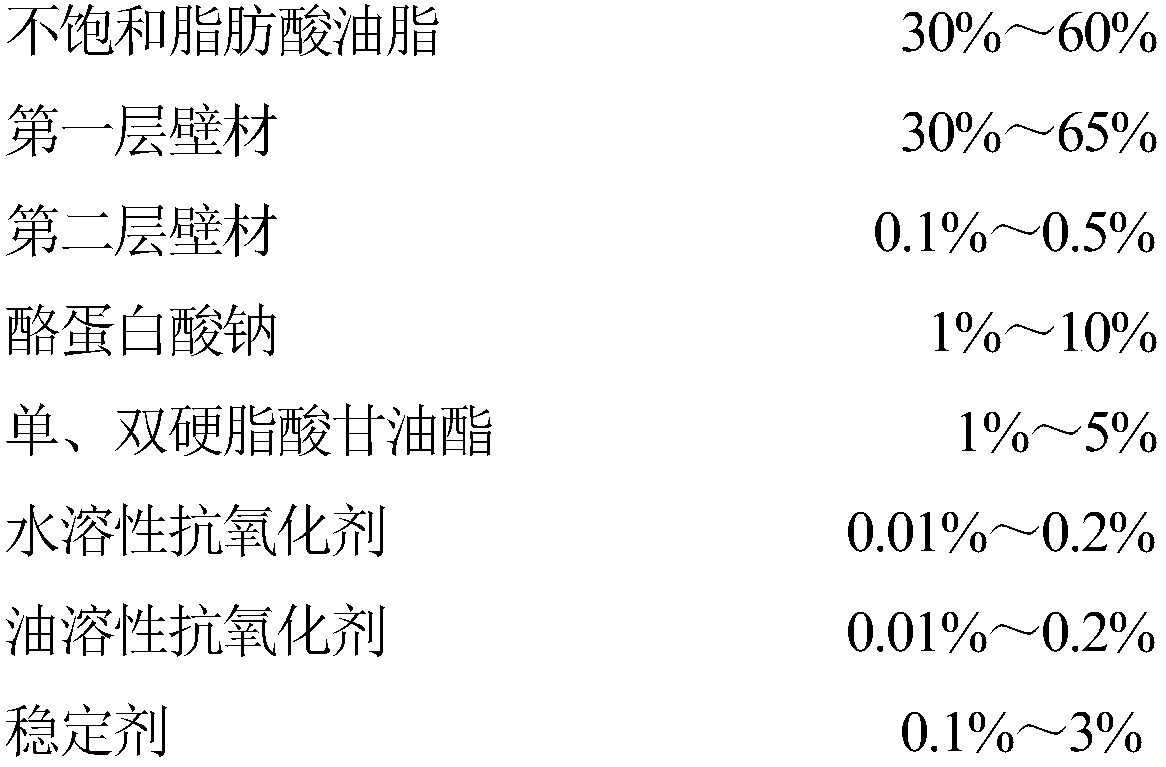

High-temperature-resistant unsaturated fatty acid fat microcapsule powder and preparation method thereof

InactiveCN108338360AGood embedding effectIsolated contactFood ingredient as antioxidantClimate change adaptationAntioxidantSodium Caseinate

The invention discloses high-temperature-resistant unsaturated fatty acid fat microcapsule powder and a preparation method thereof. The preparation method comprises the following steps of adding a first-layer wall material, sodium caseinate, a water-soluble antioxidant and a stabilizing agent to water to obtain a water phase; adding glyceryl monostearate, glycerol distearates and an oil-soluble antioxidant to unsaturated fatty acid fat to obtain an oil phase; and adding the oil phase to the water phase, performing shearing and homogenizing, adding a second-layer wall material to form final emulsion, then performing spray drying, and performing screening so as to obtain the high-temperature-resistant unsaturated fatty acid fat microcapsule powder. According to the high-temperature-resistantunsaturated fatty acid fat microcapsule powder and the preparation method thereof disclosed by the invention, a dual-embedding technique is adopted, the second-layer wall material is made from high-temperature-resistant macromolecule materials, and a layer of high-temperature-resistant films is formed on the surface of a product, so that the air permeability is low, and oxygen, nitrogen, carbon dioxide and the like can hardly pass through the film; and in addition, water and oil diphase antioxidants synergistically strengthen the oxidation resistance of the microcapsule powder, the oxidationof outside high temperature environment and the oxygen on the unsaturated fatty acid fat is effectively prevented, the shelf life of the product is prolonged, the stability of the product is improved,and the preparation process is environmental-friendly.

Owner:SHAANXI HEALTHFUL BIOLOGICAL ENG

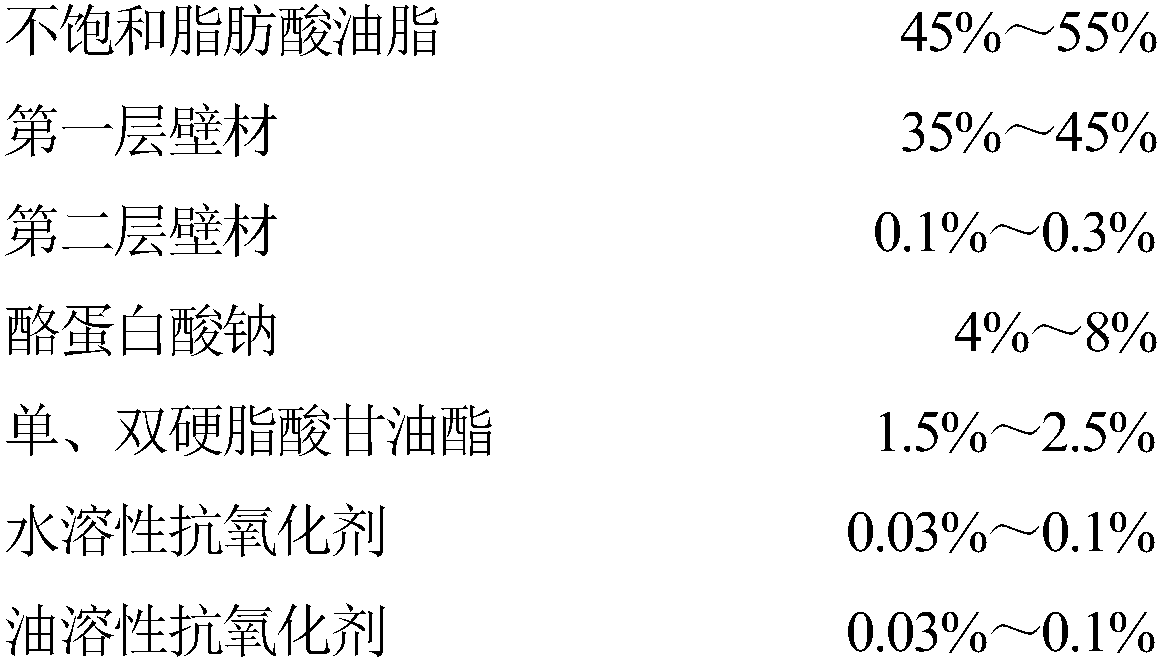

GPES rigid foam composite plastic insulation board and manufacturing method thereof

ActiveCN104231462AWell mixedRealize low temperature and high pressure mixing processPolymer sciencePolystyrene

The invention relates to a GPES rigid foam composite plastic insulation board and a manufacturing method thereof. The GPES rigid foam composite plastic insulation board comprises the following components in part by weight: 80 to 92 parts of polystyrene, 3 to 7 parts of polyethylene, 3 to 11 parts of nano graphite particles subjected to surface physical modification and 0.04 to 0.06 part of glyceryl monostearate. After the components are mixed, the mixture is molten at a temperature of 130 DEG C to 160 DEG C; then the obtained product is mixed at a temperature of 190 DEG C to 230 DEG C and under a pressure of 4MPa to 25MPa; 2 to 4 parts of supercritical carbon dioxide fluid is injected under a pressure of 25 to 35Mpa at the tail end of a seventh section of a first extruder; homogenization and transition are carried out and the obtained product is fed into a second screw extruder by a trumpet-shaped release tube and then is mechanically subjected to scattered regulation of dynamic mixing and static mixing by the second screw extruder; after being released under the conditions of a pressure of 7 to 12MPa and a temperature of 100 plus or minus 5 DEG C, the obtained product is pressed to form the GPES rigid foam composite plastic insulation board.

Owner:SHANDONG PROVINCIAL ACAD OF BUILDING RES +1

Leather maintaining cosmetic

InactiveCN101403019AEasy to useImprove anti-agingPolishing compositionsLeather surface finishingWaxCuticle

The invention relates to a leather maintenance cosmetic agent which includes the following steps: 19 to 32g of wax, 7 to 15g of glycerin, 0.1 to 0.5g of nipalgin formic ester, 1 to 5g of glyceryl monostearate, 1 to 6g of lanolin or chicken grease, 6 to 8g of stearic acid, 4 to 8g of emulsifying agent and 5 to 45g of deionized water are put into a container to be heated till fully dissolved, stirred uniformly and fully, and after the mixture is heated to 85 to 95 DEG C, 5 to 20g of oil solvent is added for continuous uniform stirring; then 33 to 40g of silicone oil and 5 to 45g of deionized water at 85 to 95 DEG C are sequentially added, stirred uniformly and rested for 10 to 15 hours, thus forming finished products. After being spread or sprayed on leather, the leather maintenance cosmetic agent of the invention can rapidly permeate into pores and furs of genuine leather, with fast varnishing, well moisturize the genuine leather to keep the leather soft, and maintain and recover the elasticity of the leather. Particularly, if the cosmetic agent which has good anti-aging performance is often used, the leather does not become hardened, the color is not torn off and the sense of beauty remains.

Owner:刘庆刚

PET (polyethylene glycol terephthalate) fiber/mineral cotton fiber composite sound absorbing cotton and preparation method of PET fiber/mineral cotton fiber composite sound absorbing cotton

InactiveCN102965844AHigh tensile strengthImprove impact resistanceConjugated synthetic polymer artificial filamentsSound producing devicesPolymer scienceAntioxidant

The invention discloses PET (polyethylene glycol terephthalate) fiber / mineral cotton fiber composite sound absorbing cotton, which is prepared from the following ingredients in pars by weight: 70 to 80 parts of PET fibers, 40 to 50 parts of mineral cotton fibers, 10 to 15 parts of emulsifying agents OP-7, 5 to 10 parts of peregal O-20, 80 to 100 parts of PP (propene polymer), 30 to 40 parts of EPDM (ethylene propylene diene monomer), 15 to 20 parts of calcined clay, 10 to 15 parts of modified kieselguhr, 2 to 3 parts of stearic acid, 5 to 8 parts of triethyl citrate, 4 to 6 parts of pentabromophenyl ethane, 2 to 3 parts of glycerin monostearate, 1 to 2 parts of isopropyl distearyl oxyaluminate, 2 to 3 parts of zinc stearate, 1 to 2 parts of calcium stearate, 0.5 to 1.5 parts of anti-aging agents TPPD and 1 to 2 parts of antioxidants 1035. The sound absorbing cotton prepared by the invention has the advantages that the appearance evenness is good, the thickness is uniform, the hand feeling is soft, the product bonding degree is good, the tensile performance is high, the sound absorbing performance is excellent, the flame retardant effect is good, and the like.

Owner:芜湖跃飞新型吸音材料股份有限公司

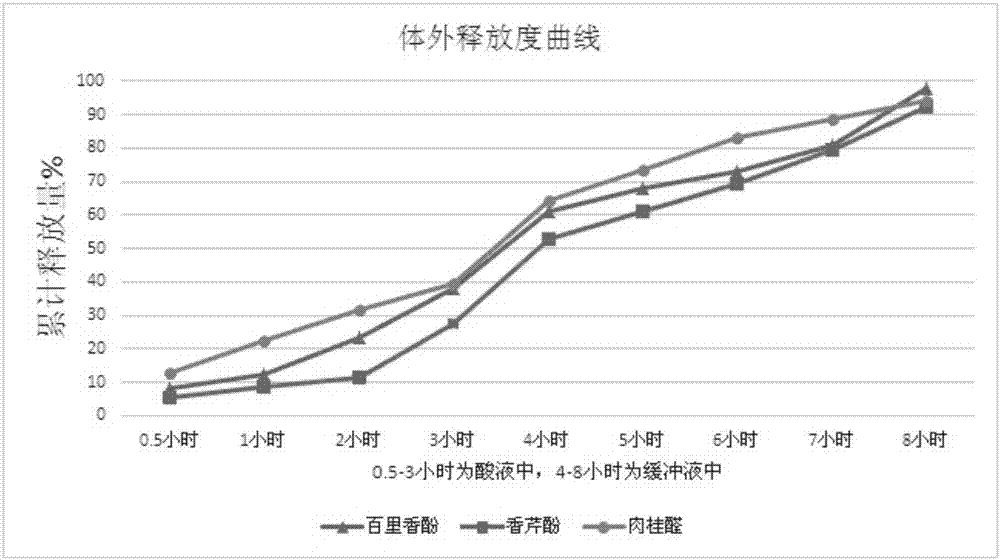

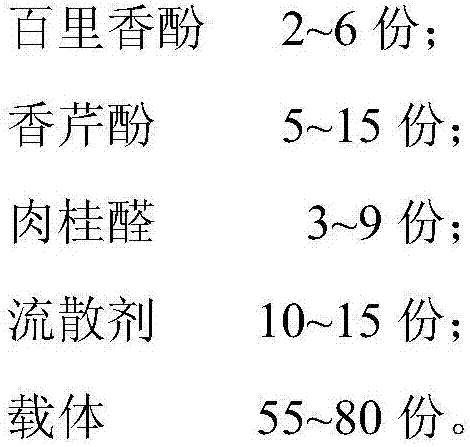

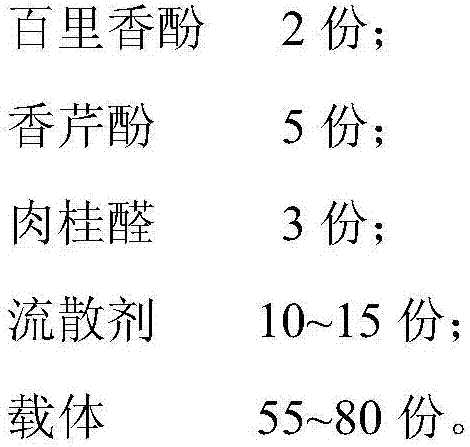

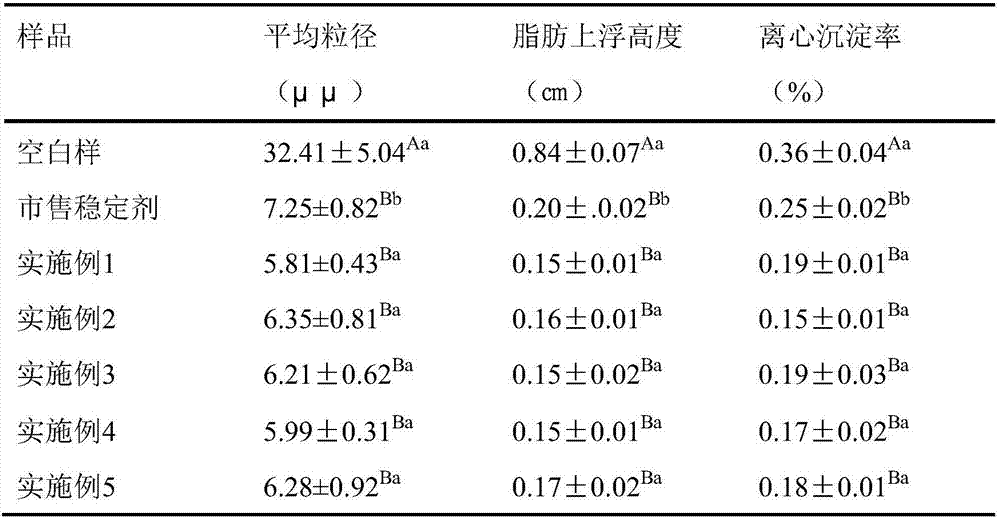

Mixed type feed additive plant essential oil particles and preparation method of plant essential oil particles

InactiveCN107242361AGood effectEffects are: 1) The present invention can obtain excellent antibacterial effect in vitro by optimizing the component distribution ratio of mixed feed additive plant essential oil particlesAccessory food factorsWorking-up animal fodderHybrid typeAdjuvant

The invention discloses mixed type feed additive plant essential oil particles. The mixed type feed additive is prepared from the following components in parts by mass: 2 to 6 parts of thymol, 5 to 15 parts of carvacrol, 3 to 9 parts of cinnamic aldehyde, 10 to 15 parts of free-flowing agent, and 55 to 80 parts of carriers. The invention also discloses a preparation method of the plant essential oil particles. By optimizing the proportion of components of the mixed type feed additive plant essential oil particles, a good in-vitro antimicrobial effect can be obtained. By using one or more of stearic acid, glyceryl monostearate, sodium monostearyl lactate and calcium monostearyl lactate as main carriers and then combining with a preparation process of the free-flowing agent, the plant essential oil and adjuvants are tightly combined and mutually inosculated, so that the contact between the plant essential oil and the air is reduced, and the stability of storage, transportation and using process of the essential oil can be improved.

Owner:JINHE ANIMAL PHARMA +1

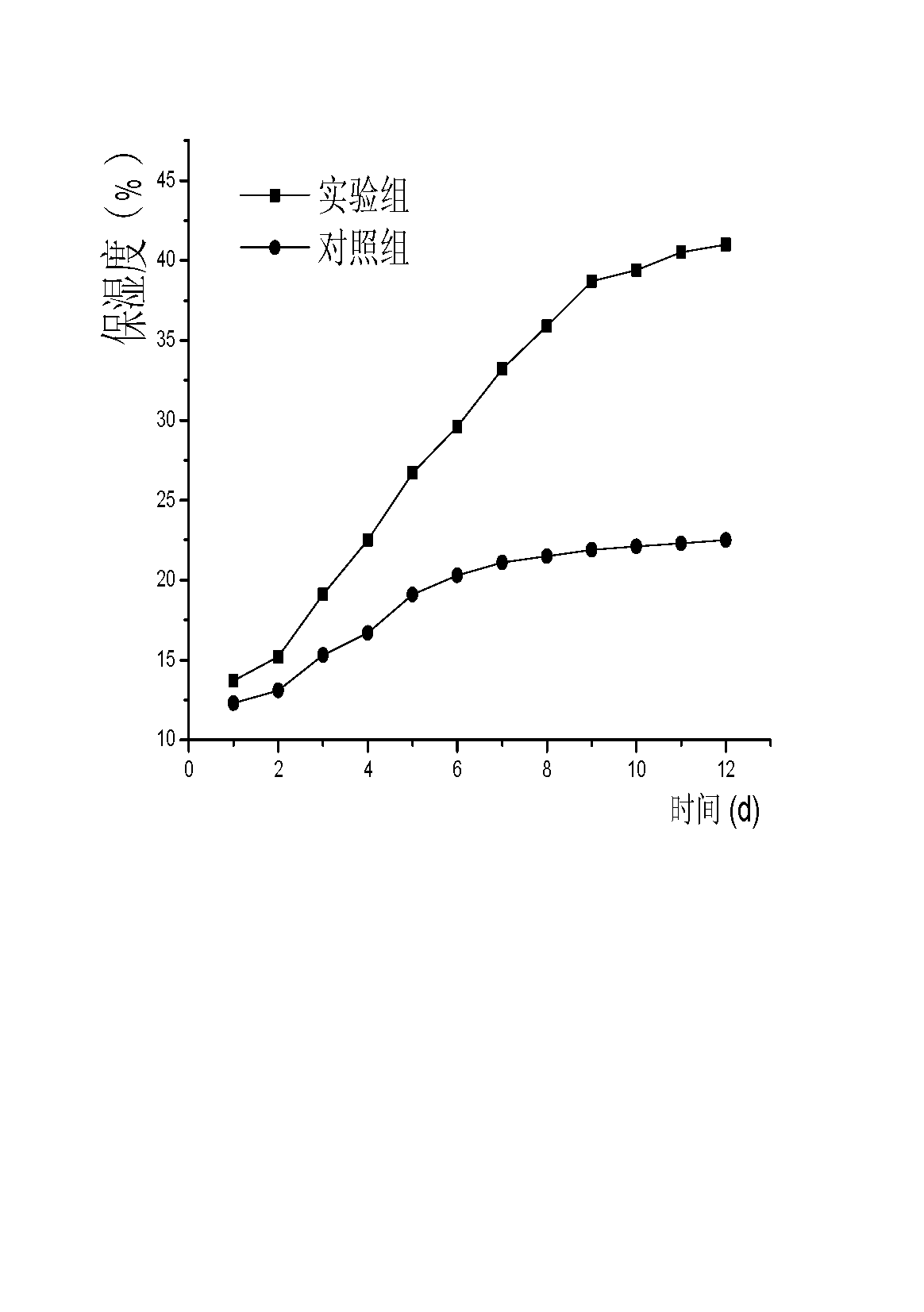

Super absorbent water-retaining agent and preparation method thereof

The invention discloses a super absorbent water-retaining agent and a preparation method thereof. Acrylic acid and acrylamide are used as monomers, potassium persulfate is used as an initiator, N-N' methylene-bisacrylamide is used as a crosslinking agent, polyethylene glycol-2000 and polyethylene glycol-6000 are used as anti-adhesive agents, and bentonite or calcined kaoline is used as an inorganic filler, so that a water phase is formed; and cyclohexane is used as a solvent, glyceryl monostearate is used as a dispersant, and oil phase is mixed with the water phase, so that the super absorbent water-retaining agent is prepared by using an inverted suspension polymerization method. The water absorbency of the prepared poly(acrylic acid / acrylamide / clay) water-retaining agent reaches between1,250 gg<-1> and 1,350 gg<-1>, salt absorbency (0.9 weight percent of NaCl) reaches between 100 gg<-1> and 120 gg<-1>, and water retention rate of a sample can still reach over 50 percent after 13 hours at the temperature of below 70 DEG C; and the super absorbent water-retaining agent can be widely applied to the fields of construction of various water conservancy works, medical treatment and environmental protection.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +2

Emulsion stabilizer for coconut juice beverage and preparation method of emulsion stabilizer

ActiveCN107950853AIncrease viscosityThick tasteFood ingredient as emulsifierFood additiveFlocculation

The invention provides an emulsion stabilizer for a coconut juice beverage and a preparation method of the emulsion stabilizer, and relates to food additives. The emulsion stabilizer for a coconut juice beverage consists of the following components in percentage by mass of 10%-45% of glyceryl monostearate, 5%-25% of sucrose fatty acid esters, 1%-10% of agar, 1%-20% of xanthan gum, 10%-45% of sodium caseinate and 5%-15% of sodium tripolyphosphate. The preparation method comprises the following steps of mixing the glyceryl monostearate with the sucrose fatty acid esters, the agar, the xanthan gum, the sodium caseinate and the sodium tripolyphosphate so as to obtain the powdery emulsion stabilizer for the coconut juice beverage. The emulsion stabilizer is used for producing the coconut juicebeverage, products are free from precipitate, flocculation or floating oil within the quality guarantee period, and the quality and the mouth feel of the products are improved.

Owner:厦门唯康食品科技有限公司

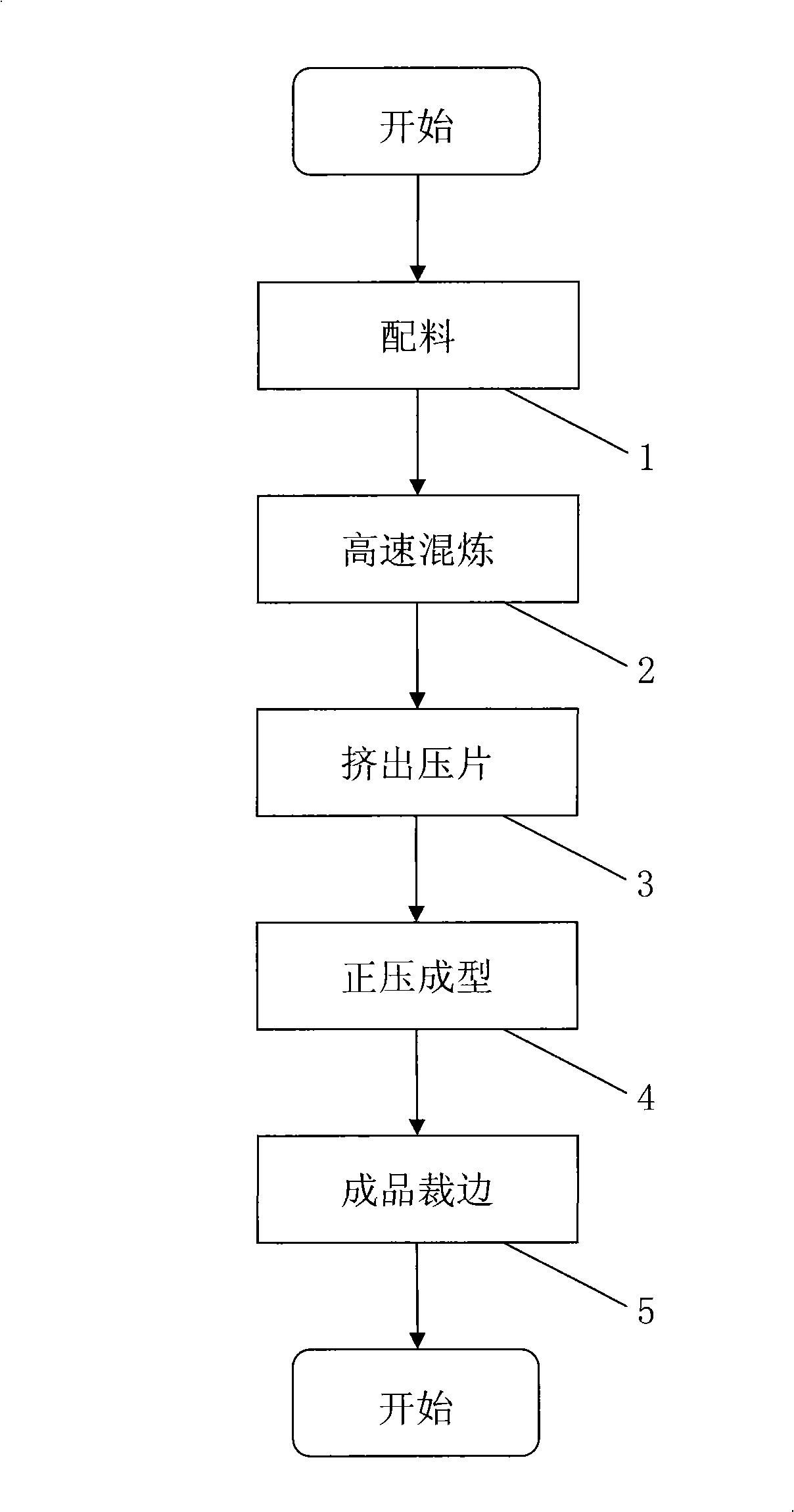

Biodegradable environment protection tableware and its processing method

ActiveCN101293975AHigh mechanical strengthEasy to useTable equipmentsLow-density polyethylenePositive pressure

The invention discloses a biodegradable tableware which contains the following components in weight percentage: 30-60% of starch, 2.5-7% of low-density polyethylene, 20-42% of polyethylene, 1-3% of polyethylene wax, 1-2% of glyceryl monostearate, 3-5% of ethylene-vinyl acetate copolymer, 1-3% of titanium white powder, 2-6% of light calcium carbonate, 1-3% of talc powder, 0.2-0.5% of Al-Ti composite coupler, 0.01-0.02% of modifier, 0.1-0.2% of anti-oxygen agent and 0.04-0.06 of antioxidant. The invention also discloses a method for processing the biodegradable tableware. The method comprises the steps of proportioning, mixing and melting at high speed, extruding and tabletting, molding under positive pressure, trimming and finishing, etc. The invention modifies the formulation and the corresponding production process, so that the biodegradable tableware is not fragile and has high mechanical strength. The biodegradable tableware has water-proof and oil-proof functions without needing inner coating, and can be degraded completely in a short degradation period.

Owner:HUZHOU GLOBAL XINYIFENG ENVIRONMENTAL PROTECTION TECH

Active dry yeast protectant and application thereof

ActiveCN102168016AHigh retention rateImprove fermentation effectMicroorganism based processesMicroorganism preservationFood additiveMicroorganism

The invention relates to an active dry yeast dehydration protectant and application thereof and belongs to the technical field of microorganism products and food additives. The active dry yeast protectant comprises the following components: glyceryl monostearate, sorbitan monostearate, sorbitan monooleate (Span80) and glycerin. The active dry yeast protectant can obviously increase the living cell rate of active dry yeast to 86 to 90 percent, obviously increase the preserving rate of active dry yeast to 88 to 90 percent and obviously increase the fermentation ability of active dry yeast to 530 to 550mL / h.

Owner:QILU UNIV OF TECH

Grape seed compounded horse oil skin care product and preparation method thereof

InactiveCN103239384AElasticAnti agingCosmetic preparationsToilet preparationsBiotechnologyGrape seed

The invention relates to the technical field of natural skin care products and production methods thereof, and more particularly relates to a grape seed compounded horse oil skin care product and a preparation method thereof. The grape seed compounded horse oil skin care product comprises the following raw materials in percentage by weight: 10%-13% of grape seed oil, 5%-7% of horse oil, 2%-3% of glyceryl monostearate, 0.5%-2% of hexadecanol, 8%-10% of glycerol, 1%-3% of triethanolamine, 1%-3% of tween-80, 0.2%-0.5% of xanthan gum, 0.2%-0.5% of grape seed procyanidine and 0.2%-0.3% of essence. The production method provided by the invention is simple and convenient in process and a safe and high-quality natural skin care product suitable for industrial production; and as the grape seed oil and the horse oil are taken as raw materials, the grape seed compounded horse oil skin care product has the advantages of moisturizing and smoothing skin, enabling skin to have high resilience, delaying senescence and preventing formation of acnes, freckles and the like.

Owner:XINJIANG UNIVERSITY

Walnut vegetable protein drink and method for producing same

InactiveCN102696770AEnhance memoryImprove memory functionMilk substitutesGlyceryl monostearateVegetable Proteins

The invention discloses a walnut vegetable protein drink and a method for producing the same. The walnut vegetable protein drink is produced from the following components in percentage by weight: 3-5% of walnut kernel, 1-2% of peanut kernel, 1-2% of brown rice, 5-10% of white granulated sugar, 0.03-0.1% of glyceryl monostearate, 0.05-0.1% of sodium alginate, 0.05-0.1% of agar, 0.01-0.03% of sodium hexametaphosphate and 0.01-0.05% of food essence, and the balance of purified water. The reasonable raw material constitution enables the product to have balanced comprehensive nutrition. The production technology does not filter the raw materials, so the raw materials are utilized to the maximum extent, a superfine technology is adopted, so the grain raw materials which contain under bark are subjected to the processing of a colloid mill, and the drink has fine mouthfeel, developmental nutrition, thicker concentration, and is the drink which is natural, nutrient and healthy.

Owner:厦门粗粮王饮品科技有限公司

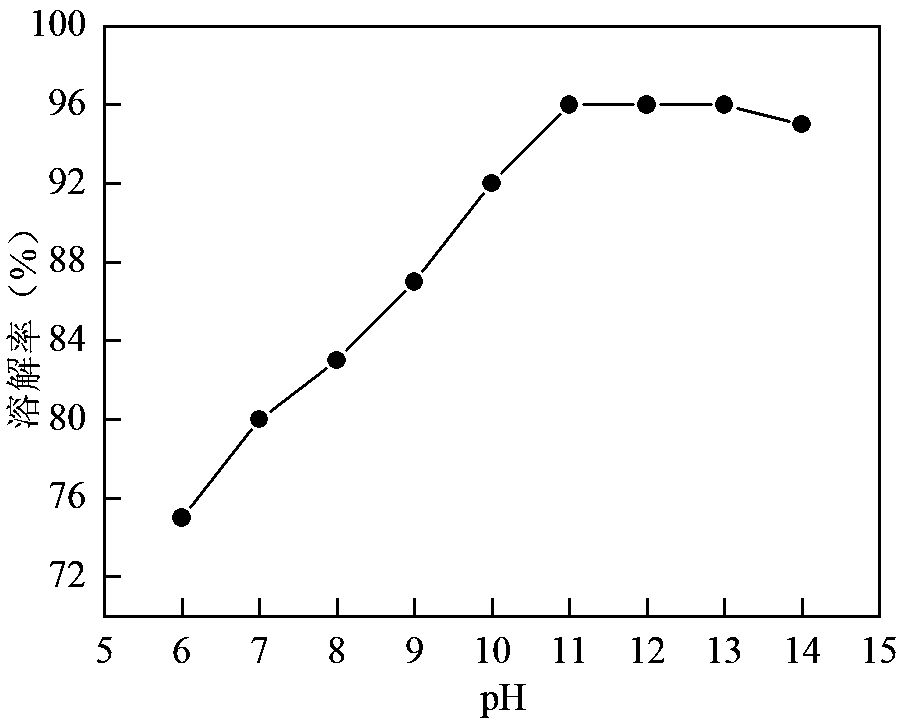

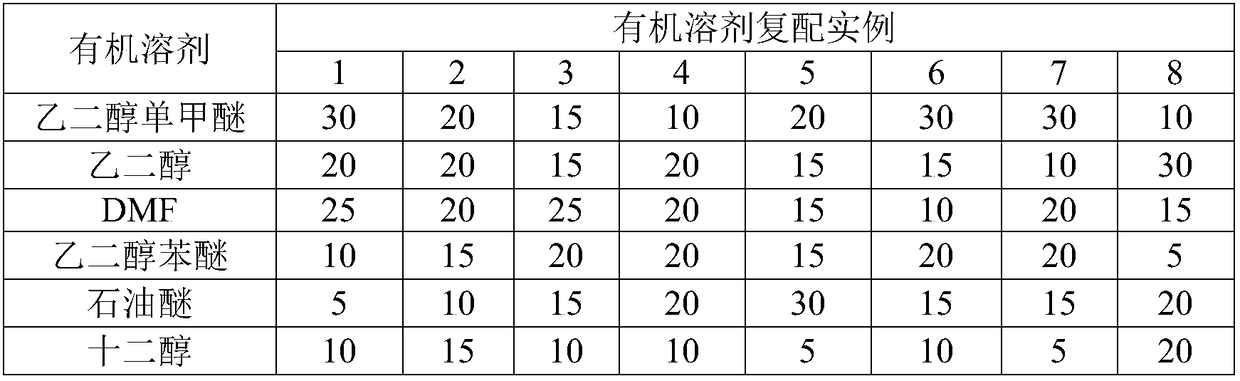

Highly-efficient blockage remover for sulfur-containing gas well

The invention provides a highly-efficient blockage remover for a sulfur-containing gas well. The highly-efficient blockage remover is composed of the following components: 10% to 35% of a high-boiling-point main agent, which is used for dissolving organic obstructions and is composed of ethylene glycol monomethyl ether, ethylene glycol, dimethylformamide, ethylene glycol phenyl ether, petroleum ether and dodecanol; 5% to 10% of an emulsifier, which is compounded from a condensate of fatty alcohol and ethylene oxide, polyoxyethylene sorbitan fatty acid ester and sorbitan fatty acid ester; 7 % to 15% of a surfactant, which is composed of sodium fatty alcohol polyoxyethylene ether sulfate, sodium dodecyl benzene sulfonate, AMALF-32, glyceryl monostearate and polyglyceryl distearate; 5% to 15%of a sulfur-dissolving agent, which is compounded from dimethyl disulfide and diaryl disulfide; 1% to 5% of a metal chelating agent, which is ethylenediaminetetraacetic acid; 8% to 15% of a dispersant, which is a naphthalene sulfonate sodium salt formaldehyde condensate; 3% to 5% of an antioxidant, which is n-octadecanol propionate; 2% to 6% of a scale inhibitor; and a proper amount of an acidity and alkalinity regulator, which is used for regulating a pH value. The blockage remover provided by the invention can resist a temperature of 140 DEG C or above, has an obstruction dissolution rateup to 96%, and has good blockage remover performances to the sulfur-containing gas well in a high-temperature environment.

Owner:SOUTHWEST PETROLEUM UNIV

Cooking-free selenium-enriched snow skin mooncake pre-mixed powder

InactiveCN104705365APromote absorptionPerfect powderDough treatmentFood preparationSelenateSorbitan monostearate

The invention discloses cooking-free selenium-enriched snow skin mooncake pre-mixed powder. The cooking-free selenium-enriched snow skin mooncake pre-mixed powder comprises the following raw materials in parts by weight: 400-450 parts of glutinous rice flour, 100-150 parts of cassava starch, 4-13 parts of selenium-enriched cardamine hupingshanensis powder, 3-6 parts of polysaccharide selenate, 10-15 parts of erythritol, 10-15 parts of maltooligosaccharide, 1-3 parts of sorbitan monostearate, 10-15 parts of glyceryl monostearate, 4-10 parts of edible gum and 30-50 parts of water. The cooking-free selenium-enriched snow skin mooncake pre-mixed powder disclosed by the invention has the characteristics that the pre-mixed powder is cooking-free, does not need to be blended again, can be instantly used after being opened, and is high in selenium content.

Owner:裴秀珍

Non-hydrogenated chocolate with cocoa butter alternatives and preparation method thereof

The invention discloses non-hydrogenated chocolate with cocoa butter alternatives and a preparation method thereof. The non-hydrogenated chocolate with cocoa butter alternatives is prepared from the following raw materials in percentage: 35-50% of non-hydrogenated vegetable oil, 30-50% of white granulated sugar, 6-30% of cocoa powder, 5-40% of milk powder, 1-10% of maltodextrin, 2-8% of soybean proteins, 1-5% of glyceryl monostearate, 0.2-0.5% of soybean lecithin, 0.1-0.3% of polyglycerol polyricinoleate, 0.1-0.3% of sucrose fatty acid ester and 0.01-0.1% of edible essence. Compared with the prior art, the non-hydrogenated chocolate with cocoa butter alternatives has the following advantages: (1), the non-hydrogenated chocolate with cocoa butter alternatives disclosed by the invention is free of hydrogenated vegetable oil and trans-fatty acids, so that the chocolate is capable of meeting the needs of the people in the present society for healthy and nutritious foods; and (2) the disadvantages of relatively soft texture and difficult operation during the production processes of the chocolate with cocoa butter alternatives by using the non-hydrogenated vegetable oil as well as bad flavor and taste of the chocolate are overcome by synergistic actions of an emulsifying agent when the non-hydrogenated vegetable oil is utilized as a raw material for preparing the chocolate with cocoa butter alternatives; thus, quality requirements of the clients are satisfied.

Owner:SHANGHAI HI ROAD FOOD TECHNOLOGY CO LTD

Low-foam water-based diamond wire cutting liquid

InactiveCN107011981AReduce stabilityReduce controllabilityLubricant compositionWater basedWire cutting

The invention provides low-foam water-based diamond wire cutting liquid which comprises the following components in percentage by weight: 3-15 percent of low-foam polyether with a molecular weight of 1500-2000, 2-10 percent of polyether modified polysiloxane with a silicone oil molecular weight of 220-20000 and a polyether molecular weight of 500-2000, 0.5-7 percent of an emulsifying agent, 0.5-5 percent of a PH regulating agent, 0.5-5 percent of a complexing agent, 0.2-1.5 percent of an extrusion agent and 70-95 percent of water, wherein the emulsifying agent uses one or more of isodecanol polyoxyethylene ether, iso-tridecanol polyoxyethylene ether, isooctyl alcohol polyoxyethylene ether, glyceryl monostearate, sorbitan polyethylene laurate and sorbitan stearate; the PH regulating agent is organic amine; the complexing agent is one of or a mixture of more of sodium gluconate, potassium gluconate, sodium nitrilotriacetate, sodium citrate, potassium citrate and sodium potassium tartrate; the extrusion agent preferably selects one or several of sodium carbonate, sodium silicate and sodium sulfate. The low-foam water-based diamond wire cutting liquid provided by the invention can realize a lubricating effect, the abrasion resistance, the cooling performance and the like required to be met in the cutting process.

Owner:ZHENJIANG RENDE NEW ENERGY TECH

Low-lactose long-shelf life yoghourt and preparation method thereof

ActiveCN103564045AImprove stabilityControl fermentation temperatureMilk preparationSodium lactateSucrose

The invention provides low-lactose long-shelf life yoghourt which comprises the following raw materials: 60-98.9 parts by weight of milk, 0.01-0.5 part by weight of emulsifiers, 3-14 parts by weight of thickening agents, and 7-12 parts by weight of sugar; the emulsifier is a combination of one or more than one of sucrose fatty acid ester, glyceryl monostearate fatty acid ester, stearoyl sodium lactate, and glycerol distearate; the thickening agent is a combination of one or more than one of pectin, sodium caseinate, agar, gelatin, modified starch, gellan gum, propylene glycol alginate, and xanthan gum. The low-lactose long-shelf life yoghourt has good stability. The invention also provides a preparation method of the low-lactose long-shelf life yoghourt; the method controls the fermentation temperature and carries out secondary sterilization; the low-lactose long-shelf life yoghourt prepared by the method has good stability.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Method for preparing potassium citrate sustained-release tablets

InactiveCN101791299ARelease stabilityGood slow-release propertiesOrganic active ingredientsPharmaceutical delivery mechanismALLYL SUCROSEStearic acid

The invention relates to a formula and a process for preparing potassium citrate sustained-release tablets, belonging to the technical field of the medicine. The potassium citrate sustained-release tablets are prepared by mixing pore-forming agent, filler, lubricant and coloring agent which are pharmaceutically acceptable to stearic acid or stearic acid derivative, ethyl cellulose, polyacrylic acid resin and glyceryl monostearate which are used as insoluble framework materials according to a certain proportion. The potassium citrate sustained-release tablets have attractive appearance and can release stably in various release medium and even for 6 months in the acceleration test at 40 DEG C.

Owner:南京泽恒医药技术开发有限公司

Mango milk and preparation method thereof

The invention discloses mango milk and a preparation method thereof. The mango milk comprises the following raw materials of: 5 to 50 percent of raw milk, 5 to 30 percent of mango concentrated juice, 3 to 7 percent of sweetening agent, 0.2 to 0.5 percent of stabilizer and water to supplement 100 percent. The stabilizer comprises glyceryl monostearate, sucrose fatty acid ester, carrageenan, modified soybean phospholipids and sodium citrate; and the preparation method comprises the following steps of: (1) mixing the sweetening agent, the stabilizer and the water to obtain liquid A; (2) mixing the liquid A with raw milk to obtain liquid B; (3) mixing mango concentrate juice with the liquid B to obtain mixed liquid; (4) grinding the mixed liquid and implementing the first-grade or the second-grade homogenization; and (5) implementing immersion-type ultrahigh temperature instantaneous sterilization. The mango milk has good flavor, color and taste and excellent stability, and the shelf lifeof the mango milk can reach up to six months. The preparation method is simple and feasible and is suitable for large-scale continuous production.

Owner:BRIGHT DAIRY & FOOD

Dandelion blood sugar lowering health noodles and preparation method thereof

InactiveCN103976365AOvercome the problem of bad taste and inconvenient eatingGreat tasteNatural extract food ingredientsFood ingredient functionsFiberWheat germ

The present invention discloses dandelion blood sugar lowering health noodles, which are prepared from the following raw materials by weight: 40-50 parts of wheat powder, 80-90 parts of buckwheat powder, 8-10 parts of mung bean powder, 8-10 parts of oat powder, 20-30 parts of defatted wheat germ, 6-10 parts of wheat dietary fiber powder, 0.1-0.5 part of glyceryl monostearate, 8-10 parts of L-lysine hydrochloride, 8-10 parts of walnut powder, 5-8 parts of black sesame powder, 30-40 parts of dandelion powder, 20-30 parts of choerospondias axillaris powder, and 1-2 parts of a nutritional additive. According to the present invention, the dandelion blood sugar lowering health flour has natural wheat aroma, is rich in dietary fibers and a variety of nutrition elements, and has complete nutrition; the problems that the wheat dietary fibers and the buckwheat powder contained in the existing blood sugar lowering health noodles do not have good taste and the eating is not convenient are overcome; and the blood sugar lowering health noodles have characteristics of lubricating taste and convenient eating, and are especially for long-term consumption of high blood sugar patients.

Owner:ANHUI YULONG NOODLES FOOD

Antibacterial peptide preparation, and preparation method and application thereof

ActiveCN104491837AHigh encapsulation efficiencyImprove stabilityAntibacterial agentsPeptide/protein ingredientsStearic acidGlyceryl monostearate

The invention discloses an antibacterial peptide preparation, and a preparation method and application thereof. The preparation method comprises the following steps: A, concentrating a thallus fermentation liquid of an antibacterial-peptide producing strain, adding beta-cyclodextrin, dextrin and Arabic gum into the concentrate, and emulsifying for 5-10 min; B, adding the mixed solution into a high-speed centrifugation spray dryer for spray drying, so as to prepare a semi-finished product particle; and C, utilizing a dressing liquid consisting of stearic acid, glyceryl monostearate and glycerol to do dressing processing on the semi-finished product particle in a fluidized-bed dressing machine, so as to prepare the finished product. The preparation method is simple in technology and low in cost, and is suitable for large-batch programmed production. The antibacterial peptide preparation prepared through the method is high in encapsulation rate and good in stability, thereby improving the stability and the shelf life of the antibacterial peptide during forage processing and storage, reducing dissolution loss of the antibacterial peptide in water during forage feeding, improving the utilization rate of the antibacterial peptide and reducing pollution to water.

Owner:GUANGDONG HINAPHARM PHARMA CO LTD

Chinese medicinal composition for beauty treatment and face nursing, and preparation method thereof

ActiveCN101401878AAccelerated agingAbundant resourcesAmphibian material medical ingredientsAerosol deliverySide effectMagnesium stearate

The invention discloses a traditional Chinese medicine composition for beautifying skin. The effective components of the composition consists of the following raw medicines in daily dosage: 2 to 8 grams of ginseng, 3 to 6 grams of angelica, 3 to 9 grams of red sage roots, 100 to 700 milligrams of forest frog oviducts and 145 to 900 milligrams of grape seed extract. The medicine composition can be added with microcrystalline cellulose or magnesium stearate as auxiliary materials to prepare tablets, or be added with stearic acid, glyceryl monostearate, hydrogenerated polyisobutene, olive oil, methyl glucose sesquistearate, glycerin, azone, ethyl nipagin ester and distilled water as the auxiliary materials to prepare cream. The composition has the advantages of high product safety performance, no toxic or side effect, speckle removal, wrinkling resistance, skin aging improvement, good skin beautifying efficacies, and stable and reliable product quality. In addition, the composition is rich in resources of the raw medicines, scientific and reasonable in formulation and simple in preparation process, and meets the requirements of industrial production.

Owner:东方药林药业有限公司

Antistatic fiber and preparation method thereof

InactiveCN103668559AGood antistatic effectAntistatic properties are permanently effectiveElectroconductive/antistatic filament manufactureMelt spinning methodsFiberPolymer science

The invention discloses antistatic fiber and a preparation method thereof. The antistatic fiber comprises the following raw materials in parts by mass: 30-40 parts of polyethylene terephthalate, 10-15 parts of polypropylene, 1-1.5 parts of teflon, 1-2 parts of glycerin monostearate, 0.1-0.2 part of lanolin, wax, polyoxypropylene and 2-3 parts of nanometer titania. The antistatic fiber has excellent antistatic property, and the antistatic property is permanently effective; the antistatic fiber can be easily blended with various other artificial fibers, and is easy to weave and dye. The preparation method is simple and practicable and can be widely popularized and applied.

Owner:NANTONG TONGZHOU DISTRICT CHUANJIANG TOWN SUNWORLD DYNASTY HOME TEXTILE DESIGN STUDIO

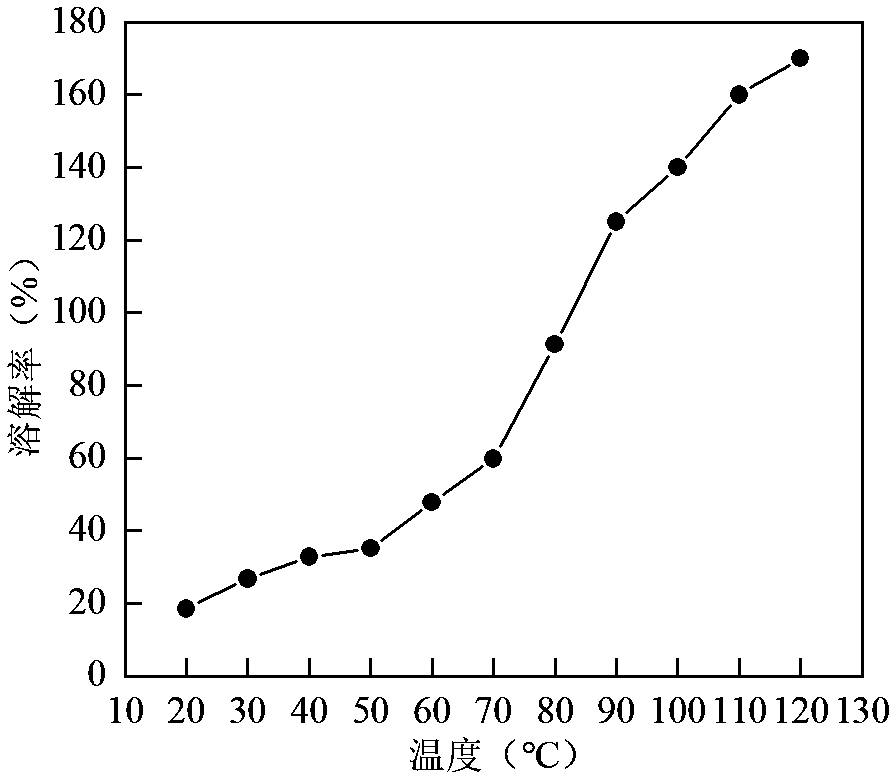

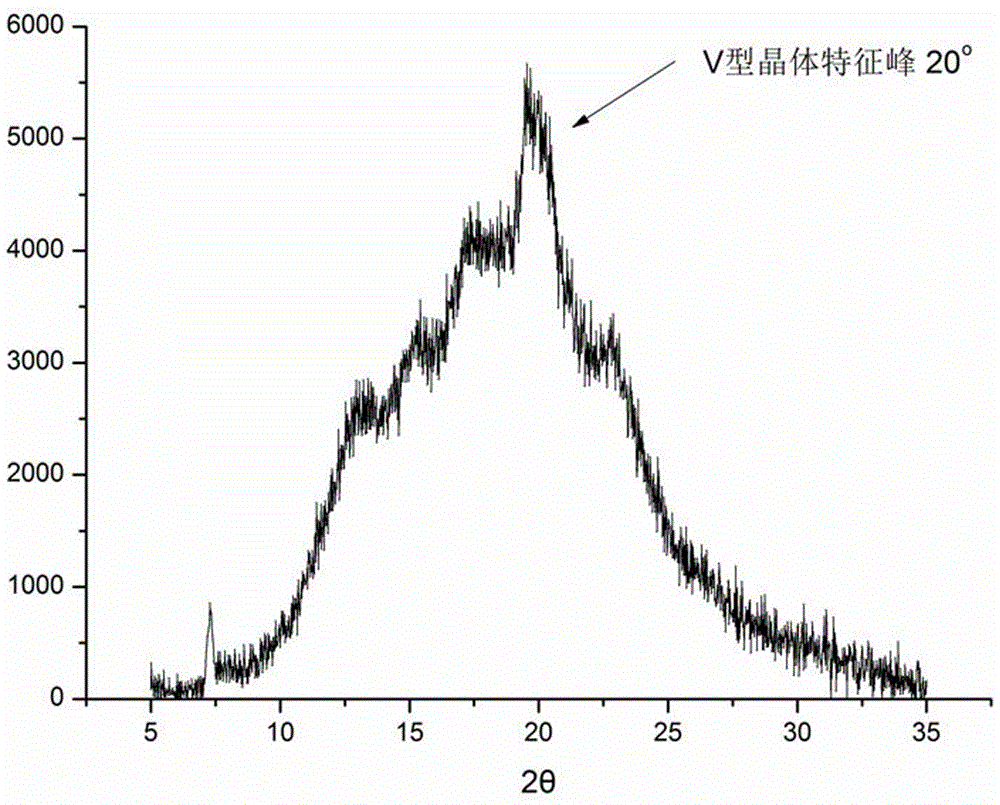

Processing method of lotus seed starch-lipid compound nanoparticles

ActiveCN106832435AIncrease production capacityHigh degree of compoundMaterial nanotechnologyFermentationMonoglycerideSide chain

The invention relates to a processing method of lotus seed starch-lipid compound nanoparticles and belongs to the field of modified starch processing. The method comprises the following steps of: by taking the lotus seed starch and glyceryl monostearate as raw materials, hydrolyzing the raw materials through alpha-amylase and isoamylase; performing high pressure microjet homogenization compounding; performing short-time low-temperature regenerating crystallization; performing washing and centrifugalization; performing freezing and drying; and performing crushing and packaging to prepare the lotus seed starch-lipid compound nanoparticles. According to the principle provided by the invention, side chain branches of branch chain starch are cut based on a double enzyme synergetic enzymatic hydrolysis technology to form a lot of long-chain straight-chain starch; the length of the chain section of the straight-chain starch is reduced by means of high pressure microjet homogenization to accelerate short-chain fragments to be compounded with monoglyceride; the nanoparticles are generated by means of short-time low-temperature regenerating crystallization. The method provided by the invention overcomes the defects that a conventional acid hydrolysis preparation method is time-consuming, low in yield, relatively high in grain size of nanoparticles and the like. Compared with a conventional acid hydrolysis method, the yield of the nanoparticles is increased by 30-45%, and the grain sizes are distributed in a range of 60-120nm.

Owner:FUJIAN AGRI & FORESTRY UNIV

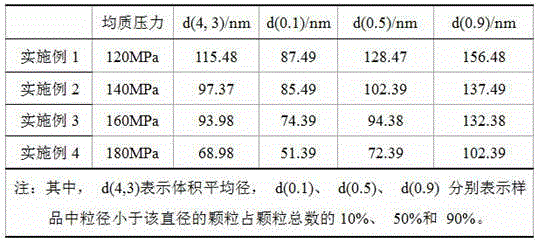

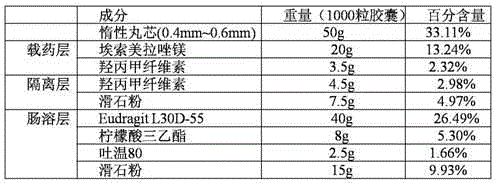

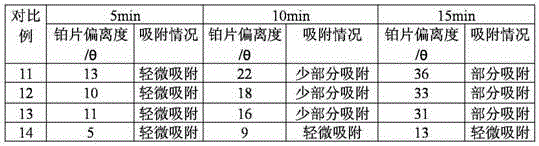

Enteric-coated micropellet containing esomeprazole magnesium

ActiveCN104414978APrevent Mutual AggregationAvoid being sucked by the wall of the fluidized cylinderOrganic active ingredientsDigestive systemMethacrylic acid-ethyl acrylate copolymerStearic acid

The invention relates to an enteric-coated micropellet containing esomeprazole magnesium. The enteric-coated micropellet comprises an inert pellet core, a medicament-loaded layer, an isolation layer and an enteric-coated layer, wherein the enteric-coated layer contains a methacrylic acid / ethyl acrylate 1: 1 copolymer, glyceryl monostearate, Tween 80 and talcum powder, wherein the methacrylic acid / ethyl acrylate 1: 1 copolymer is preferably Eudragit L30D-55. The enteric-coated micropellet containing esomeprazole magnesium, provided by the invention, can give consideration to acid resistance, release rate and stability of a product for a long time in the placement process, can meet or exceed existing preparation quality standards; and furthermore, the enteric-coated micropellet is prepared by simple process steps, is suitable for a relatively large pellet core (0.3mm-1mm), has the characteristic of low production cost, and is more suitable for large-scale industrialized production.

Owner:SICHUAN GOWELL PHARMA

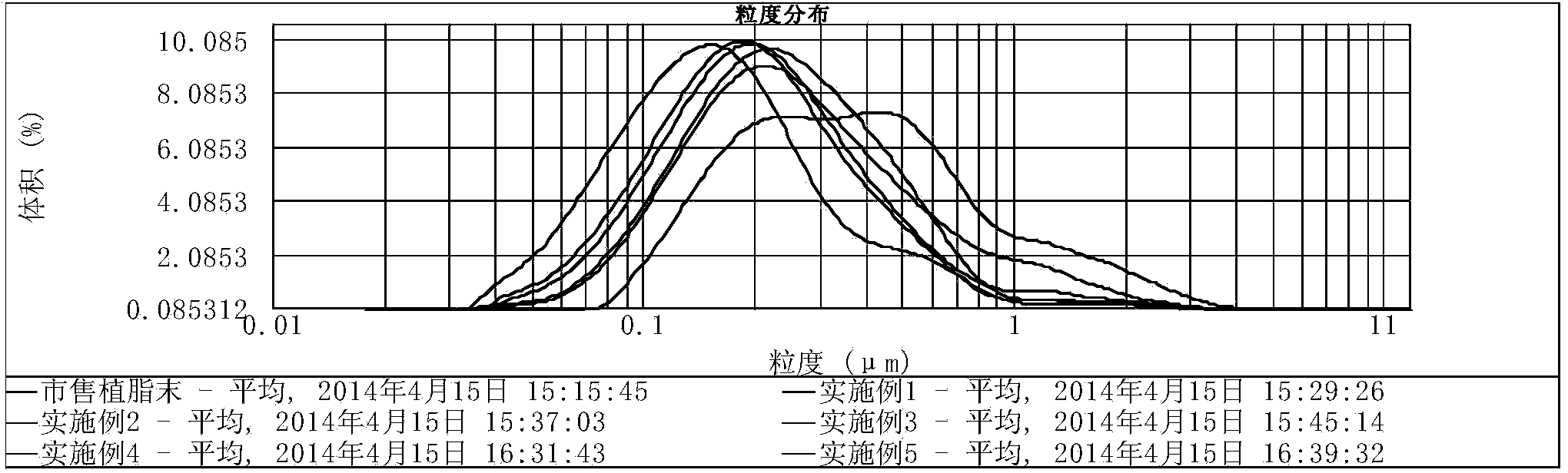

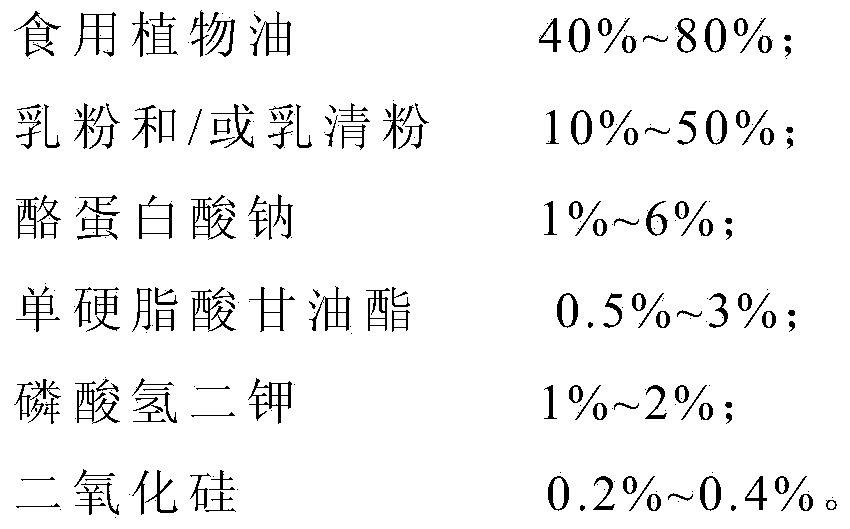

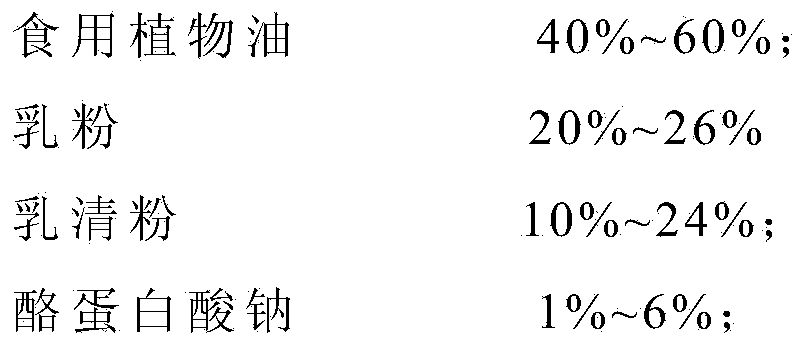

Zero-sugar creamer and preparation method thereof

The invention relates to a zero-sugar creamer and a preparation method thereof. The zero-sugar creamer comprises 40-80 percent of edible vegetable oil, 10-50 percent of milk powder and / or whey powder, 1-6 percent of sodium caseinate, 0.5-3 percent of glyceryl monostearate, 1-2 percent of dipotassium phosphate and 0.2-0.4 percent of silicon dioxide. According to the zero-sugar creamer, syrup is creatively eliminated from a creamer product, so that the net cost is reduced by about 20 percent; in addition, due to elimination of the syrup, the fat content is indirectly improved, the utilization rate of the creamer is higher, and the addition amount of the creamer in a beverage is decreased, so that the spray drying cost and the problem of carbon emission are reduced; furthermore, by improvement on a formula, the amount of the formula and the like, the stability of a product still meets the standard, and meanwhile, the product is unique in flavor and high in solvency.

Owner:JIAHE FOODS IND CO LTD

Foaming agent for mineral flotation and preparation method thereof

The invention discloses a foaming agent for mineral flotation and a preparation method thereof, and belongs to the technical field of mineral flotation. The foaming agent for mineral flotation is prepared from, by weight, 50-60 parts of methyl ester sulfonate, 25-30 parts of lauryl sodium sulfate, 20-30 parts of sodium alpha-olefin sulfonate, 10-15 parts of polyvinyl alcohol, 10-15 parts of glyceryl monostearate, 10-15 parts of polyvinyl pyrrolidone, 10-15 parts of N-lauroyl glutamic acid diester, 5-10 parts of potassium lauroyl sarcosinate, 5-10 parts of sodium lauroyl hydrolyzed silk, 5-10 parts of lauryl diethanolamide, 5-10 parts of guar gum, 5-10 parts of sodium alga acid and 5-10 parts of a foam stabilizer. The foaming agent is high in foaming agent, high in foamability, high in foaming stability and good in hard water resistance.

Owner:滦平县聚源矿业有限责任公司

Preparation method of TOPCon structure battery

ActiveCN110416359AFree from corrosionReduced diffusion rateFinal product manufactureSemiconductor devicesProduction lineSodium laurate

The invention discloses a preparation method of a TOPCon structure battery, and the method comprises the following steps: before a step of removing polycrystalline silicon winding plating, reserving aBSG on the front surface of a silicon wafer; in the step of removing the polycrystalline silicon winding plating, removing the polycrystalline silicon on the front surface of the silicon wafer by adding an alkaline solution of an additive, wherein the additive comprises the following components in percentage by mass: 2%-5% of glyceryl monostearate, 1%-2.5% of diethylene glycol, 1%-2.5% of sodiumlaurate and 1%-2% of beta-cyclodextrin and the balance of deionized water, and the alkaline solution is a KOH solution or a NaOH solution. According to the method, the polycrystalline silicon windingplating is removed by adding the alkaline solution of the additive, so that the BSG can be protected from being corroded by the alkaline solution, and furthermore, alkali cannot corrode a phosphorus diffusion part and a boron diffusion part. The process window is wider, the efficiency is more stable, the diffusion capacity can be improved, a groove type machine and a chain type machine can be applied, and a production line can conveniently use an existing machine table to achieve mass production.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com