Patents

Literature

333 results about "Sorbitan monostearate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sorbitan monostearate is an ester of sorbitan (a sorbitol derivative) and stearic acid and is sometimes referred to as a synthetic wax.

Water-in-oil microemulsions for oilfield applications

A well treatment microemulsion includes an oil external phase, an internal aqueous phase and a hydrophilic surfactant. The surfactant has a hydrophile lipophile balance of between 8-18. The oil external phase may include d-Limonene, xylenes, light mineral oil, or kerosene. The surfactant is configured to emulsify the water of the internal aqueous phase into the oil of the external (continuous) phase. The surfactant may include polyoxyethylene sorbitan monooleate, polyoxyethylene sorbitan tristearate, polyoxyethylene hydrogenated castor oil, polyoxyethylene sorbitan monostearate, polyoxyethylene sorbitan monooleate, polyoxyethylene sorbitan monolaurate or mixtures therebetween. The use of hydrophilic surfactants to emulsify an internal aqueous phase within an oil external microemulsion produces unexpected and beneficial results.

Owner:PNC BANK NAT ASSOC

Dehydrated polysaccharide gel containing microorganisms, a sugar and a polyol for producing fermented drinks

Improved fermentation activity of microorganisms in a polysaccharide gel such as an alginate gel is obtained after dehydration, staorage and rehydration by soaking the gel containing the microorganisms prior to dehydration in a sugar solution to provide in the gel an amount of sugar of at least 100 g / kg and less than 500 g / kg of gel, preferably less than 300 g / k of gel. The dehydration may be carried out in a fluidized bed or by lyophilization. The gel may be in the form of beads or fibers having a double layer structure formed by an internal layer or core of gel containing the microorganisms and an external lay er or envelope of gel essentially devoid of the microoraganisms. The sugar is preferably xylose, glucose, fructose, lactose or sucrose, and the sugar solution may contain a polyol such as sorbitol, inositol or glycerol to provide in the gel an amount of polyol of at least 30 g / kg of gel. The sugar solution may also contain a non-ionic surfactant such as sorbitan monostearate as a protecting substance to fur ther improve fermentation activity. The microorganisms in the gel are preferably yeast, and after rehydration the yeast containing gel is used in producing a fermented drink such as in secondary fermentaion of wine to produce sparkling wine or champagne.

Owner:MOET & CHANDON

Thermoplastic food casing

A porous food casing consisting essentially of a film of food grade thermoplastic having a plurality of interconnected interstices therein. The interstices are defined by a porosity modifier selected from the group consisting of soybean oil, peanut oil, corn oil, glycerin, polyethylene glycol, monolaurate, mineral oil, polyoxyethylene, sorbitan monostearate, sorbitan monooleate and glycerol monooleate. The interstices are in a range of approximately 0.002 to 1 micron and the casing has a water vapor permeability in a range of about 1 to 1500 gms / m2 / min.

Owner:YEN WILLIAM W

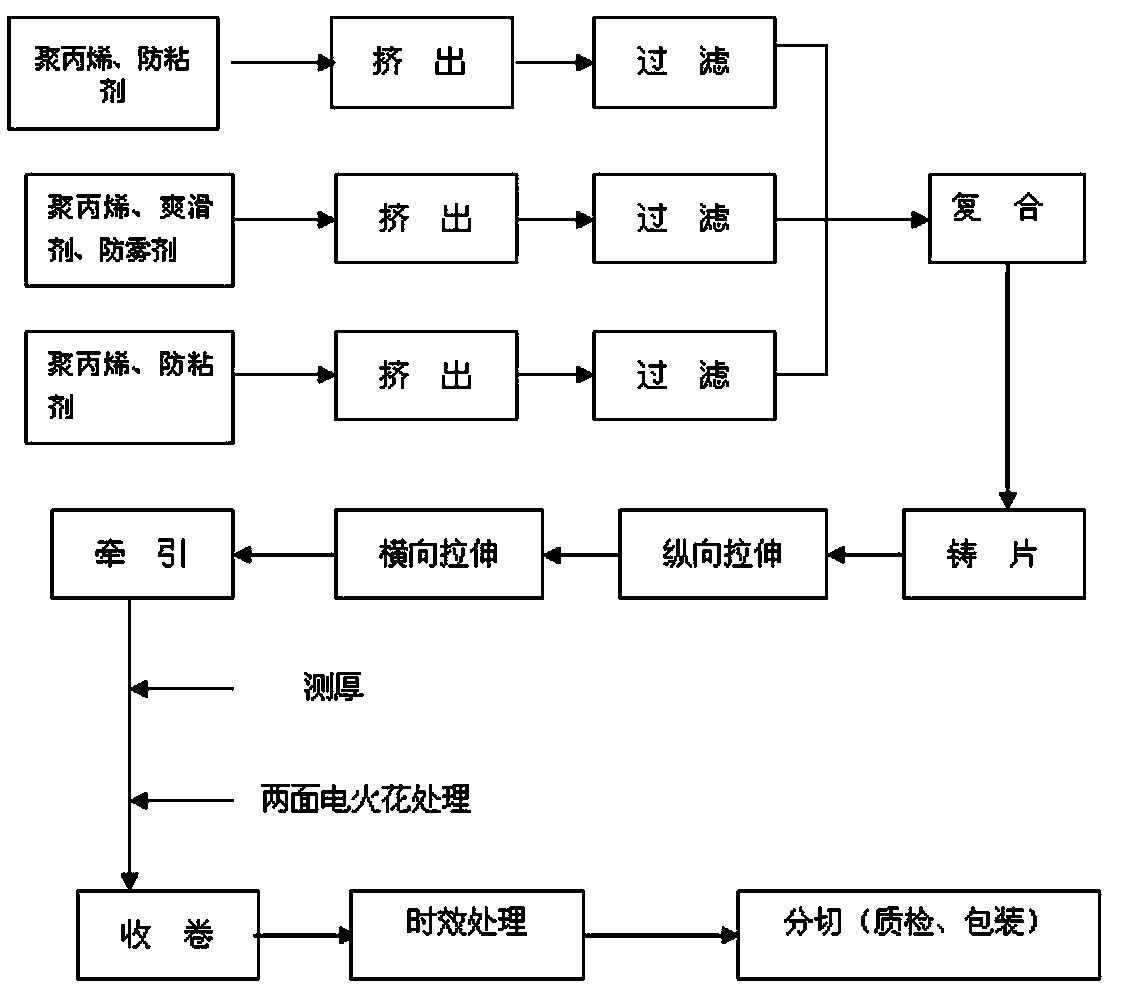

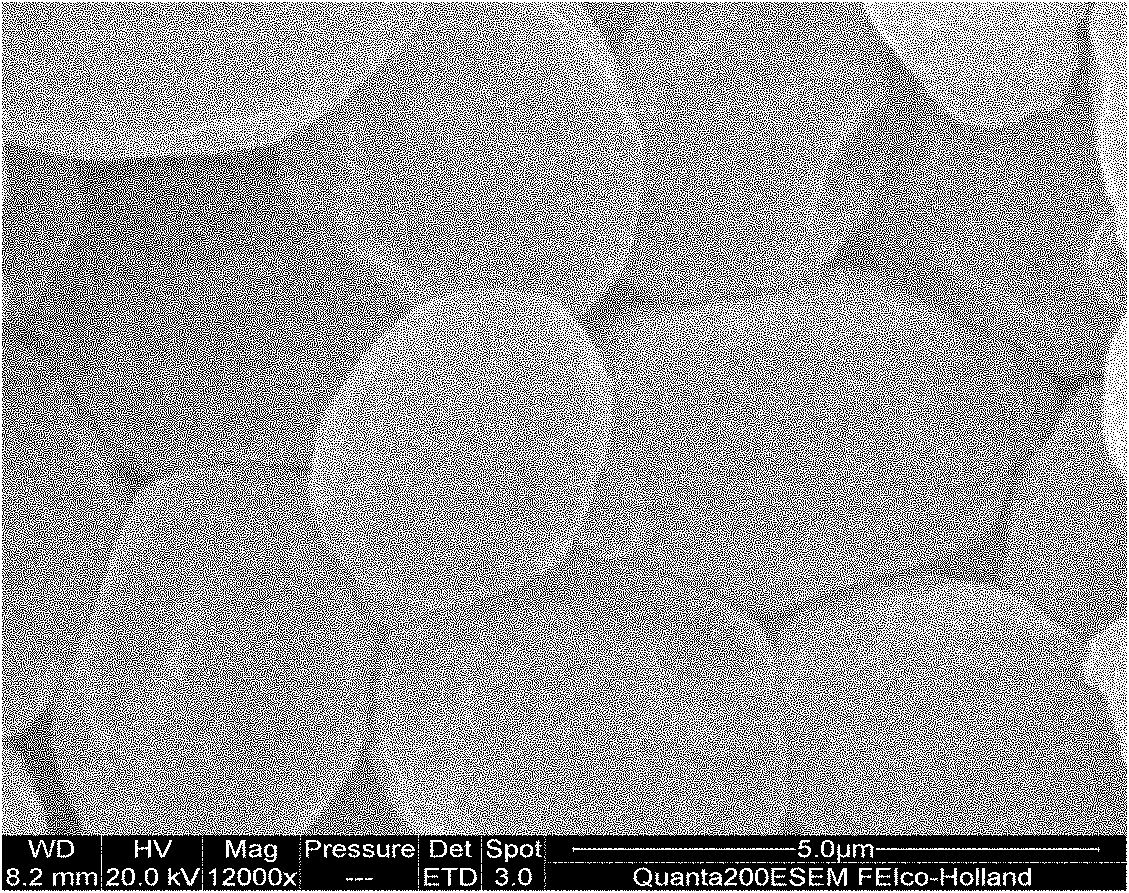

Double-face heat-sealed and anti-fogging type BOPP (biaxially-oriented polypropylene) film and preparation method thereof

ActiveCN103707603AGood anti-fog performanceSlow migration rateSynthetic resin layered productsCoatingsPolymer sciencePolyethylene oxide

The invention relates to a double-face heat-sealed and anti-fogging type BOPP (biaxially-oriented polypropylene) film and a preparation method thereof. The double-face heat-sealed and anti-fogging type BOPP film is formed by co-extruding and biaxially stretching an inner surface layer, a core layer and an outer surface layer, wherein the inner surface layer and the outer surface layer are respectively made from 97.5-98.5 mass percent of polypropylene and 1.5-2.5 mass percent of anti-sticking agent; the core layer consists of 95.9-97.1 mass percent of polypropylene, 2.5-3.5 mass percent of an anti-fogging agent and 0.4-0.6 mass percent of a slipping agent; the anti-fogging agent consists of the following components by weight percent: 50 percent of sorbitan monostearate, 35 percent of glycerin monooleate and 15 percent of polyethylene oxide (20) glycerin monostearate. The selected polypropylene raw material is good in processing performance and high in mechanical strength. The anti-fogging agent is a mixture of multiple fatty acids and is well compatible with BOPP; by the addition of the anti-fogging agent and ethylene oxide, the hydrophilic performance is greatly improved, and the anti-fogging performance is improved.

Owner:ZHEJIANG KINLEAD PACKAGING MATERIAL

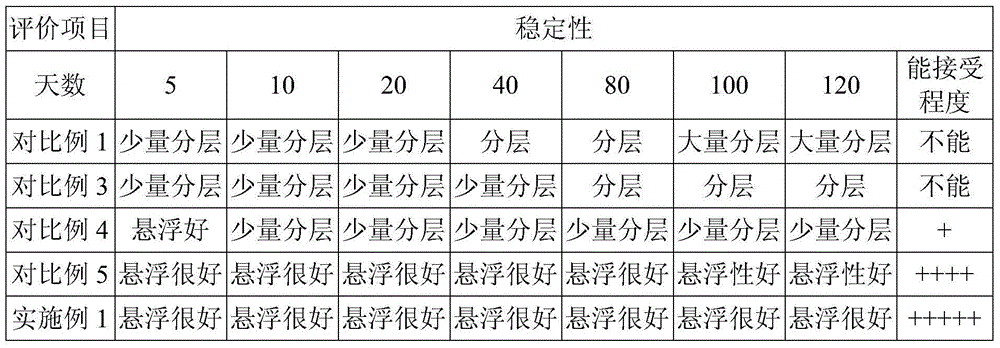

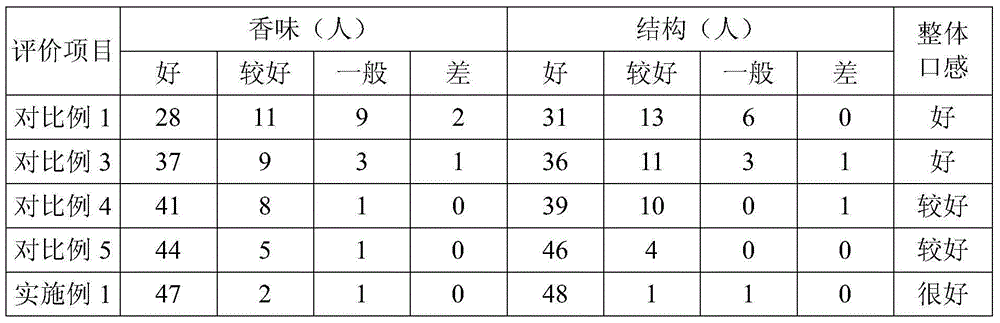

Soft ice cream mix stored at normal temperature and preparation method of soft ice cream mix

ActiveCN104543314AReduce energy consumptionReduce manufacturing costFrozen sweetsSodium bicarbonateNutritive values

The invention relates to a soft ice cream mix stored at normal temperature and a preparation method of the soft ice cream mix. The soft ice cream mix stored at normal temperature comprises the following raw materials by weight percent: 70-75 percent of cow milk, 8.5-10 percent of white granulated sugar, 3.8-4.2 percent of dried skim milk, 3.2-4 percent of maltodextrin, 6.5-7.5 percent of cream, 0.01-0.015 percent of edible salt, 0.26-0.3 percent of microcrystalline cellulose, 0.018-0.022 percent of carrageenan, 0.02-0.24 percent of monoglyceride, 0.018-0.022 percent of sorbitan monostearate, 0.016-0.018 percent of monoglyceride citrate, 0.024-0.028 percent of sodium carboxymethyl cellulose, 0.02-0.024 percent of locust bean gum, 0.12-0.14 percent of sodium bicarbonate, an appropriate amount of pigment, an appropriate amount of essence and the balance being water. The invention also provides the preparation method of the soft ice cream mix. With the adoption of the soft ice cream mix stored at normal temperature, the kinds of base materials of soft ice cream are enriched, the nutritive value of the product is improved greatly, and a brand new choice is provided for consumers.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

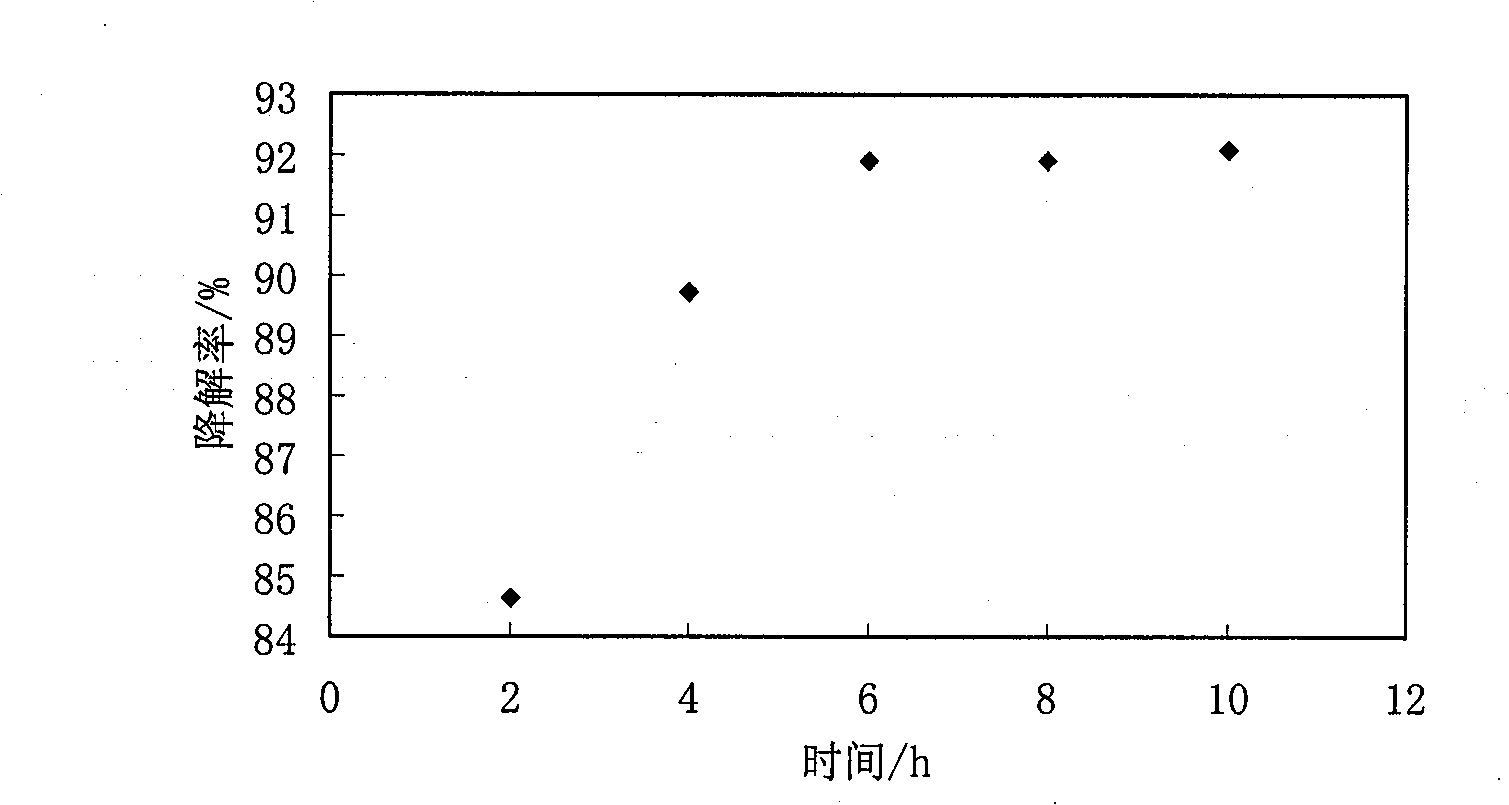

Active dry yeast protectant and application thereof

ActiveCN102168016AHigh retention rateImprove fermentation effectMicroorganism based processesMicroorganism preservationFood additiveMicroorganism

The invention relates to an active dry yeast dehydration protectant and application thereof and belongs to the technical field of microorganism products and food additives. The active dry yeast protectant comprises the following components: glyceryl monostearate, sorbitan monostearate, sorbitan monooleate (Span80) and glycerin. The active dry yeast protectant can obviously increase the living cell rate of active dry yeast to 86 to 90 percent, obviously increase the preserving rate of active dry yeast to 88 to 90 percent and obviously increase the fermentation ability of active dry yeast to 530 to 550mL / h.

Owner:QILU UNIV OF TECH

Powdery plant fat cream and preparation method thereof

InactiveCN102696784ASolve the problem of energy consumptionFix stability issuesEdible oils/fats production/working-upVegetable oilSucrose

The invention relates to a powdery plant fat cream and a preparation method thereof. The preparation method comprises the following steps: melting hydrogenated vegetable oil, and raising the temperature to 60-85 DEG C; adding sodium caseinate, sodium dihydrogen phosphate, sorbitan monostearate, sucrose fatty acid ester, soybean lecithin, hydroxypropyl methylcellulose and xanthan gum; uniformly stirring and dispersing the raw materials to obtain an oil-phase mixture; dissolving sucrose, glucose and glucose syrup in water, and heating the solution to 60-85 DEG C to obtain a water-phase mixture; uniformly mixing the oil phase mixture and the water-phase mixture, and stirring for 5-30min at a speed of 50-70rpm; homogenizing and performing spray drying; and adding food essence and food pigment, and uniformly mixing to obtain powdery plant fat cream. The plant fat cream has the advantages of convenience in operation, low preservation cost and transportation cost, good stability, high safety and the like. The powdery plant fat cream and the preparation method thereof are applicable to the field of production of powdery plant fat cream.

Owner:SOUTH CHINA UNIV OF TECH

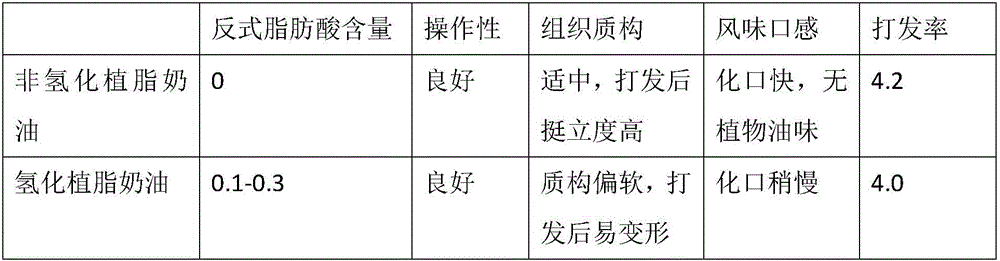

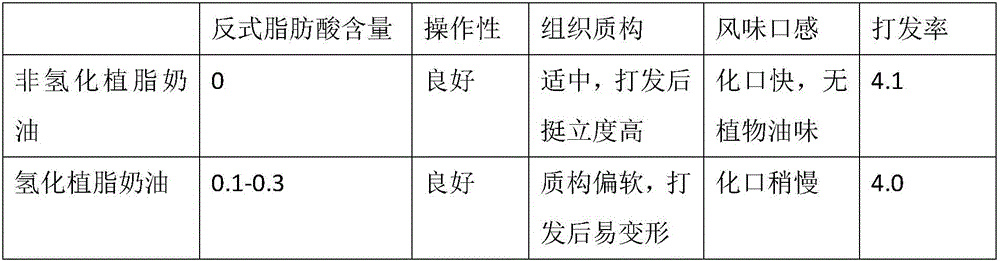

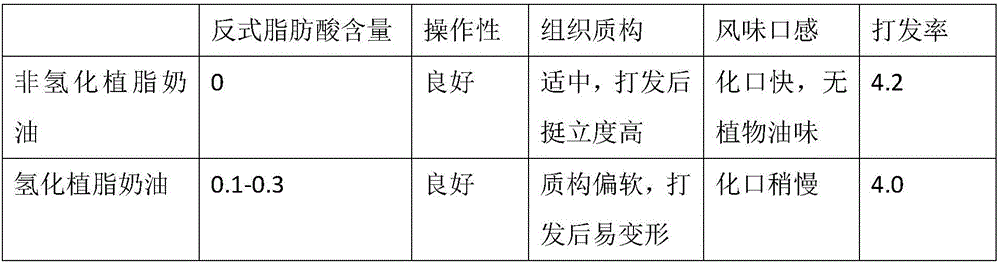

Non-hydrogenation mixed milk fat and plant fat cream and preparation method thereof

PendingCN106387092AMeet quality requirementsEdible oils/fats ingredientsCream substitutesButterfatVegetable oil

The invention discloses non-hydrogenation mixed milk fat and plant fat cream and a preparation method thereof. The non-hydrogenation mixed milk fat and plant fat cream is prepared from the following raw materials in percentage by weight: 8-18% of non-hydrogenation vegetable oil, 0.05-0.5% of dehydrated sorbitan monostearate, 0.02-0.5% of citrate fatty acid glyceride, 0.05-1% of monoglyceride fatty acid ester and diglycerol fatty acid ester, 0.02-1% of lactic acid monoglyceride, 0.02-0.5% of sodium stearoyl lactylate, 0.05-0.5% of sucrose fatty acid ester, 0.02-0.5% of polyglycerol ester, 0.01-0.1% of carrageenin, 0.05-0.8% of microcrystalline cellulose, 0.05-1% of modified cellulose, 0.1-1.5% of sodium caseinate, 0.02-0.2% of potassium dihydrogen phosphate, 2-6% of sugar, 2-12% of glucose syrup, 8-18% of dairy products containing milk fat and 20-60% of water. According to the non-hydrogenation mixed milk fat and plant fat cream and the preparation method thereof, the disadvantages that non-hydrogenation plant oil is soft in texture, not liable to operate and poor in flavor and mouth feel in the process of producing the mixed milk fat and plant fat cream are overcome.

Owner:SHANGHAI HI ROAD FOOD TECHNOLOGY CO LTD

Stomach-action molluscicides

InactiveUS6703036B1Good effectReduced availabilityBiocideHeavy metal active ingredientsSorbitan monostearateSURFACTANT BLEND

A stomach-action molluscicide, which includes a metal complexone and a suitable additive for enhancing the molluscicidal activity of the metal complexone. The additive may be selected from a surfactant or an additional source of ferric ions. Examples of the surfactant include sodium dodecyl sulphate or sorbitan monostearate, while an example of the additional source of ferric ions is ferric orthophosphate.

Owner:YOUNG COLIN LESLIE +1

Oil well cement-injection pad fluid admixture and preparation method

InactiveCN101161760AGood compatibilityFast dissolutionDrilling compositionDissolutionSilicon dioxide

The invention provides a lead admixture for oil well cement, which is used in cementing operation. The invention is characterized in that: the invention comprises microcapsule emulsified tackifier and diluting, grinding, antigelling agent, the weight percent of the two components is 40 to 50 percent:50 to 60 percent, wherein, the weight percent of the composition of microcapsule emulsified tackifier is as follows: 30 to 40 percent of Sorbitan Monostearate emulsifying agent, 60 to 70 percent of sodium carboxymethylcellulose; and the weight percent of the composition of the diluting, grinding and antigelling agent is as follows: 30 to 40 percent of sulfonated tannin, 30 to 40 percent of fine silica powder, 10 to 25 percent of sodium sulfate, and 10 to 25 percent of sodium carbonate. The invention has the advantages that: the lead compounded by the lead admixture for oil well cement has good slurrycompatibility with drilling fluid and oil well grout. And flushing fluid, weighted spacer fluid, viscoelastic spacer fluid and displacement fluid can be prepared by compounding with the lead admixture for oil well cement. The lead admixture for oil well cement has the characteristic of high dissolution rate and easy field compounding.

Owner:CNPC BOHAI DRILLING ENG

Water-in-oil microemulsions for oilfield applications

A well treatment microemulsion includes an oil external phase, an internal aqueous phase and a hydrophilic surfactant. The surfactant has a hydrophile lipophile balance of between 8-18. The oil external phase may include d-Limonene, xylenes, light mineral oil, or kerosene. The surfactant is configured to emulsify the water of the internal aqueous phase into the oil of the external (continuous) phase. The surfactant may include polyoxyethylene sorbitan monooleate, polyoxyethylene sorbitan tristearate, polyoxyethylene hydrogenated castor oil, polyoxyethylene sorbitan monostearate, polyoxyethylene sorbitan monooleate, polyoxyethylene sorbitan monolaurate or mixtures therebetween. The use of hydrophilic surfactants to emulsify an internal aqueous phase within an oil external microemulsion produces unexpected and beneficial results.

Owner:FLOTEK CHEM LLC

Production process of textile fiber color modifier

The invention relates to a production process of a textile fiber color modifier. The textile fiber color modifier is prepared from the following raw materials in percentage by weight: 52%-68% of swelling agent, 10%-30% of emulsifying and dispersing agent, and 8%-20% of solvent, wherein the swelling agent is one or more of propylene glycol monomethyl ether, phenoxy-1-propanol, cyclohexanol methyl ether, N-normal-butyl-phthalimide, and N-isopropyl-phthalimide; the emulsifying and dispersing agent is one or more of styrylphenol polyoxyethylene ether sulfonate, polyoxyethylene castor oil, iso-tridecanol polyoxyethylene ether, fatty amine polyoxyethylene ether, polyoxyethylene (60) sorbitan monostearate (namely Tween-60), polyoxyethylene (80) sorbitan monostearate (namely Tween-80), and pesticide emulsifier No.600; and the solvent is one or more of water, ethanol, isopropyl alcohol, ethylene glycol, and ethylene glycol monobutyl ether. The production process comprises the following steps of adding all the materials into a reaction kettle and stirring the materials at 30 DEG C to 50 DEG C for 60 to 90 minutes, thereby obtaining the textile fiber color modifier. The textile fiber color modifier can be used for overcoming the dyeing defects of polyester and blended fabrics of the polyester in dyeing, and the dyed fabrics can meet environmental protection standards.

Owner:冯祥茂

Water-in-oil microemulsions for oilfield applications

A well treatment microemulsion includes an oil external phase, an internal aqueous phase and a hydrophilic surfactant. The surfactant has a hydrophile lipophile balance of between 8-18. The oil external phase may include d-Limonene, xylenes, light mineral oil, or kerosene. The surfactant is configured to emulsify the water of the internal aqueous phase into the oil of the external (continuous) phase. The surfactant may include polyoxyethylene sorbitan monooleate, polyoxyethylene sorbitan tristearate, polyoxyethylene hydrogenated castor oil, polyoxyethylene sorbitan monostearate, polyoxyethylene sorbitan monooleate, polyoxyethylene sorbitan monolaurate or mixtures therebetween. The use of hydrophilic surfactants to emulsify an internal aqueous phase within an oil external microemulsion produces unexpected and beneficial results.

Owner:FLOTEK CHEM LLC

Emulsion type paraffin remover and inhibitor and preparation method thereof

The invention relates to an emulsion type paraffin remover and inhibitor and a preparation method thereof, and belongs to the technical field of oil exploitation. The emulsion type paraffin remover and inhibitor includes, by weight, 45%-60% of 150# solvent oil, 4.5%-6% of octylphenol polyoxyethylene ether, 4.5%-6% of fatty alcohol-polyoxyethylene ether, 2.25%-3% of polyoxyethylene sorbitan monostearate, 3%-4% of ether cosolvent, and the balance water or synthetic brine. According to the emulsion type paraffin remover and inhibitor, the paraffin dissolution rate is more than 0.022 g / min, the paraffin inhibition rate is more than 75%, and oil well paraffinication can be effectively prevented. The emulsion type paraffin remover and inhibitor has good paraffin removing and inhibiting effects.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cooking-free selenium-enriched snow skin mooncake pre-mixed powder

InactiveCN104705365APromote absorptionPerfect powderDough treatmentFood preparationSelenateSorbitan monostearate

The invention discloses cooking-free selenium-enriched snow skin mooncake pre-mixed powder. The cooking-free selenium-enriched snow skin mooncake pre-mixed powder comprises the following raw materials in parts by weight: 400-450 parts of glutinous rice flour, 100-150 parts of cassava starch, 4-13 parts of selenium-enriched cardamine hupingshanensis powder, 3-6 parts of polysaccharide selenate, 10-15 parts of erythritol, 10-15 parts of maltooligosaccharide, 1-3 parts of sorbitan monostearate, 10-15 parts of glyceryl monostearate, 4-10 parts of edible gum and 30-50 parts of water. The cooking-free selenium-enriched snow skin mooncake pre-mixed powder disclosed by the invention has the characteristics that the pre-mixed powder is cooking-free, does not need to be blended again, can be instantly used after being opened, and is high in selenium content.

Owner:裴秀珍

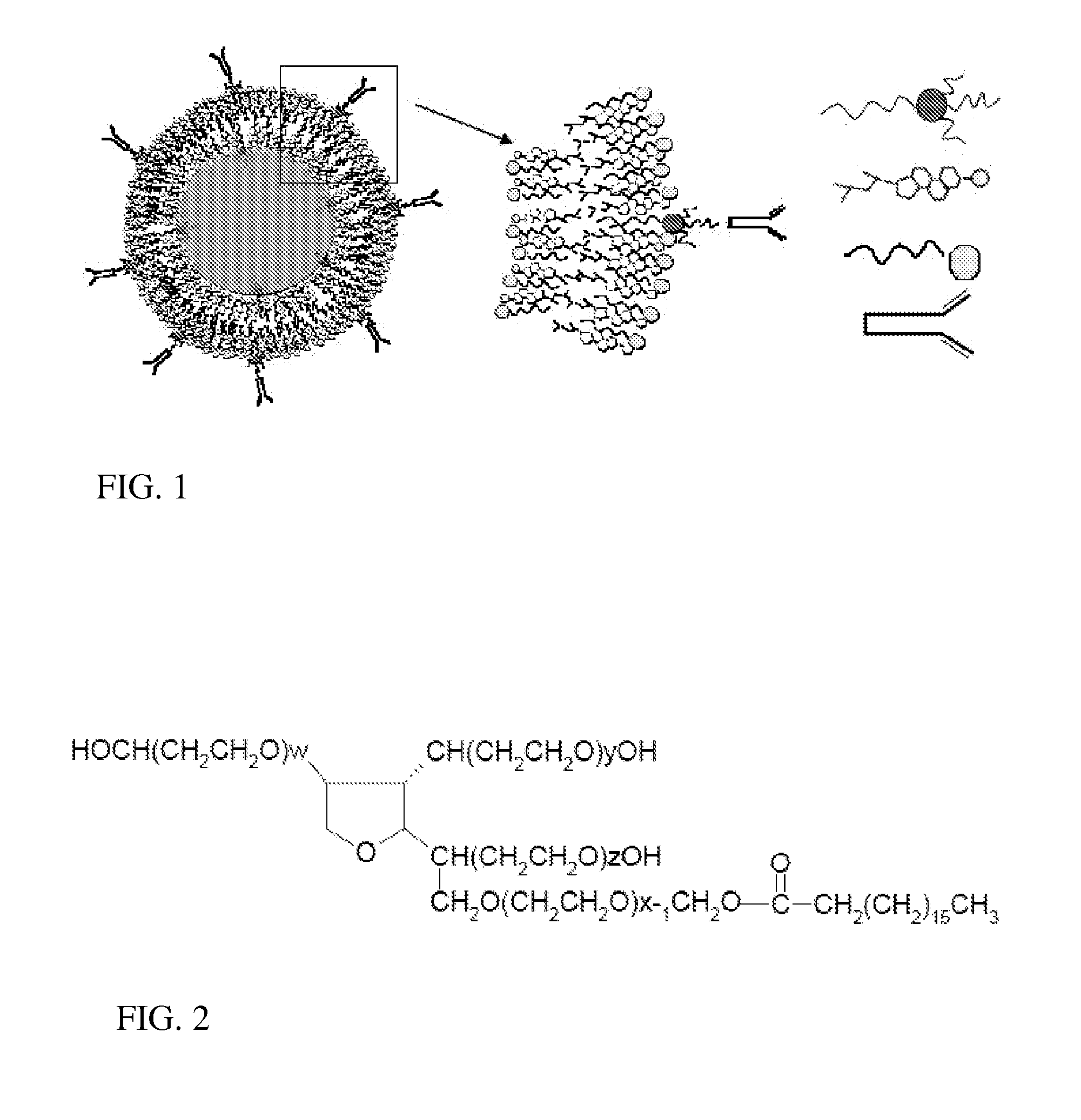

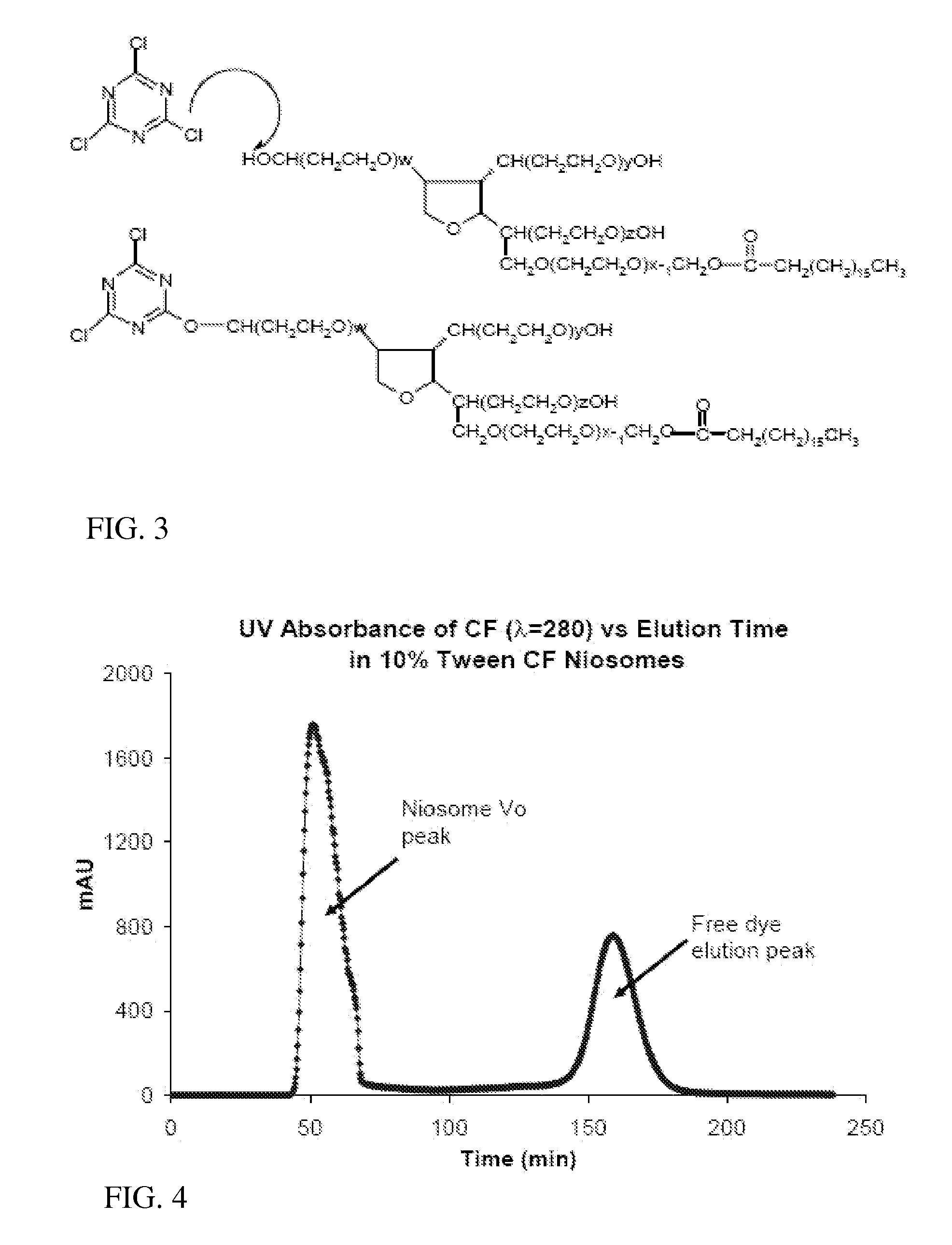

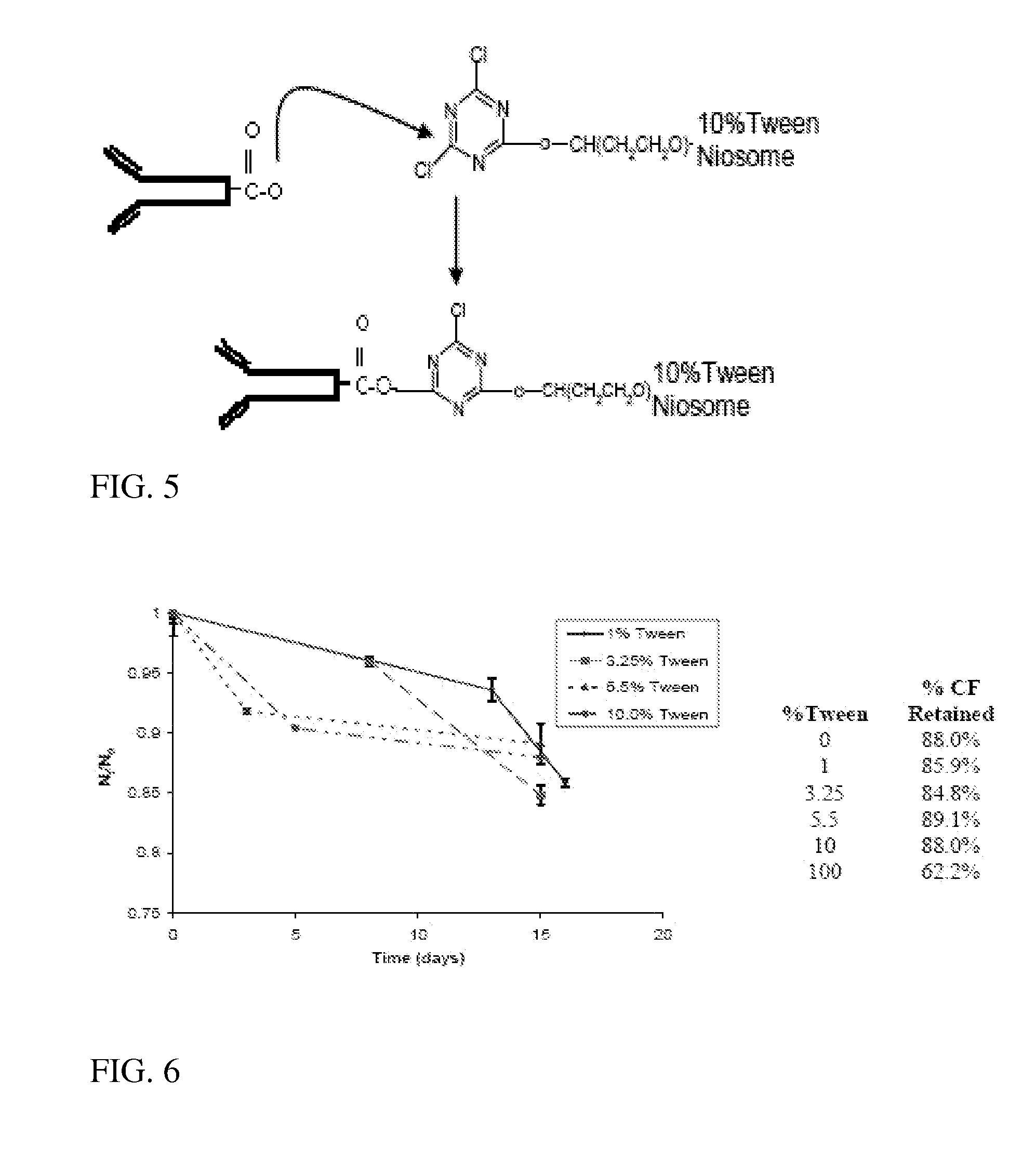

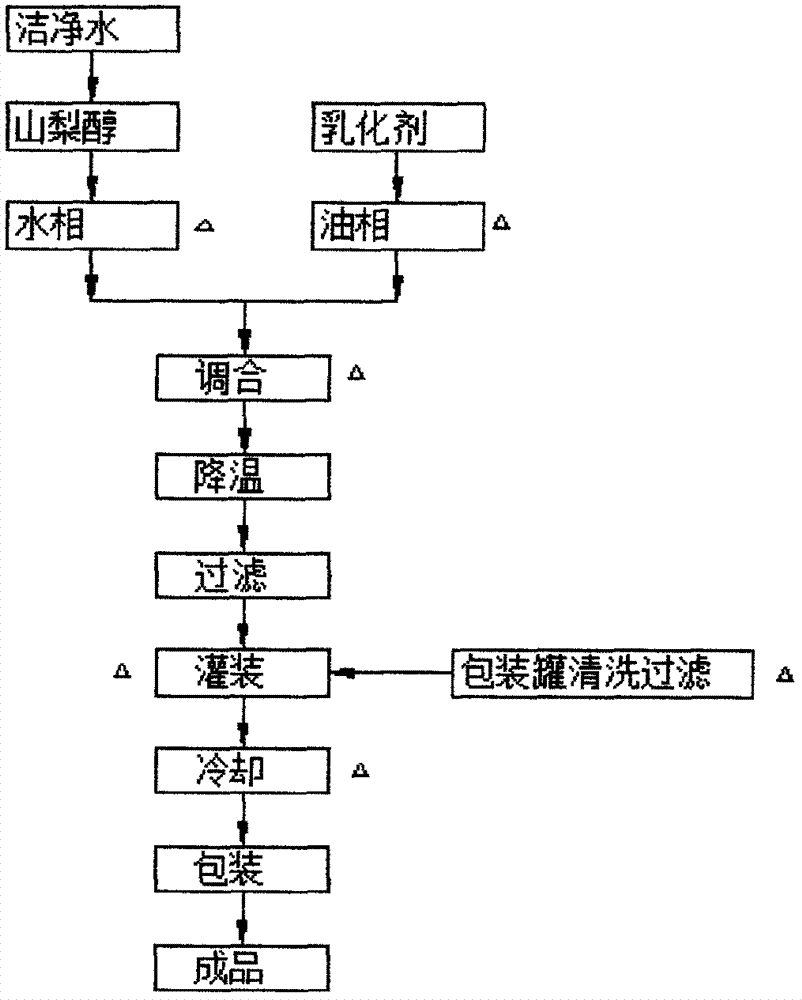

Immunotargeting of Nonionic Surfactant Vesicles

InactiveUS20070172520A1Enhances internalizationImprove retentionAntibody ingredientsPharmaceutical non-active ingredientsSurface markerActive agent

An immunoniosmes for targeted delivery of therapeutic agents to specific tissues in a host and methods of synthesis of those niosomes. An antibody molecule having specificity for a target antigen, such as a cell surface marker or other marker differentially expressed on a target cell, is covalently coupled to a functionalized membrane constituent. In a particular embodiment the functionalized membrane constituent is polyoxyethylene sorbitan monostearate functionalized with cyanuric chloride. The niosomes of this invention thus provide a composition that enhances internalization or retention of the bioactive agent of the niosome into the cytoplasm of the cells of the target tissue by providing a high degree of target specificity. Furthermore, the membrane vesicle enhances the life of the therapeutic agent by preventing its degradation in the extracellular environment, while exhibiting lower toxicity than can occur with some liposomes. The niosomes of the present invention are thus particularly useful as vehicles for the delivery of therapeutics to specific target cells.

Owner:UNIV OF SOUTH FLORIDA

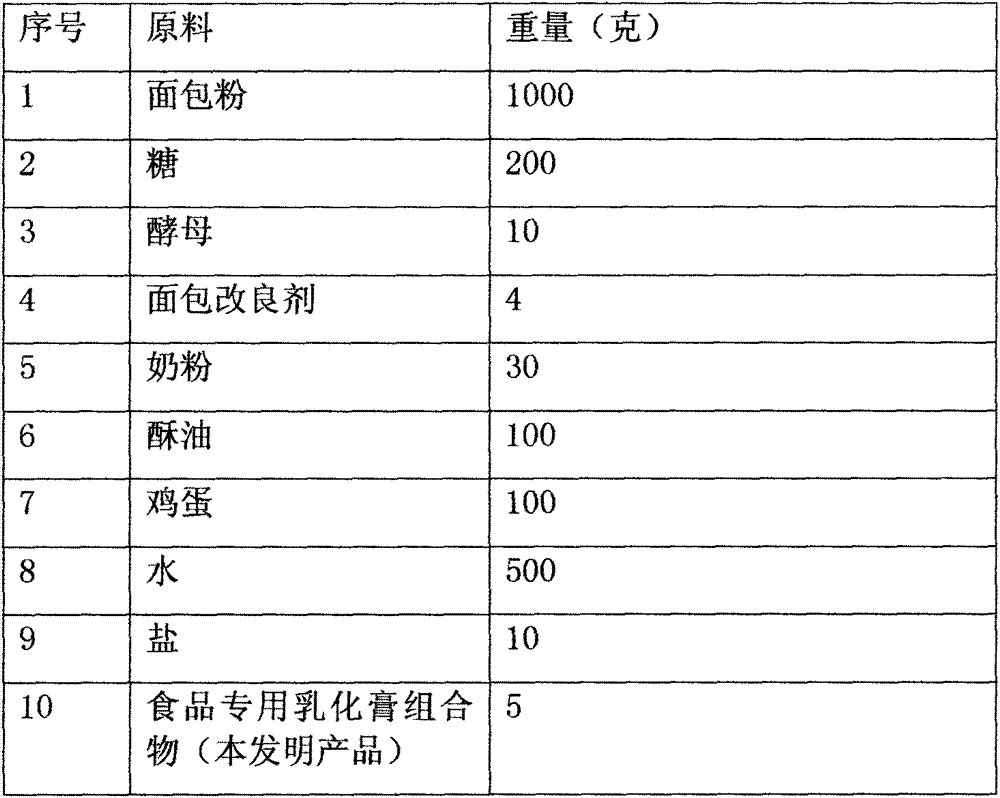

Emulsifying paste composition special for foods and production technology of emulsifying paste

InactiveCN107136149AHighlight substantive featuresSignificant progressDough treatmentSorbitan monostearateSucrose

The invention relates to an emulsifying paste composition special for foods. The emulsifying paste composition consists of 30-40% of water, 20-30% of sorbitol liquid, 6-10% of sorbitan monostearate, 10-14% of monoor / and diglyceryl stearate, 4-8% of polyglyceryl fatty ester, 6-12% of sucrose fatty acid ester and 3-8% of sodium stearoyl lactylate. The emulsifying paste composition disclosed by the invention is simple and convenient to make; and besides, a sorbitol composition and an emulsifying agent composition are processed and stirred at a special temperature, so that the application functions are effectively increased, the made emulsifying paste composition can lock moisture in bread, cakes and the like, can maintain food tissue soft, fine and smooth and increase smooth mouth feel.

Owner:广州市美日一统食品科技有限公司

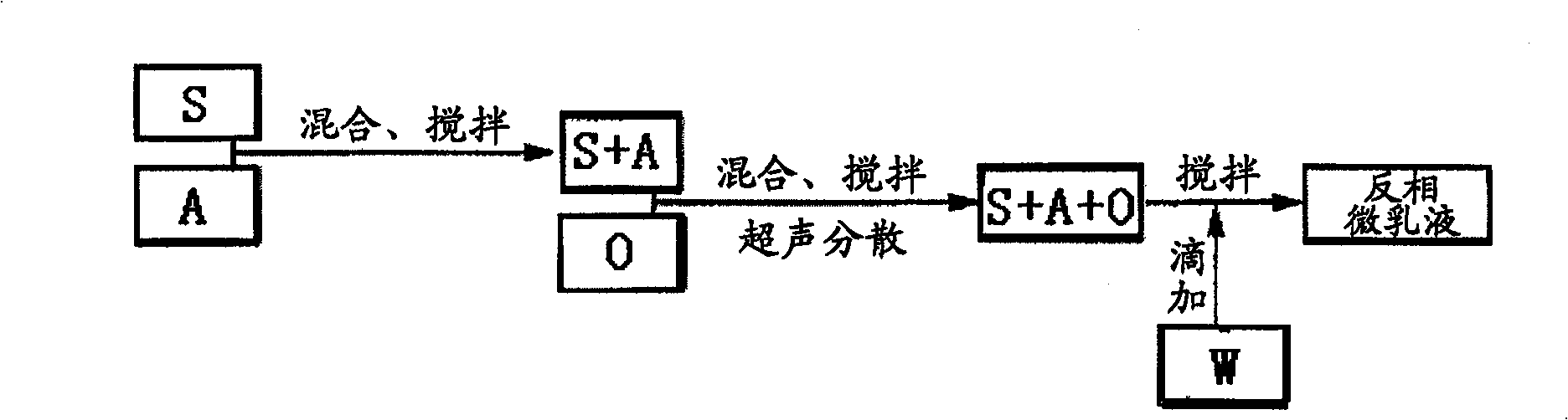

Ashless diesel fuel additive, and its preparing method and use method

InactiveCN1470618ALowering the freezing pointChange colorLiquid carbonaceous fuelsSorbitan monostearateAlcohol

The present invention relates to an ash-less diesel oil additive, its preparation and application method. Said additive is formed from sorbitan monostearate, alkylolpolyethenoxyether and its derivative, alkylphenolpolyethenoxyether and its derivative, alcohol diethoxyethane, water, medium carbon alcohol and solvent oil, and its preparation method includes: mixing sorbiton nanostearate, alkylolpolyethenoxyether and its derivative and alkylphenol polyethenoxyether and its derivative by using mechanical stirring device or ultrasonic stirrer, then adding other materials successively and fully stirring them to obtain the transparent solution, i.e. said invented product which can improve combustion property of diesel oil and reduce discharge of CO, NOx, HC and PM pollutants in the tail gas, andcan prevent secondary pollution.

Owner:SOUTH CHINA UNIV OF TECH

Additive for synthetic water-diesel oil fuel and its prepn and application

The additive for synthetic water-diesel oil fuel consists of fatty alcohol polyoxyethyleneether 6.8 wt%, alkylene phenol polyvinyl ether 5.2 wt%, amyl nitrate 7.4 wt%, high-alkali barium sulfonate 5.6 wt%, ethylene-acrylate copolymer 5.5 wt%, sorbitan monostearate polyoxyethyleneether 40 wt%, Span-60 10 wt%, sorbitan trioleate polyoxyethyleneether 10.3 wt% and ferrocene 9.2 wt%. It is produced through mixing while stirring at high speed to react and letting stand to eliminate bubble and become emulsion. The additive is used in producing mixed water-diesel oil fuel, which has the same performance as diesel oil and can save oil by 20-30 %.

Owner:石生玉

Water-in-oil type electric spark machining working solution

The invention relates to a water-in-oil type electric spark machining working solution in the field of non-traditional machining, comprising compound emulsifying agent, engine oil and deionized water. The working solution is prepared by the following steps: sorbitan monoleate and polyoxyethylene sorbitan monostearate are put together in proportion, stirring for the sorbitan monoleate and the polyoxyethylene sorbitan monostearate to mix and react and form the compound emulsifying agent; the prepared compound emulsifying agent is added into the engine oil according to a required proportion, stirring for the compound emulsifying agent to be dissolved into the engine oil and form an engine oil colliquefaction solution; and the deionized water is added into the engine oil colliquefaction solution, stirring to obtain the water-in-oil type electric spark machining working solution. The water-in-oil type electric spark machining working solution has the advantages of high dielectric strength, safe use, no pollution and high electric spark machining efficiency.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

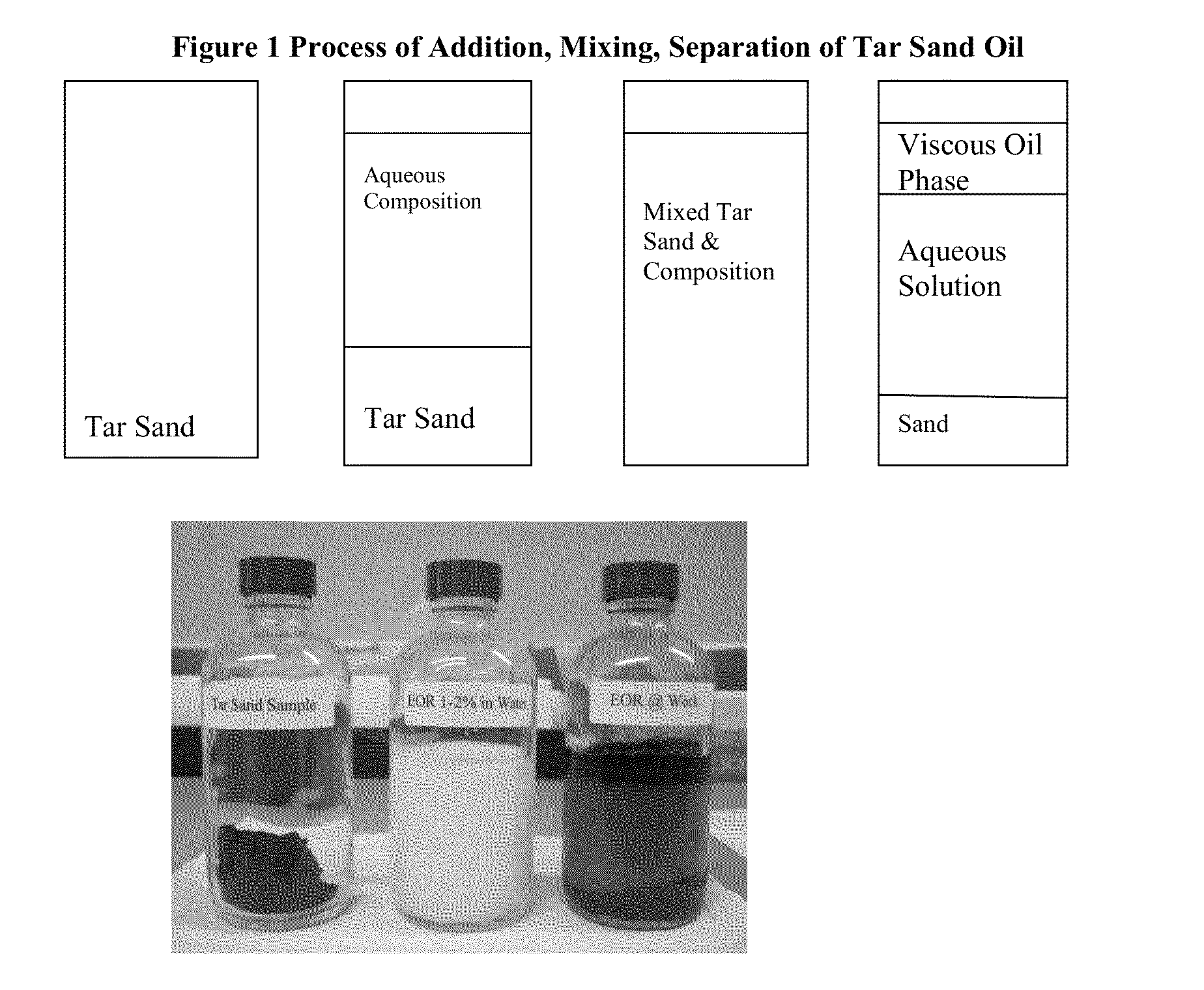

Method of Oil Extraction

ActiveUS20130109598A1Improve aspectIncrease rate is recoveredFluid removalLiquid hydrocarbon mixture productionSorbitan monostearateStearate

A composition for use in extracting oil, the composition comprising: (a) a mixture comprising, by weight, 50-55% of an aromatic alkyl, 15-19% d-limonene, 6.5-7% polyethylsorbitan monoleate, 15-15.5% PEG sorbitan monostearate, 3.4-9.9% tall fatty acid, and EDTA in an amount up to 1%; and (b) water in an amount such that the mixture is diluted to 1%-2% by weight of the composition.

Owner:NACSON SABATINO

Anti-fogging and non-dropping film and preparation method thereof

The invention provides an anti-fogging and non-dropping film. The anti-fogging and non-dropping film comprises the following components in parts by weight: 70 to 200 parts of LLDPE (Linear Low Density Polyethylene), 15 to 50 parts of LDPE (Low-Density Polyethylene), 10 to 30 parts of EVA (Ethylene-vinyl Acetate), 20 to 50 parts of DOP (Dioctyl-Phthalate), 15 to 30 parts of BBP (Butyl Benzyl Phthalate), 0.5 to 2 parts of dibutyl tin dialurate, 3 to 7 parts of 2-ethylhexyl ester of epoxy fatty acids, 4 to 8 parts of tricresyl phosphate, 1.5 to 4 parts of glyceryl monolaurate, 1 to 6 parts of triphenyl phosphate, 0.2 to 0.8 part of ultraviolet light absorber, 0.5 to 0.9 part of calcium carbonate, 1 to 5 parts of cadmium stearate, 2 to 8 parts of barium stearate, and 0.2 to 0.7 part of sorbitan monostearate. The preparation method comprises the following steps of: drying LLDPE, LDPE and EVA under vacuum; adding other components; performing film blowing through a horizontal extruding and blowing method by utilizing a single-screw extruding film blowing device, thus obtaining the anti-fogging and non-dropping film. The anti-fogging and non-dropping film shows remarkable advantages that water on the surface of the film can flow into the soil along the surface of the film, thus moisture in the air in a greenhouse is reduced, and the anti-fogging effect is realized.

Owner:WUJIANG YINGLIDA PLASTIC PACKAGING

Indometacin preparation for external use

InactiveUS20050239868A1Easy to useSatisfy the feeling of useBiocideOrganic chemistrySorbitan monostearatePolymer chemistry

An object of the present invention is to provide an indomethacin external preparation that has an excellent use feeling and excellent absorbability and causes no phase separation into an oil layer and an aqueous layer, thus exhibiting satisfactory stability of preparation with time. Provided is an indomethacin external preparation containing: 0.1 to 3 wt % of indomethacin; 25 to 50 wt % of alcohol; 0.01 to 5 wt % of gelling agent; 5 to 30 wt % of oil component; 20 to 50 wt % of water; and 0.01 to 10 wt % of one or more components selected from the group consisting of glyceryl monostearate, sorbitan monostearate, stearyl alcohol, and polyethylene glycol monostearate.

Owner:KOWA CO LTD

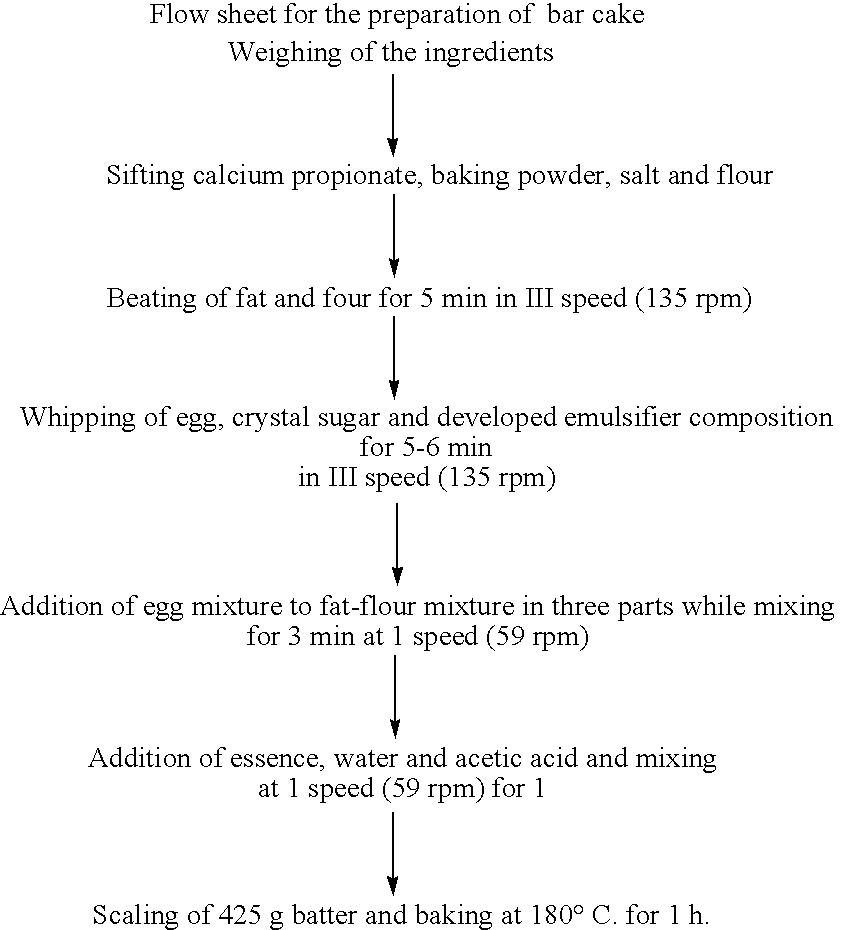

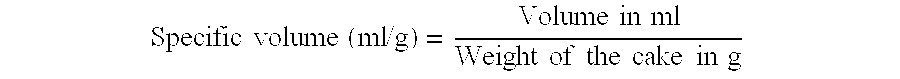

Emulsifier composition for cakes and a method of making improved quality cakes thereof

The present invention relates to an emulsifier composition useful for making improved quality cakes, said emulsifier composition comprising 15.4 to 15.8 parts of Distilled glycerol monostearate (DGMS), 15.4 to 15.8 parts of Poly glycerol monostrearate (PGMS), 1.0 to 1.4 parts of Sodium stearoyl-2-lactylate (SSL), 15.4 to 15.8 parts of Polysorbate-60 (PS-60), 15.4 to 15.8 parts of Sorbitan monostearate, 0.12 to 0.16 parts of Sodium dodeceyl sulphate (SDS), 5.0 to 7.0 parts of glycerol and 0.5 to 1.5 parts of lactic acid on 100 parts of water and also a process for preparing the same.

Owner:COUNCIL OF SCI & IND RES

Instant glutinous rice flour for nourishing kidneys and reinforcing deficiency

InactiveCN104705569ADelicate tasteImprove the value of deep processingFood preservationFood preparationSorbitan monostearateCarrageenan

The invention provides instant glutinous rice flour for nourishing the kidneys and reinforcing deficiency. The instant glutinous rice flour comprises the following raw materials in parts by weight: 80-100 parts of glutinous rice flour, 40-60 parts of beautiful millettia root powder, 10-20 parts of rice bean powder, 0.6-1.2 parts of sorbitan monostearate, 2-5 parts of glyceryl monostearate, 8-13 parts of maltose, 1-2 parts of methylcellulose, 1-3 parts of carrageenan, 1-3 parts of pectin and 100-130 parts of purified water. The instant glutinous rice flour provided by the invention is added with the beautiful millettia root powder, has the functions of nourishing the kidneys and reinforcing deficiency, also has the unique aroma of beautiful millettia root, has delicate taste, can be instantly drunk after adding water, and is a convenient food which is very beneficial to body health.

Owner:王振祥

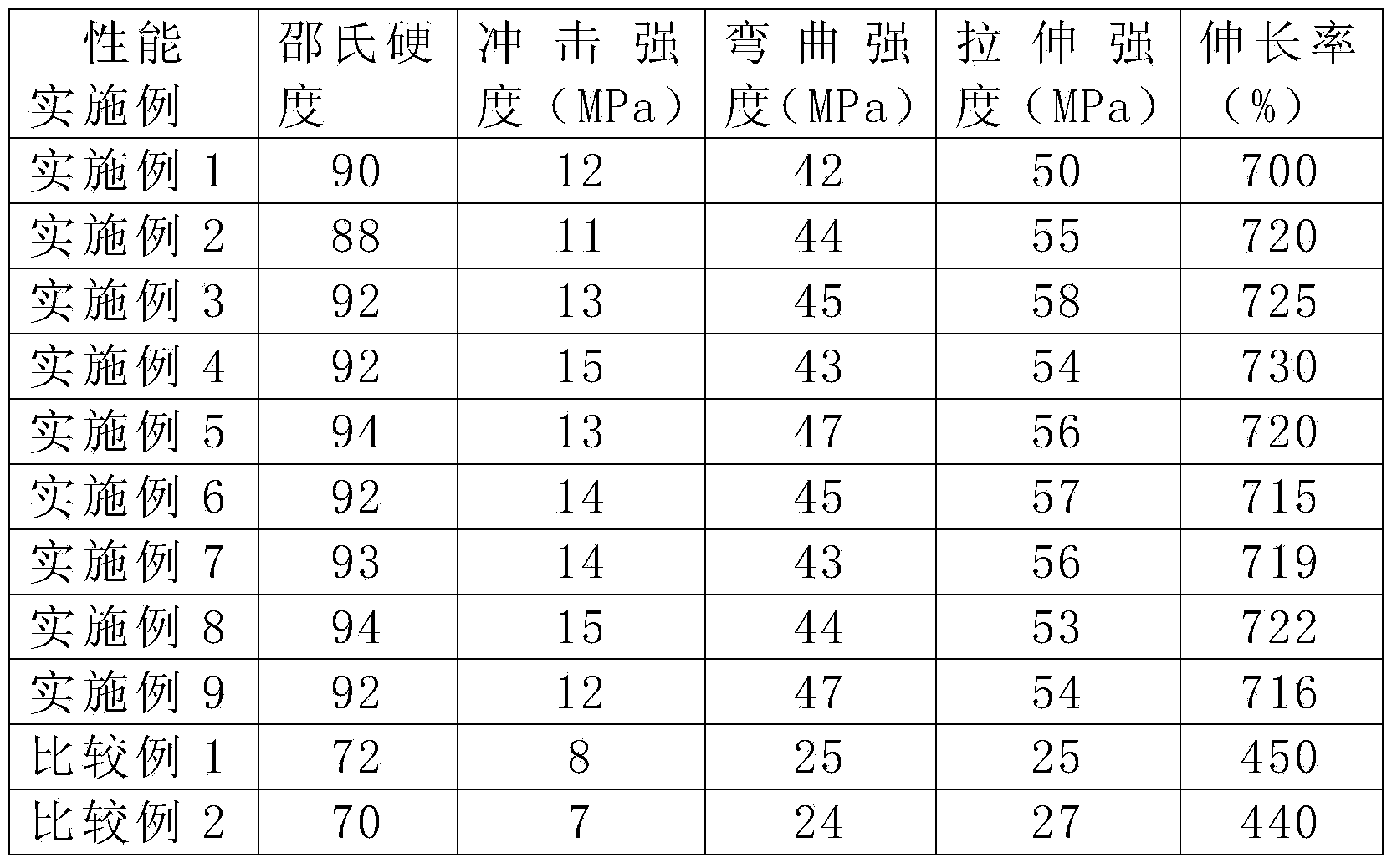

Plastic composite material for tray

The invention relates to a plastic composite material for a tray and belongs to the technical field of plastic materials. The material provided by the invention has high fracture-resistant and impact-resistant performances, high shore hardness and good mechanical property. The plastic composite material for the tray provided by the invention is mainly prepared from the following components in parts by weight: 70-85 parts of high-density polyethylene or high-density polypropylene, 2.0-3.0 parts of sorbitan monostearate, 0.5-1.0 part of polytetrafluoroethylene, 2.0-5.0 parts of ethylene-methacrylic acid copolymer, 0.5-0.8 part of silane coupling agent, 5.0-10 parts of nano inorganic filler, 10-13 parts of synthesized rubber, 8.0-12 parts of fibers, 2.0-5.0 parts of flame retardant and 1.0-2.0 parts of antioxidant. The composite material has high fracture-resistant and impact-resistant performances and high shore hardness.

Owner:ZHEJIANG XINDING PLASTIC

Improved amino baking varnish inverse emulsion, preparation method thereof, and method for preparing baking varnish coating by using improved amino baking varnish inverse emulsion

InactiveCN101538441ASolve discolorationOvercoming the disadvantage of limited lifespanPolyurea/polyurethane coatingsPolyester coatingsSorbitan monostearateEmulsion

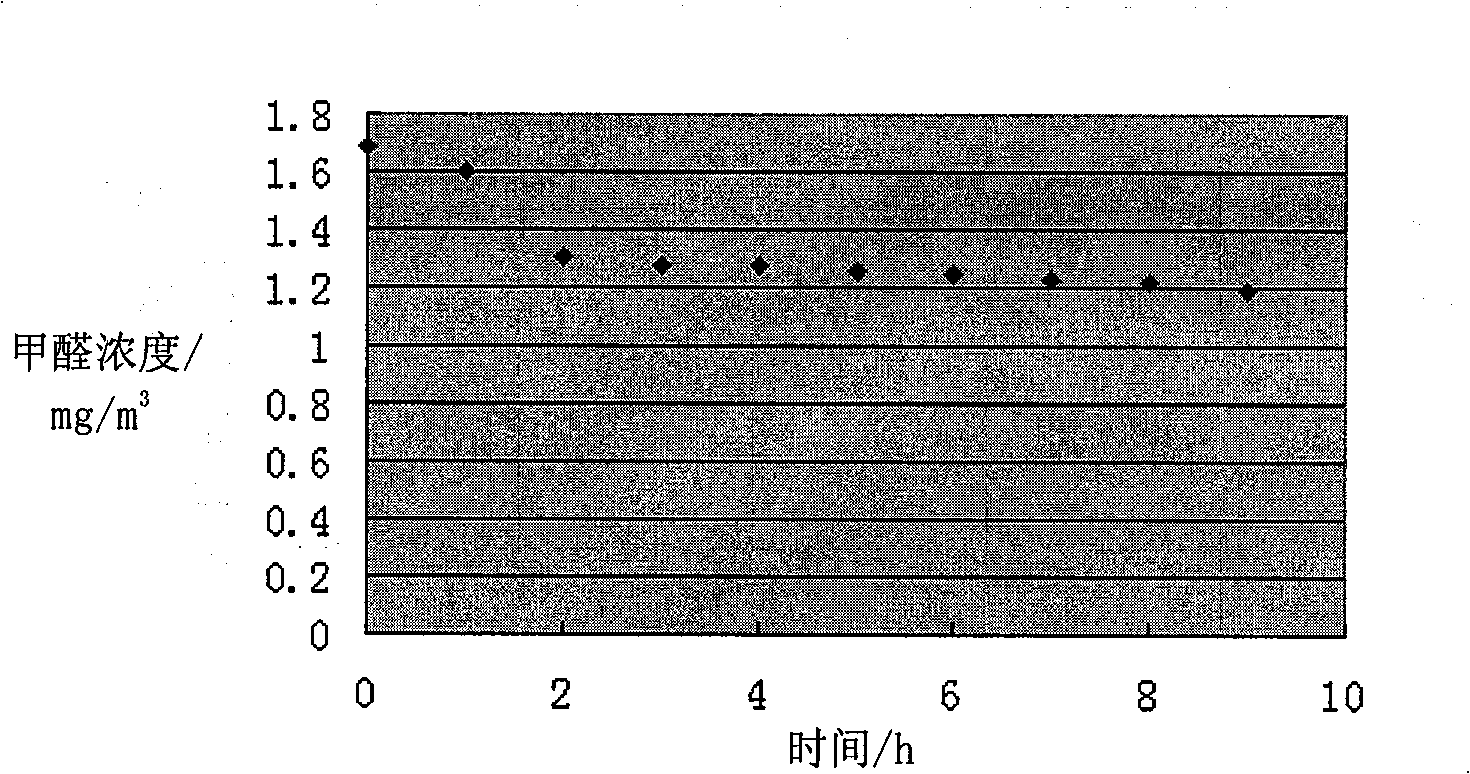

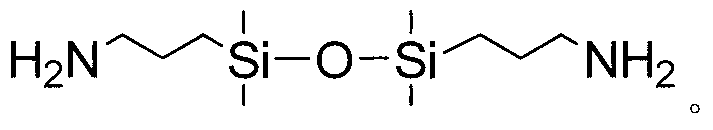

The invention relates to improved amino baking varnish inverse emulsion and a preparation method thereof. The inverse emulsion comprises a water phase system of nano-titanium dioxide, amino baking varnish emulsion, a composite emulsifier and an assistant emulsifier, wherein the composite emulsifier is the mixture of polyoxyethylene 20 sorbitan monostearate and sorbitan monooleate. The baking varnish prepared by the improved amino baking varnish inverse emulsion greatly reduces the volatilization of organic substances, has the efficacy of degrading harmful gases such as formaldehyde, benzene compounds and the like and can release negative air ions of more than 800 / cm<3> to play the functions of purifying and cleaning air. In addition, the invention also relates to a method for preparing baking varnish coatings by using the improved amino baking varnish inverse emulsion.

Owner:JIANGSU KAOPULE NEW MATERIALS

Butter capable of achieving industrial processing

The invention relates to the technical field of food raw materials, and particularly relates to butter capable of achieving industrial processing. The butter is prepared from the following raw materials: refined palm olein, refined palm kernel oil, first-grade bean oil, enzymolysis butter, yak butterfat, purified water, whey powder, phospholipid, glycerol distearate, polyoxyethylene sorbitan monostearate, refined edible salt, sodium dehydroacetate, carotene, butylated hydroxyanisole and dibutyl hydroxytoluene in combination. The buffer prepared from vegetable oil as the raw material is available in raw material and suitable for continuous industrialized production; the prepared butter is bright yellow in color and luster, fragrant and sweet in taste, and excellent in mouthfeel.

Owner:ANHUI TIANXIANG GRAIN & OIL FOOD

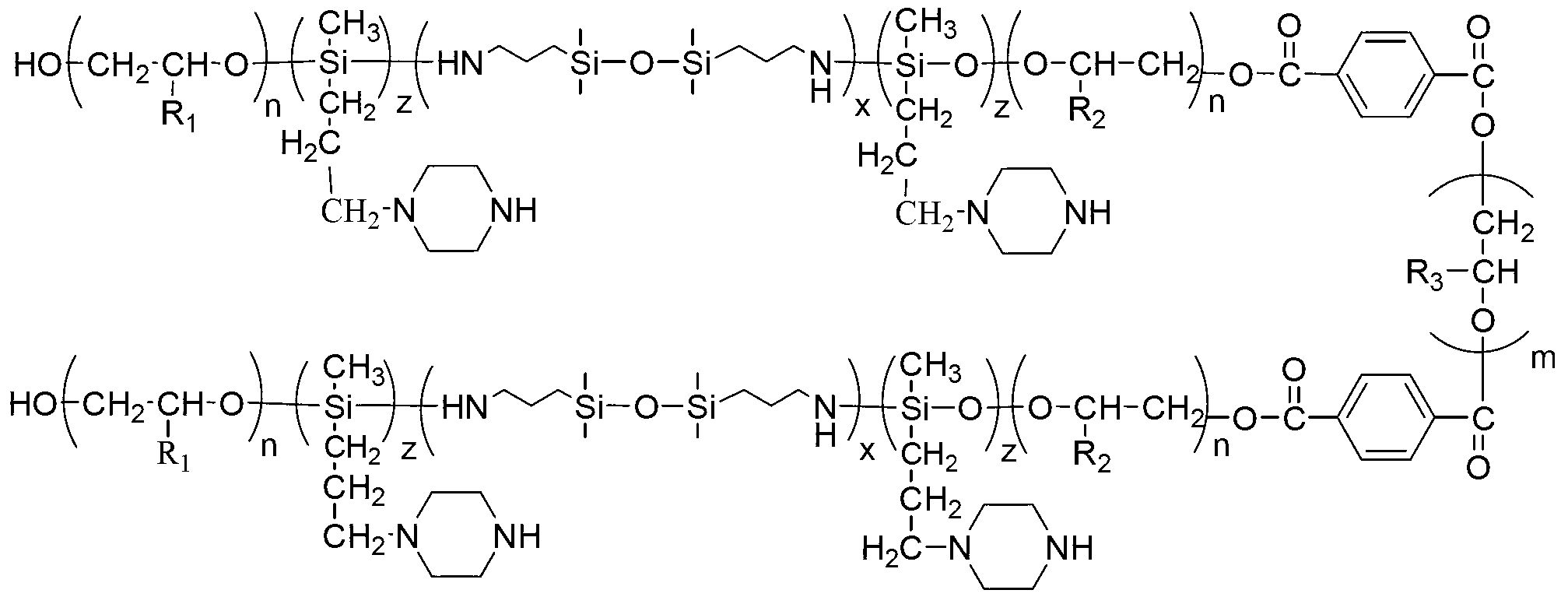

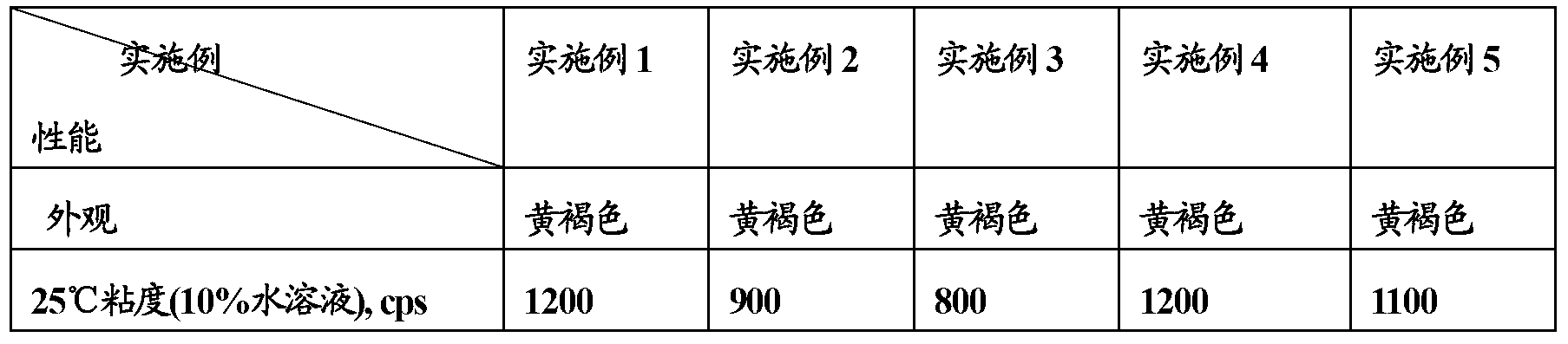

In-bath crease-resisting agent used in polyester fiber fabric, and preparation method thereof

The invention relates to an in-bath crease-resisting agent used in polyester fiber fabric, and a preparation method thereof. The agent comprises the following components, by weight: 2-5% of a polyester-polyether-silicon oil block copolymer, 1-5% of sorbitan monostearate, and balance of water. The polyester-polyether-silicon oil block copolymer is prepared from the raw materials of, by weight: 120-160 parts of polyethylene glycol, 18-30 parts of glycol, 15-25 parts of dihydroxy polyether, 20-28 parts of dimethyl terephthalate, 10-30 parts of an amino-terminated double-head sealant organosilicon, 5-10 parts of 3-piperazine propyl dimethoxysilane, and 0.2-2 parts of metal acetate. With the in-bath crease-resisting agent provided by the invention, good crease-resisting effect of the polyester fiber fabric is provided, and excellent fluffy and soft texture, good antistatic property, and good hydrophilic smoothness are provided with dyed polyester fiber fabric. Dyed polyester fiber or fabric thereof can be provided with excellent comfortableness without other finishing.

Owner:DUPLUS CHEM OF ZHANGJIAGANG CITY

Rubber containing hydrophilic sorbitan monostearate and tackifying resin and tire with sidewall thereof

A carbon black reinforced rubber composition which contains hydrophilic sorbitan monostearate and specialized tackifying resin and a pneumatic rubber tire having a visually observable rubber component, such as for example a rubber sidewall, of said rubber composition. The surface of said rubber composition, namely the tire sidewall rubber component, in its uncured state contains said hydrophilic sorbitan monostearate on its surface together with said specialized tackifying resin to promote enhanced building tack and thereby counteract building tack loss by the sorbitan monostearate having been exposed to moisture (moisture exposed surface) during the processing of the rubber composition, particularly after its high shear processing such as, for example, extrusion.

Owner:THE GOODYEAR TIRE & RUBBER CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com