In-bath crease-resisting agent used in polyester fiber fabric, and preparation method thereof

A technology of polyester fiber and anti-wrinkle agent, which is applied in the field of anti-wrinkle agent in a bath for polyester fiber fabric and its preparation, can solve the problems of fluffy softness, inability to improve antistatic performance, complicated production process, and stiff fabric feel. , to achieve good antistatic properties and hydrophilic properties, excellent comfort, and improve the effect of anti-wrinkle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

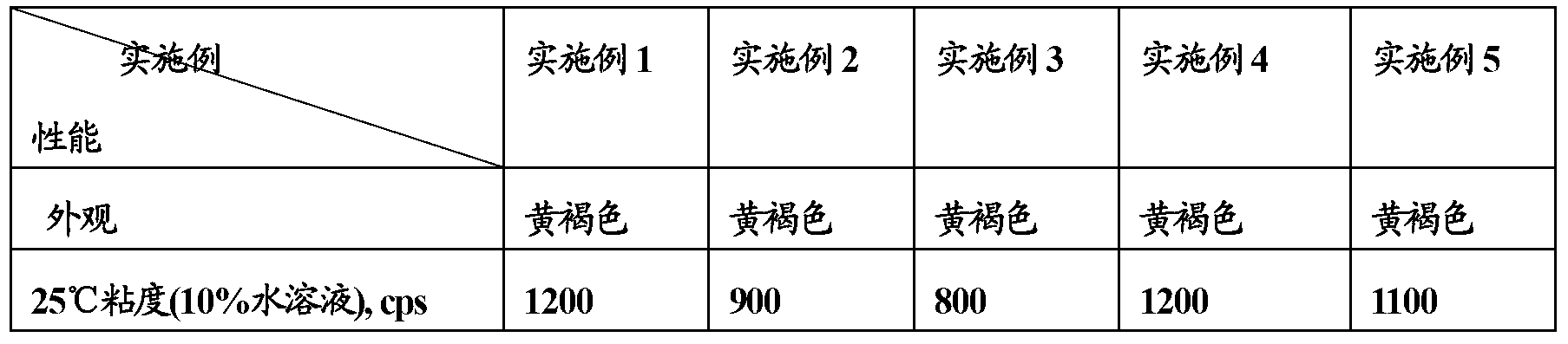

Embodiment 1

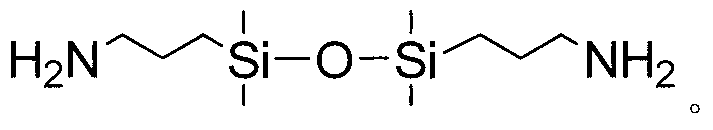

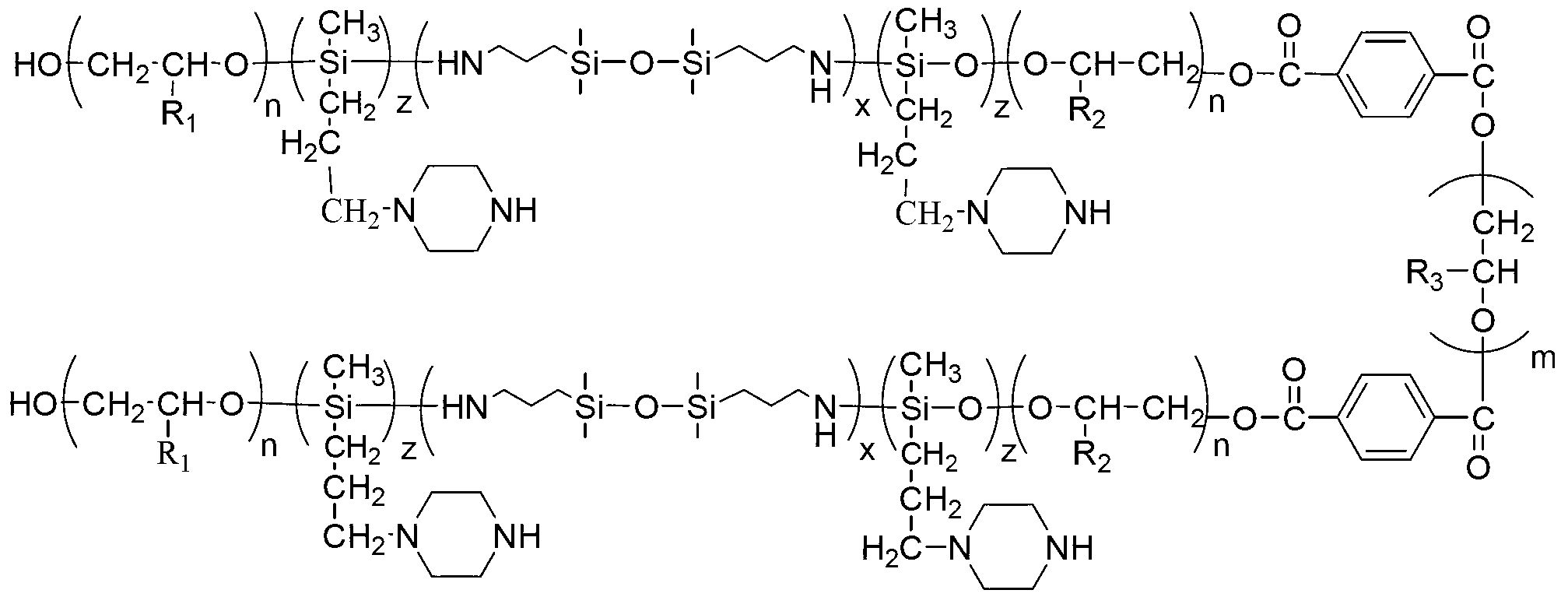

[0022] A kind of anti-wrinkle agent in bath for polyester fiber fabric, it is prepared by following steps:

[0023] (1) Weigh 800 grams of polyethylene glycol (PEG4000), 150 grams of ethylene glycol, 125 grams of dihydroxypolyether, 140 grams of dimethyl terephthalate, and 150 grams of amino-terminated double-header silicone, 50g of 3-piperazinepropylmethyldimethoxysilane, 10g of magnesium acetate;

[0024] (2) Put the above materials into the reaction kettle, raise the temperature to 140°C and keep it for 180 minutes, then continue to raise the temperature to 220°C and keep it for 60 minutes. Then carry out polymerization at a vacuum degree of -0.08MPa and a temperature of 240°C to form a polyester polyether silicone oil block copolymer, and discharge after cooling down to 190°C;

[0025] (3) Mix the polyester polyether silicone oil block copolymer obtained in step (2), sorbitan monostearate and water in a weight ratio of 2:2:96 to obtain the polyester fiber fabric bath Ant...

Embodiment 2

[0027] A kind of anti-wrinkle agent in bath for polyester fiber fabric, it is prepared by following steps:

[0028] (1) Weigh 900 grams of polyethylene glycol (PEG2000), 140 grams of ethylene glycol, 140 grams of dihydroxypolyether, 165 grams of dimethyl terephthalate, and 180 grams of amino-terminated double-header silicone, 3-piperazinepropylmethyldimethoxysilane 60g, zinc acetate 6g;

[0029] (2) Put the above materials into the reaction kettle, raise the temperature to 150°C and keep it for 180 minutes, then continue to raise the temperature to 230°C and keep it for 60 minutes. Then carry out polymerization, carry out polymerization at a vacuum degree of -0.08MPa, and a temperature of 260°C to generate a polyester polyether silicone oil block copolymer, and discharge after cooling down to 200°C;

[0030] (3) Mix the polyester polyether silicone oil block copolymer obtained in step (2), sorbitan monostearate and water in a weight ratio of 3:2:95 to obtain the polyester fib...

Embodiment 3

[0032] A kind of anti-wrinkle agent in bath for polyester fiber fabric, it is prepared by following steps:

[0033] (1) Weigh 700 grams of polyethylene glycol (PEG2000), 125 grams of ethylene glycol, 125 grams of dihydroxypolyether, 130 grams of dimethyl terephthalate, and 150 grams of amino-terminated double-header silicone, 50 grams of 3-piperazinepropylmethyldimethoxysilane, 10 grams of calcium acetate;

[0034] (2) Put the above materials into the reaction kettle, raise the temperature to 170°C and keep it for 180 minutes, continue to raise the temperature to 220°C and keep it for 60 minutes, then carry out polymerization at a vacuum degree of -0.09MPa and a temperature of 250°C to form Polyester polyether silicone oil block copolymer, discharge after cooling down to 200°C;

[0035] (3) Mix the polyester polyether silicone oil block copolymer obtained in step (2), sorbitan monostearate and water in a weight ratio of 5:3:92 to obtain the polyester fiber fabric bath Anti-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com