Patents

Literature

1618results about How to "Improve wrinkle resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing synthetic leather and synthetic leather

InactiveCN101941321AAchieving water-basedRealize cleaner productionSynthetic resin layered productsTextiles and paperLeather industryPolymer science

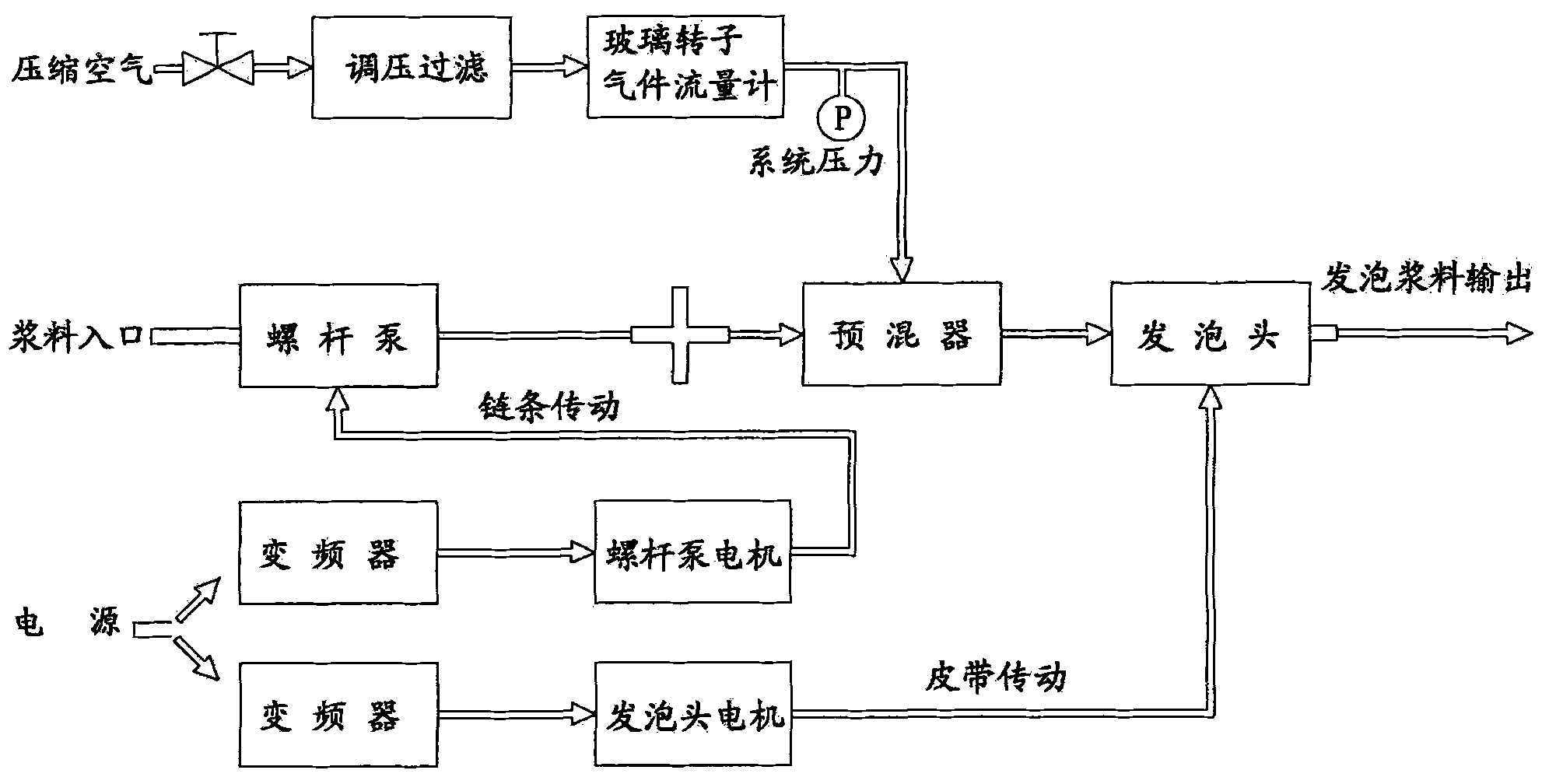

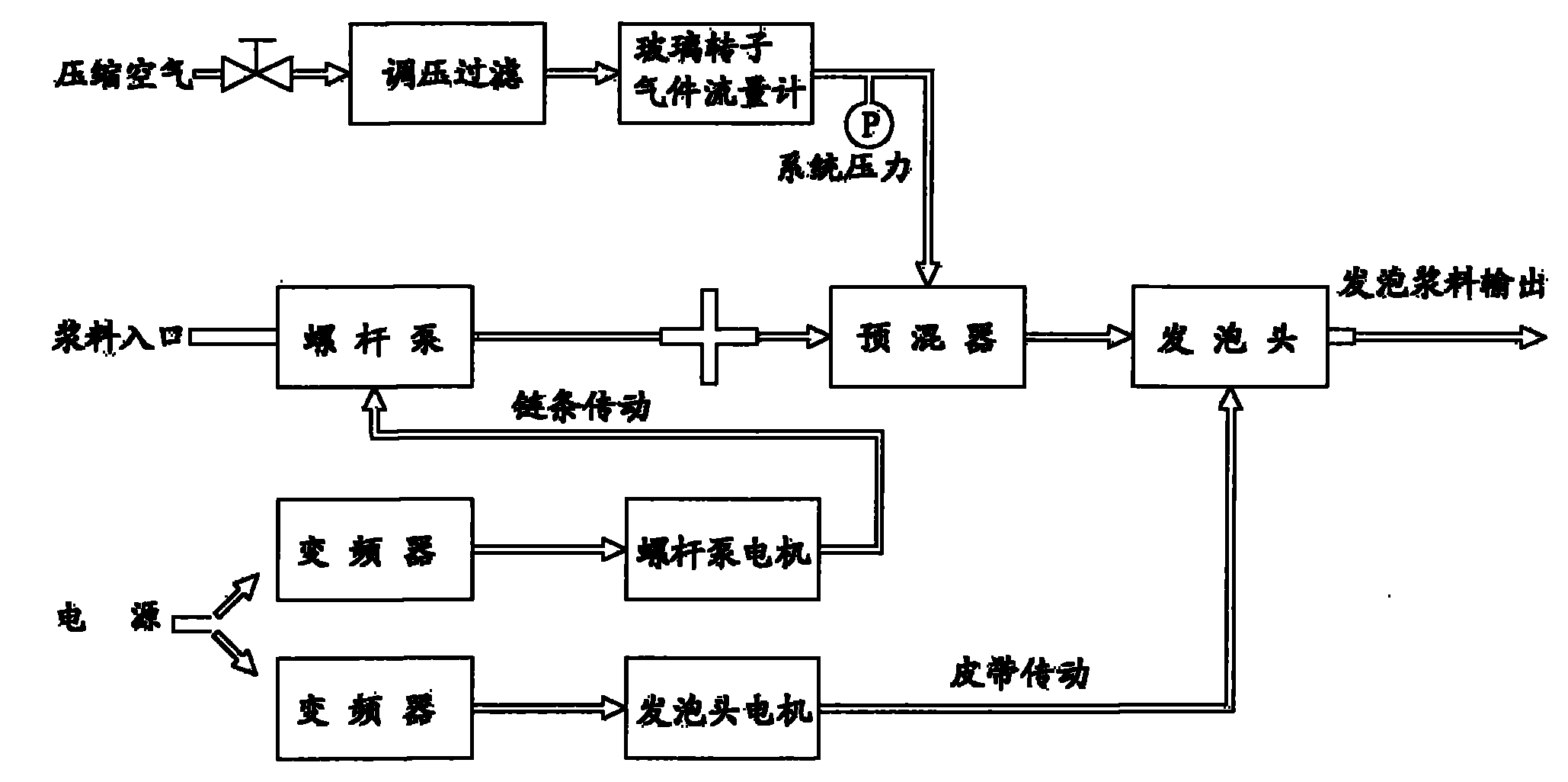

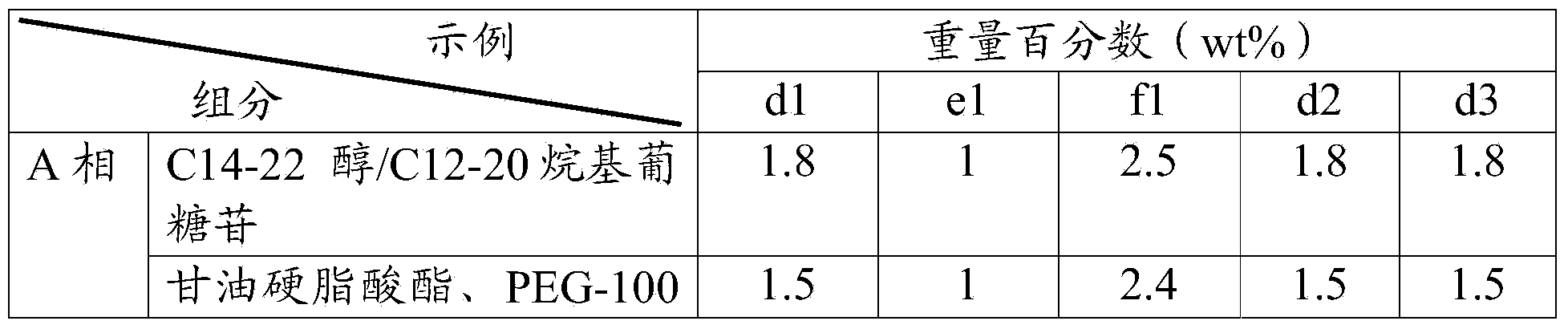

The invention provides a method for preparing synthetic leather and the synthetic leather prepared by the method. The method comprises the following steps: (1) coating slurry containing surface waterborne polyurethane resin on the surface of release paper, and drying to form a finishing coat; (2) mixing and foaming the slurry containing the foaming waterborne polyurethane resin with air by using a foaming machine, and coating the foamed slurry on the surface of the finishing layer, and drying to form a medium foaming layer; and (3) adhering the surface of the foaming layer and a basic fabric by using an adhesive containing waterborne polyurethane resin, and drying. The method uses the waterborne resin foaming layer to replace the Base leather manufacturing process, avoids using toxic and harmful organic solvents, such as dimetbyl formamide (DMF), toluene and the like, solves the pollution problem in the synthetic leather industry, and realizes clean manufacture of the synthetic leather.

Owner:丽水市优耐克水性树脂科技有限公司

Reactive aqueous polyurethane fabric finishing agent, its preparation method and application

This invention relates to an aquosity polyurethane with end-closed or polyurethane structure preparing process and finishing method for preventing the fabric from winkle and distortion, which has a new application being used as finishing agent. The agent adopts prepolymer aggregating and end terminating technology to make out stable aquosity polyurethane with response type end group, whose emulsion particle diameter ranges from 50 to 500 nm and can be adjusted. The invention has functions of high adhesive strength, good impact resistance, hydrolytic resistance and shape memorization.

Owner:THE HONG KONG POLYTECHNIC UNIV

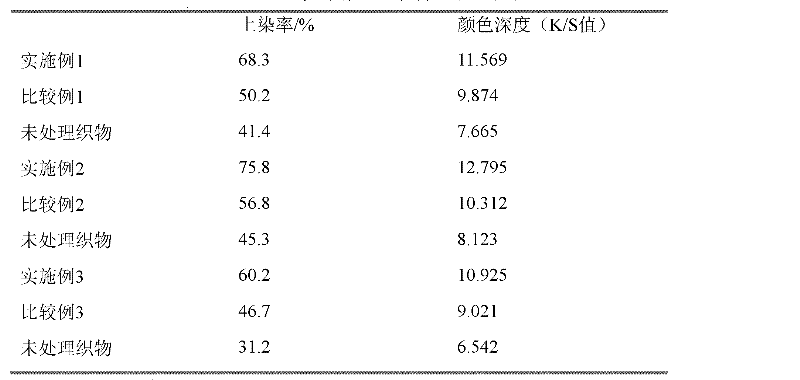

A method for improving the dyeing depth of cellulose fiber fabrics with chitosan

ActiveCN102268823AImprove accessibilityImprove responseDyeing processVegetal fibresEpoxyCooking & baking

The invention relates to a method for improving the dye depth of cellulose fiber fabrics by using chitosan. In the method, a polycarboxylic acid solution is used as a solvent and a cross-linking agent of chitosan and epoxy chloropropane is used as a cross-linking agent, and chitosan is covalently grafted to the surface of the cellulose fiber fabrics through padding, preliminary drying and baking at a high temperature. The combining strength of chitosan and the cellulose fiber fabrics is increased greatly, the electrostatic repulsion between the cellulose fiber fabrics and anionic dyes is reduced, the dye-uptake of dyes and the color depth of the fabrics are improved obviously, and the crease resistance of the cellulose fiber fabrics processed by using the method is improved obviously.

Owner:CHANGZHOU UNIV

Vegetable protein peptide stock solution as well as preparation method and application thereof

ActiveCN104382833AVisibly firmingEfficient repairCosmetic preparationsToilet preparationsChemistrySilybum marianum extract

The invention discloses a vegetable protein peptide stock solution with body firming, repairing, wrinkle resisting and skin quality improving effects as well as a preparation method and application of the vegetable protein peptide stock solution. Active ingredients of the vegetable protein peptide stock solution are from the following raw materials in parts by weight: 1-10 parts of silybum marianum extract, 0.01-0.3 part of carnosine, 0.01-0.2 part of palmitoyl tripeptide-5 and 0.1-3 parts of yeast extract. The invention also discloses a preparation method and application of the vegetable protein peptide stock solution. The prepared vegetable protein peptide stock solution is comprehensively applied to multiple ways for delaying senescence; silybum marianum extract, carnosine, palmitoyl tripeptide-5 and yeast extract are adopted in a specific ratio, and the four substances cooperate mutually to obviously take effects obvious body firming, skin repairing, wrinkle resisting and skin quality improving effects.

Owner:GUANGDONG BIYUAN COSMETICS

One-way moisture guiding and absorbing and heating knitted fabric and manufacturing method thereof

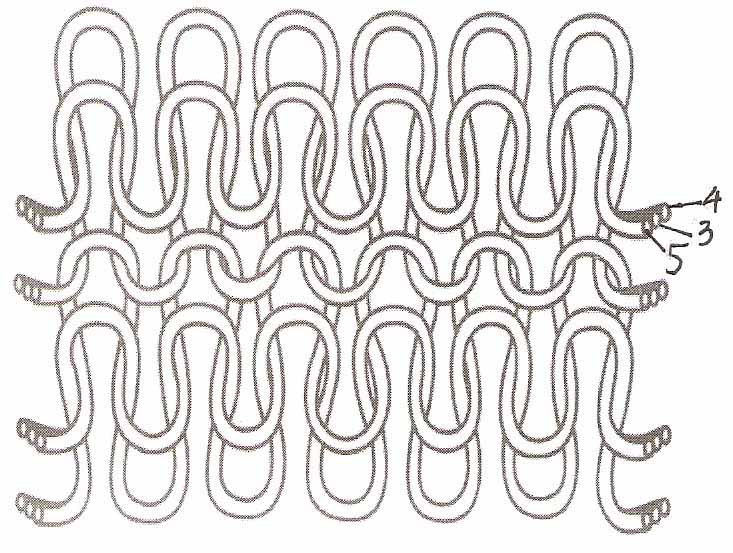

ActiveCN106192177AGood hygroscopicityStrong discomfortWeft knittingHeating/cooling textile fabricsFiberYarn

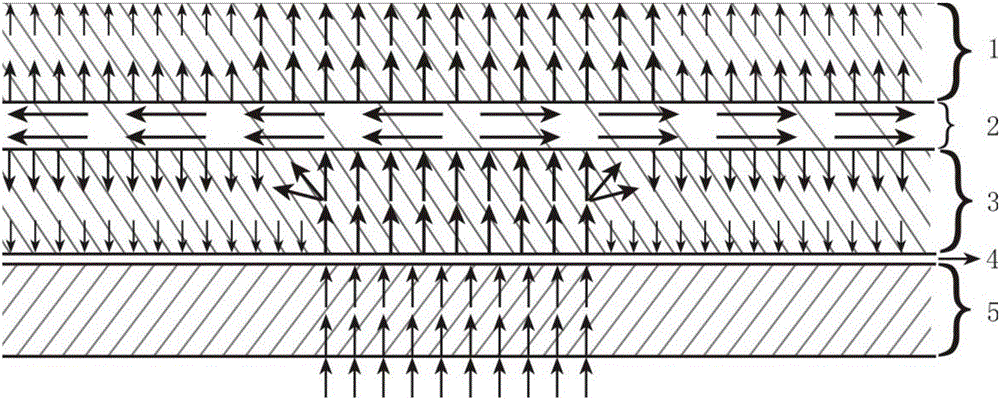

The invention discloses a one-way moisture guiding and absorbing and heating knitted fabric and a manufacturing method thereof. The fabric is knitted from first yarn, second yarn and third yarn, the first yarn is covering yarn, the second yarn is polyurethane elastic fiber yarn or polyolefin elastic fiber yarn, and the third yarn is cotton fiber blended yarn or all cotton yarn. The fabric is of a three-layer structure composed of an outer layer, a middle layer and an inner layer, the outer layer is knitted from the first yarn, the middle layer is knitted from the second yarn, and the inner layer is knitted from the third yarn. The manufacturing method of the fabric sequentially comprises the following steps of 1, yarn preparation; 2, weaving on a machine; 3, blank inspection; 4, loose fabric cylinder matching; 5, pre-sizing; 6, pretreatment; 7, dyeing; 8, soaping; 9, acid pickling; 10, in-cylinder softening; 11, dehydrating and drying; 12, re-sizing; 13, polished blank inspection. The fabric has a one-way moisture guiding function and achieves moisture absorbing and heating functions.

Owner:WUHAN LOVE GOD HIGH LEVEL DRESS & ADORNMENTS

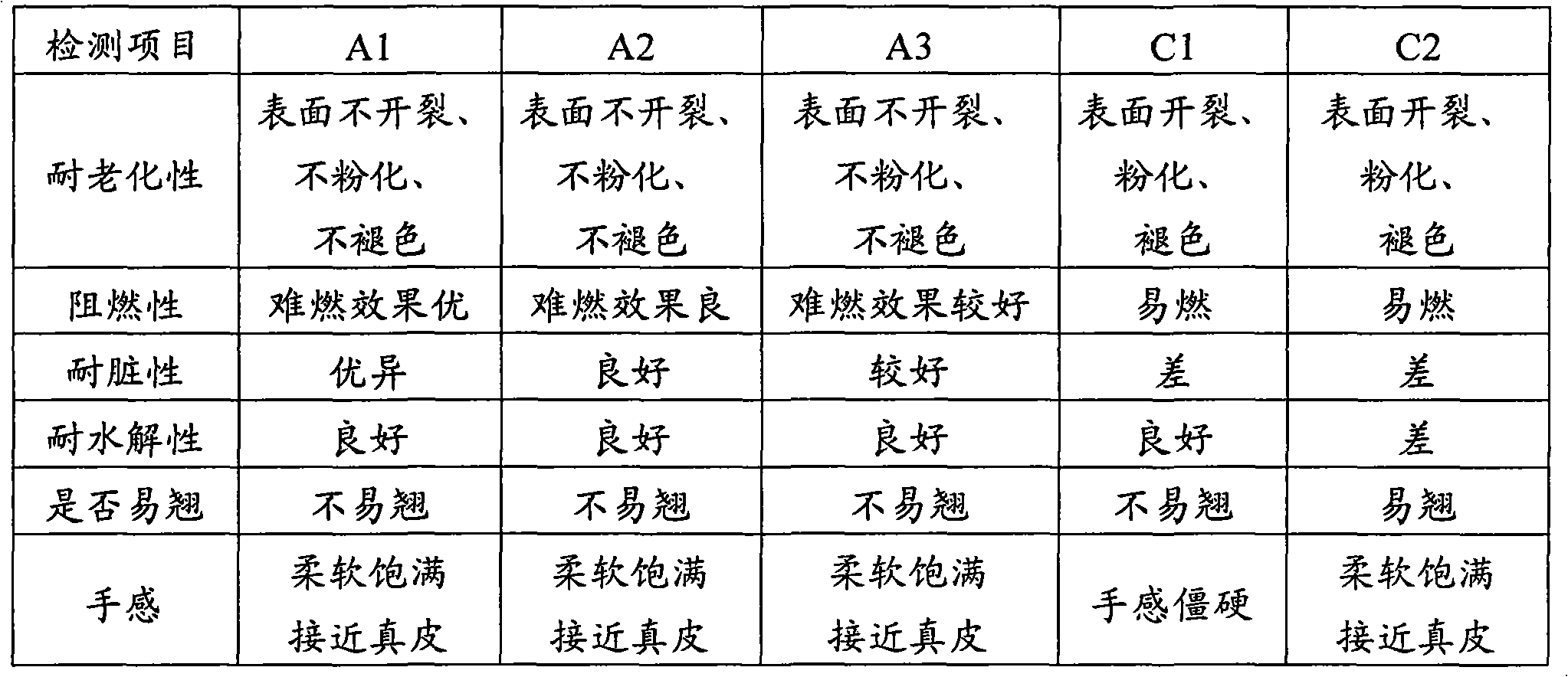

Interior wall adornment leather and preparation method

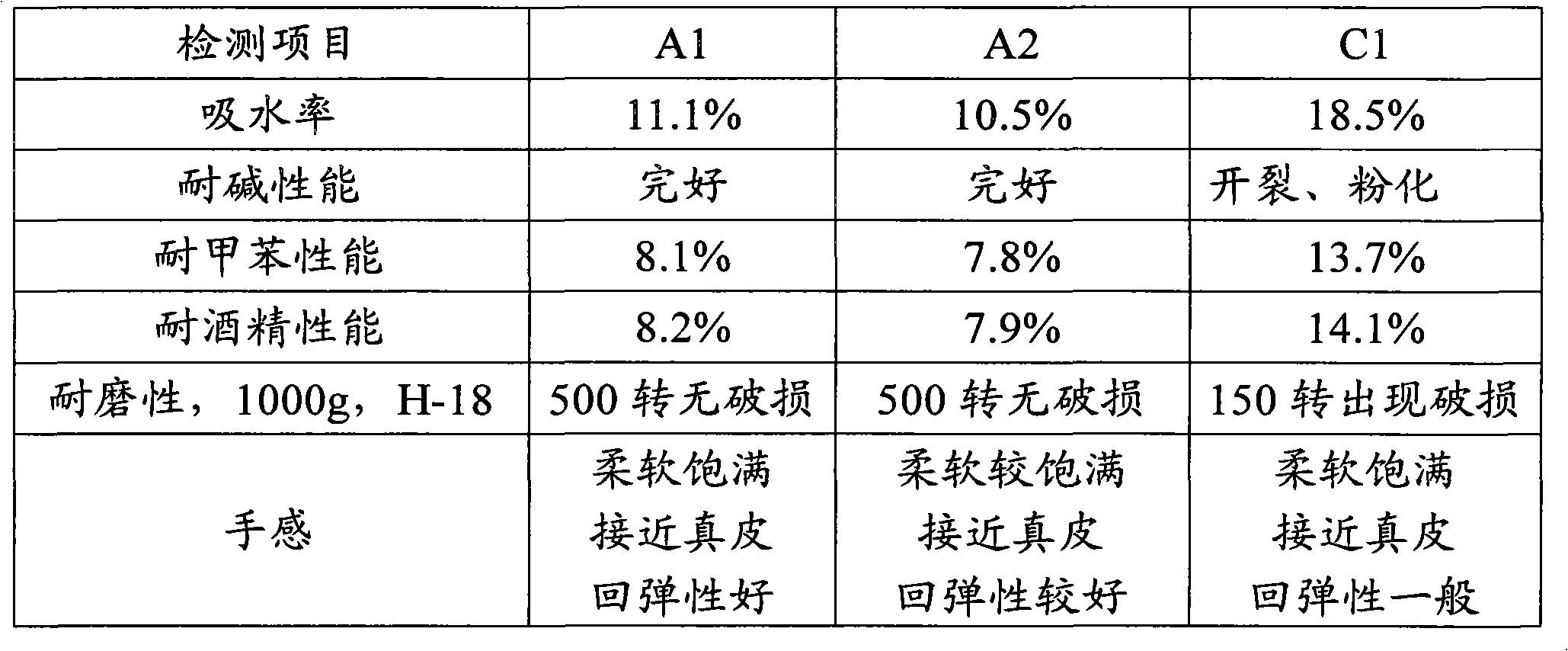

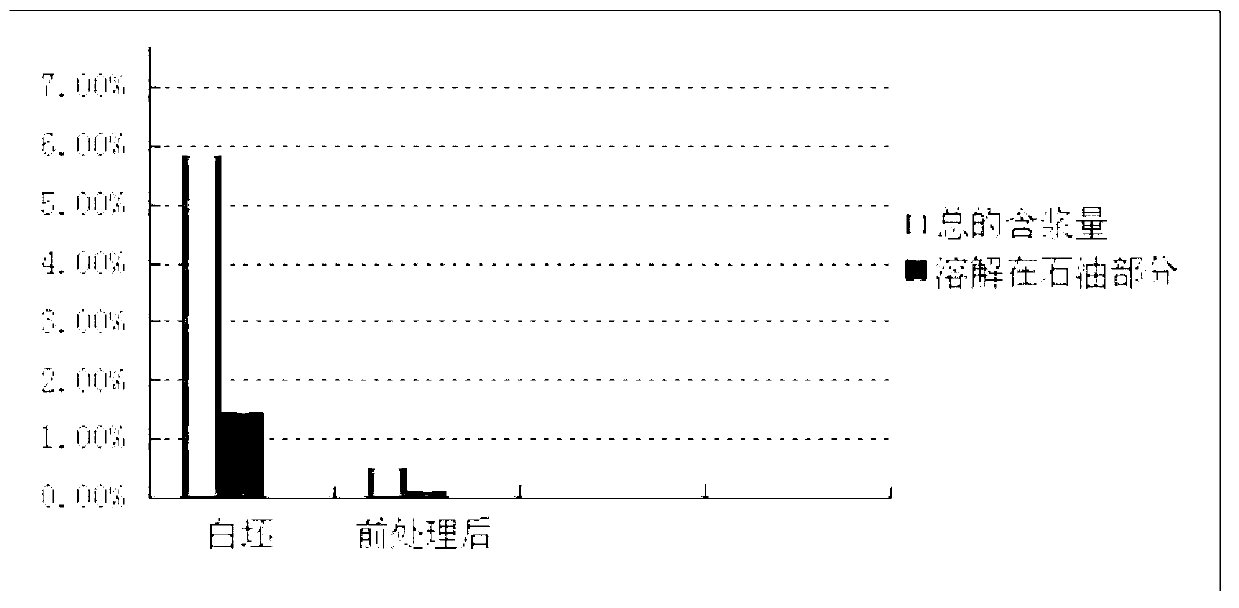

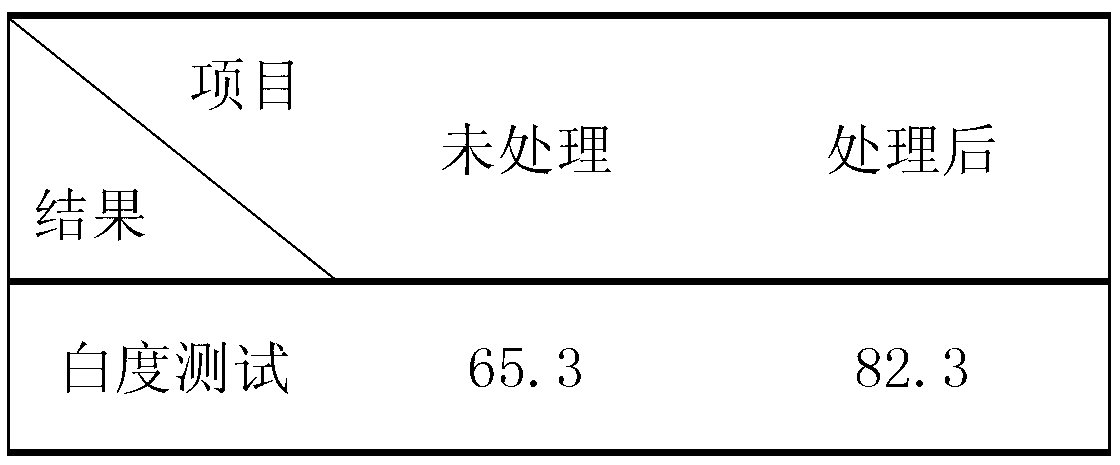

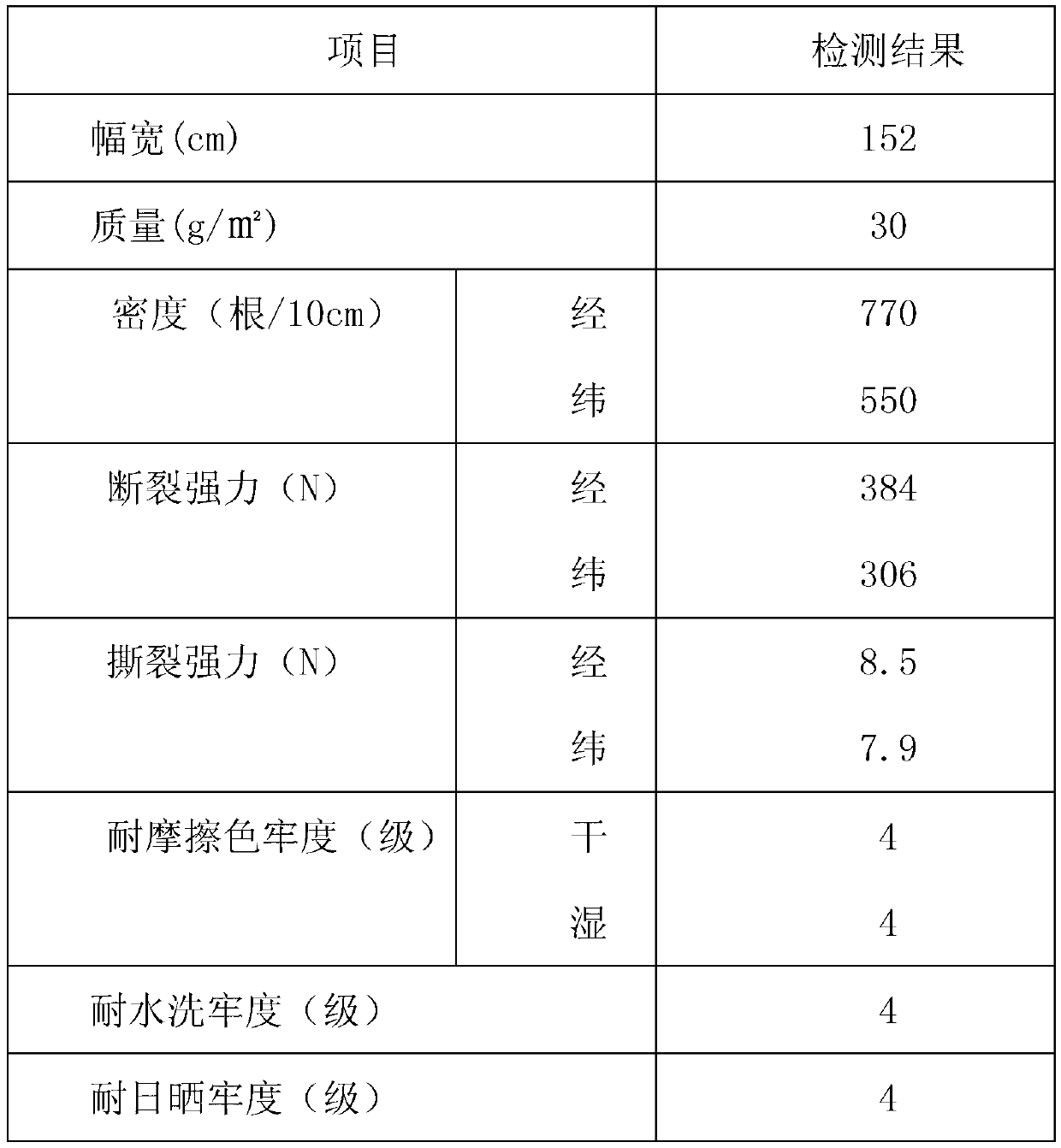

The invention provides interior wall adornment leather and a preparation method. The interior wall adornment leather comprises base fabric, a foaming layer and a surface layer, wherein an adhesive layer is arranged between the base fabric and the foaming layer; the foaming layer contains foamed water-borne polyurethane resin; the surface layer contains inflaming retardant water-borne polyurethane resin; and the adhesive layer contains adhesive water-borne polyurethane resin. The interior wall adornment leather not only has the advantages of traditional wallpaper sound insulation, heat preservation, gorgeousness and easy adornment, but also has the advantages of safety, environment protection, endurance, ageing resistance and fame resistance, which are incomparable with the traditional wallpaper, and can effectively overcome the defects that the traditional wallpaper is easy to raise margins, does not resist dirt and damp, has poor handfeel, and can not be repaired after wrinkling and the like.

Owner:丽水市优耐克水性树脂科技有限公司

Method for no-ironing finishing of pure cotton textile

The no-ironing finishing process of pure cotton textile includes the available steps of preparation, preflexibilizing, framing and settling, calendering, preshinking and packing as well as increased rolling supercrosslinking assistant, storing and water washing steps inserted between available preflexibilizing and framing steps. The textile after the said treating process is soft, permeable, water absorbing and no need of ironing and has low formaldehyde content.

Owner:LUTAI TEXTILE

Skin care composition with moisturizing and wrinkle-resistant effects

InactiveCN105919827ANot allergicGood moisturizing effectCosmetic preparationsToilet preparationsTryptophanTyrosine

The invention discloses a skin care composition with moisturizing and wrinkle-resistant effects. The composition is prepared by using sterile deionized water as a solvent, and the solute comprises amino acids, vitamins and trace elements including glycine, phenylalanine, alanine, proline, glutamine, serine, arginine, threonine, asparagine, tryptophan, aspartic acid, tyrosine, cysteine, valine, cystine, vitamin H, glutamic acid, nicotinamide, histidine, vitamin B6, isoleucine, vitamin B2, leucine, and vitamin B1. The skin care composition has good moisturizing and wrinkle-resistant effects, and has the advantages of safety without side effect, skin nourishing and good skin penetration capacity.

Owner:BEIJING SINOCELL CO LTD

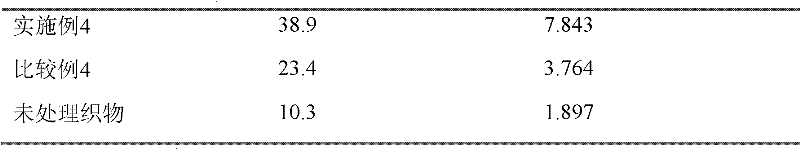

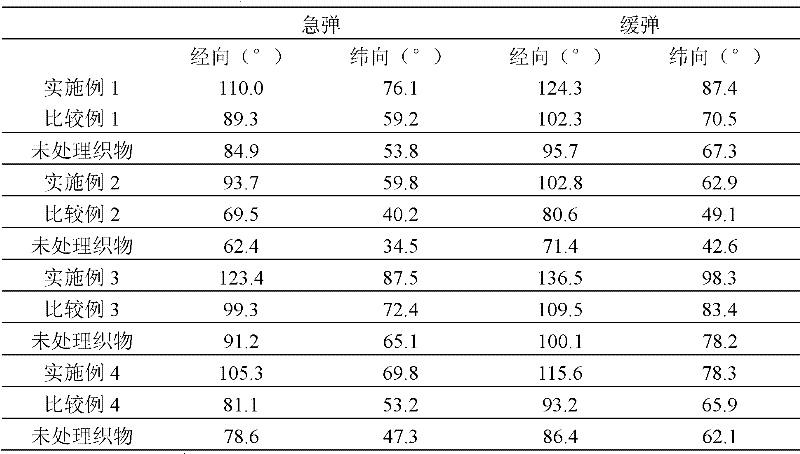

Preparation method of moisture-absorbing, sweat-permeable and anti-crease fabric

ActiveCN101949092AComfortable and breathableImprove wrinkle resistanceDyeing processWoven fabricsFiberColour fastness

The invention relates to a preparation method of a moisture-absorbing, sweat-permeable and anti-crease fabric, which comprises the following steps: weaving combed long stapled cotton and terylen fibers with grooves of a special shape into a base fabric by warp and weft interwaving based on a certain ratio, and enduing the fabric with the soft and air-permeable natural texture and permanent moisture-absorbing, sweat-permeable and anti-crease functions based on the physical structures of the raw materials; and dyeing the base fabric at high pressure and high temperature, carrying out a post-treatment on the fabric with a finishing liquid mixed according to a ratio of a special formula, and chemically finishing to enable the fabric to have high color fastness and feel soft and comfortable while having the moisture-absorbing, sweat-permeable and anti-crease functions. Thus, the invention meets the requirements for the moisture-absorbing, sweat-permeable and anti-crease fabric in the market, especially the requirements for outdoor clothes such as police uniforms, sports wears and the like.

Owner:江苏恒润盛鑫纺织实业有限公司

Ferrite stainless steel cold-rolled steel band and manufacturing method thereof

ActiveCN101649418AEasy to processReduced processing performanceTemperature control deviceManufacturing convertersSS - Stainless steelMolten steel

The invention relates to a ferrite stainless steel cold-rolled steel band and a manufacturing method thereof. The ferrite stainless steel cold-rolled steel band comprises the following chemical ingredients in percentage by weight: 0.02%-0.04% of C, 0.10%-0.50% of Si, 0.10%-1.00% of Mn, 14.0%-19.0% of Cr, less than or equal to 0.030% of P, less than or equal to 0.010% of S, more than 0% while lessthan or equal to 0.030% of N, more than 0% while less than or equal to 0.60% of Ni, and the balance of Fe and unavoidable impurities. The manufacturing method comprises the following steps: (1) smelting, i.e. smelting liquid steel according to the requirement of the steel band; (2) continuous casting, i.e. casting into a continuous casting billet; (3) casting billet hot rolling, i.e. rolling the casting billet into a hot rolled coil; (4) hot coiling annealing, i.e. preserving the temperature at 800 DEG C-880 DEG C for the temperature preserving time of 10-13 hours, freely reducing the temperature to 600 DEG C after the temperature preservation is completed; (5) cold rolling, i.e. adopting once cold rolling or twice cold rolling among cold rolled finished products; and (6) cold coiling annealing, i.e. controlling annealing temperature at 860+ / -20 DEG C, and controlling annealing time according to 2-5 minutes / mm. The ferrite stainless steel cold-rolled steel band has good cold processingforming property and excellent crinkling and breaking resistance.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Sterilizing shape-memory-fabric finishing agent and finishing method

This invention discloses a sterilization shape memory fabric finishing agent and the processing method. It is composed of the following component and the weight percentage: the river character shape memory polyurethane ranging from 2-20%, the low formaldehyde which can prevent burning the reorganization resin 3-30%, the traditional Chinese medicine extraction used to sterilize 1-10%, the catalyst 1-5%, the remainder is the water. Various components should proportionate duplicate match then. This invention's sterilization river character shape memory fabric finishing agent formaldehyde content is low, the force slightly loses. Besides, it has the shape memory property, the high crease-resist performance, and the antibacterial health care function. So it may substitute for the traditional which can prevent burning the reorganization resin finishing fabric, and the application prospect is broad.

Owner:SOUTH CHINA AGRI UNIV

Dyeing and finishing method of superfine denier nylon fabric

ActiveCN103132349AHave affinityReduce initial dyeing speedFibre typesDry-cleaning apparatus for textilesCooking & bakingColour fastness

The invention discloses a dyeing and finishing method of superfine denier nylon fabric, belongs to the field of processing on the superfine denier nylon fabric, and aims at solving the problems that dyeing defect and uneven dyeing of the superfine denier nylon fabric are easily generated in the dyeing process. The method disclosed by the invention comprises the steps of: cold heaping, open-width desizing, pre-setting, dyeing, performing fixation, baking and molding a finished product. An anionic leveling agent disclosed by the invention has affinity on nylon, and can generate an unexpectedly dyeing effect on the fiber together with anionic dye. Thus, the initial dyeing speed of the dye is reduced, so as to achieve a uniform dyeing effect; and the fold resistance of the fabric is improved when the craping style of the fabric is kept by presetting the desized fabric. By using the dyeing and finishing method, the dyeing process is even, the color and the luster are good, the colour fastness is good, and the like; and the dyeing defect can not be generated, and the fabric processed by using the method accords with the requirements of superior products specified by the standard of GB / T17253-2008 'synthetic filament yarn fabric'.

Owner:SHENGHONG GRP CO LTD

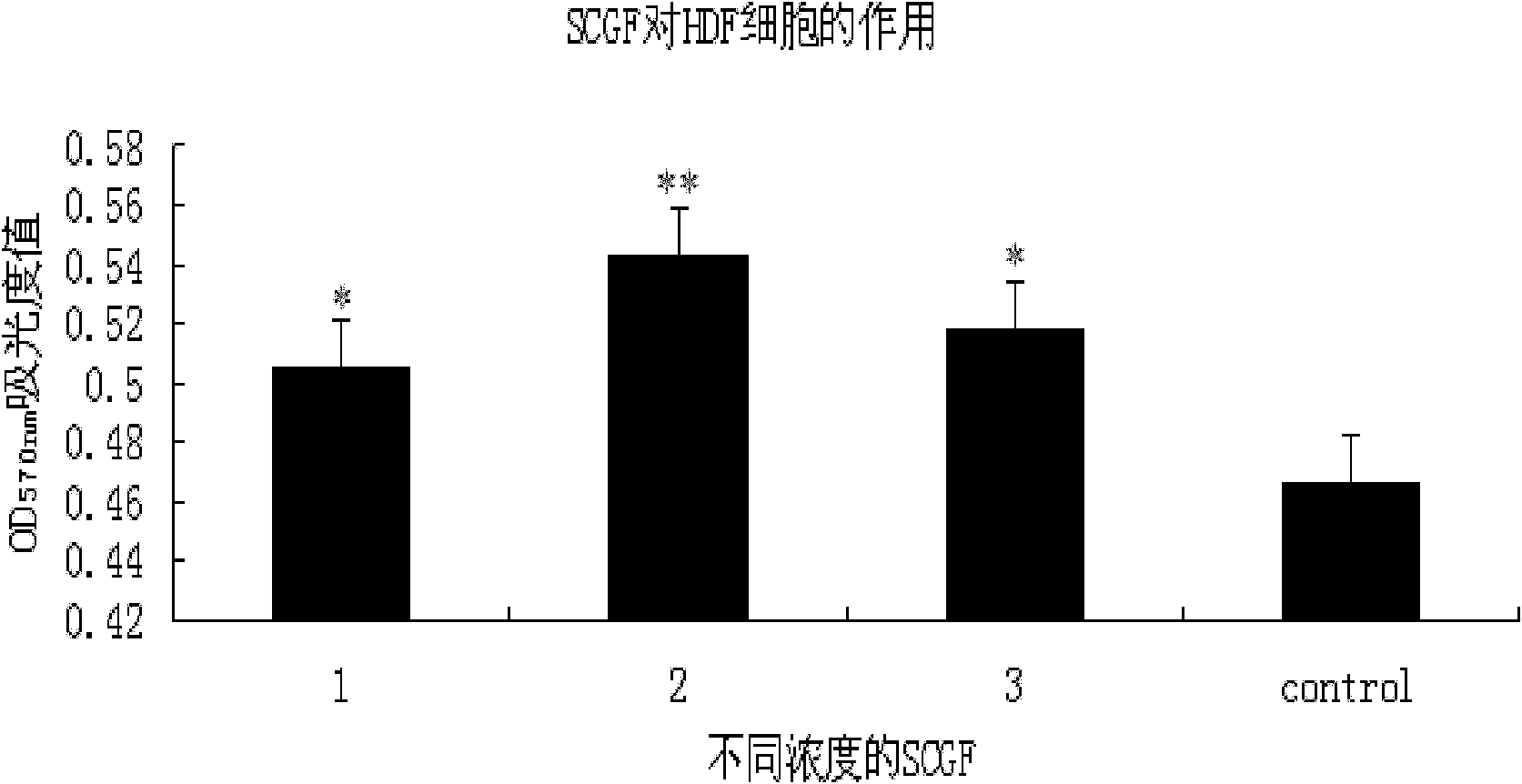

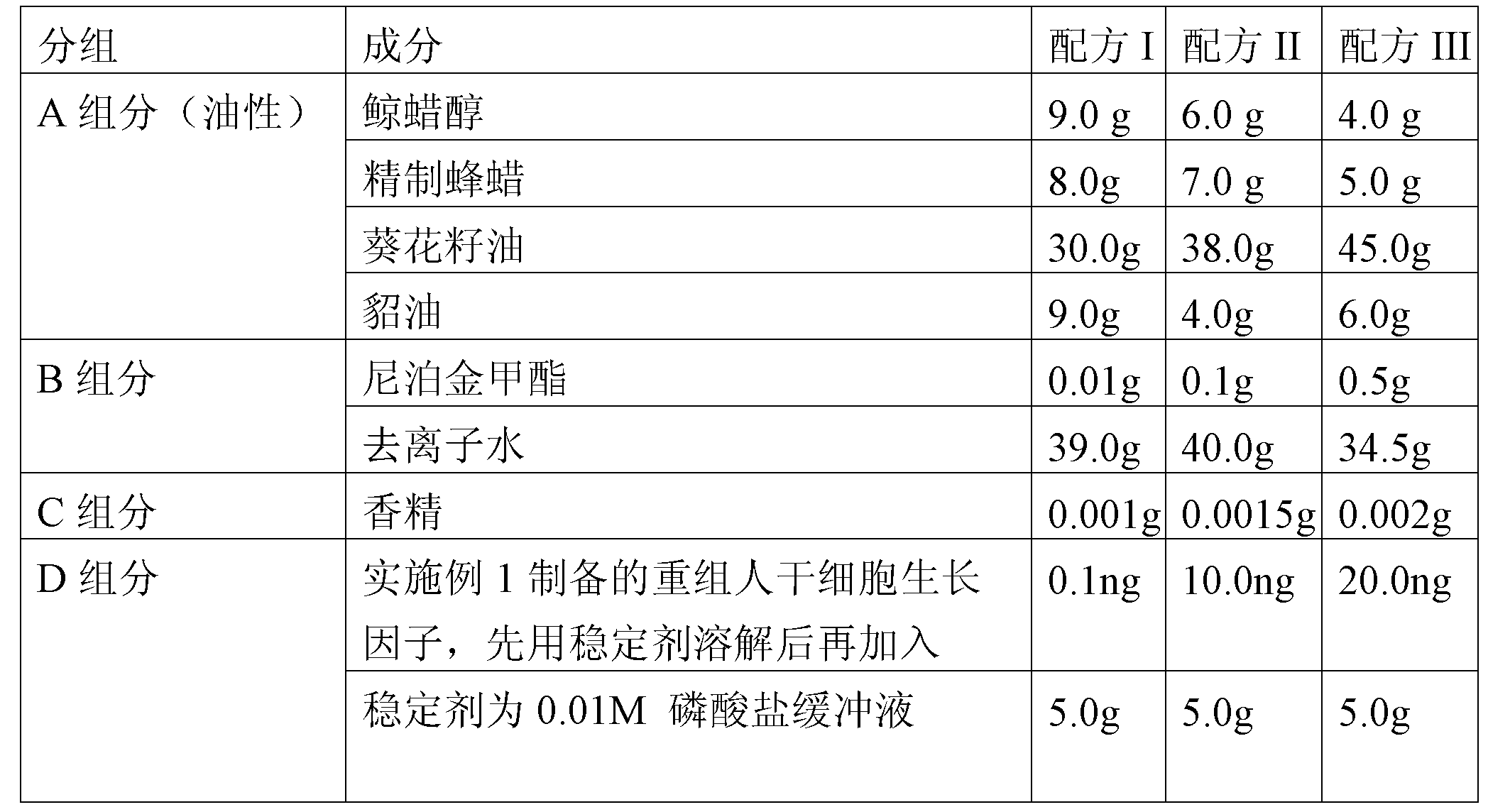

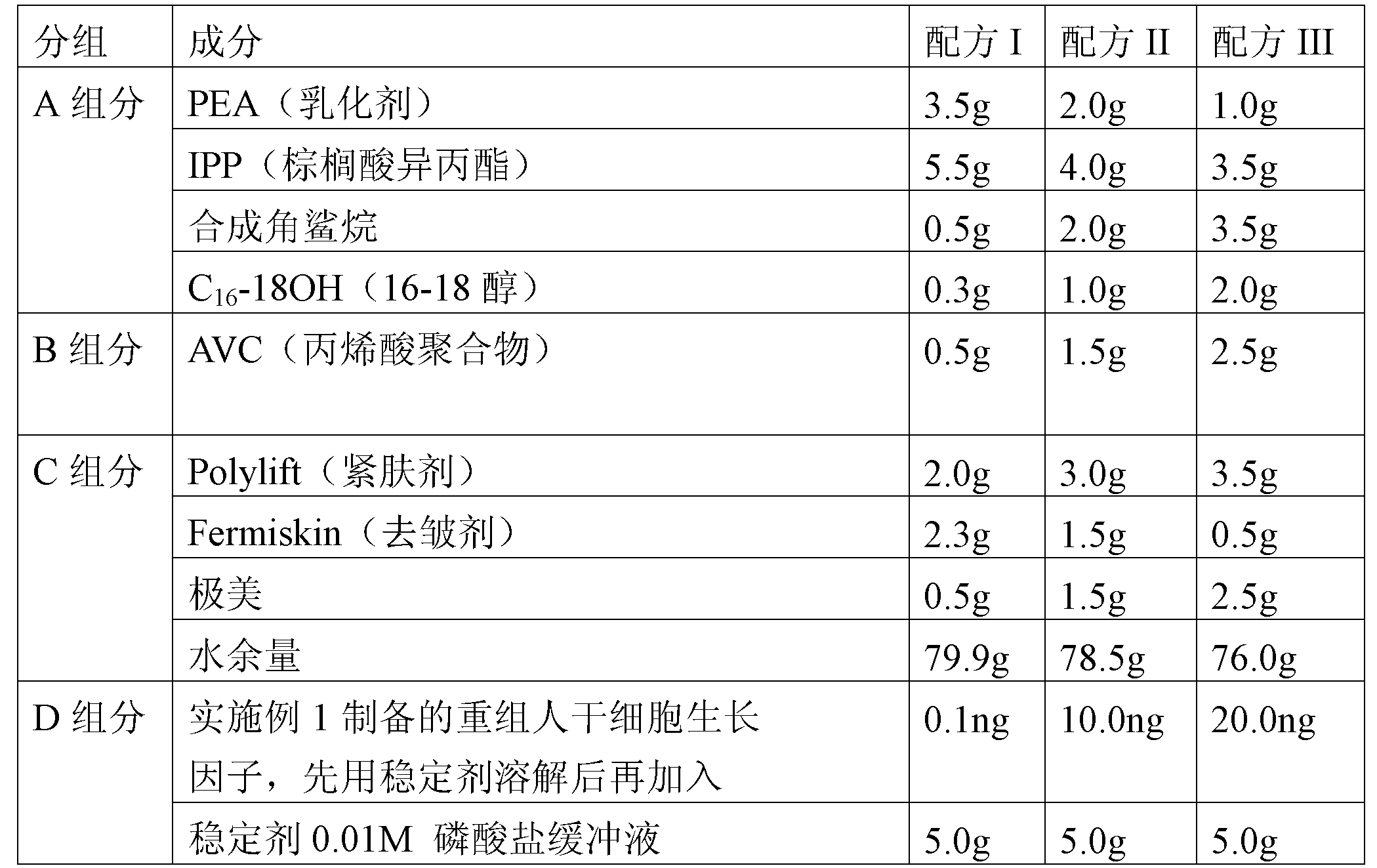

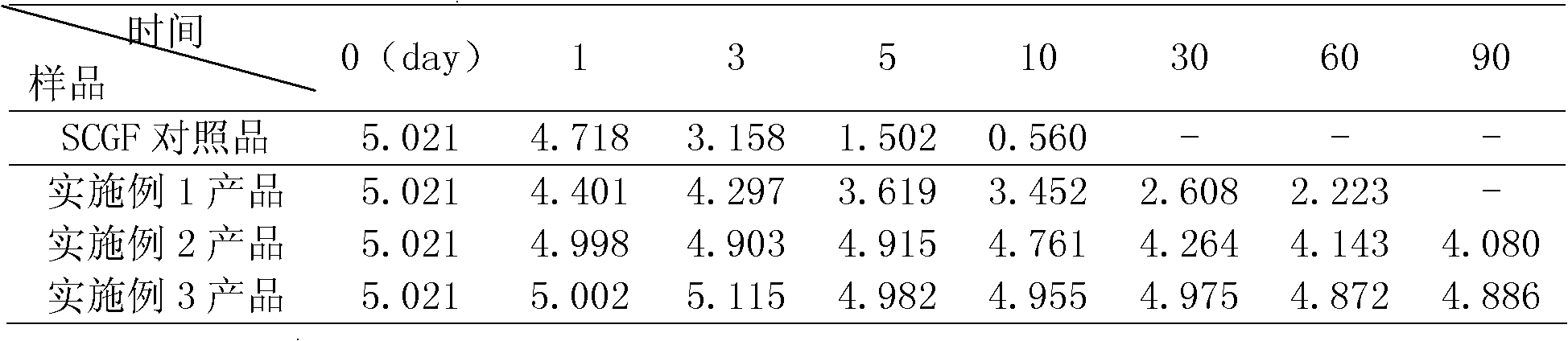

Application of human steam cell growth factors in cosmetics

ActiveCN102068391AActivity detectedImprove wrinkle resistanceCosmetic preparationsHair removalWrinkle skinWater based

The invention provides application of human steam cell growth factors in cosmetics. In an application method, human cell growth factors are added into the cosmetics by a homogenizing process, wherein the human steam cell growth factor content in each gram of cosmetics is between 0.1 and 20.0 ng, and the purity is between 85 and 99 percent. The specific application method comprises the following steps of: dividing components which need to be heated in raw materials of the cosmetics into an oil-based component and a water-based component, heating respectively, and mixing; and homogenizing and emulsifying, cooling to the temperature of between 37 and 50 DEG C, adding solution containing the human steam cell growth factors and components which do not need to be heated, stirring uniformly, and performing vacuum degassing. In the application method, the human steam cell growth factors are applied to the cosmetics for the first time, the human steam cell growth factors still can keep excellent activity in a cosmetic matrix material, and the wrinkle resistance of the cosmetics containing the human steam cell growth factors is still high after the cosmetics are stored for one month.

Owner:GUANGZHOU SALIAI STEMCELL SCI & TECH CO LTD

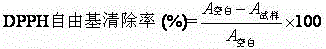

Production process of high-count and high-density long stapled cotton shirt fabric

ActiveCN105671727AImprove permeabilityImprove wear resistanceSucessive textile treatmentsDry-cleaning apparatus for textilesYarnHigh density

The invention relates to a production process of a high-count and high-density long stapled cotton shirt fabric. The finished product fabric is prepared from long stapled cotton yarns sequentially by processes of slashing, weaving, singeing, desizing, boiling-off, cold pad batch dyeing, liquid ammonia mercerized finishing, moist-cure anti-crease finishing and preshrinking, and the long stapled cotton yarns adopt 140s / 2 celo compact-spun GIZA45 long stapled cotton yarns and are woven into twill weaves. According to the production process provided by the invention, the long stapled cotton yarns are used as raw materials; technologies of cold pad batch dyeing, liquid ammonia mercerized finishing and moist-cure anti-crease finishing are combined; the energy-saving environmental-friendly high-count and high-density shirt fabric is developed; the high-count and high-density long stapled cotton shirt fabric has soft and comfortable hand feeling, fine and soft gloss and excellent wear comfort, mode-holding nature and anti-crease property and can be free of ironing; the comprehensive technology of the product reaches the domestic advanced level; the high-count and high-density long stapled cotton shirt fabric has wide market prospect and social and economic benefits; meanwhile, the energy-saving environmental-friendly fabric production process reduces pollution to the environment and makes a contribution to development of a cleaning fabric processing technology and social sustainable development.

Owner:FUJIAN SEPTWOLVES IND

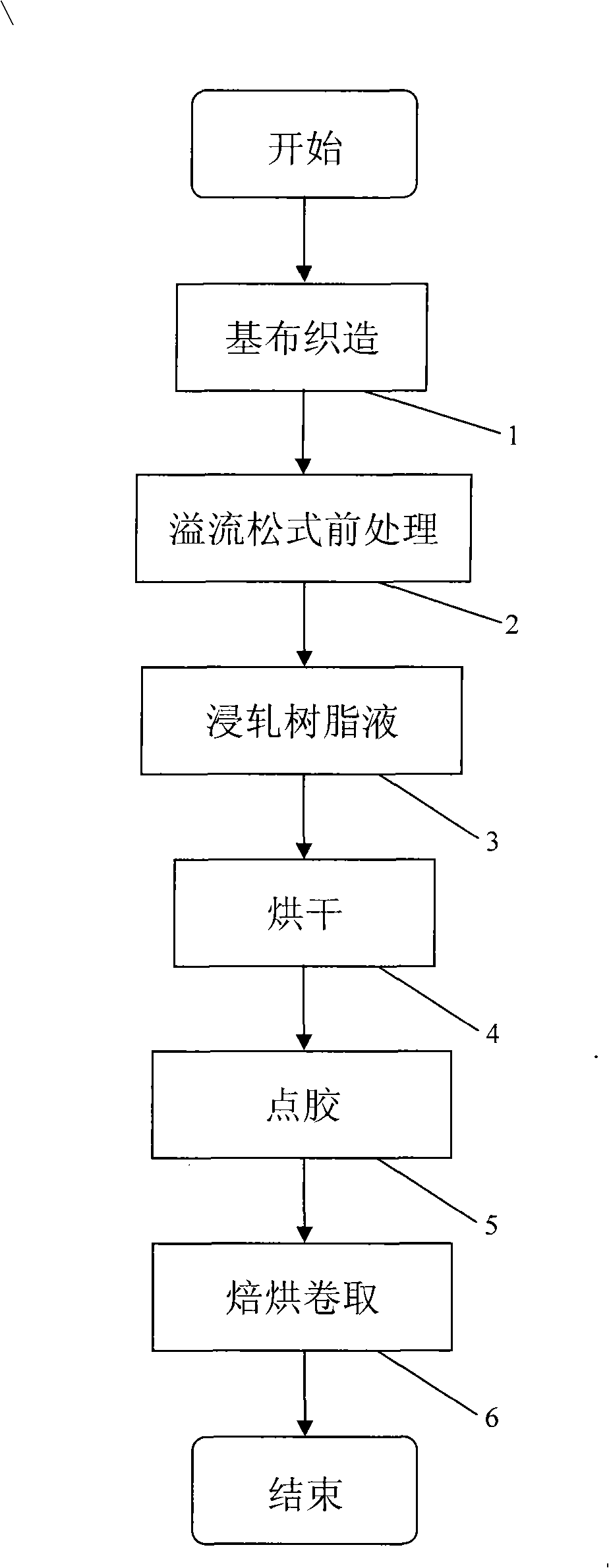

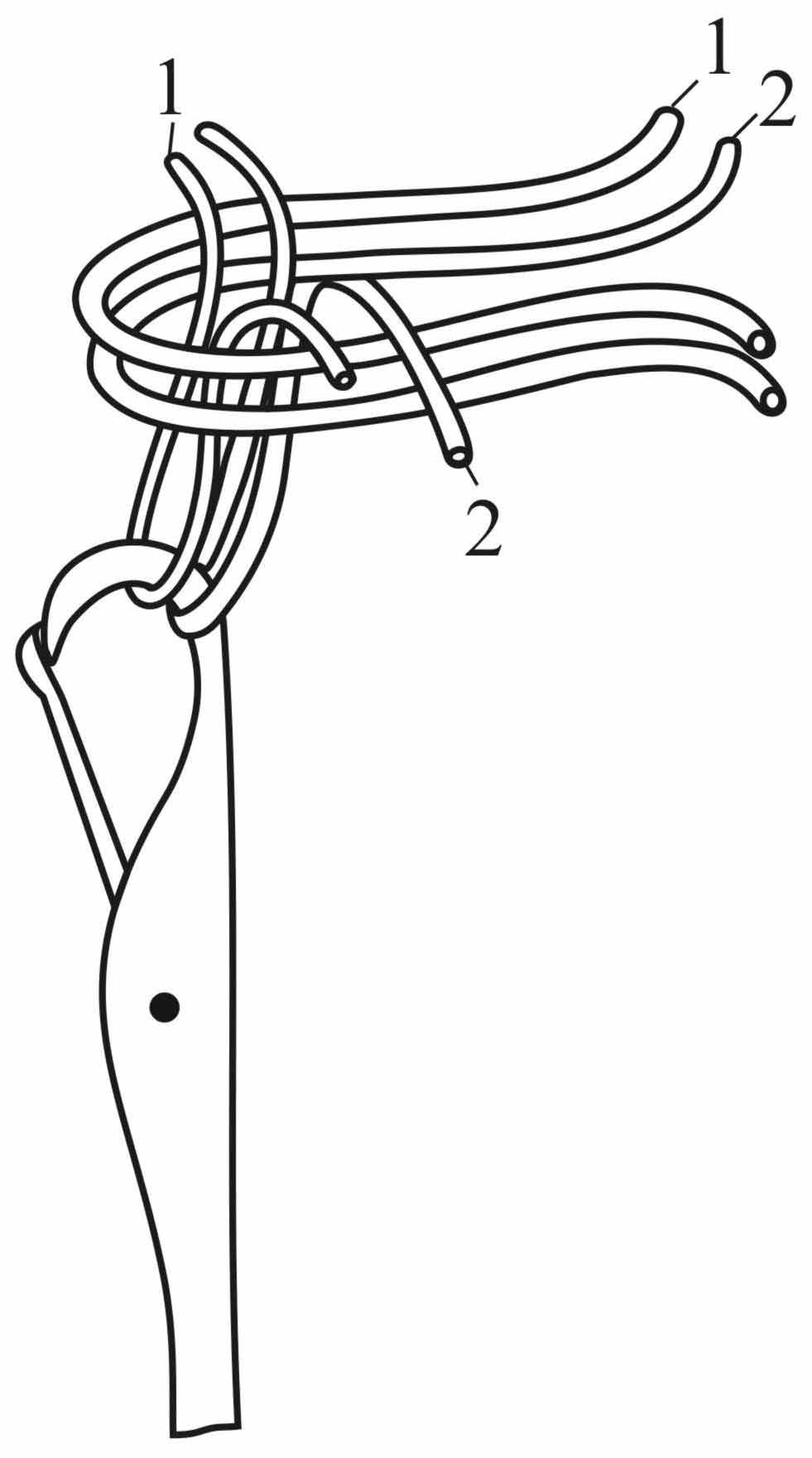

Manufacturing technique of crease-shedding uniforms lining

InactiveCN101288507AImprove deformation recovery performanceImproves wrinkle recoveryGarmentsVegetal fibresFiberPolyamide

The invention discloses a technique for manufacturing anti-wrinkle liner of suits. The technique comprises the processes of weaving base fabric, overflow and loose pre-treatment, immersing in resin liquid and rolling, drying, gluing, baking, coiling and so on. The technique adopts environment-friendly resin liquid with high quality for twice-immersing and twice-rolling treatment which causes the resin liquid to sufficiently permeate into fibers and to become uniformly cross-linking, leads the treated fabric to obtain good anti-wrinkle recoverability and solid hand feeling. Nylon polyamine hotmelt adhesive is used for double-dot coating, which is characterized by strong adhesion fastness, having good drapability after being bonded with the fabric and excellent anti-wrinkle property when in use. The lining cloth has soft hand feeling and good anti-wrinkle property. Suits made from the lining cloth have the advantages of fullness and being docile. The anti-wrinkle property and sizing property after washing are better than any other ordinary adhesive lining cloth. The lining cloth is mainly used for wash-and-wear suits and career wears.

Owner:严华荣

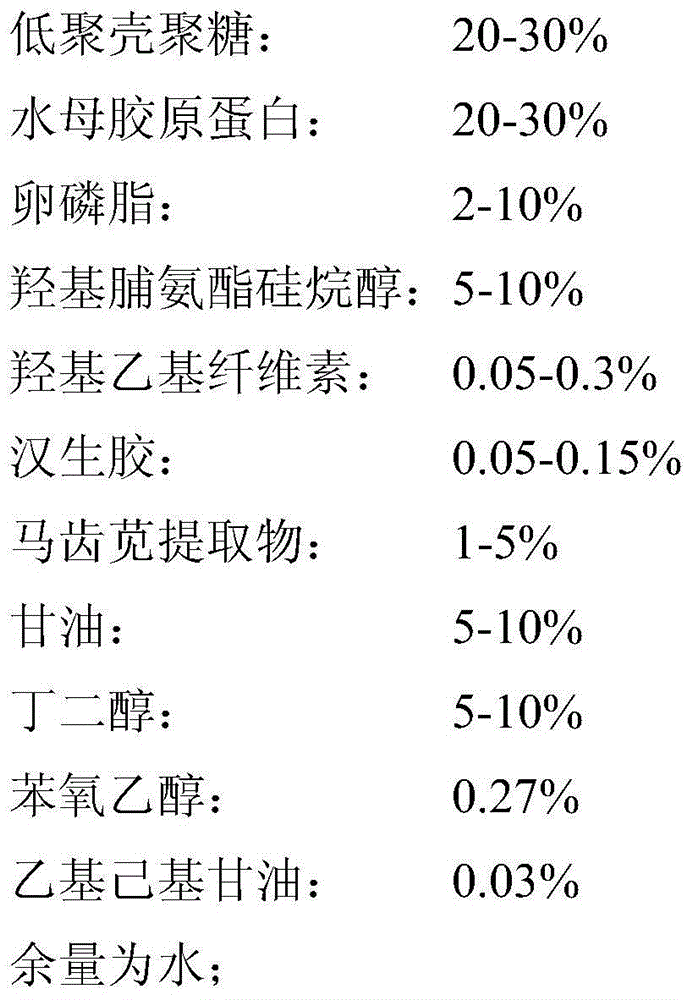

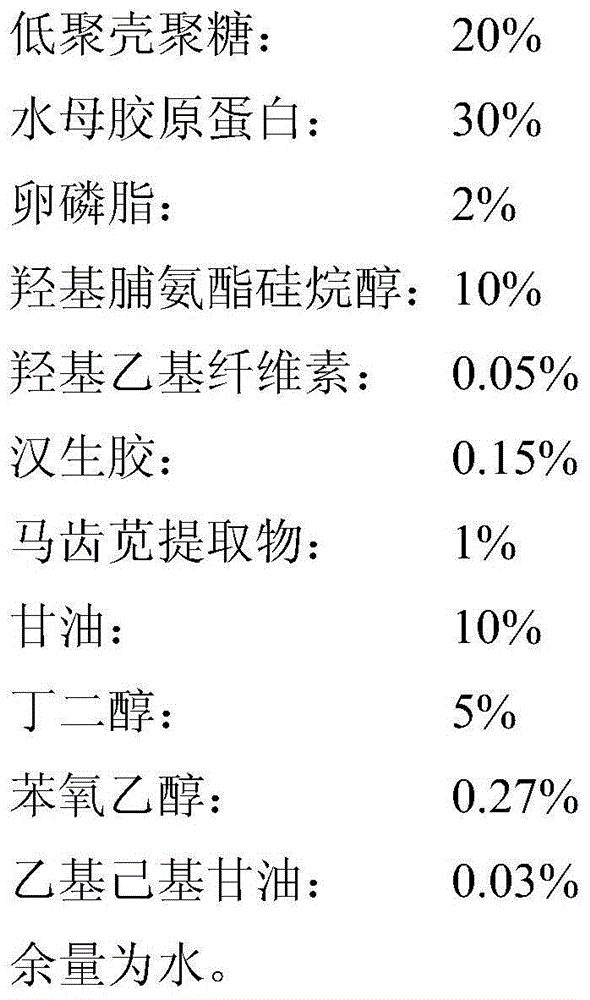

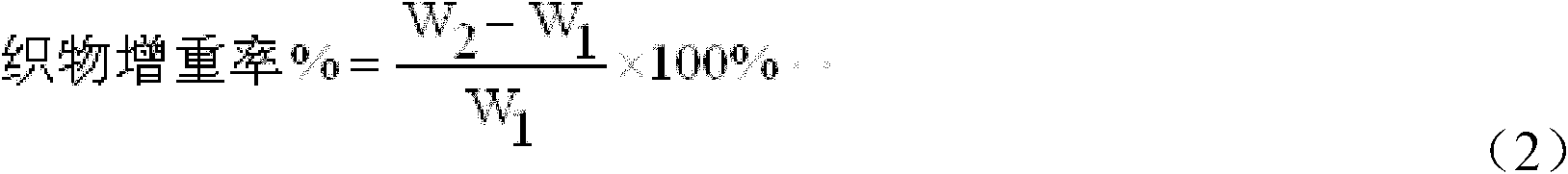

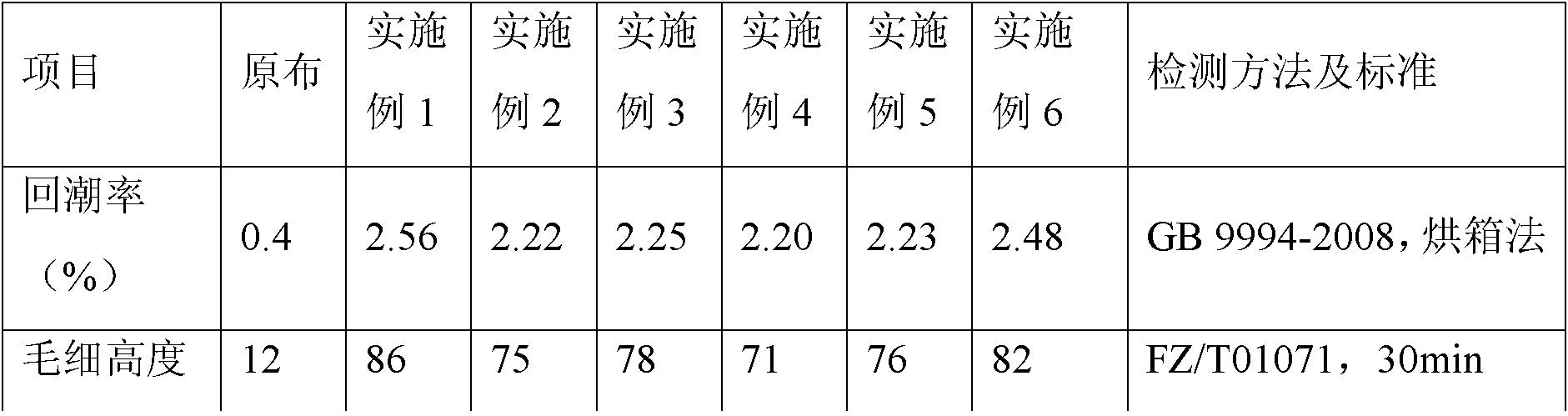

Essence containing chitosan oligosaccharide and jellyfish collagen and facial mask manufactured from essence

ActiveCN104546532ALow densityHigh affinityCosmetic preparationsToilet preparationsCelluloseHydroxyethyl ethylcellulose

The invention discloses essence containing chitosan oligosaccharide and jellyfish collagen and a facial mask manufactured from the essence. The essence is prepared by mixing the following components: chitosan oligosaccharide, jellyfish collagen, lecithin, hydroxyl prolinol ester silanol, hydroxyethyl ethylcellulose, xanthan gum, a portulaca oleracea extract, glycerol, butanediol, phenoxyethanol, ethylhexylglycerin and water. The facial mask can be manufactured by soaking a carrier facial mask, that is, a biological cellulose facial mask containing chitin, into the essence till being completed wetted. The essence of the facial mask contains chitosan oligosaccharide and jellyfish collagen, and has a good synergistic effect with the carrier facial mask (the biological cellulose facial mask containing chitin). Compared with an ordinary cellulose facial mask (such as cellulose obtained from wood pulp and cellulose obtained from coconuts), the biological cellulose facial mask containing chitin is relatively low in density, relatively large in pore surface, high in aperture, relatively strong in absorption property and capable of conducting more active matters.

Owner:广州丽丰化妆品制造有限公司

Finishing agent of polyester silk-like fabric and preparation and post-treatment methods of fabric

The invention provides a finishing agent for preparing comfortable and cool polyester silk-like fabric and a post-treatment method of the comfortable and cool polyester silk-like fabric, aiming at overcoming the defects of the finishing agent of the polyester silk-like fabric, such as high processing cost and poor durability in the prior art. The finishing agent provided by the invention is composed of the following components in parts by weight: 5-7 parts of silk peptide, 3-5 parts of polyethylene glycol, 3-5 parts of a cross-linking agent, 1.5-2.5 parts of a cross-linking catalyst, 1-2 parts of acetic acid, 1-2 parts of a softening agent, 0.5-1 part of chitosan and the balance of water. The post-treatment method of the polyester silk-like fabric comprises the following steps: desizing, alkali weight reduction treatment of the base fabric, and pad finishing. By utilizing the finishing agent and the post-treatment method in the invention, the defect, such as hard feel, of the polyester fabric is overcome so that the polyester fabric has the advantages of excellent wrinkle resistance and soft feel, and is air-permeable, cool and comfortable to wear.

Owner:ZHEJIANG TAIHUA NEW MATERIAL

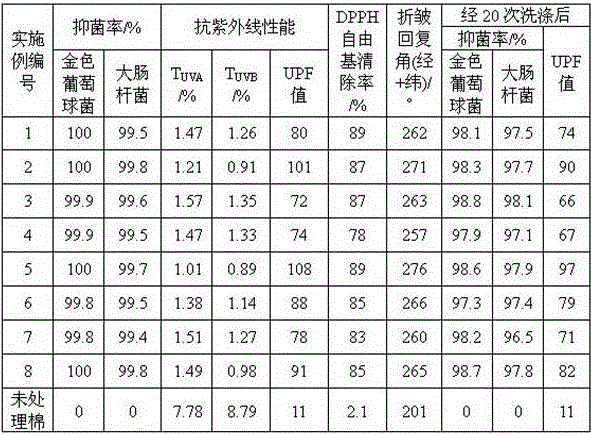

Treatment method for antibacterial and anti-ultraviolet cotton fabrics

ActiveCN106758216AImprove antibacterial propertiesImproves UV resistanceBiochemical fibre treatmentLight resistant fibresGrape seedUltraviolet

The invention discloses a treatment method for antibacterial and anti-ultraviolet cotton fabrics. The treatment method comprises the following steps: step 1, soaking the cotton fabrics with a nonionic surfactant; step 2, modifying the cotton fabrics with chitosan quaternary ammonium salt; step 3, dipping the cotton fabrics with antibacterial finishing liquid prepared by mixing 5-15 parts of a natural antibacterial agent composed of extracts of grape seeds, persimmon leaves, ginkgo leaves and licorice roots, 0.3-1 part of polyoxyethylene-40 hydrogenated castor oil and 1000 parts of water; step 4, soaking the cotton fabrics in a mixed aqueous solution containing 0.001-0.005mol / L of silver nitrate or silver sulfate or silver acetate and 1-3 g / L of soluble starch or hydroxyethyl cellulose to prepare the nano-silver attached antibacterial cotton fabrics. The prepared cotton fabrics not only have good antibacterial performance and anti-ultraviolet performance, but also have performance of resisting oxidation and scavenging free radicals, and have improved anti-wrinkle performance and good washing durability.

Owner:EASTERN LIAONING UNIV

Non-ironing post-finishing technique for cotton fabric

The invention relates to weaving cotton fabric no ironing post collating technology. It includes the following steps: face fabric preparation; padding resin; framing drying; baking; pre-shrinking; winding. The face fabric preparation includes gray cloth seaming, singeing, de-sizing, alkali mercerization, dying, framing forming, liquid ammonia collating. The padding resin includes two times. The above technology can make the cotton fabric have good feeling, gas permeability, moisture absorption, and increase wrinkle resistance, greatly reduce formaldehyde residual, energy resource consumption, sewage discharge.

Owner:上海白玉兰染整有限公司

Micro-fiber knitted fabric synthetic leather and manufacturing method thereof

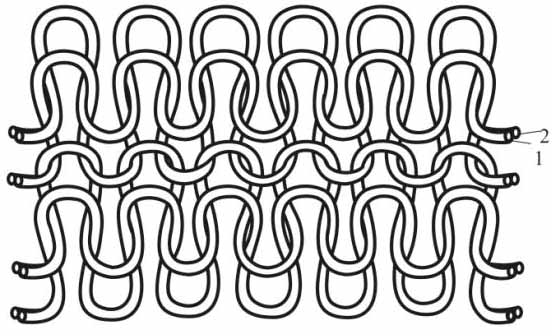

ActiveCN101629387AIncrease elasticitySoft textureSolvent-treatmentWeft knittingPolyurethane coatingBiomedical engineering

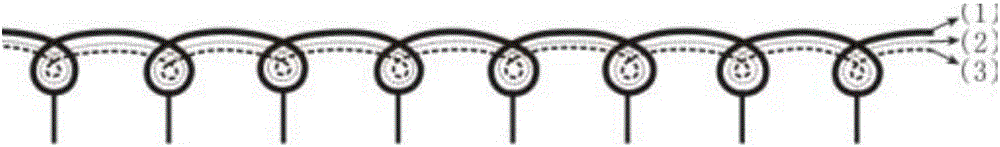

The invention relates to the technical fields of micro-fiber knitted fabric synthetic leather synthetic leather base fabrics, especially relates to a micro-fiber knitted fabric synthetic leather of which the micro-fiber knitted fabrics are base fabrics and a manufacturing method thereof. The base fabrics of the micro-fiber knitted fabric synthetic leather of the invention are sea-island type micro-fiber knitted fabrics, the thickness of which is 0.03-3.0mm, and the structure of which is warp knitting or weft knitting; the base fabrics have one layer or two layer or more than two layers between which are formed by knitting, the color is homochromy or polychrome, the base fabrics also contain soaking elastic porous polyurethane which accounts for 10-65% of the total weight of the base fabrics, 25-40% is preferred, and at least one surface is suede or elastic porous polyurethane coating.

Owner:山东瑞恒纺织有限公司

Moisture absorption sweat-releasing terylene and cotton blending coloured-woven blister fabric

A moisture absorption polyester fiber and cotton blended fabrics uses 60-70%multi grooves odd-shaped cross-section polyester fiber and cotton fiber blended spinning as material to build into 45S blended yarn and patches some of the 45S yarn into 45 / 2S blended yarn, cone dyeing these two kinds of yarns, with the 45S yarn as the twisted yarn and coiling it to the floor frame through beaming and slashing, coiling 45 / 2S yarn to the bubble shaft, through filling yarn to knit with 45S yarn, adjusting the conveying warp run-in rate of slashing and the bubble shaft 1:1.2-1.3, using all loose dressing of the grey cloth without adding any oil as auxiliary agent in the dressing process. It is beautiful and comfortable, cool, difficult to fold and low in cost.

Owner:华明浩

Double fluorescent polyester viscose wool elastic gabardine spinning yarns, lining prepared thereby and preparation method thereof

InactiveCN101397703AImproved shade perceptionHigh strengthDyeing processWoven fabricsEngineeringMaterials processing

The invention relates to a bi-fluorescent polyester-viscose wool elastic gabardine spinning yarn which is characterized in that the spinning yarn is formed by the steps of adopting 150D cationic polyester low stretch yarns and 32S polyester-viscose wool three in one blended yarns to carry out air cladding to 40D urethane elastic fibers by a networking threading machine and then twisting; the polyester-viscose wool three in one blended yarns comprise the following components according to weight ratio of blending: 14 percent to 16 percent of bright triangular polyester, 65 percent to 71 percent of viscose staple fibers and 16 percent to 18 percent of wool. The invention also discloses a fabric spun by the yarn, and a preparation method of the fabric. Compared with the prior art, the invention has the advantages of adopting the material processing method of air-cladding polyester filament yarns, the viscose staple fibers and urethane elastic fiber, making full use of the respective features of the polyester filament yarns and the viscose staple fibers, namely, different shrinking performances and coloring properties, so as to greatly improve the color light feeling, the strength and the curly and fluffy feeling of the yarn, thereby causing the fabric to have a remarkably full and smooth style; added with Lycra effect of the urethane elastic fibers, finished products have moderate elasticity and better wrinkle resistance and the fabric is reasonable in thickness and draping property.

Owner:ZHEJIANG ZHINK GROUP +1

Middle-chromium rare earth-containing high-purity ferrite wrinkle-resistant stainless steel and manufacturing method thereof

InactiveCN101148739AImprove wrinkle resistanceImprove wrinkle defectsRoll mill control devicesHeat treatment process controlChemical compositionRare earth

The RE-containing medium Cr wrinkling resistant ferritic stainless steel has the chemical components including C not more than 0.02 wt%, N not more than 0.02 wt%, Si not more than 0.50 wt%, Mn not more than 0.50 wt%, P not more than 0.03 wt%, S not more than 0.02 wt%, Cr 16-20 wt%, Ni not more than 1.00 wt%, Mo not more than 2.00 wt%, Ti not more than 0.30 wt%, Nb not more than 0.40 wt%, O not more than 0.015 wt%, RE 0.01-0.20 wt%, and Fe and inevitable impurity for the rest. The ferritic stainless steel features low C and N contents, medium Cr content, containing RE, high wrinkling resistance, etc. It is suitable for punching formation to make product.

Owner:BAOSHAN IRON & STEEL CO LTD

Skin care product having anti-wrinkle firming and beauty-maintaining moisturizing effects

InactiveCN104382799AImprove wrinkle resistanceIt also has the function of moisturizingCosmetic preparationsToilet preparationsCentella asiatica extractIrritation

The invention discloses a skin care product having anti-wrinkle firming and beauty-maintaining moisturizing effects. The skin care product is prepared from the following the following raw materials in certain proportions: ceramide 1, tripeptide-3, kirilow rhodiola root extract, asiatic pennywort herb extract, punica granatum fruit extract, hyaluronic acid, rosebud extract, lavender oil, soybean peptides, hamamelis virginiana extract and vitamin C. The raw materials of the skin care product having the anti-wrinkle firming and beauty-maintaining moisturizing effects are natural plants and Chinese herbs and no additives such as essence, pigment, mineral oil and preservative are added; the use of the skin care product brings about remarkable anti-wrinkle and moisturizing effects; the skin care product has good wrinkle removing capability and moisturizing effect, and strong moisture increasing capability and continuous moisture maintaining effect. Human body irritation and patch testing research results indicate that the skin care product has no irritation and untoward effects on a human body; the skin care product is capable of maintaining moisture, nourishing skin, preventing rough skin and skin aging, and keeping the skin bright and elastic, and has the anti-wrinkle firming and beauty-maintaining moisturizing effects.

Owner:SHANGHAI TINGLAN BIOTECH

Electromagnetic radiation resistant knitted fabric and weaving method thereof

The invention discloses a knitted electromagnetic radiation resistant fabric and a weaving method thereof. The fabric is a plain stitch-based or 1+1 rib-based all-plated tissue knitted fabric, all coils in the fabric are formed by superposing at least two coils, one kind of yarn is exposed at one side of the fabric, and the other kind of yarn is exposed at the other side of the fabric; and one kind of yarn is common yarn or polyurethane core-spun yarn, and the other kind of yarn is conductive fiber yarn. The fabric produced by adopting the weaving method organically combining the common yarn or the polyurethane core-spun yarn and the conductive fiber yarn has electromagnetic radiation resistance, and the electromagnetic radiation resisting capacity of the fabric can reach over 99 percent. The fabric has the advantages of soft and smooth handfeel, good moisture permeability, bright color, washing resistance, subtleness and good wrinkle resistance.

Owner:JIANGSU TANGWEAR IND

High-elastic non-ironing finishing method for pure cotton fabric

ActiveCN105369590AGuaranteed weft elasticityMaintain flexionDry-cleaning apparatus for textilesWrinkle resistant fibresTextile printerEngineering

The invention belongs to the technical field of textile printing and dyeing, and in particular relates to a high-elastic non-ironing finishing method for pure cotton fabric. The method includes the following steps: fabrics preparation, mercerized finish, liquid ammonia finish, pre-softening, applying of a moist crosslinking agent, pre-shrinkage, storage reaction, washing, stretching setting and second pre-shrinkage. A stenter is used for applying the moist crosslinking agent, the moist crosslinking agent comprises CMC, a catalyst, a fiber protecting agent, a softener, hydrochloric acid, and the rest of water. The temperature of a drying room is controlled at 80 to 100 DEG C, the temperature of the fabric is controlled between 35 to 40 DEG C, the falling cloth humidity is 6-8%, and the fabric is rolled at the falling position. The treated fabric has non-ironing level reaching the AATCC124 standard 4.0 or above of the U.S.A, formaldehyde content below 75ppm, warp elasticity of 4% above the ASTM D3107-2011 standard, weft elastic elongation of 17% above the ASTM D3107 standard, and has ensured sewability and non-ironing performance.

Owner:鲁丰织染有限公司

Method for producing pure wool crease-shedding facing material

ActiveCN101270528AIncreased warp and weft elasticityImprove wrinkle resistanceSingeingDyeing processEngineeringWool cloth

The invention relates to a manufacture method for a pure wool anti-crease fabric which includes the following steps of: preparing wool top-top dyeing-double combing-spinning-weaving-grey fabric-subsequent finishing-finished product. The components of the wool top material are 98.2 to 100 percent of pure wool as well as 0 to 1.8 percent of terylene. The top dyeing adopts a lanasol active dye lower temperature colorizing technique; the subsequent finishing includes the steps of: crude finishing-clearing up-singeing-open washing and continuous steaming-washing-open washing and continuous steaming-drying-middle checking-cooked finishing-brushing and cutting hair-elastic finishing-scalding-pot steaming-pre-shrinking. The western-style clothes fabric manufactured by the method has the advantages of elegant quality, smooth hand feeling, comfortable wearing, stiffness and elasticity, breaks through the defect of noble wearing and hard nursing of the clothes of wool cloth, in particular to the difficulties of easy creasing and insufficient shape retention of the high-count thin fabric currently popularizing in the market and promotes the sustainable development of woolen fabrics.

Owner:嵊州雅戈尔毛纺织有限公司

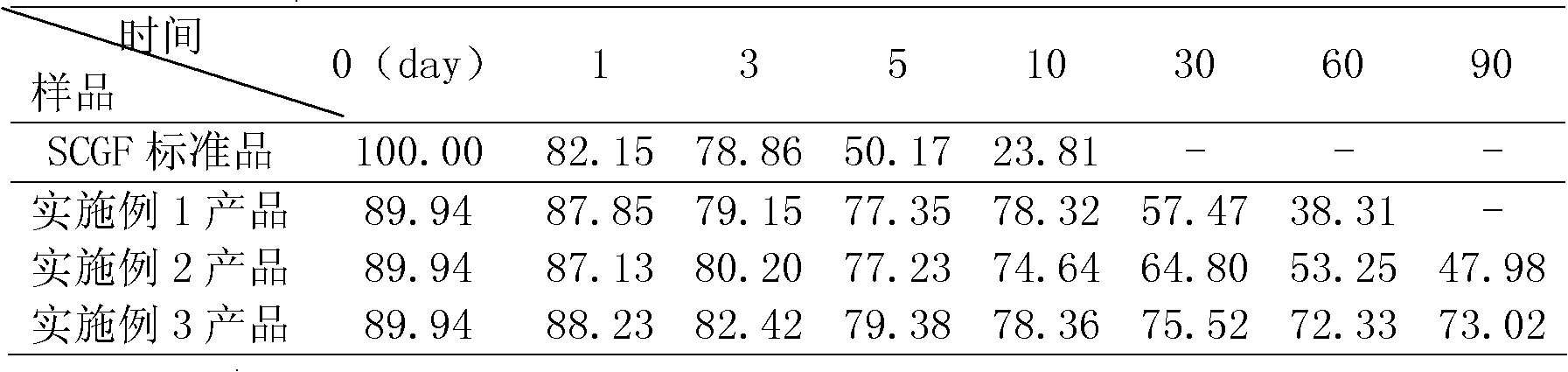

HSCGF liposome as well as preparation and application thereof

ActiveCN102512370AKeep aliveImprove stabilityCosmetic preparationsHair removalCholesterolPhospholipid

The invention discloses an HSCGF (Human Stem Cell Growth Factor) liposome as well as the preparation and the application thereof. The HSCGF liposome comprises 2.0 to 4.0 percent of HSCGF, 8.0 to 10.0 percent of phosphatide, 2.5 to 3.5 percent of cholesterol and 10 to 25 percent of protecting agents. The HSCGF is prepared into liposome, the activity of the HSCGF is kept effectively, the stability of SCGF (Stem Cell Growth Factor) can be improved obviously, skin can be promoted to absorb and utilize the SCGF, and the HSCGF liposome has the advantages of good affinity, no toxicity or side effects, and wide application range. The anti-wrinkle performance of cosmetics containing the HSCGF coated with the liposome can still be kept well after the stability is examined for three months. The HSCGF liposome is used as raw material and other active materials and auxiliary materials are used as supplements so as to prepare frequently-used medicine forms to illustrate the drug effect of the SCGF, so that the bioavailability can be improved.

Owner:GUANGZHOU SALIAI BIOLOGICAL GENETIC ENG CO LTD

Novel health-care environment-friendly textile fabric

InactiveCN103290597AImproves UV protectionPromote blood circulationWoven fabricsPolyesterCarbon fibers

The invention discloses a novel health-care environment-friendly textile fabric. The novel health-care environment-friendly textile fabric comprises the following components, by mass, 25%-30% of regenerated cellulose fibers, 15%-20% of seaweed carbon fibers, 20%-25% of polylactic acid fibers, 10%-15% of chitin fibers and 25%-30% polyester fibers, and is formed by warp and weft being interwoven, wherein the warp is made of the regenerated cellulose fibers and the seaweed carbon fibers in a blending mode and the weft is made of the polylactic acid fibers, the chitin fibers and the polyester fibers in a blending mode. Through the method, the novel health-care environment-friendly textile fabric has ultraviolet ray and infrared ray radiation resistance performance, at the same time, has superior health-care nursing functions and biodegradable performance, and is free of toxic, harmless, capable of protecting the environment and safe.

Owner:WUXI HOUSETEX INDS

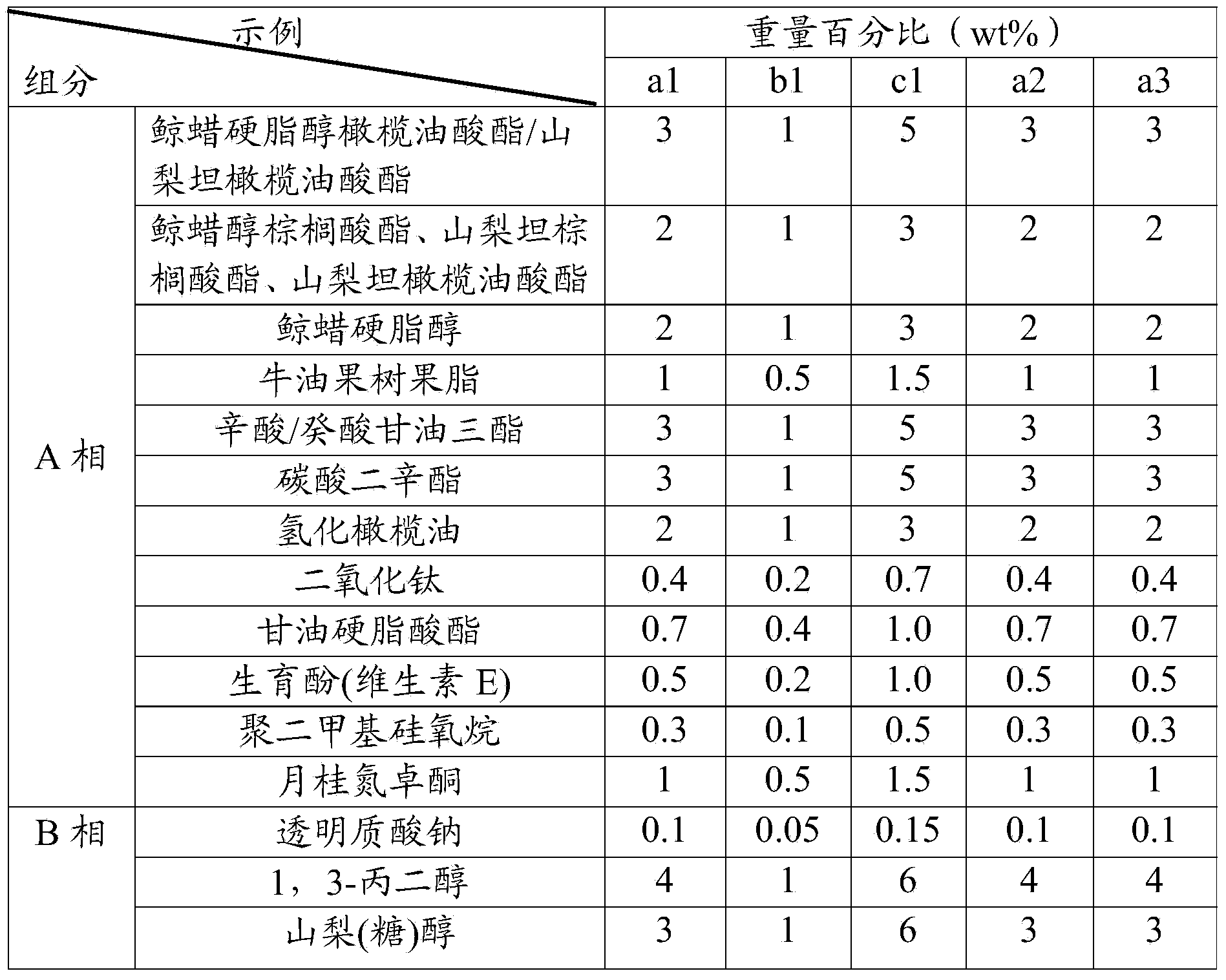

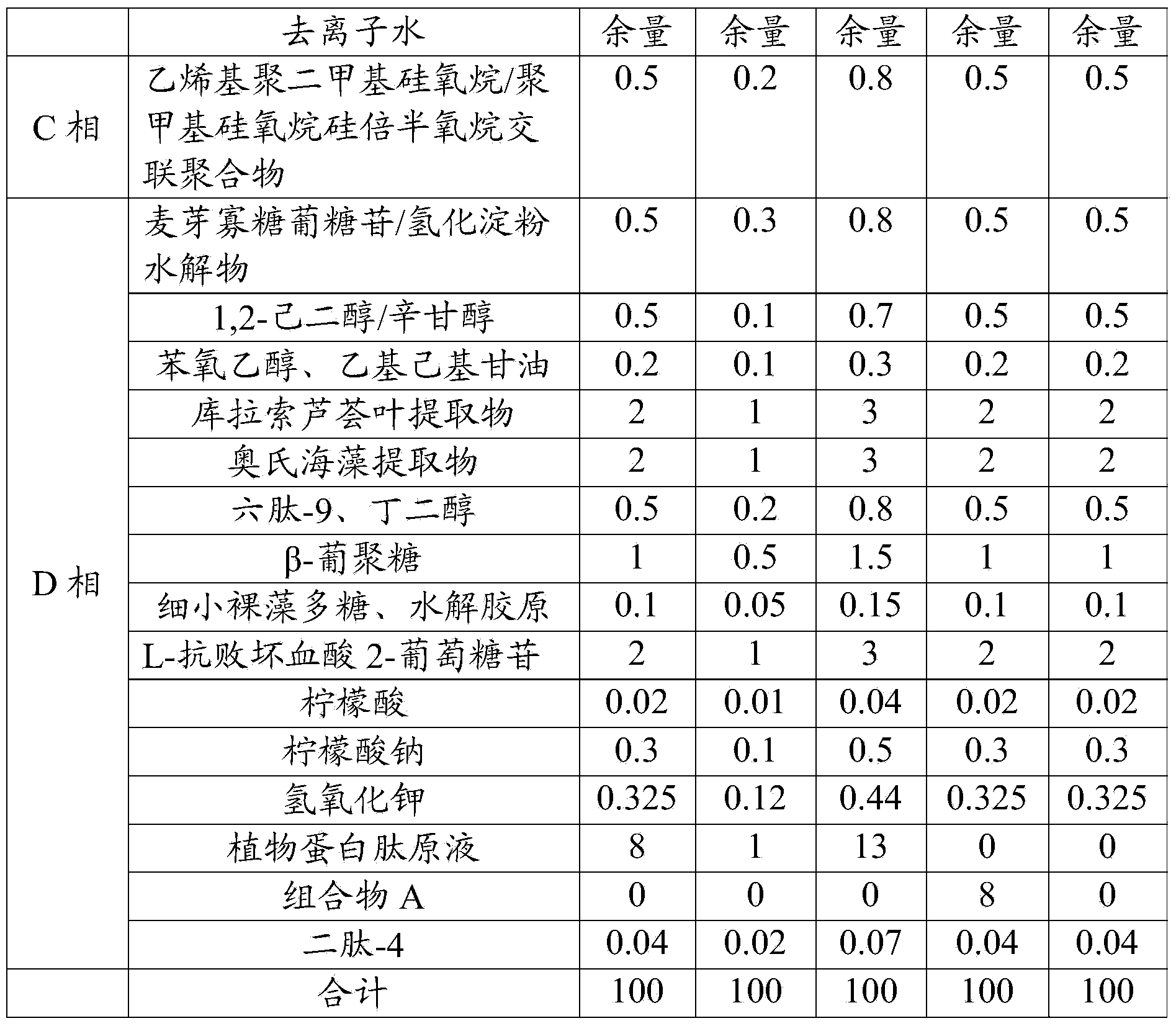

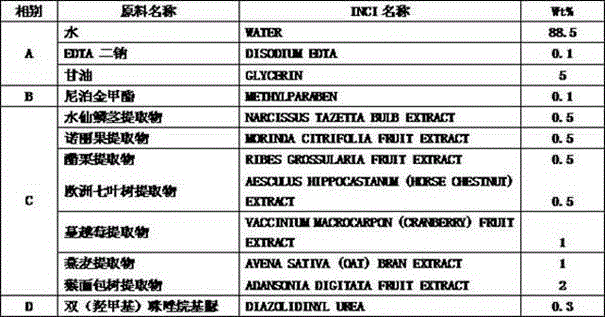

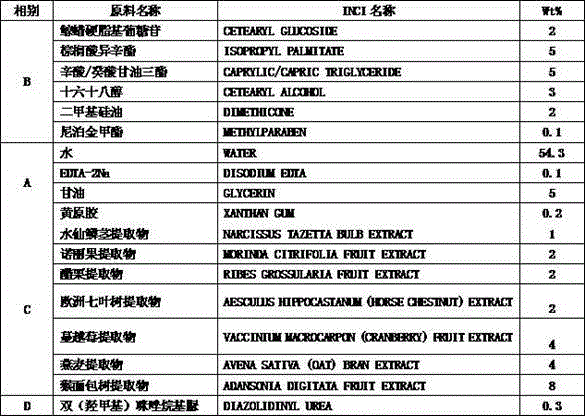

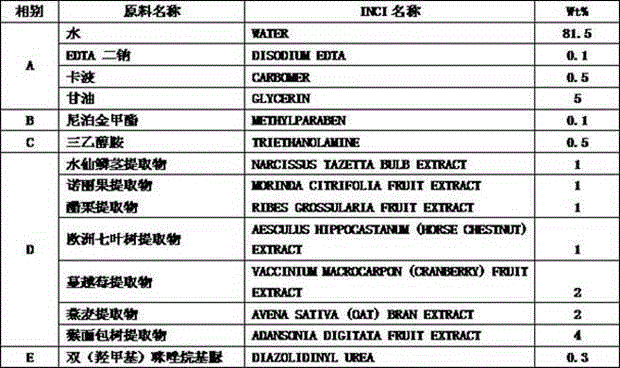

Anti-wrinkle cosmetic composition and preparation method thereof

ActiveCN104138346AImprove wrinkle resistanceDecreased skin textureCosmetic preparationsToilet preparationsSkin textureAesculus hippocastanum

The invention provides an anti-wrinkle cosmetic composition and a preparation method thereof. The anti-wrinkle cosmetic composition comprises a phase C and a phase D, wherein the phase C contains the following components in percentage by weight: 0.5-1% of narcissus bulbs, 0.5-2% of morinda citrifoli extracts, 0.5-2% of gooseberry extracts, 0.5-2% of aesculus hippocastanum extracts, 1-4% of cranberry extracts, 1-4% of oat extracts and 2-8% of baobab extracts; and the phase D contains the following components in percentage by weight: 82-94% of conventional cosmetic additives. The anti-wrinkle cosmetic composition provided by the invention is prepared from pure natural materials; after the anti-wrinkle cosmetic composition is tried, the skin elasticity of a trial person is remarkably increased and can be increased by 40.84% to the maximum extent and 21.75% to the minimum extent, and the skin texture of the trial person is remarkably reduced and can be reduced by 43.05% to the maximum extent and 34.77% to the minimum extent; and the anti-wrinkle cosmetic composition has a favorable effect on improving the skin elasticity and texture of a human body so as to be a cosmetic with a favorable anti-wrinkle effect.

Owner:广州雅纯化妆品制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com