Moisture absorption sweat-releasing terylene and cotton blending coloured-woven blister fabric

A technology of moisture absorption and perspiration and cotton blending, which is applied in the field of cotton blended yarn-dyed bubble cloth and moisture absorption and perspiration polyester, which can solve the problems of poor moisture absorption and breathability, stuffy feeling when wearing, etc., and achieve the effect of good softness and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

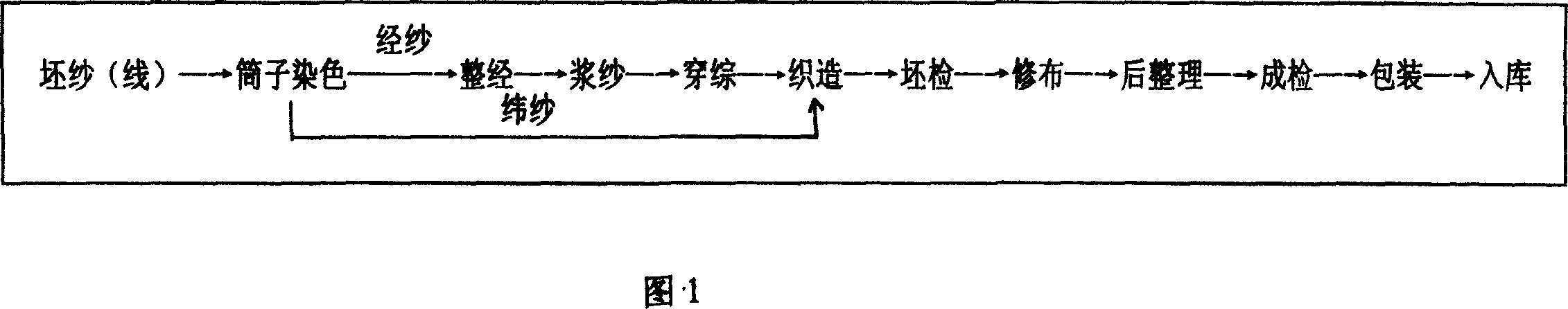

[0012] Referring to Fig. 1, the present invention is a kind of moisture-wicking polyester and cotton blended yarn-dyed bubble cloth, which is made of 65% polyester fiber with multi-groove special-shaped cross-section and 35% cotton fiber blended yarn as raw materials. 45 S blended yarn, and the part 45 S Blended yarn twisted into 45 / 2 S blended thread, will 45 S Blended yarn with 45 / 2 S The blended yarn is package dyed separately, and the 45 S The blended yarn is used as the warp yarn, and is wound on the ground shaft through the warping and sizing processes; while the 45 / 2 S The blended yarn is wound on the bubble shaft, and then the warp is worn, and the weft is 45 S Blended yarn, weaving on the machine, adjust the let-off ratio of the ground shaft and the bubble shaft to 1:1.2~1.3, because the let-off of the bubble shaft is more than the let-off of the ground shaft, the yarn on the bubble shaft is caused The surface of the cloth is foamed, and then the gray cloth is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com