Patents

Literature

364results about How to "Effective adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

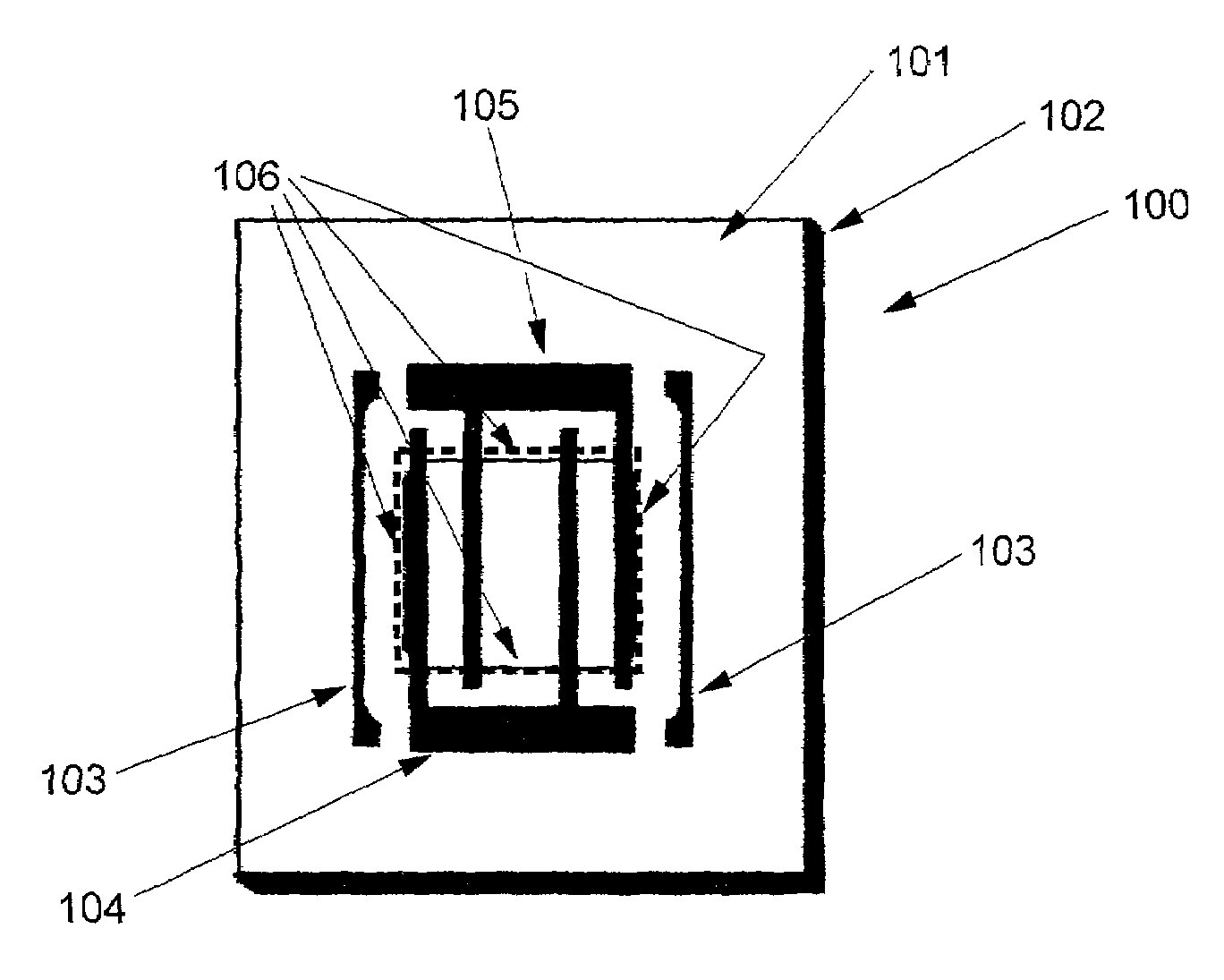

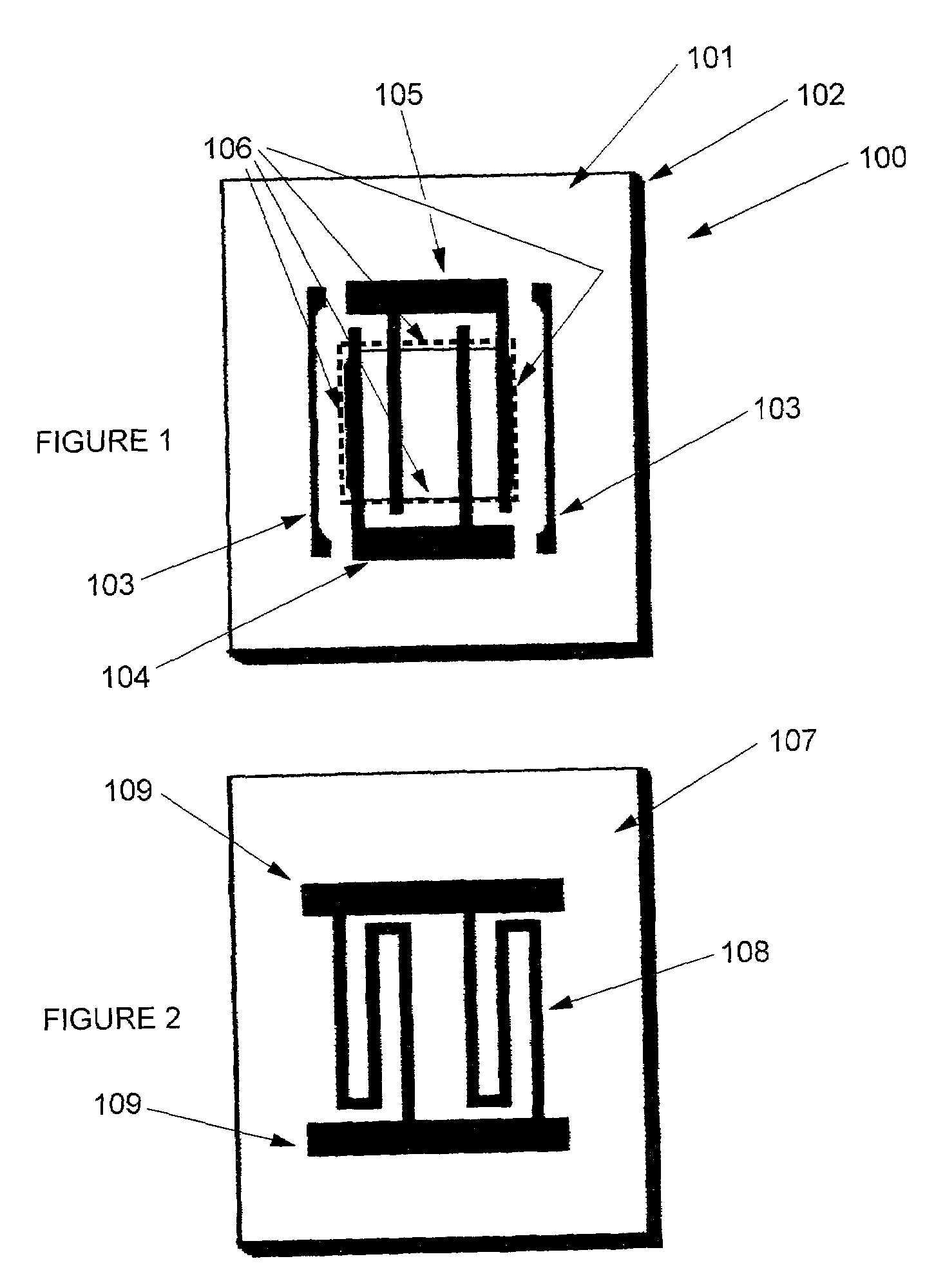

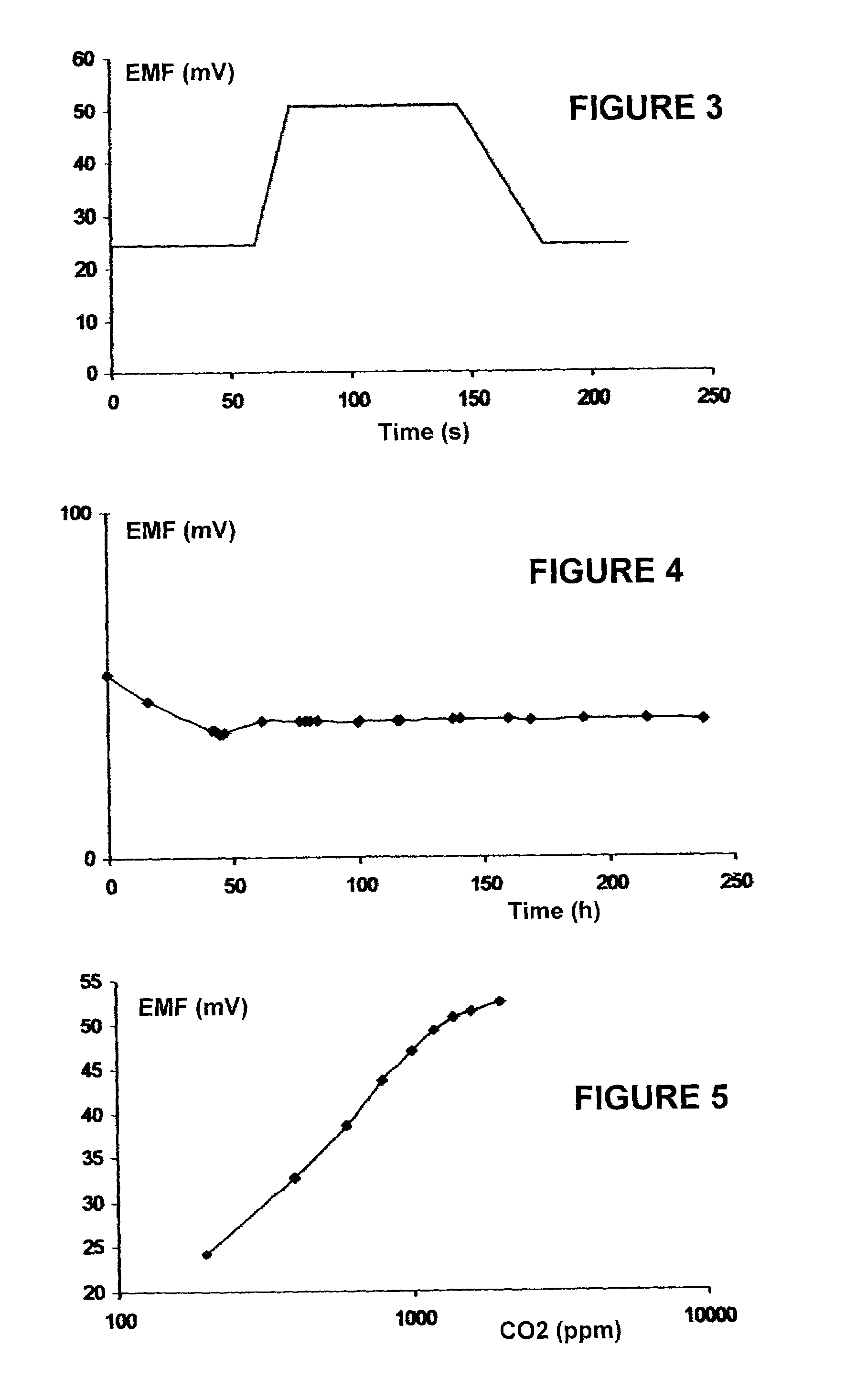

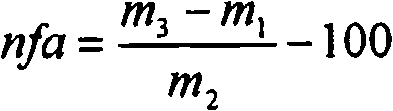

Gas component sensor for gas oxides

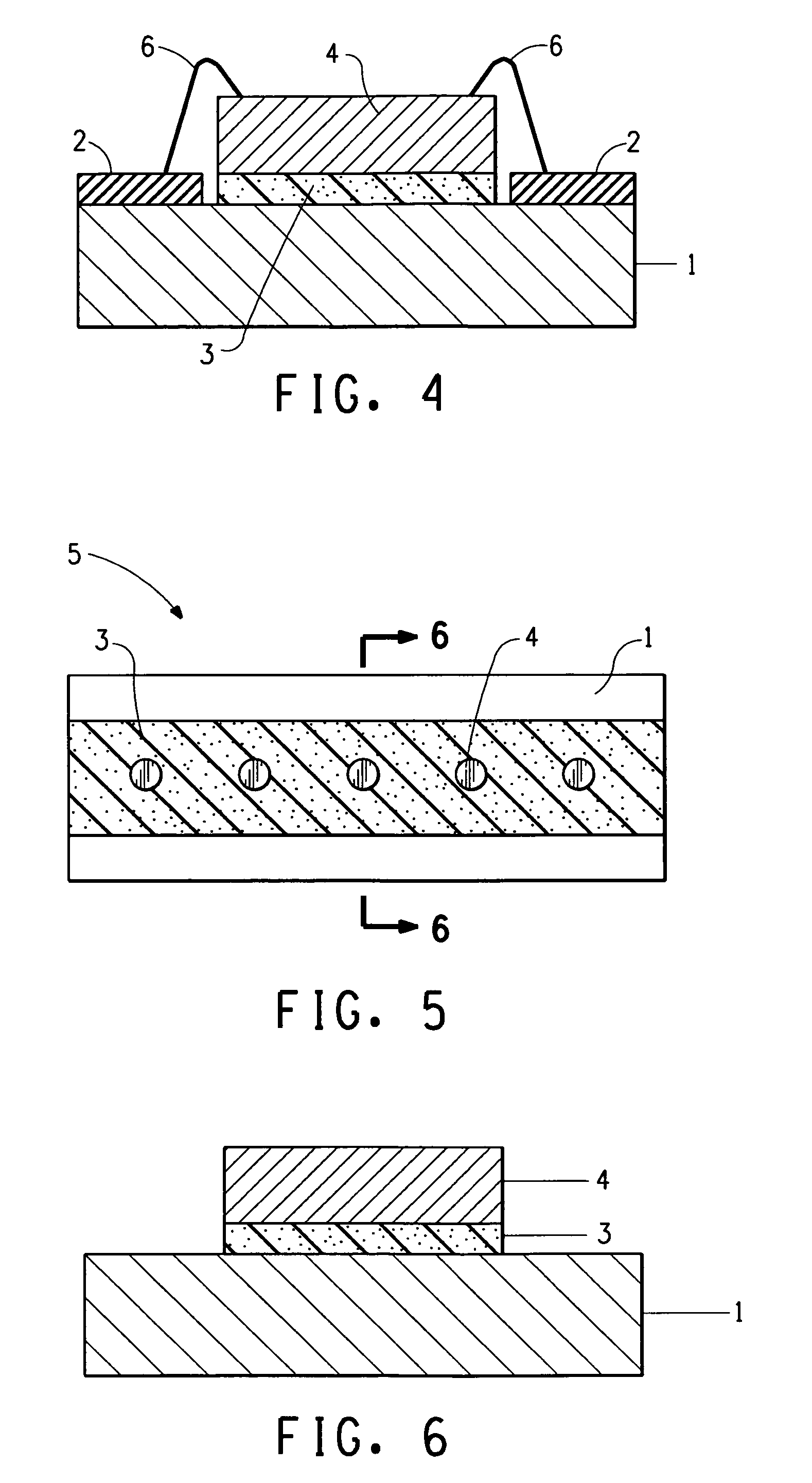

InactiveUS7001495B2Additional sensorExcellent chemical stability and thermal compatibilityWeather/light/corrosion resistanceElectrolytic capacitorsElectrochemical responseGas composition

The present invention is a gas component sensor comprising novel electrolyte compositions. The electrolyte compositions in bulk, sintered or thin film embodiments are capable of forming with different-metal sensing and reference electrodes a highly stable gas oxide sensors. The novel electrolyte composition changes electrochemical reactions at the sensing and reference electrodes and the overall reaction of the electrodes and electrolyte. The novel electrolyte compositions have: (1) excellent chemical stability and thermal compatibility as to the electrodes and a preferred ceramic substrate, (2) excellent chemical stability with the environment as to the reference and sensing electrodes, which need not be sealed against the atmosphere to be sensed, (3) effective adherence to the substrate and electrode metals.

Owner:AIR Q

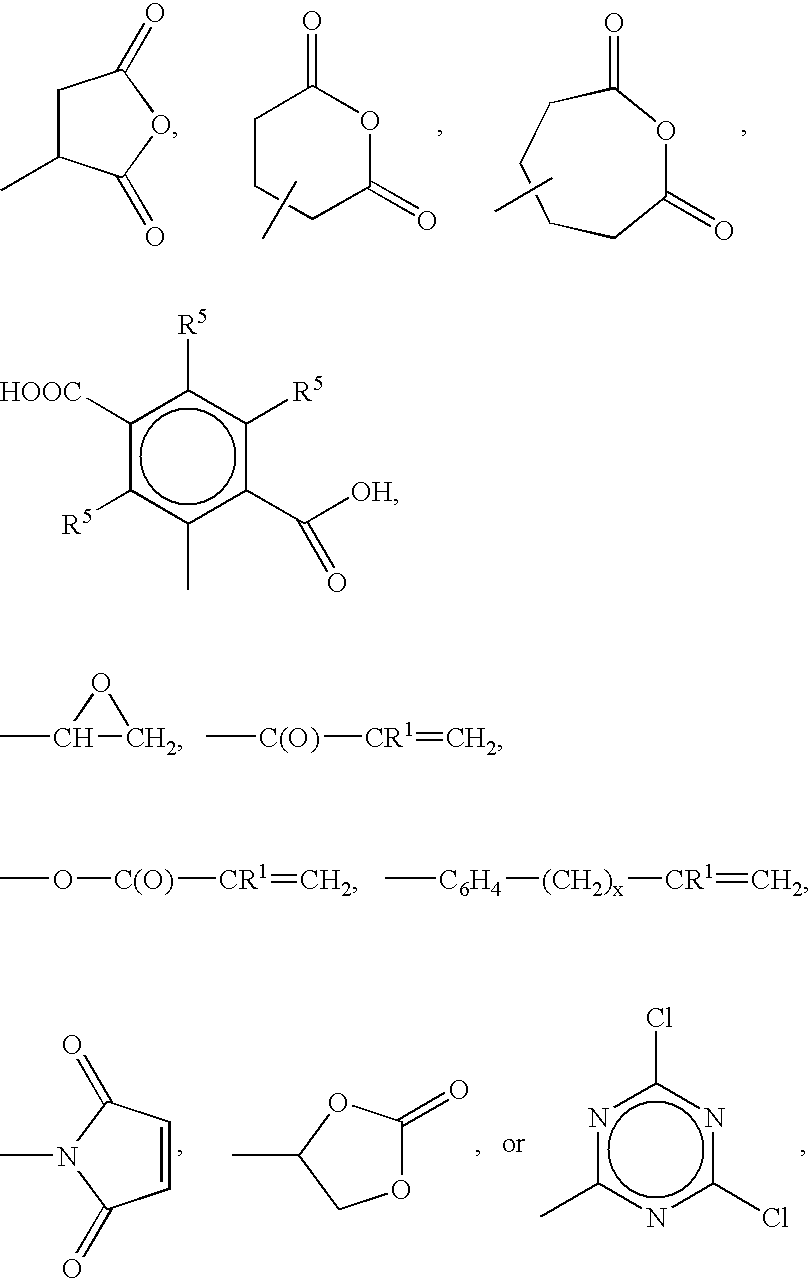

Coating material compositions

InactiveCN101353546AEffective adhesionImprove corrosion resistanceCosmetic preparationsLiquid surface applicatorsPolyesterAdditive ingredient

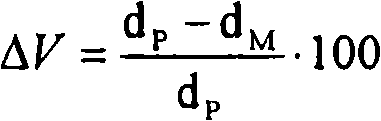

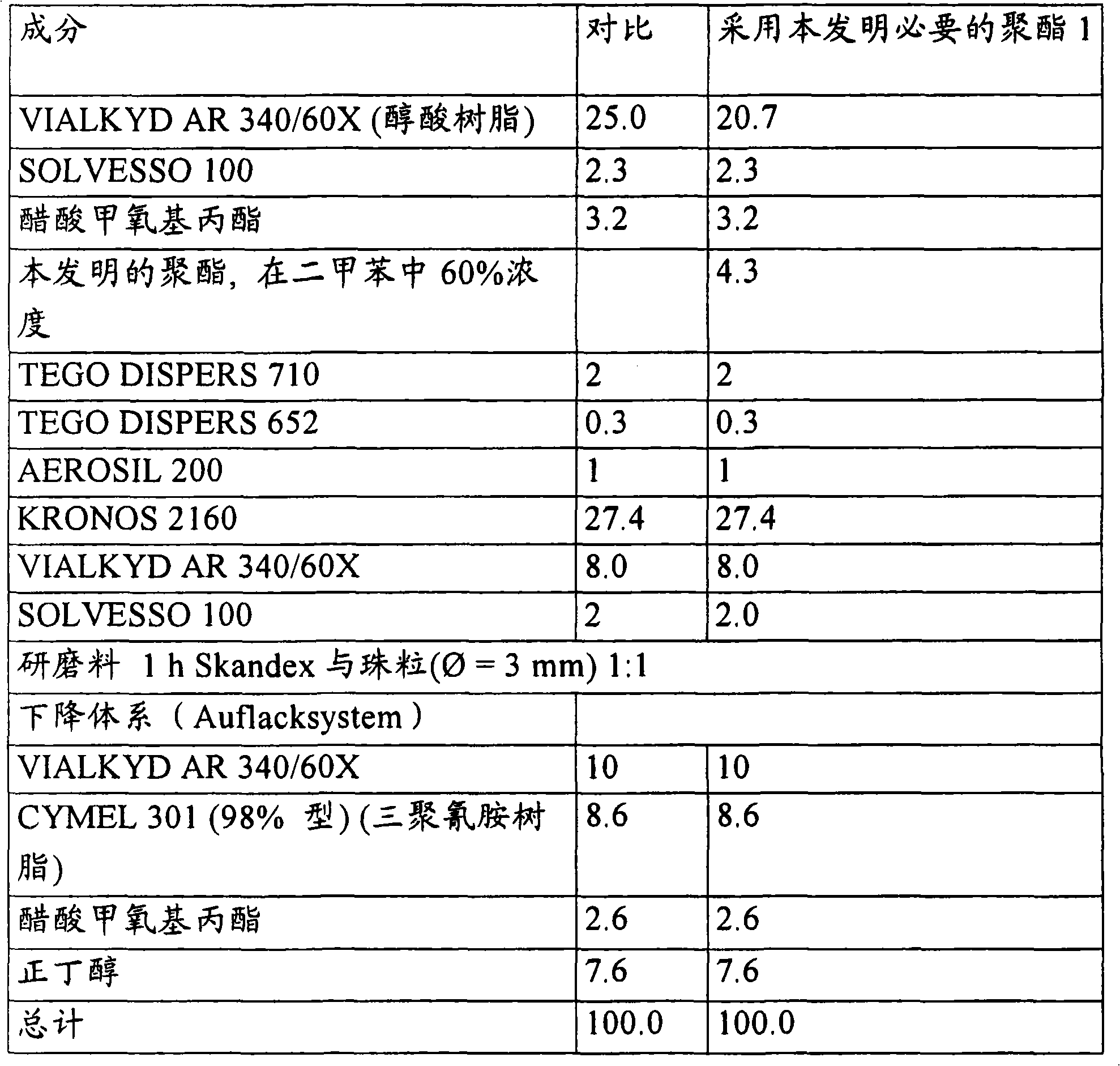

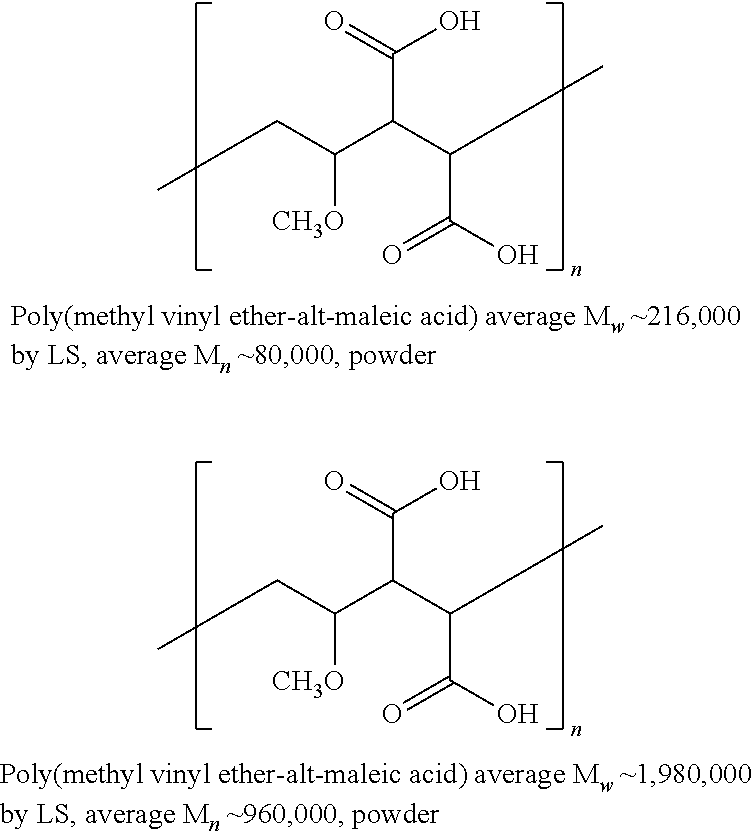

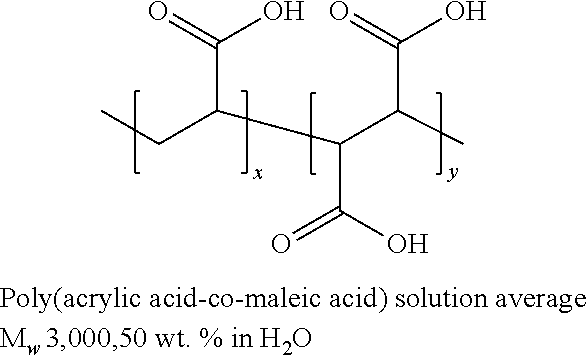

The invention relates to coating material compositions for, for example, metallic, mineral substrates or for substrates of wood, paper and plastics, which comprise yellowing-resistant, low-viscosity, unsaturated, amorphous polyesters which are very largely free of benzene and formaldehyde, as a result of which the adhesion of these coating material compositions is improved even under critical ambient conditions, and to a preparation process and use of said compositions. More specifically, the invention relates to coating material compositions, substantially including 1, yellowing-resistant, low-viscosity, unsaturated, amorphous polyesters which are very largely free of benzene and formaldehyde; 2, at least one other adhesive; 3, at least one accessory ingredient and / or additive; 4, at least one colorant and / or stuffing. The yellowing-resistant, low-viscosity, unsaturated, amorphous polyesters are composed by the following components: I. acid components, made up of A) at least one alpha, beta-unsaturated dicarboxilic acid, and B) at least one linear and / or branch fatty group and / or alicyclic and / or aromatic bifunctional and / or polyfunctional carboxyl acid, which is not provided with alpha, beta-unsaturated part; II. alcohol components, made up of C) bis(hydroxymethyl)tricyclo compounds and D) at least one bifunctional and / or polyfunctional alcohol, wherein, based on the polyesters, the content of benzene is lower than 10mg / kg and the content of formaldehyde is lower than 10mg / kg, the molecular weight distribution polydispersity of the polyesters is 1.3-4.5, the content of tricyclodecane(mono- / di-)aldehyde in the bis(hydroxymethyl)tricyclo compound C) is lower than 2 weight percent; mono(hydroxymethyl)tricyclo [5.2.1.0<2,6>] decane in the compound C) is lower than 10 weight percent, and the content of chromium, nickel, copper, cadmium and plumbum in the compound C) is lower than 2mg / kg.

Owner:EVONIK DEGUSSA GMBH

Multiple Component Materials Having A Color-Changing Composition

ActiveUS20110015599A1Effective adhesionImprove stabilityMaterial analysis by observing effect on chemical indicatorDecorative surface effectsOrganic acidColor changes

The present invention relates to a multiple-component material including a substrate and a printed layer on the substrate. The printed layer includes a color-changing composition to indicate a change in condition, such as a change in pH. The color-changing composition includes a matrix-forming component, a colorant, a surfactant and a pH adjuster. The pH adjuster includes a low molecular weight organic acid and a high molecular weight organic acid.

Owner:KIMBERLY-CLARK WORLDWIDE INC

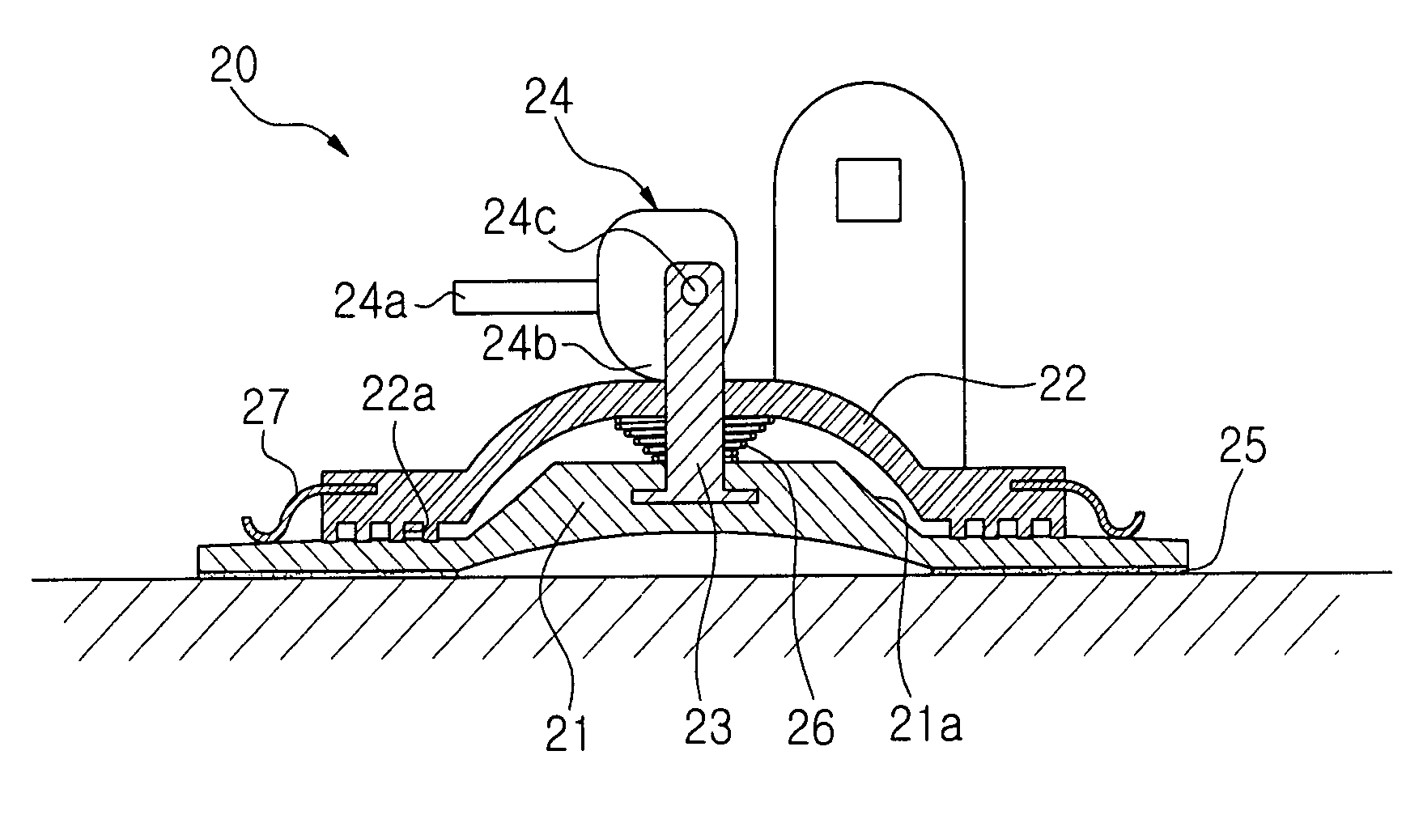

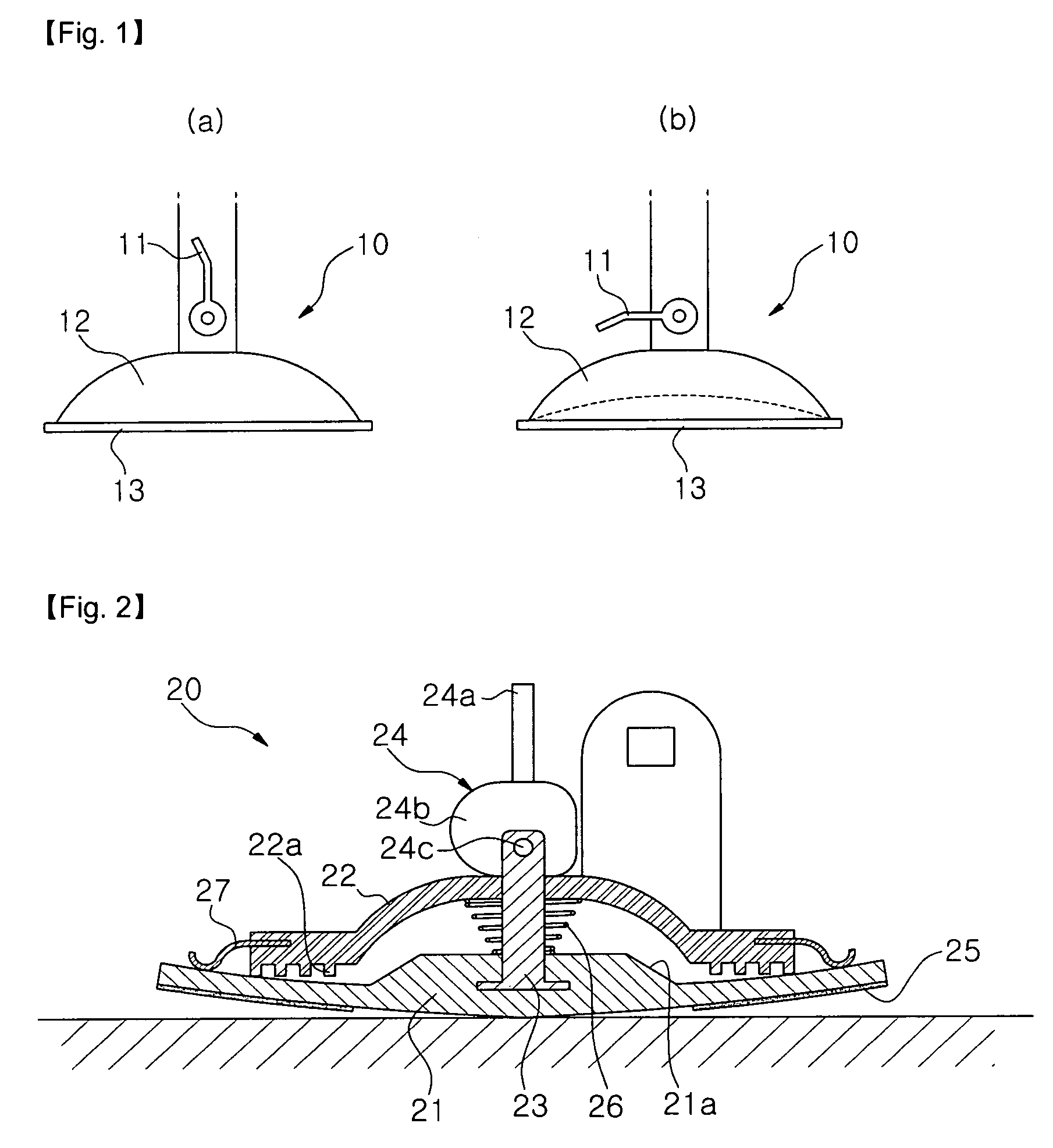

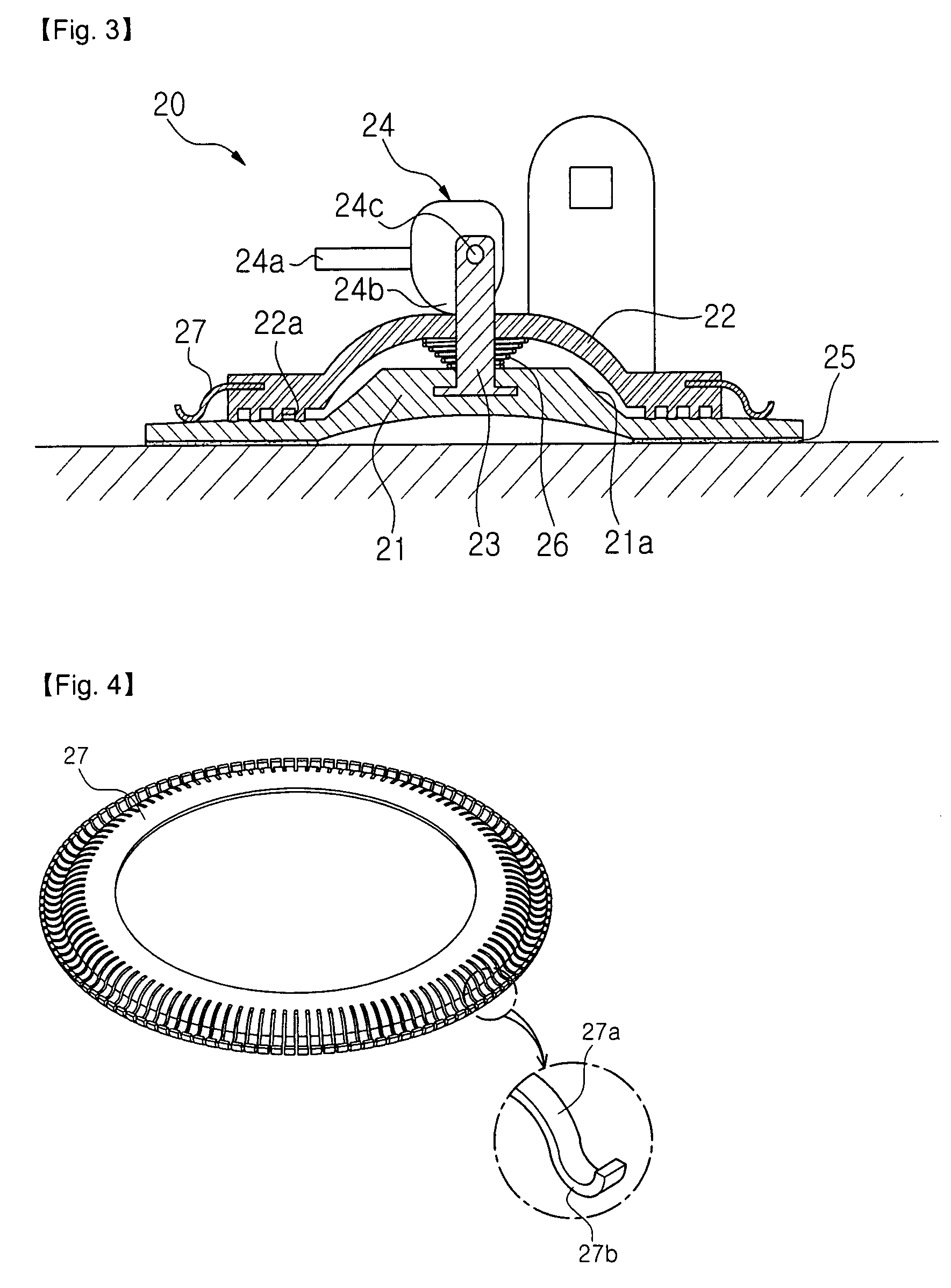

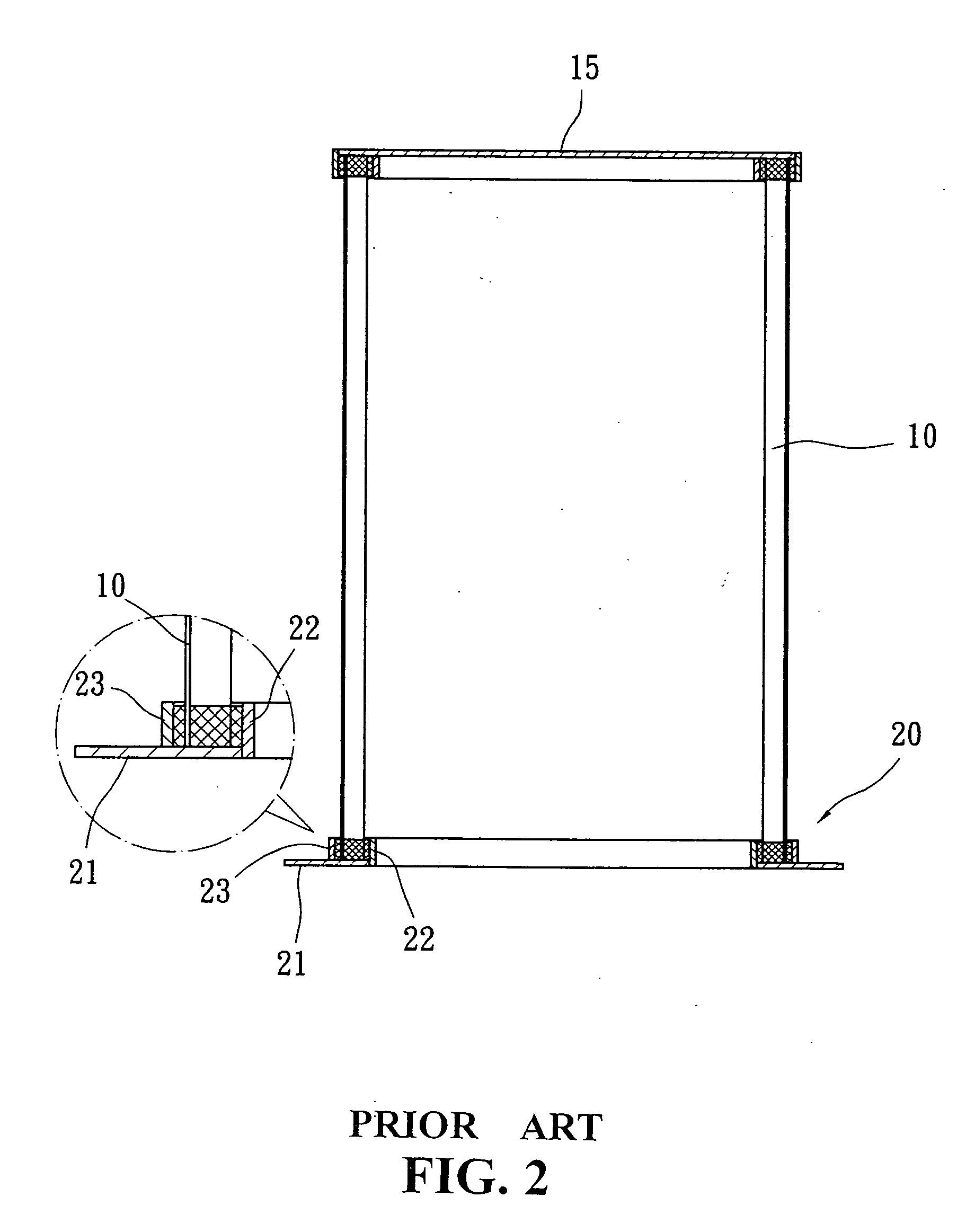

Adhesion device by holding low pressure

InactiveUS7628362B2Strong adhesionEffective adhesionStands/trestlesKitchen equipmentEngineeringAtmospheric pressure

Owner:SONG SOON YOUNG

Carbon nano material/metal nano material composite nano ink

InactiveCN102993820AReduce manufacturing costLow costConductive layers on insulating-supportsInksCyclohexanoneKetone

The invention provides a carbon nano material / metal nano material composite nano ink which comprises solvent, an additive, a carbon nano material and a metal nano material. The carbon nano material / metal nano material composite nano ink is characterized in that the solvent can comprise water, alcohol organic solvent (ethanol(alcohol), isopropanol, n-butanol and the like), ester organic solvent (ethyl acetate, butyl acetate, ethylene-propylene acetate and the like), benzene organic solvent (methylbenzene, dimethylbenzene and the like) and ketone organic solvent (cyclohexanone, acetone, methylethylketone, butanone and the like); the additive comprises surfactant, pH value stabilizer, defoaming agent, diluter, reinforcer and the like; the carbon nano material comprises a single-layer carbon nanotube, a double-layer carbon nanotube, a multi-layer carbon nanotube and graphene; the metal (copper, silver, gold, platinum, nickel and the like, also including an alloy nano material, an ITO metal composite nano material and the like) nano material further comprises a metal nanoparticle, a metal nanowire or a metal nanotube; the components of the nano ink must include one carbon nano component and one metal nano component, such as a single-layer carbon nanotube and copper nanowire composite ink, a double-layer carbon nanotube and silver nanowire composite ink, a single-layer carbon nanotube and silver nanoparticle composite ink or any other possible combination; the components can be regulated according to specific applications; and a composite nano conductive film can be formed on different bases through different electronic printing processes. The ink can be used in the printing of a flexible base material and can be conveniently prepared into a flexible conductive film.

Owner:杨阳

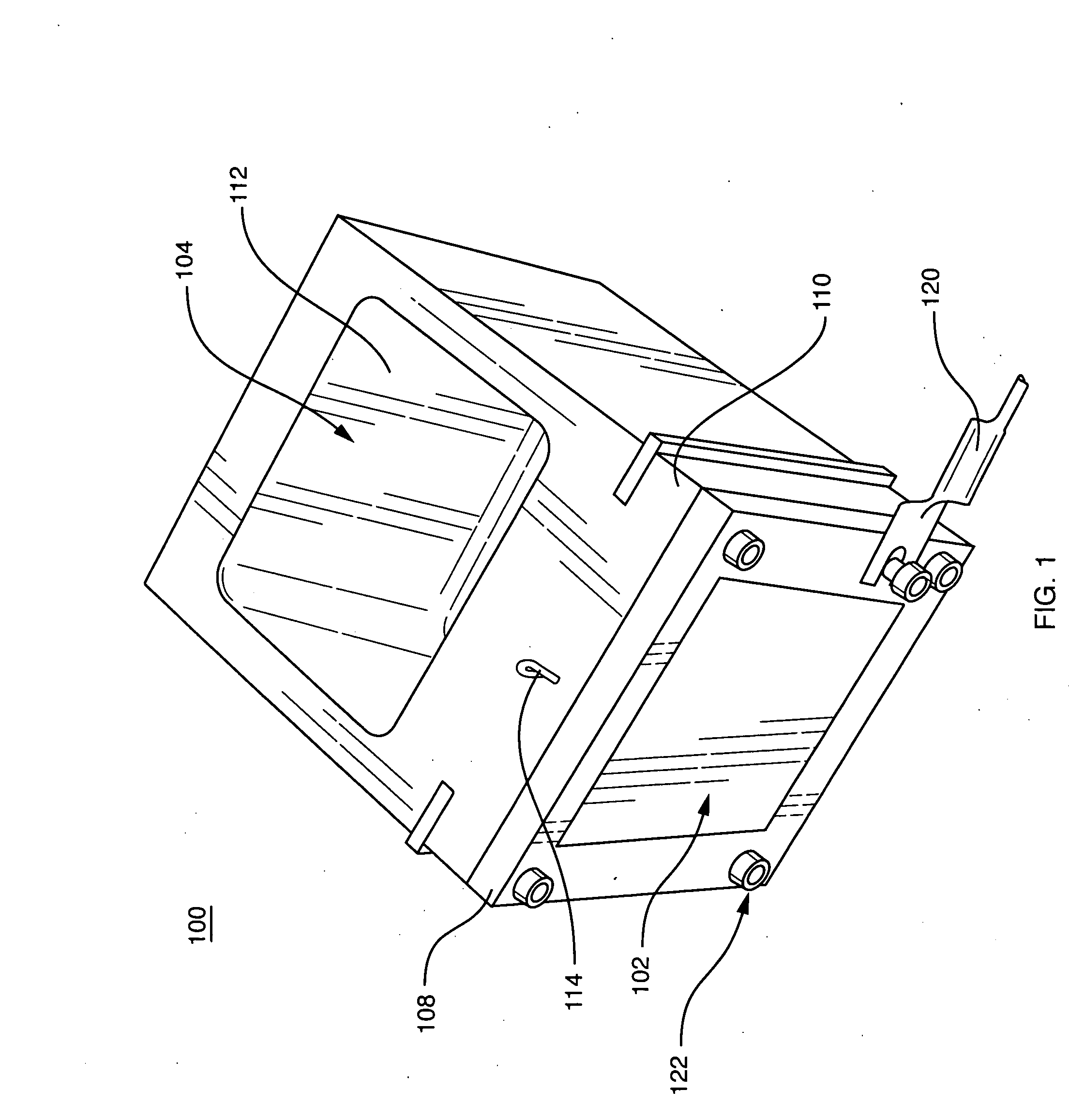

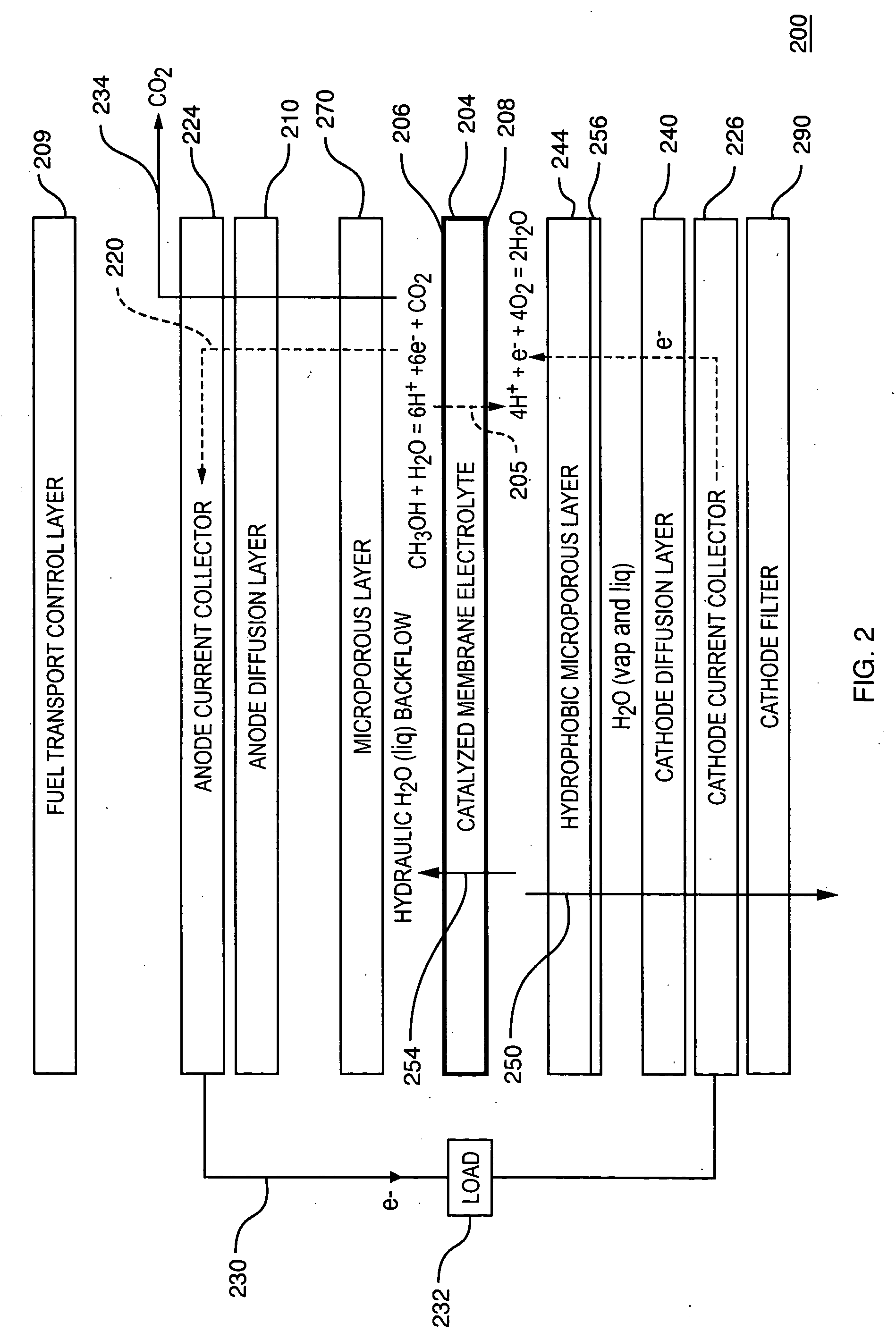

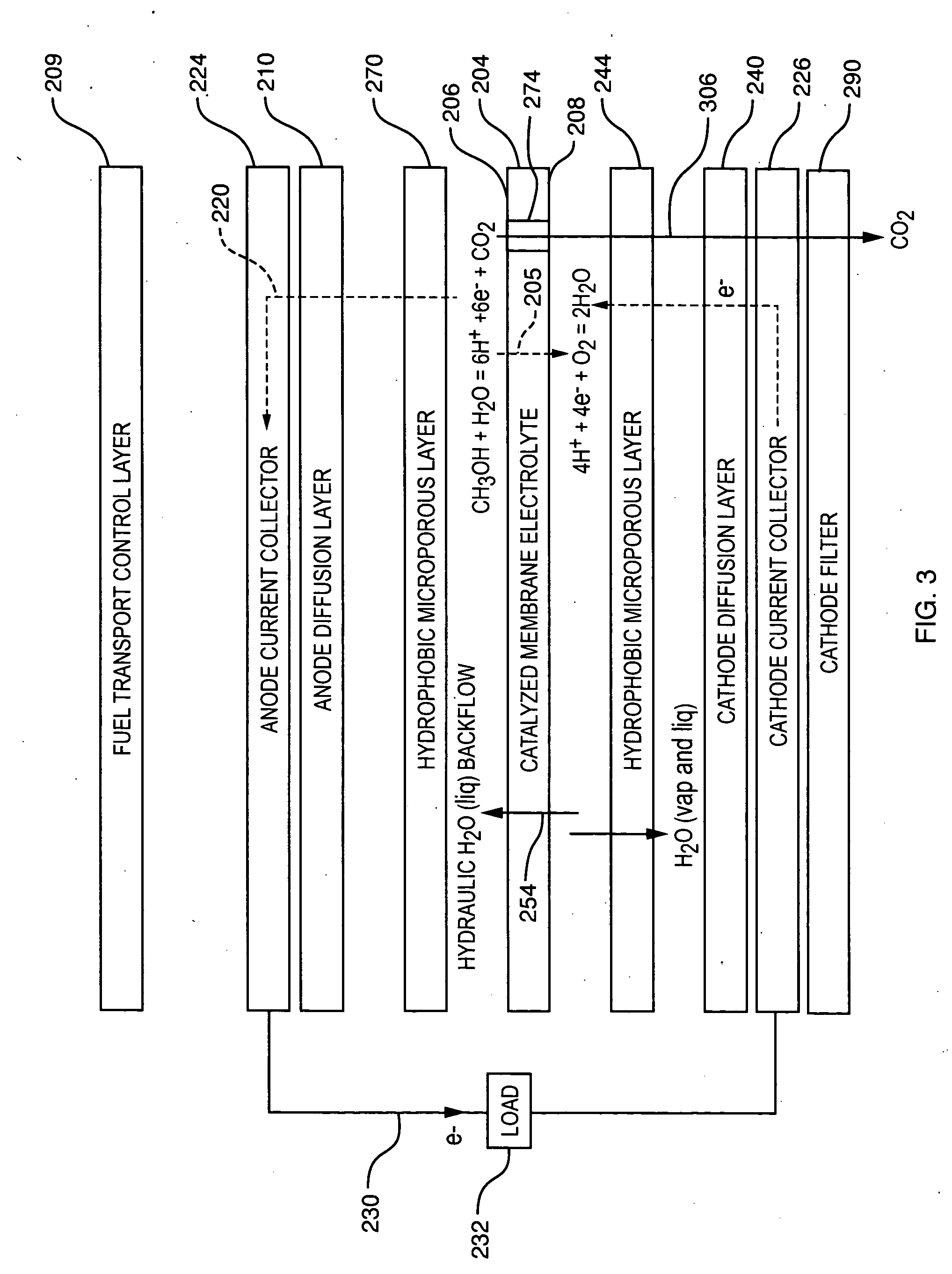

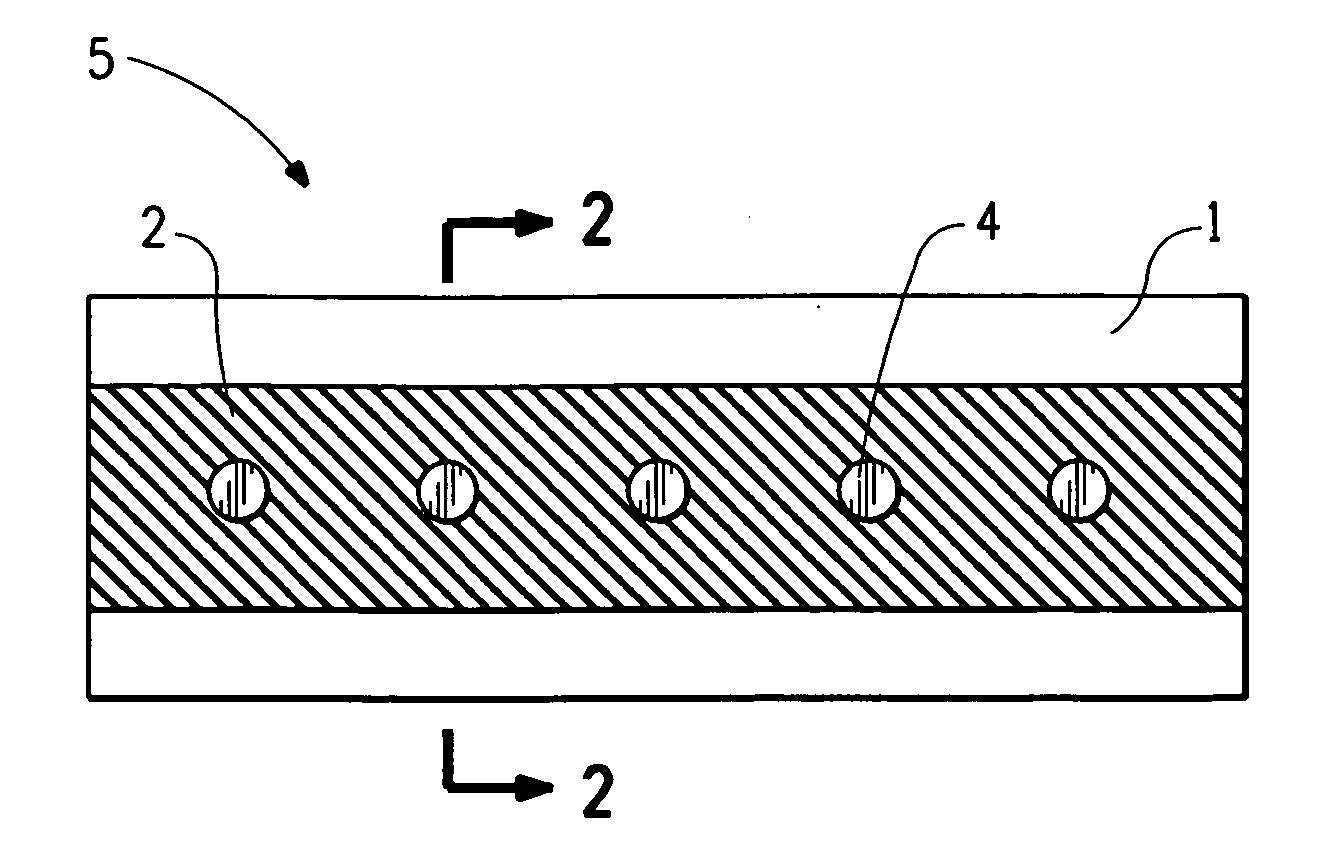

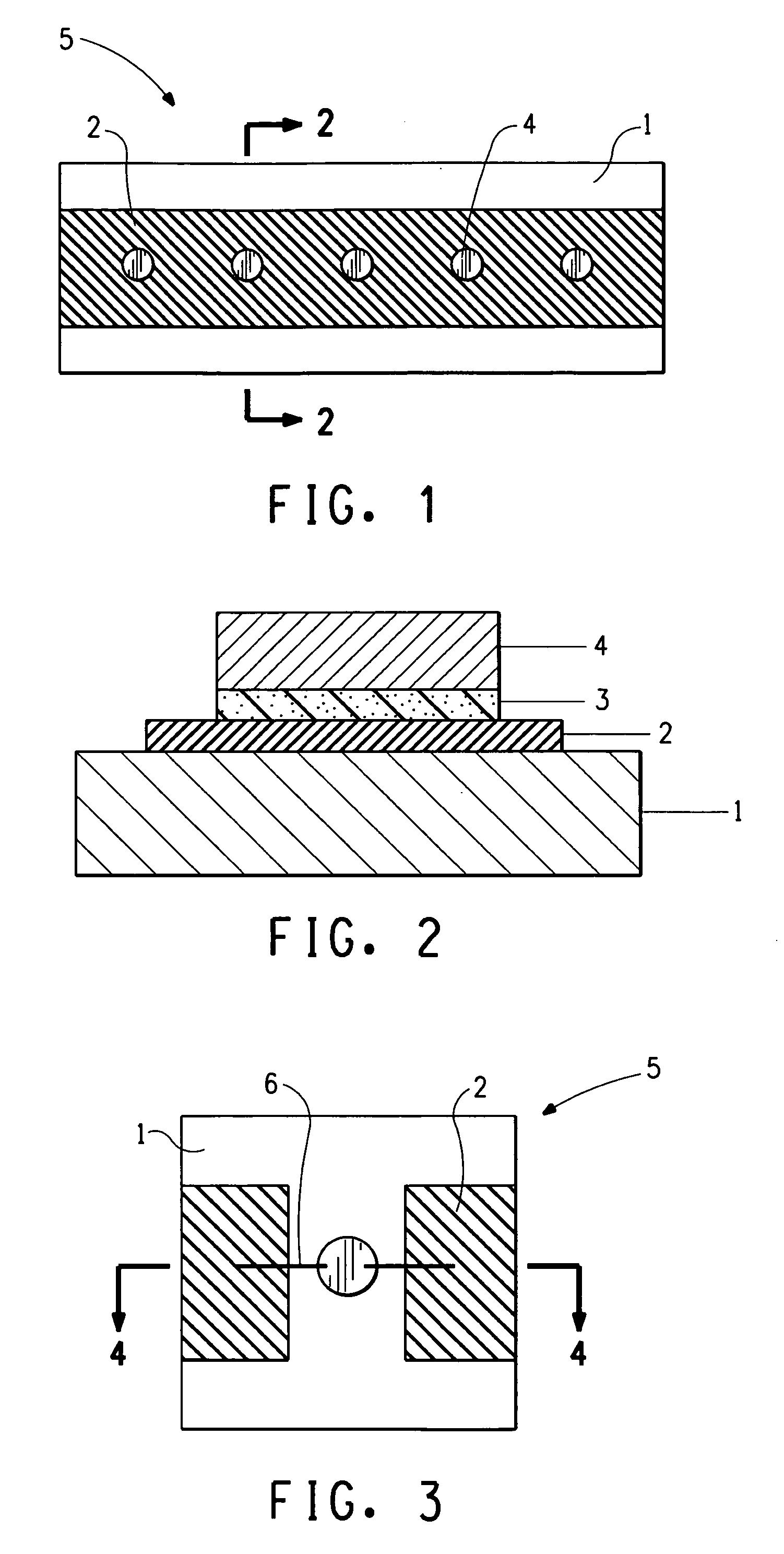

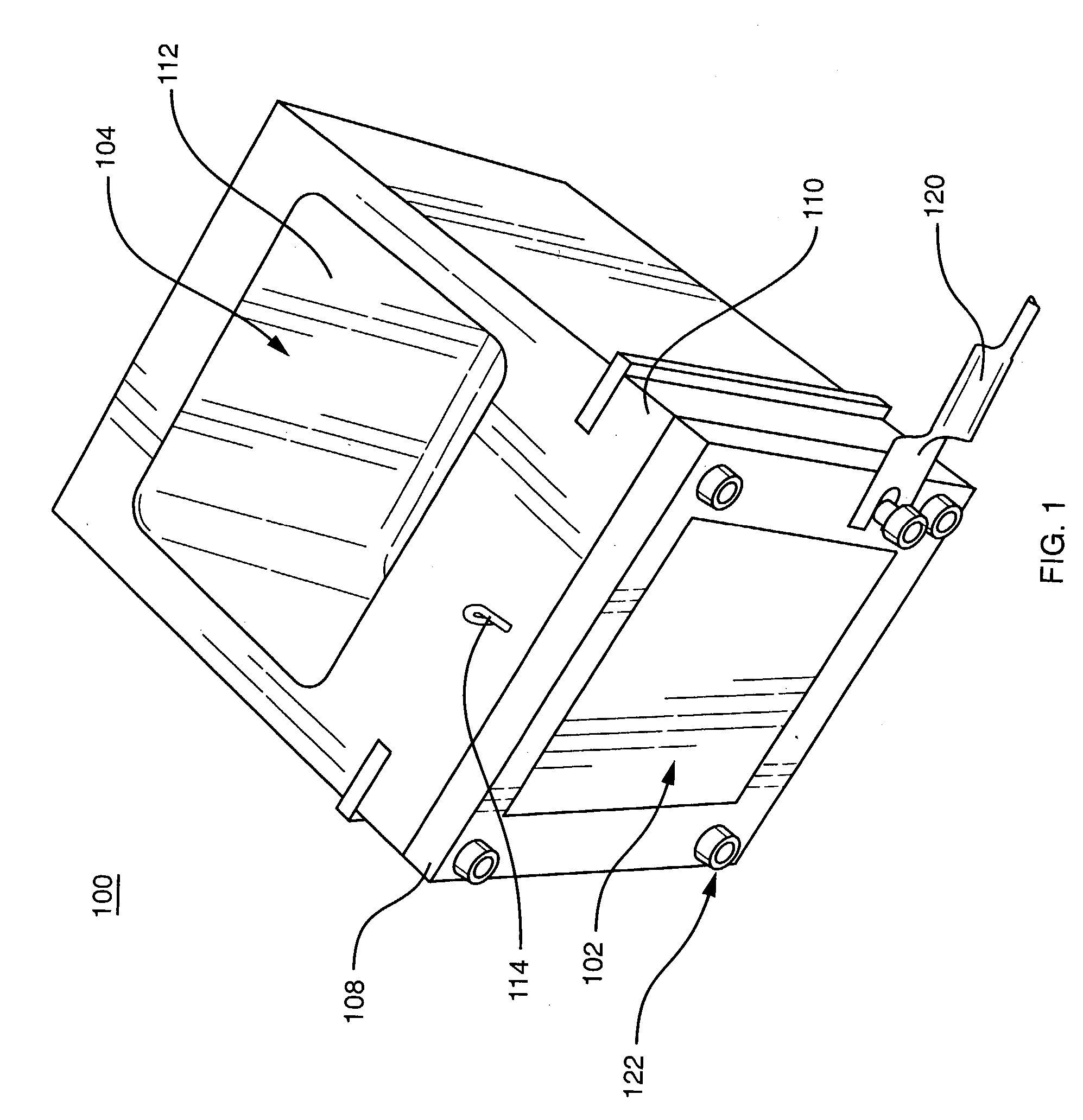

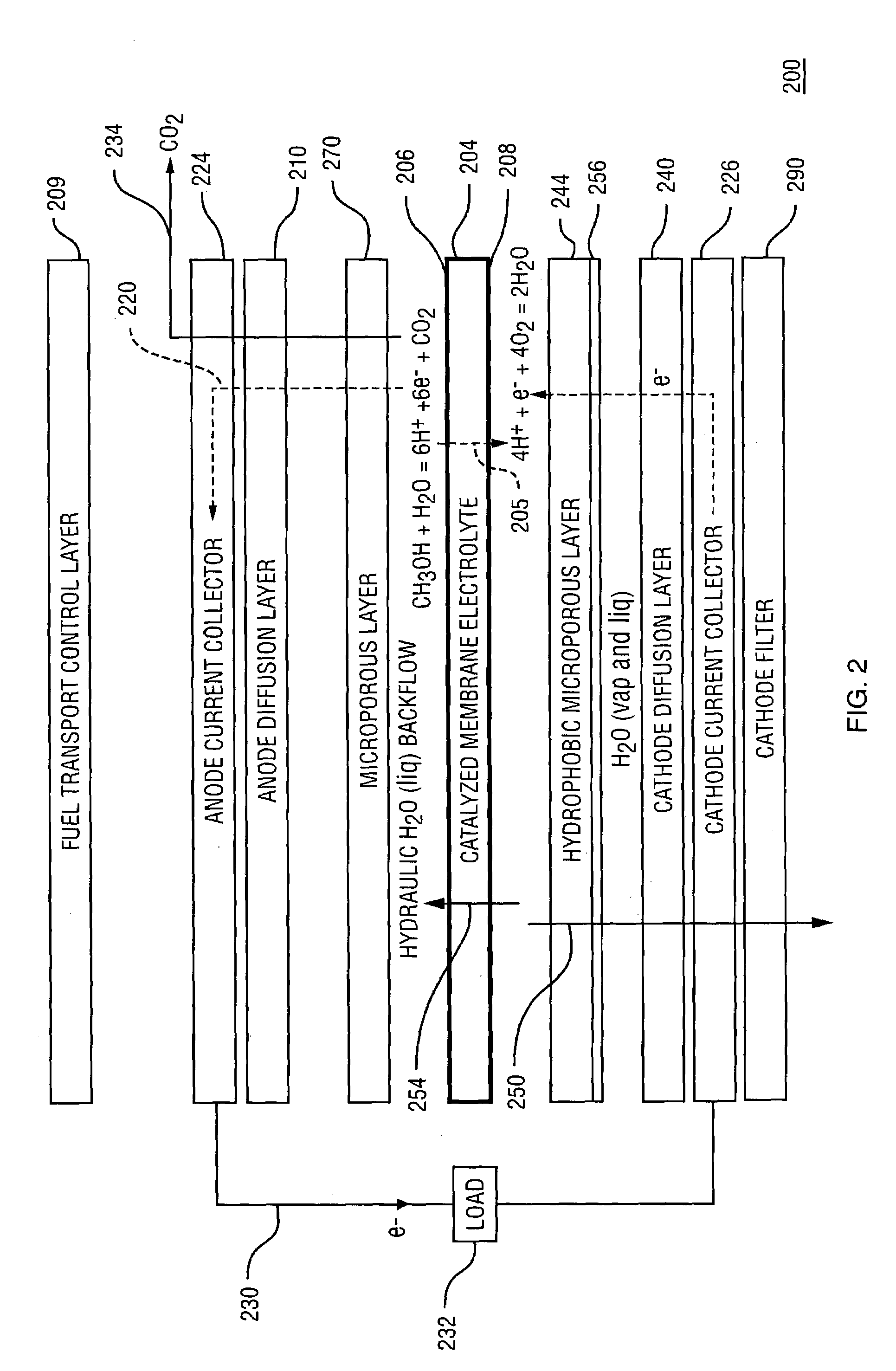

Controlled direct liquid injection vapor feed for a DMFC

InactiveUS20050170224A1Simple and effective carbon dioxide releaseEvenly distributedCell electrodesWater management in fuel cellsFuel cellsInjection port

A fuel cell system having a methanol vapor delivery component or film is provided. The component includes an evaporation pad. The evaporation pad is disposed within the fuel cell generally parallel to the anode diffusion layer, but with a vapor gap provided between the evaporation pad and the anode diffusion layer. A fuel delivery conduit having at least one injection port is provided through which liquid fuel is delivered from an associated source of highly concentrated fuel into the evaporation pad, at a controlled, adjustable rate. Multiple parallel liquid delivery points can also be provided. In order to ensure uniform delivery of fuel across the across the active area of the anode, one or more dispersion members are placed on the evaporation pad to effectively disperse the fuel laterally around each injection port.

Owner:MTI MICROFUEL CELLS

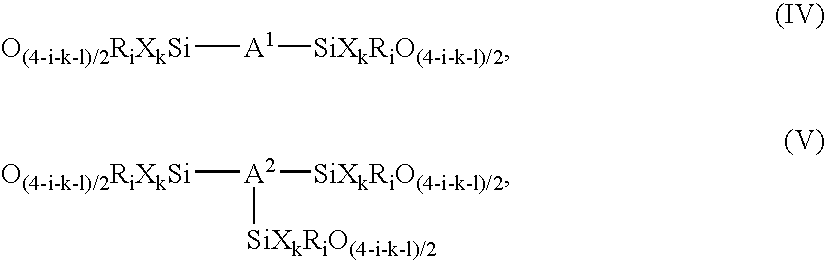

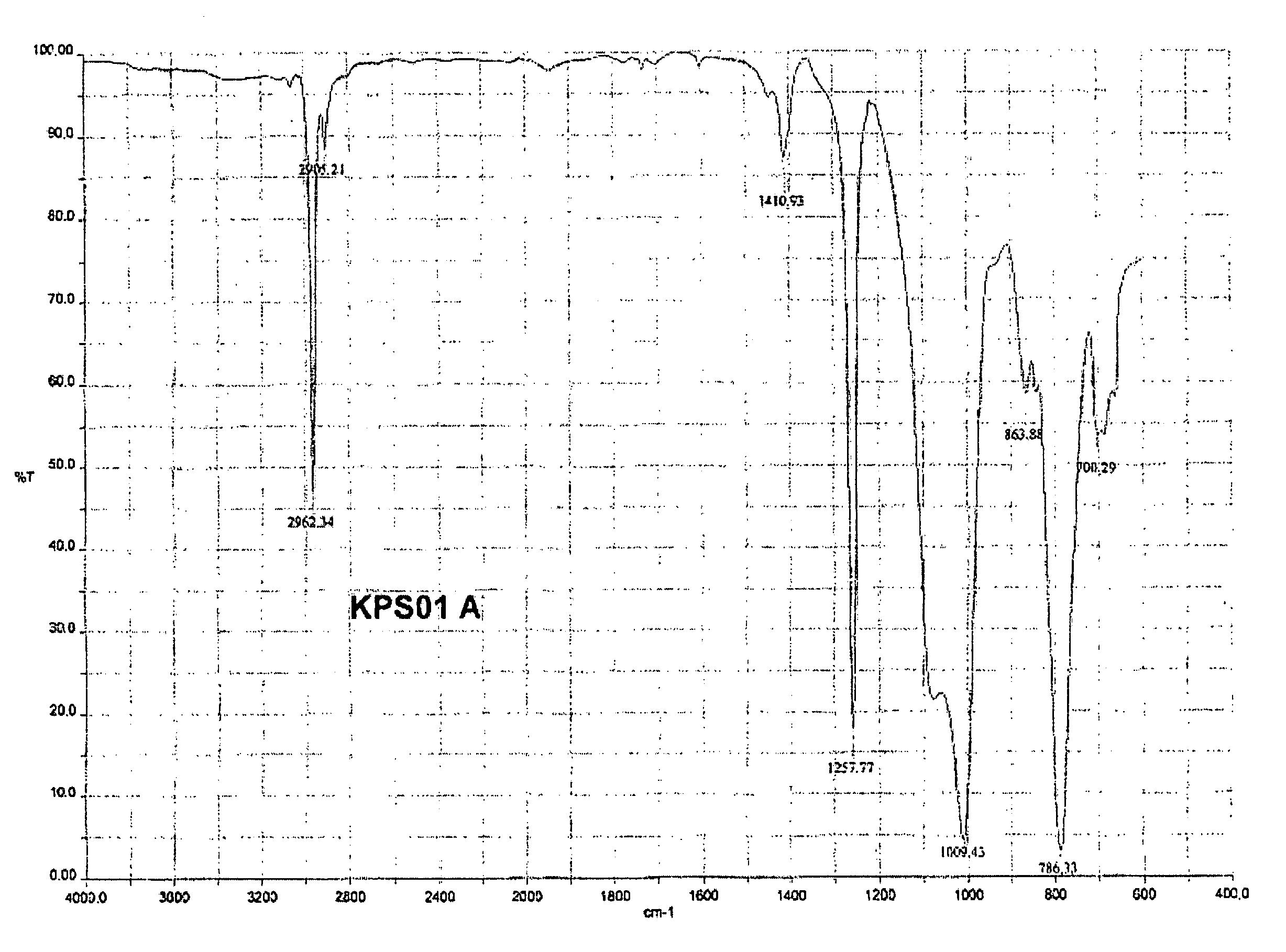

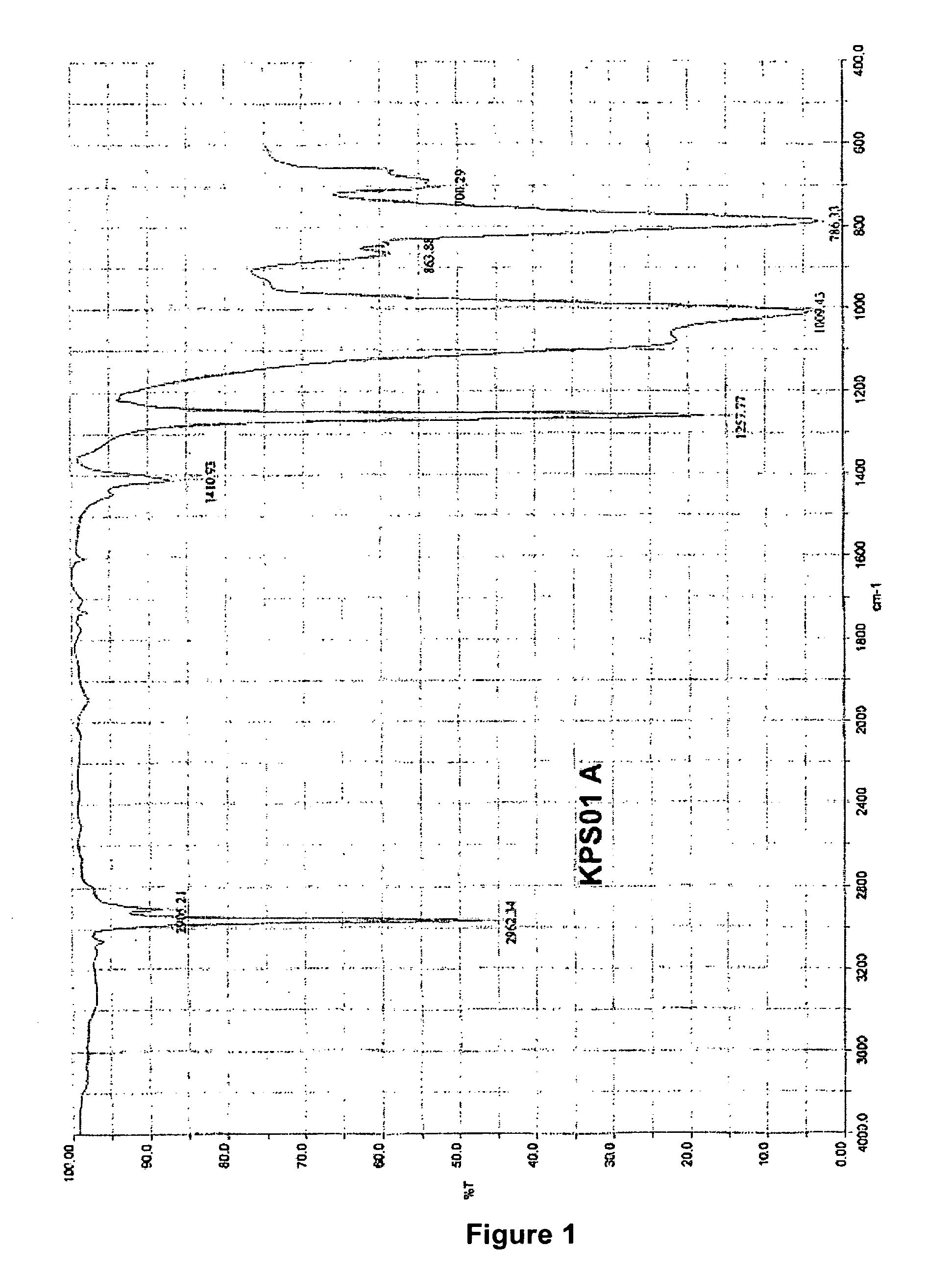

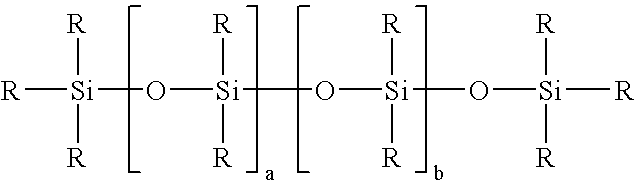

Method for producing crosslinkable organopolysiloxane dispersions

Dispersions of crosslinked organopolysiloxanes are prepared by reacting an alkoxy- or hydroxy-functional organopolysiloxane, in a dispersion medium, with an alkoxysilane bearing at least one further group which increases the reactivity of the silane alkoxy groups such that the viscosity at least doubles within a period of 2 hours.

Owner:WACKER CHEM GMBH

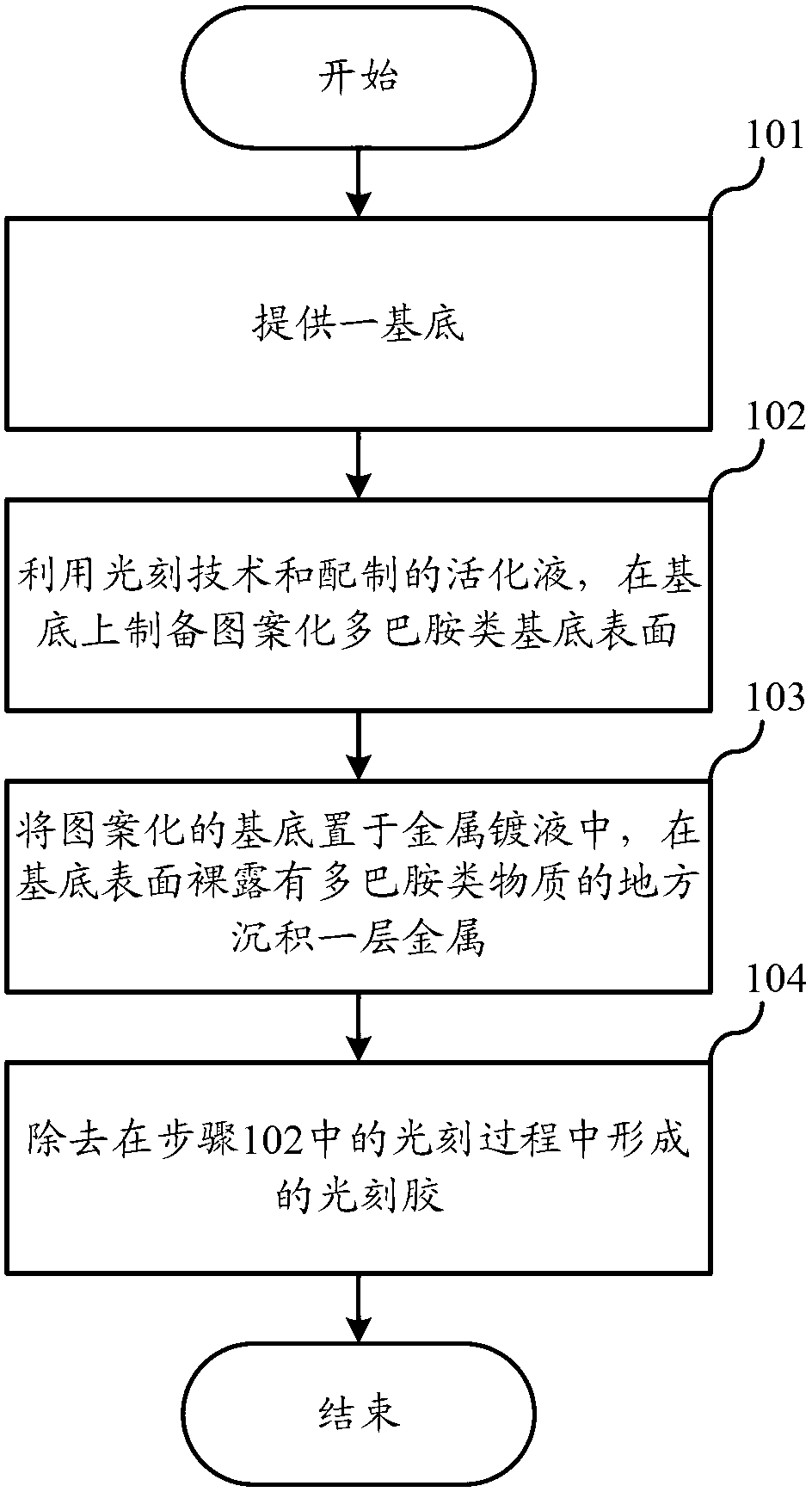

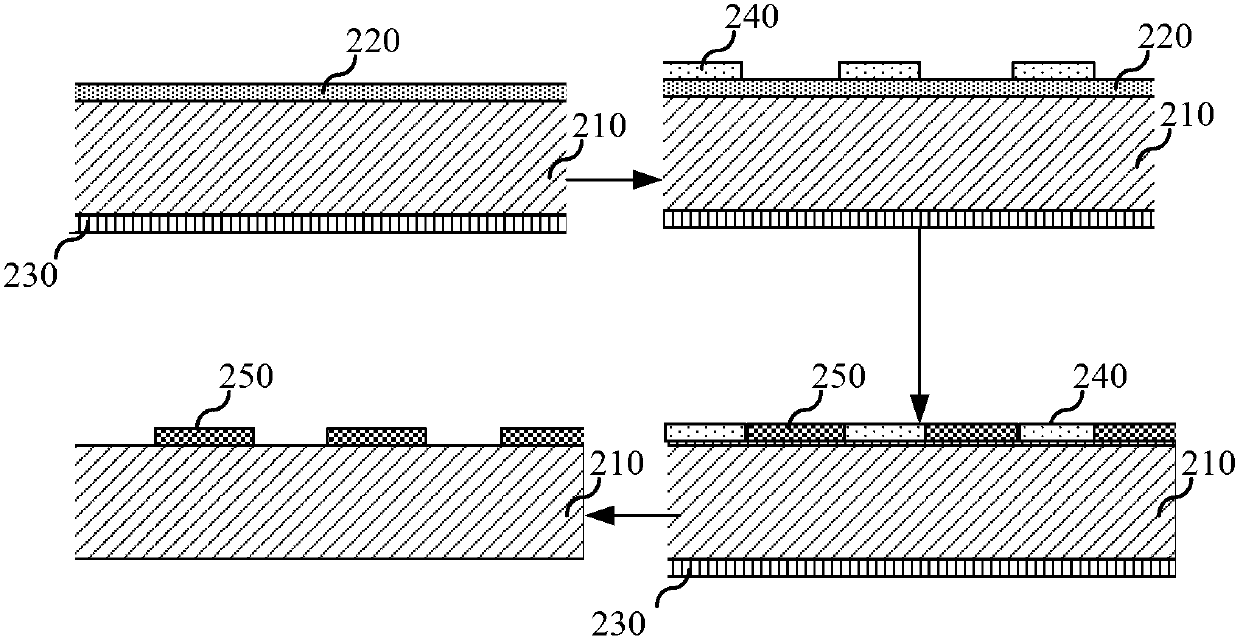

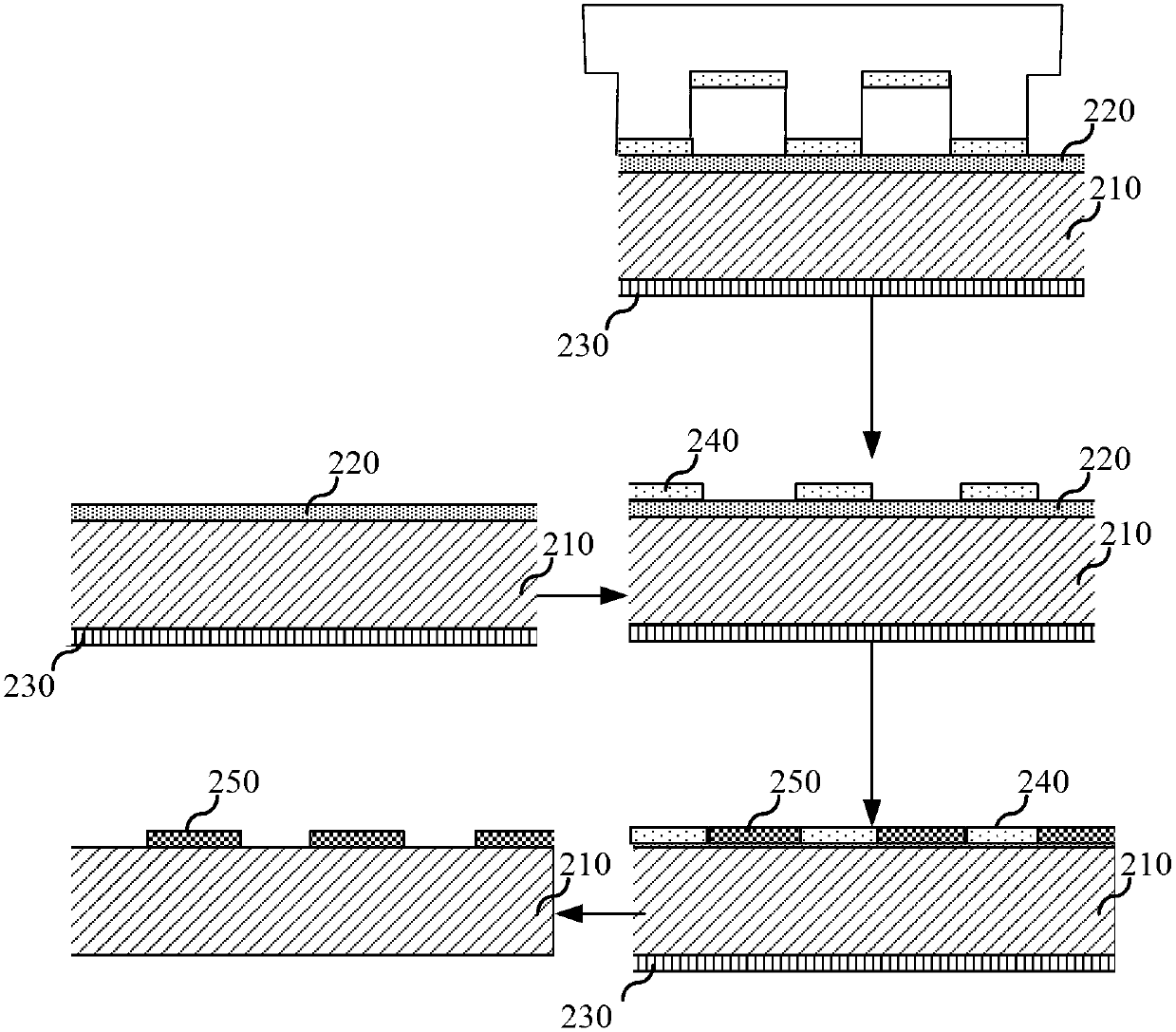

Manufacturing method of patterning metal lines

ActiveCN103219243AEffective adhesionIncrease roughnessSemiconductor/solid-state device manufacturingLiquid/solution decomposition chemical coatingPhotolithographyElectron

The invention relates to the field of electronic manufacturing, and discloses a manufacturing method of patterning metal lines. A substrate is provided. Prepared active liquid and photoetching or printing technology are utilized to manufacture the surface of a patterning dopaminergic substrate on the substrate. Dopaminergic substances are added into the active liquid. The patterning substrate is arranged inside metal plating solution, and a layer of metal is deposited at the places on which the dopaminergic substances are exposed on of the surface of the substrate. A reducing agent is added in the metal plating solution. The patterning metal lines are patterning conductive films or fine circuit lines. If the patterning conductive film to be manufactured is a single-sided patterning conductive film, then in the step of manufacturing the surface of the patterning dopaminergic substrate, a resisting layer incapable of reacting with metal is coated on one face of the substrate, and the other face of the substrate is used for manufacturing the surface of the dopaminergic substrate, or the resisting layer is coated on the face which is not patterning of the substrate before the step of arranging the patterning substrate into the metal plating solution.

Owner:FUDAN UNIV

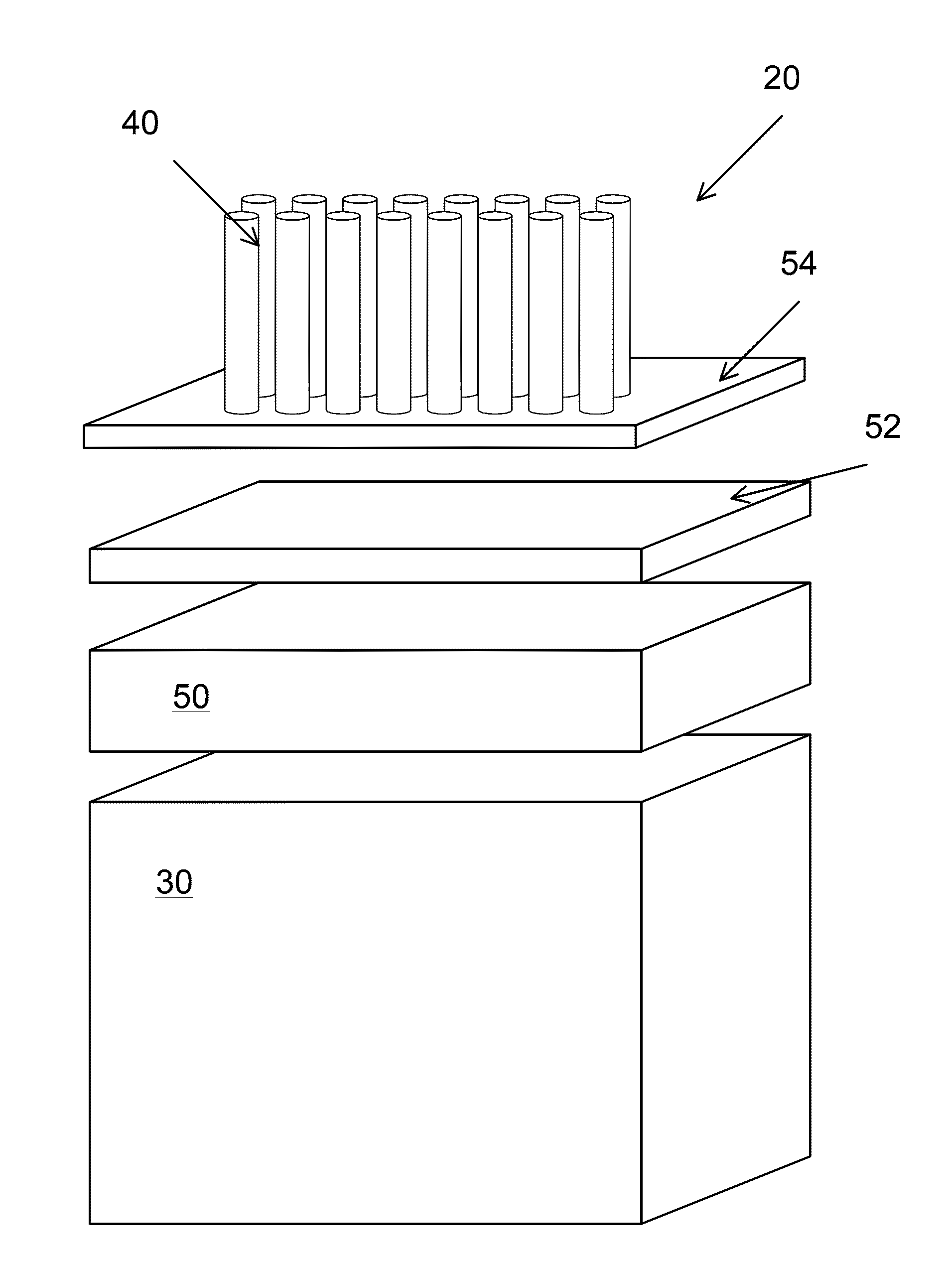

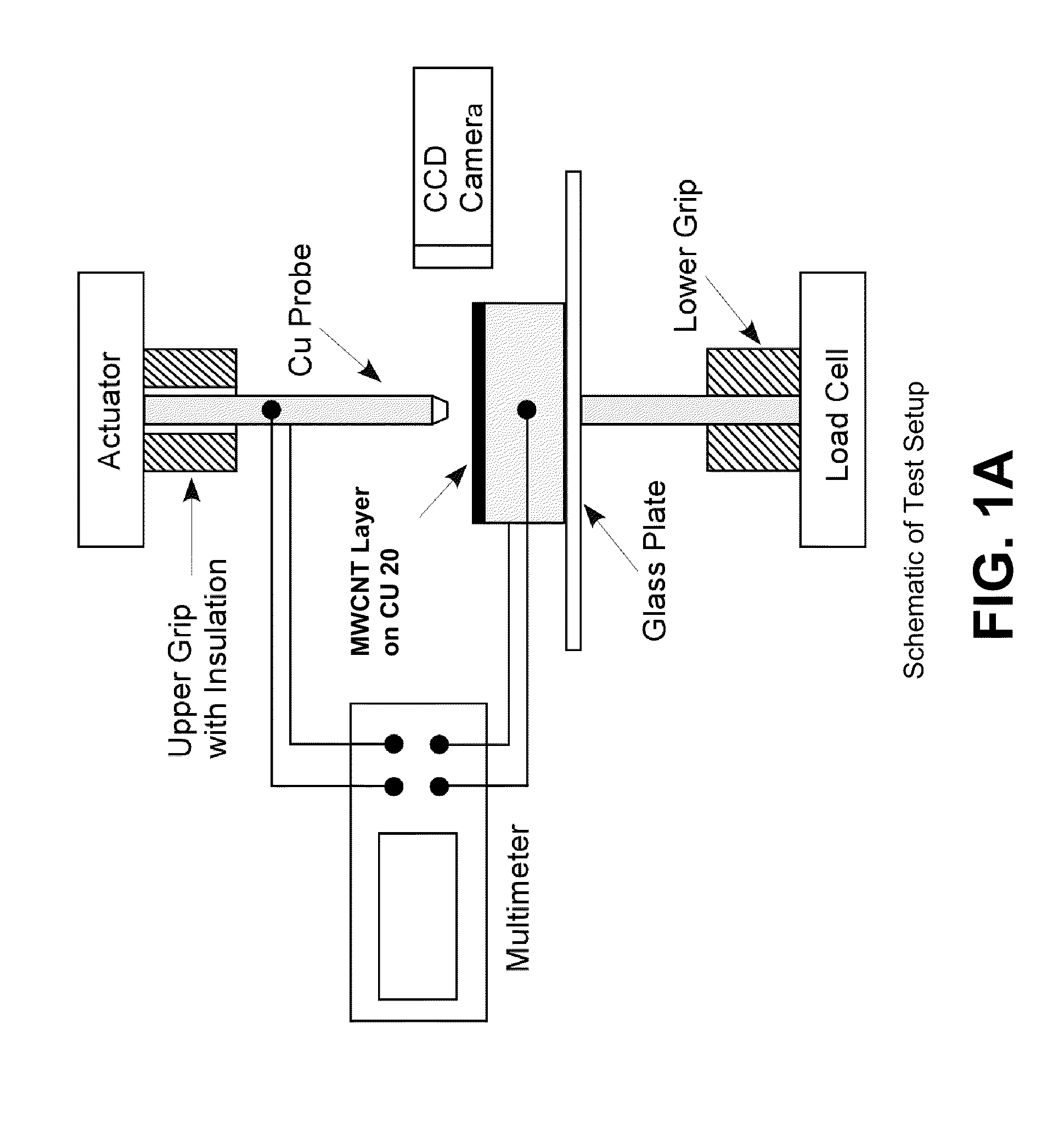

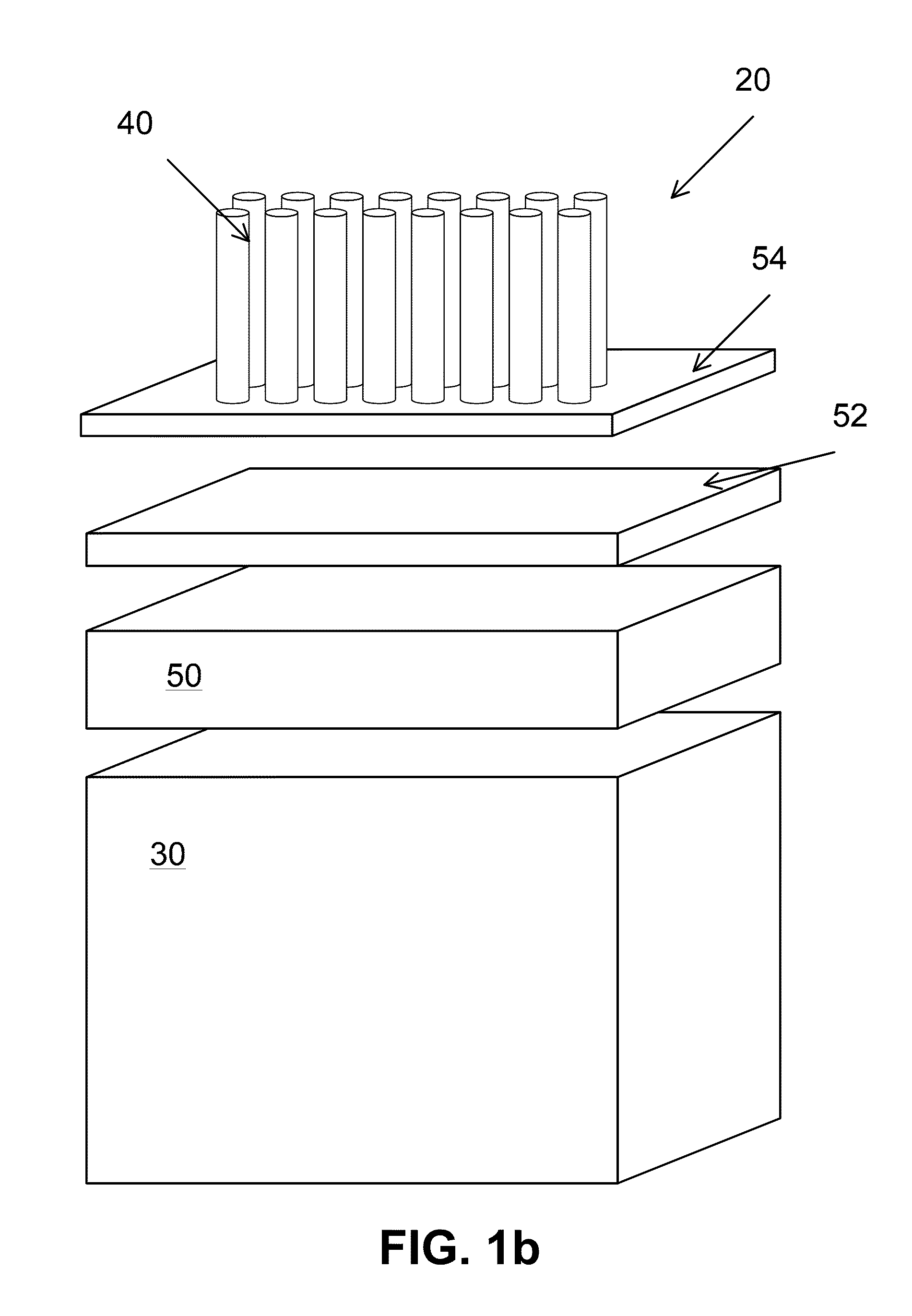

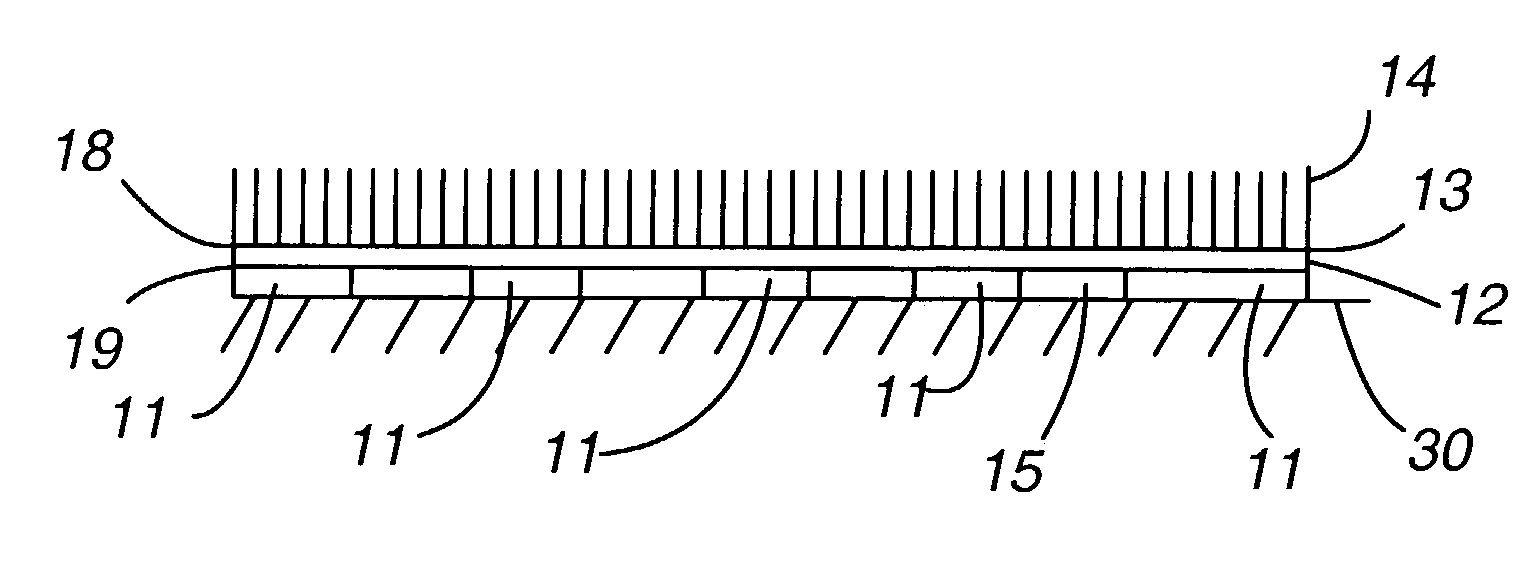

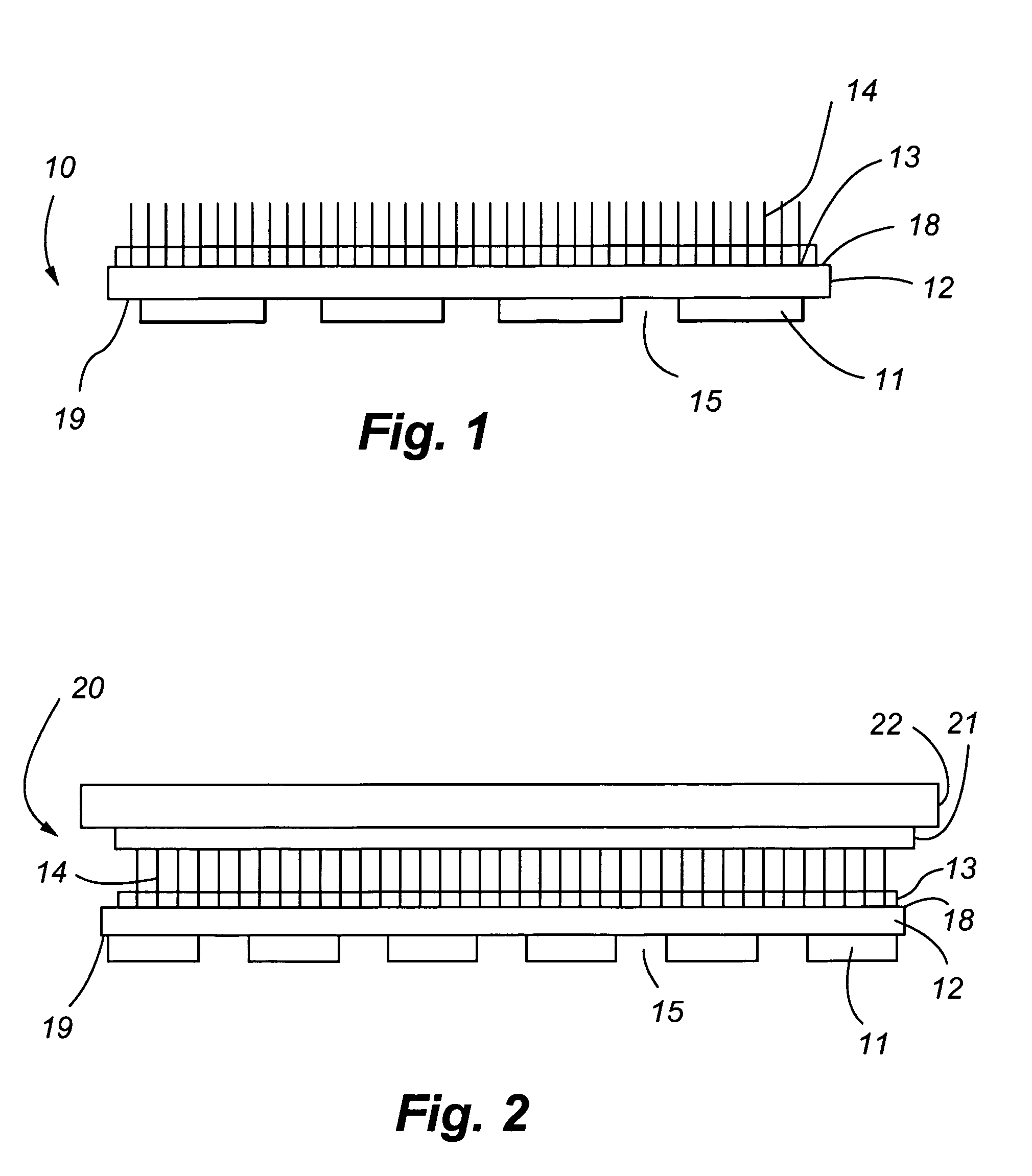

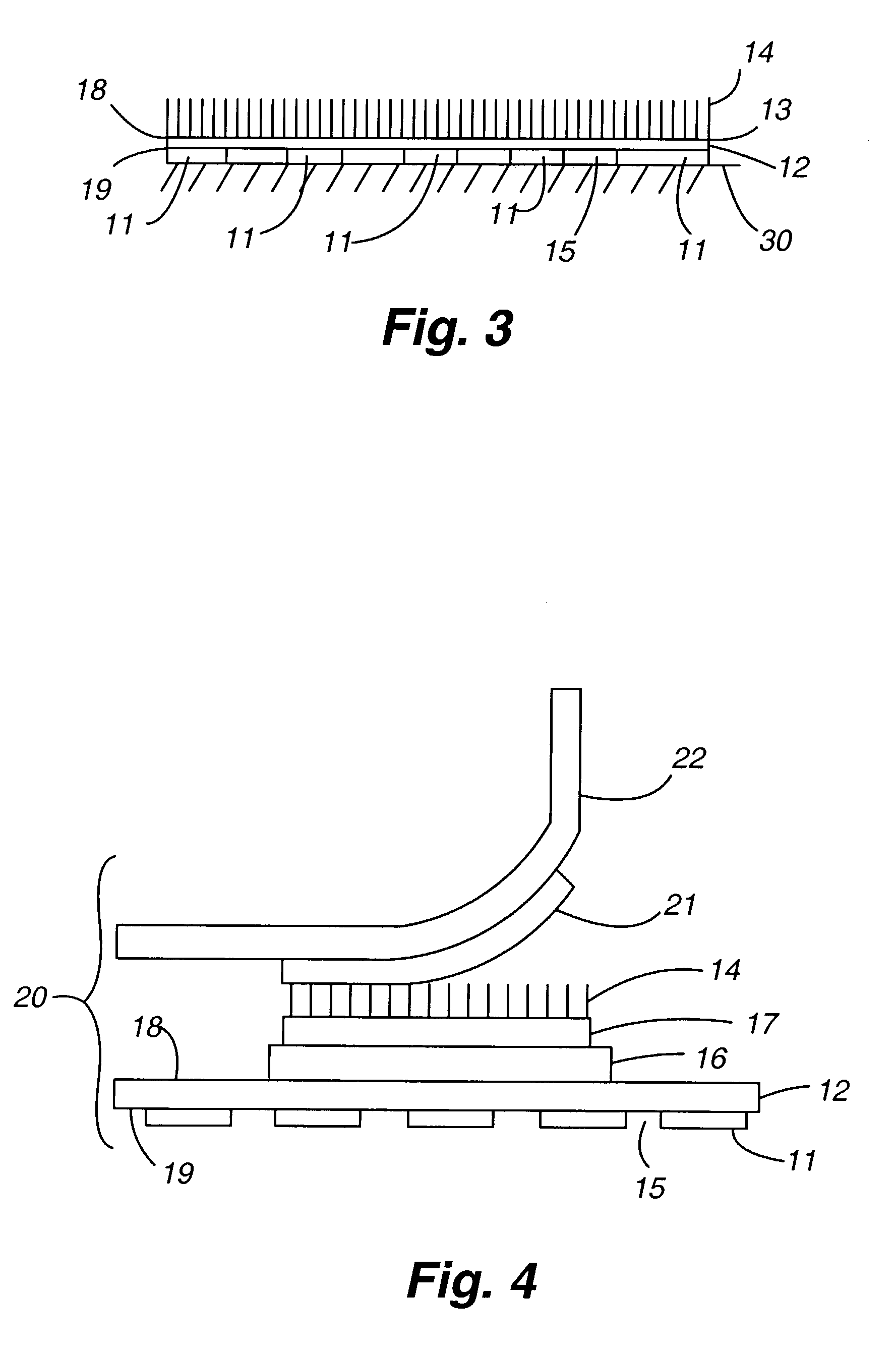

Methods for attaching carbon nanotubes to a carbon substrate

ActiveUS20100200208A1Reduce thermal (or electrical) interface resistanceHigh axial and in-plane thermal conductivityMaterial nanotechnologyLiquid surface applicatorsCarbon nanotubeGraphite

Vertically oriented carbon nanotubes (CNT) arrays have been simultaneously synthesized at relatively low growth temperatures (i.e., <700° C.) on both sides of aluminum foil via plasma enhanced chemical vapor deposition. The resulting CNT arrays were highly dense, and the average CNT diameter in the arrays was approximately 10 nm, A CNT TIM that consist of CNT arrays directly and simultaneously synthesized on both sides of various types of foil has been fabricated. The TIM is insertable and allows temperature sensitive and / or rough substrates to be interfaced by highly conductive and conformable CNT arrays. The use of foil, including substrates fabricated from carbon (CNT woven arrays, exfoliated graphite sheets, bucky paper, and the like) is disclosed.

Owner:PURDUE RES FOUND INC

Aqueous polymaine-containing anti-frizz composition for hair

InactiveUS20080085258A1Avoid absorptionAbsorption lossCosmetic preparationsHair cosmeticsPolyamine CompoundWater insoluble

The present invention is drawn to a composition and process for inhibiting hair from becoming frizzy when exposed to high and / or low humidity, the composition containing: (a) at least one polyamine compound comprising at least three amino groups; (b) at least one nonionic surfactant; (c) at least one anionic silicone; (d) at least one water-insoluble material; (e) at least one cationic polymer; and (f) at least one film former, different from (e).

Owner:LOREAL SA

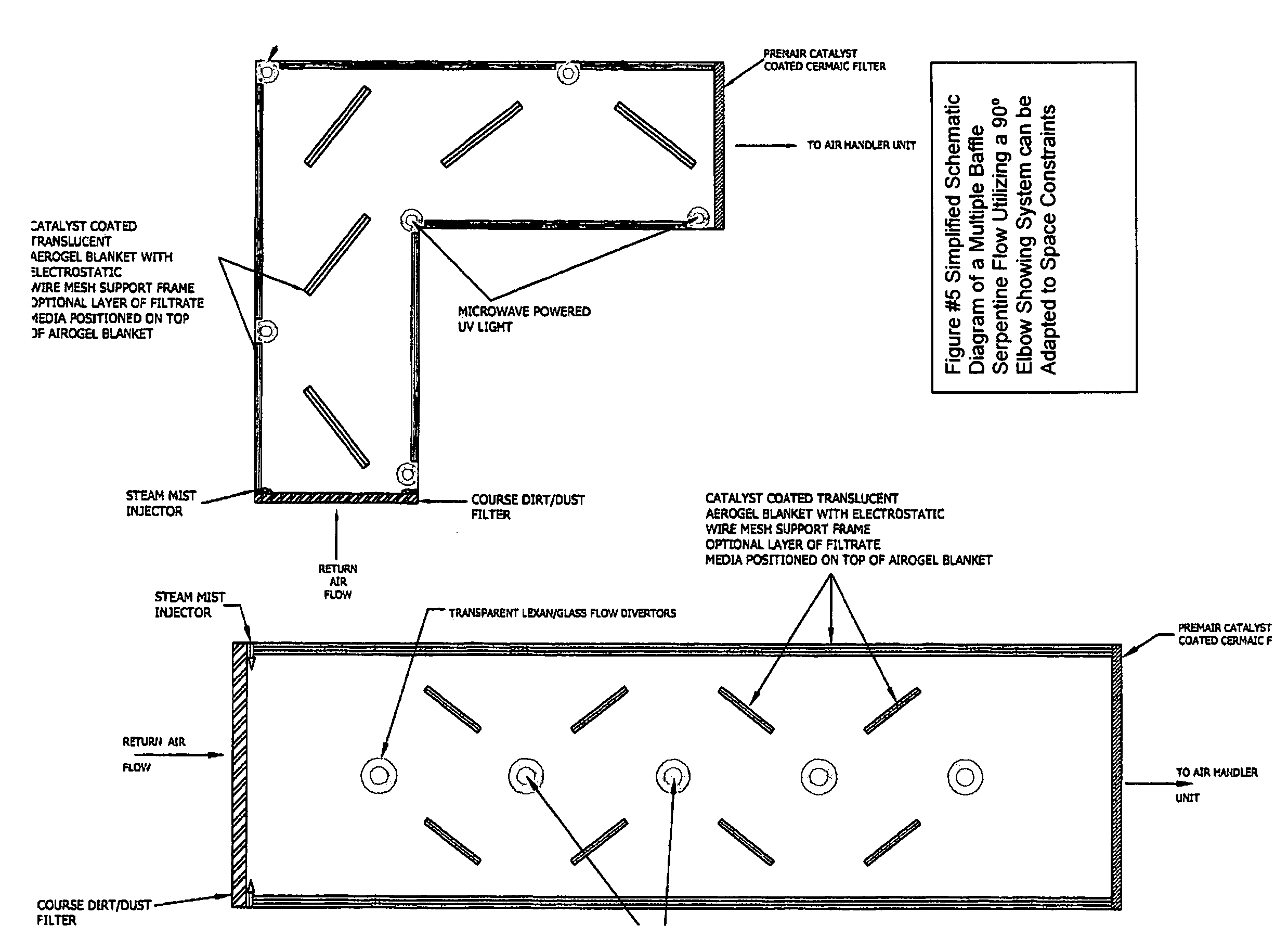

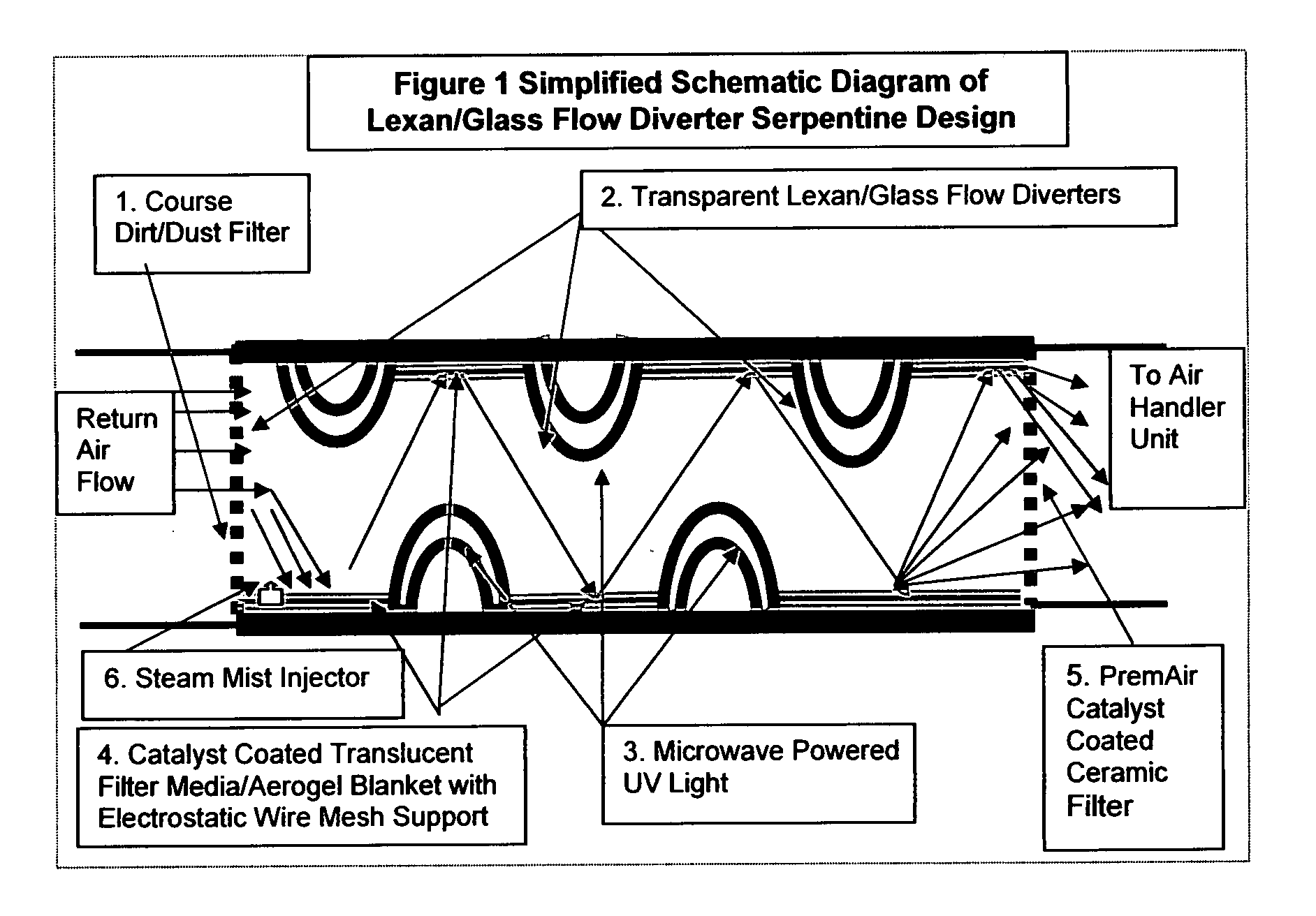

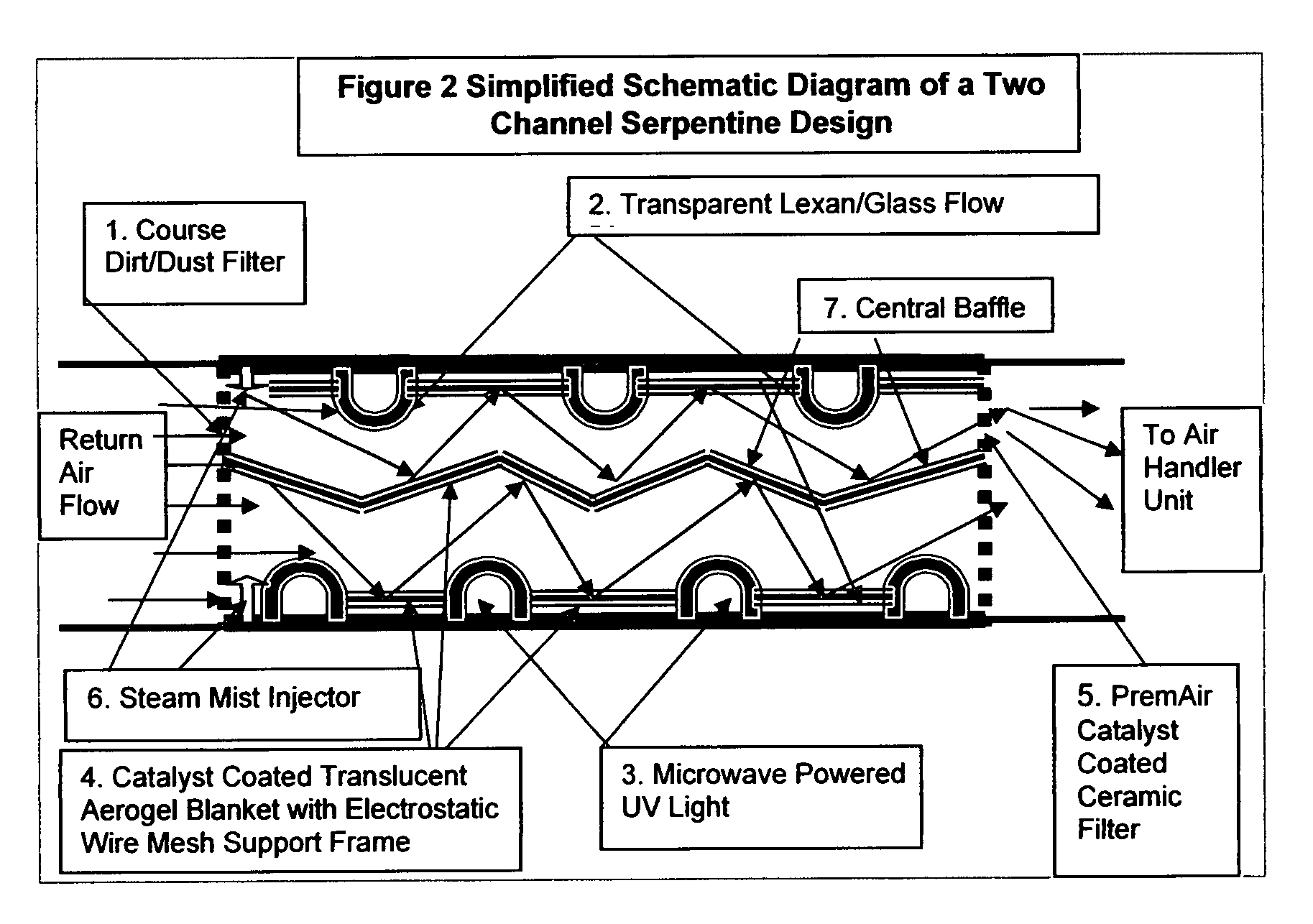

Novel HVAC pathogen neutralization system

InactiveUS20080194009A1Improve destruction efficiencyAirflow pressure dropBioreactor/fermenter combinationsMechanical apparatusDiseaseUltraviolet

A novel process neutralizes airborne pathogens by using microwave powered ultra violet light combined with catalyzed filters and impingement media made of a layer of Filtrite filter media or comparable brand filter media covering an aerogel blanket. The geometric design maximizes the efficiency of the UV light, and impingement of pathogens on the Filtrite filter media / aerogel blanket catalyzed surfaces. The system can be utilized for preventing sick building syndrome (SBS), to prevent the spread of airborne diseases in hospitals, biohazard research laboratories, food and pharmaceutical processing facilities, and biological weapons storage facilities. It can also be used in HVAC systems to minimize the contamination caused by a biological terrorist attack.

Owner:MARENTIS RODGER T

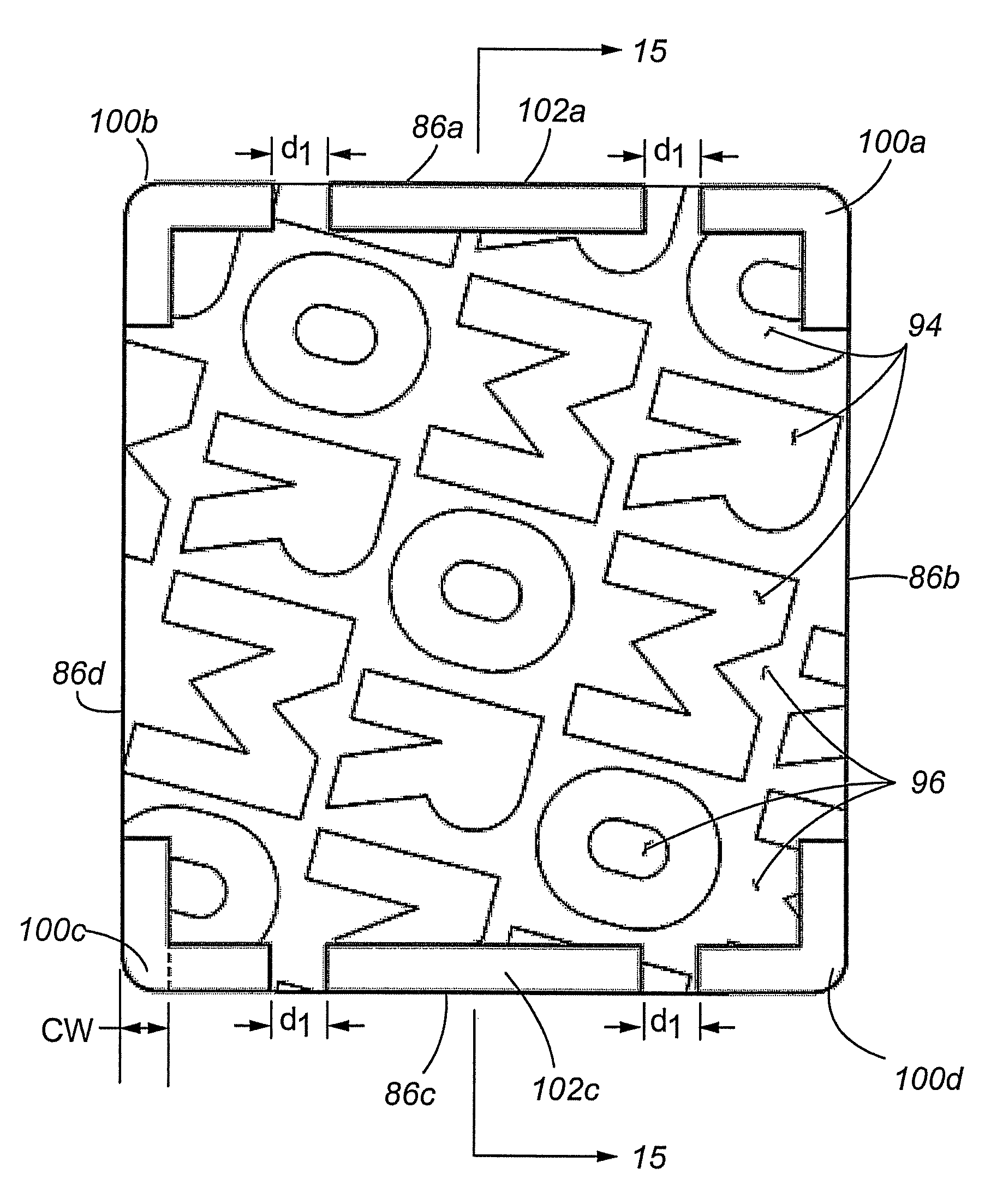

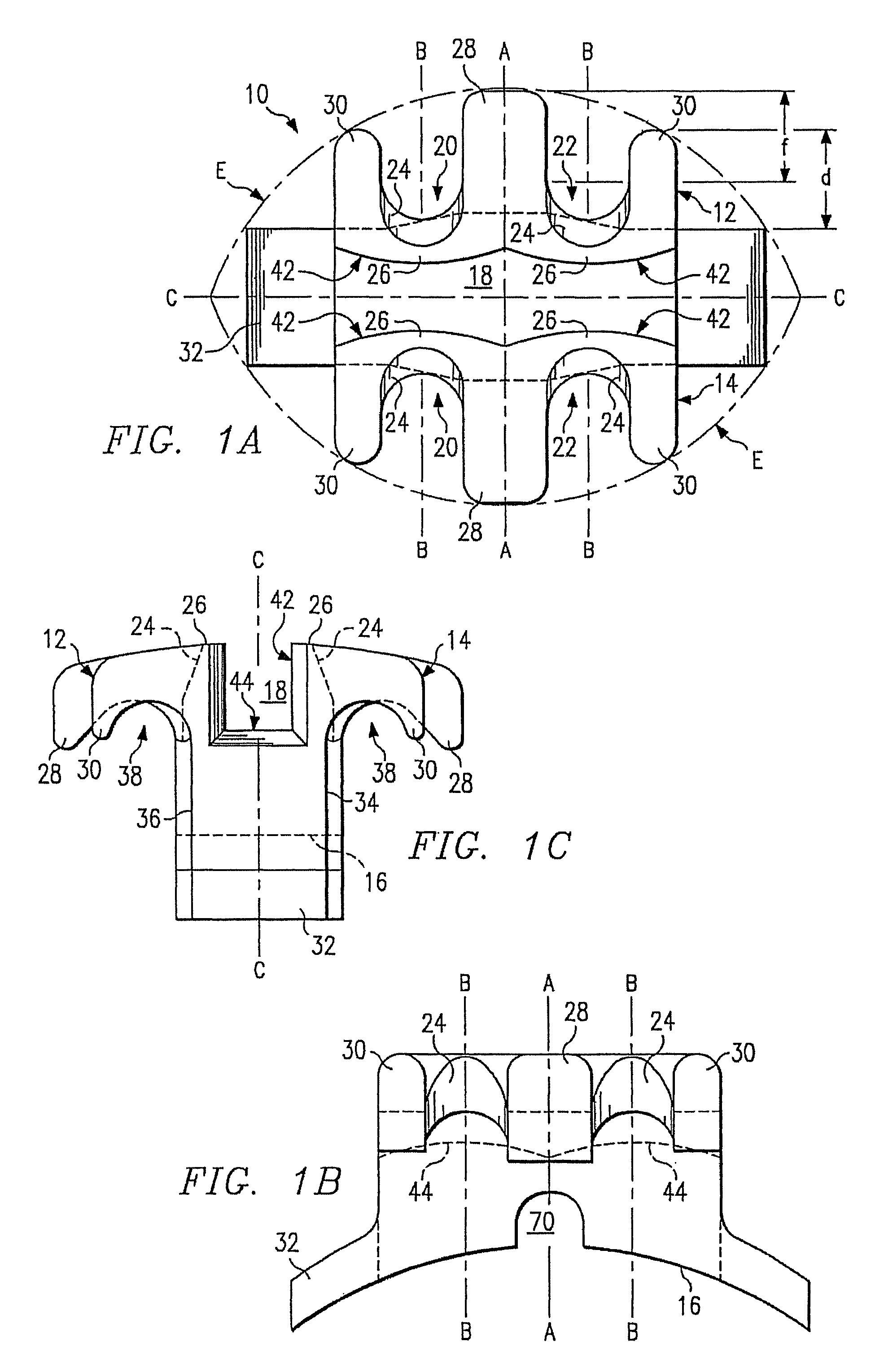

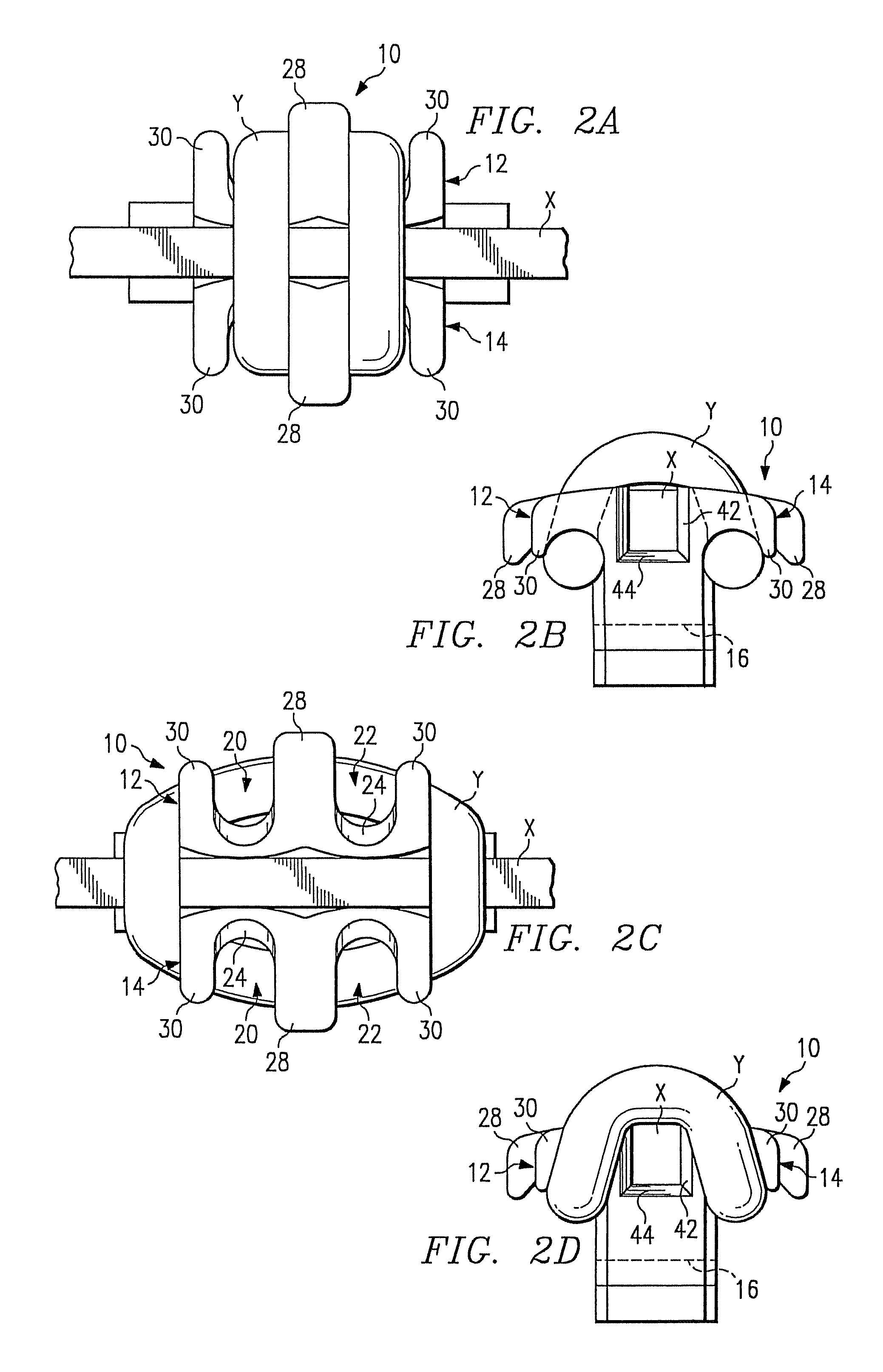

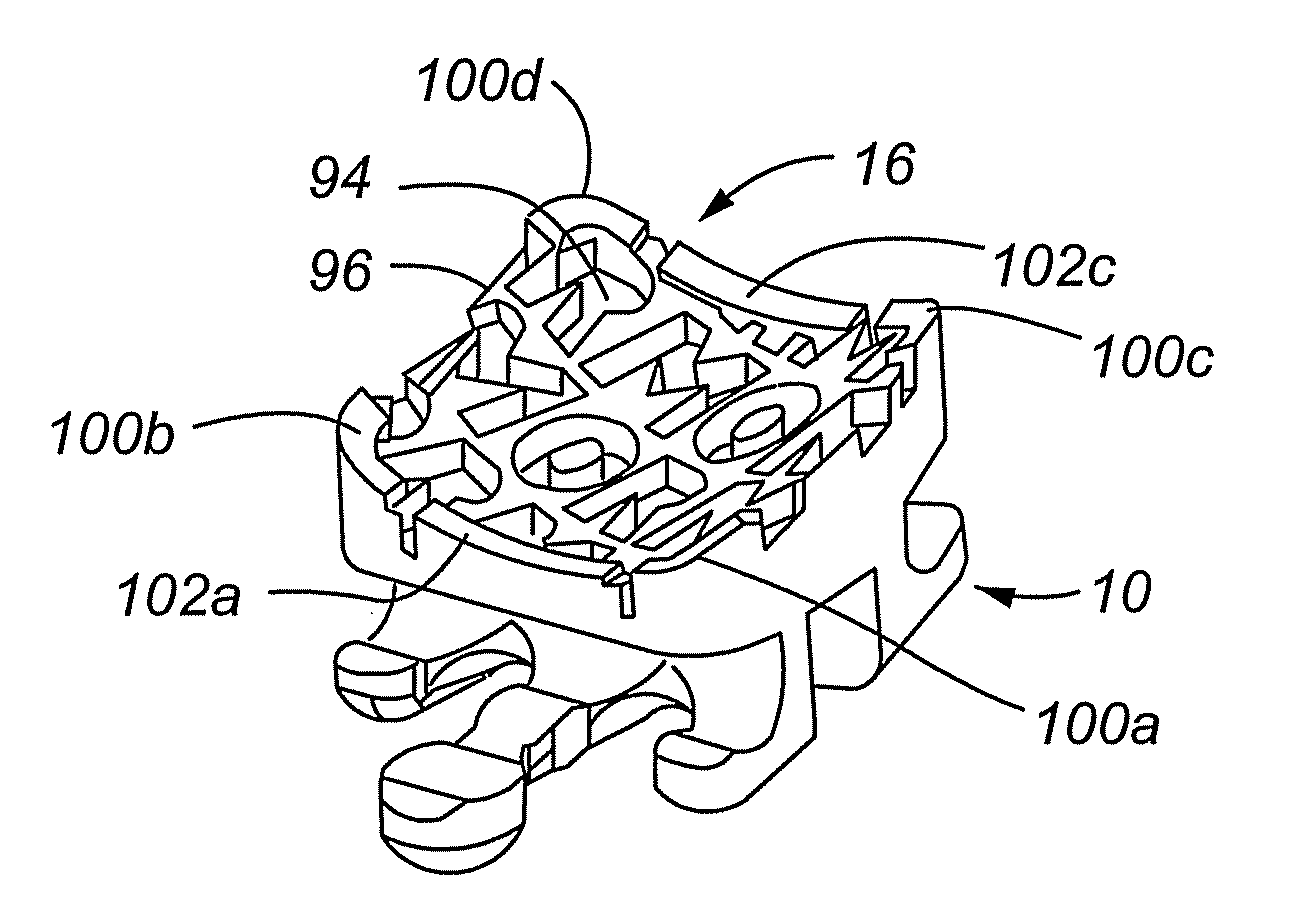

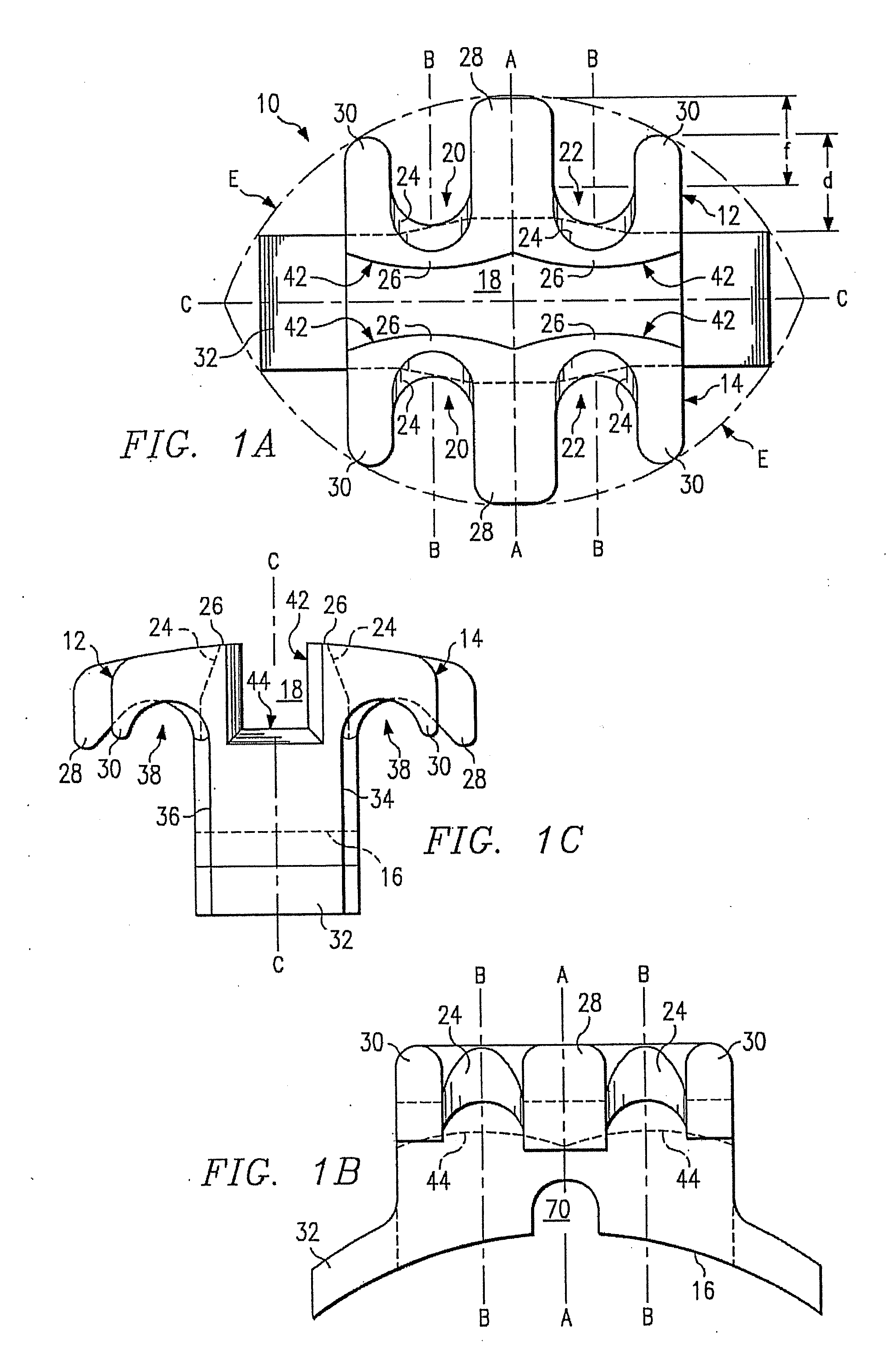

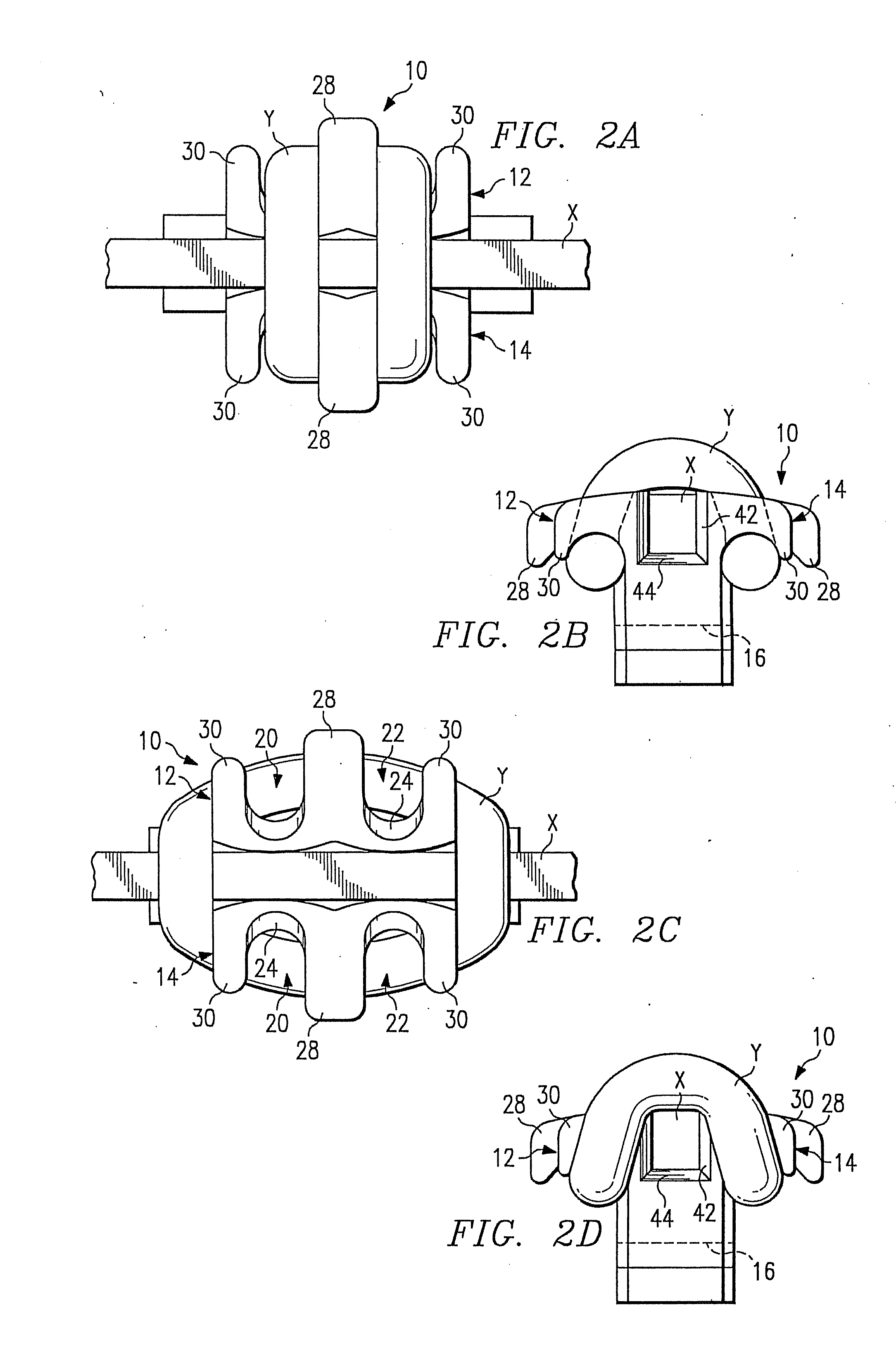

Orthodontic appliance with encoded information formed in the base

ActiveUS7959437B2Increase surface areaEffective adhesionArch wiresBracketsDentistryBiomedical engineering

Owner:ORTHOAMERICA HLDG LLC

Multiple Component Materials Having A Color-Changing Composition

InactiveUS20110015063A1Simple stepsLow costAnalysis using chemical indicatorsNon-adhesive dressingsWater insolubleColor changes

The present invention relates to a multiple-component material including a substrate and a film layer on the substrate. The film layer includes a color-changing composition to indicate a change in condition, such as a change in pH. The color-changing composition includes a water-insoluble, film-forming polymer, a charged surfactant, a charged colorant and a pH adjuster.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Elecrically conductive adhesive

ActiveUS20090186219A1Increase heatHigh strengthConductive materialSolid-state devicesSolventSilicone resin

Disclosed is an electrically conductive adhesive that includes an electrically conductive powder, a heat-curable silicone resin, and a solvent.

Owner:DU PONT CHINA LTD

Flocked stretchable design or transfer

InactiveUS7410682B2Reduce the total massEffective adhesionLiquid surface applicatorsDecorative surface effectsFiberPolymer science

The present invention describes a flocked stretchable design and a process for producing a flocked stretchable design or transfer. The design, when configured as a transfer, includes a carrier layer, a release adhesive applied to the carrier layer, a plurality of flock fibers releasably attached to the release adhesive, an elastic film, and a first adhesive layer bonded to the flock fibers and the elastic film, and a second, discontinuously distributed, adhesive layer bonded to the other side of the elastic film. The design, when direct flocked, does not include the carrier and the release adhesive. The present invention also includes methods of producing both the designs.

Owner:HIGH VOLTAGE GRAPHICS

Multiple Component Materials Having A Color-Changing Composition

InactiveUS20110015597A1Simple stepsLow costDecorative surface effectsDuplicating/marking methodsWater insolubleColor changes

The present invention relates to a multiple-component material including a substrate and a film layer on the substrate. The film layer includes a color-changing composition to indicate a change in condition, such as a change in pH. The color-changing composition includes a water-insoluble, film-forming polymer, a pH adjuster and a water-insoluble particle. The water-insoluble particle has a charged colorant immobilized on it.

Owner:KIMBERLY-CLARK WORLDWIDE INC

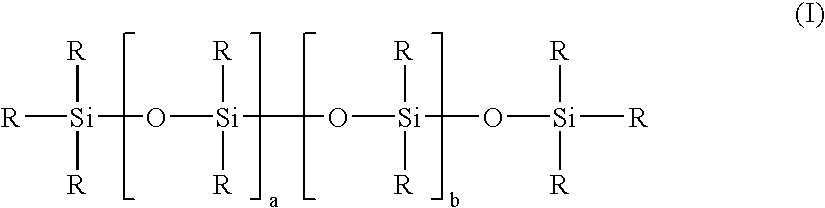

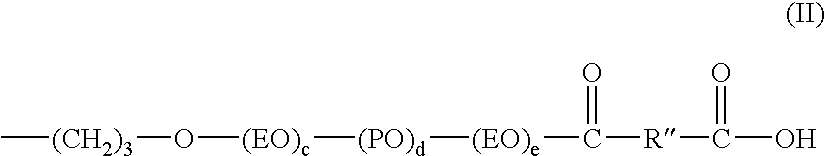

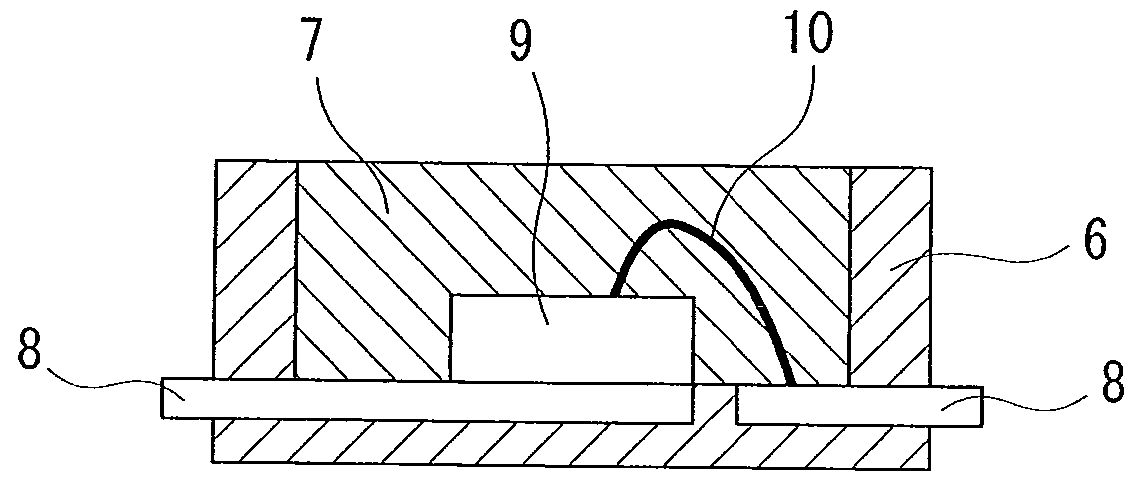

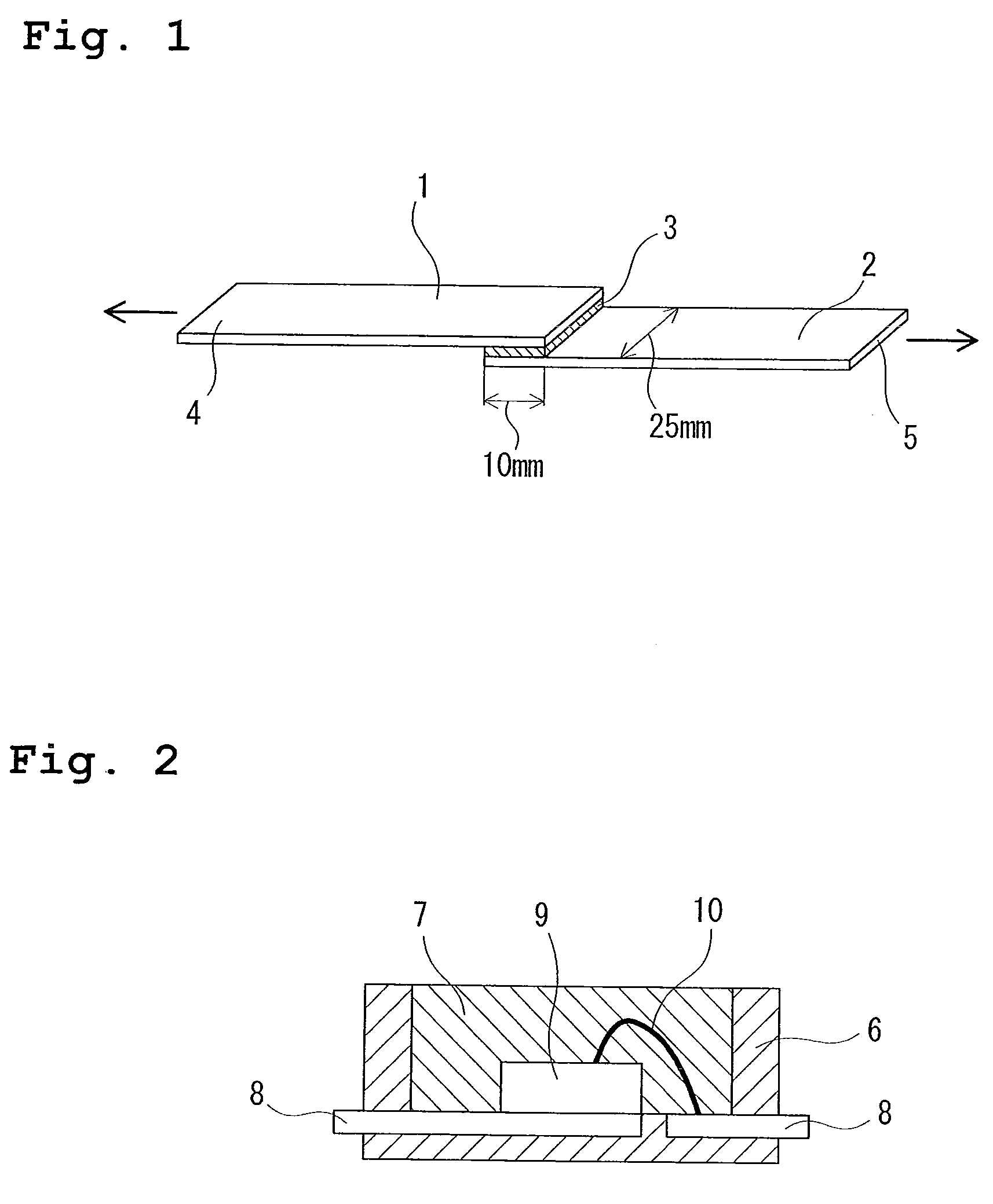

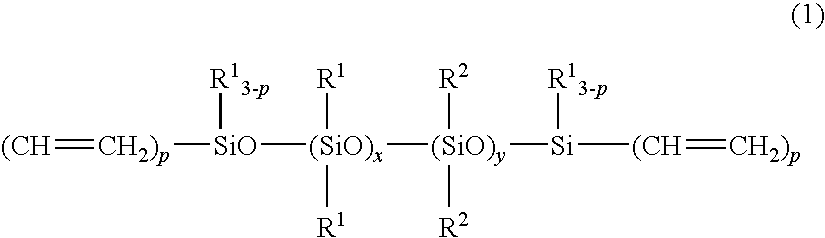

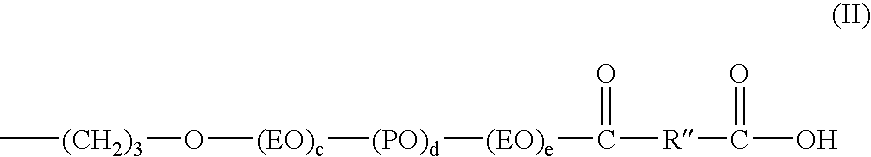

Curable silicone rubber composition and semiconductor device

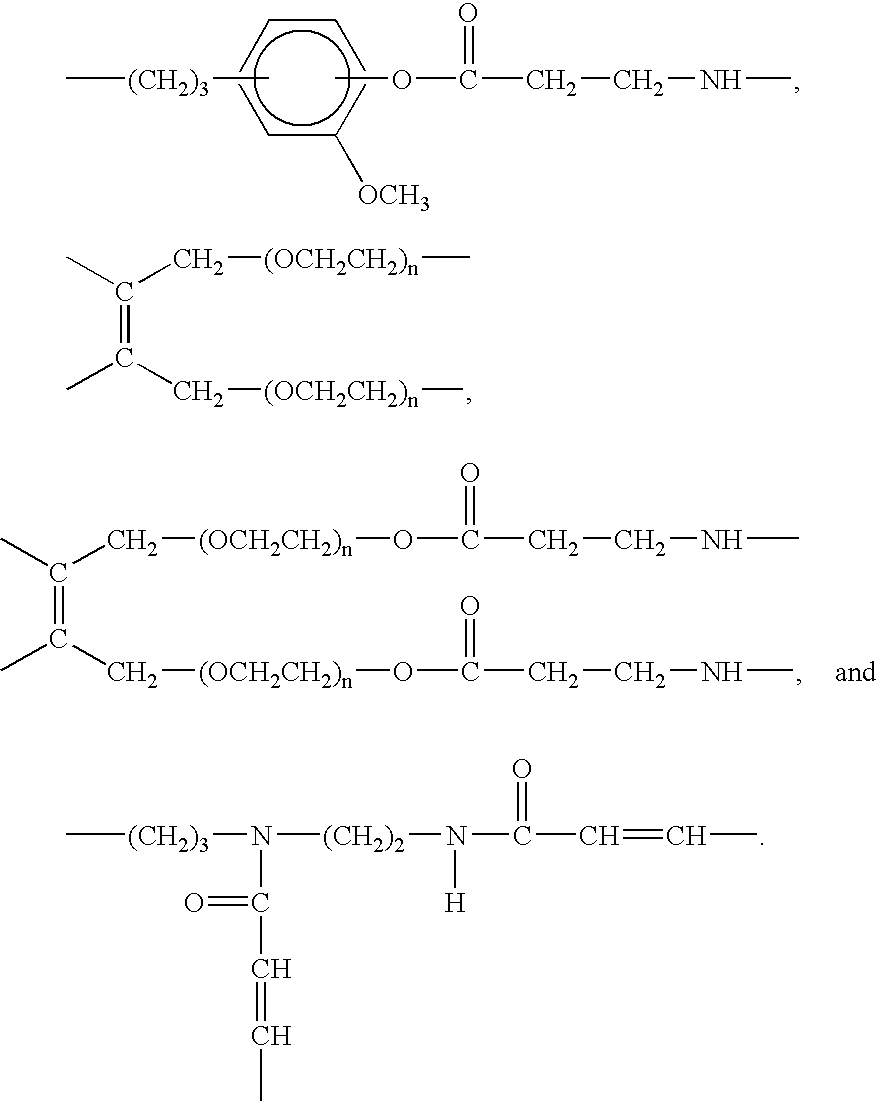

InactiveUS20090236759A1Effective adhesionHigh transparencySemiconductor/solid-state device detailsSolid-state devicesPolymer scienceHydrogen atom

A curable silicone rubber composition, comprising: (A) an organopolysiloxane containing two or more alkenyl groups within each molecule, (B) an organohydrogenpolysiloxane having two or more hydrogen atoms bonded to silicon atoms within each molecule, (C) a metal-based condensation reaction catalyst, (D) a platinum group metal-based addition reaction catalyst, and (E) an adhesion-imparting agent, wherein among the refractive indices of component (A), a mixture of component (A) and component (B), and component (E), the difference between the maximum refractive index and the minimum refractive index is not more than 0.03.

Owner:SHIN ETSU CHEM IND CO LTD

Orthodontic appliance with encoded information formed in the base

ActiveUS20080020338A1Increase surface areaEffective adhesionArch wiresBracketsEngineeringModel Number

An improved orthodontic appliance is disclosed having information encoded or formed in the base of the appliance, wherein the encoded information increases the total base surface area by an amount that is effective for increasing the adhesion of the appliance to a patient's tooth. In one embodiment, the total base surface area may increase to 140% of what such surface would be without the encoded information. The encoded information may identify: a manufacturer or supplier of the appliance, a part / model number, a location and / or date of manufacturer, a composition of material, a patent number, a logo, etc.

Owner:ORTHOAMERICA HLDG LLC

Process for preparing dispersions of crosslinked organopolysiloxanes

InactiveUS20060258820A1Small particle sizeSimple and reliable processSynthetic resin layered productsPolymer scienceHalogen

Dispersions of crosslinked organopolysiloxanes comprises reacting siloxanes (1) AaRbXcSiO4-(a+b+c)2where A, X, R, a, b, and c are defined herein, the sum a+b+c≦3, and there are at least one radical A and one radical —OR1 per molecule where R1 is H and / or siloxanes (2) containing units Rb(OR1)dSiO4-(b+d)2where d is 0 or 1, the sum b+d≦3, and there is at least one radical R1 which is hydrogen, or mixtures thereof, with silanes WRpSi(oR7)3-p or hydrolysis products thereof, where W is a monovalent radical —CR62—Y, where Y is a monofunctional halogen, monosubstituted O or S, or substituted N or P radical, R6 and R7 are as defined herein, and p is 0, 1 or 2, the presence of dispersion medium and emulsifiers, with the proviso that no metal-containing catalysts are used, and that siloxanes (1) and / or (2) and silanes (3) are present such that crosslinked organopolysiloxanes insoluble in toluene are obtained.

Owner:WACKER CHEM GMBH

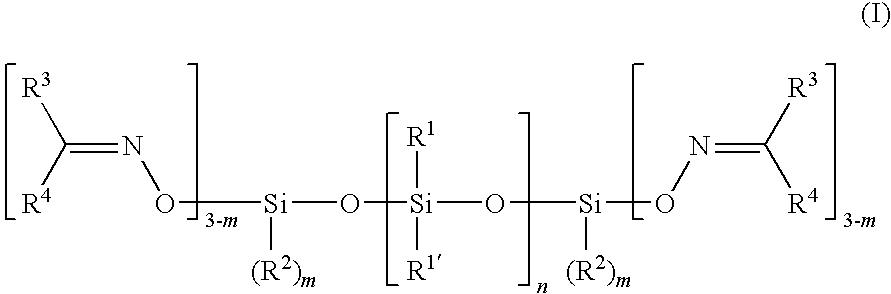

Silicone composition

ActiveUS20100063190A1Simple and rapid preparationFast chemical reactionPretreated surfacesSpecial tyresHigh adhesionSilicone

The present invention relates to silicone compositions which comprise at least one ketoximosilane-terminated polydiorganosiloxane and also at least one alkoxysilane. These compositions are neutrally crosslinking and combine a low odour with high adhesion and good storage stability.

Owner:SIKA TECH AG

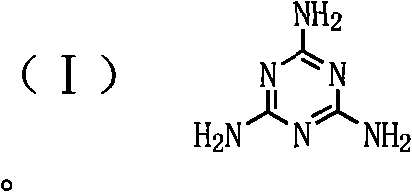

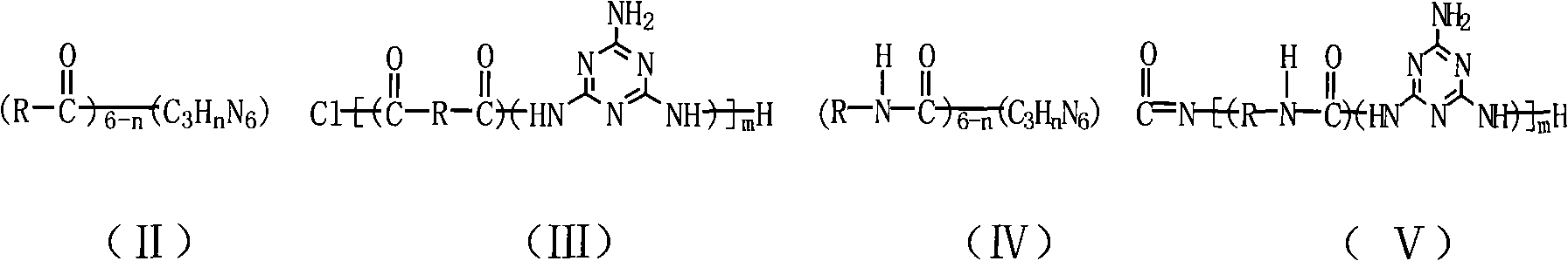

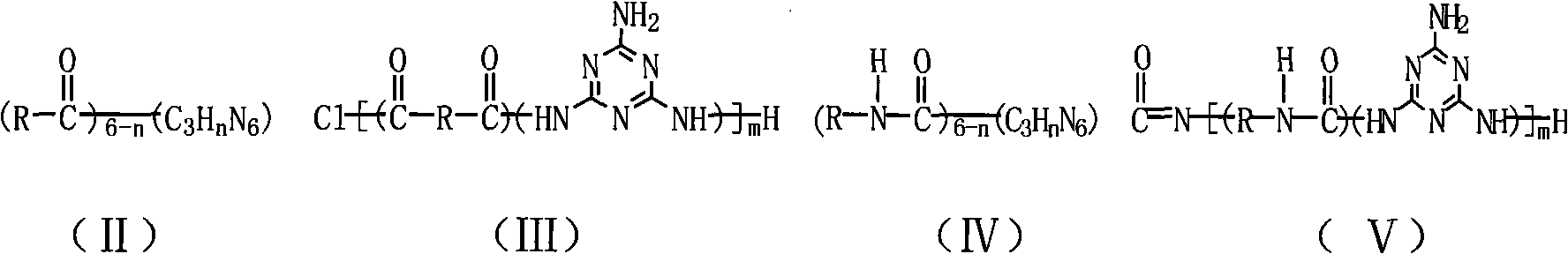

Preparation method of high flame retardant expansible graphite

The invention relates to a preparation method of high flame retardant expansible graphite, which comprises the following steps: dissolving the graphite into a mixing solution of perchloric acid and concentrated nitric acid, wherein the dosage of the solution is 100-600% of the mass of the solution; oxidizing the graphite by using solid oxidant of which the dosage is 0.5-50% of the mass of the oxidant to obtain the primary expansible graphite, wherein the temperature of the expansible graphite is 20-80 DEG C, and the reaction time is 20-300min; dissolving tripolycyanamide or the derivants thereof and the solid oxidant into phosphoric acid of which the mass fraction is 85+ / -10% to form a phosphoric acid solution, wherein the dosage of the solid oxidant is 0.5-50% of the mass thereof, and the mass concentration of the tripolycyanamide or the derivants thereof of the formed phosphoric acid solution is 0.02-2g / ml; carrying out reaction of the primary expansible graphite and the phosphoric acid solution at the temperature of 20-80 DEG C for 20-300min to prepare the high flame retardant expansible graphite. The method has the advantages that the tripolycyanamide or the derivants thereof are inserted between the expansible graphite layers, thereby improving the expansibility, start expansion temperature and fire resistance of the expansible graphite, and can be widely used for the flame retardant of multiple materials such as plastic, rubber, paint, foam and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

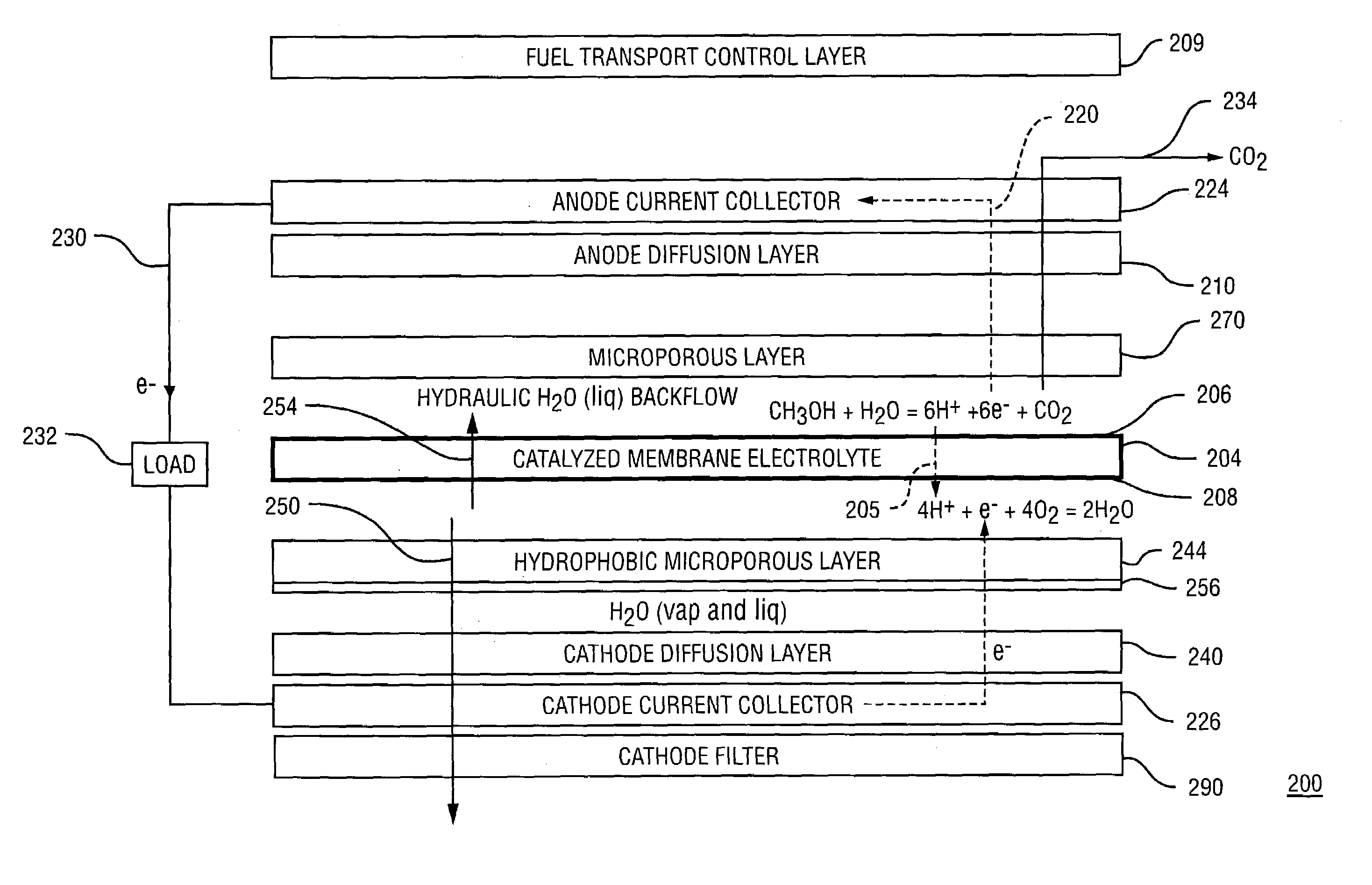

Direct oxidation fuel cell operating with direct feed of concentrated fuel under passive water management

InactiveUS7407721B2Good distribution of waterSystem is complicatedCell electrodesWater management in fuel cellsHigh concentrationFuel cells

A passive direct oxidation fuel cell system, which uses a high concentration fuel such as neat methanol as a direct feed to an anode aspect of the fuel cell, is provided. The fuel cell includes a passive water management capability, achieved by the combined functions of controlled fuel dosing, effective push back of liquid water from the cathode through the membrane electrolyte by a hydrophobic microporous layer well bonded to the cathode catalyst and the use of a thin ionomeric membrane. The rate of fuel delivery is controlled by a passive fuel transport barrier. Carbon dioxide management techniques are also provided.

Owner:MTI MICROFUEL CELLS

Flexible Watertight Roof Coatings

InactiveUS20120077906A1Efficient use ofLong drying timePaper coatingCement coatingsMaterials sciencePolymer

The invention provides for the use of coating compositions based on one or more mineral binders, one or more polymers, one or more fillers, and, if desired, one or more additives for producing roof coatings, the coating compositions comprising at least 50% by weight of polymers, based on the dry weight of the polymers and of the mineral binders.

Owner:WACKER CHEM GMBH

Aqueous fatty monoamine-containing anti-frizz composition for hair

InactiveUS20080085255A1Avoid absorptionPrevent water absorptionCosmetic preparationsHair cosmeticsWater insolublePolymer

The present invention is drawn to a composition and process for inhibiting hair from becoming frizzy when exposed to high and / or low humidity, the composition containing: (a) at least one fatty monoamine; (b) at least one nonionic surfactant; (c) at least one anionic silicone; (d) at least one water-insoluble material; (e) at least one cationic polymer; and (f) at least one film former, different from (e).

Owner:LOREAL SA

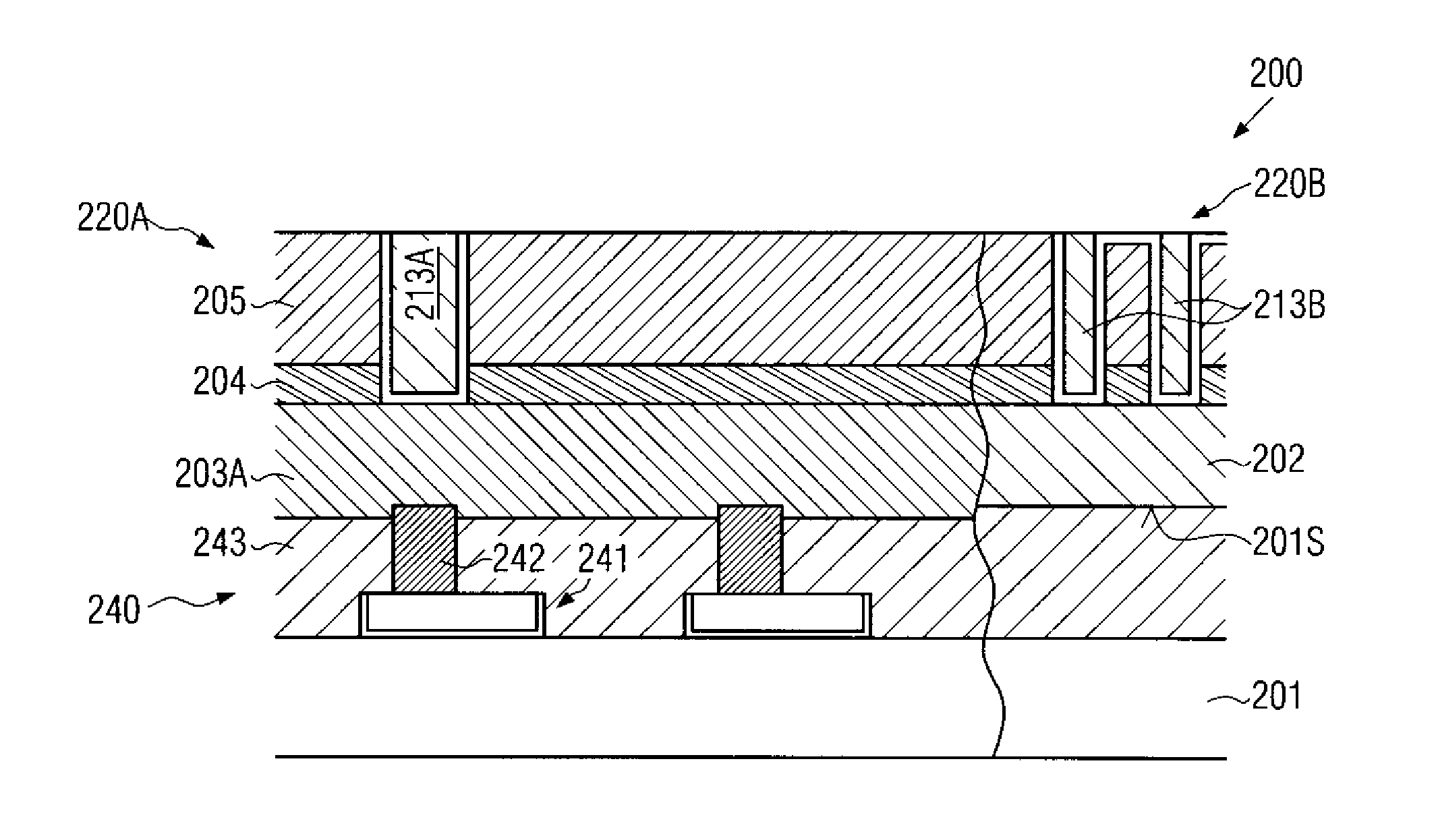

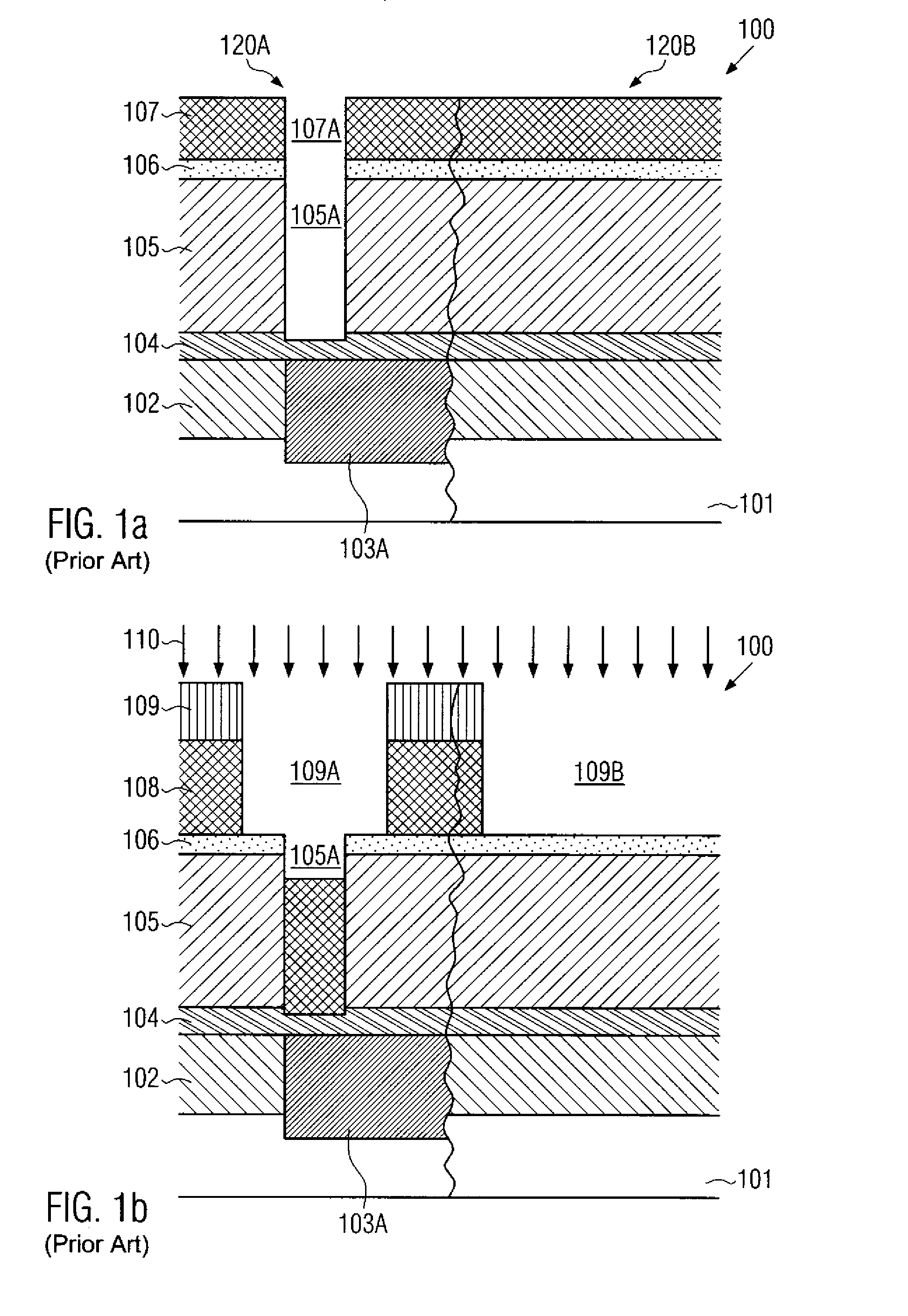

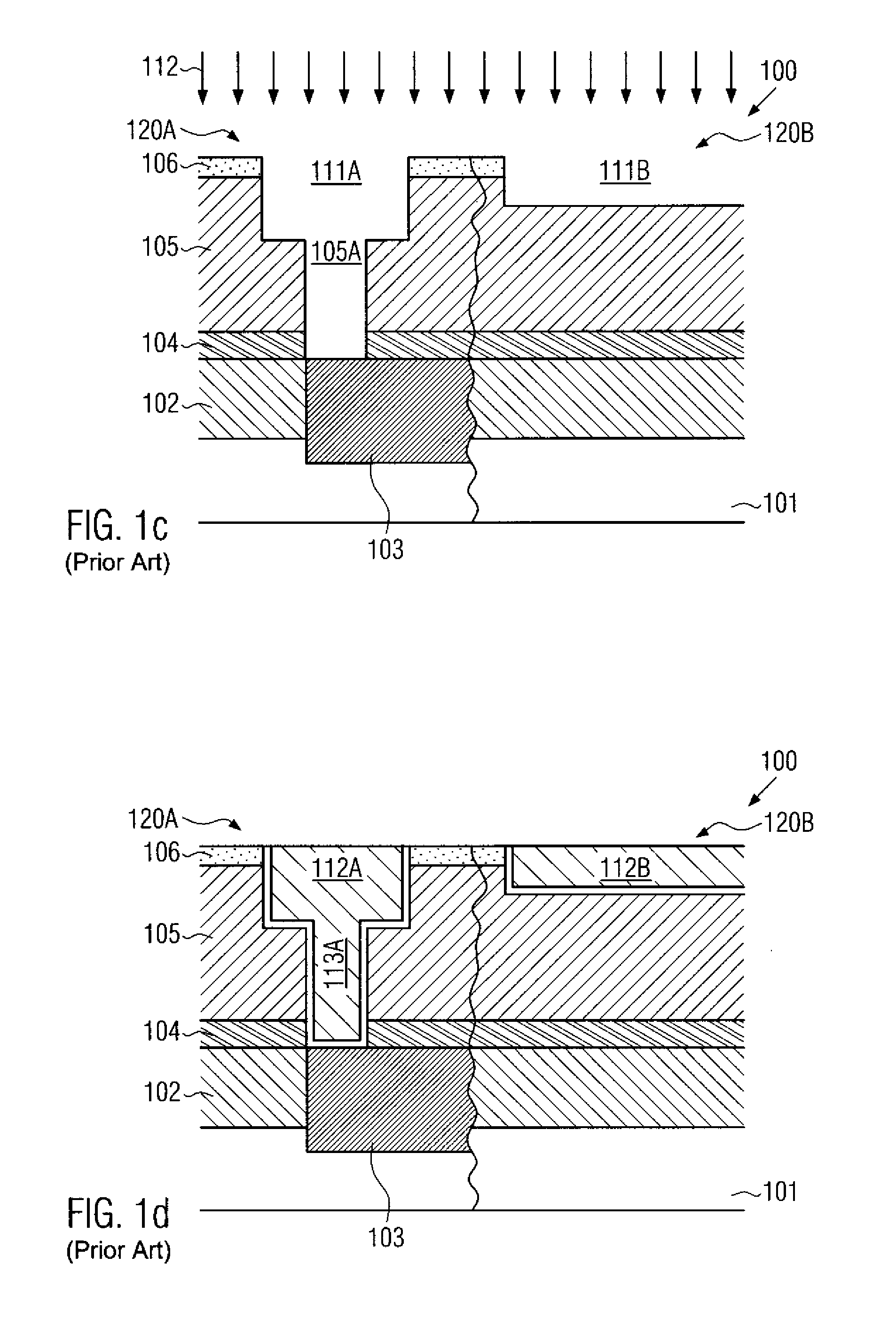

Technique for increasing adhesion of metallization layers by providing dummy vias

InactiveUS20070123009A1Improve adhesionReducing etch non-uniformitiesSemiconductor/solid-state device detailsSolid-state devicesMechanical stabilityElectrical performance

By providing dummy vias below electrically non-functional metal regions, the risk for metal delamination in subsequent processes may be significantly reduced. Moreover, in some embodiments, the mechanical strength of the resulting metallization layers may be even more enhanced by providing dummy metal regions, which may act as anchors for an overlying non-functional metal region. In addition, dummy vias may also be provided in combination with electrically functional metal lines and regions, thereby also enhancing the mechanical stability and the electrical performance thereof.

Owner:GLOBALFOUNDRIES US INC

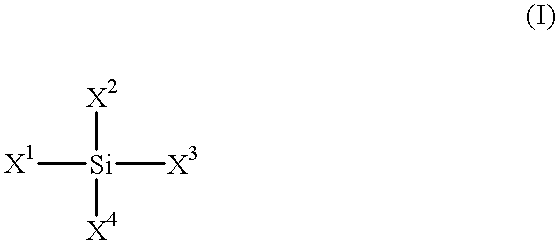

Dental and oralogic composition

InactiveUS6951463B2Avoid stickingEffective adhesionCosmetic preparationsImpression capsHalogenLiquid medium

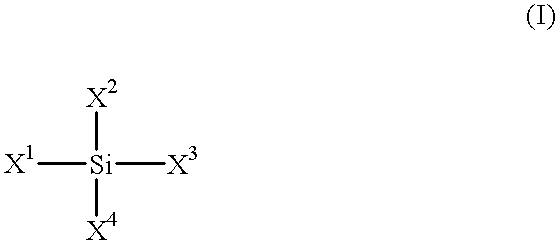

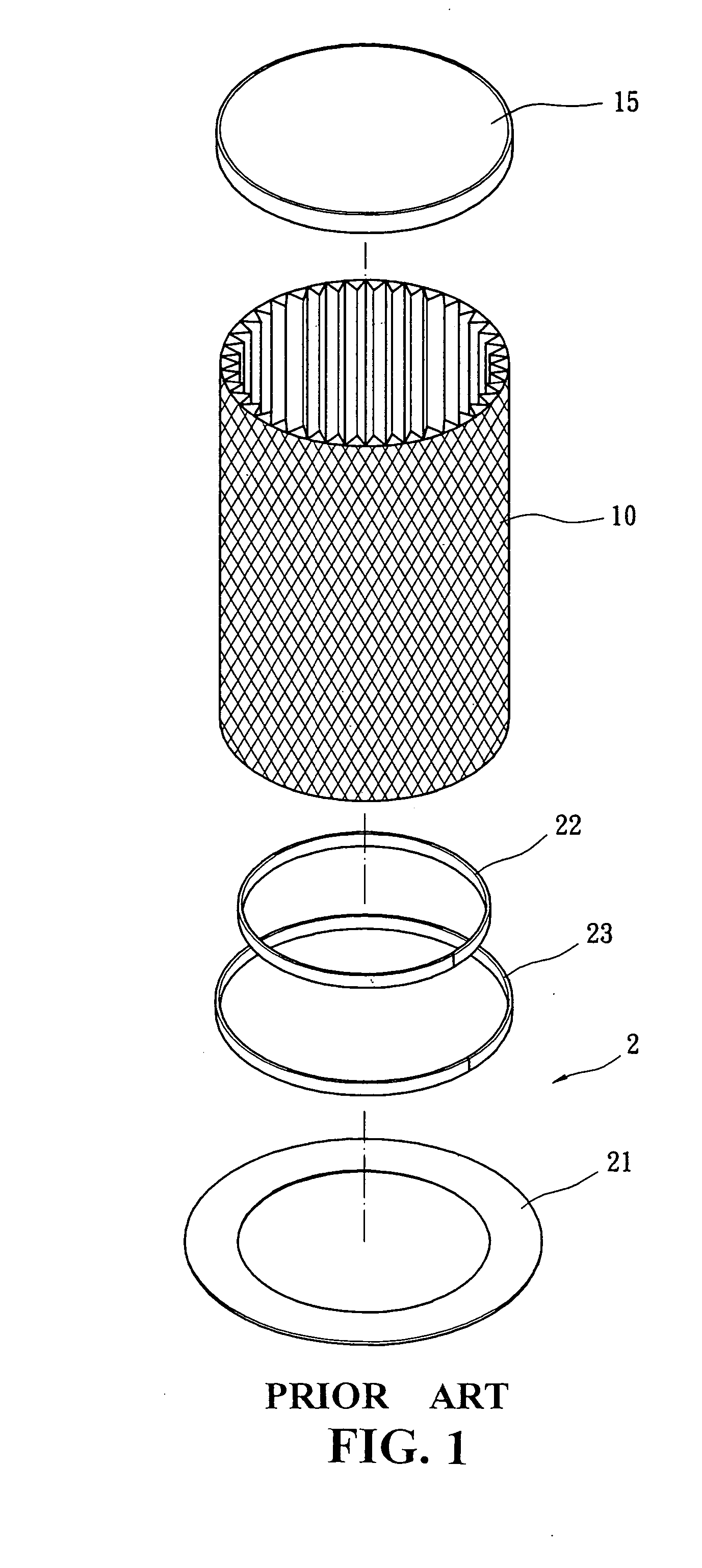

The first embodiment of present invention provides a composition, which includes:(a) a photocatalytic titanium oxide or a photocatalytic titanium oxide precursor;(b) at least one selected from the group including:a silicon compound having the following formula (I): wherein X1, X2, X3 and X4 each independently represent an alkoxy group or a halogen atom,a hydrolyzate of the silicon compound (I), a silicone resin, silicone resin precursor and silica; and(c) a liquid medium. Another embodiment of the present invention provides a dental and oralogic composition, that includes a photocatalytic titanium oxide or a photocatalytic titanium oxide precursor. Another embodiment of the present invention provides a dental and oralogic composition, that includes a photocatalytic titanium oxide or a photocatalytic titanium oxide precursor, and a liquid medium. The composition of the present invention is particularly suitable in dental and oral care, and other embodiments of the present invention provide methods of making and using the above-described compositions.

Owner:KURARAY NORITAKE DENTAL

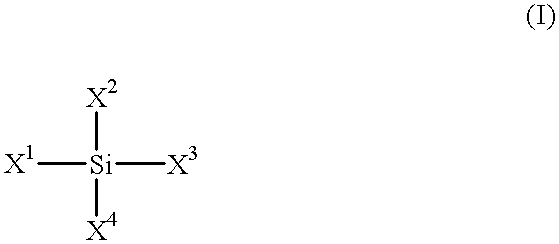

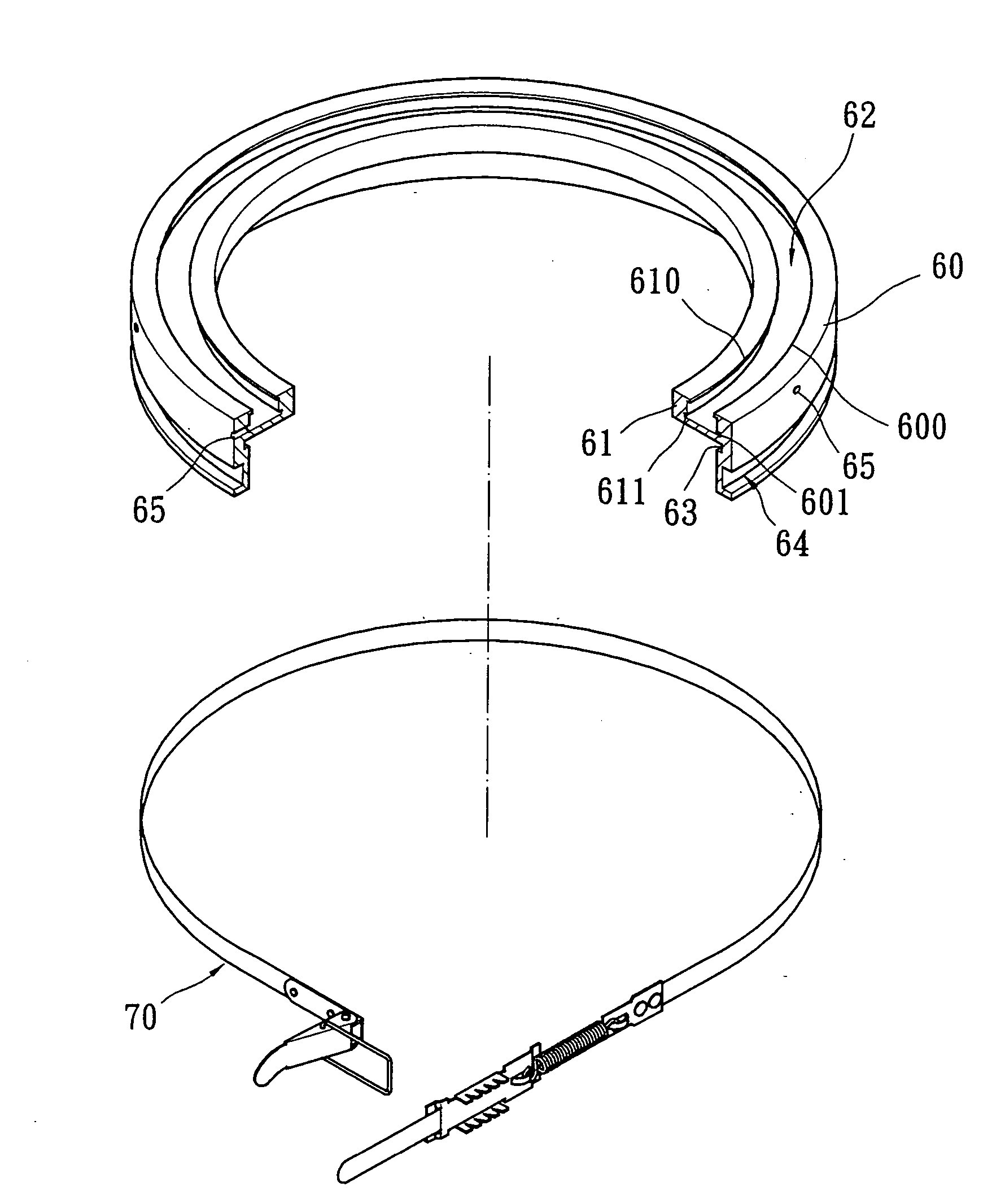

Securing seat for holding filtering cylinder of a dust collector

InactiveUS20050126137A1Excellent enclosureGood effectGas treatmentDispersed particle filtrationEngineeringAir tightness

A securing seat for holding filtering cylinder of a dust collector is disclosed. The securing seat includes a binding mount and a binding belt, and the middle section of the inner edge of the binding mount is protruded with an inverted L-shaped holding plate. The top face of the binding mount is an engaging slot for engagement with a filtering cylinder. The top edge and the bottom edge at the inner face of the binding mount and the holding plate are respectively formed into lid and fastening slot. The filtering cylinder is mounted to the engaging slot and the lid and the fastening slot are adhered to each other. Thus, the securing seat is provided with excellent air tightness and the securing seat is firmly secured, and the air suction of the dust collector is improved.

Owner:WANG CHUN HSIANG

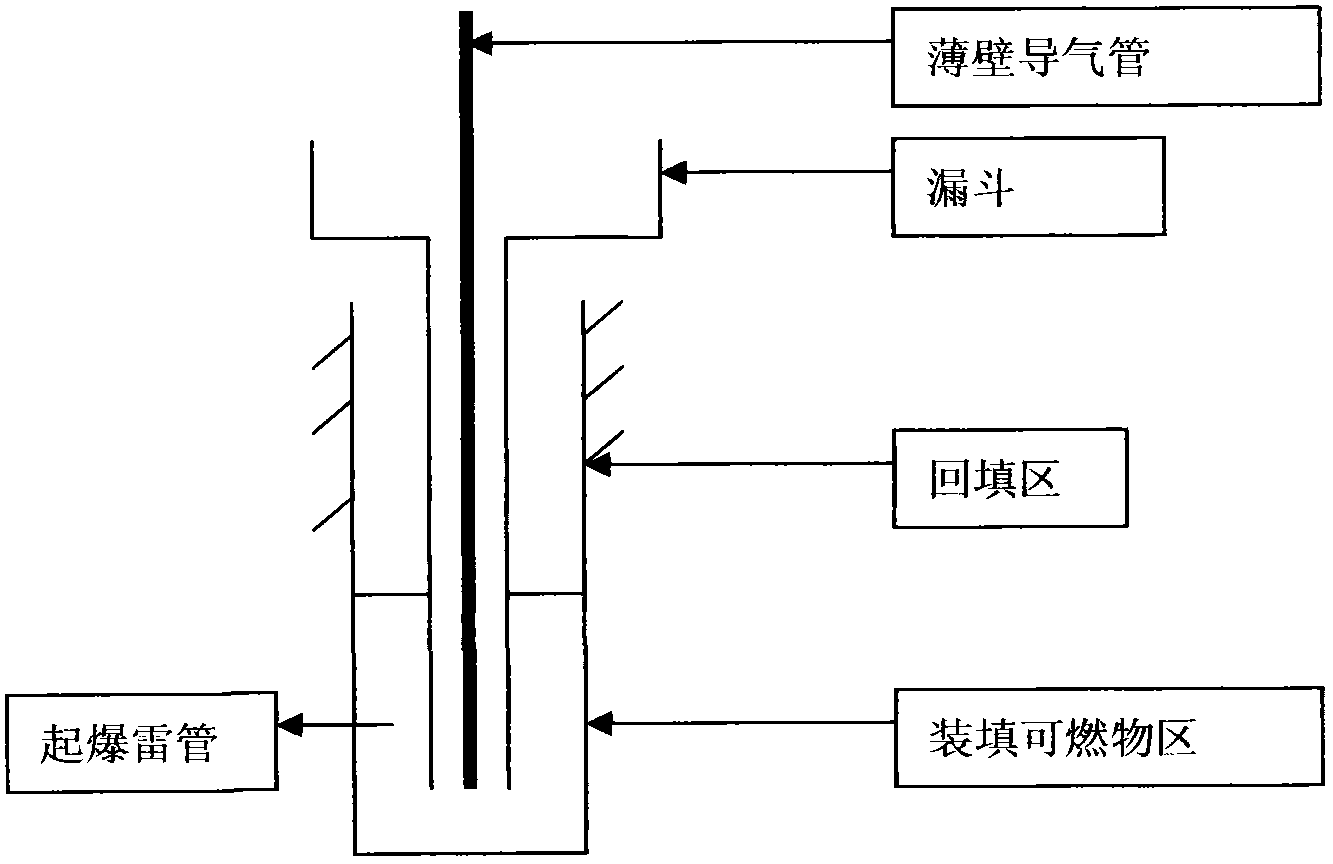

Liquid oxygen explosive composite and liquid oxygen explosive

The invention discloses a liquid oxygen explosive composite and liquid oxygen explosive, belonging to the technical field of liquid oxygen explosive materials containing fuel and enough oxidants to generate high-speed chemical changes after being exploded to generate substances used for detonation. A liquid oxygen explosive composite comprises liquid oxygen and a combustible, wherein the combustible is composed of 50-70% by mass of pulverized coal and 30-50% by mass of wet sawdust or combustible fiber, and the wet sawdust is prepared by humidifying sawdust to 5% by using a sodium chloride solution with concentration of 20%. The liquid oxygen explosive composite and liquid oxygen explosive disclosed by the invention have the advantages of preventing generation of static electricity and explosion possibility, reducing the explosive sensitivity and ensuring the explosive to be safer.

Owner:乔新明

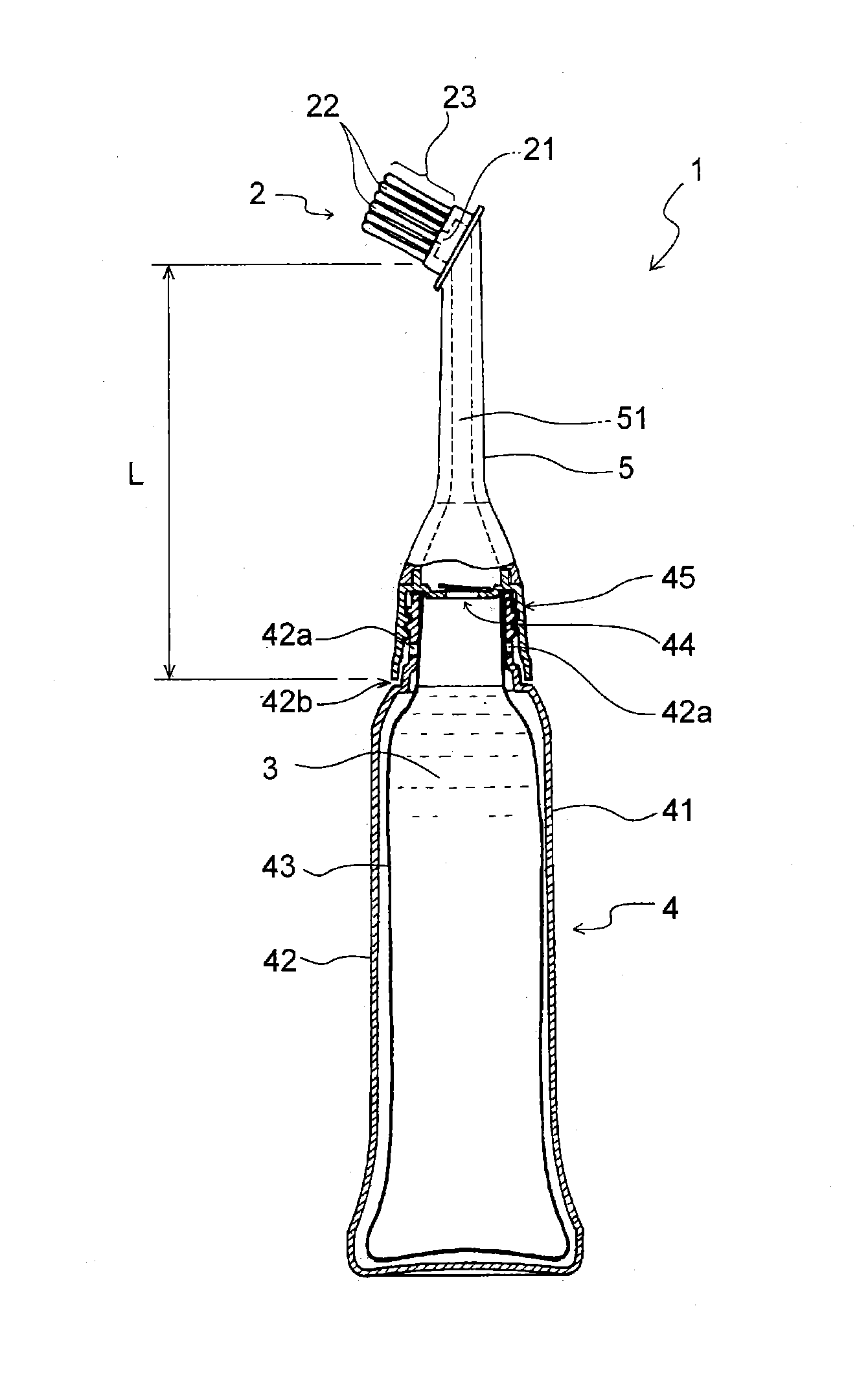

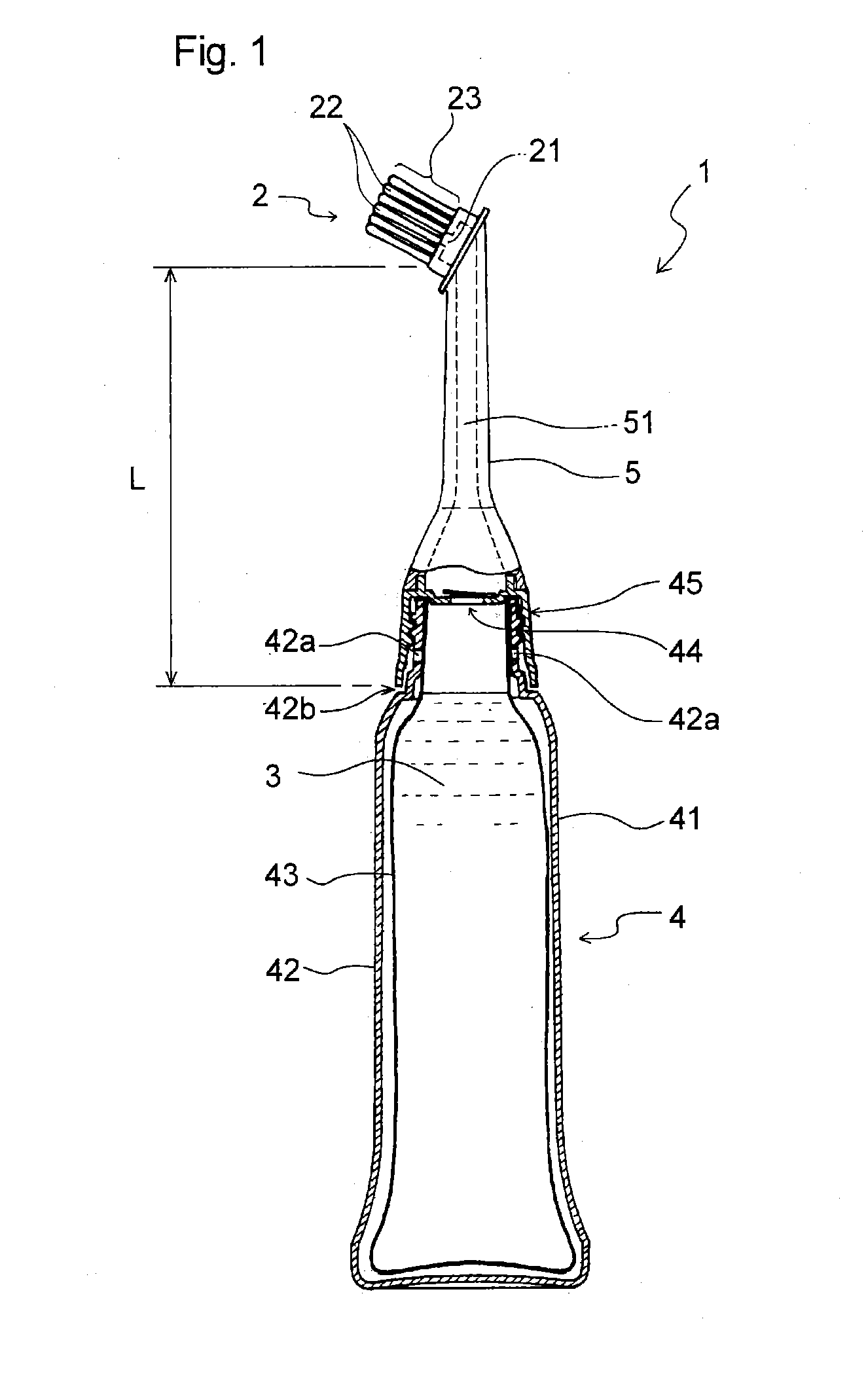

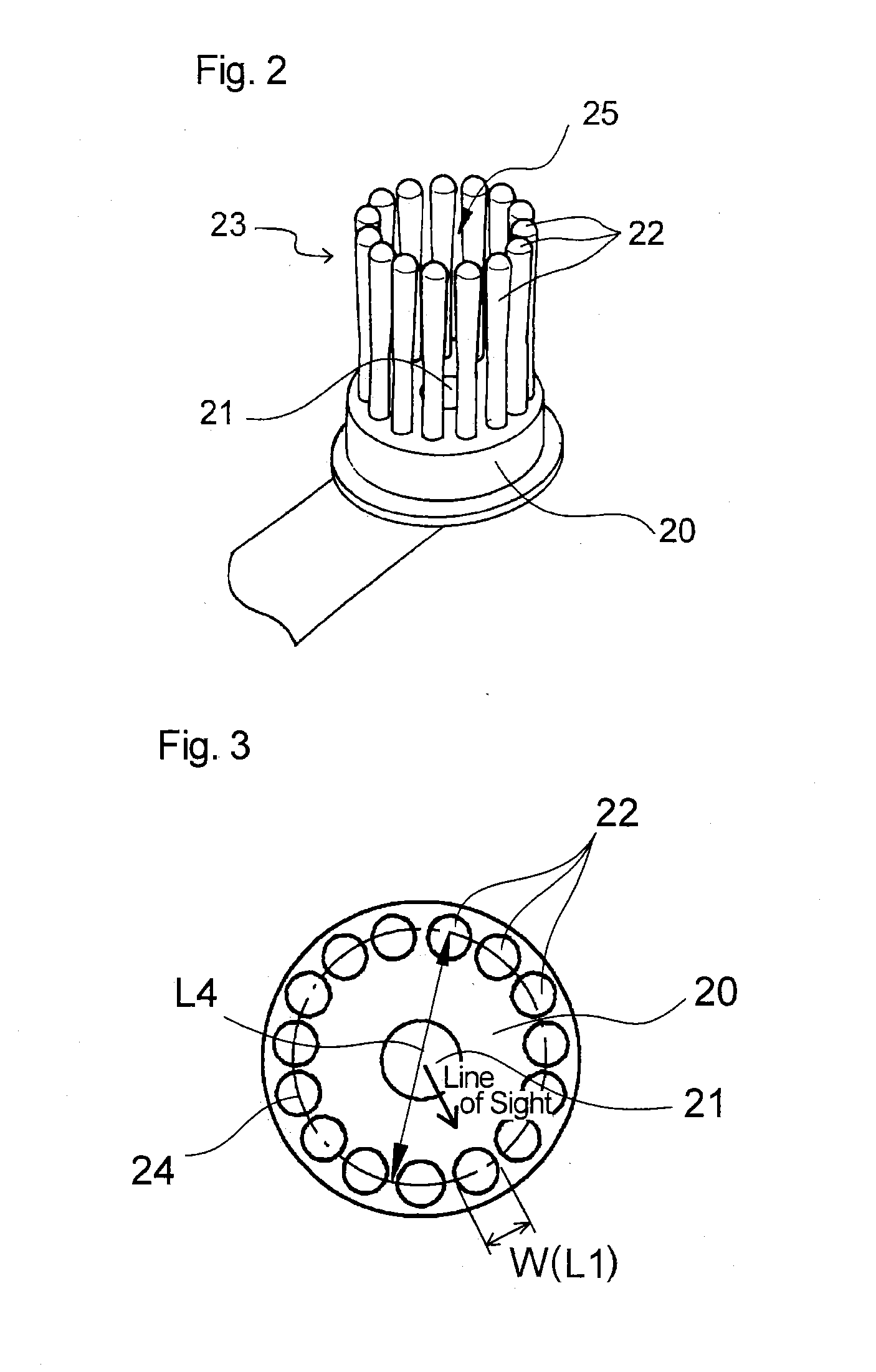

Head-hair treatment-agent applicator

A head-hair treatment-agent applicator (1) according to the present invention has an agent applying part (2) which has a comb part (23) formed with a plurality of annularly arranged comb teeth (22), and the comb teeth (22) each have an inversely-tapered part (22c) in which a comb tooth width W decreases from a vicinity of a tip (22a) to a base end (22e).

Owner:KAO CORP

Treatment Varnish Compositions for Teeth Surfaces

InactiveUS20110097368A1Effective treatmentEasy to disassembleCosmetic preparationsToilet preparationsSolventEffective treatment

Embodiments of the present invention include compositions, methods, and systems for providing an effective and efficient treatment varnish for teeth. For example, embodiments of the present invention provide a treatment varnish that comprises one or more polymers and / or copolymers that are soluble in biocompatible solvents, such as ethanol. The polymers and / or copolymers are nontoxic and form a substantially clear film that adheres effectively to teeth during treatment, but also is easily removed from teeth once the treatment is complete.

Owner:CAO GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com